Patents

Literature

44 results about "ACETONE LIQUID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well cementing high-temperature inhibiting agent for oil gas well and preparation method

InactiveCN101402849AMeet the needs of safe constructionThickening time adjustableDrilling compositionItaconic acidWell cementing

The invention discloses a novel cement high temperature retarder used for cementing an oil (gas) well as well as a preparing method thereof. The invention relates to a macromolecular polymer which has high temperature resistance and is prepared by using an acetone liquid to deposit and wash an itaconic acid, 2-acrylamide-2-methyl propane sulfonic acid (AMPS), benzoperoxide and the like which are taken as materials. The novel cement high temperature retarder added into a cement pulp has the characteristics of good retardation effect, good fluidity as well as salt and calcium resistance under high temperature and the like. The invention can meet the demands of safe construction on cementing depth wells and ultra-deep wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

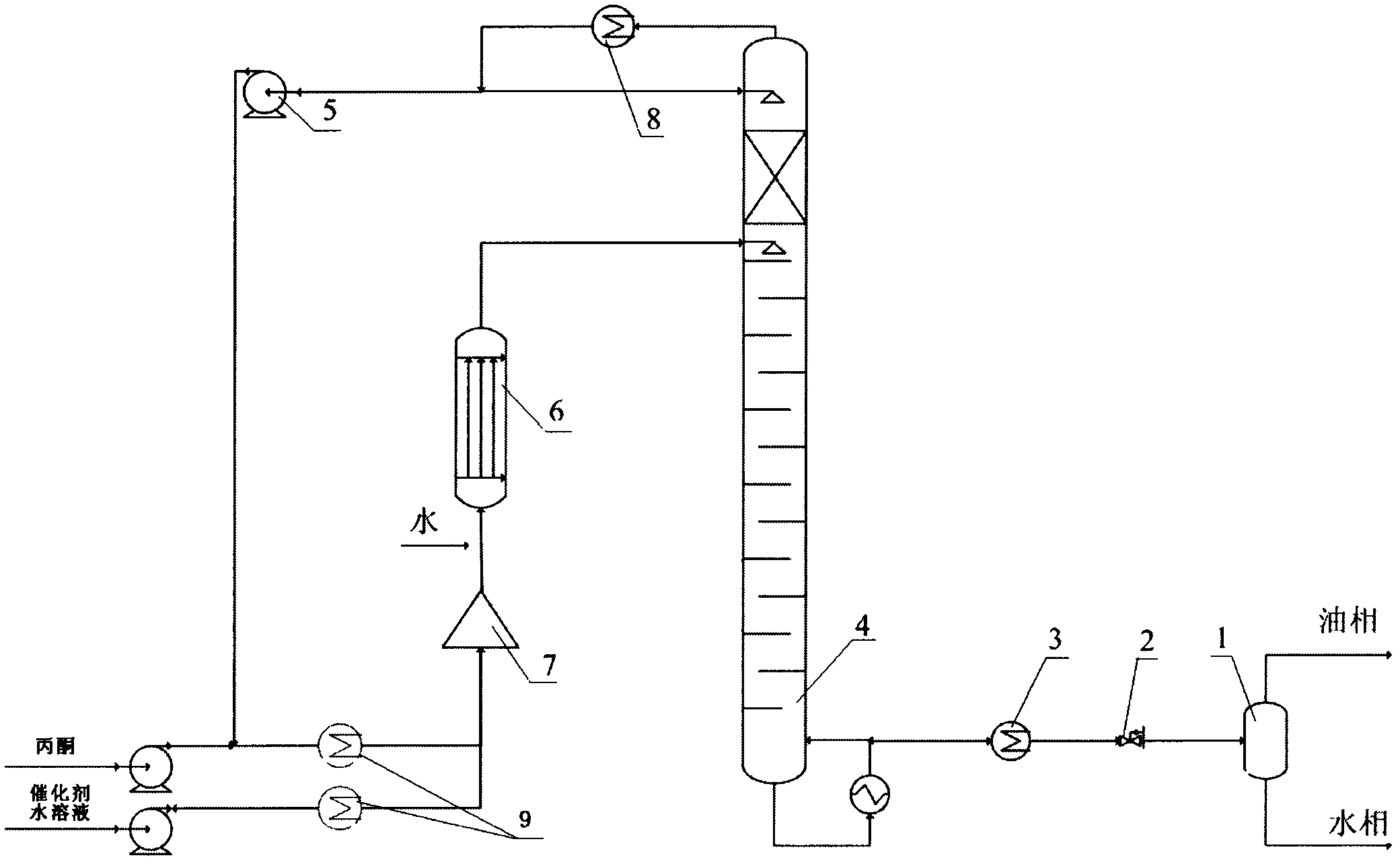

Combined production method of isopropanol and methyl isobutyl ketone

InactiveCN103420792ALow costImprove stabilityOrganic compound preparationHydroxy compound preparationChemical industryReaction temperature

The invention relates to a combined production method of isopropanol and methyl isobutyl ketone. The combined production method is shown as follows: acetone and hydrogen are used as raw materials, a non-noble metal catalyst especially a catalyst produced by Beijing research institute of chemical industry and with a brand number of BC-A-60 is used, the isopropanol and the methyl isobutyl ketone are simultaneously and combinedly produced under the reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase space velocity of 0.5-3.0 h<-1> and the hydrogen ketone molar ratio of 0.3-1. The combined production method has the following advantages that the low-cost non-noble metal catalyst is used, the technological process is simple and reasonable and low in energy consumption, two products of the isopropyl alcohol and the methyl isobutyl ketone are simultaneously and combinedly produced, wherein a gap of supply and demand of the isopropyl alcohol and the methyl isobutyl ketone is existed in markets, and by-product heavy components are few.

Owner:ZHEJIANG XINHUA CHEM +1

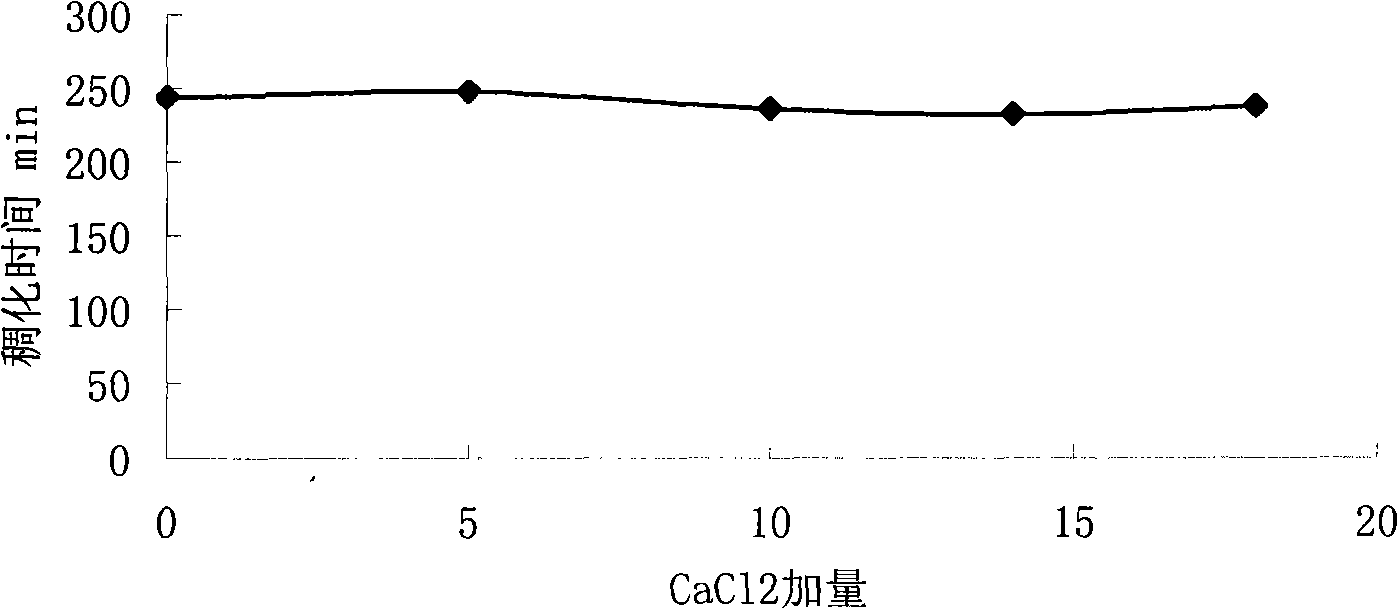

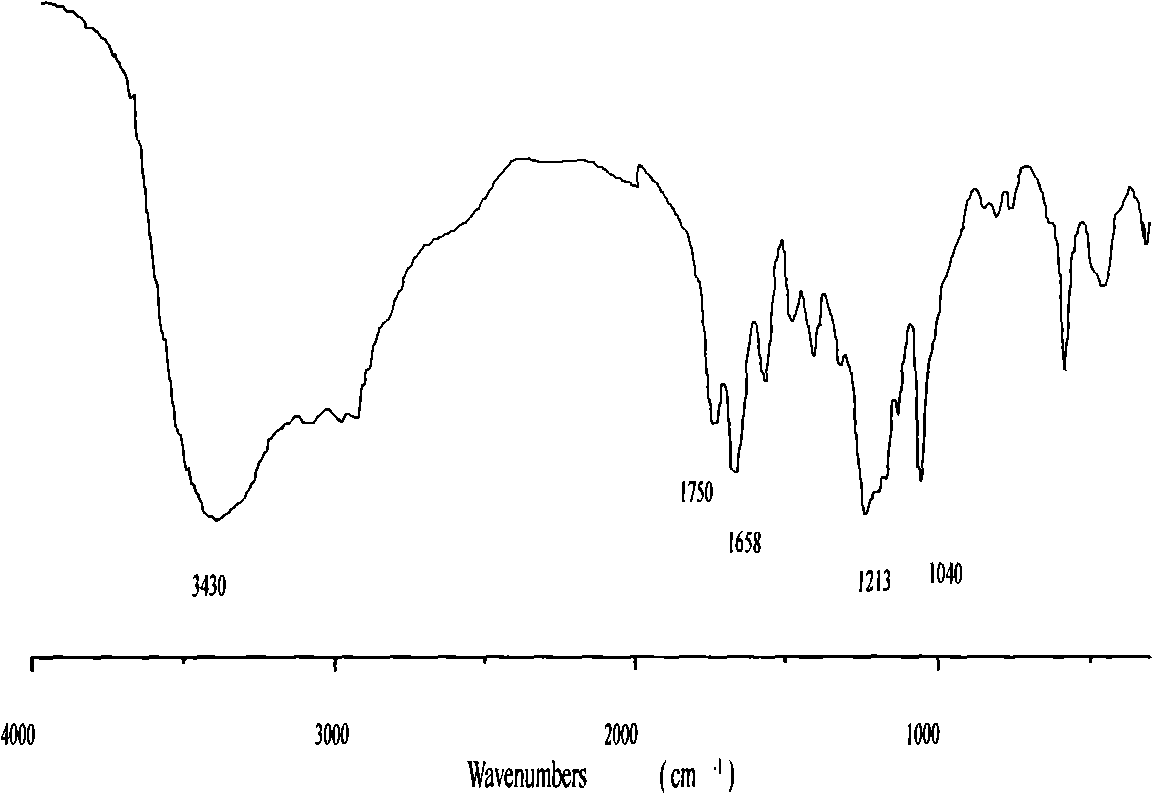

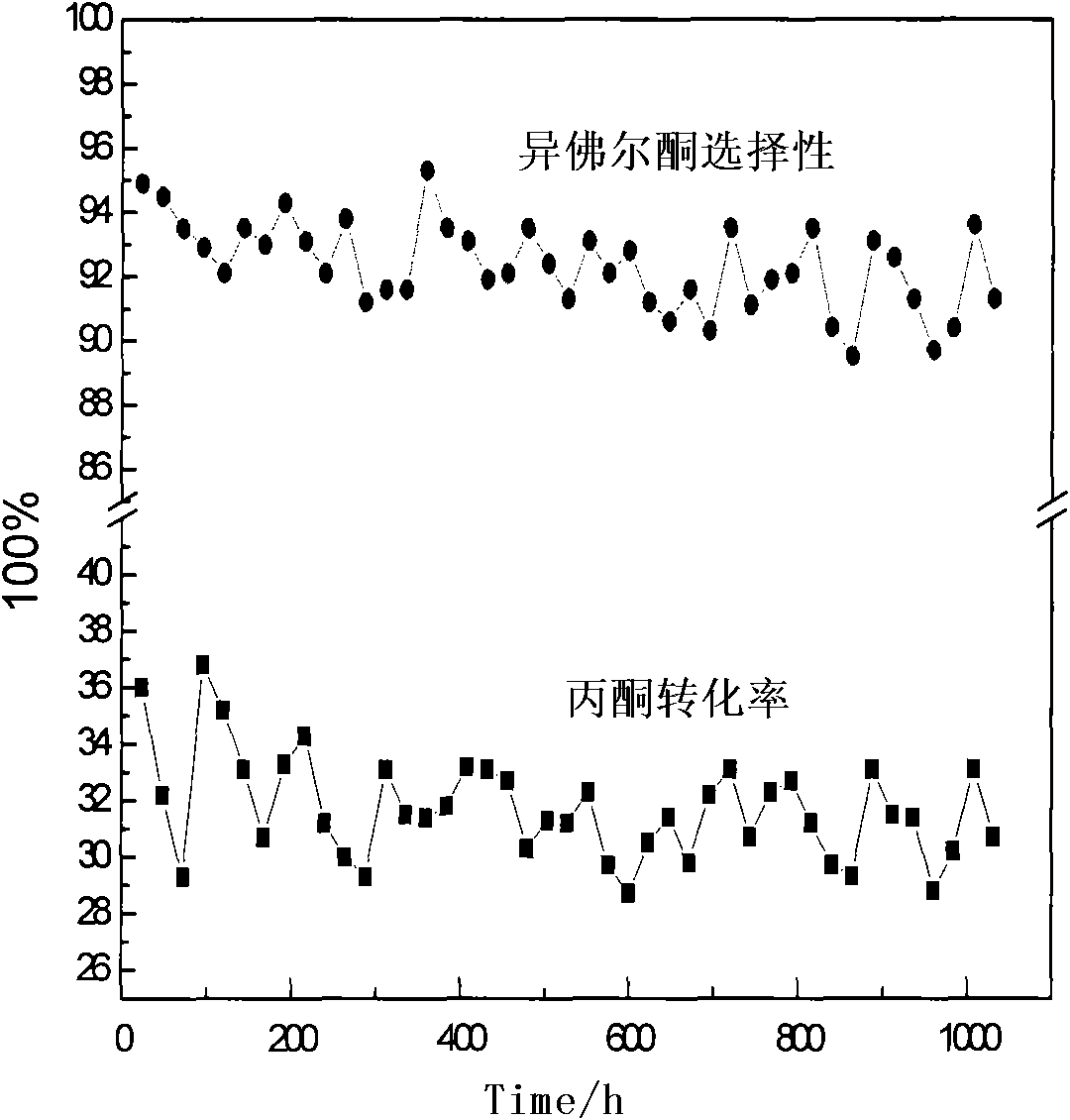

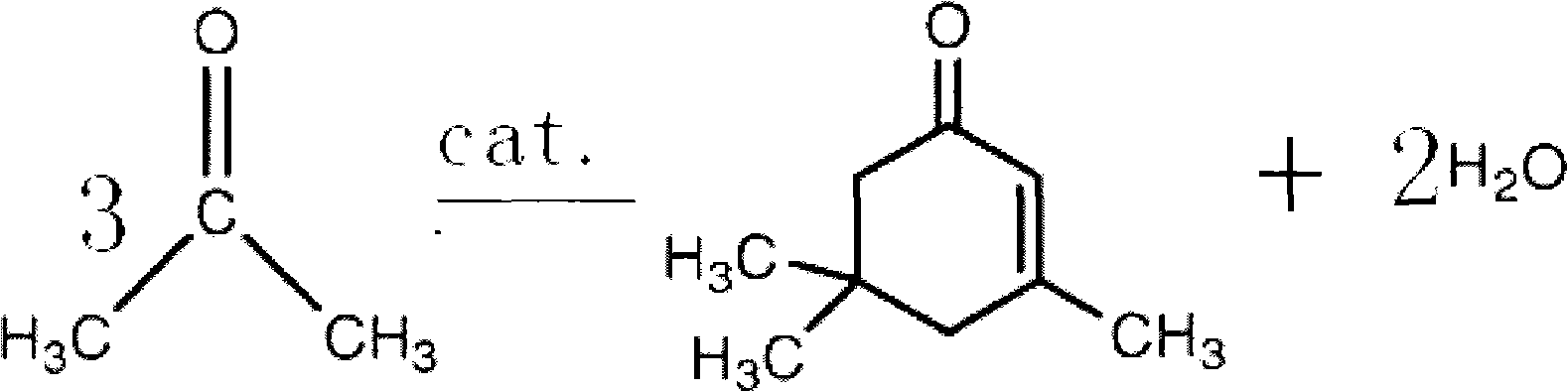

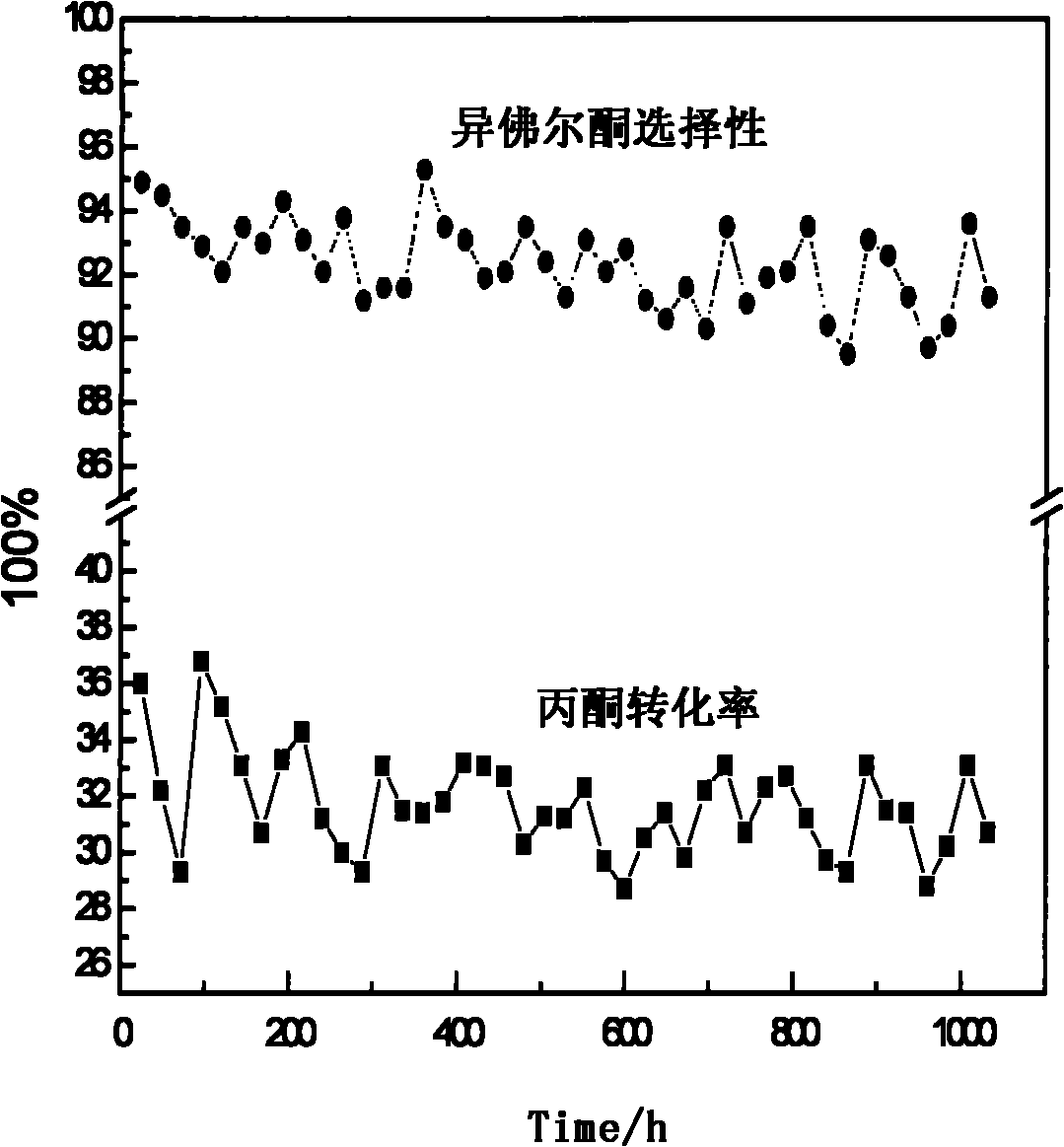

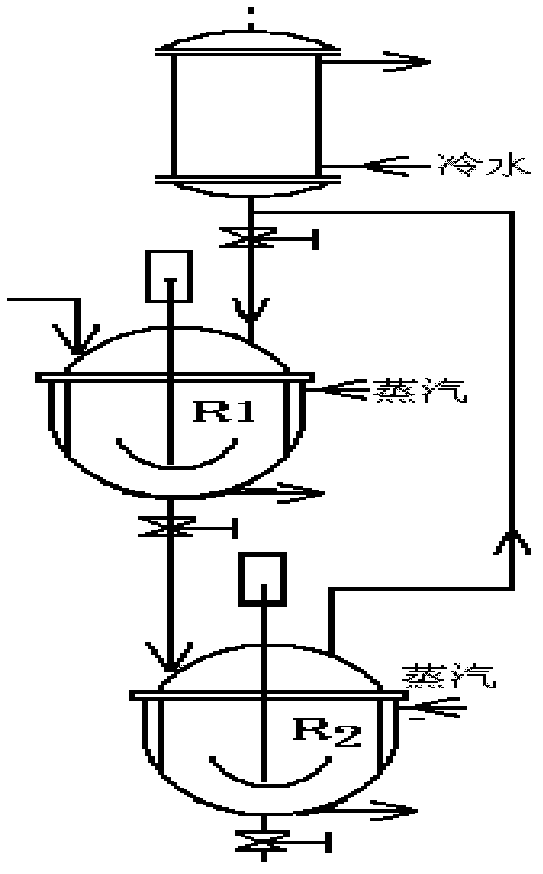

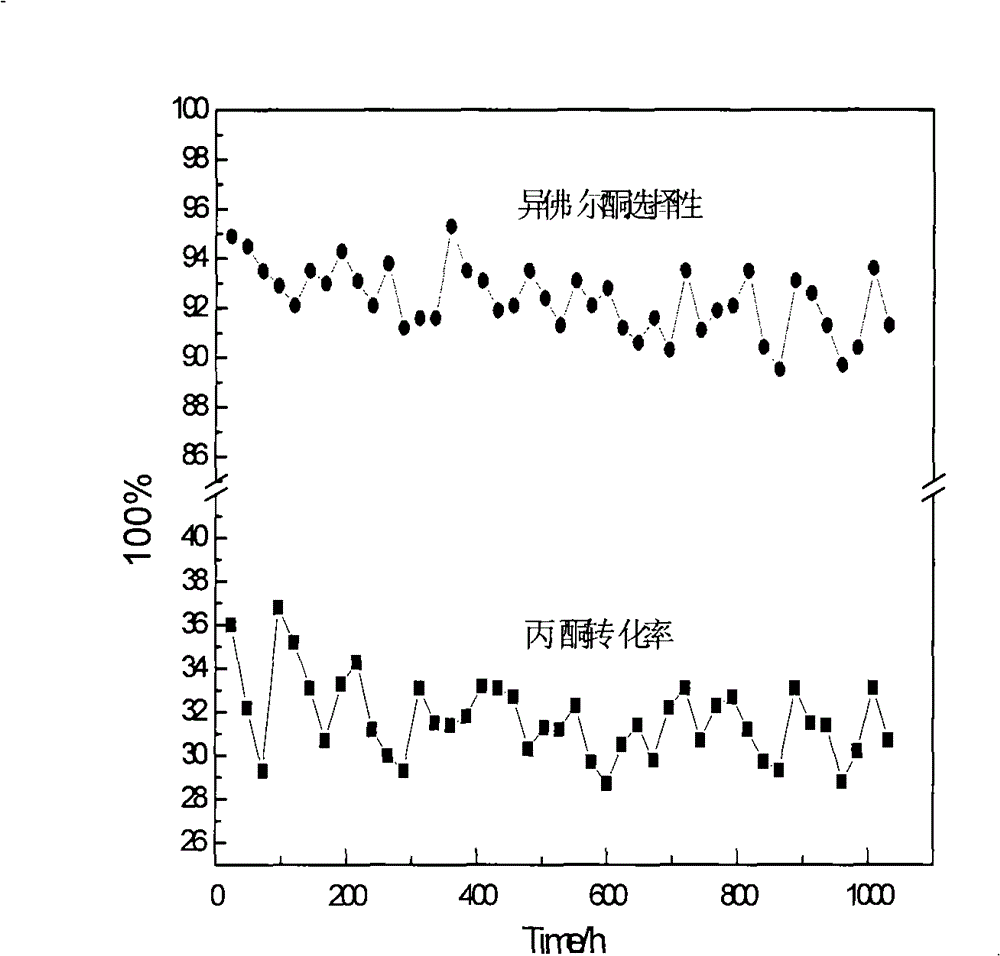

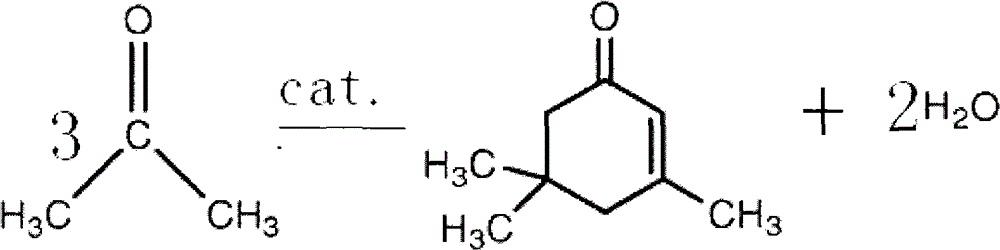

Heterogeneous catalytic method for synthesis of isophorone from acetone

ActiveCN101875602AMild reaction conditionsTechnical securityPhysical/chemical process catalystsOrganic compound preparationCatalytic methodFixed bed

The invention relates to a heterogeneous catalytic method for synthesis of isophorone from acetone. Acetone is used as a raw material, and a magnesium-aluminum composite oxide is used as a catalyst for carrying out catalytic synthesis to obtain isophorone; the magnesium-aluminum composite oxide comprises MgO, Al2O3 and MgAl2O4, the molar ratio of magnesium to aluminum is 0.3-3, the specific surface area is 80-150m<2> / g, and the pore volume is 0.2-0.3cm<3> / g; a fixed bed reactor is used for carrying out synthetic reaction, 20ml of 20 to 40-mesh catalyst is added into a stainless steel reactor of which the inner diameter is 10mm, the reactor is heated to the reaction temperature from the room temperature at the rate of 10 DED C / min after being qualified through an air-tight test, and then, the analytically pure acetone raw material is injected into the reactor by a duplex plunger pump through a preheater; the reaction temperature is 220-290 DEG C; the reaction pressure is normal pressure; and the air speed of the acetone liquid is 0.1-1.0 / h, the selectivity reaches 94.5%, the conversion rate reaches 44.8%, and the stability reaches 1000 hours.

Owner:PETROCHINA CO LTD

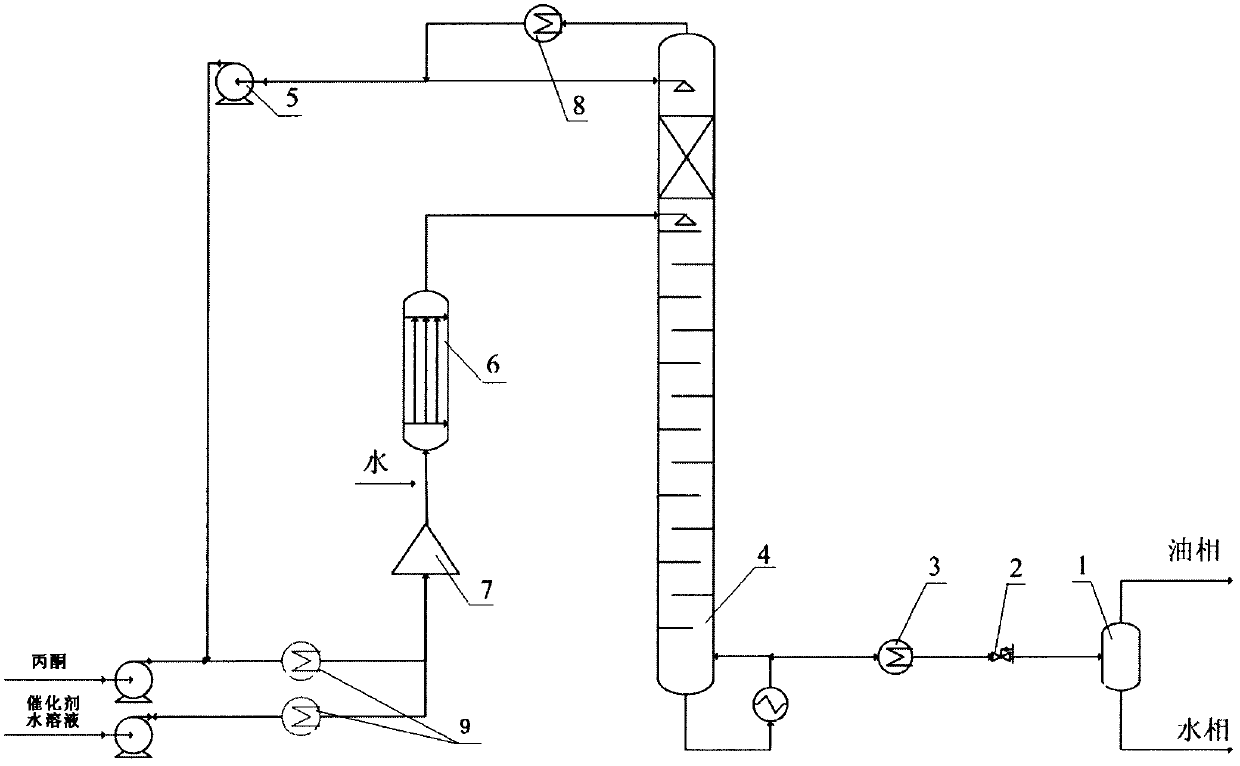

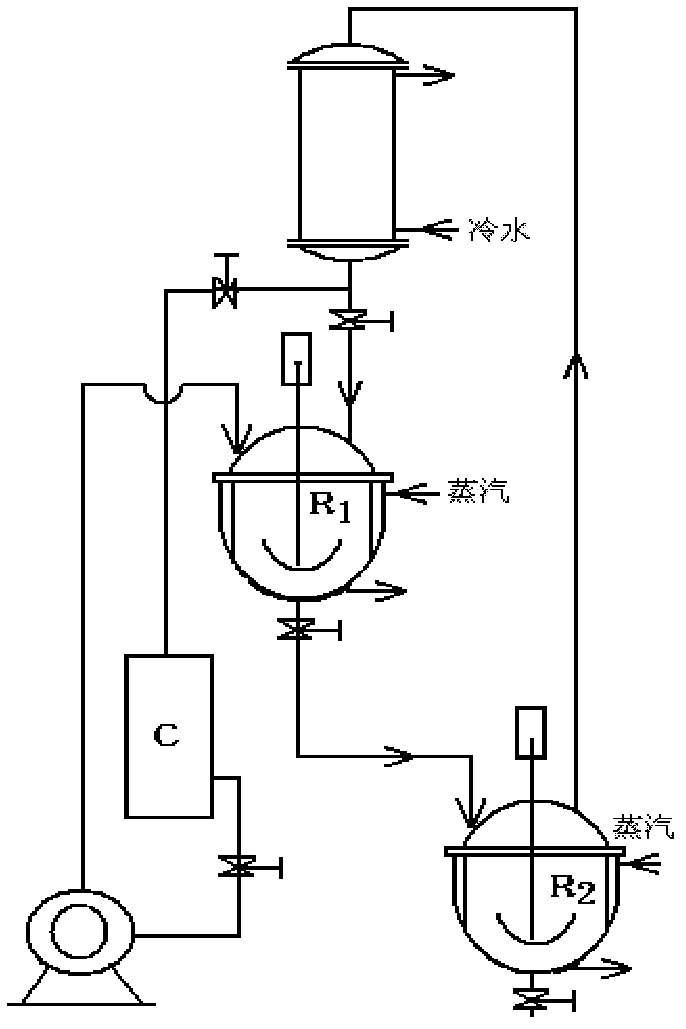

Method for preparing isophorone by acetone liquid condensation with alkali catalyst

ActiveCN102516051AOrganic compound preparationCarbonyl compound preparationIsophoroneAqueous solution

The invention discloses a method for preparing isophorone by acetone liquid condensation with an alkali catalyst. The method comprises steps of: heating an aqueous solution of acetone and the alkali catalyst to 230-280 DEG C under continuous stable operation conditions; controlling the pressure to maintain the acetone and water in liquid phase state; then introducing the two together through a mixer and a micro channel reactor with a total staying time of 3-15 min; carrying out a condensation reaction on the acetone with catalysis effect of the alkali catalyst to generate isophorone; and sending the reaction products into a reaction rectifying tower, removing unreacted acetone and hydrolyzing high boiling products with carbon atom number higher than 12, so as to obtain the isophorone crude product in a column bottom. A acetone one-way conversion rate exceeds 20%, and isophorone effective selectivity reaches higher than 90%. The method of the invention generates good mass transfer and heat transfer effects and has accurately controlled reaction time, high one-way conversion rate and good effective selectivity.

Owner:WANHUA CHEM GRP CO LTD +1

Method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol

ActiveCN103420786ALow costImprove stabilityOxygen-containing compound preparationOrganic compound preparationChemical industryReaction temperature

The invention relates to a method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol, and particularly to the production method for simultaneously coproducing methyl isobutyl ketone and methyl isobutyl carbinol with acetone and hydrogen as raw materials, employing a non-pure noble metal catalyst especially employing a catalyst with a brand number of BC-A-61 and produced by Beijing Research Institute of Chemical Industry, and under reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase airspeed of 0.5-3.0 h<-1> and the hydrogen and ketone molar ratio of 0.3-1. The method of the invention has the advantages of relatively low catalyst cost, reasonable and simple technological process and low energy consumption, simultaneously coproduces two kinds of products which are methyl isobutyl ketone and methyl isobutyl carbinol and have supply and demand gaps existing in markets, and has few by-product heavy components.

Owner:ZHEJIANG XINHUA CHEM +1

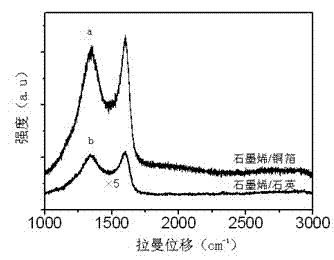

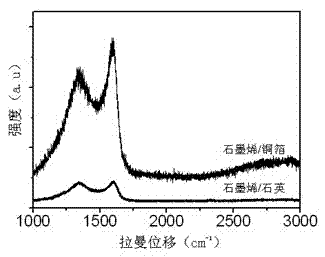

Method for detecting antibacterial drugs of furazolidone and furacilin through surface-enhanced raman spectroscopy

ActiveCN102879381AQuick analysisRapid Qualitative and Quantitative AnalysisRaman scatteringNitrofurazoneSurface-enhanced Raman spectroscopy

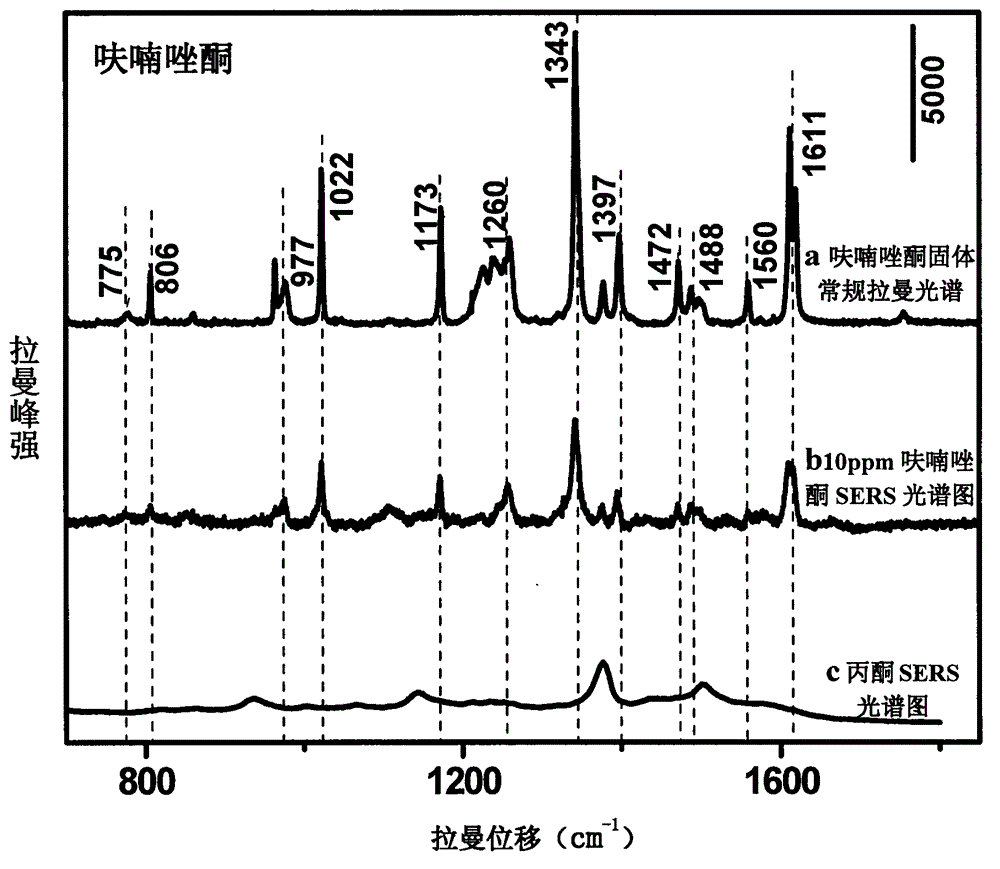

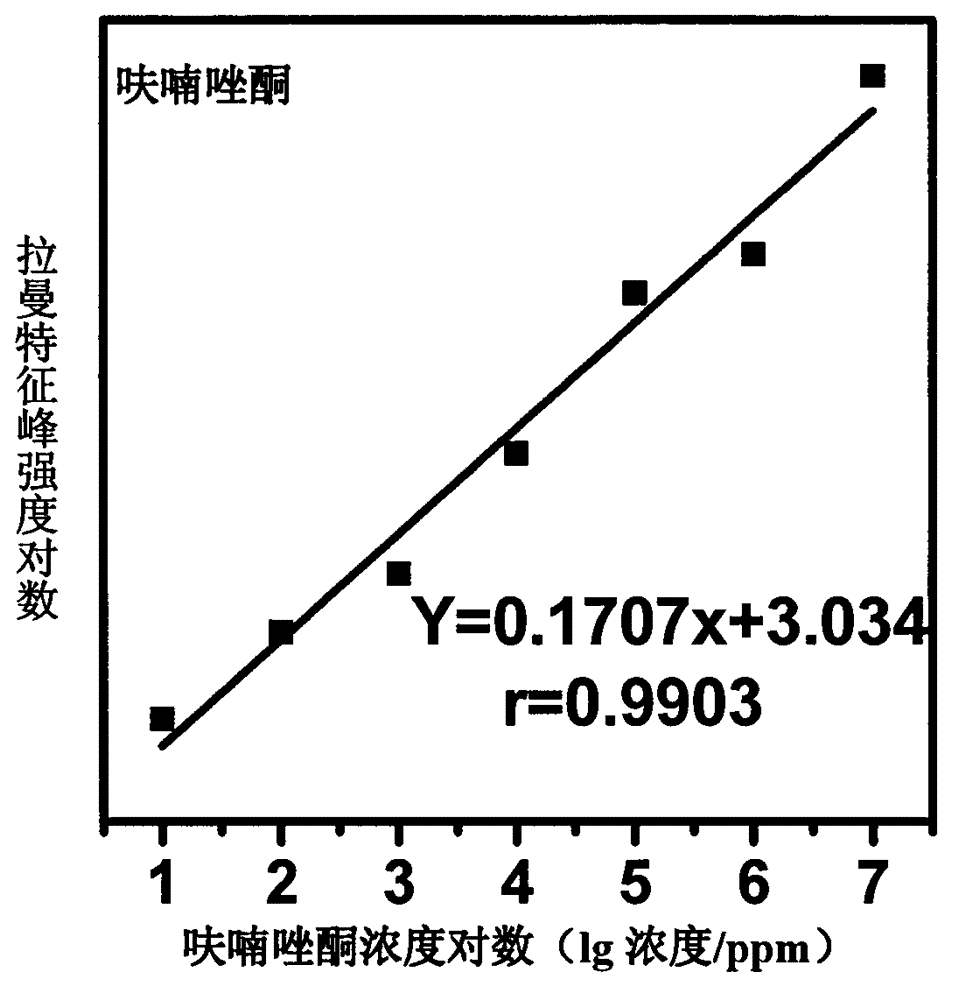

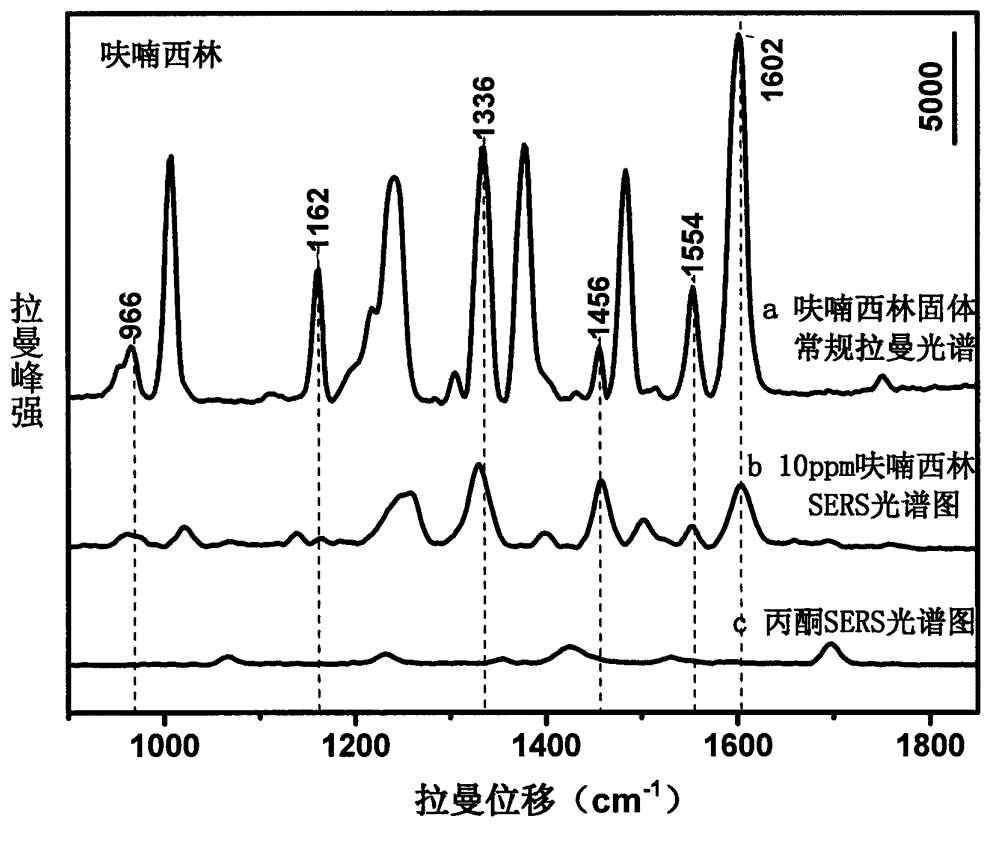

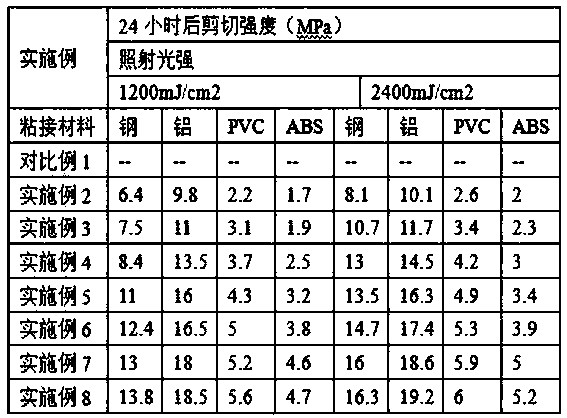

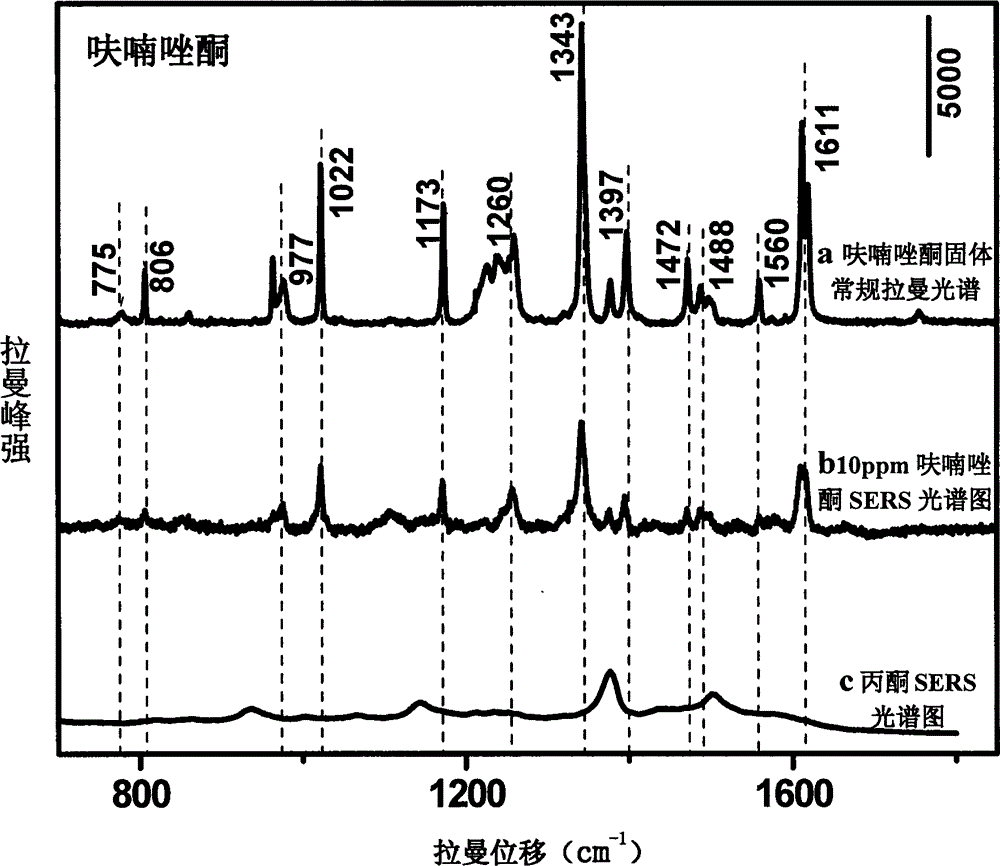

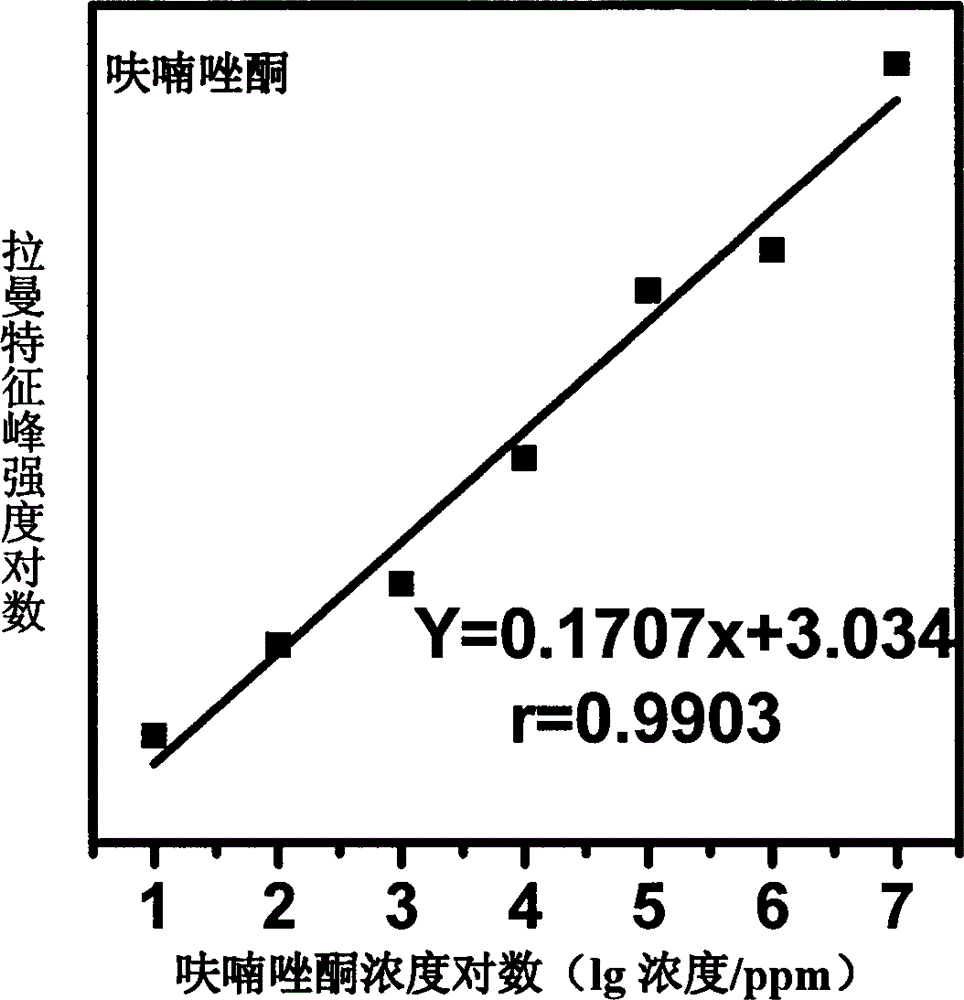

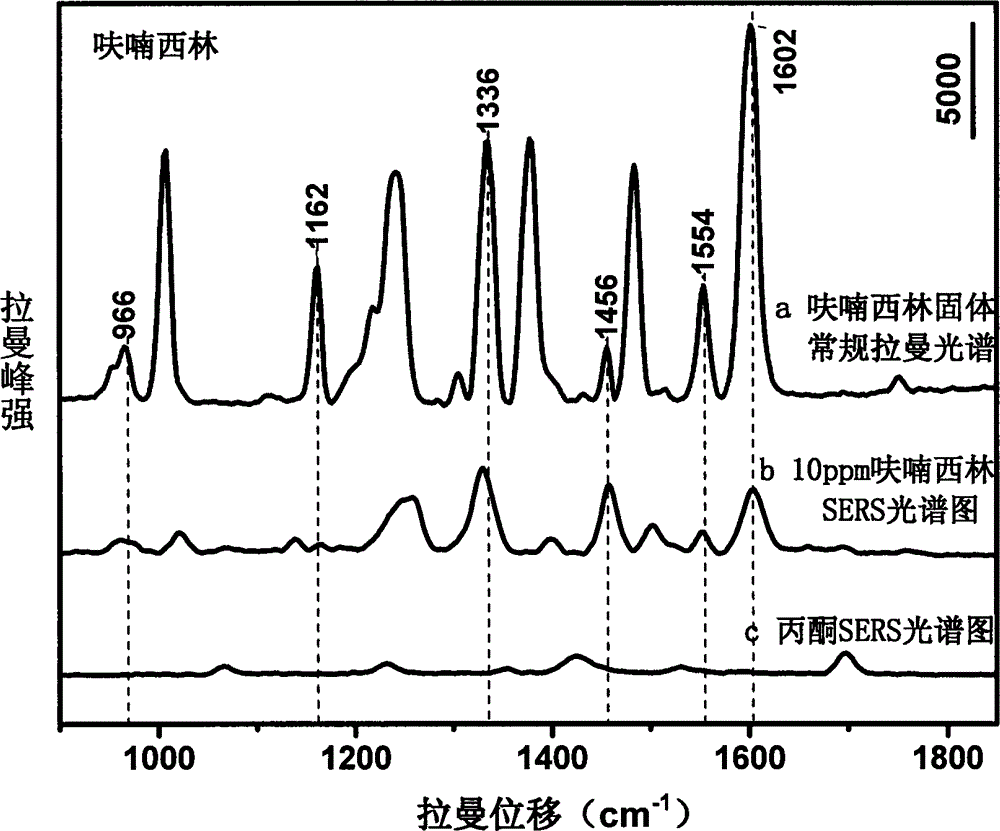

The invention utilizes a surface-enhanced raman spectroscopy to detect antibacterial drugs of furazolidone and furacilin. A method which adopts potassium chloroaurate to reduce sodium citrate is used for preparing aurosol; an acetone liquid which contains the furazolidone or the furacilin is mixed with the aerosol, the pH is regulated to 1.0-6.0, and a laser raman spectrometer with a laser light source of 785 nanometers is adopted to scan, so that a raman spectroscopy is obtained; 1611, 1560, 1488, 1472, 1397, 1343, 1260, 1173, 1022, 977, 806 and 775 centimeters <-1> are used as qualitative characteristic peaks for identifying the furazolidone, and 1602, 1554, 1456, 1336, 1162 and 966 centimeters <-l> are used as the qualitative characteristic peaks for identifying the furacilin; and moreover, the peaks of 1611centimeters <-1> and 1602 centimeters <-1> are respectively used for quantitatively determining the furazolidone and the furacilin. The method is convenient, quick, accurate and low in cost, and can be popularized and used in the fields food and drug testing.

Owner:JIANGNAN UNIV

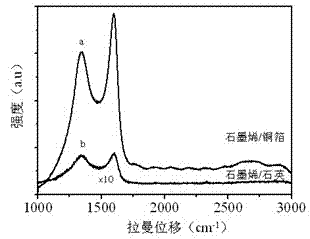

Preparation method of graphene film

InactiveCN103754864ACause some damagesThe preparation method is simple and time-savingGraphenePolymethyl methacrylateThin membrane

The invention discloses a preparation method of a graphene film. The preparation method comprises the steps: firstly, dissolving polymethyl methacrylate into acetone to obtain a polymethyl methacrylate and acetone liquid; then, dropwise adding the polymethyl methacrylate and acetone liquid on a metal to form a layer of polymethyl methacrylate film; covering a quartz glass slide on the polymethyl methacrylate film; then, simultaneously placing the metal sheet, the polymethyl methacrylate film on the metal sheet and the covered quartz glass slide into a high-temperature annealing furnace with a nitrogen condition, and carrying out high-temperature annealing while controlling the temperature at 800-1000 DEG C, wherein the polymethyl methacrylate is decomposed into a graphene film under the catalytic action of the metal in the metal film, and the graphene film is evaporated at a high temperature and is transferred on the quartz glass slide; and next, naturally cooling to room temperature to obtain a layer of graphene film on the quartz glass slide. The preparation method disclosed by the invention is simple and convenient to implement and capable of transferring graphene under the condition that the graphene is not damaged or polluted.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

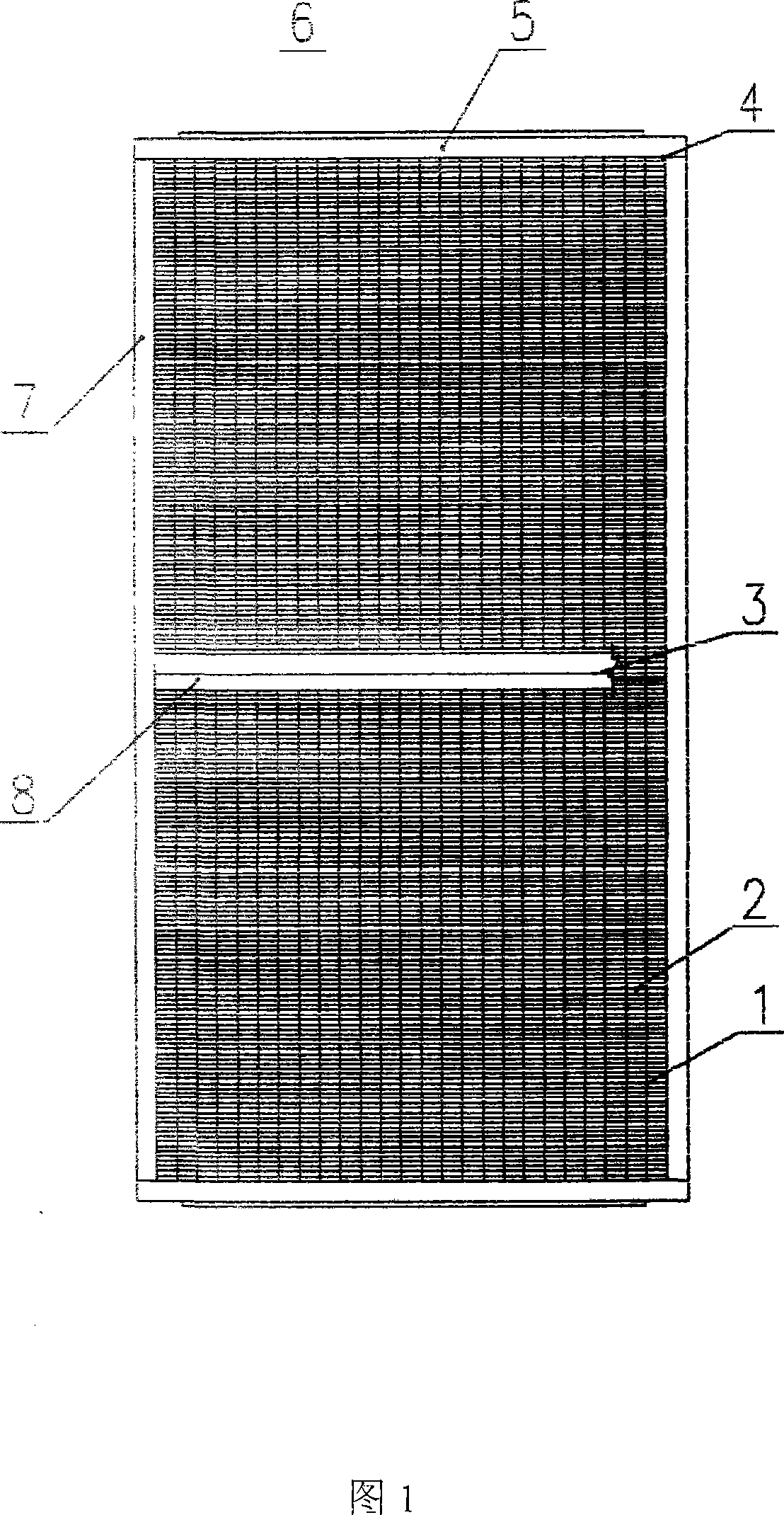

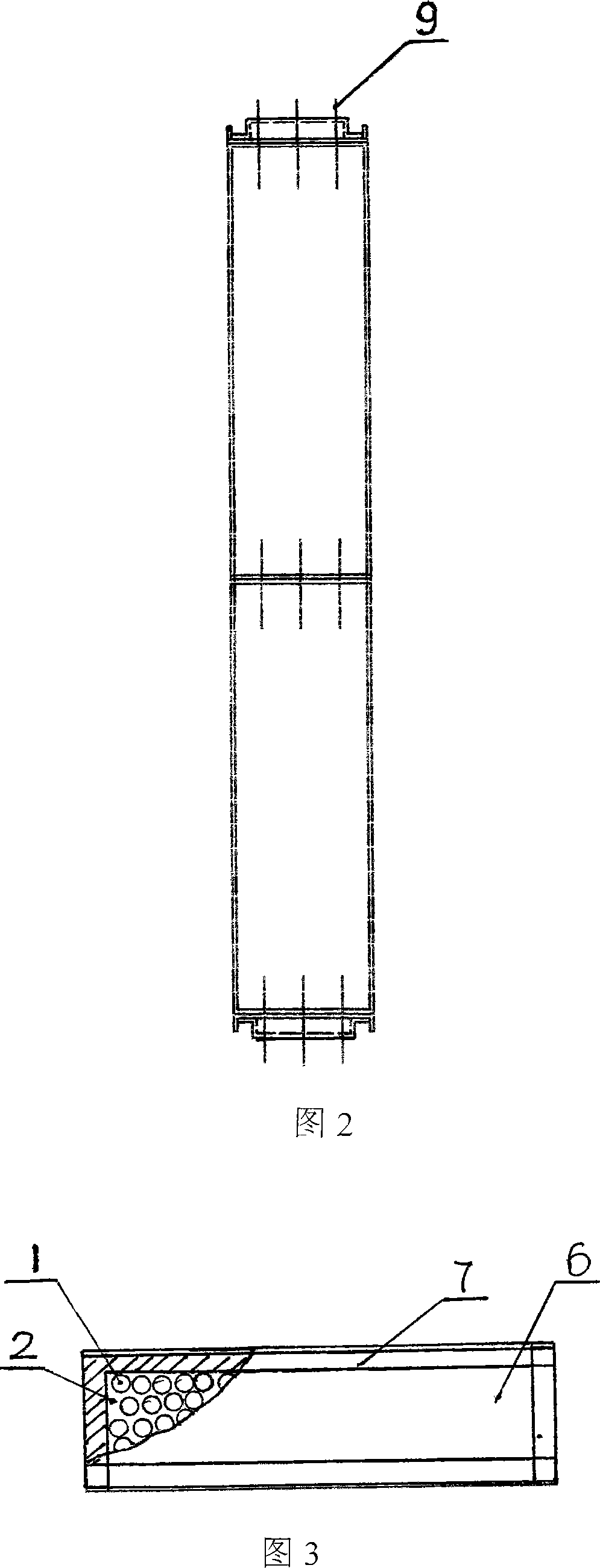

Improved low temperature heat pipe heat exchanger

InactiveCN101071050AIncreased dispersion areaReduce consumptionIndirect heat exchangersEngineeringAmmonia

The invention discloses a second generation low temperature heat pipe and its making craft way , composing of aluminum tube, aluminum plate fin, aluminum clapboard ,frame ,endplate ,cover plate ,yoke plate and fastening bolt, many rectangle alumna plate fin overlap to rectangle cubic type with inner clearance with center spacer set in the central part, on the aluminum plate fin and alumina clapboard has many regular spread turned-over edge pylomes, and alumina tubes inbesinsert in the pylomes, the aluminum tube tightly fit to the aluminum fin and alumina after extends by expanding tube machine. The two ends of aluminum tube are seal weld, and ammonia or acetone liquid is filled in the aluminum tube, forming entire aluminum heat tube's heat exchanging subject, fix the heat exchanging subject to the inner shell composed by frame, endplavte, cover plate, yoke plate through fastening bolts. The clapboard divides the inner shell space into tow sealed areas of air intaking and discharging air. In this invention, the heat exchanger's volume is small, the making craft is simple ,low cost, reducing the environment's heat pollution.

Owner:北京德天节能设备有限公司

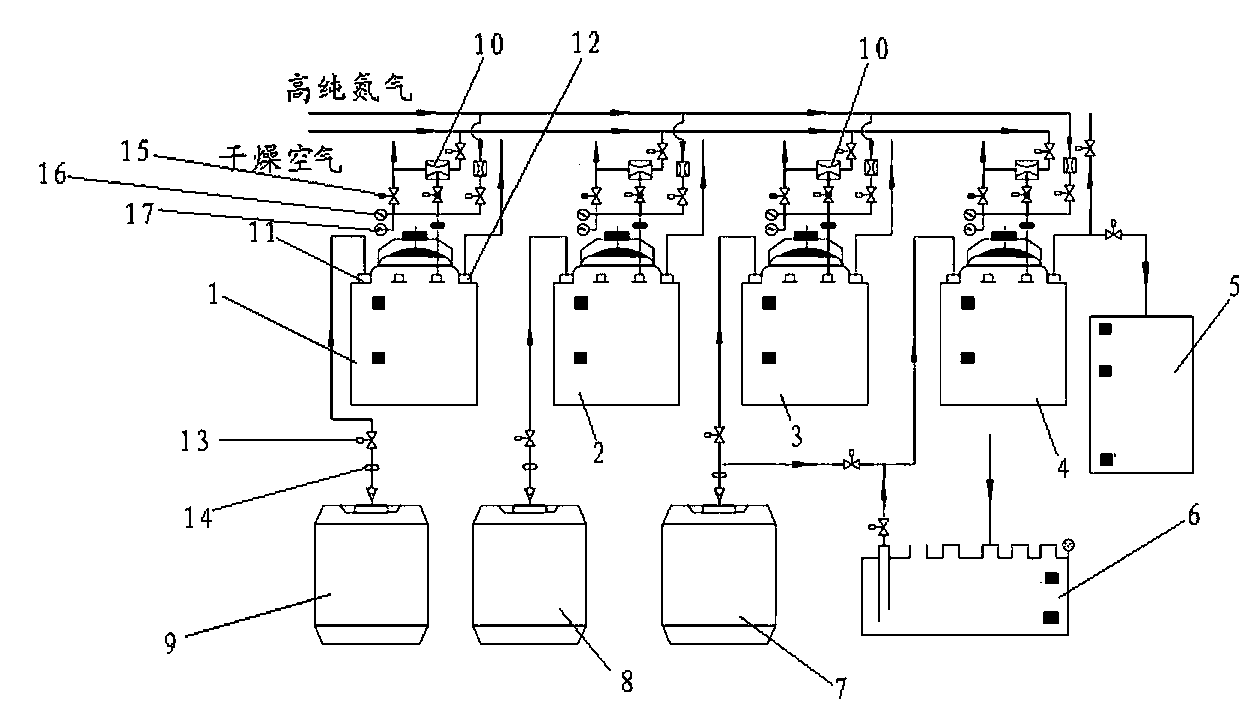

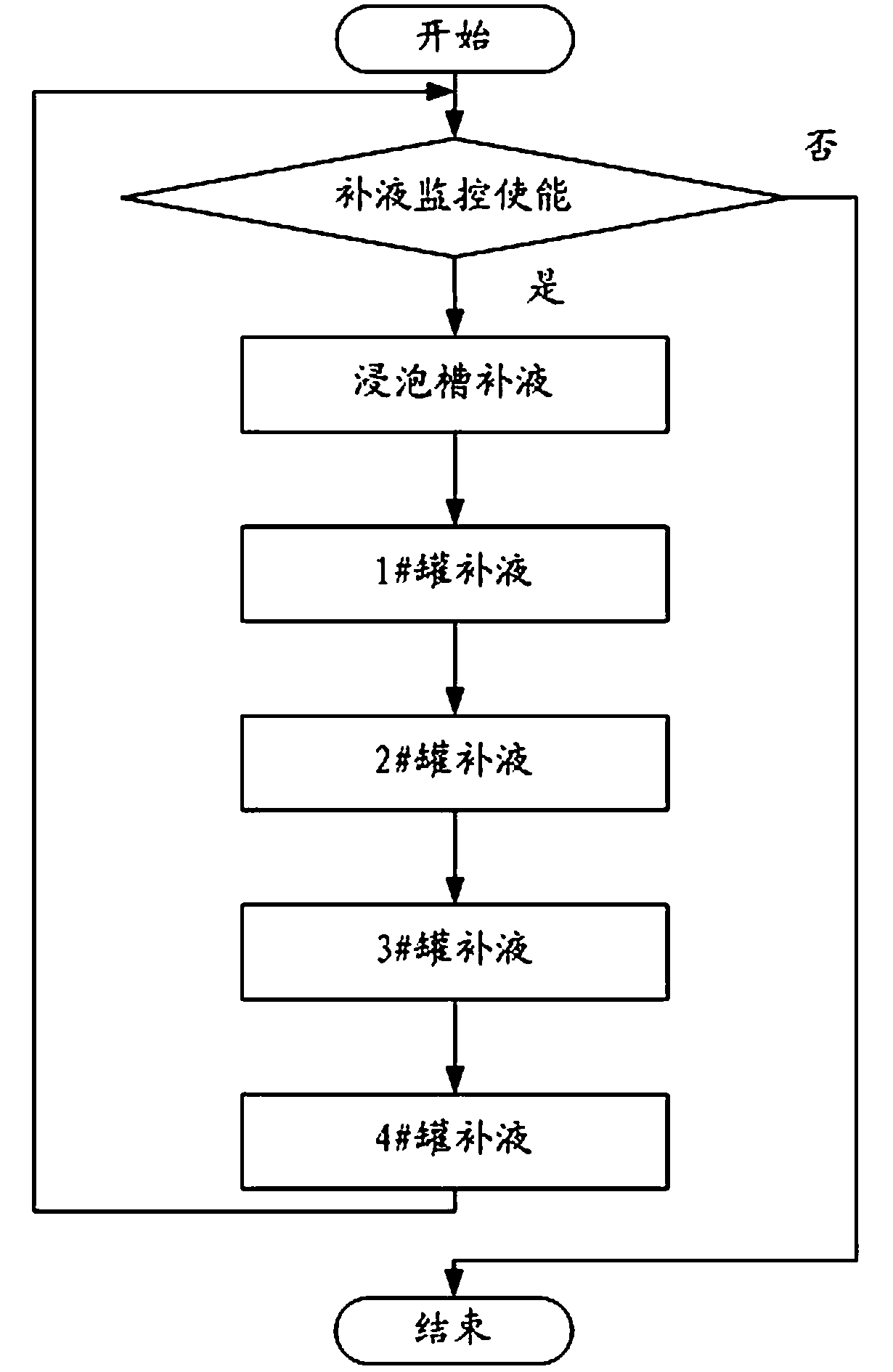

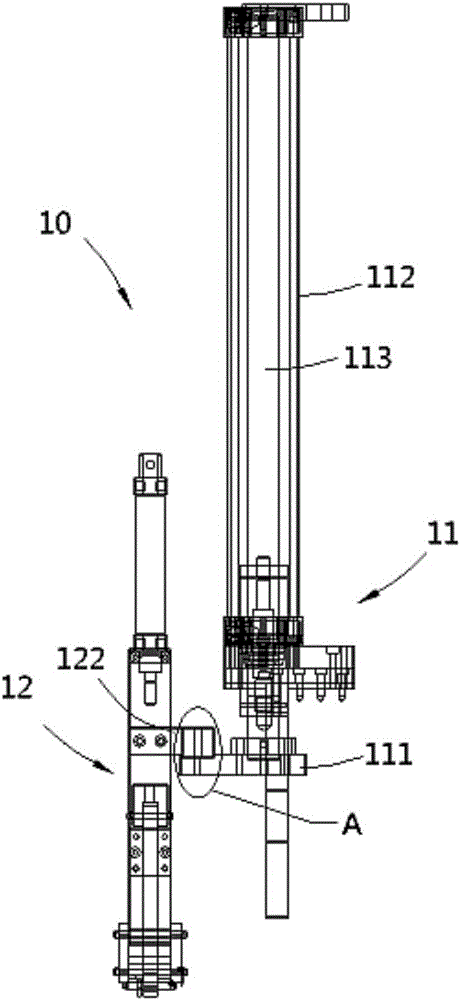

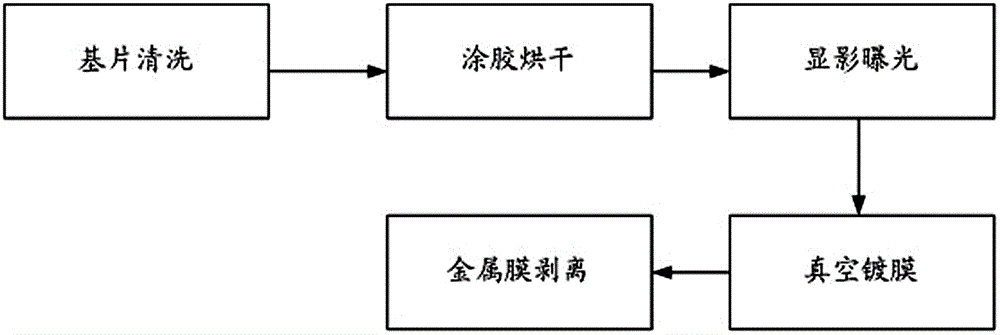

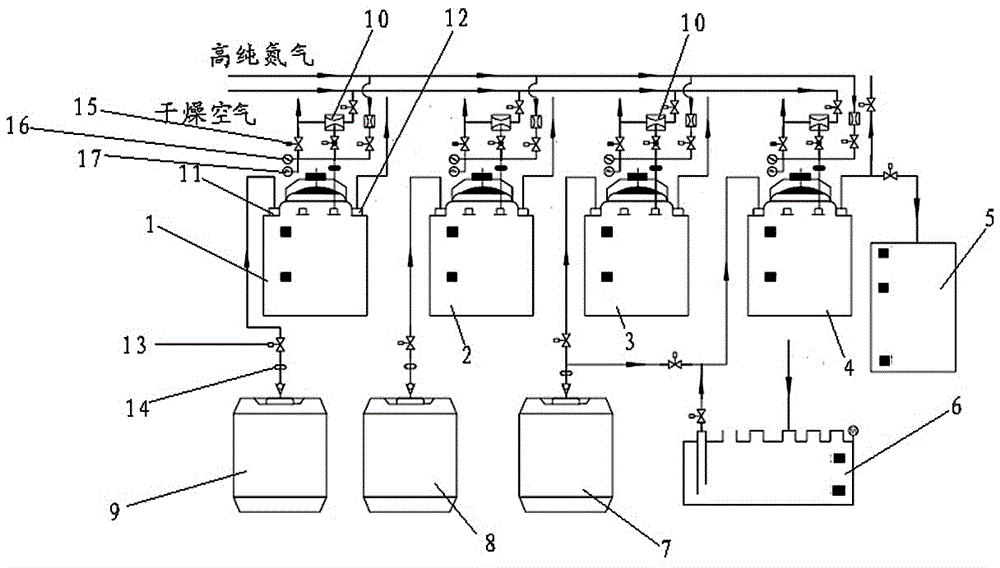

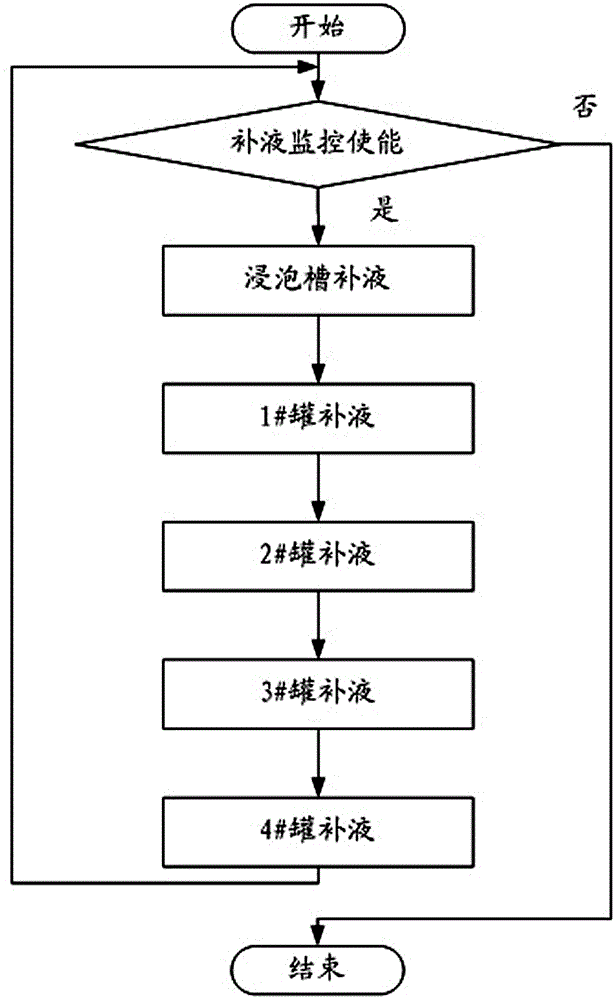

Automatic liquid adding system for metal film stripping and cleaning device

InactiveCN103295940AReasonable designEffective monitoring of liquid levelSemiconductor/solid-state device manufacturingPositive pressureNitrogen

The invention relates to an automatic liquid adding system for a metal film stripping and cleaning device. The liquid adding system comprises an NMP soaking tank, an isopropanol supply pressure tank connected with a vacuum negative pressure liquid adding device, an acetone liquid supply pressure tank connected with a nitrogen positive pressure liquid supply device, and an NMP liquid supply pressure tank for supplying NMP liquids to the NMP soaking tank. A liquid adding inlet of the isopropanol liquid supply pressure tank is connected with a isopropanol liquid storage tank through a liquid adding pipe, a liquid adding inlet of the acetone liquid supply pressure tank is connected with a acetone liquid storage tank through a liquid adding pipe, and a liquid adding inlet of the NMP liquid supply pressure tank is connected with an NMP liquid storage tank through a liquid adding pipe. A liquid level detecting switch is disposed in each of the isopropanol supply pressure tank, the acetone liquid supply pressure tank, the NMP liquid supply pressure tank and the NMP soaking tank. By the automatic liquid adding system which is capable of unattended operation, operation efficiency of the system is increased evidently, automatic liquid adding is achieved, and equipment automation level is increased. In addition, the automatic liquid adding system is applicable to other full-automatic single-chip wet processing equipment.

Owner:THE 45TH RES INST OF CETC

Polyurethane flame-retardant material and preparation method thereof

InactiveCN103788331AHigh level of flame retardantImprove water resistancePolymer scienceOctanoic Acids

The invention discloses a polyurethane flame-retardant material and a preparation method. The polyurethane flame-retardant material is prepared by virtue of the following steps: in the presence of nitrogen, fetching 10-30ml of isophorone diisocyanate and 10-30ml of dehydrated polyether diol to react for 2 hours at 90 DEG C; cooling to 60 DEG C; adding 3-5ml of dimethylolpropionic acid, 3-5ml of 1,4-butanediol, 3-5ml of trimethylolpropane and 3-5ml of 15% boron phenolic acetone liquid, and sequentially adding 1ml of stannous octoate and dibutyltin dilaurate, and reacting for 4 hours; adding 3ml of acetone to adjust the viscosity; continuously reacting until isocyanate does not change; cooling to below 30 DEG C, and adjusting the viscosity with 1ml of acetone; adding 3ml of triethylamine for neutralization for 5 minutes; adding water and emulsifying and dispersing for 3 minutes; performing reduced-pressure distillation to remove acetone to obtain the polyurethane flame-retardant material. The material prepared by the method is smoke-less in the burning process, and the flame-retardant level of the sample can reach the level UL-94V-1 which is a relatively high flame-retardant level.

Owner:GUANGXI JISHUN ENERGY TECH

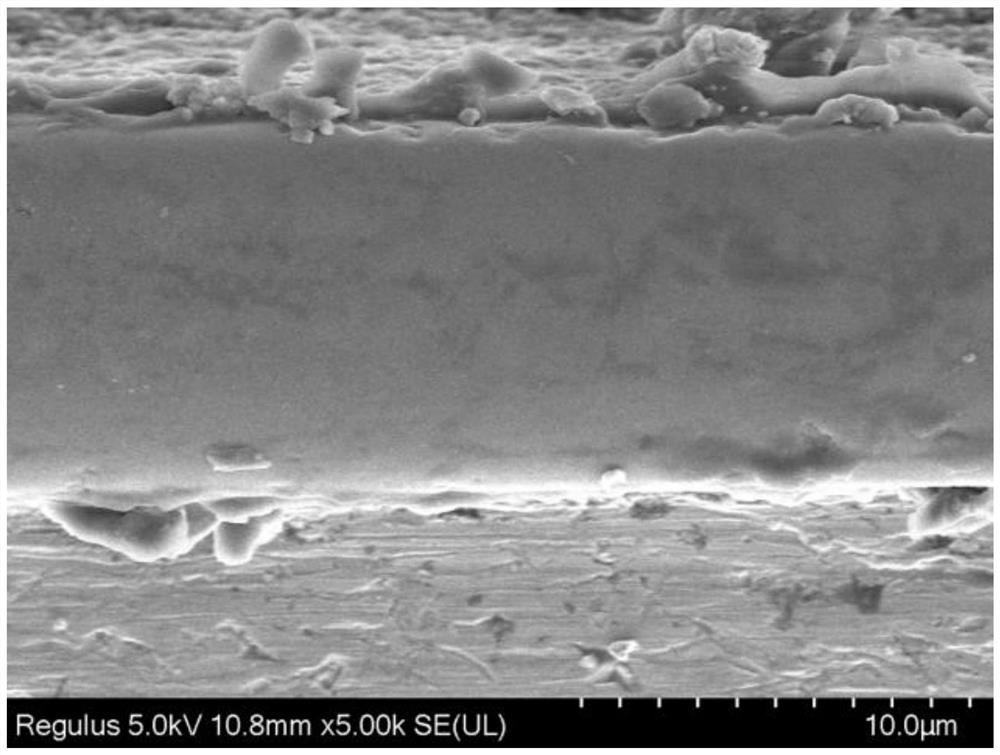

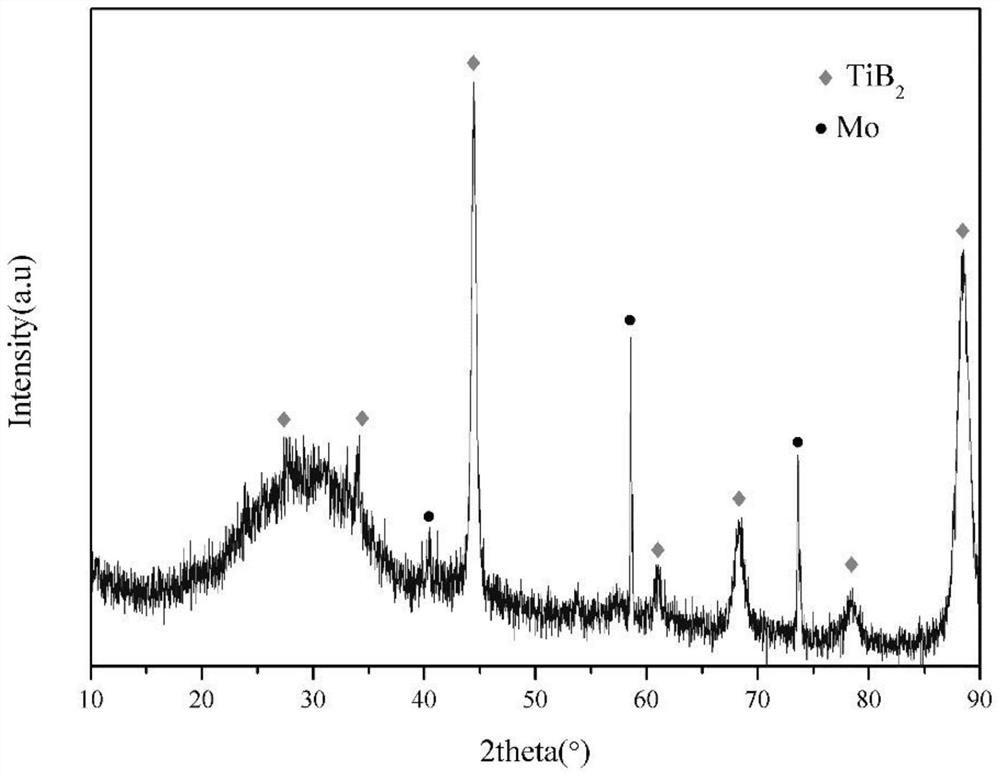

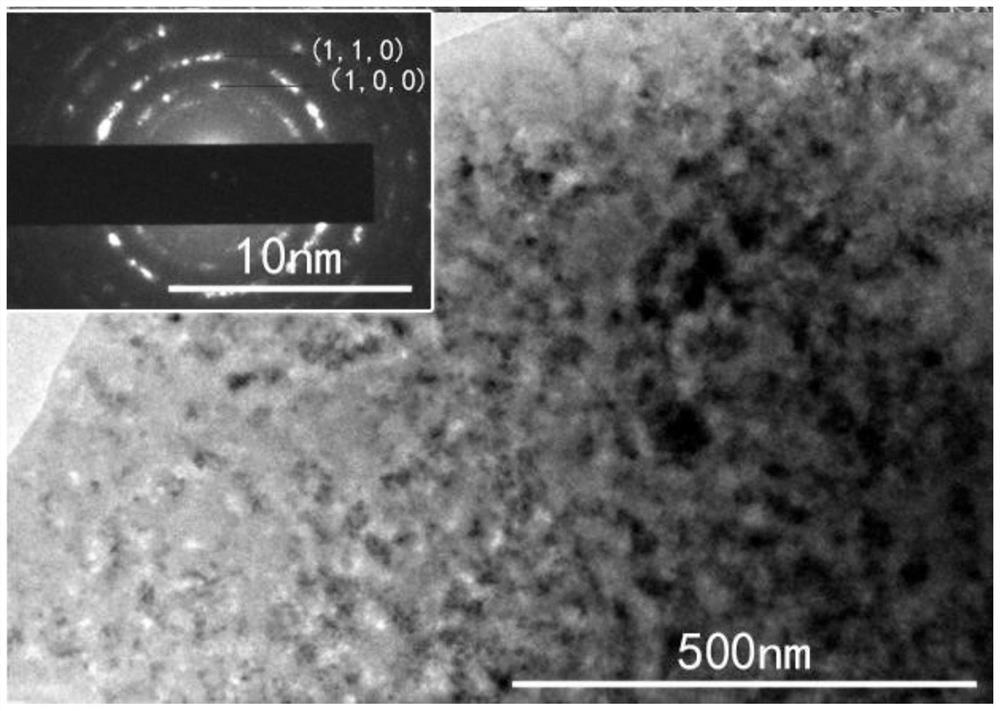

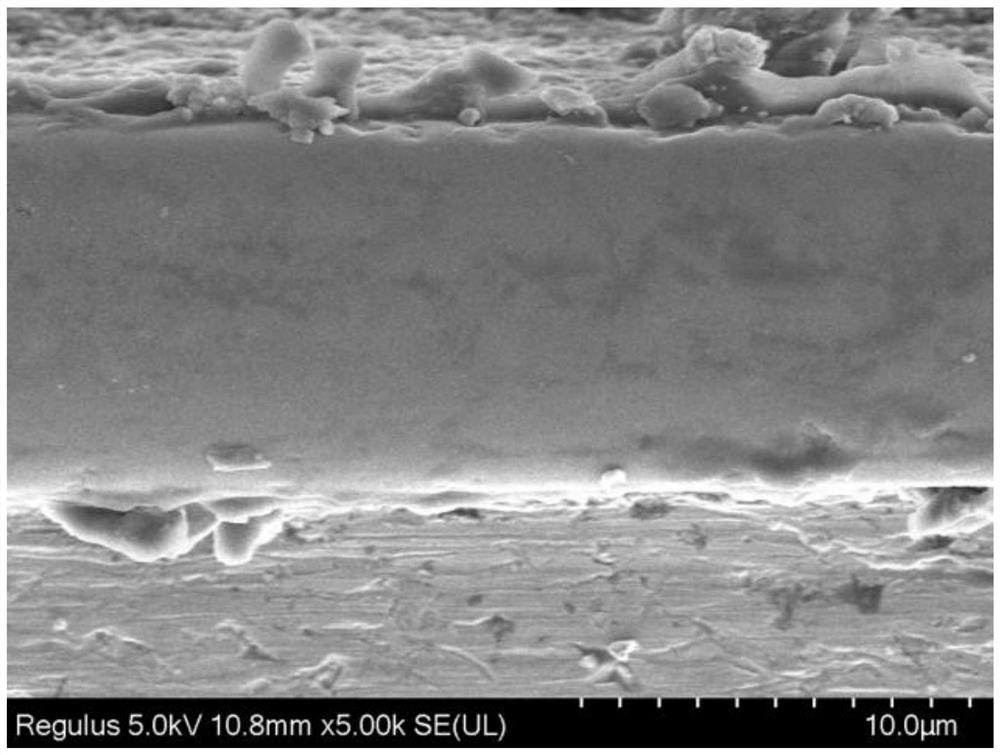

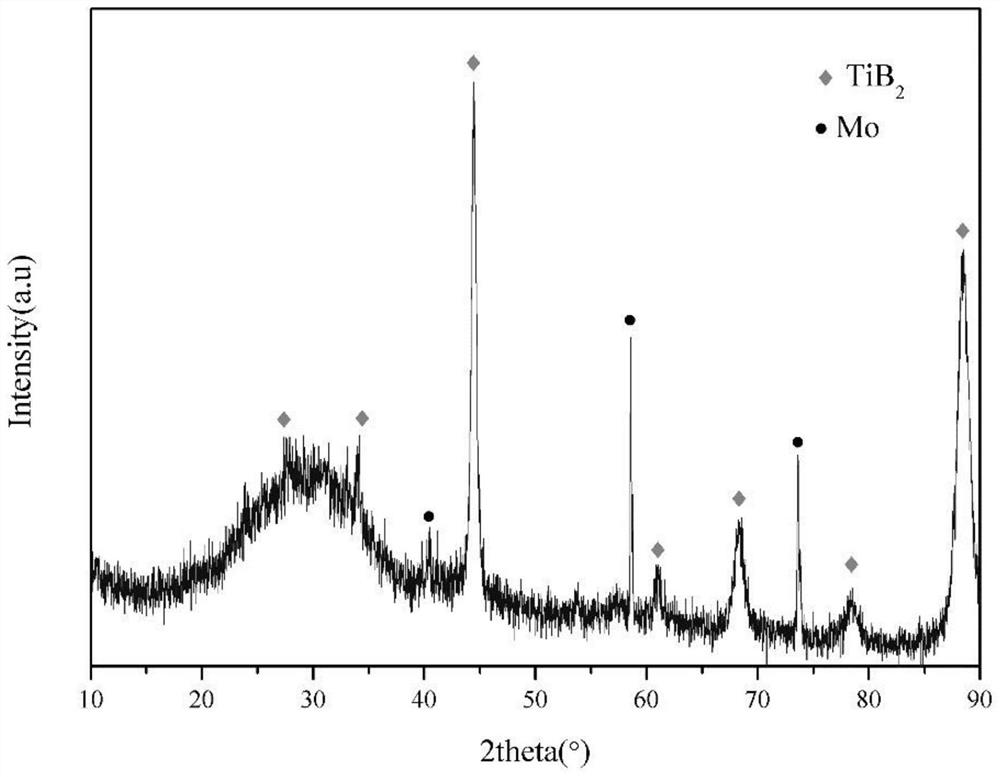

Metal boride coating and preparation method thereof

ActiveCN112359395AHigh activityStrong purityElectrophoretic coatingsMicron scaleUltrasonic dispersion

The invention discloses a metal boride coating and a preparation method thereof. The preparation method comprises the steps that solid inorganic salt is mixed and ball-milled to be micron-sized, metalboride nanoparticles are added into the ball-milled mixed salt, then acetone liquid is added, ultrasonic dispersion is conducted, and solid mixed salt containing the metal boride nanoparticles is obtained after vacuumizing and heating in a vacuum drying box; solid inorganic salt is put into a crucible, and is heated to be fused in a resistance furnace under the protection of inert gas, the solidmixed salt is added into the fused inorganic salt to form nanometer inorganic fused salt, after stabilizing, a graphite anode and a cathode to be deposited are inserted into the crucible, and the metal boride coating can be obtained after electrophoretic deposition. According to the method, the high-temperature environment of the inorganic fused salt is utilized, the two procedures of electrophoretic deposition and sintering of the metal boride nanoparticles in the inorganic fused salt are carried out at the same time, namely electrophoretic deposition and sintering are carried out at the sametime, and therefore the compact metal boride coating with high binding force is obtained.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

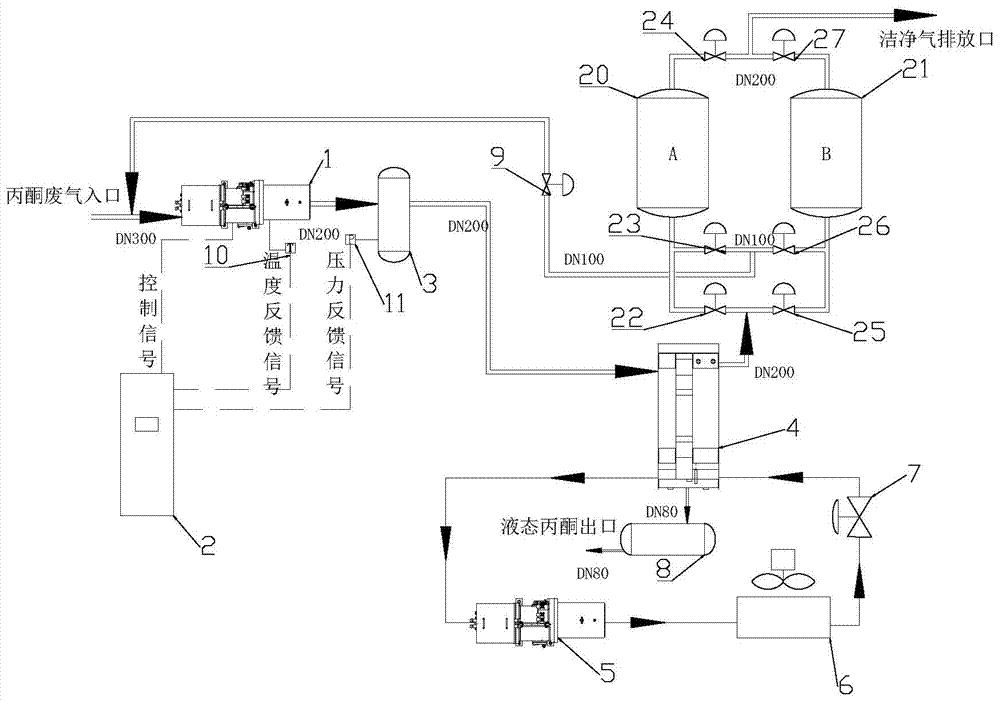

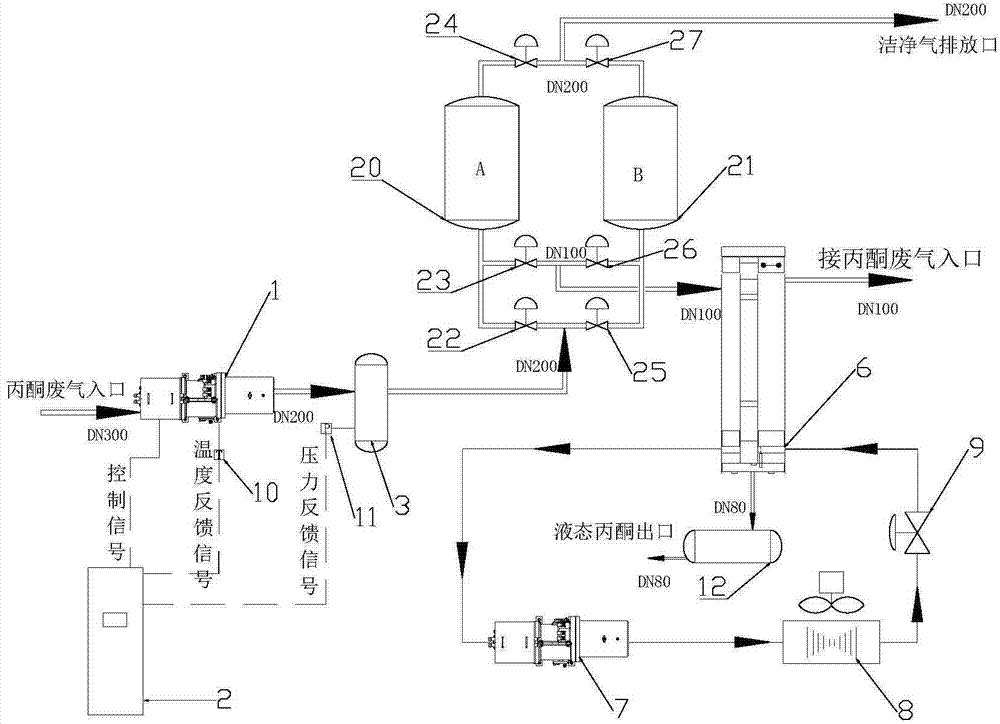

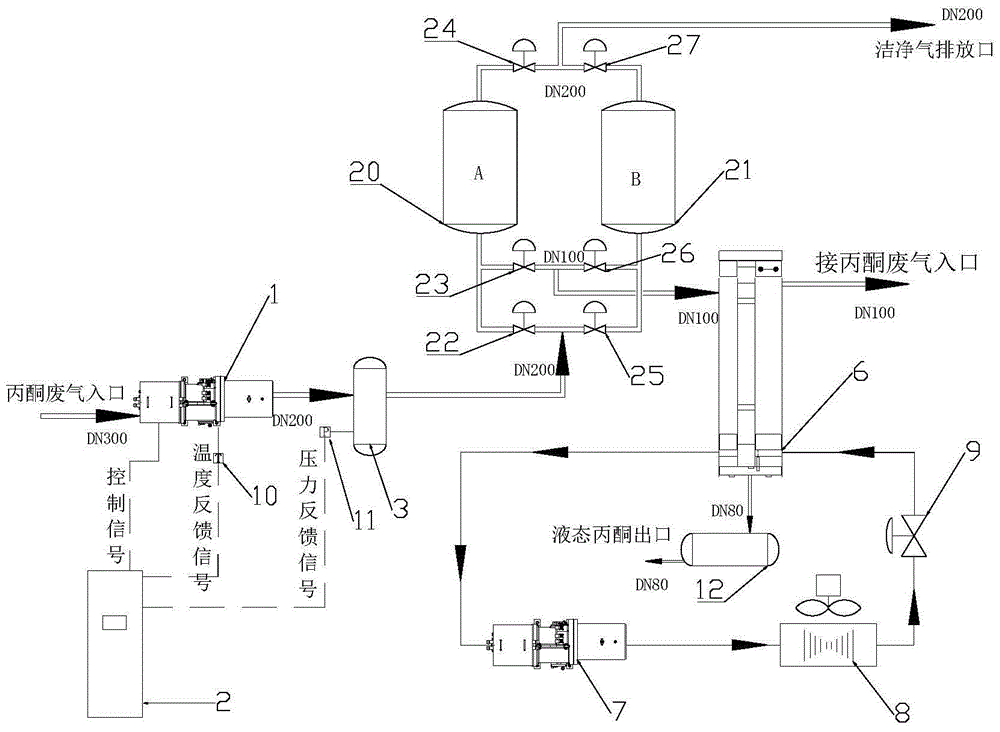

Acetone pressurized condensation adsorption type acetone recovery system and recovery method

InactiveCN104841241AReach the purpose of recyclingLower requirementSolidificationLiquefactionRecovery methodDesorption

The invention discloses an acetone pressurized condensation adsorption type acetone recovery system and a recovery method. The system comprises an acetone gas compression device, a refrigeration device, an adsorption device, an acetone liquid storage tank and an enriching gas circulation pipeline. Through the acetone gas compression device, acetone waste gas is compressed into a medium-pressure state; then, the acetone waste gas enters an evaporator of the refrigeration device for cooling and liquification; after the liquification, the acetone waste gas enters an acetone liquid storage tank to achieve the goal of recovery; unliquefied gas maintains the medium-pressure state to enter the adsorption device, and is adsorbed in the medium-pressure state; after the adsorption saturation, the pressure is reduced to the normal pressure for desorption; enriched acetone gas obtained through desorption is conveyed back into the acetone gas compression device for cyclic recovery. Compared with the prior art, the system and the method provided by the invention have the advantages that the final-stage evaporation temperature of the refrigeration device is greatly raised; the structure of the refrigeration device is simplified; meanwhile, the adsorption device omits a vacuum pump desorption mode with higher fault rate, in addition, the desorption efficiency is greatly improved, the enriched gas after the normal-pressure desorption returns to the condensing front end to be cyclically recovered, and the recovery efficiency is improved.

Owner:NANJING DOULE REFRIGERATION EQUIP

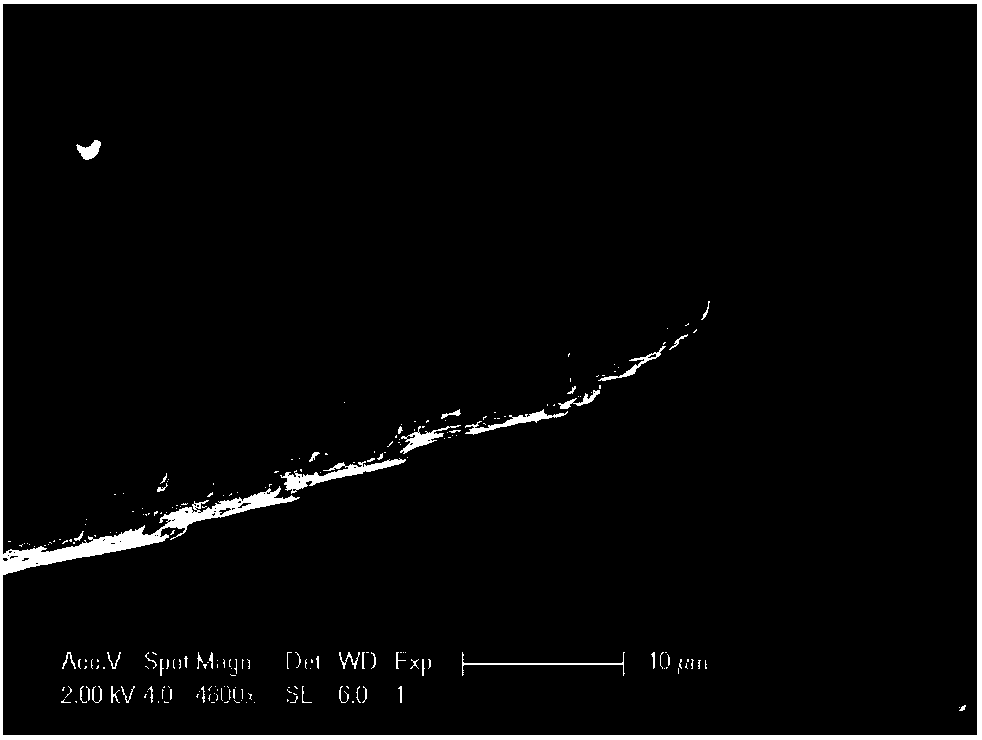

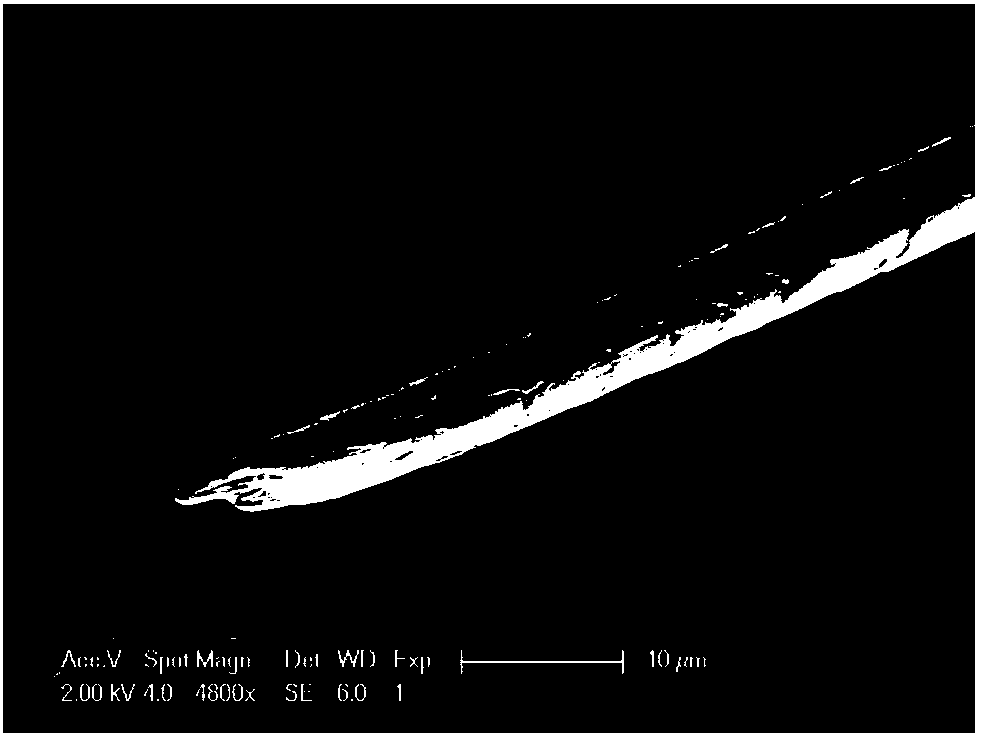

Method for moving and transferring nanowire by using micron-diameter tapered hair

ActiveCN108051613AEnable mobilityAchieve transferElectric discharge tubesNanostructure manipulationSmall dropletNanowire

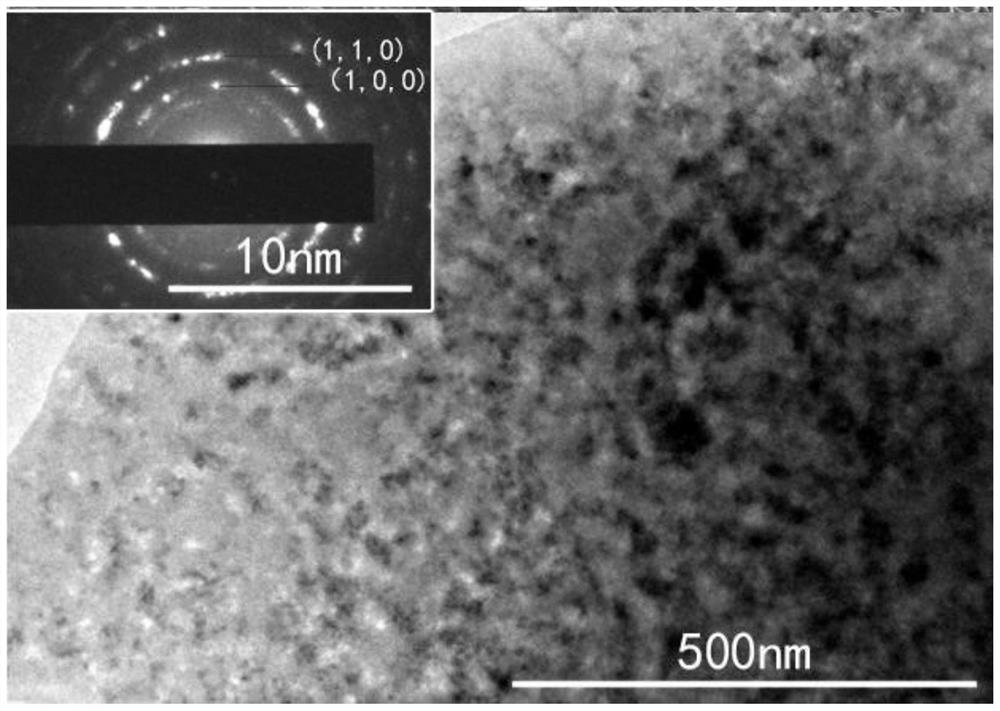

The present invention provides a method for moving and transferring a nanowire by using a micron-diameter tapered hair. The diameter of the nanowire ranges from 60 to 150 nm; the diameter of the tapered hair ranges from 1 to 100 microns, and the radius of curvature of the tip of the tapered hair ranges from 0.8 to 3 microns, and the length of the tapered hair ranges from 4 to 10 mm; a plastic filmon a copper mesh for a transmission electron microscope is removed with the copper mesh left, the diameter of the holes of the copper mesh ranging from 50 to 100 microns; the copper mesh which has been subjected to ultrasonic treatment is adopted to salvage the nanowire in an acetone liquid for the ultrasonic dispersion of the nanowire; the copper mesh on which the nanowire is distributed and thetapered hair are arranged on the movement platforms of two different optical microscopes respectively; the millimeter and micrometer-level movement of the taper hair is realized, and therefore, the movement and transfer operation of the nanowire can be realized; and the tip of the tapered hair is adopted to a small droplet of conductive silver paste and drip the conductive silver paste at two ends of the nanowire, and the radius of the dripped conductive silver paste ranges from 4 to 8 microns. According to the method for moving and transferring the nanowire by using the micron-diameter tapered hair of the present invention, the movement platforms of the two optical microscopes are adopted to realize the movement and transfer of the nanowire by using the tapered hair.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of metal boride coating

The invention discloses a method for preparing a metal boride coating, which comprises the steps of: mixing solid inorganic salts, ball milling to micron level, adding metal boride nanoparticles to the ball-milled mixed salt, adding acetone liquid and ultrasonically dispersing it. , after vacuuming and heating in a vacuum drying box, a solid mixed salt containing metal boride nanoparticles is obtained; the solid inorganic salt is put into a crucible, heated to melting in a resistance furnace protected by an inert gas, and the solid mixed salt is added to melt In the inorganic salt, nano-inorganic molten salt is formed. After stabilization, the graphite anode and the cathode to be deposited are inserted into the crucible, and after electrophoretic deposition, the metal boride coating can be obtained; the invention utilizes the high temperature environment of the inorganic molten salt to realize the inorganic molten salt. Electrophoretic deposition and sintering of metal boride nanoparticles in salt are carried out simultaneously, that is, "sintering while electrophoretic deposition", so as to obtain a dense and strong metal boride coating.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

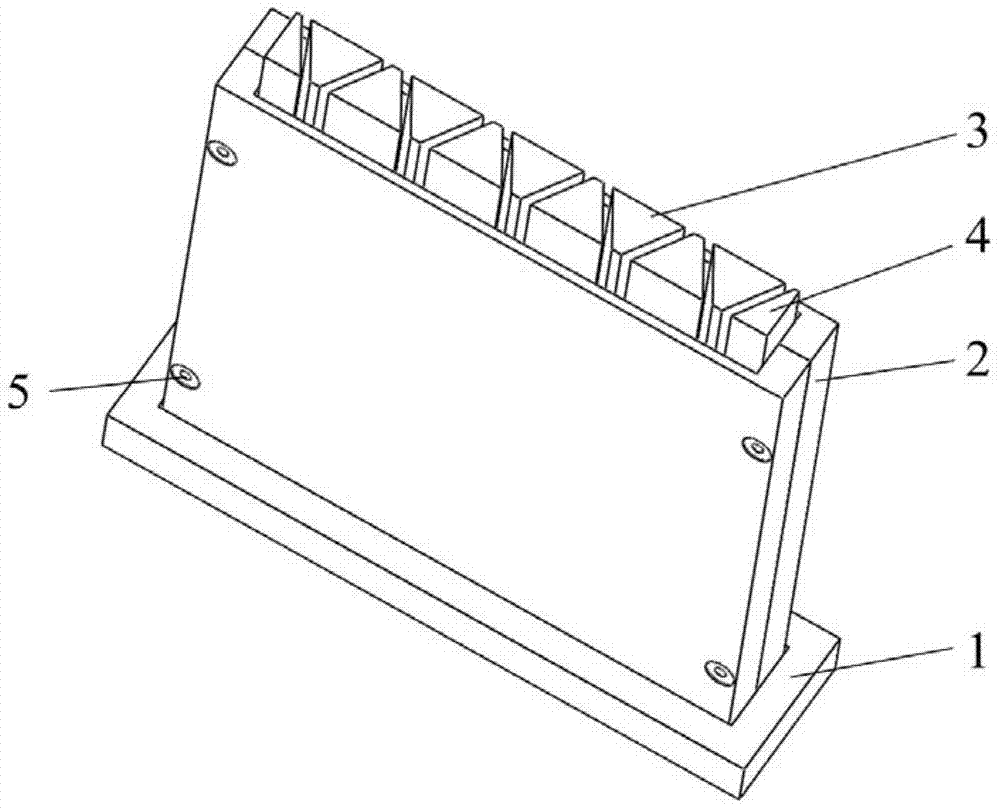

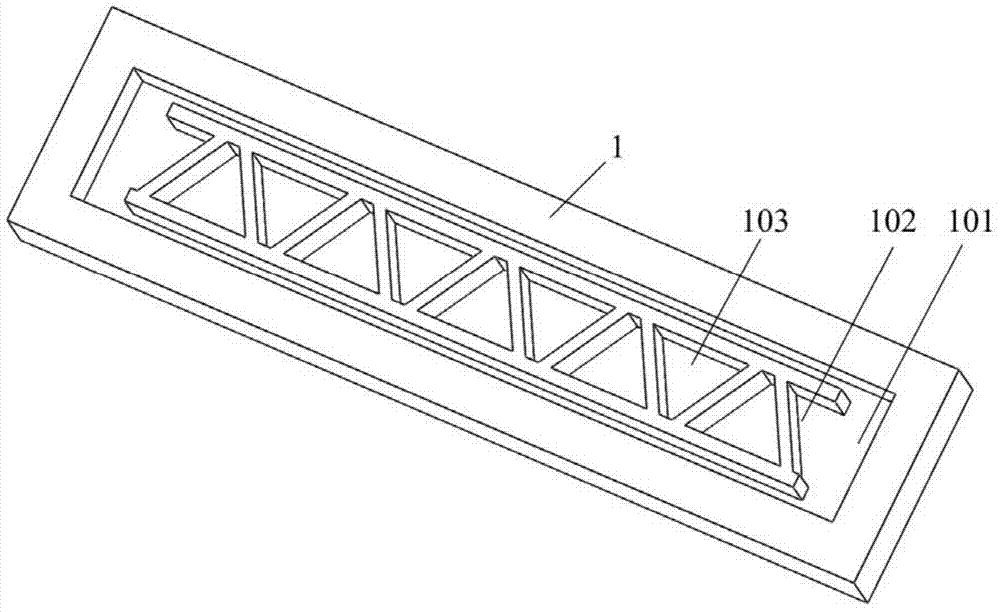

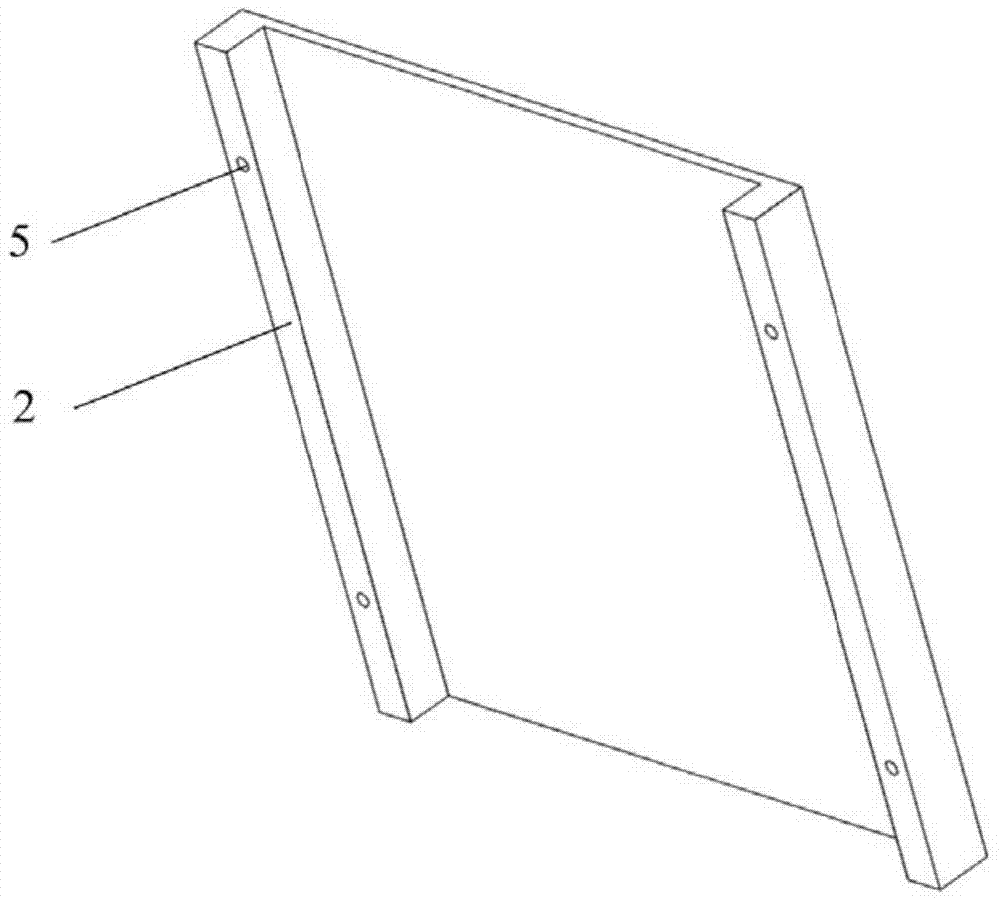

Integrated gel-casting manufacturing method of high-temperature ceramic material dot matrix laminboard

InactiveCN103934880AImprove mechanical propertiesImprove connection strengthMouldsMould auxillary partsFreeze-dryingGel casting

The invention discloses an integrated gel-casting manufacturing method of a high-temperature ceramic material dot matrix laminboard. A novel combined mold is manufactured; acetone liquid is used for cleaning the surface of the combined mold, and release agents are used for coating the surface of the combined mold; ceramic slurry is manufactured through the combined mold; gel-casting is used for integrally manufacturing the high-temperature ceramic material dot matrix laminboard; demolding is performed, and a green high-temperature ceramic material dot matrix laminboard body of a corrugated plate structure is obtained; freeze drying is performed, and the ceramic dot matrix laminboard with a certain green body strength is obtained; non-pressure sintering is finally performed, and after the ceramic dot matrix laminboard is cooled to the room temperature, the high-temperature ceramic dot matrix laminboard is obtained. The gel-casting integrated manufacturing method can be adopted, and high-temperature ceramic materials such as ZrO2 are used as parent materials to manufacture the dot matrix laminboard. The integrated gel-casting manufacturing method can be widely applied to the environment under the temperature of above 1000 DEG C. Integral forming is adopted, a panel and a core of the laminboard do not have other connection manners, the better connection strength is achieved, and the whole laminboard has the better mechanical property.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

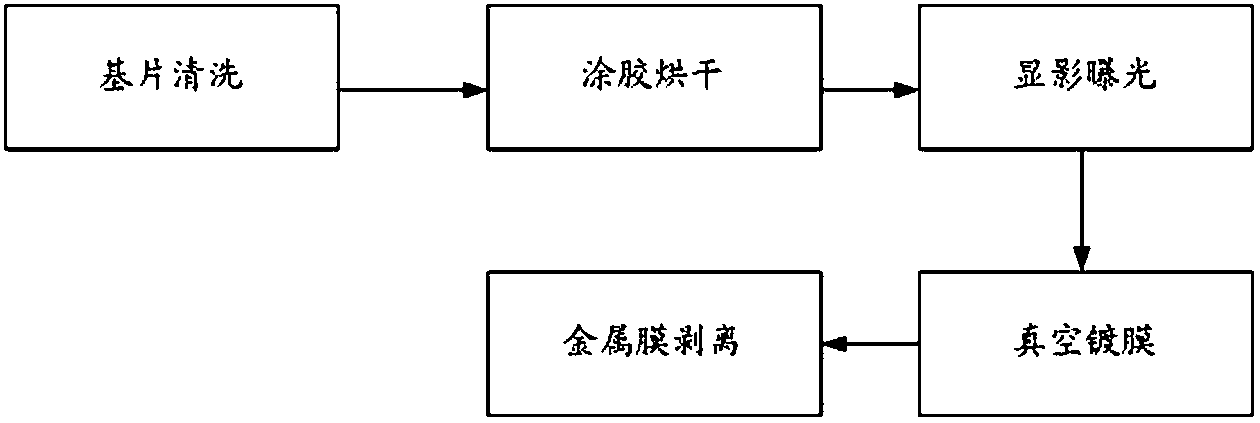

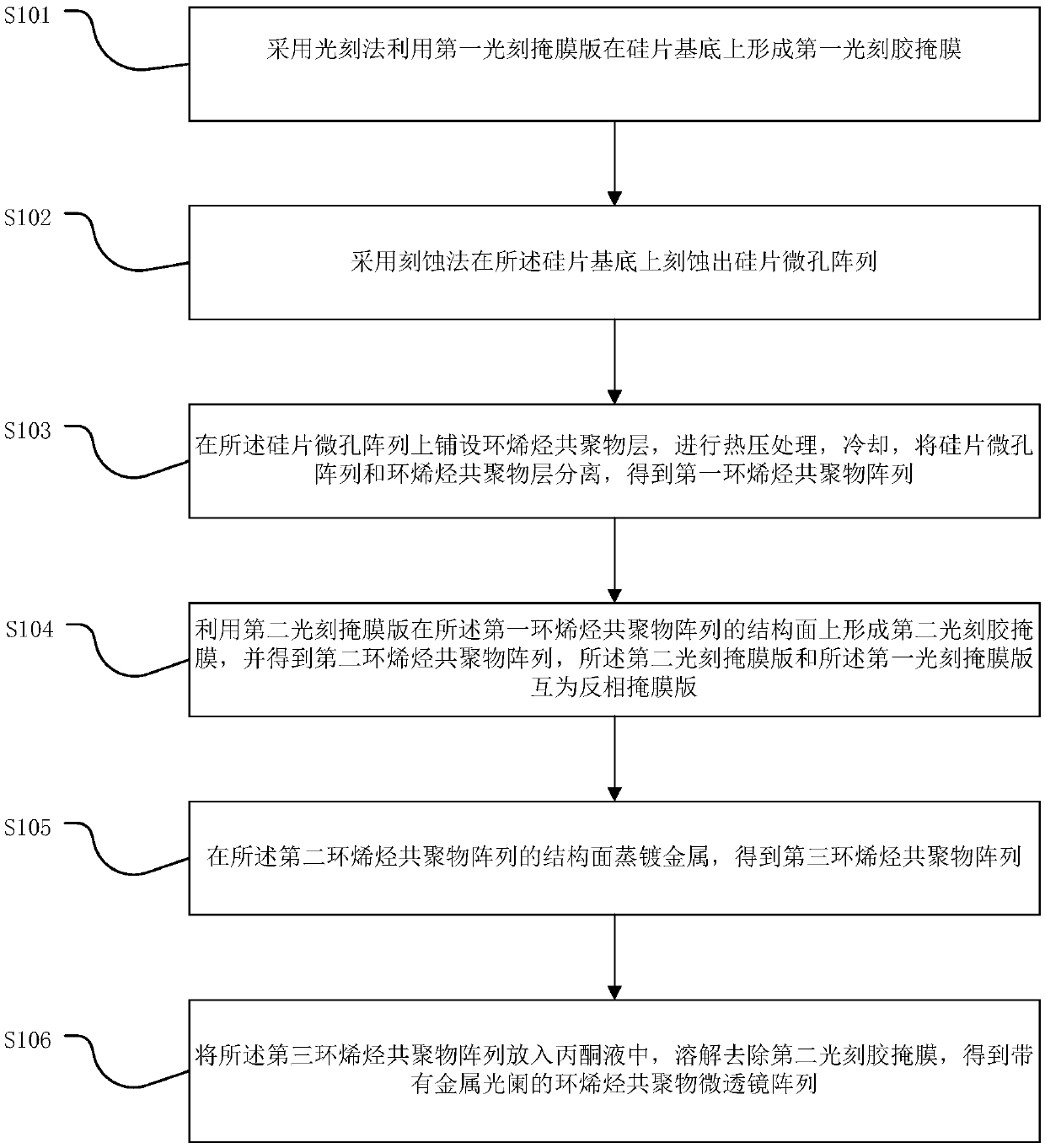

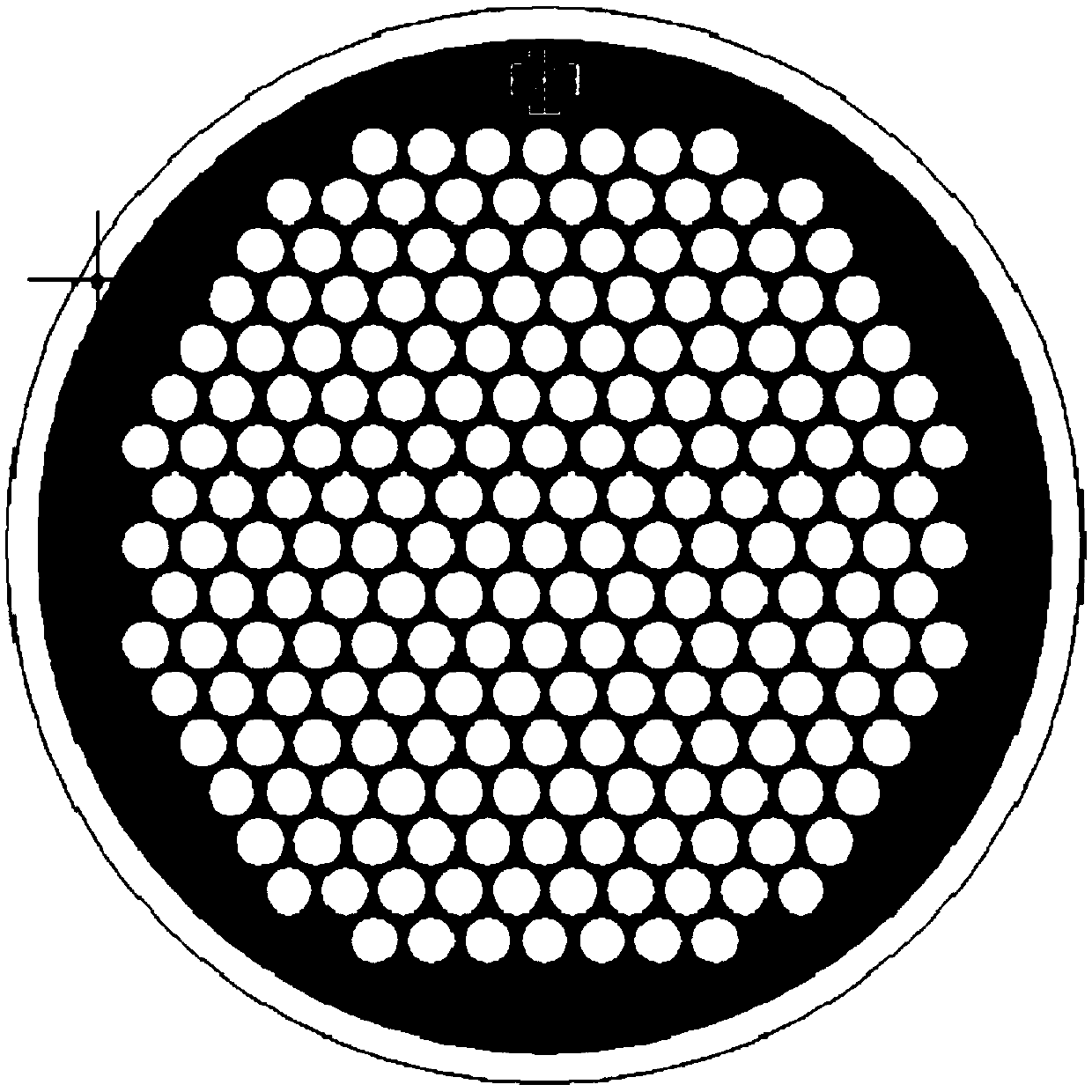

Cycloolefin copolymer micro-lens array with metal diaphragm and preparation method thereof

ActiveCN110426761ASuitable for batch preparationEasy to operatePhotomechanical apparatusLensMicro lens arrayPhotoresist

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

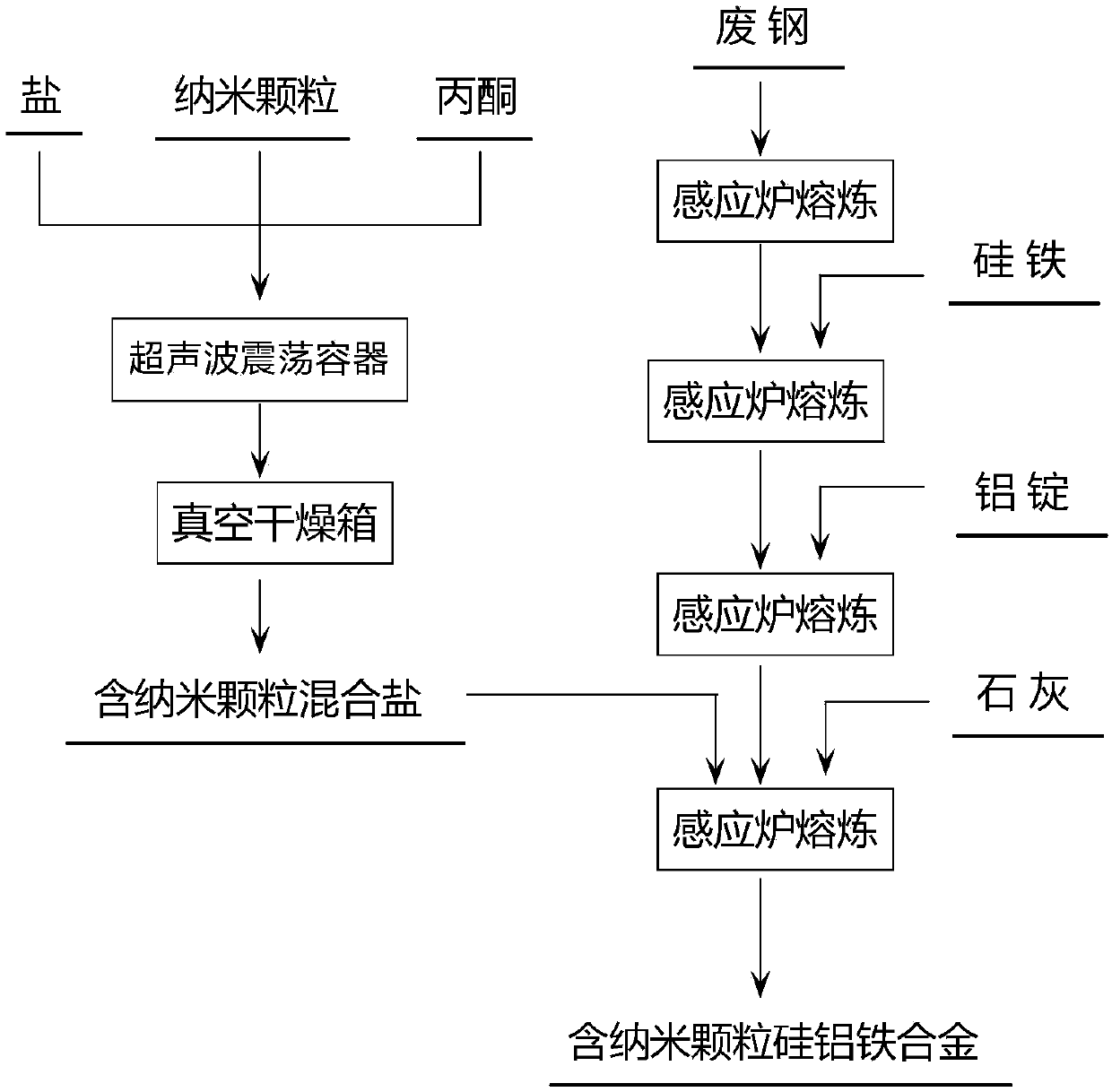

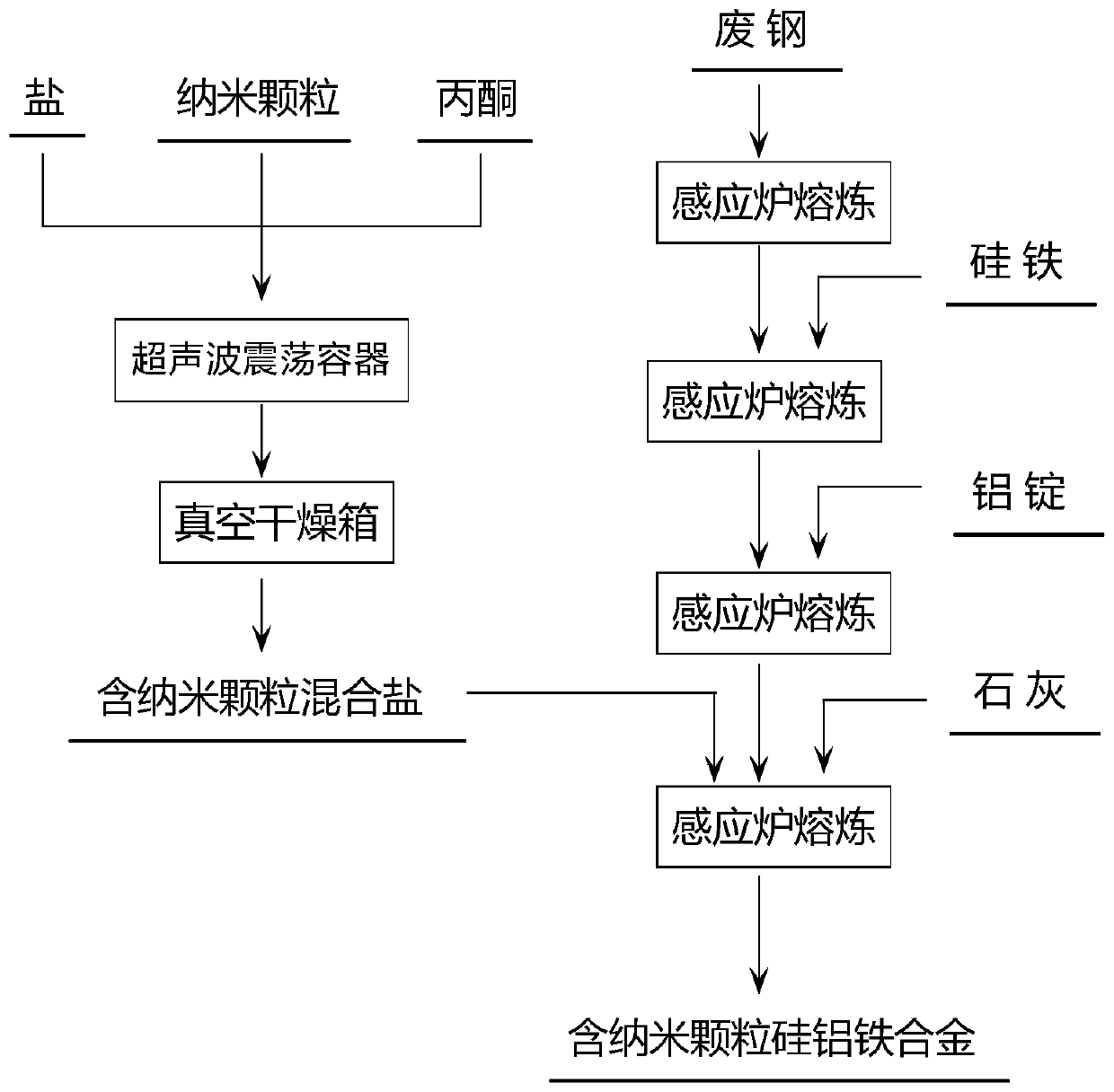

Method for preparing silicon-aluminum-iron alloy containing nano-particles by using nano-molten salt

ActiveCN109576520ALow costReduce manufacturing costProcess efficiency improvementVacuum dryingInduction furnace

The invention provides a method for preparing silicon-aluminum-iron alloy containing containing nano-particles by using nano-molten salt, and belongs to the field of special ferroalloy production. Themethod comprises the steps that step one, mixed salt containing the nano-particles is prepared, that is, the nano-particles are mechanically mixed with the salt and then acetone liquid is added, vacuum-pumping and heating are carried out in a vacuum drying oven after ultrasonic vibration treatment, and the acetone is completely volatilized to obtain evenly mixed salt containing the nano-particles; and step two, the silicon-aluminum-iron alloy containing the nano-particles is smelted in an induction furnace, that is, scrap steel, seventy-fifth silicon iron, aluminum ingot, mixed salt containing the nano-particles and lime are sequentially added in an medium frequency induction furnace, the scrap steel, the seventy-fifth silicon iron, the aluminum ingot, the mixed salt containing the nano-particles and the lime are melted, keeping warm, stopping heating and standing are carried out, the silicon-aluminum-iron alloy containing the nano-particles is obtained by cast molding. According to the method, the nano-particles are added in the production process of silicon-aluminum-iron alloy to obtain the silicon-aluminum-iron alloy with even distribution of the nano-particles, and intermediate alloy is provided for preparing nano-particle containing steel at low cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing isophorone by acetone liquid condensation with alkali catalyst

ActiveCN102516051BOrganic compound preparationCarbonyl compound preparationIsophoroneAqueous solution

The invention discloses a method for preparing isophorone by acetone liquid condensation with an alkali catalyst. The method comprises steps of: heating an aqueous solution of acetone and the alkali catalyst to 230-280 DEG C under continuous stable operation conditions; controlling the pressure to maintain the acetone and water in liquid phase state; then introducing the two together through a mixer and a micro channel reactor with a total staying time of 3-15 min; carrying out a condensation reaction on the acetone with catalysis effect of the alkali catalyst to generate isophorone; and sending the reaction products into a reaction rectifying tower, removing unreacted acetone and hydrolyzing high boiling products with carbon atom number higher than 12, so as to obtain the isophorone crude product in a column bottom. A acetone one-way conversion rate exceeds 20%, and isophorone effective selectivity reaches higher than 90%. The method of the invention generates good mass transfer and heat transfer effects and has accurately controlled reaction time, high one-way conversion rate and good effective selectivity.

Owner:WANHUA CHEM GRP CO LTD +1

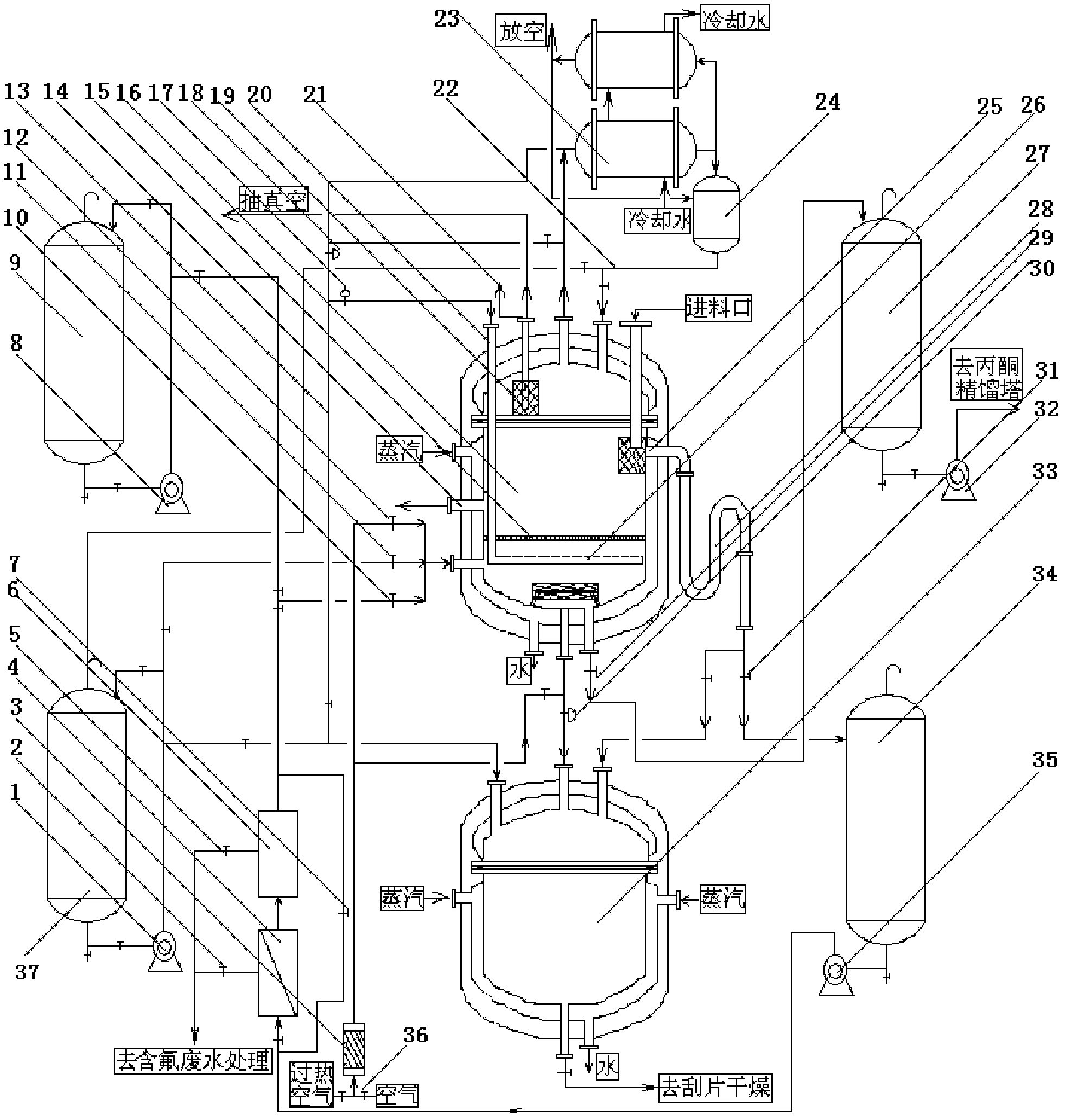

Novel polyether ketone refining process

The invention discloses a novel polyether ketone refining process, belonging to the fields of chemical engineering and fine chemistry industry, and particularly relates to a process for refinishing polyether ketone. A technical process comprises the following steps of: I, extensively leaching acetone repeatedly, and quickly feeding all diphenyl sulfone in polyether ketone in a refining kettle into an acetone solution of an acetone evaporation kettle to realize separation of diphenyl sulfone from polyether ketone; II, washing with water; III, drying; and IV, extracting a material, and cleaning the material in an air purging state. The process has the advantages of centralized equipment, small floor area, small overall investment, short production period, high efficiency, small quantity of operating personnel, convenience for managing, high production benefit, saving in energy consumption, zero discharge of pollutants in a production process, realization of high diphenyl sulfone leaching efficiency, low boiling point of acetone, small storage amount of an acetone tank and reduction in the energy consumption in the extensive leaching process of an acetone liquid, and capability of greatly saving energy since the waste water handling capacity is low in a water washing process, and is a novel environmentally-friendly chemical process.

Owner:CHANGCHUN UNIV OF TECH

Normal pressure analyzing adsorption type acetone recovery system and method of shoemaking industry

ActiveCN104841244ALow costLow failure rateDispersed particle separationVapor condensationFailure rateRecovery method

The invention discloses a normal pressure analyzing adsorption type acetone recovery system and method of the shoemaking industry. The normal pressure analyzing adsorption type acetone recovery system comprises an acetone gas compression device, an adsorption device, a refrigerator and an acetone liquid storage tank. Acetone gases are compressed to be in the medium pressure state through the compression device and then enter the adsorption device to be adsorbed; after saturation adsorption, the acetone gases are reduced to the normal pressure to be desorbed; the analyzed concentrated acetone gases enter an evaporator of the refrigerator to be cooled and liquefied, and the liquefied acetone gases enter the acetone liquid storage tank to be recovered. The normal pressure analyzing adsorption type acetone recovery system and method solve the problem that the common vacuum pressure swing adsorption acetone recovery devices are low in desorption efficiency or the vacuum pump is high in failure rate which influences use, do not adopt the vacuum pressure swing adsorption system, use a screw type booster compressor to replace the complex vacuum pump, so desorption can be finished at normal pressure, the desorption efficiency is improved greatly, the system cost and failure rate are reduced greatly, and further the efficient, safe and reliable acetone recovery system is provided.

Owner:NANJING DOULE REFRIGERATION EQUIP

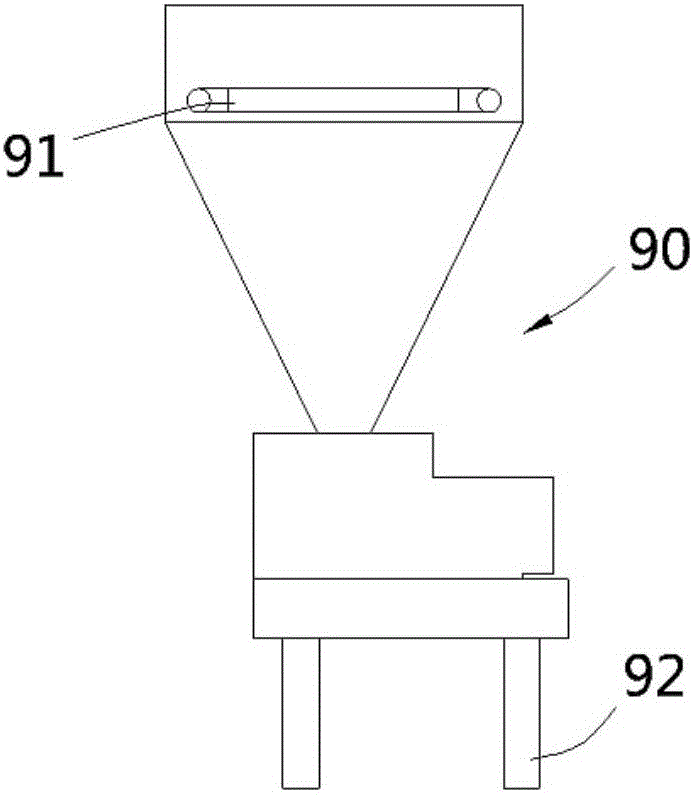

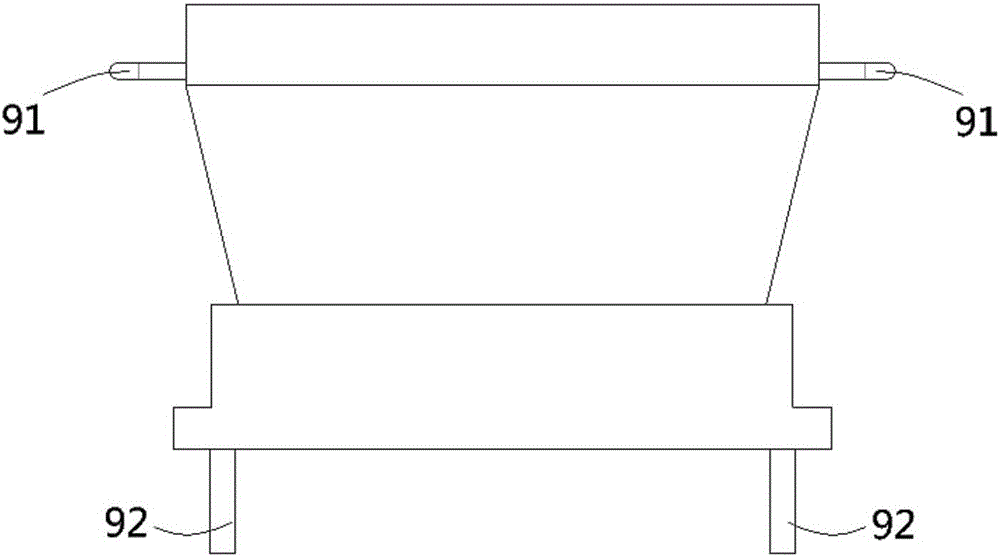

Cleaning device for metal product

ActiveCN105728378AImprove cleaning efficiencyImprove drying efficiencyDrying gas arrangementsCleaning using liquidsEngineeringTransfer mechanism

The invention discloses a cleaning device for a metal product. The cleaning device for the metal product comprises a transferring mechanism, a cleaning box, a main pipeline, an air injection mechanism, a cleaning mechanism, a drying mechanism and a product moving mechanism, wherein the transferring mechanism is composed of a lifting unit and a manipulator installed on the lifting unit; the cleaning box is arranged below the transferring mechanism; the cleaning mechanism is composed of a cleaning pipeline, a first switching valve, an acetone liquid tank which is connected with the cleaning pipeline and a pressure pump arranged in the acetone liquid tank; the drying mechanism is composed of a drying pipeline, a second witching valve and a hot gas pump which is connected with the drying pipeline; the drying pipeline communicates with the main pipeline; the second witching valve is formed on the drying pipeline on one side of the main pipeline; and the product moving mechanism is composed of a rotary unit and an up and down unit. According to the cleaning device, the metal product can be instantly dried in situ after being cleaned and then needs to be transferred by the transferring mechanism, and thus the production efficiency is improved.

Owner:宝嘉智能科技(南通)有限公司

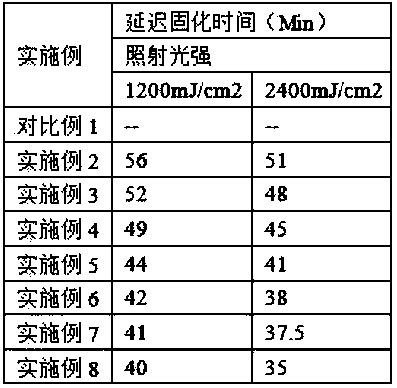

One-component epoxy adhesive capable of delayed curing induced by ultraviolet light and preparation method thereof

ActiveCN104592923BSimple operation processCuring without heatNon-macromolecular adhesive additivesMacromolecular adhesive additivesIon exchangeAlpha-bromoacetophenone

The invention relates to a UV-initiated delay-curable one-component epoxy adhesive. The adhesive is prepared from the following raw materials in percentages by weight: 30-60% of epoxy resin, 5-30% of a homemade quaternary photobase generator, 10-30% of a toughening agent and 5-20% of a filling agent, wherein the homemade quaternary photobase generator is synthesized from the following components of alpha-bromoacetophenone, terephthalic acid (TPA) and sodium tetraphenylborate by the following processes: reacting alpha-bromoacetophenone and an acetone liquid of terephthalic acid (TPA) at room temperature to prepare bromo-quaternary ammonium salt, filtering, drying and recrystallizing the product to obtain a crystal substance, dissolving the crystal substance in distilled water and carrying out anion exchange reaction on the distilled water with the crystal substance and sodium tetraphenylborate at room temperature to obtain a product, washing the product with distilled water and drying to obtain anion quaternary ammonium salt paired with tetraphenylborate. Compared with the prior art, the curing speed can be delayed to 30 minutes-60 minutes, the process is simple, neither heat curing nor mixing is needed, the adhesive is environmentally friendly and is convenient to use and is also simultaneously suitable for multiple opaque materials and can be widely used in the field of structural bonding.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Method for detecting antibacterial drugs of furazolidone and furacilin through surface-enhanced raman spectroscopy

ActiveCN102879381BQuick analysisRapid Qualitative and Quantitative AnalysisRaman scatteringNitrofurazoneSurface-enhanced Raman spectroscopy

The invention utilizes a surface-enhanced raman spectroscopy to detect antibacterial drugs of furazolidone and furacilin. A method which adopts potassium chloroaurate to reduce sodium citrate is used for preparing aurosol; an acetone liquid which contains the furazolidone or the furacilin is mixed with the aerosol, the pH is regulated to 1.0-6.0, and a laser raman spectrometer with a laser light source of 785 nanometers is adopted to scan, so that a raman spectroscopy is obtained; 1611, 1560, 1488, 1472, 1397, 1343, 1260, 1173, 1022, 977, 806 and 775 centimeters <-1> are used as qualitative characteristic peaks for identifying the furazolidone, and 1602, 1554, 1456, 1336, 1162 and 966 centimeters <-l> are used as the qualitative characteristic peaks for identifying the furacilin; and moreover, the peaks of 1611centimeters <-1> and 1602 centimeters <-1> are respectively used for quantitatively determining the furazolidone and the furacilin. The method is convenient, quick, accurate and low in cost, and can be popularized and used in the fields food and drug testing.

Owner:JIANGNAN UNIV

Adsorption acetone recovery system and recovery method using atmospheric pressure analysis in shoemaking industry

ActiveCN104841244BLow costLow failure rateDispersed particle separationVapor condensationRecovery methodFailure rate

The invention discloses a normal pressure analyzing adsorption type acetone recovery system and method of the shoemaking industry. The normal pressure analyzing adsorption type acetone recovery system comprises an acetone gas compression device, an adsorption device, a refrigerator and an acetone liquid storage tank. Acetone gases are compressed to be in the medium pressure state through the compression device and then enter the adsorption device to be adsorbed; after saturation adsorption, the acetone gases are reduced to the normal pressure to be desorbed; the analyzed concentrated acetone gases enter an evaporator of the refrigerator to be cooled and liquefied, and the liquefied acetone gases enter the acetone liquid storage tank to be recovered. The normal pressure analyzing adsorption type acetone recovery system and method solve the problem that the common vacuum pressure swing adsorption acetone recovery devices are low in desorption efficiency or the vacuum pump is high in failure rate which influences use, do not adopt the vacuum pressure swing adsorption system, use a screw type booster compressor to replace the complex vacuum pump, so desorption can be finished at normal pressure, the desorption efficiency is improved greatly, the system cost and failure rate are reduced greatly, and further the efficient, safe and reliable acetone recovery system is provided.

Owner:NANJING DOULE REFRIGERATION EQUIP

An automatic liquid replenishment system for metal film peeling and cleaning equipment

InactiveCN103295940BReasonable designEffective monitoring of liquid levelSemiconductor/solid-state device manufacturingPositive pressureLiquid storage tank

The invention relates to an automatic liquid adding system for a metal film stripping and cleaning device. The liquid adding system comprises an NMP soaking tank, an isopropanol supply pressure tank connected with a vacuum negative pressure liquid adding device, an acetone liquid supply pressure tank connected with a nitrogen positive pressure liquid supply device, and an NMP liquid supply pressure tank for supplying NMP liquids to the NMP soaking tank. A liquid adding inlet of the isopropanol liquid supply pressure tank is connected with a isopropanol liquid storage tank through a liquid adding pipe, a liquid adding inlet of the acetone liquid supply pressure tank is connected with a acetone liquid storage tank through a liquid adding pipe, and a liquid adding inlet of the NMP liquid supply pressure tank is connected with an NMP liquid storage tank through a liquid adding pipe. A liquid level detecting switch is disposed in each of the isopropanol supply pressure tank, the acetone liquid supply pressure tank, the NMP liquid supply pressure tank and the NMP soaking tank. By the automatic liquid adding system which is capable of unattended operation, operation efficiency of the system is increased evidently, automatic liquid adding is achieved, and equipment automation level is increased. In addition, the automatic liquid adding system is applicable to other full-automatic single-chip wet processing equipment.

Owner:THE 45TH RES INST OF CETC

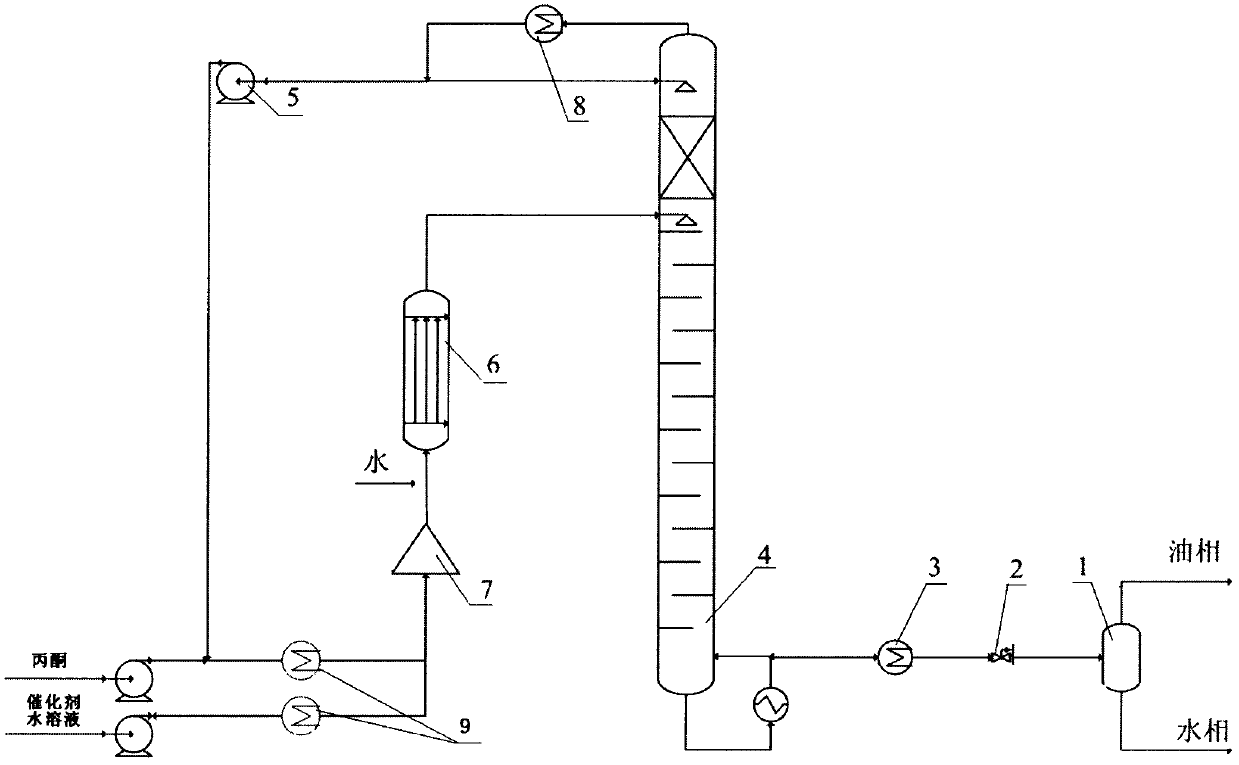

A kind of post-processing technology of isophorone prepared by liquid-phase condensation method of acetone

ActiveCN111377806BRaise the ratioReduce energy consumptionOrganic compound preparationChemical industryPtru catalystIsophorone

The invention discloses a post-treatment process for preparing isophorone by acetone liquid-phase condensation method. The process includes: extracting a part of the liquid-phase stream of the tower bottom of the reactive distillation column and sending it to the isophorone demulsification recovery tower for disposal, and recovering the isophorone in the stream without additional additives, containing isophorone The top stream of the demulsification tower of phorone is then partially or fully returned to the reactive distillation tower; the isophorone-containing water phase is flashed or distilled to recover isophorone, and the water is returned to the reactive distillation tower for recycling. ; The liquid phase catalyst recovered by flash evaporation or distillation is concentrated and sent back to the reaction unit for recycling. By adopting the process of the invention, the energy consumption can be greatly reduced, the loss of isophorone and the catalyst in the wastewater can be significantly reduced, and the amount of the wastewater can be significantly reduced.

Owner:WANHUA CHEM GRP CO LTD +1

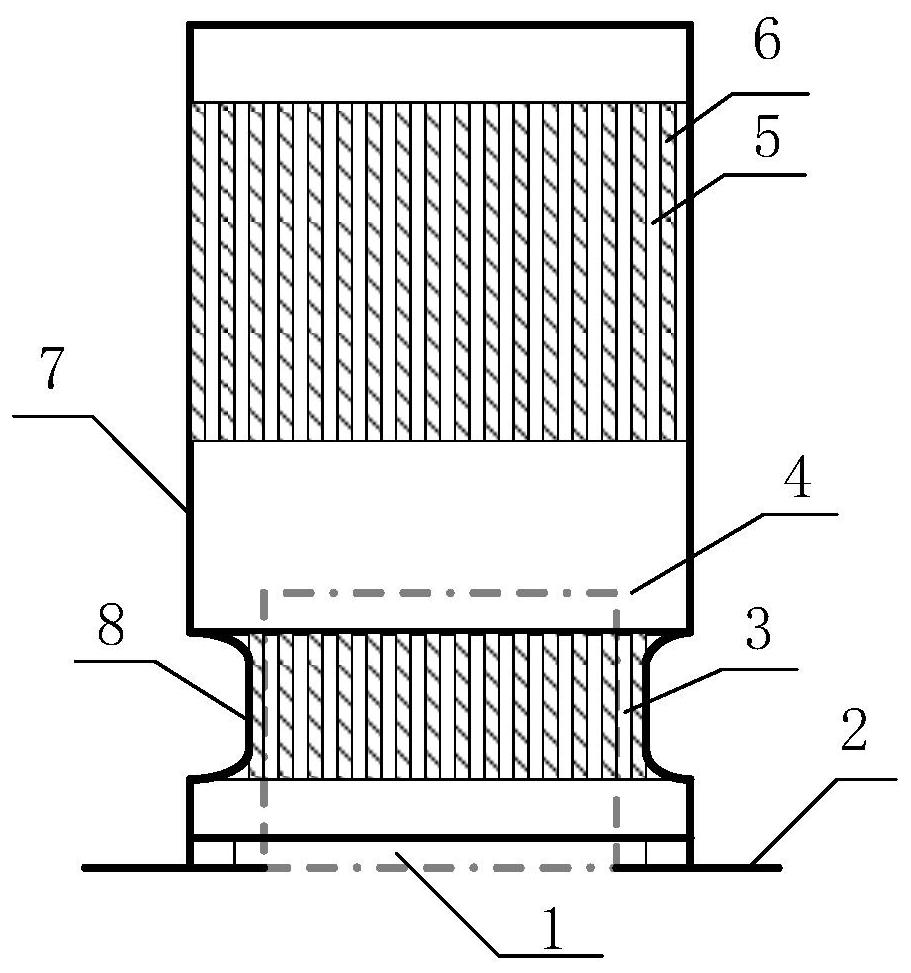

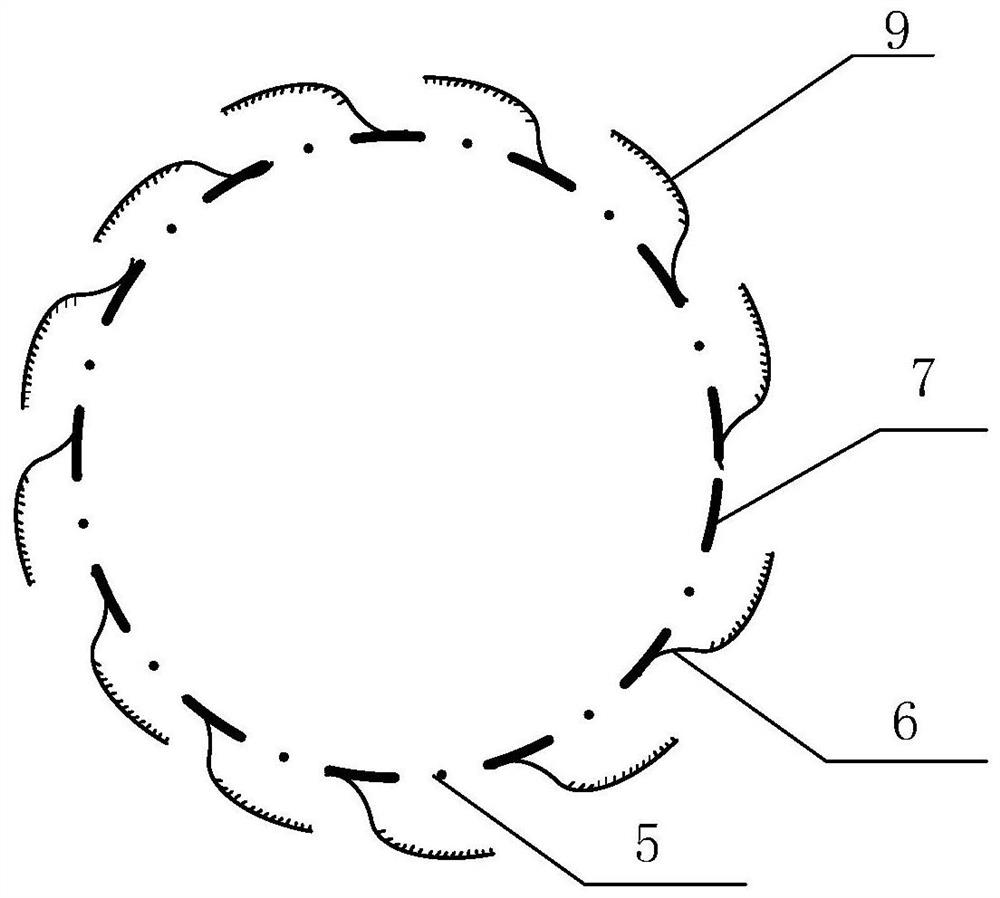

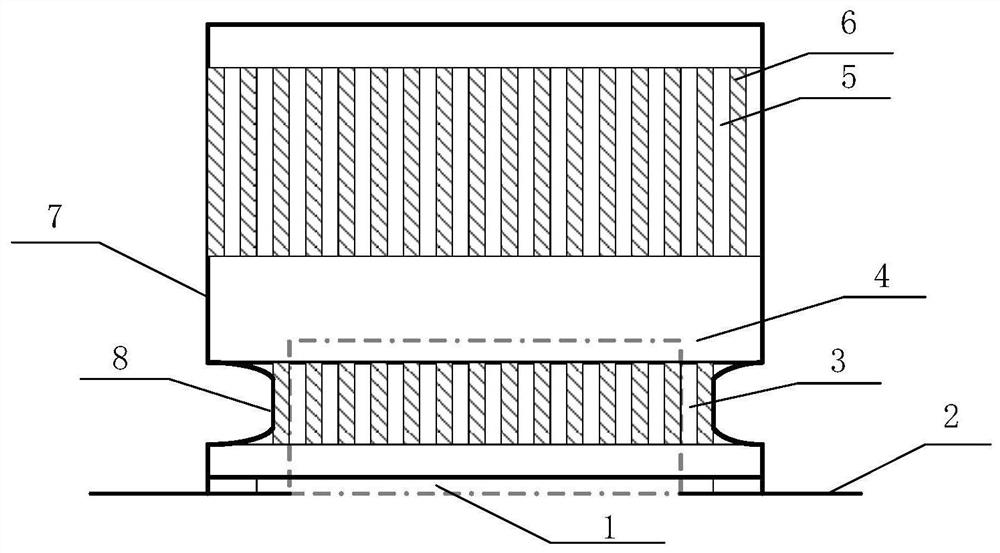

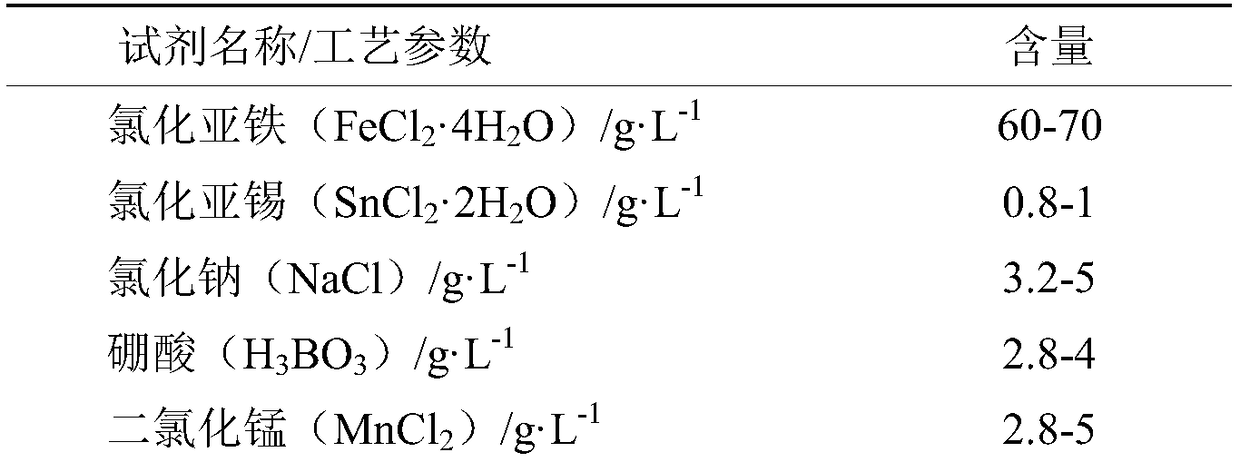

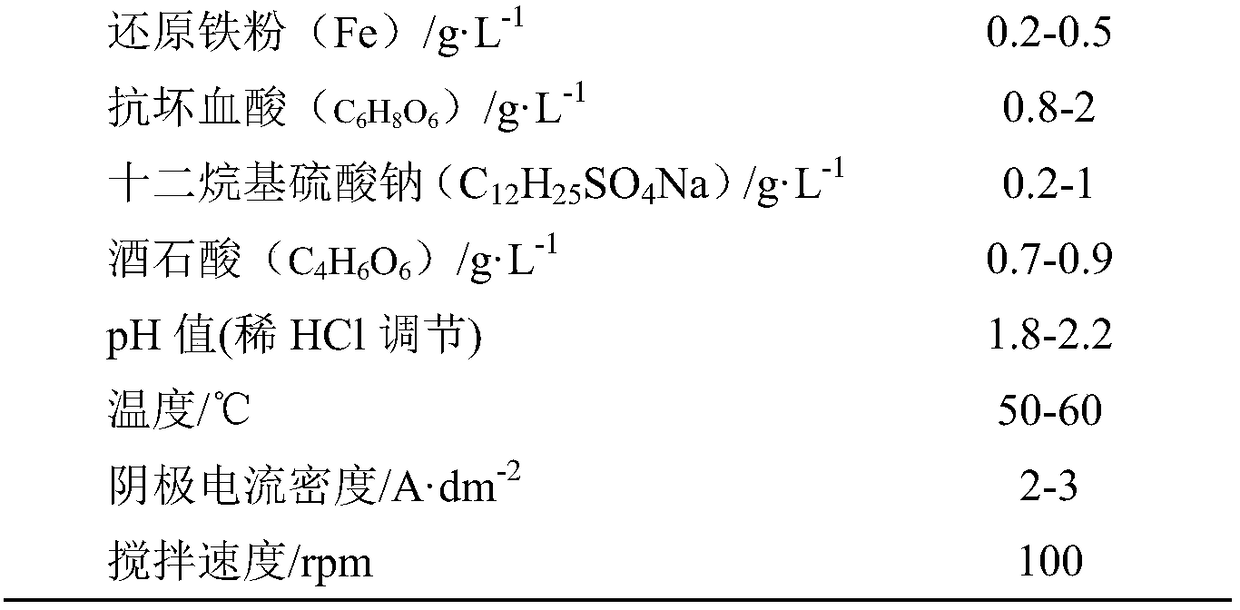

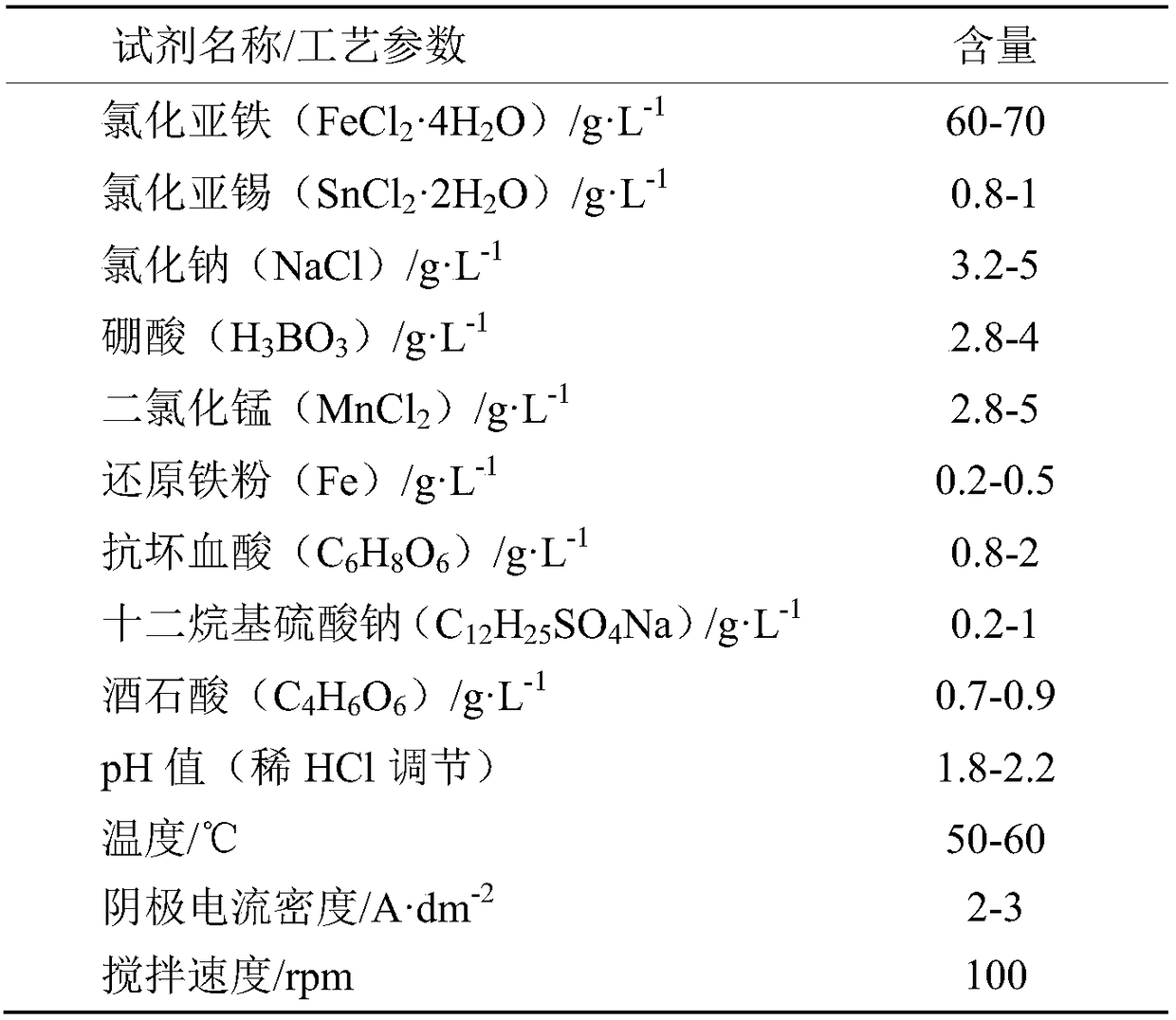

Electroplating solution composition and technology for electroplating high-iron and low-tin alloy

The invention relates to an electroplating solution composition and technology for electroplating a high-iron and low-tin alloy containing 75 wt%-85 wt% of iron in a chloride system, and belongs to the field of material surface electroplating. According to the technology method, treatment before electroplating is conducted, an electroplated part made of copper or brass is ground and polished and then placed in an organic solvent such as acetone liquid to be subjected to oil dirt removal, tap water is used for cleaning, then, the electroplated part is placed in a hydrochloric acid solution withthe temperature being 30-40 DEG C and the concentration being 4-6 g.L<-1> to be immersed for 10-20 min, and accordingly surface oxide is removed. For non-copper electroplated parts made of iron, an alloy of the iron and the like, polishing copper electroplating is conducted on the surfaces of the non-copper electroplated parts through a traditional method; an electroplating solution is prepared for electroplating according to the chart 1, and electroplating is conducted according to technology parameters; treatment is conducted after electroplating, an electroplated part obtained after electroplating is placed in a 5 wt%-10 wt% of NaOH solution to be immersed for 20-30 min, cleaning is conducted through tap water and distilled water or deionized water, an air blowing machine is used for blowing dry, and the high-iron and low-tin alloy containing 75 wt%-85 wt% of iron is obtained.

Owner:YUNNAN NORMAL UNIV

Technology of preparing lithium ion electrode material by Ce and WO3 modification

The invention discloses a technology of preparing a lithium ion electrode material by Ce and WO3 modification. The technology comprises the steps of mixing Li2CO3, FeC2O4-2H2O, NH4H2PO4, WO3 and Ce asraw materials according to according to a certain proportion, cleaning the raw materials with an acetone solution, filling a mixture into a ball milling jar, adding an appropriate amount of sucrose and steel balls, performing ball milling under the protection of acetone liquid sealing, airing powder after the ball milling, performing vacuum sealing, putting at high temperature for calcining, andobtaining the lithium ion electrode material after a calcining reaction.

Owner:郑观情

A kind of method that adopts nano-molten salt to prepare silicon-aluminum-iron alloy containing nanoparticle

ActiveCN109576520BLow costReduce manufacturing costProcess efficiency improvementNanoparticleFerrosilicon

The invention provides a method for preparing silicon-aluminum-iron alloy containing containing nano-particles by using nano-molten salt, and belongs to the field of special ferroalloy production. Themethod comprises the steps that step one, mixed salt containing the nano-particles is prepared, that is, the nano-particles are mechanically mixed with the salt and then acetone liquid is added, vacuum-pumping and heating are carried out in a vacuum drying oven after ultrasonic vibration treatment, and the acetone is completely volatilized to obtain evenly mixed salt containing the nano-particles; and step two, the silicon-aluminum-iron alloy containing the nano-particles is smelted in an induction furnace, that is, scrap steel, seventy-fifth silicon iron, aluminum ingot, mixed salt containing the nano-particles and lime are sequentially added in an medium frequency induction furnace, the scrap steel, the seventy-fifth silicon iron, the aluminum ingot, the mixed salt containing the nano-particles and the lime are melted, keeping warm, stopping heating and standing are carried out, the silicon-aluminum-iron alloy containing the nano-particles is obtained by cast molding. According to the method, the nano-particles are added in the production process of silicon-aluminum-iron alloy to obtain the silicon-aluminum-iron alloy with even distribution of the nano-particles, and intermediate alloy is provided for preparing nano-particle containing steel at low cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Heterogeneous catalytic method for synthesis of isophorone from acetone

ActiveCN101875602BMild reaction conditionsTechnical securityPhysical/chemical process catalystsOrganic compound preparationCatalytic methodPtru catalyst

The invention relates to a heterogeneous catalytic method for synthesis of isophorone from acetone. Acetone is used as a raw material, and a magnesium-aluminum composite oxide is used as a catalyst for carrying out catalytic synthesis to obtain isophorone; the magnesium-aluminum composite oxide comprises MgO, Al2O3 and MgAl2O4, the molar ratio of magnesium to aluminum is 0.3-3, the specific surface area is 80-150m<2> / g, and the pore volume is 0.2-0.3cm<3> / g; a fixed bed reactor is used for carrying out synthetic reaction, 20ml of 20 to 40-mesh catalyst is added into a stainless steel reactor of which the inner diameter is 10mm, the reactor is heated to the reaction temperature from the room temperature at the rate of 10 DED C / min after being qualified through an air-tight test, and then, the analytically pure acetone raw material is injected into the reactor by a duplex plunger pump through a preheater; the reaction temperature is 220-290 DEG C; the reaction pressure is normal pressure; and the air speed of the acetone liquid is 0.1-1.0 / h, the selectivity reaches 94.5%, the conversion rate reaches 44.8%, and the stability reaches 1000 hours.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com