Production method for eliminating surface color difference of cold-rolled sheet

A production method and technology of cold-rolled sheet, applied in the field of metallurgy, can solve the problems of serious smooth rolling, serious color difference on the upper surface of strip steel, adding auxiliary nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

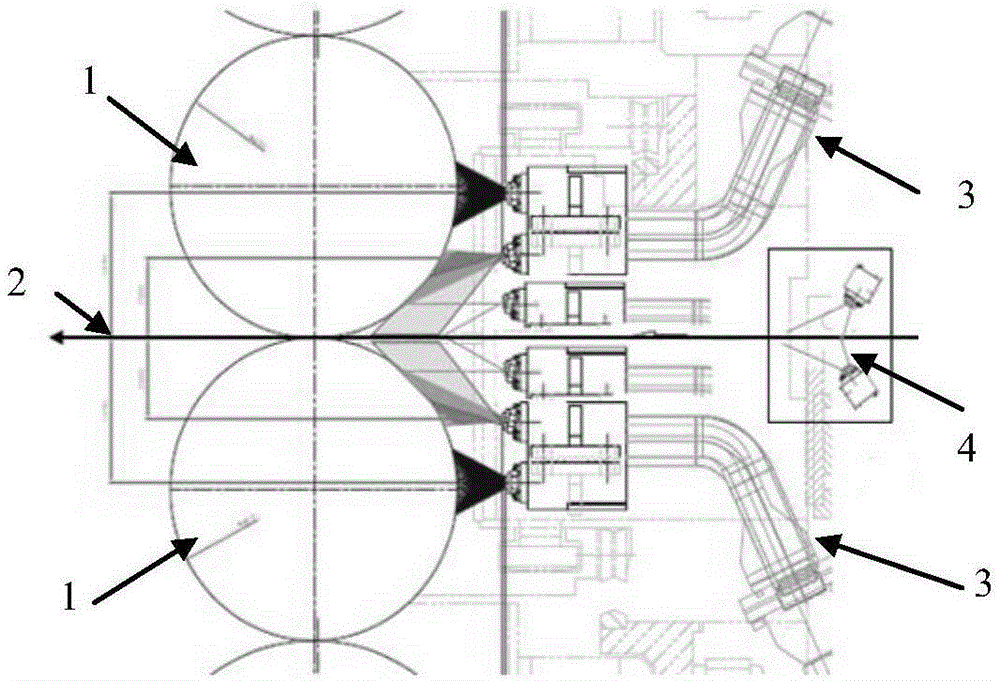

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

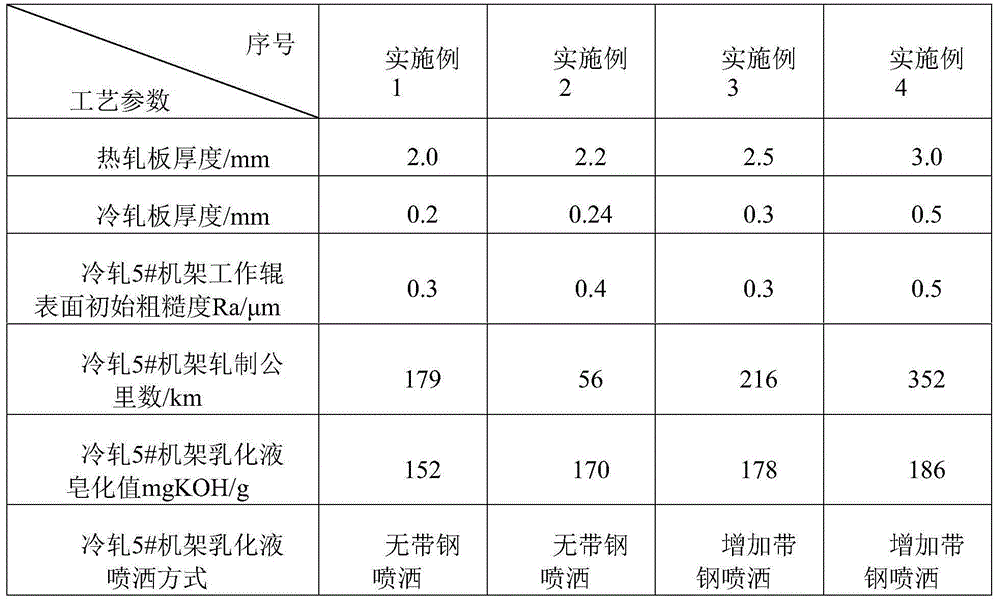

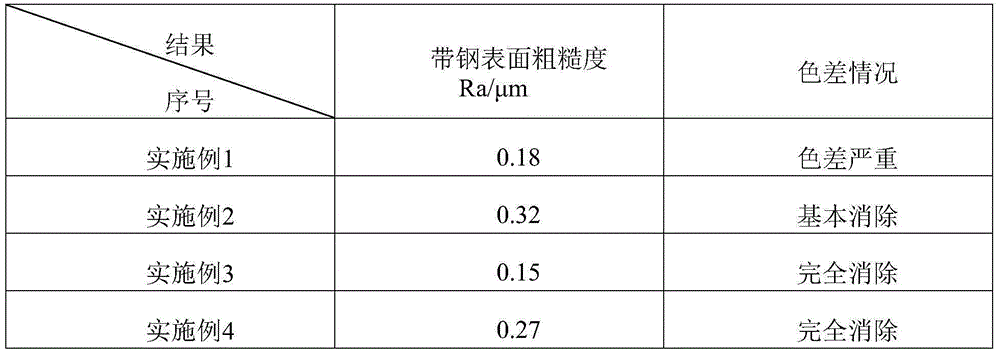

[0023] In the present invention, the production method for eliminating the surface chromatic aberration of the cold-rolled sheet adopts shallow groove turbulent flow pickling and five-stand continuous rolling production technology, and improves the initial surface roughness of the 5# stand work roll in the five stands of cold-rolling from the original 0.2~0.3μm increased to 0.4~0.5μm, and the roughness of work rolls of other racks was 0.7~0.8μm for 1# rack, 0.7~0.8μm for 2# rack, 0.5~0.6μm for 3# rack, 4 #Frame 0.4~0.5μm; increase the saponification value of the emulsion to 180±10mgKOH / g, control the concentration of the emulsion at 2~5%, and control the temperature of the emulsion at 50~60°C; in the cold rolling 5# stand Add auxiliary nozzles to spray the work roll and strip surface.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com