Patents

Literature

40results about How to "Accurate and efficient adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

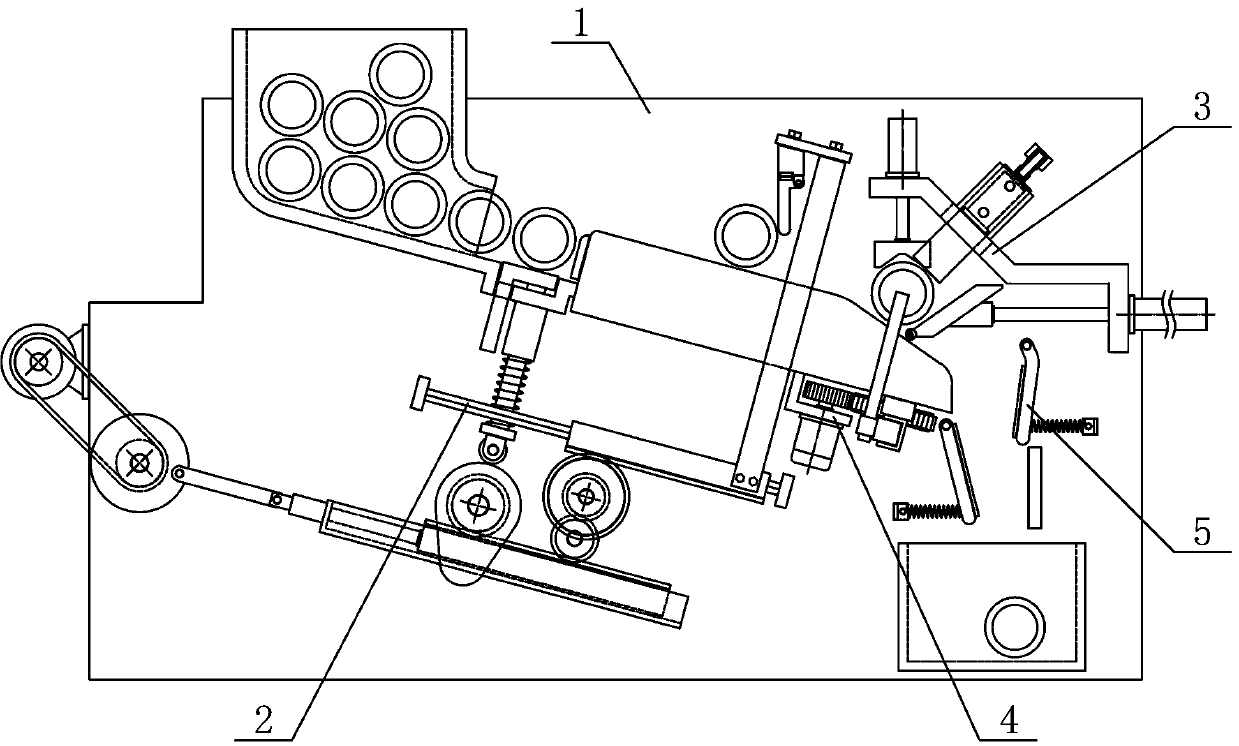

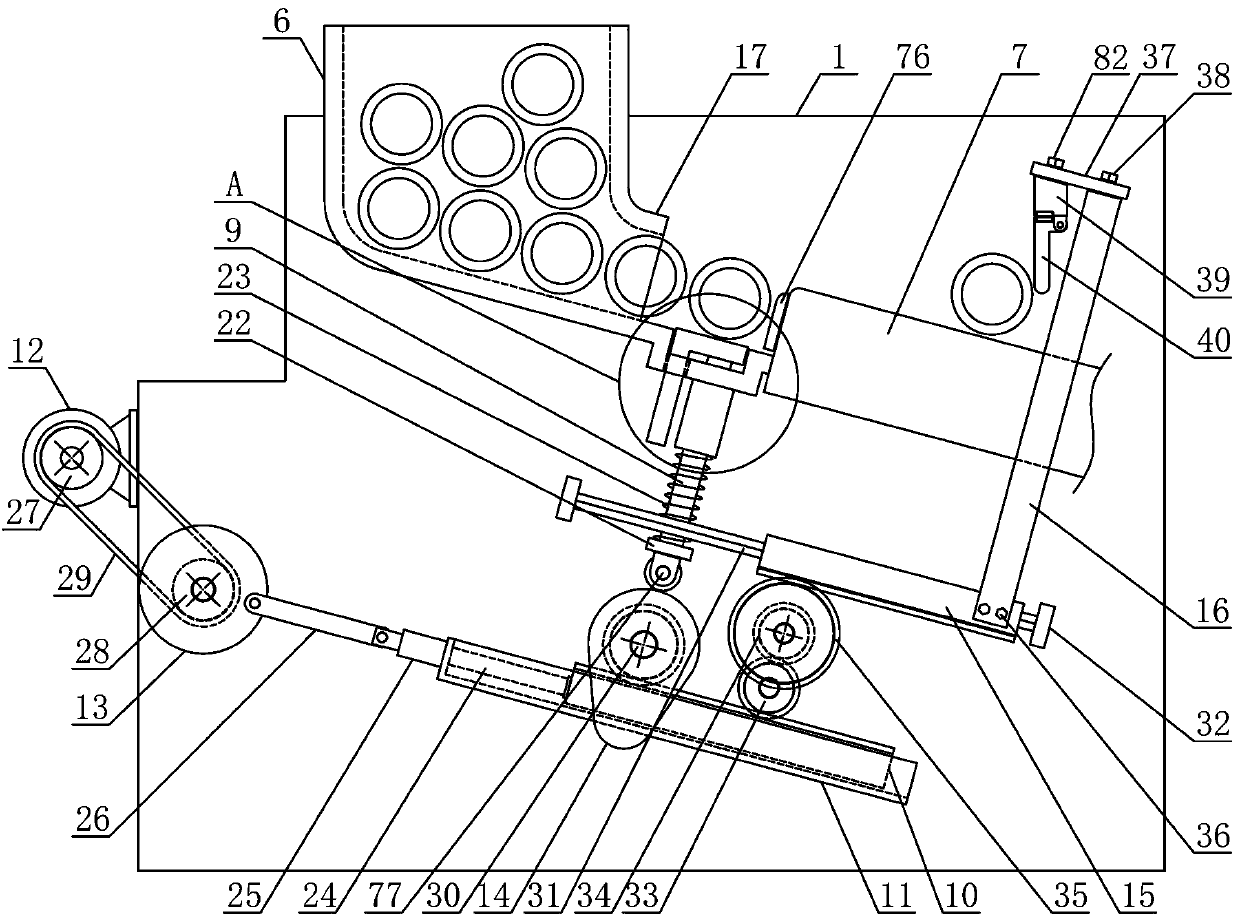

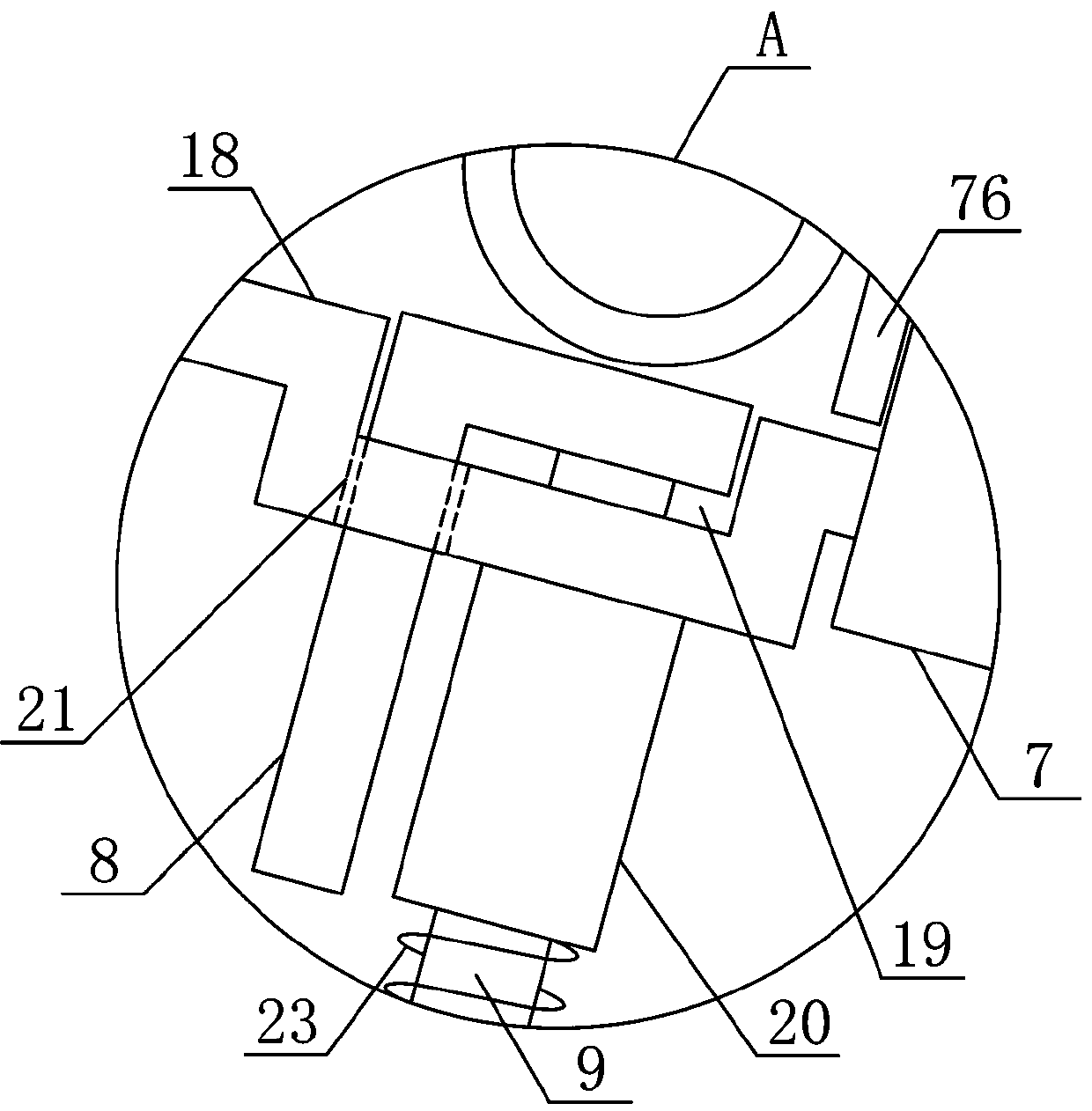

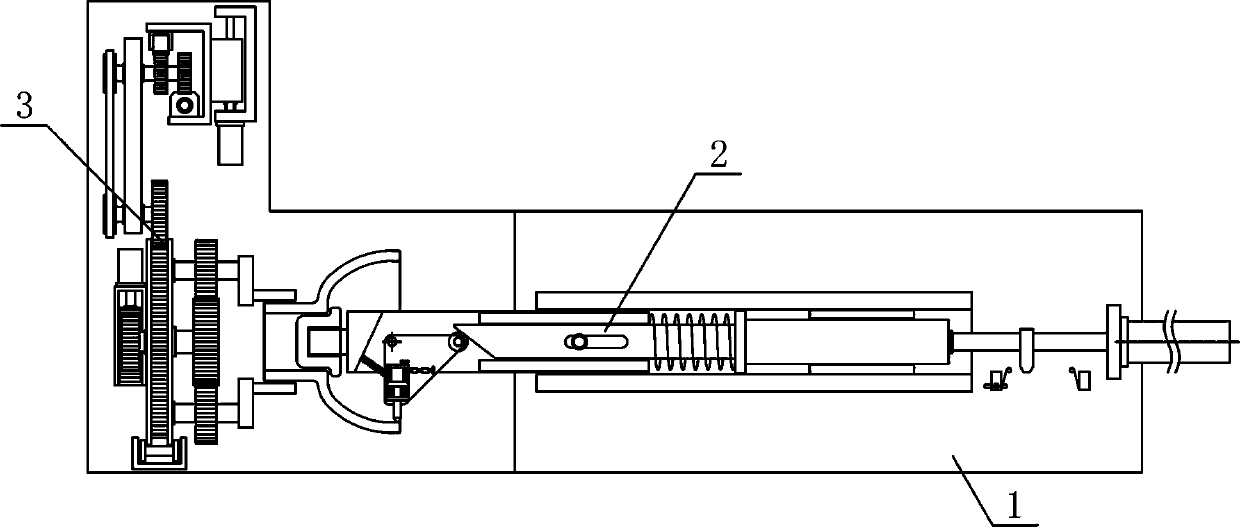

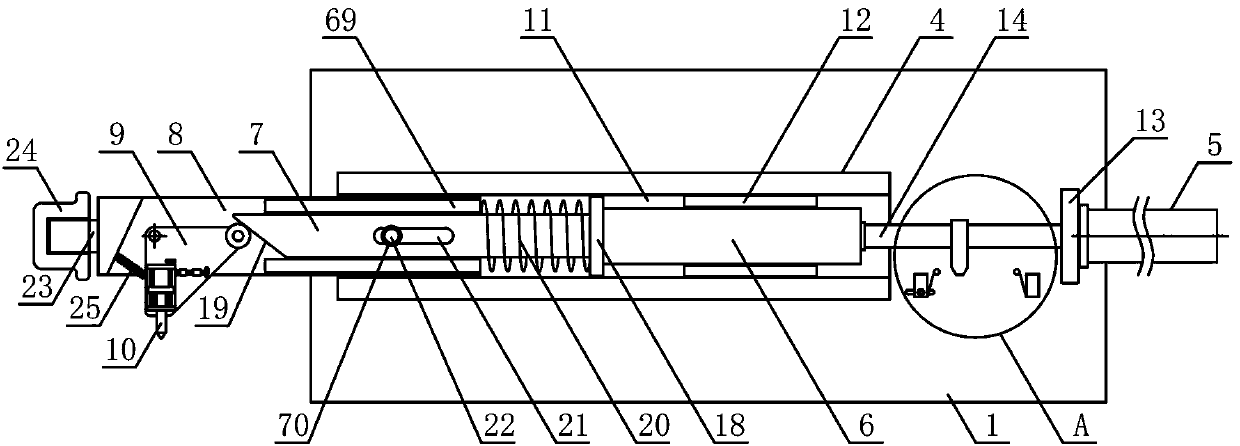

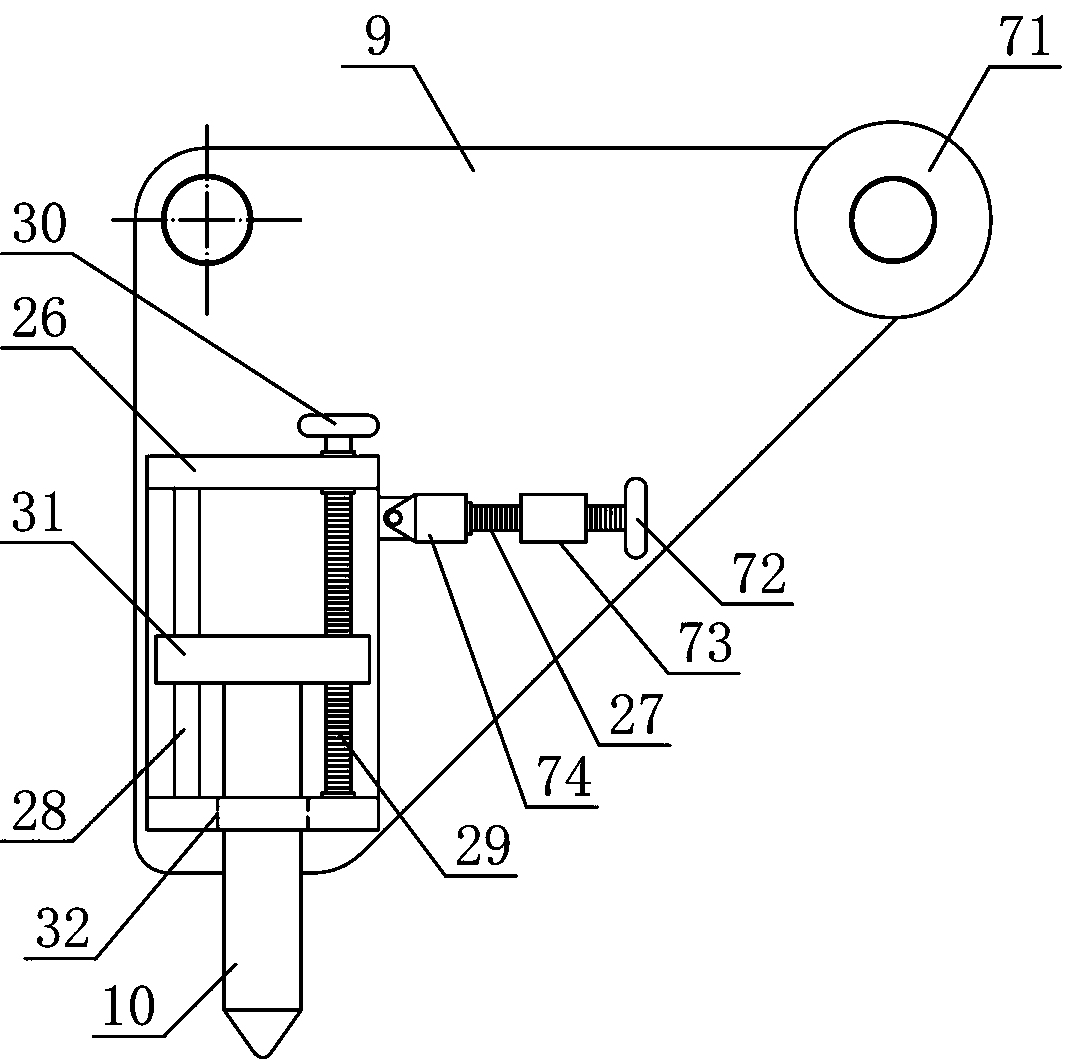

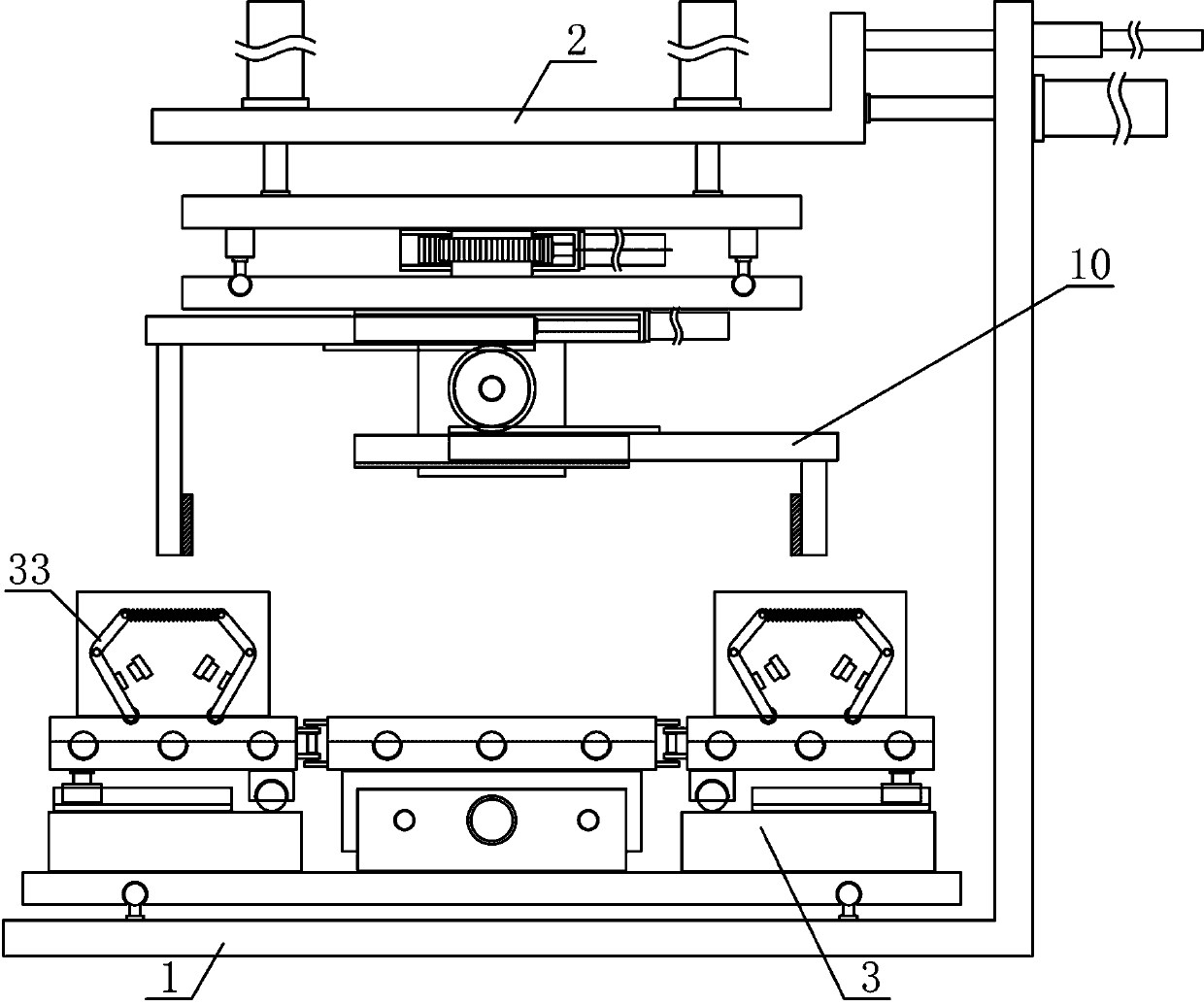

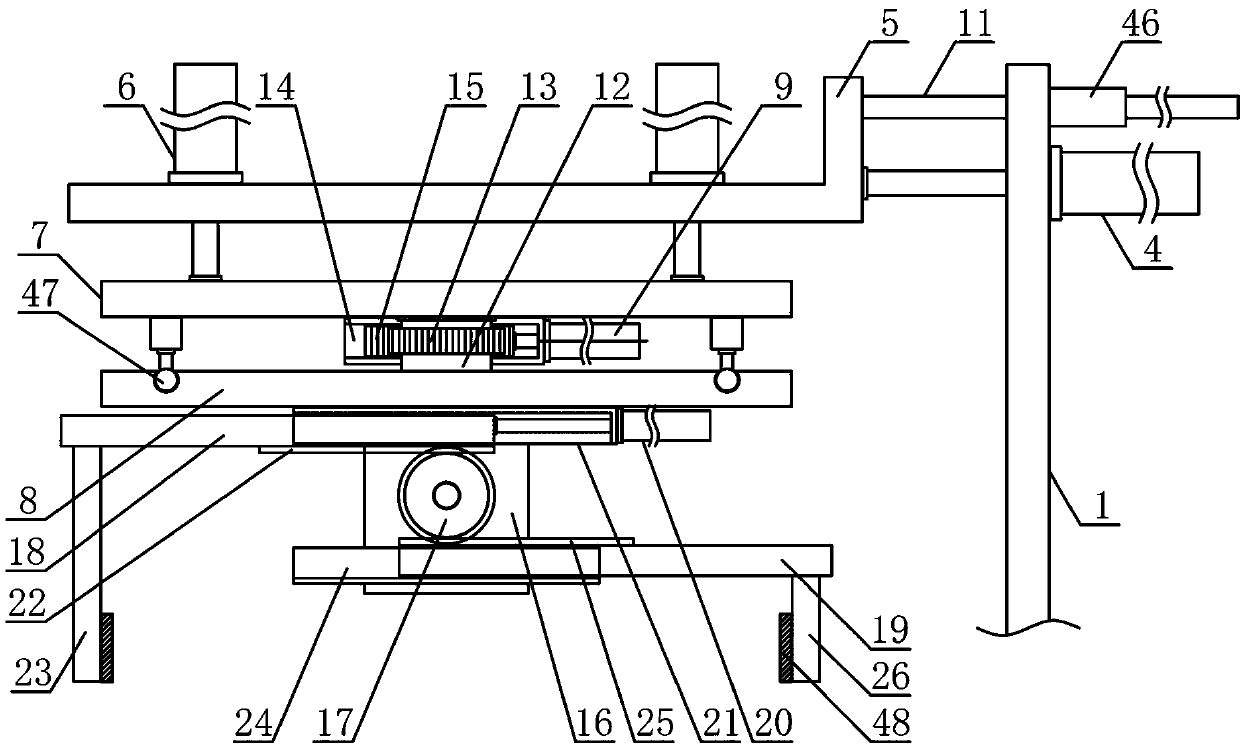

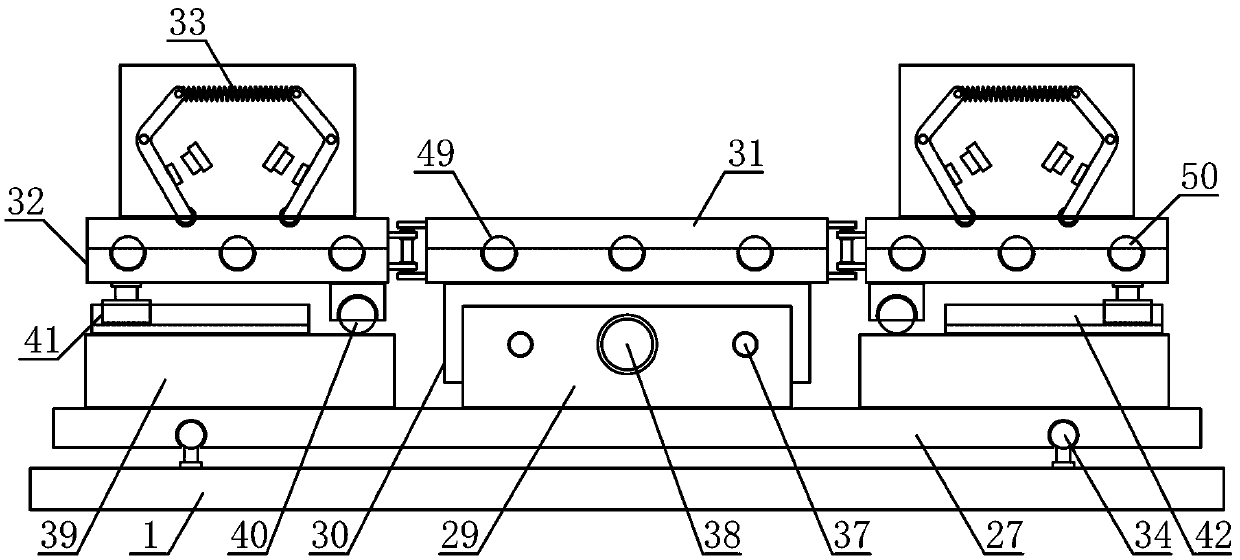

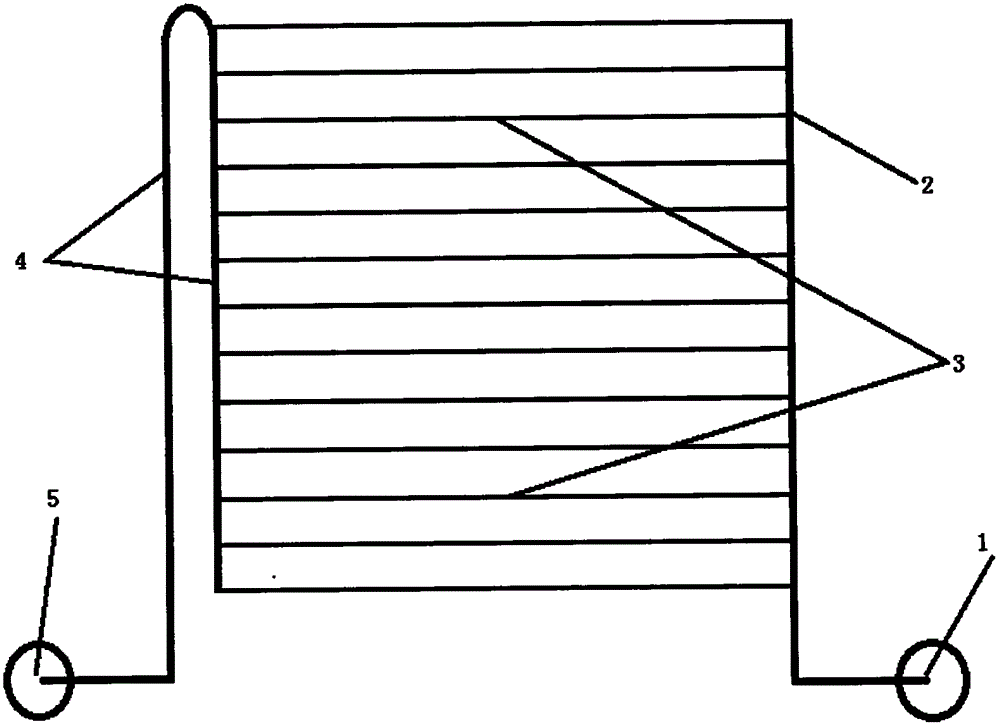

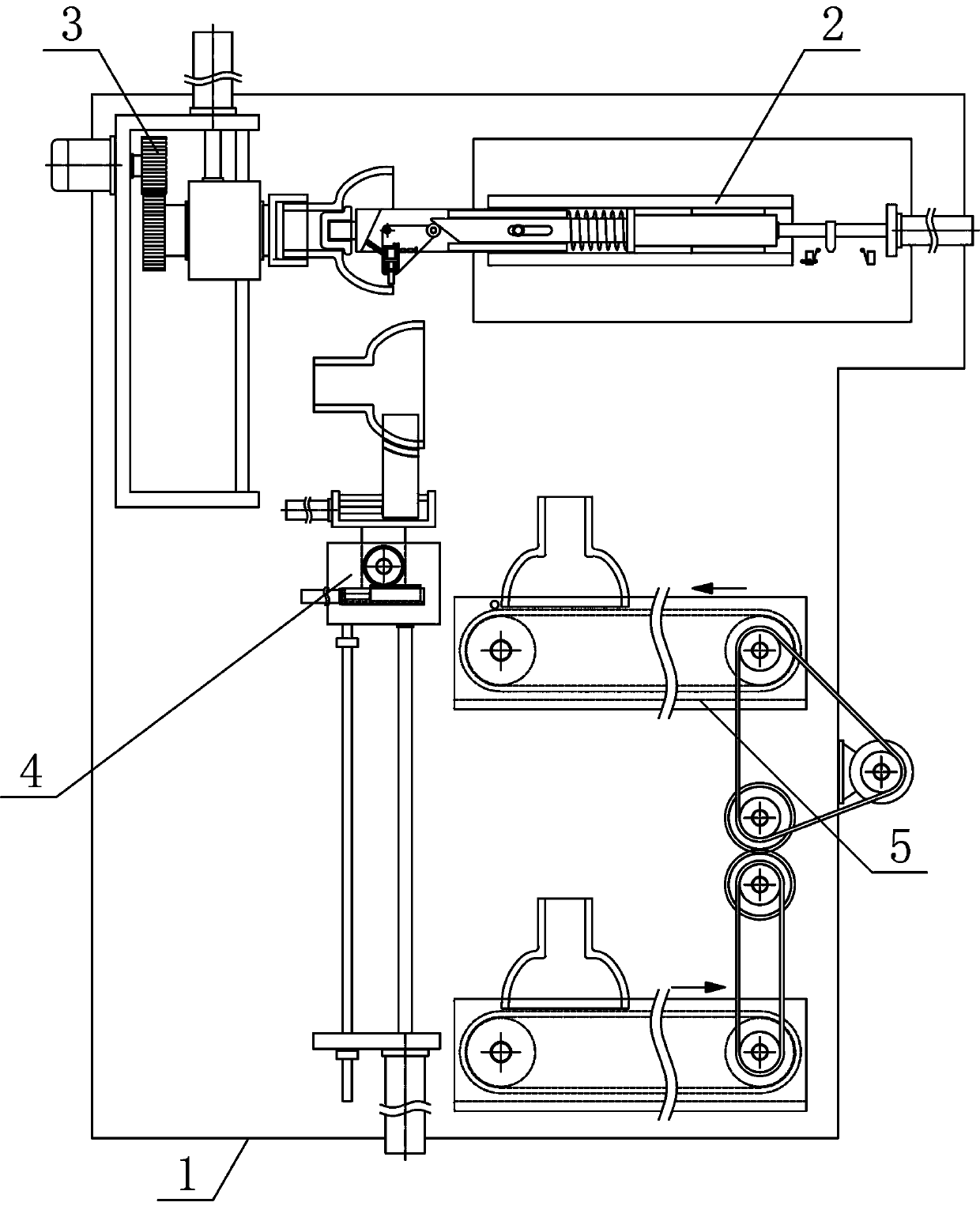

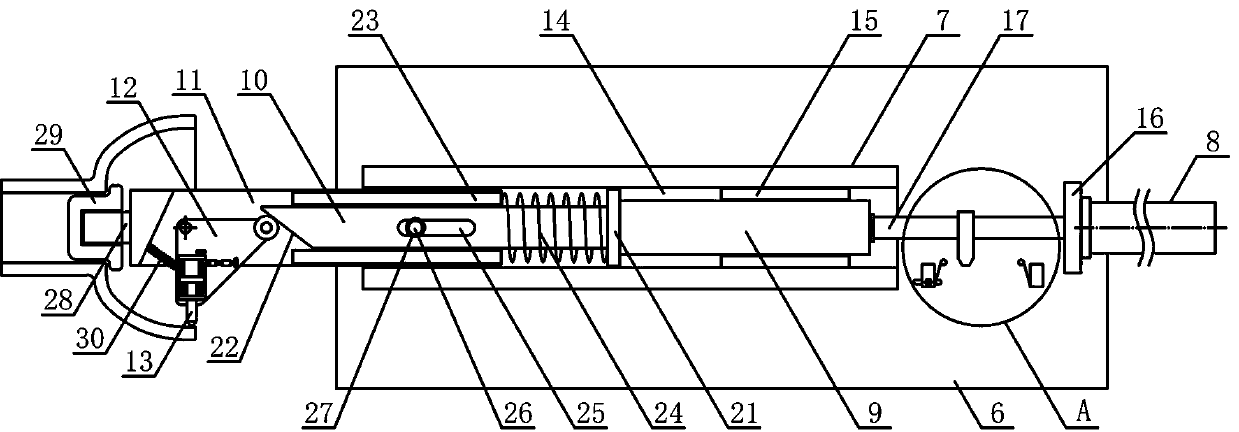

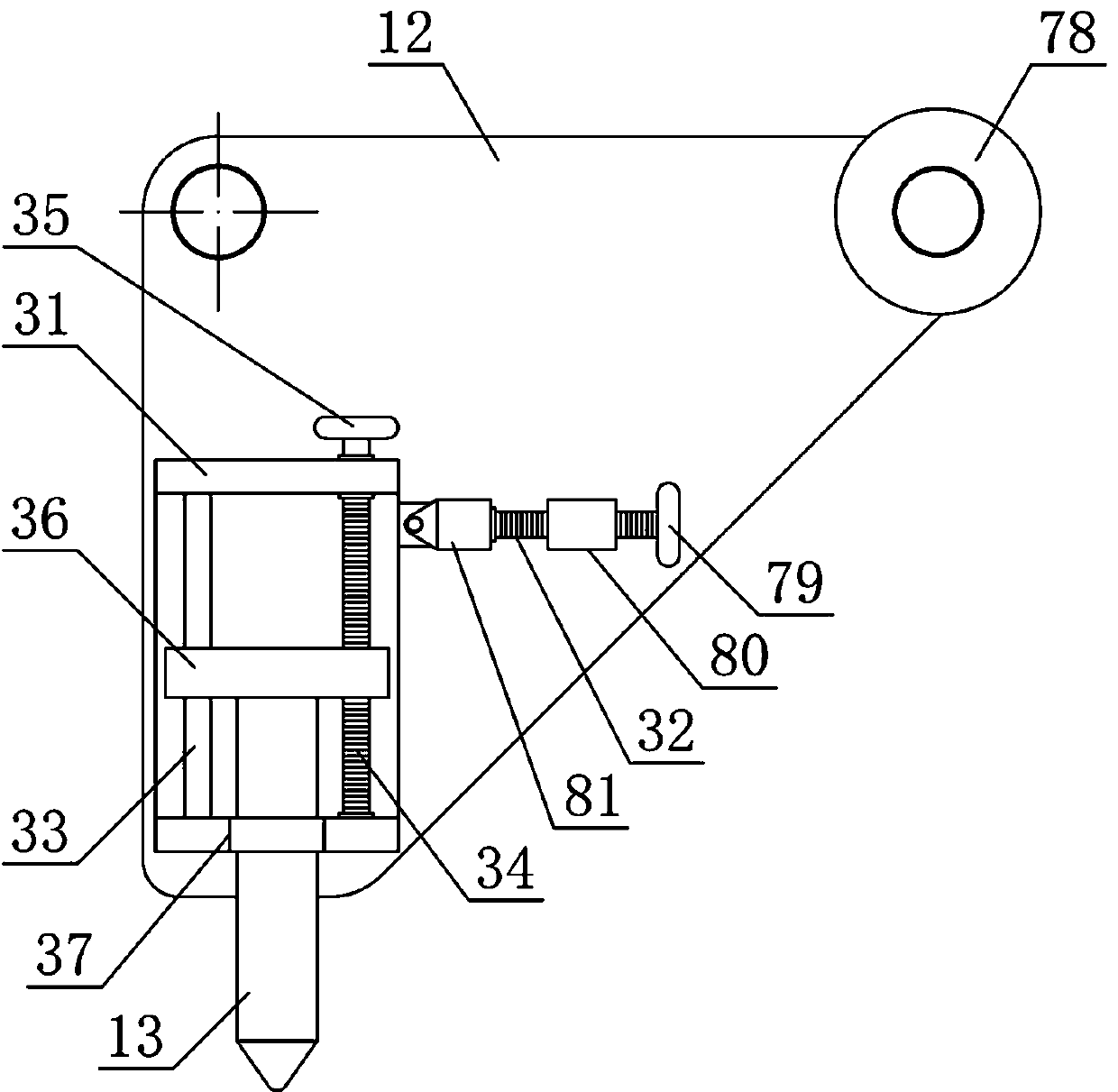

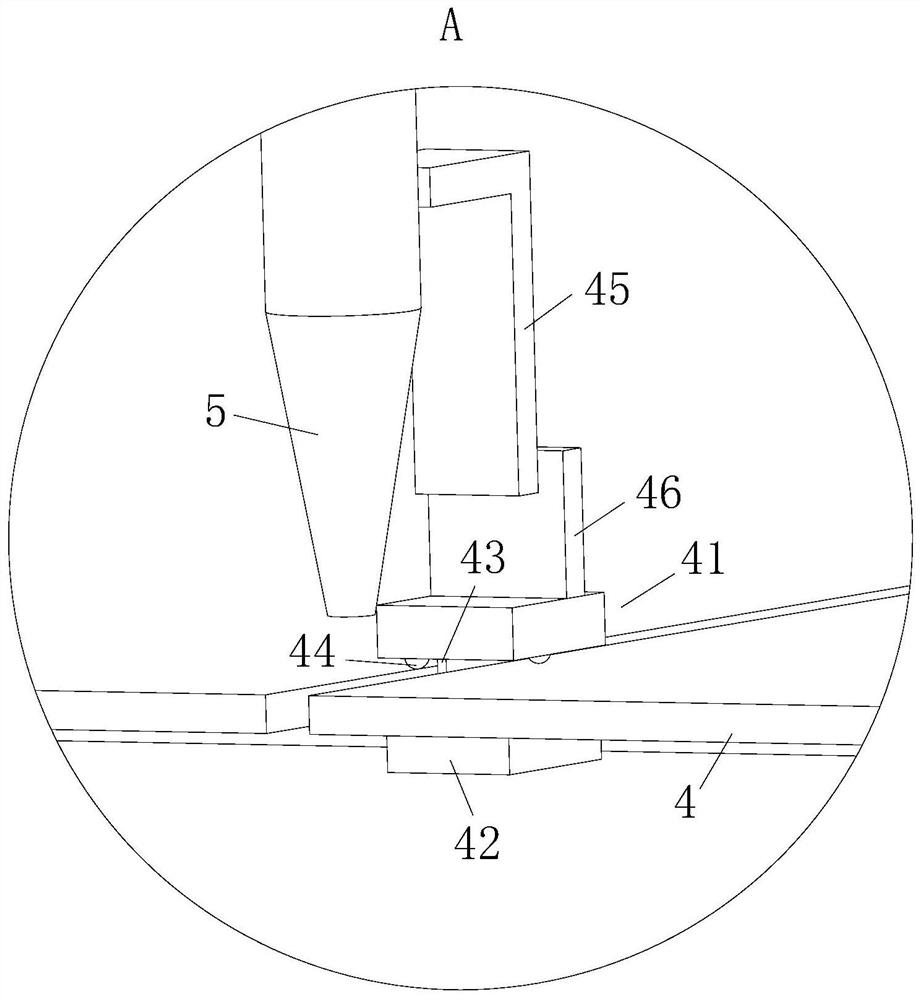

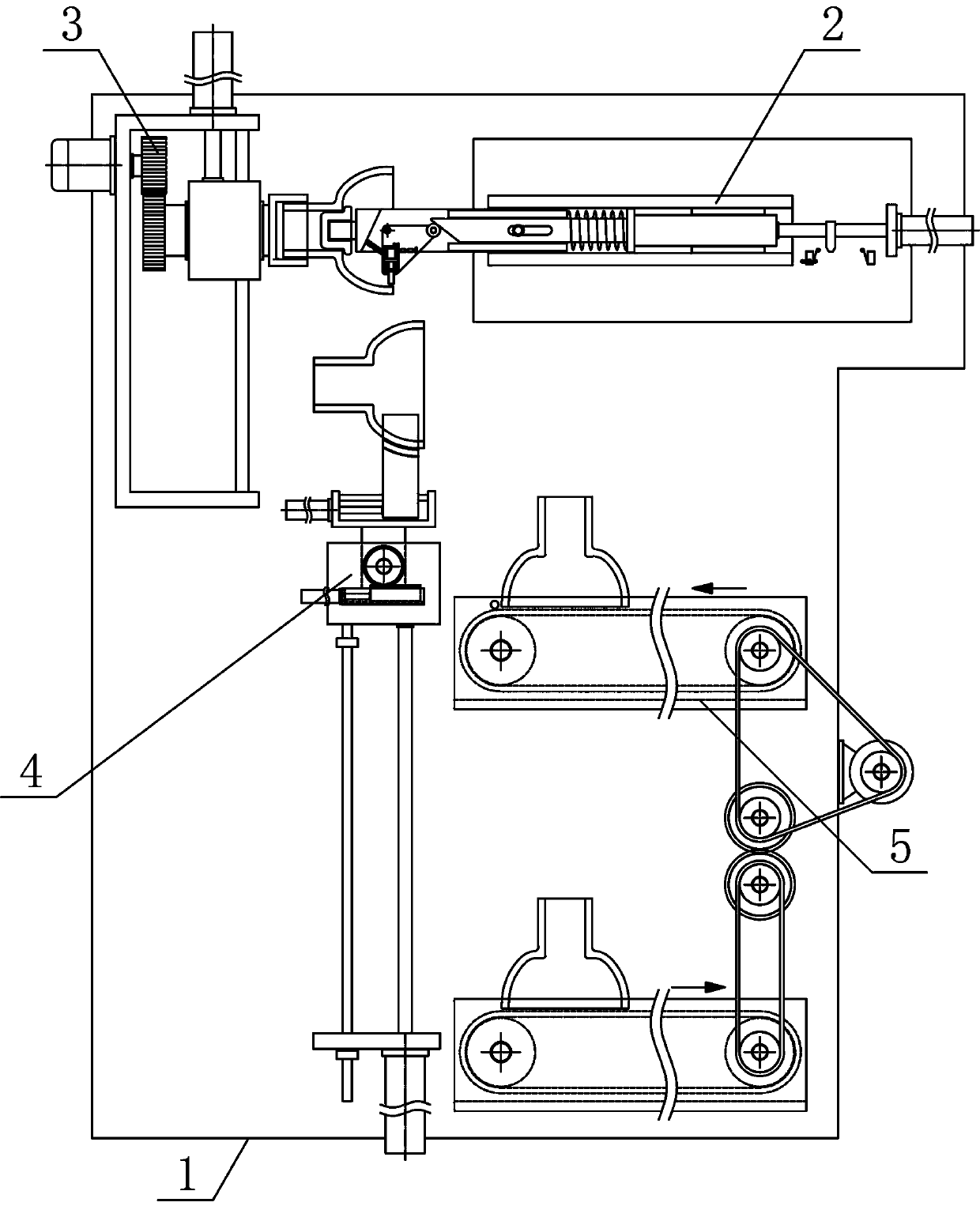

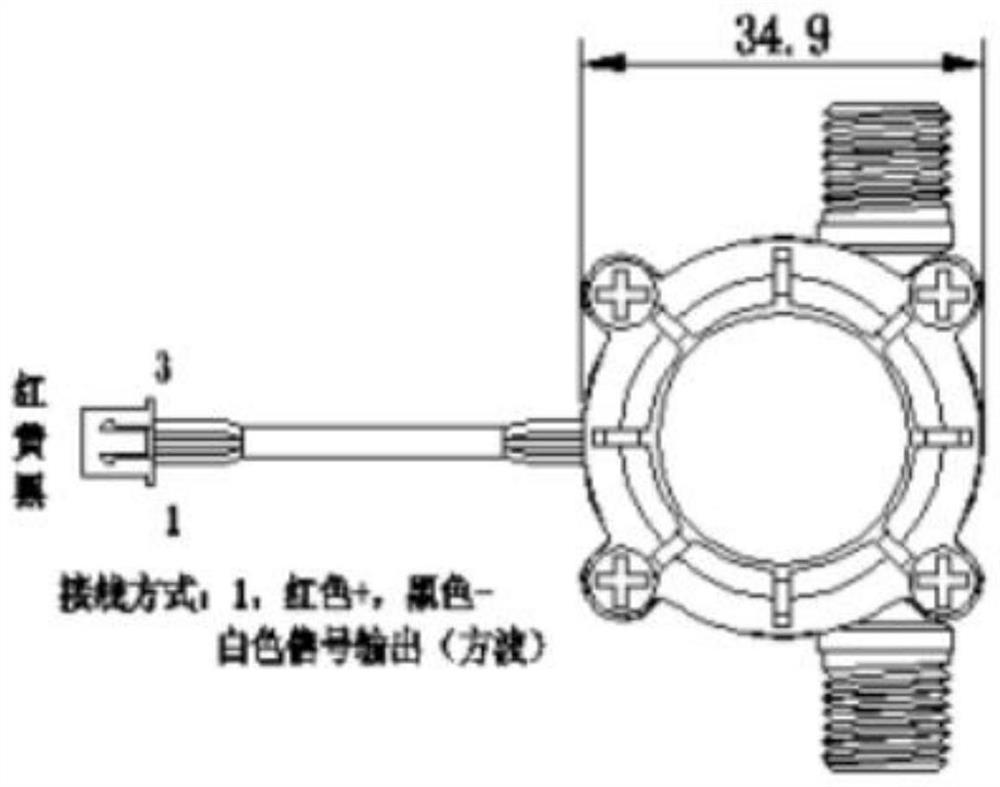

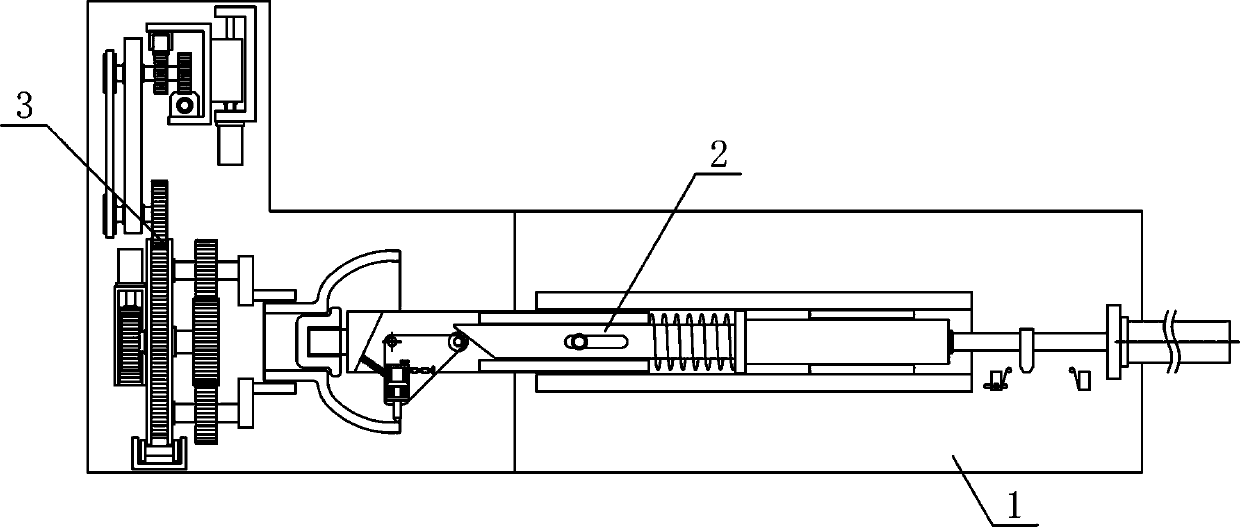

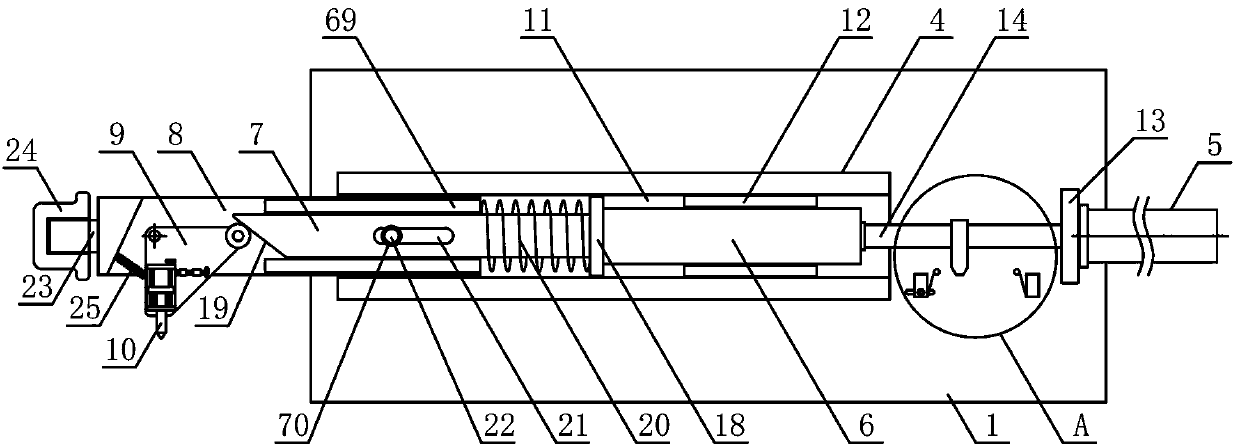

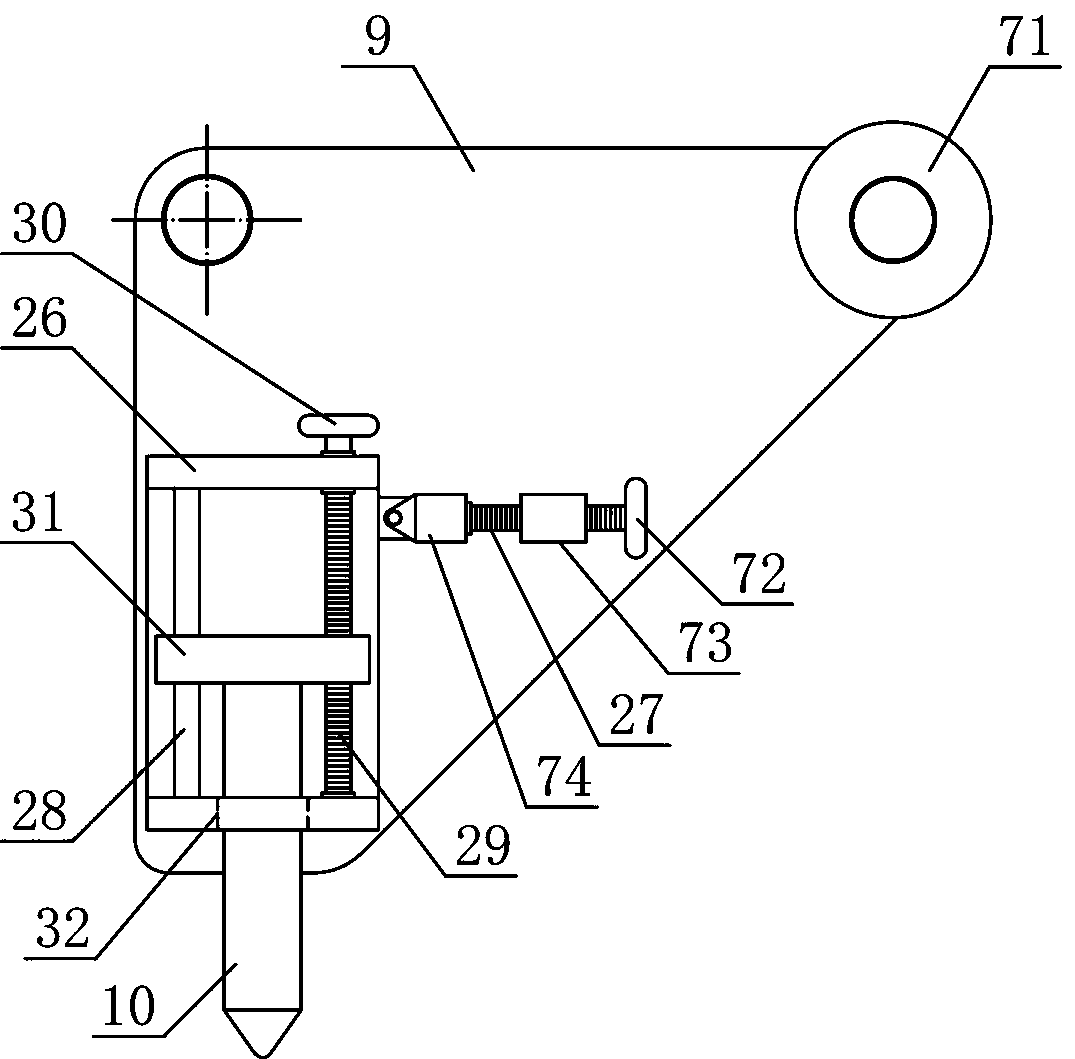

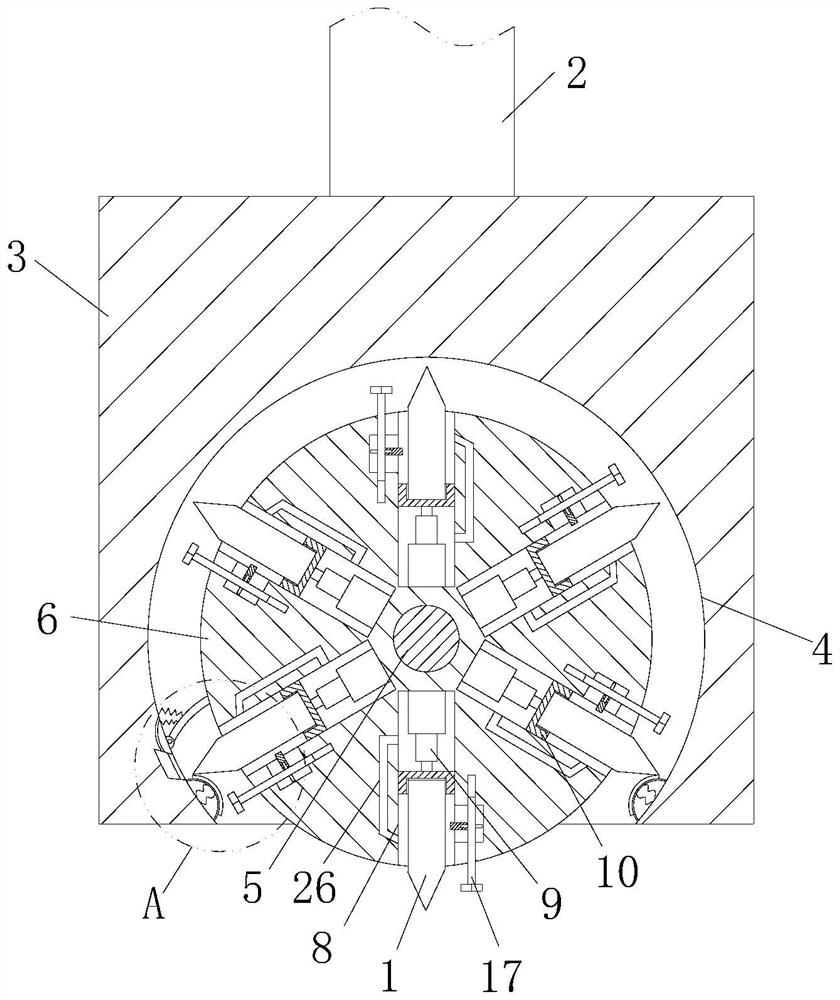

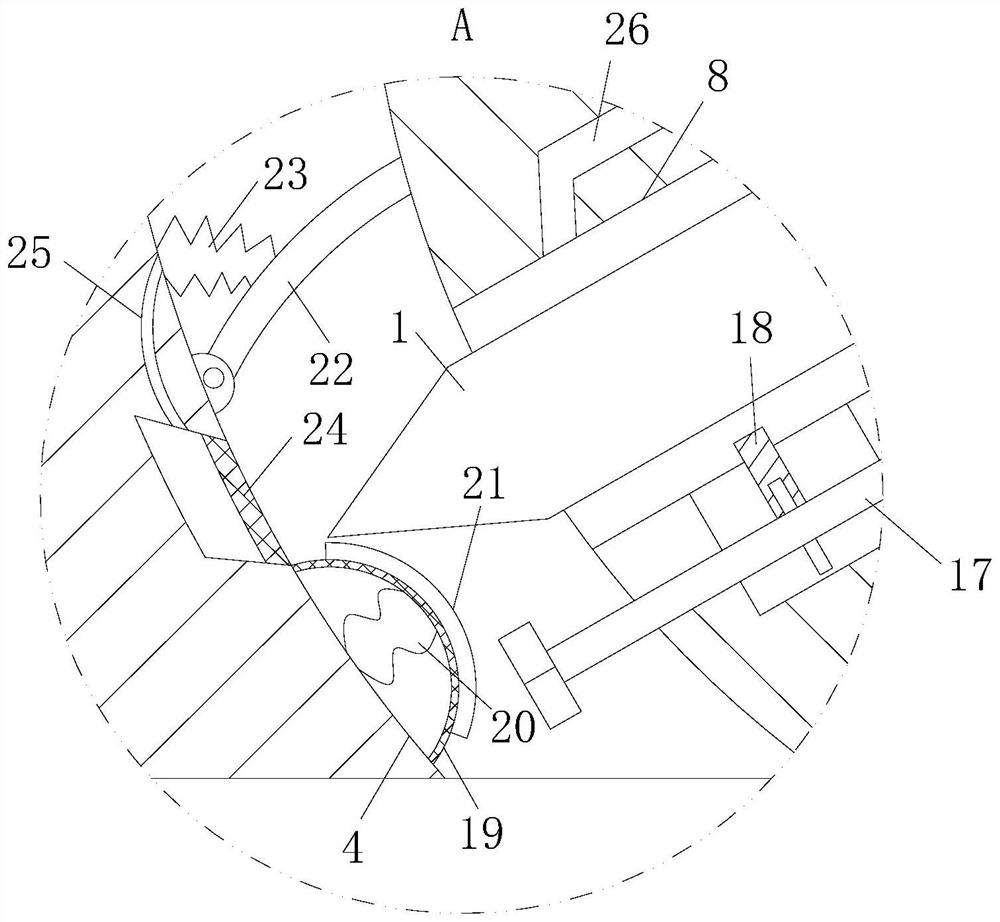

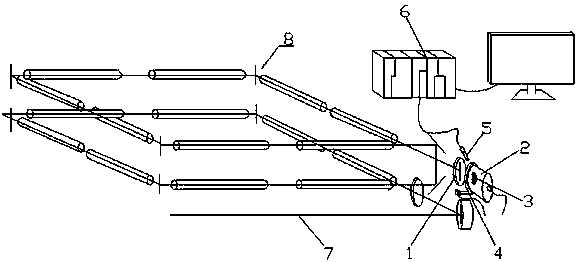

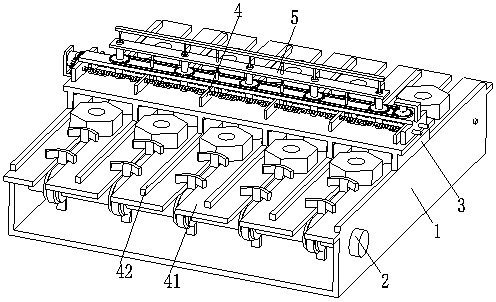

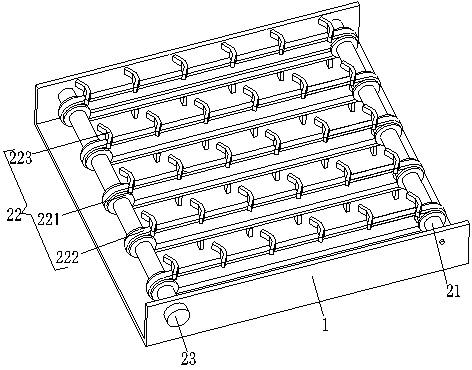

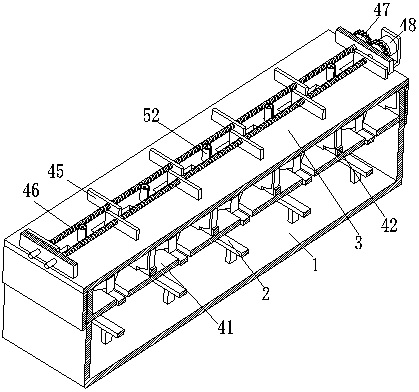

Automatic machining device for metal round pipes

InactiveCN111185522AEfficient and accurate processingAccurate and efficient adjustmentPerforating toolsMetal-working feeding devicesStructural engineeringMachining

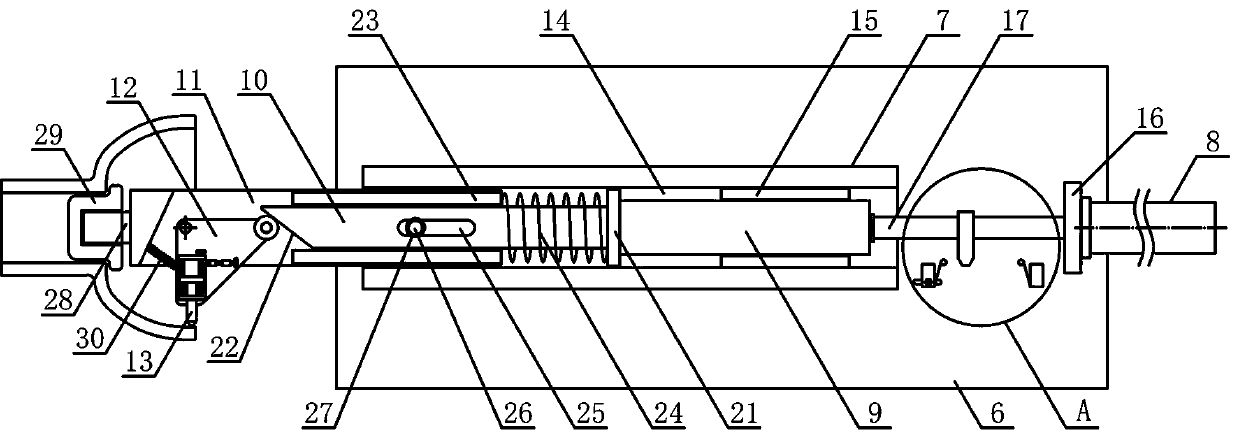

The invention discloses an automatic machining device for metal round pipes, and belongs to the field of mechanical workpiece machining equipment. The device comprises a round pipe machining support,a round pipe guiding and conveying mechanism, a round pipe machining mechanism, a round pipe positioning mechanism and a round pipe discharging mechanism, wherein the round pipe guiding and conveyingmechanism is obliquely and fixedly arranged on the round pipe machining support in a downward mode, a pipe storage hopper and a guide pipe table plate of the round pipe guiding and conveying mechanismare sequentially and fixedly arranged on the upper side of the round pipe machining support in the oblique direction from top to bottom, the round pipe machining mechanism is fixedly arranged at theposition, on the upper side of the end of the round pipe guiding and conveying mechanism, of the round pipe machining support, the round pipe positioning mechanism is horizontally arranged on the lower side of the end of the round pipe guiding and conveying mechanism, and the round pipe discharging mechanism is vertically arranged at the position, on the lower side of the round pipe machining mechanism, of the round pipe machining support. The automatic machining device is reasonable in structural design, can efficiently, stably and continuously convey the metal round pipes for perforating machining, and achieves automatic and accurate machining of the metal round pipes, the machining efficiency and the machining quality of the metal round pipes are improved, and the requirements of production and use are met.

Owner:黄薇婷

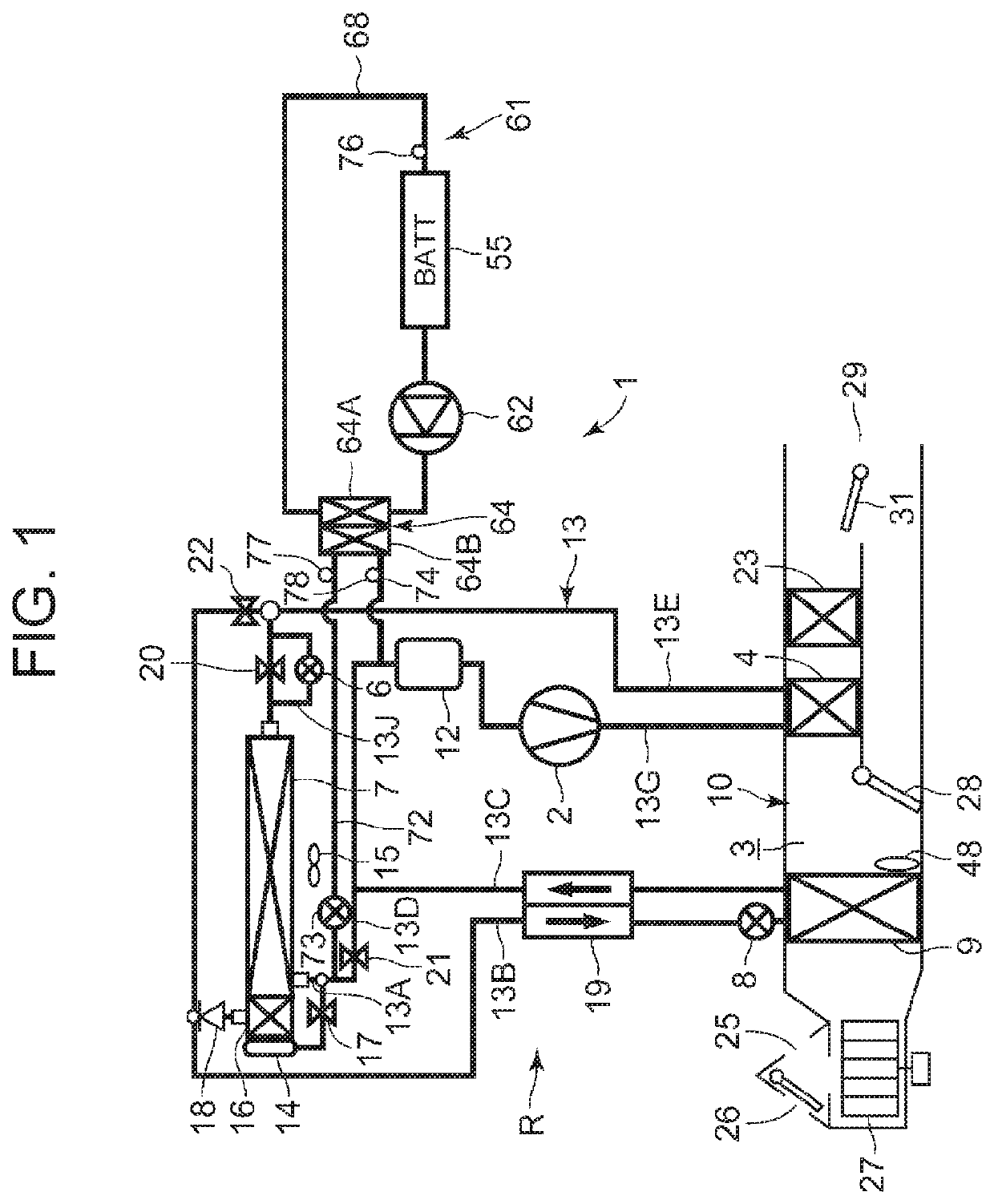

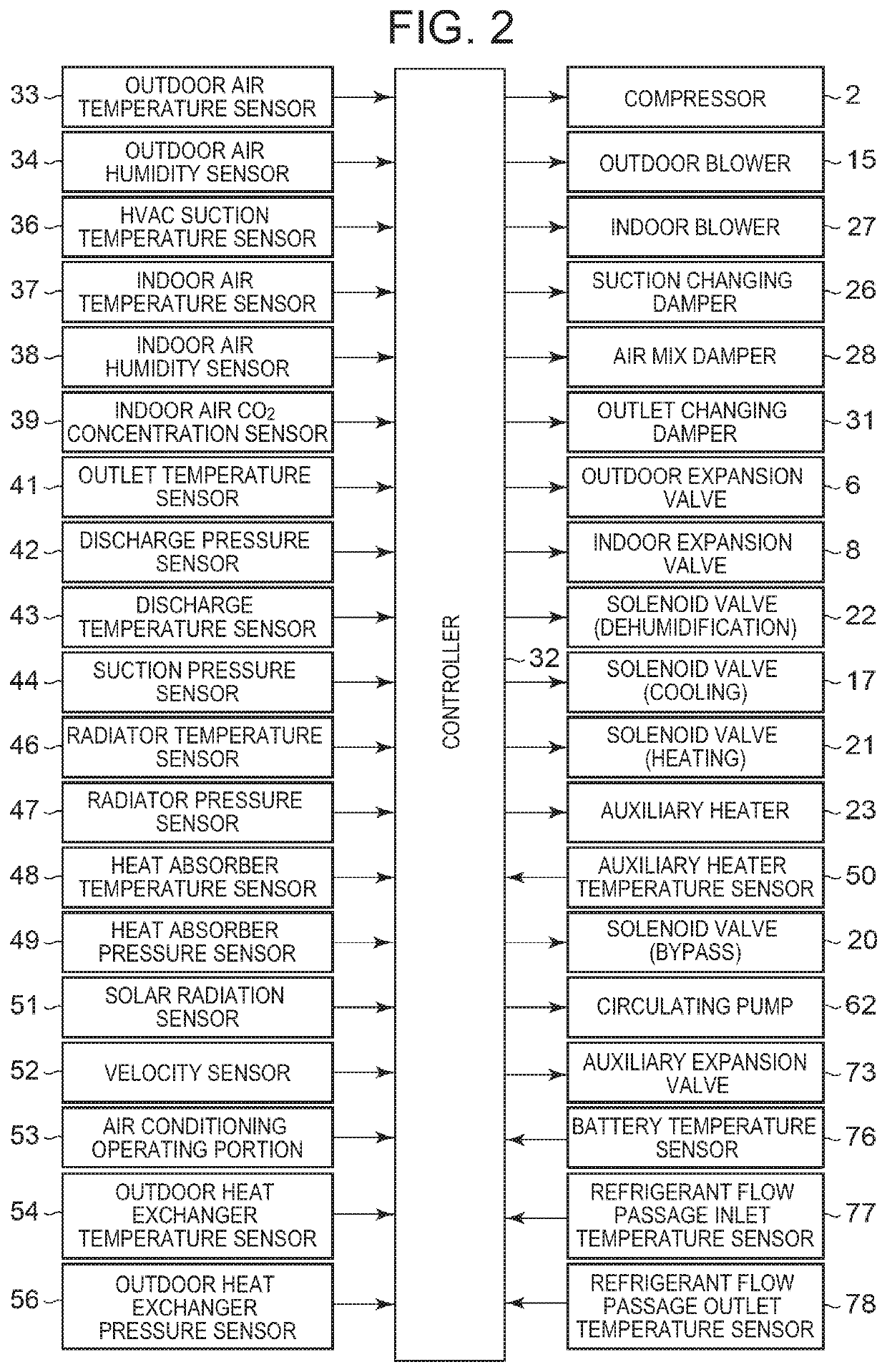

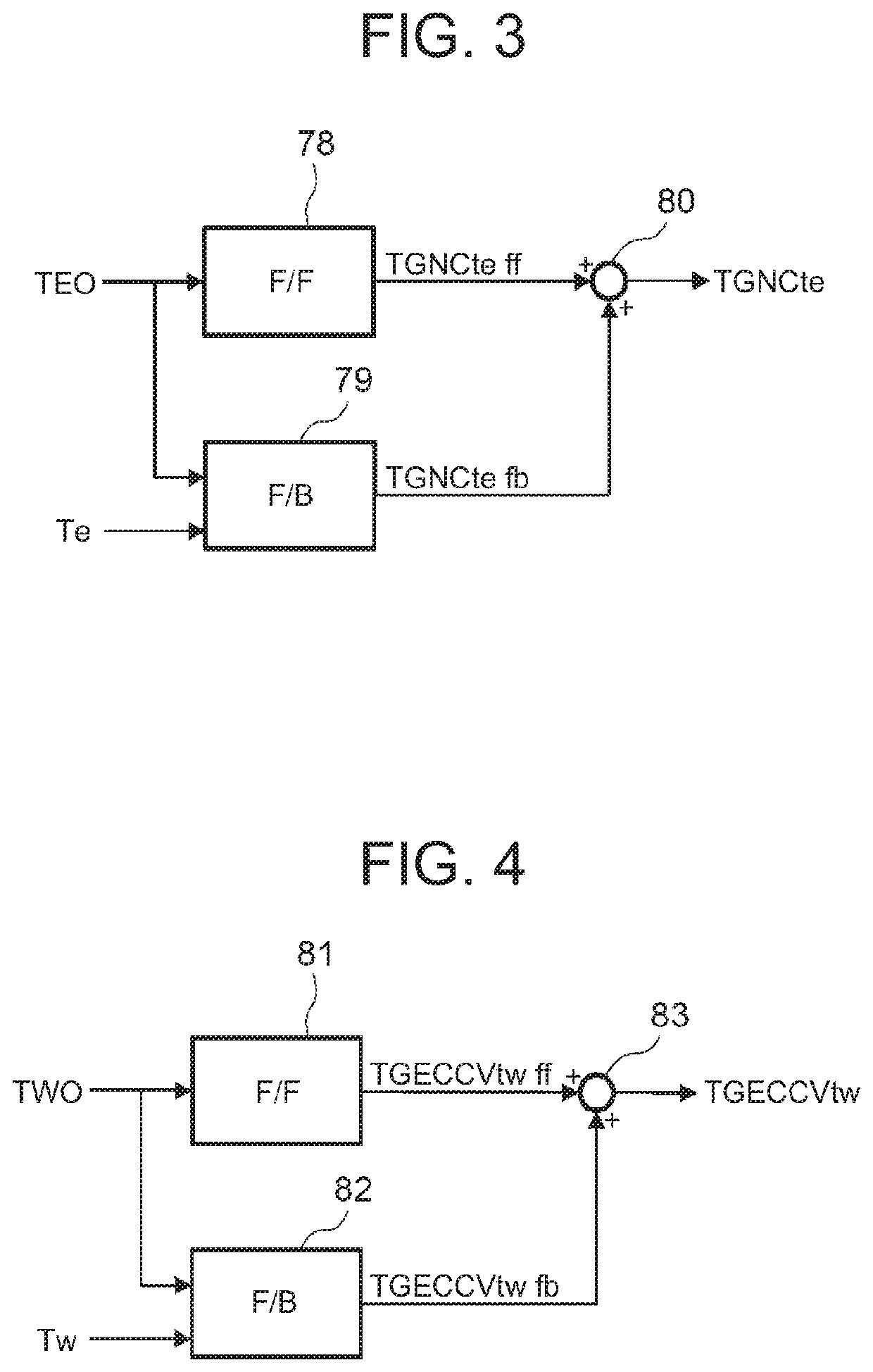

Vehicular air conditioning device

ActiveUS20200122544A1Consuming wasteful powerAccurate and efficient adjustmentAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

A vehicular air conditioning device is provided which is capable of cooling a heat medium of a battery temperature adjustment device by a refrigerant in a refrigerant circuit to improve operation efficiency when a battery is to be cooled. The vehicular air conditioning device includes a battery temperature adjustment device (61) for circulating a heat medium in a battery (55) to cool the same, a refrigerant-heat medium heat exchanger (64) for exchanging heat between at least part of the refrigerant flowing out from an outdoor heat exchanger (7) and the heat medium circulating in the battery temperature adjustment device, and an auxiliary expansion valve (73) for decompressing the refrigerant flowing into the refrigerant-heat medium heat exchanger. A control device controls a compressor (2) or the auxiliary expansion valve on the basis of a temperature Tw of the refrigerant of the refrigerant-heat medium heat exchanger to thereby adjust a battery temperature Tb to a target battery temperature TBO.

Owner:SANDEN CORP

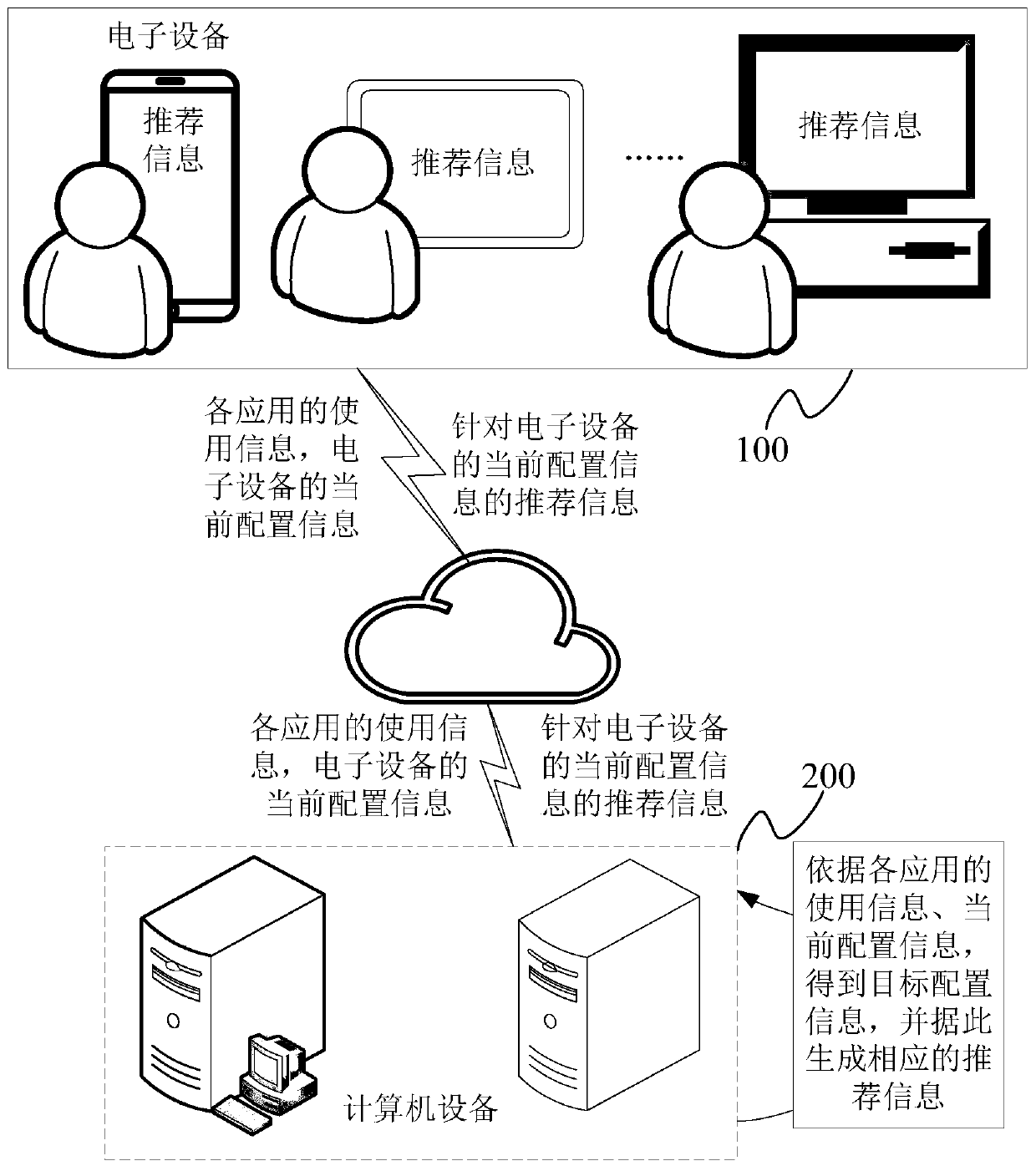

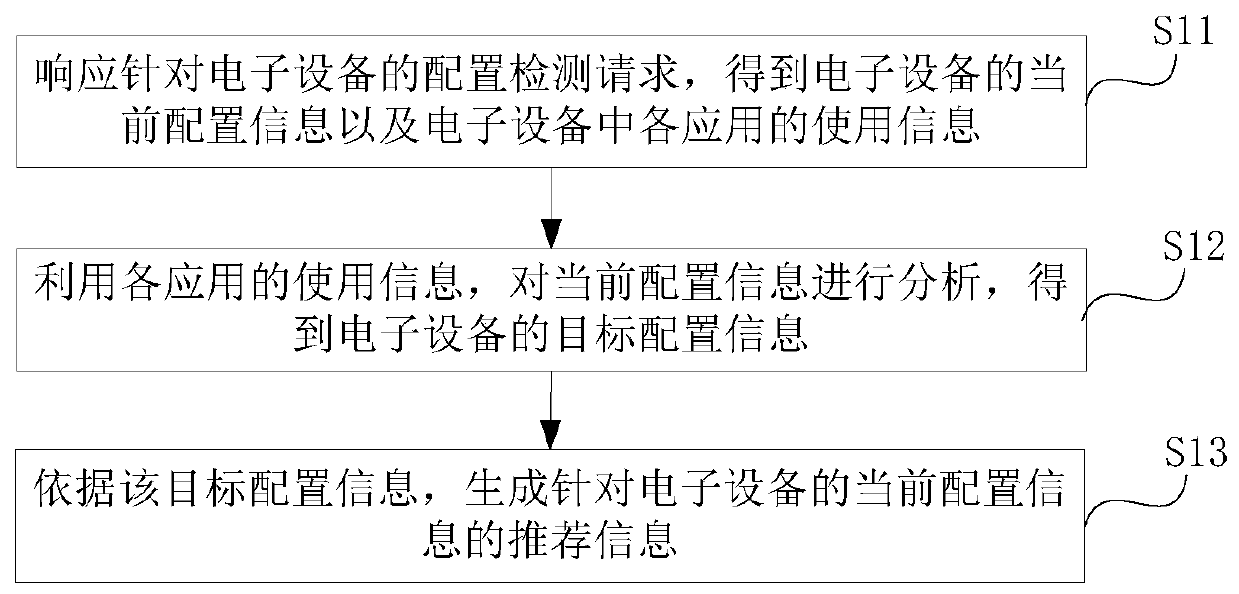

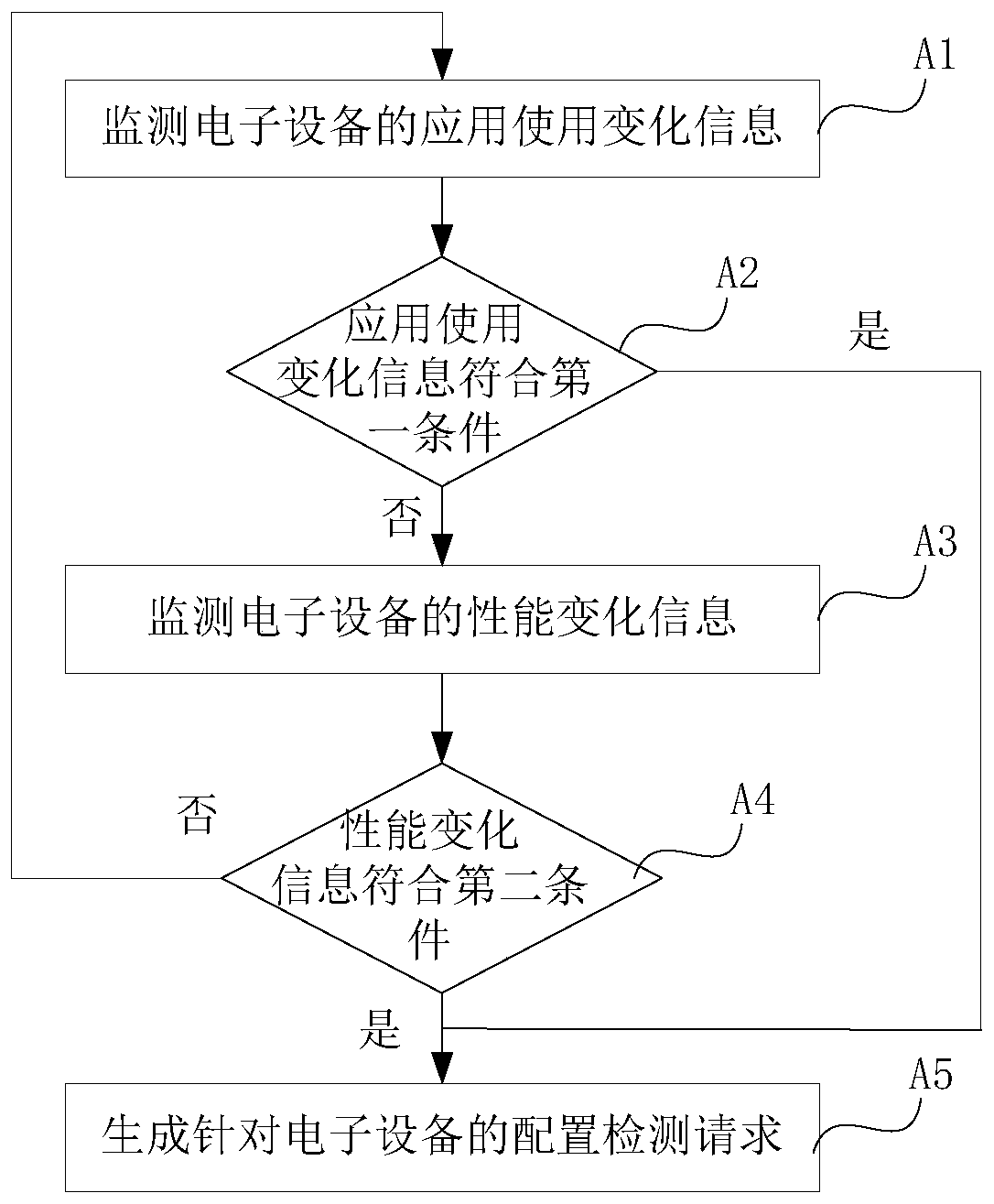

Electronic equipment configuration recommendation processing method and device and storage medium

InactiveCN111142968AMeet the needs of useAccurate and Efficient GuidanceHardware monitoringProgram loading/initiatingComputer hardwareSoftware engineering

The invention provides an electronic equipment configuration recommendation method and device and a storage medium. The method includes that the computer equipment responds to a configuration detection request for the electronic equipment, obtains the current configuration information of the electronic equipment and the use information of each application; the information can be combined and analyzed to obtain the expected optimal hardware configuration of the electronic equipment which meets use requirements of an electronic equipment user on each application, i.e., the target configuration information that can improve the performance of running the target application by the electronic equipment can be obtained. Visibly, the target configuration information considers the hardware configuration of the electronic equipment; and meanwhile, the use conditions of the user of the electronic equipment for each application are considered, so that the user can be accurately and efficiently guided to adjust the current configuration of the electronic equipment according to the recommendation information which is generated according to the target configuration information and aims at the current configuration information of the electronic equipment, and the use requirements of the user for specific applications in the electronic equipment are met.

Owner:LENOVO (BEIJING) CO LTD

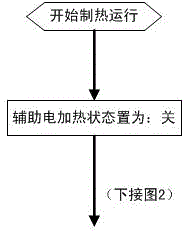

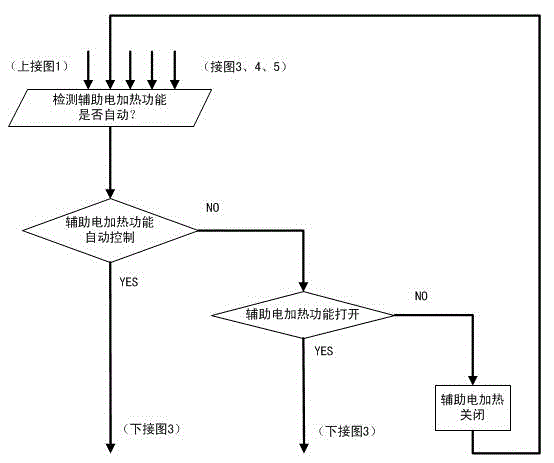

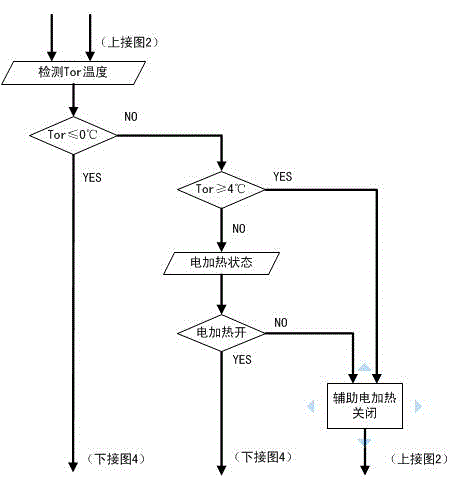

Control method for auxiliary electric heating of air conditioner

ActiveCN104596022AMeeting comfort needsAccurate and efficient adjustmentMechanical apparatusSpace heating and ventilation safety systemsElectric heatingEnvironmentally friendly

The invention relates to the field of air conditioners, in particular to a control method for auxiliary electric heating of an air conditioner. The control method comprises the steps that the auxiliary electric heating functions can be achieved manually and automatically, the auxiliary electric heating function is controlled by detecting the outdoor environment temperature, the indoor environment temperature and the indoor coiled pipe temperature, each detected temperature is divided into a plurality of sections to be controlled, and the auxiliary electric heating function is precisely and efficiently adjusted, so that the auxiliary electric heating function meets the requirement for auxiliary electric heating of different users under different environments, and energy waste caused by excessive electric heating will not be caused. The control method for auxiliary electric heating of the air conditioner meets the requirement of users for comfort and is intelligent and environmentally friendly.

Owner:安徽奥克斯智能电气有限公司

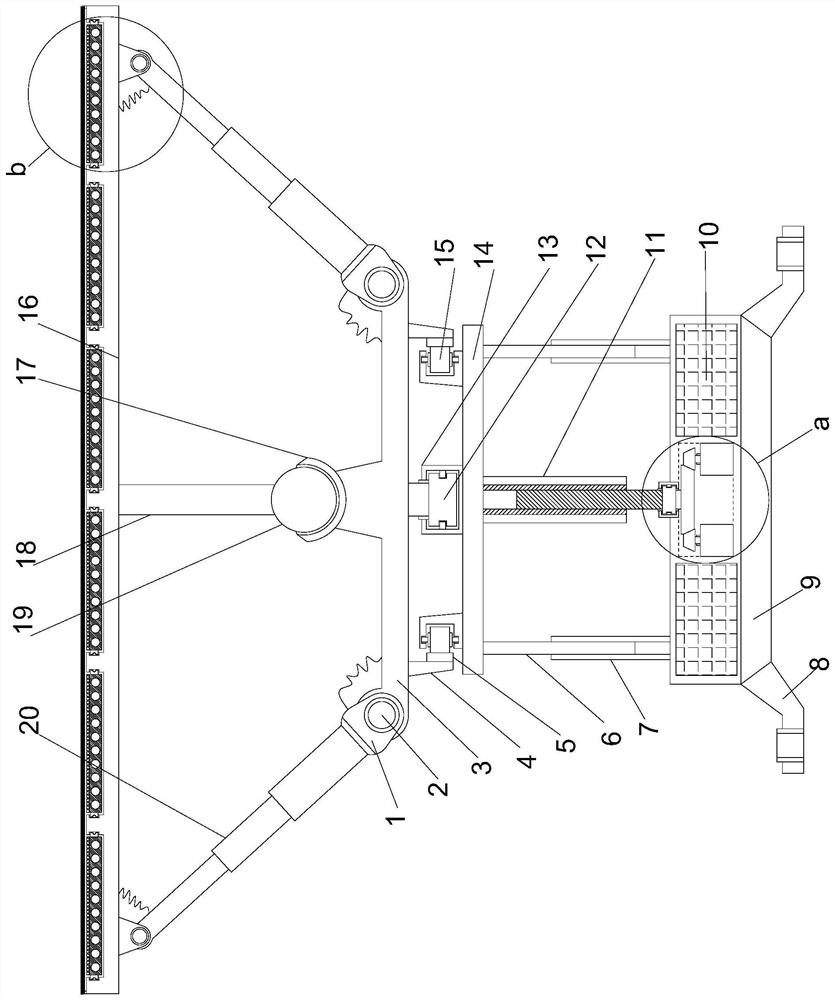

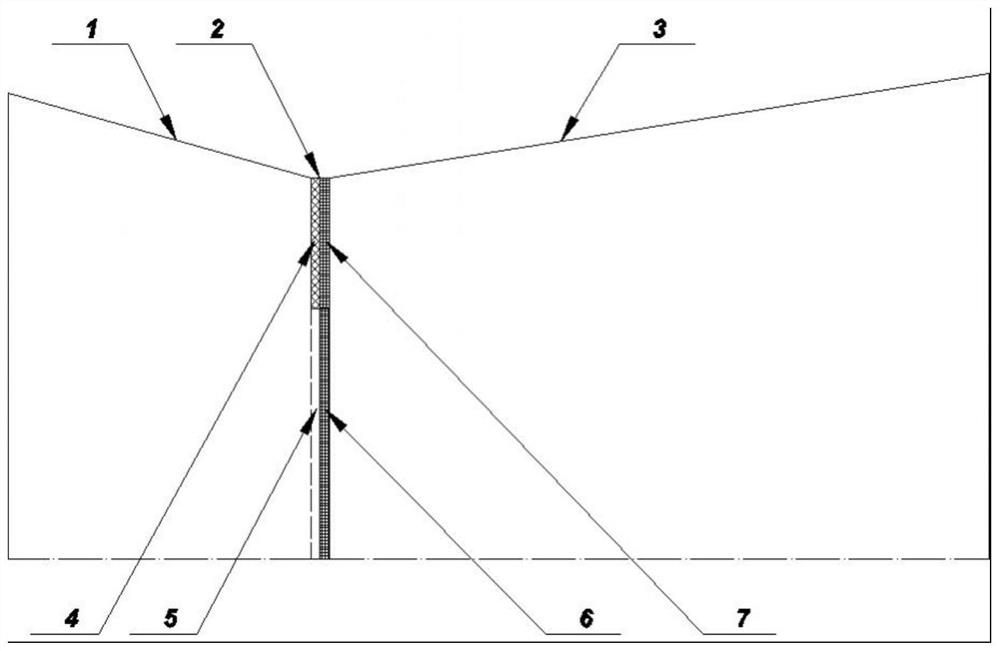

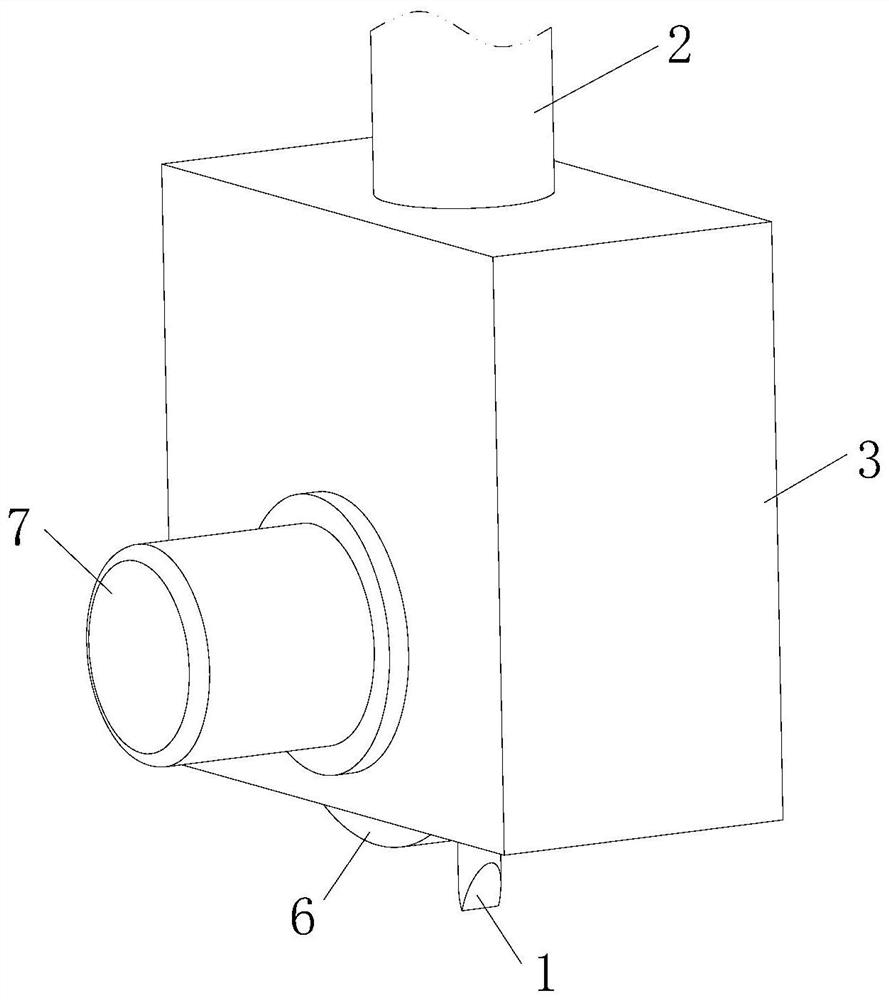

Grooving device for camber surface of inner side of shaft sleeve workpiece

ActiveCN110560706AEfficient and convenient clamping and fixingClamping and fixing is stable and accurateAutomatic control devicesFeeding apparatusMachiningAutomation

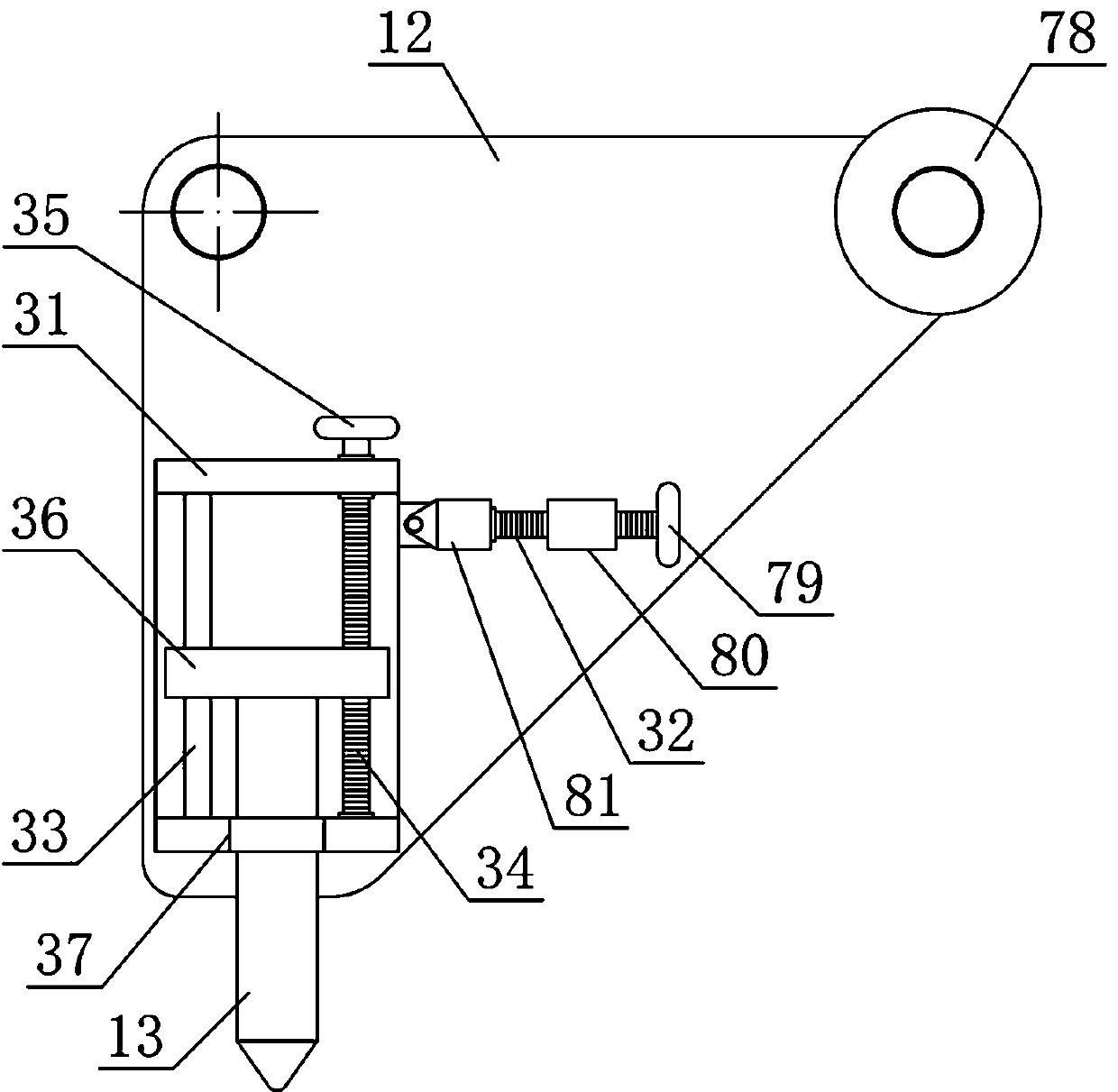

The invention discloses a grooving device for a camber surface of the inner side of a shaft sleeve workpiece and belongs to the field of machinery equipment for machining the workpiece. According to the grooving device, a workpiece clamping mechanism is arranged at a machining bracket positioned at one side of a translational grooving mechanism; a translational guide plate is horizontally and slidably arranged on a guide support; a push plate bevel is arranged at the lower side of the end part of a translational pressing plate; the translational pressing plate is slidably arranged at a tool bit bracket; a grooving rotary plate is arranged at the tool bit bracket, positioned along the underside of the end of the push plate bevel, of the translational pressing plate; a machining rotary platerotates along bearing plate rotating wheels; the machining rotary plate positioned at the outer side of a clamping main gear is provided with a plurality of clamping auxiliary gears; a rotary gear ofa driving bracket is engaged with a rotary rack of the machining rotary plate; and a converting bracket is horizontally arranged at one side of a lifting bracket. The grooving device is reasonable instructural design, can be used for efficiently and conveniently clamping and fixing the shaft sleeve workpiece and realizing stable and accurate rotation, thereby realizing automatic grooving machining of the camber surface of the inner side of the shaft sleeve workpiece, achieving a high machining automation degree and meeting the use demands of machining of the workpiece.

Owner:常熟市万顺轴承有限公司

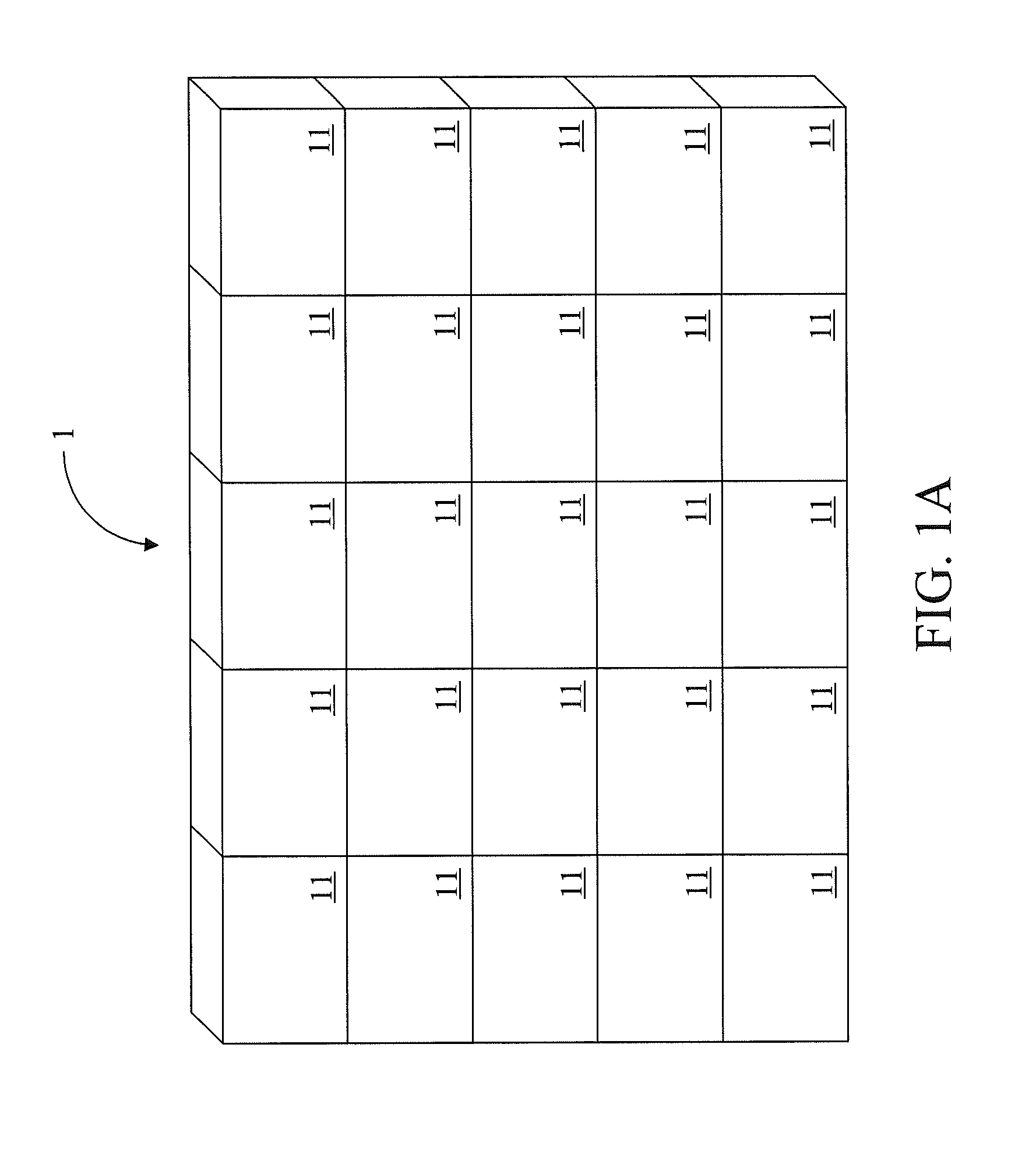

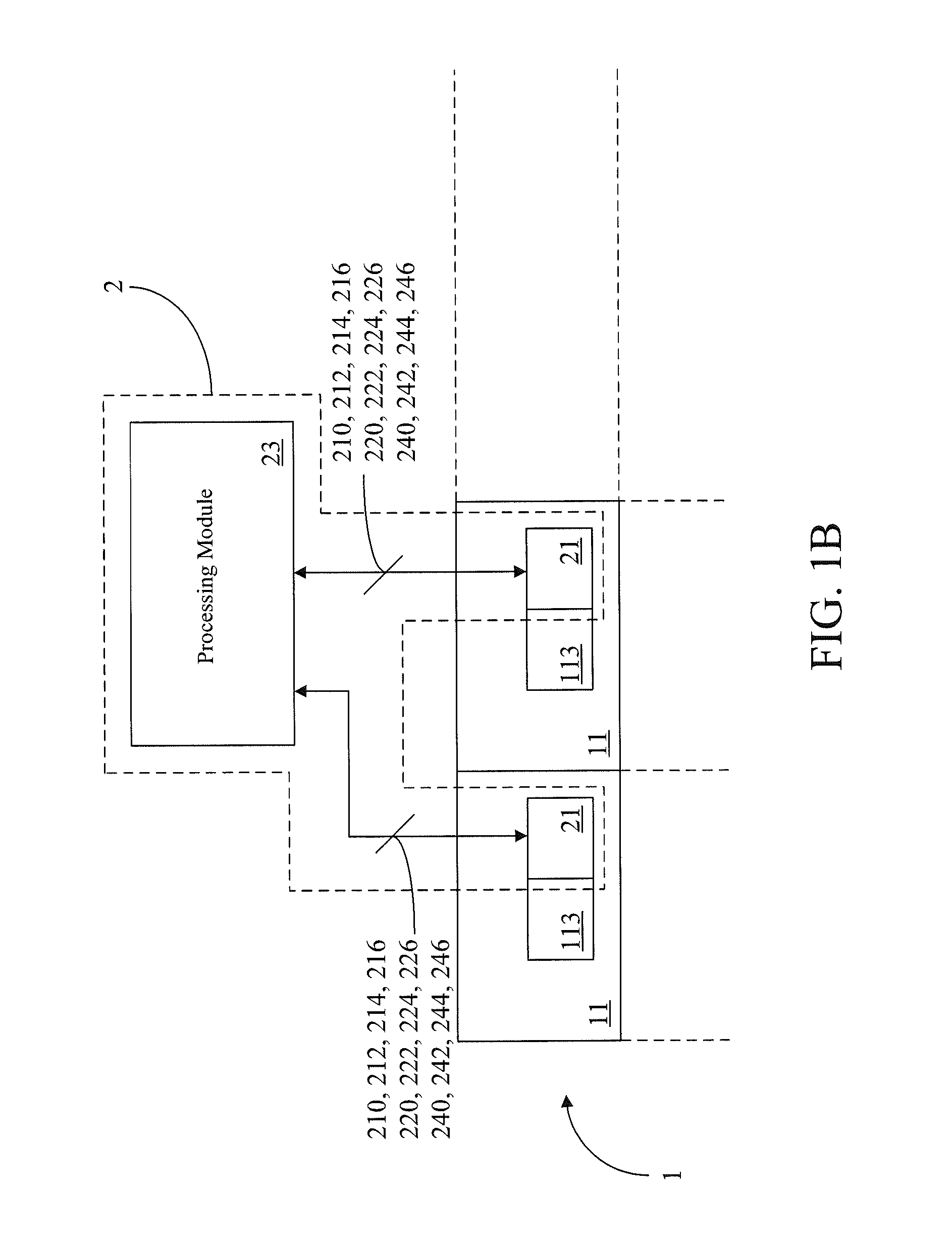

Color adjusting system for use in video wall

InactiveUS20130057592A1Accurate and efficient adjustmentCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceGreen-light

A color adjusting system for use in a video wall is provided. The color adjusting system comprises a plurality of color sensors and a processing module. The color sensors are configured to sense a plurality of red light signals, a plurality of green light signals, a plurality of blue light signals and a plurality of white light signals generated from a plurality of light modules of a plurality of display devices of the video wall. The processing module is configured to calculate a red light color space coordinate criterion value of the red light signals, a green light color space coordinate criterion value of the green light signals, a blue light color space coordinate criterion value of the blue light signals and a white light color space coordinate criterion value of the white light signals respectively so that the display devices can adjust the light modules accordingly.

Owner:DELTA ELECTRONICS INC

Prop plate clamping device

ActiveCN110405657AEfficient and accurate clamping and fixingClamping and fixing is convenient and stableWork holdersPositioning apparatusRapid processingEngineering

The invention discloses a prop plate clamping device, and belongs to the field of display prop machining mechanical equipment. According to the device, a plate adjusting mechanism and a plate placingmechanism are sequentially and horizontally arranged on a plate machining support from top to bottom, a lifting connecting plate is horizontally arranged on the lower side of an adjusting support, a rotating support is horizontally arranged on the lower side of the lifting connecting plate, a plate clamping mechanism is horizontally arranged on the lower side of the rotating support, translation bottom plates are horizontally arranged on the two sides of the upper portion of the plate machining support correspondingly, a translation support is fixedly arranged in the middle of the upper side of each translation bottom plate, a middle bearing plate is horizontally and fixedly arranged on the upper side of a translation guide plate, side bearing plates are horizontally and symmetrically arranged on the two sides of the middle bearing plate, and a plate fastening mechanism is vertically and fixedly arranged on the upper side of each side bearing plate. The device has the advantages that the structural design is reasonable, station adjusting of prop plates can be conveniently and stably realized according to the machining requirements, the prop plates can be clamped and fixed efficiently and accurately, so that rapid machining of the prop plates is realized, and the requirements of machining and use are met.

Owner:浙江高人道具有限公司

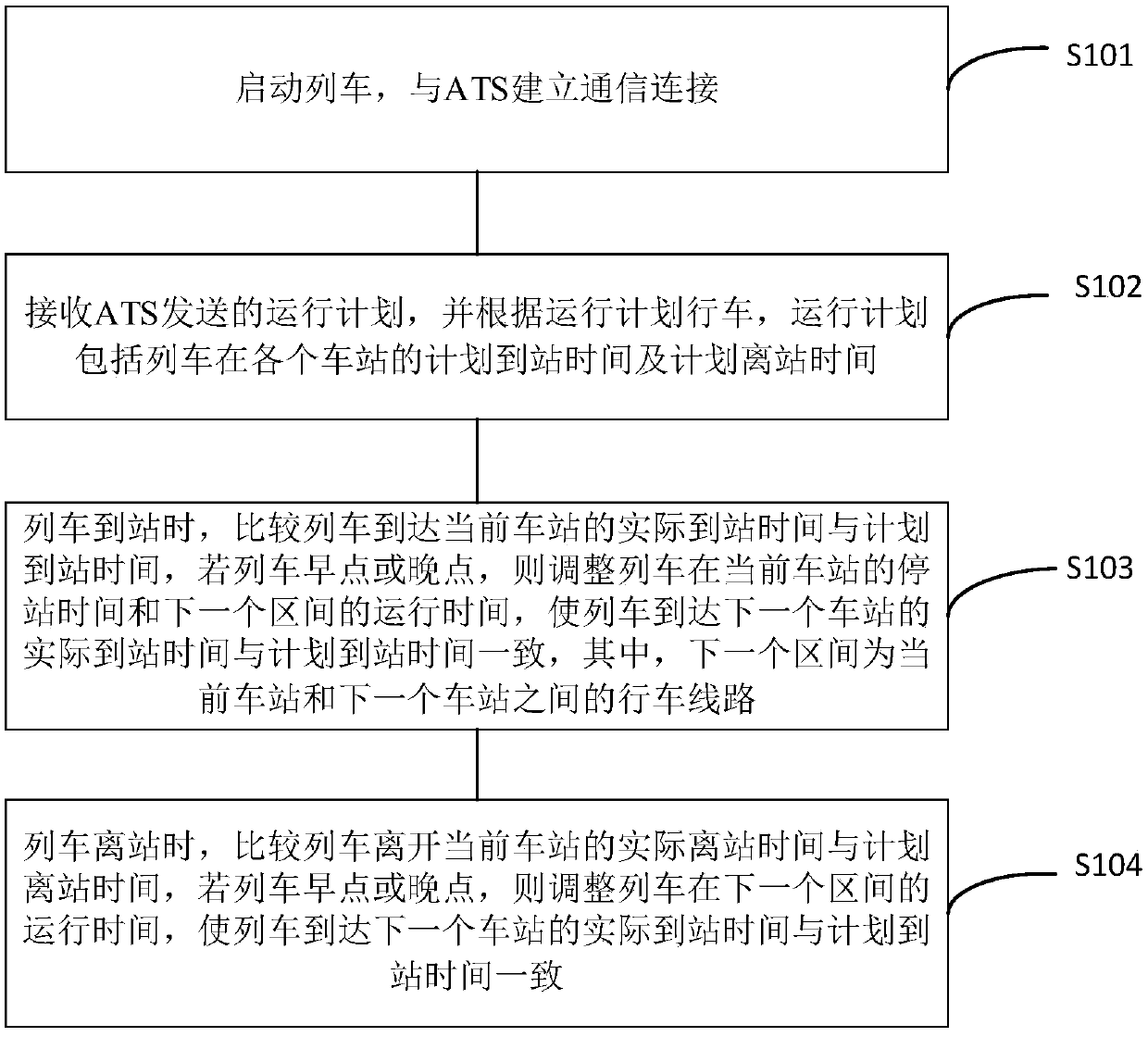

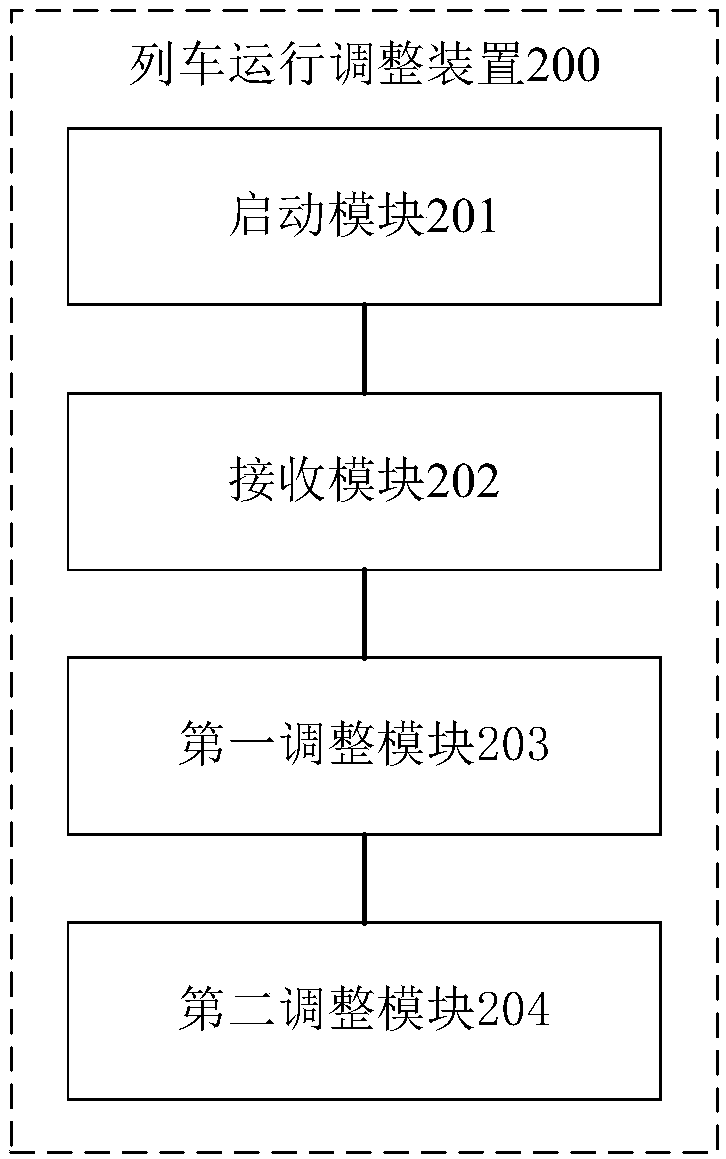

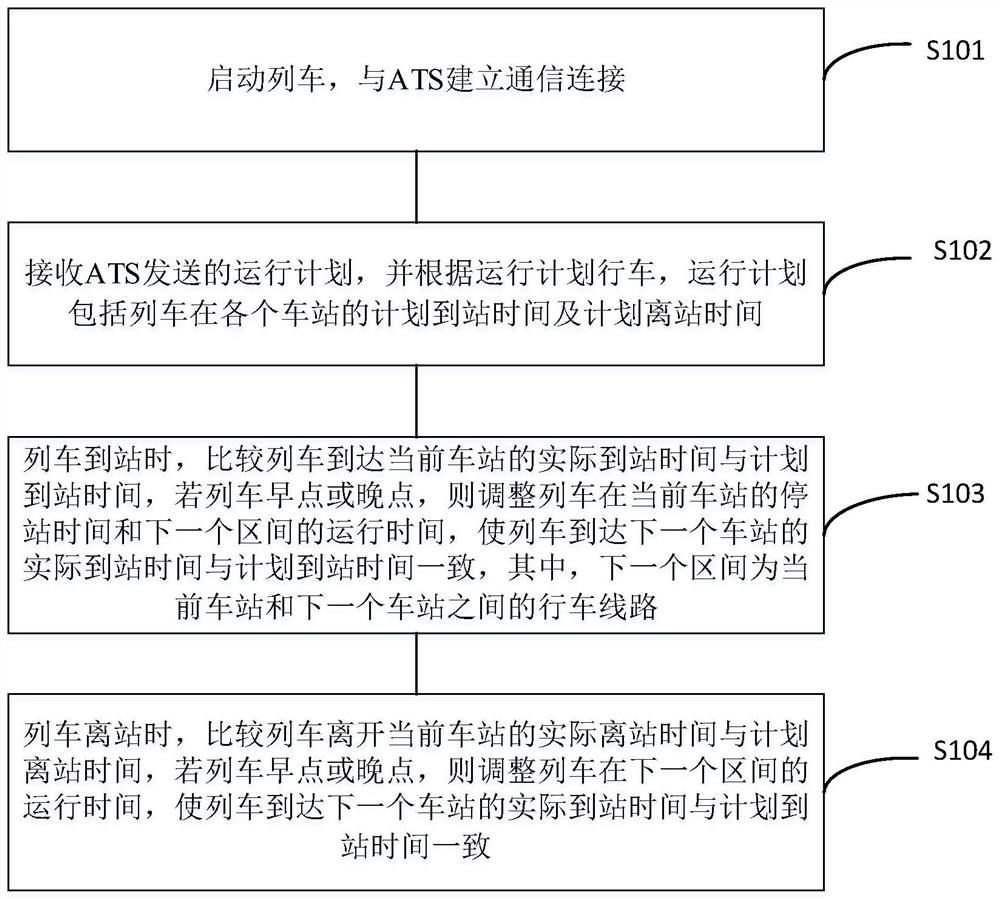

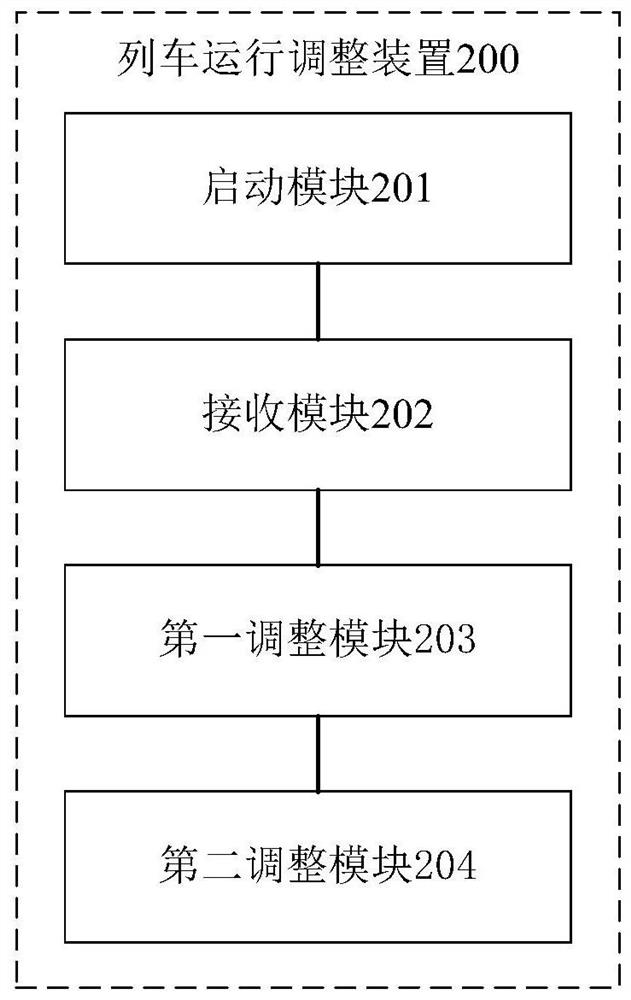

Train operation adjusting method, device and system, and train

ActiveCN111361609AAccurate and efficient adjustmentRealize proactive adjustmentAutomatic systemsSimulationStop time

The invention discloses a train operation adjusting method, device and system, and a train. The method comprises the following steps: building communication connection with an ATS, and receiving an operation plan transmitted by the ATS; driving according to the operation plan; when the train arrives at the station, comparing the actual arrival time with a planned arrival time, and if the train arrives early or late, enabling the train to adjust the stop time of the train at the station and the running time of the train in the next section in order to make the actual arrival time of the train arriving at the next station consistent with the planned arrival time; and when the train leaves the station, comparing the actual departure time with the planned departure time, and if the train arrives early or late, adjusting the operation time of the train in the next interval by the train in order to make the actual arrival time of the train reaching the next station consistent with the planned arrival time. Therefore, active adjustment of train operation is realized, the adjustment of the train is more accurate and efficient, and the load of a train-ground communication network is reduced.

Owner:BYD CO LTD

Greenhouse energy-saving auxiliary temperature control system

InactiveCN102715044AIncrease or decrease in temperatureReduce the temperatureClimate change adaptationSaving energy measuresTemperature controlGreenhouse

The invention discloses a greenhouse energy-saving auxiliary temperature control system, which comprises a water supply well, a main water supply pipe, heat exchange pipes, a main water return pipe and a water return well and is characterized in that the main water supply pipe and the main water return pipe are in parallel arrangement, the heat exchange pipes are vertically and uniformly connected with the main water supply pipe and the main water return pipe, the two ends of each heat exchange pipe are respectively connected with the main water return pipe and the main water supply pipe, the main water supply pipe is connected to a submersible pump positioned in the water supply well, and the main water return pipe is connected to the water return well. When the greenhouse energy-saving auxiliary temperature control system is adopted, the temperature in a greenhouse can be more efficiently and accurately regulated, the system utilizes the temperature differences between the underground water and the natural temperature for raising or lowering the temperature in the greenhouse, the great nonregenerative resource waste can be prevented, and the effect of protecting the environment can also be reached, so the temperature regulating cost of the greenhouse is further reduced, good economic benefits can be generated, in addition, the structure is simple, and the popularization and the use are convenient.

Owner:李泮禄

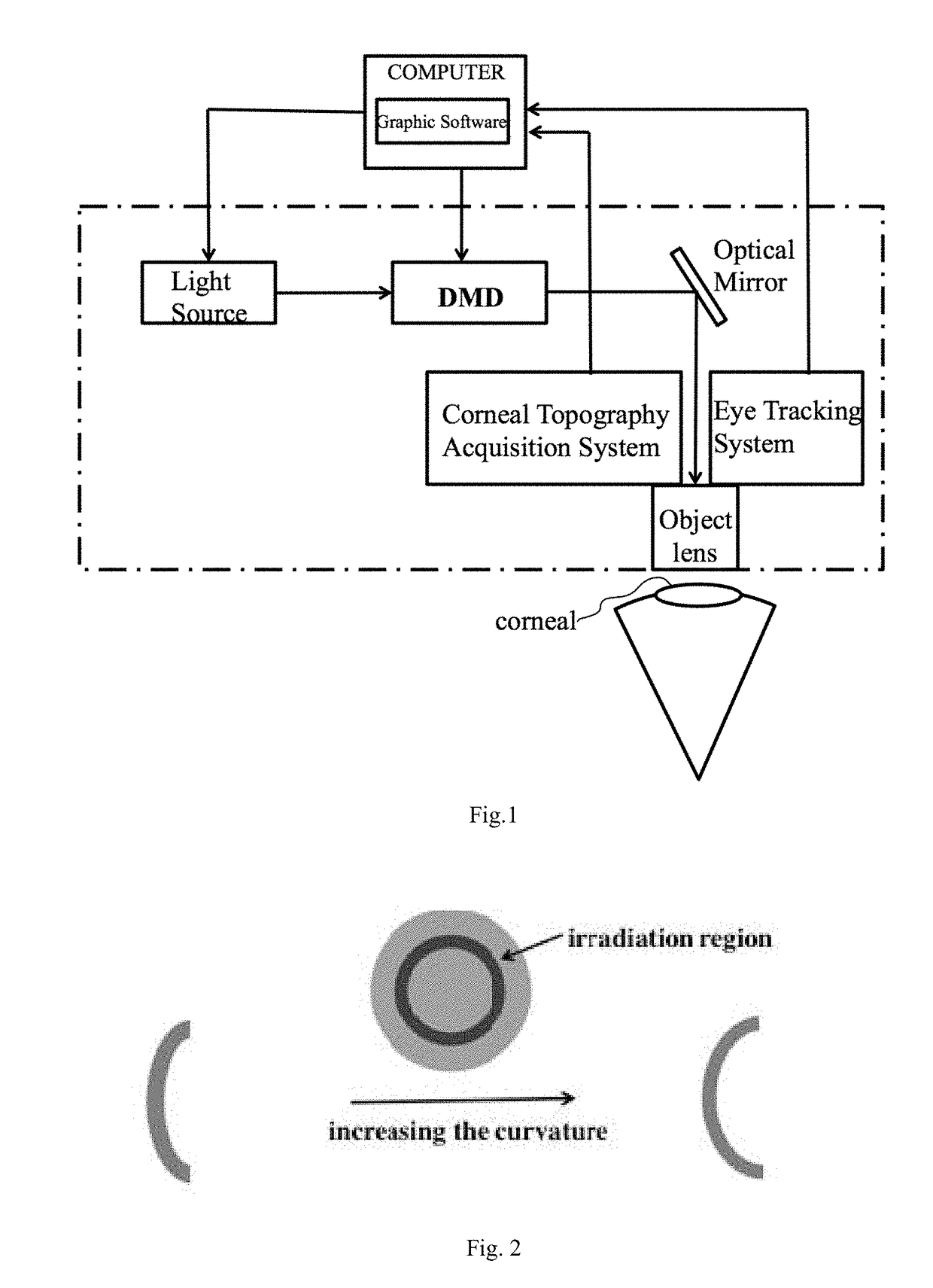

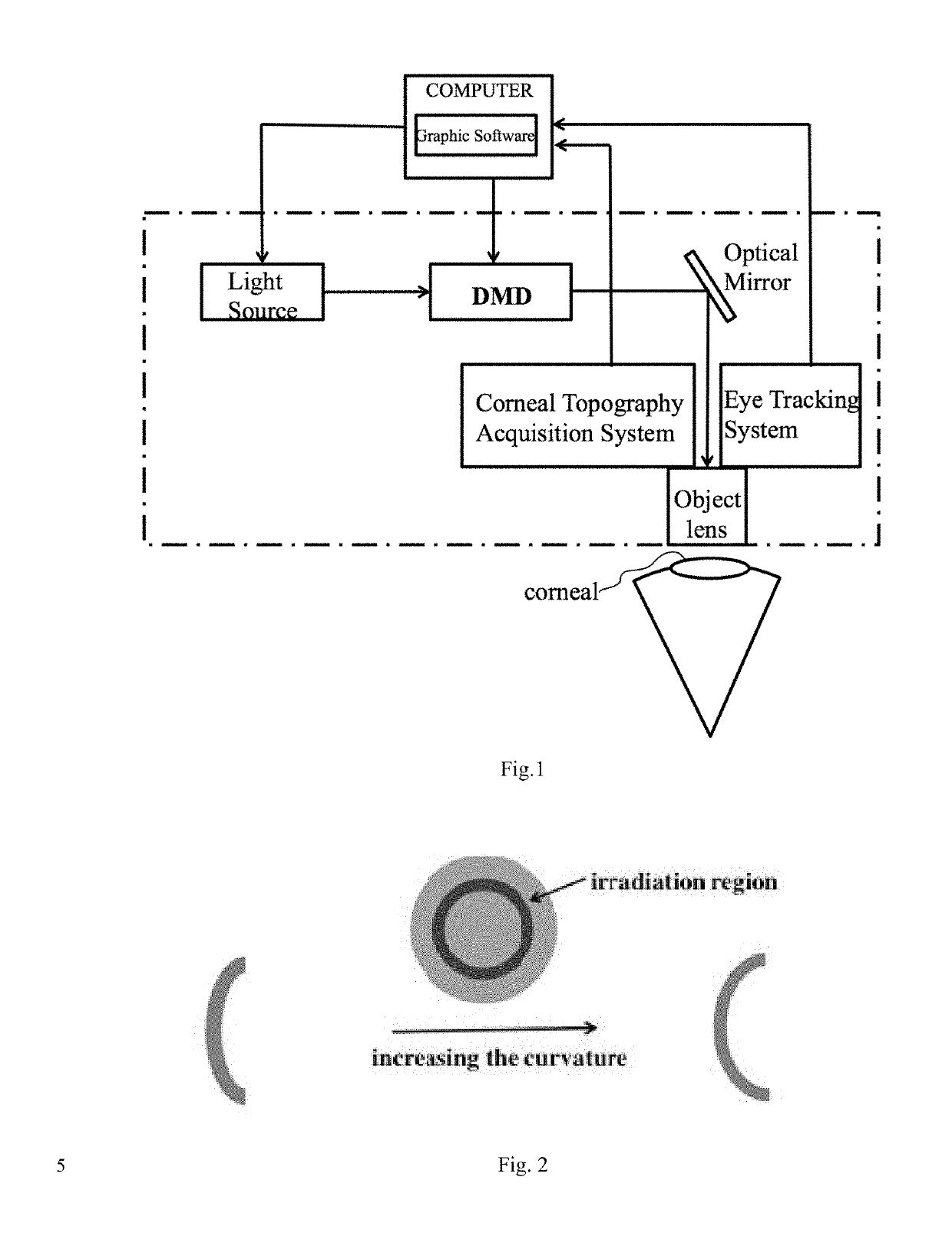

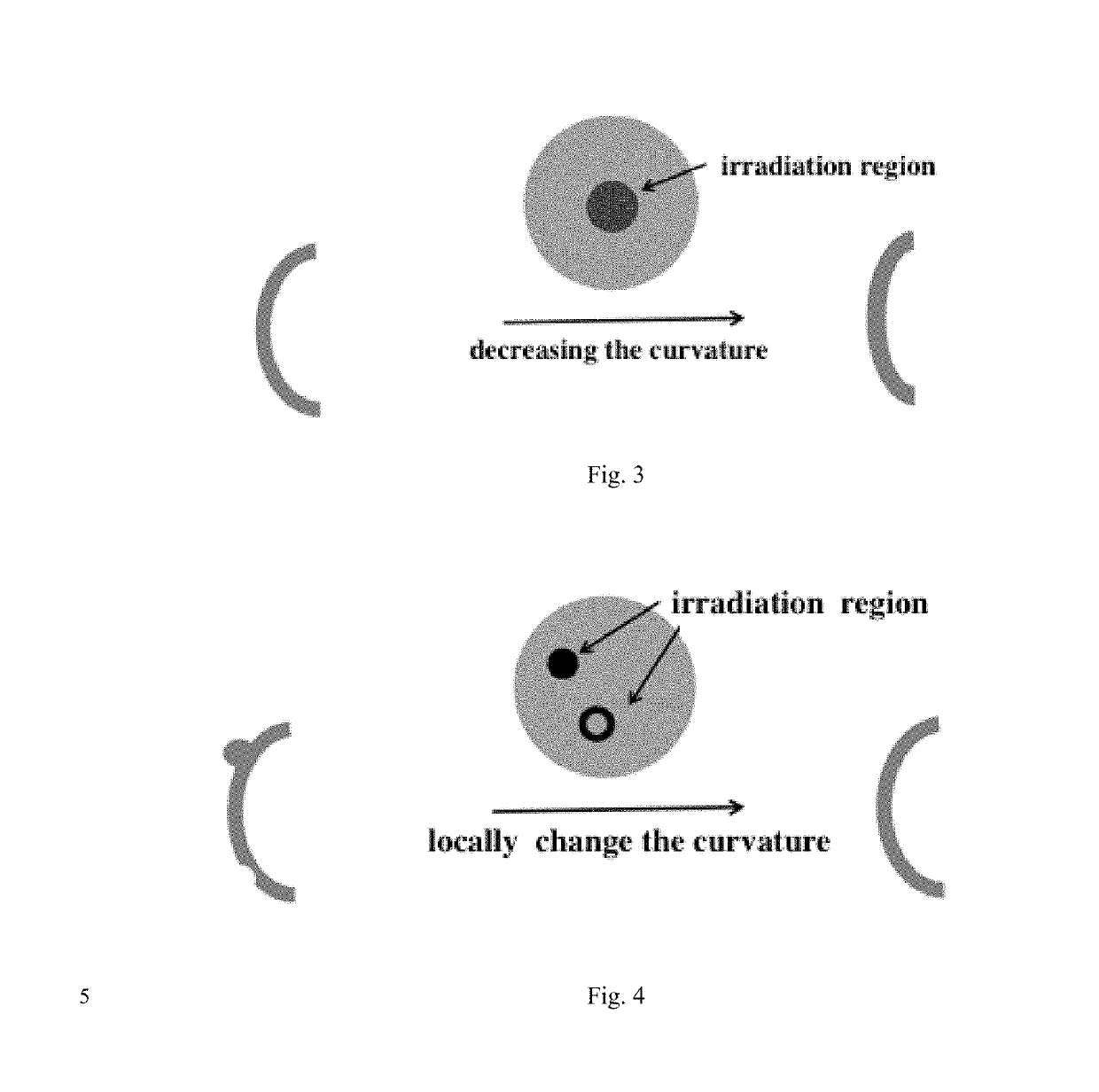

Method and apparatus for adjusting corneal curvature through digital corneal crosslinking

ActiveUS20180050104A1Minimal invasiveAccurate and efficient adjustmentLaser surgeryPhotodynamic therapyCorneal curvaturePhotoinitiator

The present disclosure concerns a digital corneal crosslinking technology for adjusting the corneal curvature, comprising the following steps: administering in drops a composition comprising a photoinitiator compound to the corneal stromal of the subject, locally irradiating the corneal by utilizing digital micromirror device controlled by computer. The corneal curvature can be adjusted totally or locally. The invention also discloses an apparatus for the digital corneal crosslinking. The method and apparatus is minimum invasive and can be used to accurately and efficiently adjust the corneal curvature.

Owner:ZHEJIANG UNIV

Method and apparatus for adjusting corneal curvature through digital corneal crosslinking

ActiveUS10463735B2Accurate and efficient adjustmentMinimal invasiveLaser surgeryPhotodynamic therapyCorneal curvatureConfocal

The present disclosure concerns a digital corneal crosslinking technology for adjusting the corneal curvature, comprising the following steps: administering in drops a composition comprising a photoinitiator compound to the corneal stromal of the subject, locally irradiating the corneal by utilizing digital micromirror device controlled by computer. The corneal curvature can be adjusted totally or locally. The invention also discloses an apparatus for the digital corneal crosslinking. The method and apparatus is minimum invasive and can be used to accurately and efficiently adjust the corneal curvature.

Owner:ZHEJIANG UNIV

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

Solar photovoltaic panel convenient to adjust

PendingCN111769788AImprove power generation efficiencyImprove power generation qualityPhotovoltaic supportsSolar heating energyNew energyEngineering

The invention relates to the field of new energy, in particular to a convenient-to-adjust solar photovoltaic panel. The solar photovoltaic panel comprises a supporting mounting plate which is horizontally arranged, a plurality of fixed mounting frames are arranged on the lower end edge of the supporting mounting plate at equal angles; fixed mounting cylinders are vertically arranged on the fixed mounting frames; a lifting mounting plate is horizontally arranged over the supporting mounting plate, a rotary mounting plate is horizontally arranged right above the lifting mounting plate; a transmission mounting cavity is vertically formed in the middle position of the supporting mounting plate; the lifting of a stud and a screw cylinder is controlled, the steering control of a gear ring is realized, the swing control is achieved through swing telescopic structures arranged at equal angles, so that the angle, the height and the steering direction of a photovoltaic power generation device can be efficiently and accurately adjusted, the photovoltaic power generation efficiency and quality of the device are remarkably improved, and the maintainability and the operation stability of the device are improved through flow guide heat dissipation and interchangeable installation.

Owner:李明

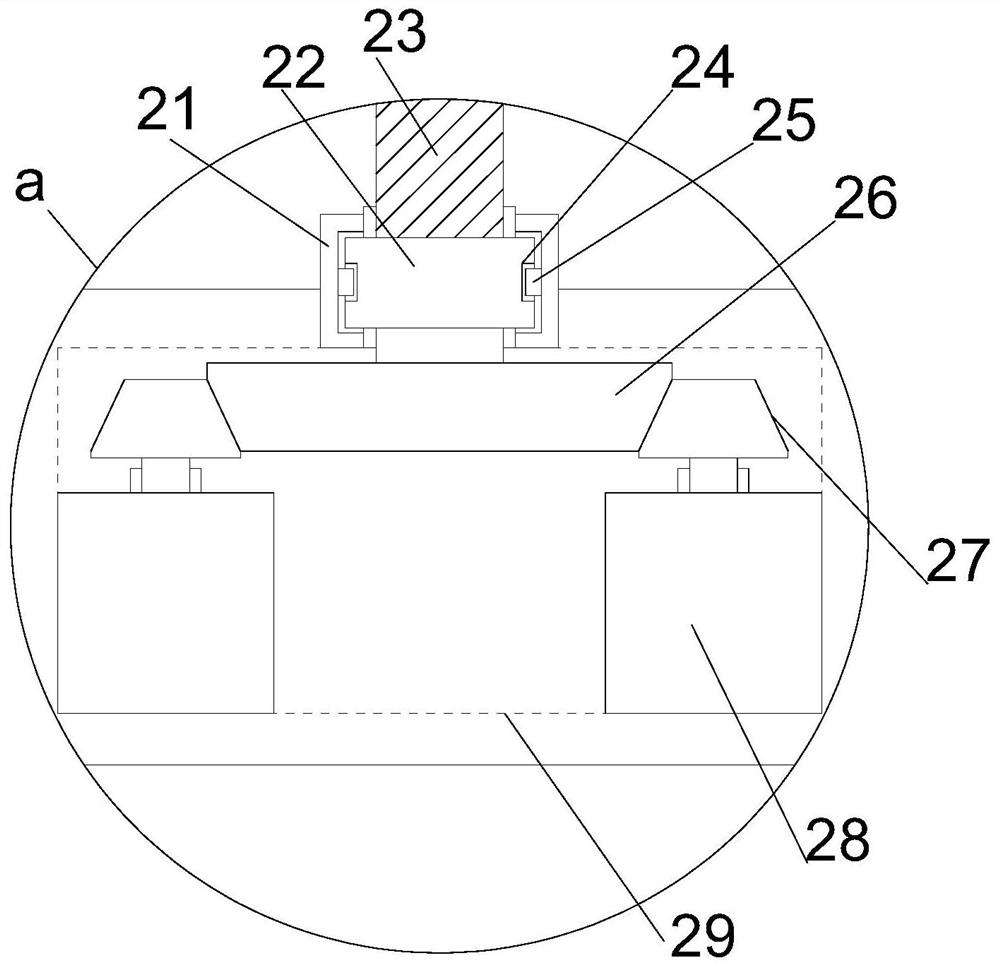

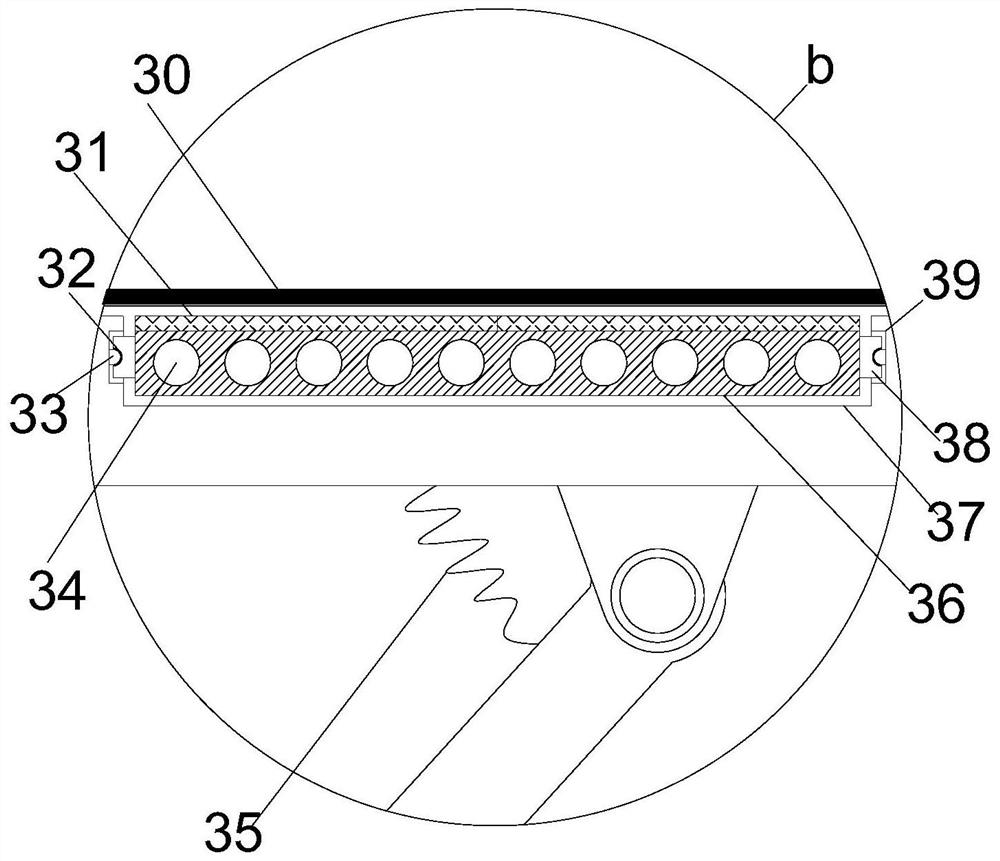

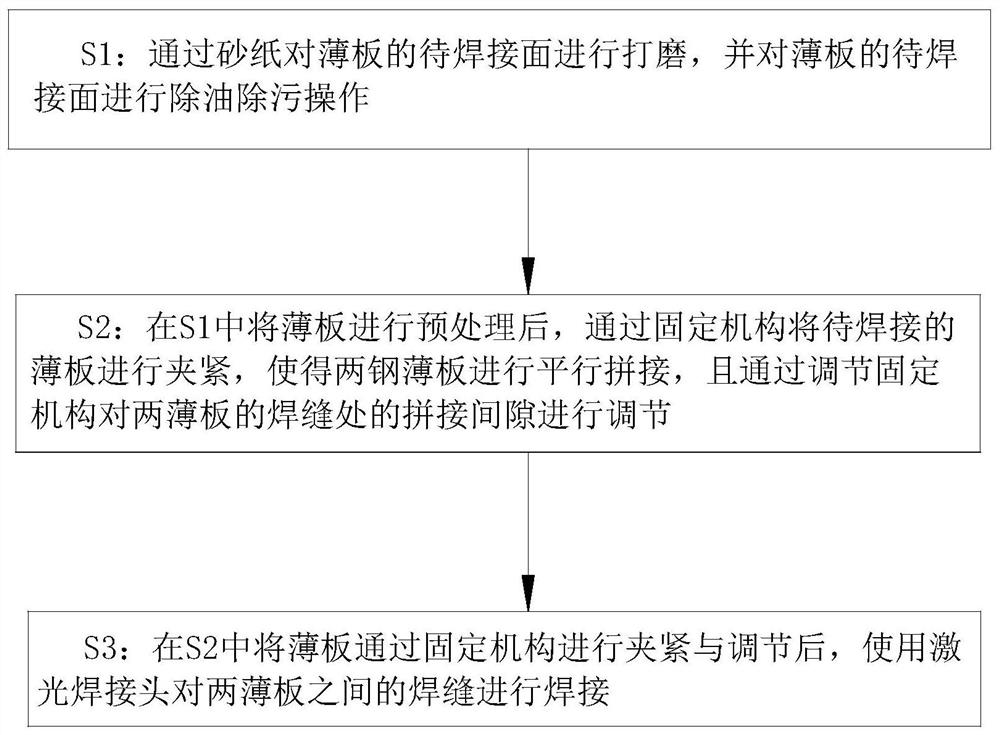

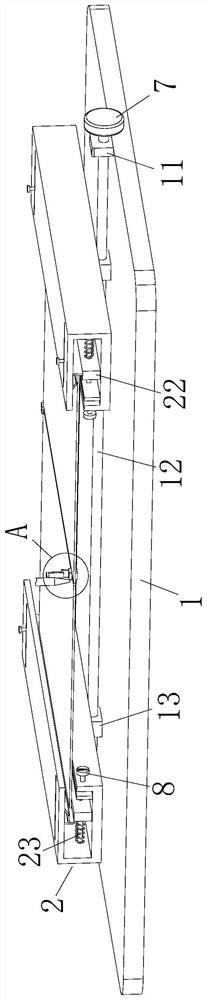

Sheet welding technology of high-power laser welding equipment

InactiveCN111843205APrecise positioningQuality improvementLaser beam welding apparatusBall screwEngineering

The invention belongs to the technical field of sheet welding, in particular to a sheet welding technology of a high-power laser welding equipment. A fixing mechanism included in the sheet welding technology comprises a supporting plate. A ball screw is arranged between the two ends of the supporting plate in a connected manner. A fixing chamber is connected to the ball screw through a sliding platform. An insertion opening is formed in the top end of the side face of the fixing chamber. A sliding plate is in sliding connection with the bottom surface of the fixing chamber. A baffle and a locking plate are arranged at the top end of the sliding plate. A press plate is arranged between the sliding plate and the locking plate. A fastening bolt is in thread connection with the locking plate.Sheets are fixed to the fixing chamber. A positioning frame is arranged at the two ends of a weld joint between the two sheets in a sleeving manner. Laser welding heads are arranged at the two ends ofthe positioning frame. According to the sheet welding technology of the high-power laser welding equipment, the two sheets to be welded are stably positioned through the fixing mechanism, accurate and high-efficiency adjustment can be carried out on a gap of the weld joint between the two sheets, the welding technology is greatly optimized, and the quality of the welded sheets is improved.

Owner:程业品

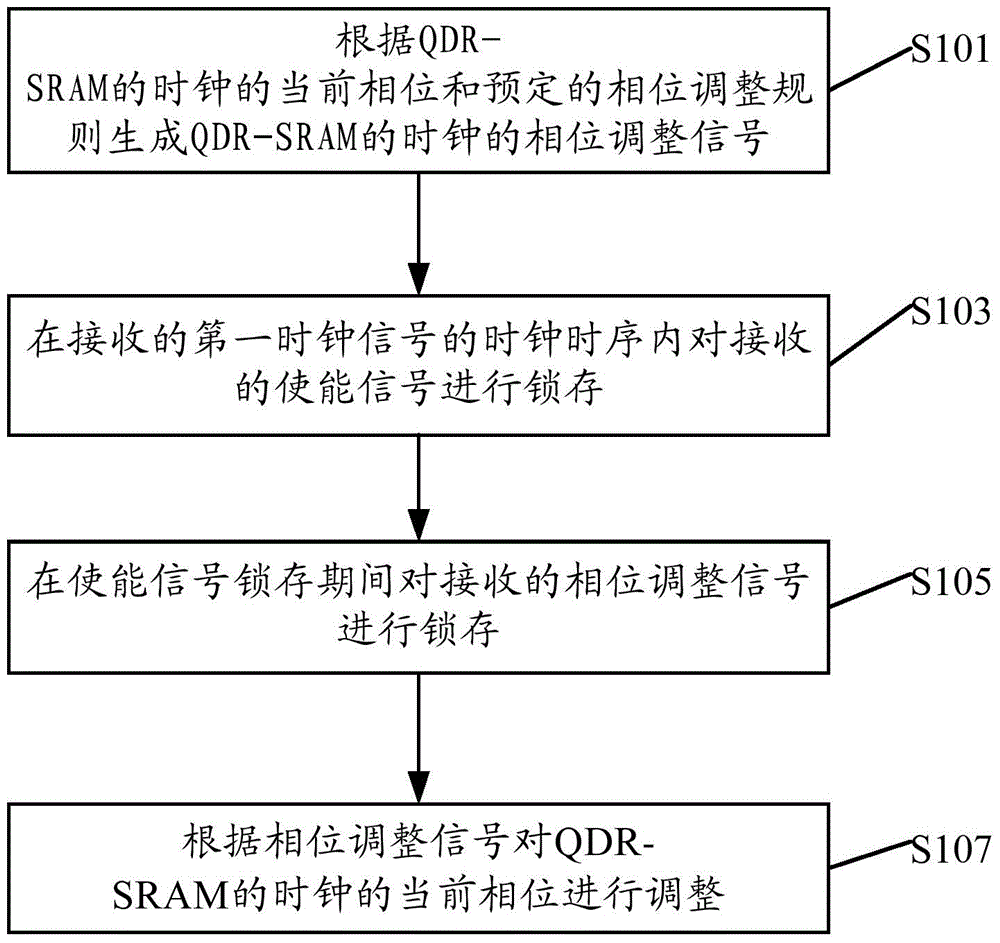

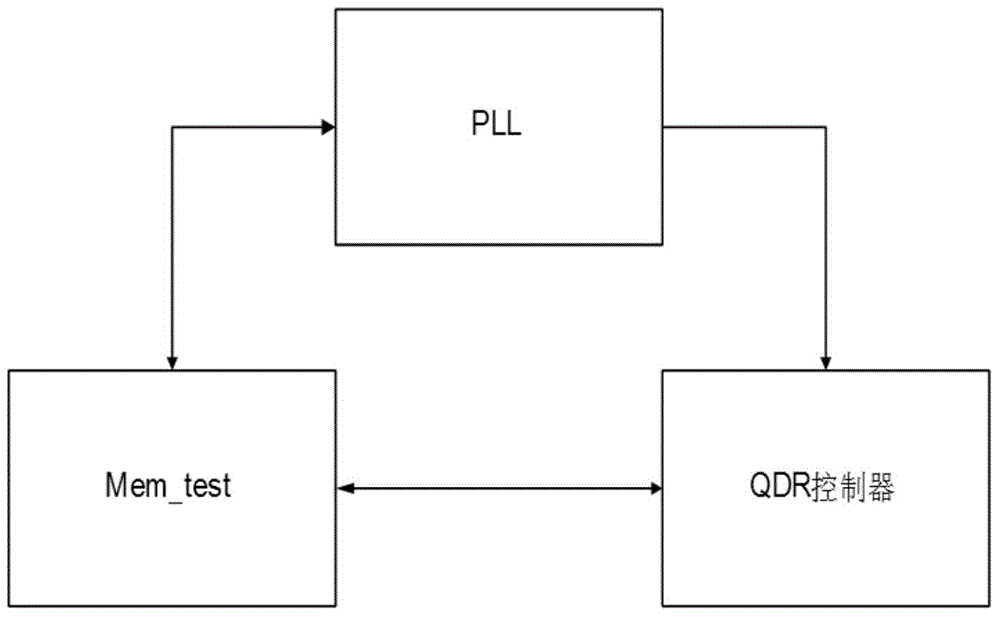

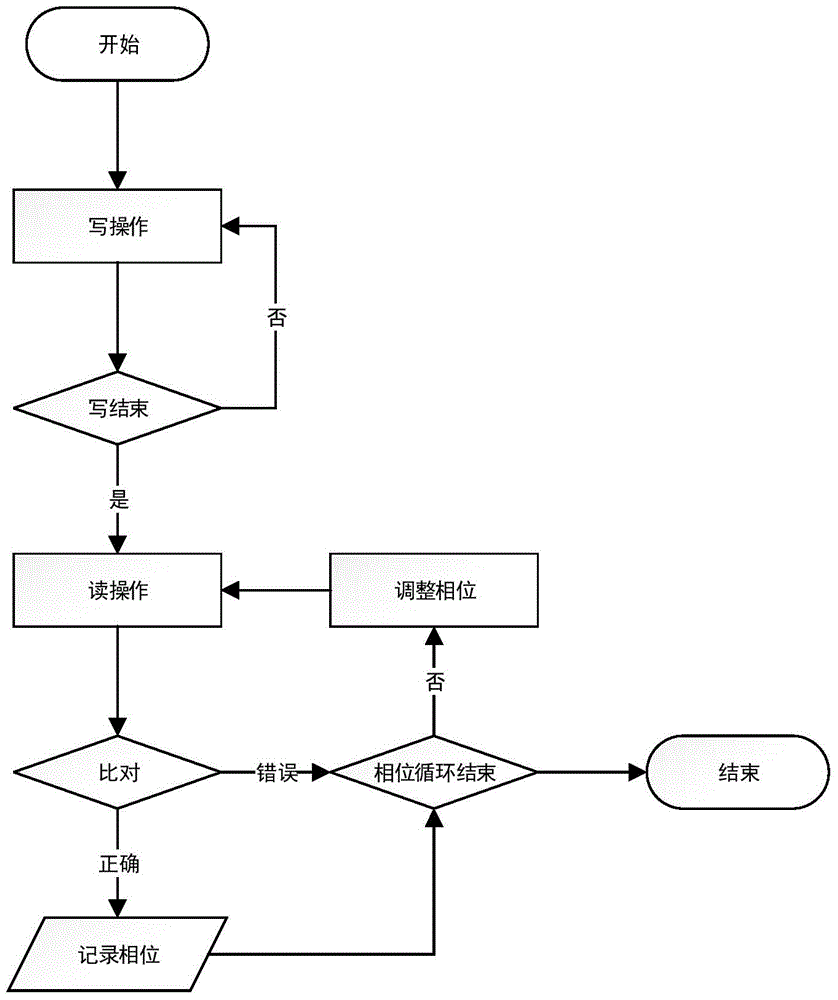

QDR-SRAM (Quad data rate-static random access memory) clock phase adjusting method and device

InactiveCN104616697AReduced commissioning timeReduce debugging error rateStatic storageQuad data rateRandom access memory

The invention discloses a QDR-SRAM (quad data rate-static random access memory) clock phase adjusting method and device. The method is as follows: according to current phase and predetermined phase regulation rules of a QDR-SRAM clock, a phase adjustment signal of the QDR-SRAM clock can be generated, a received enable signal can be latched in the clock timing sequence of a received clock signal, the received phase adjustment signal can be latched in the latching period of the enable signal, and according to the phase adjustment signal, the current phase of the QDR-SRAM clock can be adjusted. According to automatic dynamic adjustment of the phase of the QDR-SRAM clock, the adjustment efficiency of the phase of the QDR-SRAM clock can be improved, phase debugging time and debugging error rate can be reduced, and fast, efficient and accurate clock phase adjustment can be achieved.

Owner:DAWNING INFORMATION IND BEIJING

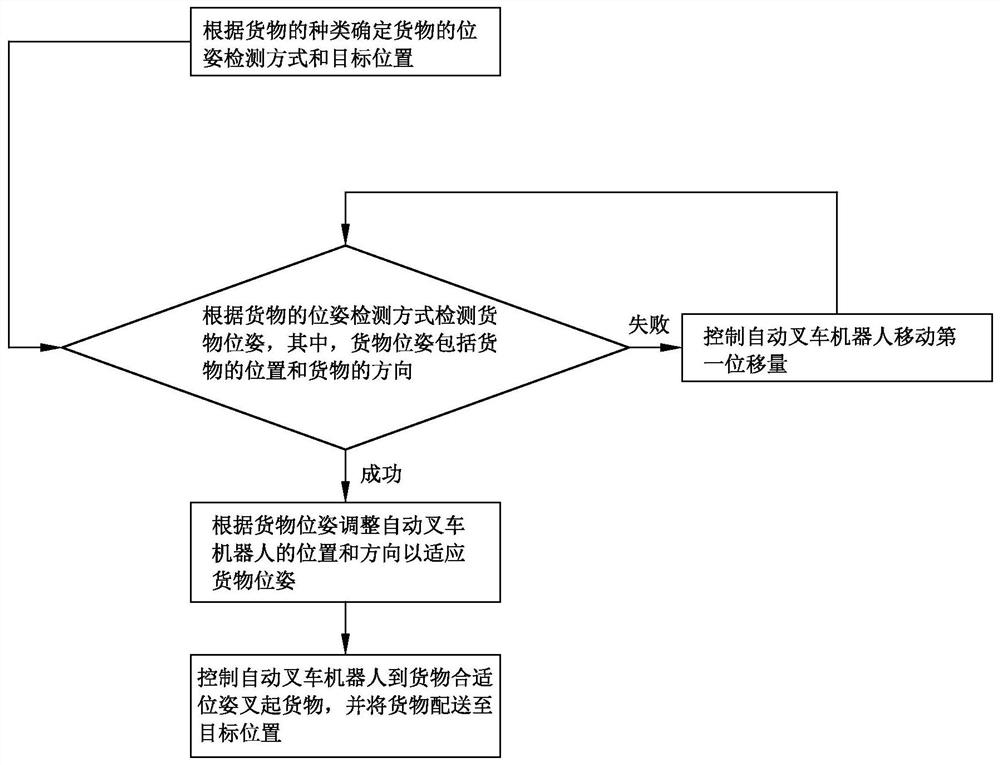

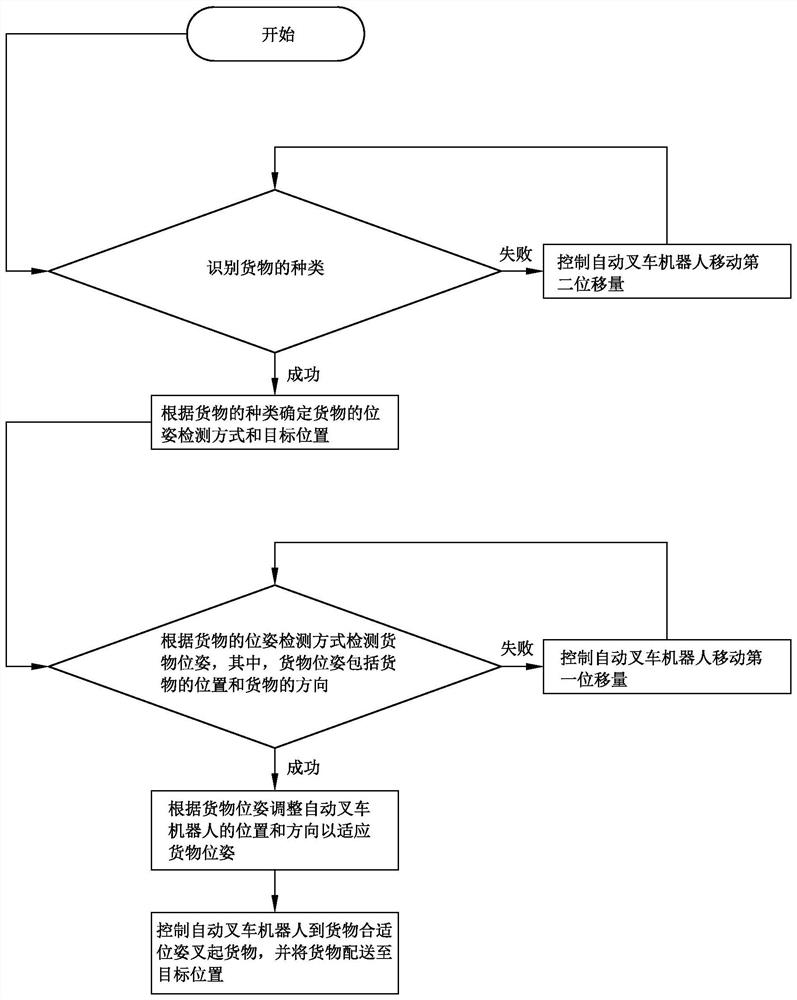

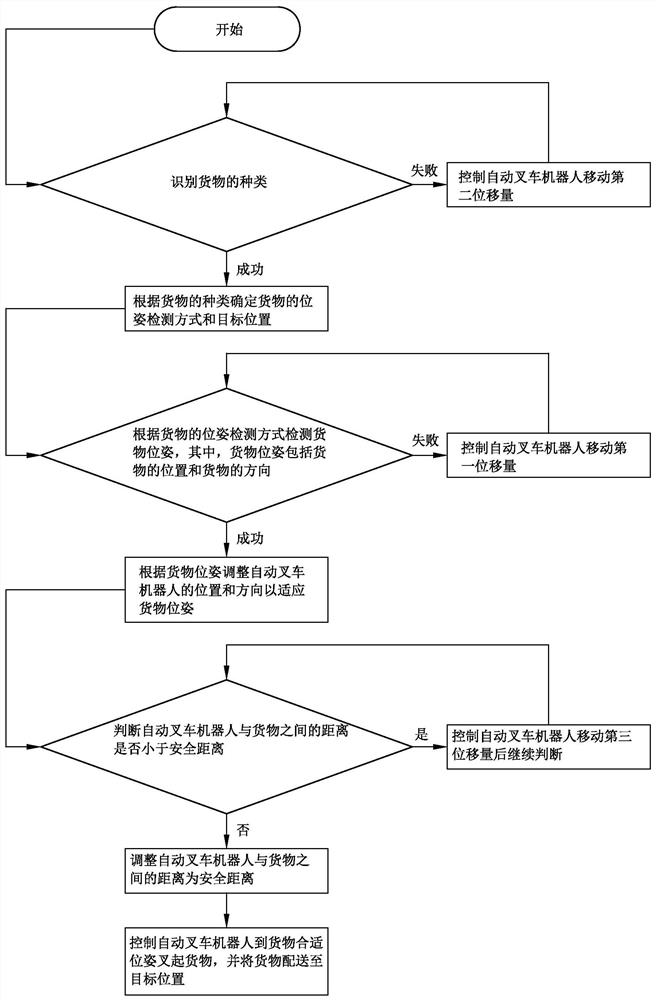

Automatic forklift robot butt joint method and automatic forklift robot

PendingCN113072009AImprove automation performanceSave human effortLifting devicesAutomotive engineeringForklift truck

The invention relates to the technical field of forklifts, in particular to an automatic forklift robot butt joint method and an automatic forklift robot. The automatic forklift robot butt joint method comprises the steps that firstly, a pose detection mode and a target position of a cargo are determined according to the type of the cargo, the pose of the cargo is detected according to the pose detection mode of the cargo, if cargo pose detection fails, the automatic forklift robot is controlled to move by the first displacement amount and then continues to detect the pose of the cargo, then the position and direction of the automatic forklift robot are adjusted according to the pose of the cargo to adapt to the pose of the cargo, the automatic forklift robot is controlled to fork the cargo at the proper pose of the cargo, and the cargo is distributed to the target position. When the automatic forklift robot carries the cargoes through the method, the cargoes do not need to be placed at accurate positions, the automatic forklift robot can be automatically adjusted to carry the cargoes at different positions, and the automation capacity of the automatic forklift robot is further improved.

Owner:北京捷象灵越科技有限公司

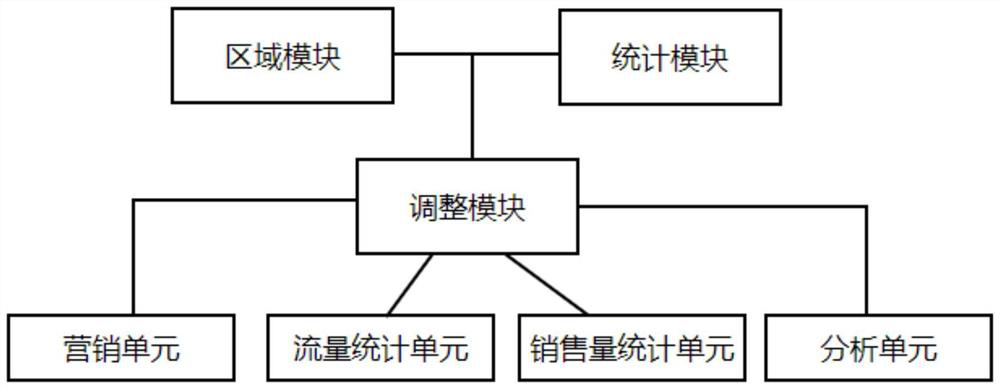

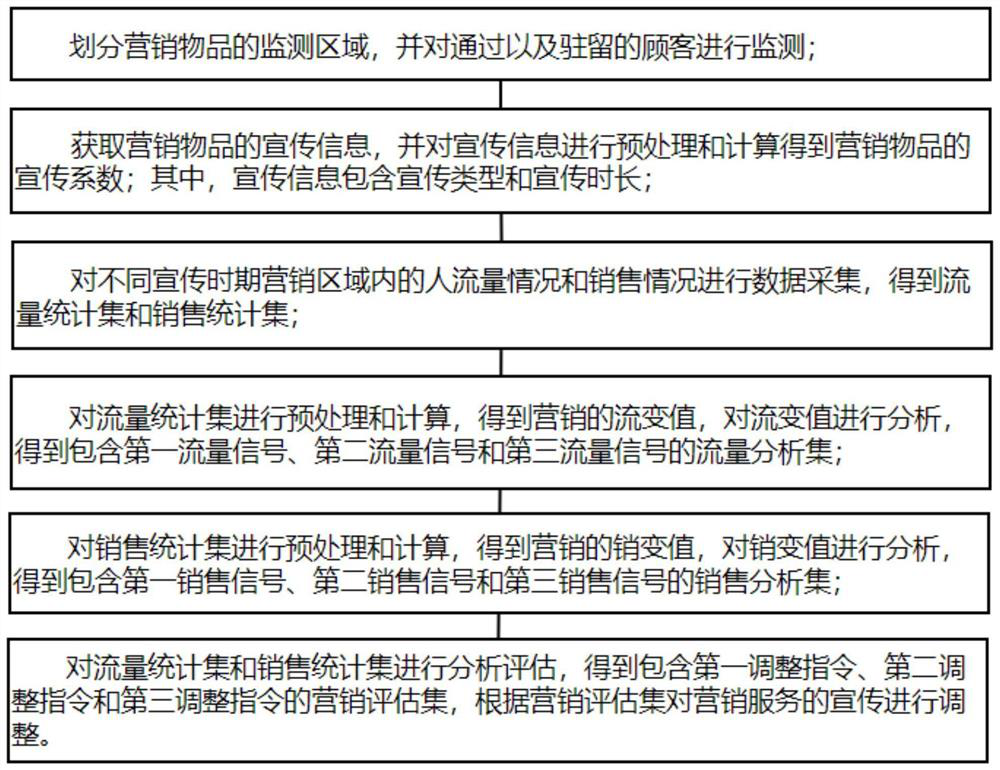

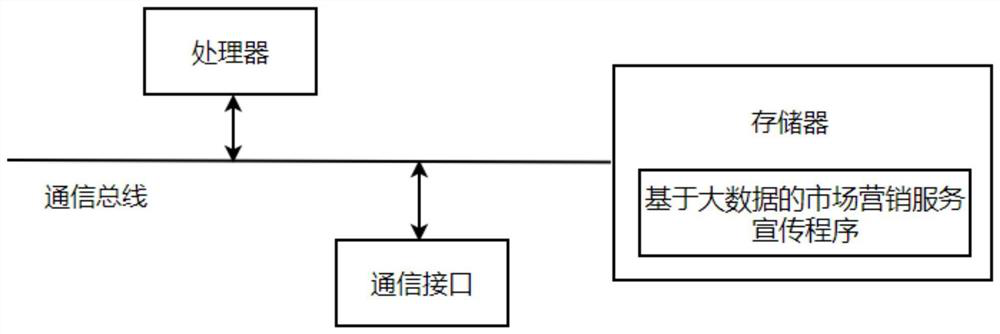

Marketing service propaganda system and method based on big data

InactiveCN114565410AEasy to adjustIncrease diversityMarket data gatheringOperations researchIndustrial engineering

The invention discloses a marketing service propaganda system and method based on big data. Belongs to the technical field of marketing service propaganda. Comprising the steps that different propaganda types and propaganda durations are combined to obtain propaganda coefficients, and evaluation conditions are provided for overall evaluation of subsequent propaganda schemes based on the propaganda coefficients; the method comprises the following steps: dividing monitoring areas, monitoring people flow conditions and sales conditions of the divided monitoring areas, processing and calculating an obtained flow statistical set and an obtained sales statistical set to obtain a flow change value and a sales change value, and evaluating an existing marketing service scheme from different aspects based on the flow change value and the sales change value. The diversity and comprehensiveness of marketing service evaluation are improved, so that the marketing service can be adjusted more accurately and efficiently; the method and the device are used for solving the technical problem that the overall effect of marketing service propaganda is poor due to the fact that the effect of a marketing scheme cannot be monitored and adaptively adjusted in an existing scheme.

Owner:派趣(盐城)信息技术有限公司

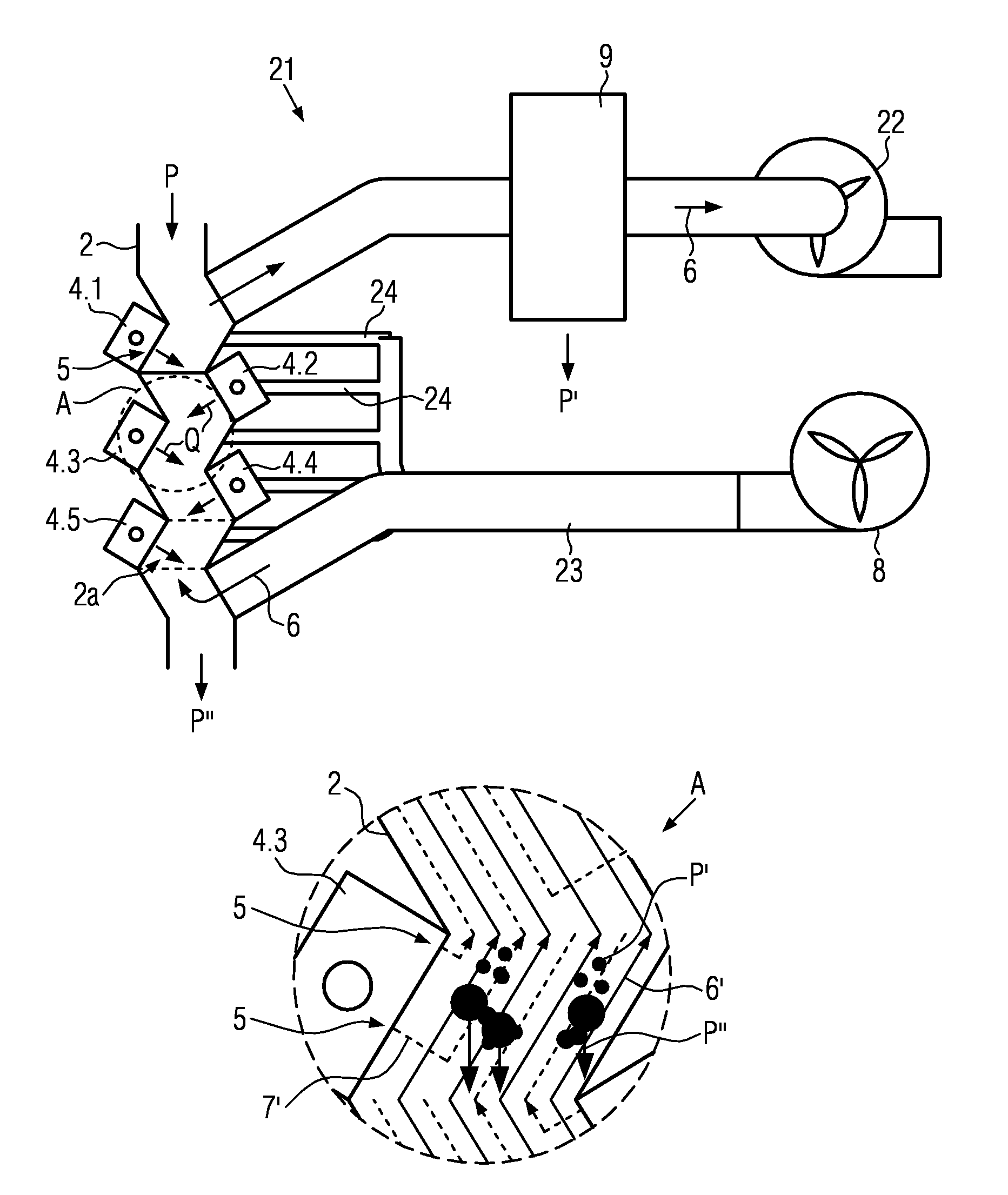

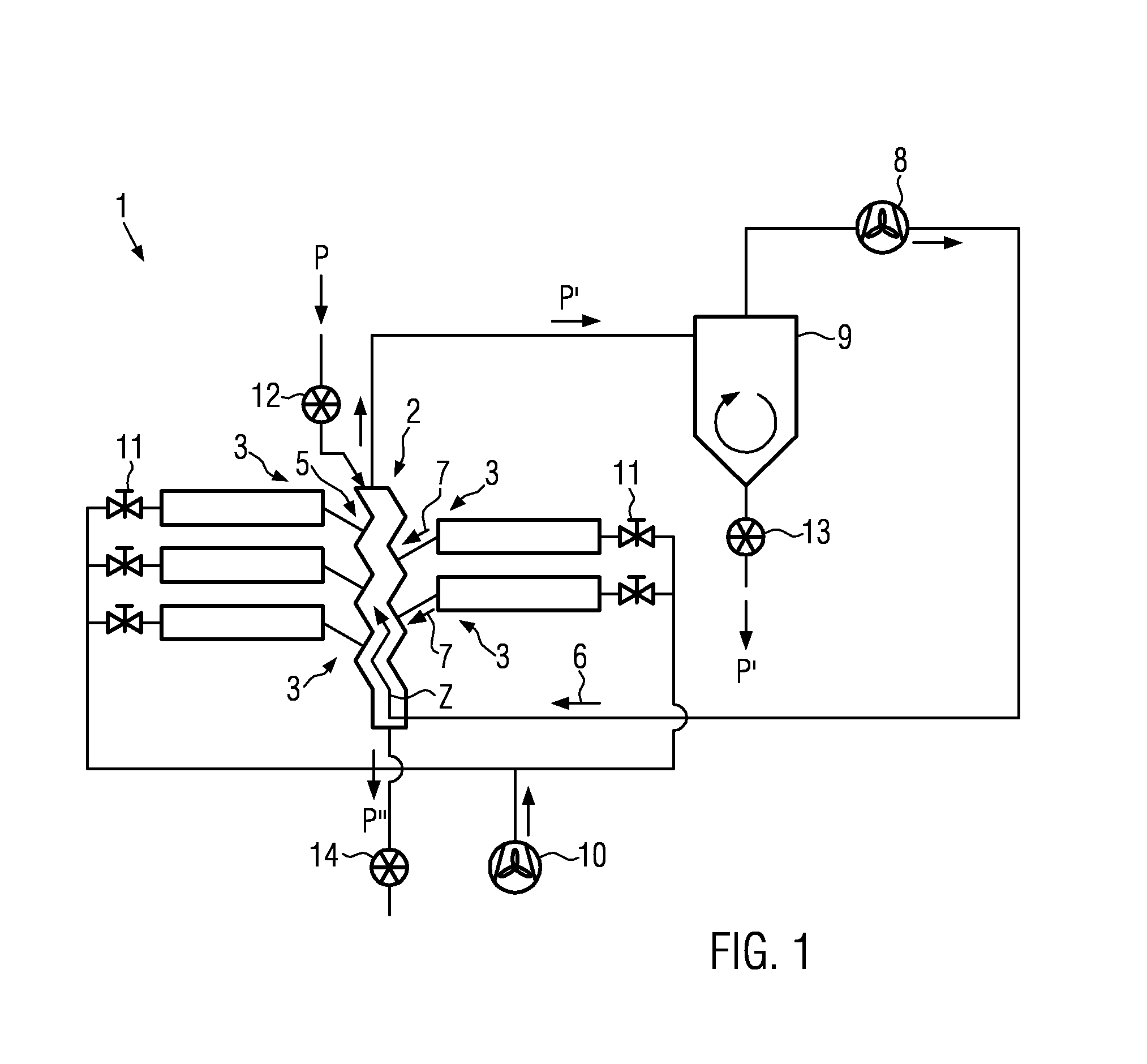

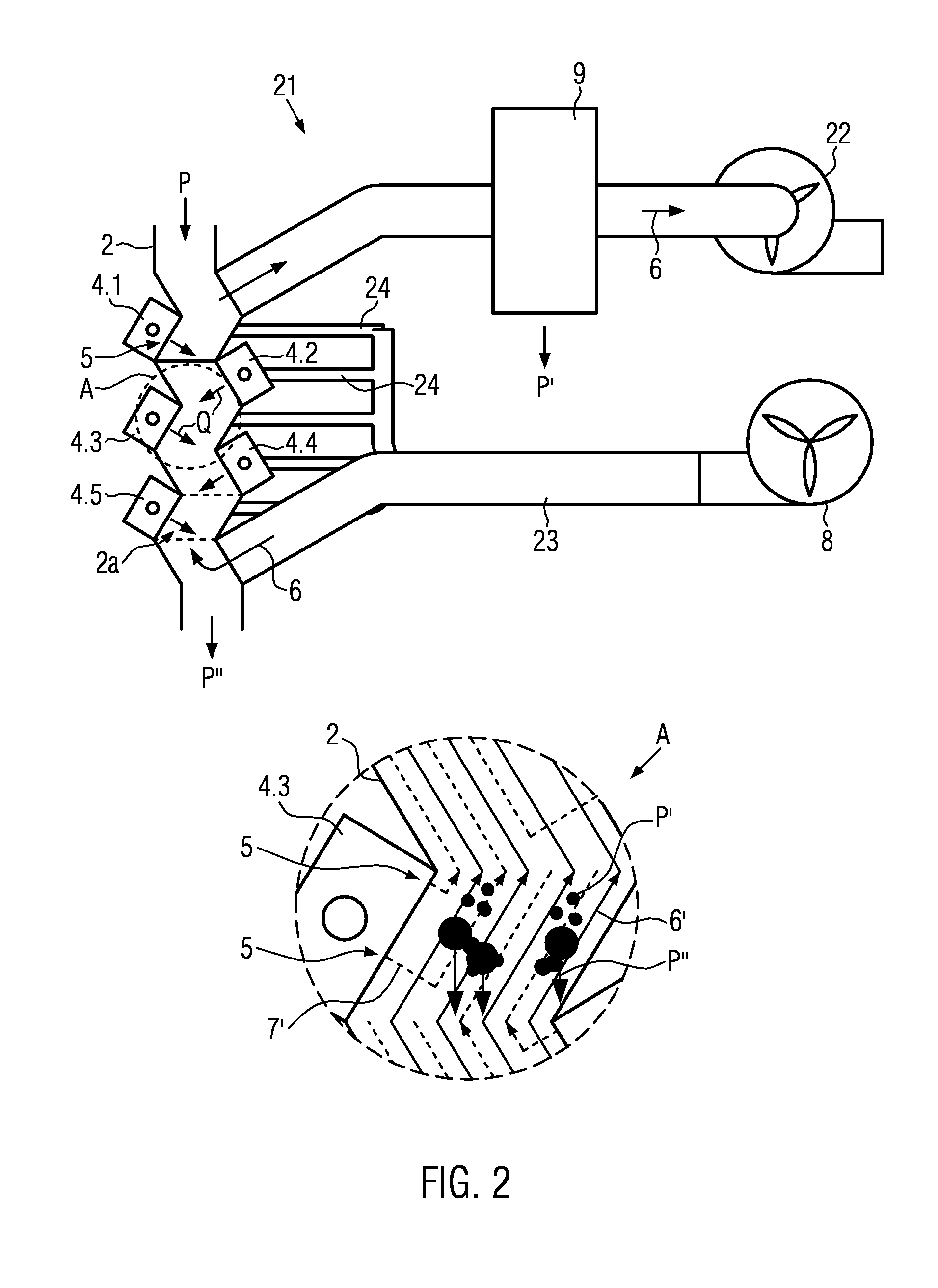

Method for gravity separation of plastic particles and gravity separator for plastic particles

InactiveUS20140083916A1Effectively and efficiently reducedReduce static chargeGas current separationSortingGravity separationGravitation

A method and a device for gravity separation of plastics particles, in particular of plastic flakes, where separation gas is guided upwardly in the counter stream against the plastic particles to be separated. Due to the fact that the separation gas is at least partially ionized, the selectivity of the separation can be increased with low energy input.

Owner:KRONES AG

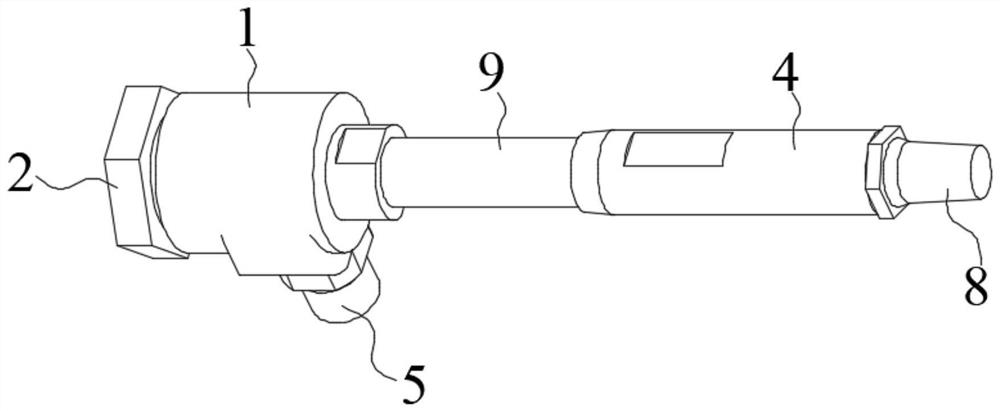

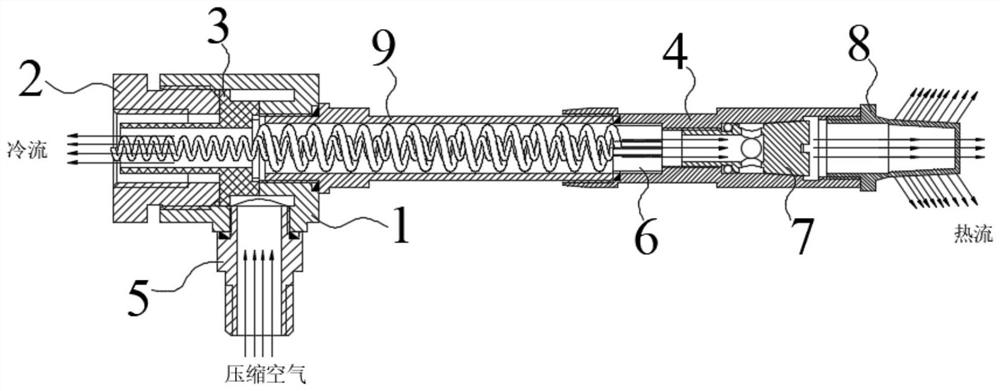

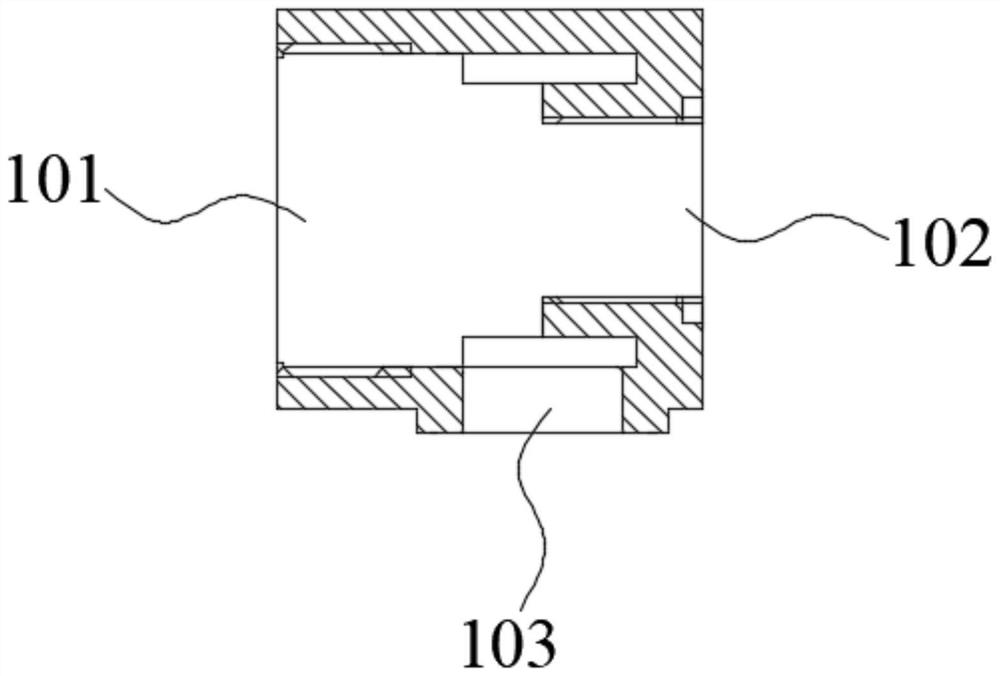

Assembled refrigeration vortex tube

PendingCN114264083AImprove cooling efficiencyEasy to divertCompression machinesTemperature controlEngineering

The invention discloses an assembled refrigeration vortex tube, which belongs to the technical field of temperature control, and comprises a vortex cavity connected with a cold end output tube and a spiral generator, and a hot end output tube is arranged at one end of the spiral generator deviating from the cold end output tube; the swirl flow generator comprises a swirl flow ring, an annular gap is reserved between the swirl flow ring and the inner wall of the second flow channel, and at least one notch for communicating the inside and the outside is formed in the periphery of the swirl flow ring in the tangential direction of the inner circumference of the swirl flow ring. And airflow introduced by the inlet connector forms annular airflow along the periphery of the rotational flow ring, and the annular airflow enters the rotational flow ring through the notch. According to the assembly type refrigeration vortex tube, high-pressure airflow and cold and hot airflow are divided through the rotational flow rings, the airflow forms annular airflow through the rotational flow rings before entering the pipeline, the problem that the high-pressure airflow and the separated cold and hot airflow interfere with each other is solved, and the refrigeration efficiency of the assembly type refrigeration vortex tube is improved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

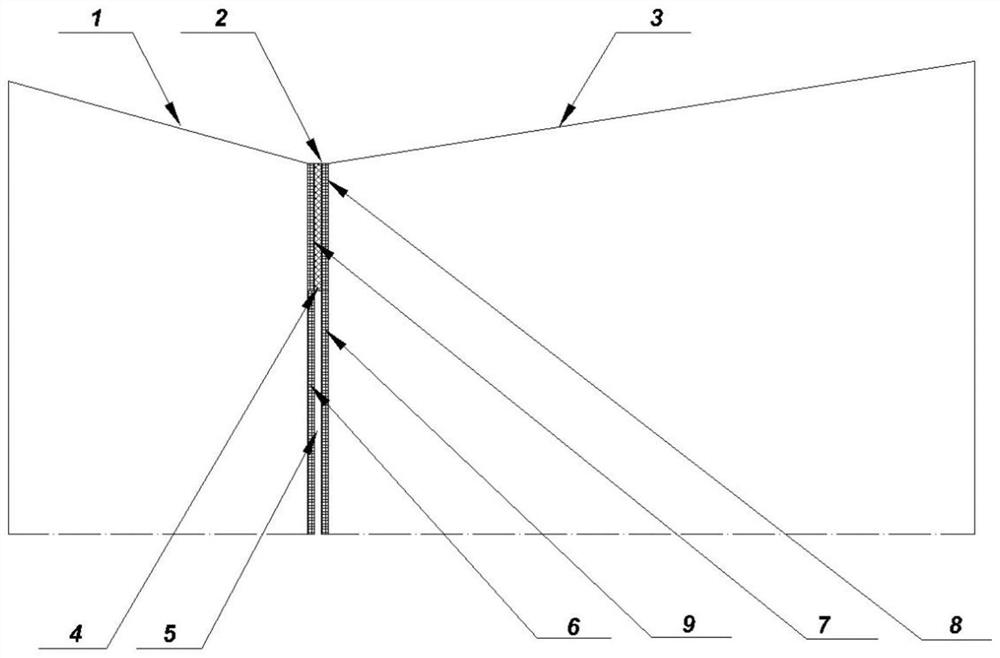

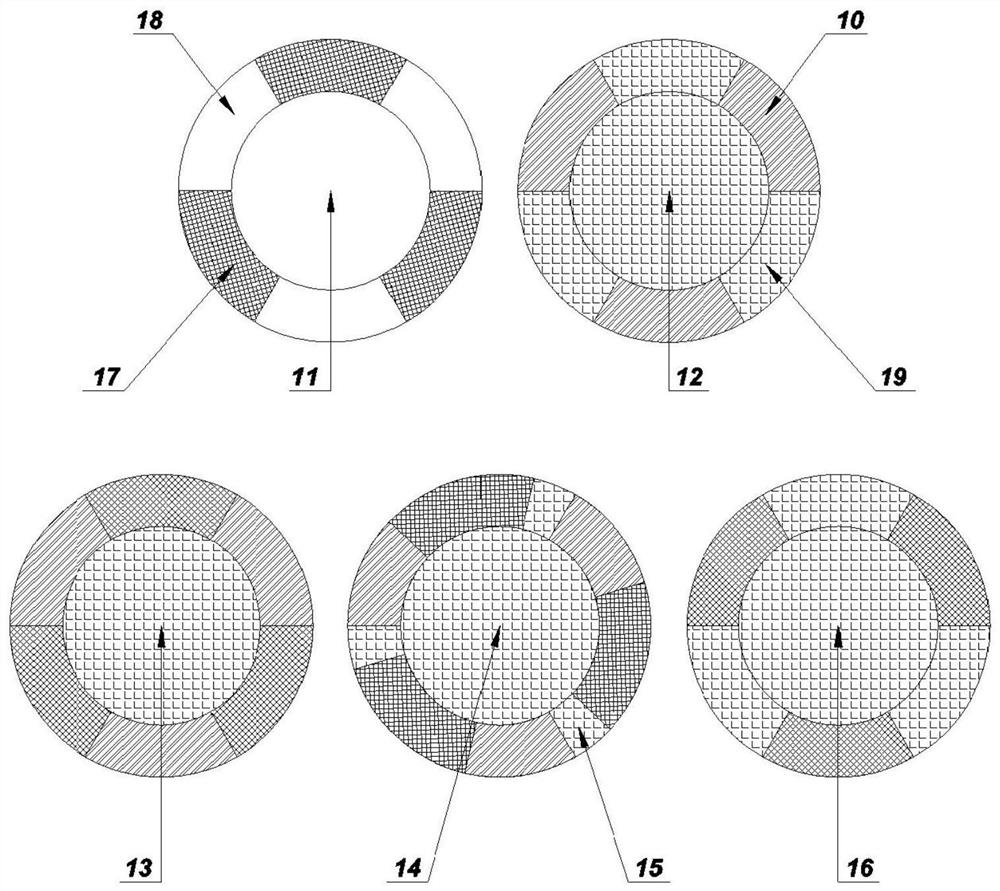

Flow adjustment device for axisymmetric channel, tail nozzle using said device and adjustment method

ActiveCN112855380BMeet flow regulation needsSimple structureJet propulsion plantsFlight vehicleStructural engineering

The invention discloses a flow regulating device for an axisymmetric channel, a tail nozzle using the device and a regulating method. Both the plate and the basic plate are axisymmetric structures with a lobed design; the tail nozzle using the device includes a constriction section, a throat and an expansion section according to the flow direction of the nozzle, and the rotating stopper and the basic plate are arranged at the throat. By rotating the baffle around the axis of the tail nozzle, the mutual cooperation with the relative position of the basic plate is completed, and the adjustment of the actual flow geometric area of the axisymmetric tail nozzle is realized, thereby meeting the flow adjustment requirements of the axisymmetric tail nozzle. The flow regulating device of the present invention is simple, light in weight, large in adjustable range, and high in regulating efficiency. The structure of the tail nozzle adopting the flow regulating device of the present invention is simpler, and the thrust performance is still maintained at a relatively high level, which better satisfies the needs of engines and aircraft. usage requirements.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Using method of spherical workpiece cutting machining device

InactiveCN111531227AAccurate and efficient reciprocating translational movementHigh degree of processing automationAutomatic control devicesFeeding apparatusMechanical equipmentMaterial transfer

The invention discloses a using method of a spherical workpiece cutting machining device, and belongs to the field of workpiece machining mechanical equipment. The spherical workpiece cutting machining device comprises a machining material conveying support, a translation cutting mechanism, a material clamping lifting mechanism, a turnover material transferring mechanism and a workpiece conveyingmechanism; the translation cutting mechanism is horizontally and fixedly arranged on one side above the machining material conveying support, the material clamping lifting mechanism is vertically arranged on the machining material conveying support on one side of the translation cutting mechanism, the turnover material transferring mechanism is vertically arranged on the machining material conveying support on one side below the material clamping lifting mechanism, and the workpiece conveying mechanism is horizontally and adjacently arranged on the machining material conveying support on one side of the turnover material transferring mechanism. The spherical workpiece cutting machining device is reasonable in structural design, capable of efficiently and stably cutting spherical workpiecesone by one, capable of achieving automatic transferring, feeding and returning of the spherical workpieces, high in machining automation degree and capable of meeting the requirements for workpiece machining and use.

Owner:黄明珠

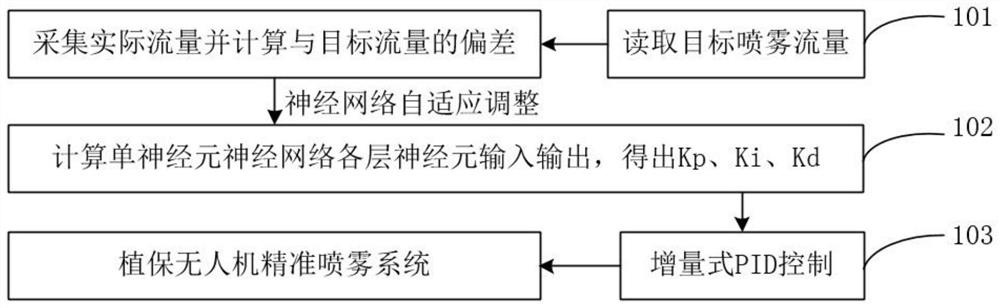

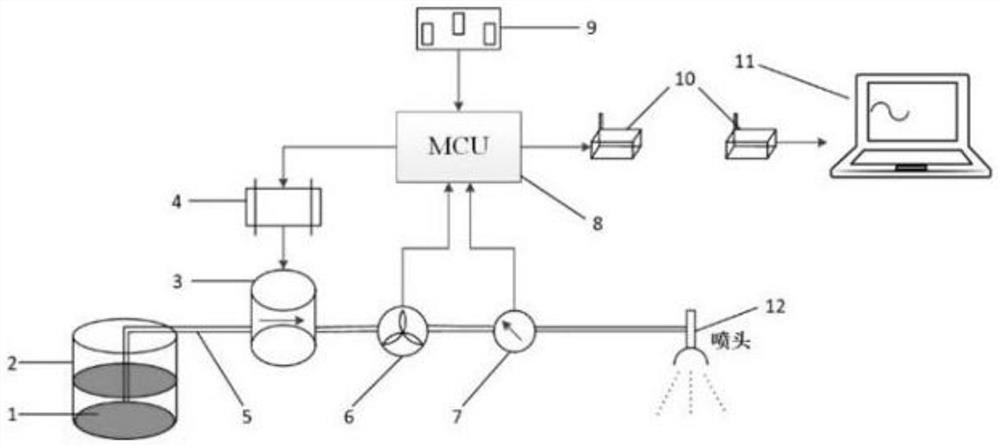

A UAV precision spray control system and control method

ActiveCN113303309BGuaranteed accuracyMeet the quantitative application methodAircraft componentsInternal combustion piston enginesDiaphragm pumpProportional control

Owner:SHENYANG AGRI UNIV

Train operation adjustment method, device, system and train

ActiveCN111361609BImplement the run tuning methodAccurate and efficient adjustmentAutomatic systemsSimulationStop time

The invention discloses a train operation adjustment method, device, system and train, wherein the method includes: establishing a communication connection with an ATS, receiving an operation plan sent by the ATS; driving according to the operation plan; and comparing the actual arrival time with the Planned arrival time, if the train is early or late, the train will adjust the stop time of the train at the station and the running time of the next section, so that the actual arrival time of the train at the next station is consistent with the planned arrival time; when leaving the station , compare the actual departure time with the planned departure time, if the train is early or late, the train will adjust the running time of the train in the next interval, so that the actual arrival time of the train at the next station is consistent with the planned arrival time. Thus, the present invention realizes the active adjustment of the train operation, makes the adjustment of the train more accurate and efficient, and reduces the load of the train-ground communication network.

Owner:BYD CO LTD

A groove cutting device for inner arc surface of shaft sleeve workpiece

ActiveCN110560706BEfficient and convenient clamping and fixingClamping and fixing is stable and accurateAutomatic control devicesFeeding apparatusTool bitGear wheel

Owner:常熟市万顺轴承有限公司

Concave edging machining hard alloy chopper convenient to replace

The invention belongs to the technical field of turning tools, and particularly relates to a concave edging machining hard alloy chopper convenient to replace. The device further comprises a working column and a switching block, a switching cavity is formed in the bottom face of the switching block, a rotating column is rotationally connected to the interior of the switching cavity through a rotating rod, a set of storage cavities are formed in the side wall of the rotating column, first push rods are installed in the storage cavities, and sliding plates are connected to the ends of the first push rods. The outer end of the sliding plate is in threaded connection with the end part of the body; the mounting height of the body can be adjusted more accurately and efficiently, so that the body is mounted more conveniently and quickly, quick switching of the body can be realized by mounting a plurality of chopper bodies in the switching cavity in advance, the machining efficiency of a workpiece is improved, and the machining cost is reduced. And meanwhile, the pre-installed body can be effectively stored through the switching cavity, and the adverse effect of external dust and impurities on the body is reduced.

Owner:HEYUAN YONGXING CEMENTED CARBIDE

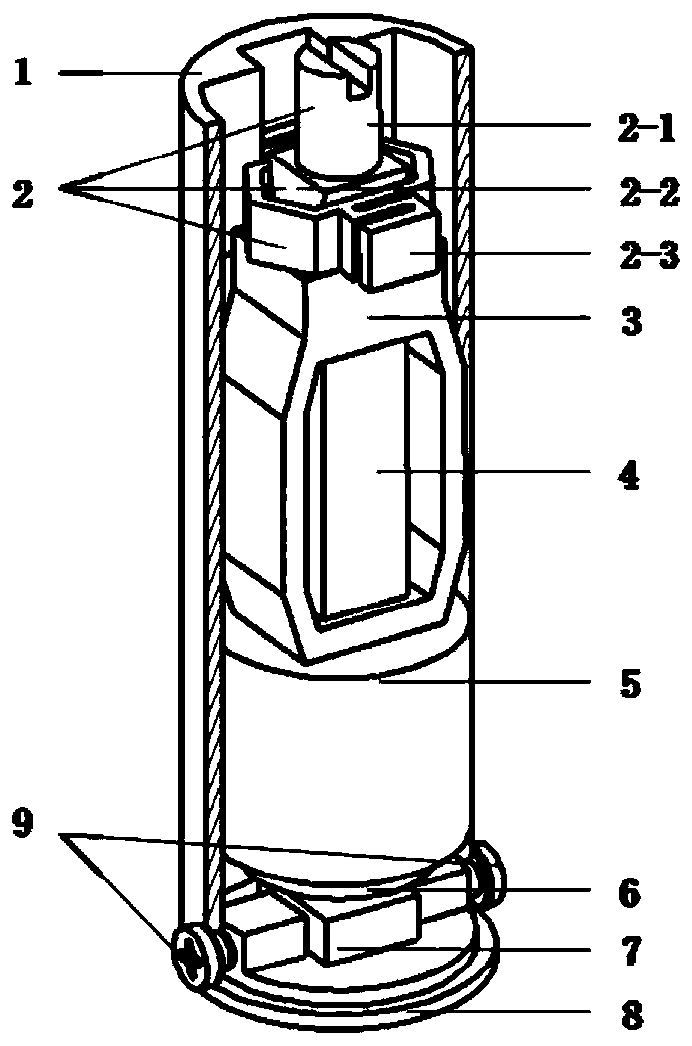

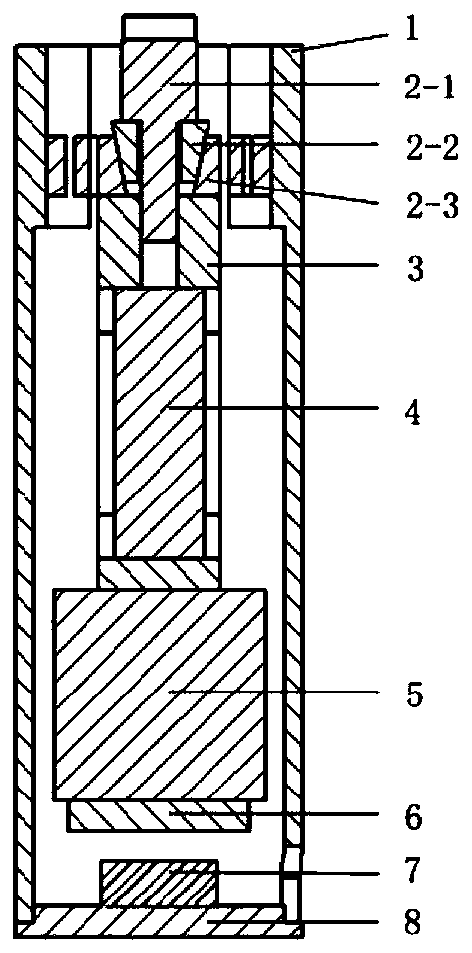

Linear inertial piezoelectric actuator with displacement sensing function and its actuation method

ActiveCN108512457BSmall structure sizeReduce stiffnessPiezoelectric/electrostriction/magnetostriction machinesInertial massPiezoelectric actuators

The invention relates to a linear inertial piezoelectric actuator with a displacement sensing function and an actuating method. The actuator consists of a cylindrical housing, a base, a moving unit, adiamond ring, a piezoelectric stack, an inertial mass block, a permanent magnet and a proportional linear Hall sensor, wherein the bottom end of the cylindrical housing is fixedly connected with thebase; the interior of the cylindrical housing is as follows from top to bottom successively: the moving unit whose left and right ends are closely attached to a rail square groove in the casing, the diamond ring which is connected with the moving unit through an adjusting screw, the piezoelectric stack which is mounted in the diamond ring in an interference manner, the inertial mass block which isbonded under the diamond ring, the permanent magnet which is fixed to the lower surface of the inertial mass block, and the proportional linear Hall sensor which is mounted on the upper surface of the base. The linear inertial piezoelectric actuator with the displacement sensing function and the actuating method in the invention use an asymmetric sawtooth wave to drive the piezoelectric stack; actuation is performed through the principle of inertial impact; the proportional linear Hall sensor is adopted to sense the displacement in real time; the structure is compact and easy to install, theactuation is fast and accurate, the outage is locking, and the clamping force is adjustable.

Owner:西安朗威科技有限公司

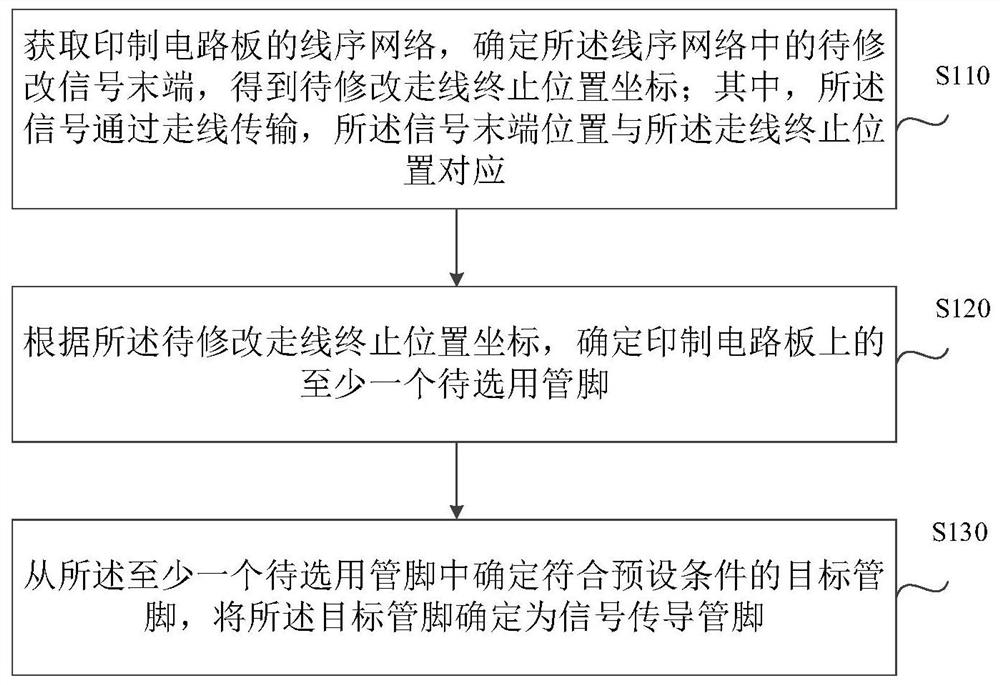

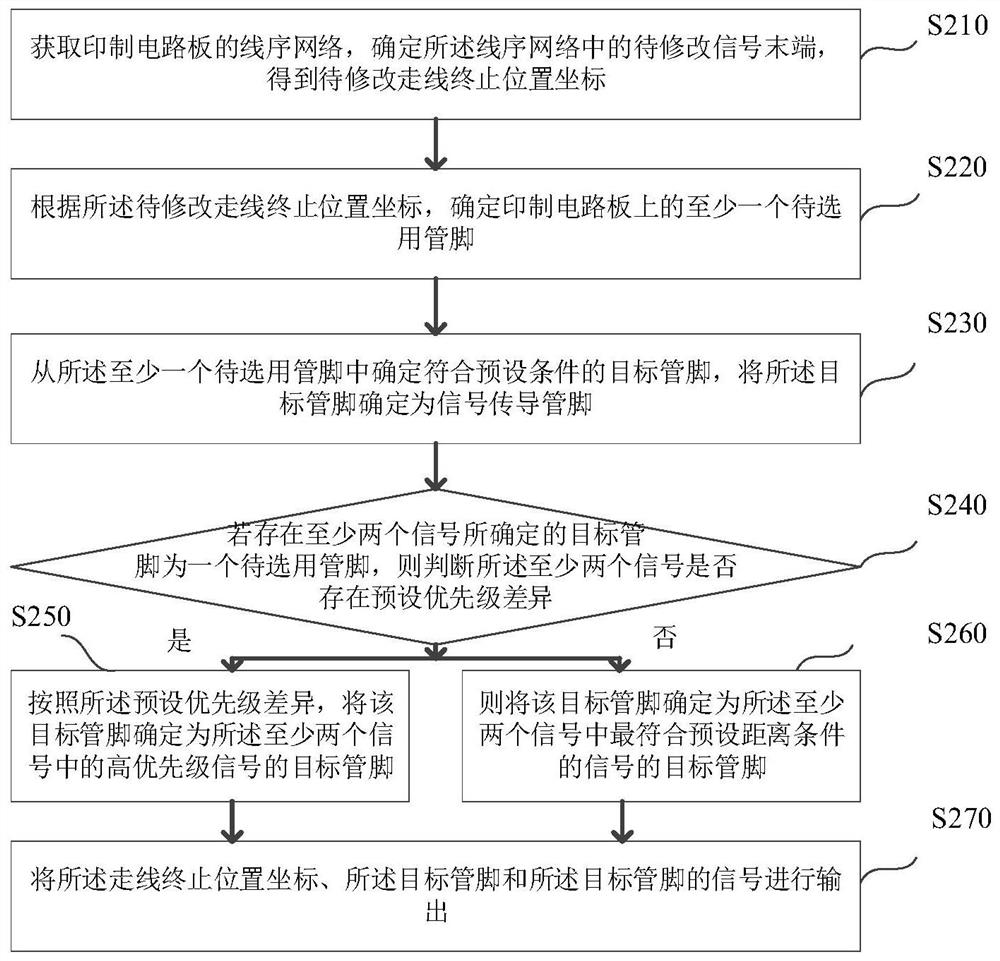

Wiring layout adjustment method and device, electronic equipment and storage medium

ActiveCN113378505AAccurate and efficient adjustmentComputer aided designSpecial data processing applicationsLayoutPrinted circuit board

The invention discloses a routing layout adjustment method and device, electronic equipment and a storage medium. The method comprises the following steps: collecting a line sequence network of the printed circuit board, determining a to-be-modified signal tail end in the line sequence network, and obtaining a to-be-modified wiring termination position coordinate; wherein the signal is transmitted through a wire, and the tail end position of the signal corresponds to the end position of the wire; determining at least one pin to be selected on the printed circuit board according to the termination position coordinates of the wiring to be modified; and determining a target pin meeting a preset condition from the at least one to-be-selected pin, and determining the target pin as a signal conduction pin. By adopting the technical scheme, the pin signal can be more efficiently and accurately adjusted when the line outgoing of the printed circuit board is difficult.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

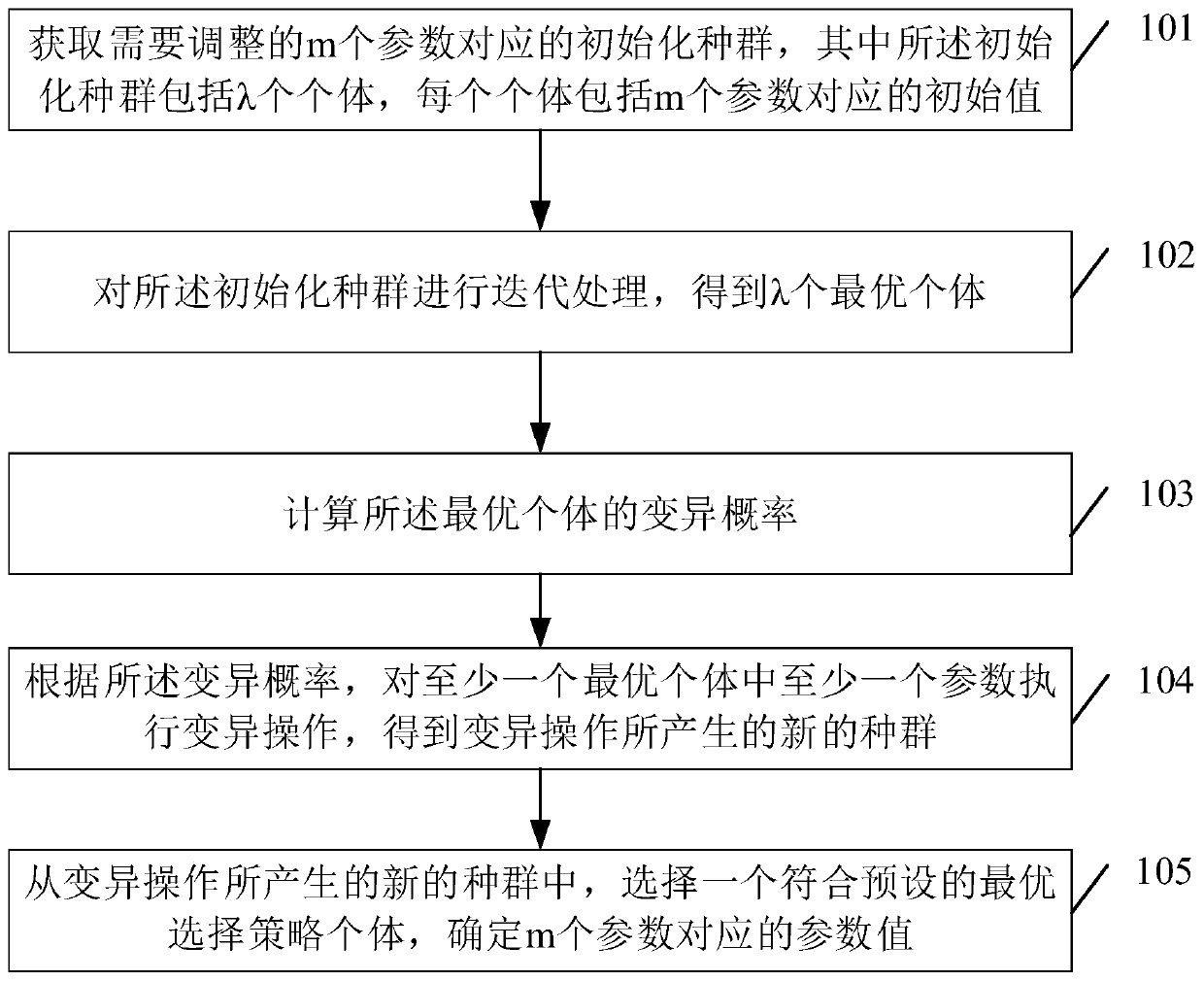

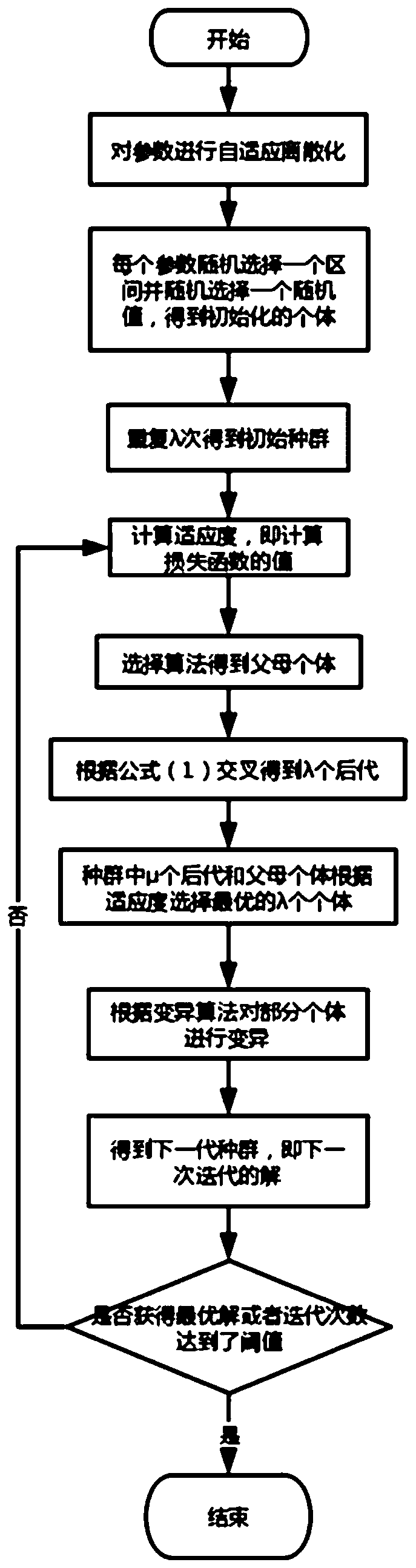

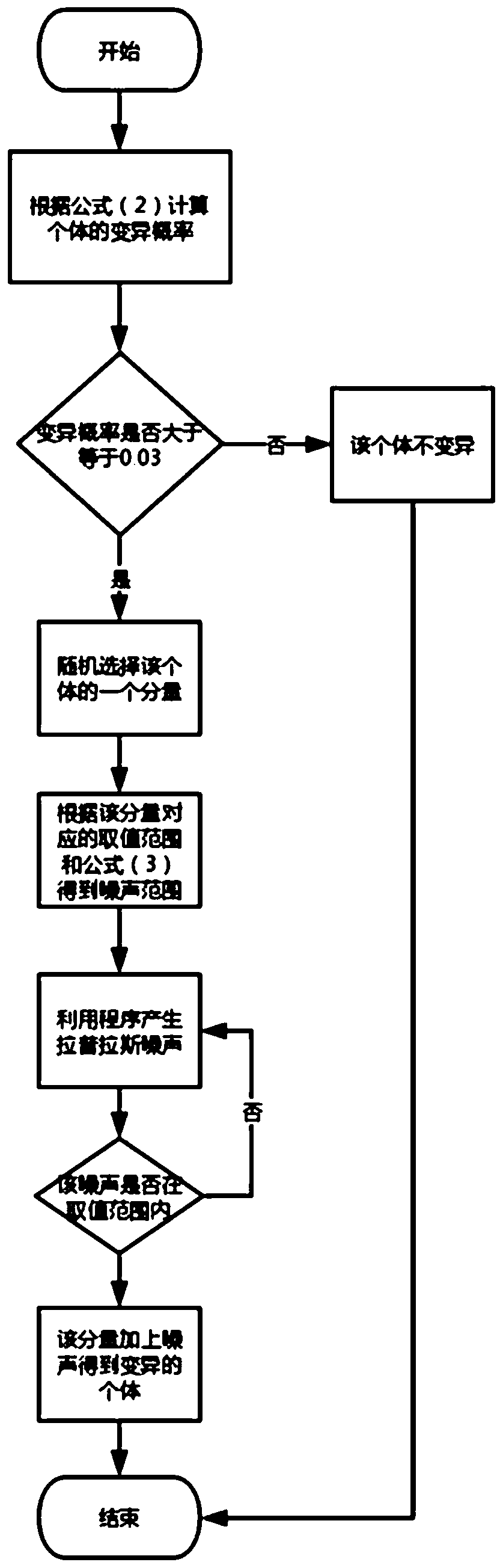

Data processing method and data processing device

The embodiment of the invention discloses a data processing method and a data processing device. The method comprises the following steps: obtaining initialized populations corresponding to m parameters needing to be adjusted, wherein the initialized populations comprise lambda individuals, each individual comprises initial values corresponding to the m parameters, and m is a positive integer; performing iterative processing on the initialized populations to obtain lambda optimal individuals; calculating the mutation probability of the optimal individuals; executing mutation operation on at least one parameter in at least one optimal individual according to the mutation probability to obtain a new population generated by the mutation operation; and selecting an individual meeting a presetoptimal selection strategy from the new population generated by the mutation operation, and determining parameter values corresponding to the m parameters.

Owner:恩亿科(北京)数据科技有限公司

Welding machine laser beam optical mode detection system and method

ActiveCN106141460BRealize real-time detectionImprove accuracyLaser beam welding apparatusCamera imageUltraviolet

The invention relates to the field of laser welding of plate and strip steel, in particular to a laser calibration device and method for welding. A welding machine laser beam optical mode detection system, including a photosensitive developing coating coated on the photosensitive surface of a laser power measuring head; an ultraviolet projection lamp and a camera are also arranged near the laser power measuring head, and the irradiation direction of the ultraviolet projection lamp points to the photosensitive The shooting direction of the camera points to the photosensitive surface. A method for detecting the laser beam optical mode of a welding machine. A standard laser is selected, the standard laser is turned on, and the standard laser mode pattern is obtained from the photosensitive surface; the laser output unit to be detected is opened to obtain the laser mode pattern to be detected; the laser pattern pattern to be detected is obtained The deviation of the laser to be detected is obtained by comparing with the standard laser mode graph. The invention realizes the real-time detection of the laser beam optical mode of the butt welding machine in the production process, is beneficial to improving the accuracy of weld quality judgment, greatly shortens the required inspection and maintenance time, and improves the production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

Nut fastener manufacturing and machining equipment

InactiveCN113245639AImprove turning efficiencyEasy to operateThread cutting machinesLarge fixed membersScrew threadMachining

The invention relates to nut fastener manufacturing and machining equipment. The equipment comprises a machining rack, wherein a conveying mechanism is arranged in the middle of the machining rack, a fixing support is arranged at the upper end of the machining rack, an auxiliary mechanism is arranged at the lower end of the fixing support, and a turning executing mechanism is arranged on the fixing support. The equipment solves the problems that in an existing nut production and manufacturing process, after being formed, a nut blank needs to be manually fixed by means of a clamp, internal thread turning machining is conducted only after a nut is manually fixed, the stability of manually fixing the nut by means of a tool is poor, and the clamp needs to be manually adjusted when nuts with different specifications are machined, so that operation is complicated and the stability is poor; and secondly, the nuts cannot be manually turned in batches, and corresponding thread turning tools need to be manually replaced when the nuts of the different specifications are machined.

Owner:芜湖腾锢五金销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com