Filter wrench with novel structure

A new type of structure and filter technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of clamping and disassembling filters with different diameters that cannot be easily changed, and achieve efficient and convenient clamping and disassembly. The effect of convenient and stable clamping, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

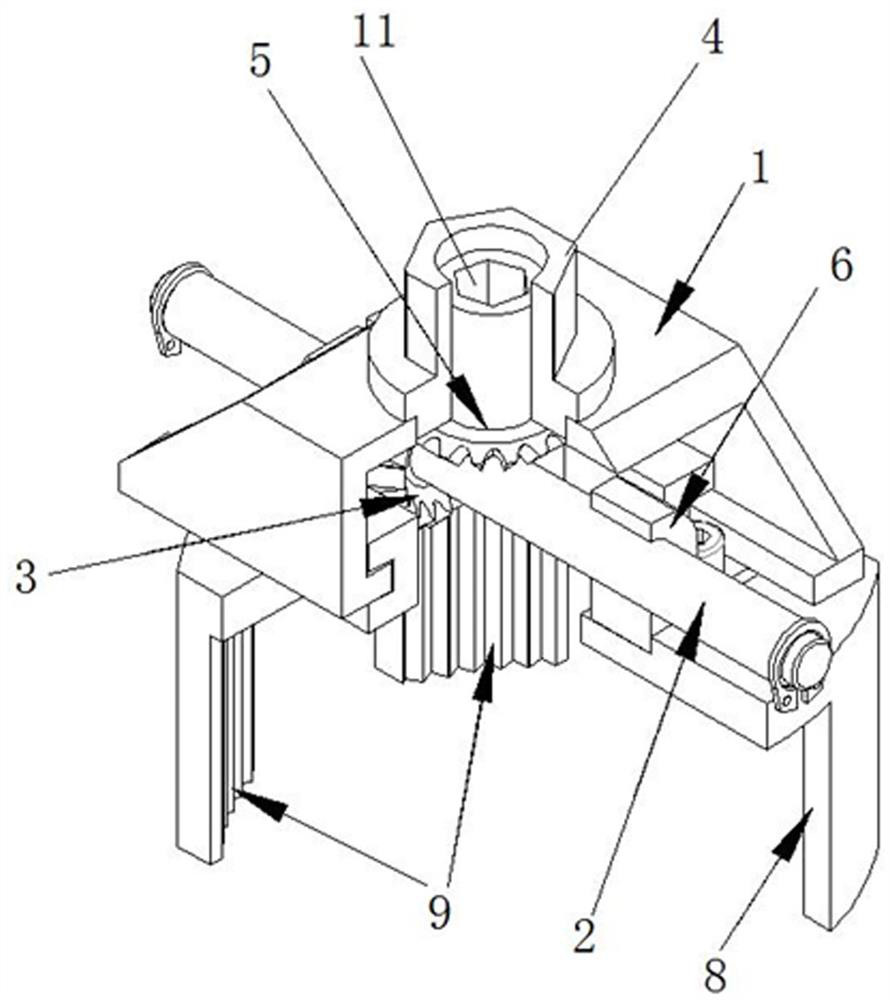

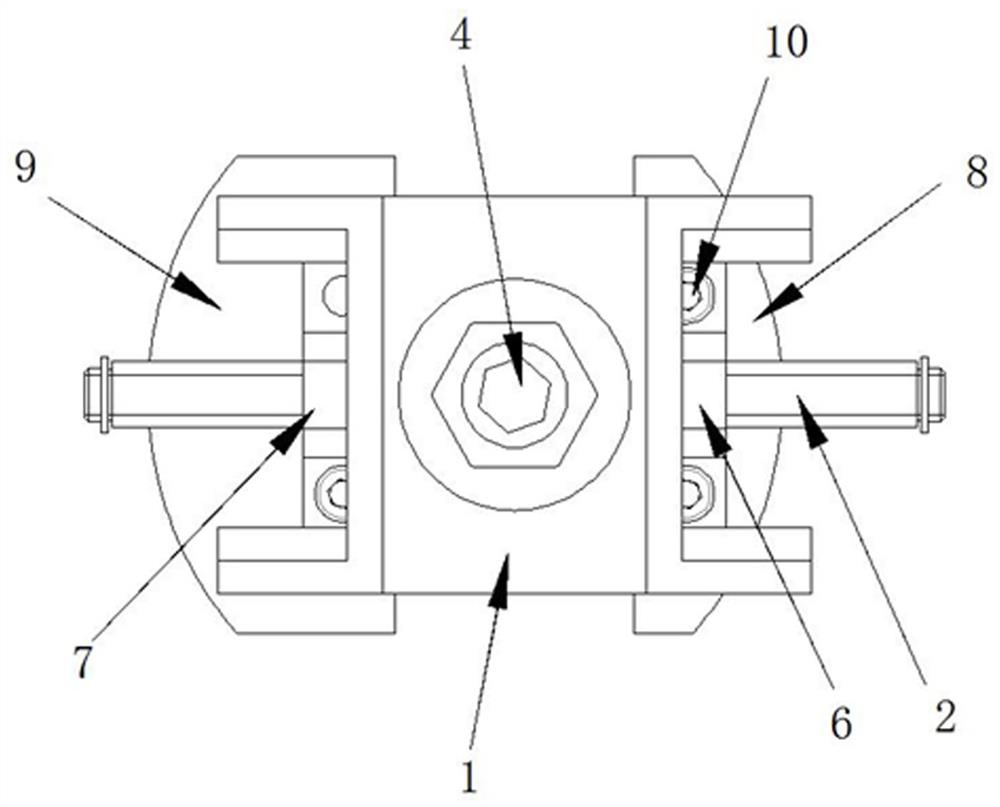

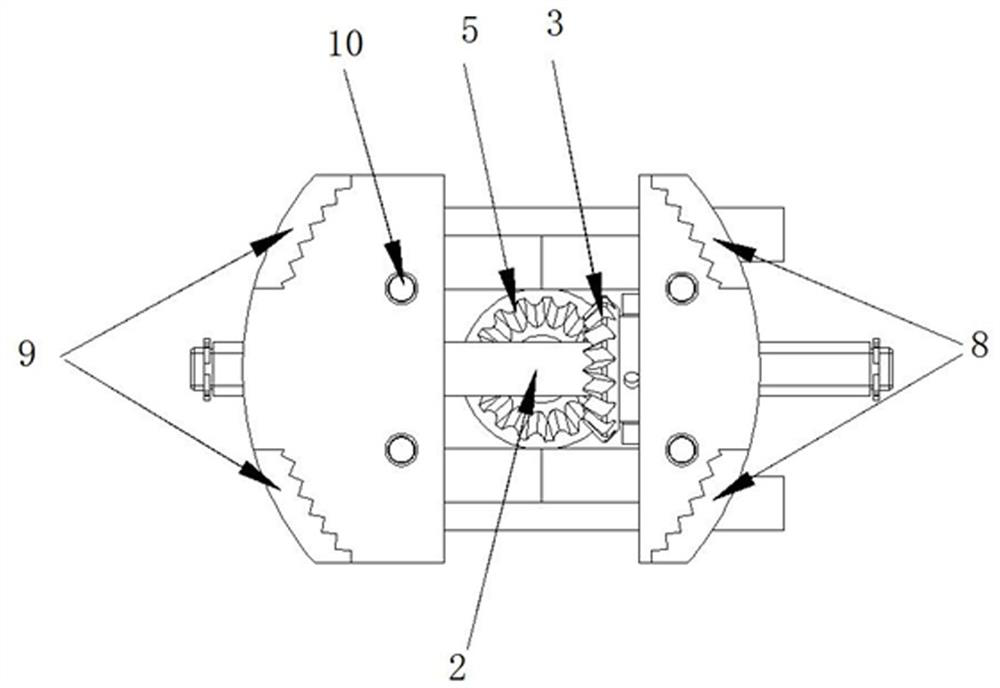

[0017] like Figure 1-3 As shown, a filter wrench with a new structure includes a base slide rail 1, a screw rod 2, a passive bevel gear 3, a hexagonal sleeve 4, an active bevel gear 5, a left nut slider 6, and a right nut slider 7 , the first claw A8, the second claw A9 and the bolt 10, the screw 2 is installed on the base slide rail 1, and the left nut slider 6 is installed on one end of the screw 2, so The other end of the screw mandrel 2 is equipped with the right screw nut slider 7, the left screw nut slider 6 is fixed with the first claw A8 by a bolt 10, and the right screw nut slider 7 is passed The bolt 10 is fixed with the second claw A9, the middle part of the screw mandrel 2 is fixed with the passive bevel gear 3, the base slide rail 1 is fixed with the hexagonal sleeve 4, and the hexagonal sleeve 4 is installed There is the driving bevel gear 5 , and the driving bevel gear 5 is in drive connection with the passive bevel gear 3 .

[0018] In this embodiment, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com