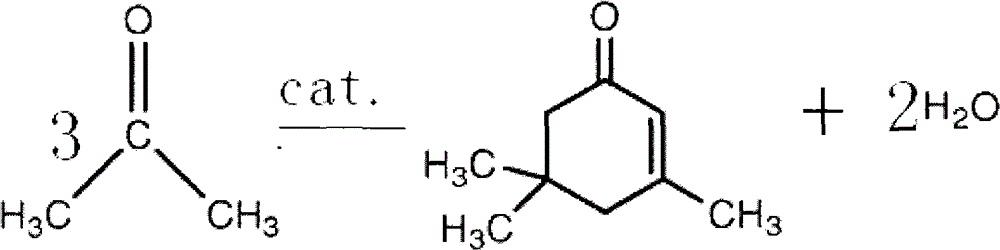

Heterogeneous catalytic method for synthesis of isophorone from acetone

A heterogeneous catalysis and isophorone technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve complex catalyst preparation process, low selectivity of isophorone, difficult regeneration and other problems, to achieve the effect of green and low toxicity in the process, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

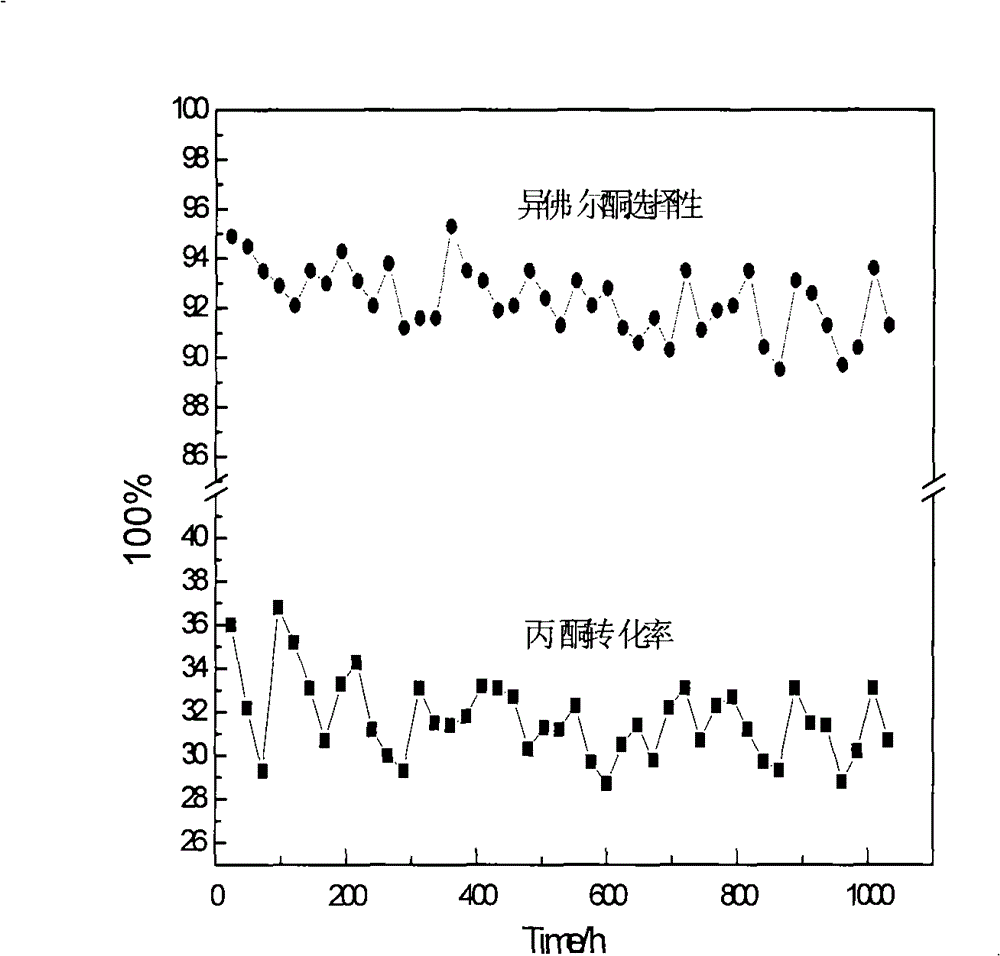

Embodiment 1

[0024] Dissolve 23.08 g of magnesium nitrate hexahydrate and 56.27 g of aluminum nitrate nonahydrate in 2000 ml of deionized water, and add ammonia water dropwise at 38°C until the pH is 8.5. Aging at 70°C for 12 hours and standing for cooling for 1 hour. Filter and rinse the filter cake with deionized water until the pH of the filtrate is 7.0. Dry overnight at 80°C, and calcinate at 350°C for 7 hours in an air atmosphere to prepare the catalyst. Catalyst evaluation conditions were: normal pressure, 220°C, acetone feed rate of 0.33ml / mim, after 24 hours of reaction, samples were taken for analysis, the conversion rate of acetone was 20.3%, and the selectivity of isophorone was 86.5%.

Embodiment 2

[0026] Catalyst preparation is the same as embodiment 1. Catalyst evaluation conditions were: normal pressure, 250°C, acetone feed rate of 0.33ml / mim, after 24 hours of reaction, samples were taken for analysis, the conversion rate of acetone was 25.2%, and the selectivity of isophorone was 90.0%.

Embodiment 3

[0028] Catalyst preparation is the same as embodiment 1. Catalyst evaluation conditions were: normal pressure, 290°C, acetone feed rate of 0.33ml / mim, after 24 hours of reaction, samples were taken for analysis, the conversion rate of acetone was 34.5%, and the selectivity of isophorone was 90.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com