Patents

Literature

68results about How to "Easy and efficient replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

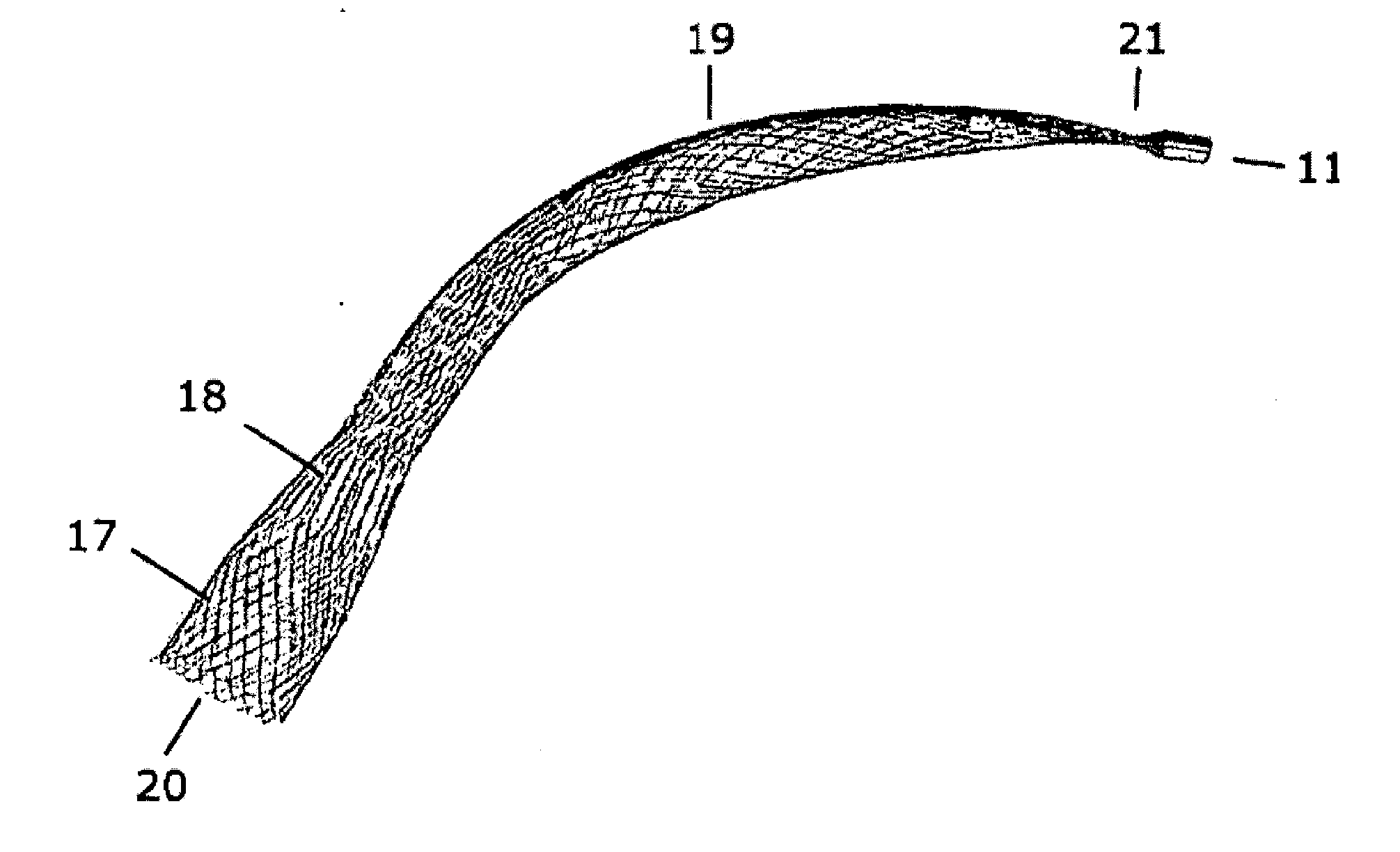

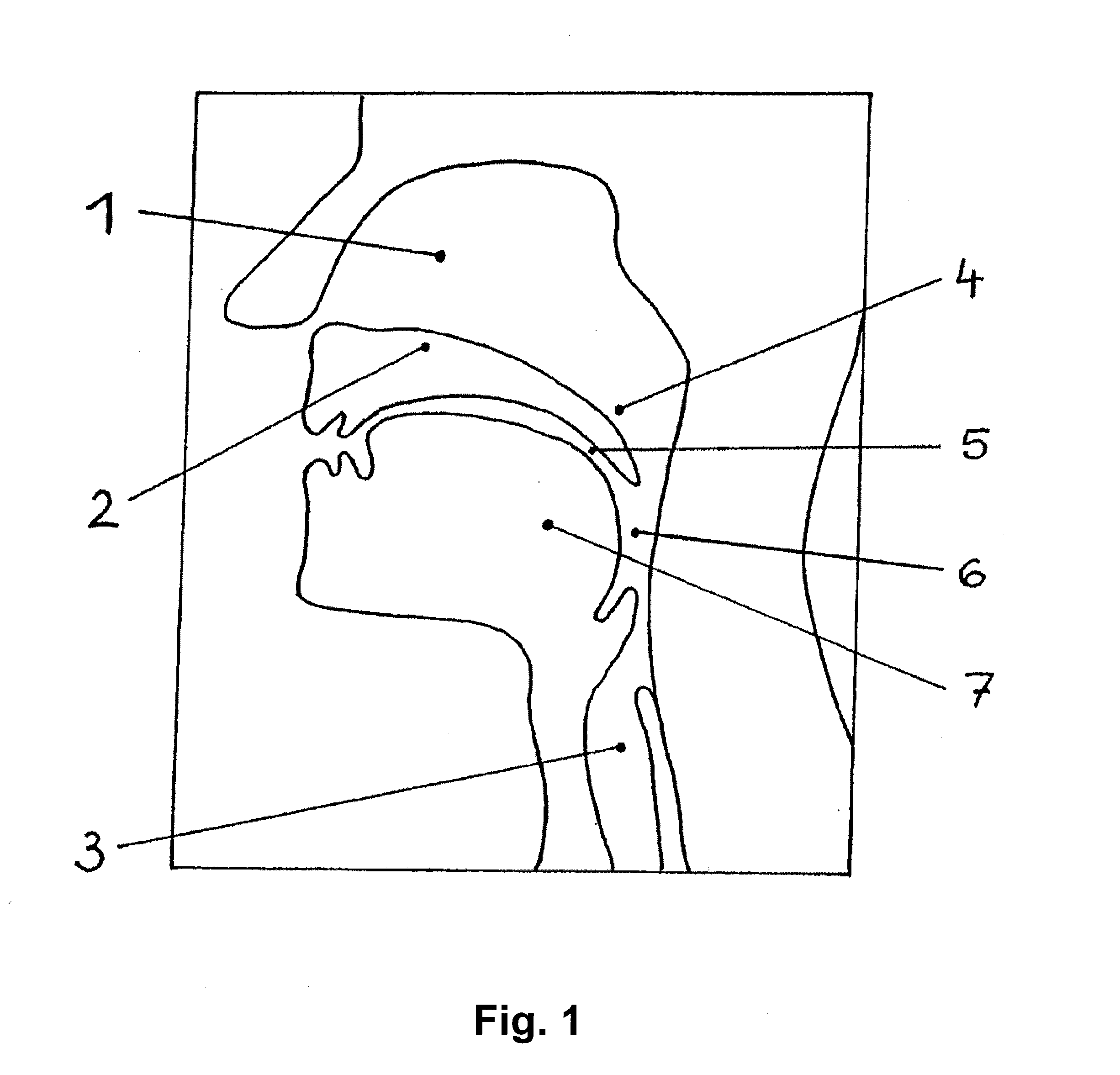

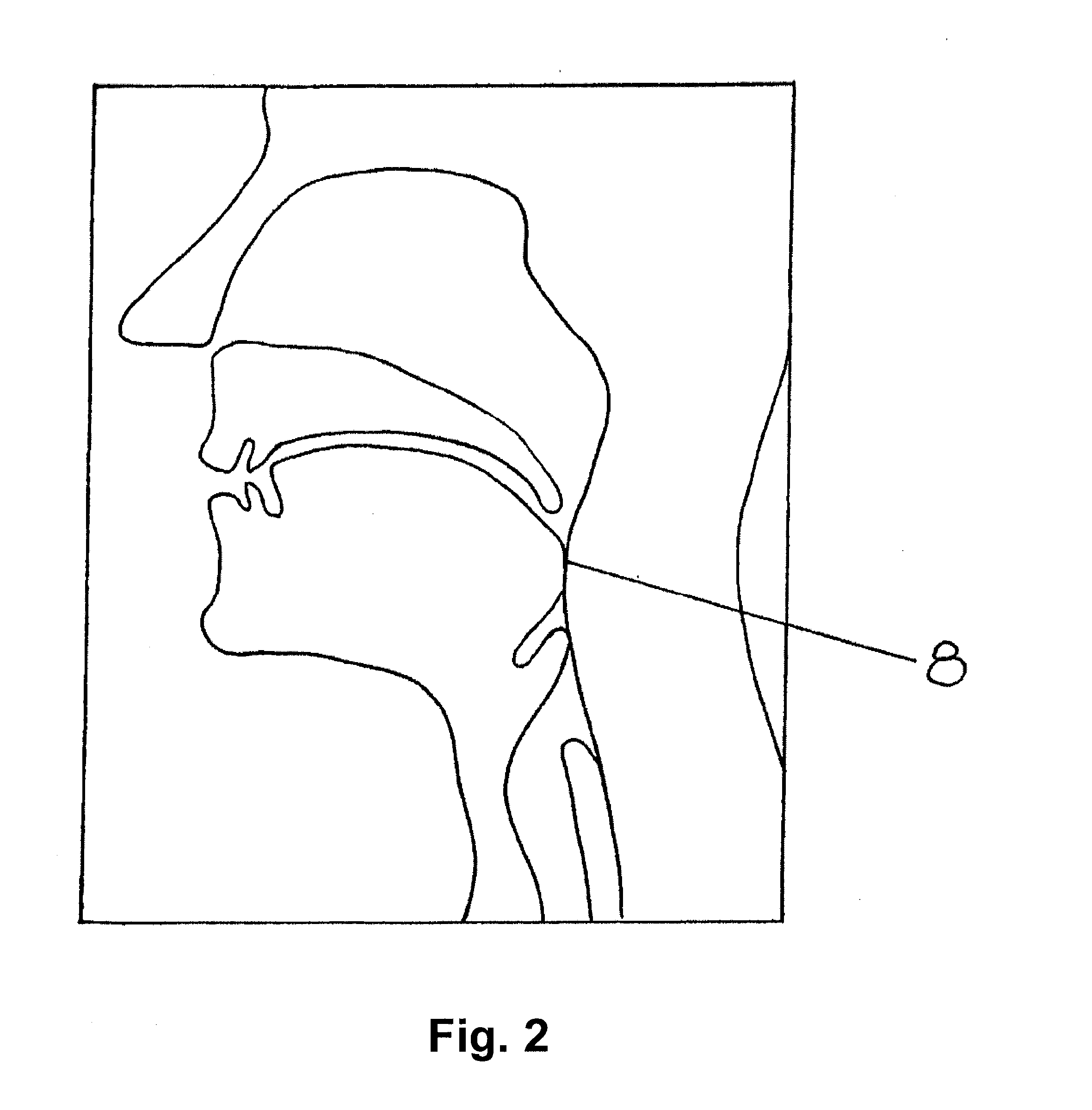

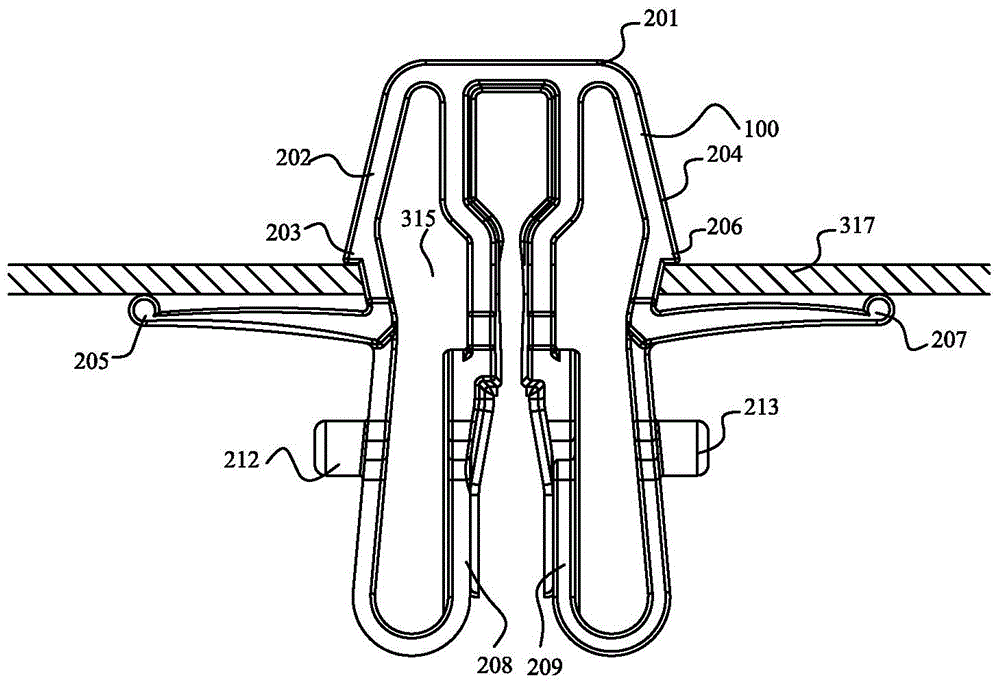

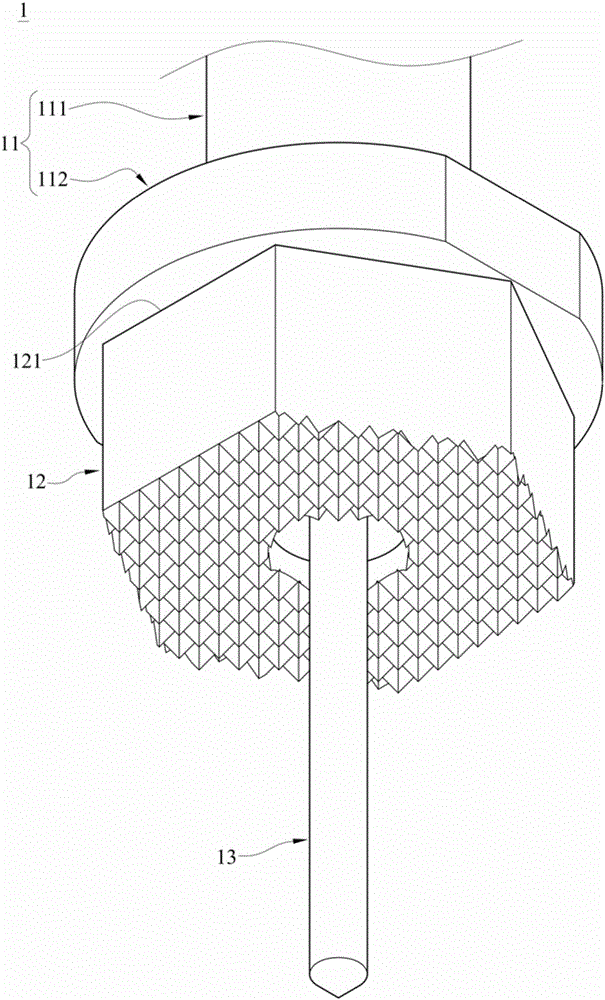

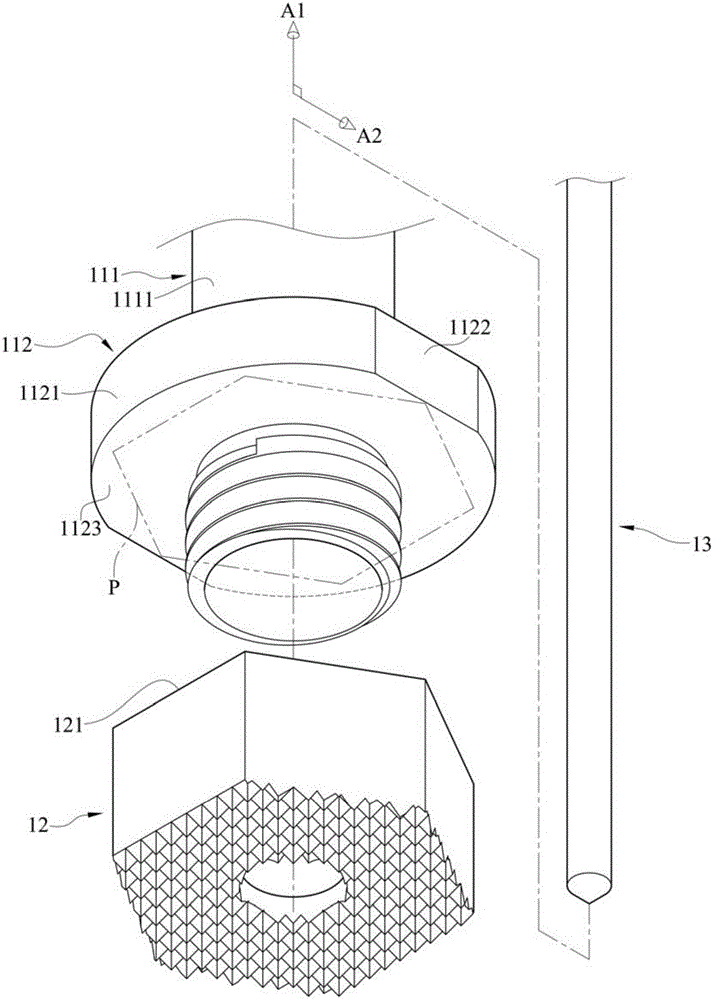

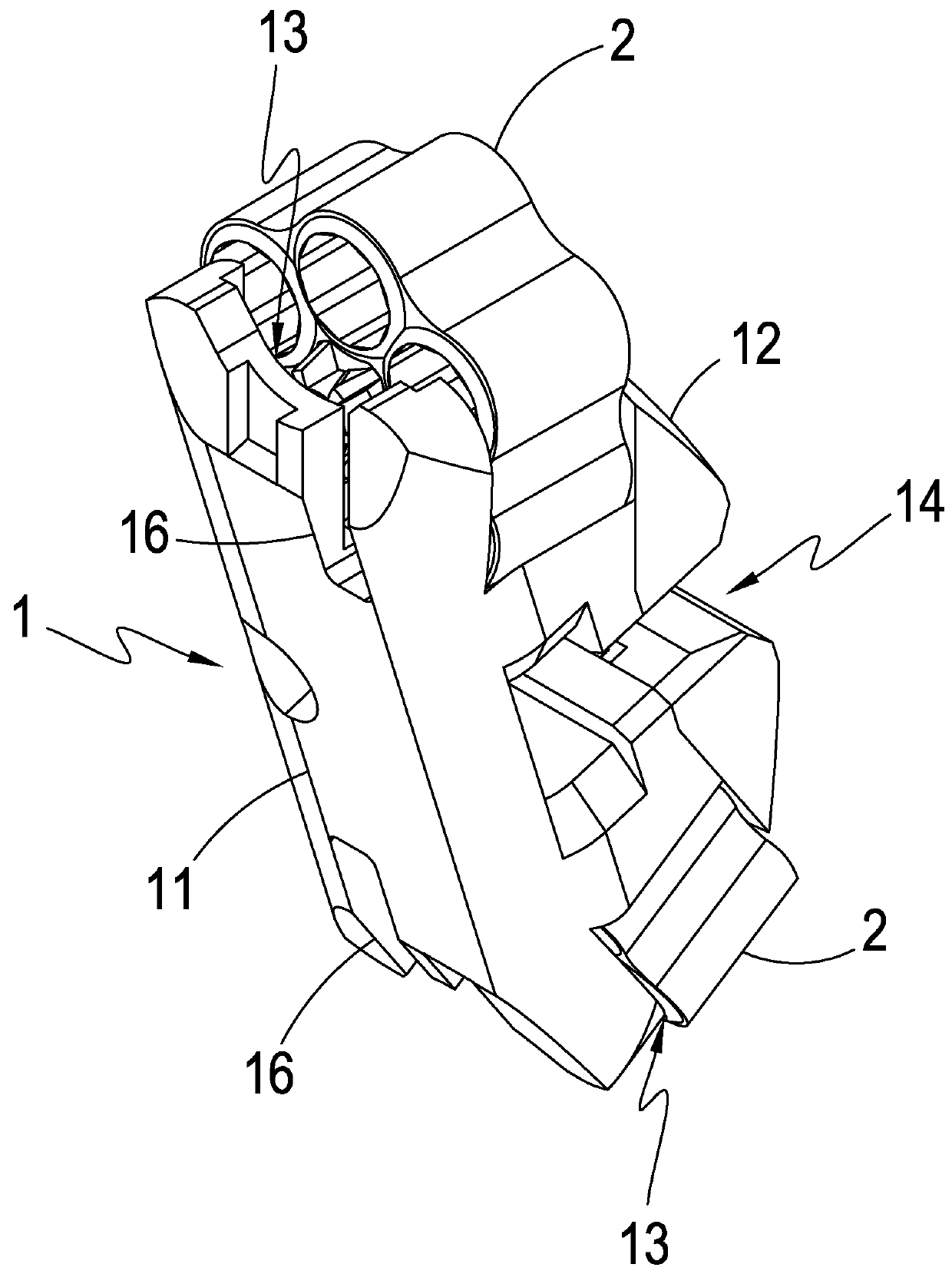

Device for splinting a cavity, organ duct and/or vessel

ActiveUS20130090720A1Easy to disassembleEasy to insertMechanical cleaningPressure cleaningSurgeryAnimal body

The invention relates to a device for splinting and / or maintaining a cavity, an organ duct and or a vessel in a human or animal body, said device including at least one compressible and self-expanding stent that is composed of at least three phases.

Owner:DURING KLAUS

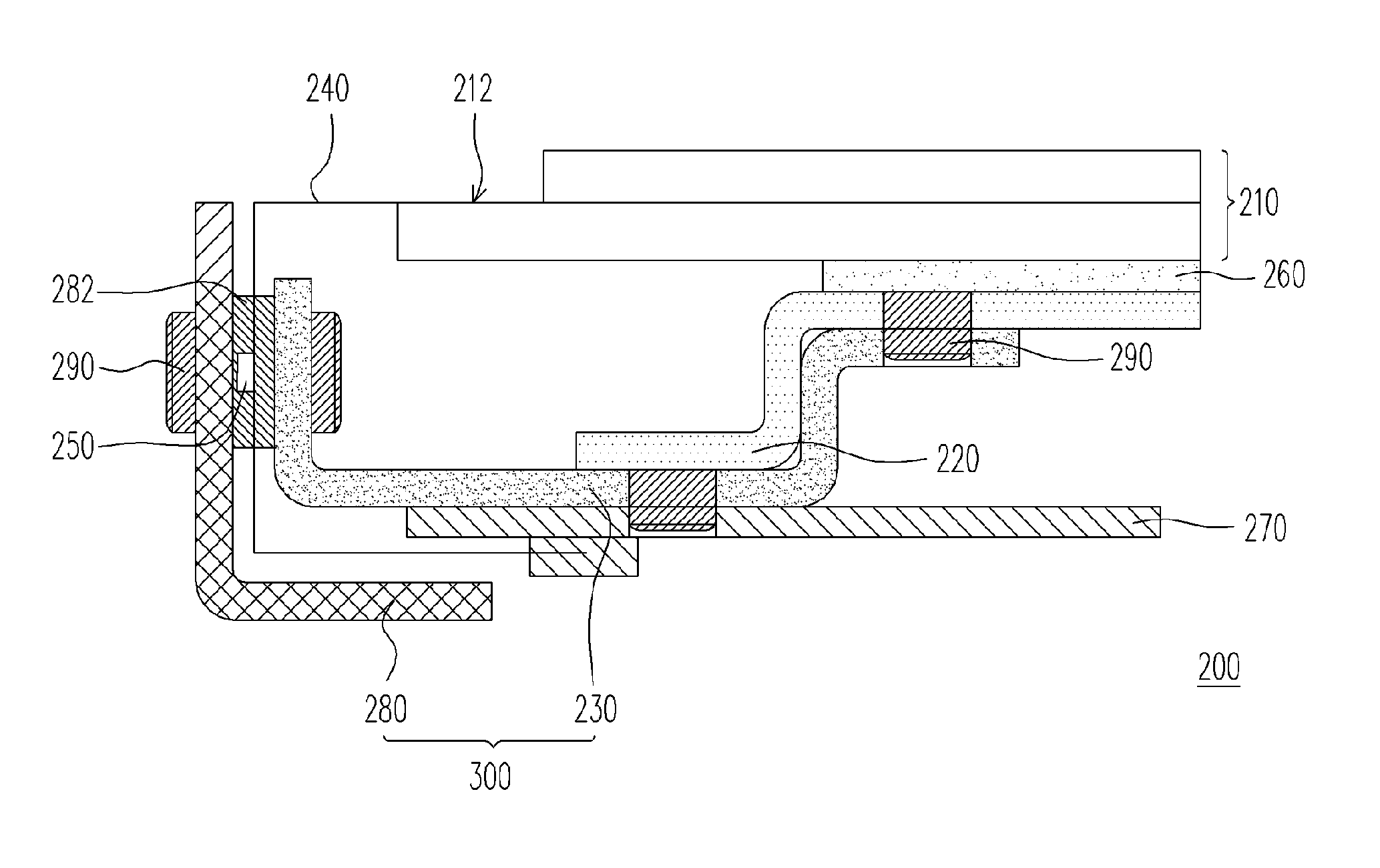

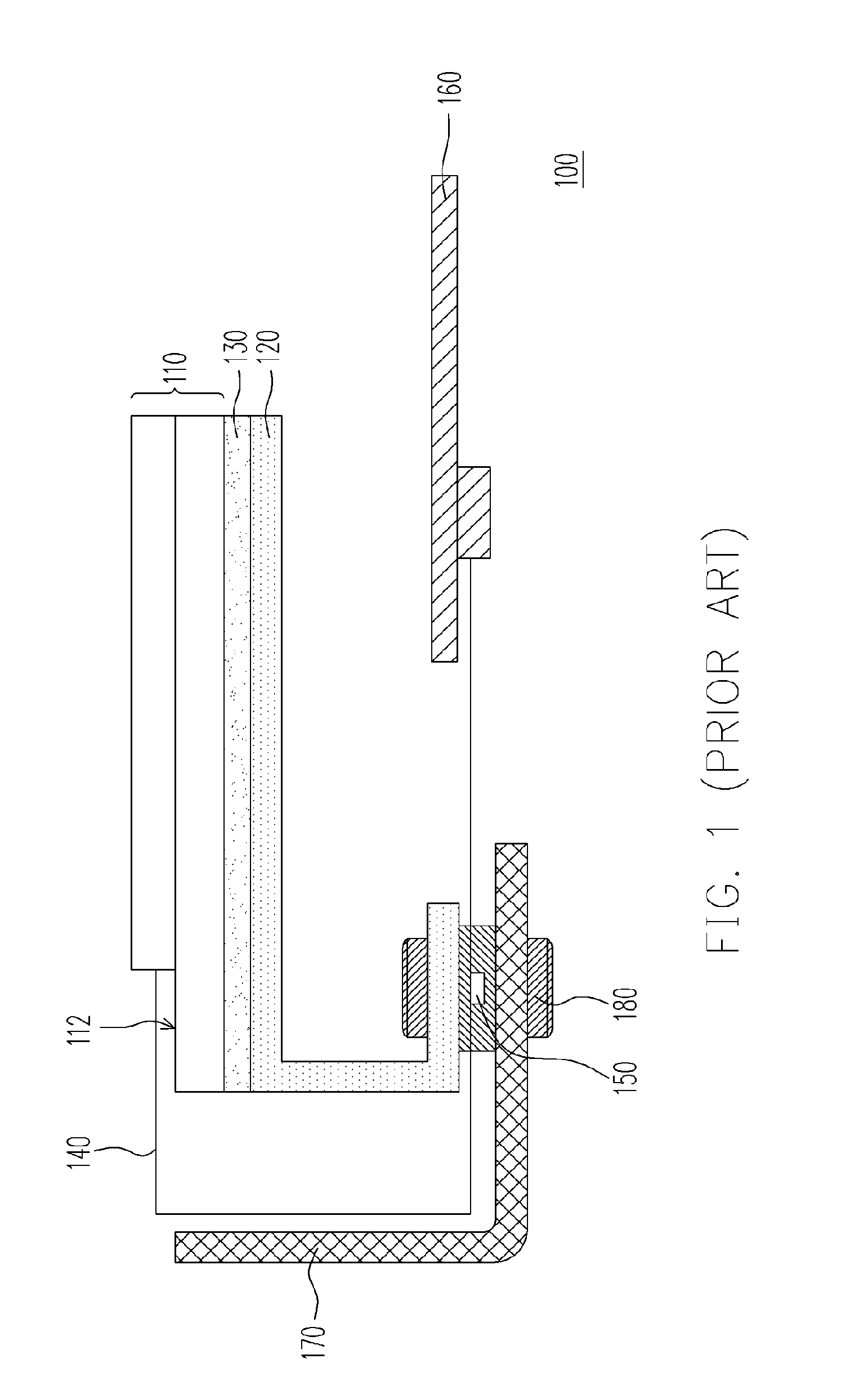

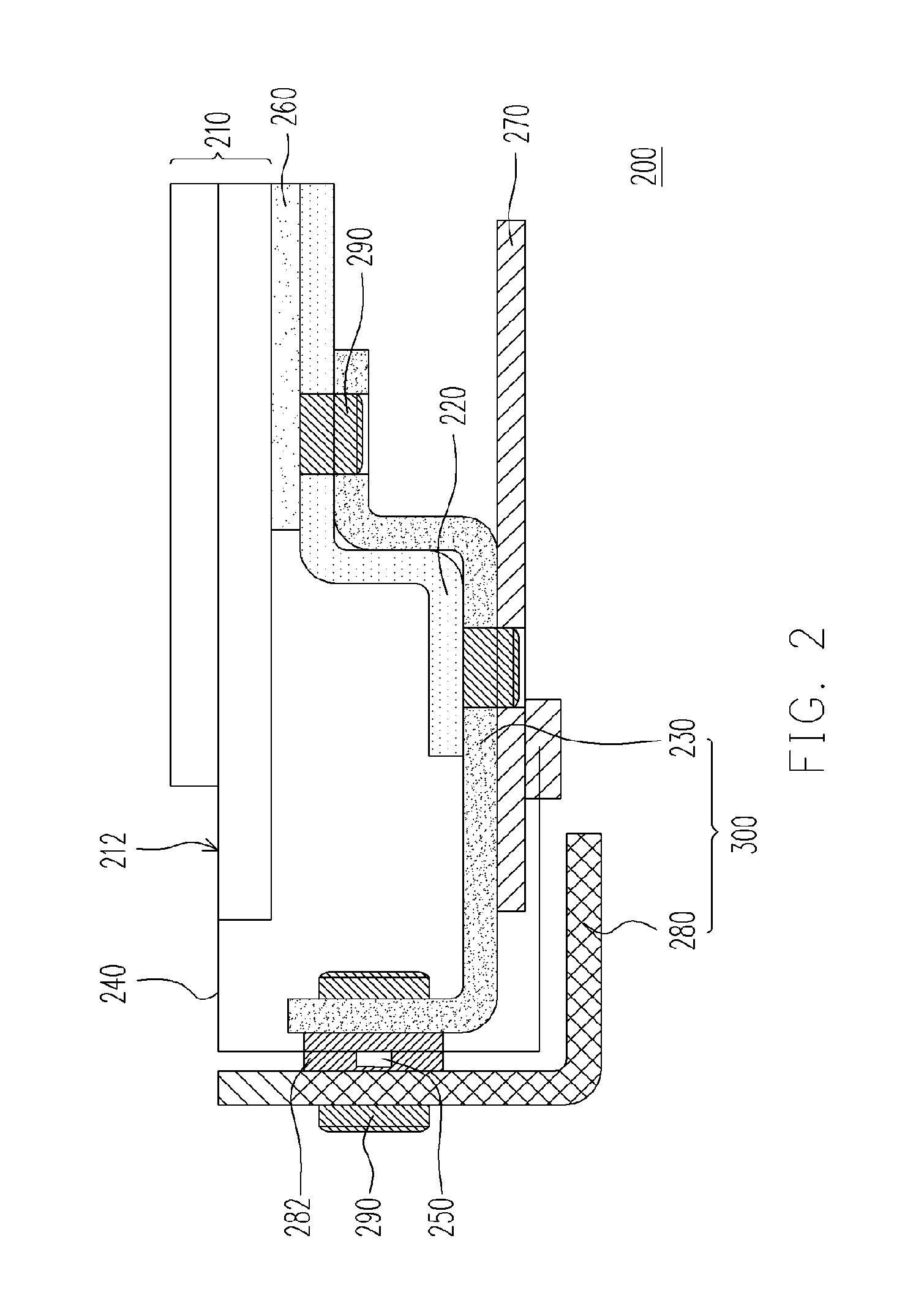

Display device with detachable heat-sink structure thereof

ActiveUS7064952B1Reduce rework timeShorten the lengthCasings/cabinets/drawers detailsNon-linear opticsElectricityDisplay device

A display device comprises a display panel, a back plate, a fixing plate, a flexible printed circuit board and a driving chip. The display panel has a peripheral circuit area. The back plate is fixed on the display panel such that the peripheral circuit area remains exposed. The fixing plate is detachably installed on the back plate, and the flexible printed circuit board is disposed on the fixing plate, wherein the flexible printed circuit board is electrically connected with the peripheral circuit area. The driving chip is electrically connected with the flexible printed circuit board. Compared with the back plate, the driving chip is disposed adjacent to the peripheral circuit area. Because the peripheral circuit area of the display panel is exposed, the flexible printed circuit board can be directly reworked to shorten its rework time on the premise of no separation between the display panel and the back plate.

Owner:NYTELL SOFTWARE LLC

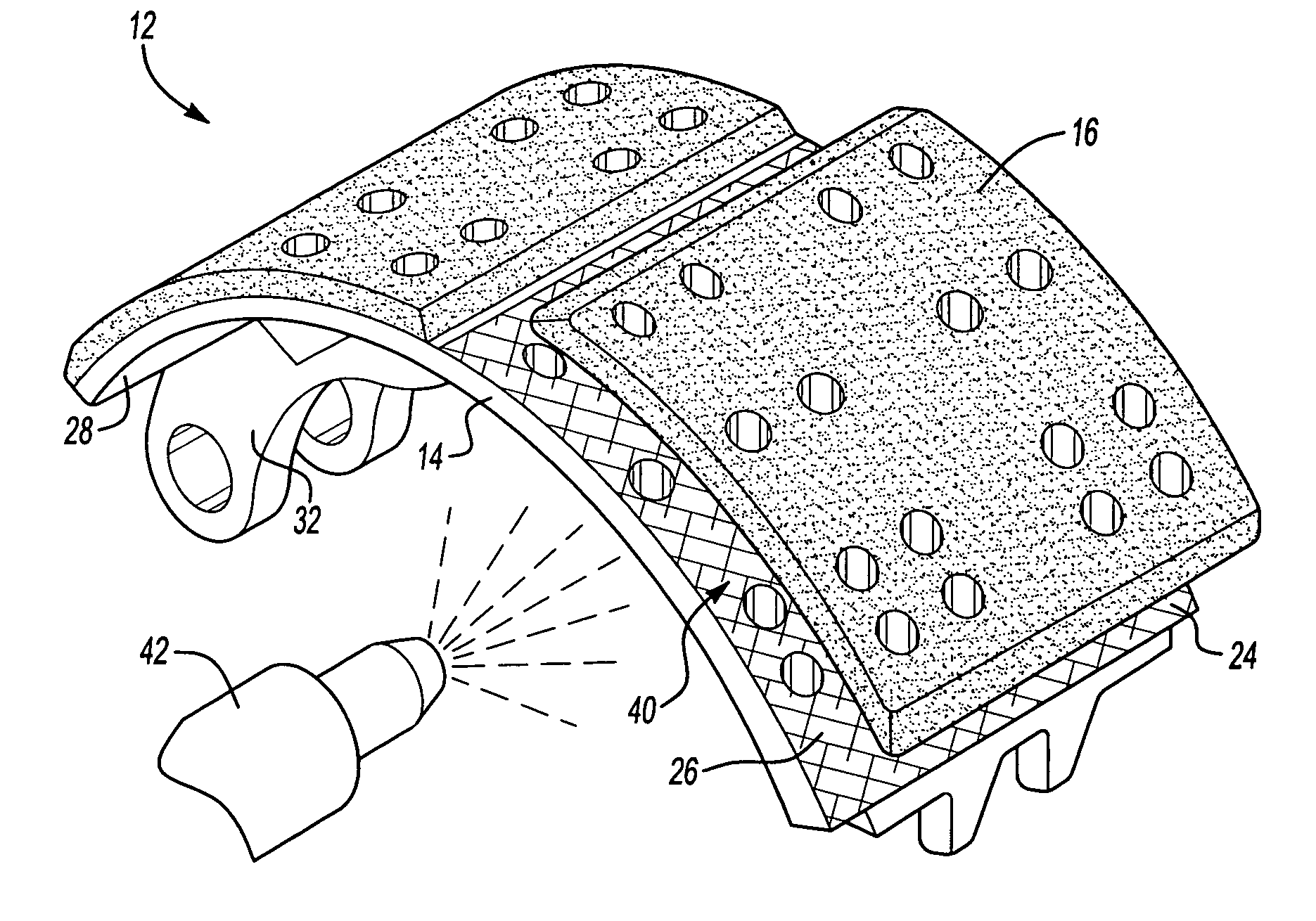

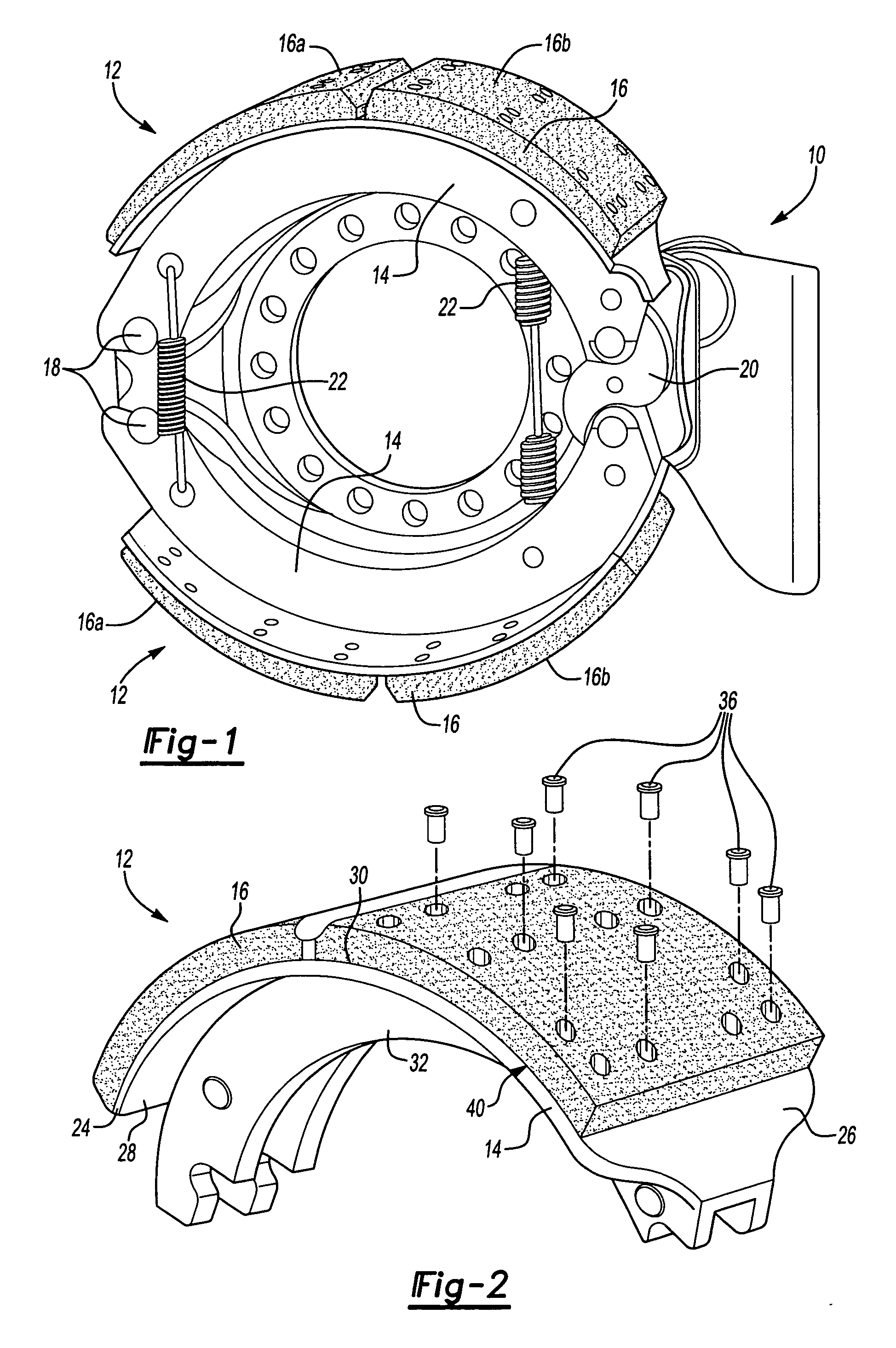

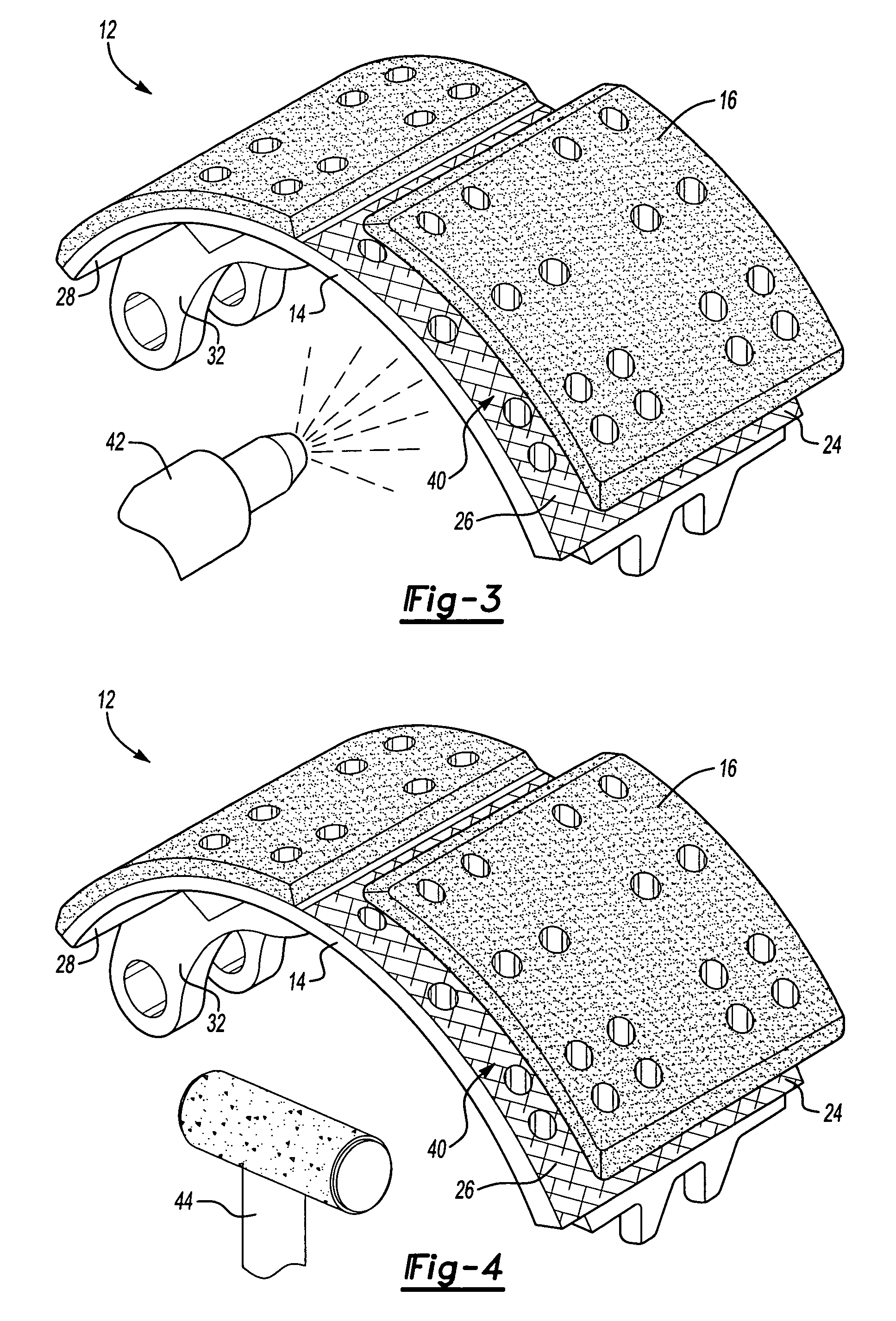

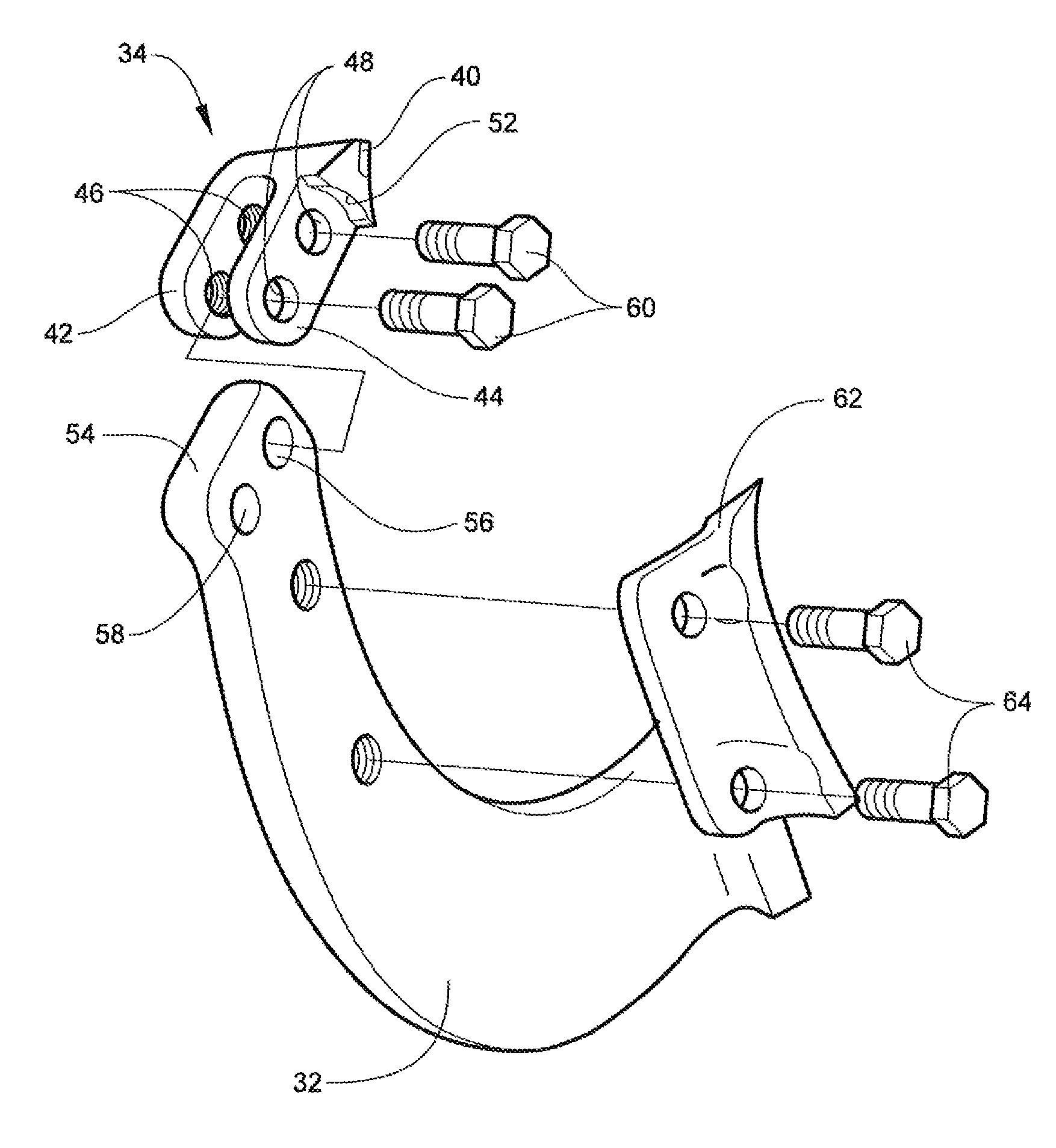

Brake assembly with rust jacking

InactiveUS20070056816A1Avoid corrosionEasy and efficient replacementBraking membersCoatingsEngineeringRust

A brake component assembly includes a support plate and a friction lining mounted to the support plate with a plurality of fasteners. A sealing barrier is formed between the support plate and the friction lining. A liquid material is initially applied to at least one of the support plate and friction lining, which are then fastened together. The liquid material subsequently forms the sealing barrier between the support plate and the friction lining. Optionally, a flexible gasket is used to form the sealing barrier. The flexible gasket is sandwiched between the support plate and friction lining when the support plate and friction lining are fastened together.

Owner:ARVINMERITOR TECH

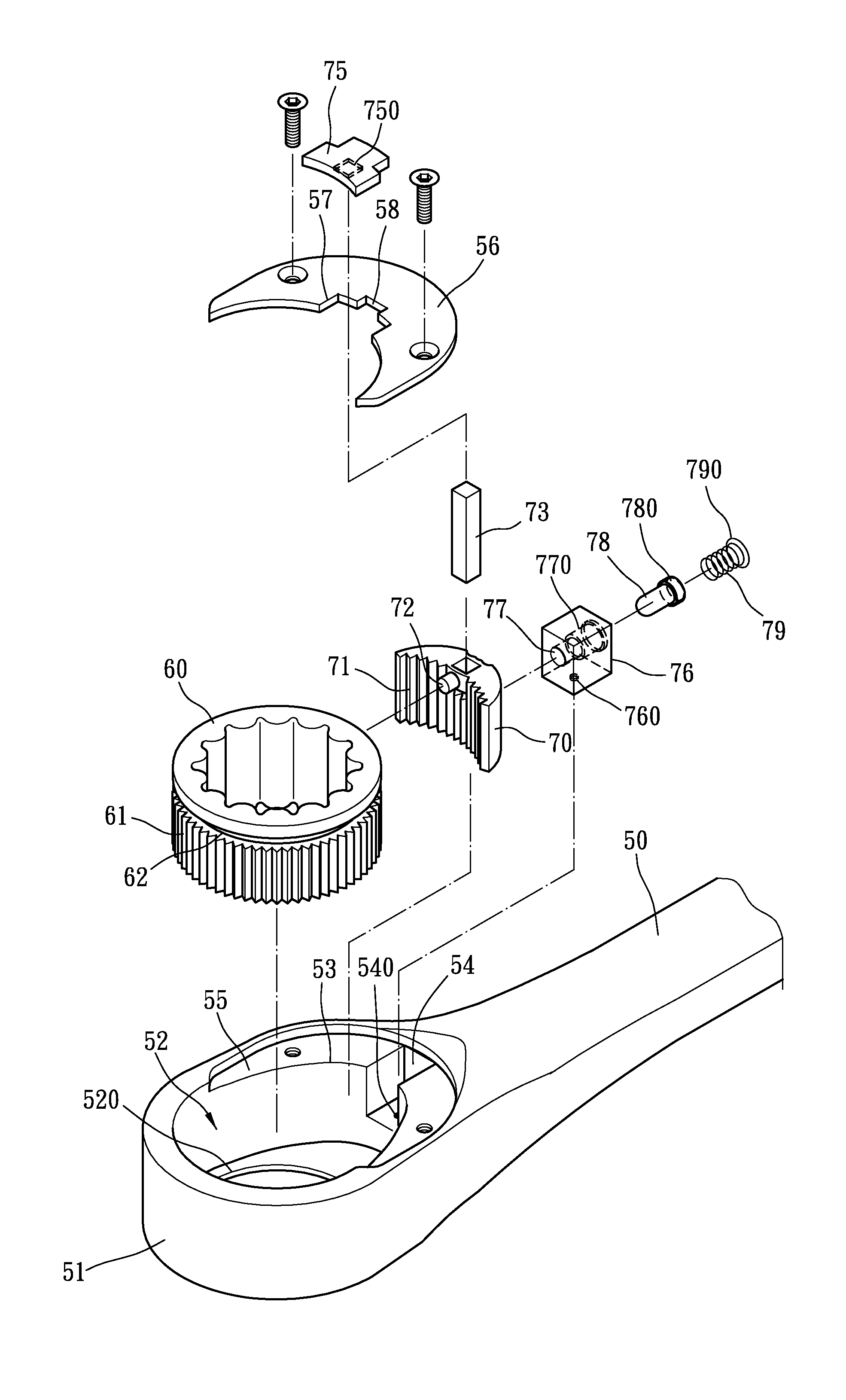

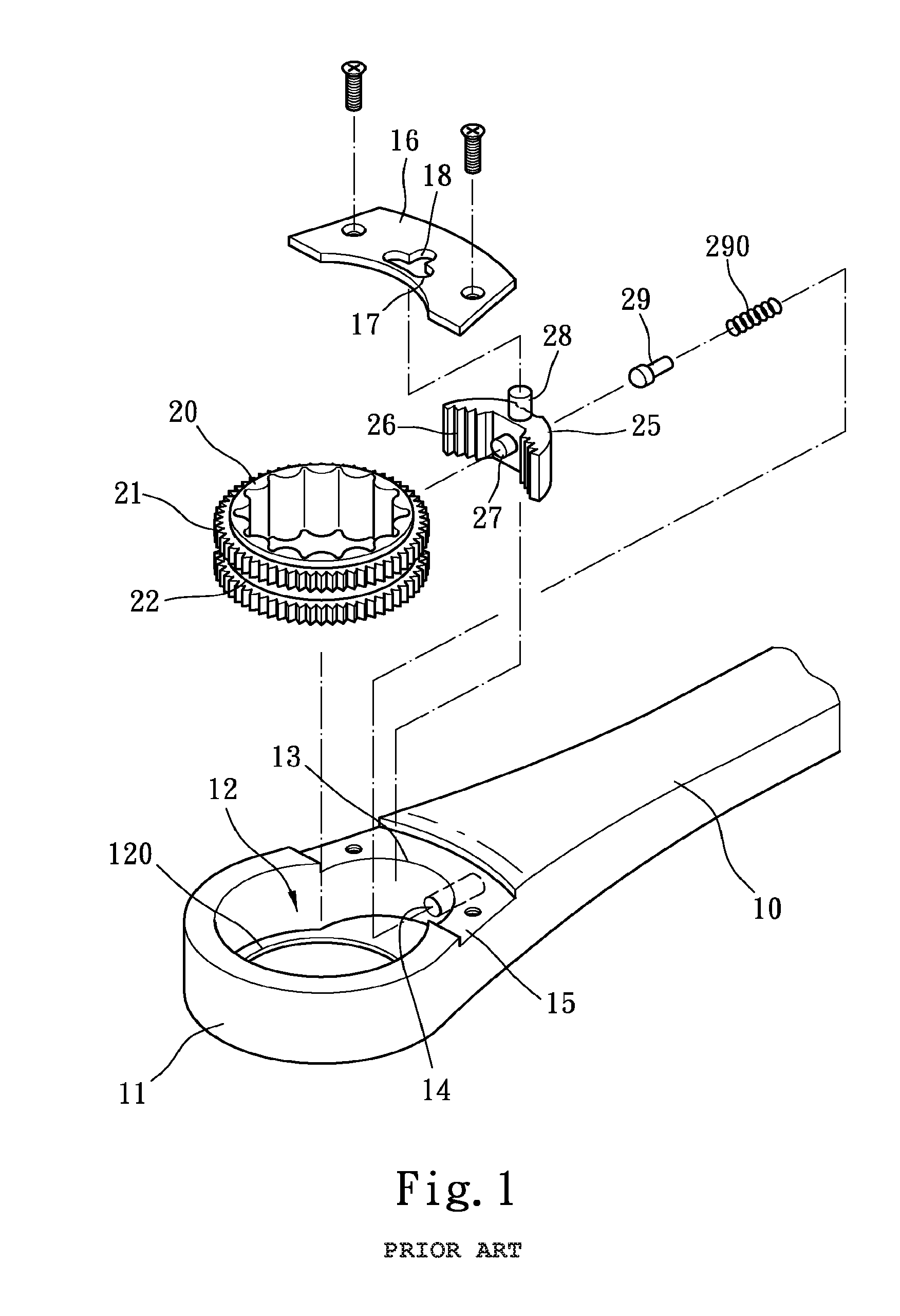

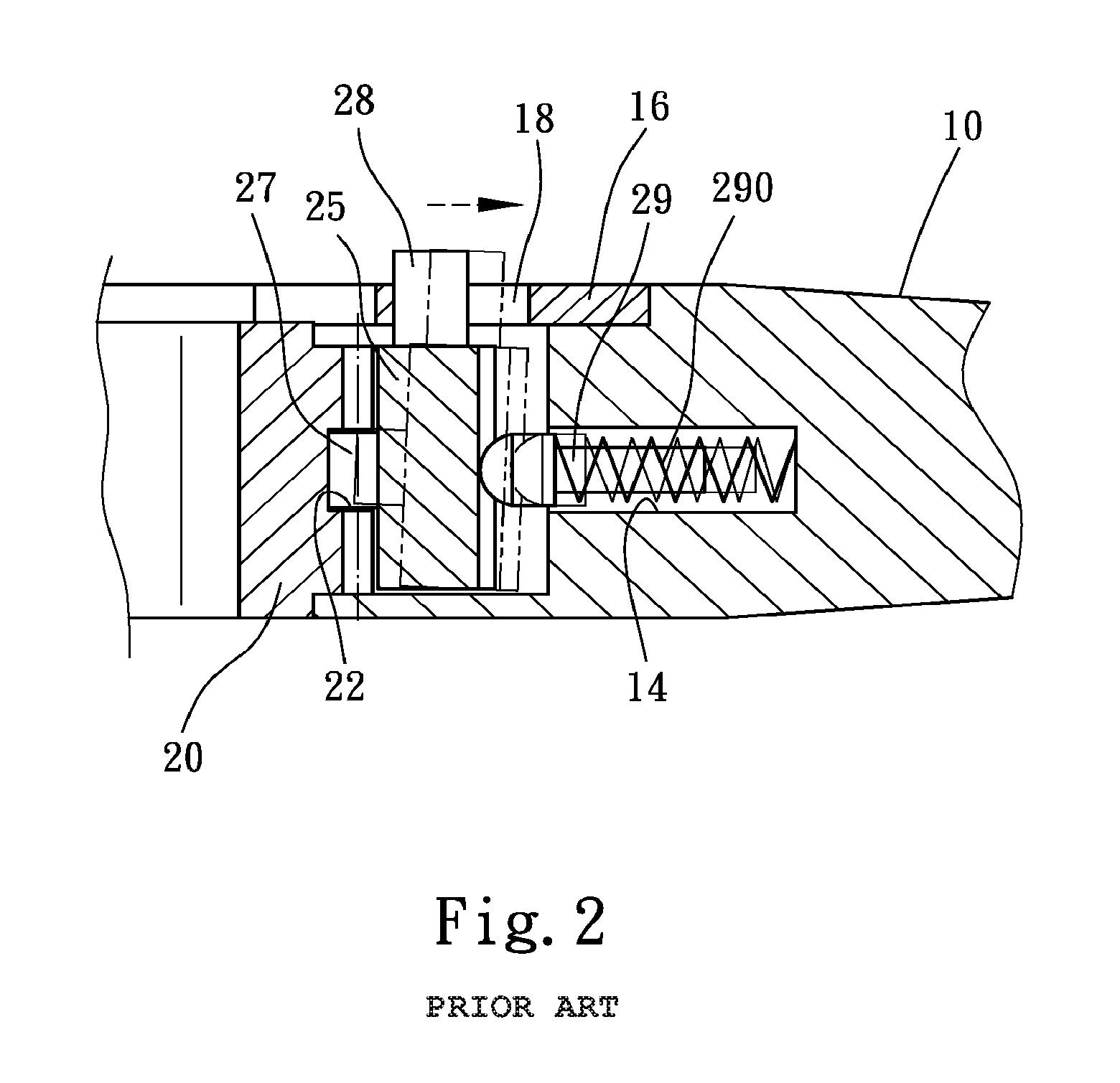

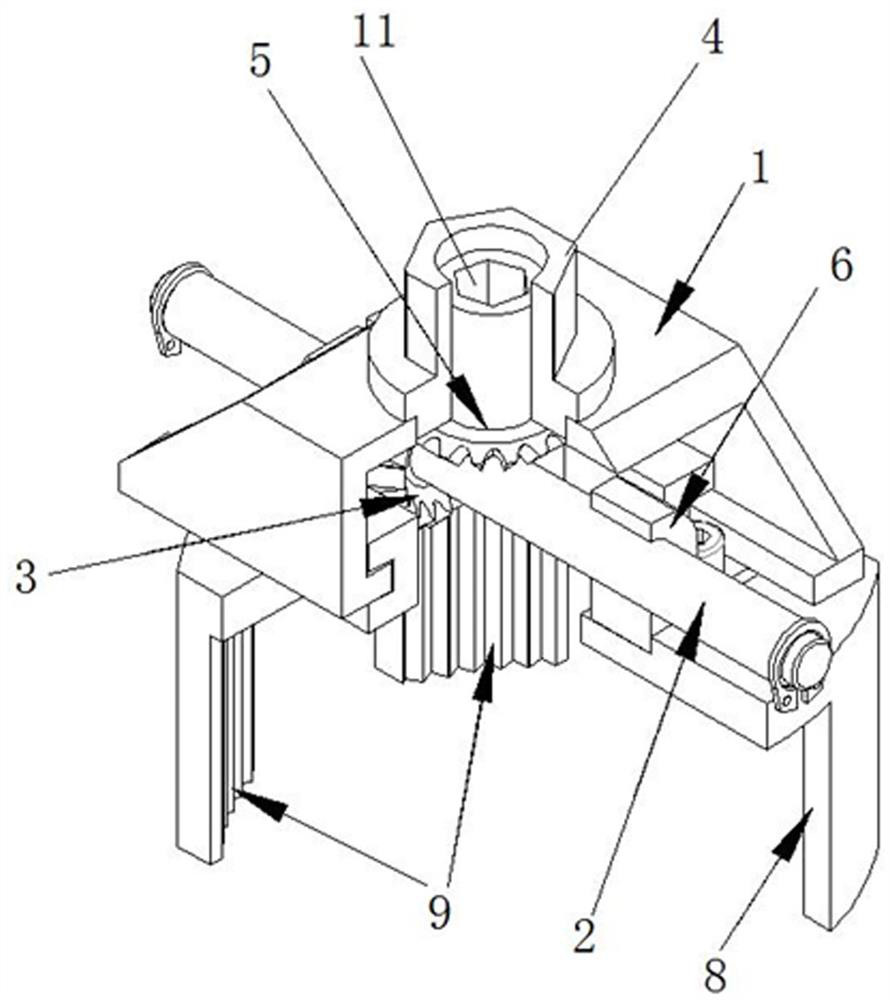

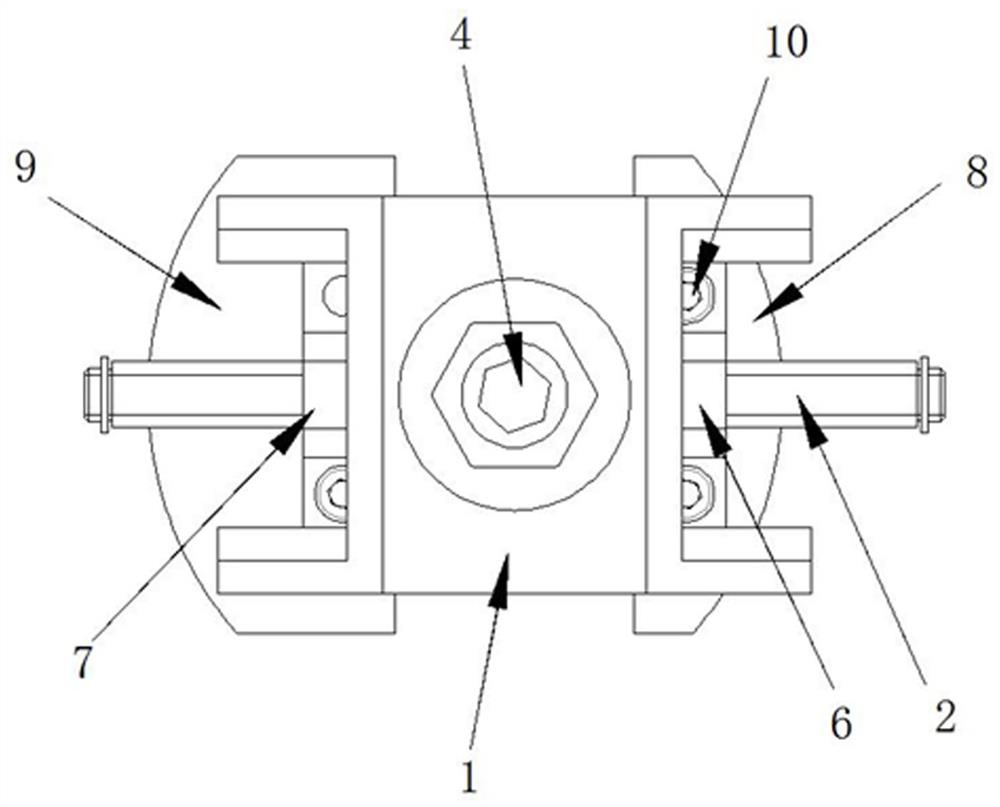

Replacement structure of ratchet wrench

InactiveUS8042433B2Facilitates effort-saving and operation smoothnessReplacement of a driving collar smooth and efficientSpannersWrenchesShaft collarWrench

Owner:JIUTSANG

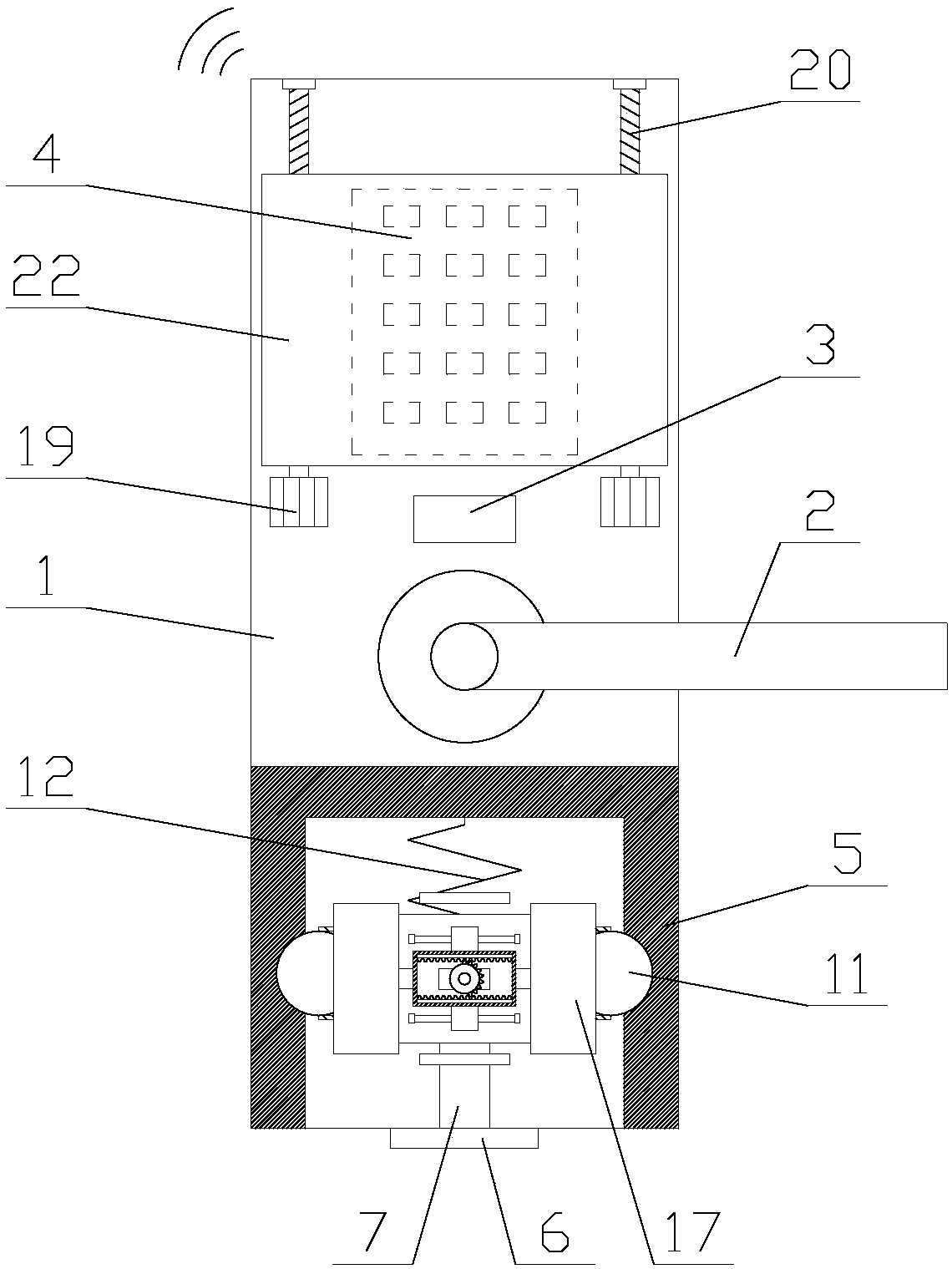

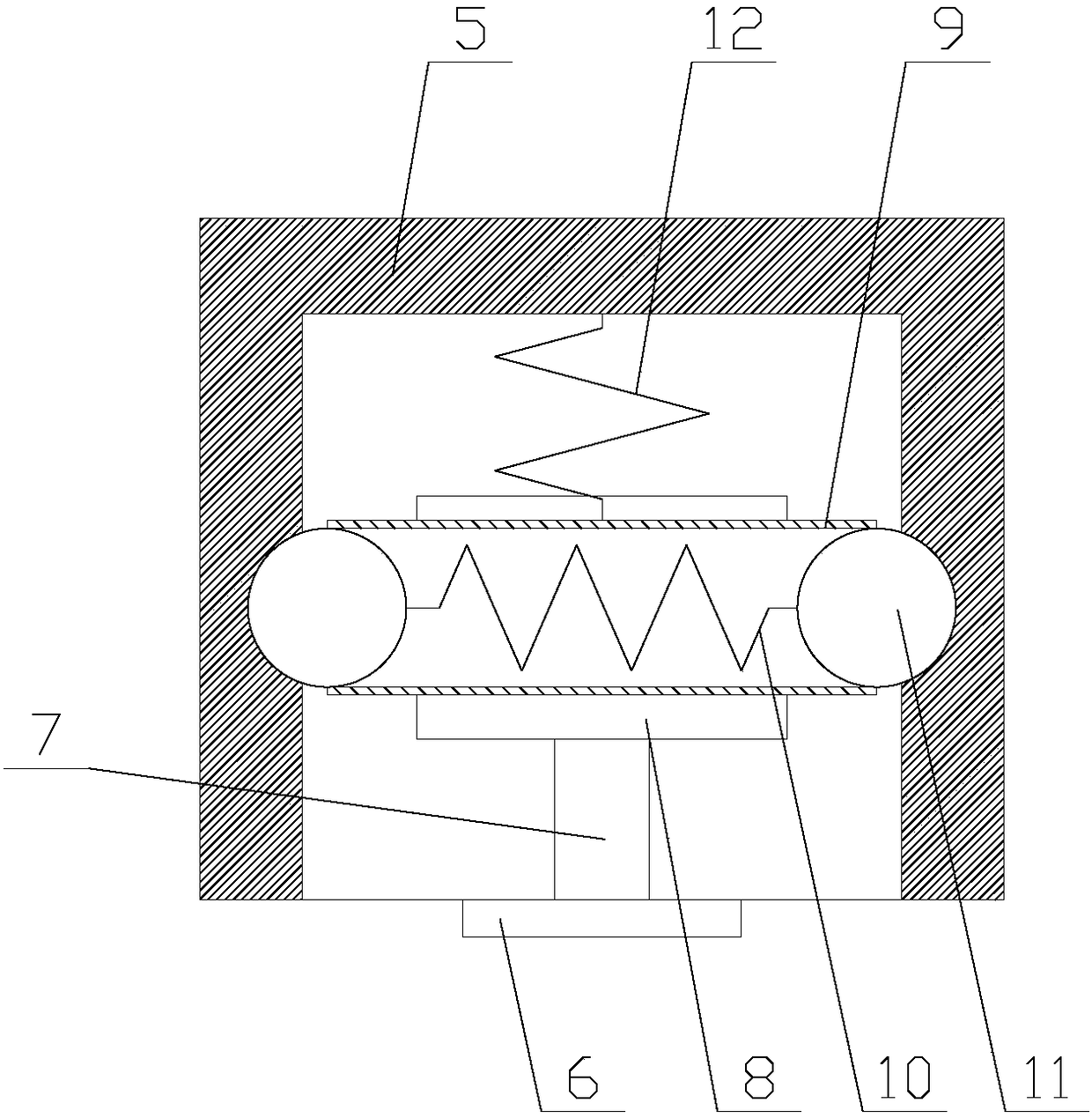

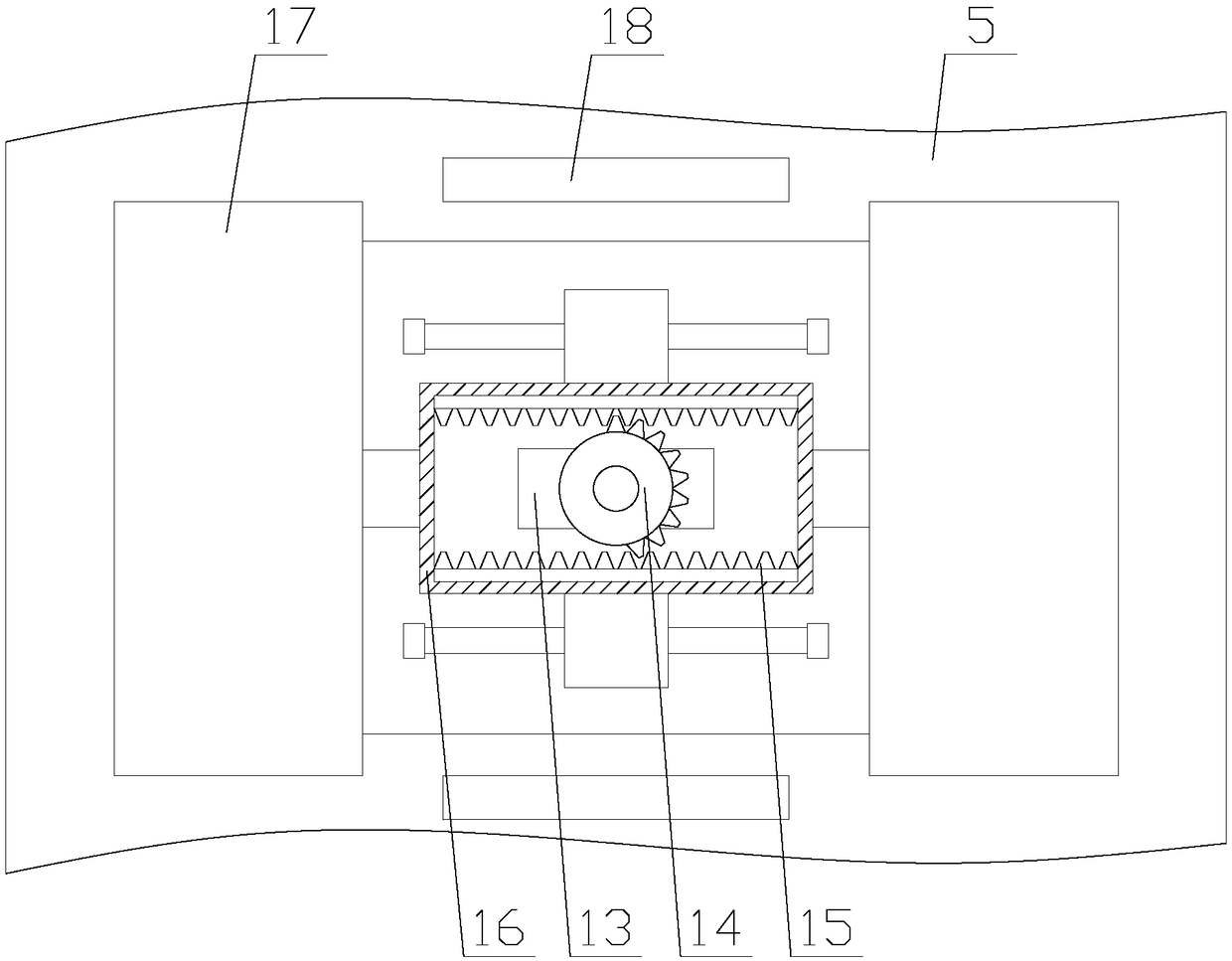

Intelligent lock with battery replacement and screen touch protection functions

ActiveCN108316771AImprove battery lifeImprove securityNon-mechanical controlsCleaning using toolsEndurance capacityProtection mechanism

The invention relates to an intelligent lock with battery replacement and screen touch protection functions. The intelligent lock comprises a lock body, a handle, a touch screen and an unlocking device, and further comprises a replacement mechanism and a protection mechanism. The replacement mechanism comprises a shell, a telescopic assembly and a switch assembly. The protection mechanism comprises a cover plate, a cleaning block and two lifting assemblies. In the intelligent lock with battery replacement and screen touch protection functions, a button can be controlled to enable battery packsto pop out of or draw back into the shell through the replacement mechanism, continuous running can be achieved through switching of the two battery packs, and the endurance capacity of the intelligent lock is improved; compared with a battery pack replacement mode of an existing intelligent lock, damage caused by frequent replacement of the battery packs is avoided, and replacement is conductedmore conveniently and efficiently; and the touch screen can be protected and cleaned by means of the protection mechanism, compared with the existing intelligent lock, the touch effect of the displayscreen is enhanced, the situation of illegal unlocking caused by malignant damage to the touch screen is prevented, and the safety and reliability of the intelligent lock are improved.

Owner:YONGKANG SHUOXIN IND & TRADE CO LTD

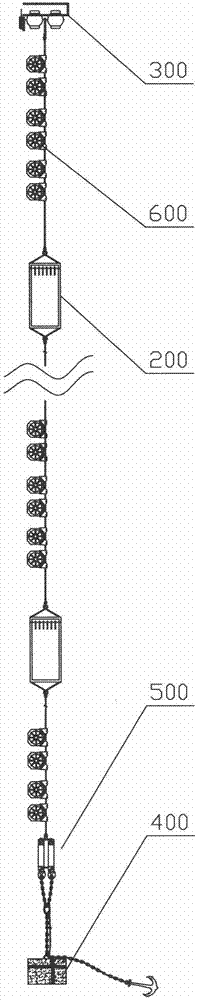

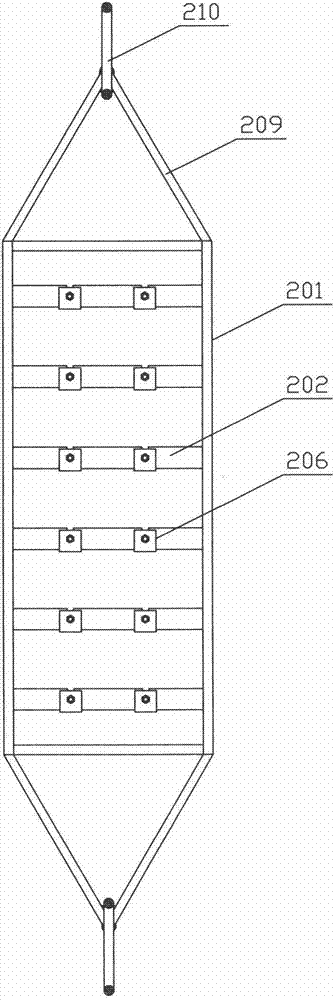

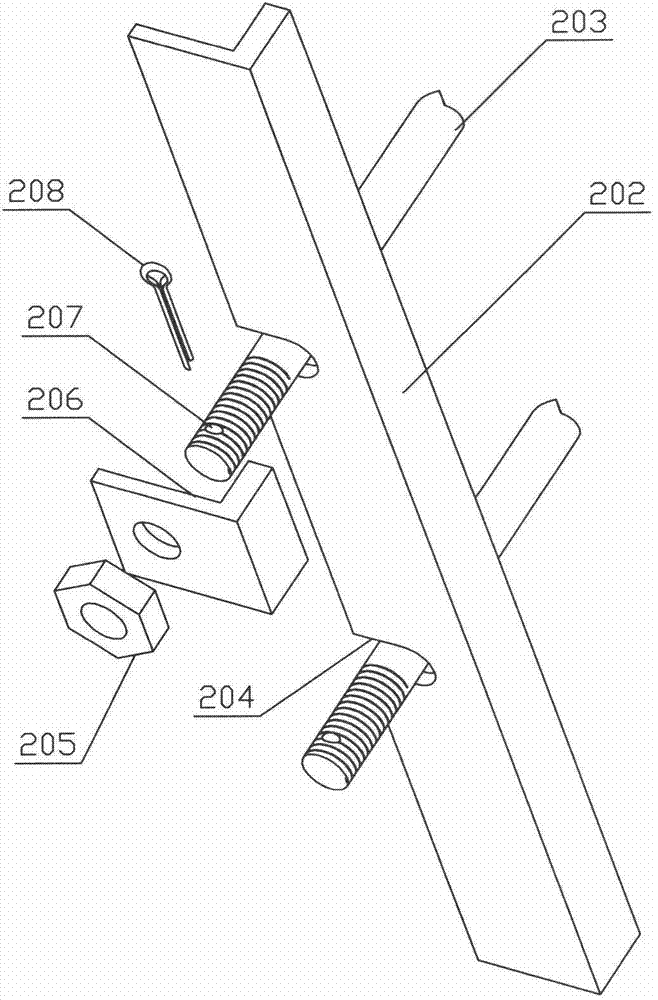

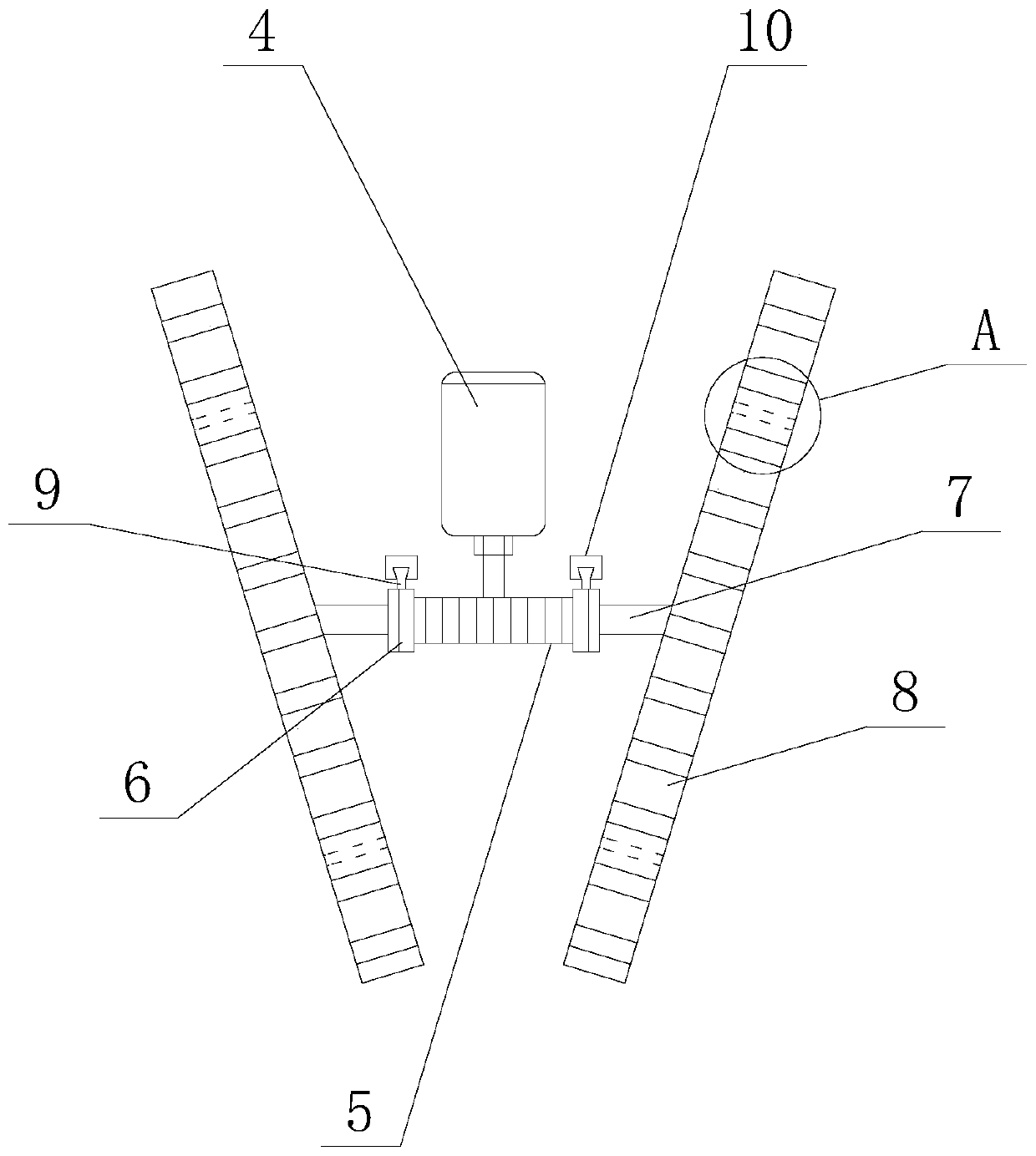

Efficient string type deep sea environment testing device

InactiveCN105445174ACompact structureEasy and efficient replacementWeather/light/corrosion resistanceOcean bottomMetallic materials

The invention provides an efficient string type deep sea environment testing device. The efficient string type deep sea environment testing device is used for performing medium-and-long-term deep sea environment exposure tests in the 500-3,000 m deep sea water environment and can perform multi-form corrosion and aging tests of metal materials, so that the deep sea environment tests can be carried out more efficiently and more flexibly. The device comprises ropes, sample frames, a buoy and a bottom anchor block, wherein the sample frames are connected with the adjacent ropes to form a straight line, one end of the straight line is connected with the buoy, and the other end of the straight line is connected with the bottom anchor block through a releaser; the sample frames are made of titanium or titanium alloys, and samples for the tests are modularly mounted on the sample frames. The efficient string type deep sea environment testing device performs the tests at the 500-3,000 m seabed, the multiple sample frames are connected to form a string, the samples are modularly mounted on the sample frames, the distance between adjacent sample frames is flexibly adjusted according to the exposure depth required by the tests, different types of samples can be selected for the exposure tests at different depths in the same sea area simultaneously, marine operation time is shortened, and the marine operation intensity is reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

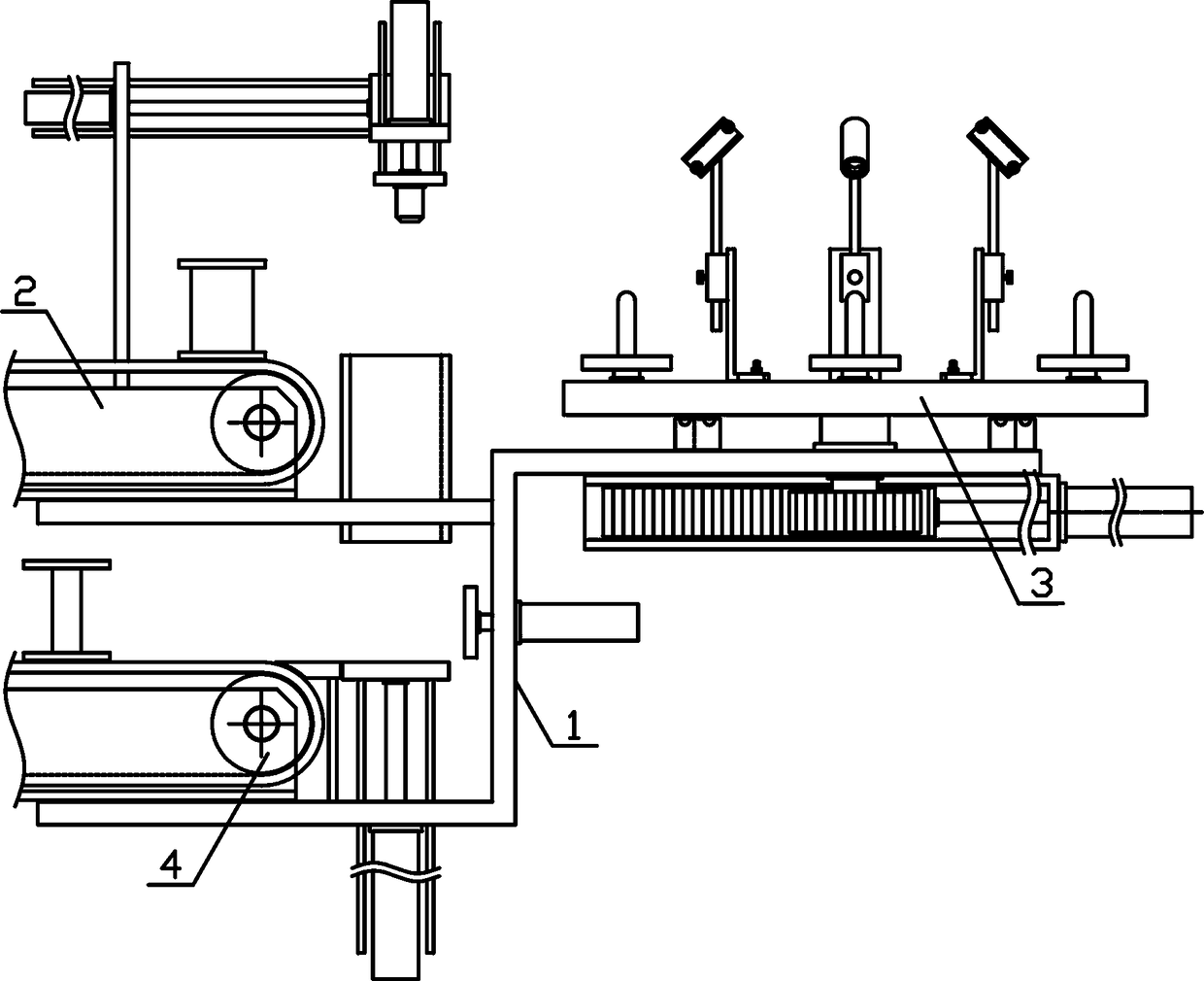

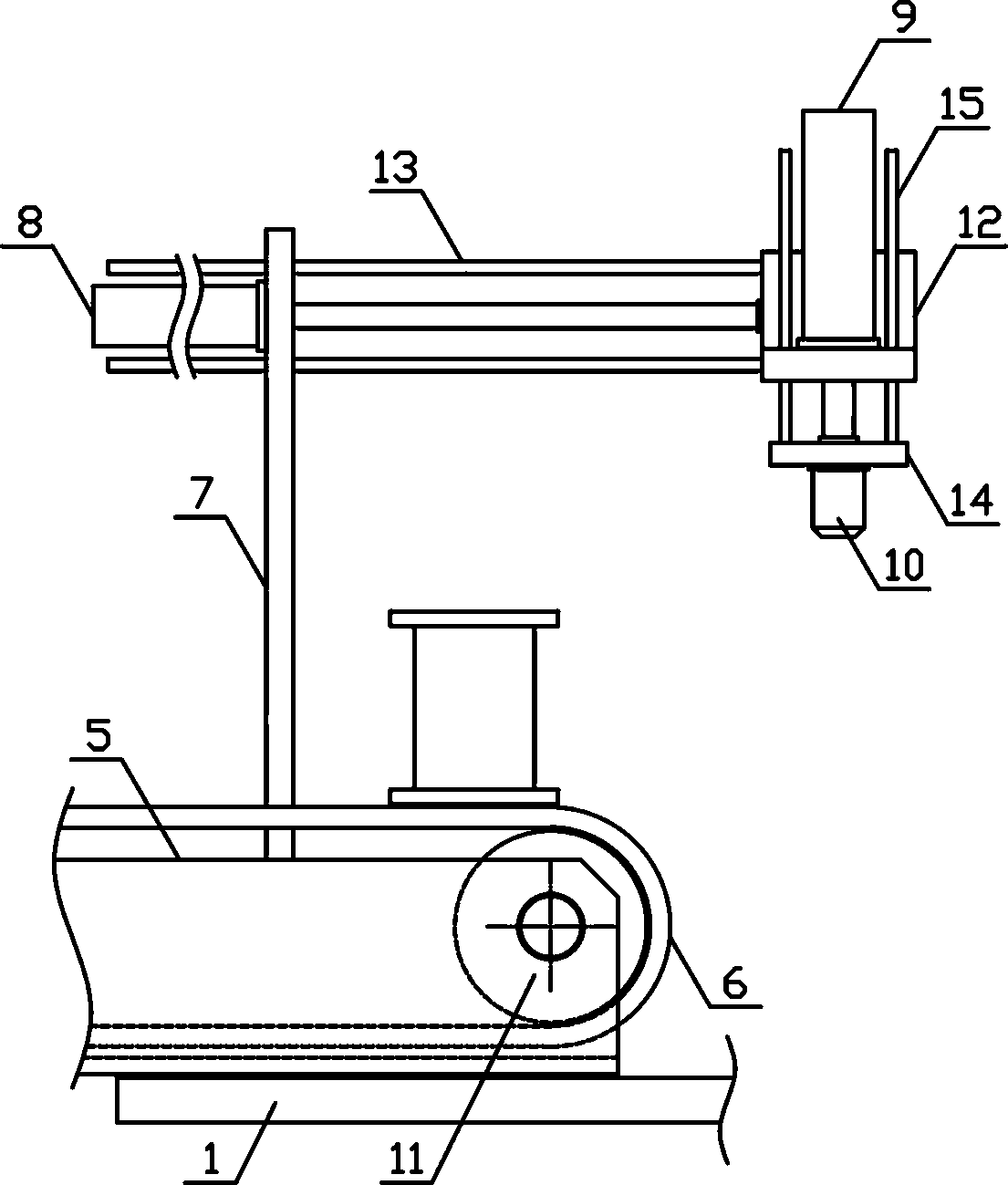

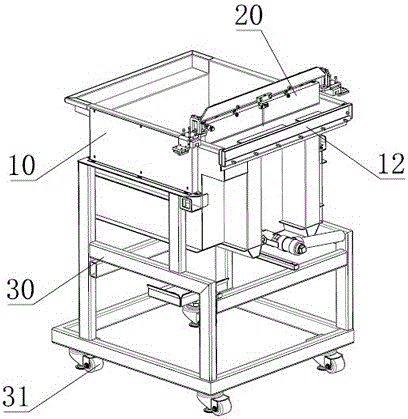

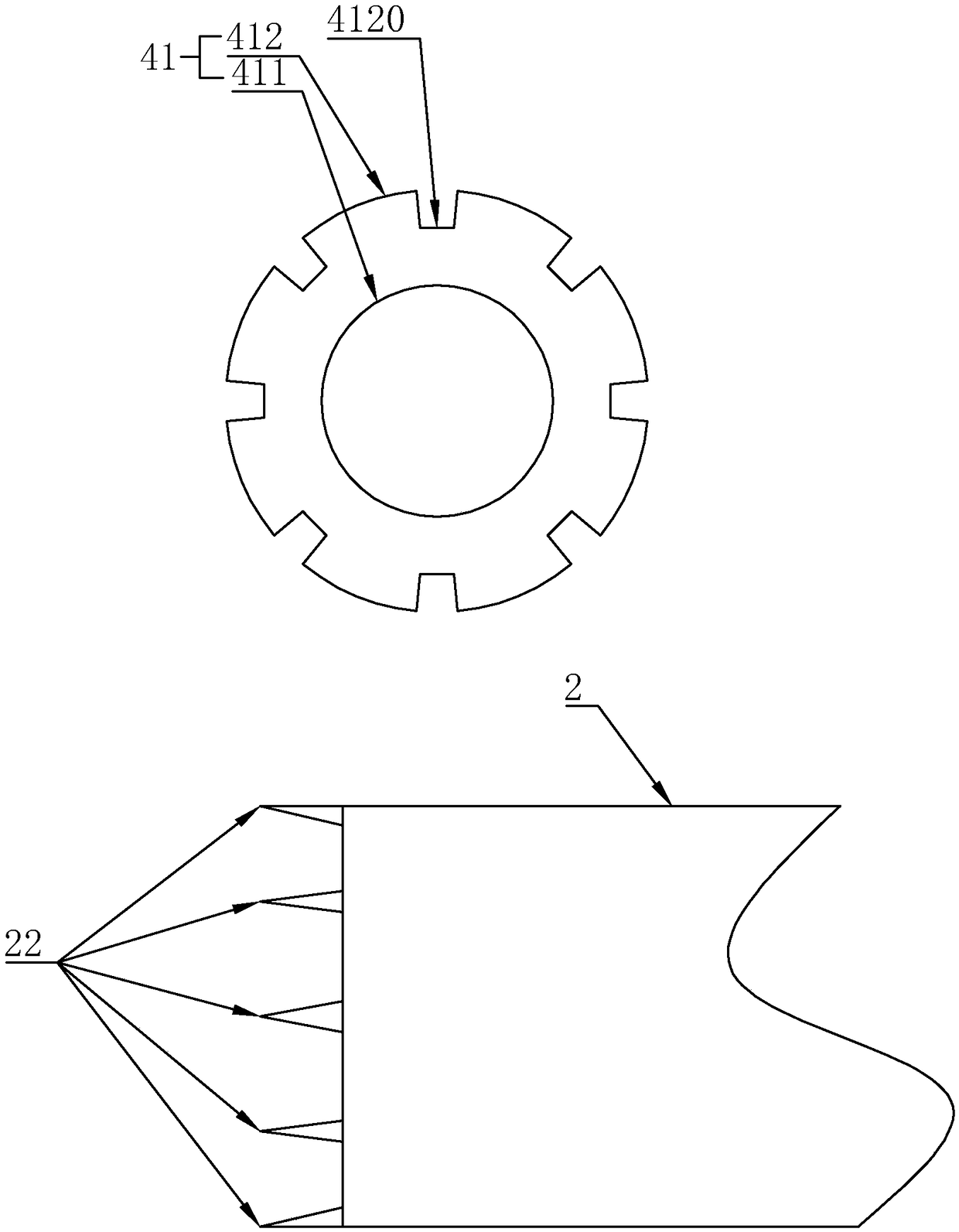

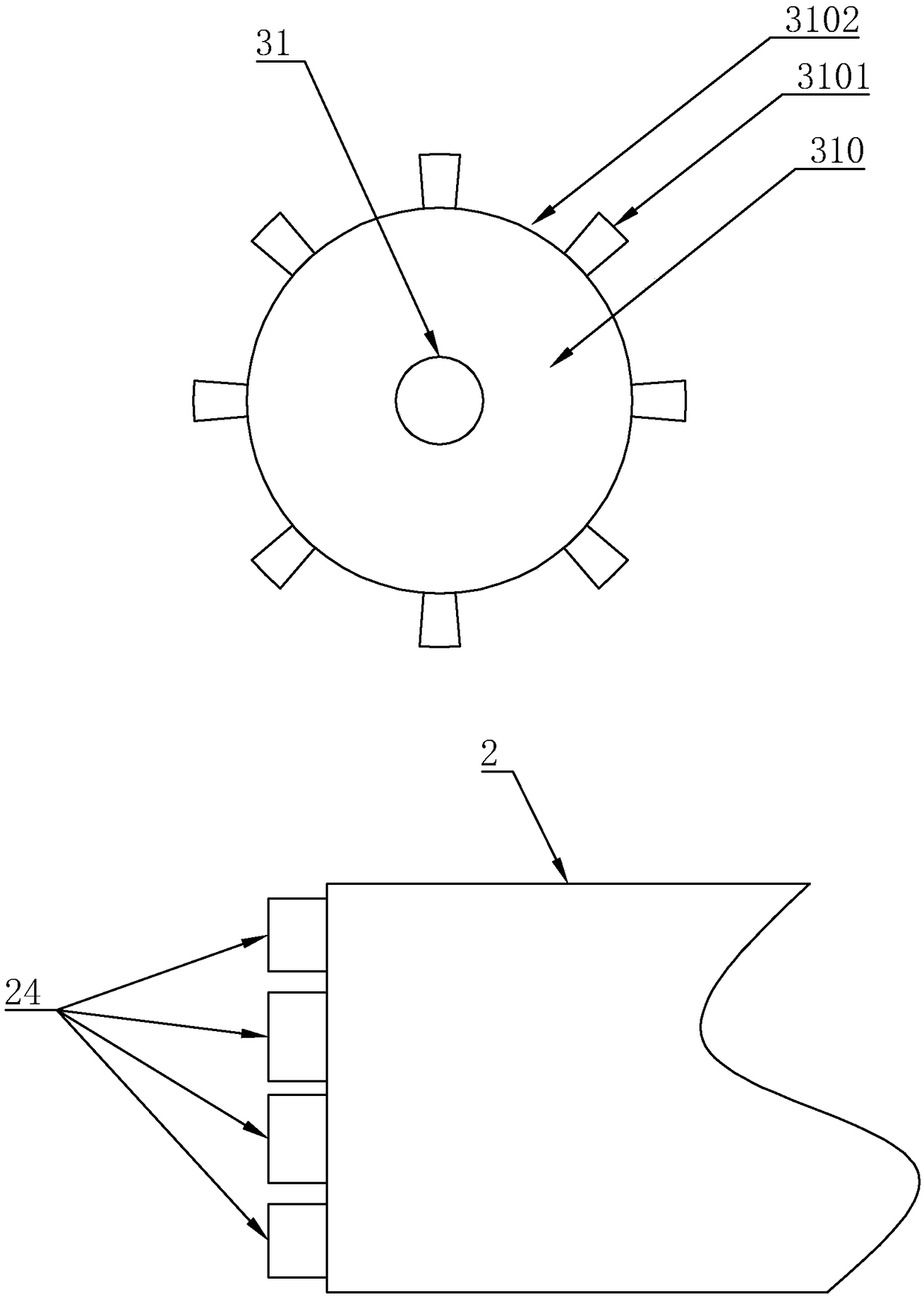

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

Accumulator frame used for electric automobile and method for installing and removing accumulator

PendingCN106784502AEasy and efficient maintenanceEasy and efficient replacementCell component detailsEngineeringIdler-wheel

The invention discloses an accumulator frame used for an electric automobile. The accumulator frame comprises a chassis and a bracket, wherein the chassis comprises two bottom plates, a connection plate, U-shaped plates, idler wheels and a baffle; two side plates of each U-shaped plate comprise a low plate and a high plate; the U-shaped plates are arranged on the bottom plates; the idler wheels are arranged in the U-shaped plates; the connection plate is arranged on the same end of the two bottom plates; the connection plate is provided with connection holes; the connection plate and the baffle are connected through a connecting piece; the bracket comprises a tray, pull rods and a top spacing device; the pull rods are fixed on the side panel of the tray; the upper part of each pull rod is provided with an external thread; the upper part of each pull rod is provided with a nut; the upper part of each pull rod penetrates through the top spacing device and is cooperated with the nut; the bottom plate of the tray is provided with a wear-proof rubber pad; after a storage battery is arranged on the tray, a filling layer is arranged between the storage battery and the side panel of the tray. The accumulator frame is convenient in assembling and can be operated by single person, manpower and disassembling time can be saved, and the maintenance and the replacement of the storage battery are convenient and efficient.

Owner:四川新筑通工汽车有限公司

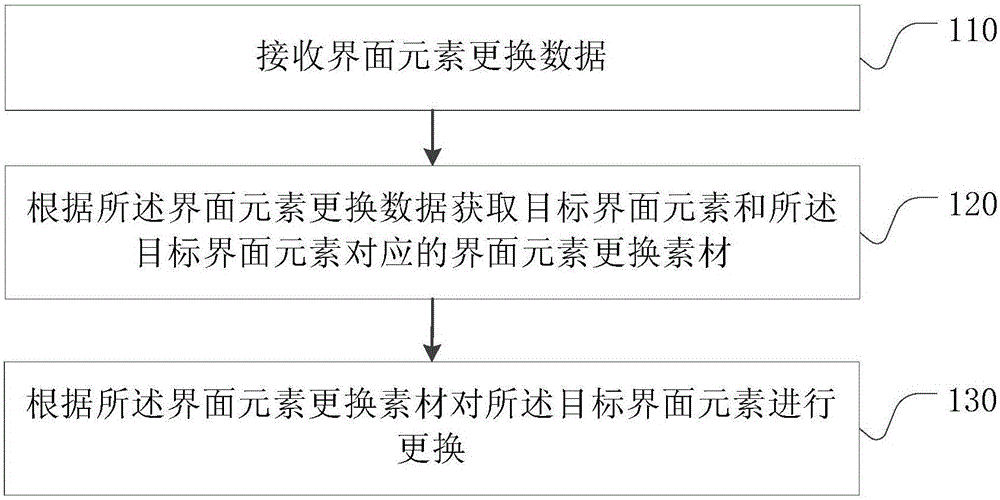

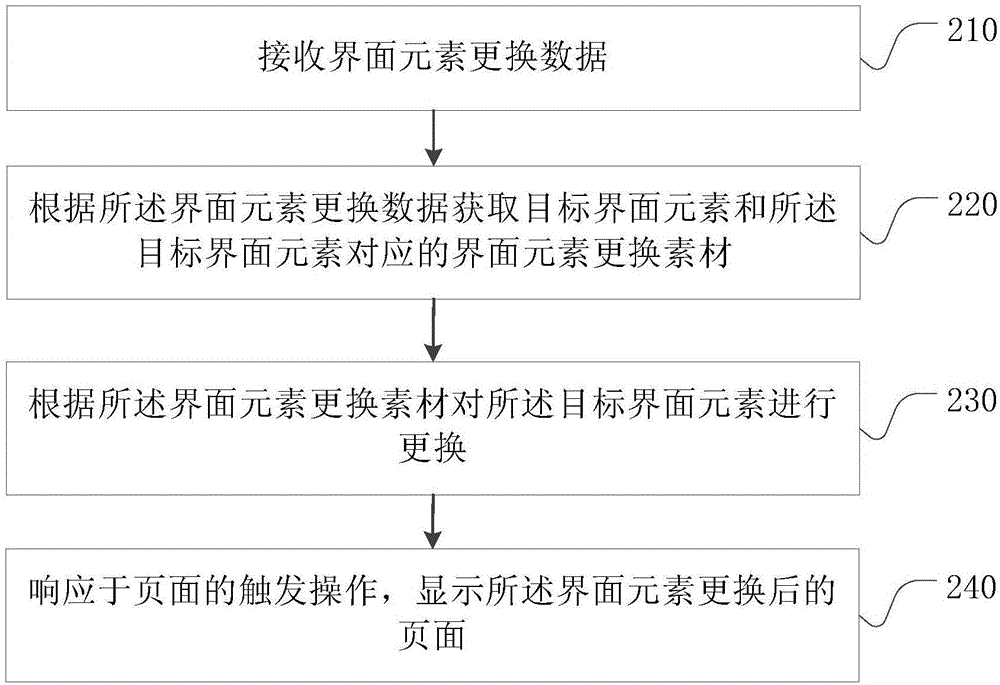

Interface element change method and device

InactiveCN106201532AEasy and efficient replacementImprove experienceProgram loading/initiatingExecution for user interfacesReplacement methodHuman–computer interaction

Owner:LETV HLDG BEIJING CO LTD +1

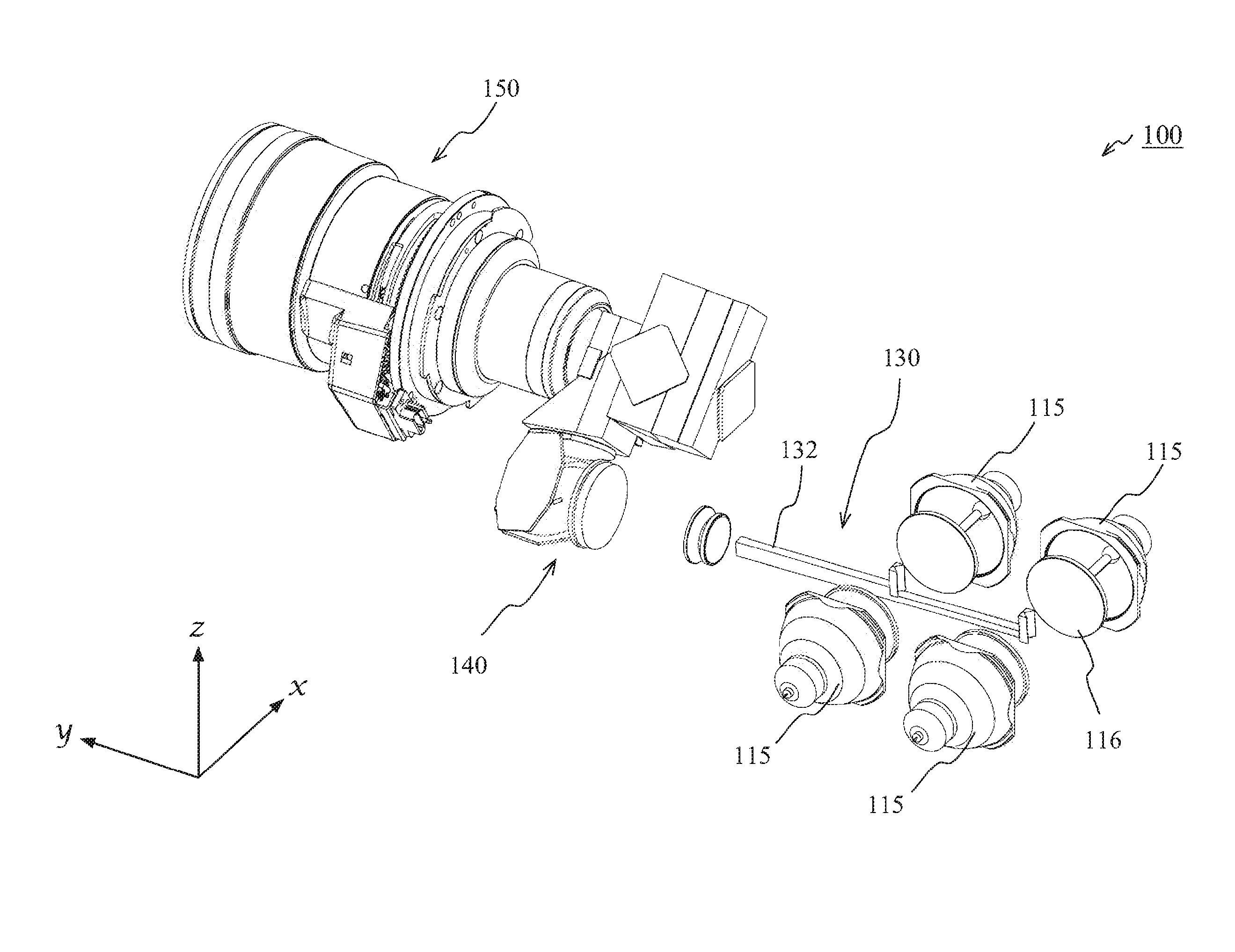

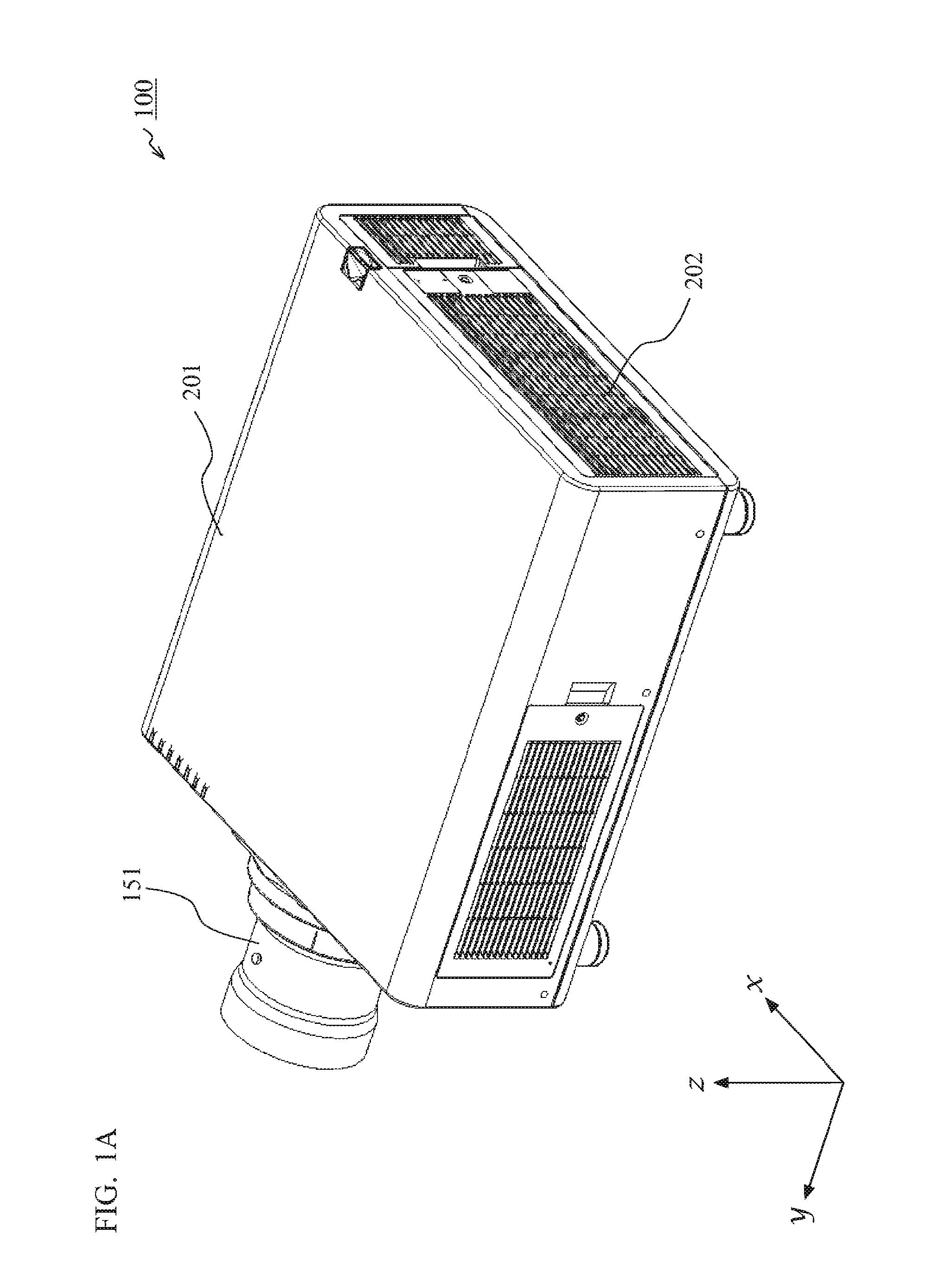

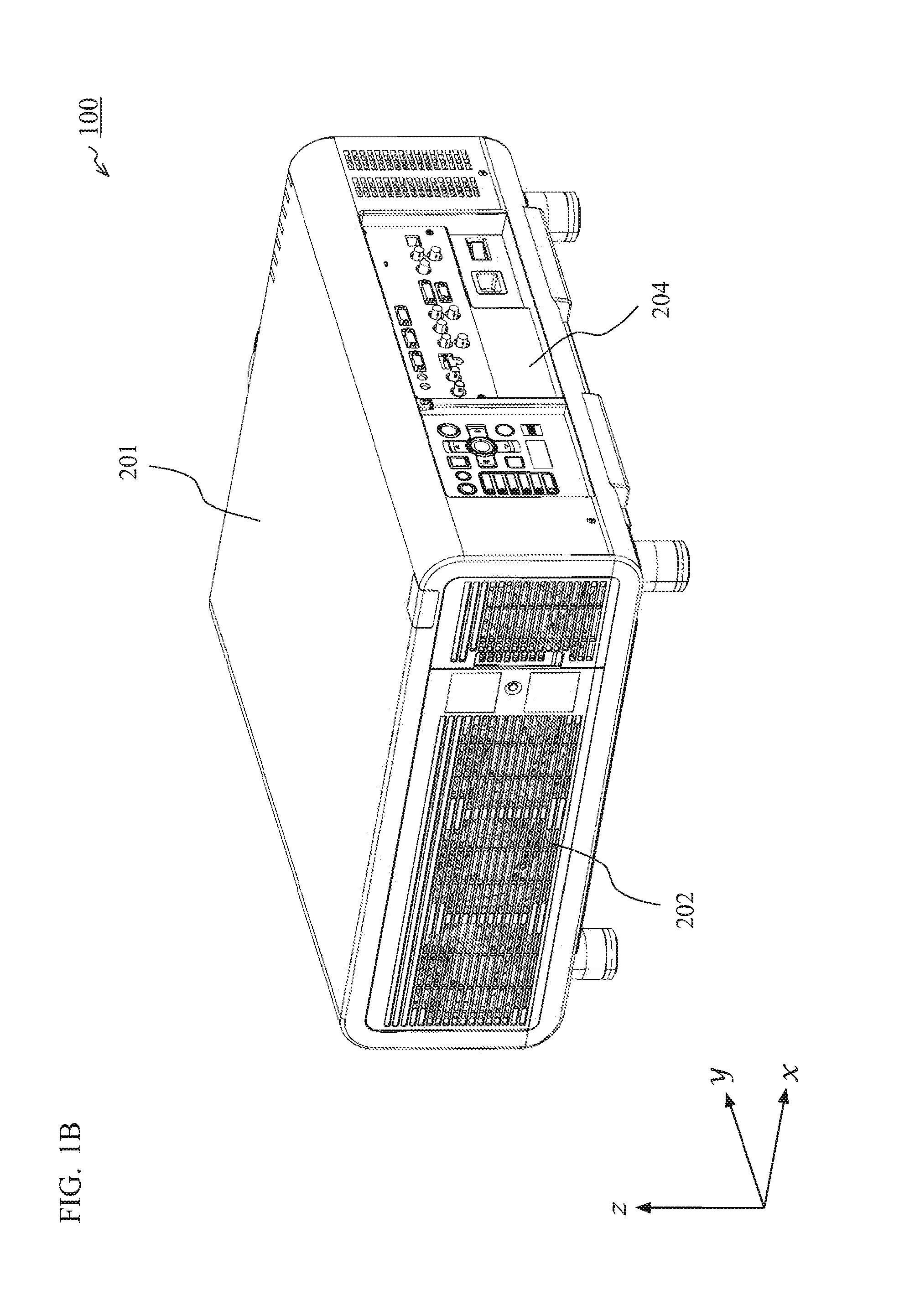

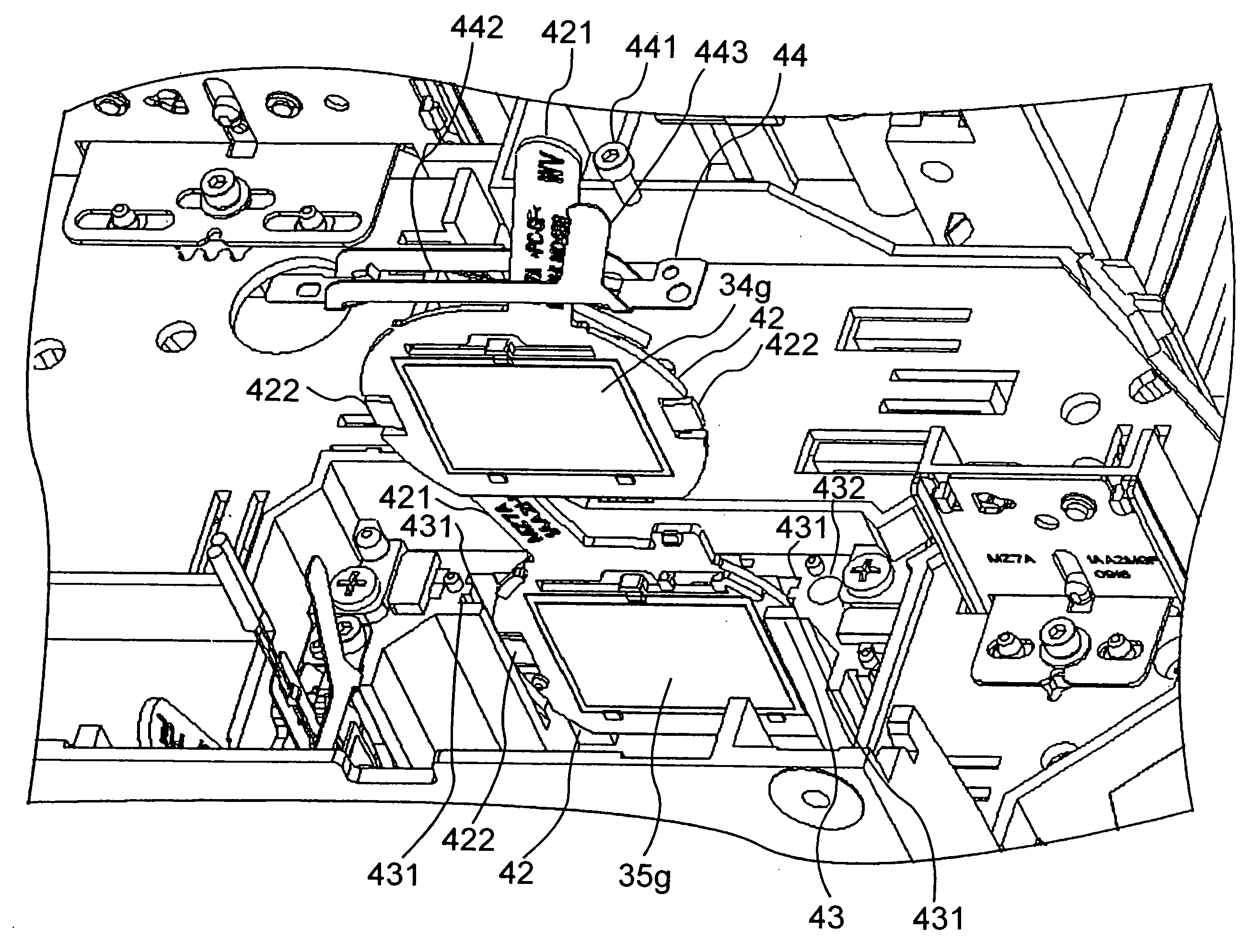

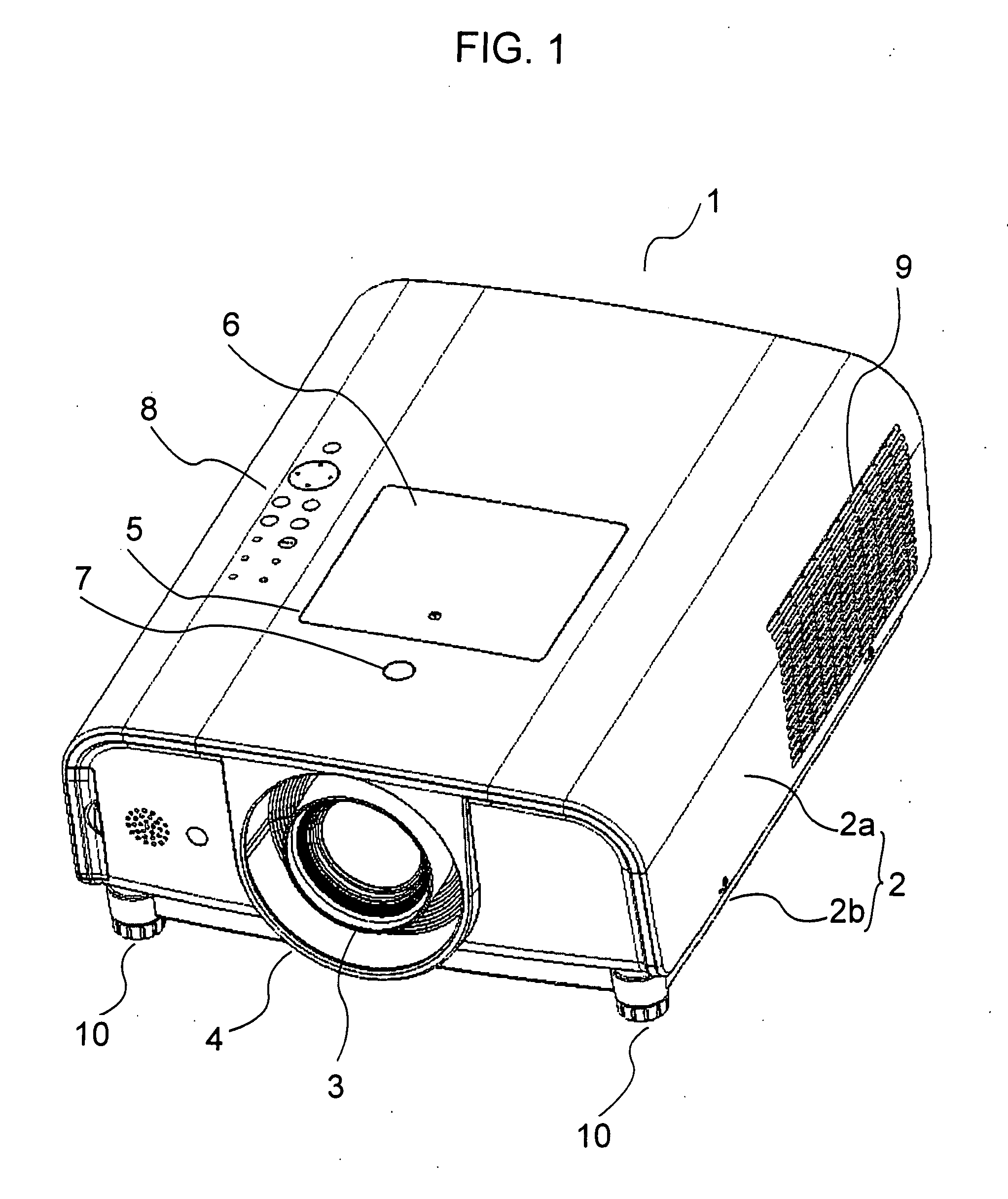

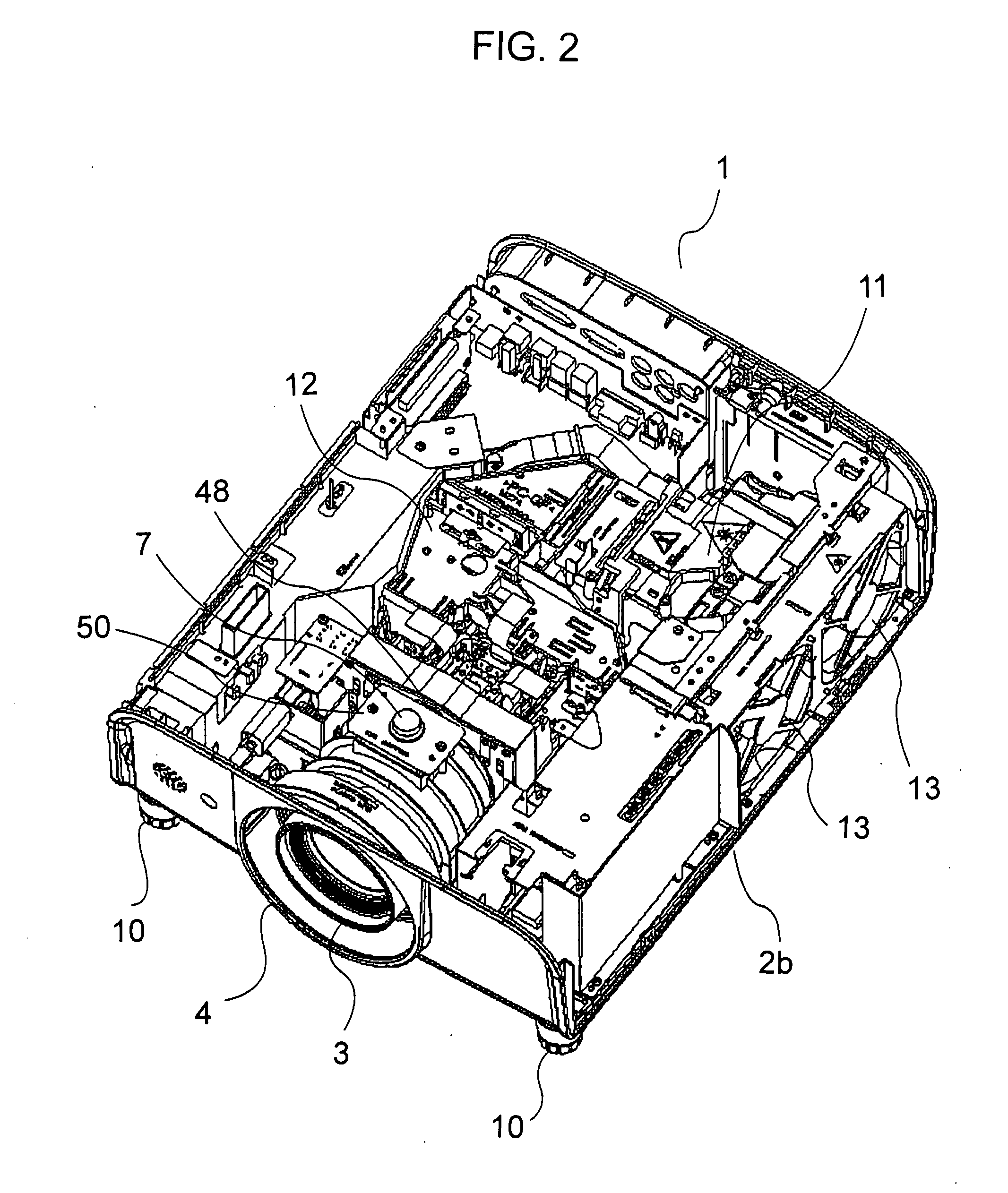

Projection type image display apparatus

InactiveUS20130182229A1Easy and efficient removalEasy and efficient replacementProjectorsColor television detailsEngineeringOptic system

An opening cover of a case is removed. A light source module is held, and the light source module is pulled outside an opening of the case while guide groove parts and guide-rail parts slide along each other approximately parallelly to a case base. At this moment, junction cable connection terminals of the light source module become separated from power-supply connection terminals of a composite optical system. Replacement of a light source is conducted by replacing the light source module as a unit, or by replacing a light source section or a light source section each as a unit.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

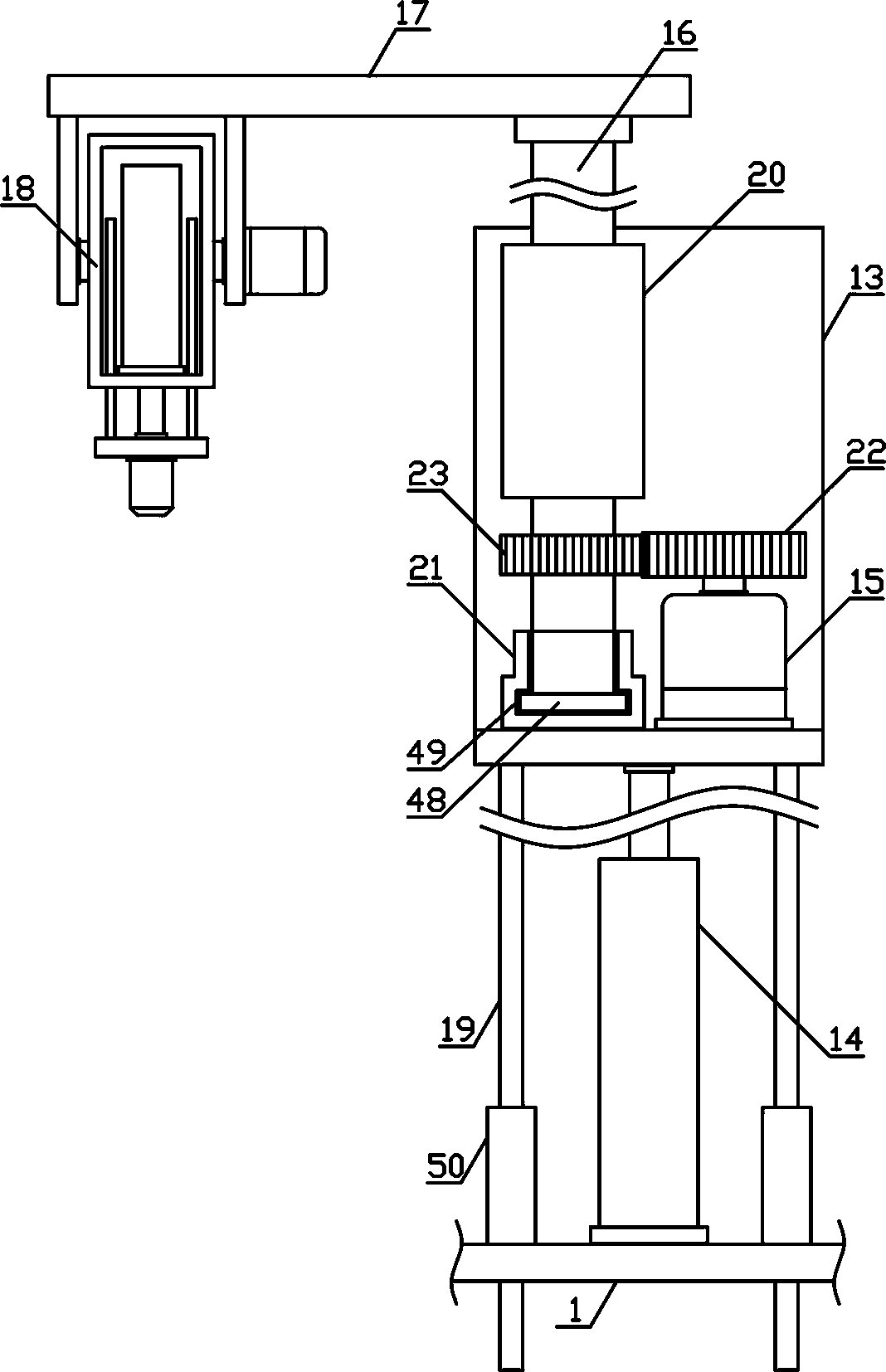

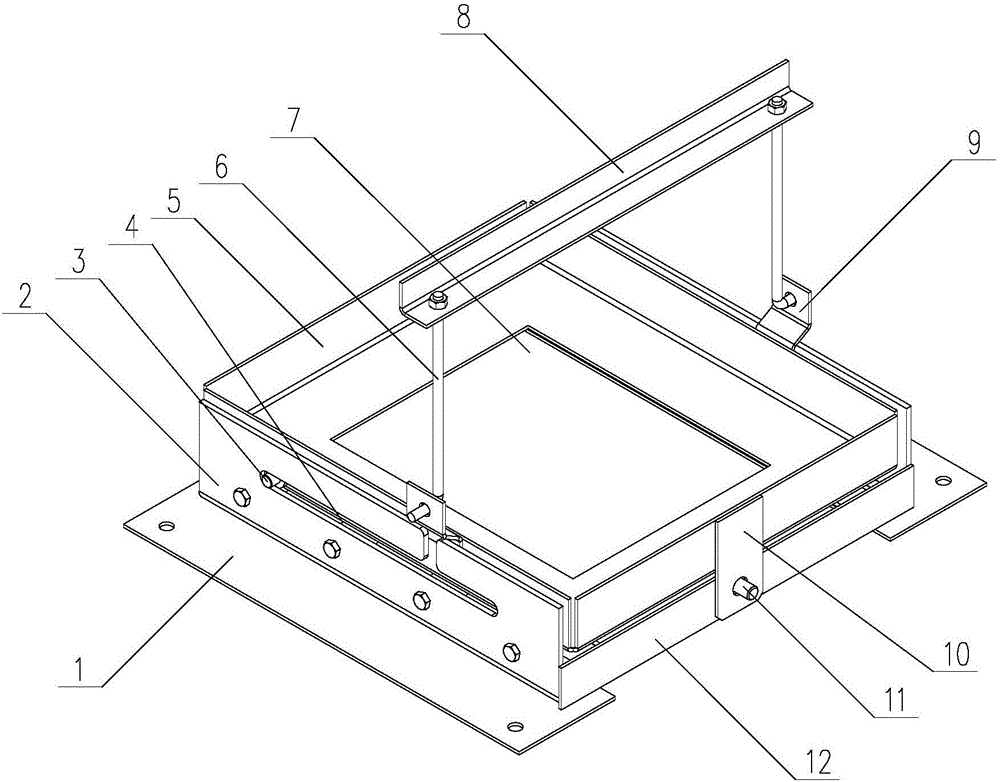

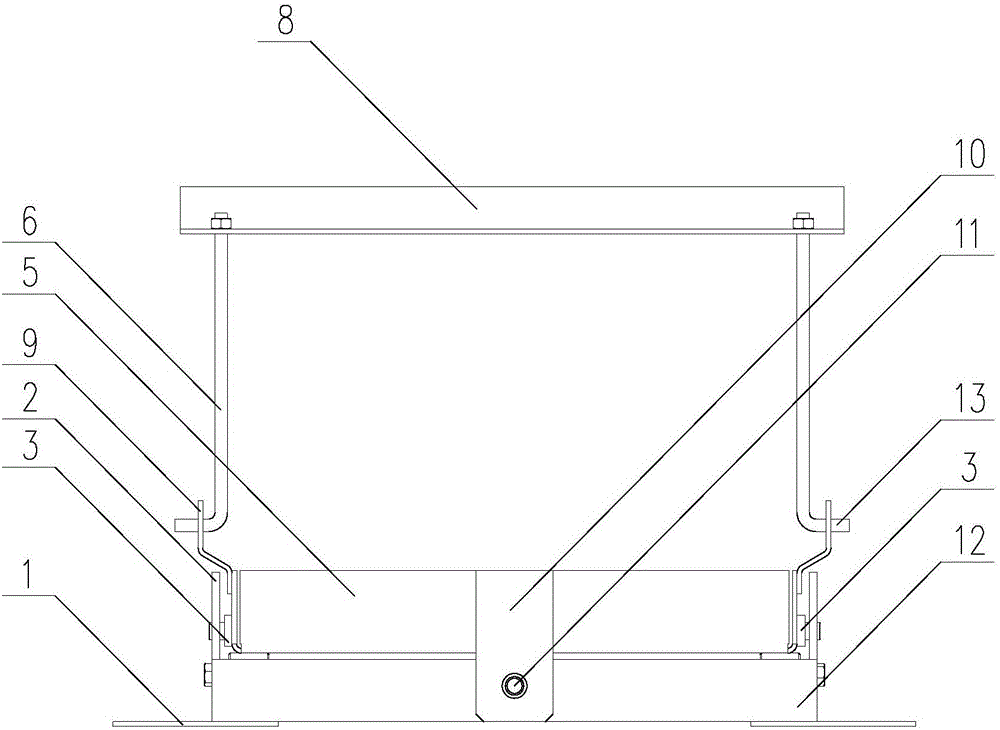

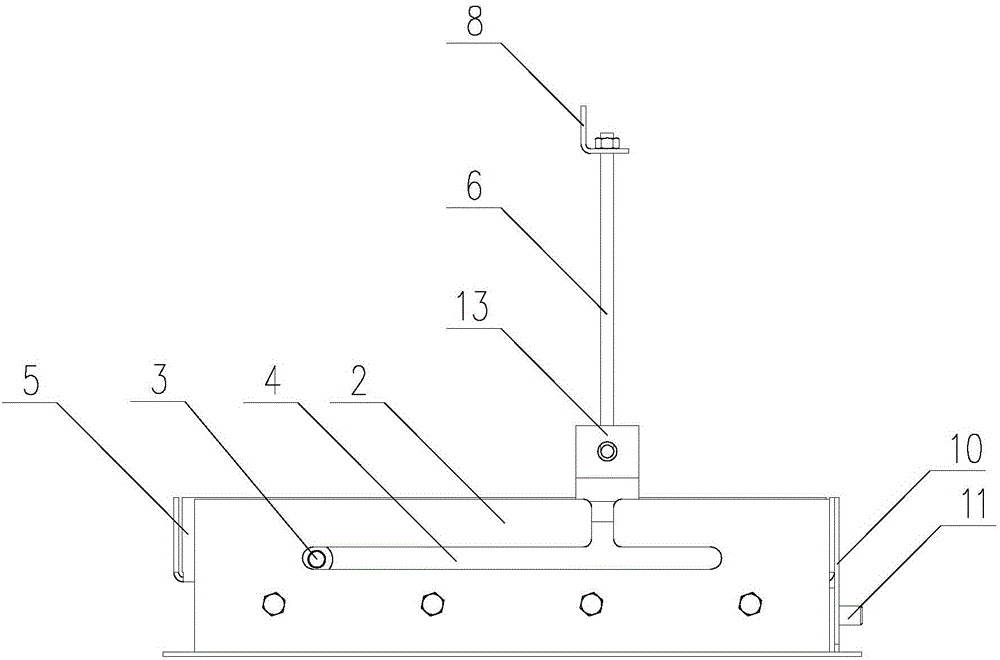

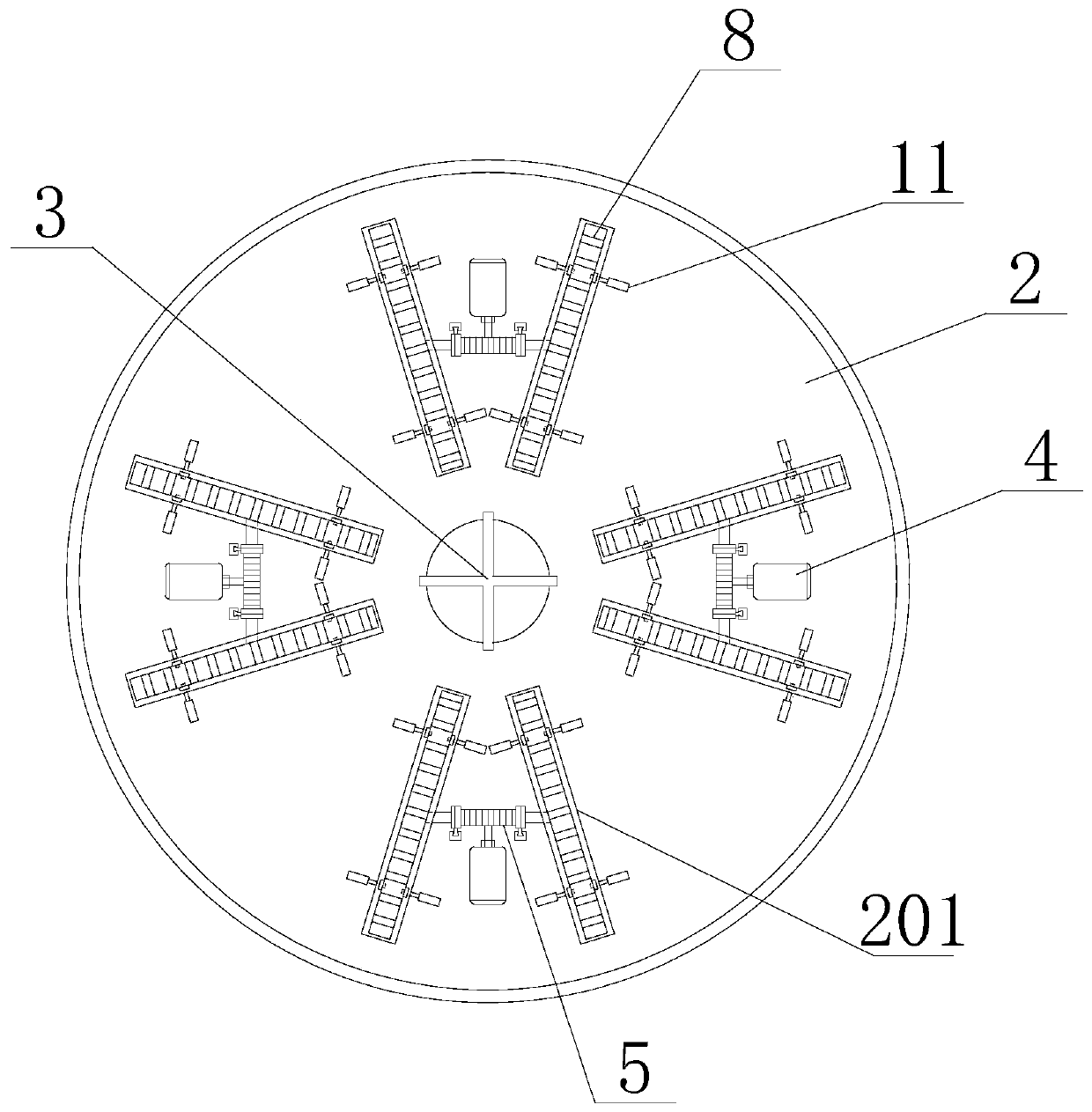

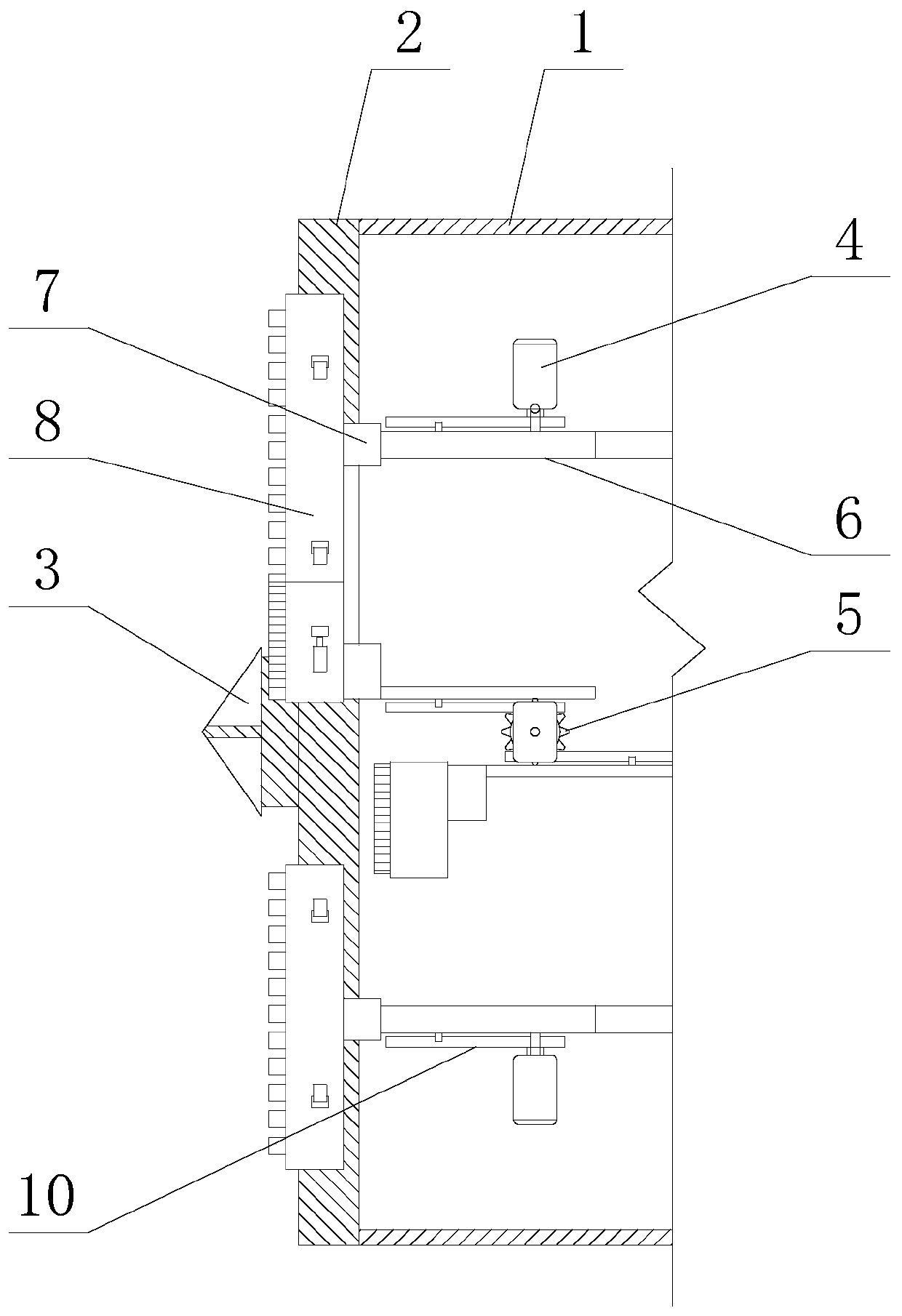

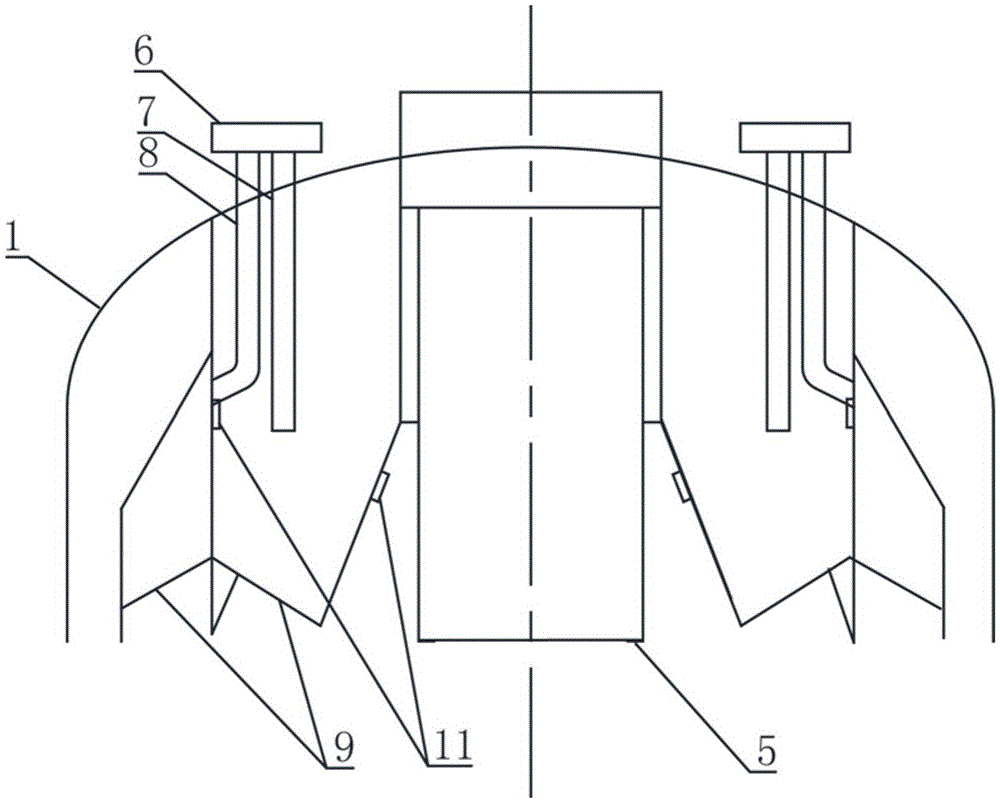

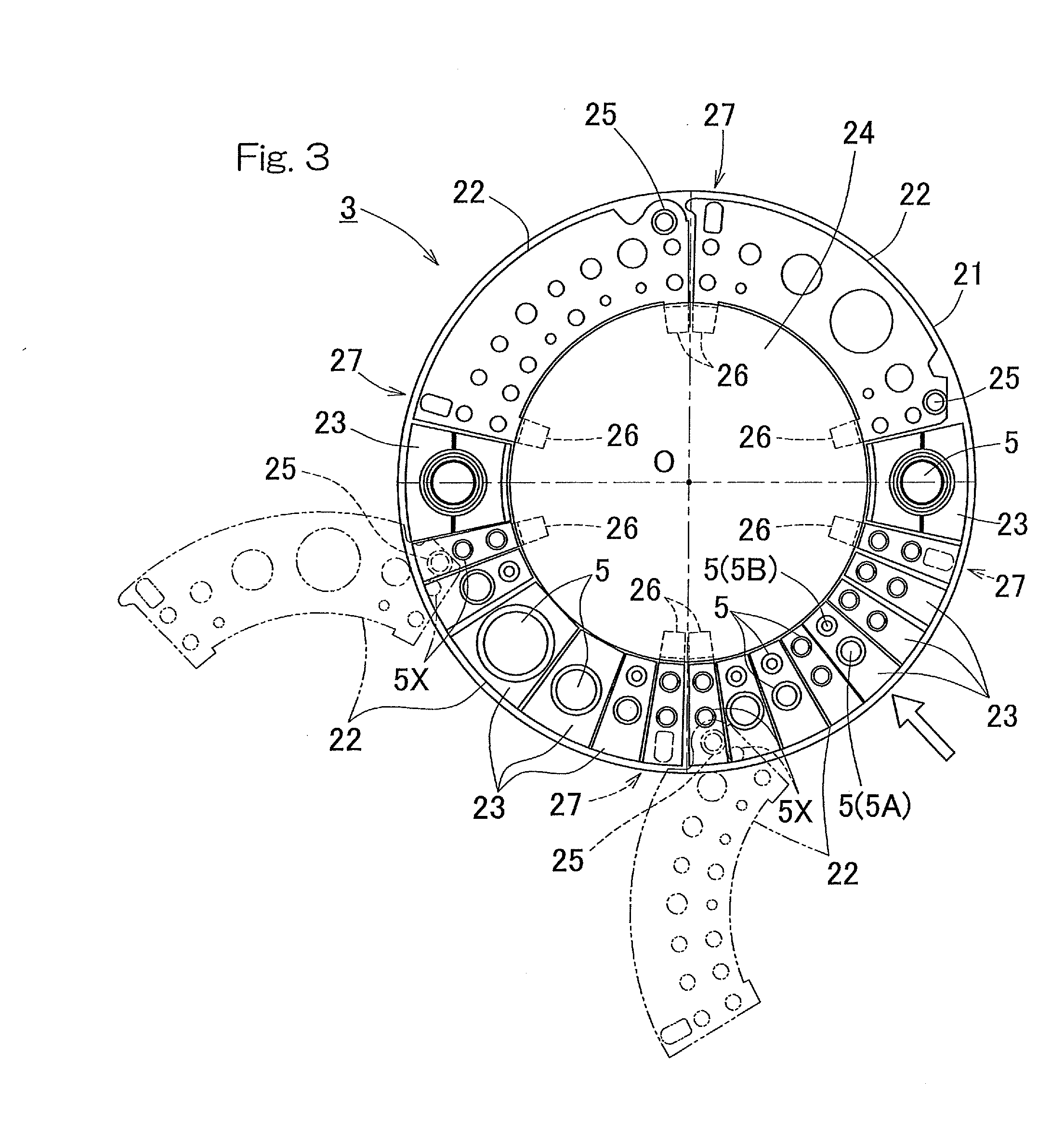

Slurry balanced pipe jacking machine with replaceable cutter rows

The invention relates to a slurry balanced pipe jacking machine with replaceable cutter rows. The slurry balanced pipe jacking machine with the replaceable cutter rows comprises a cylindrical shell, wherein the shell is internally provided with cutter changing mechanisms, a cutter head is arranged at one end of the shell, and a center cutter bit is arranged at the center position of the cutter head; switching groove groups are arranged on the cutter head, each switching groove group comprises two oppositely-arranged cutter grooves, and fixing mechanisms are arranged on the outer sides of the cutter grooves; each cutter changing mechanism comprises a motor, a gear and two telescopic units, wherein the telescopic units comprise racks, connectors and the cutter rows; and each fixing mechanism comprises two steadying assemblies correspondingly arranged at the two ends of the corresponding cutter groove, each steadying assembly comprises two control units, and the control units comprise clamping blocks and air cylinders. According to the slurry balanced pipe jacking machine with the replaceable cutter rows, the cutter rows can be replaced in real time in the construction process, the cutter rows are enabled to be applicable to complex soil property environment, cutter abrasion is reduced, and the service life is prolonged; replacing of the cutter rows is convenient, fast and efficient, the fixing effect is reliable, the construction period is shortened, and the construction cost is reduced.

Owner:ZHONGYIFENG CONSTR GRP +1

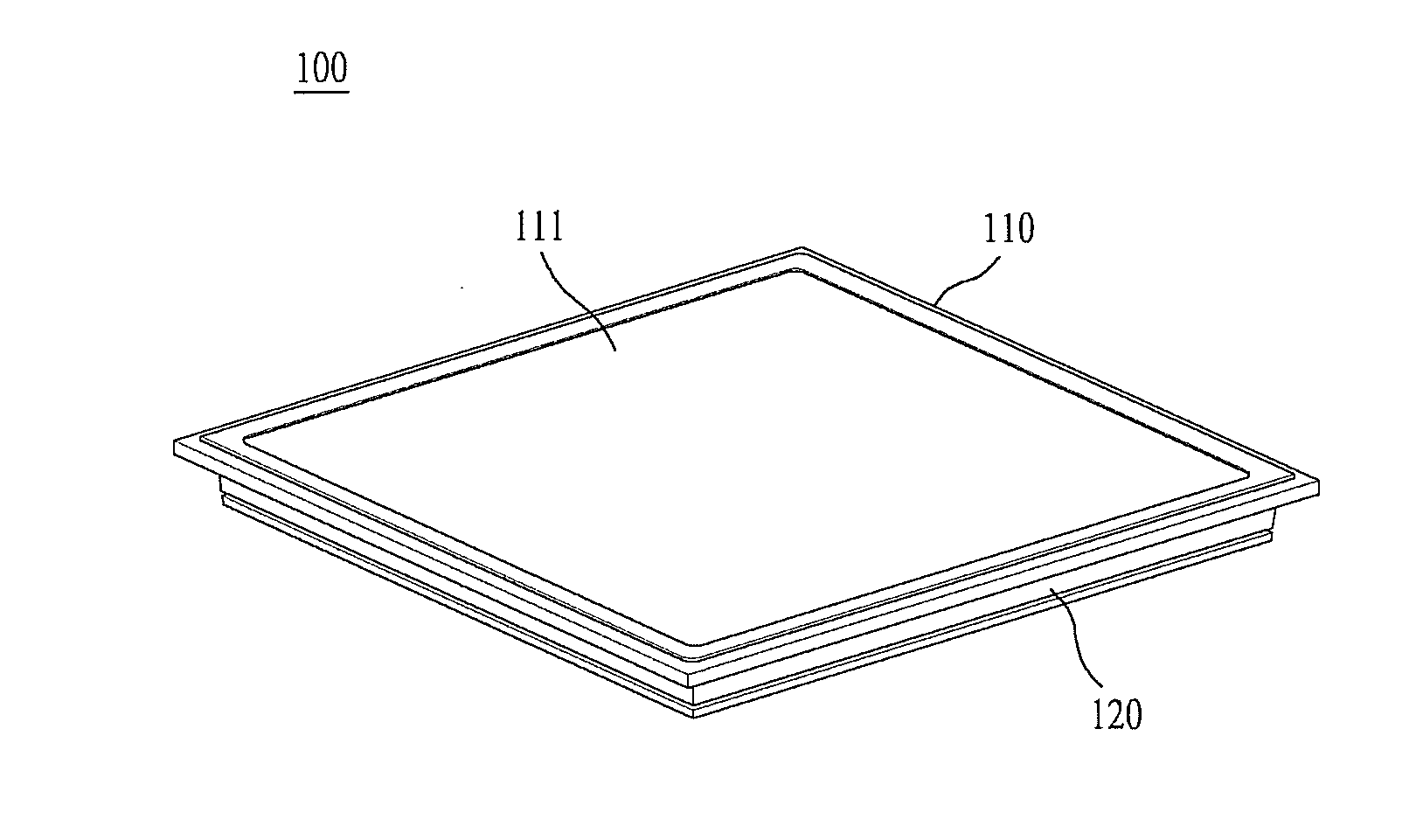

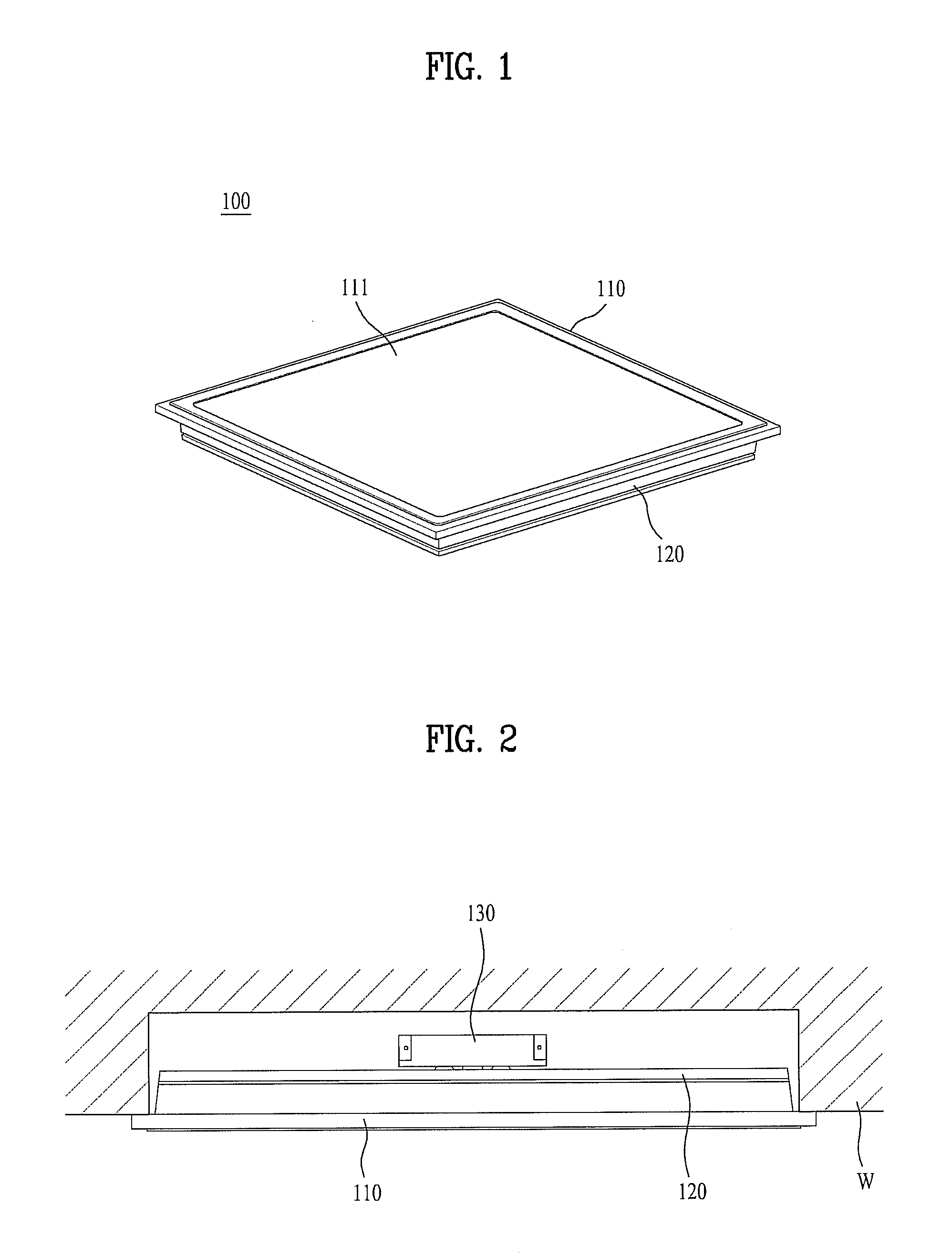

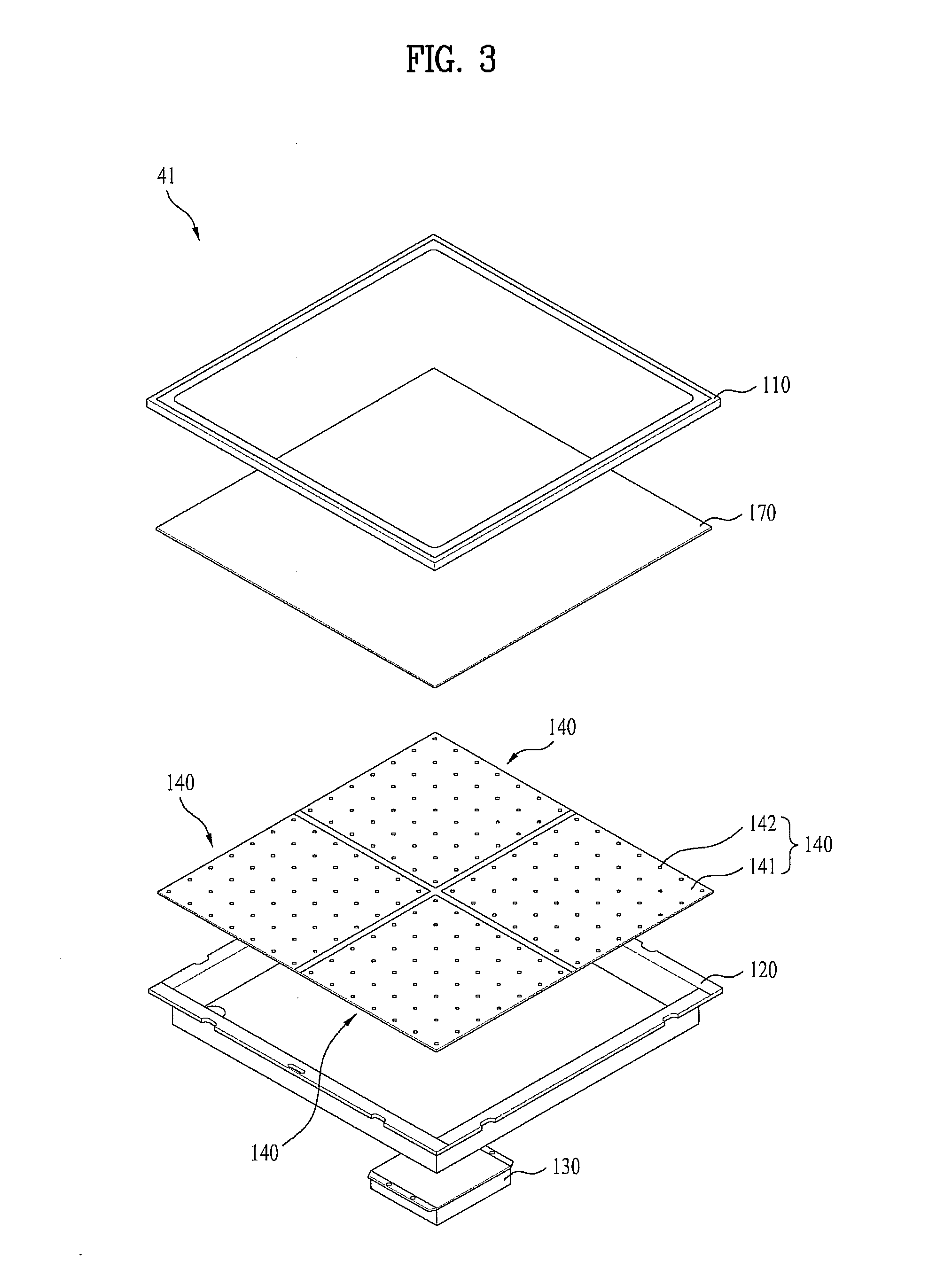

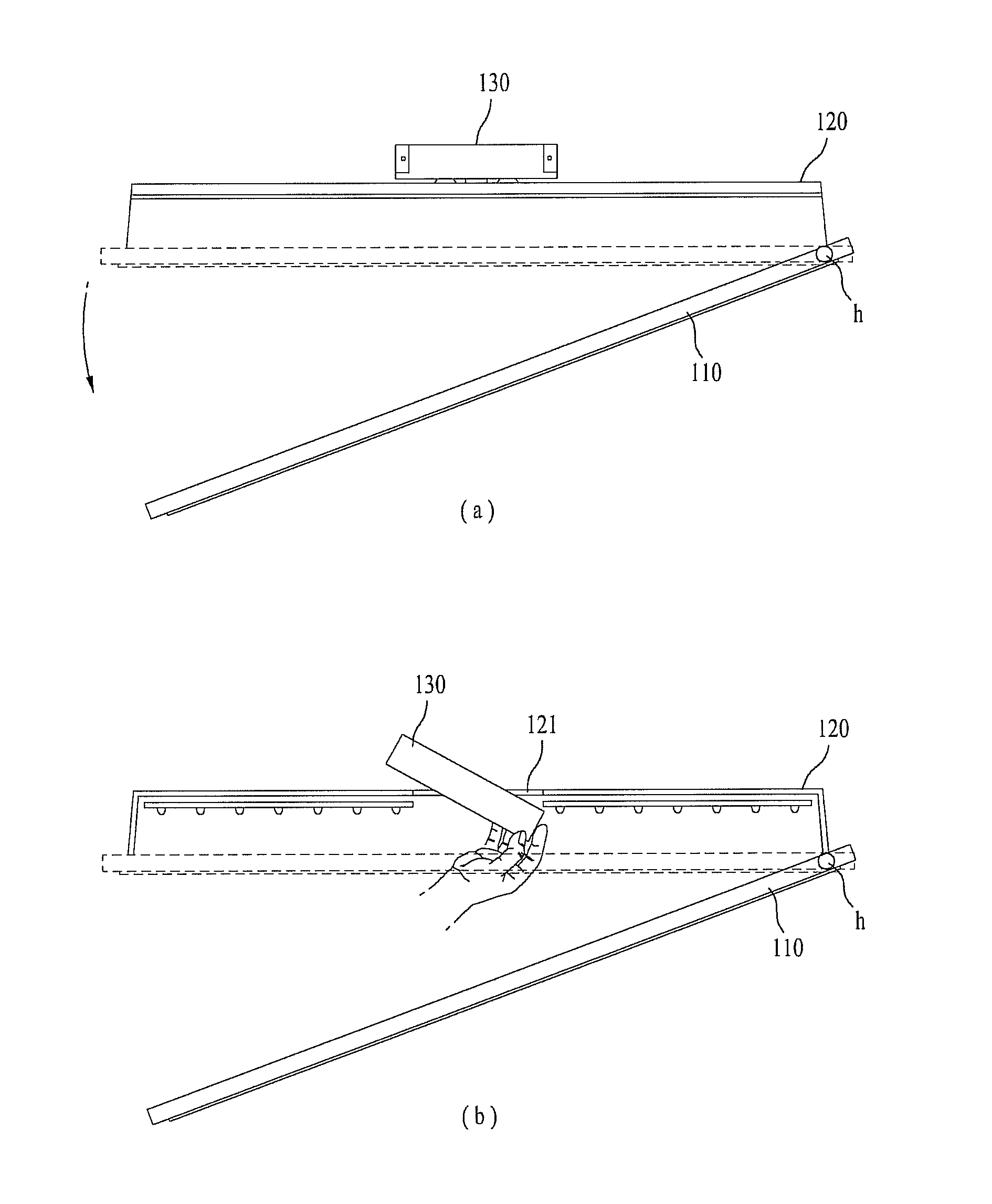

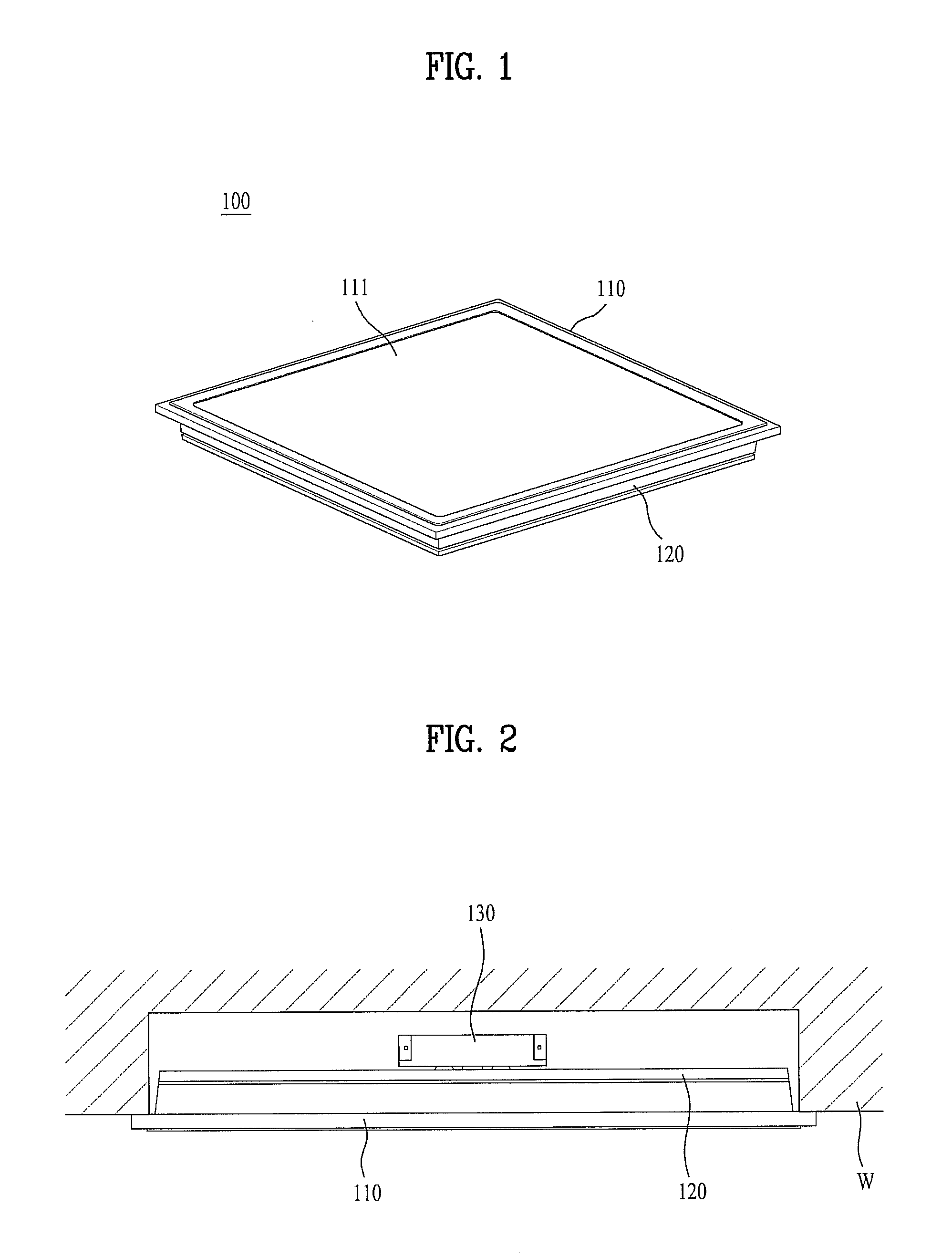

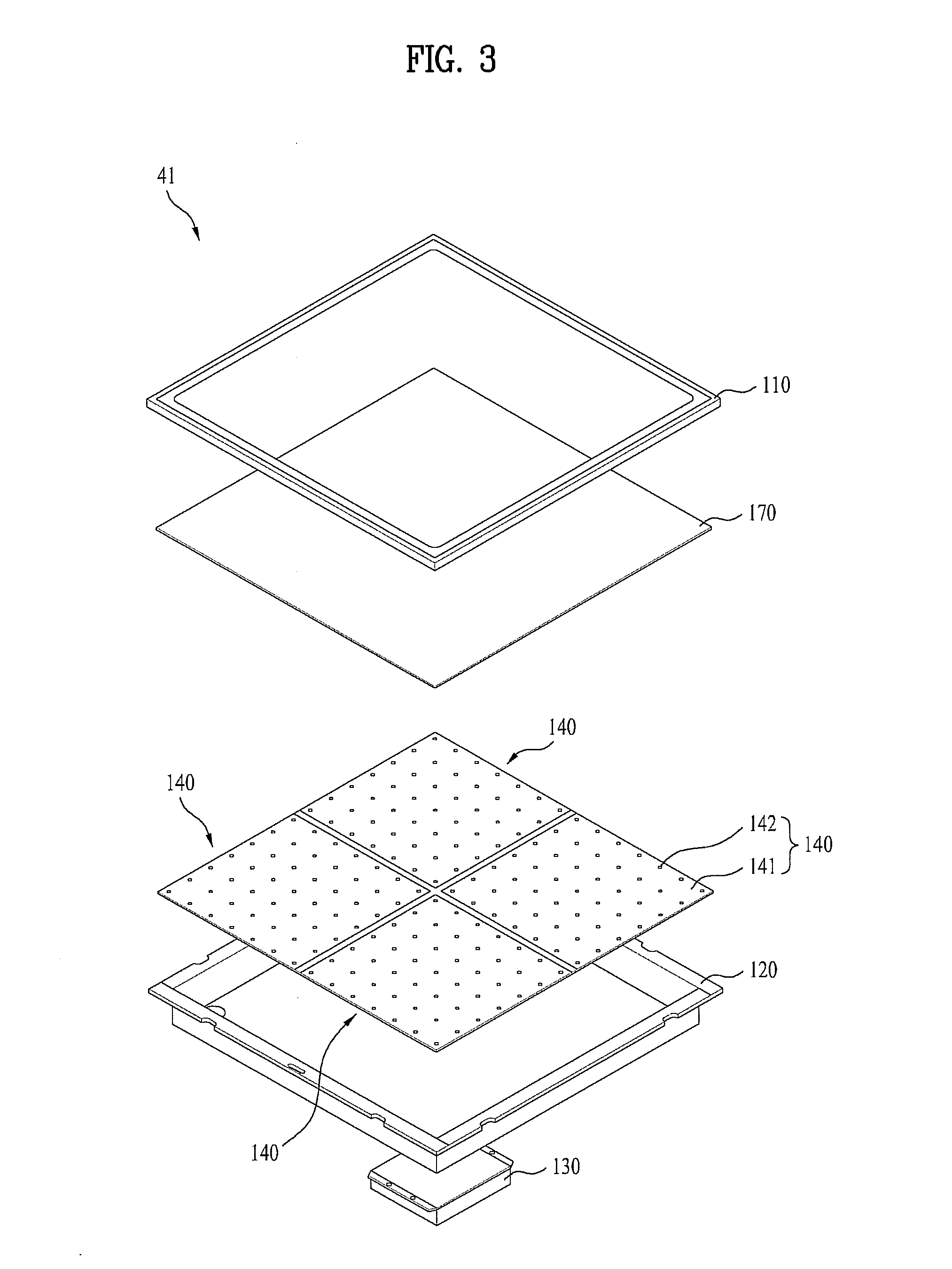

Lighting apparatus

InactiveUS20130094212A1Easy and smooth to replaceEasy and smooth to and repairPlanar light sourcesPoint-like light sourceEngineeringForeign matter

Owner:LG ELECTRONICS INC

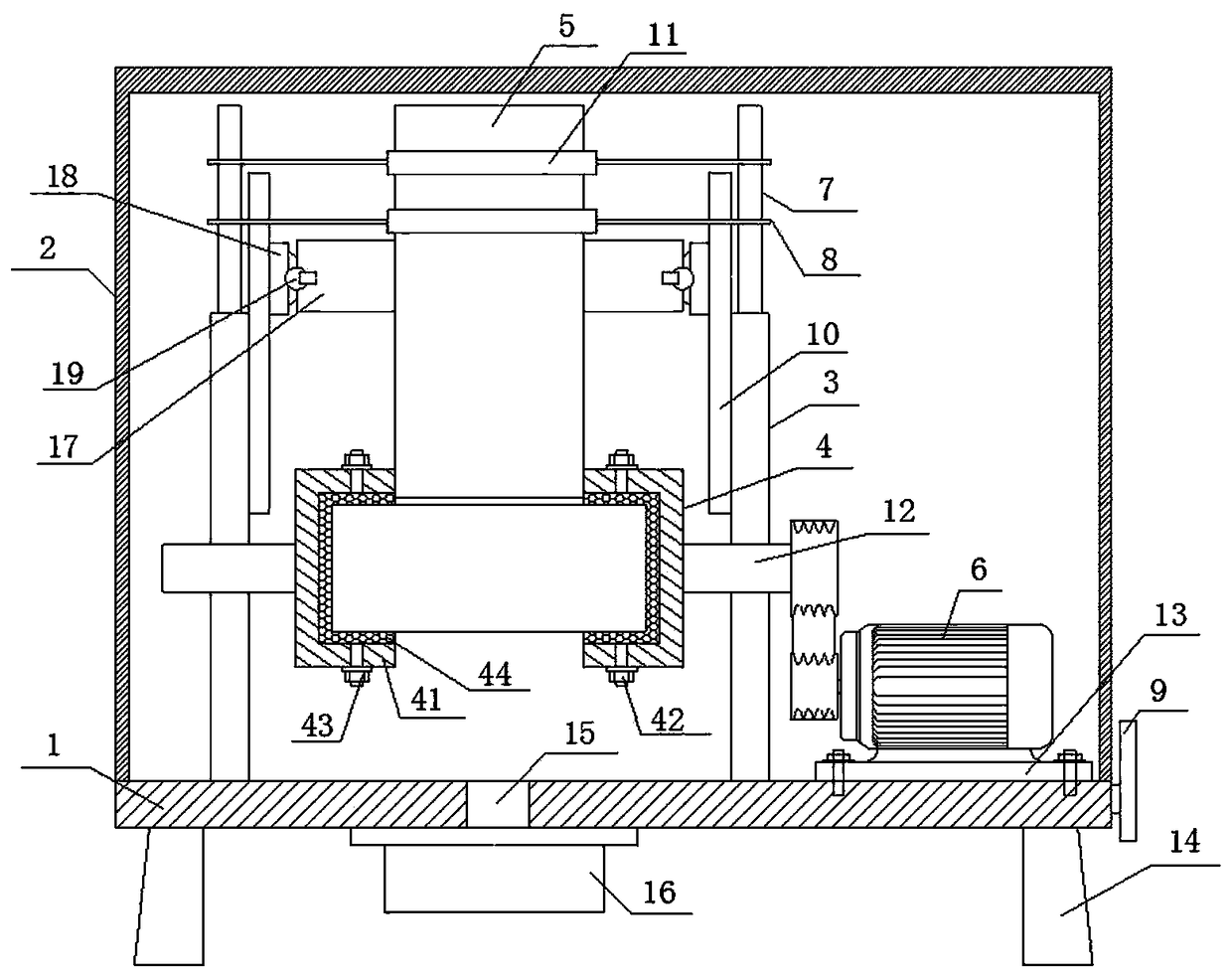

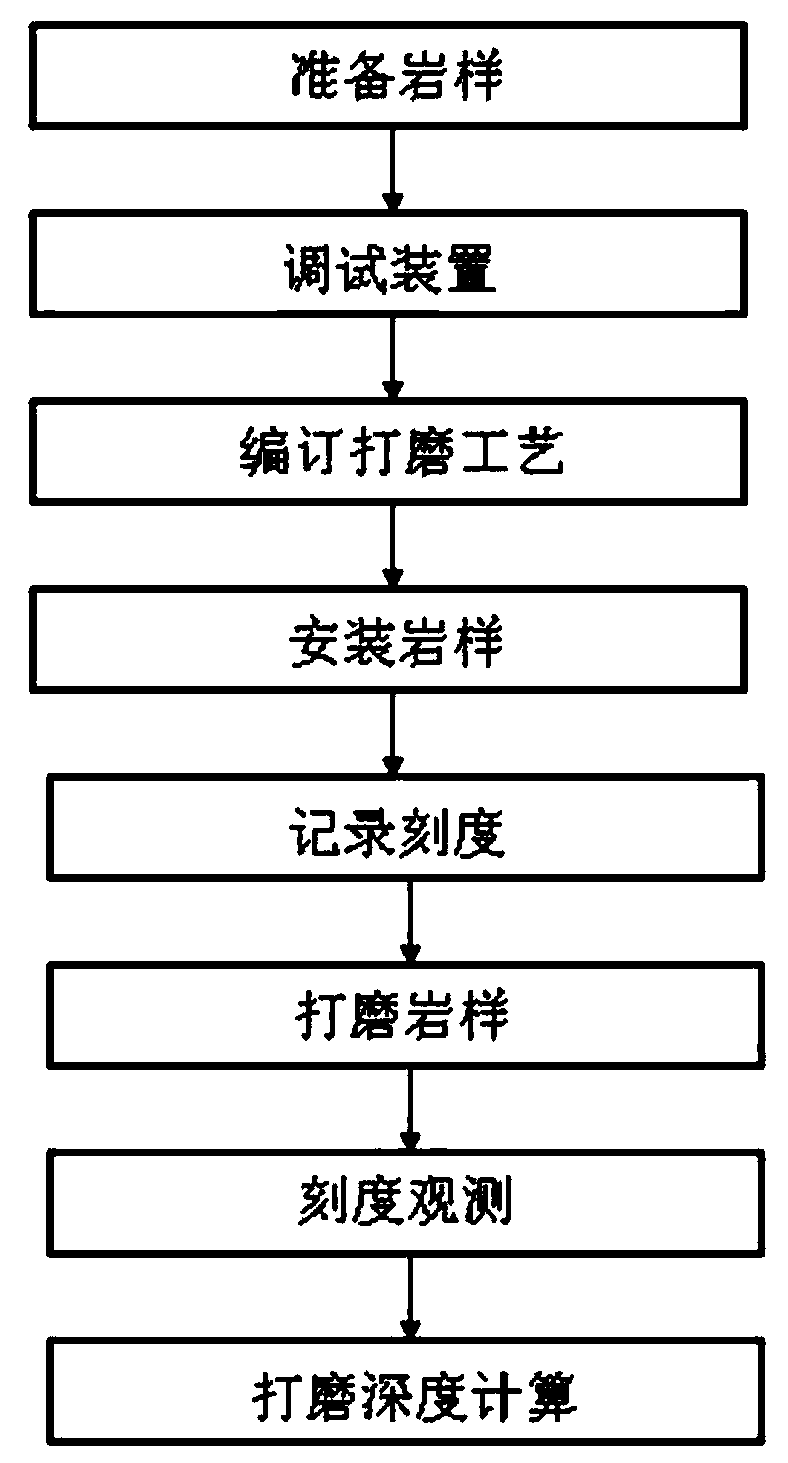

Dumbbell rock sample preparation device and processing method

InactiveCN108844798AImprove processing efficiencyHigh precisionPreparing sample for investigationMicrometerEngineering

The invention relates to a dumbbell rock sample preparation device which comprises a base, a protection box, a fixed bracket, a rock sample clamp, a grinding tool, a driving motor, a micrometer, a graduated scale and a control circuit, wherein the protection box wraps the exterior of the base; the fixed bracket is mounted on the upper end surface of the base; the grinding tool is connected with the inner side of the fixed bracket in a sliding manner; the micrometer is mounted on the upper end surface of the fixed bracket; the graduated scale is located right above the base; the rock sample clamp is located in the fixed bracket; and the control circuit is embedded into the side surface of the base. The processing method thereof comprises eight steps of preparing a rock sample, debugging thedevice, making a grinding process, mounting the rock sample, recording scales, grinding the rock sample, observing the scales, and calculating grinding depth. The dumbbell rock sample preparation device, on the one hand, has a simple structure and a good adaptive capacity to environment and can effectively meet use needs of different occasions, and on the other hand, is high integration degree and automation degree, and is flexible and convenient in part replacement and simple and convenient to operate; and the processing process is easy to grasp.

Owner:HENAN POLYTECHNIC UNIV

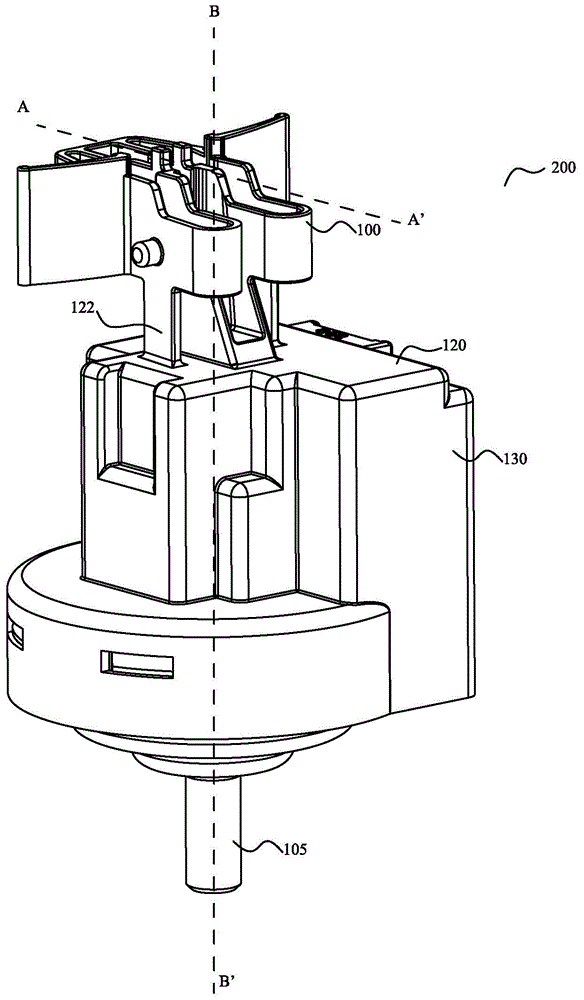

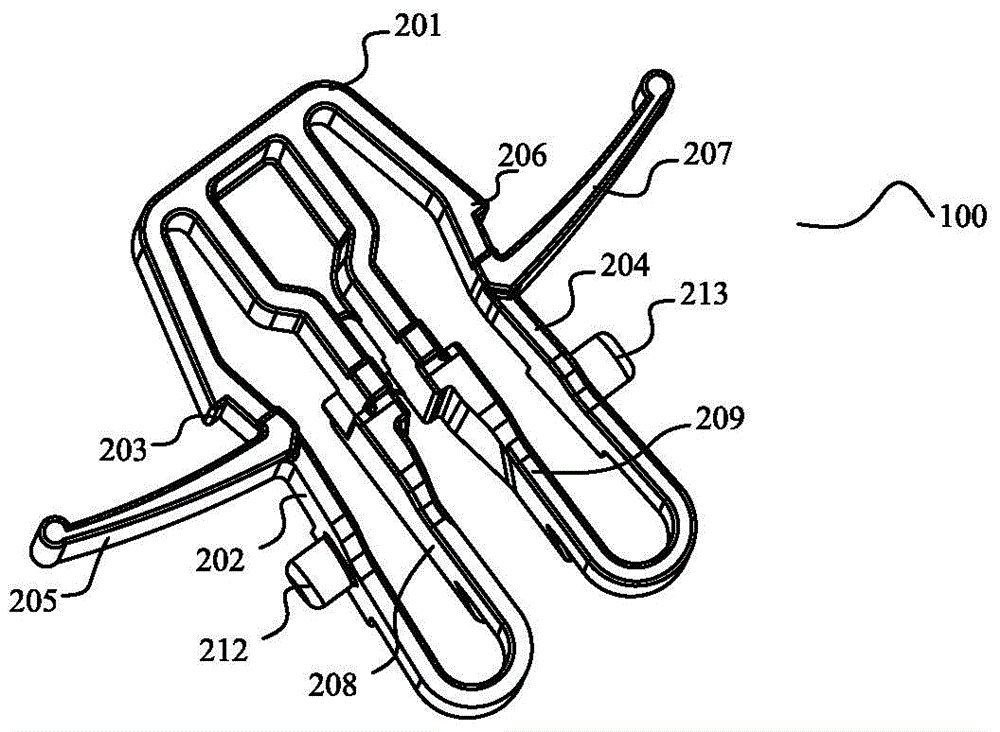

Pressure sensor

ActiveCN106197603AEasy to fixEasy to installLevel indicators by pressure measurementEngineeringPressure sensor

A pressure sensor comprises a pressure sensor body, wherein the pressure sensor body comprises a casing and a buckle, wherein a hydraulically sensitive deformable membrane is accommodated in the casing; the buckle is arranged at the top of the casing, buckle bodies and buckle wings are arranged on the buckle, and the buckle is detachably buckled and fixed with an electric appliance fixing rack. A first clamping foot and a second clamping foot on an elastic first arm and an elastic second arm are extruded and inserted into a hole of an electric appliance panel by means of the buckle and are firmly fixed through a first clamping wing and a second clamping wing on the outer side of the hole, so that the pressure sensor can be tightly hung on the panel and is convenient to mount and firmly fixed. The buckle can be pinched and extruded from outer sides of the first arm and the second arm and can be taken out of the hole of the panel when the width of the first clamping foot and the second clamping foot is smaller than the hole of the panel, and the pressure sensor is convenient and efficient to replace.

Owner:ILLINOIS TOOL WORKS INC

Lighting apparatus

InactiveUS8550666B2Repaired and easily and efficientlyEasy and efficient replacementPlanar light sourcesPoint-like light sourceForeign matterEffect light

Owner:LG ELECTRONICS INC

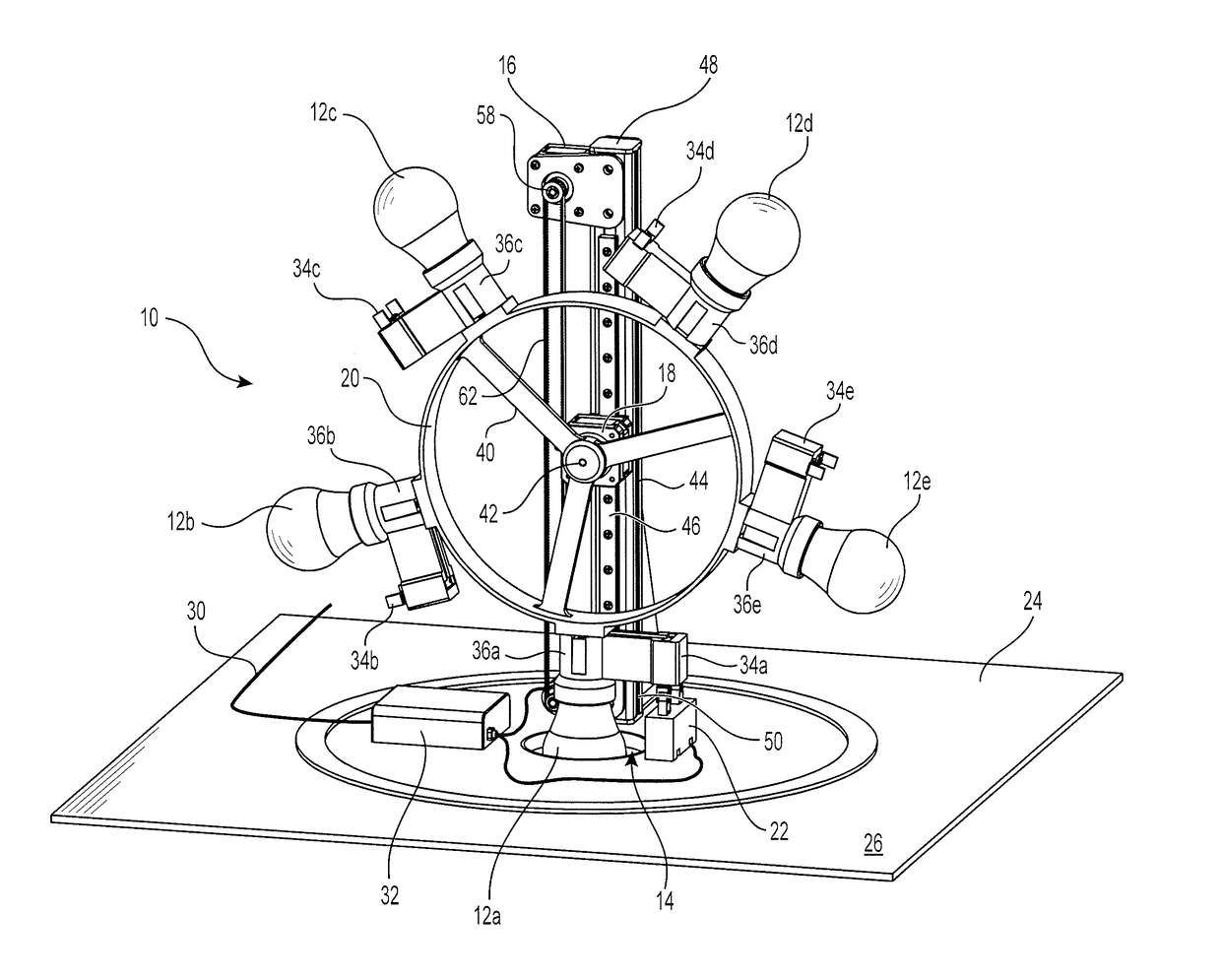

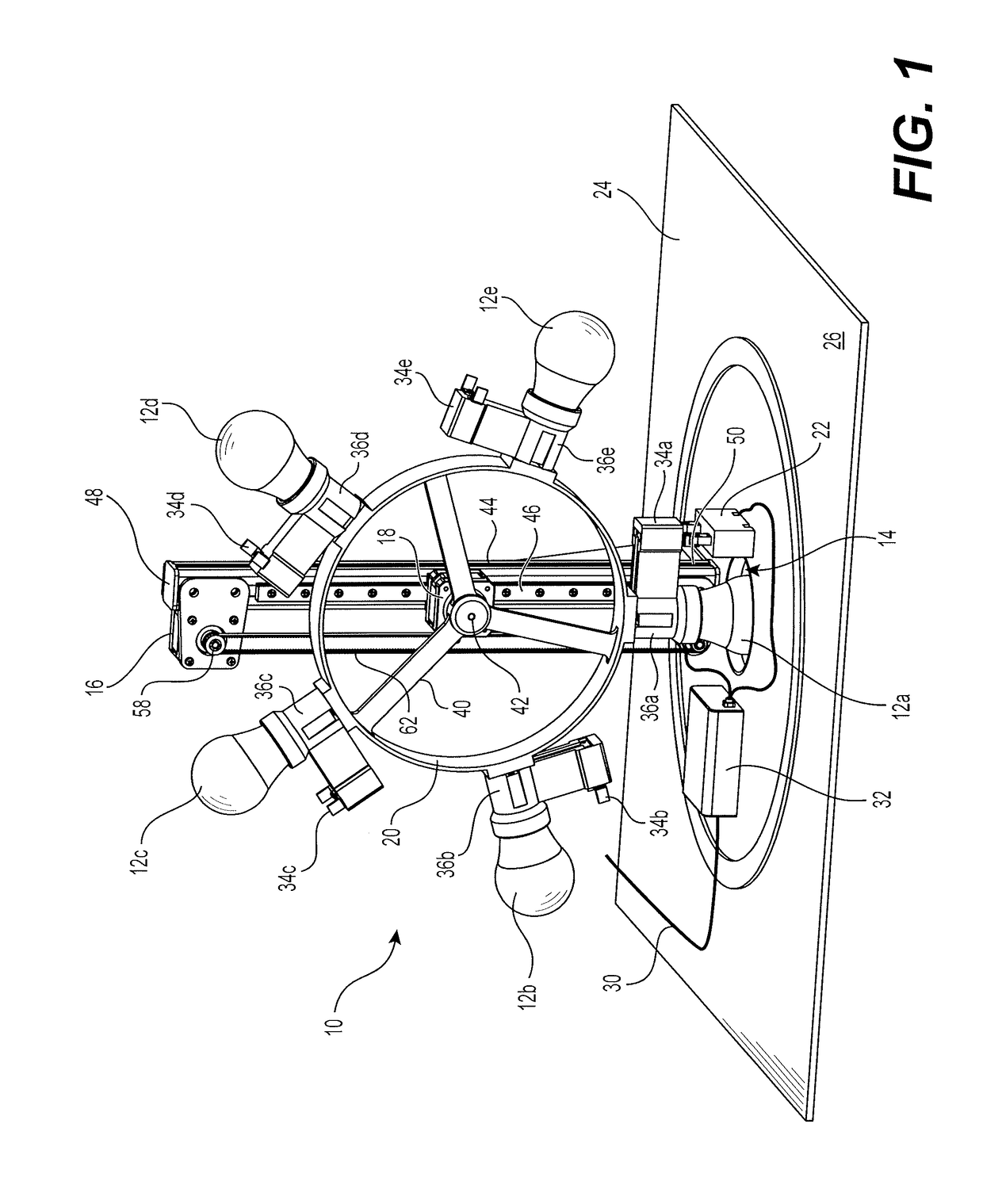

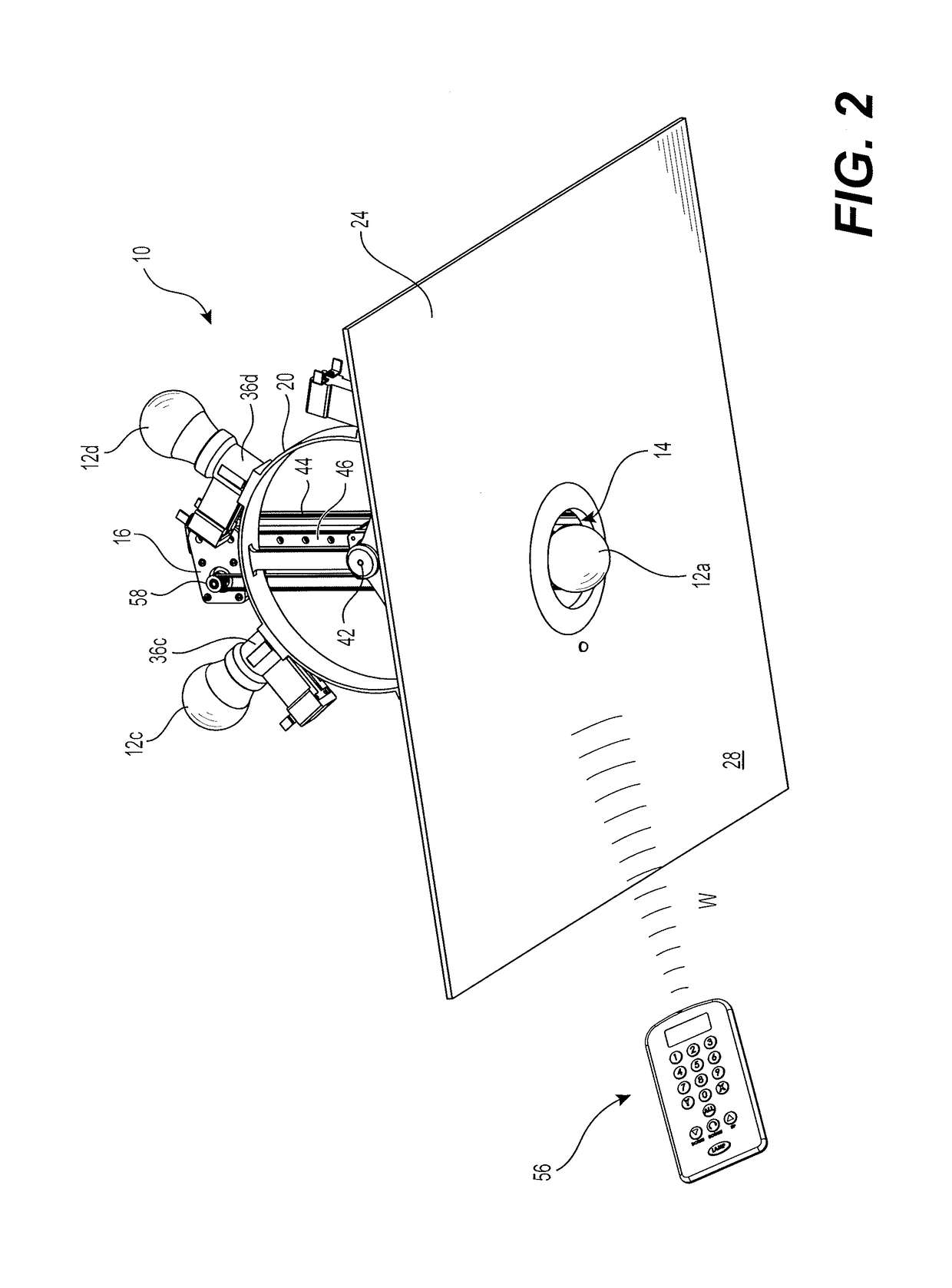

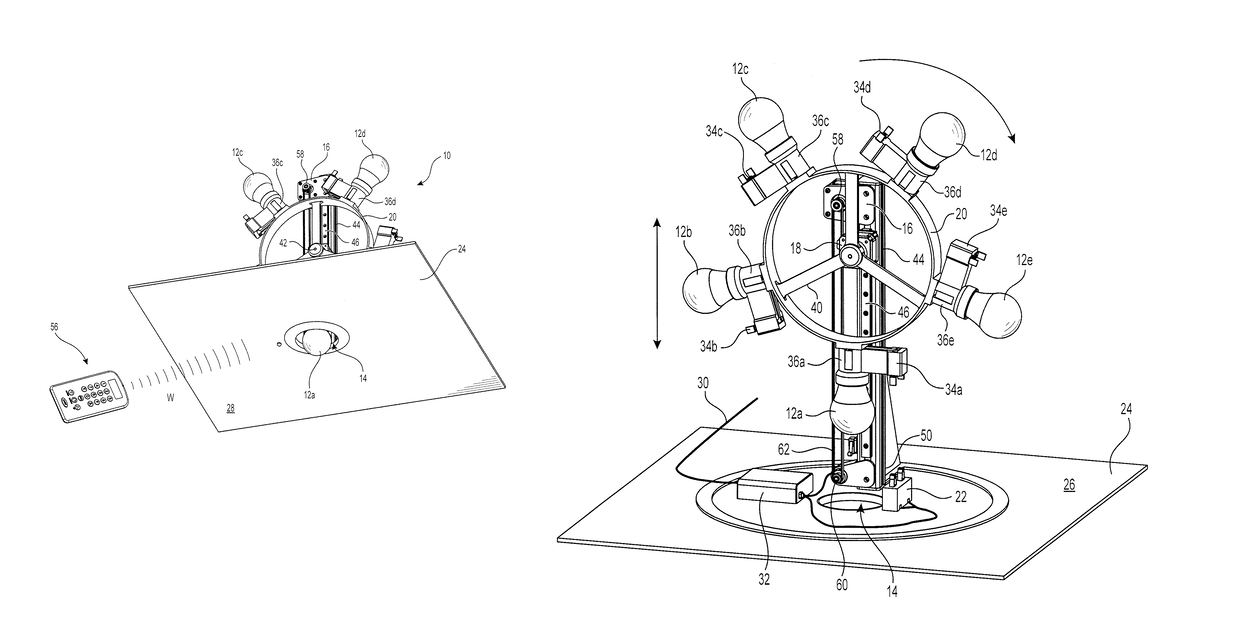

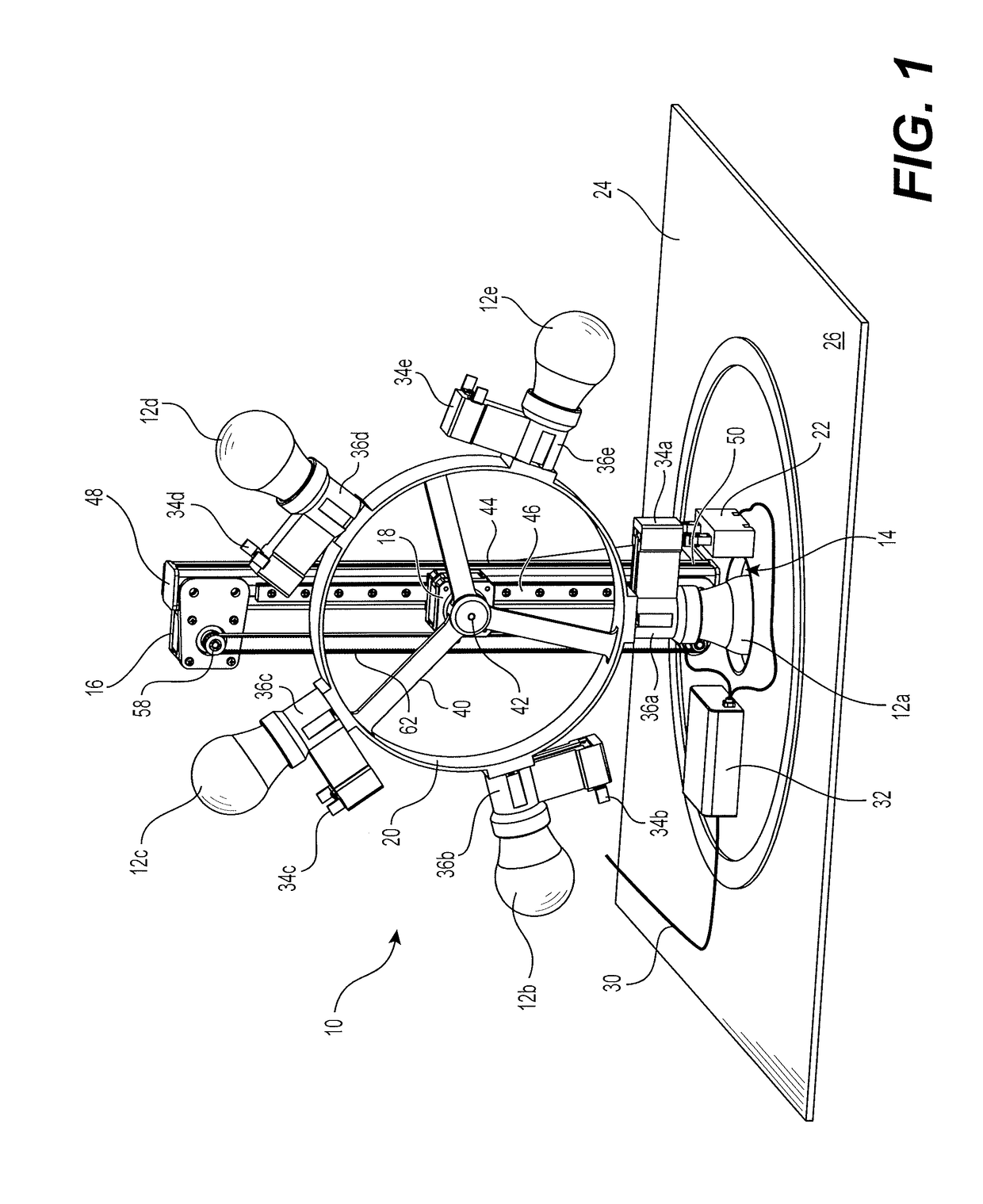

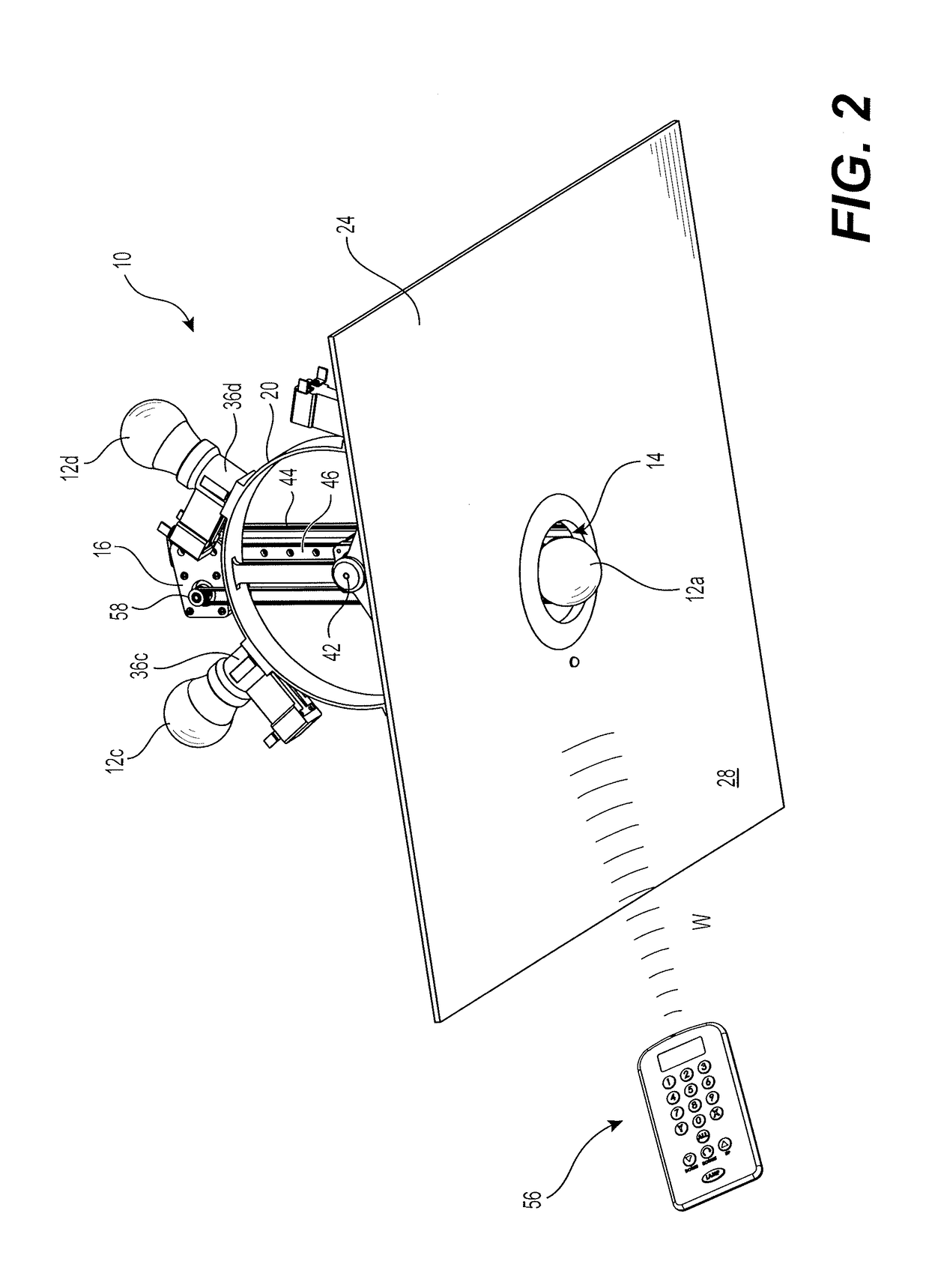

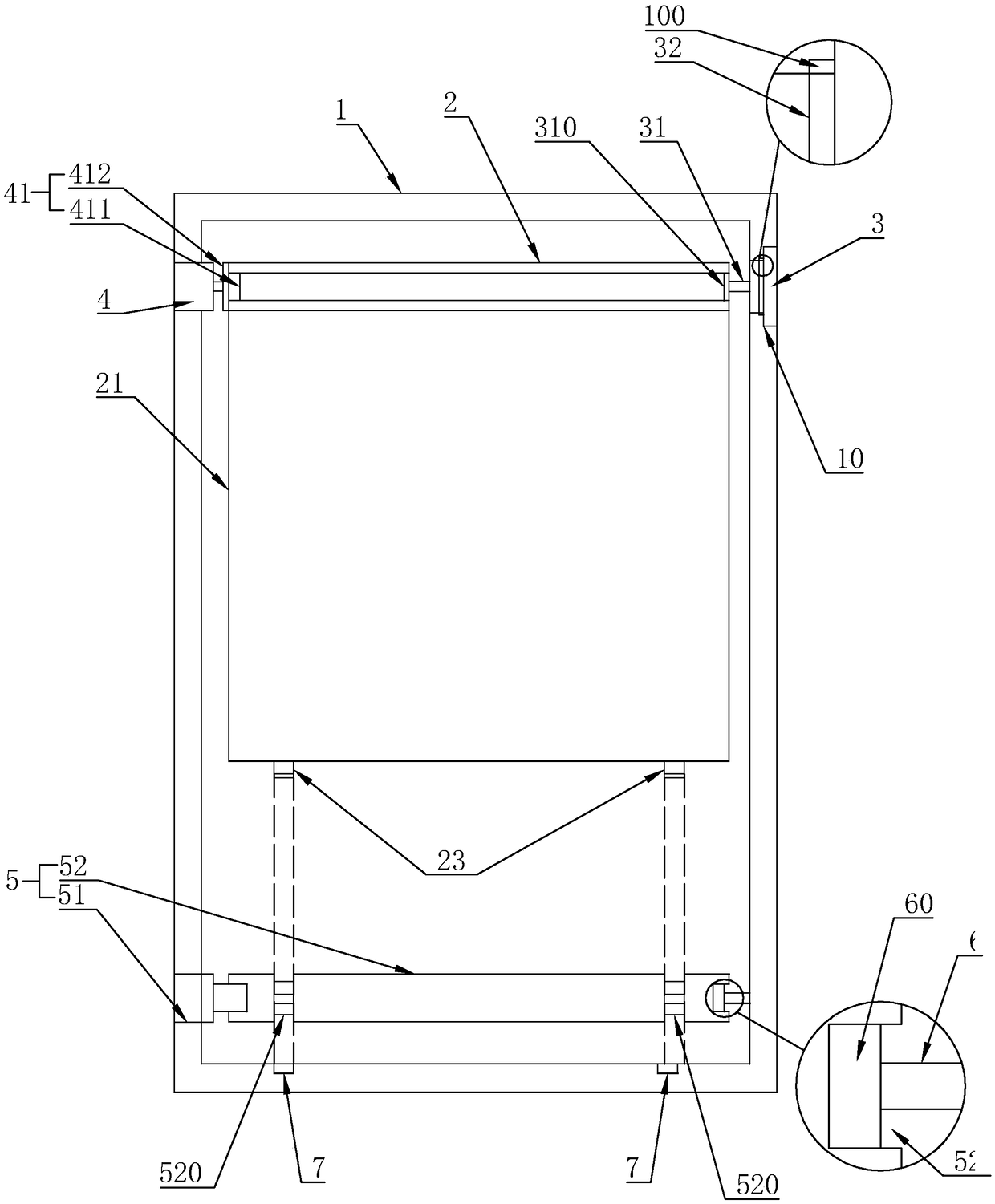

Rotating multi-socket light fixture

ActiveUS20180224094A1Easy and efficient replacementLight source combinationsLighting support devicesDrive motorVertical translation

The rotating multi-socket light fixture may be used in combination with a ceiling panel or the like, allowing for changing of light bulbs for a recessed light, for example. The rotating multi-socket light fixture includes a plurality of light bulb sockets mounted circumferentially on a wheel for respectively removably receiving a plurality of light bulbs. The wheel is mounted on, and rotationally driven by, a rotational drive motor. The rotational drive motor is mounted on a vertical support such that the rotational drive motor may be vertically adjusted with respect to the vertical support. A vertical drive motor may be mounted on an upper end of the vertical support for selectively driving vertical translation of the rotational drive motor with respect to the vertical support. A lower end of the vertical support is mounted on an upper surface of the ceiling panel, such that the vertical support extends upwardly therefrom.

Owner:AL KHULAIFI KHALED A M A A

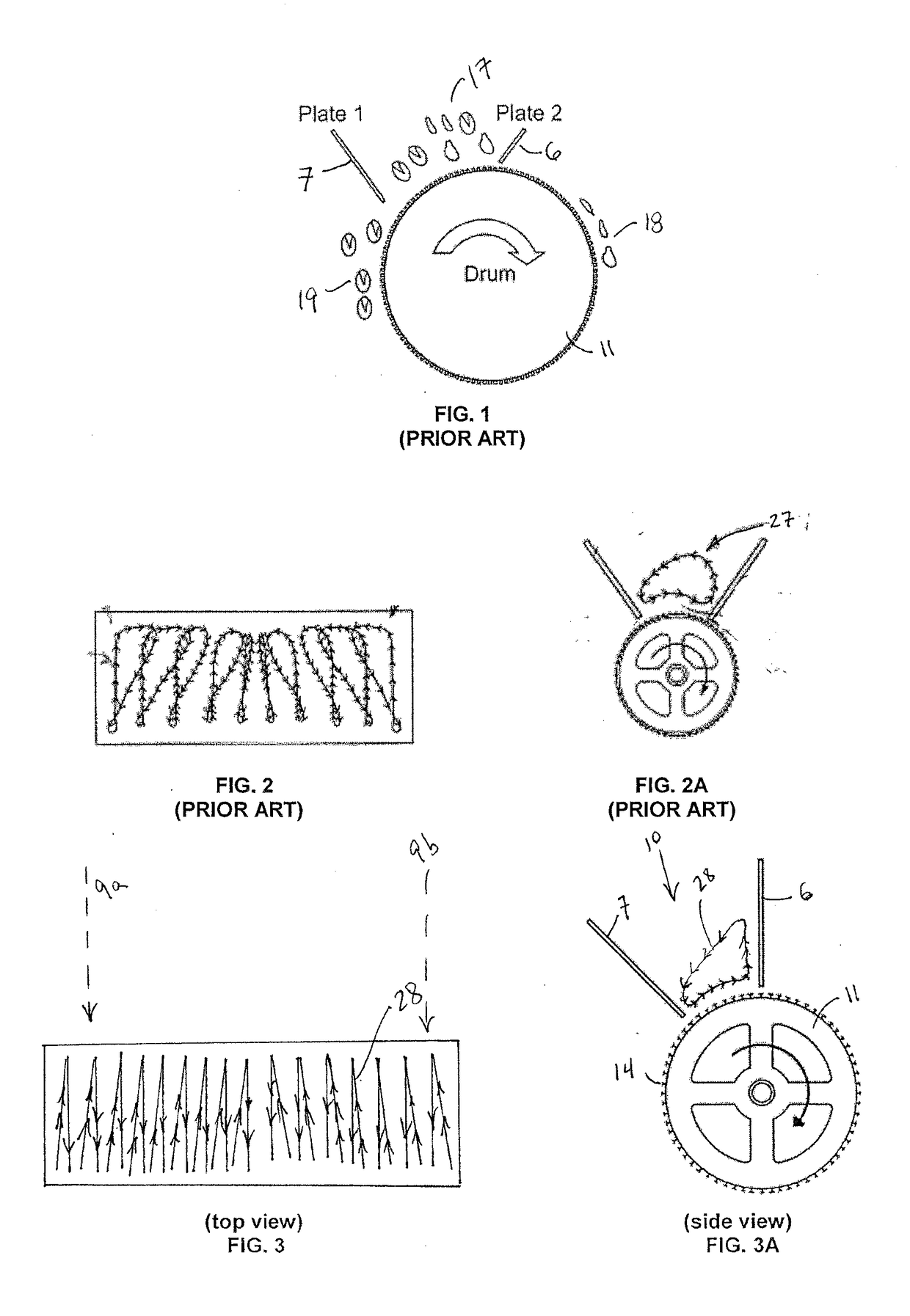

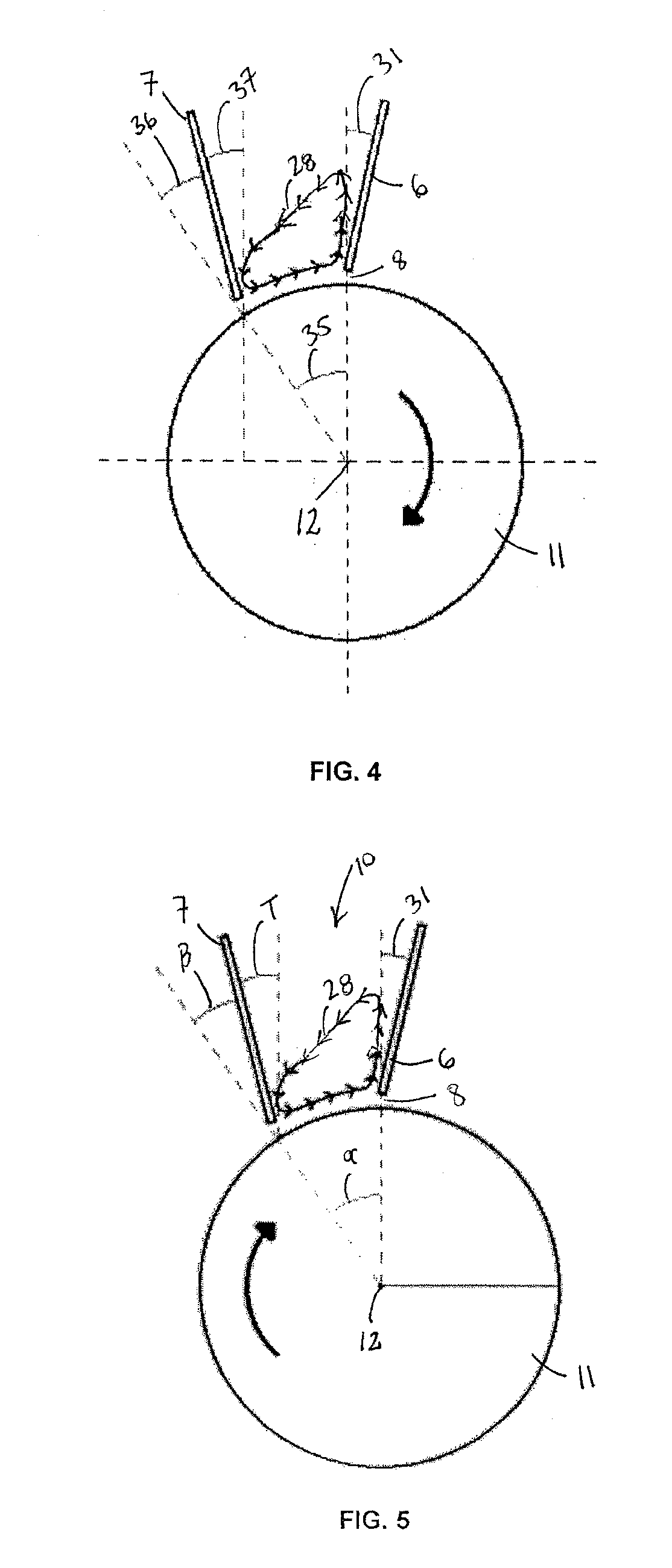

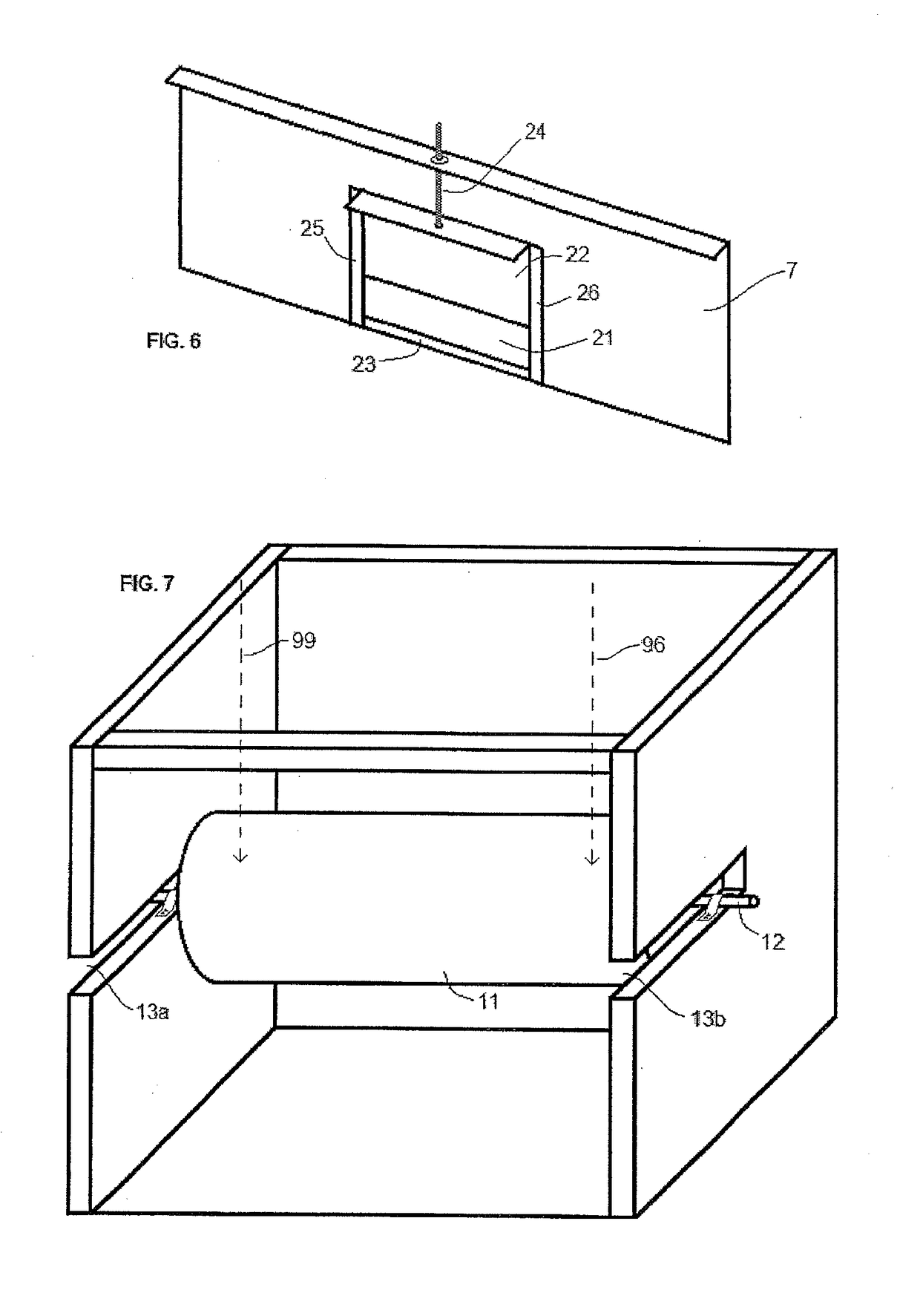

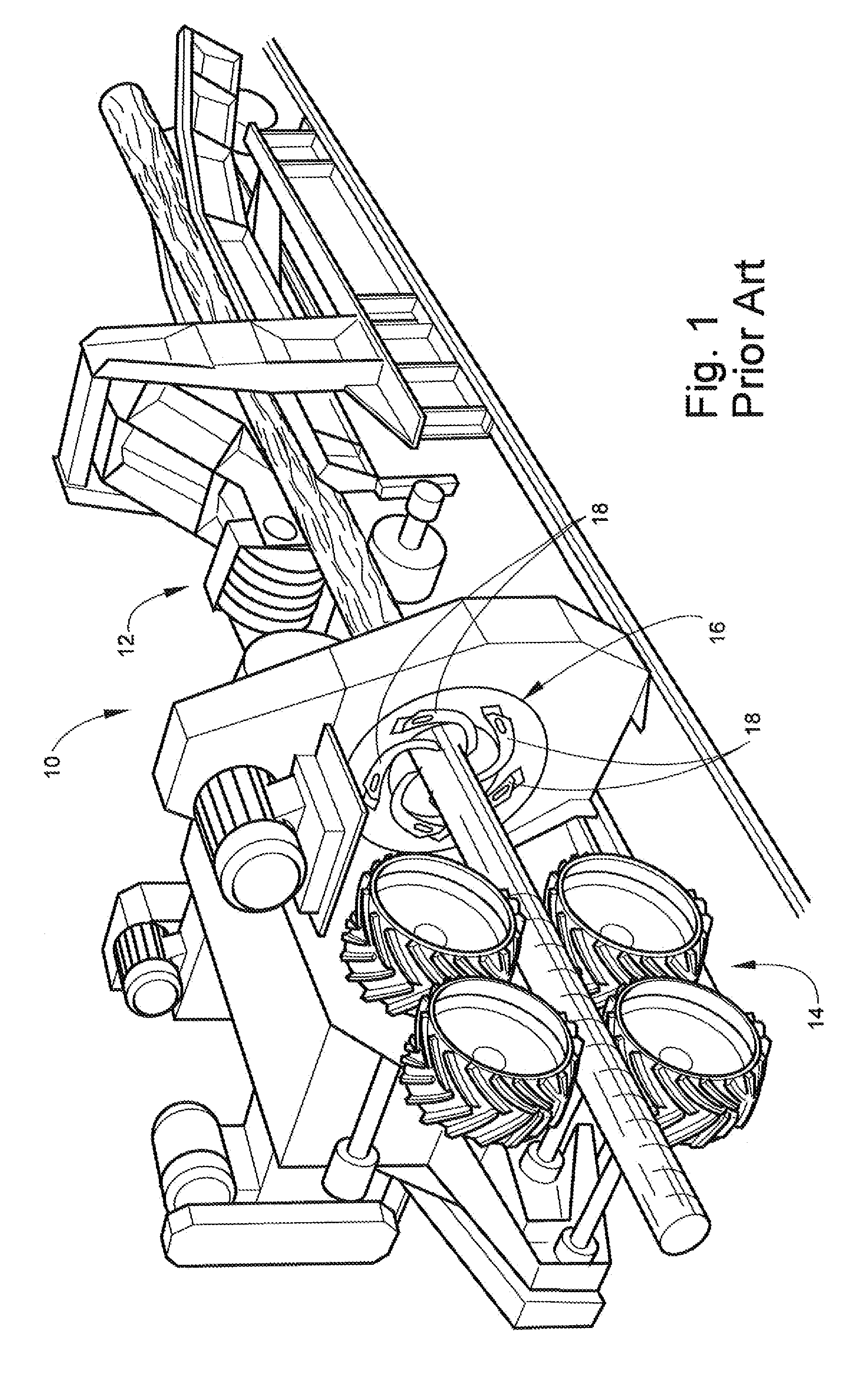

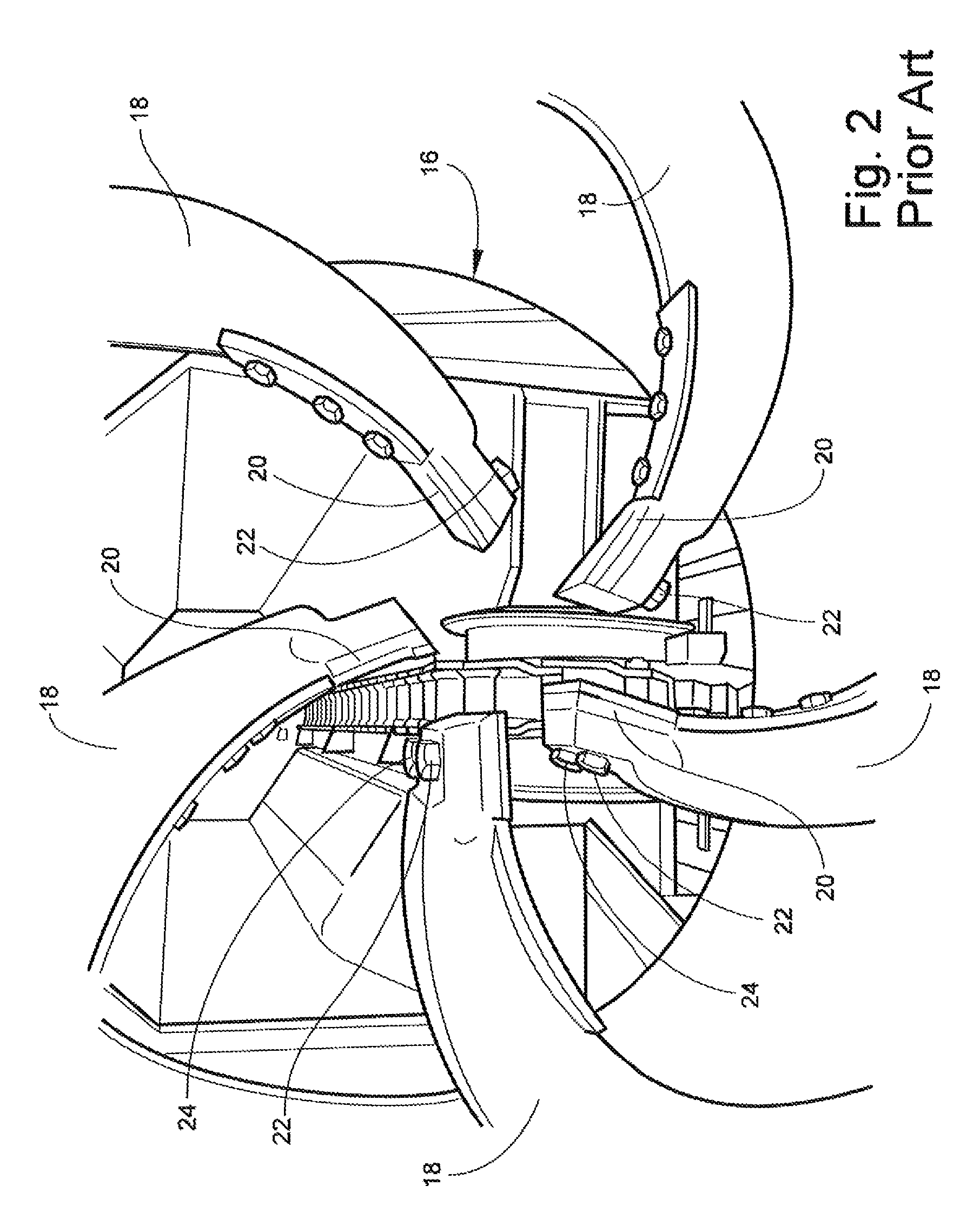

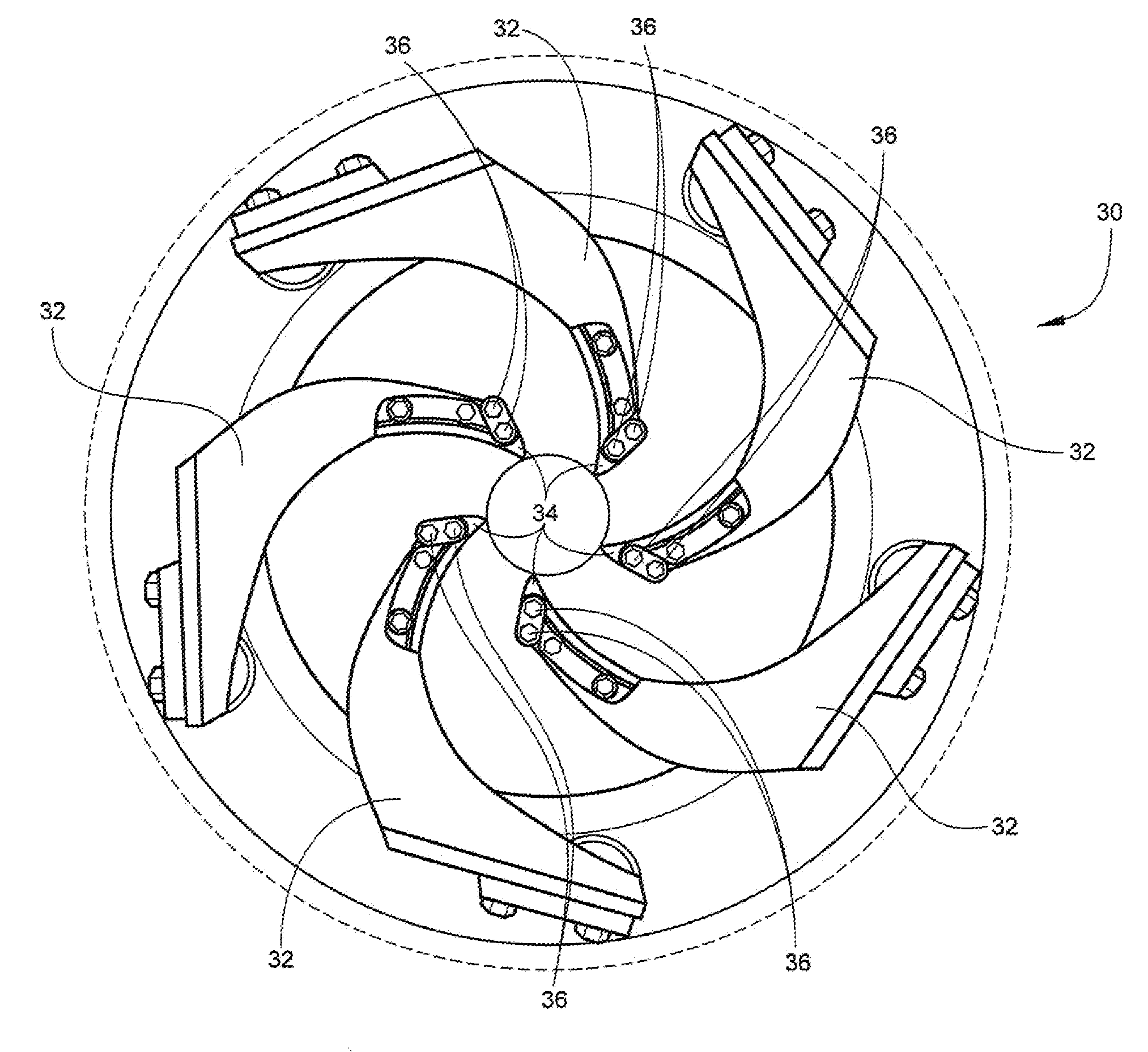

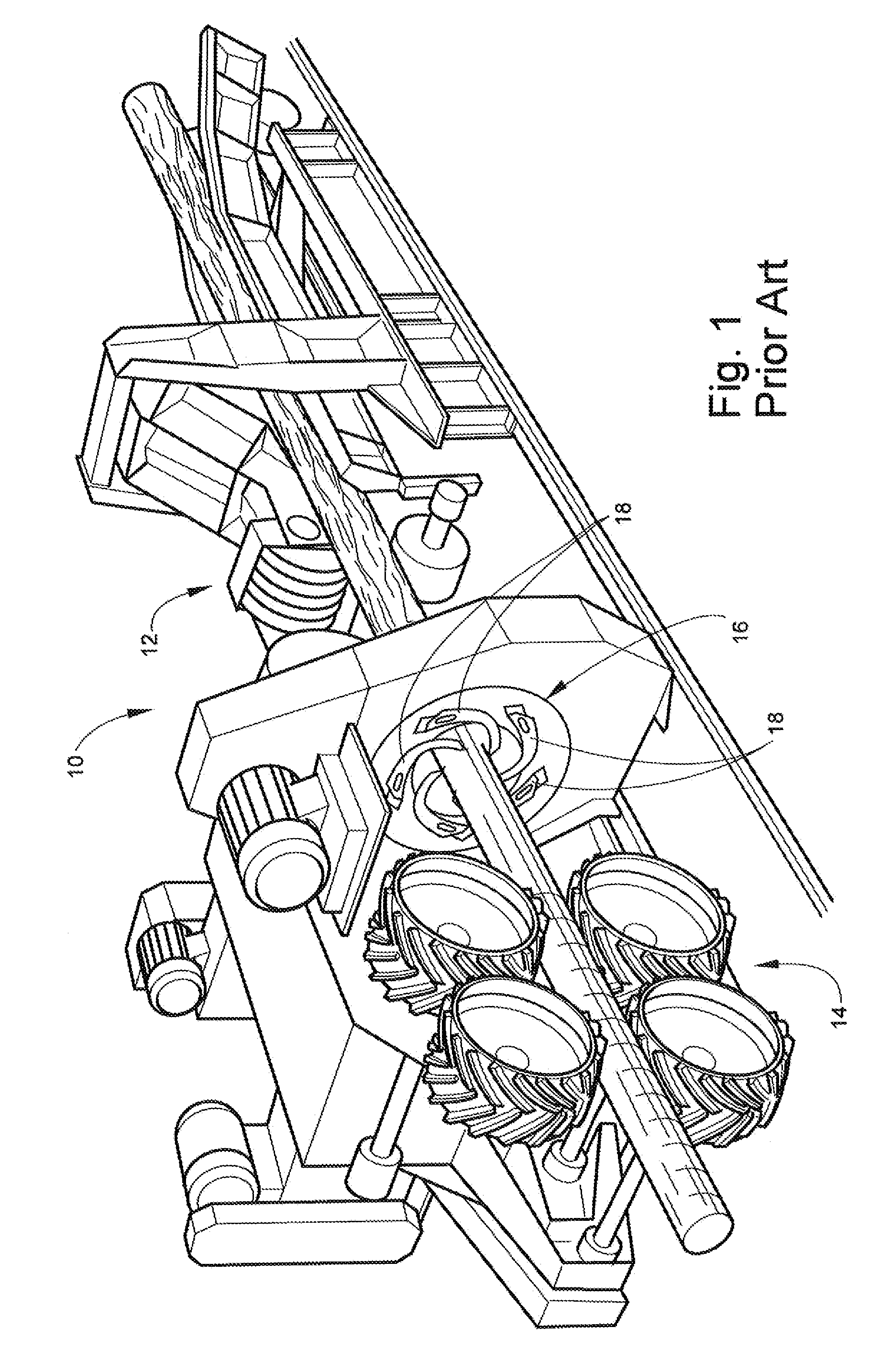

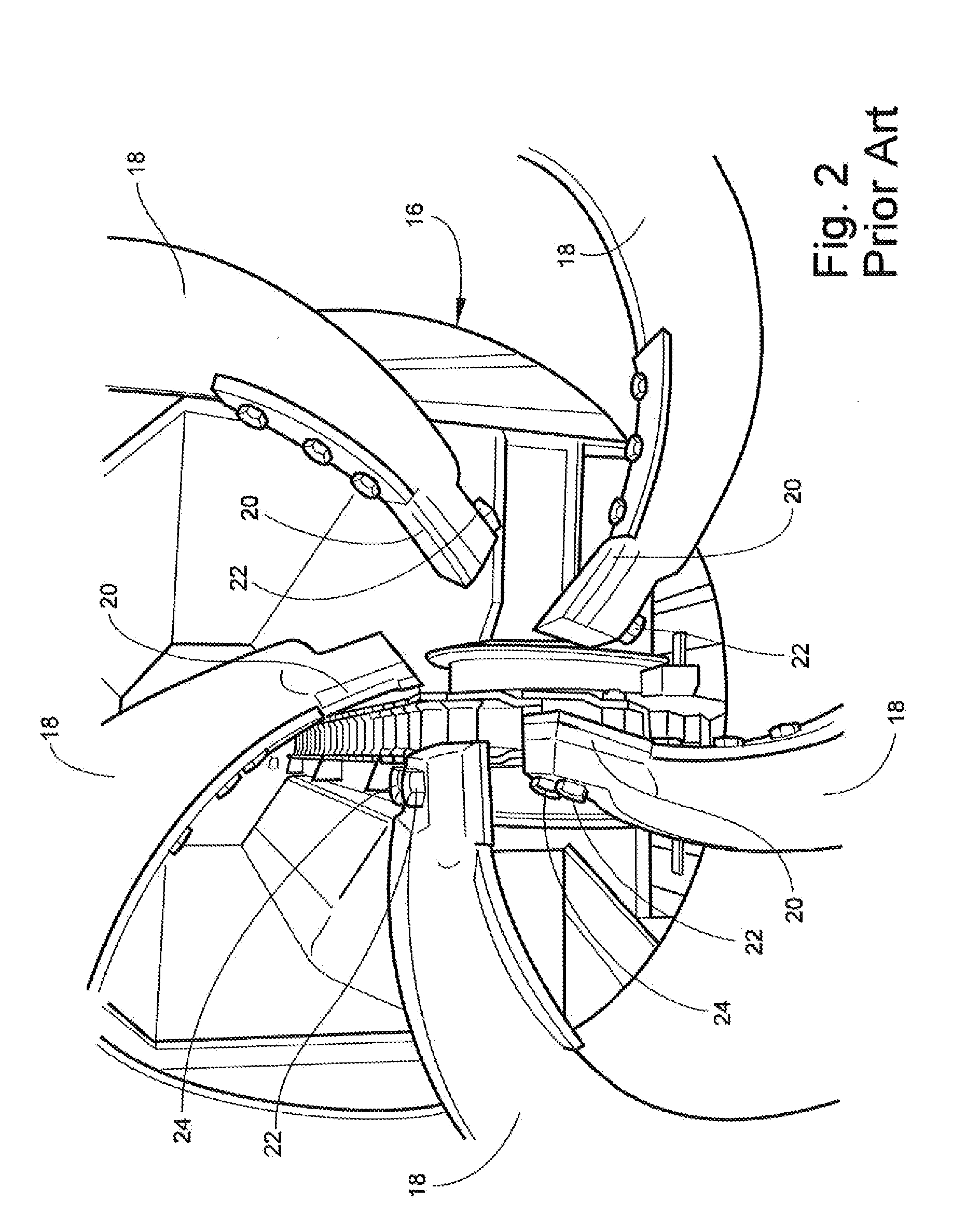

Methods and Apparatus for Hulling Crops

InactiveUS20190059436A1Increase percentageExtended processing timeGrain huskingGrain polishingEngineeringImproved method

Improved methods and apparatus for dry hulling or dry peeling harvested crops, particularly pistachio nuts, are disclosed. The methods and apparatus of the present invention provide crop harvesting with great efficiency resulting in consistently high percentages of hulled or peeled crops and low percentages of nut breakage, without increasing processing times regardless of the sizes of the crops being hulled or peeled. The methods and apparatus of the present invention also provide for a relatively small overall machine footprint, plus easy and efficient removal and replacement of the impingement drum to accommodate for different drum speeds, different crop sizes, different bolt patterns, different bolt sizes, and other variations allowing embodiments of the invention to be used on a wide range of nuts and vegetables of different varieties, sizes and shapes.

Owner:ZYMEX IND INC

Current probe and jig suitable for replacing current probe

InactiveCN107525952AEasy and efficient replacementAvoid reducing replacement efficiencyElectrical measurement instrument detailsElectrical testingBiomedical engineering

Owner:致茂电子(苏州)有限公司

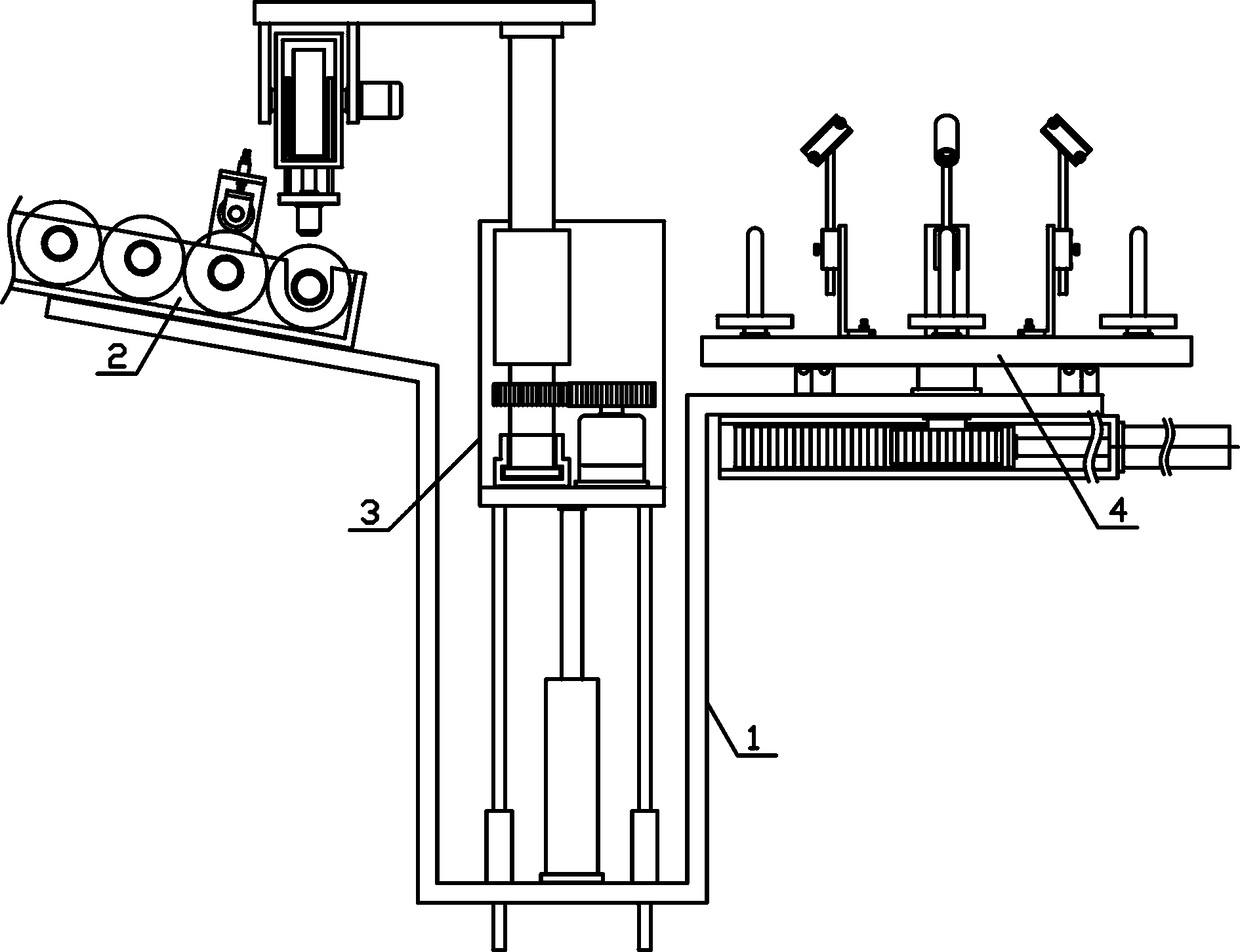

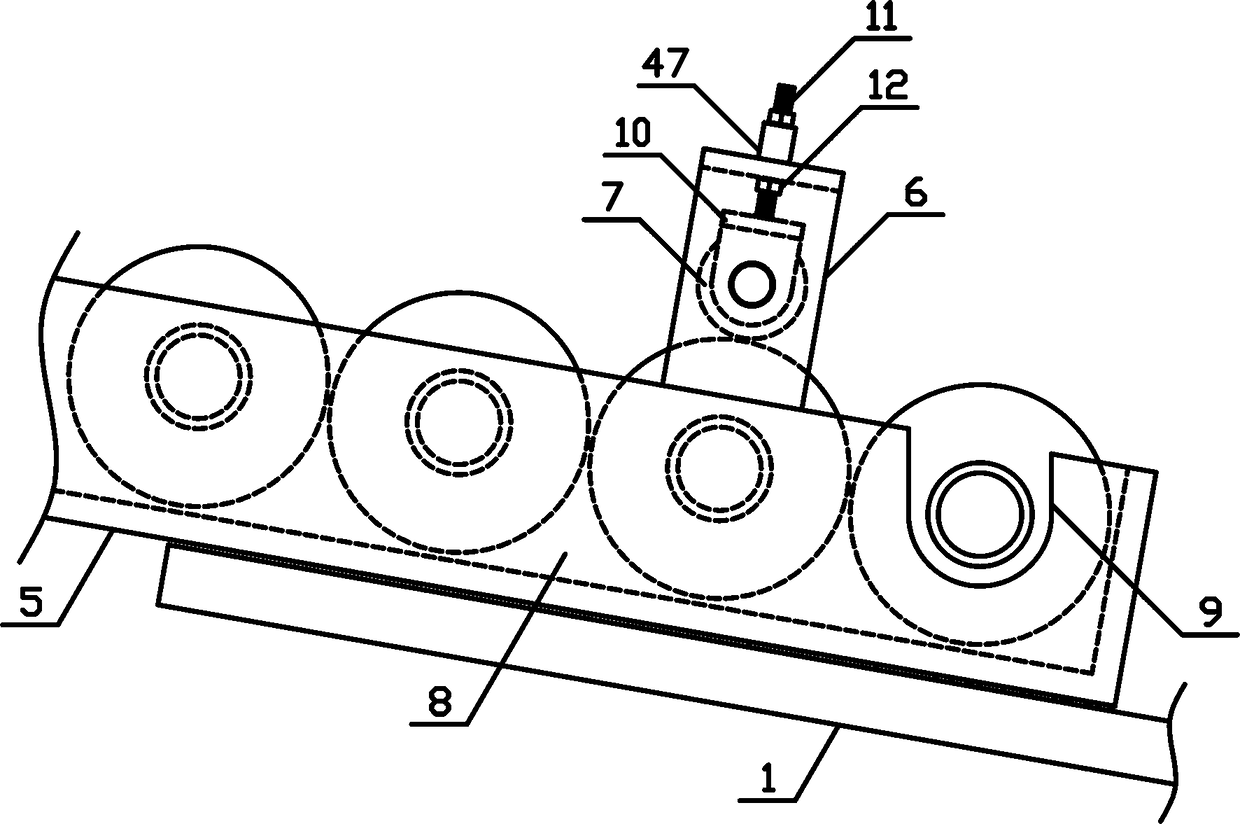

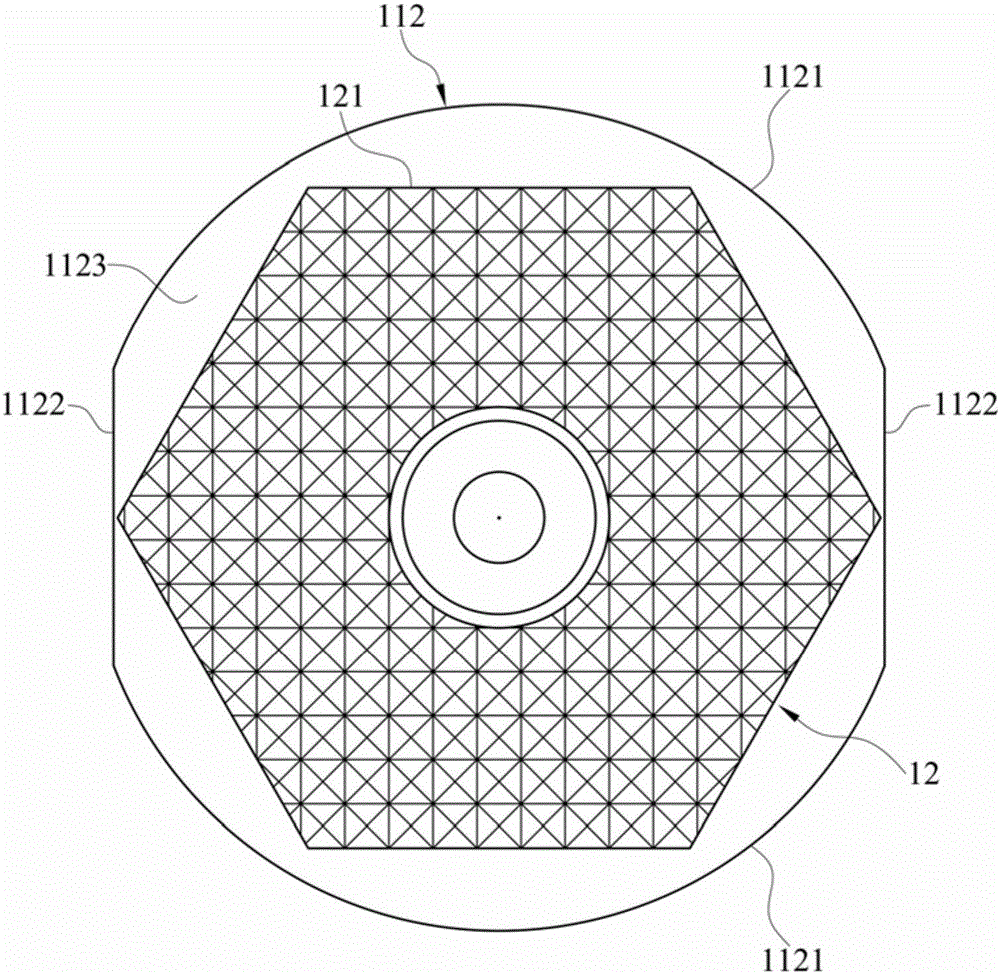

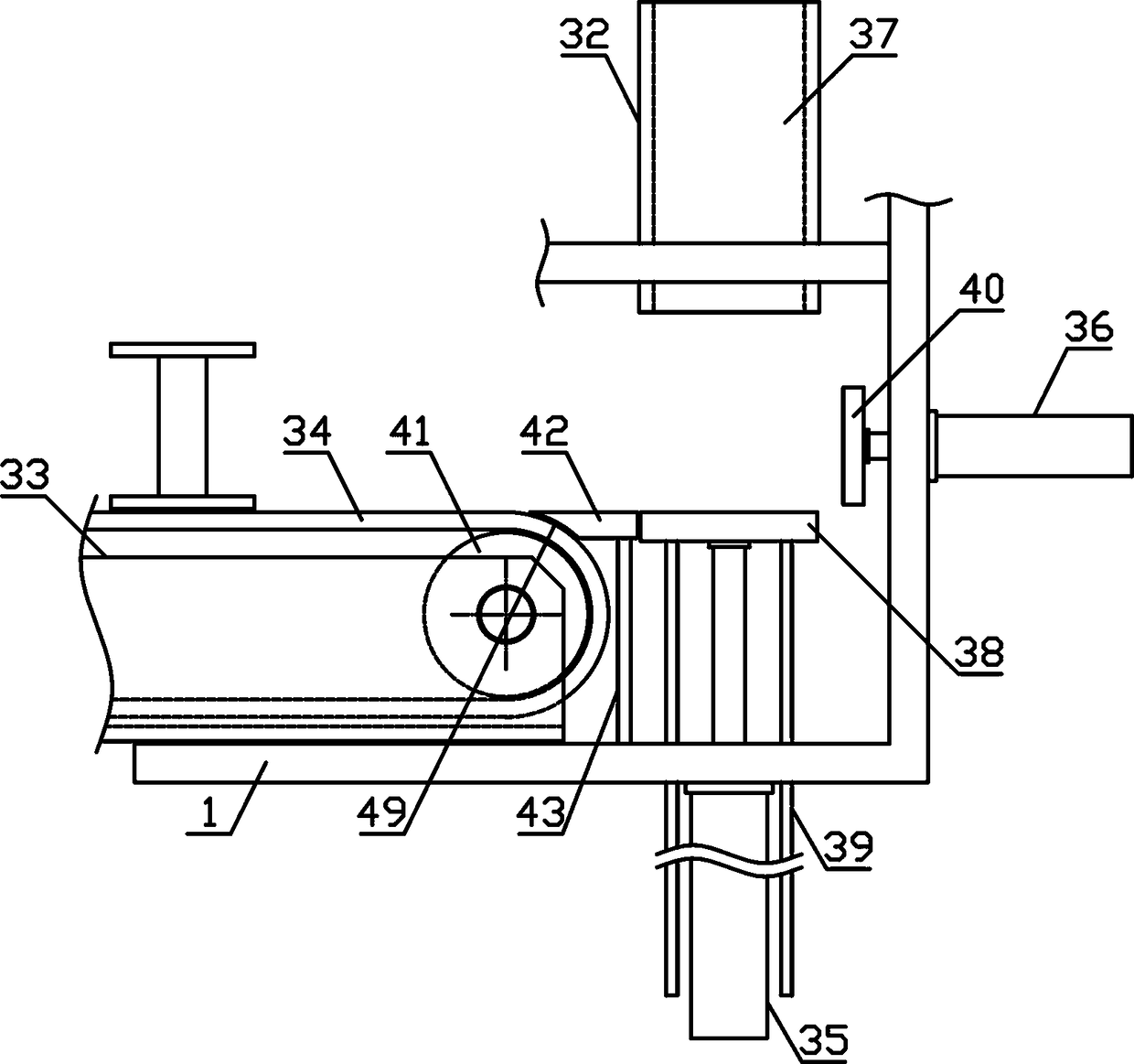

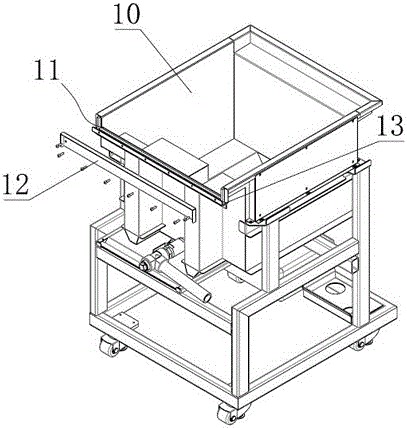

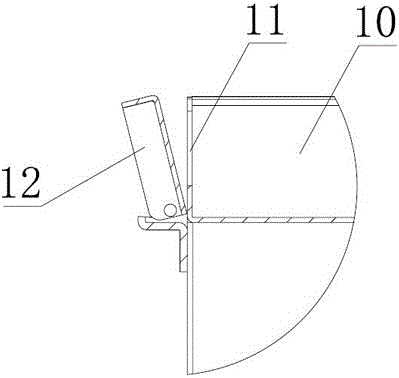

Automatic replacement mechanism for chemical fiber cone yarns

The invention discloses an automatic replacement mechanism for chemical fiber cone yarns, and belongs to the field of chemical fiber conveying processing mechanical equipment. A cone yarn feeding mechanism and a cone yarn retreating mechanism of the automatic replacement mechanism are arranged on a fixed bracket from top to bottom in sequence, a yarn unwinding mechanism is horizontally arranged atthe position, on one side of the cone yarn feeding mechanism, of the fixed bracket, a cone yarn feeding material belt is horizontally arranged on the upper side of a cone yarn feeding bracket, the output end of a cone yarn feeding air cylinder is fixedly provided with a cone yarn feeding connecting plate, and a cone yarn clamping gas expansion shaft is vertically and fixedly arranged at the portion, on the middle portion of the lower side of a cone yarn clamping connecting plate, of a cone yarn clamping air cylinder; and the middle portion of the lower side of a yarn guiding rotary disc is fixedly connected with the upper end of a reciprocating rotating shaft, a plurality of yarn guiding mechanisms on the upper side of the yarn guiding rotary disc and cone yarn containing circular platesare arranged correspondingly, the output end of a cone yarn bearing air cylinder is horizontally and fixedly provided with a cone yarn bearing connecting plate, and a cone yarn retreating material belt is horizontally arranged on the upper side of a cone yarn retreating bracket. The automatic replacement mechanism is reasonable in structure design, a plurality of chemical fiber cone yarns can be continuously and conveniently transferred and replaced one by one in a convenient and efficient manner, so that multi-strand chemical fiber silks can be stably, accurately and synchronously transmitted, and the needs of production and use are met.

Owner:桐乡市宏力纺织股份有限公司

Log debarking tool and tool tip

ActiveUS7931055B2Convenient and efficient accessEasy and efficient removalMulti-purpose machinesTree debarkingMechanical engineeringEngineering

Owner:REIMLER JAMES L

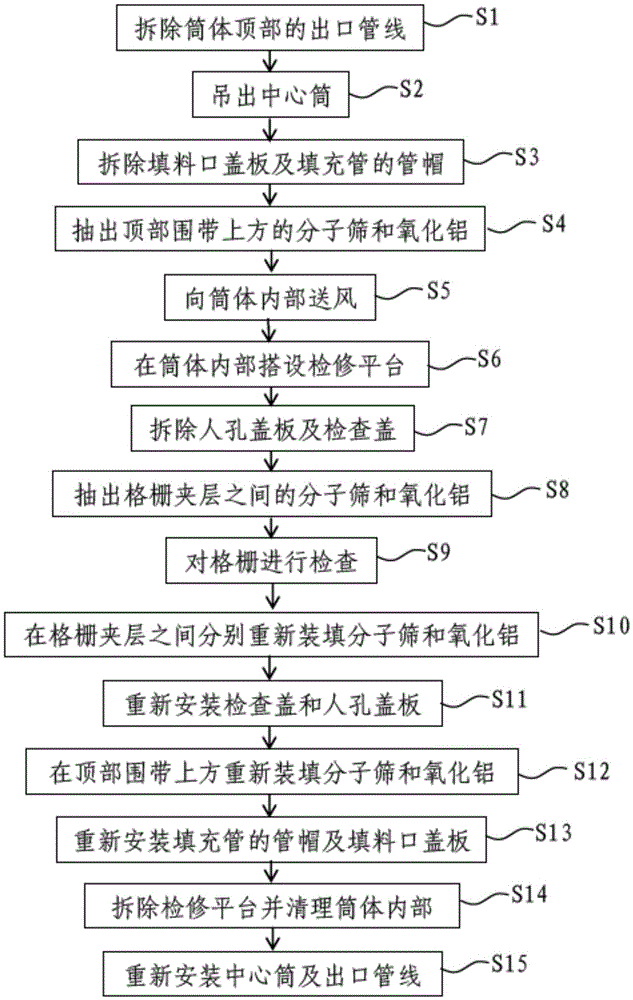

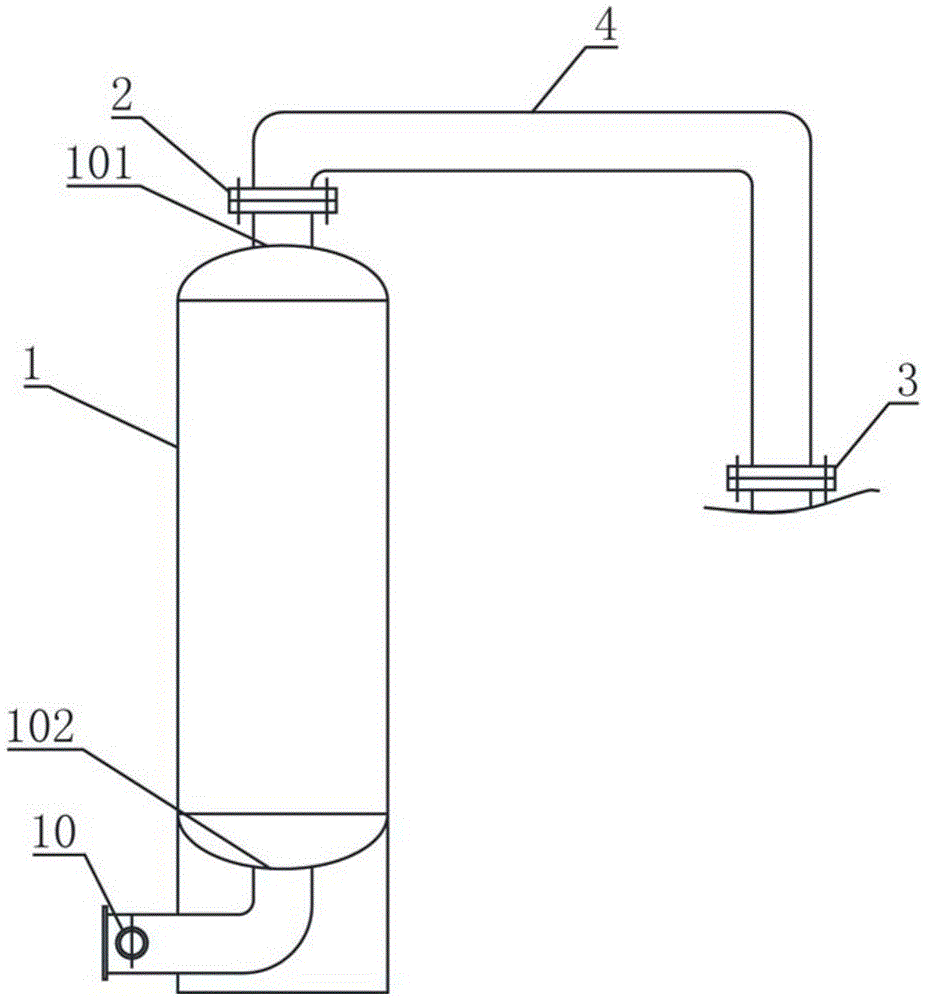

Method for replacing molecular sieves and aluminum oxide in vertical type dual bed radial flow purifier

ActiveCN105536430AEasy and efficient replacementShorten maintenance cycleDispersed particle separationMolecular sieveGrating

The invention relates to the field of gas separating technology, and especially relates to a method for replacing molecular sieves and aluminum oxide in a vertical type dual bed radial flow purifier. The method comprises the following steps: dismounting an outlet pipeline at the top of a cylindrical shell; hoisting a center cylinder out; dismounting a material filling port cover plate and dismounting a filling tube cap; extracting molecular sieves and aluminum oxide above a top surrounding strap; supplying air into the cylindrical shell for allowing air content in the cylindrical shell to reach the standard; setting a maintenance platform up in the cylindrical shell; dismounting manhole plates and an inspection cover at a top surrounding strap inspection hole; extracting molecular sieves and aluminum oxide between two grating interlayers; inspecting gratings; refilling molecular sieves and aluminum oxide between the two grating interlayers; reinstalling the inspection cover and the manhole plate; refilling molecular sieves and aluminum oxide above the top surrounding strap, and reinstalling the filling tube cap and the material filling port cover plate; dismounting the maintenance platform and cleaning the inner side of the cylindrical shell; reinstalling the center cylinder and the outlet pipeline. Replacing process of molecular sieves and aluminum oxide is simple and highly efficient.

Owner:INNER MONGOLIA YITAI CTO

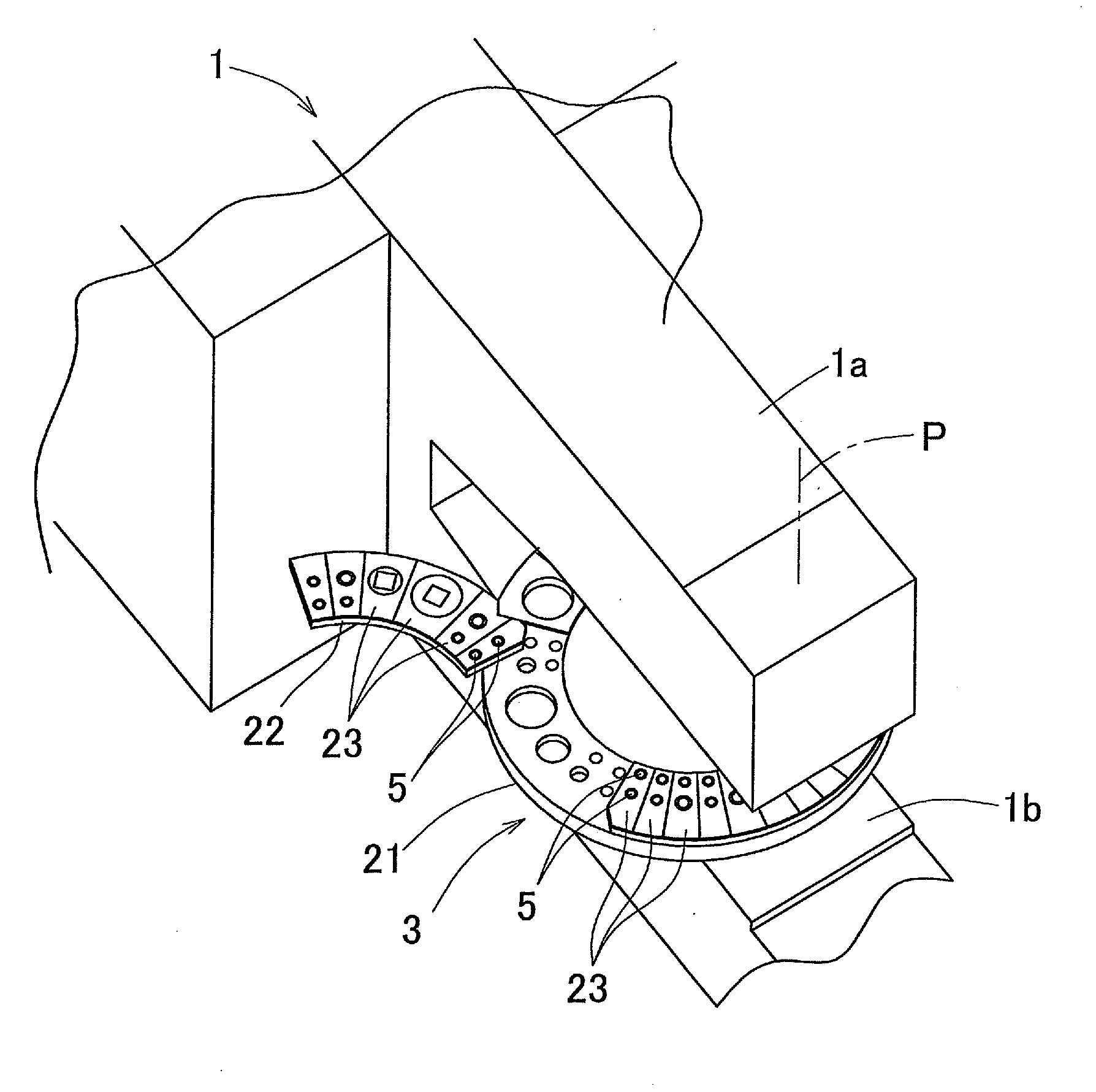

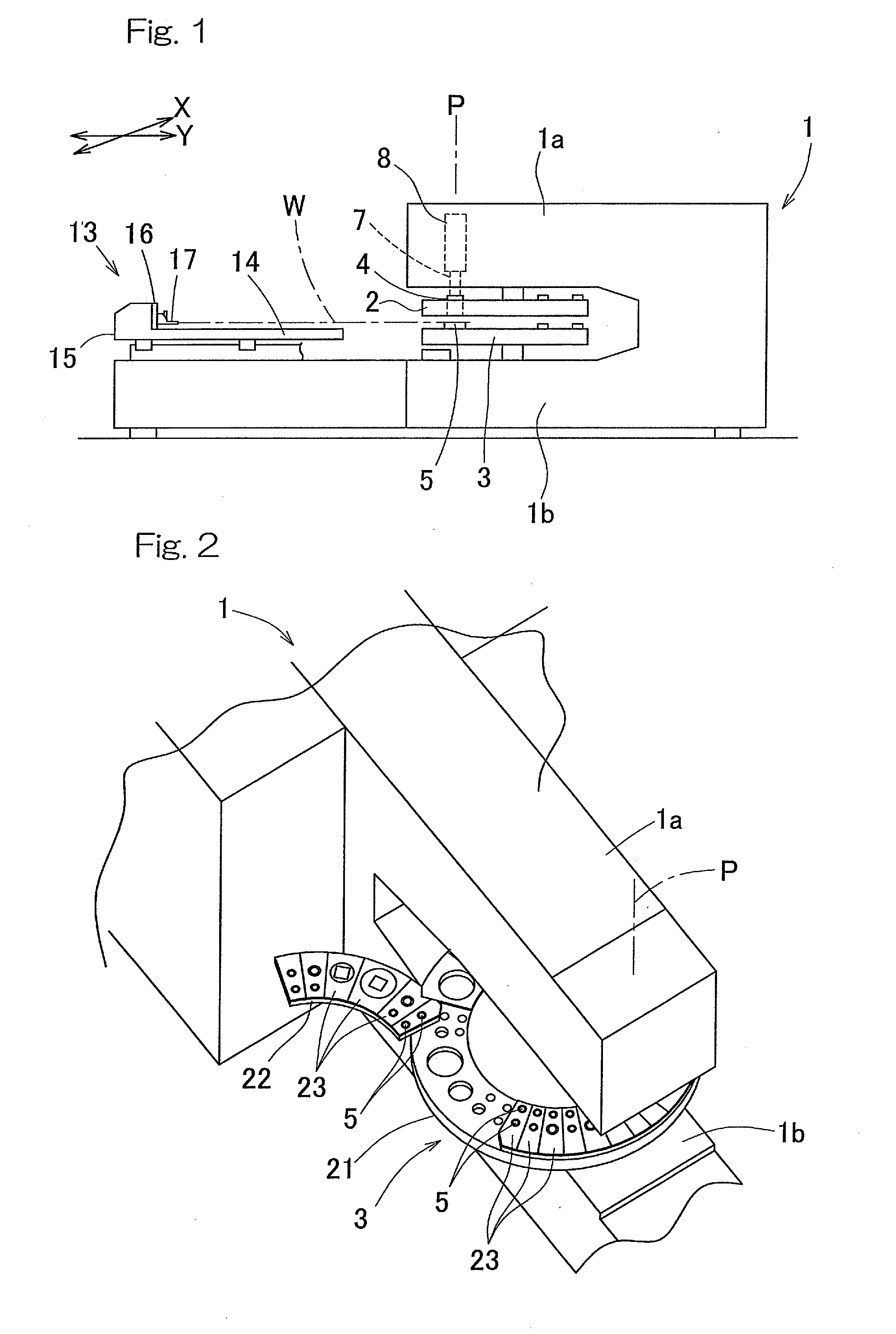

Punch press

InactiveUS20160089710A1Simple structurePerformed easily and efficientlyShaping toolsPerforating toolsPunch pressBody positions

A punch press includes a punch support body, on which a plurality of punches are mounted, and an integrated die support body positioned below the integrated punch support body and including a plurality of dies mounted thereon to perform a punching process in cooperation with the punches. The plurality of the dies are juxtaposed along a rim of the integrated die support body. The integrated die support body includes an integrated die support main body and an in-and-out moving body that enables at least a portion thereof to assume a condition emerging out of the rim of the integrated die support body while its connection with the integrated die support main body is retained. Some of the dies disposed in the integrated die support body are disposed in the in-and-out moving body.

Owner:MURATA MASCH LTD

Resin tank and 3D printing equipment

ActiveCN106515011ASimple structureLow manufacturing and modification costsManufacturing platforms/substrates3D object support structuresCavity wall3D printing

The invention discloses a resin tank and 3D printing equipment comprising the resin tank. The resin tank comprises a tank body, wherein the tank body is provided with an accommodation cavity; an opening is formed in an accommodation cavity wall at one side of the tank body; the resin tank further comprises a tank door which is matched with the opening in shape; the tank door is detachably connected with the tank body; and when the tank door and the tank body are at a connection state, the tank door and the opening are sealed. According to the resin tank and the 3D printing equipment comprising the resin tank, during a process of changing the resin tank, a user only needs to open the tank door which is detachably connected with the tank body, so that interference with a slicking mechanism can be avoided, and the resin tank can be smoothly pulled out for changing; in a similar way, a new resin tank is pushed to be below the slicking mechanism when the tank door is opened; and after the slicking mechanism is located in the accommodation cavity, the tank door can be closed. The resin tank is simple in structure; manufacture and transformation cost is low; besides, precision of the slicking mechanism cannot be affected; and meanwhile, resin tank changing is more convenient and high-efficient.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

Rotating multi-socket light fixture

ActiveUS10113722B2Easy and efficient replacementLight source combinationsLighting support devicesDrive motorEngineering

The rotating multi-socket light fixture may be used in combination with a ceiling panel or the like, allowing for changing of light bulbs for a recessed light, for example. The rotating multi-socket light fixture includes a plurality of light bulb sockets mounted circumferentially on a wheel for respectively removably receiving a plurality of light bulbs. The wheel is mounted on, and rotationally driven by, a rotational drive motor. The rotational drive motor is mounted on a vertical support such that the rotational drive motor may be vertically adjusted with respect to the vertical support. A vertical drive motor may be mounted on an upper end of the vertical support for selectively driving vertical translation of the rotational drive motor with respect to the vertical support. A lower end of the vertical support is mounted on an upper surface of the ceiling panel, such that the vertical support extends upwardly therefrom.

Owner:AL KHULAIFI KHALED A M A A

Projection type image display apparatus

InactiveUS20080055552A1Eliminate riskEfficient and low-cost maintenanceProjectorsCompound prismPrism

An openable lid is provided to cover an opening formed in the upper end of a casing of a projection type image display apparatus. Formed on the base of the casing and underneath the opening is a first mount section, on which a plinth is mounted with fixing screws. A prism assembly incorporating at least three liquid crystal panels and three polarization plates for RGB colors integrally attached to a color compounding prism is securely fixed on the plinth. The first mount section is provided with engagement members fixed thereon for temporarily holding the plinth that bears thereon the prism assembly to thereby prevent the plinth from falling downward if the screws are removed to dismount the plinth from the first mount section even when the image display apparatus is installed upside down on a ceiling for example and the lid is open. This permits easy replacement of parts of the projection type image display apparatus that is installed upside down, and thus greatly improves maintenance efficiency of the projector.

Owner:SANYO ELECTRIC CO LTD

A street sign convenient for changing advertisements

Owner:温州锦丽斯企业有限公司

Log debarking tool and tool tip

ActiveUS20100200116A1Increase chanceConvenient and efficient accessTree debarkingMulti-purpose machinesMechanical engineeringHole size

Owner:REIMLER JAMES L

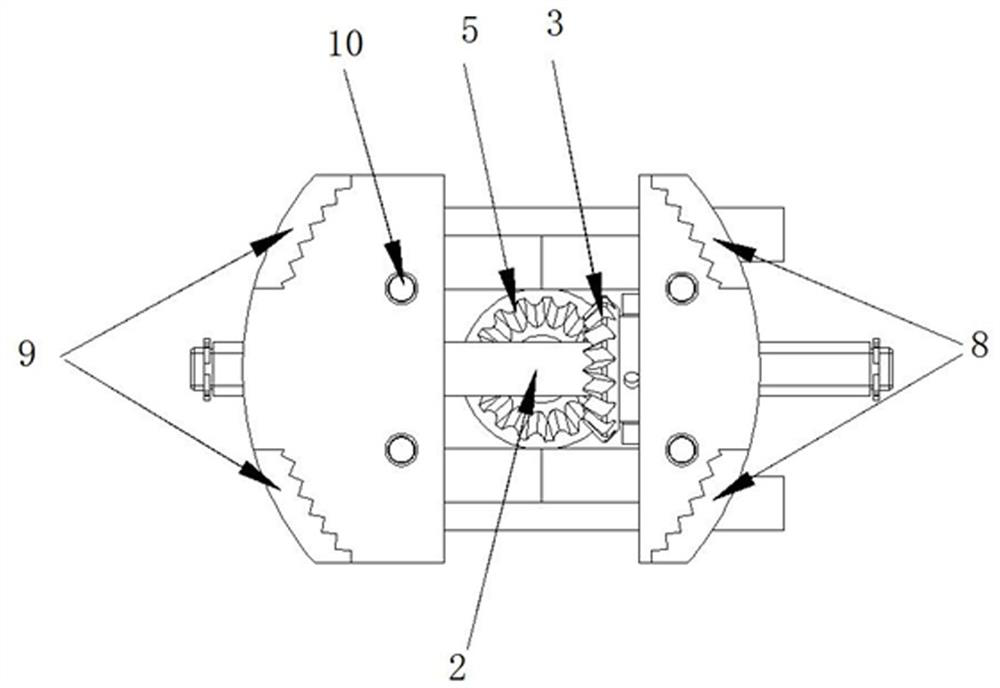

Filter wrench with novel structure

InactiveCN112847222AEfficient and convenient clamping and disassemblyEasy and efficient disassemblySpannersWrenchesControl engineeringBevel gear

The invention discloses a filter wrench of a novel structure. The filter wrench comprises a base sliding rail, a lead screw, a driven bevel gear, a hexagonal sleeve, a driving bevel gear, a left nut sliding block, a right nut sliding block, a first clamping jaw A, a second clamping jaw A and bolts; the lead screw is installed on the base sliding rail; the left nut sliding block is installed at one end of the lead screw, and the right nut sliding block is installed at the other end of the lead screw; the first clamping jaw A is fixed to the left nut sliding block through the bolt, and the second clamping jaw A is fixed to the right nut sliding block through the bolt; the driven bevel gear is fixed to the middle of the lead screw, and the hexagonal sleeve is fixed to the base sliding rail; and the driving bevel gear is installed on the hexagonal sleeve and is in transmission connection with the driven bevel gear. The filter wrench has the technical effect that filters with different diameters can be efficiently and conveniently clamped, disassembled and assembled.

Owner:衡阳市恒锋机械制造有限公司

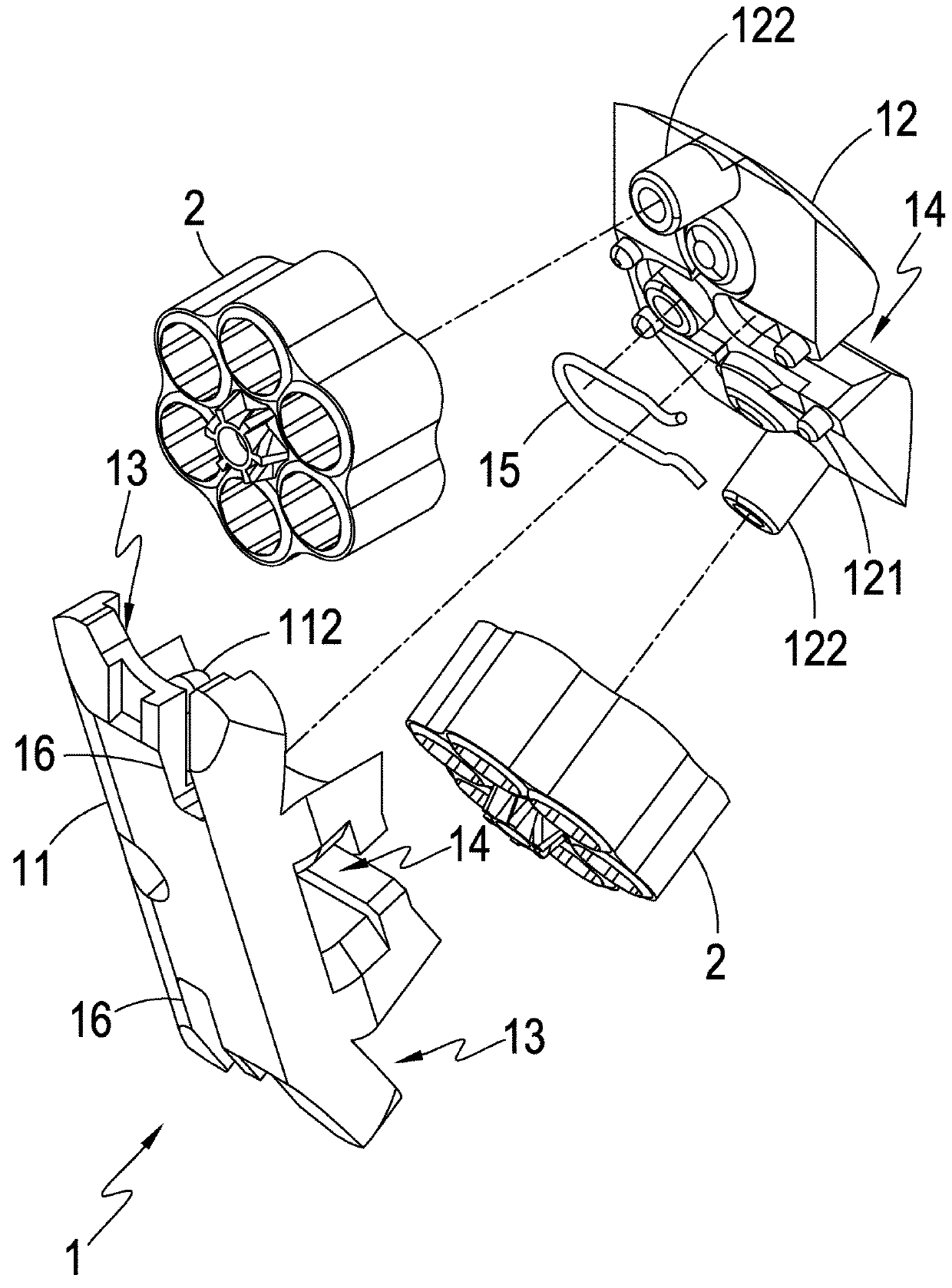

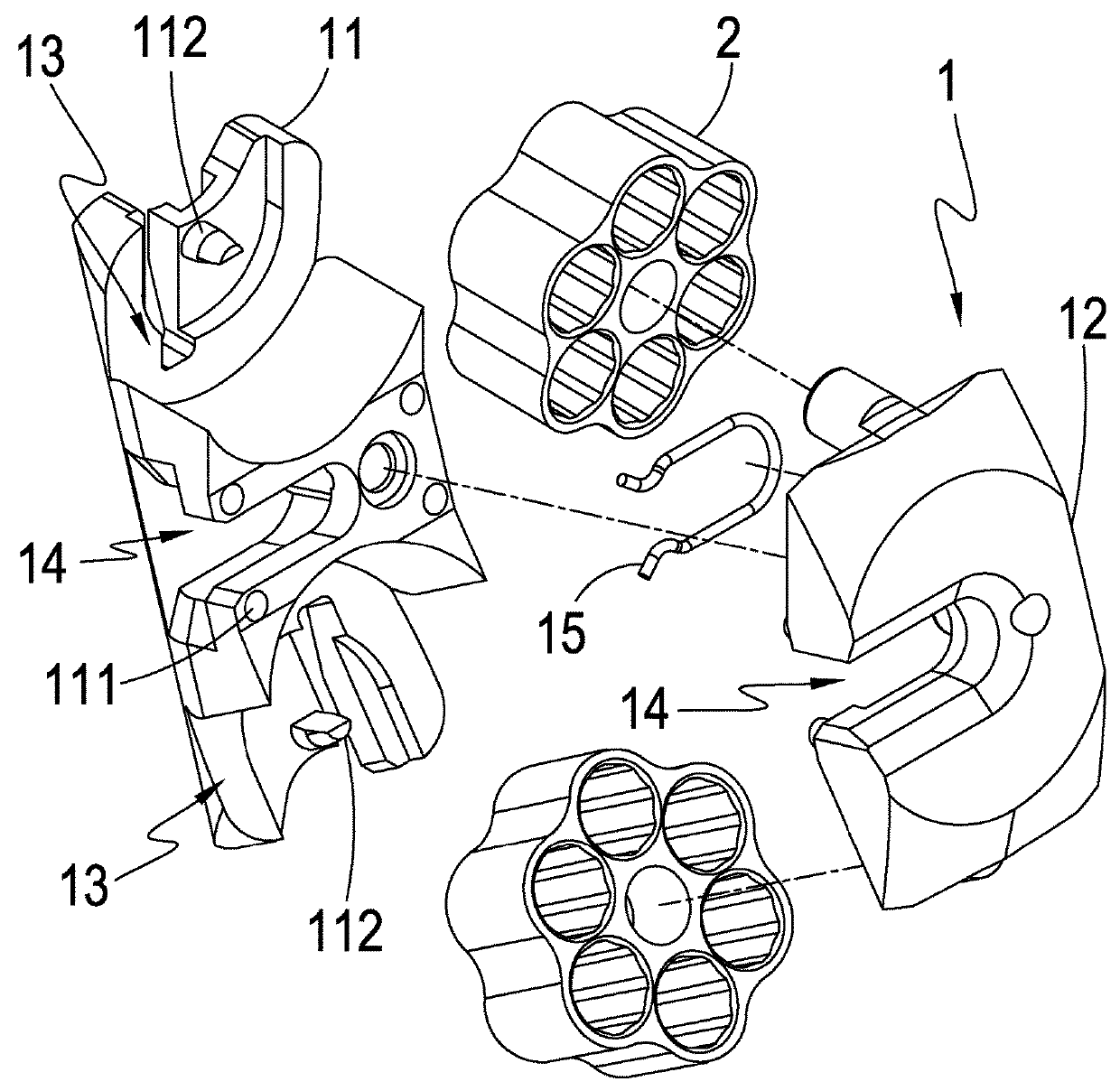

Toy gun bullet container structure

ActiveUS20180164068A1Mounting and easy and efficientEasy and efficient removalSpring gunsAmmunition loadingFree rotationEngineering

An improved toy gun bullet container structure includes a bullet container device, which is selectively and movable mounted in a magazine, a receiving space, which is defined in the bullet container device, and a plurality of bullet compartments, which are arranged in the receiving space in a manner of being free to rotate. The bullet compartments each receive and hold therein a plurality of bullets. The magazine is can be mounted and removed so as to achieve imitation of a genuine device. When one of the bullet compartments runs out of bullets, the magazine can be first removed and the bullet container device rotated to switch the other one of the bullet compartments to the position for shooting. When all the bullet compartments run of bullets, the bullet container device can be detached from the magazine for reloading of bullets.

Owner:KIEN WELL TOY IND

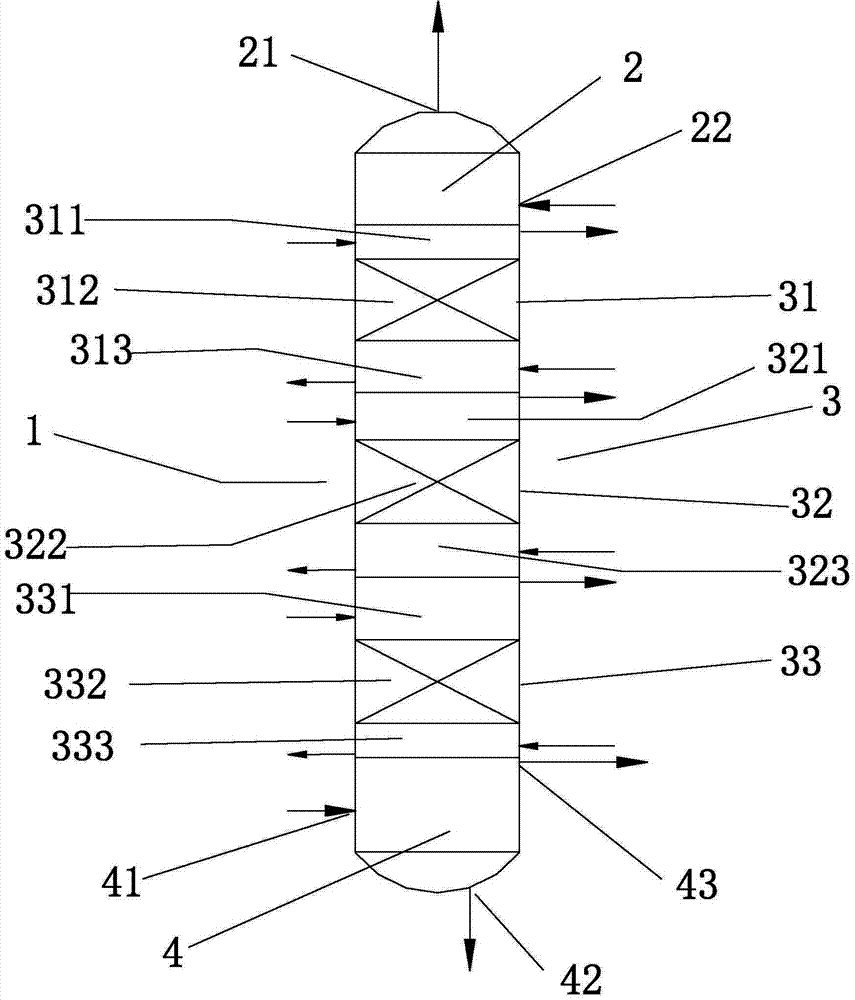

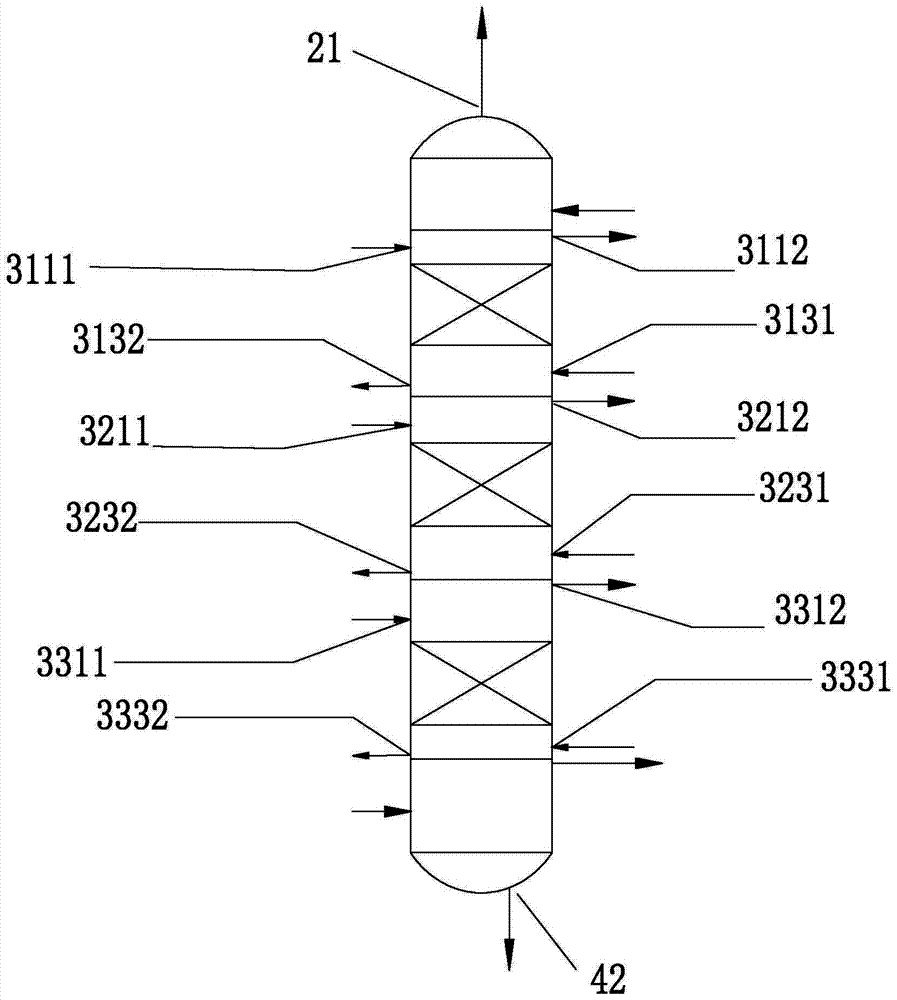

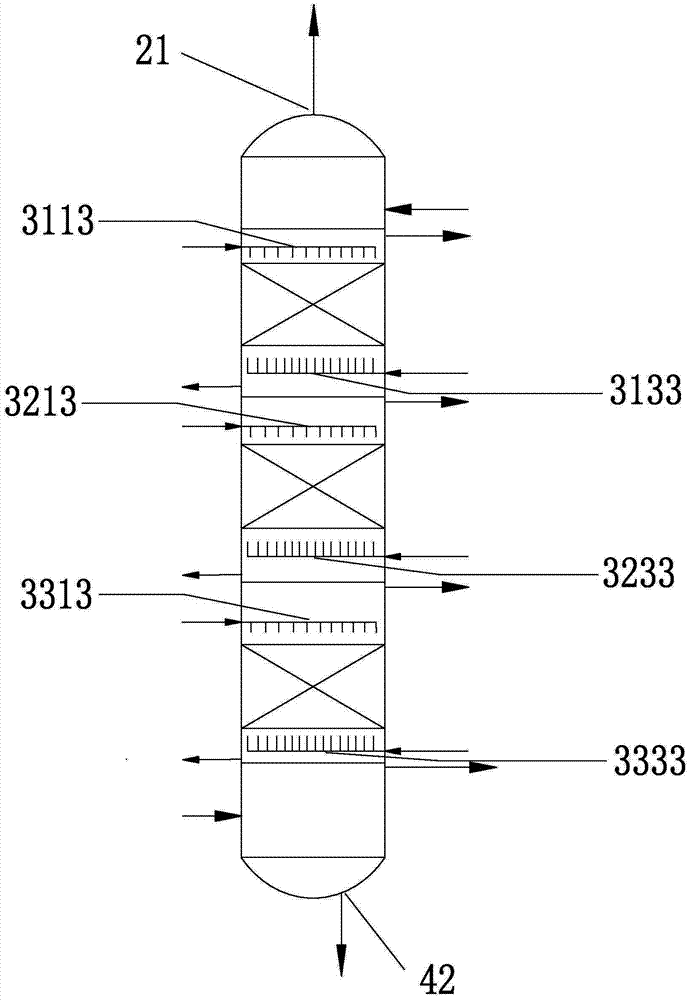

Reactive distillation column and device for preparing methylal

ActiveCN104190103AAchieve regenerationReduce wasteOrganic chemistryOrganic compound preparationInterior spaceReboiler

A reactive distillation column and a device for preparing methylal are provided. The reactive distillation column comprises a top gas section with an independent interior space, a plurality of catalyst filling sections in the middle and a bottom liquid section. The top gas section is provided with a top gas outlet and a top gas material returning port. The bottom liquid section is provided with a liquid inlet, a bottom liquid outlet and a bottom gas outlet. The plurality of catalyst filling sections are independent of one another, and each catalyst filling section comprises a liquid-feeding gas-discharging part, a catalyst filling layer part and a gas-feeding liquid-discharging part. Each liquid-feeding gas-discharging part is provided with a liquid feeding port and a gas discharging port. Each gas-feeding liquid-discharging part is provided with a gas material returning port and a liquid discharging port. The device for preparing the methylal is also provided. The device comprises the reactive distillation column, a condenser, a condensate storage tank and a reboiler. With the reactive distillation column and the device, online processing of regenerated catalysts without shut-down can be achieved.

Owner:SHANDONG CHENXIN NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com