Pressure sensor

A pressure sensor and sensor body technology, applied in the direction of displaying the liquid level indicator through pressure measurement, can solve the problems of inconvenient plugging and unplugging, damage to the electrical panel or frame, etc., to achieve convenient and efficient replacement of the pressure sensor, firm fixation, The effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

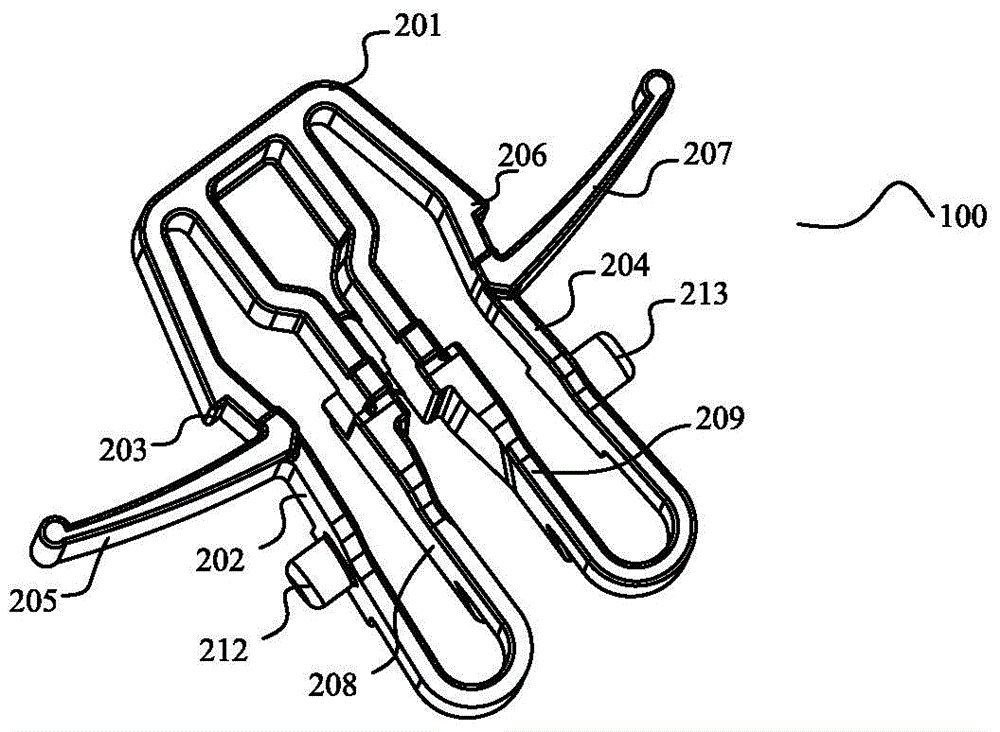

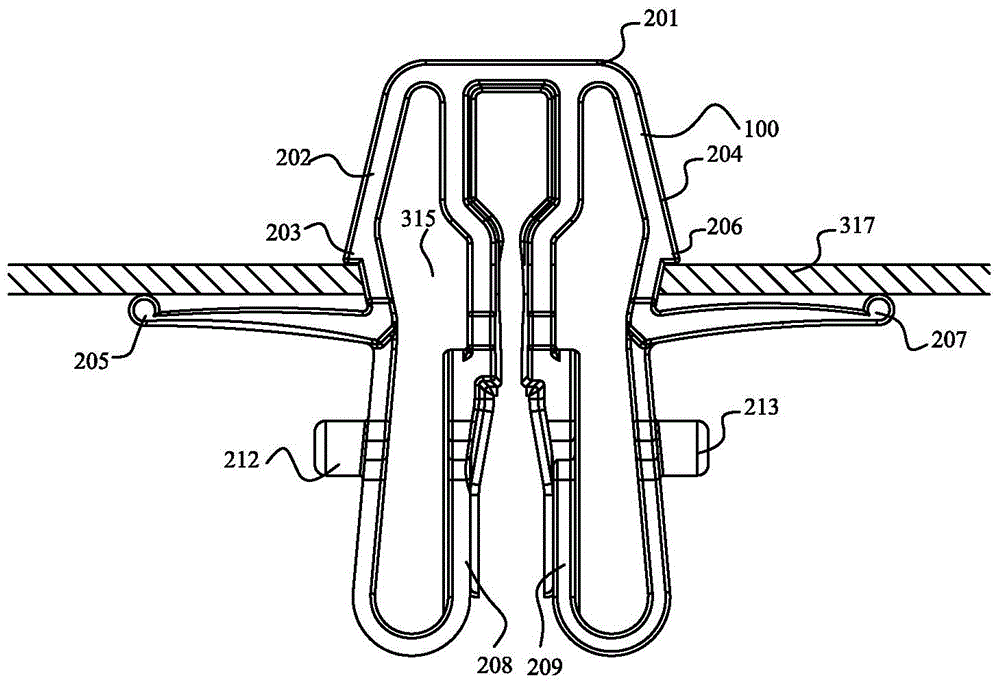

[0042] Various embodiments of the invention will be described below with reference to the accompanying drawings, which form a part hereof. It should be understood that although directional terms such as "front", "rear", "upper", "lower", "left", "right", etc. are used herein to describe various exemplary structural parts of the invention and elements, but these terms are used herein for explanatory purposes only, based on the example orientations shown in the figures. Since the disclosed embodiments of the present invention may be arranged in different orientations, these directional terms are for illustration only and should not be viewed as limiting. Where possible, the same or similar reference numerals used in the present invention refer to the same components.

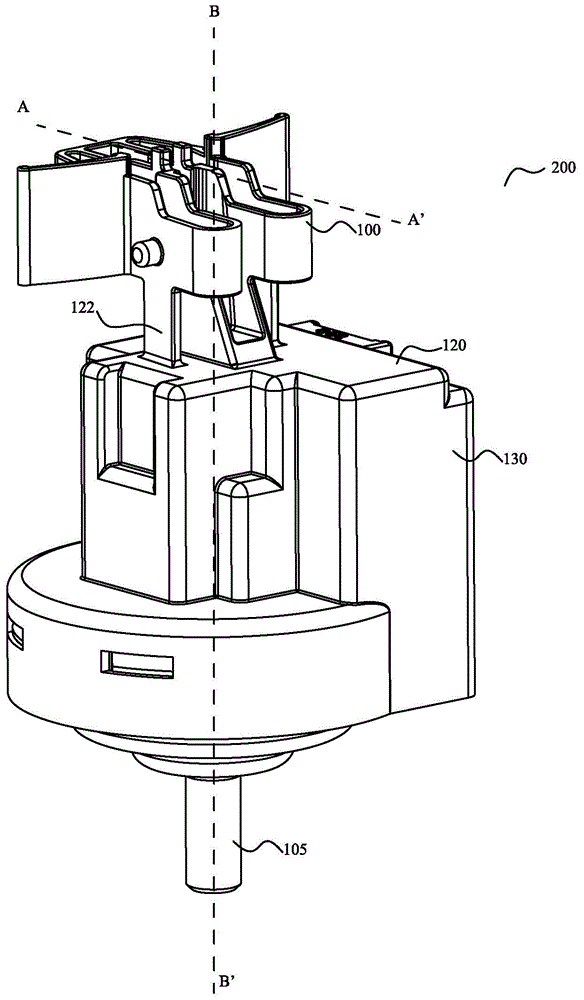

[0043] figure 1 It is a perspective view of the structure of the pressure sensor 200 of the present invention.

[0044] Such as figure 1 As shown, the pressure sensor 200 includes a pressure sensor body and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com