Dewaxing cleaning liquid as well as preparation method and application thereof

A wax liquid and formula technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of difficult to eliminate foam, easy volatilization, and more foam, so as to facilitate the operation of workers and reduce volatilization loss. , good cleaning effect

Inactive Publication Date: 2016-07-20

BEIJING POLYSTAR HITECH CO LTD

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, two liquids, acetone or blue syrup, are mainly used for wax removal and cleaning during chip manufacturing in the LED chip industry. These two liquids have their own characteristics and shortcomings in wax removal; acetone is a commonly used and cheap organic solvent. , the wax removal efficiency is high and fast when cleaning chips, but because high-temperature wax is a special mixed material, when cleaning with acetone, although acetone can quickly peel off the wax on the surface of the chip, it cannot dissolve the wax well. The wax becomes insoluble and suspended in the acetone liquid, which will affect the recycling of acetone. In addition, acetone has a low boiling point and is volatile, which causes a large loss during use and will cause certain adverse effects on the operator and the environment; The cleaning agent specially developed for wax removal and cleaning is currently widely used in the industry, but due to the large amount of foam in use, and the foam is not easy to eliminate, and the price is too high, it is unacceptable for some enterprise users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

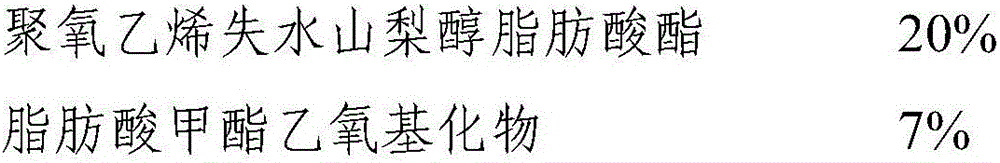

Embodiment 1

[0033] This embodiment relates to a kind of dewaxing cleaning solution, and formula is as follows (weight percentage meter):

[0034]

[0035]

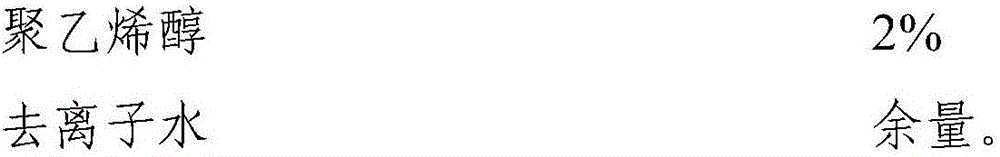

Embodiment 2

[0037] This embodiment relates to a kind of dewaxing cleaning solution, and formula is as follows (weight percentage meter):

[0038]

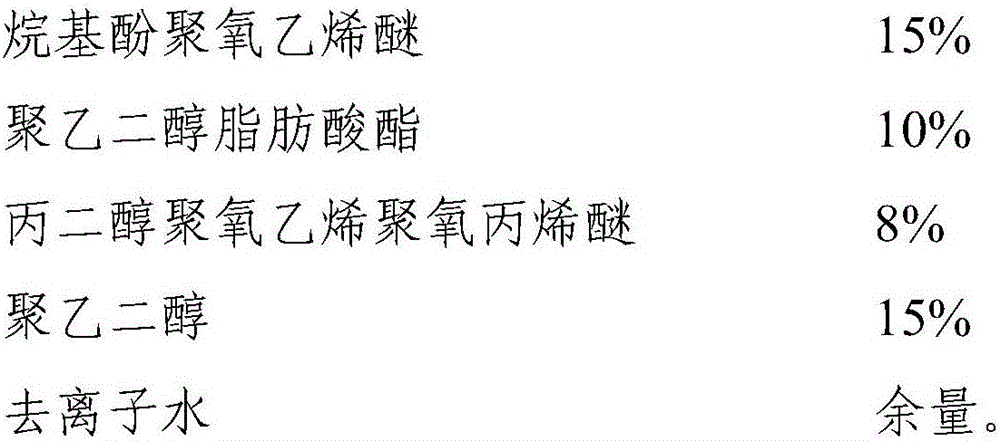

Embodiment 3

[0040] This embodiment relates to a kind of dewaxing cleaning solution, and formula is as follows (weight percentage meter):

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a dewaxing cleaning liquid as well as a preparation method and application thereof. The dewaxing cleaning liquid comprises the following active components in parts by weight: 5-70 parts of an efficientnonionic surfactant, 0.1-20 parts of a low-foam foam-inhibiting type surfactant and 1-20 parts of a dispersion stabilizer. The dewaxing cleaning liquid provided by the invention is obtained by compounding the efficientnonionic surfactant, the low-foam foam-inhibiting type surfactant and the dispersion stabilizer, and has the following propertyadvantages when being compared with a conventionalindustrial product: 1, the cleaning property is good, and the service life is prolonged by more than 20% when being compared with that of a conventional dewaxing liquid (generally the requirement is 60 pieces / L); 2, the dewaxing cleaning liquid is environmentally friendly and free of pollution, small in volatilization loss when being compared with a solvent dewaxing liquid, and is harmless for human bodies and environments; 3, the cleaning effect is good, the wax can be stably retained in dewaxing cleaning liquid for a long time and is not easy to be layered or separated, and granular muddy matters which can interfere the cleaning effect can be avoided; 4, the dewaxing cleaning liquid has no or a small amount of foams, when being filled into a cleaning tank or mechanically stirred, the dewaxing cleaning liquid does not generate a great amount of foam, and thus convenience can be brought to manual operation.

Description

technical field [0001] The invention relates to a wax-removing cleaning liquid and a preparation method thereof, which is applied to remove high-temperature wax on the surface of the chip after the grinding and polishing process in the manufacturing process of the LED lighting chip. Background technique [0002] LED is the English abbreviation of light-emitting diode. LED lighting chips are GaN diode chips. With their own characteristics of energy saving, environmental protection, long life and small size, they have been valued by governments of various countries and have issued relevant support policies. In recent years, my country's LED lighting industry has developed very rapidly. Soon, Chinese LED chip companies completed the "curve overtaking" and became the world's largest LED chip manufacturing country, with production capacity far exceeding that of Taiwan, Japan and other countries. Especially during 2010-2014, with the support of local government subsidies, equipment ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D1/825C11D1/83C11D3/37

CPCC11D1/825C11D1/28C11D1/667C11D1/72C11D1/722C11D1/74C11D1/82C11D1/83C11D3/3753C11D3/3765

Inventor 张航海董小翠

Owner BEIJING POLYSTAR HITECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com