Patents

Literature

498 results about "Dicing tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

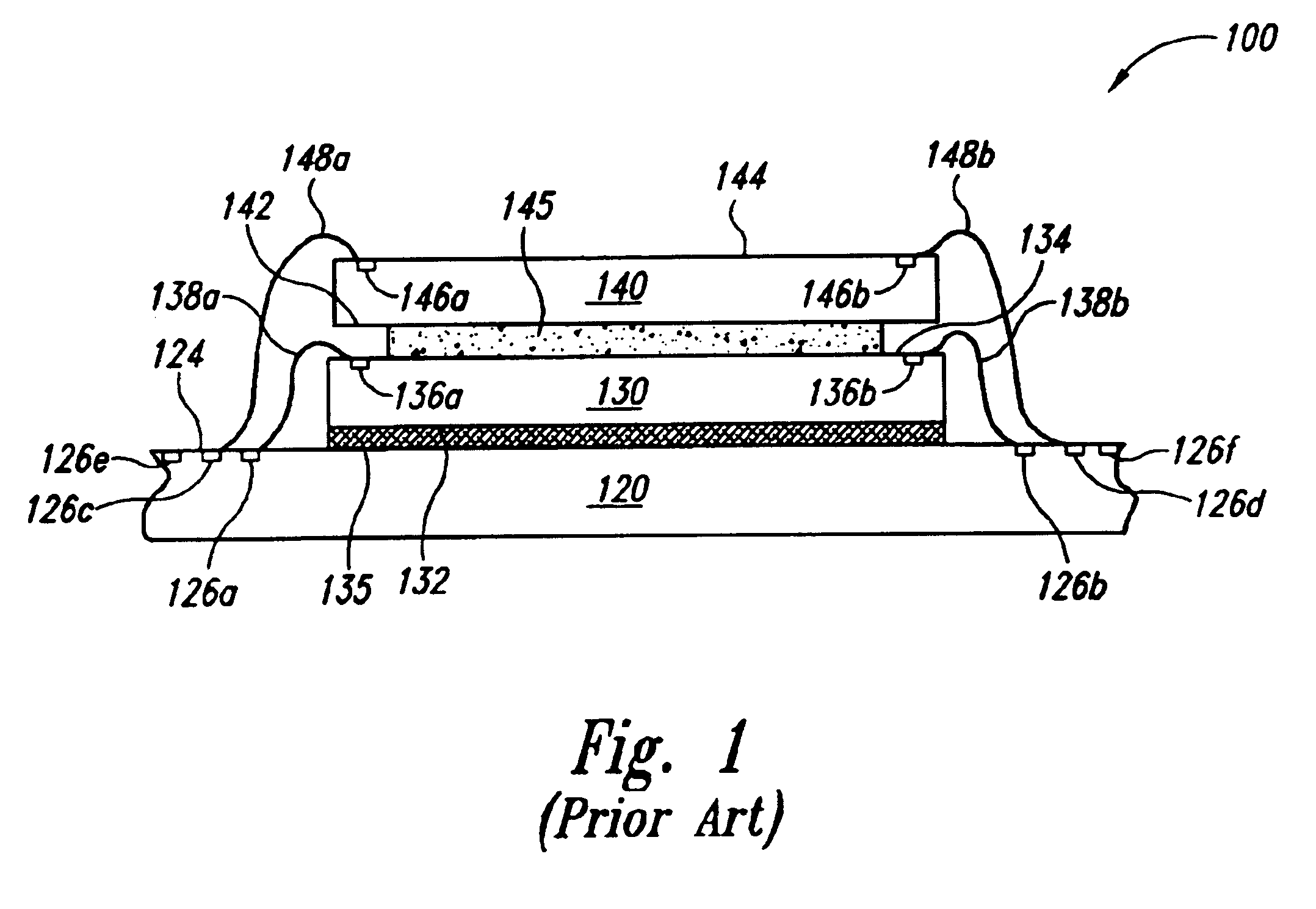

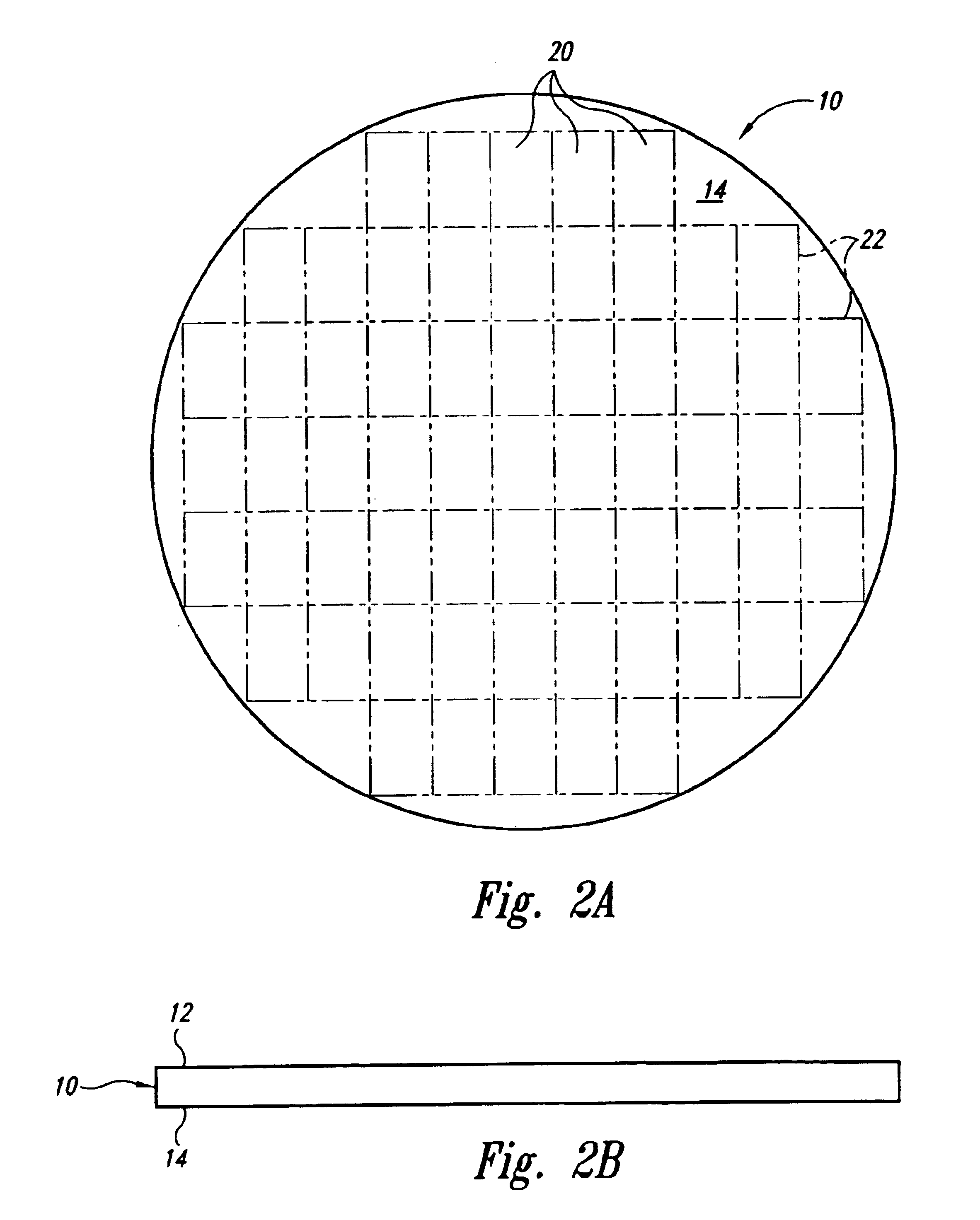

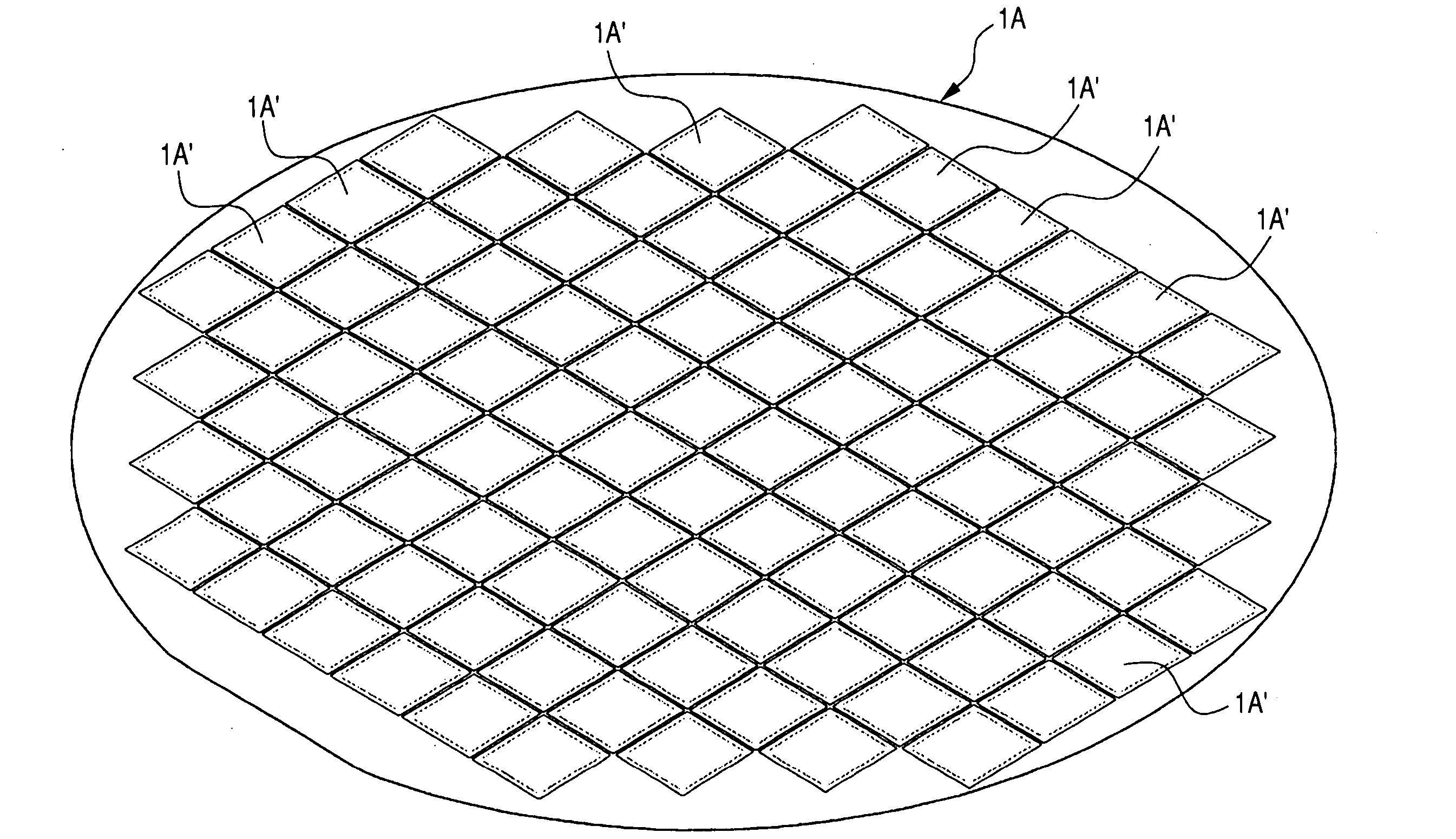

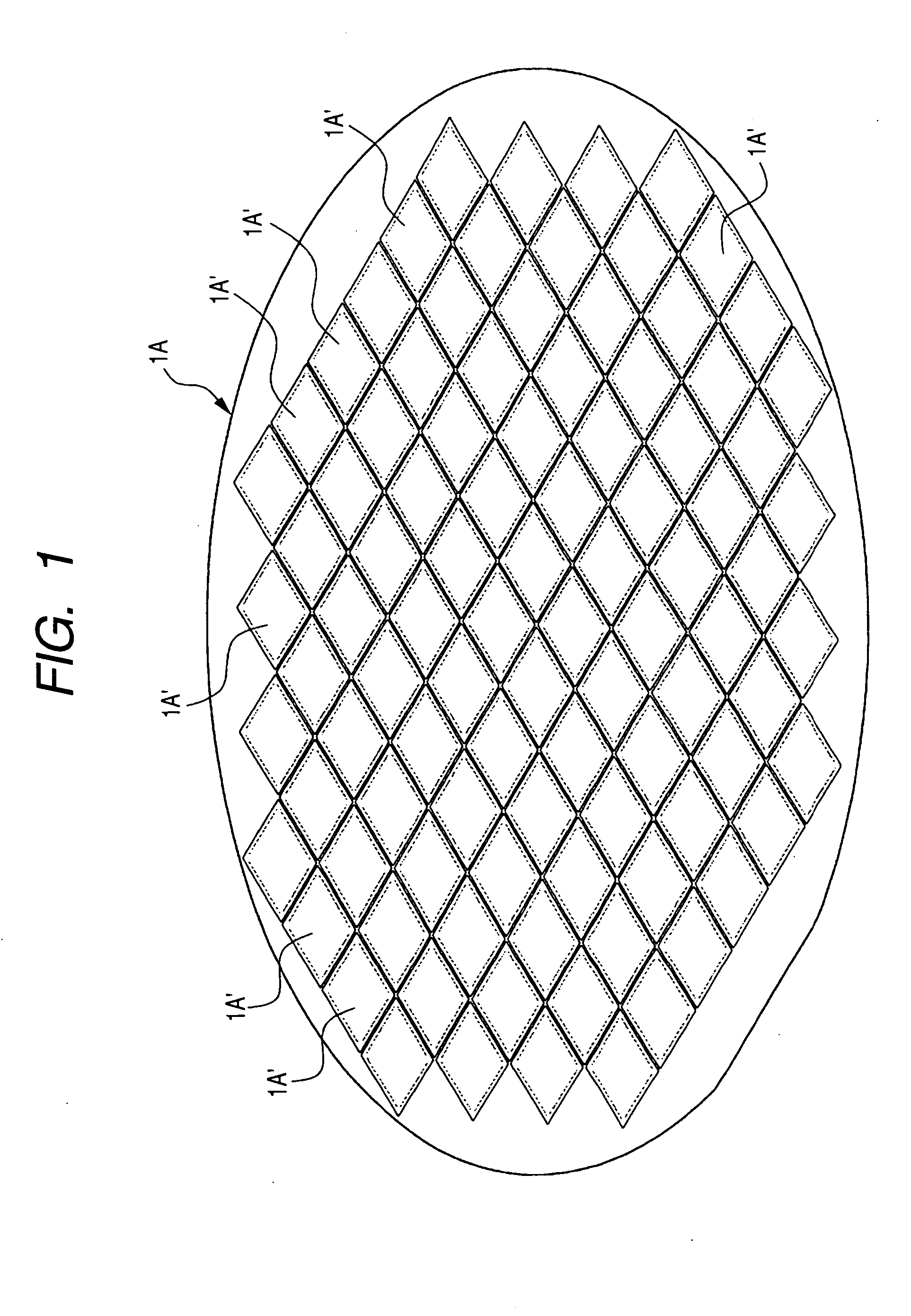

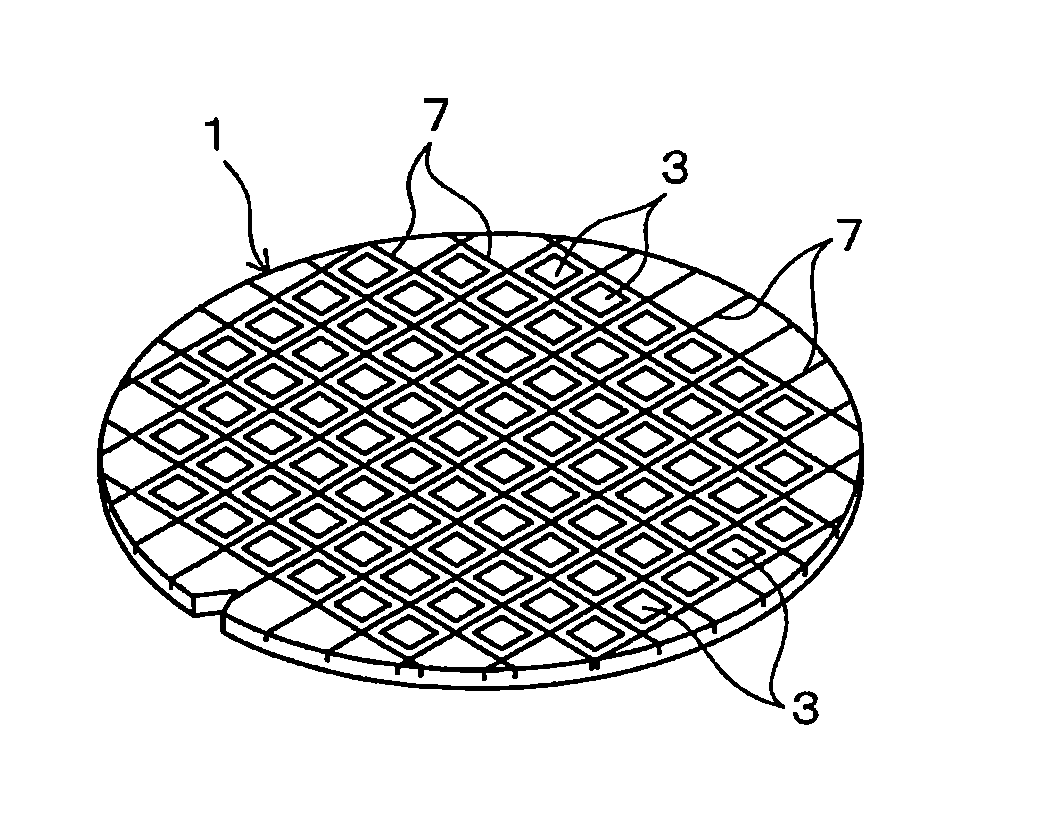

Dicing tape is a backing tape used during wafer dicing, the cutting apart of pieces of semiconductor material following wafer microfabrication. The tape holds the pieces of semiconductor, known as die, together during the cutting process, mounting them to a thin metal frame. The die are removed from the dicing tape later on in the electronics manufacturing process.

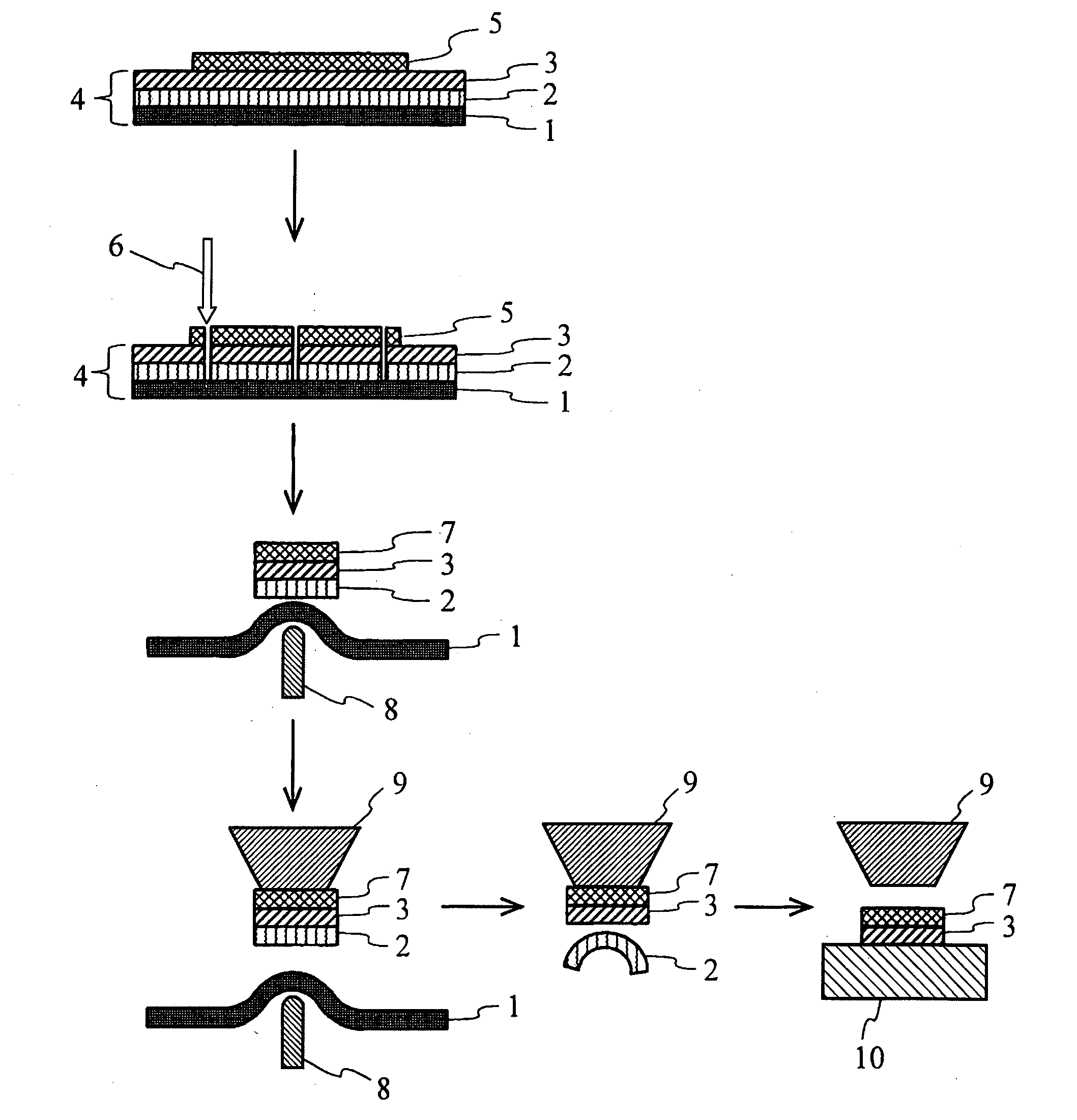

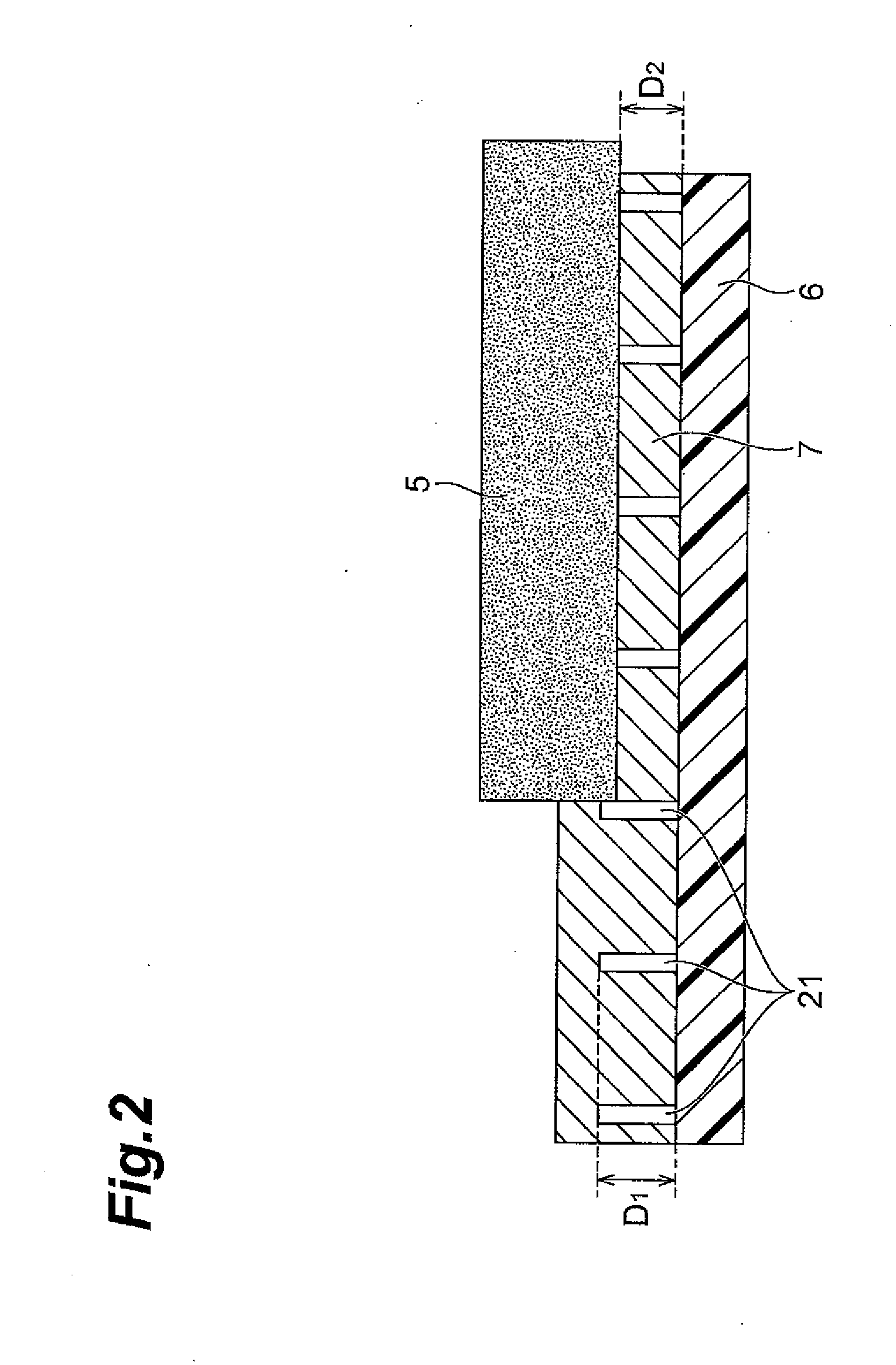

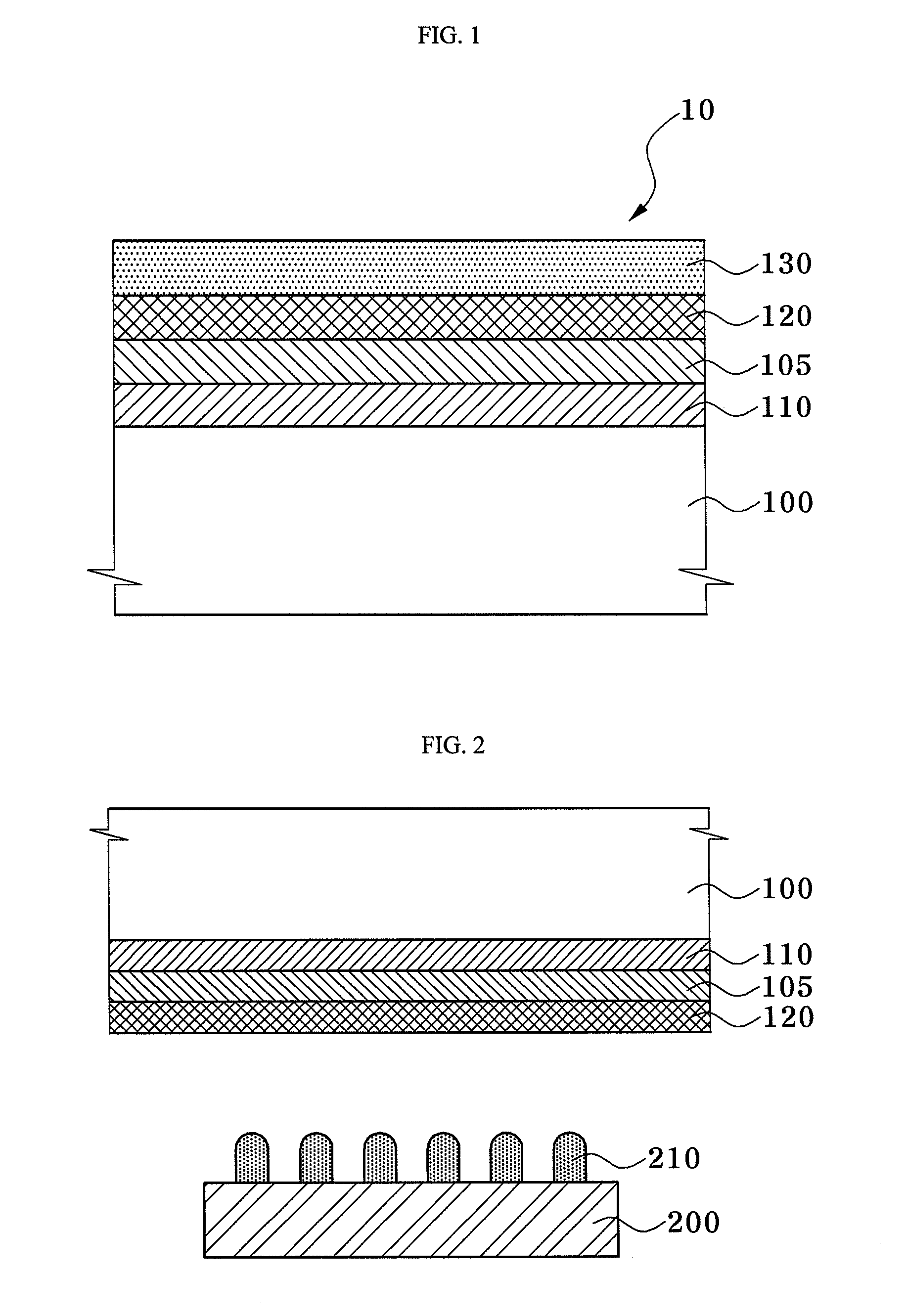

Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

InactiveUS20060128065A1Efficient cuttingImprove bond reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeDevice material

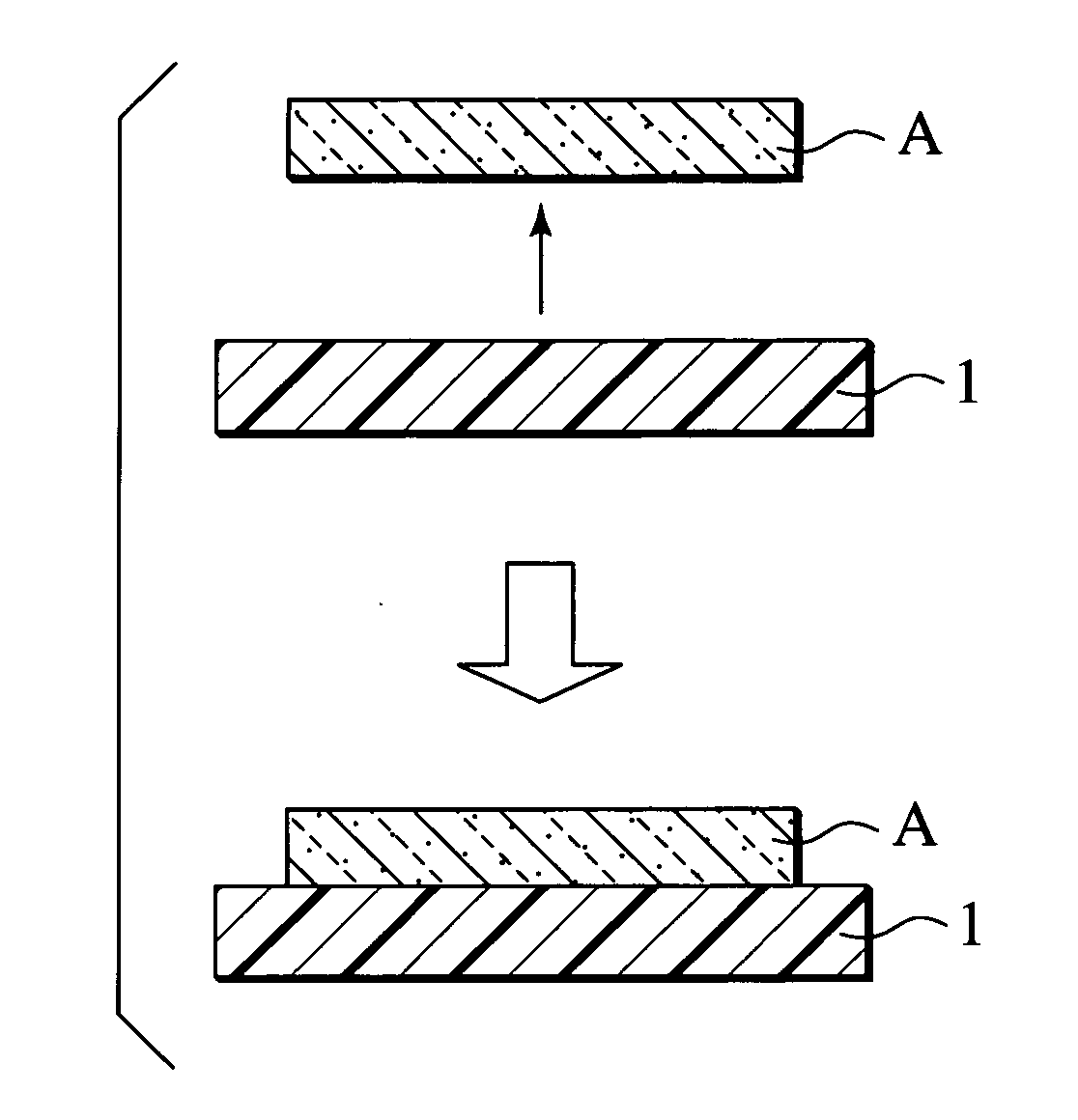

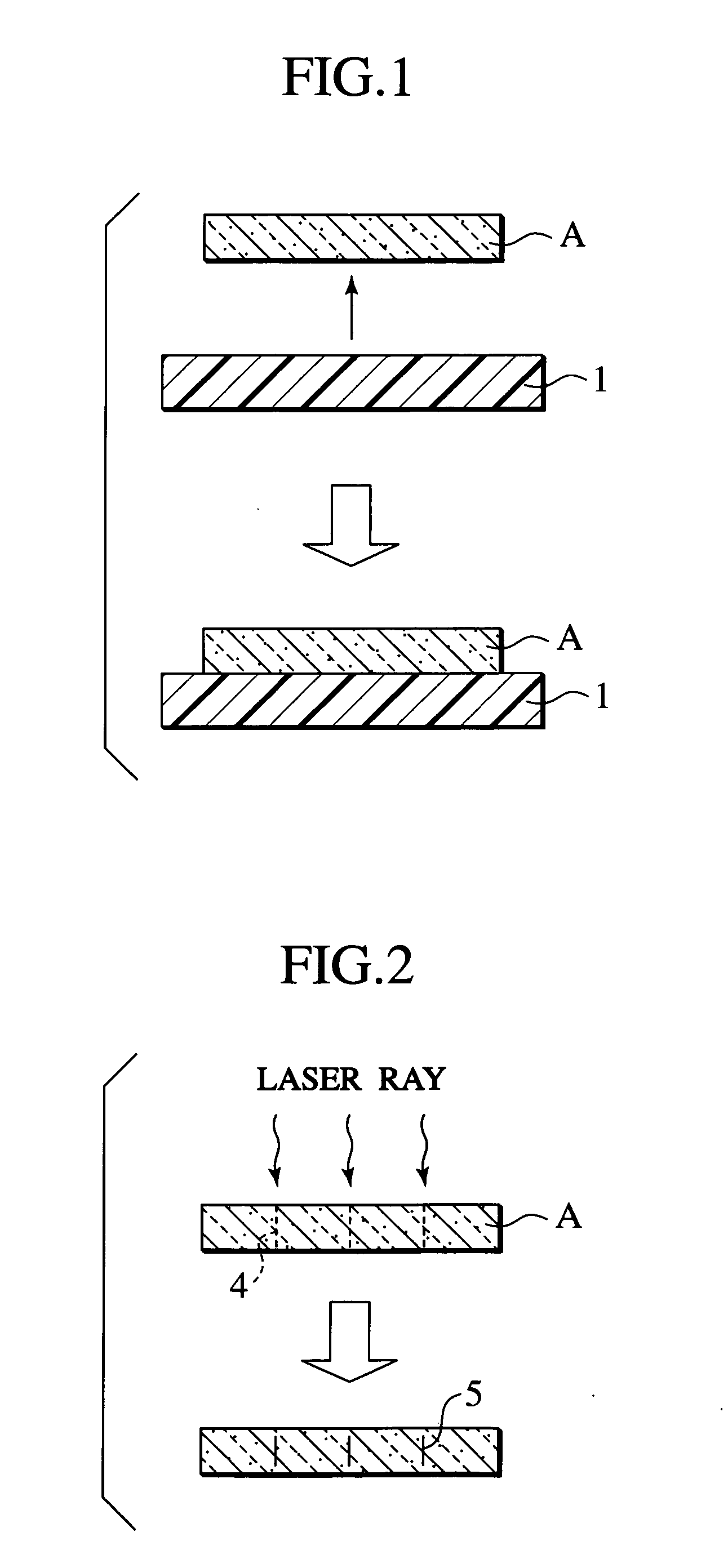

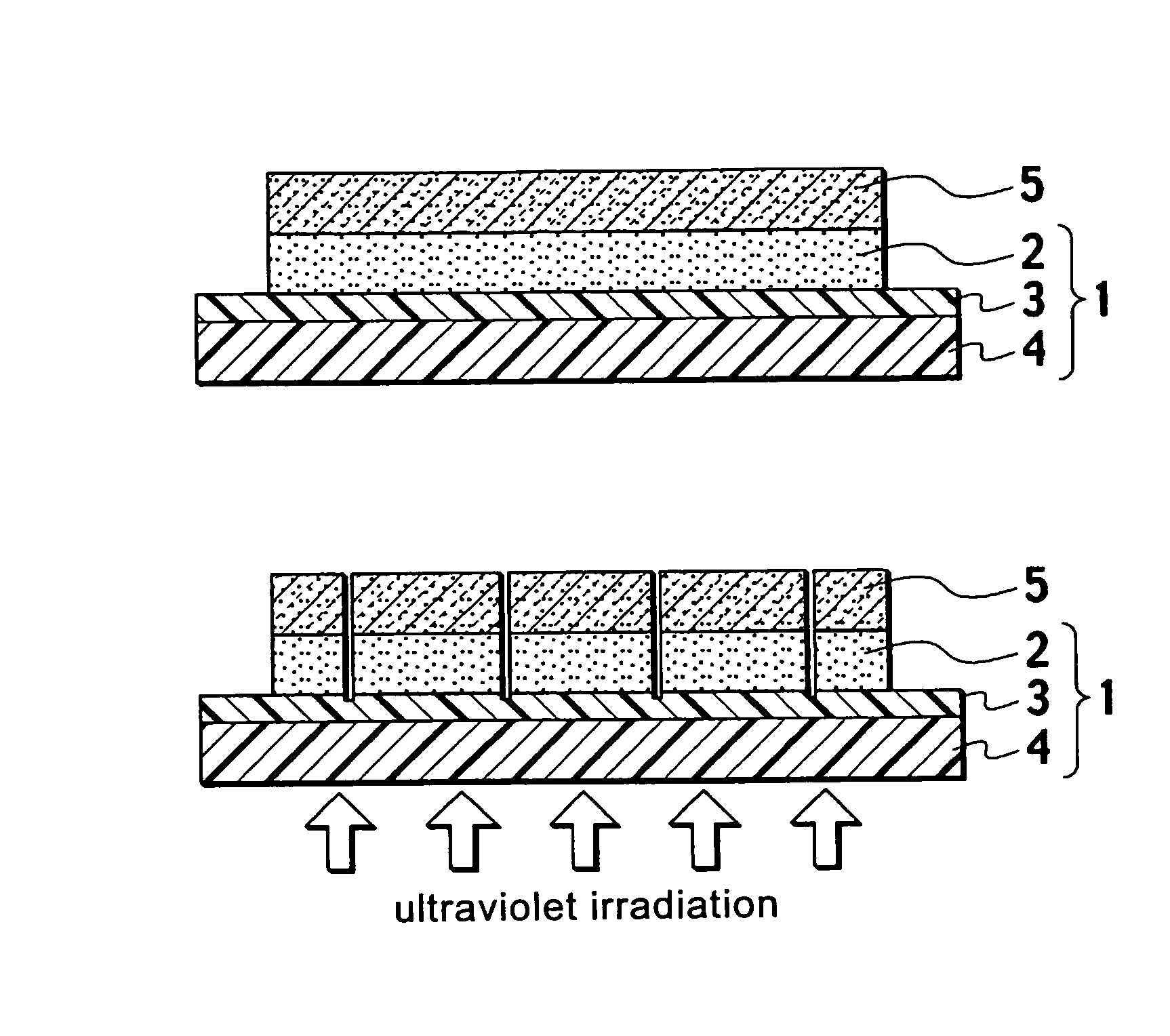

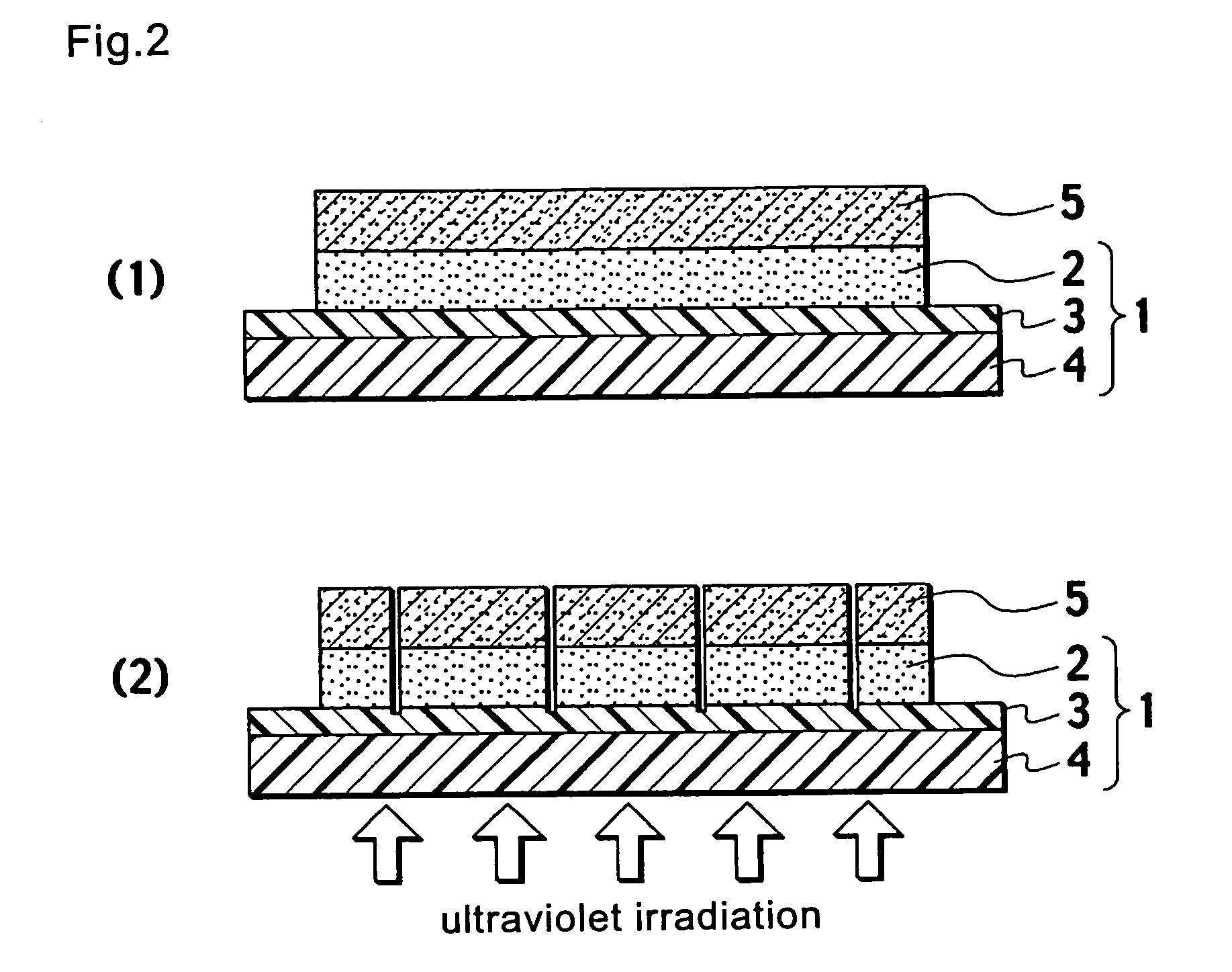

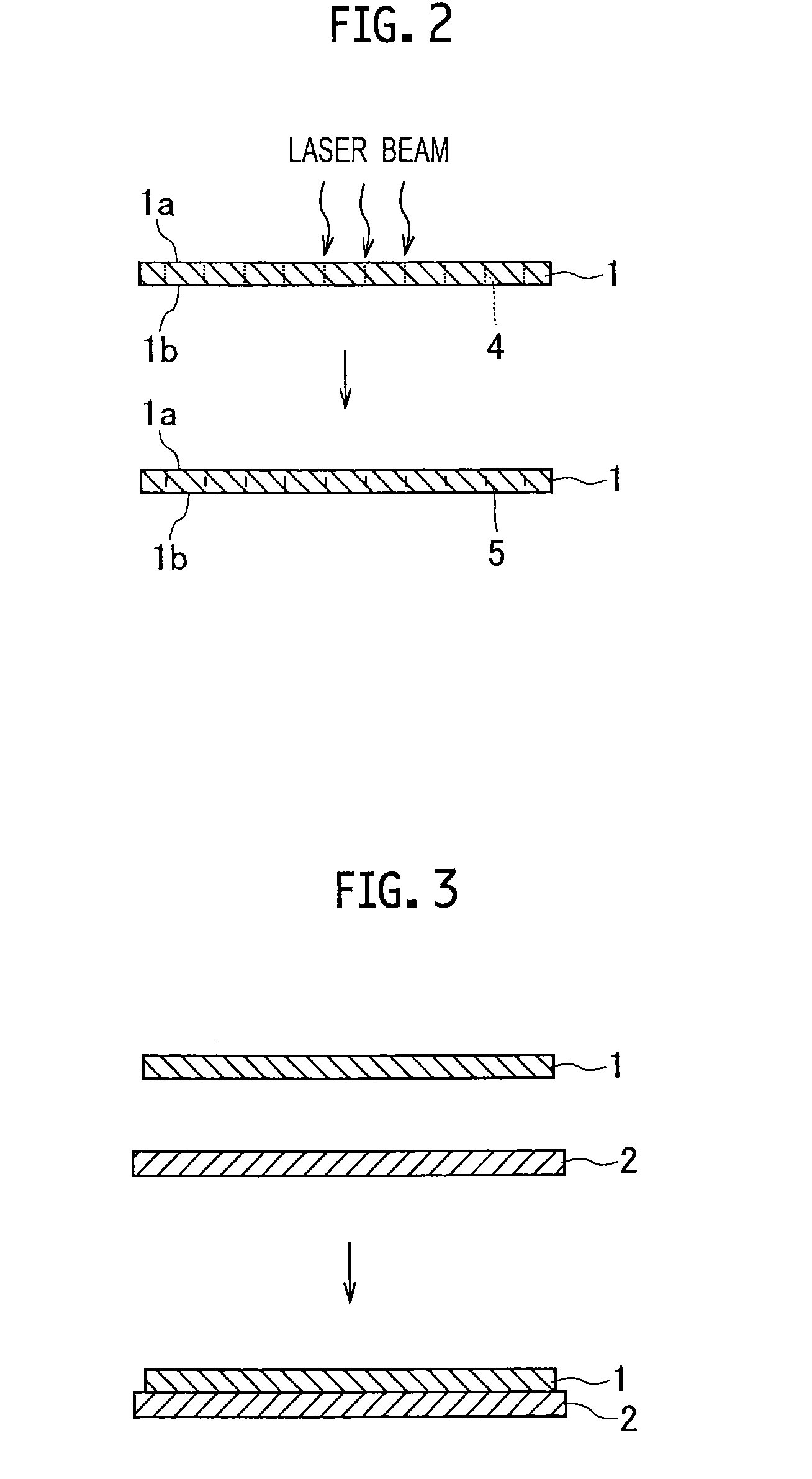

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:HITACHI CHEM CO LTD

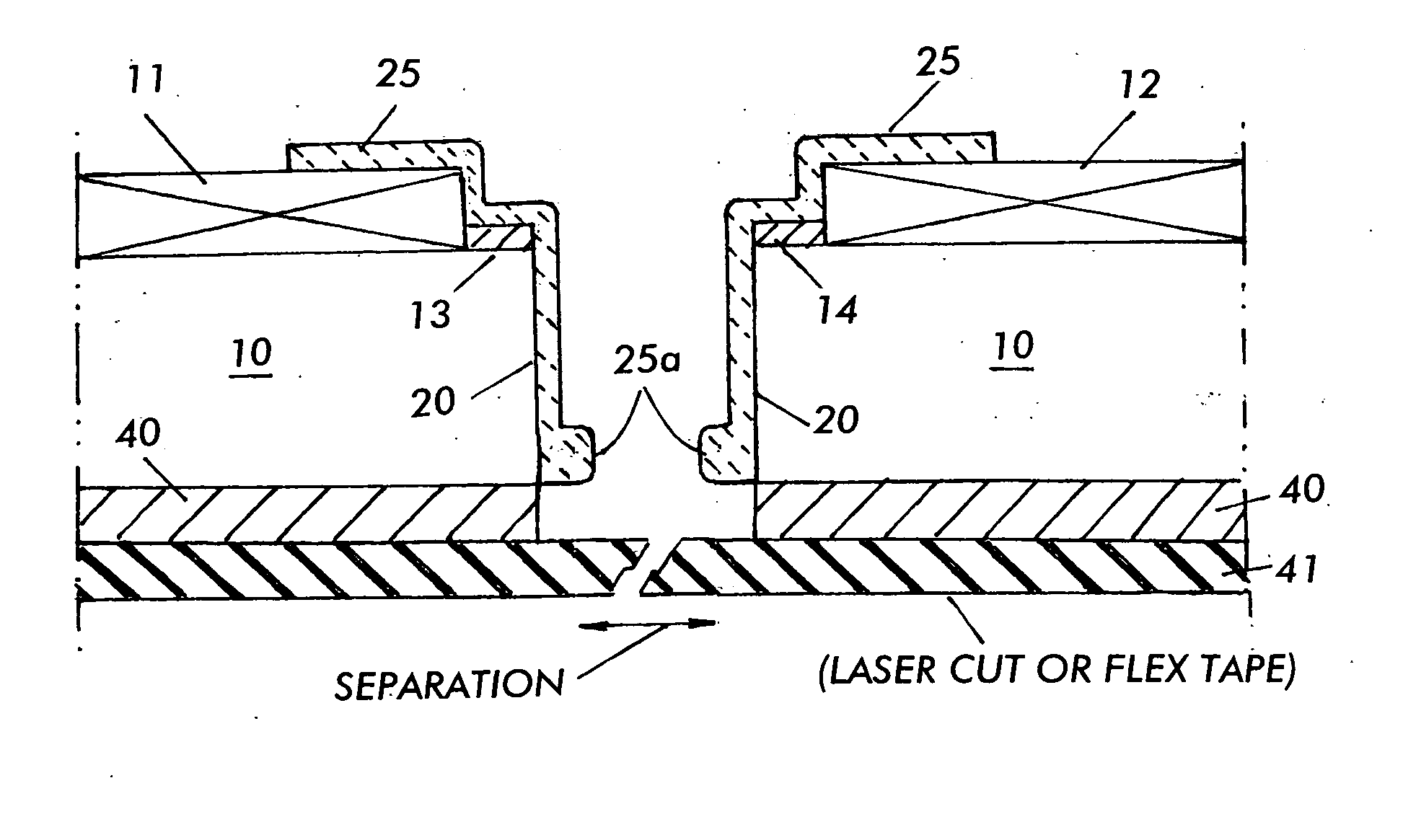

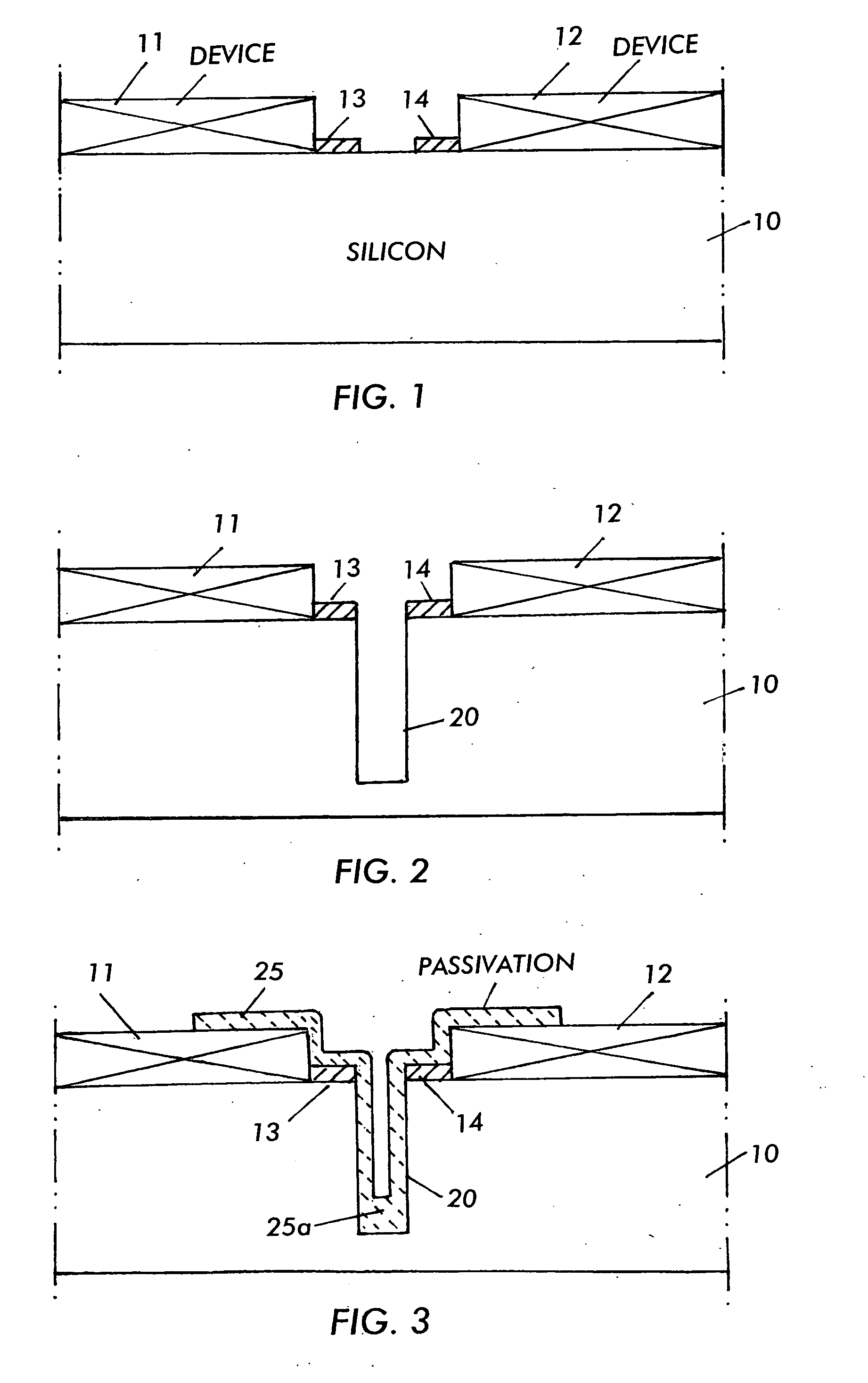

Wafer singulation process

A method of singulating a semiconductor die from a wafer is provided. The method includes etching or cutting several trenches into the wafer from a front surface of the wafer, such that each trench extends along an entire side of the die; depositing a passivation layer into the trenches to form a passivation plug on at least a bottom of the trenches to protect the dies and immobilize them during singulation; and forming a rigid carrier layer or plate at the first side of the wafer to secure the dies. The wafer is then ground from the back side to expose the bottom of each trench, a metal layer is formed on the back surface of the wafer; dicing tape is added, the carrier layer is removed, and the die is separated from the wafer by laser cutting or by flexing the tape.

Owner:INFINEON TECH AMERICAS CORP

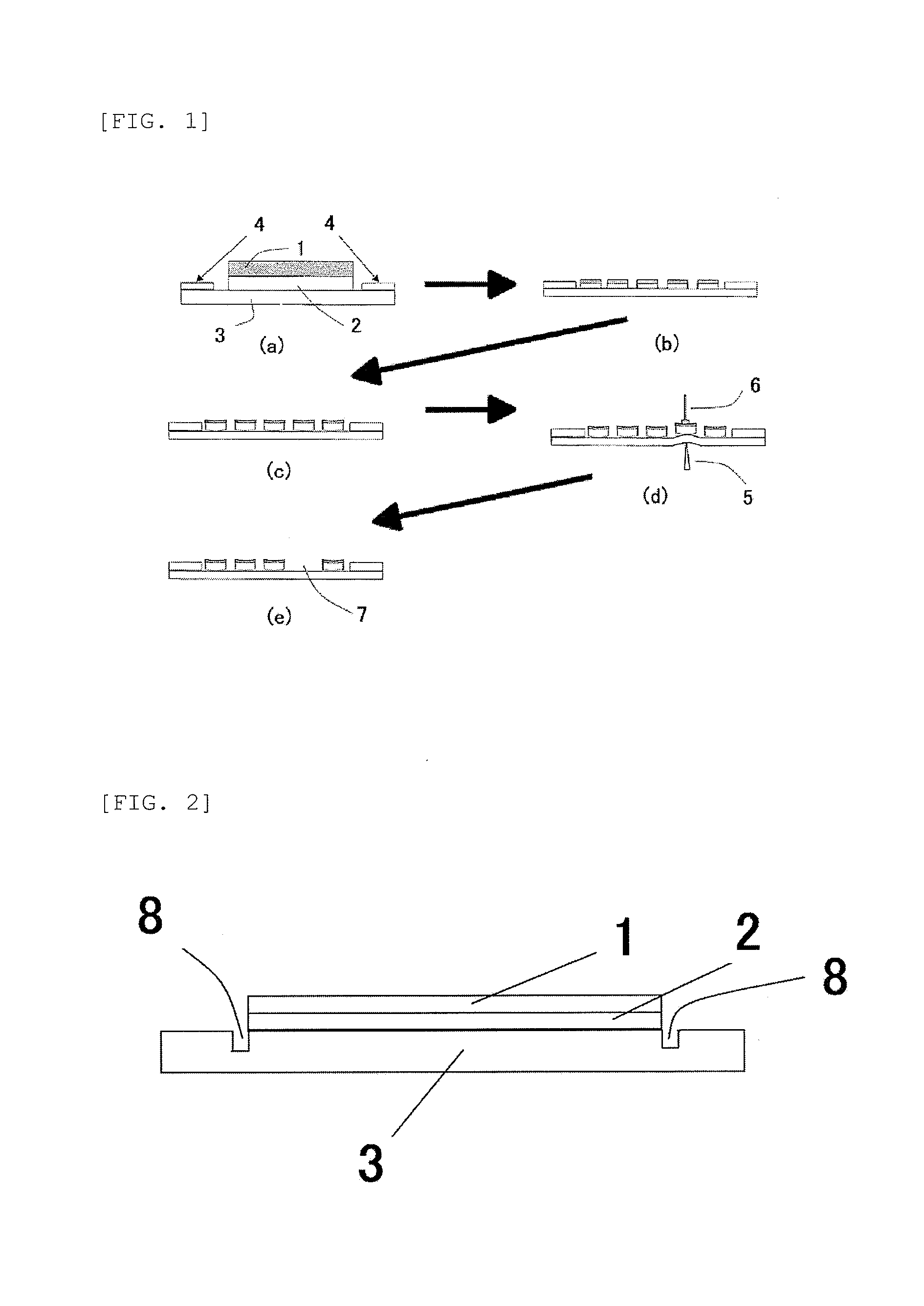

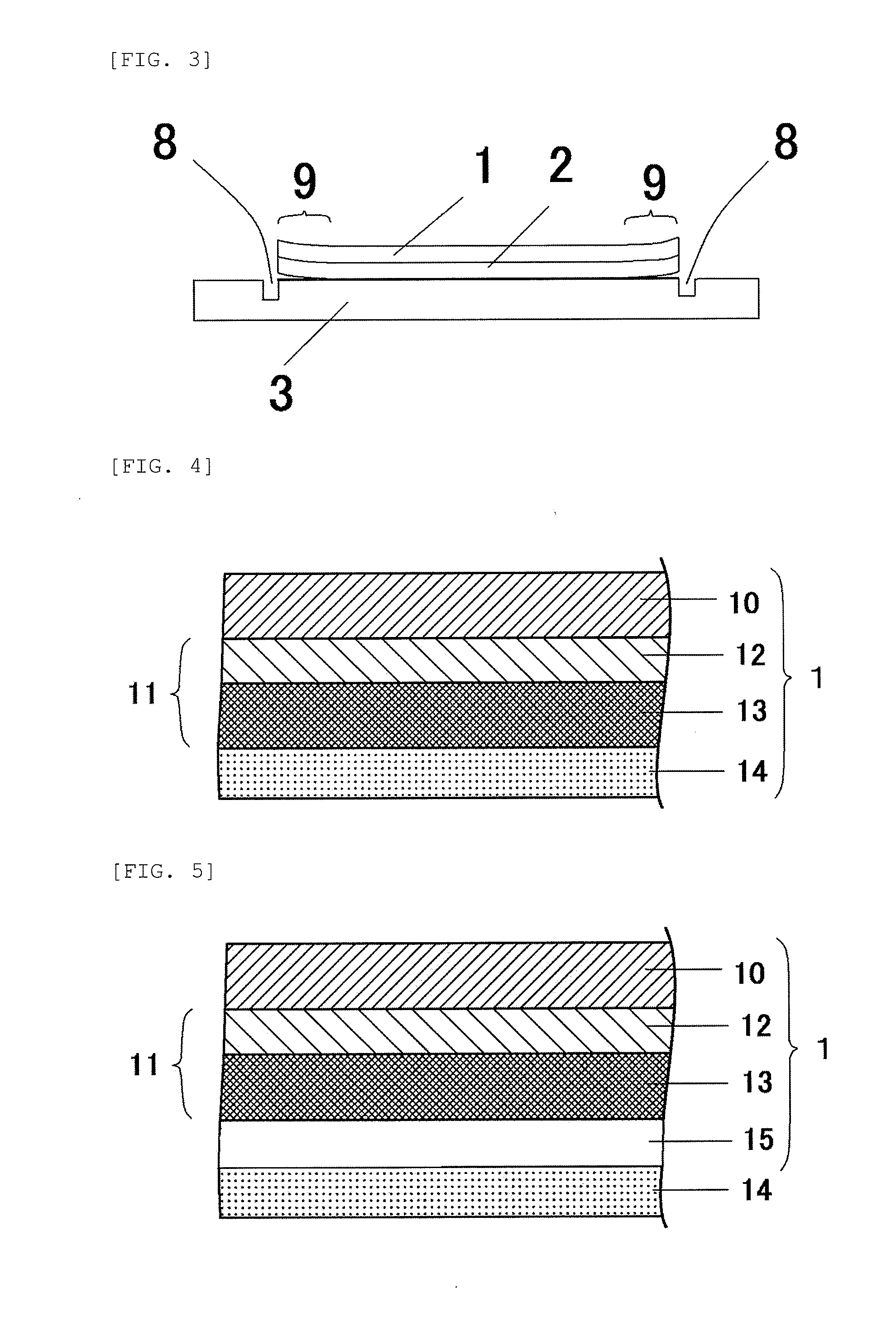

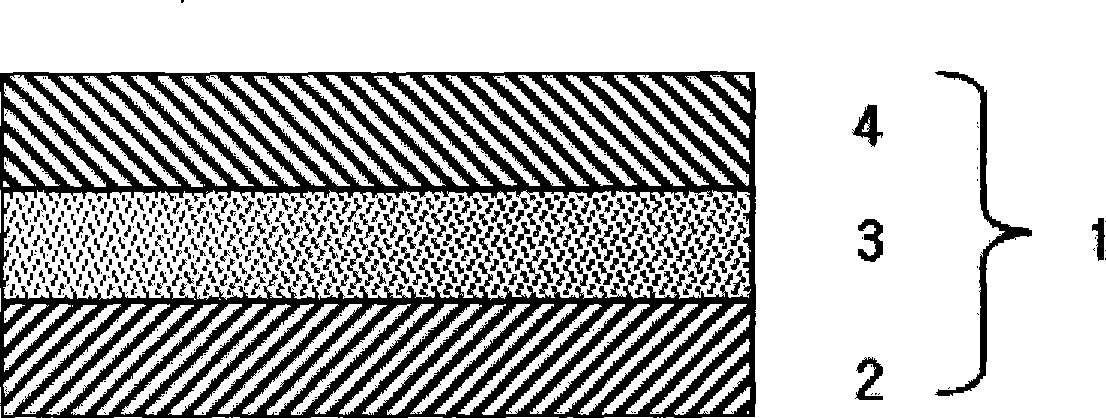

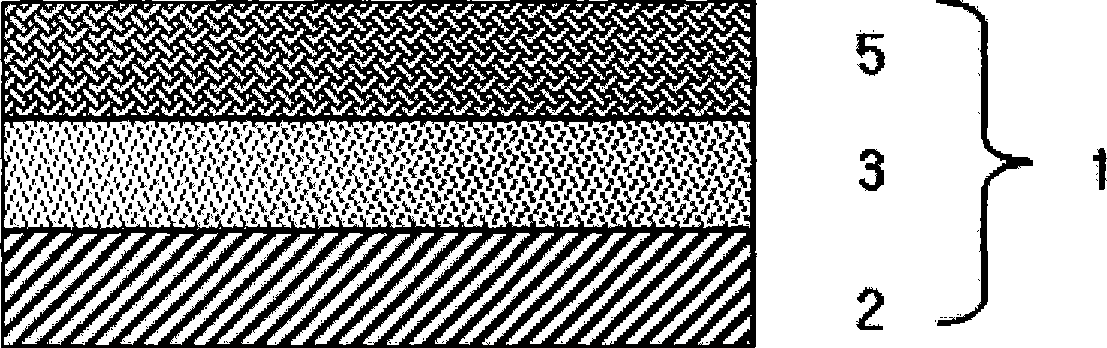

Die attach film-provided dicing tape and production process of semiconductor device

InactiveUS20100279491A1Efficient productionImprove productivityAdhesive articlesSynthetic resin layered productsDicing tapeDevice material

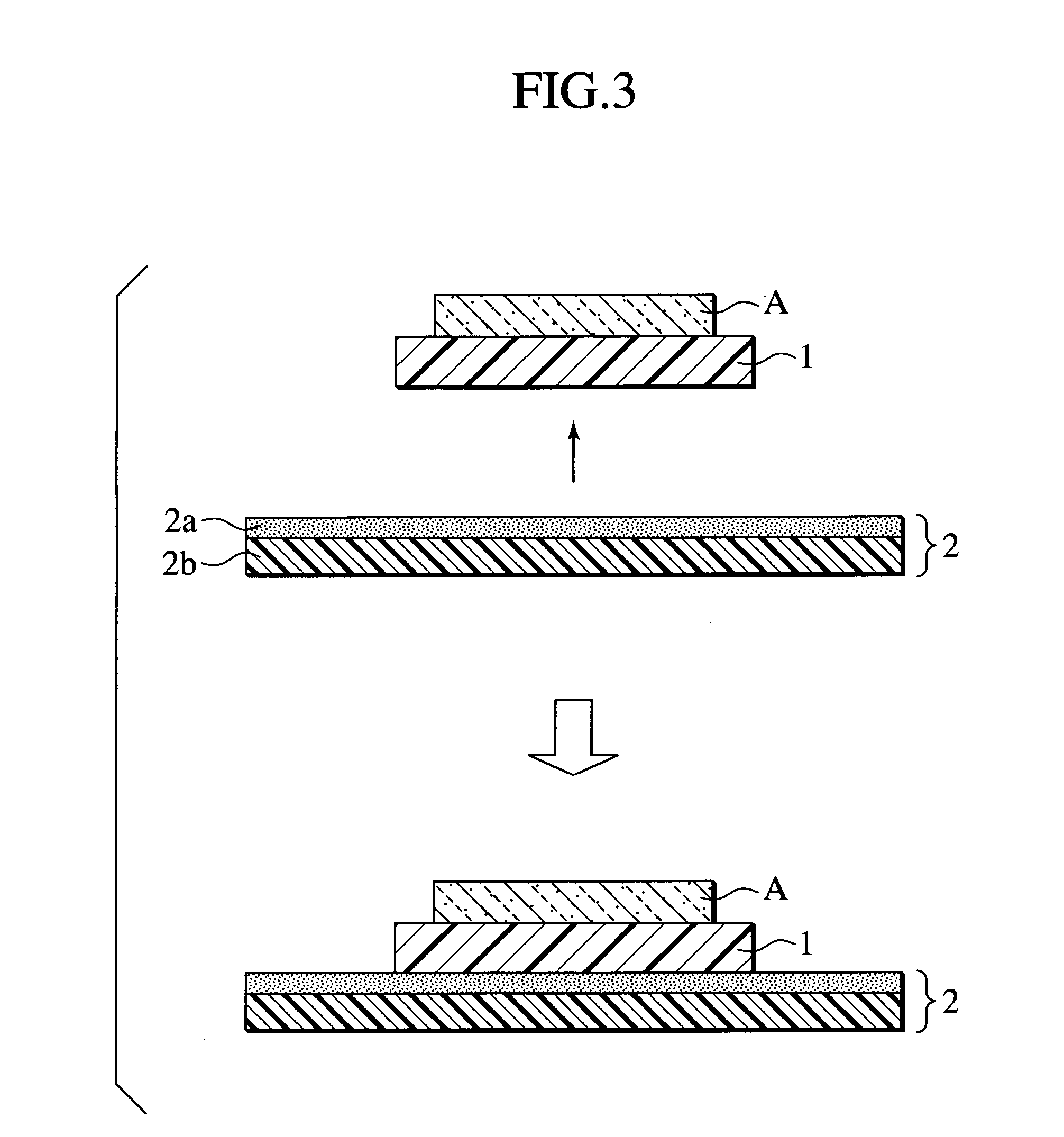

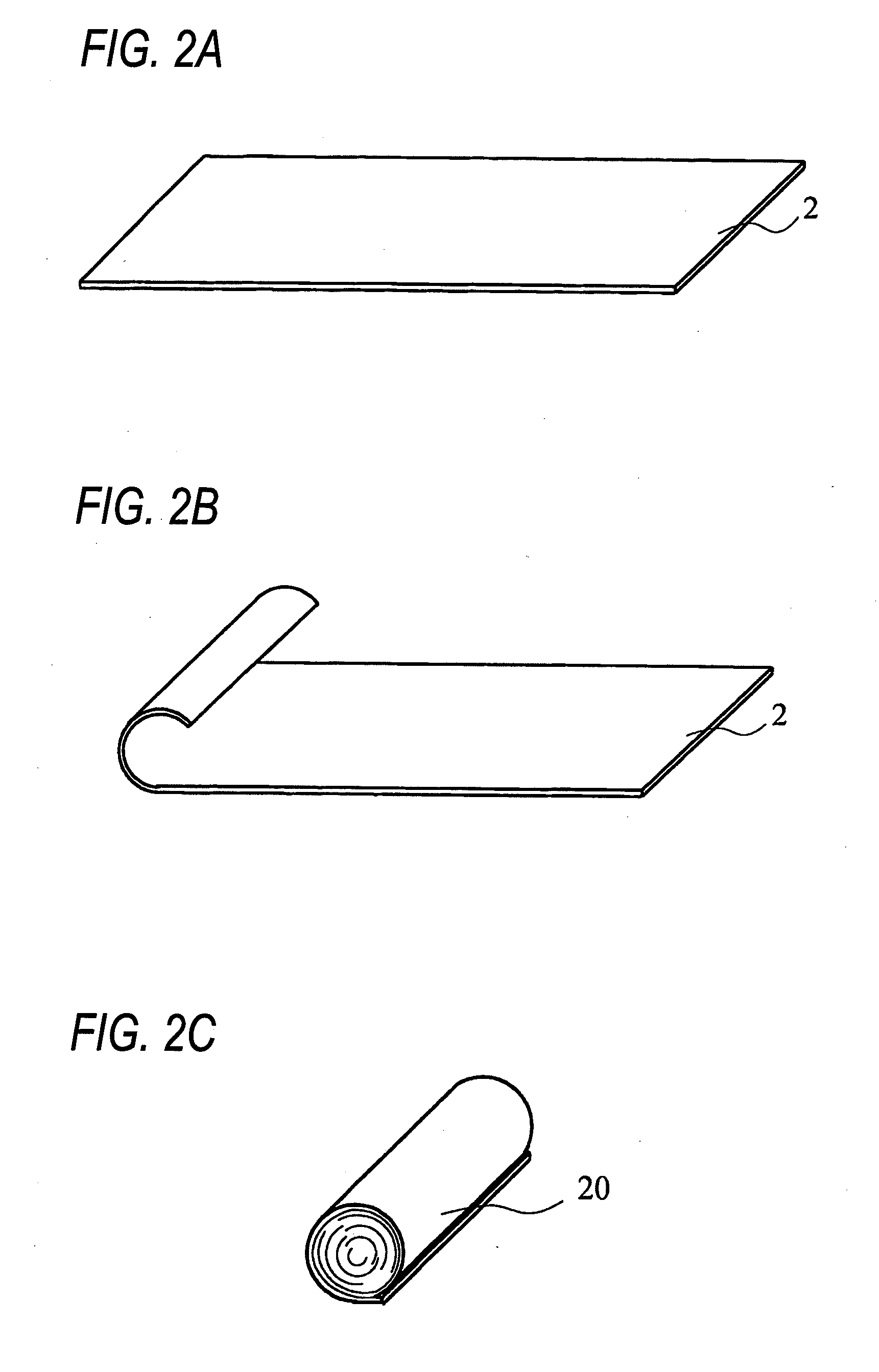

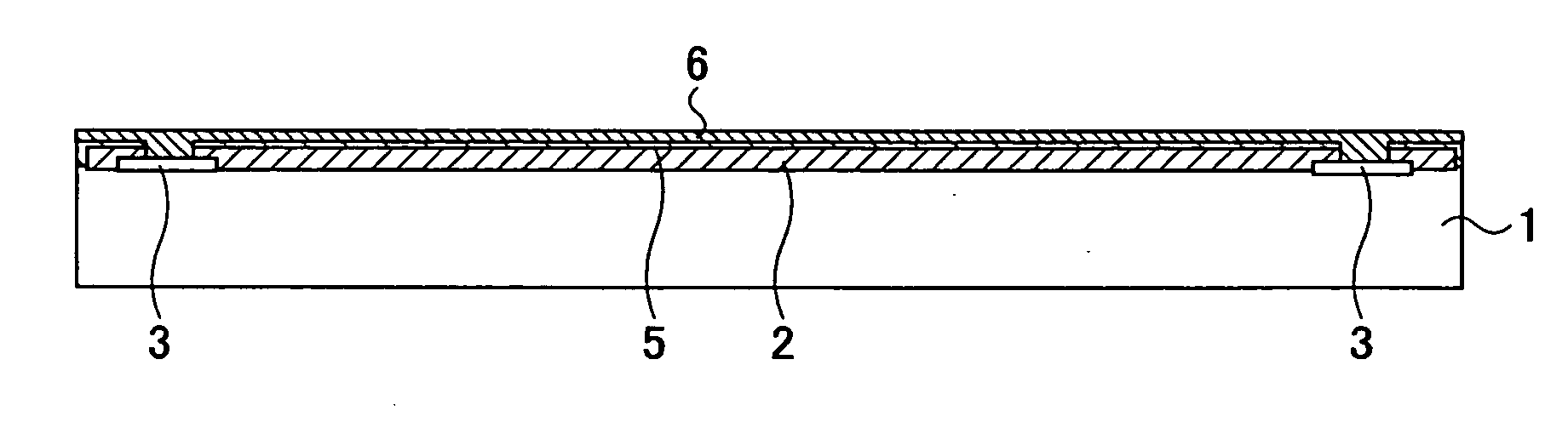

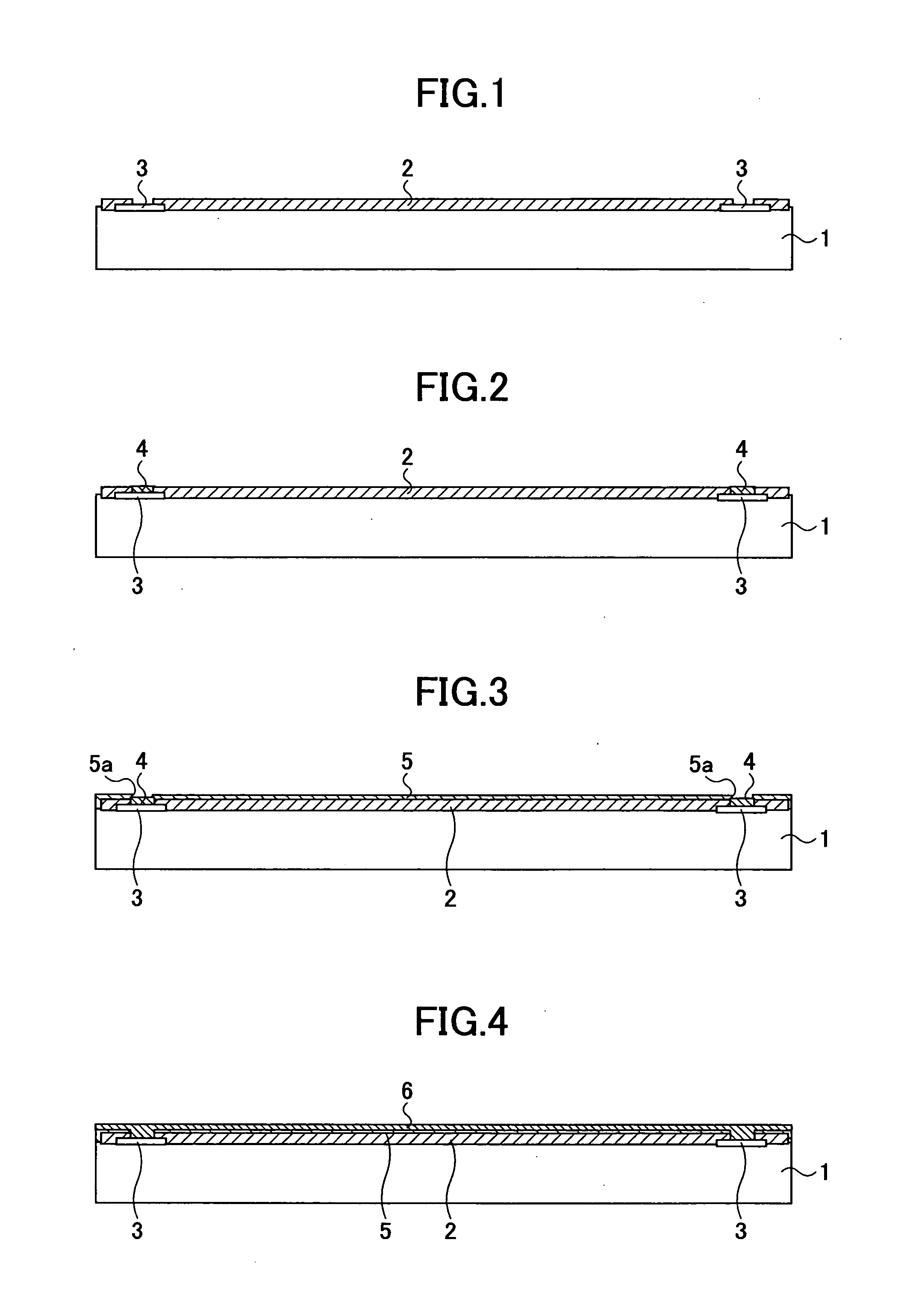

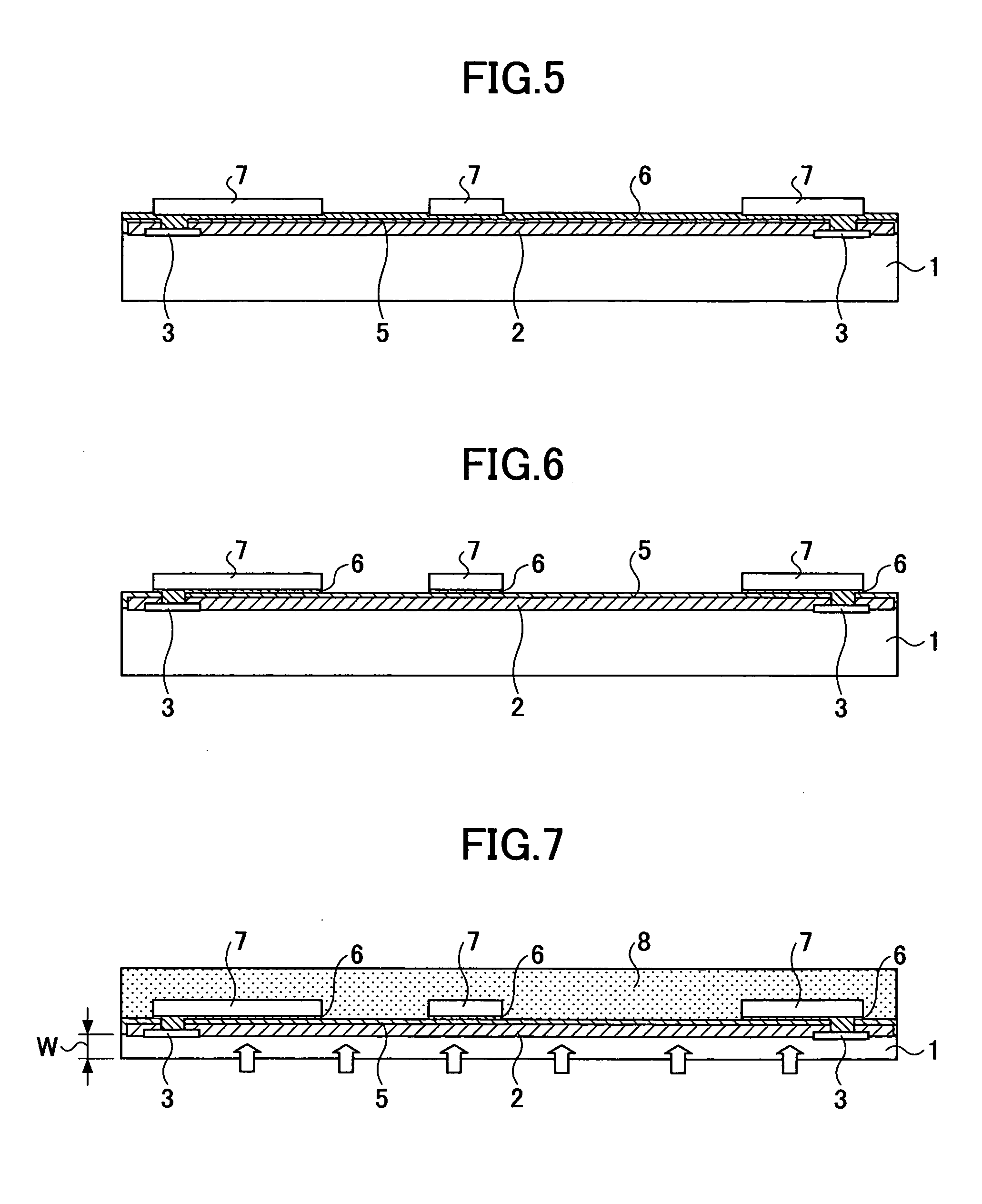

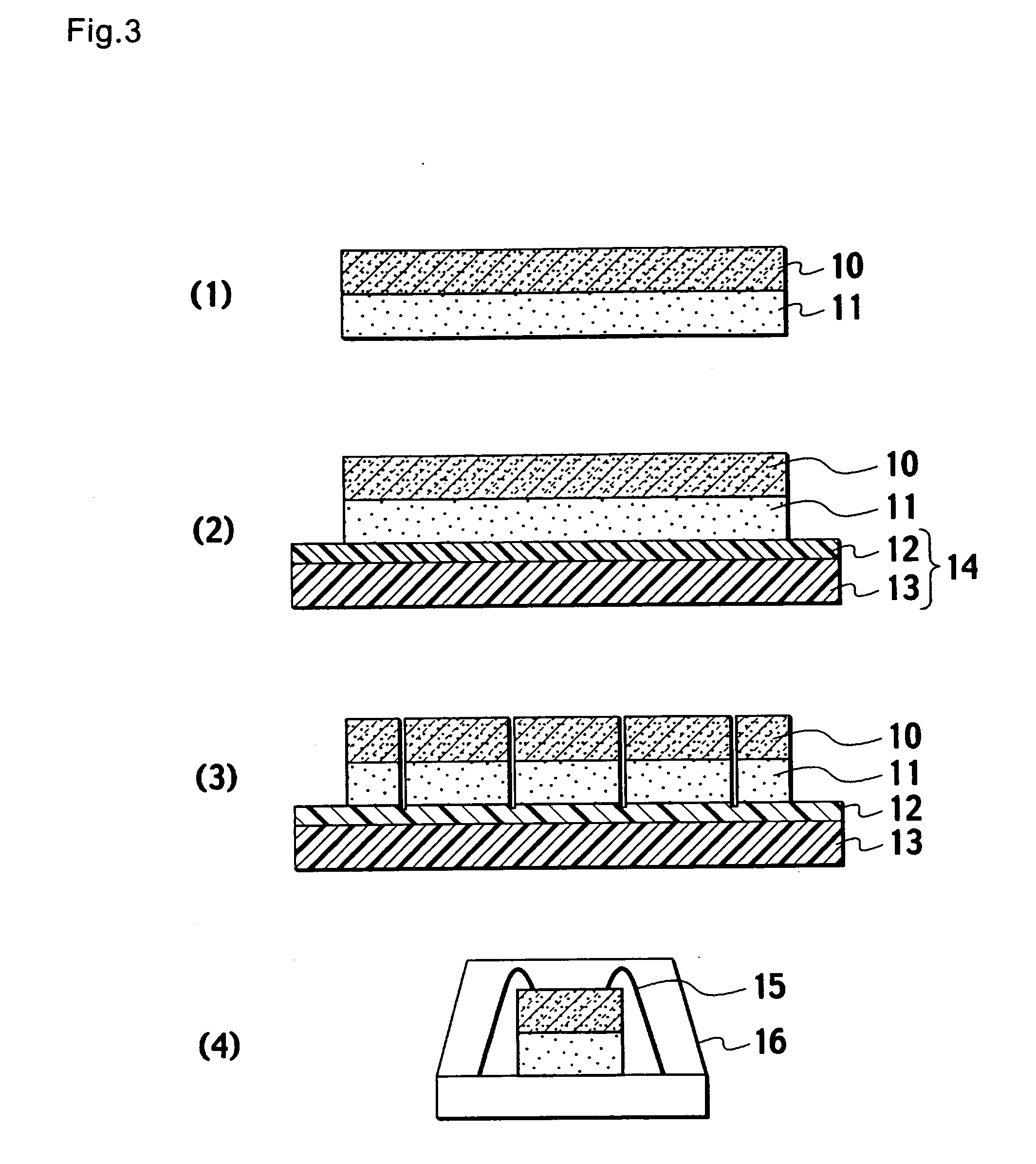

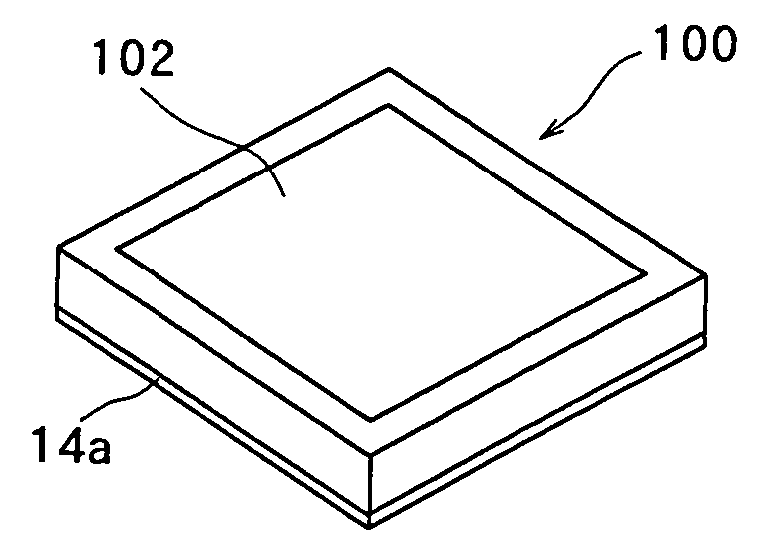

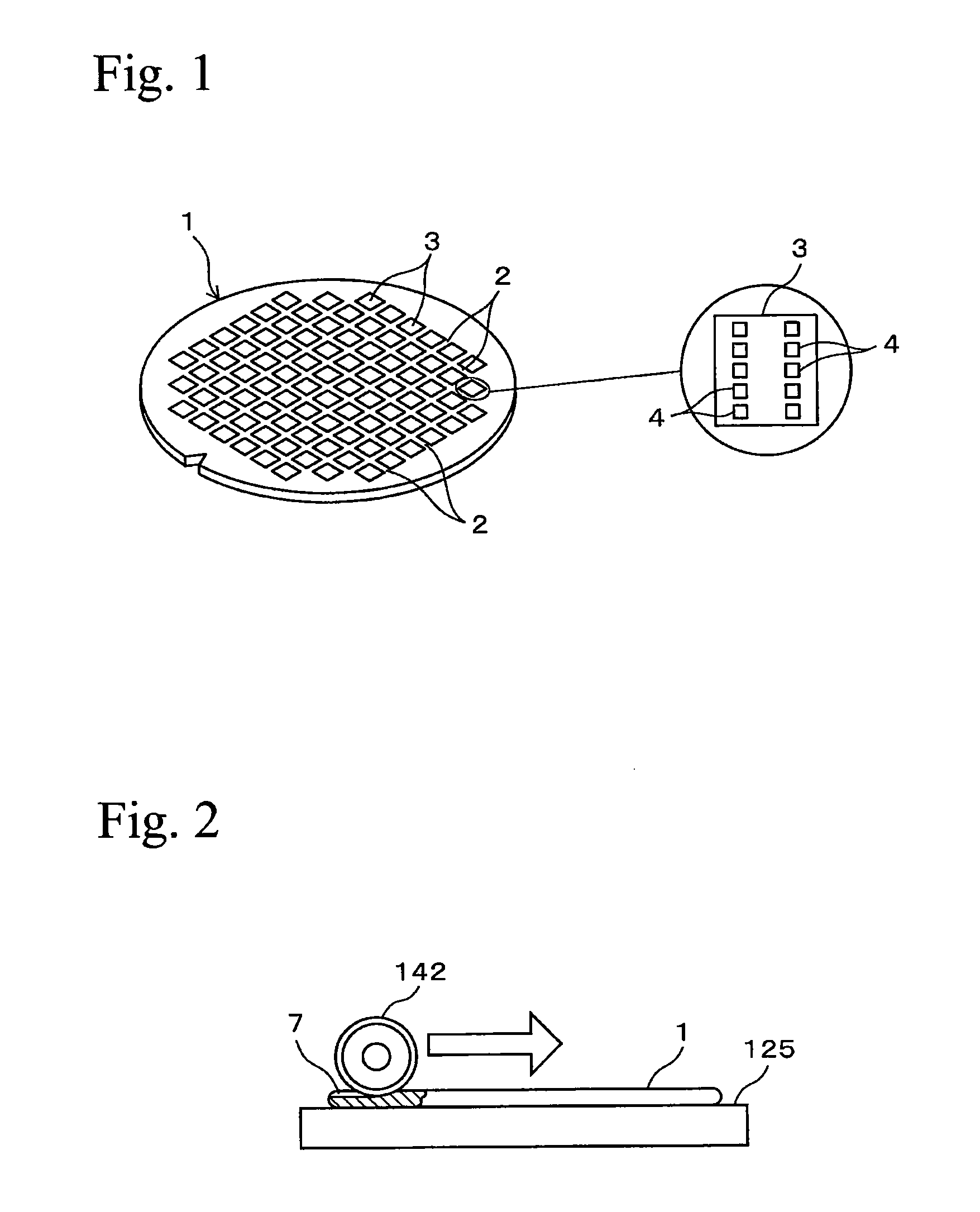

The present invention provides a die attach film-provided dicing tape, which includes a dicing tape, a supporting tape and a die attach film laminated in this order, wherein the supporting tape is a tape having a self-rolling peelability, and a process for producing a semiconductor device by using the die attach film-provided dicing tape.

Owner:NITTO DENKO CORP

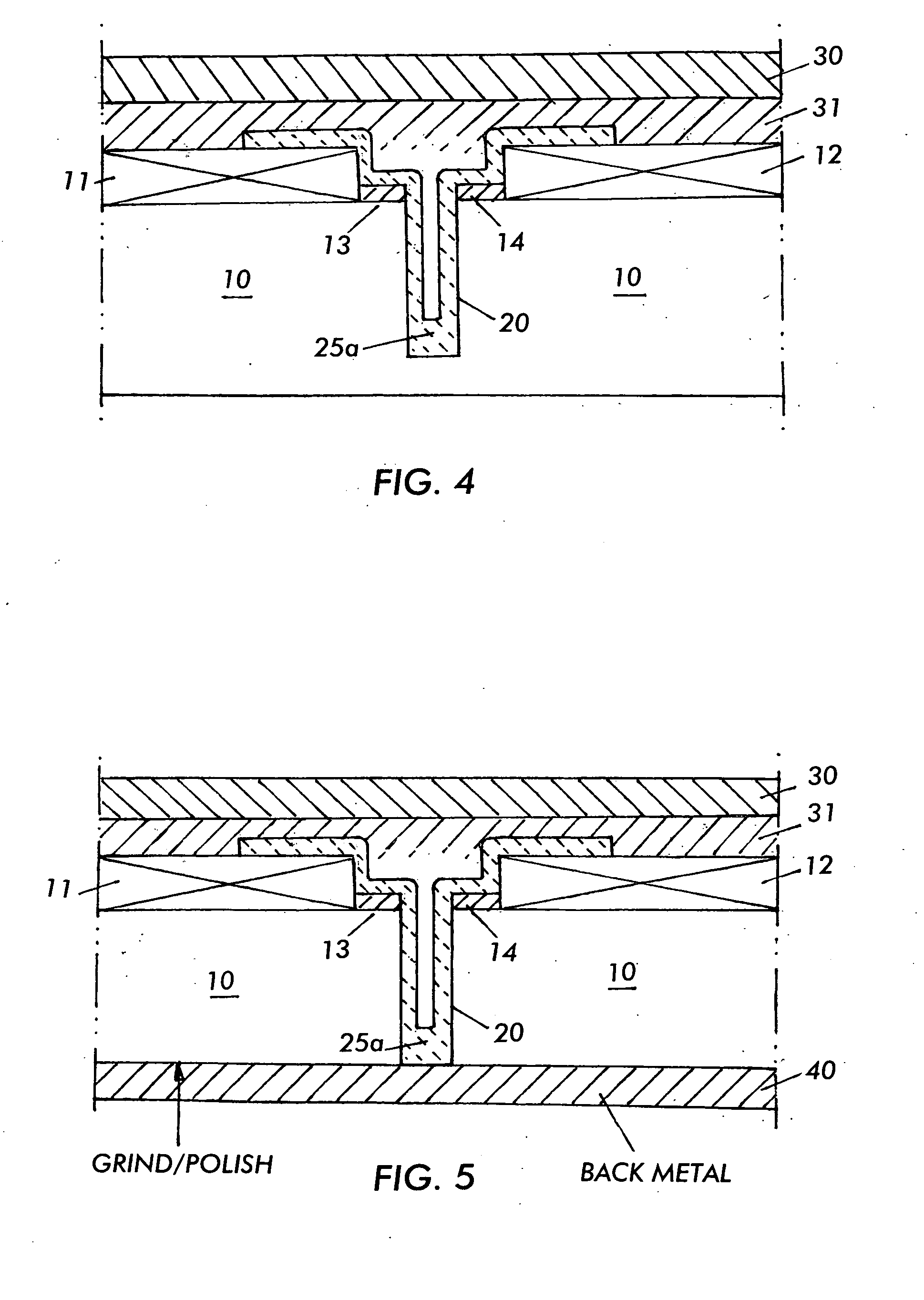

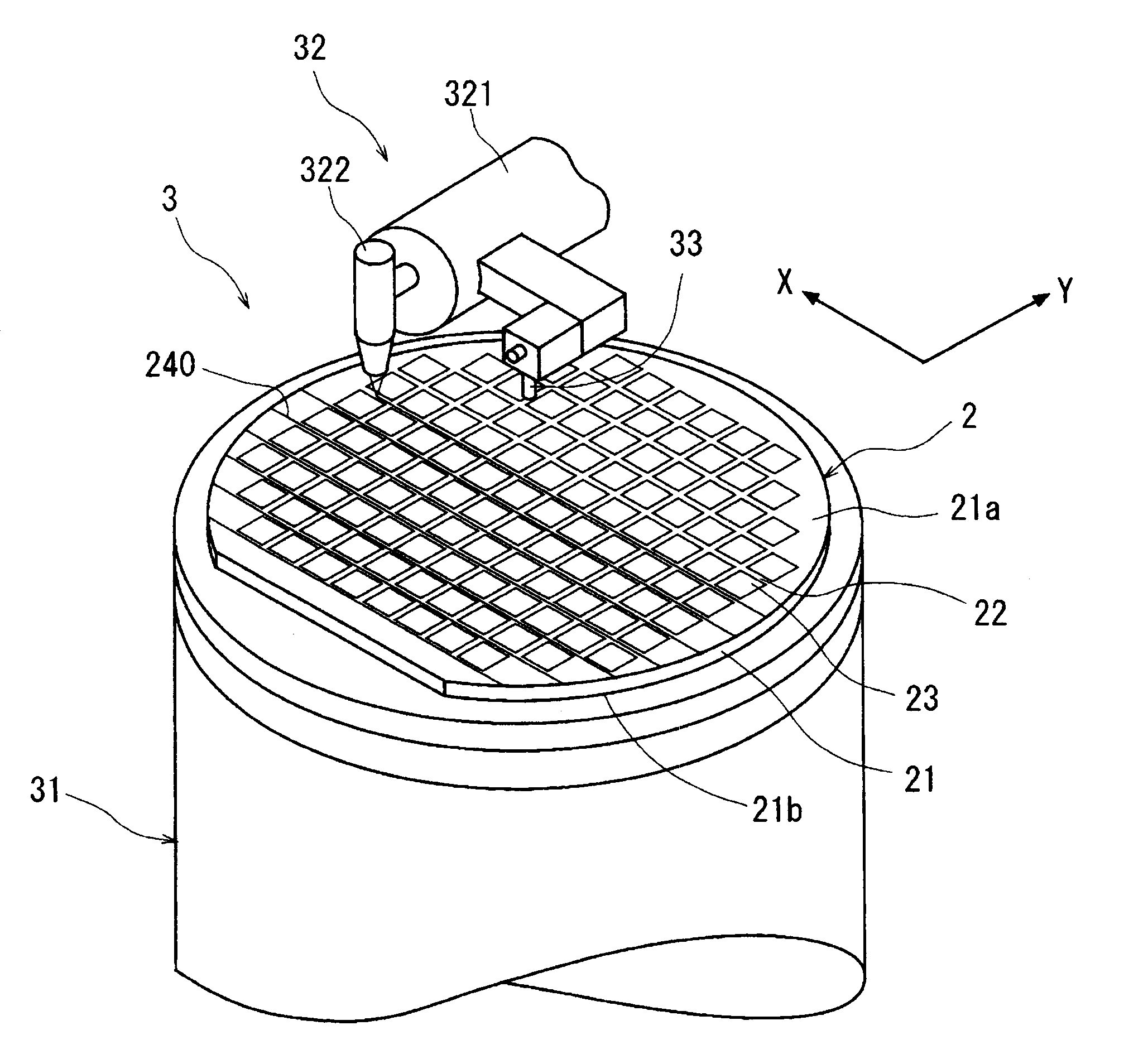

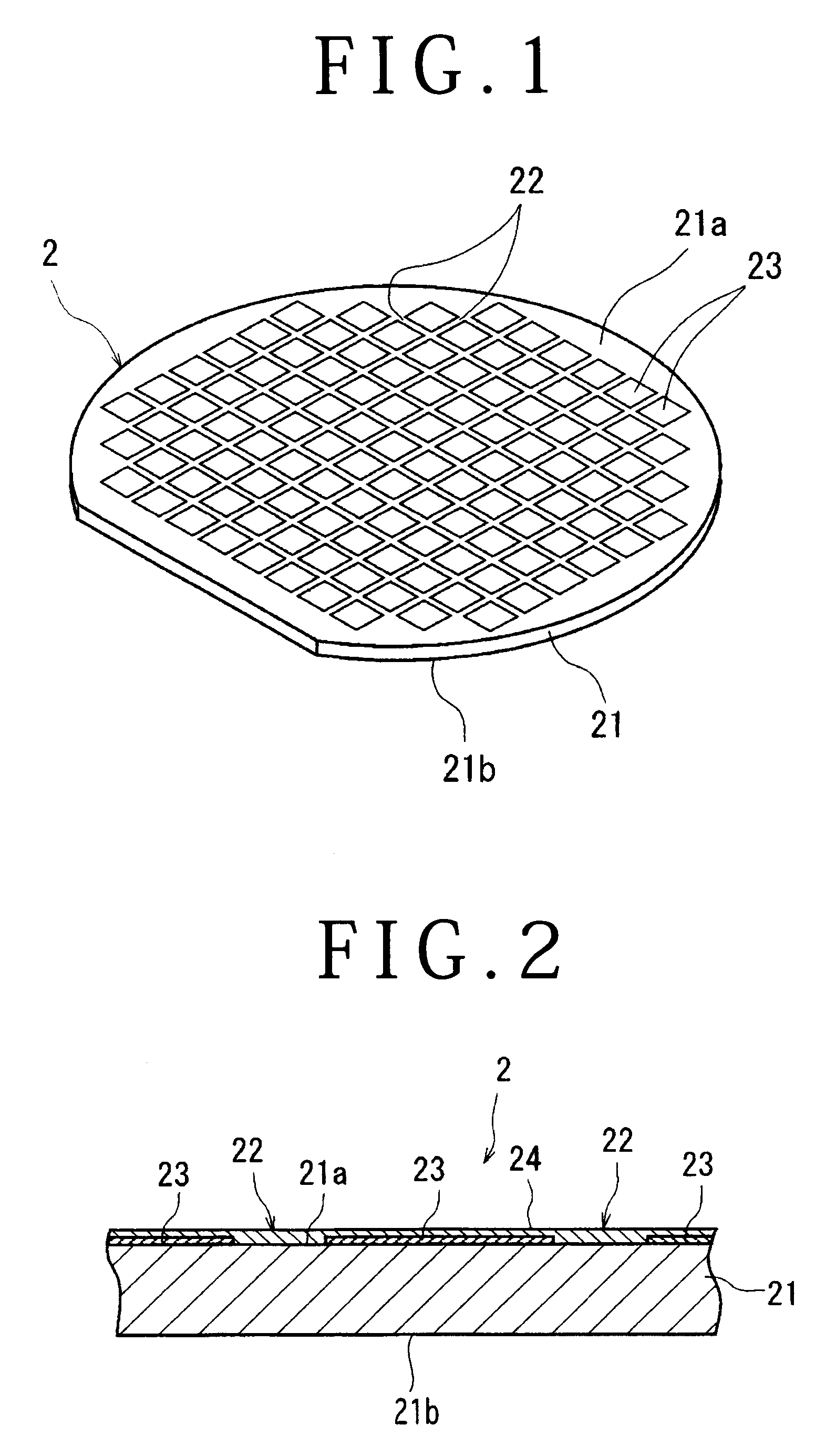

Method of manufacturing semiconductor device

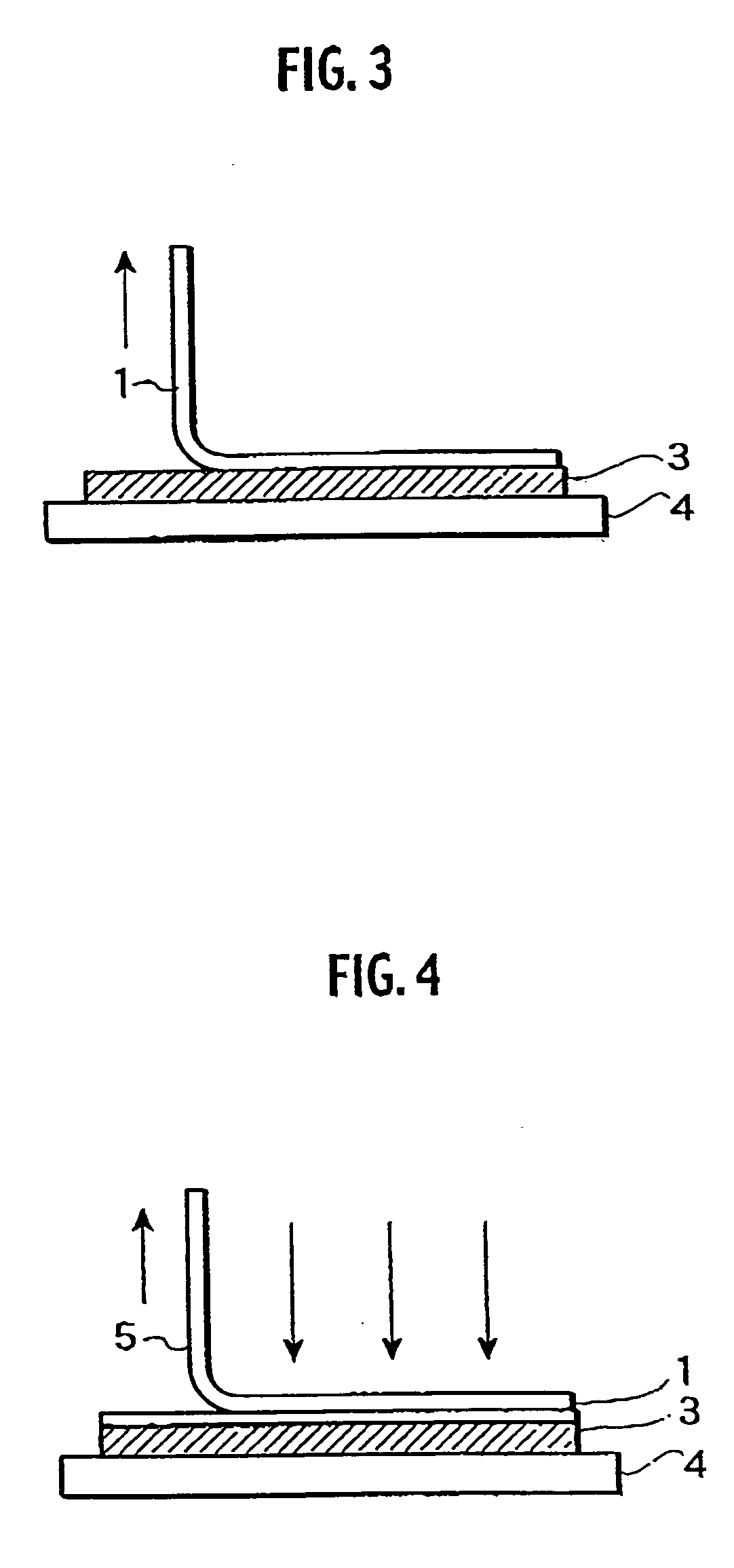

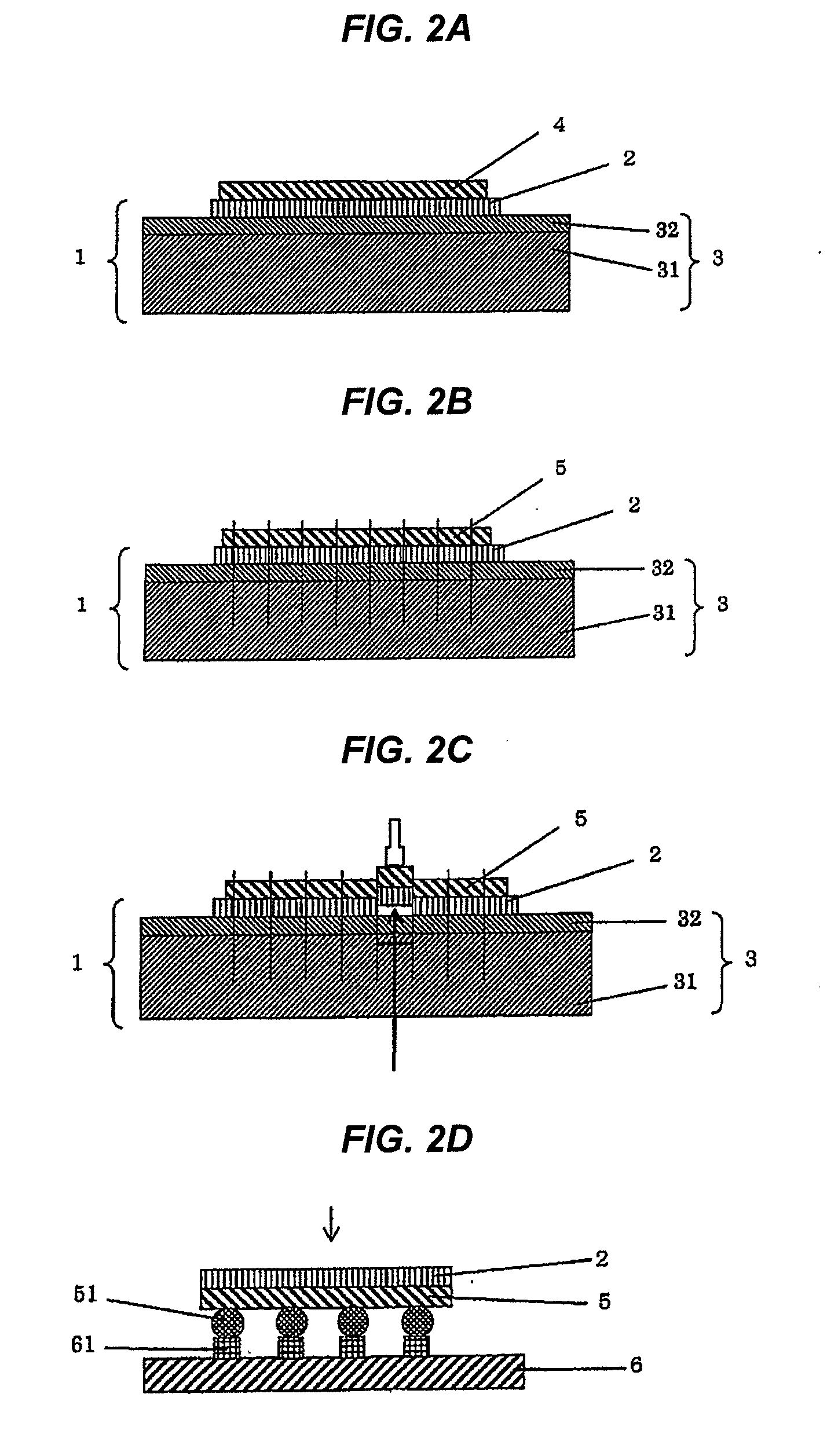

InactiveUS20050255686A1Reduce thicknessEasy and efficient cuttingSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

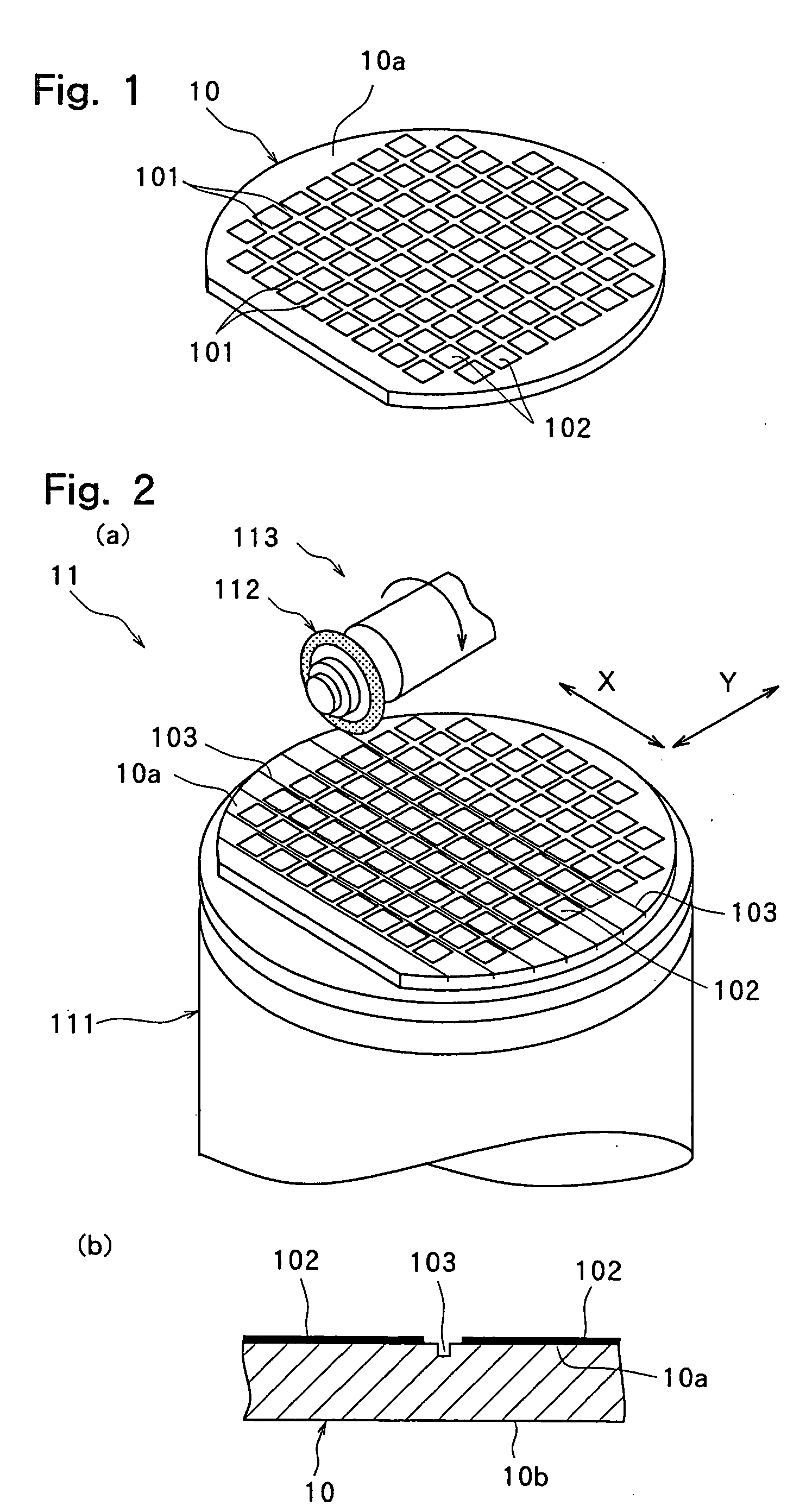

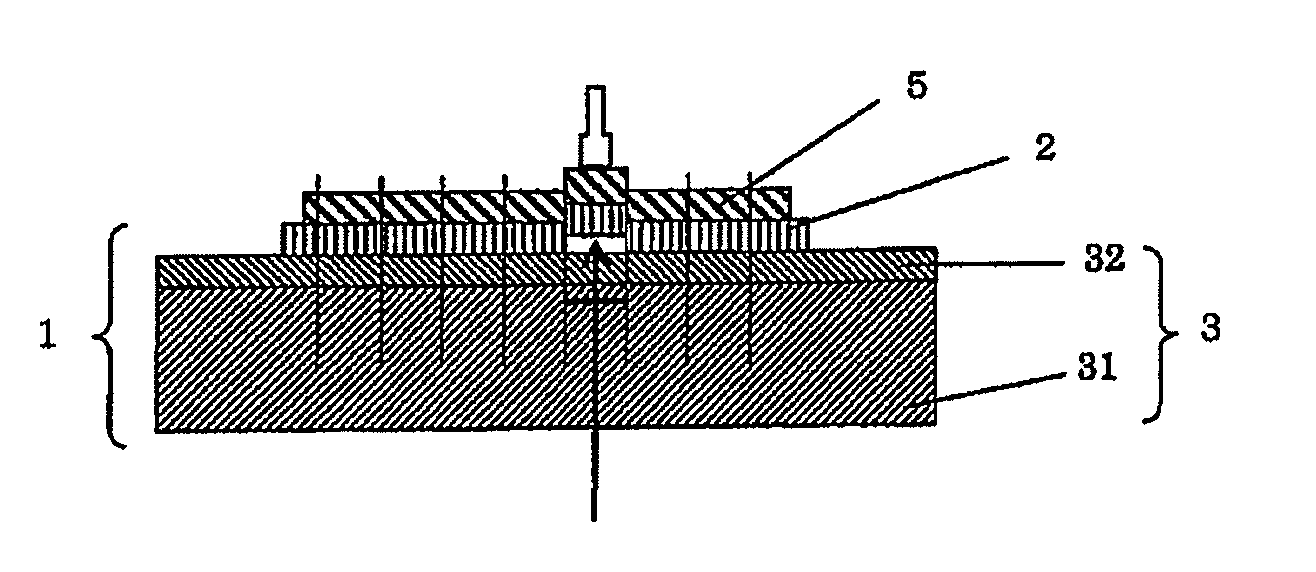

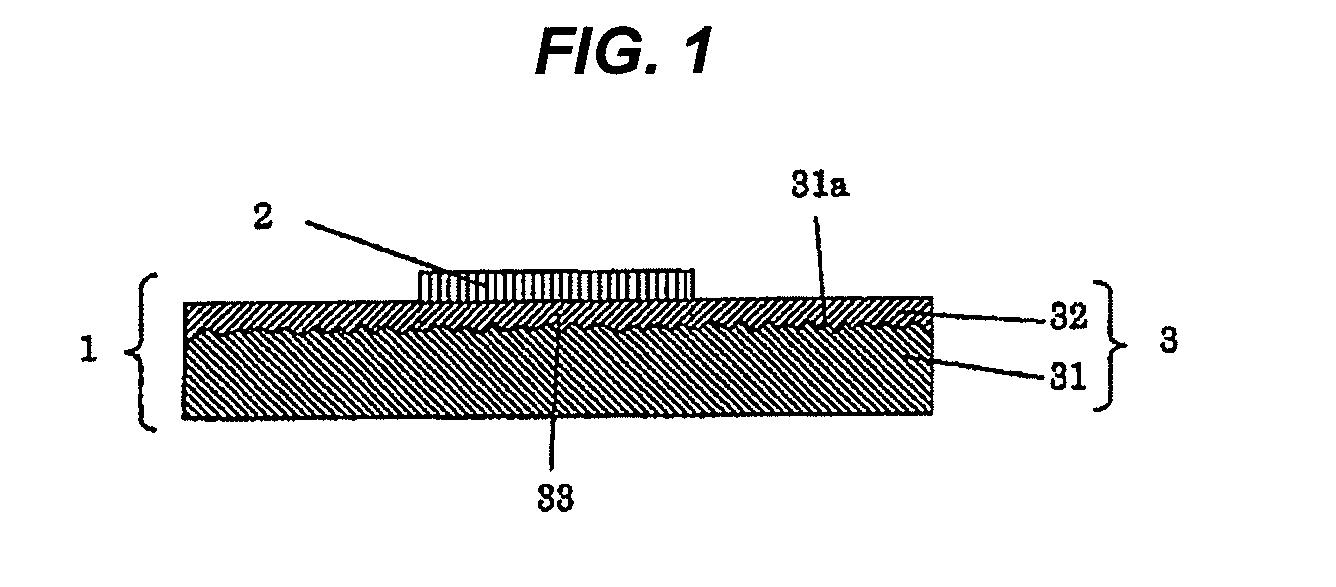

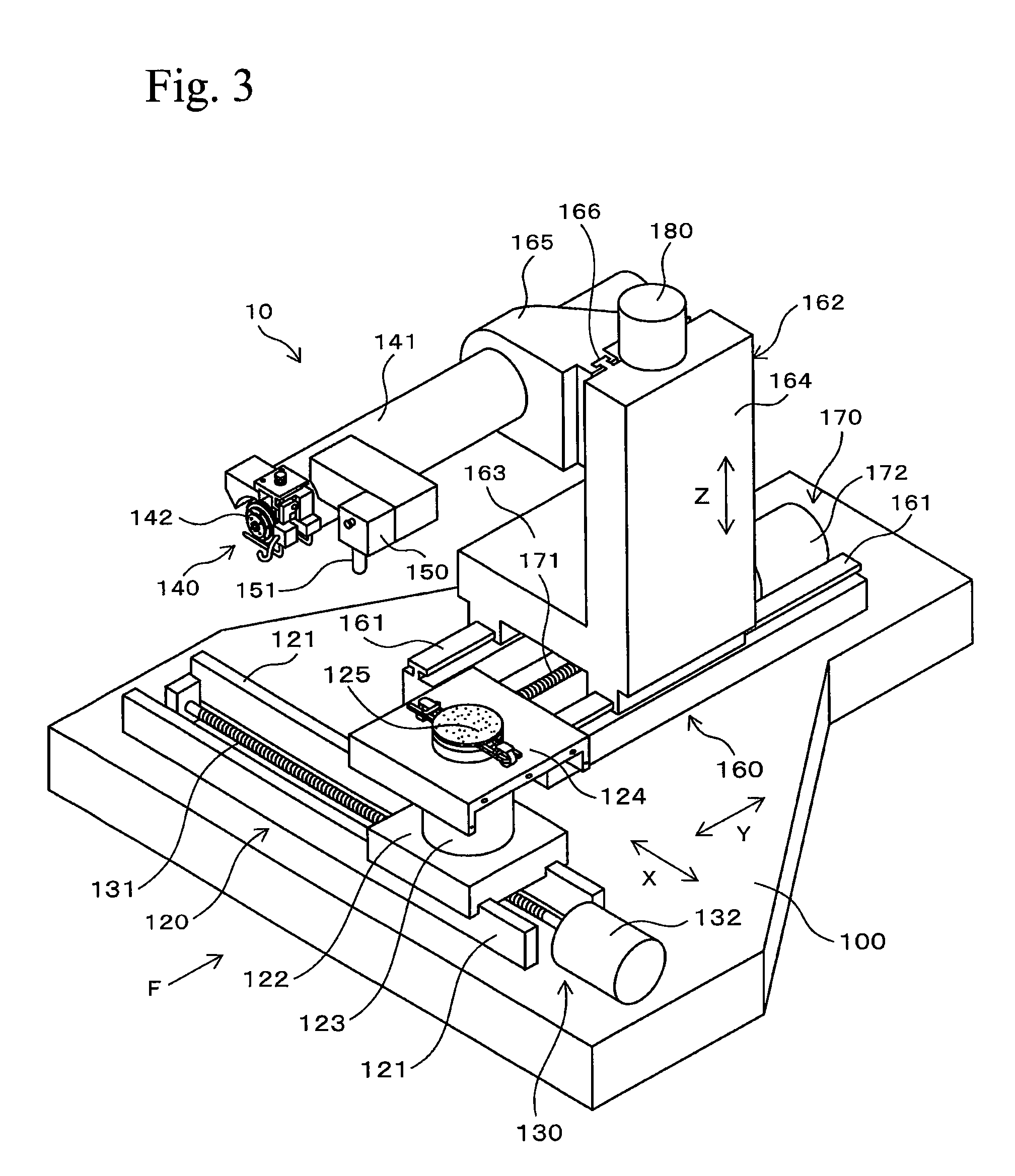

A method of manufacturing a semiconductor device having a build-up layer for wiring between semiconductor elements and external connection terminals is disclosed. The method comprises steps of forming a rewiring layer on a wafer, placing the wafer on a stretchable dicing tape, dicing the wafer placed on the dicing tape, forming a clearance between adjacent semiconductor elements by stretching the dicing tape, forming a semiconductor device continuous body by forming a build-up layer on the semiconductor elements and the clearance, and forming semiconductor devices by dicing the semiconductor device continuous body.

Owner:SHINKO ELECTRIC IND CO LTD

Dicing/die bonding sheet

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

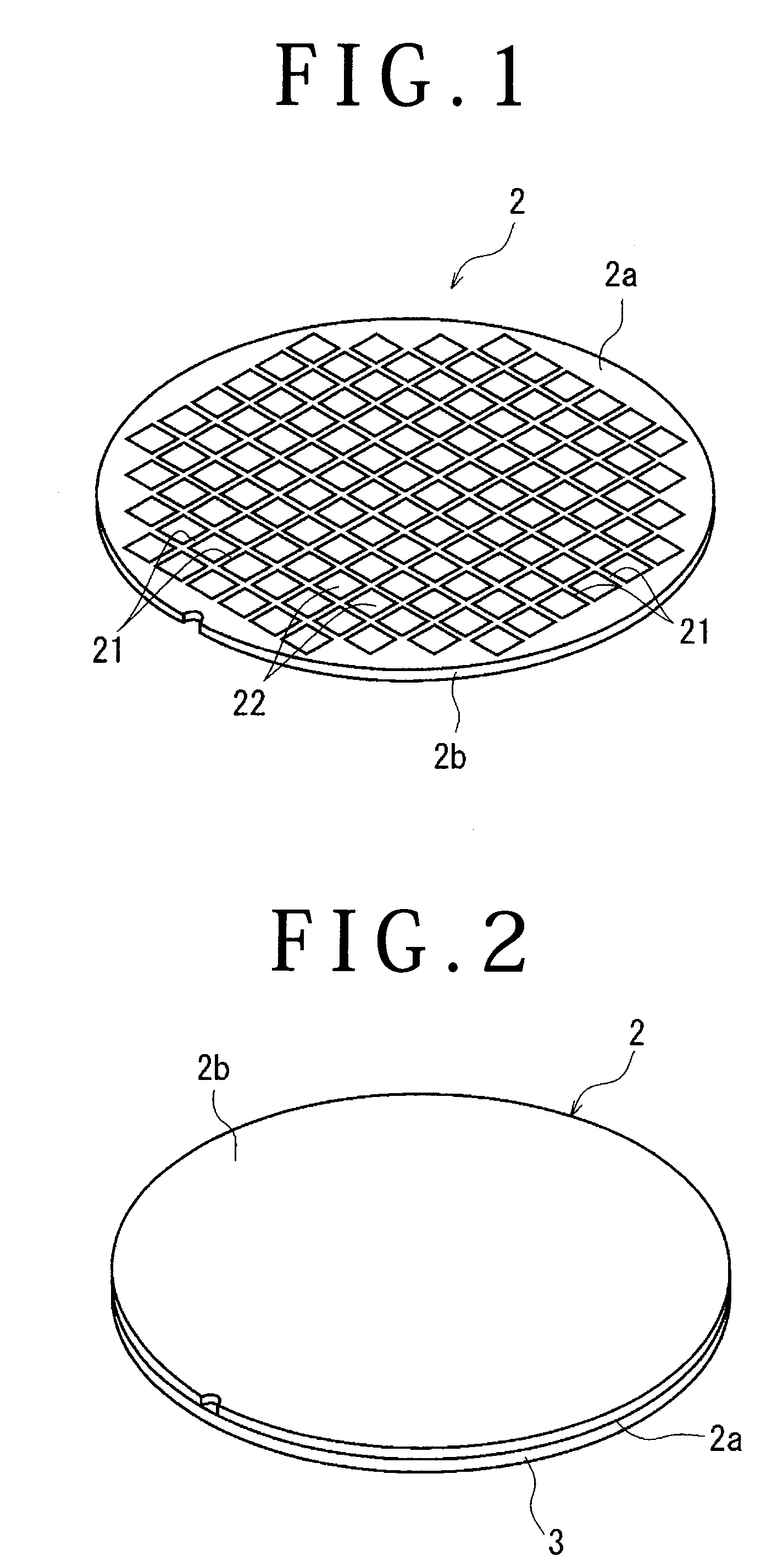

Expansion method, method for manufacturing semiconductor device, and semiconductor device

ActiveUS20150348821A1Efficient preparationEasy to cutSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

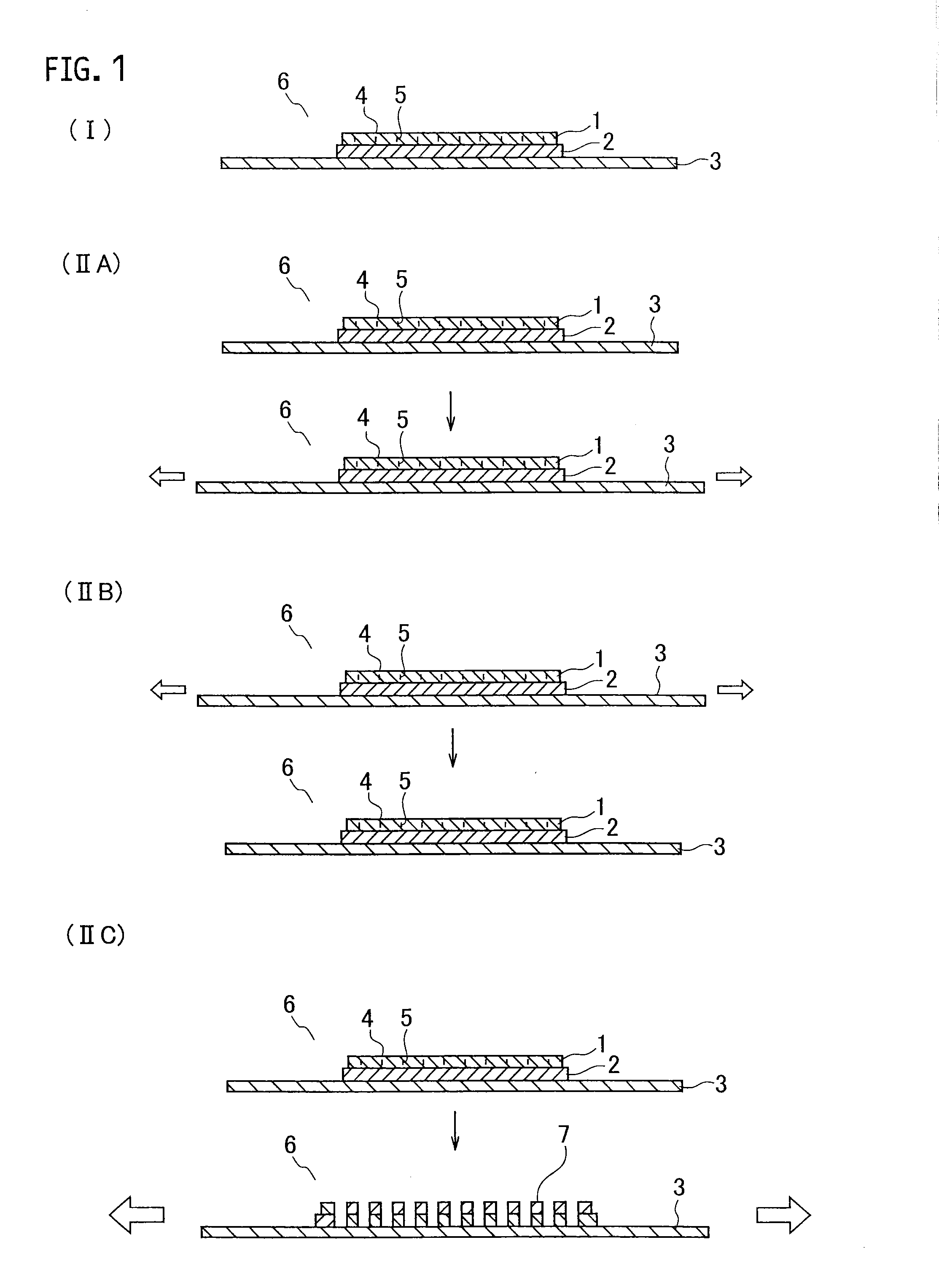

An embodiment of the present invention relates to an expansion method comprising: a step (I) of preparing a laminate having a semiconductor wafer in which modified sections have been formed along intended cutting lines, a die bonding film and a dicing tape, a step (IIA) of expanding the dicing tape with the laminate in a cooled state, a step (IIB) of loosening the expanded dicing tape, and a step (IIC) of expanding the dicing tape with the laminate in a cooled state, dividing the semiconductor wafer and the die bonding film into chips along the intended cutting lines, and widening the spaces between the chips.

Owner:RESONAC CORP

Method of manufacturing semiconductor device

ActiveUS7115482B2Solid-state devicesSemiconductor/solid-state device manufacturingUV curingDicing tape

Extremely thin chips laminated to a non-ultraviolet ray curing type adhesive tape are peeled from the tape without giving rise to cracks and chippings. In a center portion of a suction block used for peeling off a chip laminated to a dicing tape, three blocks which push the dicing tape upwardly are incorporated. With respect to these blocks, inside the first block having a largest diameter, there is a second block having a diameter smaller than the diameter of the first block. Further, inside the second block, there is a third block having the smallest diameter. To peel off a chip by pushing a back surface of the dicing tape with the blocks, first of all, the three blocks are simultaneously pushed upwardly by a certain amount and, thereafter, the intermediate block and the inner block are further pushed upward, and, finally, the inner block is further pushed upward.

Owner:RENESAS EASTERN JAPAN SEMICON INC +1

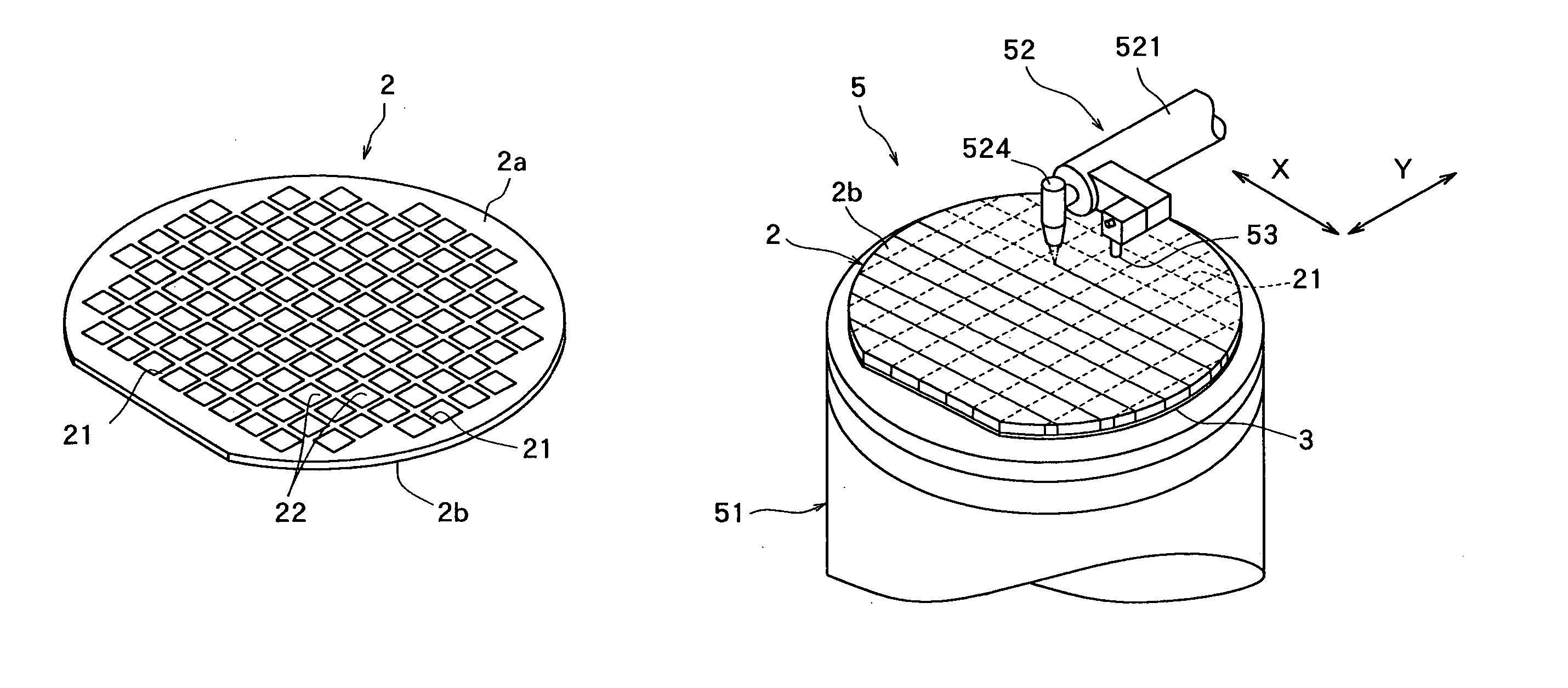

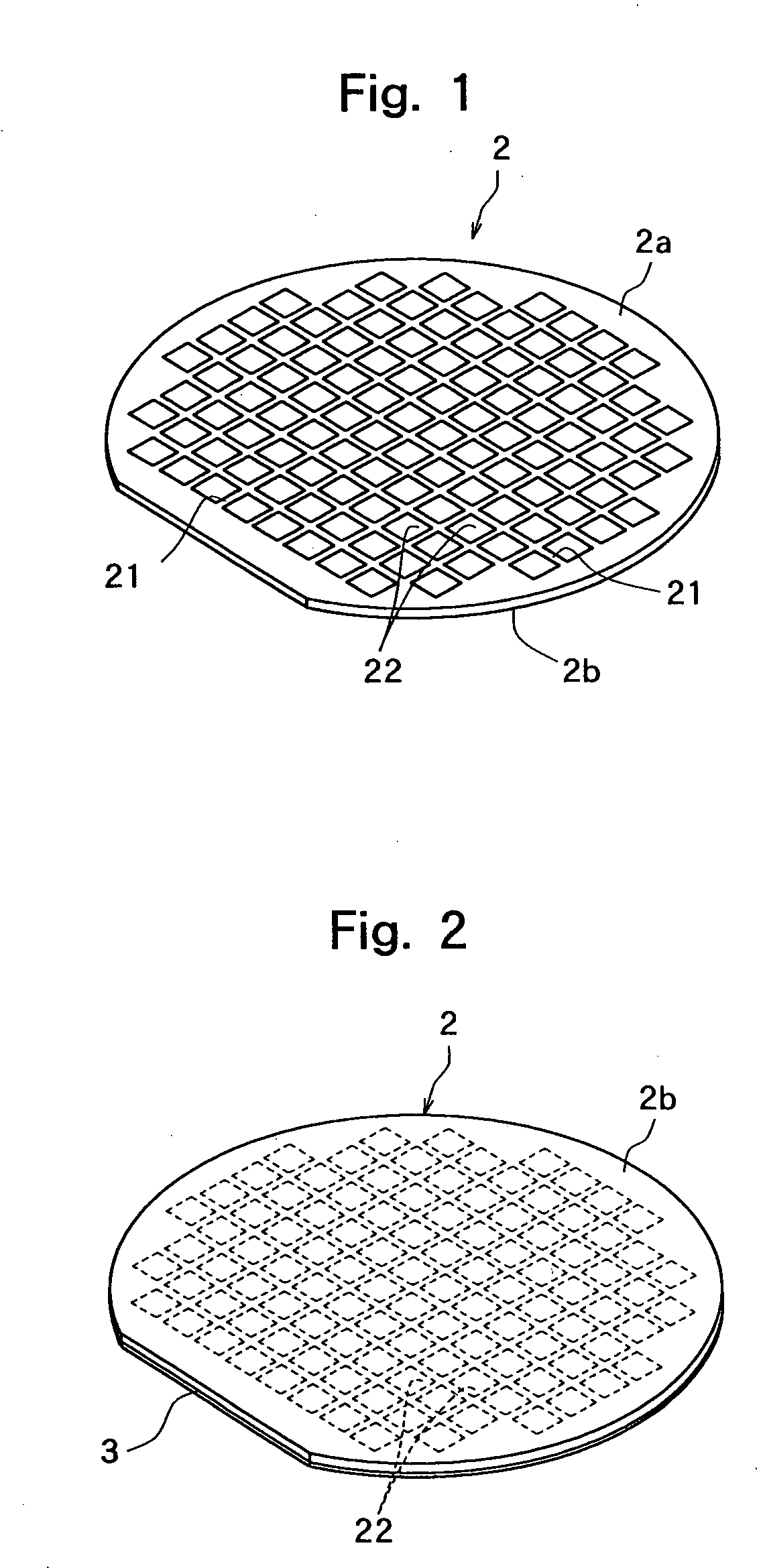

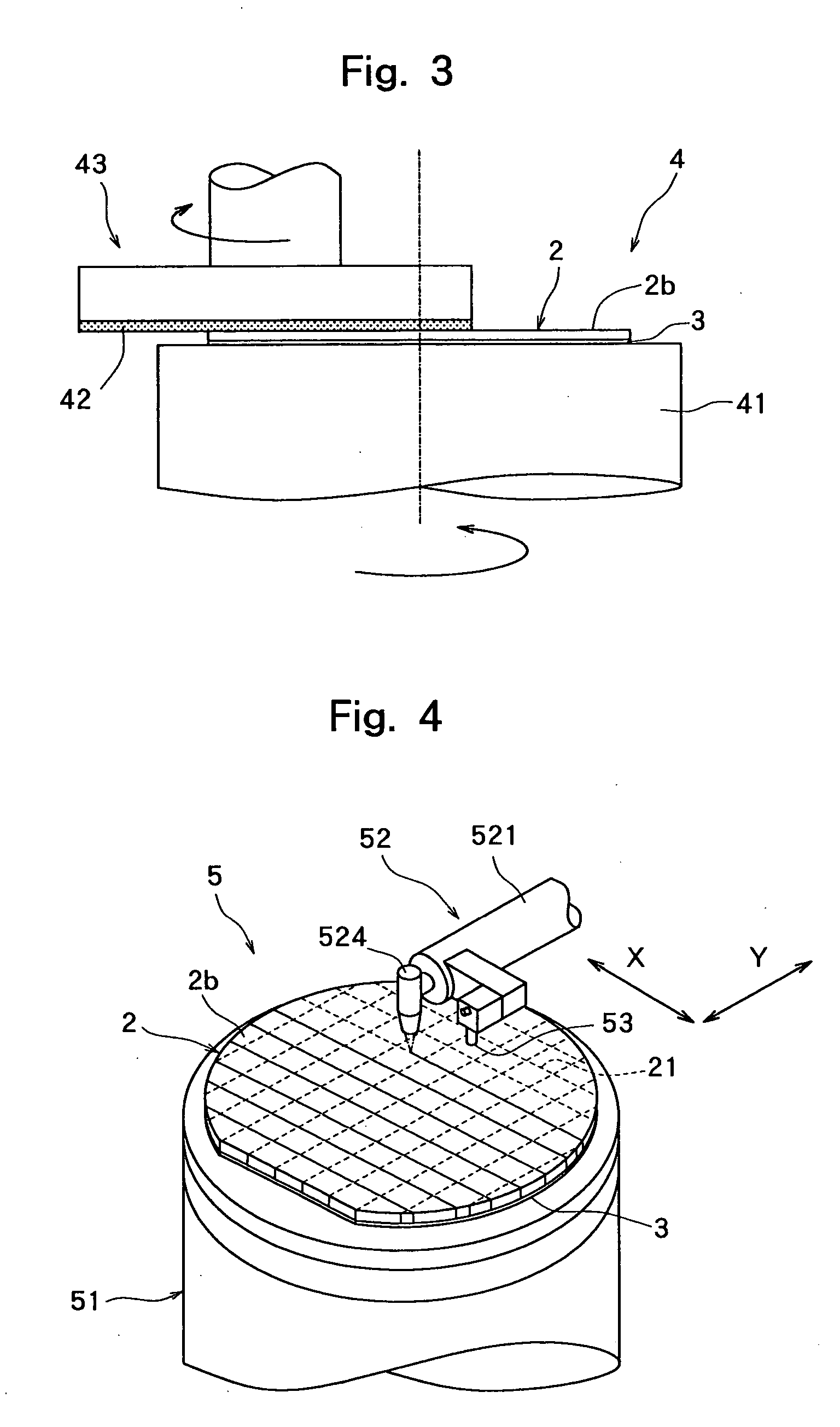

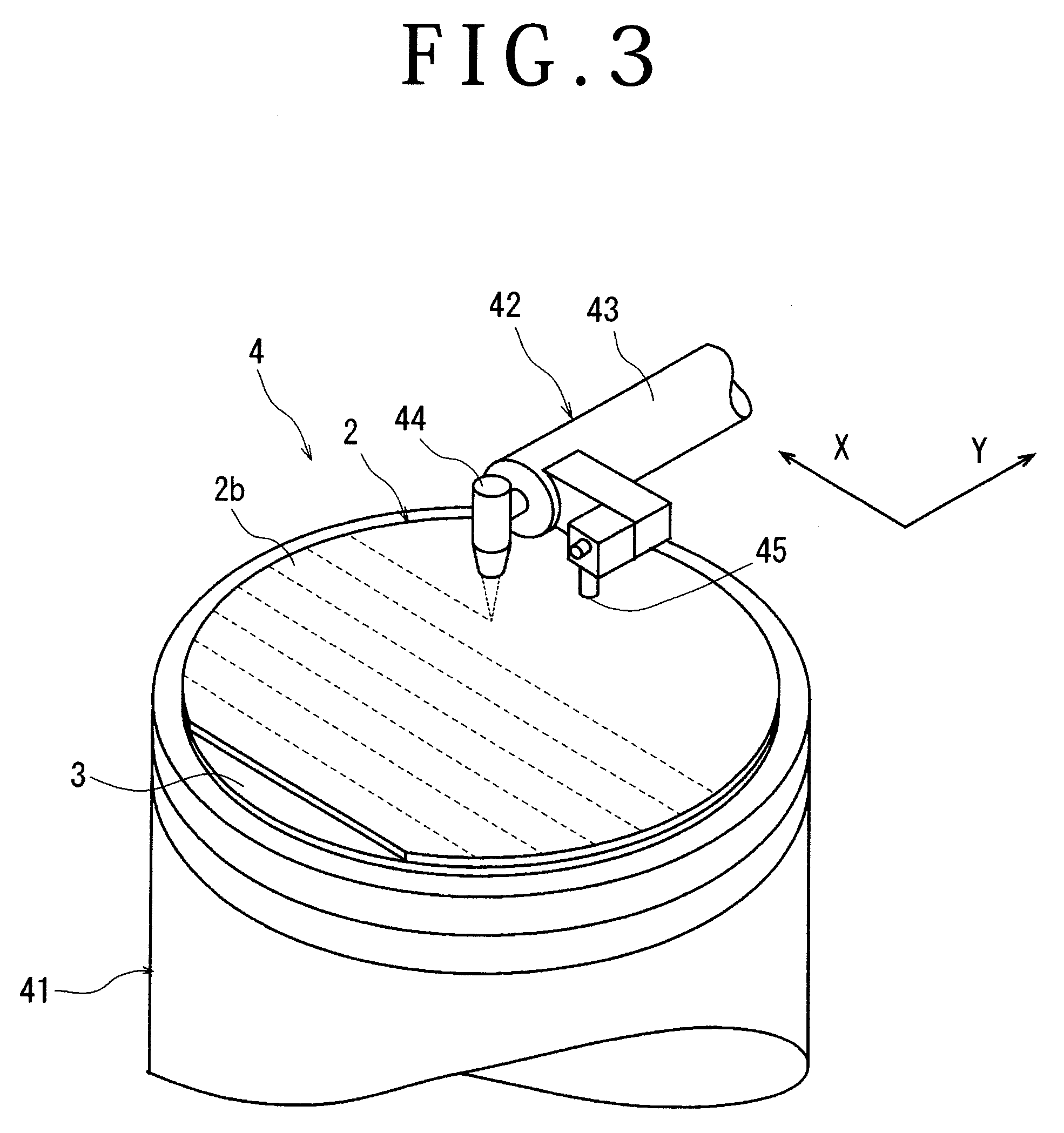

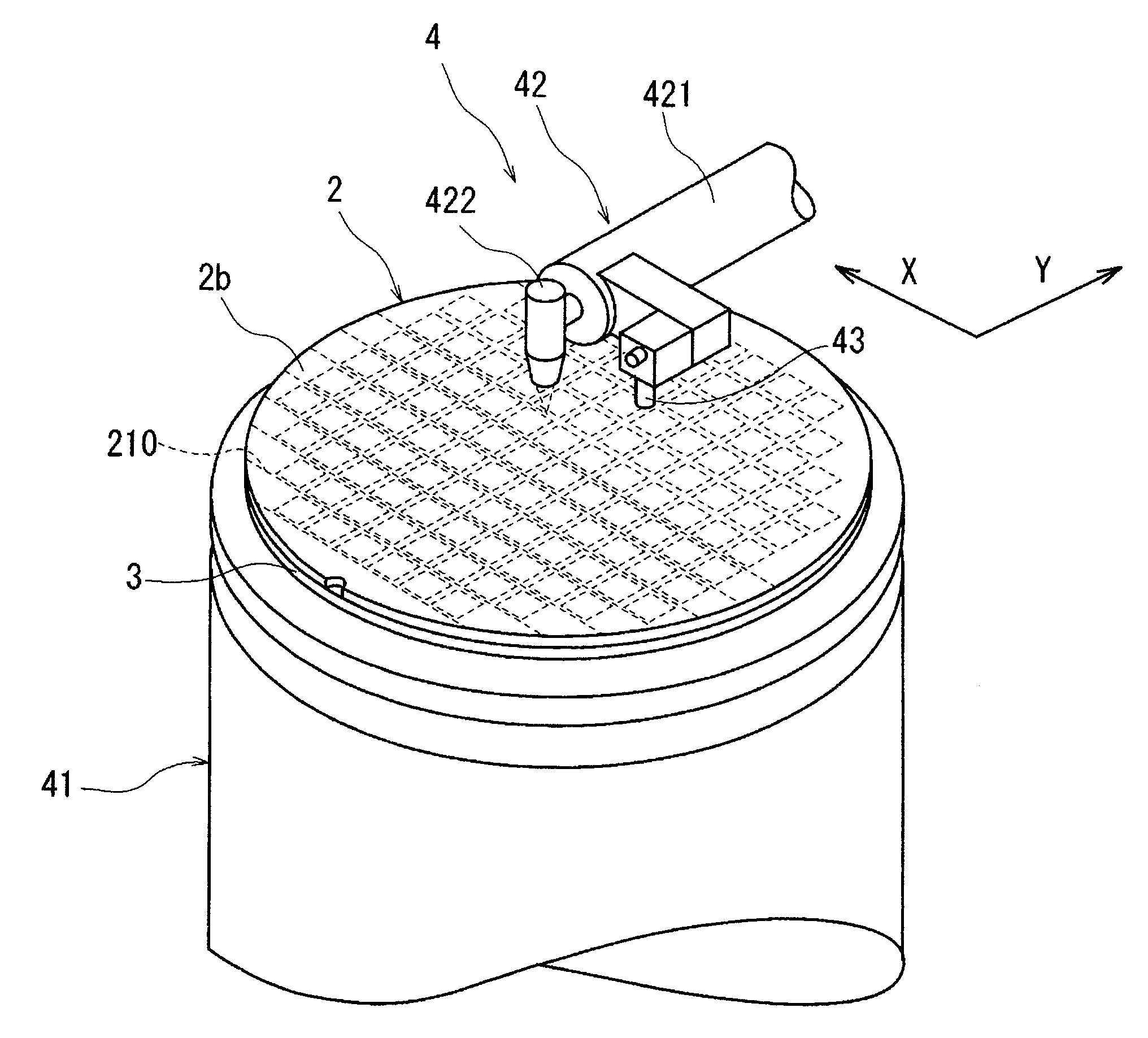

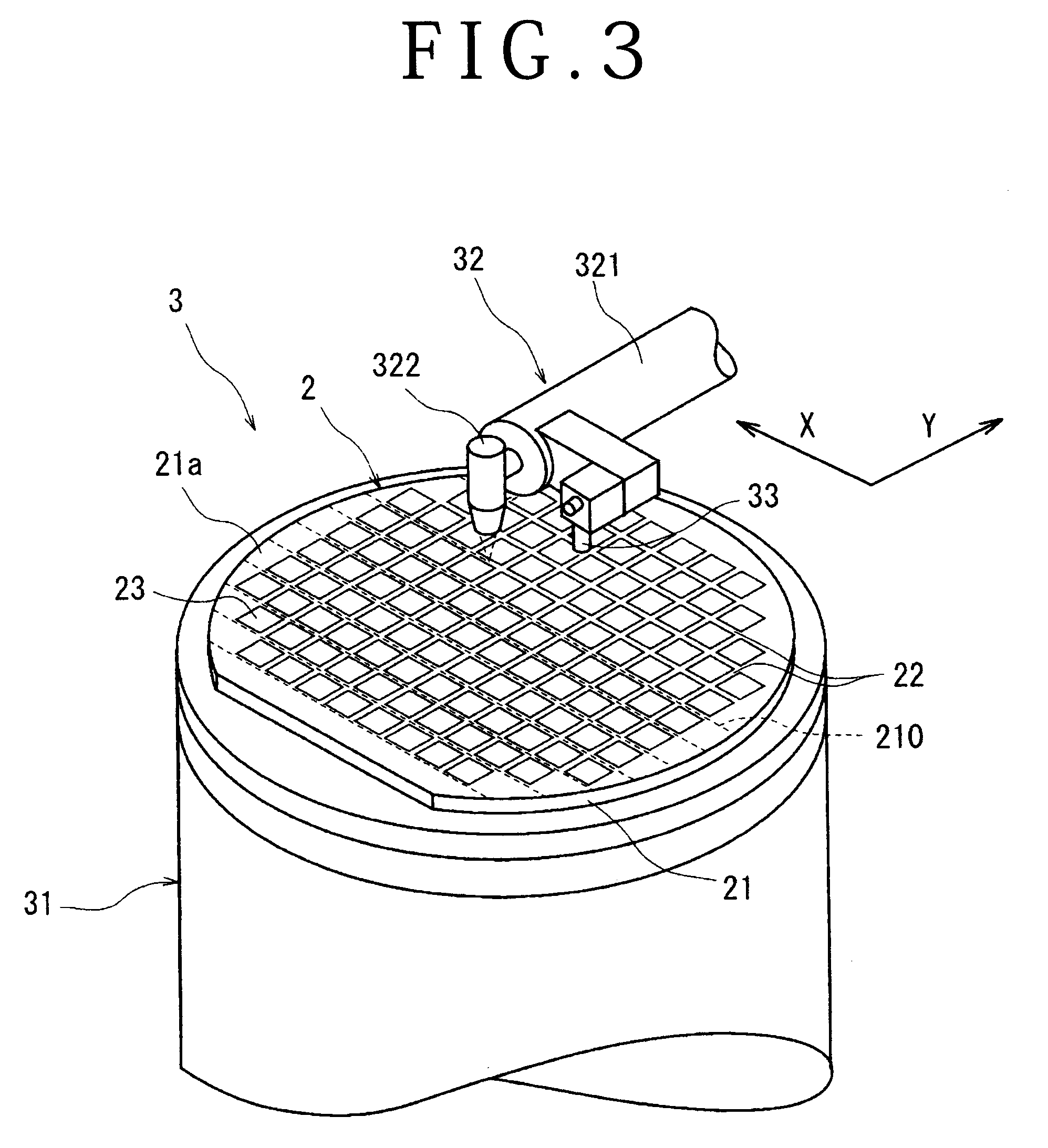

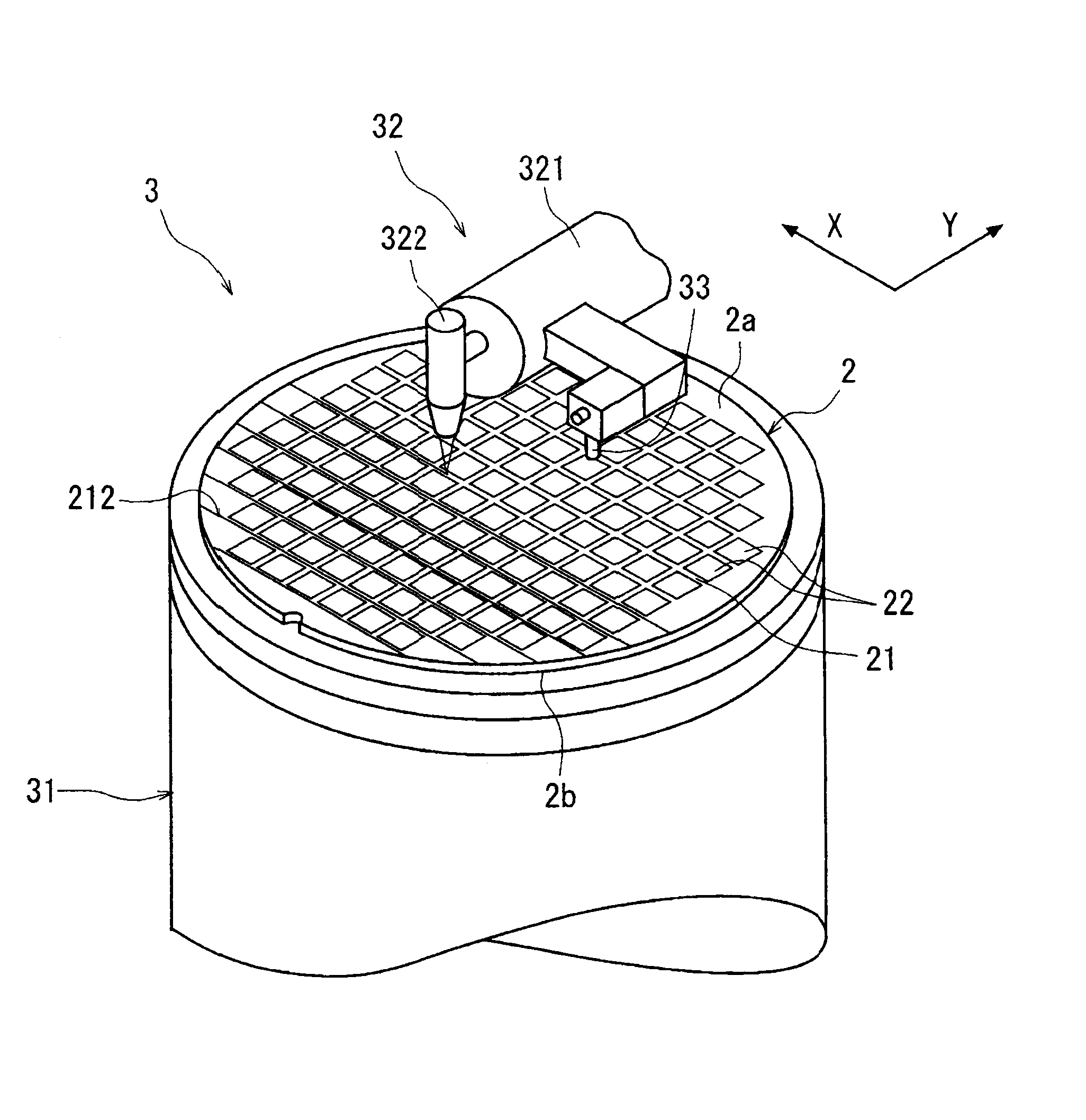

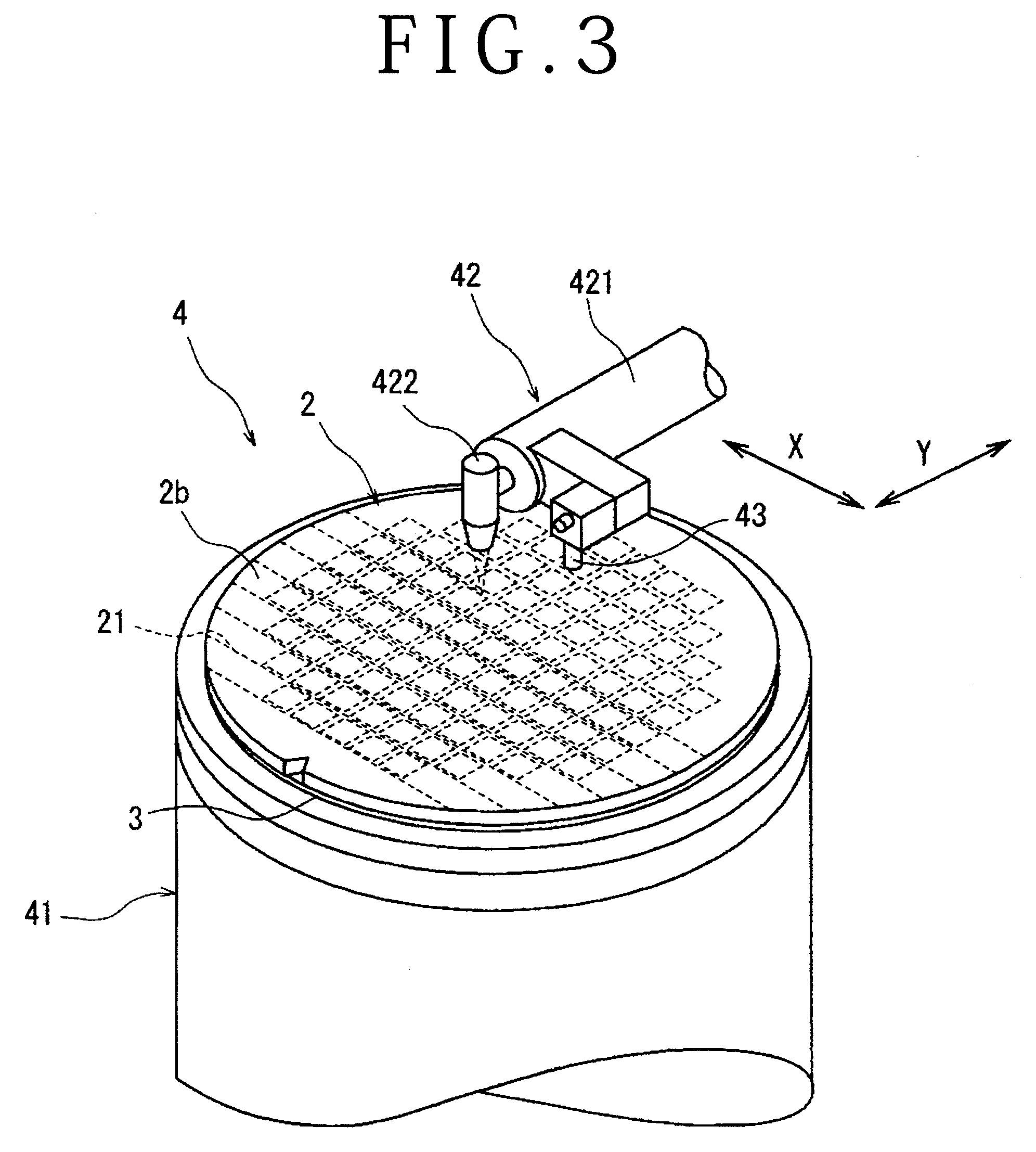

Laser processing method and laser beam processing machine

InactiveUS20060197260A1Solid-state devicesSemiconductor/solid-state device manufacturingLaser processingDicing tape

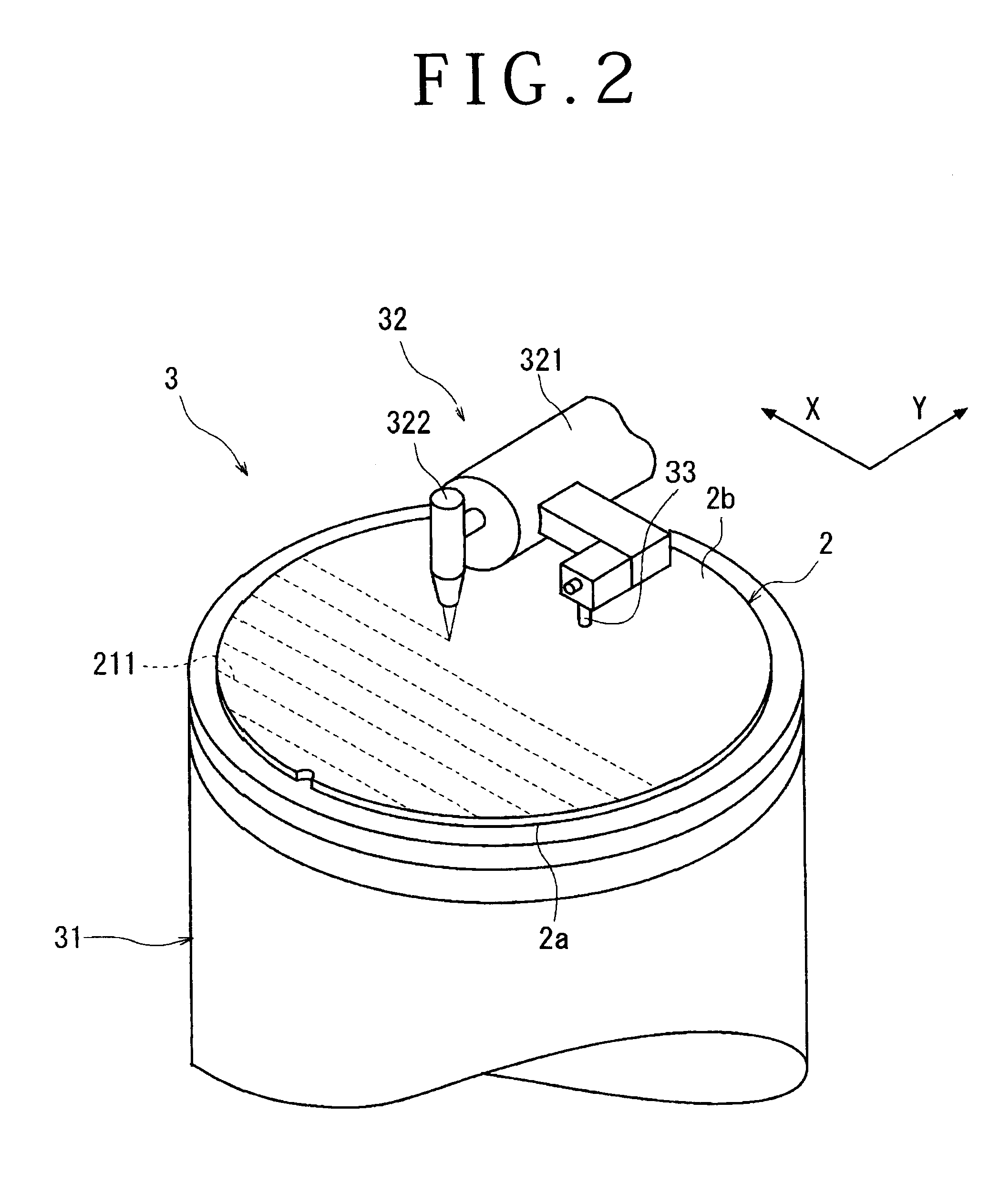

A laser processing method for melt-dividing an adhesive film for die bonding affixed to the back surface of a semiconductor wafer which has been separated into a plurality of semiconductor chips and which is put on an extensible dicing tape mounted on an annular frame along dividing grooves for separating the plurality of semiconductor chips from one another, comprising the steps of a tape expanding step for expanding the dicing tape affixed to the semiconductor wafer to increase the width of the dividing grooves for separating the plurality of semiconductor chips from one another; and an adhesive film melt-dividing step for melt-dividing the adhesive film along the dividing grooves by applying a laser beam to the adhesive film along the dividing grooves in a state where the width of the dividing grooves for separating the plurality of semiconductor chips from one another has been increased.

Owner:DISCO CORP

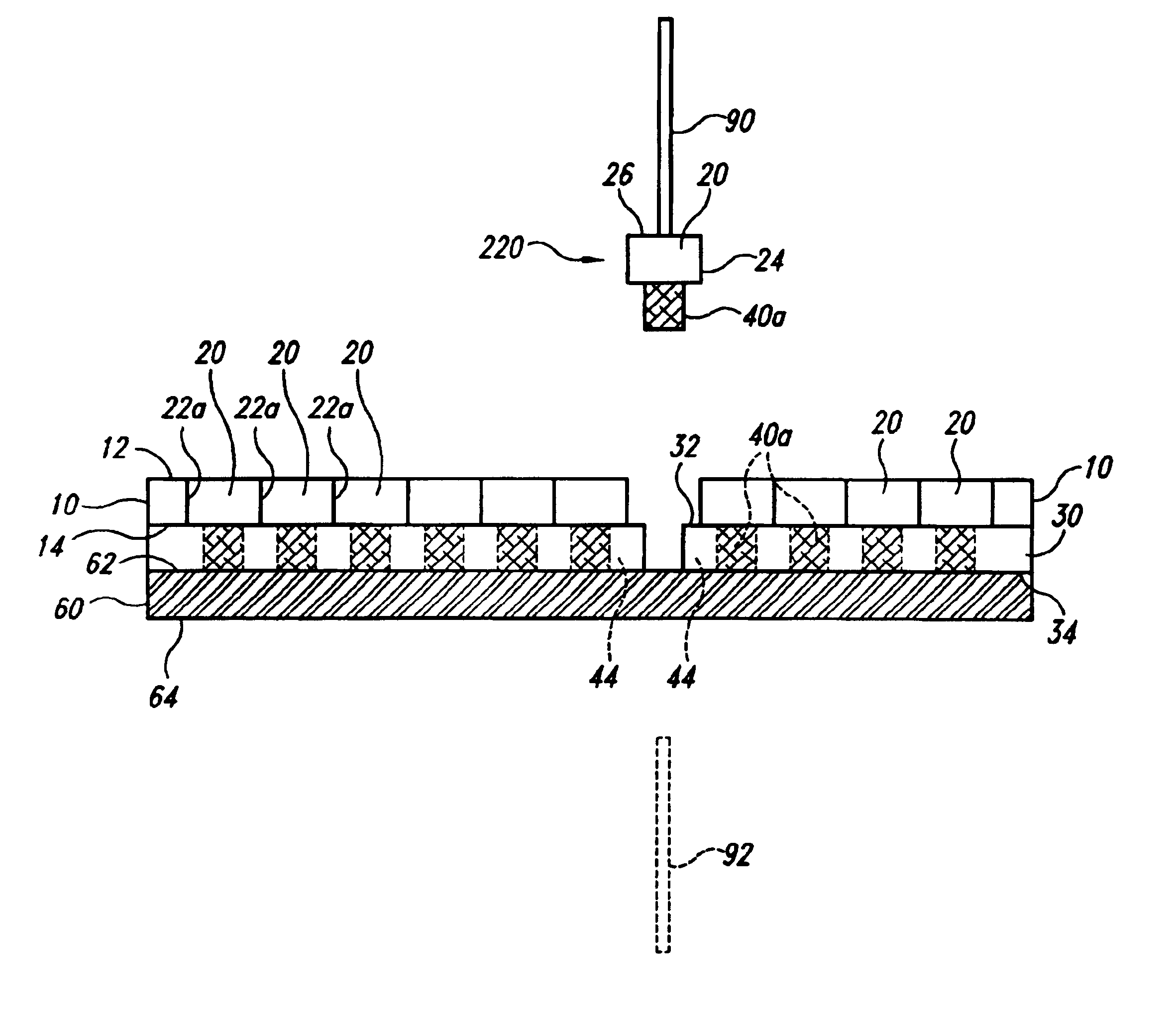

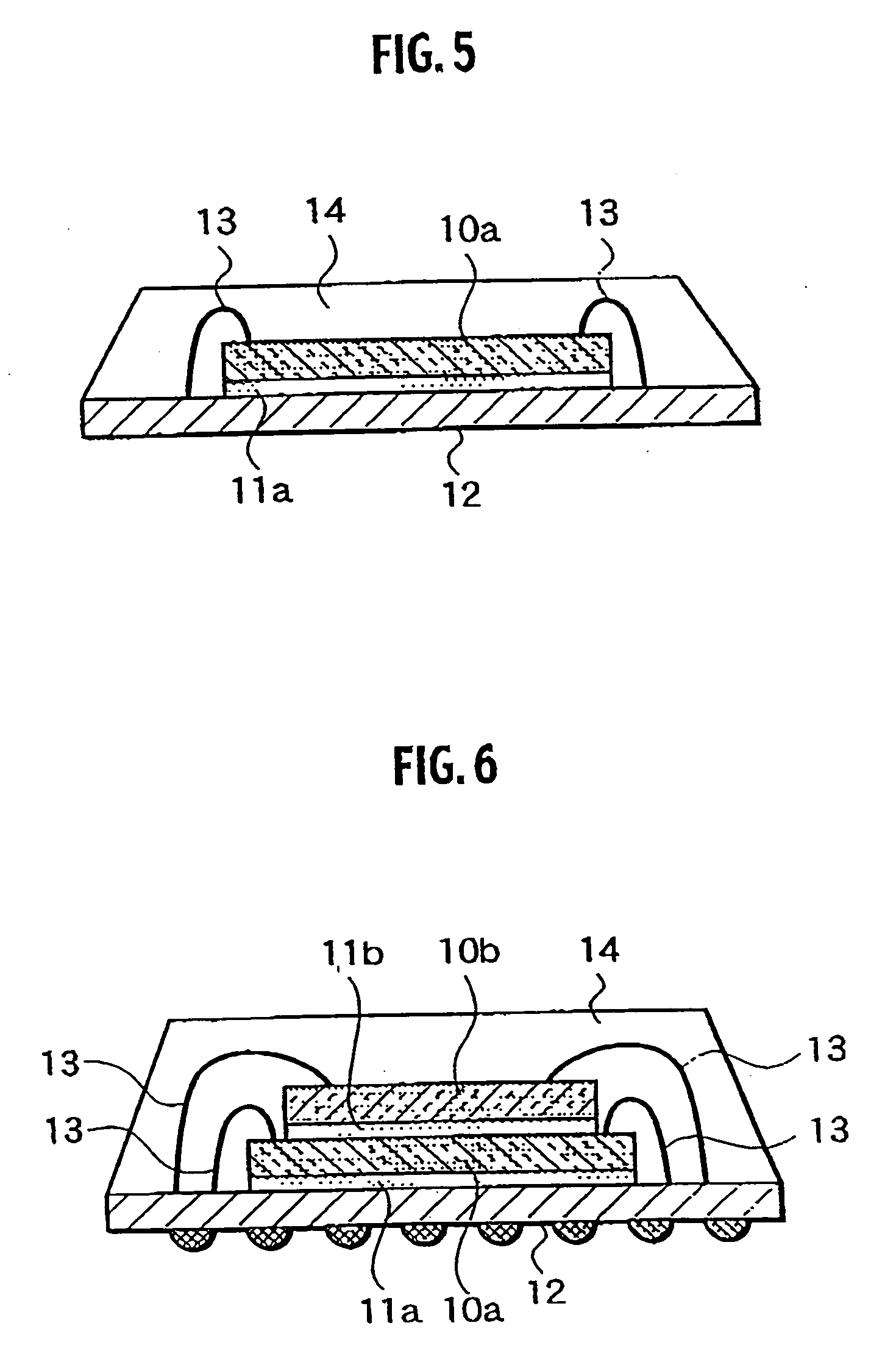

Fabrication of stacked microelectronic devices

Manufacture of stacked microelectronic devices is facilitated by producing subassemblies wherein adhesive pads are applied to the back surfaces of a plurality of microelectronic components in a batch fashion. In one embodiment, an adhesive payer is applied on a rear surface of a wafer. A plurality of spaced-apart adhesive pads are defined within the adhesive layer. Each adhesive pad may cover less than the entire back surface area of the component to which it is attached. A mounting member (e.g., dicing tape) may be attached to the adhesive layer and, in some embodiments, the adhesive layer may be treated so that the mounting member is less adherent to the adhesive pads than to other parts of the adhesive layer, easing removal of the adhesive pads with the microelectronic components.

Owner:MICRON TECH INC

Method of manufacturing semiconductor device

ActiveUS20050059205A1Solid-state devicesSemiconductor/solid-state device manufacturingDicing tapeDevice material

Extremely thin chips laminated to a non-ultraviolet ray curing type adhesive tape are peeled from the tape without giving rise to cracks and chippings. In a center portion of a suction block used for peeling off a chip laminated to a dicing tape, three blocks which push the dicing tape upwardly are incorporated. With respect to these blocks, inside the first block having a largest diameter, there is a second block having a diameter smaller than the diameter of the first block. Further, inside the second block, there is a third block having the smallest diameter. To peel off a chip by pushing a back surface of the dicing tape with the blocks, first of all, the three blocks are simultaneously pushed upwardly by a certain amount and, thereafter, the intermediate block and the inner block are further pushed upward, and, finally, the inner block is further pushed upward.

Owner:RENESAS EASTERN JAPAN SEMICON INC +1

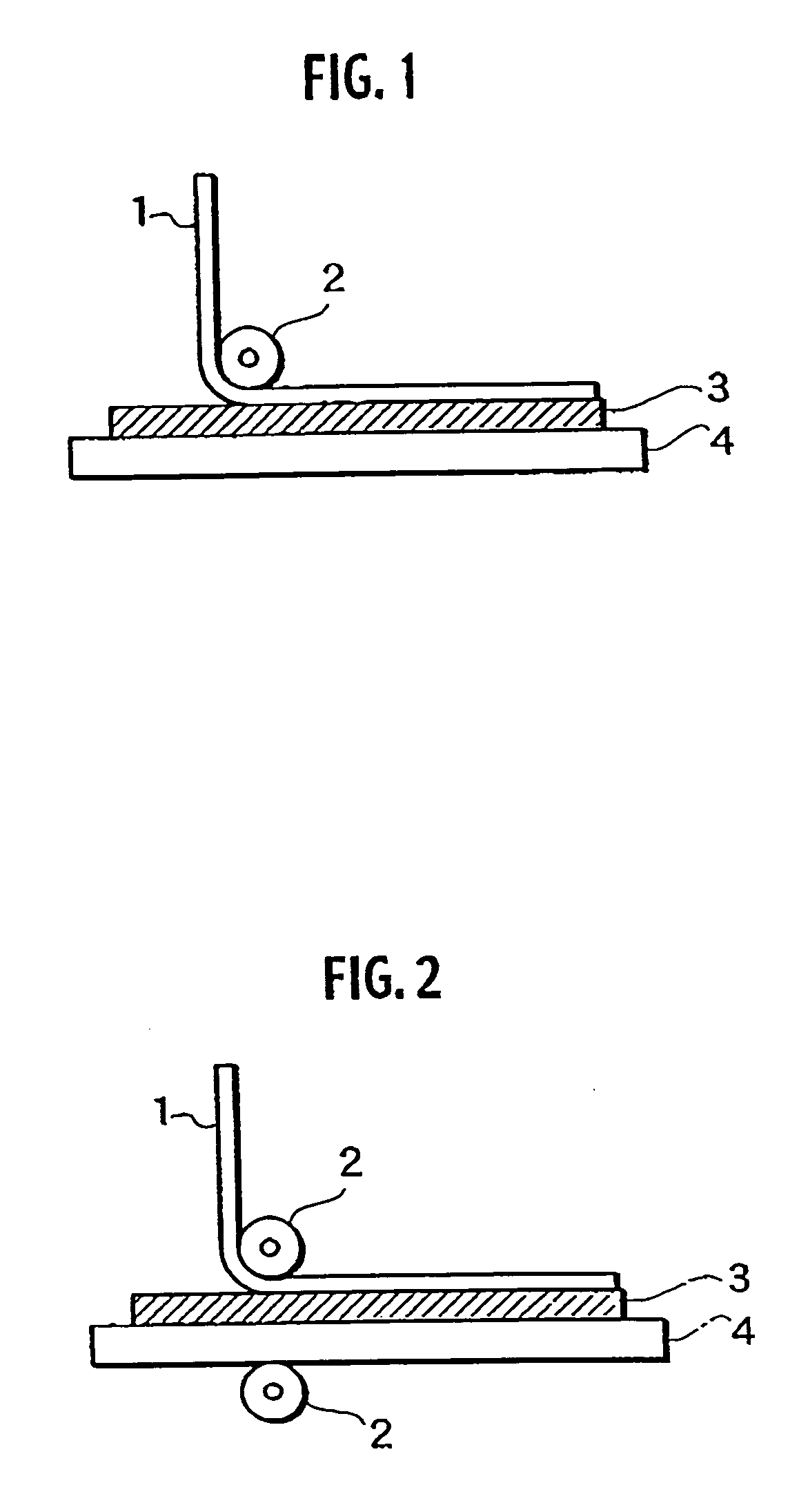

Dicing tape and a method of dicing a semiconductor wafer

InactiveUS6444310B1Rarely brokenMechanical working/deformationLamination ancillary operationsDicing tapeEngineering

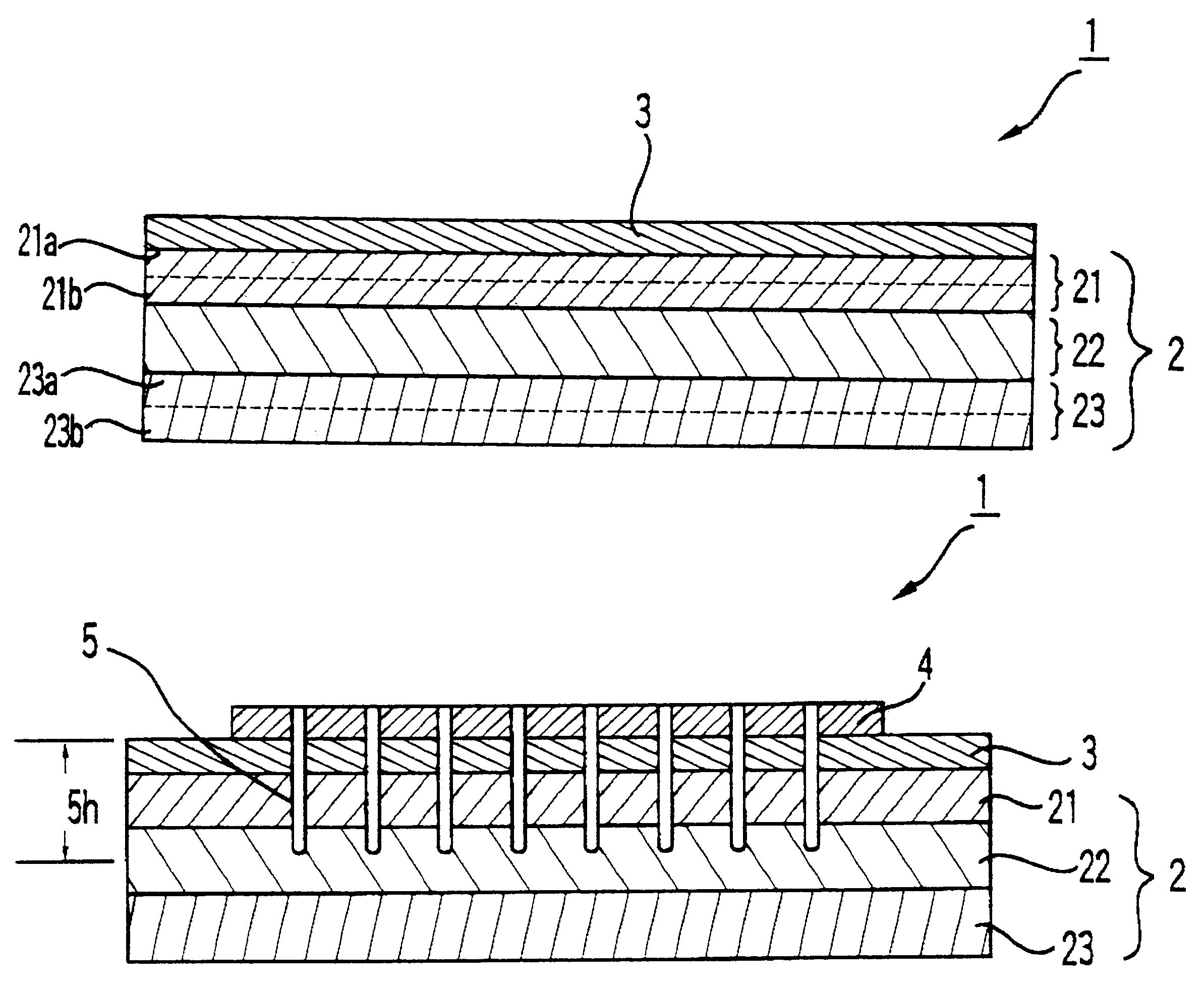

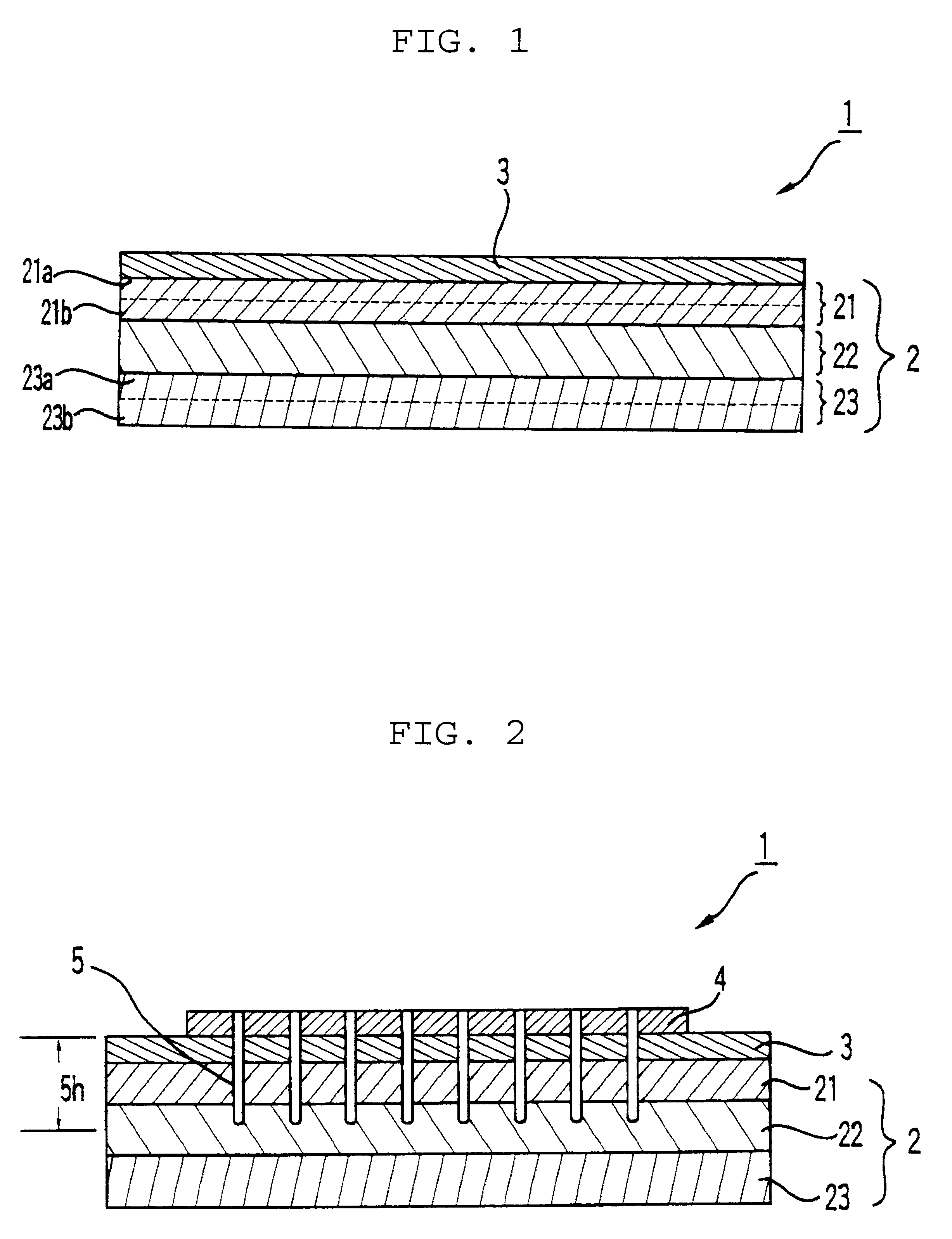

A dicing tape comprising a substrate sheet and a pressure-sensitive adhesive layer formed on one surface of the substrate sheet, wherein the substrate sheet comprises an upper layer in direct contact with the pressure-sensitive adhesive layer, an intermediate layer adjacent to the upper layer, and a lower layer adjacent to the intermediate layer, and an anti-extensibility (A) of the upper layer, an anti-extensibility (B) of the intermediate layer, and an anti-extensibility (C) of the lower layer satisfy the equation (I): the anti-extensibility being a product of a modulus of elasticity and a layer thickness, is disclosed. The present dicing tape can uniformly and sufficiently enlarge dicing lines without affect by a modulus of elasticity of a pressure-sensitive adhesive, and is rarely broken at the dicing lines.

Owner:LINTEC CORP

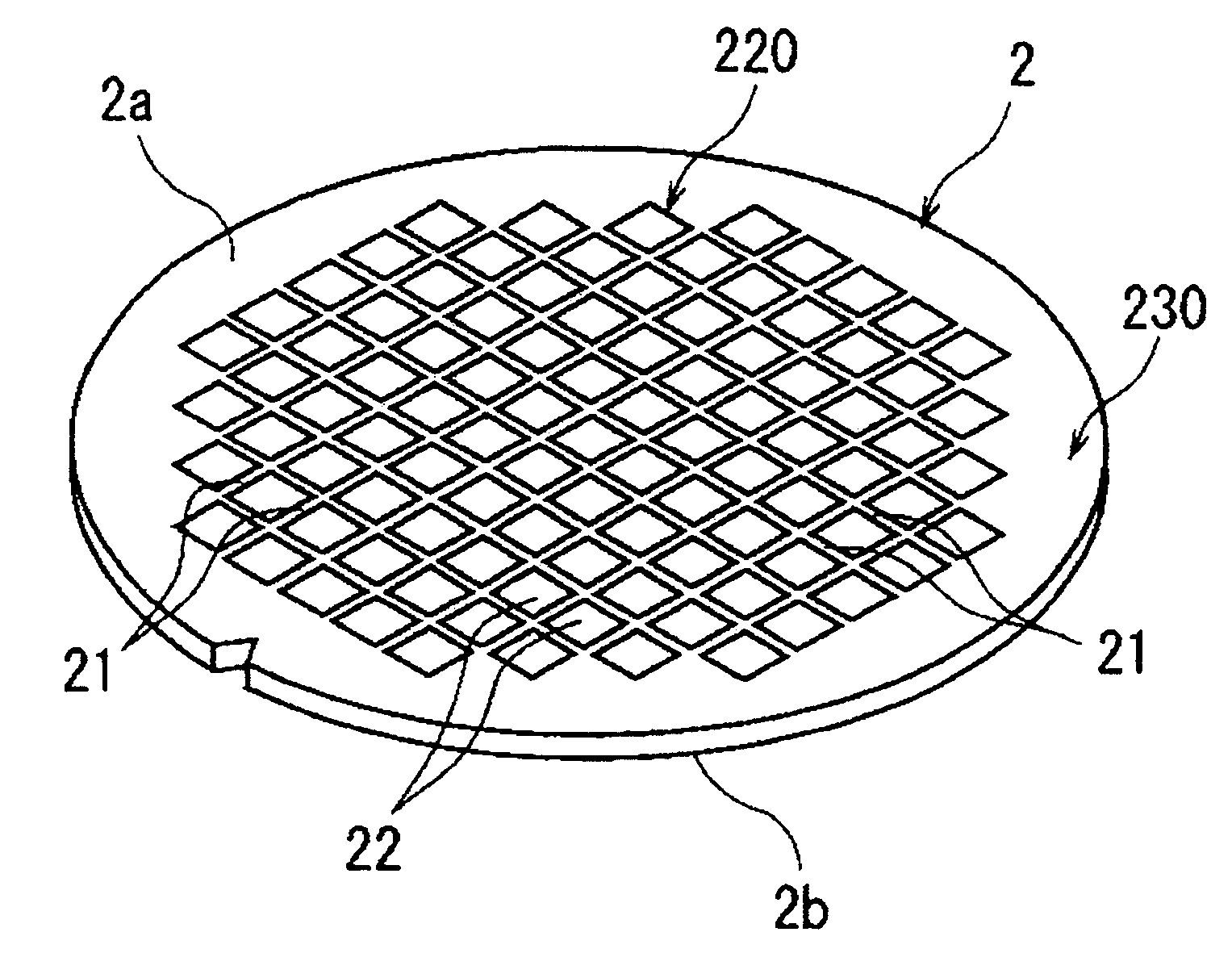

Wafer dividing method

ActiveUS20050170616A1Solid-state devicesSemiconductor/solid-state device manufacturingSplit linesDicing tape

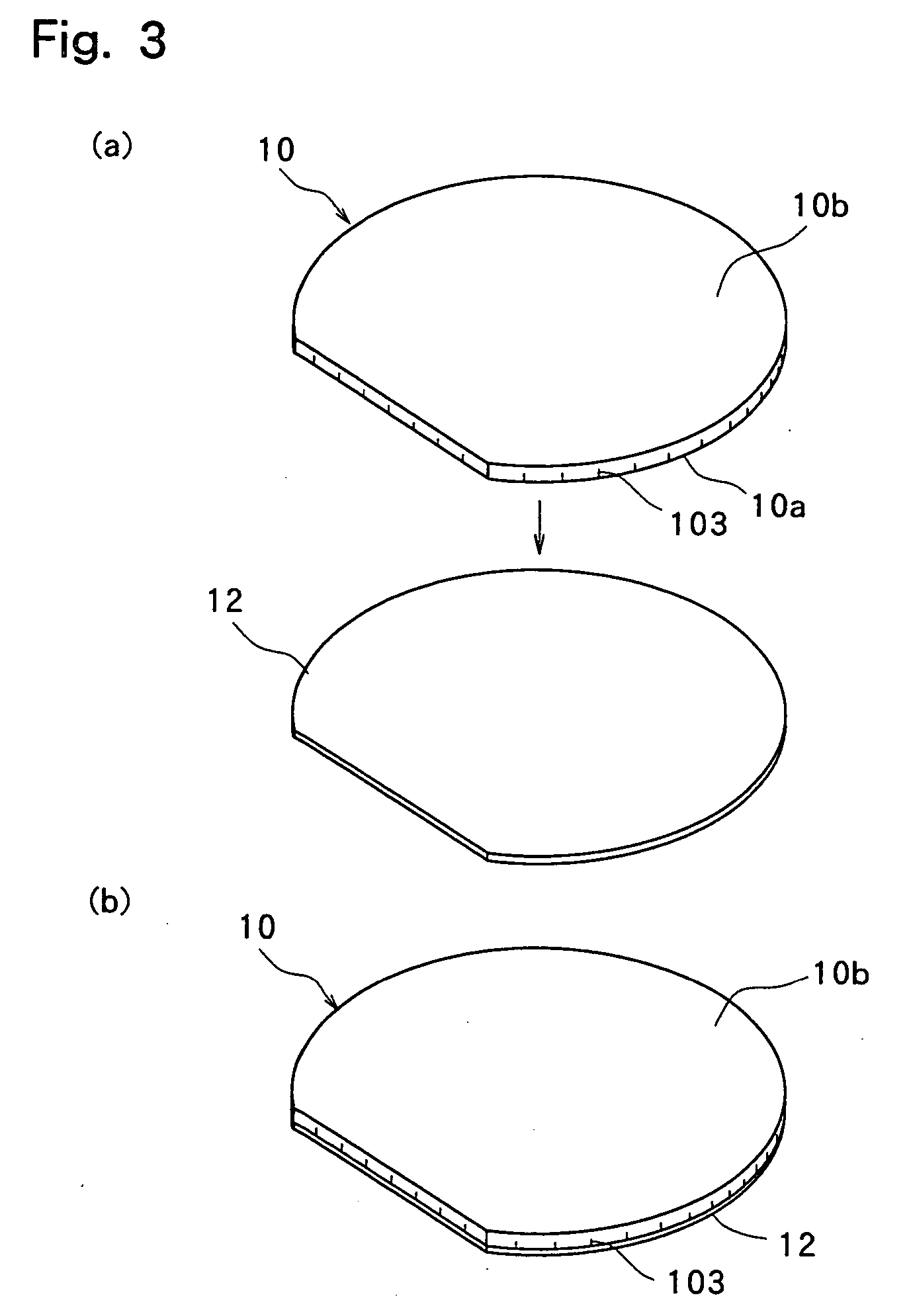

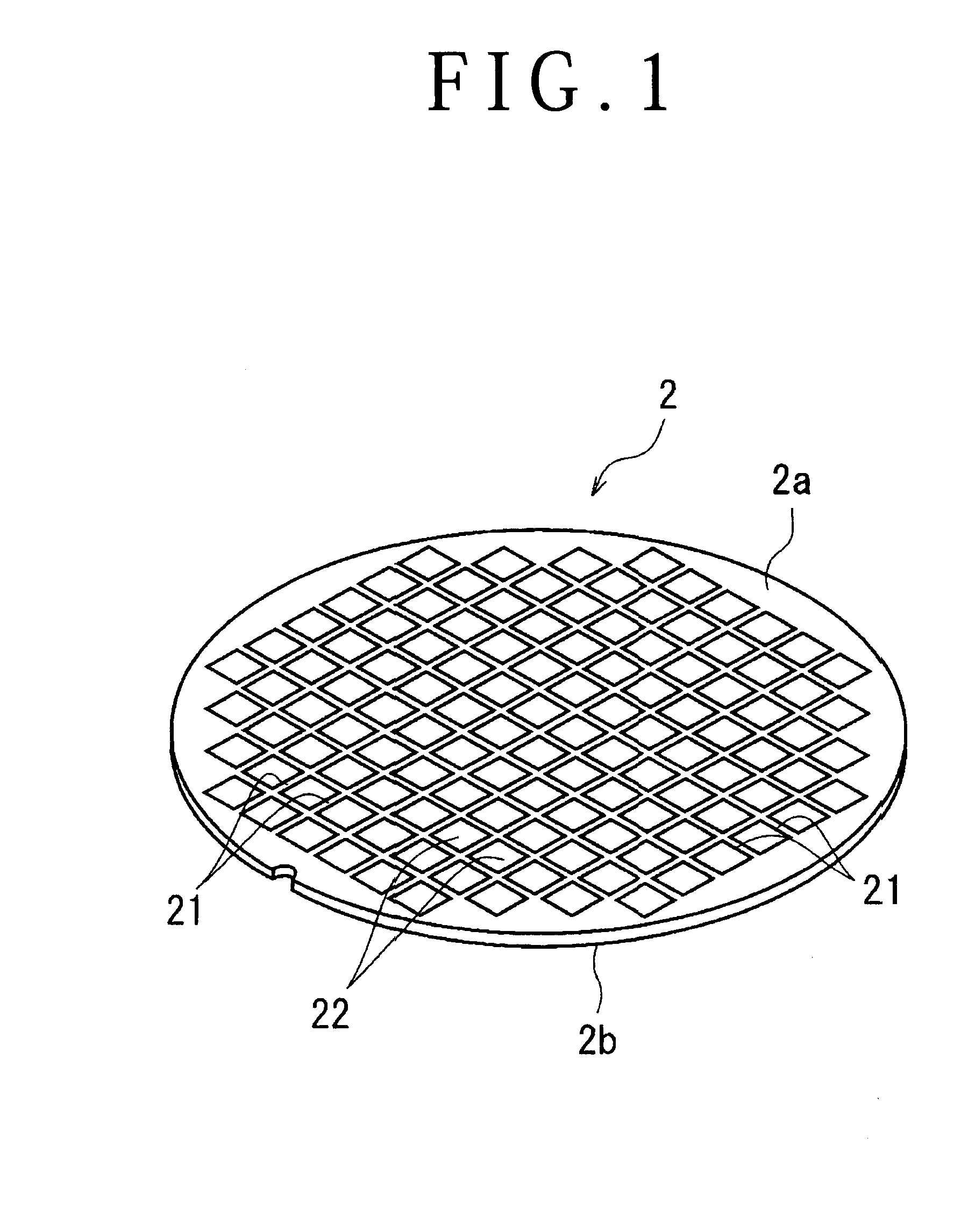

A method of dividing, along dividing lines, a wafer having function elements formed in areas sectioned by the dividing lines formed in a lattice pattern on the front surface, which comprises: a protective member affixing step for affixing a protective member to the front surface of the wafer; a polishing step for polishing the back surface of the wafer having the protective member affixed to the front surface; a deteriorated layer formation step for forming a deteriorated layer along the dividing lines in the inside of the wafer by applying a pulse laser beam capable of passing through the wafer to the wafer along the dividing lines from the polished back surface side of the wafer; a frame holding step for affixing the back surface of the wafer in which the deteriorated layers have been formed along the dividing lines, to a dicing tape mounted on an annular frame; a dividing step for dividing the wafer into individual chips along the dividing lines by exerting external force along the dividing lines where the deteriorated layers have been formed, of the wafer held on the frame; an expansion step for enlarging the interval between chips by stretching the dicing tape affixed to the wafer divided into individual chips; and a pick up step for picking up the chips from the stretched dicing tape.

Owner:DISCO CORP

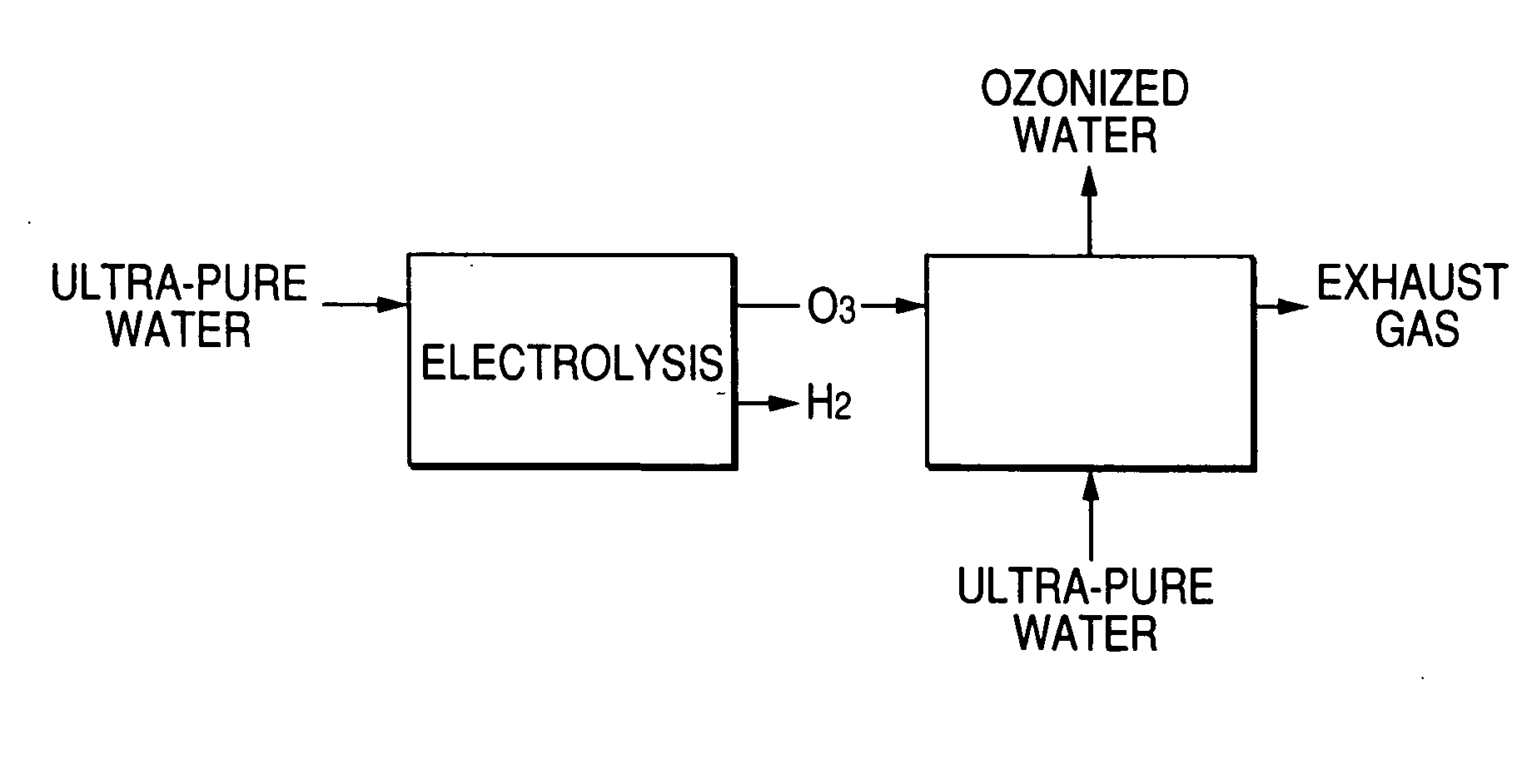

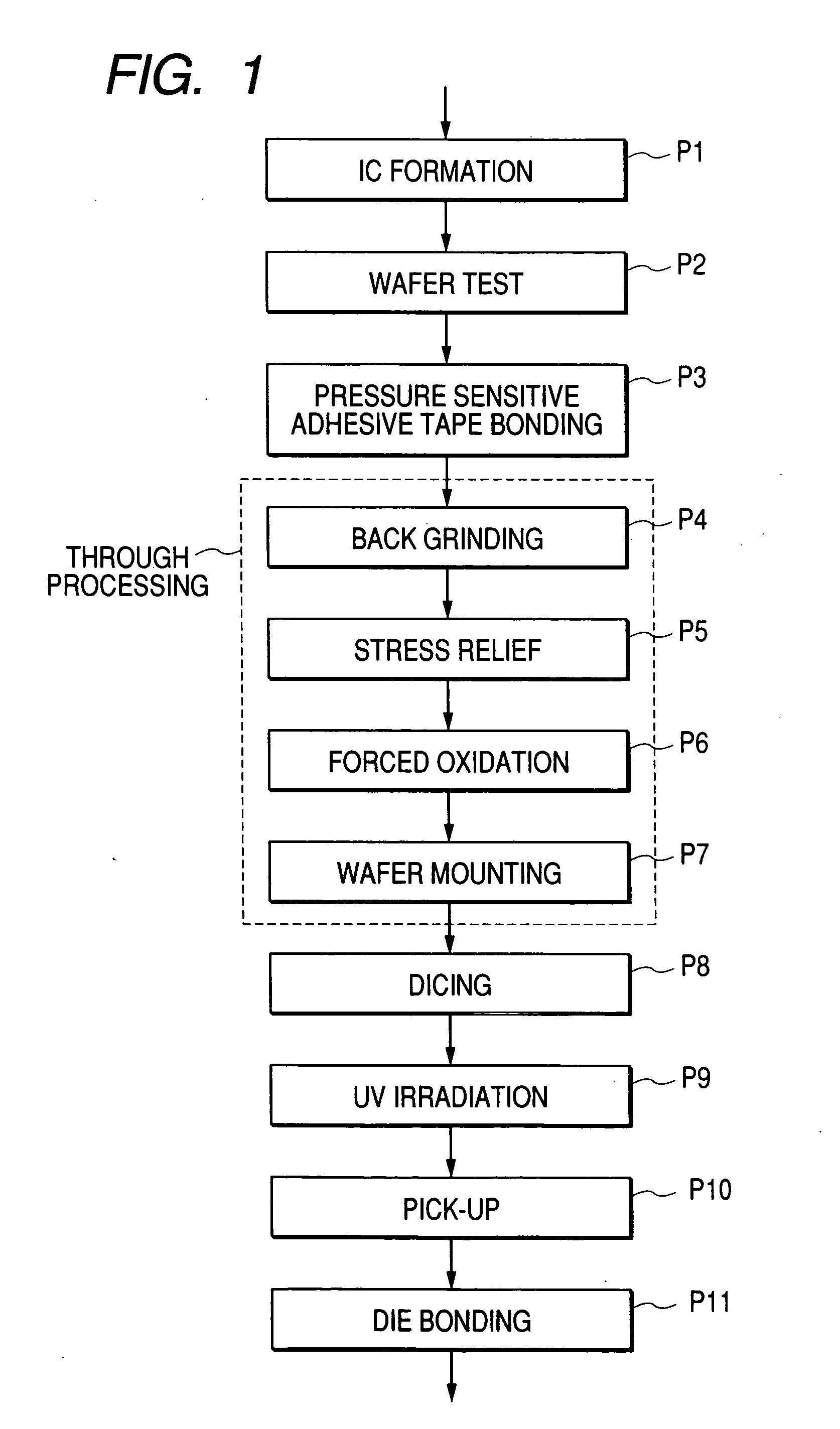

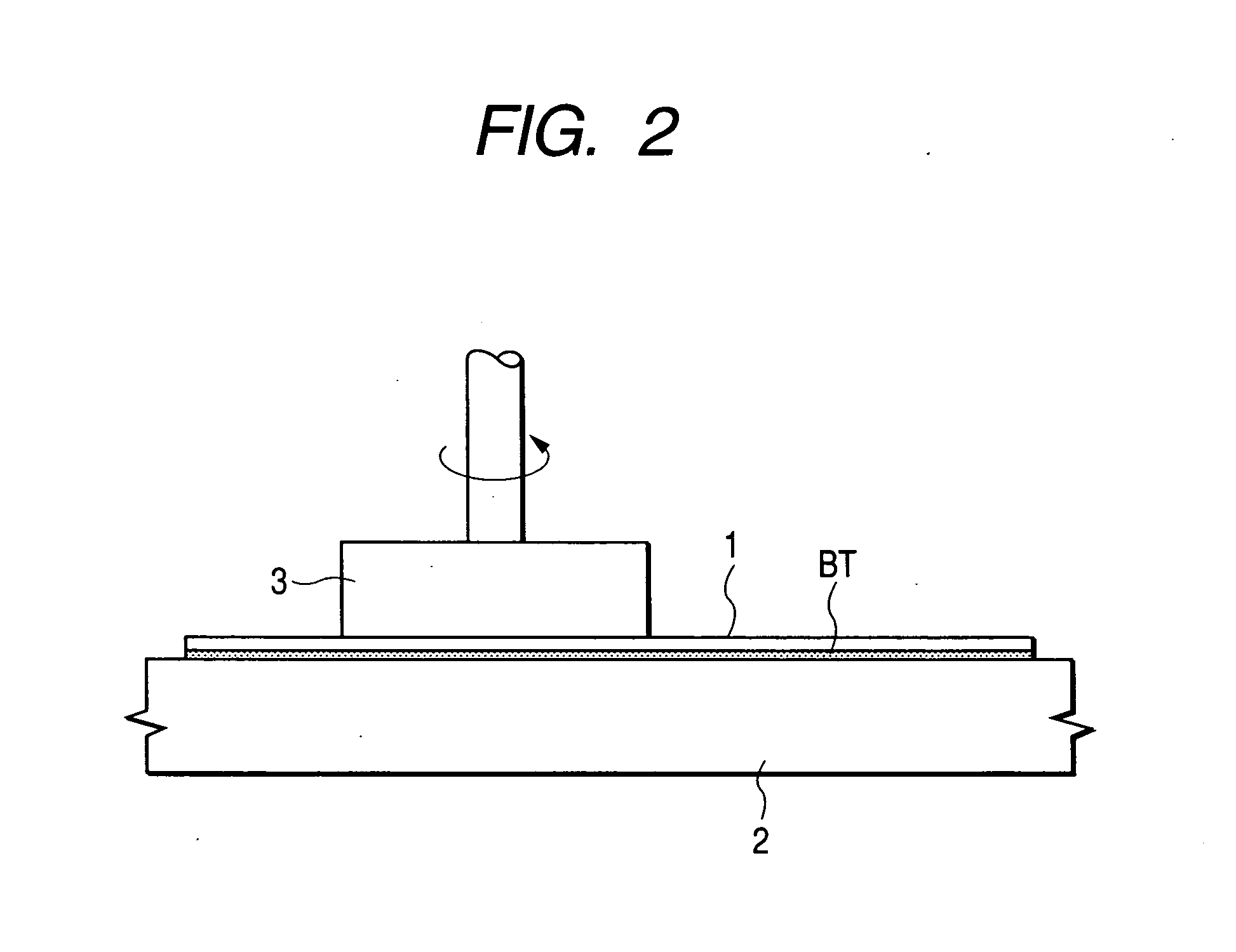

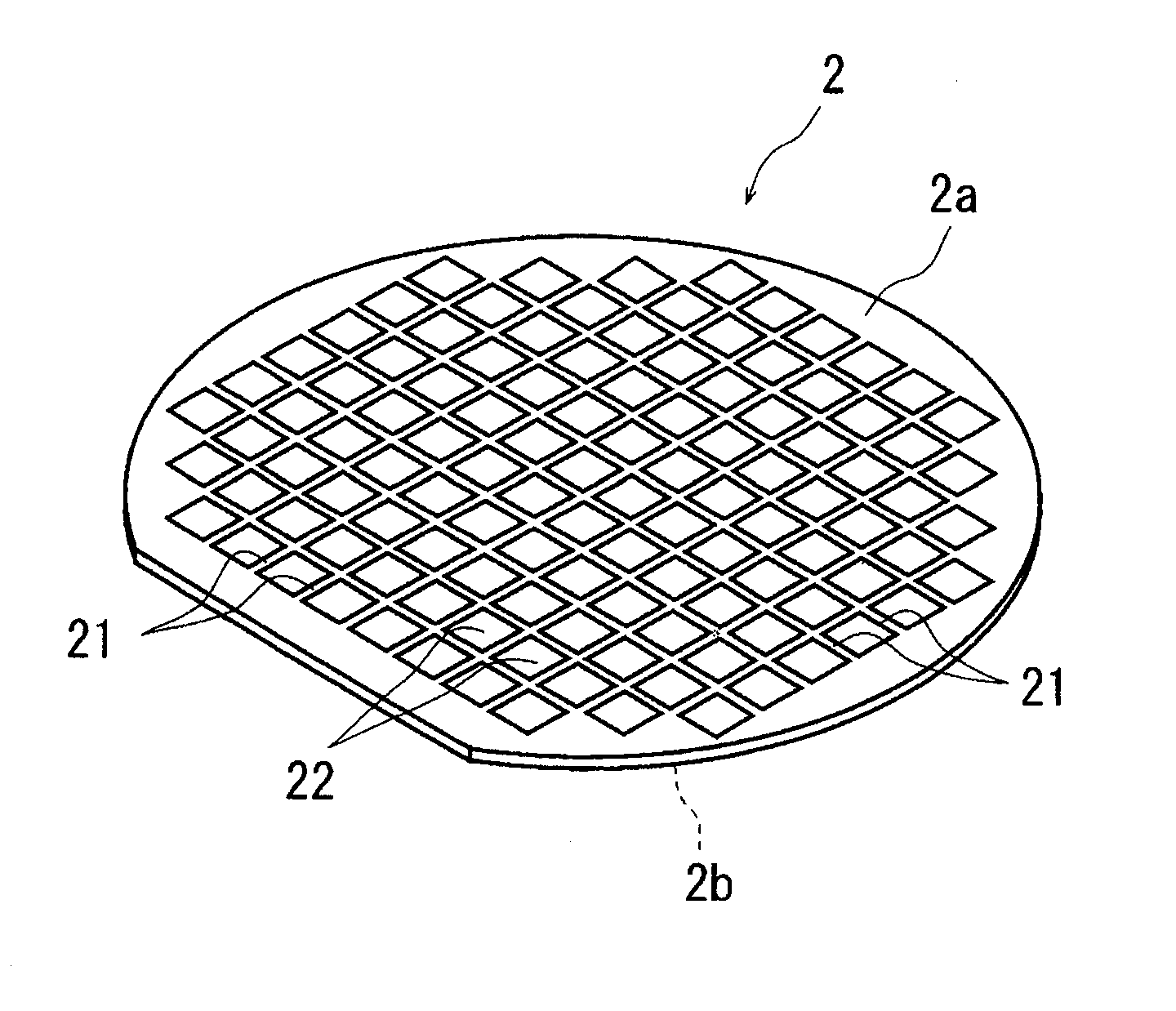

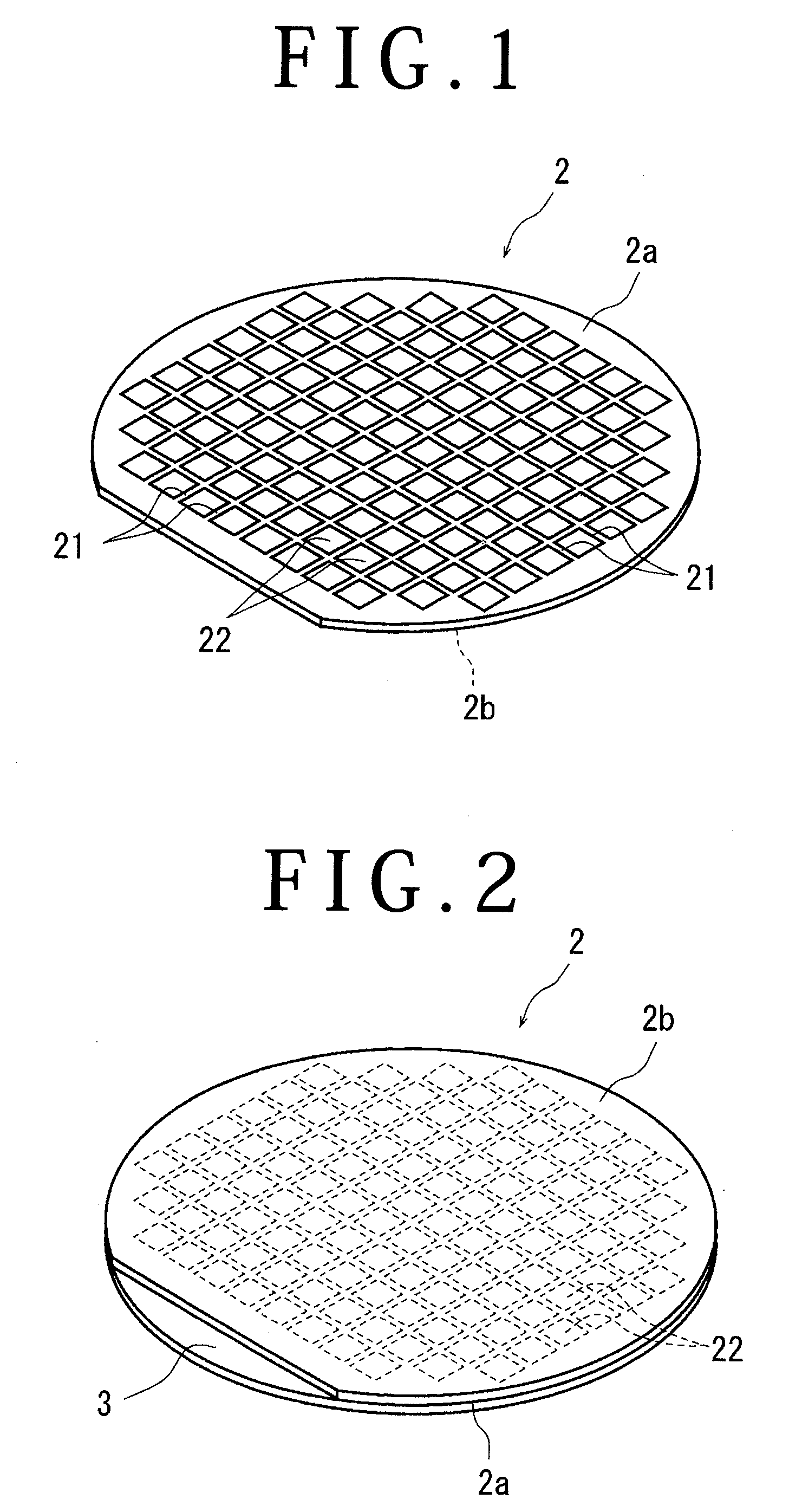

Fabrication method of semiconductor integrated circuit device

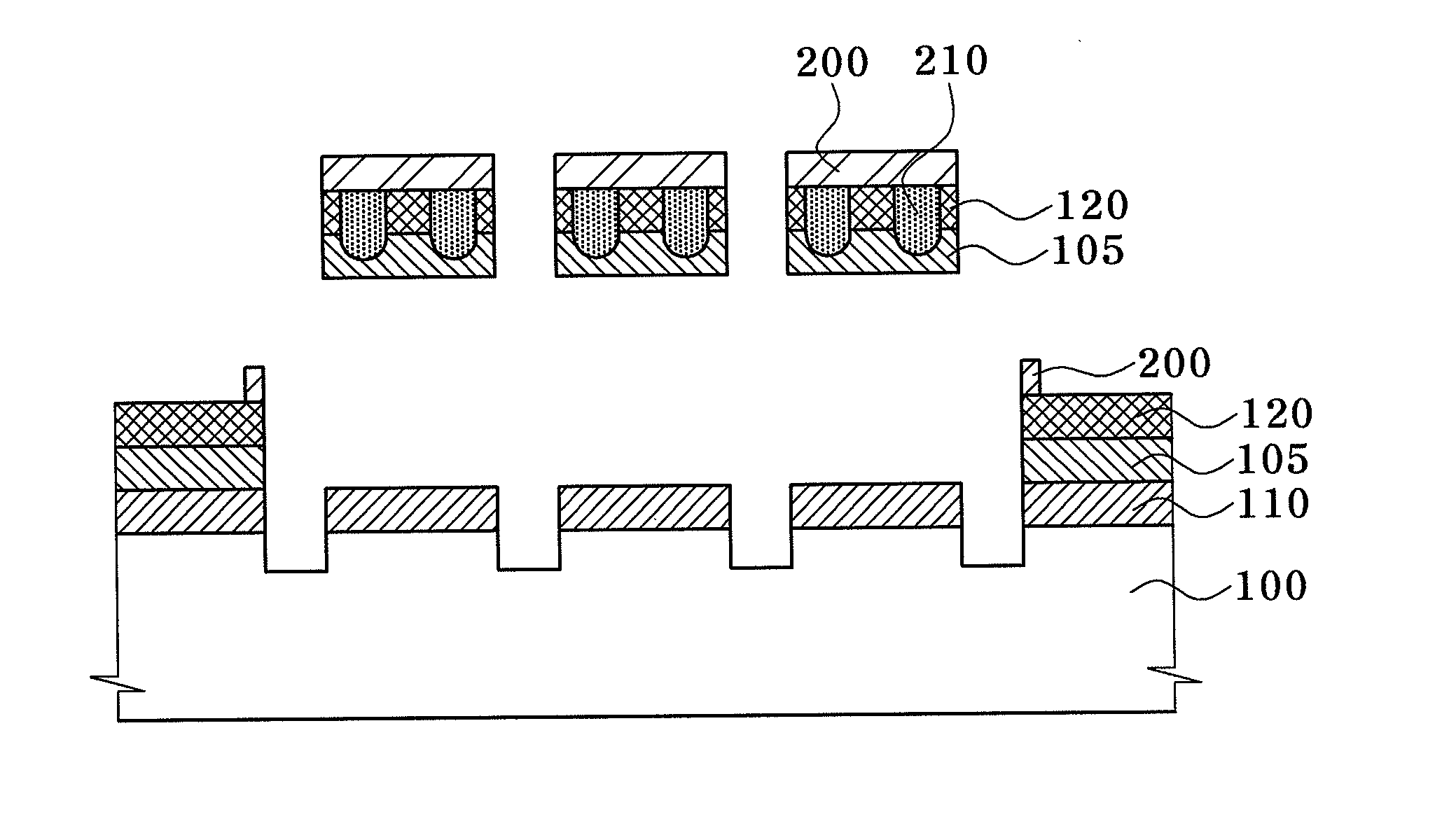

InactiveUS20050142815A1Wafer thickness reductionEasy to separateSolid-state devicesSemiconductor/solid-state device manufacturingWaferingDicing tape

A technique capable of stably releasing chips from a dicing tape, includes grinding a back surface of a semiconductor wafer, while adhering a pressure sensitive adhesive tape to a circuit forming surface of the semiconductor wafer formed with an integrated circuit, to achieve a predetermined thickness and forcibly oxidizing the back surface of the semiconductor wafer. Then, the pressure sensitive adhesive tape adhered to the circuit forming surface of the semiconductor wafer is released, and a dicing tape is adhered to the back surface of the semiconductor wafer. Further, the semiconductor wafer is divided by dicing it into individual chips, and then the back surface of the chip is pressed by way of the dicing tape, thereby releasing the chips from the dicing tape.

Owner:RENESAS ELECTRONICS CORP

Method of manufacturing device

ActiveUS20090197395A1Improve device qualityLowering transverse rupture strengthSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDicing tapeLaser beam machining

A method of manufacturing a device includes: a laser beam-machined groove forming step of irradiating a wafer with a laser beam from the back side of the wafer along planned dividing lines so as to form laser beam-machined grooves along the planned dividing lines; an etching step of etching a back-side surface of the wafer having been subjected to the laser beam-machined groove forming step, so as to remove denatured layers formed at processed surfaces of the laser beam-machined grooves; an adhesive film attaching step of attaching an adhesive film to the back-side surface of the wafer having been subjected to the etching step, and adhering the adhesive film side of the wafer to a surface of a dicing tape; and an adhesive film rupturing step of expanding the dicing tape so as to rupture the adhesive film along individual devices.

Owner:DISCO CORP

Semiconductor wafer with assisting dicing structure and dicing method thereof

A semiconductor wafer with an assisting dicing structure. The wafer comprises a substrate having a front surface and a rear surface. The front surface of the substrate comprises at least two device regions separated by at least one dicing lane. The rear surface of the substrate comprises at least one pre-dicing trench formed therein and substantially aligned with the dicing lane. A method for dicing a semiconductor wafer is also disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

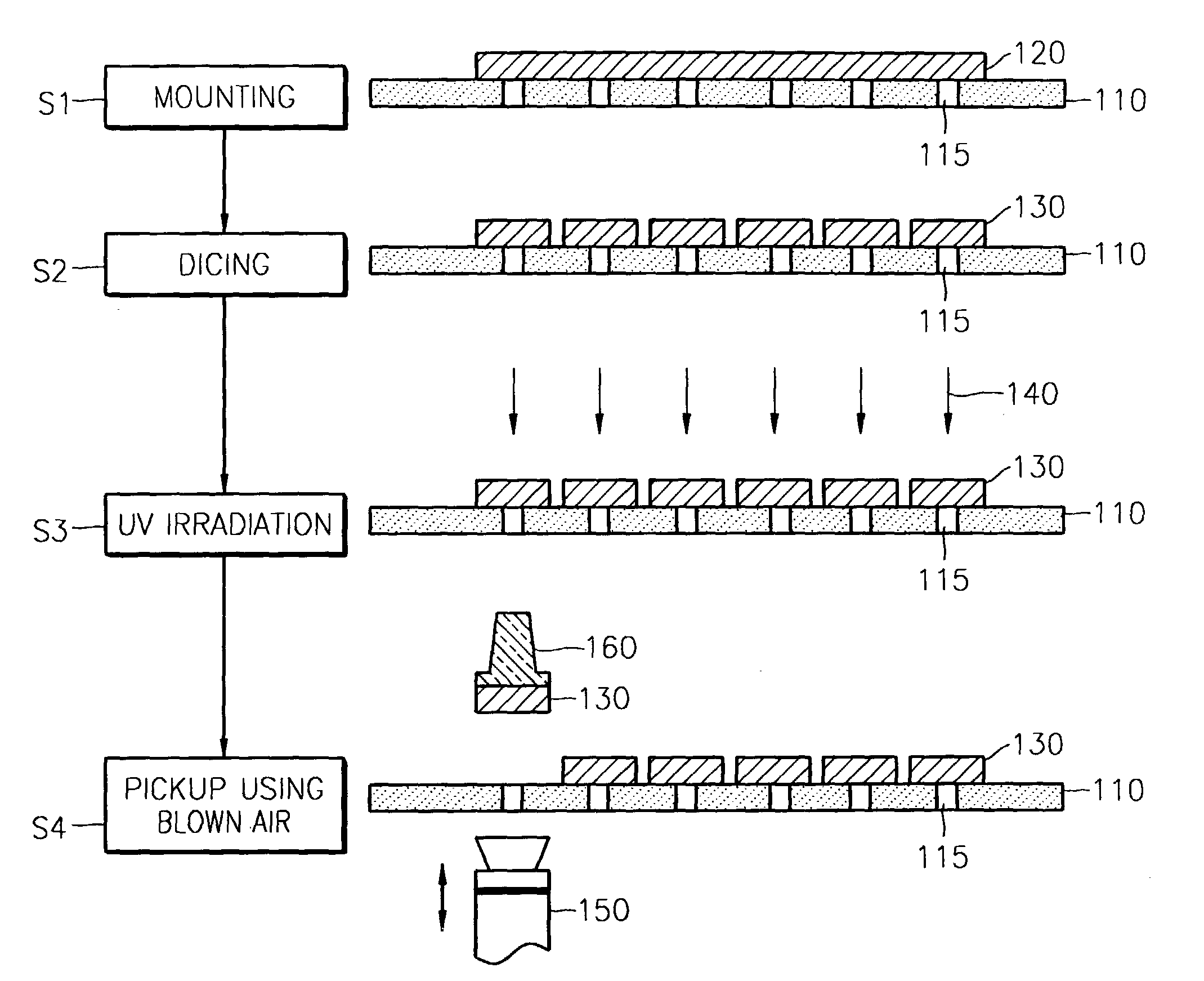

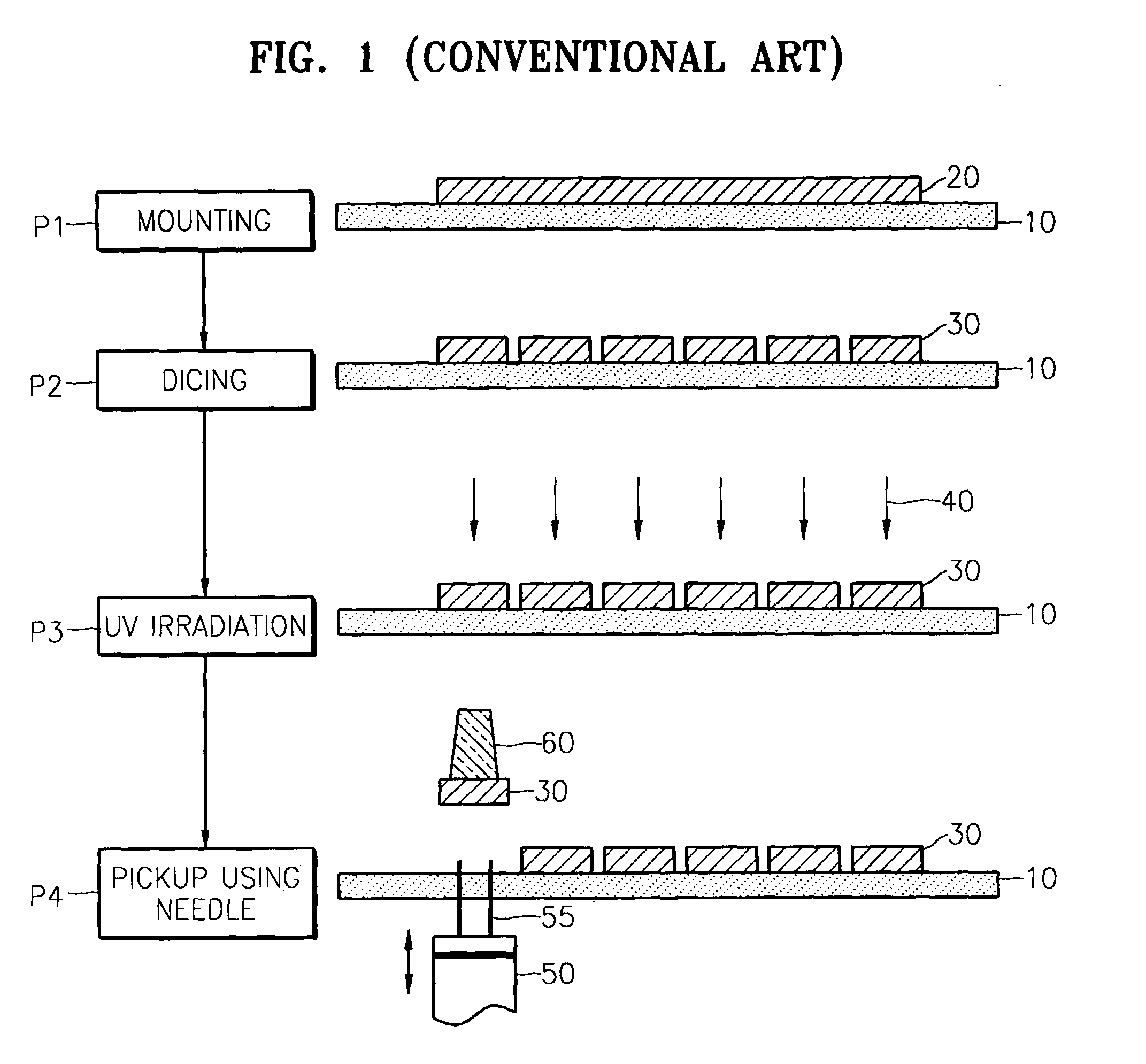

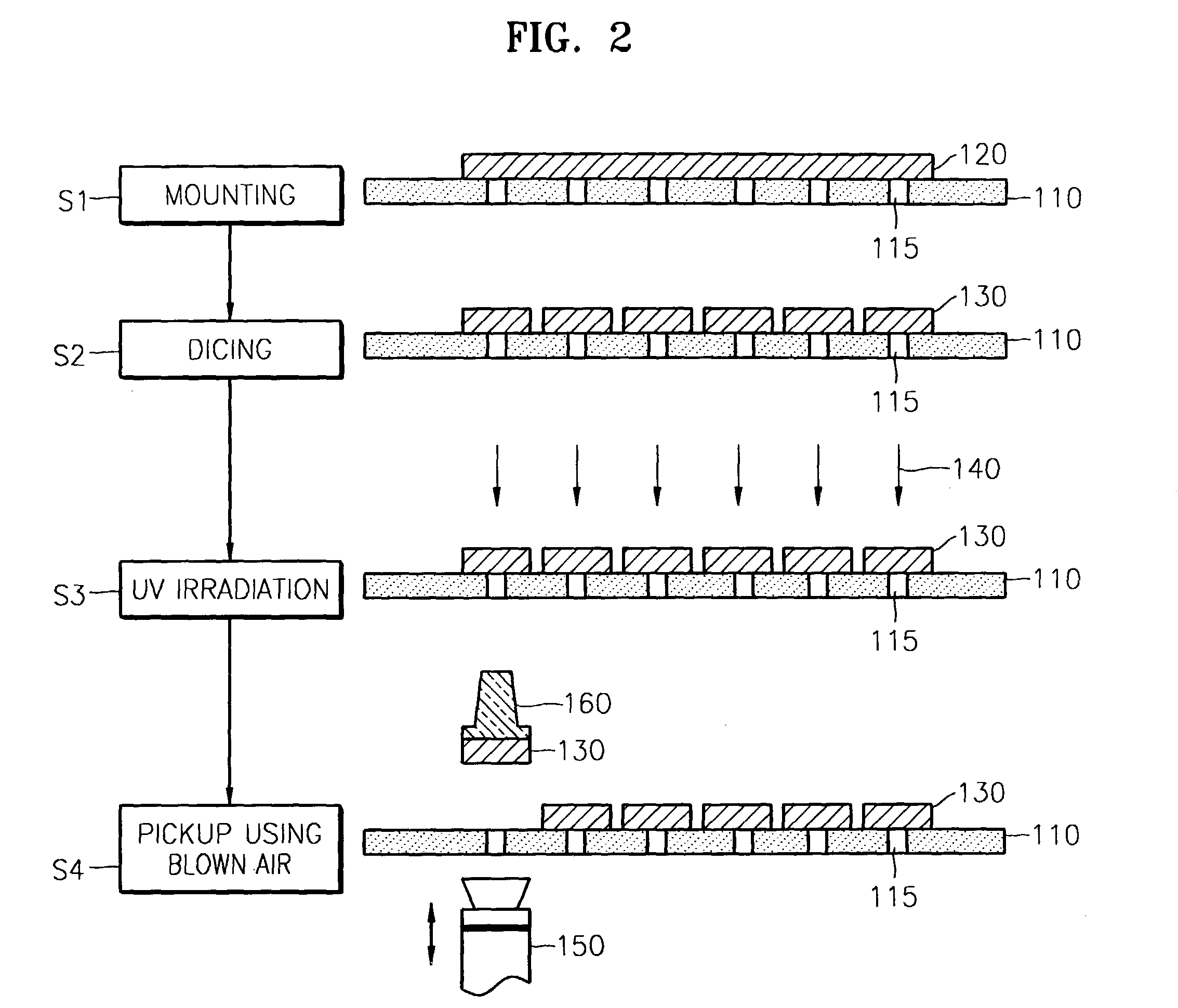

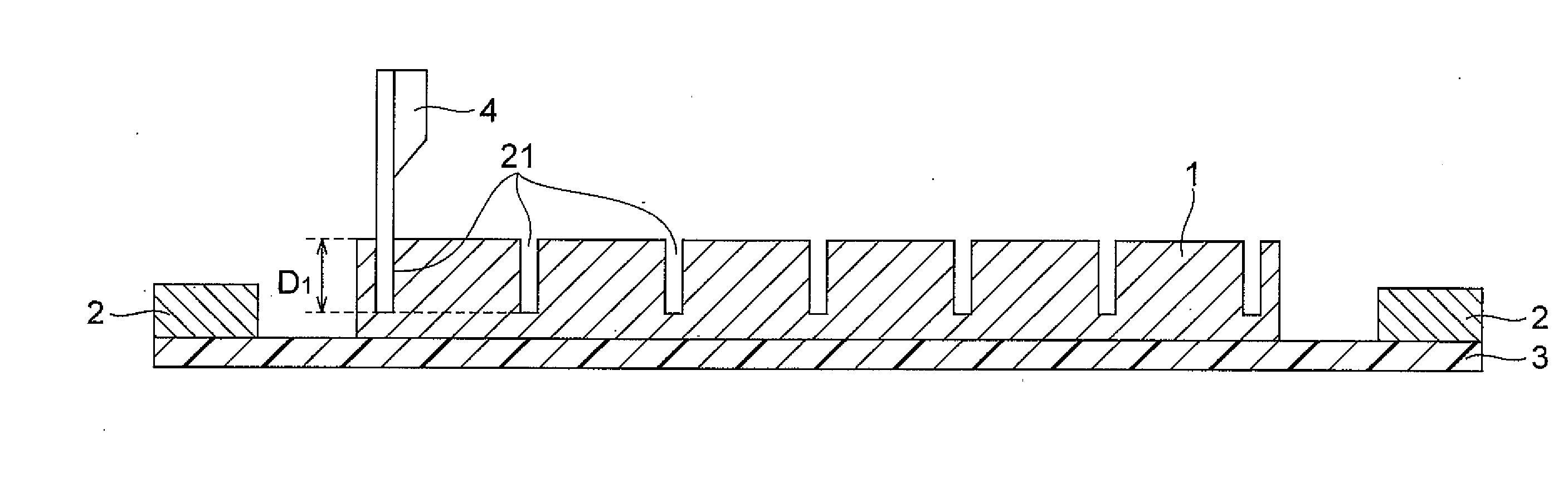

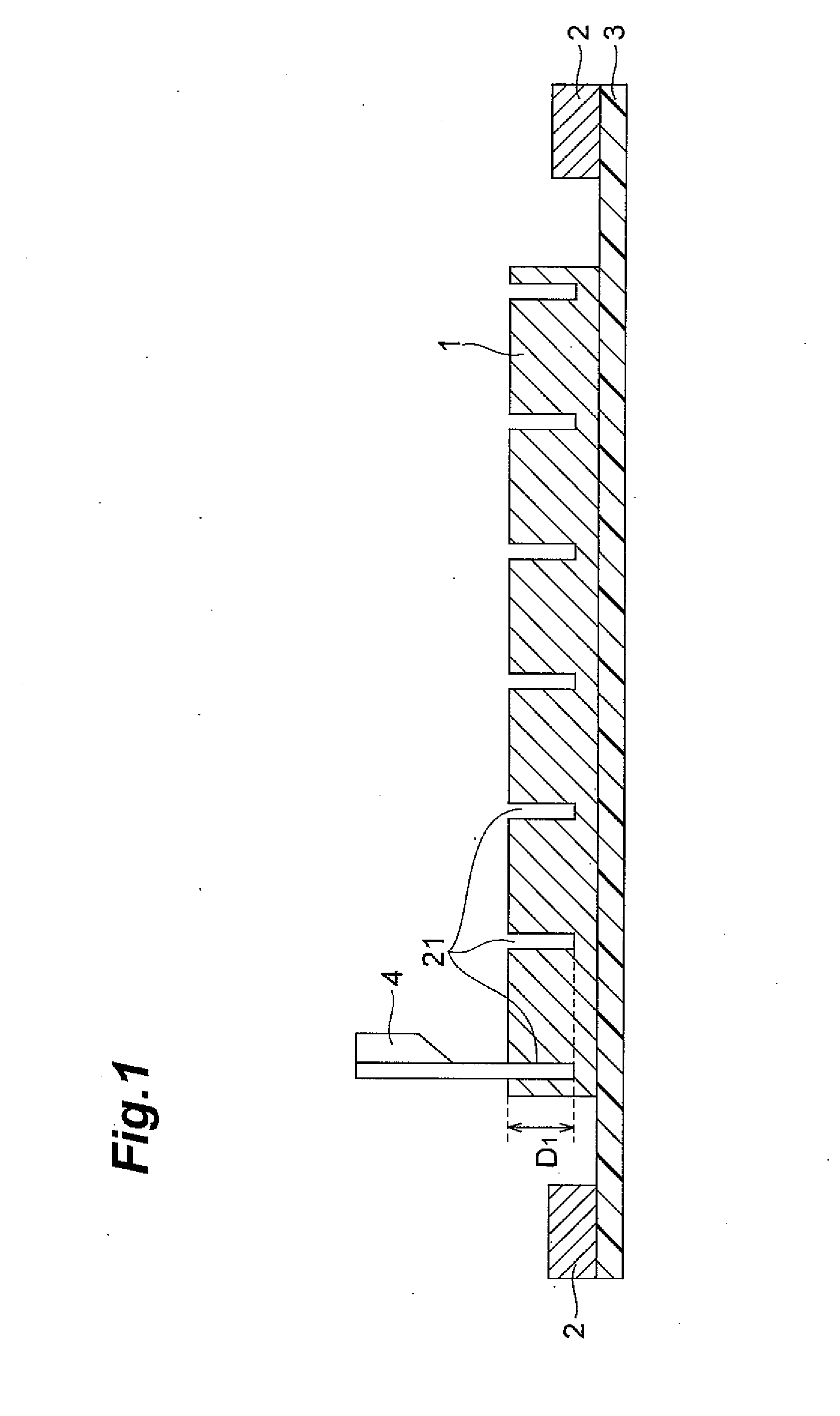

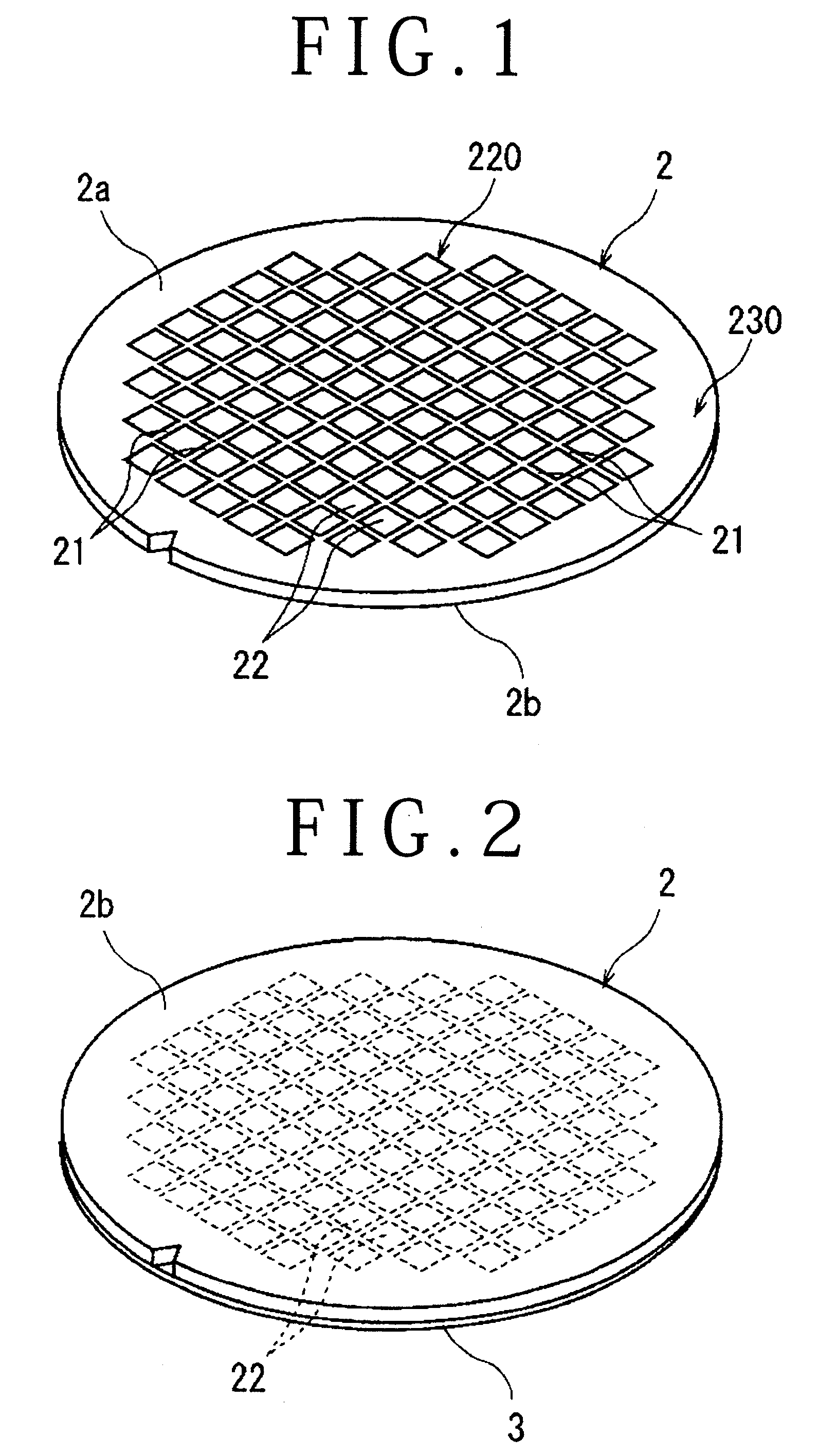

Method and apparatus for picking up a semiconductor chip, method and apparatus for removing a semiconductor chip from a dicing tape, and a method of forming a perforated dicing tape

InactiveUS20040089515A1Solid-state devicesSemiconductor/solid-state device manufacturingDicing tapeSemiconductor chip

A method and apparatus for picking up a semiconductor chip, a method and apparatus for removing a semiconductor chip from a dicing tape, and a method of forming a perforated dicing tape are provided. Air may be blown through air holes in a dicing tape to at least partially separate the semiconductor chip from the dicing tape and / or create a space between the semiconductor chip to weaken the adhesion of the dicing tape to the semiconductor chip. The semiconductor chip may then be picked up by a removal member and completely removed from the dicing tape. Semiconductor chips that are not to be removed may be vacuum-suctioned to the dicing tape. UV radiation or heat may be applied to weaken the adhesion of the dicing tape. The semiconductor chip may be detected by an optical detector. Removing the semiconductor chips by air reduces stress and damage to the semiconductor chips.

Owner:SAMSUNG ELECTRONICS CO LTD

Adhesive film and process for preparing the same as well as adhesive sheet and semiconductor device

InactiveUS20070098995A1Improve workabilityLow heating temperatureNon-macromolecular adhesive additivesSynthetic resin layered productsHeat resistanceDicing tape

An object of the present invention is to provide a die-adhering adhesive film which can be laminated on a back of a wafer at a temperature lower than a softening temperature of a protecting tape for an ultra-thin wafer, or a dicing tape to be laminated, can reduce a thermal stress such as warpage of a wafer, can simplify a step of manufacturing a semiconductor device, and is excellent in heat resistance and humidity resistance reliance, an adhesive sheet in which the adhesive film and a dicing tape are laminated, as well as a semiconductor device.

Owner:HITACHI CHEM CO LTD

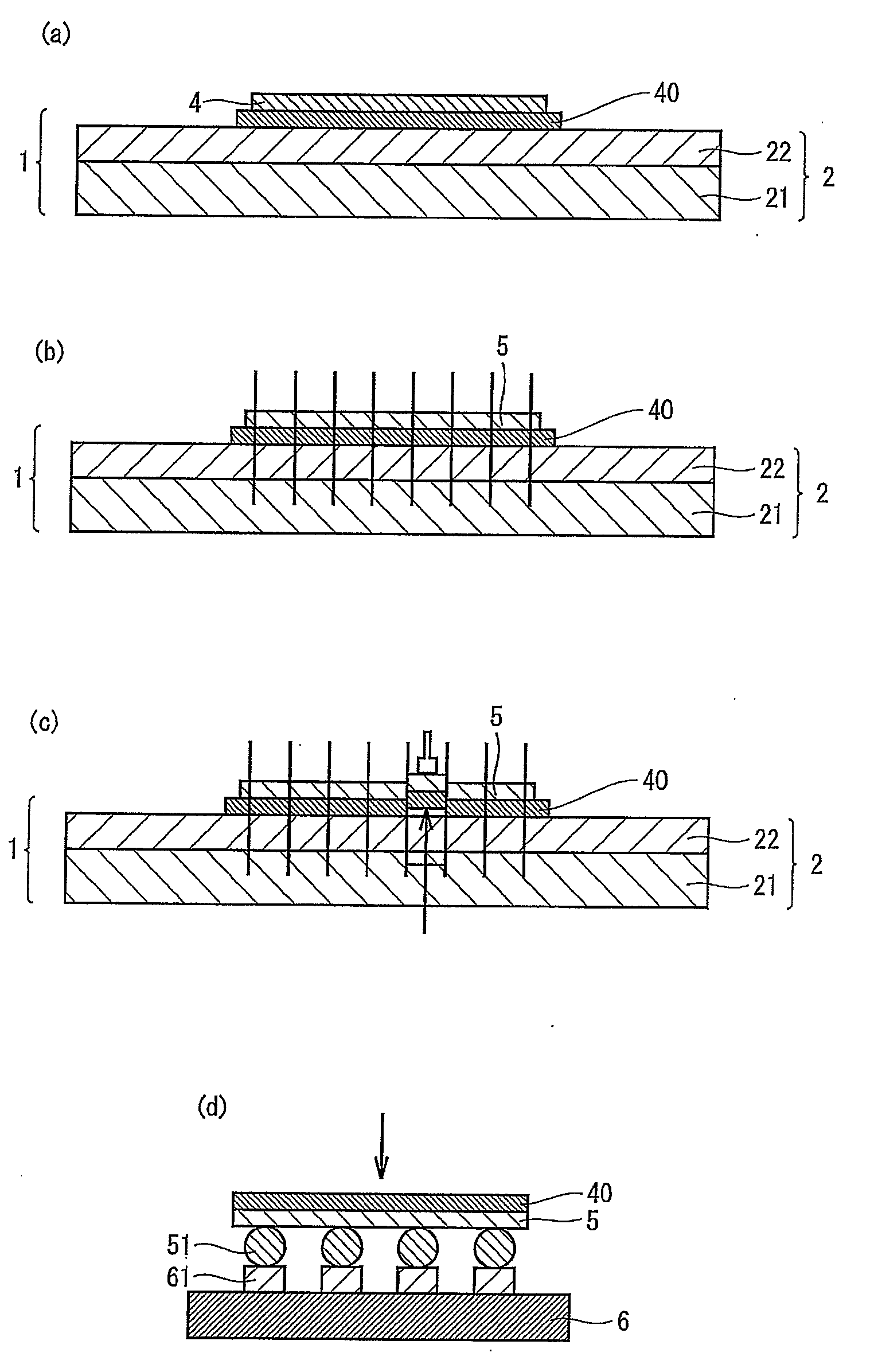

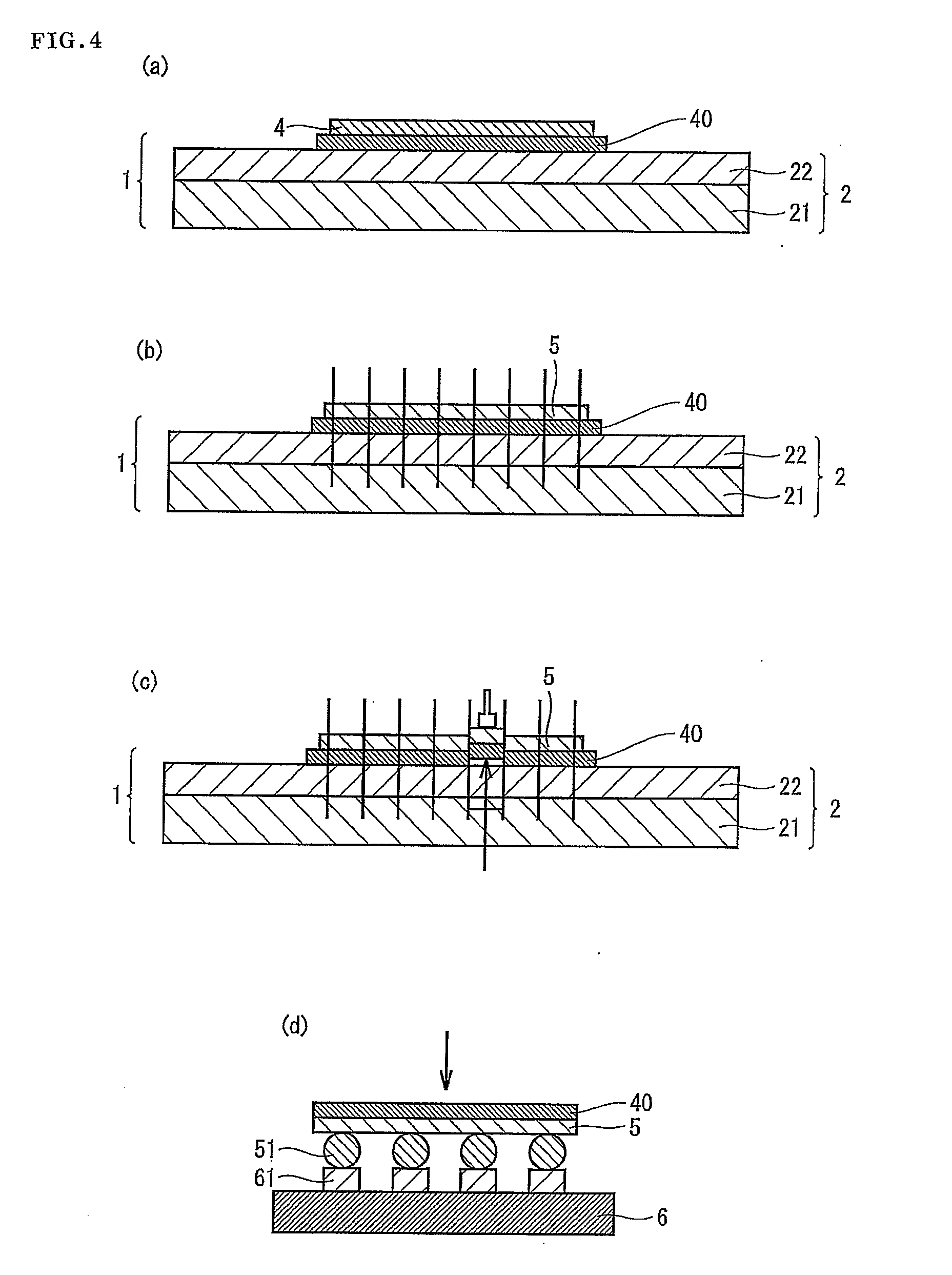

Method for producing semiconductor chip with adhesive film, adhesive film for semiconductor used in the method, and method for producing semiconductor device

ActiveUS20100311227A1High yieldFilm/foil adhesivesSemiconductor/solid-state device detailsEngineeringDicing tape

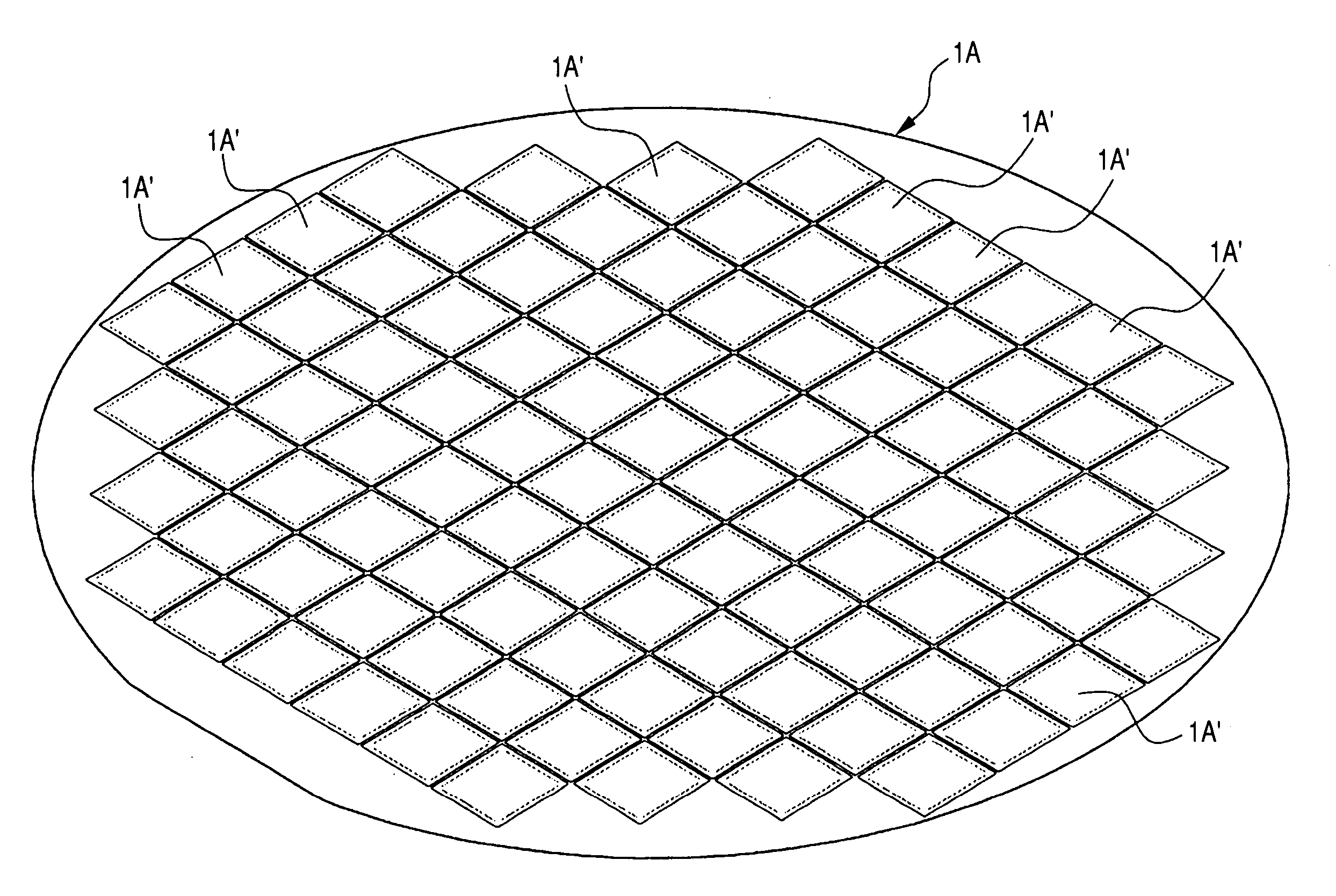

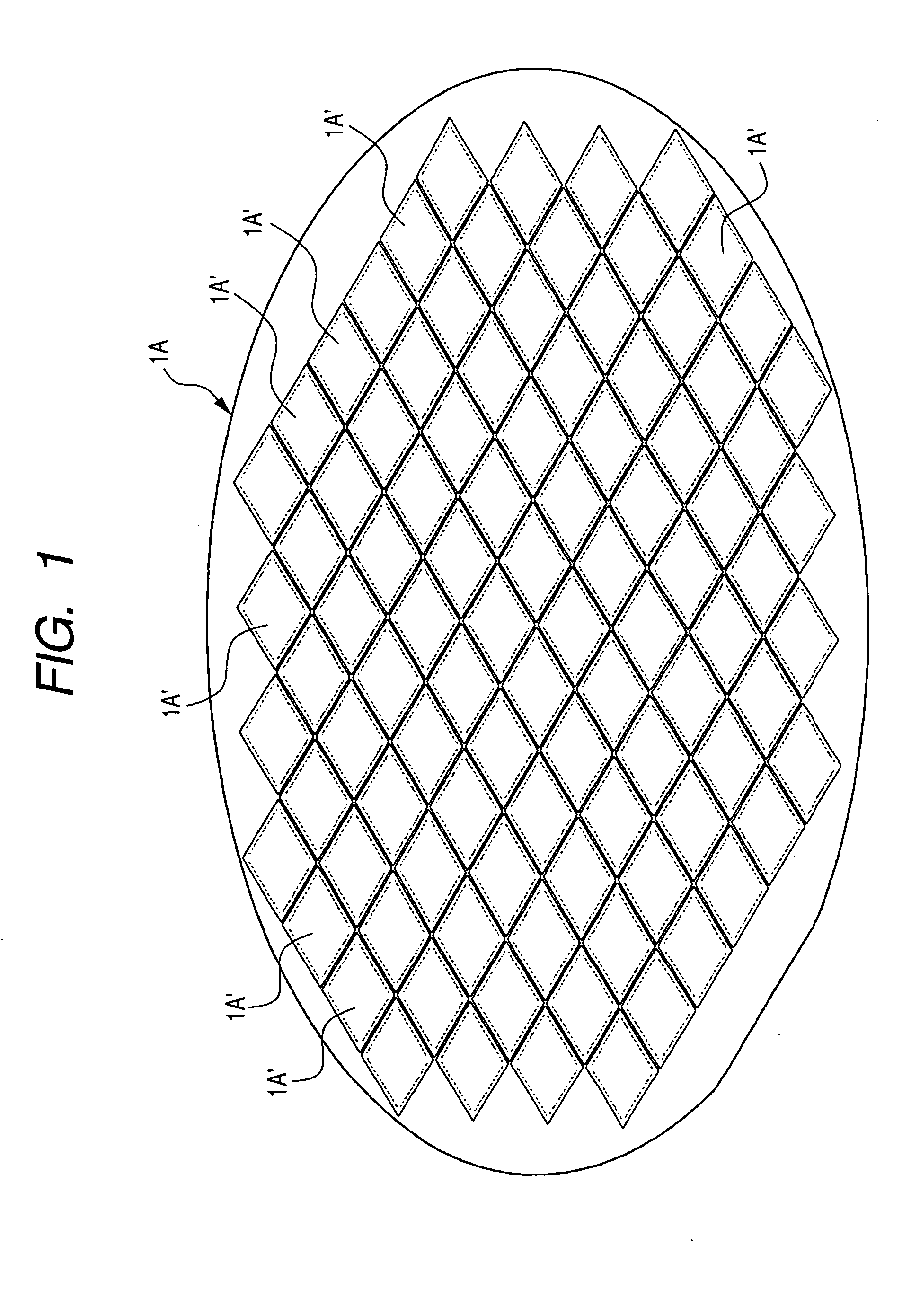

The method for producing a semiconductor chip with an adhesive film of the present invention comprises steps of preparing a laminate in which at least a divided semiconductor wafer comprising a plurality of semiconductor chips, obtained by forming a cut which separates the semiconductor wafer into a plurality of semiconductor chips on one side of the semiconductor wafer in a thickness less than that of the semiconductor wafer and by grinding the other side of the semiconductor wafer on which no cut is formed to reach the cut, an adhesive film for a semiconductor and a dicing tape are laminated, the adhesive film for a semiconductor having a thickness in the range of 1 to 15 μm and a tensile elongation at break of less than 5%, and the tensile elongation at break being less than 110% of the elongation at a maximum load; and dividing the adhesive film for a semiconductor by picking up the plurality of semiconductor chips in a laminating direction of the laminate, thereby preparing a semiconductor chip with an adhesive film.

Owner:RESONAC CORP

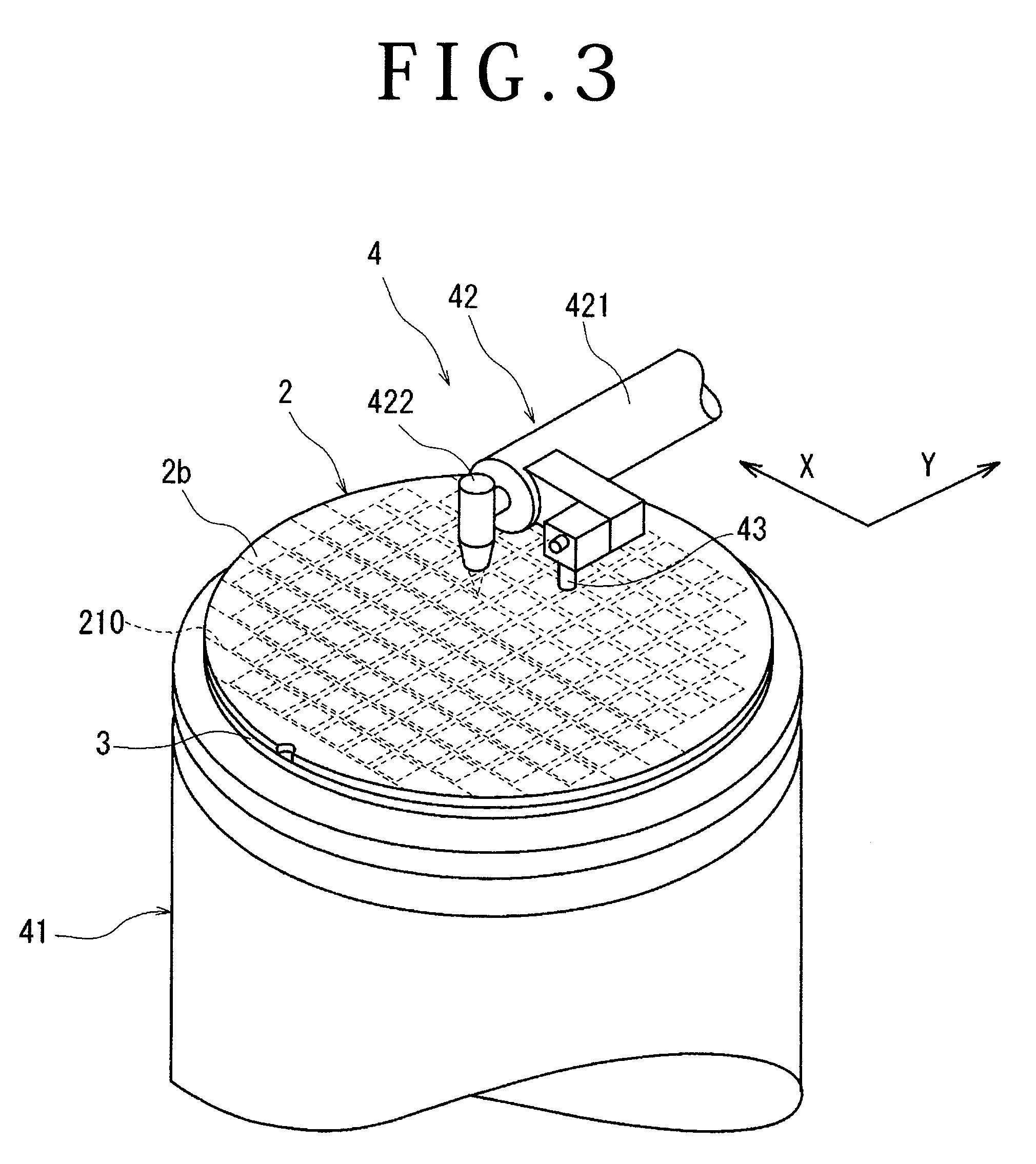

Method of dividing wafer

ActiveUS20090142906A1Semiconductor/solid-state device manufacturingDicing tapeElectrical and Electronics engineering

A method of dividing a wafer includes: a denatured layer forming step of forming a denatured layer in the inside of the wafer along streets; a first feeding step in which the whole area of the wafer's back-side surface is suction held, and the wafer is mounted on a support base of a tape adhering unit, with the wafer's back-side surface on the upper side; a dicing tape adhering step of adhering a dicing tape to the wafer's back-side surface and an annular frame; a wafer reversing step of reversing the wafer and the annular frame face side back; a second feeding step of feeding said wafer and said annular frame to a tape expanding unit whole holding them by suction; a protective tape peeling step of peeling off a protective tape adhered to the wafer's face-side surface; and a wafer dividing step of expanding the dicing tape so as to divide the wafer along the streets along which the denatured layer has been formed.

Owner:DISCO CORP

Dividing method for wafer having film on the front side thereof

ActiveUS20090298263A1Reduce thicknessSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDicing tapeLength wave

A wafer dividing method for dividing a wafer having a film on the front side thereof. The wafer dividing method includes a modified layer forming step of applying a laser beam having a transmission wavelength to the substrate of the wafer from the front side thereof along the streets so that a focal point of the laser beam is set inside the substrate, thereby forming a modified layer in the substrate along each street, a film dividing step of applying a laser beam having an absorption wavelength to the film from the front side of the wafer along each street to thereby form a laser processed groove for dividing the film along each street, a back grinding step of grinding the back side of the substrate of the wafer to thereby reduce the thickness of the wafer to a predetermined thickness, a wafer supporting step of attaching the wafer to a dicing tape supported to an annular frame, and a wafer breaking step of applying an external force to the wafer by expanding the dicing tape to thereby break the wafer along each street.

Owner:DISCO CORP

Method of processing optical device wafer

ActiveUS20100041210A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDicing tapeEngineering

A method of dividing an optical device wafer includes: a laser beam processing step of performing laser beam processing on the face side of an optical device wafer so as to form breakage starting points along streets; a protective plate bonding step of bonding the face side of the optical device wafer to a surface of a highly rigid protective plate with a bonding agent permitting peeling; a back side grinding step of grinding the back side of the optical device wafer so as to form the optical device wafer to a finished thickness of optical devices; a dicing tape adhering step of adhering the back-side surface of the optical device wafer to a dicing tape; a cut groove forming step of cutting the protective plate bonded to the optical device wafer along the streets so as to form cut grooves; and a wafer dividing step of exerting an external force on the optical device wafer through the protective plate, so as to break up the optical device wafer along the breakage starting points formed along the streets, thereby dividing the optical device wafer into the individual optical devices.

Owner:DISCO CORP

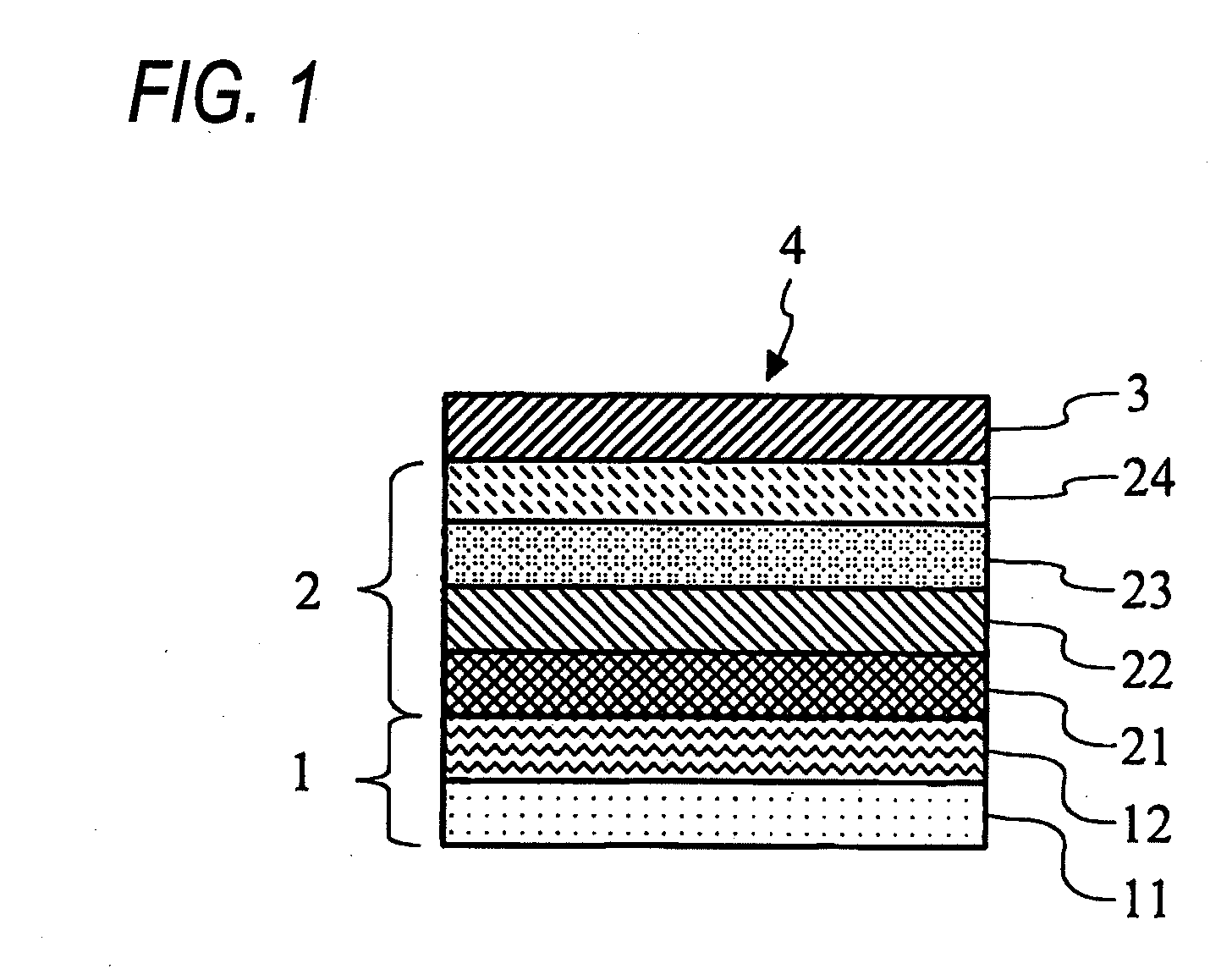

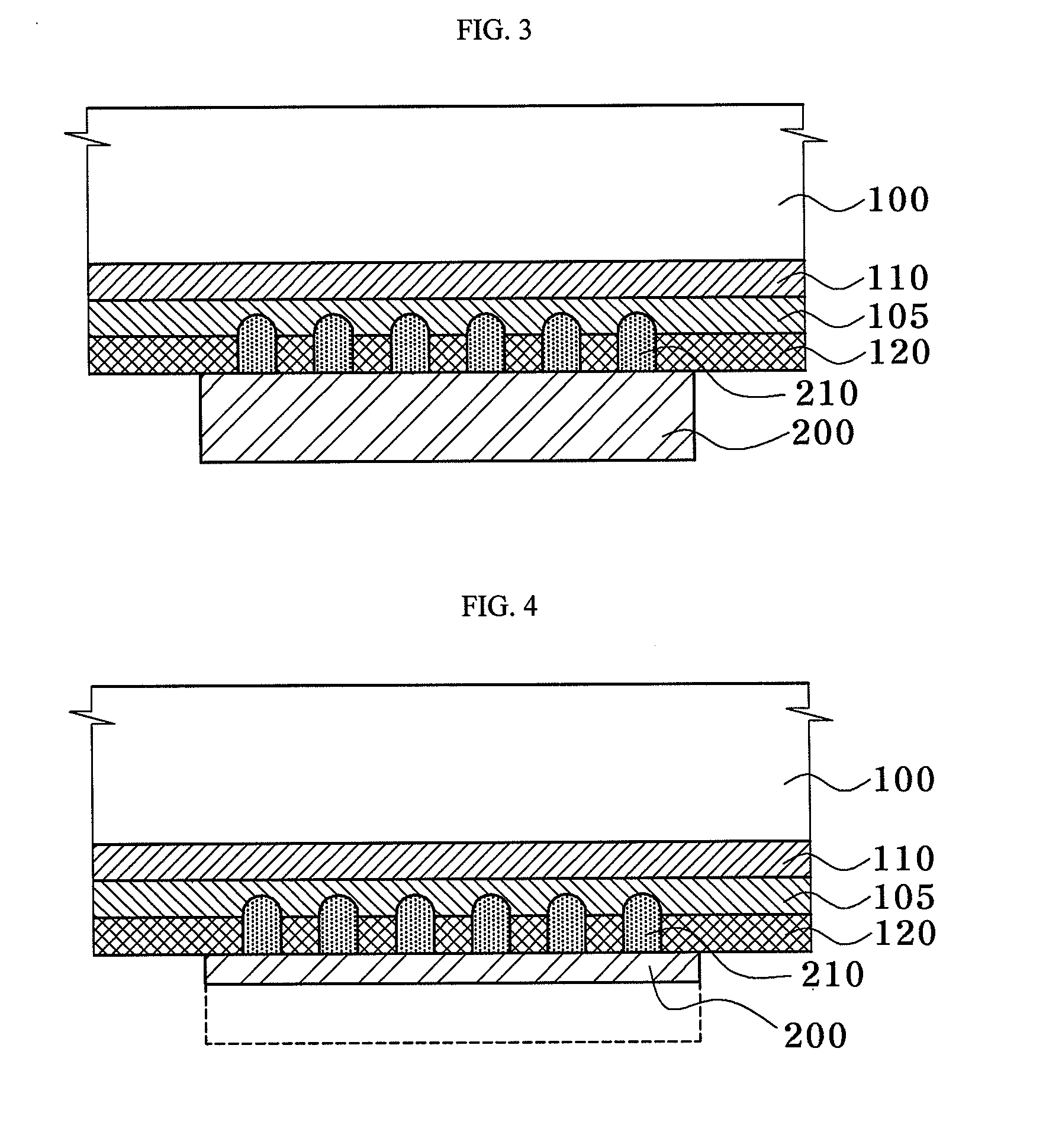

Dicing tape-integrated film for semiconductor back surface and method for producing the film, and method for producing semiconductor device

InactiveUS20120028380A1Easy to peelSmall sizeSemiconductor/solid-state device testing/measurementSolid-state devicesDicing tapeEngineering

The present invention relates to a dicing tape-integrated film for semiconductor back surface, which includes: a dicing tape including a base material having an asperities-formed surface, and a pressure-sensitive adhesive layer laminated on the base material, and a film for semiconductor back surface laminated on the pressure-sensitive adhesive layer of the dicing tape, in which the dicing tape has a haze of at most 45%.

Owner:NITTO DENKO CORP

Film for the backside of flip-chip type semiconductor, dicing tape-integrated film for the backside of semiconductor, method of manufacturing film for the backside of flip-chip type semiconductor, and semiconductor device

InactiveUS20120126380A1Lower manufacturing requirementsWithout deteriorating productivityFilm/foil adhesivesSemiconductor/solid-state device detailsProduction rateDicing tape

An electromagnetic wave shielding layer can be provided on the backside of a semiconductor element that is flip-chip connected to an adherend, and a semiconductor device having the electromagnetic wave shielding layer can be manufactured without deteriorating productivity. The present invention provides a film for the backside of a flip-chip type semiconductor to be formed on the backside of a semiconductor element that is flip-chip connected to an adherend, having an adhesive layer and an electromagnetic wave shielding layer.

Owner:NITTO DENKO CORP

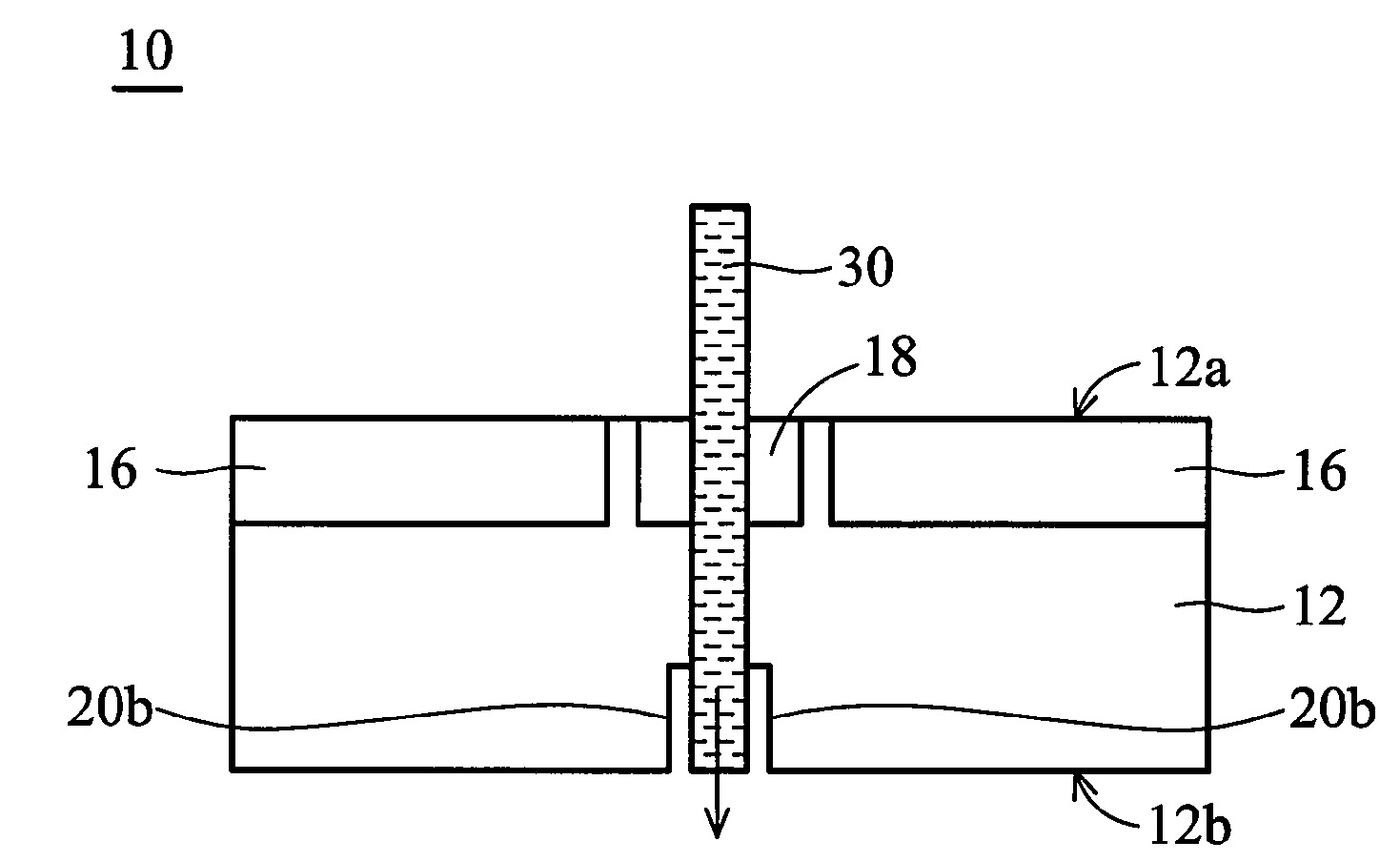

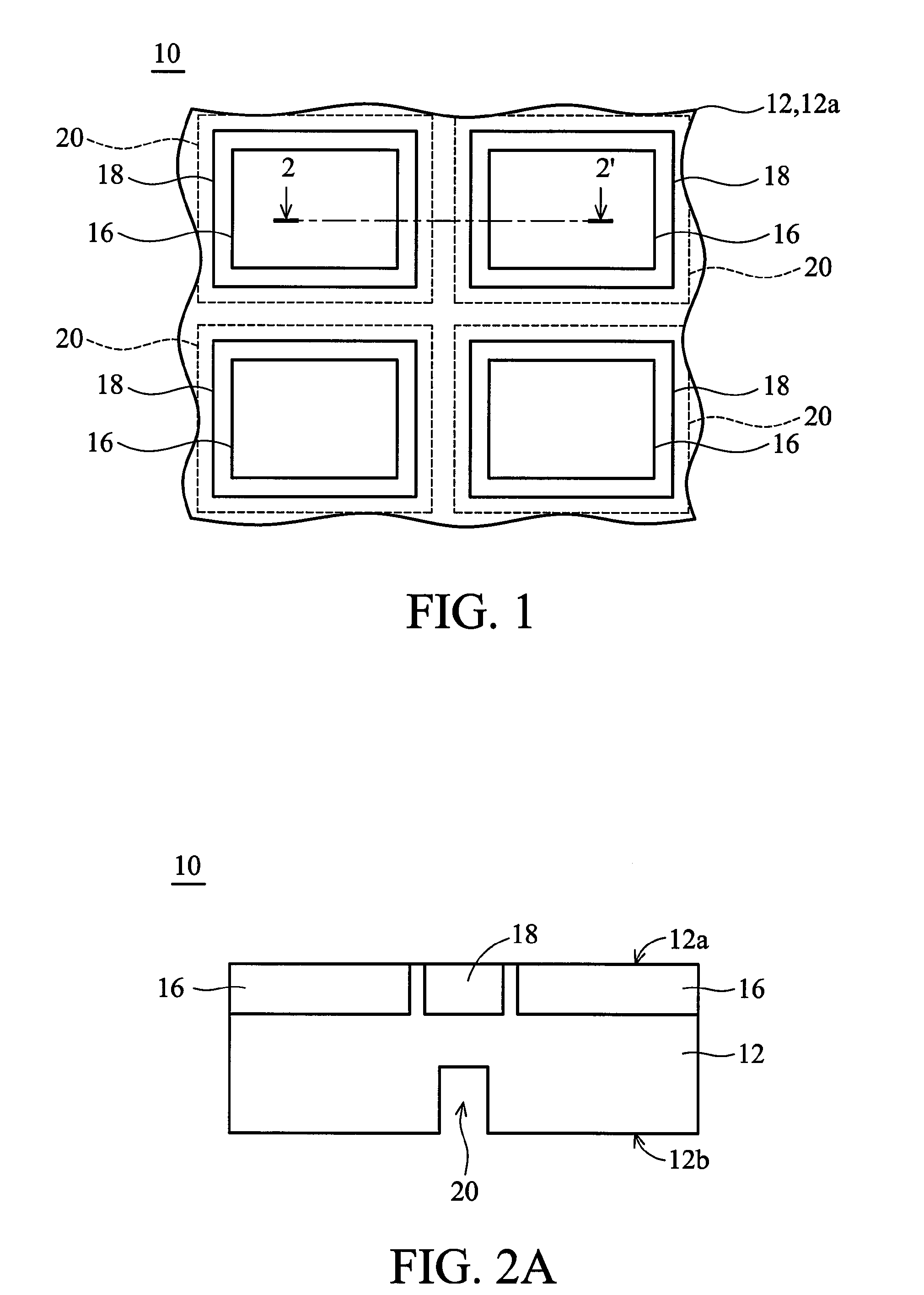

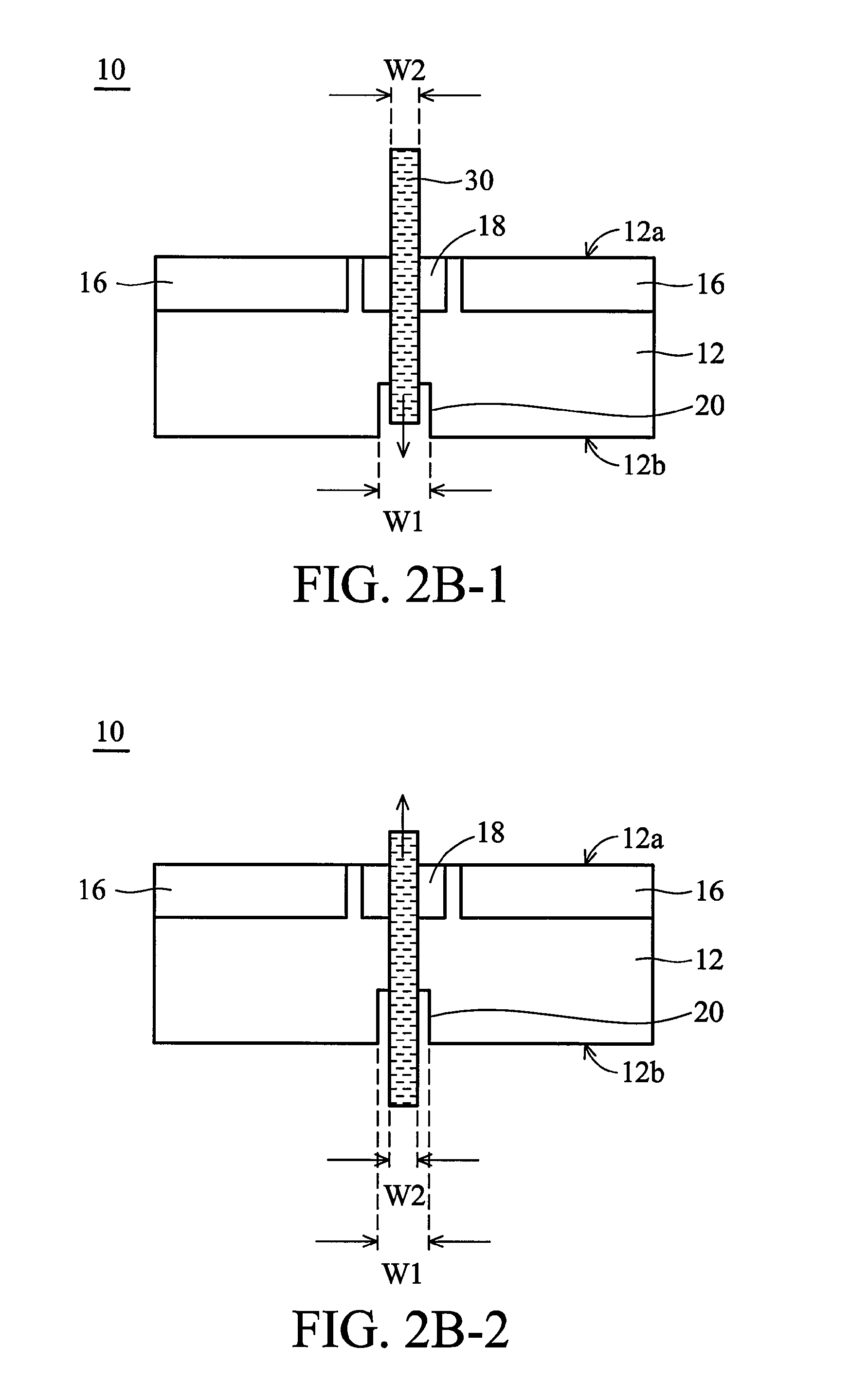

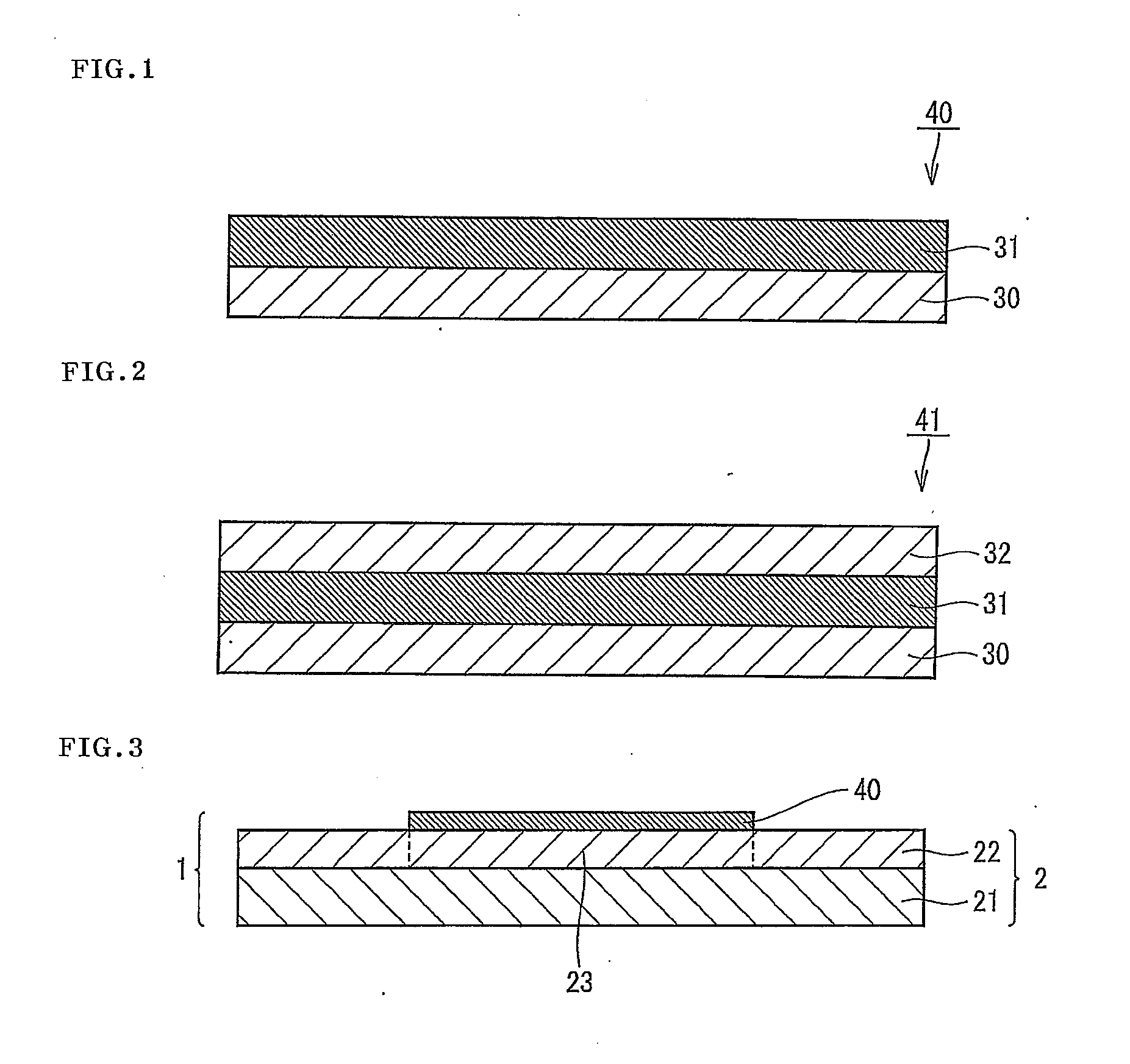

Production method of semiconductor device and bonding film

ActiveUS20100003771A1No pollution in the processPollution-free singulated semiconductor chipSemiconductor/solid-state device testing/measurementSolid-state devicesAdhesiveDicing tape

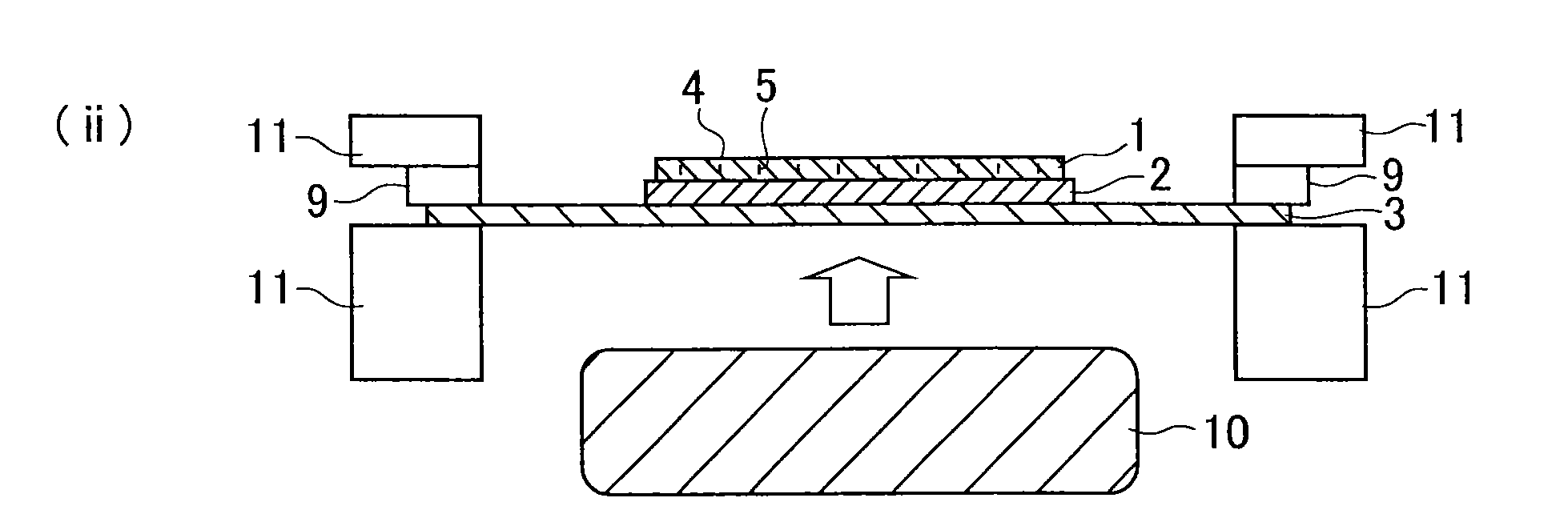

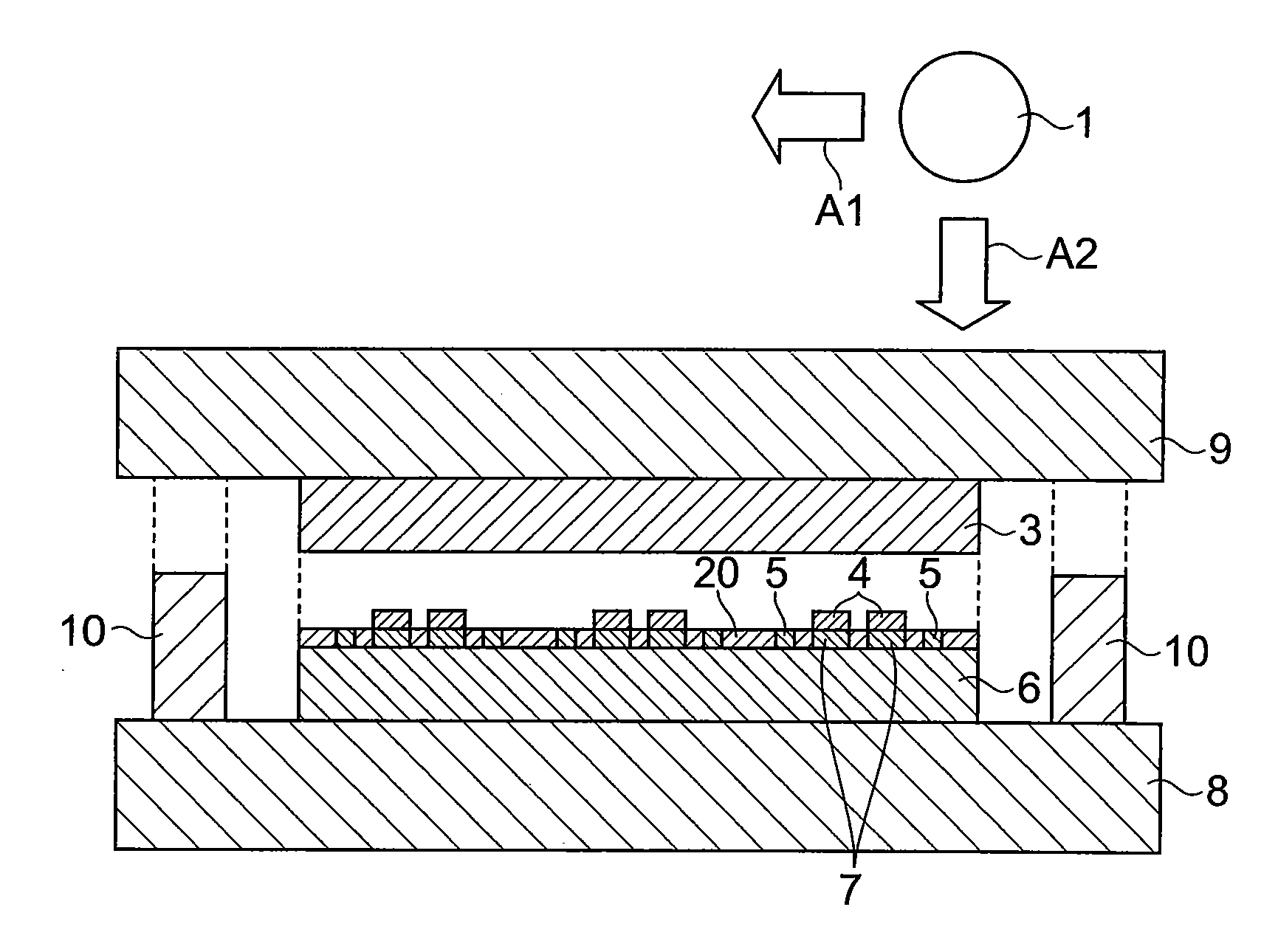

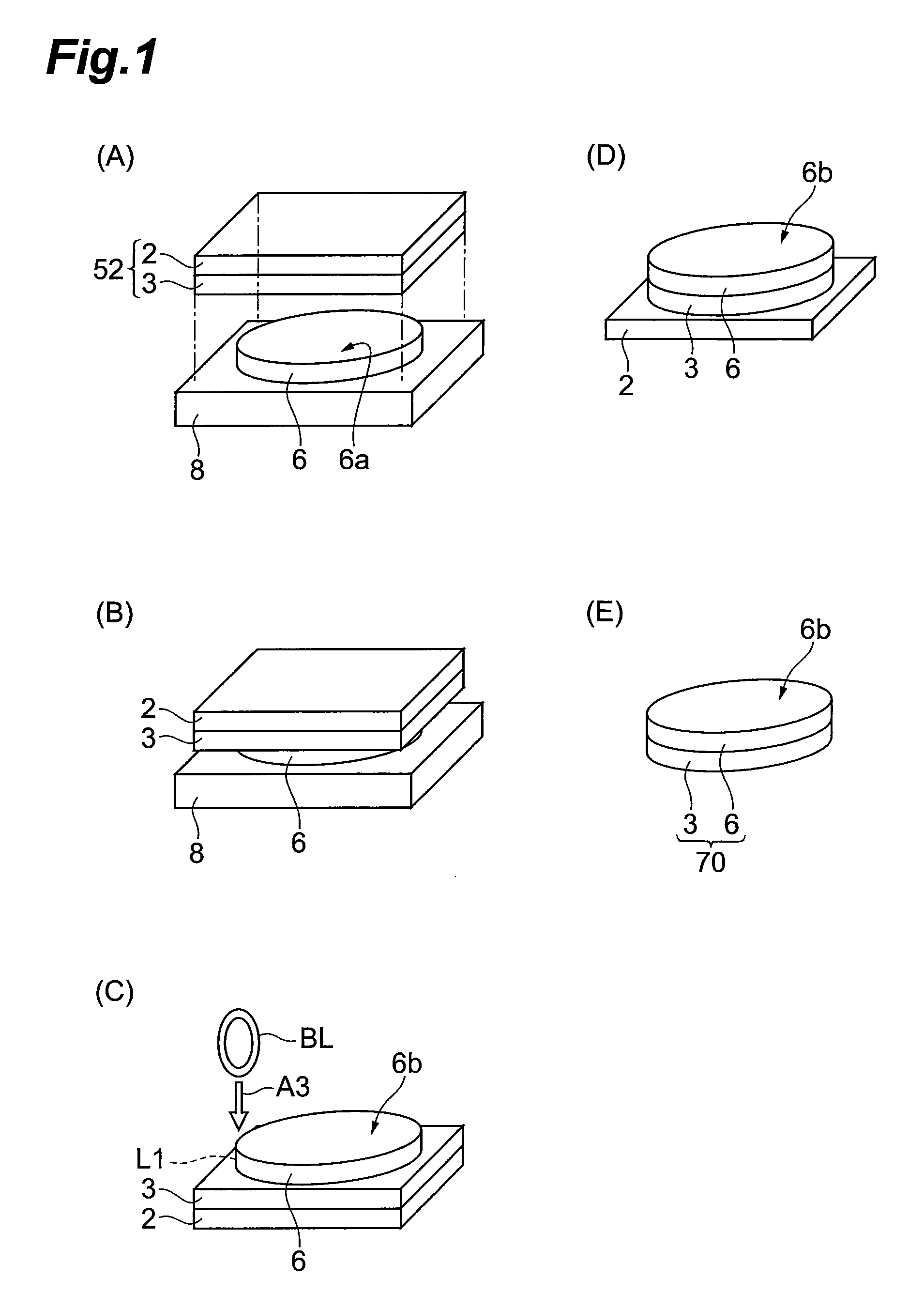

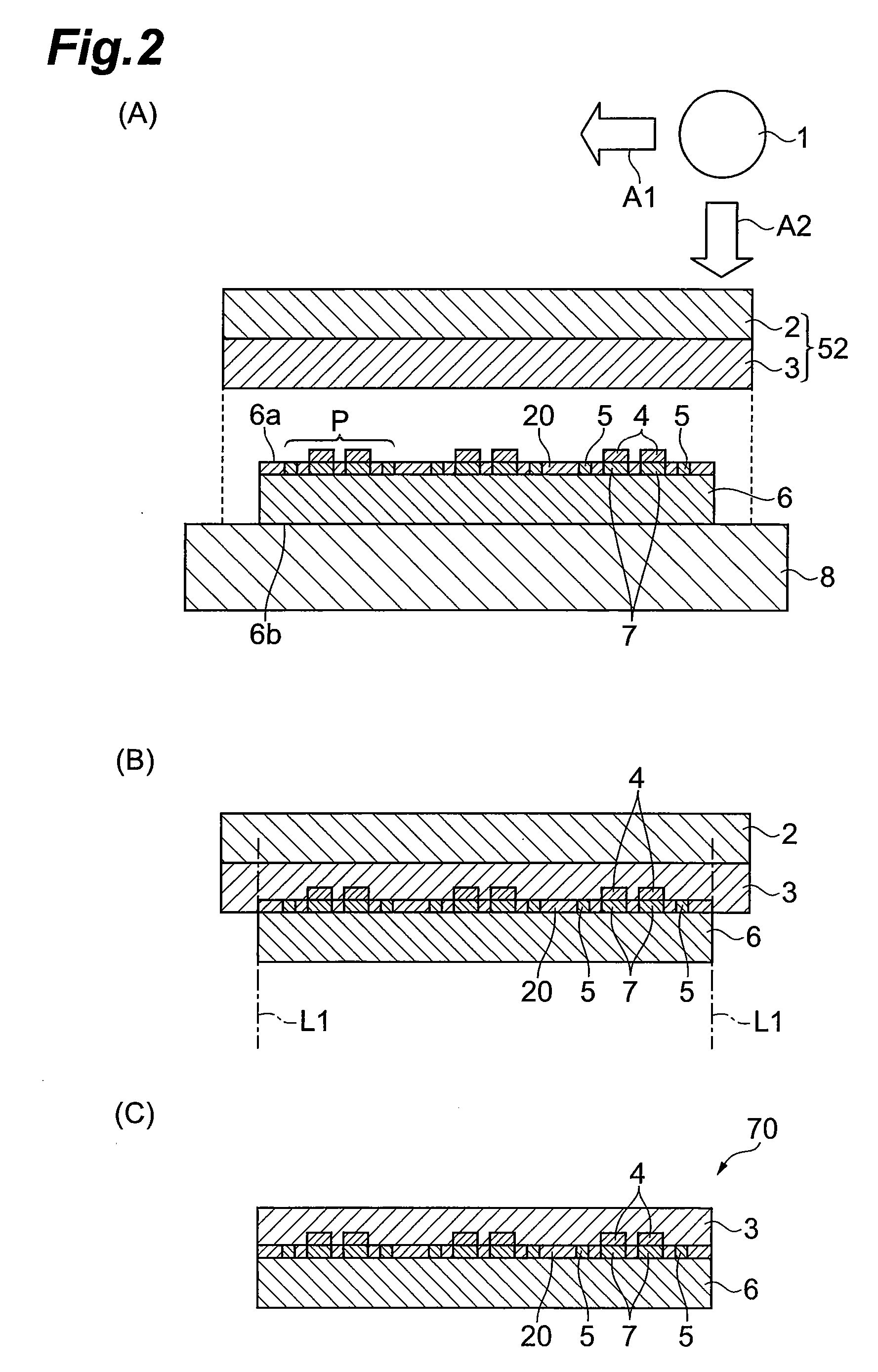

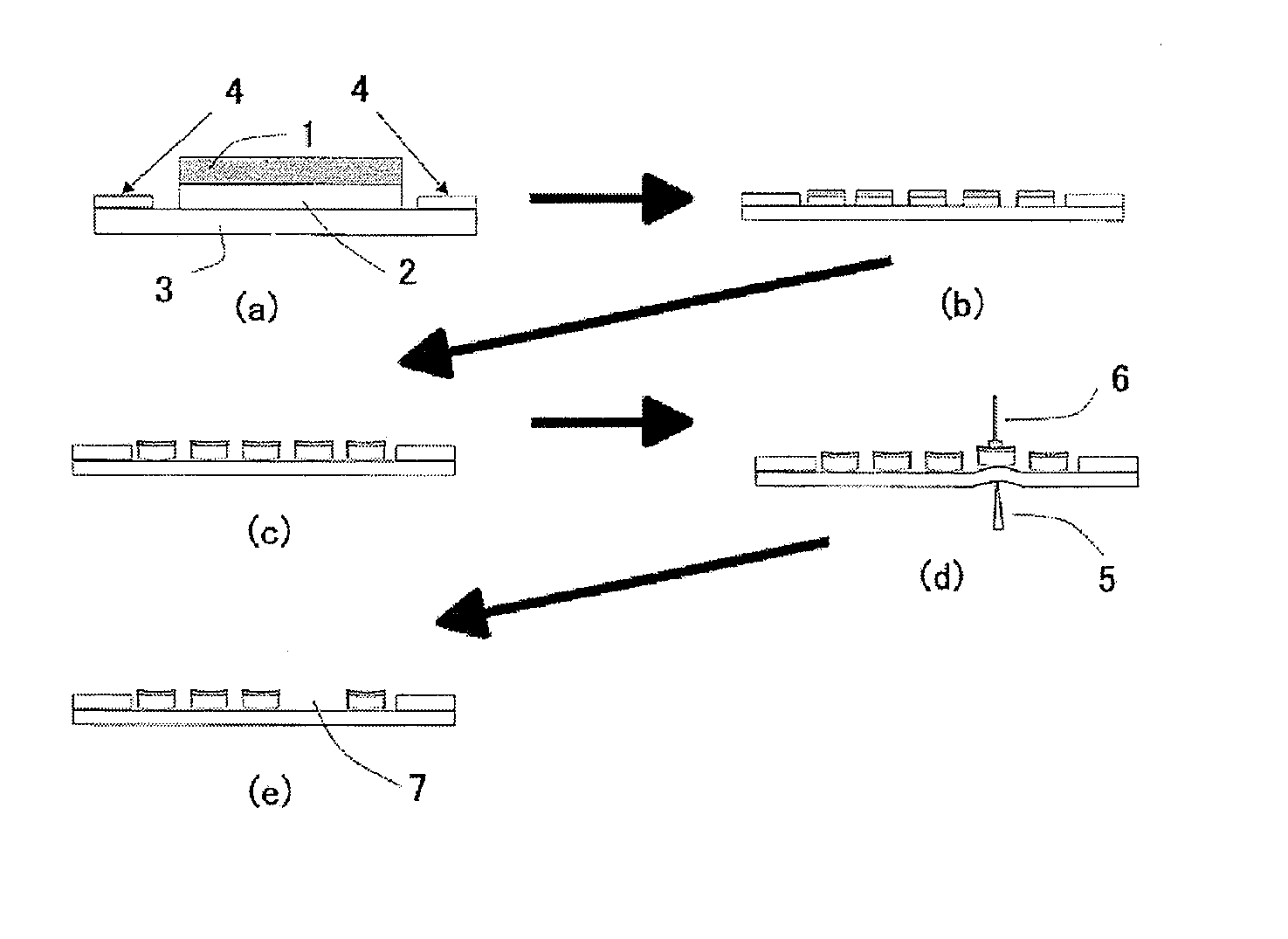

To provide a method of manufacturing semiconductor devices, the method being capable of efficiently obtaining a singulated semiconductor chip upon which an adhesive is adhered and also capable of excellently bonding a semiconductor chip to a wiring substrate, and provide an adhesive film. A layered product 60 in which a dicing tape 9, an adhesive layer 3, and a semiconductor wafer 6 are stacked in this order so that a circuit surface 6a of the semiconductor wafer 6 may face the dicing tape 9 side. A cutting position is recognized by recognizing a circuit pattern P in the circuit surface 6a from a rear surface 6b of the semiconductor wafer 6. At least the semiconductor wafer 6 and the adhesive layer 3 are cut in the thickness direction of the layered product 60. The dicing tape 9 is cured to peel off the dicing tape 9 and the adhesive layer 3. A projection electrode 4 of a semiconductor chip 26 is aligned with a wiring 12 of a wiring substrate 40. The wiring substrate 40 and the semiconductor chip 26 are bonded via an adhesive layer 23 so that the wiring 12 and the projection electrode 4 may be electrically connected to each other.

Owner:RESONAC CORP

Method for processing wafer

InactiveUS20110237050A1Facilitate strippingReduce adhesionSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

The present invention provides a method which includes sticking a surface protection sheet for dicing onto a surface of a wafer and cutting the sheet together with the wafer to protect the surface of the wafer from being contaminated by deposition of a dust such as swarf and the like, and picking up a chip without causing cracking or chipping in the chip after a dicing step, in the steps of dicing the wafer and then picking up the chip. The method includes: sticking the surface protection sheet for dicing onto the surface of the wafer; cutting the sheet together with the wafer; subsequently giving a stimulus to the surface protection sheet for dicing to peel the end of the chip from the dicing tape; and then picking up the chip.

Owner:NITTO DENKO CORP

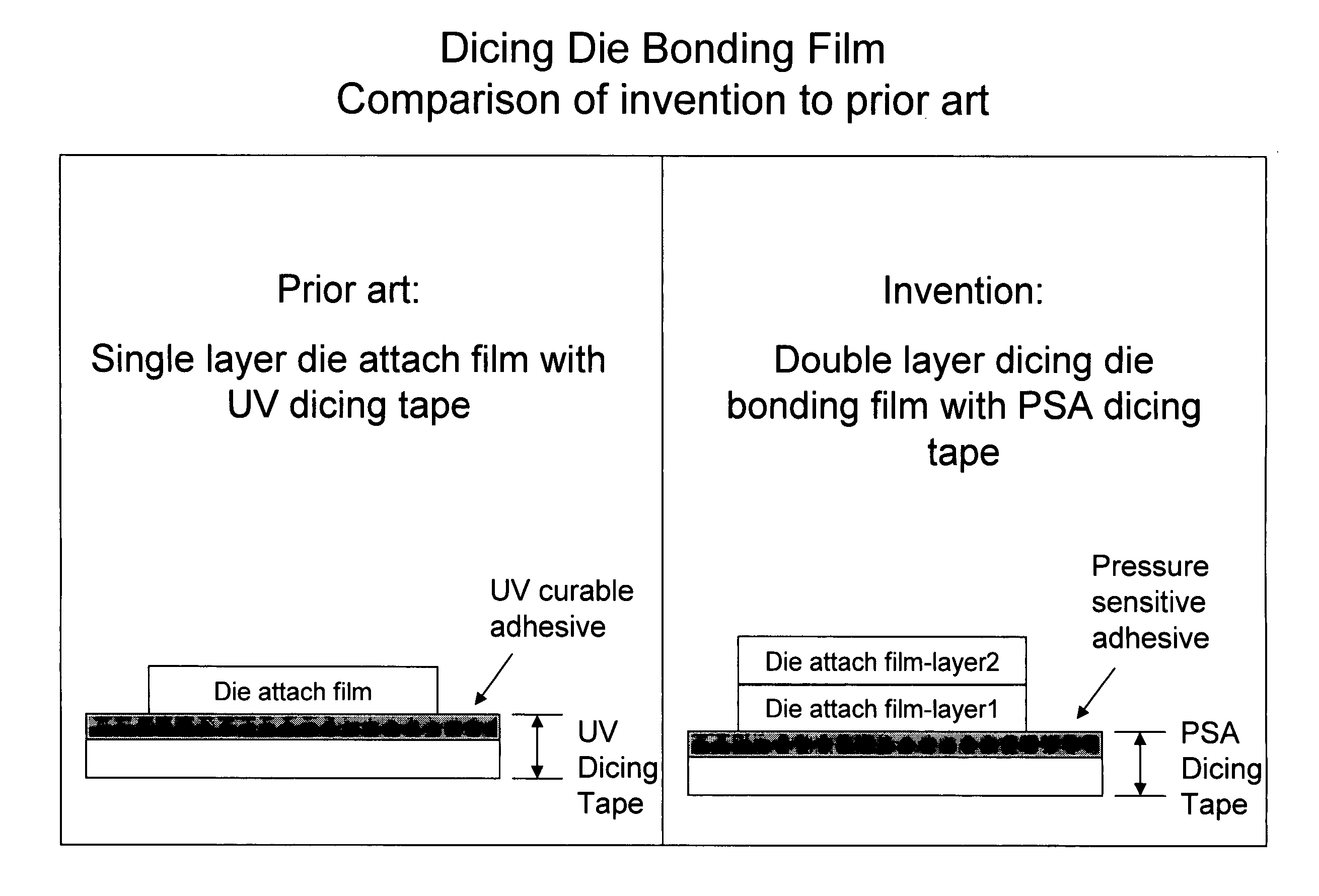

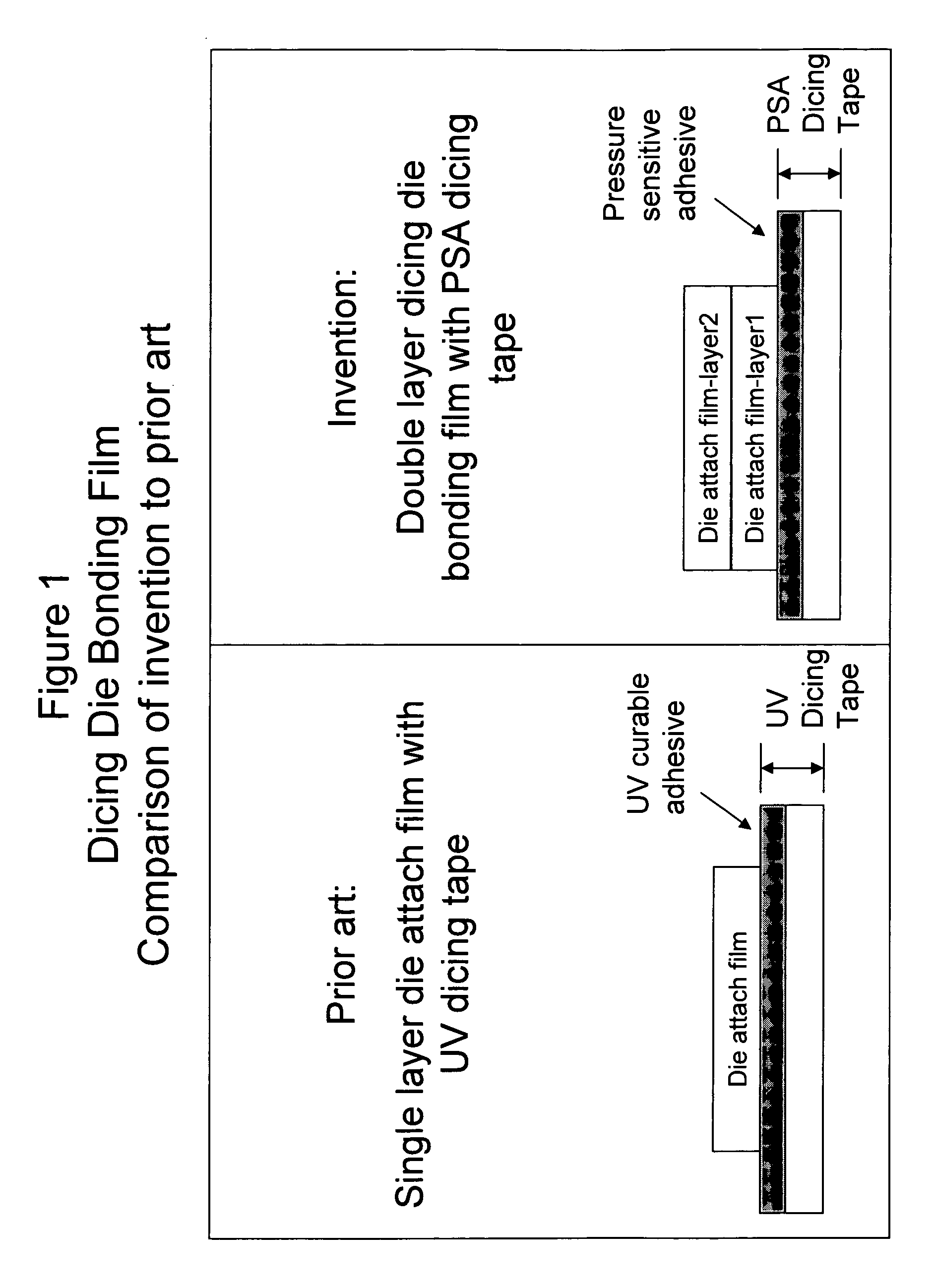

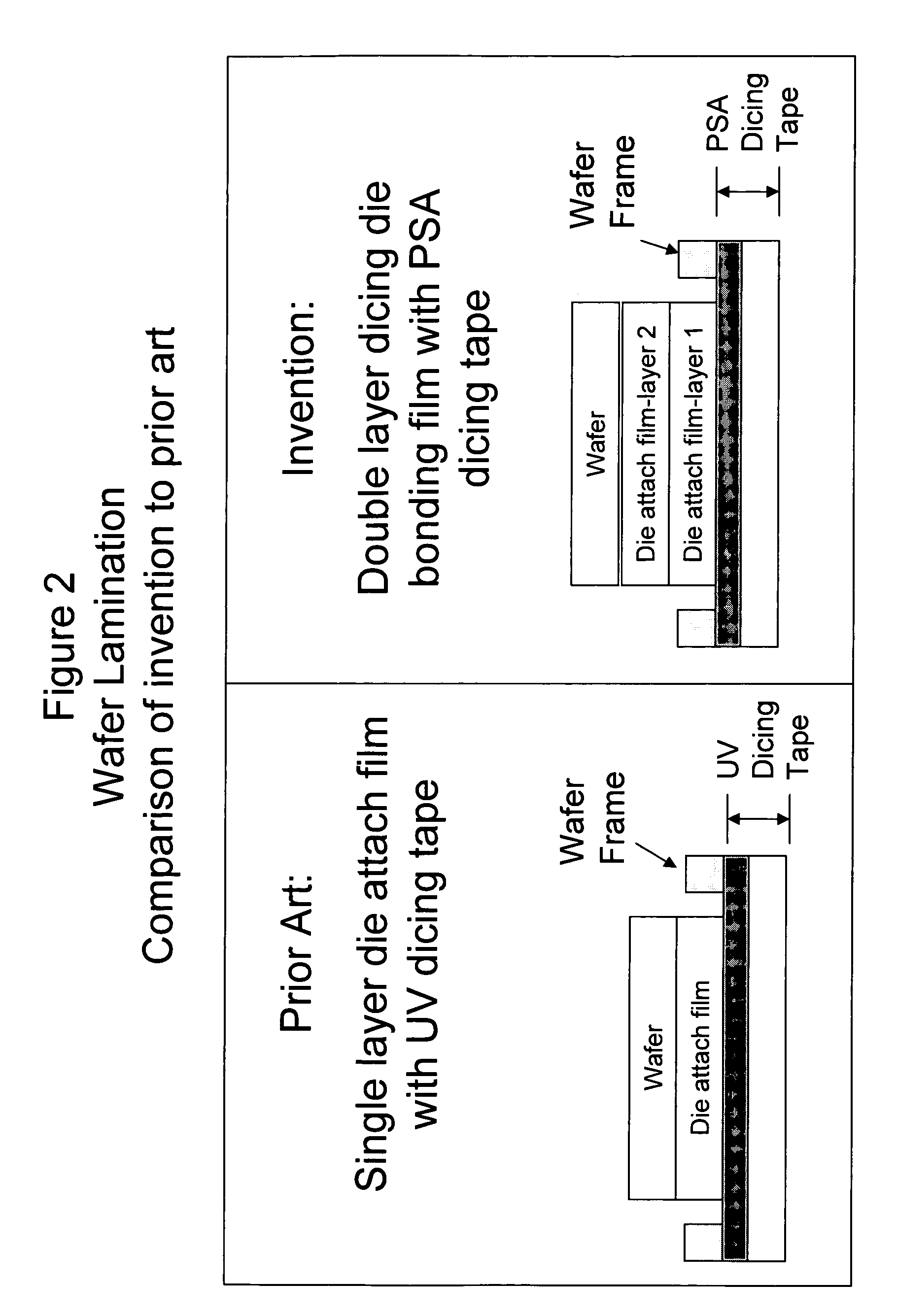

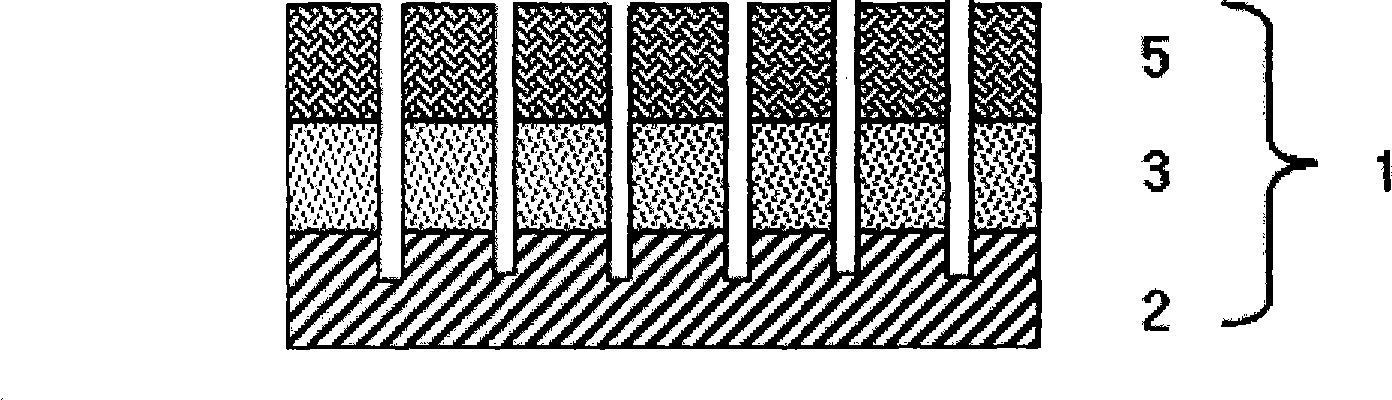

Dicing die bonding film

InactiveUS20070003758A1Eliminate needCharacteristic peel strengthSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

A dicing die bonding adhesive film for disposition between a semiconductor silicon wafer and a dicing support tape comprises a Layer-1 adhesive, which comes in contact with the dicing tape, and a Layer-2 adhesive, which comes in contact with the silicon semiconductor wafer, in which the adhesion of Layer 2 to the silicon wafer is higher than the adhesion of Layer 1 to the dicing tape by at least 0.1 N / cm.

Owner:HENKEL KGAA

Photocurable composition for the formation of pressure-sensitive adhesive layer and dicing tape produced using the same

InactiveCN101376797ALow maximum peel strengthGood pickupNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer resinDicing tape

The present invention discloses a photocurable composition used for forming pressure sensitive adhesive layer. The photocurable composition comprises pressure sensitive adhesive binder, reactive acrylate, thermal curing agent and phtoinitiator. The pressure sensitive adhesive binder is composed of pressure sensitive adhesive polymer resin and low molecular weight acrylate which comprises carbon-carbon double bond and is led into side chain of pressure sensitive adhesive resin. The reactive acrylate comprises dimethyl cyclosiloxane unit in molecular chain. The invention also discloses a cutting rubber belt which comprises a pressure sensitive adhesive layer formed by the photocurable composition. When a thin wafer is installed on cutting rubber belt, cut and radiated by UV, no connection occurs. Therefore the maximum peeling strength between the pressure sensitive adhesive layer and thin wafer is quite low, and the collecting capability of thin wafer is excellent.

Owner:CHEIL IND INC

Method of cutting adhesive film on a singulated wafer backside

InactiveUS20090298264A1Avoid problemsShort and leakage is preventedSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeSemiconductor chip

On the back surface of the chip of which a front surface is formed with an electronic circuit, an adhesive film of a shape and dimensions corresponding to at least the back surface of the chip is adhered to obtain the semiconductor chip with the entire back surface covered with the adhesive film. Such a semiconductor chip is obtained by forming a division groove in the front surface of a semiconductor wafer to be divided into plural chips, grinding a back surface of the wafer until the division groove appears to divide the wafer into plural chips, adhering the adhesive film and a dicing tape on the entire back surface of the wafer, and stretching the dicing tape to cut the adhesive film along the division groove.

Owner:DISCO CORP

Multi-function tape for a semiconductor package and method of manufacturing a semiconductor device using the same

ActiveUS20100330780A1Semiconductor/solid-state device detailsSolid-state devicesDicing tapeDevice form

A multifunction tape for a semiconductor package and configured to bond to a device-formed side of a semiconductor substrate having a plurality of devices thereon while performing a process of grinding a side of the semiconductor substrate opposite to the device-formed side and a process of dicing the semiconductor substrate into individual chips with a dicing tape having a UV-curable adhesive layer bonded to the ground side of the semiconductor substrate, the multifunction tape being bonded to the individual chips while the individual chips, separated from each other by the dicing process, are picked up and die-attached and a method of manufacturing a semiconductor device using the same, the multifunction tape including a base film; a UV-curable adhesive layer on one side of the base film; and first and second bonding layers on the adhesive layer.

Owner:CHEIL IND INC

Wafer dividing method

InactiveUS20080280421A1Small thicknessFormed surelySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

A wafer dividing method that includes a modifying layer forming step in which a laser beam with a wavelength that can pass through the wafer is focused on the inside of the wafer from a rear surface side thereof, and applied along the street to form a modifying layer having a thickness corresponding to at least a device-finishing thickness from the front surface of the wafer; a rear surface grinding step in which an area, corresponding to the device area, of the rear surface of the wafer subjected to the modifying layer forming step is ground and formed to have a thickness corresponding to the device-finishing thickness and to have an annular reinforcing section at an area corresponding to the outer circumferential redundant area; a reinforcing section cutting step in which the wafer is cut along the inner circumference of the annular reinforcing section; a wafer support step in which the rear surface of the wafer whose annular reinforcing section is cut is stuck to a dicing tape attached to an annular frame; and a wafer rupture step in which an external force is applied to the wafer stuck to the dicing tape to rupture it along the street formed with the modifying layer.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com