Patents

Literature

152results about How to "Falling steadily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

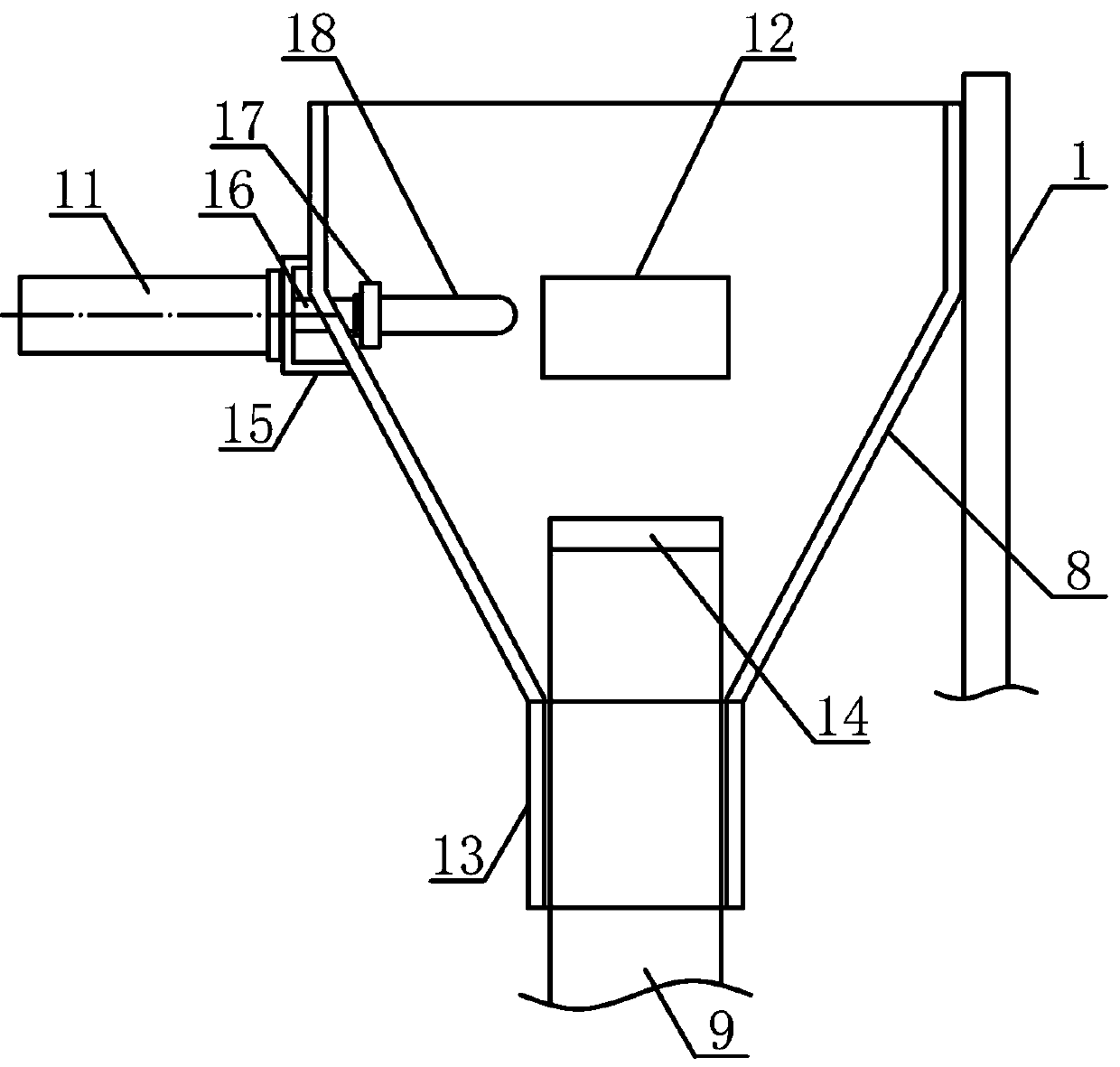

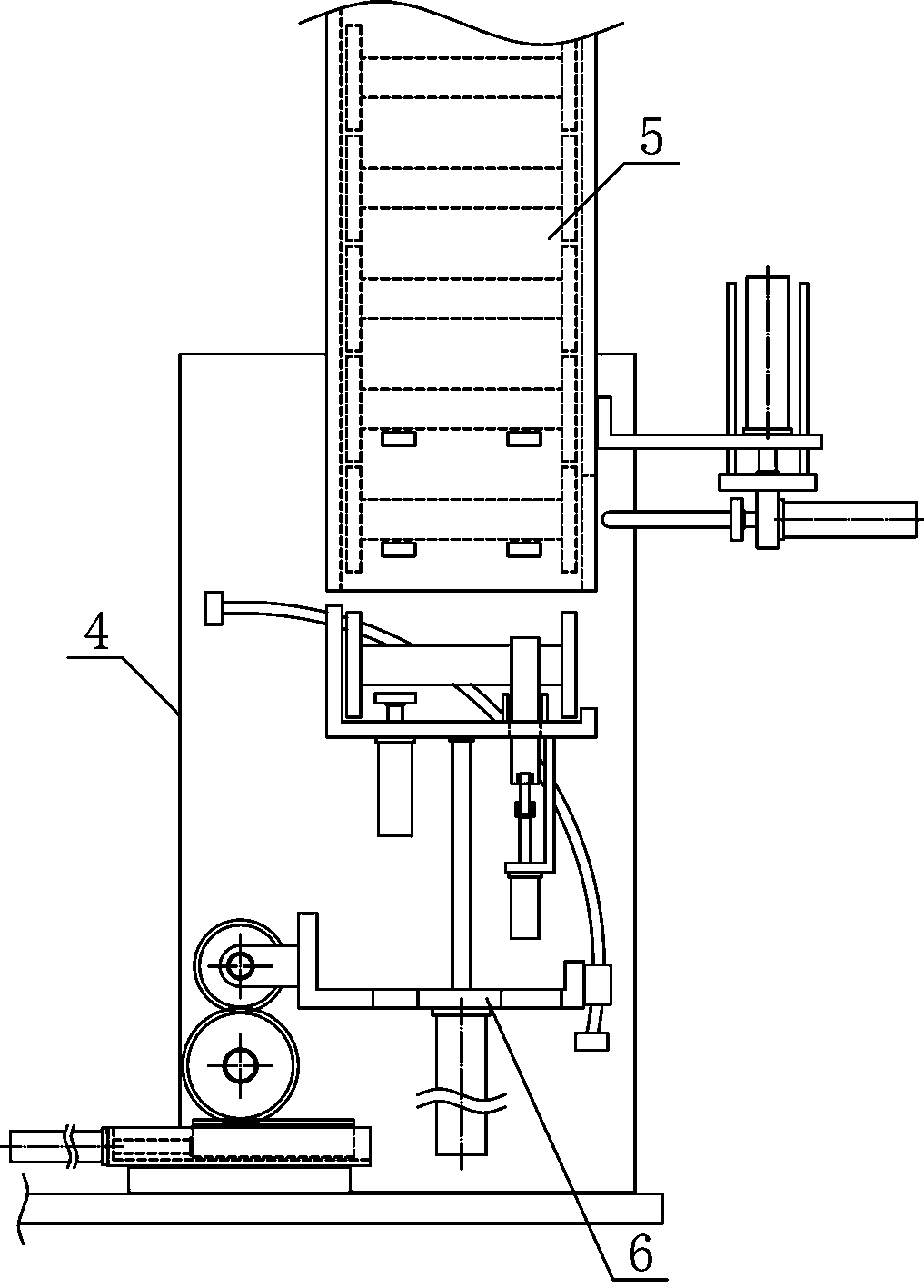

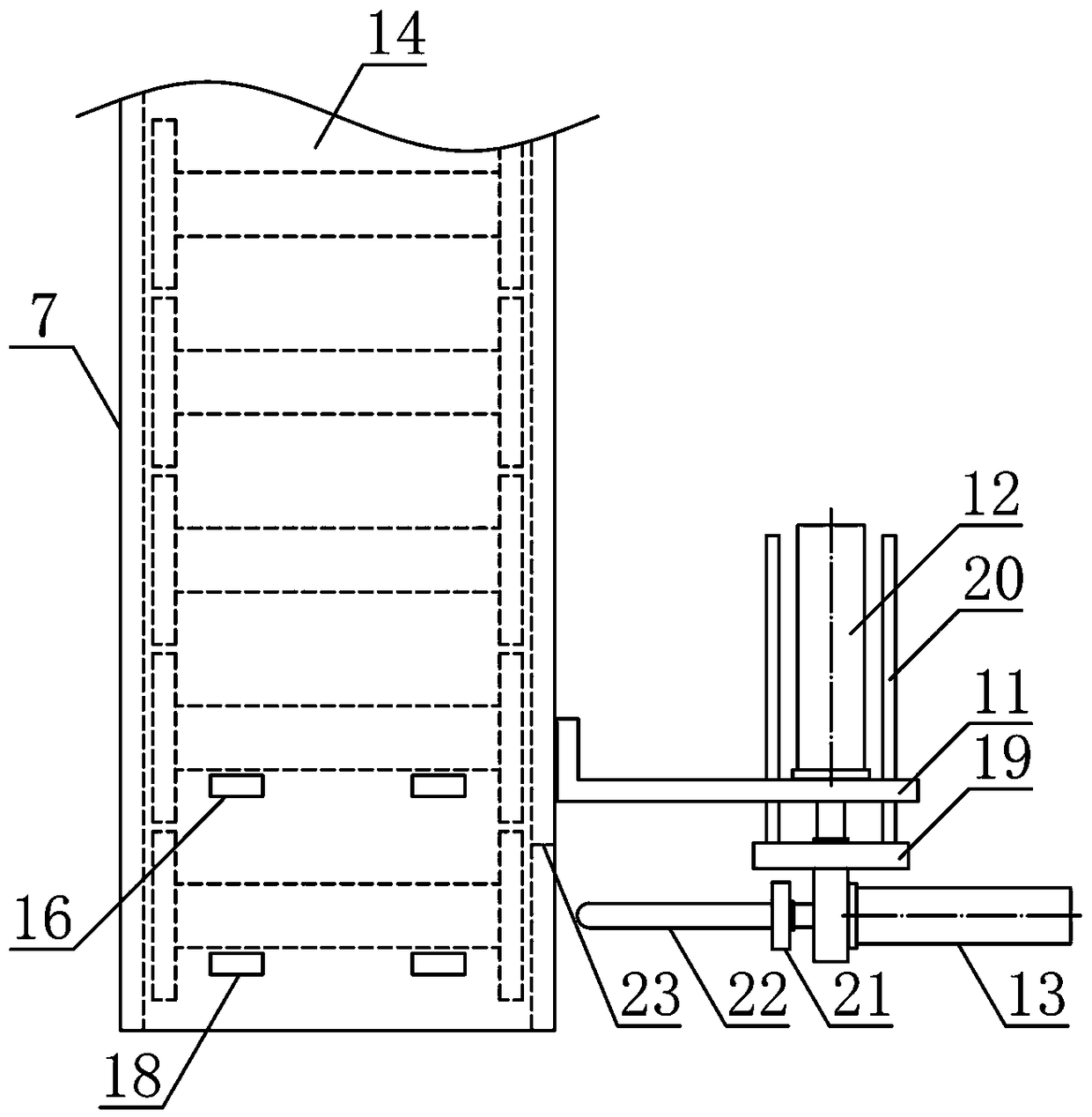

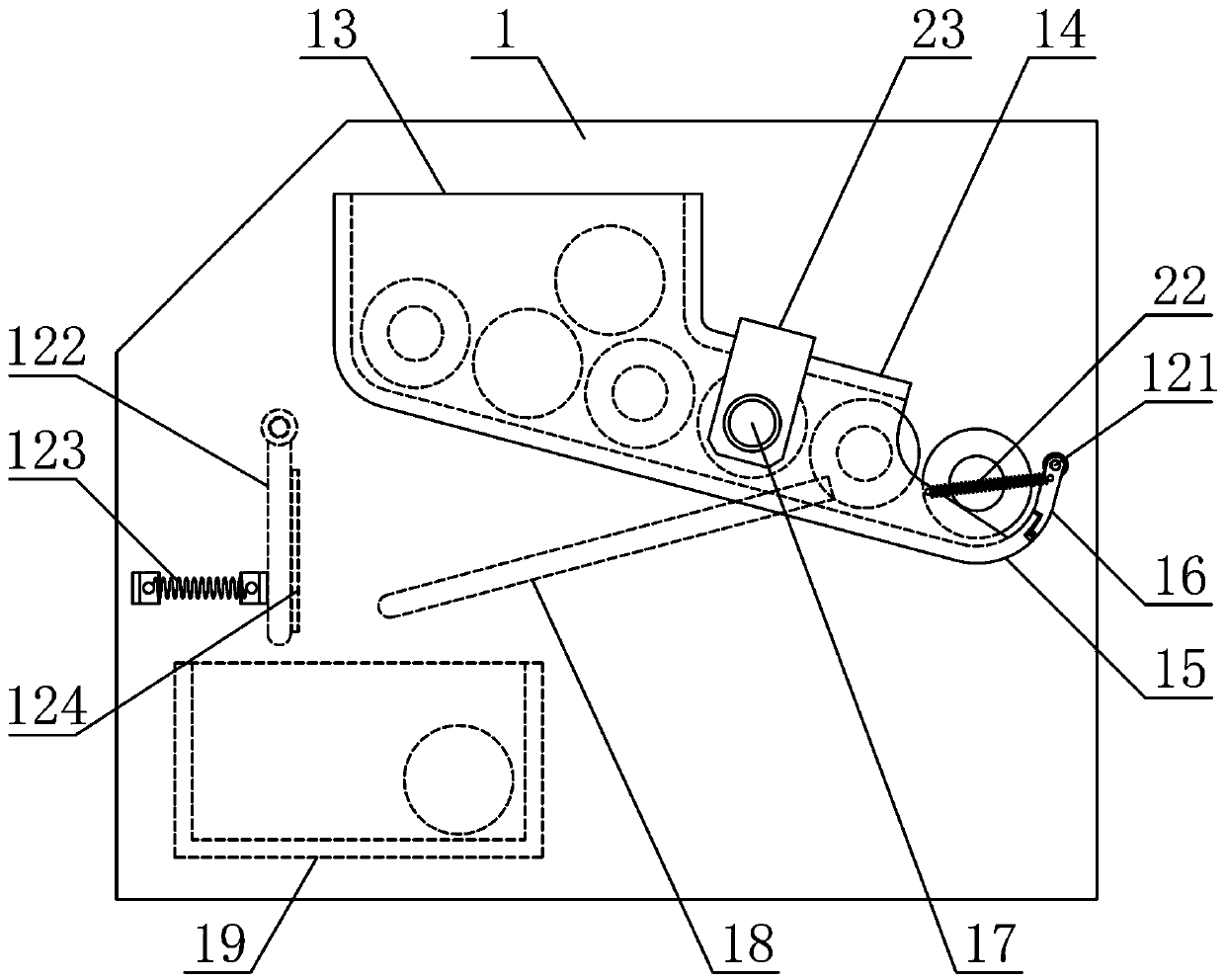

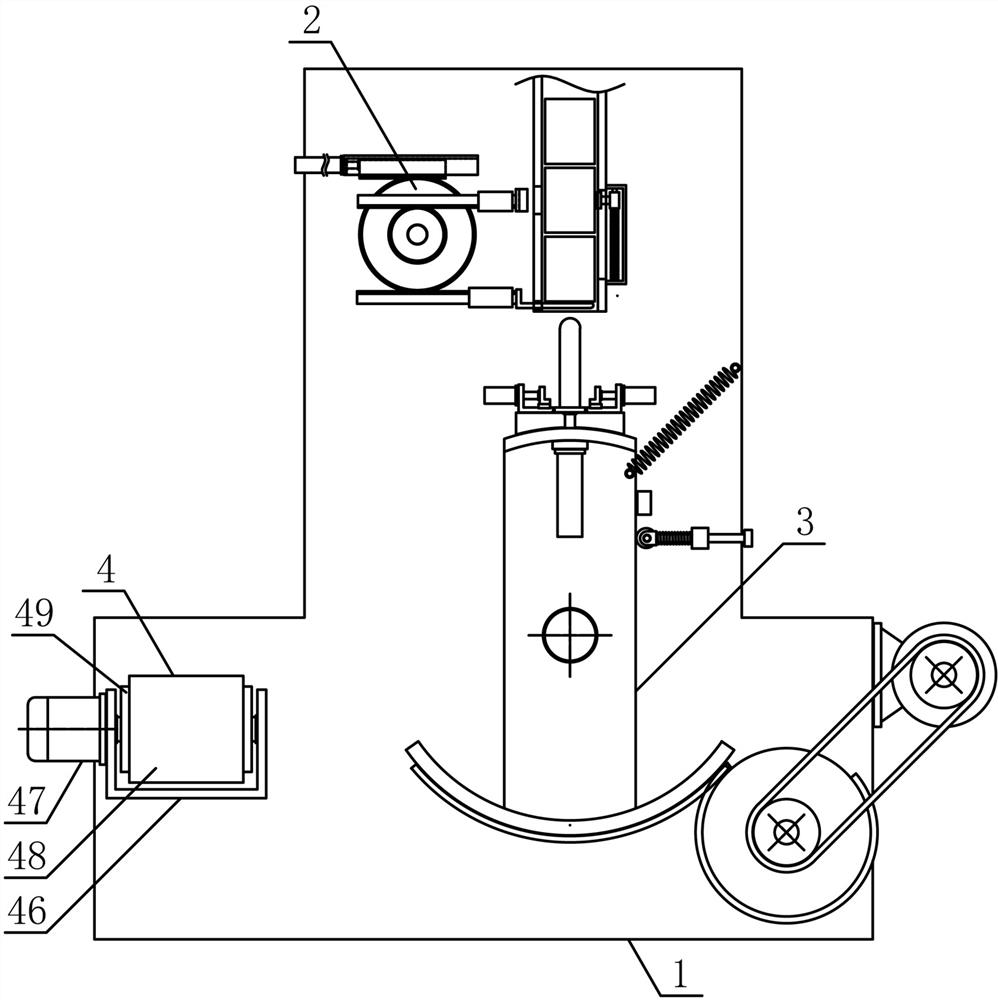

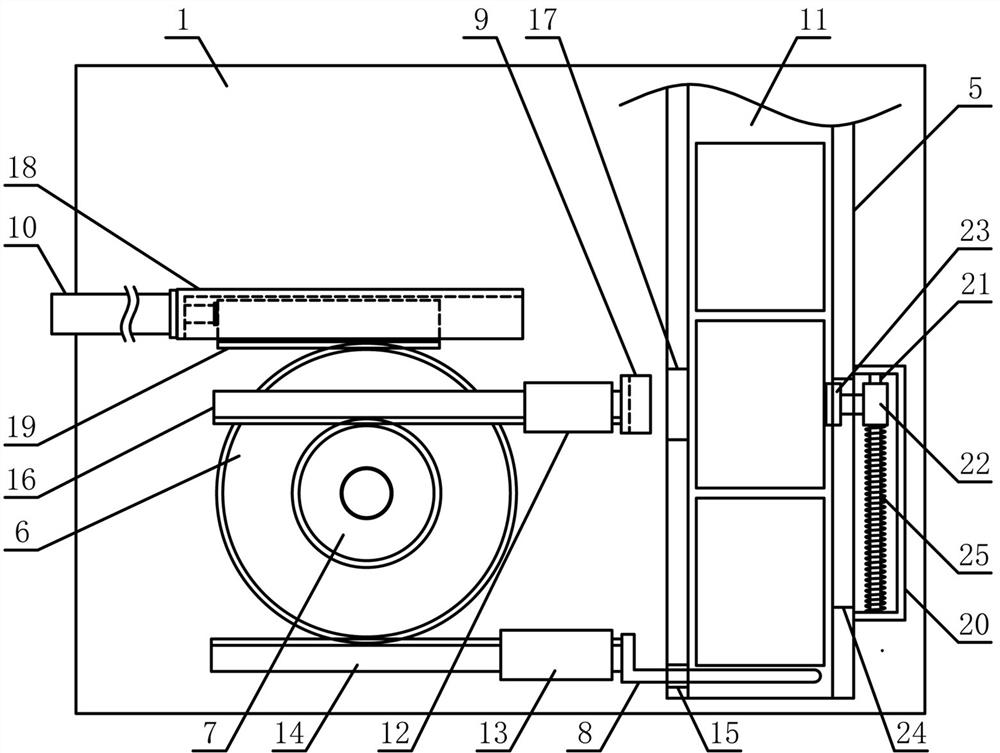

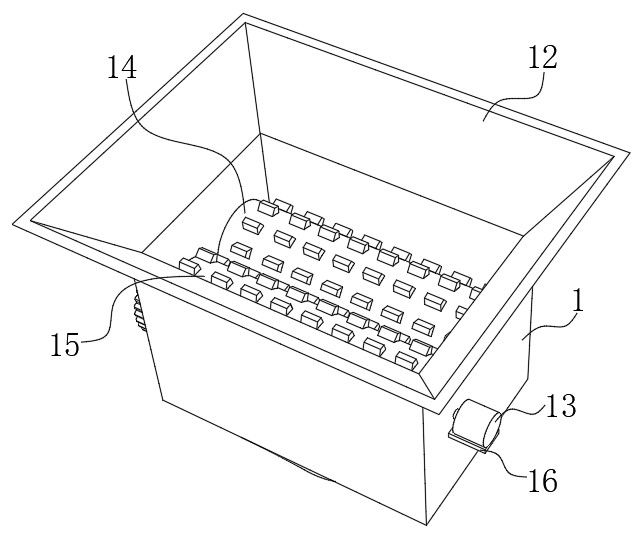

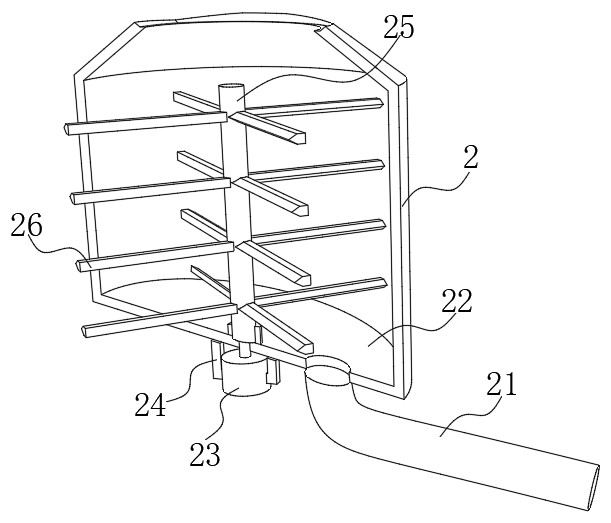

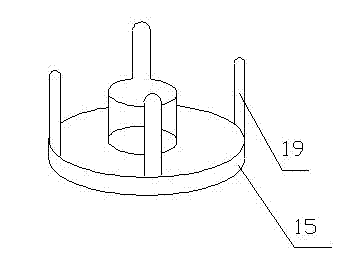

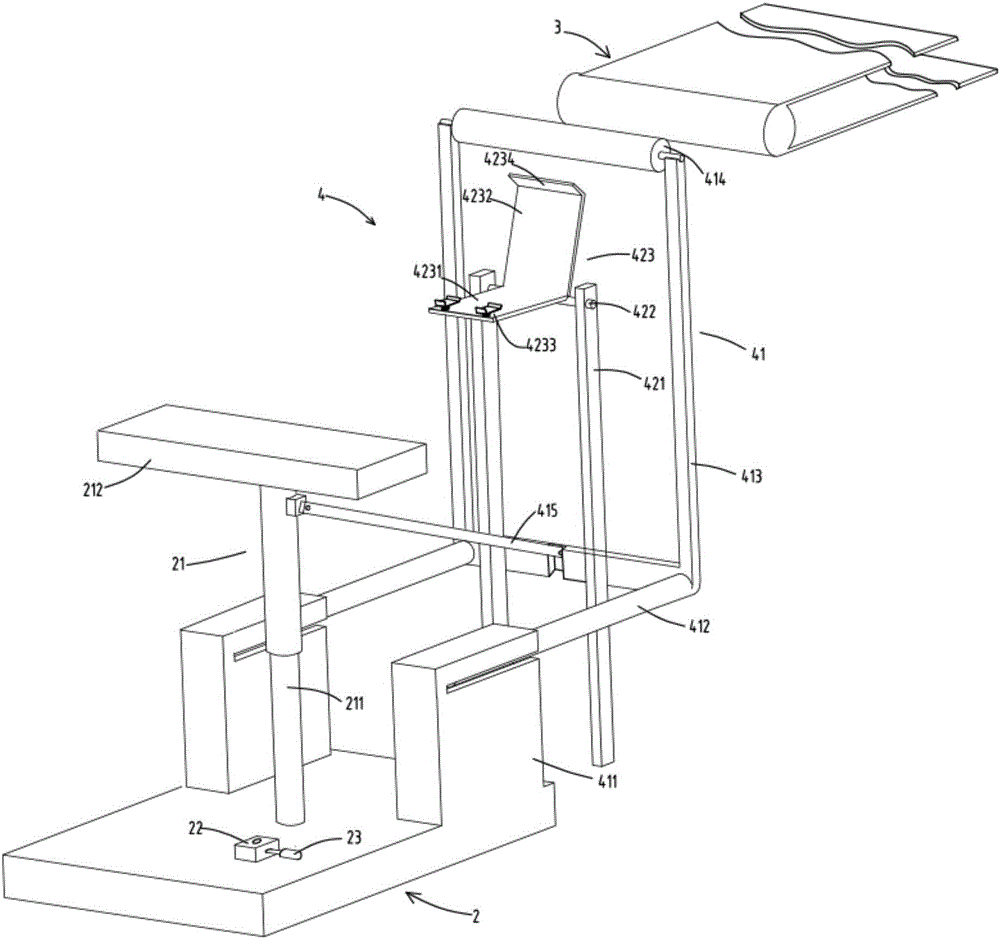

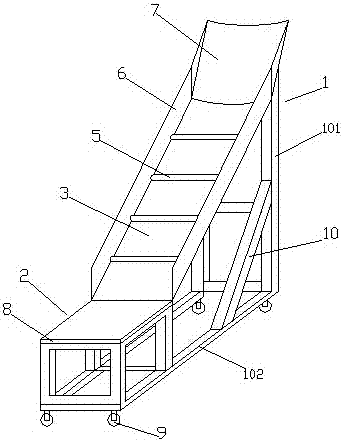

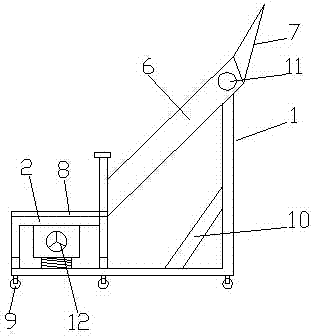

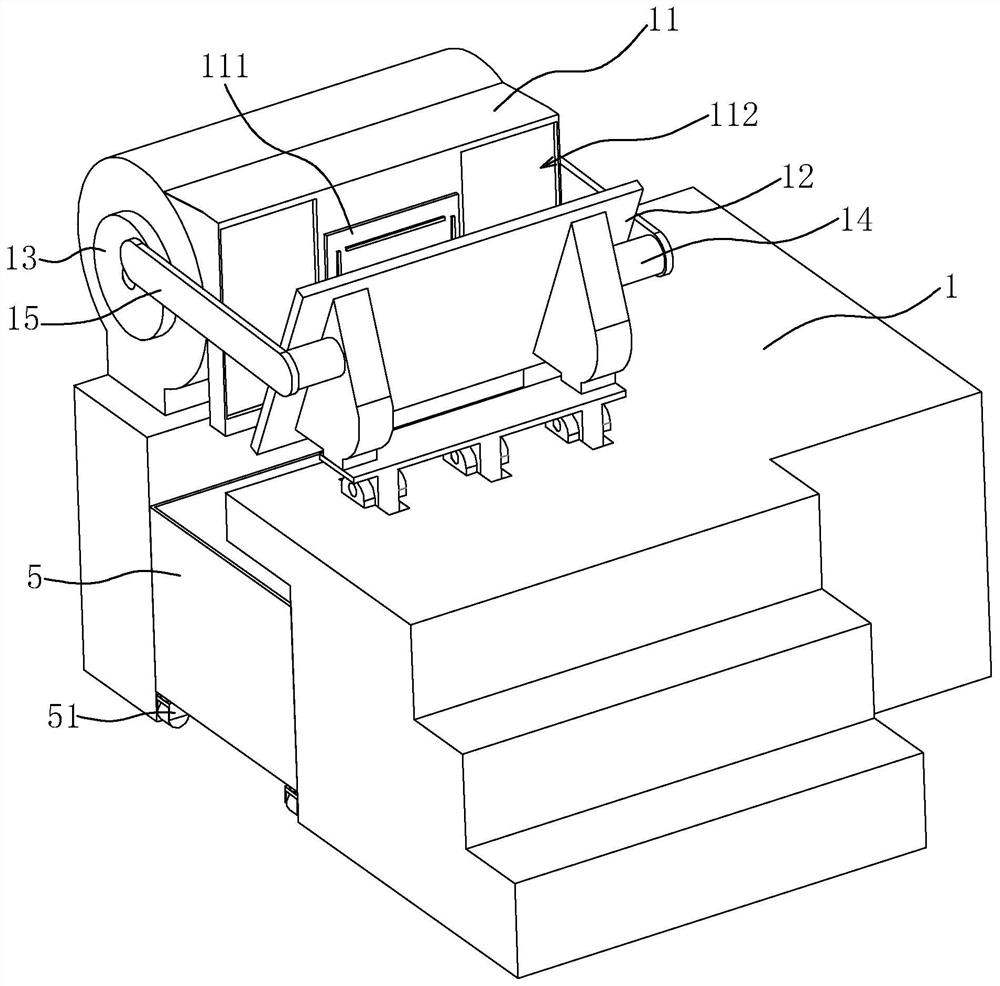

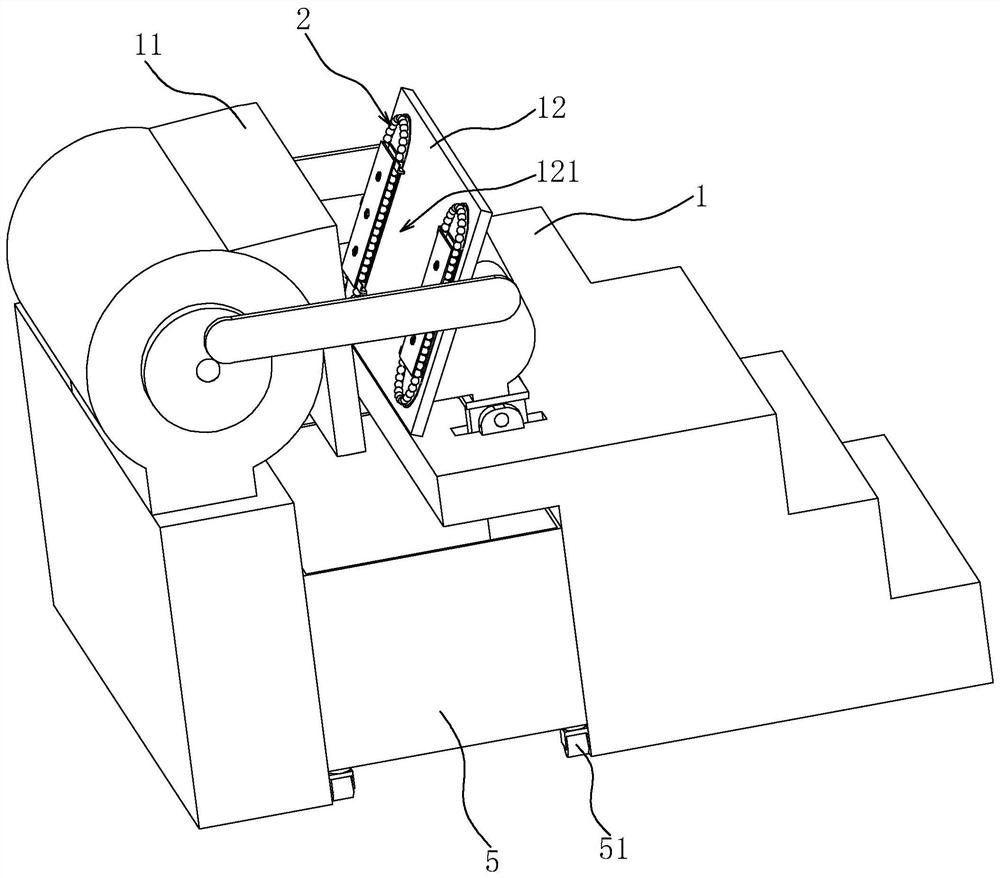

Automatic feeding mechanism for yarn winding drums

InactiveCN109292541AHigh degree of automationSmooth vertical flip loadingFilament handlingYarnEngineering

The invention discloses an automatic feeding mechanism for yarn winding drums, and belongs to the field of fabric production and processing machinery and equipment. A transfer mechanism and barrel moving mechanism of the automatic feeding mechanism are sequentially, vertically and fixedly arranged on the two sides of the upper portion of a feeding base in the horizontal direction. A barrel guidingmechanism and a barrel turning mechanism are sequentially, vertically and fixedly arranged on one side of a transfer bracket from top to bottom. A barrel guiding material pipe is vertically and fixedly arranged on one side of the transfer bracket. A barrel placing bracket is horizontally and fixedly arranged at the output end of a barrel bearing cylinder in the middle of the lower side of a reciprocating bracket. A rotating bracket is horizontally and fixedly arranged on the middle portion of a rotating sleeve of a barrel moving bracket. A barrel moving connecting plate is horizontally arranged at the lower side of a translation connecting plate, and a barrel bearing clamping plate is horizontally and fixedly arranged at the output end of a clamping plate cylinder. The automatic feeding mechanism is reasonable in structural design, can smoothly transfer and feed the yarn winding drums one by one and smoothly transfer and place the yarn winding drums to required positions, improves theautomation degree of feeding the yarn winding drums, and meets the requirements of production and use.

Owner:桐乡市富利来针织股份有限公司

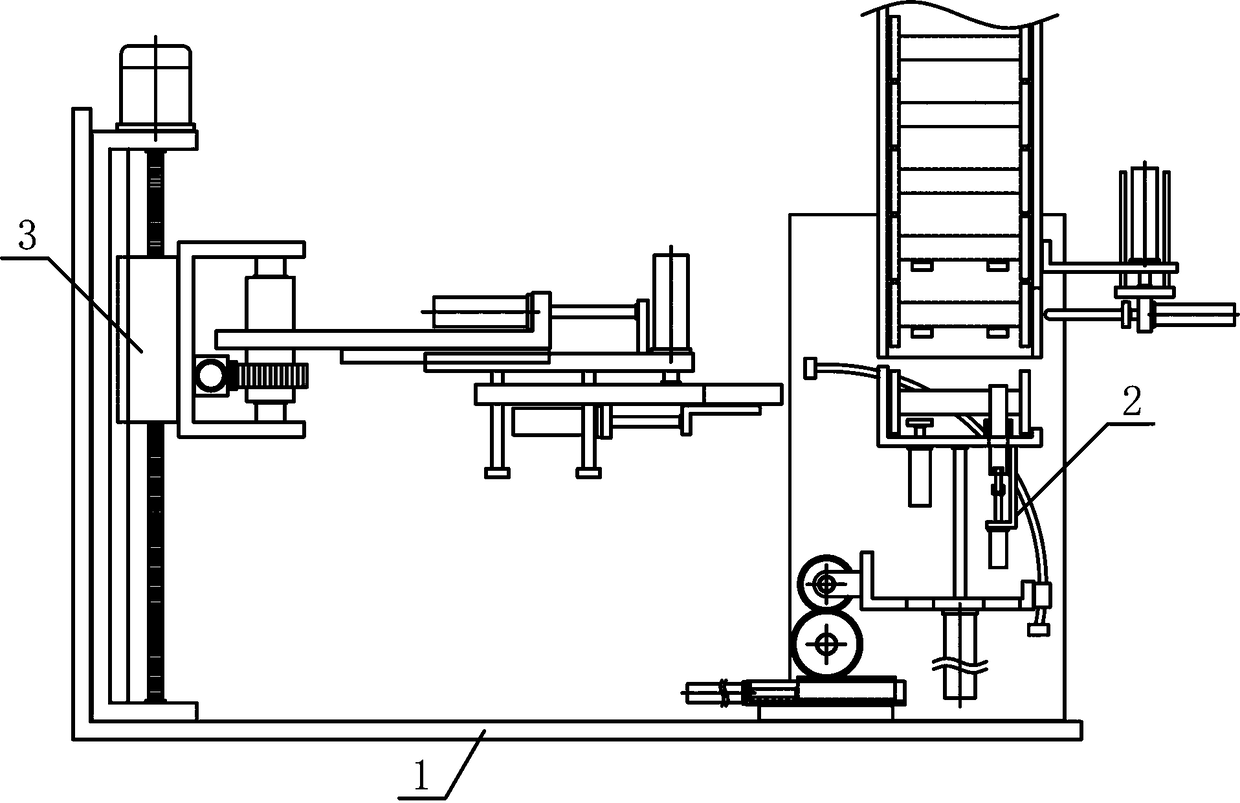

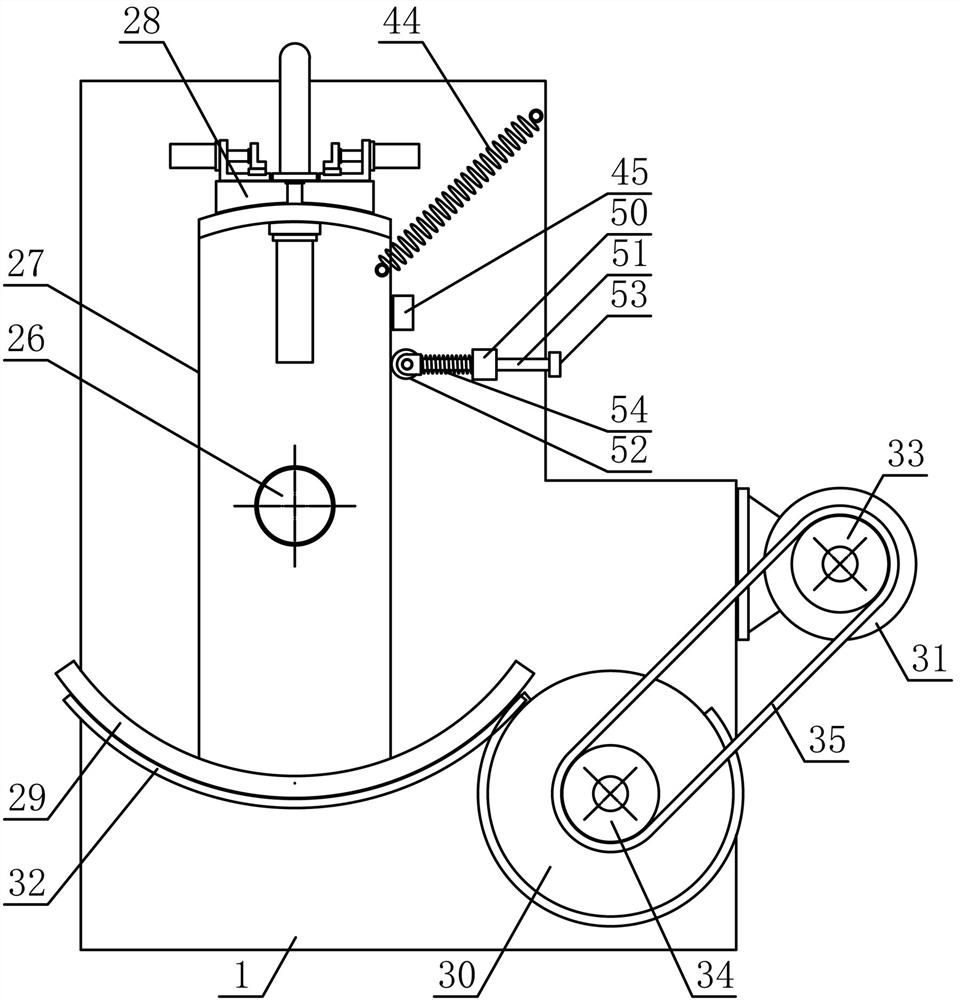

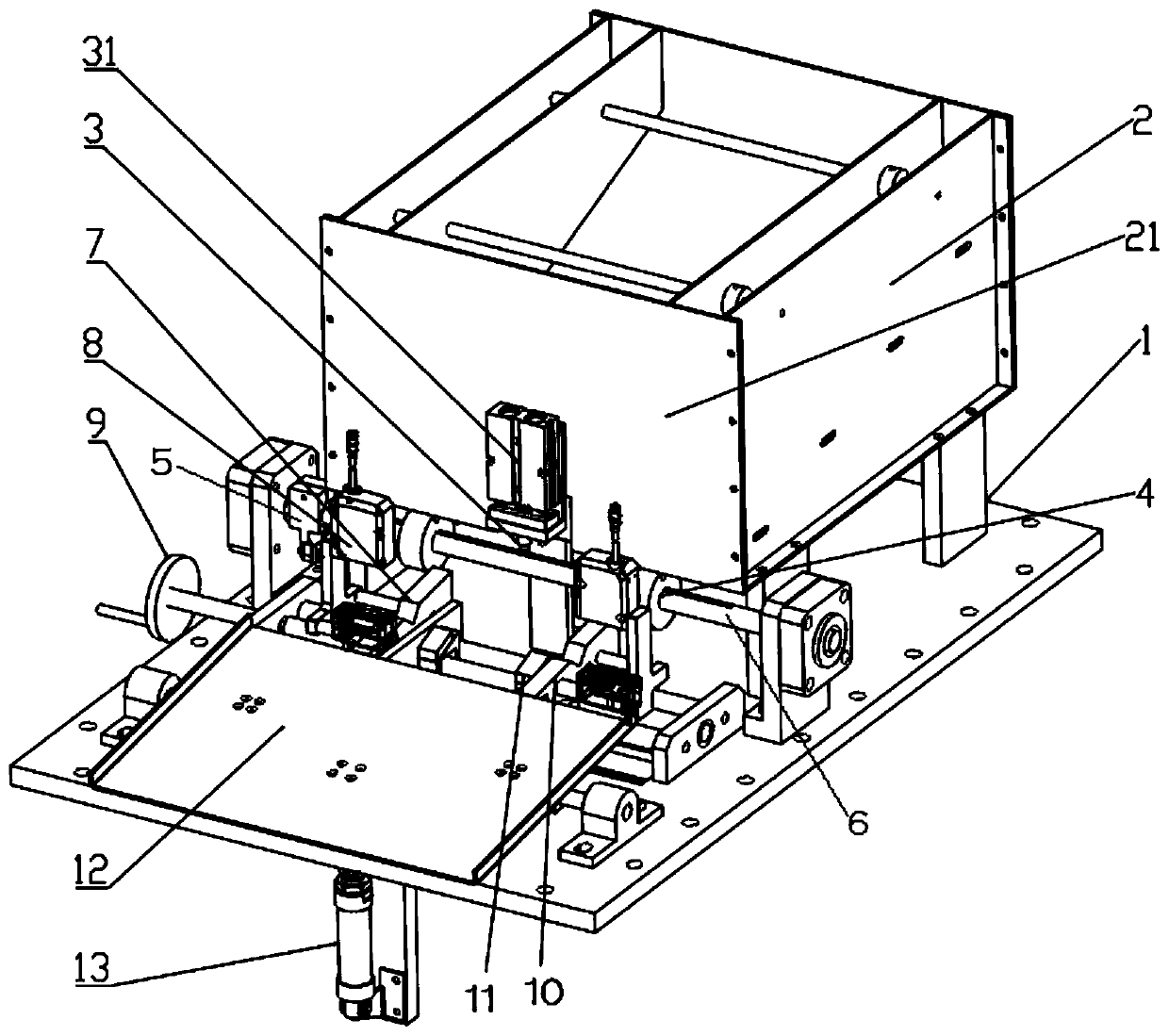

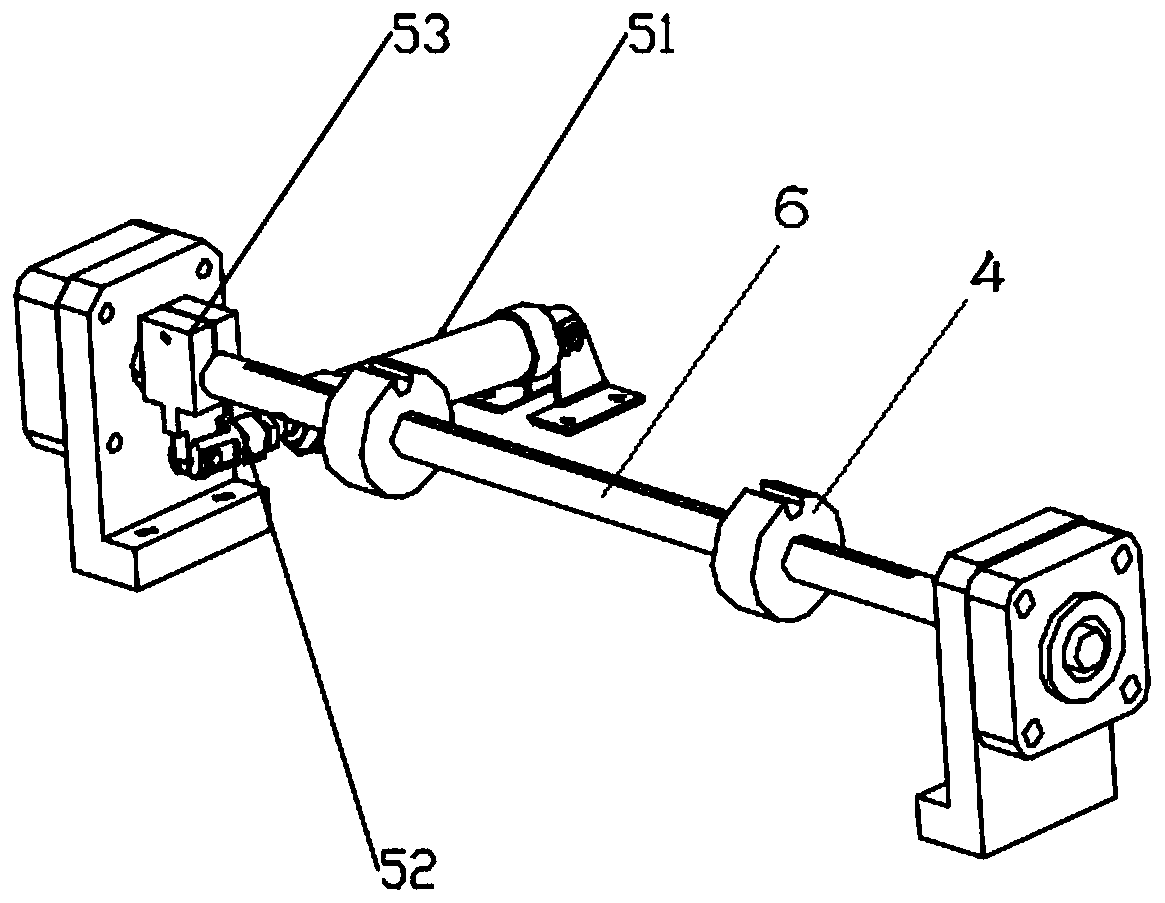

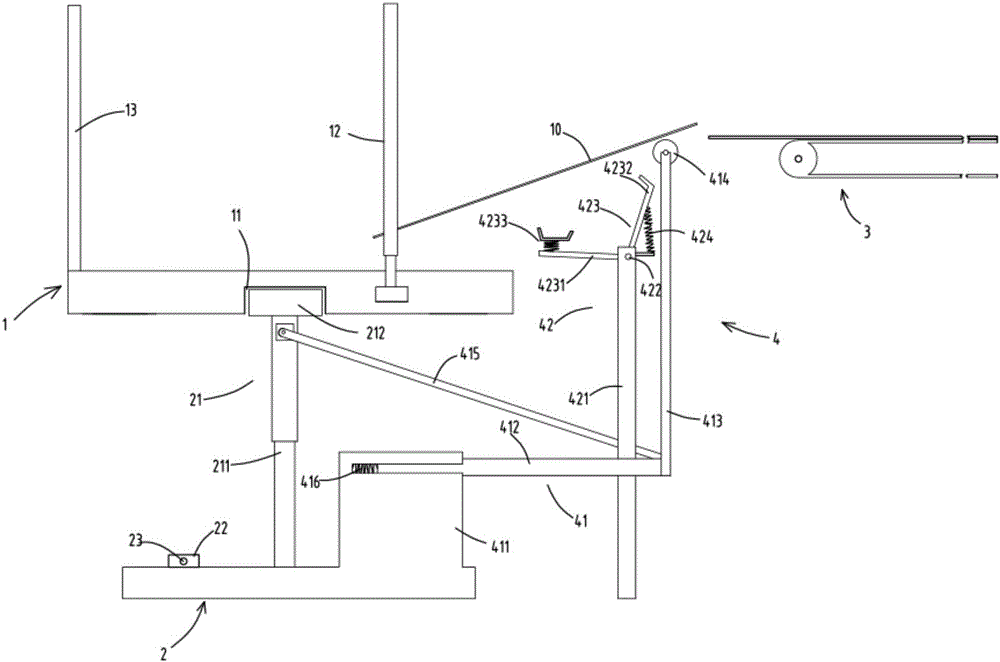

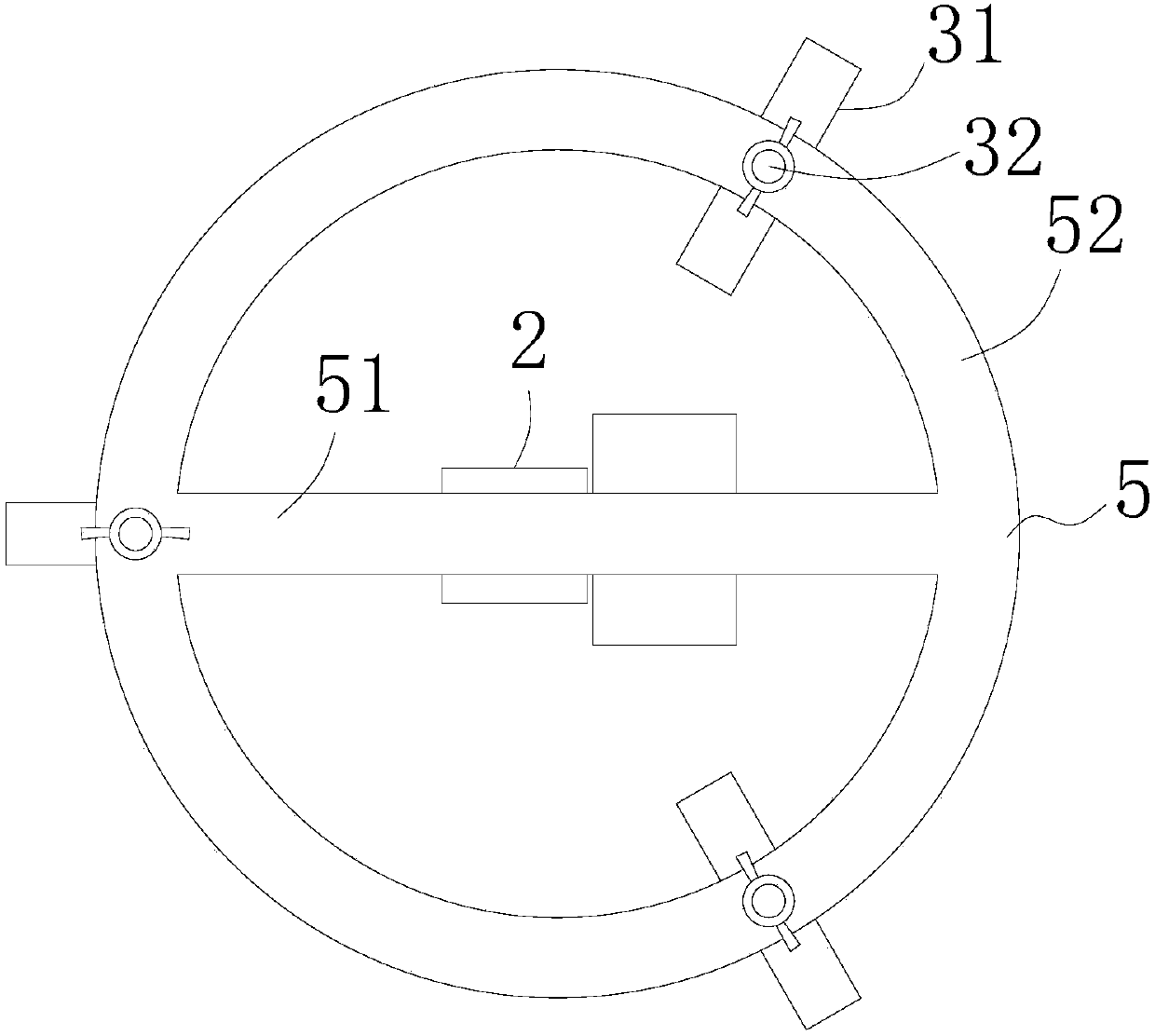

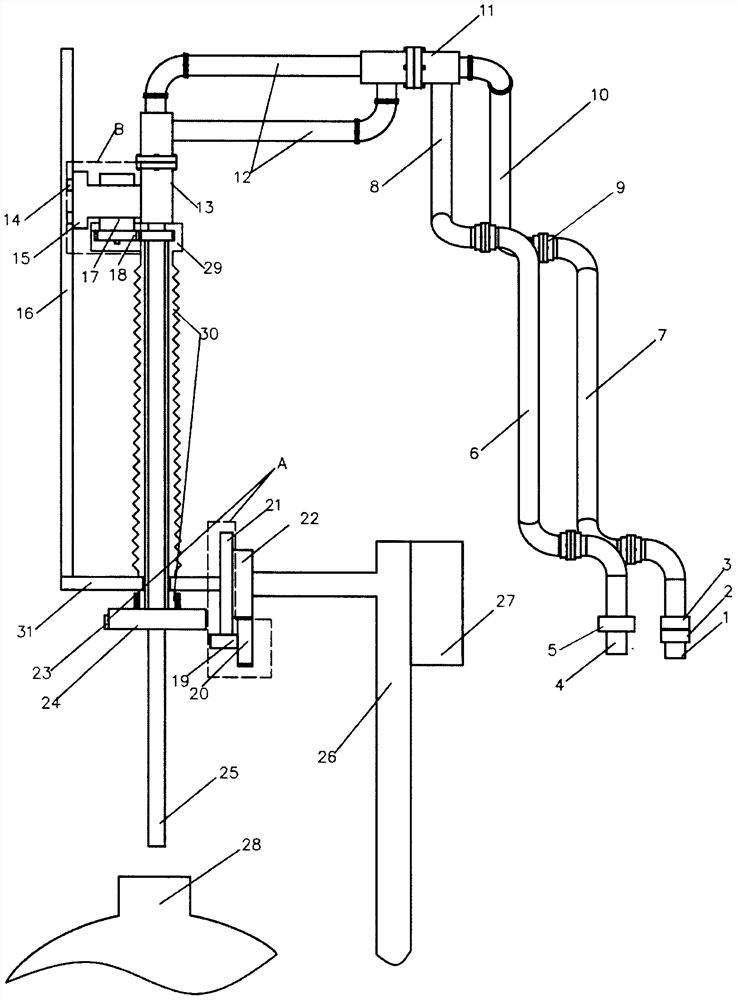

Metal round pipe continuous conveying machining device

InactiveCN111229923AStable processingAutomatic and stable processingPerforating toolsMetal-working feeding devicesStructural engineeringMachining

The invention discloses a metal round pipe continuous conveying machining device, and belongs to the field of mechanical workpiece machining equipment. A round pipe guide storage pipe and a guide pipeinclined table plate are sequentially and fixedly mounted on the upper side of a round pipe conveying support in the inclined direction, a guide pipe driving mechanism and a round pipe guide conveying mechanism are sequentially mounted at the position, on the upper side of the guide pipe inclined table plate, of the round pipe conveying support from top to bottom, a round pipe machining mechanismis fixedly mounted at the position, above the lower end of the guide pipe inclined table plate, of the round pipe conveying support, a round pipe positioning mechanism is horizontally and fixedly mounted on the lower side of the end of the guide pipe inclined table plate, and a round pipe falling mechanism is fixedly and vertically mounted at the position, on the lower side of the round pipe machining mechanism, of the round pipe conveying support. Structural design is reasonable, a metal round pipe can be efficiently and stably guided and conveyed continuously to be punched, the machined round pipe can be conveniently, rapidly and smoothly conveyed and discharged, automatic and accurate machining of the metal round pipe can be achieved, machining efficiency and machining quality of the metal round pipe can be improved, and needs of production use can be met.

Owner:黄薇婷

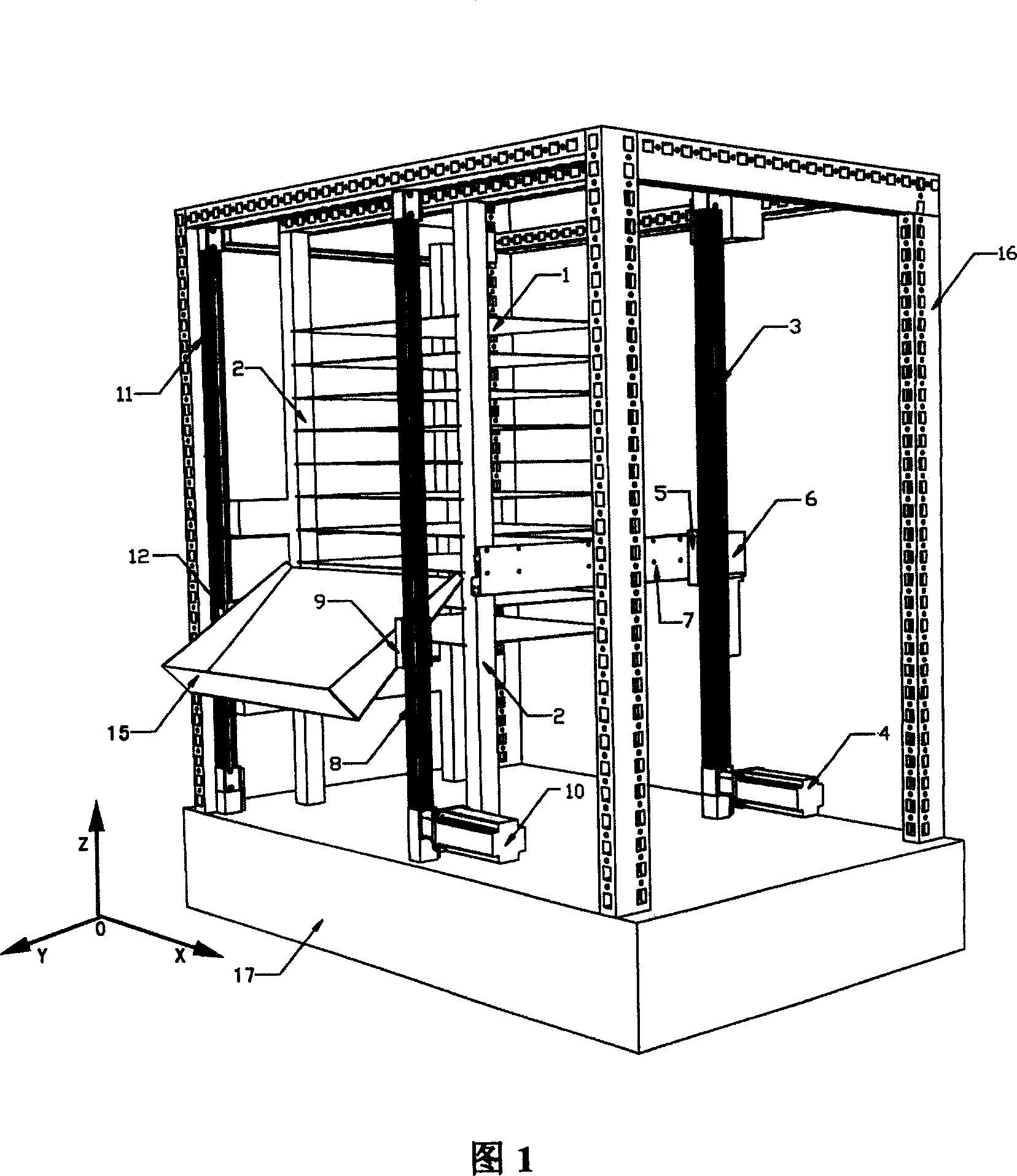

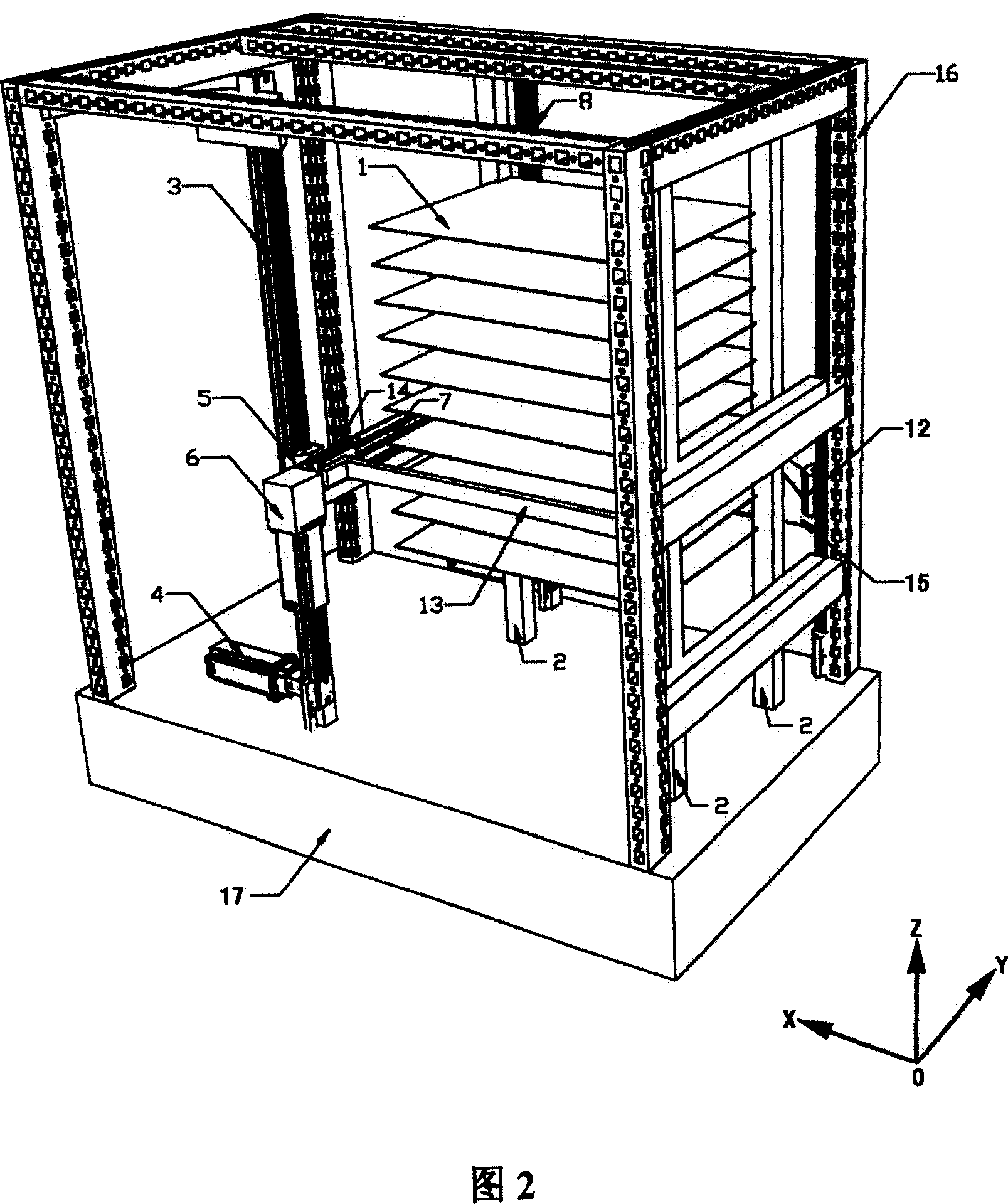

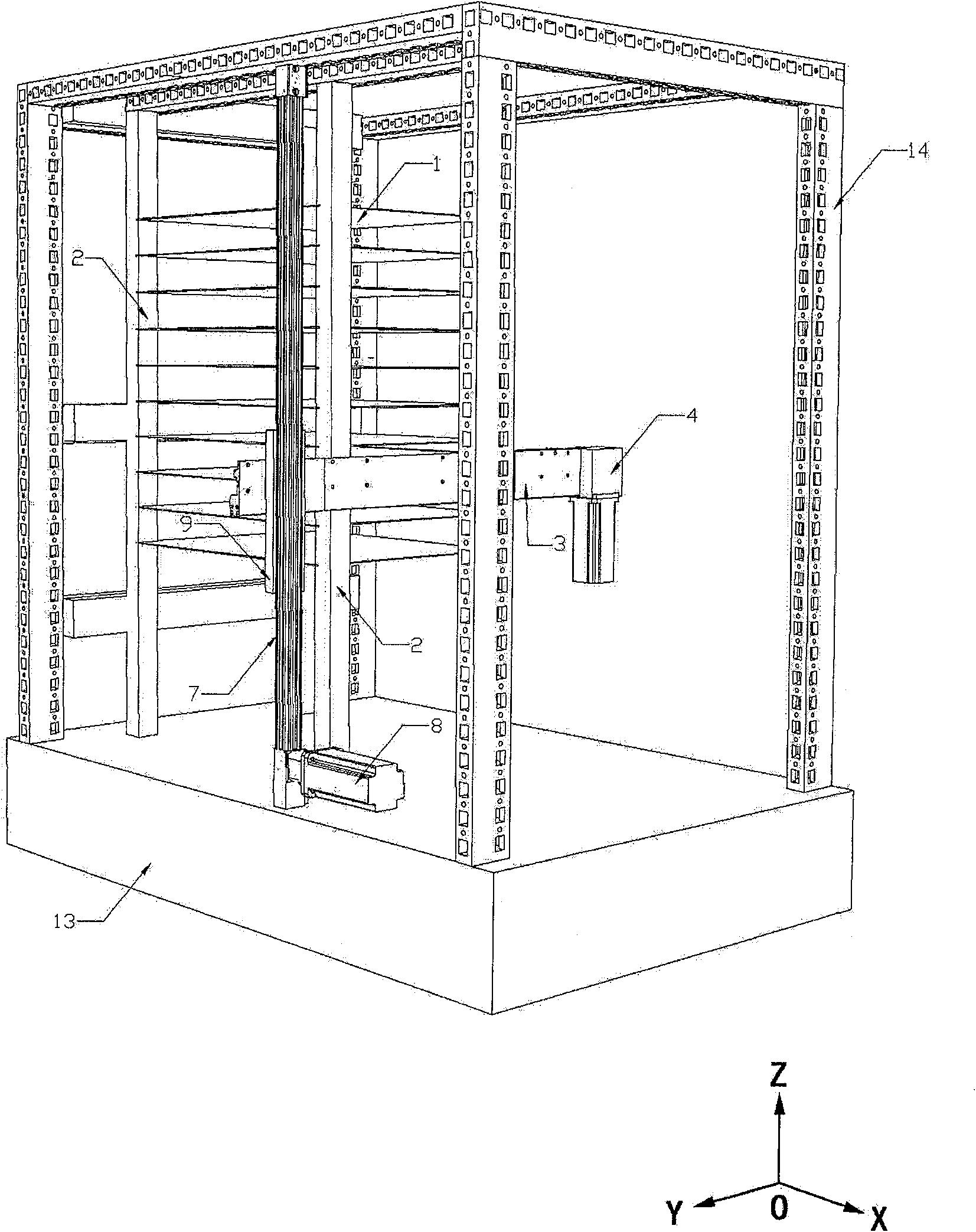

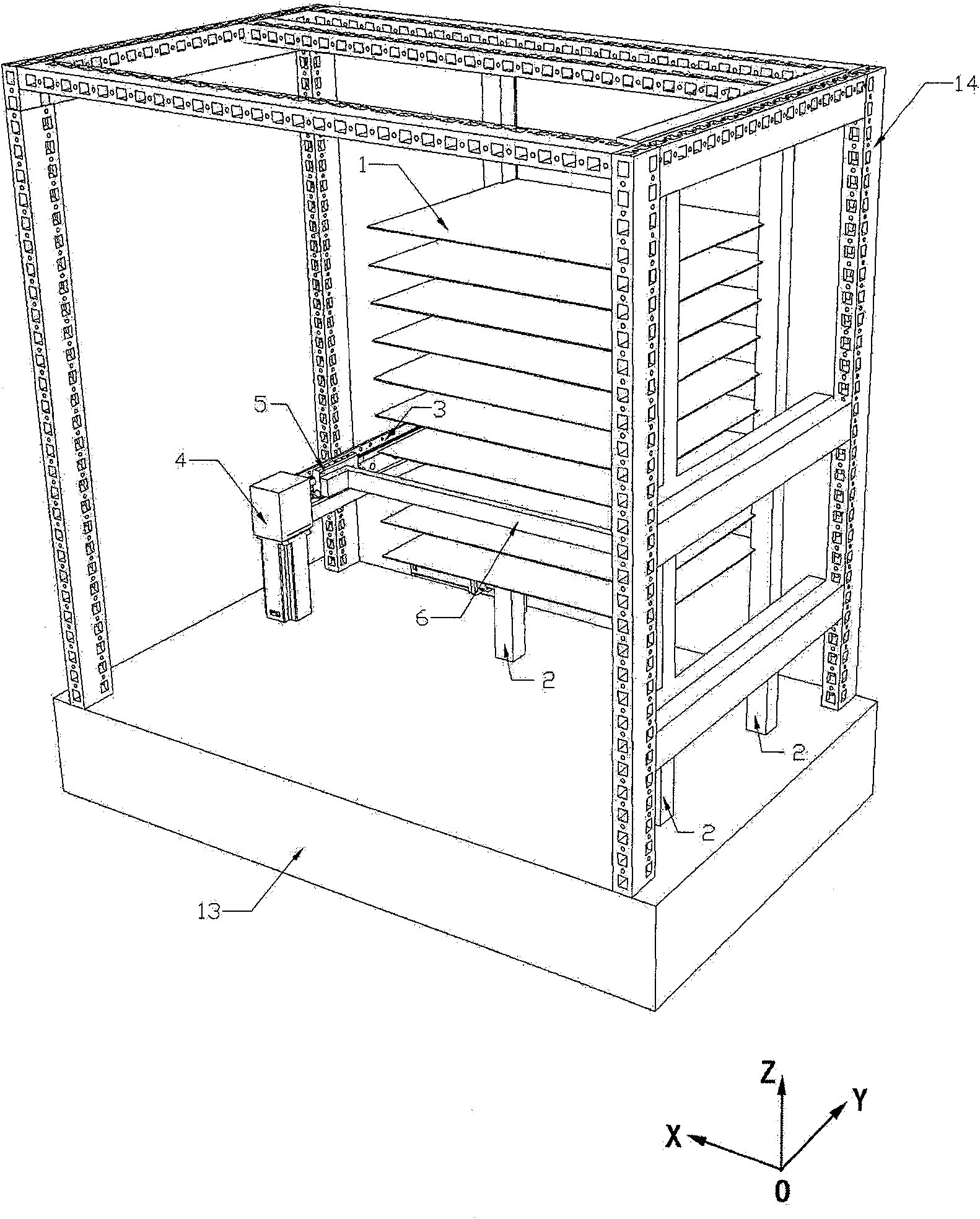

Device for containing and outputting flat articles automatically

InactiveCN1941004AEasy to storeEasy maintenanceCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringPower unit

A flat goods store and auto-transmission device includes shelf and auto-transmission unit. The shelf is composed by vertical columns and clapboards attached to the columns. The auto-transmission unit includes the first linear driver parallel to the shelf columns, the third linear driver vertical to the shelf columns, goods receiving unit and power unit. On the first slid block of the first linear driver fixed the third linear driver, and on the third slid block of the third linear driver fixed a shift lever crossing the clapboards.

Owner:陈家聪

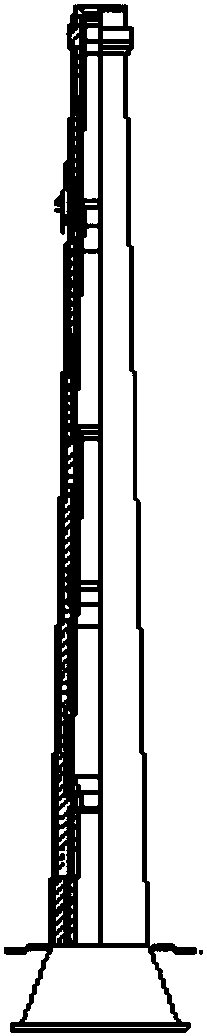

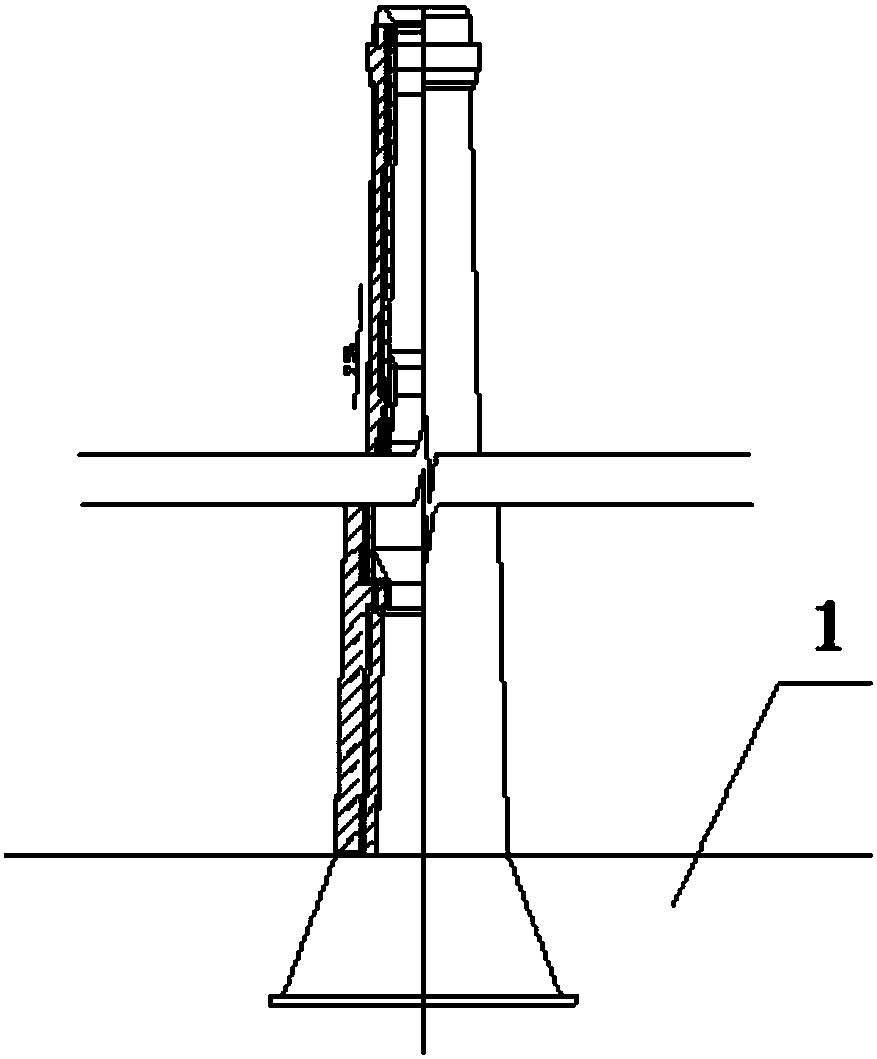

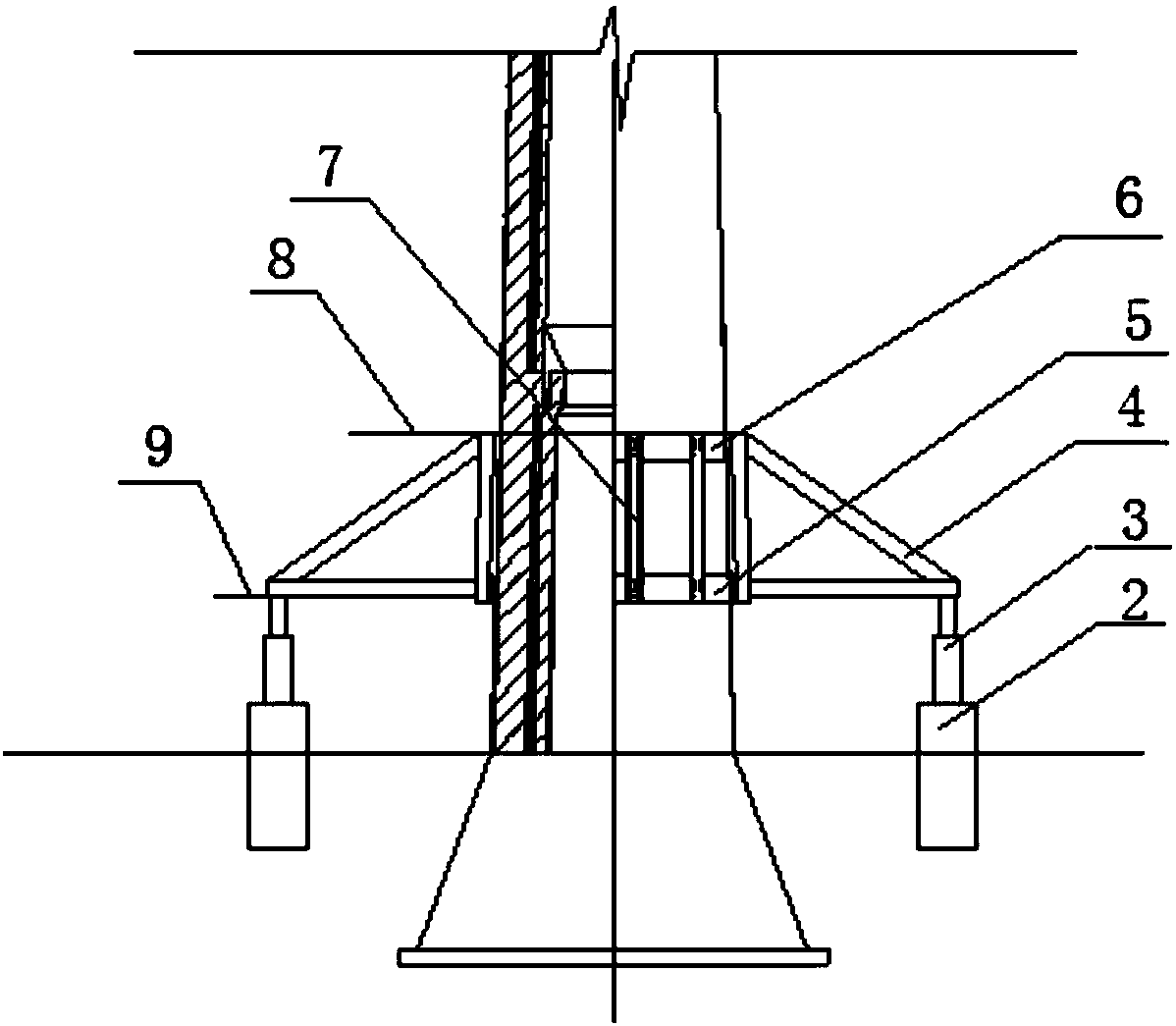

Reverse dismantling device for chimney and dismantling method

The invention discloses a reverse dismantling device for a chimney and a dismantling method. The reverse dismantling device for the chimney comprises a first horizontal steel plate belt and a second horizontal steel plate belt, wherein the first horizontal steel plate belt and the second horizontal steel plate belt are arranged around the chimney; the diameter of each steel plate belt can be adjusted according to the different diameters of different sections of the chimney, and a plurality of vertical connecting steel channels and steel brackets are arranged between the two steel plate belts and used for transmitting gravity of the chimney and vertical acting force converted by horizontal force to a hydraulic jack and a buttress; transverse tie rods are arranged at the ends of the steel brackets and used for preventing instability and increasing the bearing capacity; and reliable connection is conducted between the steel brackets and the hydraulic jack as well as the steel brackets andthe buttress, the effects of pressure and pulling force can be borne, and the buttress is fixed to a raft formed by pouring of reinforced concrete. According to the reverse dismantling device for thechimney and the dismantling method, after the chimney portion between the two lower sets of horizontal steel plate belts are cut and moved, the jack is utilized to make a part of the chimney to fall,then cutting is continued, and the steps are repeated until the whole chimney is dismantled.

Owner:山东省建筑科学研究院有限公司 +2

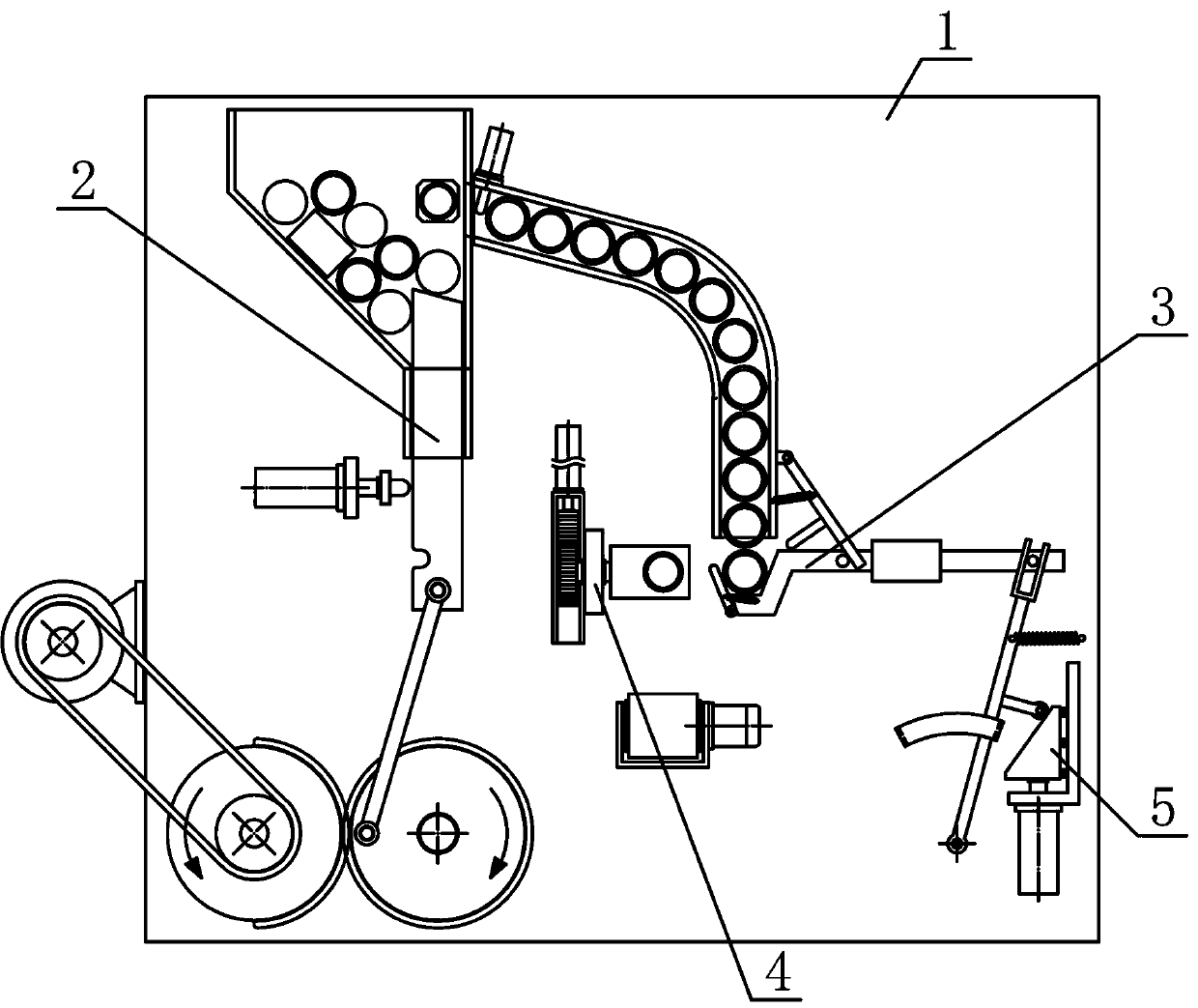

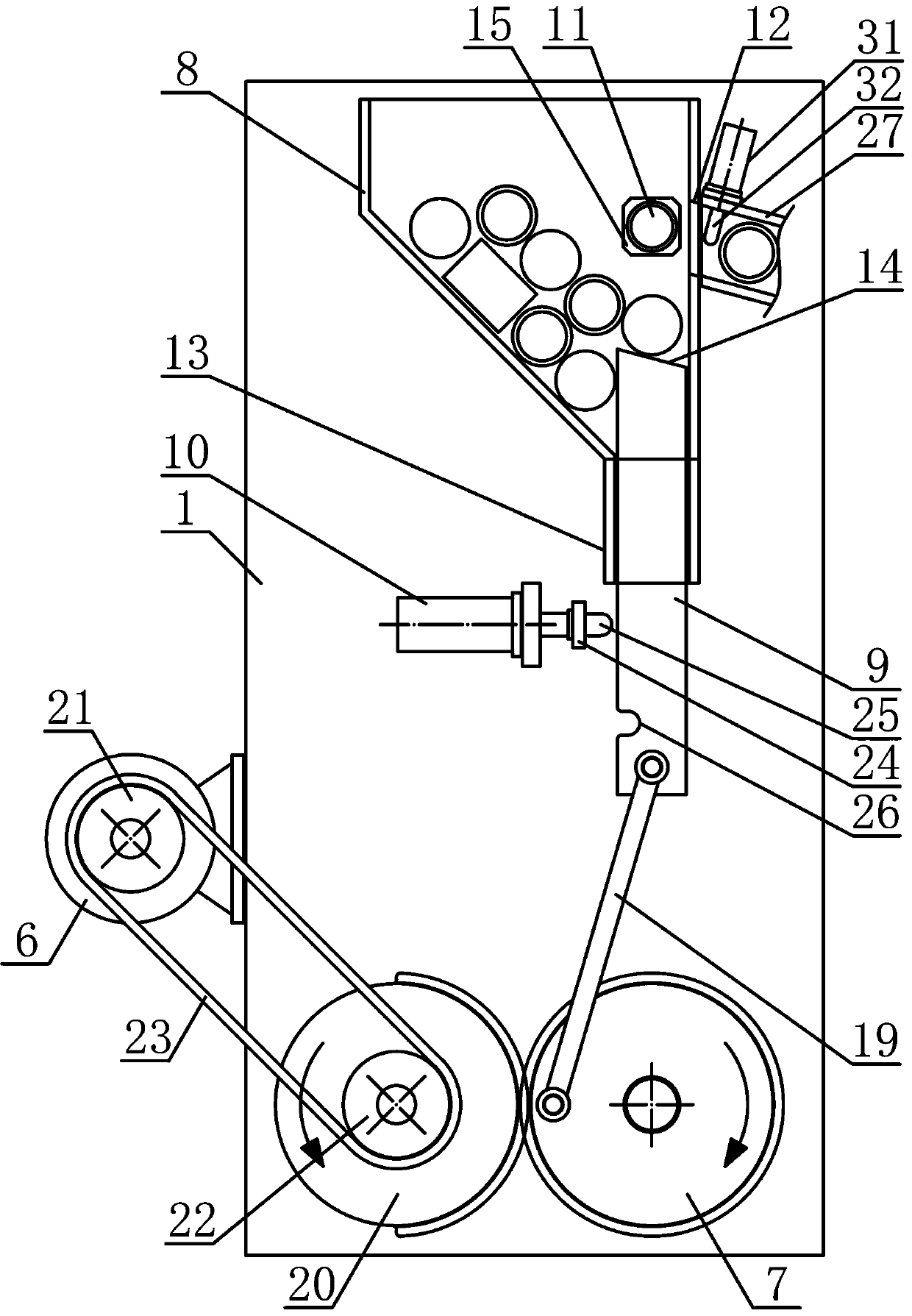

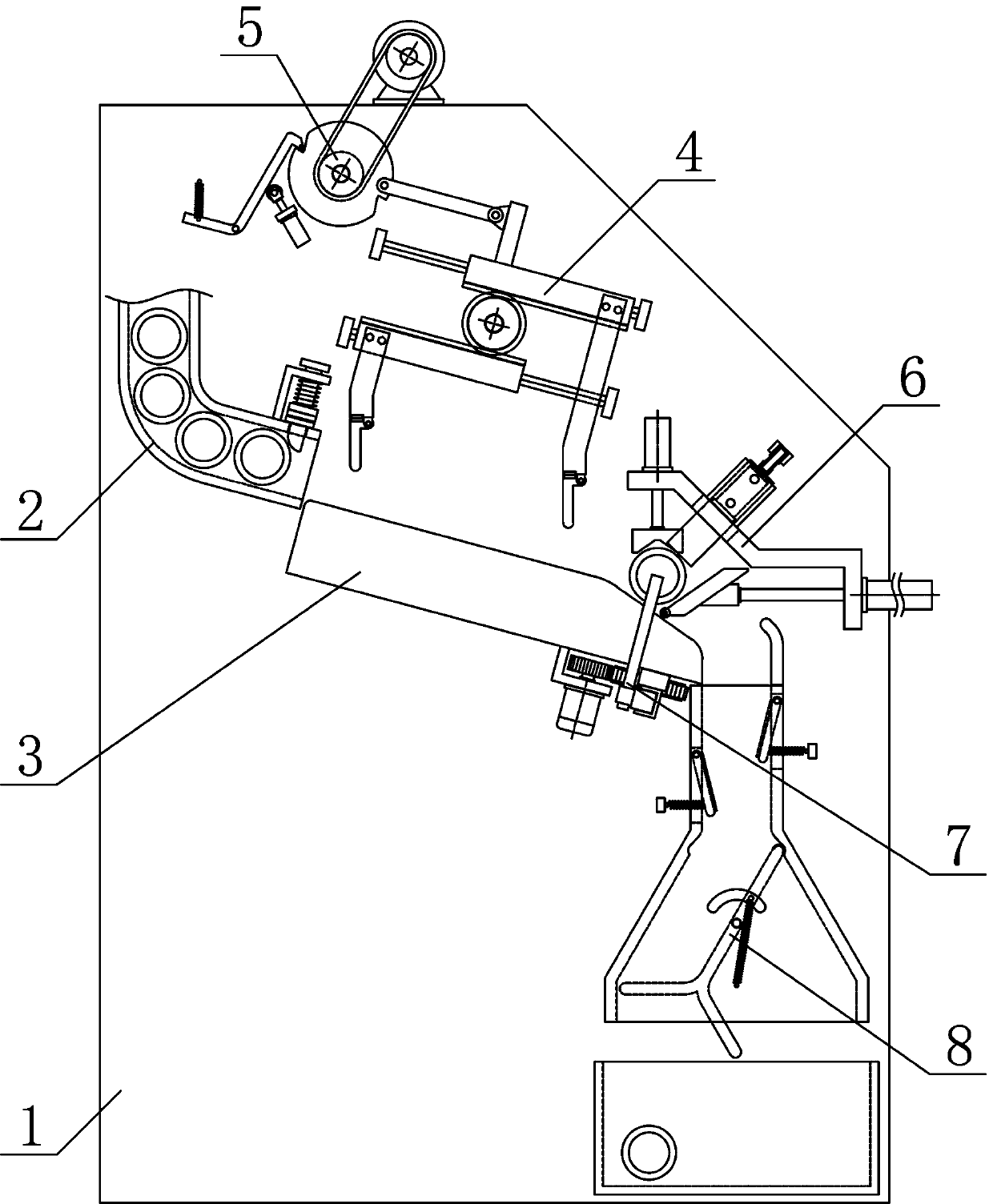

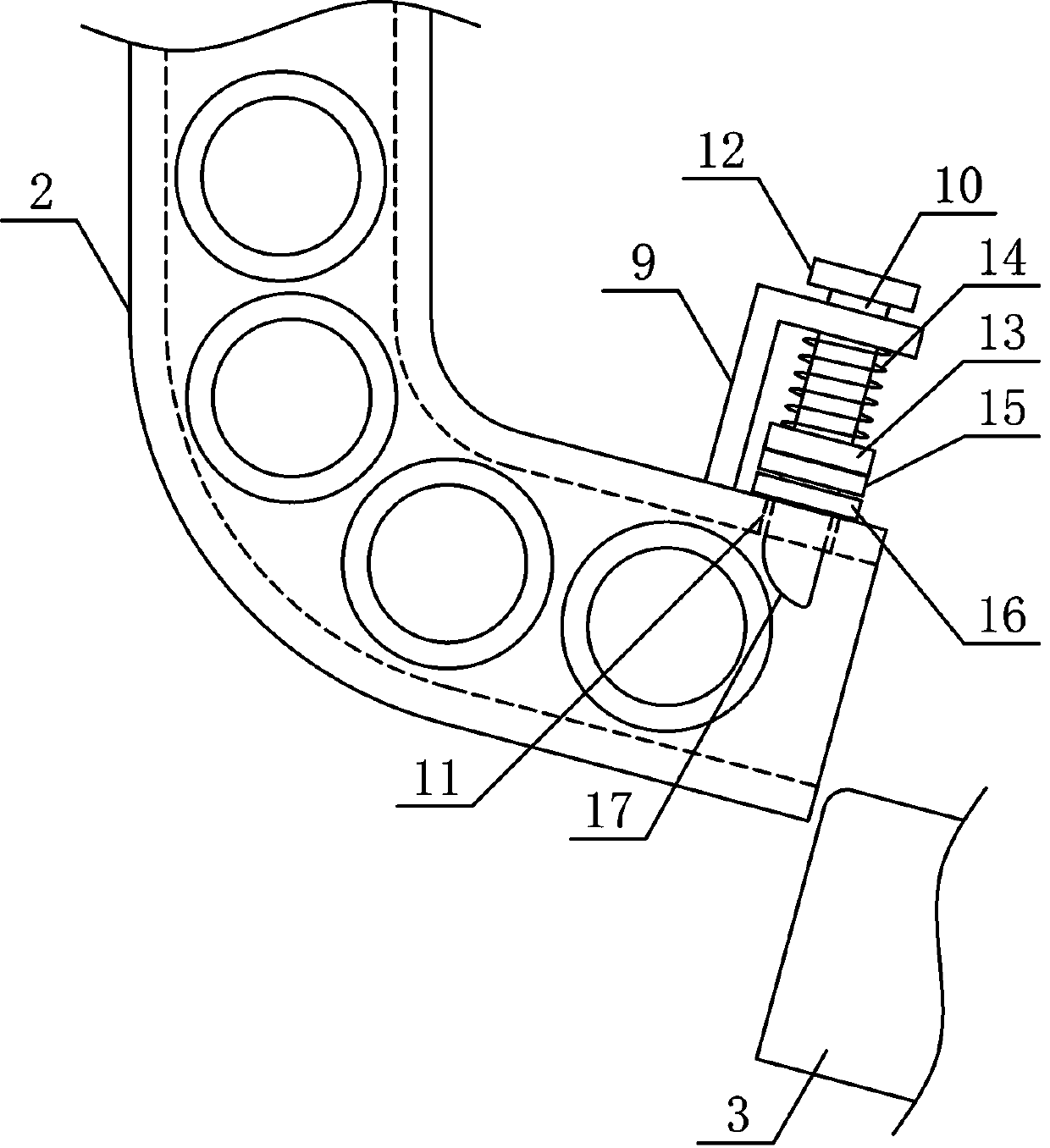

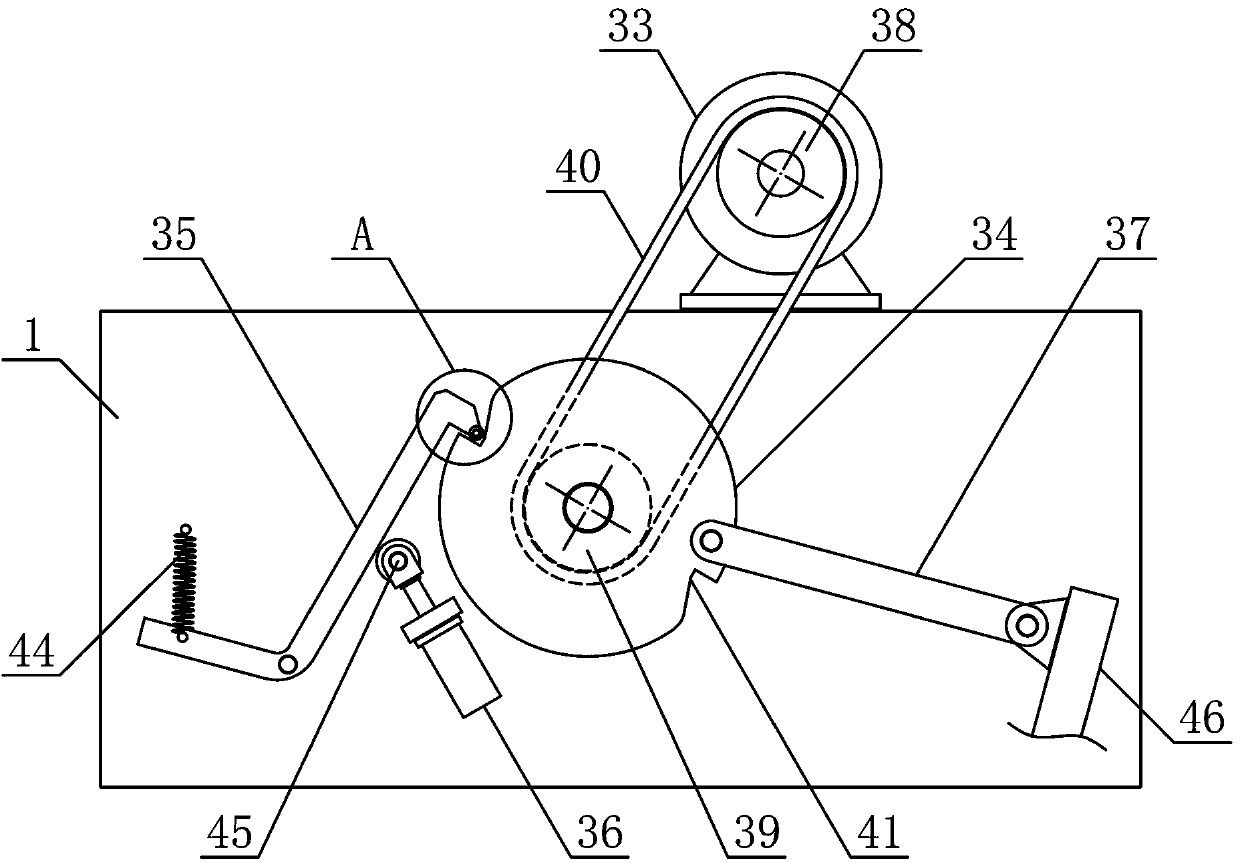

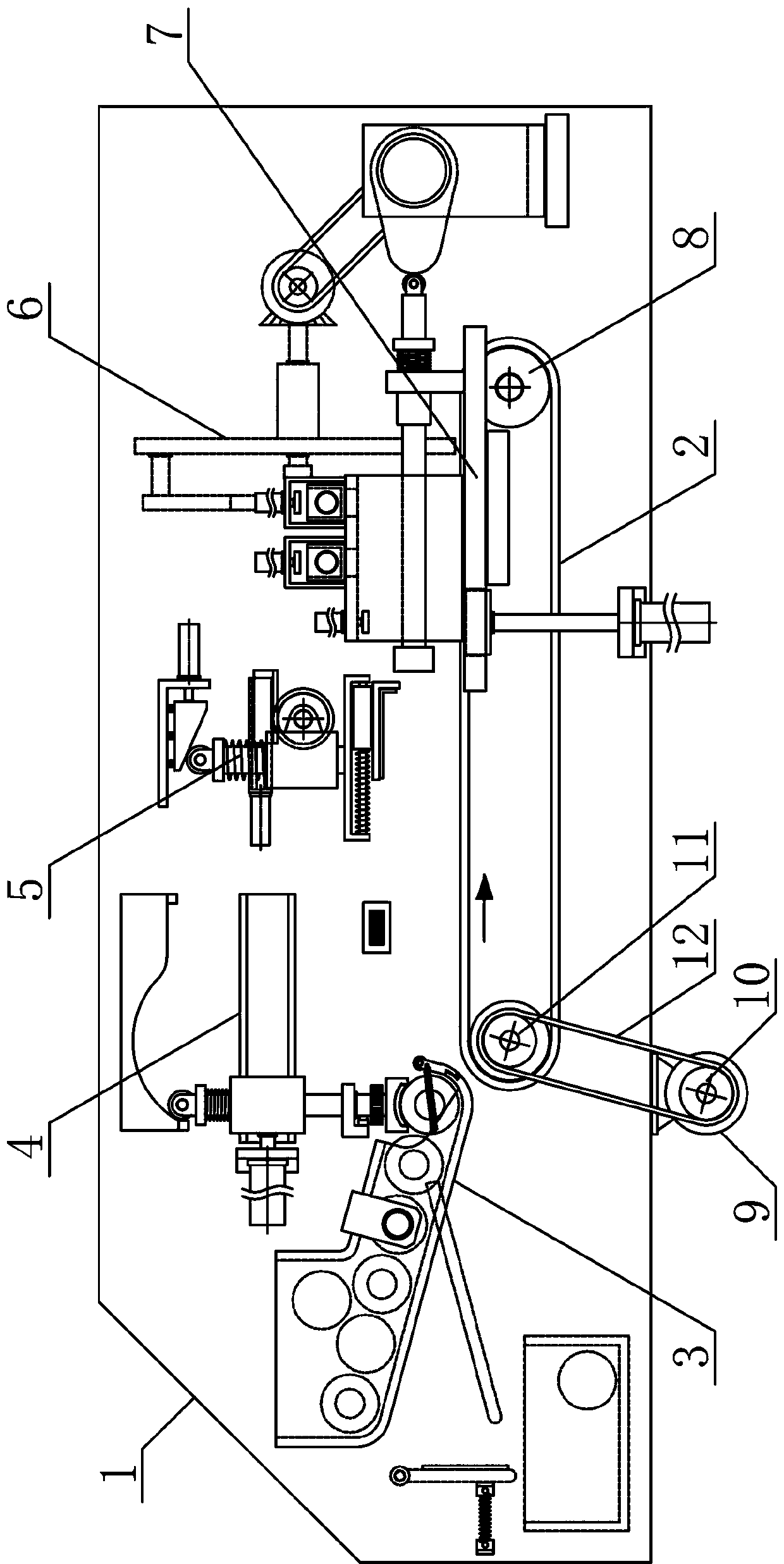

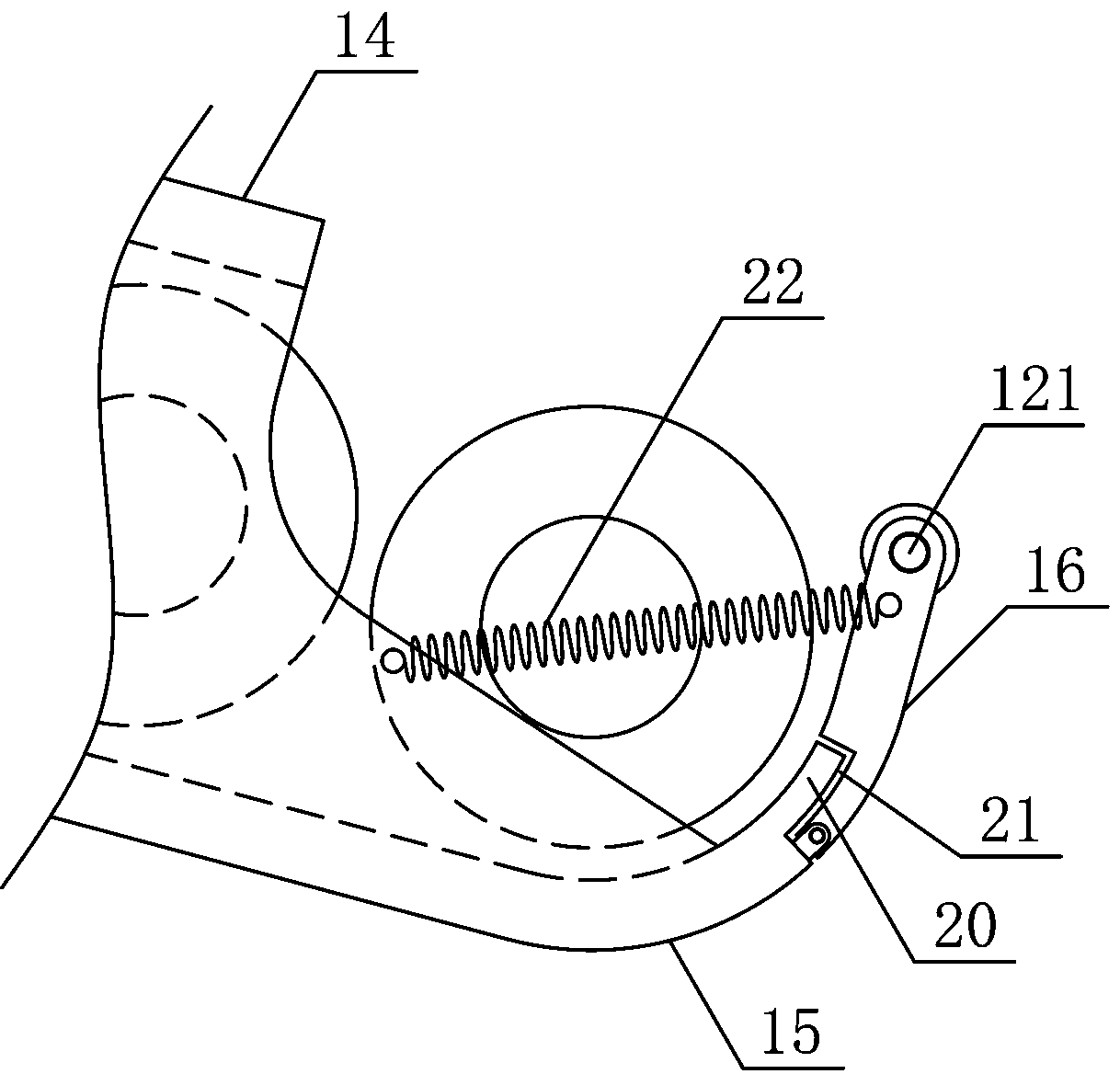

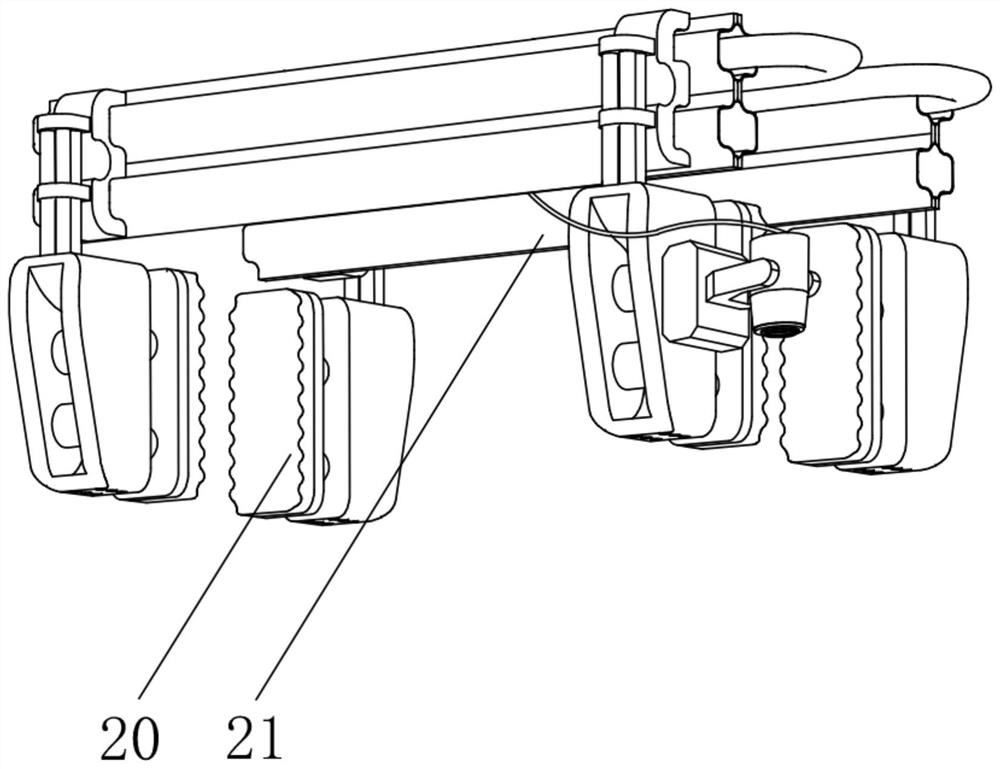

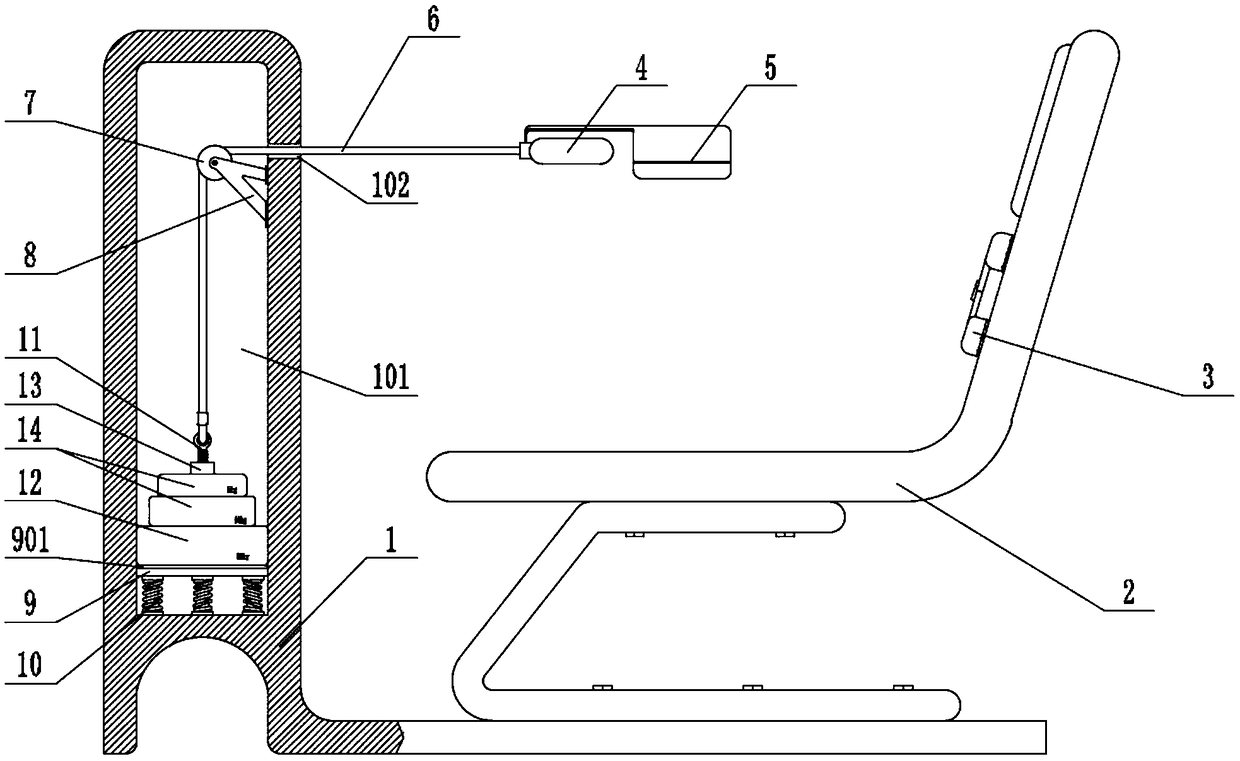

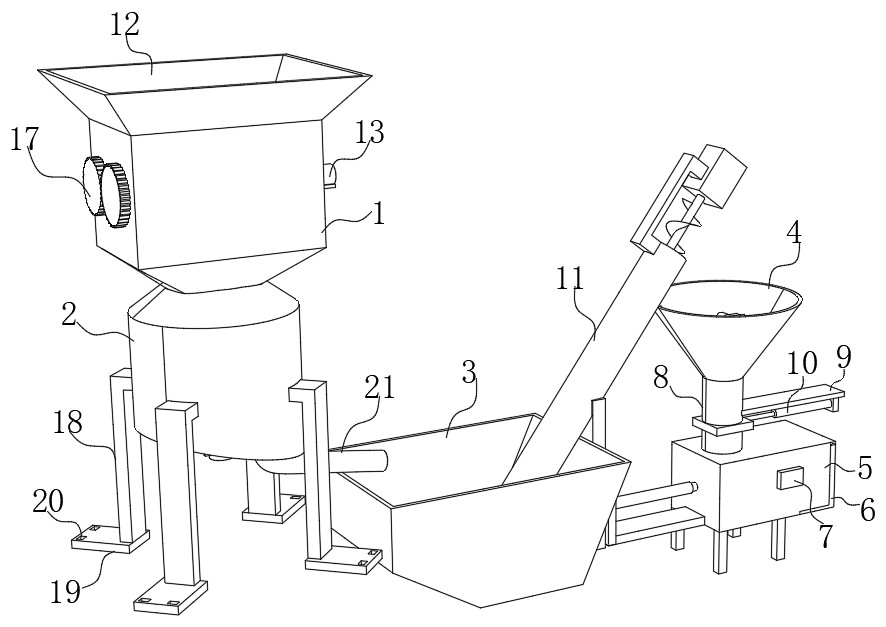

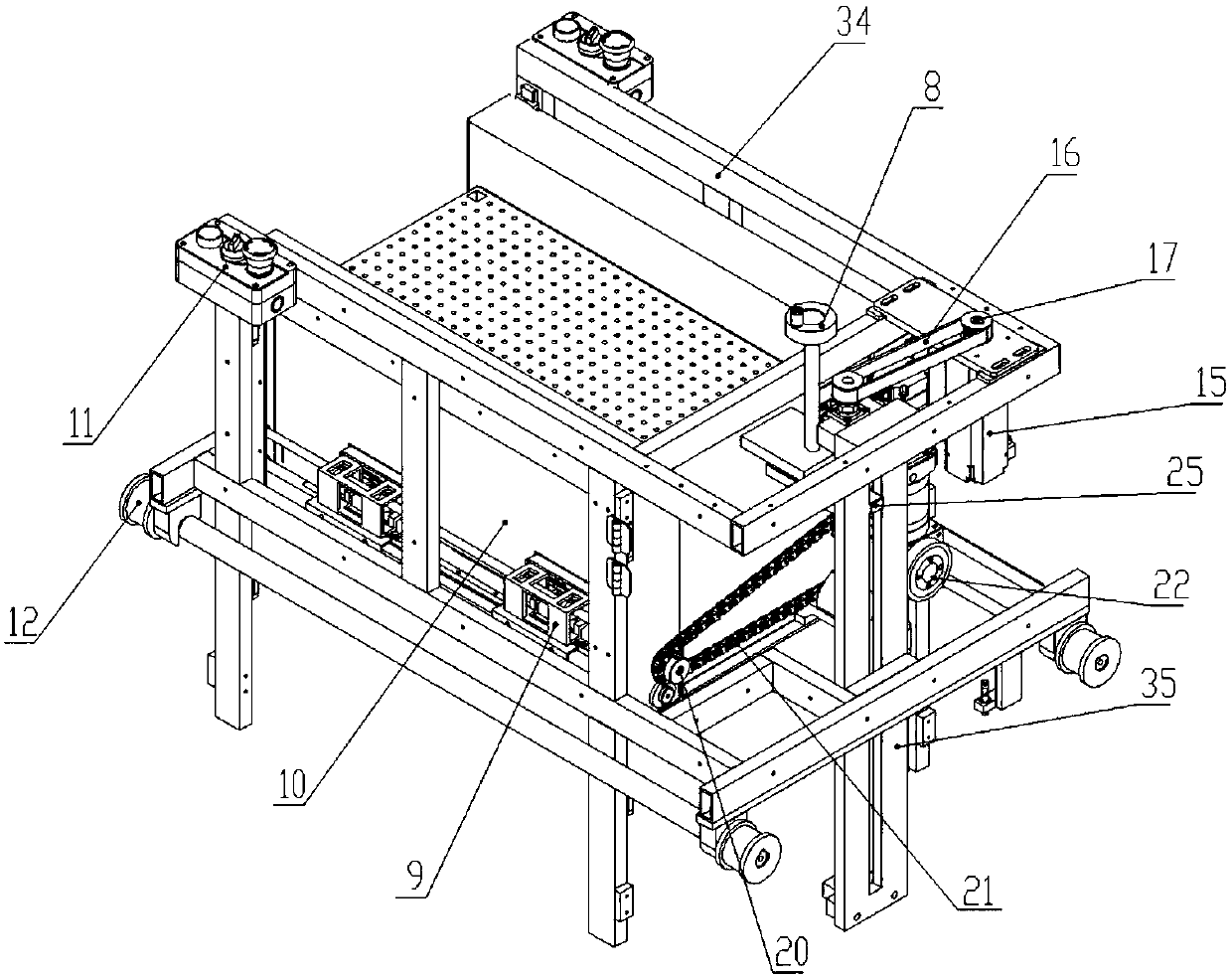

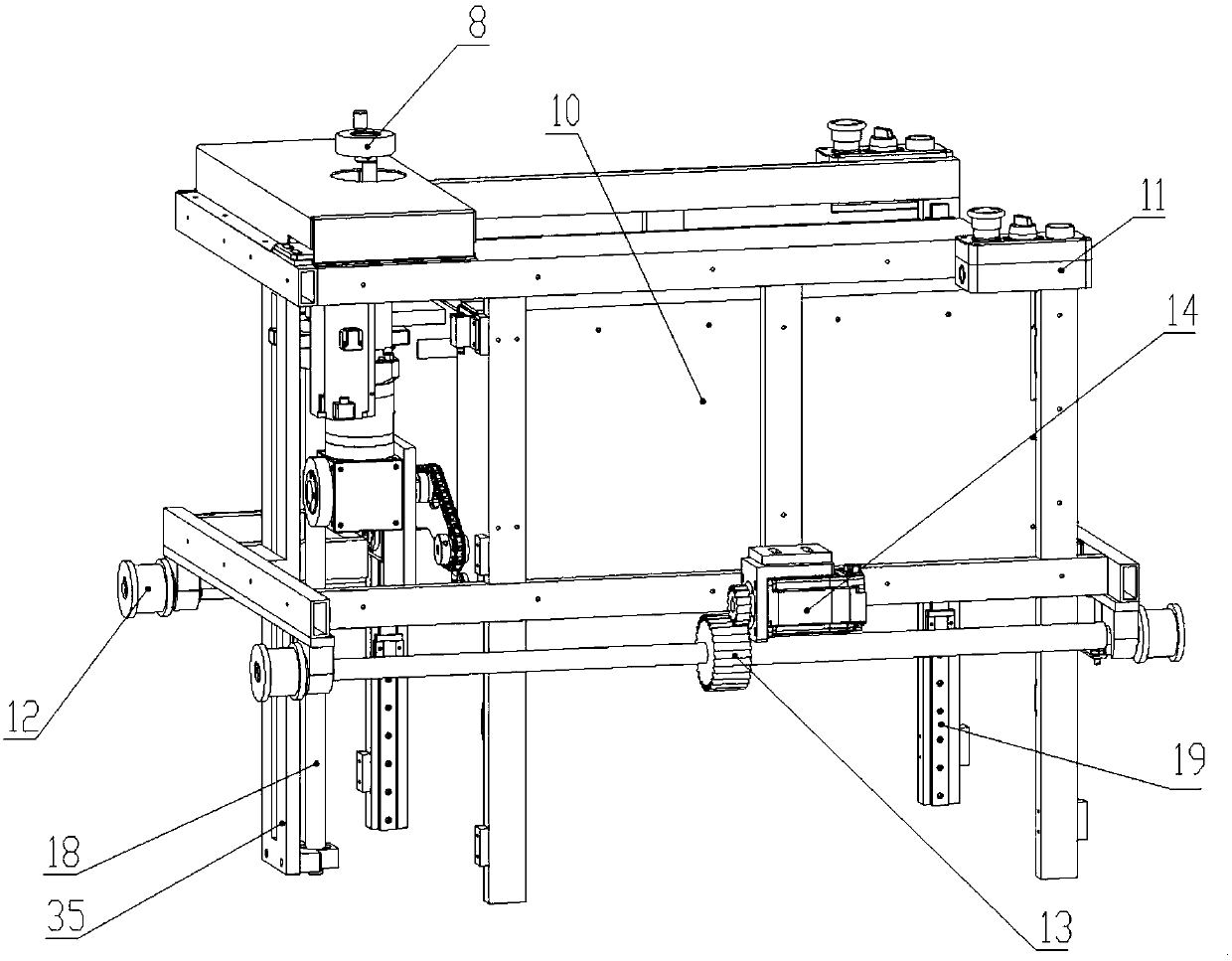

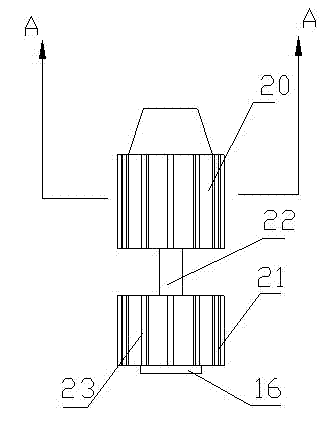

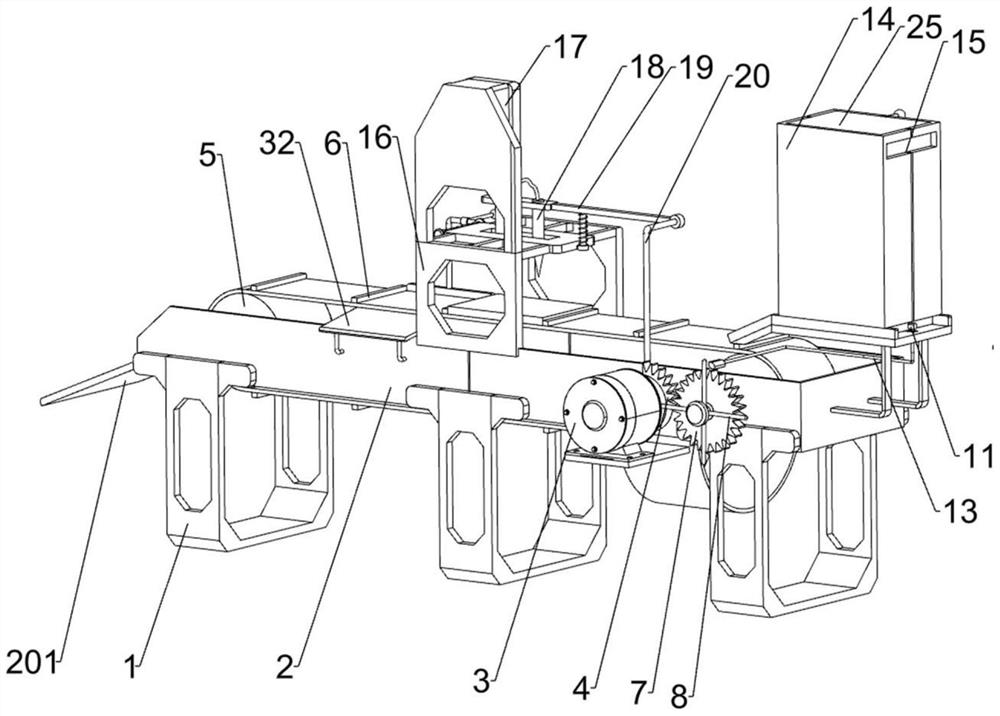

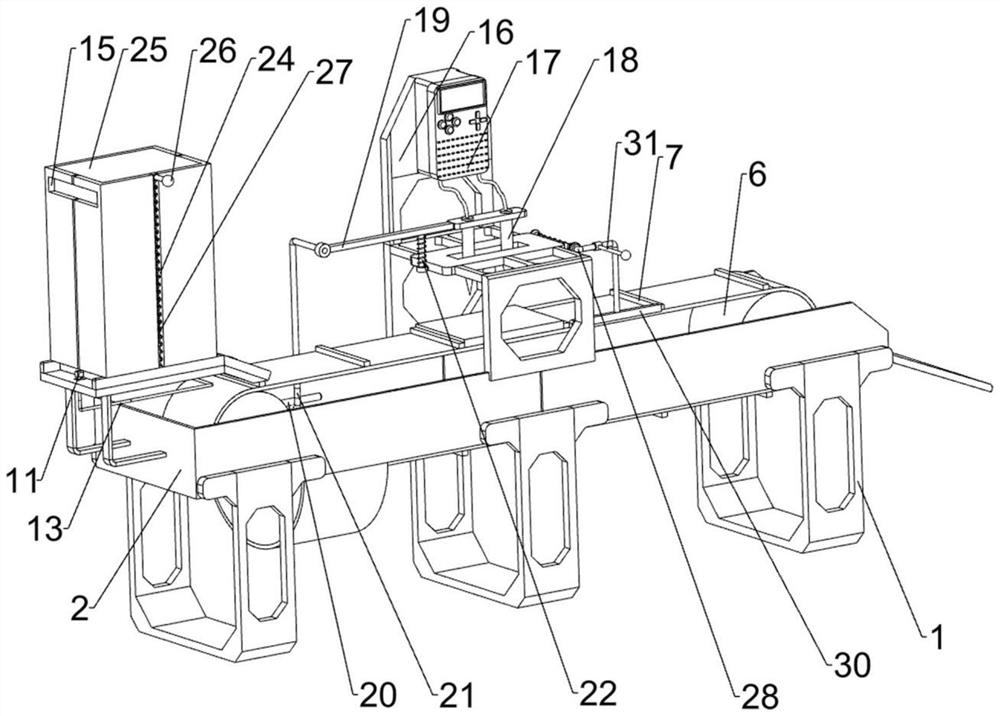

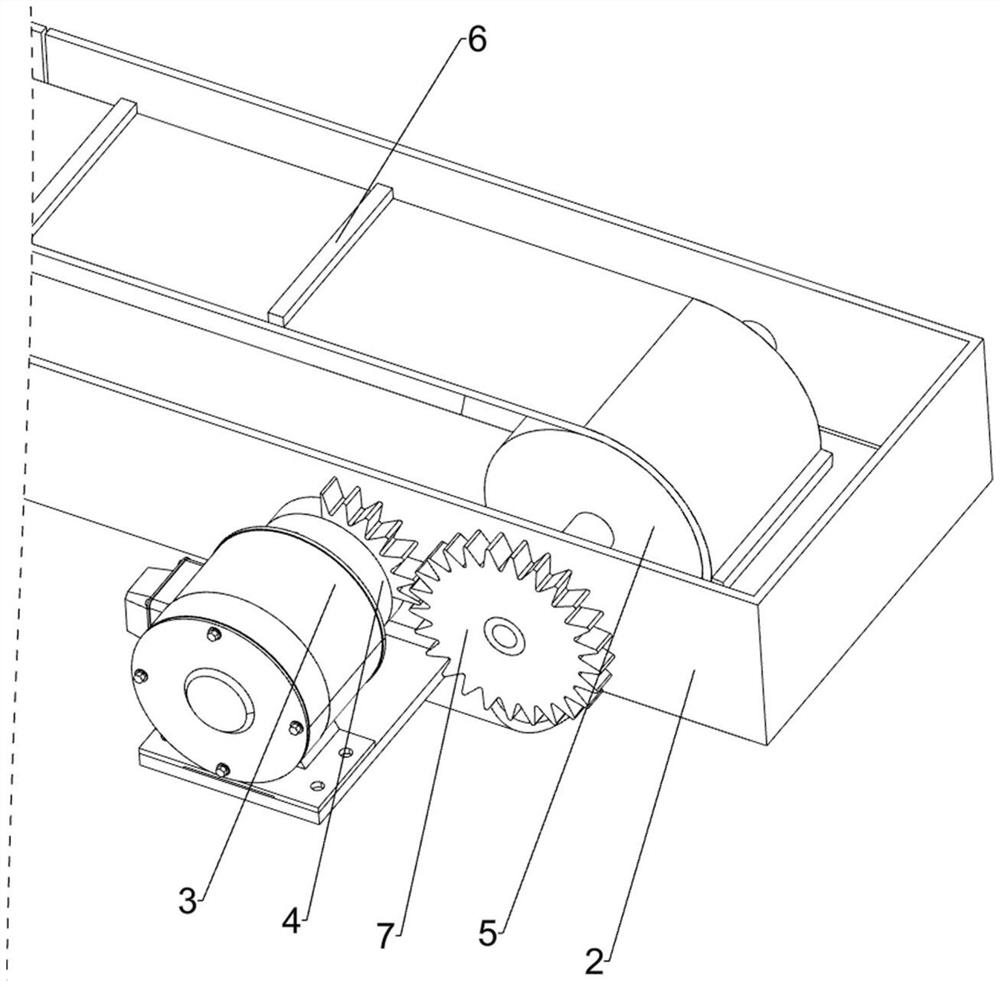

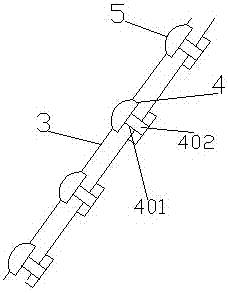

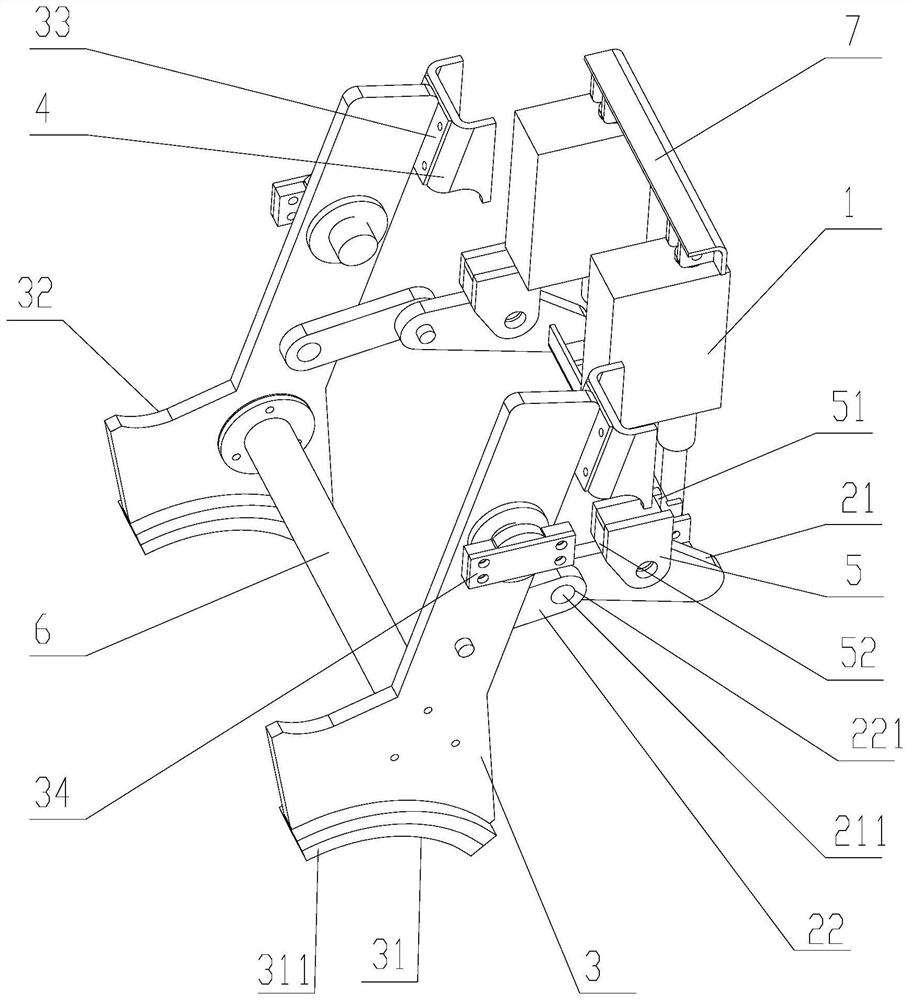

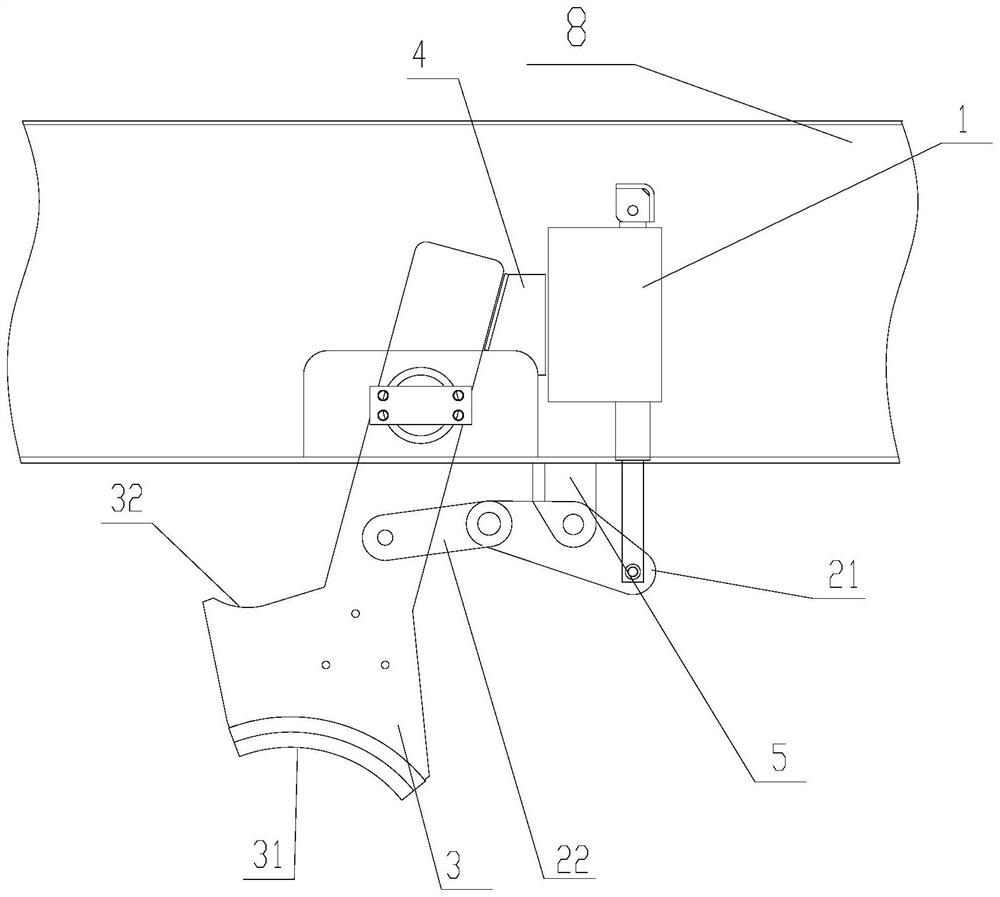

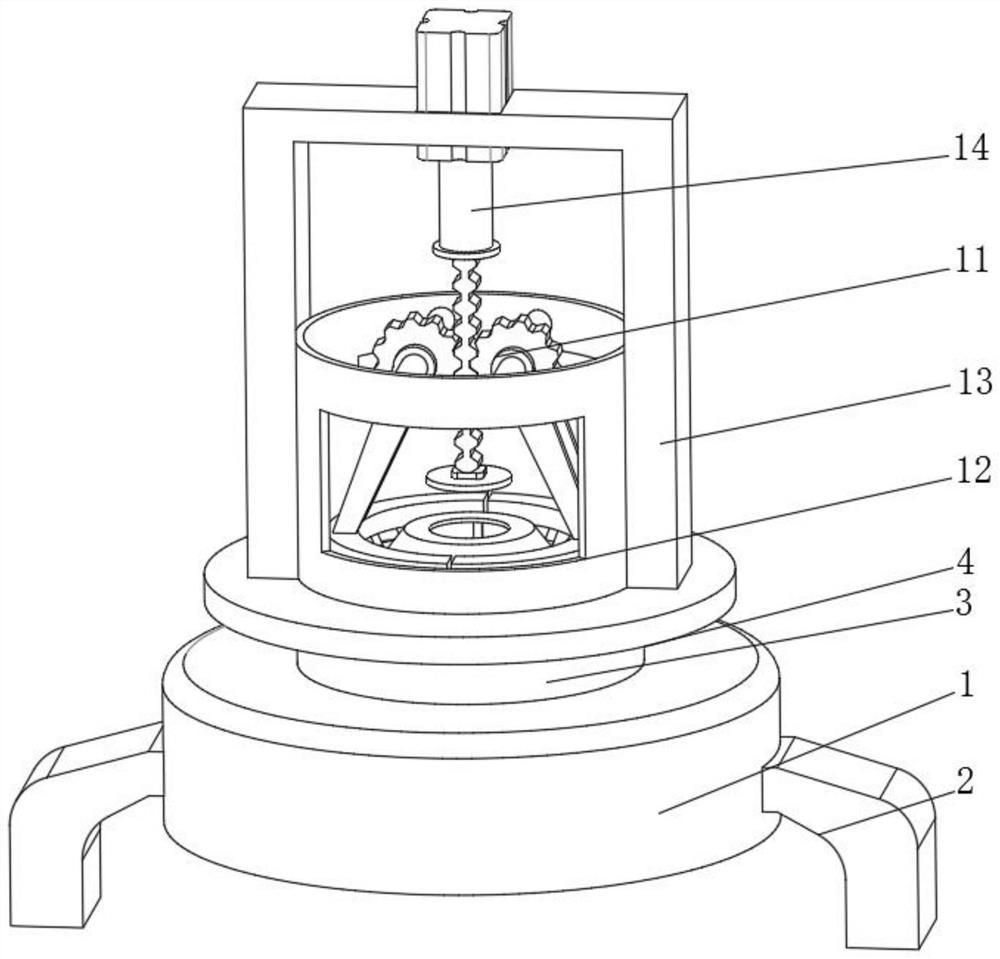

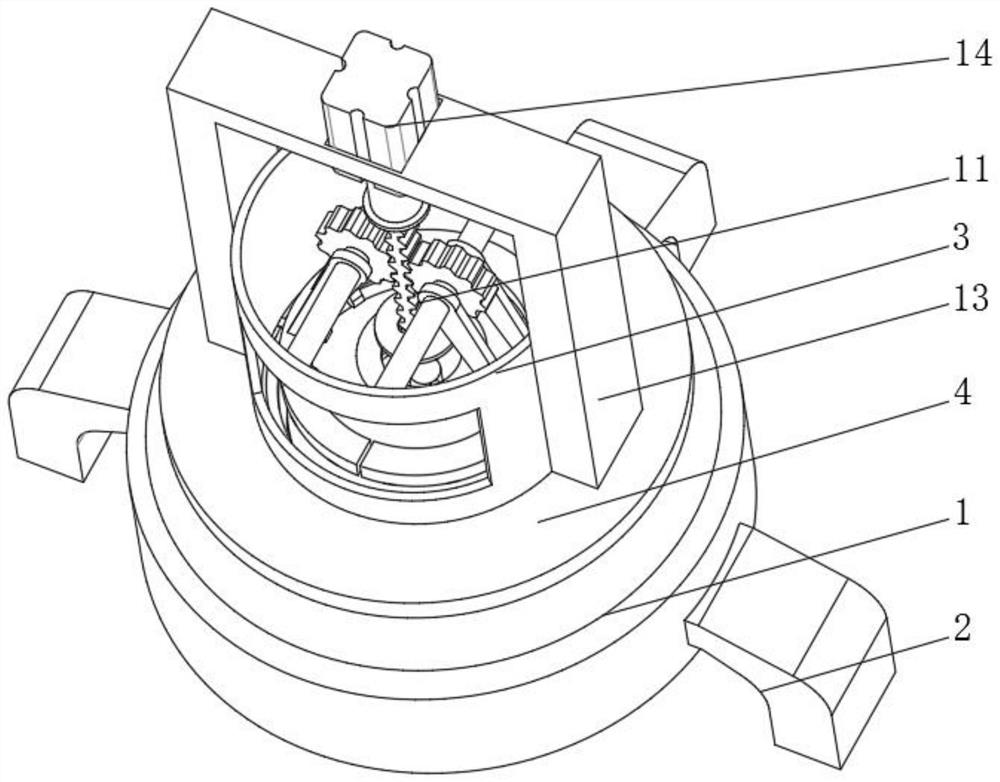

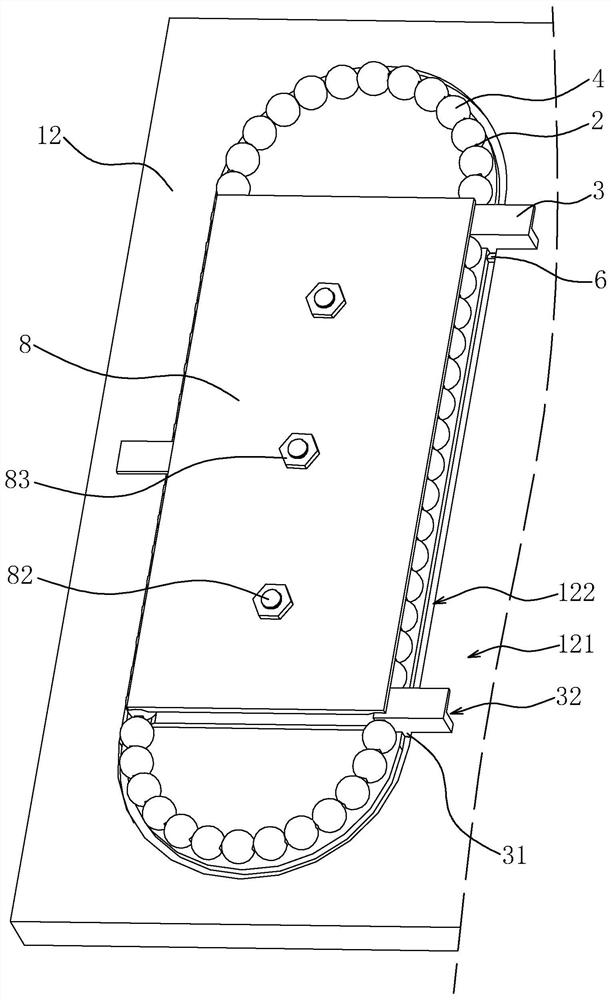

Continuous press fitting equipment for tubular workpieces

ActiveCN111230458AFalling steadilyEfficient and smooth flip adjustmentMetal working apparatusElectric machineryMechanical equipment

The invention discloses continuous press fitting equipment for tubular workpieces, and belongs to the field of workpiece production and processing mechanical equipment. A workpiece conveying belt is arranged on the lower side of a workpiece conveying support, the two sides of the workpiece conveying belt are wound and connected with workpiece conveying rotating rollers on the two sides of the workpiece conveying support respectively, and a workpiece conveying motor is in transmission connection with the workpiece conveying rotating rollers through a workpiece conveying chain. A workpiece guidemechanism, a workpiece transfer mechanism and a workpiece turnover mechanism are sequentially arranged on the workpiece conveying support on the upper side of the workpiece conveying belt in the conveying direction of the workpiece conveying belt. A workpiece push mechanism and a workpiece press fitting mechanism are arranged on the workpiece conveying support on the two sides of the ends in theconveying direction of the workpiece conveying belt respectively. The continuous press fitting equipment is reasonable in structural design, can guide and transfer the tubular workpieces one by one conveniently and smoothly, can realize successive and continuous press fitting processing of multiple assemblies in the transfer process of the tubular workpieces, improves the automation degree of workpiece processing and meets the needs of production and use.

Owner:SUZHOU ZHIYUN CHUANGYU INFORMATION TECH CO LTD

Working method of pipe fitting feeding and transferring mechanism

InactiveCN112830195AHigh degree of processing automationReasonable structural designConveyorsConveyor partsGear wheelMechanical equipment

Owner:龚文科

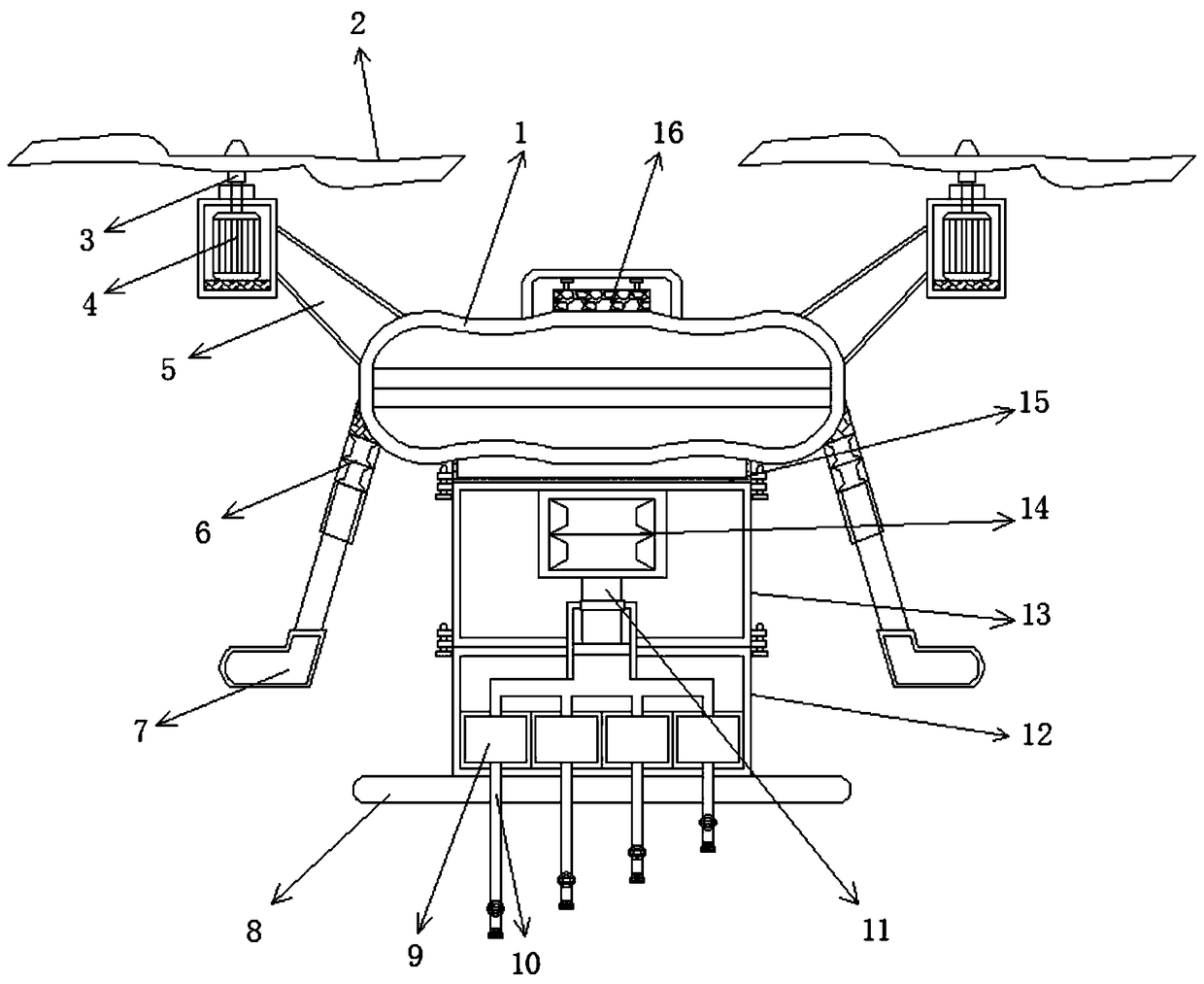

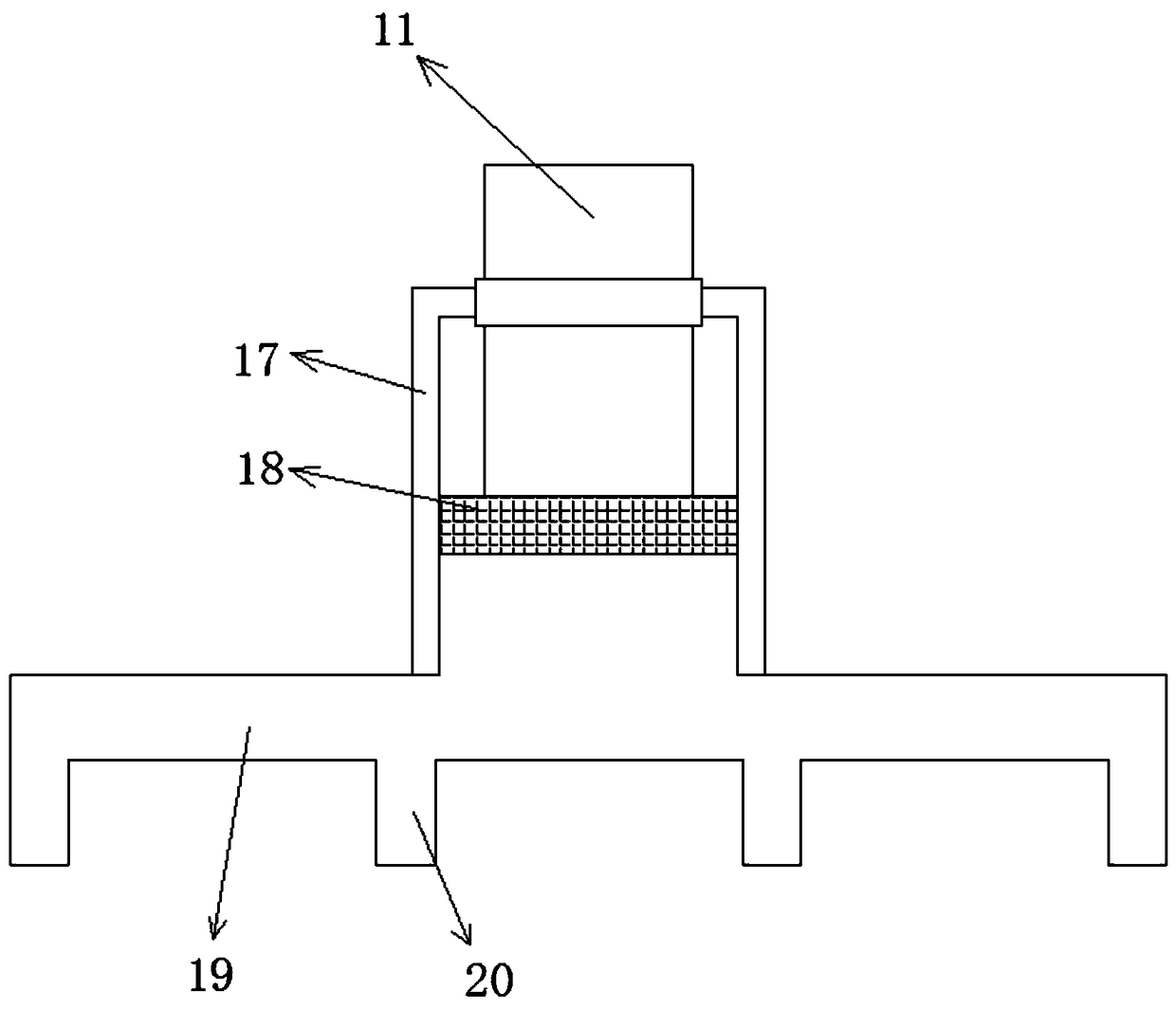

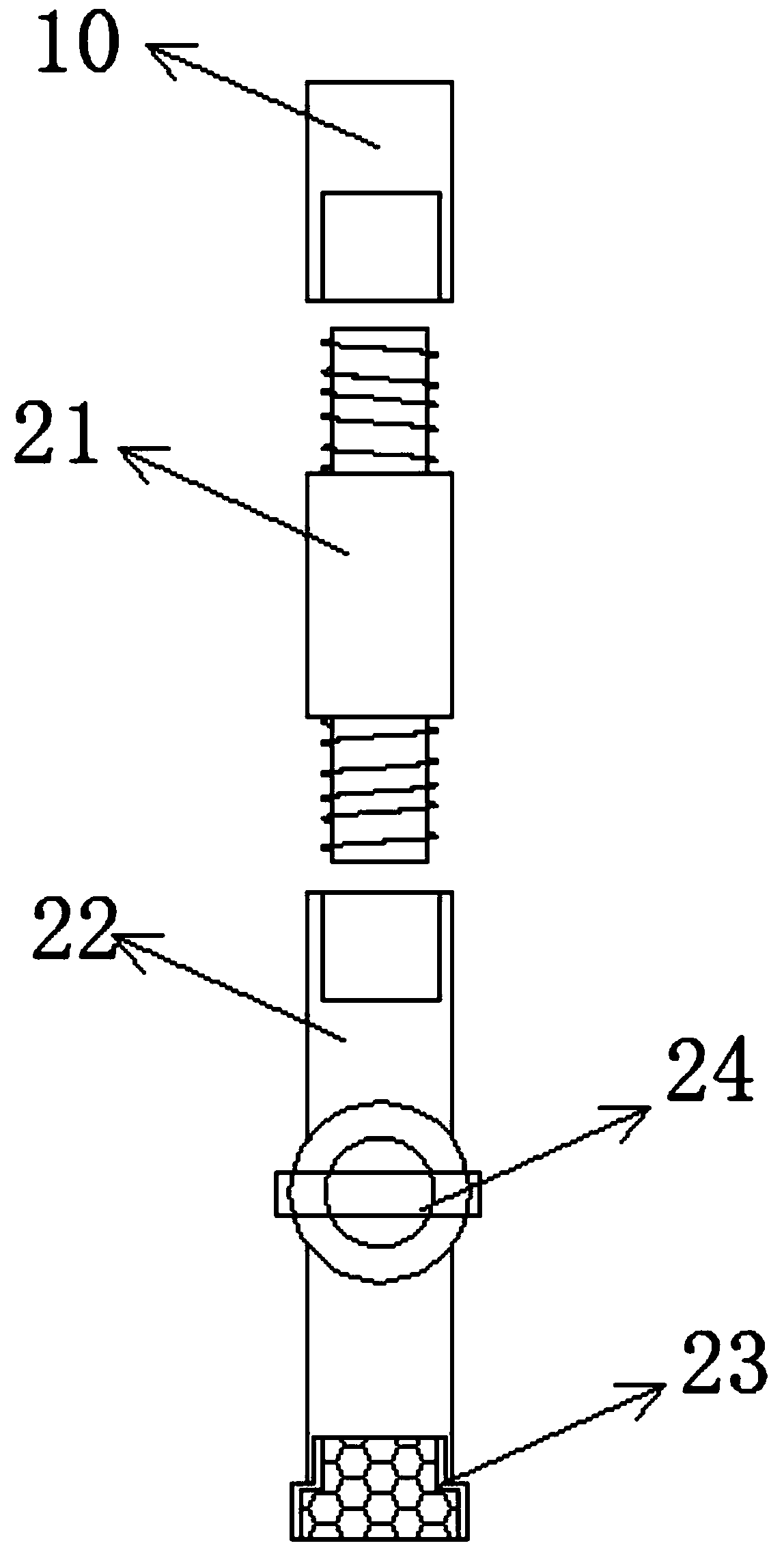

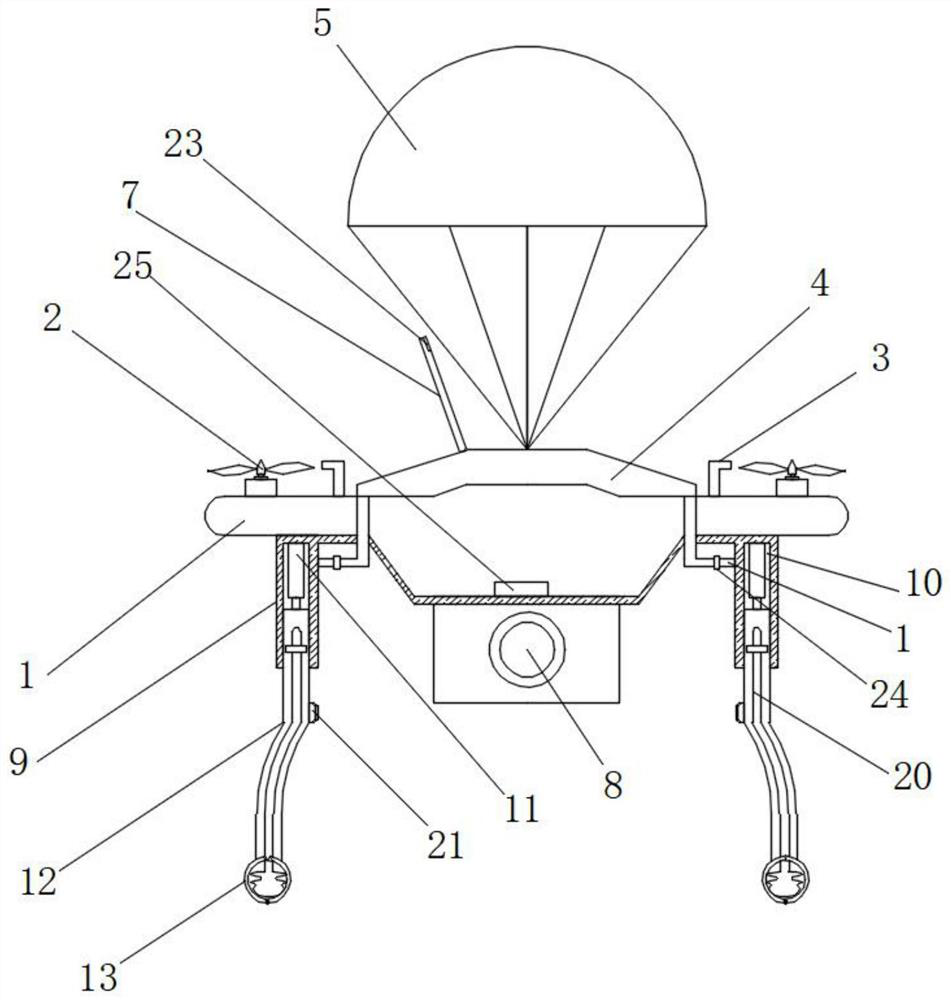

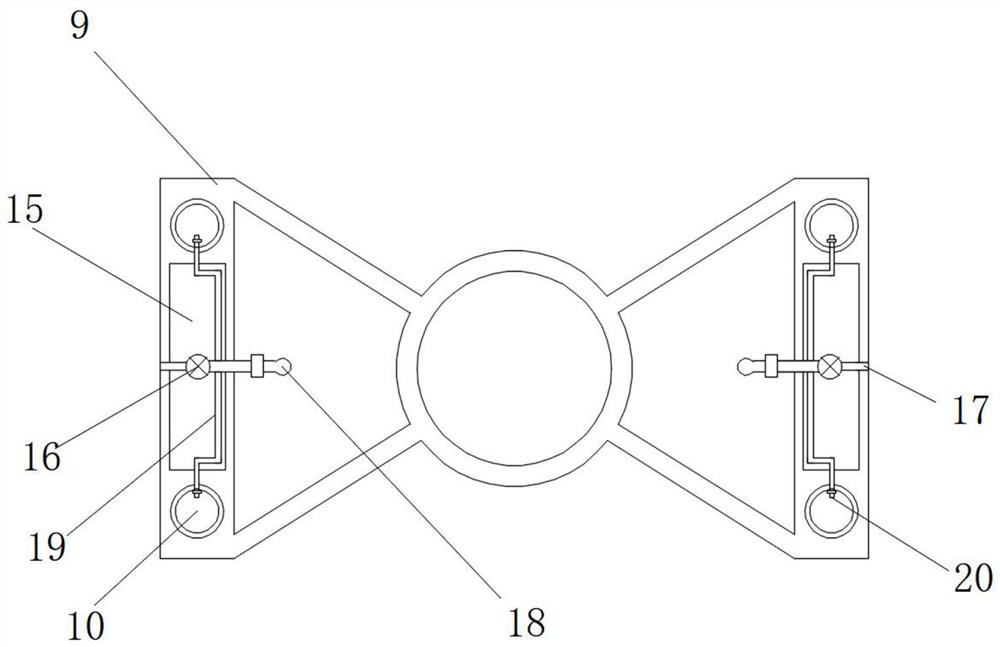

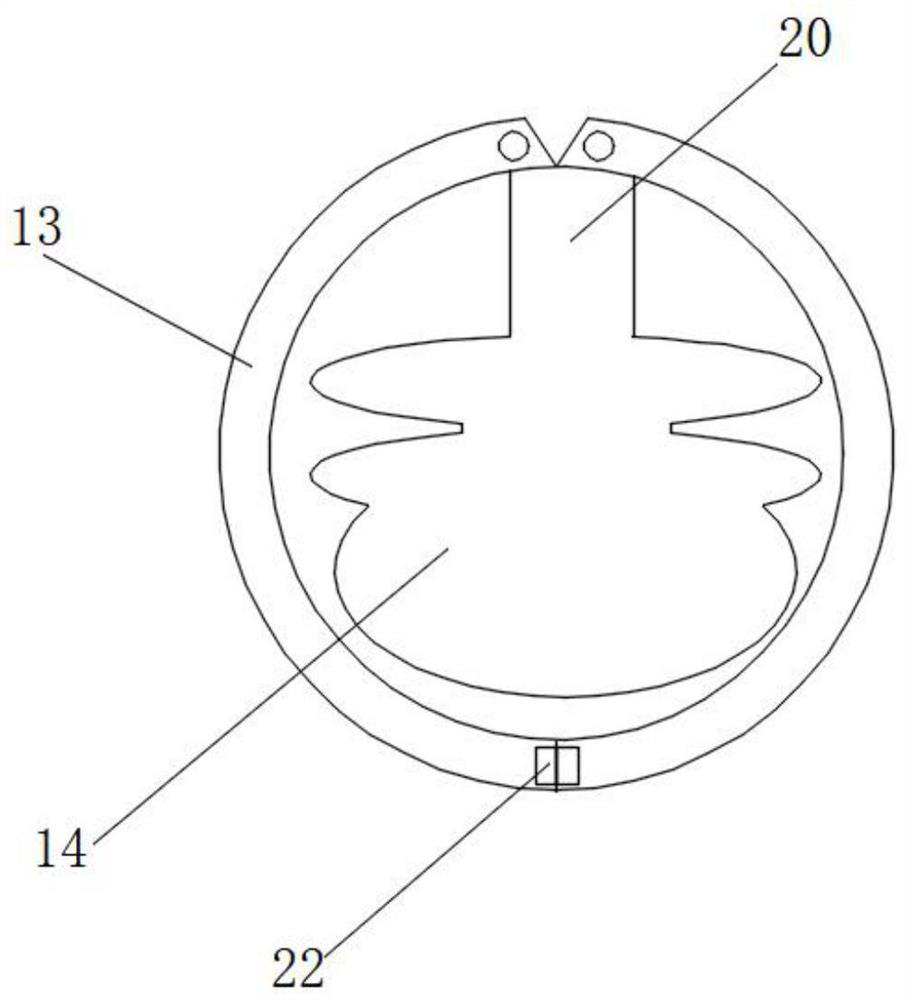

Water quality sampling unmanned aerial vehicle

InactiveCN109459276AFalling steadilyAffect the normal whereaboutsWithdrawing sample devicesWater storageHydraulic cylinder

The invention discloses a water quality sampling unmanned aerial vehicle which comprises an unmanned aerial vehicle body. Four support frames are arranged on the outer wall of a side of the top of theunmanned aerial vehicle body, a motor shell is arranged on the outer wall of a side of the top of each support frame, driving motors are arranged on the inner walls of the bottoms of the motor shells, output shafts of the driving motors are provided with rotary rods, propeller blades are arranged on the outer walls of the rotary rods, a mounting frame is arranged in the middle of the outer wall of the bottom of the unmanned aerial vehicle body, a fixing frame is arranged on the outer wall of the bottom of the mounting frame, a hydraulic cylinder is arranged in the middle of the inner wall ofthe top of the fixing frame, and a telescopic rod is arranged on the inner wall of the bottom of the hydraulic cylinder. The water quality sampling unmanned aerial vehicle has the advantages that theintegral height of the water quality sampling unmanned aerial vehicle can be adjusted, and the water quality sampling unmanned aerial vehicle can be prevented from crashing; negative pressures can beformed inside water storage cavities to carry out sampling, the stability of the water quality sampling unmanned aerial vehicle can be guaranteed in sampling procedures, water quality sampling at fourdifferent depths can be conveniently simultaneously carried out by the water quality sampling unmanned aerial vehicle, and the use performance of devices can be improved.

Owner:易蕾

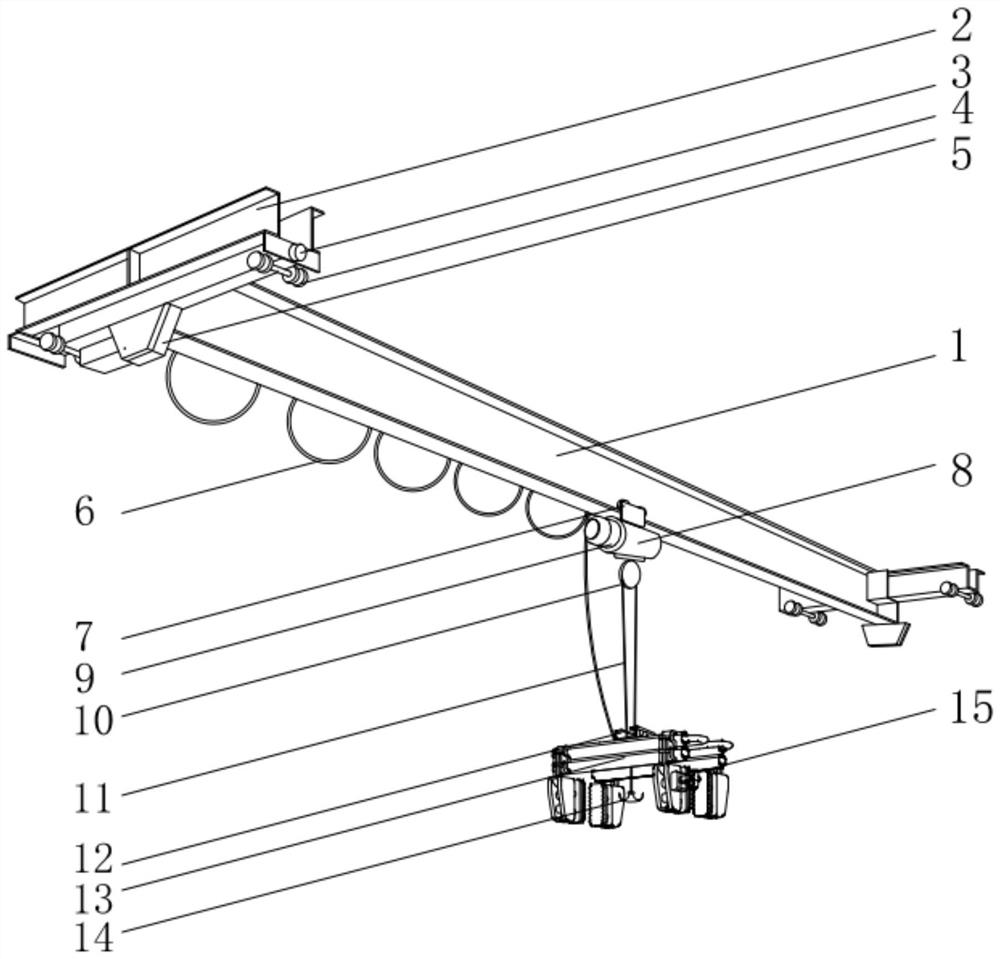

Electric single-beam crane

The invention provides an electric single-beam crane. The electric single-beam crane comprises a main beam, end beams are fixedly mounted on the outer surfaces of the two sides of the main beam, operation signal lamps are fixedly mounted on the outer surfaces of one sides of the end beams, and pulleys are fixedly mounted on the two sides of the outer surfaces of the lower ends of the end beam. Buffer air cushions are fixedly mounted in the middle of the outer surfaces of the lower ends of the end beams, a cable is movably connected to the outer surface of the lower end of the main beam, a running trolley is slidably connected to the outer surface of the lower end of the main beam, an electric hoist is fixedly mounted at the lower end of the running trolley, and rubber air springs are arranged on the outer surfaces of the two sides of the electric hoist. According to the electric single-beam crane, the hoisting position and the falling point position can be accurately positioned when large instruments and equipment are hoisted and moved, stable movement and accurate direction of the hoisting and falling points are ensured, the risk of wall collision is avoided, and the stability ofthe large instruments and equipment is ensured.

Owner:安徽奋途建设工程有限公司

Steel pipe length measuring device

The invention relates to a steel pipe length measuring device which is provided with a discharging table and at least two light transmitting type digital laser sensors for measuring the lengths of steel pipes. The discharging table is installed on the rear of a rack, two dies for containing the steel pipes are arranged below a discharging opening in the front portion of the discharging table, thetwo dies are connected to crank slider mechanisms through shafts, stopping block structures capable of moving left and right are arranged below the dies, two V-shaped groove stopping blocks of the stopping block structures capable of moving left and right are fixedly connected with the light transmitting type digital laser sensors, the crank slider mechanisms drive the dies and the steel pipes tooverturn, the steel pipes fall into V-shaped grooves of the V-shaped groove stopping blocks from the interiors of the dies, and the lengths of the steel pipes are measured through the light transmitting type digital laser sensors; tray structures capable of rising and falling are installed in the middles of the two V-shaped groove stopping blocks of the stopping block structures capable of movingleft and right; and the tray structures capable of rising and falling eject the measured steel pipes out of the V-shaped grooves of the V-shaped groove stopping blocks, and the steel pipes enter a sorting device.

Owner:江苏统联科技股份有限公司

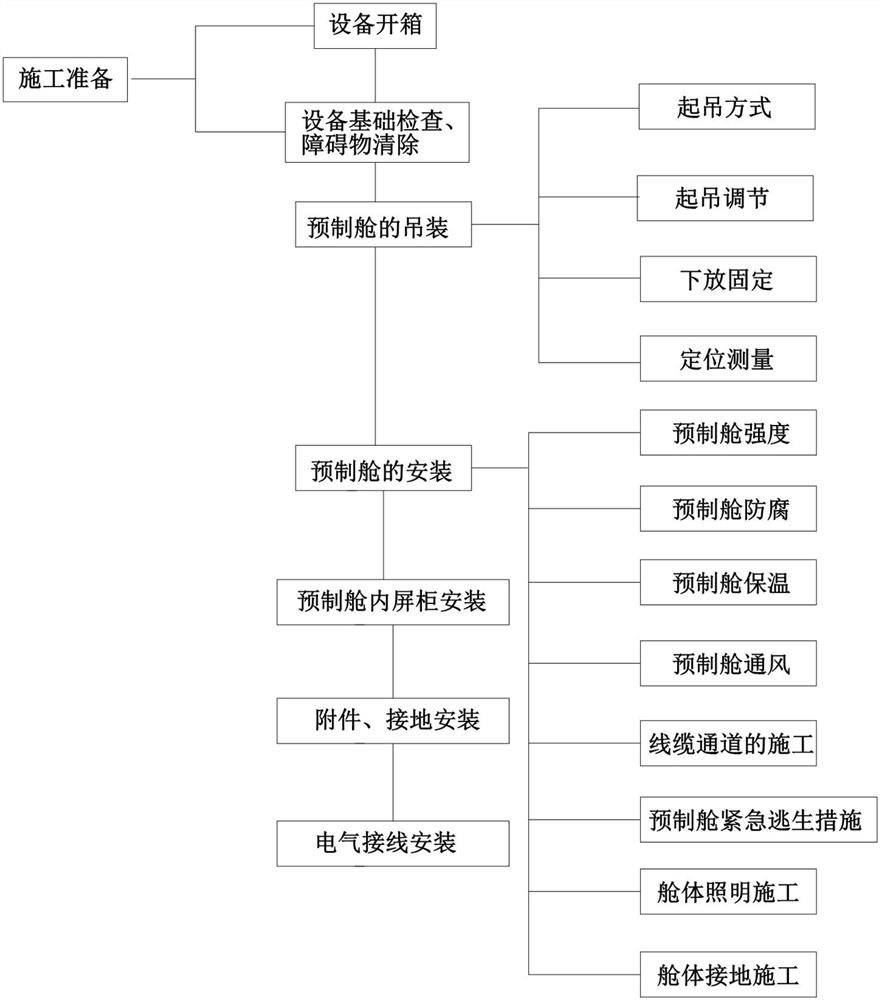

Installation and construction method for prefabricated cabin of 110-kilovolt transformer substation

PendingCN112366578AImprove construction qualityShort cycleSwitchgearTransformerArchitectural engineering

The invention discloses an installation and construction method for a prefabricated cabin of a 110-kilovolt transformer substation. The installation and construction method specifically comprises thefollowing steps of equipment unpacking; equipment basic inspection; obstacle removal; equipment hoisting and installation; equipment adjustment, fastening and inspection; accessory installation; grounding installation; and electrical wiring installation. With the installation and construction method for a prefabricated cabin of a 110-kilovolt transformer substation adopted, the situation that collision damage occurs when the prefabricated cabin is hoisted is avoided, a set of complete operation process and operation procedures are provided, the construction quality is improved, the construction period is shortened, the overall stability and safety of construction are guaranteed. The installation and construction method is easy to popularize.

Owner:国网河南省电力公司中牟县供电公司 +1

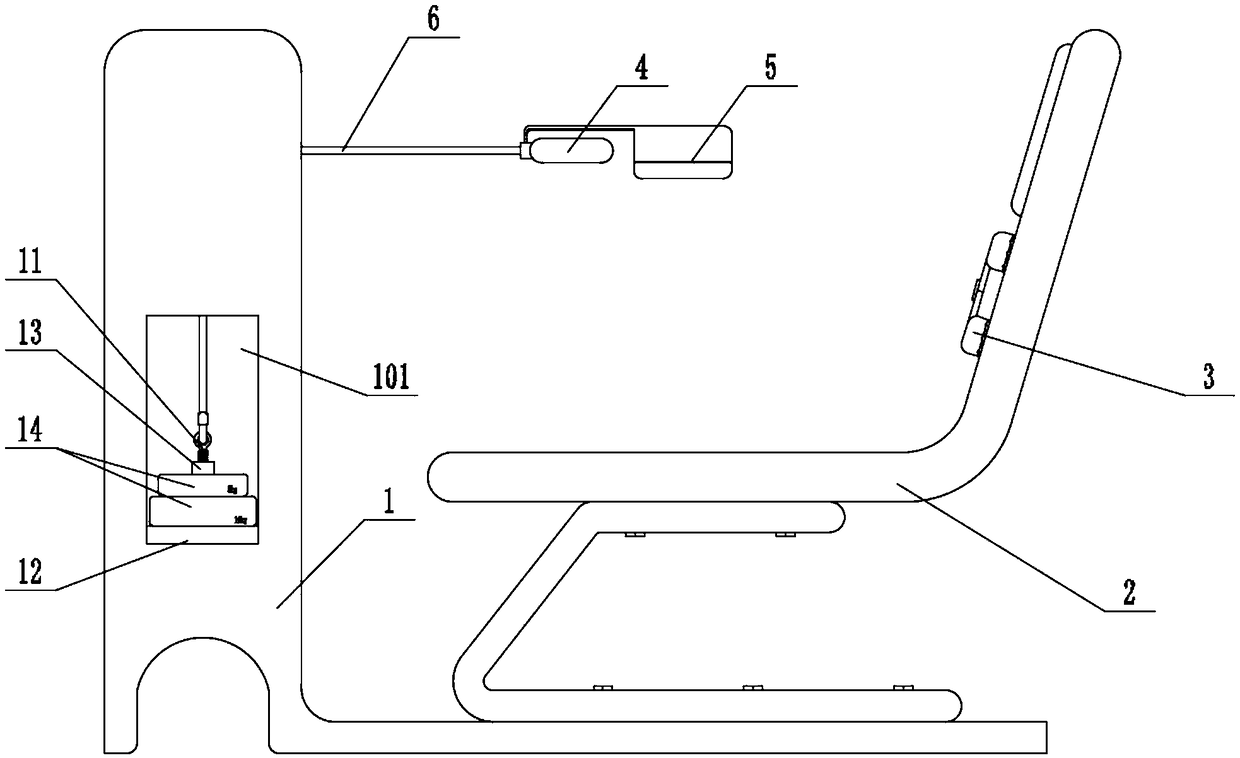

Physical exercise operation method based on upper limb muscle exercise device

PendingCN109276855AAffect continuous exercise effectAffect exercise effectMuscle exercising devicesPull forceUpper limb muscle

The invention provides a physical exercise operation method based on an upper limb muscle exercise device. The upper limb muscle exercise device comprises movable weight balancing blocks and a connecting groove, wherein two weight balancing cavities are formed inside the front end of a main body; two pulling holes are formed in the back end surface of the main body and are communicated with the two weight balancing cavities; a chair is arranged at the back end of the top end surface of the main body through a screw bolt; a fixing belt is arranged on the chair; two pulley support frames are used; and the pulley support frames are respectively arranged on the inner walls of the two weight balancing cavities through screw bolts. Pulling force generated by the arms of a person can favorably drive main weight balancing blocks to vertically move inside the device; through the self weight of the main weight balancing blocks, the upper limbs of the person maintain the reverse stress state whenthe main weight balancing blocks move; and the exercise effect on the upper limb muscle of the person can be achieved.

Owner:唐雄丹

Compaction equipment for solid waste treatment

The invention discloses compaction equipment for solid waste treatment, and belongs to the technical field of waste treatment equipment. The compaction equipment comprises a crushing box, a storage box, a feeding hopper, a feeding cylinder and a compression box. The bottom of the crushing box fixedly communicates with a smashing box, a first crushing roller and a second crushing roller are rotationally connected into the crushing box, rotating shafts of the first crushing roller and the second crushing roller penetrate through the crushing box and are fixedly provided with gears, and the two gears are in engaged connection. A first motor is fixed to one side of the crushing box, an inclined bottom plate is fixed to the bottom of the crushing box, a rotating rod is rotationally connected tothe inner top face of the inclined bottom plate, and multiple cutters are fixed to the circumferential side face of the rotating rod. According to the compaction equipment for solid waste treatment,by arranging the crushing box, the smashing box, the feeding cylinder, an anti-blocking assembly, a plug plate, a discharging plate, a second electric telescopic rod and the feeding hopper, solid waste can be smashed into fine pieces in advance, the solid waste is compacted more thoroughly, continuous and stable feeding of the solid waste is achieved, and compressed waste blocks are automaticallyremoved.

Owner:宁波阅荷思山智能科技有限公司

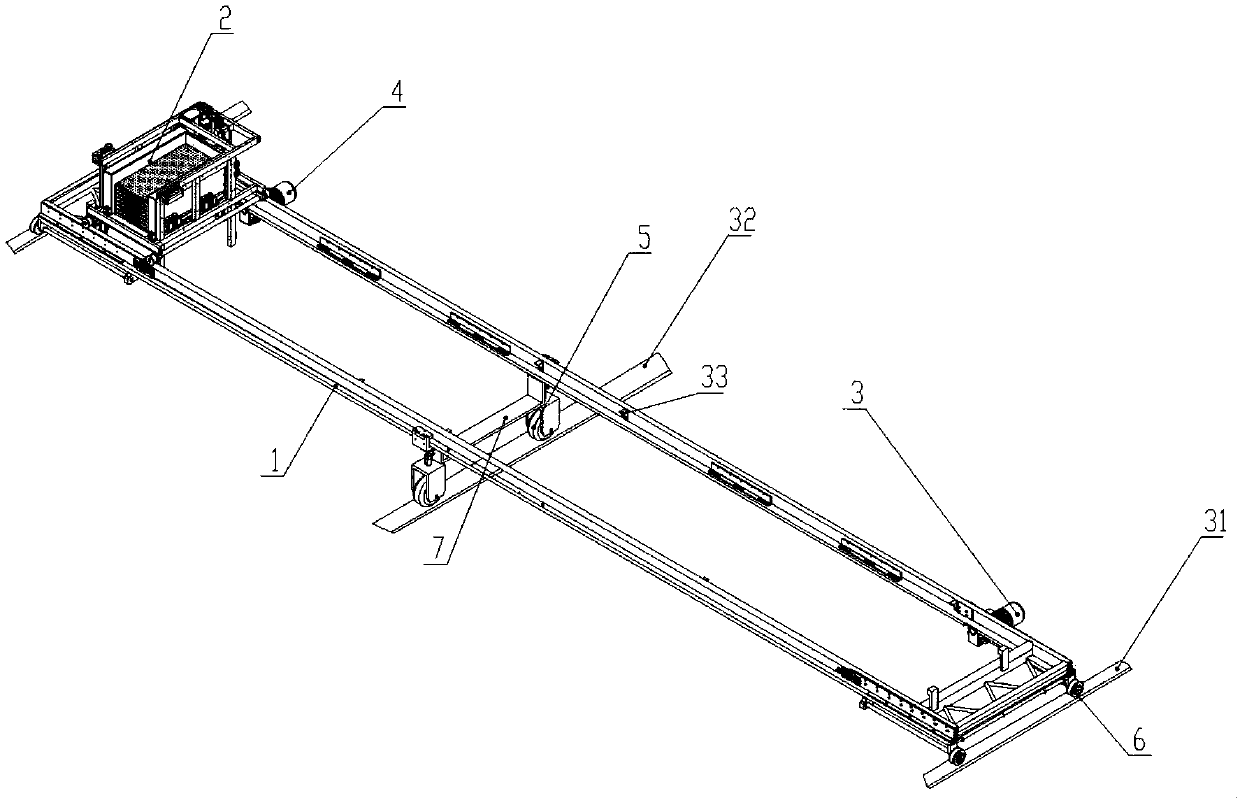

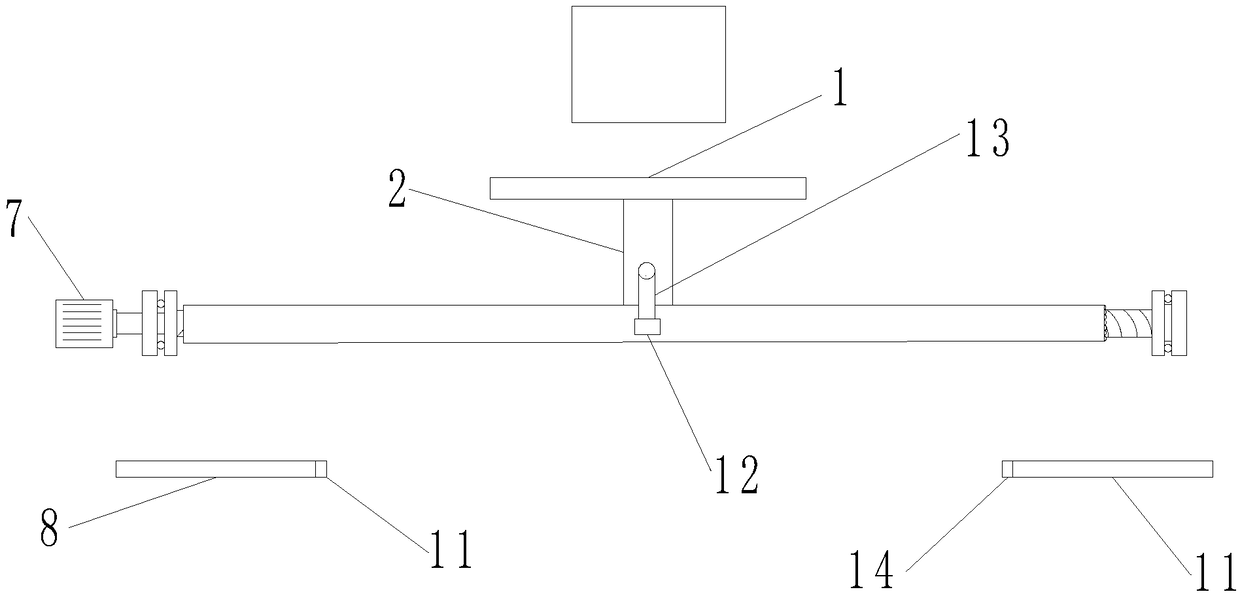

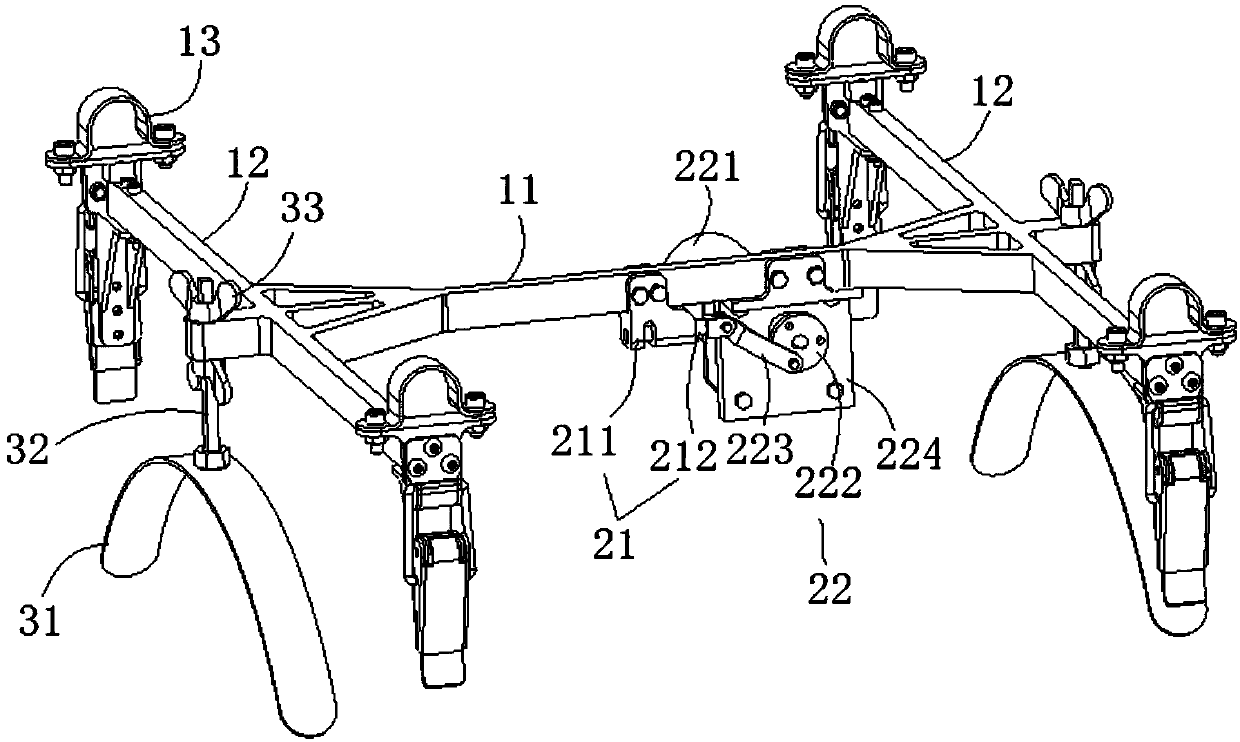

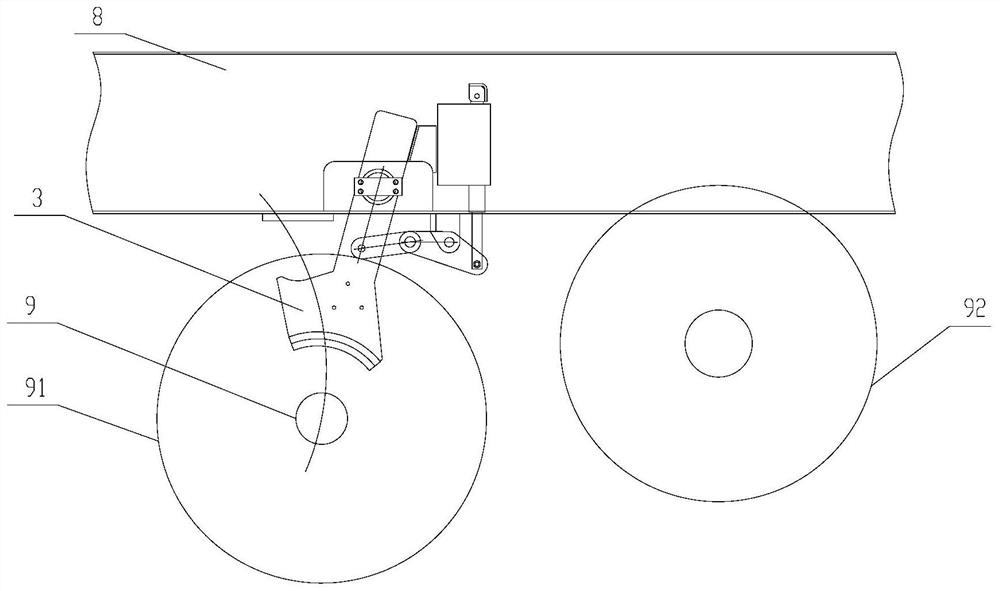

Field tray laying machine

ActiveCN109673324ARich paving pathsFlexible moving processCultivating equipmentsFlower-pot fillingVehicle frameReciprocating motion

The invention discloses a field tray laying machine. The workload of manually laying growing trays is high, and people are easily fatigued due to the field operating environment. The field tray layingmachine disclosed by the invention comprises a ridge power guide rail, a ridge assisted guide rail, a lengthways moving device and a tray laying trolley. The lengthways moving device comprises a Hallsensor, a movable guide rail, a connecting rack, a support frame, a first geared motor, a second geared motor, a middle wheel and a side wheel group. The tray laying trolley comprises a frame, a wheel axle, a transverse moving drive part, a position regulation mechanism, a tray clip mechanism, a lifting mechanism and wheels. The position regulation mechanism comprises a regulation block, a hand wheel, a screw and a handle. The tray clip mechanism comprises a tray laying drive component, a tray laying frame and a clamping jaw component. The tray clamping jaw is driven by a cam, the action of laying a stack of growing trays one by one is realized by virtue of a telescopic reciprocating motion of the tray clamping jaw, the structure is compact, the motion is reliable, and the tray laying reliability is greatly improved.

Owner:ZHEJIANG SCI-TECH UNIV

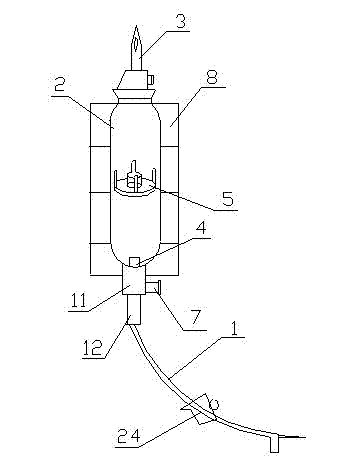

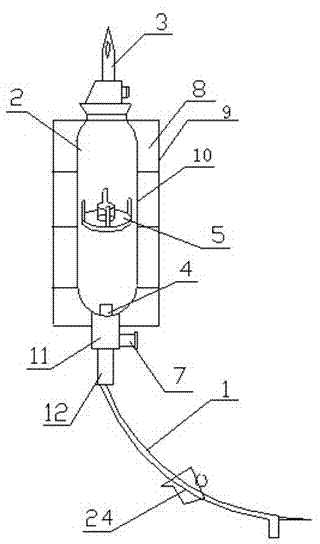

Stopping alarming device used during liquid medicine and blood transfusion

The invention relates to a transfusion device, in particular to a stopping alarming device which is used during liquid medicine and blood transfusion and can perform sensing and exhaust air timely, and belongs to the technical field of medical instruments. The alarming device comprises a transfusion soft tube, a drip tube and a puncture needle, wherein the puncture needle is arranged on the upper part of the drip tube, a liquid outlet is formed on the lower part of the drip tube, the puncture needle is used for being connected with a transfusion bottle, the liquid outlet is connected with the transfusion soft tube, a safety valve is arranged in the drip tube, and the inner diameter of the safety valve is smaller than that of the drip tube; a connector is arranged at the joint of the transfusion soft tube and the liquid outlet, and the connector is used for being communicated and connected with the transfusion soft tube and the liquid outlet; and an air inlet which can control opening and closing is formed on the connector. By the stopping alarming device used during liquid medicine and blood transfusion, blood return can be prevented, a liquid medicine can also be transfused totally, and waste can be avoided; and therefore, the stopping alarming device has the significance to transfusion of expensive liquid medicines such as antitumor medicines.

Owner:汪贤宗

Iron part and cutting chip separating device

ActiveCN109015092AEfficient separationImprove work efficiencyMaintainance and safety accessoriesEngineeringScrew thread

The invention provides an iron part and cutting chip separating device which comprises a magnetism-controllable electromagnetic tray. The initial position of the electromagnetic tray is arranged belowa turning position. The electromagnetic tray is fixedly connected with a screw nut part. The screw nut part is in connected with a screw rod in a threaded fit manner. The screw rod is fixedly installed in a guide rail and is driven by a motor. The motor can rotate forwards and backwards. A notch capable of making the screw nut part rotate by a certain angle is formed in each of the left end portion and the right end portion of the guide rail. A tray is arranged below each notch. The guide rail is further provided with an optical fiber sensor used for positioning the initial position. When aniron part is machined, cutting chips can be effectively separated from the part, the work efficiency is improved, the labor intensity of workers is lowered, meanwhile, impacts on a workpiece are further relieved, the precision of the workpiece is effectively protected, and the workpiece is prevented from being damaged.

Owner:安徽上禾阜机械配件有限公司

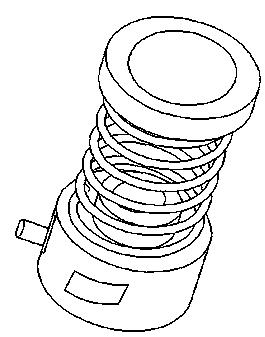

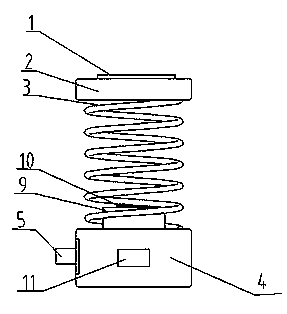

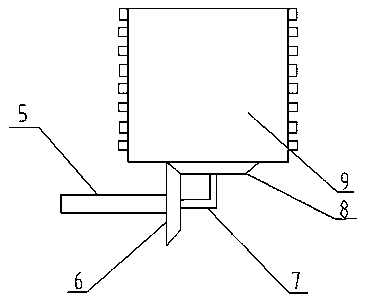

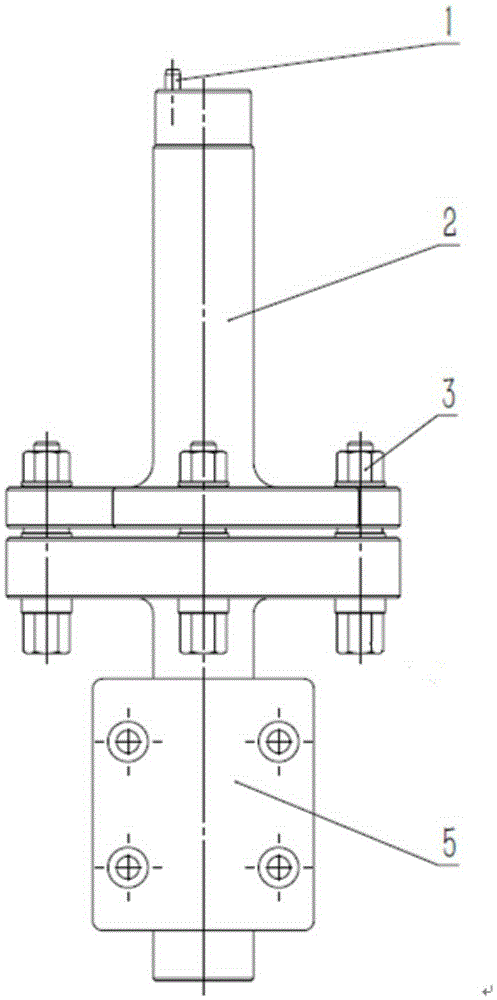

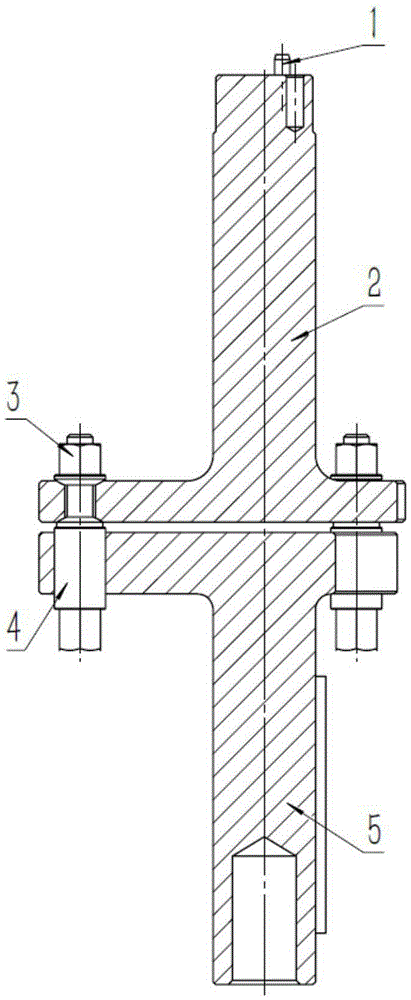

Stabilizing foot piece

InactiveCN103791201AFalling steadilyHeight adjustableMachine framesMaterial resourcesMechanical devices

The invention relates to a stabilizing foot piece. By the aid of the stabilizing foot piece, the problem of consumption of large quantities of human and material resources and energy for safely and stably dropping mechanical devices under normal circumstances due to deficiency of special devices for safely dropping objects in the prior art can be solved. The stabilizing foot piece comprises a supporting portion and a lifting portion. An elastic support can be sucked on the surface of an object. The stabilizing foot piece has the advantages that heavy objects can be effectively prevented from being violently collided with the ground to be damaged in dropping procedures, large mechanical devices can be stably dropped by the stabilizing foot piece, and the height of a certain position of the object further can be adjusted by the aid of the stabilizing foot piece.

Owner:QINGDAO TECHCAL UNIV QINDAO COLLEGE

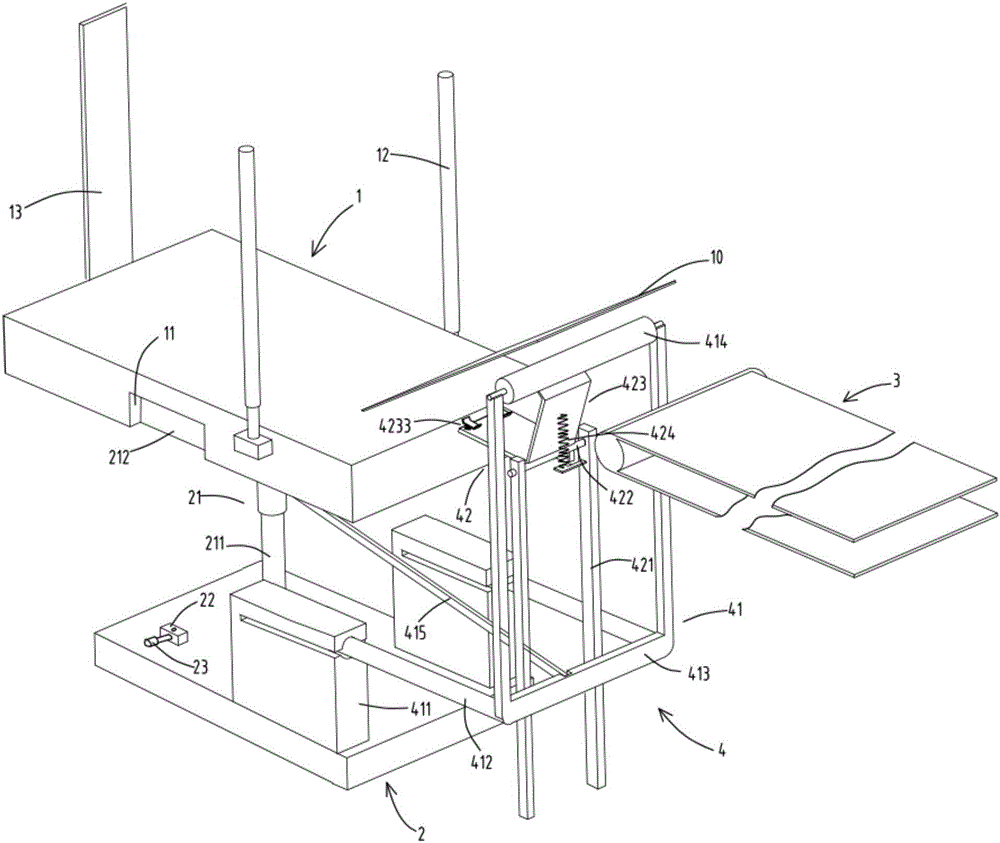

Paperboard conveying device with overturning function

The invention discloses a paperboard conveying device with an overturning function. The paperboard conveying device comprises a tray, a supporting base, a conveying device and an overturning mechanism. The supporting base is provided with an elastic supporting device. The tray is arranged on the elastic supporting device. The overturning mechanism comprises a sliding supporting device and an overturning frame. The sliding supporting device comprises a sliding base arranged on the supporting base, a sliding rod arranged on the sliding base in a sliding manner, a support a arranged at the end portion of the sliding rod, a roll wheel arranged on the support a, and a push-pull rod, wherein one end of the push-pull rod is rotationally arranged on the support a, and the other end of the push-pull rod is rotationally arranged on the elastic supporting device. A spring a is further connected between a V-shaped overturning plate and a support b. The V-shaped overturning plate is provided with a material supporting base. The problems that in the prior art, a tray does not have a lifting function, the fall difference change is large when a paperboard falls down onto the tray, falling is not stable, and manpower is consumed for paperboard flattening are solved.

Owner:佛山市顺德区永一印刷包装实业有限公司

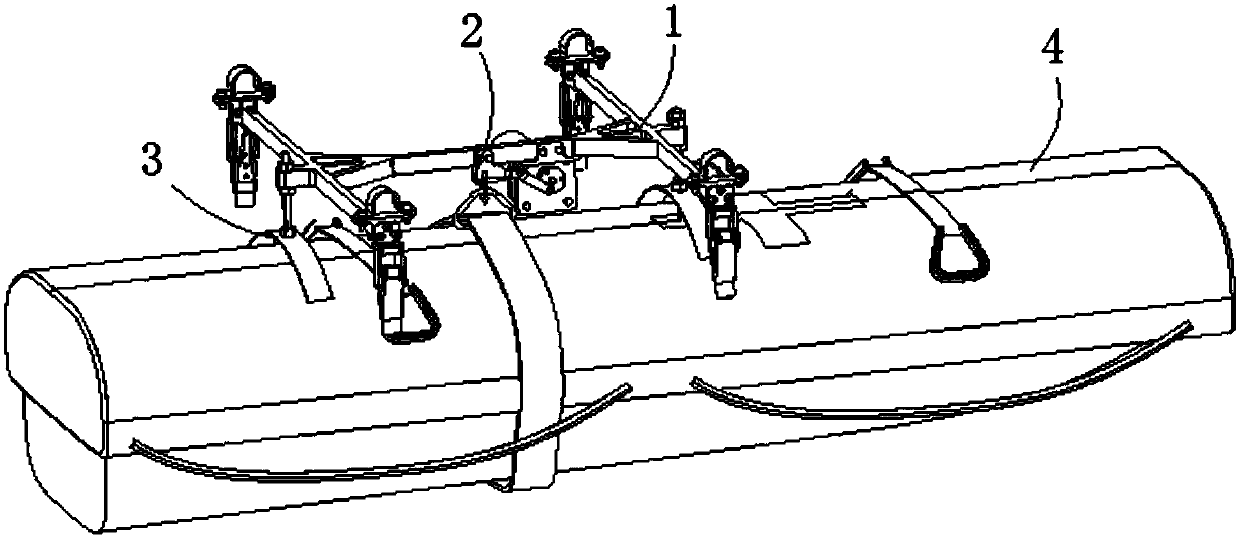

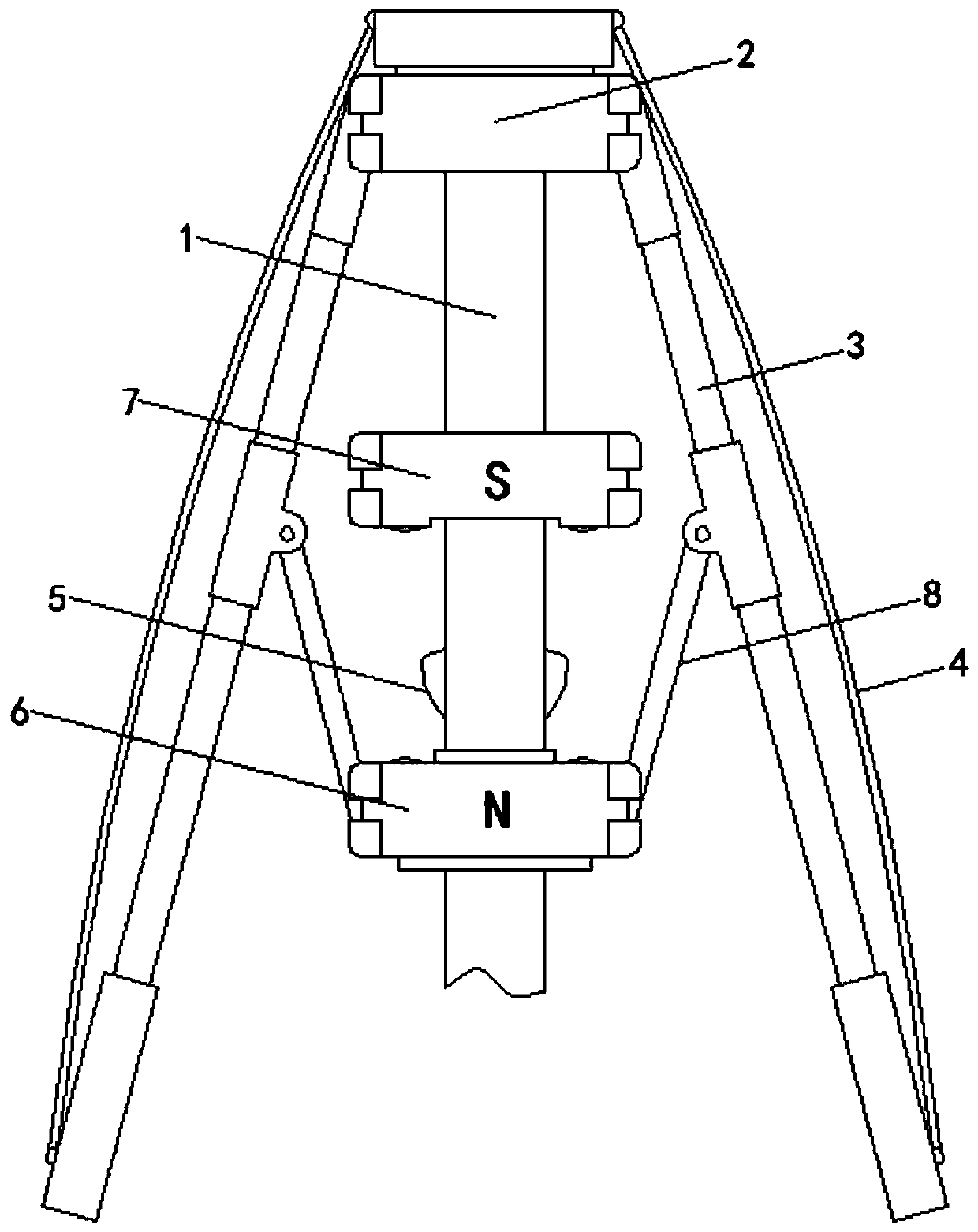

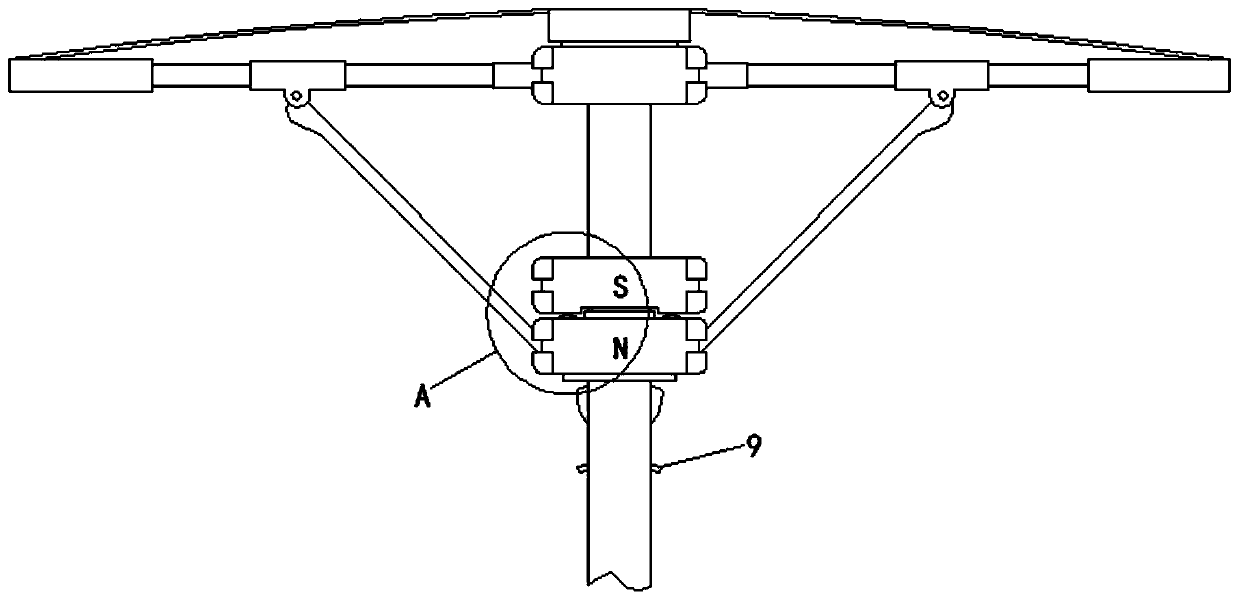

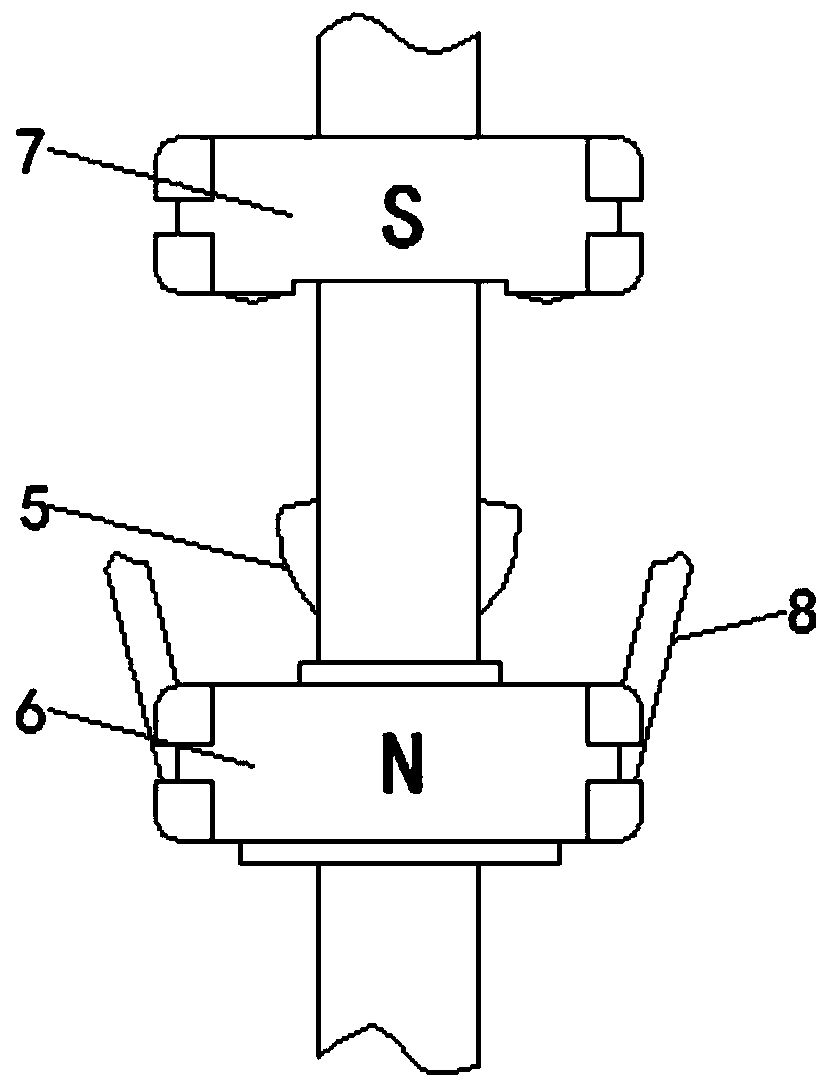

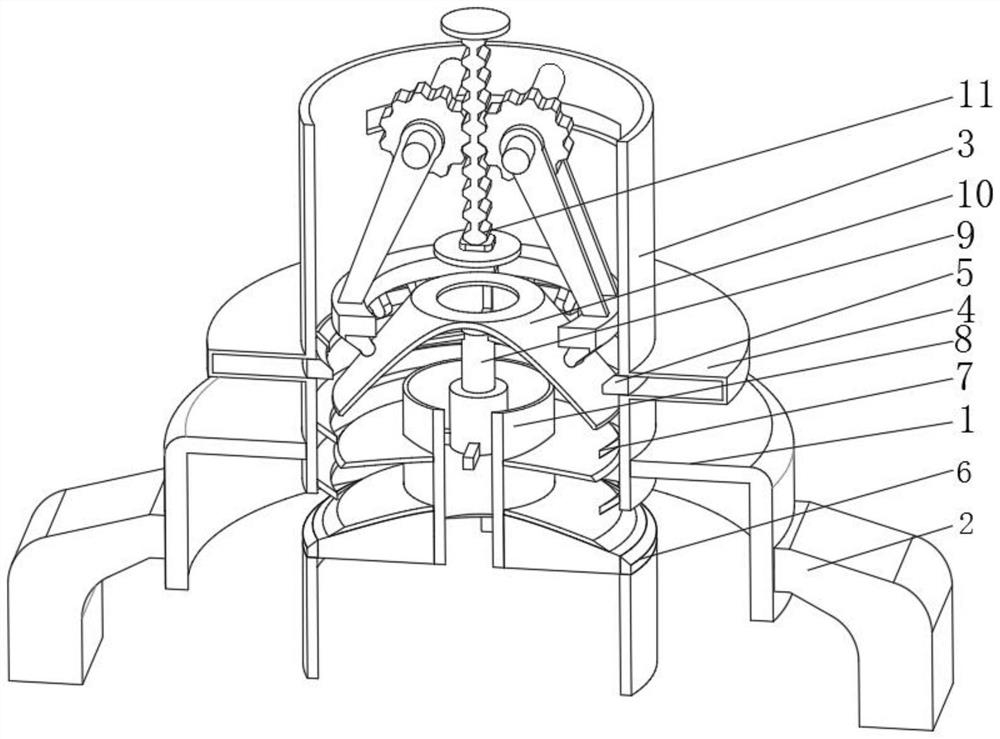

Throwing device applied to water rescue unmanned aerial vehicle system

PendingCN110576971AEasy to hangFalling steadilyLife-raftsAir-sea rescue devicesEngineeringMarine engineering

The invention discloses a throwing device applied to a water rescue unmanned aerial vehicle system. The throwing device comprises a support, a suspension assembly and a limiting assembly; the suspension assembly comprises a suspension part and a driving part, wherein the suspension part is used for suspending rescue materials; the suspension part is arranged at the lower end of the middle of the support; the driving part is arranged on the support, is connected to the suspension part and is used for driving the suspension part to be opened and closed; the limiting assembly comprises at least two limiting parts used for limiting shaking of the rescue materials; and the limiting parts are arranged at the lower end of the edge of the support. According to the throwing device, the suspension assembly is arranged at the lower end of the middle of the support, the at least two limiting parts are arranged at the edge of the support, the rescue materials can be fixed through the suspension part located in the middle and then are limited through the limiting parts located at the edge so as to prevent the rescue materials from shaking, so that only one driving part needs to be arranged to drive the suspension part to be opened and closed so as to complete suspension and throwing of the rescue materials, one suspension point and two limiting points are arranged, so that the rescue materials can fall stably in the throwing process, and therefore the flight of an unmanned aerial vehicle is guaranteed, and suspension of the rescue materials is also facilitated.

Owner:CHENGDU TIANFU NEW DISTRICT KUANG CHI FUTURE TECH INST

Electronic product chip detection equipment

InactiveCN112269094AQuick pickFalling steadilyElectrical testingMechanical engineeringEmbedded system

The invention relates to chip detection equipment, in particular to electronic product chip detection equipment. The electronic product chip detection equipment provided by the invention can automatically detect a chip and rapidly place the chip. The electronic product chip detection equipment comprises a frame used for installing the whole device; a driving assembly, mounted on the rack and provides power for transmission; a discharging assembly, installed on the driving assembly and conducting discharging in a sliding mode; and a detection assembly, installed on the driving assembly and carrying out detection in a contact mode. Through cooperation of the transmission belt and the push block, a chip can be automatically transmitted, the working efficiency is improved, through cooperationof the first push rod and the contact rod, the chip can be automatically discharged, manual placement is not needed, and through cooperation of the detection pen and the second push rod, the chip canbe automatically detected.

Owner:江西国丰电子科技有限公司

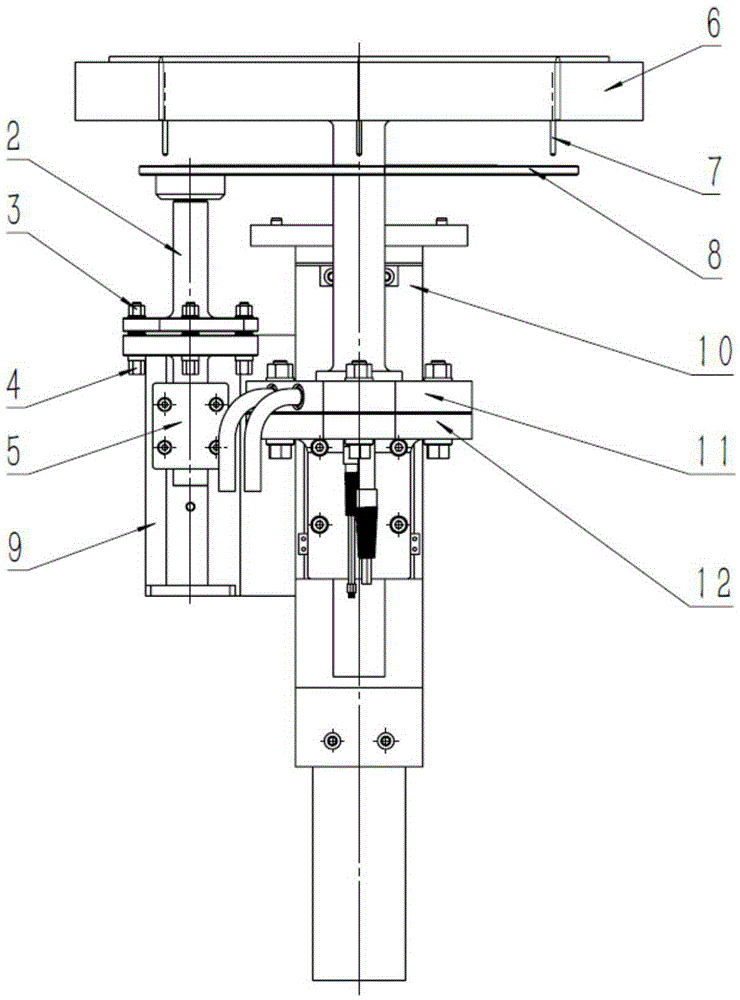

Automatic fluid canning crane pipe system

ActiveCN113148937AAvoid safety hazardsGuaranteed uptimeNuclear energy generationLiquid transferring devicesMarine engineeringScrew thread

The invention discloses an automatic fluid canning crane pipe system. The motion mode of the existing technical scheme is improved, and the improved automatic fluid canning crane pipe system comprises a vertical driving module, a transmission system, a guide rail, a connecting plate and a crane pipe body structure. The guide rail is fixed to the connecting plate, the connecting plate is provided with a threaded hole and fixed to a joist barrow, and the crane pipe body structure comprises a vertical pipe. The vertical driving module is provided with a driving device which is output to the vertical pipe through the transmission system and movably connected to the guide rail, and the vertical pipe is movably connected to the threaded hole. According to the automatic fluid canning crane pipe system, the problem of electrostatic potential safety hazards caused by collision between the vertical pipe and a tank opening due to shaking is effectively solved; and meanwhile, the structure of the system is simplified, the design is reasonable, operation is convenient, reliability and safety are good, and the automatic fluid canning crane pipe system is suitable for popularization and application.

Owner:HEBEI UNIV OF TECH

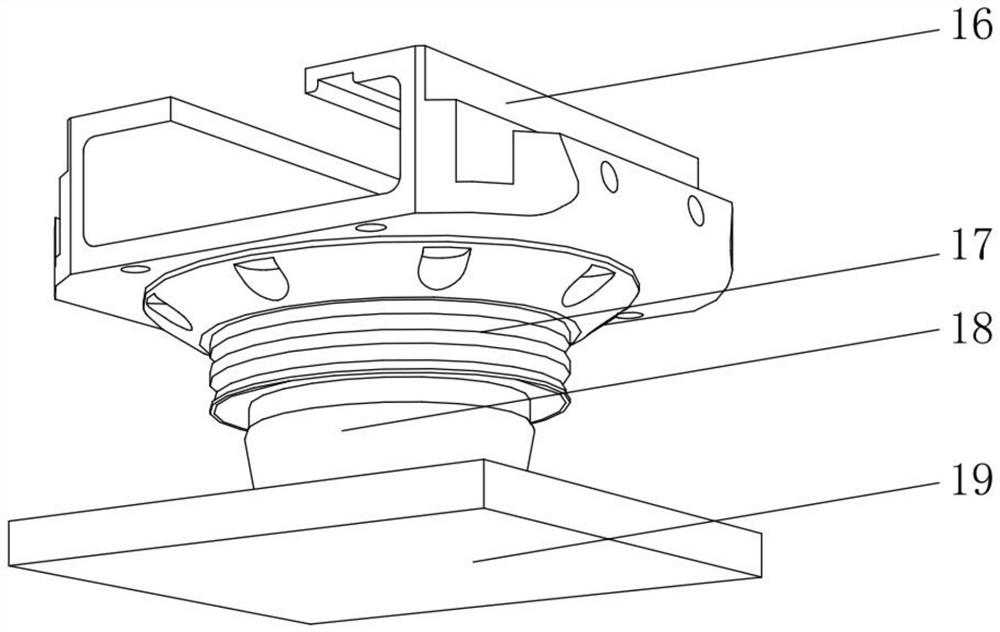

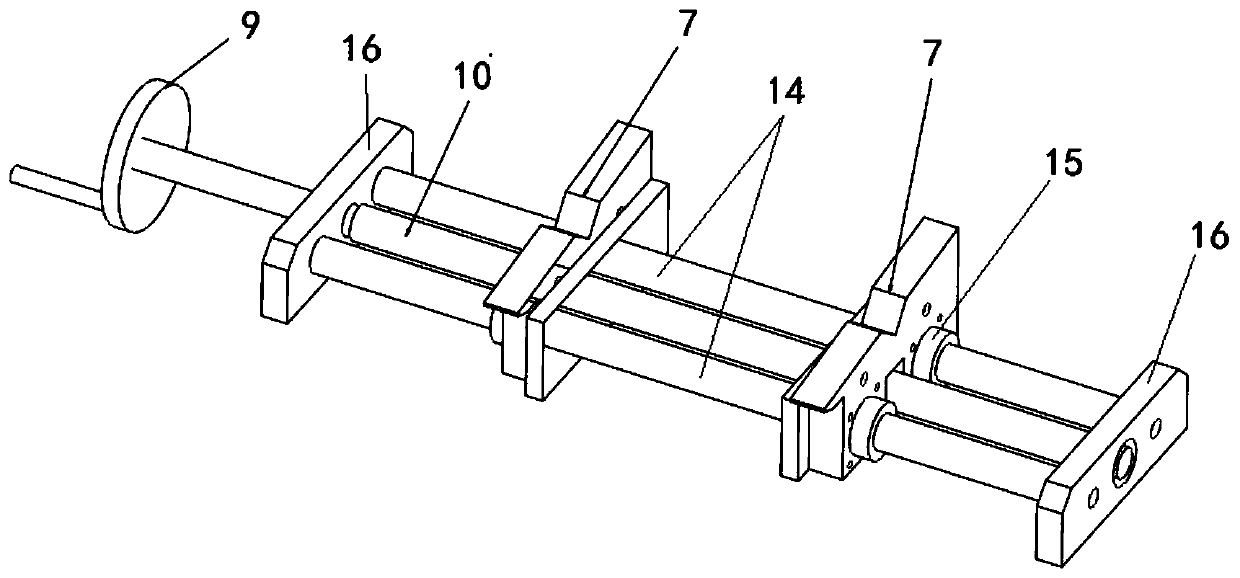

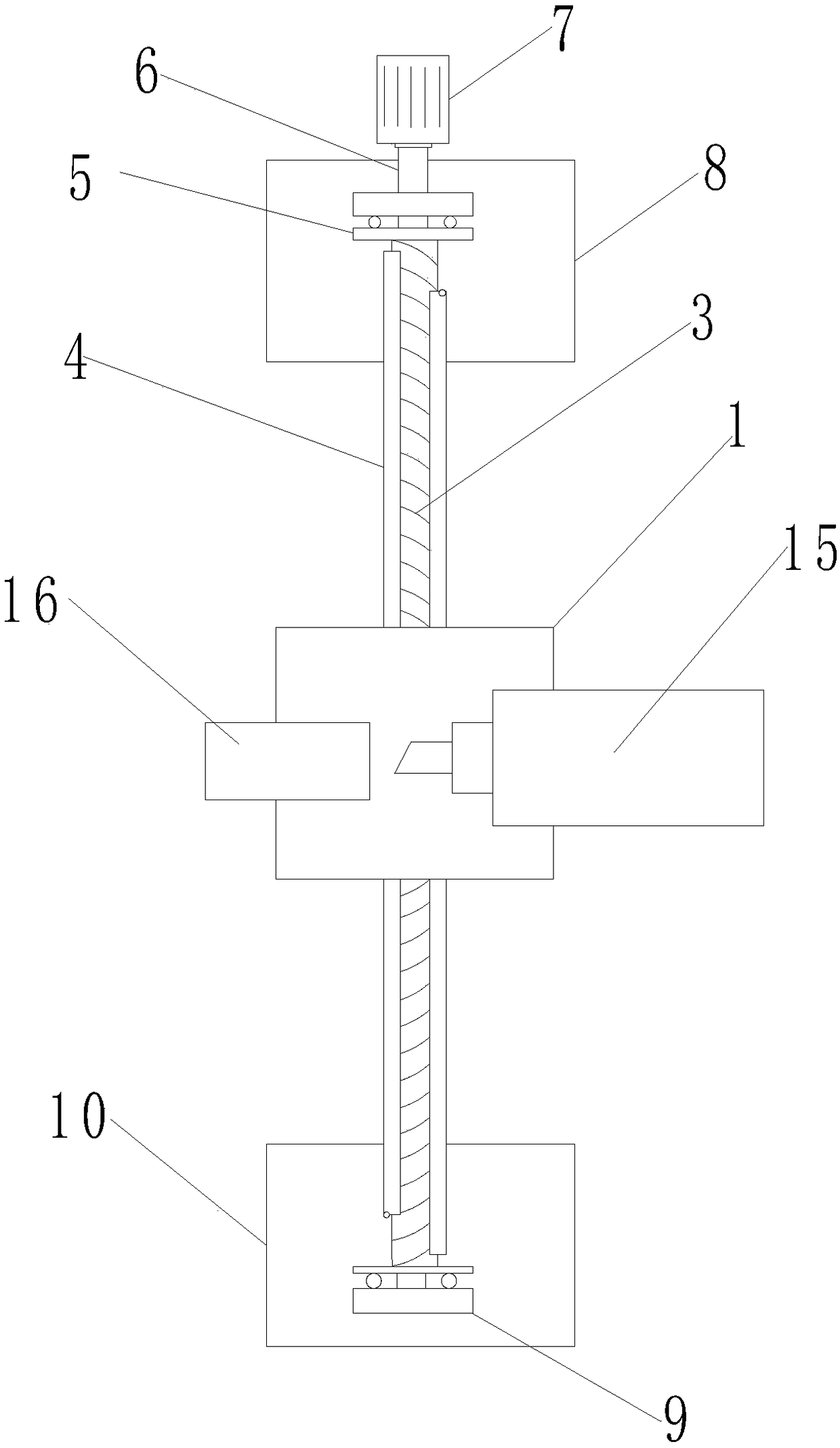

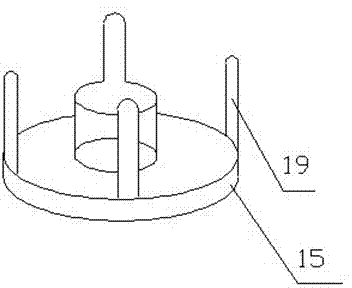

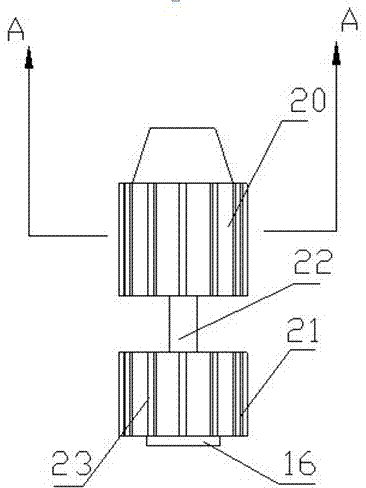

Thimble supporting plate adjustment tool structure and leveling method

ActiveCN106571330AHigh speedQuality improvementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a thimble supporting plate adjustment tool structure and a leveling method and aims to solve a horizontal adjustment problem of an upper surface of a thimble supporting plate. The tool structure comprises a positioning pin, a supporting rod, an adjusting nut, an adjusting thread bolt and a supporting seat, wherein the positioning pin is mainly used for determining a mounting direction of the thimble supporting plate so as to conveniently mount the thimble supporting plate, the supporting seat is fixed on a sliding block to drive the thimble supporting plate to adjust a tool to slide on a foundation, the supporting seat is provided with three 120-DEG distributed thread holes, the adjusting thread bolt employs fine thread, the thread bolt is turned to adjust relative height of the supporting rod and the supporting seat, the adjusting thread bolt is turned by one circle, one-pitch height can be adjusted, the adjusting thread bolt is adjusted, the thimble supporting plate is in a horizontal state when three thimbles supported by the thimble supporting plate have same height relative to a plane of a heating disc, the adjusting nut is fastened, the thimble supporting plate is fixed to adjust relative height of the supporting rod and the supporting seat, and horizontal adjustment of the thimble supporting plate is accomplished. The tool structure is advantaged in that the structure is reasonable, an operation method is simple and convenient, horizontal adjustment efficiency of the upper surface of the thimble supporting plate is effectively improved, and the tool structure can be widely applied to the technical field of semiconductor film plating equipment.

Owner:PIOTECH CO LTD

Device for flour bag stacking

The invention relates to a device for flour bag stacking. The device for flour bag stacking comprises a device body and a placement platform, wherein the device body comprises an L-shaped beam frame formed through connecting a vertical beam with a bottom beam, the placement platform is connected together with the vertical beam through a conveying slide way, a plurality of transversally-arranged grooves are formed in the conveying slide way at intervals, and a buffer belt used for reducing a flour bag falling speed is embedded in the groove; and protection edges are arranged at the two sides ofthe conveying slide way, and the top ends of the protection edges at the two sides extend upwards to form a flour bag bearing port with a concave surface and used for smoothly bearing flour bags falling off from the upper space. The device for flour bag stacking is reasonable in structure, ingenious in design, convenient in flour bag stacking, and free from blockage on a circular-barrel-shaped channel, thereby increasing the working efficiency; the device for flour bag stacking solves the technical problems that a conveying channel is unreasonable in structure, so that flour bags are accumulated to block the circular-barrel-shaped channel, and the stacking efficiency and enterprise benefits are influenced, and the like, in the existing flour bag stacking process; and the device has greatmarket prospect and development space compared with the prior art.

Owner:平顶山豫皓面业有限公司

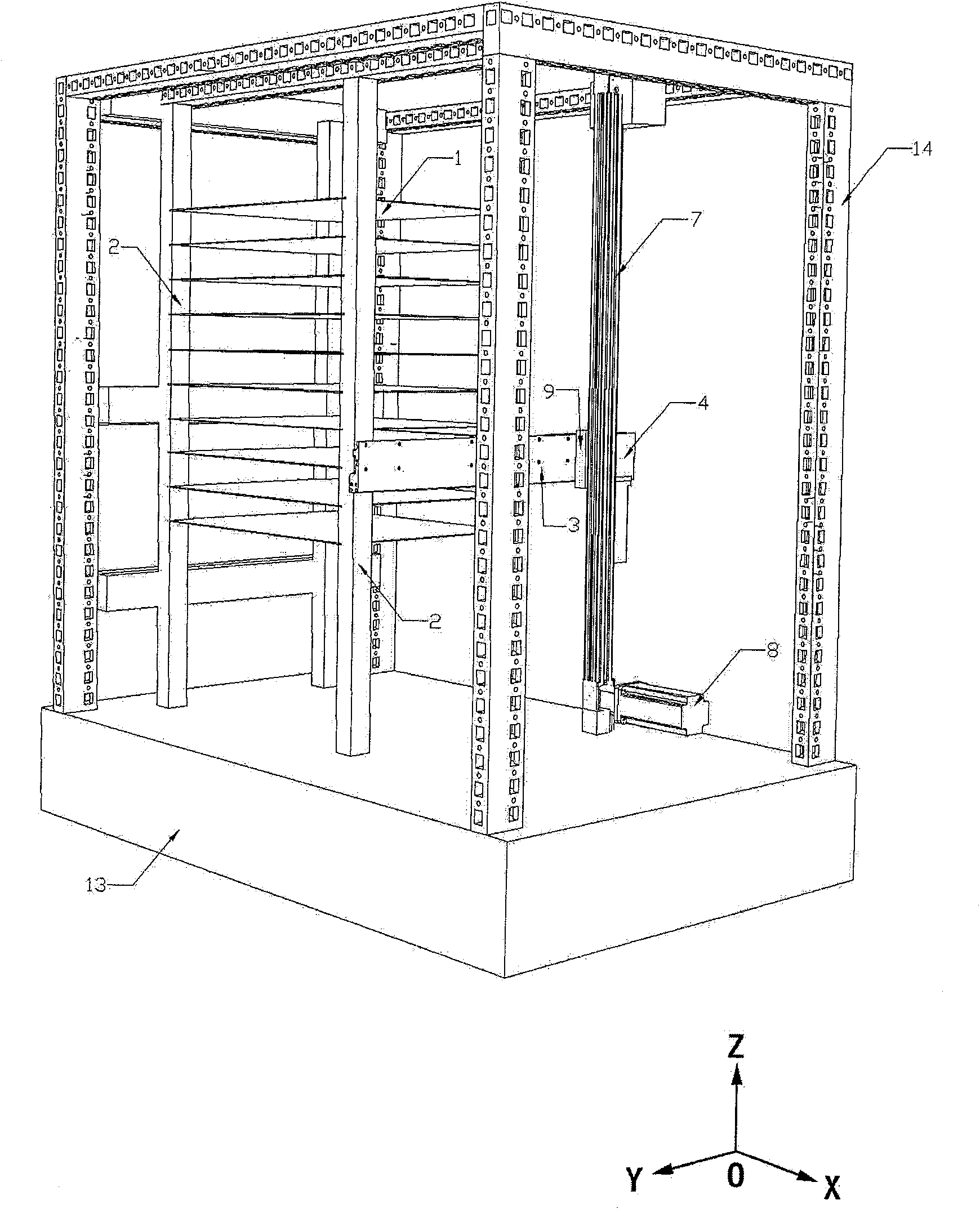

Storage and output device of flat things

InactiveCN100576269CEasy to storeFlexible allocationCoin-freed apparatus detailsApparatus for dispensing discrete articlesOutput deviceEngineering

This invention relates to a flat object memory and output device, which comprises cabinet with memory rack and send machine with object out hole, wherein, the send structure comprises first linear driver vertical set and second linear driver vertical to first linear driver and driver structure; the first driver linear driver has first slide block; the second linear driver device is fixed on first slide block; the second linear driver has second slide block and the second slide block is fixed with memory rack dial bar.

Owner:陈家聪

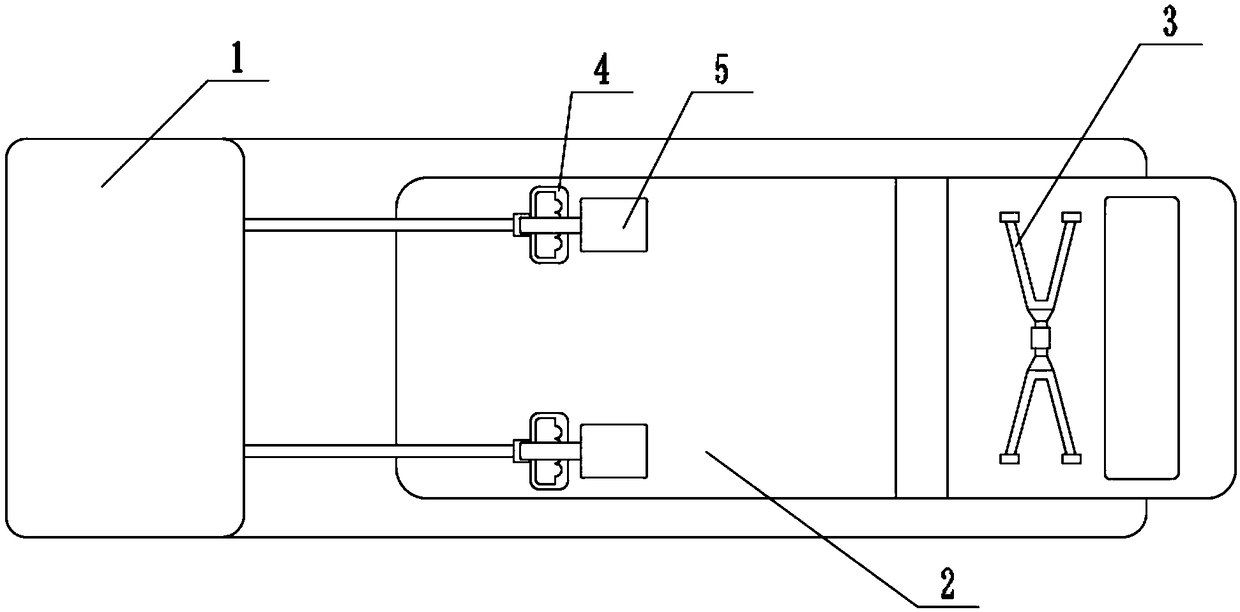

Bidirectional locking mechanism of axle and highway-railway transport vehicle

ActiveCN114228400AAvoid failureFalling steadilyRail and road vehiclesRailway transportRailroad wheelControl theory

The bidirectional locking mechanism comprises a first execution part, a stop seat, a support and a locking part, a second execution block is hinged between the middle of the locking part and a first execution block, and the locking part rotates along with the output end of the first execution part through the first execution block and the second execution block. The locking part is provided with an abutting position and a bearing position; the first execution part drives the locking part to abut against the stop seat, at the moment, the road axle is located below the abutting position so as to limit the road axle to continue to be recycled, and therefore the situation that railway wheels floor the ground and the road wheels fail during road driving is effectively avoided; when the highway-railway transport vehicle runs on the railway, the highway axle is limited by the bearing position, the highway wheels are effectively and stably prevented from falling, the driving safety is improved, and in the retraction process of the output end of the first execution part, the locking part is driven to be separated from the stop seat and separated from the moving path of the highway axle, so that the highway axle is switched in different states; and the operation convenience is improved.

Owner:CRRC YANGTZE GRP CO LTD

Liquid stop alarm device

InactiveCN103566443AReduce material usageFlat sealingIntravenous devicesFlow controlBottleSafety valve

The invention relates to a transfusion device, in particular to a liquid medicine and blood transfusion liquid stop alarm device which can realize timely sensing and exhaust, belonging to the technical field of medical appliances. The liquid medicine and blood transfusion liquid stop alarm device comprises a transfusion hose, a dropper and a puncture needle. The puncture needle is arranged at the upper part of the dropper. A liquid outlet is formed in the lower part of the dropper. The puncture needle is used for being connected with a transfusion bottle. The liquid outlet is connected with the transfusion hose. A safety valve is arranged in the dropper. The inner diameter of the safety valve is smaller than the inner diameter of the dropper. A connector is arranged at the connecting position between the transfusion hose and the liquid outlet. The connector is used for being communicatively connected with the transfusion hose and the liquid outlet. An air inlet which can be controlled to be opened and closed is formed in the connector. The liquid medicine and blood transfusion liquid stop alarm device provided by the invention not only can prevent blood from returning, but also can enable liquid medicine to be fully transfused and prevent waste, and is of a great significance to the transfusion of expensive liquid medicine such as anti-tumor medicine.

Owner:汪贤宗

Fire-fighting robot high-altitude falling emergency device capable of climbing wall

ActiveCN111348117AFalling steadilyAvoid dangerParachutesFire rescueStructural engineeringControl theory

The invention discloses a fire-fighting robot high-altitude falling emergency device capable of climbing a wall, and relates to the technical field of fire-fighting robots. The fire-fighting robot high-altitude falling emergency device comprises a positioning rod, a cover shell is movably connected to the top of the positioning rod, a supporting rod is movably connected to the outer side of the cover shell, tent cloth is movably connected to the outer side of the supporting rod, a limiting mechanism is movably connected to the interior of the positioning rod, a movable block is movably connected to the outer side of the positioning rod, and a fixing block is movably connected to the upper portion of the movable block. According to the fire-fighting robot high-altitude falling emergency device capable of climbing a wall, the awning cloth, the air spraying pipe and the self-locking block are arranged; principle of using parachute is used to effectively prevent the device from falling from the high altitude, damage to the equipment and possible high-altitude object falling risks are avoided, certain reverse thrust can be formed through gas spraying, the falling speed of the equipmentis further decreased, effective buffering is achieved when the equipment falls to the ground, the device is triggered to work through the weightlessness phenomenon caused by falling of the equipment,and the cost is lower.

Owner:南京市六合区金牛湖新市镇建设投资有限公司

Winter jujube picking and classifying automation device

ActiveCN112772149AImprove sorting effectGood effectPicking devicesAutomationElectrical and Electronics engineering

The invention belongs to the technical field of sorting devices, and discloses a winter jujube picking and classifying automation device which comprises an outer cover. Three supporting legs are fixedly installed on the periphery of the outer cover at equal angles, a guide barrel is fixedly installed in the middle of the outer cover, and a hidden disc is fixedly installed at the lower end of the periphery of the outer cover. Six extrusion devices are annularly mounted in the hidden disc, a lower barrel is placed at the bottom in the outer cover, a middle barrel is fixedly mounted in the middle of the top of the lower barrel, and buffer discs are fixedly mounted at the lower end in the guide barrel and the periphery of the middle barrel. According to the winter jujube picking and classifying automation device, the purpose of good sorting effect is achieved by arranging a grabbing device, a guide cover, the extrusion devices and the like, an operator can adjust the distance between the extrusion devices and the periphery of the guide cover in advance, then winter jujubes enter the area, the winter jujubes with small sizes can directly fall off the gap, the winter jujubes with large sizes are left in the area, and meanwhile, the situation that winter jujubes with the small size are stacked in the area and are difficult to fall is avoided.

Owner:QINGDAO HUANGHAI UNIV

Corrugated paperboard production equipment and processing technology

ActiveCN113002070AEasy to processReduce work intensityMechanical working/deformationPile receiversPaperboardStructural engineering

The invention discloses corrugated paperboard production equipment and a processing technology, relates to the technical field of corrugated paperboards, and solves the problem that the labor intensity of workers is relatively large in the corrugated paper processing process. The corrugated paperboard production equipment comprises a workbench, a fixed pressing plate and a movable pressing plate are mounted on the workbench, and a guide rail is mounted on the movable pressing plate; a plurality of limiting blocks are connected to the guide rail in series, the sides, close to the movable pressing plate, of the limiting blocks are glidingly connected with the movable pressing plate, the limiting blocks are evenly distributed along the guide rail at intervals, a plurality of beads are arranged between every two adjacent limiting blocks, and limiting grooves are formed in the limiting blocks; the movable pressing plate is provided with a positioning block, the upper end of the movable pressing plate is provided with a positioning groove, the movable plate is provided with a compression spring, the positioning block is provided with an inclined surface, the limiting blocks are glidingly connected with the inclined surface, and when the limiting blocks abut against the positioning block, the corrugated paperboards are mounted in the pressing area; and a collecting part is arranged on the workbench. When the corrugated paperboards are processed, all that is required is to continuously repeat the process of placing the corrugated paperboards, so that the working intensity of operators is reduced.

Owner:福建榕升纸业有限公司

Liftable undercarriage

PendingCN113044208AFalling steadilyAvoid breakingFloatsParachutesUncrewed vehicleMicrocomputer control

The invention relates to the technical field of undercarriages, and discloses a liftable undercarriage which comprises an unmanned aerial vehicle body, a single chip microcomputer is arranged in the unmanned aerial vehicle body, driving mechanisms are arranged at the four corners of the top side of the unmanned aerial vehicle body, and a rotating speed sensor is arranged on one side of each driving mechanism. And the bottom side of the rotating speed sensor is fixedly installed on the top side of the unmanned aerial vehicle body, a storage bin is fixedly installed on the top side of the unmanned aerial vehicle body, and a parachute is arranged in the storage bin. Through arrangement of the rotating speed sensor, an electromagnetic valve, a sucking pump, an air bag and the parachute, during use, when the unmanned aerial vehicle body stops running due to a fault in the flight process, the rotating speed sensor detects that the driving mechanism stops rotating, so that the single chip microcomputer controls the sucking pump and the electromagnetic valve to inflate air into the air bag and the storage bin; and the parachute is opened while the airbag expands, so that the unmanned aerial vehicle body stably falls, and the unmanned aerial vehicle body is prevented from being broken.

Owner:南京云将新材料应用科技研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com