Patents

Literature

328results about How to "Non-foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

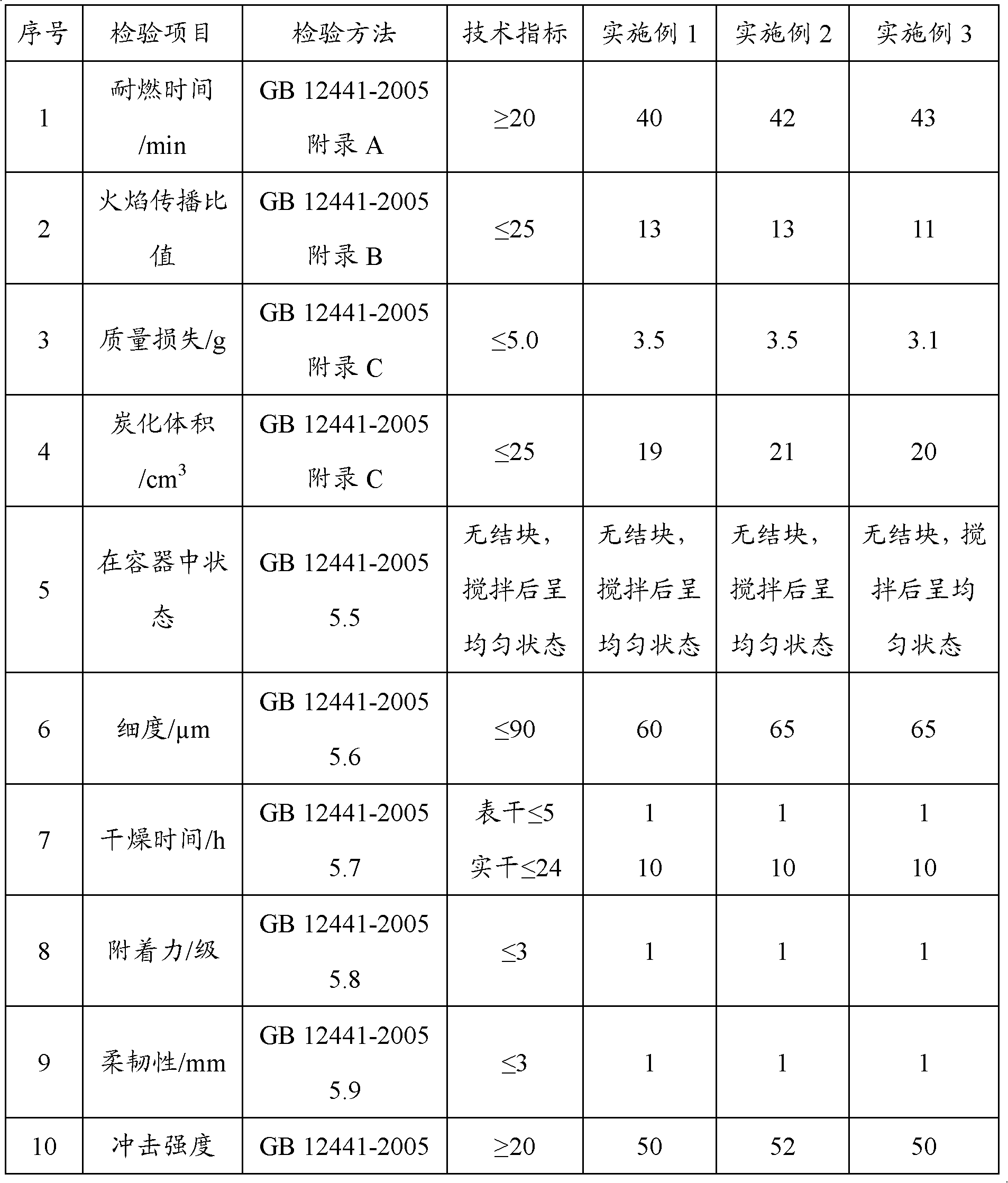

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

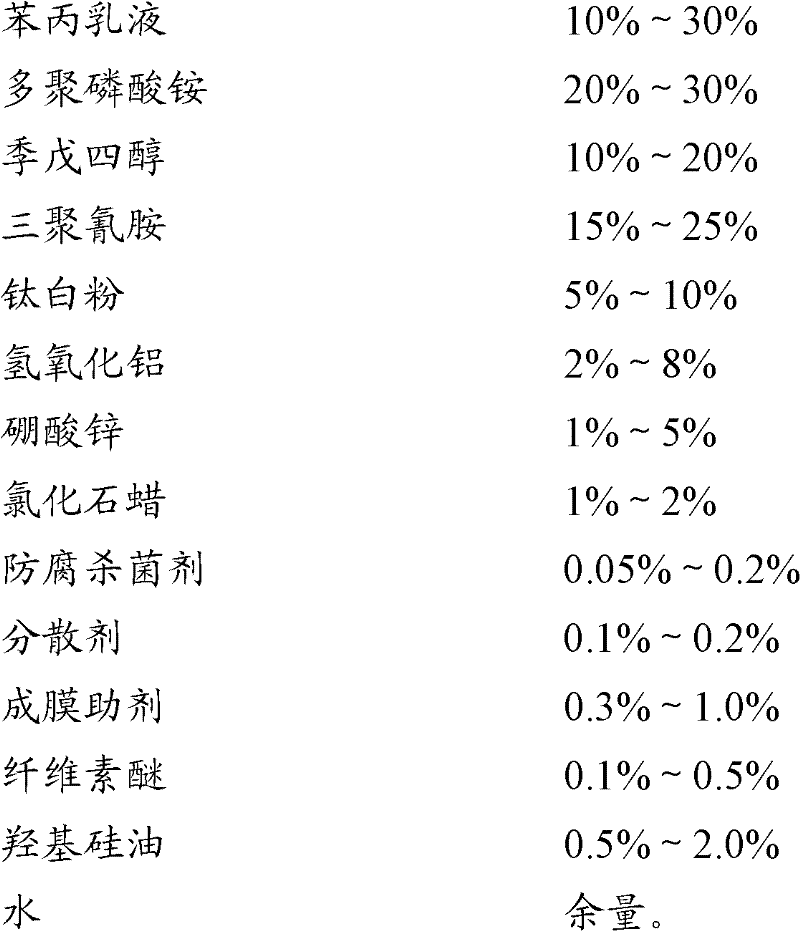

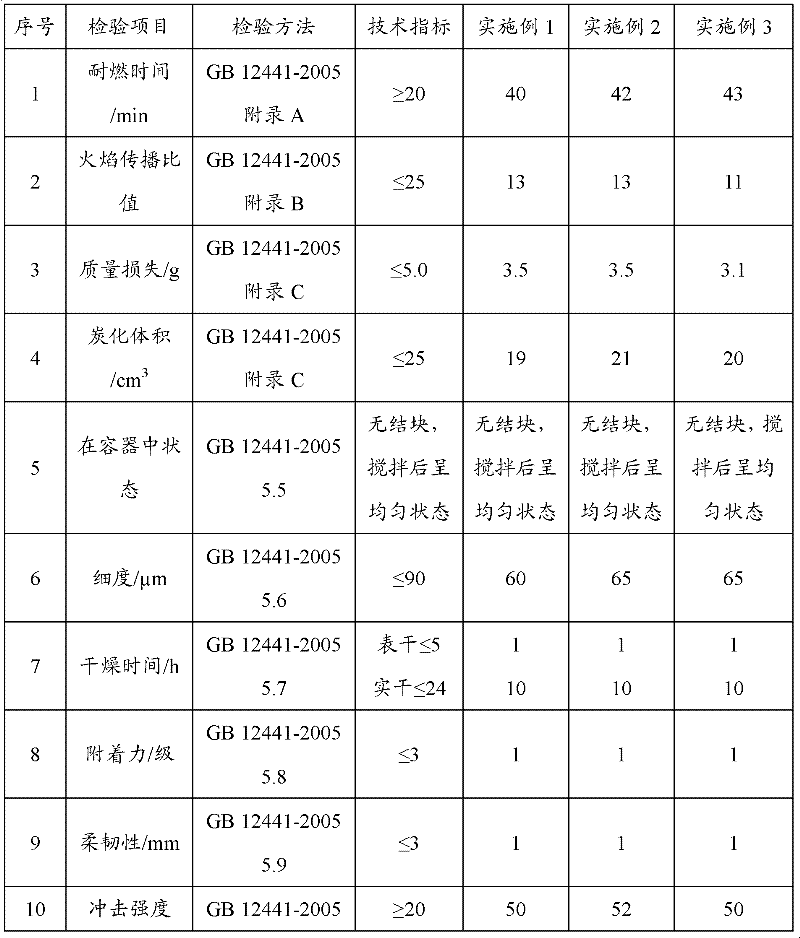

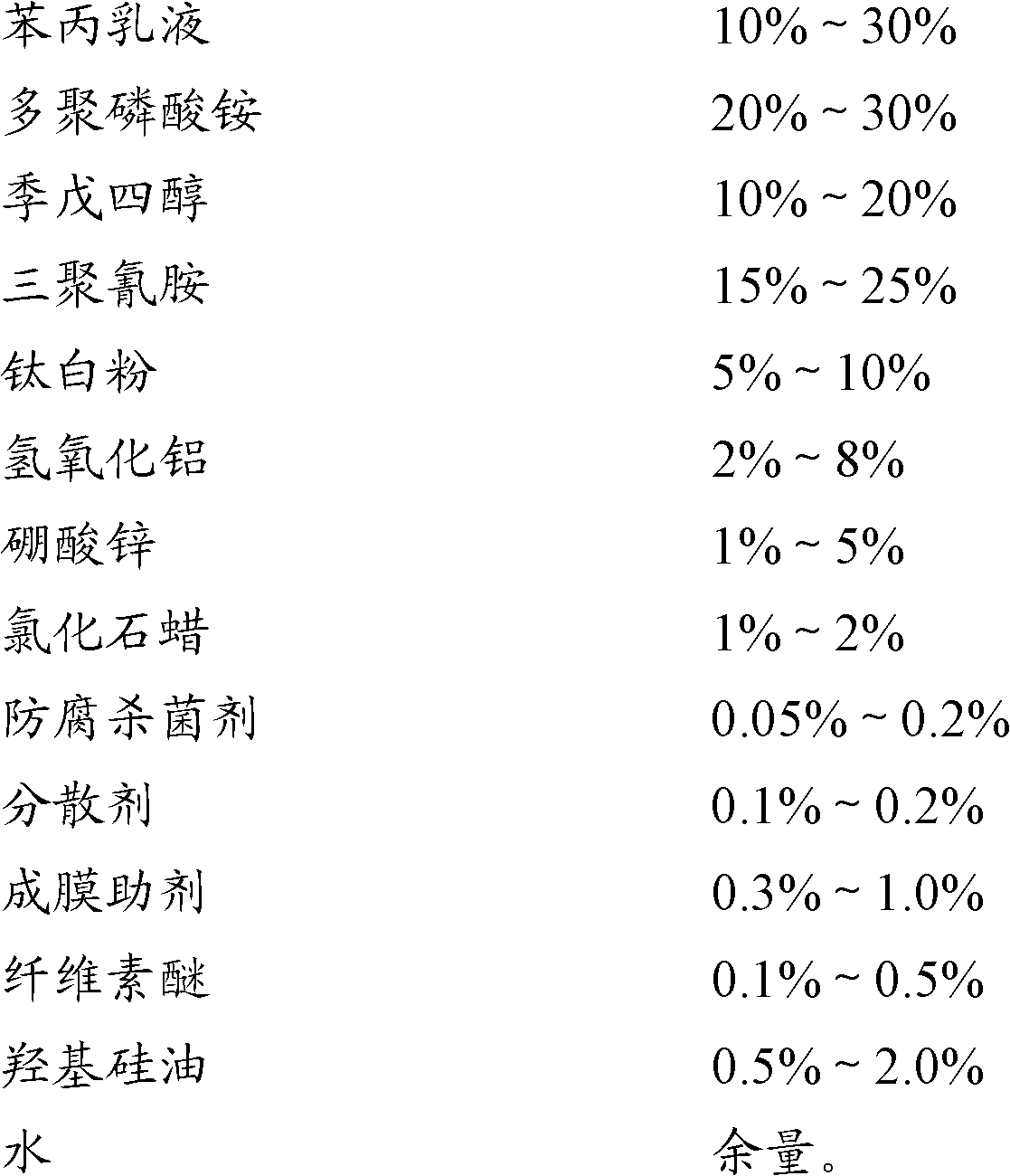

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

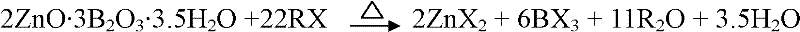

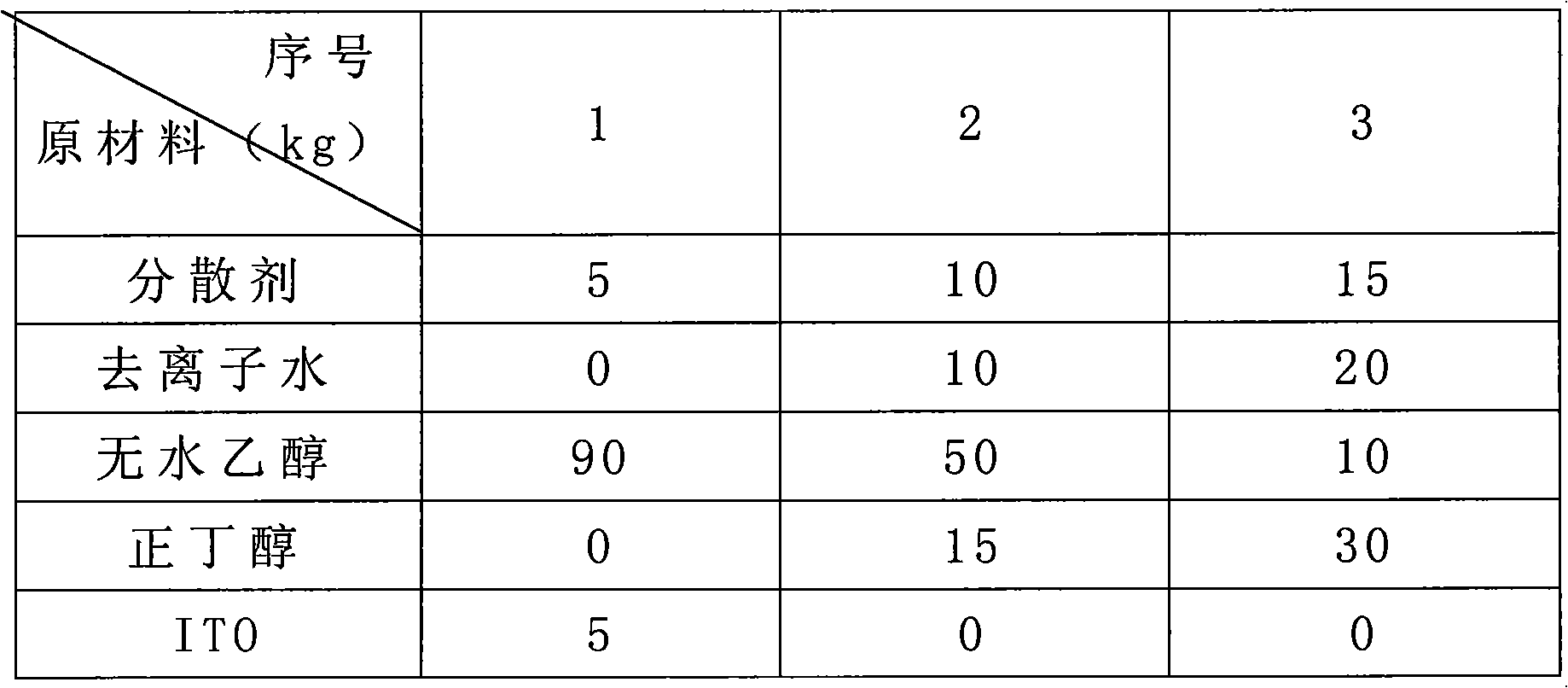

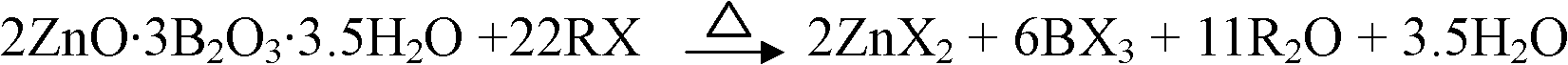

Insulating mould coating, laminated glass intermediate film, heat-protecting glass and laminated glass thereof

The invention relates to an insulating mould coating, a laminated glass intermediate film, a piece of heat-protecting glass and a piece of laminated glass thereof. The transparent insulating mould coating is prepared by dissolving a thermal plastic macromolecule resin into a solvent, then adding a nanometer material body sizing agent and other auxiliary agents and stirring the mixture evenly. Theinsulating mould coating can be coated on glass and transparent resin film materials, and has very strong bonding strength, and refraction coefficients similar to that of the glass and the laminated glass intermediate film; and the insulating laminated glass prepared by using the insulating mould coating has the characteristics of high visible light transmittance, infrared ray shielding, heat insulation, ultraviolet ageing resistance and the like. The insulating mould coating is simple to prepare, needs no large-scale equipment, and is favorable for popularization.

Owner:HUNAN MASHI NANOMETER NEW MATERIAL

Water-based fluorocarbon top coat for wind-powered blades and method for preparing water-based fluorocarbon top coat

ActiveCN102675998AImprove adhesionGood flexibilityAntifouling/underwater paintsPaints with biocidesWater basedLow speed

The invention discloses a water-based fluorocarbon top coat for wind-powered blades and a method for preparing the water-based fluorocarbon top coat and relates to the field of protective paint. According to the water-based fluorocarbon topcoat for wind powered blades, through compounding an hydroxyl acrylic emulsion and a water-based fluorocarbon emulsion and crosslinking hydroxyl acyclic acid with isocyanate so as to form a netted film, thus the coating adhesion, flexibility, chemical medium resistance, wear resistance of a coating are increased; due to the addition of the water-based fluorocarbon emulsion, the weather fastness of the coating is improved, and the gloss retention, color retention and chalking resistance of the coating are excellent; under the condition of stirring a water-dispersed isocyanate curing agent at a lower speed, an ideal emulsion is formed easily through mixing, thereby ensuring the performance of paint; and because of the introduction of a light stabilizer, the lightfastness, color retention and chalking resistance of the coating are improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

High molecular waterproof coating and preparation method thereof

The invention relates to a waterproof coating, in particular to a high molecular waterproof coating and a preparation method thereof. The high molecular waterproof coating is prepared from a powder material and a liquid material in the weight ratio of (1-5):1, wherein the powder material comprises the following components in parts by weight: 0.1-5 parts of reactive polysiloxane compound, 1-5 parts of polypropylene chopped fiber, 10-50 parts of quartz powder, 30-70 parts of calcium carbonate and 1-15 parts of bentonite; and the liquid material comprises the following components in parts by weight: 30-80 parts of polyvinyl acetate emulsion, 0.5-5 parts of thickening agent, 0.5-5 parts of sterilizing agent, 0.1-3 parts of organic silicon antifoaming agent and 10-40 parts of water. The high molecular waterproof coating has the advantages of no pollution to human bodies and the environment, readily-available raw materials, low cost, easiness for preparing, convenience for construction, safety, environment friendliness, excellent physical property, strong bonding force, high extensibility, prevention of water and rust and the like, and can be applied to waterproofness of indoor and outdoor buildings.

Owner:TIANCHANG JULONG TRAVEL PAINT

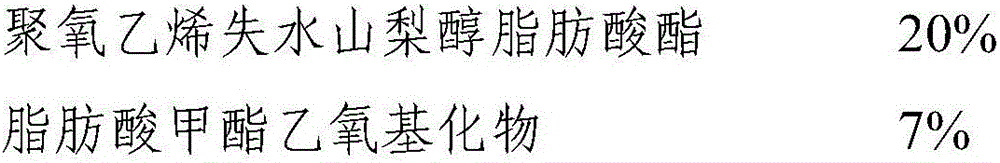

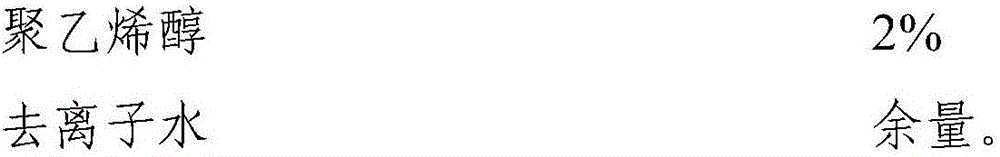

Dewaxing cleaning liquid as well as preparation method and application thereof

InactiveCN105779151AEffective removalGood cleaning performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsWaxSolvent

The invention relates to a dewaxing cleaning liquid as well as a preparation method and application thereof. The dewaxing cleaning liquid comprises the following active components in parts by weight: 5-70 parts of an efficientnonionic surfactant, 0.1-20 parts of a low-foam foam-inhibiting type surfactant and 1-20 parts of a dispersion stabilizer. The dewaxing cleaning liquid provided by the invention is obtained by compounding the efficientnonionic surfactant, the low-foam foam-inhibiting type surfactant and the dispersion stabilizer, and has the following propertyadvantages when being compared with a conventionalindustrial product: 1, the cleaning property is good, and the service life is prolonged by more than 20% when being compared with that of a conventional dewaxing liquid (generally the requirement is 60 pieces / L); 2, the dewaxing cleaning liquid is environmentally friendly and free of pollution, small in volatilization loss when being compared with a solvent dewaxing liquid, and is harmless for human bodies and environments; 3, the cleaning effect is good, the wax can be stably retained in dewaxing cleaning liquid for a long time and is not easy to be layered or separated, and granular muddy matters which can interfere the cleaning effect can be avoided; 4, the dewaxing cleaning liquid has no or a small amount of foams, when being filled into a cleaning tank or mechanically stirred, the dewaxing cleaning liquid does not generate a great amount of foam, and thus convenience can be brought to manual operation.

Owner:BEIJING POLYSTAR HITECH CO LTD

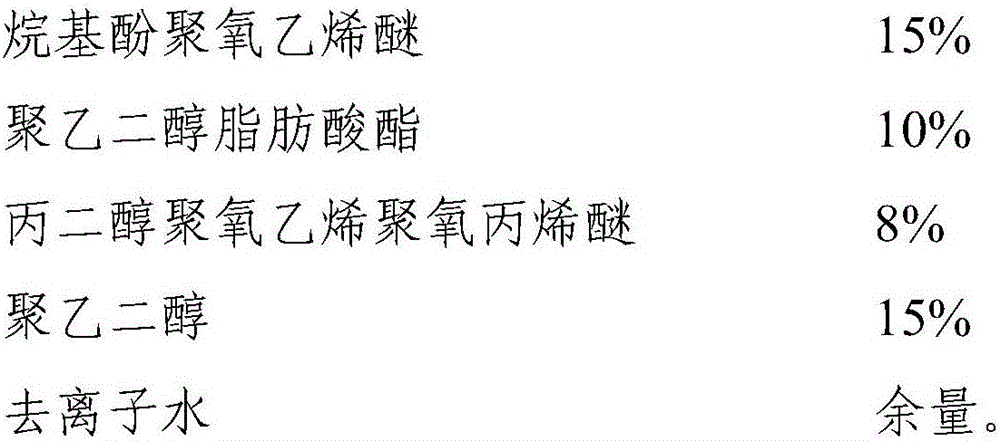

Process for welding electronic microcomponents based on multi-temperature gradient

InactiveCN102950350AEfficient removalNo discharge restrictionsSoldering apparatusElectronic componentRecoil pressure

The invention discloses a process for welding electronic microcomponents based on a multi-temperature gradient. The process is simple, convenient, efficient, stable and reliable in processing quality, good in welding flowability and little in welding hollows. The process is realized by the following technical scheme: designing the temperature gradient of welding fluxes according to melting points of different welding fluxes and respectively manufacturing welding flux slices at different temperature gradients from a secondary high temperature to a minimum temperature; dividing a function substrate and a transition parent plate on each electronic microcomponent into welding surfaces of the welding fluxes at different temperature gradients and coating a welding flux film coating layer on the welding surfaces directly and respectively by sputter coating; arranging welding flux thickness control pins at more points on the welding surfaces of the electronic component; laminating the electronic microcomponents (1), the welding flux slices (3) and the substrate component (5) sequentially, putting into a clamp with a counter-recoil pressure holding mechanism and putting the clamp into a furnace for vacuum welding; firstly completing the welding at a high temperature gradient, and then protecting other surfaces, which are not used for the welding at the next temperature gradient, of the substrate component, and coating one welding flux film coating layer on the welding surfaces respectively by the sputter coating at the next temperature gradient.

Owner:10TH RES INST OF CETC

Compound water-based inorganic anticorrosive paint and preparation method

InactiveCN104877402ANo changeNon-foamingAnti-corrosive paintsElectrically-conductive paintsSilicic acidPotassium silicate

The invention relates to an anticorrosive paint, particularly to a compound water-based inorganic anticorrosive paint with the functions of cathode protection and anti-static electricity and a preparation method. The compound water-based inorganic anticorrosive paint comprises the following components in mass percent: 0.1-4% of oxidized graphene, 22-34% of zinc powder, 1-3% of attapulgite AT, 15-18% of potassium silicate, 11% of iron oxide red, 30-45% of distilled water and 0.2-0.8% of sodium polyacrylate. The anticorrosive paint has the characteristics that oxidized graphene and zinc powder are used as the main raw materials of the anticorrosive paint, the use amount of zinc powder is greatly reduced, the electrical conductivity and hardness of the paint are improved, the technology is simple, the anticorrosive paint is green, environment-friendly and good in corrosion resistance, and can be applicable to anticorrosive painting of various metal pipelines and metal members.

Owner:CHANGZHOU UNIV

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992BImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Water-based paint and its preparation technique

InactiveCN101240139AReduce labor intensityProtect your healthEmulsion paintsBuilding materialEmulsion

The invention relates to a waterproof paint for architecture and building materials, especially to a water-base paint which is widely applied to brushing objects such as boarded floor, toy for children, corrugated paper, inner wall, outer wall, woodwork, damp proofing, cement, leak stopping, metal product, etc. The prescription of water-base paint totally differs from the traditional one, comprising: adding raw materials such as glycerin, xylitol, etc., except crylic acid emulsion, which are food-grade raw materials substantially, nontoxic and environmental-friendly absolutely. The water-base paint can be constructed directly, bring handsome looking and relieving labor strength of constructors. Furthermore, the water-base paint does not damage health of constructors, with multiple advantages of current waterproof paints.

Owner:黄敏文

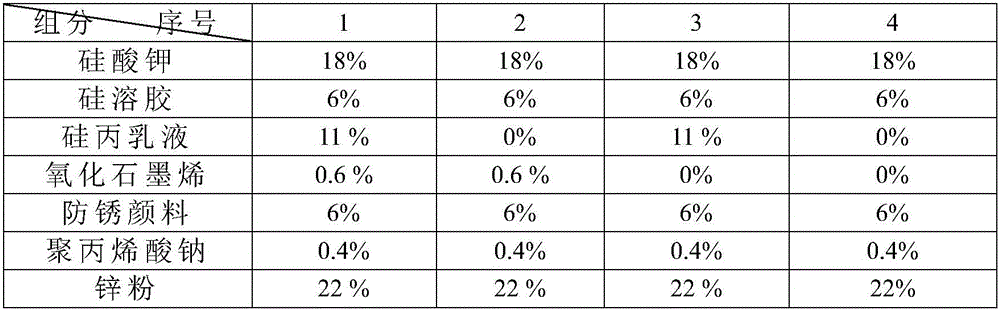

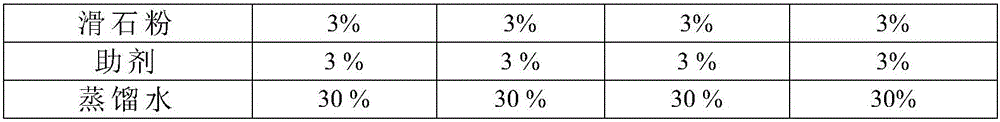

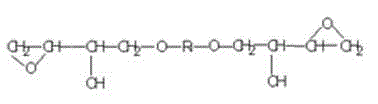

Silicone acrylate emulsion and graphene oxide-modified inorganic paint and preparation method thereof

InactiveCN106634320ANo spotsNon-foamingAnti-corrosive paintsElectrically-conductive paintsMechanical propertyAlkali metal

The invention provides a silicone acrylate emulsion and graphene oxide-modified inorganic paint and a preparation method thereof. The paint is an anticorrosion priming paint which takes an alkali metal aqueous solution as a film forming substance, takes graphene oxide and zinc dust as a main filling material, and takes the silicone acrylate emulsion as a modifier. The silicone acrylate emulsion is obtained by the processes that an appropriate auxiliary agent is added in an organosilicon monomer containing an unsaturated bond as well as an acrylic acids monomer, and the materials are polymerized through a core-shell coating polymerization technology; flexibility of a film is improved when the emulsion is added in the inorganic paint, and Van der Waals force of a coating on a base material is increased. and the graphene oxide has excellent conductive performance and mechanical property. The experiment proves that flexibility, salt fog resistance, adhesive force and conductivity of the paint are obviously increased.

Owner:CHANGZHOU UNIV

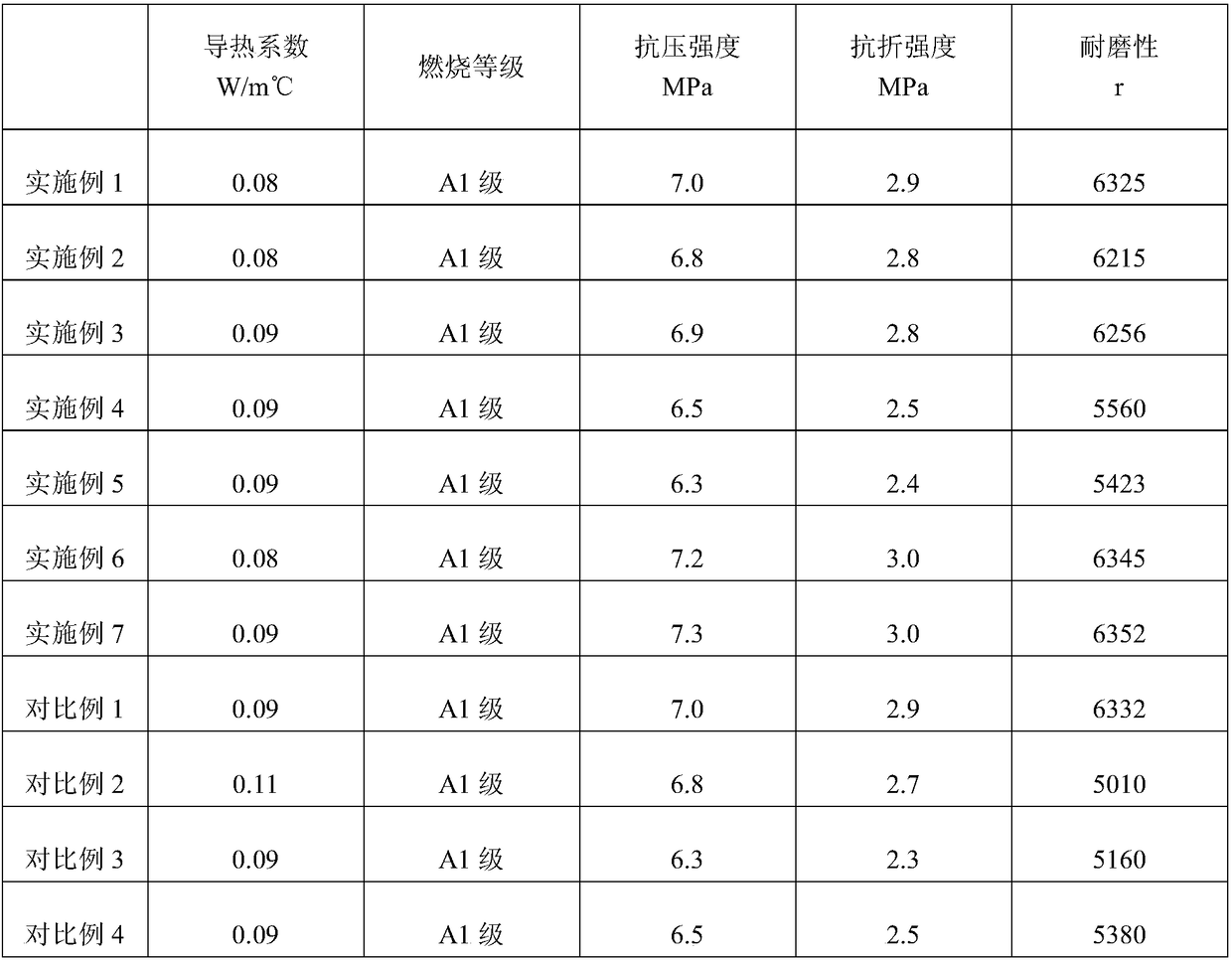

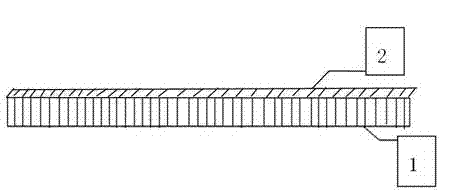

Lightweight, high-strength and high-toughness foamed ceramic decorative integrated board and production method thereof

ActiveCN109291549AFlame retardantWith insulationLaminationLamination apparatusSodium phosphatesWear resistant

The invention discloses a lightweight, high-strength and high-toughness foamed ceramic decorative integrated board. The board comprises a foamed lightweight material layer, a high-toughness decorativesurface layer and a wear-resistant coating layer; the foamed lightweight material layer comprises stone tailings, graphene, zirconia, a high-temperature flux, clay, a stabilizer and a dispergator; and the high-toughness decorative surface layer includes an AC foaming agent, the stabilizer, calcium carbonate, high-strength resin, a processing aid and a lubricant. The wear-resistant coating layer comprises graphene, silicon carbide whiskers, corundum powder, vermiculite, kaolin, a flame retardant, nanometer titanium dioxide, sodium phosphate, sodium silicate, hydroxyethyl cellulose, a silicone-acrylic emulsion and silica sol. The high-toughness decorative surface layer made from soft porcelain and the foamed lightweight material layer are bonded by compression molding, and the surface of the high-toughness decorative surface layer is coated with the wear-resistant coating layer, so the board has the advantages of good toughness, light weight, high strength, flame retardation, thermal insulation, good waterproof and impermeable effects and good anti-aging effect.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Moisture-curing polyurethane epoxy coal-tar bitumastic

InactiveCN101760135AUniform thicknessNo effect on cure speedAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention relates to a moisture-curing polyurethane epoxy coal-tar bitumastic. The invention adopts a technical scheme that: the bitumastic is formed by a component A and a component B in a weight ratio of 1:1-1:2; and the preparation method comprises the following steps of: placing 37 to 40 parts of polymethylene polyphenyl isocyanate, 11 to 13 parts of polyether 330 or 3,030, 2 to 3 parts of polyether 635 or 450, 8 to 9 parts of DOP or DBP, 3 to 4 parts of epoxy resin, 0.002 to 0.003 part of phosphoric acid and 33 to 37 parts of solvent No.S10,000 or industrial xylene in a reaction kettle at the temperature of between 81 and 86 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component A; and placing 62 to 66 parts of coal-tar, 9 to 10 parts of cyclohexanone, 10 to 11.5 parts of toluene, and 7 to 8 parts of solvent No.S1,000or industrial xylene in the reaction kettle at the temperature of between 115 and 120 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component B. The coating applied by the bitumastic is waterproof and long in life time and can further protect equipment and pipes.

Owner:孙锡宁

Modified polyurethane asphalt corrosion-resistant coating

InactiveCN101906266AGood moisture permeabilityGood temperature resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSolventPolyphenyl isocyanate

The invention relates to a modified polyurethane asphalt corrosion-resistant coating. In the adopted technical scheme, the corrosion-resistant coating is prepared by mixing a component A and a component B in weight ratio of 1:0.5-1.5, wherein polymethylene polyphenyl isocyanate, isophorone diisocyanate, acrylate, polyether 3031K, polyether 450, dioctyl ester, epoxy resin, phosphate, solvent No.S1000 or industrial xylene are put into a reaction kettle, and react for 0.5 hour at the temperature of 40-42 DEG C, the temperature is raised to 80-82 DEG C, the heat is preserved for 2 hours, the temperature is decreased, and then the component A is prepared; and petroleum asphalt, coal tar asphalt, cyclohexanone, toluene, solvent No.S1000 or industrial xylene and epoxy rein are put into the reaction kettle, the heat is preserved for 2 hours at the temperature of 135-140 DEG C, and the temperature is decreased to room temperature; then, aluminum triphosphate, strontium chromate, mica powder and glass flake are added, grounded, and dispersed, and then the component B is prepared. The coating adopting the invention has the advantages of strong adhesive force, no moisture permeation, strong corrosion resistance, and long service life.

Owner:索慈利

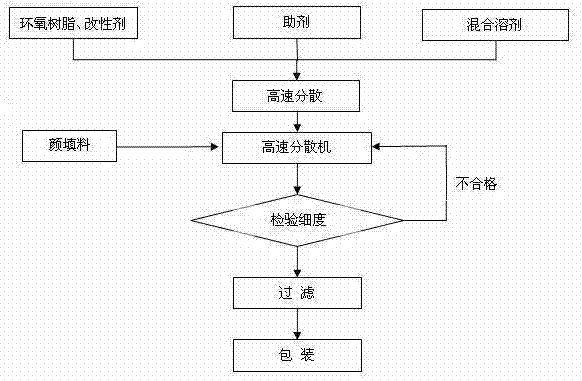

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

High-temperature-resisting conveying belt of steel wire rope

ActiveCN102745460AImprove high temperature resistanceHigh heat resistanceConveyorsCarbon blackDicumyl peroxide

The invention discloses a high-temperature-resisting conveying belt of a steel wire rope and solves the problem that the conveying belt of the existing steel wire rope core can not resist high temperature. According to the high-temperature-resisting conveying belt of the steel wire rope, the formula of rubber materials of upper and lower covered rubber layers comprises the following components in parts by weight: 70-80 parts of ethylene propylene diene monomer, 20-30 parts of chlorosulfonated polyethylene rubber or chlorinated polyethylene rubber or acrylate rubber, 6-8 parts of dicumyl peroxide, 0.5-1.5 parts of sulfur, 10-15 parts of zinc oxide, 1-3 parts of ethylene dimethyl acrylate ester, 1-2 parts of stearic acid, 2-8 parts of an accelerating agent, 2-4 parts of an anti-ageing agent, 15-25 parts of paraffin oil, 20-30 parts of high-wear-resisting carbon black, 30-50 parts of semi-reinforcing carbon black and 10-15 parts of active glass fiber powder. A glass fiber canvas heat-insulating layer is arranged between a middle rubber layer and an upper covered rubber layer, and a glass fiber canvas heat-insulating layer is arranged between the middle rubber layer and a lower covered rubber layer. The high-temperature-resisting conveying belt of the steel wire rope can be used under an environment of 250 DEG C for long time and the conveying requirements of some special high-temperature materials are met.

Owner:ANHUI ZHONGYI RUBBER BELTS

Water metal anti-corrosion paint and preparation method thereof

InactiveCN101148553ANo pollution in the processEasy to transportAnti-corrosive paintsFluorocarbon ResinsWeather resistance

The water soluble anticorrosive paint for metal is prepared with deionized water, titanium white powder, wollastonite powder, kaolin, water soluble fluorocarbon resin, organosilicon emulsion, acrylate emulsion, hydrazyl adipate, film forming assistant and other materials, and through dispersing and mixing. The water soluble anticorrosive paint for metal has high weather resistance, high water resistance, high scrubbing resistance, good adhering performance, great adhesion, capacity of being painted onto rusty surface and wide application range. It may be applied for anticorrosive protection of iron and steel structure in building decoration, petrochemical, bridge, ship, container, etc.

Owner:山西天时涂料装饰有限公司

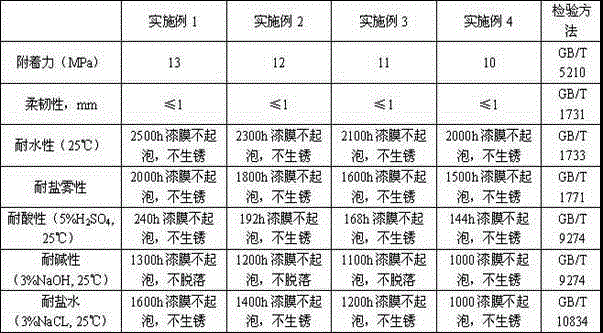

Preparation method for high-performance water-based environmentally-friendly anticorrosive paint used for metal base material

ActiveCN104530911AImprove adhesionNon-foamingAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

A preparation method for high-performance water-based environmentally-friendly anticorrosive paint used for a metal base material comprises the step that a component A and a component B are blended with the ratio being 1: (0.3-1.2), and then the high-performance water-based environmentally-friendly anticorrosive paint can be prepared, wherein the component A comprises, by weight, 30-45 parts of waterborne epoxy curing agents, 10-15 parts of non-heavy-metal antirust paint, 11-28 parts of de-ionized water, 15-30 parts of packing, 2-7 parts of thickening agents, 0.3-1.3 parts of dispersing agents, 0.1-0.5 part of flatting agent, 0.1-0.4 part of de-foaming agent, 0.1-0.8 part of PH conditioning agent and 1-4 parts of film coalescing aid; the component B comprises, by weight, 85-95 parts of water-borne epoxy resin and 5-15 parts of mussel adhesive proteins. The mussel adhesive proteins in the paint are utilized to perform a strong coordination complexation effect with ions in the non-heavy-metal antirust paint, and the adhesive force of a coating to the metal base material is increased to 10 MPa; at the temperature of 25 DEG C, the water resistance reaches 1,400 h, the salt fog resistance reaches 2,000 h, and coated films do not foam or rust.

Owner:XIAMEN SUNRUI SHIP COATING

Construction exterior wall paint with superior heat preserving performance

InactiveCN101434772AImprove waterproof and thermal insulation performanceImprove adhesionCellulose derivative coatingsFiberChemical Linkage

A building exterior wall coating with good thermal insulation property is characterized by the compositions of polyvinyl alcohol, expanded perlite, aluminium silicate powder, oyster shell whiting, methylcellulose, glass microballoon, fiber glass, nanometer silicon dioxide, acryloid cement, elm bast fiber, an antifoaming agent and calcium carbonate. By virtue of methyl silica high polymer formed after the reaction among heated silicate, nanometer silica powder and organosilicone, the coating can form the binding of chemical bonds when being coated on the rigid surface of a concrete wall, with the fastness being far superior to that of the physical covering of a conventional coating; in the coating, the expanded perlite is further adopted as heat insulation base material and therefore, the coating is characterized by good waterproof and thermal insulation property, no bubbling and cracking and good adhesive force.

Owner:于士井

Wear-resistant high-temperature resistant coating having high adhesive force

InactiveCN107201168AImprove high temperature resistanceNon-foamingFireproof paintsAnti-corrosive paintsWear resistantInorganic pigments

The invention belongs to the technical field of equipment coating, and particularly relates to wear-resistant high-temperature resistant coating having high adhesive force. The coating includes silicone resin, a high-temperature resistant filler, aluminum paste, inorganic pigment, a film forming agent, nanometer zirconia ceramic micropowder, a curing agent and a solvent. The high-temperature resistant filler of the coating is quartz powder, mica powder or talcum powder, and the fineness of the filler is 700-800 meshes. The solvent is one of butyl acetate, xylene and n-butanol. The coating has uniform properties. An obtained coating layer of the coating is smooth, fine and good in adhesive force. The coating has excellent high-temperature resistance, good impact resistance, god wear resistance and good corrosion resistance. The coating is particularly suitable for surface protection of high-temperature motors, high-temperature electric resistance furnaces, and other devices.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

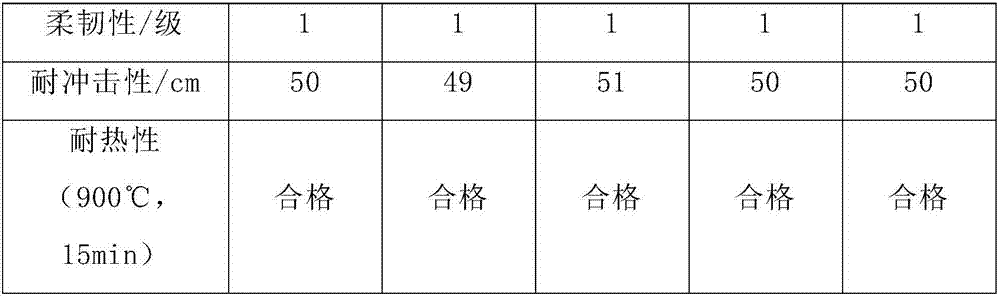

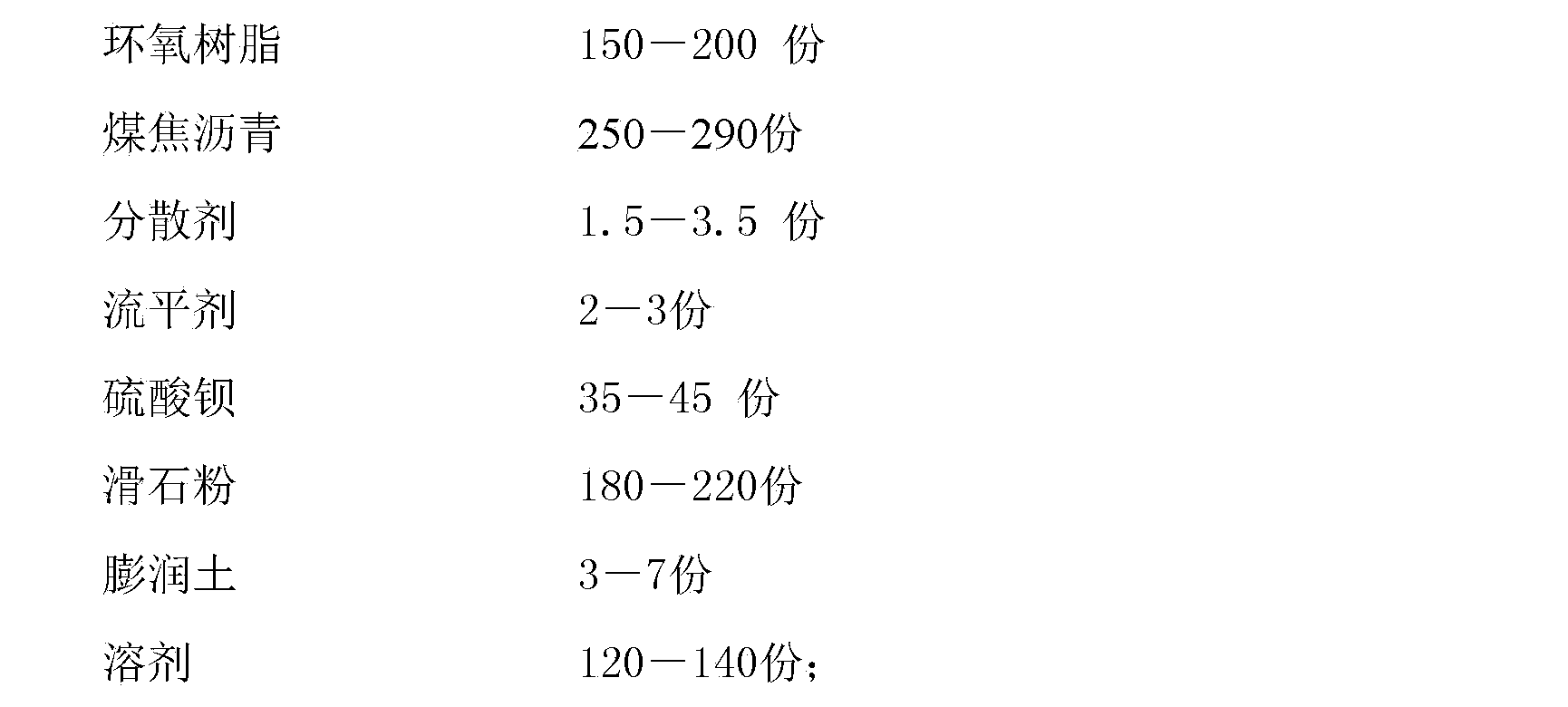

Low temperature resistant winter epoxy coal tar pitch coating

InactiveCN103360948AGood film formingImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyBituminous materials

The invention provides a low temperature resistant winter epoxy coal tar pitch coating comprising a component A and a component B according to a weight ratio of 5-7:1. The component A is prepared from an epoxy resin, coal tar pitch, a dispersing agent, flatting agents, barium sulfate, a talcum powder, bentonite, and solvents in parts by weight; the component B comprises polyamide and xylene according to a weight ratio of 1:1. With combination of the epoxy resin and the coal tar pitch, not only excellent film-forming and corrosion resistance properties of the epoxy resin are exerted, but also the problems of high temperature flow and low temperature cold brittleness of a pitch material are better solved, the coating layer is resistant to low temperature and can be used in winter, and the service life of the coating is prolonged.

Owner:TIANCHANG YINHU PAINT

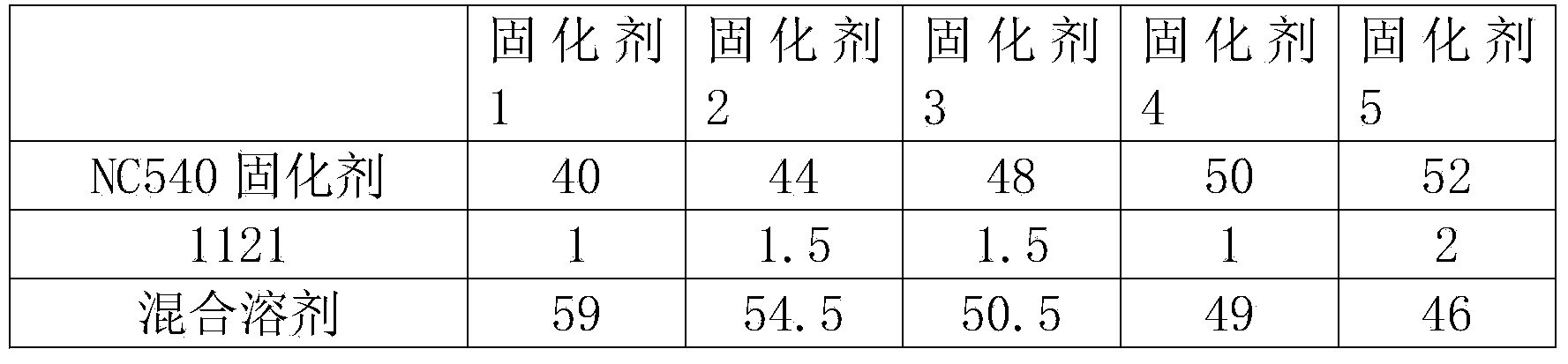

Environment-friendly anticorrosive coating and preparation method thereof

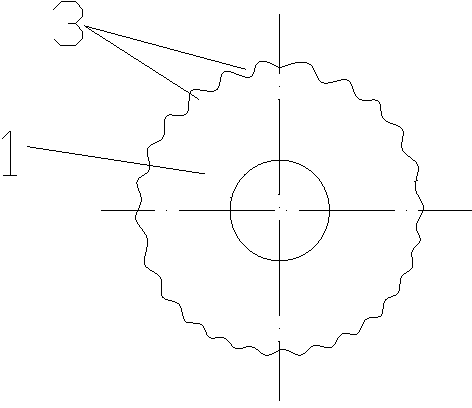

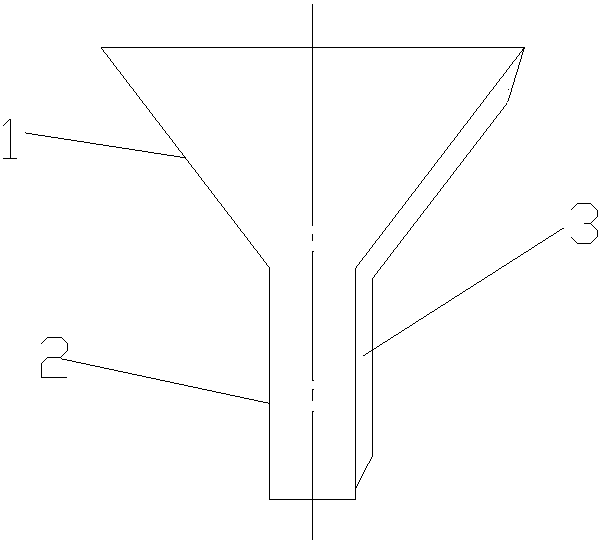

The invention belongs to the field of preparation of coatings and particularly relates to an environment-friendly anticorrosive coating and a preparation method thereof. The coating is prepared by mixing an oil paint component and a curing agent component in a weight ratio of 100 to (20-30). The oil paint component is prepared from the following components in percentage by weight: 55-70wt% of acrylic resin, 5-15wt% of tea stem powder, 10-15wt% of organic pigments, 3-5wt% of rosin, 10-15wt% of solvent and 2-5wt% of surfactant. The curing agent component is prepared from the following components in percentage by weight: 60-69wt% of curing agent, 30-39wt% of solvent and 0.05-1wt% of dehydrating agent, wherein the dehydrating agent is one or two of butyl ester, cyclohexanone and butyl cellosolve. The added tea stem powder can react with harmful gases such as formaldehyde and dimethylbenzene to form non-volatile harmless macromolecular chain substances, so as to effectively eliminate harmful gases in the atmosphere, so that the prepared coating is relatively environmentally friendly and pollution-free. Due to the design of a stepwise feeding device, the raw materials are fully and uniformly mixed, thereby improving the performance of the coating. Due to adoption of a discharging spill-proof hopper, the packaging process is simple, convenient and efficient.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

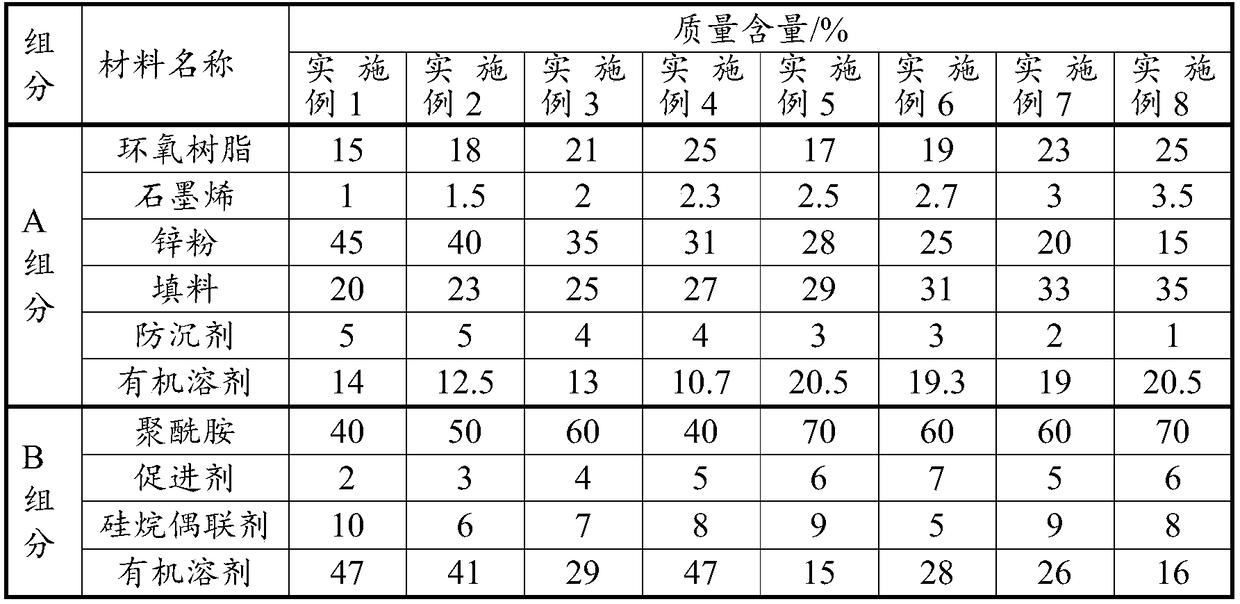

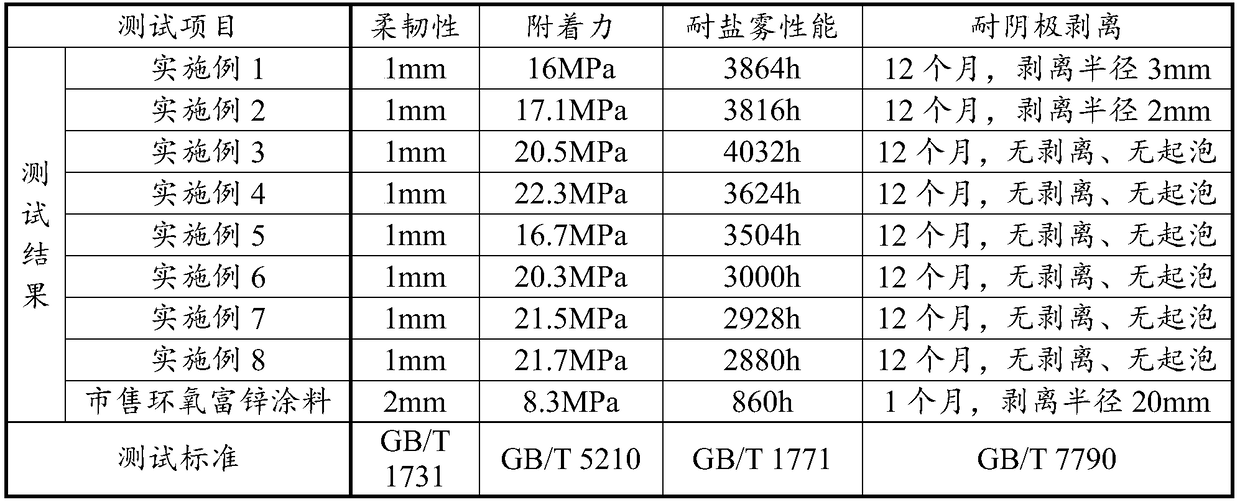

Long-acting heavy anti-corrosion coating containing graphene-zinc powder and preparation method thereof

InactiveCN109486359AReduce contentLarge specific surface areaAnti-corrosive paintsPolyamide coatingsZincCvd graphene

The invention discloses long-acting heavy anti-corrosion coating containing graphene-zinc powder and a preparation method thereof. According to the anti-corrosion coating, graphene is added into anti-corrosion paint, the content of zinc powder is greatly reduced, zinc fog during welding and cutting can be reduced, by utilizing the super-large specific surface area, excellent conductivity and corrosion resistance of the graphene, and environmental-friendliness is achieved; the usage of zinc powder is far lower than that of existing HG / T3668-2009 standard, but the coating does not have bubble orrust in 3500 hours of salt fog tests, and has the adhesive force being more than 16MPa, which is far higher than that of the existing HG / T3668-2009 standard; and the coating does not have bubble or peeling in cathode spalling tests for a year.

Owner:CHINA SPECIAL TYPE FLIER RES INST

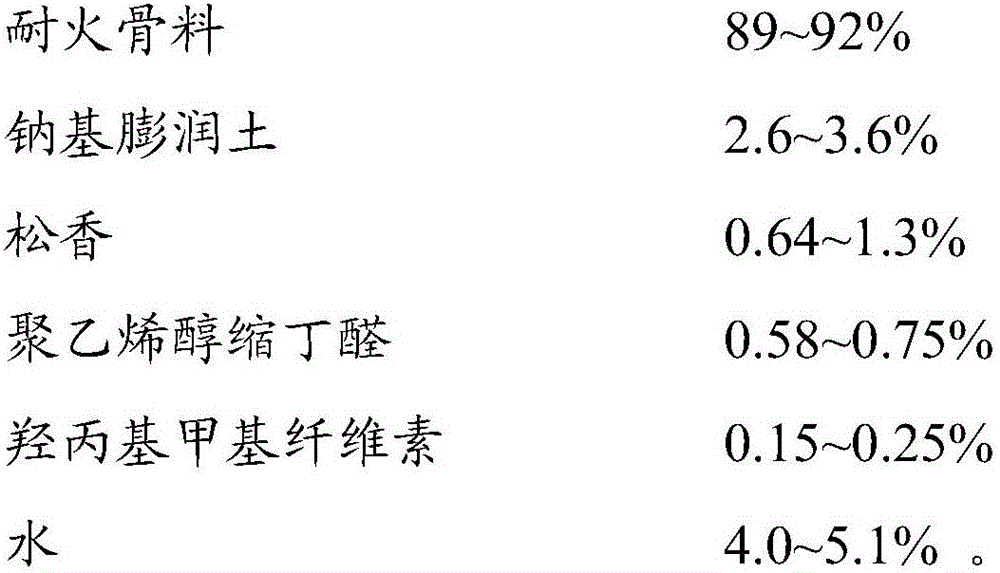

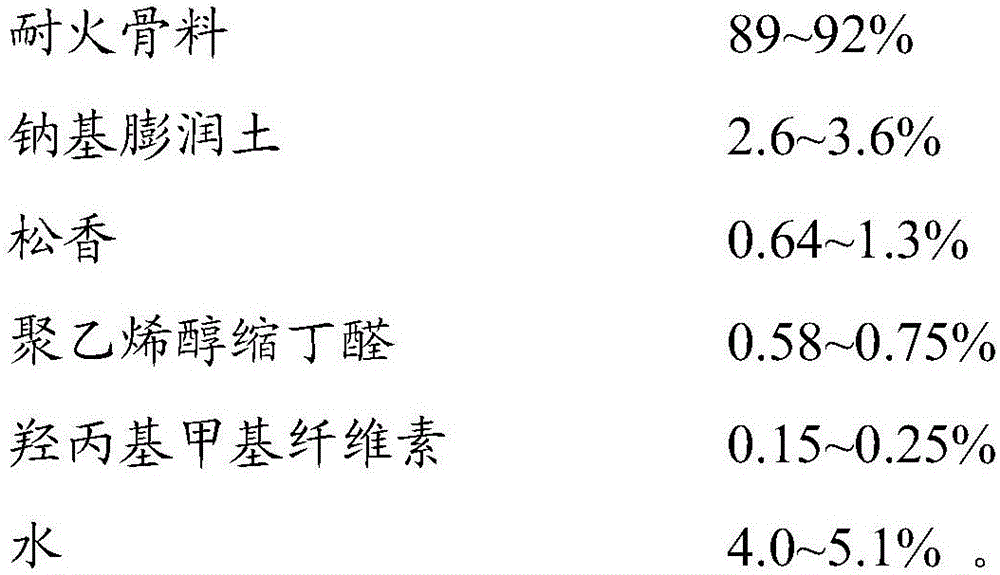

Powdery casting coating as well as preparation method and use method thereof

InactiveCN105935742AImprove performanceImprove suspension stabilityFoundry mouldsFoundry coresAlcohol freeSodium Bentonite

The invention provides a powdery casting coating as well as a preparation method and a use method thereof. The powdery casting coating provided by the invention is composed of the following components in percentage by weight: 89-92% of refractory aggregates, 2.6-3.6% of sodium bentonite, 0.64-1.3% of rosin, 0.58-0.75% of polyvinyl butyral, 0.15-0.25% of hydroxypropyl methyl cellulose, and 4.0-5.1% of water. The powdery casting coating provided by the invention is alcohol-free, and capable of being mutually infiltrated and fused with alcohol in use to obtain a qualified coating.

Owner:HUBEI UNIV OF TECH

Formula and technique of full-mould casting coating

InactiveCN103394631ANo brush marksImprove thixotropyFoundry mouldsFoundry coresCrack resistancePolyvinyl alcohol

The invention discloses a coating formula and particularly discloses a formula and technique of a full-mould casting coating. The formula of the full-mould casting coating contains 30-40% of bauxite, 40-50% of quartz powder, 10-20% of flake graphite, 1-3% of lithium-based bentonite, 0.5-1.5% of phenolic resin and 2-4.5% of polyvinyl butyral. The technique of the full-mould casting coating comprises the following steps of: according to different products to be painted, diluting the full-mould casting coating to the required viscosity, density or baume degree by adopting industrial alcohol, and fully and uniformly stirring before the full-mould casting coating is used, and painting a casting once or twice. The full-mould casting coating is better in suspension stability, low in gas evolution and high in crack resistance.

Owner:翼城县福旺铸造实业有限公司

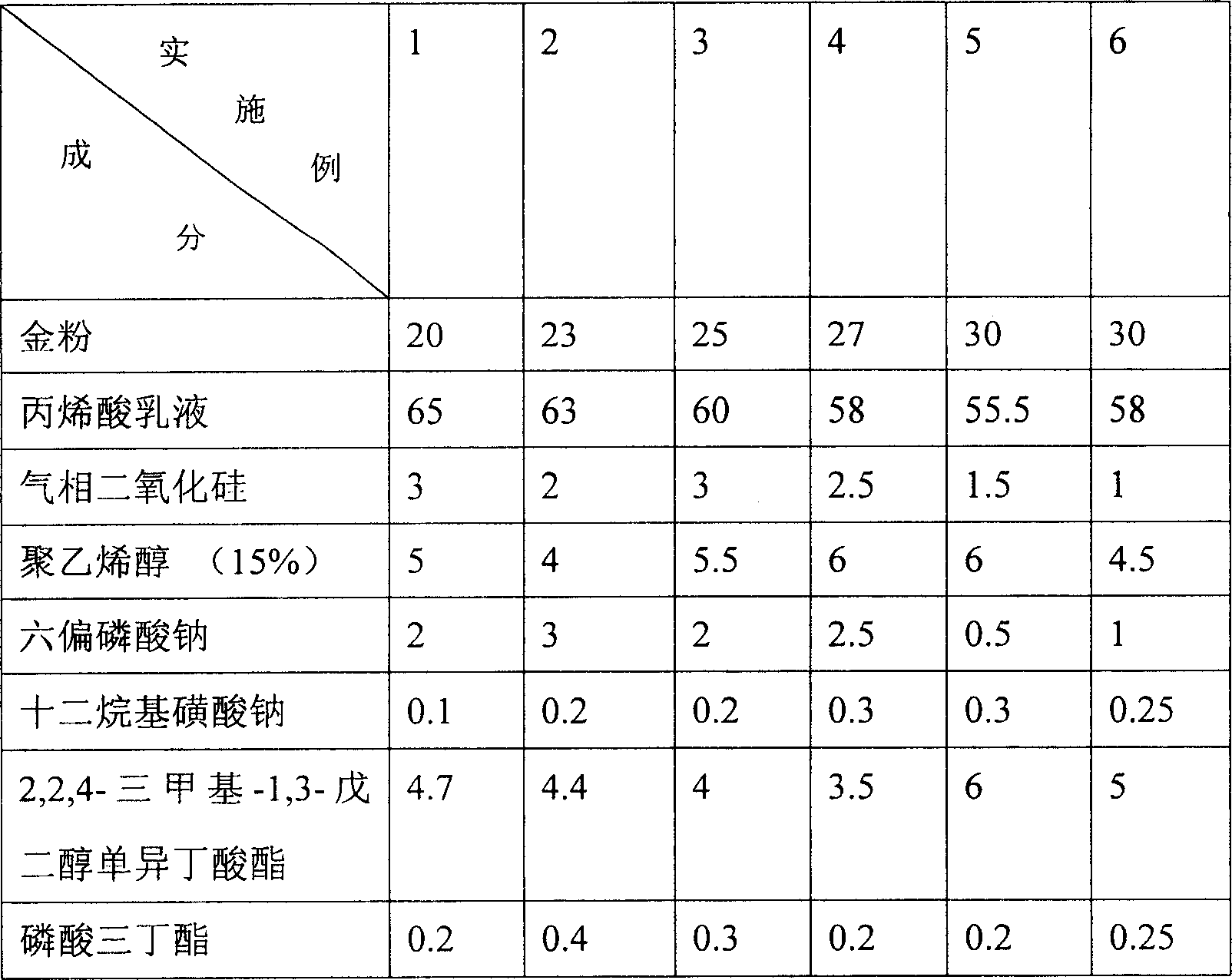

Water-soluble gold and silver inks, and preparation method

This invention relates to a method for preparing water-soluble Au / Ag ink, which comprises: Au / Ag powder 20-30 wt.%, acrylic acid emulsion 55-65 wt.%, 15% polyvinyl alcohol 4-6 wt.%, gaseous SiO2 1-3 wt.%, dispersant 2-4 wt.%, wetting agent 0.3-1.0 wt.%, film-forming agent 3-5 wt.% and antifoam 0.2-0.4 wt.%. The water-soluble Au / Ag ink has such advantages as high water leakage resistance, high adhesiveness, high corrosion resistance, high electrostatic resistance, good anti-aging capacity, no color change, no fading, simple application process, no toxicity to operators, no environmental pollution, no flammability and no explosion. The water-soluble Au / Ag ink can be used to paint packages of cigarette and food as a substitute for Al / Pt composite paper.

Owner:常德市东正环保材料科技有限公司

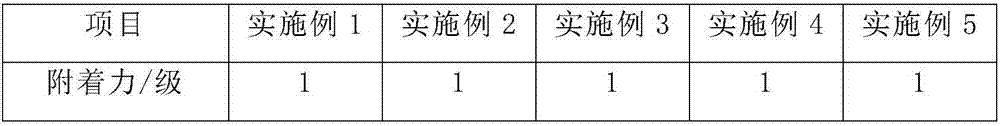

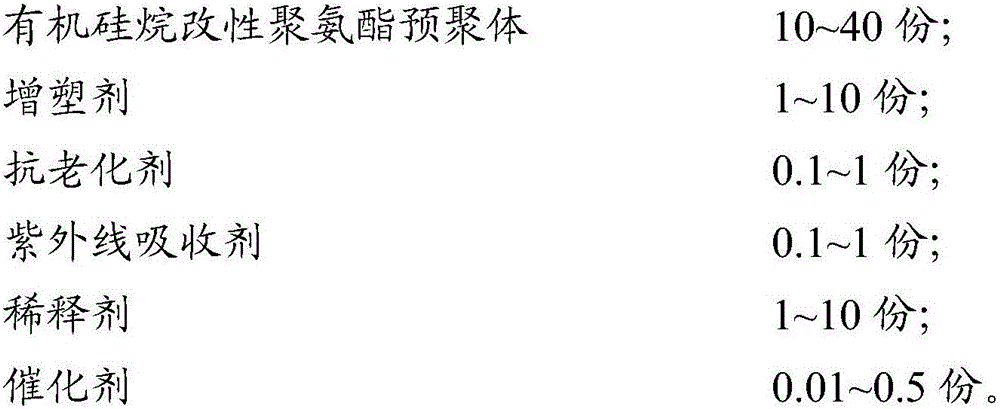

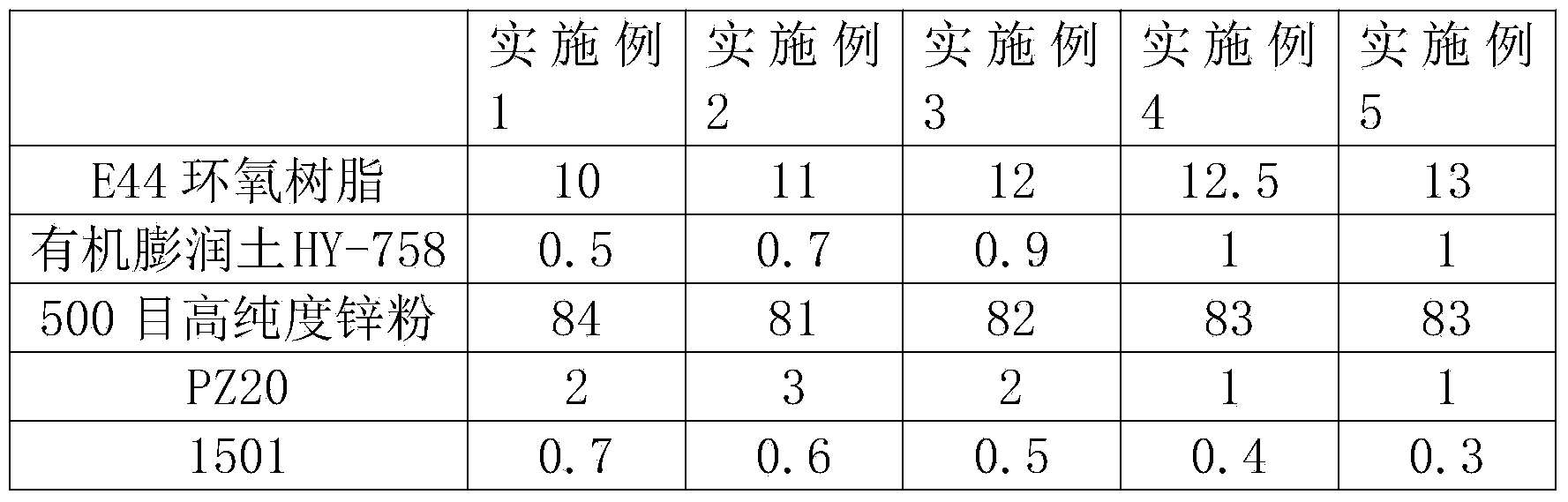

Polyurethane adhesive and plastic track prime material as well as preparation methods thereof

ActiveCN106675490AImprove performanceLow content of free isohydrocyanic acidNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerPolyurethane adhesive

The invention belongs to the field of fine chemical engineering, and particularly relates to a polyurethane adhesive and a plastic track prime material as well as preparation methods thereof. The polyurethane adhesive and the plastic track prime material are mainly prepared from organosilane modified polyurethane prepolymer serving as a main raw material, are low in content of free hydrogen isocyanide, green and environment-friendly, have high mechanical strength and good product heat stability, do not blister after being formed, have strong adhesive property and can serve as ball park plastic materials with excellent performances. Poly (propylene carbonate) polyols used in the preparation process of the polyurethane prepolymer take carbon dioxide as a raw material and are low in cost, have important significance for environmental protection, energy conservation and emission reduction after scale production and can be widely applied to a lot of fields such as the production of traditional adhesives, sealants, coating and elastomers.

Owner:GUANGDONG UNIV OF TECH

Waterborne silane modified polyurethane bonding agent and preparation method thereof

ActiveCN105462536AImprove performanceHigh strengthPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention discloses a waterborne silane modified polyurethane bonding agent and a preparation method thereof. The waterborne silane modified polyurethane bonding agent is prepared from the following raw materials in parts by weight: 15-20 parts of polyether glycol, 8-10 parts of diisocyanate, 1-2 parts of an acid, 2-5 parts of a silane coupling agent, 8-10 parts of epoxy resin, 5-10 parts of acetone, 0.5-1 part of a catalyst, 2-5 parts of an end-capping agent, 1-2 parts of trimethylamine, 10-15 parts of 1-methyl-2-pyrrolidinone and 45-50 parts of deionized water. According to the waterborne silane modified polyurethane bonding agent provided by the invention, the silane coupling agent and polyurethane resin are compounded, and the silane coupling agent has the characteristics of being fast to cure, free of foaming during curing, and excellent in dampness-heat and aging resistance, so that the performance of a polyurethane bonding agent is improved; meanwhile, through addition of tetramethyl isophthalylidene diisocyanate, the strength, bonding force, appearance, flexibility and durability of the a waterborne polyurethane adhesive can be improved. Therefore, the developed waterborne silane modified polyurethane can be resistant to 60 minutes' boiling at 100 DEG C, and has high bonding strength to various hydrophilic and hydrophobic substrates.

Owner:SHANGHAI JINQIANG ADHESIVE

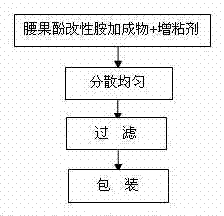

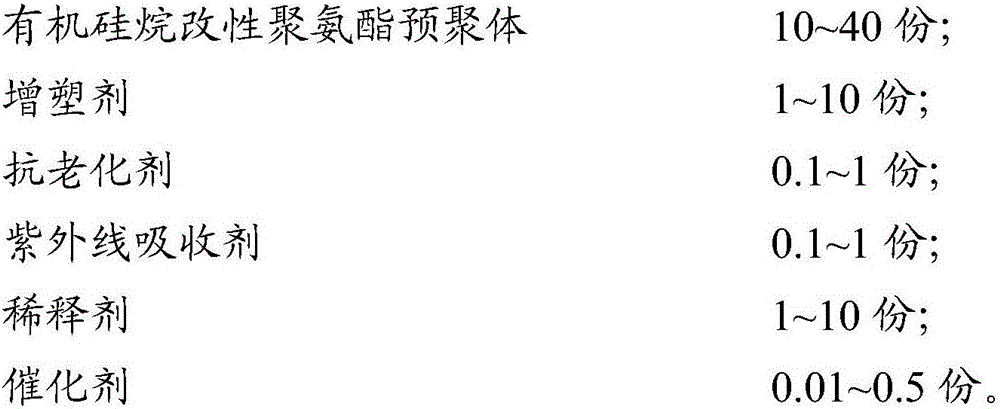

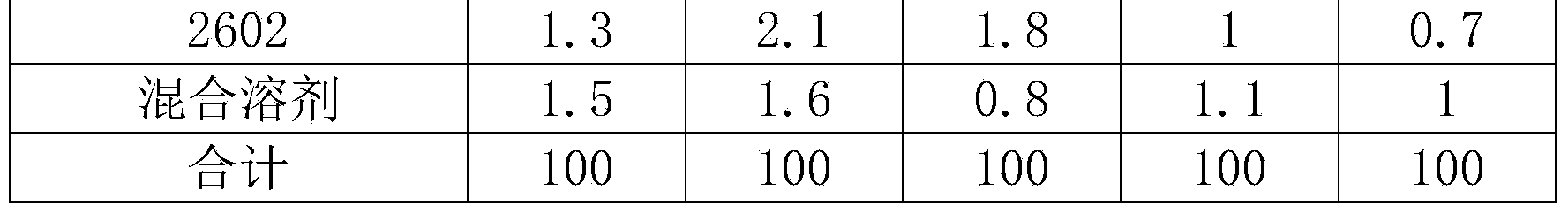

High-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer and preparation method thereof

InactiveCN104140735ANon-foamingNo rustAnti-corrosive paintsEpoxy resin coatingsZinc phosphateSodium Bentonite

The invention provides a high-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer. The primer contains a component A and a component B and is characterized in that the component A contains epoxy resin, high-purity zinc powder, environment-friendly zinc phosphate, an assistant A / B, organic bentonite and a mixed solvent; the component B contains cardanol modified polyamide resin, an assistant C and a mixed solvent. The product provided by the invention has the characteristics of salt mist resistance and high specific weight, the solid content reaches 95%, the zinc content reaches 80%, the primer solid proportion reaches 3.0g / ml, and the salt mist resistance can achieve that a primer film is free from bubbling, rusting and peeling for more than 5,000 hours; the product can be extensively applied to the field of metallic heavy-duty products in relatively adverse climates and seaboards, such as bridges, steel structures, ships and petroleum pipelines.

Owner:成都拜迪新材料有限公司

Heat-dissipation paint for iron casting surfaces

The invention provides a heat-dissipation paint for iron casting surfaces, relating to the technical field of heat-dissipation paints. The invention is characterized in that the heat-dissipation paint is composed of the following components in parts by weight: 30 parts of water-soluble epoxy resin, 5 parts of kyanite powder, 3 parts of silica sol, 4 parts of zircon flour, 3 parts of aluminum oxide, 5 parts of calcined potash feldspar, 2 parts of xylitol, 2 parts of calcined kaolin, 3 parts of barite powder, 5 parts of large-granule graphite, 50 parts of deionized water 2 parts of hexatitanium crystal whisker, 2 parts of flake graphite, 2 parts of zirconia, 5 parts of modifier, 2 parts of nano anion powder, 2 parts of silicon nitride, 2 parts of chromite powder, 2 parts of boric acid water solution, 1 part of nano titanium dioxide, 2 parts of polyester polyol and 2 parts of slaked lime powder. By adding the modifier into the traditional formula to perform modification treatment, the coated heat-dissipation paint can effectively achieve the effects of radiation and heat dissipation, has the advantages of low cost, low harm to the human body, high coating strength, no crack, no blister, uniform coating and high surface quality.

Owner:NINGGUO WANNAN FITNESS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com