Non-ionic waterborne polyurethane coating agent for leather and preparation method thereof

A water-based polyurethane and non-ionic technology, applied in the direction of polyurea/polyurethane coating, application, coating, etc., can solve the problems such as the use and technical effect of the leather finishing agent that have not been stated, and achieve the improvement of fastness, leather grade and production cost Low, reduce the effect of production and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

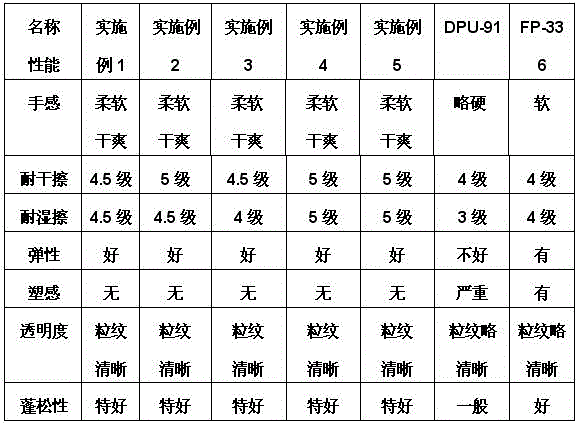

Examples

Embodiment 1

[0052] Raw material ratio by weight:

[0053] (1) Prepolymerization reaction: 28.8 parts of isophorone diisocyanate (IPDI), 5.6 parts of hexamethylene diisocyanate, 21 parts of polytetramethylene glycol (molecular weight 800), polycarbonate diol (molecular weight Add 40 parts of 1000) and 25 parts of acetone into the reaction kettle, heat up to 80-85°C and stir for 1.5 hours;

[0054] (2) Chain extension reaction: add 5 parts of polyethylene glycol monomethyl ether (molecular weight 800), 10 parts of polyethylene glycol ether (molecular weight 220), and continue to react for 3.5 hours at 80-85 °C;

[0055] (3) Emulsification reaction: Add 180 parts of deionized water, quickly disperse, stir and react at 50-55°C for 0.5 hours;

[0056] (4) Chain extension reaction: Add 8.2 parts of small molecule chain extender isophorone diamine, stir and react at 50-55°C for 2.5 hours, cool down to 40-45°C, extract the solvent acetone under reduced pressure to obtain the product, cool down f...

Embodiment 2

[0059] Raw material ratio by weight:

[0060] (1) Prepolymerization reaction: 35 parts of isophorone diisocyanate (IPDI), 17 parts of hexamethylene diisocyanate, 28 parts of polytetramethylene glycol (molecular weight 1000), polycarbonate diol (molecular weight Add 70 parts of 3000) and 25 parts of acetone into the reaction kettle, heat up to 80-85°C and stir for 2 hours;

[0061] (2) Chain extension reaction: add 10 parts of polyethylene glycol monomethyl ether (molecular weight 800), 10 parts of polyethylene glycol ether (molecular weight 200), ethylene oxide, propylene oxide block copolyether (molecular weight 300) Continue to react 10 parts at 80-85°C for 4 hours;

[0062] (3) Emulsification reaction: Add 280 parts of deionized water, quickly disperse, stir and react at 50-60°C for 0.5 hours;

[0063] (4) Chain extension reaction: Add 7.3 parts of small molecule chain extender ethylenediamine, stir and react at 55-60°C for 2-3 hours, cool down to 40-45°C, extract the sol...

Embodiment 3

[0066] Raw material ratio by weight:

[0067] (1) Prepolymerization reaction: 20 parts of isophorone diisocyanate (IPDI), 15 parts of hexamethylene diisocyanate, 15 parts of polytetramethylene glycol (molecular weight 500), polycarbonate diol (molecular weight 2000) 60 parts and 29 parts of acetone were added to the reaction kettle, and the temperature was raised to 80-85°C and stirred for 1.5 hours;

[0068] (2) Chain extension reaction: Add 8 parts of polyethylene glycol monomethyl ether (molecular weight 1200), 15 parts of ethylene oxide and propylene oxide block copolyether (molecular weight 400), and continue to react for 4 hours at 80-85 °C;

[0069] (3) Emulsification reaction: add 210.6 parts of deionized water, quickly disperse, stir and react at 55-60°C for 1 hour;

[0070] (4) Chain extension reaction: Add 5.6 parts of small molecule chain extender triethylenediamine and 1.8 parts of ethylenediamine, stir and react at 50-55°C for 2.5 hours, cool down to 40-45°C, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com