Patents

Literature

137results about How to "Easy and efficient removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

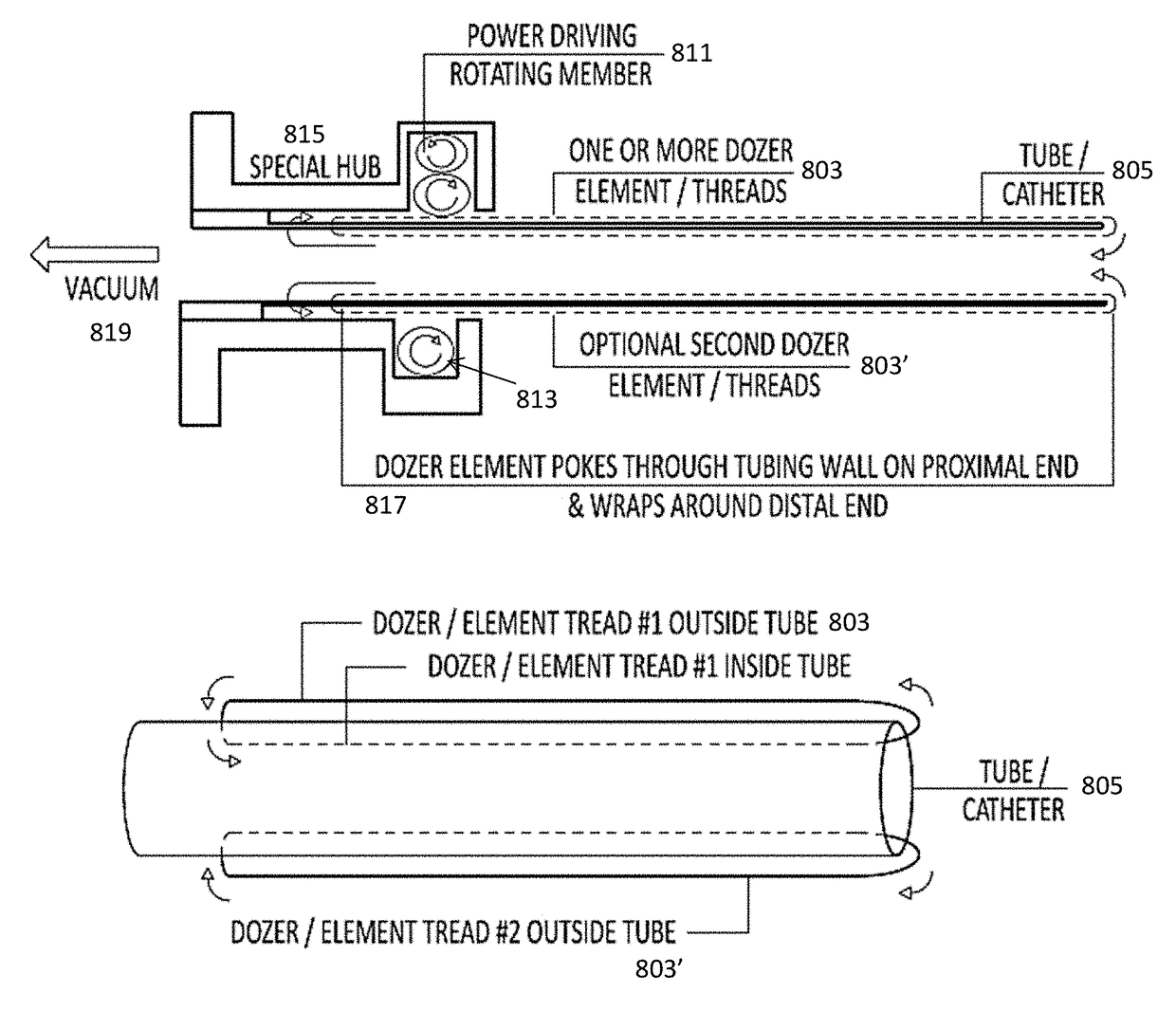

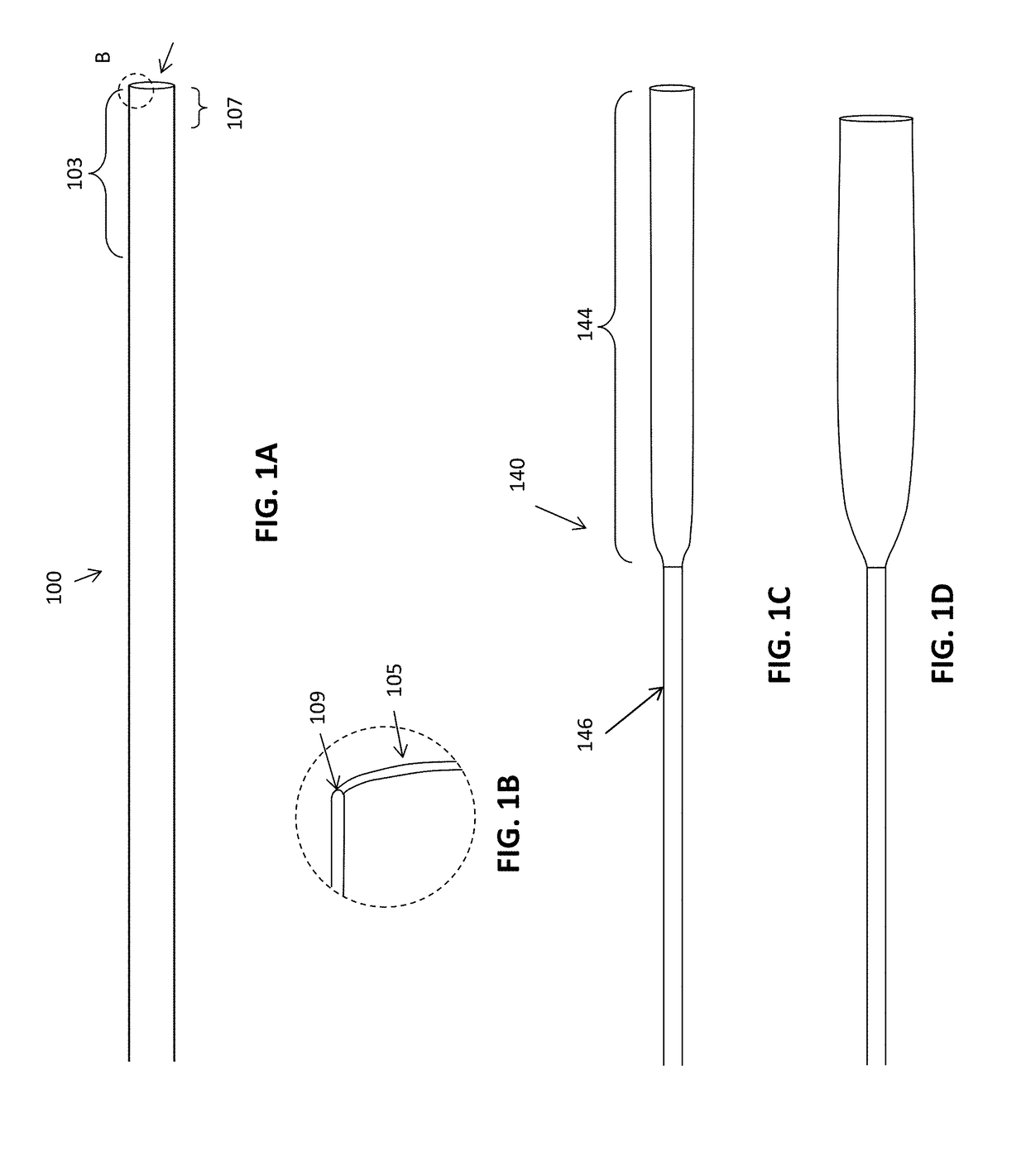

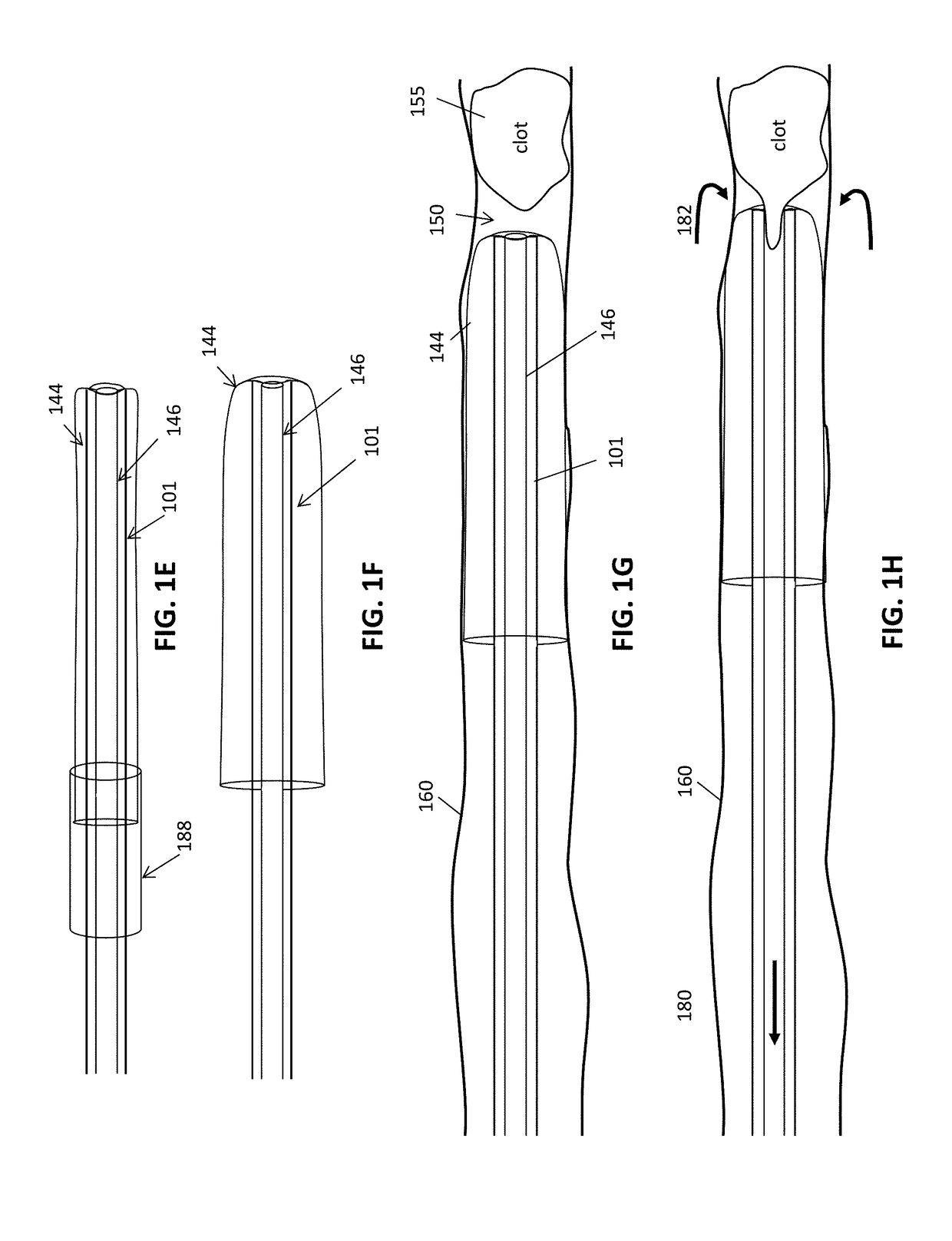

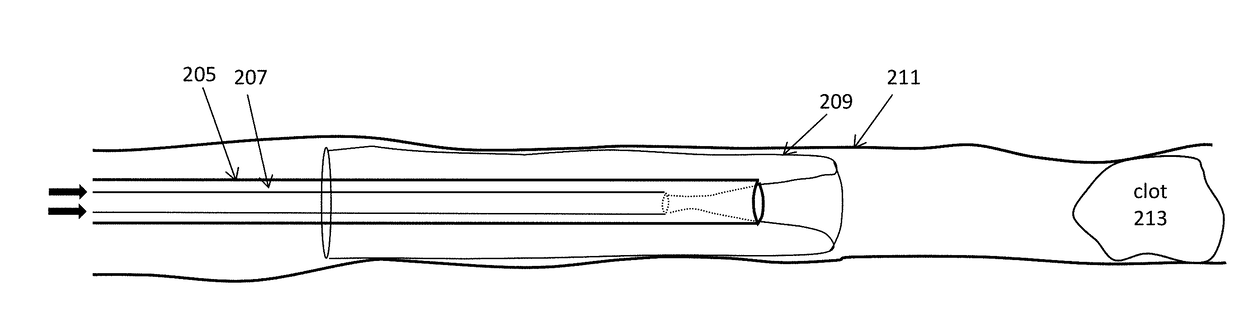

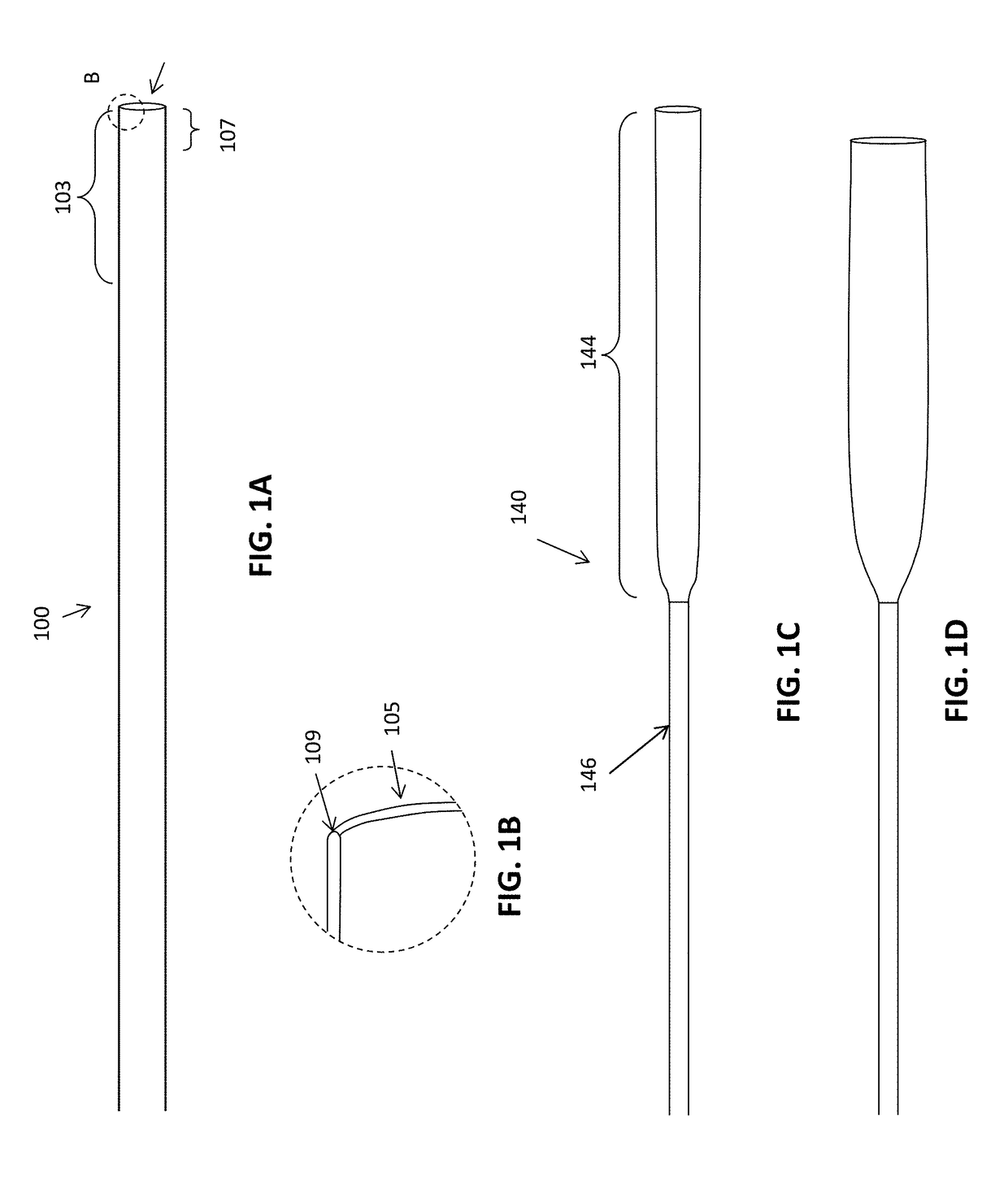

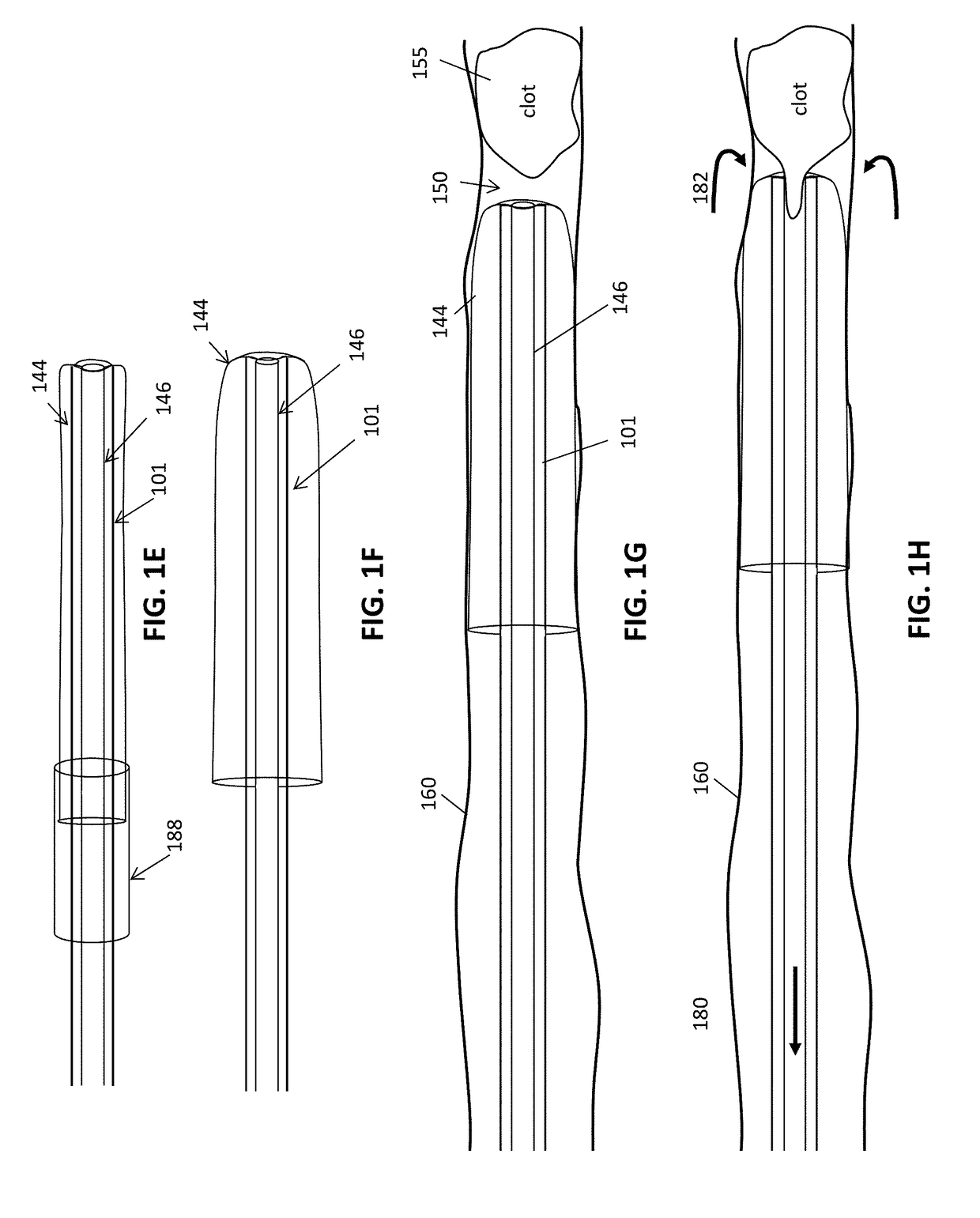

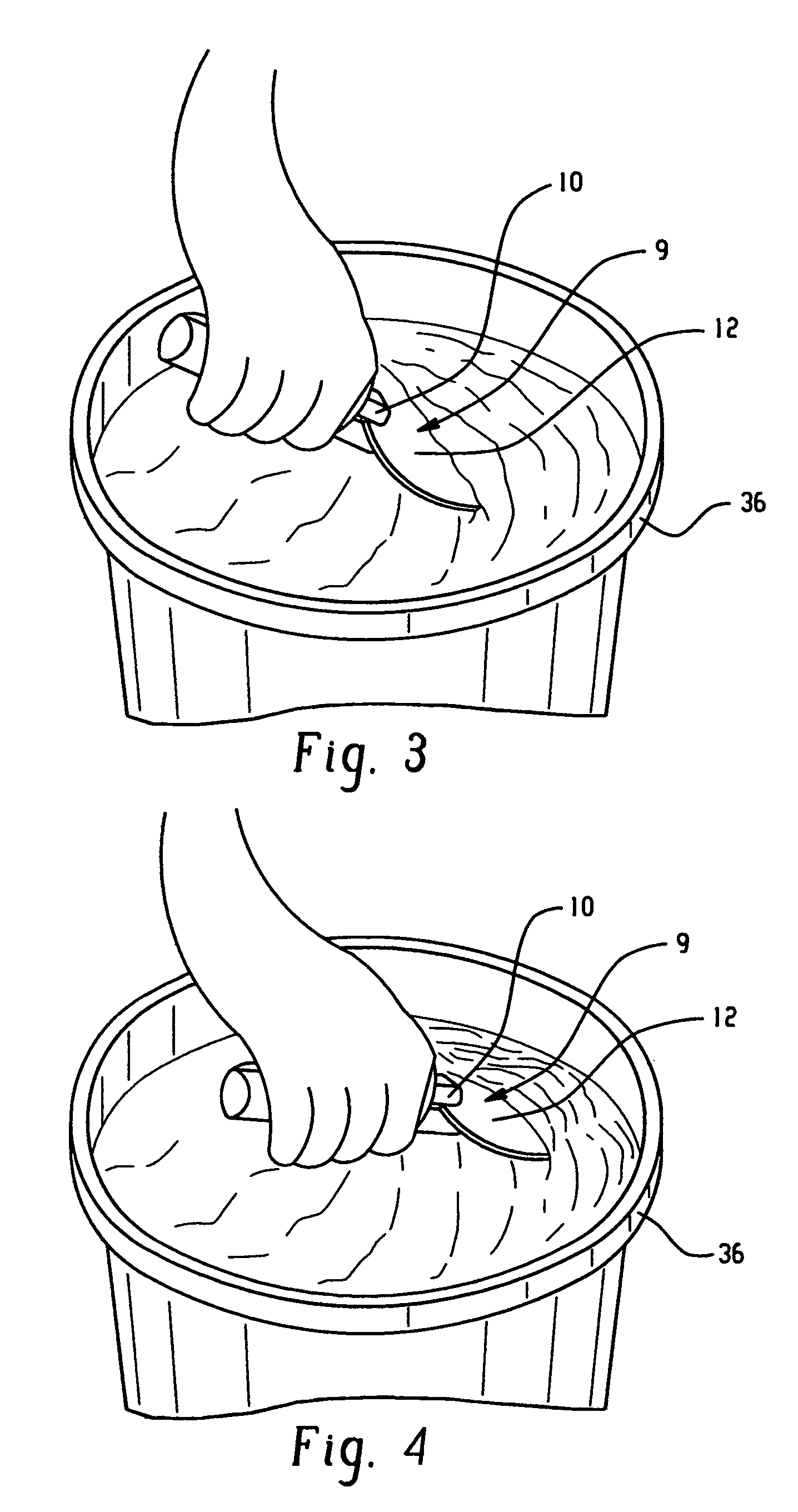

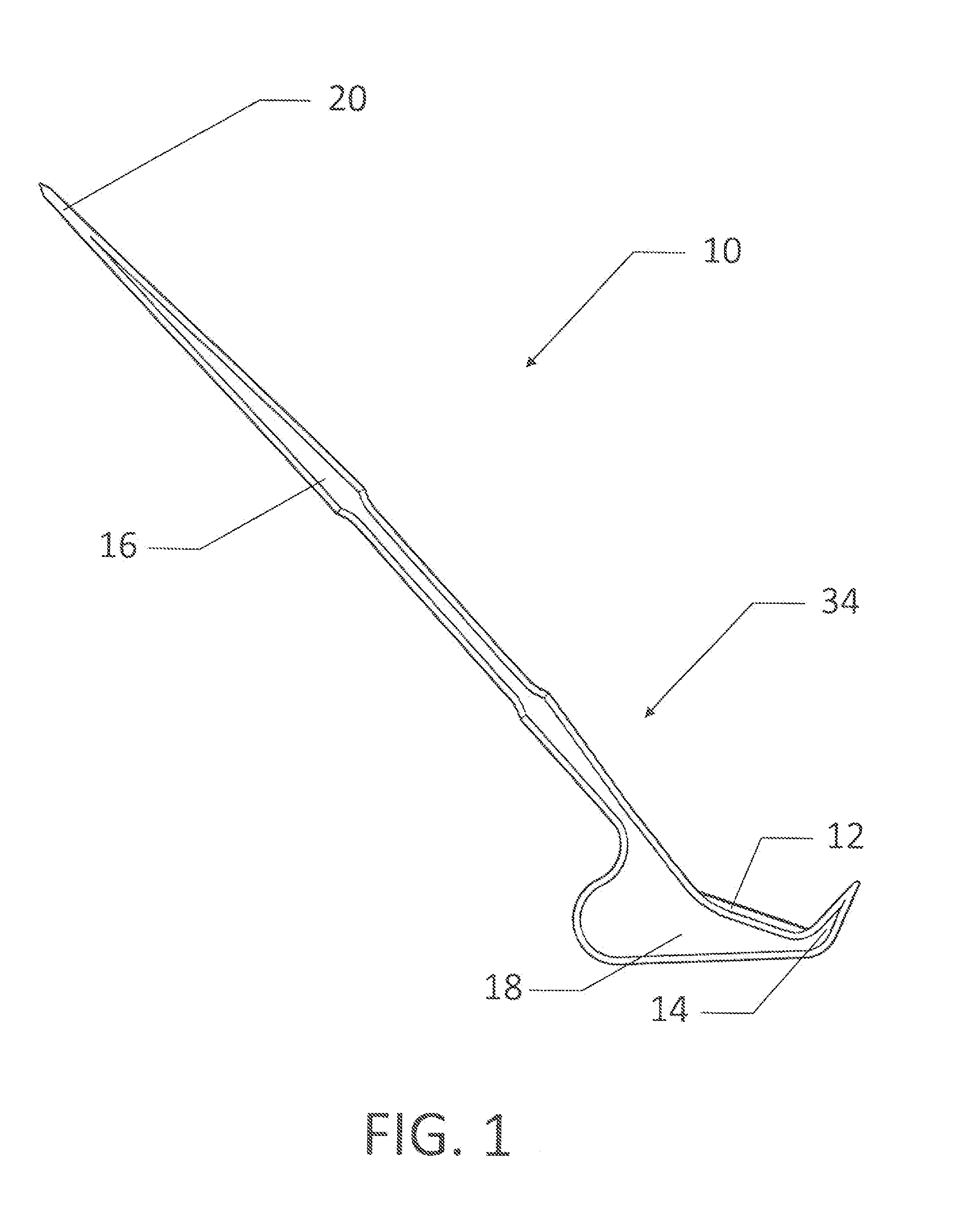

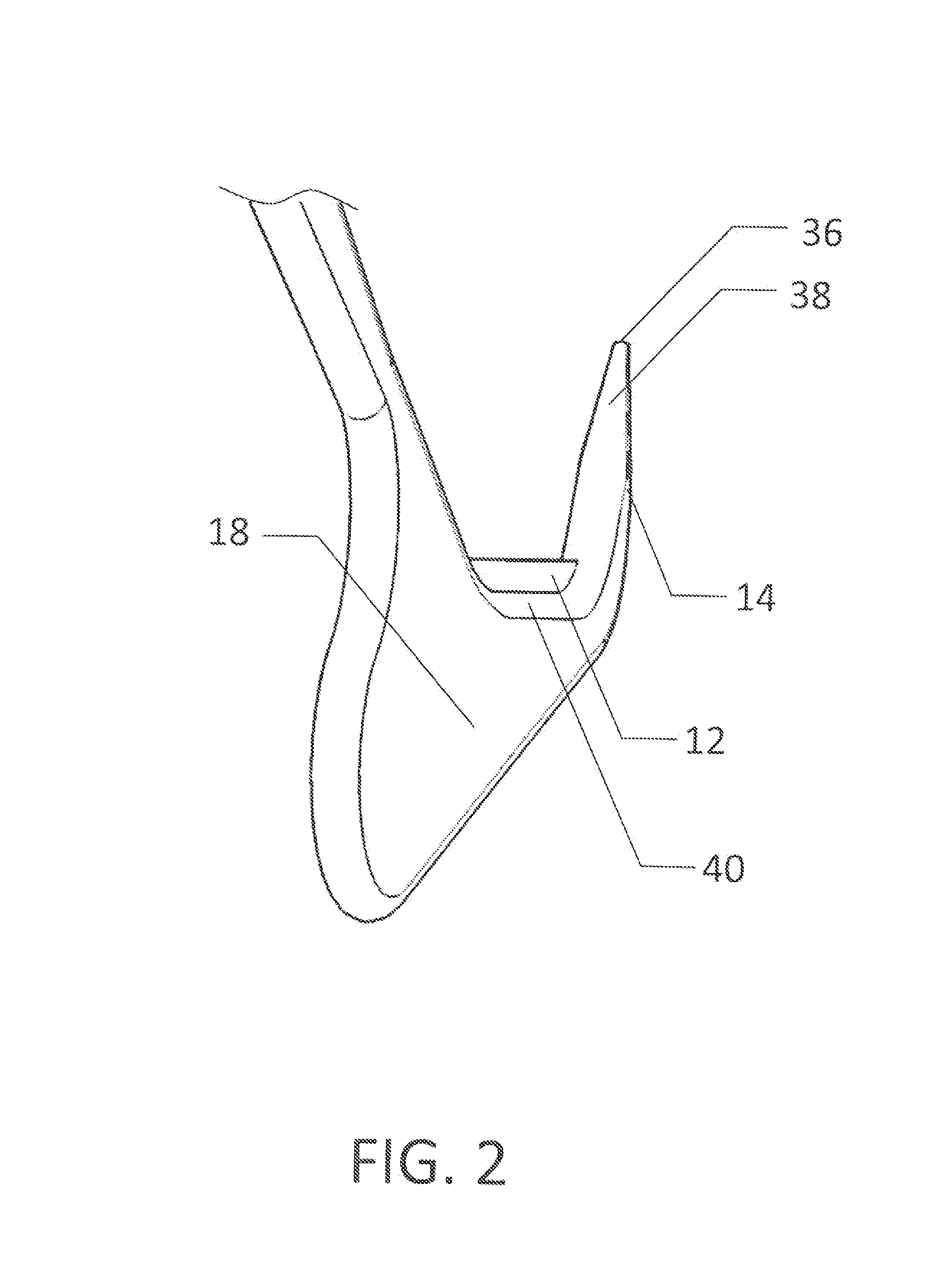

Methods for advancing inverting mechanical thrombectomy apparatuses in the vasculature

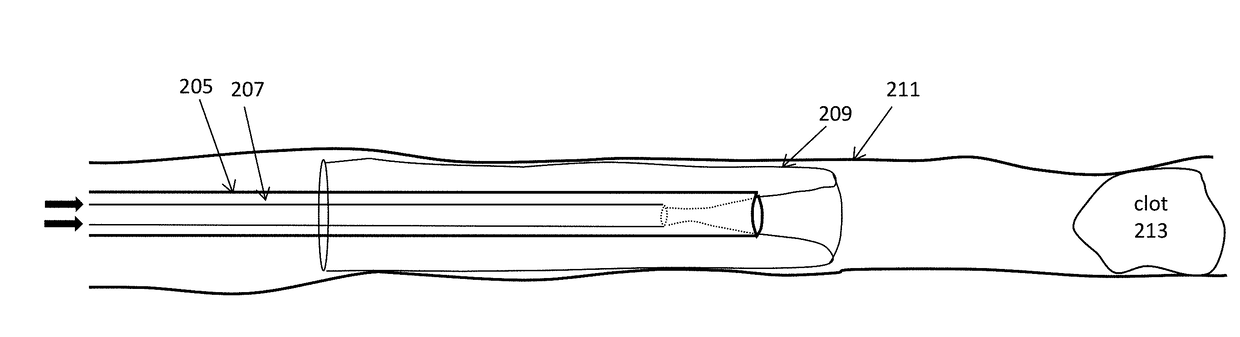

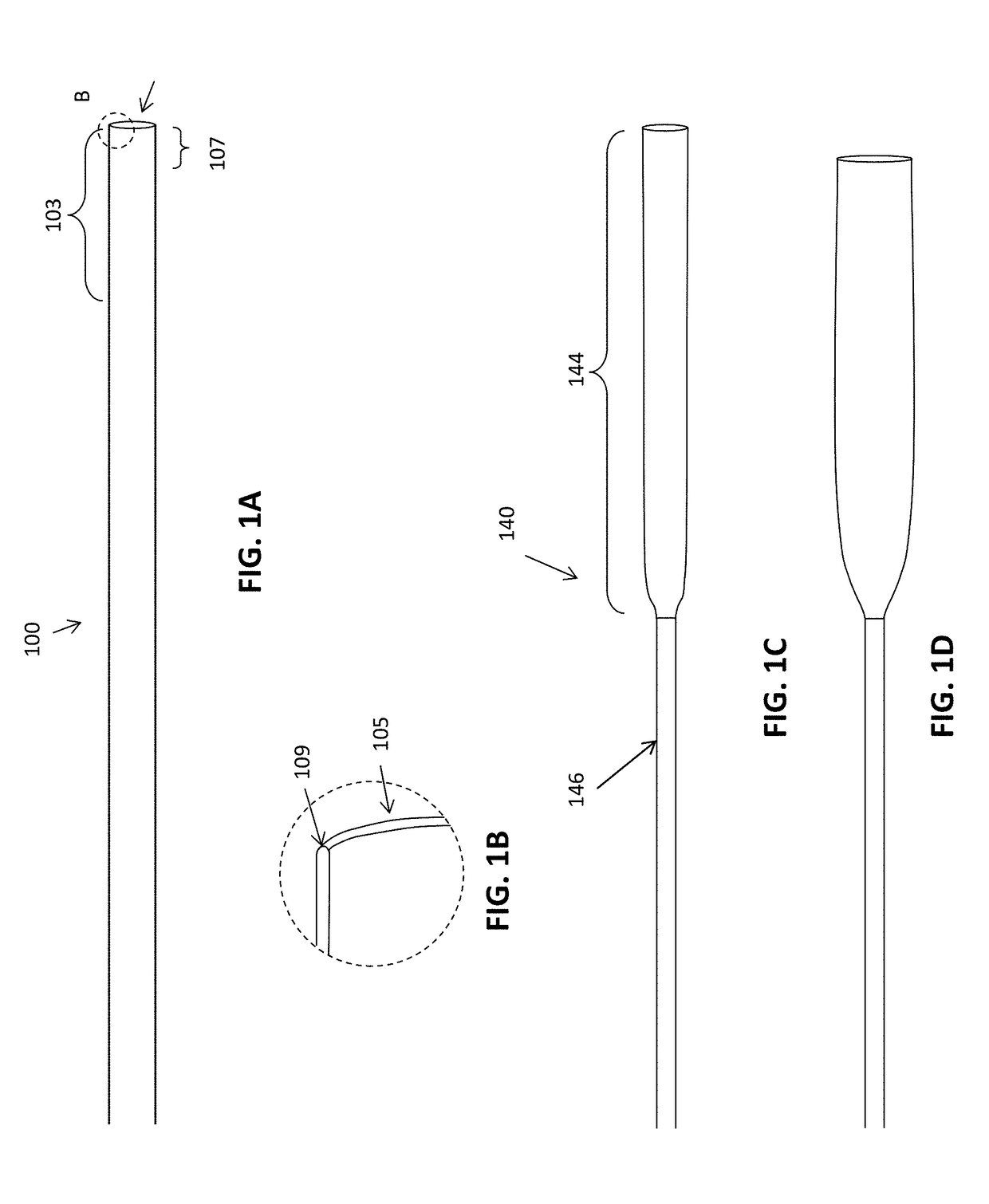

Mechanical thrombectomy apparatuses (devices, systems, etc.) and methods for positioning them within a vessel and using them to remove a thrombus, e.g., clot, from within a vessel. In particular, described herein are methods of advancing an inverting tractor thrombectomy apparatus having a tractor comprising a flexible tube of material that inverts over itself as it rolls over a distal end opening of an elongate inversion support by extending the tractor region and / or a puller coupled to the tractor distally beyond the end of the catheter. Also described herein are power-driven mechanical thrombectomy apparatuses.

Owner:STRYKER CORP

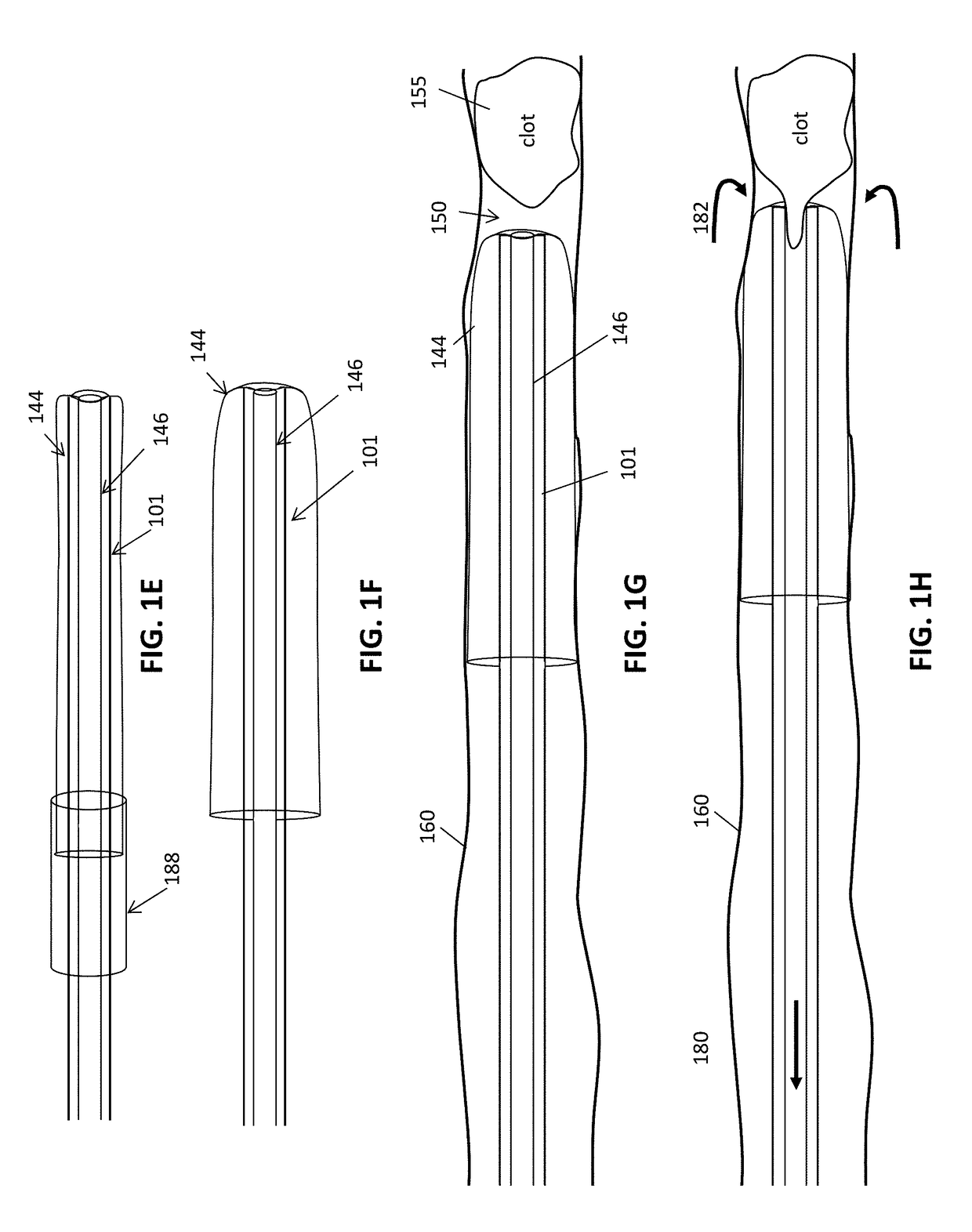

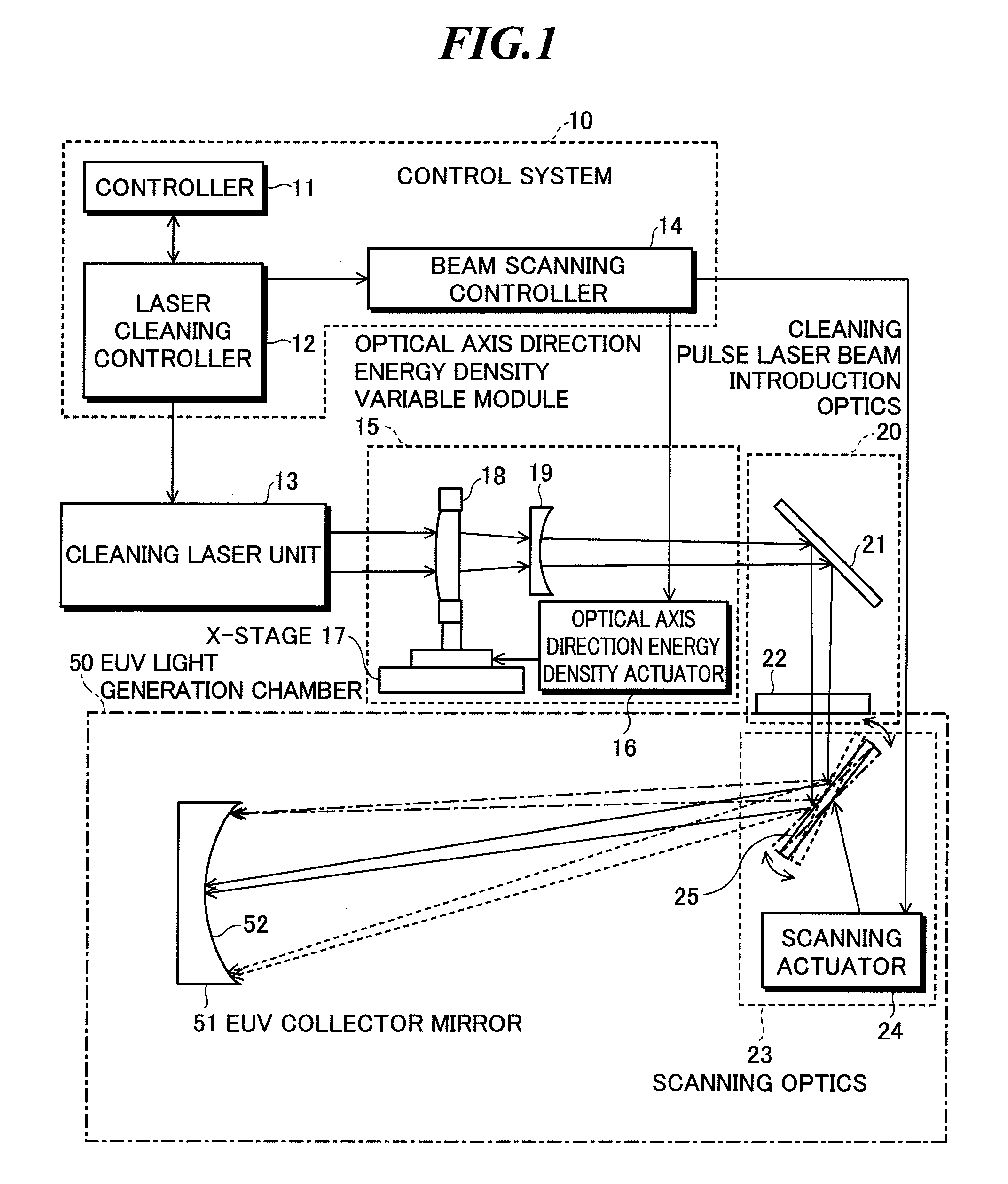

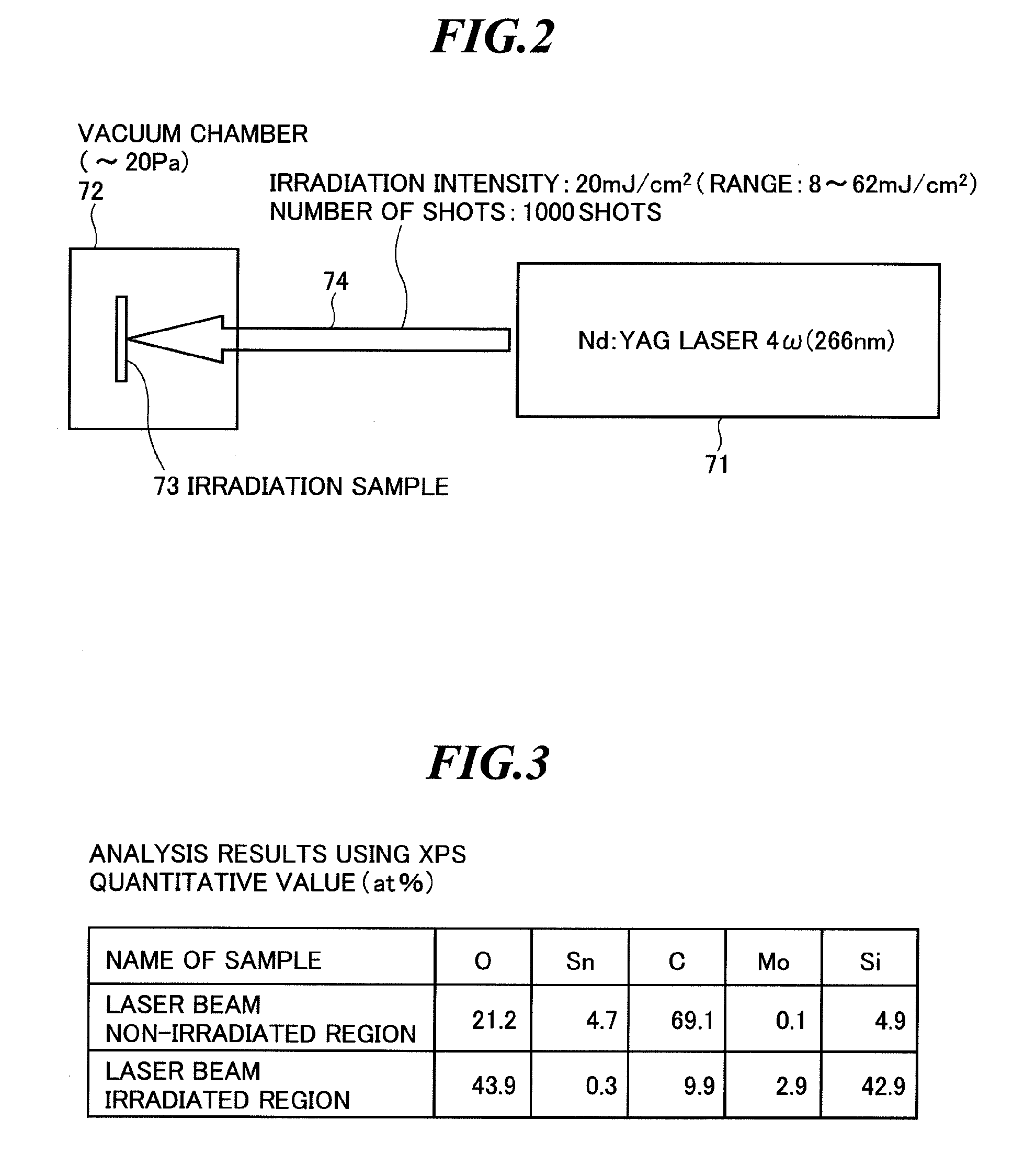

Extreme ultraviolet light source apparatus and cleaning method

InactiveUS20100192973A1Eliminate adhesionEfficient removalSimulator controlPhotomechanical apparatusLight beamPulsed laser beam

An extreme ultraviolet light source apparatus that can eliminate debris adhering to a component such as optical elements provided within a chamber. The extreme ultraviolet light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target material supply unit for supplying a target material into the chamber; a driver laser unit for irradiating the target material with a driver pulse laser beam to generate plasma; a cleaning laser unit for emitting a cleaning pulse laser beam; and a control unit for controlling an irradiation position of the cleaning pulse laser beam emitted from the cleaning laser unit so as to irradiate a component provided within the chamber with the cleaning pulse laser beam to remove debris adhering to a surface of the component.

Owner:GIGAPHOTON

Inverting mechanical thrombectomy apparatuses

Mechanical thrombectomy apparatuses (devices, systems, etc.) and methods for positioning them within a vessel and using them to remove a thrombus, e.g., clot, from within a vessel. In particular, described herein are methods of advancing an inverting tractor thrombectomy apparatus having a tractor comprising a flexible tube of material that inverts over itself as it rolls over a distal end opening of an elongate inversion support by extending the tractor region and / or a puller coupled to the tractor distally beyond the end of the catheter. Also described herein are power-driven mechanical thrombectomy apparatuses.

Owner:STRYKER CORP

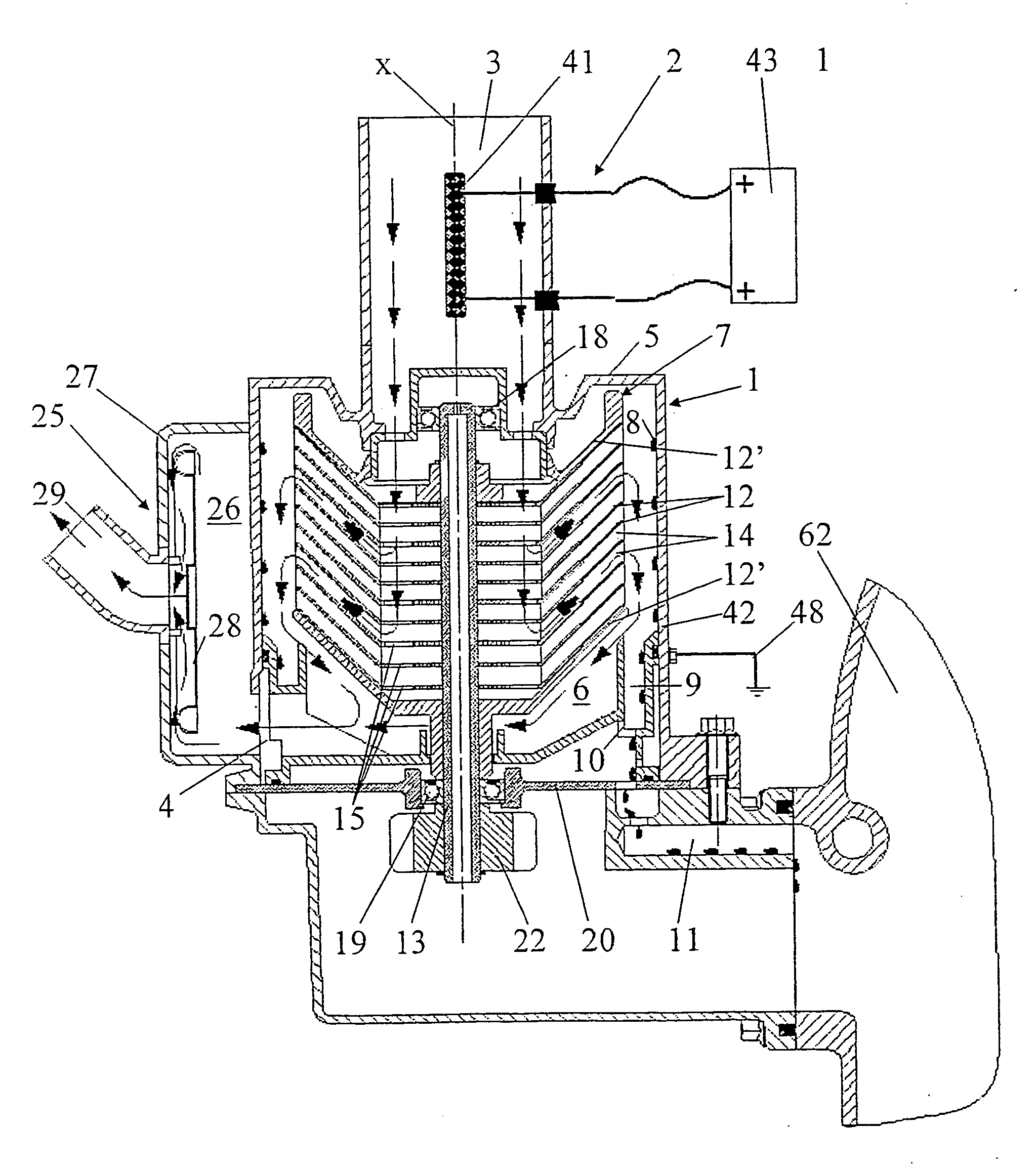

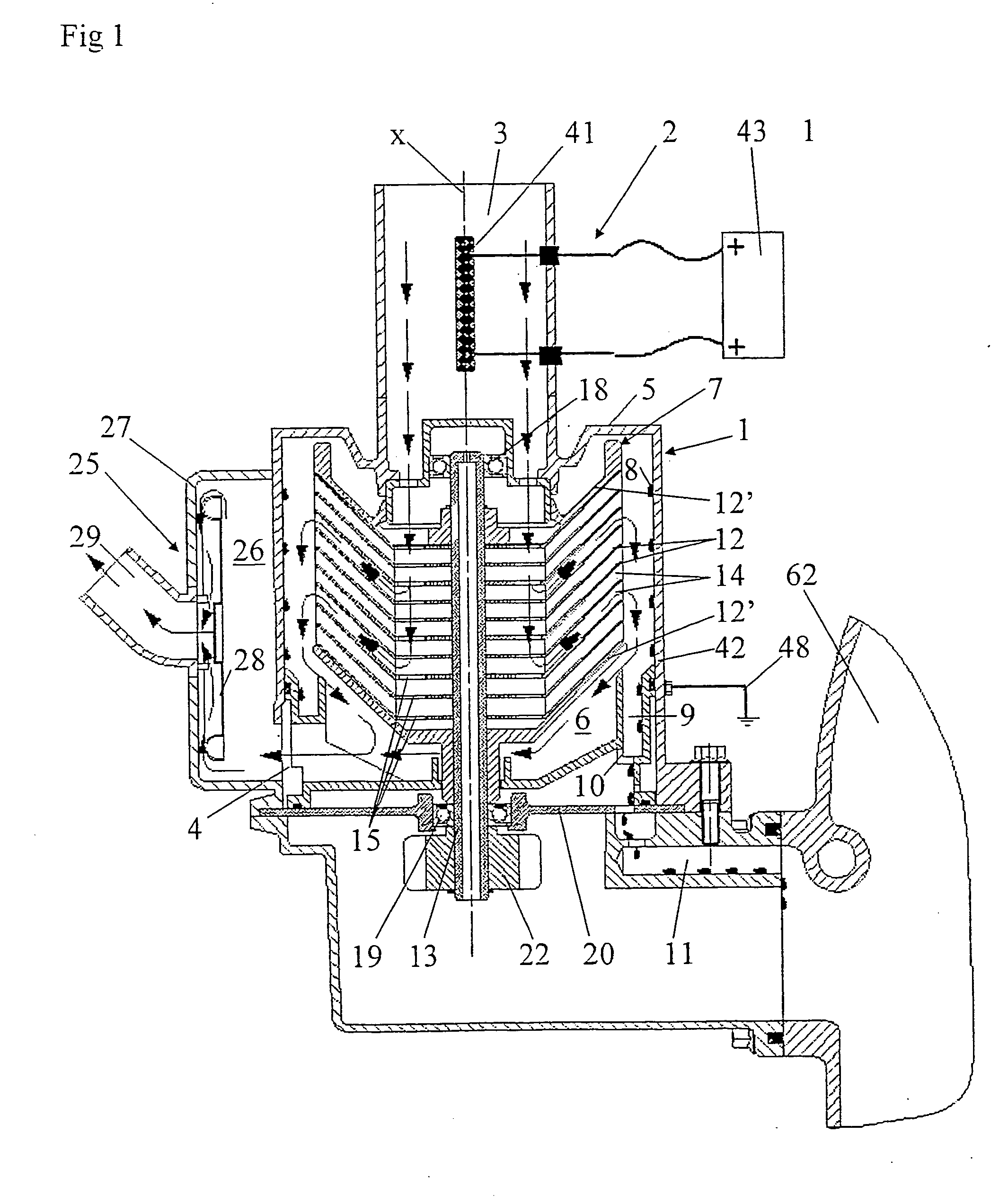

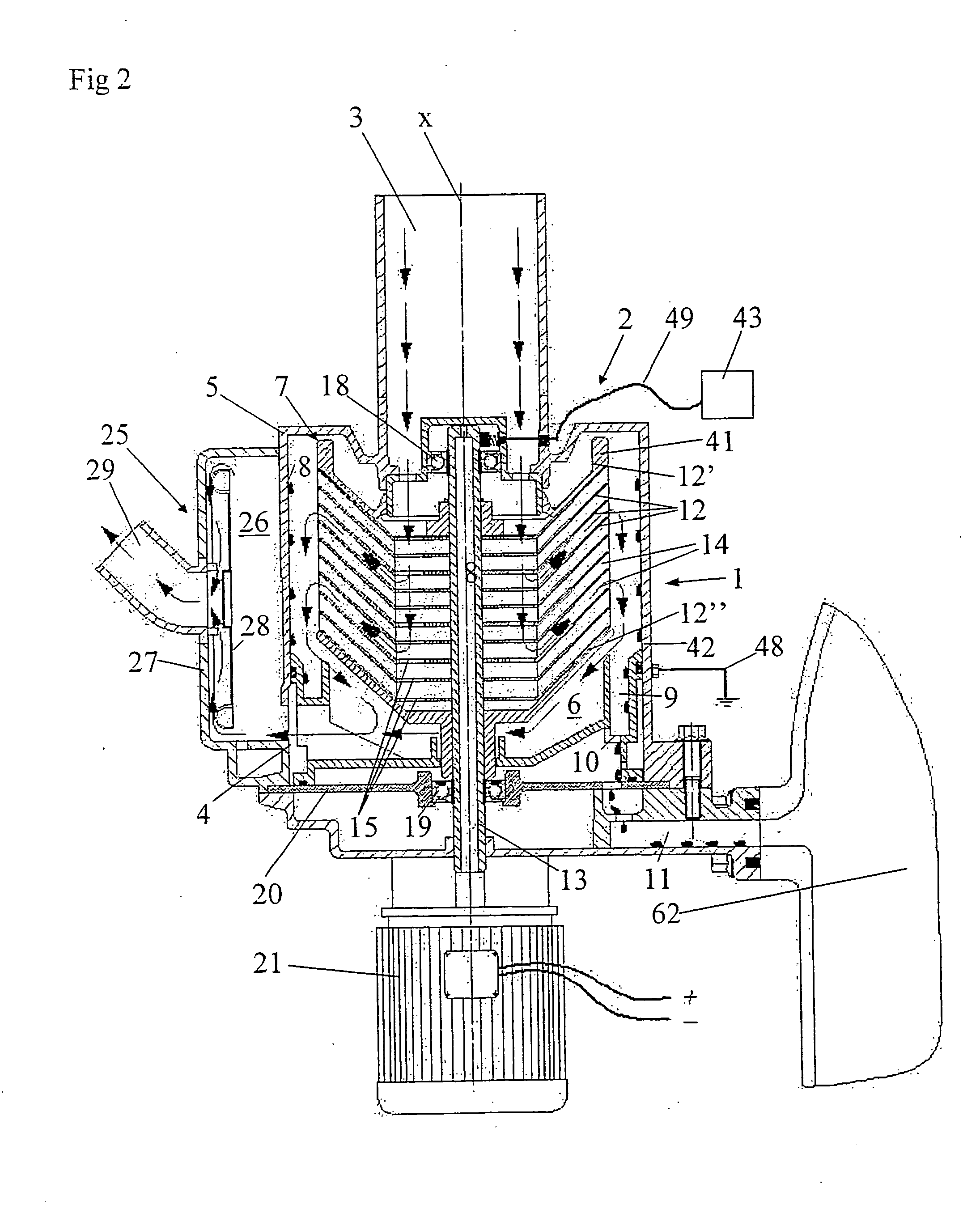

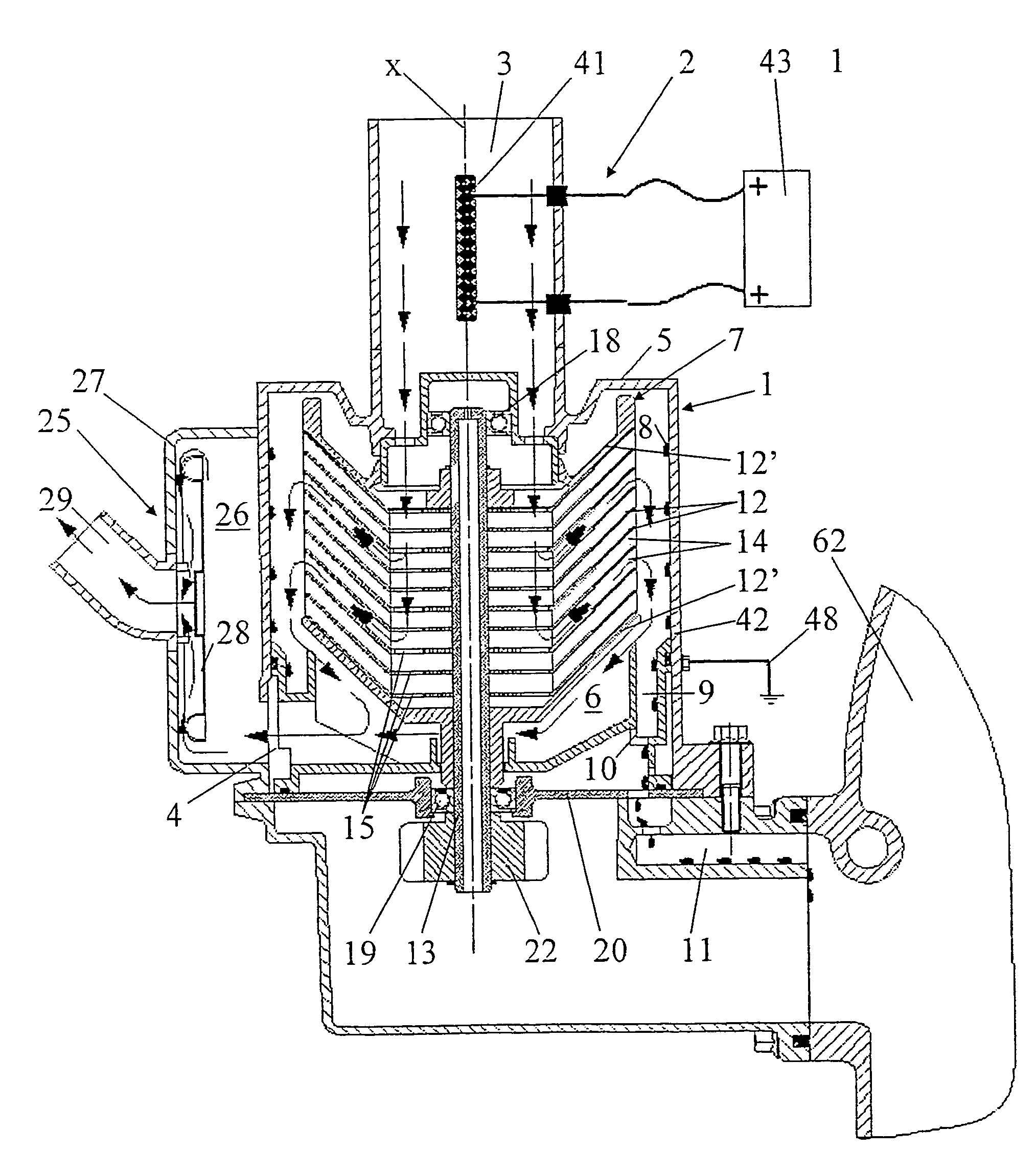

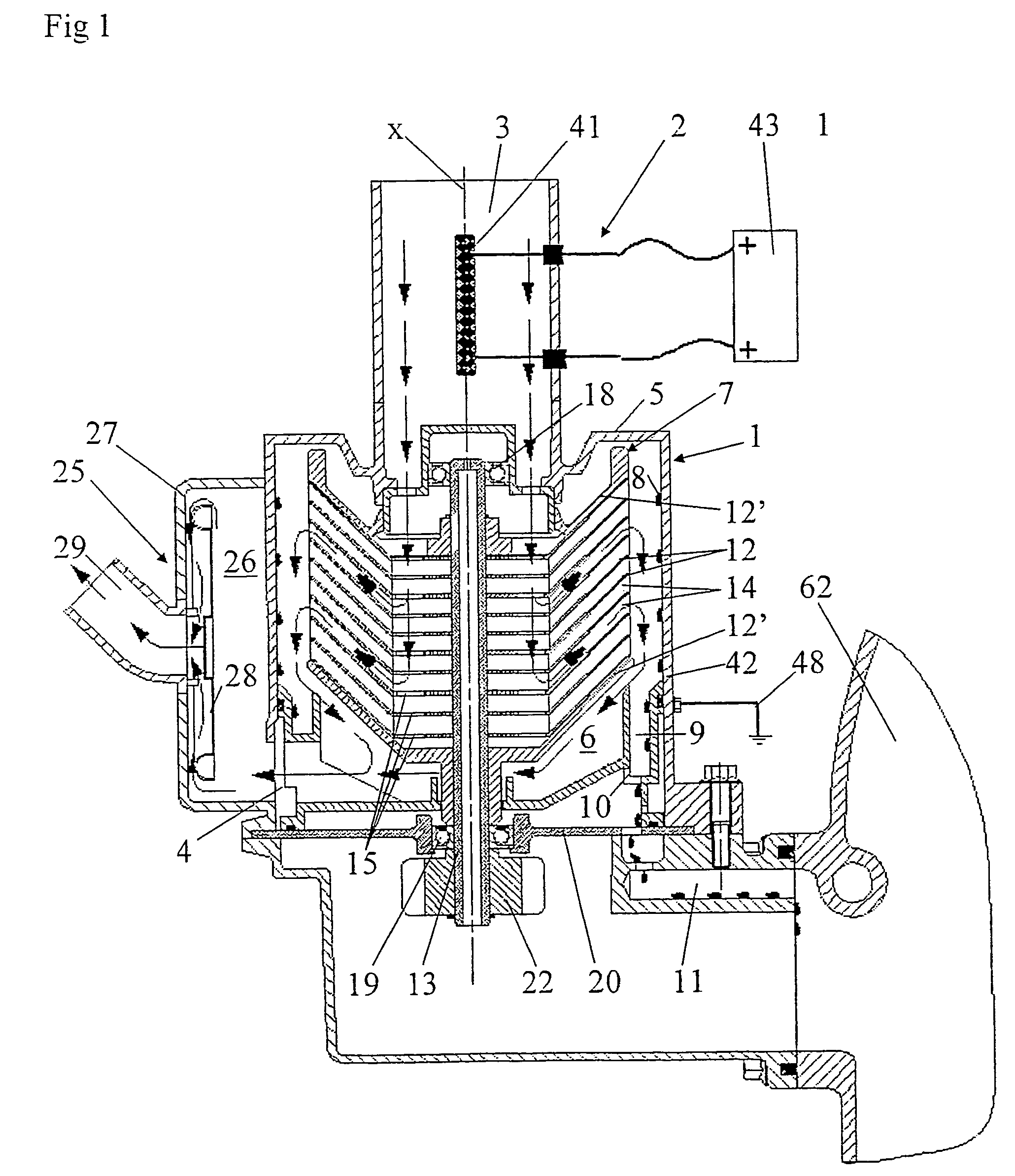

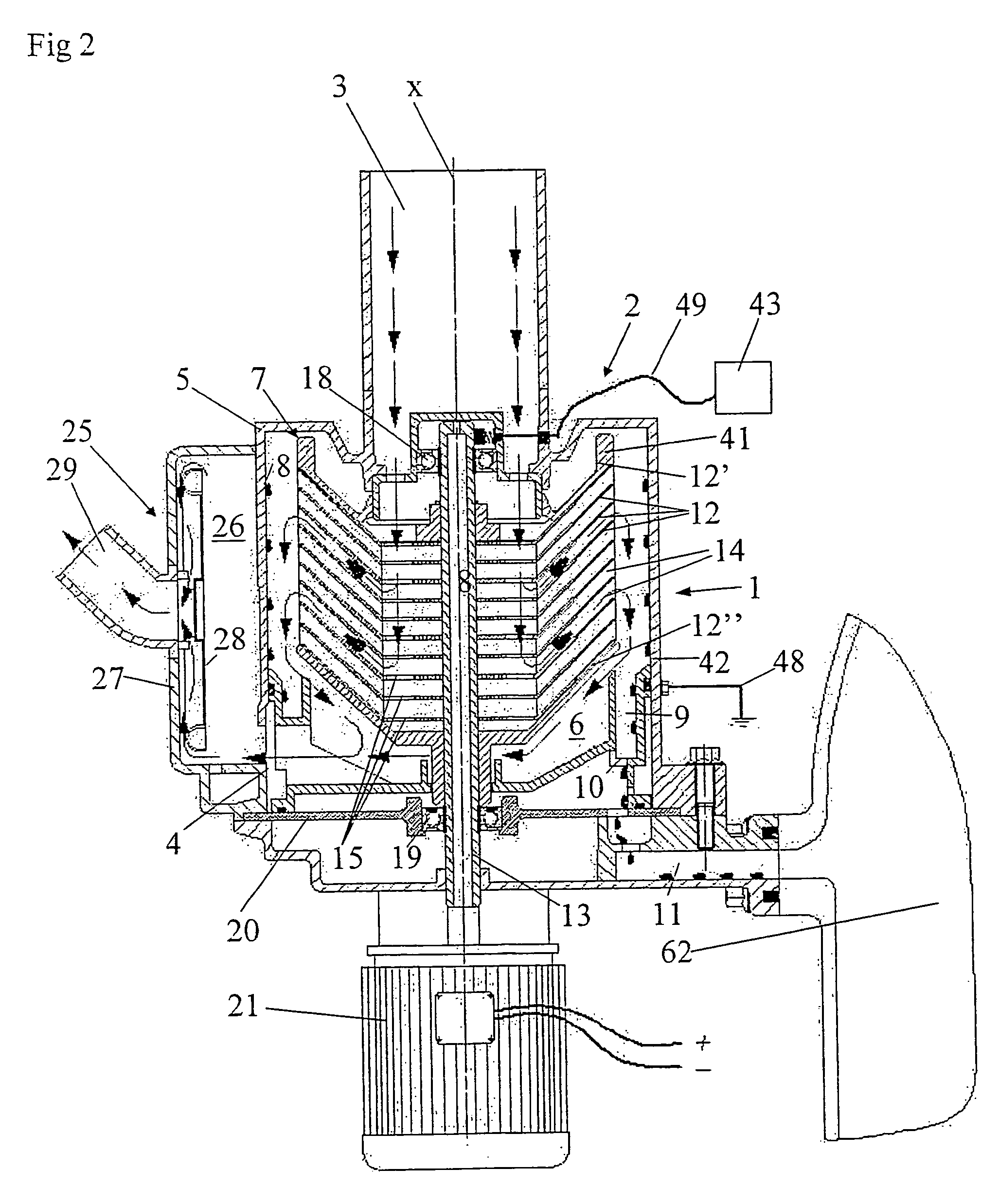

Device and a Method for Cleaning of a Gas

ActiveUS20080264251A1Efficient separationEasy and efficient removalCombination devicesDispersed particle filtrationParticulatesEngineering

Owner:ALFA LAVAL CORP AB

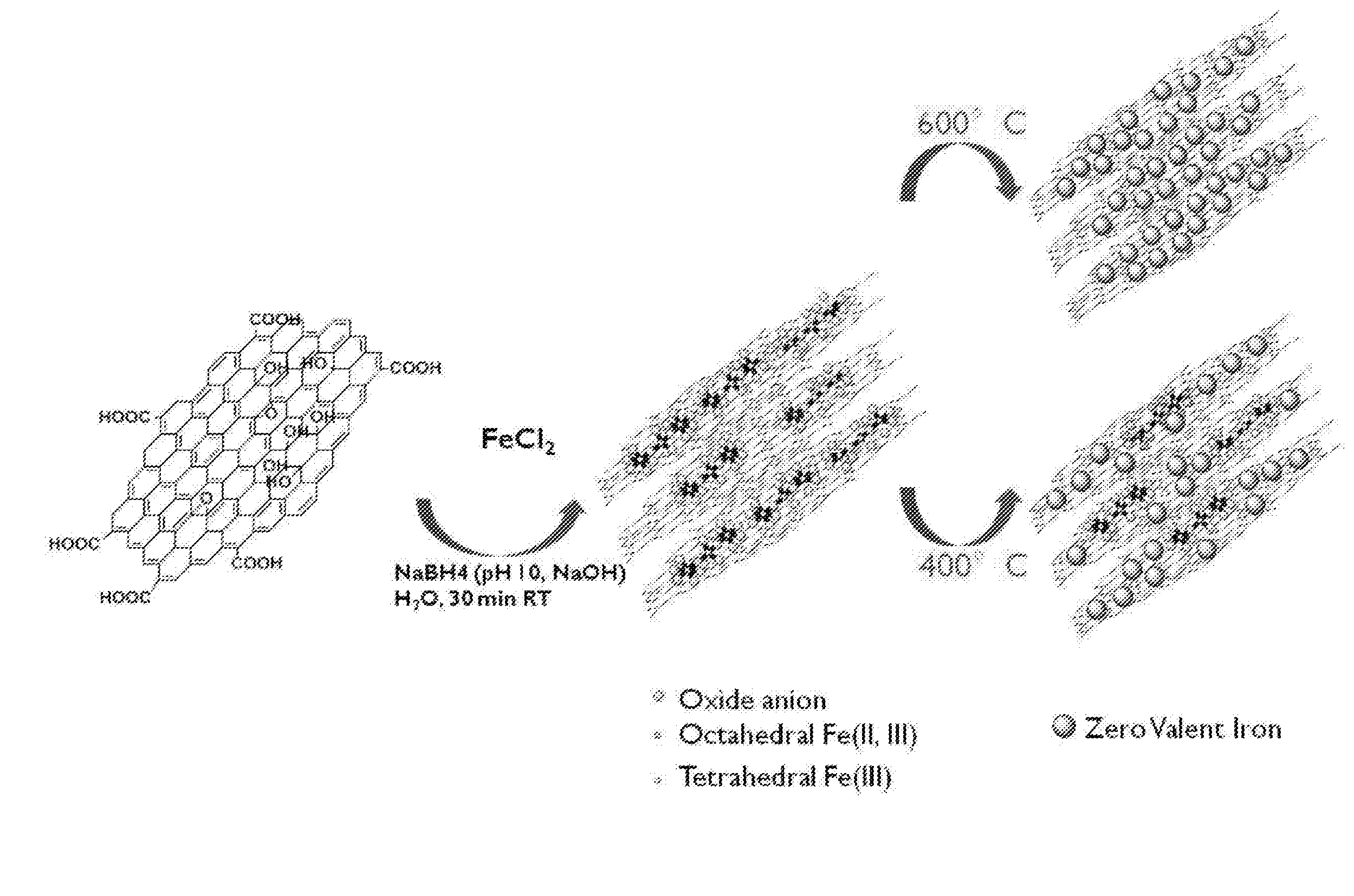

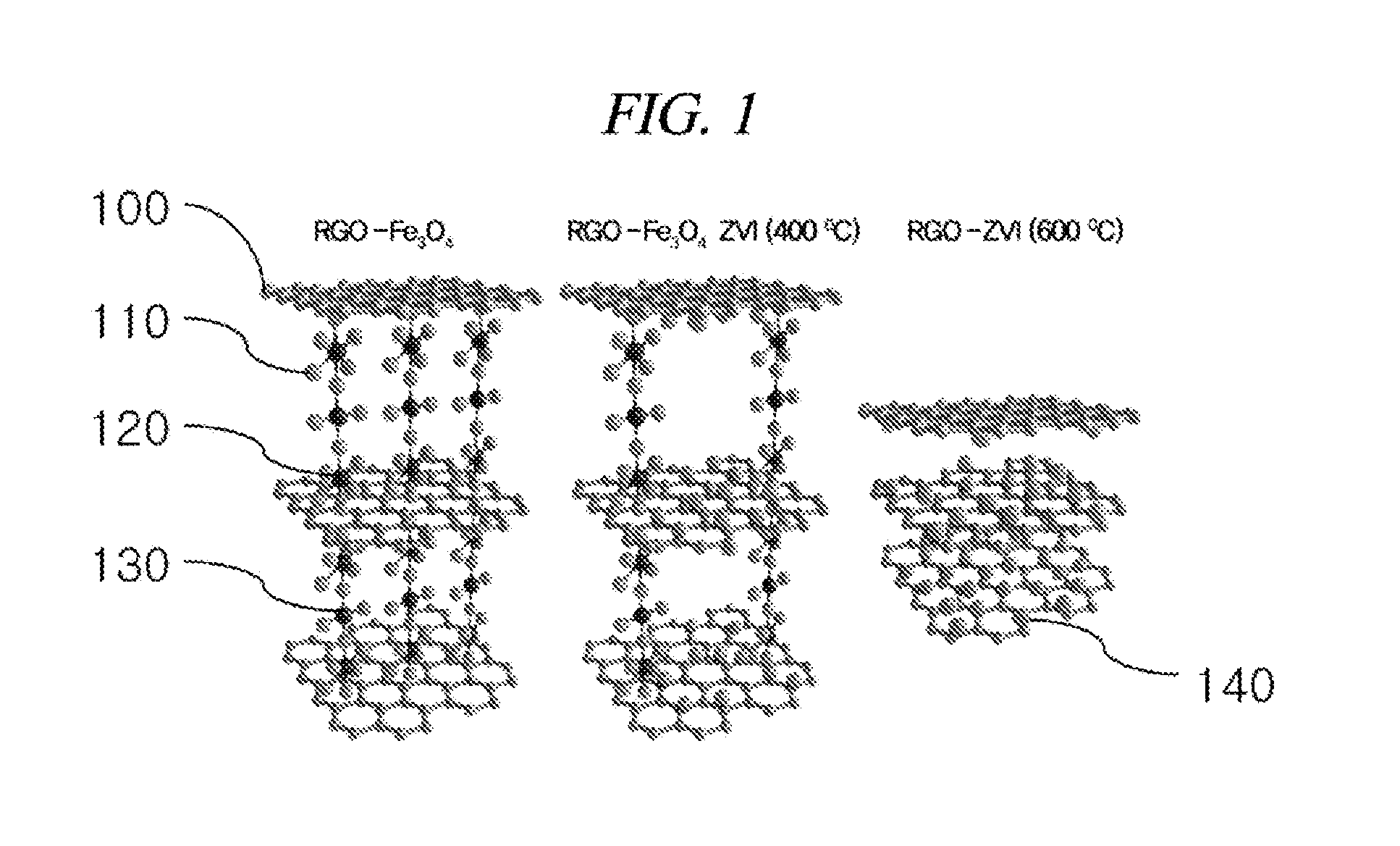

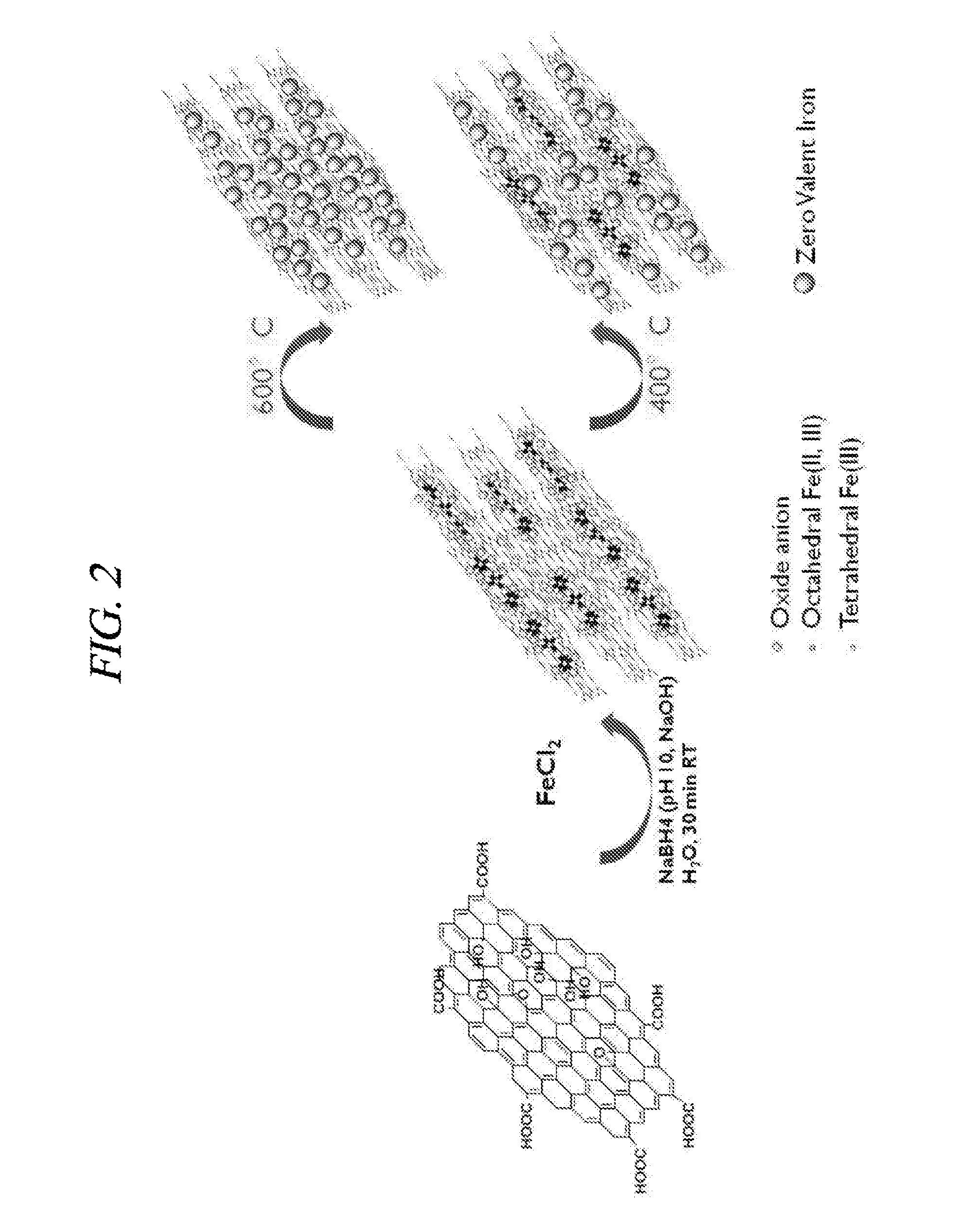

Composite containing metal component supported on graphene, preparing method of the same, and uses of the same

InactiveUS20130105400A1Quality improvementGood dispersionMaterial nanotechnologyOther chemical processesGrapheneMaterials science

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

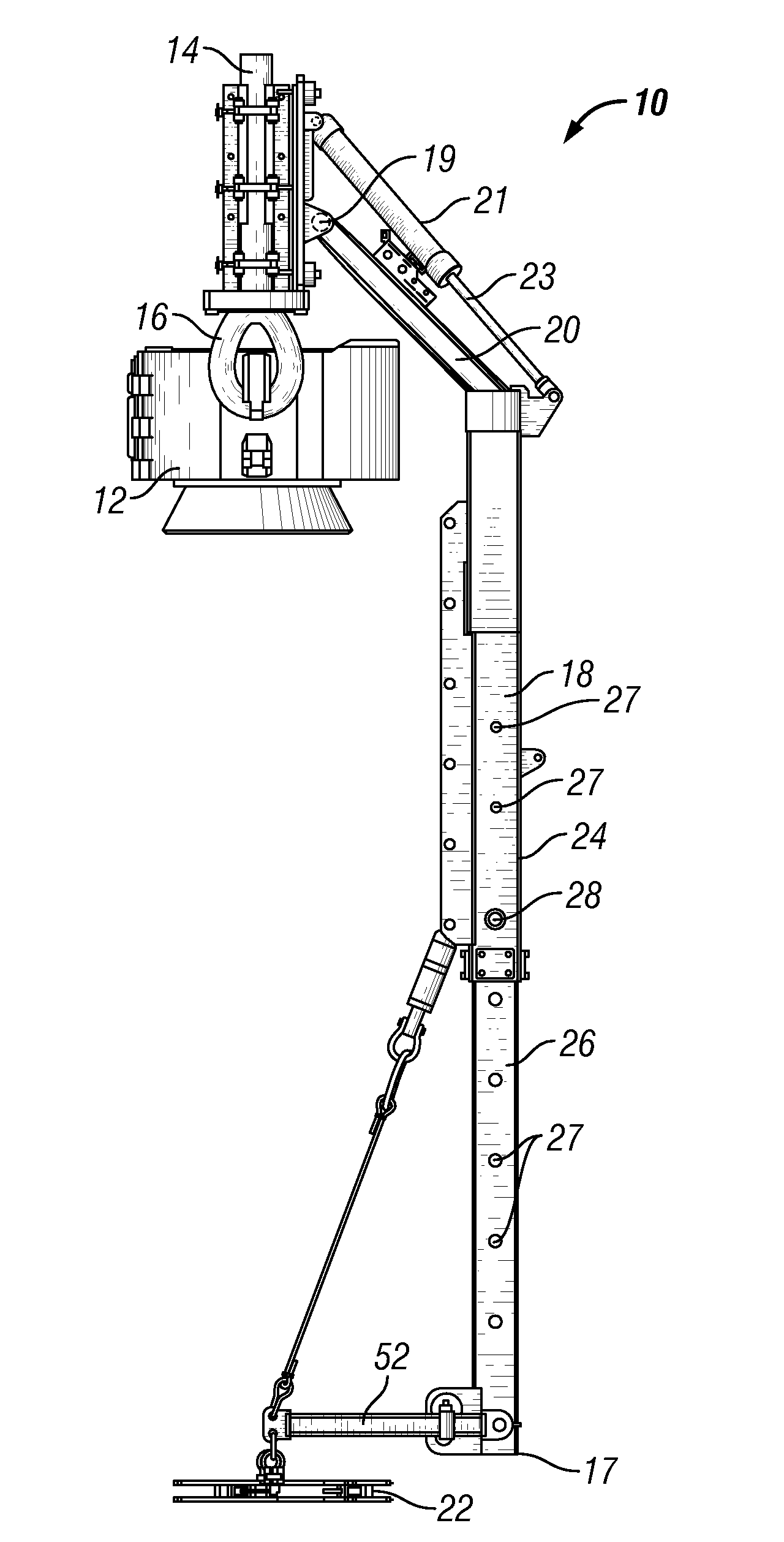

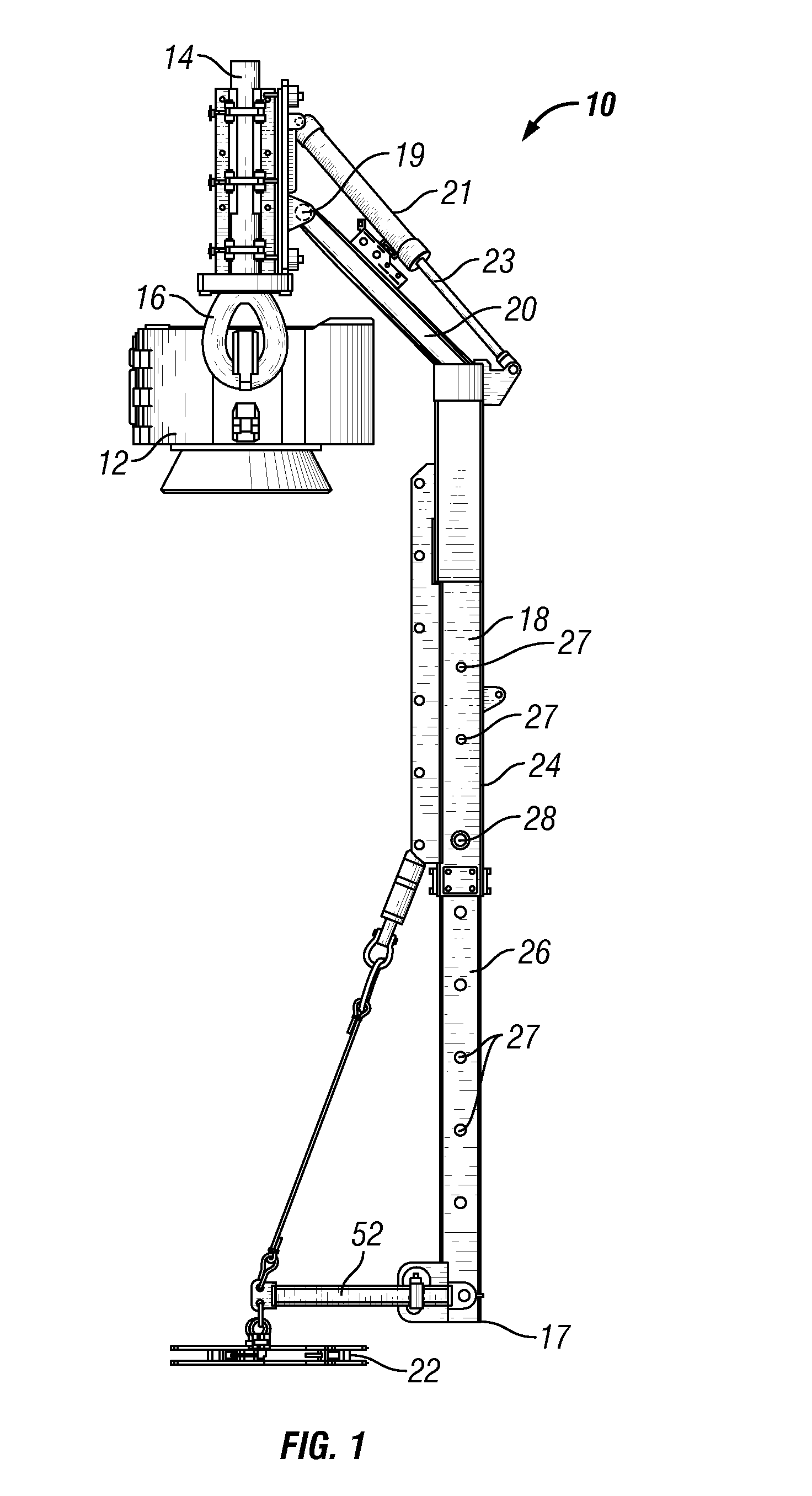

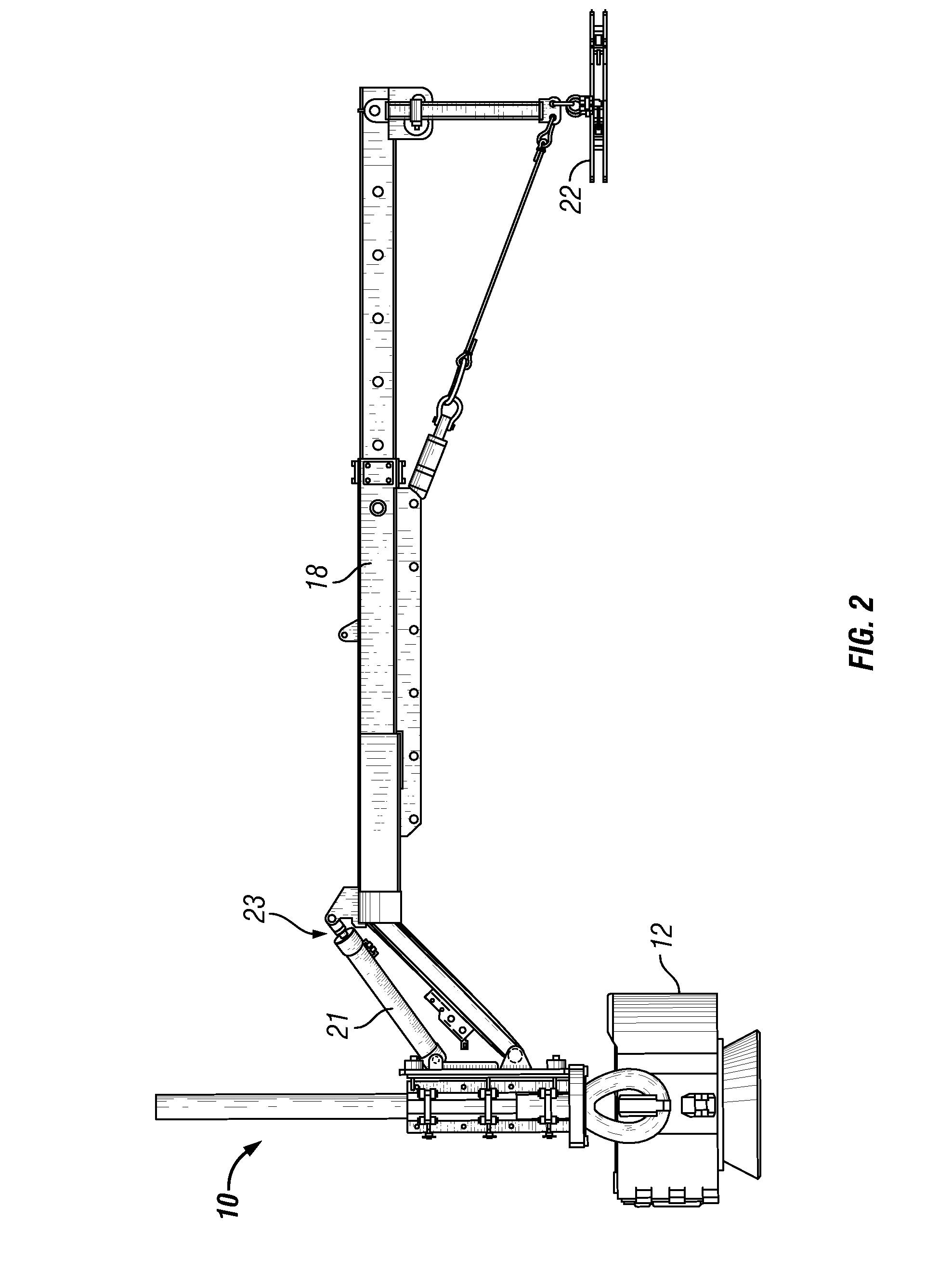

Light-weight single joint manipulator arm

The present invention provides an apparatus and a method for making up tubular strings in a well. The present invention provides a single joint manipulator arm for manipulating and positioning tubing joints for coupling into a tubular string. In one embodiment, a string elevator is supported by a hoist. A single joint elevator is supported on a swing arm that is pivotally secured to the sub-hoist assembly. An actuator rotates the swing arm to an initial position for securing to an add-on tubular joint whereby the single joint elevator engages a proximate end of the add-on tubular joint. As the hoist is lifted, a damper dampens rotation of the swing arm as it finds gravitational equilibrium with the single joint held in a substantially vertical orientation. A distal end of the tubular joint is aligned with a casing string supported by a spider, and the tubular joint is threadably coupled to the tubular string. The actuator may include provisions to power the arm from the vertical orientation to a substantially horizontal orientation and also to dampen the movement of the arm as it moves from the substantially horizontal or an intermediate position to the vertical orientation once the single joint elevator engages the add-on tubular joint and the hoist suspends the joint for rotation.

Owner:FRANKS CASING CREW & RENTAL TOOLS

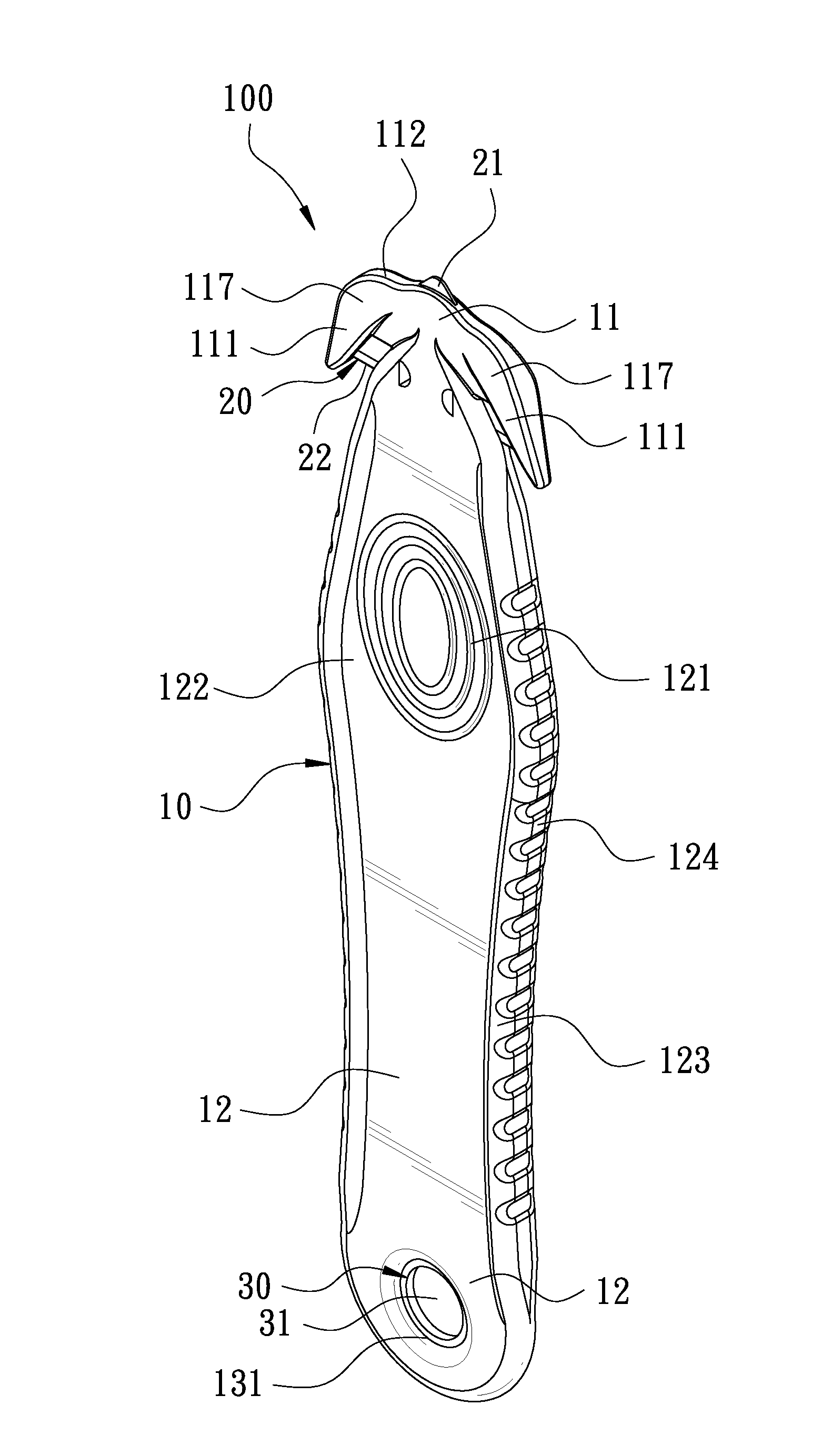

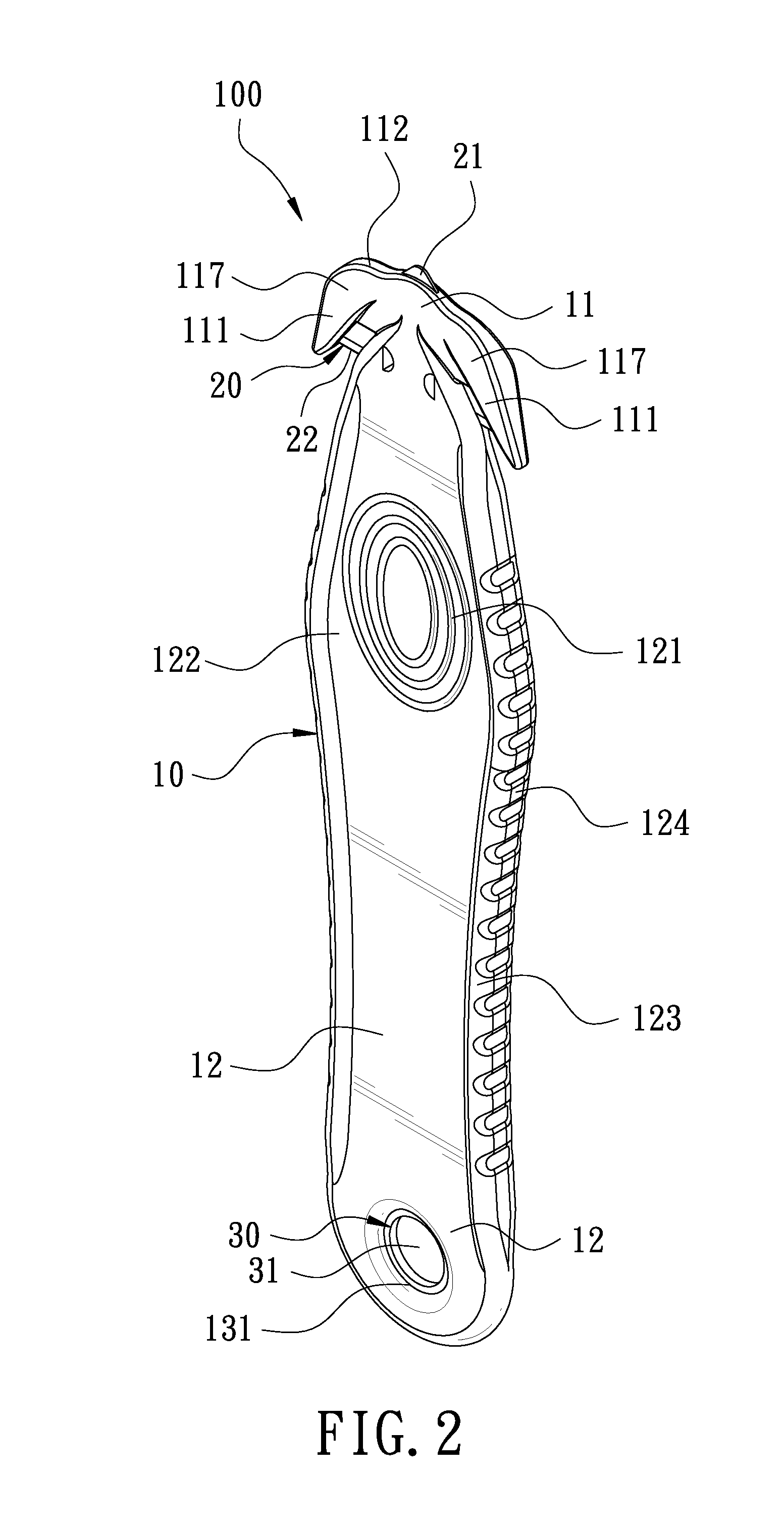

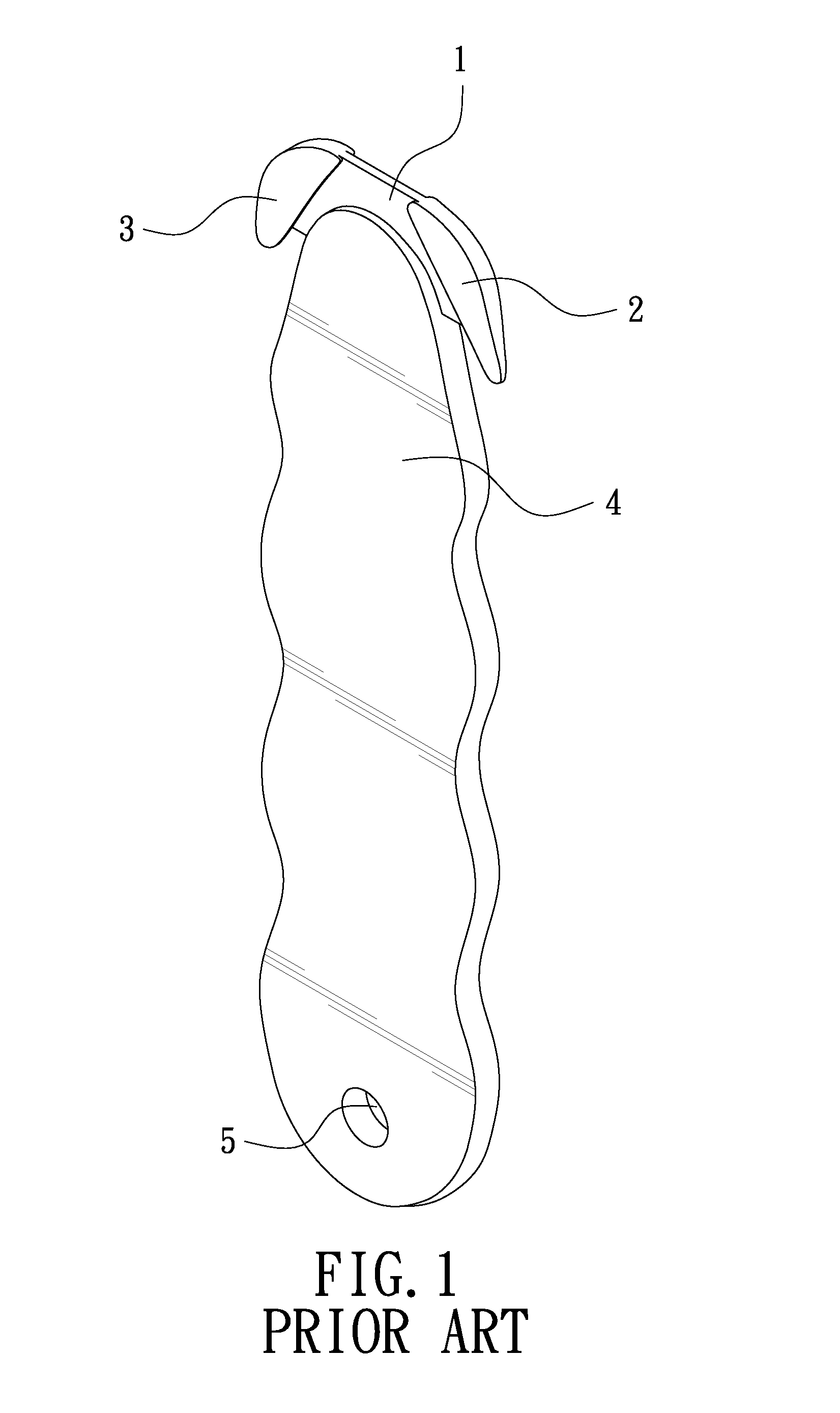

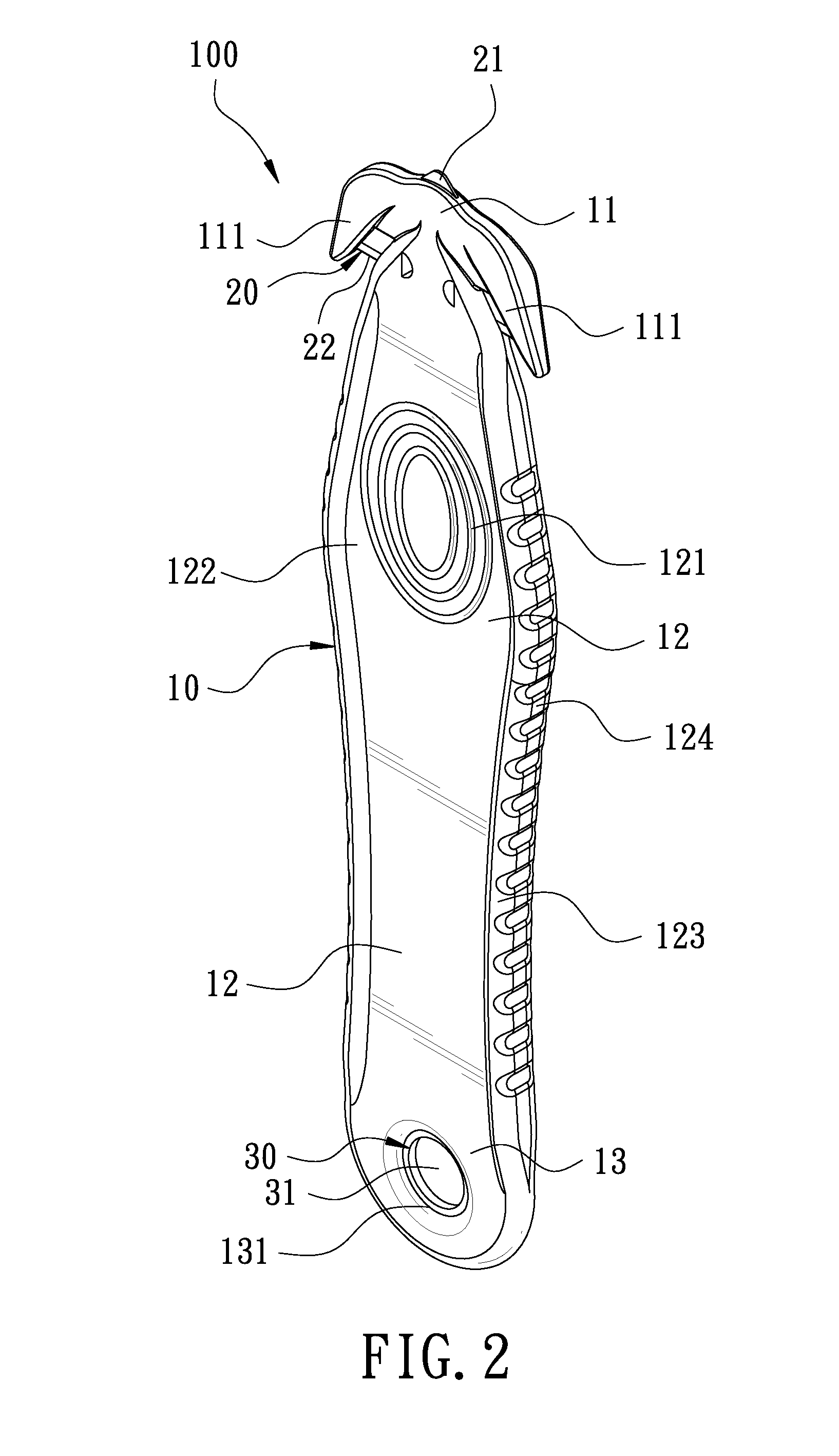

Cutter

InactiveUS20150298330A1Avoid damageCutting be removeMetal working apparatusMetal-working hand toolsEngineeringMechanical engineering

A cutter includes a main body. The top edge of the main body is provided with a holding portion, and its two sides extend outward to form a pair of lugs. A pair of gaps is formed between the main body and the pair of lugs. The cutter further includes a cutting unit wrapped by the main body. The cutting unit has one side formed with a pointed end portion and another side formed with a cutter edge. The pointed end portion protrudes out of the holding portion, and the cutter edge is exposed out of the gaps. The multi-function cutter is able to cut and remove various packaging members easily and efficiently.

Owner:YU CHEN HSIU MAN

Methods for advancing inverting mechanical thrombectomy apparatuses in the vasculature

ActiveUS20180042624A1Precise positioningEasy and efficientCannulasSurgical needlesThrombusGuide tube

Mechanical thrombectomy apparatuses (devices, systems, etc.) and methods for positioning them within a vessel and using them to remove a thrombus, e.g., clot, from within a vessel. In particular, described herein are methods of advancing an inverting tractor thrombectomy apparatus having a tractor comprising a flexible tube of material that inverts over itself as it rolls over a distal end opening of an elongate inversion support by extending the tractor region and / or a puller coupled to the tractor distally beyond the end of the catheter. Also described herein are power-driven mechanical thrombectomy apparatuses.

Owner:STRYKER CORP

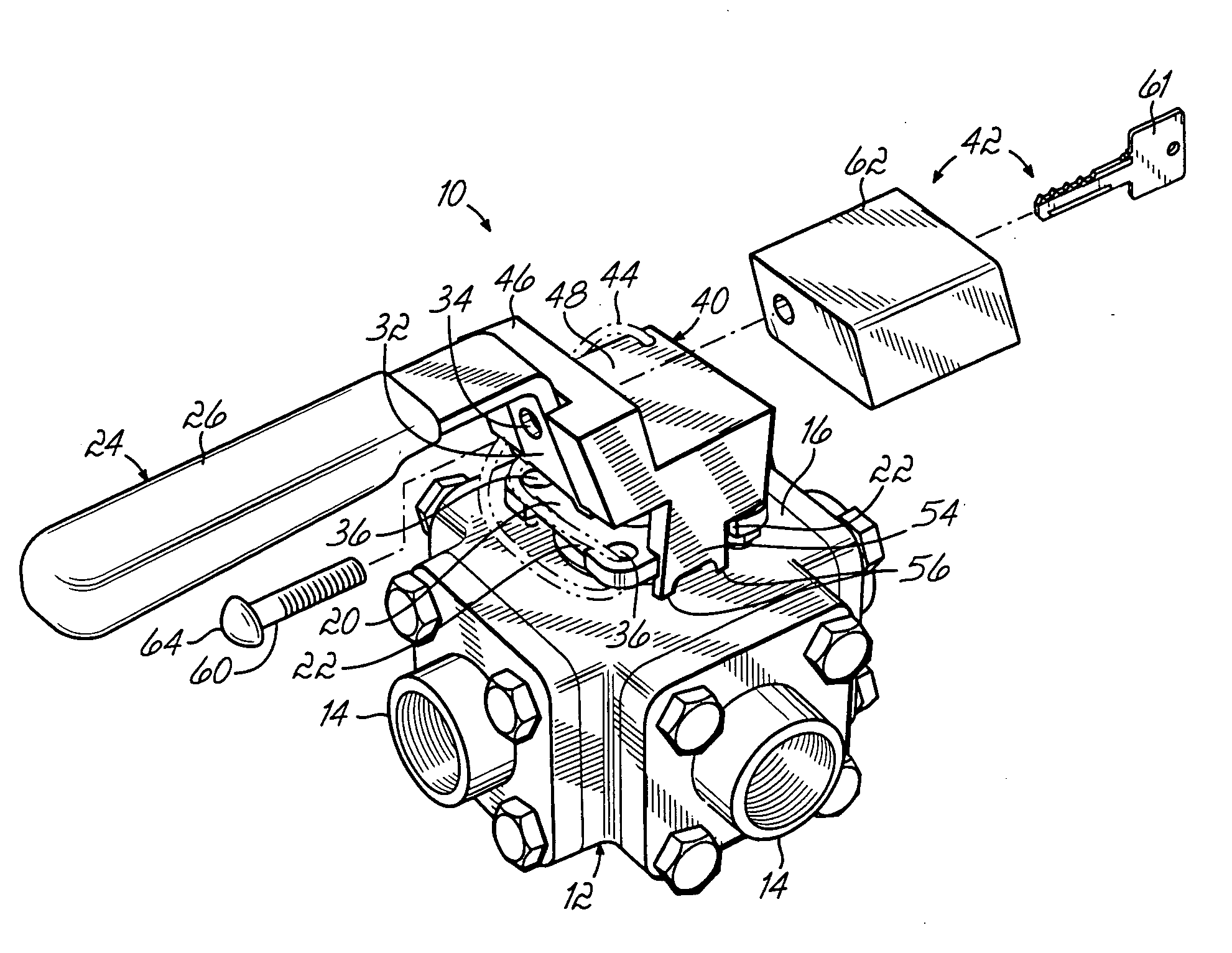

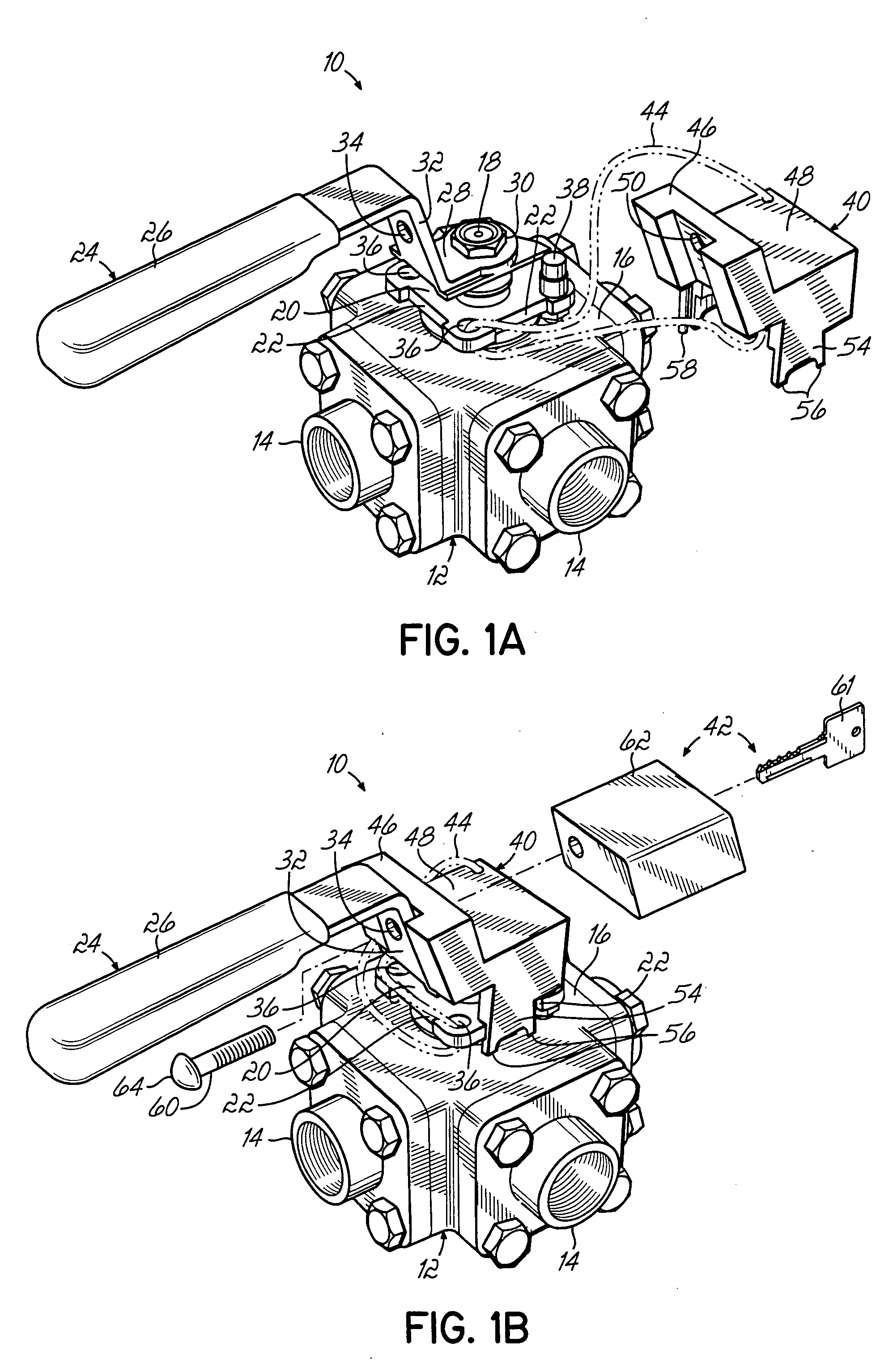

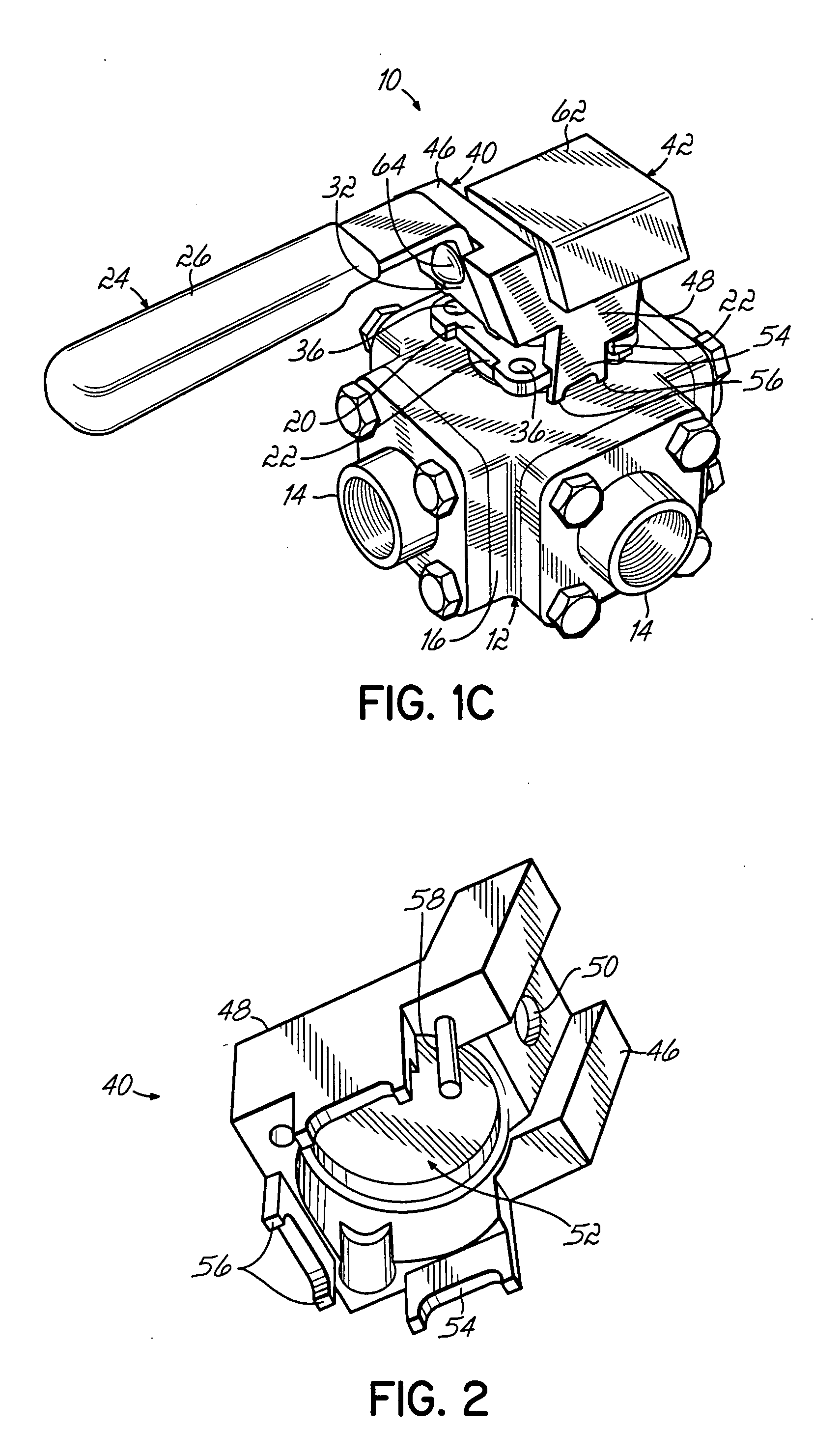

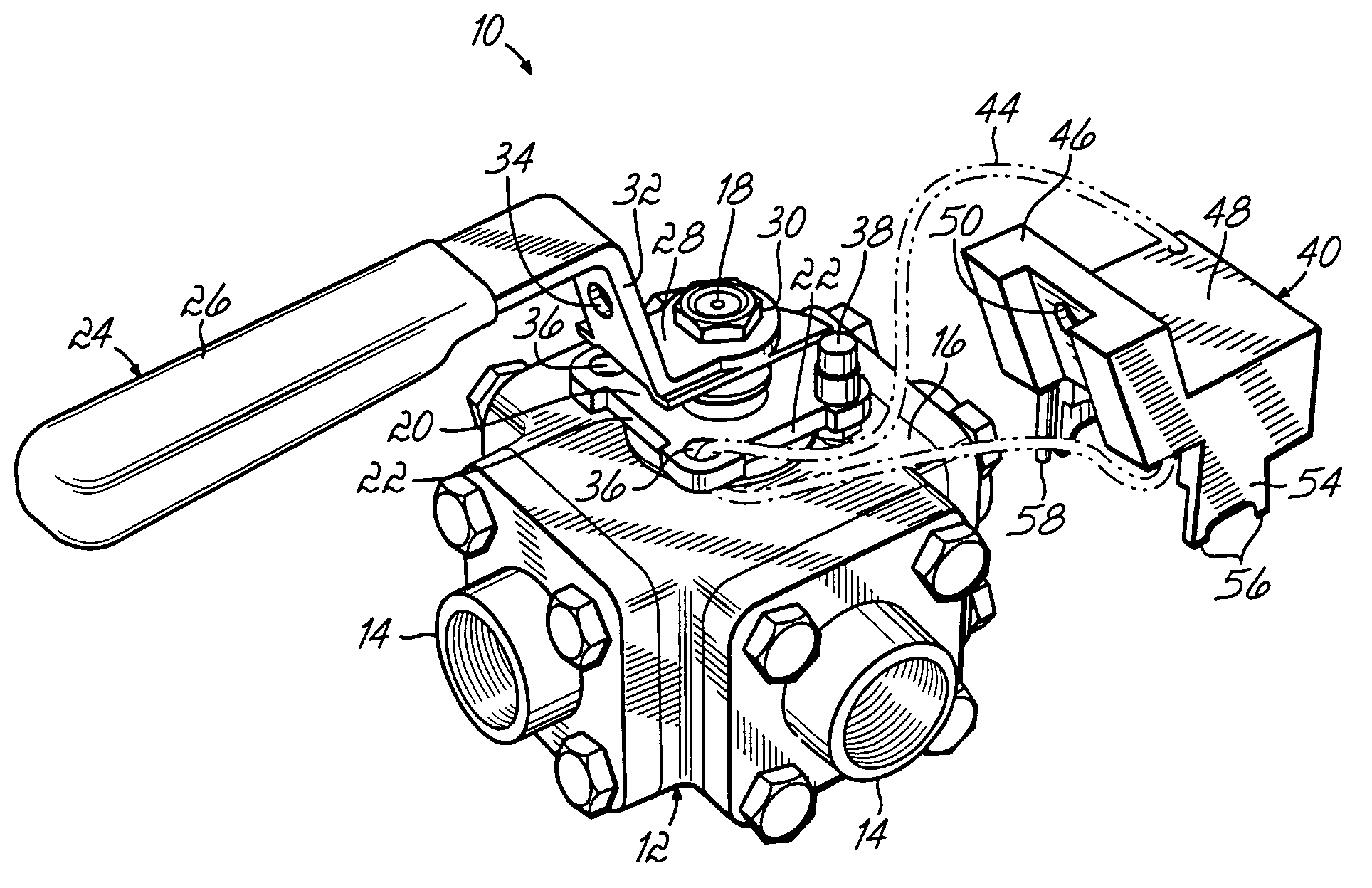

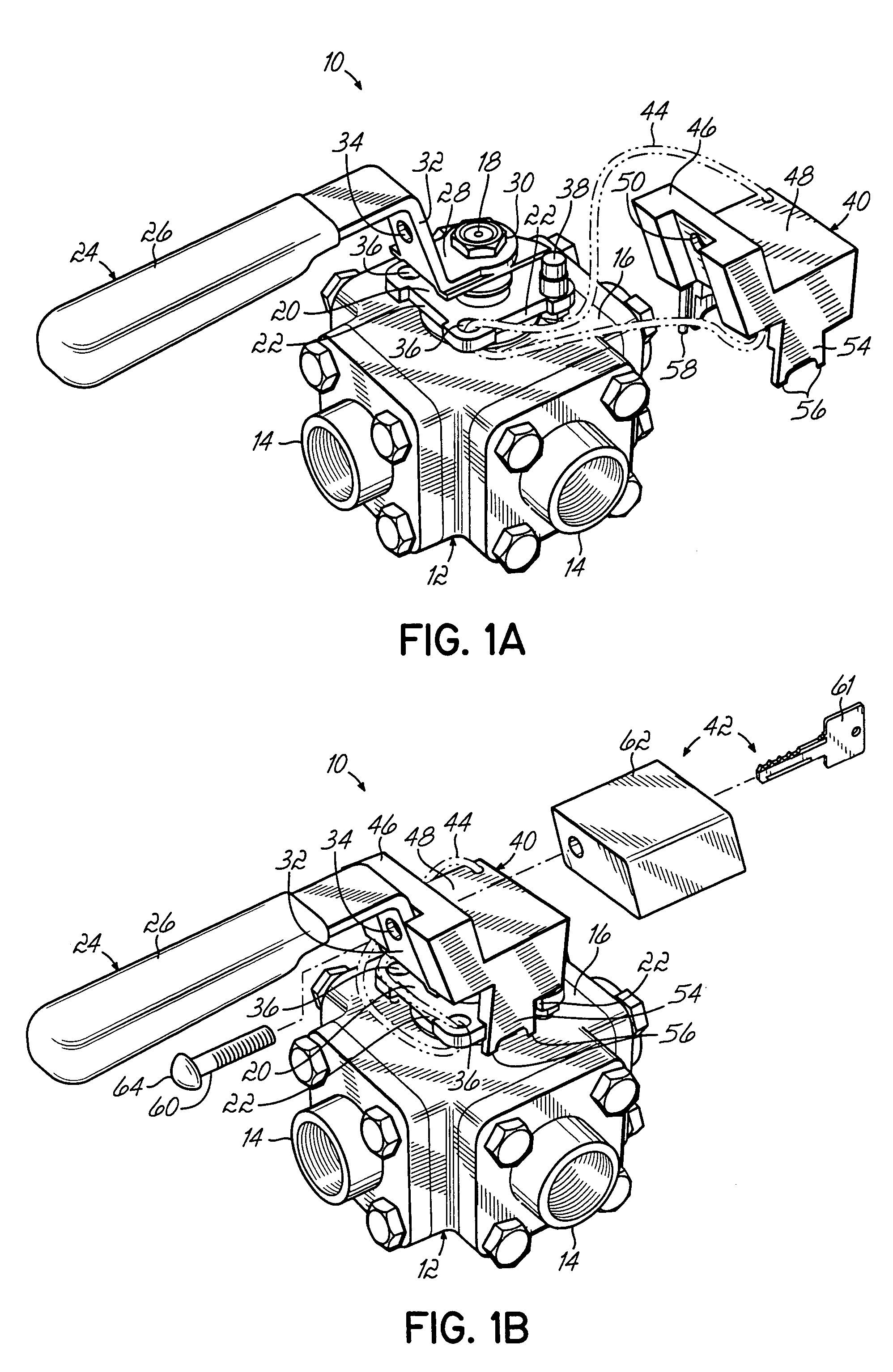

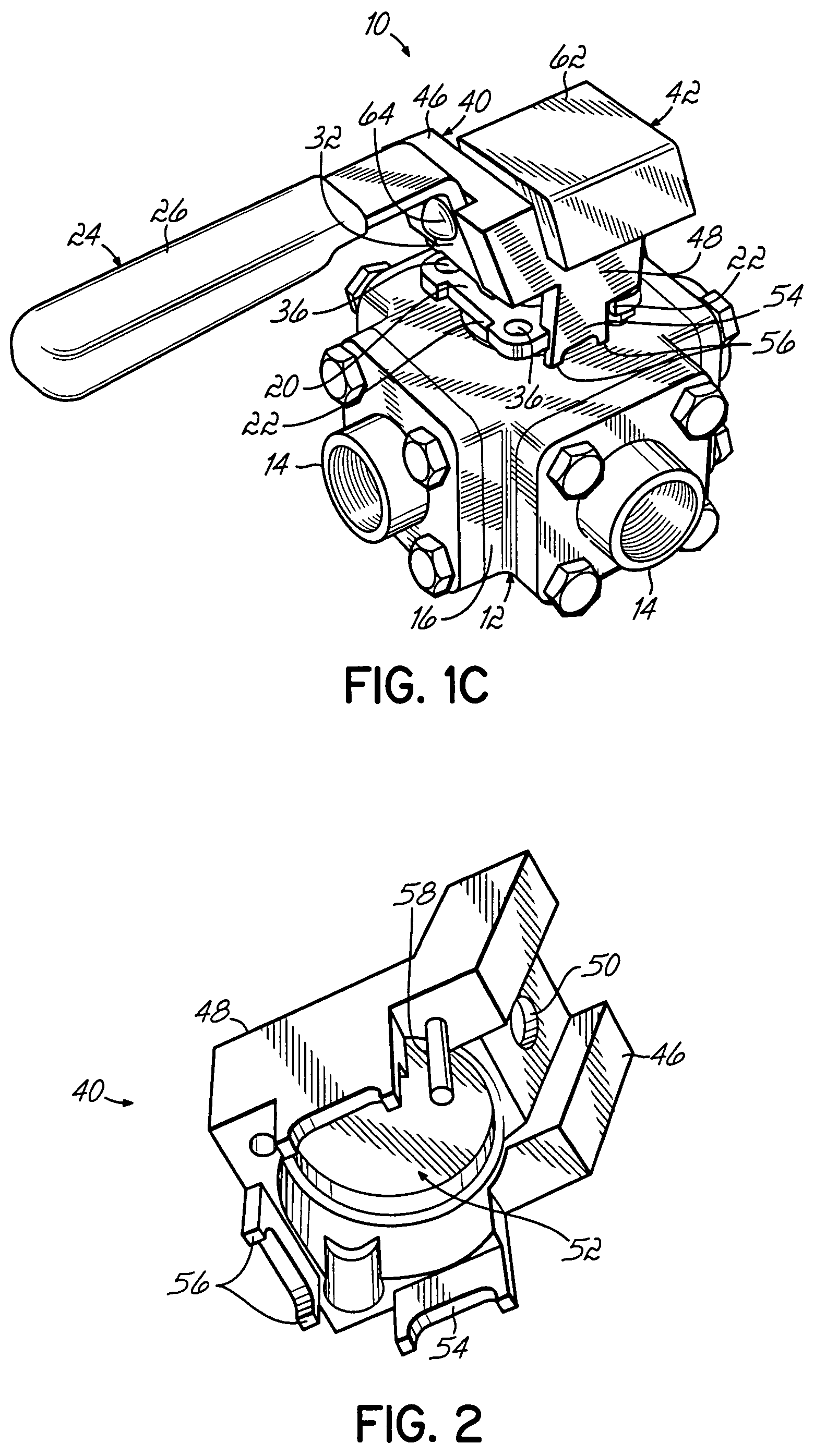

Quarter turn valve locking device

InactiveUS20050092367A1Easy and efficient installationEasy and efficient removalThin material handlingPreventing unauthorised/accidental actuationEngineeringVALVE PORT

A locking device for quarter turn valves avoids the inadvertent, unauthorized or careless manipulation of quarter turn valves from a desired position thereby minimizing, if not eliminating, the likelihood for damage or injury in an industrial or other setting as a result of the unauthorized opening / closing of the valve. The locking device includes a shroud which is adapted to be placed over the upper end of the stem and adjacent portion of the handle on the valve. The shroud has a capping portion which securely engages a mounting pad of the valve and an upwardly extending channel designed to at least partially surround a portion of the handle. A hole is provided in the channel and aligns with a hole in an adjacent portion of the handle when the shroud is placed on the valve. As such, the post of a lock is easily inserted through the aligned holes. The locking device according to this invention advantageously prevents the unauthorized manipulation of the handle and the resulting rotation of the valve member to / from the open / closed positions.

Owner:ESPINOZA ROGER

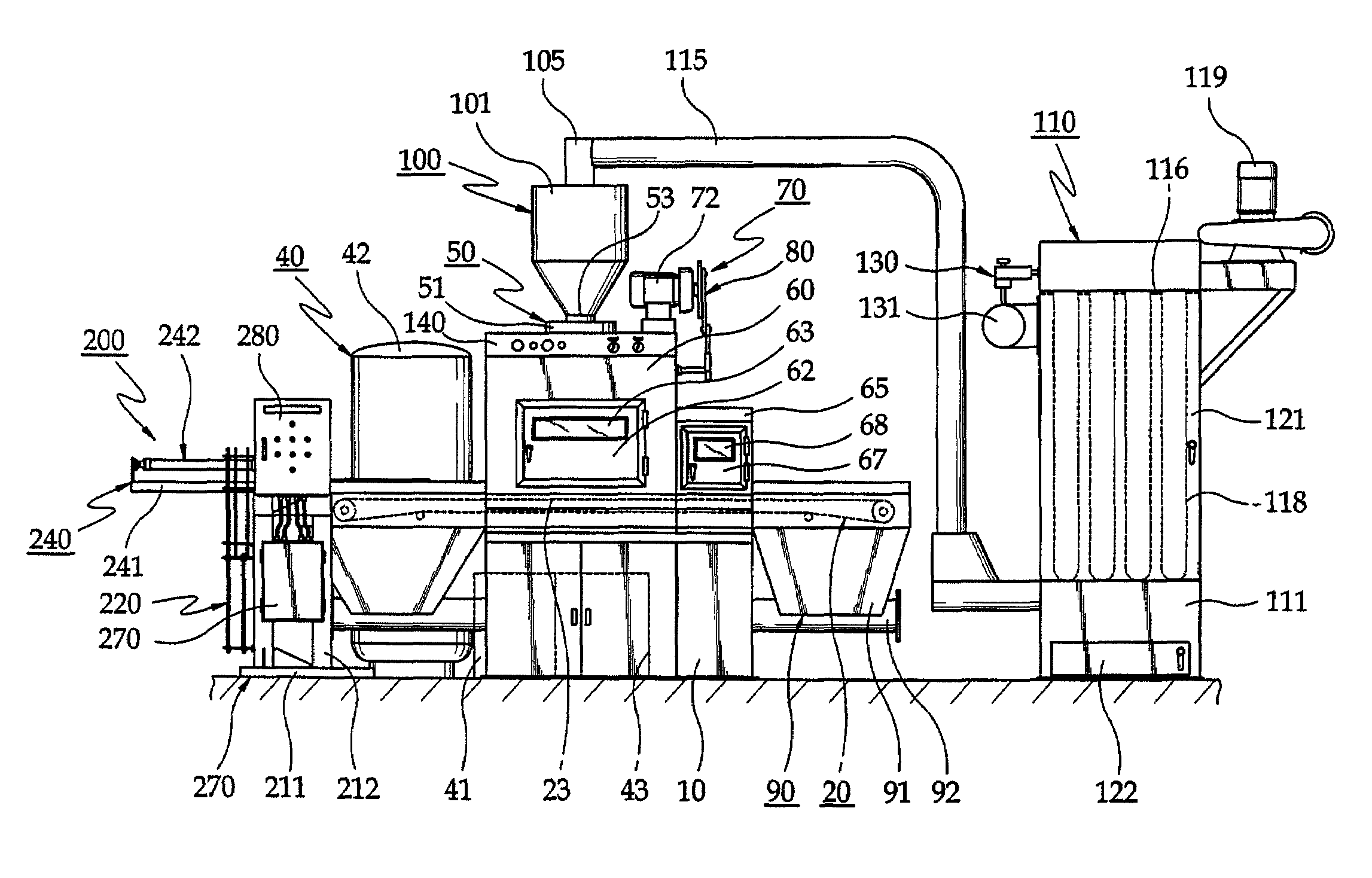

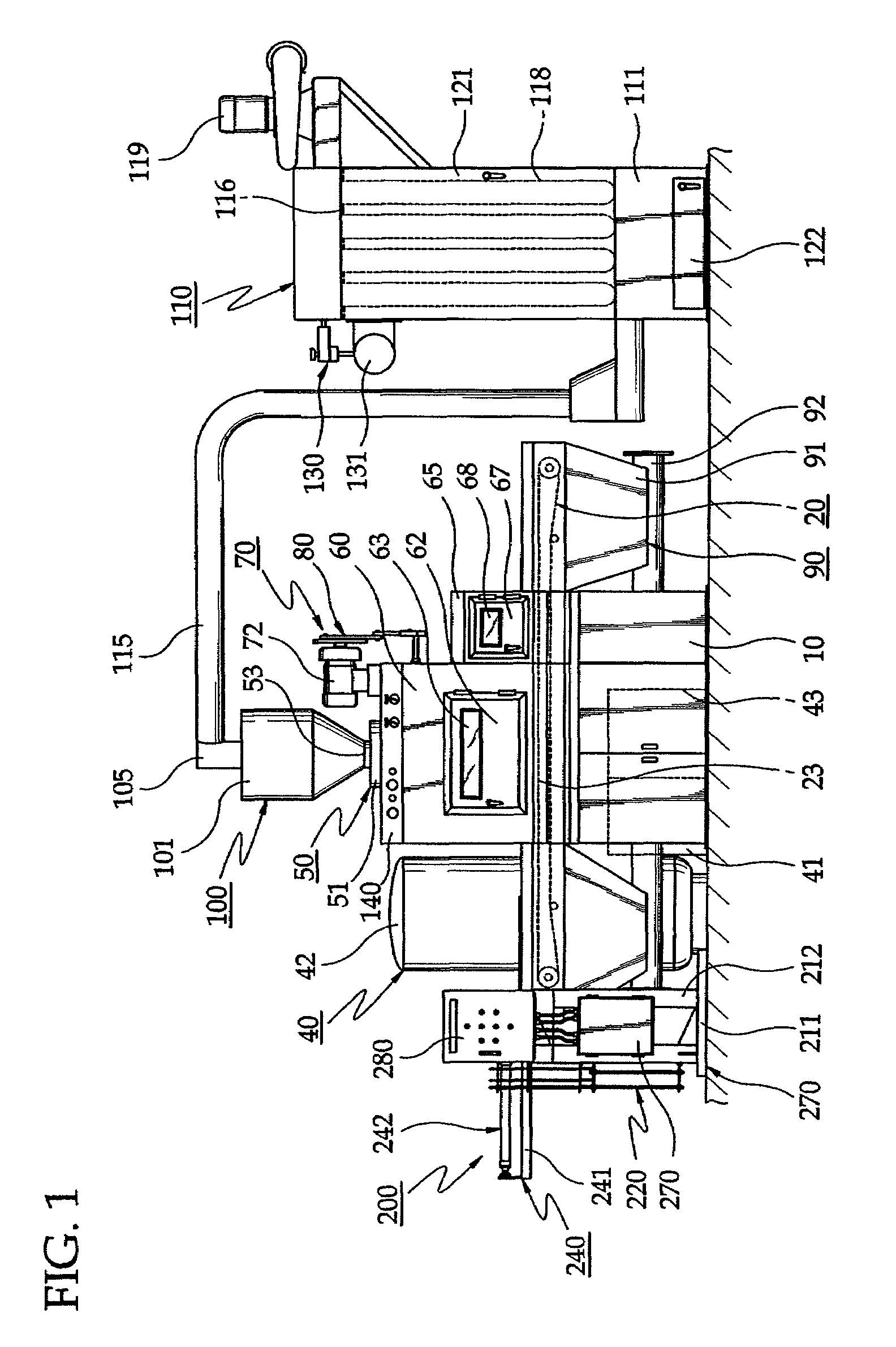

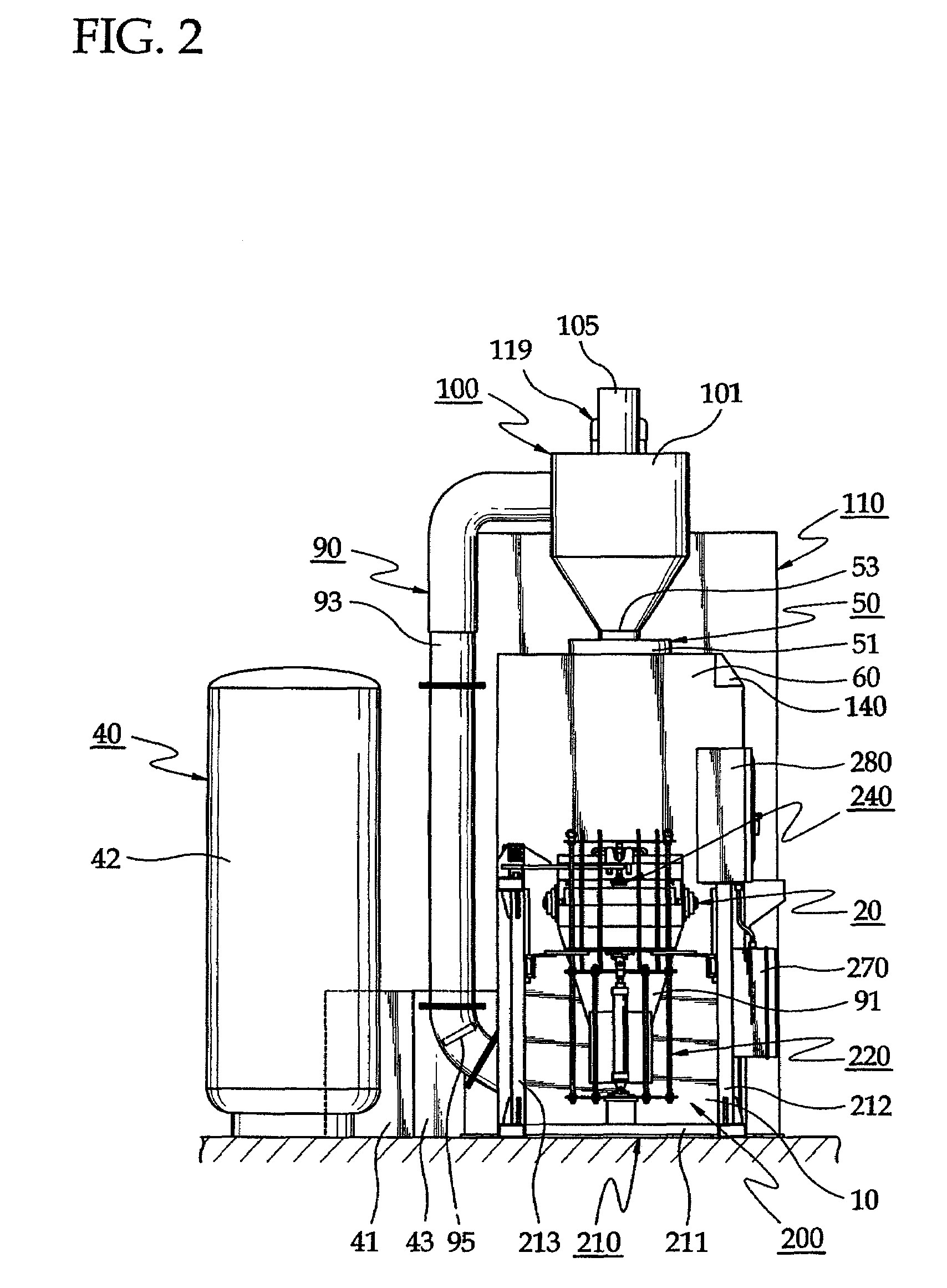

Semiconductor wafer regenerating system and method

InactiveUS7261617B1Less planarityLess purityAbrasive feedersAbrasive blasting machinesSand blastingSemiconductor

A semiconductor wafer regenerating system is capable of easily and efficiently removing fabricating patterns formed on a semiconductor wafer to enable reuse of the semiconductor wafer. The system, which removes patterns of the semiconductor wafer in a dry manner by using blasting grit, includes a mesh conveyor, a grit blaster, a swinging element, a collecting element, a separating element, and a dust collector. The mesh conveyor transports the semiconductor wafer so that the patterns face upward. The grit blaster is installed above the mesh conveyor and has at least one blasting nozzle for blasting grits toward the semiconductor wafer to remove the patterns from the semiconductor wafer. The swinging element swings the blasting nozzle in a plane perpendicular to a transporting path of the semiconductor wafer along the mesh conveyor. The collecting element underneath the mesh conveyor collects pulverulent bodies including grits, chips, and dusts falling from the mesh conveyor. The separating element is connected to the collecting element to separate the grits and chips from the dusts. The dust collector is connected to the separating element to collect the dusts separated by the separating element.

Owner:SILFINE

Storage system

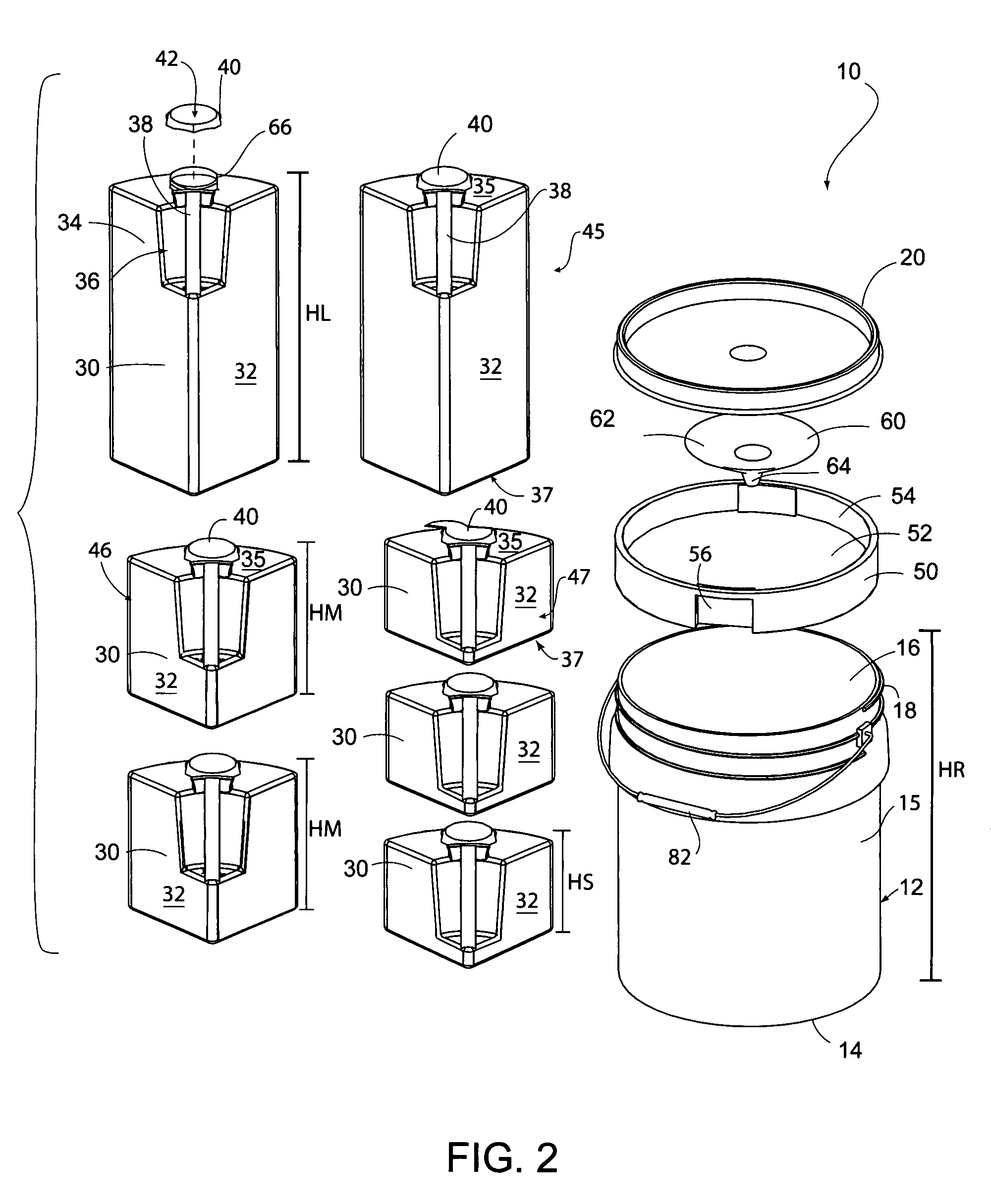

InactiveUS7988005B2Fill the volume of the receptacleMaximize system capacityInternal framesTable equipmentsEngineeringMechanical engineering

A storage system for storing a plurality of fluids or other goods has a plurality of containers adapted to fit within a receptacle. Each of the containers has an inner sidewall, an outer sidewall, and a top sidewall having a spout sealable with a cap such that the container contains the fluid or other goods when the cap is engaged with the spout. The plurality of containers are shaped such that the containers are stackable or nestable within the receptacle such that the containers tessellate, the inner sidewalls of the containers abutting each other, and the outer sidewalls abutting the inner surface of the receptacle, completely filling substantially all of the receptacle.

Owner:WAGNER PAUL

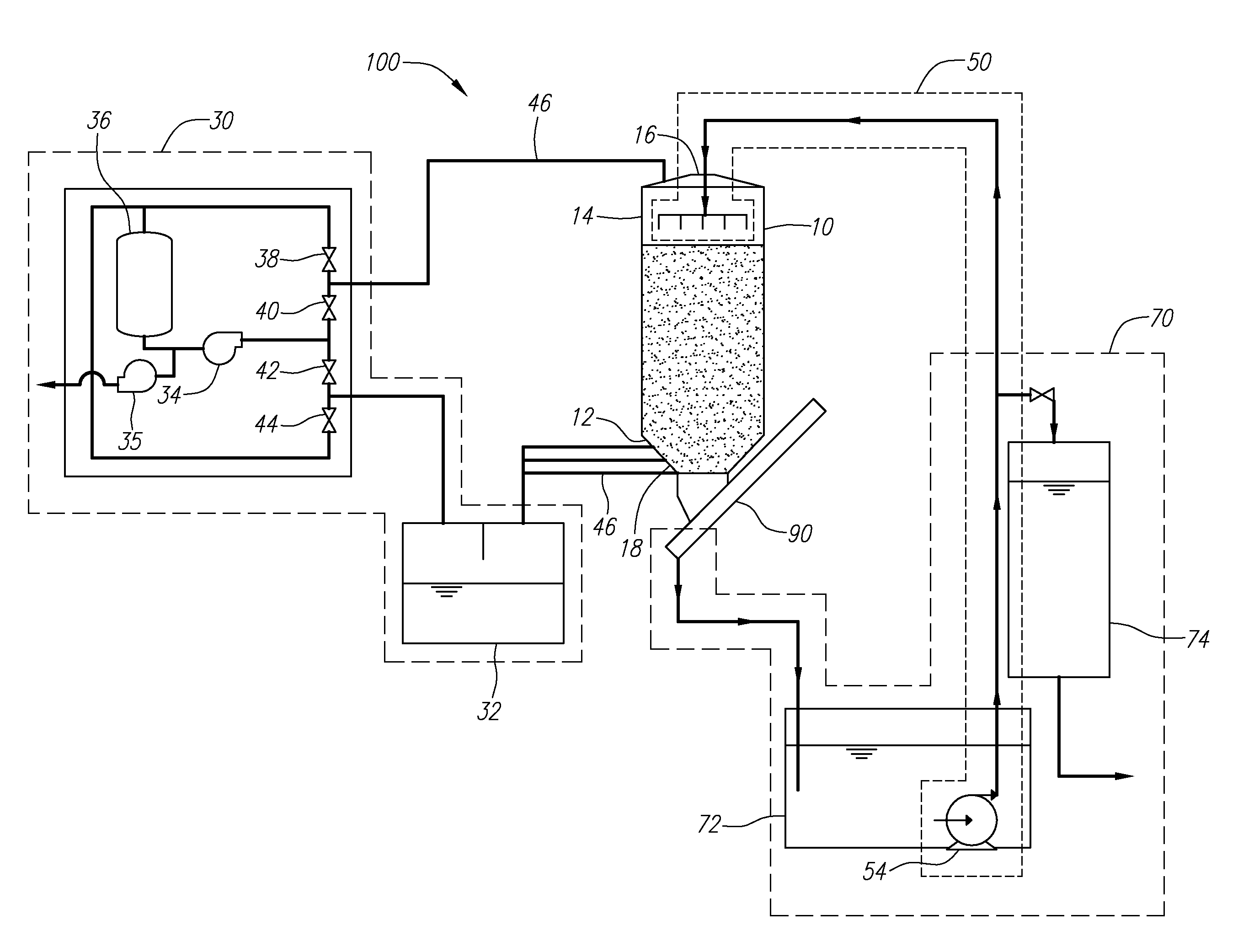

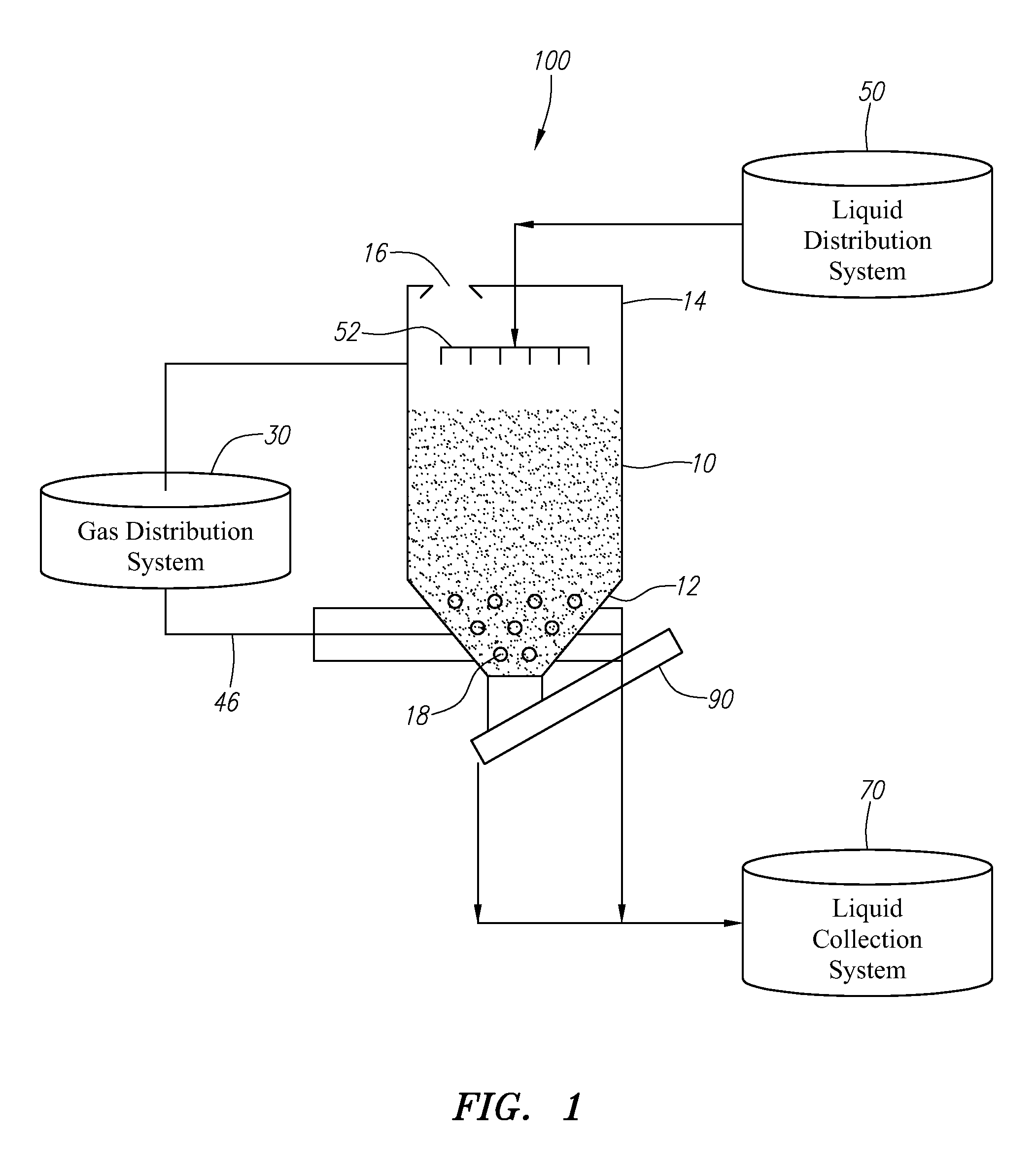

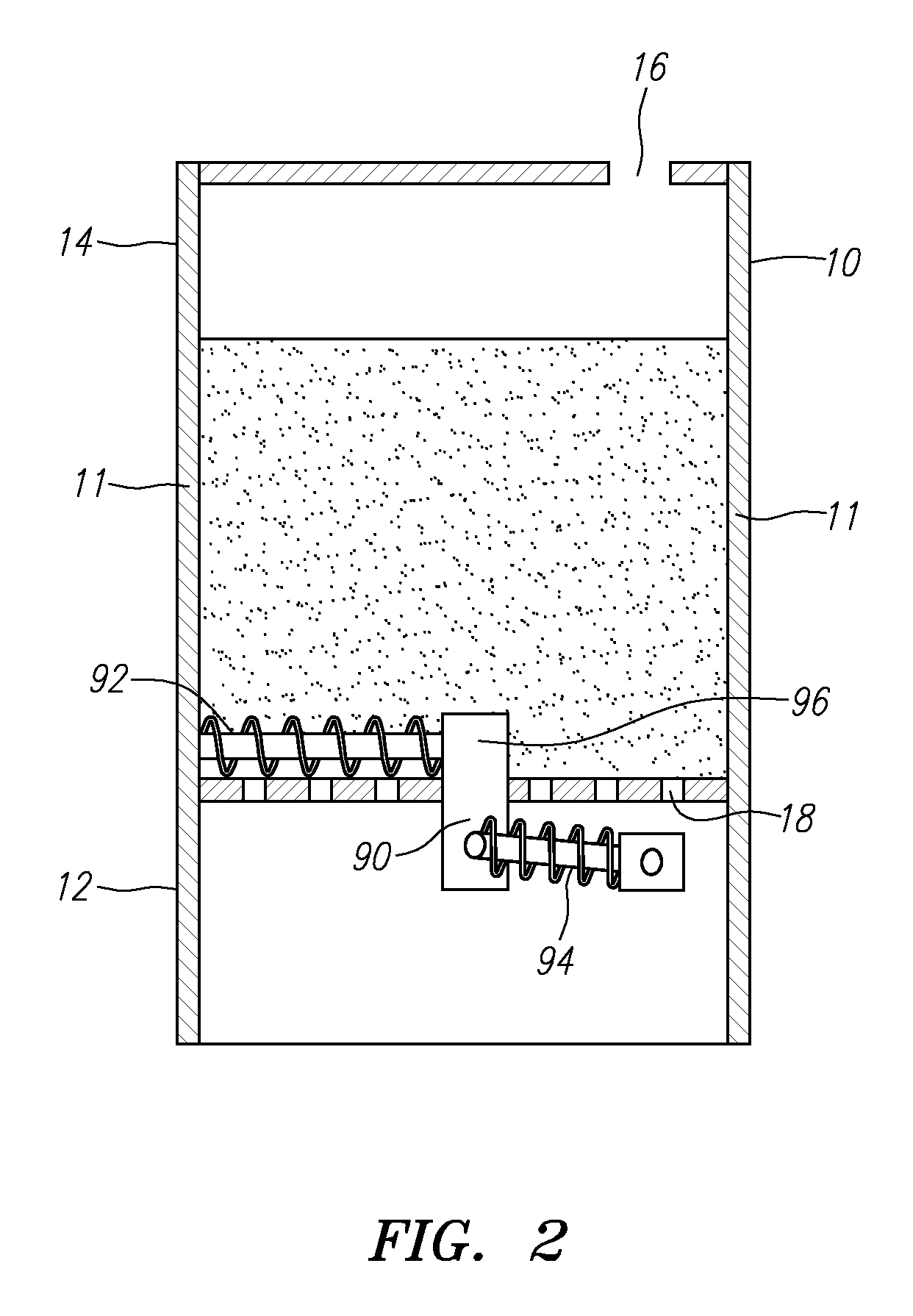

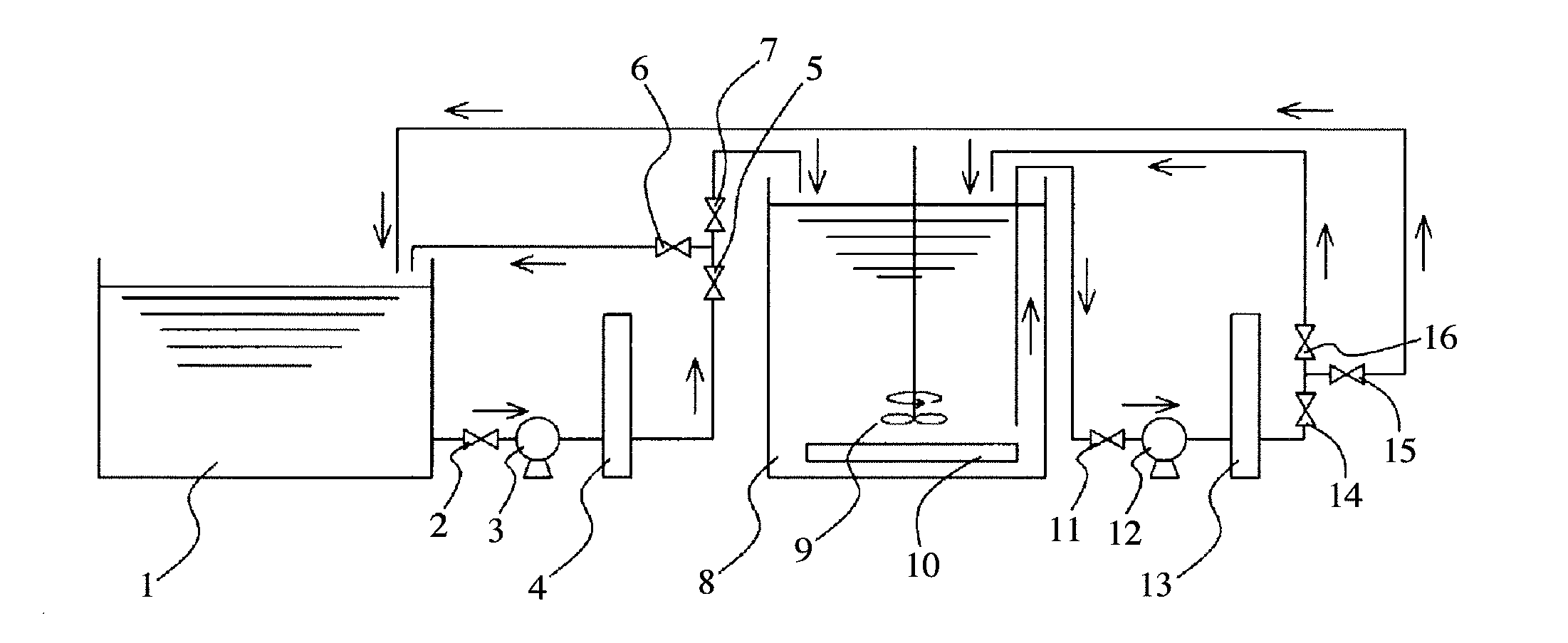

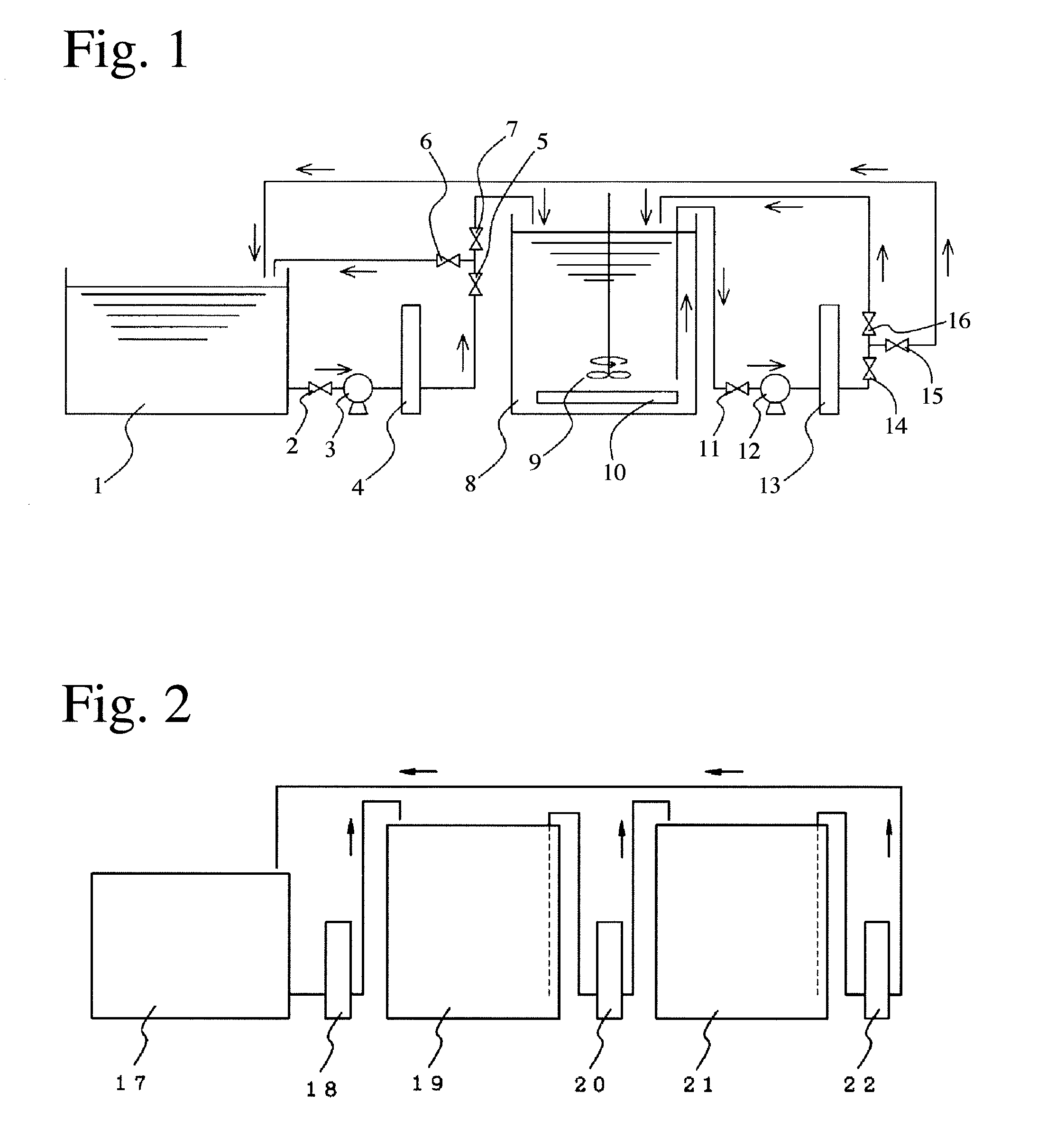

Static solid state bioreactor and method for using same

InactiveUS20100261242A1Quantity minimizationReadily and cost-effectivelyBioreactor/fermenter combinationsBio-organic fraction processingMaterial removalMarine engineering

A static solid state bioreactor and method of using same. The bioreactor comprises a vessel having an upper end and a lower end, the upper end having a sealable opening. A gas distribution system in communication with the upper end and the lower end of the vessel. A liquid distribution system in communication with the upper end of the vessel. A liquid recovery system in communication with the lower end of the vessel. A material removal system disposed at the lower end of the vessel for removing biomass from the vessel.

Owner:GEOSYNFUELS

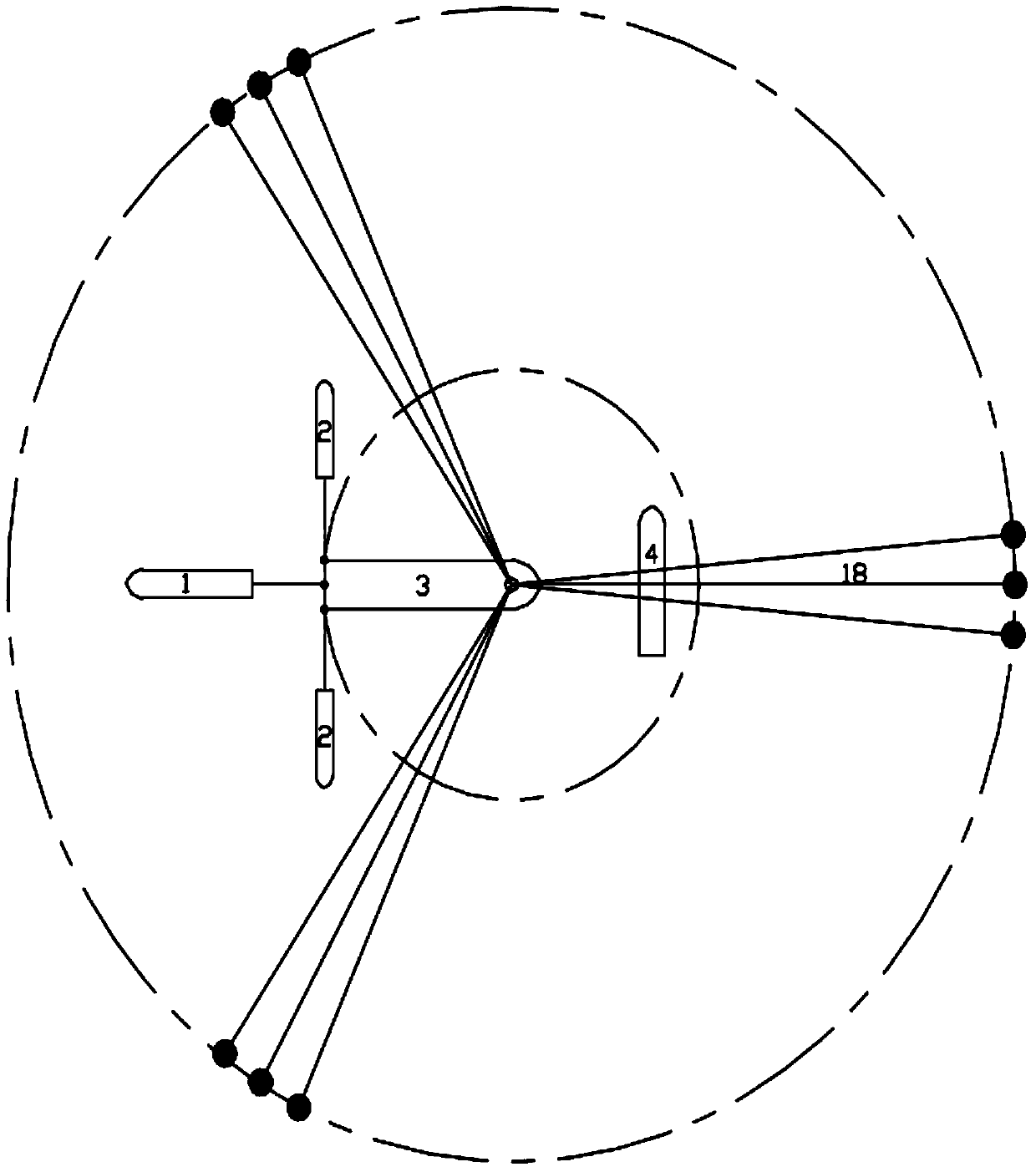

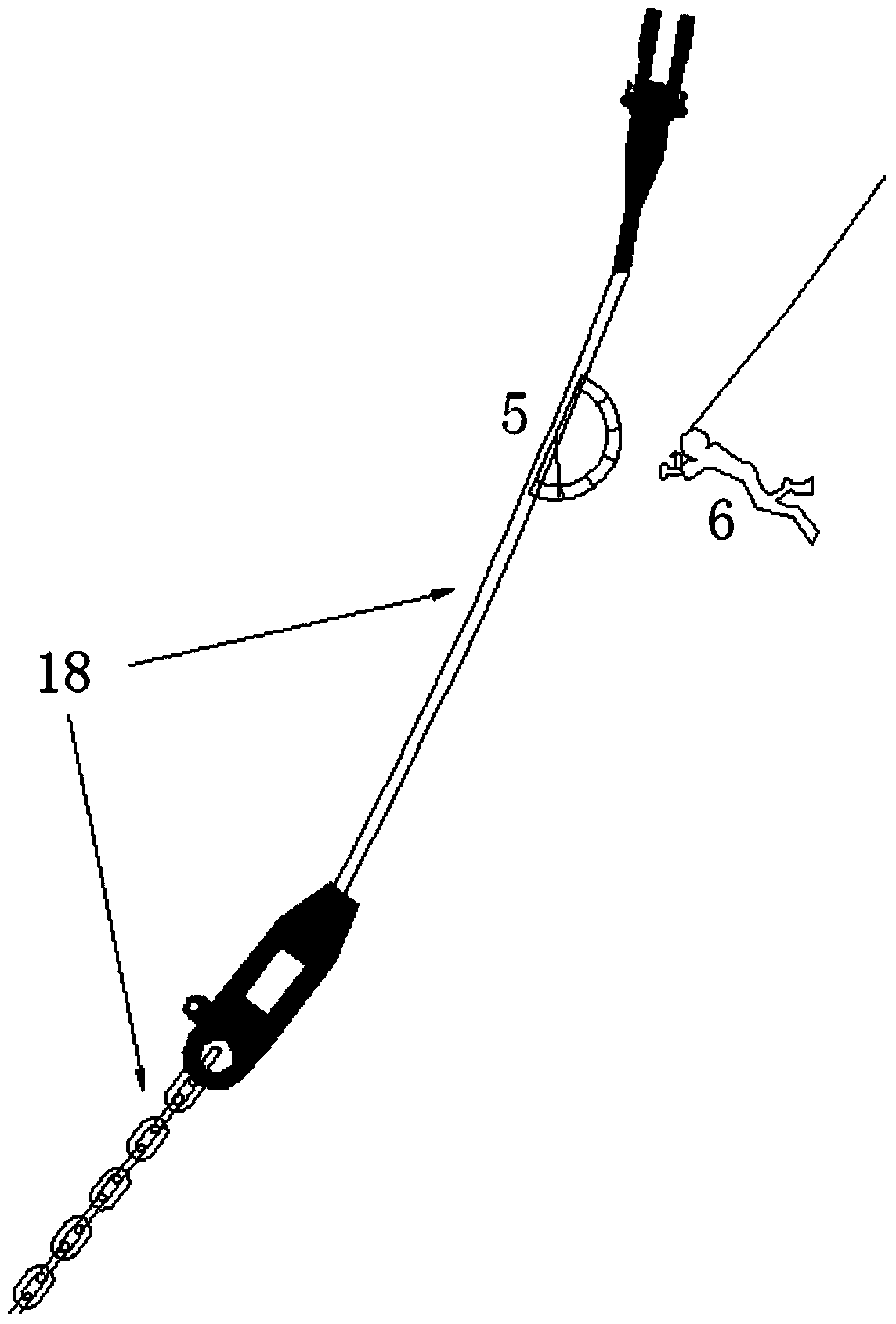

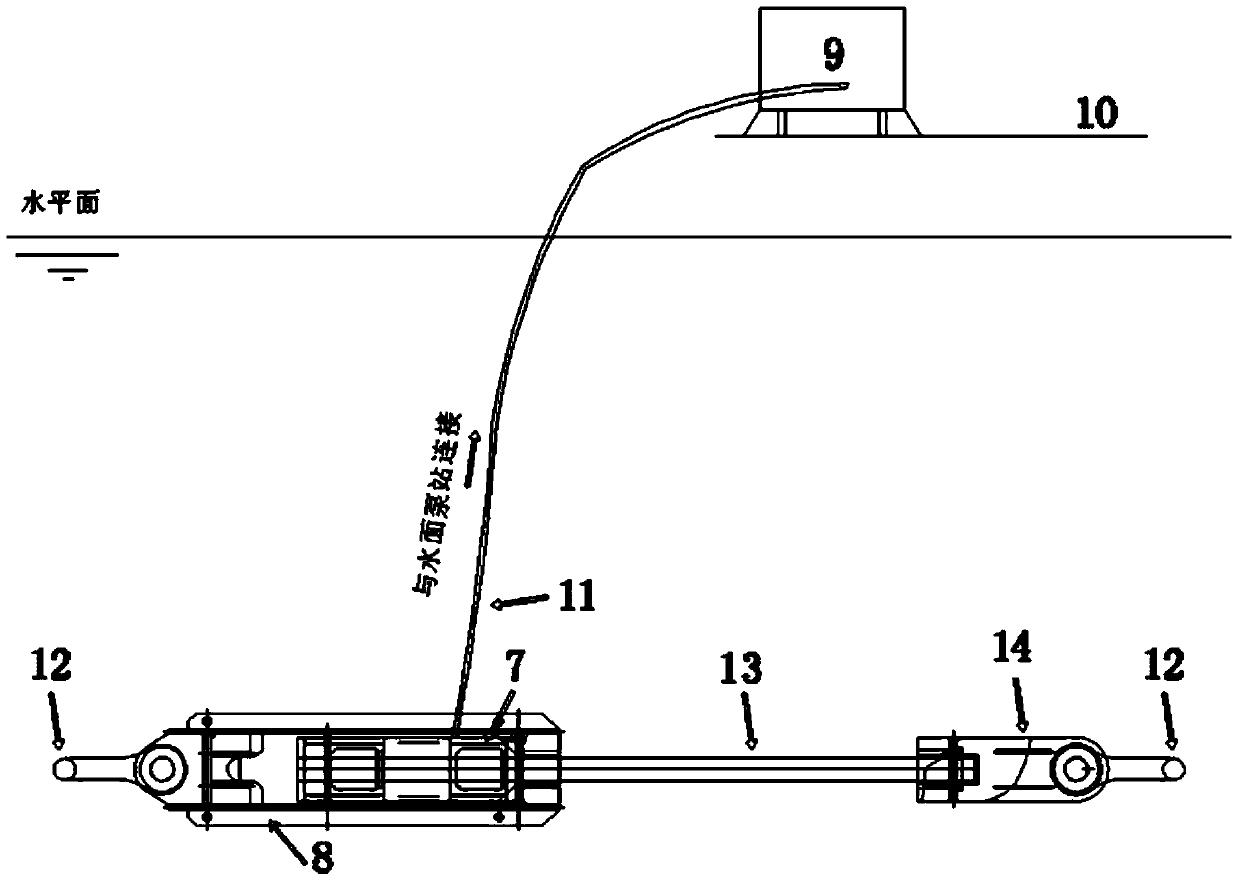

Method for replacing upper anchor cable of mooring anchor legs

ActiveCN103738477AReduce workloadReduce yield lossAnchoring arrangementsEnvironmental geologyStructural engineering

Disclosed is a method for replacing an upper anchor cable of mooring anchor legs. The method includes 1), arranging a plurality of limiting tugs on the stem of a floating production storage and offloading oil tanker; 2), mounting protractors on the mooring anchor legs; 3), descending a tensioner to the sea floor and then tightening an anchor chain; 4), cutting a loosened anchor chain ring; 5), demounting the tensioner; 6), regulating heading of the oil tanker to be perpendicular to the anchor legs; 7), uplifting the upper anchor cable; 8), demounting an old upper anchor cable section head; 9), pulling a new upper anchor cable section head to the bottom of a single point; 10), mounting the new upper anchor cable section head; 11), connecting the new upper anchor cable section head with one section of the anchor chain to form a complete anchor leg; 12), releasing an underwater hydraulic tensioner steel strand to a natural state and demounting the same; 13), remeasuring water entry angle of the anchor legs and water depth and position of an lower anchor cable section head of the anchor legs. By the application of the method, all construction work like recycling the old anchor cable and mounting the new anchor cable are realized under the condition of not releasing the floating production storage and offloading oil tanker; therefore, production efficiency and reliability are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +3

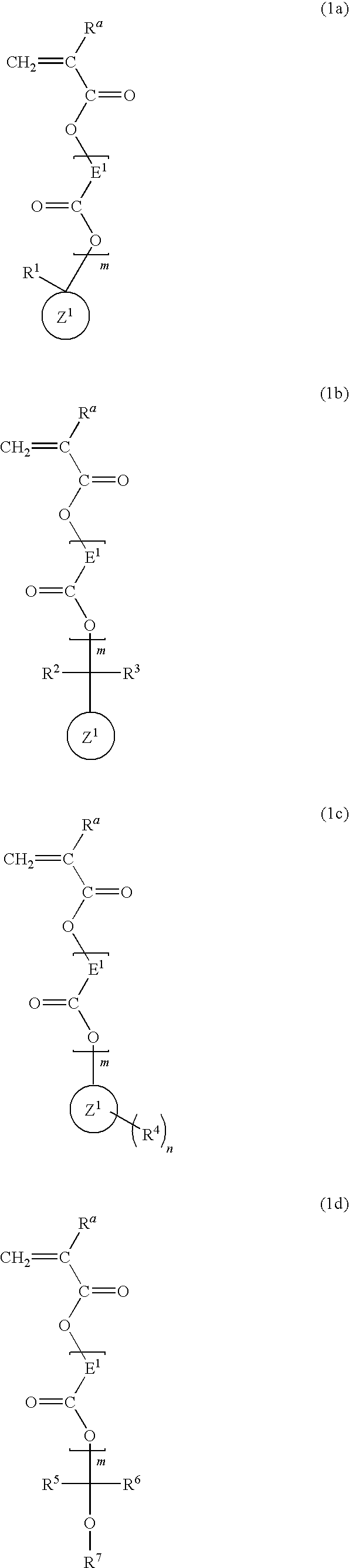

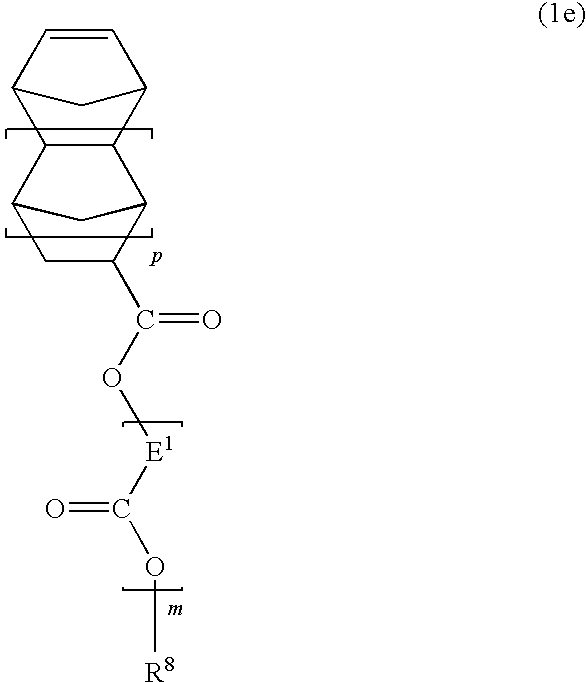

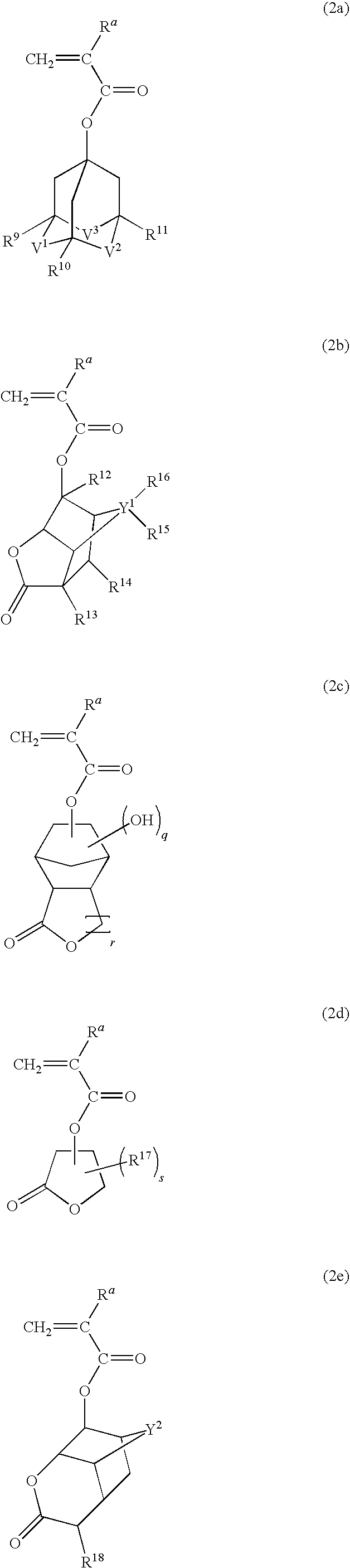

Process for producing photoresist polymeric compounds

InactiveUS20100297551A1Efficient productionReduce metal contentPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer sciencePorous membrane

Disclosed is a process for producing a photoresist polymeric compound. The process includes the steps of polymerizing a monomer mixture containing at least one monomer selected from a monomer (a) containing a group capable of leaving with an acid to allow the polymeric compound to be soluble in an alkali, a monomer (b) having a lactone skeleton, and a monomer (c) having a hydroxyl-containing alicyclic skeleton, to give a polymer; passing a solution containing the polymer through a filter including a porous membrane having an anion-exchange group to give a polymer solution; and thereafter passing the polymer solution through a filter including a porous membrane having a cation-exchange group. The polymer solution before passing through the filter including a porous membrane having a cation-exchange group preferably has a content of metals of 1000 ppb by weight or less per the weight of the polymer.

Owner:DAICEL CHEM IND LTD

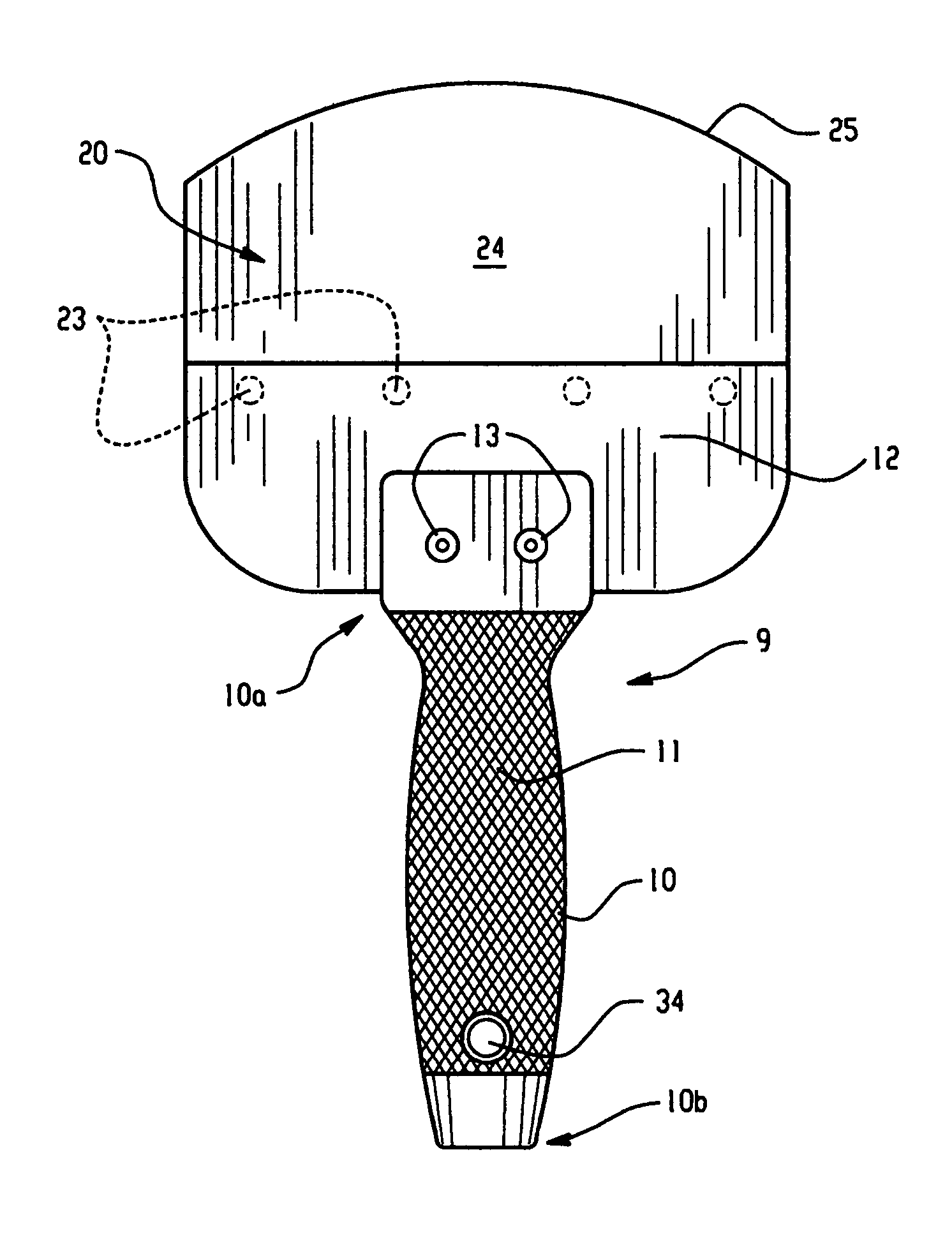

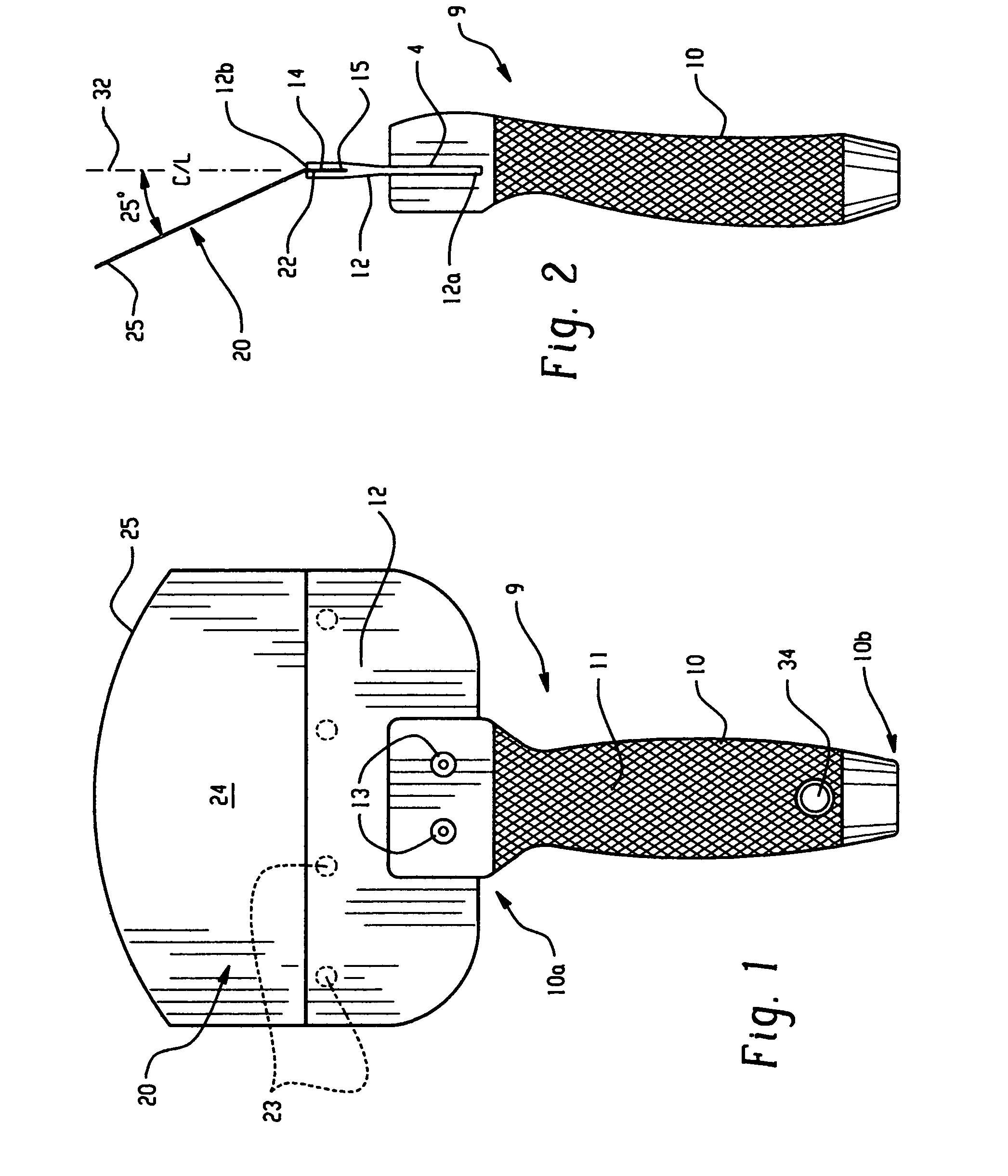

Transfer tool

InactiveUS7788760B2Easy and efficient removalQuantity minimizationLiquid surface applicatorsCarpet cleanersAcute angleEngineering

A tool is provided for use in removing pliable surface compounds from a container and efficiently transferring the compound to a tray or the like. The tool comprises a handle having a longitudinal axis and having first and second ends. The tool also includes a blade secured to the first end of the handle and having first and second adjacent sections. The first section of the blade defines a generally planar controlling section and the second section of the blade defines a generally planar working section, wherein the plane of the second section extends at an acute angle relative to the plane of the first section. The second section defines a contoured edge of predetermined curvature corresponding to the curvature of the container such that the blade can be used to remove surface compounds from the container.

Owner:SCHNEBLE TOLLS L L C

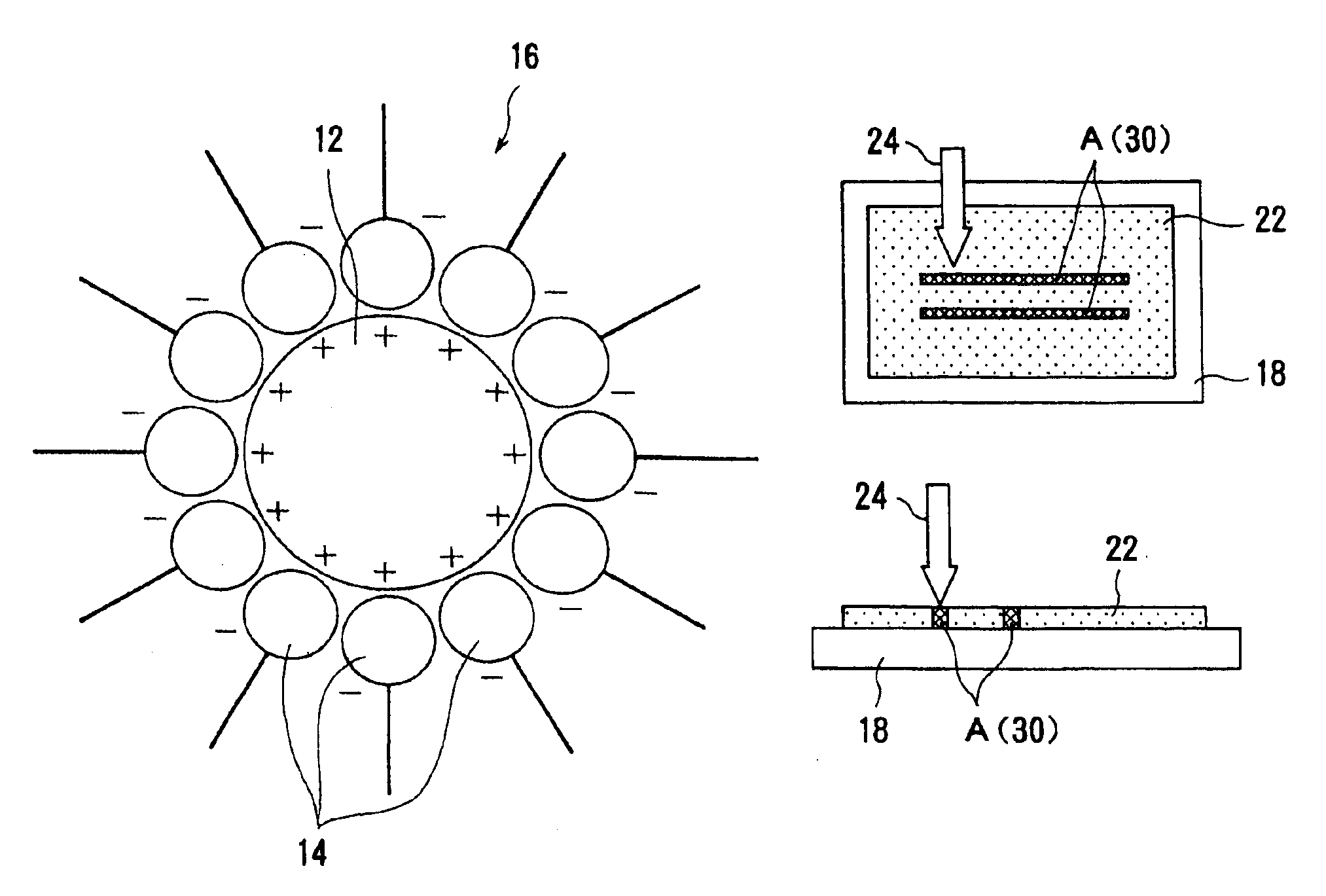

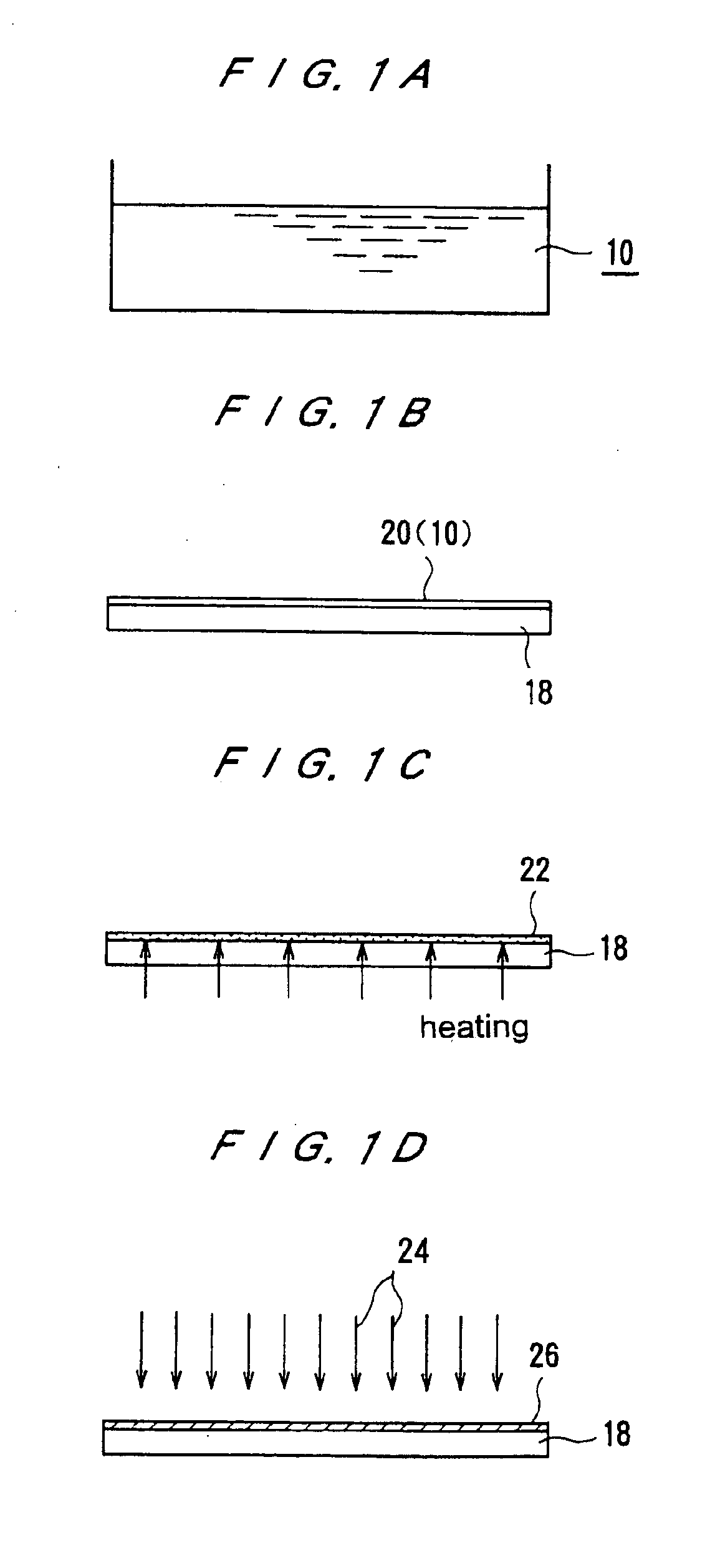

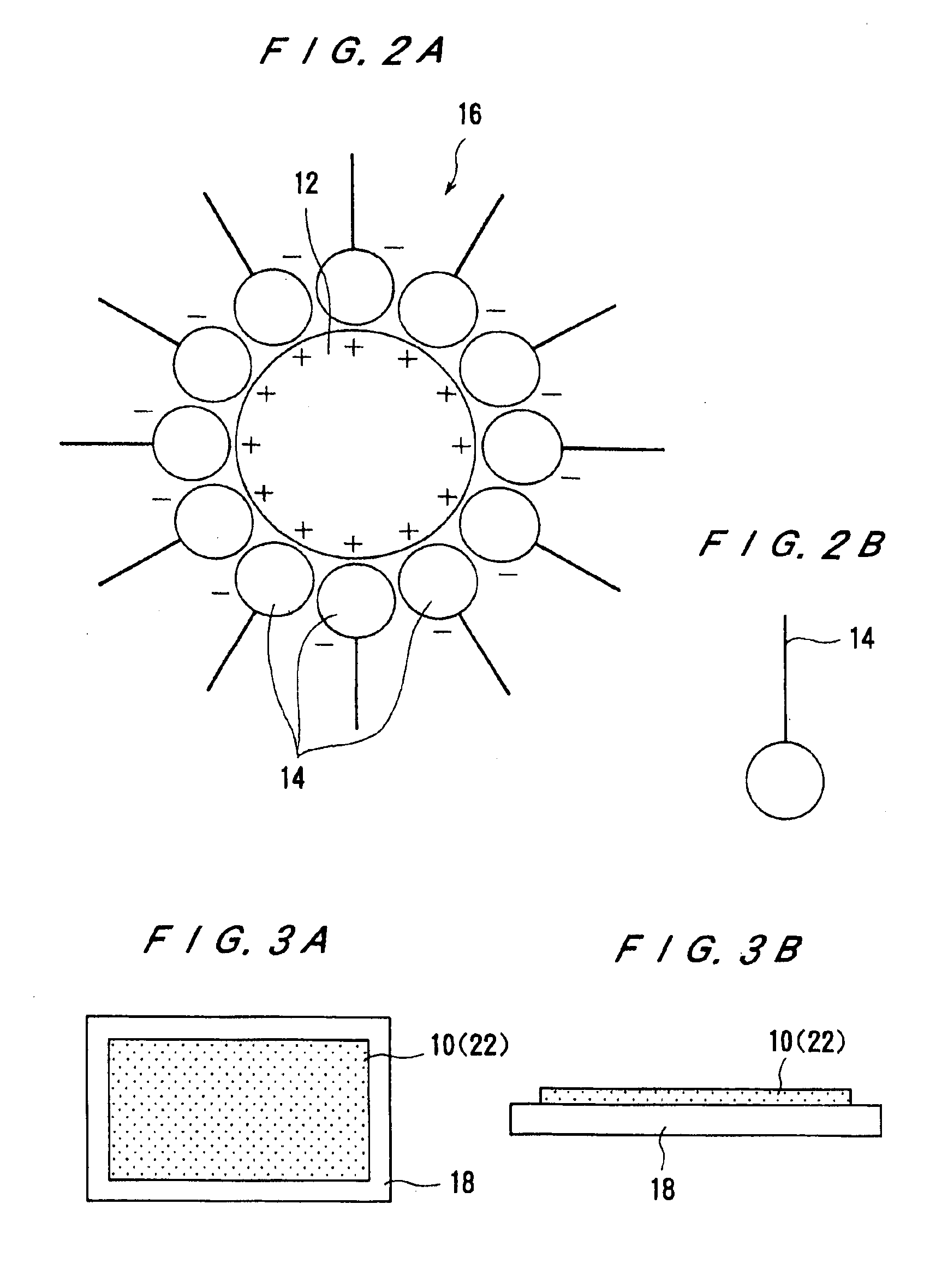

Method and apparatus for forming thin film of metal

InactiveUS6972256B2Efficient qualityEasy and efficient removalSemiconductor/solid-state device manufacturingPretreated surfacesThin metalMetal interconnect

The present invention relates to a method of and an apparatus for forming a thin metal film of copper, silver, or the like on a surface of a semiconductor or another substrate. A method of forming a thin metal film, comprises preparing a dispersed liquid having a metal-containing organic compound dispersed in a predetermined solvent, coating the dispersed liquid on a surface of a substrate and evaporating the solvent to form a coating layer, and applying an energy beam to the coating layer to decompose away an organic substance contained in the coating layer in an area irradiated with the energy beam and bond metal contained in the coating layer.According to the present invention, it is possible to form a thin metal film of good quality efficiently and stably. The thin metal film used as metal interconnects in highly integrated semiconductor circuits contributes to the progress of a process of fabricating semiconductor devices.

Owner:EBARA CORP

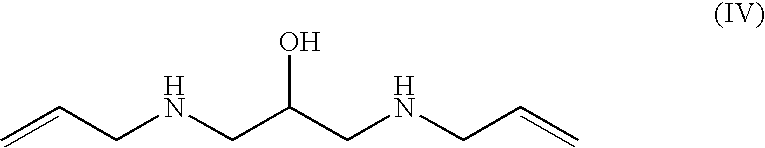

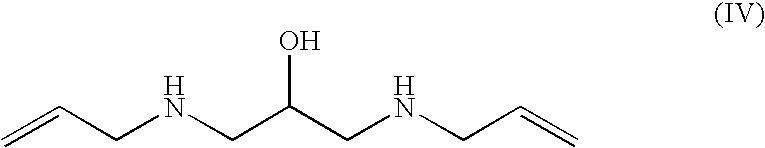

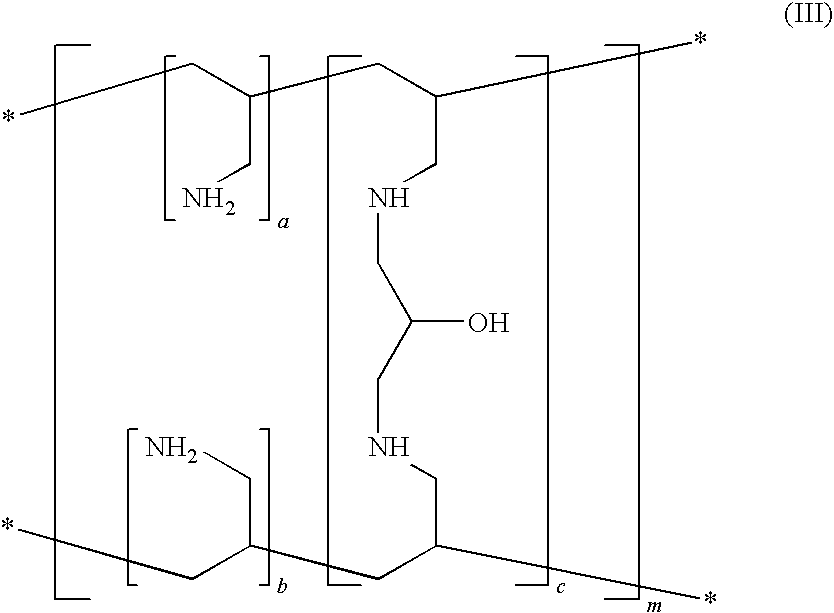

One step process for preparing cross-linked poly(allylamine) polymers

InactiveUS8394416B2Lower energy requirementsGood chemical uniformityOrganic active ingredientsOrganic chemistryCross-linkChemistry

The present invention relates to a novel one step process for preparing cross-linked poly(allylamine) polymers or salts thereof using the novel cross-linking agent of Formula (IV).This invention also relates to the compound of Formula (IV) as well as to a process to obtain it. The cross-linked poly(allylamine) polymers of the invention are useful in medicine as substrate-binding polymers.

Owner:QUIMICA SINTETICA

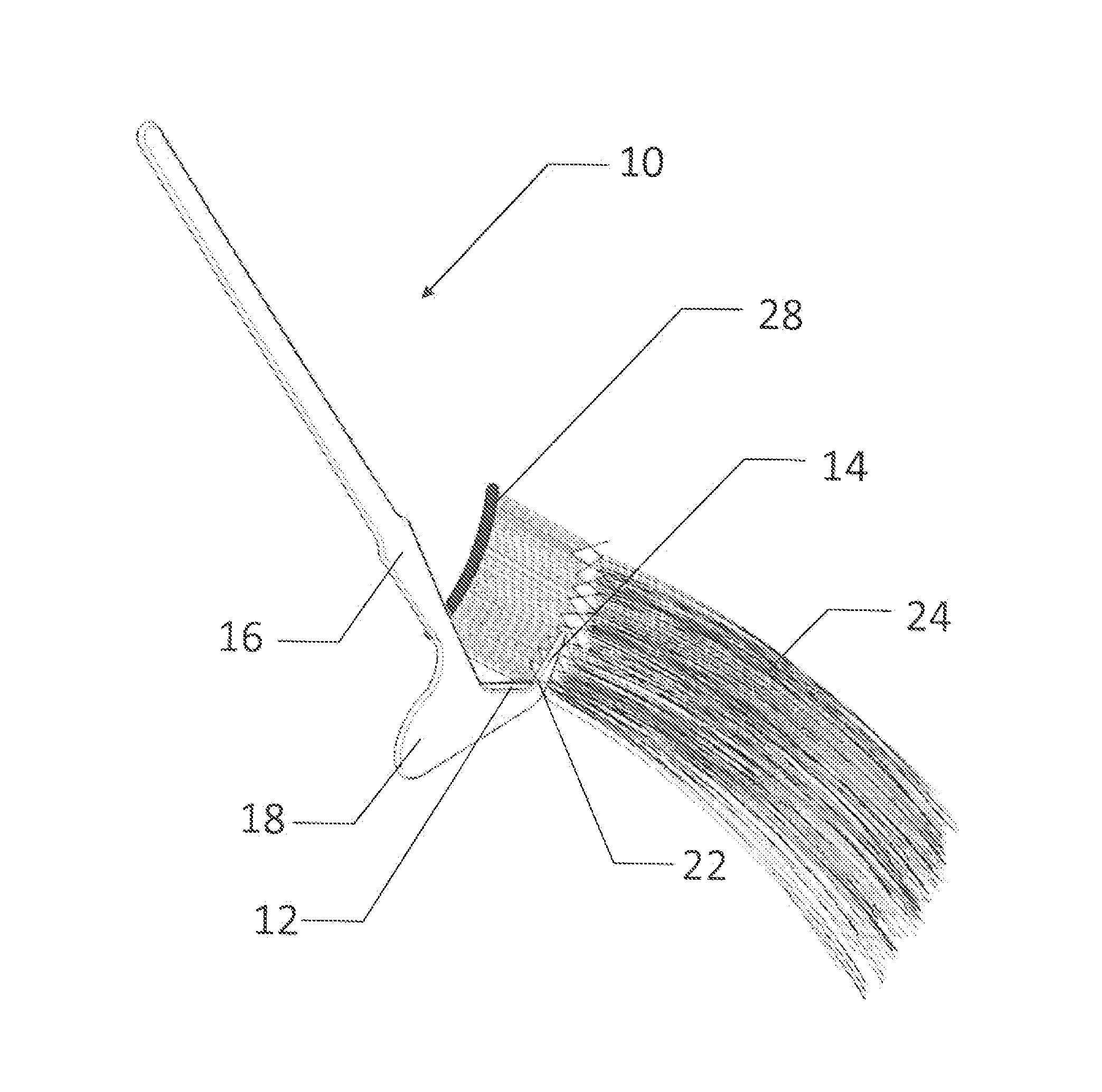

Cutting Tool

InactiveUS20140033442A1Easy and efficient removalSafe and efficientPackaging toiletriesPackaging cosmeticsMechanical engineering

A cutting tool designed to easily and efficiently remove a hair weave. The tool has a main body including a fully integrated handle, central portion and slide portion. The central portion has a top edge and the slide portion has a guiding edge and a pointed tip. The main body houses a blade which is partially enclosed by the central portion of the main body and exposed along a sharpened edge along the top edge of the central portion. The sharpened edge of the blade extends into the guide edge of the slide. The blade is designed to cut the thread of a hair weave in order to remove it from the existing hair.

Owner:BETHEA TORRIS L

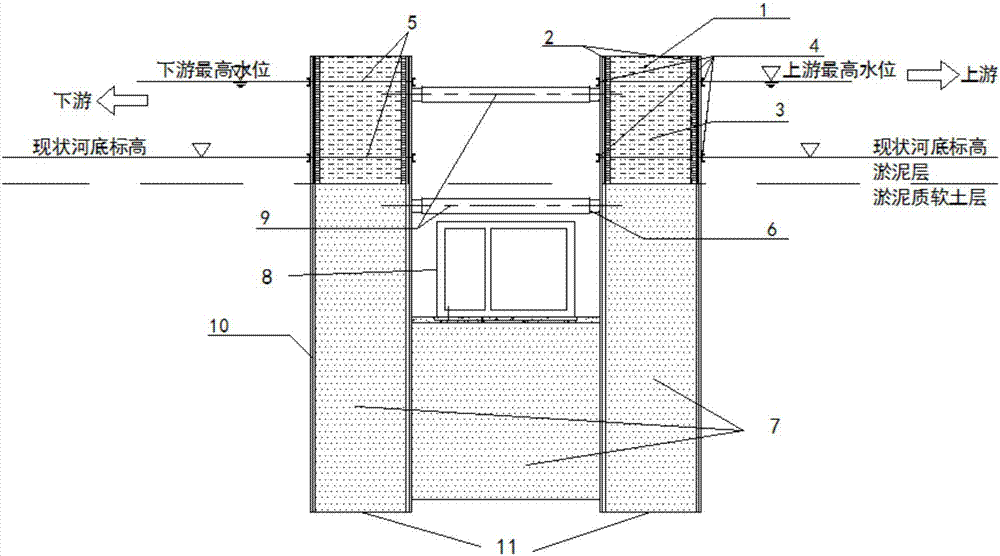

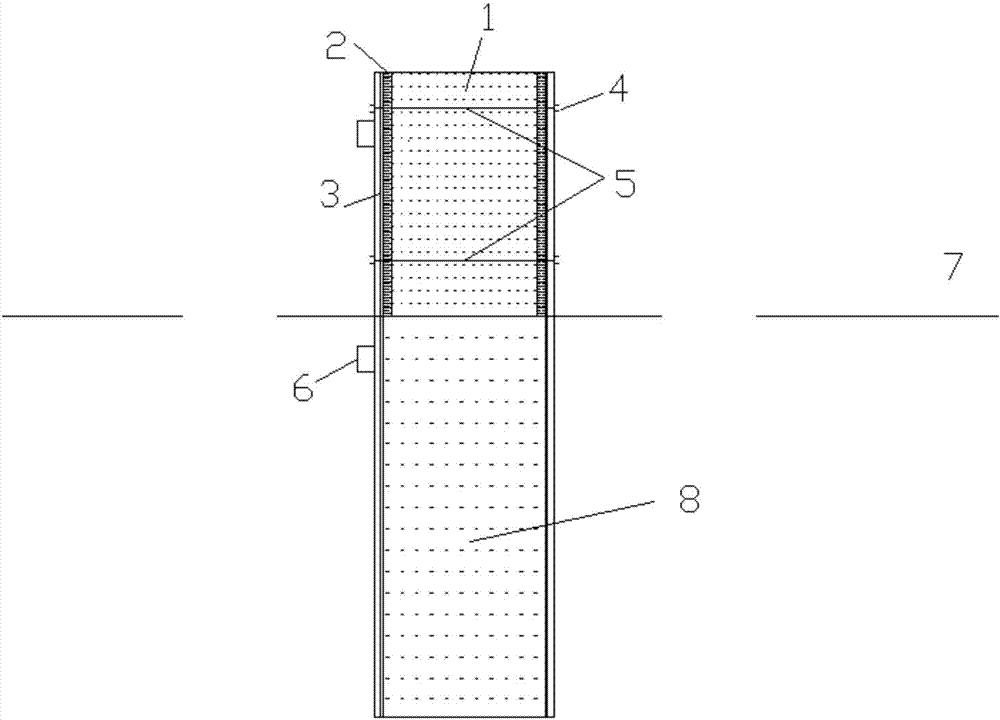

Deep mucky riverbed pipe gallery river crossing dual-steel-plate pile cofferdam structure and construction method

PendingCN107299630AImprove stabilityImprove securityProtective foundationBulkheads/pilesPurlinSludge

The invention relates to a deep mucky riverbed pipe gallery river crossing dual-steel-plate pile cofferdam structure; upstream and downstream of a river are provided with dual-steel-plate piles; each dual-steel-plate pile is enclosed by two lines of Larsen steel plate piles, the inner parts of the Larsen steel plate piles are connected through channel steel circuit purlin split bolts and a tie bar; adjacent Larsen steel plate piles are connected through a lock opening; the riverbed sludge between two steel plate piles is compacted and grouted to form compaction grouting soil; the inside walls of the dual-steel-plate piles are provided with the channel steel circuit purlin split bolt; one layer of anti-seepage film is arranged at inside of each dual-steel-plate pile, and a layer of bagged soil closes to the anti-seepage film; ash mixing soil is filled between the dual-steel-plate piles layer by layer. The deep mucky riverbed pipe gallery river crossing dual-steel-plate pile cofferdam structure has the beneficial effects that on the basis of waterproof dual-steel-plate piles, the ash mixing soil core with good anti-seepage ability is arranged between dual-steel-plate piles; the anti-seepage film is further arranged; the substrate of the ash mixing soil core is compacted and grouted to further improve the substrate waterproof effect, thus the waterproof effect of the whole cofferdam is improved through multiple waterproof effects.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

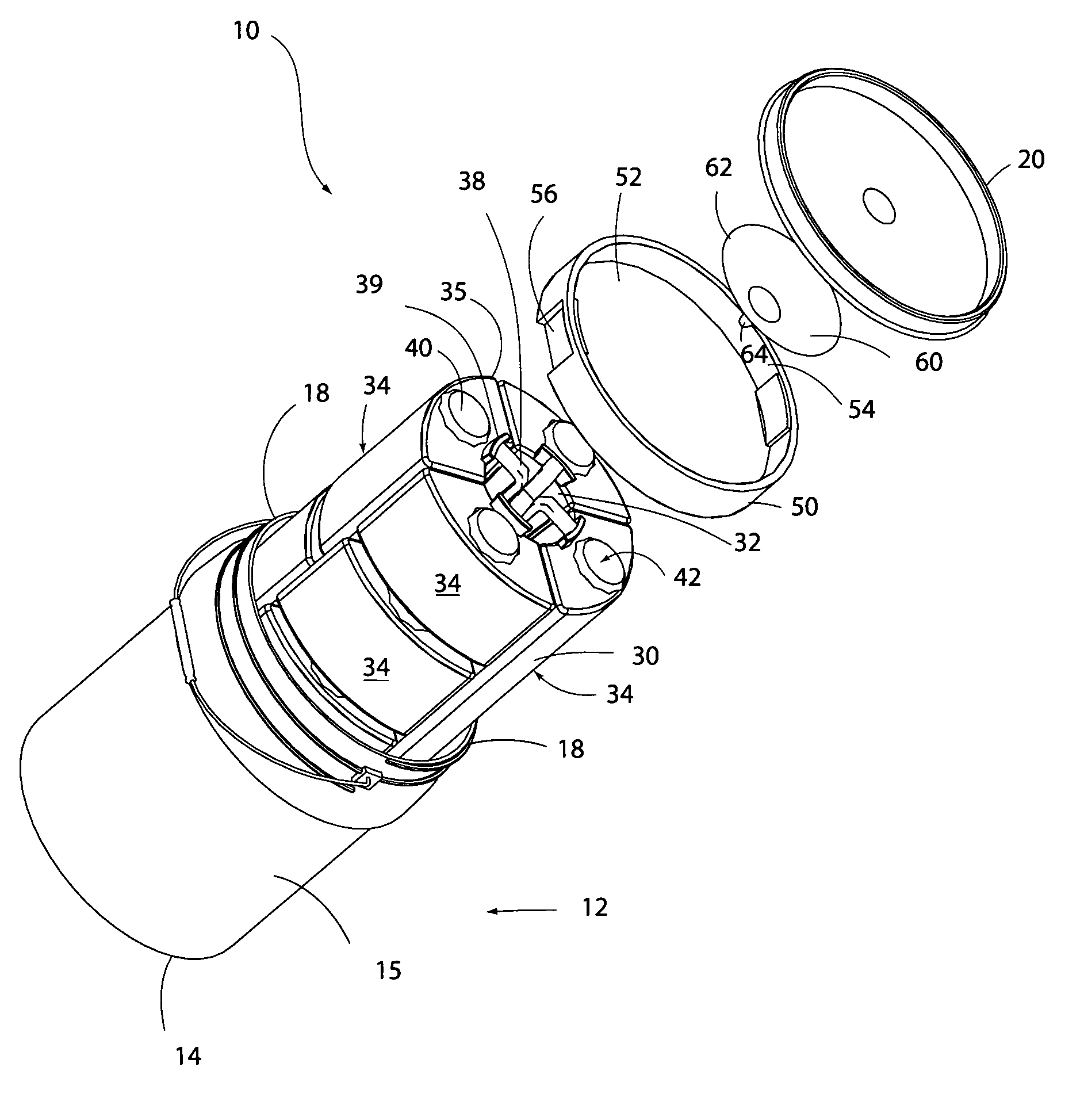

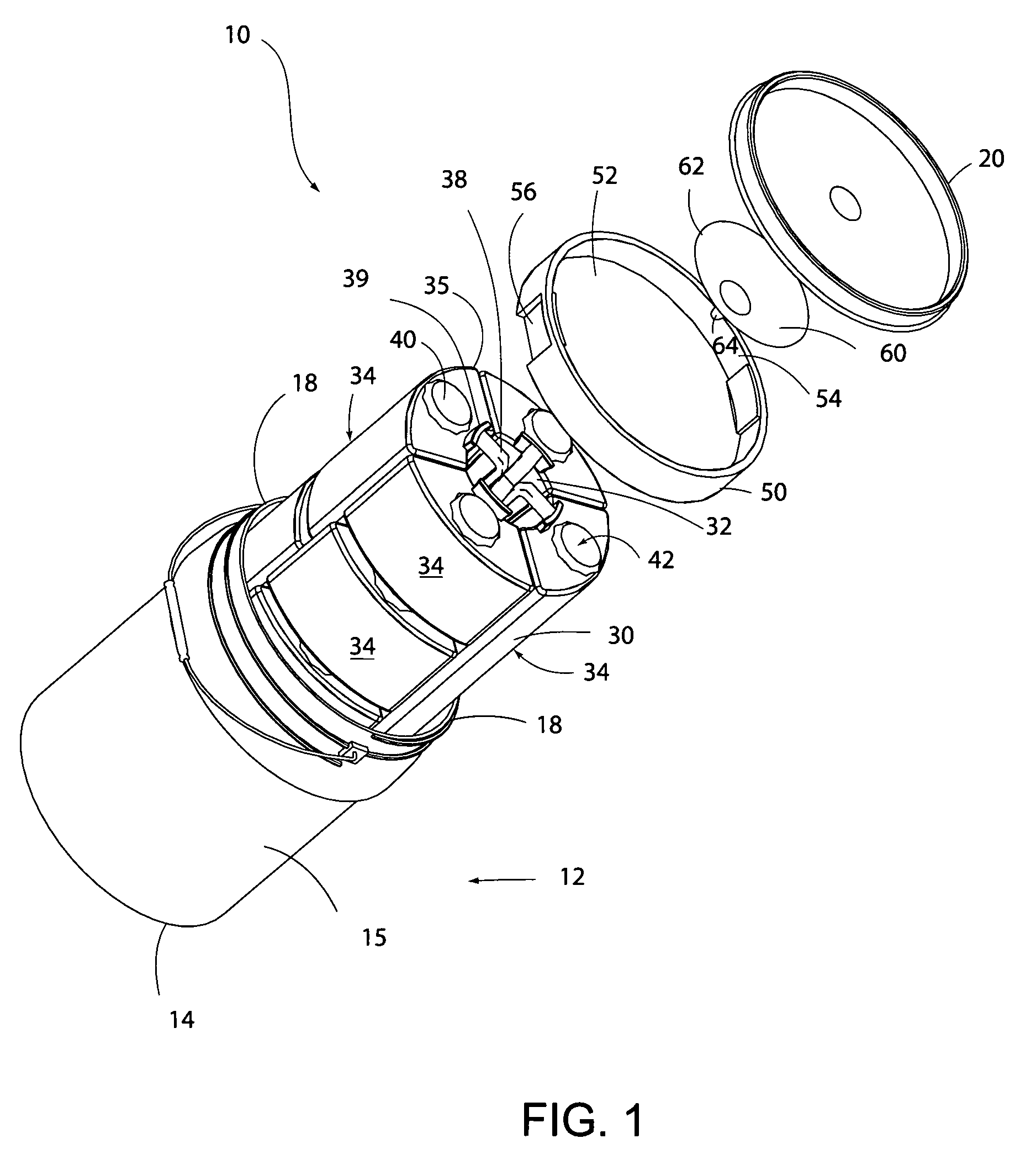

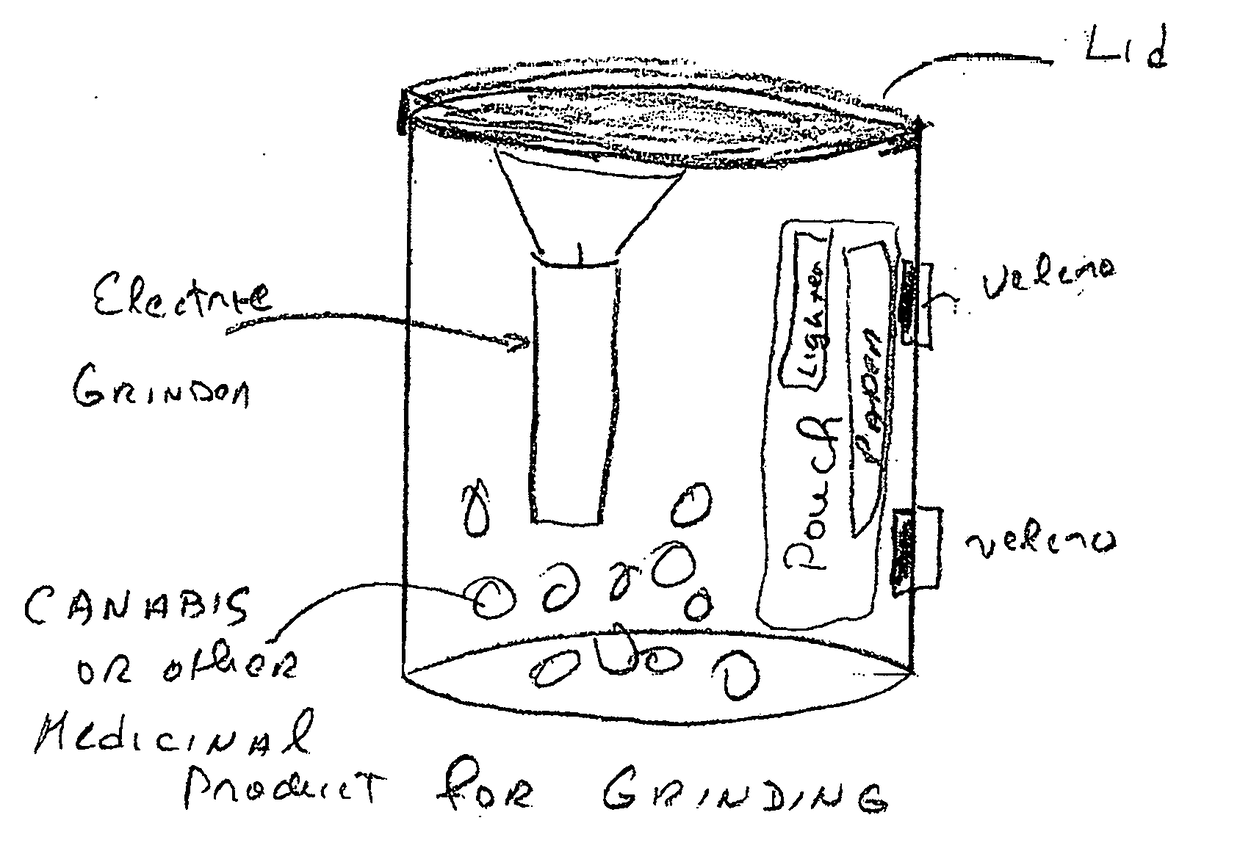

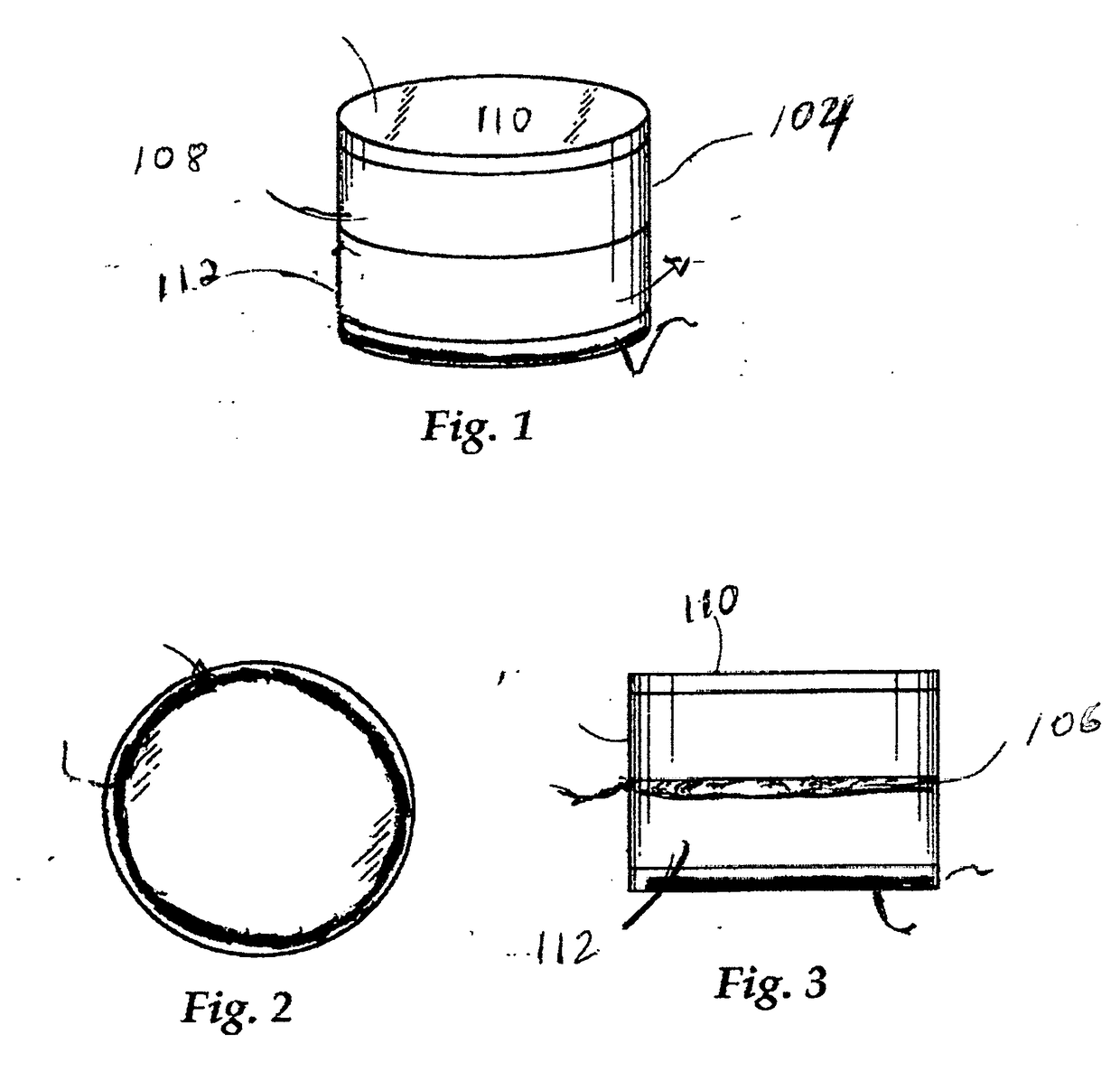

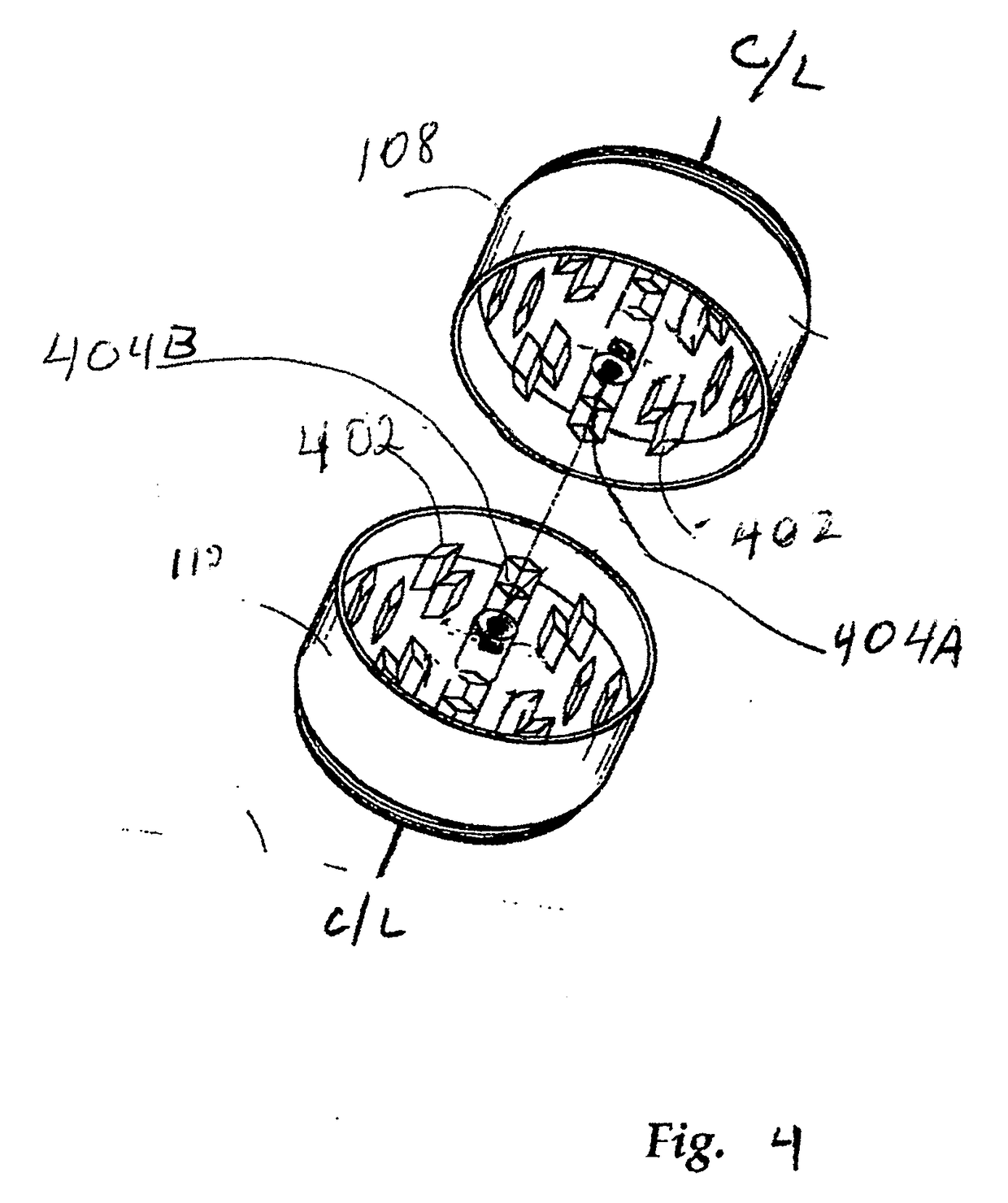

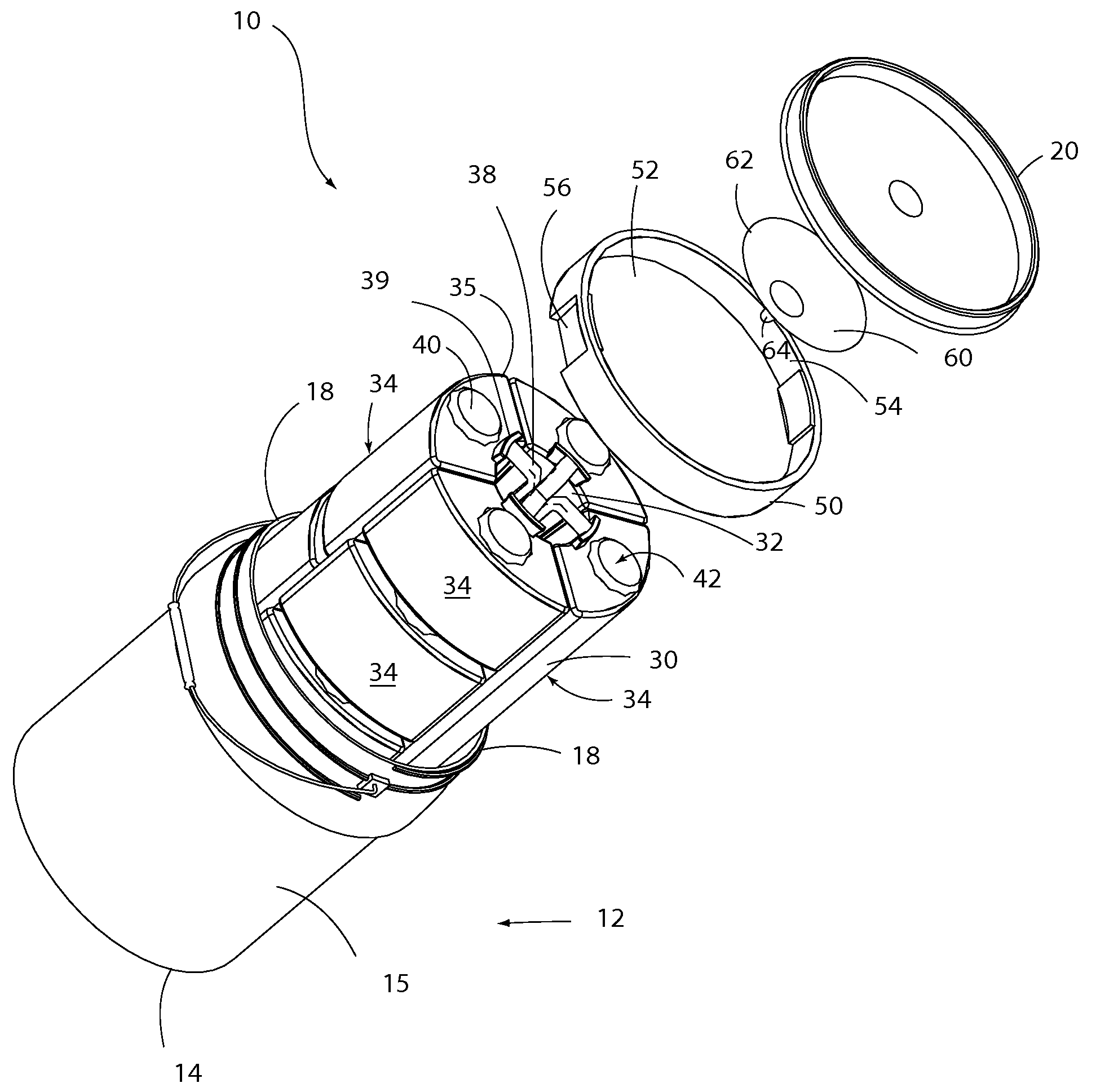

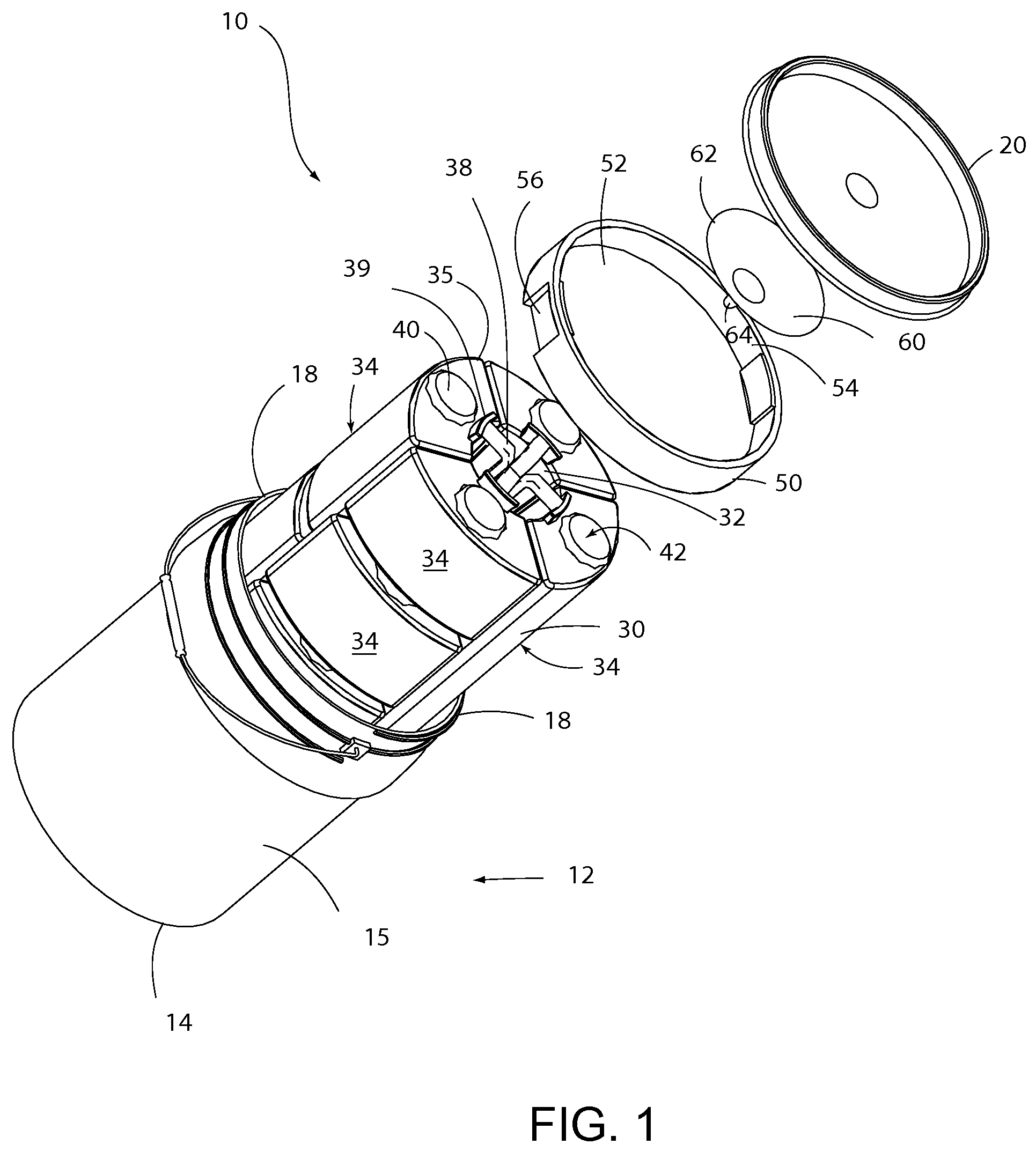

Integrated grinding and storage system for optimizing and enhancing plant performance of plant-based medical therapies and related cannabis usage

InactiveUS20170368554A1Easy and convenient accessReduce the possibilityCoffee millsSpice millsCannabisEngineering

An integrated grinding and storage system for optimizing and enhancing plant performance for plant-based medical therapies and related uses of cannabis including an apparatus for grinding that includes a head operable to be removably attached to a receptacle or container. The head includes a magnet, an upper, inner grinding element, a lower grinding element, a shaft, and a neck sleeve. The upper, inner grinding element is in communication with the lower grinding element within the head. The grinding elements are operable to rotate relative to each other. The shaft extends between the upper and lower sections and magnetically couples with the grinding elements and orients them in relation to one another. The head may be manually or electrically activated.

Owner:NICHOLS WILLIAM

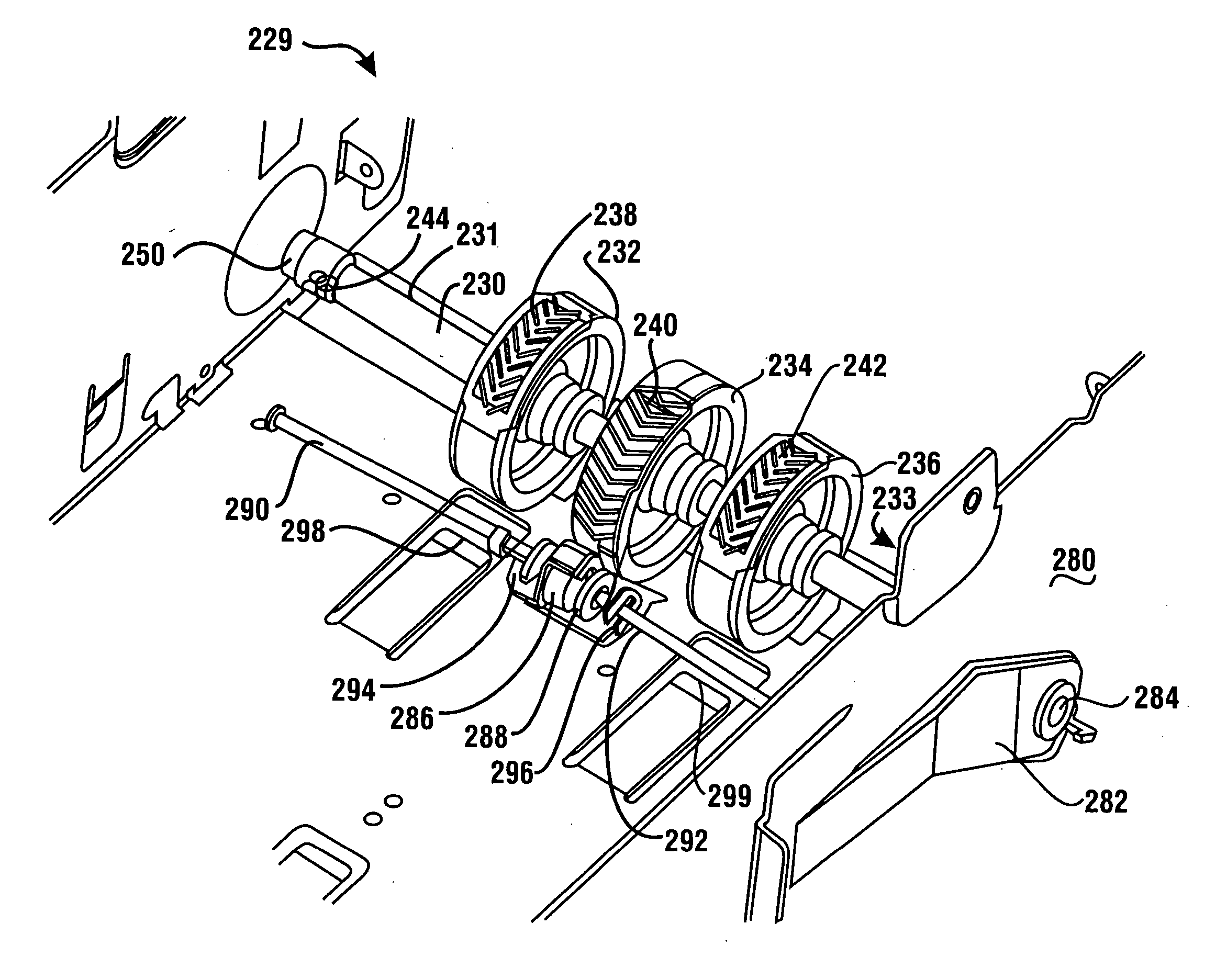

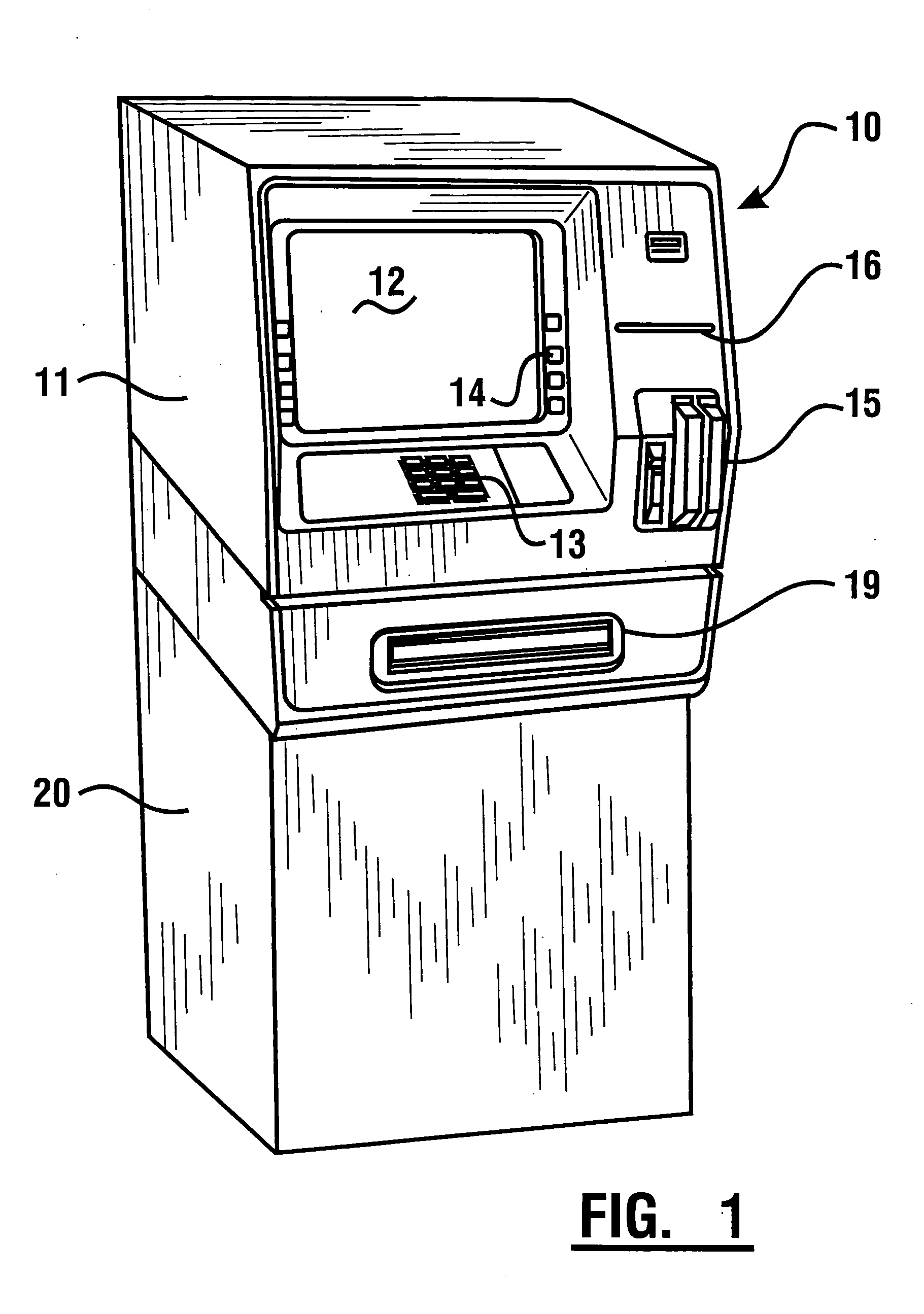

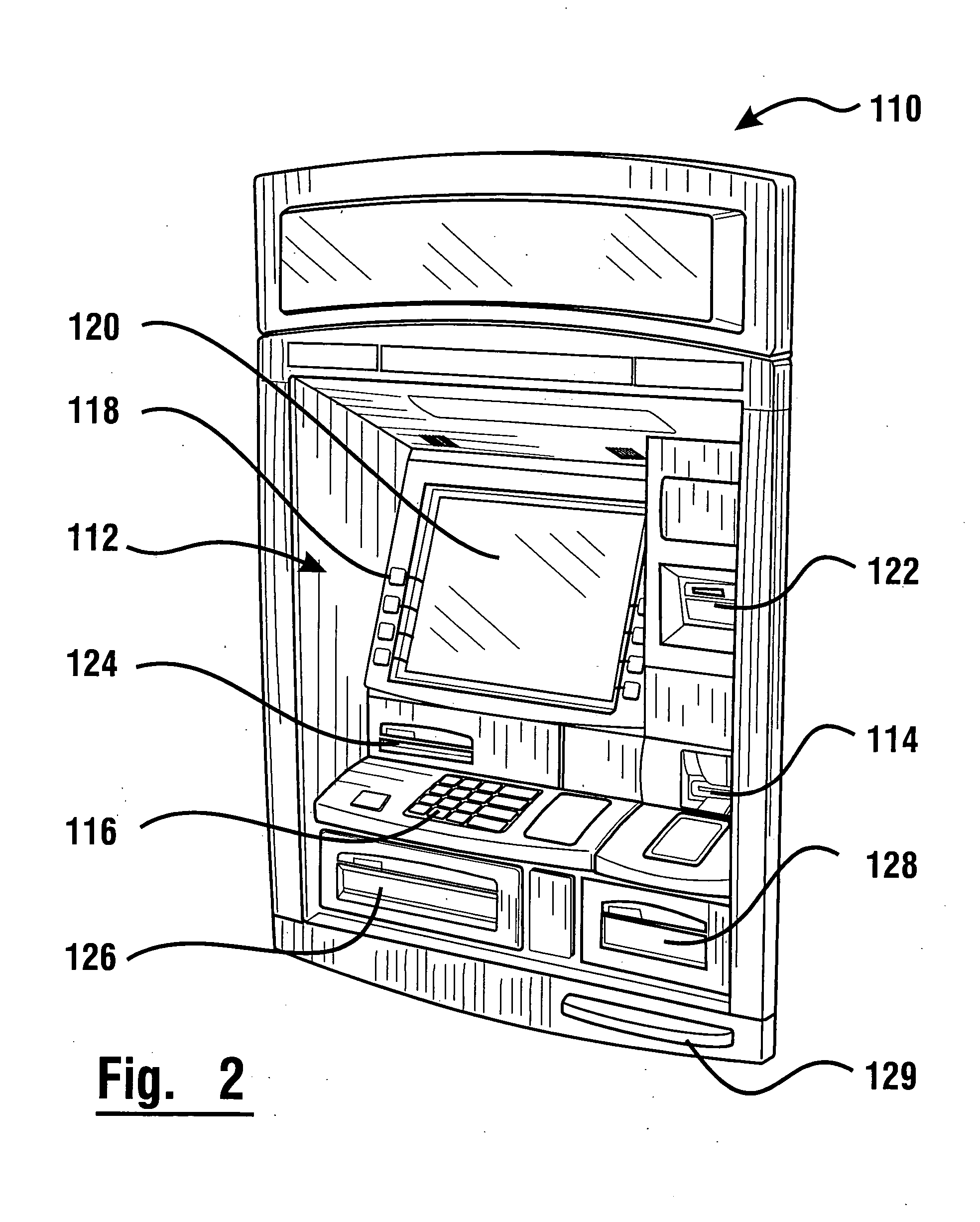

Picker shaft arrangement for ATM currency dispenser

InactiveUS20040178559A1Easy and efficient disassemblySimple and efficient operationComplete banking machinesCoin-freed apparatus detailsMating connectionDrive shaft

An ATM includes a currency note dispenser having a currency cassette, a note picker, a note transporter, and a note presenter. A cassette tambour door automatically opens during insertion of the cassette into the dispenser. The picker can pick notes through the opening. A spring loaded housing wall tab retains the picker shaft in mating connection with a drive pin. The transporter can move notes vertically and horizontally. The transporter includes belts between an idle shaft and a drive shaft. The idle shaft is vertically movable relative to a drive shaft to maintain belt tension. The transporter also includes convexly tapered rollers that automatically recenter a loose belt. A presenter gate is at a note dispensing outlet of the ATM. The gate is opened by actuating a lever linked with an arm connected to the gate. The gate opens by moving a pin upward in an angled slot.

Owner:DIEBOLD NIXDORF

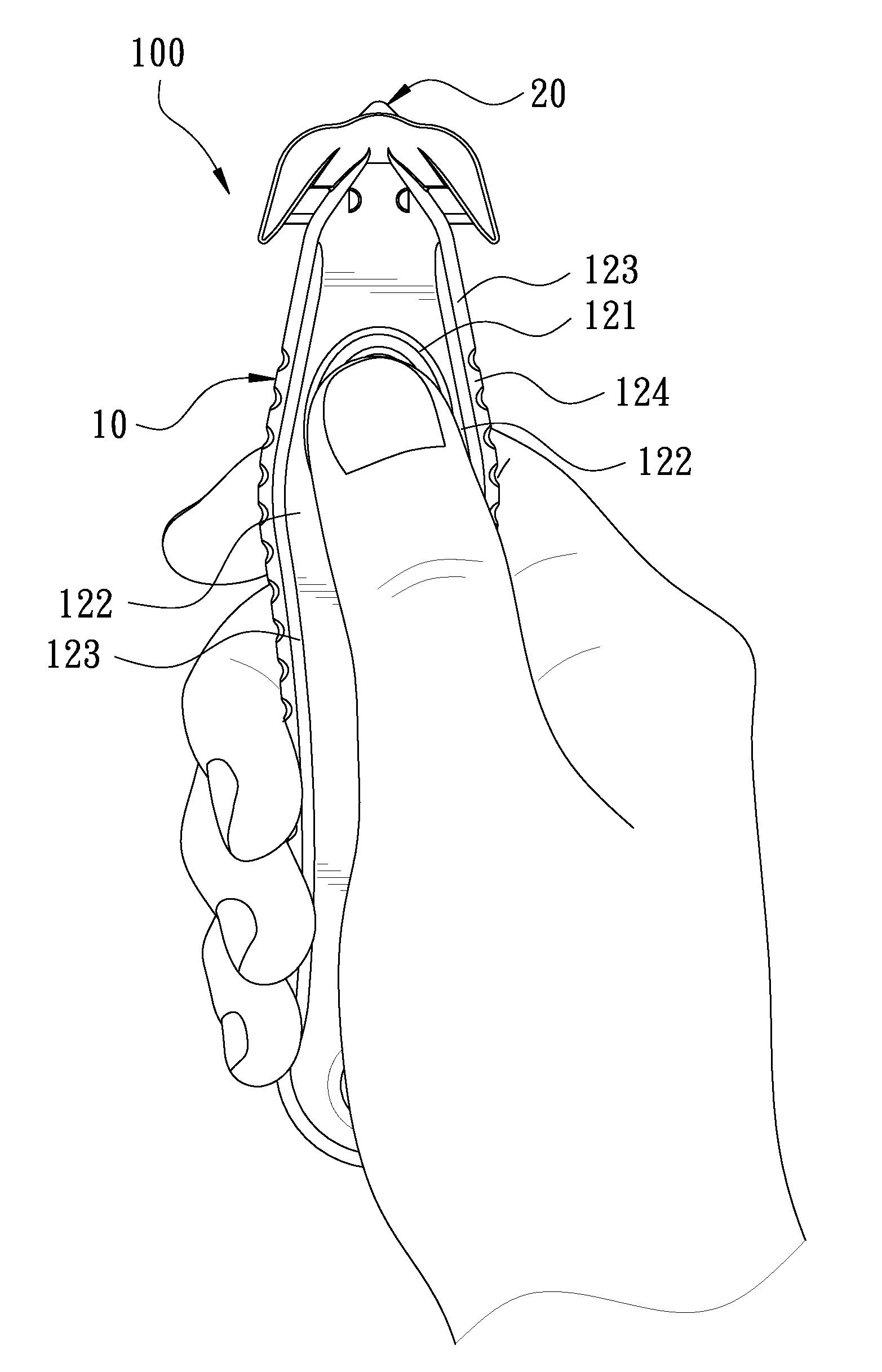

Cutter

InactiveUS20140173914A1Easy and efficient cuttingEasy and efficient removalHand equipmentsMetal working apparatusEngineeringMechanical engineering

A cutter includes a main body and a cutting unit. The main body is lengthwise defined to have a dispensing section, a holding section and a storage section in sequence. The holding section is gradually contracted toward two ends and defined to be a stop portion, and the storage section is bored with a through hole. The cutting section has one side formed with a pointed end and another side provided with a cutting edge. The main body is integrally covered on the cutting unit, leaving the pointed end and the cutting edge exposed and letting the pointed end located at a central upper edge of the dispensing section. By so designing, the cutter of this invention can easily cut off and remove various kinds of packaging members, able to elevate efficiency of removing packaging members from a packing box and integral in functional design.

Owner:YU CHEN HSIU MAN

Device and a method for cleaning of a gas

ActiveUS7704300B2Efficient separationEasy and efficient removalCombination devicesDispersed particle filtrationParticulatesProduct gas

Owner:ALFA LAVAL CORP AB

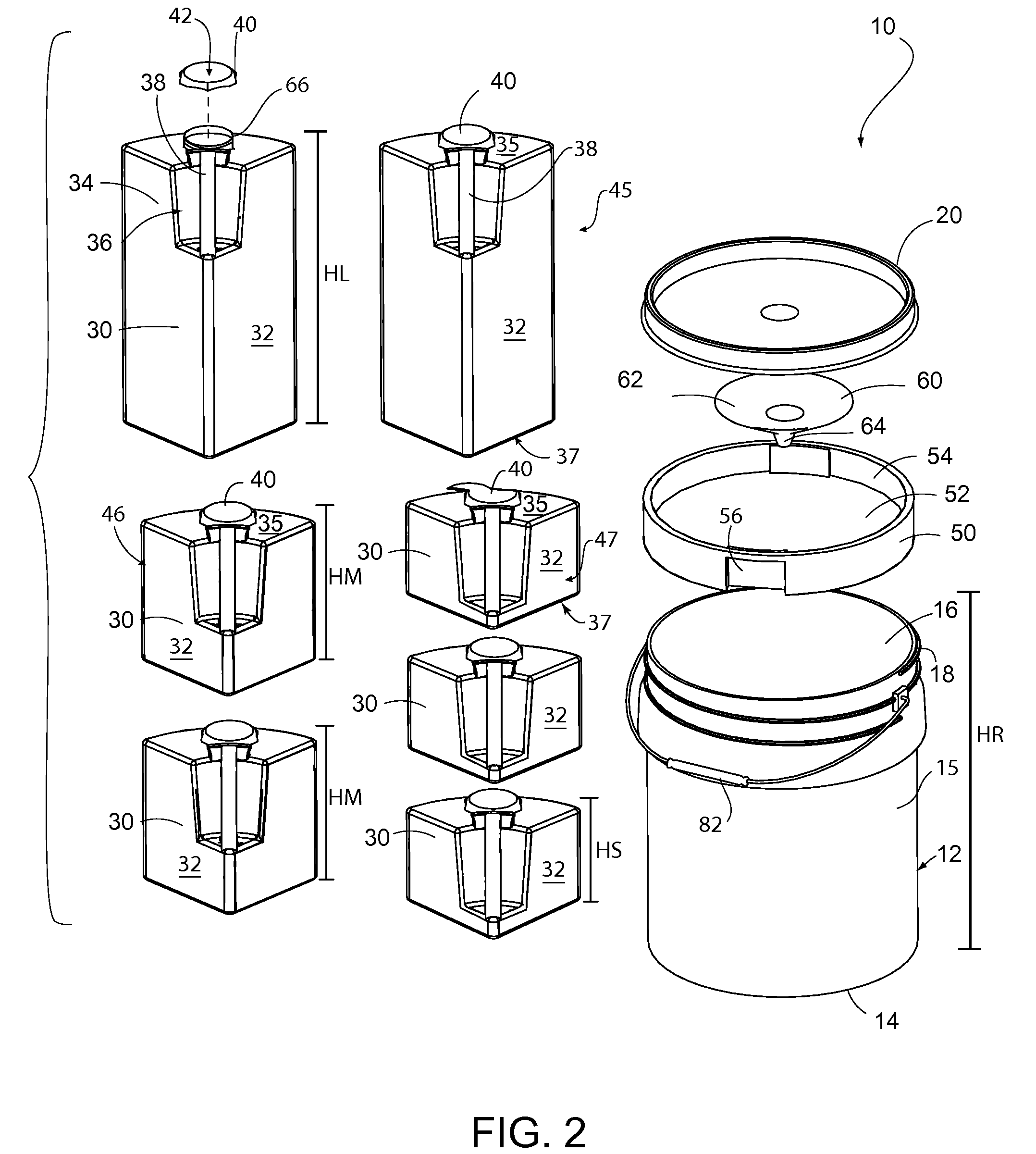

Storage system

InactiveUS8381932B2Fill the volume of the receptacleMaximize system capacityFlexible coversWrappersEngineeringMechanical engineering

A storage system for storing a plurality of fluids or other goods has a plurality of containers adapted to fit within a receptacle. Each of the containers has an inner sidewall, an outer sidewall, and a top sidewall having a spout sealable with a cap such that the container contains the fluid or other goods when the cap is engaged with the spout. The plurality of containers are shaped such that the containers are stackable or nestable within the receptacle such that the containers tessellate, the inner sidewalls of the containers abutting each other, and the outer sidewalls abutting the inner surface of the receptacle, filling substantially all of the receptacle.

Owner:WAGNER PAUL

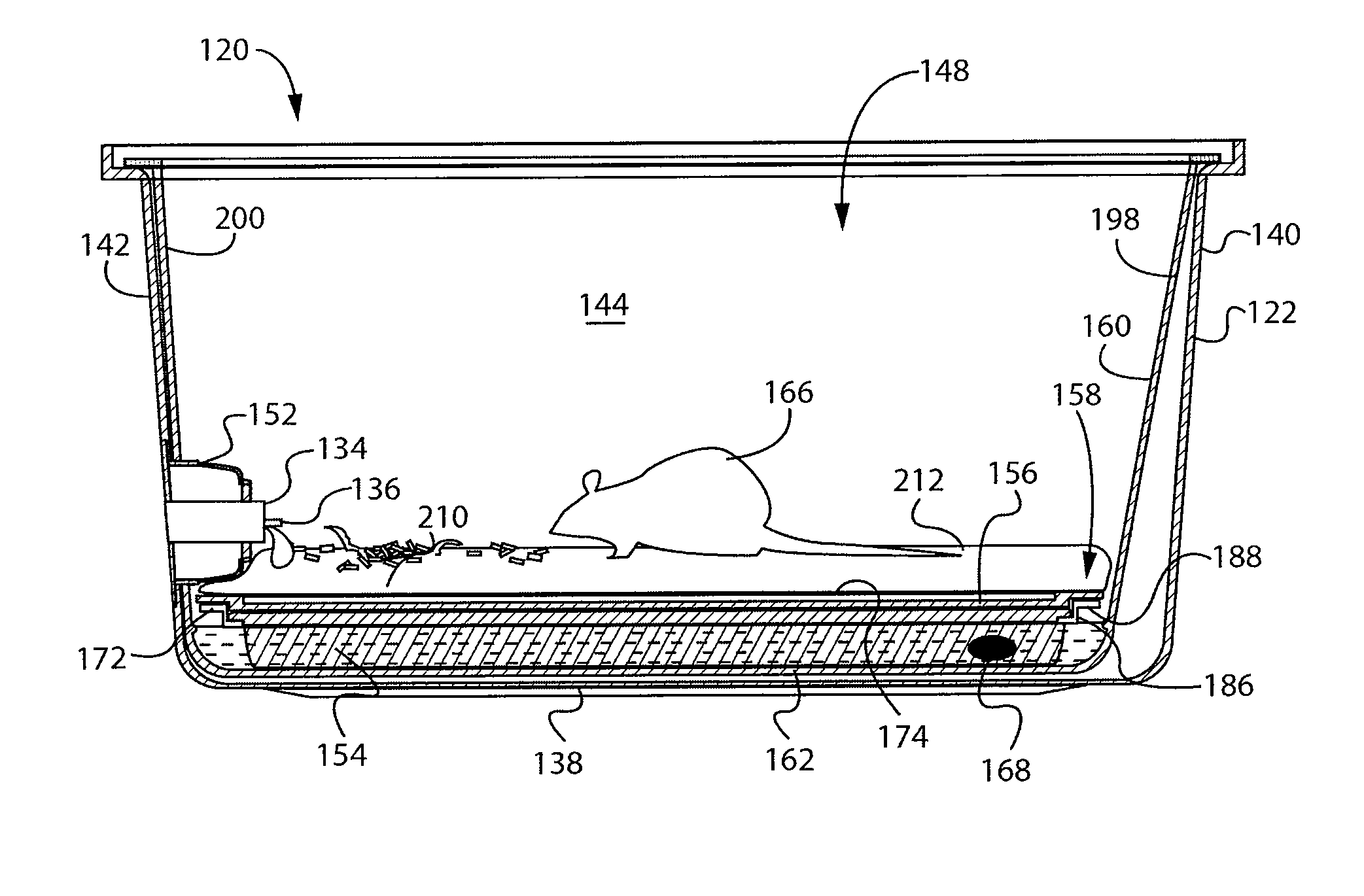

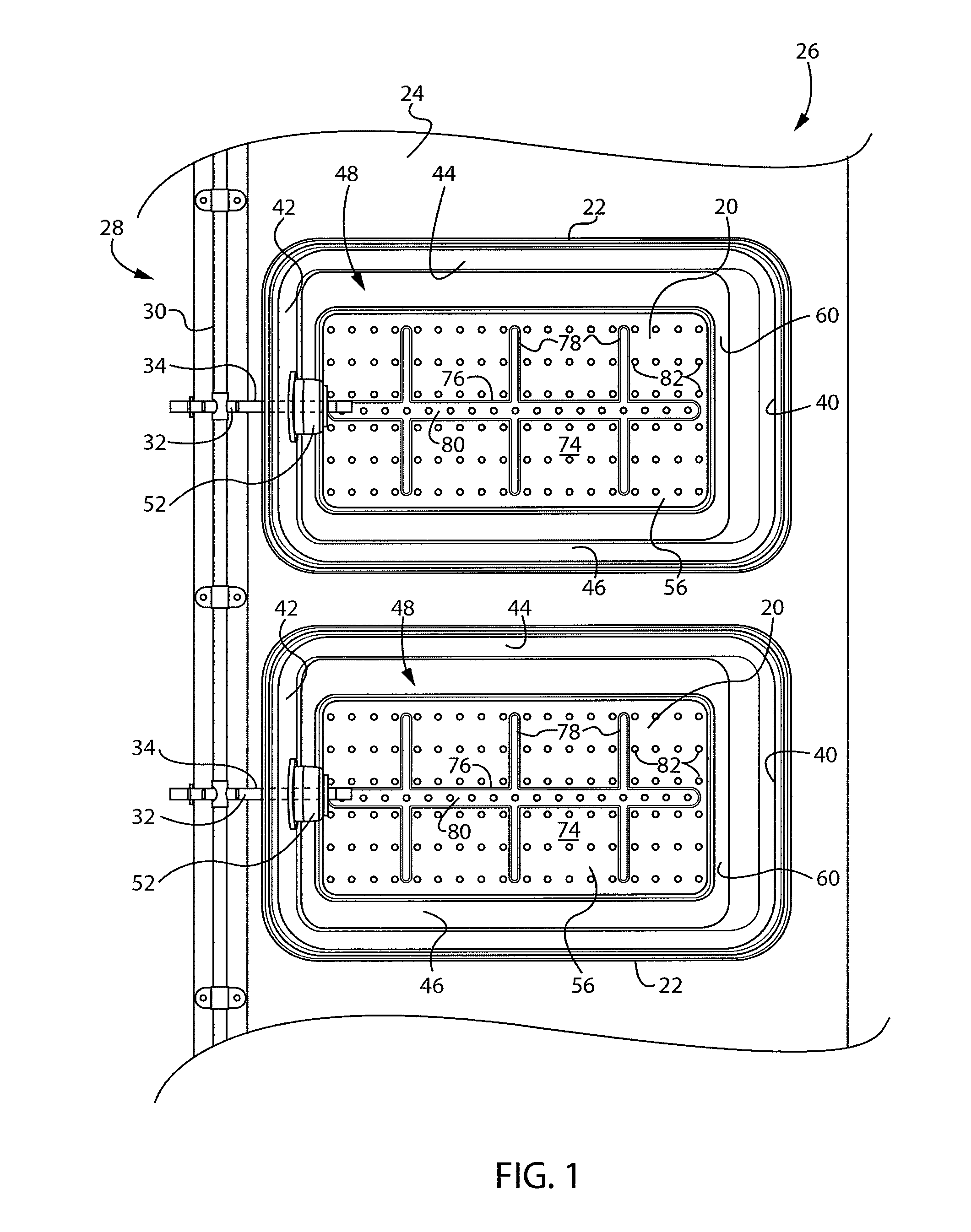

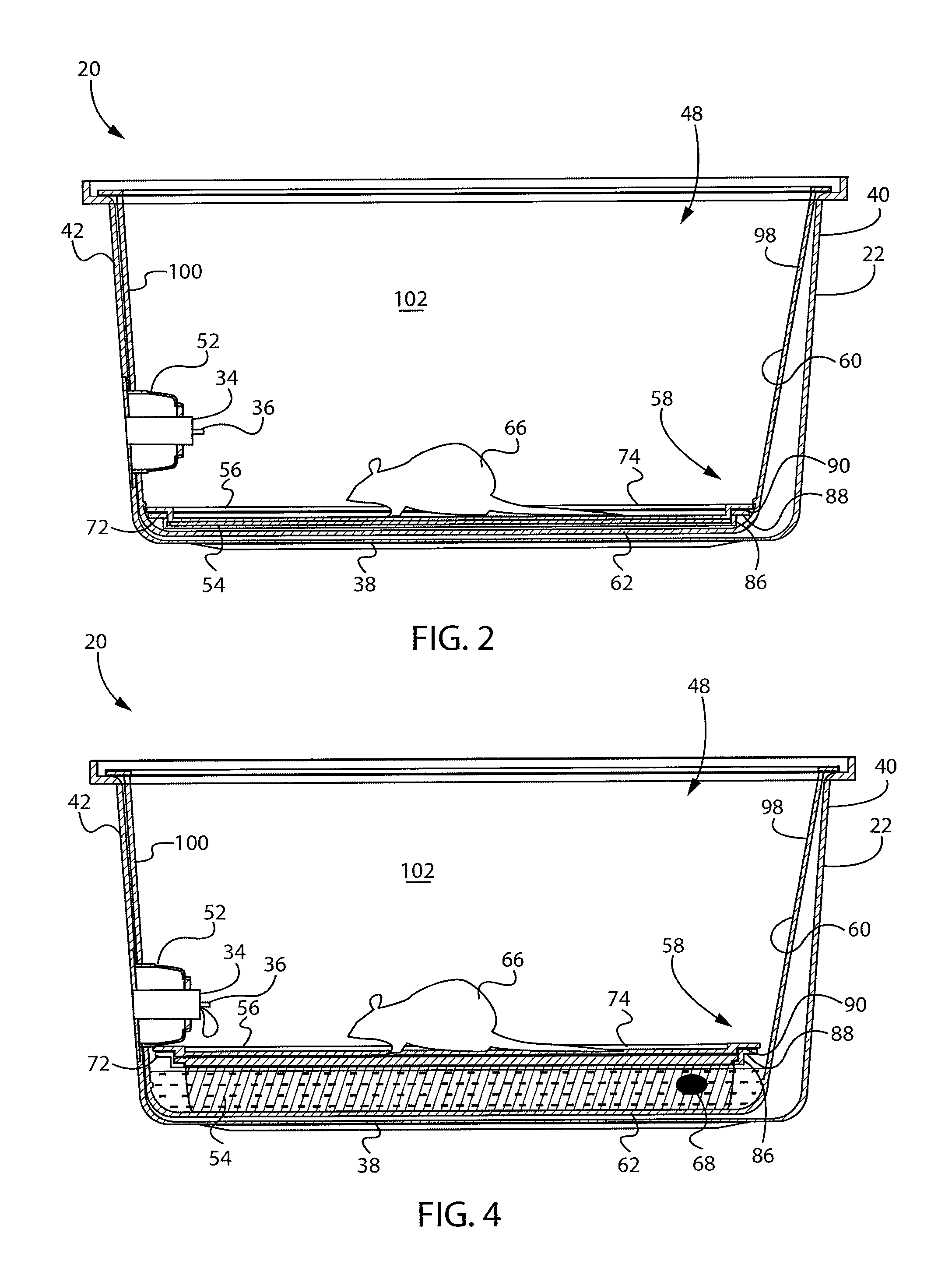

Absorbent pad for use with animal caging systems

InactiveUS20140196666A1Improve efficiencyQuality improvementAnimal housingOther apparatusAbsorbent PadsAbsorbent material

A fluid absorbent assembly includes a fluid absorbent material located in an animal cage or in a liner inserted into the cage. The fluid absorbent material may comprise or be combined with a material that absorbs or neutralizes noxious vapors. A fluid permeable animal support structure may be located over the fluid absorbent material. The fluid absorbent material, which may be contained in a pad, may be contained in a housing that also forms the animal support structure. In the event of a drinking valve leak or other fluid leak within the cage, the fluid absorbent material expands and raises any animals located within the cage.

Owner:EDSTROM IND LLC

Quarter turn valve locking device

InactiveUS7114698B2Economical and easily implemented solutionEasy to insertThin material handlingPreventing unauthorised/accidental actuationEngineeringMechanical engineering

A locking device for quarter turn valves avoids the inadvertent, unauthorized or careless manipulation of quarter turn valves from a desired position thereby minimizing, if not eliminating, the likelihood for damage or injury in an industrial or other setting as a result of the unauthorized opening / closing of the valve. The locking device includes a shroud which is adapted to be placed over the upper end of the stem and adjacent portion of the handle on the valve. The shroud has a capping portion which securely engages a mounting pad of the valve and an upwardly extending channel designed to at least partially surround a portion of the handle. A hole is provided in the channel and aligns with a hole in an adjacent portion of the handle when the shroud is placed on the valve. As such, the post of a lock is easily inserted through the aligned holes. The locking device according to this invention advantageously prevents the unauthorized manipulation of the handle and the resulting rotation of the valve member to / from the open / closed positions.

Owner:ESPINOZA ROGER

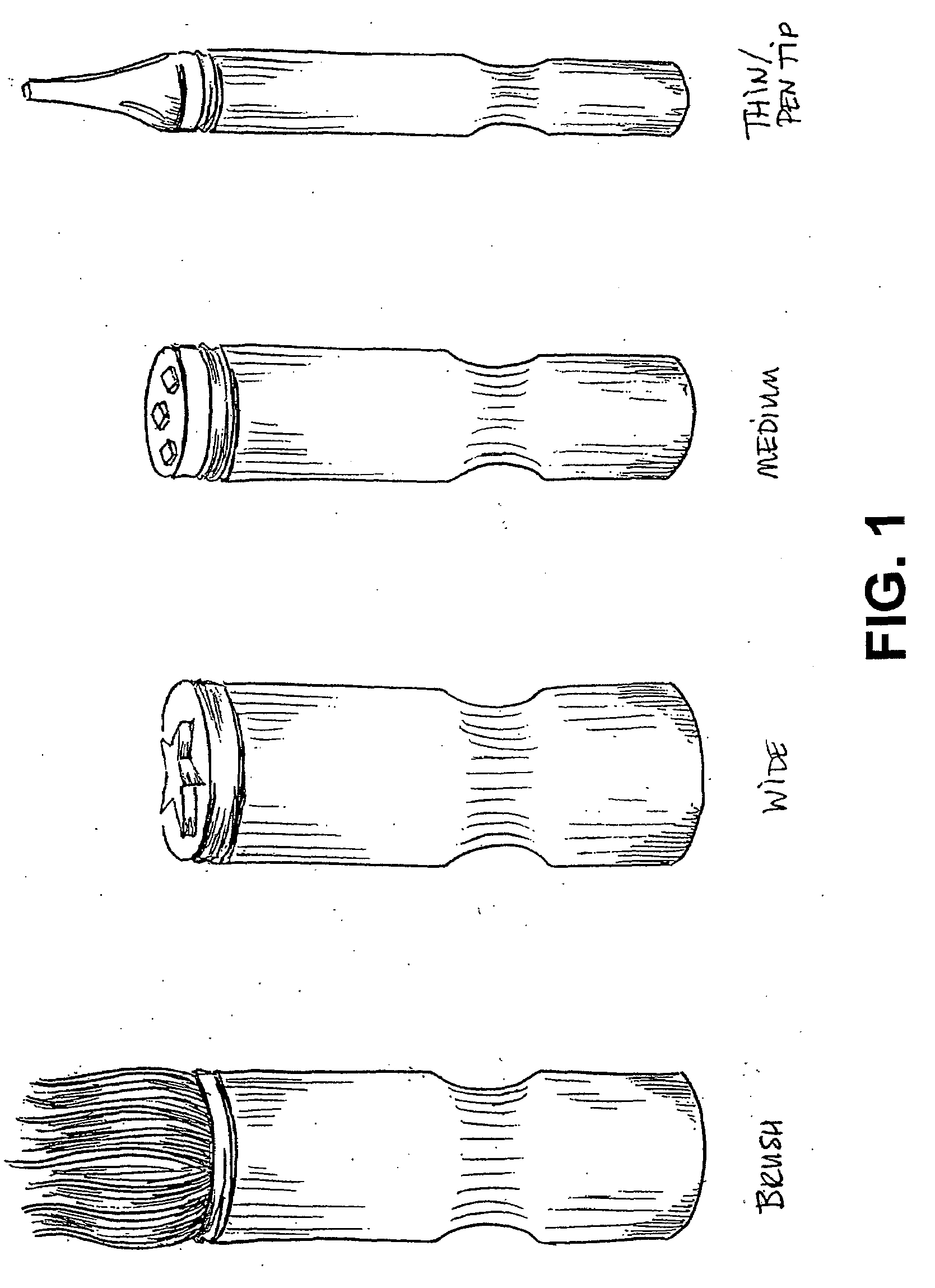

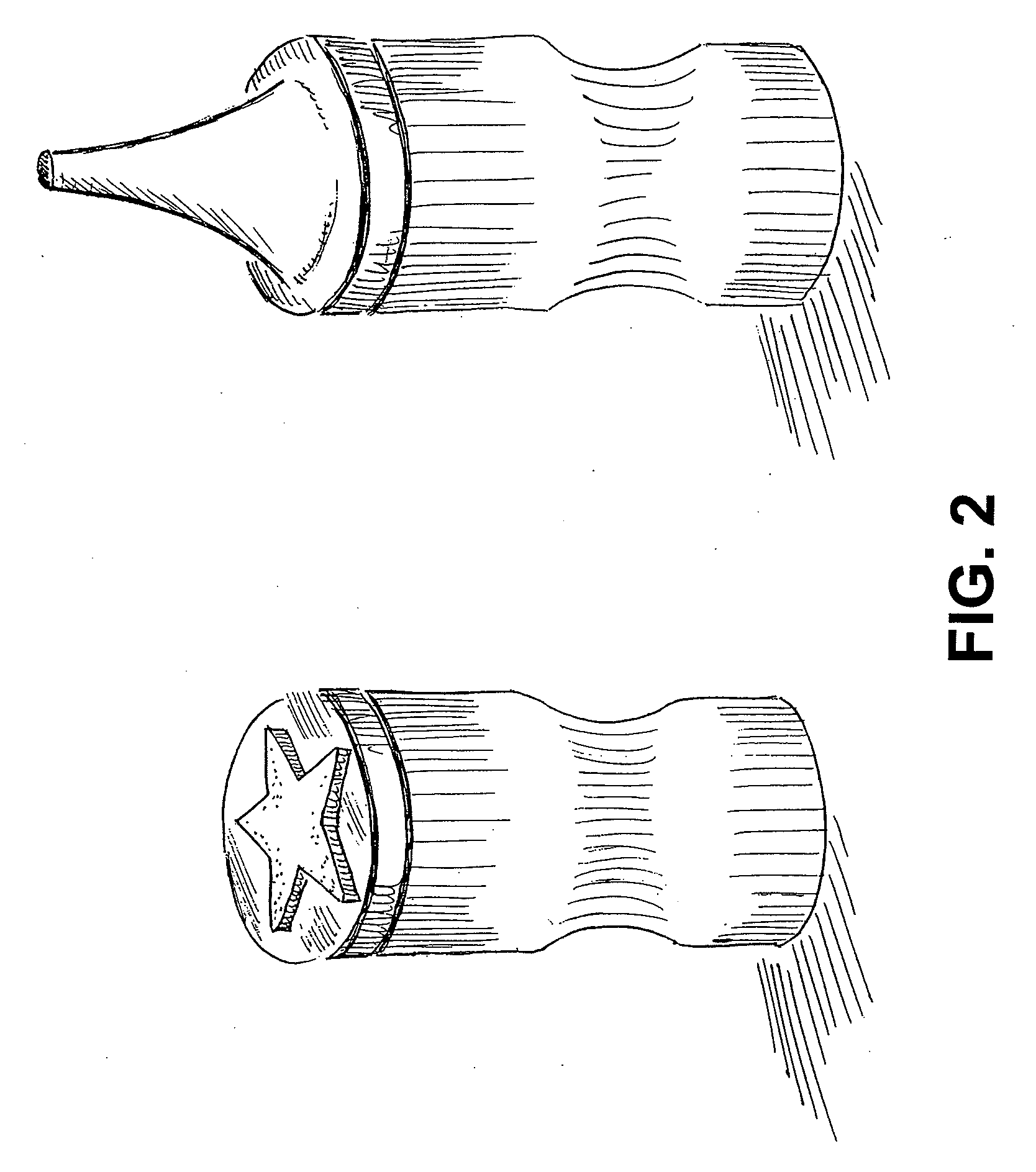

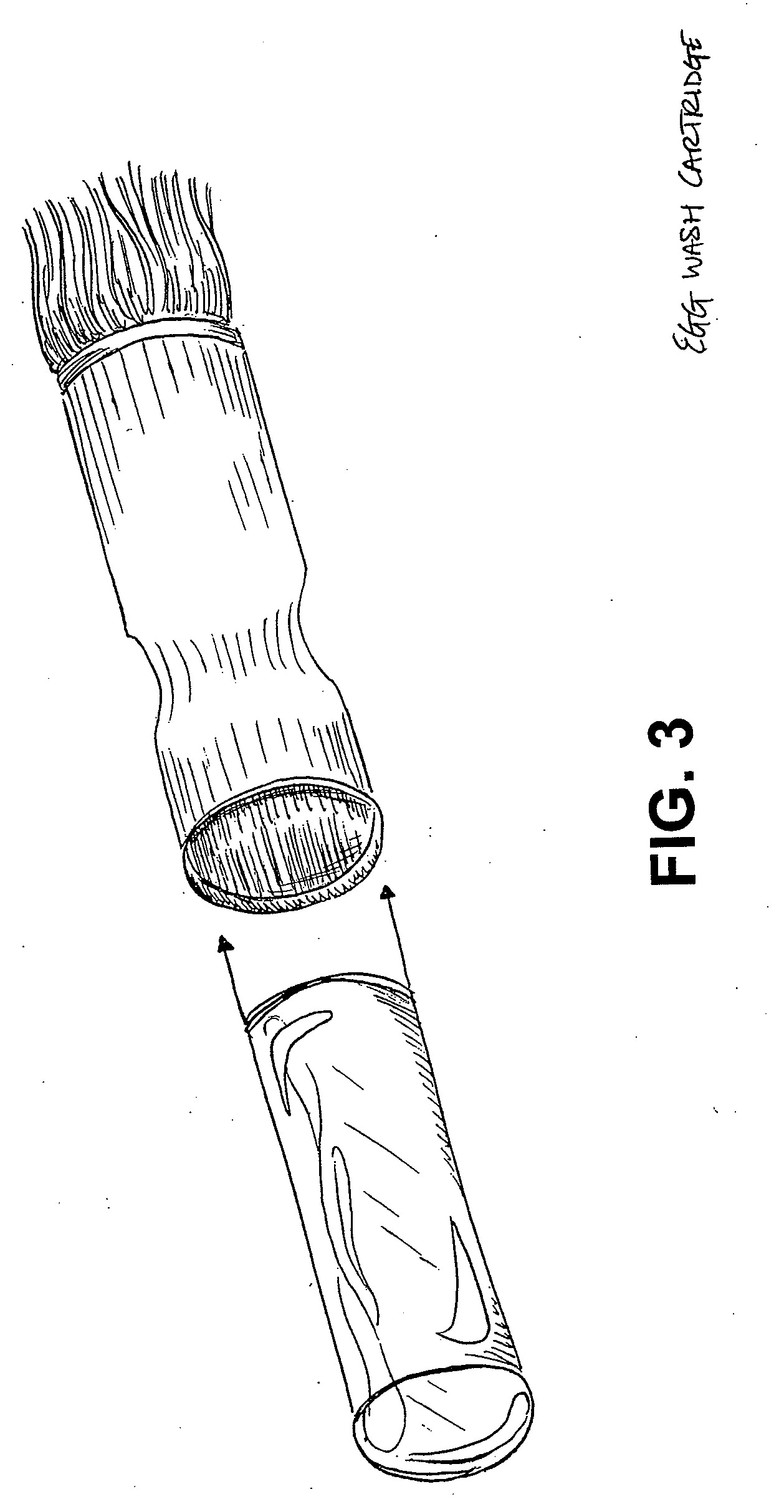

Foodware Decorating System and Method

The present disclosure provides advantageous decorating systems for use with foodware, i.e., food and beverage-related items, such as platters, glasses, trays and the like. The present disclosure further provides decorating methods that may be employed to decorate and / or customize foodware. The disclosed systems and methods generally involve application of a priming material (e.g., an egg white-based material) to a desired region of a foodware surface, and then application of a decorative / customization material to the primed surface. The decorative / customization material is stable during use, but may be washed (with the priming material) from the foodware surface using conventional washing techniques.

Owner:PERRY ALISON +1

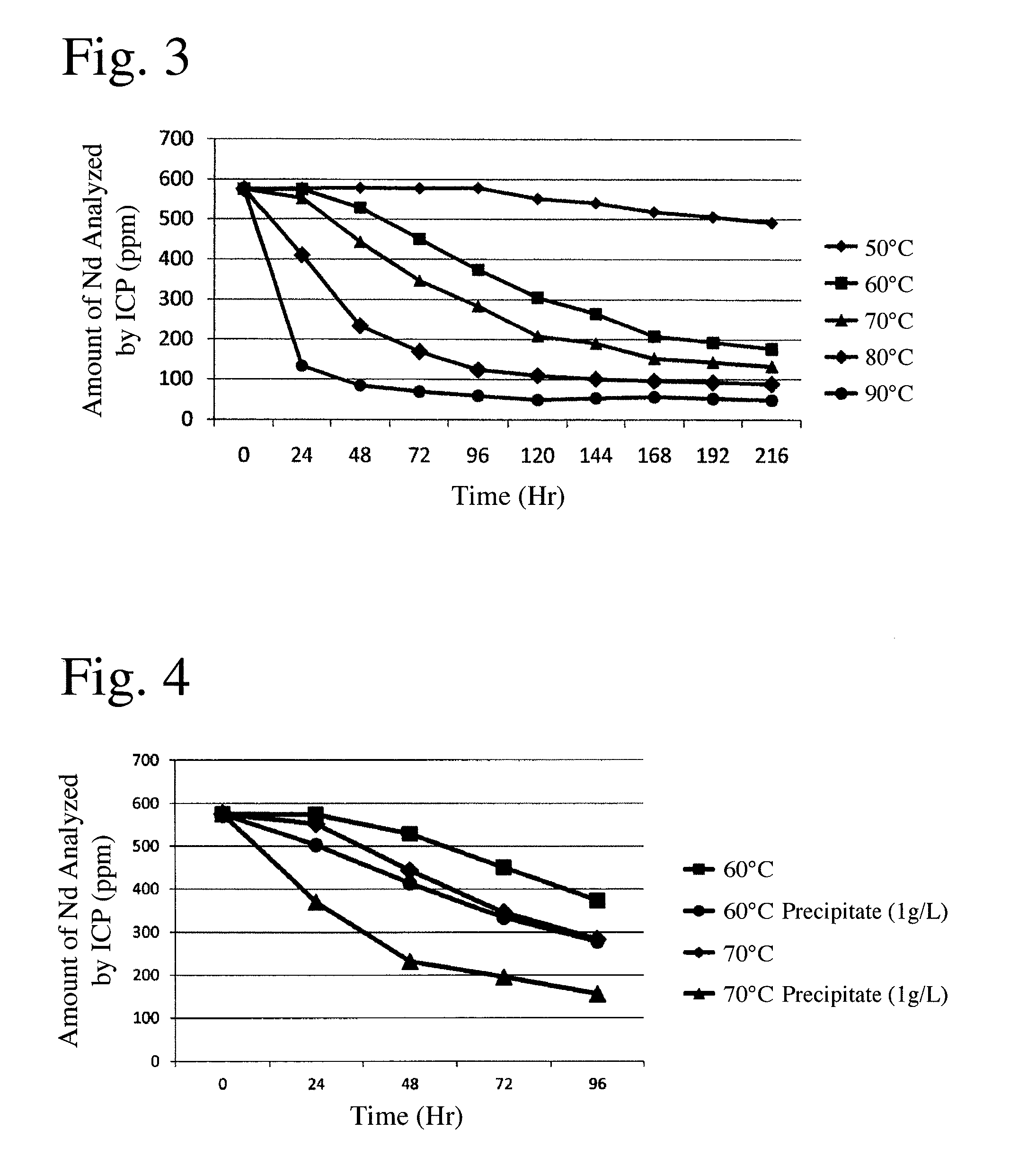

Method for removing rare earth impurities from nickel-electroplating solution

[Object] When rare earth magnets are plated, components of the rare earth magnets are dissolved in the plating solution, causing plating defects. Thus, an easy method for removing rare earth impurities has been necessary.[Means for Solution] A nickel-electroplating solution containing rare earth impurities is kept at 60° C. or higher for a predetermined period of time to precipitate rare earth impurities for separation by sedimentation or filtration. Rare earth impurities can be precipitated further efficiently by adding precipitate to the nickel-electroplating solution, or by concentrating the nickel-electroplating solution by heating.

Owner:HITACHI METALS LTD

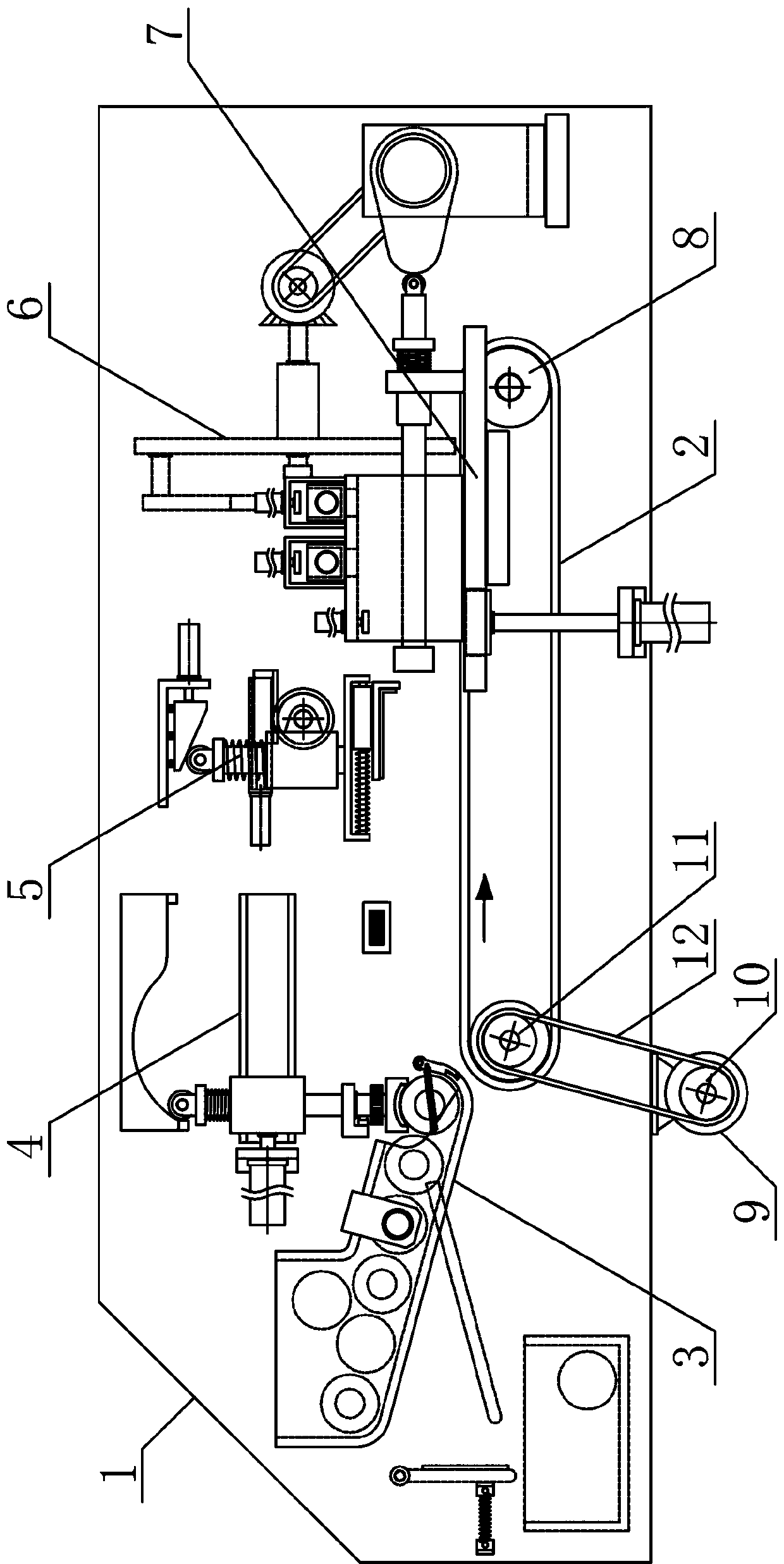

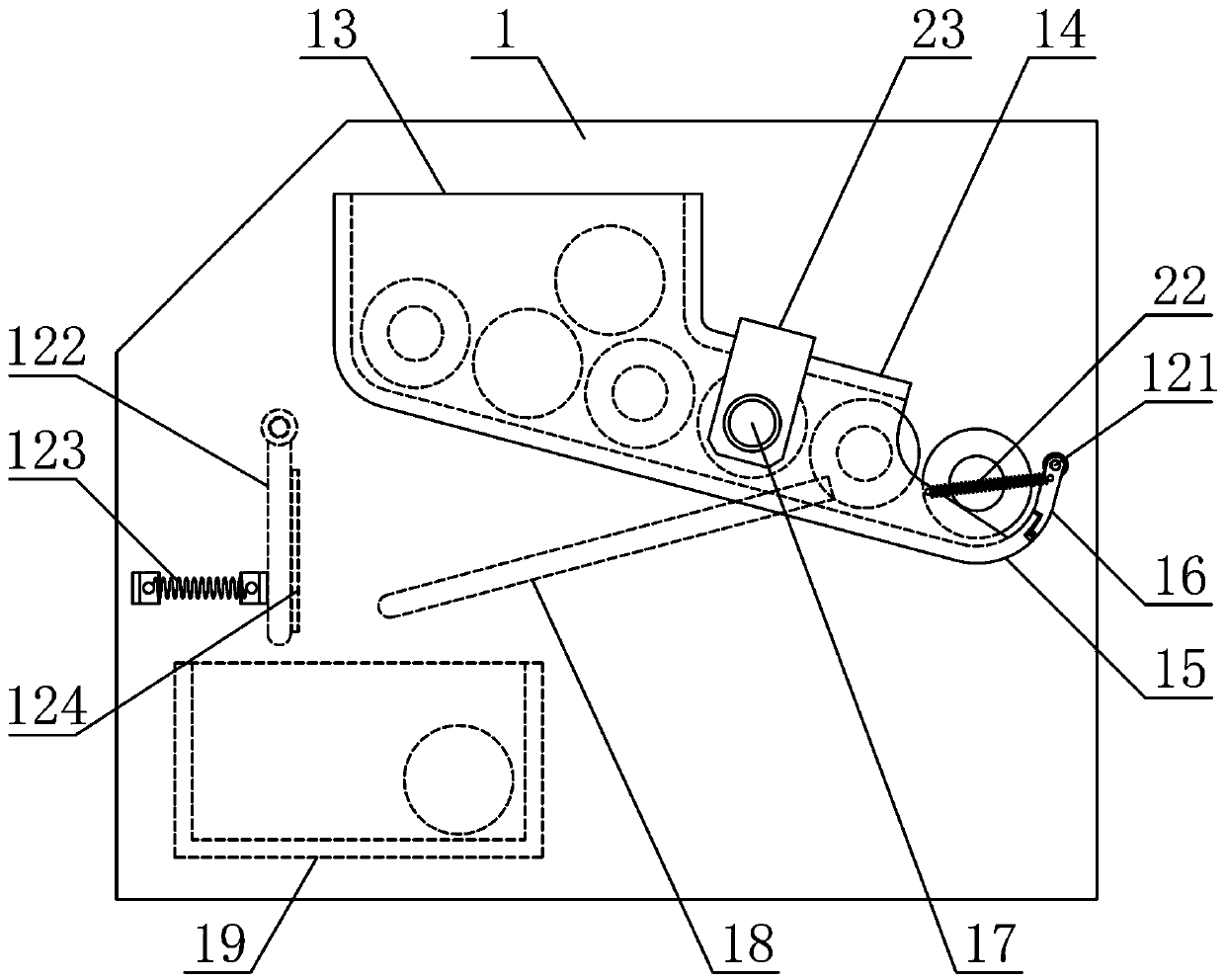

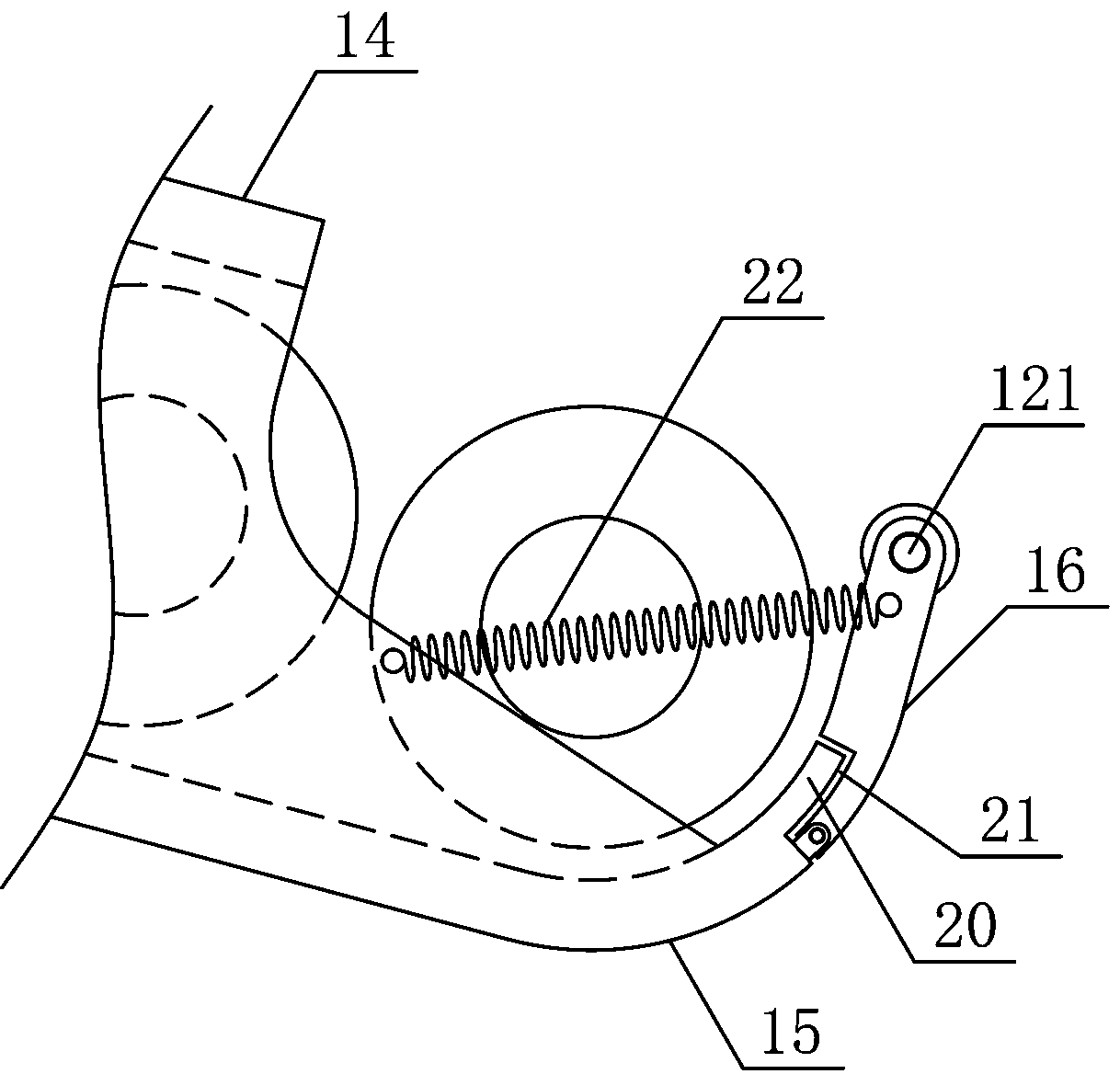

Continuous press fitting equipment for tubular workpieces

ActiveCN111230458AFalling steadilyEfficient and smooth flip adjustmentMetal working apparatusElectric machineryMechanical equipment

The invention discloses continuous press fitting equipment for tubular workpieces, and belongs to the field of workpiece production and processing mechanical equipment. A workpiece conveying belt is arranged on the lower side of a workpiece conveying support, the two sides of the workpiece conveying belt are wound and connected with workpiece conveying rotating rollers on the two sides of the workpiece conveying support respectively, and a workpiece conveying motor is in transmission connection with the workpiece conveying rotating rollers through a workpiece conveying chain. A workpiece guidemechanism, a workpiece transfer mechanism and a workpiece turnover mechanism are sequentially arranged on the workpiece conveying support on the upper side of the workpiece conveying belt in the conveying direction of the workpiece conveying belt. A workpiece push mechanism and a workpiece press fitting mechanism are arranged on the workpiece conveying support on the two sides of the ends in theconveying direction of the workpiece conveying belt respectively. The continuous press fitting equipment is reasonable in structural design, can guide and transfer the tubular workpieces one by one conveniently and smoothly, can realize successive and continuous press fitting processing of multiple assemblies in the transfer process of the tubular workpieces, improves the automation degree of workpiece processing and meets the needs of production and use.

Owner:SUZHOU ZHIYUN CHUANGYU INFORMATION TECH CO LTD

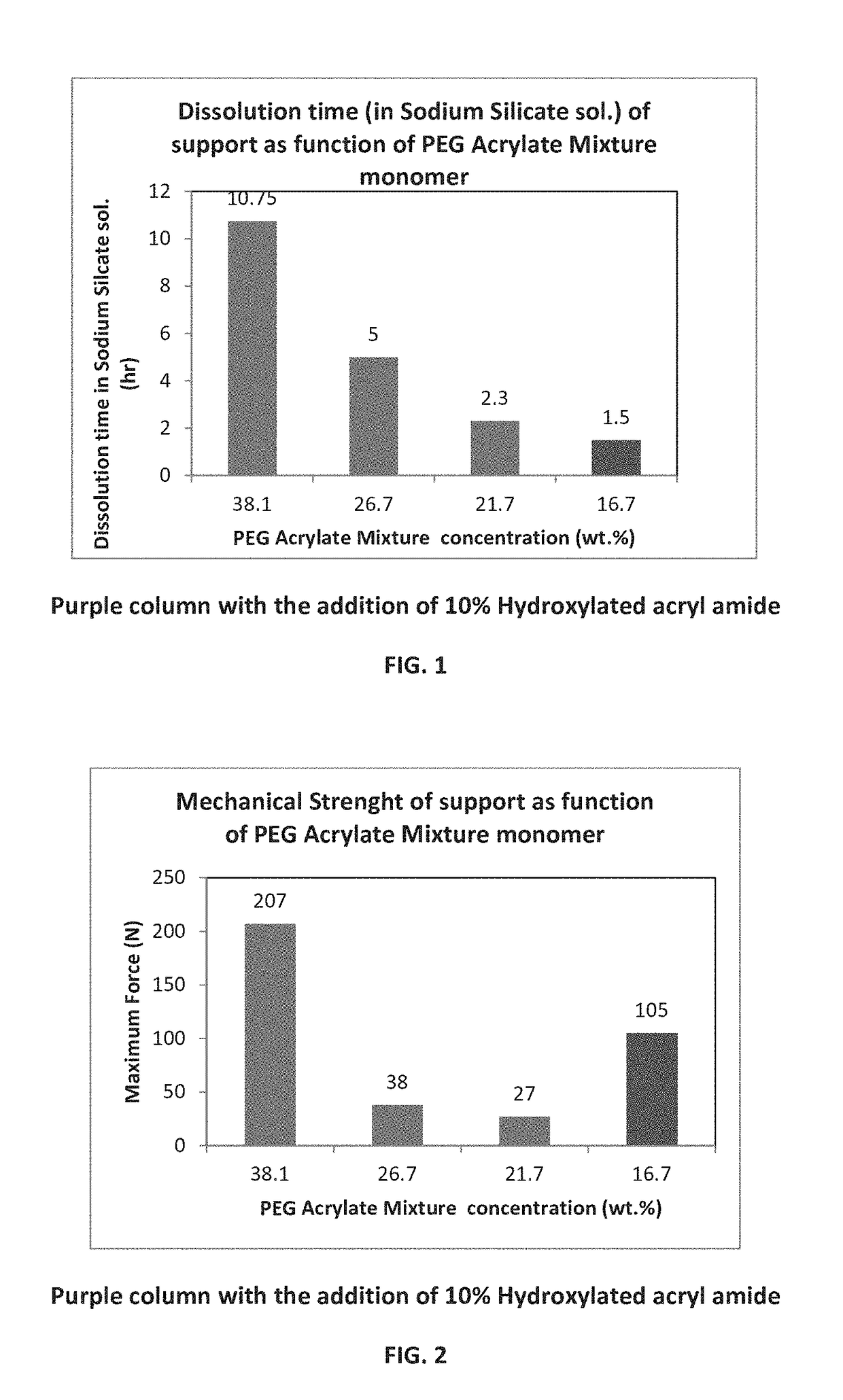

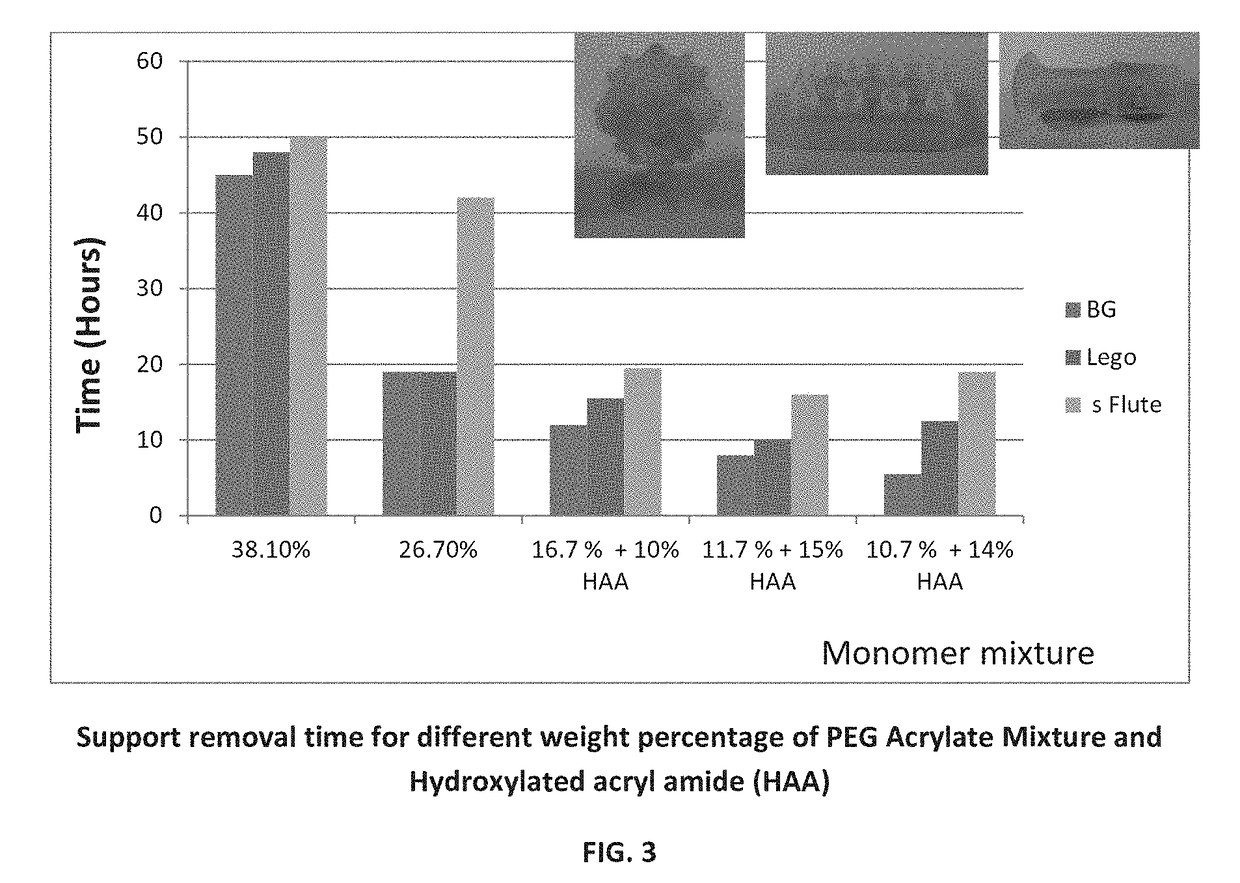

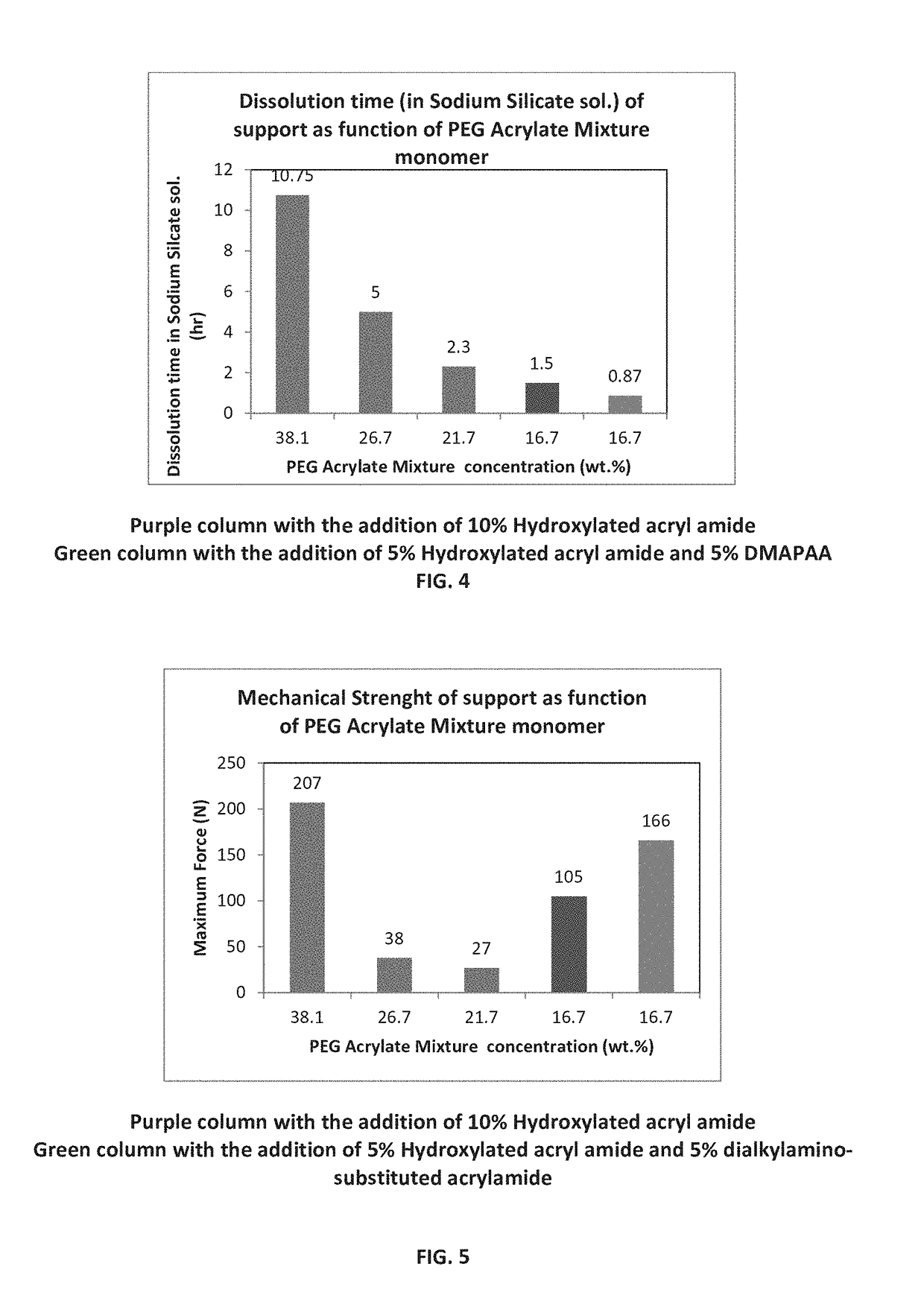

Support material formulation and additive manufacturing processes employing same

ActiveUS20180230246A1Not compromising mechanical propertyEasy and efficient removalInorganic/elemental detergent compounding agentsAdditive manufacturing apparatusDissolutionPolymer

Novel support material formulations, characterized as providing a cured support material with improved dissolution rate, while maintaining sufficient mechanical strength, are disclosed. The formulations comprise a water-miscible non-curable polymer, a first water-miscible, curable material and a second, water-miscible material that is selected capable of interfering with intermolecular interactions between polymeric chains formed upon exposing the first water-miscible material to curing energy. Methods of fabricating a three-dimensional object, and a three-dimensional object fabricated thereby are also disclosed.

Owner:STRATASYS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com