Reversible deformation correcting method for elliptical gear ring subjected to deformation after carburization

A technology of anti-deformation after carburizing, applied in the field of heat treatment, can solve the problems of high cost of tooling, difficult operation, low success rate, etc., and achieve the effects of cost saving, obvious economic benefits, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

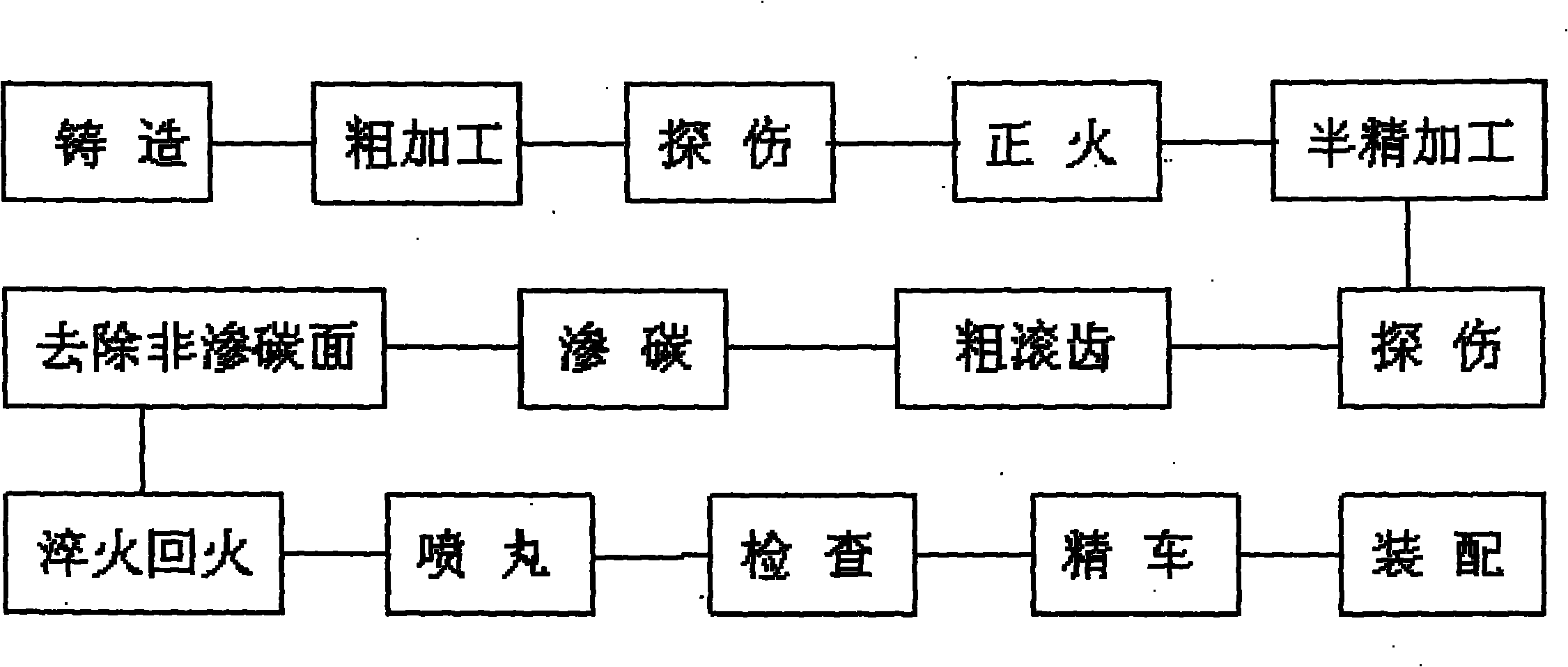

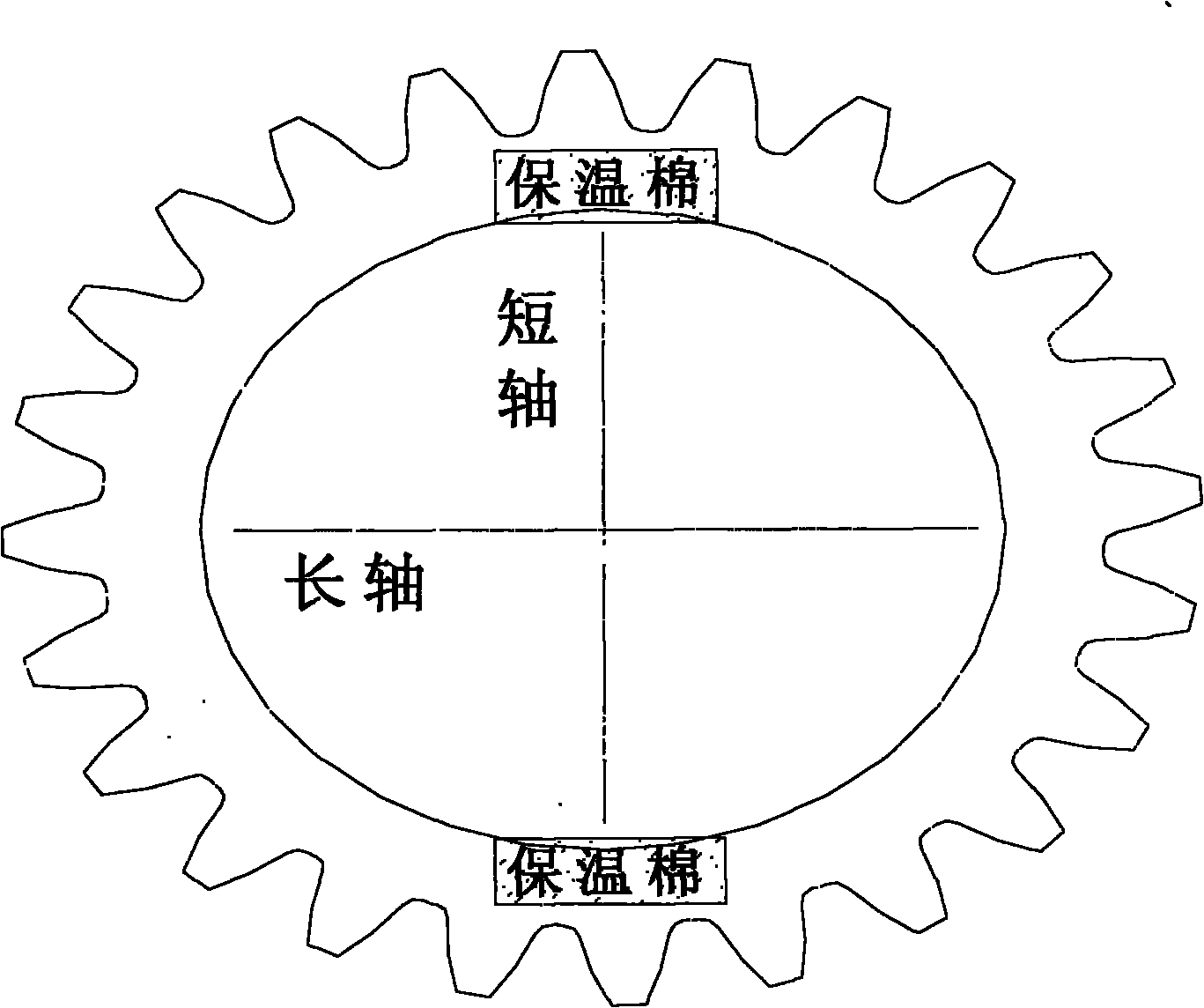

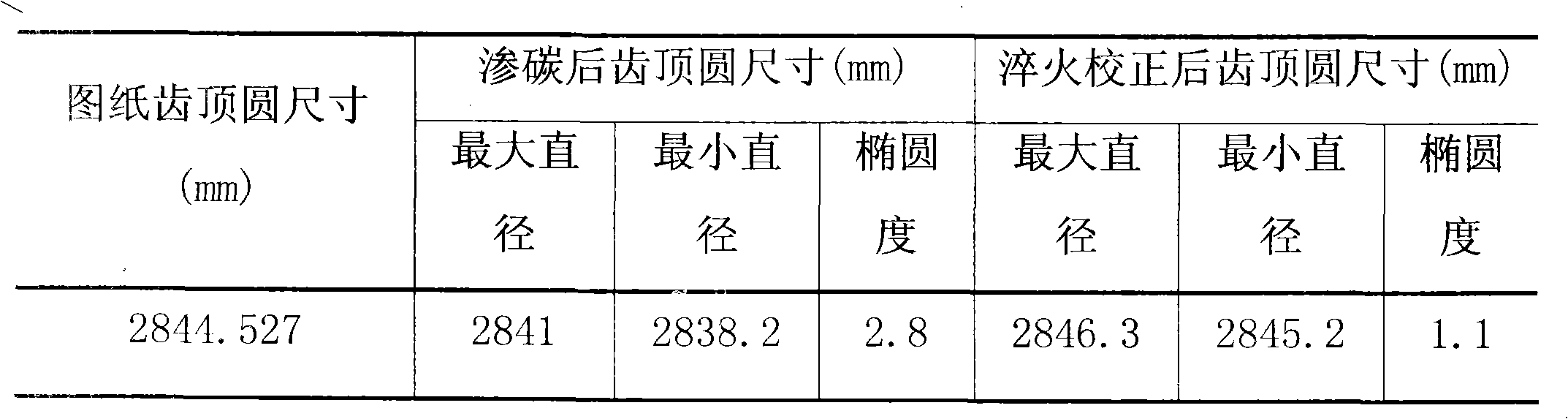

[0023] The anti-deformation correction method for the elliptical ring gear deformed after carburizing of the present invention is to measure the diameter of the addendum circle at intervals of 30° for the elliptical deformed ring gear after carburizing, and measure the tooth diameter six times within 180°. The difference between the diameter of the top circle, this difference is the long axis and short axis of the elliptical deformation of the ring gear, and then carefully measure and determine the distribution area of the long axis and short axis of the ring gear near the maximum and minimum points. A layer of insulation cotton is bound with iron wire on both sides of the inner end surface of the ring gear in the distribution area of the short axis. When the difference between the major axis and the short axis is <3mm, the thickness of the insulation cotton is controlled within 15mm. ≥3mm, the thickness of the insulation cotton is ≥15mm, the tightness of the iron wire bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com