Preparation method of high-acid saponified oxidized wax

A technology for oxidizing wax and high-acid soap, applied in the chemical industry, can solve the problems of less oxidation reports of paraffin wax and microcrystalline wax, and achieve the effects of short reaction time, low reaction temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

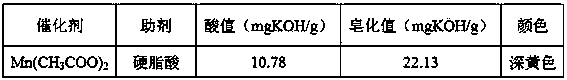

[0020] Weigh a certain mass ratio of paraffin wax and microcrystalline wax, heat the three-necked flask with an oil bath to make it melt completely, and at 140°C, use manganese acetate as a catalyst and stearic acid as an auxiliary agent, and control the oxygen flow rate to 80mL / min. After oxidizing for 4 hours, after the reaction, the sample was taken out, molded, and its properties were measured. The results are shown in Table 1.

[0021] Table 1 Catalytic oxidation results of manganese acetate

[0022]

[0023] As can be seen from Table 1, when manganese acetate is used as a catalyst and stearic acid is used as an auxiliary agent, the obtained oxidized wax product has a lower acid value, saponification value, and darker color.

Embodiment 2

[0025] Using manganese sulfate as a catalyst and stearic acid as an auxiliary agent, the method is the same as in Example 1, and the results are shown in Table 2.

[0026] Table 2 Catalytic oxidation results of manganese sulfate

[0027]

[0028] Comparing Table 1 and Table 2, under the same conditions, when manganese sulfate is used as catalyst and stearic acid is used as auxiliary agent, the obtained oxidized wax product has higher acid value, saponification value and lighter color.

Embodiment 3

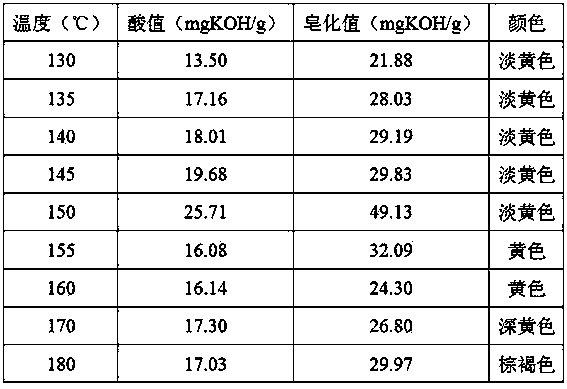

[0030] Weigh a certain mass ratio of paraffin wax and microcrystalline wax, add it to a three-necked flask, heat it in an oil bath to make it melt completely, and at a certain temperature, use manganese sulfate as a catalyst and stearic acid as an auxiliary agent to control the oxygen flow rate to 80mL / min, oxidized for 4h, after the reaction, the sample was taken out, molded, and its properties were measured. The results are shown in Table 3.

[0031] Table 3 Effect of reaction temperature on properties of oxidized wax

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com