Preparation method for polyisobutylene succinimide

A technology of polyisobutylene succinimide and polyisobutylene succinic anhydride, which is applied in the field of technical chemical industry, can solve problems such as difficult control, wide molecular weight distribution, complex product components, etc., to reduce viscosity, improve dispersibility, and improve effective utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

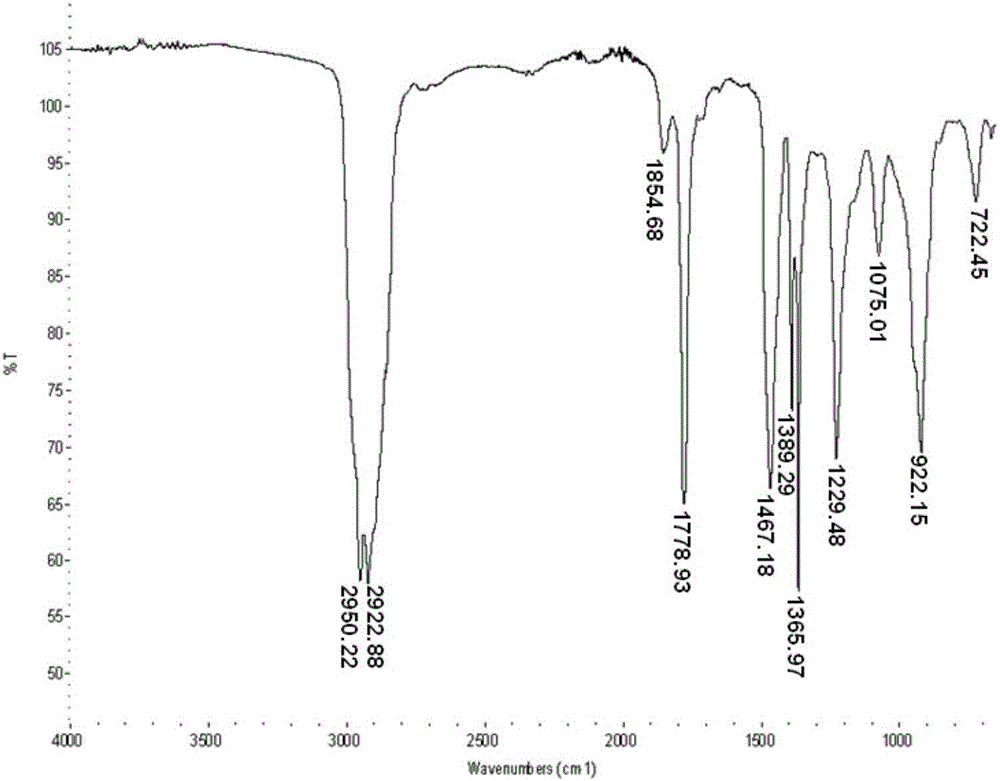

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of polyisobutylene succinimide, comprising:

[0024] A) the mixture of free radical initiator and base oil, maleic anhydride are added dropwise respectively in polyisobutene and react, obtain the mixture of polyisobutylene succinic anhydride and base oil;

[0025] B) mixing the mixture of polyisobutylene succinic anhydride and base oil obtained in step A) with polyethylene polyamine and the second base oil, and performing an amination reaction to obtain polyisobutylene succinimide.

[0026] The preparation method provided by the invention reduces the generation of by-products such as maleic anhydride autopolymer, polyisobutylene and maleic anhydride polymer, reduces the viscosity of polyisobutylene succinic anhydride intermediate, and improves the maleic anhydride Effective utilization rate of acid anhydride and saponification value of polyisobutylene succinic anhydride intermediate. And the dispersibility of the prep...

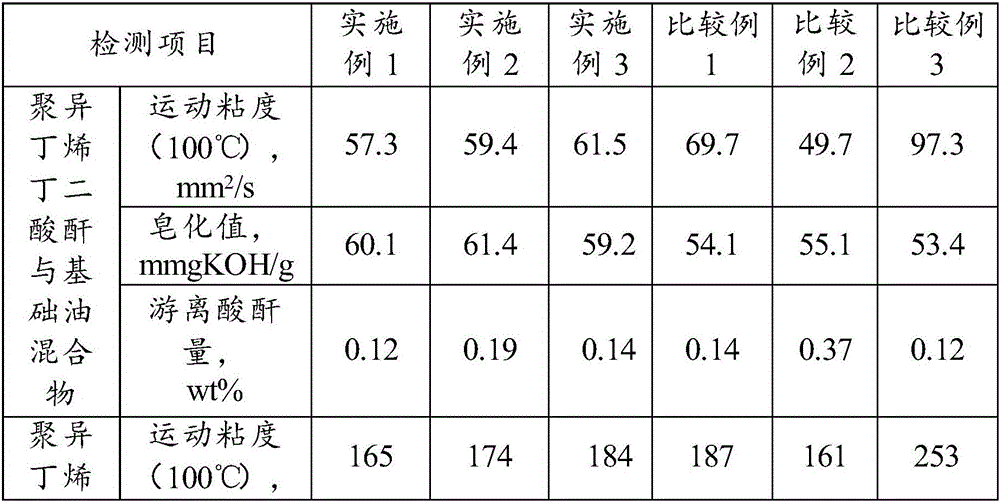

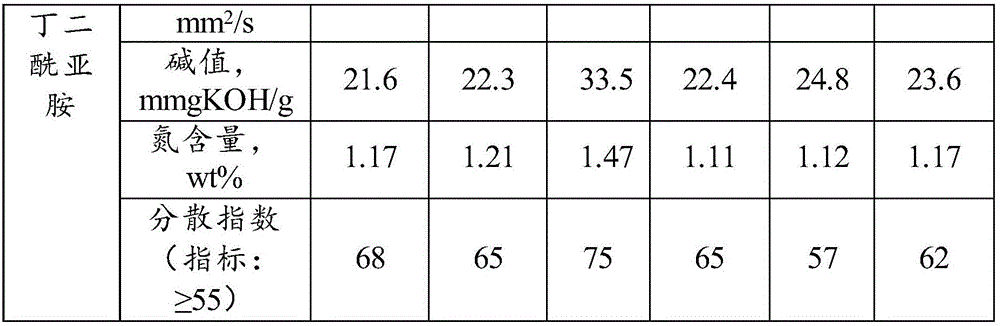

Embodiment 1

[0050] Add 150 grams of highly active polyisobutene (number average molecular weight 1000, alpha olefin content 84.65wt%) in the 500ml four-necked bottle, protect with nitrogen, stir and be warming up to 150 ℃; Weigh 2.0g di-tert-butyl peroxide in 150ml beaker, then pour 100g 150SN non-hydrogenated base oil, stir and mix evenly, add to the burette fixed on the four-necked bottle, and start to add dropwise; at the same time, start to add dropwise at the other port of the four-necked bottle Melted maleic anhydride, the dropwise amount of maleic anhydride was 20.6 g. The dropping speed of the mixture of di-tert-butyl peroxide and base oil should be equivalent to that of maleic anhydride, and the dropping time is 2 hours. After the two materials are added dropwise, continue to keep the temperature at 150°C for 2 hours, then adjust the temperature to 190°C, separate the light component under negative pressure, and add 70g of 150SN to the material after the light component has been ...

Embodiment 2

[0054] Add 150 grams of highly active polyisobutylene (number average molecular weight 1000, α-olefin content 84.65wt%) in the 500ml four-necked bottle, protect with nitrogen, stir and heat up to 150°C; weigh 2.0g dicumyl peroxide in 150ml Then pour 100g of 150SN non-hydrogenated base oil into the beaker, stir and mix evenly, add it into the burette fixed on the four-necked bottle, and start to add dropwise; at the same time, start to drop the molten The maleic anhydride, the dropwise amount of maleic anhydride is 20.6g. The dropping speed of the mixture of dicumyl peroxide and base oil should be equivalent to that of maleic anhydride, and the dropping time is 2 hours. After the two materials are added dropwise, continue to keep the temperature at 150°C for 2 hours, then adjust the temperature to 190°C, separate the light component under negative pressure, and add 70g of 150SN to the material after the light component has been separated. Hydrogen base oil to obtain a mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com