Method for preparing isophorone by acetone liquid condensation with alkali catalyst

A technology of isophorone and catalyst, applied in the field of preparation of isophorone, can solve the problems of high process cost, low effective selectivity of isophorone, low conversion rate of acetone per pass and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

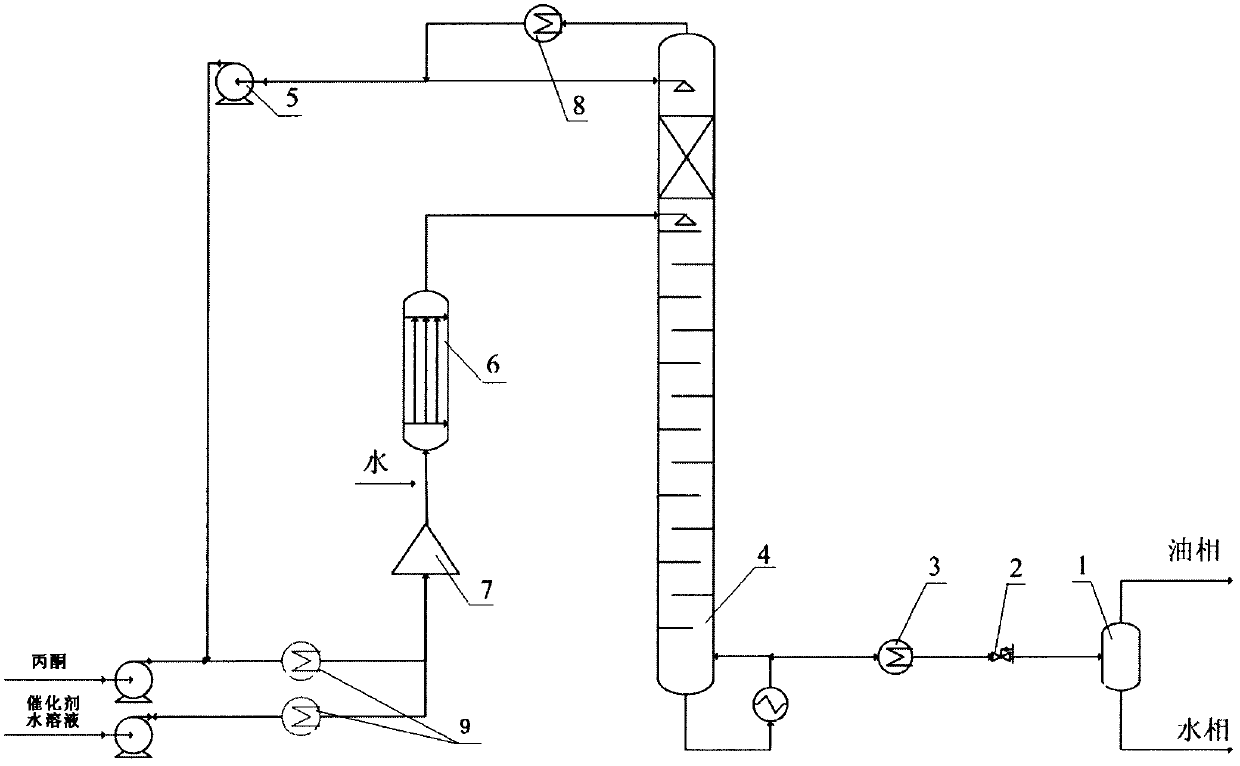

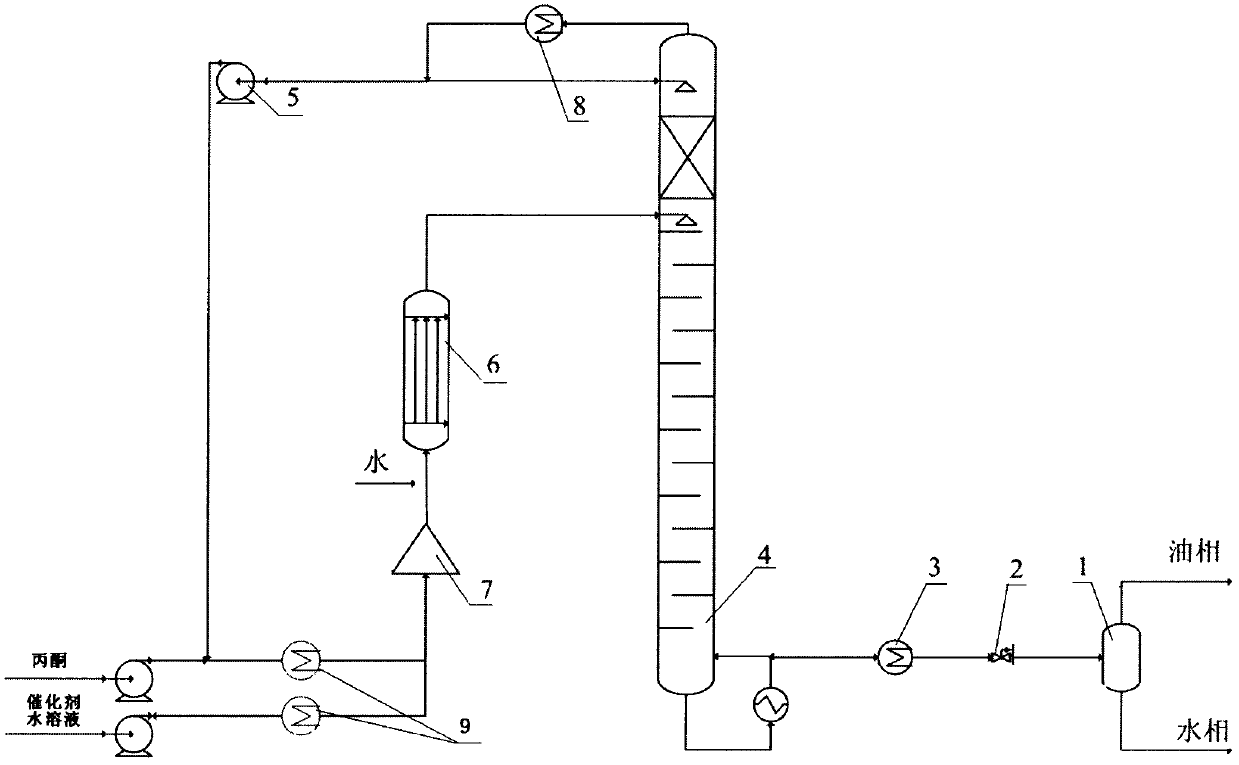

[0032] according to figure 1 The technological process, under continuous steady-state operating conditions, fresh acetone is heated to 230 ℃ through heat exchanger 9 with the flow rate of 100kg / h and the reclaimed acetone (mainly acetone, other about 18wt%) of rectification step from the back , and then preheated to the same temperature, flow rate 38kg / h, KOH aqueous solution with a concentration of 1.8% enters the mixer 7 and mixes fully. After mixing, the mass flow ratio of acetone and water is about 4: 1, and KOH is in the total mixture. The mass fraction is about 0.1%. The mixer adopts SV-type high-efficiency static mixer with a pipe diameter of 20mm and a length of 1m. The residence time of the reaction liquid in the mixer is 15s. The acetone conversion rate is 2% through gas chromatography analysis. Then the reaction solution enters the microchannel reactor 6 produced by Wanhua Polyurethane Company to react. The channel cross section is circular, the inner diameter of t...

Embodiment 2

[0034] according to figure 1 The technological process, under continuous steady-state operating conditions, after fresh acetone is mixed with the reclaimed acetone (mainly acetone, about 18wt% of water) from the rectification step behind with the flow rate of 100kg / h, it is pre-heated by heat exchanger 9 Heat to 280°C, and then fully mix with the KOH solution with a flow rate of 12kg / h and a concentration of 5.0% that is preheated to the same temperature through the mixer 7. At this time, the mass ratio of acetone and water is about 5:1, and KOH is in the total mixture. The mass fraction in is 0.12%. The mixer adopts SV type high-efficiency static mixer with a pipe diameter of 20mm and a length of 1m, and the residence time of the reaction liquid in the mixer is 3s. Then the reaction solution enters the microchannel reactor 6 produced by Wanhua Polyurethane Company for reaction. The inner diameter of the microchannel is 1.5 mm, the number of channels is 1200, the reaction tem...

Embodiment 3

[0036] according to figure 1 The technical process, under continuous steady-state operating conditions, fresh acetone is mixed with reclaimed acetone (mainly acetone, about 18% by weight of water) from the rectification step behind with the flow rate of 100kg / h after fresh acetone is preheated through heat exchanger 9 Heat to 250°C, then fully mix with the KOH solution that is preheated to the same temperature and have a flow rate of 13kg / h and a concentration of 3.2% through the mixer 7. The mass ratio of the mixed acetone and KOH solution is about 5: 1, and KOH is in the The mass fraction in the total mixture is about 0.08%. The mixer adopts SV-type high-efficiency static mixer, with a pipe diameter of 10mm, a pipe number of 30, and a length of 10m. The residence time of the reaction solution in the mixer is 1min. The acetone conversion rate is 6% through gas chromatography, and then the reaction solution is mixed with a 120kg Enter the microchannel reactor 6 that Wanhua Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com