Patents

Literature

383results about "Carboxyl rubber adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

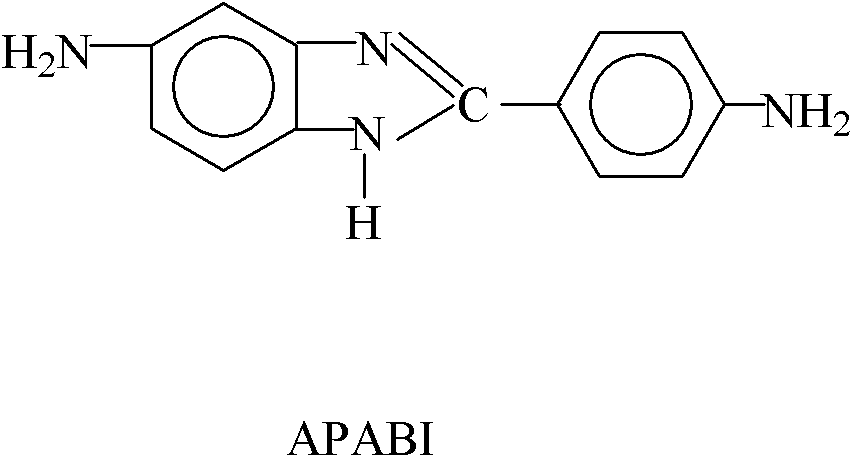

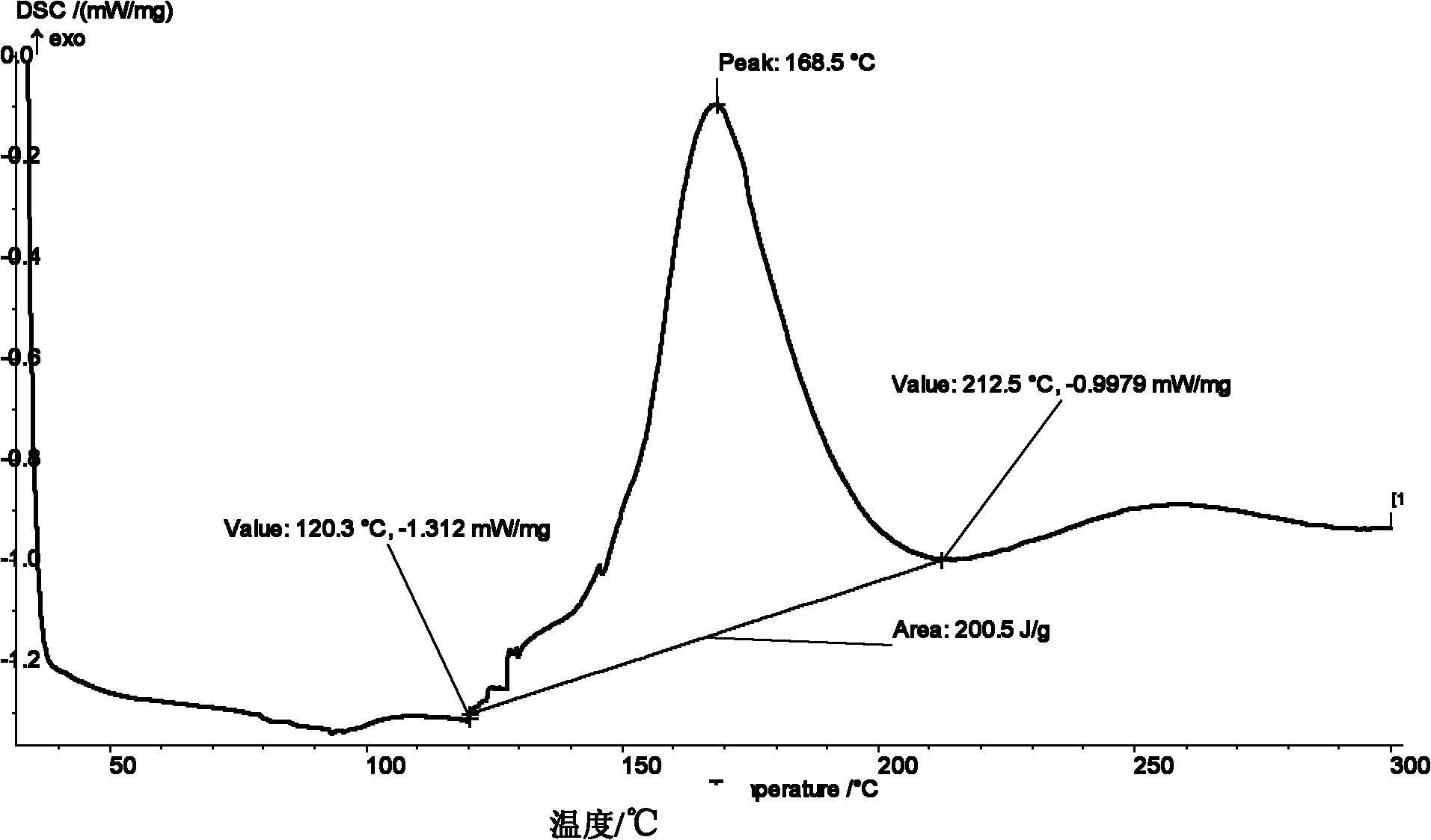

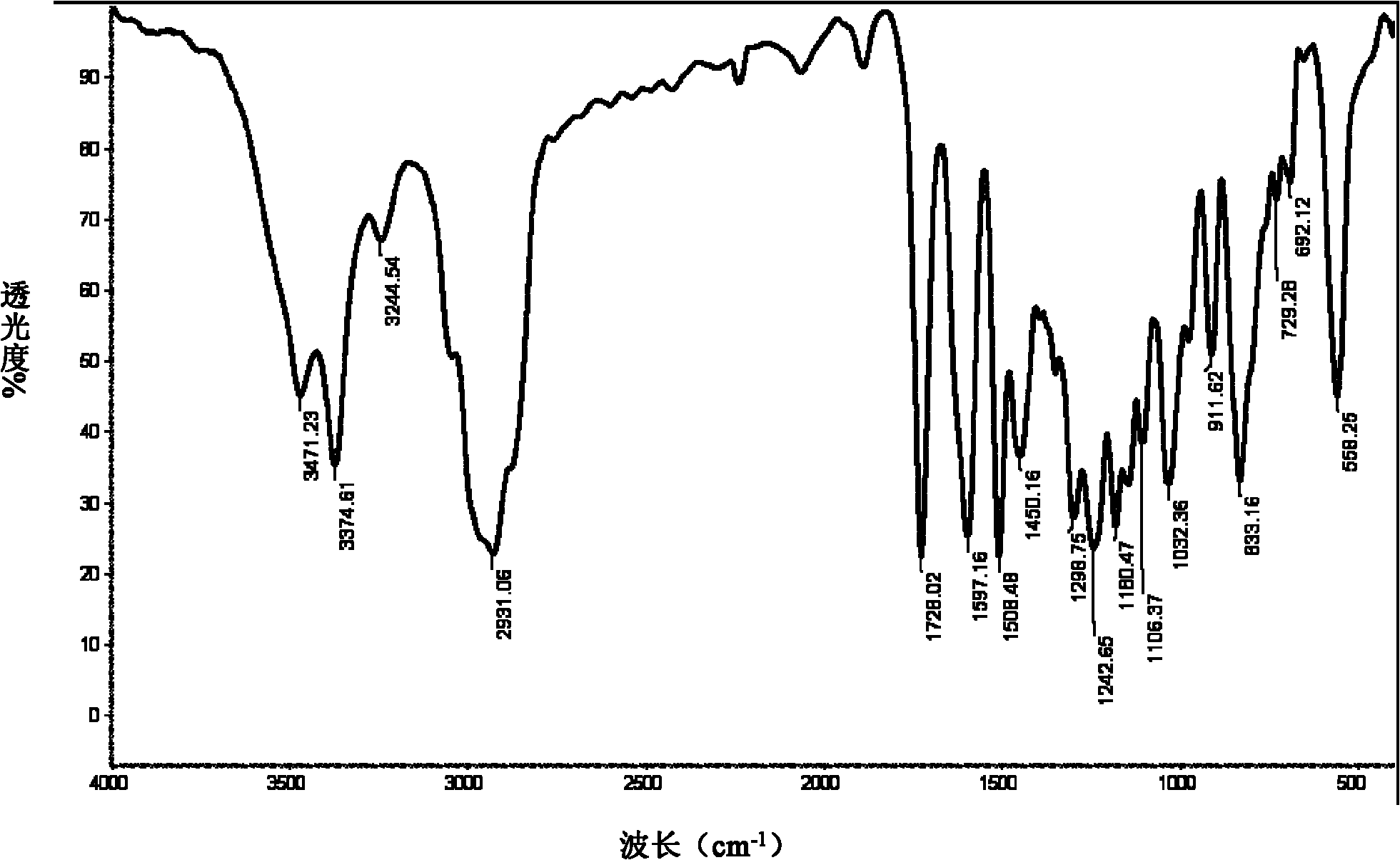

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

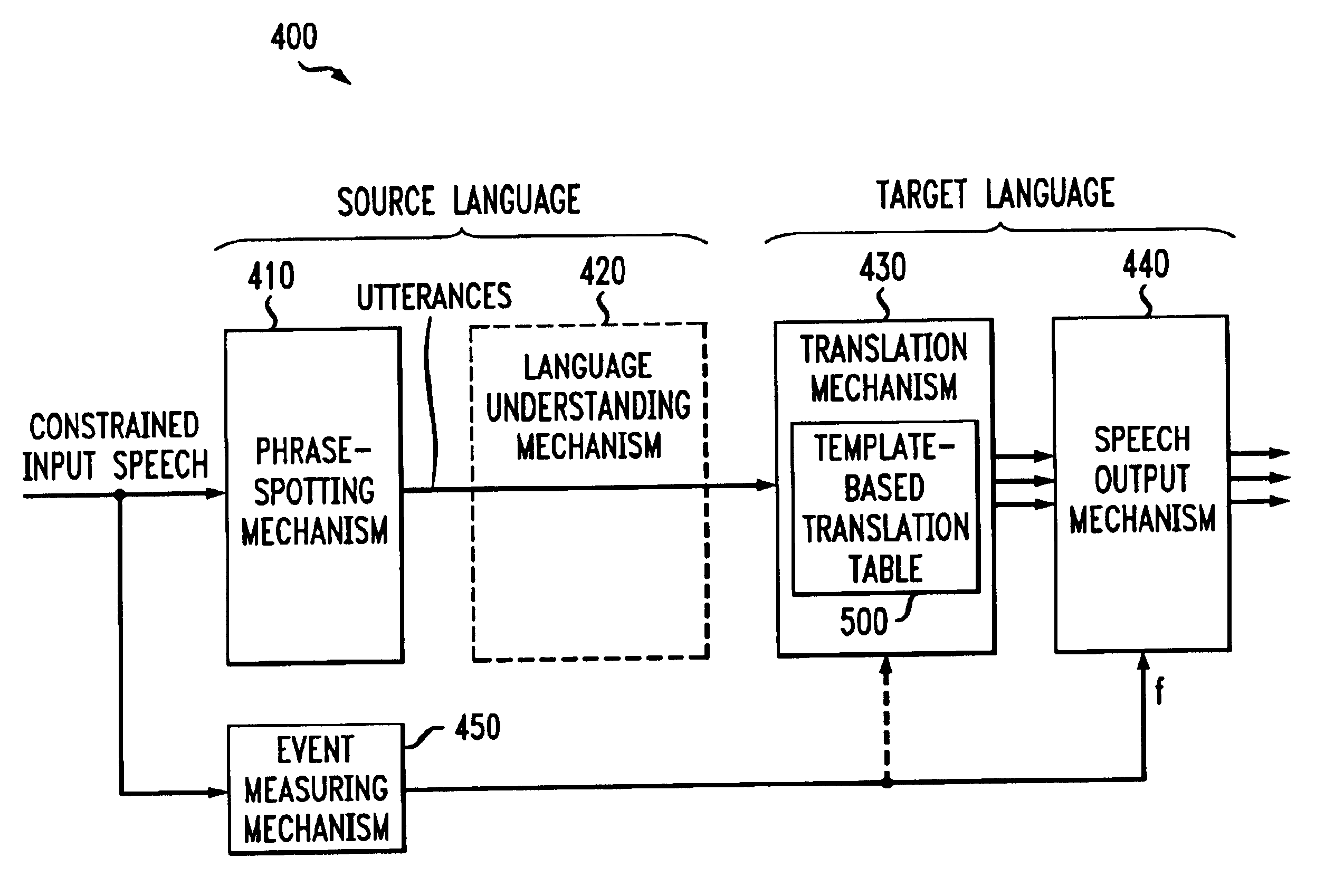

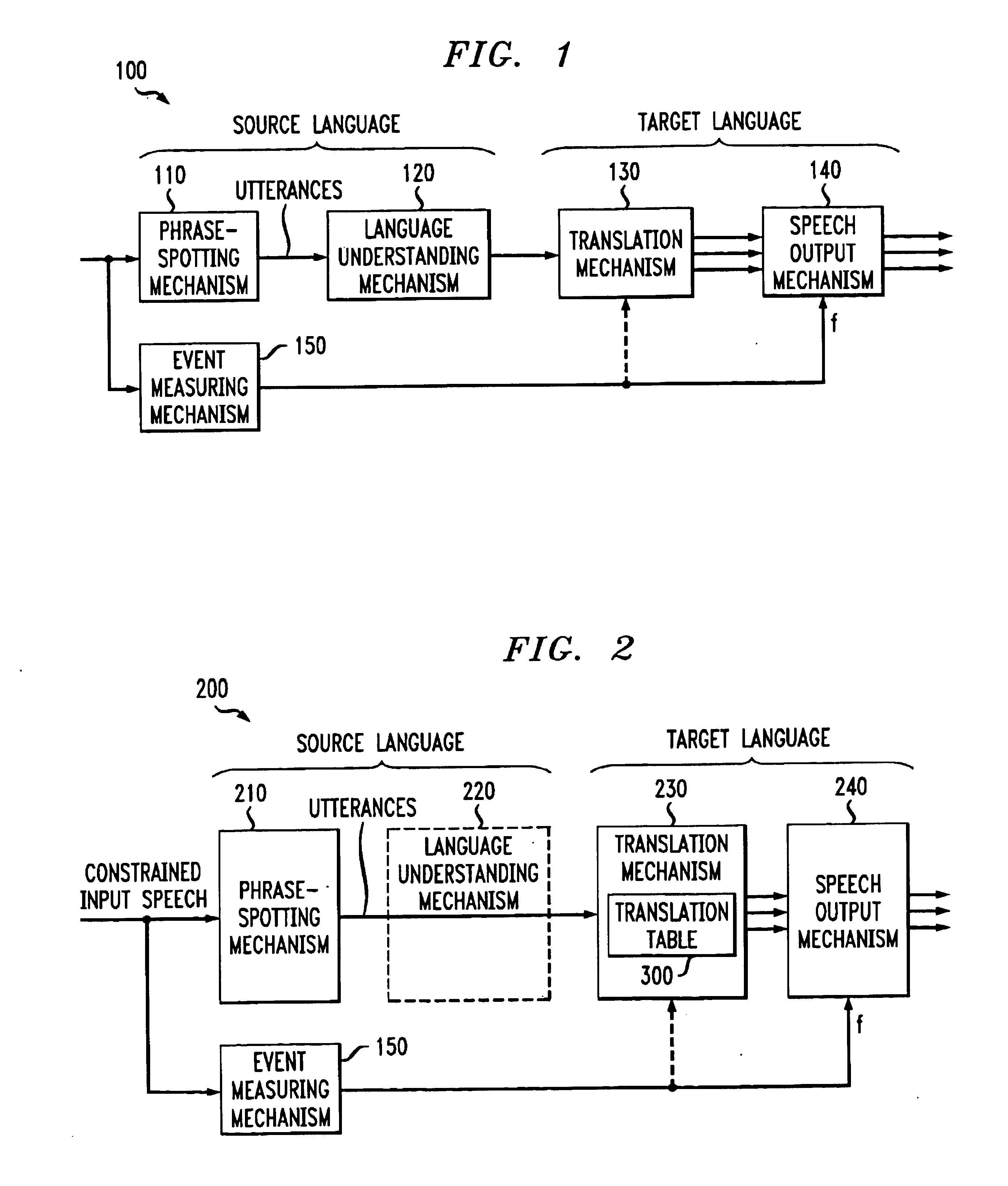

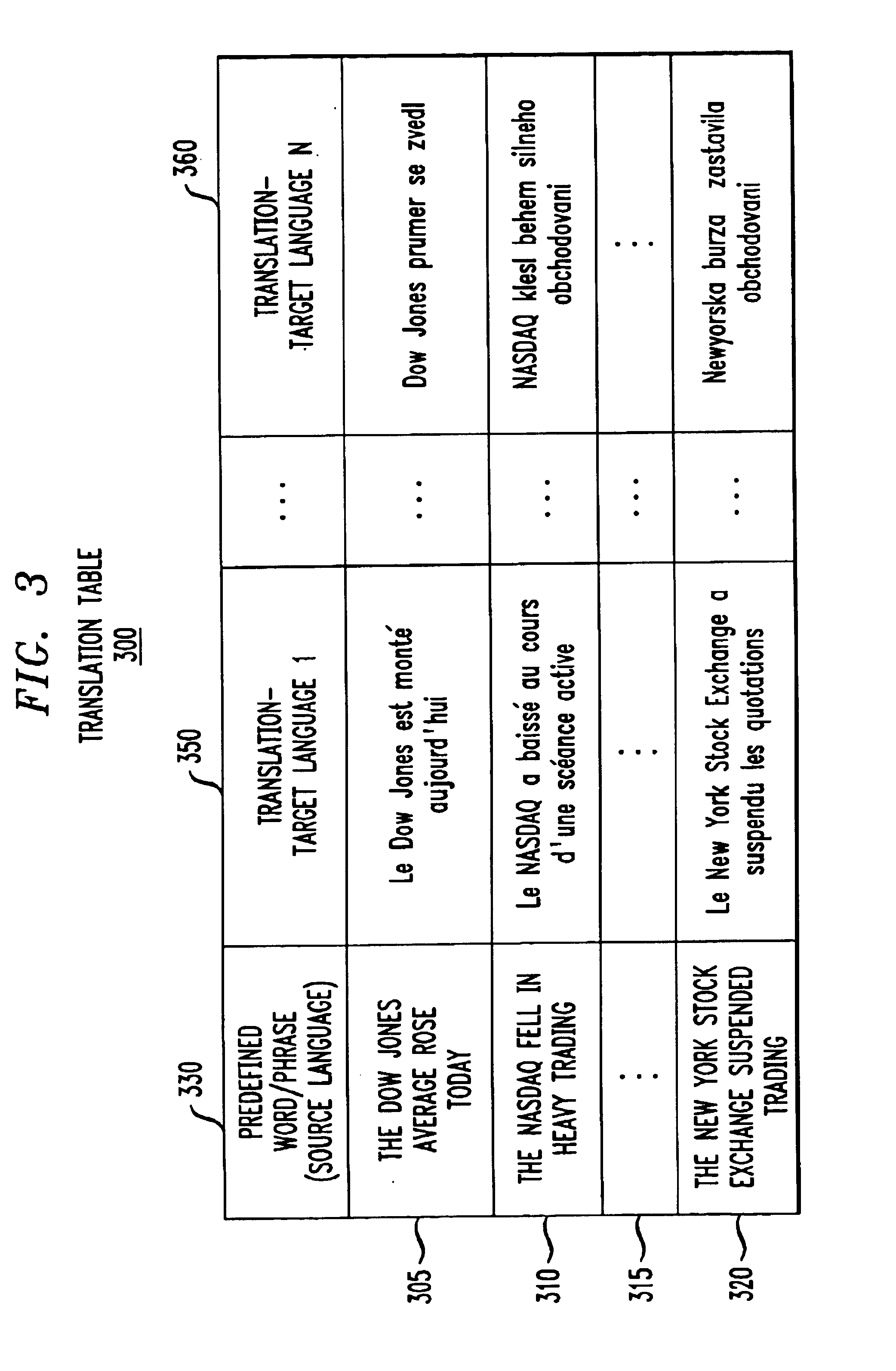

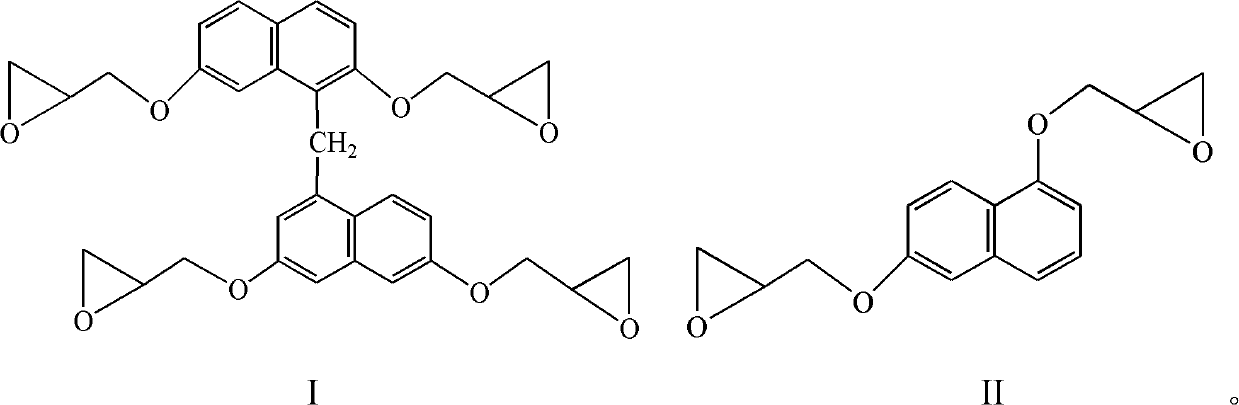

Method and apparatus for translating natural-language speech using multiple output phrases

InactiveUS6859778B1Accurate synchronizationQuality improvementNatural language translationAdhesive processes with adhesive heatingLanguage understandingSadness

A multi-lingual translation system that provides multiple output sentences for a given word or phrase. Each output sentence for a given word or phrase reflects, for example, a different emotional emphasis, dialect, accents, loudness or rates of speech. A given output sentence could be selected automatically, or manually as desired, to create a desired effect. For example, the same output sentence for a given word or phrase can be recorded three times, to selectively reflect excitement, sadness or fear. The multi-lingual translation system includes a phrase-spotting mechanism, a translation mechanism, a speech output mechanism and optionally, a language understanding mechanism or an event measuring mechanism or both. The phrase-spotting mechanism identifies a spoken phrase from a restricted domain of phrases. The language understanding mechanism, if present, maps the identified phrase onto a small set of formal phrases. The translation mechanism maps the formal phrase onto a well-formed phrase in one or more target languages. The speech output mechanism produces high-quality output speech. The speech output may be time synchronized to the spoken phrase using the output of the event measuring mechanism.

Owner:IBM CORP +1

Bi-component adhesive composition and preparation method thereof

ActiveCN103305170AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNitrile rubberHeat resistance

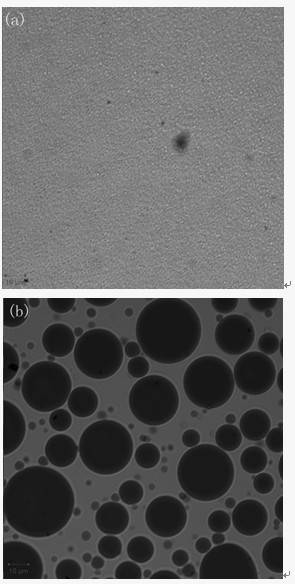

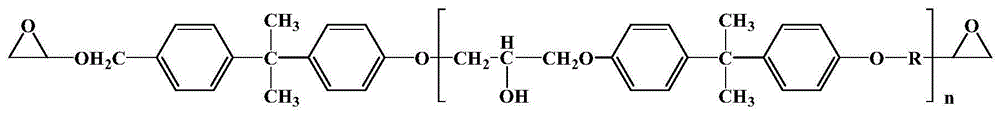

The invention provides a bi-component adhesive composition composed of an A component and a B component. The A component contains an epoxy resin mixture, a first toughening agent, filler and a thixotropic agent; the B component contains a second toughening agent, a normal temperature curing agent, a high-temperature curing agent and an accelerant; the epoxy resin mixture contains a first epoxy resin, a second epoxy resin and a third epoxy resin, the first epoxy resin is a bisphenol A epoxy resin or a bisphenol A epoxy resin, the second epoxy resin is a chelate modified epoxy resin, and the third epoxy resin is a naphthalene-nucleus modified epoxy resin; the first toughening agent is a core-shell structure rubber nano particle, the second toughening agent is an end-isocyanate polyurethane and / or end-carboxy nitrile rubber. The invention further provides a preparation method of the bi-component adhesive. The adhesive composition provided by the invention is high in adhesion strength, high in heat resistance, low in water adsorption, high in impact resistance, and capable of satisfying the use requirement of structural adhesive for connecting structural members of an automobile.

Owner:BYD CO LTD

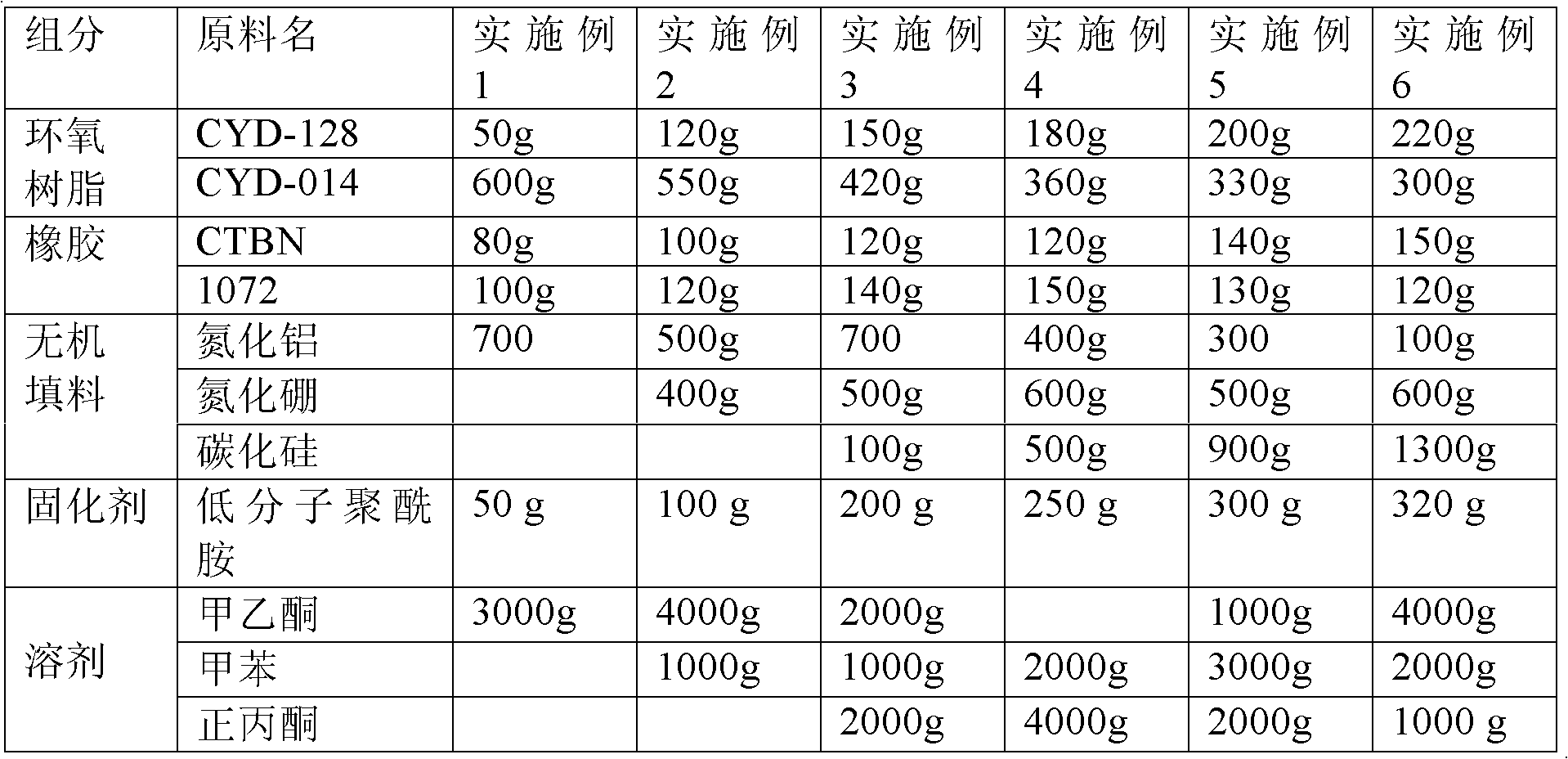

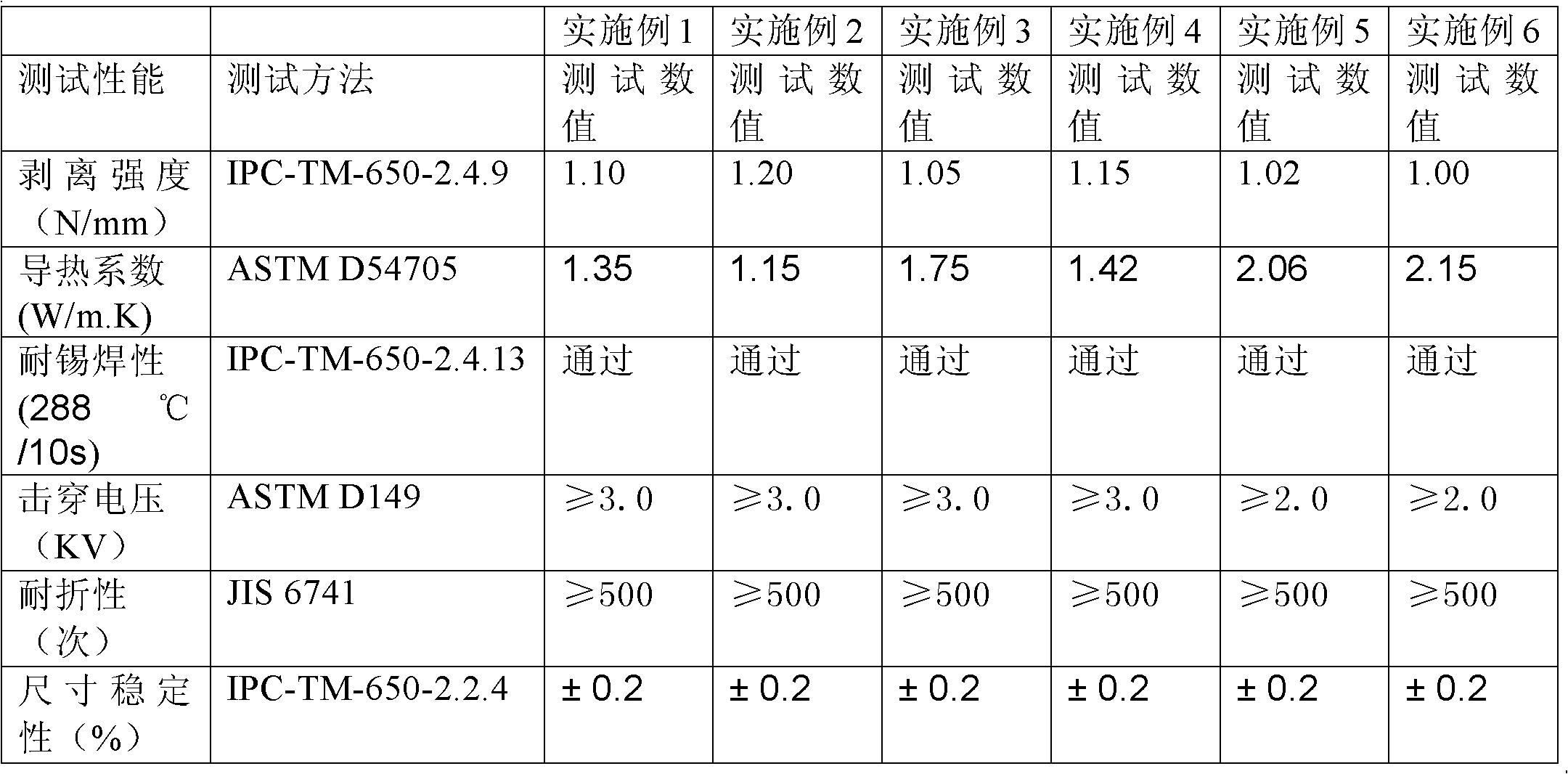

Modified epoxy resin adhesive and preparation method thereof

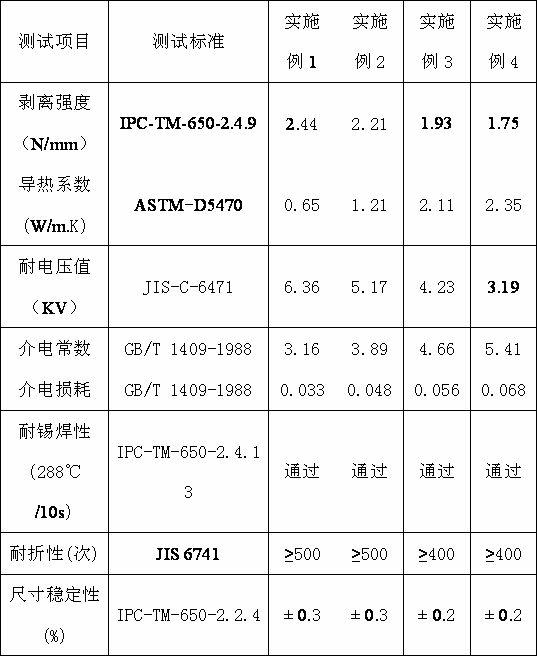

ActiveCN101654605AGood flexibilityHigh peel strengthInsulating substrate metal adhesion improvementCarboxyl rubber adhesivesEpoxyPliability

The invention discloses a modified epoxy resin adhesive, which comprises the following components in portion by weight: 10 to 50 portions of epoxy resin, 20 to 80 portions of toughening agent, 0.2 to 5 portions of curing agent, 0 to 2 portions of curing accelerant, 0 to 1 portion of assistant, 2 to 15 portions of inorganic filler and 20 to 80 portions of solvent. In order to overcome the defects in the prior art, the invention provides the modified epoxy resin adhesive with strong flexibility, high peeling strength, good flexure property, good size stability, strong chemical corrosion resistance and excellent electric performance, and a method for producing the modified epoxy resin adhesive.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

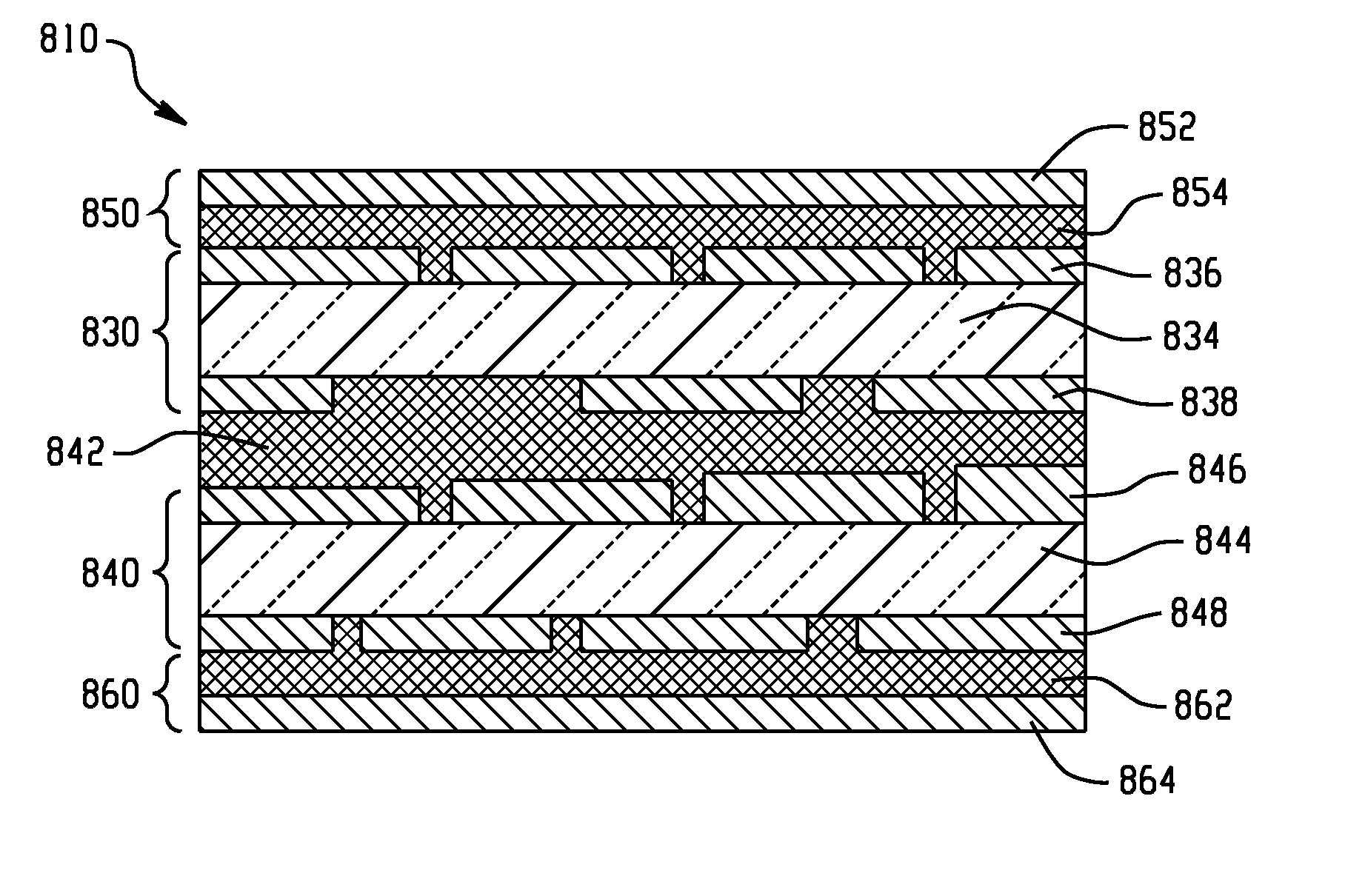

Dielectric materials, methods of forming subassemblies therefrom, and the subassemblies formed therewith

A circuit subassembly, comprising a dielectric layer formed from a dielectric composition comprising, based on the total volume of the composition: about 15 to about 65 volume percent of a dielectric filler; and about 35 to about 85 volume percent of a thermosetting composition comprising: a poly(arylene ether), and a carboxy-functionalized polybutadiene or polyisoprene polymer.

Owner:ROGERS CORP

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

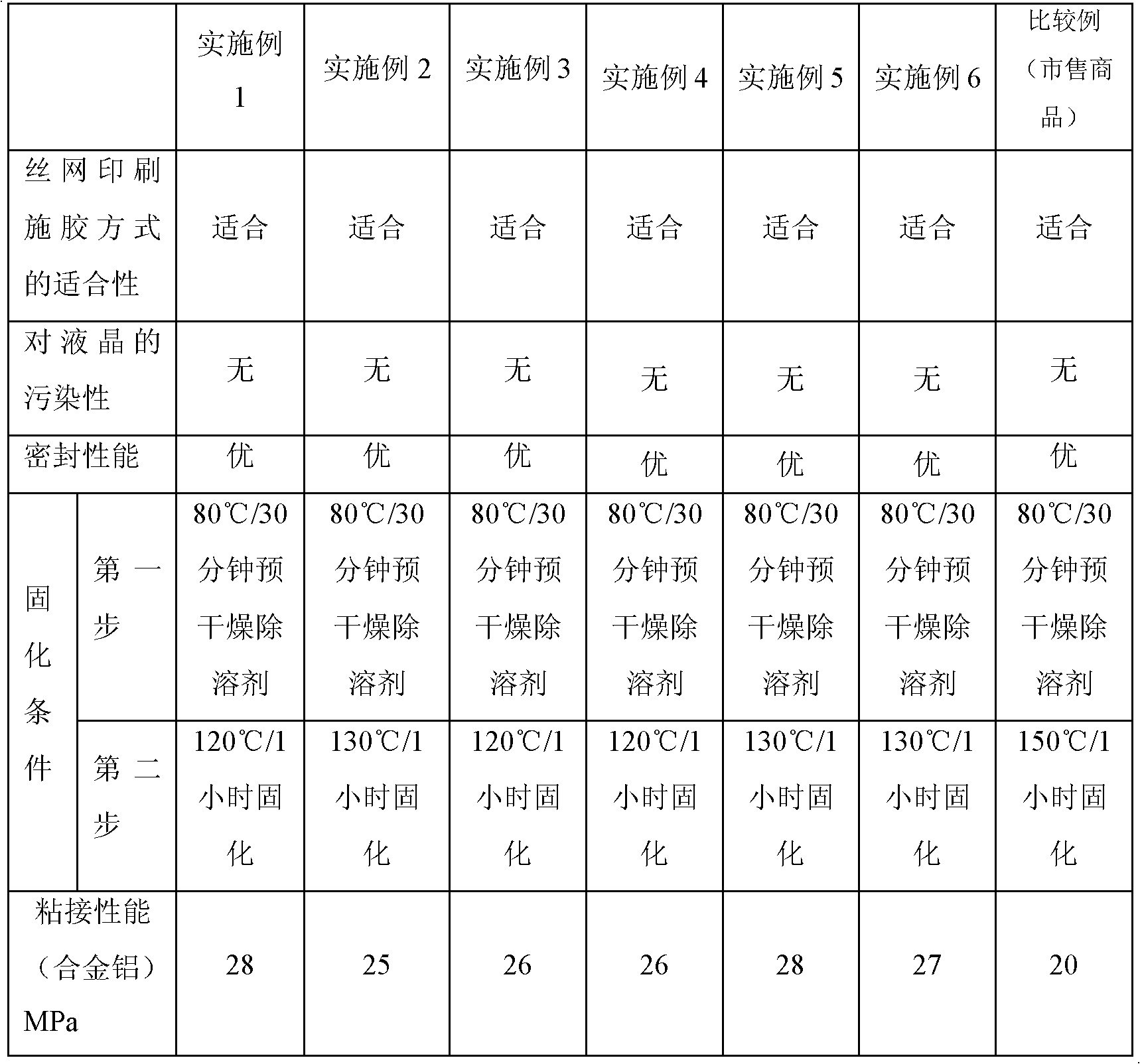

Frame sealing adhesive, and preparation method and application thereof

InactiveCN102585745AEasy to storeSmall water absorptionNon-macromolecular adhesive additivesOther chemical processesScreen printingEpoxy

The invention discloses a frame sealing adhesive and a preparation method and application thereof. The frame sealing adhesive comprises the following component: epoxy resin, a curing agent, a rubber powder, an organic filler, a thixotropic agent, a silane coupling agent and a solvent. The frame sealing adhesive has excellent storage performance and an adhesive applying manner suitable for screen printing and is used for sealing a side frame of a TN (twisted nematic) (STN-super twisted nematic) liquid crystal box; in addition, the solidified frame sealing adhesive has the advantages of low hydroscopic property, long-lasting and excellent sealing performance, excellent heat resistance and electric insulation performance, no pollution to liquid crystal, high rigidity, high toughness and high size stability, and important application value.

Owner:绵阳艾萨斯电子材料有限公司

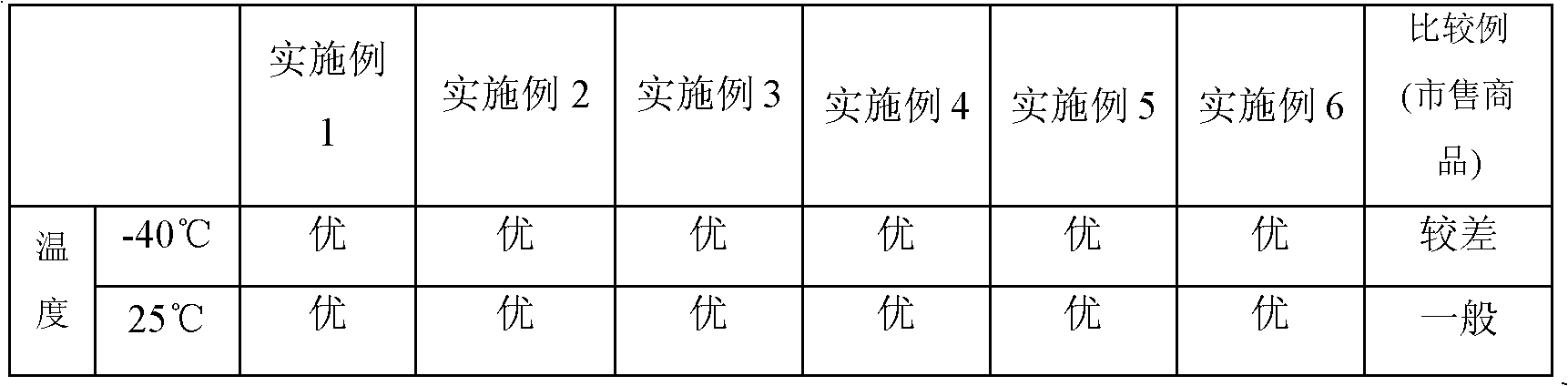

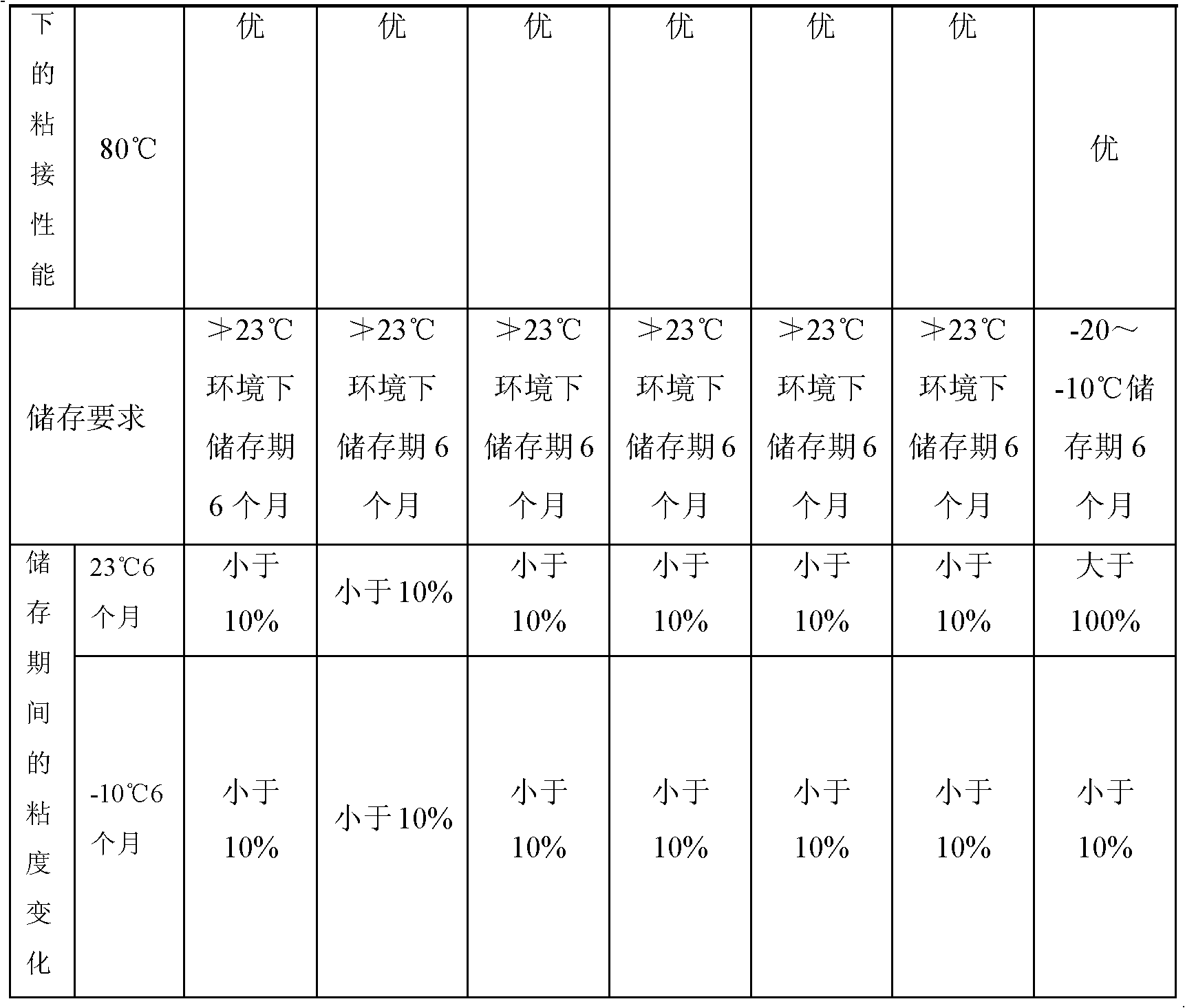

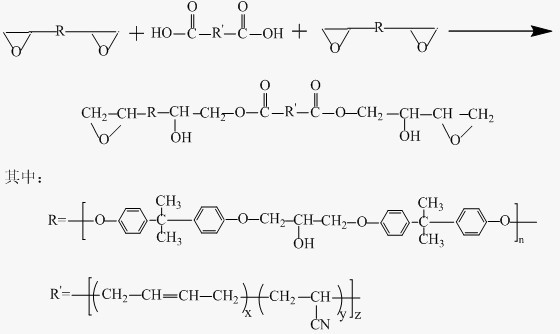

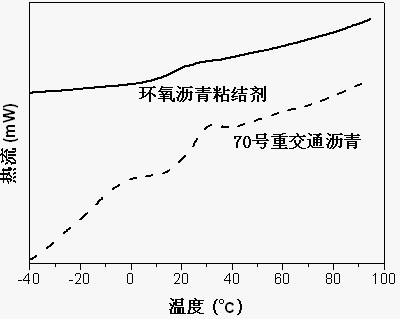

High-performance thermosetting epoxy asphalt binder and preparation method thereof

InactiveCN102559136AImprove adhesionImprove water resistanceBituminous material adhesivesCarboxyl rubber adhesivesLong chain fatty acidCross-link

The invention discloses a high-performance thermosetting epoxy asphalt binder, comprising a part A component and a part B compound, wherein the part A component comprises 100 weight parts of epoxy resin, 20-35 weight parts of flexibilizer, 0.5-2 weight parts of promoter, and 8-20 weight parts of diluent; the part B component comprises 300-350 weight parts of asphalt, 150-160 weight parts of flexible curing agent, 10-15 weight parts of promoter, 2-5 weight parts of compatilizer, and 100 weight parts of diluent; and the ratio of the part A component to the part B component is 100:350-440. According to the invention, by using flexible long-chain fatty acid anhydride as the curing agent and carrying out solidification reaction on the curing agent with the epoxy resin, a stereo cross-linked structure is formed, and the bonding capability and water resistance of asphalt are increased; by using liquid rubber as the flexibilizer, the flexibility of the epoxy asphalt binder is raised to adapt to the flexibility of a steel plate, and by prereacting the flexibilizer with epoxy resin firstly for grafting, the compatibility between the epoxy asphalt binder and asphalt is raised. The epoxy asphalt binder is suitable for bonding and waterproofing of steel bridge floor, cement concrete bridge floor, tunnel, highway and other pavements. The invention also discloses a preparation method of the epoxy asphalt binder.

Owner:NANJING UNIV

High-performance tyre curtain glue stock containing resorcinol-formaldehyde adhesion system

InactiveCN101191040AImprove dynamic performanceHigh bonding strengthNatural rubber adhesivesPneumatic tyre reinforcementsAdhesiveEngineering

The invention relates to a high performance tire fabric rubber compound with a resorcinol-formaldehyde adhesion system, and comprises outer layer cord fabric rubber compound and cushion rubber compound. The key points are that: the invention is made by a plurality of raw materials, wherein, the adhesion system thereof adopts the resorcinol-formaldehyde adhesion system. The raw materials of the outer layer cord fabric rubber compound are natural rubber, rosin extended styrene-butadiene rubber, butadiene rubber, carbon black N330 / N660, zinc oxide, stearic acid, age inhibitor 4010NA / RD / BLE, oil-extended butadiene sulphur powder (S), aromatic oil, accelerant CZ / TMTD, RF-90 resin and adhesive RA-65. The raw materials of cushion the rubber compound are natural rubber, rosin extended styrene-butadiene rubber, carbon black N330 / N660, zinc oxide, stearic acid, age inhibitor 4020 / RD, oil-extended butadiene sulphur powder (S), aromatic oil, accelerant CZ / TMTD / DM, vulcanized agent DTDM, RF-90 resin and adhesive RA-65. The invention is essentially used for the outer layer cord fabric rubber compound and the cushion rubber compound in a bias tire. H pullout force can be obviously enhanced by using the rubber compound of the invention; the problem of cord fabric delaminating in practical use can be reduced by using the bias tire made from the rubber compound of the invention.

Owner:SICHUAN TYRE & RUBBER CO LTD

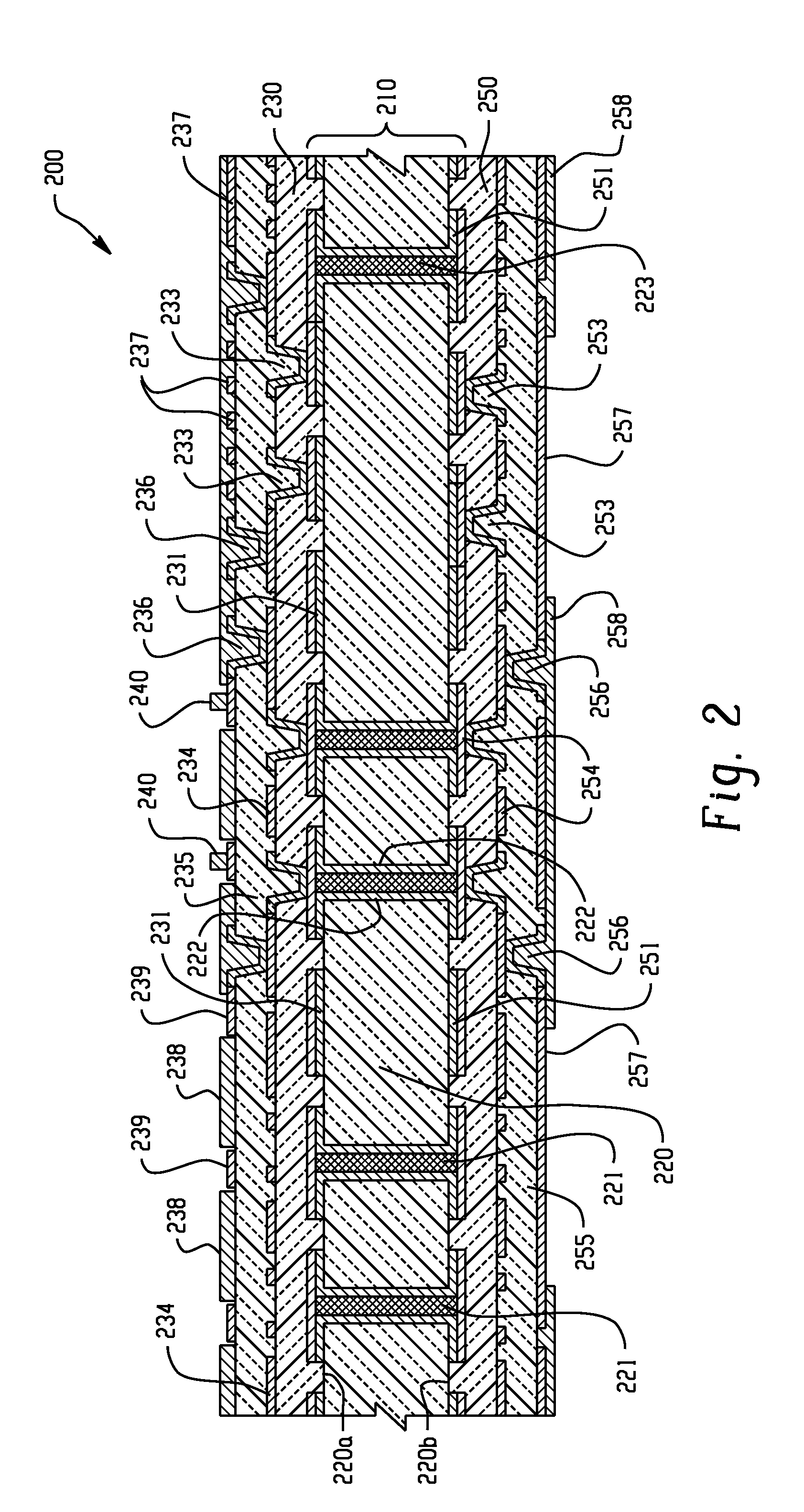

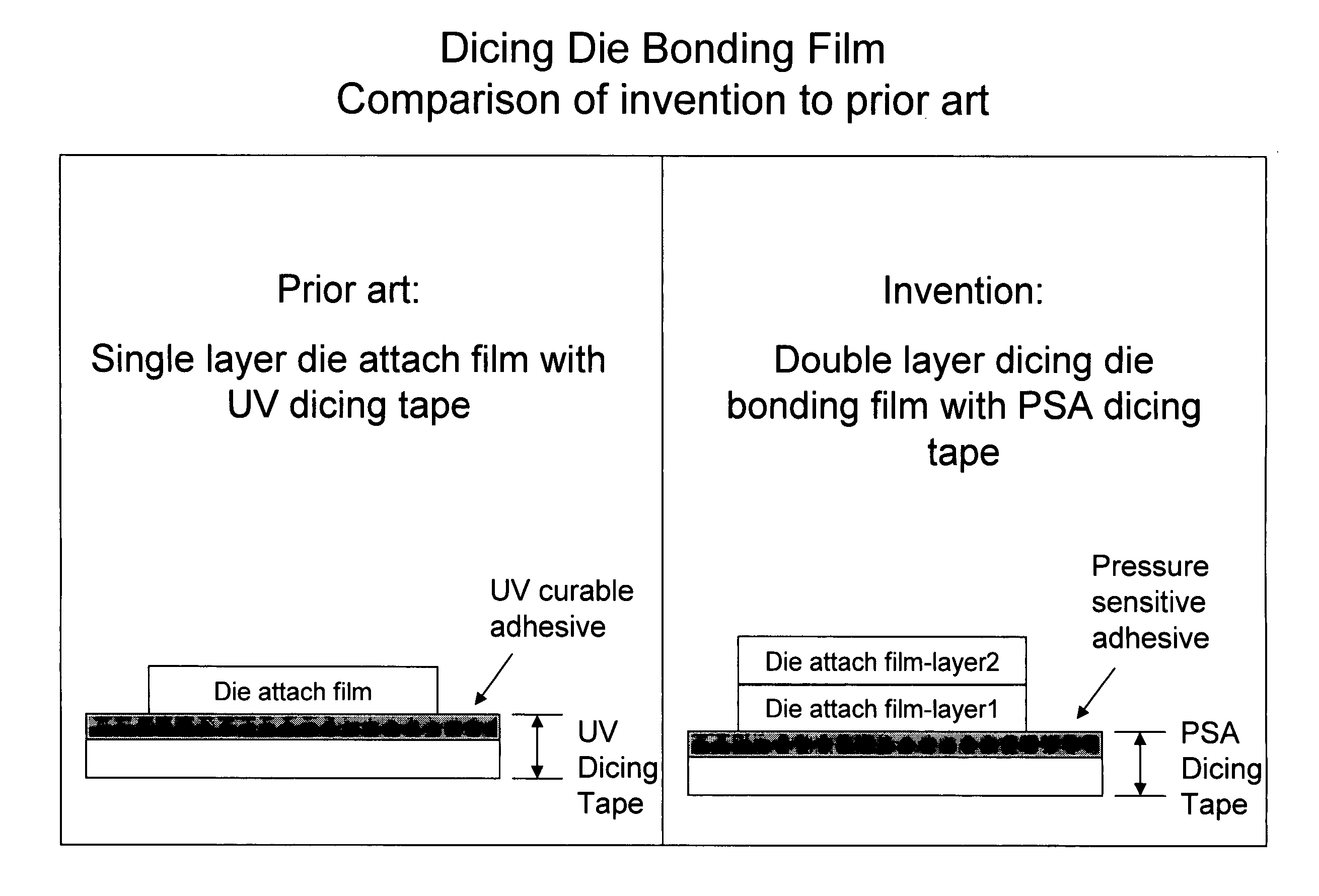

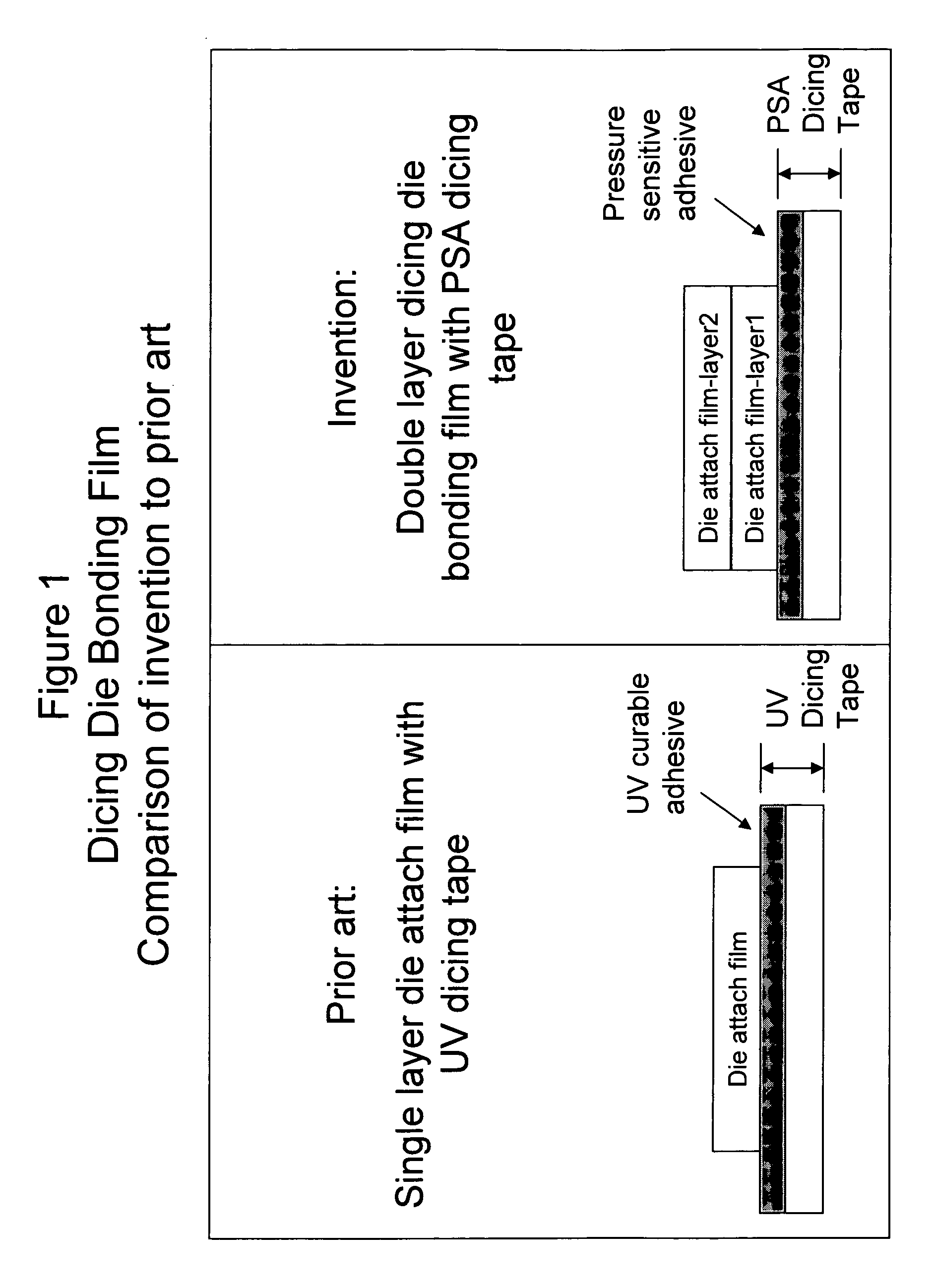

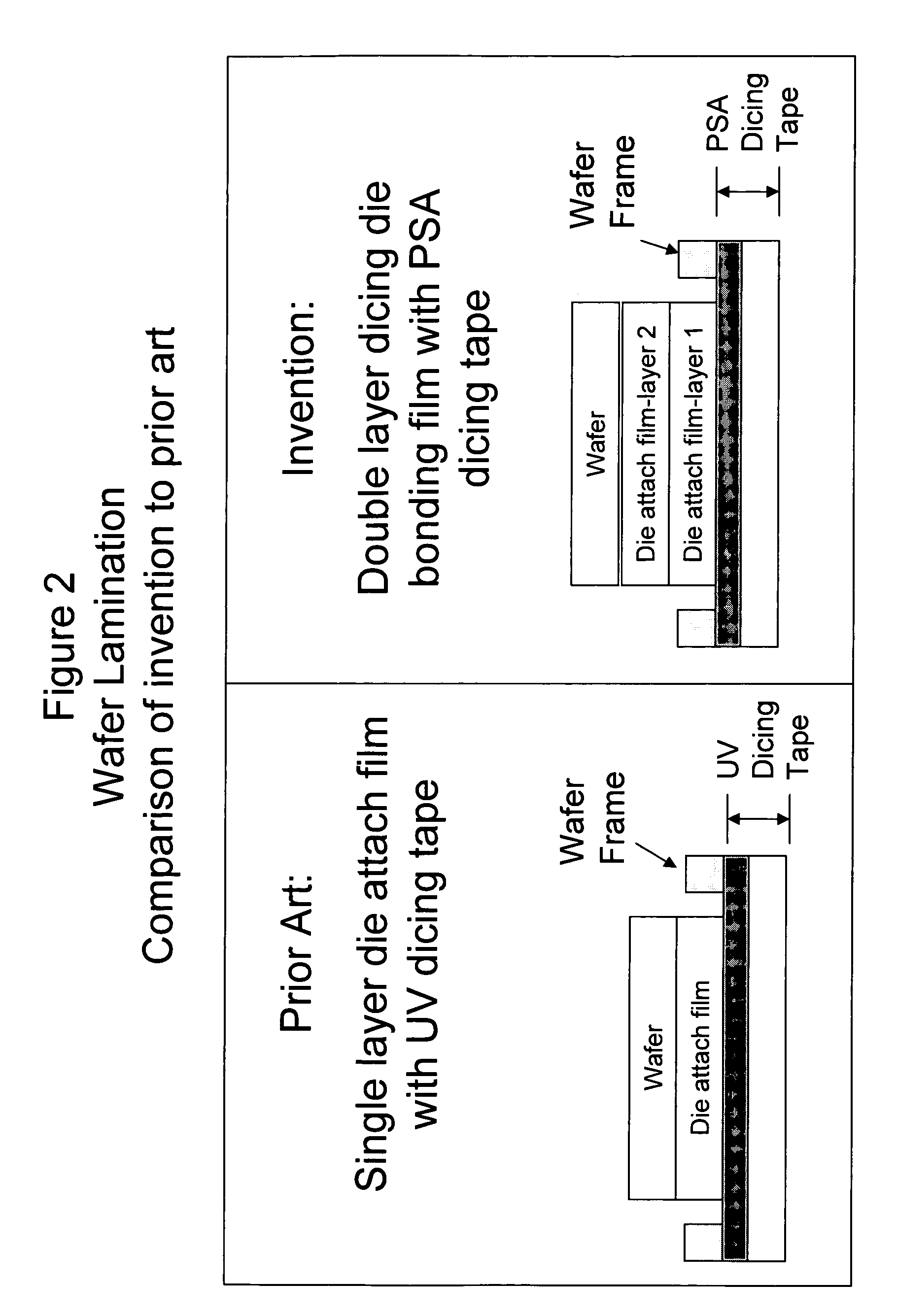

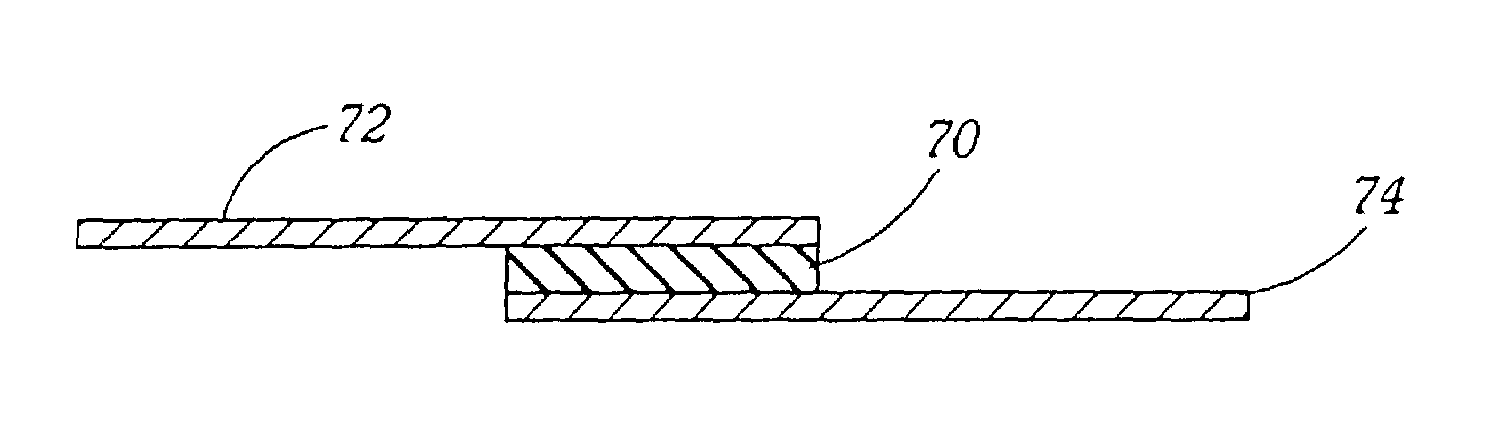

Dicing die bonding film

InactiveUS20070003758A1Eliminate needCharacteristic peel strengthSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

A dicing die bonding adhesive film for disposition between a semiconductor silicon wafer and a dicing support tape comprises a Layer-1 adhesive, which comes in contact with the dicing tape, and a Layer-2 adhesive, which comes in contact with the silicon semiconductor wafer, in which the adhesion of Layer 2 to the silicon wafer is higher than the adhesion of Layer 1 to the dicing tape by at least 0.1 N / cm.

Owner:HENKEL KGAA

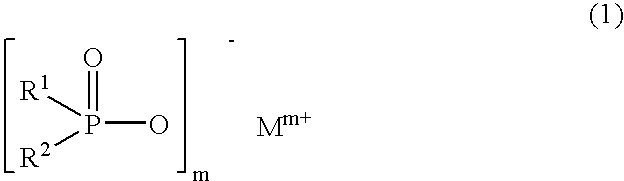

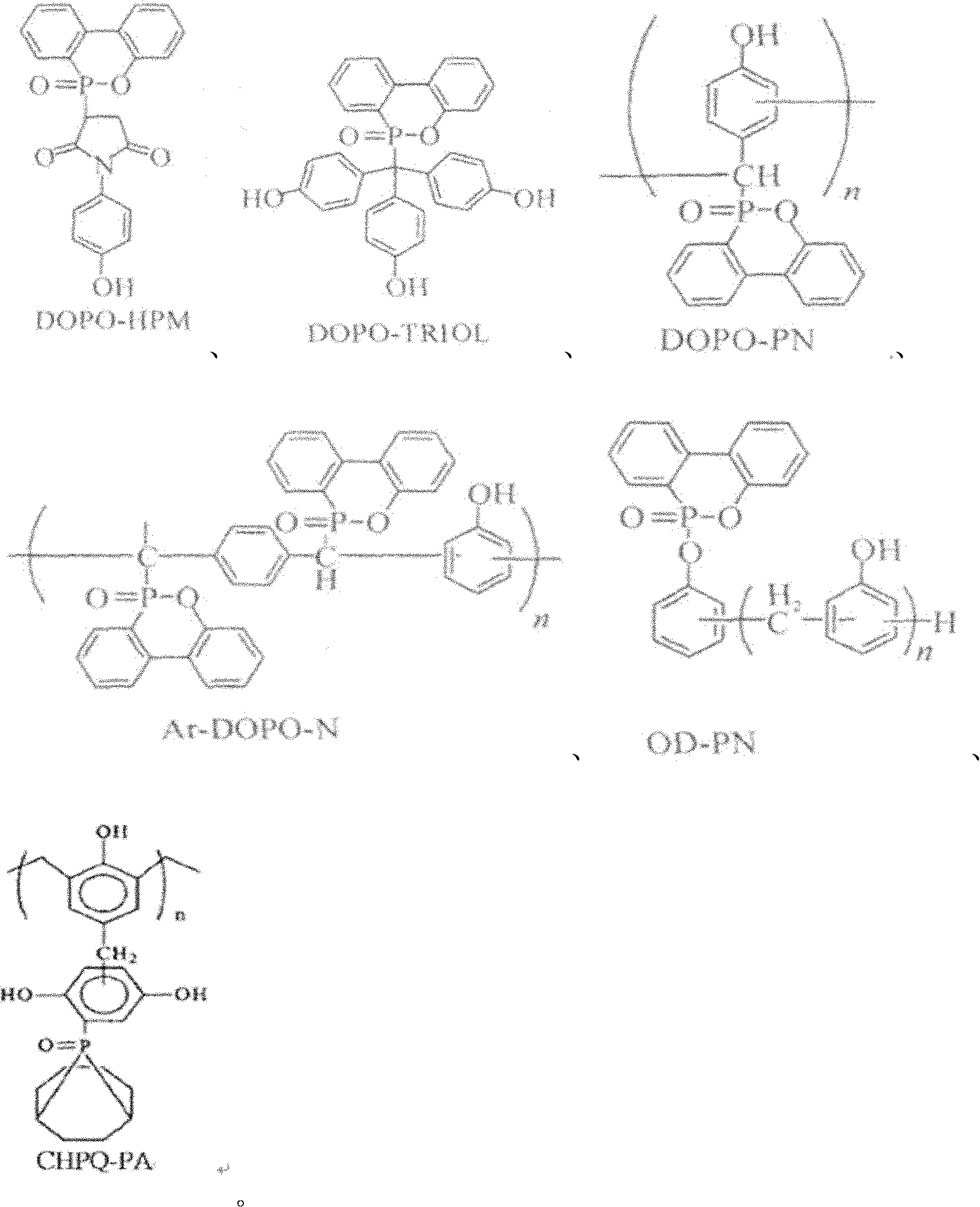

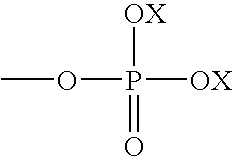

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234045A1Excellent flame retardancy and electrical characteristicPromote migrationNon-macromolecular adhesive additivesNitrile polymer adhesivesEpoxyCopper foil

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) an organophosphinate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

High-solid-content aqueous adhesive for shoes and preparation method thereof

InactiveCN102827570AHigh solid contentIncrease drying speedMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesAdhesiveSolid content

The invention discloses a high-solid-content aqueous adhesive for shoes and a preparation method thereof. The aqueous adhesive is prepared from an aqueous resin and a deionized water-emulsified polyurethane prepolymer, wherein the polyurethane prepolymer is synthesized from isocyanate, polylol, a hydrophilic chain extender, a crosslinking agent and a neutralizing agent. The preparation method comprises the following steps of: preparing a polyurethane prepolymer through pre-polymerizing and neutralizing processes; and preparing the aqueous adhesive for a high-solid-content shoe by using an aqueous resin in cooperation with deionized water emulsification. The aqueous adhesive for shoes disclosed by the invention has the advantages of high solid content, low cost, excellent performance and the like.

Owner:SHAANXI UNIV OF SCI & TECH

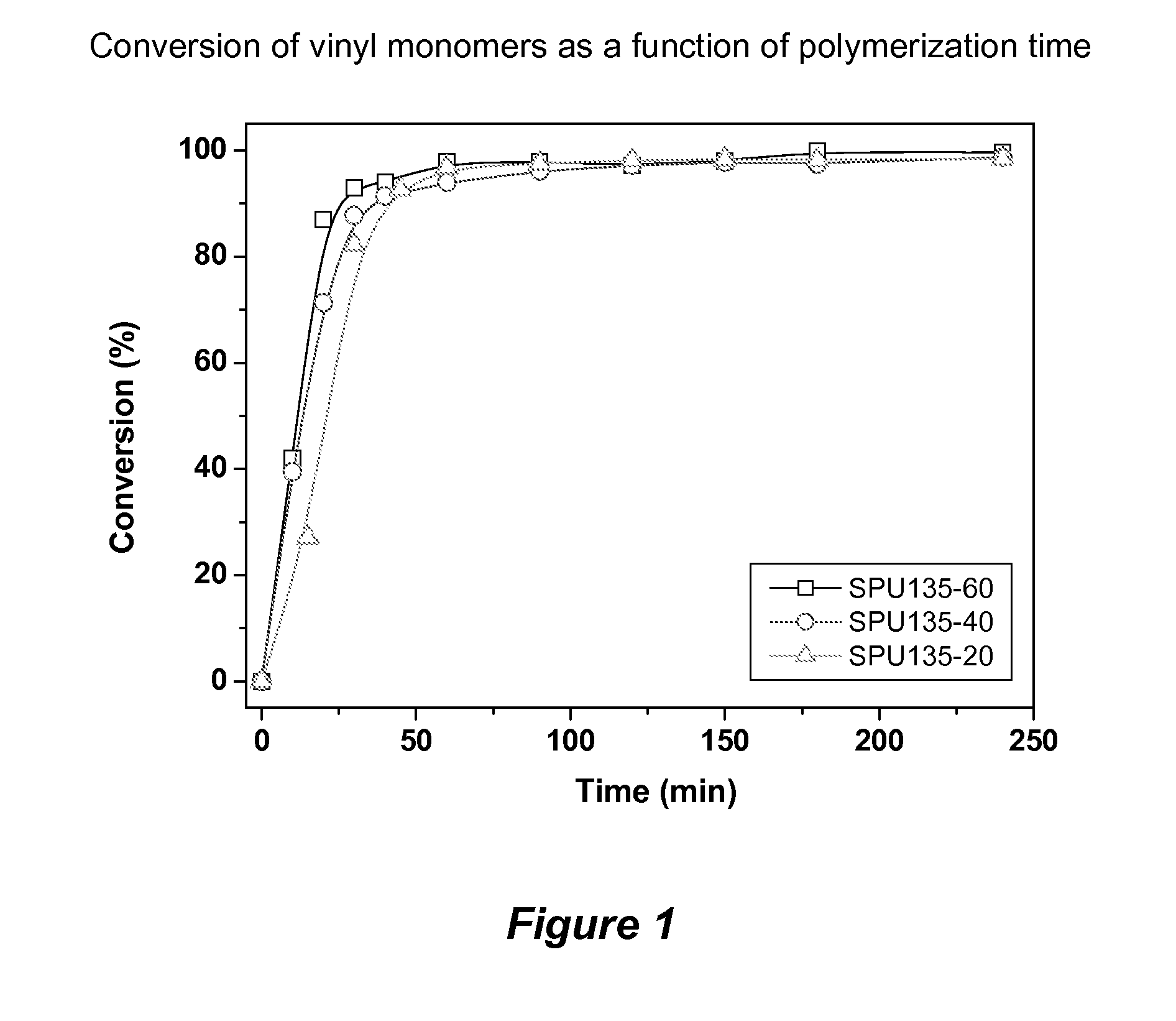

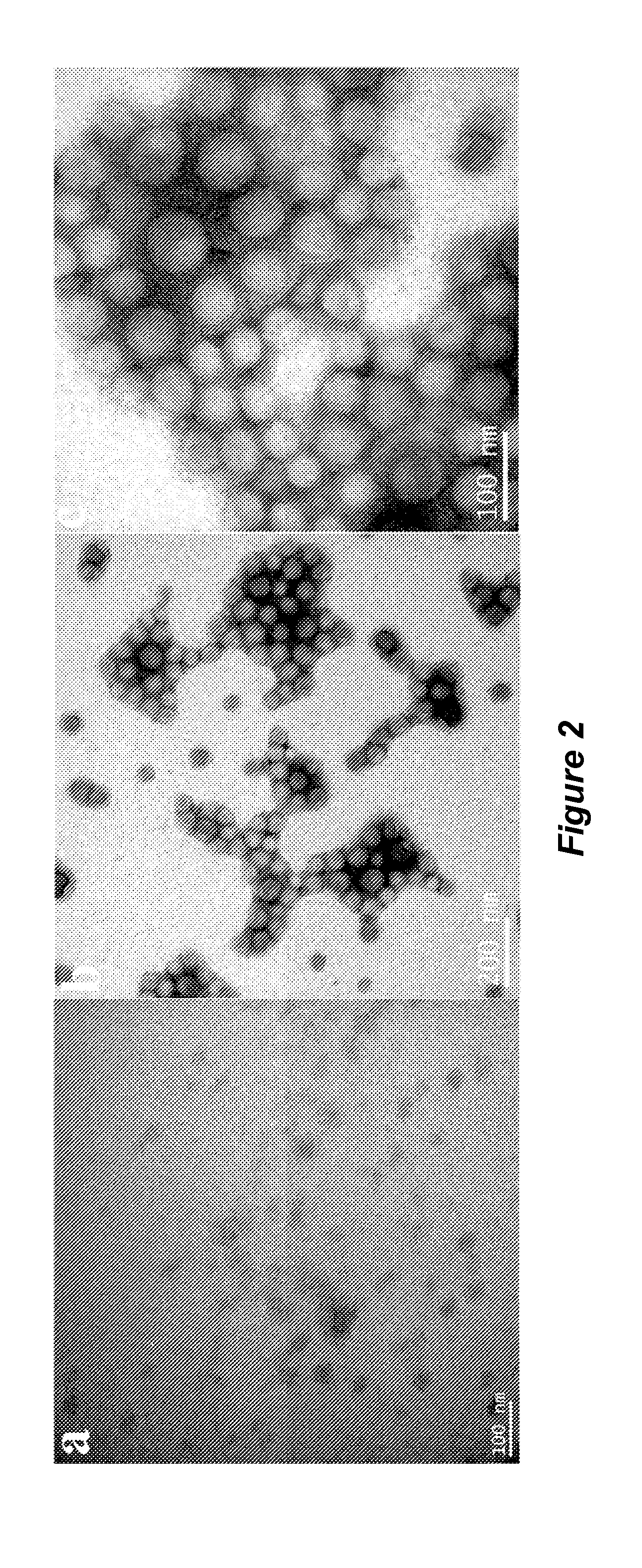

Surfactant-free core-shell hybrid latexes

InactiveUS20120270992A1Improve thermal stabilityHigh tensile strengthMaterial nanotechnologyCarboxyl rubber coatingsPolyolVegetable oil

The invention provides core-shell hybrid latexes wherein the core comprises poly(acrylate)polymers and the shell comprises vegetable oil-based waterborne polyurethanes, and the latexes lack surfactants. Surfactant-free core-shell hybrid latexes with waterborne vegetable oil-based polyurethanes as the shell and poly(acrylate) as the core have been successfully prepared by seeded emulsion polymerization. The crosslink densities of the polymers obtained can be controlled by using modified vegetable oil polyols with various hydroxyl numbers or by adding a multifunctional vinyl crosslinker to the poly(acrylate) core.

Owner:IOWA STATE UNIV RES FOUND

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234043A1Excellent flame retardancy and electrical characteristicExcellent characteristicsNon-macromolecular adhesive additivesAdhesive articlesEpoxyCopper foil

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a nitrogen-containing polyphosphate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil; and a method of bonding two substrates, including the steps of sandwiching the above adhesive sheet between two substrates, and curing the adhesive sheet. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and anti-migration properties. The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate. The adhesive sheet can be used for a method of bonding two substrates.

Owner:SHIN ETSU CHEM IND CO LTD

Halogen-free flame-retardant epoxy resin composition, and adhesive film and copper-clad plate prepared from same

ActiveCN102127289AHigh tracking characteristicsHigh CTIFilm/foil adhesivesSynthetic resin layered productsOrganic solventCopper foil

The invention relates to a halogen-free flame-retardant epoxy resin composition, and an adhesive film and a copper-clad plate prepared from same. The halogen-free flame-retardant epoxy resin composition comprises bisphenol A type epoxy resin, carboxylic group terminated butylnitrile rubber, phosphorus-containing resin, nitrogen flame retardants, amine curing agents, a curing accelerator, a fillerand an organic solvent. The adhesive film prepared from the halogen-free flame-retardant epoxy resin composition comprises a release film and the halogen-free flame-retardant epoxy resin composition coated on the release film. The copper-clad plate prepared from the halogen-free flame-retardant epoxy resin composition comprises a laminated sheet, an adhesive film clad on one side or two sides of the laminated sheet, and a copper foil pressed and clad on the adhesive film, wherein the laminated sheet comprises a plurality of glued bonding sheets; and the adhesive film comprises a release film and the halogen-free flame-retardant epoxy resin composition coated on the release film. The halogen-free flame-retardant epoxy resin composition has a high creepage tracking characteristic and good comprehensive performance such as flame retardancy and the like.

Owner:GUANGDONG SHENGYI SCI TECH

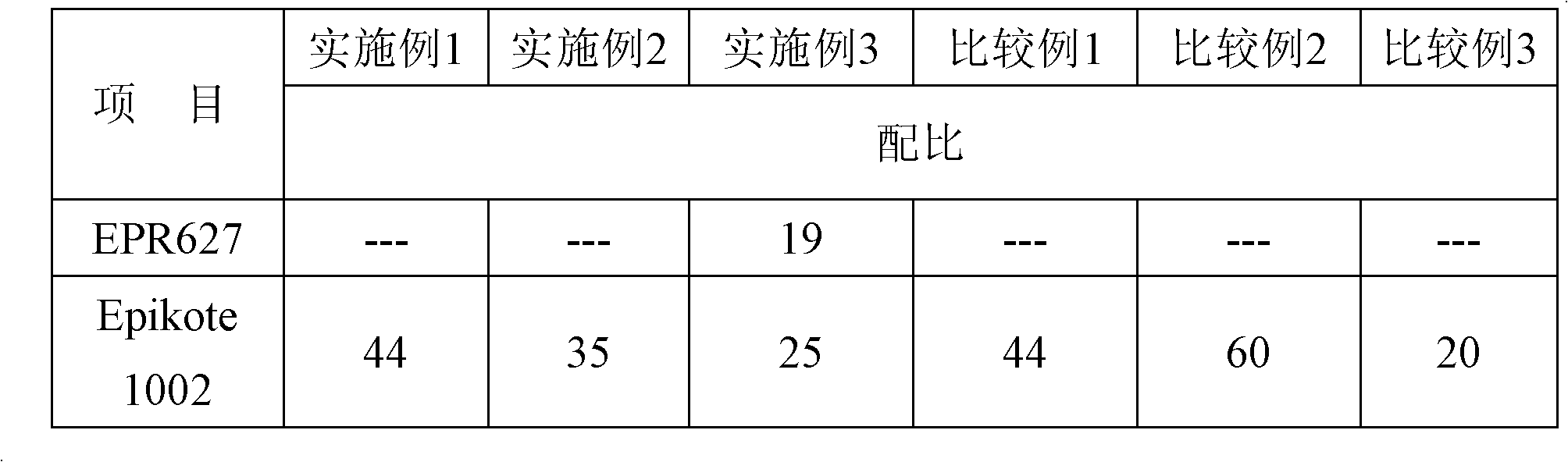

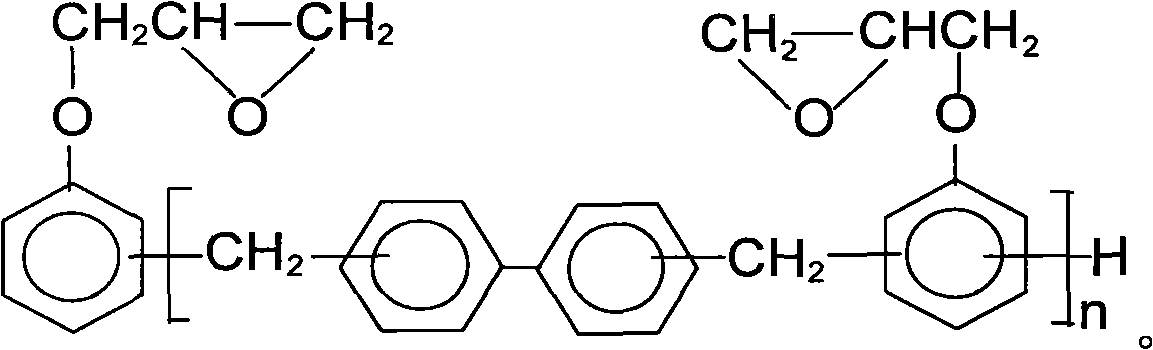

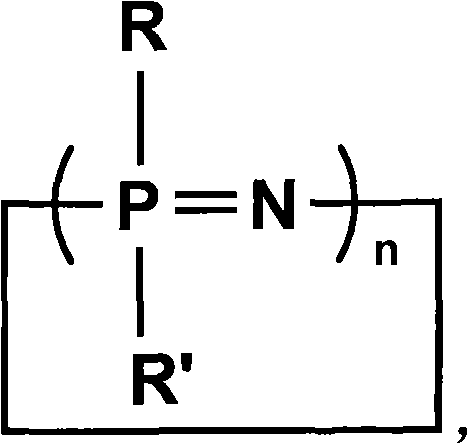

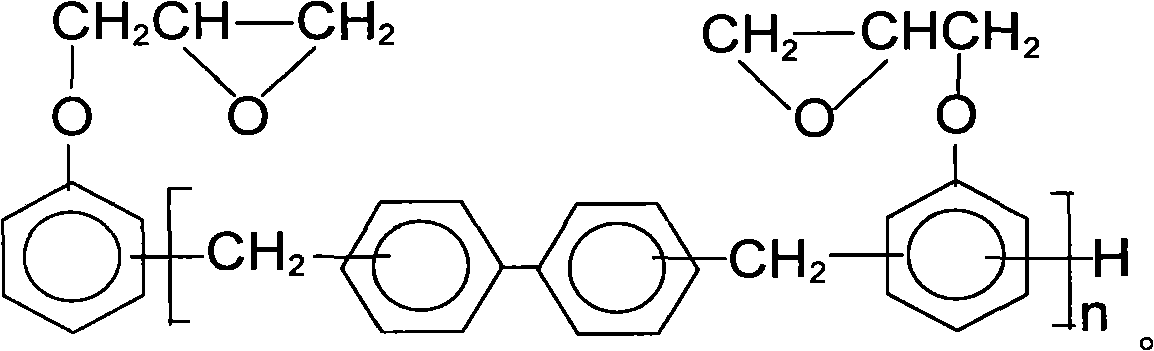

Low-halogen-content fire-retardant adhesive and flexible copper clad laminate prepared from same

InactiveCN101892027ALow halogen contentLow heat resistanceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyDip soldering

The invention relates to a low-halogen-content fire-retardant adhesive and a flexible copper clad laminate prepared from the same. The low-halogen-content fire-retardant adhesive comprises synthetic rubber, brominated epoxy resin, biphenyl type epoxy resin, phosphonitrile compounds, an aromatic amine curing agent, an imidazole curing accelerator, inorganic filler, an ion exchanger, an oxidation inhibitor and a solvent. The flexible copper clad laminate prepared from the fire-retardant adhesive comprises a polyimide film, a low-halogen-content fire-retardant adhesive layer and copper foil, wherein the low-halogen-content fire-retardant adhesive layer is coated on the polyimide film, and the copper foil is pressed on the low-halogen-content fire-retardant adhesive layer. The fire-retardant adhesive has low halogen content, excellent flexibility, heat resistance, adhesion property and humidity resistance. The flexible copper clad laminate has excellent flexibility, folding resistance, deflection resistance, dip soldering resistance, ion mobility resistance and high peeling strength, the flame retardance reaches the UL94V-0 grade, and the flexible copper clad laminate is suitable for manufacturing a flexible printed circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

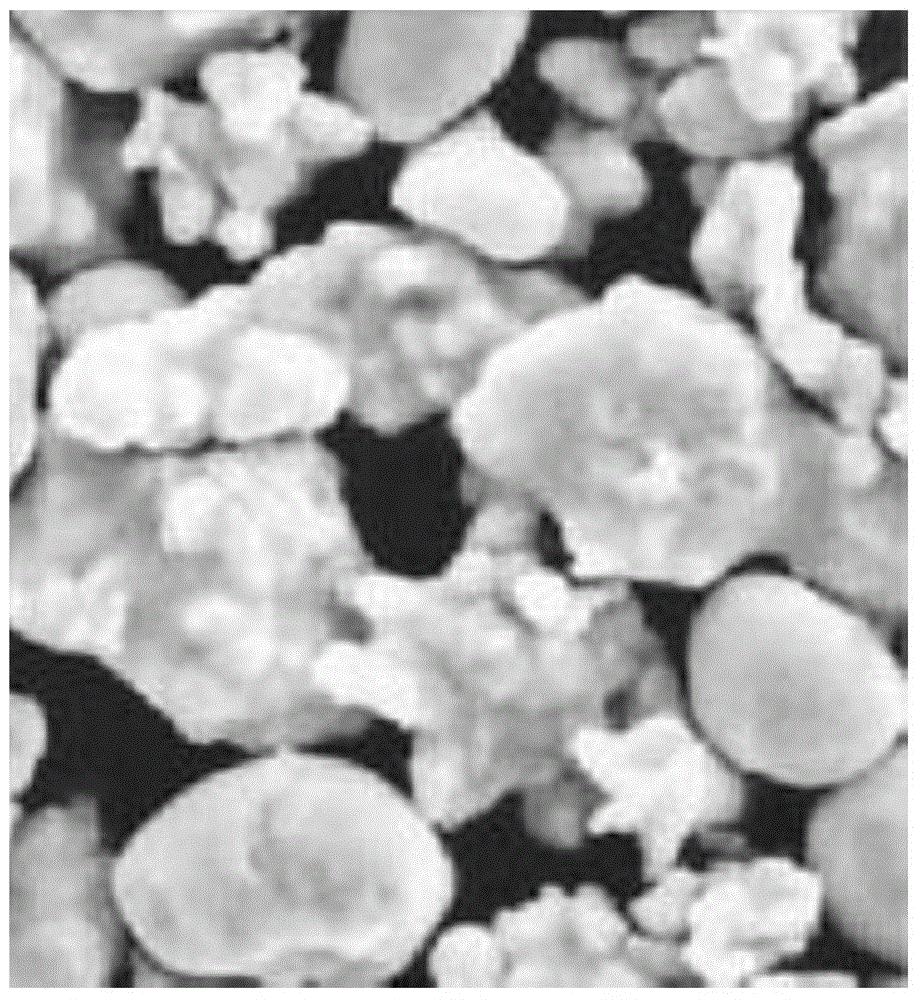

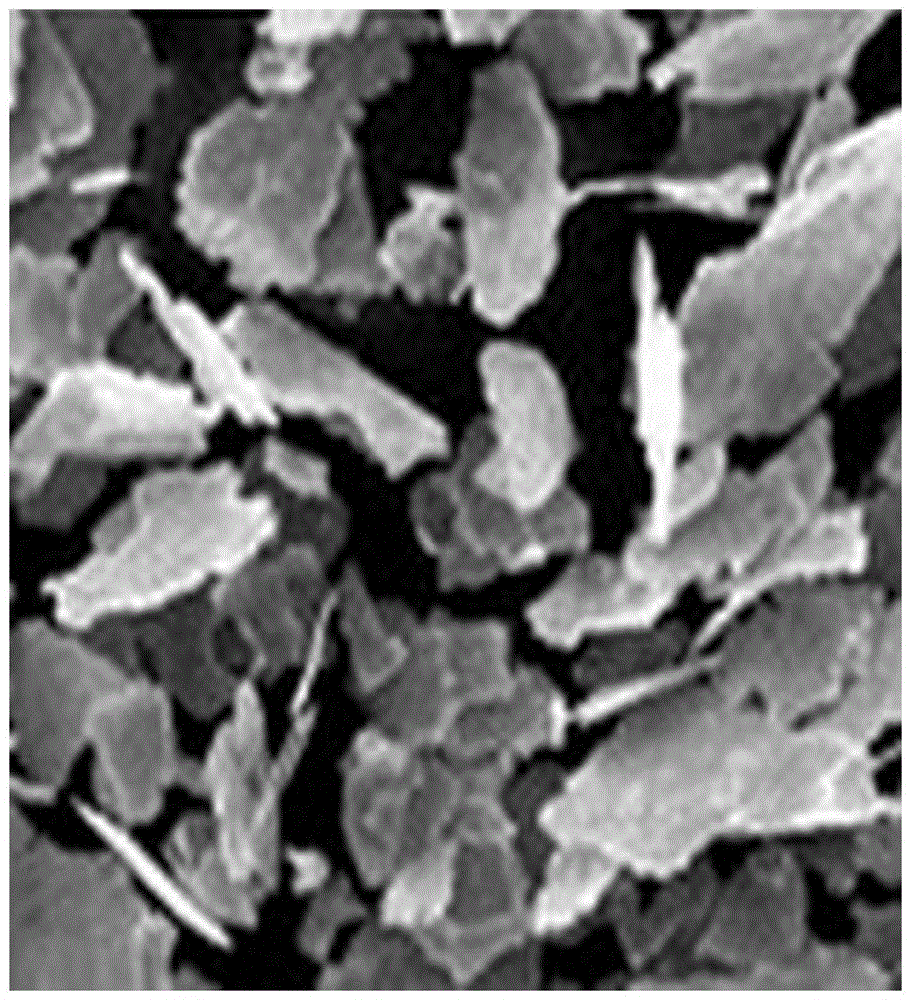

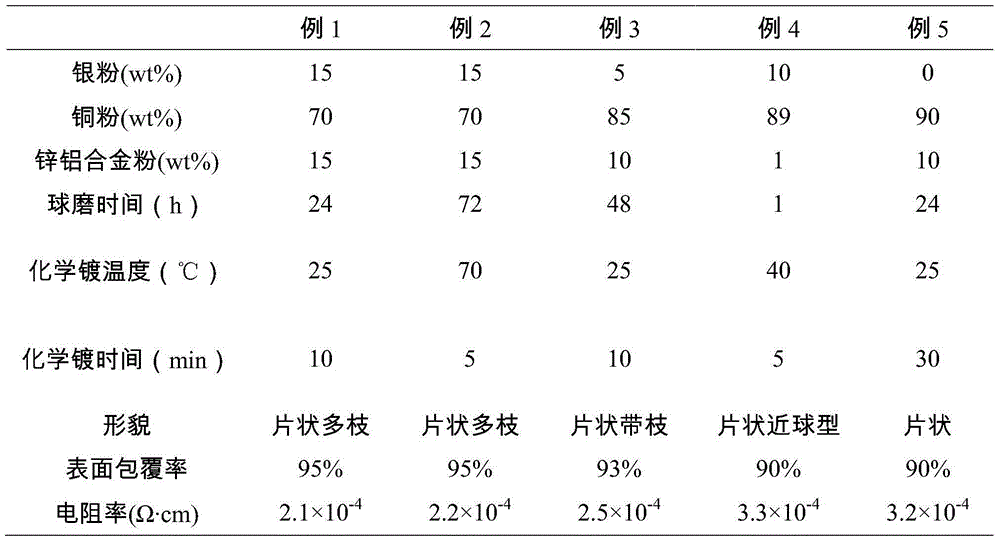

Sheet/branch silver-coated copper powder and green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents

ActiveCN104830247AIncrease coverageImprove conductivityNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyIntrinsic conductivity

The invention relates to sheet / branch silver-coated copper powder, a green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents, and a preparing method of the electrically conductive adhesive. The morphology of the sheet / branch silver-coated copper powder is in a sheet shape and / or a branch shape. The silver coating area rate on the surface of copper powder is 90-95%. The content of a zinc-aluminum alloy in the silver-coated copper powder is lower than 15 wt%. The electrically conductive adhesive comprises following raw materials by weight: 60-90% of the sheet / branch silver-coated copper powder, 0-30% of micron order silver power, 6-12% of epoxy resin, 1-8% of an active diluting agent, 1-6% of toughening resin, 1-3% of a curing agent, 0-1% of a curing promoter and 0.5-2% of a coupling agent. The sheet / branch silver-coated copper powder is high in silver coating rate on the surface of Cu and excellent in electrically conductive performance, so that the electrically conductive adhesive prepared from the sheet / branch silver-coated copper powder is excellent in performance, low in cost and good in intrinsic conductivity.

Owner:重庆邦锐特新材料有限公司

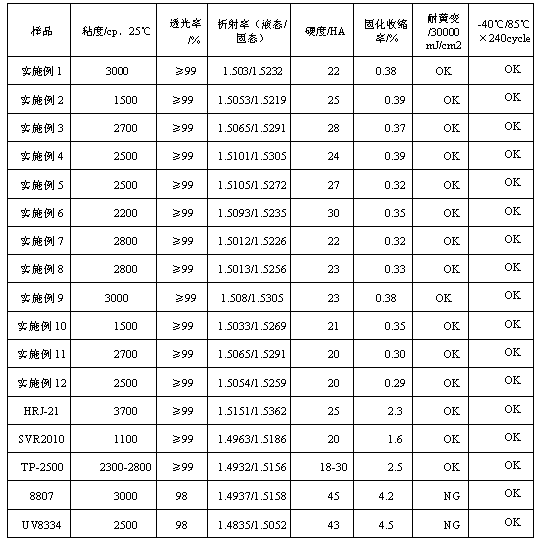

Light curing adhesive for splicing capacitive touch screen and preparation method of light curing adhesive

InactiveCN103184029AHigh refractive indexHigh light transmittancePolyureas/polyurethane adhesivesRubber derivative adhesivesVinyl etherPolymer science

The invention discloses a light curing adhesive for splicing a capacitive touch screen. The light curing adhesive is prepared from the following components by weight percent: 30-50% of main body resin, 20-40% of auxiliary resin, 10-30% of an active monomer, 0.5-5% of a photoinitiator, and 0.1-5% of an auxiliary agent, wherein the main body resin is aliphatic urethane acrylate resin; the auxiliary resin is one substance or a mixture of more substances: cyanuric acid resin modified by acrylic ester, liquid nitrile rubber, liquid polybutadiene rubber and liquid isoprene rubber; the active monomer is one or a mixture of more of a vinyl ether monomer and an acrylate monomer; the photoinitiator is one or a mixture of two of a free radical initiator and a cationic photoinitiator; and the auxiliary agent is one or mixture of two of a silane coupling agent and a flatting agent. The light curing adhesive for splicing the capacitive touch screen has the advantages of high refractive index, high light transmittance, low color brightness, low hardness, low cure shrinkage rate, good reliability, good yellowing resistance and the like.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

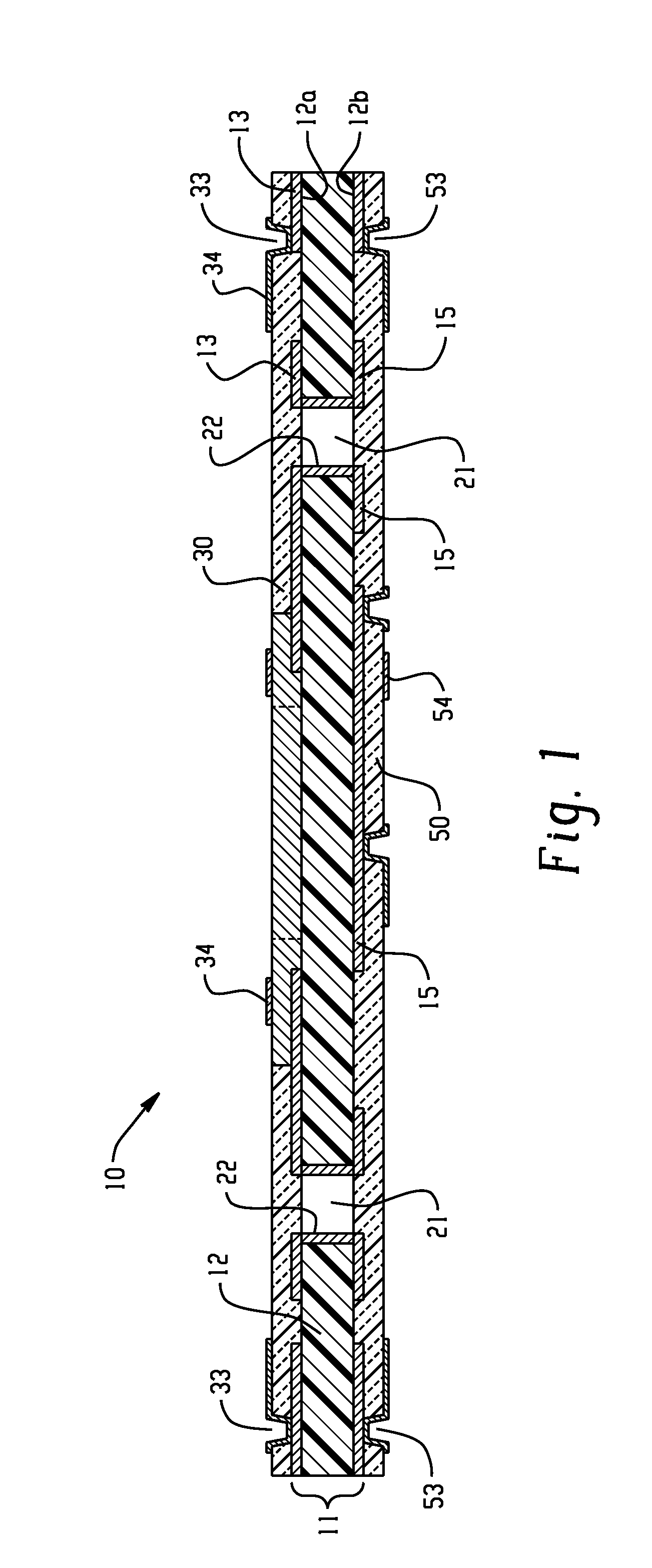

Dicing die bonding film

InactiveUS20050227064A1Improve adhesionCharacteristic peel strengthElectrically conductive connectionsFilm/foil adhesivesDicing tapeSilicone tape

A dicing die bonding adhesive film for disposition between a semiconductor silicon wafer and a dicing support tape comprises a Layer-1 adhesive, which comes in contact with the dicing tape, and a Layer-2 adhesive, which comes in contact with the silicon semiconductor wafer, in which the adhesion of Layer 2 to the silicon wafer is higher than the adhesion of Layer 1 to the dicing tape by at least 0.1 N / cm.

Owner:HENKEL KGAA

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveCN1865382AImprove flame retardant performanceHigh peel strengthNon-macromolecular adhesive additivesAdhesive articlesPolymer sciencePolyphosphate

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a nitrogen-containing polyphosphate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil; and a method of bonding two substrates, including the steps of sandwiching the above adhesive sheet between two substrates, and curing the adhesive sheet. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and anti-migration properties. The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate. The adhesive sheet can be used for a method of bonding two substrates.

Owner:SHIN ETSU CHEM CO LTD

Heat-cured high-intensity flaky adhesive for automobile and preparation method thereof

ActiveCN102181238AReduce noiseComfortable and safeNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAdhesive

The invention provides a heat-cured high-intensity flaky adhesive for an automobile and a preparation method thereof. The heat-cured high-intensity flaky adhesive for the automobile comprises three layers, wherein the upper layer is made of glass fiber cloth, the middle layer is made of a high-intensity adhesive, and the bottom layer is made of barrier paper. The high-intensity adhesive is prepared from synthetic rubber, a plasticizer, epoxy resin, thermoplastic resin, tackifying resin, a curing agent, a vulcanizing agent, an accelerating agent, an anti-aging agent and calcium carbonate. Due to the adoption of the flaky adhesive, the rigidity of a metal sheet can be increased greatly in the automobile manufacturing process, the running noise of the automobile can be reduced, and the comfort and the safety of the automobile are ensured. The heat-cured high-intensity flaky adhesive has high adhesion to an oil surface metal material, can be operated manually and directly in the construction process, is non-sticky, nontoxic and tasteless, has high manufacturability, is prevented from moving, and is convenient to use. The flaky adhesive can be cut according to different requirements onpositions, sizes and shapes and can be stored for over 3 months at the temperature of 25 DEG C.

Owner:三友(天津)高分子技术有限公司

Halogen-free flame-retardant epoxy resin composition and high-flexibility halogen-free cover film prepared from same

InactiveCN103555242AImprove mechanical propertiesGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesSolid componentAdhesive

The invention provides a halogen-free flame-retardant resin composition which comprises the following components in parts by weight: (A) 1-30 parts of flexible epoxy resin, (B) 10-50 parts of special-type epoxy resin, (C) 10-50 parts of bisphenol A epoxy resin, (D) 10-40 parts of synthetic rubber, (E) 1-20 parts of flexible amine curing agent, (F) 1-15 parts of aromatic amine curing agent, (G) 0.01-1.0 part of imidazole curing accelerator, (H) 0.01-1.0 part of anti-aging agent, (I) 5-30 parts of phosphorus-containing flame retardant, (J) 0-100 parts of filler and (K) organic solvent. The solid components are proportionally dispersed in the organic solvent to obtain the adhesive with the solid content of 30-40 wt%. The halogen-free flame-retardant epoxy resin composition is free of halogens, uses the flexible epoxy resin and special-type epoxy resin as the main body resins, uses the flexible amine oligomer and aromatic diamine as a composite curing system, and also uses a small amount of organic-phosphorus flame retardant; and thus, the resin composition has favorable mechanical properties and softness, and the flame retardancy is up to UL94VTM-0.

Owner:GUANGDONG SHENGYI SCI TECH

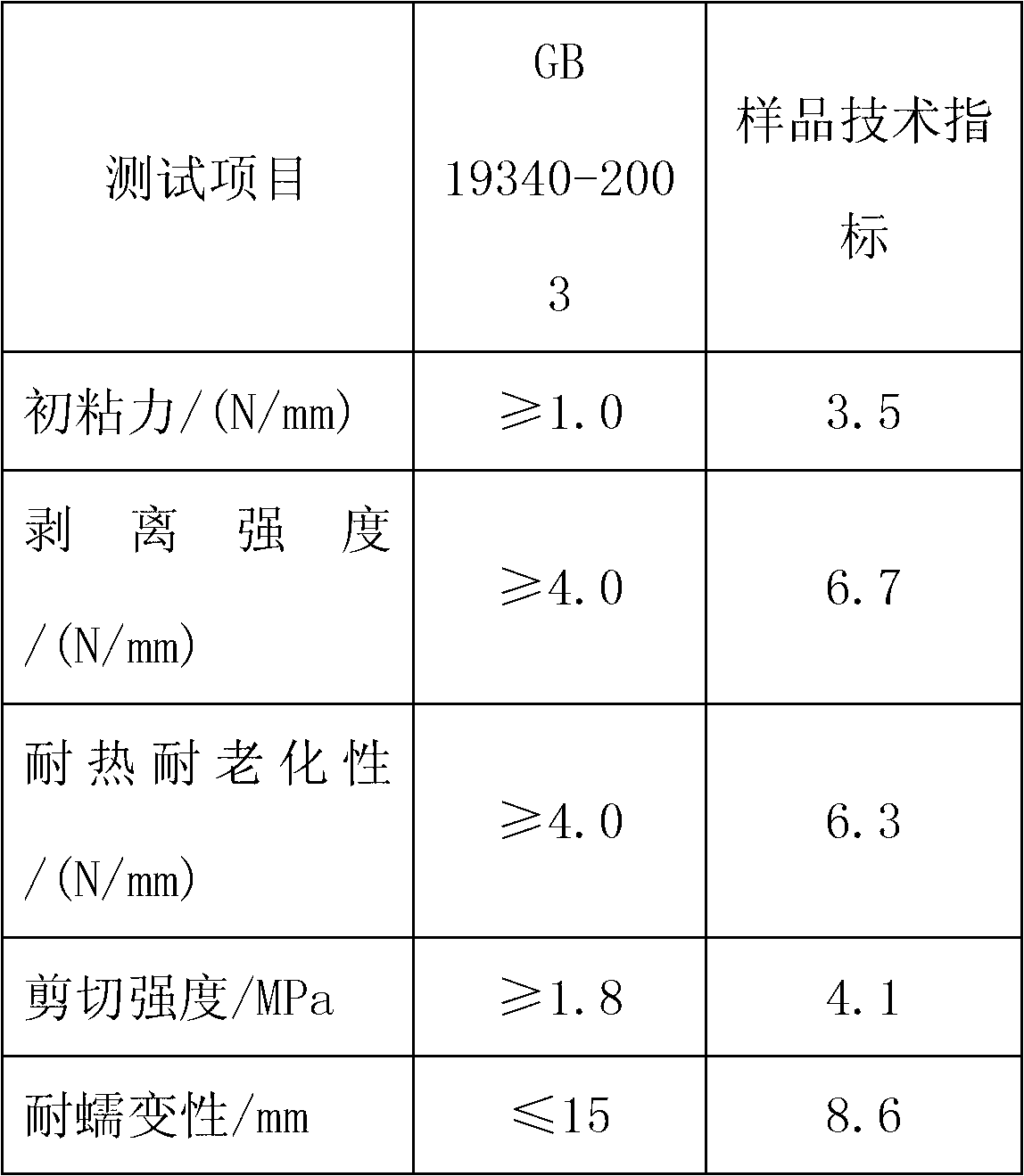

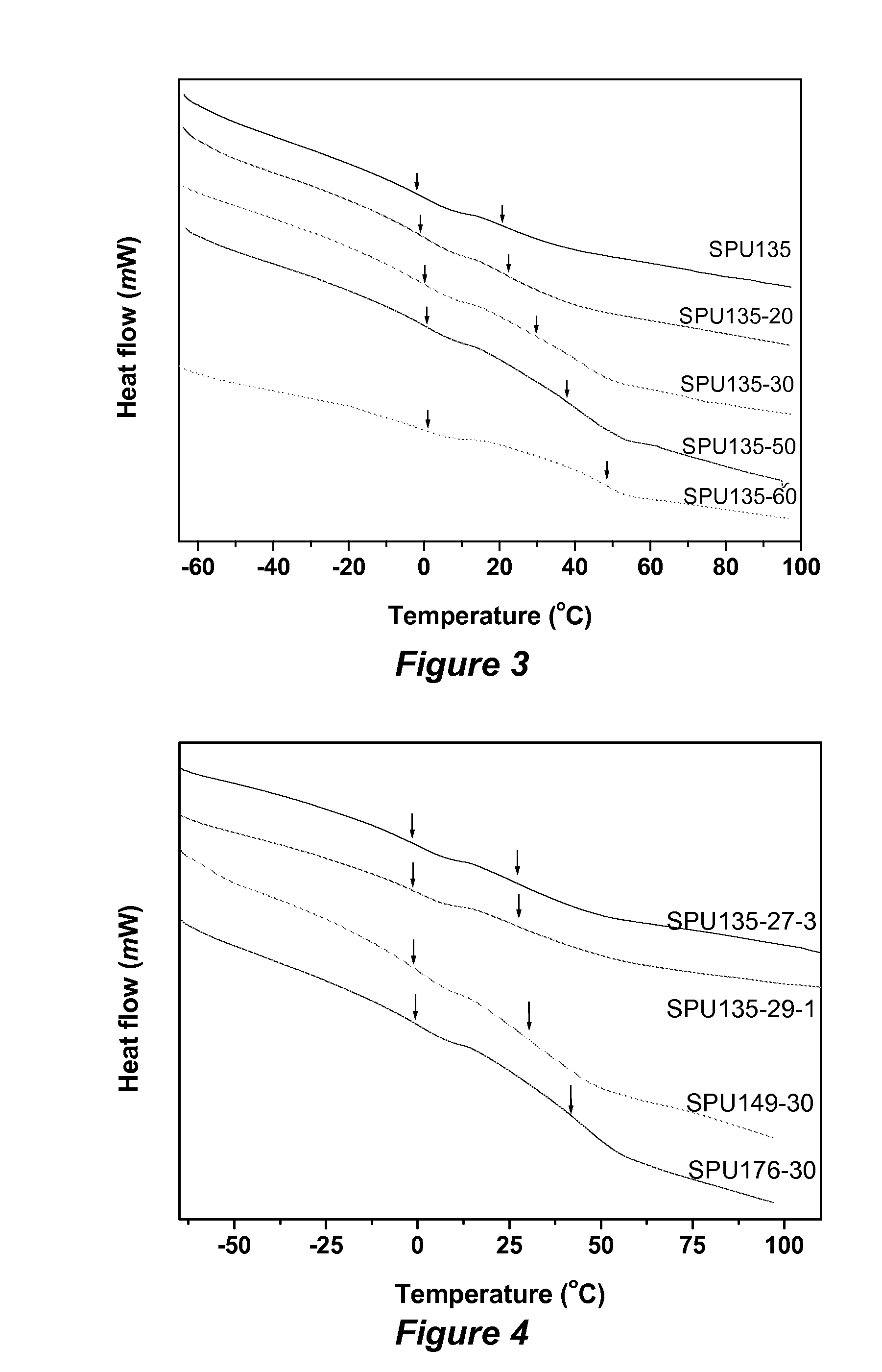

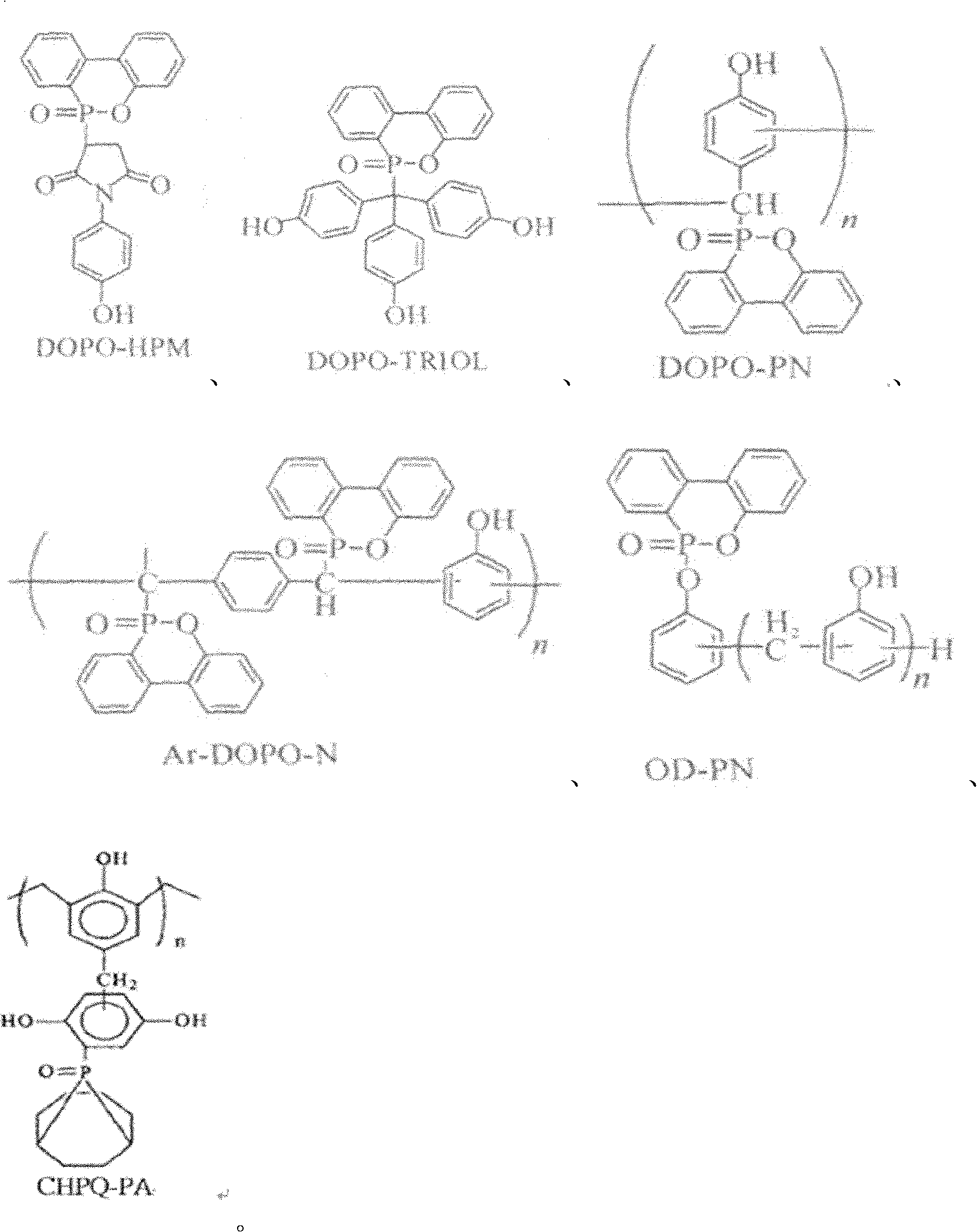

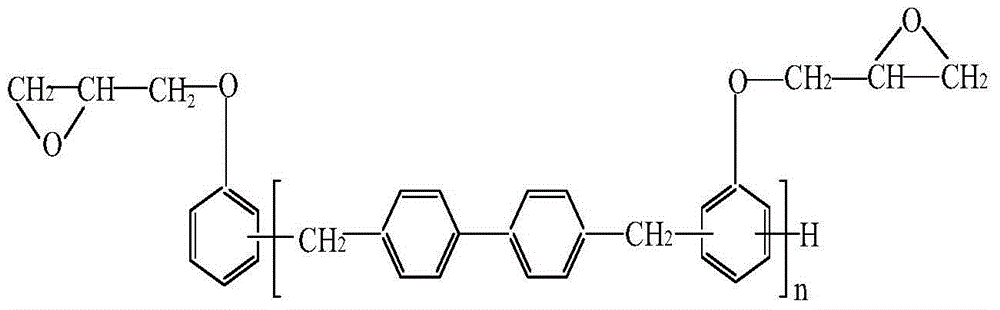

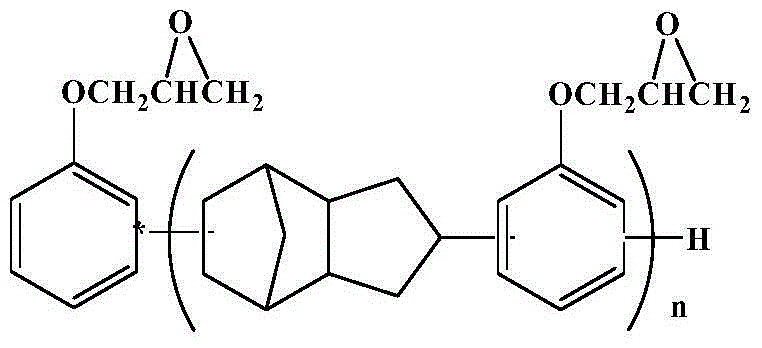

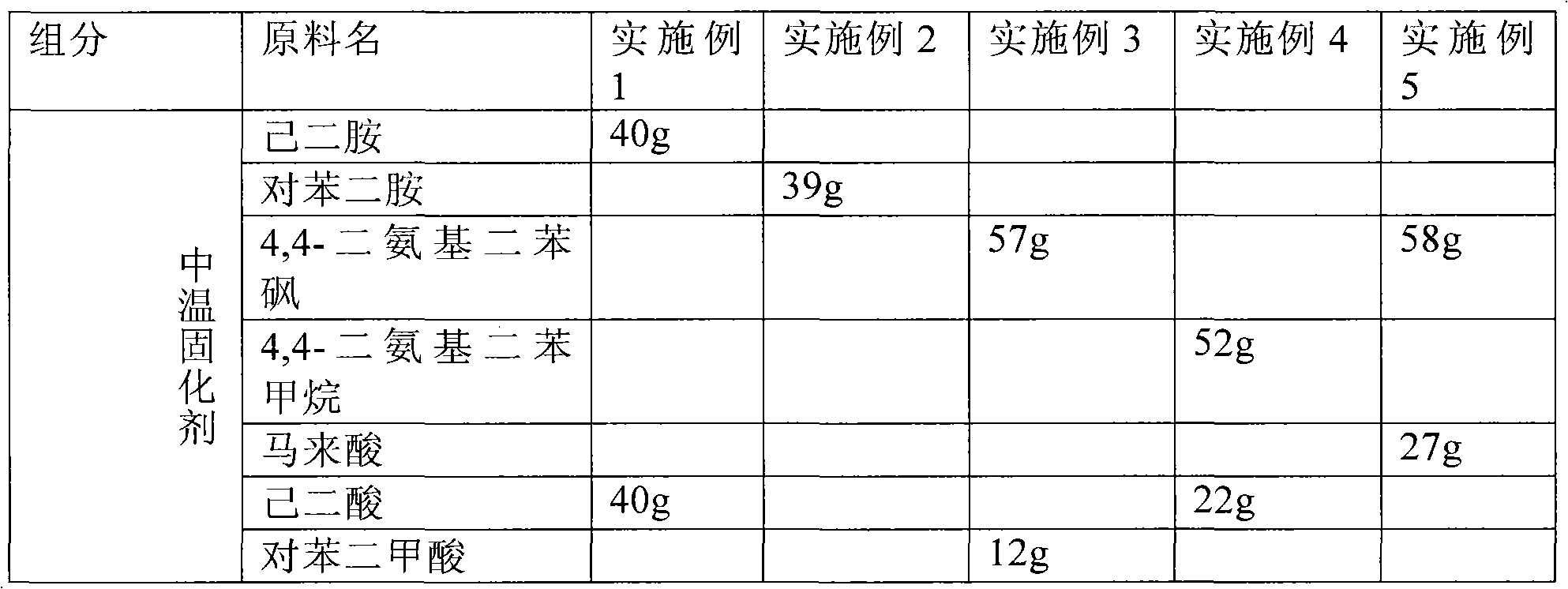

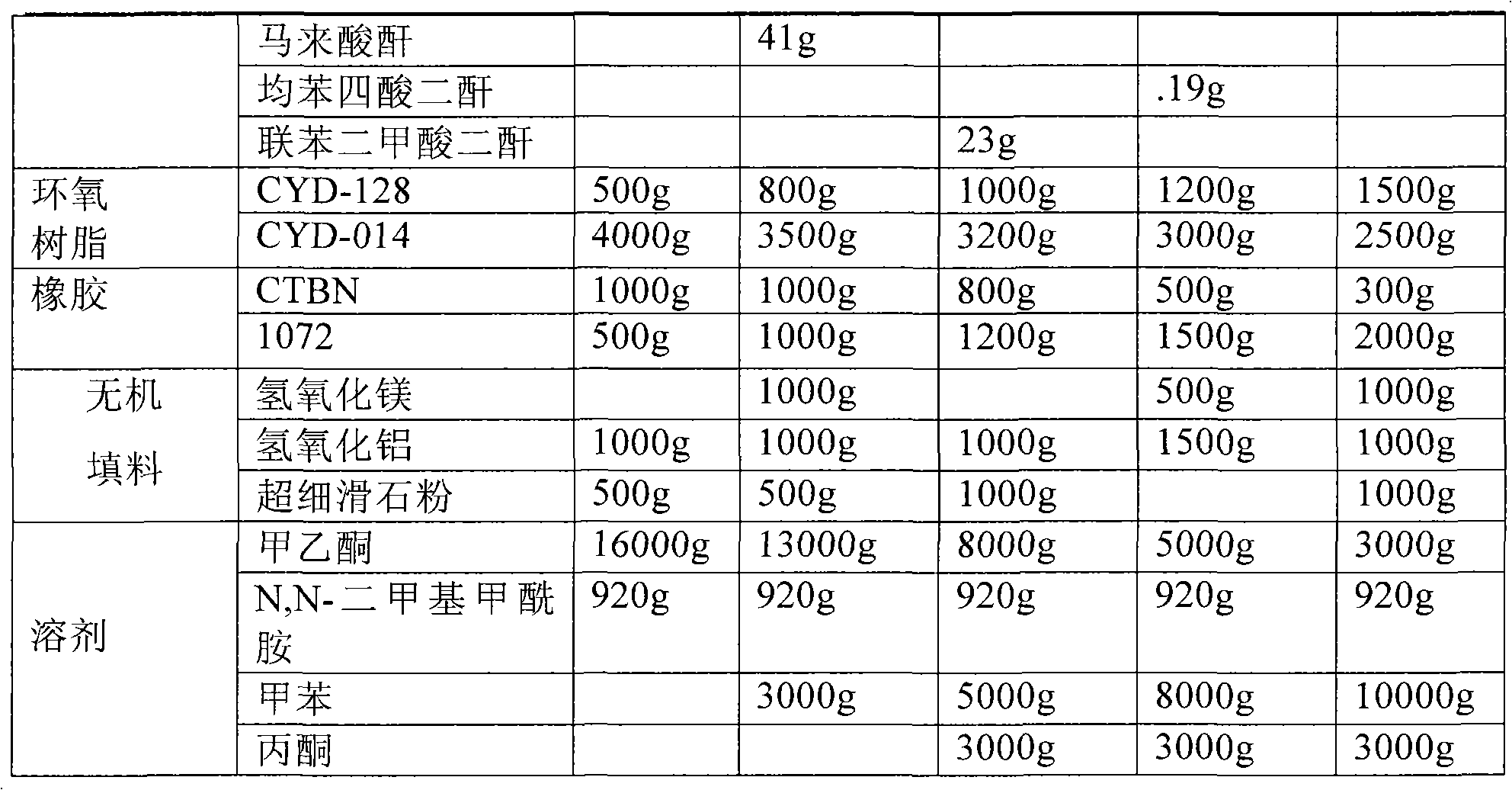

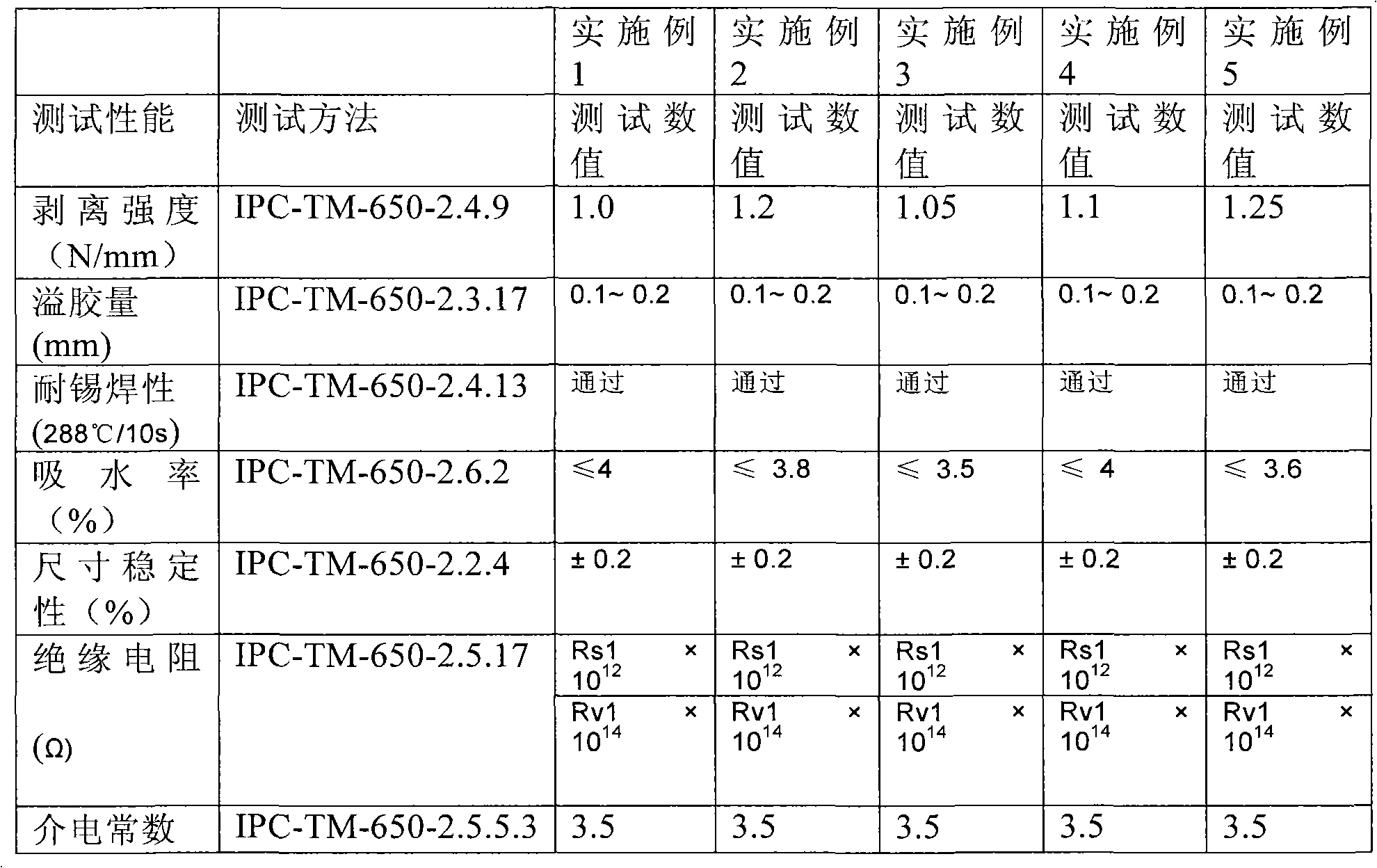

Intermediate temperature-cured epoxy adhesive for coverlay of flexible printed circuit and preparation method thereof

ActiveCN101845287ASolve the technical problem of high curing temperatureImprove performancePrinted circuit detailsFilm/foil adhesivesSolubilityPolyamide

The invention provides an intermediate temperature-cured epoxy adhesive for a coverlay of a flexible printed circuit and a preparation method thereof. The adhesive comprises the following main components: liquid epoxy CYD-128, solid epoxy CYD-014, liquid carboxy terminated nitrile rubber CTBN, solid carboxy terminated nitrile rubber 1072, a versamid intermediate temperature curing agent, and one or more inorganic fillers, wherein the intermediate temperature curing agent is a core component of the epoxy adhesive, and is synthesized by reacting diamine with diacid or di-anhydride in a polar solvent at the temperature of between 10 and 80 DEG C, wherein the molar ratio of the diamine to the diacid or di-anhydride is 0.25-4, and the polar solvent accounts for 50 to 90 mass percent of the reactants. The epoxy coverlay prepared from the adhesive can be completely cured at the temperature of between 135 and 145 DEG C, and the curing time is 60 to 120 minutes. The sample has the peel strength of over 1.0N / mm, good soldering resistance, small color change and low water absorption.

Owner:华烁电子材料(武汉)有限公司

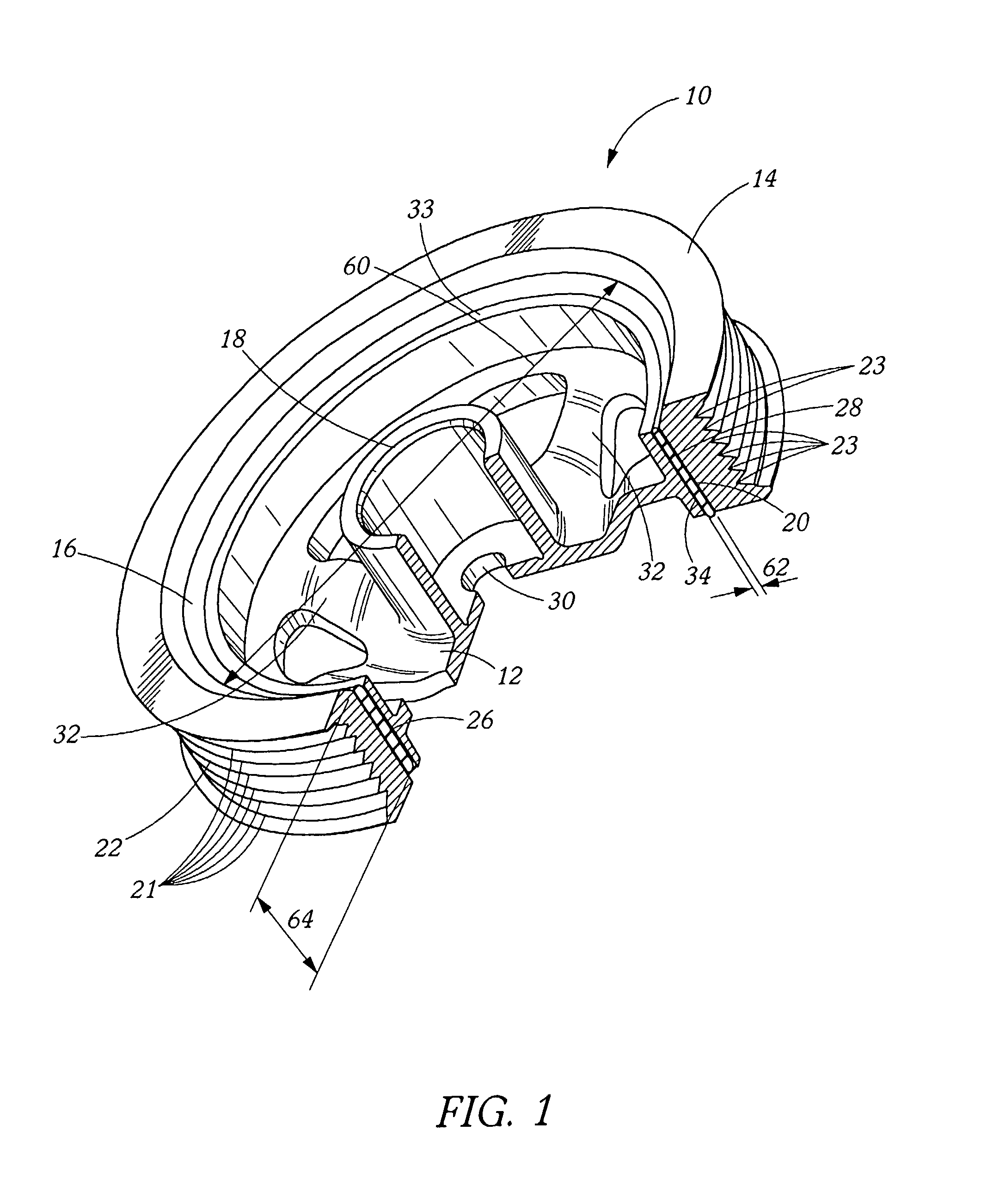

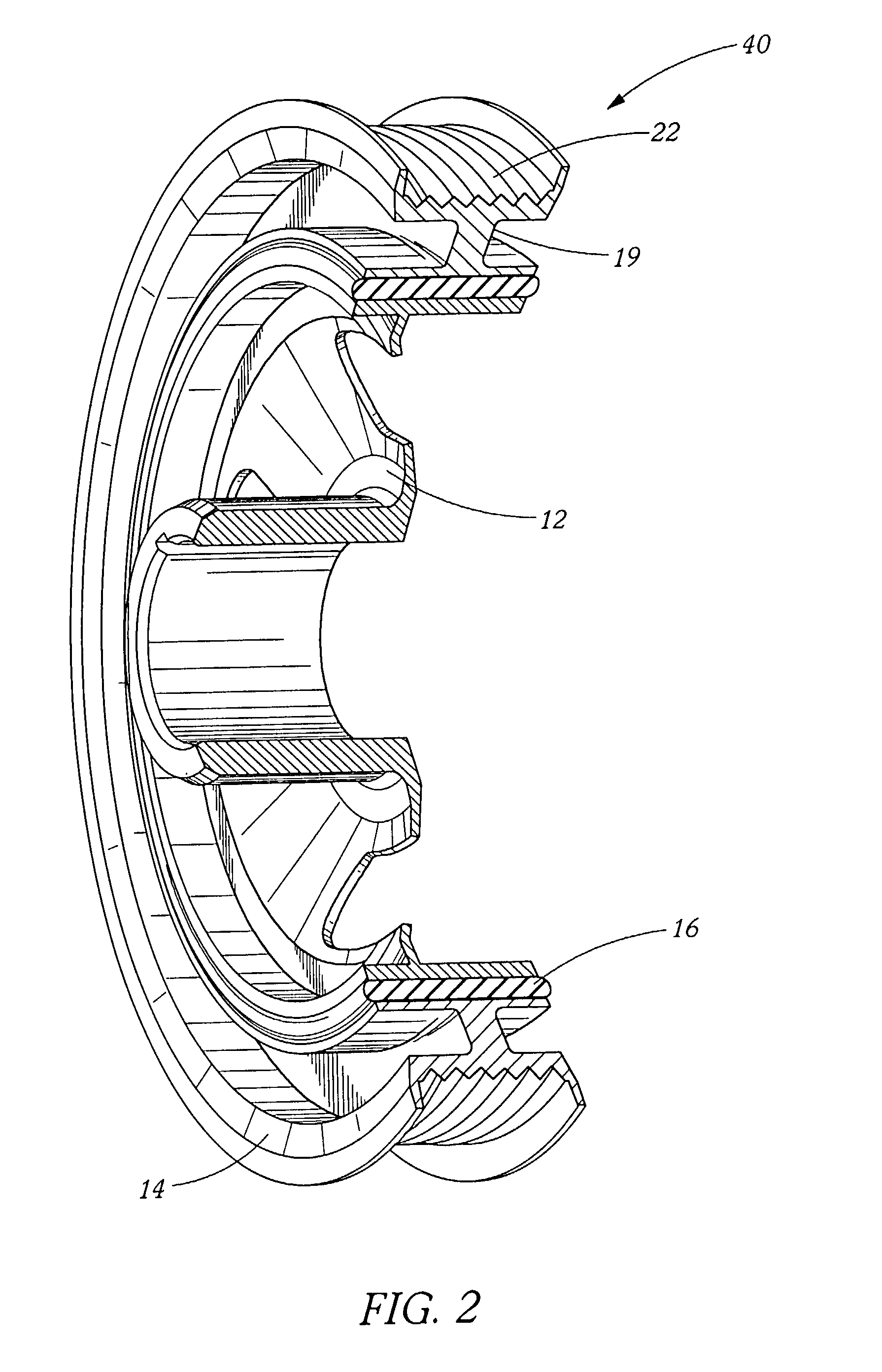

Bonded part and method for producing same

InactiveUS7078104B2Exemption stepsAdhesive processesSynthetic resin layered productsElastomerAdhesive

A bonded part such as a rubber to metal bonded part and process for producing a bonded part including a rubber and metal part, and particularly for producing an automotive torsional vibration damper, comprising the steps of placing uncured elastomer composition comprising an elastomer, at least one curative, and preferably, at least one rubber-to-metal adhesive adjuvant into a shape-forming mold, and curing the elastomer in two stages, wherein in the first curing stage the elastomer composition is less than fully cured and in the second curing stage, preferably performed with the elastomer composition in contact with a metal surface of the rubber and metal part, the elastomer composition is at least substantially fully cured. According to one embodiment, the present invention allows for the elimination of the step of applying an adhesive to the metal surface prior to application of the elastomer composition.

Owner:THE GATES CORP

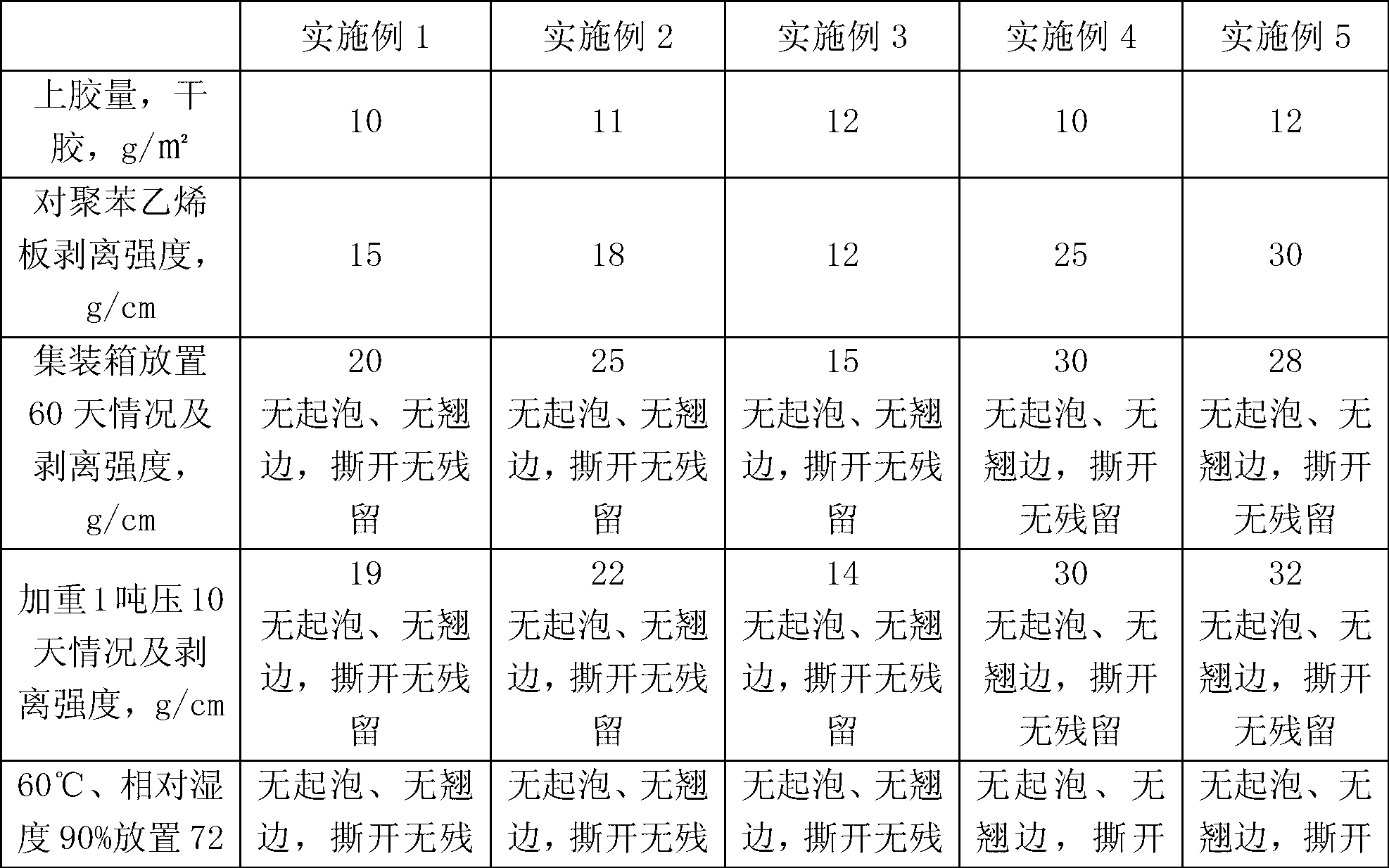

Aqueous pressure-sensitive adhesive and preparation method thereof

InactiveCN103013383AAchieve protectionMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesPolycarbonate plasticPolymer science

The invention provides an aqueous pressure-sensitive adhesive, which comprises the following components in percentage by weight: 54-81% of rubber latex, 5-10% of acrylic resin emulsion, 10-30% of tackifying resin emulsion and 4-6% of anti-aging agent emulsion, wherein the weight percentages of the various components are dry basis weights of the components. The invention further provides a preparation method of the aqueous pressure-sensitive adhesive. When being applied to surface protective paper, the aqueous pressure-sensitive adhesive provided by the invention is capable of protecting surfaces of products, such as acrylic plates, polycarbonate plastic plates, polystyrene plates, polyvinyl chloride plates, glass, marble and wood furniture decorative plates, under the ultra-low peeling strength, and avoiding the conditions, such as foaming, edge warping, and residual after tearing.

Owner:麦广明

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234044A1Excellent flame retardancy and electrical characteristicExcellent characteristicsNon-macromolecular adhesive additivesAdhesive articlesEpoxyHalogen

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a phytate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing flexible heat conducting insulating adhesive film used in LED heat radiation substrate

InactiveCN102676109AGood flexibilityImprove insulation performanceNon-macromolecular adhesive additivesLaminationAdhesive cementTemperature control

A method for preparing flexible heat conducting insulating adhesive film used in an LED heat radiation substrate comprises the preparation of a flexible heat conducting insulating adhesive and that of the flexible heat conducting insulating adhesive film, wherein the flexible heat conducting insulating adhesive comprises liquid epoxy resin, solid epoxy resin, flexibilizer, curing agent, high-heat conductivity inorganic packing, organic solvent, coupling agent, dispersing agent and flatting agent. The method for preparing the flexible heat conducting insulating adhesive film comprises the following steps: coating the flexible heat conducting insulating adhesive on a release film through a coating machine; baking through a temperature control baking channel to obtain an flexible heat conducting insulating adhesive layer used in the LED heat radiation substrate; coating the release film on the adhesive surface in a compounding manner; and rolling and forming to obtain the flexible heat conducting insulating adhesive film used in the LED heat radiation substrate. The adhesive film used in the LED heat radiation substrate has the characteristics of high heat dissipation, insulation, heat resistance and peel strength, flexibility and the like.

Owner:HAISO TECH

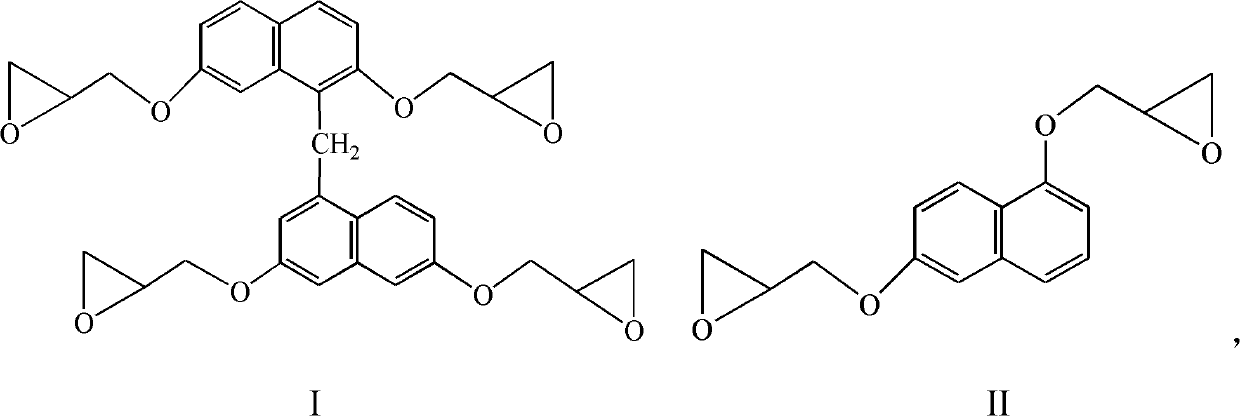

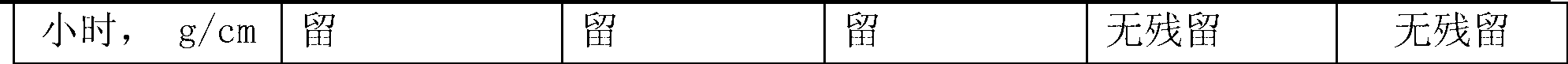

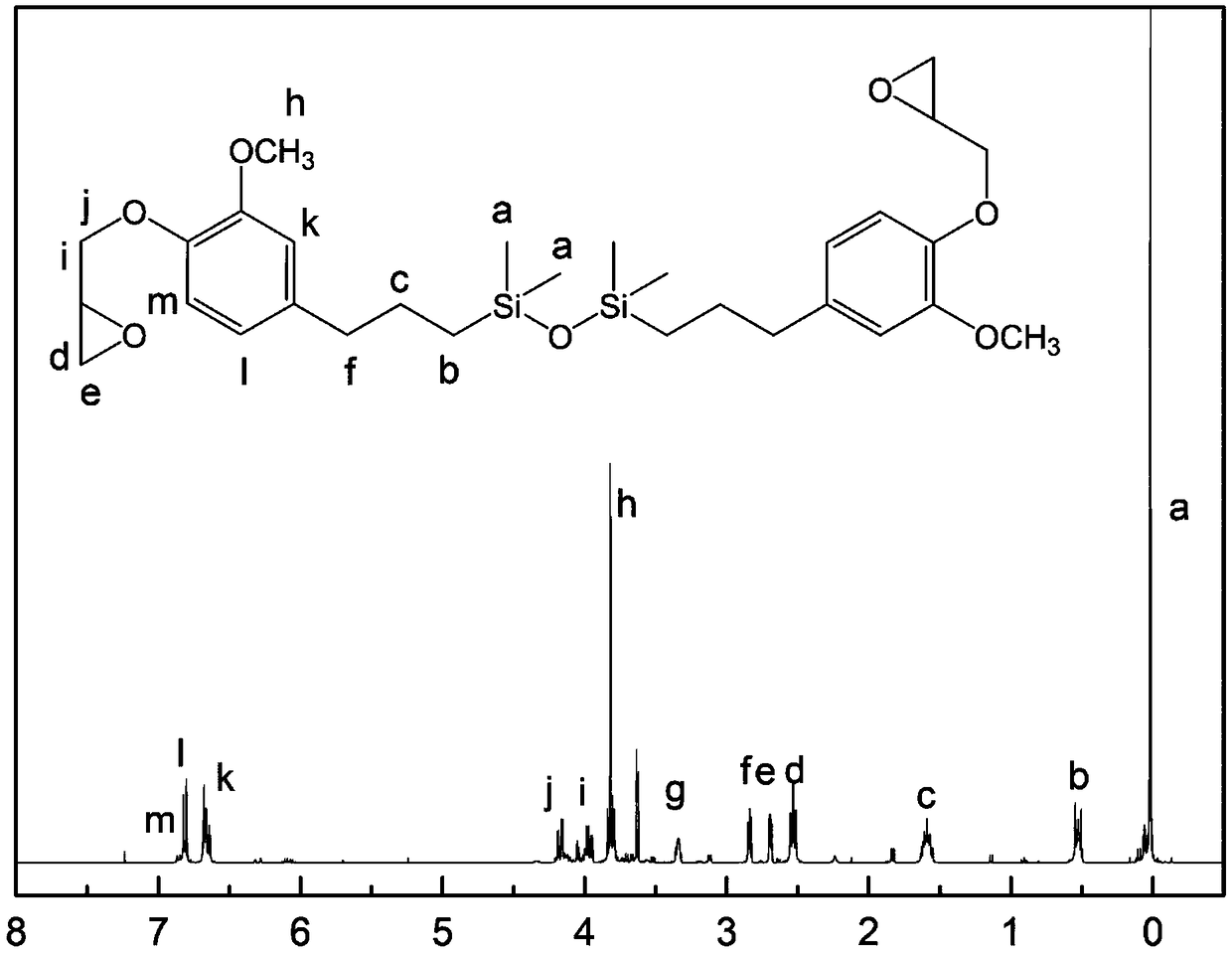

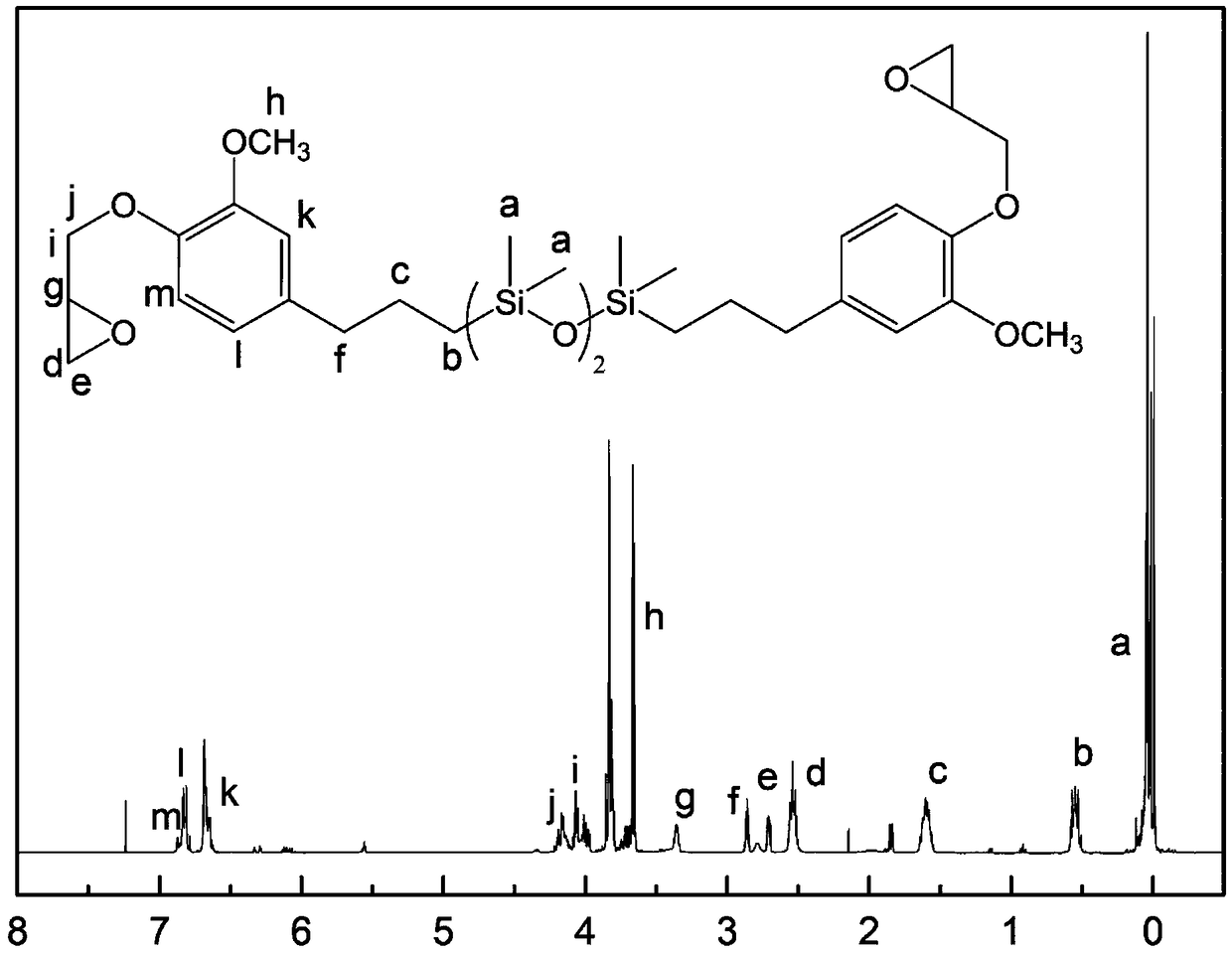

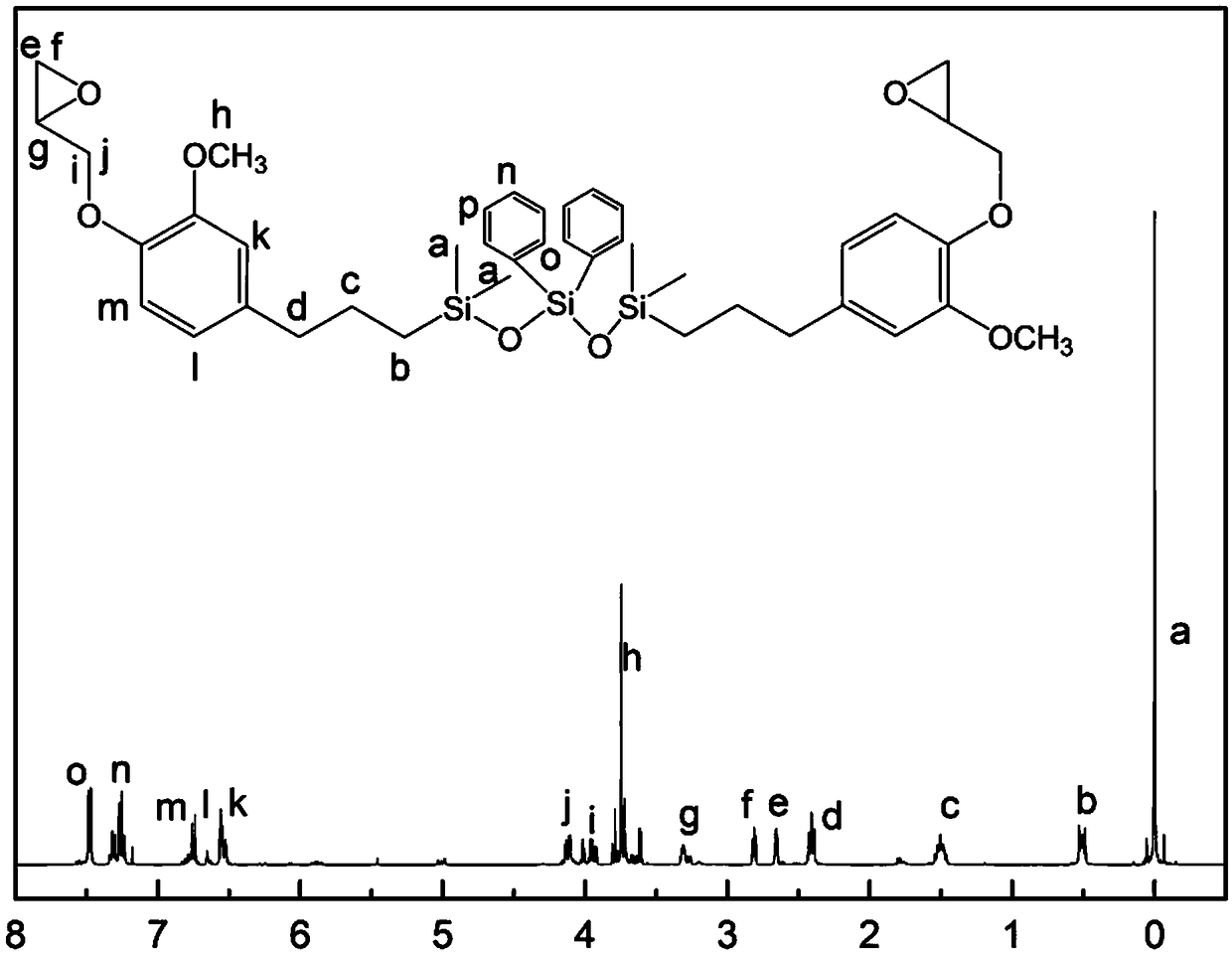

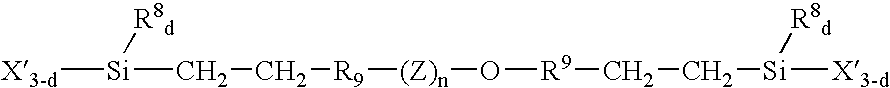

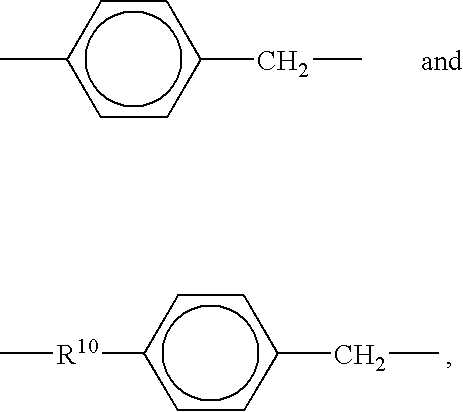

Bio-based epoxy resin composition and application thereof in preparing epoxy resin film

InactiveCN109467677AExcellent dielectric propertiesLow dielectric constantSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCarbon numberEpoxy

The invention discloses a bio-based epoxy resin composition. The bio-based epoxy resin composition comprises the following raw materials: 100 parts of bio-based epoxy resin and 5 to 50 parts of a curing agent; and the structural general formula of the bio-based epoxy resin is shown in the following formula. In the formula, x is an integer selected from 1 to 5, R1 to R4 are independently selected from a phenyl, a vinyl group, and an alkyl group having 1 to 10 carbon numbers. The bio-based epoxy resin is siloxane chain segment-containing eugenol bio-based epoxy resin, and main reaction functional groups are eugenol epoxy groups, and siloxane chain segments are introduced in a molecular skeleton, thereby being capable of greatly reducing the viscosity of the system and improving the processing fluidity, siloxane in macromolecular volume can further greatly improve dielectric properties and reduce dielectric constants, and has intrinsic flame retardant properties. The epoxy resin composition taking siloxane as a substrate can realize intrinsic flame retardation without adding a flame retardant, and the epoxy resin film prepared by using the composition has outstanding flame retardancy,adhesive properties and bending strength, and further is high in dielectric strength.

Owner:江苏和和新材料股份有限公司

High-heat-conduction flexible aluminum base copper-clad plate for LED heat radiating substrate

InactiveCN102020961ANon-macromolecular adhesive additivesCarboxyl rubber adhesivesOptoelectronicsCopper foil

The invention provides a production method of a high-heat-conduction flexible aluminum base copper-clad plate for an LED heat radiating substrate. The method mainly comprises the following step of preparing a high-heat-conduction epoxy adhesive. In the method, the high-heat-conduction epoxy adhesive is coated at two sides of a polyimide membrane, wherein a copper foil is bonded at one side, an aluminum foil is bonded at the other side, and then a high-heat-conduction flexible aluminum base copper-clad plate which can be used for an LED heat radiating substrate is prepared through continuous hot-pressing molding and high-temperature post-curing treatment. The substrate has the advantages of ultrathin thickness, high temperature resistance, flexibility, high heat condition, good insulating property, high peel strength, and the like.

Owner:HAISO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com