Paperboard conveying device with overturning function

A technology of transmission equipment and cardboard, which is applied in the direction of overturning objects, transportation and packaging, and pile separation, etc. It can solve the problems that the pallet does not have lifting function, cardboard flattening consumes manpower, and the drop changes greatly, so as to achieve the effect of cardboard flipping and structure The effect of simplicity and mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

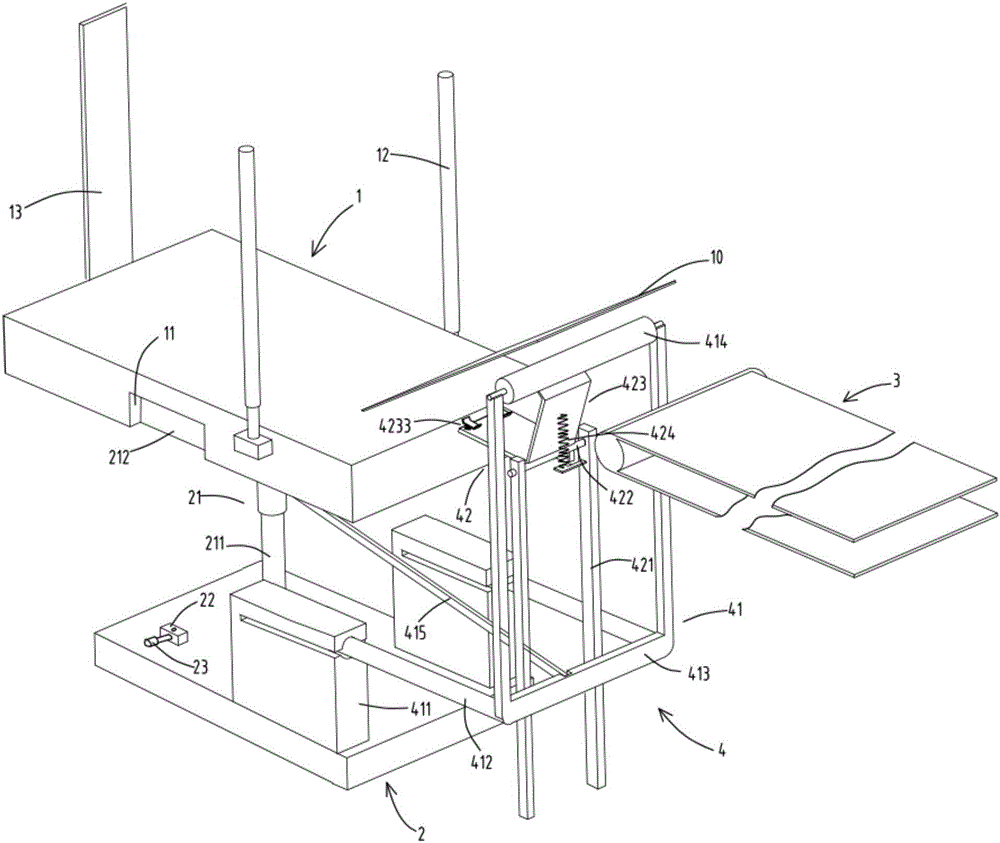

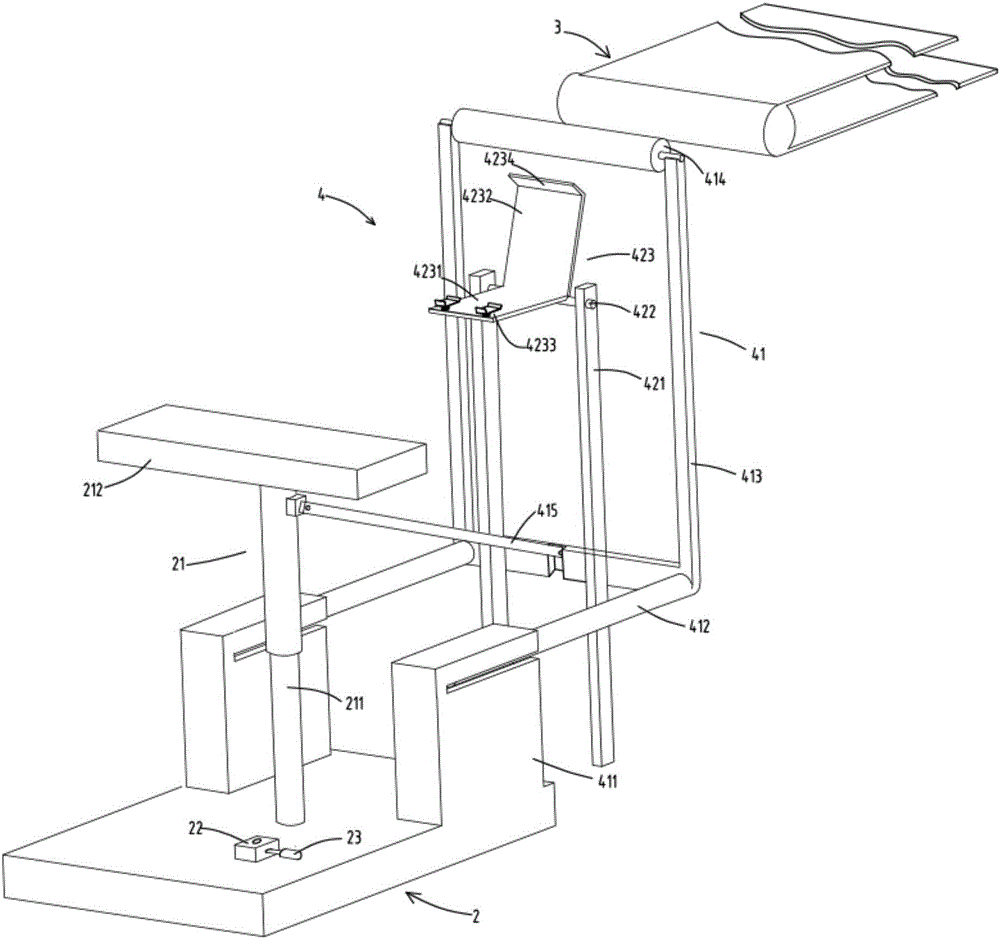

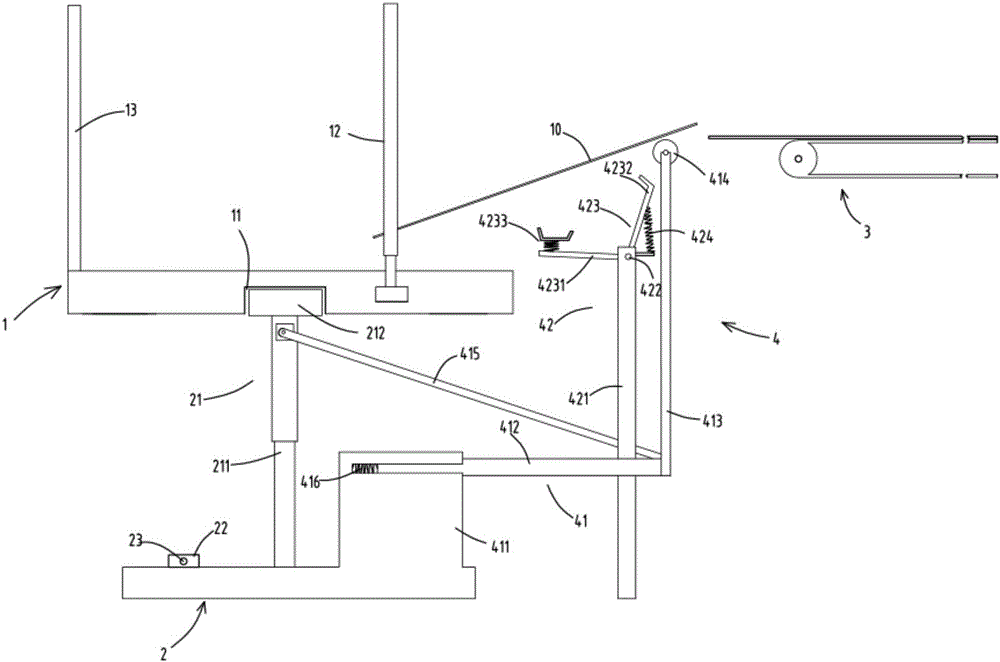

[0032] figure 1 It is a schematic diagram of the structure of the cardboard conveying equipment with the function of turning over, figure 2 It is a schematic diagram of the structure of the base and the turning mechanism, image 3 It is a schematic diagram of the front view when the tray of the cardboard conveying equipment with flip function starts to pick up materials, Figure 4 It is a schematic diagram of the front view of the cardboard conveying equipment with the function of turning over when the tray receives a certain amount and starts to turn over the material, Figure 5 It is a schematic diagram of the front view of the cardboard starting to bounce off the support seat when the tray of the cardboard conveying equipment with turning function is turned over and spliced. Image 6 Schematic diagram of the structure of the flip frame. like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a cardboard conveying device with an overturnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com