Punch press

a technology of punch press and punch plate, which is applied in the field of punch plate, can solve the problems of substantial time required, difficult replacement work, and substantial inability to achieve replacement, and achieve the effect of simple structure and easy and efficient replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

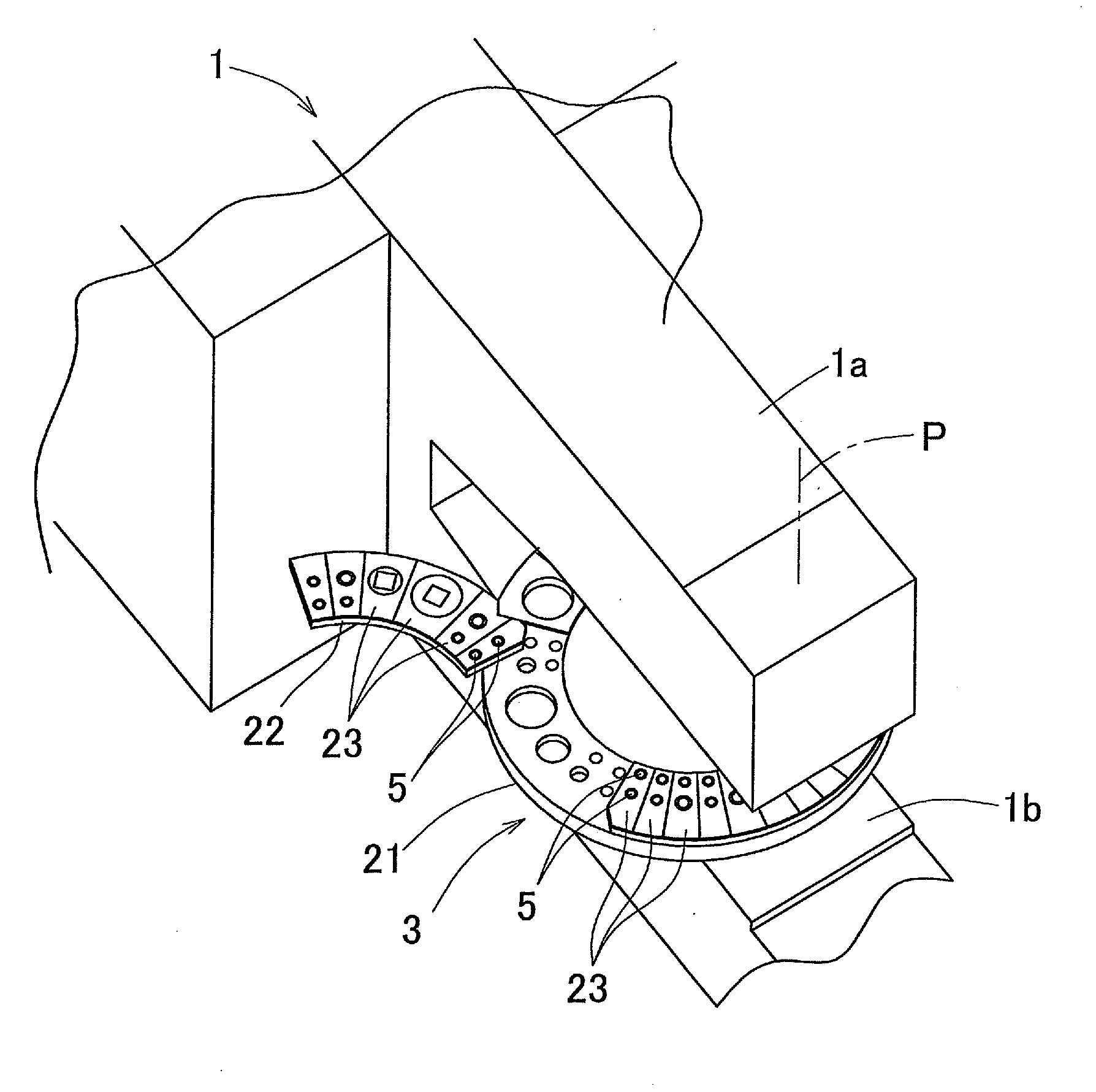

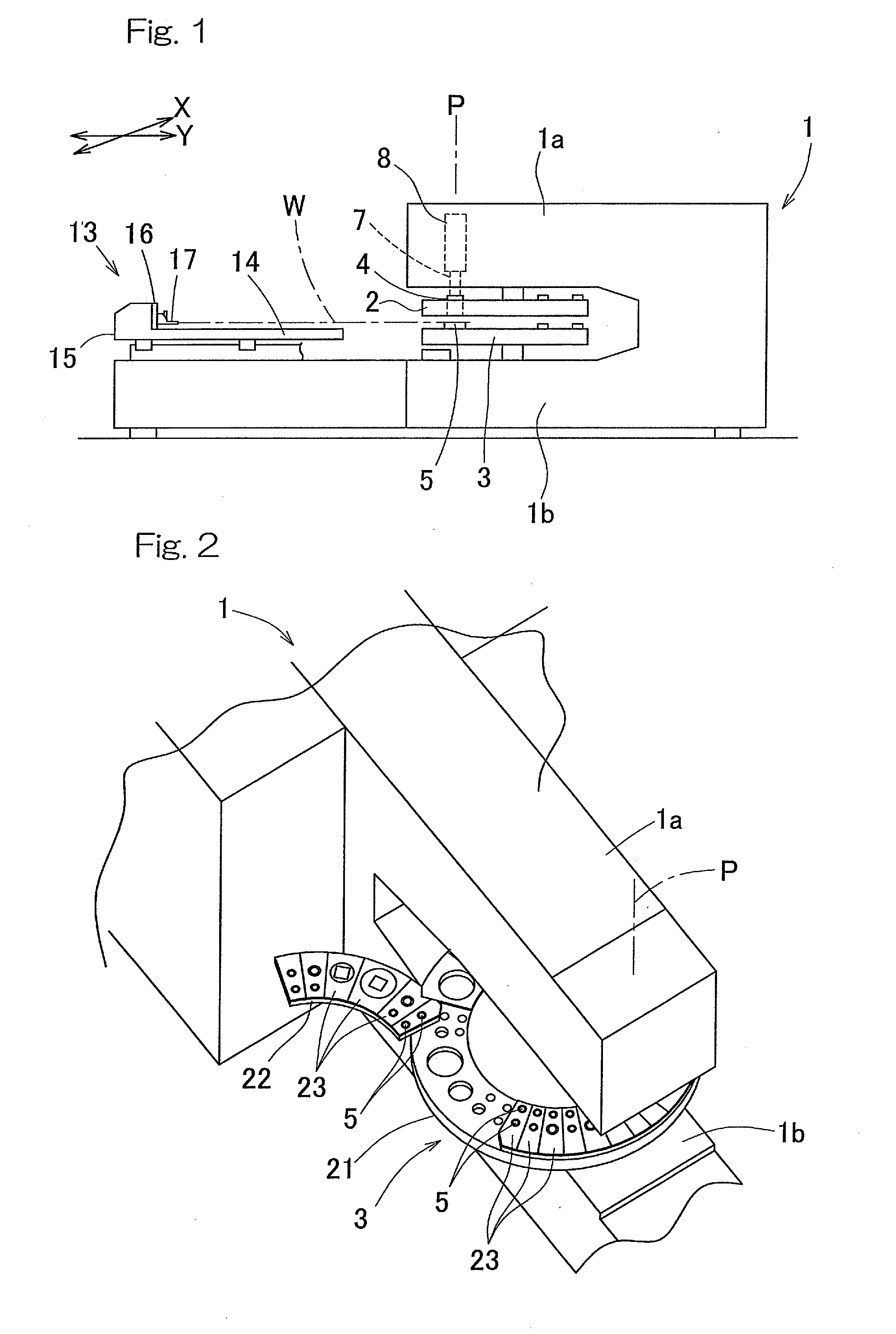

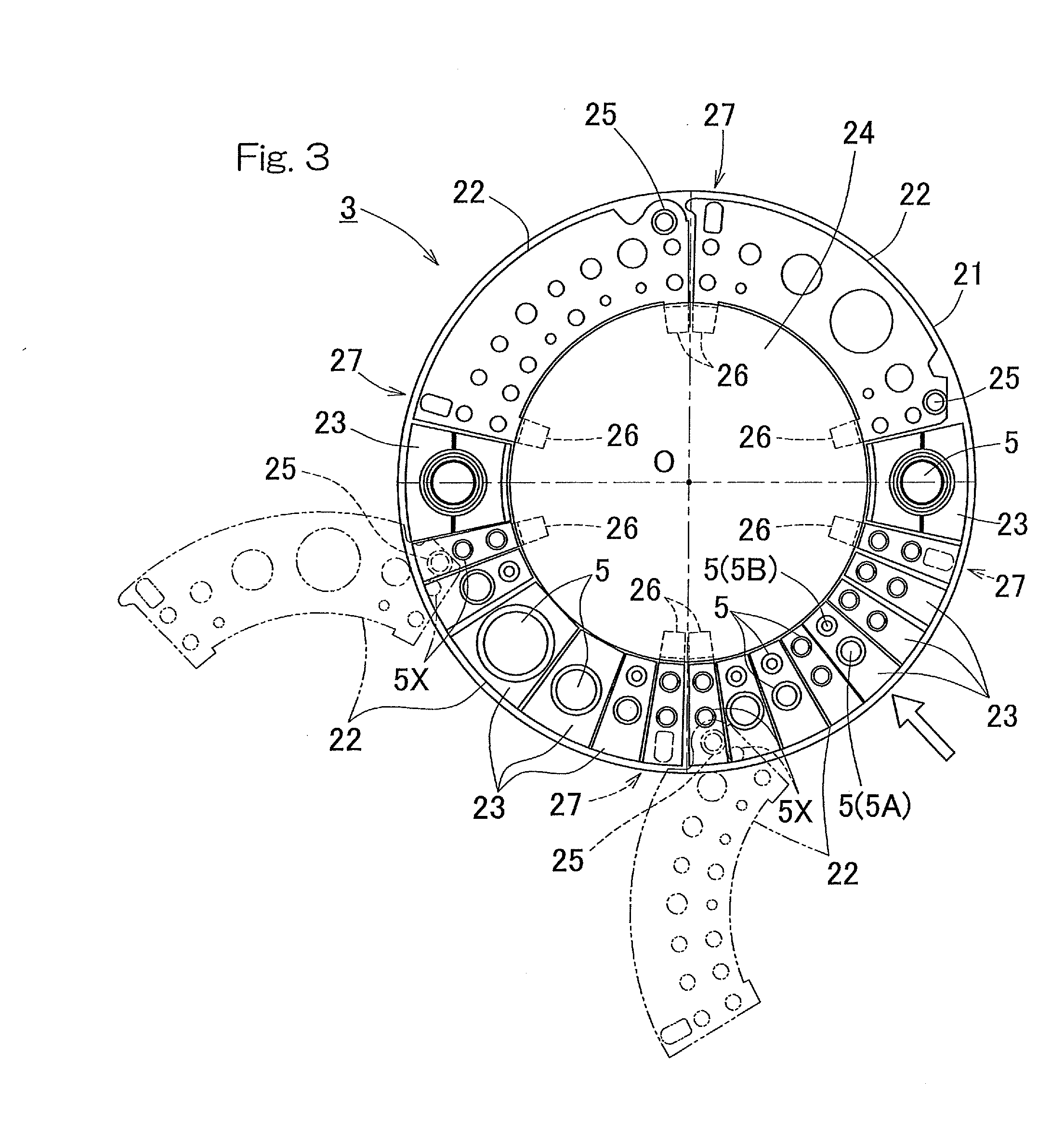

[0027]The present invention will now be described in detail in connection with a preferred embodiment thereof with reference to the accompanying drawings. In particular, FIG. 1 is a schematic side view of a punch press in its entirety according to a preferred embodiment of the present invention, and FIG. 2 is a perspective view showing the punch press with a portion thereof removed. The illustrated punch press preferably is of a type having upper and lower turrets 2 and 3, for example. It is to be noted that the upper turret 2 is not shown in FIG. 2 for the sake of brevity. Each of the upper and lower turrets 2 and 3 is of a substantially flat round configuration, and those upper and lower turrets 2 and 3 are supported respectively by upper and lower horizontal frame sections 1a and 1b of a press frame structure 1 for rotation coaxially about associated vertical shafts. The upper turret 2 defines an integrated punch support body and has a plurality of punches 4 arranged in line alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com