A kind of environment-friendly impact-resistant water-based acrylic amino glass wine bottle baking varnish and its preparation method and application

A technology of acrylic acid amino and water-based acrylic acid, which is applied in the direction of epoxy resin coating, coating, pigment slurry, etc. It can solve the problems of poor recoatability, poor impact resistance, and adhesion to be further improved, so as to improve environmental protection characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of above-mentioned glass wine bottle baking varnish comprises the following steps:

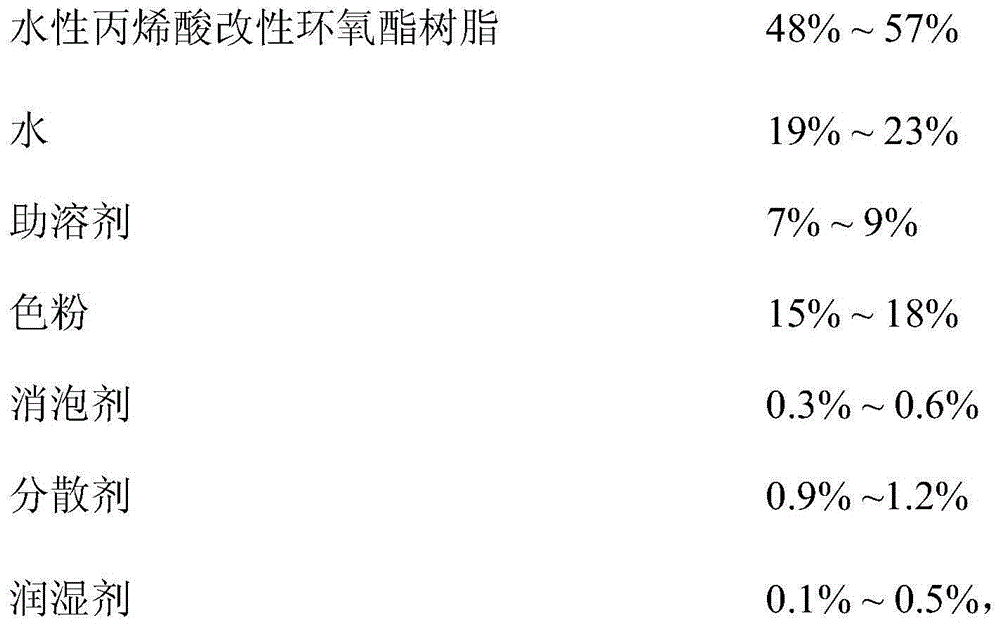

[0073] a. Preparation of color paste: Add water-based acrylic modified epoxy ester resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15 minutes, then slowly add co-solvent, toner, defoamer, dispersant and wetting agent agent, high speed 1000~1500r / min disperse for 25~35min, grind the high speed dispersed slurry twice with a sand mill, and prepare the color paste for later use;

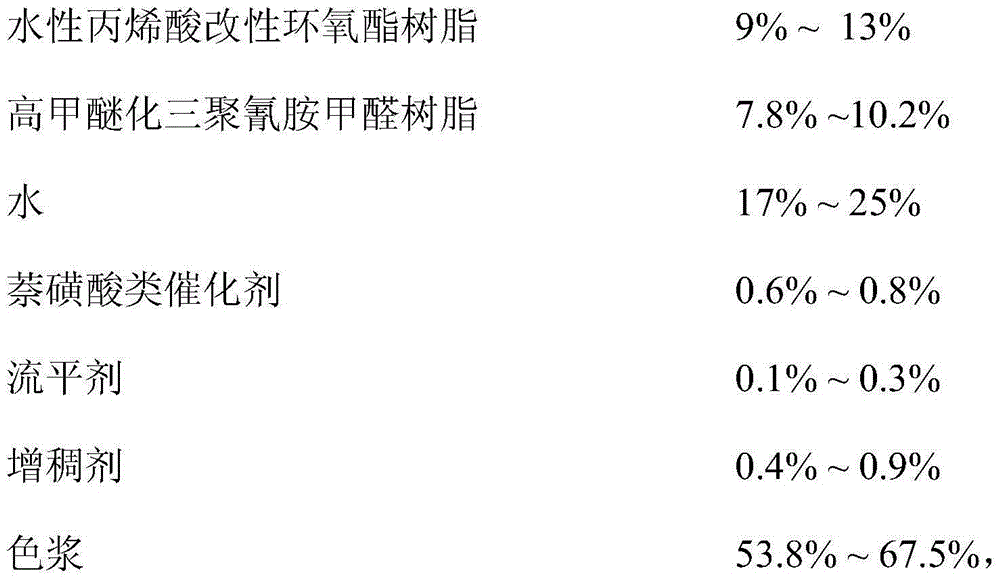

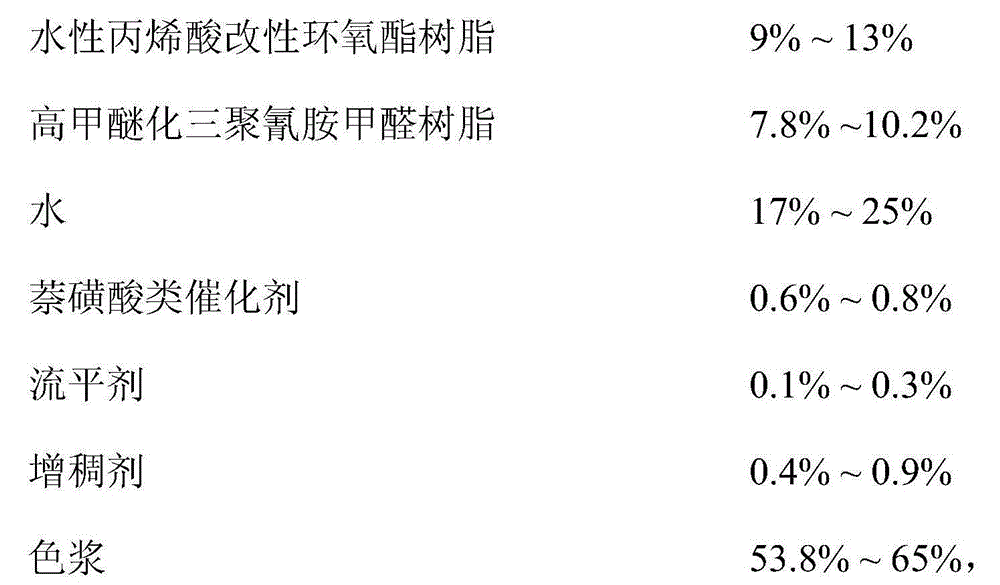

[0074] b. Preparation of component 1: Add water-based acrylic modified epoxy resin, high methyl etherified melamine formaldehyde resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15min, then slowly add leveling agent to thicken agent and the color paste prepared in step a, disperse at a high speed of 1000-1500r / min for 30-35min, take a sample to detect that the finished product fineness of component 1 is less tha...

Embodiment 1

[0082] Prepare color paste:

[0083] Waterborne acrylic modified epoxy ester resin 53.5%, water 19%, cosolvent 8%, toner 18%, defoamer 0.3%, dispersant 1.0%, wetting agent 0.2%;

[0084] Add water-based acrylic modified epoxy ester resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15min, then slowly add co-solvent, toner, defoamer, dispersant and wetting agent, at a high speed of 1000-1500r / min disperse for 25-35min, and use a sand mill to grind the high-speed dispersed slurry twice to prepare the color paste for later use;

[0085] Preparation component 1:

[0086] 10% water-based acrylic modified epoxy ester resin, 9% high methyl etherified melamine formaldehyde resin, 19.8% water, 0.6% naphthalenesulfonic acid catalyst, 0.15% leveling agent, 0.45% thickener, 60% color paste;

[0087] Add water-based acrylic modified epoxy ester resin, high methyl etherified melamine formaldehyde resin and water into the dispersion tank, disperse at ...

Embodiment 2

[0095] Prepare color paste:

[0096] Water-based acrylic modified epoxy ester resin 57%, water 19.5%, cosolvent 7%, toner 15%, defoamer 0.3%, dispersant 0.9%, wetting agent 0.3%;

[0097] Add water-based acrylic modified epoxy ester resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15min, then slowly add co-solvent, toner, defoamer, dispersant and wetting agent, at a high speed of 1000-1500r / min disperse for 25-35min, and use a sand mill to grind the high-speed dispersed slurry twice to prepare the color paste for later use;

[0098] Preparation component 1:

[0099] Water-based acrylic modified epoxy ester resin 13%, high etherified melamine formaldehyde resin 10.2%, water 21.25%, naphthalenesulfonic acid catalyst 0.6%, leveling agent 0.15%, thickener 0.4%, color paste 54.4%;

[0100] Add water-based acrylic modified epoxy ester resin, high methyl etherified melamine formaldehyde resin and water into the dispersion tank, disperse at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Luster | aaaaa | aaaaa |

| Luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com