Patents

Literature

404results about How to "Meet the needs of production use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

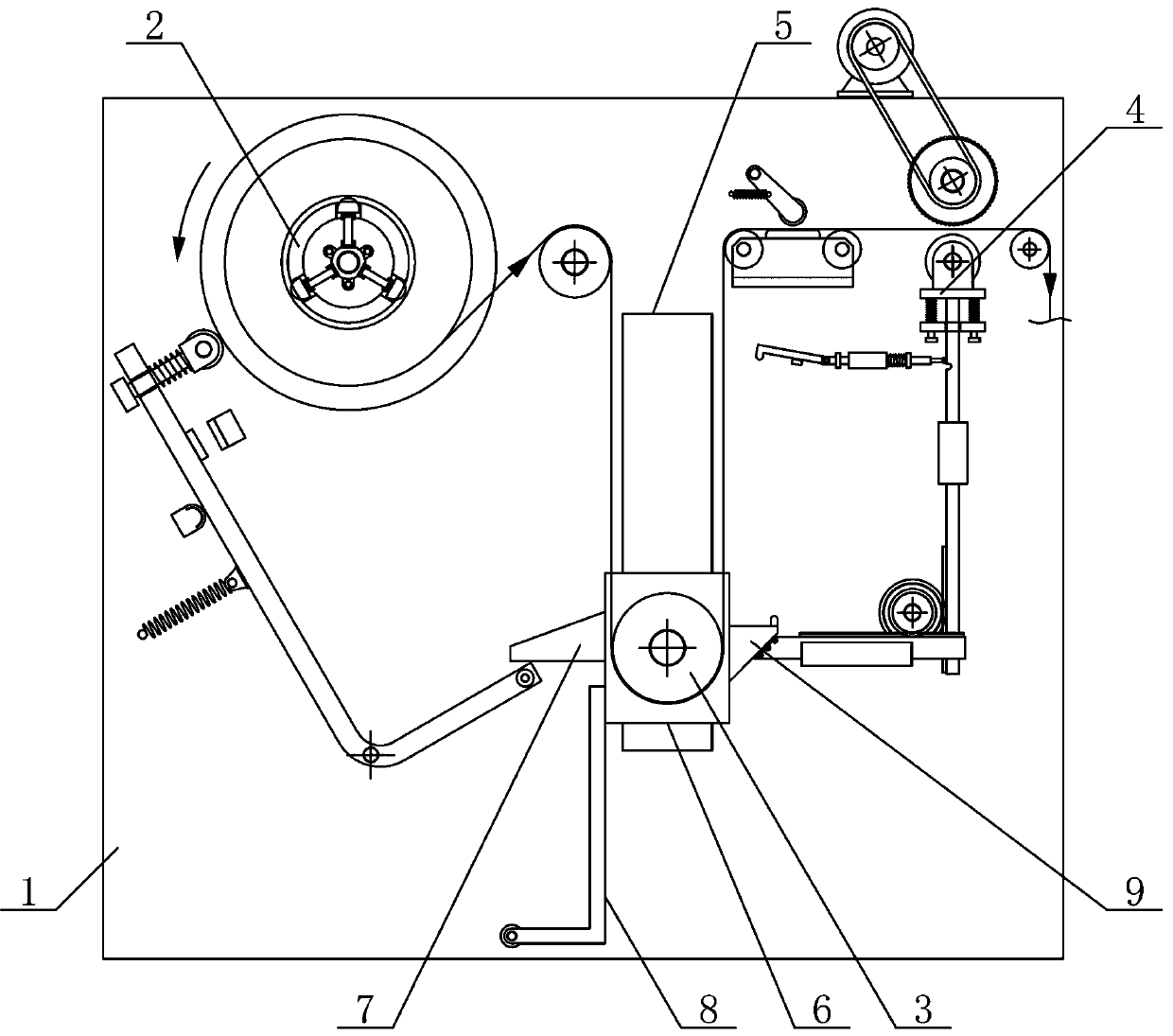

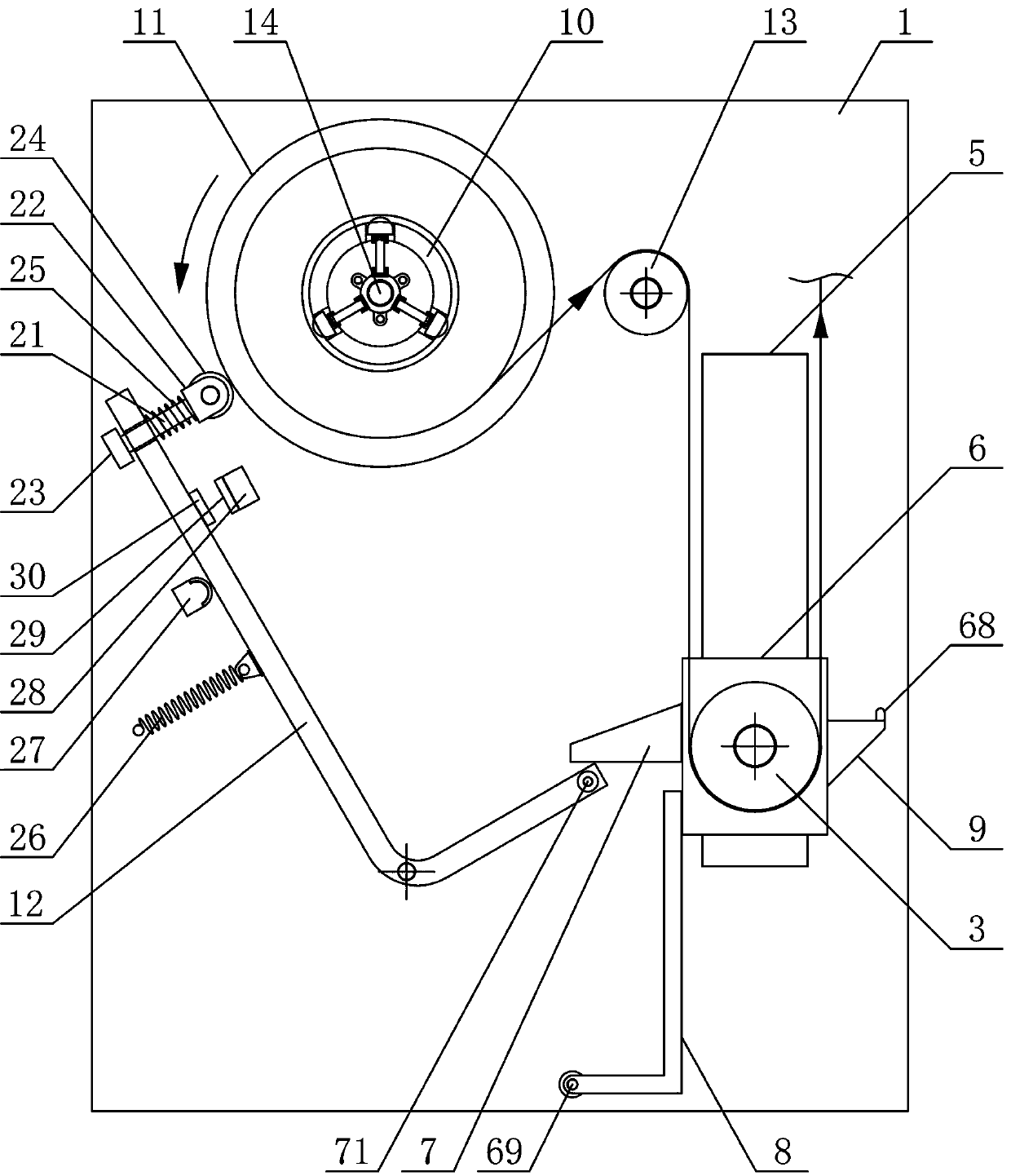

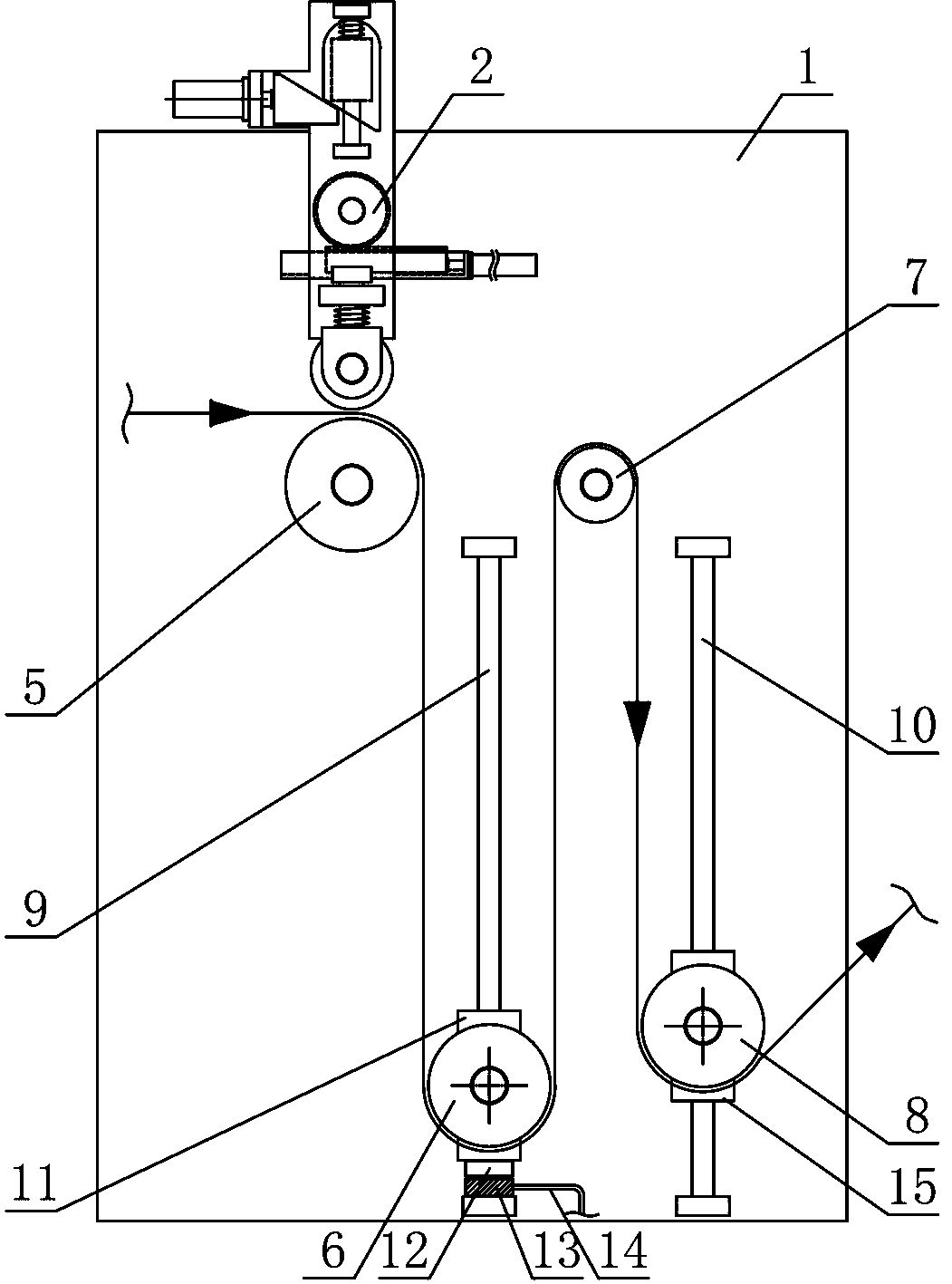

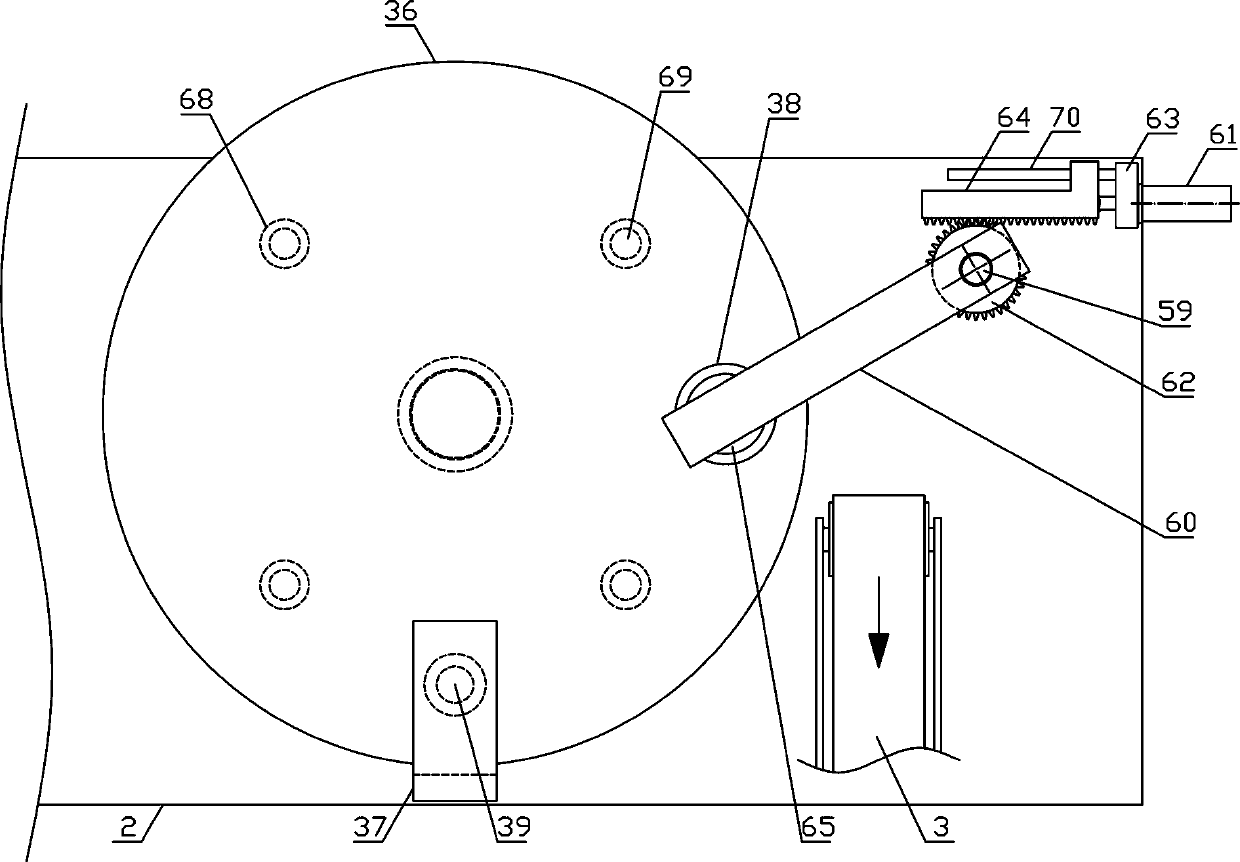

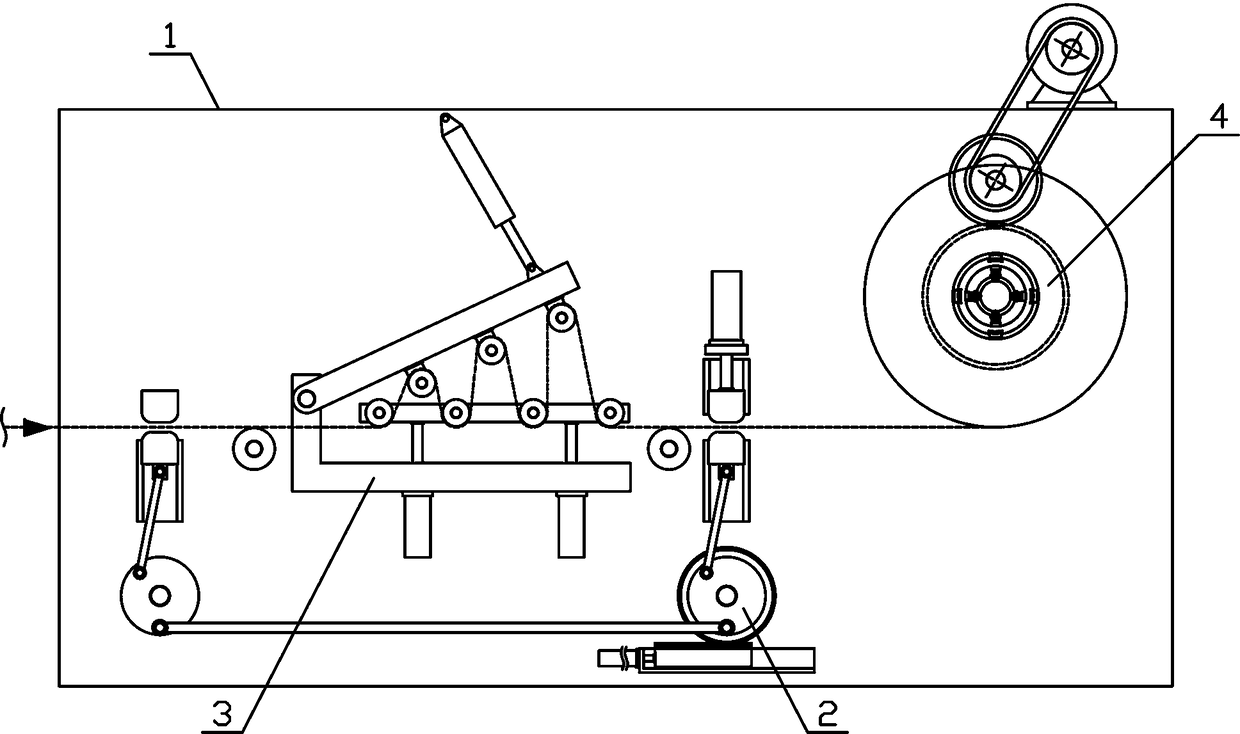

Continuous filling mechanism

InactiveCN107055439ASmooth transmissionThe conveyor belt can be moved intermittently according to the needs, and the transmission is smoothLiquid bottlingFilling materialsEngineering

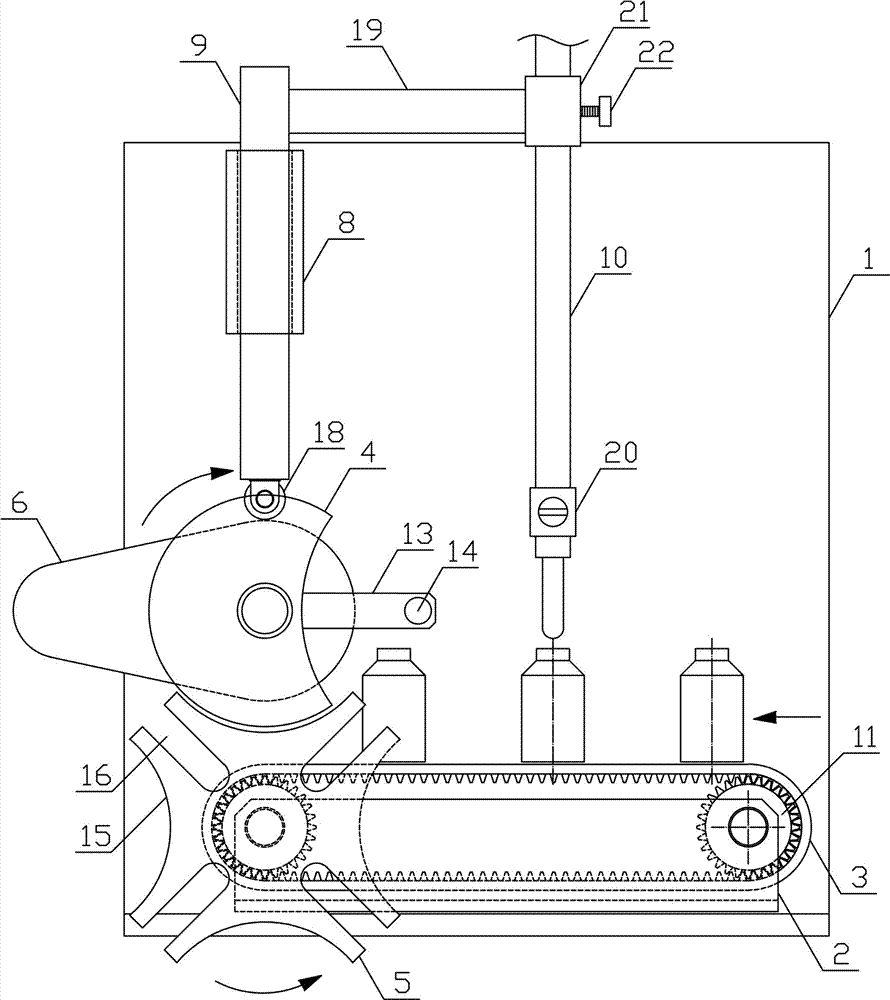

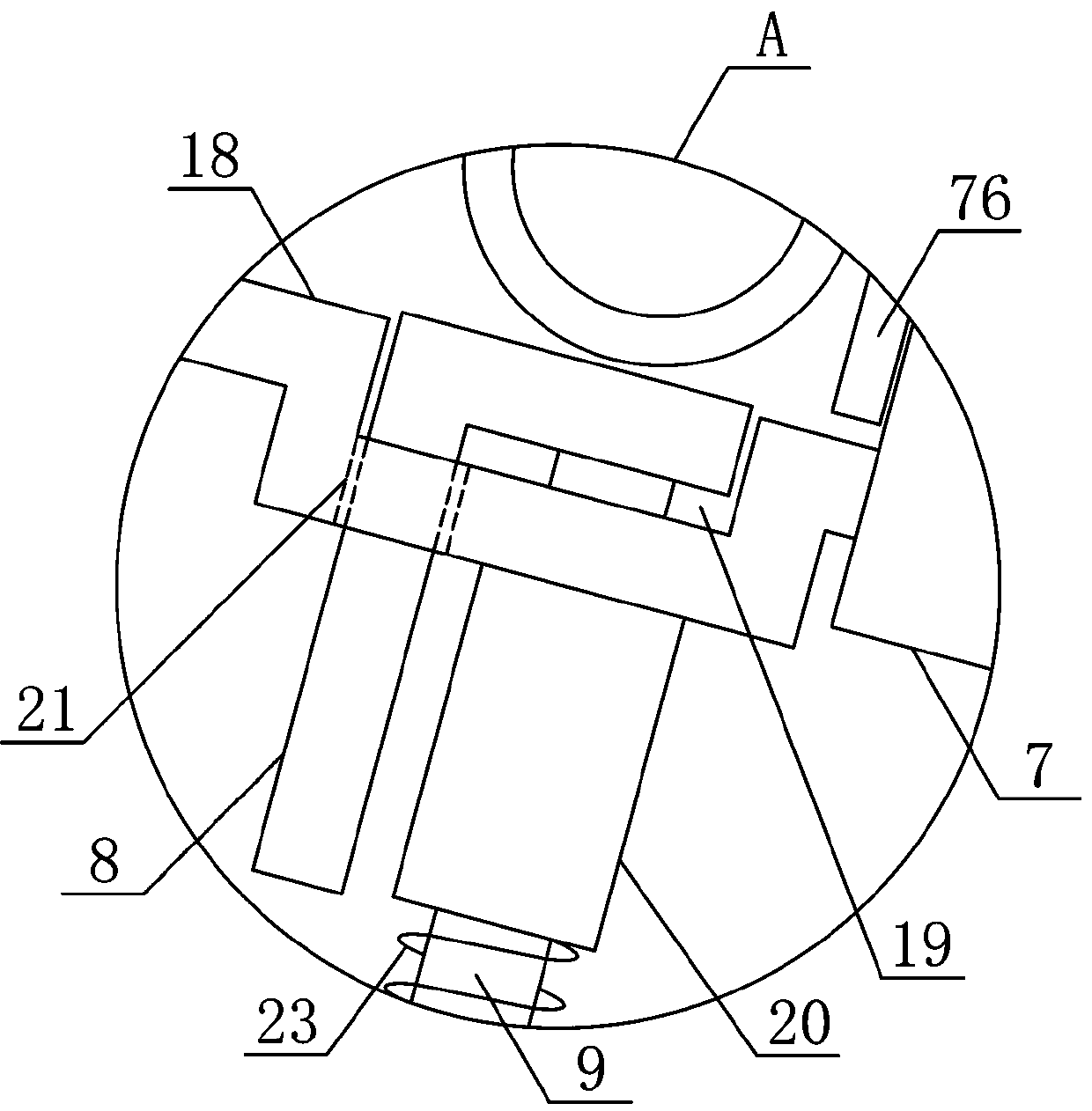

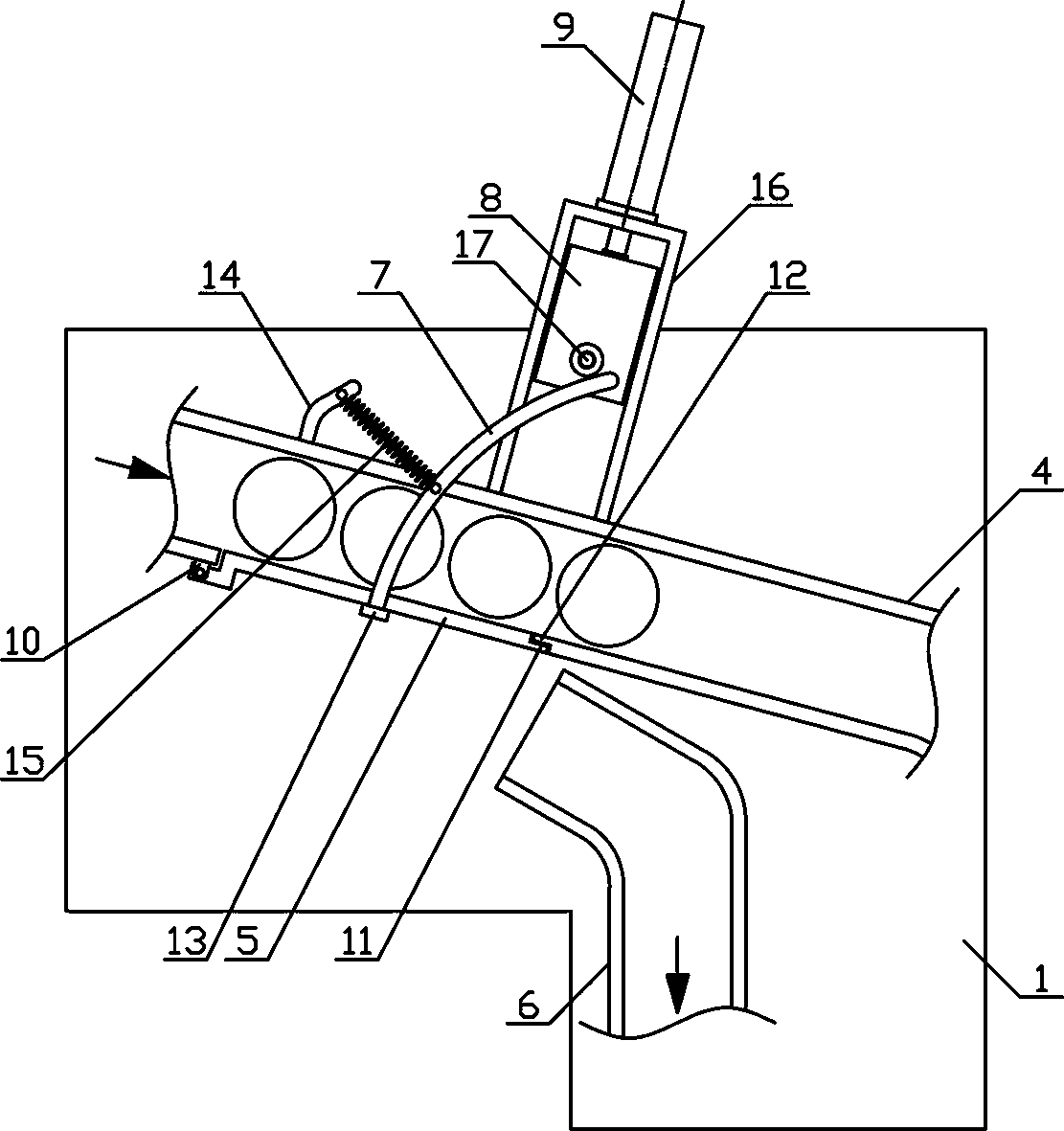

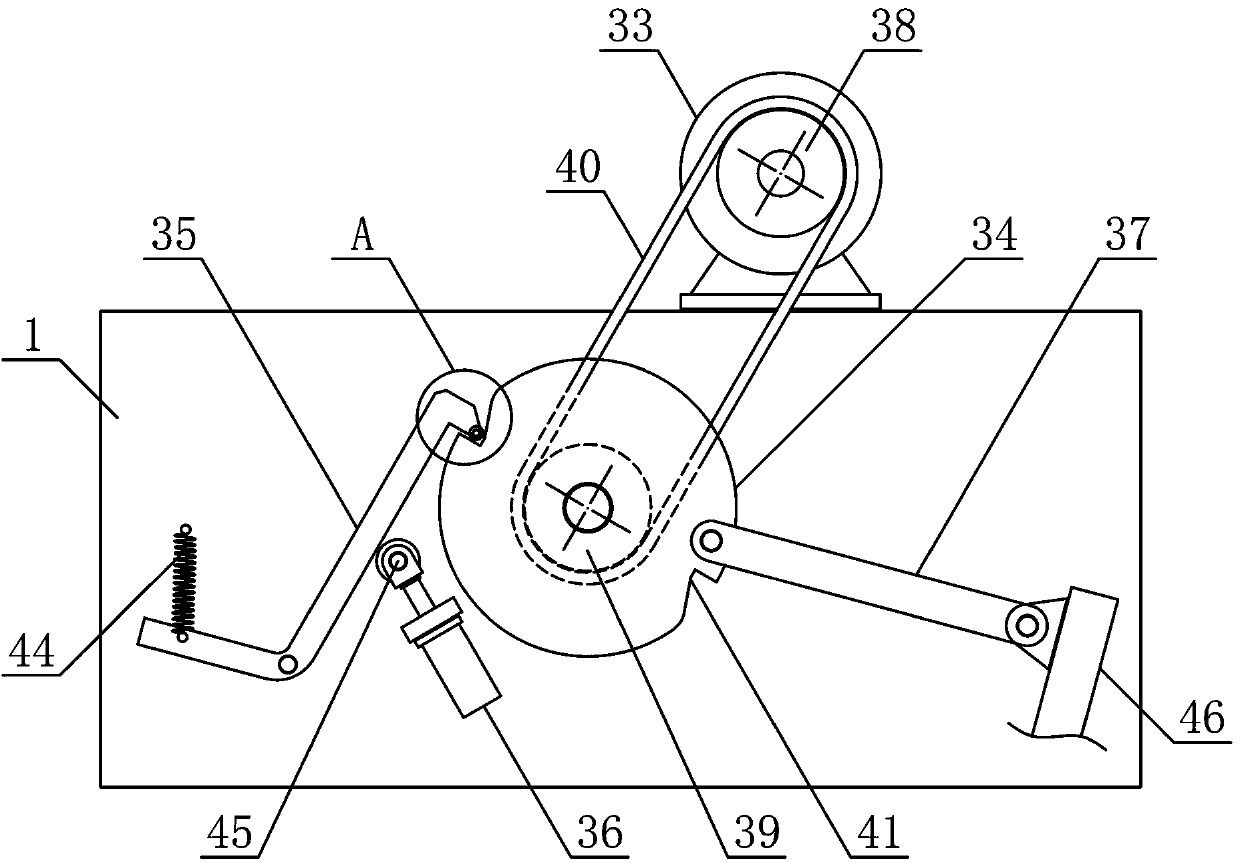

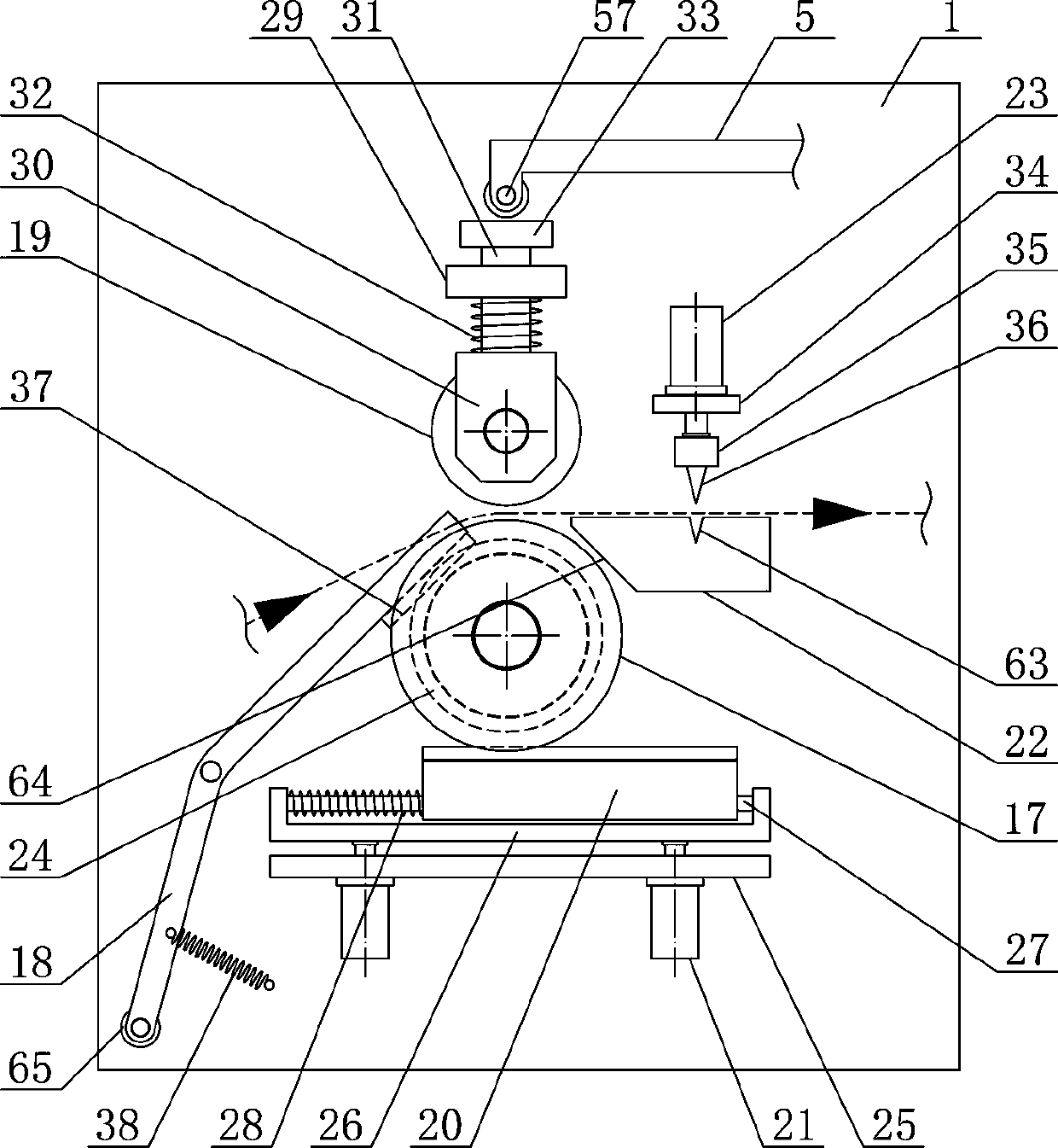

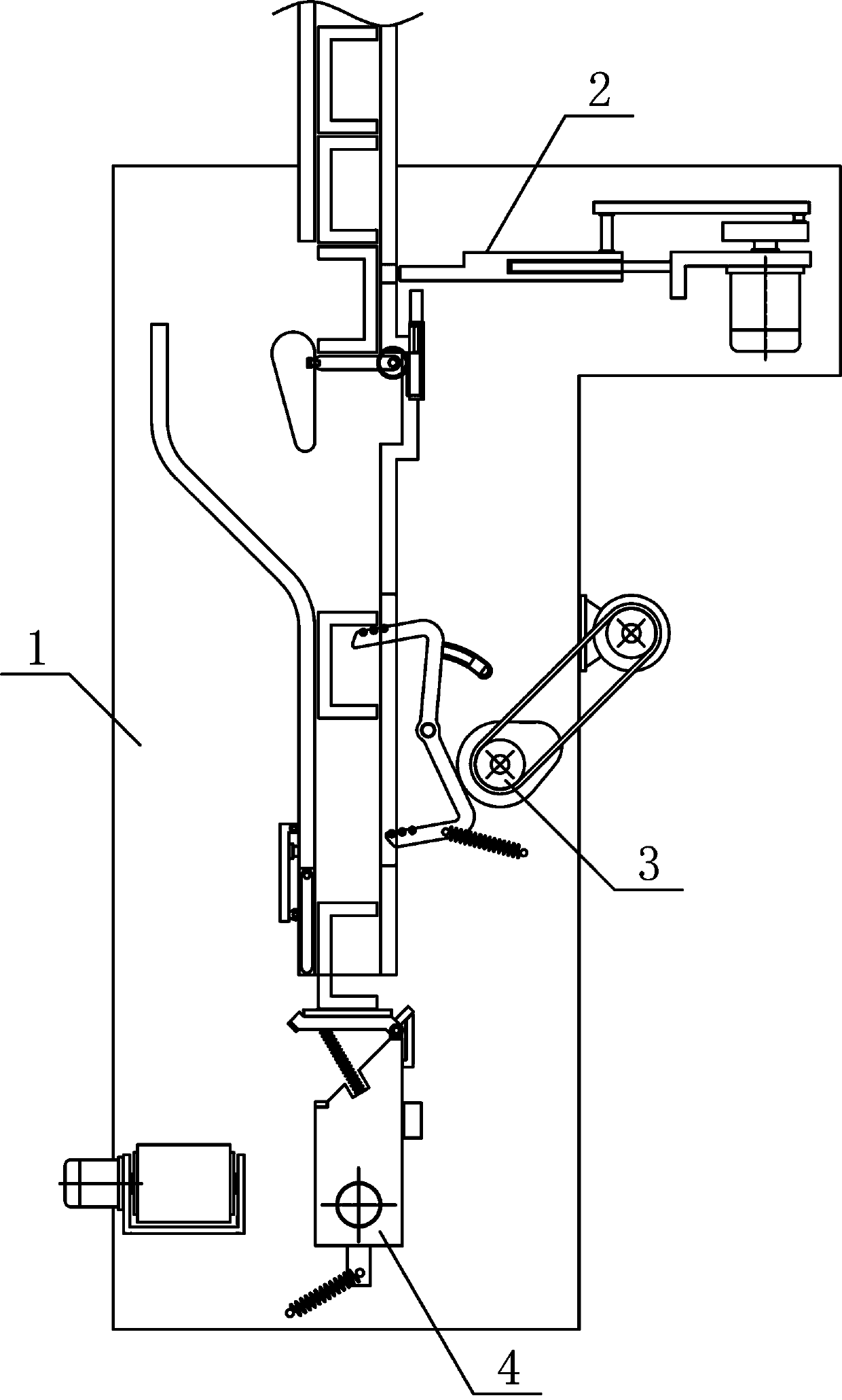

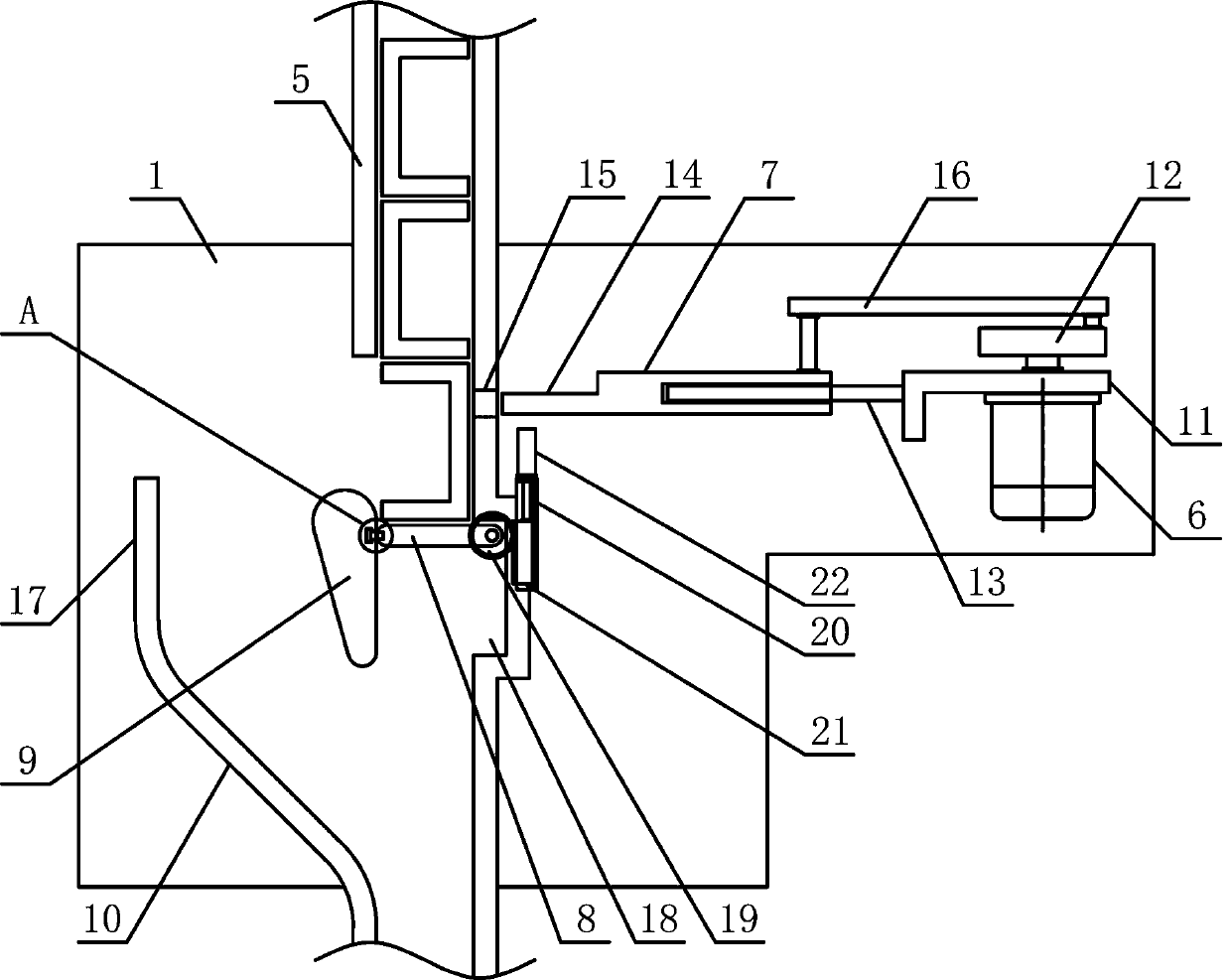

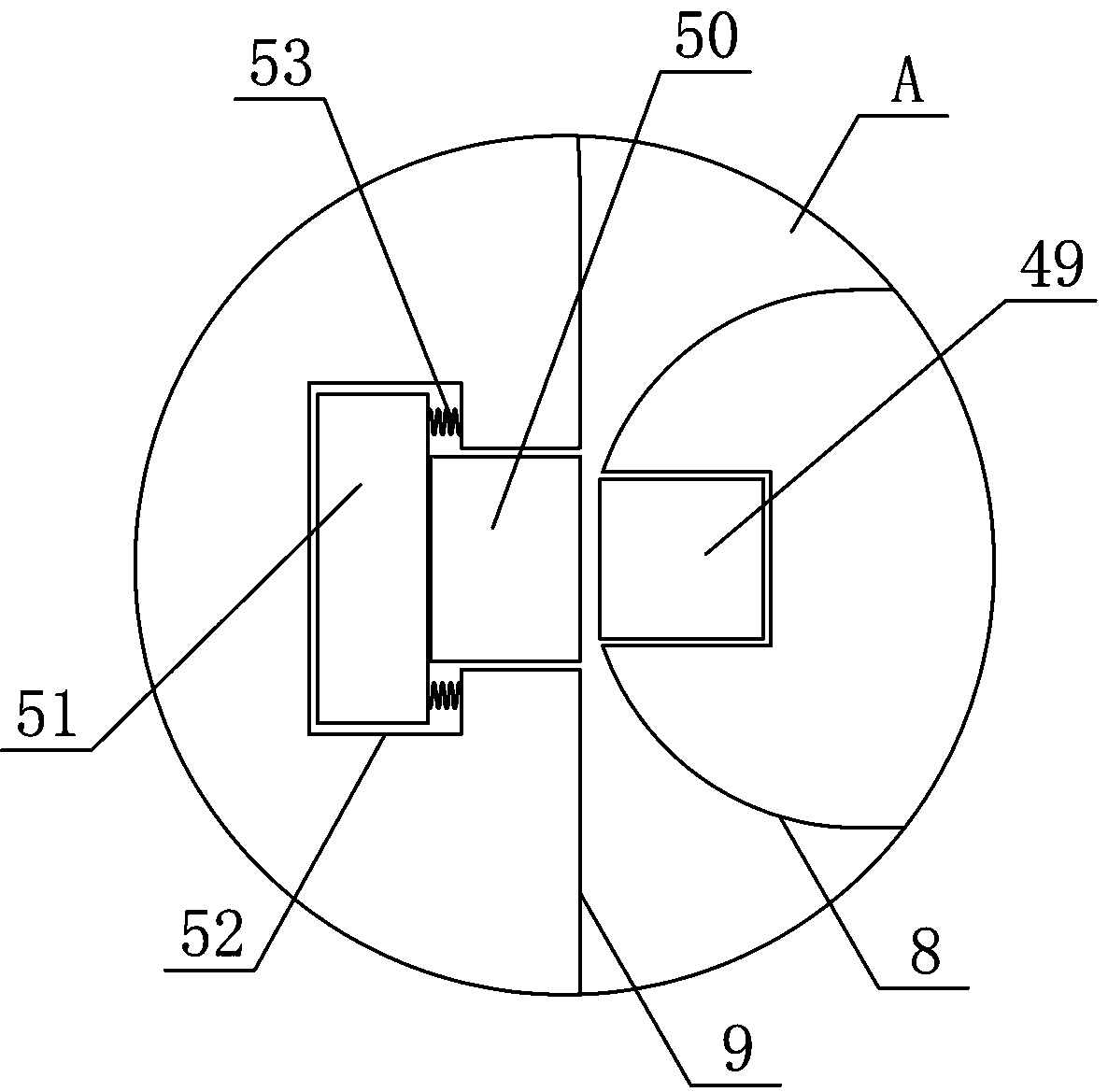

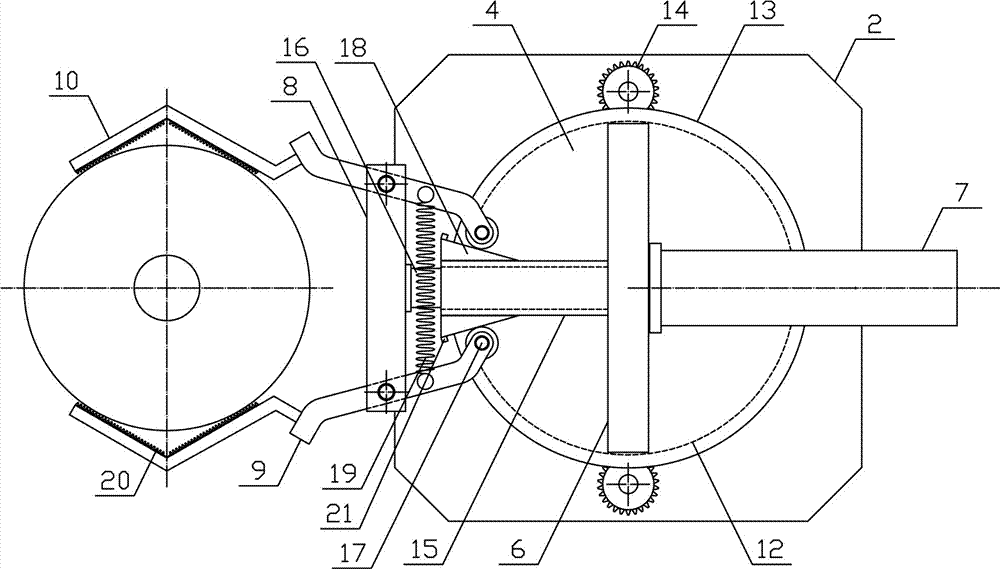

The invention discloses a continuous filling mechanism, which belongs to the field of material filling machinery and equipment. The invention includes a fixed bracket, a transmission bracket, a round can conveyor belt, a rotating circular plate, a slotted rotary plate, a rotating cam, a rotating motor, a lifting sleeve, a lifting guide rod and a filling material tube, and the round can conveyor belt is horizontally arranged on the transmission bracket. On the side, the rotating circular plate is vertically arranged at one end of the rotating shaft, and the card slot rotating plate is vertically arranged on one side of the translation pulley. Between two adjacent rotating arc surfaces, there are drive slots along the radial direction of the card slot rotating plate. The rotating card slot matching the wheel, the rotating motor and the rotating shaft are connected by a transmission belt transmission, the lifting sleeve is slid along the vertical direction and a lifting guide rod is installed, and the filling material tube is vertically set at one end of the filling support plate . The invention has a reasonable structural design, can quickly, efficiently and smoothly fill the round cans one by one continuously, improves the efficiency and quality of filling, and meets the needs of production and use.

Owner:屠明州

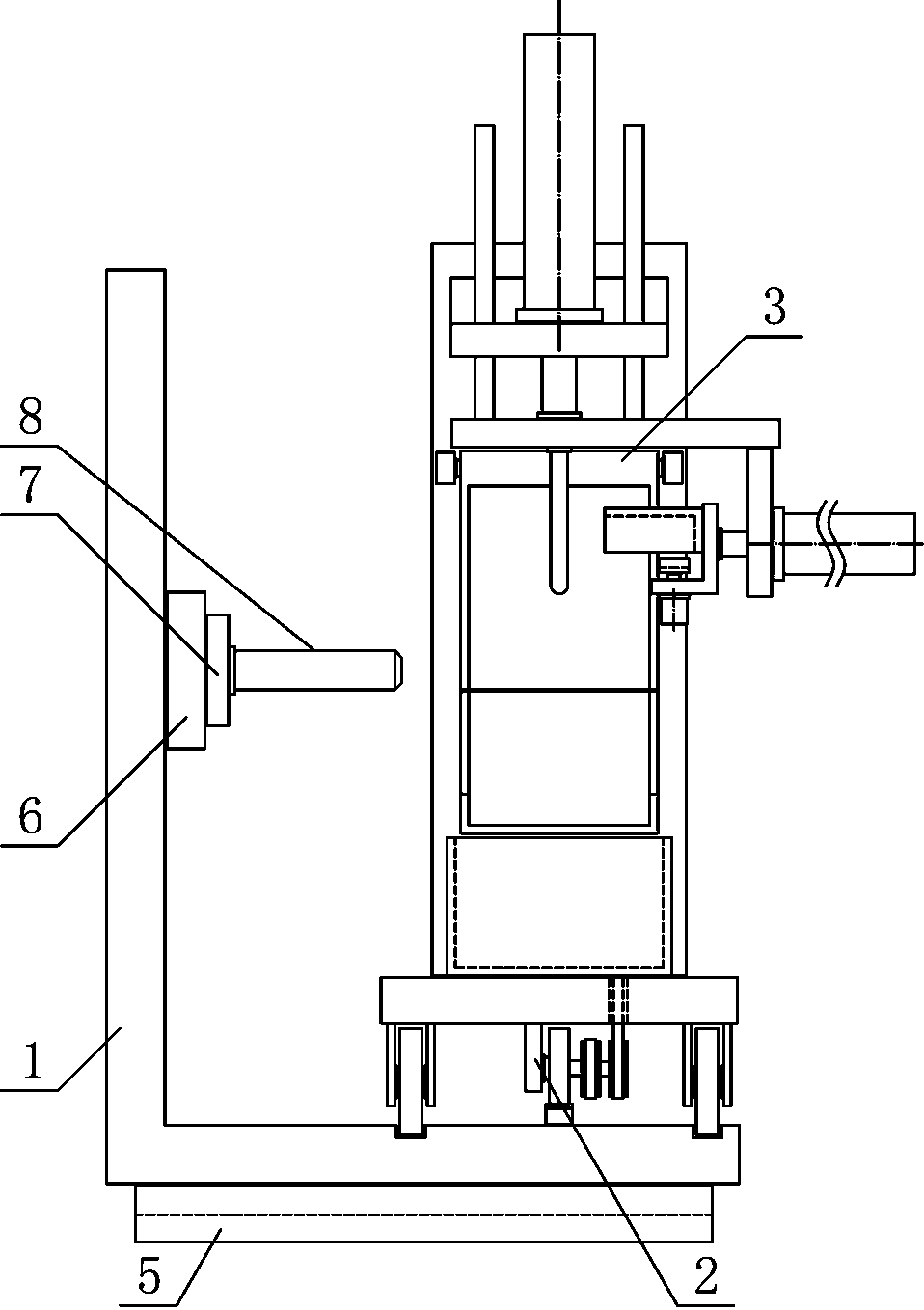

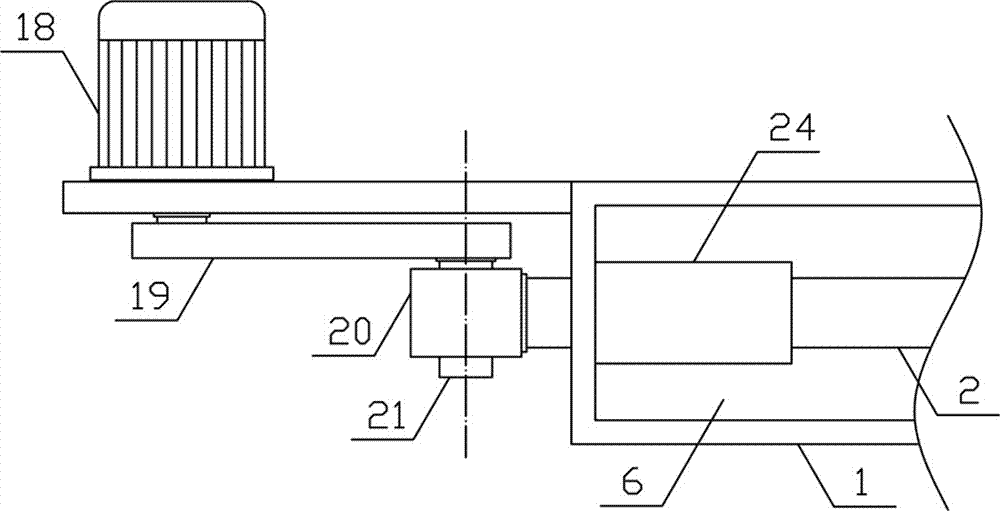

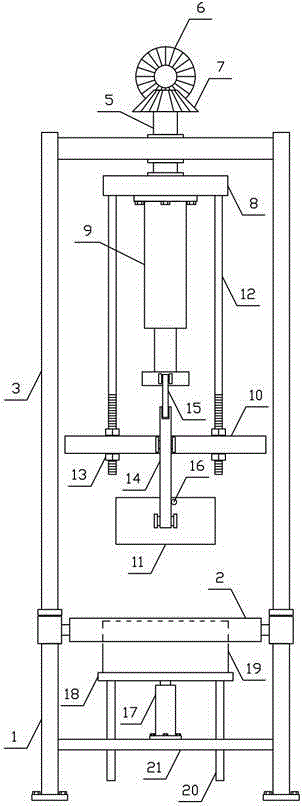

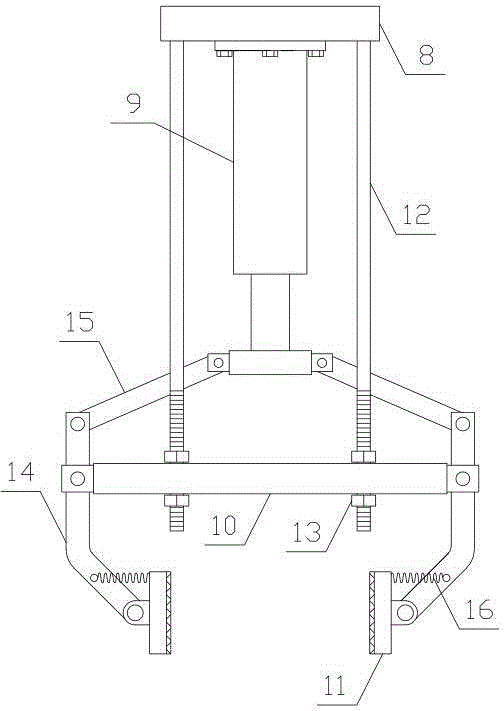

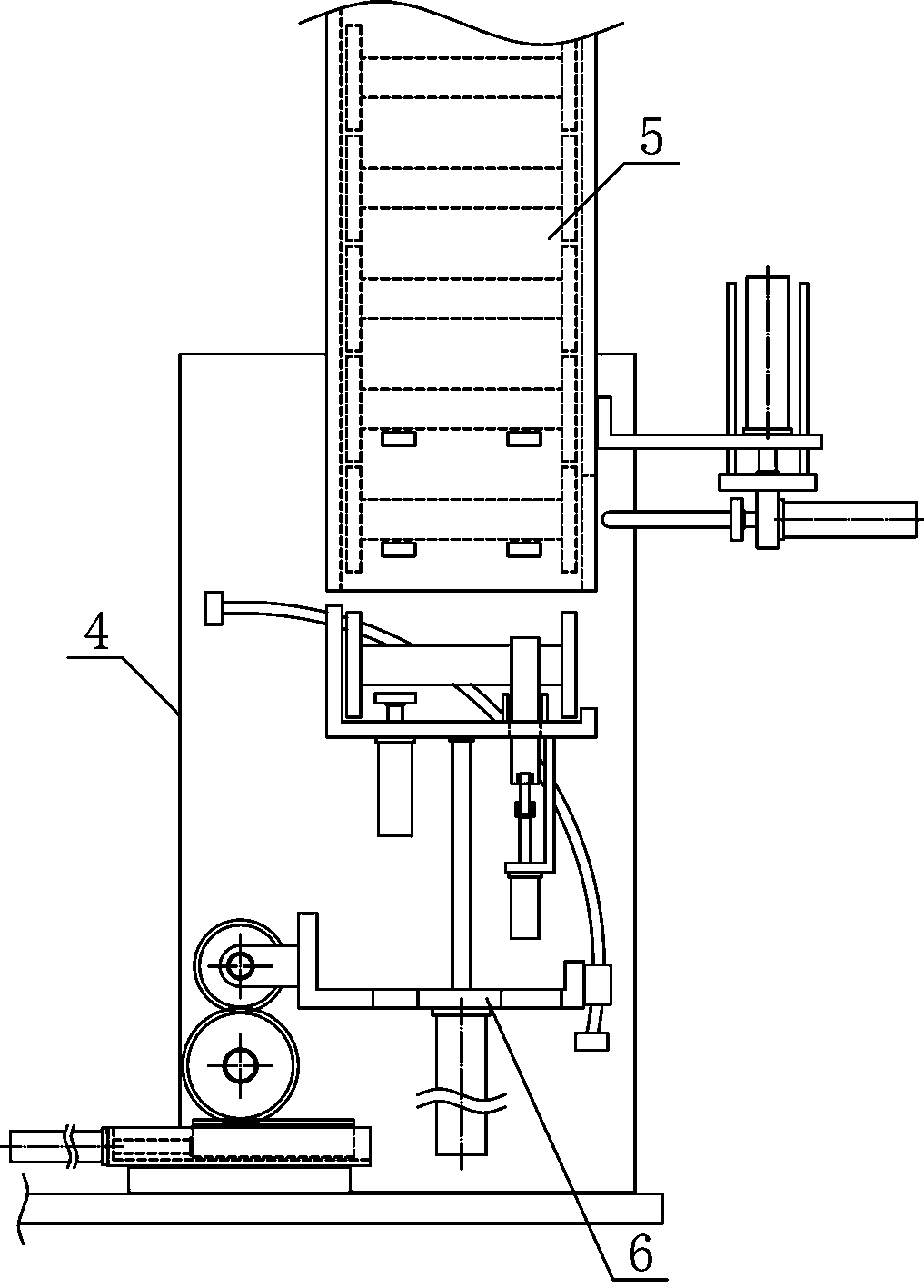

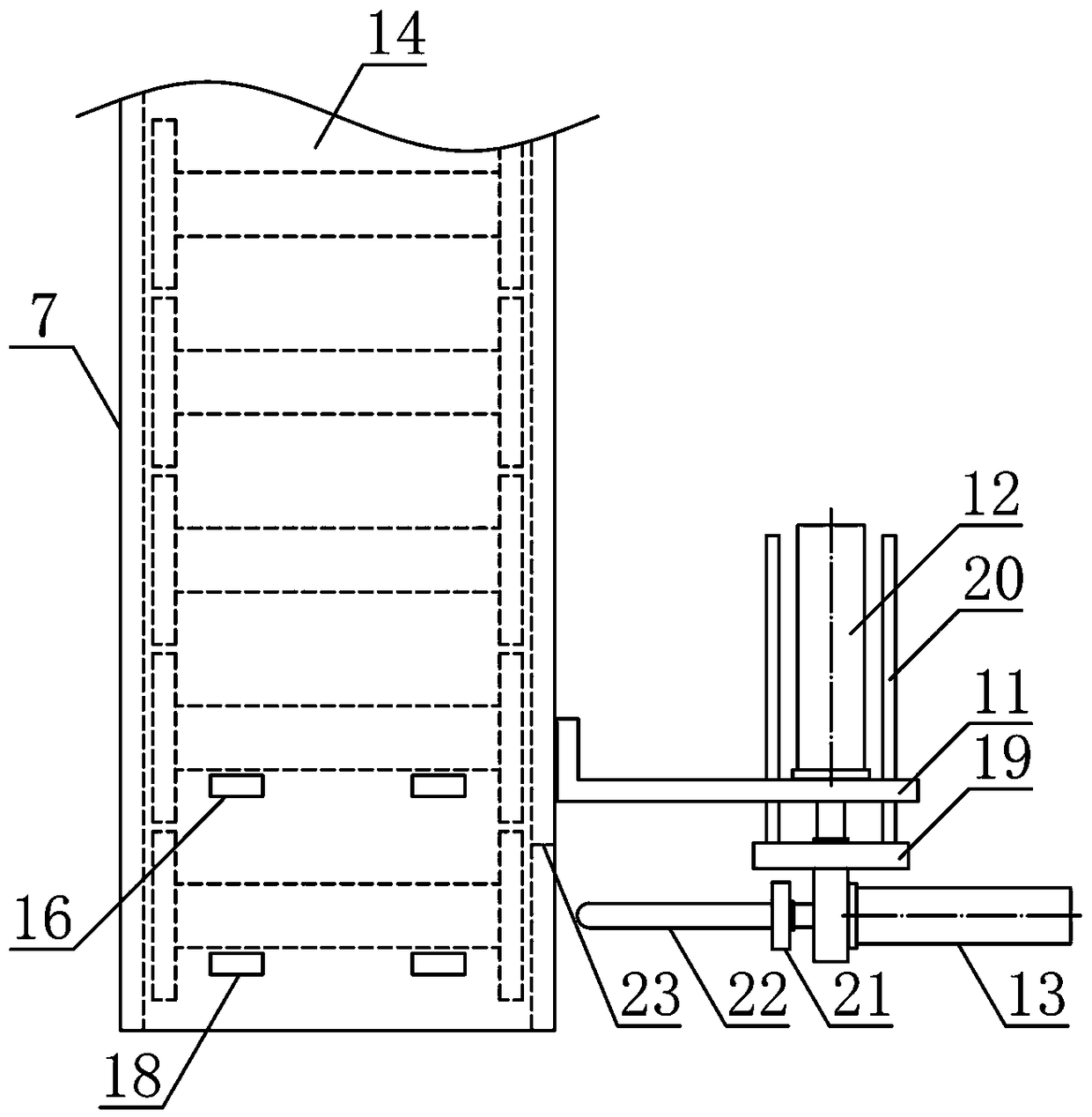

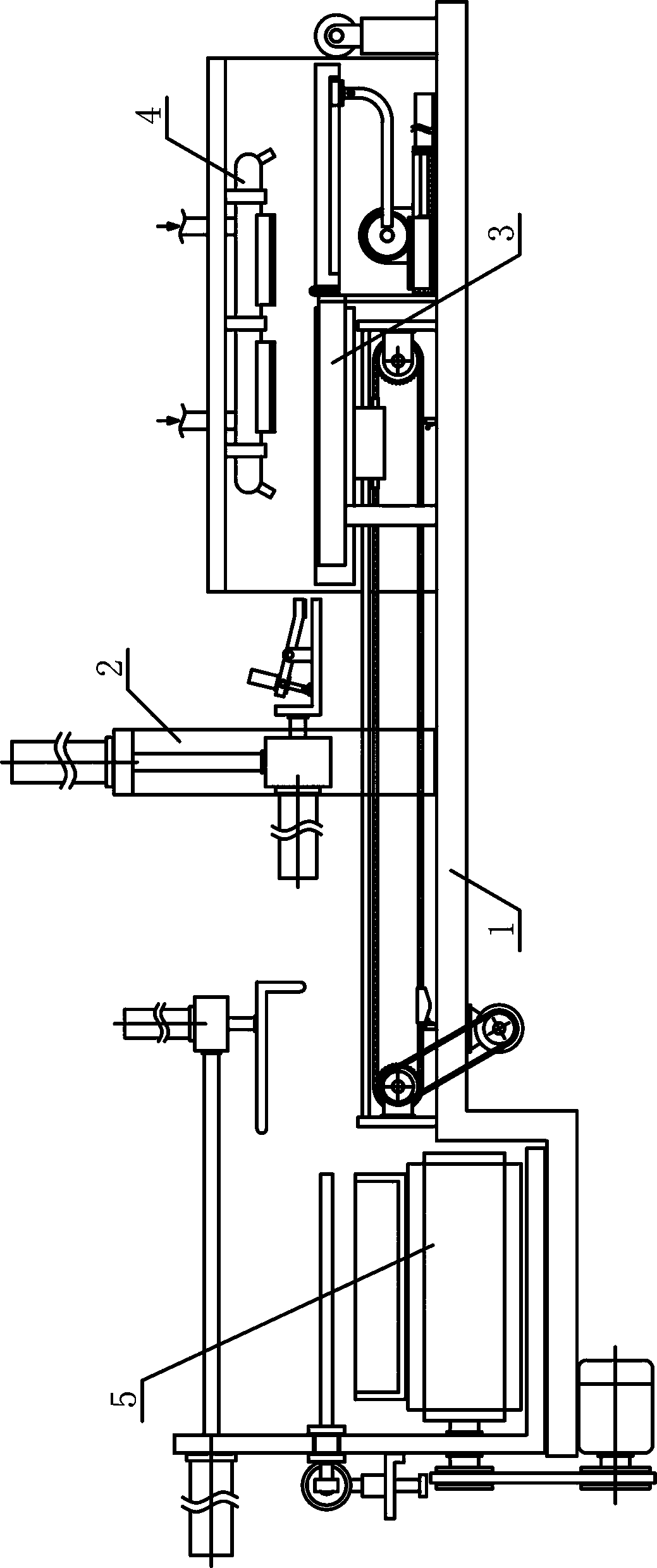

Tray unstacking devcie

InactiveCN106429472ASmooth liftSimple structureDe-stacking articlesEngineeringMechanical engineering

Owner:浙江曼得丽涂料有限公司

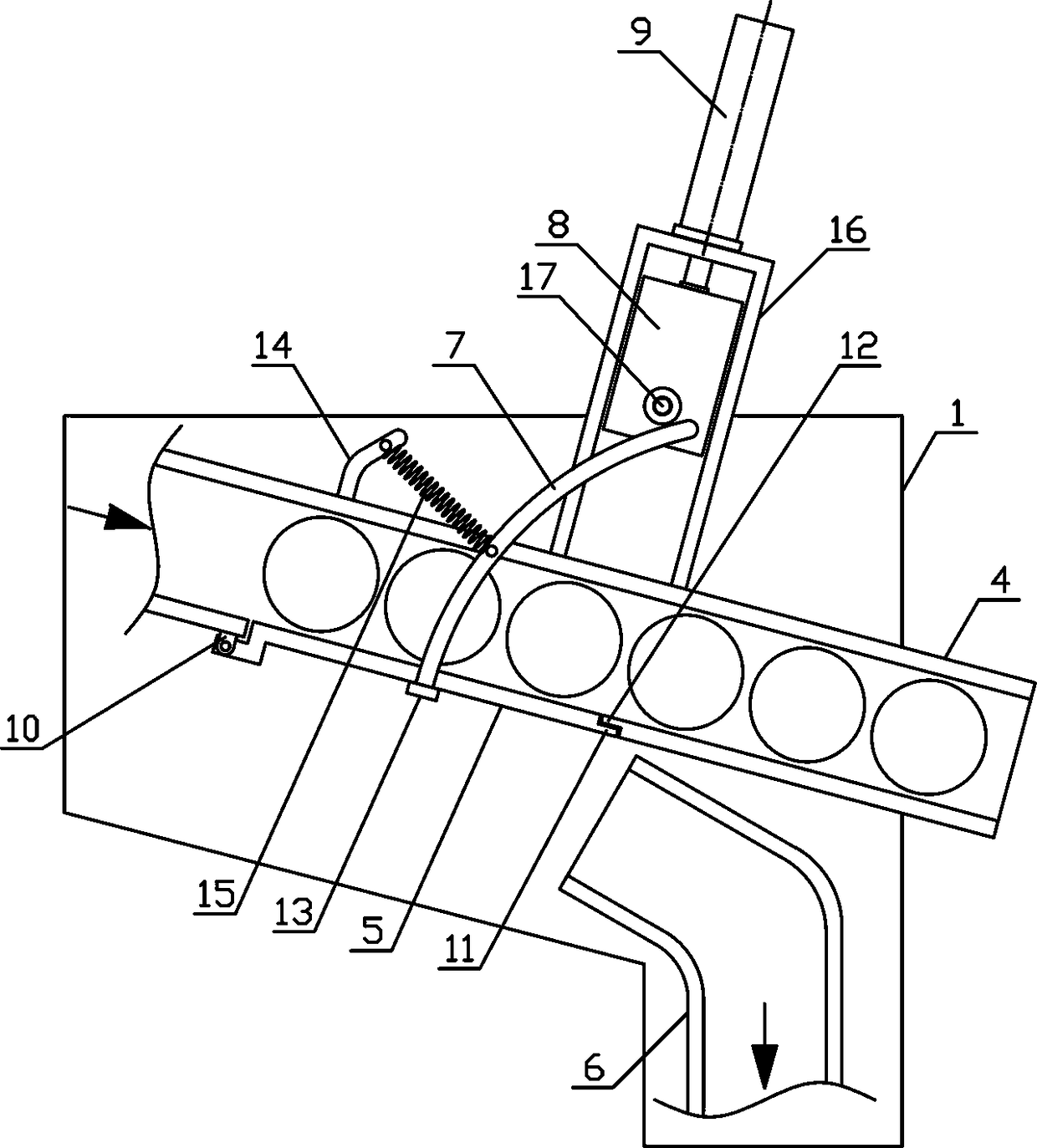

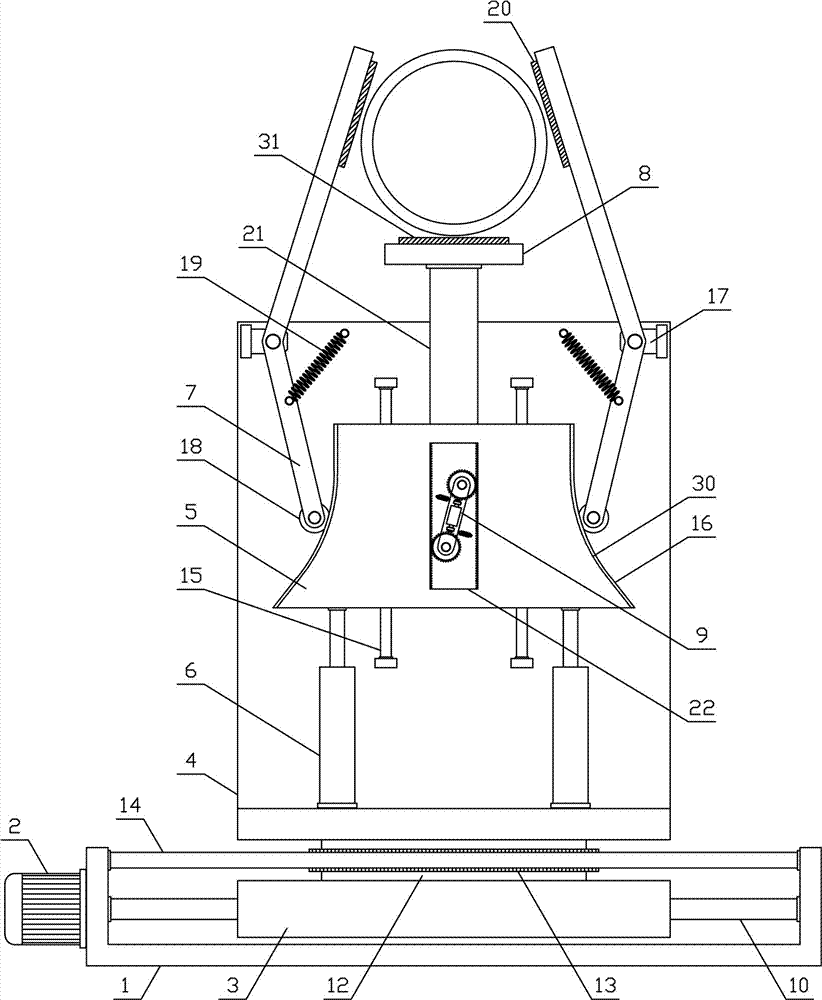

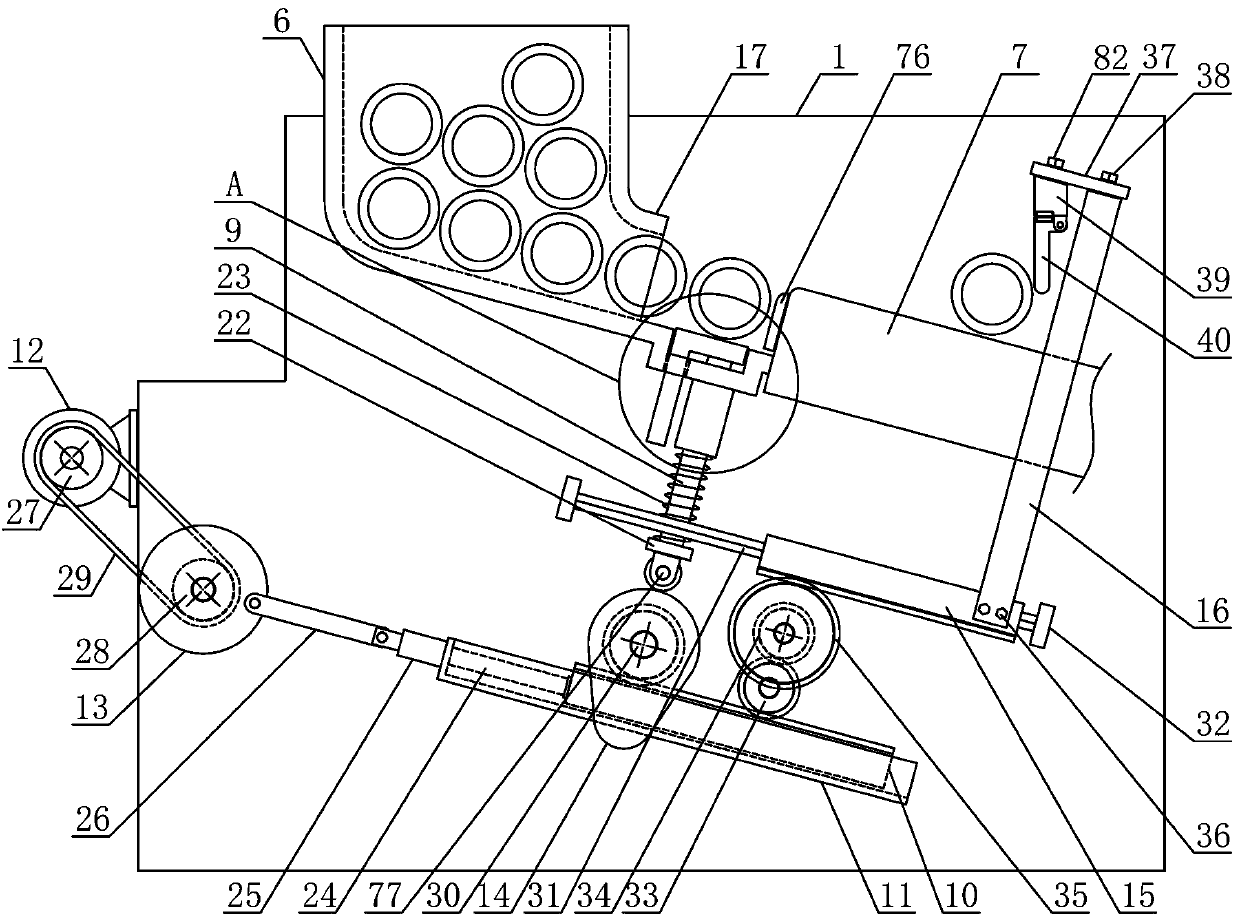

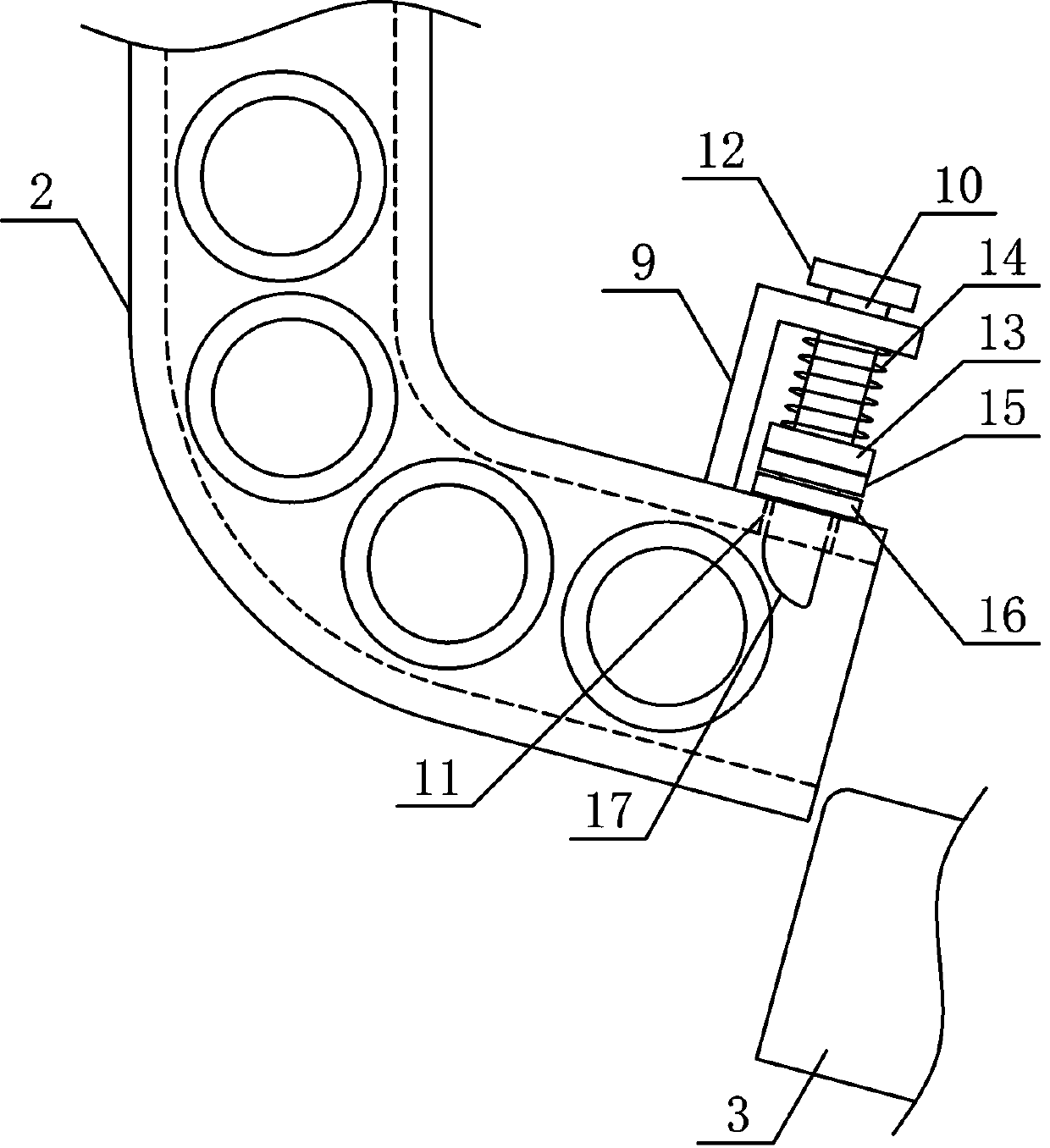

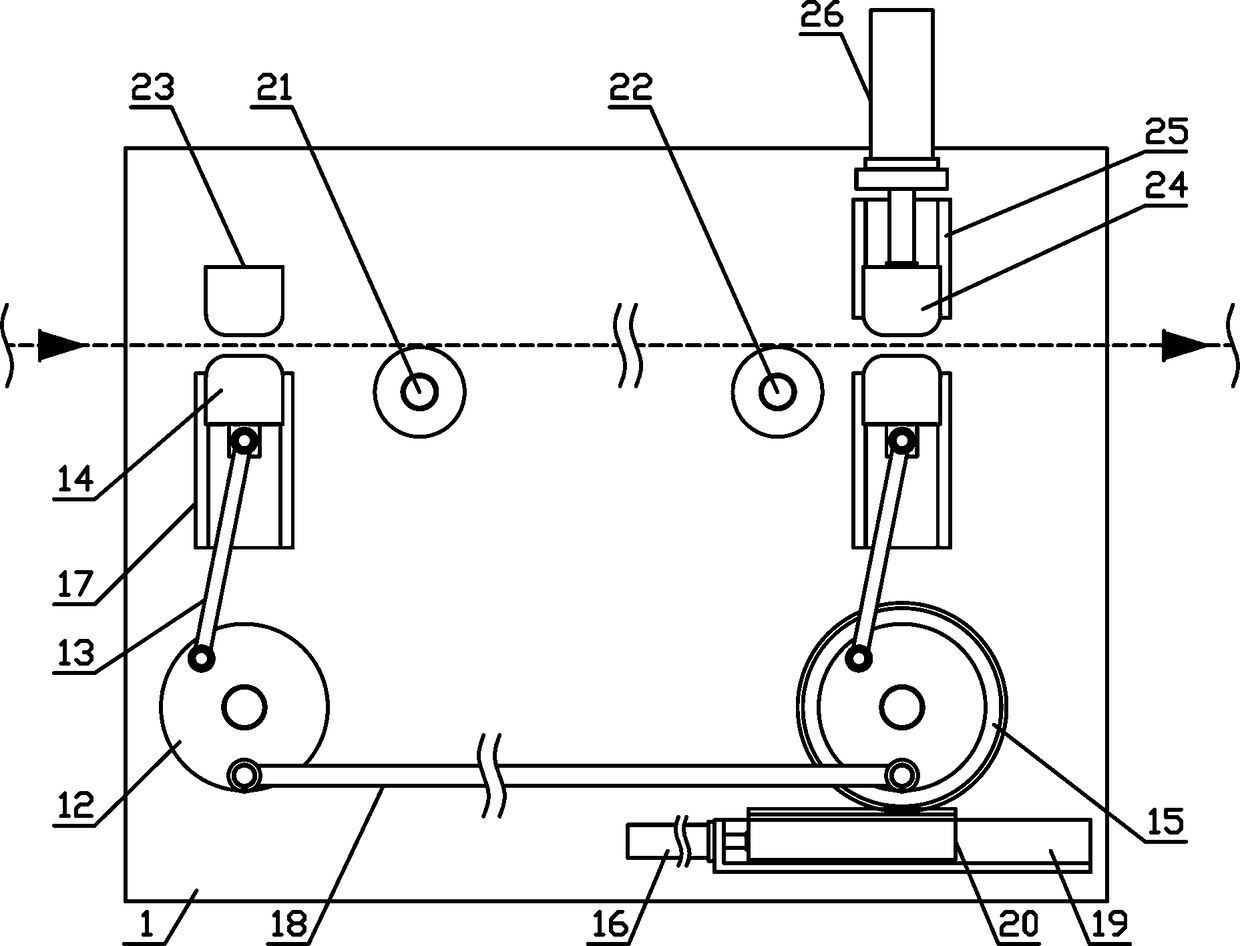

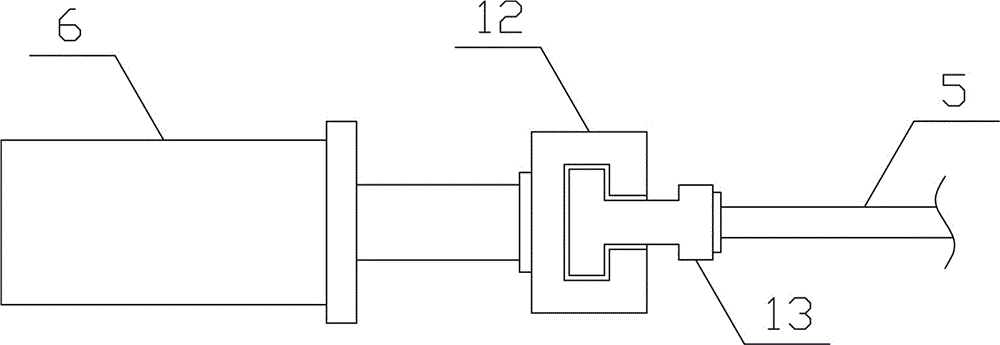

Pipe continuous supplying mechanism

InactiveCN108639721AAvoid stackingTo achieve the effect of diversionConveyorsConveyor partsMechanical equipmentGuide tube

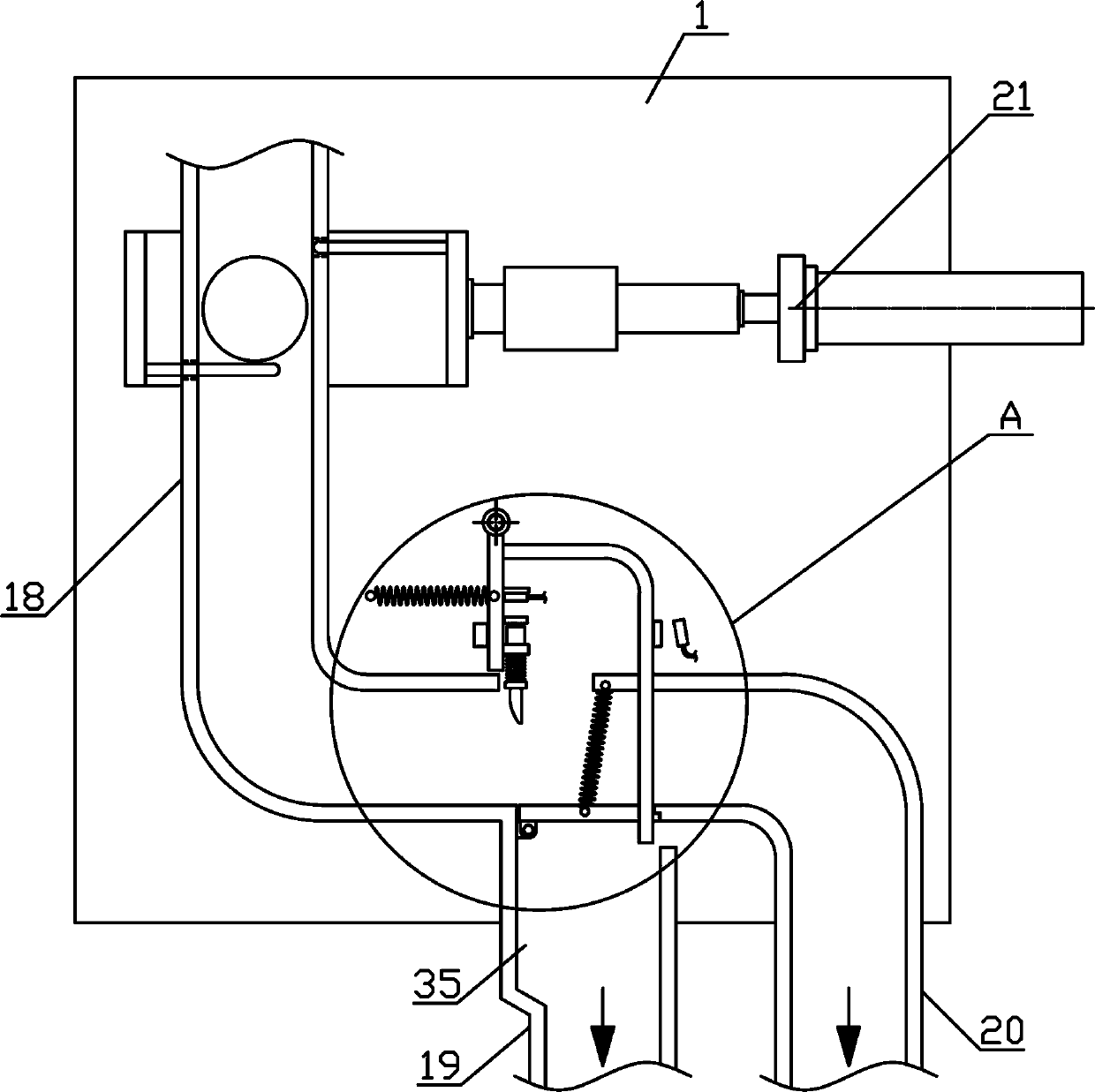

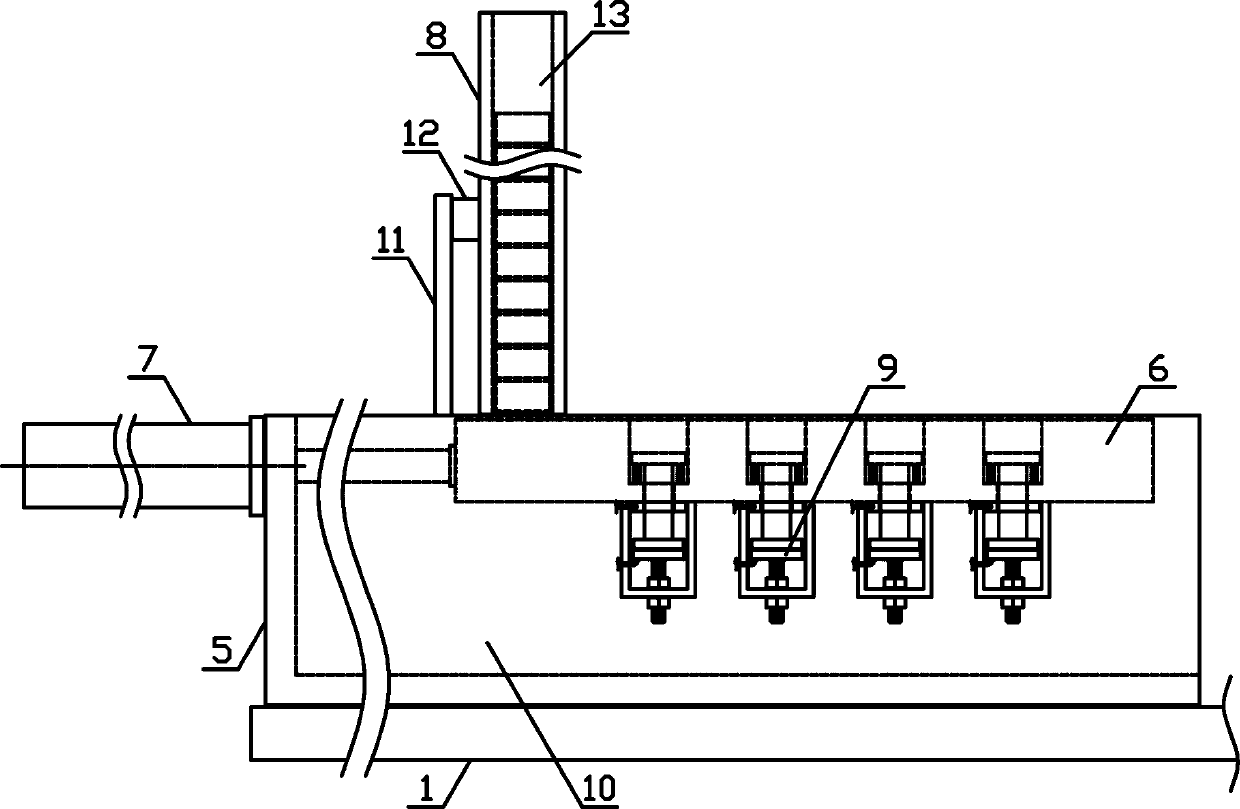

The invention discloses a pipe continuous supplying mechanism and belongs to the field of workpiece machining mechanical equipment. A pipe guide mechanism and a pipe feeding mechanism of the pipe continuous supplying mechanism are sequentially arranged on one side of a fixed support in an inclination direction from top to bottom. A pipe distributing charge pipe is vertically arranged in the position, on the lower side of a pipe guide charge pipe, of the fixed support. A pipe bearing baffle is arranged on the lower side of the pipe guide charge pipe. A baffle tension spring is arranged betweena spring connecting rod and a pushing plate pressing rod in an obliquely connected mode. A pressing rod roller is horizontally and rotationally connected to one side of a lifting pressing block. A pipe feeding motor and a pipe feeding rotary shaft are connected through a pipe supplying belt in a transmission mode. A plurality of pipe feeding bearing plates are fixedly arranged on the outer side ofa pipe feeding guide wheel in the radial direction of the pipe feeding guide wheel. A supplying charge pipe is obliquely arranged in the position, on the lower side of the pipe feeding guide wheel, of the fixed support. A pipe collecting charge pipe is obliquely arranged in the position, on the lower side of the supplying charge pipe, of the fixed support. The pipe continuous supplying mechanismis reasonable in structural design, can achieve continuous and stable conveying and supplying of pipes, can discharge pipes in a branched mode according to the requirements of next pipe machining loads, and meets the requirements of production and using.

Owner:海宁市波菲特进出口有限公司

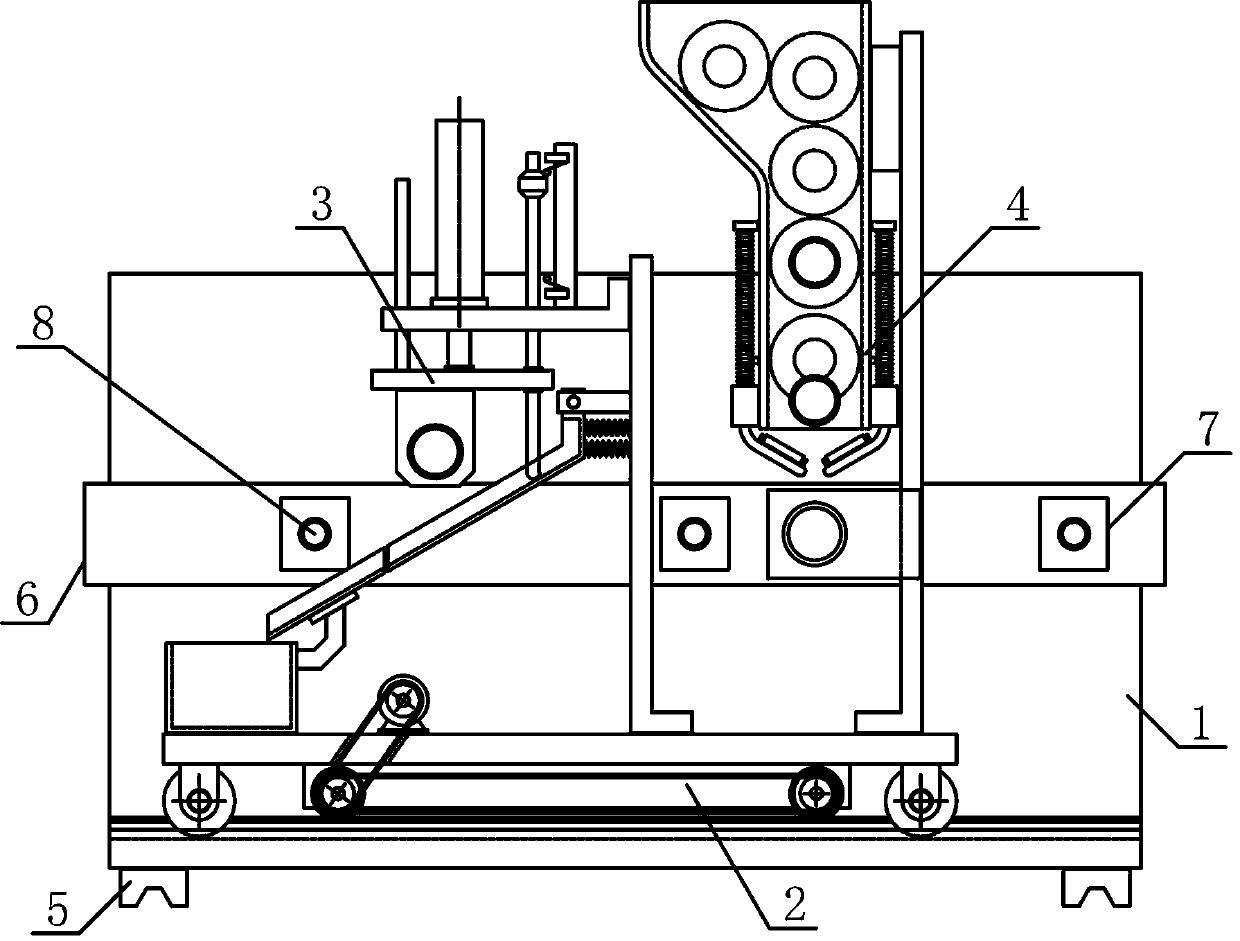

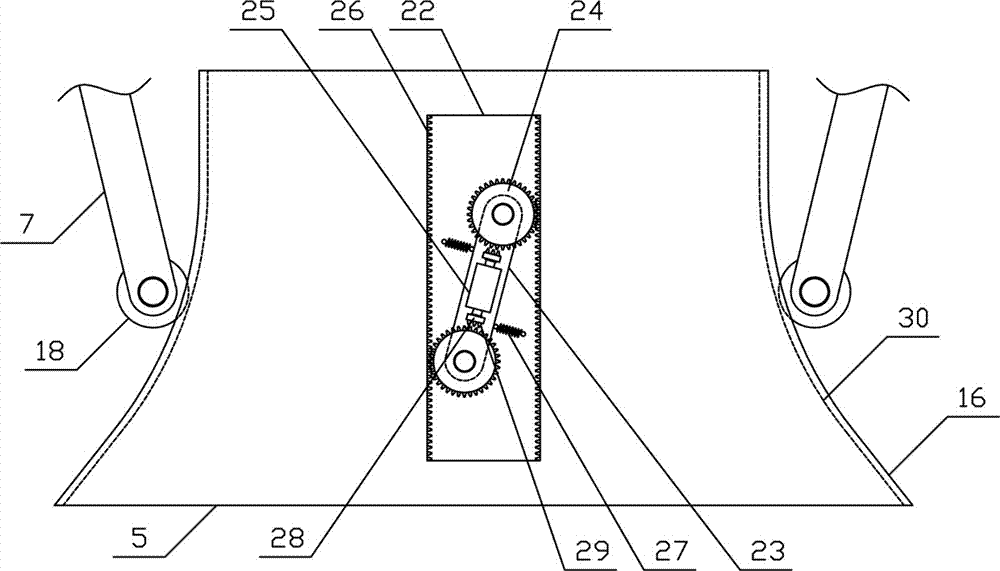

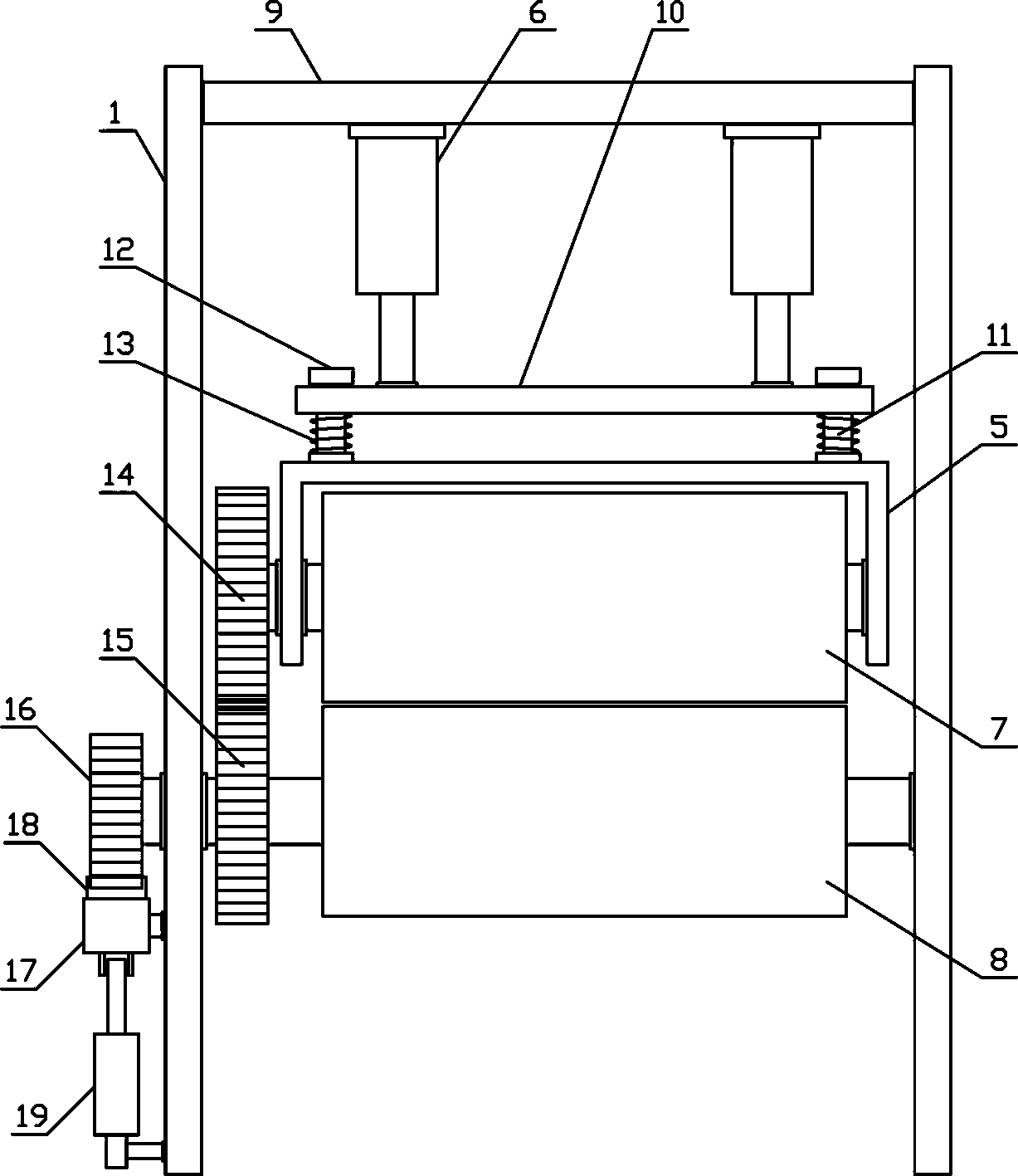

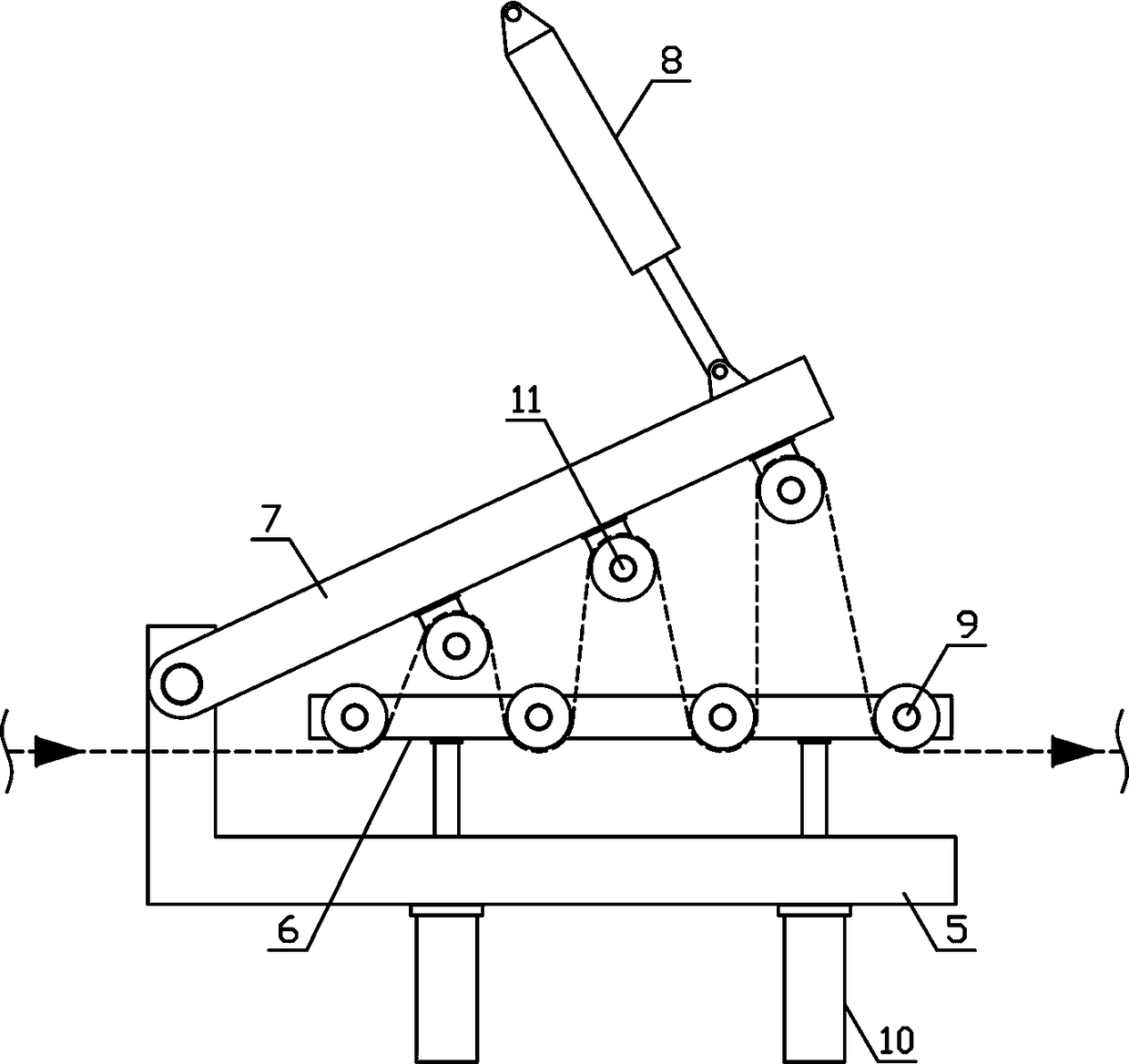

Panel compositing and pressing device

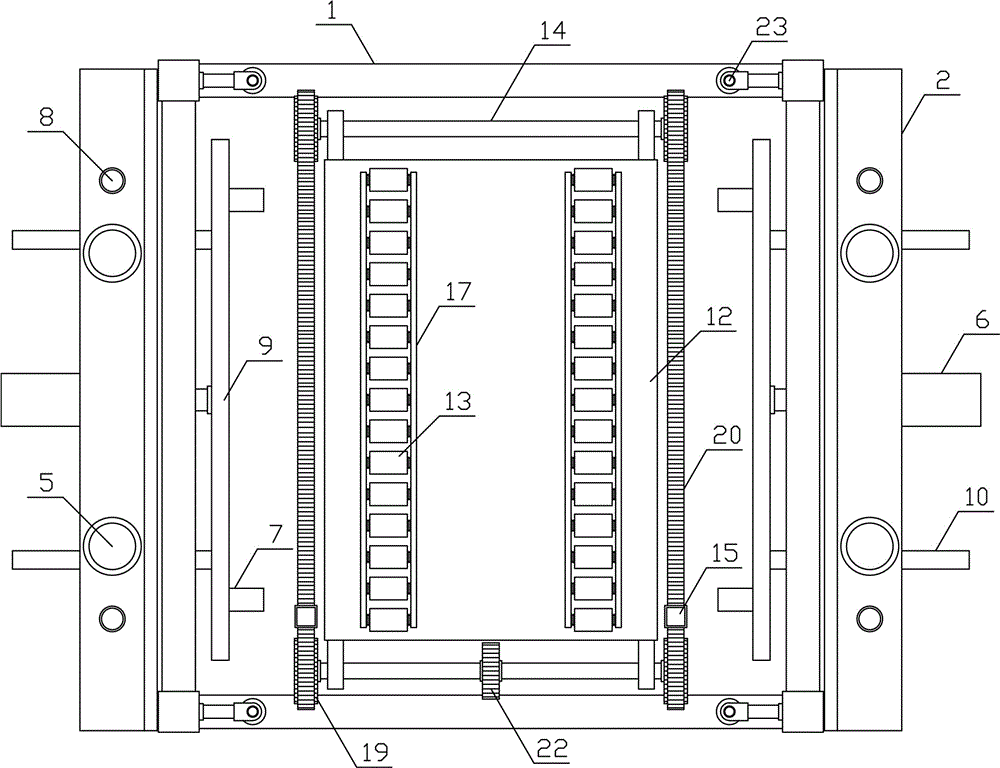

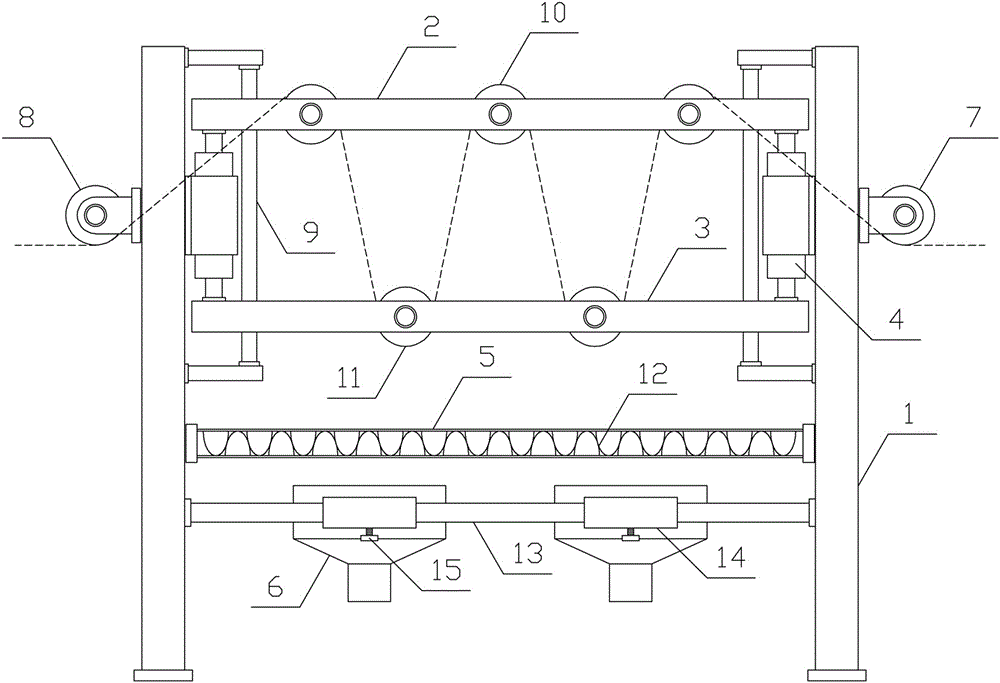

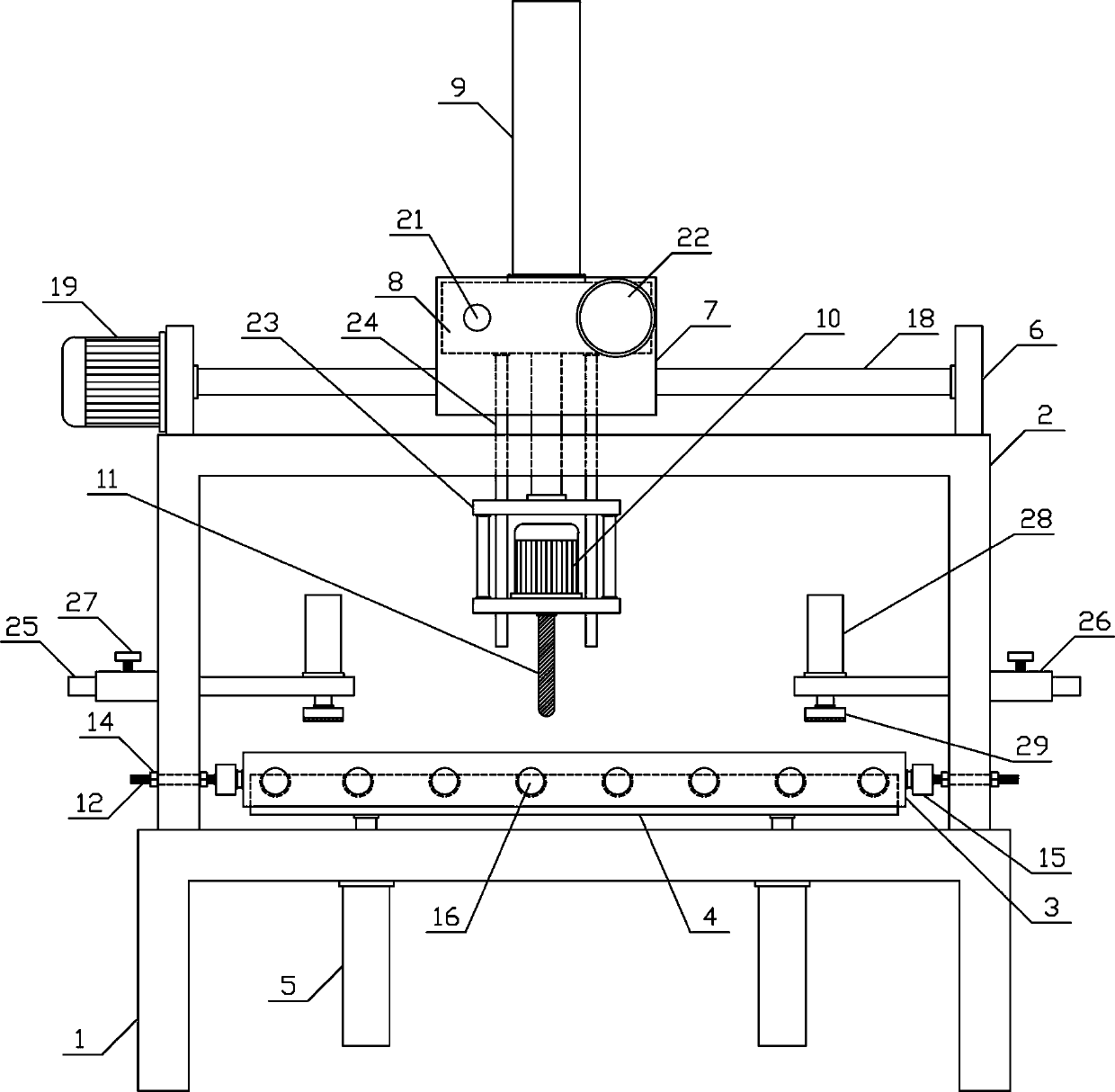

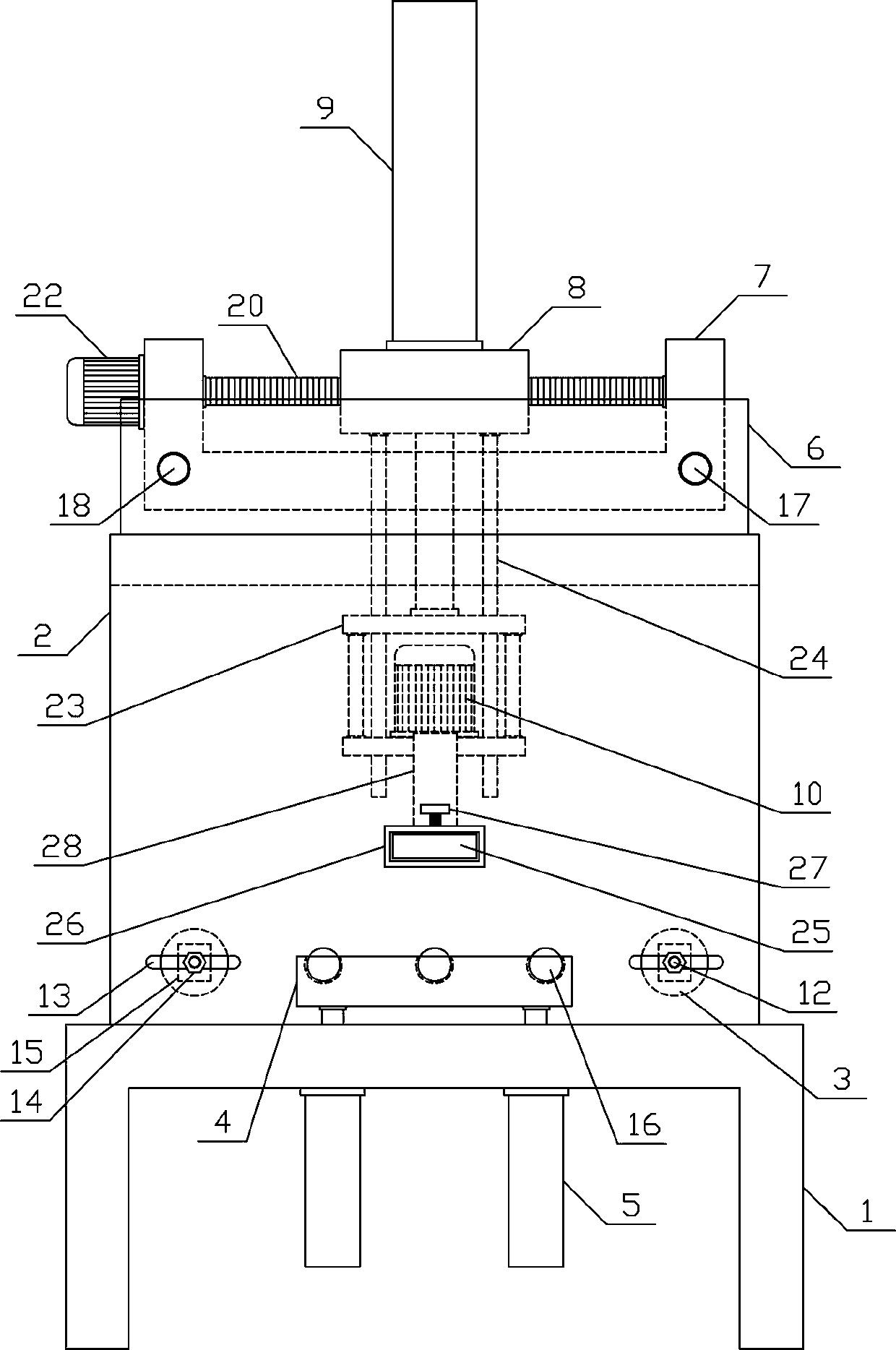

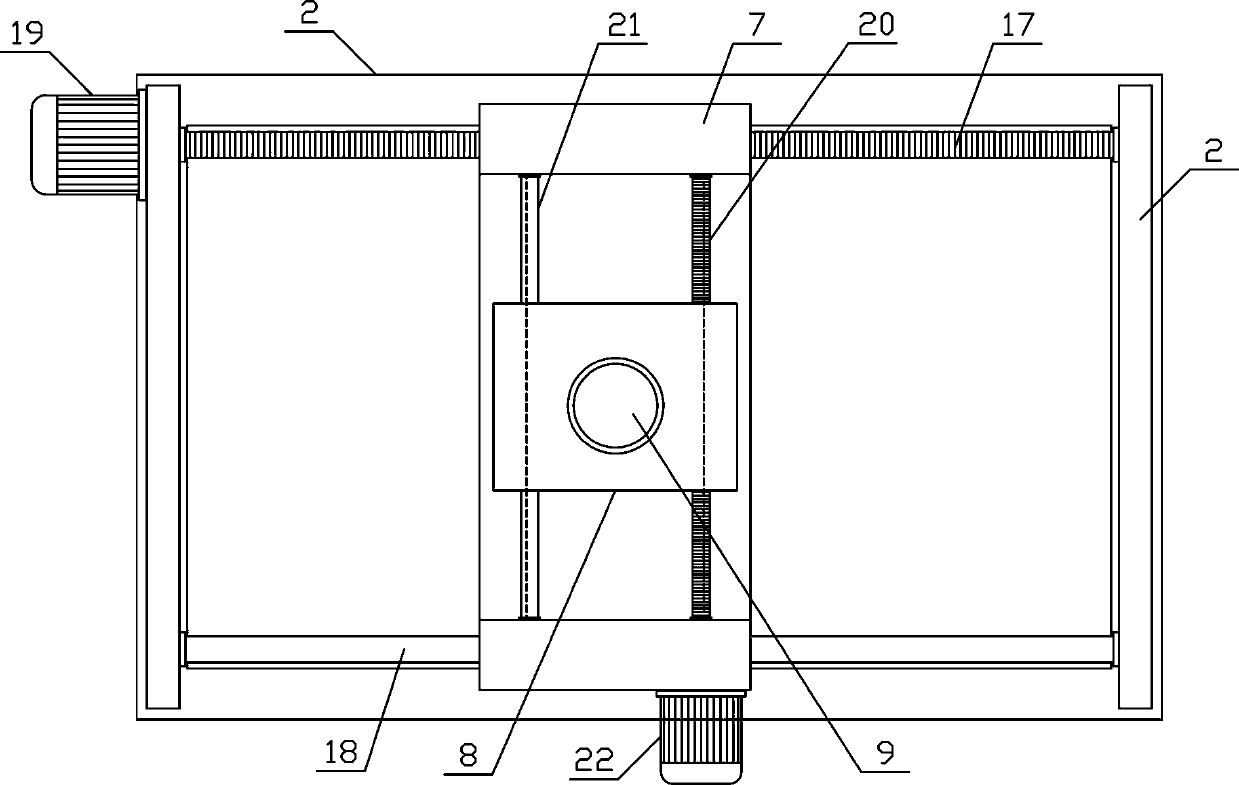

InactiveCN105856346AImprove efficiencyQuality improvementPlywood pressesLaminationHydraulic cylinderMechanical devices

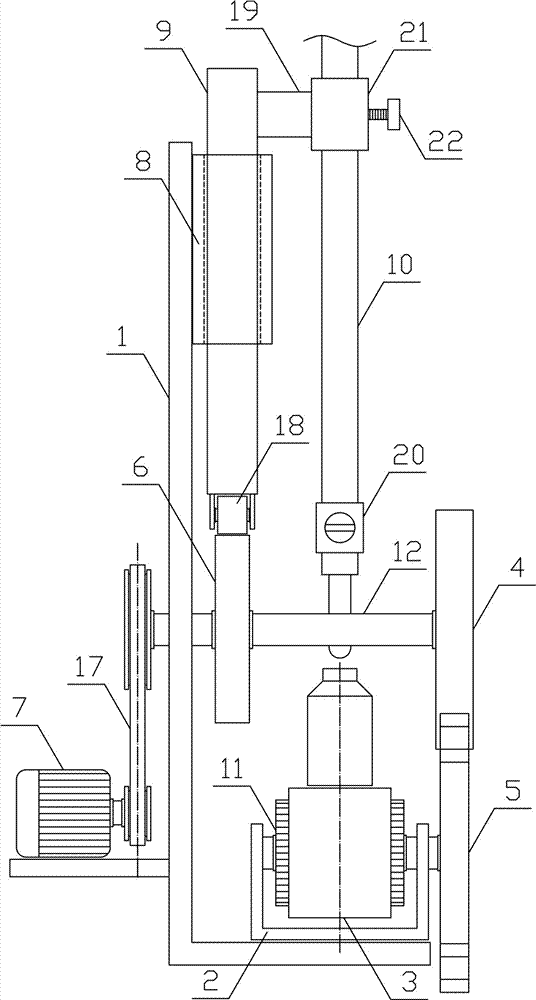

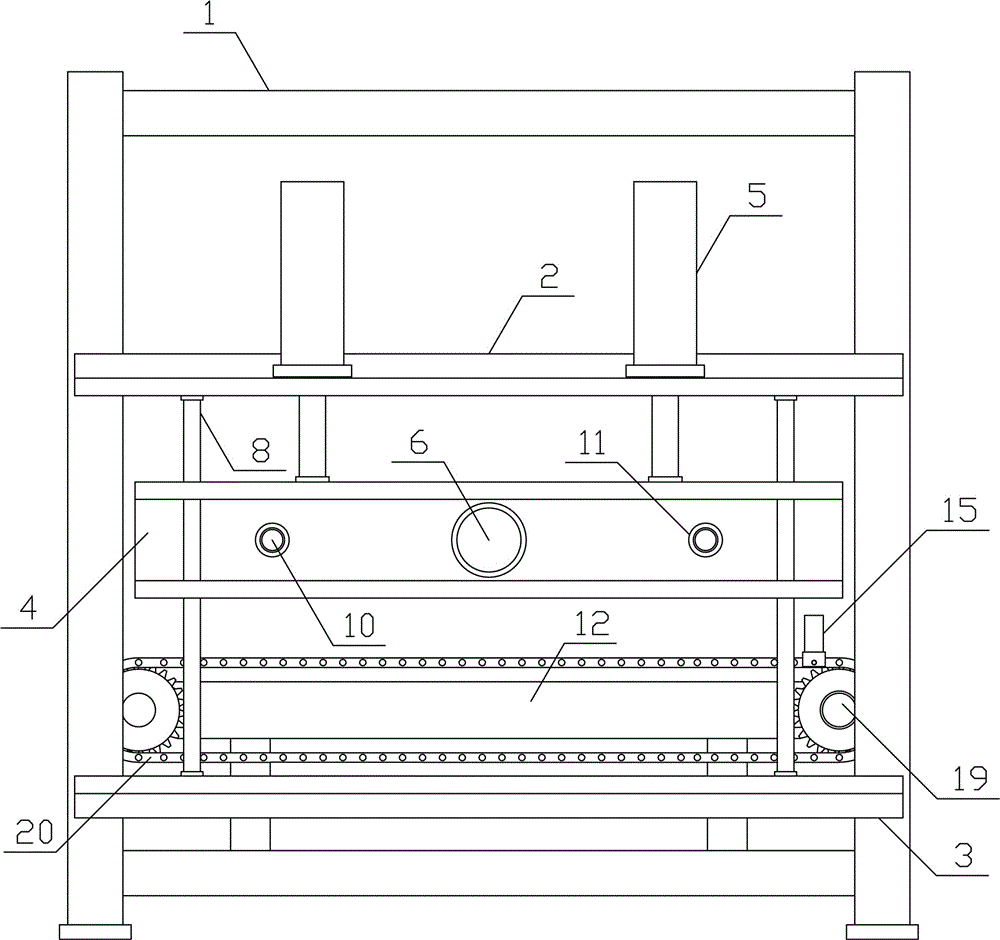

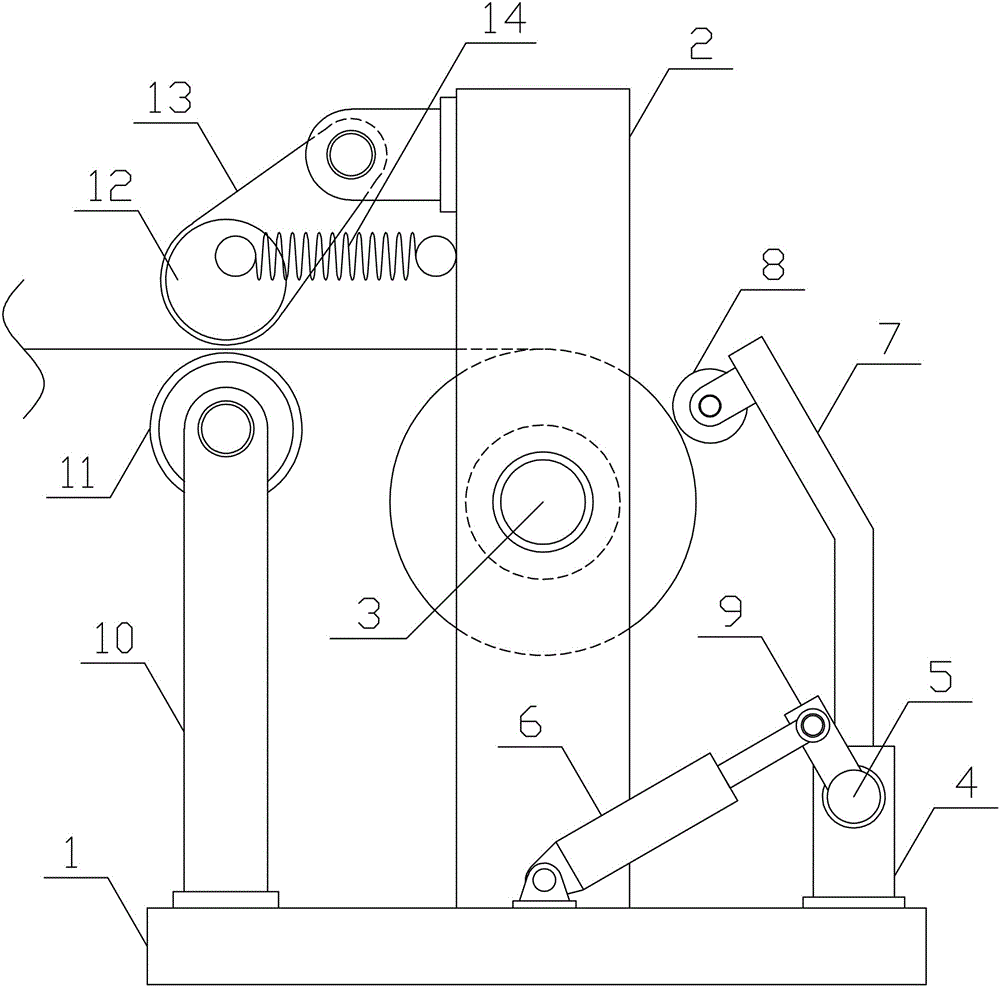

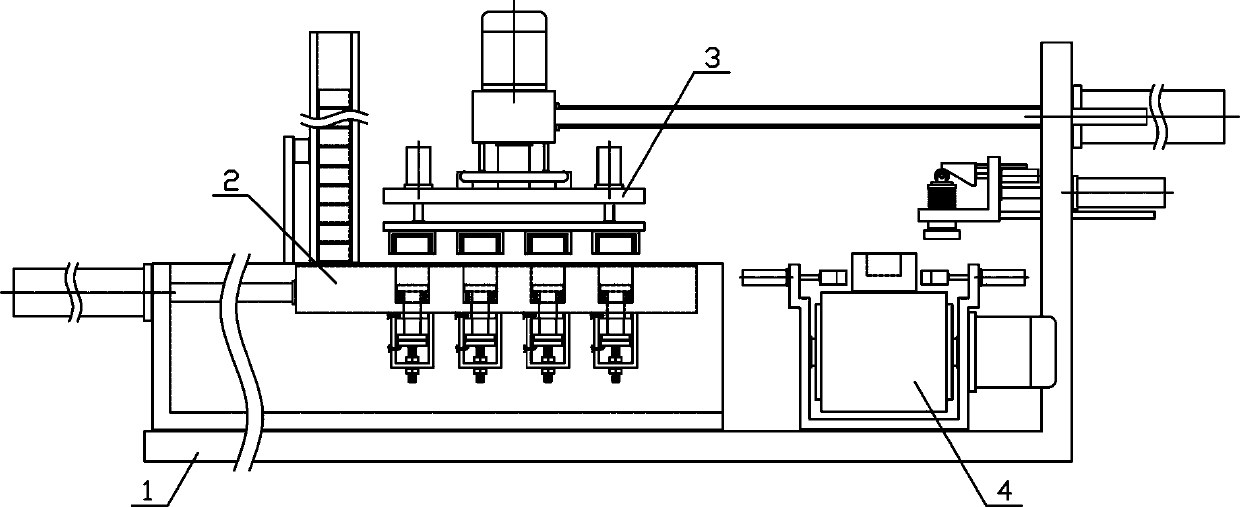

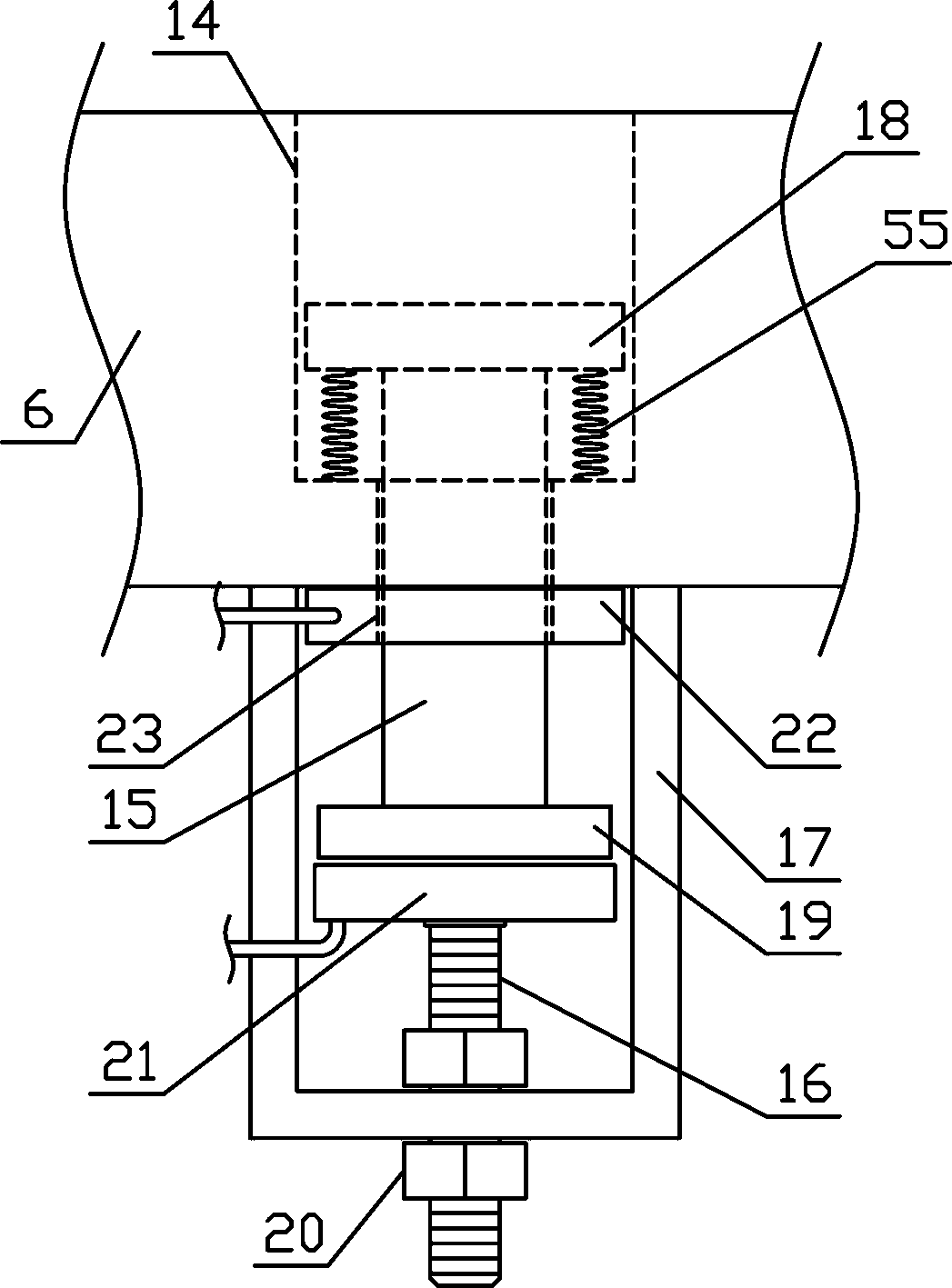

The invention discloses a panel compositing and pressing device, and belongs to the field of building machining mechanical devices. The panel compositing and pressing device comprises a fixed support, panel bearing rollers, panel pressing rollers, pressing hydraulic cylinders and a panel guide support. The two sides of the fixed support are horizontally and rotationally connected with a panel input roller and a panel output roller respectively. The middle of the fixed support is horizontally, evenly and rotationally connected with the panel bearing rollers. The panel guide support is horizontally, evenly and rotationally connected with a plurality of panel guide rollers. Connecting rods are arranged between the two ends of the lower side of the panel guide support and the fixed support respectively. The two pressing hydraulic cylinders are vertically downwards arranged on the upper side of the fixed support. The output ends of the pressing hydraulic cylinders are horizontally provided with a lifting plate. The lower side of a pressing plate is horizontally, evenly and rotationally connected with the panel pressing rollers. Panel pressing springs are arranged on lifting guide rods between the lifting plate and the pressing plate. The panel compositing and pressing device is reasonable in structural design, firm pressing of composited panels can be rapidly and efficiently achieved, panel compositing efficiency and quality are improved, and requirements of machining and using are met.

Owner:晋正正

Automatic spool replacing device for woolen sweater fabric weaving

PendingCN110077906AHigh degree of automationImprove replacement efficiencyConveyorsFilament handlingYarnEngineering

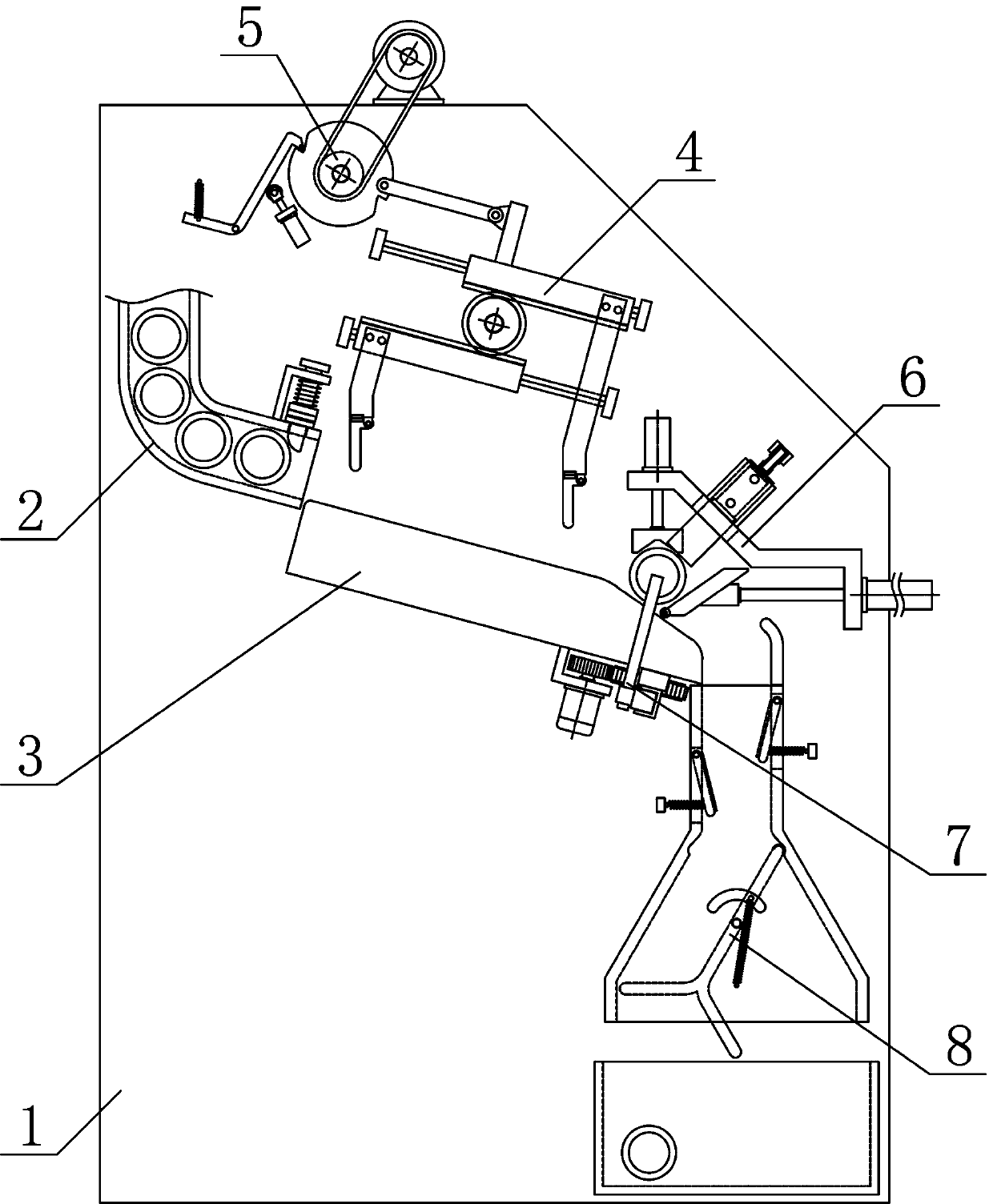

The invention discloses an automatic spool replacing device for woolen sweater fabric weaving and belongs to the field of textile and garment machining mechanical devices. An empty spool discharging mechanism and a full spool feeding mechanism are sequentially and vertically arranged on the two sides of the upper side of a reciprocating horizontal movement mechanism in the horizontal direction. Air expansion rotating shafts are horizontally and rotationally connected to yarn conveying bases. The two sides of the lower side of a reciprocating support are symmetrically and rotationally connectedwith two horizontal movement guide wheels correspondingly. The output end of a lifting air cylinder is horizontally and fixedly provided with a spool fetching connection plate. The end of the upper side of a rotational sliding groove is hinged to a rotating support seat. A fixed sliding groove is fixedly arranged on the upper side of a spool holding material frame in the inclined direction. The upper side of a full-spool holding pipe is provided with a full-spool storage hopper in a communicating manner. The lower end of a full-spool falling guide rod is fixedly provided with a full-spool bearing inclined rod. A full-spool pushing connection plate is fixedly arranged at the output end of the full-spool pushing air cylinder. The automatic spool replacing device for woolen sweater fabric weaving is reasonable in structural design and can achieve one-by-one continuous feeding and replacing of the spool after yarn taking-off is completed, the automation degree of spool replacement is improved, and production and use demands are met.

Owner:浙江富士佳实业有限公司

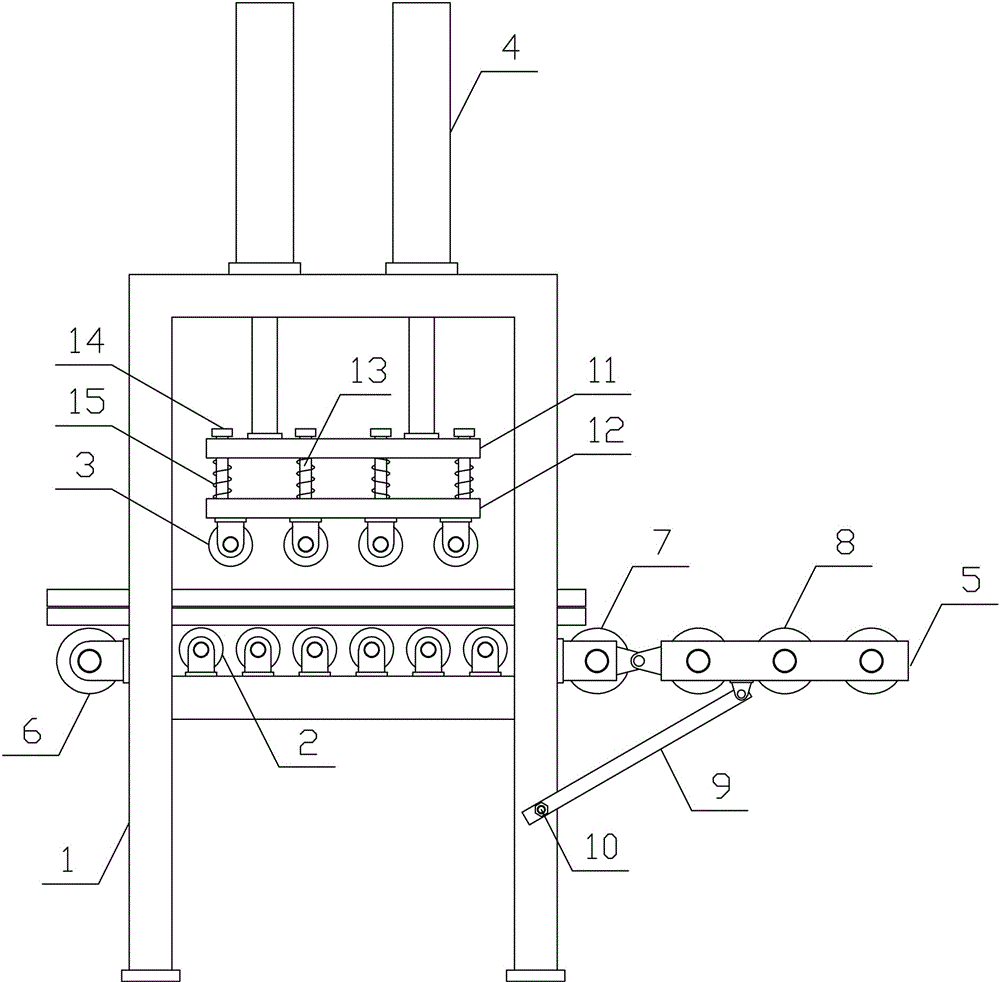

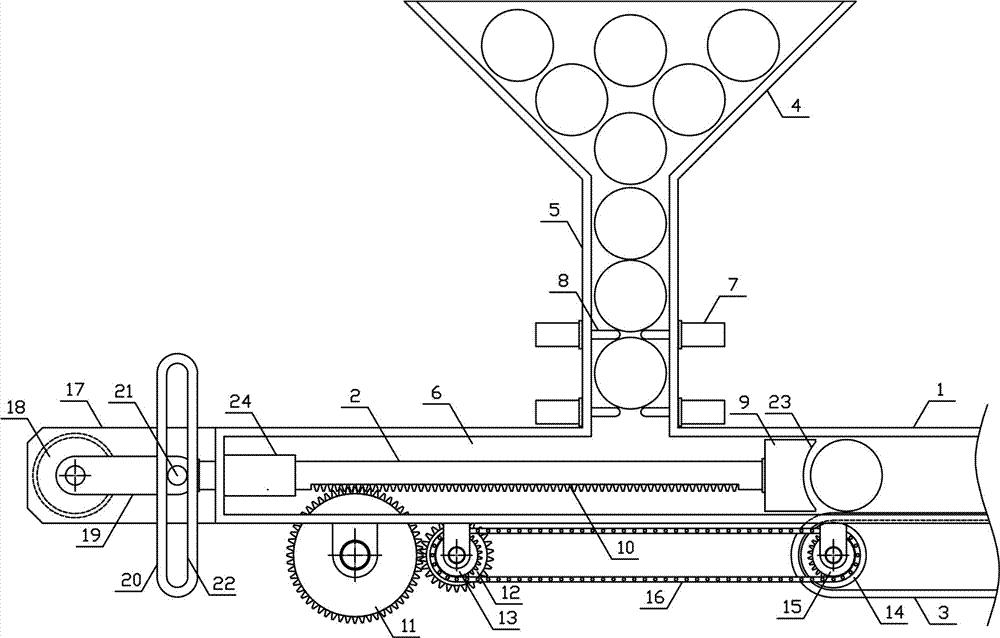

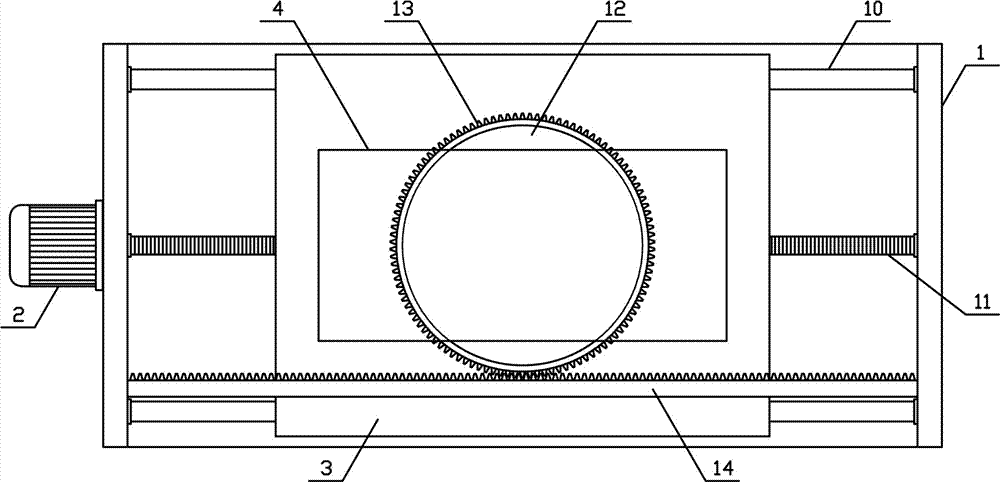

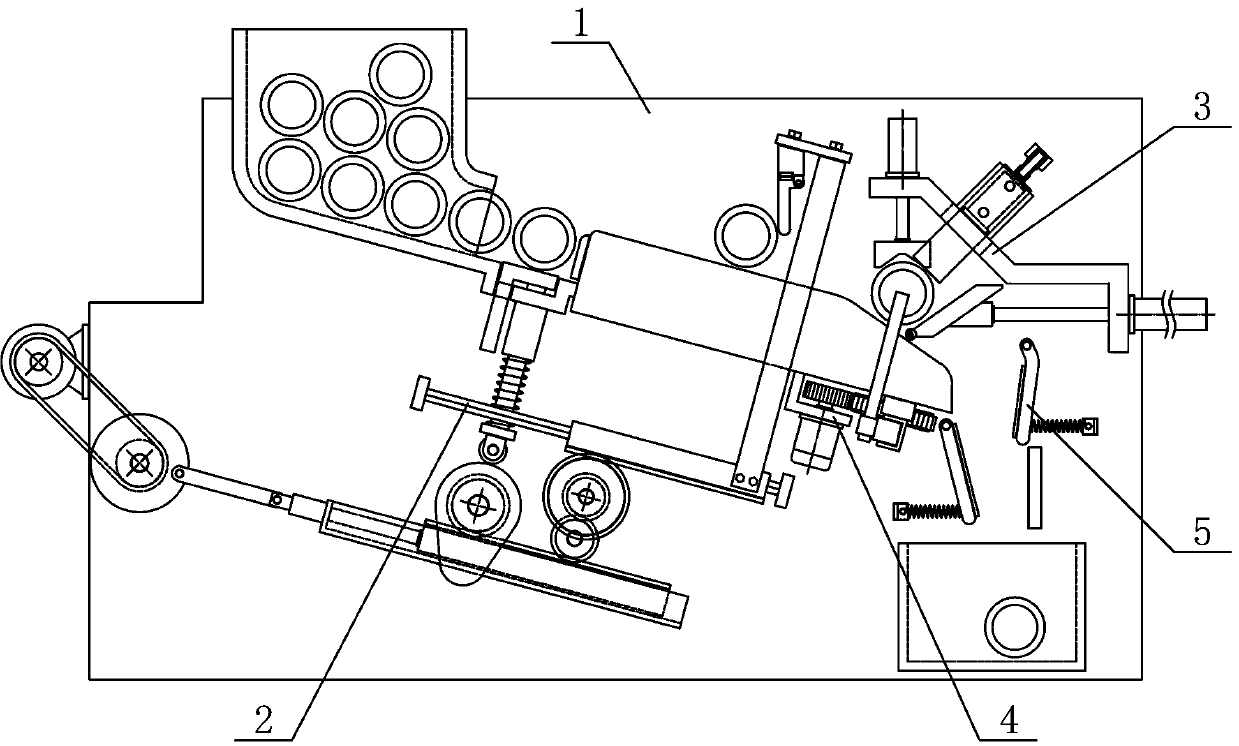

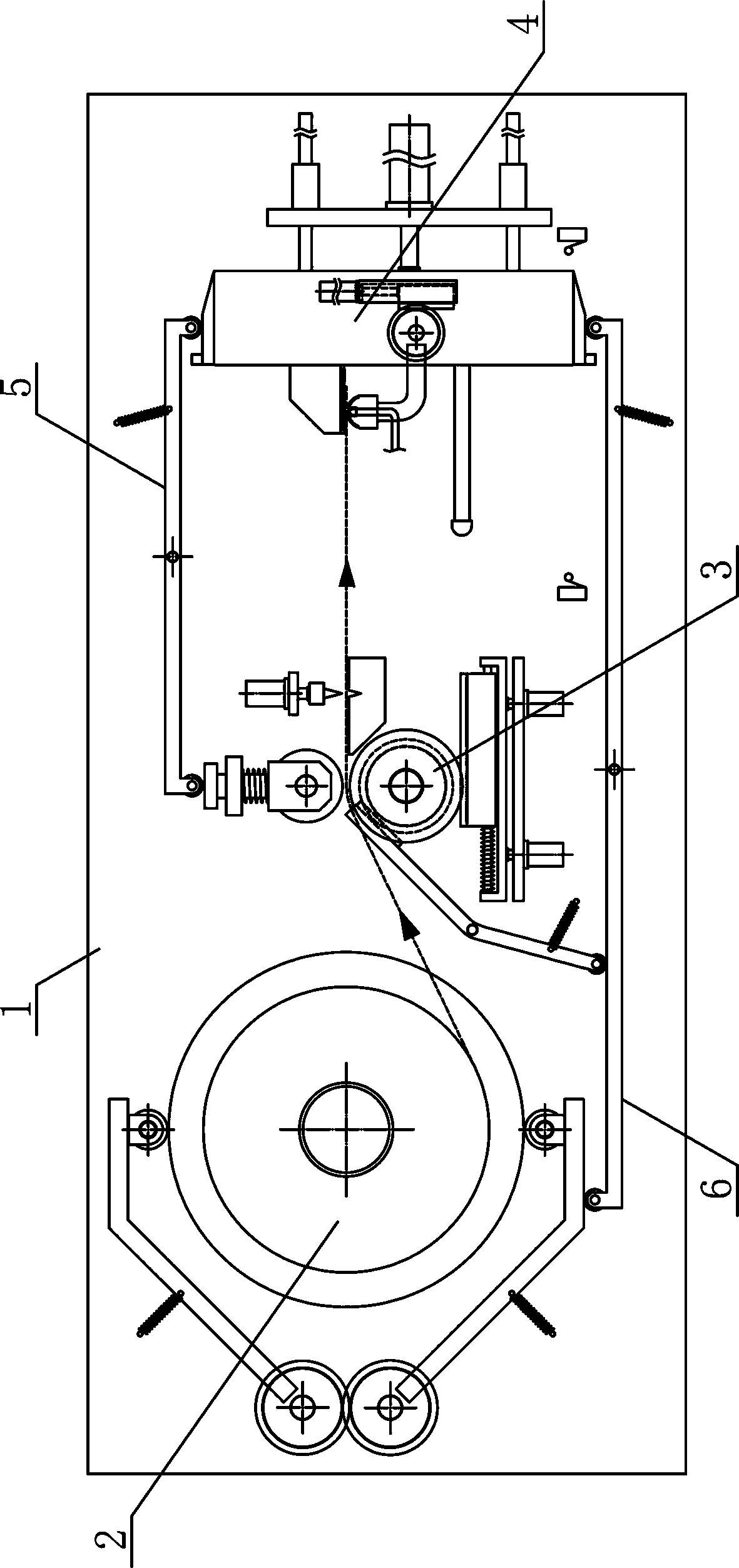

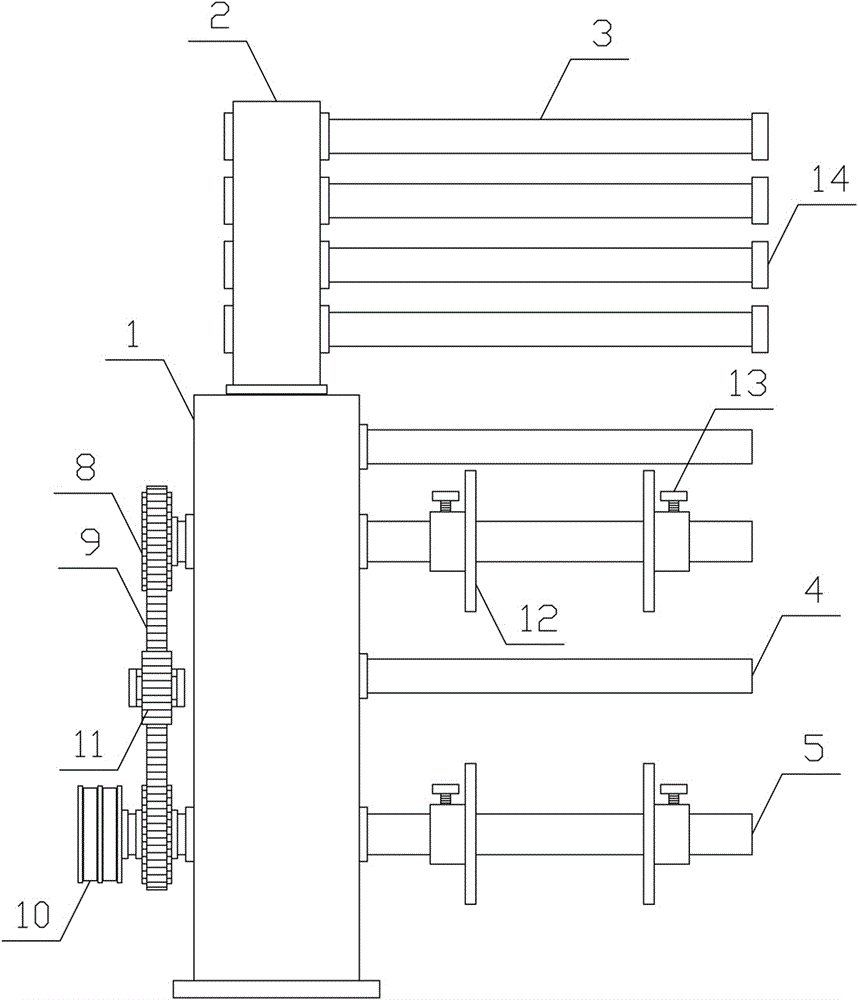

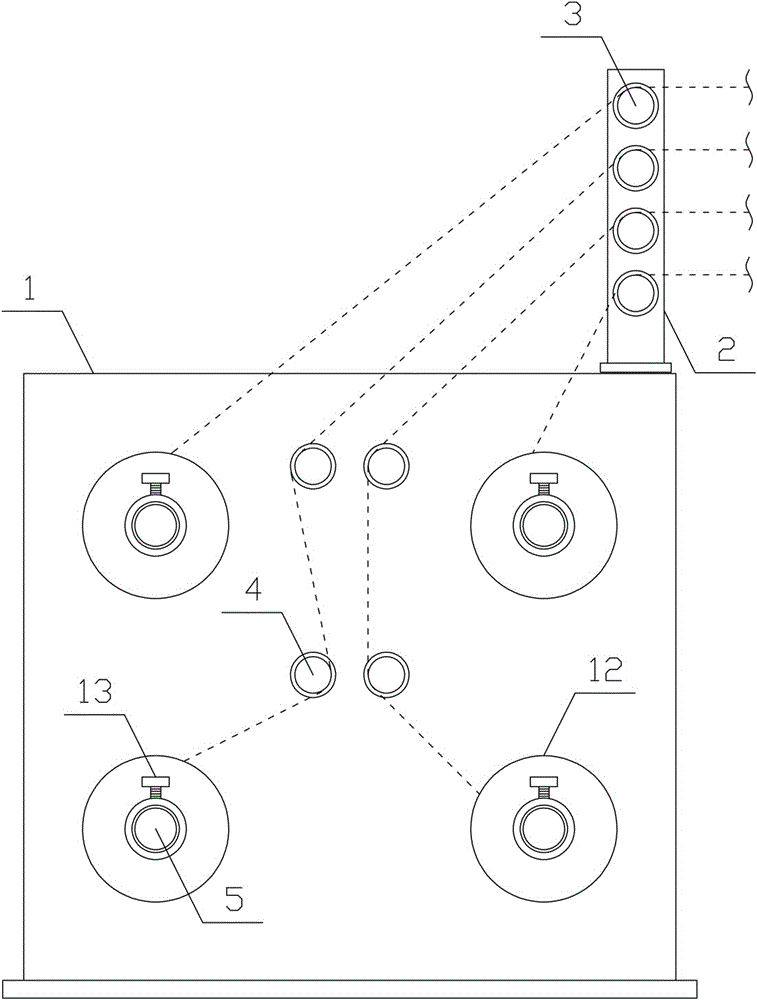

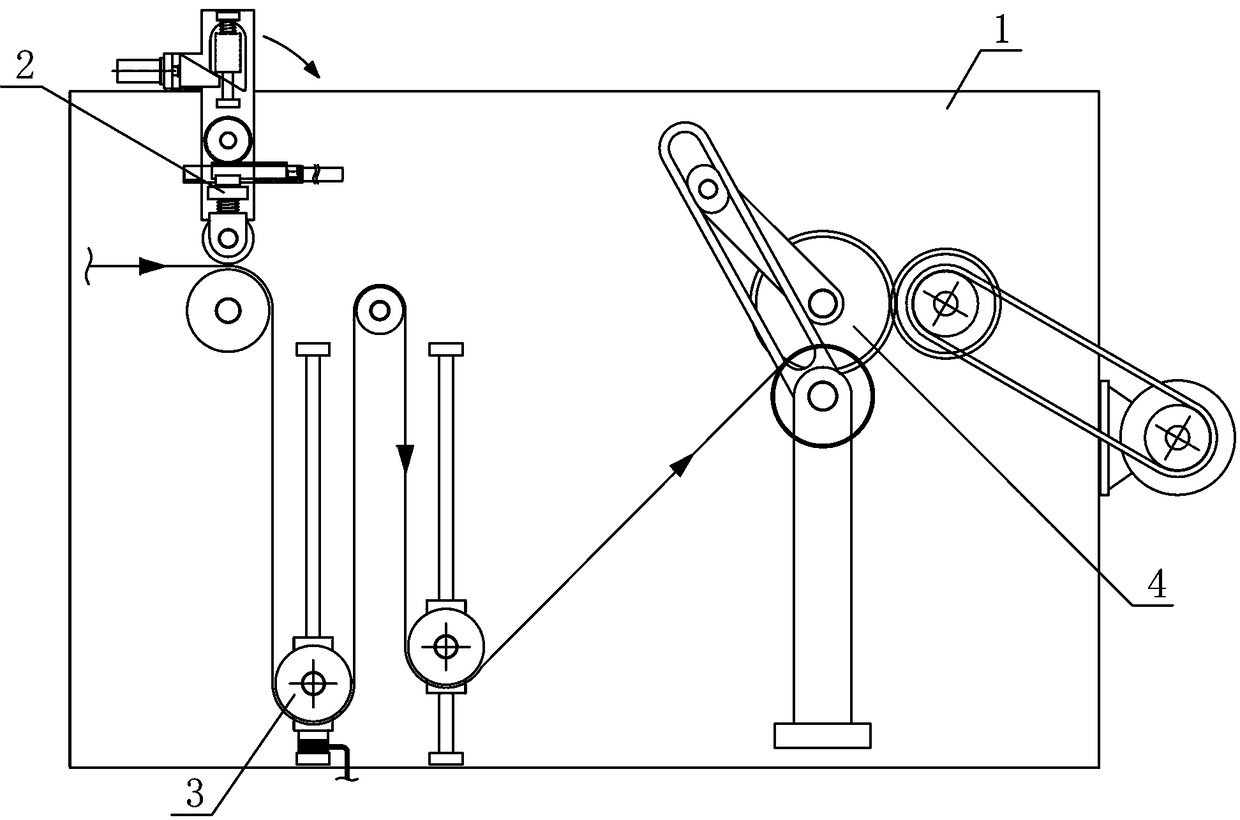

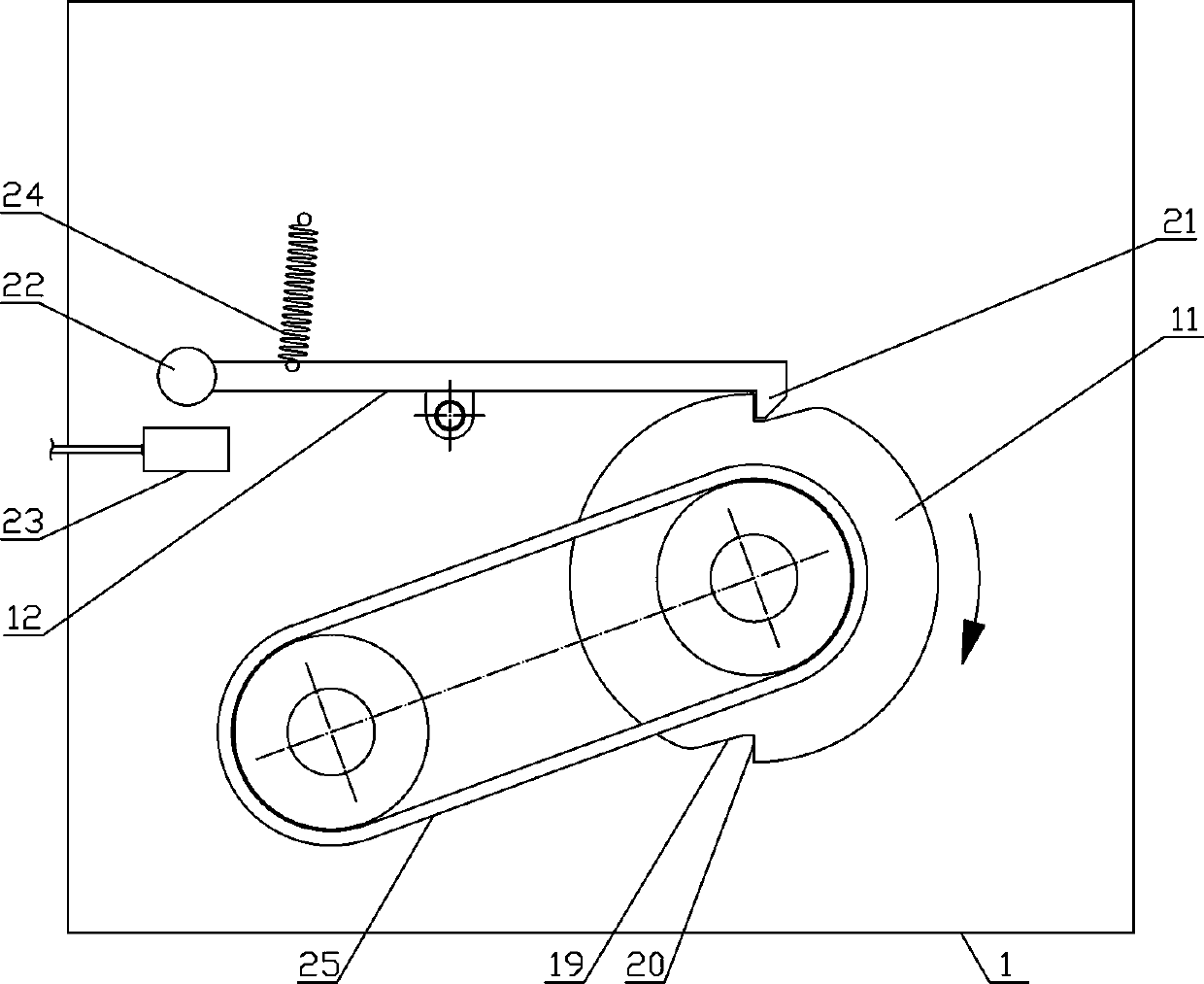

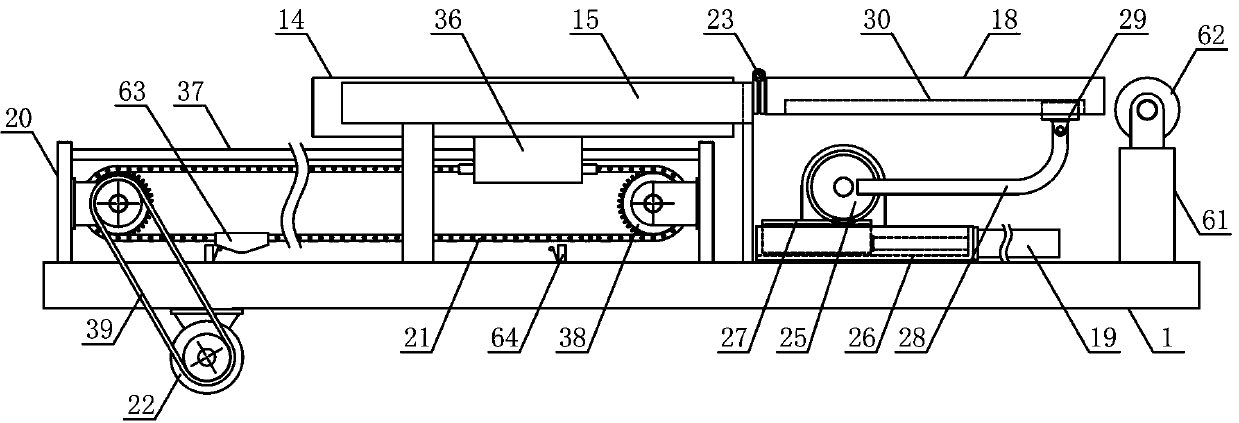

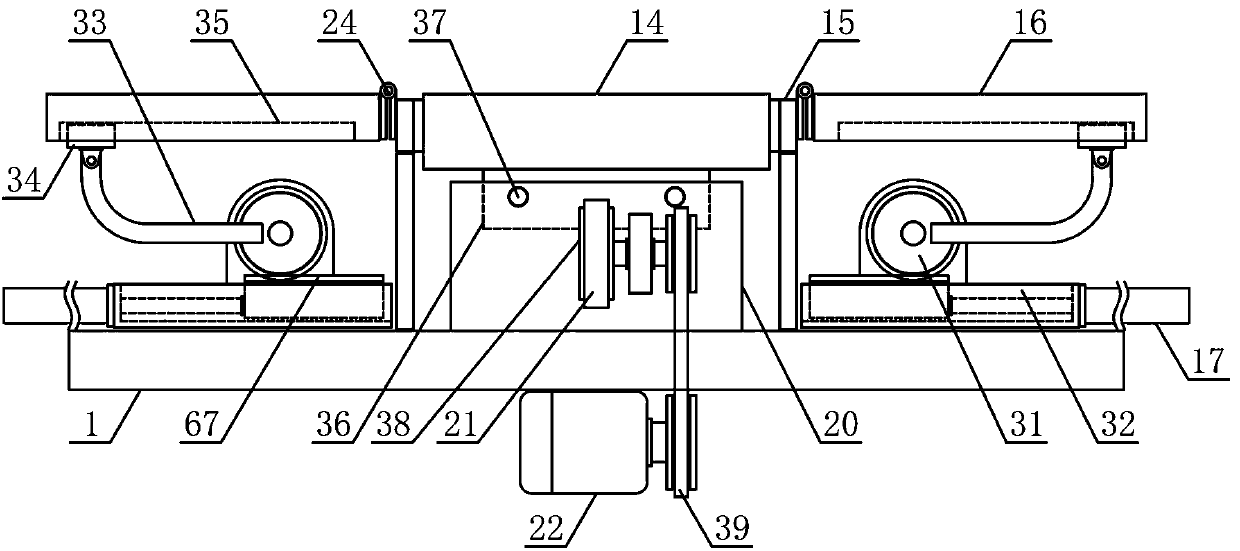

Automatic feed mechanism for round cans

InactiveCN107284978AReasonable structural designIncrease teleportation distanceConveyorsConveyor partsSprocketEngineering

The invention discloses an automatic feeding mechanism for round cans, which belongs to the field of can body processing machinery and equipment. The invention includes a can pushing bracket, a translational push plate, a can transfer belt, a lower tank hopper, a lower tank pipe and a driving mechanism, the lower tank tube is vertically arranged on the upper side of the push tank support, and the lower tank hopper is horizontally arranged on the upper side of the lower tank pipe. The output end of the can-stopping cylinder is horizontally provided with a can-stopping round rod, and the translation push plate is slid on the can push bracket along the horizontal direction. There is a translation rack in the horizontal direction, and a translation gear meshing with the translation rack is connected to the vertical rotation of the lower side of the push can support. Translating chain drive connection. The invention has a reasonable structural design, can quickly and efficiently unload the round cans one by one, and can push the round cans to be horizontally and smoothly translated and transported to meet the needs of production and use.

Owner:TONGXIANG FENGMING TIN MAKING FACTORY

Pipe fitting pinching mechanism

InactiveCN107416518AReasonable structural designEasy clampingConveyorsConveyor partsPipe fittingElectric machinery

The invention discloses a pipe fitting pinching mechanism, and belongs to the field of pipe machining conveyance mechanical equipment. The pipe fitting pinching mechanism comprises a translation base, a translation motor, a translation support, a pipe clamping support, a lifting push plate, lifting air cylinders, pipe clamping plates, a pipe bearing plate and a plate clamping mechanism. The translation support is arranged on translation guide rods in a sliding mode in the horizontal direction. The pipe clamping support is vertically arranged at the upper side of a fixed rotating shaft. The lifting push plate is arranged on lifting guide rods in a sliding mode in the vertical direction. Arc-shaped plate push surfaces are symmetrically arranged at the two sides of the lifting push plate correspondingly. The pipe clamping plates are symmetrically arranged at the two sides of the pipe clamping support separately. The pipe bearing plate is horizontally arranged at the upper side of a pipe bearing supporting rod. The plate clamping mechanism is arranged on the pipe clamping support and located at one side of a lifting clamping groove. The pipe fitting pinching mechanism is reasonable in structural design, pipe fittings of various sizes and dimensions can be clamped and fixed firmly, the pipe fittings can be stably rotated and adjusted synchronously in the translation process of the pipe fittings, and the production and use needs are met.

Owner:浙江绿康农产品配送有限公司

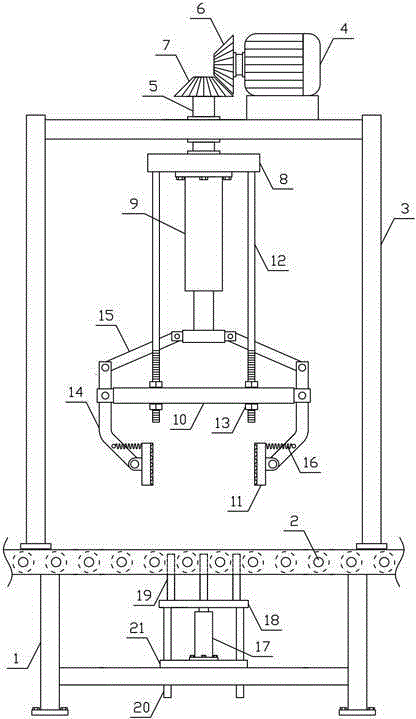

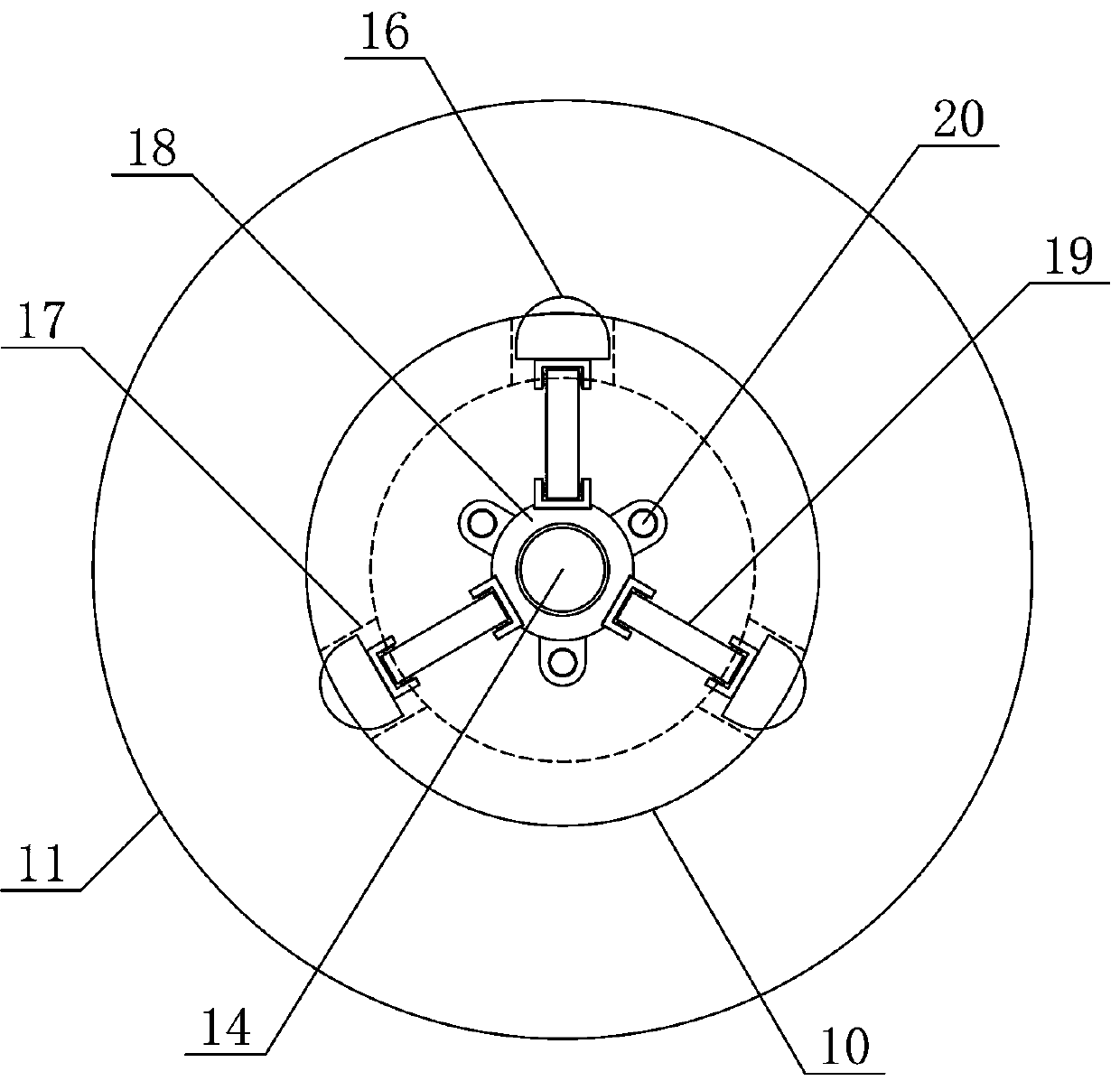

Packing container rotating device

InactiveCN105083942AImprove the level ofClamping effectConveyor partsEngineeringMechanical engineering

The invention discloses a packing container rotating device, and belongs to the field of packing transportation equipment. The packing container rotating device comprises a conveying bracket and a rotating mechanism, wherein the rotating mechanism is vertically arranged at the upper side of the conveying bracket; a lifting mechanism is vertically upwards arranged at the lower side of the conveying bracket; the rotating mechanism comprises a rotating bracket, a rotating motor, a rotating shaft and a container clamping mechanism; a main bevel gear is vertically arranged at the output end of the rotating motor; an auxiliary bevel gear in engaged connection with the main bevel gear is horizontally arranged at the upper end of the rotating shaft; the container clamping mechanism is vertically downwards arranged at the lower end of the rotating shaft; a container clamping cylinder is vertically downwards arranged in middle of the lower side of a rotating plate; a support plate is horizontally arranged at the lower end of an adjusting lead screw; connecting rods are respectively arranged at the two sides of the support plate; driving rods are arranged between the connecting rods and the container clamping cylinder; and the middle part of one side of a container clamping plate is hinged to the lower ends of the connecting rods. The packing container rotating device is simple in structure, and can quickly and efficiently rotate packing containers according to machining demands to satisfy the production and use demands.

Owner:蔡雁行

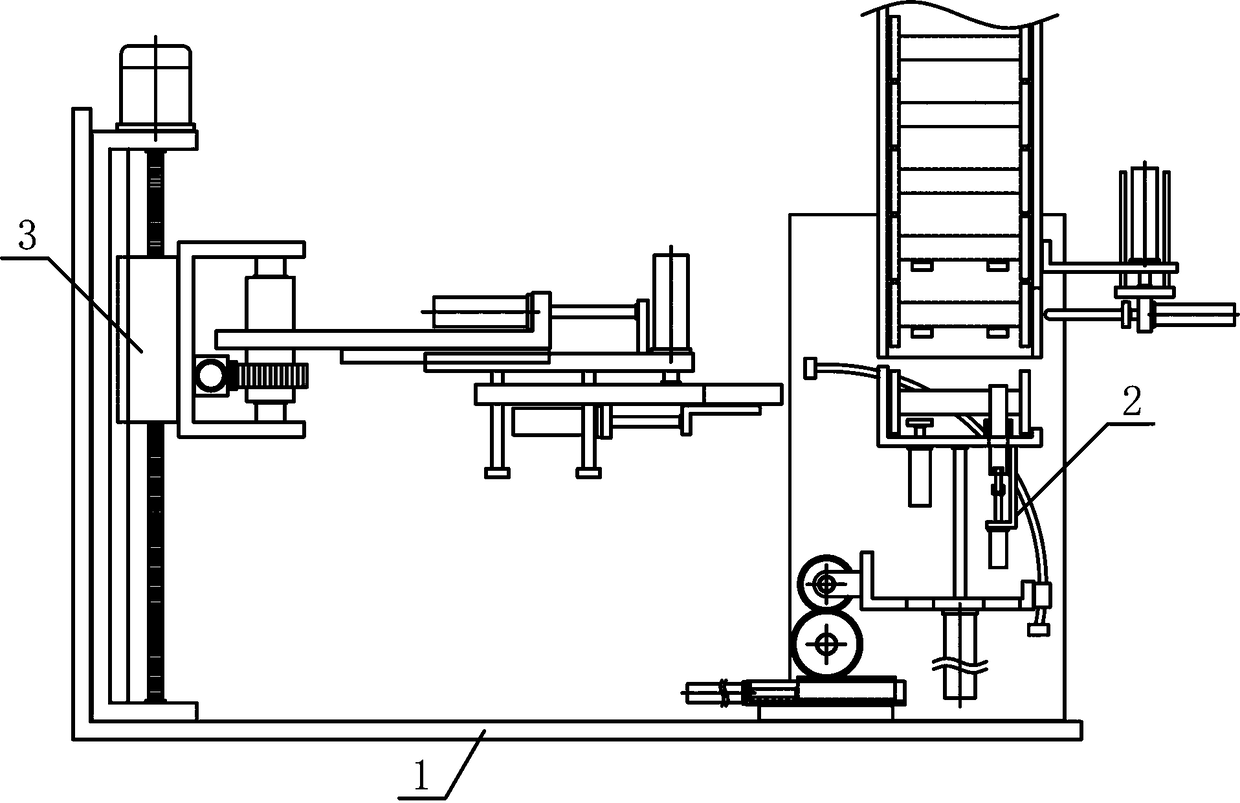

Automatic machining device for metal round pipes

InactiveCN111185522AEfficient and accurate processingAccurate and efficient adjustmentPerforating toolsMetal-working feeding devicesStructural engineeringMachining

The invention discloses an automatic machining device for metal round pipes, and belongs to the field of mechanical workpiece machining equipment. The device comprises a round pipe machining support,a round pipe guiding and conveying mechanism, a round pipe machining mechanism, a round pipe positioning mechanism and a round pipe discharging mechanism, wherein the round pipe guiding and conveyingmechanism is obliquely and fixedly arranged on the round pipe machining support in a downward mode, a pipe storage hopper and a guide pipe table plate of the round pipe guiding and conveying mechanismare sequentially and fixedly arranged on the upper side of the round pipe machining support in the oblique direction from top to bottom, the round pipe machining mechanism is fixedly arranged at theposition, on the upper side of the end of the round pipe guiding and conveying mechanism, of the round pipe machining support, the round pipe positioning mechanism is horizontally arranged on the lower side of the end of the round pipe guiding and conveying mechanism, and the round pipe discharging mechanism is vertically arranged at the position, on the lower side of the round pipe machining mechanism, of the round pipe machining support. The automatic machining device is reasonable in structural design, can efficiently, stably and continuously convey the metal round pipes for perforating machining, and achieves automatic and accurate machining of the metal round pipes, the machining efficiency and the machining quality of the metal round pipes are improved, and the requirements of production and use are met.

Owner:黄薇婷

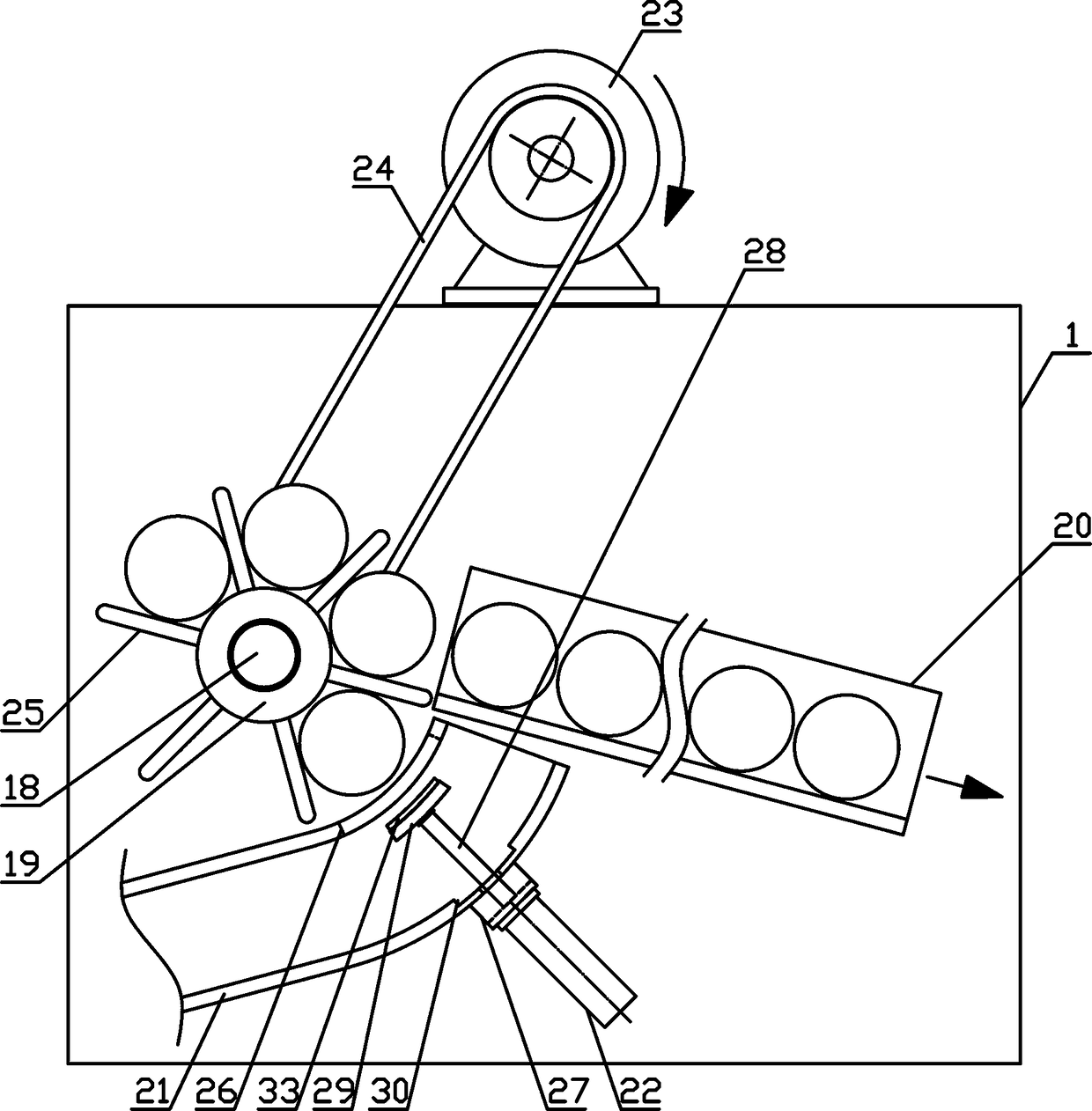

Automatic feeding mechanism for yarn winding drums

InactiveCN109292541AHigh degree of automationSmooth vertical flip loadingFilament handlingYarnEngineering

The invention discloses an automatic feeding mechanism for yarn winding drums, and belongs to the field of fabric production and processing machinery and equipment. A transfer mechanism and barrel moving mechanism of the automatic feeding mechanism are sequentially, vertically and fixedly arranged on the two sides of the upper portion of a feeding base in the horizontal direction. A barrel guidingmechanism and a barrel turning mechanism are sequentially, vertically and fixedly arranged on one side of a transfer bracket from top to bottom. A barrel guiding material pipe is vertically and fixedly arranged on one side of the transfer bracket. A barrel placing bracket is horizontally and fixedly arranged at the output end of a barrel bearing cylinder in the middle of the lower side of a reciprocating bracket. A rotating bracket is horizontally and fixedly arranged on the middle portion of a rotating sleeve of a barrel moving bracket. A barrel moving connecting plate is horizontally arranged at the lower side of a translation connecting plate, and a barrel bearing clamping plate is horizontally and fixedly arranged at the output end of a clamping plate cylinder. The automatic feeding mechanism is reasonable in structural design, can smoothly transfer and feed the yarn winding drums one by one and smoothly transfer and place the yarn winding drums to required positions, improves theautomation degree of feeding the yarn winding drums, and meets the requirements of production and use.

Owner:桐乡市富利来针织股份有限公司

Adjustable cloth drying mechanism

InactiveCN106123535AAdjustable lengthFully efficient dryingDrying gas arrangementsDrying machines with progressive movementsHydraulic cylinderEngineering

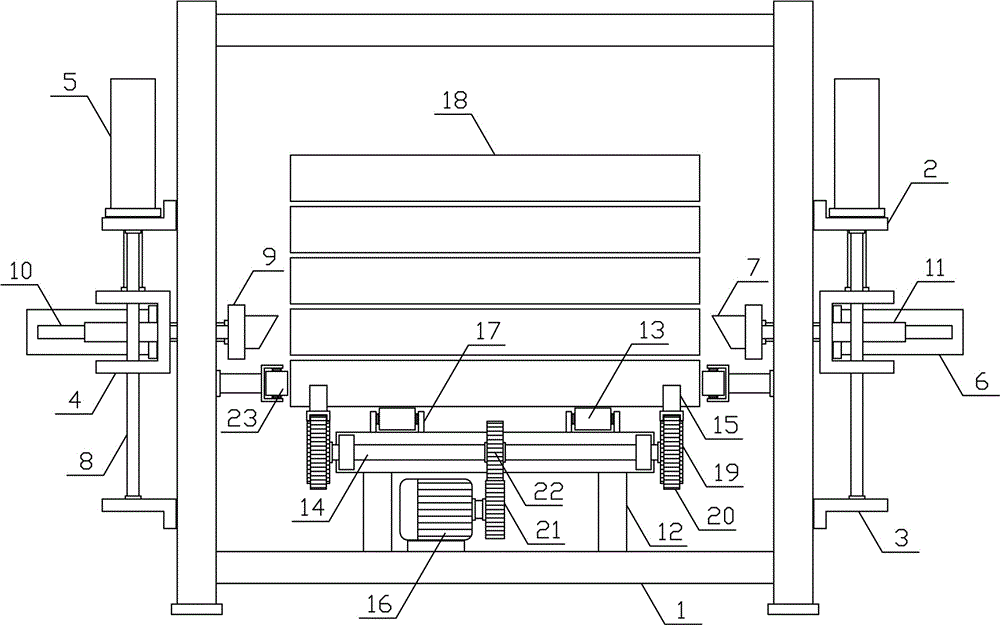

The invention discloses an adjustable cloth drying mechanism and belongs to the field of textile processing machines. The adjustable cloth drying mechanism comprises a conveying support, an upper adjusting support, a lower adjusting support, an adjusting hydraulic cylinder, a heating plate and cloth drying fans. The upper adjusting support, the lower adjusting support, the heating plate and the cloth drying fans are sequentially and horizontally arranged on the conveying support from top to bottom. A cloth input roll and a cloth output roll are correspondingly, horizontally and rotationally connected to the two sides of the upper portion of the conveying support. Multiple upper adjusting rolls are horizontally and rotationally connected to the upper adjusting support. Multiple lower adjusting rolls are horizontally and rotationally connected to the lower adjusting support. The heating plate is horizontally arranged on the lower side of the conveying support. An electric heating wire is arranged on the heating plate. Translation guide rods are horizontally arranged on the two sides of the lower portion of the conveying support. The multiple cloth drying fans are horizontally arranged between the two translation guide rods. The adjustable cloth drying mechanism is reasonable in structural design and capable of drying cloth in the conveying process quickly and efficiently according to the demands and meeting the demands of production and use.

Owner:ZHEJIANG ZHONGSHI MACHINERY CO LTD

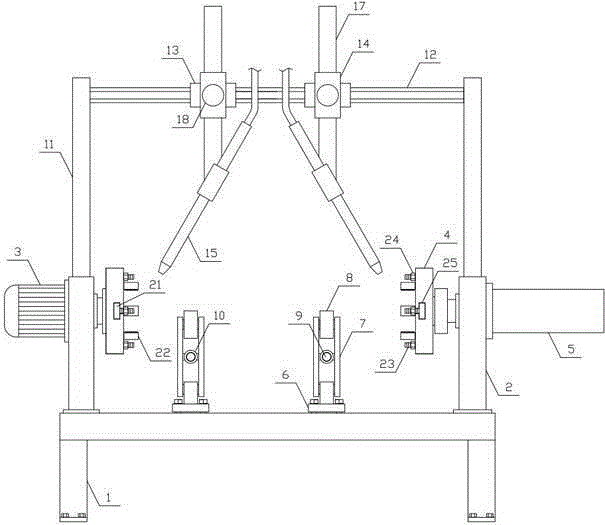

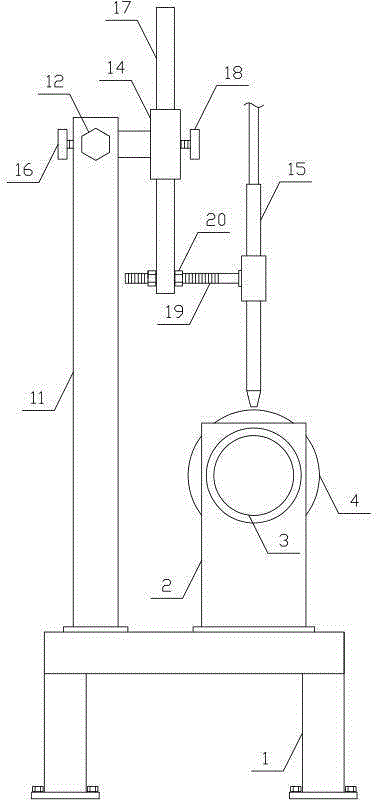

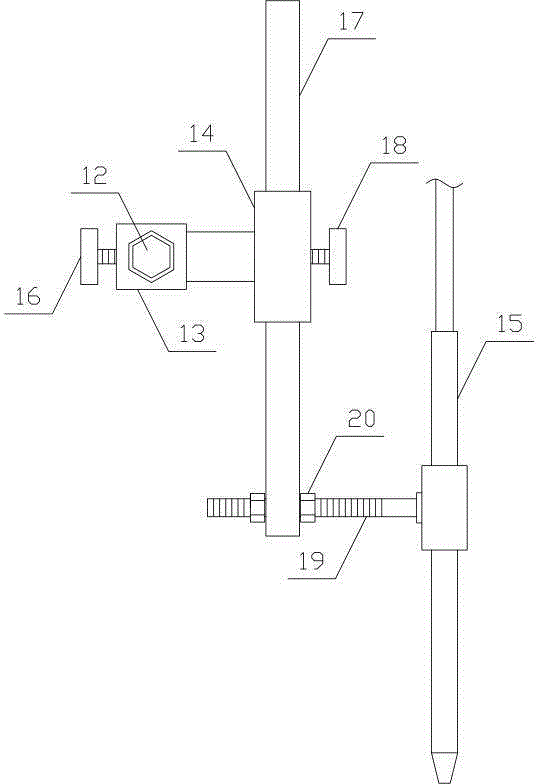

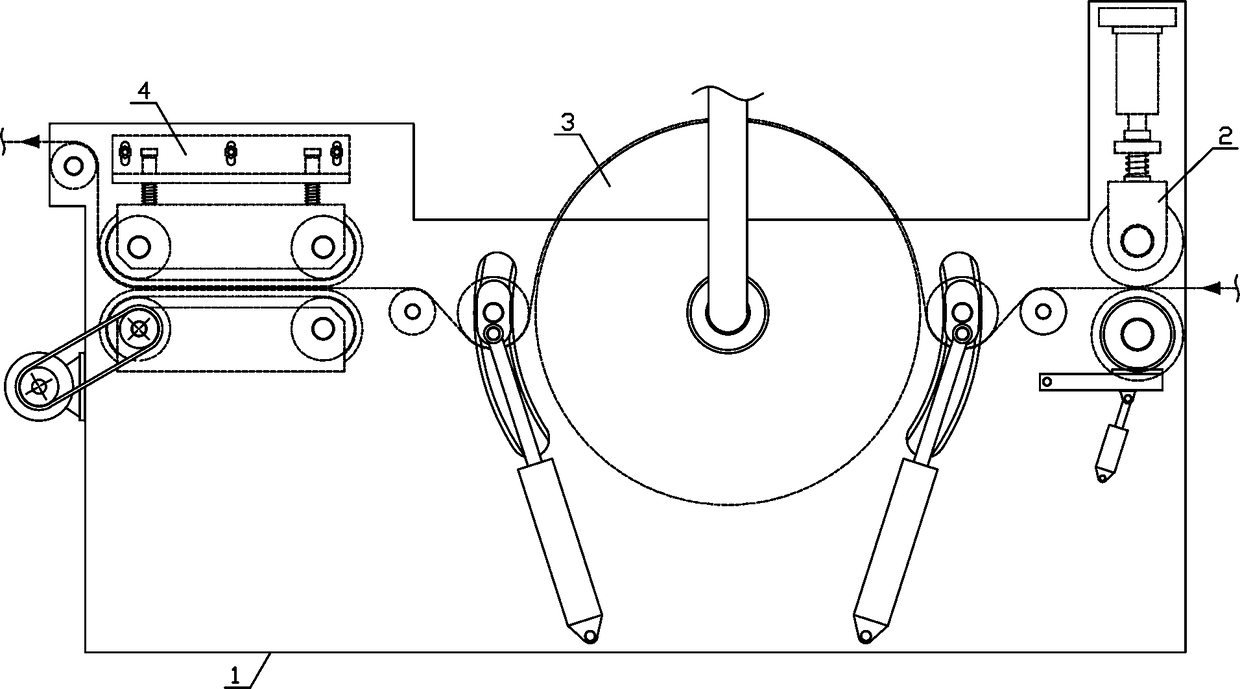

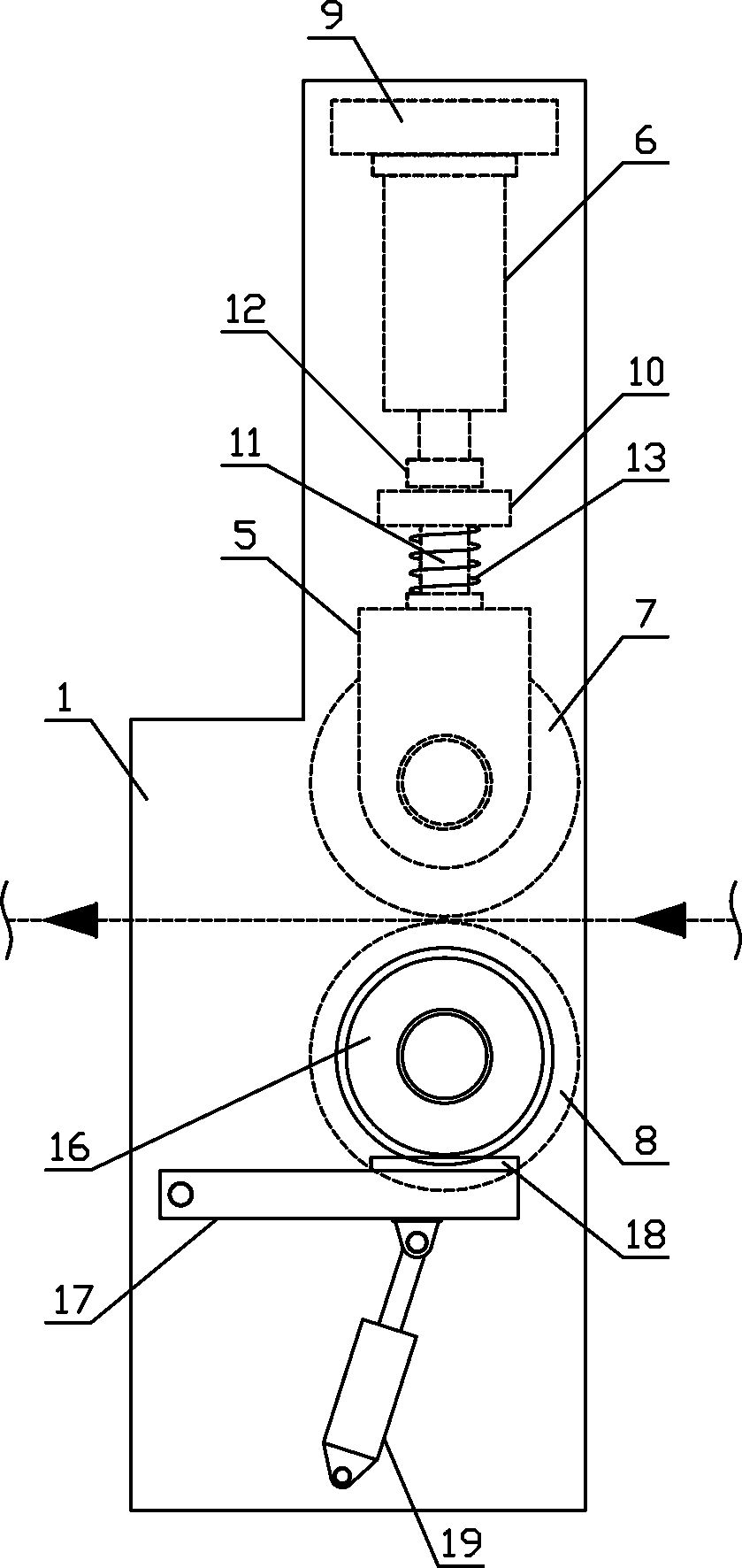

Round tube welding device

InactiveCN105215561AGuarantee welding qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderMachining

The invention discloses a round tube welding device and belongs to the field of machining equipment. The round tube welding device comprises a main support, a round tube containing mechanism and a welding mechanism. The round tube containing mechanism is horizontally arranged on one side above the main support. The welding mechanism is vertically arranged on one side of the round tube containing mechanism. The round tube containing mechanism comprises a containing support, a rotary motor, round tube fixing boards, a horizontally-moving hydraulic cylinder and tube bearing mechanisms. The rotary motor is horizontally arranged on one side of the containing support. The horizontally-moving hydraulic cylinder is horizontally arranged on the other side of the containing support. The two round tube fixing boards are vertically and symmetrically arranged. Multiple round tube clamping mechanisms are symmetrically arranged on the round tube fixing boards in the radial direction. The tube bearing mechanisms are vertically and symmetrically arranged at the portion, between the two round tube fixing boards, of the main support. The welding mechanism comprises a welding support, a horizontally-moving rod, horizontally-moving sleeves, lifting sleeves and round tube welding guns. The round tube welding device is simple in structure, round tubes can be rapidly and efficiently welded, round tube welding efficiency and quality are improved, and the production requirement is met.

Owner:魏俊杰

Textile fabric conveying device

ActiveCN111532827ASmooth and orderly unwinding transmissionEfficient and smooth unwinding transmissionWebs handlingMechanical equipmentIndustrial engineering

The invention discloses a textile fabric conveying device, and belongs to the field of textile processing mechanical equipment. According to the textile fabric conveying device, a fabric unwinding mechanism and a fabric conveying mechanism are arranged on the two sides of a fabric conveying support correspondingly, a lifting fabric guide roller is horizontally arranged on the fabric conveying support between the fabric unwinding mechanism and the fabric conveying mechanism, the lifting fabric guide roller is horizontally and rotationally connected to a reciprocating lifting guide block, a fabric unwinding roller is horizontally, coaxially and fixedly arranged in the middle of a fabric unwinding rotary plate, a pressing plate damping swing rod is arranged on a fabric conveying support on the lower side of the fabric unwinding rotary plate, the two sides of a fabric non-return support are horizontally and rotationally connected with a front material guiding rotary roller and a rear material guiding rotary roller correspondingly, and a lifting material pressing rotary roller is arranged on the lower side of a fabric conveying rotary roller. The textile fabric conveying device is reasonable in structural design, textile fabrics can be efficiently, smoothly, sequentially and intermittently conveyed, stable, accurate and continuous sectional conveying of textile fabrics is achieved,the automation degree of textile fabric conveying and processing is improved, and the requirements of production and use are met.

Owner:山东新天合包装制品有限公司

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

Plate perforating mechanism

InactiveCN107718152AAvoid offsetReasonable structural designMetal working apparatusElectric machinerySlide plate

The invention discloses a plate punching mechanism, which belongs to the field of material processing mechanical equipment. The invention includes a fixed bracket, a punching bracket, a guide roller, a bearing bracket, a bearing cylinder, a translation bracket, a lower translation plate, an upper translation plate, a punching cylinder, a drilling motor and a punching rod, and the bearing bracket is horizontally arranged on the On the fixed bracket between the two guide rollers, the output end of the bearing plate cylinder is fixed to the lower side of the bearing plate support, and the upper side of the bearing plate support is evenly rolled. A plurality of bearing plate rollers are installed, and the lower translation plate slides along the horizontal direction and is set on the lower translation Guide rod, the upper translation plate is horizontally arranged on the upper side of the lower translation plate, the upper middle part of the upper translation plate is vertically provided with a punching cylinder downward, and the output end of the punching motor is vertically provided with a punching rod. The invention has a reasonable structural design, and can quickly and conveniently translate, rotate, and compress and fix plates of various sizes and specifications, so that the plates can be punched efficiently and accurately to meet the needs of production and use.

Owner:桐乡市红旗塑料包装袋厂

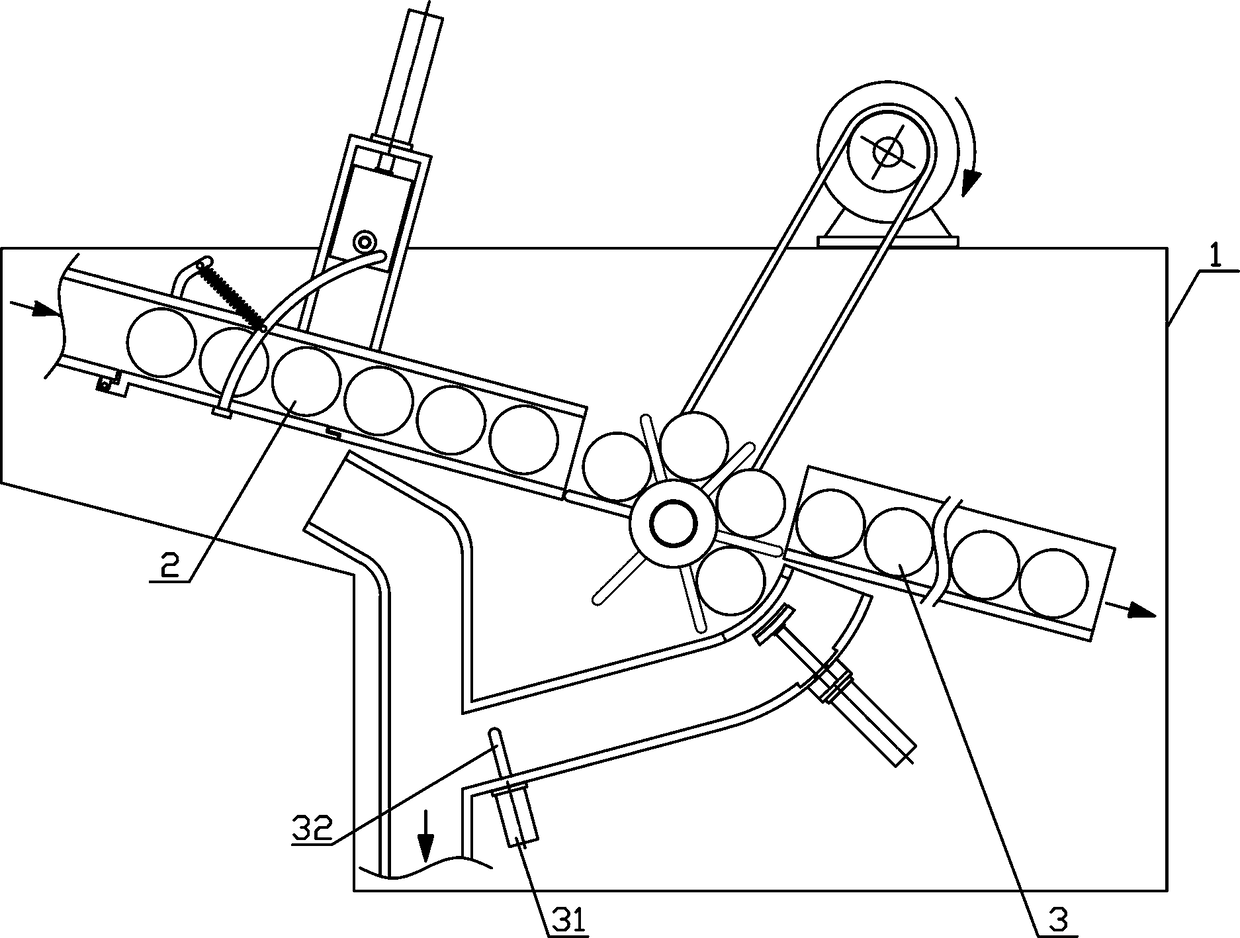

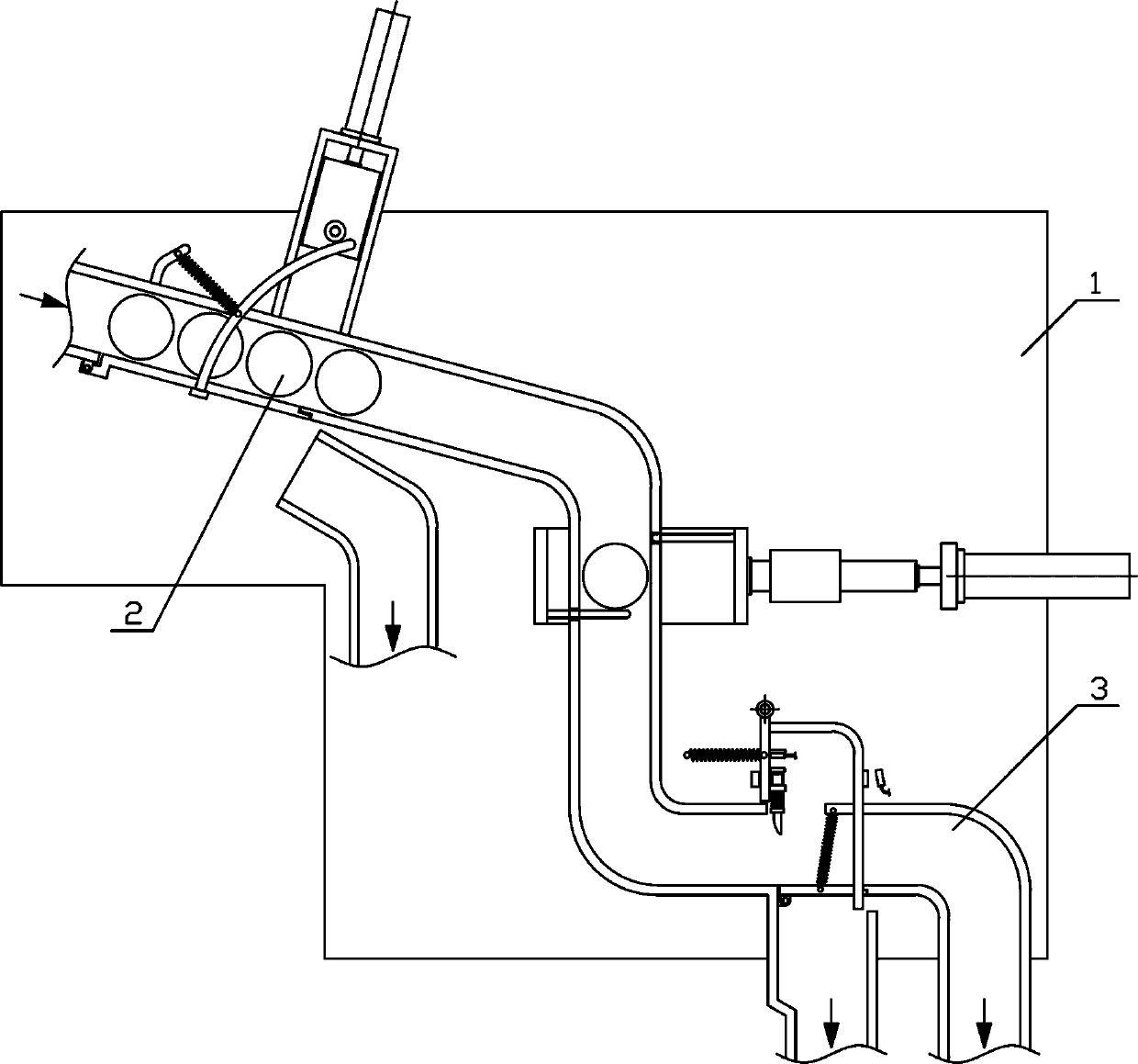

Automatic pipe fitting path distribution conveying mechanism

InactiveCN108674955AAvoid stackingTo achieve the effect of diversionConveyorsConveyor partsPipe fittingMechanical equipment

The invention discloses an automatic pipe fitting path distribution conveying mechanism, and belongs to the field of workpiece machining conveying mechanical equipment. A guide pipe mechanism and a path distribution mechanism of the automatic pipe fitting path distribution conveying mechanism are sequentially arranged on one side of a fixed bracket from top to bottom; a distribution pipe materialpipe is obliquely arranged in the position, on the lower side of a guide pipe material pipe, of the fixed bracket; the lower side of the guide pipe material pipe is provided with a bearing pipe baffle; the upper end of a material supplying pipe communicates with the lower end of the guide pipe material pipe; a front path distribution material pipe is vertically arranged in the middle of the lowerside of the material supplying pipe, and a rear path distribution material pipe is vertically arranged at the tail end of the lower side of the material supplying pipe; a material separation mechanismis horizontally arranged on the upper side of the material supplying pipe; and the upper end of the front path distribution material pipe is provided with a rotary baffle, and one side of the lower end of a hook rotary plate located on one side of a reciprocating rotary plate is provided with a hook mechanism. The automatic pipe fitting path distribution conveying mechanism is reasonable in structural design, can stably and efficiently distribute pipe fittings into paths for conveying and can discharge the pipe fittings according to the rear path pipe fitting machining load requirement, the automation degree of pipe fitting path distribution conveying is increased, and the production using requirements are met.

Owner:海宁市波菲特进出口有限公司

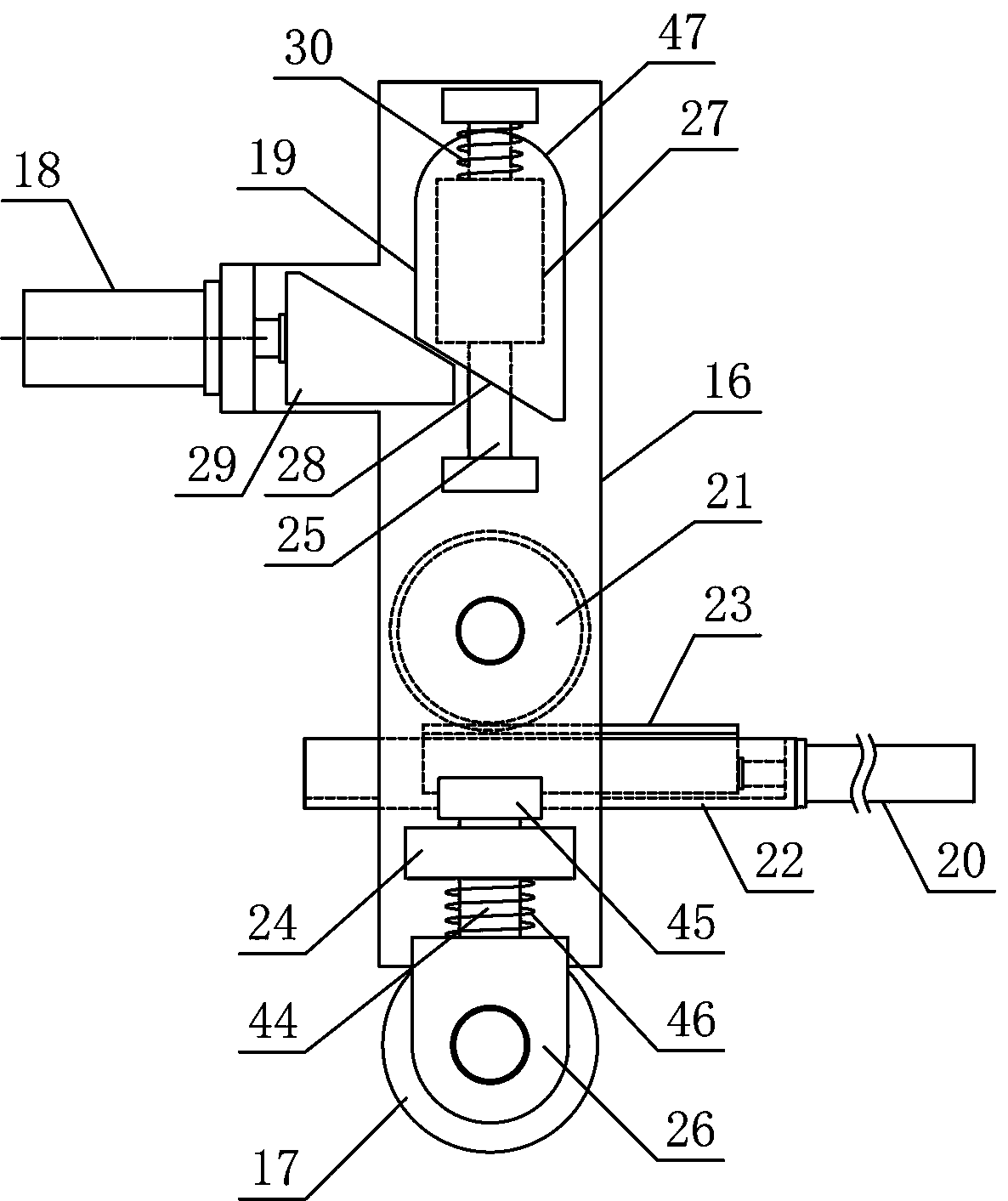

Print cloth unwinding mechanism with damping

ActiveCN105947727ASimple structureAvoid over-windingMeasurement devicesFunction indicatorsEngineeringTextile

The invention discloses a print cloth unwinding mechanism with damping and belongs to the field of poster printing mechanical equipment. The print cloth unwinding mechanism with the damping comprises a fixed base, an unwinding bracket, an unwinding metering mechanism body and an unwinding damping mechanism body. An unwinding roller is horizontally and rotationally connected to the unwinding bracket. A rotating shaft is rotationally connected to a rotary bracket. Rotary air cylinders are symmetrically and obliquely arranged on the two sides of the fixed base correspondingly. Connection plates are arranged between the output ends of the rotary air cylinders and the rotating shaft. A pressing rod is arranged on the upper side of the rotating shaft. A metering rolling wheel is horizontally and rotationally connected to the side, close to the unwinding roller, of the pressing rod. A cloth bearing roller is horizontally and rotationally connected to the upper side of a cloth bearing bracket. A damping roller is horizontally arranged on the upper side of the cloth bearing roller. A stretched spring is arranged between a supporting plate and the unwinding bracket. According to the print cloth unwinding mechanism with the damping, the structural design is reasonable, unwinding can be conducted on print cloth quickly, efficiently, stably and precisely as required, and the production and using requirements are met.

Owner:绍兴市梁辉文化传媒科技有限公司

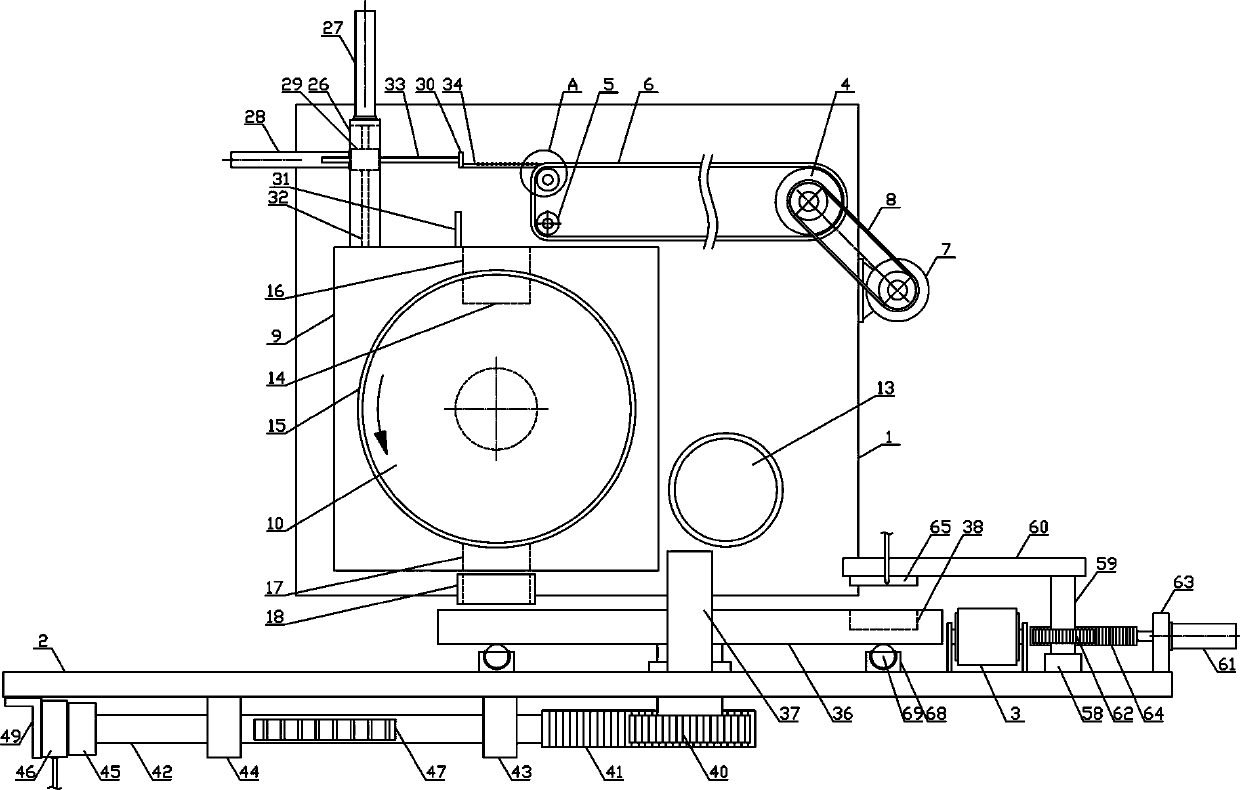

Metal round pipe continuous conveying machining device

InactiveCN111229923AStable processingAutomatic and stable processingPerforating toolsMetal-working feeding devicesStructural engineeringMachining

The invention discloses a metal round pipe continuous conveying machining device, and belongs to the field of mechanical workpiece machining equipment. A round pipe guide storage pipe and a guide pipeinclined table plate are sequentially and fixedly mounted on the upper side of a round pipe conveying support in the inclined direction, a guide pipe driving mechanism and a round pipe guide conveying mechanism are sequentially mounted at the position, on the upper side of the guide pipe inclined table plate, of the round pipe conveying support from top to bottom, a round pipe machining mechanismis fixedly mounted at the position, above the lower end of the guide pipe inclined table plate, of the round pipe conveying support, a round pipe positioning mechanism is horizontally and fixedly mounted on the lower side of the end of the guide pipe inclined table plate, and a round pipe falling mechanism is fixedly and vertically mounted at the position, on the lower side of the round pipe machining mechanism, of the round pipe conveying support. Structural design is reasonable, a metal round pipe can be efficiently and stably guided and conveyed continuously to be punched, the machined round pipe can be conveniently, rapidly and smoothly conveyed and discharged, automatic and accurate machining of the metal round pipe can be achieved, machining efficiency and machining quality of the metal round pipe can be improved, and needs of production use can be met.

Owner:黄薇婷

Textile fabric pulling-feeding-cutting device

ActiveCN111532826AEfficient and convenient clamping and fixingAchieve rotational positioningArticle deliveryWebs handlingStructural engineeringMechanical equipment

The invention discloses a textile fabric pulling-feeding-cutting device and belongs to the field of textile fabric processing mechanical equipment. A fabric unwinding mechanism, a material guiding cutting mechanism and a fabric pulling-feeding mechanism are arranged in sequence on one side of a fabric conveying stand in the horizontal direction; a fabric compaction connecting rod is horizontally arranged between the material guiding cutting mechanism and the fabric pulling-feeding mechanism; a rotating disc damping connecting rod is horizontally arranged between the fabric unwinding mechanismand the fabric pulling-feeding mechanism; a fabric unwinding supporting roller is horizontally and fixedly arranged on a fabric unwinding rotating disc; a fabric cutting base is horizontally and fixedly arranged on the fabric conveying stand which is positioned on one side of a fabric guiding-feeding rotating roller; a fabric cutting tool is arranged on the lower side of a lifting cutting plate which is positioned at an output end of a fabric cutting air cylinder; and the output end of the fabric cutting air cylinder is fixedly connected with a fabric pulling-feeding guiding plate. The deviceis of a reasonably designed structure, and can realize continuous pulling, feeding and cutting of textile fabrics in a high-efficiency and accurate way, improve the degree of automatic processing in textile fabric cutting, and satisfy production and application needs.

Owner:桐庐恒浩服装有限公司

Sorting and conveying mechanism for groove workpieces

ActiveCN110451228AReasonable structural designHigh degree of automationConveyor partsEngineeringMechanical equipment

The invention discloses a sorting and conveying mechanism for groove workpieces, and belongs to the field of workpiece conveying and machining mechanical equipment. A material transferring pipe is vertically and fixedly arranged in the middle of the upper side of a material transferring support, a horizontal moving push plate is horizontally and fixedly provided with a material pushing pressing rod along the side of the material transferring material pipe, a material guide inclined plate is obliquely and downwards fixedly arranged on one side below the material transferring material pipe, anda material bearing baffle is arranged on one side of a turnover baffle; a material guiding pipe is vertically and fixedly arranged on the material transferring support at the lower side of the material transferring pipe, a material guiding rotating plate is arranged on the material transferring support on one side of the material guiding pipe, the end part the lower side of a transferring guide plate is rotationally connected to the material transferring support, a material bearing rotating plate is arranged on the upper side of the transferring guide plate, and a material transferring belt ishorizontally arranged on the upper side of a conveying base. The sorting and conveying mechanism has the advantages that the structural design is reasonable, the groove workpieces can be convenientlyand efficiently subjected to directional arrangement in the discharging process, automatic overturning and conveying of the groove workpieces can be realized, the workpiece feeding and conveying automation degree is improved, and the requirements of production and use are met.

Owner:泰州市宠友宠物服务有限公司

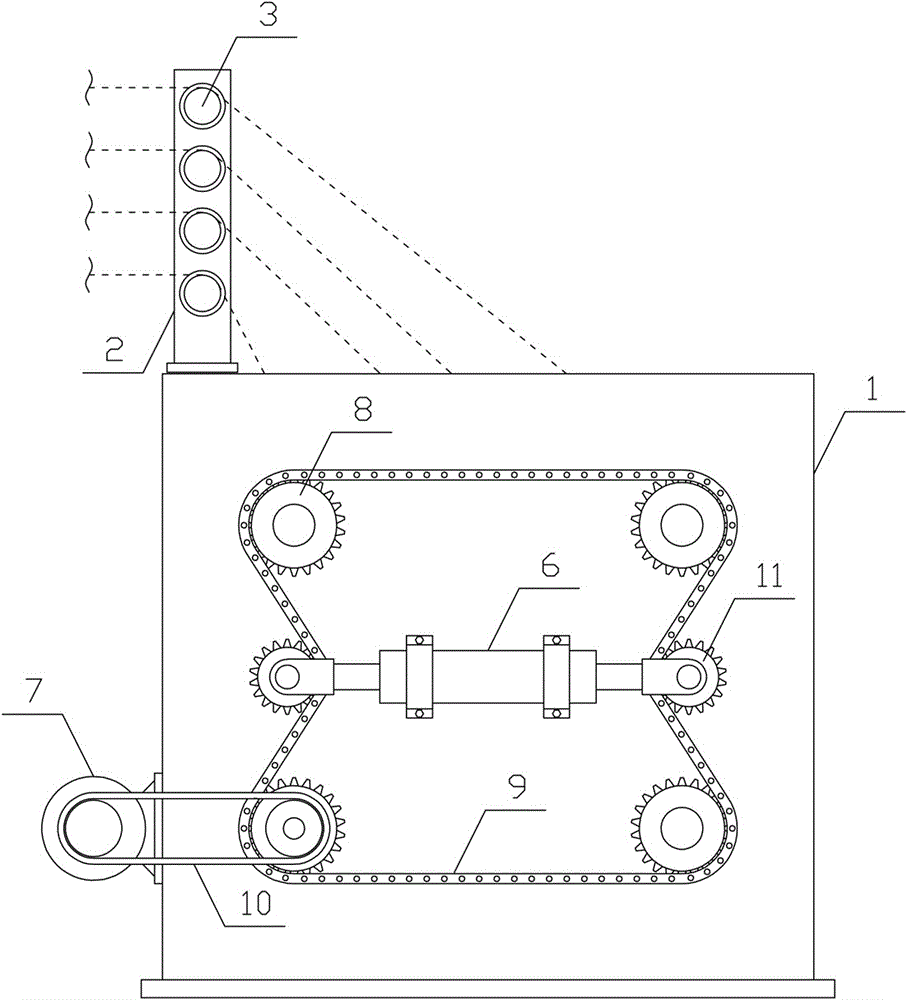

Thin film strip conveying and winding device

InactiveCN106081687ARotation synchronization is efficient and smoothThere are multiple film feeding rollers connected by rotation, and the winding is synchronously efficient and stableWebs handlingHydraulic cylinderSprocket

The invention discloses a thin film strip conveying and winding device and belongs to the field of packaging and machining mechanical equipment. The thin film strip conveying and winding device comprises a winding support, a film feeding support, film feeding rollers, film guiding rollers, winding rollers, a tensioning hydraulic cylinder and a winding motor; one side of the film feeding support is sequentially, horizontally, evenly and rotationally connected with the multiple film feeding rollers from top to bottom; the multiple winding rollers are horizontally, evenly and rotationally connected to the outer side of the winding support; the two sides of the middle portion of the winding support are sequentially, horizontally and rotationally connected with the film guiding rollers from top to bottom; one ends of the multiple winding rollers are each vertically provided with a winding chain wheel; a winding chain is connected to the winding chain wheels in an engaged manner; the winding motor and one winding chain wheel are in transmission connection through a conveying belt; the two ends of the tensioning hydraulic cylinder are vertically and rotationally connected with tensioning chain wheels correspondingly; and the winding chain is connected with the inner sides of the tensioning chain wheels in an engaged manner. The thin film strip conveying and winding device is reasonable in structural design and capable of fast and efficiently conveying and winding a plurality of thin film strips synchronously and steadily and meeting the production and use requirement.

Owner:浙江耀阳新材料科技有限公司

Spool transferring and feeding mechanism

InactiveCN107298303AEfficient and accurate transferReasonable structural designConveyorsKnittingMotor driveEngineering

The invention discloses a spool transferring and feeding mechanism and belongs to the field of textile processing machinery and equipment. The spool transferring and feeding mechanism comprises a fixing support, a lifting support, a lifting cylinder, a rotating disc, a transferring motor, a grabbing support, a grabbing cylinder, a translation plate, grabbing connection rods and clamping rods, the lifting support is horizontally arranged on the upper side of the lifting support, the rotating disc is horizontally arranged on the upper side of the lifting support, a rotating rack is horizontally arranged in the middle of the outer side of the rotating disc, the transferring motor drives a rotating gear, the grabbing cylinder is horizontally arranged in the middle of one side of the grabbing support, a piston rod is slidably arranged on a translation sleeve along the horizontal direction, the translation plate is horizontally arranged at one end of the piston rod, the grabbing connection rods are symmetrically arranged on two sides of the translation plate horizontally, and the clamping rods are horizontally arranged at one ends of the grabbing connection rods. The spool transferring and feeding mechanism is reasonable in structural design and can quickly and firmly clamp a spool and stably and accurately transfer the spool to realize automatic feeding of the spool so as to meet needs of production and use.

Owner:浙江正辉针织科技股份有限公司

Sleeve column feeding and pressing mechanism

InactiveCN109664088AHigh degree of automationReasonable structural designMetal working apparatusMechanical engineering

Owner:嘉兴汉羿文化传播有限公司

Yarn variable speed winding mechanism

The invention discloses a yarn variable speed winding mechanism, and belongs to the field of textile machining mechanical equipment. A yarn guide mechanism and a rolling mechanism are sequentially arranged on a conveying support in the horizontal direction, yarn is sequentially connected to a yarn inlet rotating roller, a yarn storage rotating roller, a yarn guide rotating roller and a lifting rotating roller in a wound manner, a yarn compressing mechanism is vertically arranged on at the position, on the upper side of the yarn inlet rotating roller, of the conveying support, a rolling motor is in transmission connection with an output gear, a rotating crank is arranged on one side of a rolling gear in the radial direction of the rolling gear, a crank sliding block of the outer end of therotating crank is in rotatable connection to the end of one side of the rotating crank, a rolling rotating shaft is horizontally and rotatably connected to the upper side of a rolling support, a rotating rocker arm is fixedly arranged on one side of the rolling rotating shaft in the radial direction of the rolling rotating shaft, and the crank sliding block is arranged in a rolling guide groove inthe rotating rocker arm in a sliding manner. The yarn variable speed winding mechanism is reasonable in structural design, yarn can be continuously rolled efficiently and compactly, the yarn conveying and rolling automation degree is improved, and the production use needs are met.

Owner:浙江云飞扬羊绒有限公司

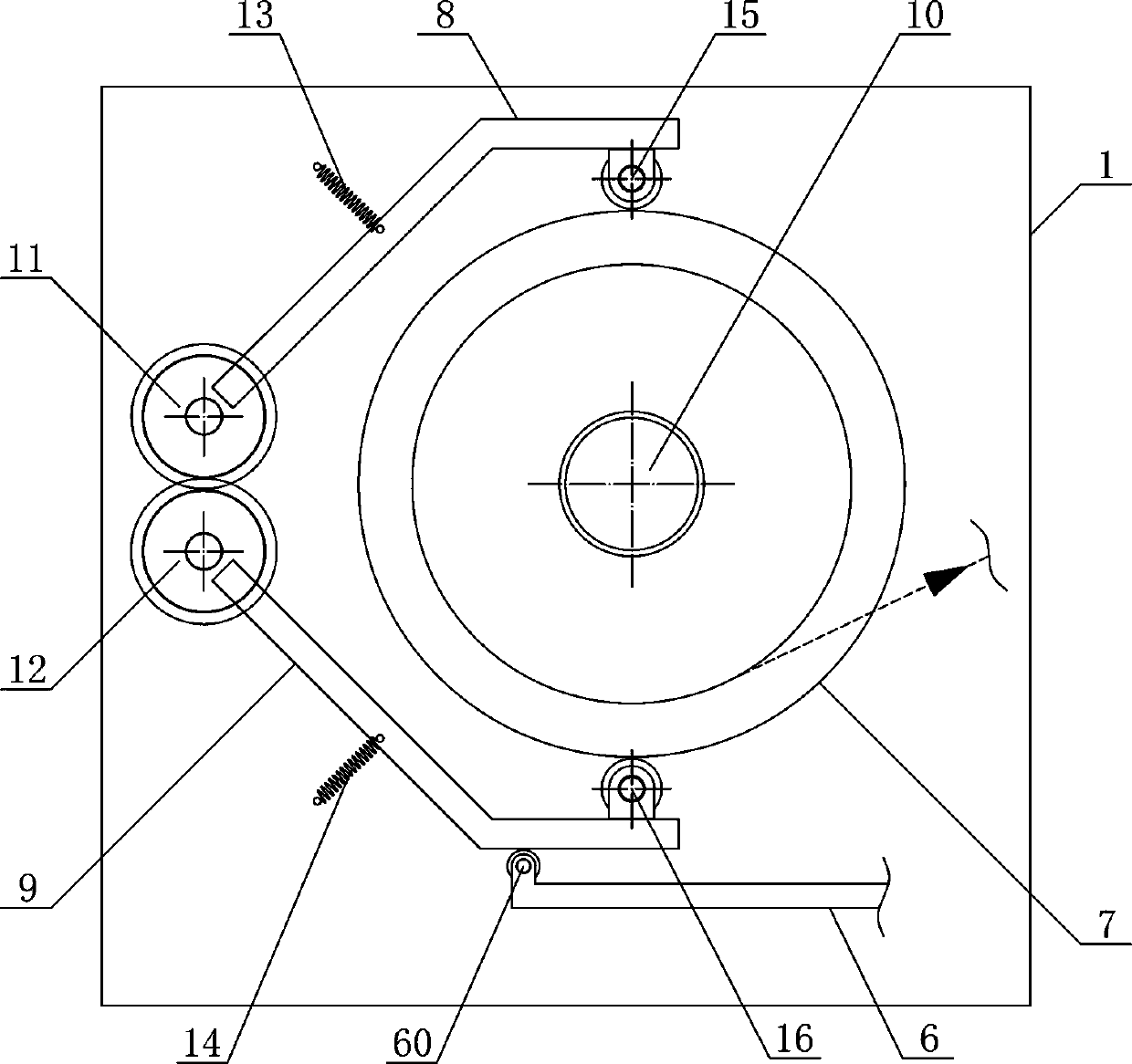

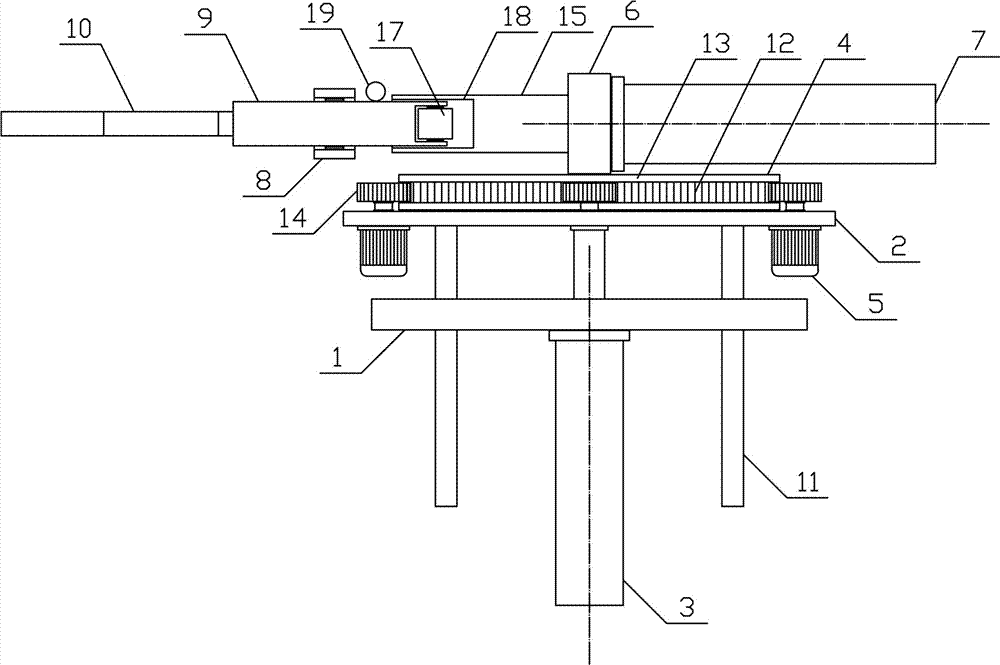

Mechanism for turning and processing disk workpiece

ActiveCN108673219AEasy to sendReasonable structural designMetal working apparatusConveyor partsCircular discMechanical equipment

The invention discloses a mechanism for turning and processing disc workpiece, which belongs to the field of workpiece continuous processing auxiliary mechanical equipment. According to the invention,an upper fixing bracket is vertically disposed on the upper side of a lower fixing bracket, a front conveying mechanism is horizontally disposed on the upper side of the upper fixing bracket, a feeding mechanism is horizontally fixed and disposed on one side of the front conveying mechanism, a turning mechanism is vertically disposed on the upper fixing bracket at the lower side of the feeding mechanism, a material guiding mechanism is horizontally disposed on the upper side of the lower fixing bracket at the lower side of the turning mechanism, an unloading mechanism is horizontally disposedon the lower fixing bracket at one side of the material guiding mechanism, and a rear conveying mechanism is horizontally fixed and disposed on the lower fixing bracket between the unloading mechanism and a material-guiding rotating plate. The invention is reasonable in design, and can turn the disc workpiece over one by one smoothly and steadily, and can further process and convey the disc workpiece after turning efficiently and accurately, which improves processing efficiency and quality of workpiece and meets the needs of production and use.

Owner:NANTONG HAIGAO CNC MACHINERY CO LTD

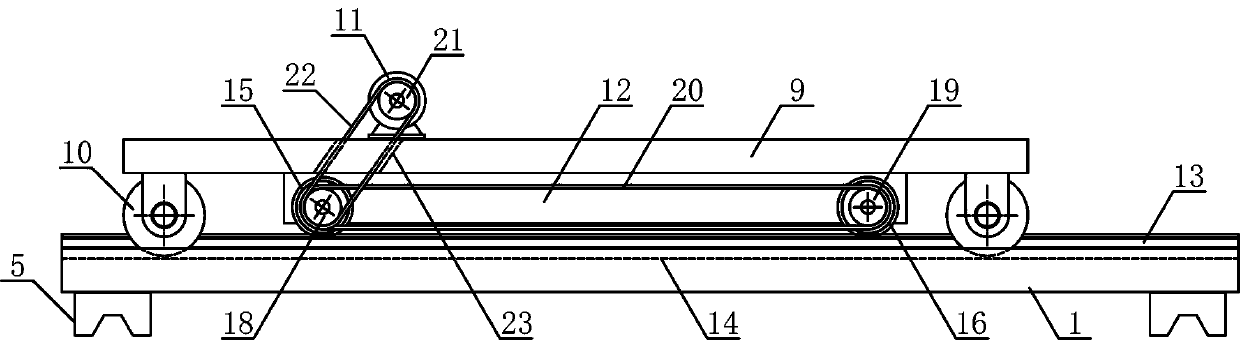

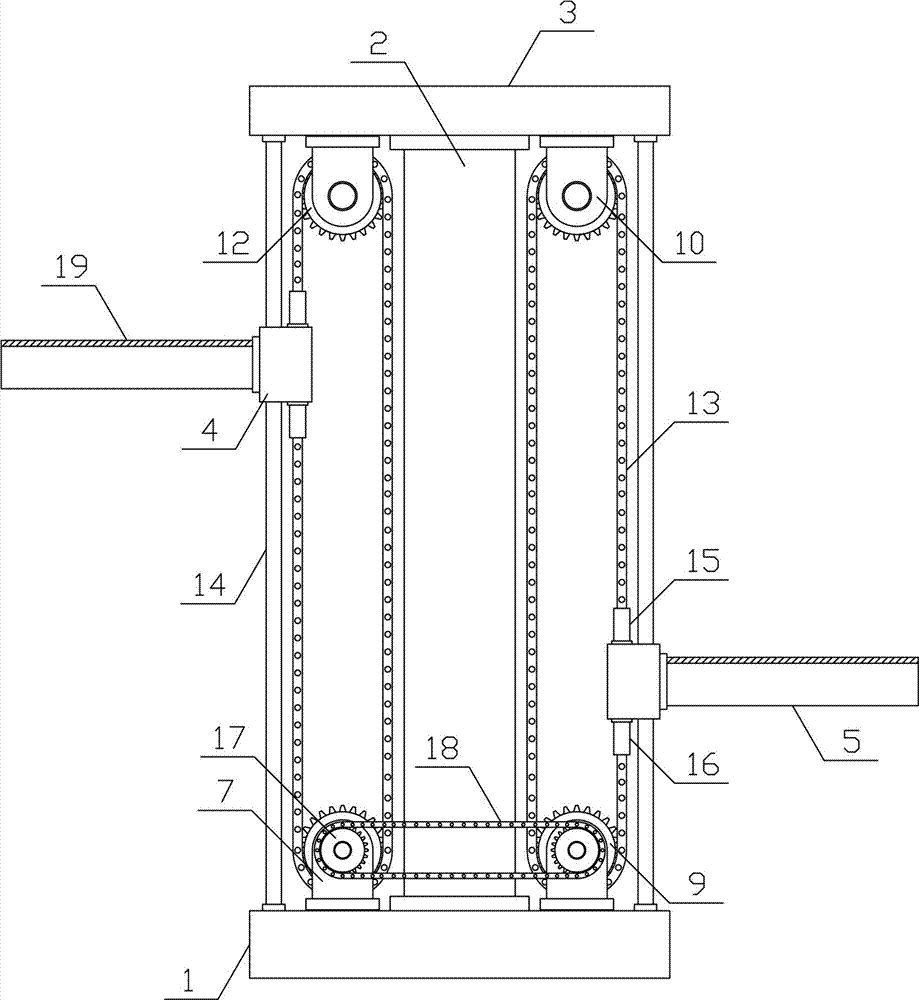

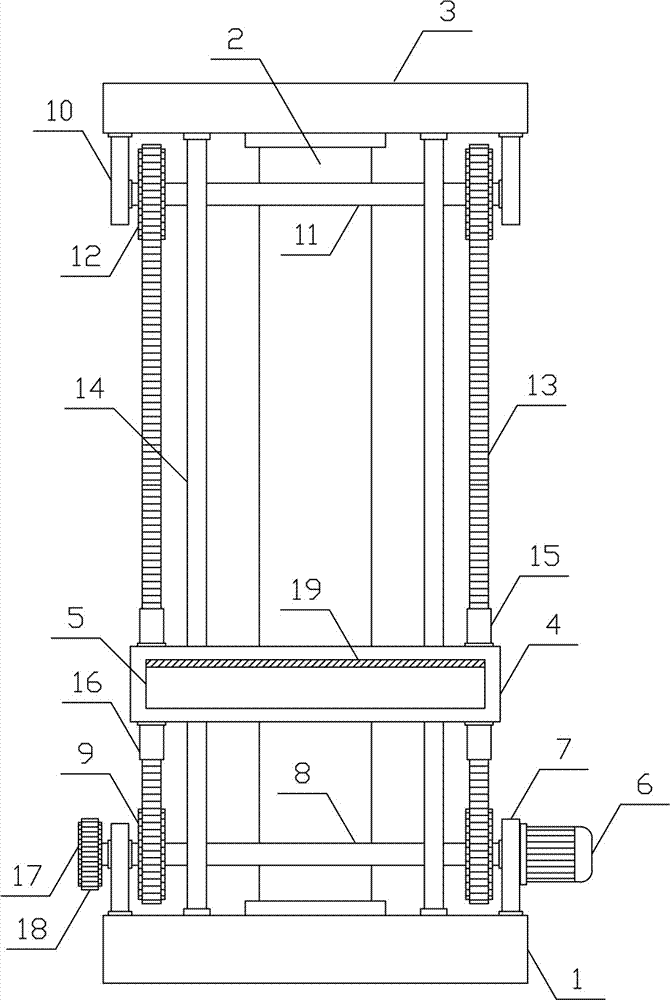

Double-platform reciprocating lifting device

The invention discloses a double-platform reciprocating lifting device and belongs to the field of conveying mechanical equipment. The double-platform reciprocating lifting device comprises a fixed base, a fixed upright column, a supporting and connecting plate, lifting plates, material bearing platforms and a lifting motor; the fixed upright column is vertically arranged in the middle of the upper side of the fixed base; each of two sides of each lower rotating shaft is vertically provided with a lower lifting chain wheel; each of two sides of an upper rotating shaft is vertically provided with an upper lifting chain wheel; a lifting chain is vertically meshed and connected between each lower lifting chain wheel and each corresponding upper lifting chain wheel; each of two sides above the fixed base is horizontally provided with one of the lifting plates vertically and slidably connected to lifting guide rods; each material bearing platform is horizontally arranged at one side of each lifting plate; the lower rotating shafts are driven by the lifting motor; and the two lower rotating shafts located at two sides above the fixed base are connected in a driving way. The double-platform reciprocating lifting device is reasonable in structural design and capable of rapidly and efficiently realizing the synchronous, opposite and stable lifting of the two material lifting platforms, increasing the material lifting efficiency, improving the material lifting quality and meeting production and use requirements.

Owner:桐乡市民安纺织有限责任公司

Yarn drafting and rolling mechanism

InactiveCN109230836AHigh degree of processing automationReasonable structural designFilament handlingTextiles and paperYarnMechanical equipment

The invention discloses a yarn drafting and rolling mechanism and belongs to the field of mechanical equipment for yarn conveying processing. Yarn press mechanisms are vertically arranged at the two sides of a drafting mechanism of the yarn drafting and rolling mechanism respectively, a rolling mechanism is arranged on a rolling support of one side of a yarn press mechanism, and multiple draftingrotation rollers are horizontally and rotatably connected to a lifting support of the upper side of a drafting support in the horizontal direction in sequence; multiple rotation rollers are horizontally and rotatably connected to a rotation support in the inclination direction in sequence, yarn press rotation discs are vertically and rotatably connected to rolling supports of the two sides of thelower portion of the drafting mechanism respectively, yarn press connection rods is arranged between lifting yarn press plates and the yarn press rotation discs, and a rolling yarn cylinder slidinglysleeves a rolling rotation roller in the horizontal direction. The yarn drafting and rolling mechanism is reasonable in structural design, the yarn can be stably and evenly drafted and processed segment by segment and can be conveniently and efficiently rolled, the automation degree of yarn processing is improved, and the demands of production and application are met.

Owner:桐乡市澳得利纤维股份有限公司

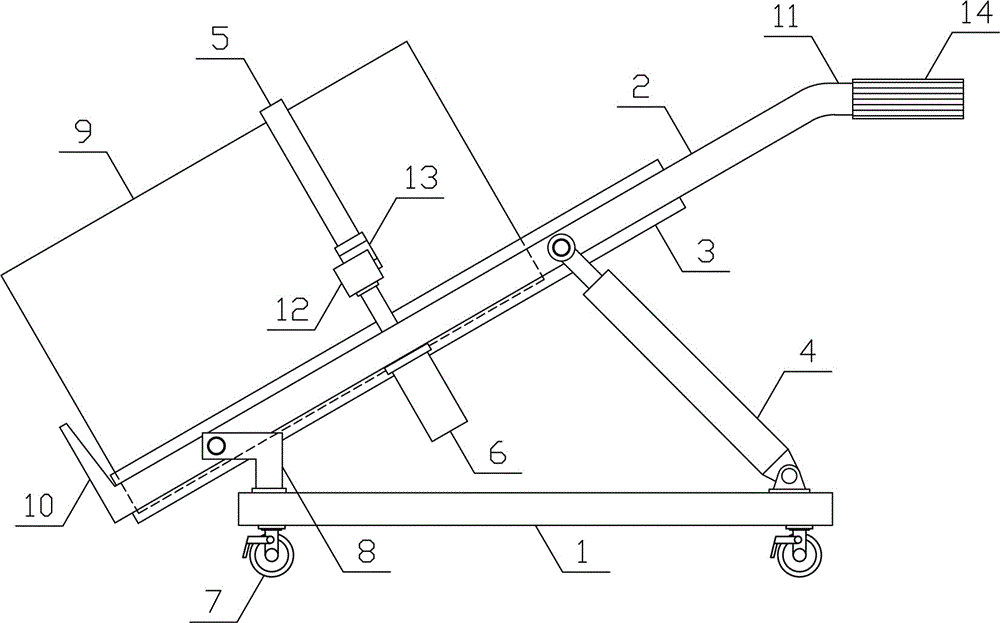

Round barrel fixing and transporting mechanism

InactiveCN106114577AEasy to fixImprove efficiencySledge wheelsSupporting partsHydraulic cylinderEngineering

The invention discloses a round barrel fixing and transporting mechanism and belongs to the field of transporting mechanical equipment. The round barrel fixing and transporting mechanism comprises a horizontally-moving base, a rotary support, a barrel bearing board, rotary hydraulic cylinders, a fixing belt and tensioning hydraulic cylinders. Multiple universal wheels with brakes are evenly arranged on the lower side of the horizontally-moving base. The two sides below the rotary support are hinged to a rotation supporting seat. The barrel bearing board is arranged on the rotary support. Barrel stopping boards are arranged on the two sides of the lower end of the rotary support. A horizontally-moving handle is arranged at the upper end of the rotary support. The rotary hydraulic cylinders are obliquely arranged between the two sides of the middle portion of the rotary support and the horizontally-moving base. The tensioning hydraulic cylinders are arranged on the two sides below the rotary support. T-shaped connecting blocks matched with T-shaped buckles are arranged at the two ends of the fixing belt. The round barrel fixing and transporting mechanism is reasonable in structural design, a round barrel can be stably locked and fixed and can be conveniently and quickly transported, and the requirements for production use are met.

Owner:ZHEJIANG ZHONGSHI MACHINERY CO LTD

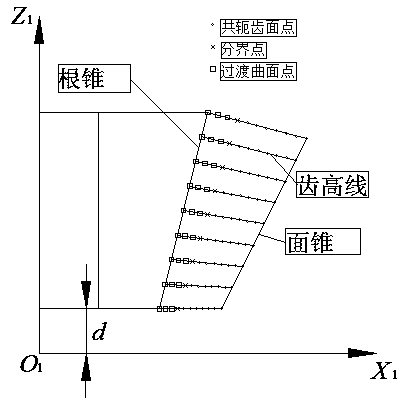

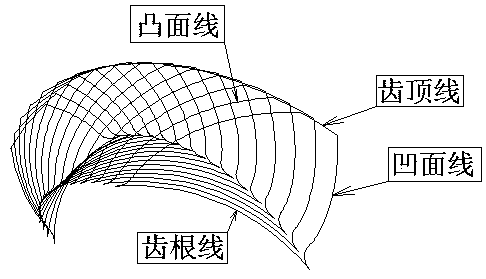

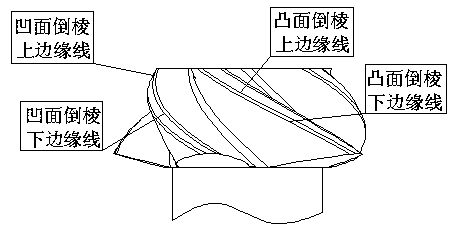

Method for calculating chamfering of tooth tip of spiral bevel gear based on discretization of curved surface

InactiveCN109190313AMeet the needs of production useSolve efficiency problemsArtificial lifeDesign optimisation/simulationMilling cutterMathematical model

The invention relates to a method for calculating the chamfering of the tooth tip of a spiral bevel gear, in particular to a method for calculating the chamfering of the tooth tip of the spiral bevelgear based on the discretization of a curved surface. The chamfering calculation method comprises the steps of: firstly creating a gear solid model according to the mathematical model of the tooth surface, and then creating a chamfering feature expression on the gear solid model, extracting the coordinates of the discrete points of the upper and lower edge lines of the chamfering tooth top, and obtaining the chamfering ball-end milling cutter path by numerical algorithm; according to the relationship between the axial direction of the ball end milling cutter and the contact position of the surface of the ball end milling cutter, installing the unchamfered gear on the four-axis machine tool, and completing the axial and circumferential tool alignment of the gear through the edge finder, andcompleting the chamfering of the tooth tip according to the ball-end milling cutter path. The chamfering calculation method can make the chamfering of tooth tip be finished by a four-axis machine, and solve the problems of low production efficiency and big machining error in manual chamfering, and meet the needs of production and use of enterprises.

Owner:YANGTZE UNIVERSITY

Automatic clothing stacking equipment

ActiveCN110451039ARealize automatic finishing and processingAchieve compactionPackagingBiochemical engineering

The invention discloses automatic clothing stacking equipment, and belongs to the field of clothing production and finishing processing. A laminating translation mechanism, a clamping and clothes pulling mechanism and a clothes placing and conveying mechanism are sequentially and fixedly arranged on the upper side of a clothes stacking support in the horizontal direction, a clothes clamping pressing plate is arranged on the upper side of a clothes clamping bearing plate, a main folding plate is arranged on one side of the middle of the clothes stacking frame, side folding plates are symmetrically arranged on the two sides of the clothes stacking frame correspondingly, a clothes placing plate is horizontally arranged in the clothes stacking frame, the clothes placing plate is arranged on atranslation guide rod in a sliding mode, a flattening ring tube is arranged on an arrangement support on the upper side of the clothes stacking frame, and a material falling mechanism is horizontallyarranged on a clothes conveying support on the upper side of a clothes conveying belt. According to the automatic clothing stacking equipment, the structural design is reasonable, the clothes can be stably and efficiently folded and processed, the clothes which can be folded and processed can be conveniently and smoothly placed into a packaging box in a convenient and smooth manner, automatic finishing processing of the clothes is realized, and the requirements of production and use are met.

Owner:亘美集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com