Light antiseptic latex paint

A latex paint and acrylic emulsion technology, applied in latex paint, anti-corrosion paint, coating, etc., can solve the problems of poor water resistance, poor adhesion, poor paint film hardness, etc., and achieve good water resistance, good hardness, and coating method convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of a light anti-corrosion latex paint, comprising the following steps: first adding 0.5-5 parts by mass of water, 0.015-1 part by mass of a defoamer, and 0.1-3 parts by mass of a dispersant into a batching tank and mixing evenly, and then Add 0.1-3 parts by mass of thickener and stir evenly; then add 0-30 parts of pigment and grind for 10-20 minutes; then add 1-10 parts of film-forming aid, 0.1-5 parts of co-solvent, 70 parts of film-forming substances, stirred evenly, then added 0-1 parts by mass of antifungal agent, 0-1 parts by mass of preservative, pH regulator of 0-1 parts by mass, filtered, packaged to obtain light anti-corrosion latex paint finished product.

[0018] The film-forming substance is an aqueous acrylic emulsion, preferably HD1092 aqueous acrylic emulsion. The film-forming aid is one of Texanol ester alcohol, LusolvanFBH, Coasol, DBE-IB, DPNB, Dowanol pph. The co-solvent includes one of 1,2-propanediol and absolute ethanol. The...

Embodiment 1

[0022] A kind of light anticorrosion latex paint, its formula is composed as following table 1:

[0023]

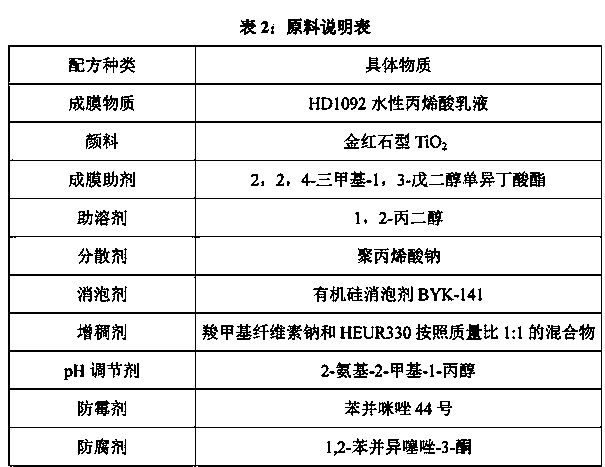

[0024] The raw material description of this embodiment is as follows table 2:

[0025]

Embodiment 2

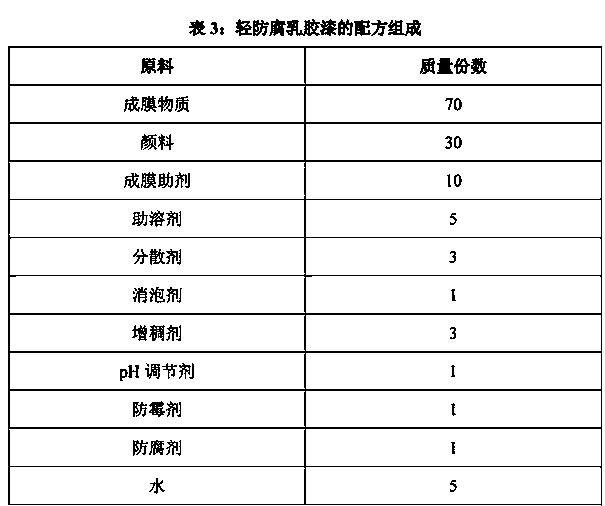

[0027] A kind of light anticorrosion latex paint, its formula is composed as following table 3:

[0028]

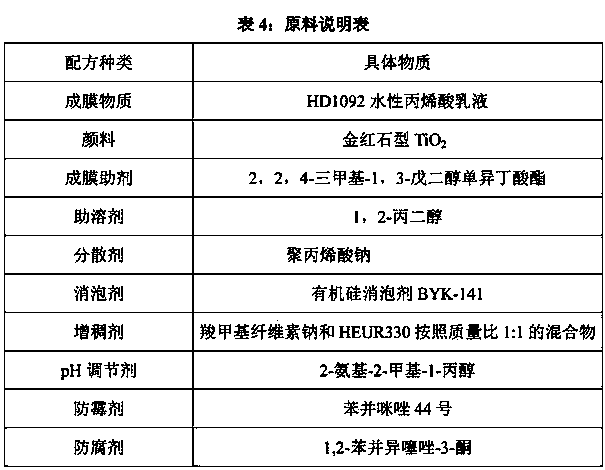

[0029] The raw material description of this embodiment is as follows table 4:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com