Patents

Literature

59results about How to "Avoid Offset Skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

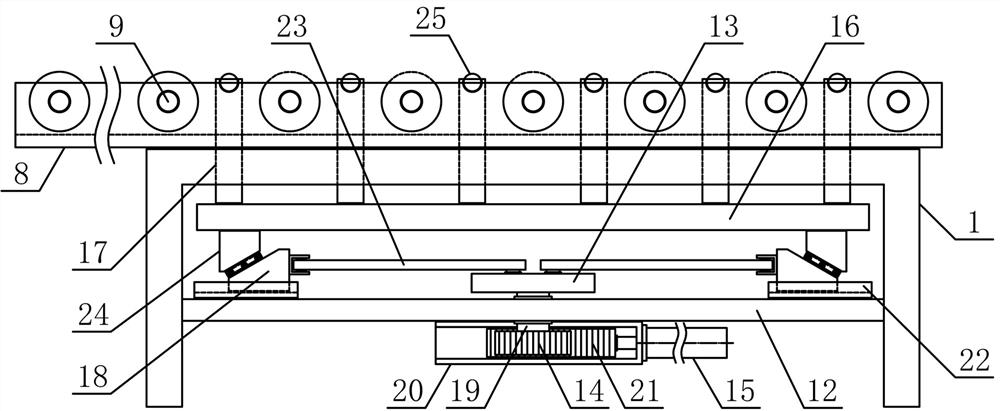

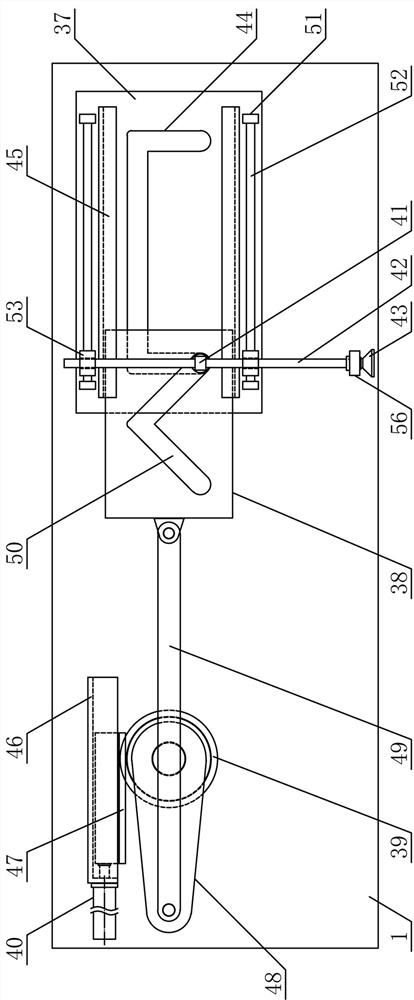

Sorting and conveying mechanism for groove workpieces

ActiveCN110451228AReasonable structural designHigh degree of automationConveyor partsEngineeringMechanical equipment

The invention discloses a sorting and conveying mechanism for groove workpieces, and belongs to the field of workpiece conveying and machining mechanical equipment. A material transferring pipe is vertically and fixedly arranged in the middle of the upper side of a material transferring support, a horizontal moving push plate is horizontally and fixedly provided with a material pushing pressing rod along the side of the material transferring material pipe, a material guide inclined plate is obliquely and downwards fixedly arranged on one side below the material transferring material pipe, anda material bearing baffle is arranged on one side of a turnover baffle; a material guiding pipe is vertically and fixedly arranged on the material transferring support at the lower side of the material transferring pipe, a material guiding rotating plate is arranged on the material transferring support on one side of the material guiding pipe, the end part the lower side of a transferring guide plate is rotationally connected to the material transferring support, a material bearing rotating plate is arranged on the upper side of the transferring guide plate, and a material transferring belt ishorizontally arranged on the upper side of a conveying base. The sorting and conveying mechanism has the advantages that the structural design is reasonable, the groove workpieces can be convenientlyand efficiently subjected to directional arrangement in the discharging process, automatic overturning and conveying of the groove workpieces can be realized, the workpiece feeding and conveying automation degree is improved, and the requirements of production and use are met.

Owner:泰州市宠友宠物服务有限公司

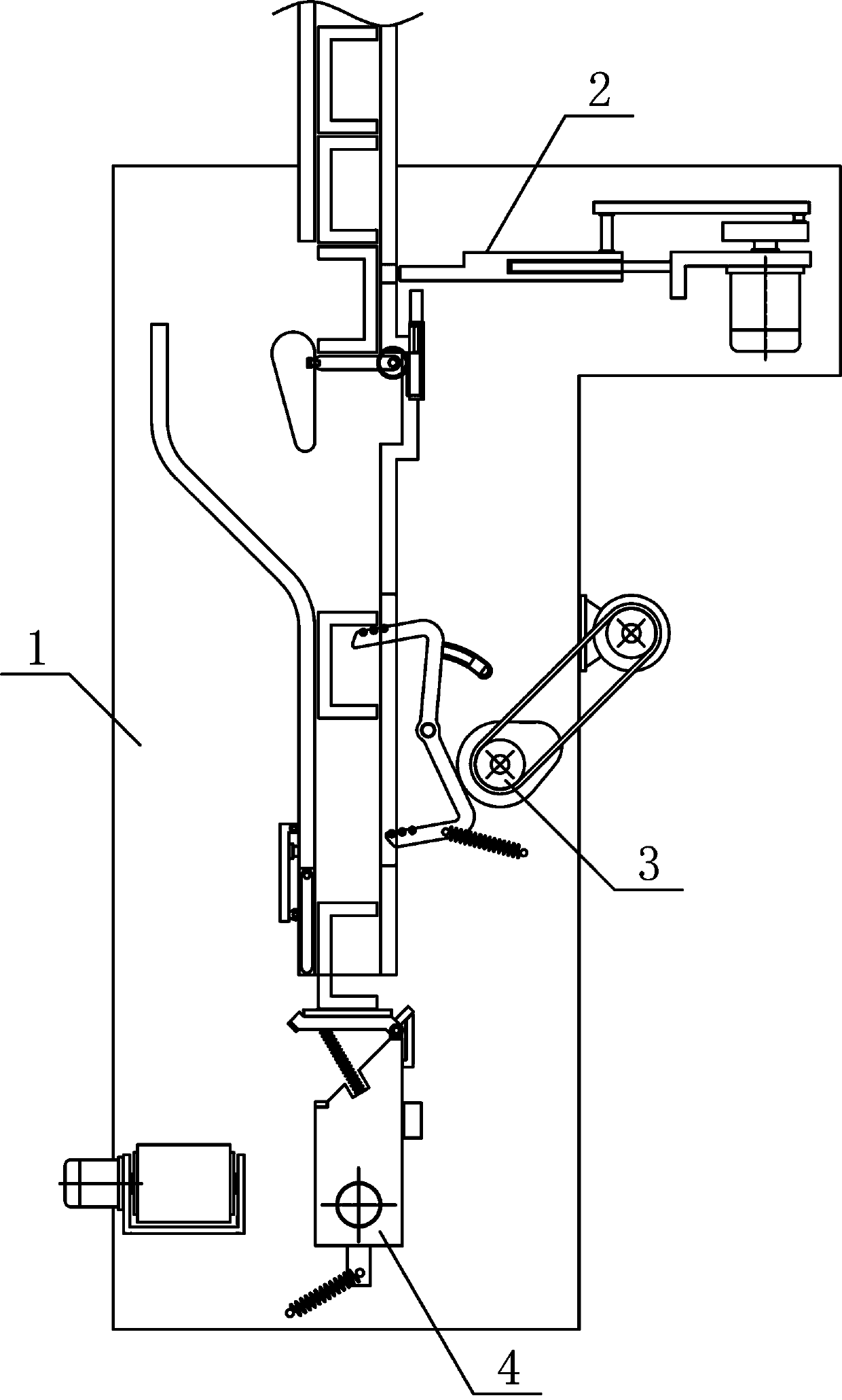

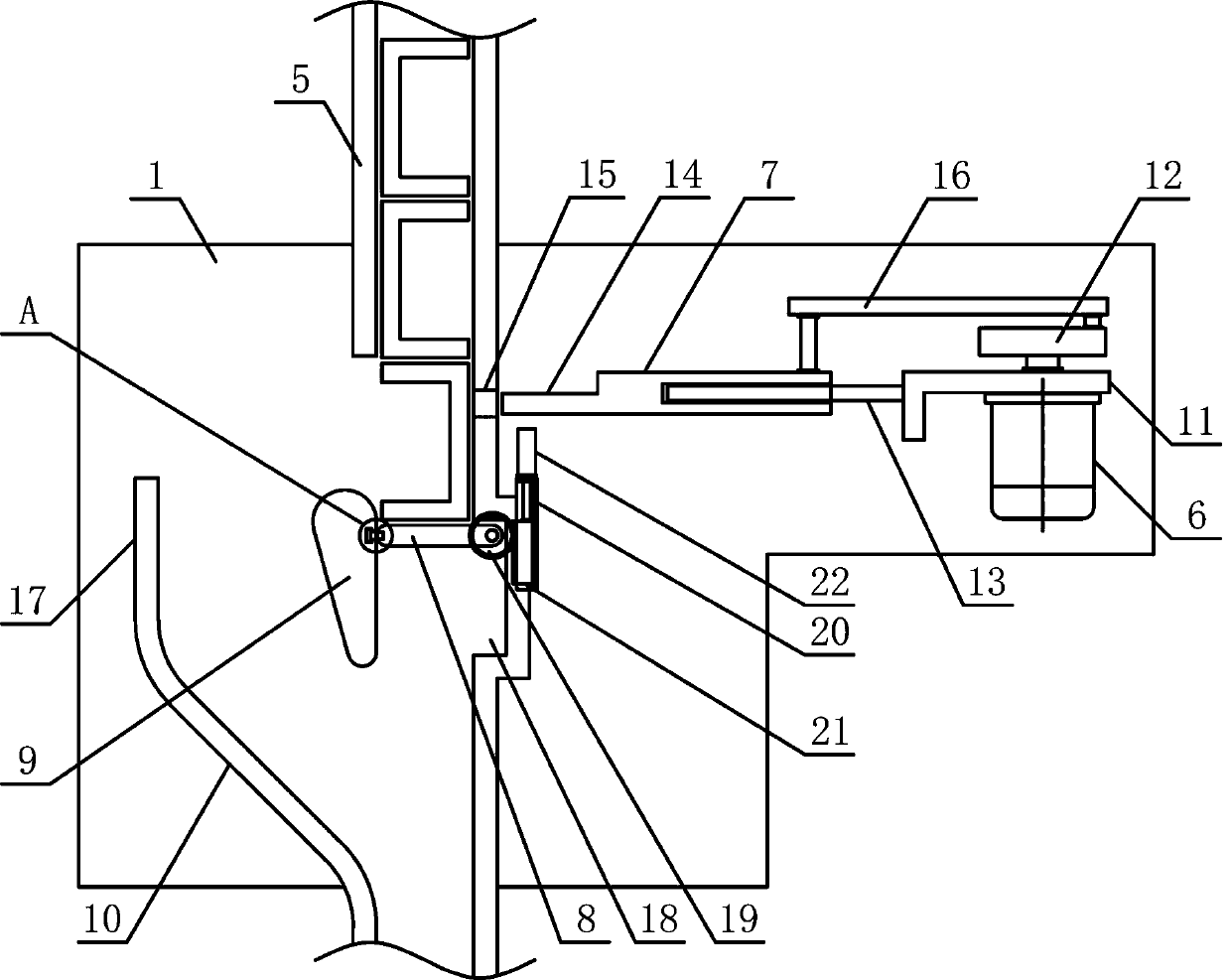

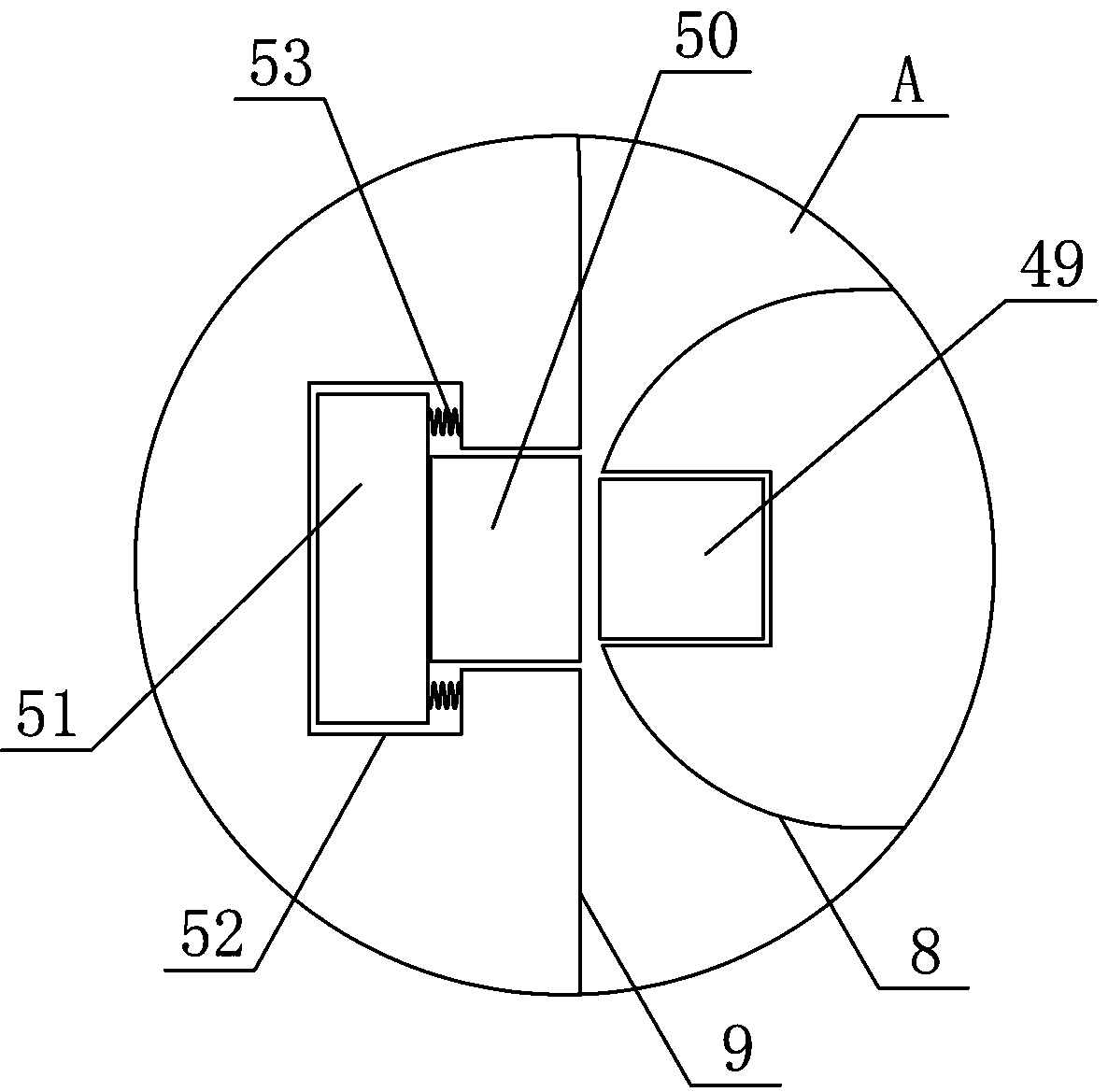

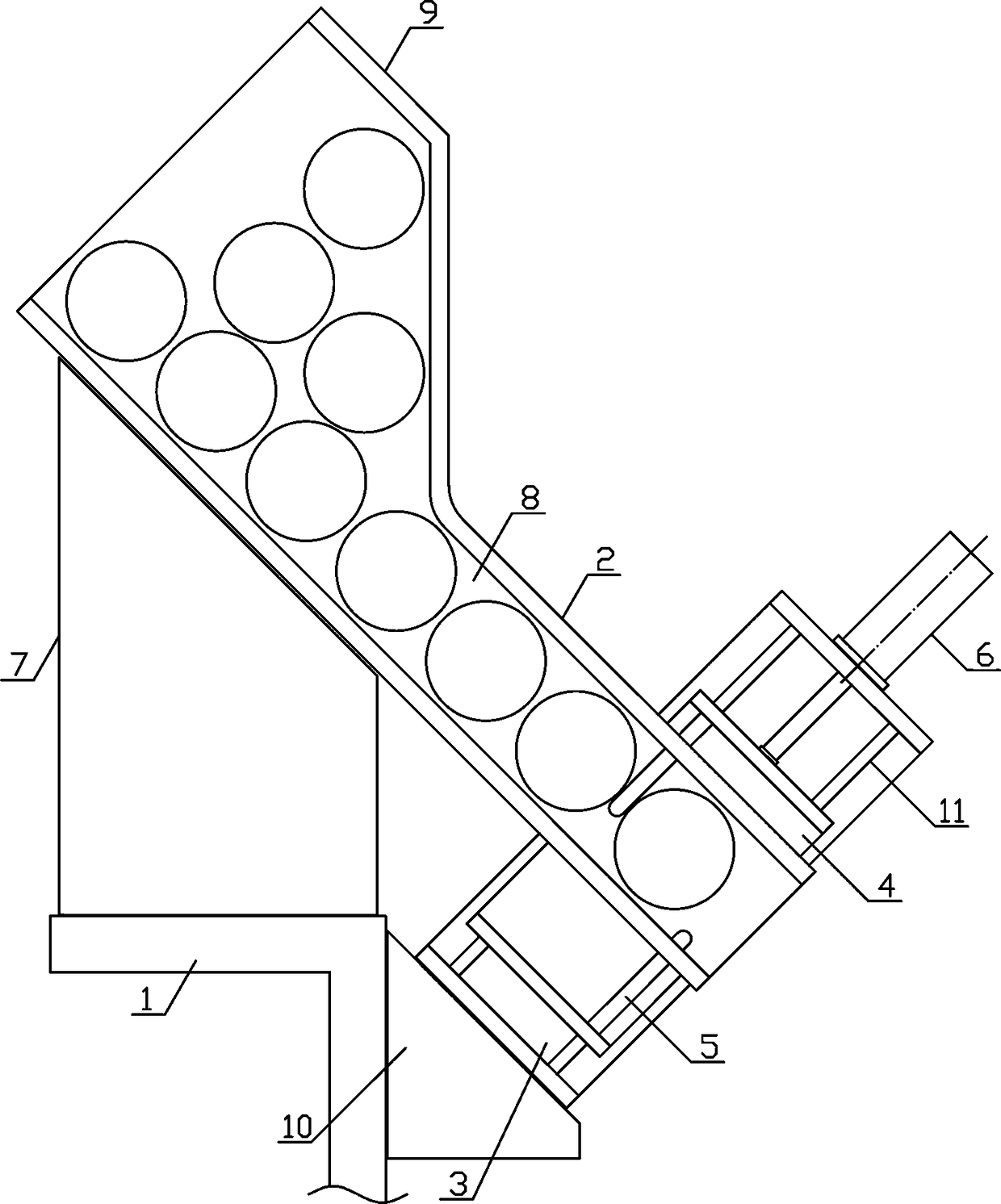

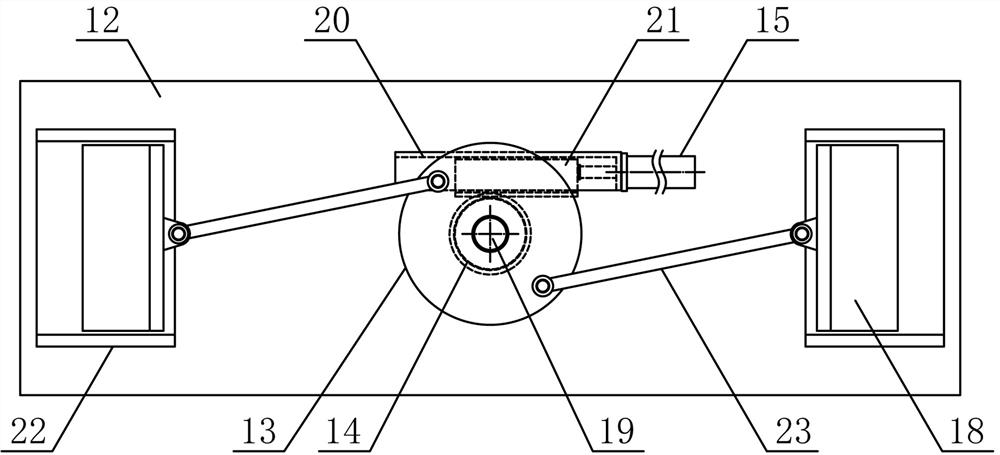

Tubing processing and branching conveying mechanism

InactiveCN108555659AReasonable structural designHigh degree of automationMetal working apparatusPunchingMechanical equipment

The invention discloses a tubing processing and branching conveying mechanism, and belongs to the field of material processing and conveying mechanical equipment. A punching mechanism of the tubing processing and branching delivery mechanism is obliquely and fixedly arranged on a processing base between a blanking mechanism and a guiding mechanism, a tubing storage hopper is arranged on the upperside of a tubing blanking pipe in a communicated mode, a punching rotating rod is rotatably connected with the output end of a punching motor at the middle part of the upper side of a lifting connecting board, a board rotating air cylinder is obliquely arranged between a punching bearing board and the processing base, a tubing bearing mechanism is arranged on one side above a guiding disc in the radial direction of the guiding disc, branching conveyor belts are horizontally and symmetrically arranged on the parts, on the two sides of the guiding disc, of the processing base in the radial direction of the guiding disc, and a driving mechanism is arranged on the part, on one side of the lower end of a guiding rotating shaft, on the processing base. The tubing processing and branching delivery mechanism is reasonable in structural design, tubing can be subjected to steady and intermittent blanking one by one and subjected to punching processing, and the processed tubing can be subjected to branching conveying, so that the tubing processing and conveying automation degree is improved, and the requirements of processing use are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

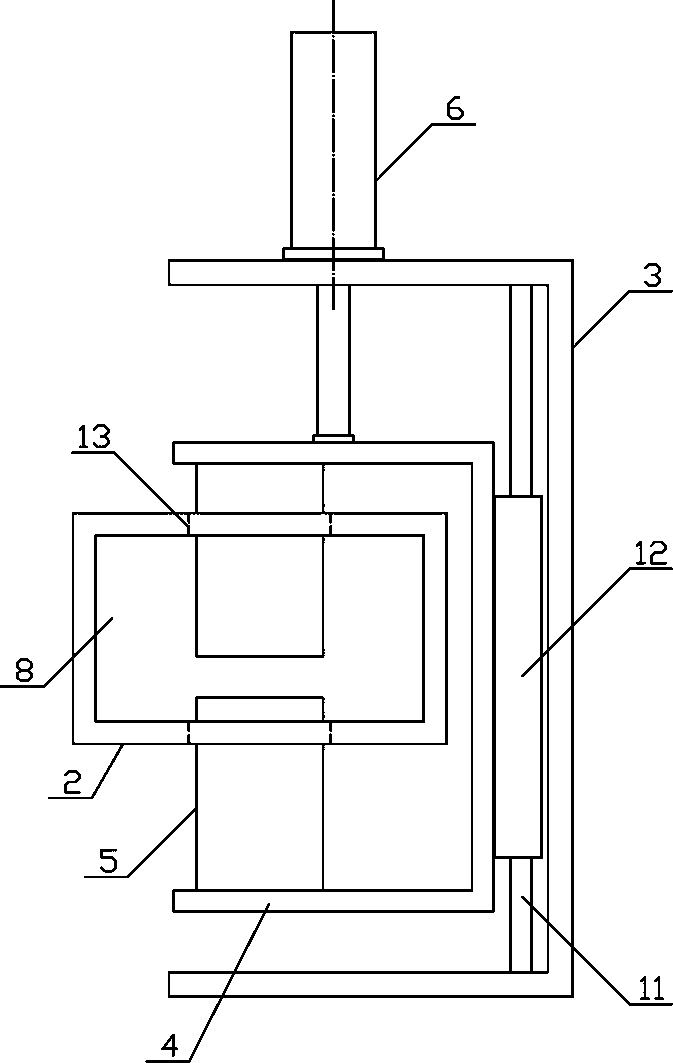

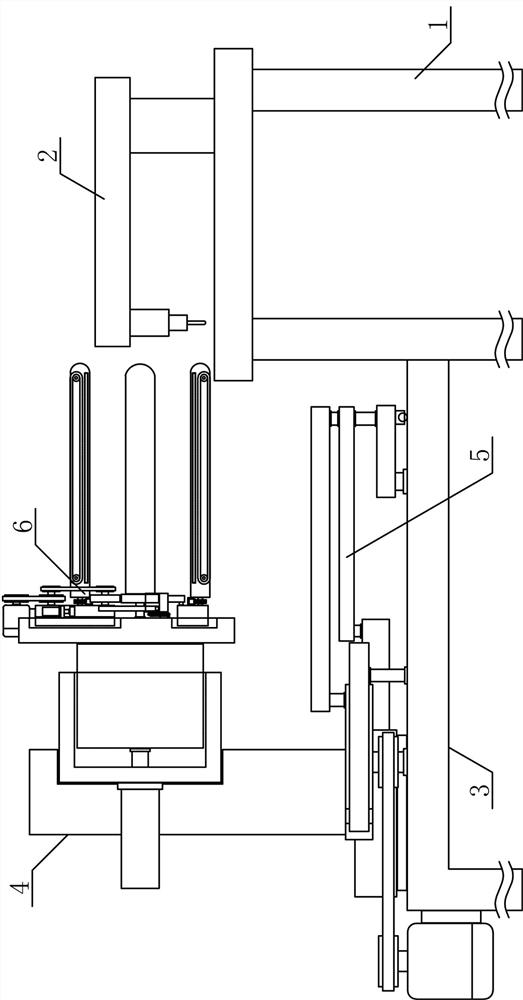

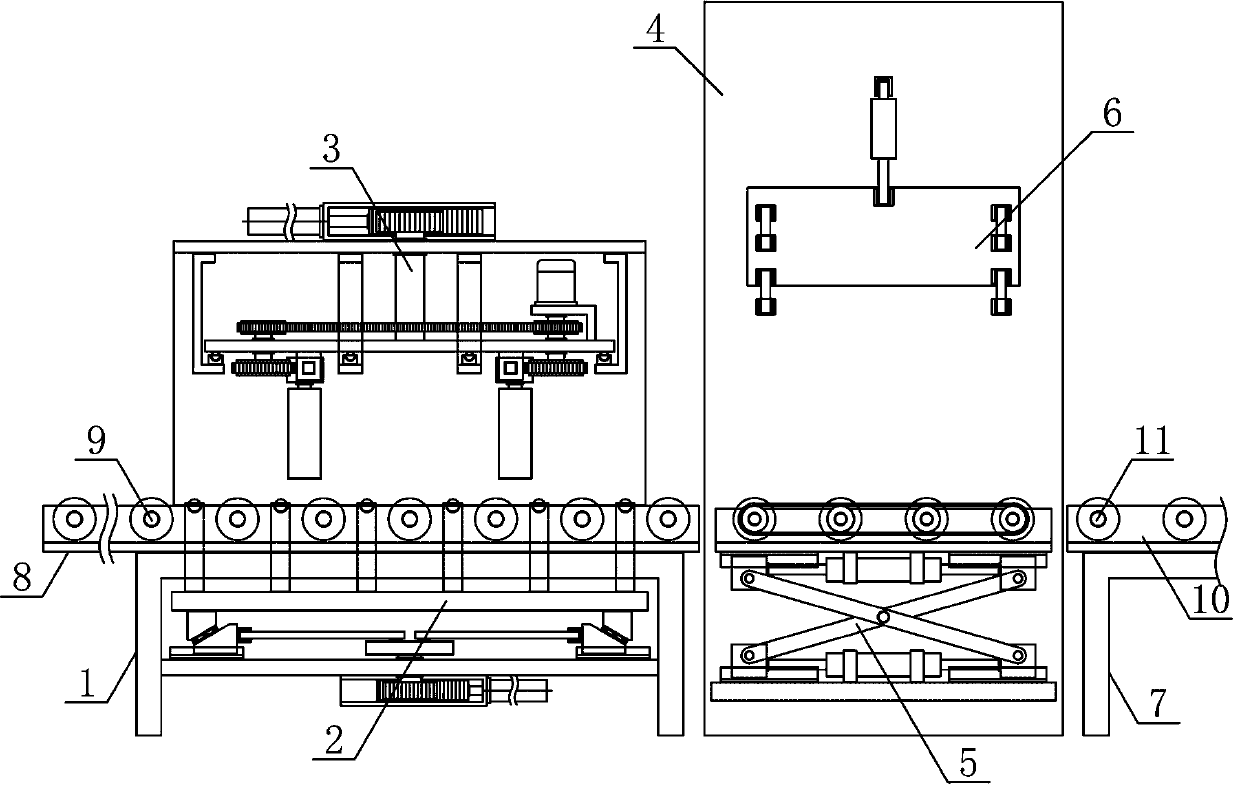

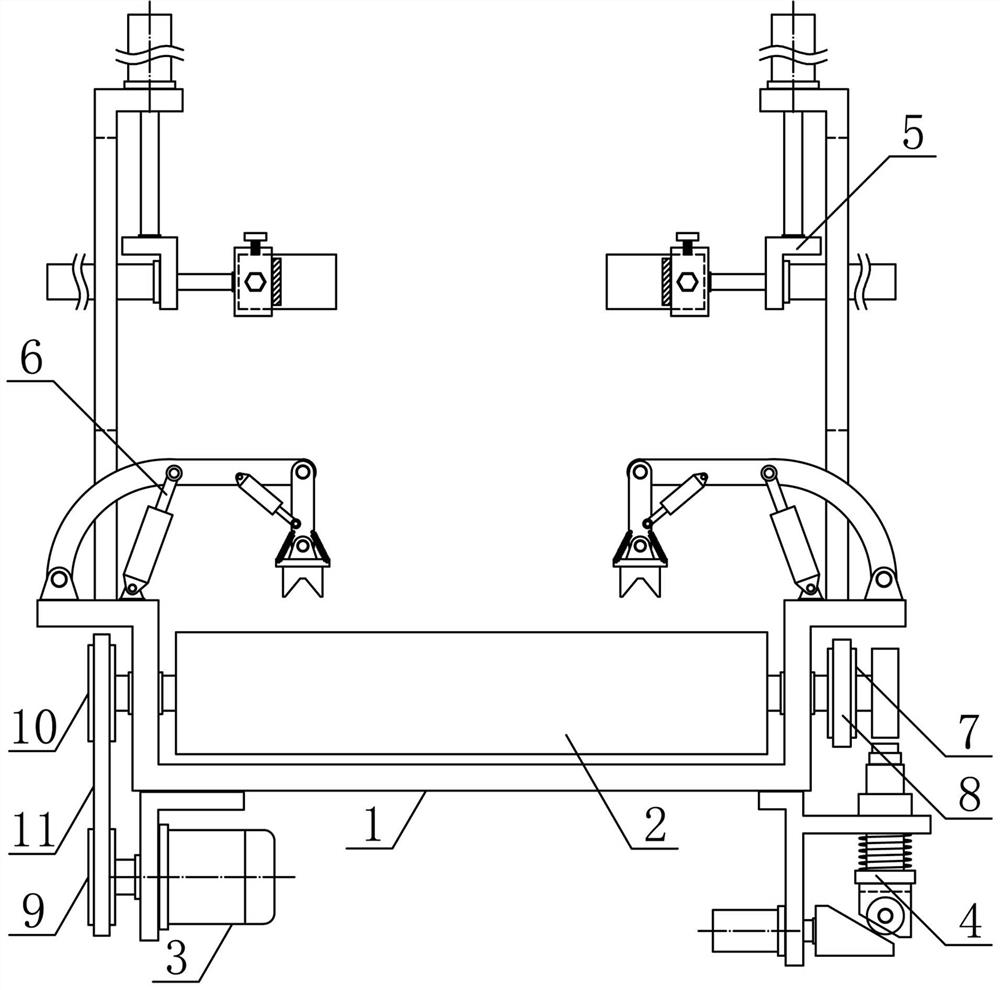

Plate transferring and feeding mechanism

InactiveCN108792566APrevent slippageReasonable structural designConveyorsConveyor partsArchitectural engineeringMechanical equipment

The invention discloses a plate transferring and feeding mechanism and belongs to the field of mechanical equipment for construction material processing. As for the plate transferring and feeding mechanism, a roller guide groove of an arc structure is formed in the outer side of a rotating base; a transferring gear is fixedly arranged in the middle of the lower side of the rotating base in a horizontally coaxial mode; a drive gear at the output end of a rotary electromagnet is in engaged connection with the transferring gear; guide supports are vertically and symmetrically arranged on the twosides of the upper portion of the rotating base in the radial direction of the rotating base; a lifting support is slidably arranged on the guide supports in the vertical direction; lifting cylindersare fixedly arranged at the positions, below the two sides of the lifting support, of the rotating base in a vertically upward mode; a lifting guide plate is slidably arranged on a feeding guide rod in the vertical direction; and feeding bearing rods are horizontally and fixedly arranged at the two ends of one side of the lifting guide plate. The plate transferring and feeding mechanism is reasonable in structural design, plates can be stably supported and fixed and can be horizontally transferred as needed, the degree of automation of plate transferring is increased, and the processing and usage requirements are met.

Owner:晋正正

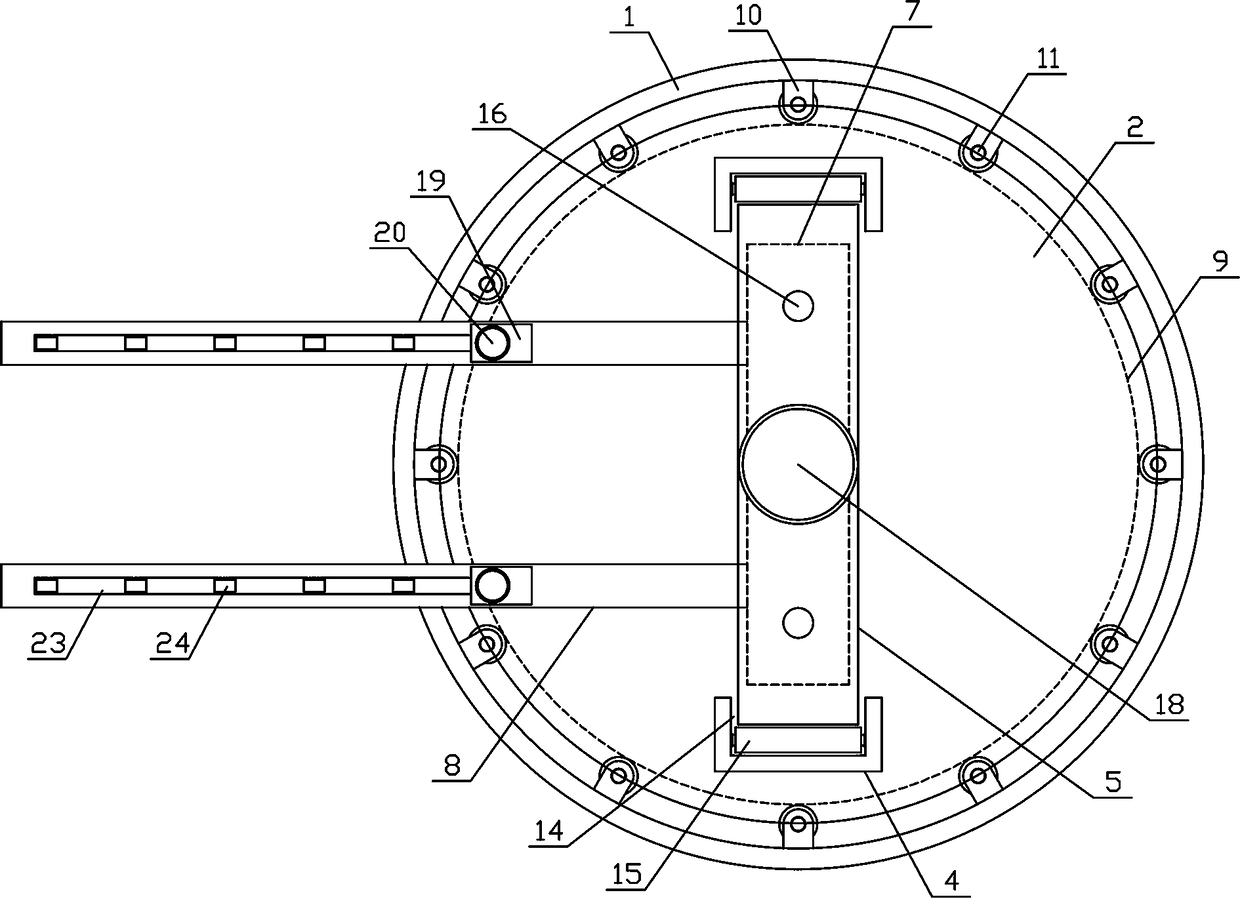

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

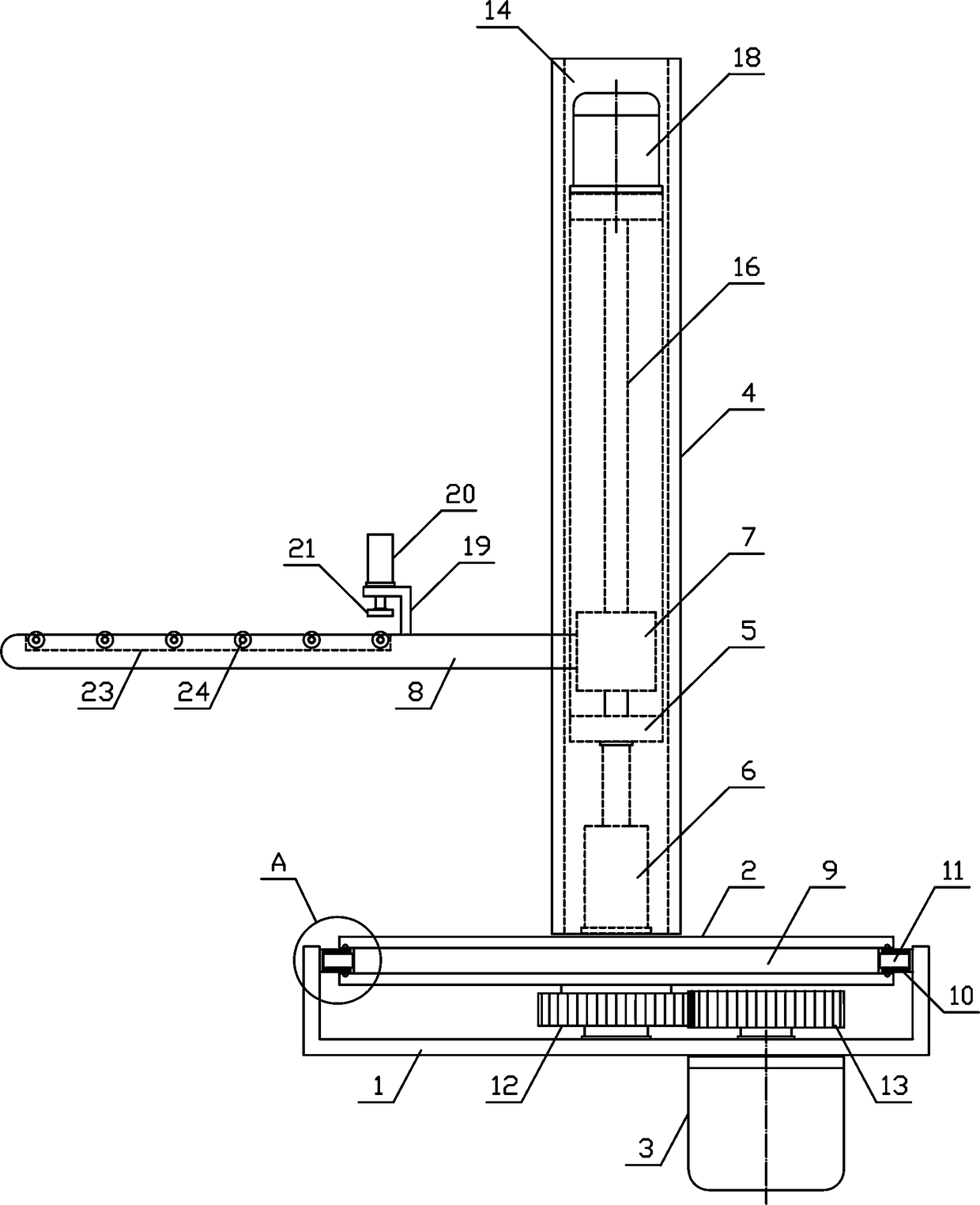

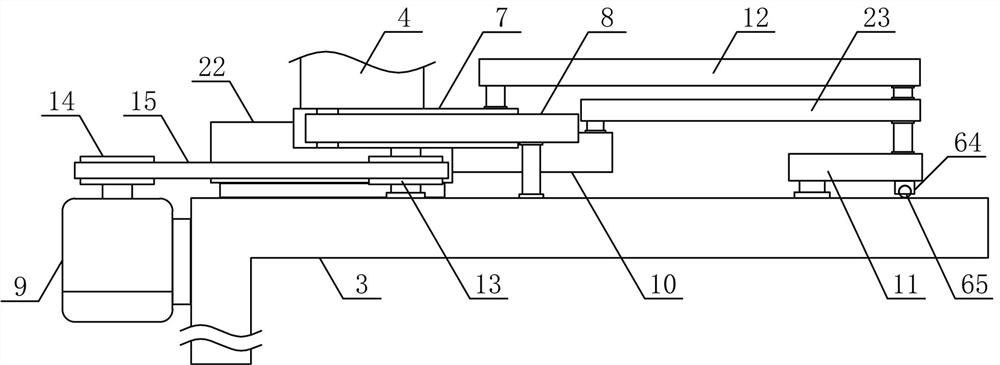

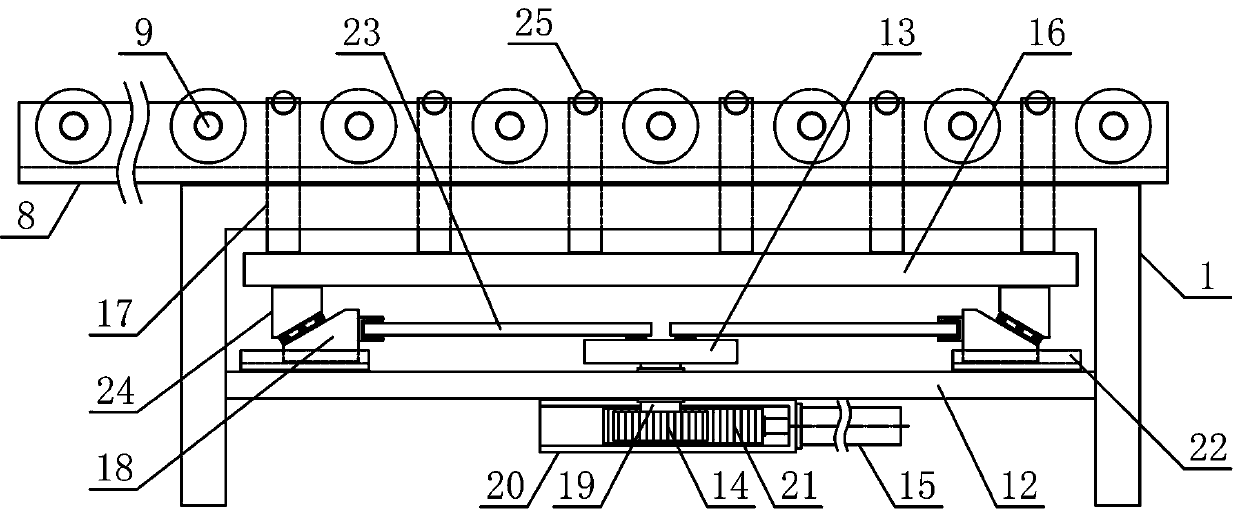

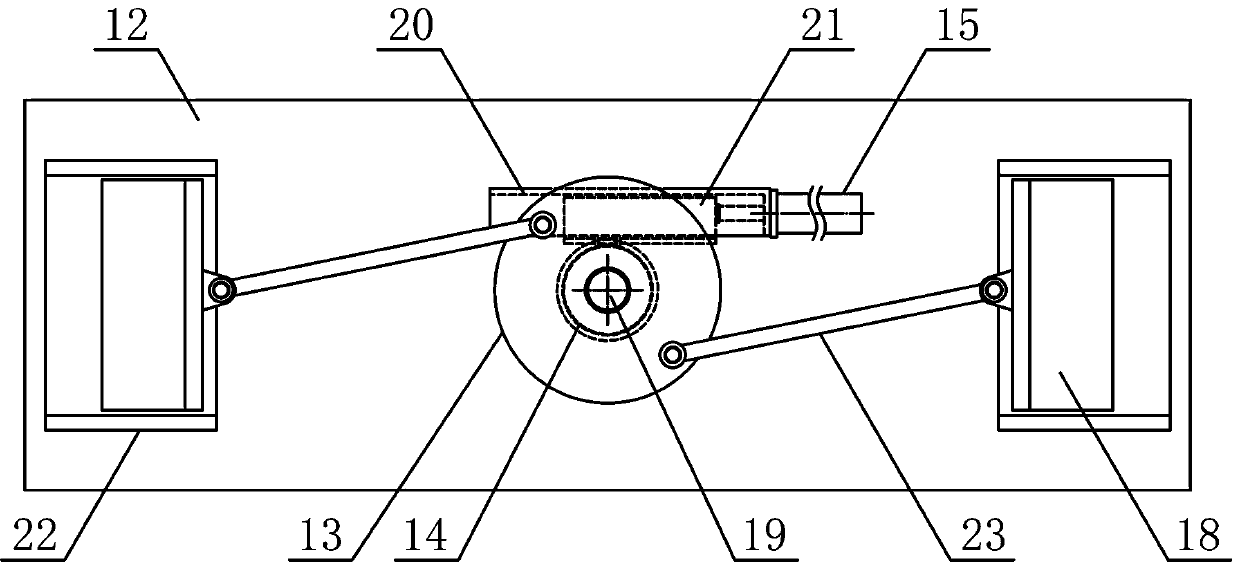

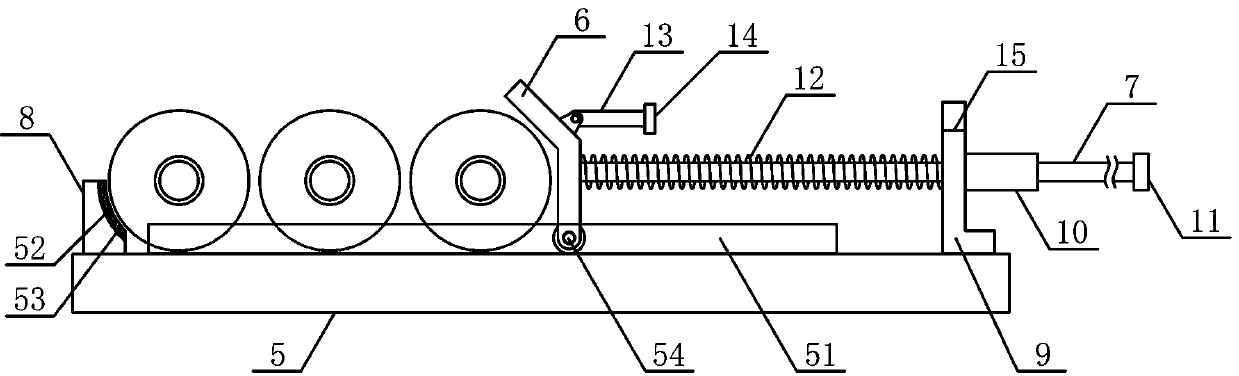

Continuous guiding and feeding device for metal round pipes

ActiveCN111573245AConvenient and smooth translation loadingHigh degree of automationConveyorsConveyor partsCircular discPipe fitting

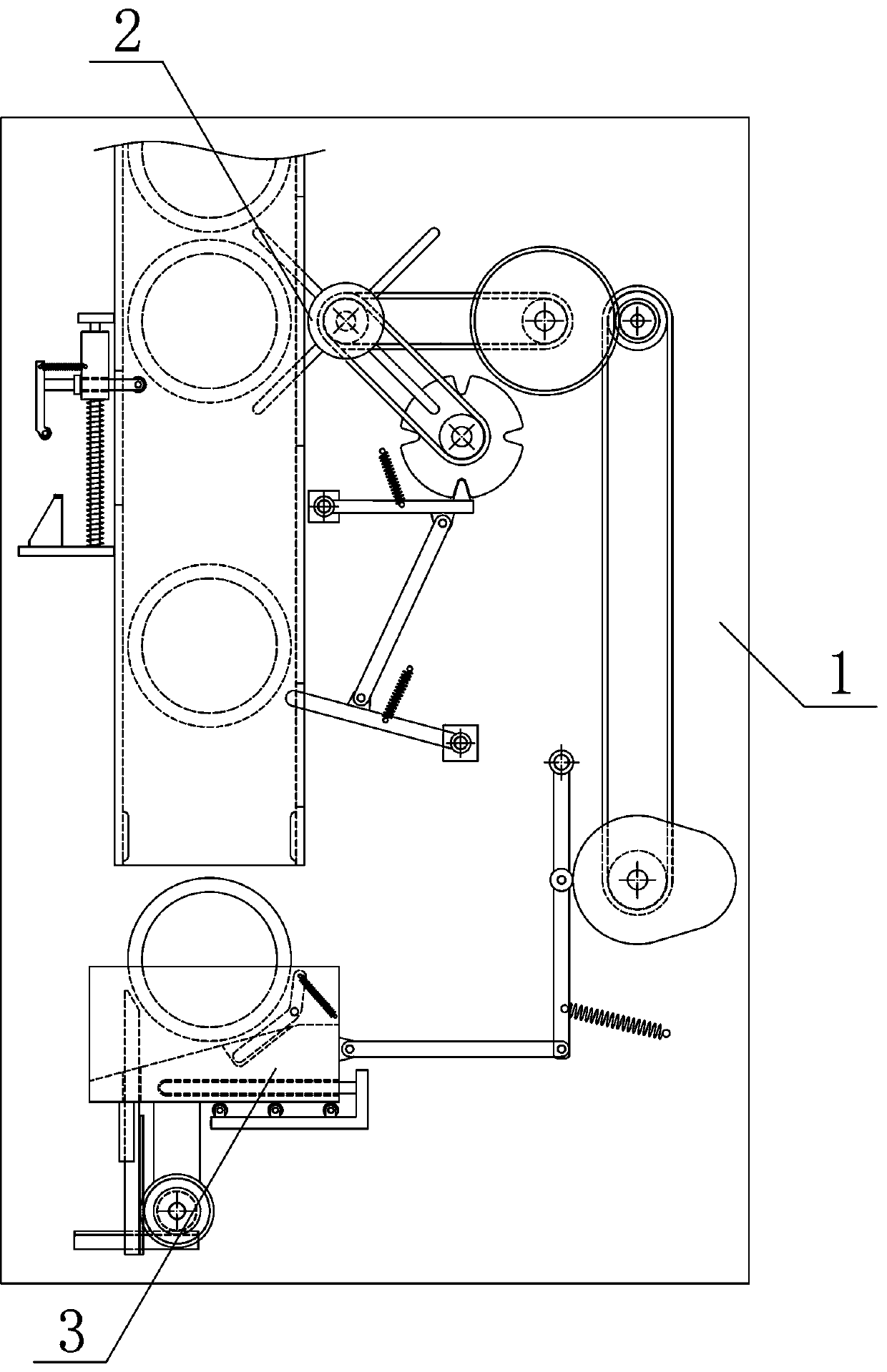

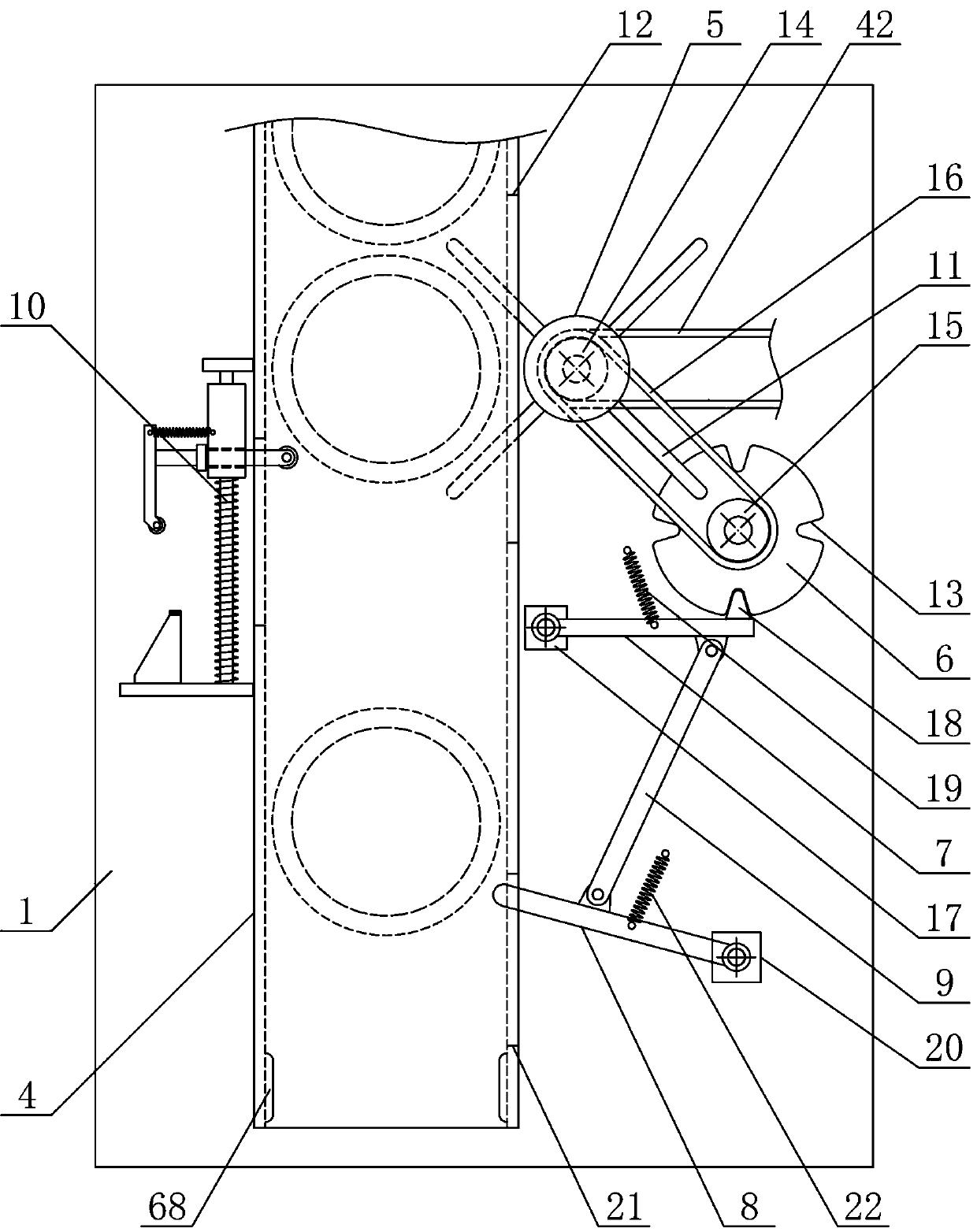

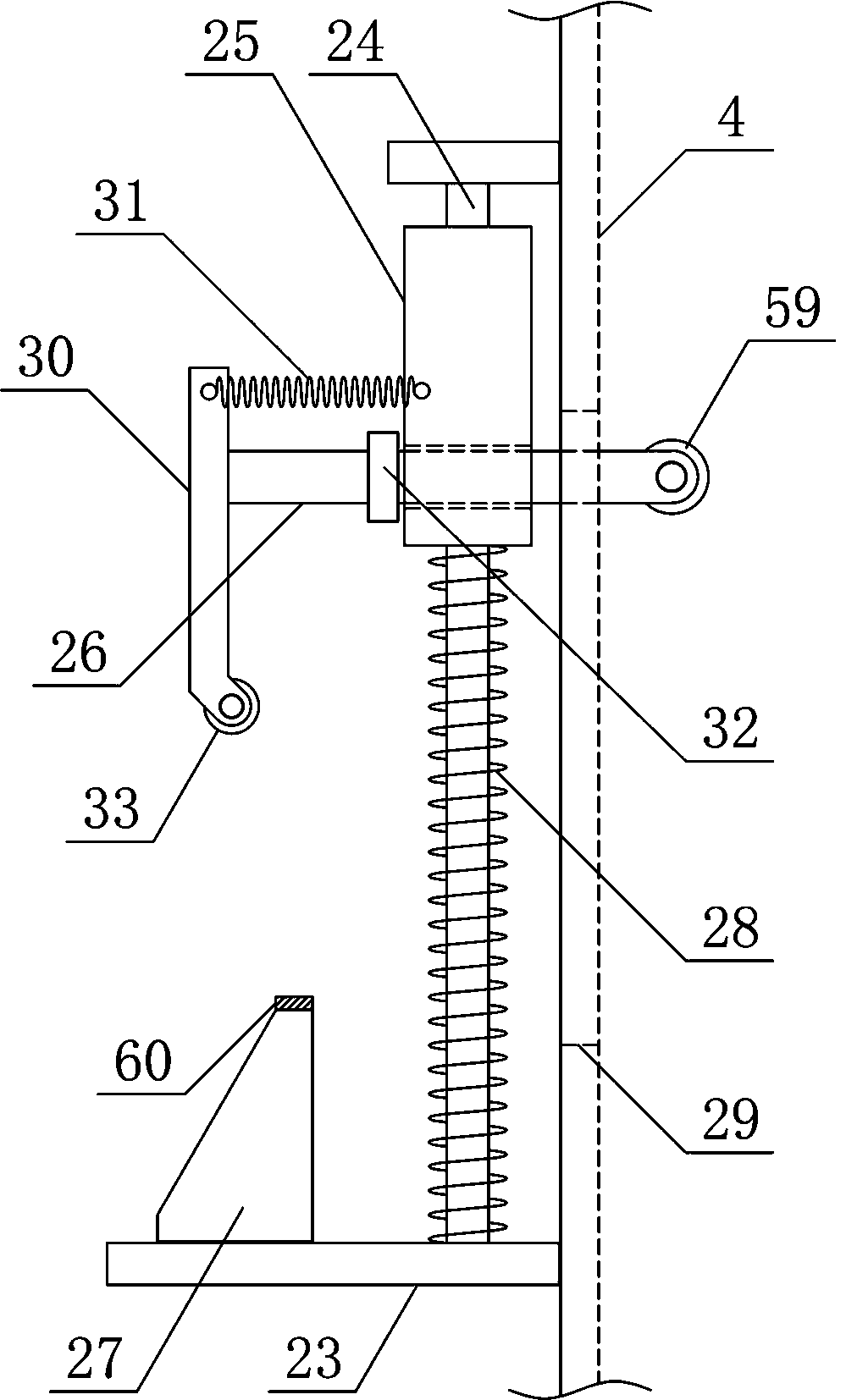

The invention discloses a continuous guiding and feeding device for metal round pipes, and belongs to the field of pipe conveying mechanical equipment. A round pipe discharging mechanism and a round pipe transferring mechanism are sequentially and vertically arranged on a round pipe conveying support from top to bottom, a discharging rotating disc and a rotating positioning disc on the outer sideof the upper portion of a round pipe discharging guide pipe are in transmission connection through a discharging connecting chain, a reciprocating positioning swing rod is arranged on the lower side of the rotating positioning disc, a synchronous traction connecting rod is arranged between the reciprocating positioning swing rod and a discharging swing bearing rod, a bearing pipe discharging mechanism and the discharging rotating disc are arranged on the two sides of the round pipe discharging guide pipe respectively, a bearing plate translation swing rod is arranged on the round pipe conveying support on one side of a push rod rotating cam, and the push plate translation connecting rod is arranged between the bearing plate translation swing rod and a round pipe transferring bearing plate.According to the continuous guiding and feeding device for the metal round pipes, the structural design is reasonable, the metal round pipes can be stably, efficiently, continuously and smoothly guided and fed one by one, the conveying automation degree of the metal round pipes is improved, and the machining and using requirements are met.

Owner:新昌县哈坎机械配件厂

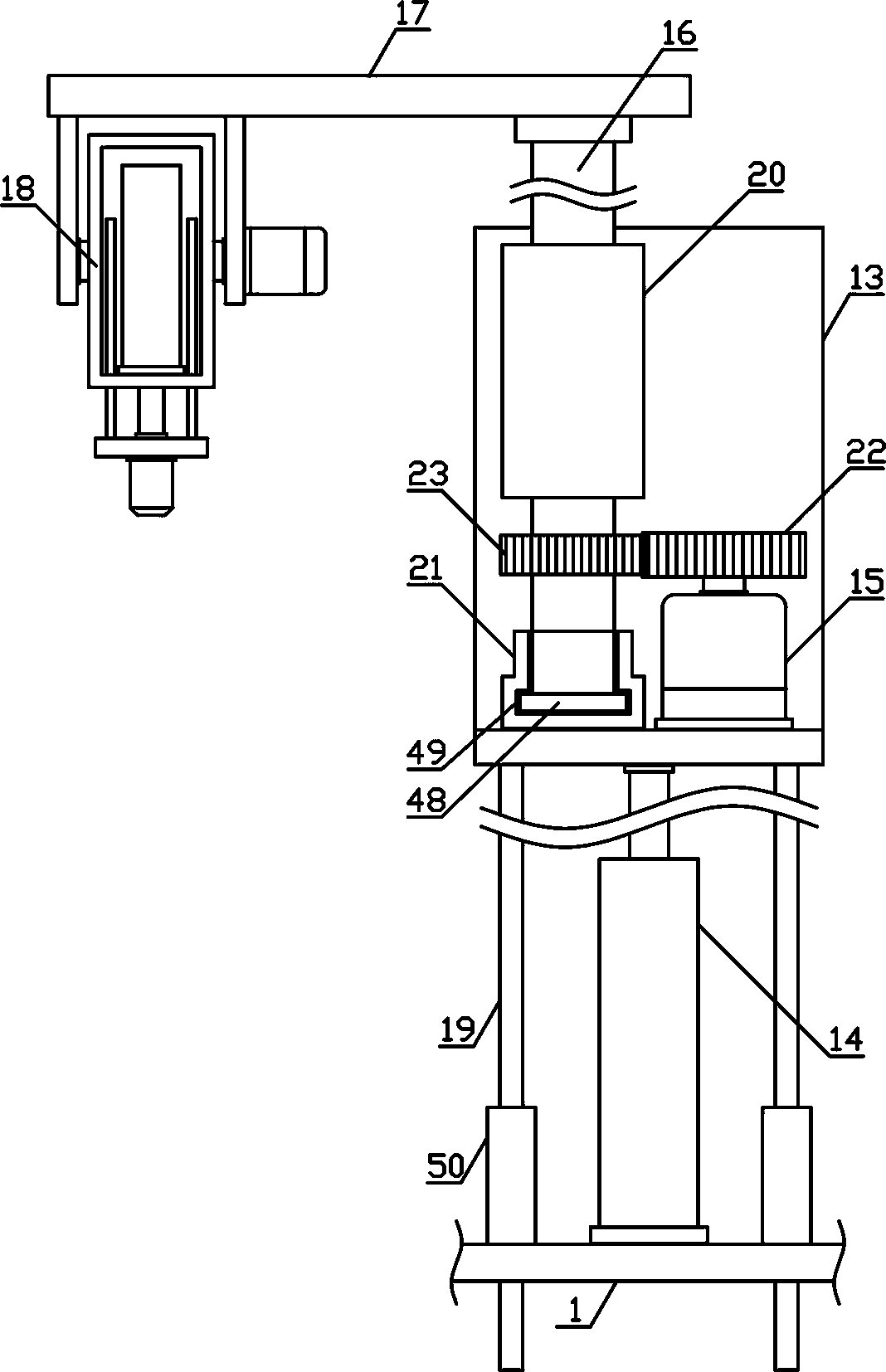

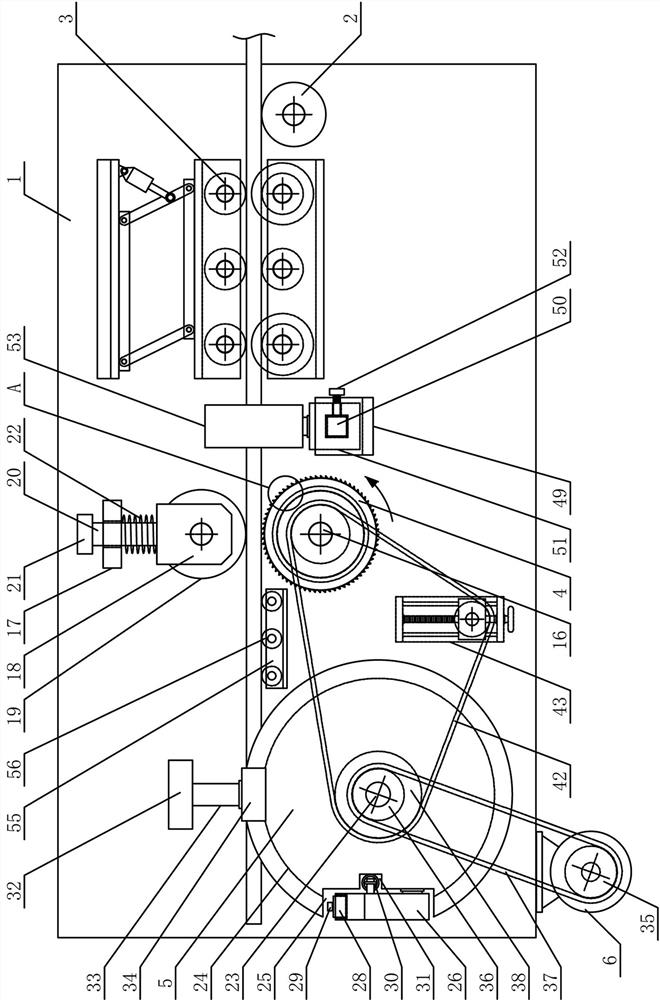

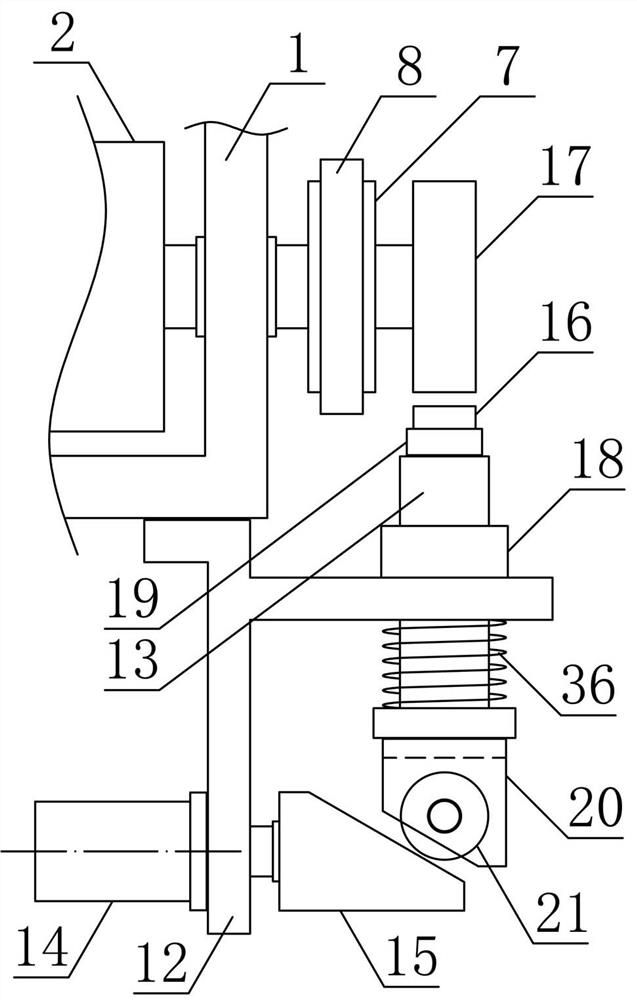

Grooving device for camber surface of inner side of shaft sleeve workpiece

ActiveCN110560706AEfficient and convenient clamping and fixingClamping and fixing is stable and accurateAutomatic control devicesFeeding apparatusMachiningAutomation

The invention discloses a grooving device for a camber surface of the inner side of a shaft sleeve workpiece and belongs to the field of machinery equipment for machining the workpiece. According to the grooving device, a workpiece clamping mechanism is arranged at a machining bracket positioned at one side of a translational grooving mechanism; a translational guide plate is horizontally and slidably arranged on a guide support; a push plate bevel is arranged at the lower side of the end part of a translational pressing plate; the translational pressing plate is slidably arranged at a tool bit bracket; a grooving rotary plate is arranged at the tool bit bracket, positioned along the underside of the end of the push plate bevel, of the translational pressing plate; a machining rotary platerotates along bearing plate rotating wheels; the machining rotary plate positioned at the outer side of a clamping main gear is provided with a plurality of clamping auxiliary gears; a rotary gear ofa driving bracket is engaged with a rotary rack of the machining rotary plate; and a converting bracket is horizontally arranged at one side of a lifting bracket. The grooving device is reasonable instructural design, can be used for efficiently and conveniently clamping and fixing the shaft sleeve workpiece and realizing stable and accurate rotation, thereby realizing automatic grooving machining of the camber surface of the inner side of the shaft sleeve workpiece, achieving a high machining automation degree and meeting the use demands of machining of the workpiece.

Owner:常熟市万顺轴承有限公司

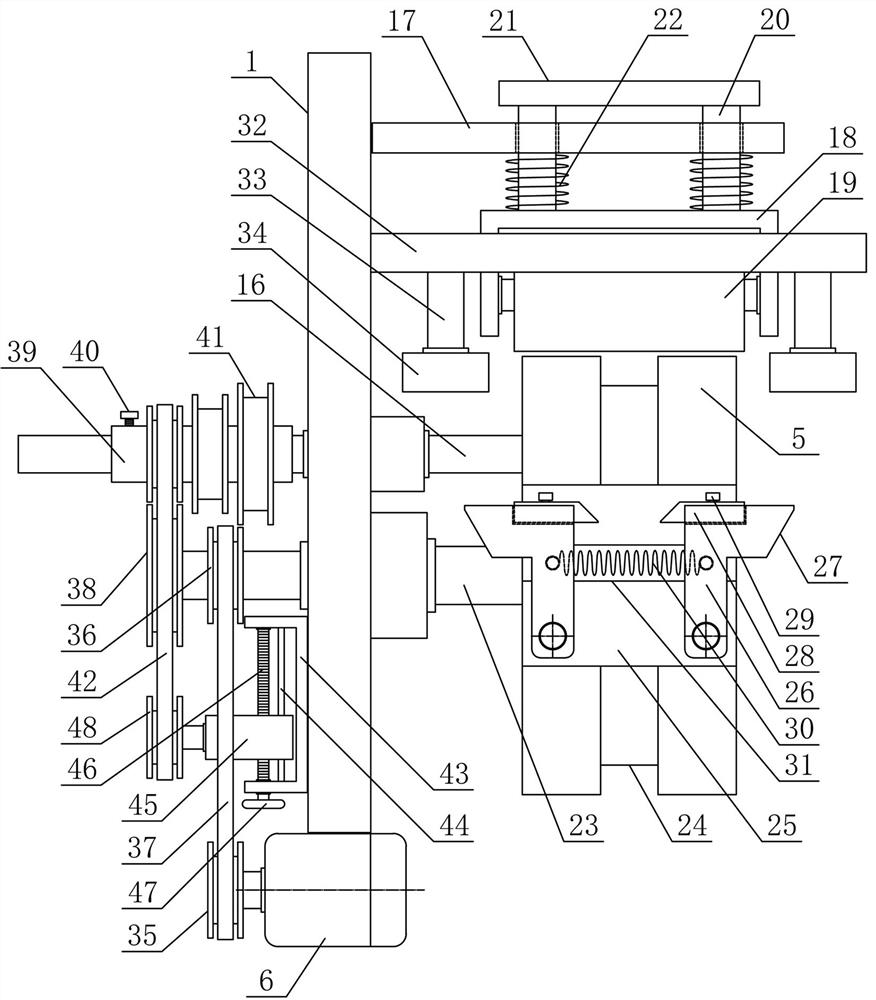

Prop plate clamping device

ActiveCN110405657AEfficient and accurate clamping and fixingClamping and fixing is convenient and stableWork holdersPositioning apparatusRapid processingEngineering

The invention discloses a prop plate clamping device, and belongs to the field of display prop machining mechanical equipment. According to the device, a plate adjusting mechanism and a plate placingmechanism are sequentially and horizontally arranged on a plate machining support from top to bottom, a lifting connecting plate is horizontally arranged on the lower side of an adjusting support, a rotating support is horizontally arranged on the lower side of the lifting connecting plate, a plate clamping mechanism is horizontally arranged on the lower side of the rotating support, translation bottom plates are horizontally arranged on the two sides of the upper portion of the plate machining support correspondingly, a translation support is fixedly arranged in the middle of the upper side of each translation bottom plate, a middle bearing plate is horizontally and fixedly arranged on the upper side of a translation guide plate, side bearing plates are horizontally and symmetrically arranged on the two sides of the middle bearing plate, and a plate fastening mechanism is vertically and fixedly arranged on the upper side of each side bearing plate. The device has the advantages that the structural design is reasonable, station adjusting of prop plates can be conveniently and stably realized according to the machining requirements, the prop plates can be clamped and fixed efficiently and accurately, so that rapid machining of the prop plates is realized, and the requirements of machining and use are met.

Owner:浙江高人道具有限公司

Power cable shearing device

PendingCN113458288AHigh degree of processing automationReasonable structural designFilament handlingStructural engineeringMaterials processing

The invention discloses a power cable shearing device, and belongs to the field of power material processing equipment. According to the invention, a cable straightening mechanism is horizontally arranged on a cable conveying support between a feeding guide roller and a cable pulling roller; the cable pulling roller is horizontally, coaxially and fixedly arranged at the end of a cable pulling rotating shaft; a cable pressing roller is horizontally and rotationally connected to the portion, on the upper side of the cable pulling roller, of a pressing conveying support; a cable shearing rotating disc is horizontally, coaxially and fixedly arranged at the end of the cable shearing rotating shaft; a cable guiding and conveying groove of an annular structure is formed in the middle of the outer side of the cable shearing rotating disc; a cable shearing chamber is arranged on the outer side of the cable shearing rotating disc; and cable shearing pressing plates are symmetrically arranged on the two sides of the cable shearing chamber. The power cable shearing device disclosed by the invention is reasonable in structural design; power cables can be cut and processed smoothly and orderly in the conveying process efficiently and stably; furthermore, the cutting length of power cable sections can be adjusted conveniently and accurately; the automation degree of power cable processing is improved; and the requirements of production and use are met.

Owner:嘉兴市创辉电气工程有限公司

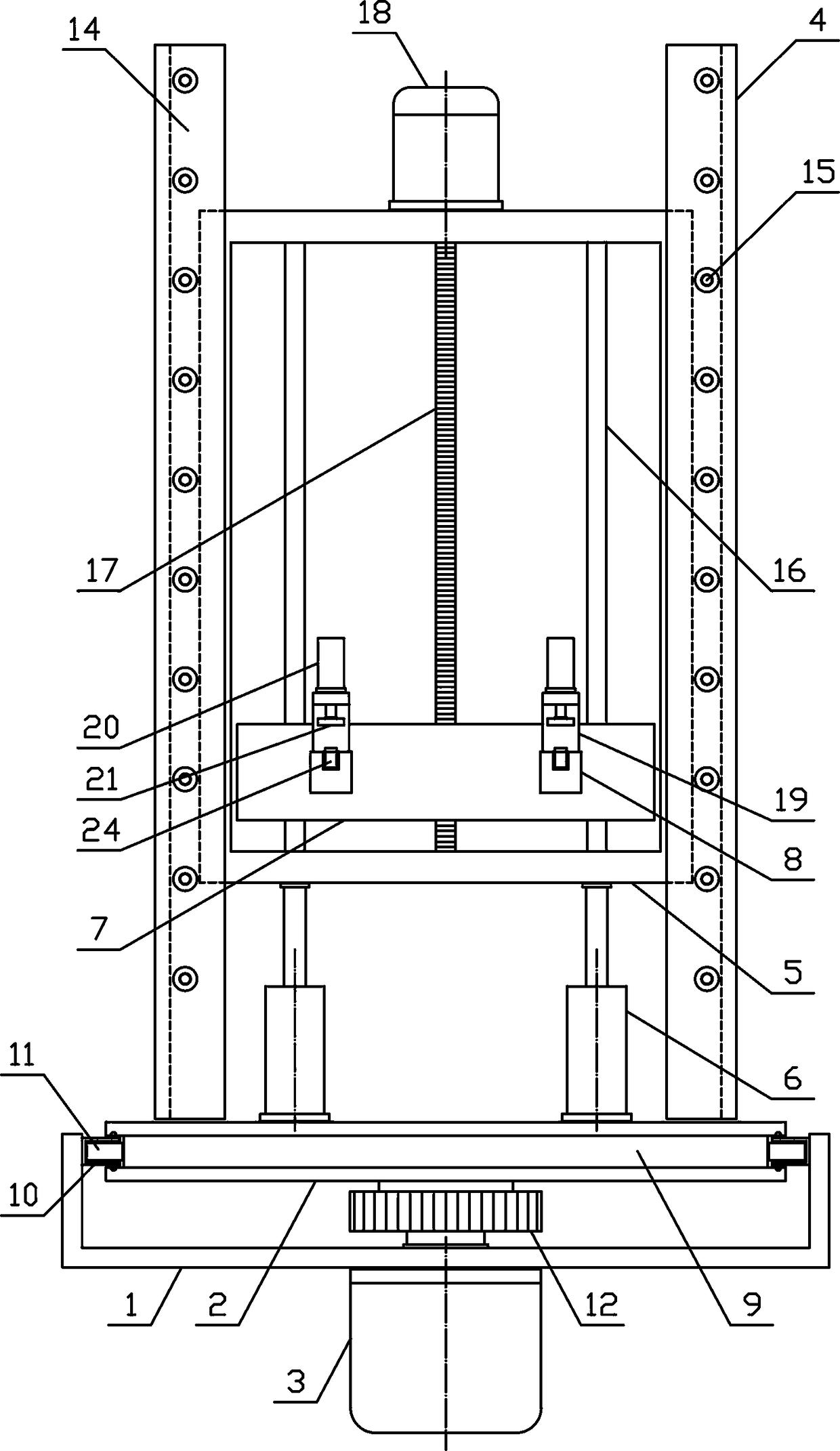

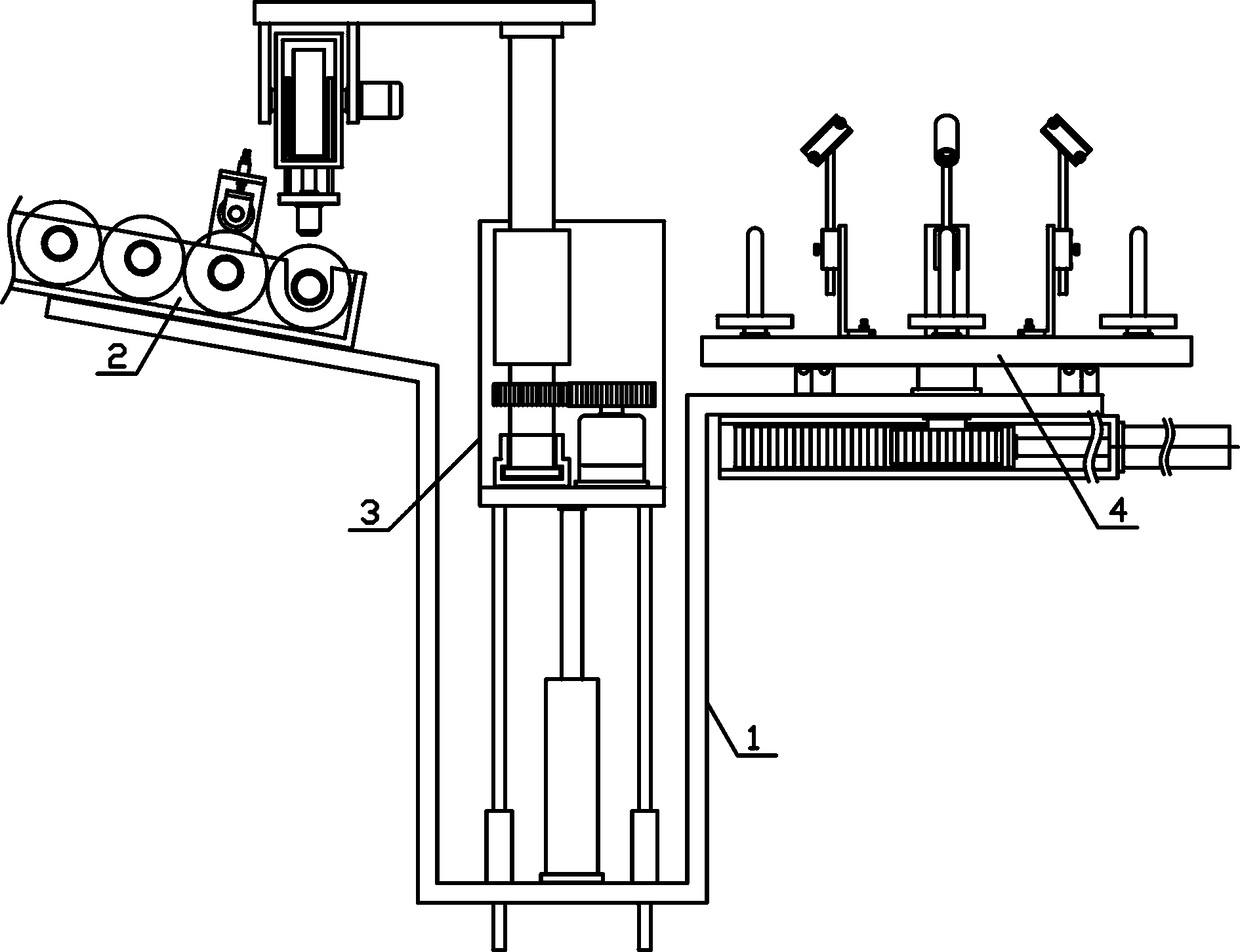

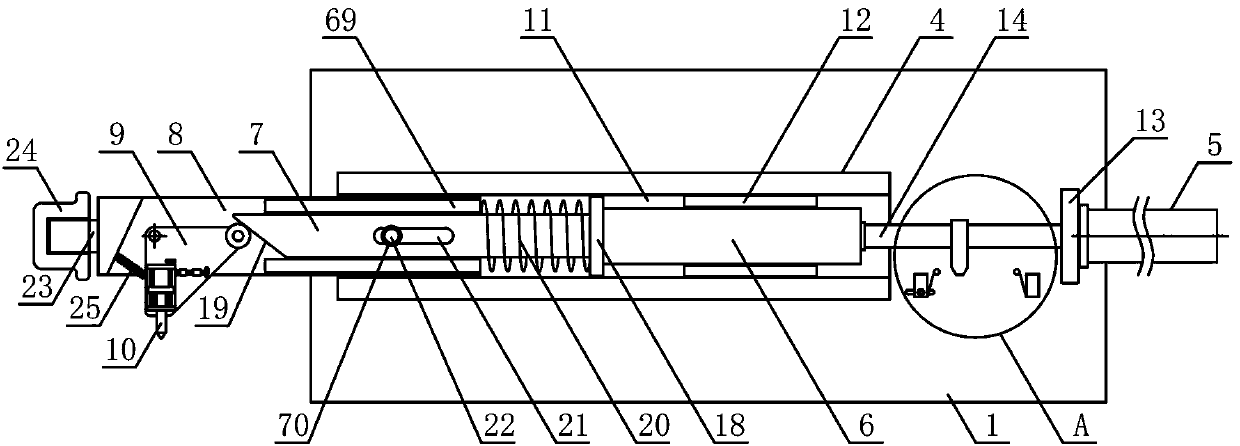

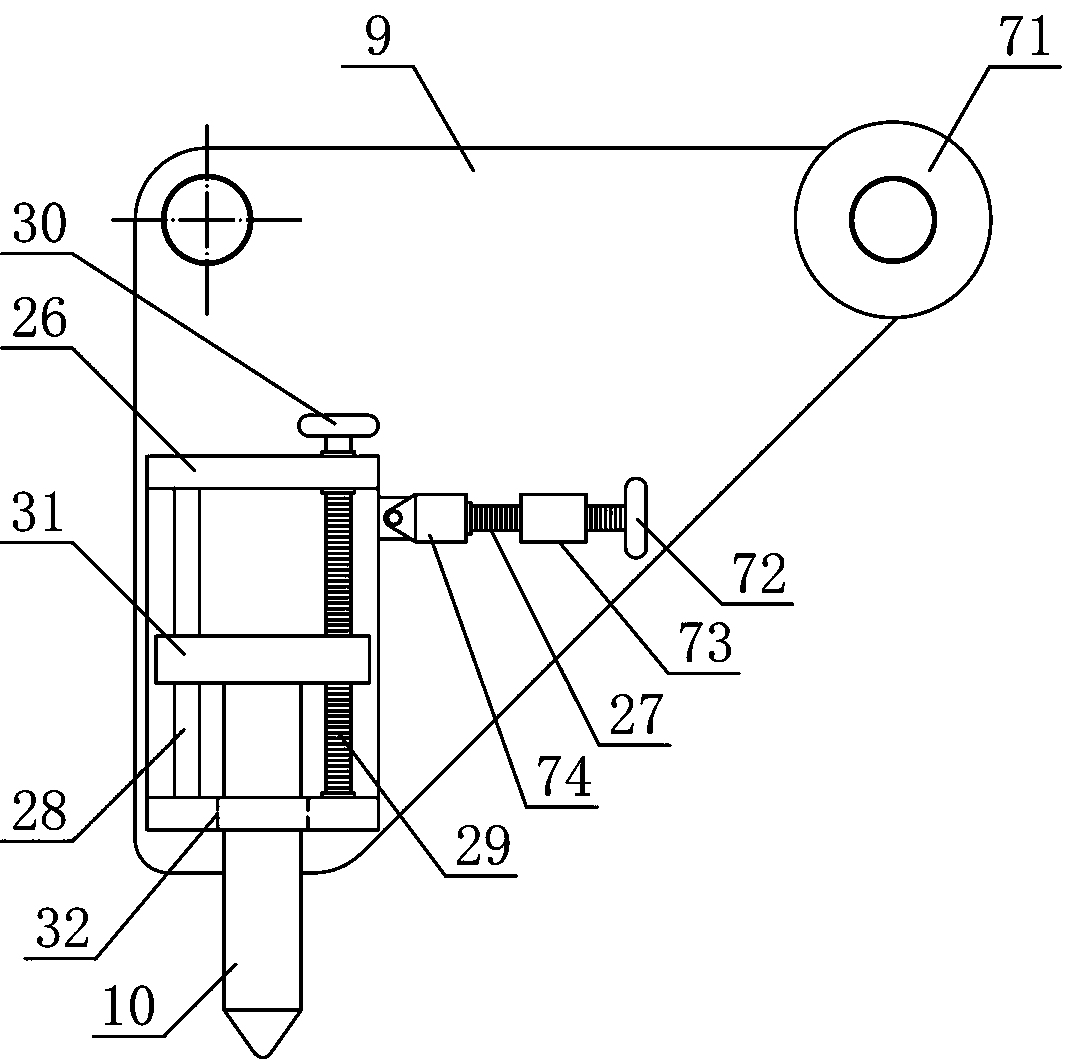

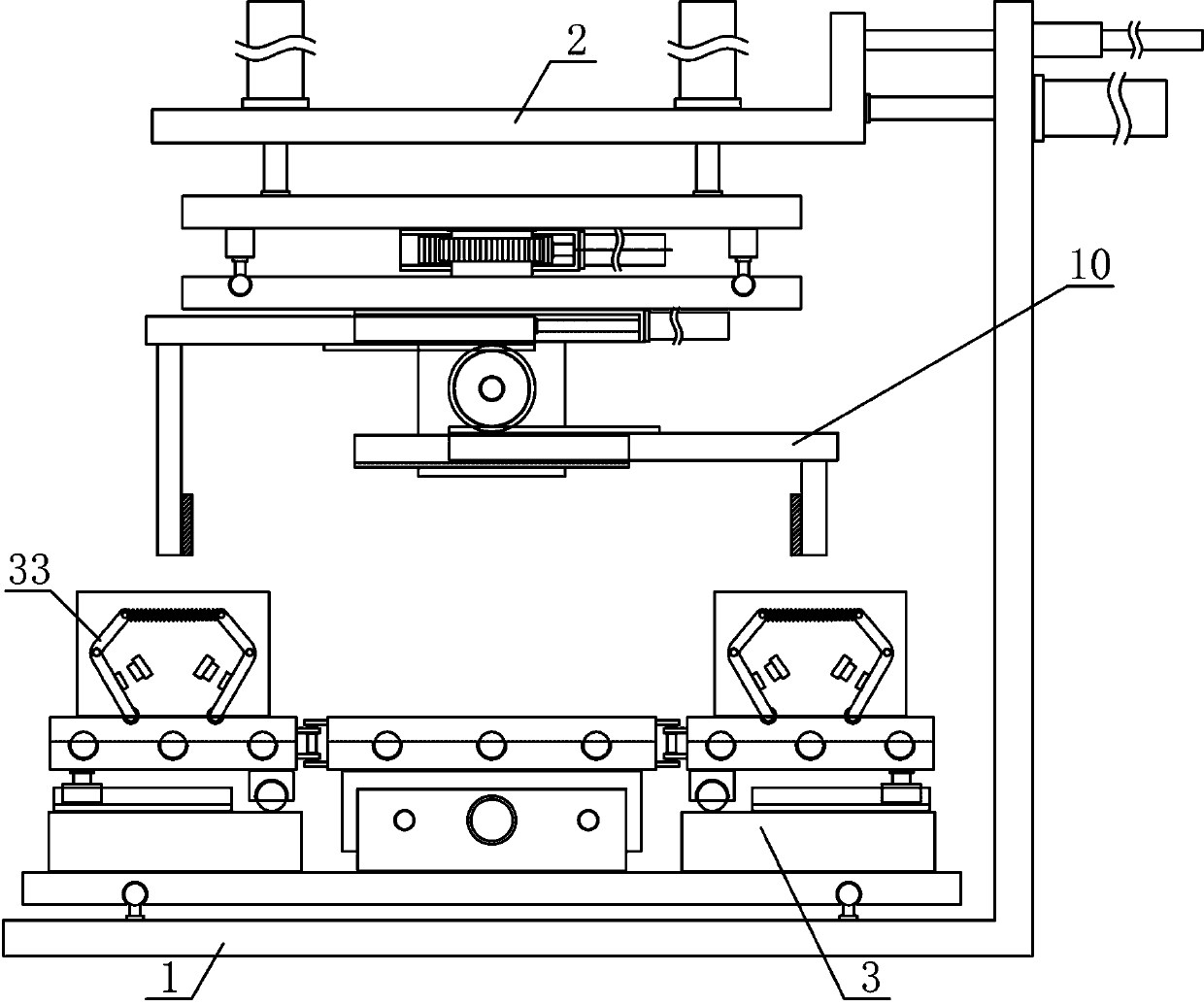

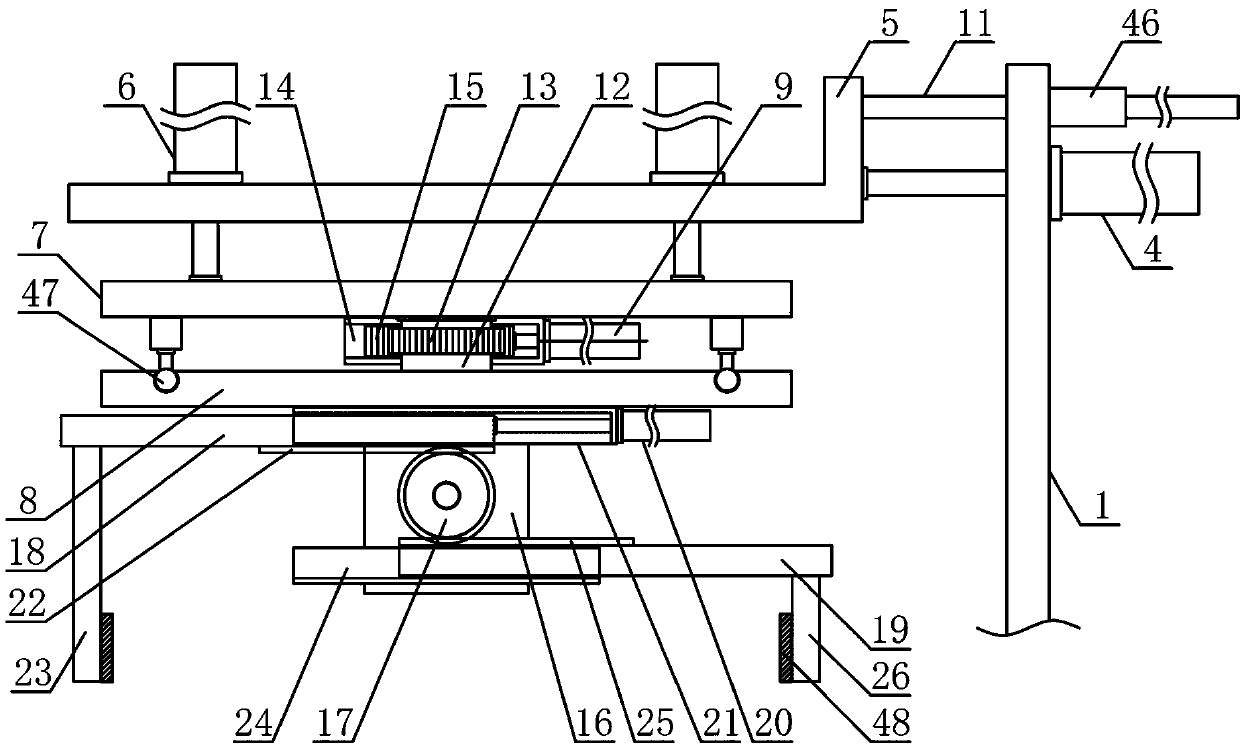

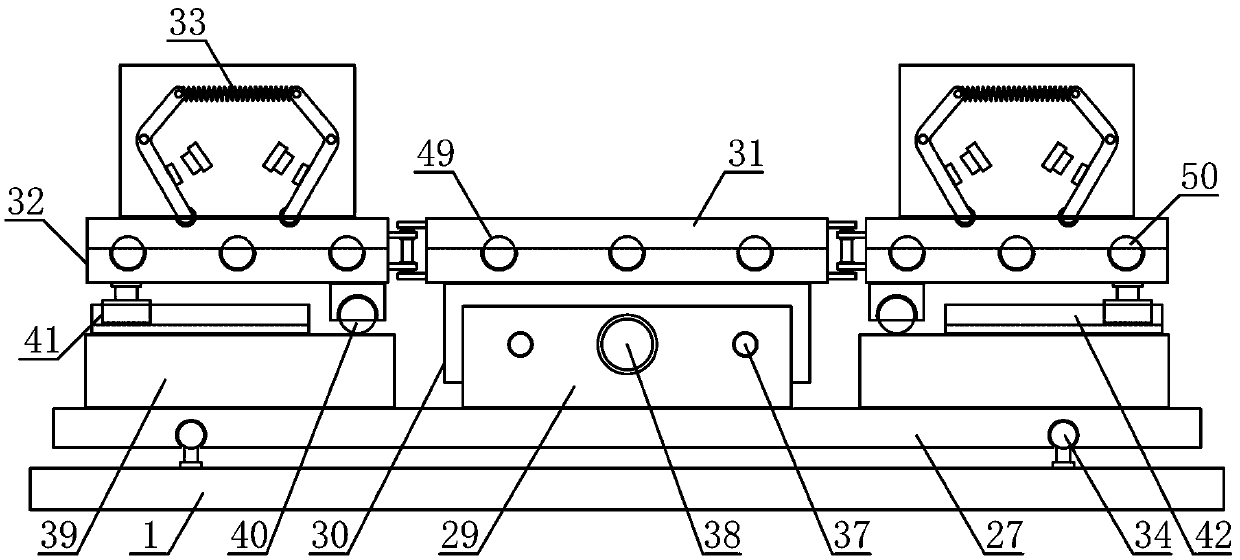

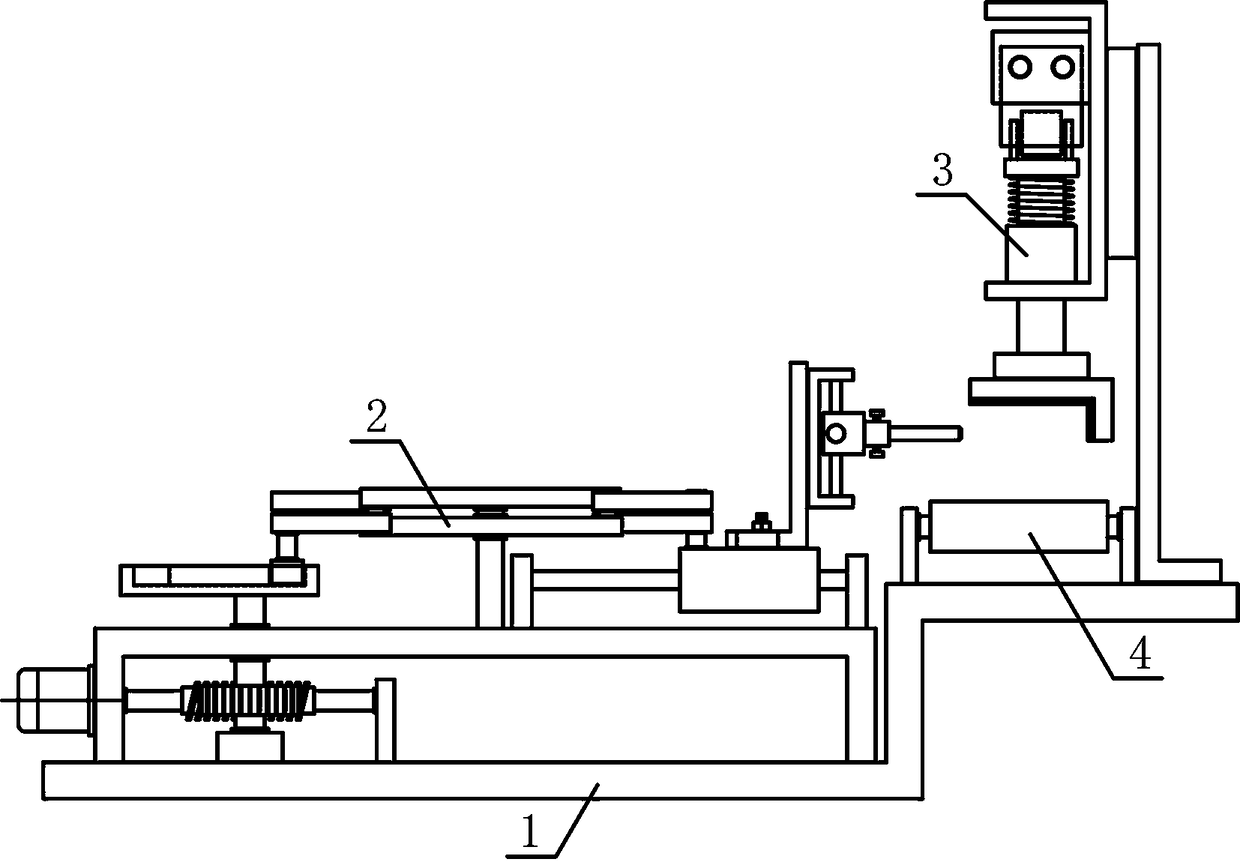

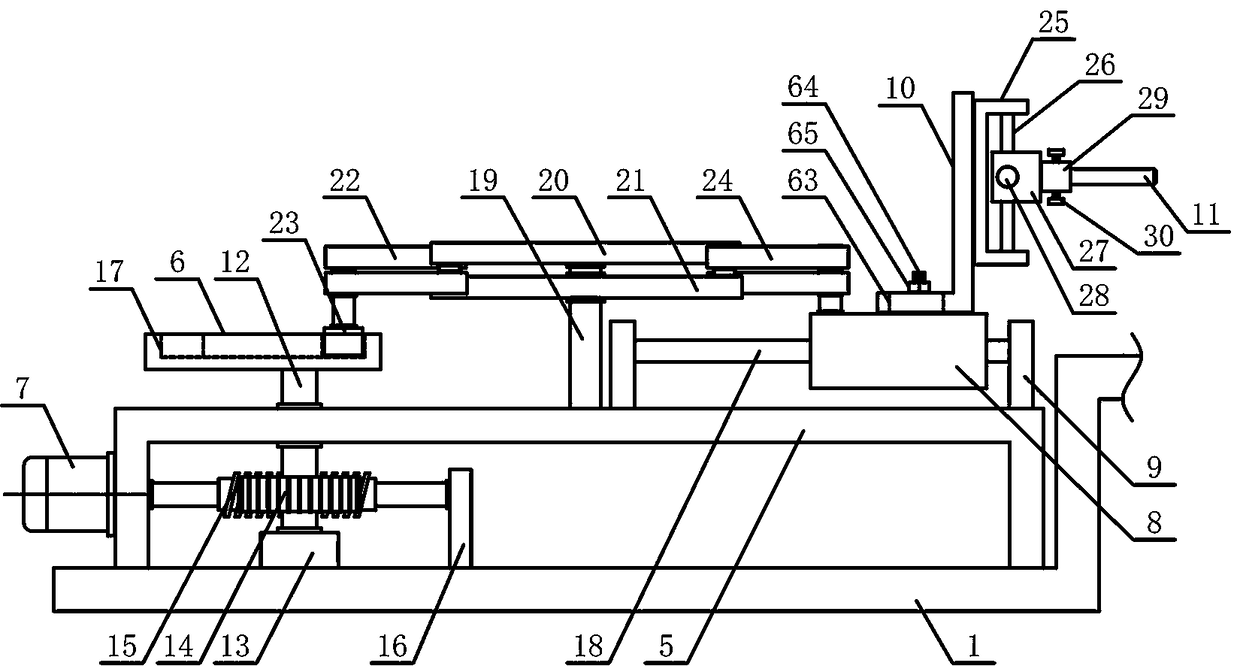

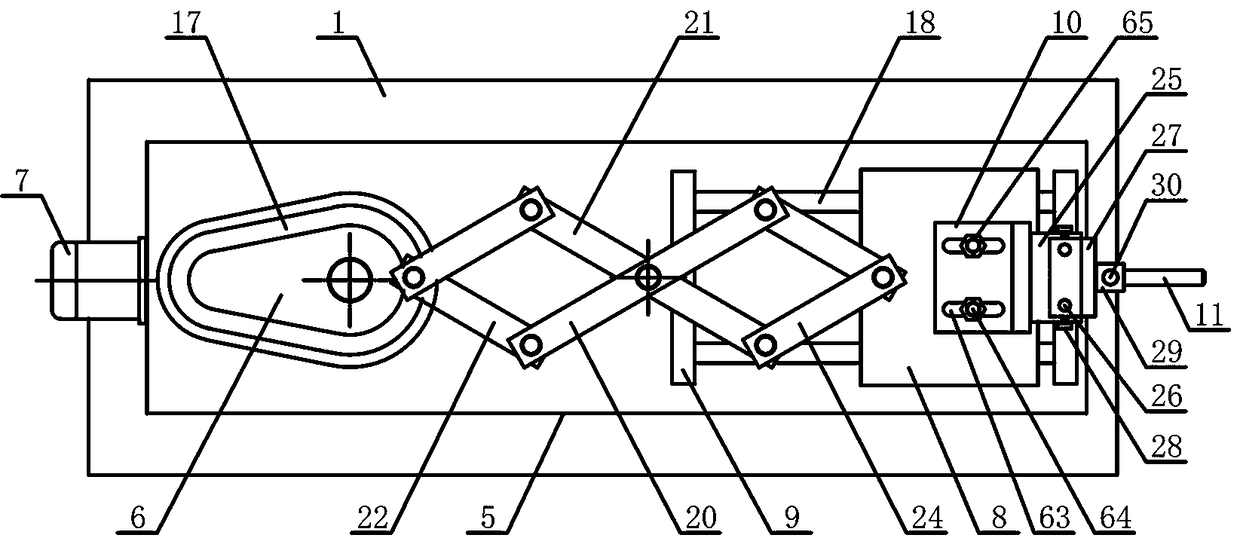

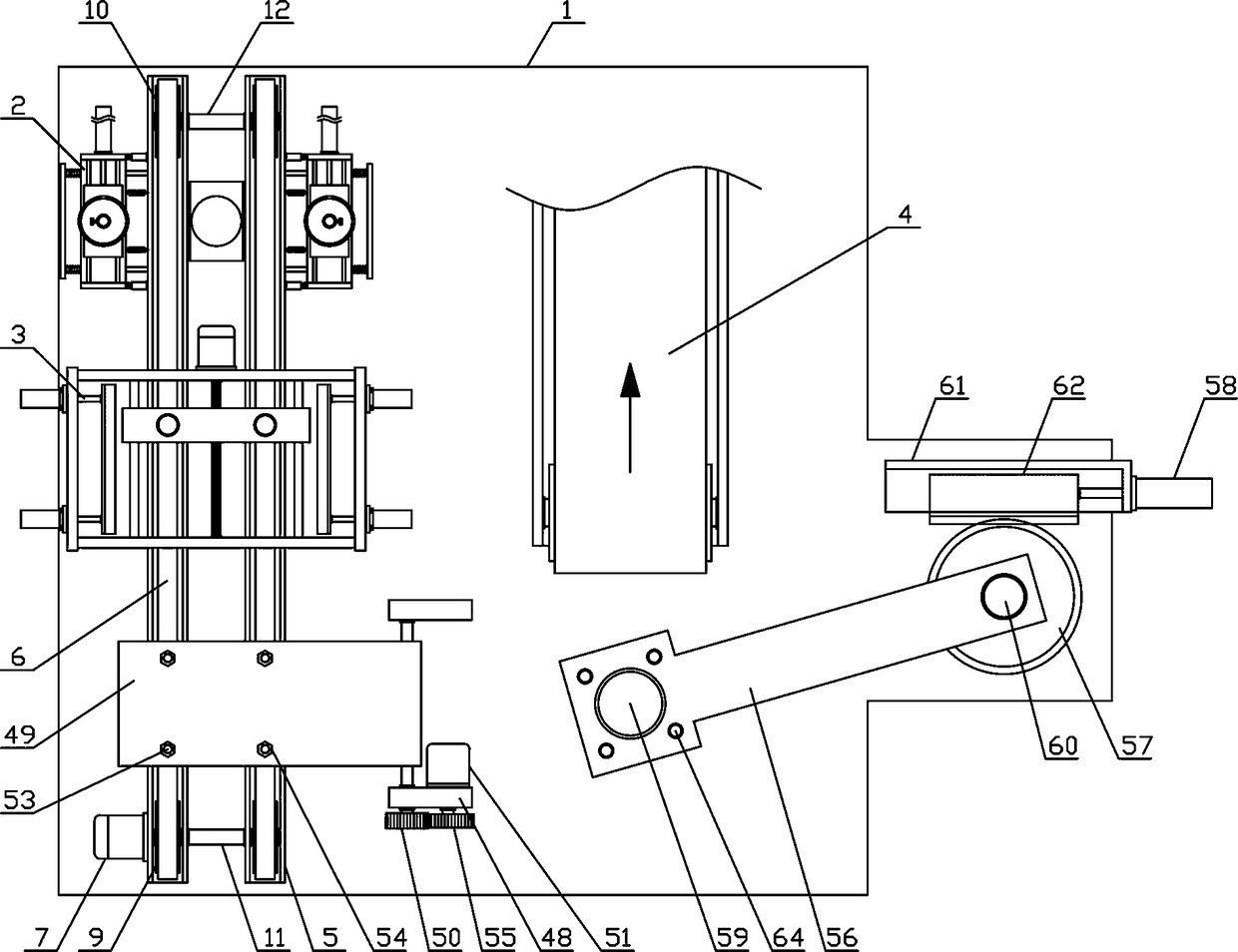

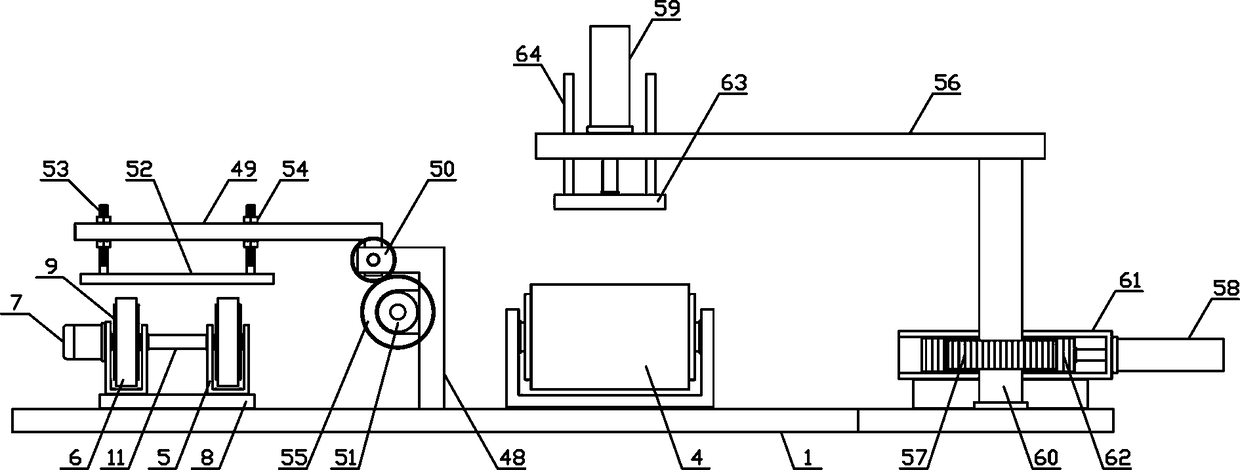

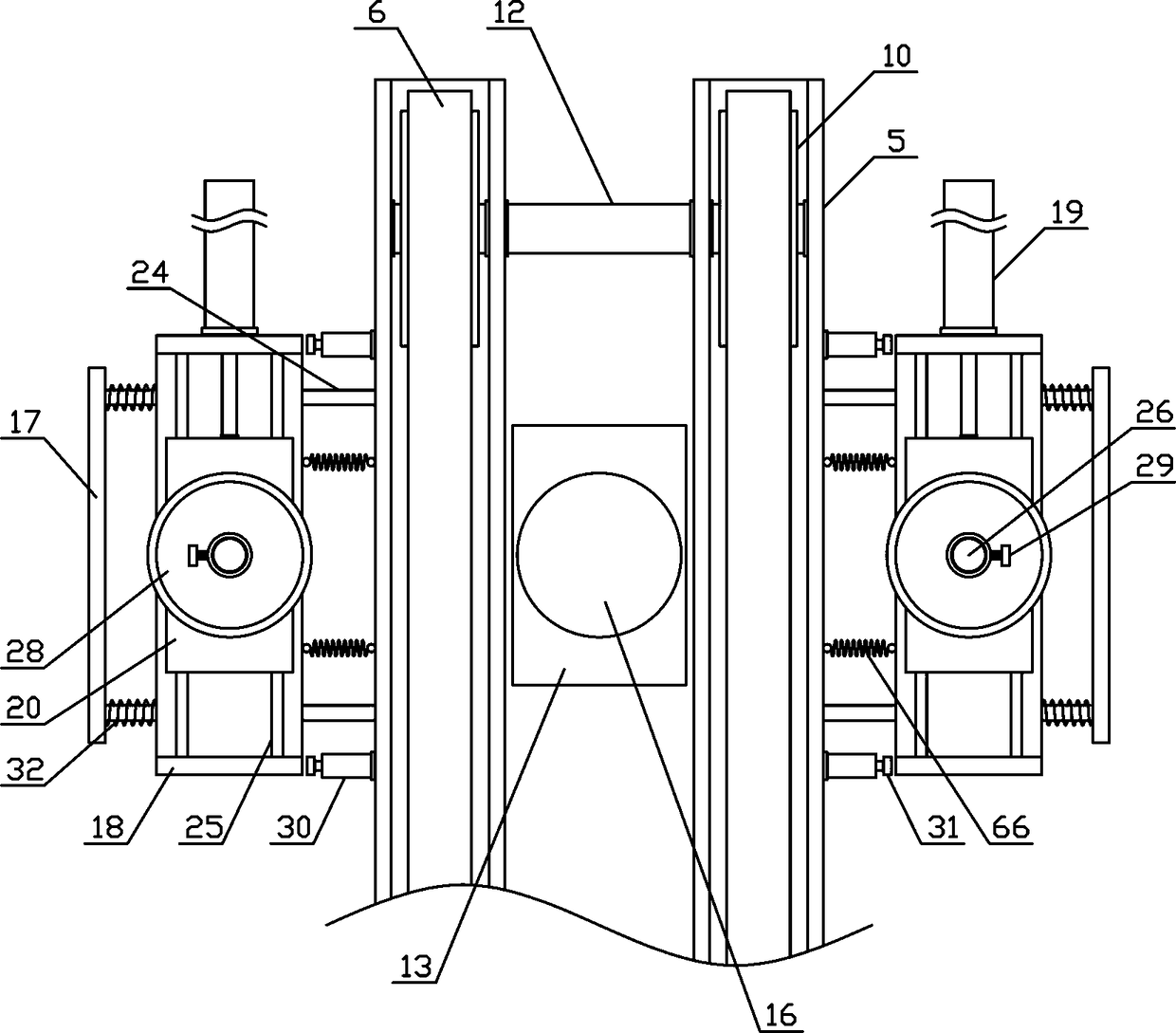

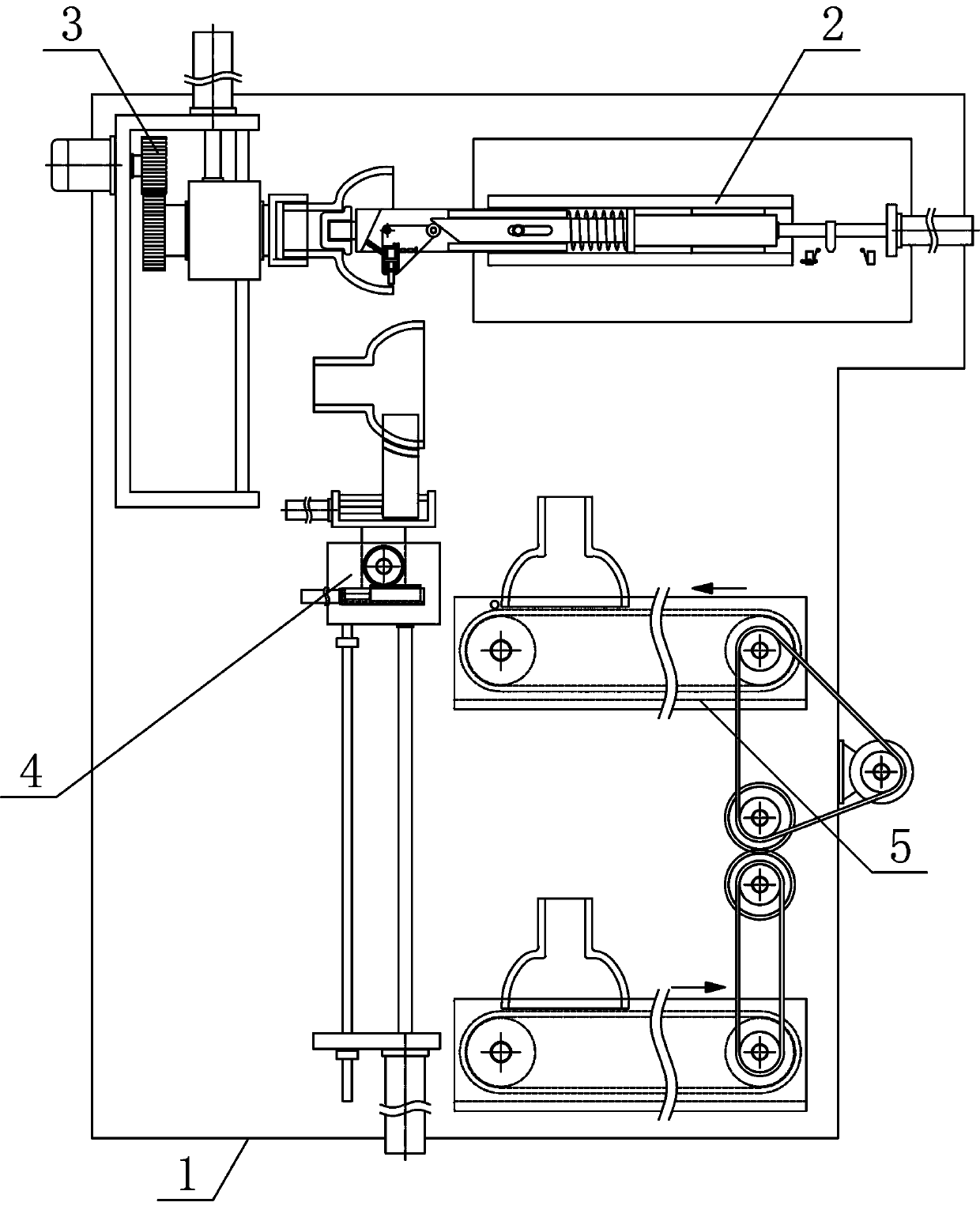

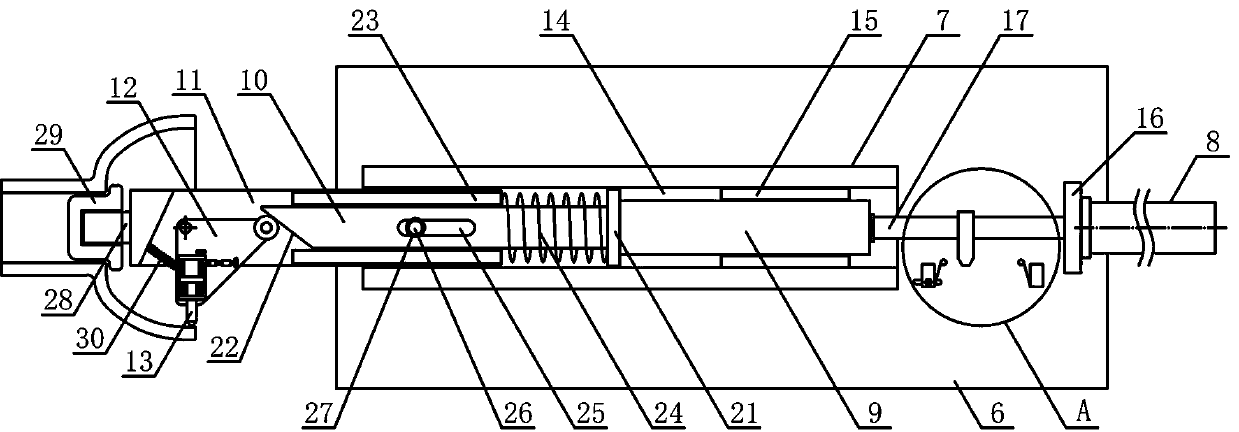

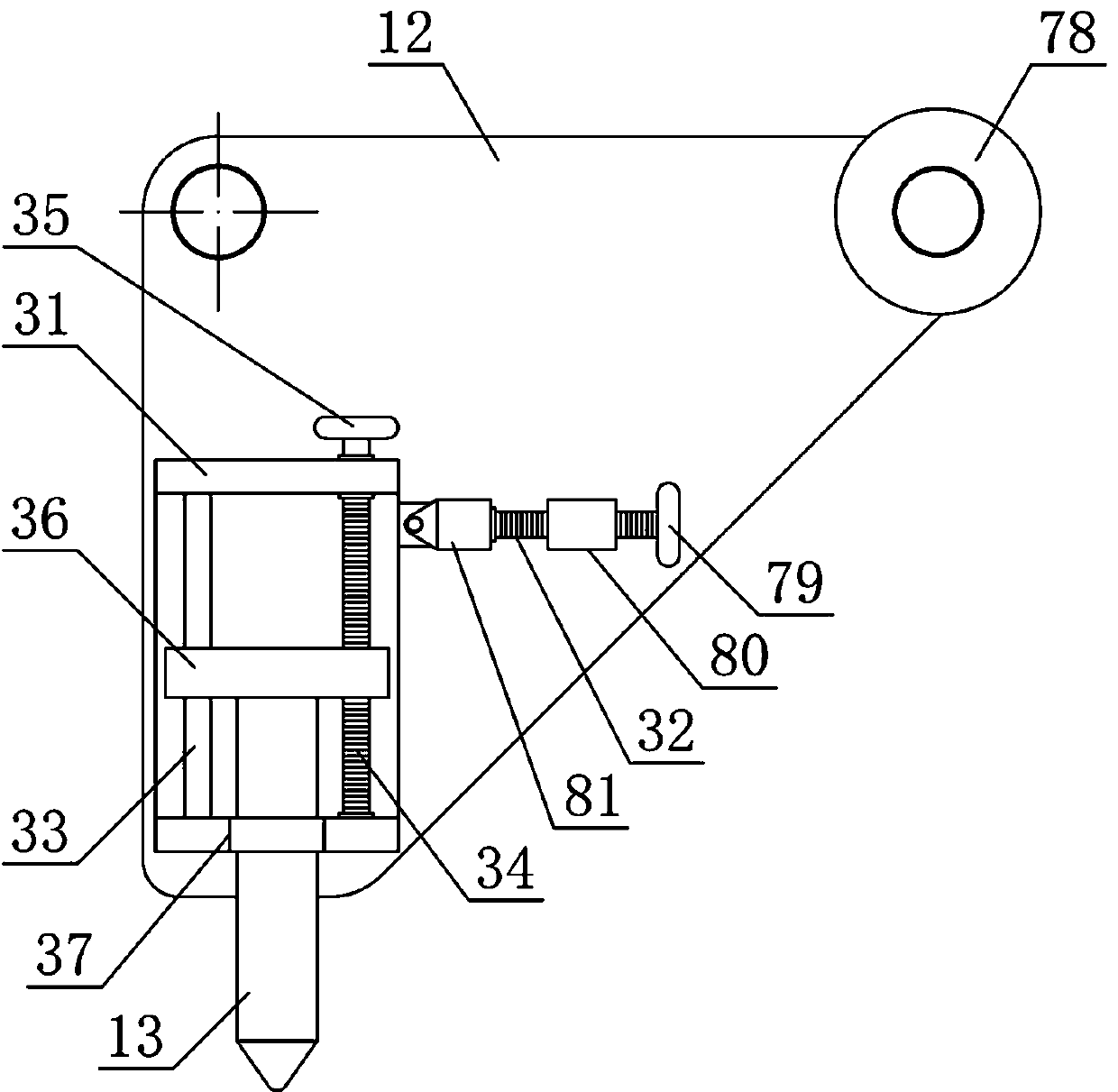

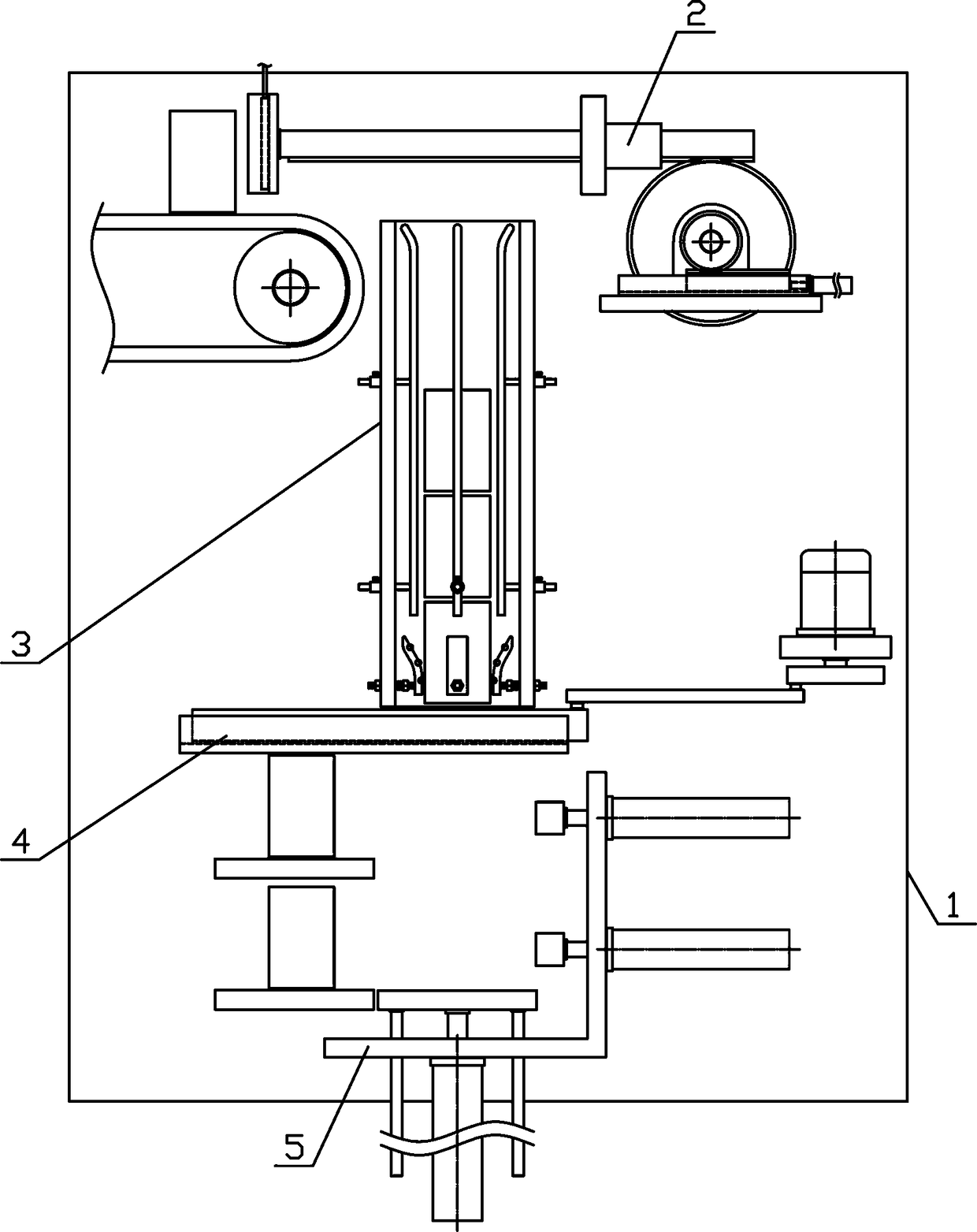

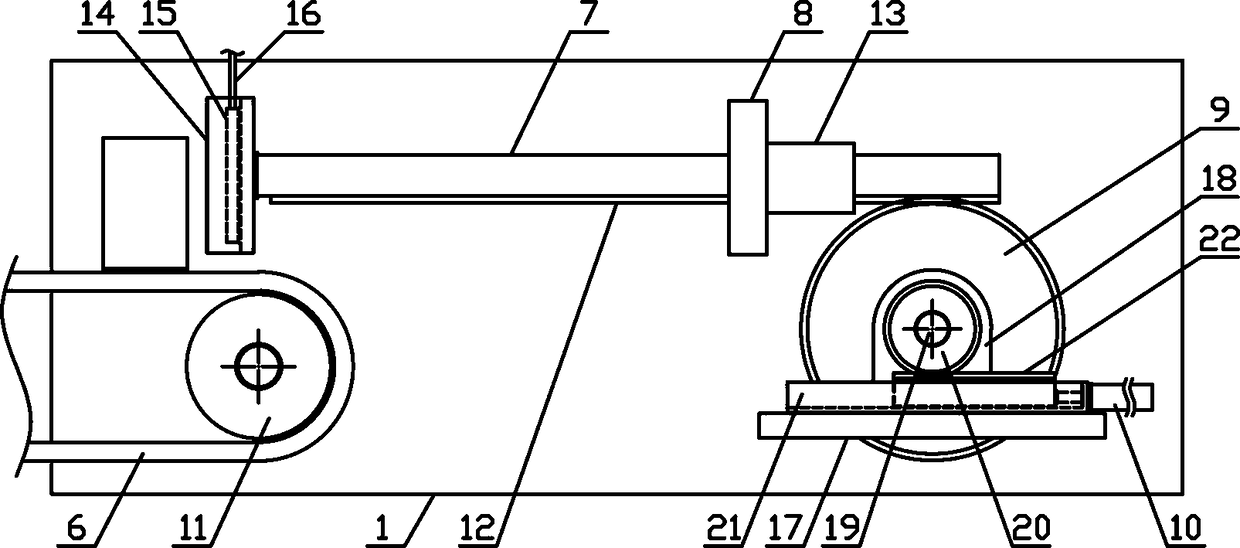

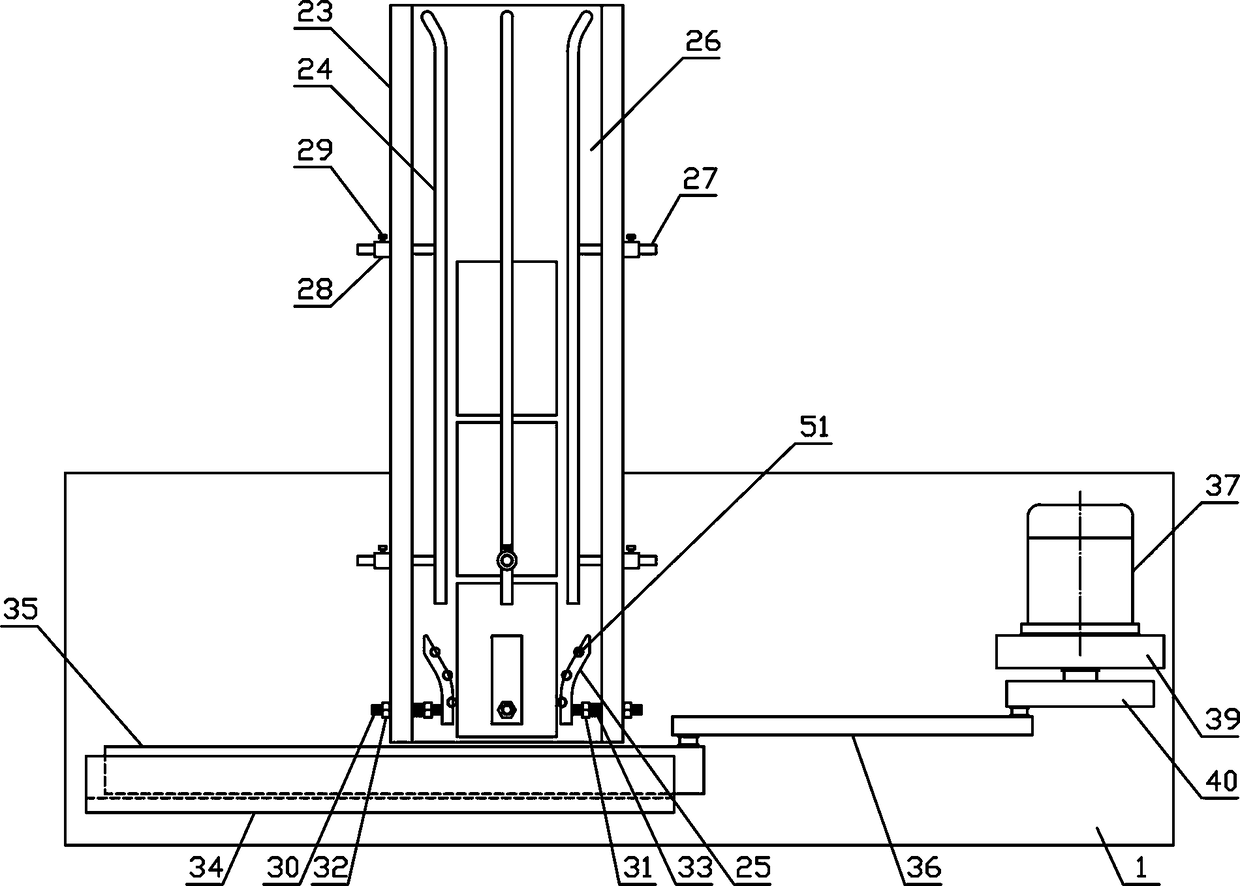

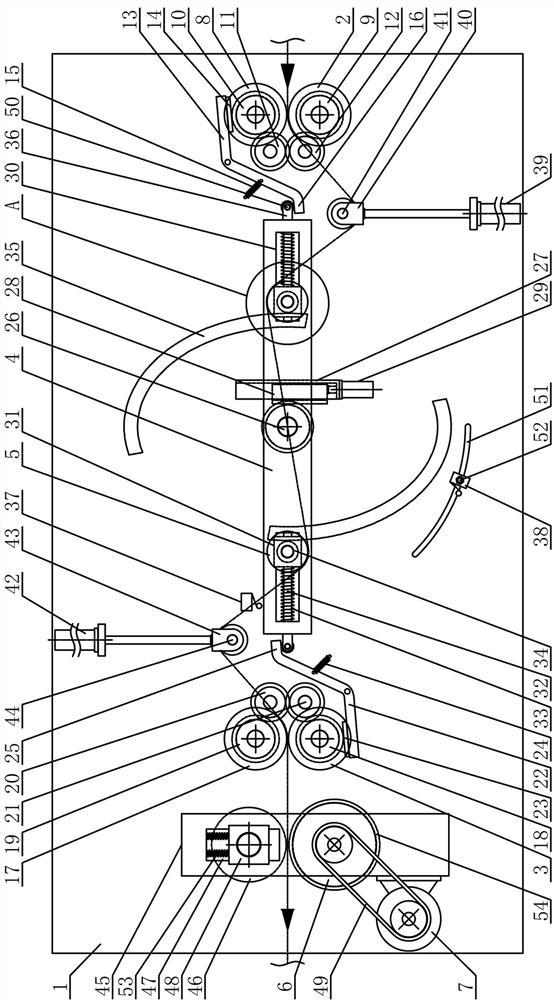

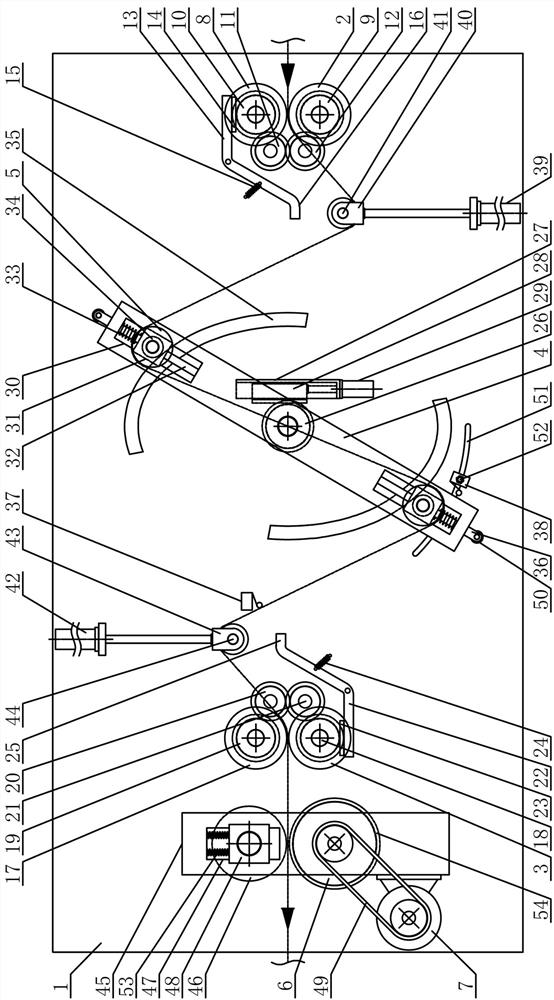

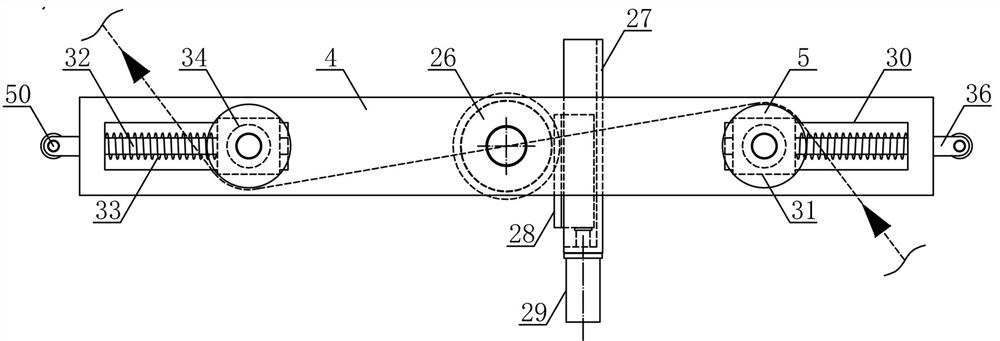

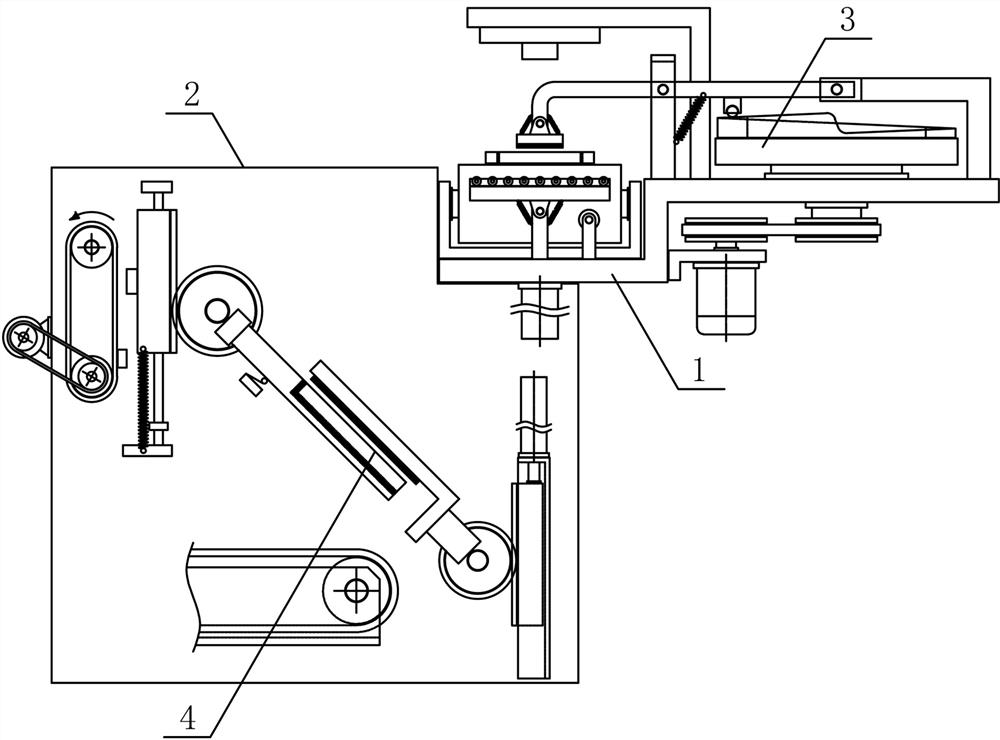

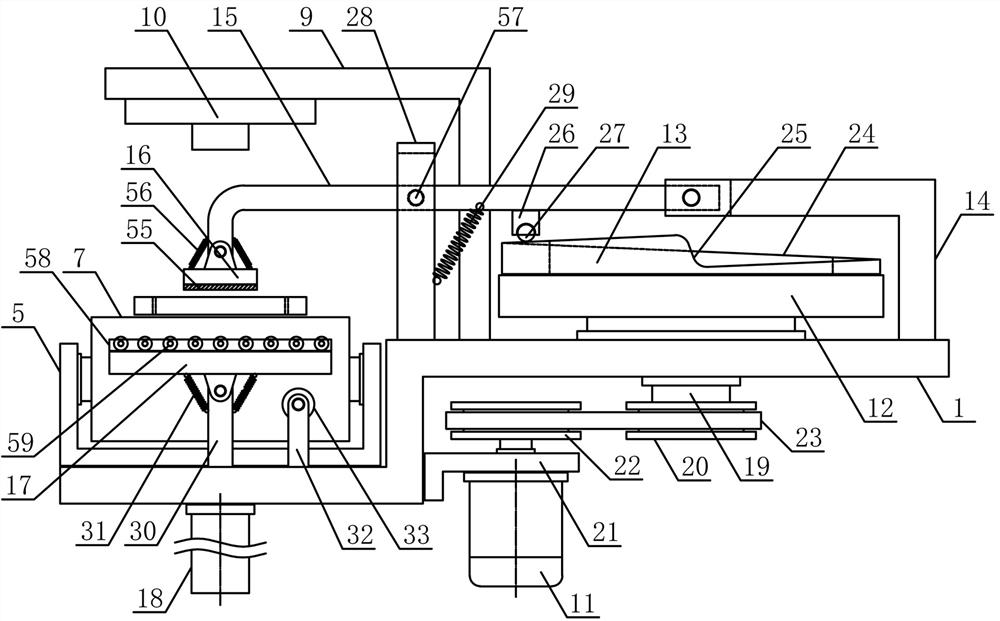

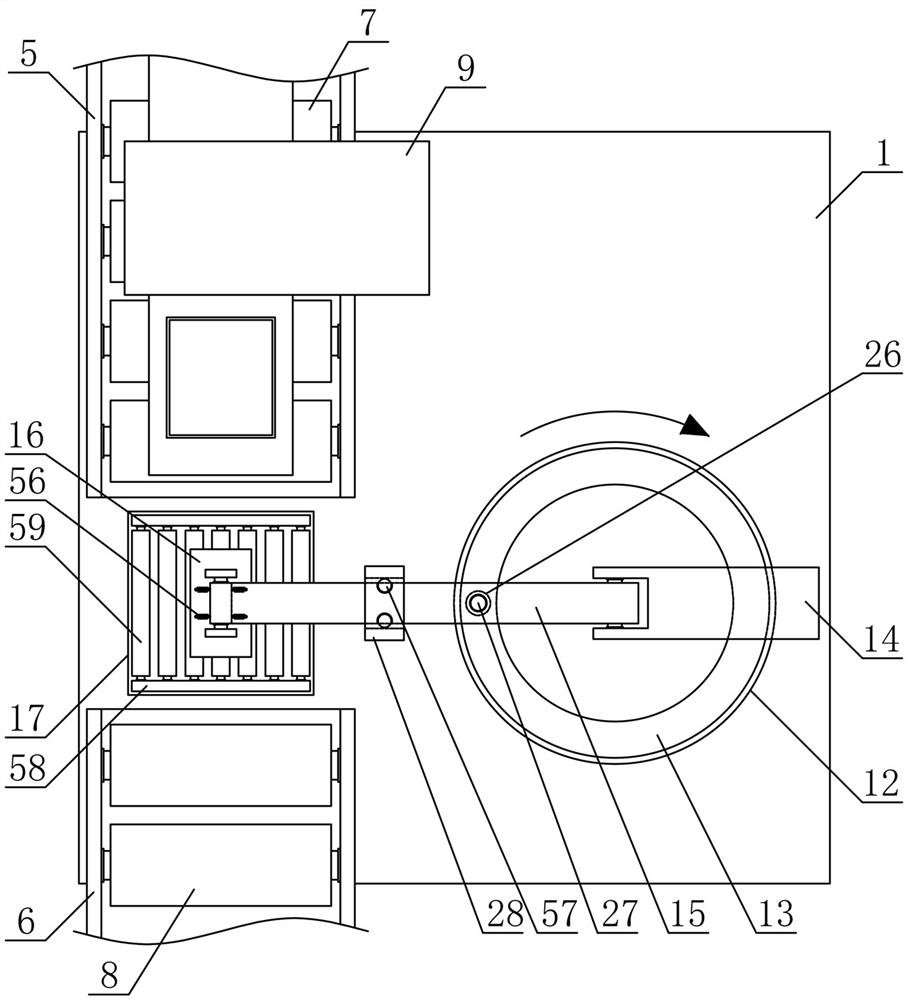

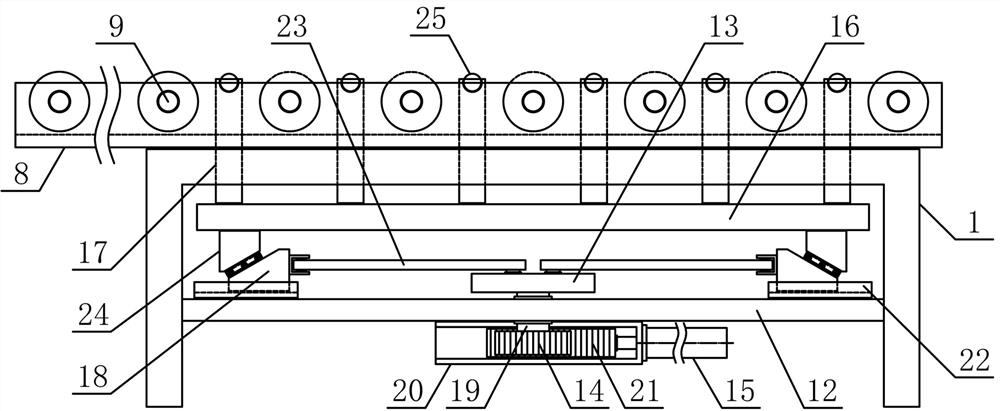

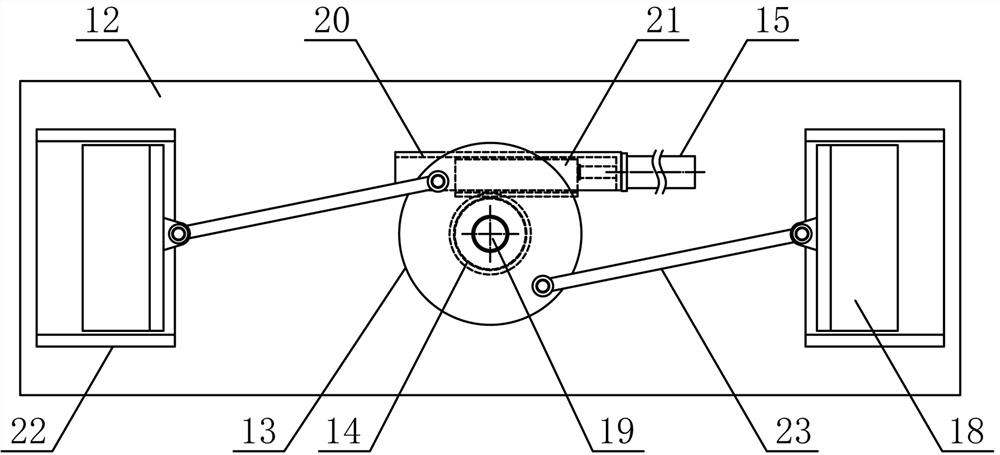

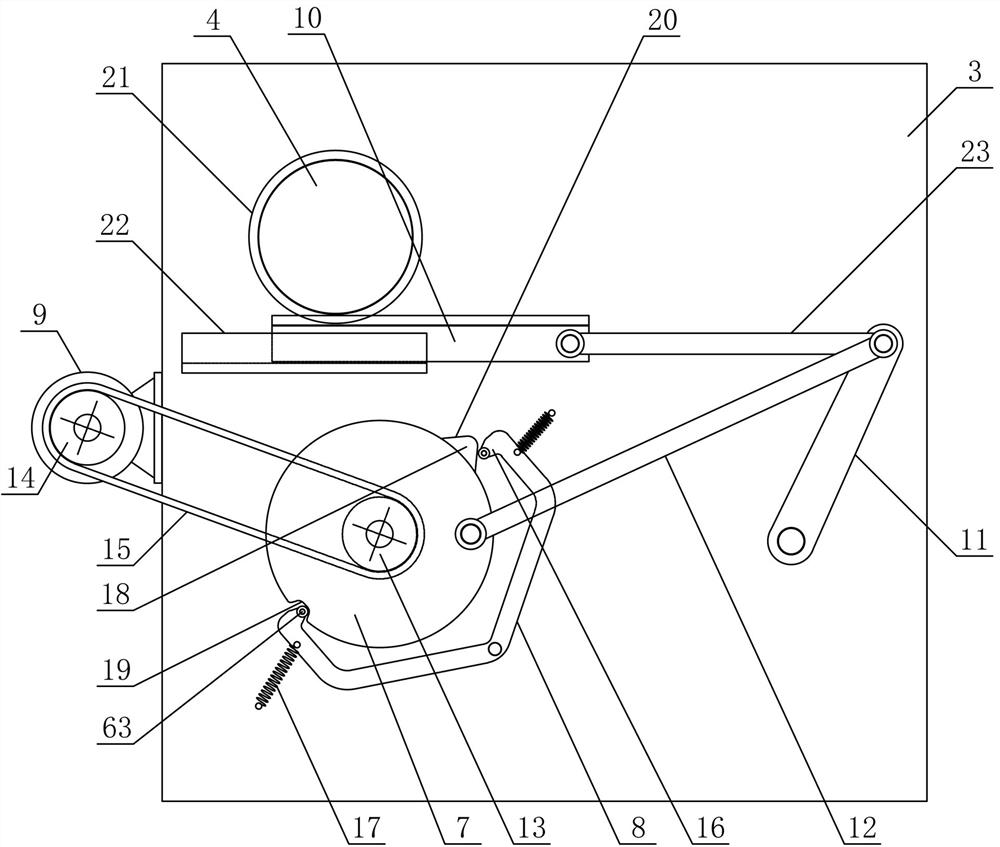

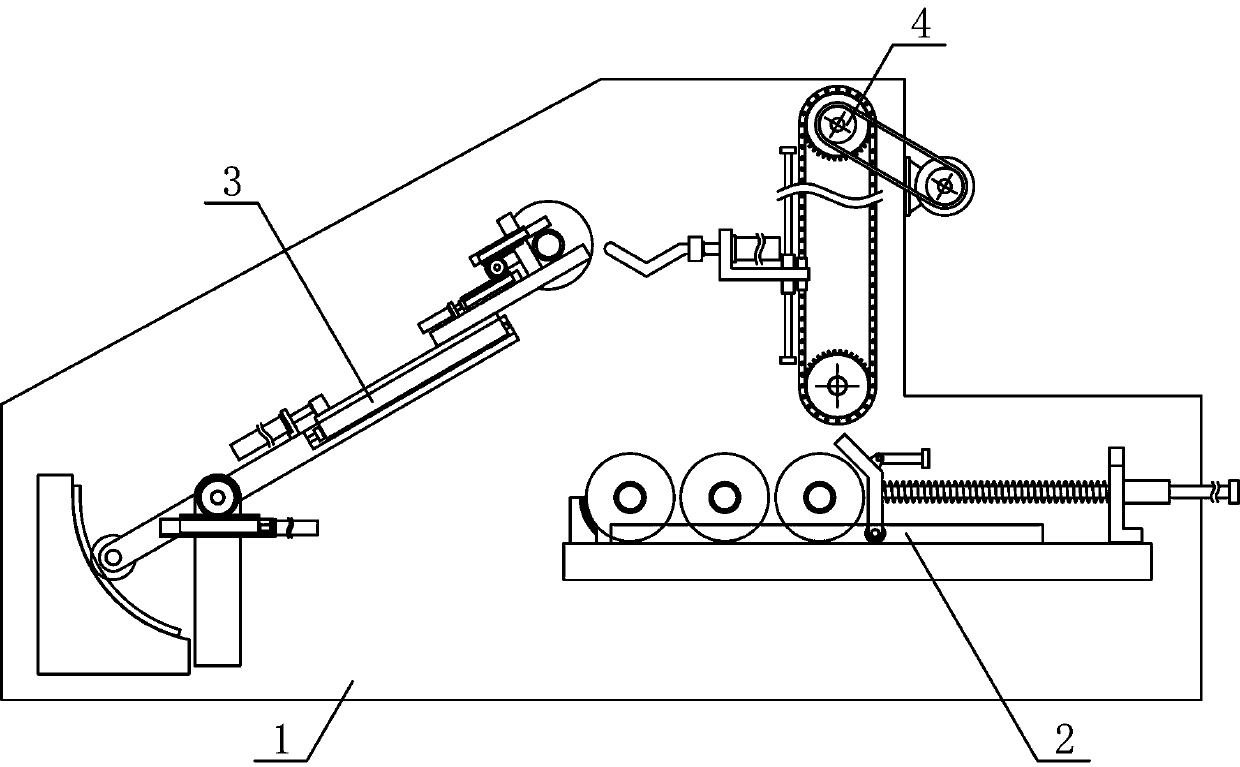

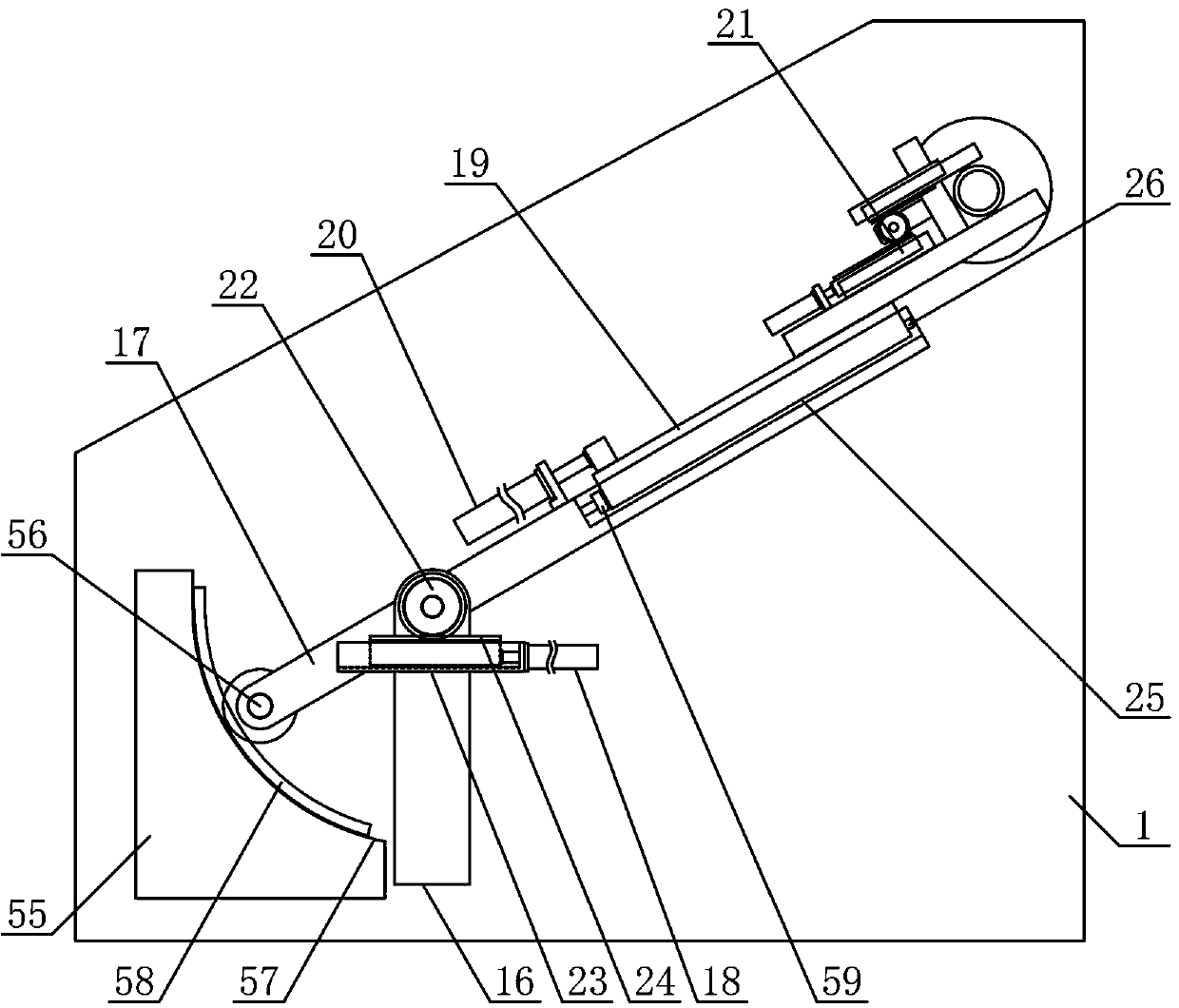

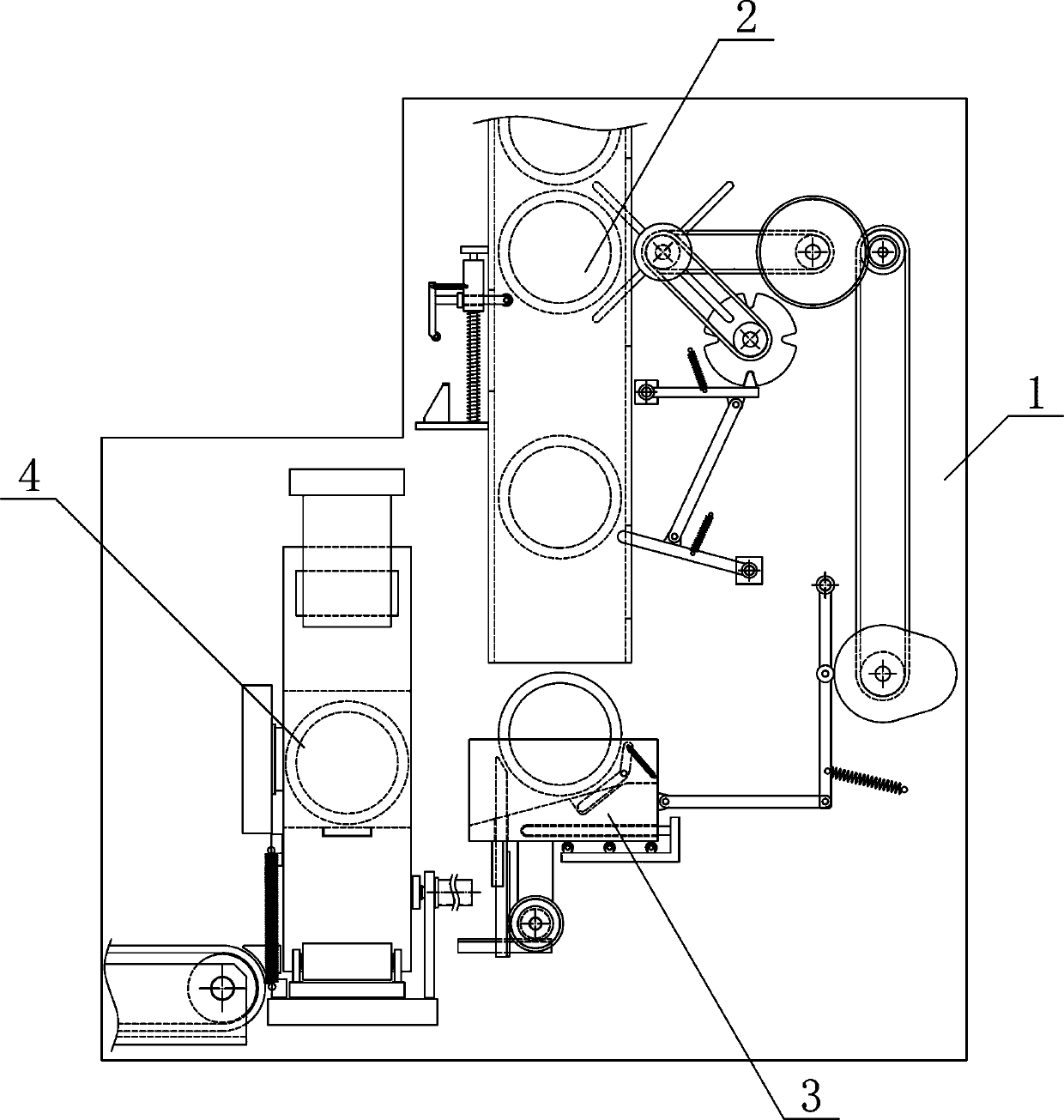

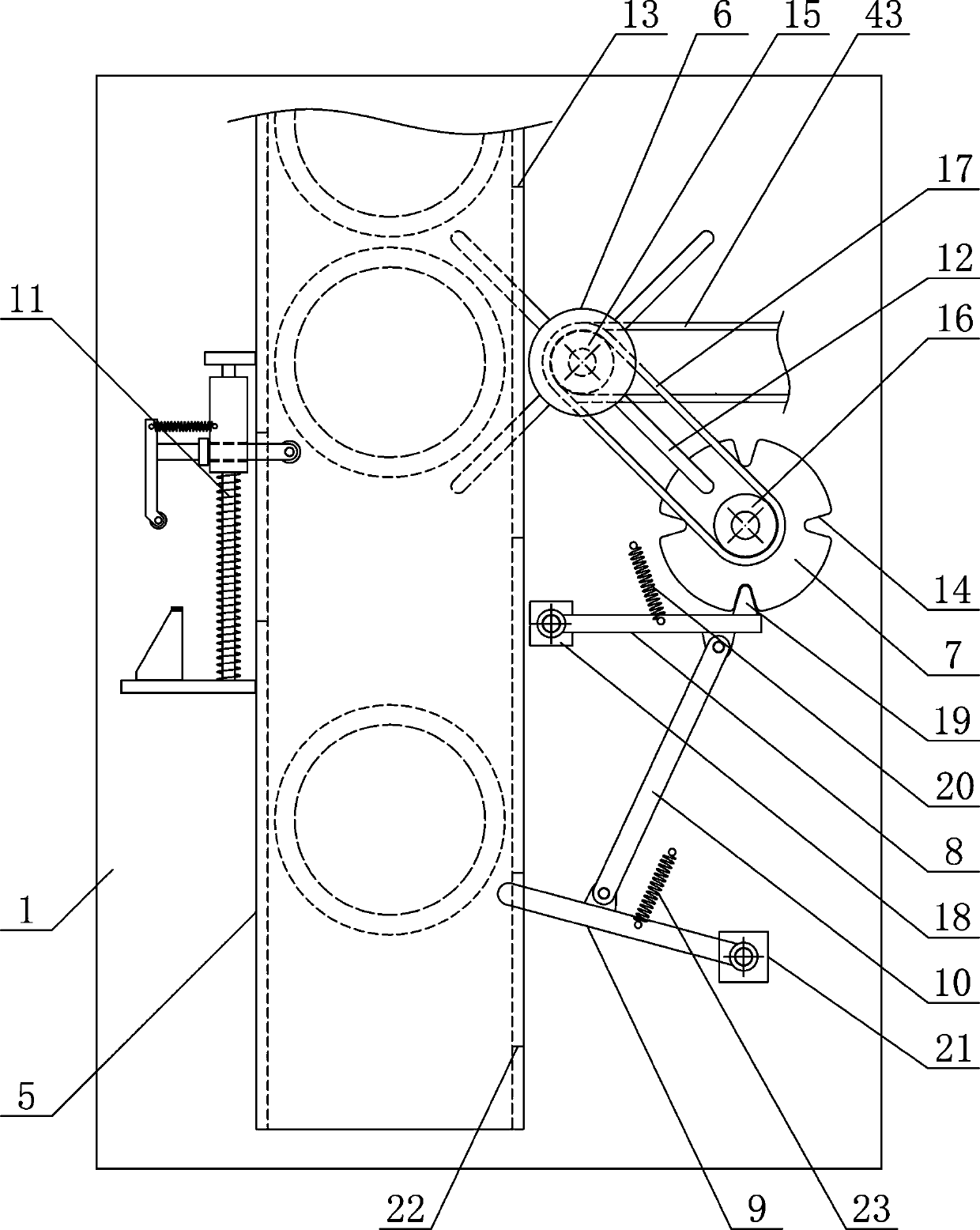

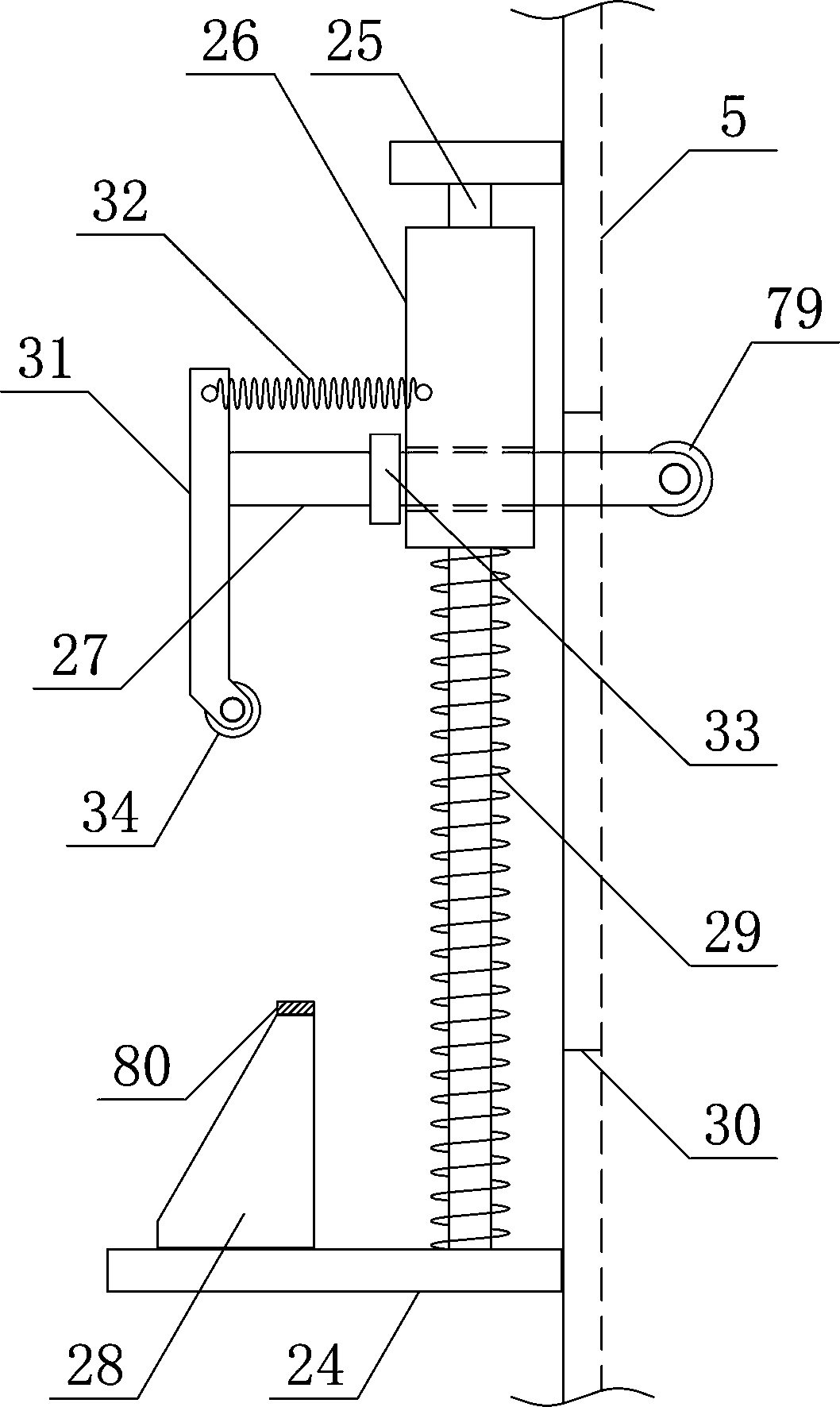

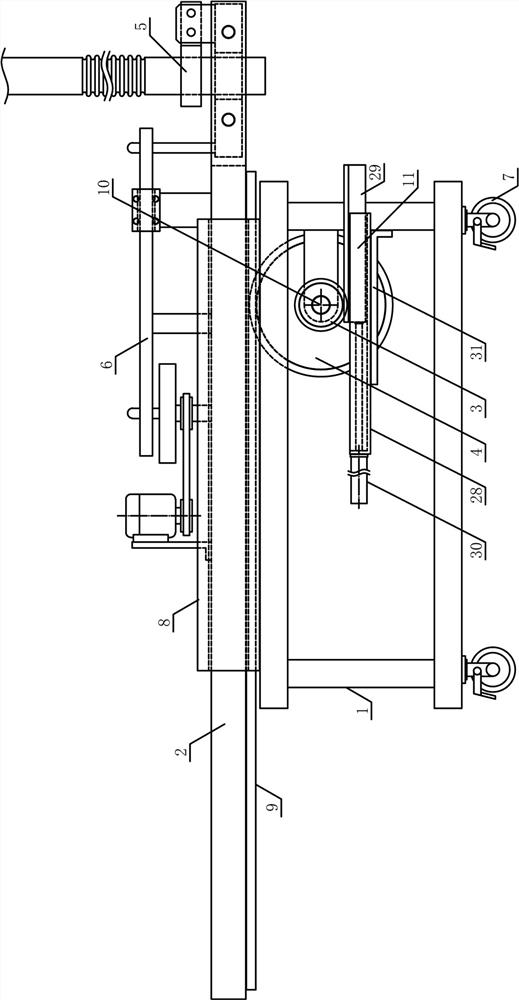

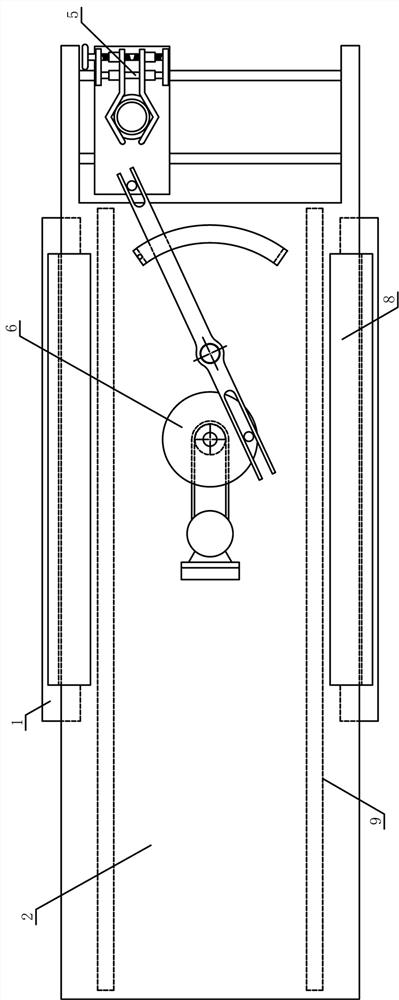

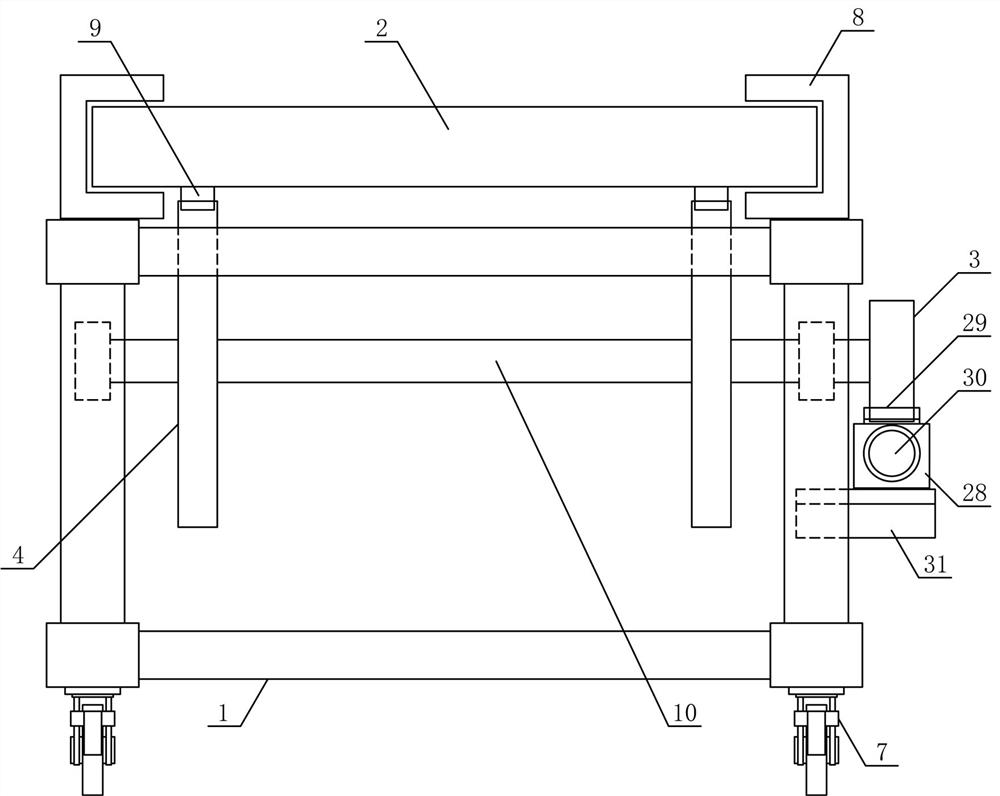

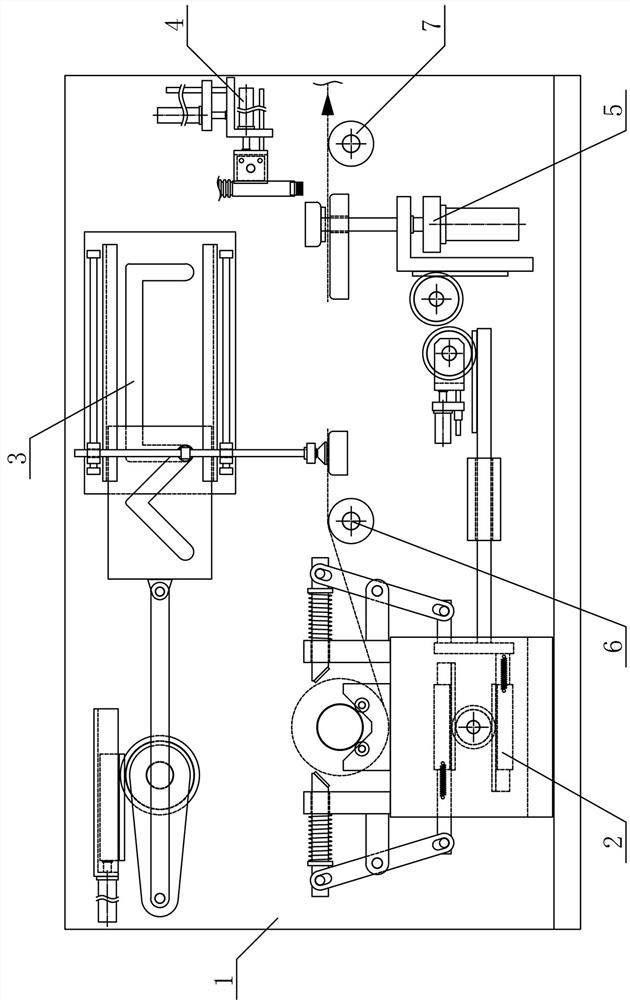

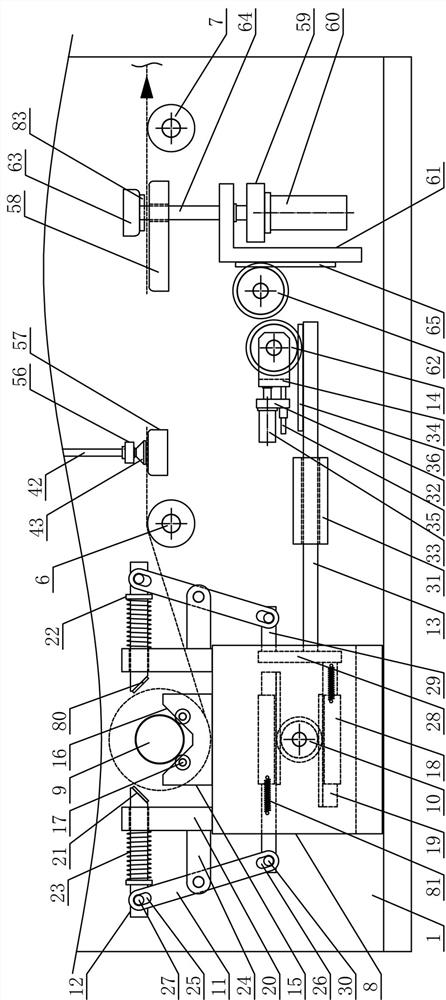

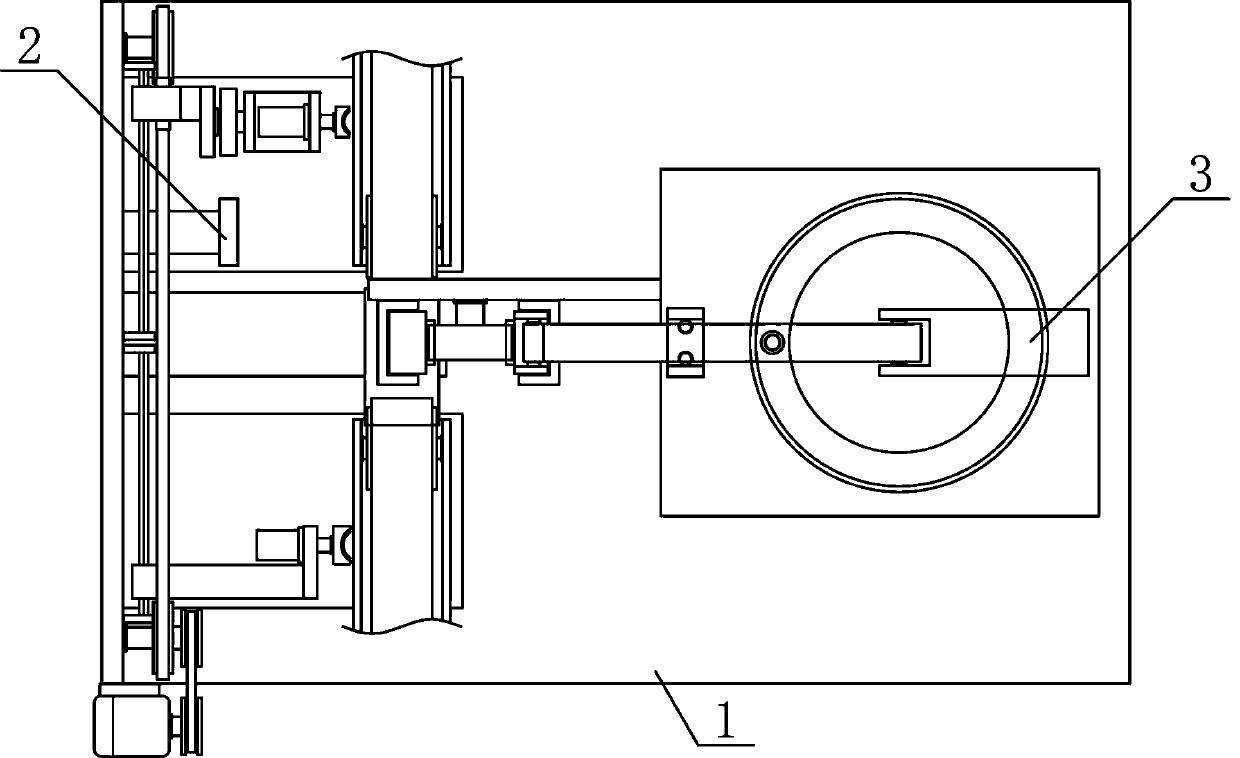

Automatic transferring and punching mechanism for aluminum profile

PendingCN109351843AAvoid Offset SkewHigh degree of automationPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an automatic transferring and punching mechanism for an aluminum profile, and belongs to the field of profile processing machines. A profile compressing mechanism and a profilepushing mechanism are sequentially and fixedly arranged on a fixed base above one side of a profile punching mechanism in the horizontal direction. The middle of the lower side of one end of a rotarycam is fixedly connected with the upper end of a cam rotary shaft, and a translation connecting plate is slidingly arranged on a translation guide rod in the horizontal direction. An adjusting connecting plate is vertically arranged on the upper side of the translation connecting plate, and a punching round rod is horizontally arranged on one side of an adjusting guide plate. Lifting pressing plates are vertically arranged on the two sides of the lower portion of a compressing support correspondingly. A plurality of translation guide rolls are sequentially arranged on a discharging support onthe lower side of a profile compressing plate in the horizontal direction. A pushing guide plate is slidingly arranged on a pushing guide rod in the horizontal direction. The automatic transferring and punching mechanism is reasonable in structural design, an aluminum profile is subjected to translation and pushing intermittently, the aluminum profile can be continuously punched, the automation degree of aluminum profile punching is improved, and the needs of processing use are met.

Owner:ZHEJIANG ZHUOYI ALUMINUM

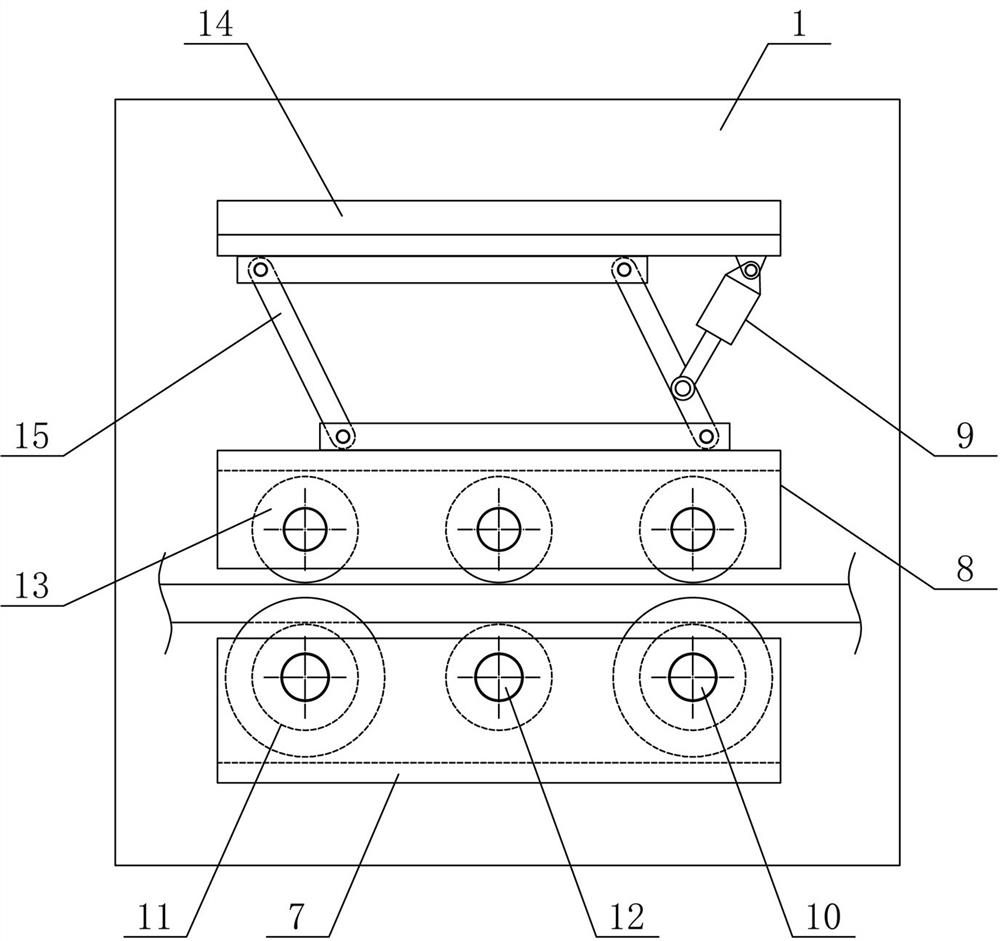

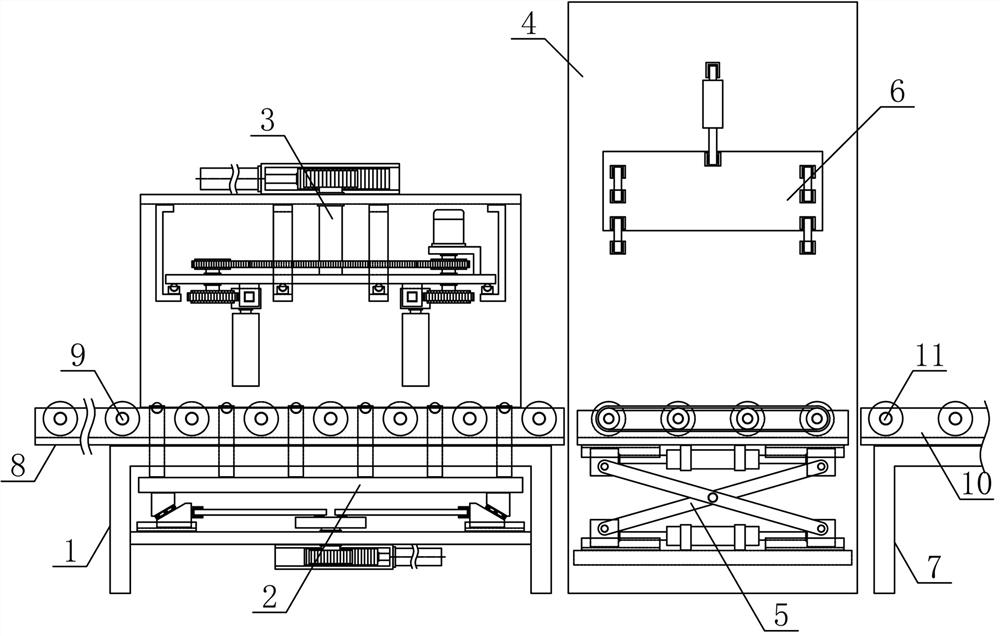

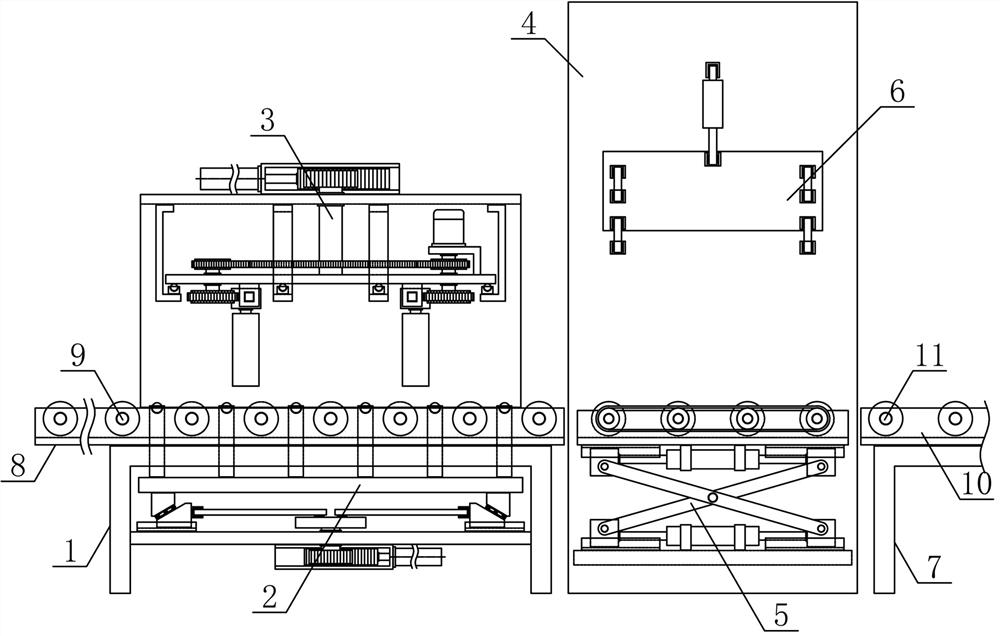

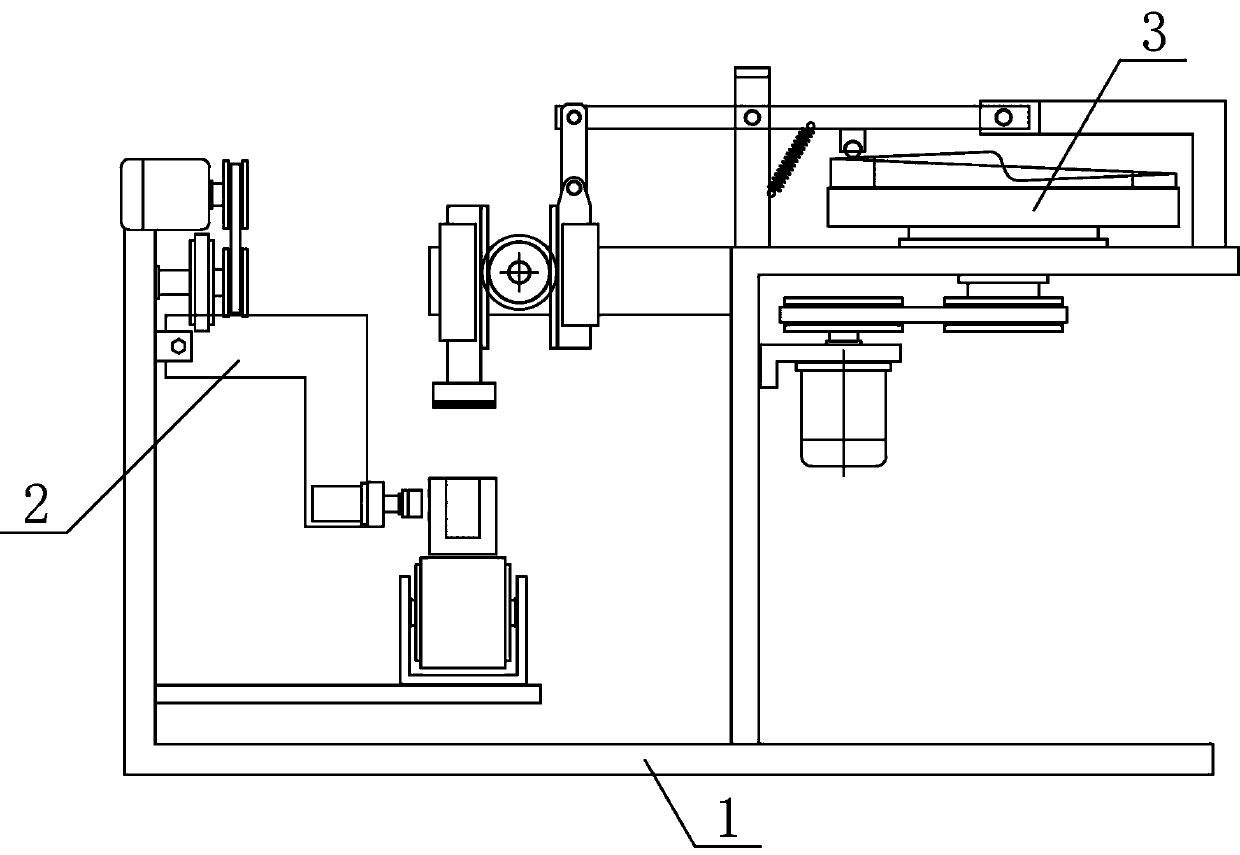

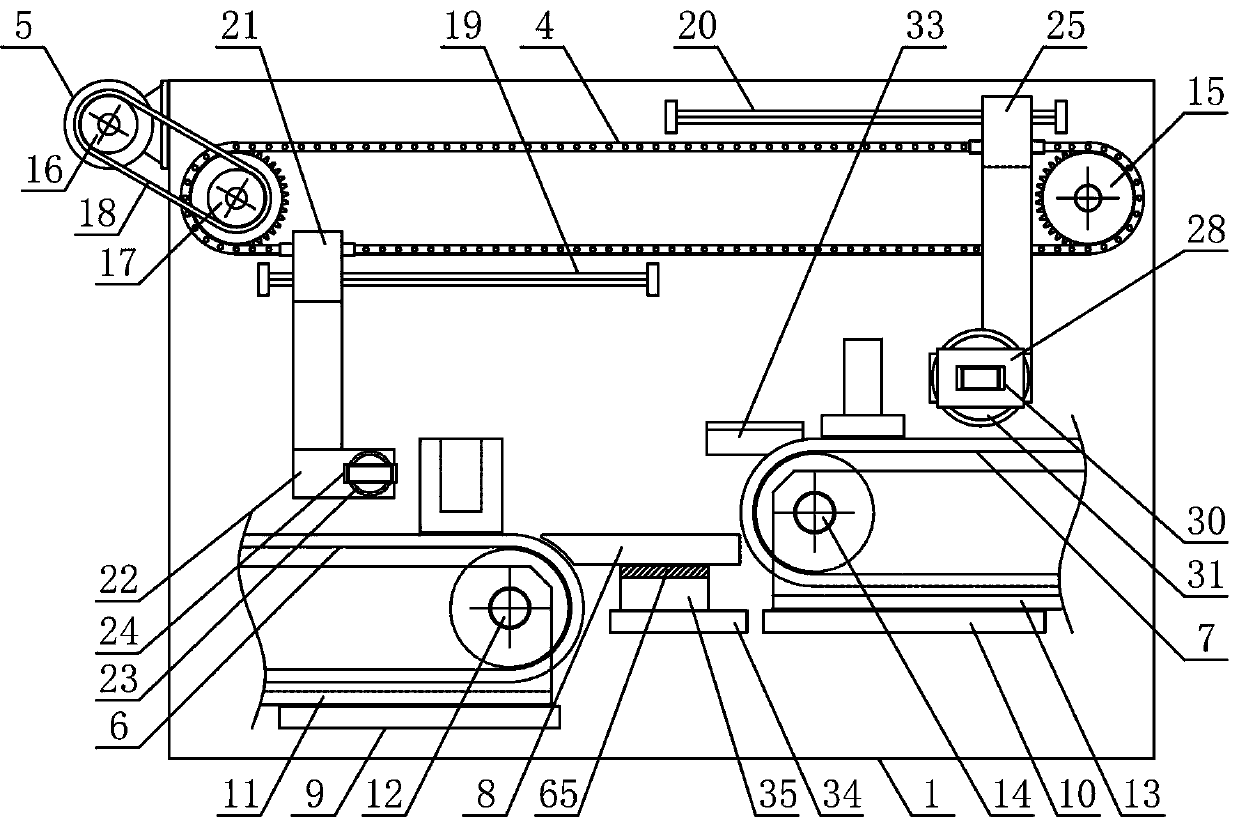

Sheet conveying and edge grinding mechanism

InactiveCN108527053AImprove efficiencyQuality improvementEdge grinding machinesGrinding feedersMechanical equipmentEngineering

The invention discloses a sheet conveying and edge grinding mechanism, and belongs to the field of material conveying and machining mechanical equipment. The sheet conveying and edge grinding mechanism comprises a fixed base, a front conveying mechanism, a front edge grinding mechanism, a back edge grinding mechanism, an overturning mechanism, an unloading mechanism and a back conveying belt; thefront conveying mechanism and the back conveying belt are horizontally fixed on the two sides above the fixed base; the front conveying mechanism and the back conveying belt are in parallel; the frontedge grinding mechanism, the back edge grinding mechanism and the overturning mechanism are arranged on the front conveying mechanism in sequence in the horizontal direction; and the unloading mechanism is horizontally arranged on the fixed base on one side of the back conveying belt. The sheet conveying and edge grinding mechanism is reasonable in structural design, can grind four side edges ofsheets in the sheet conveying process in sequence, can continuously convey the sheets after stable overturning, improves the sheet production automation degree, and meets the production and application demands.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

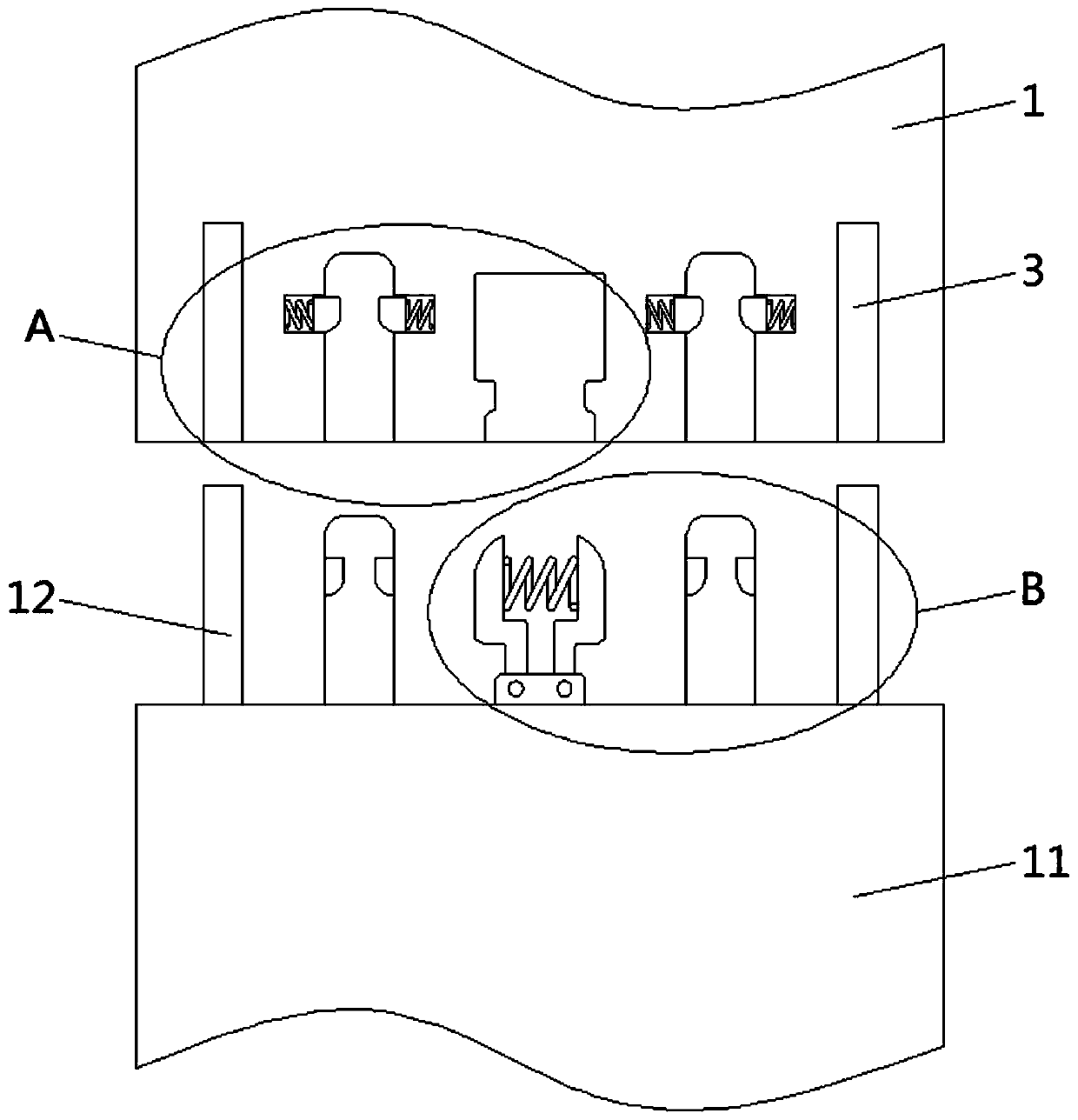

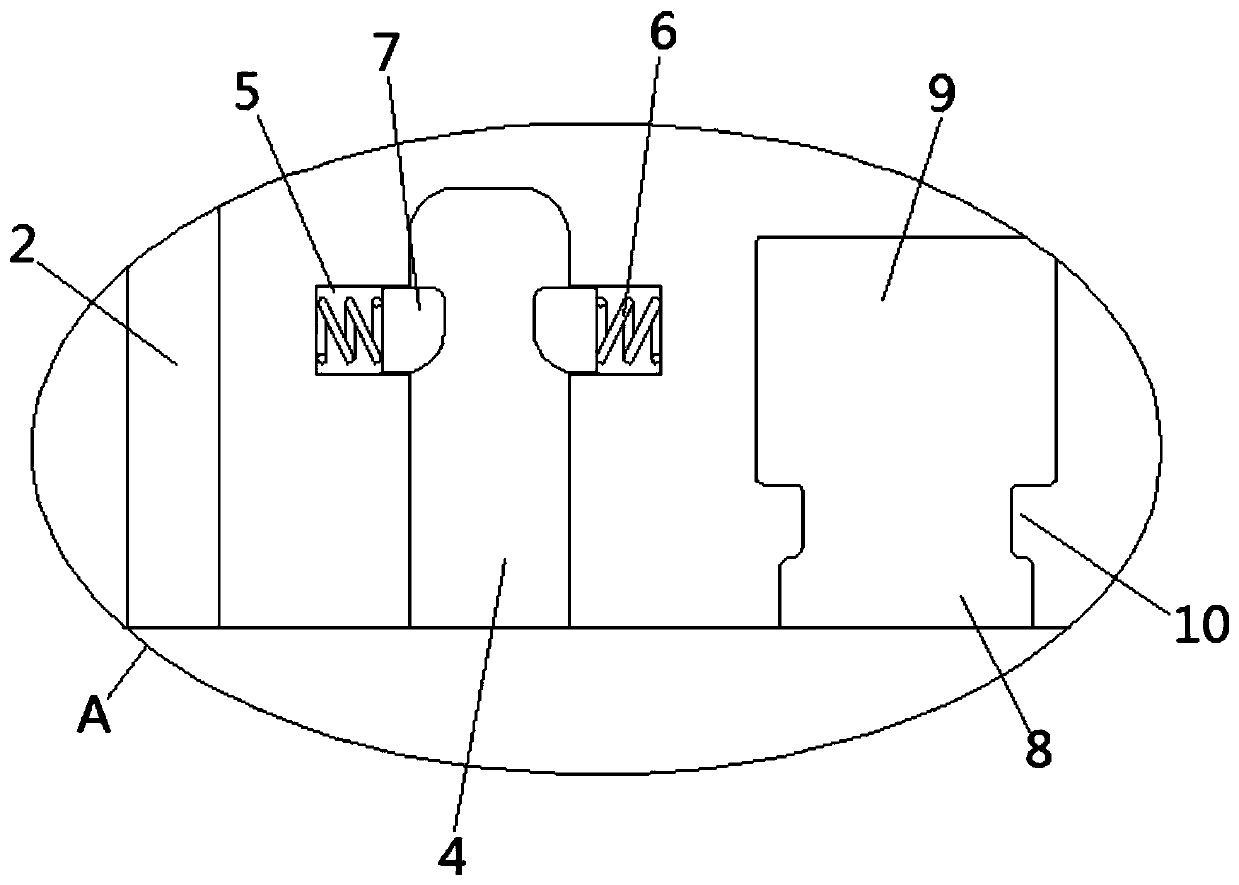

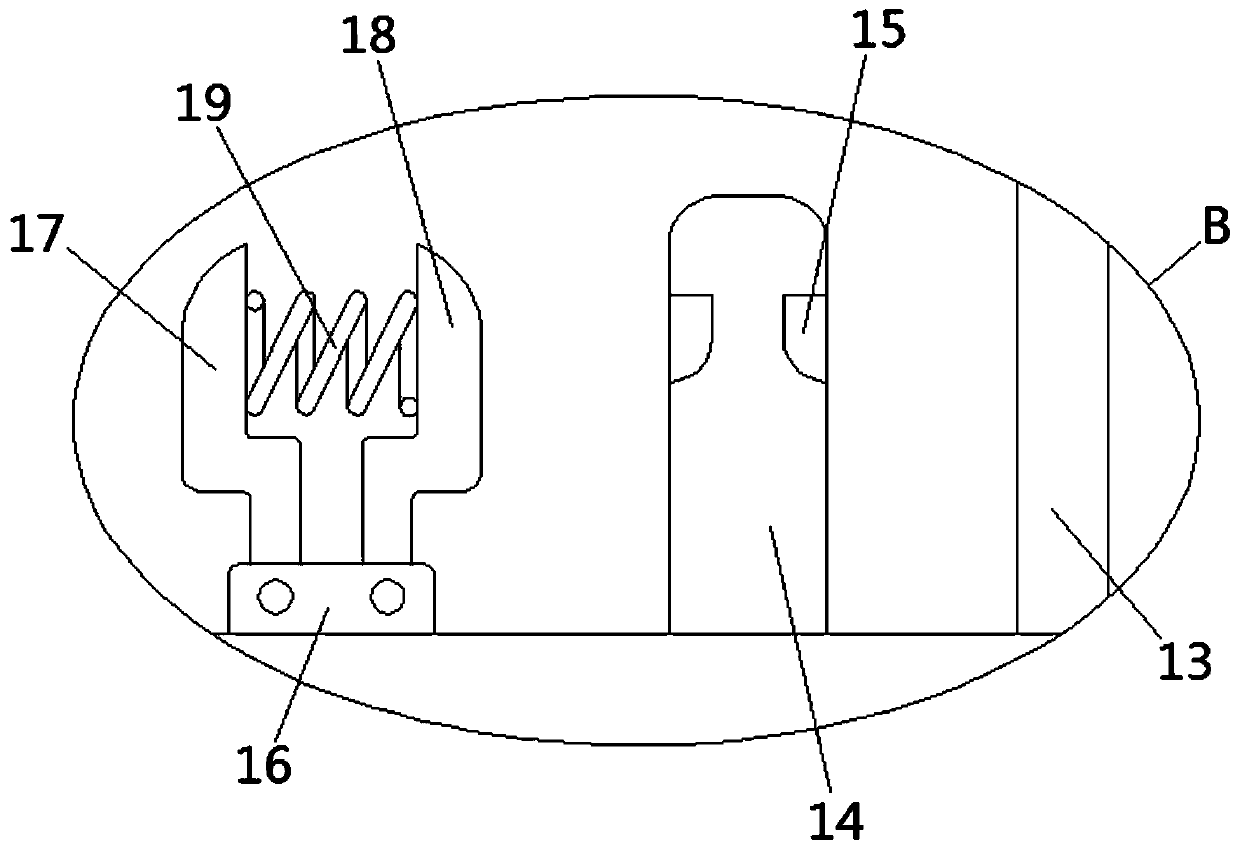

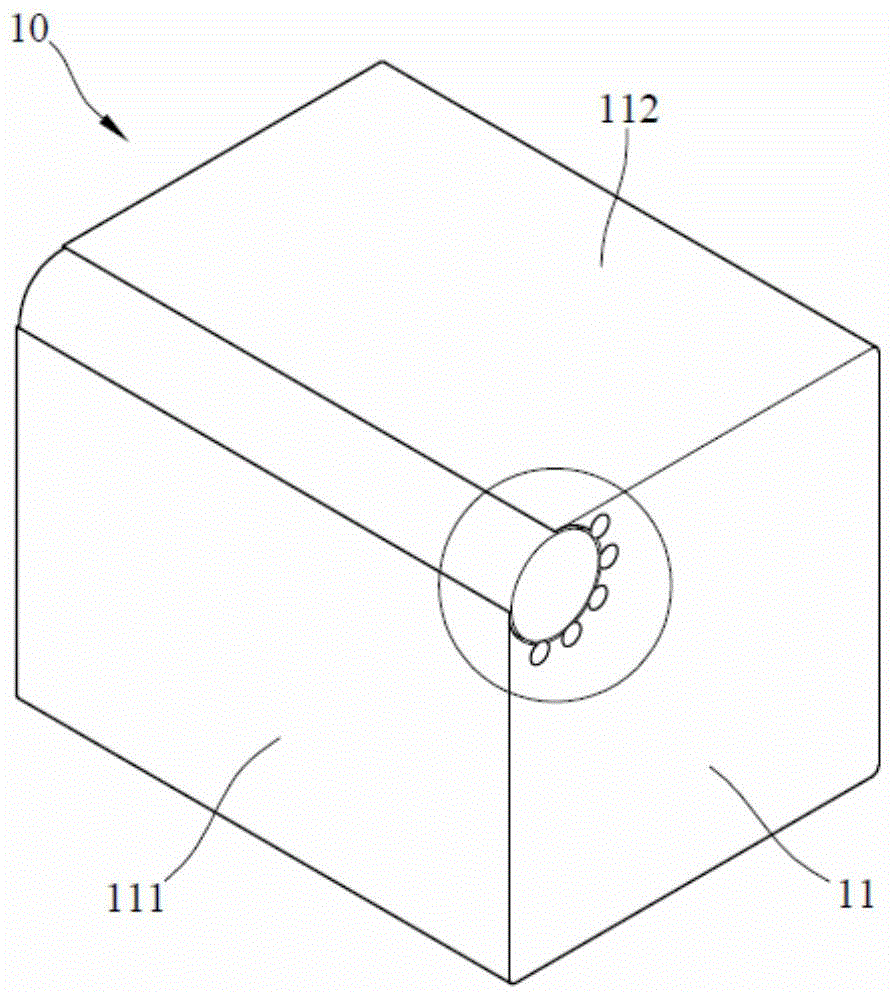

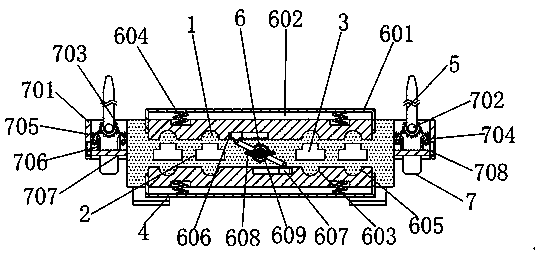

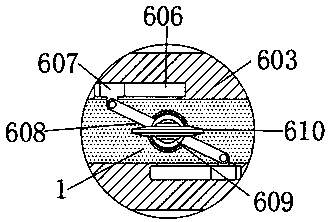

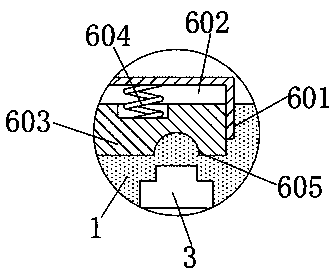

PVC assembled wallboard capable of ensuring smooth surface after installation

InactiveCN110905146AGuaranteed smoothFirmly connectedCovering/liningsMechanical engineeringIndustrial engineering

The invention relates to the technical field of wallboard assembly, and discloses a PVC assembled wallboard capable of ensuring a smooth surface after installation. The PVC assembled wallboard comprises a first wallboard, wherein a first meshing nozzle and a second meshing nozzle gradually penetrate into a clamping groove through the mutual approach of the first wallboard and a second wallboard, asecond spring is compressed at the moment, when the first meshing nozzle and the second meshing nozzle reach the top of the clamping groove, the first meshing nozzle and the second meshing nozzle areopened under the action of the second spring and are blocked by a clamping piece so as to not be pulled out again, thus connecting a first wall plate and a second wall plate, the first meshing nozzleand the second meshing nozzle penetrate gradually, meanwhile, a insertion rod is gradually inserted into a slot, when the insertion rod is inserted into the top of the slot, a clamping block and a clamping slot are also clamped with each other, the positions of the first wallboard and the second wallboard are further fixed, and deviation and skew of the first wallboard and the second wallboard are prevented. The PVC assembled wallboard has a simple structure, solves the problem of uneven splicing of PVC assembled wall plates, and has the advantage of smoother installation surface.

Owner:怀化市智锋装饰材料有限责任公司

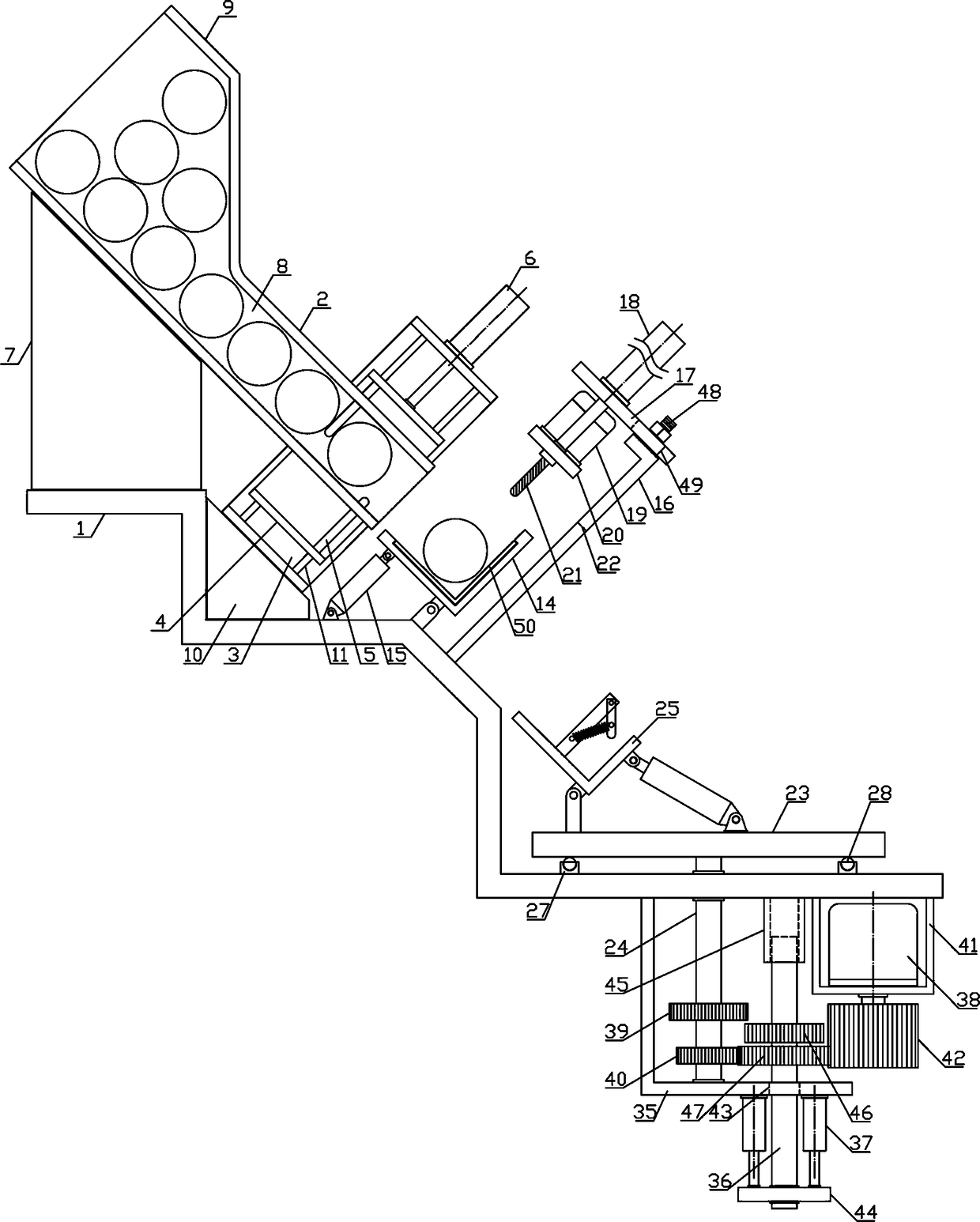

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

Continuous round can discharging and conveying mechanism

InactiveCN108840094AReasonable structural designAccurate placementConveyorsStacking articlesEngineeringTransfer mechanism

The invention discloses a continuous round can discharging and transferring mechanism, and belongs to the field of vessel processing machinery and equipment. According to the continuous round can discharging and transferring mechanism, a can moving mechanism, a can guide mechanism, a can discharging mechanism and a can pushing mechanism are arranged on one side of a fixed bracket in sequence fromtop to bottom, a material moving guide rod is arranged on a guide bracket in a sliding mode in a horizontal direction, a plurality of limiting stop levers are vertically and uniformly arranged on theupper side of a can guide channel, a plurality of buffer pressing plates are vertically and uniformly arranged on the lower side of the can guide channel, a translating connecting plate is arranged ona translating bracket in the sliding mode in the horizontal direction, a discharge through hole is horizontally formed in one side of the translating connecting plate, a can supporting cylinder is vertically and fixedly arranged on the lower side of a can pushing bracket upwards, and an upper station connecting plate and a lower station connecting plate are horizontally and fixedly arranged on the fixed bracket on one side of the can pushing bracket in sequence from top to bottom. The continuous round can discharging and transferring mechanism has the advantage of reasonable structural design, round cans can be continuously and stably discharged one by one, the round cans can be precisely pushed in several directions one by one, and the production and use requirements are met.

Owner:徐晓杰

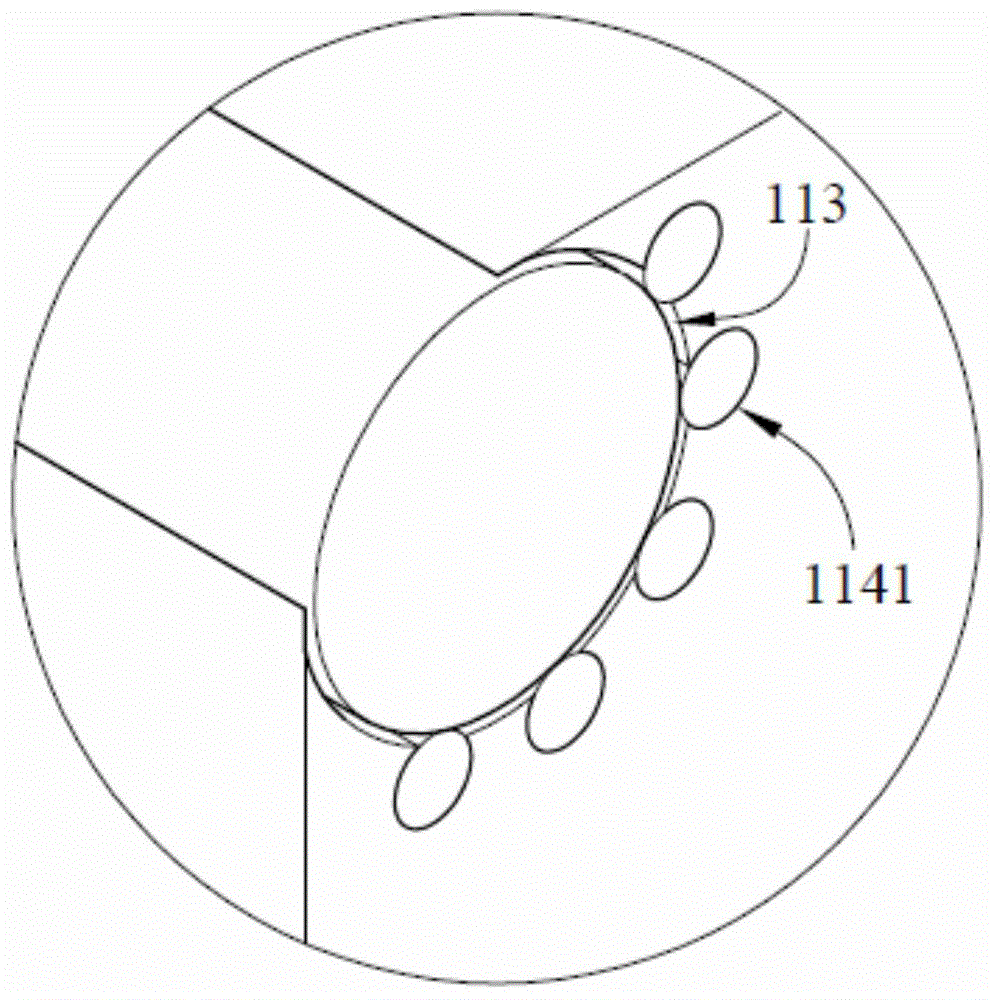

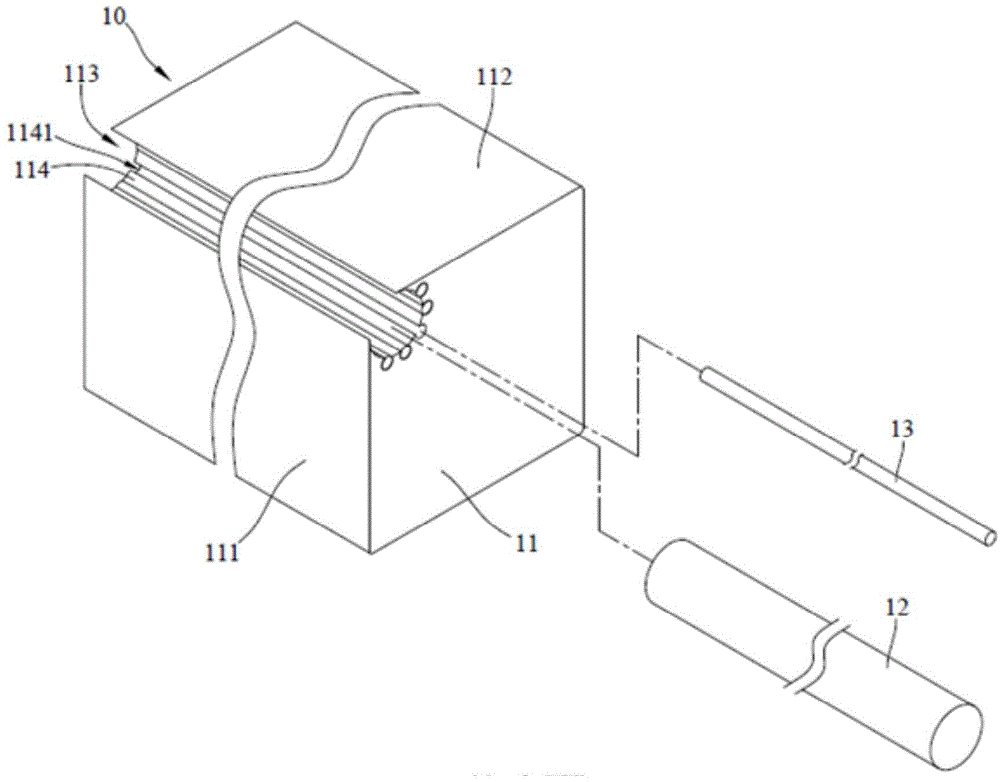

Stamping device

A stamping device comprises a bending insert, a bearing stripper plate and a puncher pin. The bending insert comprises a body, a rolling wheel and multiple rollers. The body is provided with a bending face, a top face and an embedding groove. The position where the bending face is adjacent to the top face forms a corner part of the body. The embedding groove is embedded in the corner part. Multiple grooves are formed in the inner wall of the embedding groove. The rolling wheel is embedded in the embedding groove. The rollers are arranged in the grooves, and a part of each roller protrudes out of the inner wall and makes contact with the rolling wheel. The bearing stripper plate is provided with a bearing face and is located on one side of the bending face. A height difference exists between the bearing face and the top face, so that a part of the bending face is exposed. The bearing face and a part of the bending face jointly form a bending work area. The puncher pin is located above the bearing face and corresponds to the bending work area.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

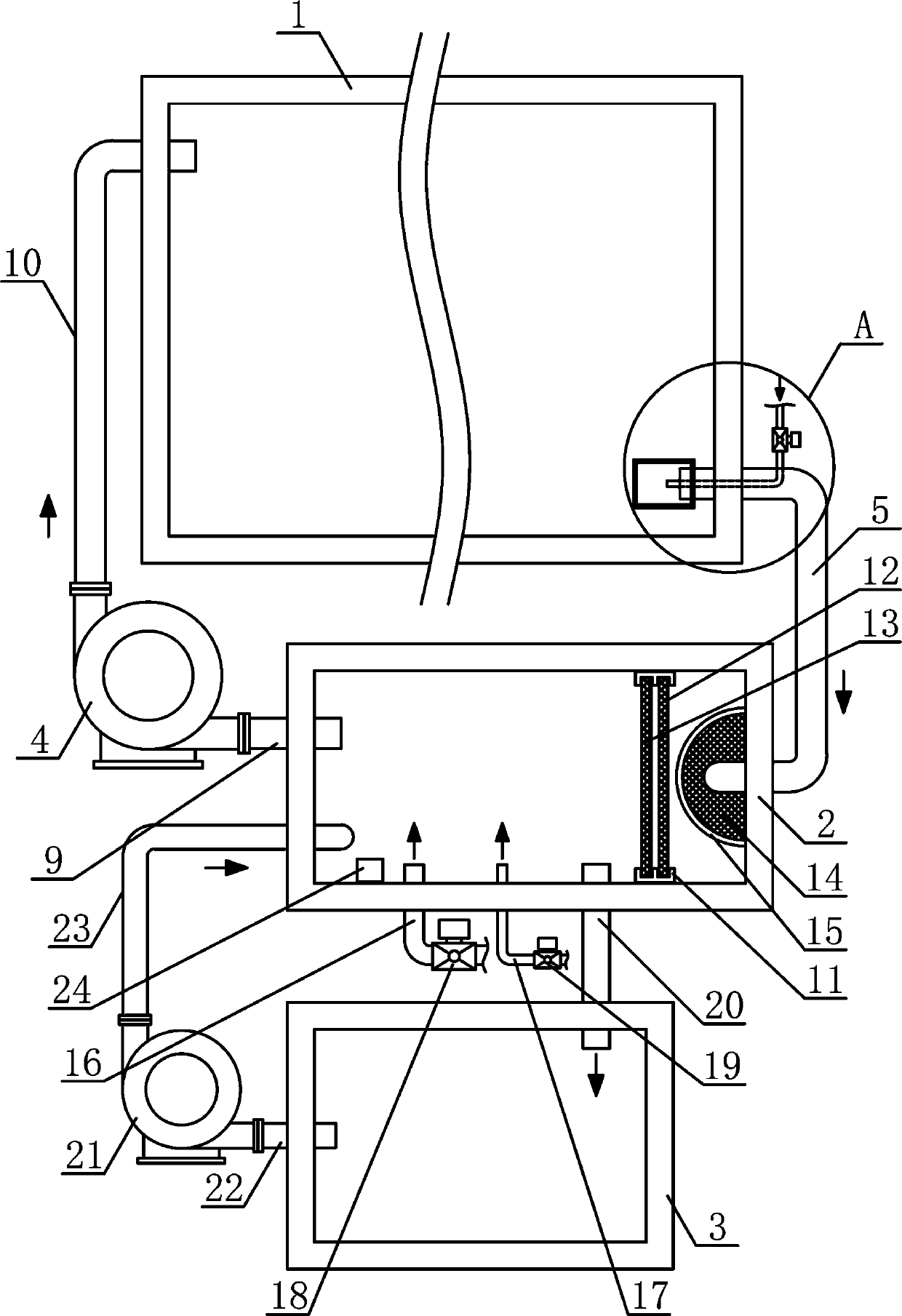

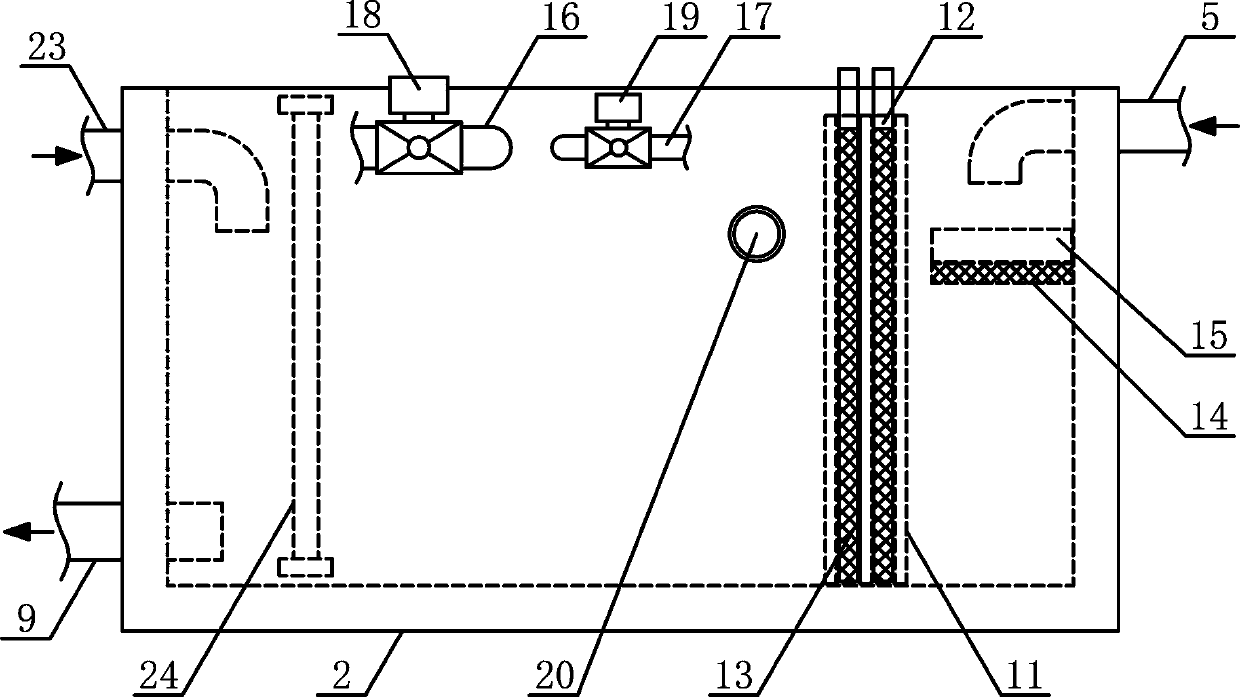

Drafting and setting device for polyester knitted fabric

ActiveCN113529322AReasonable structural designEfficient and smooth at restHeating/cooling textile fabricsStretchingPolyesterElectric machinery

The invention discloses a drafting and setting device for a polyester knitted fabric, and belongs to the field of fabric production and processing mechanical equipment. A fabric feeding guide roller and a fabric discharging guide roller are sequentially, horizontally and rotationally connected to a fabric processing support; a fabric reciprocating rotating plate is arranged on the fabric processing support between the fabric feeding guide roller and the fabric discharging guide roller; a fabric drafting gear is coaxially, vertically and fixedly arranged in the middle of the fabric reciprocating rotating plate along the side of the fabric processing support; a fabric drafting toothed plate at the output end of a fabric drafting air cylinder is in meshed connection with the fabric drafting gear coaxially fixed to the middle of the fabric reciprocating rotating plate; reciprocating drafting rotating rollers are symmetrically arranged on the two sides of the fabric reciprocating rotating plate; and the output end of a fabric pulling and conveying motor is in transmission connection with a fabric pulling and conveying guide roller through a fabric pulling and conveying belt. The device is reasonable in structural design, can efficiently and stably perform sectional drafting and setting processing in the knitted fabric conveying process, improves the production and processing automation degree of the knitted fabric, and meets the processing and using requirements.

Owner:浙江正辉针织科技股份有限公司

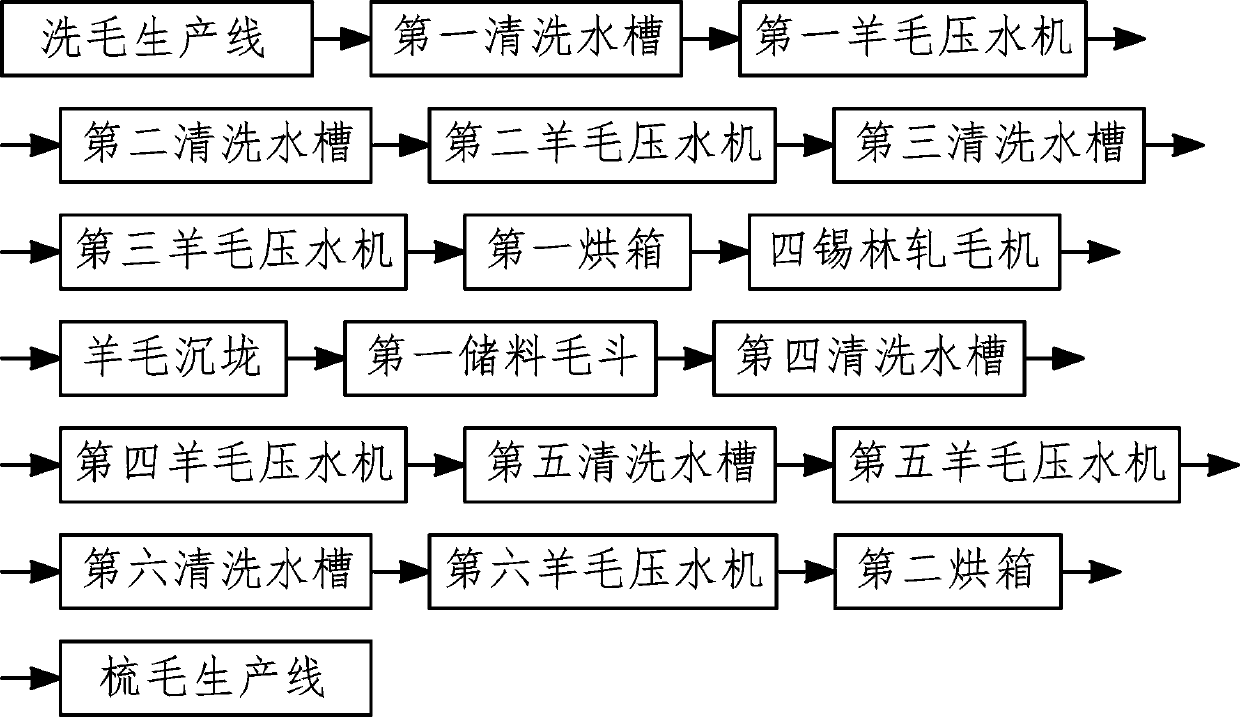

Wool light-carbonization weeding process

ActiveCN110685017AProtect fiber stateMeet production requirementsWool fibre washing/scouringFiberCarbonization

The invention discloses a wool light-carbonization weeding process and belongs to the technical field of textile processing. According to the wool light-carbonization weeding process, wool which is processed by the previous wool washing line is conveyed sequentially to a first washing sink, a second washing sink and a third washing sink to be washed, the washed wool is then conveyed to a first oven to be dried by heating, the dried wool is conveyed and rolled through a four-cylinder wool rolling mill, and is separated from weeds through a wool sinking ridge, the wool separated is conveyed to afourth washing sink, a fifth washing sink and a sixth washing sink sequentially to be washed, and then conveyed to a second oven to be dried by heating, finally, the dried wool is cooled and then conveyed to a carding production line to be carded and slivered. The wool light-carbonization weeding process is reasonable in design and can remove weeds in wool effectively while effectively protectingwool fiber, the yield of wool finished products is high, and requirements on processing are met.

Owner:张琦

Working method of metal plate transferring mechanism

InactiveCN112623720AFast and efficient transferConvenient Guided DeliveryConveyorsConveyor partsGear wheelEngineering

The invention discloses a working method of a metal plate transferring mechanism, and belongs to the field of profile machining mechanical equipment. A push plate guide mechanism is horizontally arranged on the upper side of a machining support; a transferring mechanism is vertically arranged on one side of a transferring support; a front conveying support and a rear conveying support are horizontally and fixedly arranged at the two ends of one side of the upper portion of the machining support in the horizontal direction; a laser cutting machine is horizontally and fixedly arranged at the position, on one side of the upper portion of the front conveying support, of the machining support; the push plate guide mechanism is horizontally arranged at the position, on one side of the front conveying support and one side of the rear conveying support, of the machining support; a transferring guide plate is fixedly arranged on one side of a transferring gear in the radial direction of the transferring gear; a transferring belt is horizontally arranged on the upper side of a conveying support; and the transferring guide plate is fixedly arranged on one side of a plate containing gear in the radial direction of the plate containing gear. The mechanism is reasonable in structural design, a metal plate obtained through cutting machining can be rapidly and efficiently transferred, the automation degree is high, and the machining and use needs are met.

Owner:黄明珠

Packaging box conveying and stacking device

InactiveCN112607435AEfficient and stable adjustment stationSmooth and firm clampingStacking articlesConveyor partsStructural engineeringMechanical equipment

The invention discloses a packaging box conveying and stacking device, and belongs to the field of packaging machining mechanical equipment. A storage box feeding support, a storage box stacking support and a storage box discharging support are sequentially and fixedly arranged in a horizontal conveying direction of packaging boxes, a plurality of front box conveying rotating rollers are sequentially and rotatably connected to a front box conveying support in the horizontal direction, and a box bearing lifting mechanism is horizontally and fixedly arranged on the storage box feeding support on the lower side of the front box conveying support. A rotary reversing mechanism is horizontally and fixedly arranged on a front box conveying support above the box bearing lifting mechanism, a box clamping fixing mechanism and a storage box lifting mechanism are sequentially and fixedly arranged on the storage box stacking support from top to bottom in the vertical direction, and a rear box conveying support is sequentially and rotatably connected with a plurality of rear box conveying rollers in the horizontal direction. The packaging box conveying and stacking device is reasonable in structural design, the packing boxes can be efficiently and stably stacked in sequence, operation is reliable, the packing box stacking efficiency and quality can be ensured, the packing box stacking automation degree is improved, and the production and use requirements are met.

Owner:潘宇力

Turning-free sewing equipment

ActiveCN112011905APrecise positioningStable removalWork-feeding meansMechanical equipmentIndustrial engineering

The invention discloses turning-free sewing equipment, and belongs to the field of garment manufacturing and processing mechanical equipment. A sewing processing machine head is horizontally and fixedly arranged on the upper side of a sewing processing bracket; a clothes transferring rotating shaft is rotationally connected to an adjusting supporting base. A reciprocating driving mechanism is horizontally arranged on the adjusting supporting base on one side of the bottom of the clothes transferring rotating shaft; a clothes sleeving mechanism is horizontally and fixedly arranged at the end ofthe upper side of the clothes transferring rotating shaft; a clothing transferring guide plate is arranged on a translation guide bracket in a sliding manner in the horizontal direction; a garment sewing bearing plate is vertically and fixedly arranged on one side of the garment transferring guide plate, garment transferring rotating rollers are horizontally and rotationally connected to the twosides of the middle of the garment sewing bearing plate respectively, and garment sleeving round rollers are horizontally arranged on the upper sides and the lower sides of tensioning reciprocating piston rods at the output ends of the two sides of a garment tensioning air cylinder respectively. The turning-free sewing equipment is reasonable in structural design, clothes can be efficiently and accurately transferred to a required sewing station, stable and smooth automatic sewing processing of hems is achieved, and the requirements of production and use are met.

Owner:亘美集团有限公司

Automatic packaging box stacking device

ActiveCN111153224AReasonable structural designEfficient and stable adjustment stationStacking articlesDe-stacking articlesStructural engineeringMechanical equipment

The invention discloses an automatic packaging box stacking device and belongs to the field of packaging processing mechanical equipment. A box storage feeding support, a box storage stacking supportand a box storage discharging support of the automatic packaging box stacking device are sequentially and fixedly arranged in the horizontal conveying direction of packaging boxes. Multiple front boxconveying rollers are sequentially and rotationally connected to a front box conveying support in the horizontal direction. A box carrying lifting mechanism is horizontally and fixedly arranged on theportion, on the lower side of the front box conveying support, of the box storage feeding support. A rotation reversing mechanism is horizontally and fixedly arranged on the portion, above the box carrying lifting mechanism, of the front box conveying support. A box clamping fixing mechanism and a box storage lifting mechanism are sequentially and fixedly arranged on the box storage stacking support in the vertical direction from top to bottom. Multiple rear box conveying rollers are sequentially and rotationally connected to a rear box conveying support in the horizontal direction. The automatic packaging box stacking device is reasonable in structural design, the packaging boxes can be efficiently and stably stacked sequentially, operation is reliable, packaging box stacking efficiencyand quality can be guaranteed, the packaging box stacking automation degree is increased, and the requirements of production and use are met.

Owner:上海晟诠包装制品有限公司

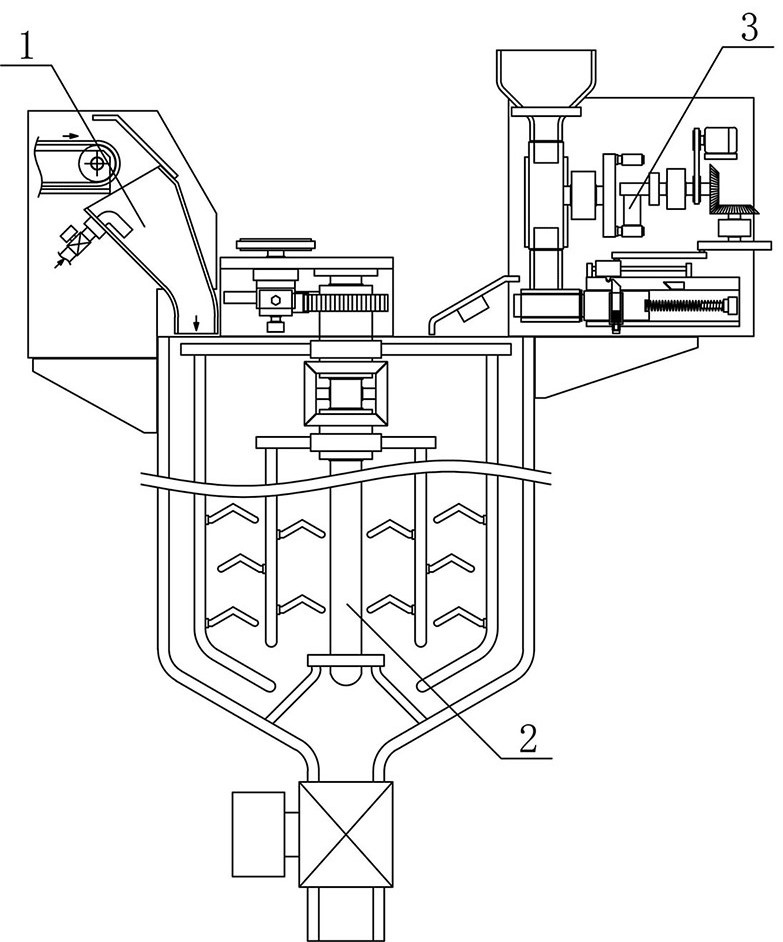

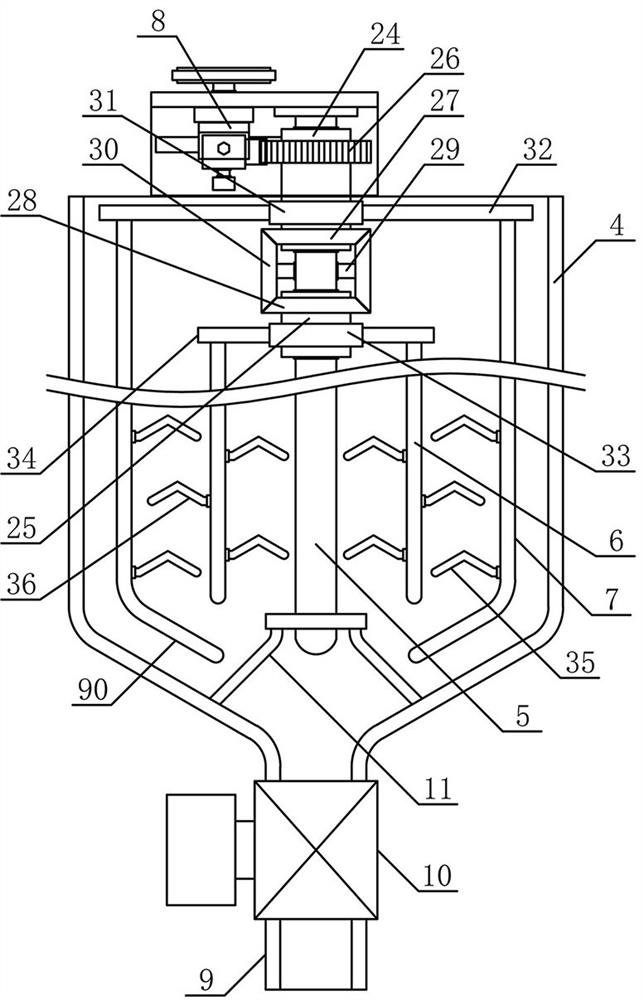

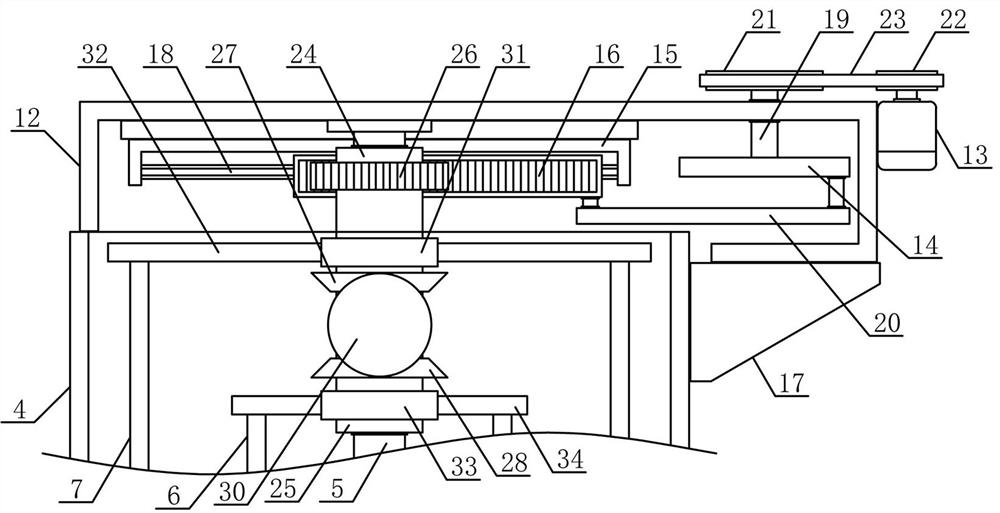

Processing system for steel pipe filled concrete

ActiveCN112356278AEfficient productionReasonable structural designMixing operation control apparatusCement mixing apparatusCircular discArchitectural engineering

The invention discloses a processing system for steel pipe filled concrete, and belongs to the field of building material processing mechanical equipment. A main material conveying mechanism and an auxiliary material filling mechanism are arranged on the two sides of the upper portion of a processing stirring mechanism, a stirring driving mechanism of the processing stirring mechanism is fixedly arranged on the upper side of a preparation stirring tank, processing outer stirring rods are arranged on the lower sides of the outer ends of a plurality of outer stirring supporting connecting plateson the outer side of an outer stirring fixing sleeve, processing inner stirring rods are vertically and fixedly arranged on the lower sides of the outer ends of a plurality of inner stirring supporting connecting plates on the outer side of an inner stirring fixing sleeve, a feeding guide pipe is arranged on a main material conveying support, auxiliary material storage grooves are formed in the two sides of a guide rotating disc respectively, and an auxiliary material pushing mechanism is arranged on an auxiliary material guide support on the adjacent side of an auxiliary material filling guide pipe. The processing system for steel pipe filled concrete is reasonable in structural design, can be used for quickly and efficiently producing and preparing the steel pipe filled concrete, can beused for conveniently and accurately adding production auxiliary materials as required, is high in processing automation degree and meets the requirements of production and use.

Owner:桐乡市钟大建材有限公司

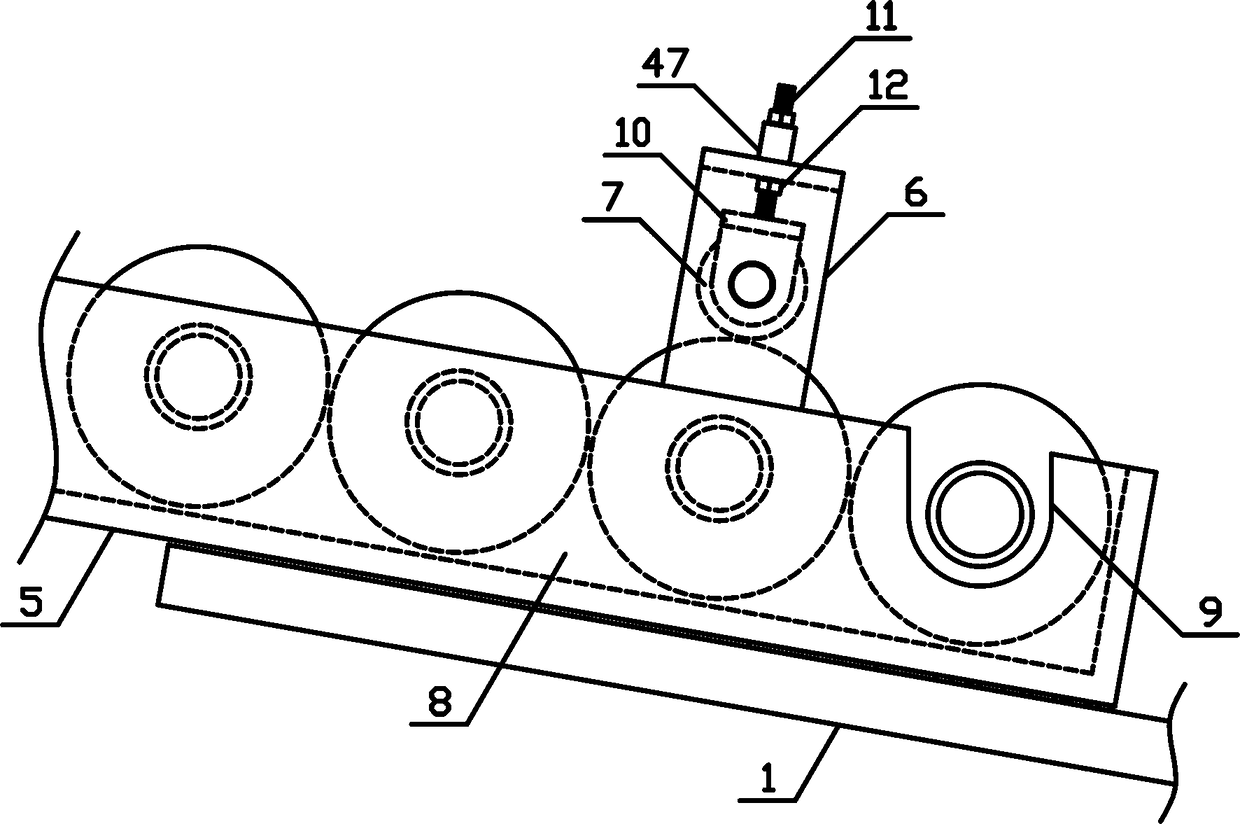

Textile yarn roll continuous feeding device

ActiveCN110803585ARealize flat pushHigh degree of automationFilament handlingConveyor partsTextile yarnMechanical equipment

The invention discloses a textile yarn roll continuous feeding device, and belongs to the field of textile processing mechanical equipment. A roll pushing and translation plate of the device is placedon the upper side of an unwinding bearing plate, the two ends of one side of the roll pushing and translation plate are fixedly connected with ends of roll pushing guide rods on the two sides of a guide rod support, a reciprocating guide plate sliding groove is formed in the upper side of a roll moving rotary plate, a roll pushing guide plate is arranged in the reciprocating guide plate sliding groove, and the output end of a roll pushing cylinder is fixedly connected with one side of the roll pushing guide plate. A roll clamping mechanism is fixedly arranged on the upper side of the roll pushing guide plate, two sides of a roll feeding chain are in wound connection with an upper rotating chain wheel and a lower rotating chain wheel respectively, a lifting support is vertically and slidably arranged on a lifting guide rod, the upper and lower ends of one side of the roll feeding chain are fixedly connected with the upper and lower sides of the lifting support respectively, and a rollfeeding baring plate is horizontally and fixedly disposed on one side of a horizontal pushing connecting plate. The device is reasonable in structural design, textile yarn rolls can be quickly and efficiently transferred and conveyed stably and smoothly one by one, the automation degree of feeding is high, and production and use requirements are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

Internet of Things engineering communication equipment

ActiveCN111131056AScientific and reasonable structureEasy to useData switching networksSelection arrangementsEngineering communicationEmbedded system

The invention discloses Internet of Things engineering communication equipment, which comprises a router; a WAN interface and an LAN interface are fixedly connected to the left side and the right sideof the front surface of the router respectively, a base is fixedly connected to the bottom of the router, antennas are arranged on the left side and the right side of the router respectively, and a clamping assembly is arranged on the front surface of the router. Through cooperation ofthe router, the base, the antenna and the clamping assembly, when an external plug is connected with aWAN interface or anLAN interface, the plugcan be clamped through the opposite movement of the two clamping plates; the situation of poor contact caused by accidental dislocation of the plug is avoided; through cooperation of the router, the base, the antenna and anadjusting assembly, when supporting the antenna, the antenna can be fixed through clamping connection of a pawl and a gear, the antenna is prevented from deviating and inclining due to accidental stress in use, and the signal receiving and transmitting effect is greatly improved.

Owner:无锡辰涵信息科技有限公司

Automatic conveying device of metal round pipes

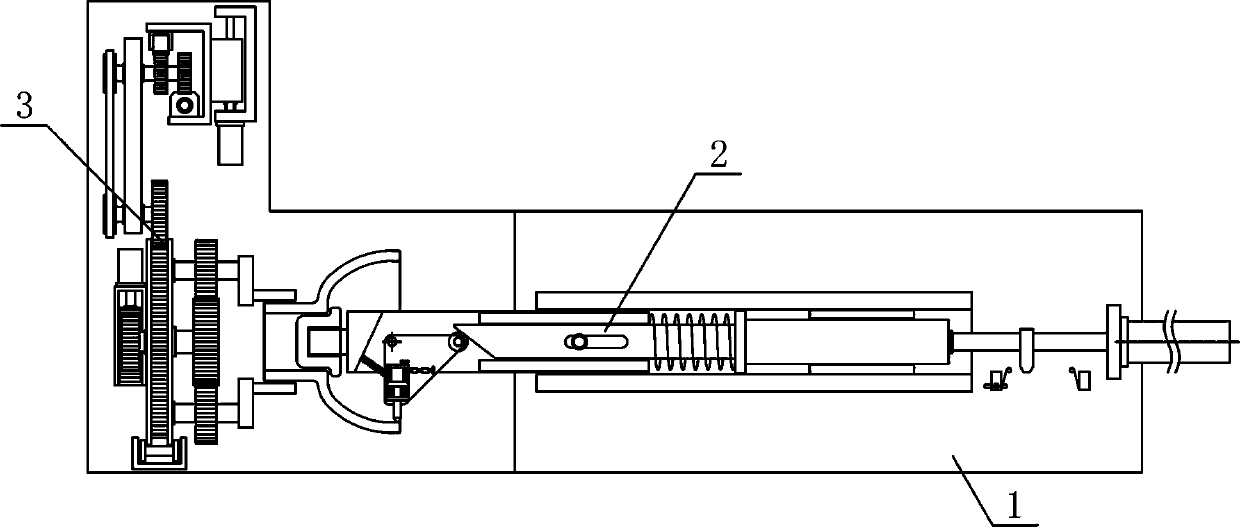

ActiveCN111532754ARealize automatic flipConvenient and smooth translation guideConveyorsConveyor partsCircular discPipe fitting

The invention discloses an automatic conveying device of metal round pipes and belongs to the field of pipe fitting conveying mechanical equipment. A round pipe falling mechanism and a round pipe transferring mechanism are sequentially arranged on a round pipe conveying support from top to bottom. A round pipe overturning mechanism is arranged at the position, on one side of the round pipe transferring mechanism, of the round pipe conveying support. A pipe bearing falling mechanism and a falling rotating disc are arranged on the two sides of a round pipe falling guide pipe correspondingly. A round pipe transferring bearing plate is arranged on a horizontal moving limiting support in a sliding manner. A reciprocating rotating round plate is arranged on a guide plate rotating support. A round pipe overturning containing chamber of a square structure is arranged on the outer side of the reciprocating rotating round plate. A round pipe conveying belt is arranged at the position, on one side of the lower end of the reciprocating rotating round plate, of the round pipe conveying support. The automatic conveying device is reasonable in structural design, the metal round pipes can be stably and efficiently guided and conveyed one by one smoothly and continuously, the metal round pipes can be automatically and accurately overturned to adjust the stations, the automatic degree of metal round pipe conveying is increased, and the machining use requirement is met.

Owner:肇庆智达自动化设备有限公司

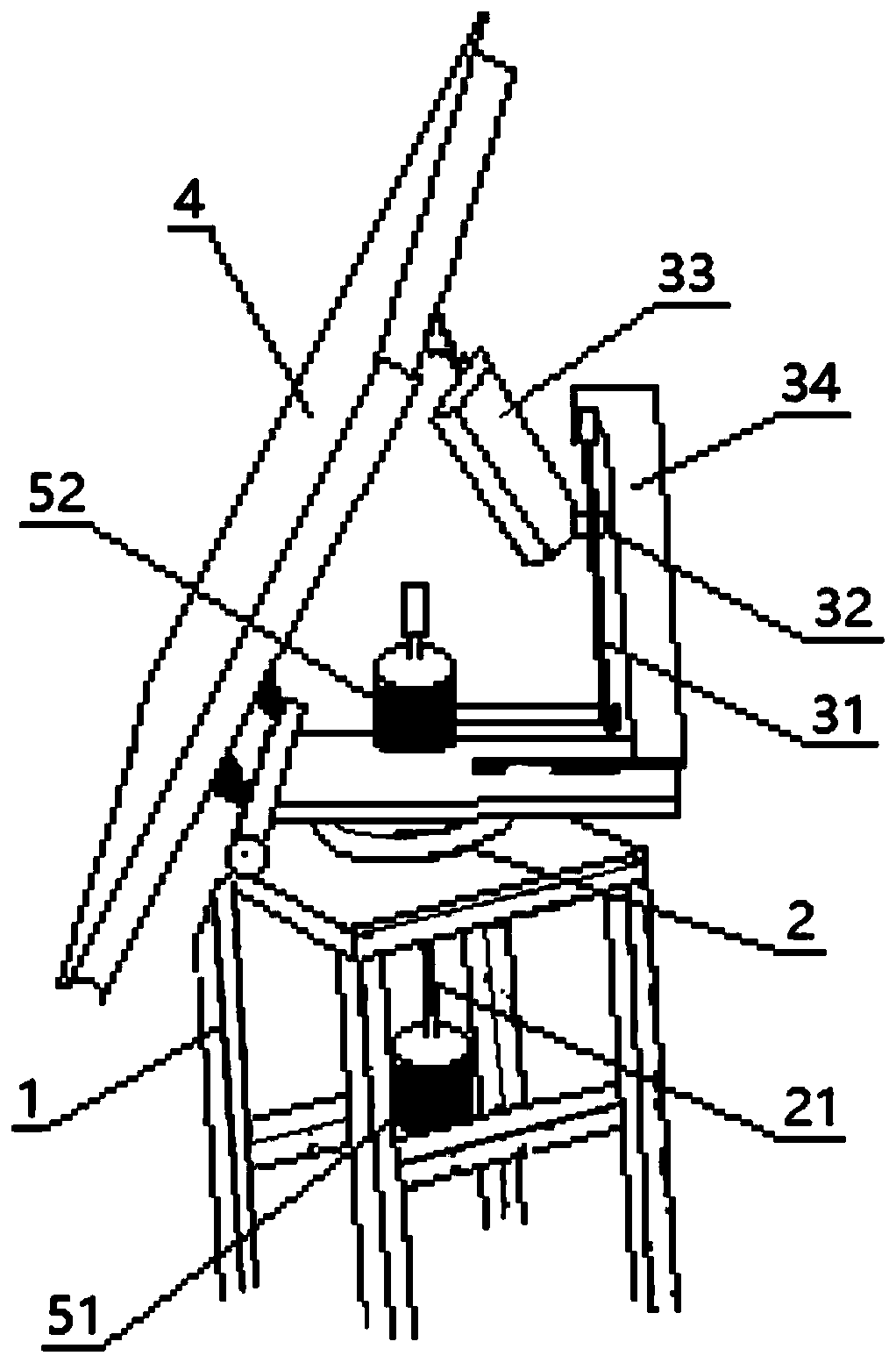

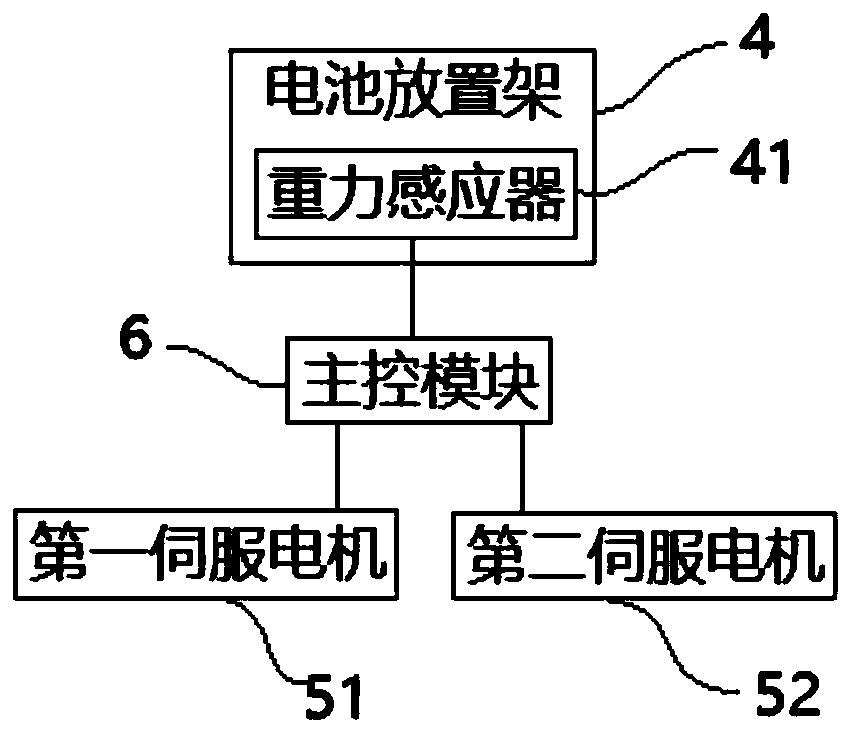

Solar cell panel angle adjusting support

InactiveCN110707999APromote absorptionPrecise adjustment and controlPhotovoltaic supportsSolar heating energyElectrical batteryEngineering

The invention discloses a solar cell panel angle adjusting support which comprises a base; a rotating table is movably arranged on the base; a lifting module and a battery placing frame used for installing a solar cell panel are arranged on the rotating table; one end of the battery placing frame is hinged to the rotating table, and the other end of the battery placing frame is in transmission connection with the lifting module. The rotating table is arranged on the base to drive the horizontal angle of the solar cell panel to change; the lifting module is arranged on the base, so that the placing angle of the solar cell panel is adjusted, the angle of the solar cell panel can be adjusted according to the irradiation direction of sunlight in different time periods every day and the heightof the sun in different seasons; the solar cell panel is always kept in the most efficient sunlight utilization state, and the power generation efficiency is improved.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Working method of packaging box stacking device

InactiveCN112607434AEfficient and stable adjustment stationSmooth and firm clampingStacking articlesConveyor partsStructural engineeringMechanical equipment

The invention discloses a working method of a packaging box stacking device, and belongs to the field of packaging machining mechanical equipment. A storage box feeding support, a storage box stacking support and a storage box discharging support are sequentially and fixedly arranged in a horizontal conveying direction of packaging boxes, a plurality of front box conveying rotating rollers are sequentially and rotatably connected to a front box conveying support in the horizontal direction, and a box bearing lifting mechanism is horizontally and fixedly arranged on the storage box feeding support on the lower side of the front box conveying support. A rotary reversing mechanism is horizontally and fixedly arranged on the front box conveying support above the box bearing lifting mechanism, a box clamping fixing mechanism and a storage box lifting mechanism are sequentially and fixedly arranged on the storage box stacking support from top to bottom in the vertical direction, and a rear box conveying support is sequentially and rotatably connected with a plurality of rear box conveying rollers in the horizontal direction. The working method is reasonable in structural design, the packing boxes can be efficiently and stably stacked in sequence, operation is reliable, the packing box stacking efficiency and quality can be ensured, the packing box stacking automation degree is improved, and the production and use requirements are met.

Owner:潘宇力

Concrete pouring guide mechanism

PendingCN114718319AEasy to moveConvenient and smooth translation adjustmentHydro energy generationBuilding material handlingConstruction automationMechanical equipment

The invention discloses a concrete pouring material guiding mechanism, and belongs to the field of building construction mechanical equipment. A plurality of universal wheels with brakes are evenly arranged on the lower side of a pouring material guide frame, a reciprocating flat guide plate is horizontally arranged on a reciprocating flat guide rail in a sliding mode, material guide auxiliary gears are arranged on the two sides of a material guide driving rotating shaft below the reciprocating flat guide plate respectively, and the material guide auxiliary gears are connected with a translation rack below the reciprocating flat guide plate in a meshed mode. A material guiding main gear is vertically and fixedly arranged at the end of one side of the material pouring driving rotating shaft, a translation driving mechanism is arranged on the pouring material guiding frame on the side adjacent to the material guiding main gear, the reciprocating material distributing mechanism is horizontally arranged at the end of the reciprocating flat guide plate, and the material distributing driving mechanism is adjacent to the reciprocating flat guide plate on the side adjacent to the reciprocating material distributing mechanism. The concrete pouring device is reasonable in structural design, the concrete guide pipe can perform efficient and stable translational motion in the pouring process, efficient and uniform falling and pouring of concrete are achieved, the automation degree of concrete pouring construction is improved, and the use requirements of buildings are met.

Owner:桐乡市钟大建材有限公司

Film conveying device

ActiveCN113023412AConvenient and smooth pressing and fixingSmooth and smooth rotation unwindingWebs handlingThin membraneTransfer mechanism

The invention discloses a film conveying device, and belongs to the field of film conveying mechanical equipment. The film conveying device comprises a film conveying support, a film unwinding mechanism, a film drawing and transferring mechanism, a film gluing mechanism and a film pressing and fixing mechanism. The film unwinding mechanism and the film pressing and fixing mechanism are sequentially and fixedly arranged on the lower side of the film conveying support in the horizontal direction, the film drawing and transferring mechanism is horizontally arranged on the upper side of the film conveying support, the film gluing mechanism is arranged adjacent to the film conveying support on one side above the film pressing and fixing mechanism, and the film conveying support on one side of the film unwinding mechanism is horizontally and rotationally connected with a front film guiding rotating roller and a rear film guiding rotating roller in sequence in the horizontal direction. The film conveying device is reasonable in structural design, films can be efficiently, stably, accurately and smoothly guided and conveyed, the ends of the two rolls of films conveyed in sequence can be rapidly and conveniently bonded in the film roll changing process, the film conveying automation degree is improved, and the production and use requirements are met.

Owner:浙江耀阳新材料科技有限公司

Using method of workpiece continuous press mounting device

InactiveCN111571161ASmooth and efficient transferRealize automatic assemblyMetal working apparatusCircular discGear wheel

The invention discloses a using method of a workpiece continuous press mounting device, and belongs to the field of workpiece machining machinery. A workpiece transfer mechanism and a workpiece pressmounting mechanism are sequentially arranged on the upper side of a workpiece machining bracket, a material transfer chain is arranged on one side of the upper part of the workpiece machining bracket,a first adsorption connecting plate is horizontally and fixedly arranged at the output end of a first air cylinder, a second adsorption connecting plate is horizontally and fixedly arranged at the output end of a second air cylinder, a material placing bearing plate is horizontally arranged between a first conveyor belt and a second conveyor belt, an annular guide plate is arranged on the outer side of the upper part of a rotating disc, a rotating pressing rod is arranged on the upper side of the rotating disc, the two sides of a press mounting gear are correspondingly connected with a lifting rack and a press mounting rack in an engaged mode, and a lifting connecting rod is arranged between the rotating pressing rod and the lifting rack. According to the using method, the structural design is reasonable, a workpiece can be conveniently and accurately transferred to a required press mounting station, the workpiece can be stably and efficiently machined by press mounting, the degree ofautomation is high, and the needs of machining and using are met.

Owner:黄明珠

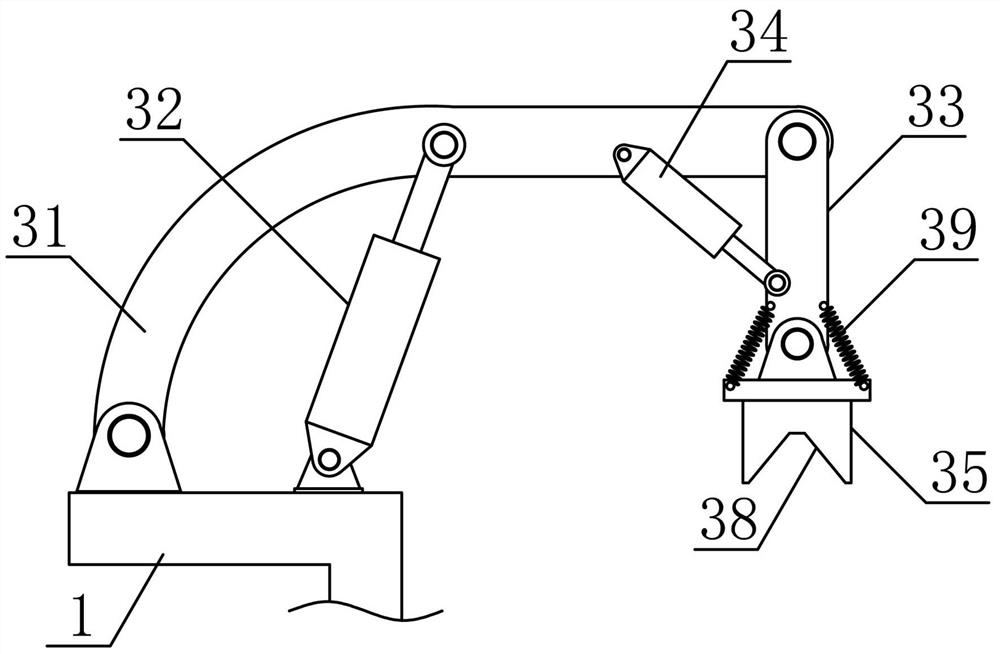

A positioning and clamping device for a clothing display rack

The invention discloses a positioning and clamping device for a clothing display rack, which belongs to the technical field of display equipment processing machinery. The material guide bracket of the invention rotates horizontally in sequence along the horizontal direction to connect a plurality of transfer rollers. The gear rack is matched with the lifting rack, the output end of the lifting cylinder is provided with a positioning connecting plate, the output end of the positioning cylinder is provided with a flat push baffle, and a clamping cylinder is installed between the rotating main clamping rod and the material guide bracket to adjust the inclination of the cylinder. The bottom is arranged between the rotating main clamping rod and the adjusting auxiliary clamping rod, and the clamping clamp is hingedly connected to the lower end of the adjusting auxiliary clamping rod. The invention has a reasonable structural design, can quickly and stably clamp and fix clothing display racks of various sizes and specifications efficiently and accurately, improves the efficiency and quality of the production and processing of the clothing display racks, has a high degree of automation, and meets the needs of processing and use.

Owner:浙江高人道具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com