Patents

Literature

37results about How to "Easy and efficient cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic knife

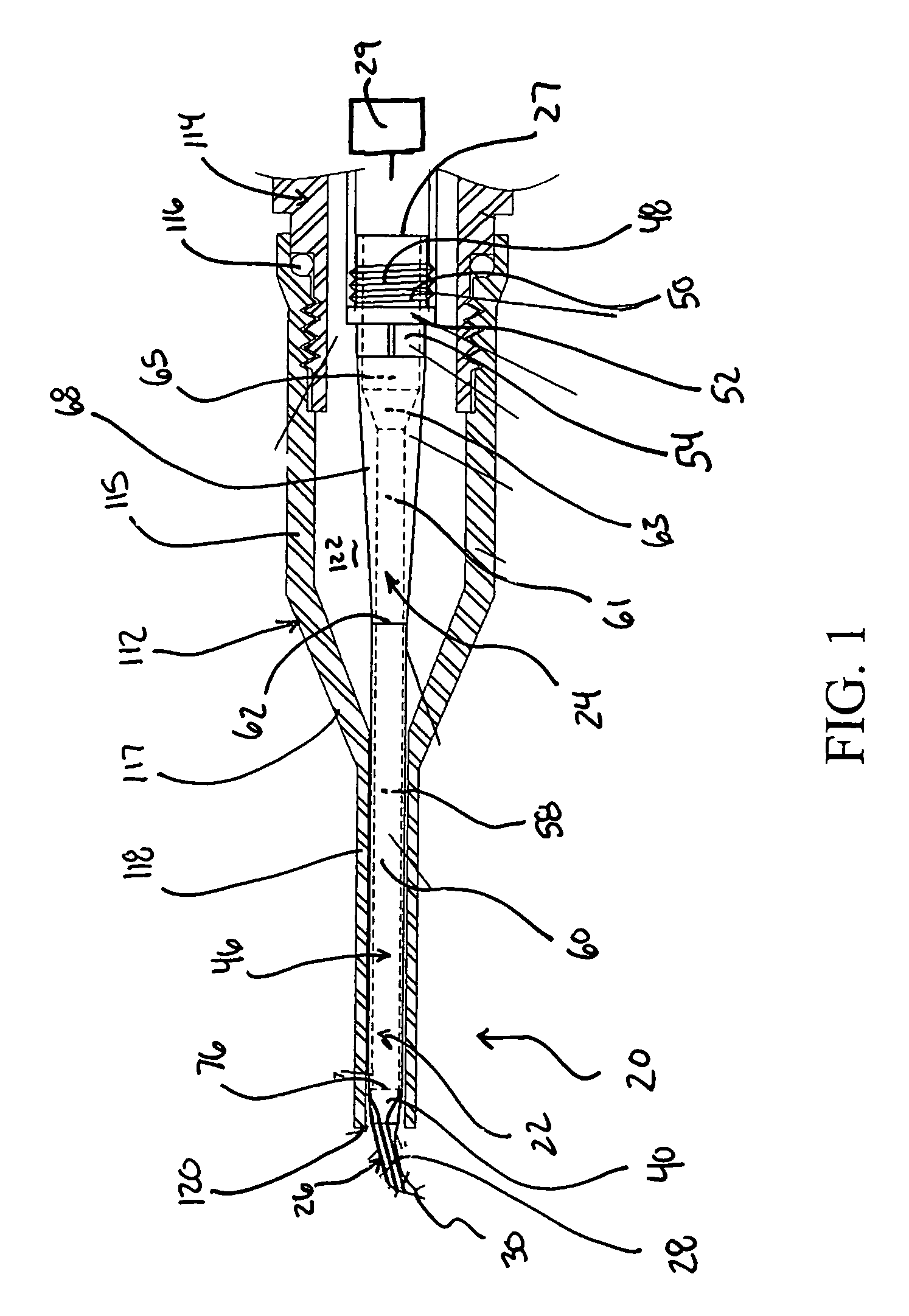

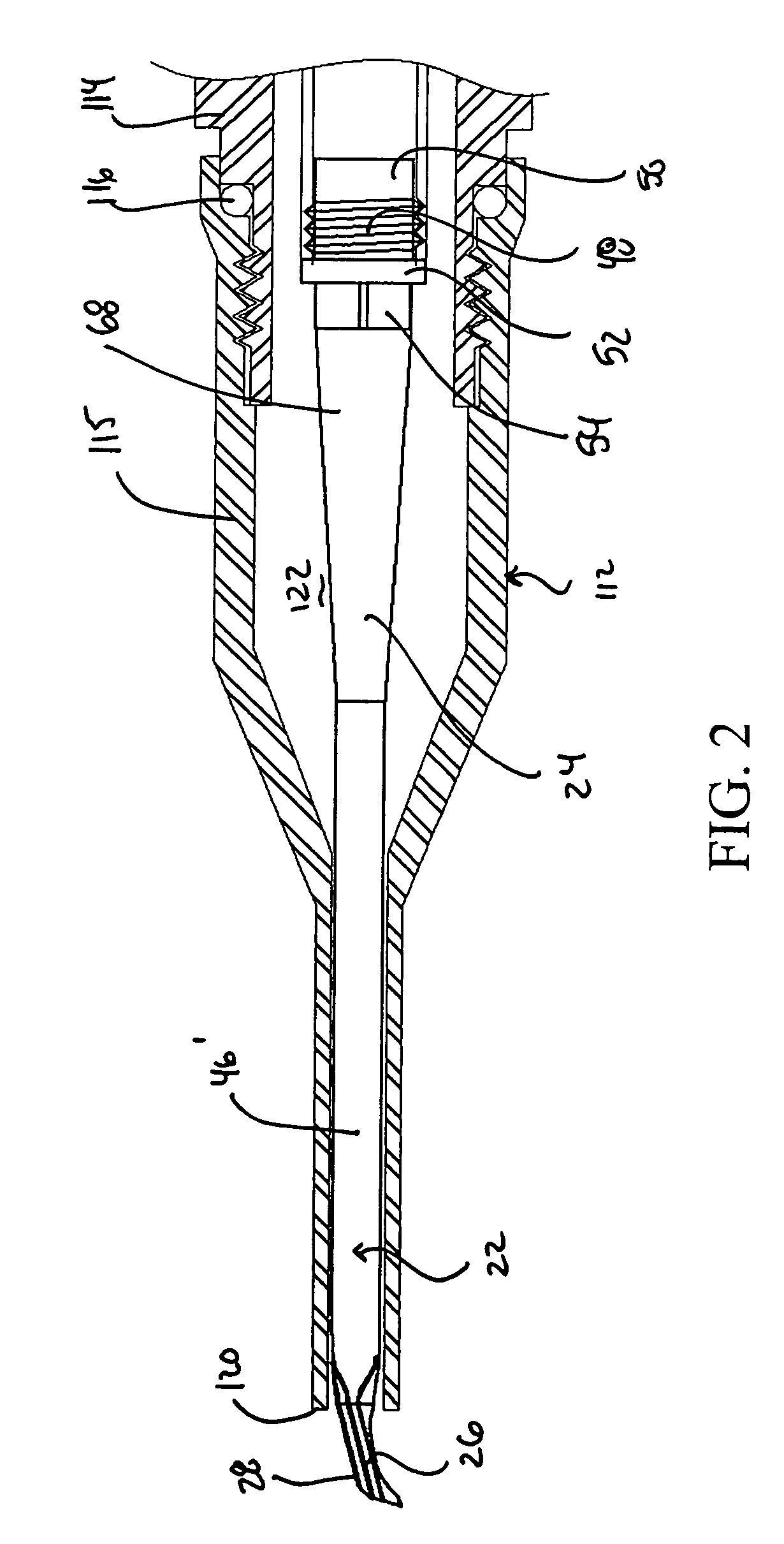

ActiveUS20070060926A1Promote capabilityLow possibilityIncision instrumentsEye surgeryEdge regionAerospace engineering

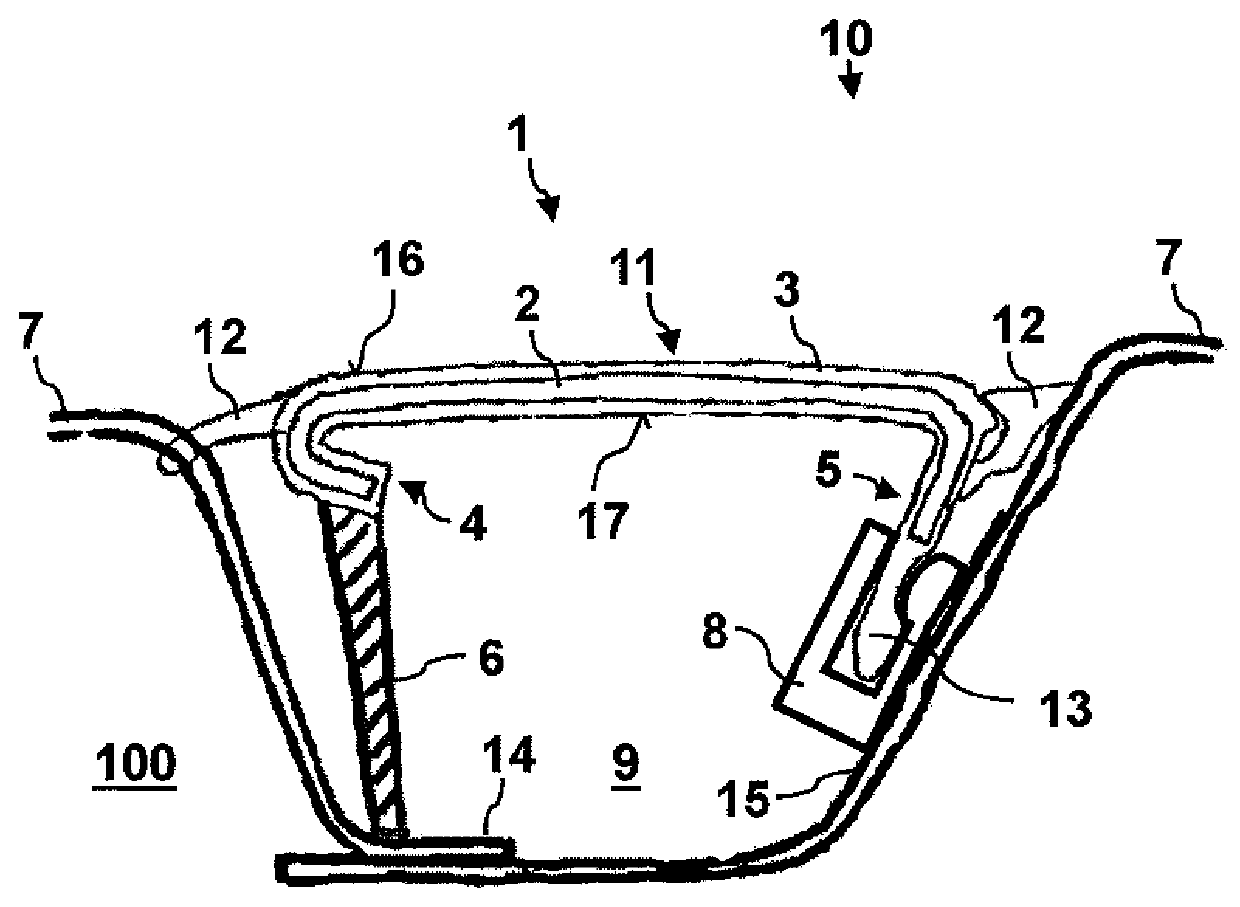

An ophthalmologic cutting device having a base support section for attachment with a movement generating device and a tip with a blade section. The blade section preferably has upper and lower edges, and a forward aspiration free edge extending between them, with the upper edge having a shorter longitudinal length compared with the lower edge and where the forward edge slopes down from a distal end of the upper edge to a distal end of the lower edge, and the lower edge presenting a material contact surface that is thinner in thickness than the upper edge. A slope back in the proximal direction of the forward edge of, for example, 10 to 45 degrees with a straight and / or curving forward edge or a combination of a straight and forward edge sections is preferred. Embodiments of the blade include a blade converging in thickness from top to bottom and one having a curved upper forward edge region and one with a lower edge that has a distal straight section and a recessed section positioned proximal of said distal straight section. The forward edge is also preferably defined by longitudinally diverging, opposing side walls.

Owner:ALCON INC

Ultrasonic knife

InactiveUS8016843B2Easy to useEasily and efficiently divideIncision instrumentsEye surgeryFree edgeEdge region

An ophthalmologic cutting device having a base support section for attachment with a movement generating device and a tip with a blade section. The blade section preferably has upper and lower edges, and a forward aspiration free edge extending between them, with the upper edge having a shorter longitudinal length compared with the lower edge and where the forward edge slopes down from a distal end of the upper edge to a distal end of the lower edge, and the lower edge presenting a material contact surface that is thinner in thickness than the upper edge. A slope back in the proximal direction of the forward edge of, for example, 10 to 45 degrees with a straight and / or curving forward edge or a combination of a straight and forward edge sections is preferred. Embodiments of the blade include a blade converging in thickness from top to bottom and one having a curved upper forward edge region and one with a lower edge that has a distal straight section and a recessed section positioned proximal of said distal straight section. The forward edge is also preferably defined by longitudinally diverging, opposing side walls.

Owner:ALCON INC

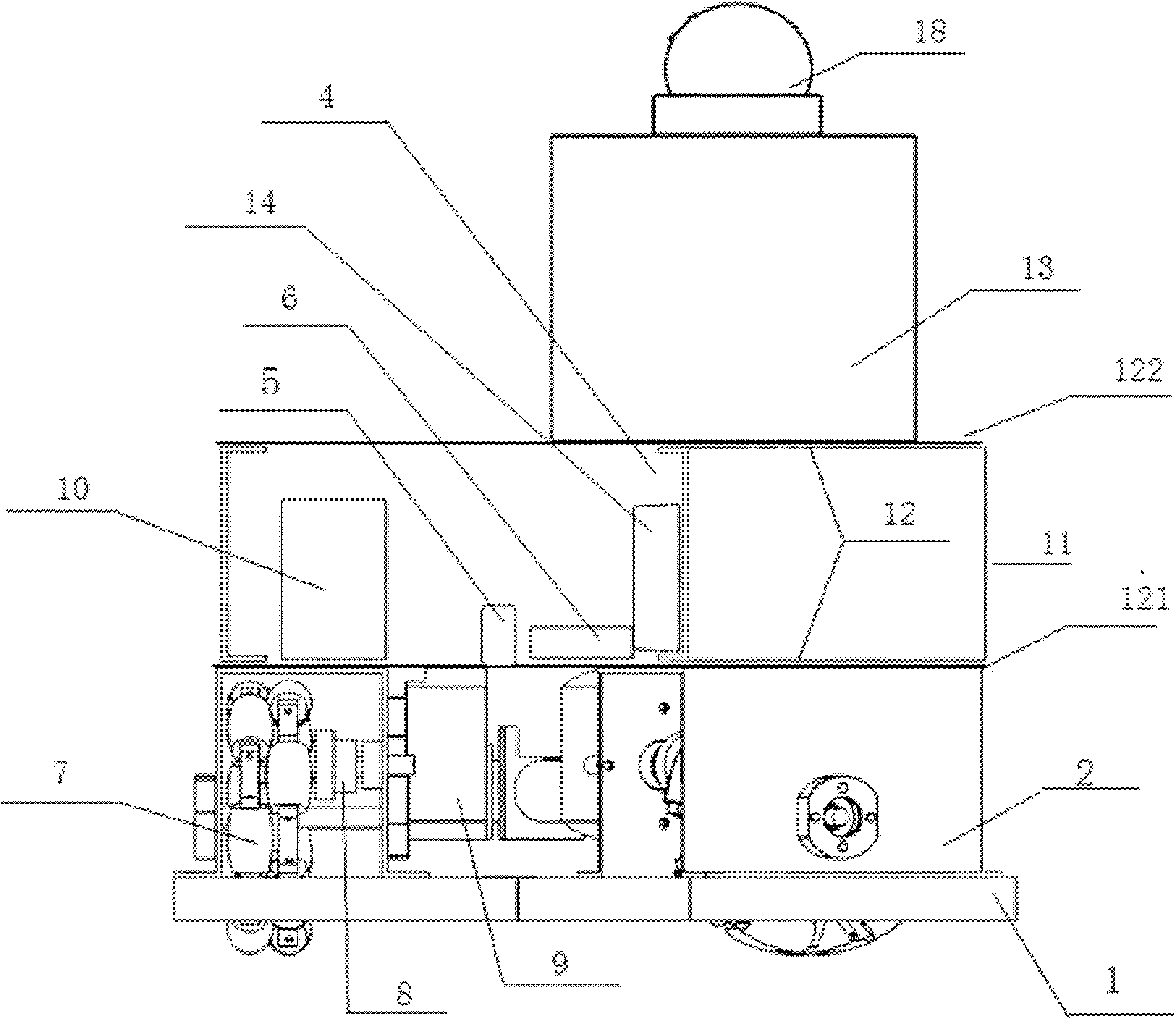

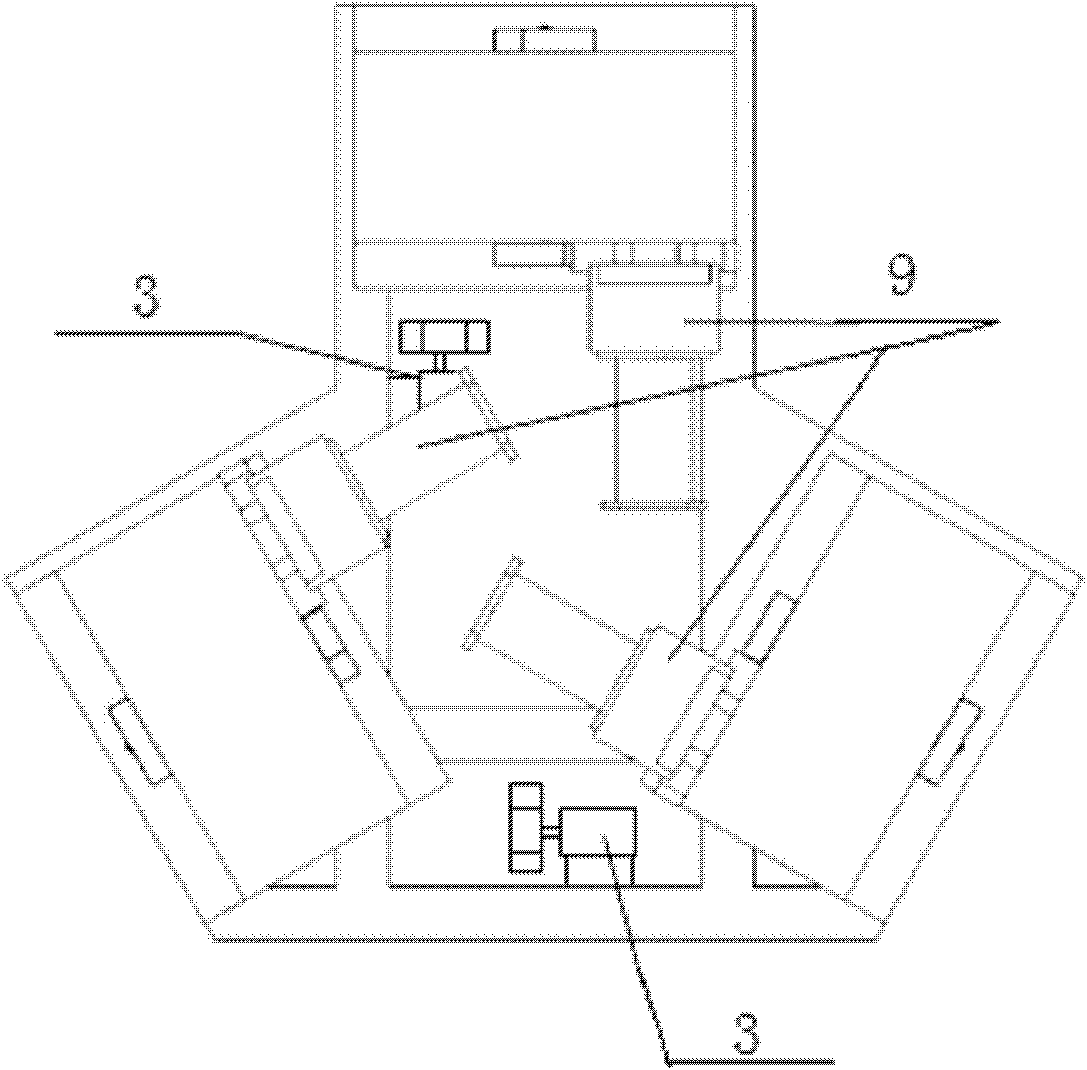

Multi-sensor information collection analyzing system and autism children monitoring auxiliary system

InactiveCN102176222AImprove environmental adaptabilityFlexiblePsychotechnic devicesSpecial data processing applicationsArea networkPhysical medicine and rehabilitation

The invention belongs to the field of robots, and relates to a multi-sensor information collection analyzing system, a robot device which performs real-time monitor and adjuvant treatment for autism children by using the system and a control technology of the robot device. In the multi-sensor information collection analyzing system, a plurality of sensors, collectors and information output equipment transmit communication information by adopting a controller area network (CAN) fieldbus, and the distribution type information fusion technology ensures that mounting and clipping of the equipmentto be more convenient and efficient. By adopting the multi-information fusion technology, the ways for the robot to collect interactive object emotions are increased, and the affinity and interactivesuccessful rate of human-machine interaction are improved.

Owner:UNIV OF SCI & TECH BEIJING

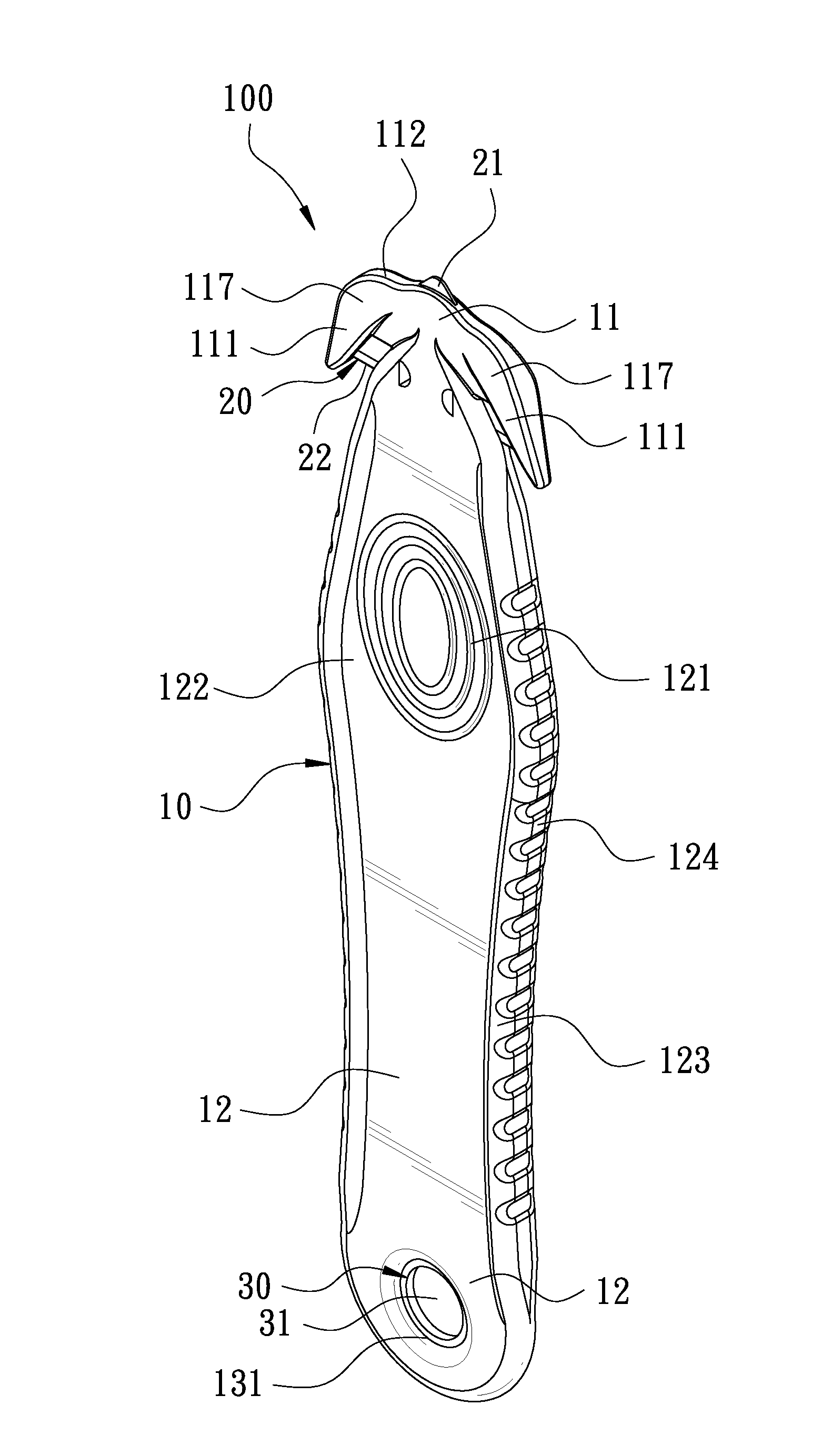

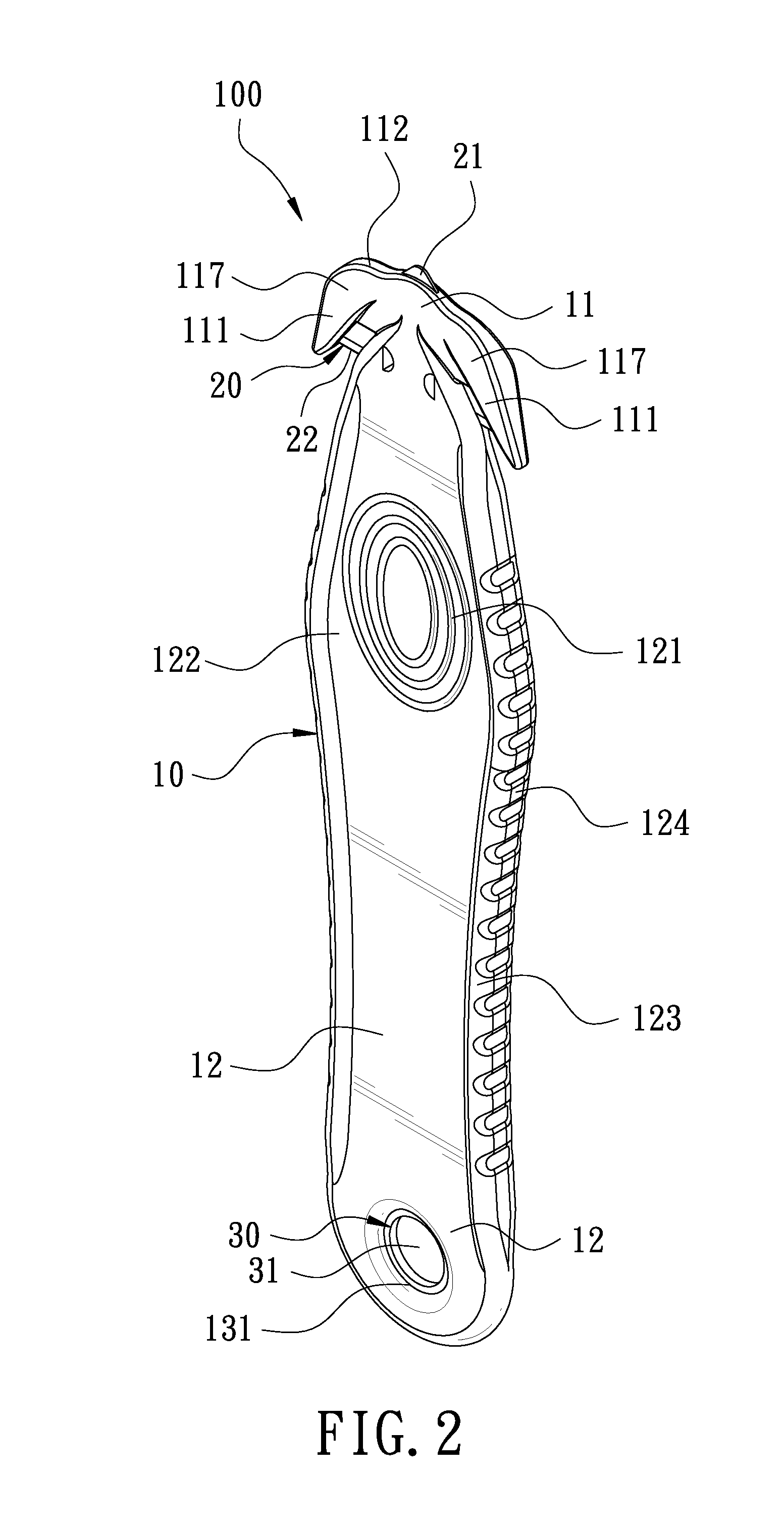

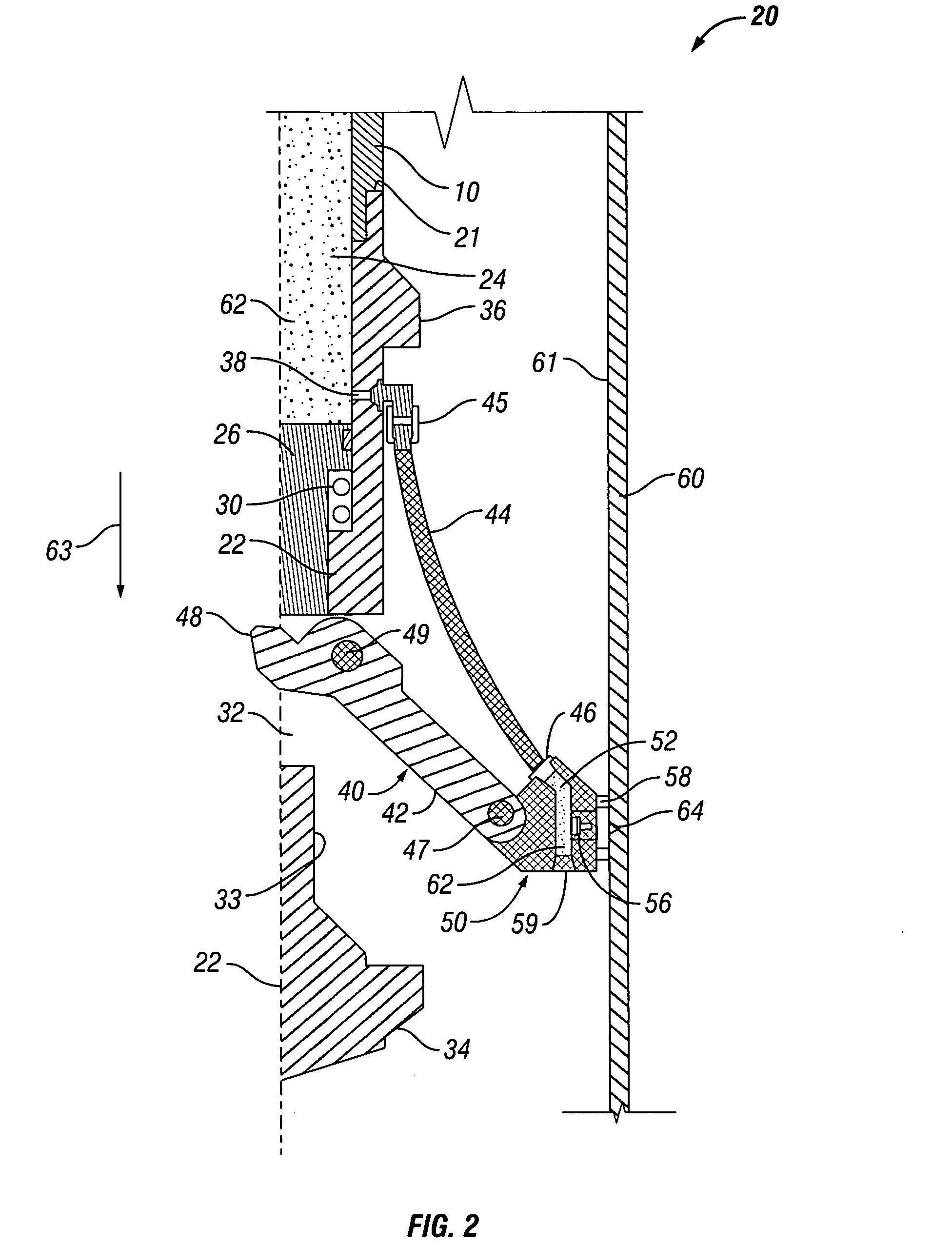

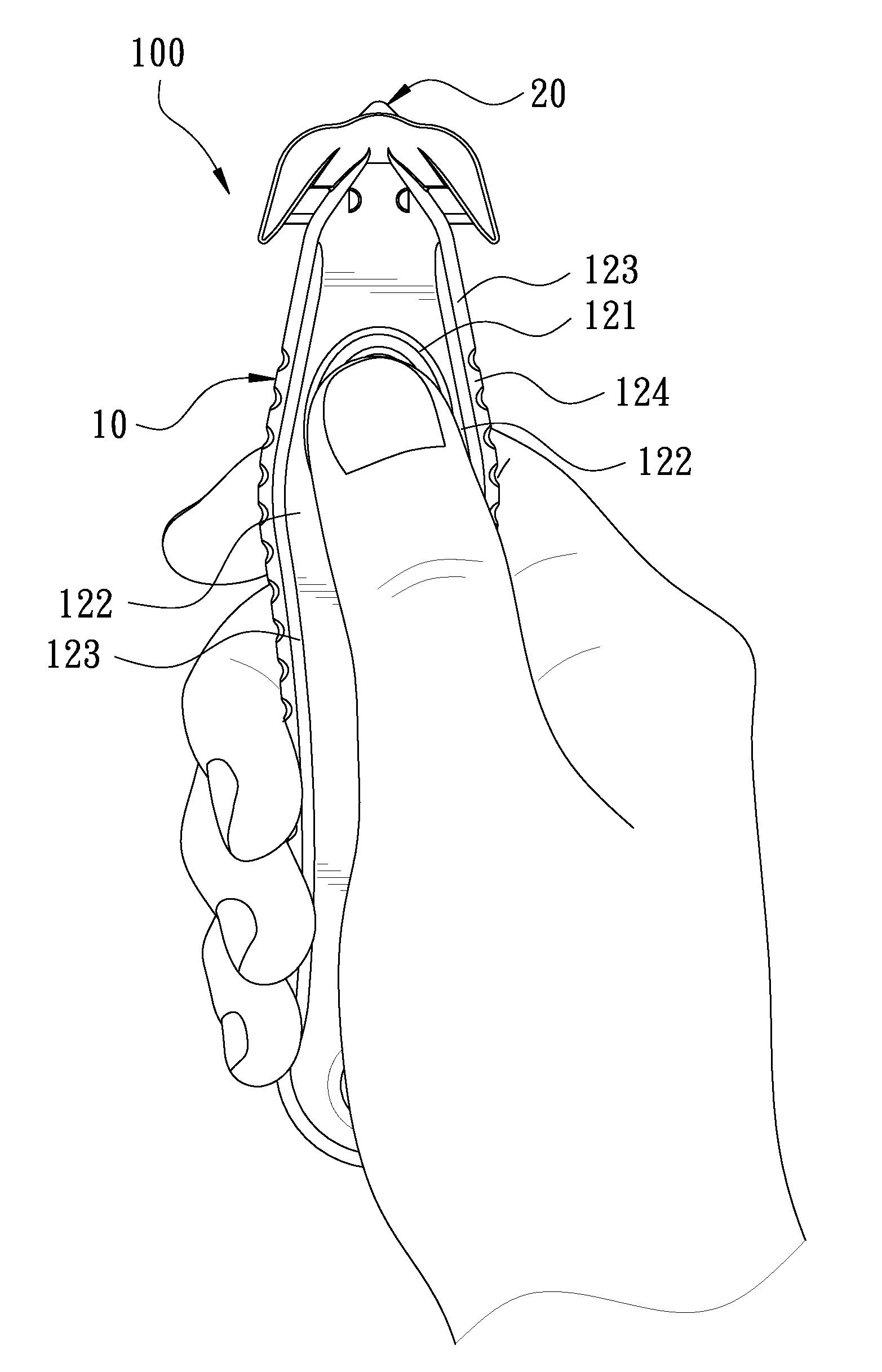

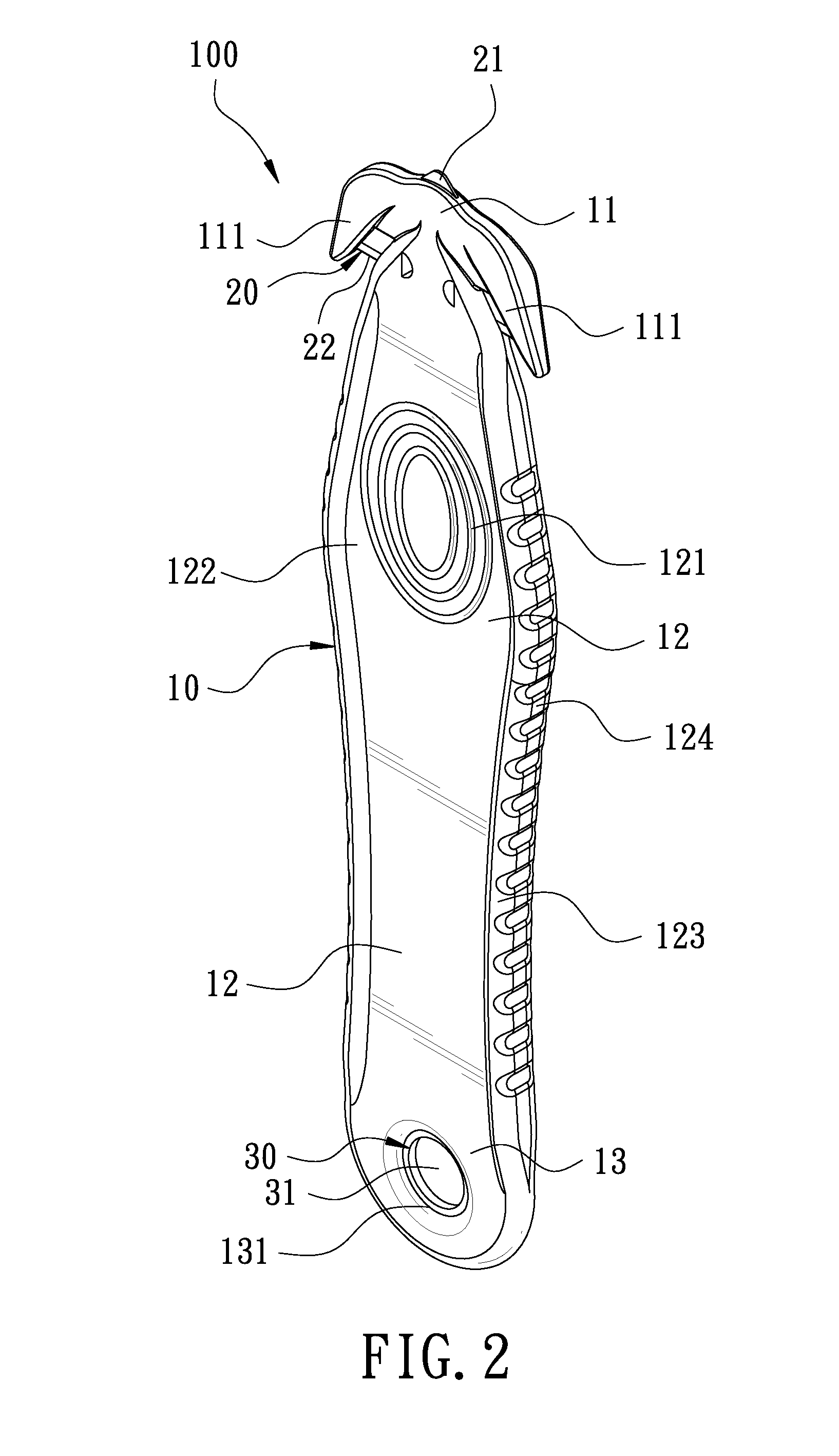

Cutter

InactiveUS20150298330A1Avoid damageCutting be removeMetal working apparatusMetal-working hand toolsEngineeringMechanical engineering

A cutter includes a main body. The top edge of the main body is provided with a holding portion, and its two sides extend outward to form a pair of lugs. A pair of gaps is formed between the main body and the pair of lugs. The cutter further includes a cutting unit wrapped by the main body. The cutting unit has one side formed with a pointed end portion and another side formed with a cutter edge. The pointed end portion protrudes out of the holding portion, and the cutter edge is exposed out of the gaps. The multi-function cutter is able to cut and remove various packaging members easily and efficiently.

Owner:YU CHEN HSIU MAN

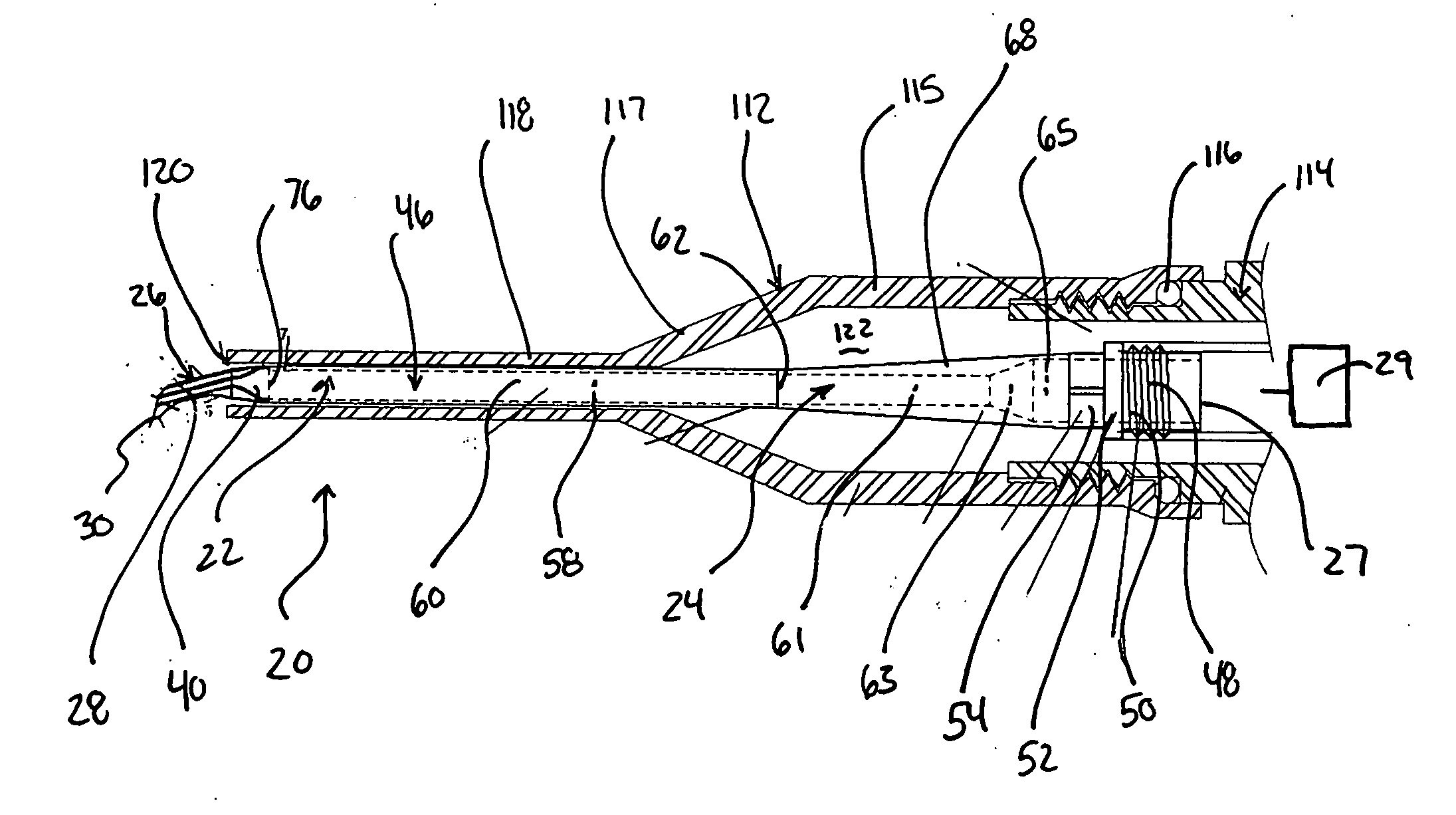

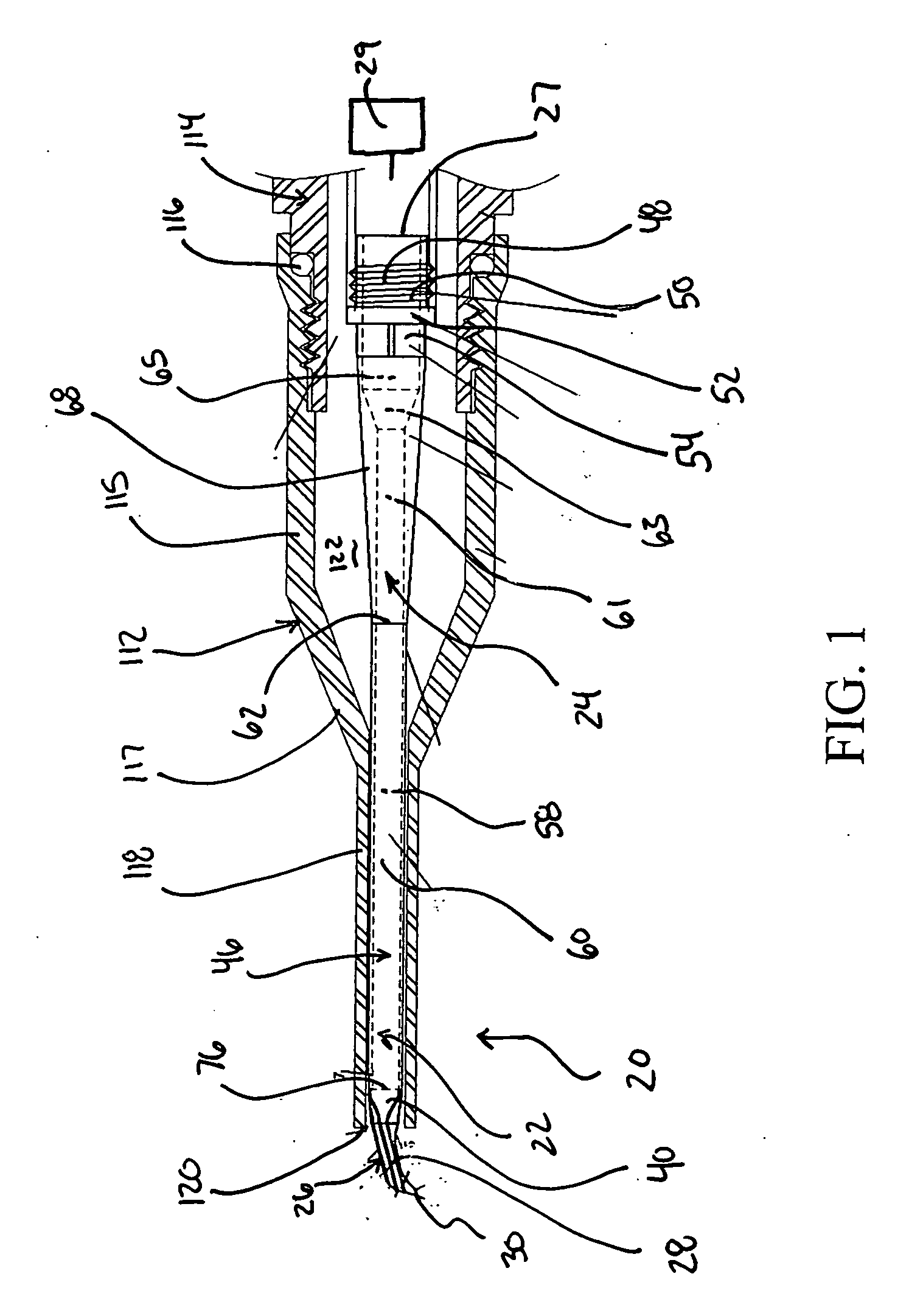

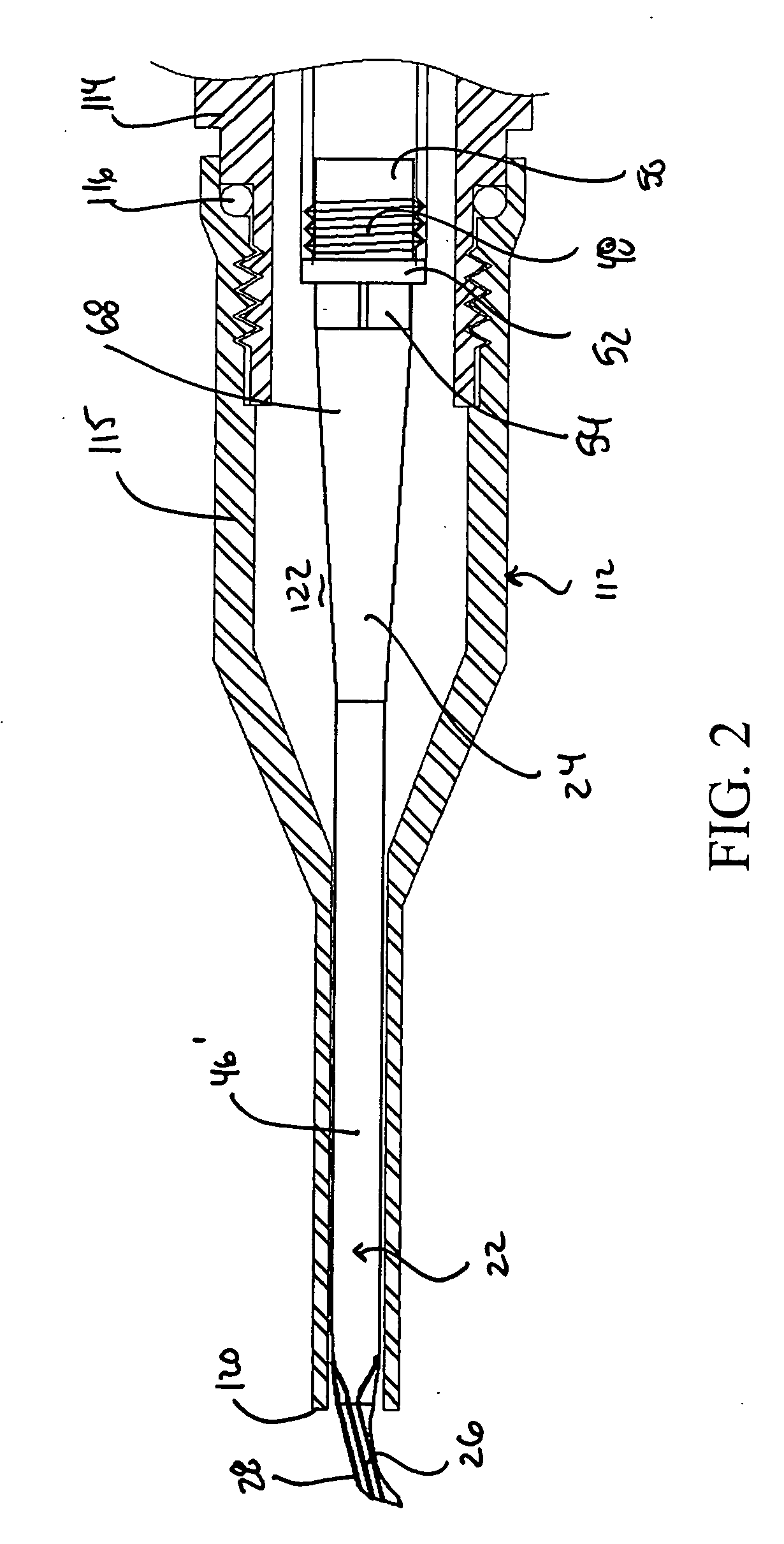

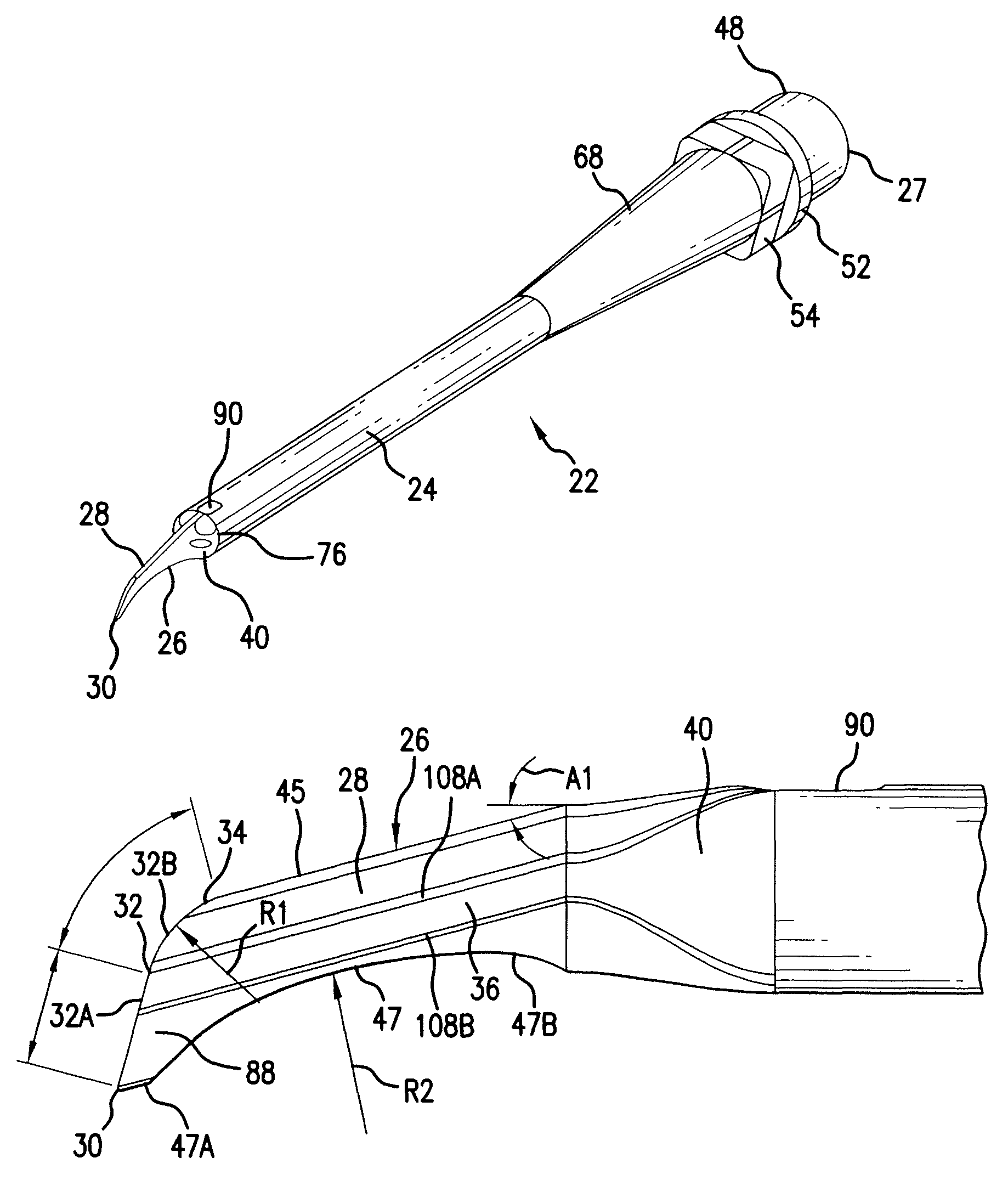

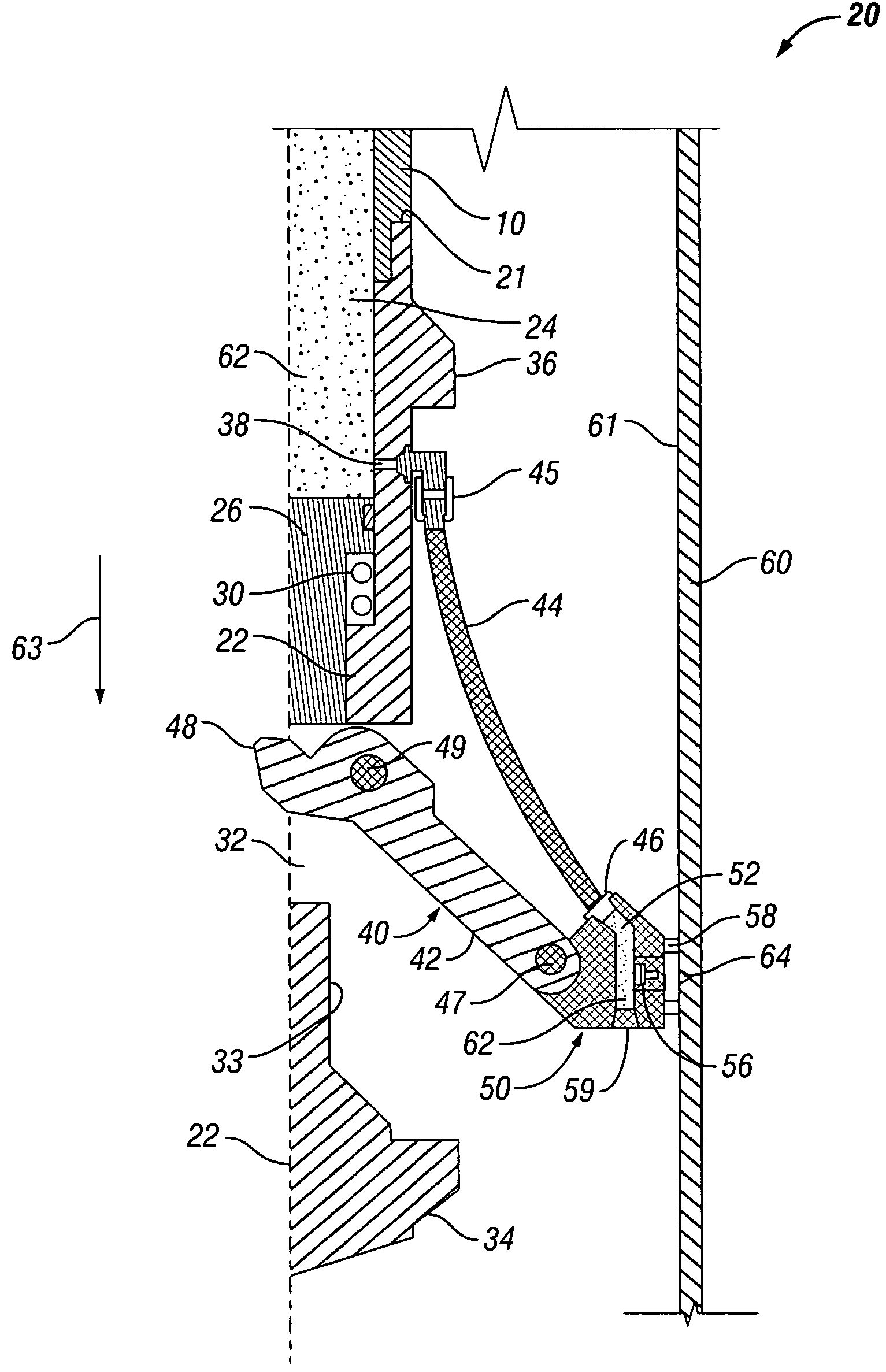

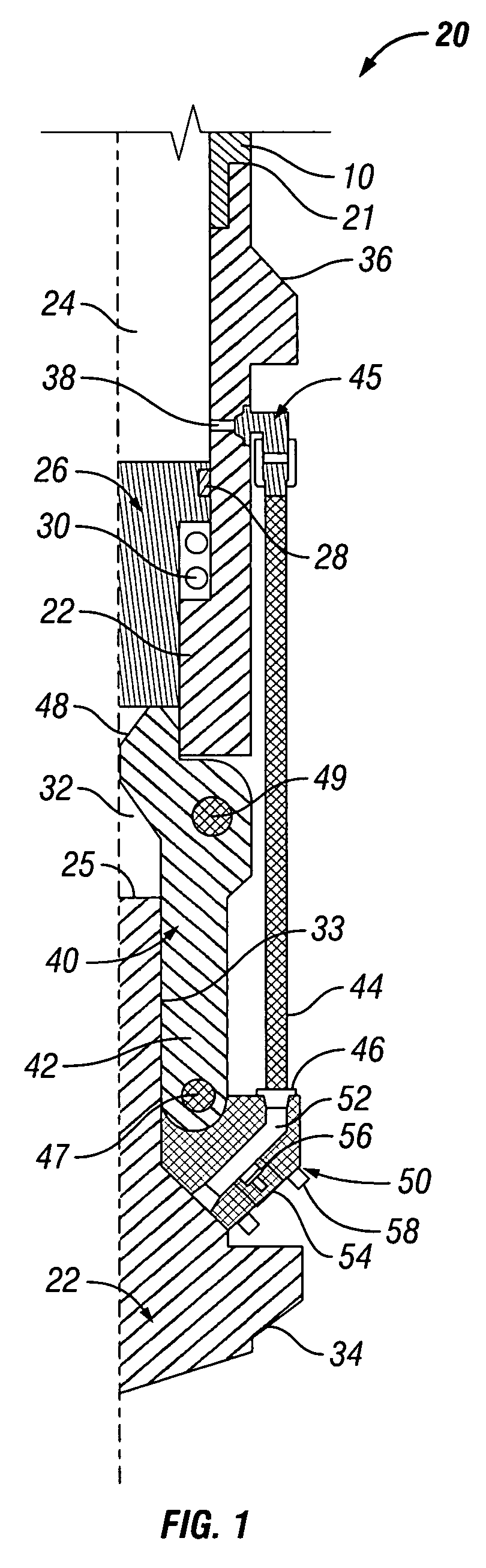

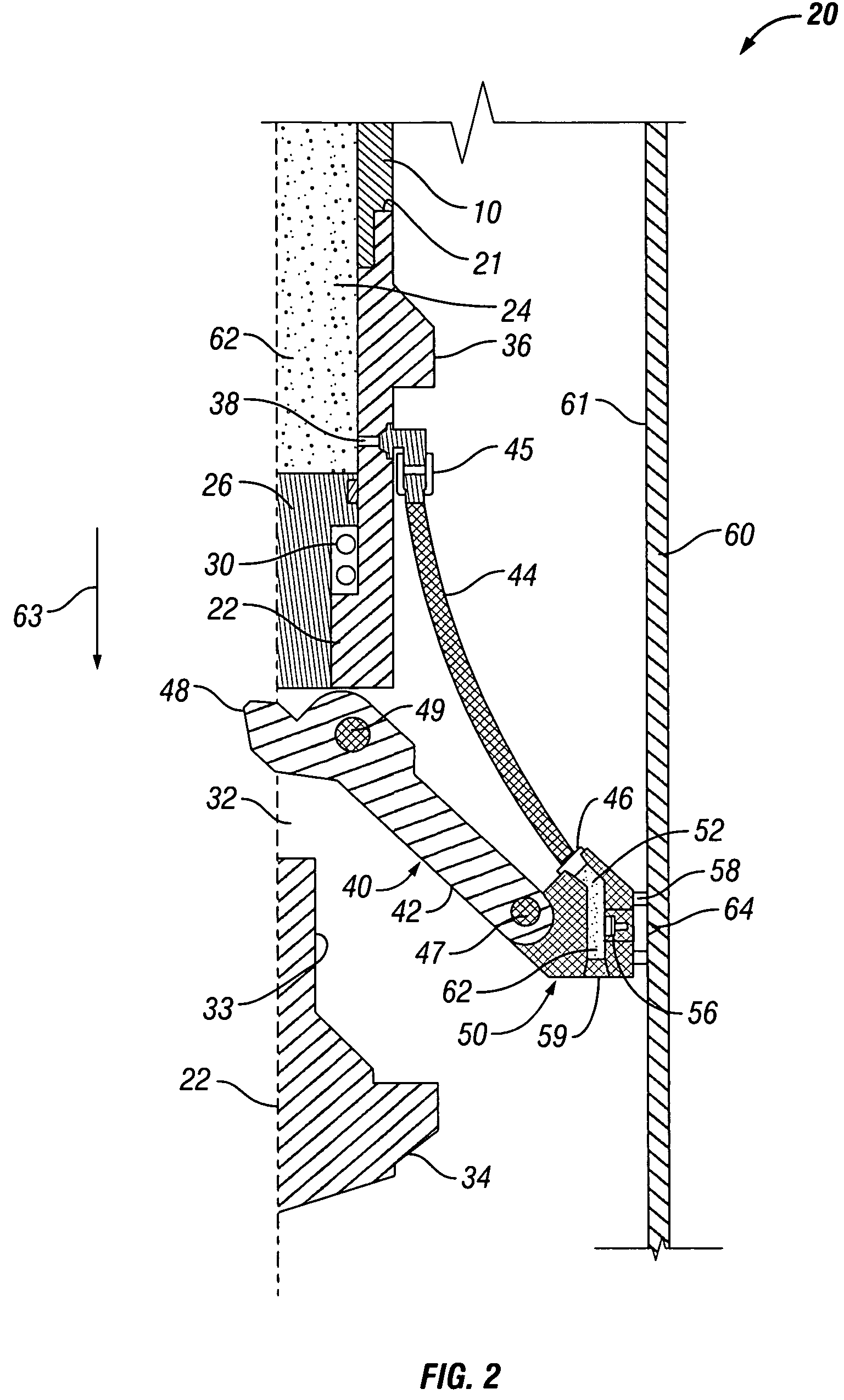

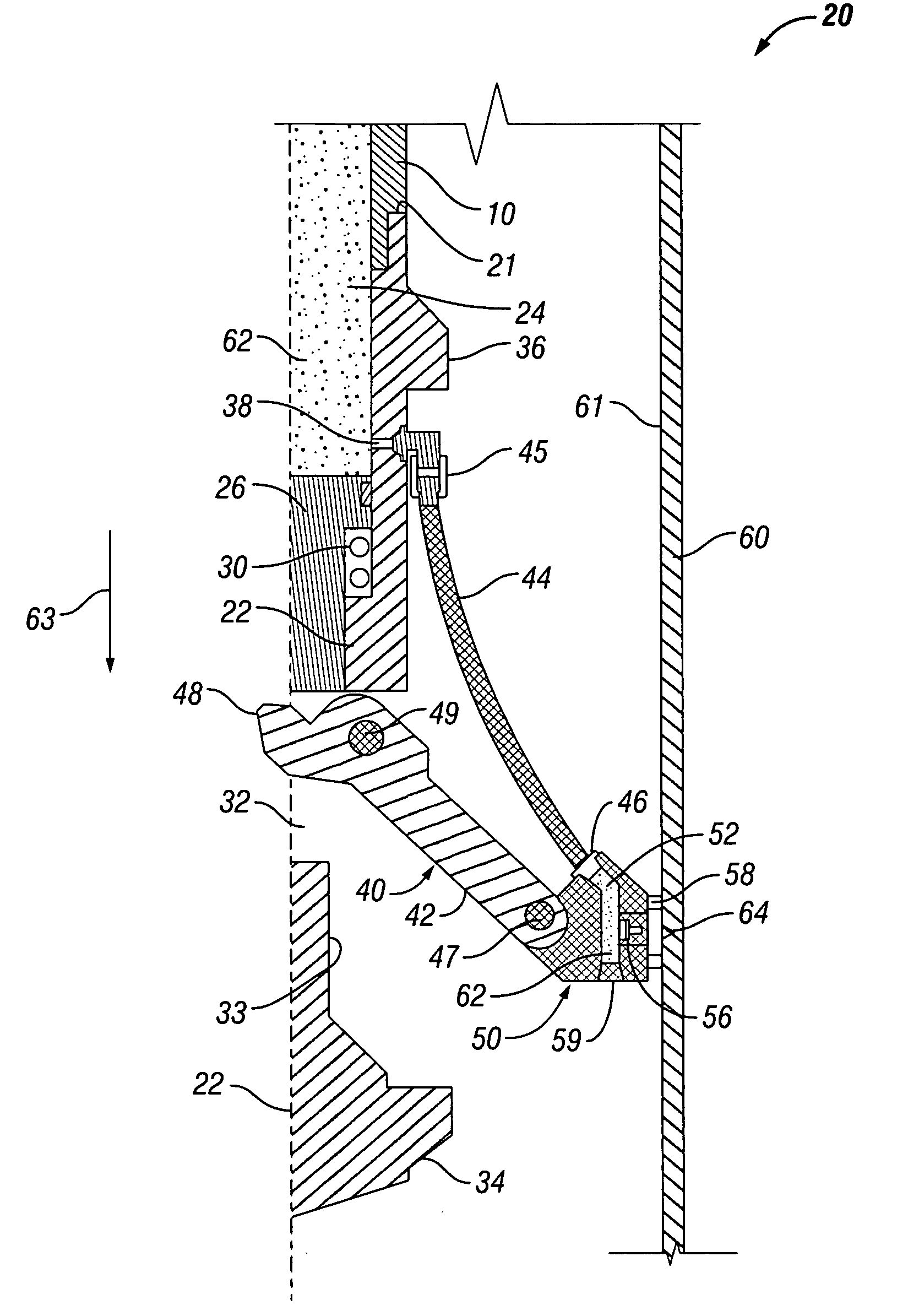

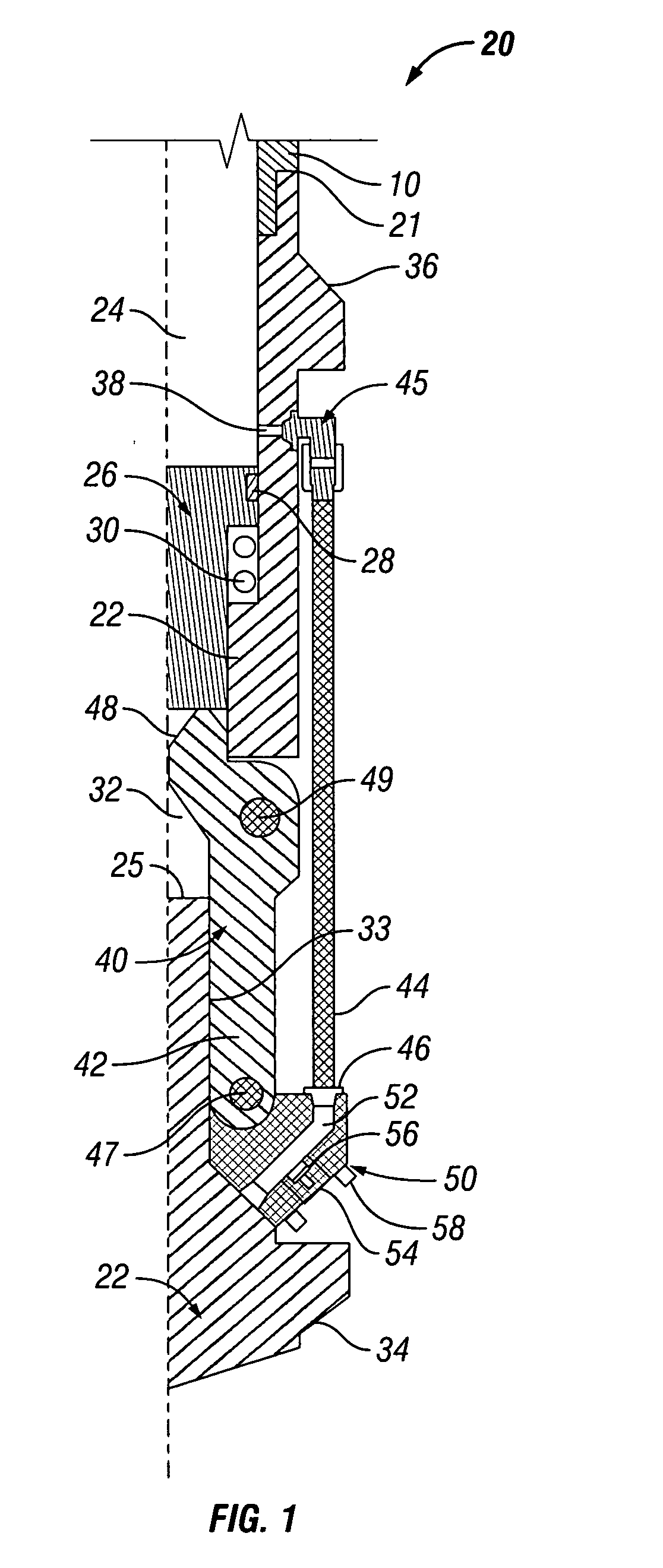

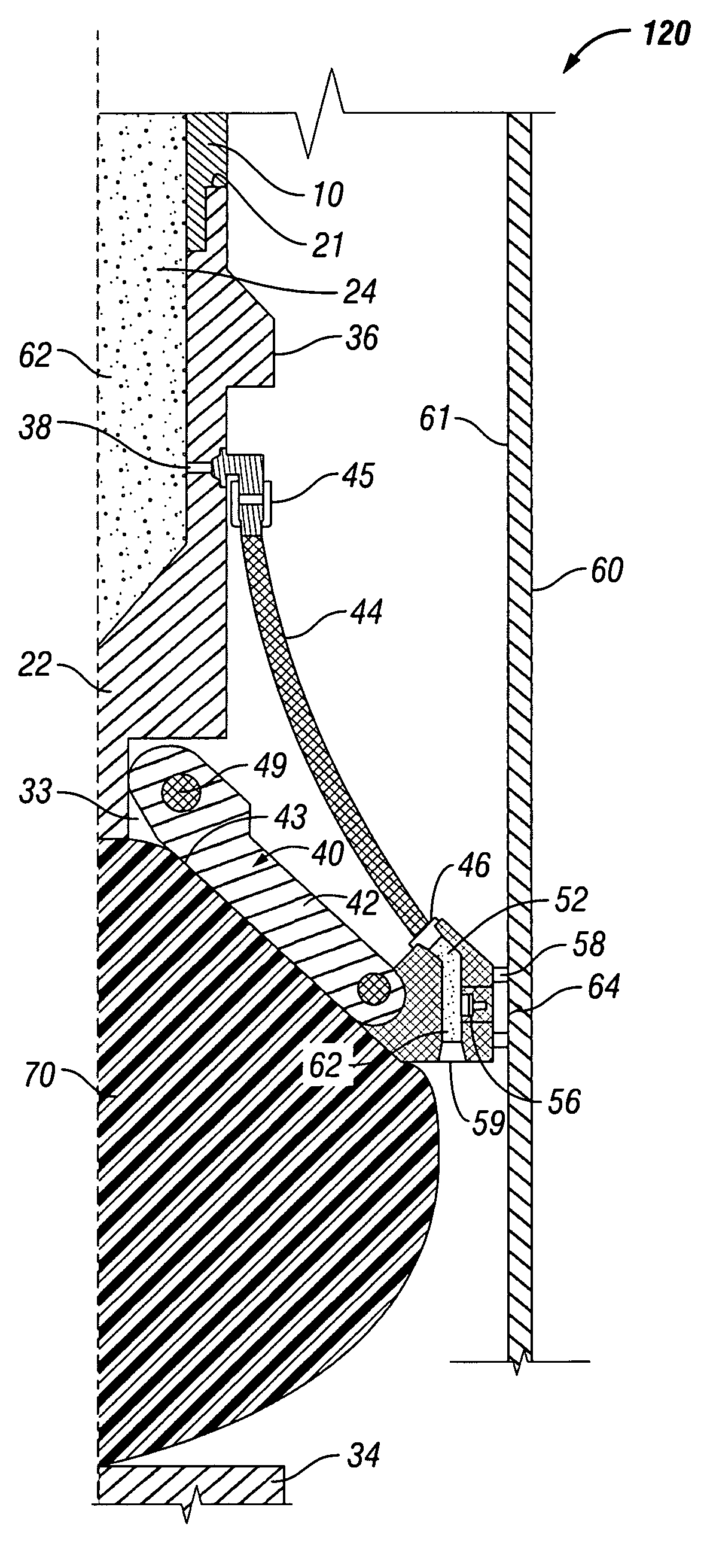

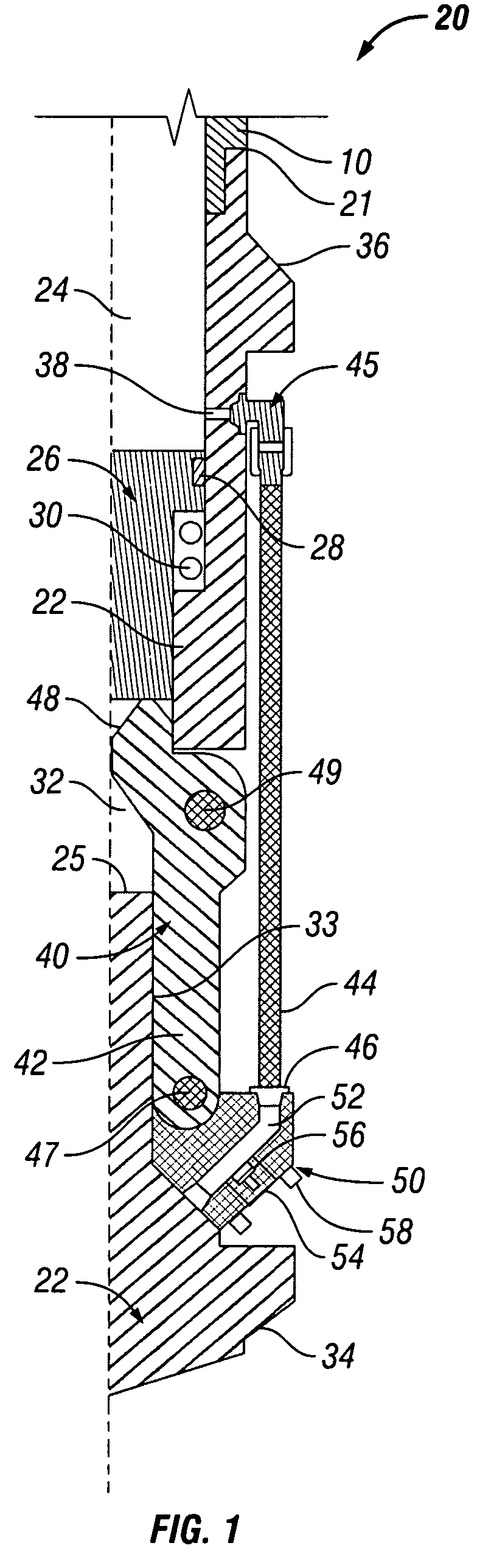

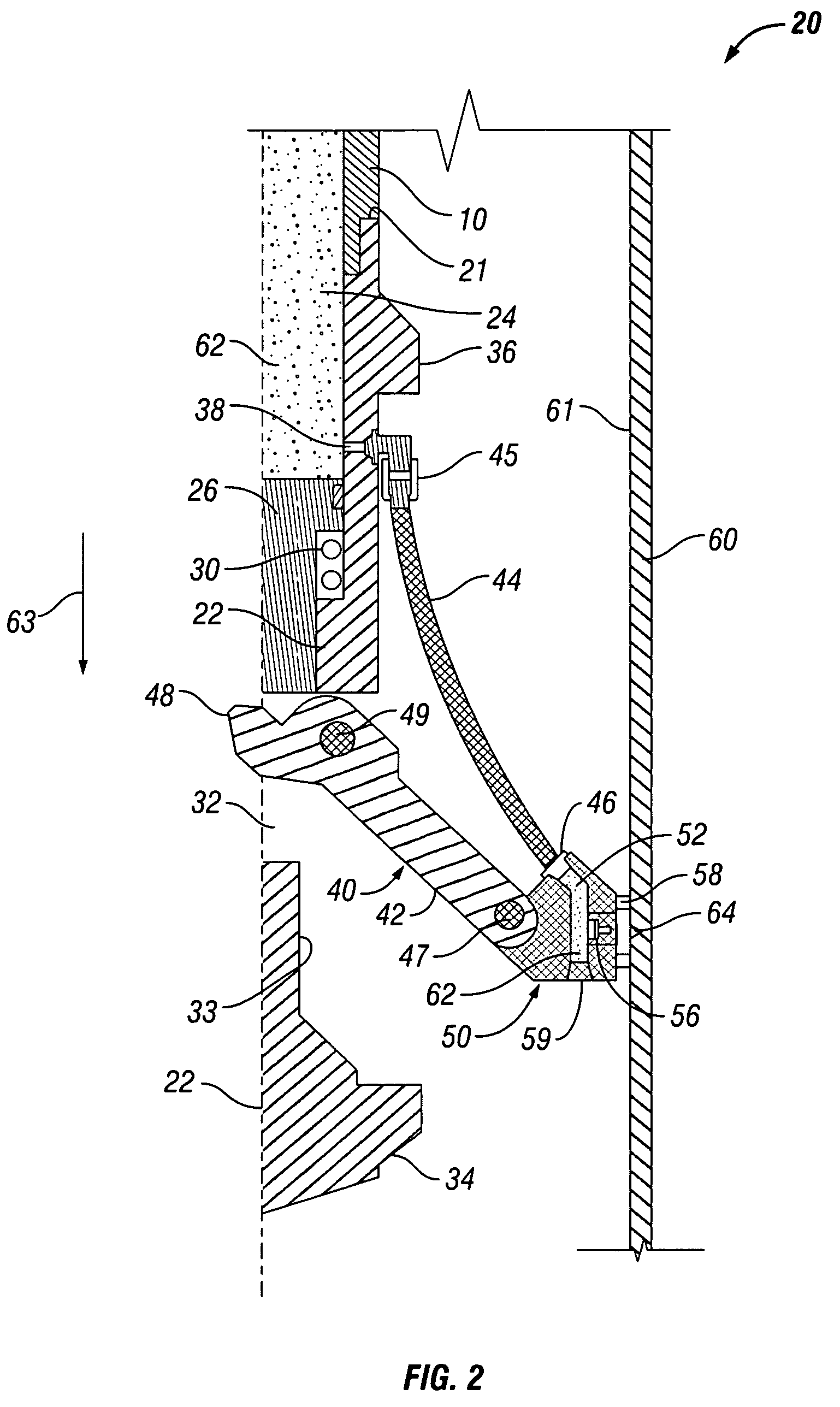

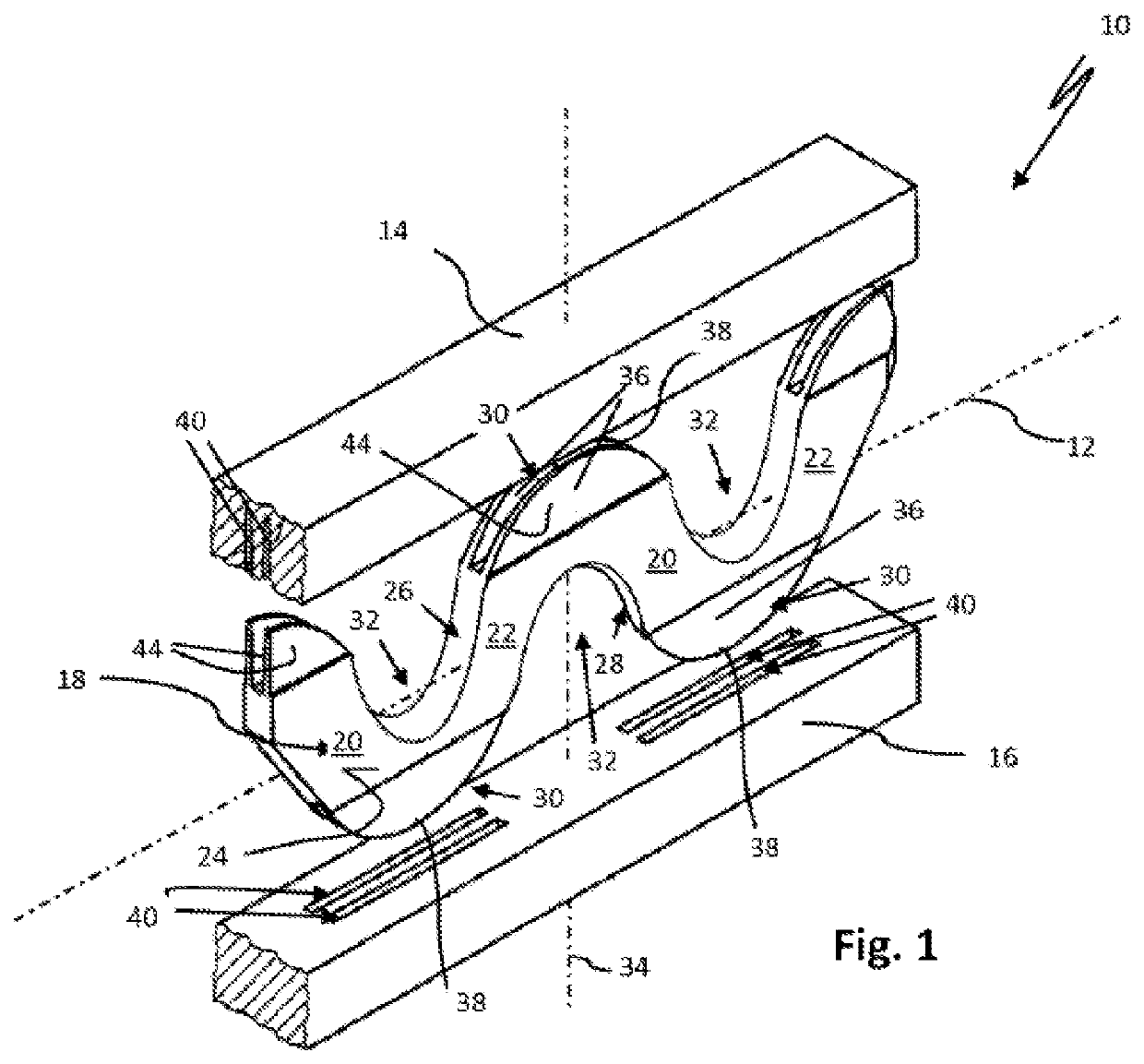

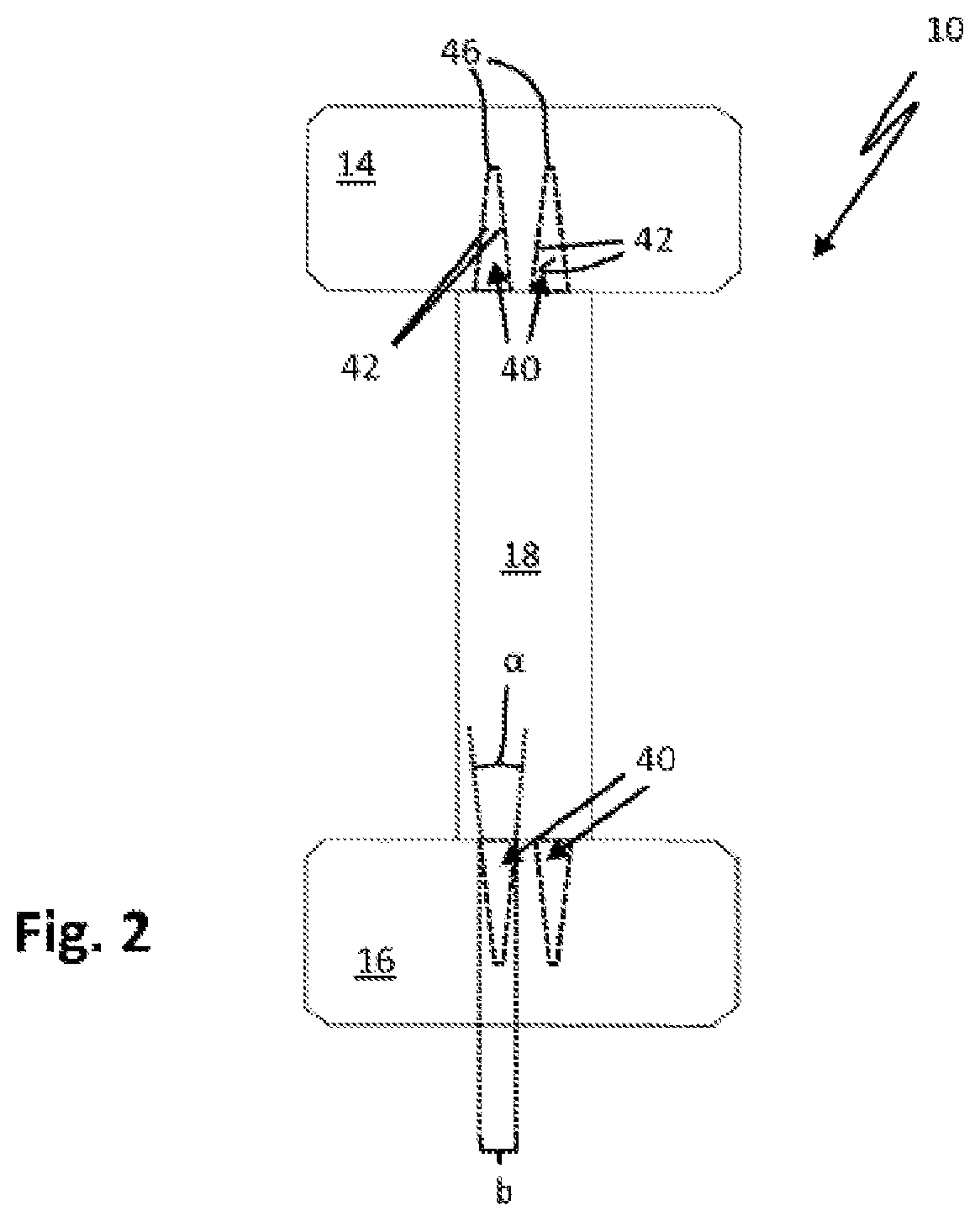

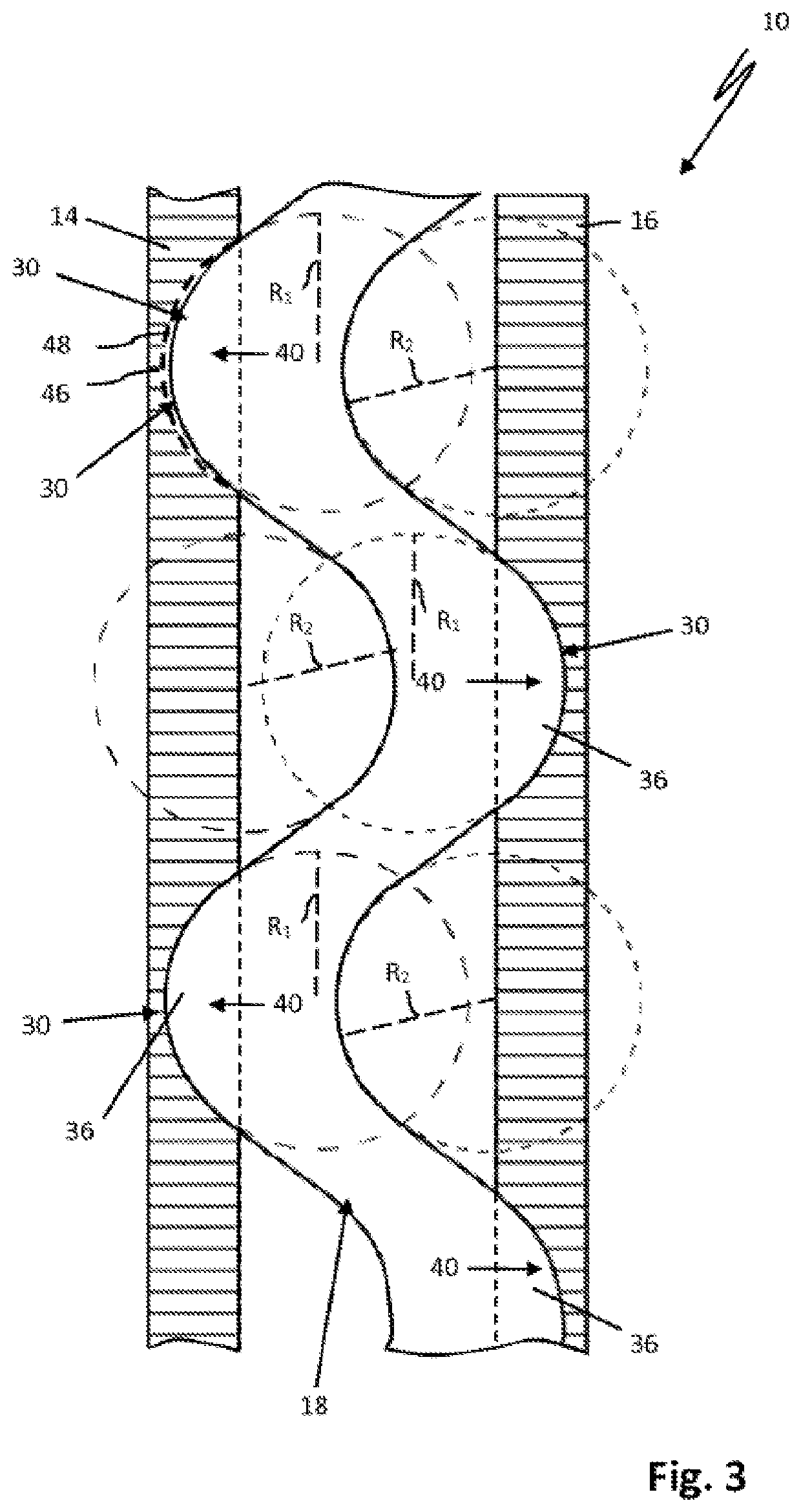

Radially expandable downhole fluid jet cutting tool

ActiveUS7434633B2Easy and efficient cuttingOvercomes the deficiencies of U.SLiquid/gas jet drillingFluid removalEngineeringHigh pressure

Downhole fluid jet cutting tools having extendible and retractable arms with cutting heads on the ends are disclosed. The jet cutting tools permit casing and other downhole surfaces to be cut utilizing a cutting fluid forced through a jet nozzle assembly. Movement of a piston slidingly engaged within the passageway of the tool actuates the arms when cutting fluid pressure acts on the piston. As a result, the arms are extended and cutting fluid is forced at high pressure from the passageway to the cutting head where it is expelled through nozzles for cutting casing and the like. The jet cutting tools permit the arms to be extended, retracted, and re-extended or redeployed multiple times without the need for being retrieved from the wellbore.

Owner:BAKER HUGHES HLDG LLC

Radially expandable downhole fluid jet cutting tool

ActiveUS20080066913A1Easy and efficient cuttingOvercomes the deficiencies of U.SLiquid/gas jet drillingFluid removalEngineeringHigh pressure

Downhole fluid jet cutting tools having extendible and retractable arms with cutting heads on the ends are disclosed. The jet cutting tools permit casing and other downhole surfaces to be cut utilizing a cutting fluid forced through a jet nozzle assembly. Movement of a piston slidingly engaged within the passageway of the tool actuates the arms when cutting fluid pressure acts on the piston. As a result, the arms are extended and cutting fluid is forced at high pressure from the passageway to the cutting head where it is expelled through nozzles for cutting casing and the like. The jet cutting tools permit the arms to be extended, retracted, and re-extended or redeployed multiple times without the need for being retrieved from the wellbore.

Owner:BAKER HUGHES INC

Cutter

InactiveUS20140173914A1Easy and efficient cuttingEasy and efficient removalHand equipmentsMetal working apparatusEngineeringMechanical engineering

A cutter includes a main body and a cutting unit. The main body is lengthwise defined to have a dispensing section, a holding section and a storage section in sequence. The holding section is gradually contracted toward two ends and defined to be a stop portion, and the storage section is bored with a through hole. The cutting section has one side formed with a pointed end and another side provided with a cutting edge. The main body is integrally covered on the cutting unit, leaving the pointed end and the cutting edge exposed and letting the pointed end located at a central upper edge of the dispensing section. By so designing, the cutter of this invention can easily cut off and remove various kinds of packaging members, able to elevate efficiency of removing packaging members from a packing box and integral in functional design.

Owner:YU CHEN HSIU MAN

Radially expandable downhole fluid jet cutting tool having an inflatable member

ActiveUS7588101B2Easy and efficient cuttingOvercomes the deficiencies of U.SLiquid/gas jet drillingFluid removalEngineeringHigh pressure

Downhole fluid jet cutting tools having extendible and retractable arms with cutting heads on the ends are disclosed. The jet cutting tools permit casing and other downhole surfaces to be cut utilizing a cutting fluid forced through a jet nozzle assembly. Inflation of an inflatable member within the passageway of the tool moves the jet nozzle assembly when cutting fluid pressure inflates the inflatable member. As a result, a cutting head of the jet nozzle assembly is extended and cutting fluid is forced at high pressure from the passageway to the cutting head where it is expelled through nozzles for cutting casing and the like. The jet cutting tools permit the cutting head to be extended, retracted, and re-extended or redeployed multiple times without the need for being retrieved from the wellbore.

Owner:BAKER HUGHES INC

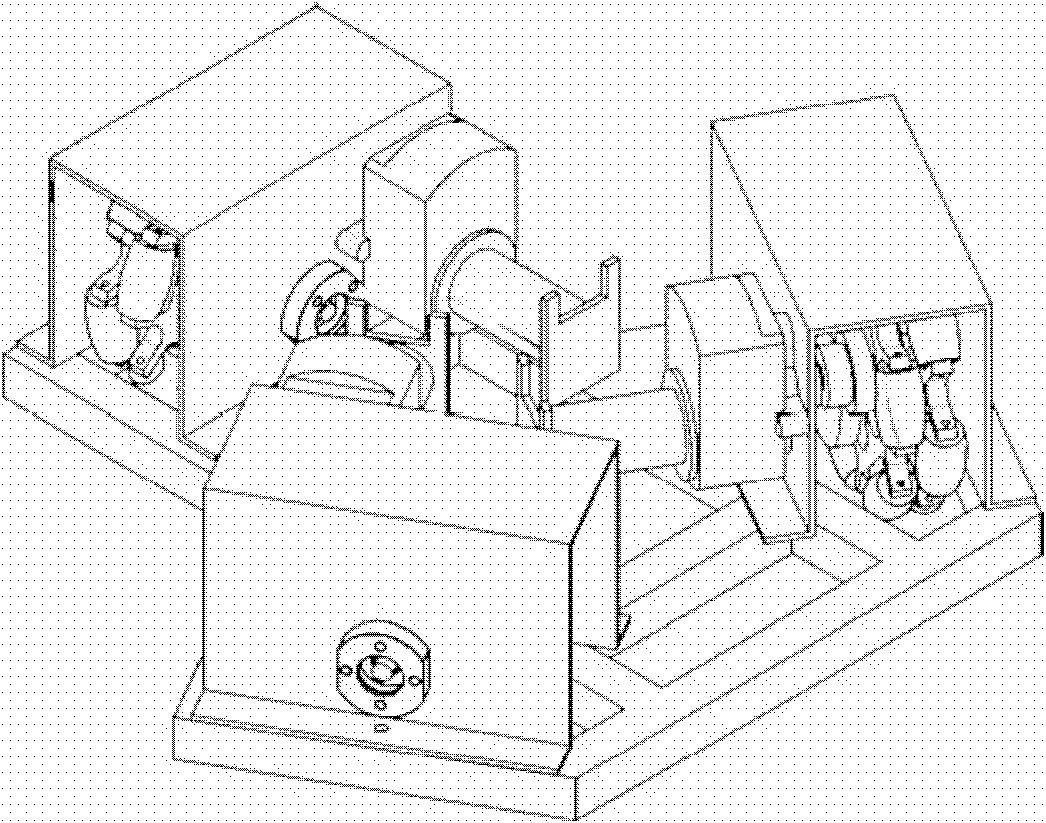

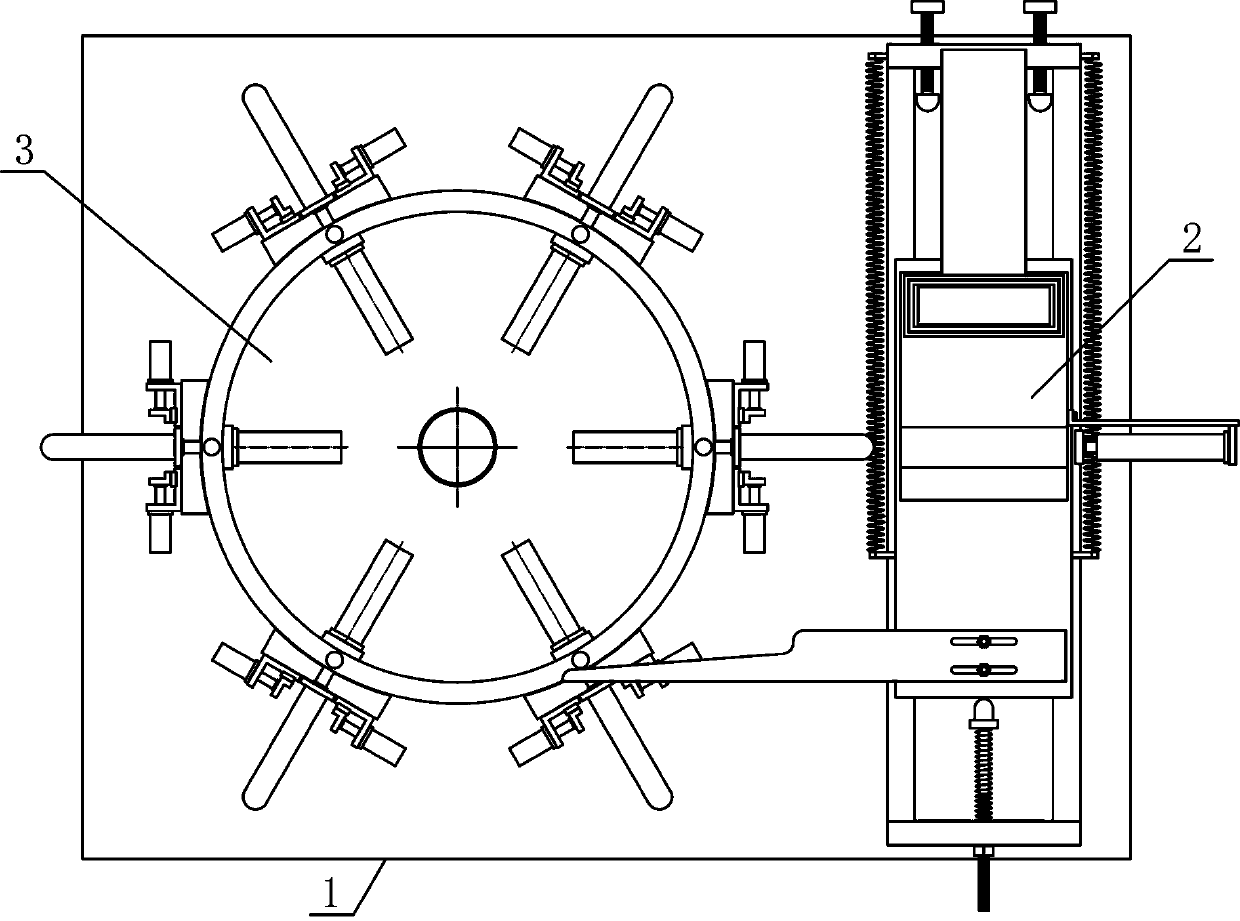

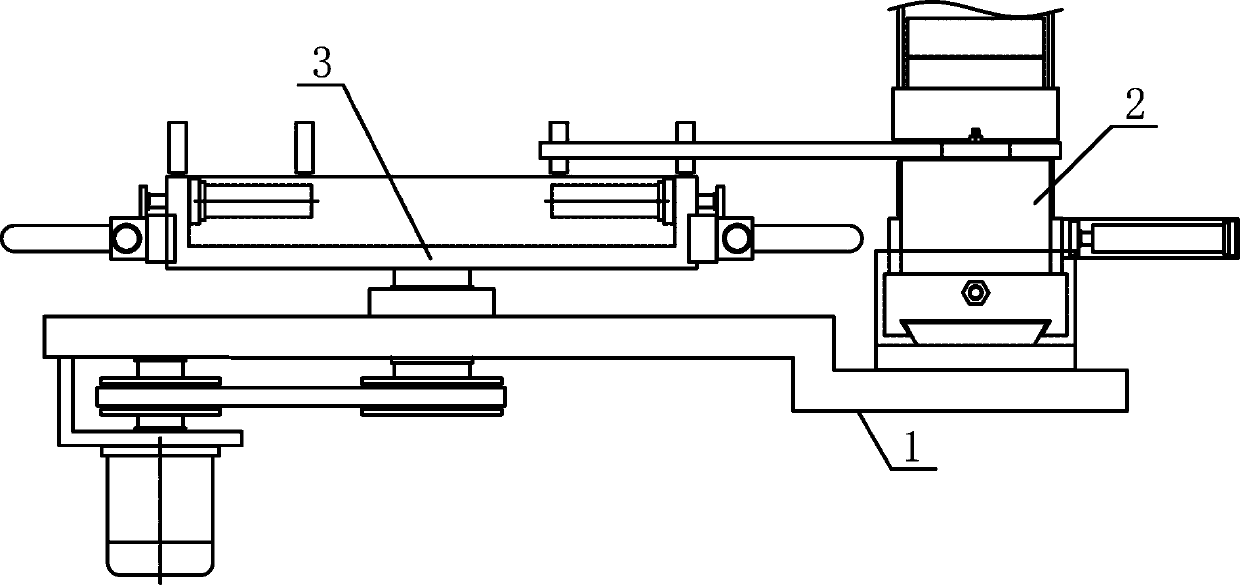

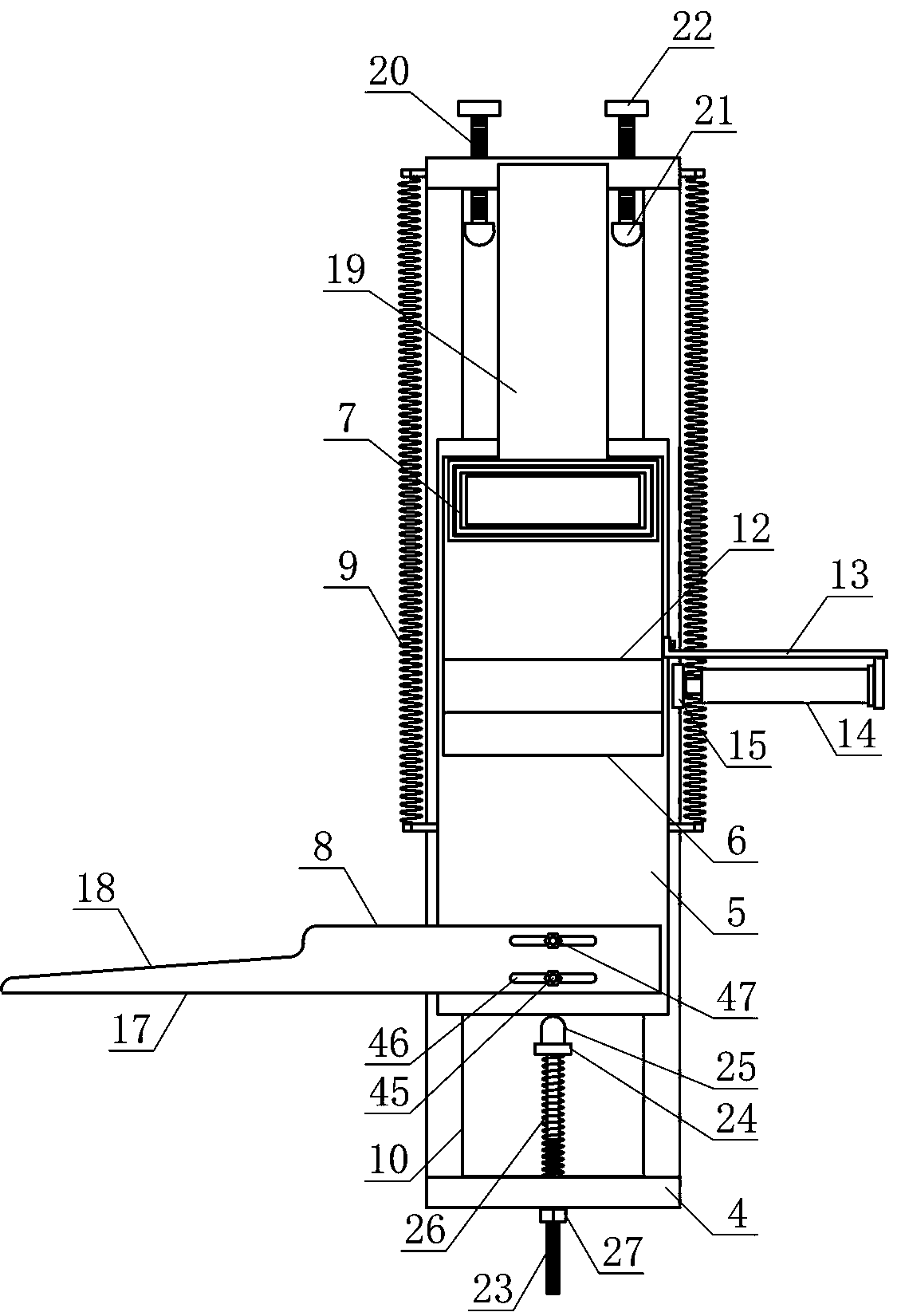

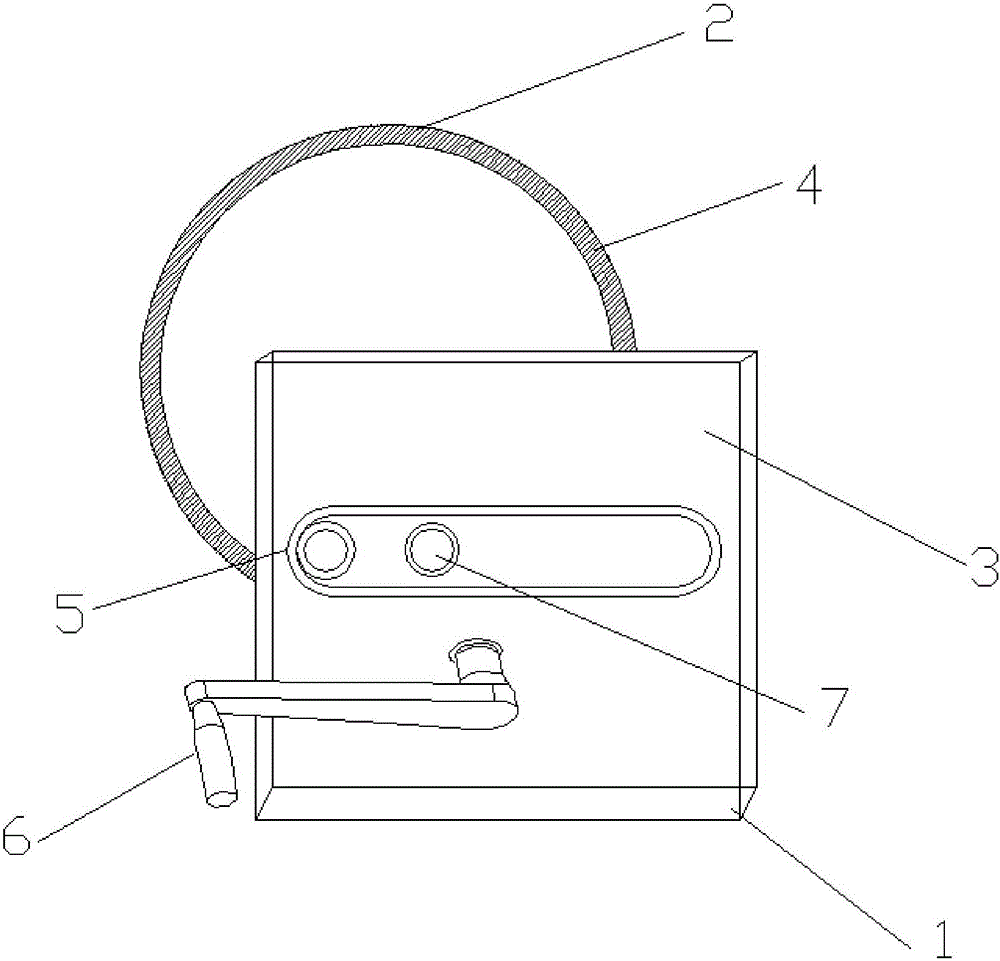

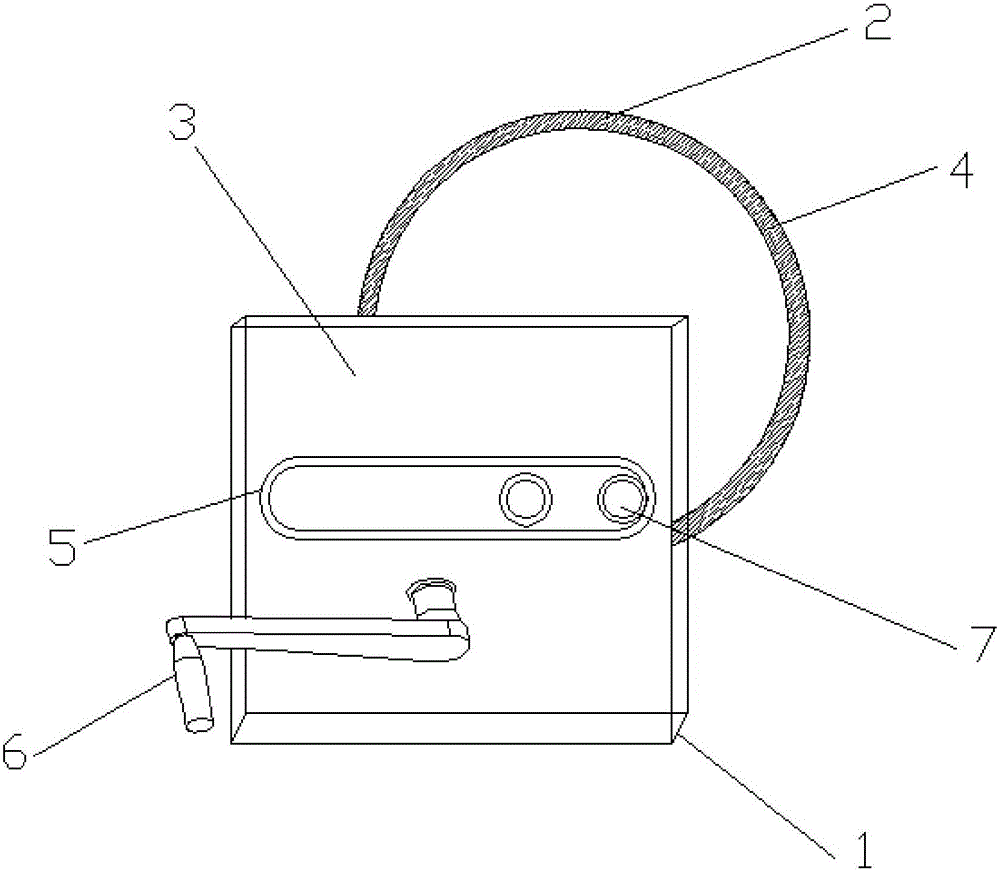

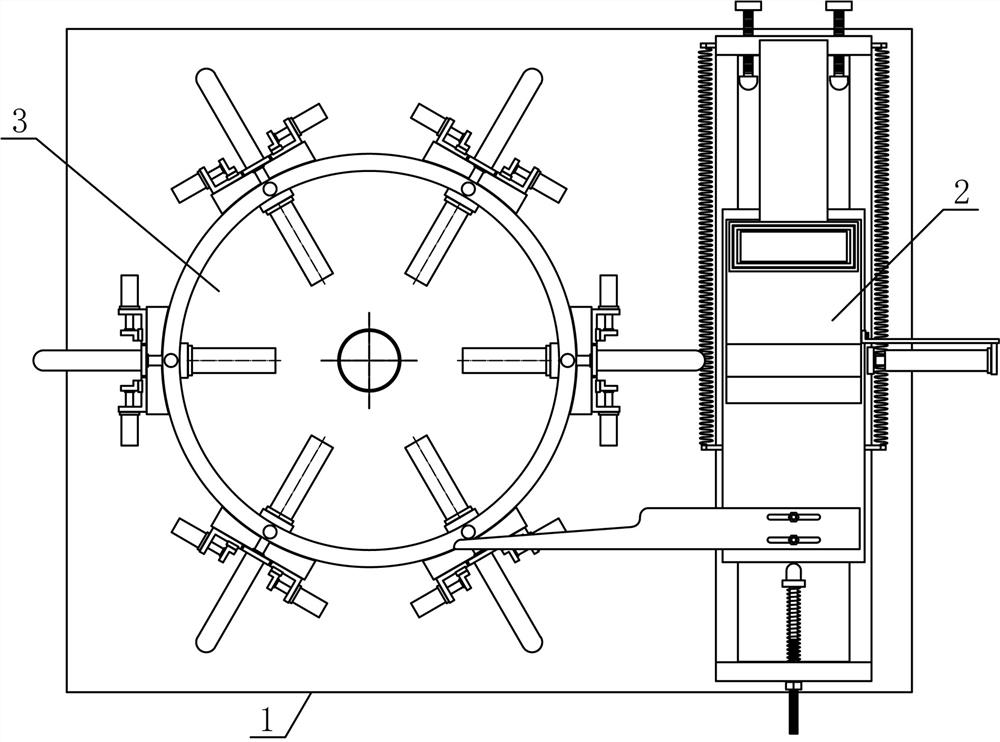

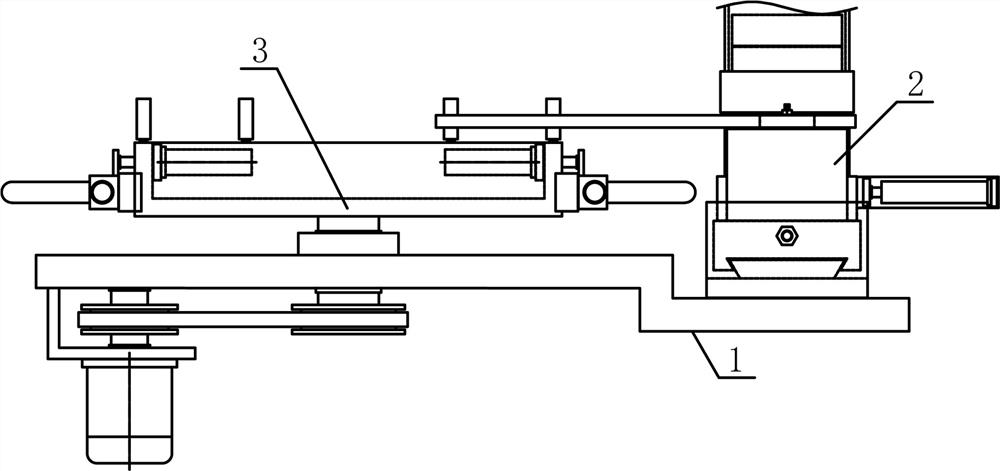

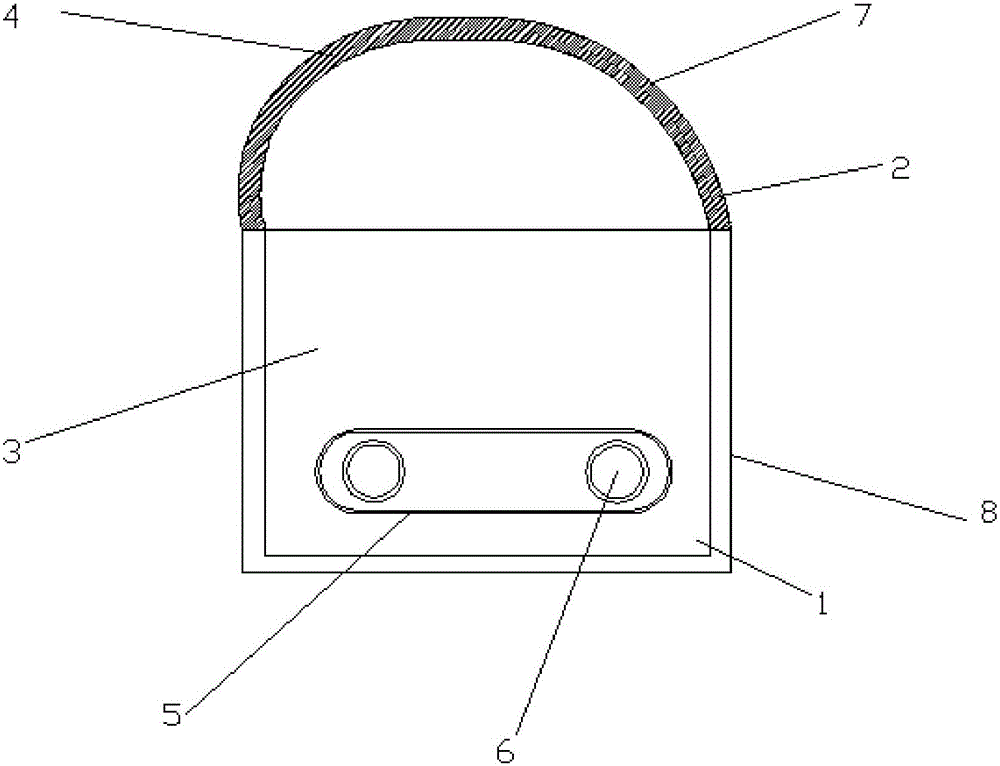

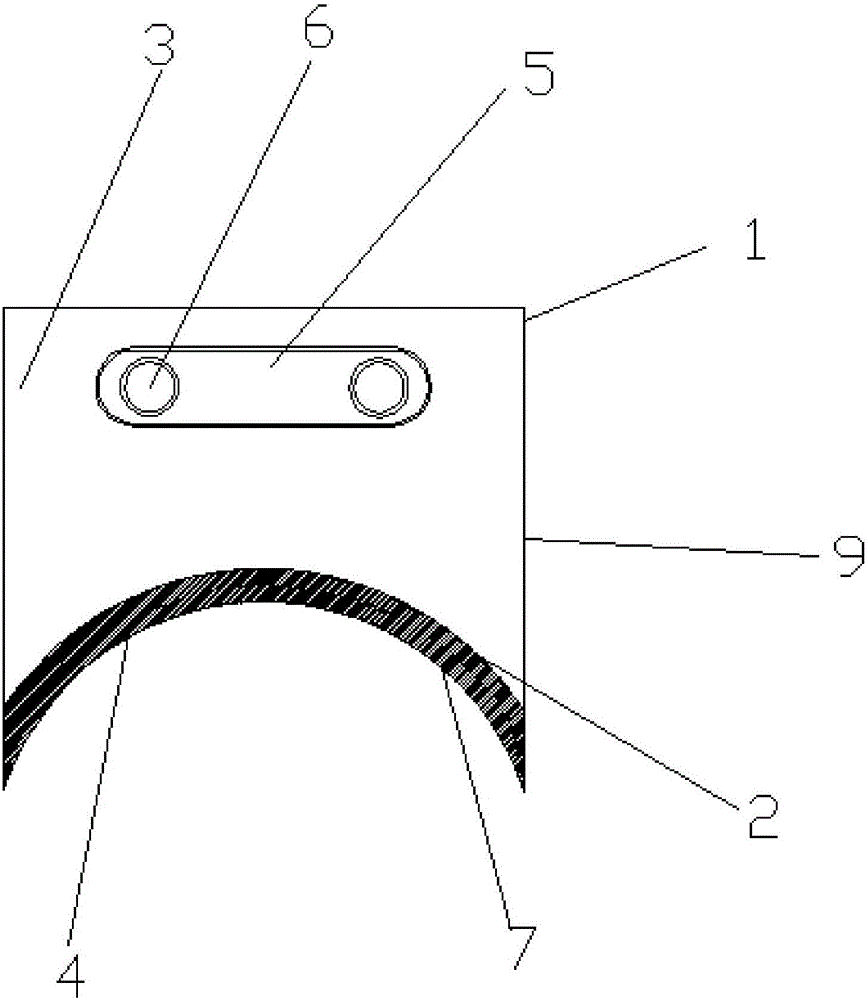

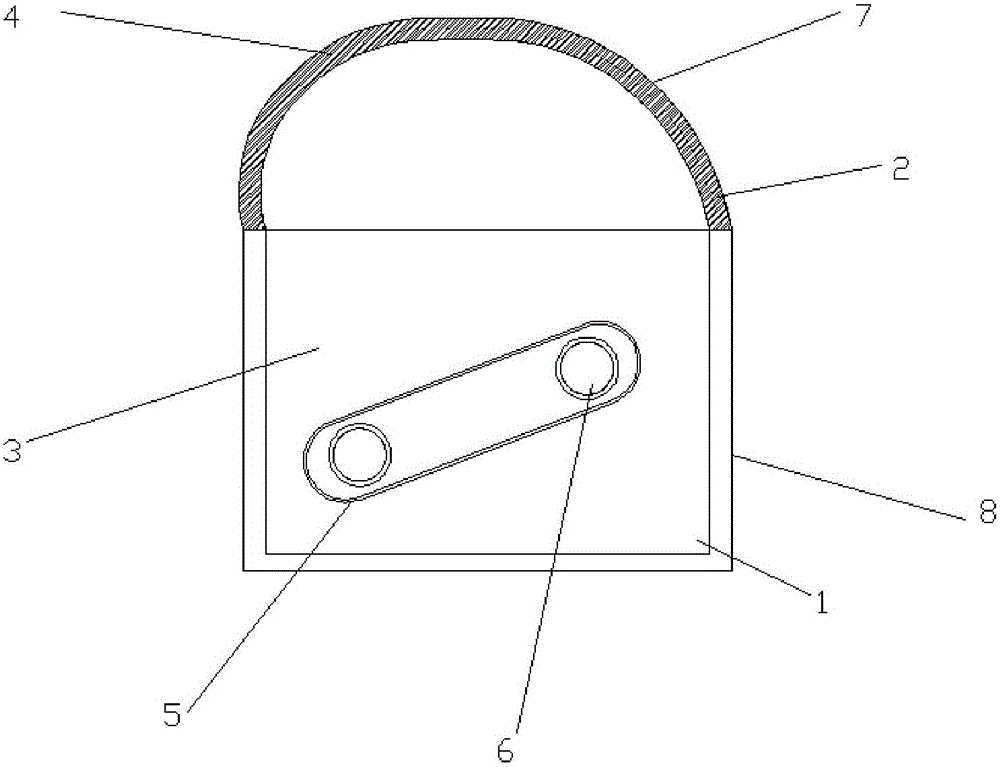

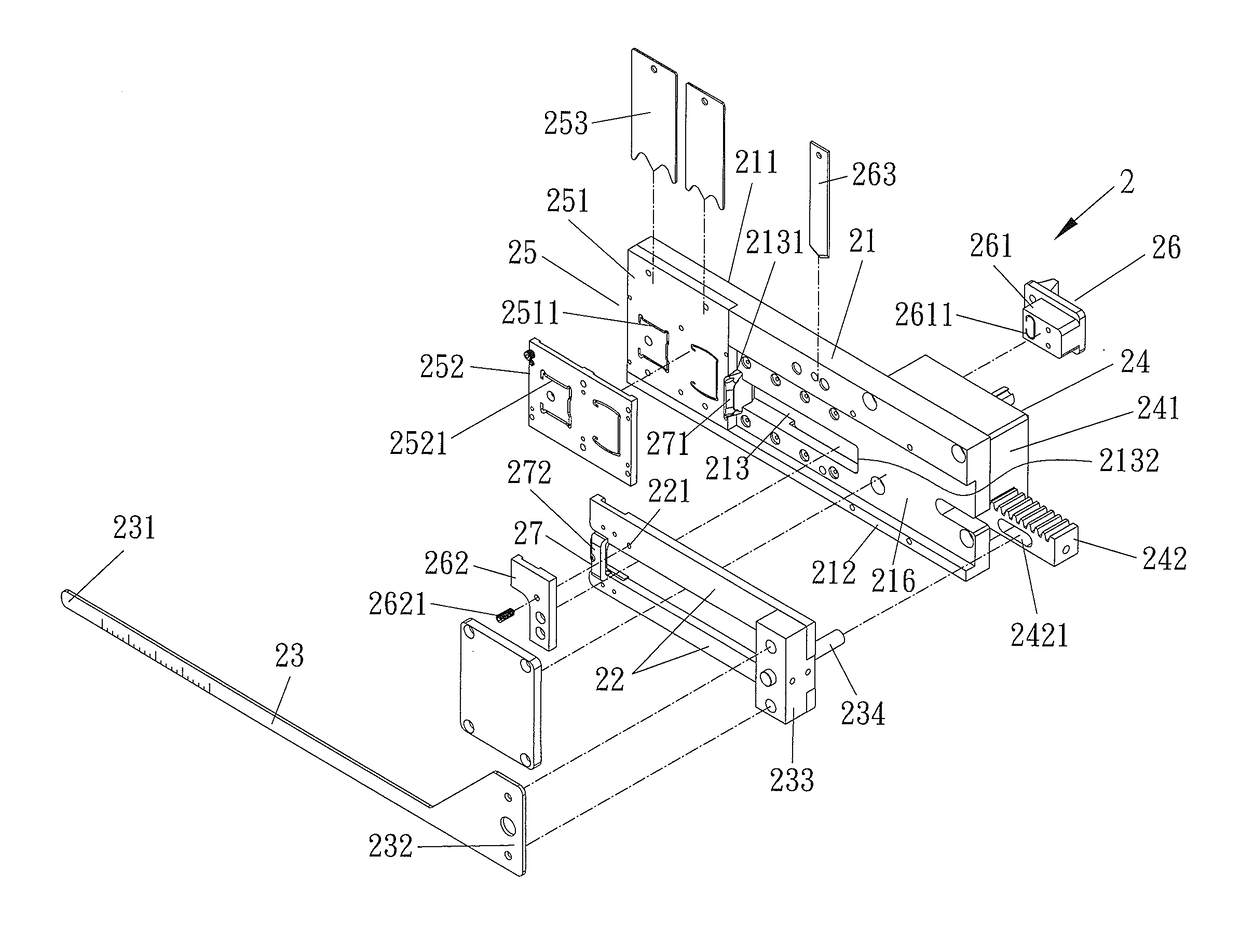

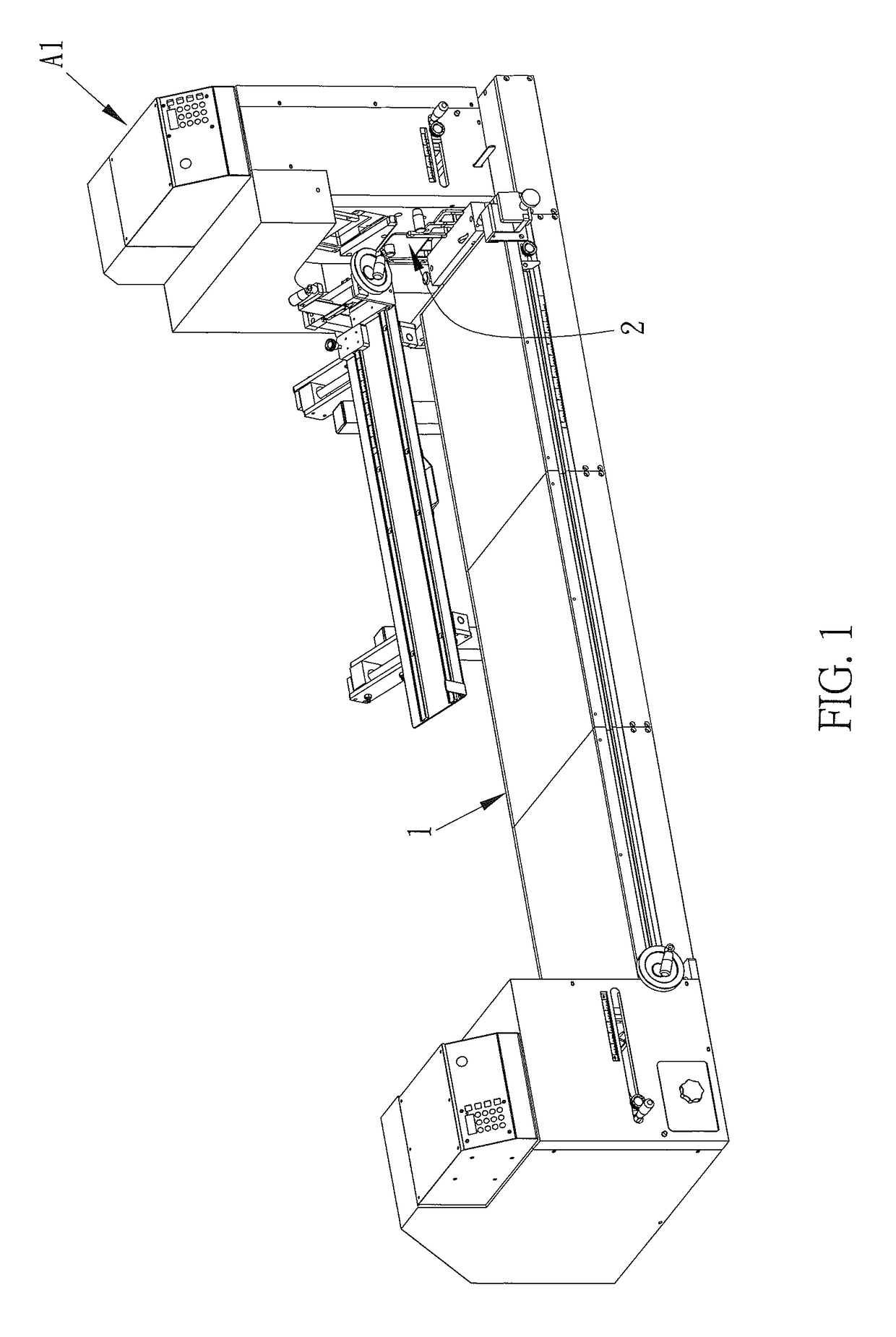

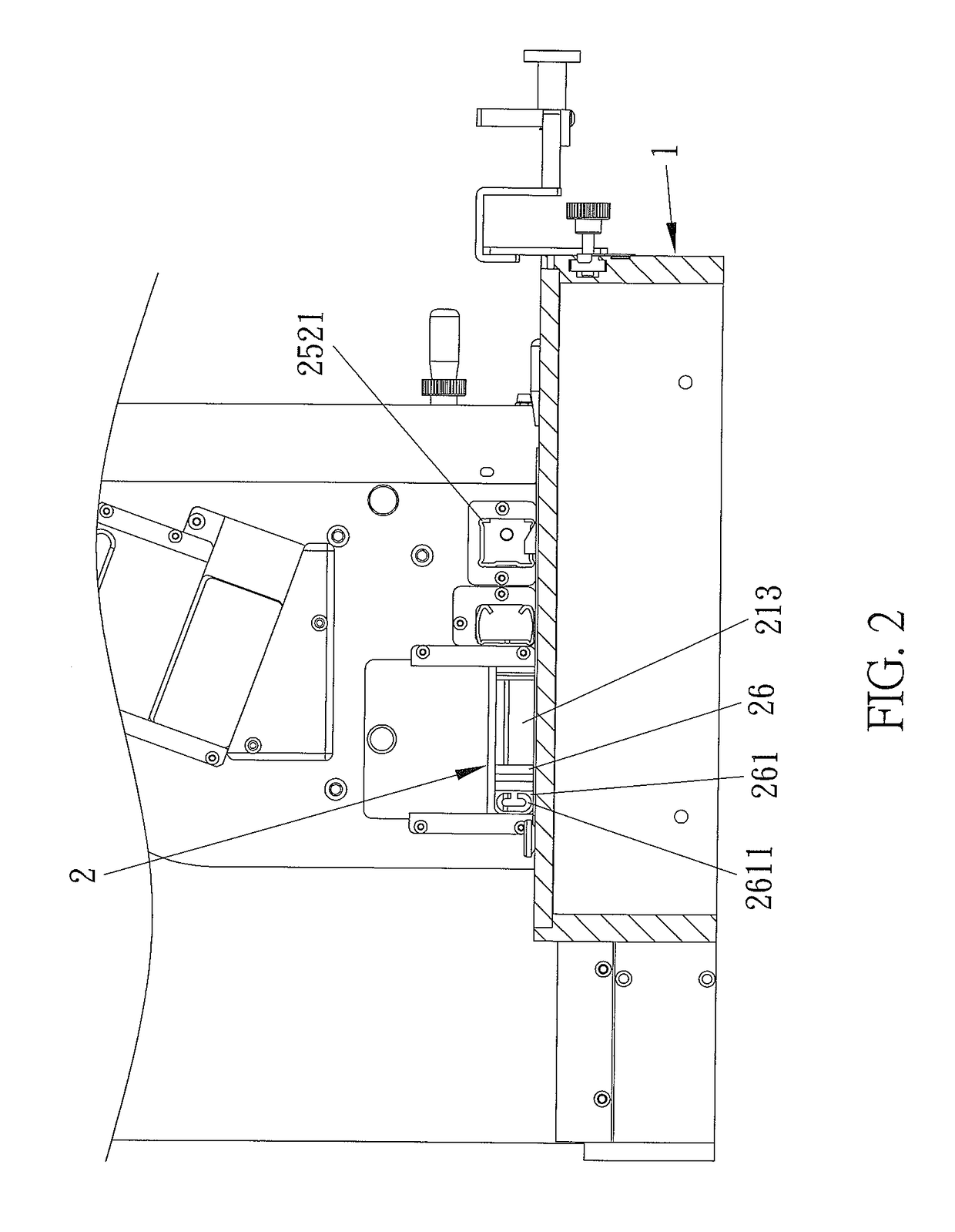

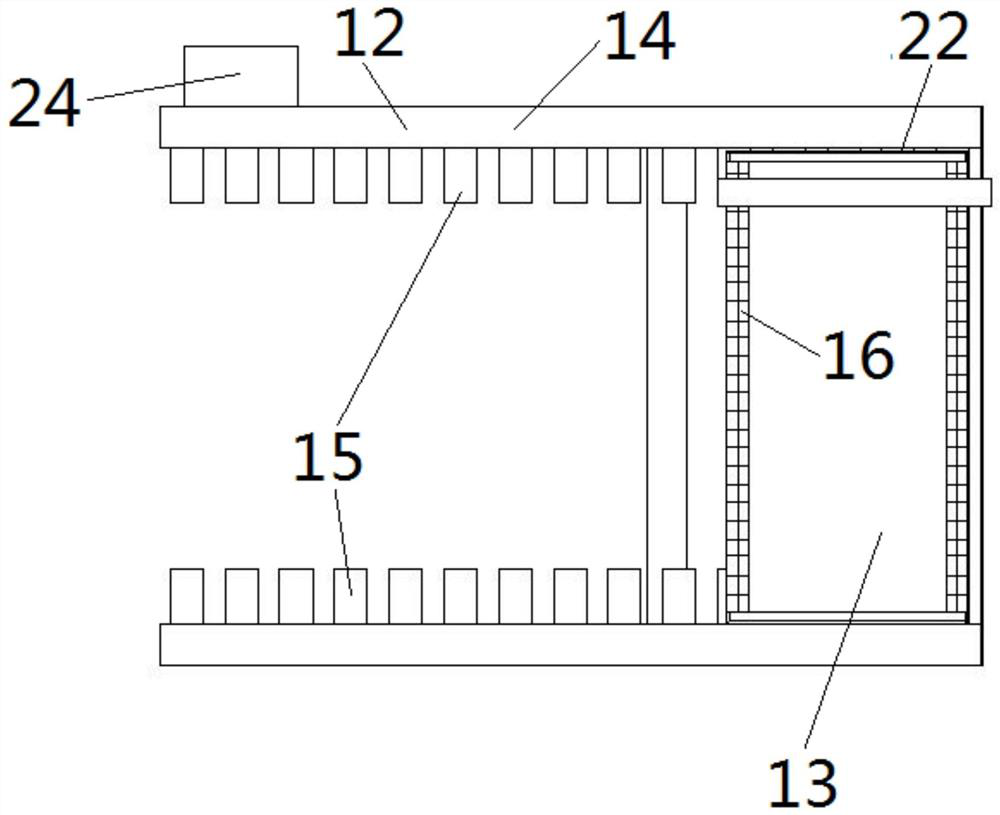

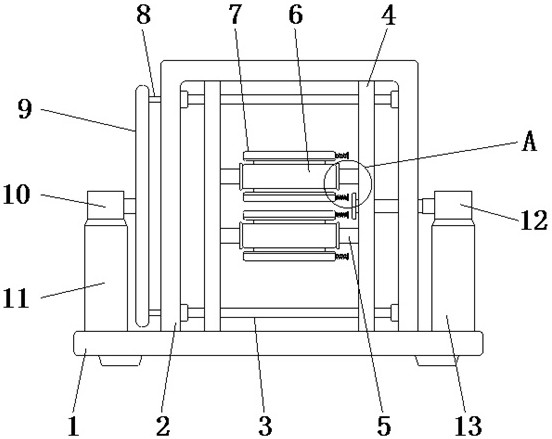

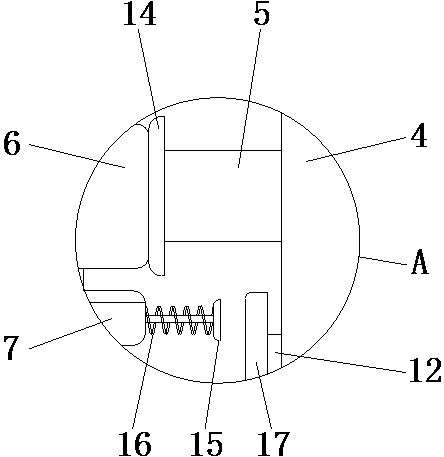

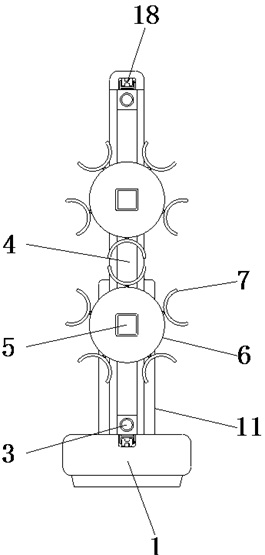

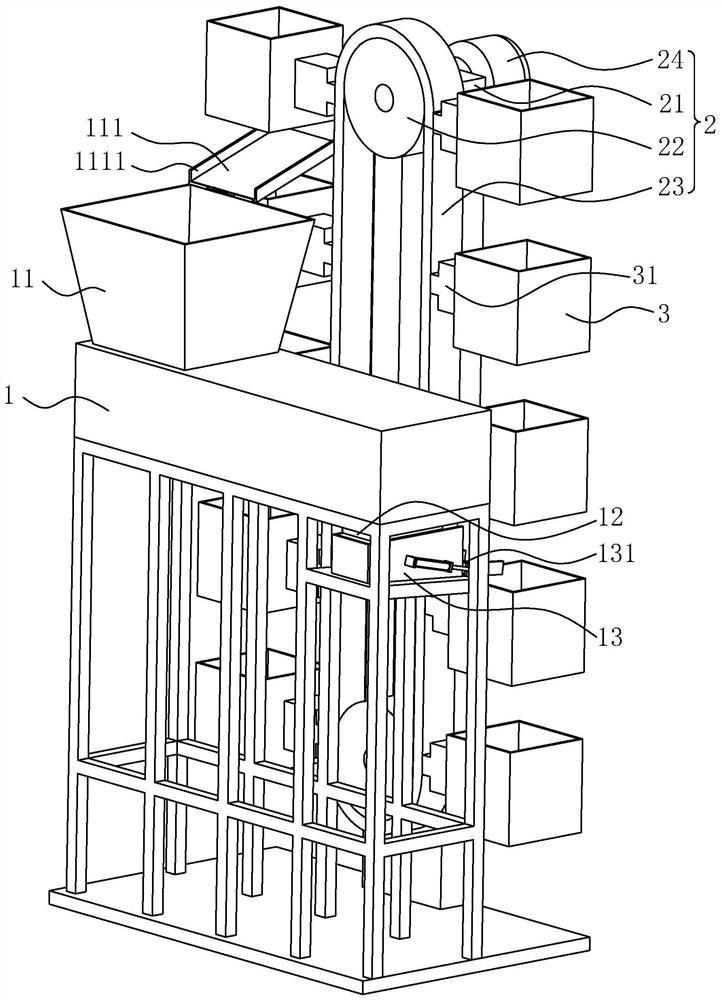

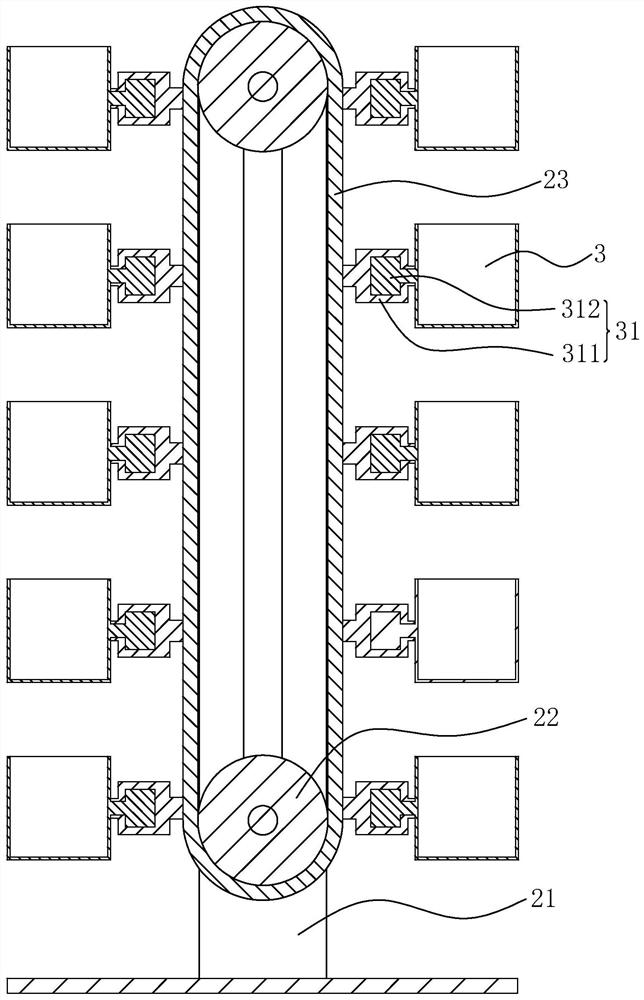

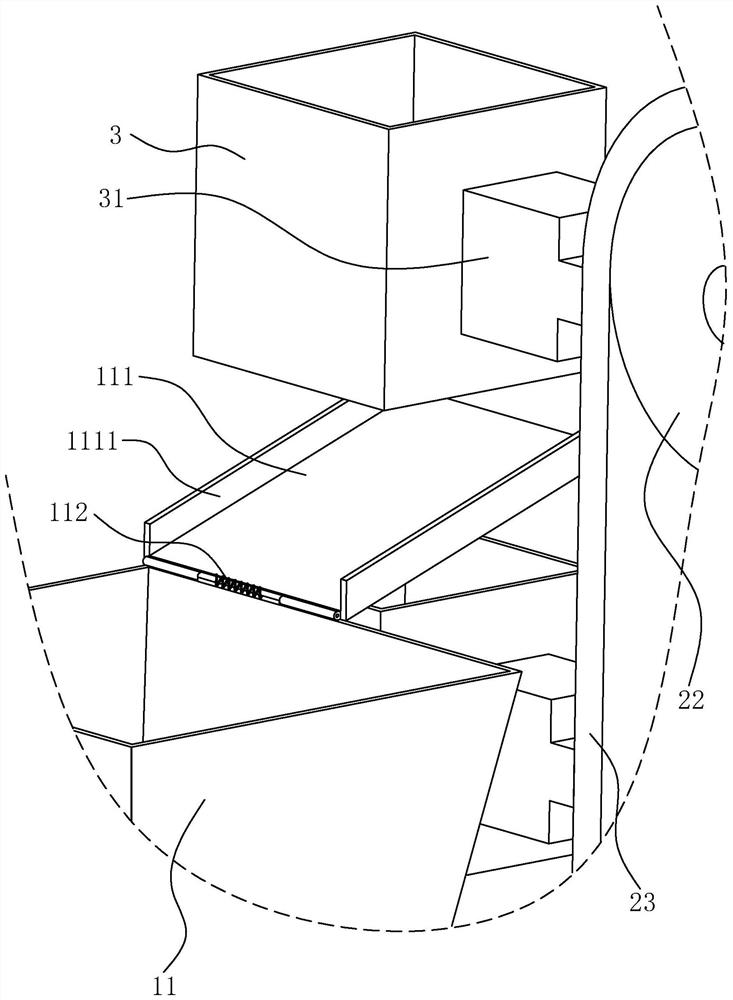

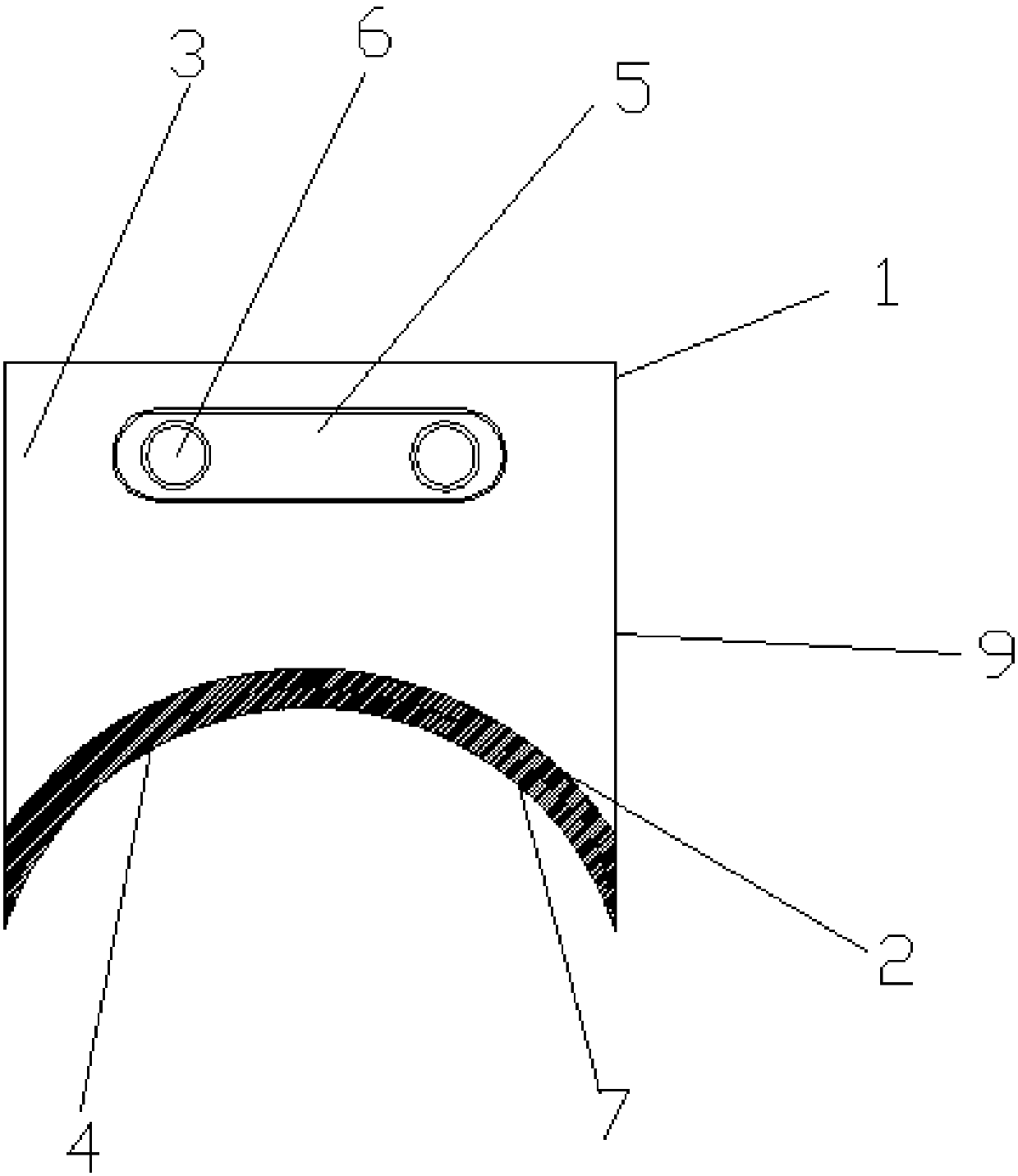

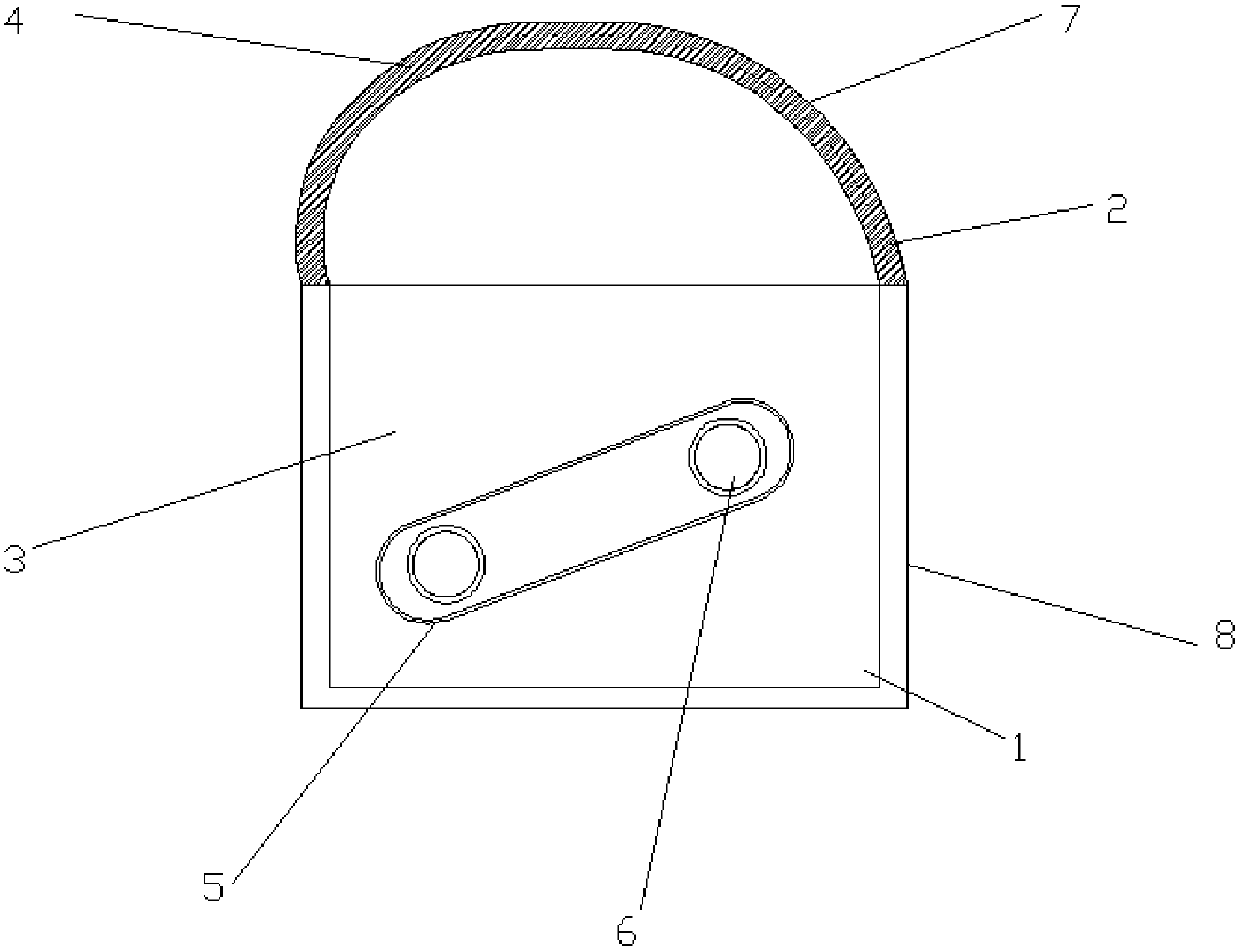

Sleeve workpiece continuous feeding mechanism

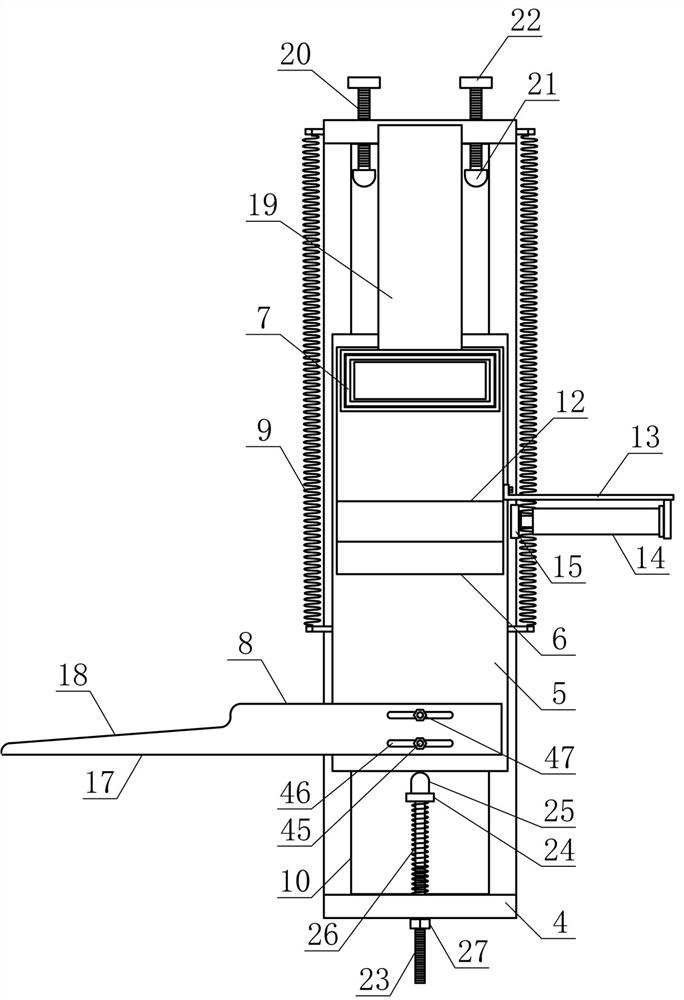

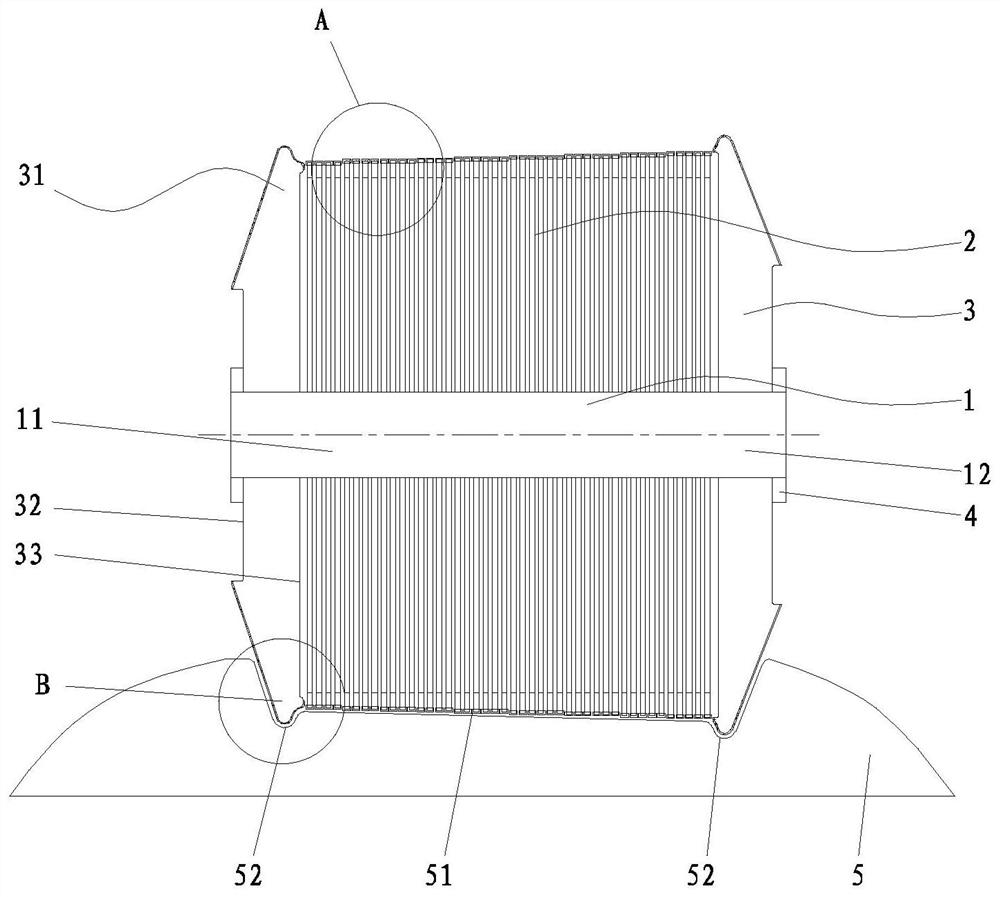

ActiveCN110921282AEfficient and accurate transfer and loadingReasonable structural designConveyor partsRotary conveyorsTransfer mechanismStructural engineering

The invention discloses a sleeve workpiece continuous feeding mechanism, and belongs to the field of workpiece machining and conveying mechanical equipment. A pushing mechanism and a transfer mechanism of the invention are successively and horizontally fixed to the upper side of a loading base in the horizontal direction. A reciprocating guide plate is slidably disposed on the translation guide ofa translation bracket in the horizontal direction. A translational push plate in circular structure and matching a bearing cylinder material path is vertically fixed to the output end of a pushing cylinder. The two sides of the reciprocating guide plate and the tube material end of a translation support are provided with reset tension springs. The middle of the lower side of a transfer circular plate is fixed to the end of the upper side of a loading shaft. A plurality of bearing cylinder mechanisms are evenly arranged in order on the transfer circular plate along the radial direction of thetransfer circular plate. The sleeve workpiece continuous feeding mechanism is reasonable in structural design, can translate, push, and accurately place the sleeve workpieces one by one, transfers, loads and machines the sleeve workpieces smoothly and efficiently, achieves the degree of automation of the workpiece loading, and satisfies the needs of production and use.

Owner:新昌县澄潭镇科创机械配件厂

Sliding slot type cutter device

InactiveCN105773723ASimple structureLow costWood splittingPortable power driven sawsEngineeringClockwise

The invention discloses a sliding slot type cutter device. The sliding slot type cutter device comprises a cutter head. The cutter head comprises a cutting edge and a cutter body. The cutting edge comprises a special-shaped cutting edge body. A guide groove is formed in the cutter body and comprises guide rolls clamped to a cutter. A manually operated type drive device is arranged on the cutter body and pushes the guide groove to move or slide. The cutting edge advances while sliding or rotating during cutting. The sliding slot type cutter device is simple in structure, time and labor are saved during operation, cutting is convenient and efficient, cost is low, cutting quality is good, the situation that cut ends or residual slag are / is left on cut objects is avoided, and the cutter head rotates clockwise to pull-cut and saw-cut the cut objects and rotates counterclockwise to cleave the cut objects.

Owner:蔡锦霞

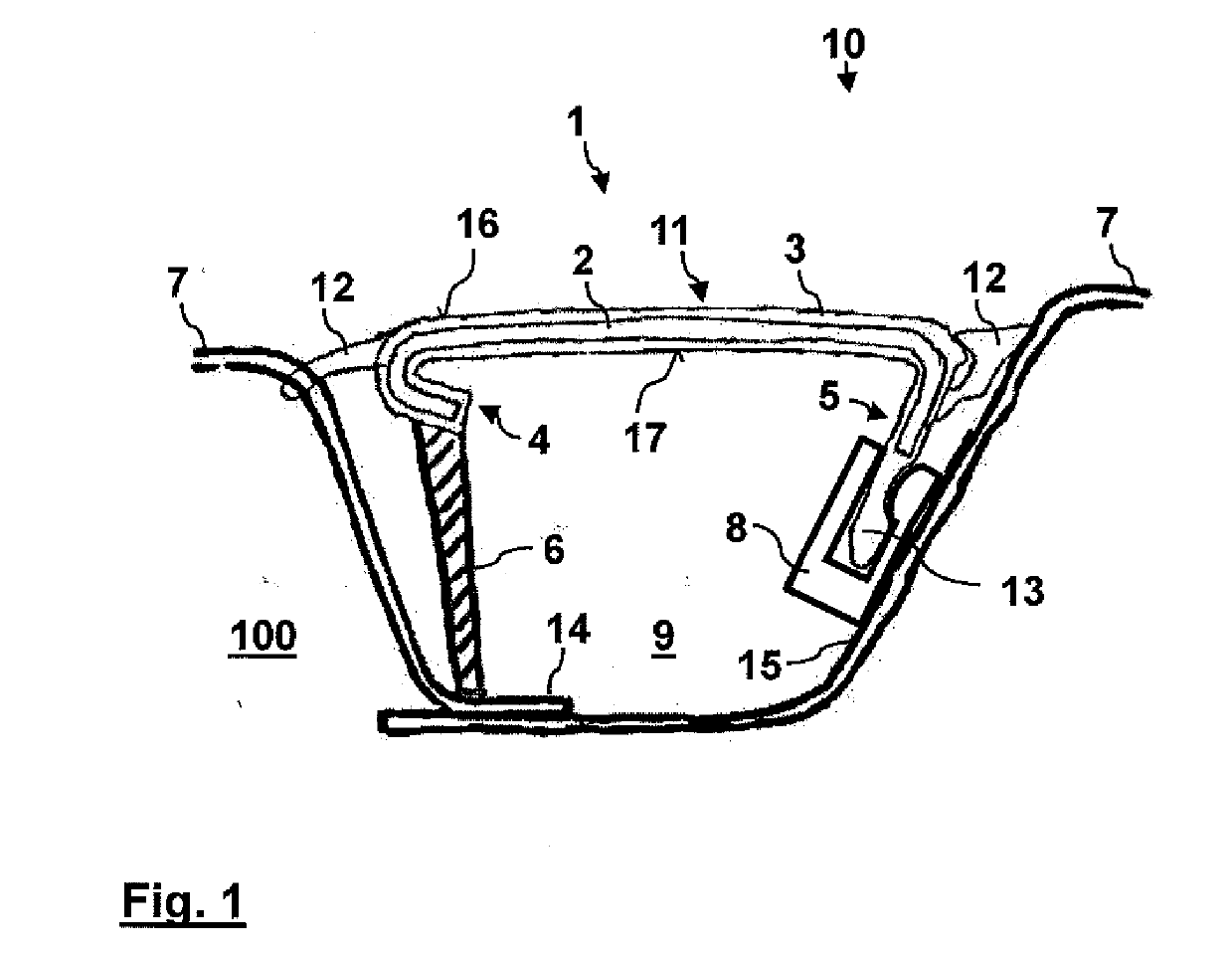

Vehicle Trim Bar and Fixing Arrangement for a Vehicle Trim Bar

Owner:MOTHERSON INNOVATIONS CO LTD

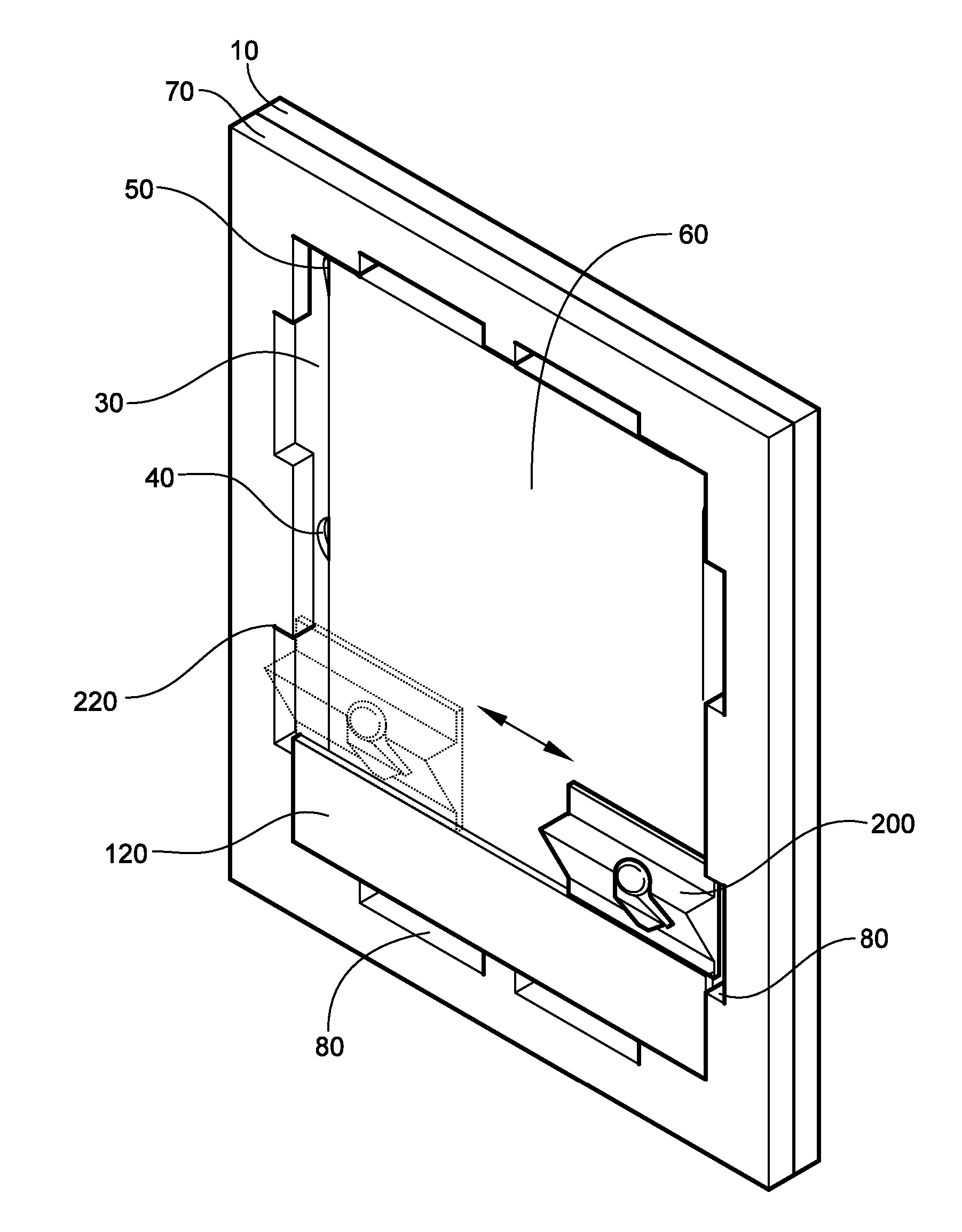

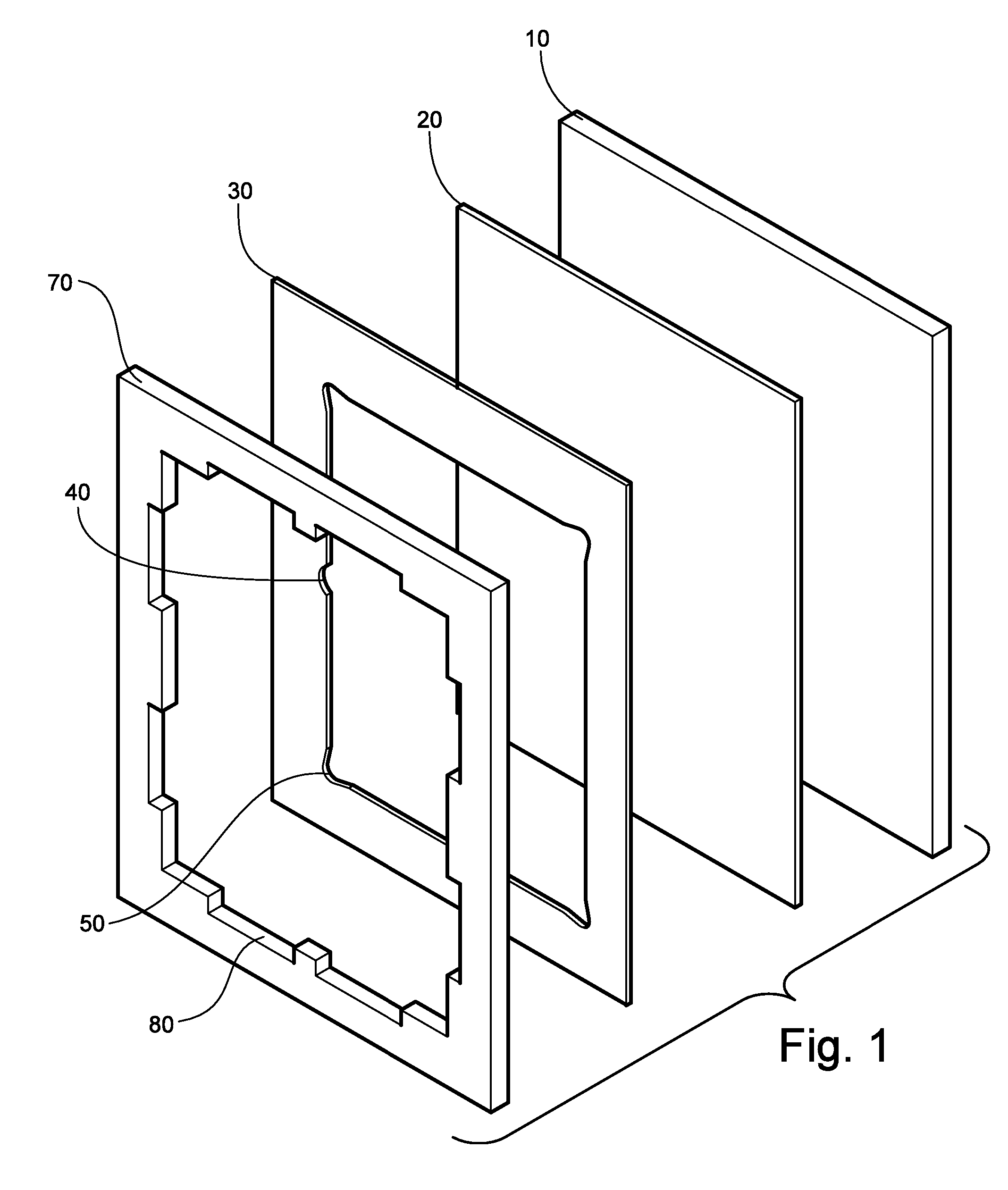

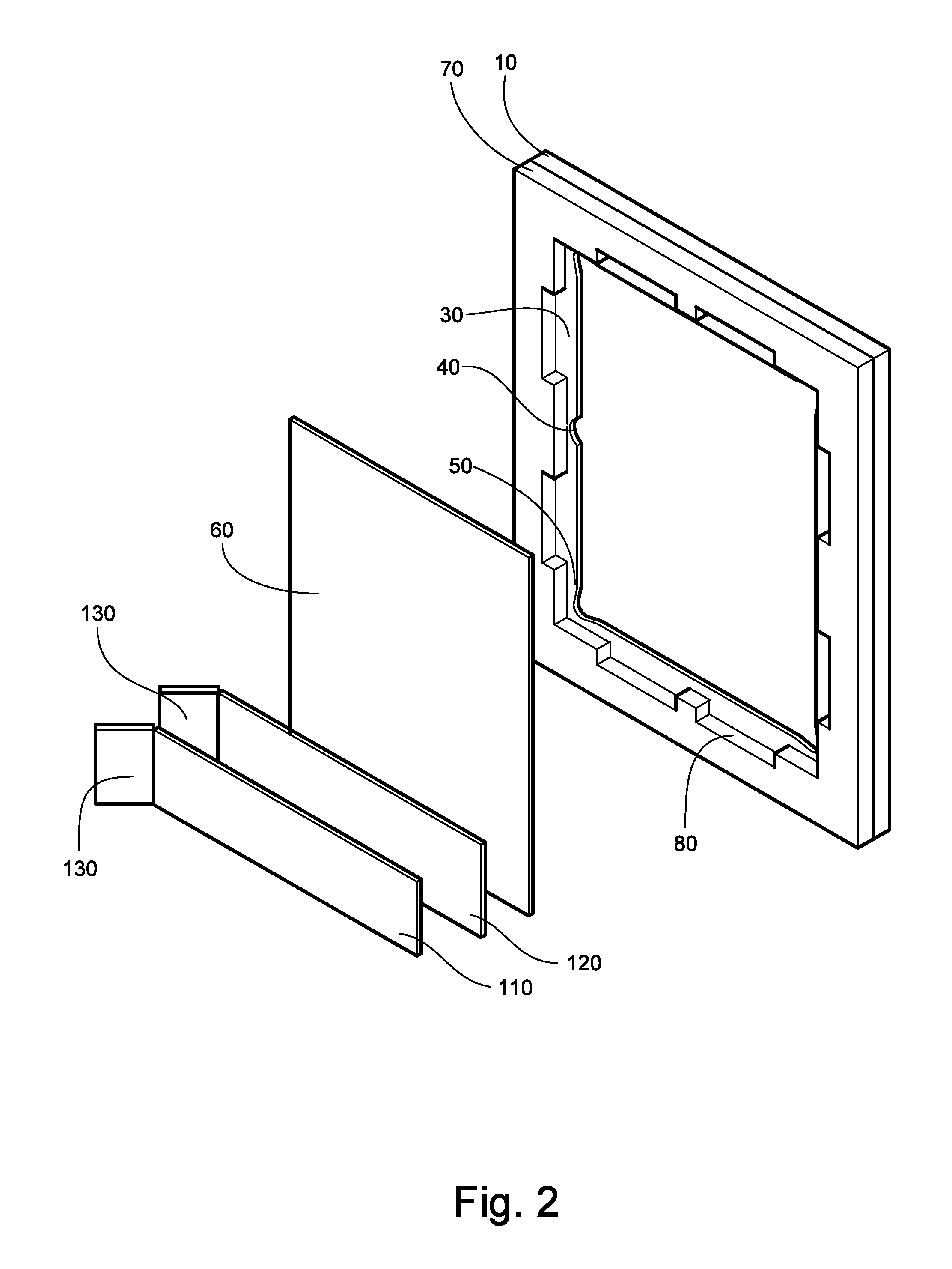

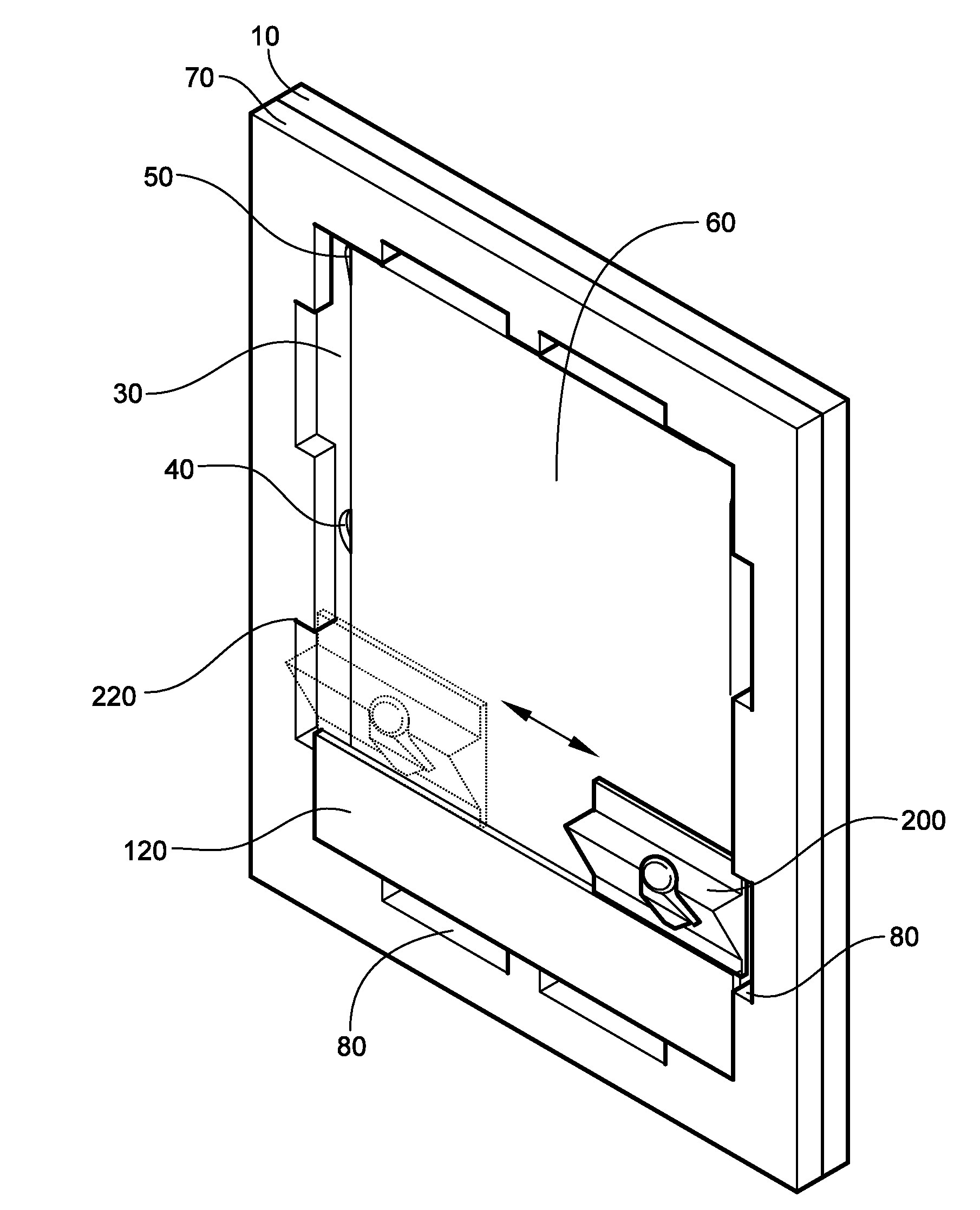

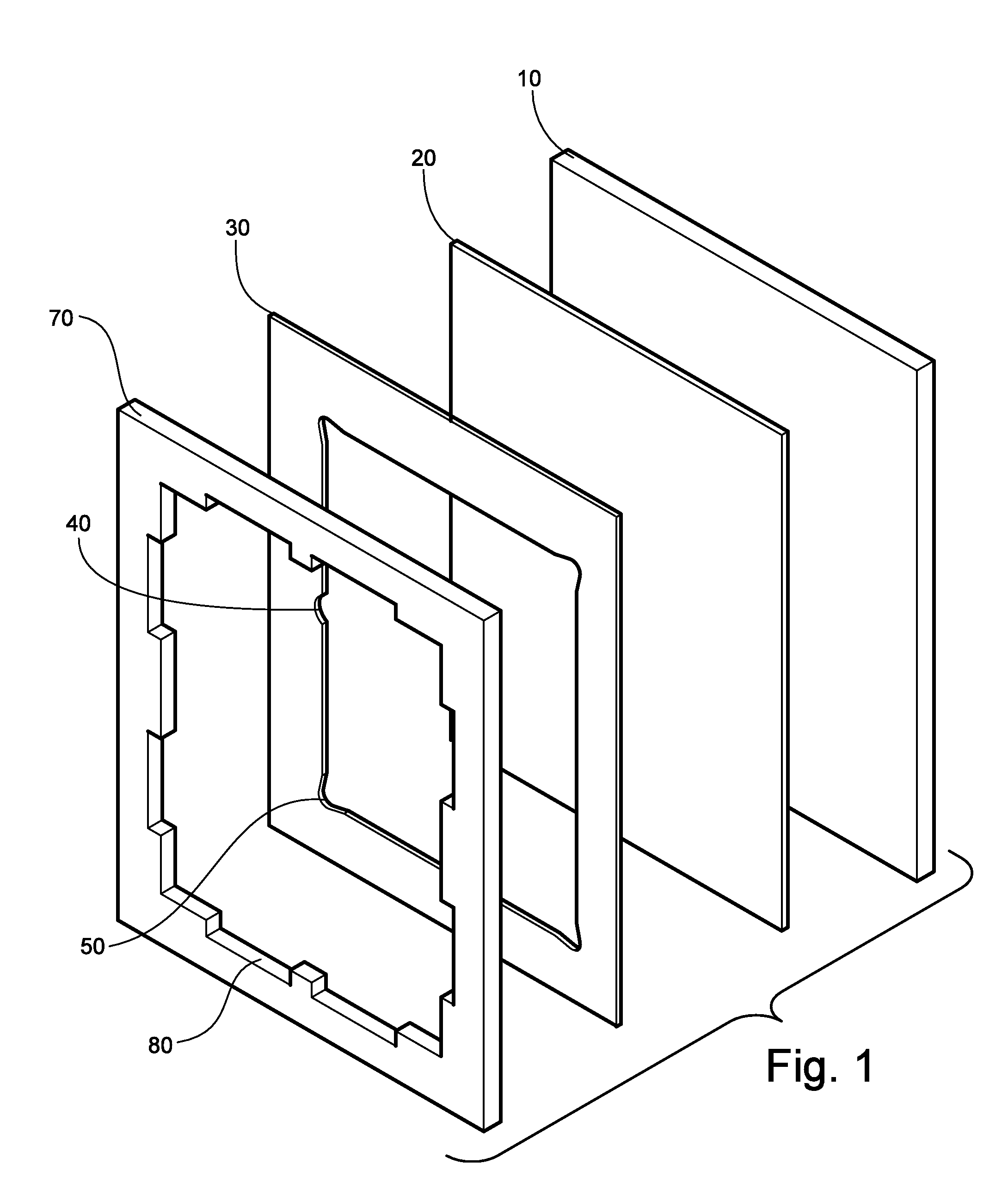

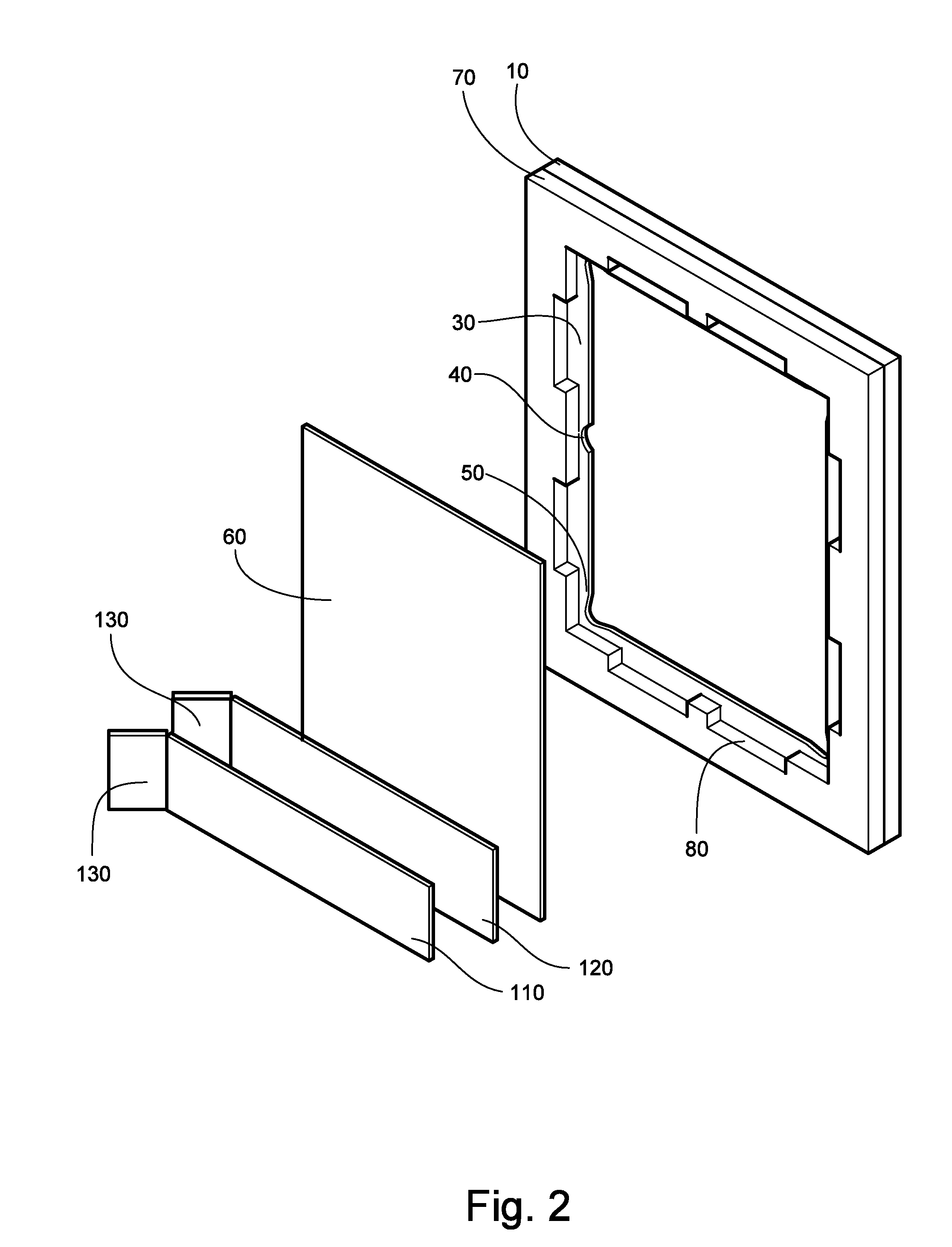

Device and Method for Cutting Mat and Liner for Double Matted Framed Artwork

InactiveUS20060283293A1Easy and efficient cuttingFacilitates speed and safetyWriting aidsGang saw millsEngineeringCurrent technology

The invention is a device and method that allows a user to easily and efficiently hand cut a mat and liner without the need to reposition the mat board. The notched features of the top frame and the different widths of the cutter guides set the parameters for the beginning and of each cut on a mat or a liner for a framed and double matted piece of artwork. Consequently these cuts may be made by a user with limited need for the degree of care which is commonly required in mat cutting using current technology.

Owner:WEST ALLAN

Working method of sleeve workpiece feeding mechanism

InactiveCN112707151AEfficient and accurate transfer and loadingReasonable structural designConveyor partsRotary conveyorsEngineeringMechanical equipment

The invention discloses a working method of a sleeve workpiece feeding mechanism, and belongs to the field of workpiece machining and conveying mechanical equipment. A pushing mechanism and a transferring mechanism are sequentially, horizontally and fixedly arranged on the upper side of a feeding base in the horizontal direction, a reciprocating guide plate is arranged on a translation guide strip of a translation support in a sliding mode in the horizontal direction, a translation push plate which is of a circular structure and is matched with a bearing barrel material channel is vertically and fixedly arranged at the output end of a pushing air cylinder, reset tension springs are horizontally arranged on the two sides of the reciprocating guide plate and the ends of guide pipes of the translation support, the middle of the lower side of a circular transferring plate is fixedly connected with the end of the upper side of a feeding rotating shaft, and a plurality of bearing barrel mechanisms are sequentially and evenly arranged on the circular transferring plate in the radial direction of the circular transferring plate. The structural design is reasonable, sleeve workpieces can be horizontally moved, pushed and accurately placed one by one, stable and efficient transferring, feeding and machining of the sleeve workpieces are achieved, the automation degree of workpiece feeding is improved, and the requirements of production and use are met.

Owner:龚文科

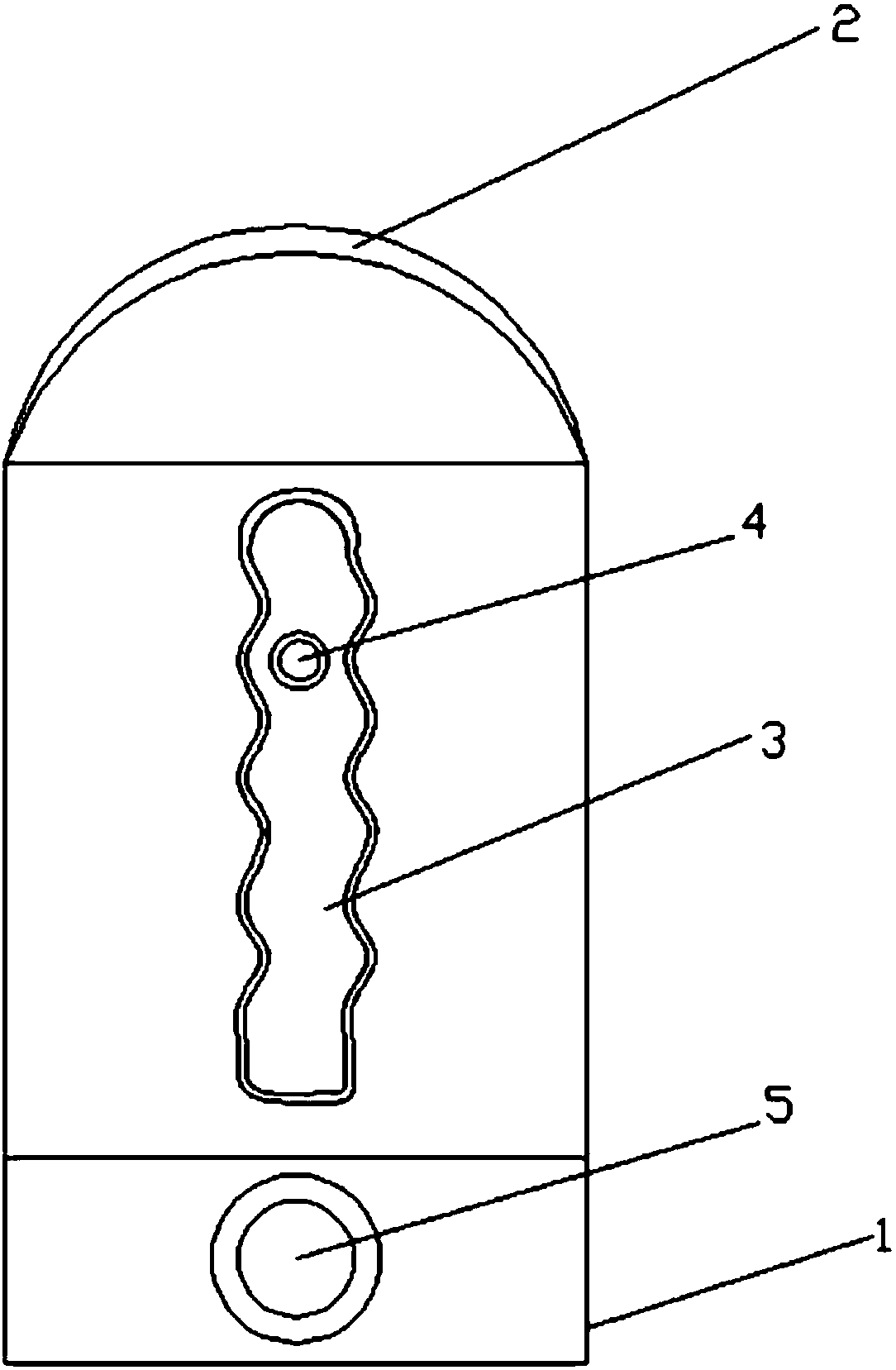

Trussed girder for the construction industry and method for producing a trussed girder of this kind

ActiveUS11346104B2Improve carrying capacityEasy to handleGirdersJoistsStructural engineeringMechanical engineering

A trussed girder for the construction industry, having an upper flange and having a lower flange made of square timber, which extend along the longitudinal axis of the trussed girder and which are connected to one another by a plurality of struts, which are each arranged so as to extend obliquely to the flanges. The struts are formed by at least one strut run, the upper side and underside of which are formed in an undulating manner in the axial direction and are arranged so as to extend parallel to one another with radii corresponding to one another. The strut run is mortised or dovetailed in the axial direction alternately by means of the upper flange and the lower flange and is formed as a single-piece wood material part. The invention additionally relates to a method for producing trussed girders of this kind, in particular on a mass scale.

Owner:PERI AG

Sliding chute type cutter structure

The invention discloses a sliding chute type cutter structure which comprises a cutterhead, wherein the cutterhead comprises a cutting edge part or a cutter body; the cutting edge part is provided with a specially-shaped cutting edge; a guide slot is formed in the cutter body; the specially-shaped cutting edge is a part of the contour line of a cam; the guide slot is provided with a reinforcing structure; the cutting edge part can forwards while sliding or rotating during cutting. The sliding chute type cutter structure is simple in structure, is time-saving and labor-saving in operation, and is convenient and efficient for cutting; the cutterhead clockwise rotates to realize pull-cutting and saw-cutting and anticlockwise rotates to chop objects.

Owner:蔡锦霞

Multi-sensor information collection analyzing system and autism children monitoring auxiliary system

InactiveCN102176222BImprove environmental adaptabilityFlexiblePsychotechnic devicesSpecial data processing applicationsArea networkCollection analysis

The invention belongs to the field of robots, and relates to a multi-sensor information collection analyzing system, a robot device which performs real-time monitor and adjuvant treatment for autism children by using the system and a control technology of the robot device. In the multi-sensor information collection analyzing system, a plurality of sensors, collectors and information output equipment transmit communication information by adopting a controller area network (CAN) fieldbus, and the distribution type information fusion technology ensures that mounting and clipping of the equipmentto be more convenient and efficient. By adopting the multi-information fusion technology, the ways for the robot to collect interactive object emotions are increased, and the affinity and interactivesuccessful rate of human-machine interaction are improved.

Owner:UNIV OF SCI & TECH BEIJING

Adjusting structure for curtain cutting machine

ActiveUS9643331B2Easy and efficient cuttingReduce labor costsMetal working apparatusEngineeringMechanical engineering

Owner:SHEEN WORLD TECH CORP

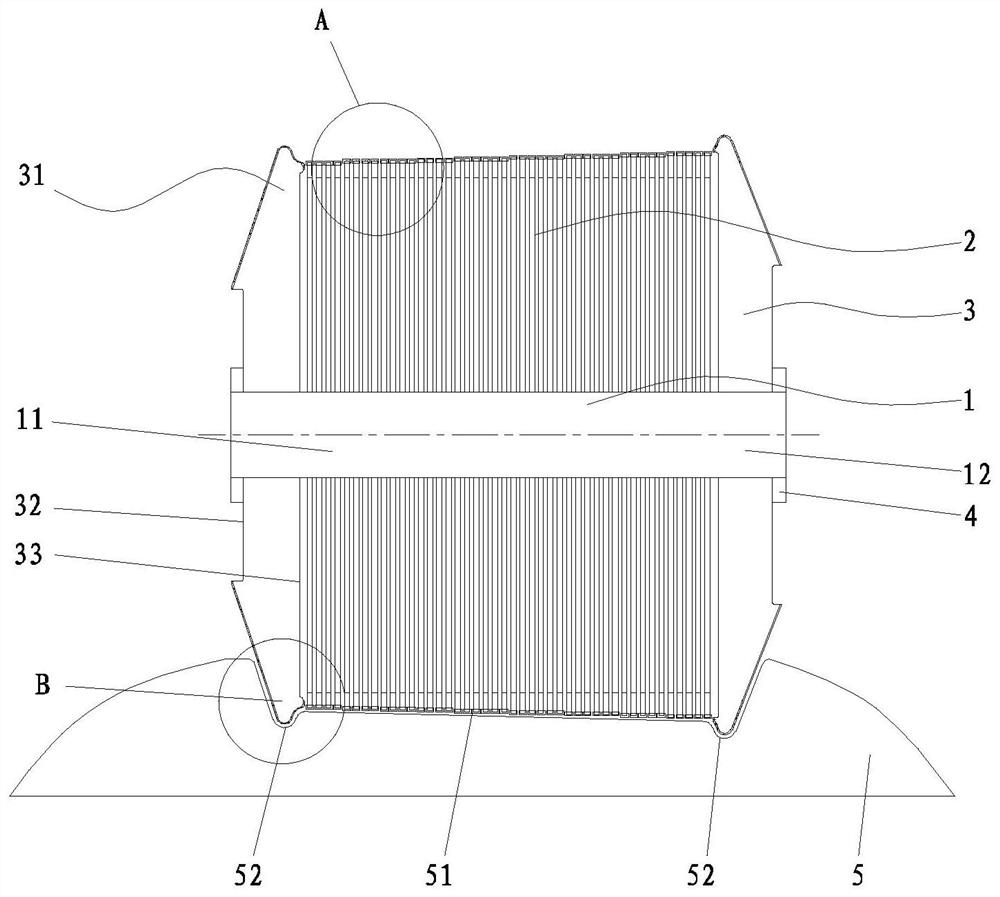

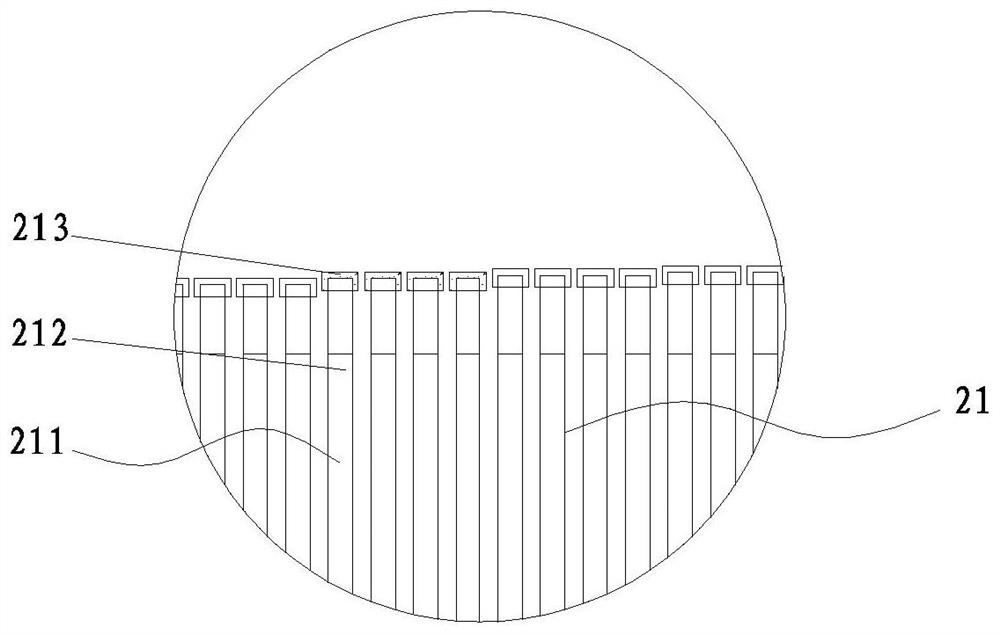

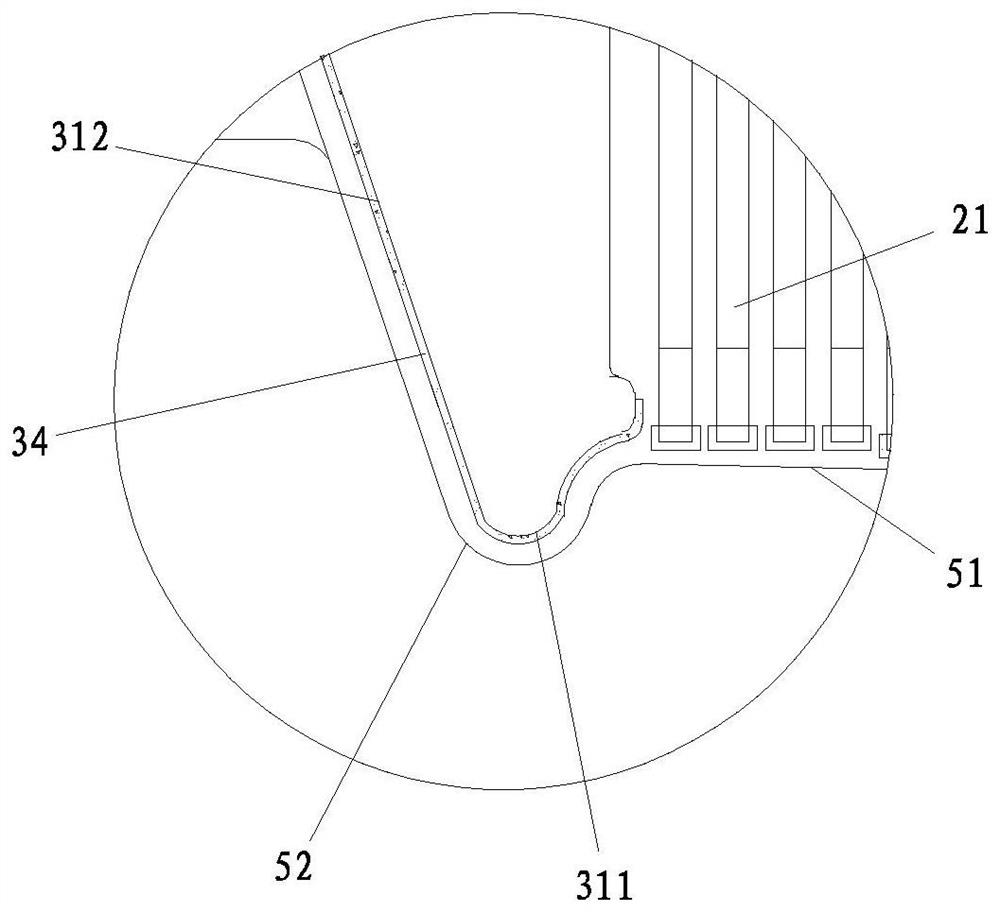

Sleeper cutting tool bit

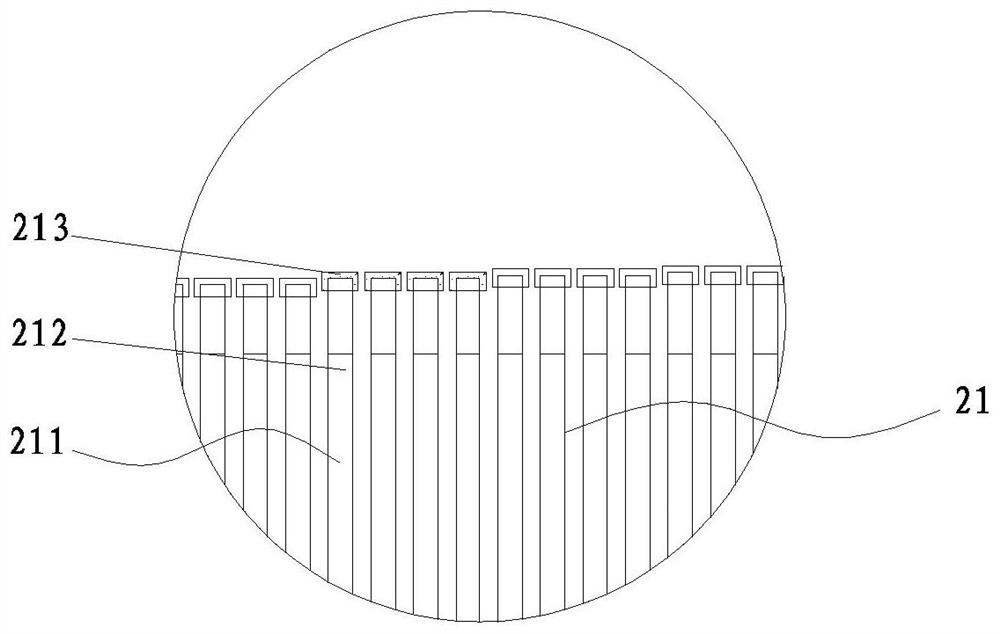

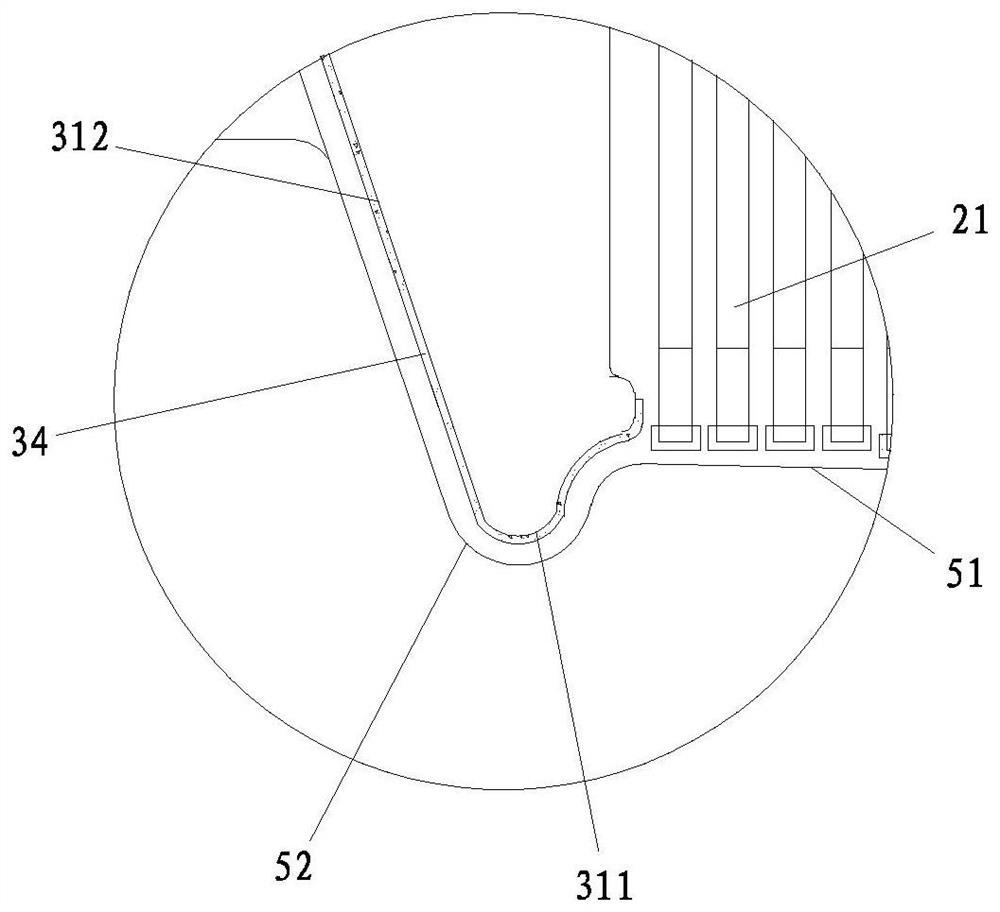

ActiveCN112108715AFit tightlyImprove cutting accuracyFeeding apparatusPositioning apparatusEngineeringStructural engineering

The invention discloses a sleeper cutting tool bit which comprises a rotating shaft, as well as a first cutting body used for cutting an inclined plane of a sleeper, and a second cutting body used forcutting an arc-shaped surface of the sleeper; the first cutting body is arranged in the middle of the rotating shaft in a sleeving mode, and comprises a plurality of cutter sets; and the second cutting body comprises two ends arranged on the rotating shaft in a sleeving mode. After the structure is adopted, during cutting, the sleeper cutting tool bit is close to and is embedded into the profilesurface of the sleeper, the first cutting body is attached to the inclined plane of the profile surface, and the second cutting body is embedded and attached to the arc-shaped surfaces of the right and left sides of the inclined plane; and then, the rotating shaft is driven by a power unit to drive the first cutting body and the second cutting body to cut the profile surface of the sleeper. Compared with the prior art, the sleeper cutting tool bit has the beneficial effects that the sleeper cutting tool bit can be tightly attached to the profile surface of a sleeper, and the cutting precisionand the cutting quality are improved; and only one-time positioning is needed during machining, and the cutting process is more convenient and efficient.

Owner:FUJIAN QUANZHOU HUAZUAN DIAMOND TOOLS CO LTD

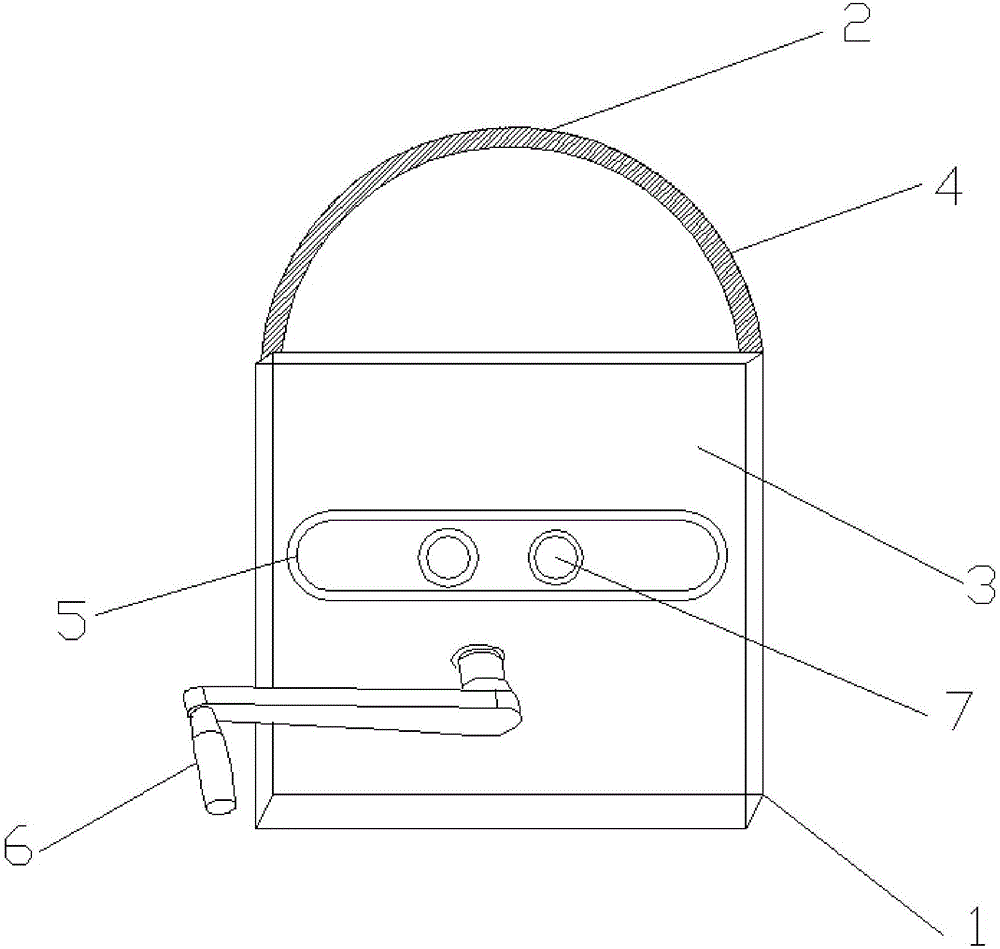

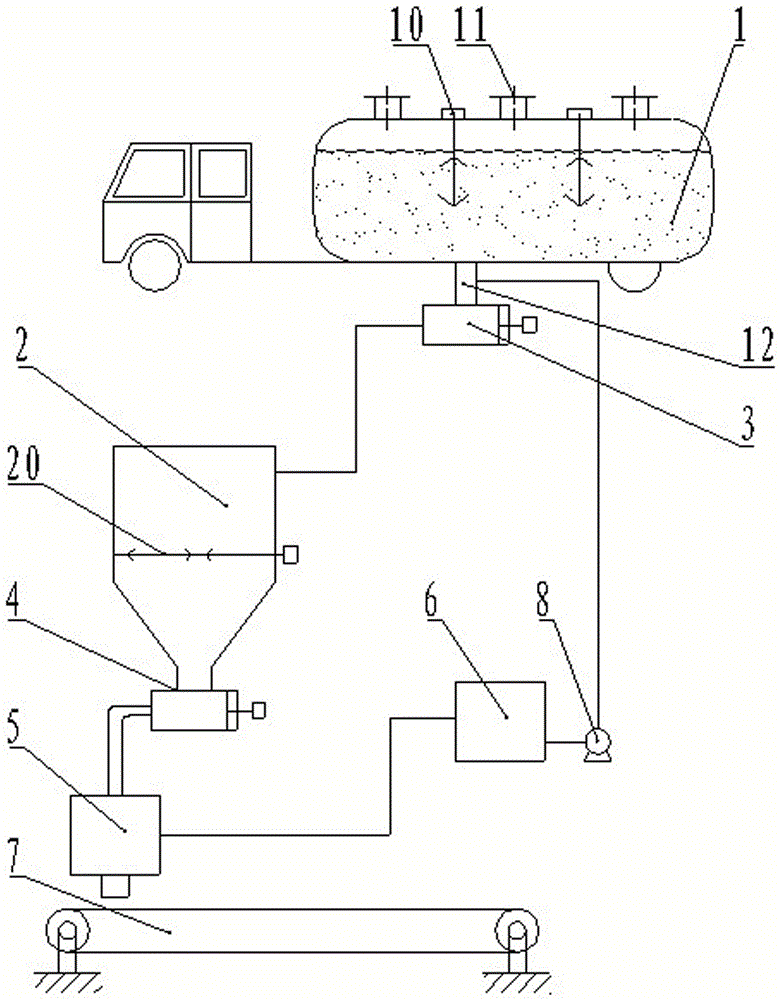

Brine-circulation industrial waste salt discharge device and use method thereof

InactiveCN106115303ANo pollution in the processNo secondary pollutionLarge containersBulk conveyorsTank truckCirculating pump

The invention provides a brine-circulation industrial waste salt discharge device capable of carrying out automatic discharge on industrial waste salt conveyed by a tank truck, the operation is completely carried out in a closed pipeline, and the discharge is thorough and free from secondary pollution. The brine-circulation industrial waste salt discharge device comprises the tank truck bearing a storage tank, and an unloading tank, wherein a plunger pump A is connected to a bottom pipeline of the storage tank, and the plunger pump A is connected with the unloading tank through a pipeline; the bottom of the unloading tank is connected with a centrifugal machine via a plunger pump B, a brine pond and a conveying device are further comprised, a solid-phase outlet of the centrifugal machine and the conveying device are arranged in a matching manner, and a liquid-phase outlet of the centrifugal machine is connected with the brine pond through a pipeline; and the brine pond is connected with the plunger pump A through a pipeline via a circulation pump. At least one group of vibration devices is arranged in the storage tank. A stirring device is arranged in the unloading tank.

Owner:安徽今朝环保科技有限公司

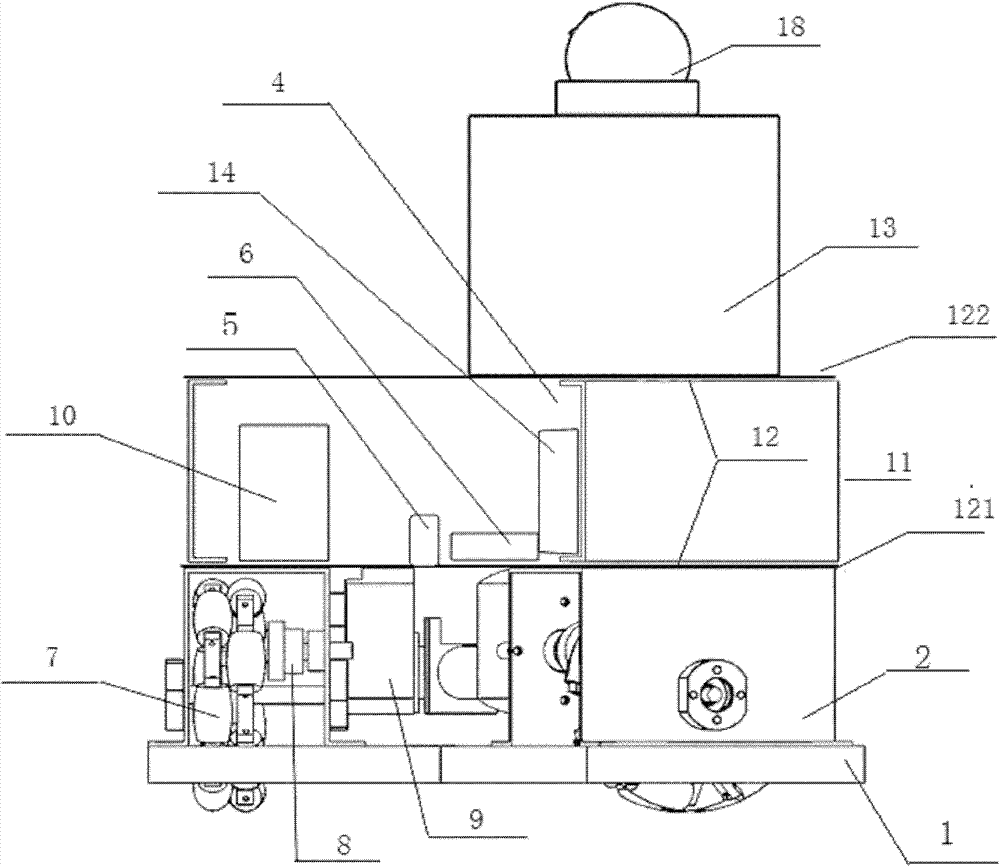

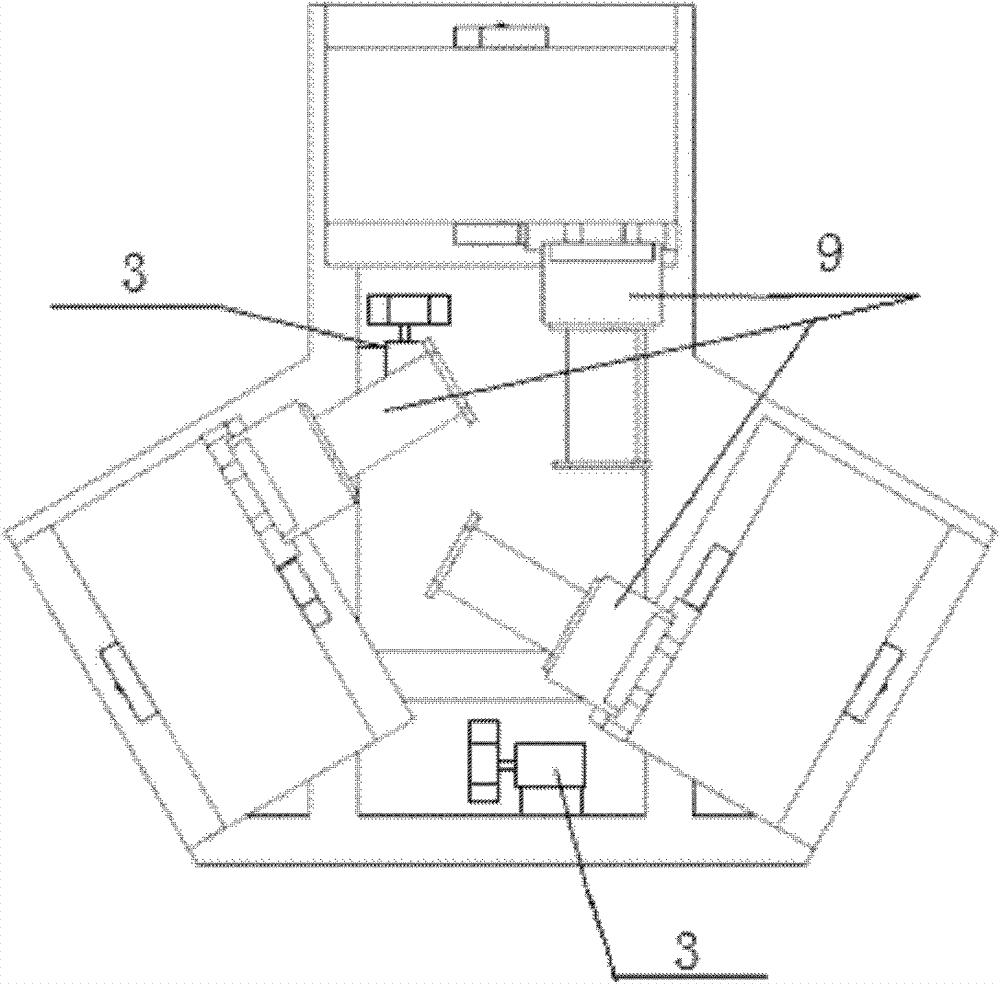

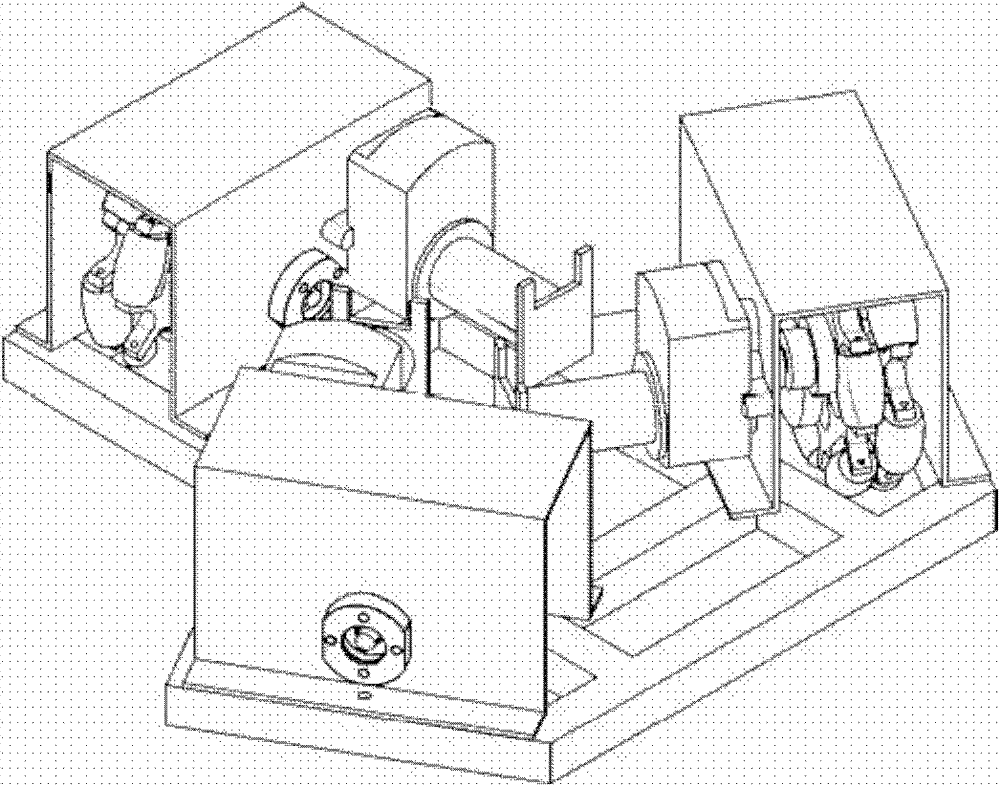

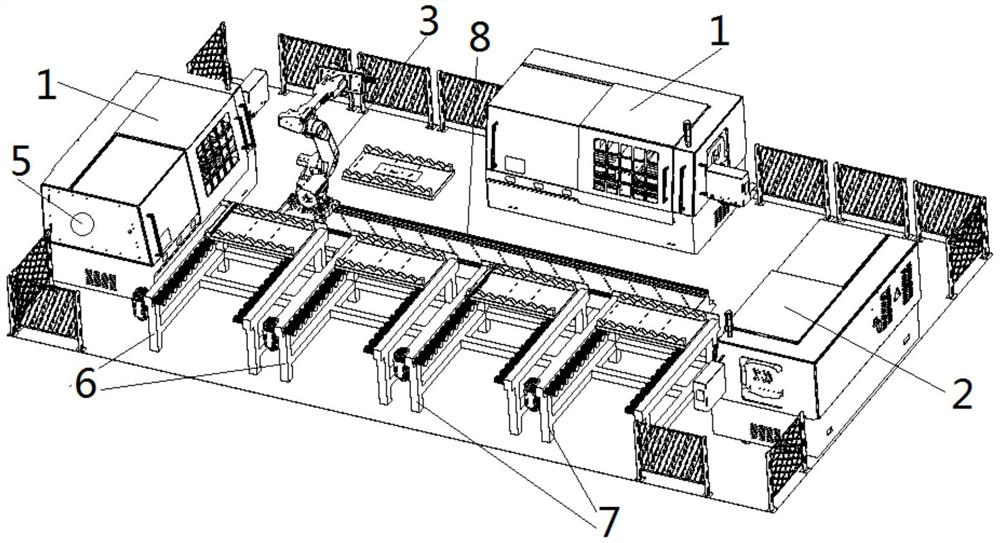

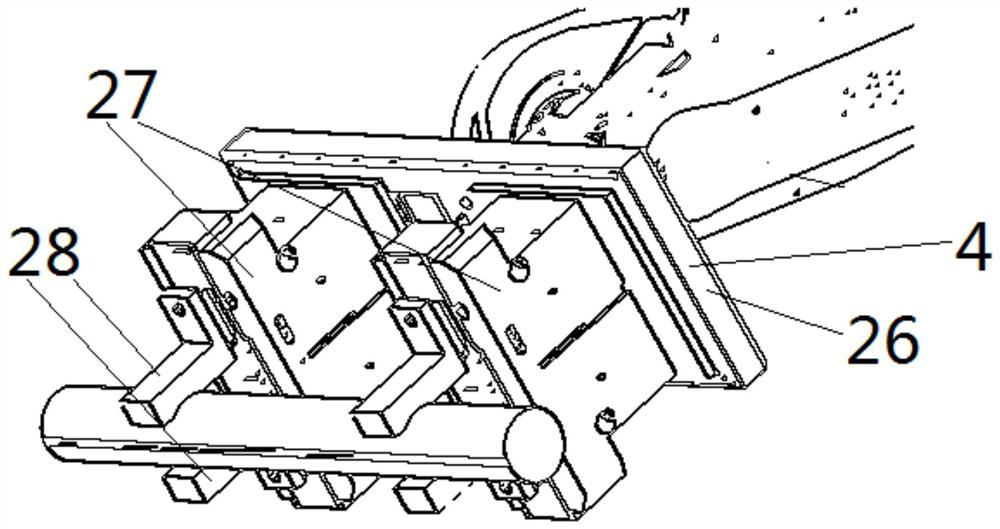

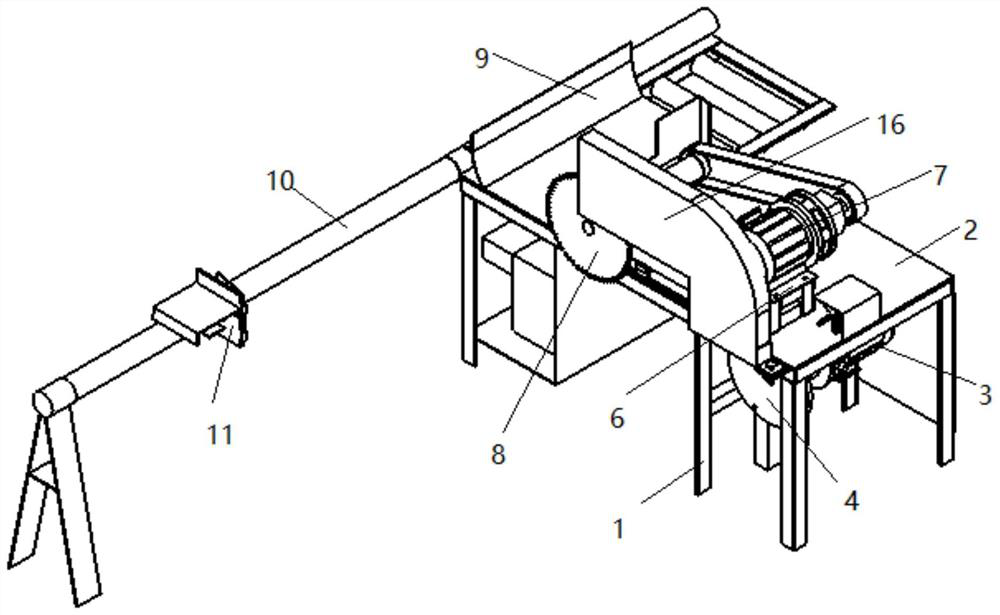

An automatic processing line for shaft parts

ActiveCN108161553BRealize automatic processingEnsure processing quality meets requirementsMetal working apparatusNumerical controlProduction line

The invention provides an automatic shaft-kind part machining production line applied to the technical field of automatic production of shaft-kind parts. According to the technical scheme, the tail end of a robot moving arm of a six-axis industrial robot (3) of the automatic shaft-kind part machining production line is provided with a tail end clamp (4), the six-axis industrial robot (3) is connected with a control part (5), a feeding conveying part (6) is arranged at the position close to a numerical control lathe (1), and a discharging conveying part (7) is arranged at the position close toa numerical control milling machine (2); and the control part (5) is arranged to be a structure capable of controlling the tail end clamp (4) at the tail end of the robot moving arm to clamp a part raw material or a part finished product. According to the automatic shaft-kind part machining production line, the structure is simple, automatic feeding, machining and discharging of the shaft-kind part can be realized conveniently and efficiently, then manual operation can be converted into robot automatic operation, so that the machining efficiency is improved, the labor intensity of workers is reduced, the occurrence rate of manual accidents is reduced, and the production cost is reduced.

Owner:WUHU HIT ROBOT TECH RES INST

Vehicle trim bar and fixing arrangement for a vehicle trim bar

Owner:MOTHERSON INNOVATIONS CO LTD

A sleeper cutting head

ActiveCN112108715BFit tightlyImprove cutting accuracyFeeding apparatusPositioning apparatusClassical mechanicsStructural engineering

The invention discloses a sleeper cutting cutter head, which includes a rotating shaft, and further includes a first cutting body for cutting the inclined surface of the sleeper, and a second cutting body for cutting the arc surface of the sleeper; the first cutting body Sleeved in the middle of the rotating shaft, the first cutting body includes several cutting knife groups; the second cutting body includes both ends of the rotating shaft. After adopting the above-mentioned structure, when cutting, the present invention is approached and embedded in the profile surface of the sleeper, the first cutting body is attached to the inclined surface of the profile surface, and the second cutting body is embedded in the arc-shaped surfaces on the left and right sides of the inclined surface Fitting; then the first cutting body and the second cutting body are driven by the power device to drive the rotating shaft to cut the profile surface of the sleeper. Compared with the prior art, the beneficial effect is that the present invention can closely fit the profile surface of the sleeper, improve the cutting precision and cutting quality, and only need one positioning during processing, making the cutting process more convenient and efficient.

Owner:FUJIAN QUANZHOU HUAZUAN DIAMOND TOOLS CO LTD

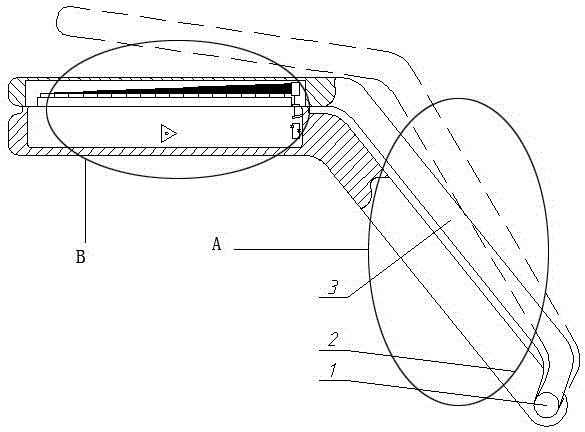

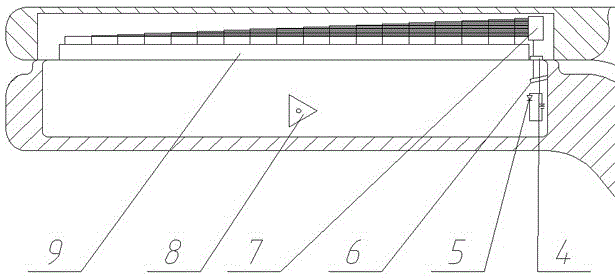

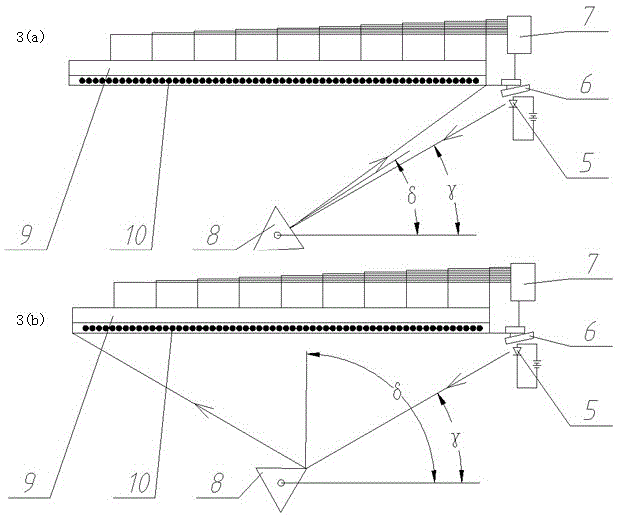

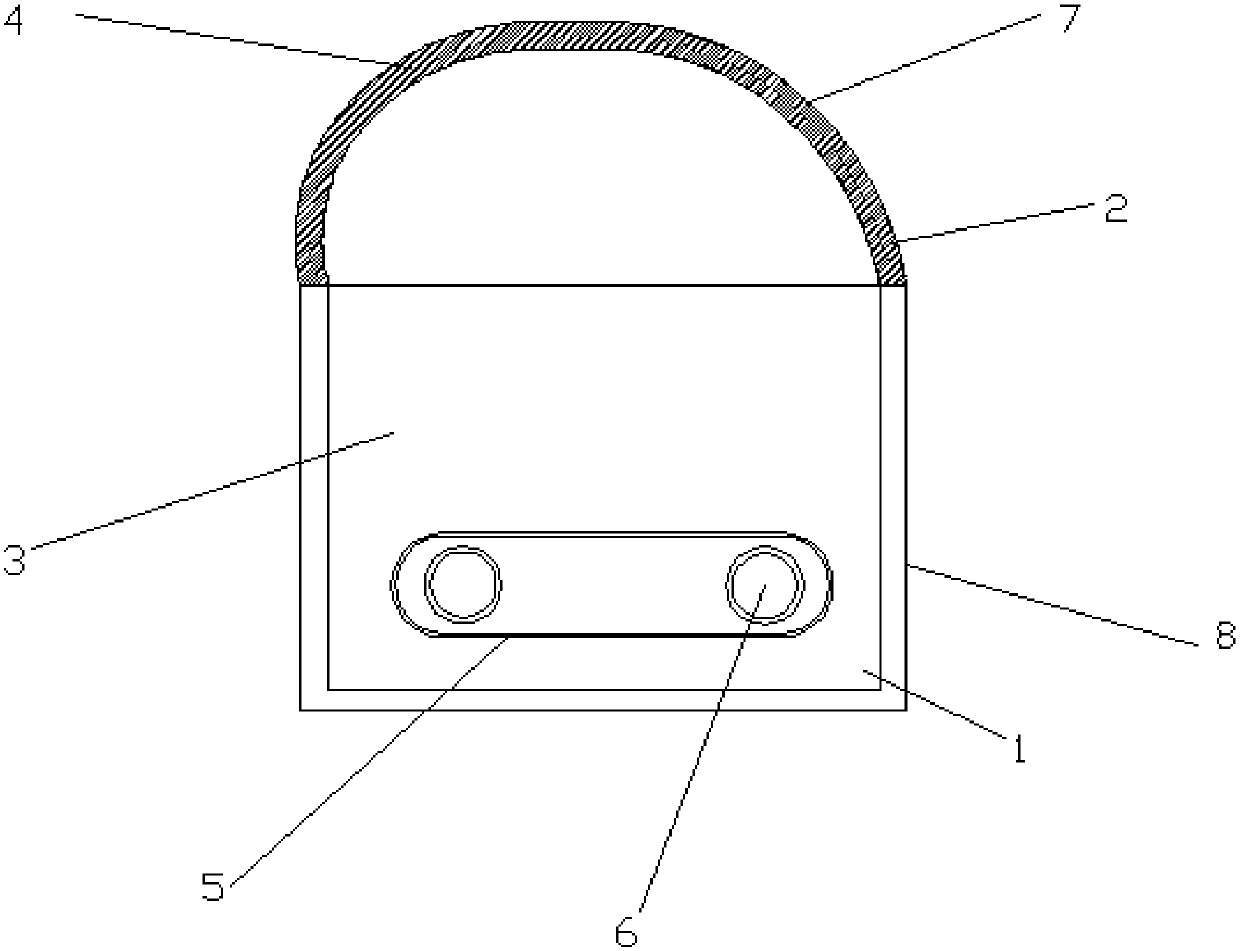

Device and method for detecting and cutting off white hair

InactiveCN103921002BPrevent openingErgonomicMaterial analysis by optical meansLaser beam welding apparatusLaser transmitterEngineering

The invention relates to a device and a method for detecting and cutting white hair. The device comprises a pull-back spring, a lower clamping plate, an upper clamping plate, a touch switch, a laser diode, a burning laser transmitter, a processor, a rotary triangular prism and a CCD (charge coupled device). The lower clamping plate and the upper clamping plate are connected through a pin shaft and the pull-back spring, the CCD is installed in a notch of the upper clamping plate and is connected with the processor and the touch switch which are arranged at the tail end of the inner groove of the upper clamping plate, the rotary triangular prism is installed at the bottom of an inner groove of the lower clamping plate, and the burning laser transmitter and the laser diode are installed at the tail end of the inner groove of the lower clamping plate from top to bottom. The white hair can be cut conveniently and efficiently under the premises of no side effects and no hurt to the hair and scalp; people can get rid of trouble of the white hair, and living quality can be improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

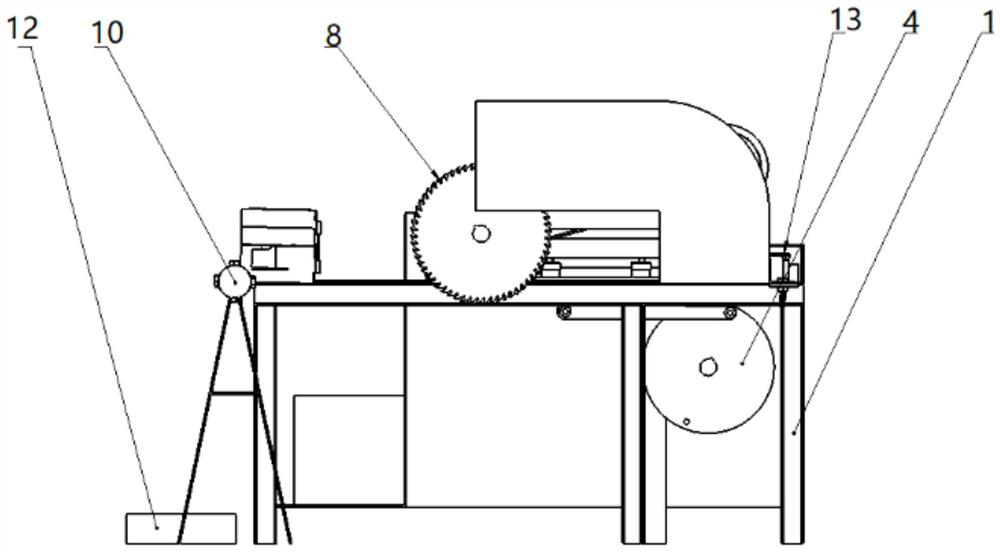

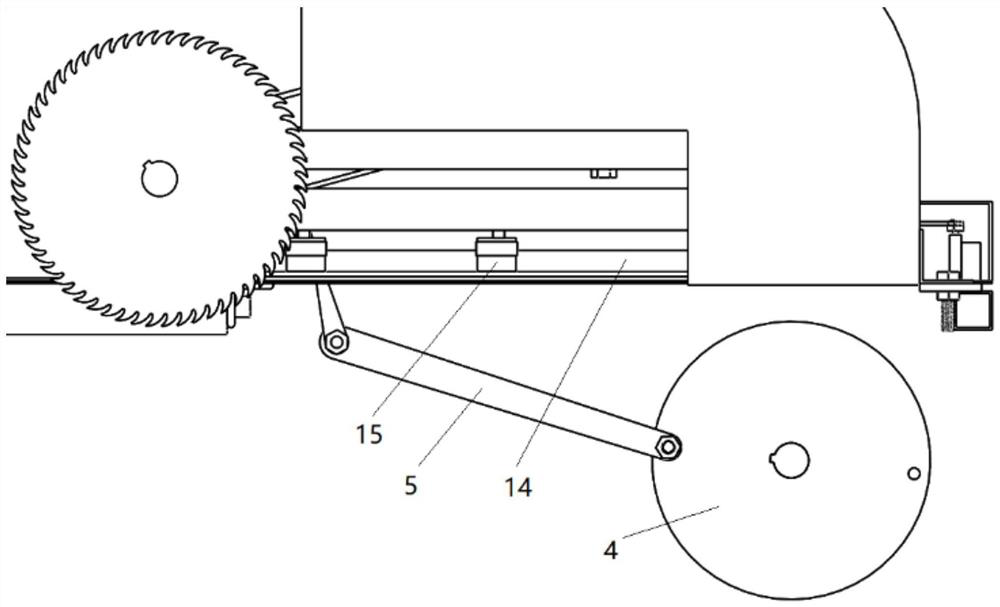

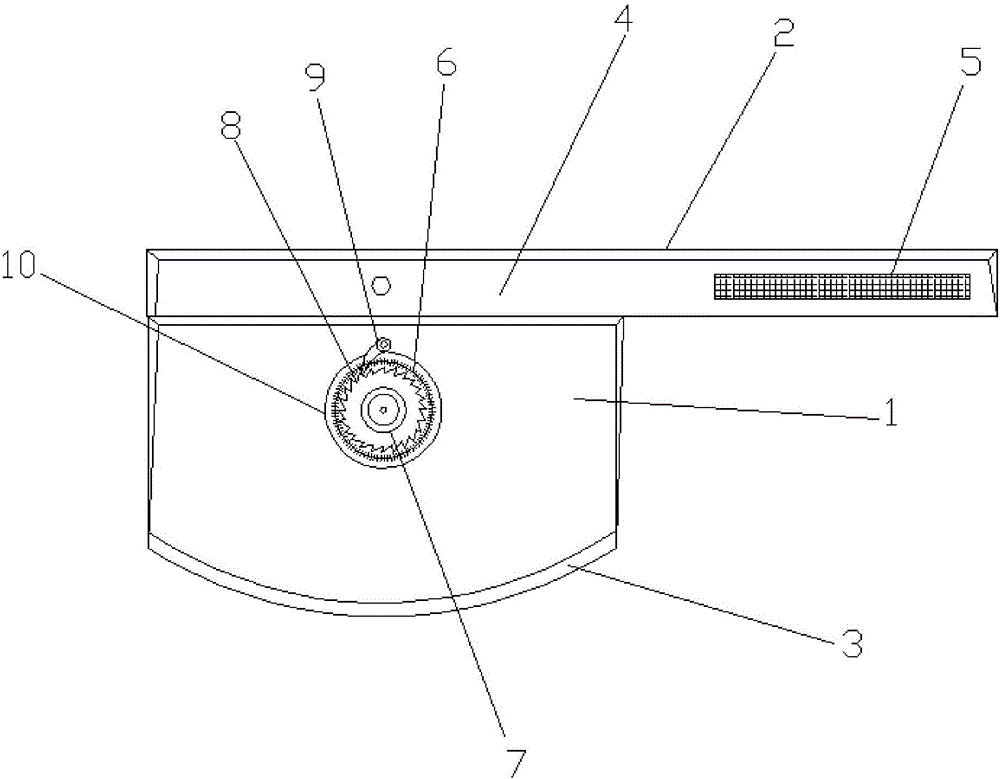

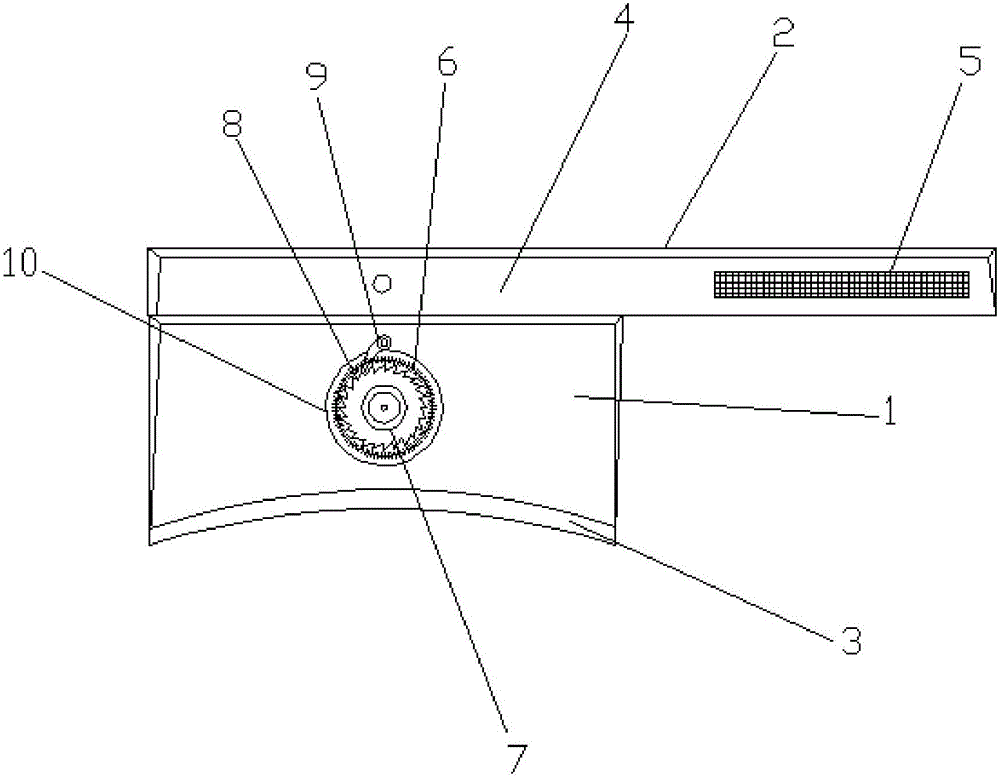

Novel moso bamboo saw bench

PendingCN112339020AEfficient cuttingEasy and efficient cuttingCane mechanical workingCircular sawsElectric machineryAutomatic control

The invention discloses a novel moso bamboo saw bench which comprises a saw bench table frame. A speed reduction motor is mounted on the lower side of a table top of the saw bench table frame; the output shaft end of the speed reduction motor is fixedly connected with an eccentric wheel; a momunting frame is arranged on the upper side of the table top in a sliding mode; the bottom of the mountingframe is connected with an eccentric shaft of the eccentric wheel through a transmission rod; a cutting motor and a cutting saw blade are mounted on the mounting frame; a feeding groove is fixedly formed on the table top on the right side of the cutting saw blade; a fixed-length rod is fixedly arranged on the right side of the saw bench table frame; and the fixed-length rod is sleeved with a baffle. Compared with the prior art, the novel moso bamboo cutting saw bench disclosed by the invention has the advantages that the moso bamboo cutting saw bench is simple in structure, low in cost, easy to operate and higher in practicability; redundant bamboo heads on moso bamboos can be efficiently cut off; the moso bamboos with different lengths can be conveniently and efficiently cut so as to adapt to market requirements better; and the cutting saw bench adopts automatic control, so that a large amount of human resources are saved.

Owner:冉玥

Strut type cutter device

The invention discloses a strut type cutter device. The strut type cutter device comprises a cutter body and a cutter body clamping and driving device, wherein the cutter body comprises a blade; the blade is a special-shaped blade; the special-shaped blade comprises one part of a cam profile or involute shape; a rotational structure is arranged on the cutter body; the cutter body can rotate around the rotational structure; the cutter body clamping and driving device comprises a cutter body clamping device and a driving device; a rotational structure clamping body is arranged on the cutter body clamping device and is matched with the rotational structure; the rotational structure can rotate in the rotational structure clamping body; the cutter body clamping device is connected with the cutter body; and the driving device drives the blade to simultaneously advance and rotate while cutting. The strut type cutter device disclosed by the invention has the advantages of simple structure, low cost, convenience in cutting, high efficiency, time conservation, labor conservation, good cutting quality and capability of cutting stubborn objects.

Owner:蔡锦霞

An air column automatic cutting robot for express packaging

The invention discloses an air column coil material automatic cutting robot for express packaging, comprising a support base, a support frame is fixedly connected to the middle part of the upper surface of the support base, and two inner bearings of the support frame are connected with one upper and one lower. Pipe fittings, the upper and lower pipe fittings on the inner side of the support frame respectively run through the upper and lower ends of the support plate, and the upper and lower ends of the support plate are respectively connected to the inner top of the support frame and the upper surface of the support base through the pulley slide structure. The bearings on the opposite sides of the support plate are connected with damping connectors, and the outer side of the damping connectors is fixedly connected with the limit piece, and the coaxial damping connectors are connected by rotating rollers, and the outer sides of the rotating rollers The shaft is connected with a guard plate. The air column coil material automatic cutting robot for express packaging can facilitate efficient cutting of the air column coil material, and when cutting, it is not necessary to make the air column coil material straight, which is beneficial to reduce the damage of the air column coil material, thereby It is easy to use.

Owner:绍兴市森辉机械有限公司

A saw blade structure

Owner:蔡锦霞

Garbage disposal crusher facilitating feeding and discharging

The invention relates to a garbage disposal crusher facilitating feeding and discharging, and relates to the field of garbage disposal equipment. The garbage disposal crusher comprises a machine body, a feeding hopper and a discharging opening are formed in the machine body, and a conveying assembly is arranged at one side of the machine body; the conveying assembly comprises a supporting frame, two conveying wheels rotationally connected to the supporting frame, a conveying belt installed between the two conveying wheels and a driving piece used for driving one conveying wheel to rotate; and a plurality of conveying boxes are evenly arranged on the conveying belt, conversion parts used for pouring out garbage in the conveying boxes are arranged on the conveying boxes, and a gate plate is arranged at the discharging opening. The crusher has the beneficial effects that the occupied space of the crusher is reduced, and the feeding and discharging processes of the crusher are more convenient.

Owner:湖南宏祥万景环境工程有限公司

A chute type cutter structure

The invention discloses a sliding chute type cutter structure which comprises a cutterhead, wherein the cutterhead comprises a cutting edge part or a cutter body; the cutting edge part is provided with a specially-shaped cutting edge; a guide slot is formed in the cutter body; the specially-shaped cutting edge is a part of the contour line of a cam; the guide slot is provided with a reinforcing structure; the cutting edge part can forwards while sliding or rotating during cutting. The sliding chute type cutter structure is simple in structure, is time-saving and labor-saving in operation, and is convenient and efficient for cutting; the cutterhead clockwise rotates to realize pull-cutting and saw-cutting and anticlockwise rotates to chop objects.

Owner:蔡锦霞

Device for cutting mat and liner for double matted framed artwork

InactiveUS7568415B2Easy and efficient cuttingFacilitates speed and safetyWriting aidsGang saw millsEngineeringCurrent technology

The invention is a device and method that allows a user to easily and efficiently hand cut a mat and liner without the need to reposition the mat board. The notched features of the top frame and the different widths of the cutter guides set the parameters for the beginning and of each cut on a mat or a liner for a framed and double matted piece of artwork. Consequently these cuts may be made by a user with limited need for the degree of care which is commonly required in mat cutting using current technology.

Owner:WEST ALLAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com