Light-weight single joint manipulator arm

a manipulator arm and single joint technology, applied in the direction of drilling pipes, drilling casings, borehole/well accessories, etc., can solve the problems of difficult and awkward maneuvering of pipe segments into vertical positions, many limitations in the efficiency of the process of adding pipe segments, etc., to achieve the effect of easy and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

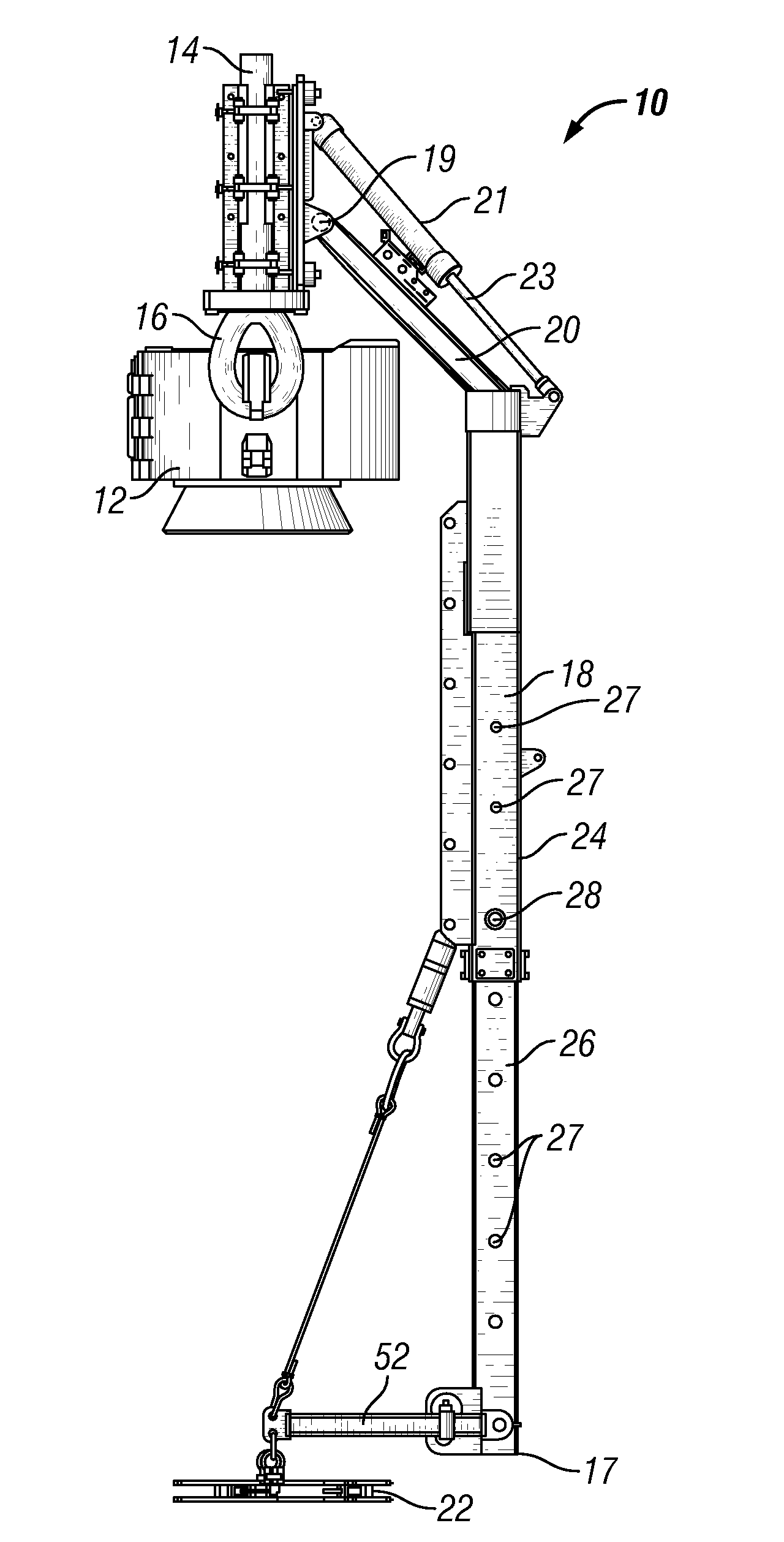

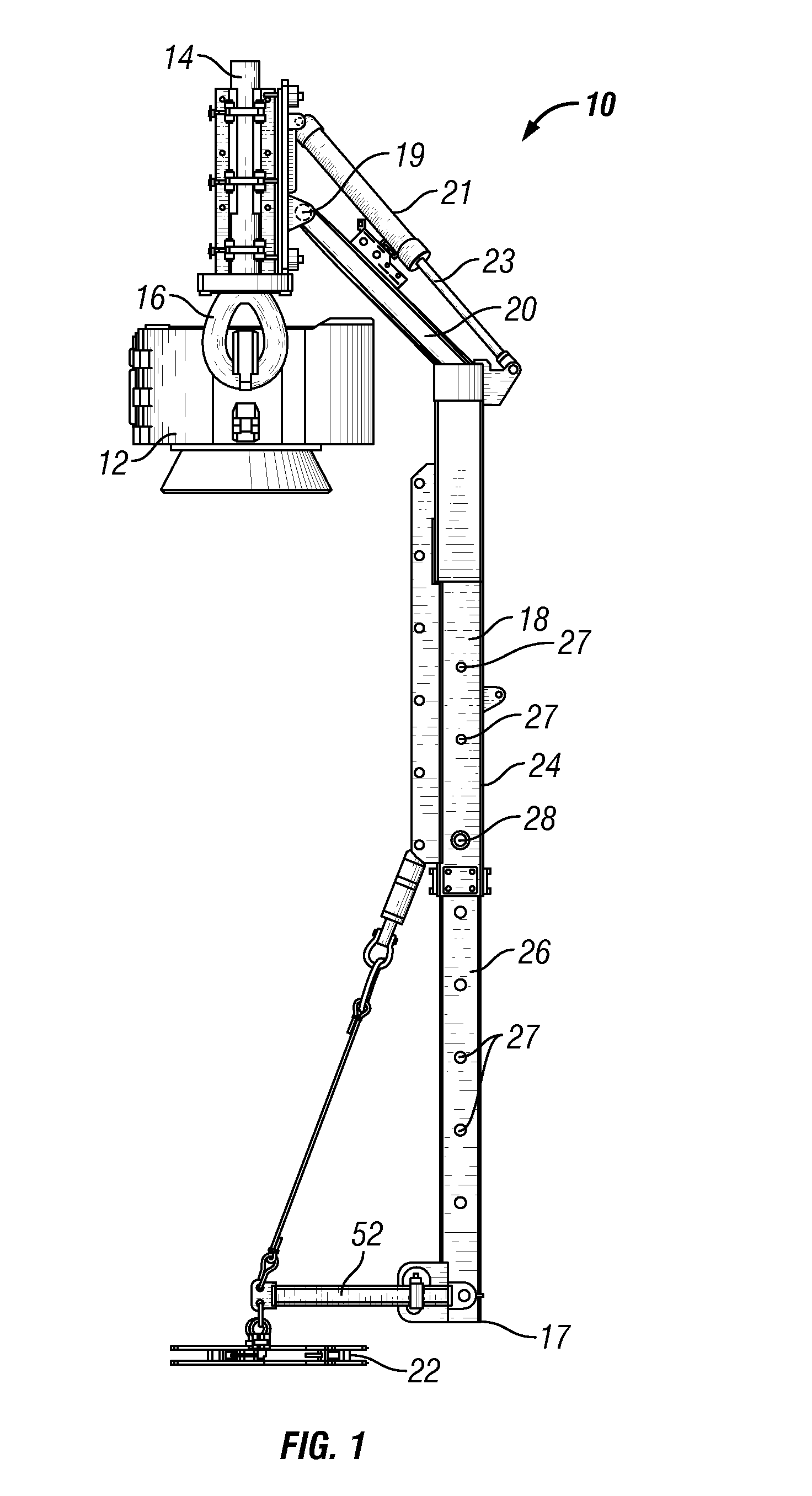

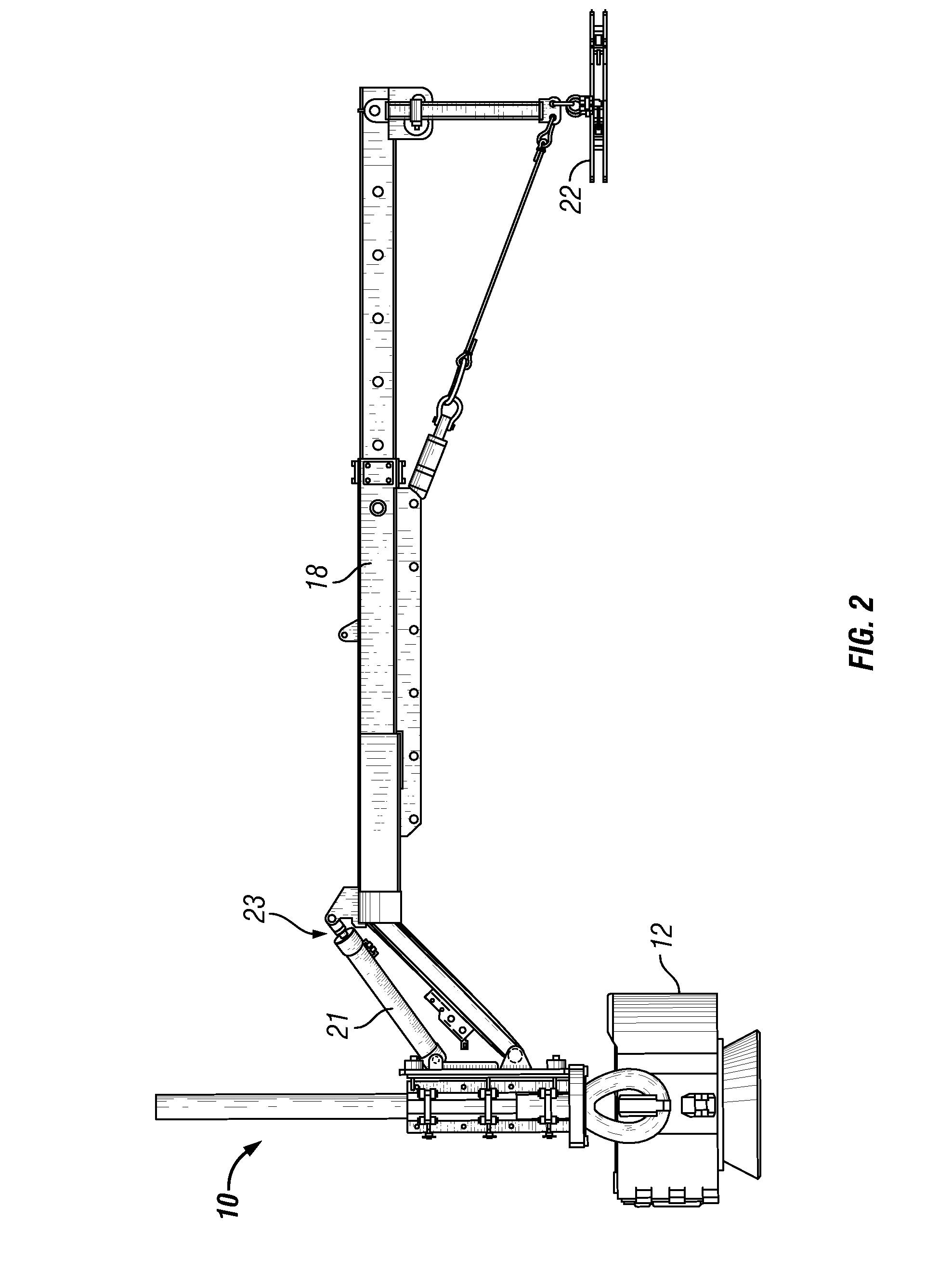

[0022]The present invention provides an apparatus and method for manipulating casing segments to assemble a casing string in a borehole. A single joint manipulator arm may be used to safely and reliably manipulate casing segments as they are made up into a casing string and installed in a well. The embodiments disclosed below describe the manipulation of casing segments to assemble a casing string using the present invention. It is to be understood, however, that other types of tubular segments, including drill pipe and production tubing, may be similarly manipulated to assemble strings without departing from the scope of the invention. For the reason, the terms “pipe”, “tubular” and “casing” are used interchangeably, as are the terms “segment” and “joint.”

[0023]In one embodiment, an apparatus and method of the present invention are used to assemble and run a casing string. Once assembled, the casing string will include a plurality of casing segments threadedly coupled end-to-end an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com