Chinese oak plate archaizing treatment method

A board and oak wood technology, which is applied in wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems that the mechanical properties of the processed board are greatly affected, the wood performance is greatly affected, and the bending strength is reduced, so as to improve the defect of color difference , reduce temperature and time, reduce the effect of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

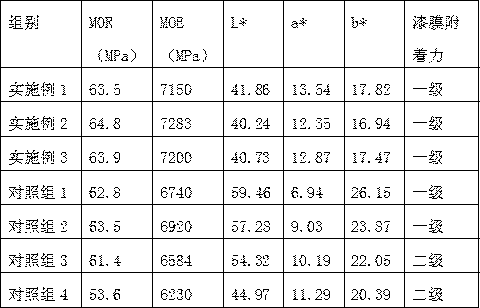

Embodiment 1

[0014] A method for antique treatment of oak wood boards, comprising the following contents: drying the oak wood boards in drying equipment with dry bulbs and wet balls until the water content of the oak wood boards is 10wt%; then drying the oak wood boards Vacuum impregnation in the pig blood extract diluent at room temperature, the vacuum degree is 0.07, the pressurization pressure is 2.15MPa, and the pressurization time is 15 minutes; 6 times of light irradiation, 3.5 seconds each time, the time interval between the two pulses of strong light irradiation time is 6 minutes; after completion, water vapor is introduced, the ambient pressure is adjusted to 170kPa, the heat treatment temperature is 135°C, and the treatment time is 50 minutes; After the heat treatment is completed, it is pressed with poplar core, rotary cut poplar backboard and powdery urea-formaldehyde glue to form a composite floor;

[0015] The preparation method of the pig blood extract dilution comprises the...

Embodiment 2

[0018] A method for antique treatment of oak wood boards, comprising the following contents: placing the oak wood boards in drying equipment with dry balls and wet balls for drying until the moisture content of the oak wood boards is 8wt%; and then drying the oak wood boards Vacuum impregnation in the pig blood extract diluent at room temperature, the vacuum degree is 0.08, the pressurization pressure is 2.2MPa, and the pressurization time is 14 minutes; 7 times of light irradiation, 3 seconds each time, the time interval between the two pulses of strong light irradiation is 8 minutes; after completion, water vapor is introduced, the ambient pressure is adjusted to 175kPa, the heat treatment temperature is 130°C, and the treatment time is 60 minutes; After the heat treatment is completed, it is pressed with poplar core, rotary cut poplar backboard and powdery urea-formaldehyde glue to form a composite floor;

[0019] The preparation method of the pig blood extract dilution com...

Embodiment 3

[0022] A method for antique treatment of oak boards, comprising the following contents: placing the oak boards in drying equipment with dry balls and wet balls for drying until the moisture content of the oak boards is 12wt%; then drying the oak boards Vacuum impregnation in the pig blood extract diluent at room temperature, the vacuum degree is 0.06, the pressurization pressure is 2.1MPa, and the pressurization time is 16 minutes; 5 times of light irradiation, 4 seconds each time, the time interval between the two pulses of strong light irradiation time is 5 minutes; after completion, water vapor is introduced, the ambient pressure is adjusted to 165kPa, the heat treatment temperature is 140°C, and the treatment time is 40 minutes; After the heat treatment is completed, it is pressed with poplar core, rotary cut poplar backboard and powdery urea-formaldehyde glue to form a composite floor;

[0023] The preparation method of the pig blood extract dilution comprises the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com