Efficient string type deep sea environment testing device

A deep-sea environment and test device technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as type and quantity limitations, small sample size, test efficiency and flexibility that do not meet the needs of deep-sea tests, and easy operation. , Guaranteed accuracy, convenient and efficient modular replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

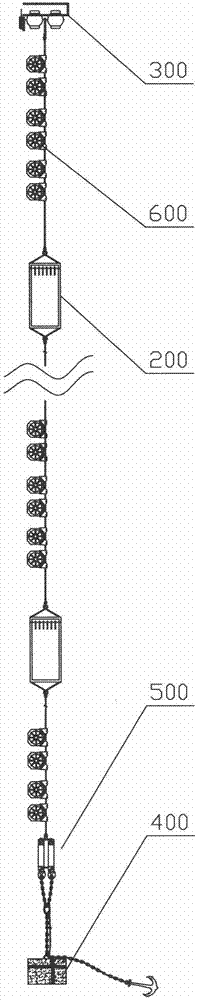

[0047] as attached Figure 1-4 As shown, the high-efficiency string type deep-sea environmental test device of the present invention has a structure comprising four ropes 100, three sample frames 200, buoys 300 and sinking anchor blocks 400, and the three sample frames 200 connect the four ropes 100 In a straight line, and the free end of one of the ropes 100 at the straight end is connected to the buoy 300, and the free end of the other rope 100 at the straight end is connected to the sinking anchor block 400 through the releaser 500; the sample frame 200 It is made of titanium or titanium alloy, and the test sample is modularly installed in the sample frame 200 .

[0048] Each of the above-mentioned ropes 100 is provided with a glass float group 600 .

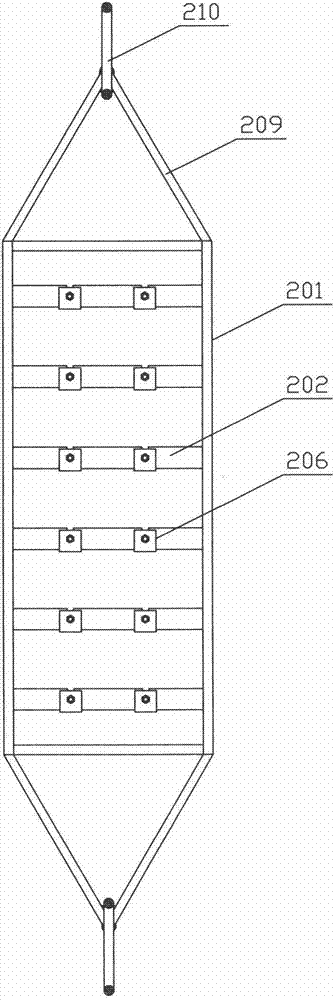

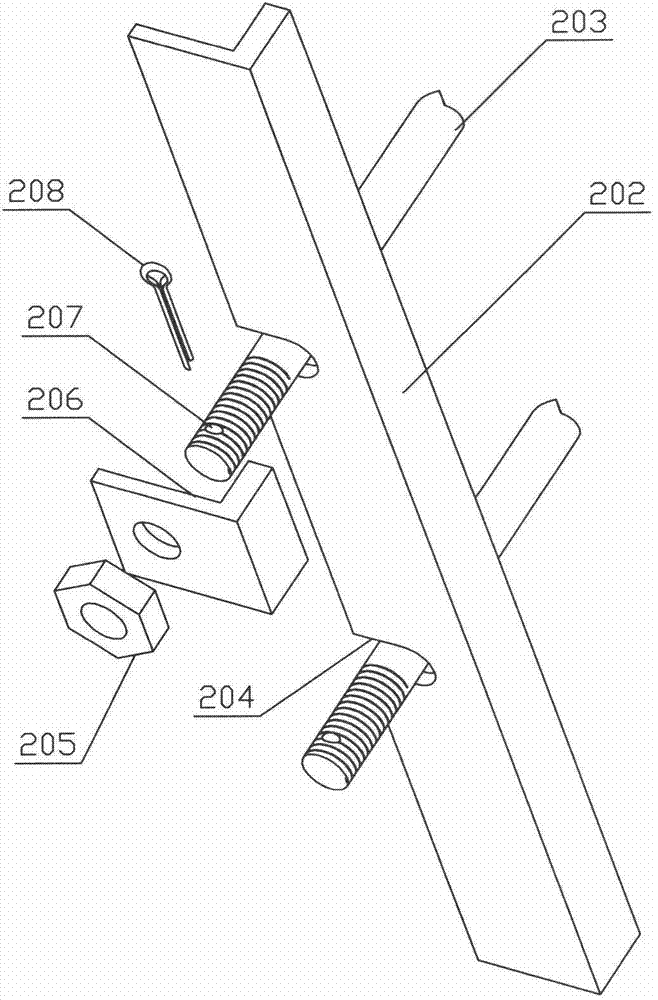

[0049] The sample frame 200 includes a rectangular outer frame 201 , six L-shaped connectors 202 and twelve titanium rods 203 with threads on the surface. The six connectors 202 are parallel to each other and integrally wel...

Embodiment 2

[0054] as attached Figure 1-3 Shown in and 5, the high-efficiency string type deep-sea environmental test device of the present invention, its structure comprises four ropes 100, three sample frames 200, buoys 300 and sinking anchor block 400, three sample frames 200 connect four ropes 100 are connected in a straight line, and the free end of one of the ropes 100 at the end of the straight line is connected to the buoy 300, and the free end of the other rope 100 at the end of the straight line is connected to the sinking anchor block 400 through the releaser 500; The frame 200 is made of titanium or titanium alloy, and the samples for testing are modularly installed on the sample frame 200 .

[0055] Each of the above-mentioned ropes 100 is provided with a glass float group 600 .

[0056] The sample frame 200 includes a rectangular outer frame 201 , six L-shaped connectors 202 and twelve titanium rods 203 with threads on the surface. The six connectors 202 are parallel to e...

Embodiment 3

[0061] as attached Figure 1-3 Shown in and 6, the high-efficiency string type deep-sea environmental test device of the present invention, its structure comprises four ropes 100, three sample frames 200, buoys 300 and sinking anchor block 400, three sample frames 200 connect four ropes 100 are connected in a straight line, and the free end of one of the ropes 100 at the end of the straight line is connected to the buoy 300, and the free end of the other rope 100 at the end of the straight line is connected to the sinking anchor block 400 through the releaser 500; The frame 200 is made of titanium or titanium alloy, and the samples for testing are modularly installed on the sample frame 200 .

[0062] Each of the above-mentioned ropes 100 is provided with a glass float group 600 .

[0063] The sample frame 200 includes a rectangular outer frame 201 , six L-shaped connectors 202 and twelve titanium rods 203 with threads on the surface. The six connectors 202 are parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com