Patents

Literature

286results about How to "Control expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

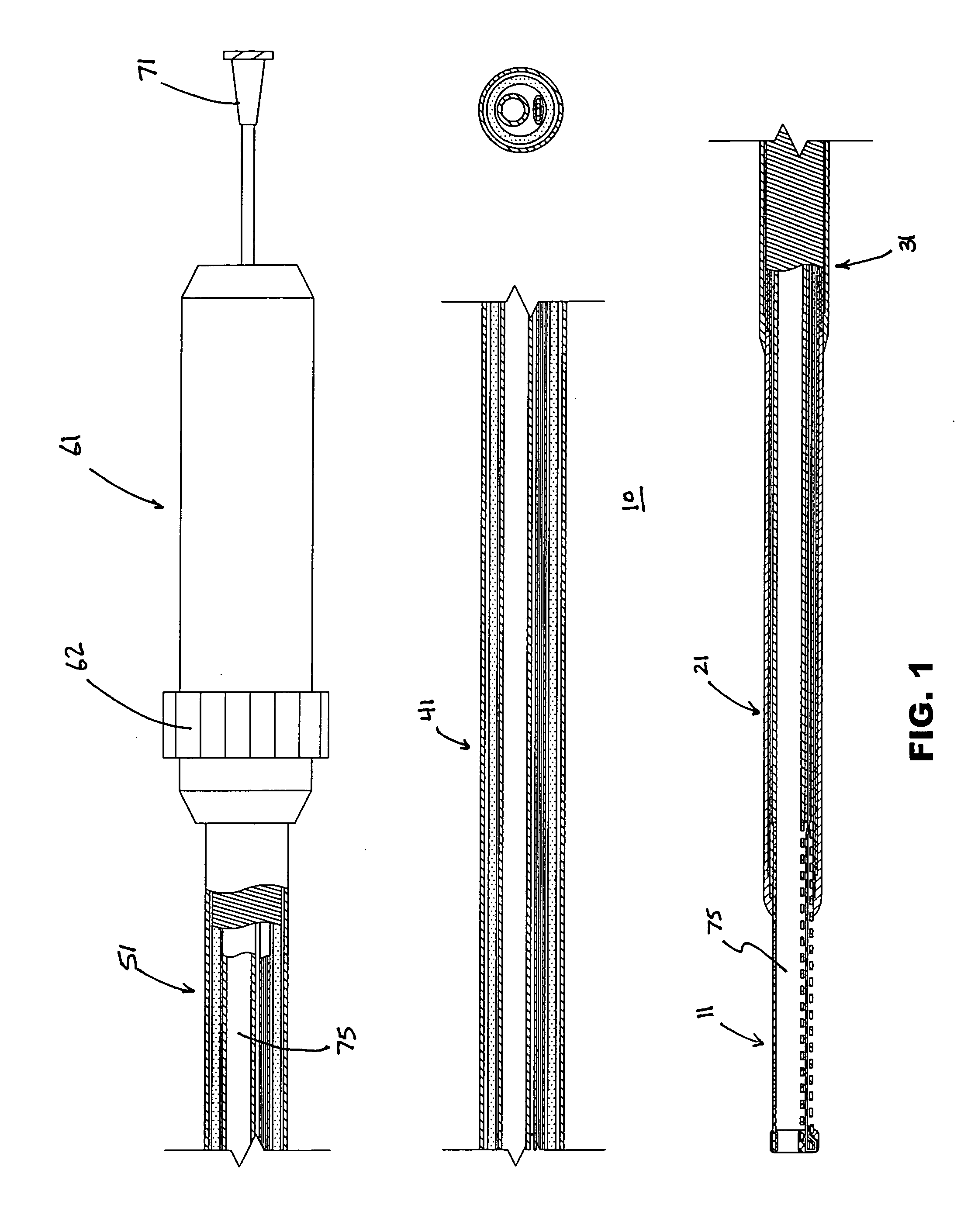

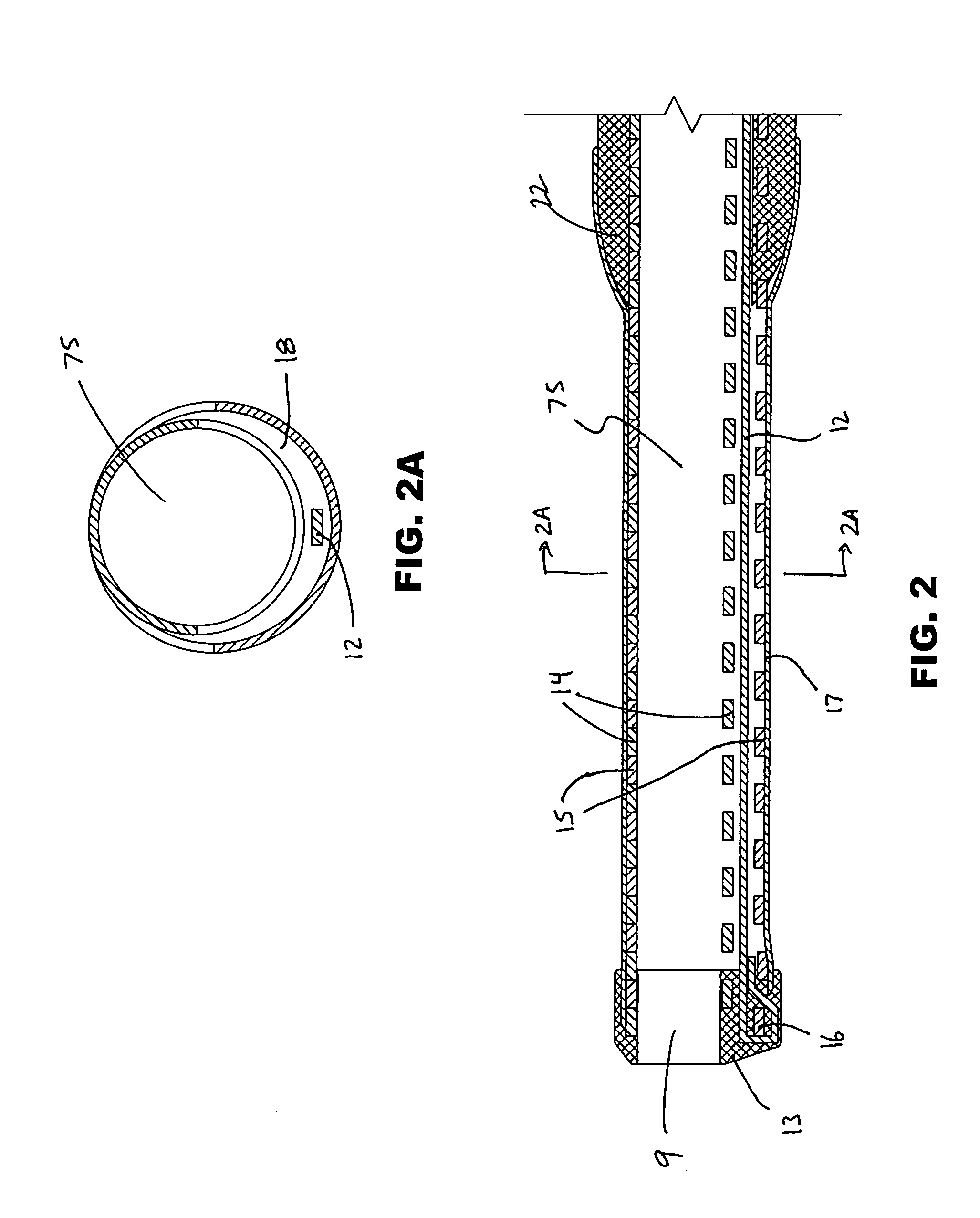

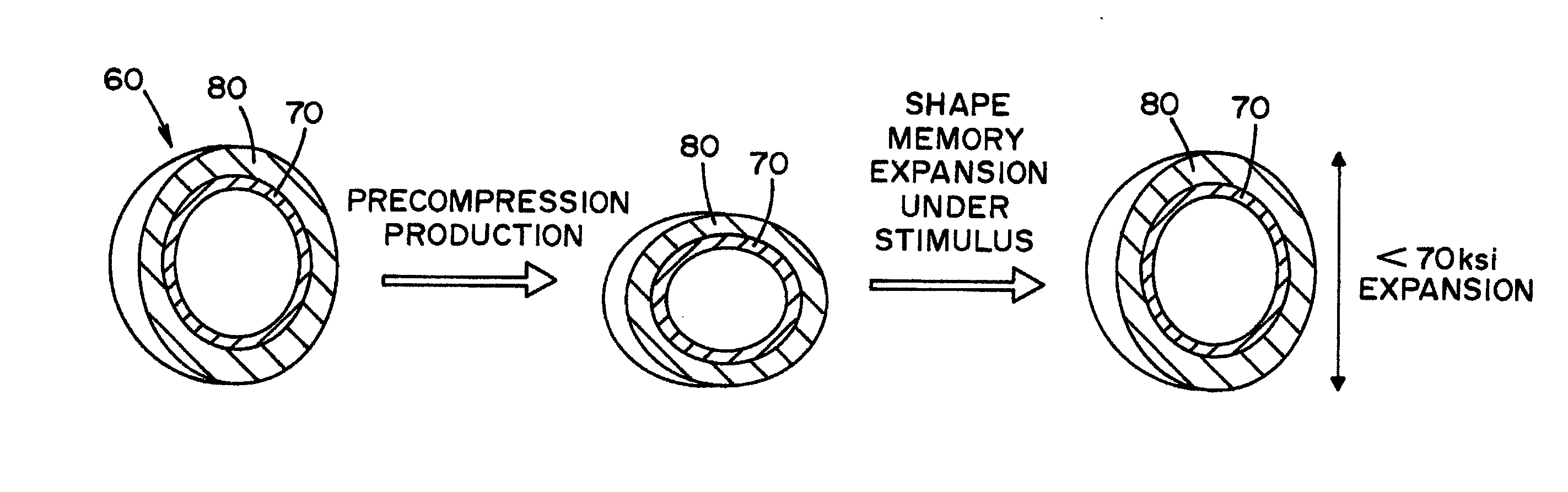

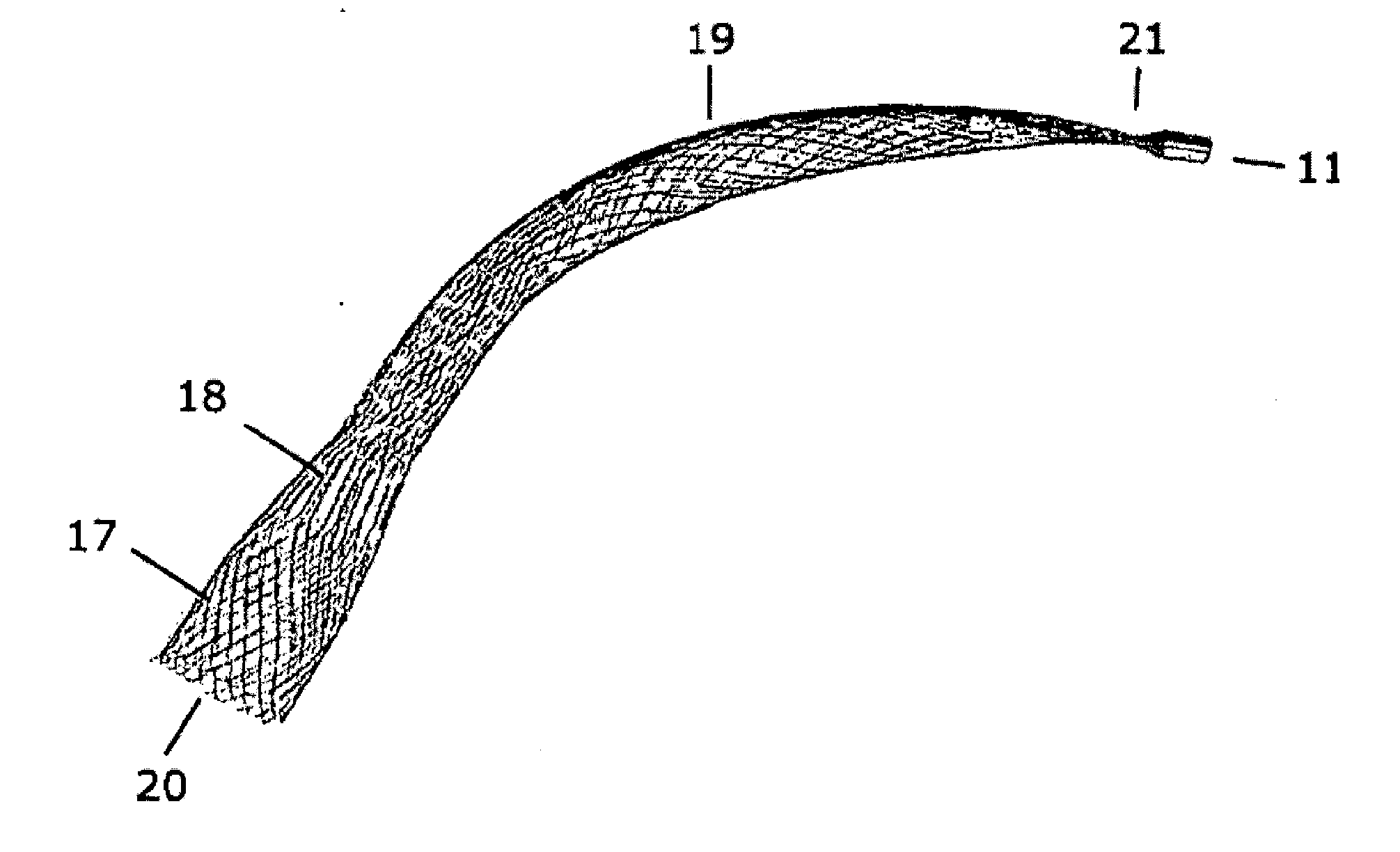

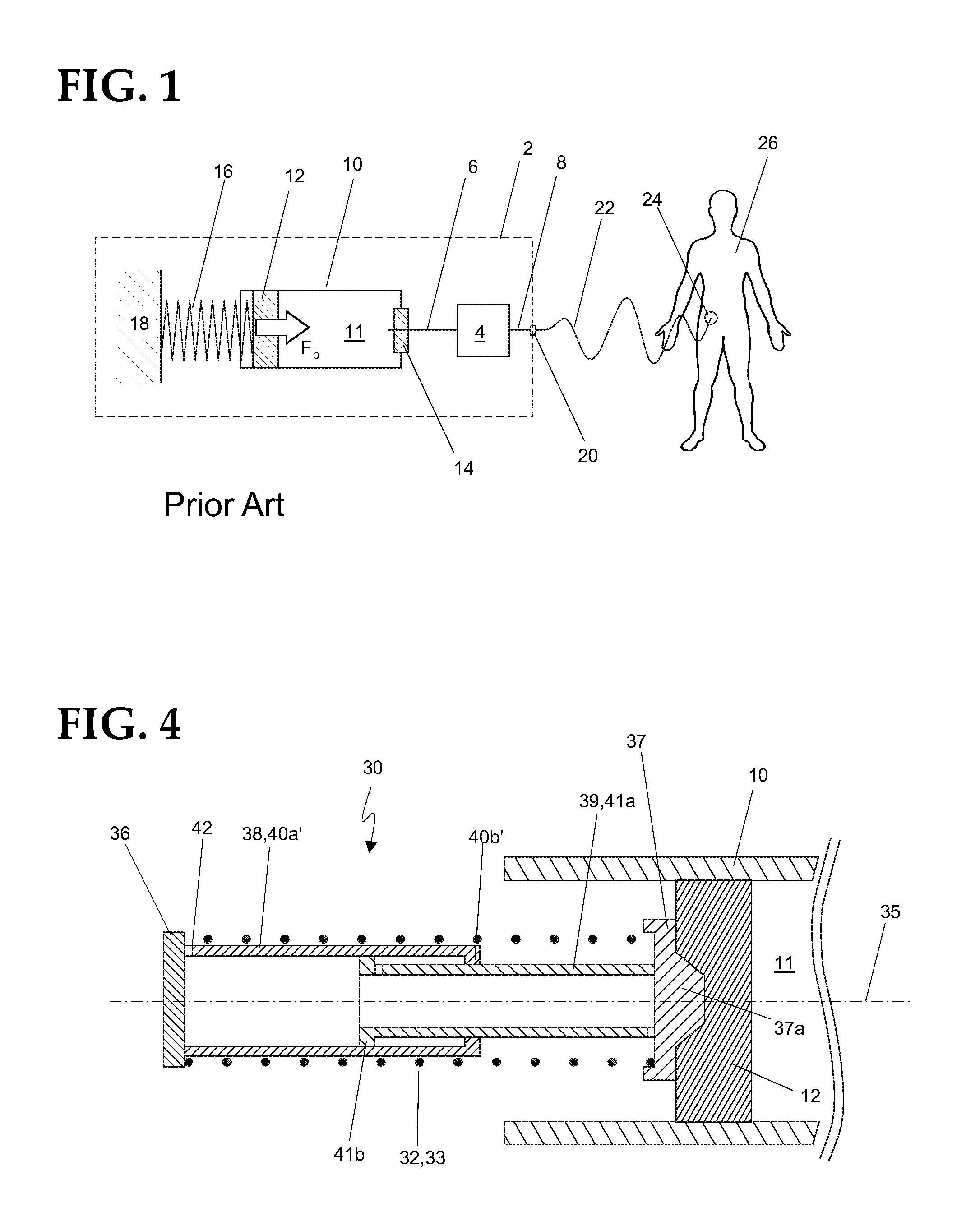

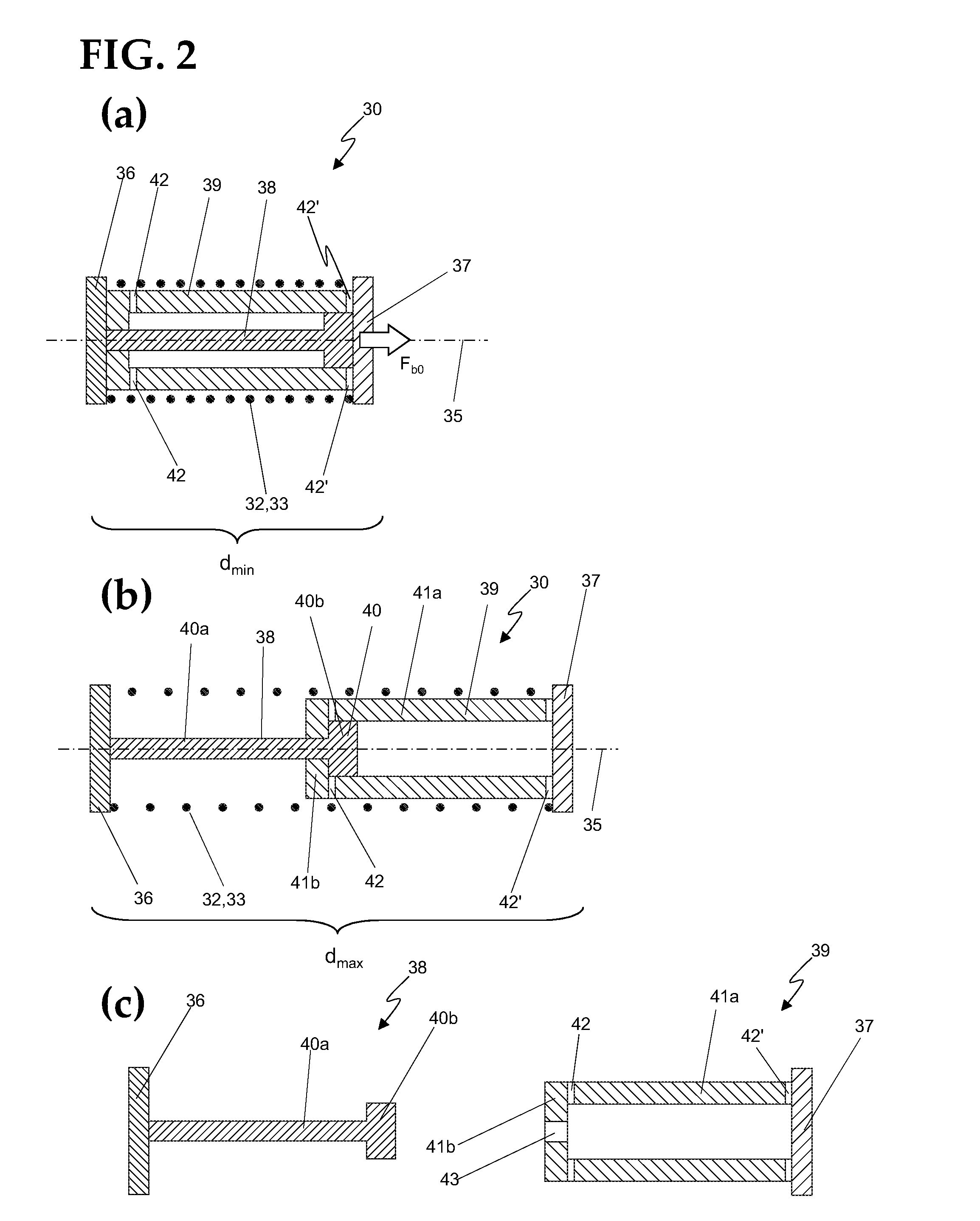

Methods for delivering, repositioning and/or retrieving self-expanding stents

InactiveUS6837901B2Deployment securityRule out the possibilityStentsSurgeryShape-memory alloyCatheter device

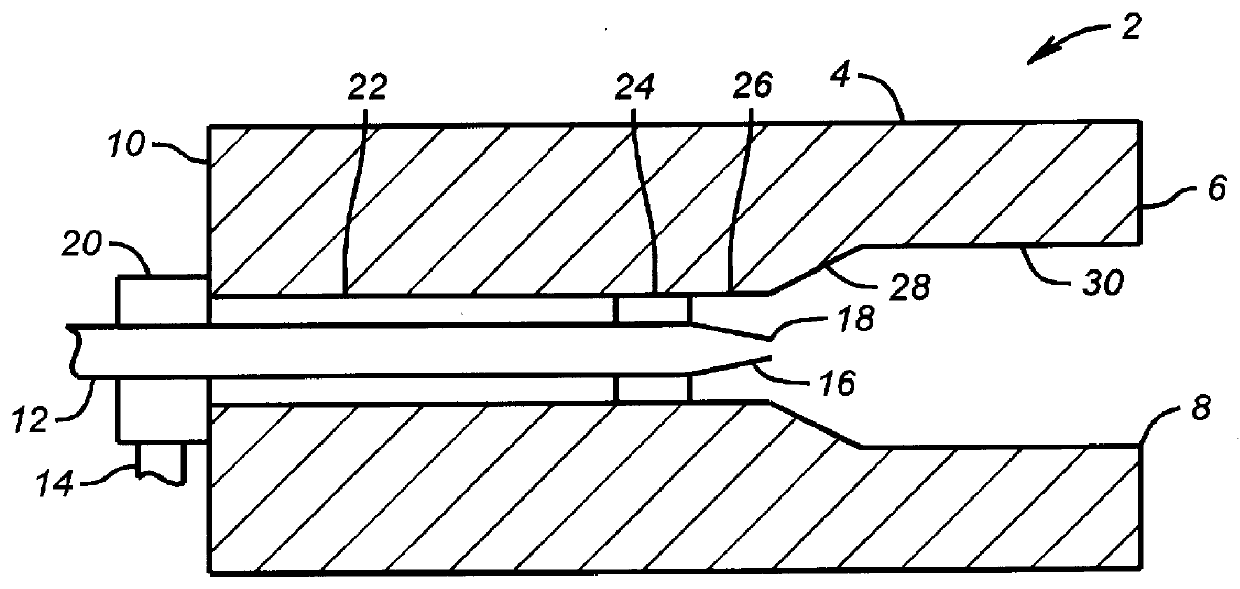

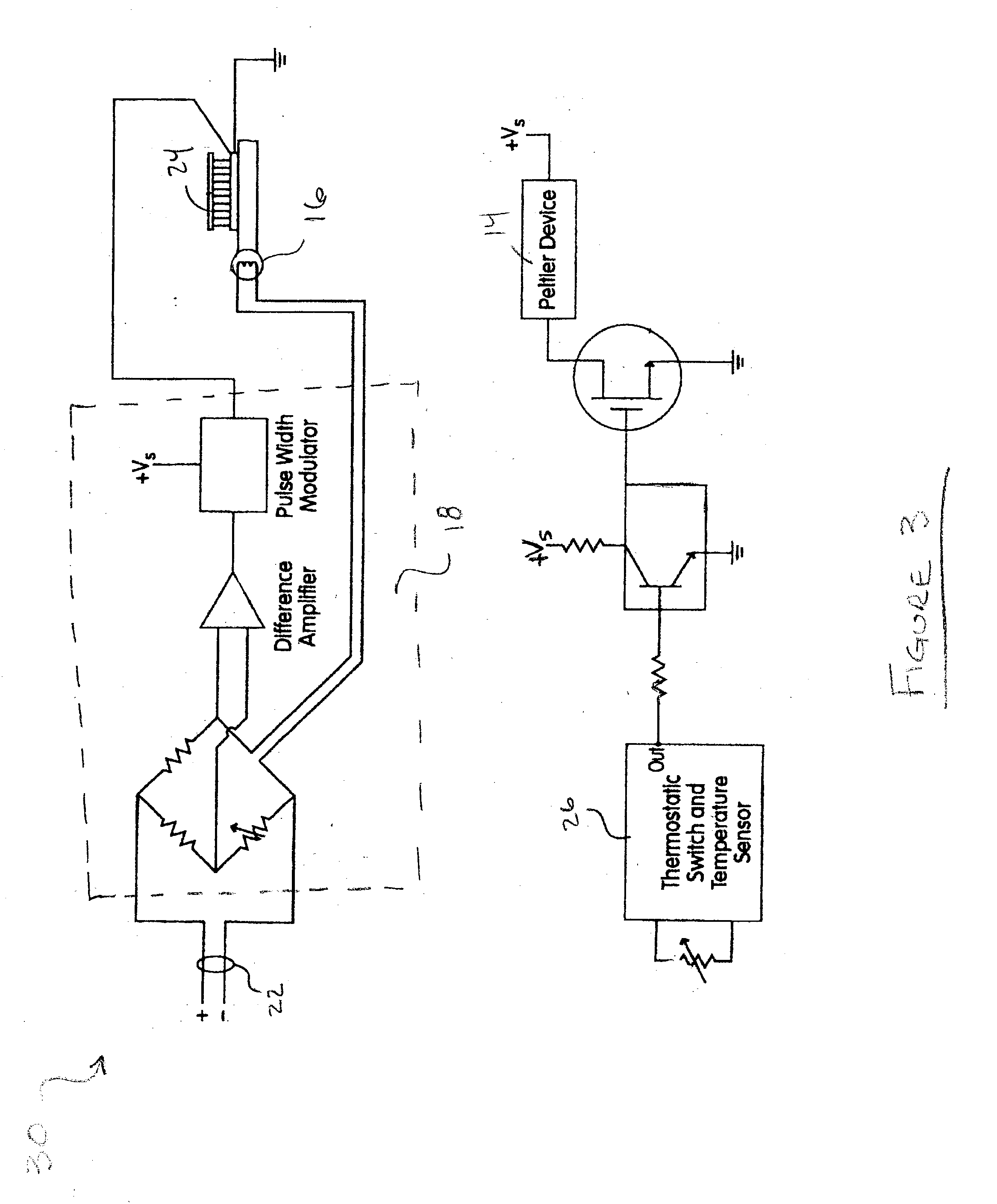

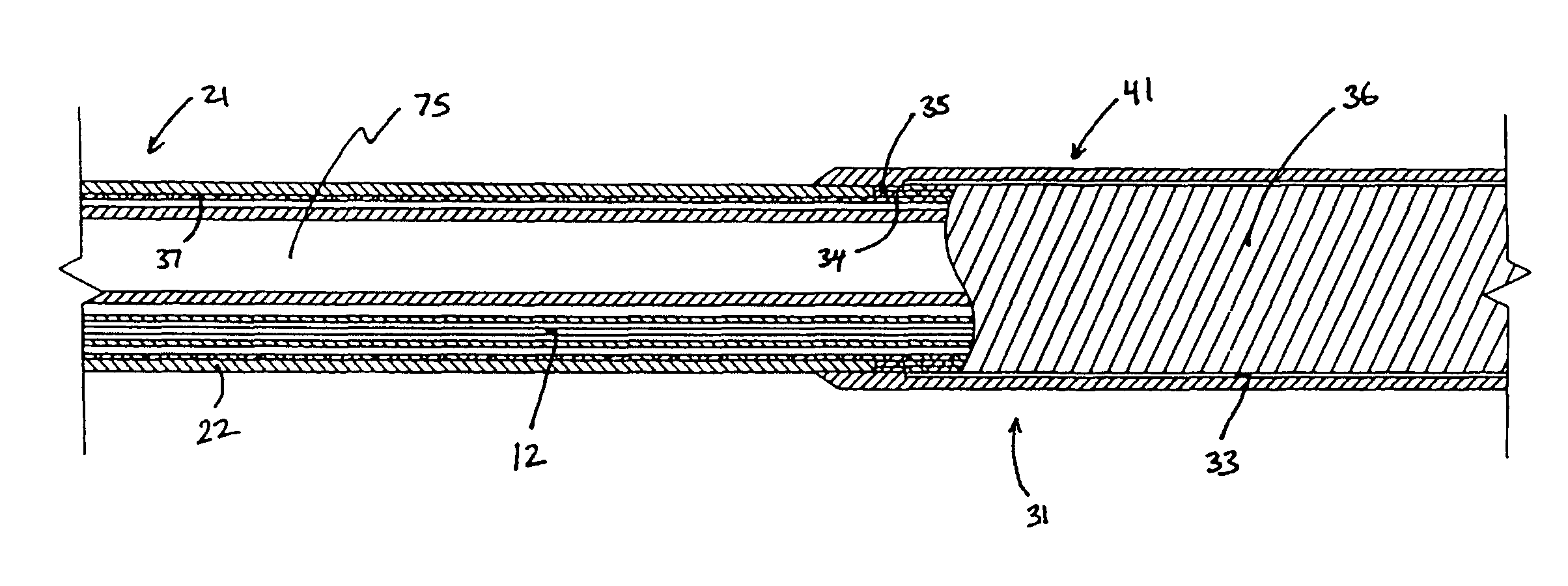

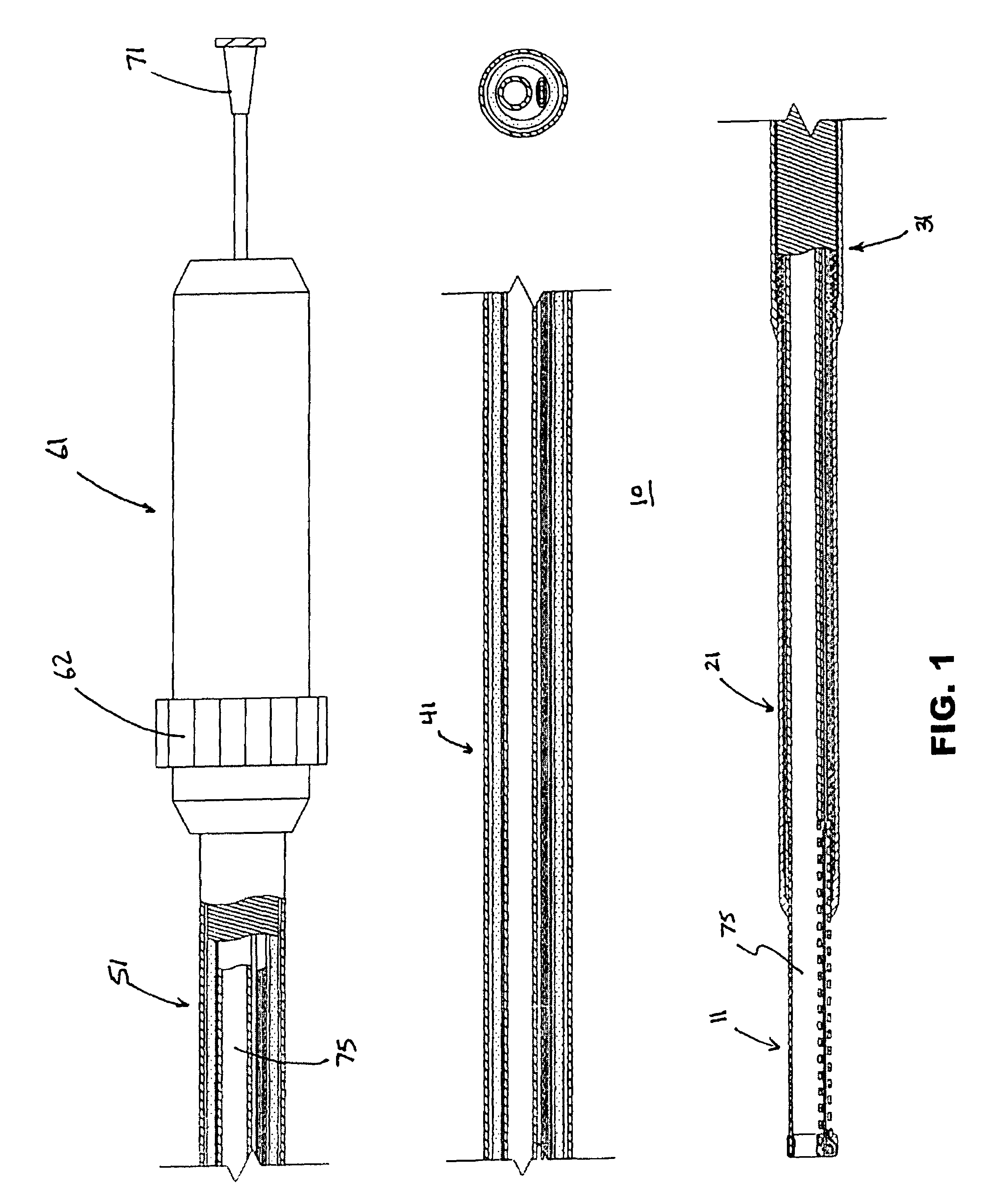

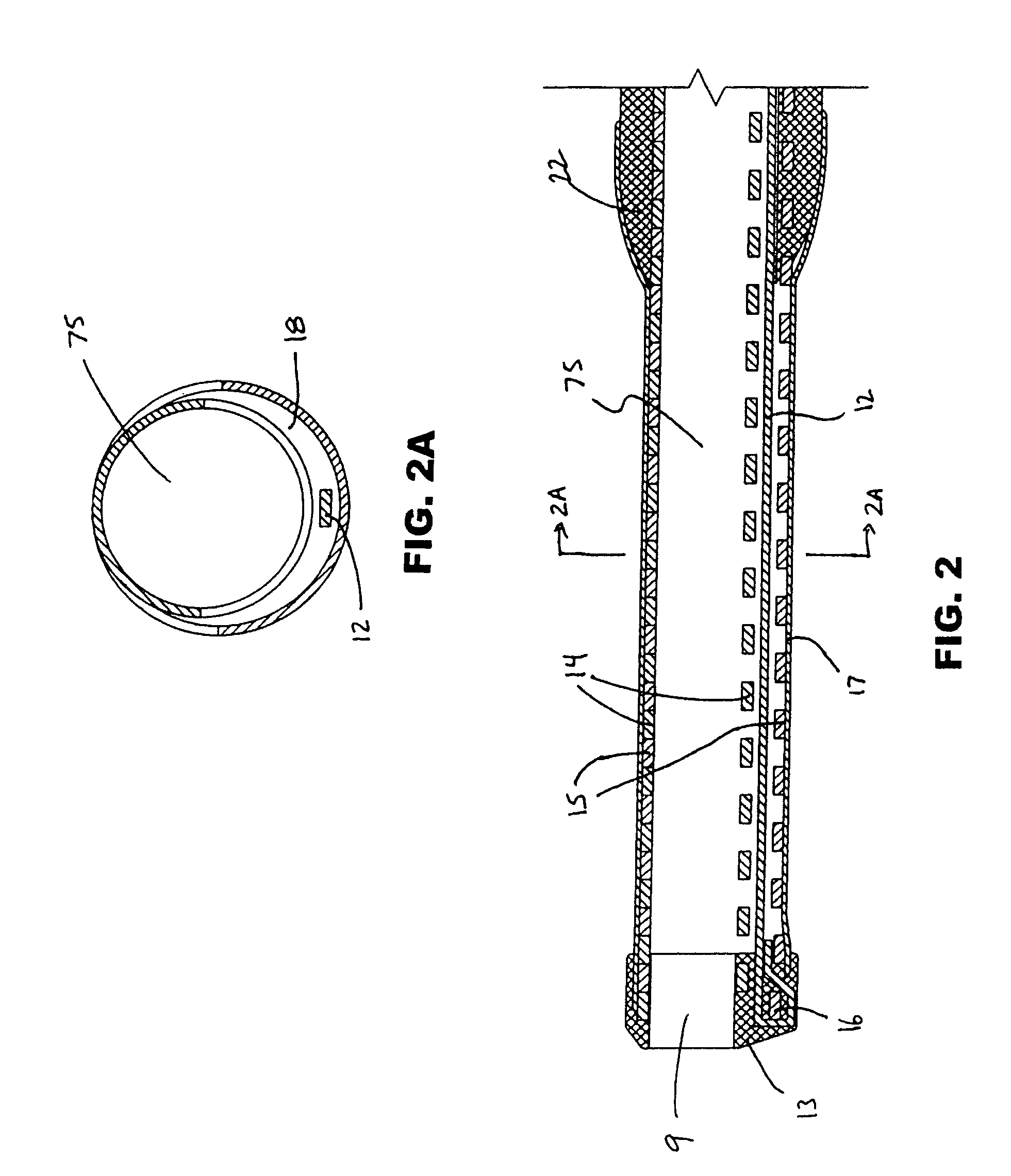

Methods for delivery and deploying a stent formed of a shape memory alloy to a desired position in a tubular area of the body, and / or for repositioning and / or retrieving a stent formed of a two-way shape memory alloy. An arrangement is provided by which the temperature of the stent is locally adjusted during delivery, repositioning and / or retrieval in a safe and controlled manner by engagement with an expandable and collapsible thermal transfer member situated on a catheter assembly.

Owner:INTEK TECH

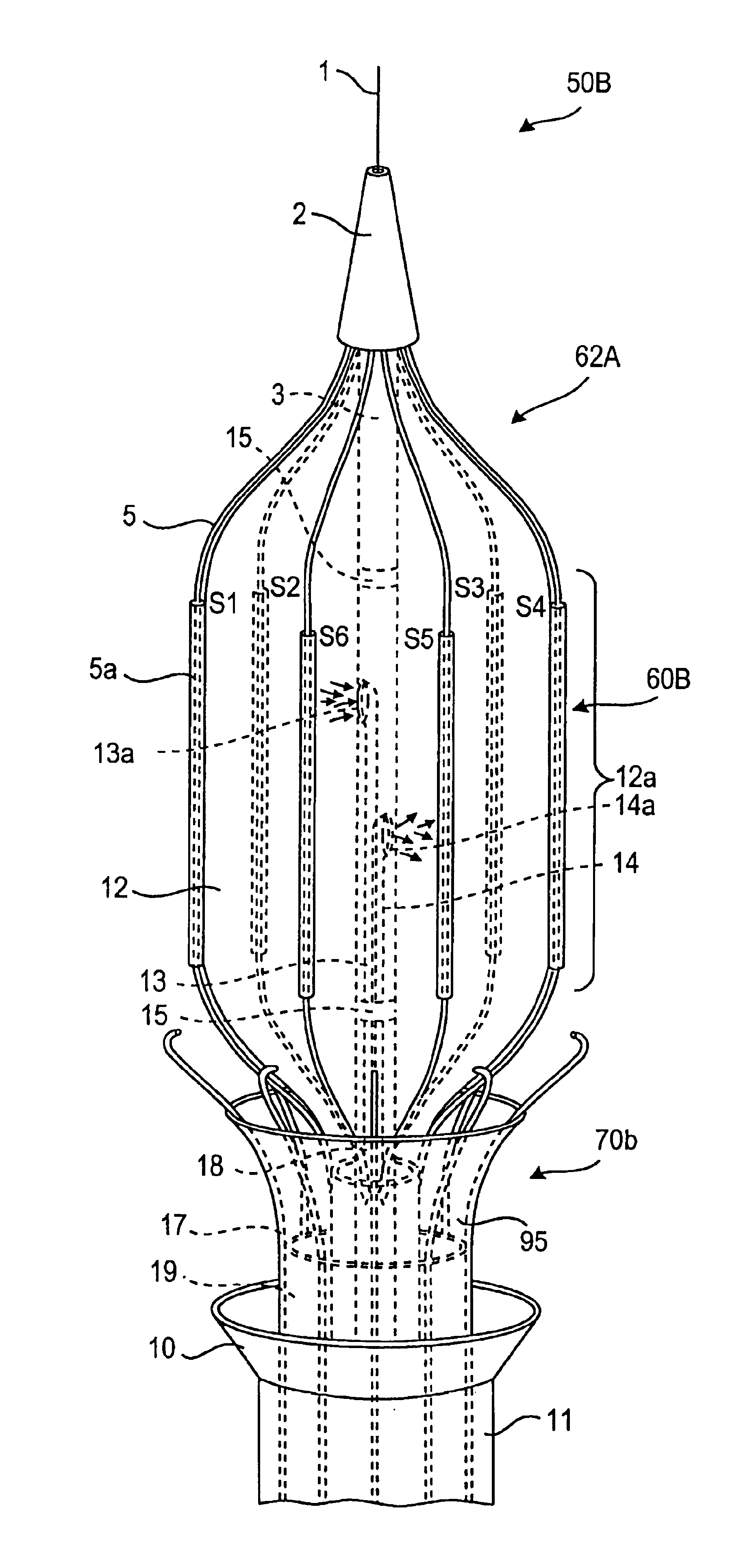

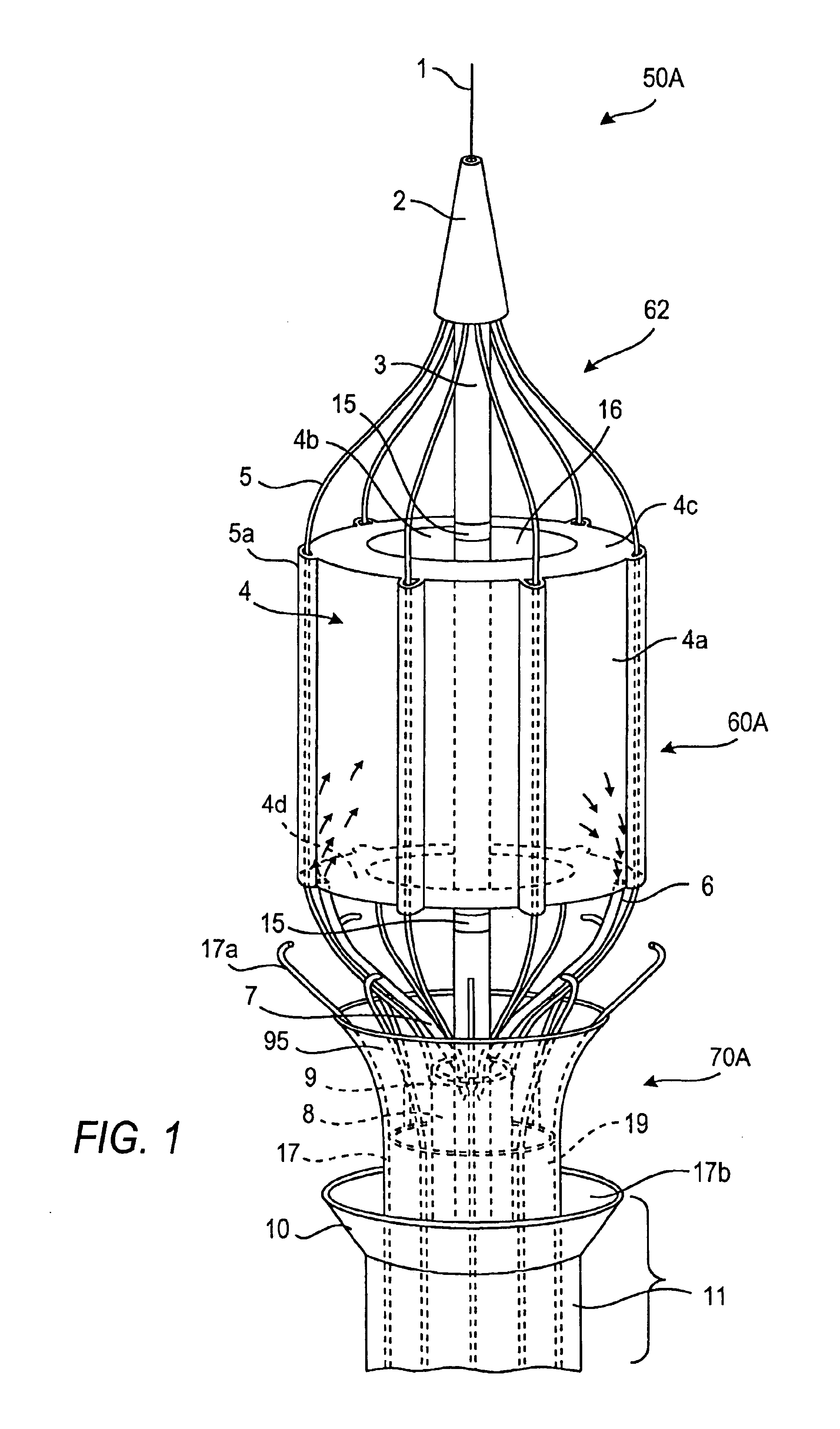

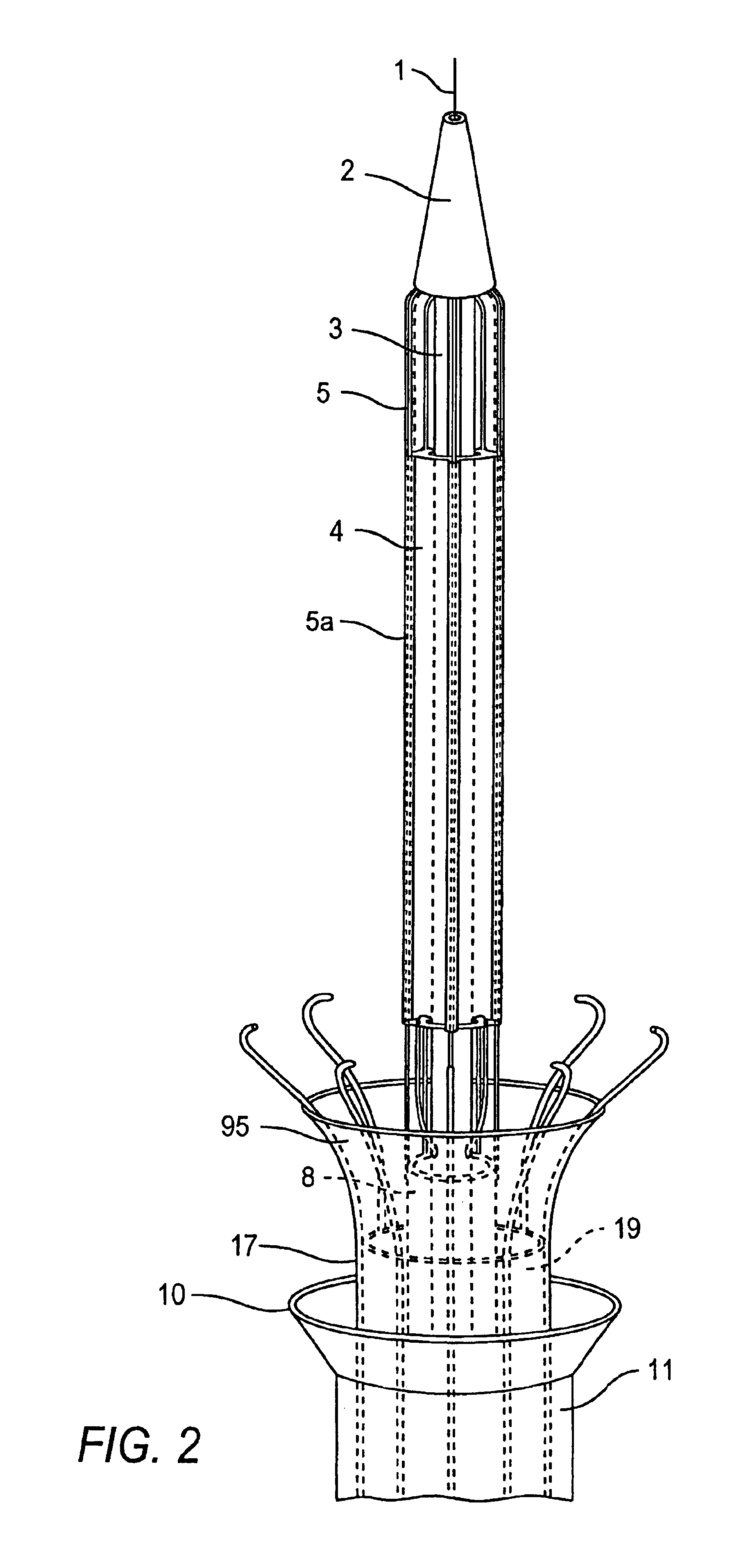

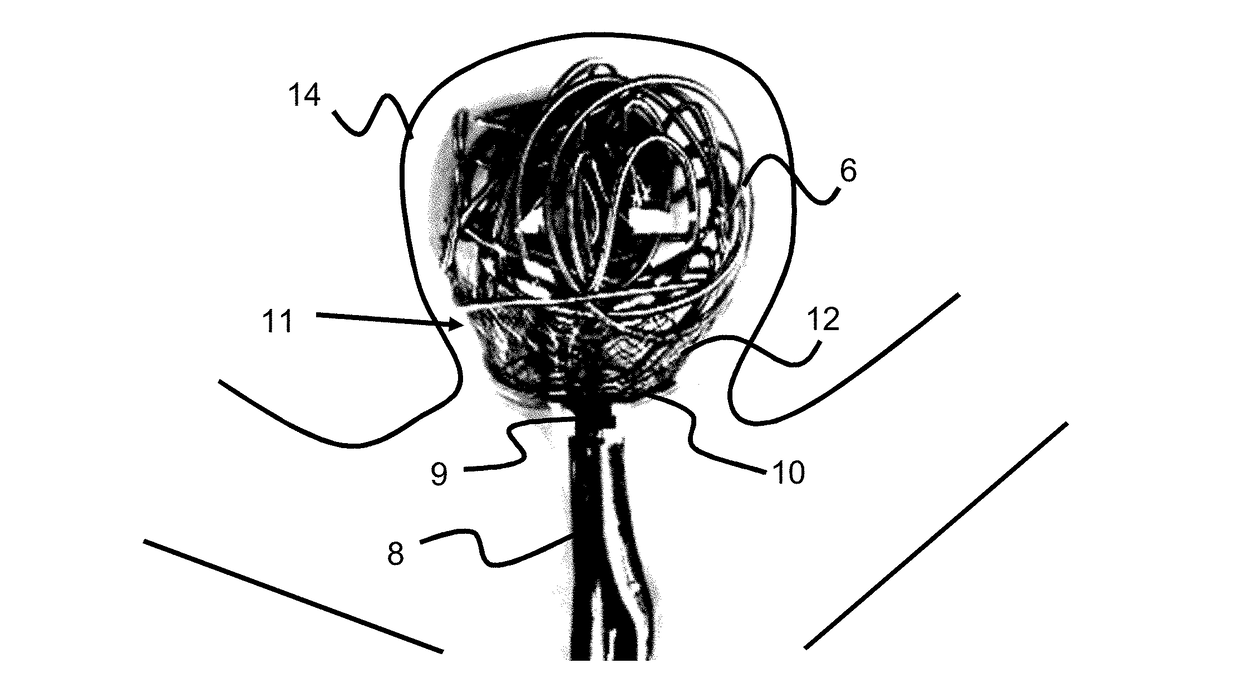

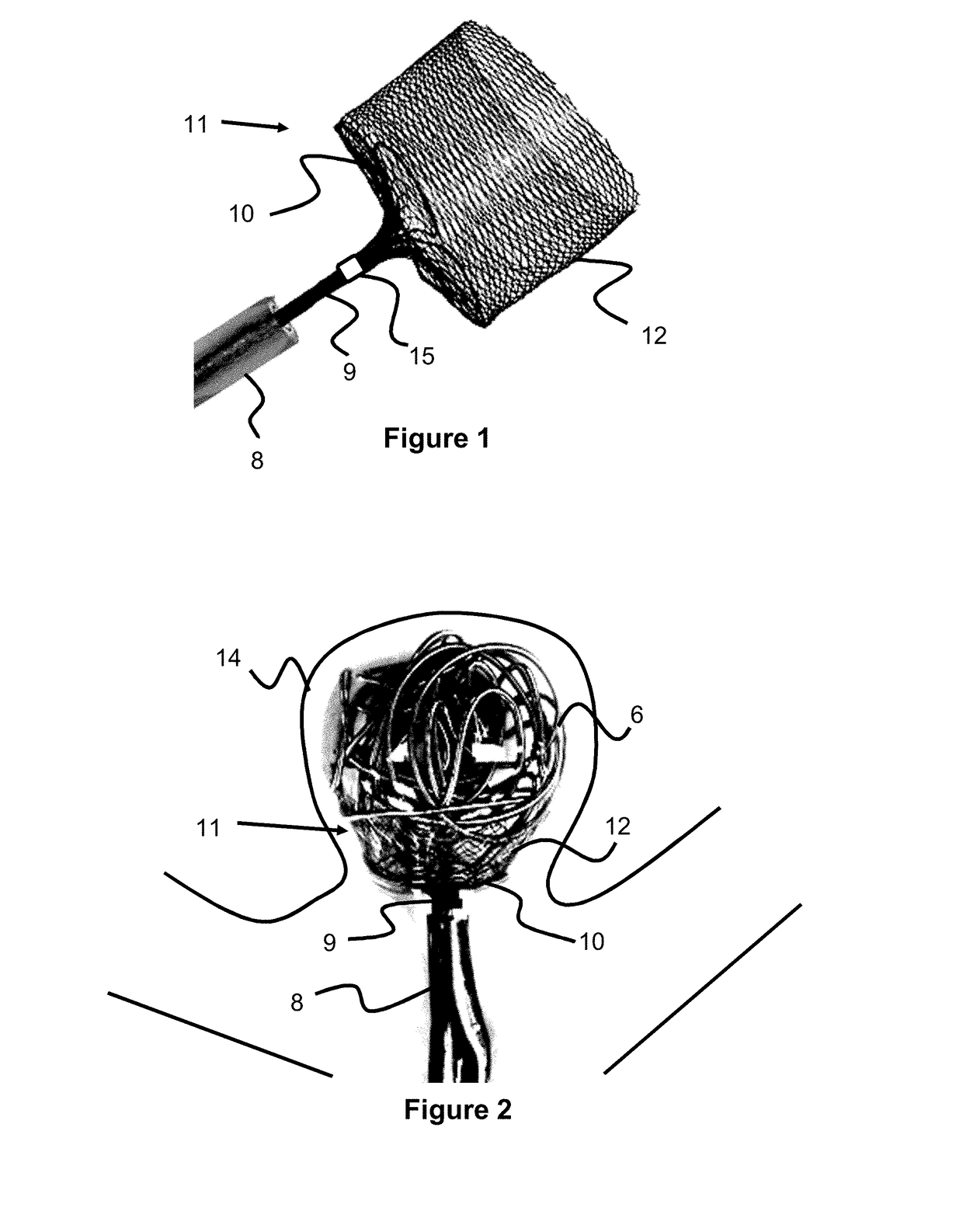

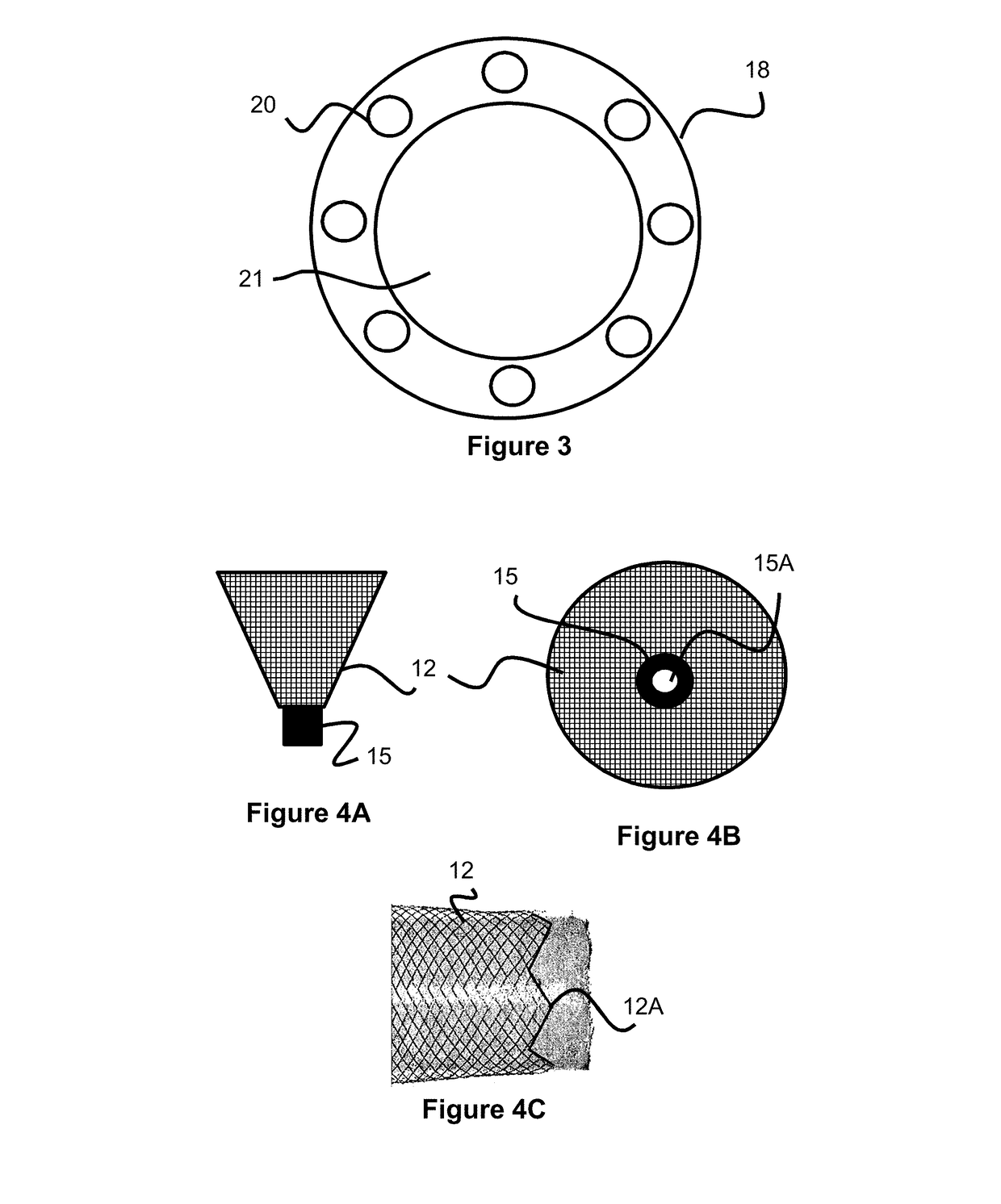

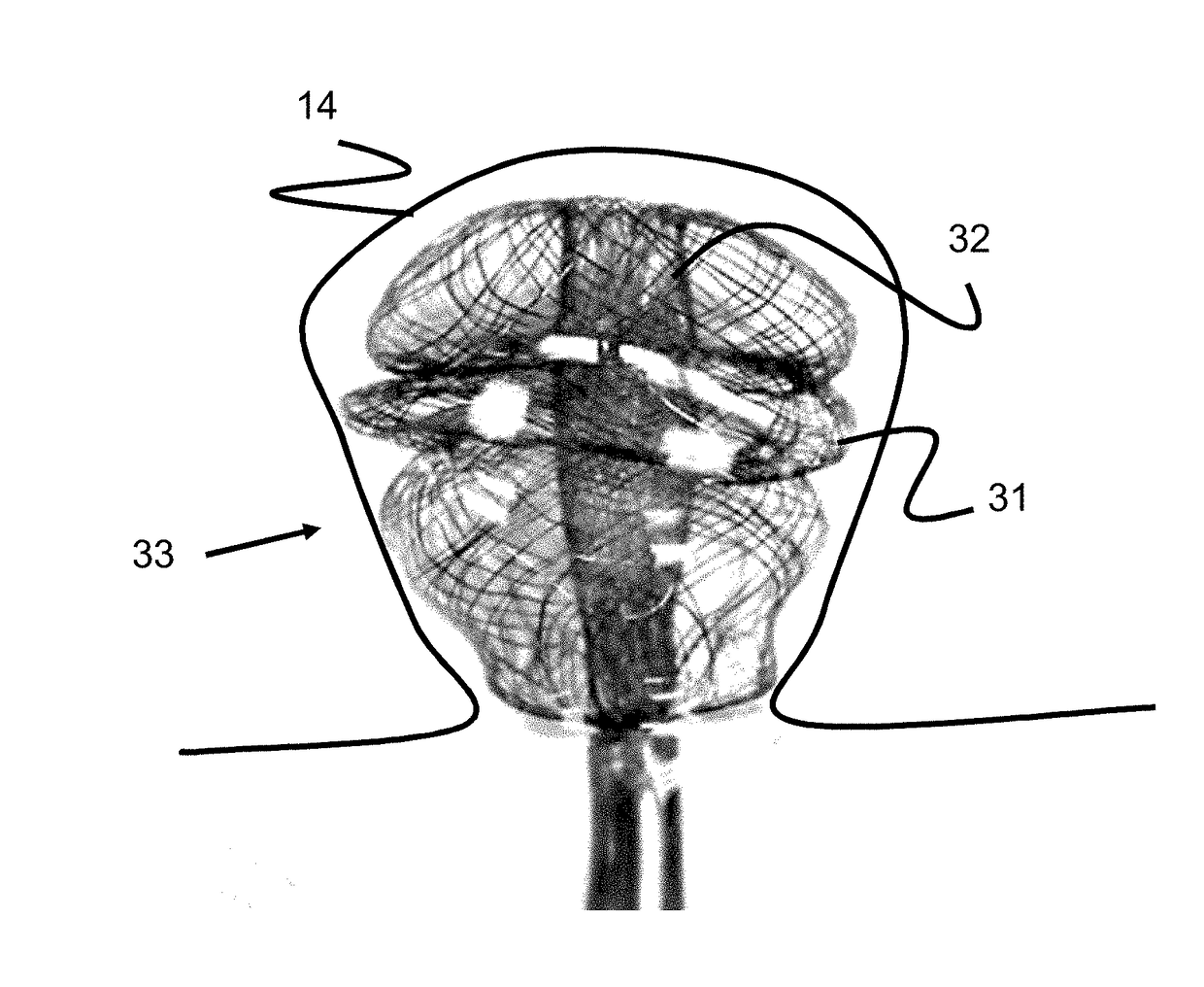

Devices for Vascular Occlusion

An occlusive device, occlusive device delivery system, method of using, and method of delivering an occlusive device, and method of making an occlusive device to treat various intravascular conditions is described.

Owner:MICROVENTION INC

Devices for Vascular Occlusion

An occlusive device, occlusive device delivery system, method of using, and method of delivering an occlusive device, and method of making an occlusive device to treat various intravascular conditions is described.

Owner:MICROVENTION INC

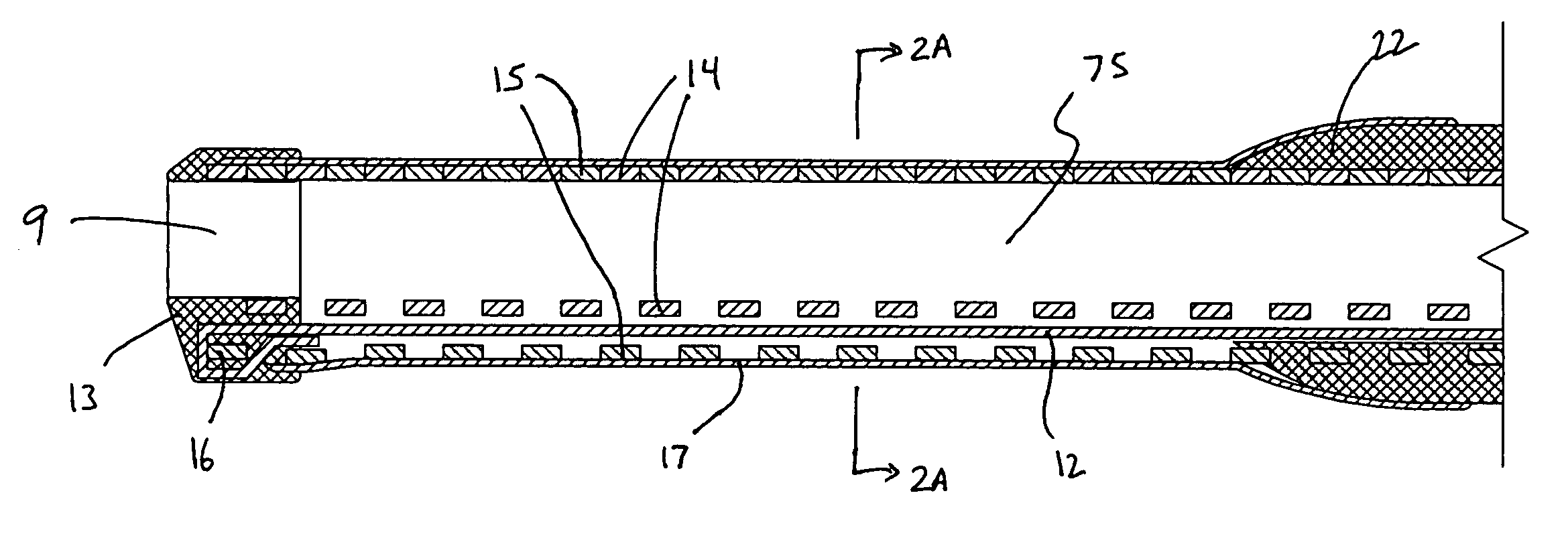

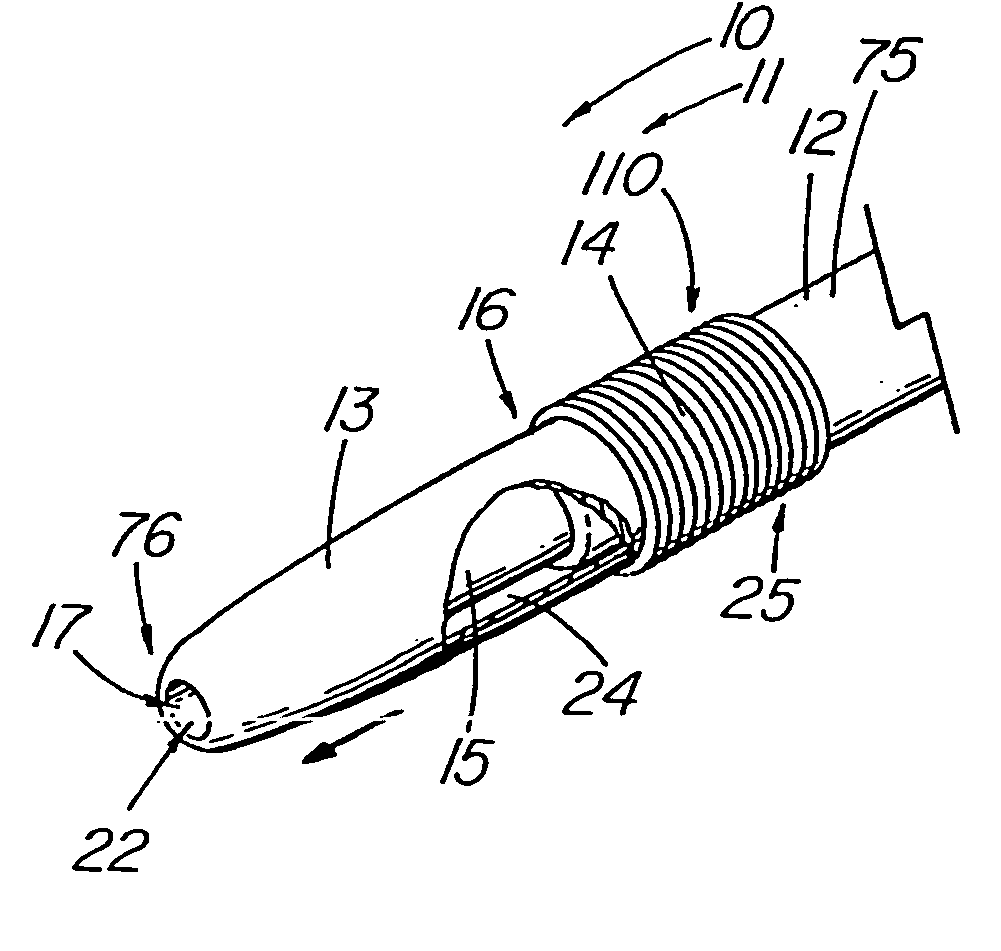

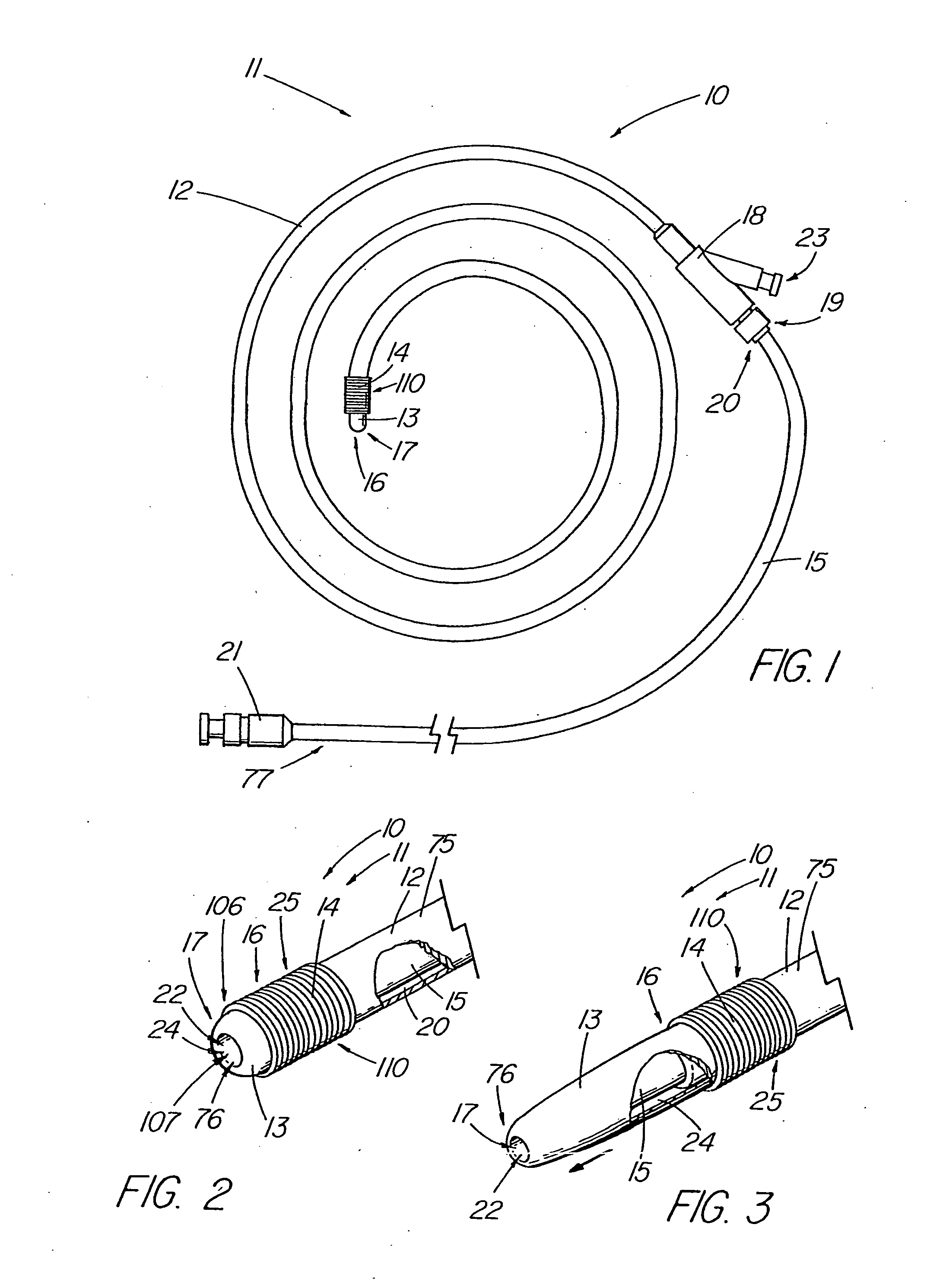

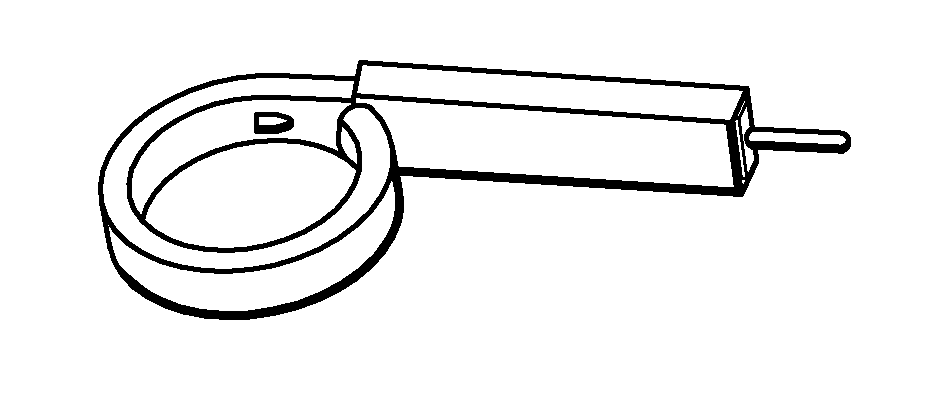

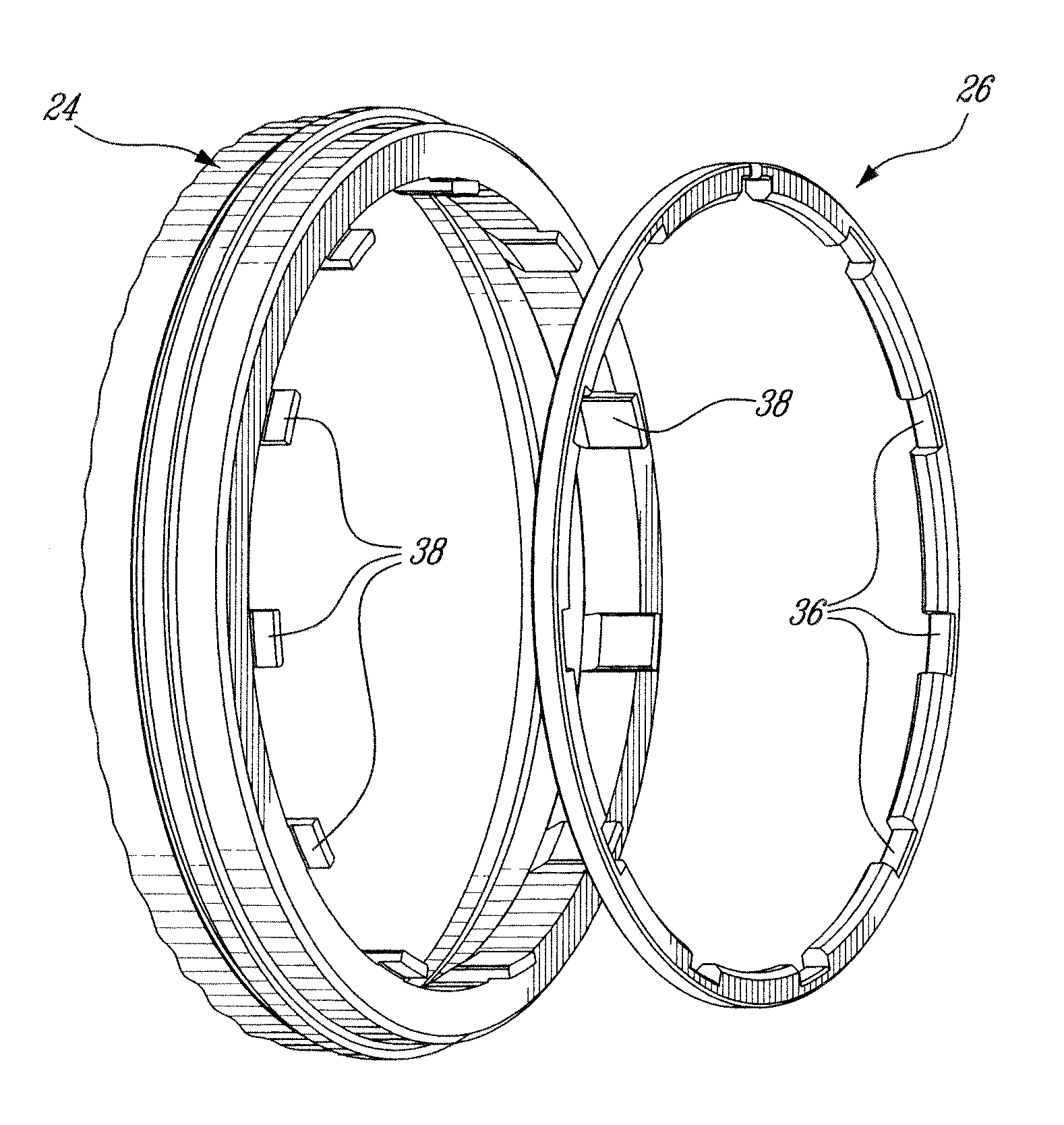

Devices and methods for crossing a chronic total occlusion

ActiveUS20050049574A1Increase pitchTendency increaseStentsBalloon catheterTotal occlusionHelical coil

A catheter comprising an elongate tubular member having a proximal end and a distal end, and a deflectable tip at the distal end of the elongate tubular member. The deflectable tip comprises a first helical coil having a first diameter and a second helical coil having a second diameter, the first diameter being larger than the second diameter. The first and second helical coils are arranged in the manner of a double helix. When viewed in cross-section, the first helical coil and the second helical coil are aligned at a first point on a circumference of each coil and misaligned at a second point on the circumference of each coil, where the second point is approximately 180 degrees from the first point. In certain embodiments the catheter further includes a dilatation balloon. Methods of use for crossing a chronic total occlusion are also described.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC +1

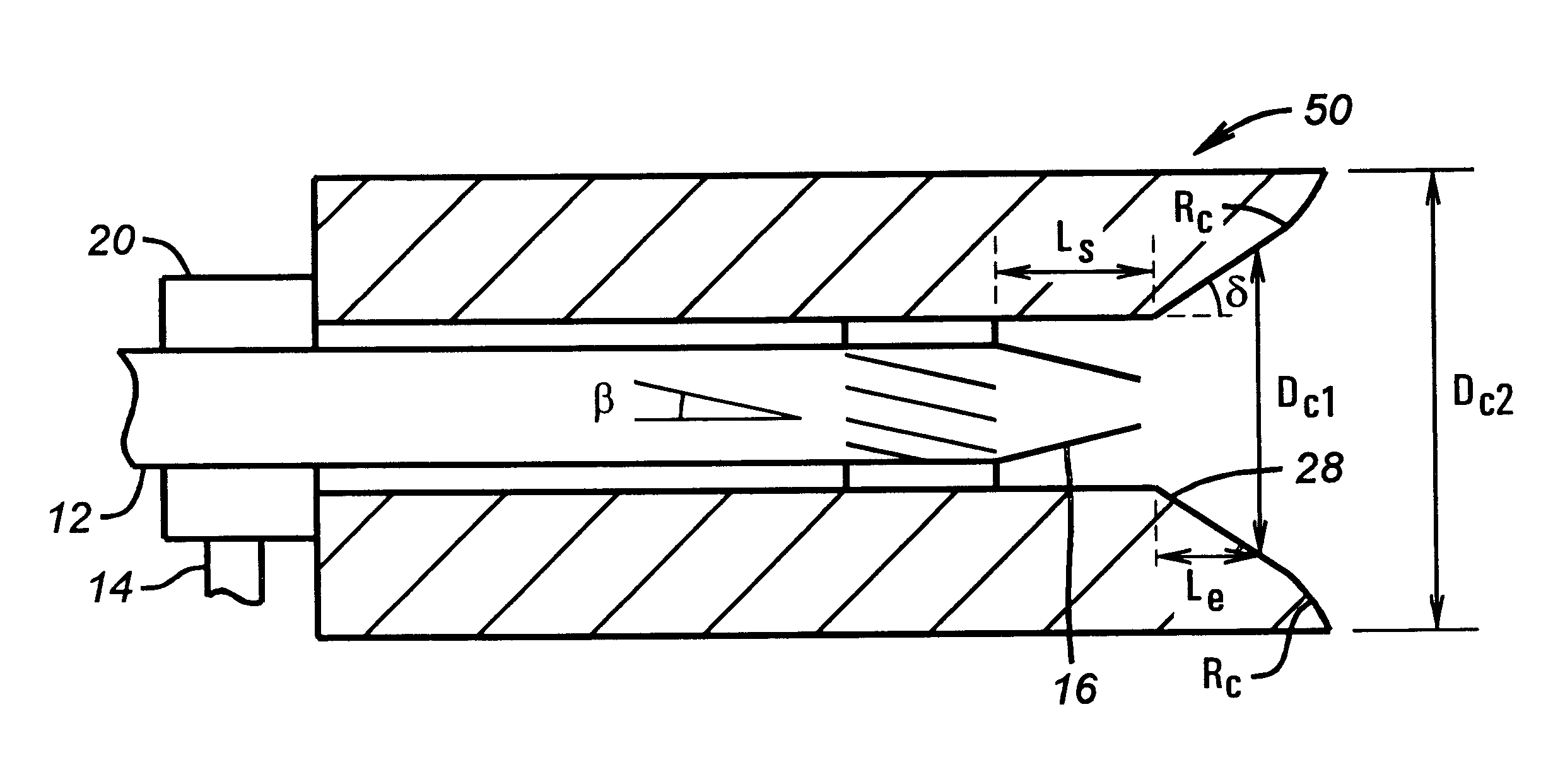

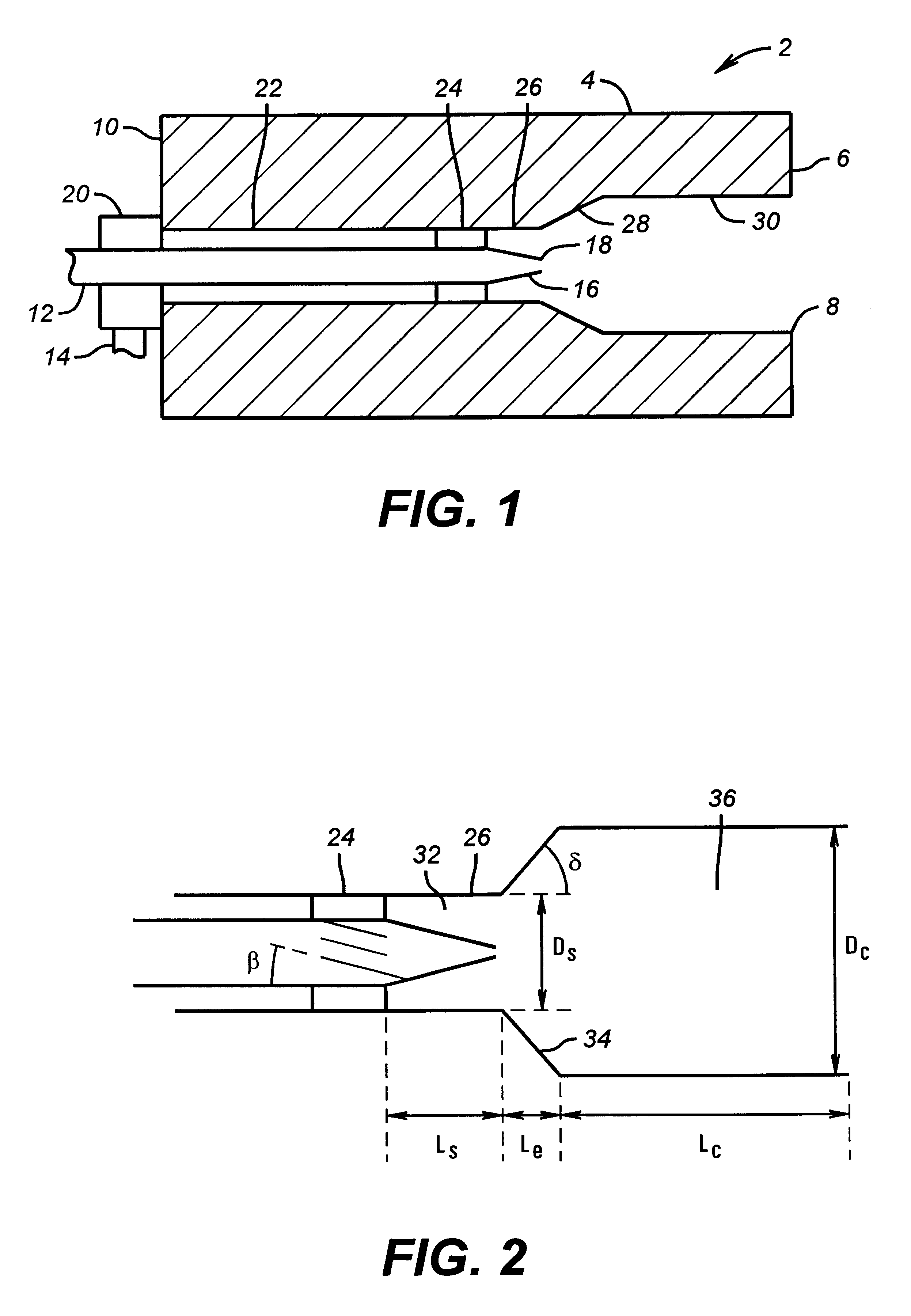

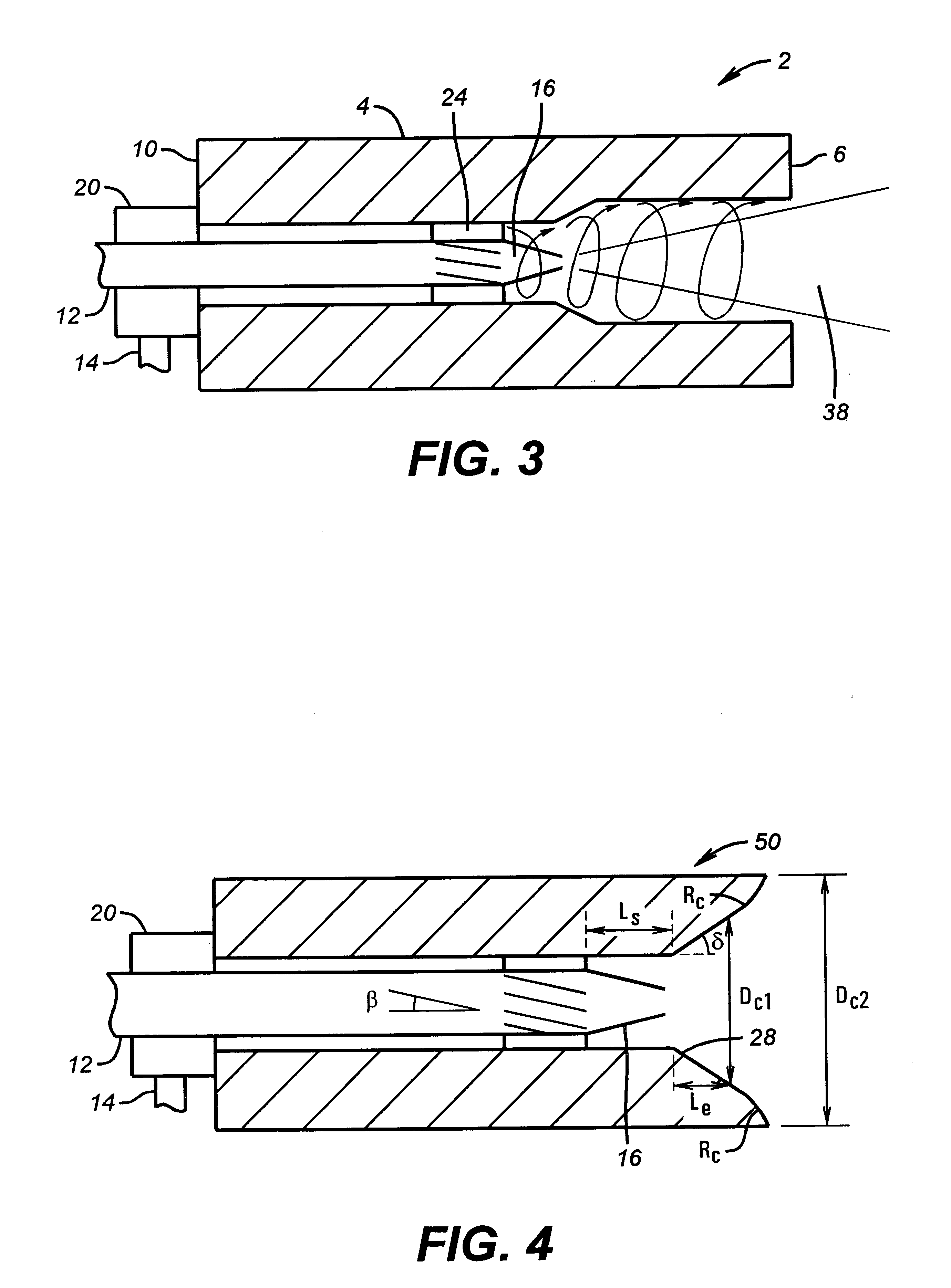

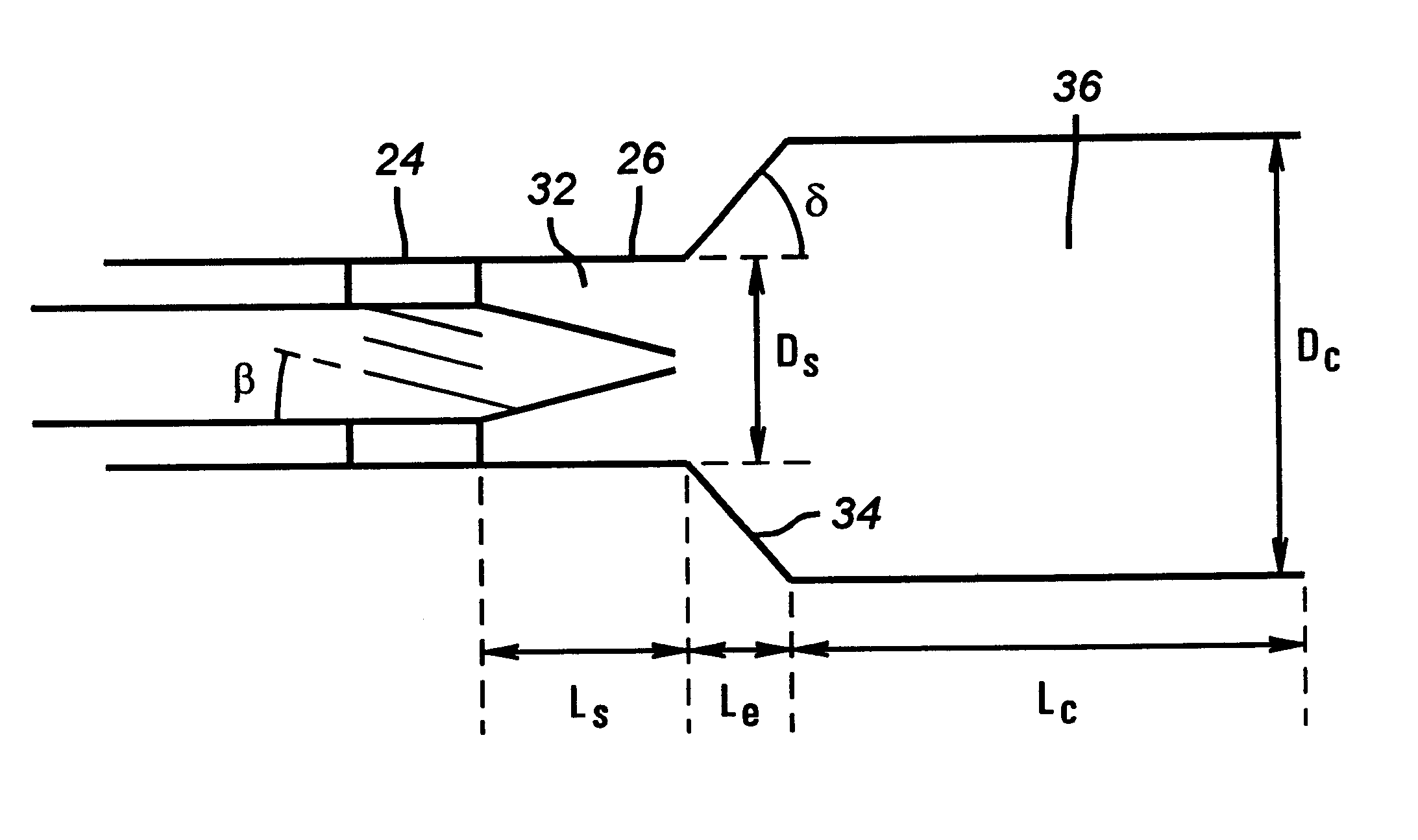

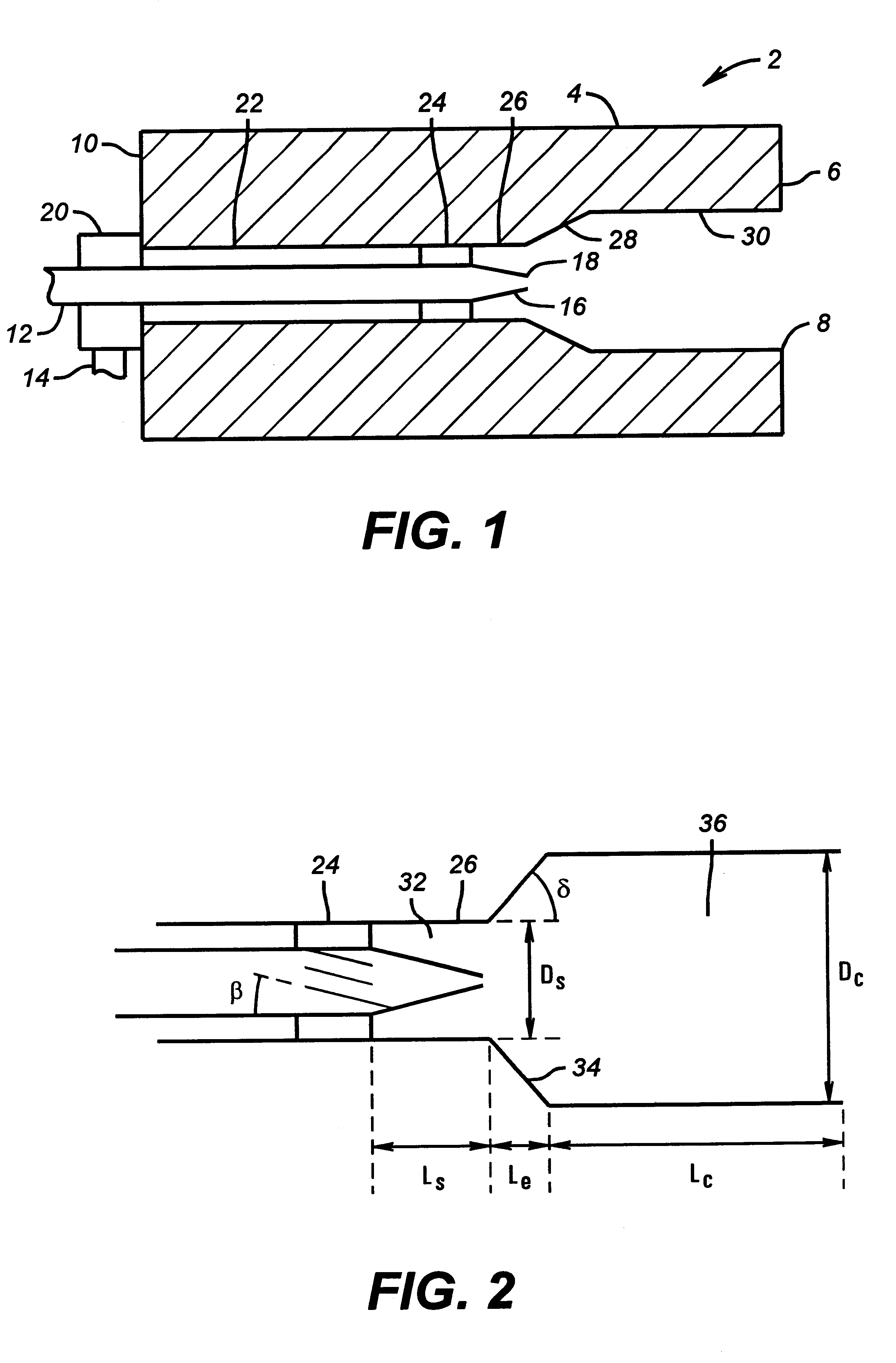

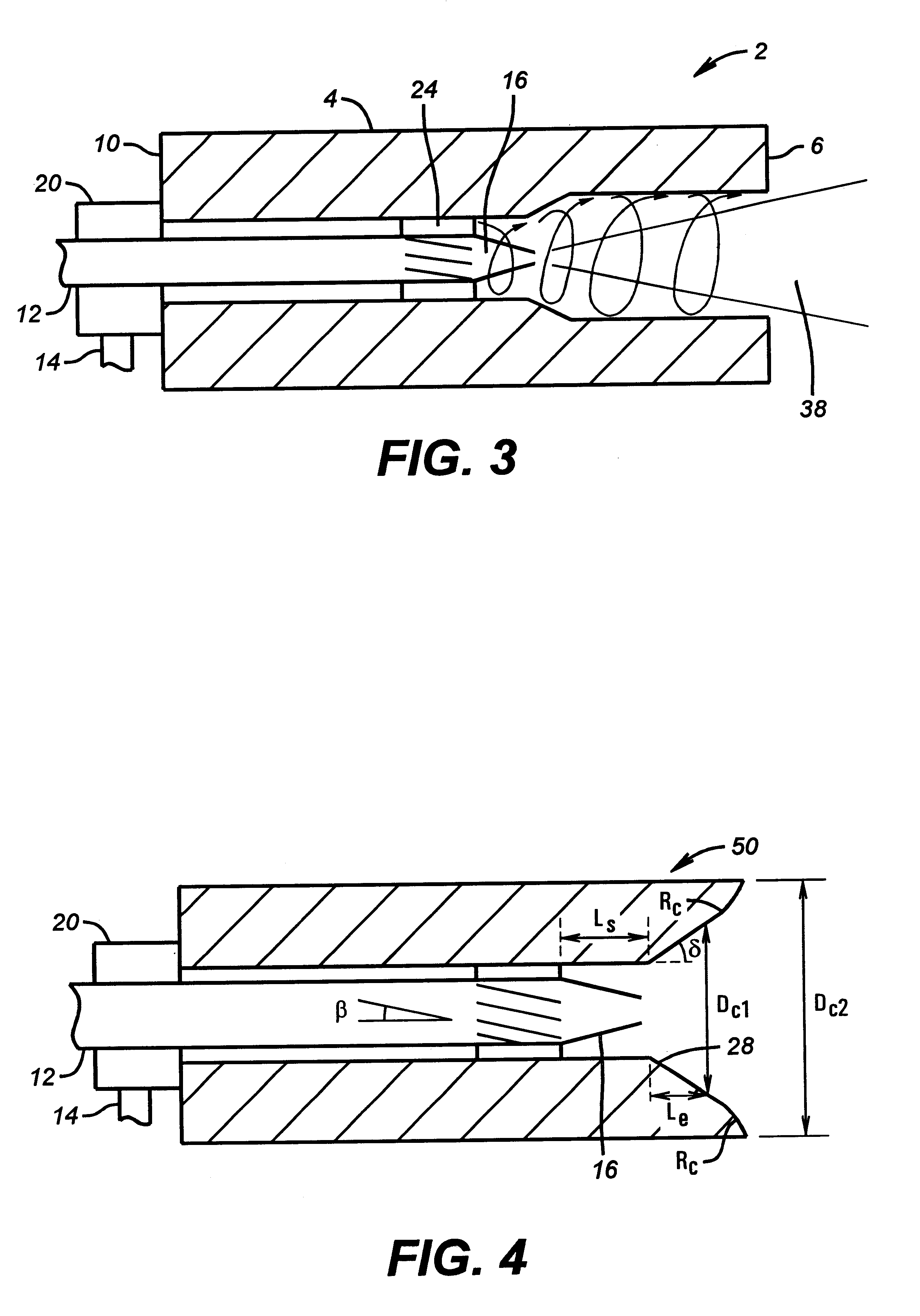

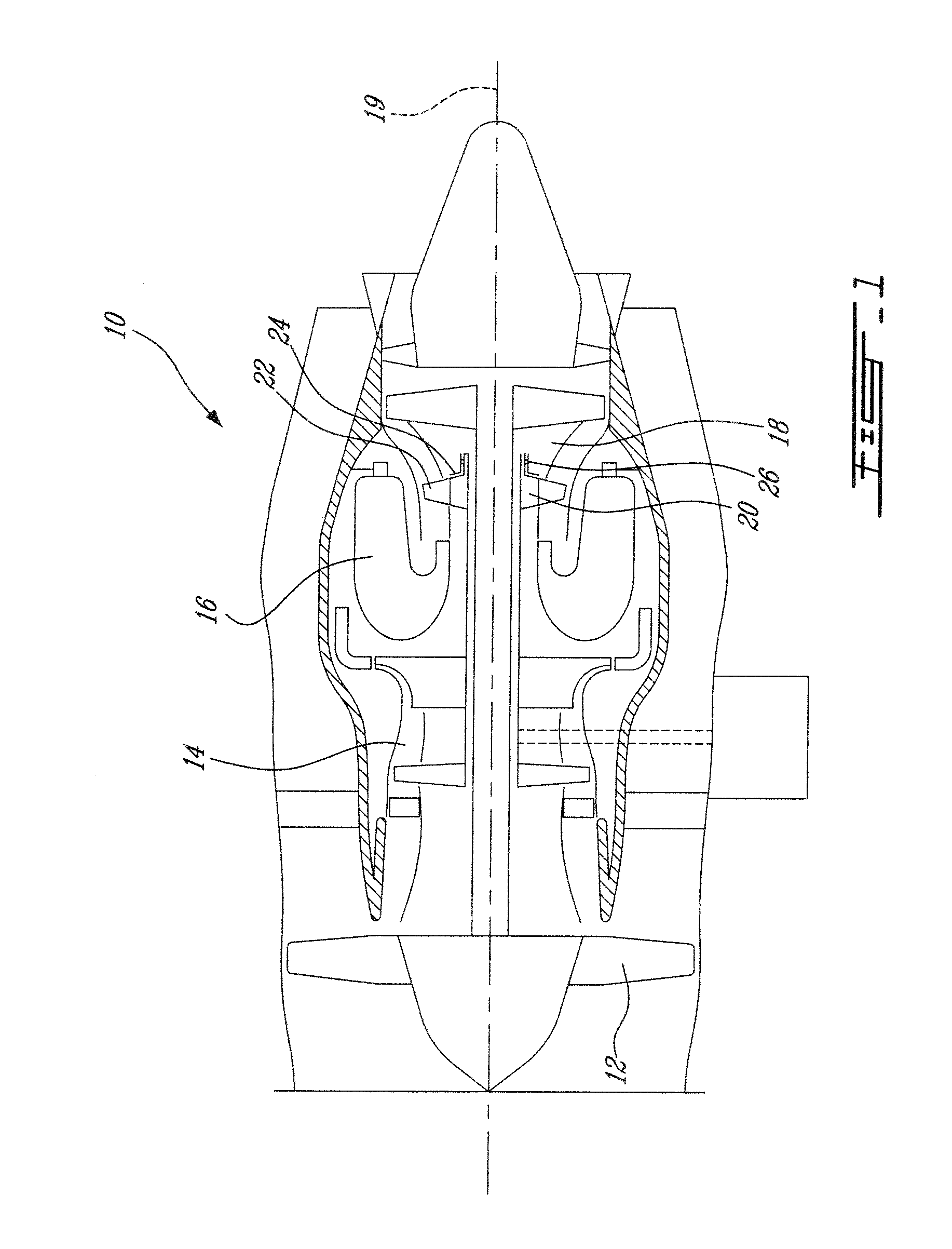

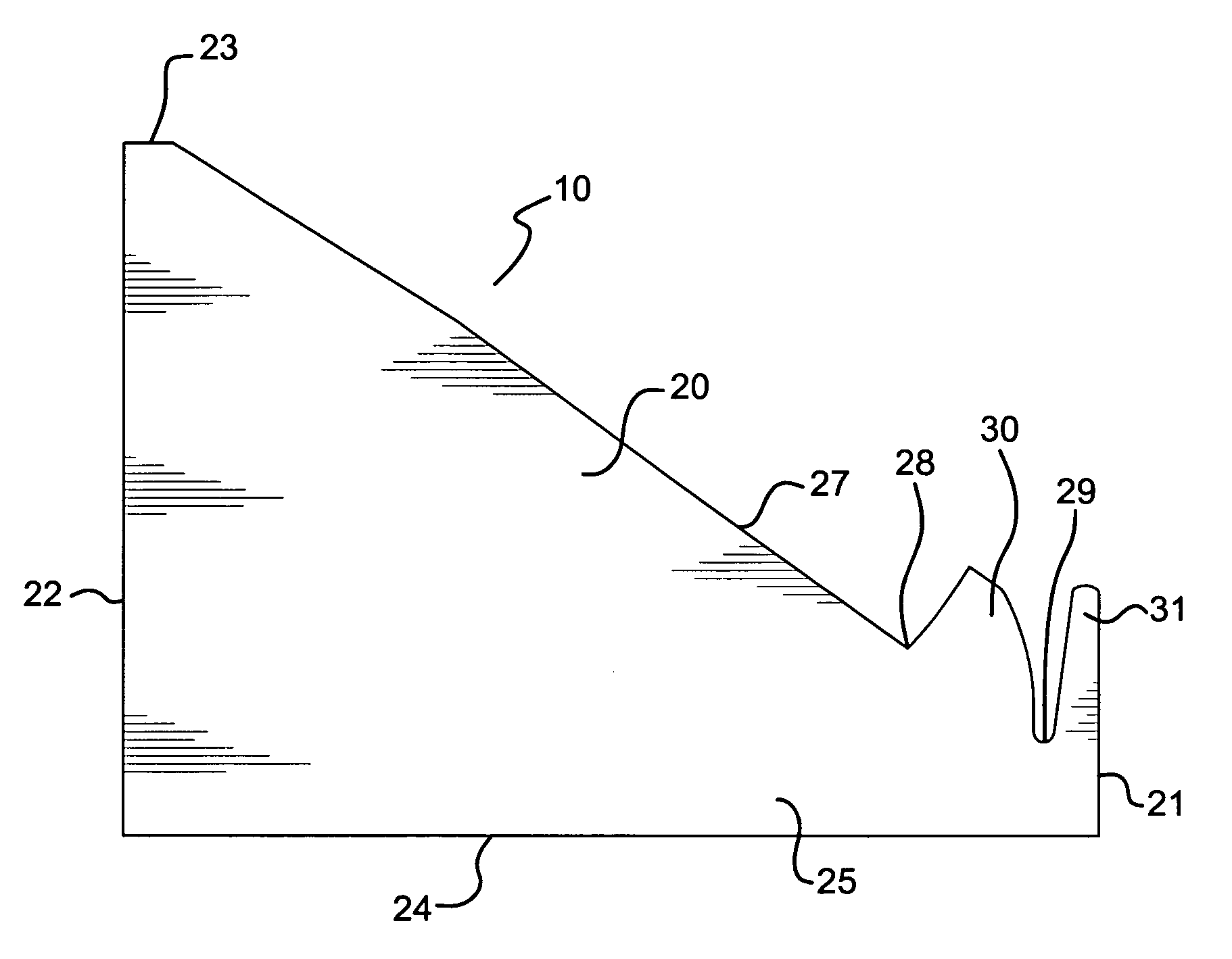

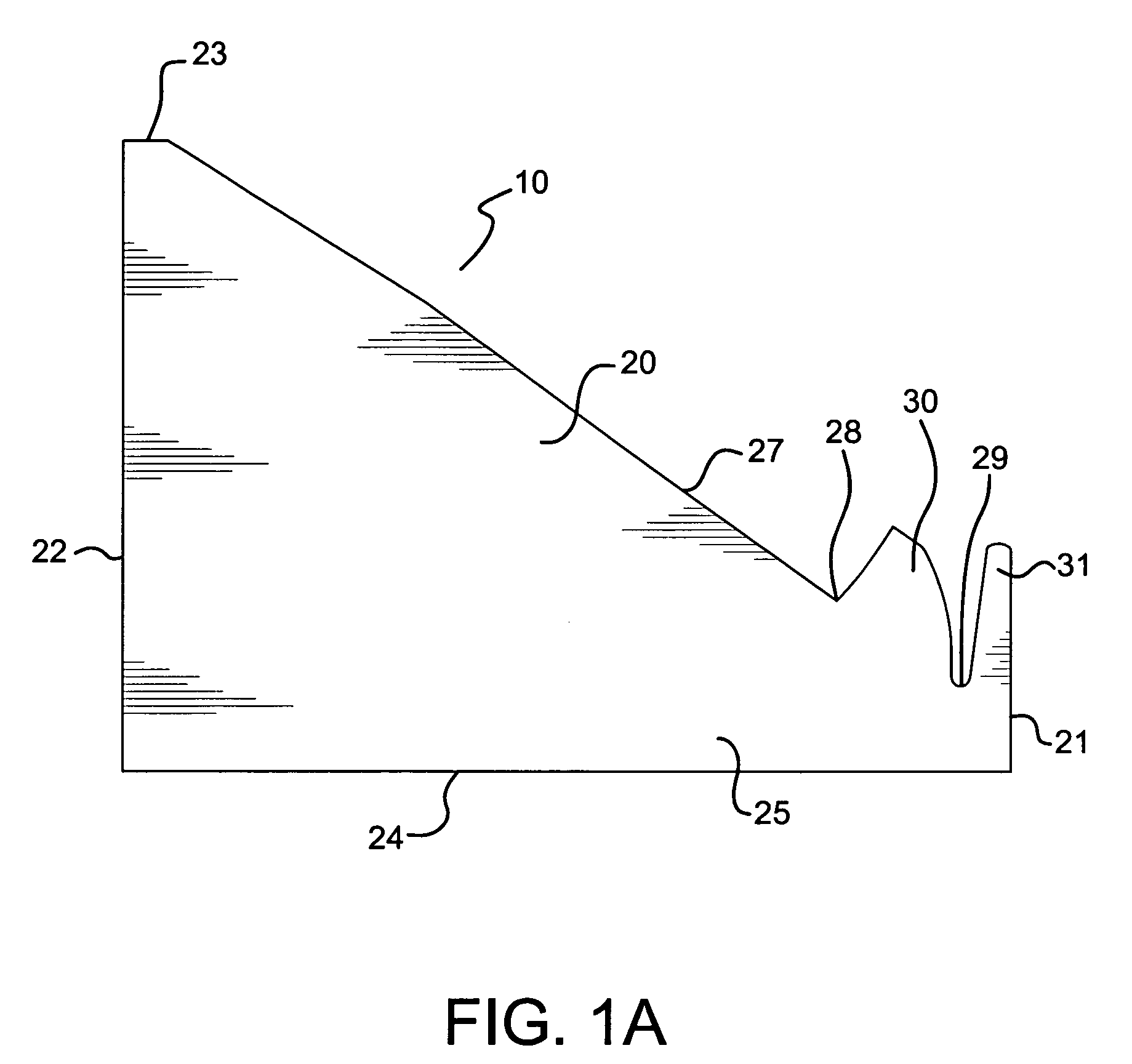

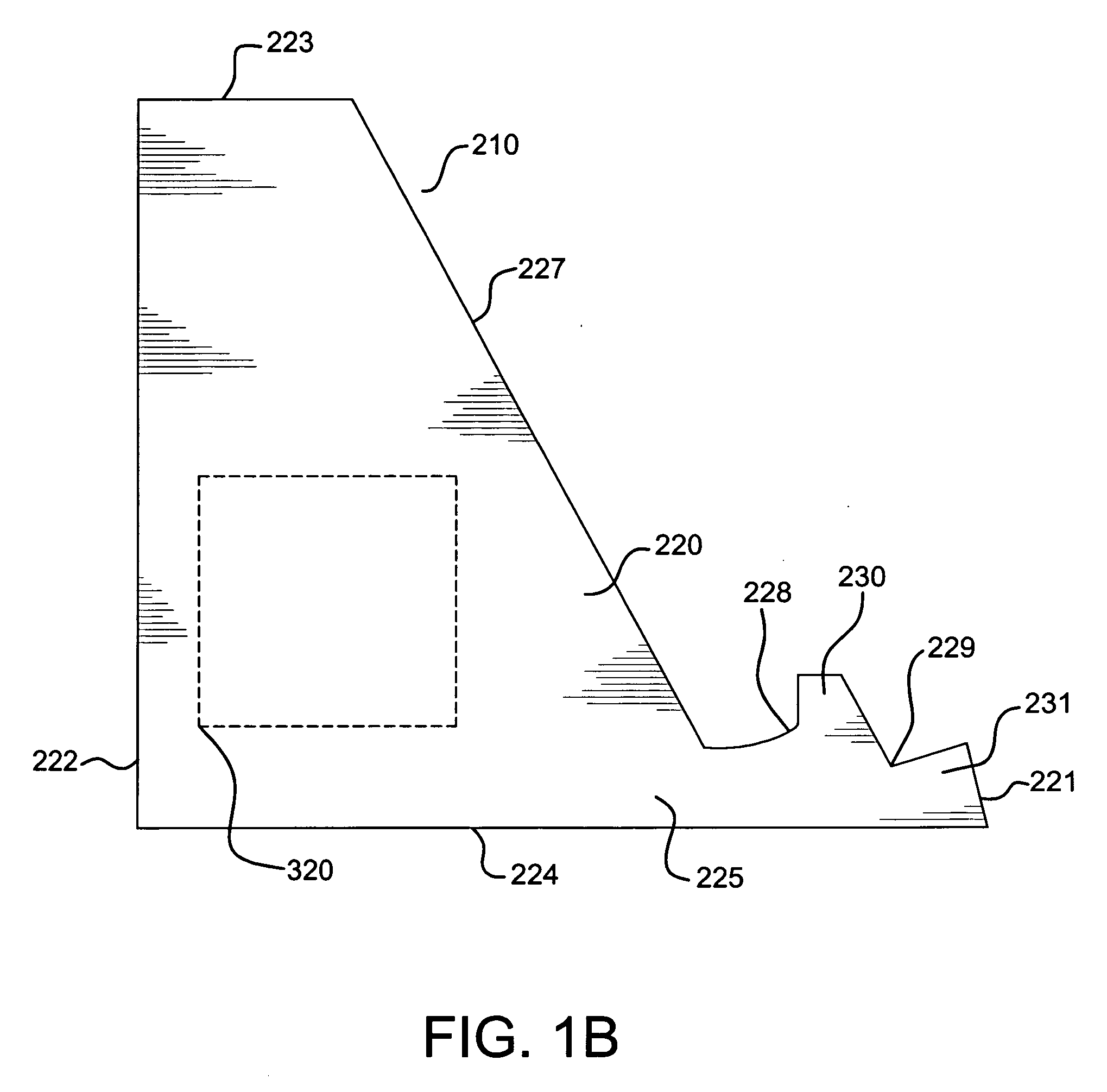

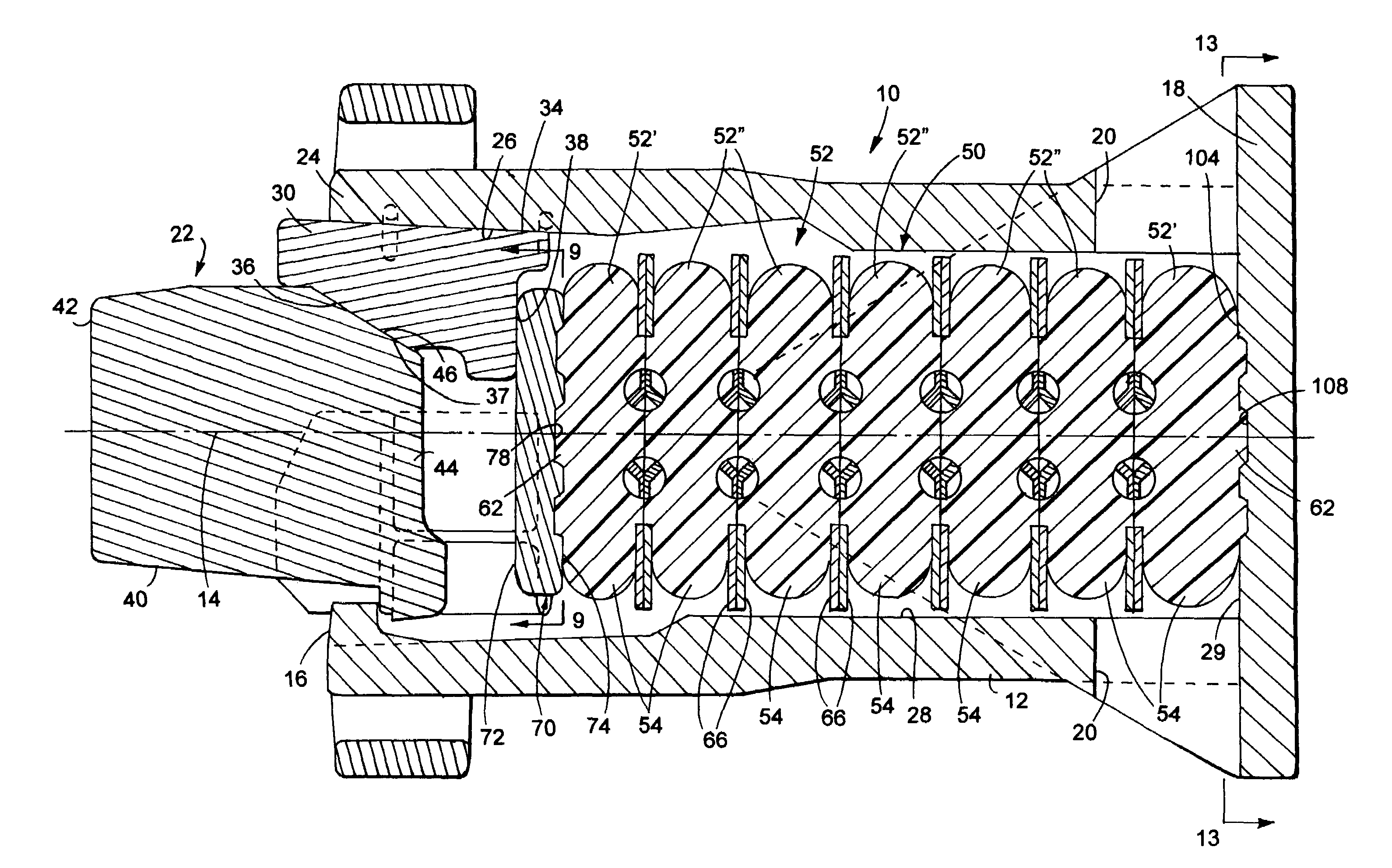

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

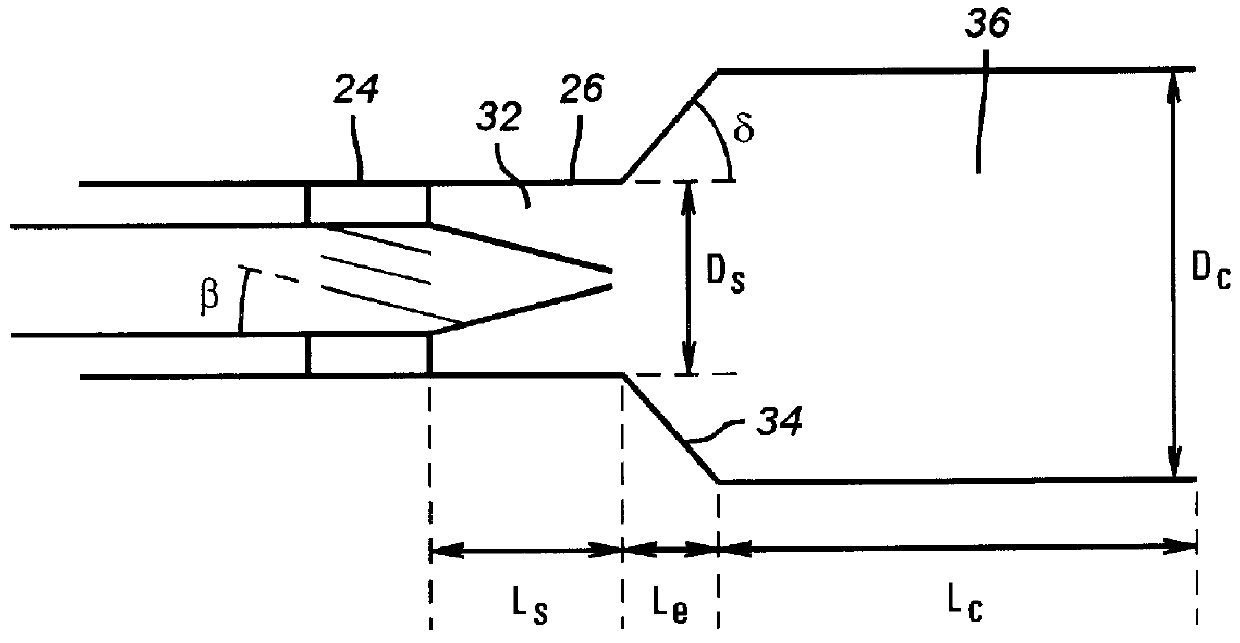

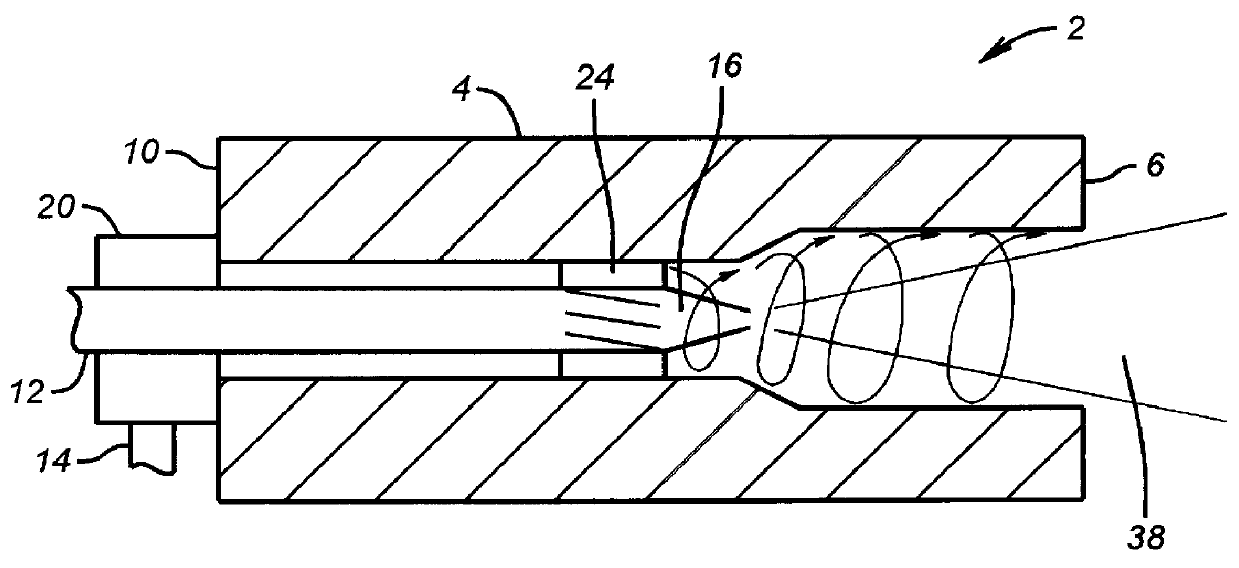

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

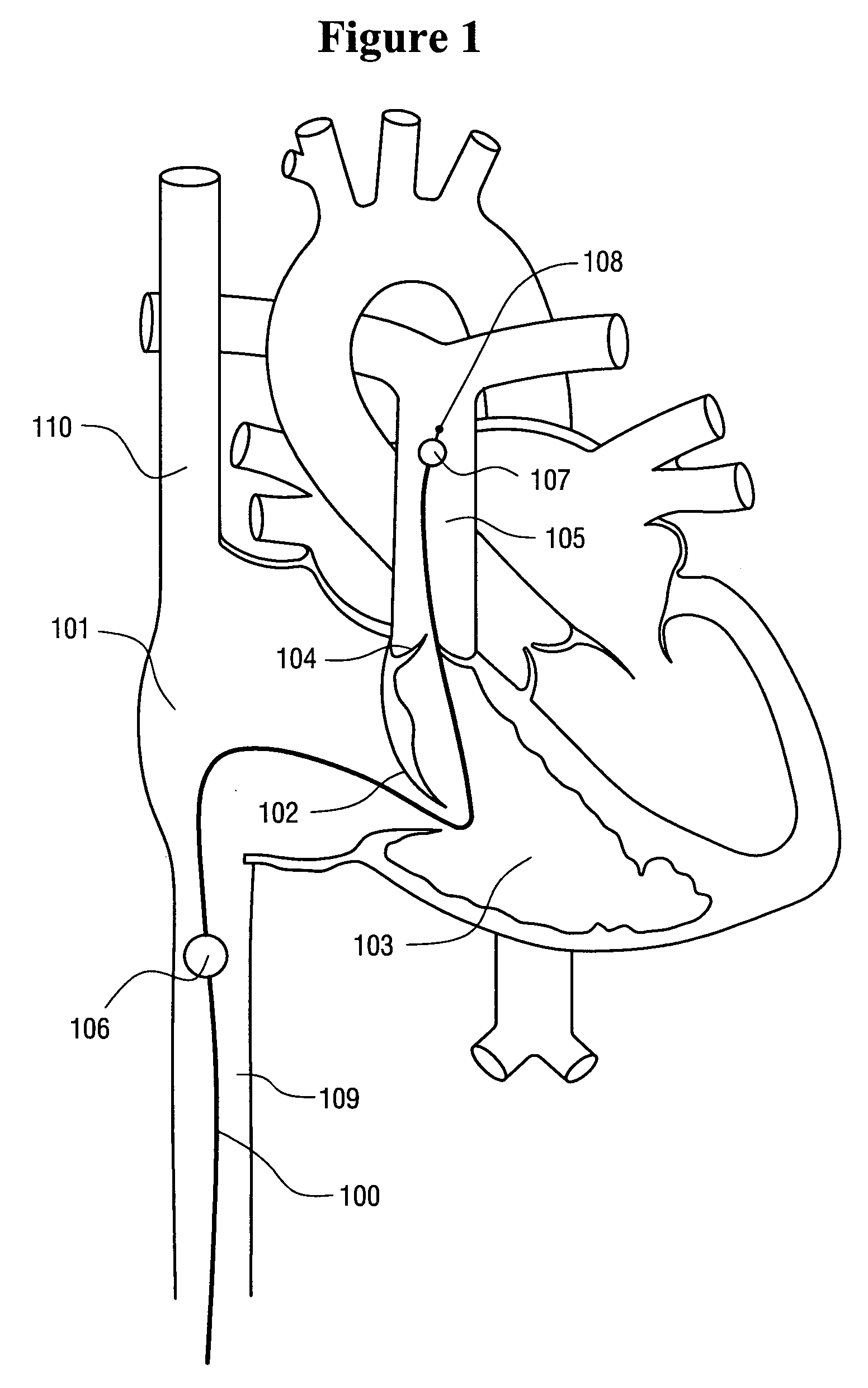

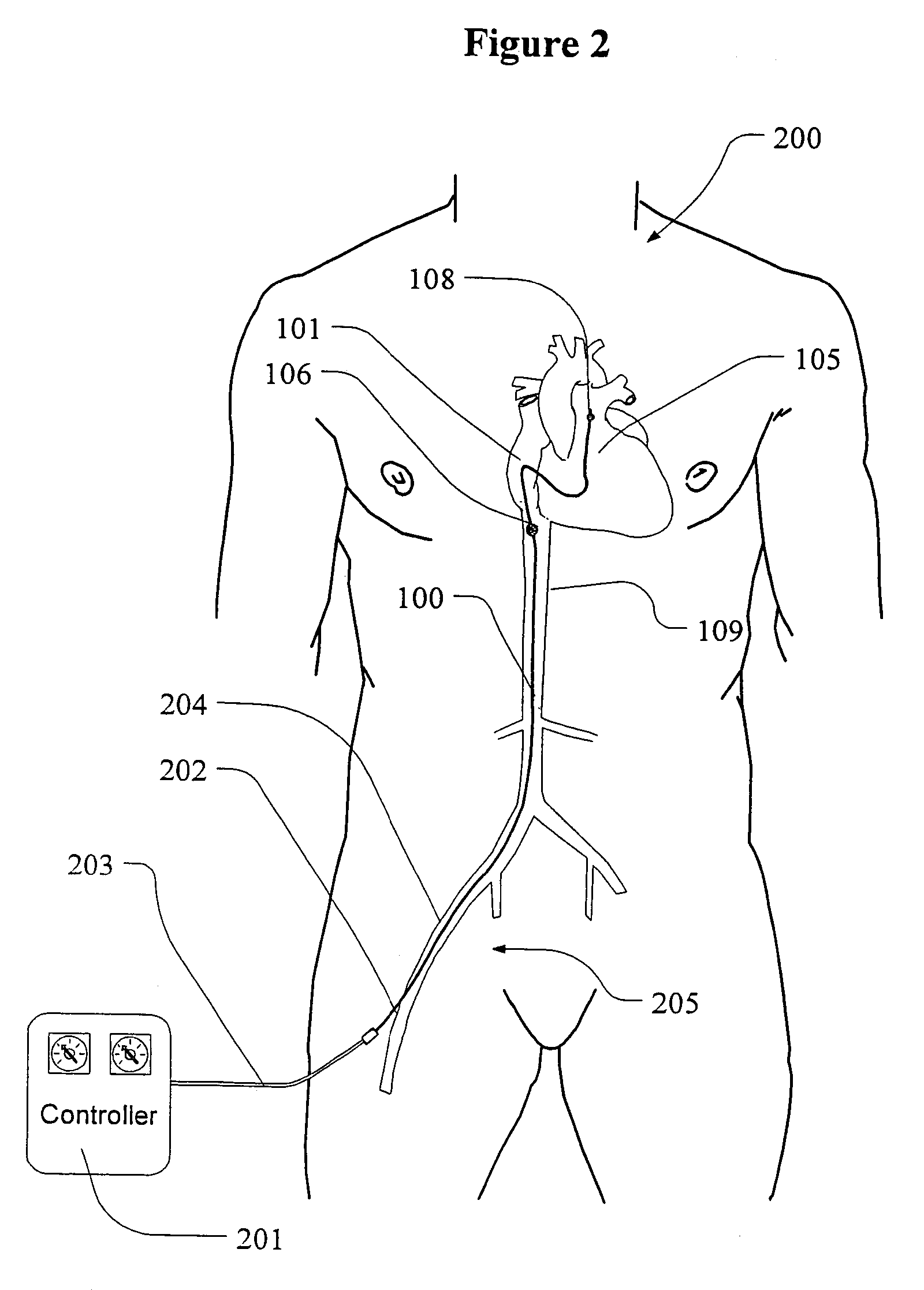

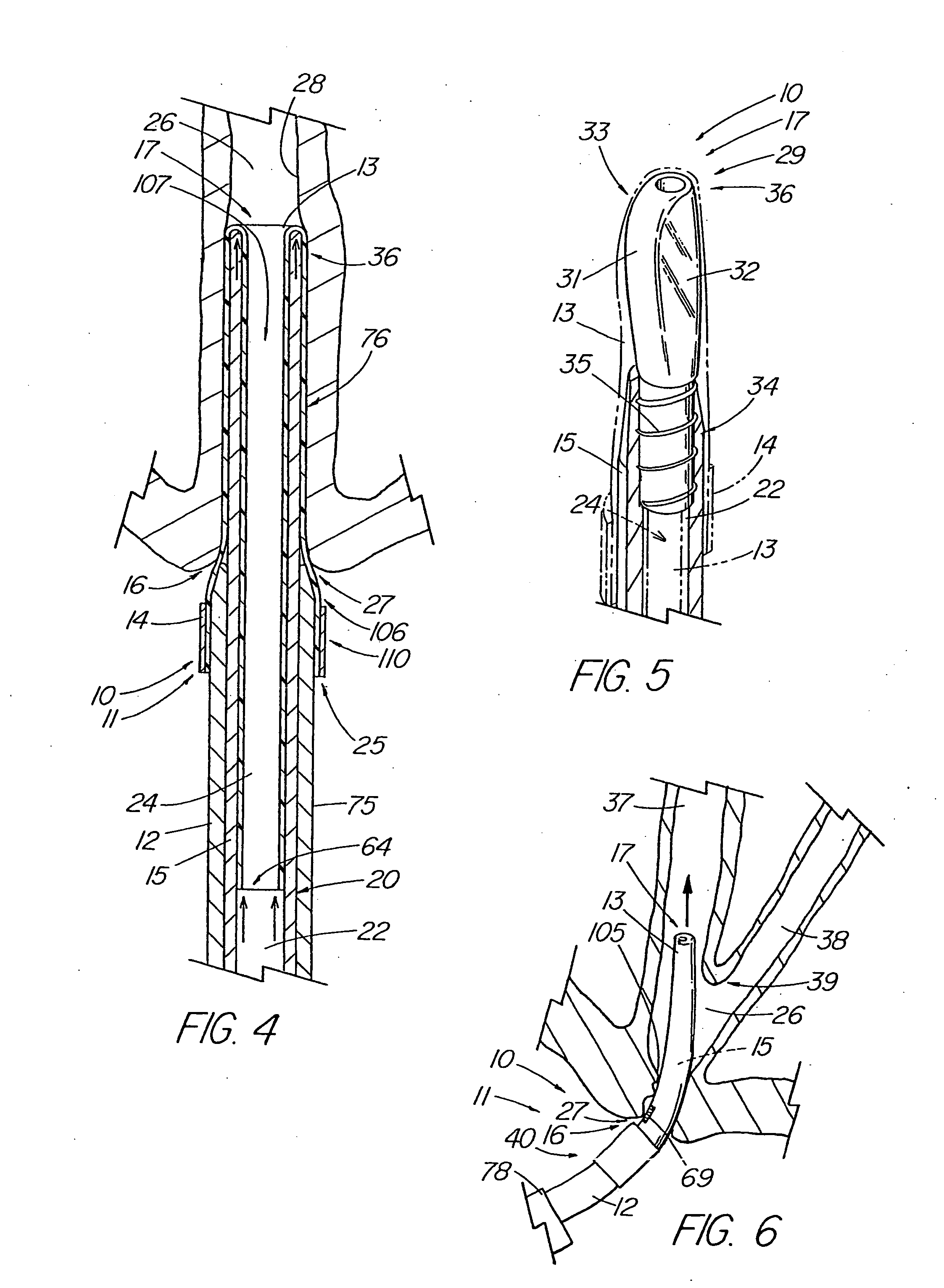

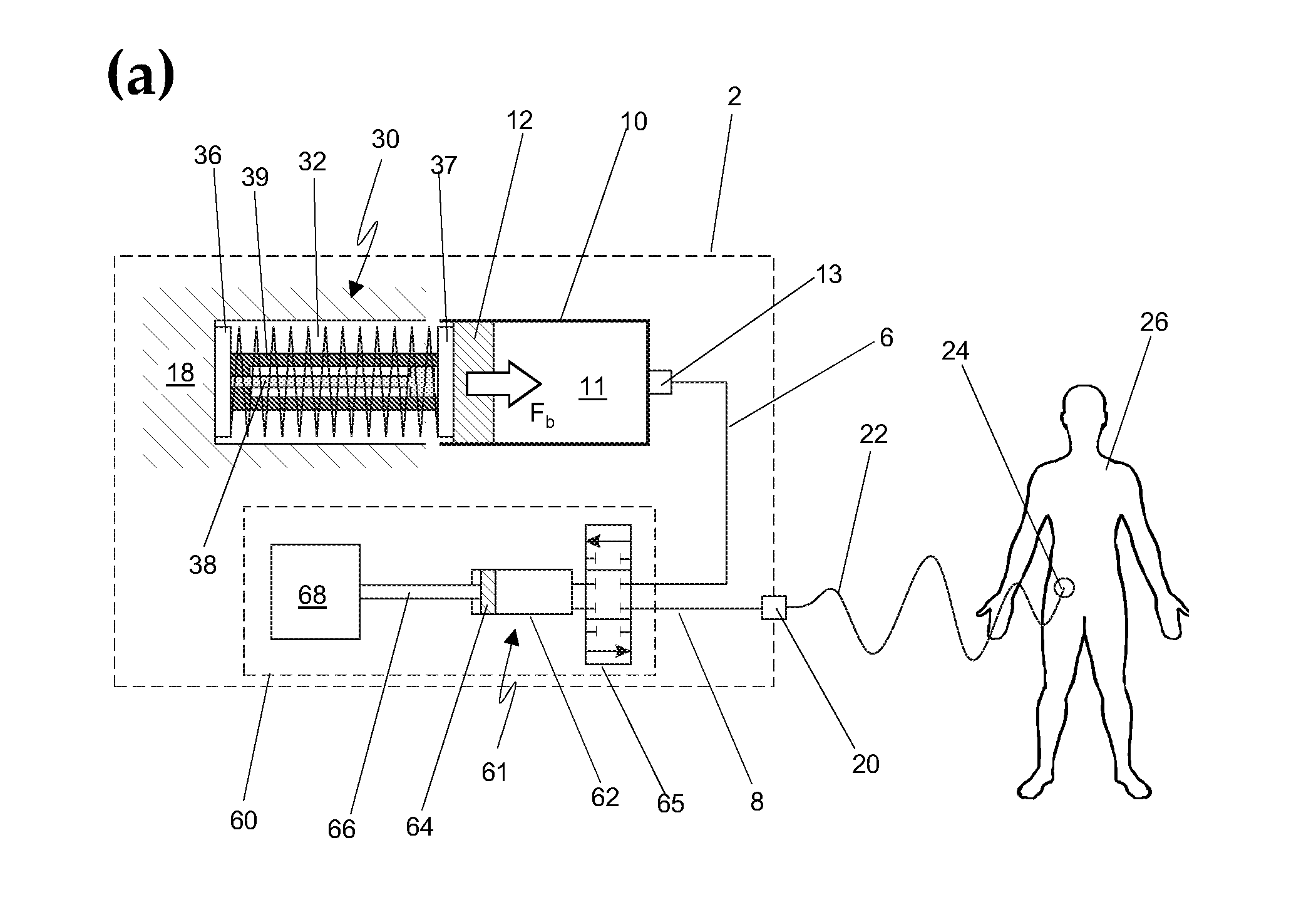

Treatment of infarct expansion by partially occluding vena cava

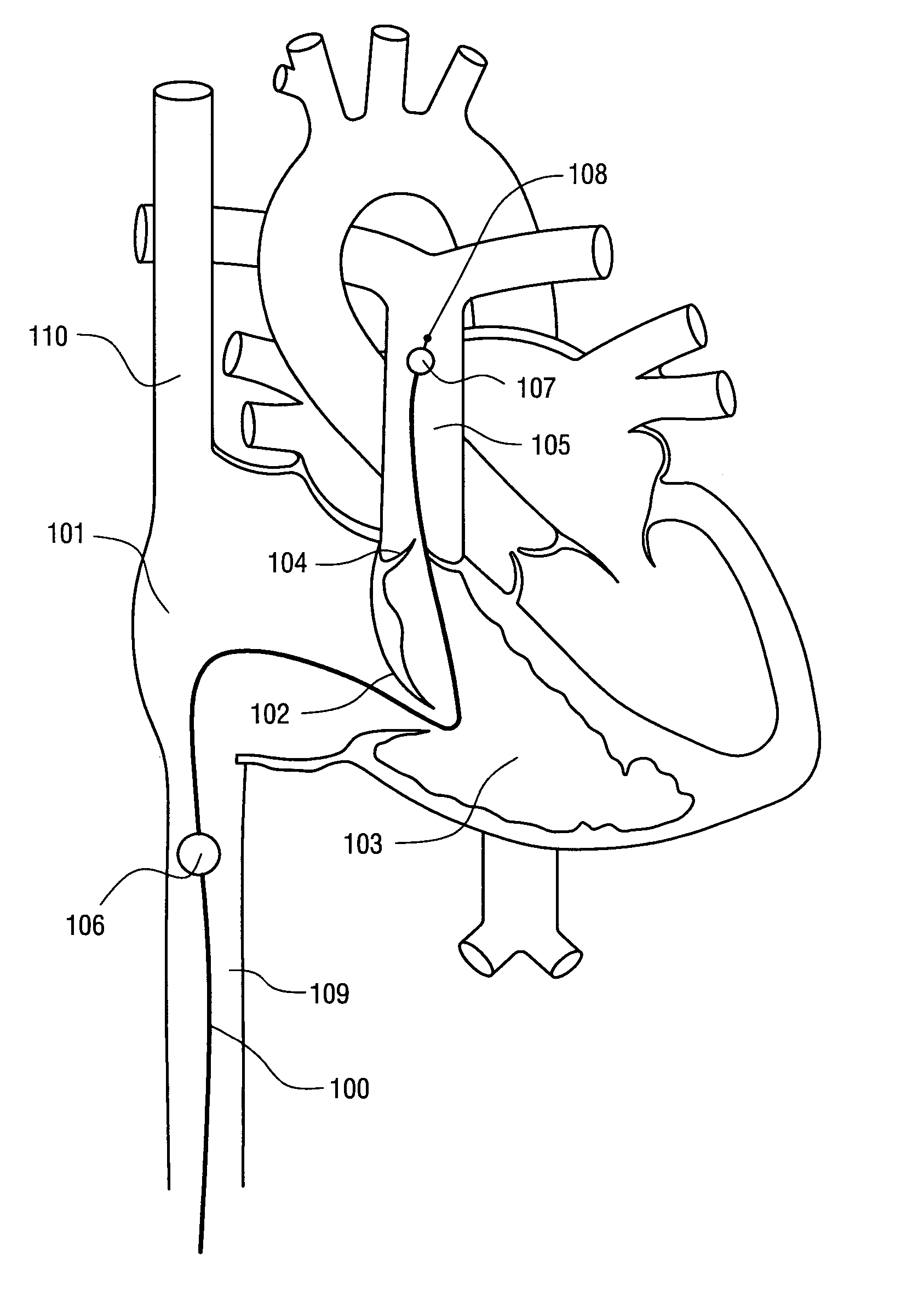

InactiveUS20060064059A1Reduces severity and complicationReduce expansionBalloon catheterSurgeryVeinVenous blood flow

A method and apparatus for prevention and reduction of myocardial infarct size and / or expansion and heart remodeling by partial, controllable and reversible obstruction of the venous blood flow to the heart. As a result, the ventricular wall stress and dilation are reduced. Blood flow is maintained at a safe level for the duration of treatment. The apparatus consists of a catheter with an occlusion balloon and a control and monitoring system.

Owner:GELFAND MARK +1

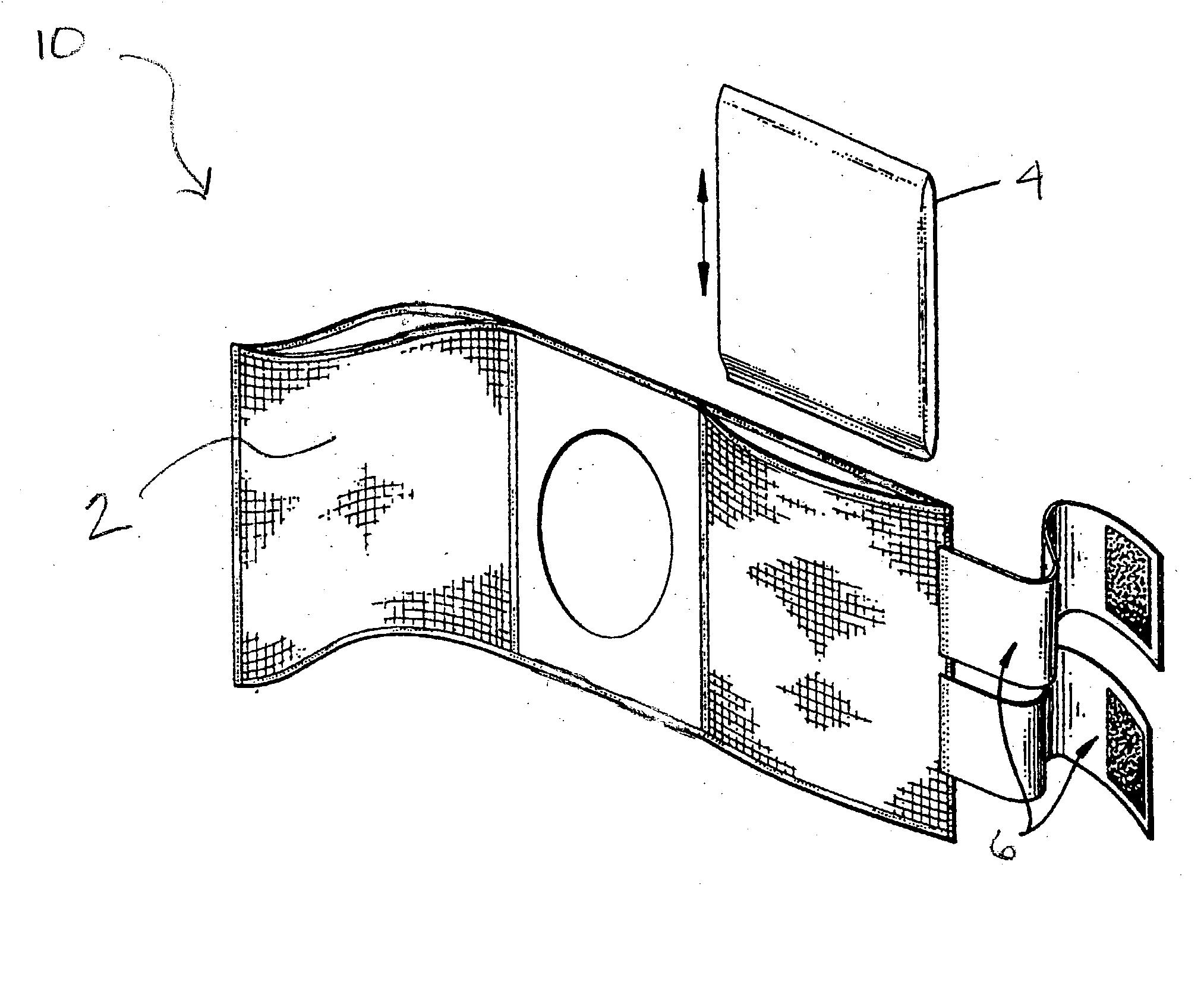

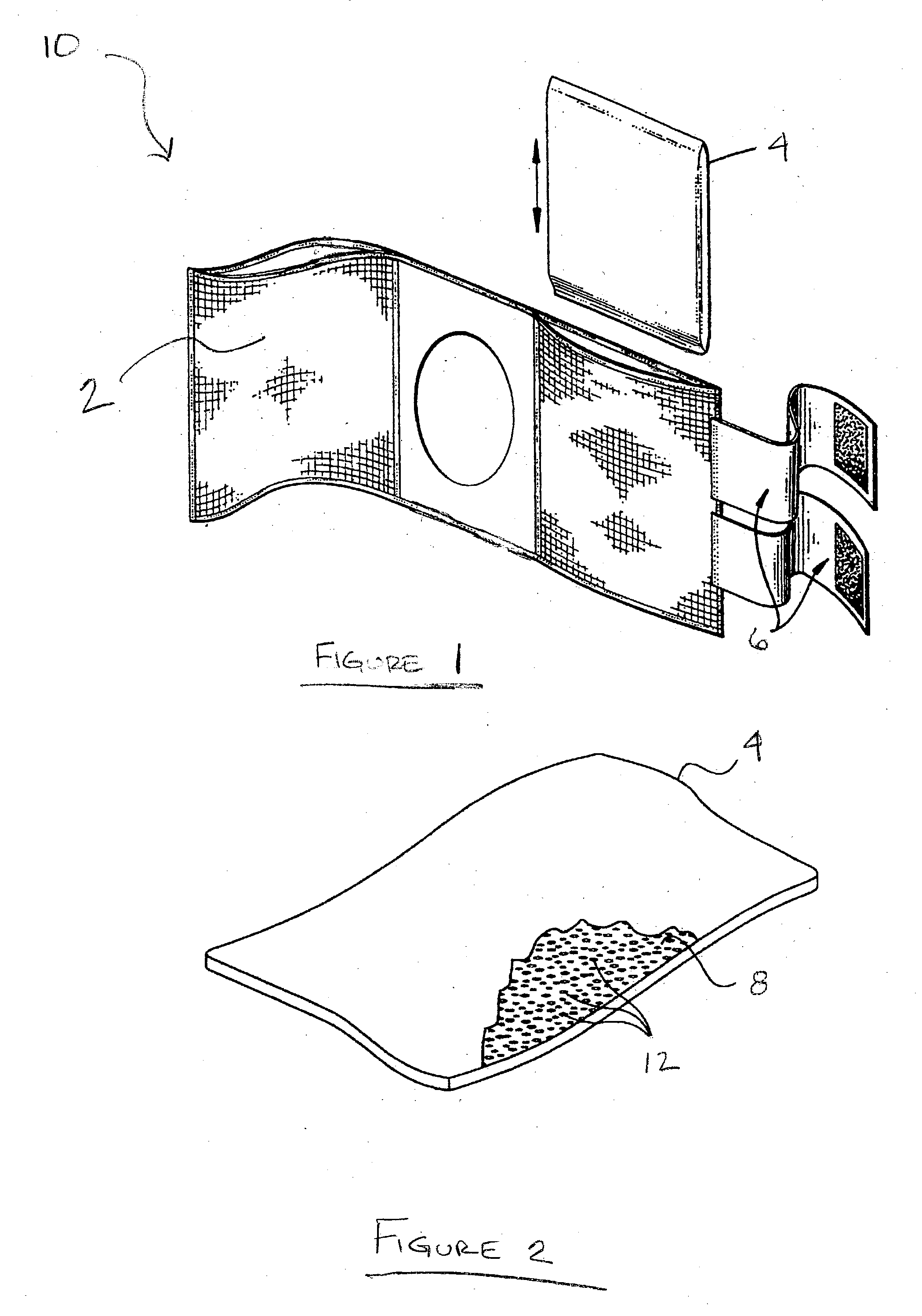

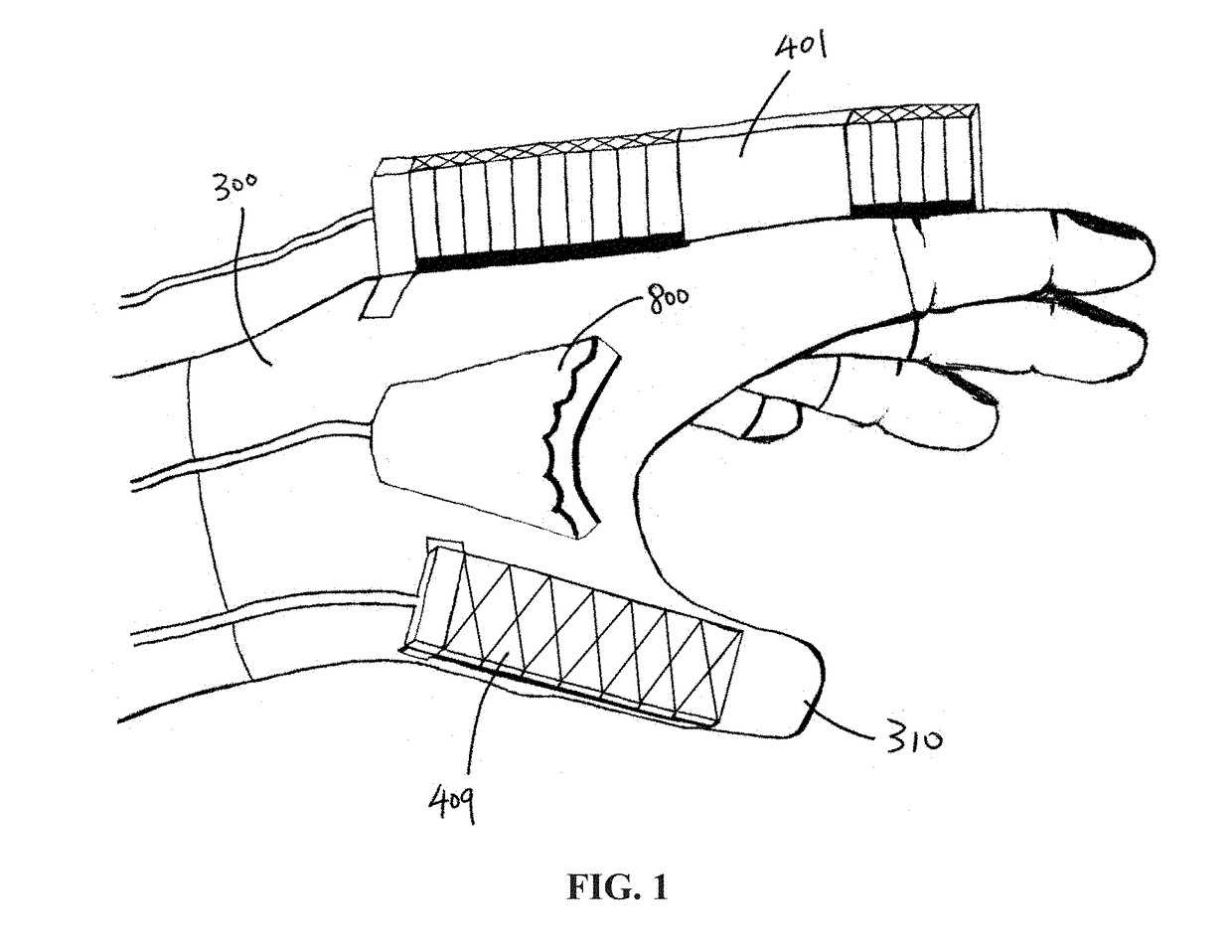

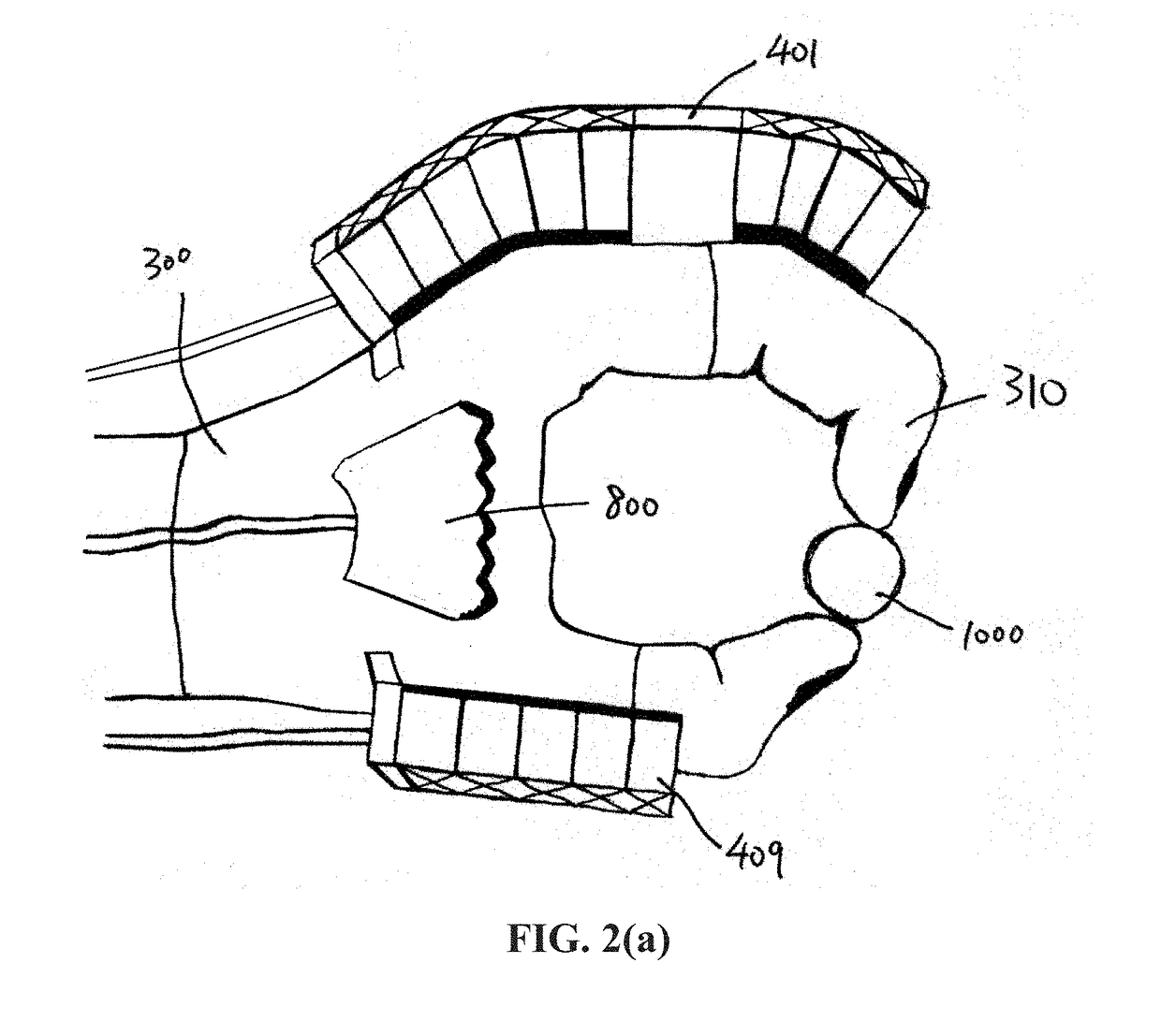

Portable cooling or heating device for applying cryotherapy

InactiveUS20040210287A1Maintain a constant temperatureLimit bruising and swellingTherapeutic coolingTherapeutic heatingBody regionCryotherapy

An apparatus used to apply cryotherapy comprising at least one gel pack of a predetermined size and predetermined shape, a retaining means of a predetermined size and predetermined shape which is engageable with at least a portion of a gel pack and at least a portion of a body part for retaining the gel pack in any desired orientation while being disposed on the body part. It also includes at least one variable temperature means that is engageable with at least a portion of the gel pack for sustaining a predetermined temperature the gel pack during a predetermined time period.

Owner:GREENE JUDY L

Devices and methods for crossing a chronic total occlusion

A catheter comprises an elongate tubular member having a proximal end and a distal end, and a deflectable tip at the distal end of the elongate tubular member. The deflectable tip comprises a first helical coil having a first diameter and a second helical coil having a second diameter, the first diameter being larger than the second diameter. The first and second helical coils are arranged in the manner of a double helix. When viewed in cross-section, the first helical coil and the second helical coil are aligned at a first point on a circumference of each coil and misaligned at a second point on the circumference of each coil, where the second point is approximately 180 degrees from the first point. In certain embodiments the catheter further includes a dilatation balloon. Methods of use for crossing a chronic total occlusion are also described.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC +1

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

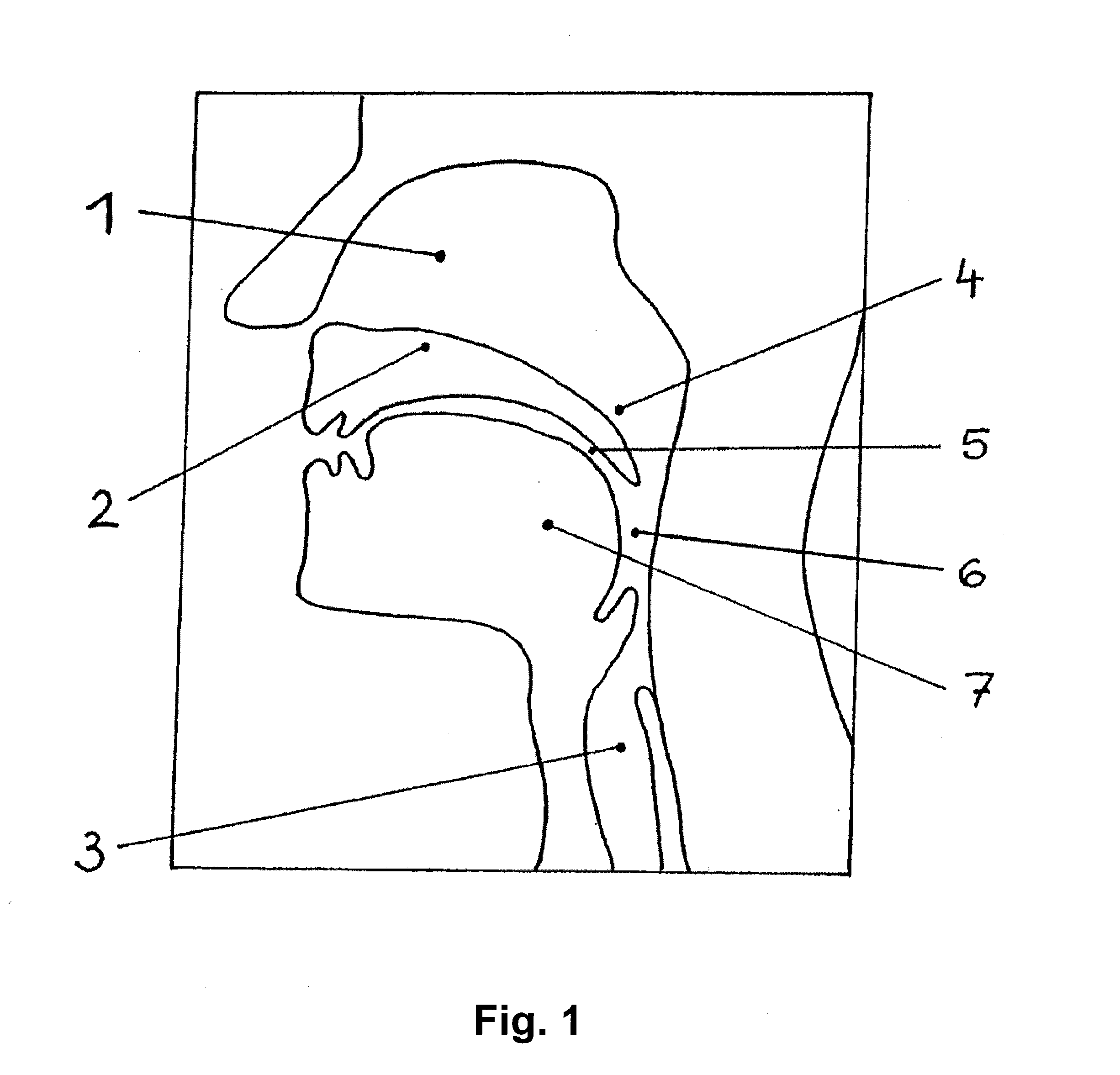

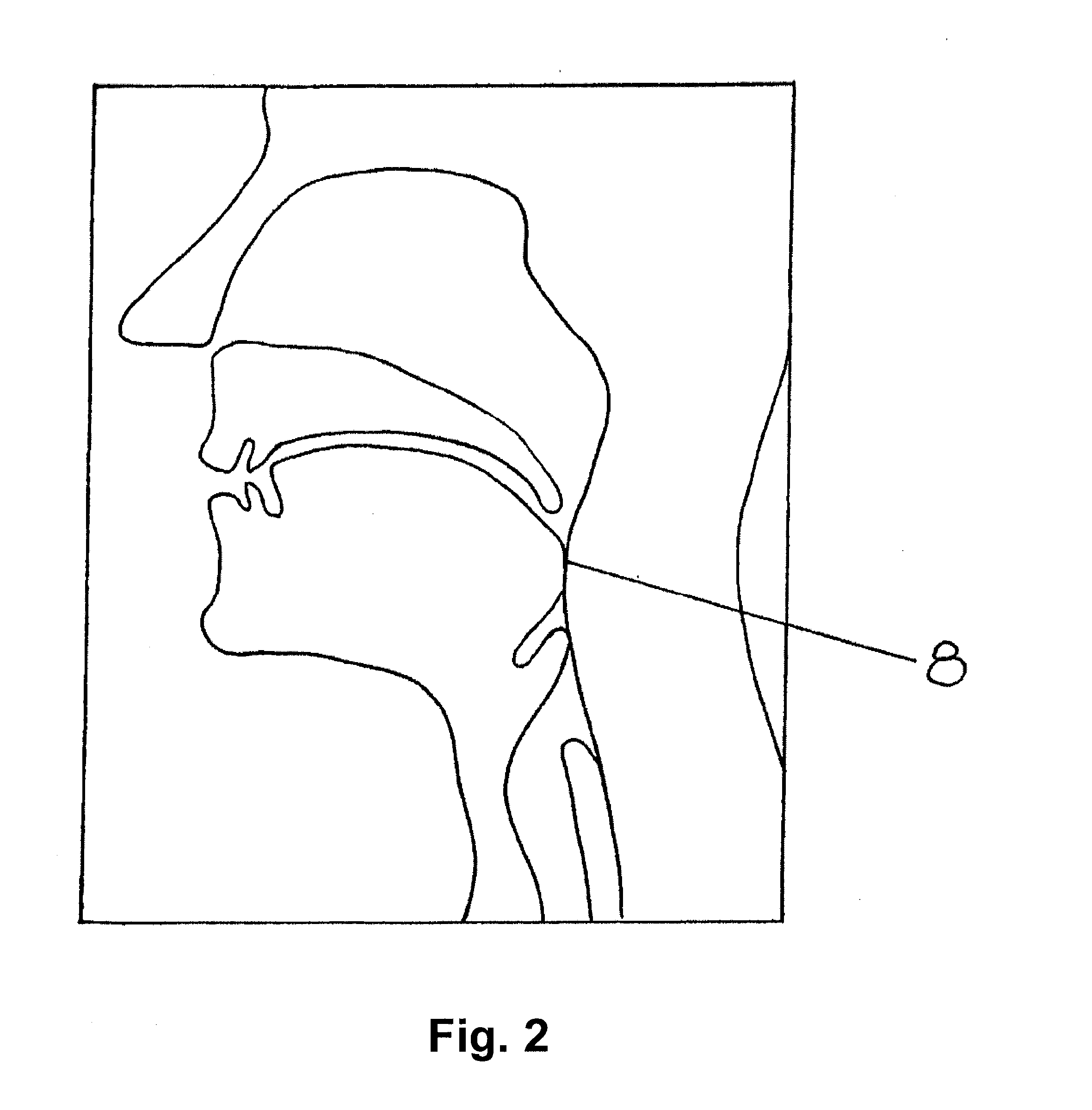

Introducer apparatus with eversible sleeve

InactiveUS20060173422A1Control expansionReduce patient discomfortGuide needlesStentsNasal passageNasal passages

Disclosed is an introducer apparatus comprising an sleeve fixation mechanism or introducer member, such as a catheter, introducer, or ring-like structure, which is attached to a protective sleeve comprising a thin flexible material such a polymeric film. The sleeve is inverted into the passageway of a second member, such as a catheter, feeding tube, introducer, etc., that is advanced through the passageway of the introducer member and is introduced into a bodily passage of a patient, such as the bile duct, nasal passages, colon, etc. The sleeve everts from the passageway of the second member during its advancement to lay down a friction-reducing surface. The sleeve prevents frictional contact between the second member and delicate or sensitive tissues.

Owner:COOK MEDICAL TECH LLC

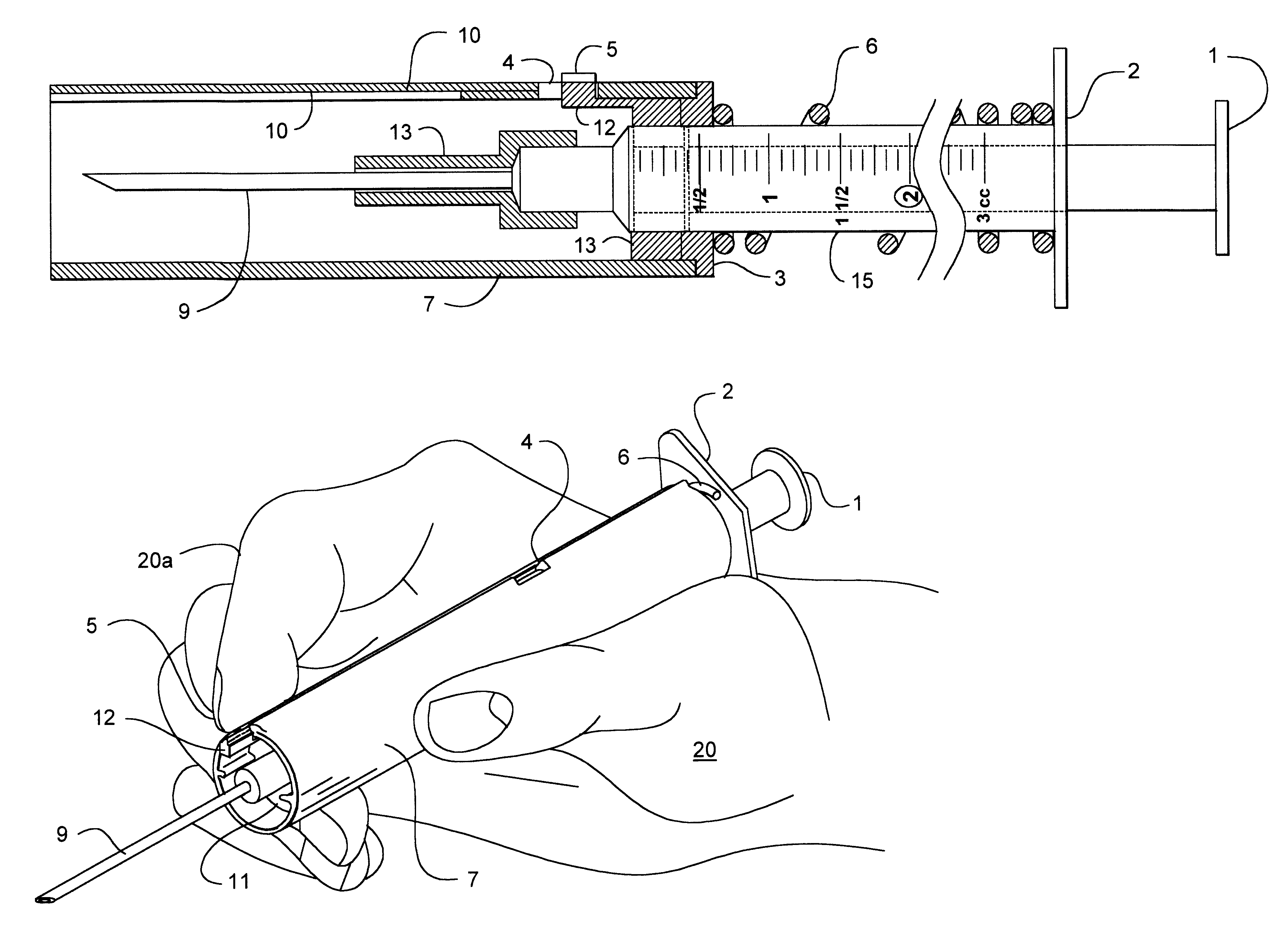

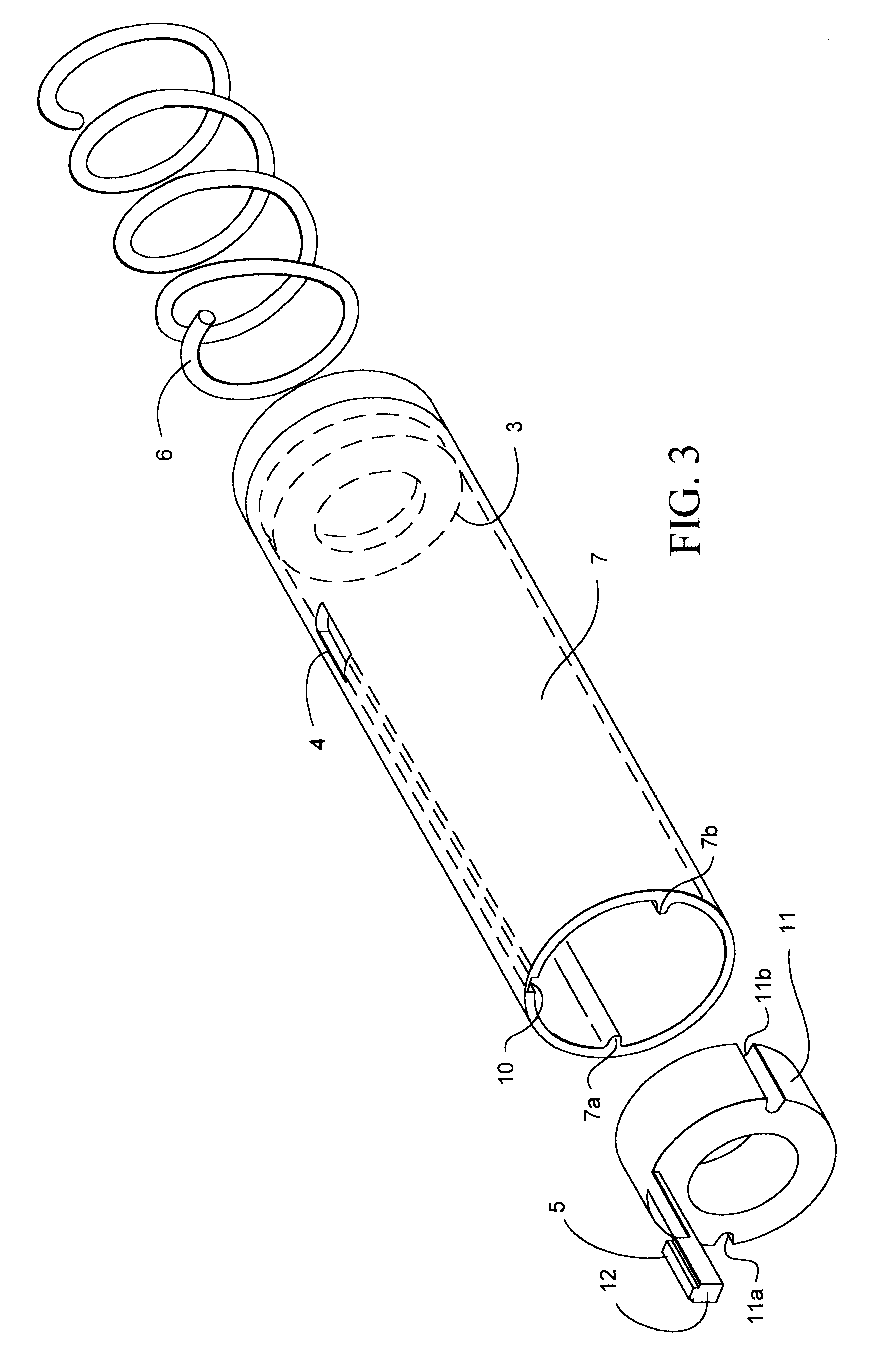

Safe needle device for syringe

A needle stick safety syringe includes a outer tubular protective cover or sleeve for the inner syringe body where a concentric coil spring is compressed against the normal flange of the inner syringe body and retained there by a stop which is cantilevered from a collar affixed to the distal end of the inner syringe body. This cantilevered stop also includes a convenient button which may be easily depressed by a finger of one hand holding the outer tubular body to allow the sleeve to be slid over the needle under the bias of the spring. The cantilevered button and stop rides in a groove in the inner diameter of the tubular outer protective body and is captured by a slot which effectively prevents reuse.

Owner:INT TECH GROUP

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

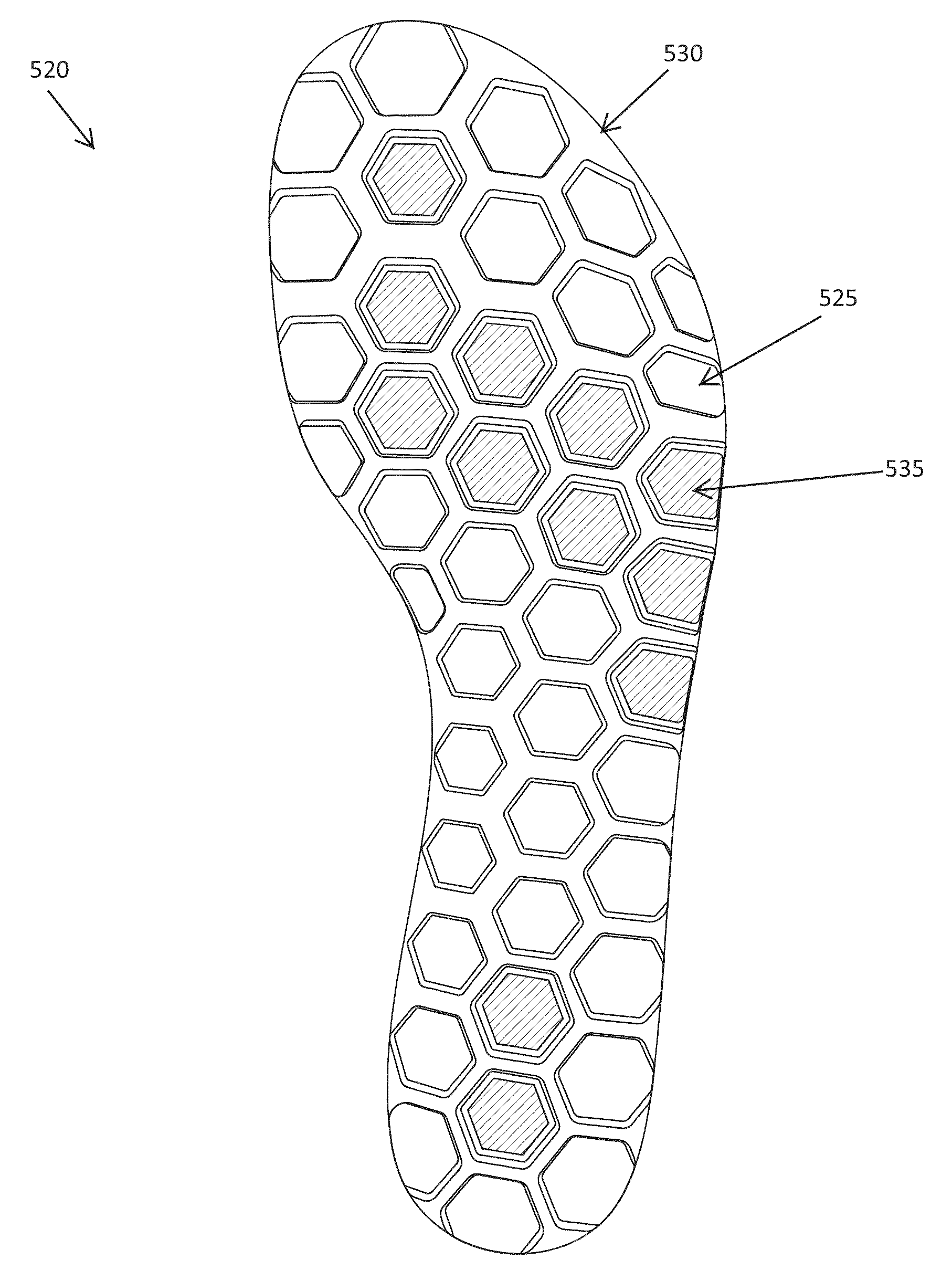

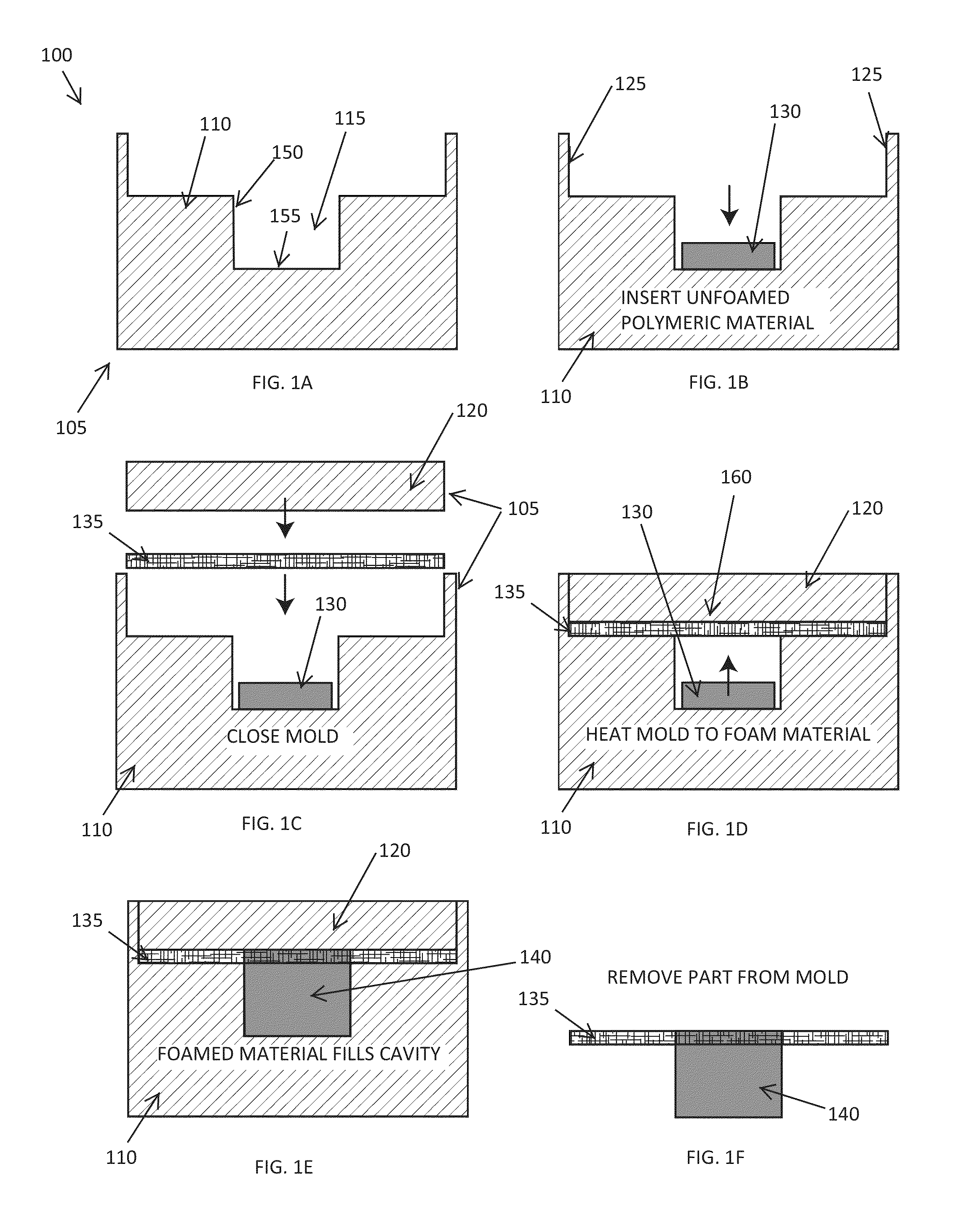

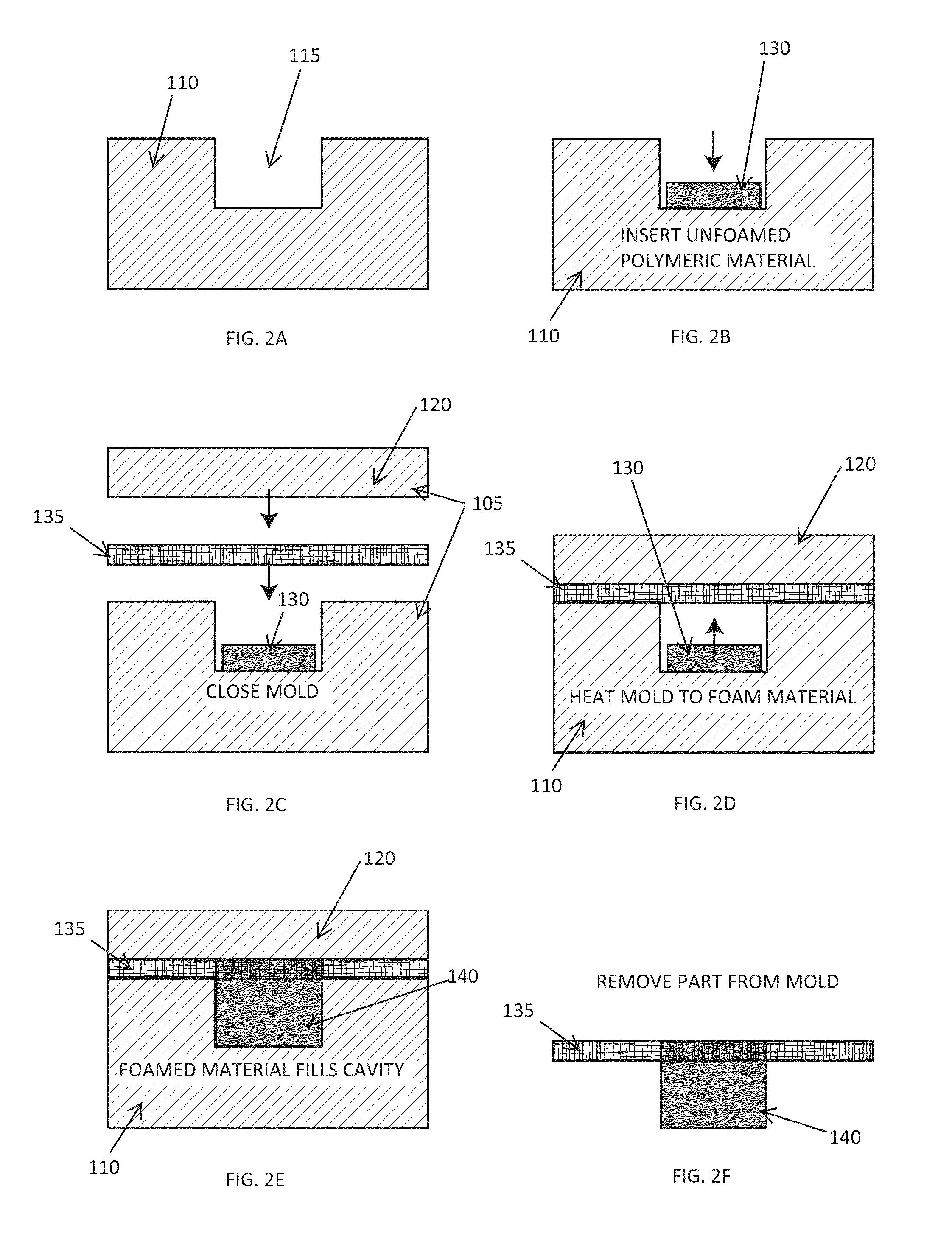

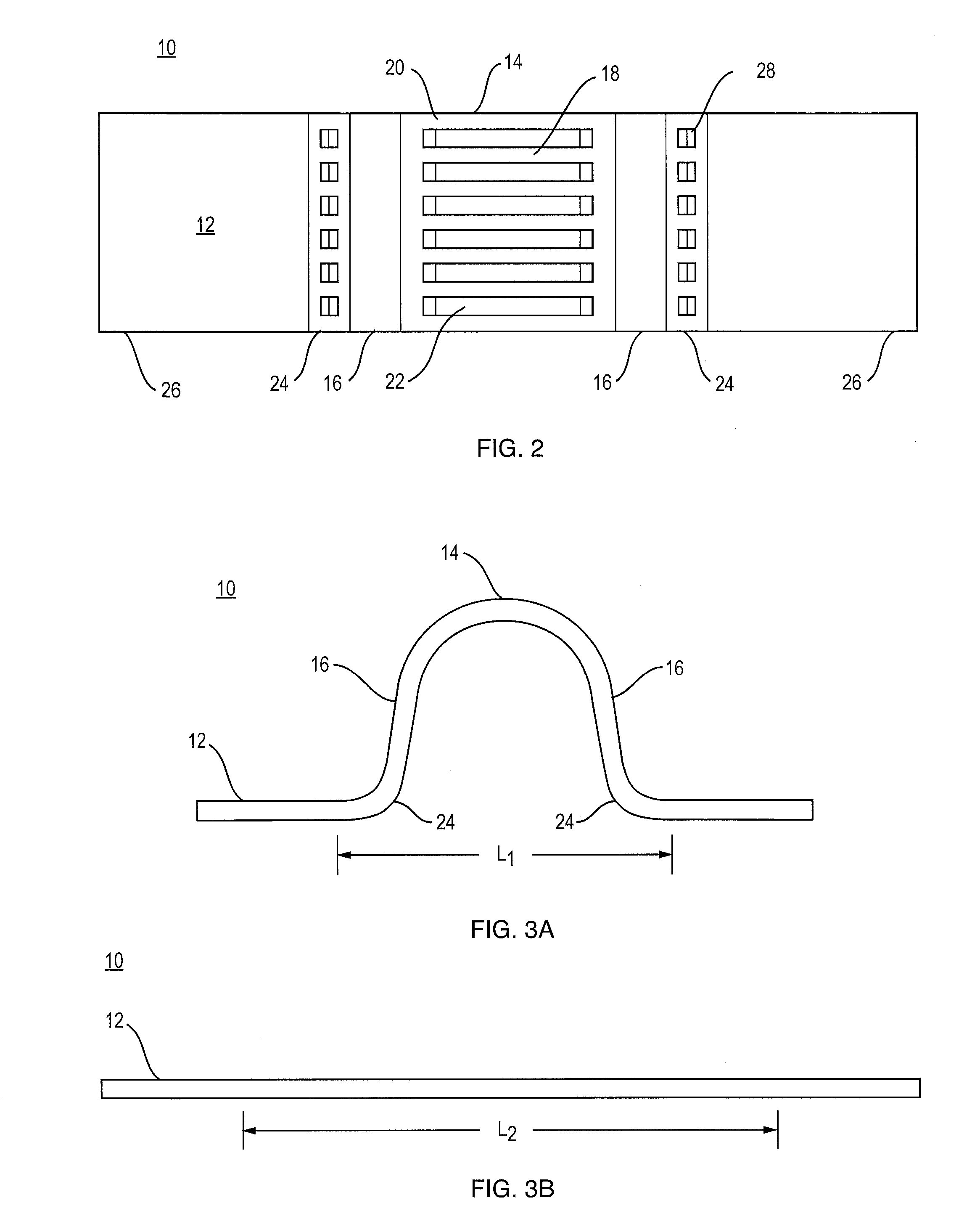

Foamed Parts Having a Fabric Component, and Systems and Methods for Manufacturing Same

The invention relates to parts having a foamed polymeric material attached to a fabric, and systems and methods for forming same. An example method of attaching foamed polymeric material to a fabric layer includes providing a mold having at least one cavity and at least one material injection channel in fluid communication with the cavity, disposing a fabric over the at least one cavity, closing the mold, injecting unfoamed polymeric material into the at least one cavity through the material injection channel, wherein the unfoamed polymeric material penetrates at least a portion of the fabric proximate the at least one cavity to attach the polymeric material to the fabric layer, and foaming the unfoamed polymeric material.

Owner:NEW BALANCE ATHLETICS

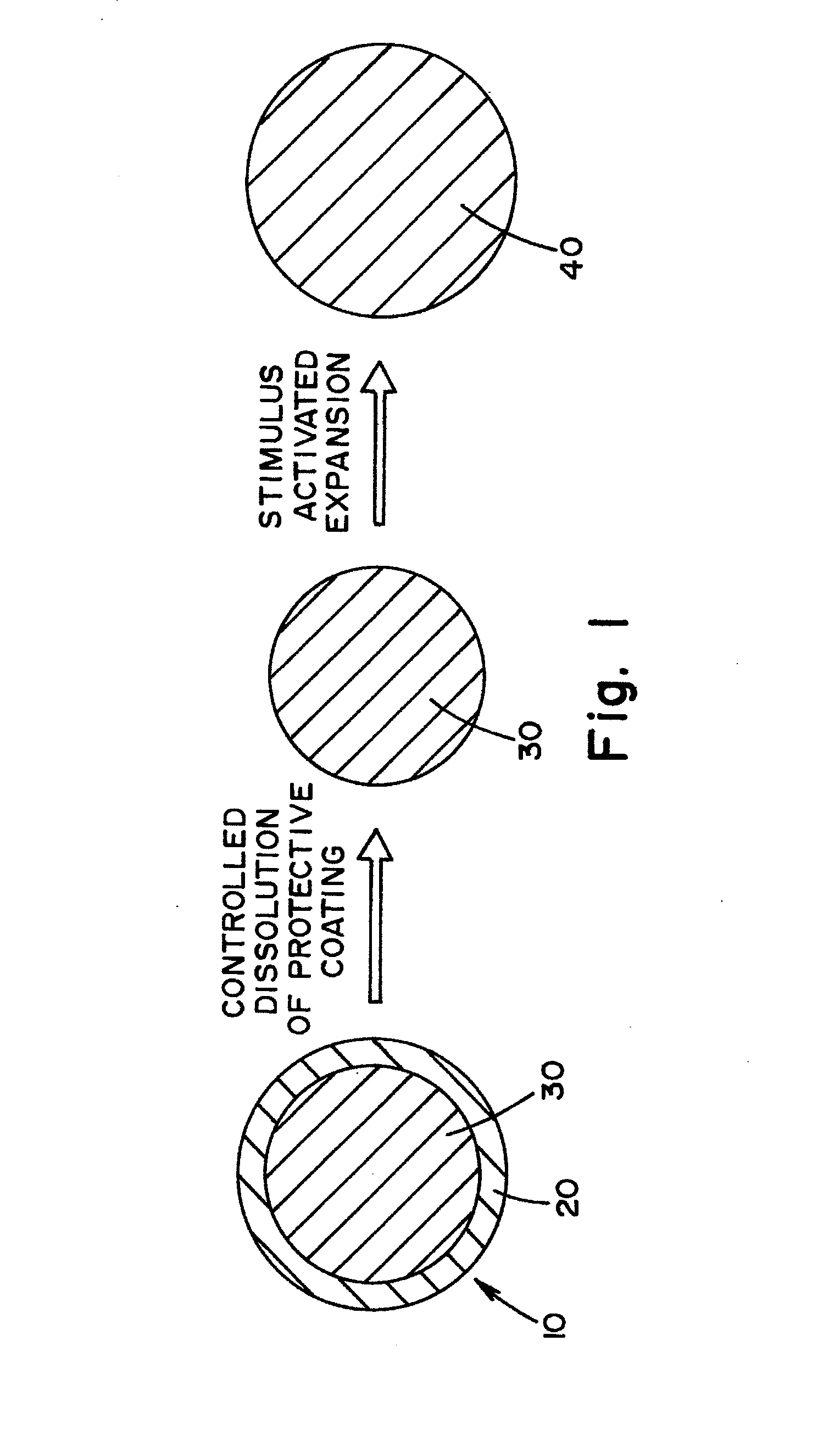

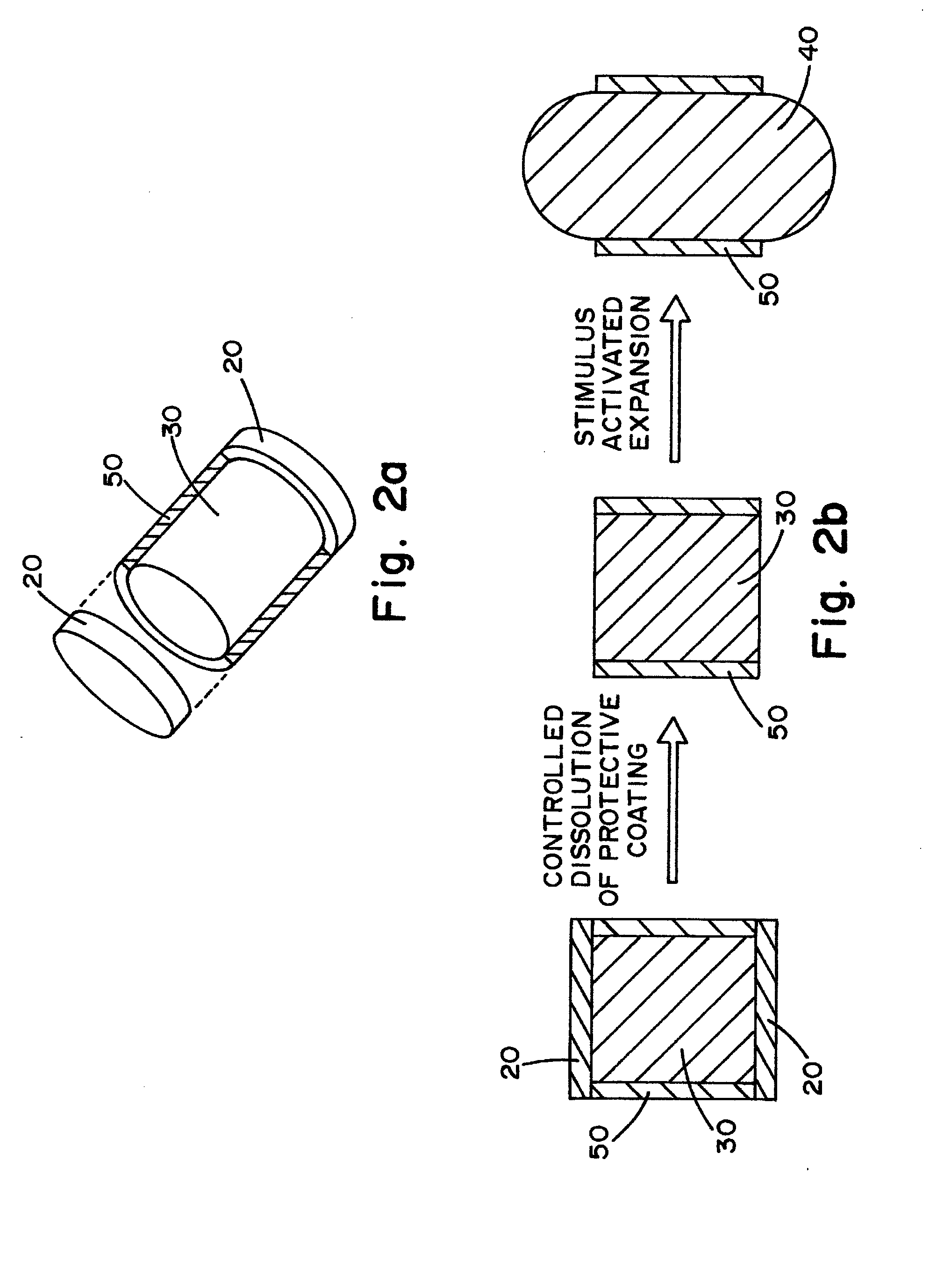

Structural Expandable Materials

ActiveUS20160137912A1Control expansionReduce the amount of waterFluid removalFlushingMaterials scienceChemical change

A composite particle that incorporates a material and is designed to undergo a reaction and / or mechanical or chemical change with the environment to increase in volume. The composite particle can be combined with a constraining matrix to create an expandable particle upon reaction. These particles can be used in stimulating wells, including oil and gas reservoirs.

Owner:POWDERMET

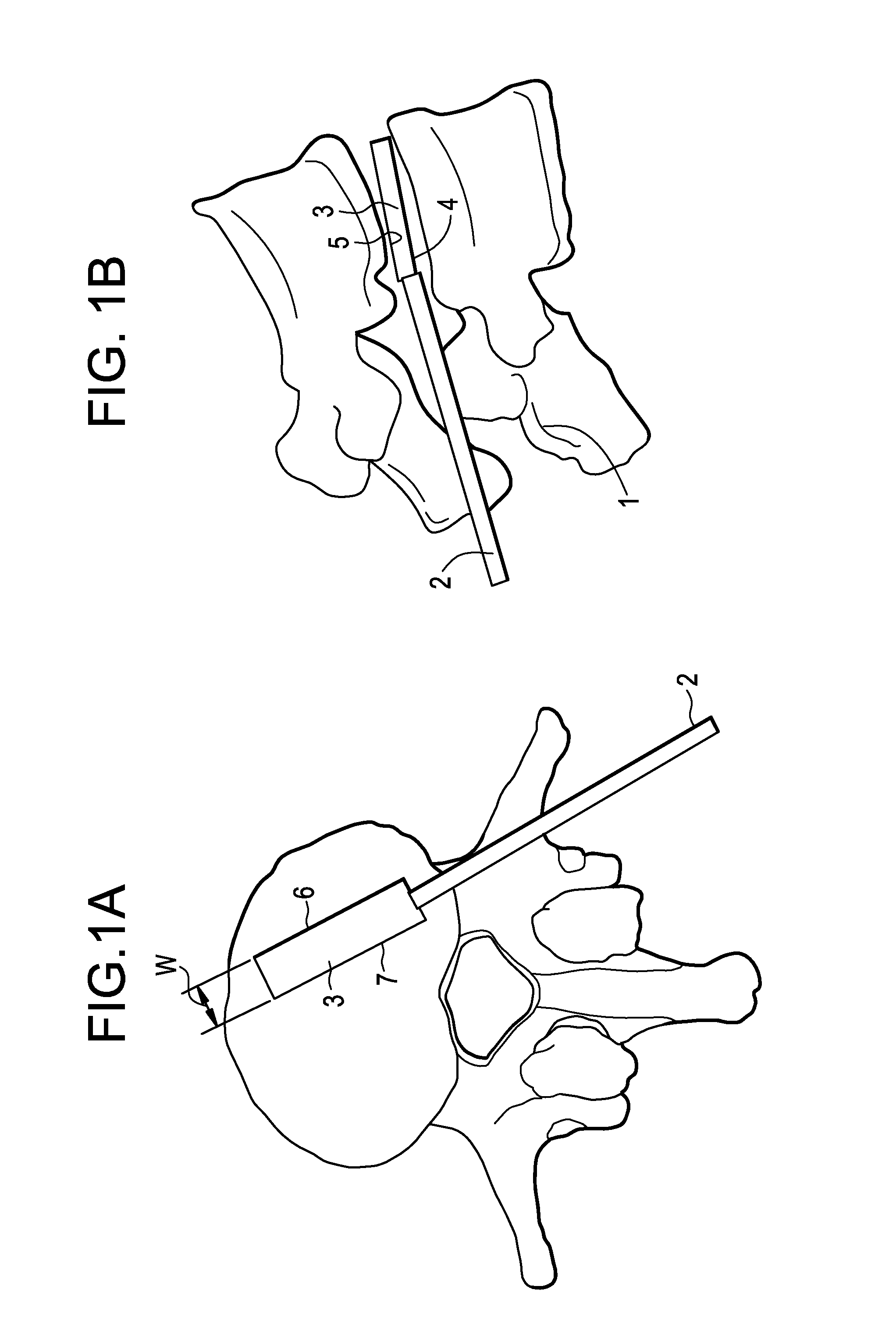

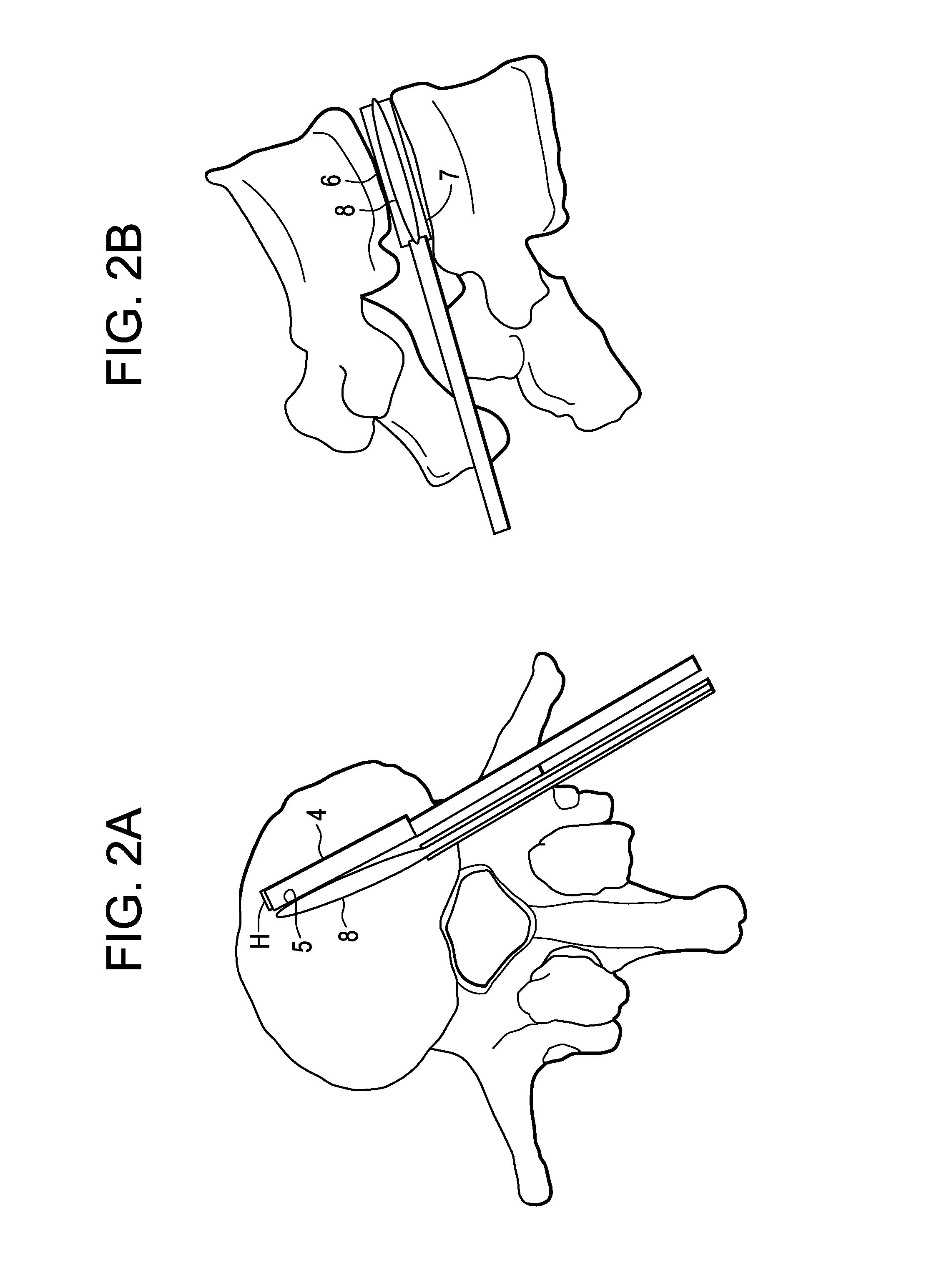

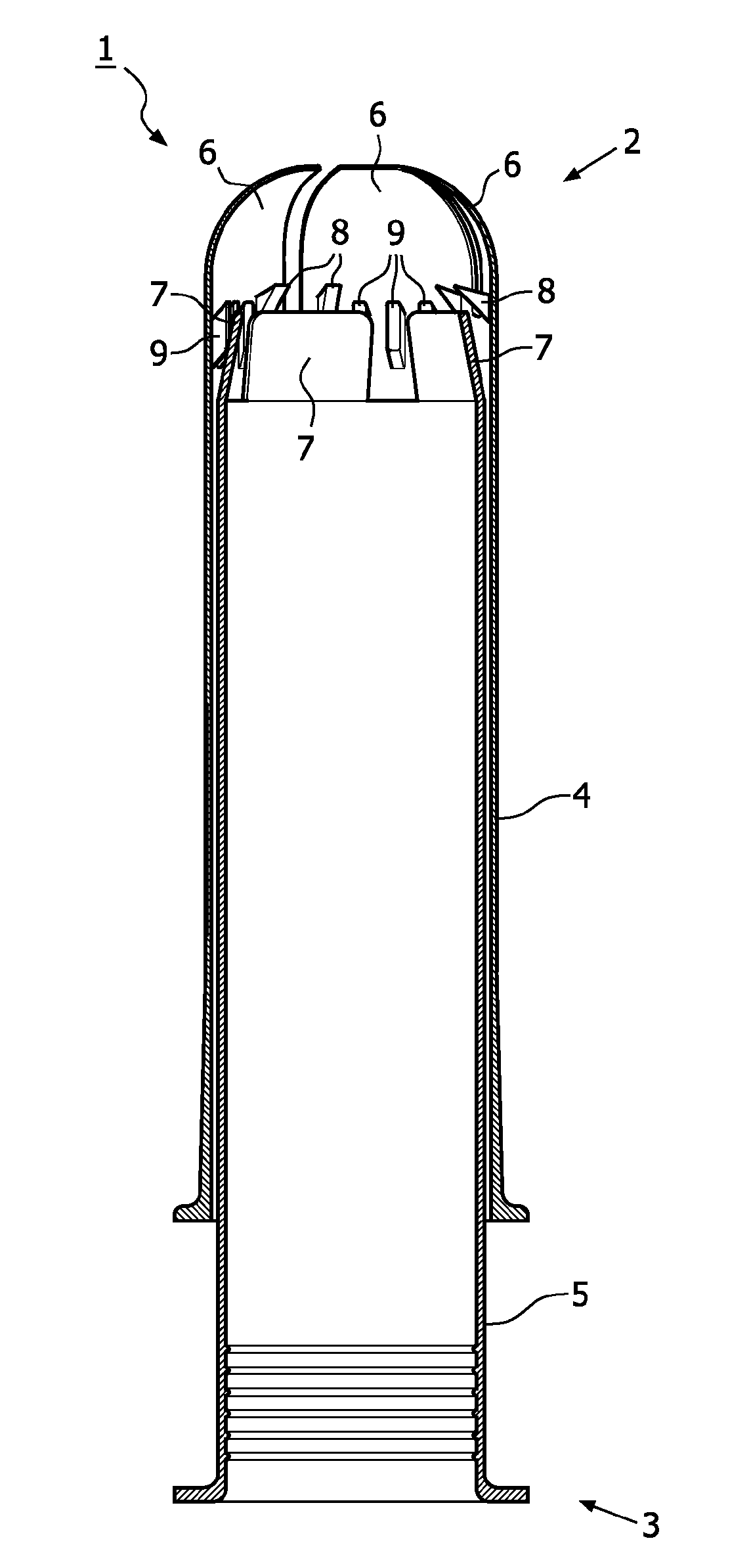

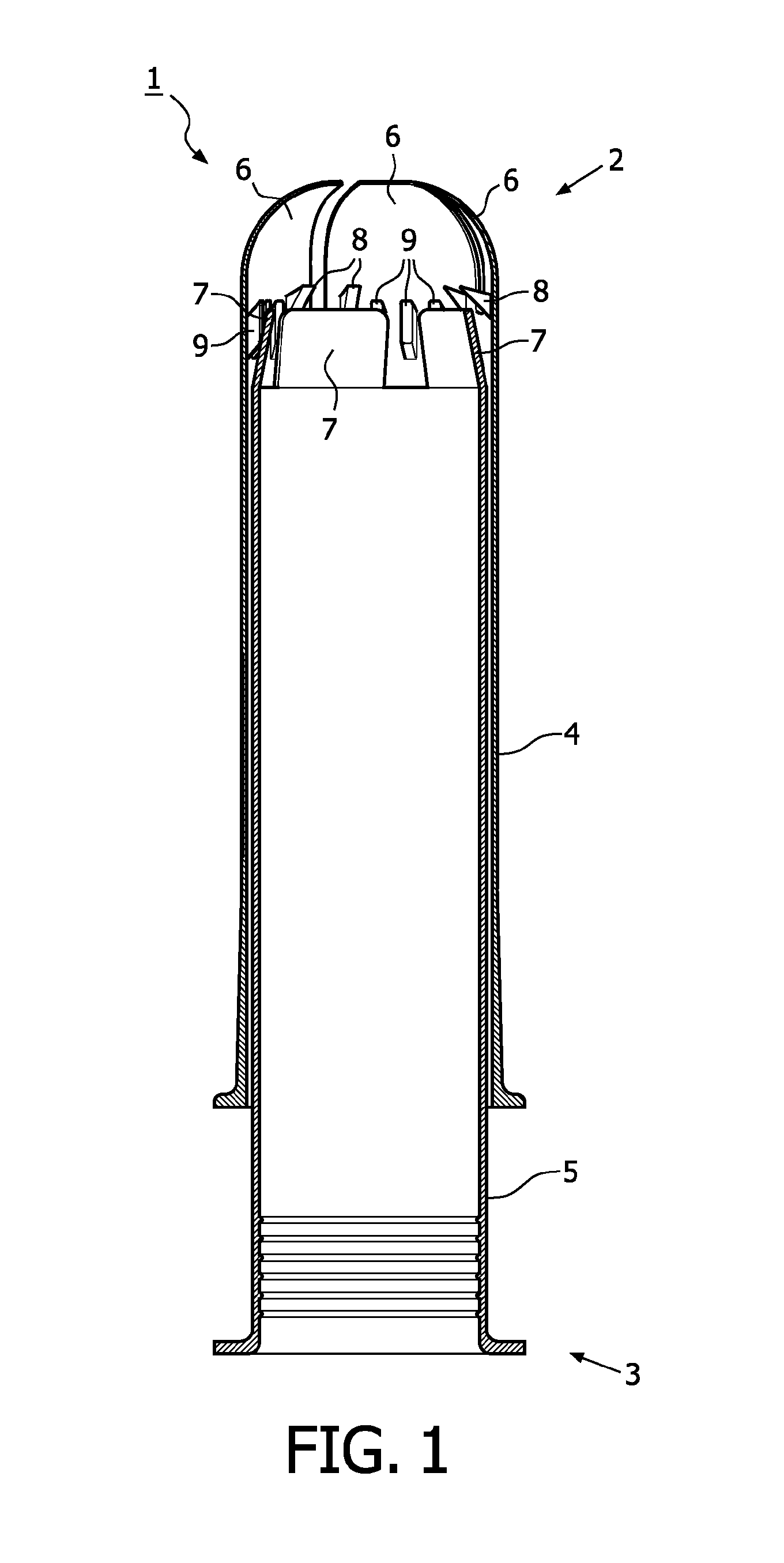

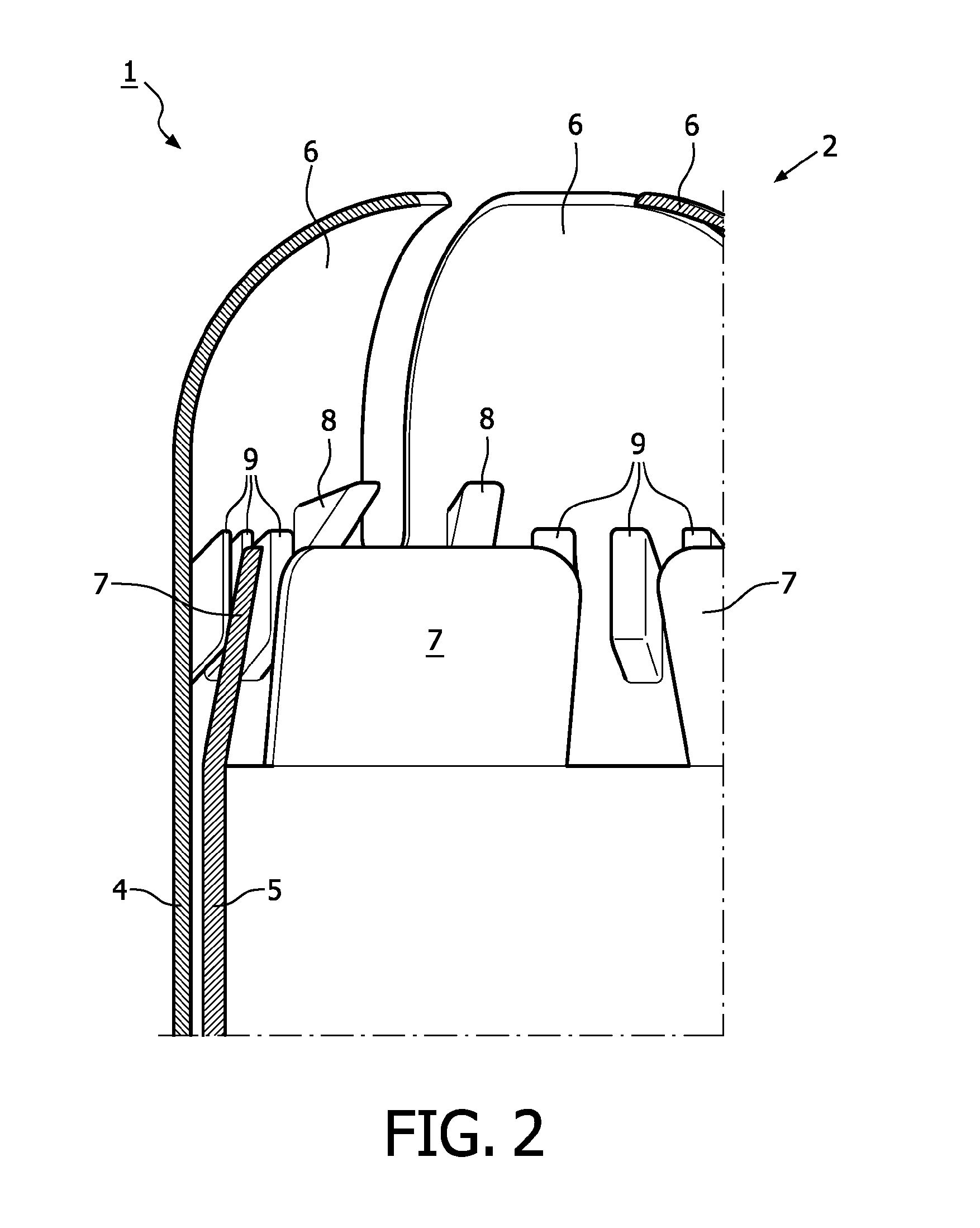

Balloon With Shape Control For Spinal Procedures

InactiveUS20090088789A1Limit radial expansionRegain even more disc heightBalloon catheterDilatorsDividing attentionSurgery spine

In intervertebral operative spinal procedures, using separate or pre-attached spreader blocks to control the directional growth of a distracting balloon.

Owner:DEPUY SYNTHES PROD INC

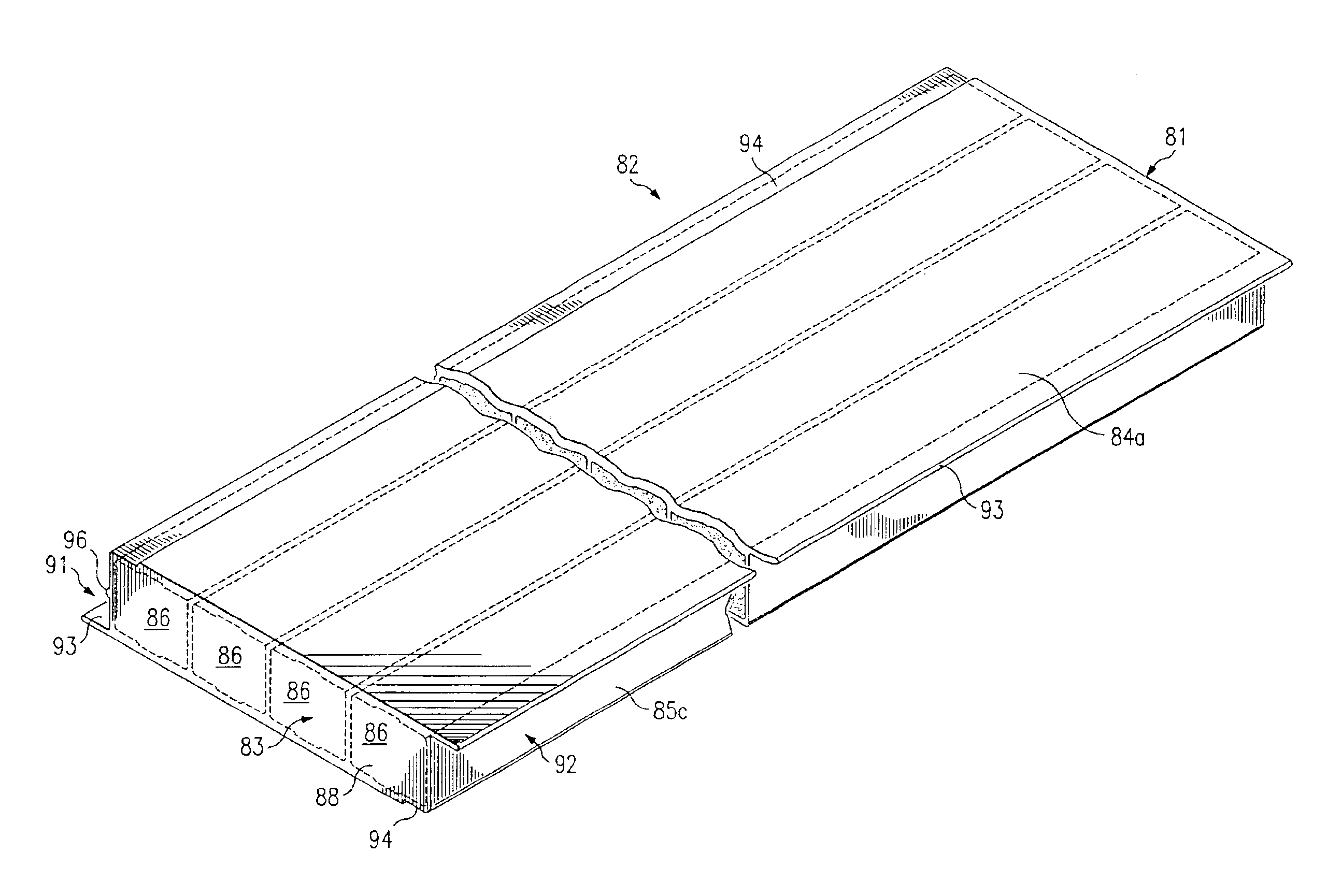

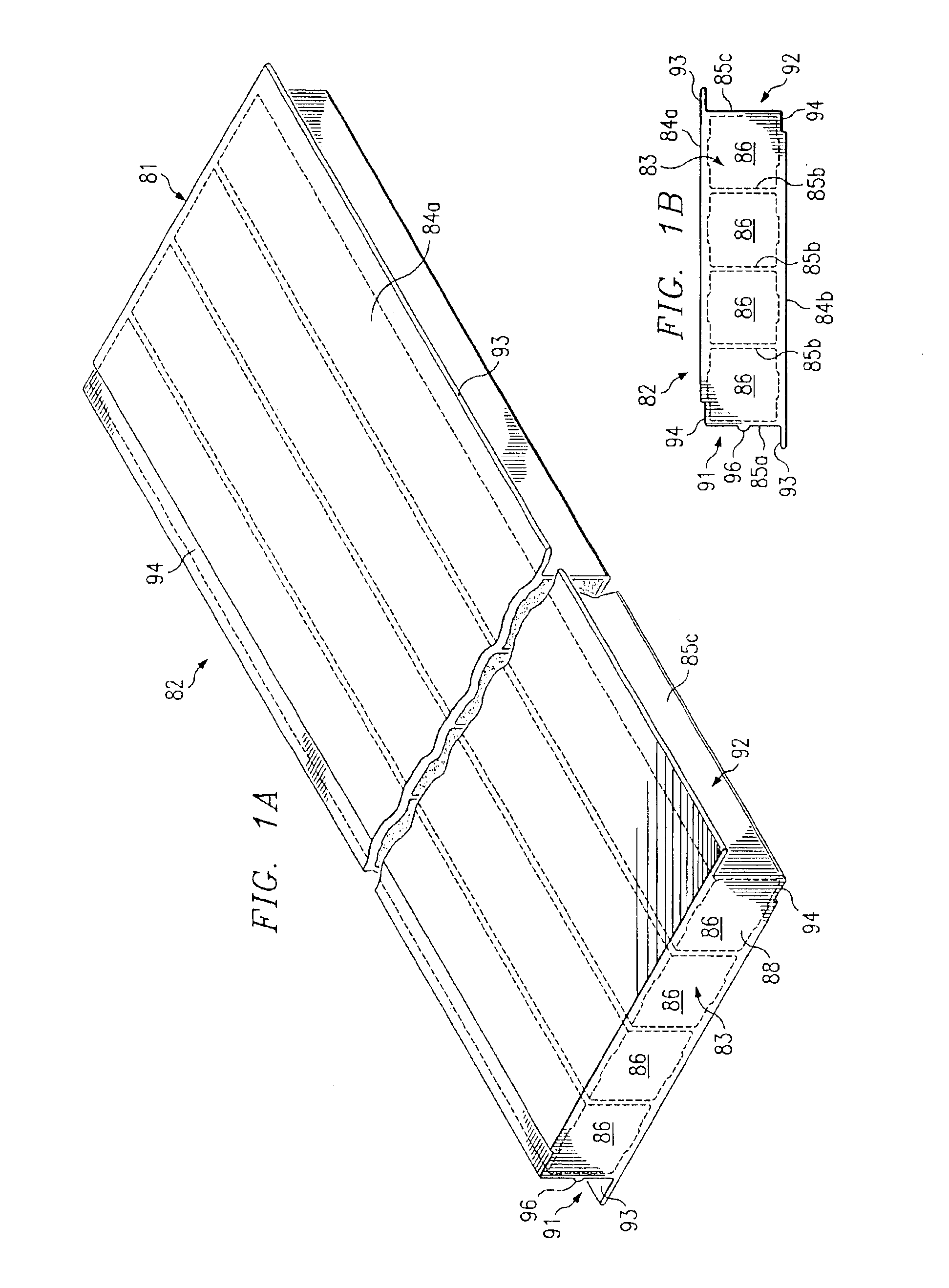

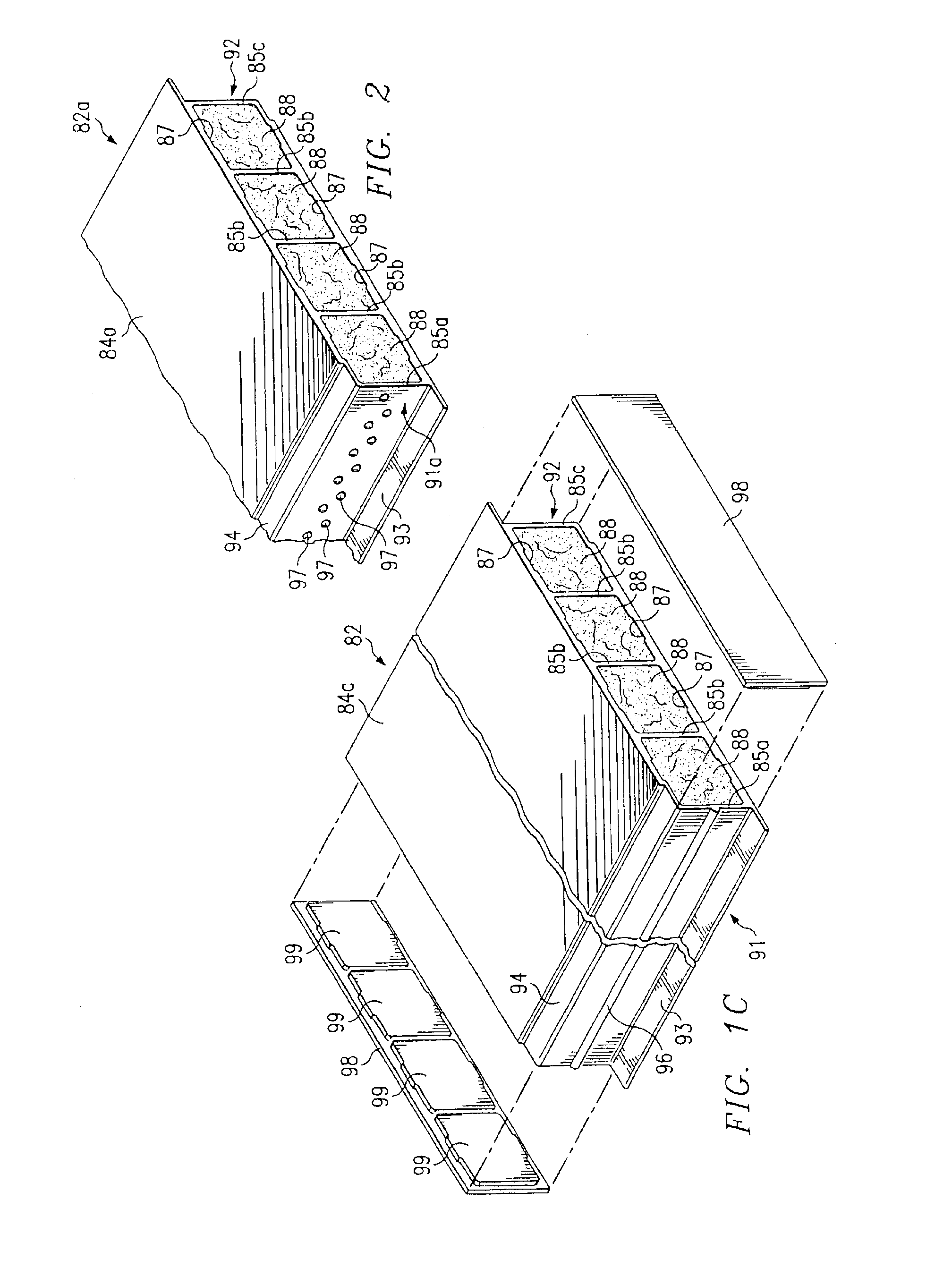

Pultruded panel

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

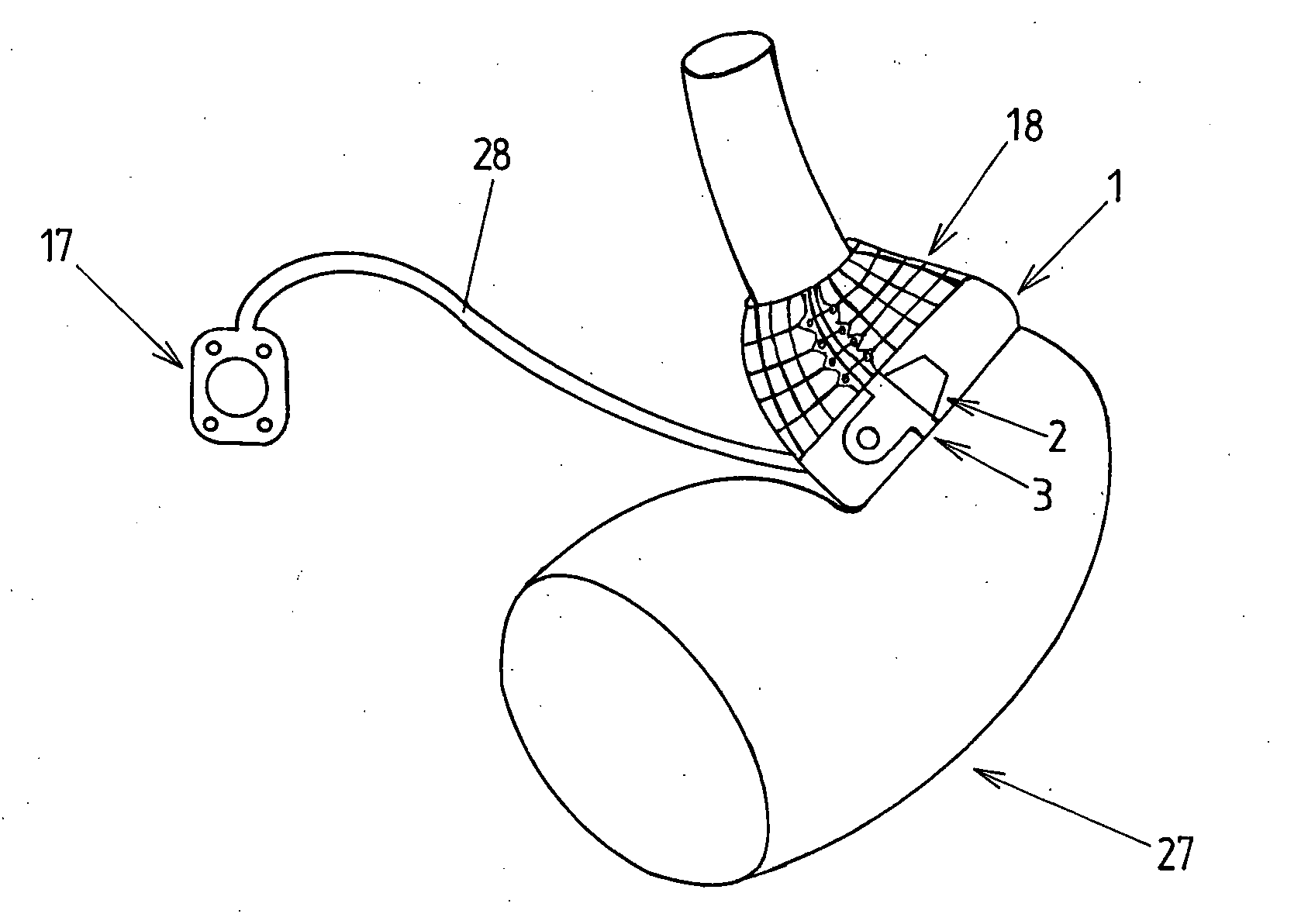

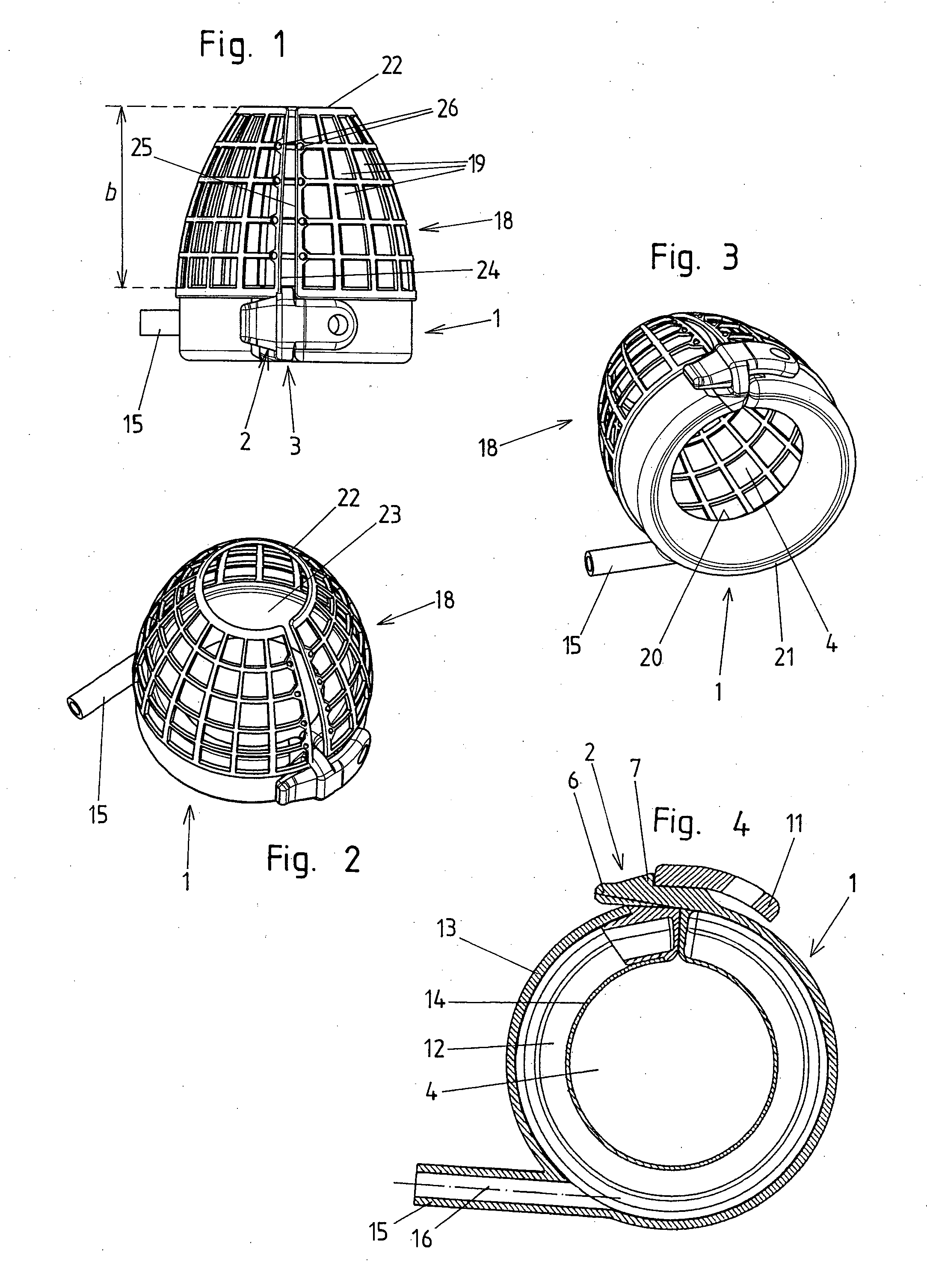

Device for splinting a cavity, organ duct and/or vessel

ActiveUS20130090720A1Easy to disassembleEasy to insertMechanical cleaningPressure cleaningSurgeryAnimal body

The invention relates to a device for splinting and / or maintaining a cavity, an organ duct and or a vessel in a human or animal body, said device including at least one compressible and self-expanding stent that is composed of at least three phases.

Owner:DURING KLAUS

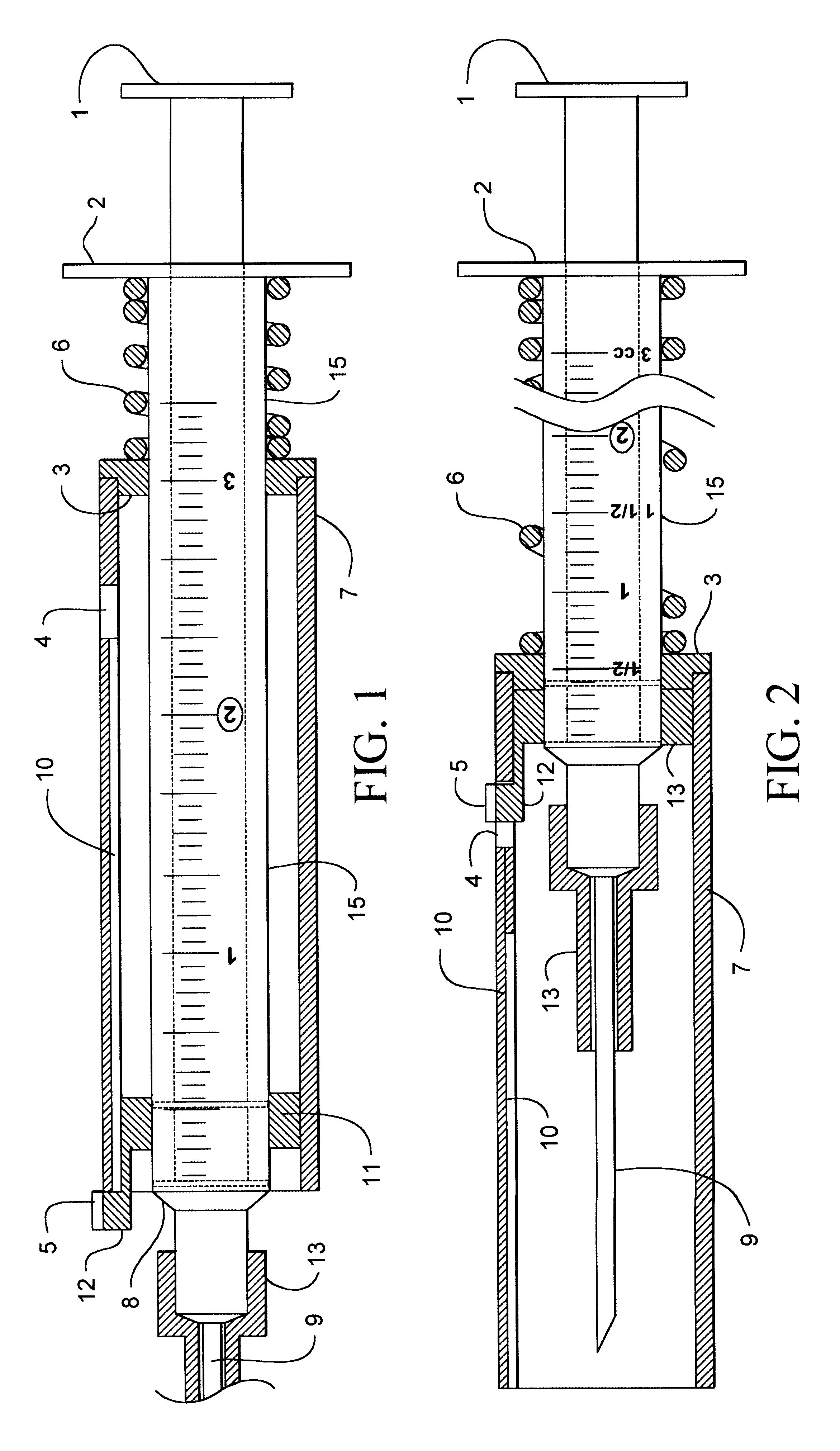

Spring force assembly for biasing or actuating stoppers of syringes, injection pen cartridges and the like

A spring force assembly for biasing a displaceable stopper of a liquid medicament cartridge including a spring element arranged along a longitudinal axis, with brace elements and coupling elements, with the coupling elements restricting the distance between the brace elements which also restricts the possible expansion of the spring element.

Owner:ROCHE DIABETES CARE INC

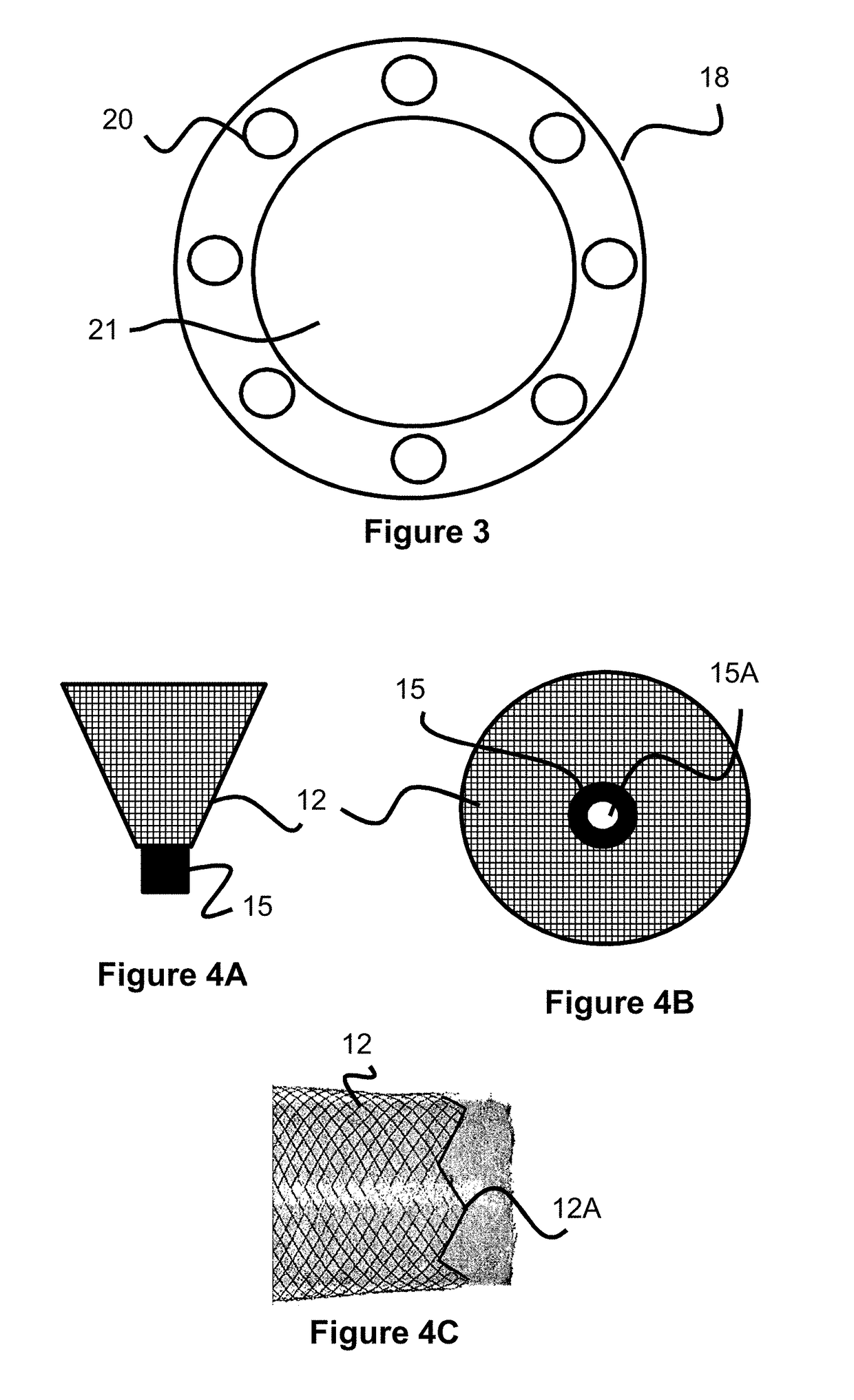

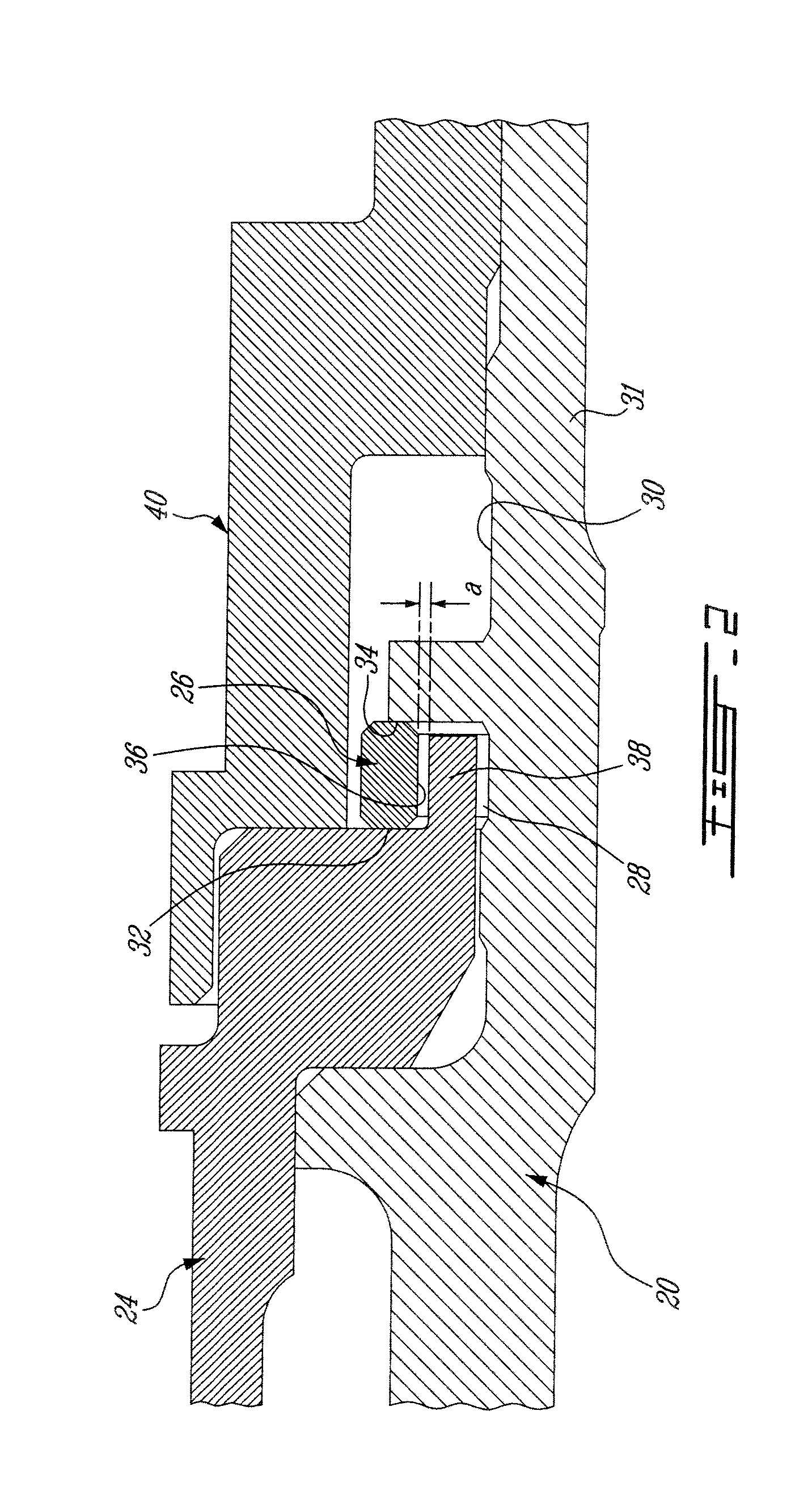

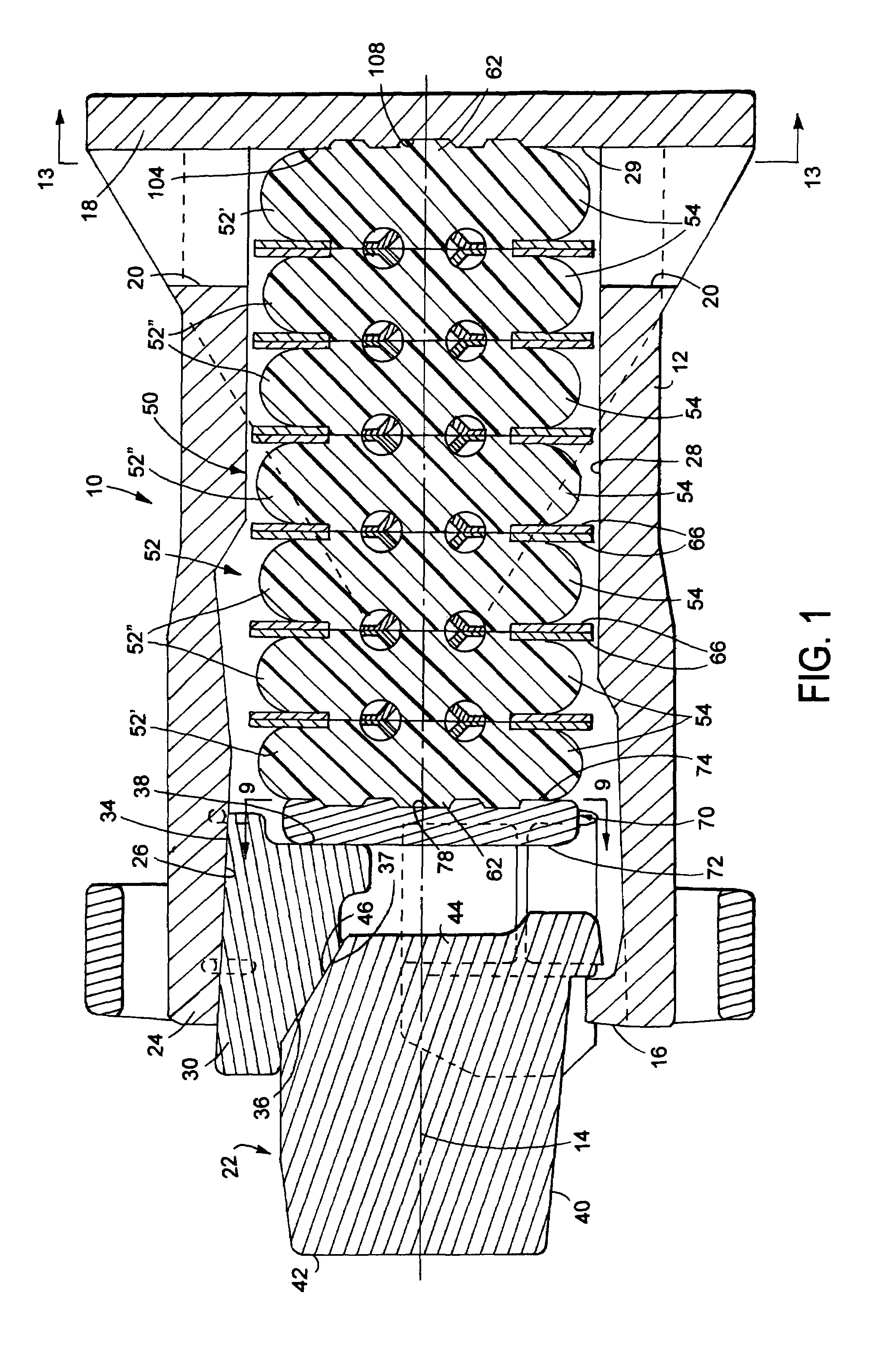

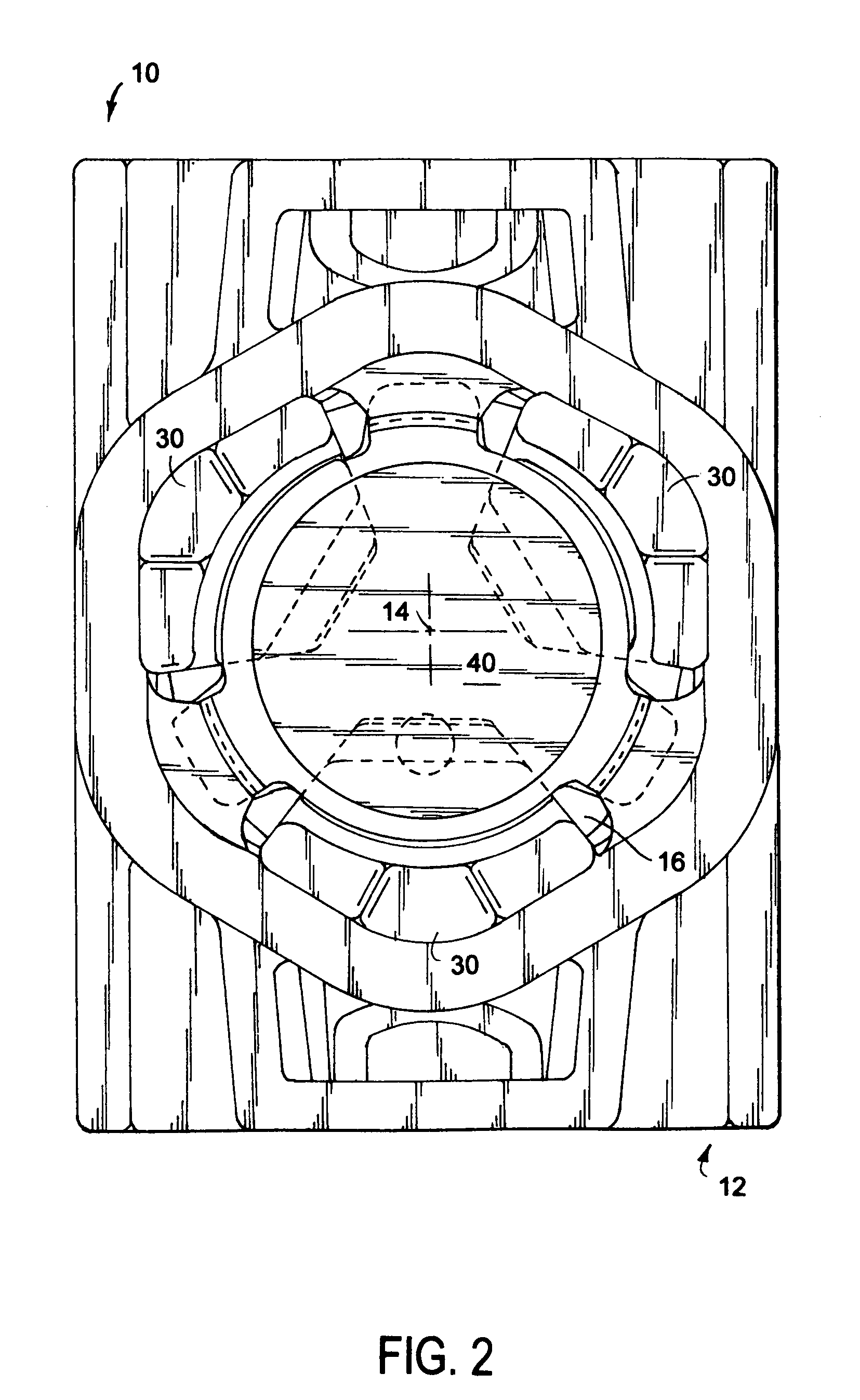

Retaining ring arrangement for a rotary assembly

ActiveUS20120051918A1Prevent disengagementPrevent rotationPropellersRotary propellersEngineeringCentrifugal force

A retaining ring arrangement is provided for axially holding a component on a rotating component of a gas turbine engine. The retaining ring arrangement comprises a split retaining ring mounted in a circumferential groove defined in a radially outer surface of the rotating component. The inner diameter of the retaining ring is biased inwardly in radial contact with a radially outer facing seat provided on one of the two components to be assembled. An anti-rotation feature is provided at the inner diameter of the retaining ring for restraining the ring against rotation. A sleeve surrounds the retaining ring to limit radial expansion thereof when subject to centrifugal forces during engine operation.

Owner:PRATT & WHITNEY CANADA CORP

Computer and document stand

A stand is provided for holding and elevating a laptop, notebook, or portable personal computer substantially to a user's eye level when facing forward, while at the same time minimizing the amount of desktop space occupied by the laptop. The stand comprises two panels pivotally attached through at least one hinge mechanism and, optionally, a brace mechanism. The stand may be expanded for use or collapsed for storage and transport. The stand is inexpensive to manufacture, lightweight, and easily portable because it is substantially flat when collapsed. The stand may include a built-in document holder that positions documents, notepads, or other materials directly in front of the user and just below the laptop's display and may also include at least one built-in cavity designed to hold a pad of paper, writing instruments, or other devices.

Owner:NALPAC INGENUITY

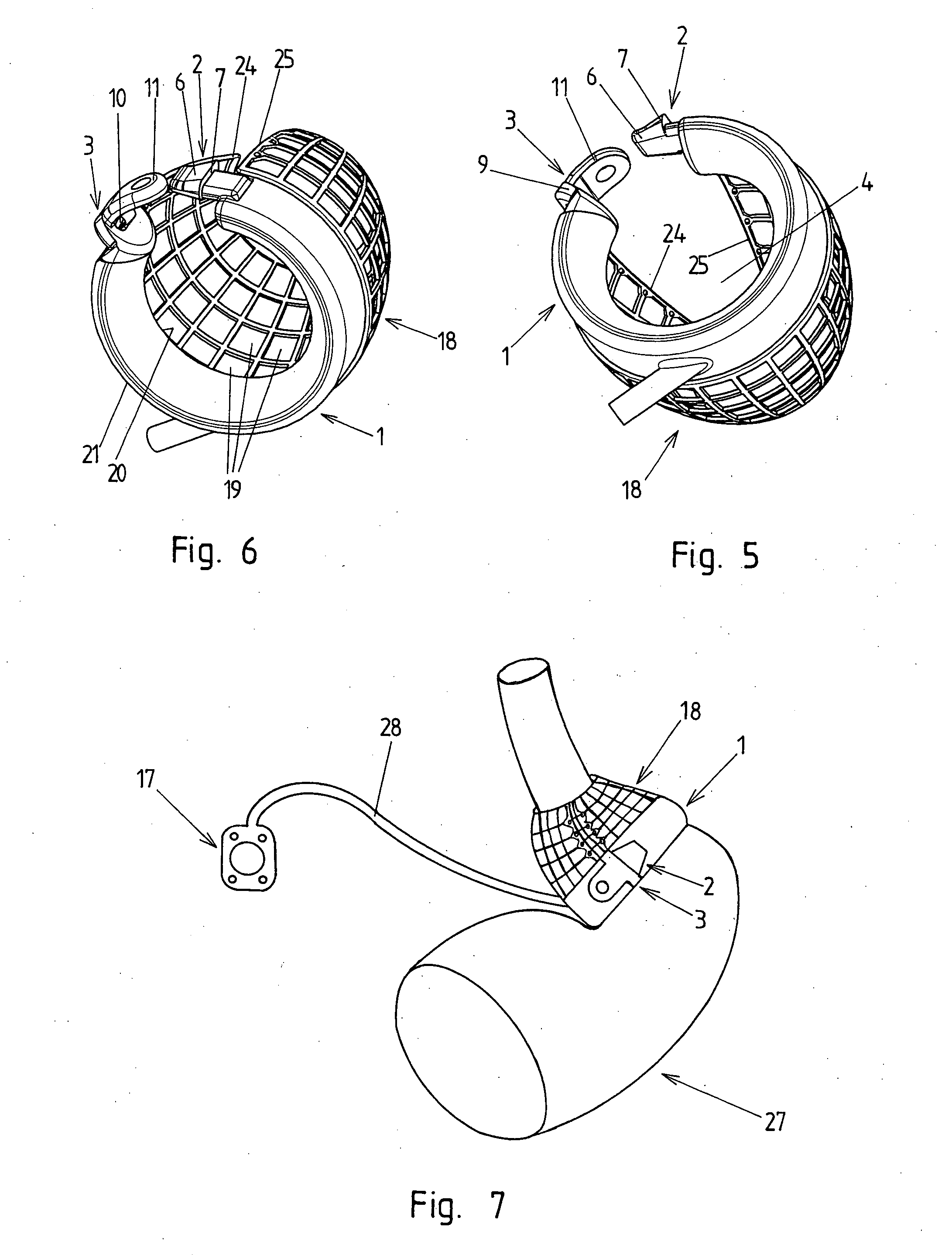

Device for treating obesity

InactiveUS20060129027A1Control expansionSimple and reliable implantationObesity treatmentProsthesisBand shapeGastric band

A device for treating obesity comprises a band part (1), which can be placed annularly about the stomach and includes a closure means (2, 3) for closing the gastric band after it has been placed annularly about the stomach, and an enveloping part (18) for enveloping and supporting a stomach region proximal with respect to the applied band part (1). The band part (1) and the enveloping part (18), secured in position on the band part (1) and laterally projecting from it, are implemented as a unit prefabricated by the manufacturer.

Owner:A M I AGENCY FOR MEDICAL INNOVATIONS GMBH

Railroad car draft gear

A railroad car draft gear including a housing having an open end with a friction clutch assembly arranged in operable combination therewith. An elongated elastomeric spring assembly is disposed within the housing for storing energy during axial compression of the draft gear. A spring seat is arranged within the housing between the spring assembly and an end portion of each friction member forming part of the friction clutch assembly. The spring seat defines a surface, arranged in direct contacting relation with an end of the spring assembly, and defines at least one surface incongruity for limiting radial expansion with the elastomeric spring at the end of the spring assembly arranged in direct contacting relation with the spring seat along at least two axes when an axial load is applied to the draft gear.

Owner:MINER ENTERPRISES INC

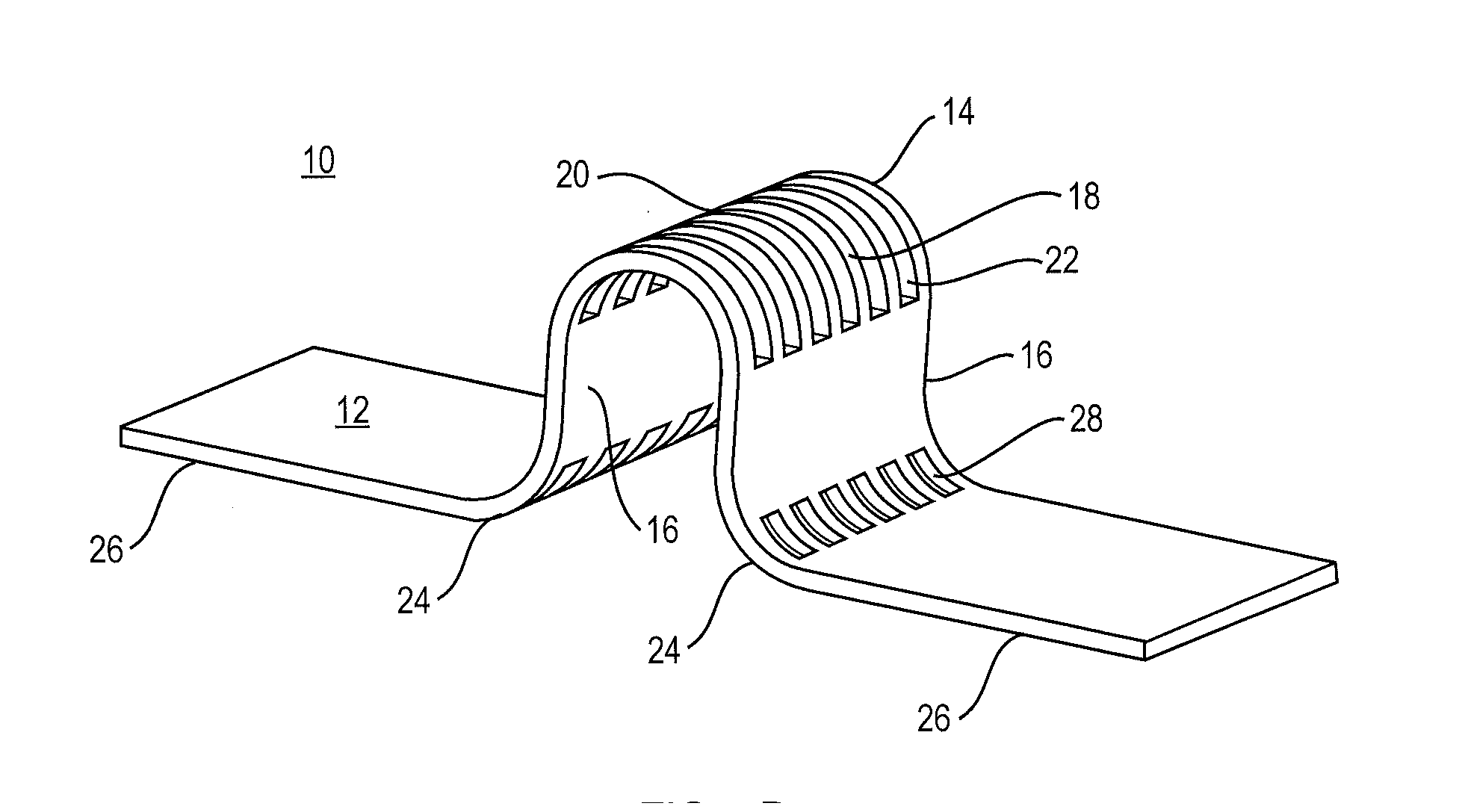

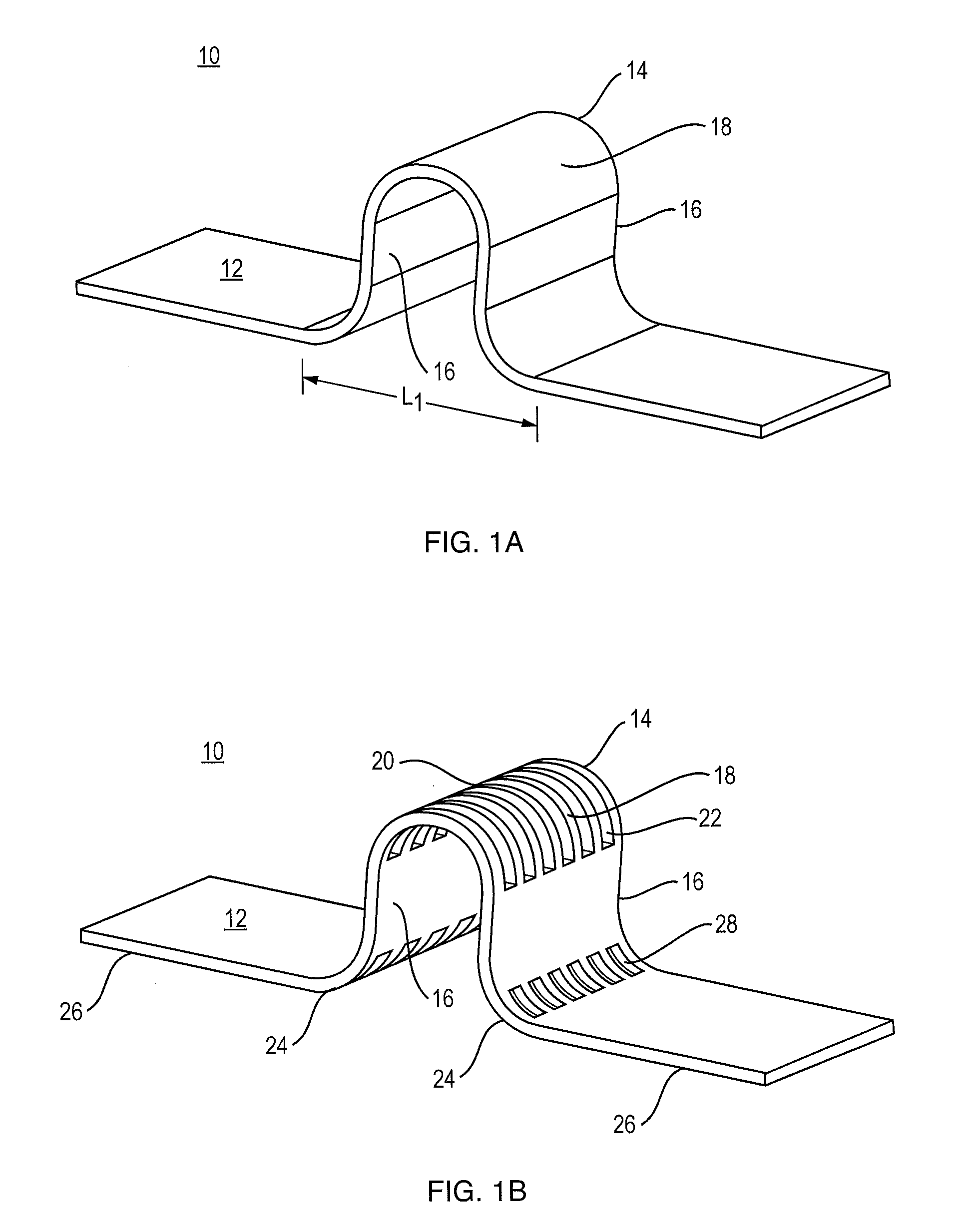

Flexible actuator based on shape memory alloy sheet

InactiveUS20110173970A1Raise the ratioReduce the cross-sectional areaMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceElectricity

A flexible unit-cell actuator includes a shape memory alloy sheet having a fold between adjacent legs in one state and a heat source that upon activation concentrates heating of the shape memory alloy sheet at the fold relative to the legs to change the fold between one state and another state. The heat source may include resistive heating due to an electric current passing through the shape memory alloy sheet. The fold typically includes a reduced cross-sectional area and may include slits to increase electrical resistance at the fold relative to the adjacent legs. An actuator array includes a plurality of flexible unit-cell actuators formed in a sheet, each unit-cell actuator mechanically coupled to at least one other unit-cell actuator at a coupling region. Plural unit-cell actuators may be mechanically coupled in series, in parallel, or both, may be electrically connected in series, and may move along a defined curve or surface. A linear or curvilinear actuator includes a guide, a plurality of bearings or support elements slidable along the guide, and an array of actuators coupled between adjacent bearings and circumferentially about the bearings. An actuator includes a plurality of segments fanning from a hinge and shape memory alloy actuators coupled between adjacent segments to cause the segments to fan in an out about the hinge.

Owner:MASSACHUSETTS INST OF TECH

Catalyzed filter for treating exhaust gas

InactiveUS20120258032A1Less-optimal interactionThermal expansion is very limitedCombination devicesGas treatmentMolecular sieveMetal

Provided is a wall-flow filter coated with an SCR catalyst composition, wherein the catalyst composition contains transition metal promoted molecular sieve crystals, and wherein (i) the crystals have a mean crystalline size of about 0.5 μm to about 15 μm, (ii) the crystals are present in said composition as individual crystals, agglomerations having a mean particle size of less than about 15 μm, or a combination of said individual crystals and said agglomerations; and (iii) said molecular sieve is an aluminosilicate or a silico-aluminophosphate of a Framework Type having a maximum ring size of eight tetrahedral atoms.

Owner:JOHNSON MATTHEY PLC

Tampon applicator

InactiveUS20110201992A1Reduce decreaseIncrease engagementHollow filament manufactureFilament/thread formingEngineeringTampon

A tampon applicator is described which comprises an ejector tube and an outer tube. The outer tube is dimensioned to fit closely and telescopically over the ejector tube. The outer tube has a distal discharge end. The distal end of the ejector tube is formed with one or more radially inwardly slanted fingers. The outer tube can comprise supporting means configured to restrict radially outward expansion of the fingers of the ejector tube when the tampon applicator is in telescopically compacted position.

Owner:ONTEX HIGIENEARTIKEL DEUT GMBH

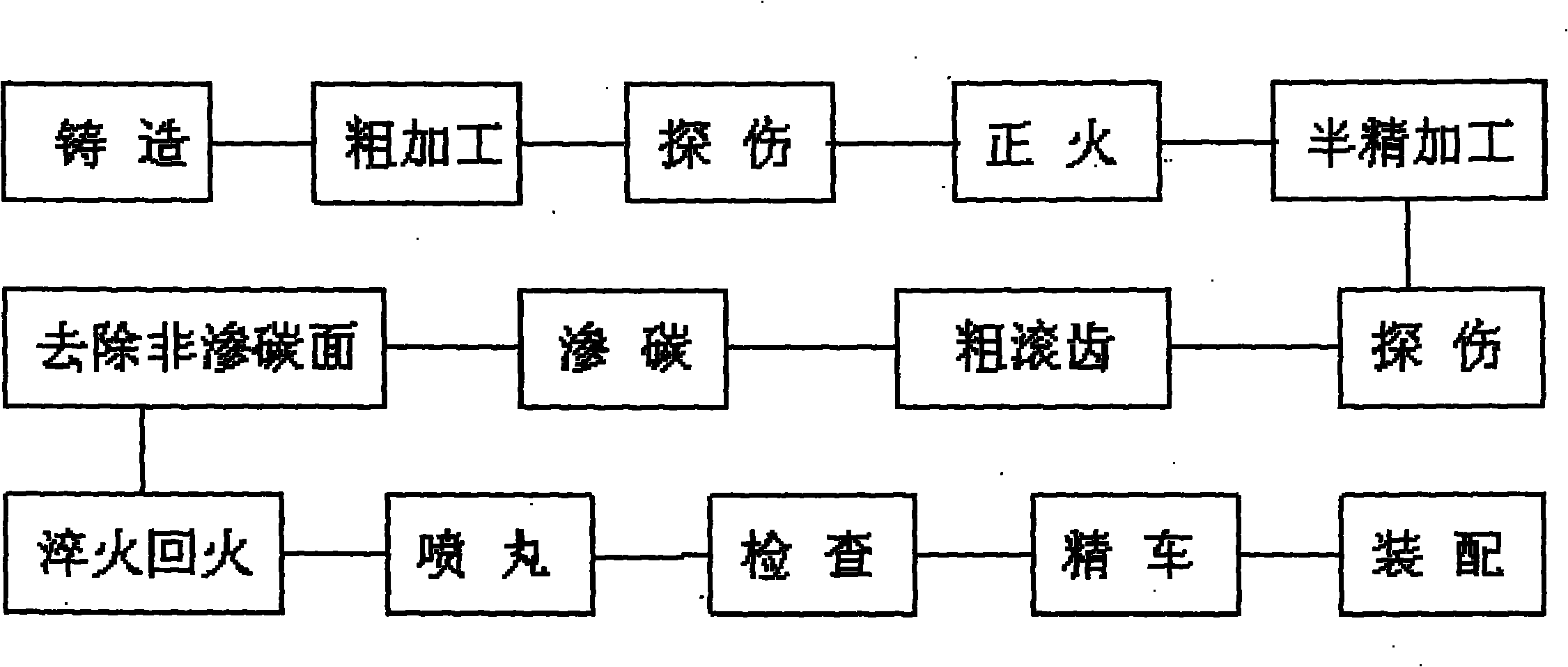

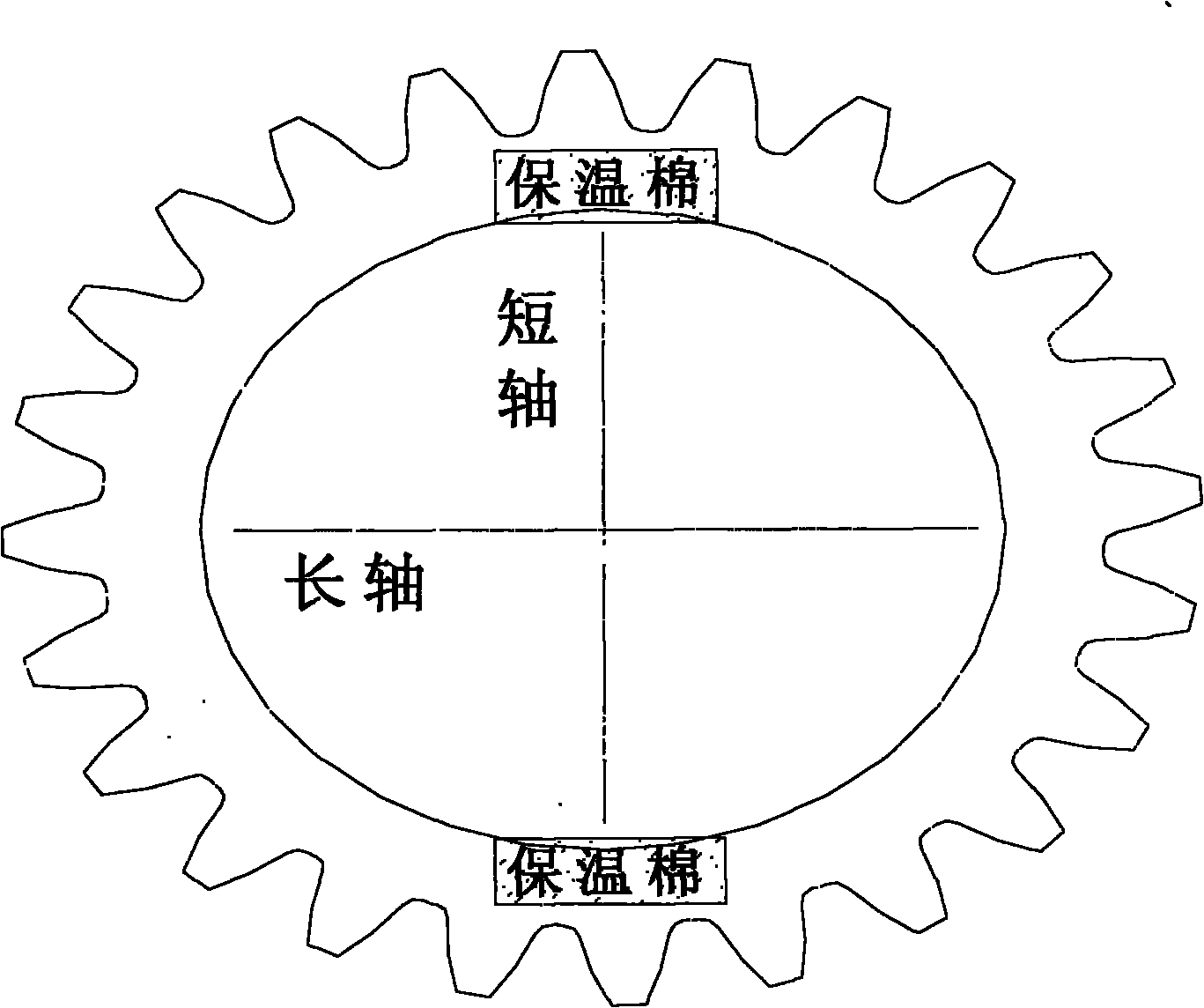

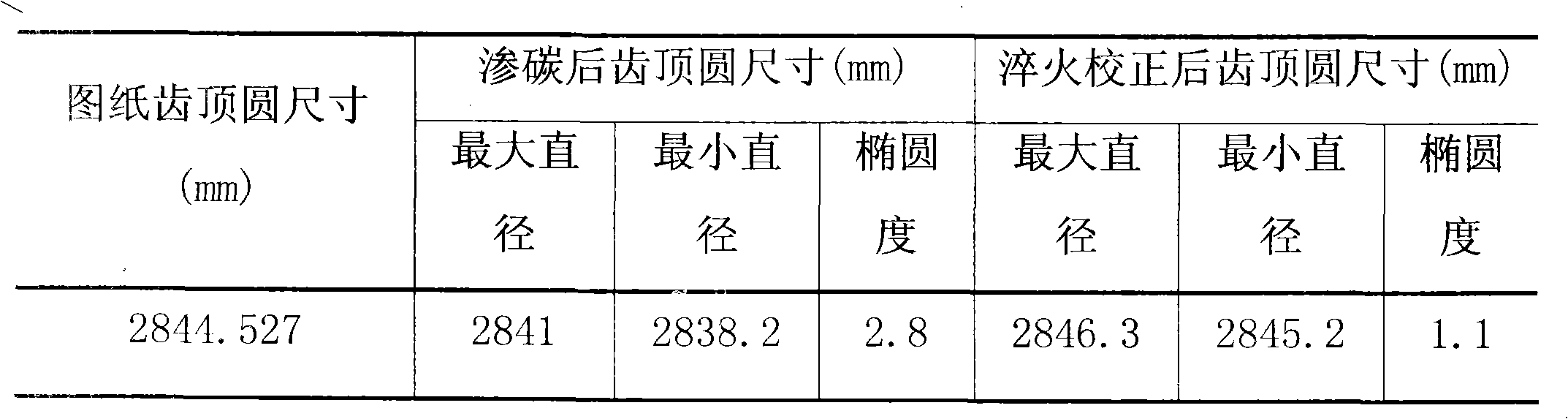

Reversible deformation correcting method for elliptical gear ring subjected to deformation after carburization

InactiveCN101838730AControl expansionLow costFurnace typesHeat treatment furnacesOil coolingMinor axis

The invention provides a reversible deformation correcting method for an elliptical gear ring subjected to deformation after carburization, which comprises the following steps of: measuring the addendum circle diameters of a gear ring which is subjected to ellipse deformation after carburization every 30 degrees, wherein the difference between the measured addendum circle diameters is the major axis and the minor axis of the gear ring which is subjected to ellipse deformation; binding a layer of heat insulation cotton at both sides of the inner end surface of the gear ring in the minor axis-distributed area with iron wires at a moderate tightening degree; and exposing other gear rings and external gear parts. In the quenching process, the elliptical gear ring is heated to 810 DEG C at a heating rate of 60 DEG C / h and is kept for 4 hours. Because the minor axis-distributed area is covered with the heat insulation cotton, the heating rate of the minor axis-distributed area covered with the heat insulation cotton is smaller than that of the major axis-distributed area uncovered with the heat insulation cotton, and the cooling speed of the minor axis-distributed area of the gear ring is smaller than that of the major axis-distributed area in the quenching oil cooling process, thereby correspondingly reducing the difference between the distributed areas with different addendum circle diameters of the gear ring and consequently realizing the reversible deformation correction of the elliptical gear ring.

Owner:CITIC HEAVY INDUSTRIES CO LTD

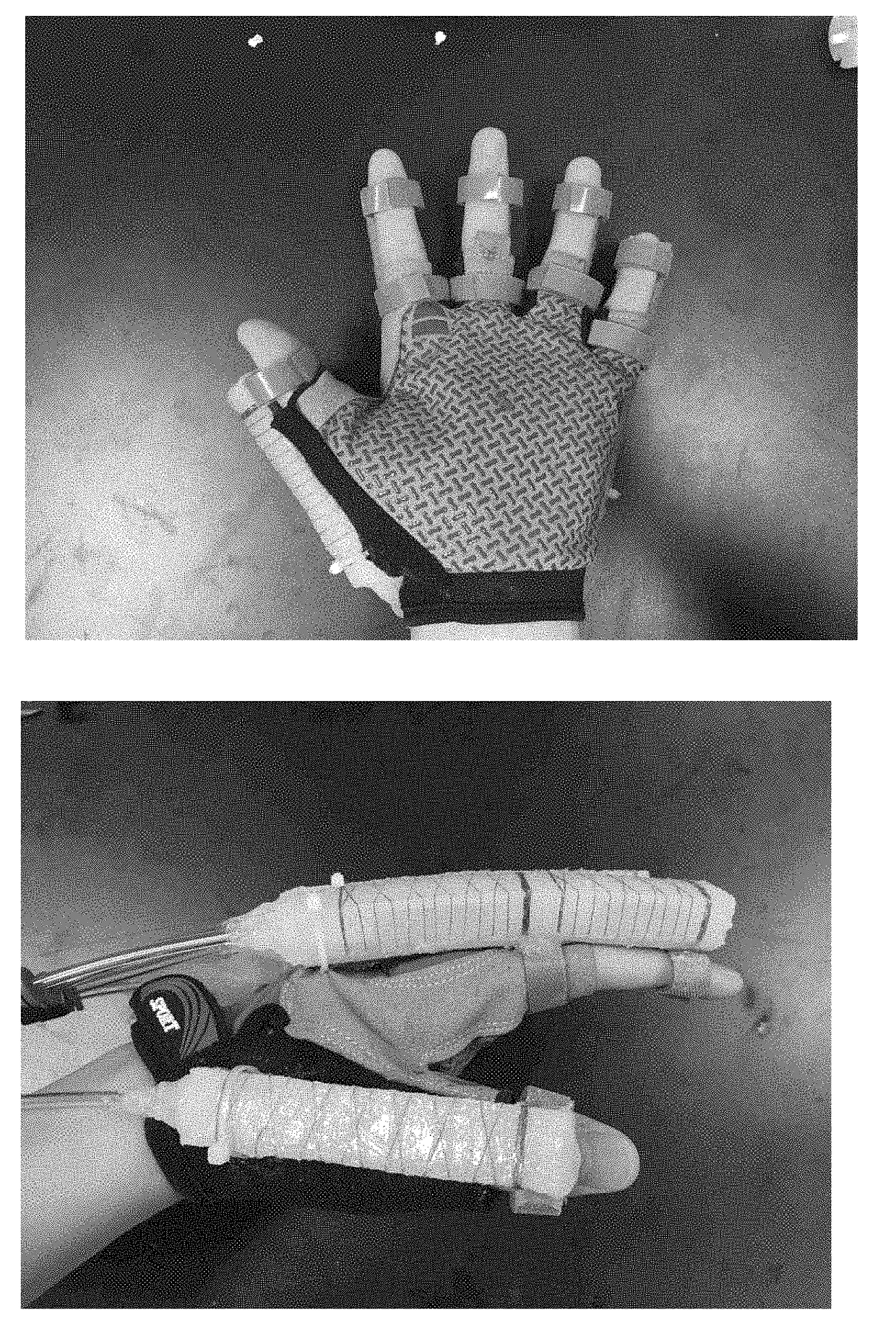

Flexibly driven robotic hands

ActiveUS20180296419A1Increase muscle strengthRecovery functionProgramme-controlled manipulatorDiagnosticsRobot handActuator

Systems and methods for robotic and exoskeleton hands are provided. An exoskeleton hand can include a flexible actuator having a cavity and a reinforcement band. The cavity can be filled with a fluid from a pressure source, forcing the actuator to deform, bend or extend. The fluid that fills the cavity as a driving force can be a gas or liquid, which can be recyclable or disposable.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

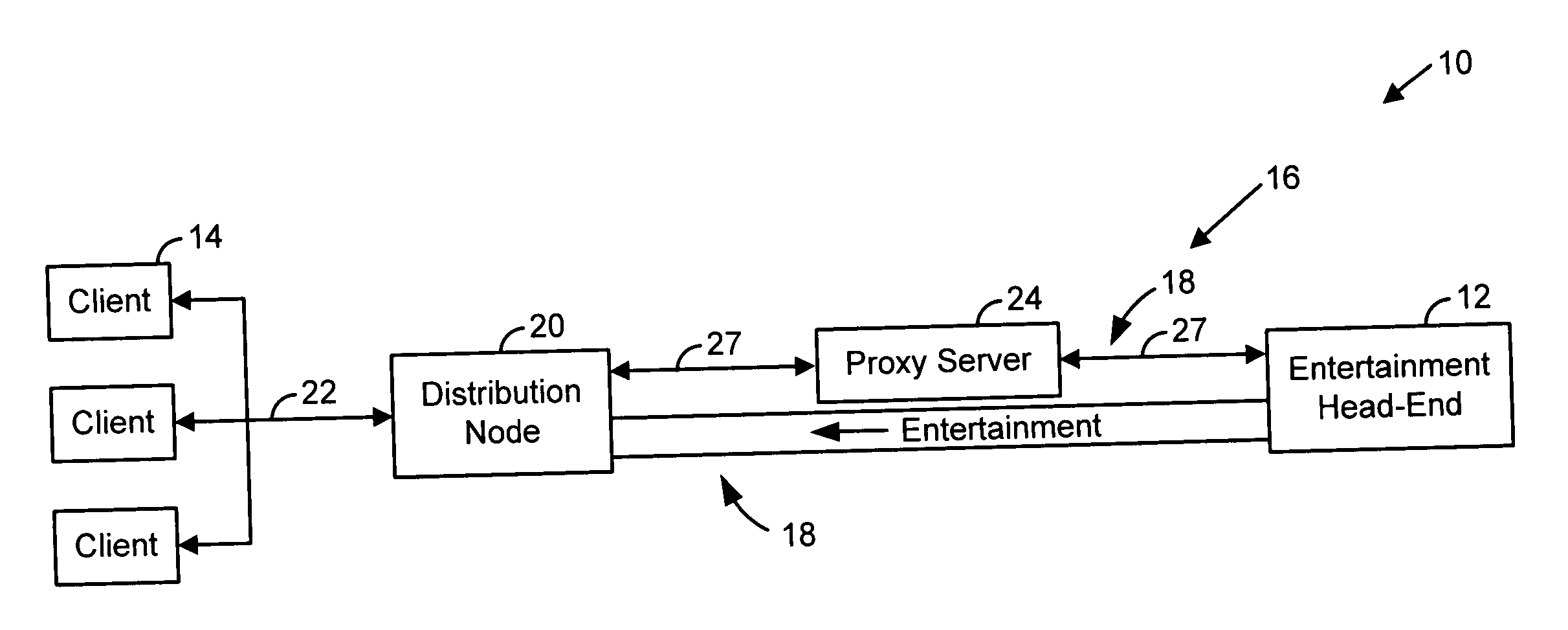

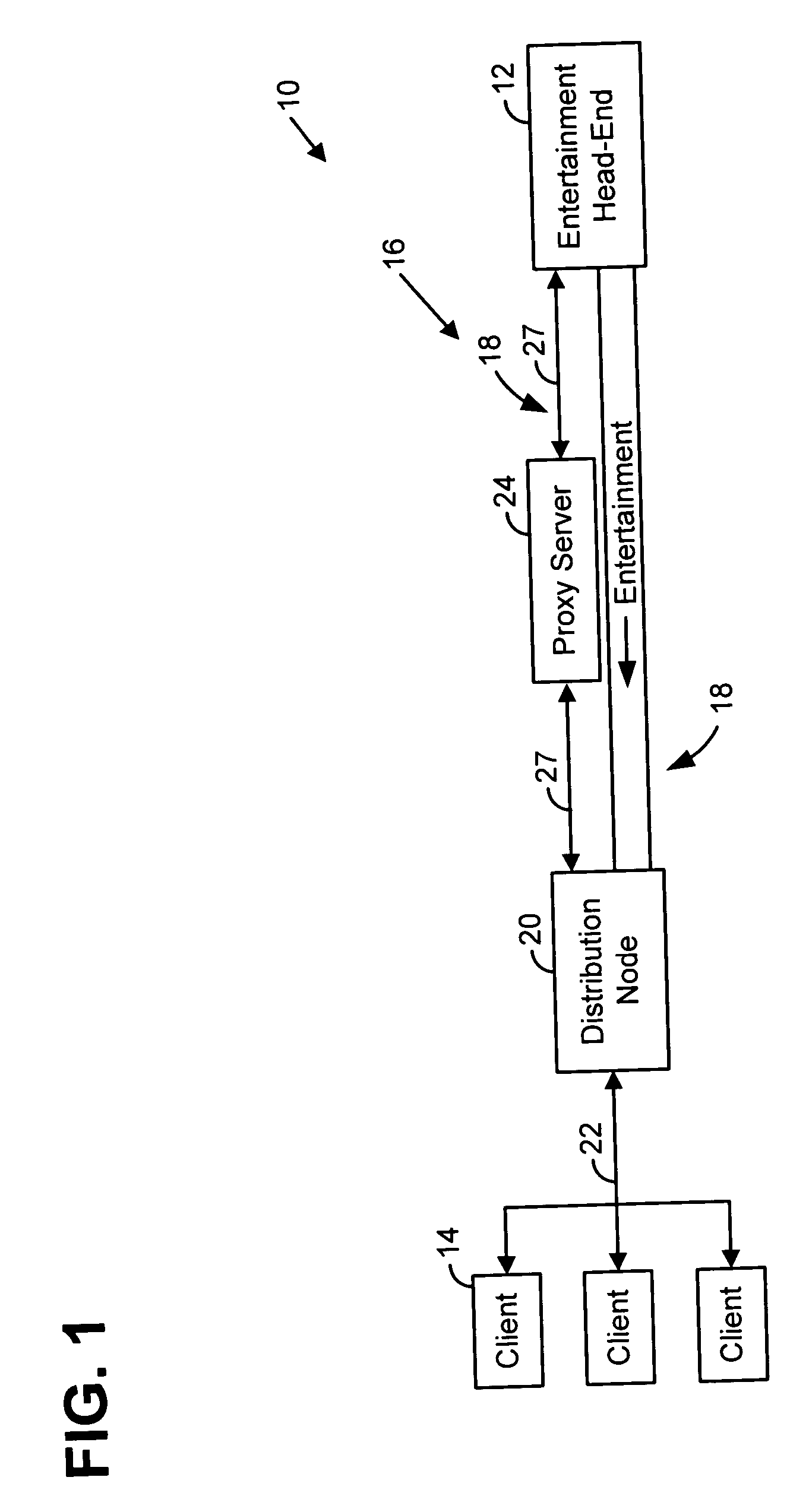

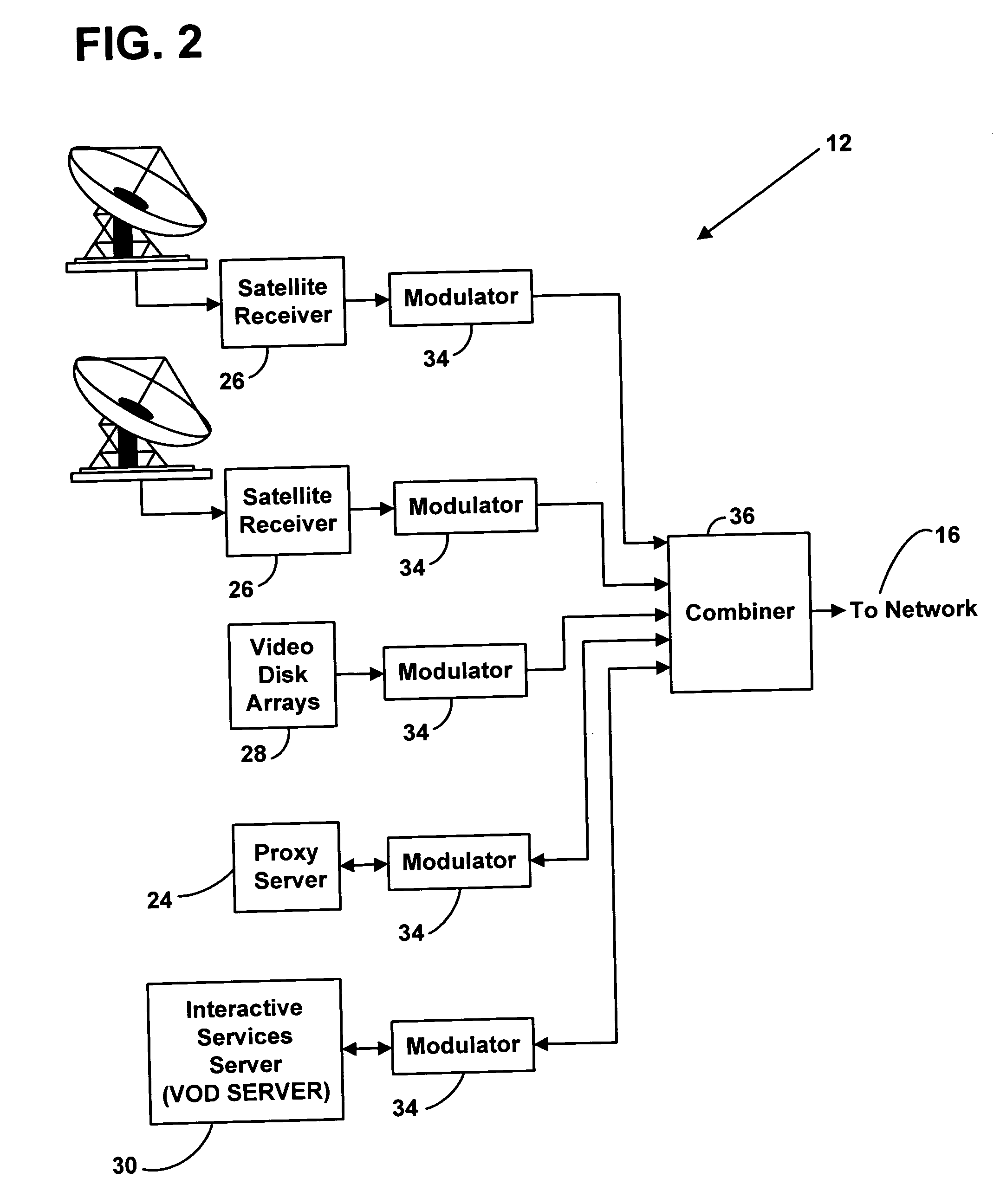

Proxy for video on demand server control

InactiveUS20060095945A1NetworkingControl expansionTelevision system detailsColor television detailsClient-sideVideo on demand

A video on demand system includes a head-end coupled through a proxy server to plural client terminals. The proxy server performs (or cooperates with another component in performing) various functions, including user interface definition, security, system administration (e.g. channel management, load distribution, and failover), and protocol translation.

Owner:MICROSOFT TECH LICENSING LLC

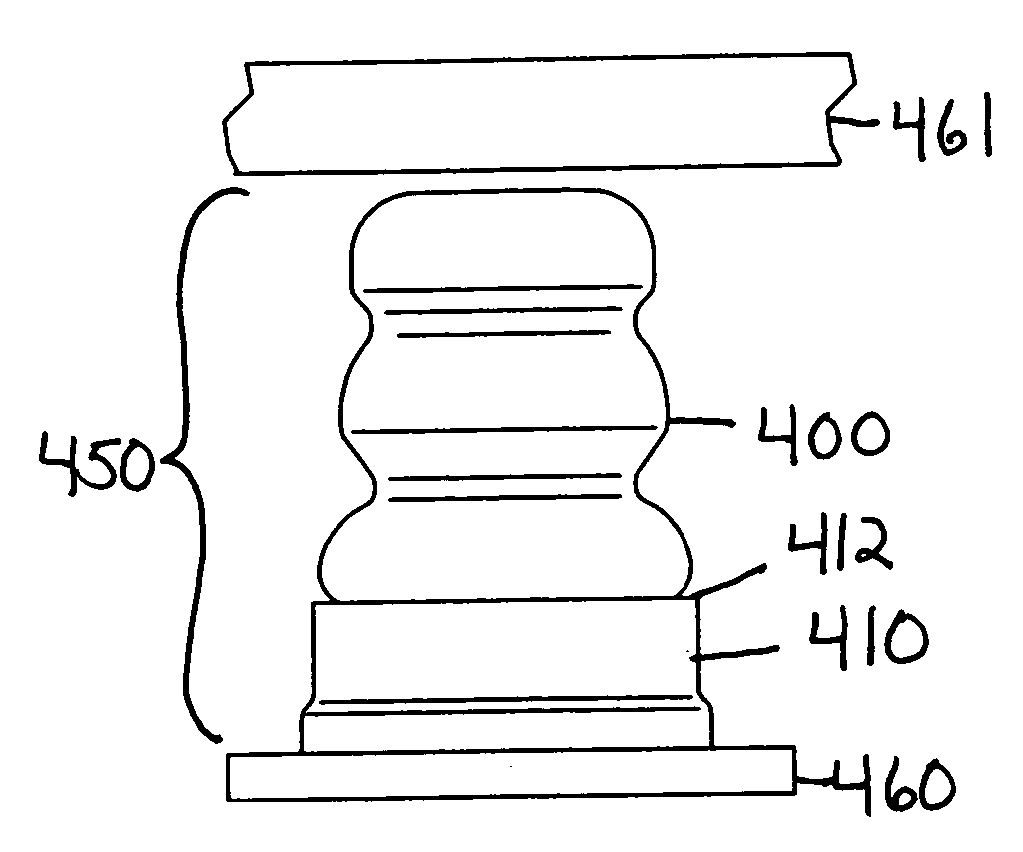

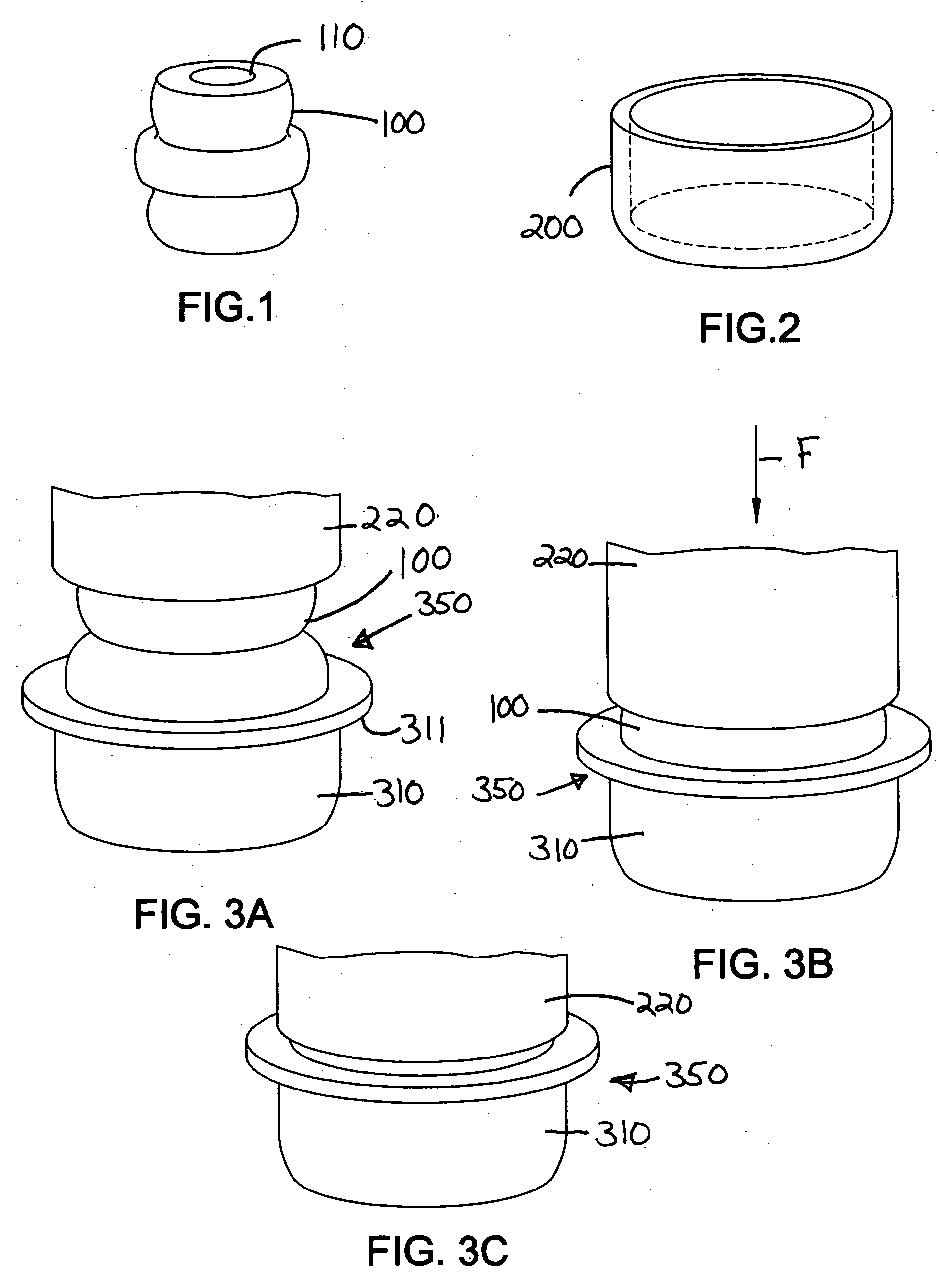

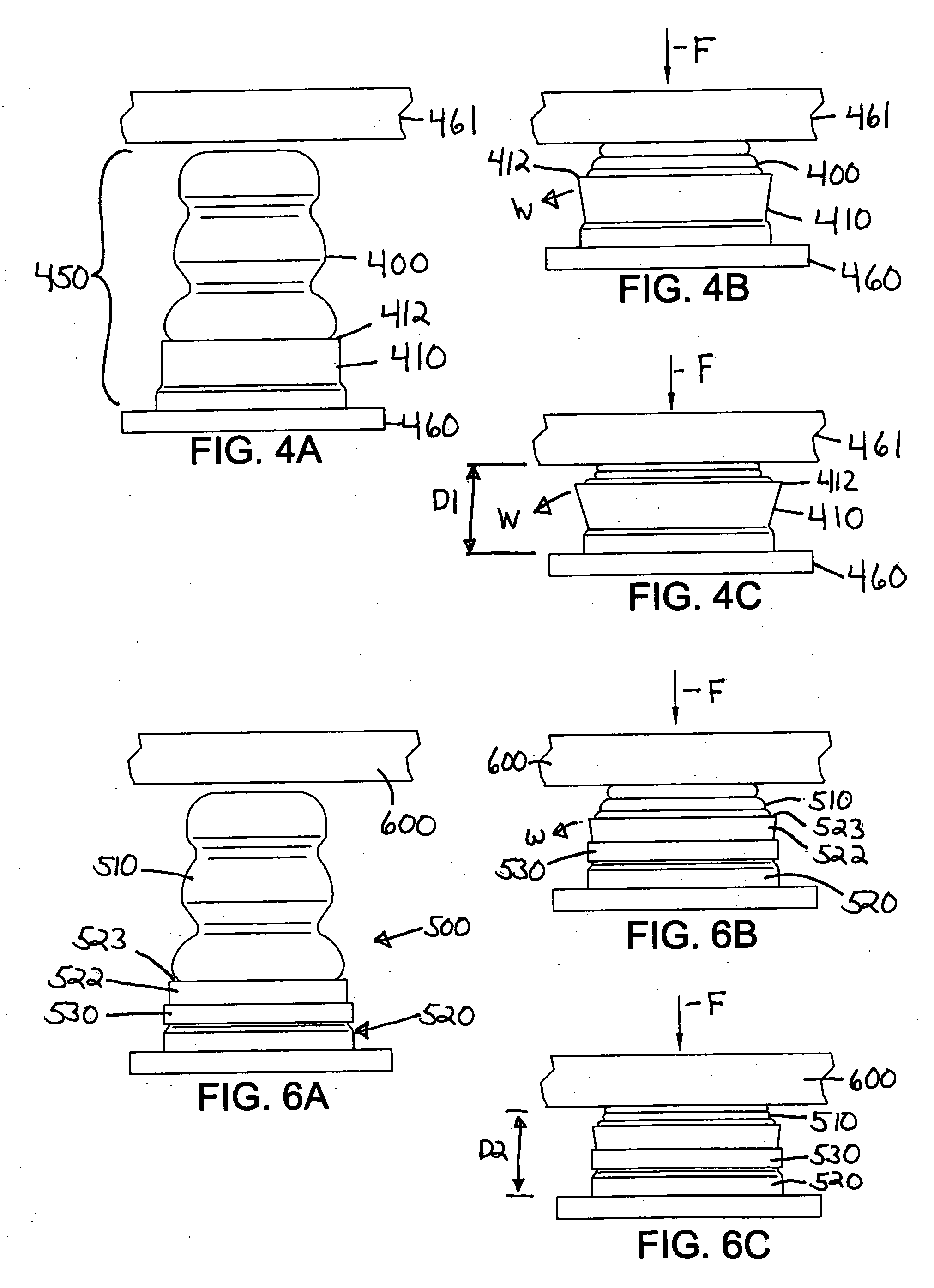

Jounce bumper

InactiveUS20050230891A1More travelOvercome effectMultiple spring combinationsResilient suspensionsEnergy absorptionEngineering

An energy absorption device for providing a softer stop arrangement between a pair of components. A compressible bumper is placed into a flexible cup. A ring is place around the flexible cup. Upon application of force between the components, the compressible bumper collapses into the flexible cup and the cup begins to expand radially. The ring prevents the cup from expanding to the point of flattening and provides the device with a definite rigid stop. The device is usable between any two components to prevent collisions between the components up to a certain force between them and is also usable between a strut assembly and a vehicle suspension frame.

Owner:EDWARDS INDS

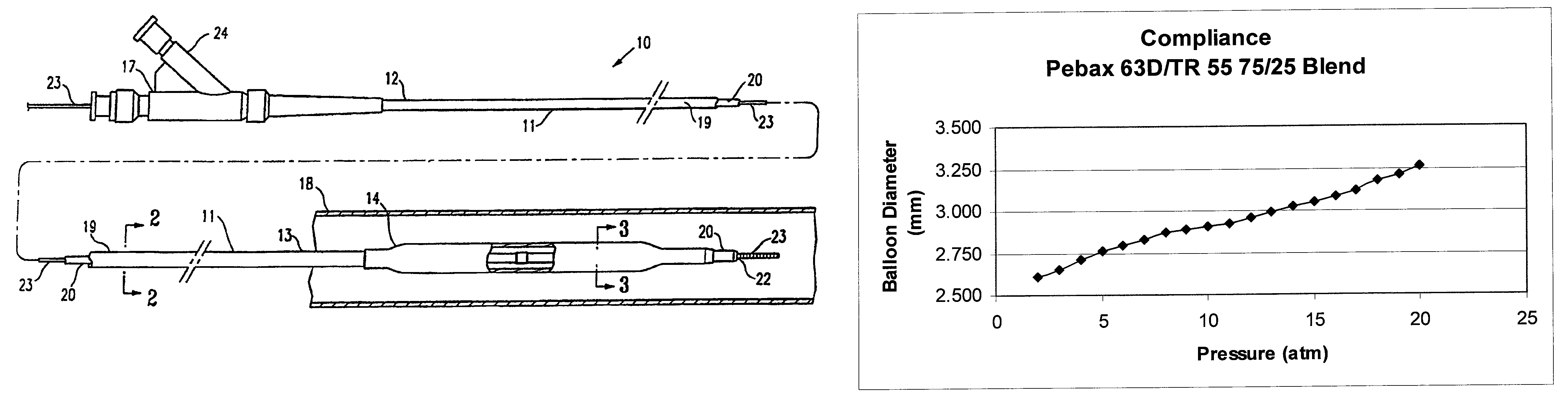

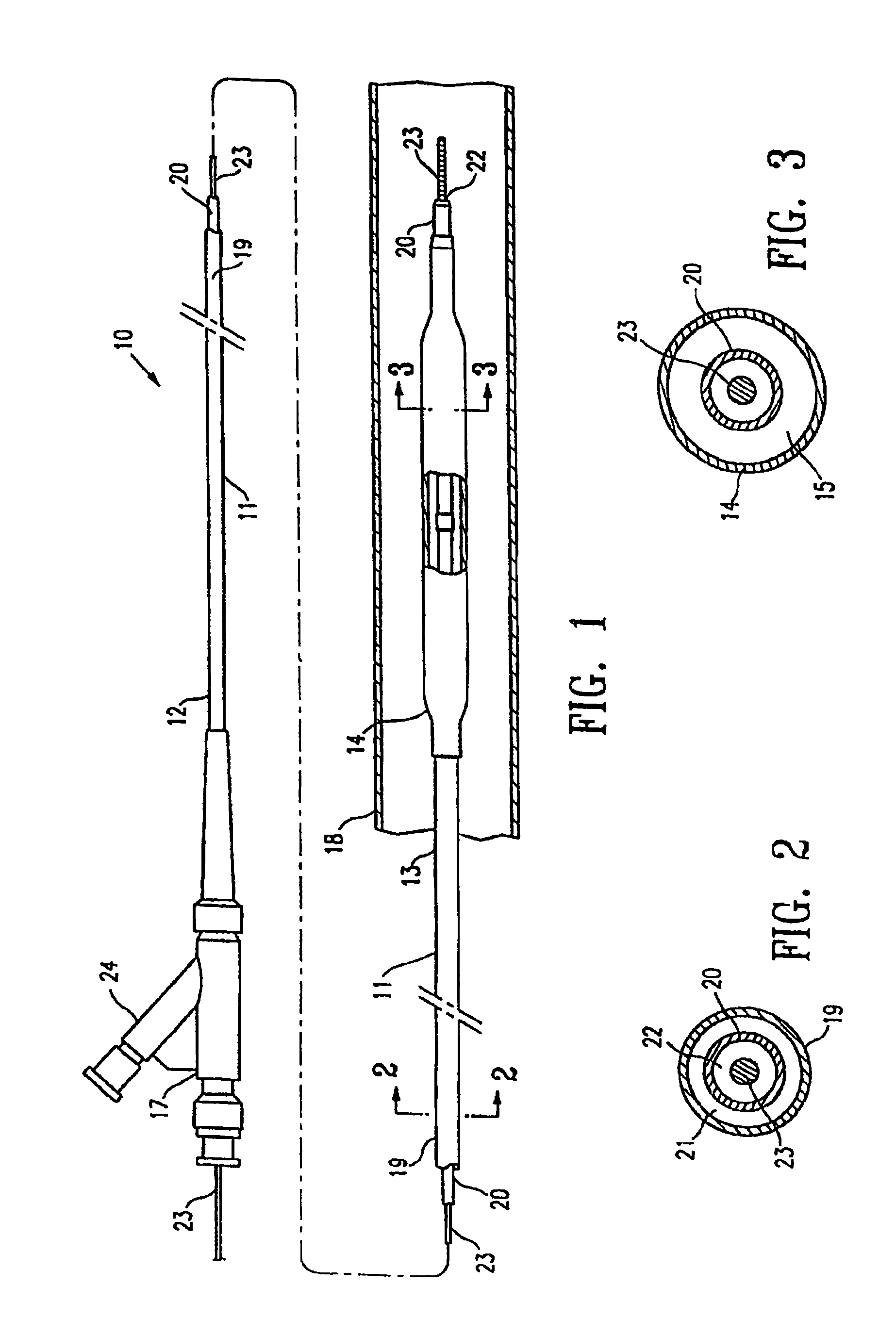

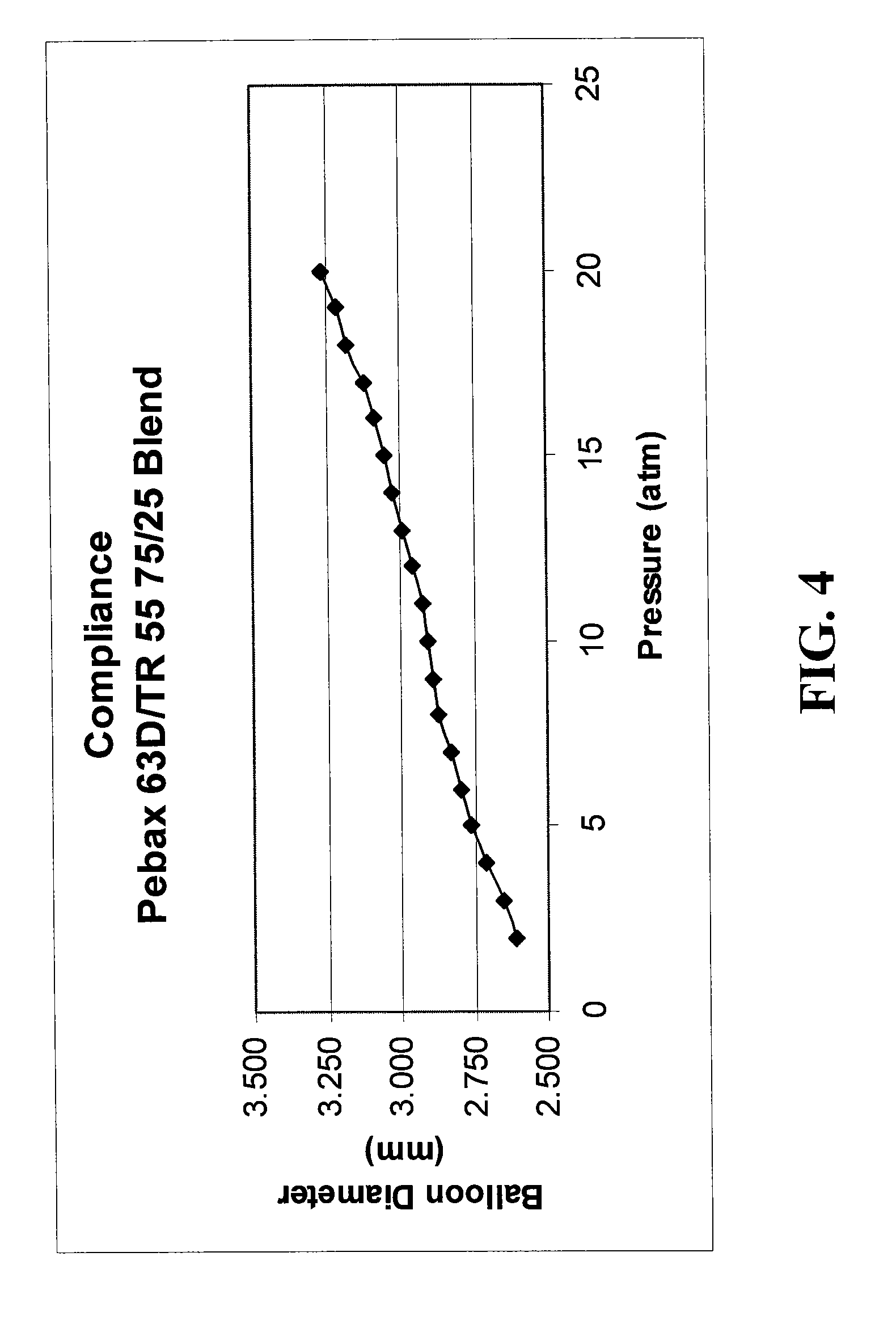

Low compliant catheter tubing

ActiveUS8070719B2Improve complianceImproves strength and modulusStentsSurgeryPolyamideBalloon catheter

Balloon catheter comprises a shaft having a proximal end, a distal end, and an inflation lumen extending therein, and a balloon on the shaft which has an interior in fluid communication with the inflation lumen. The balloon is formed of a blend of polymeric materials comprising a transparent amorphous nylon having a Shore D duromcter hardness of not less than 77D and being not more than about 40% by weight of the blend, and a polyamide or a polyether block amide having a Shore D duromcter hardness of no more than 73D. An increase in radial diameter of the balloon above nominal pressure for one atmosphere of pressure is no greater than 0.025 mm / atm. A guidewire catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com