Patents

Literature

264results about How to "Smooth through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

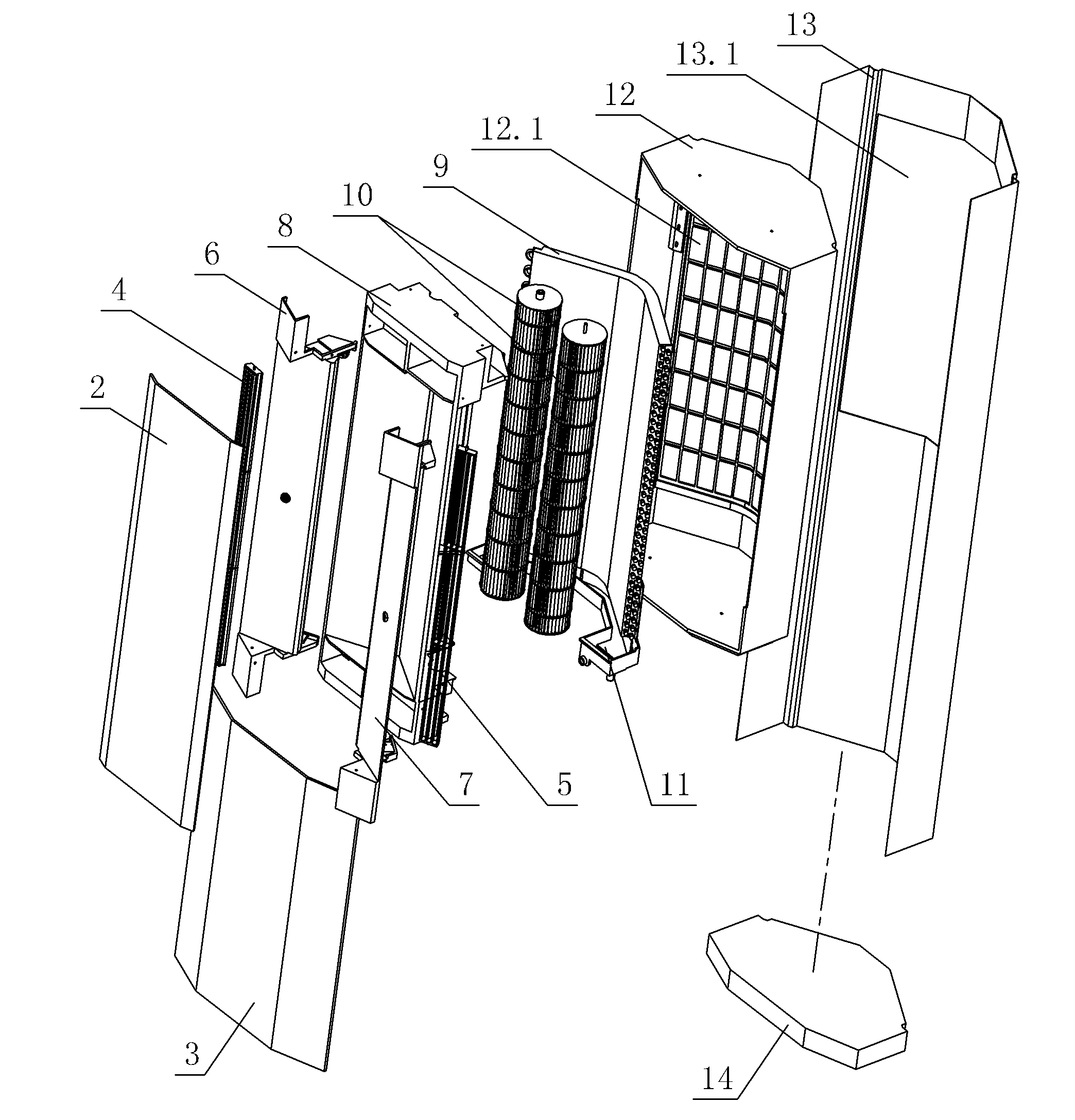

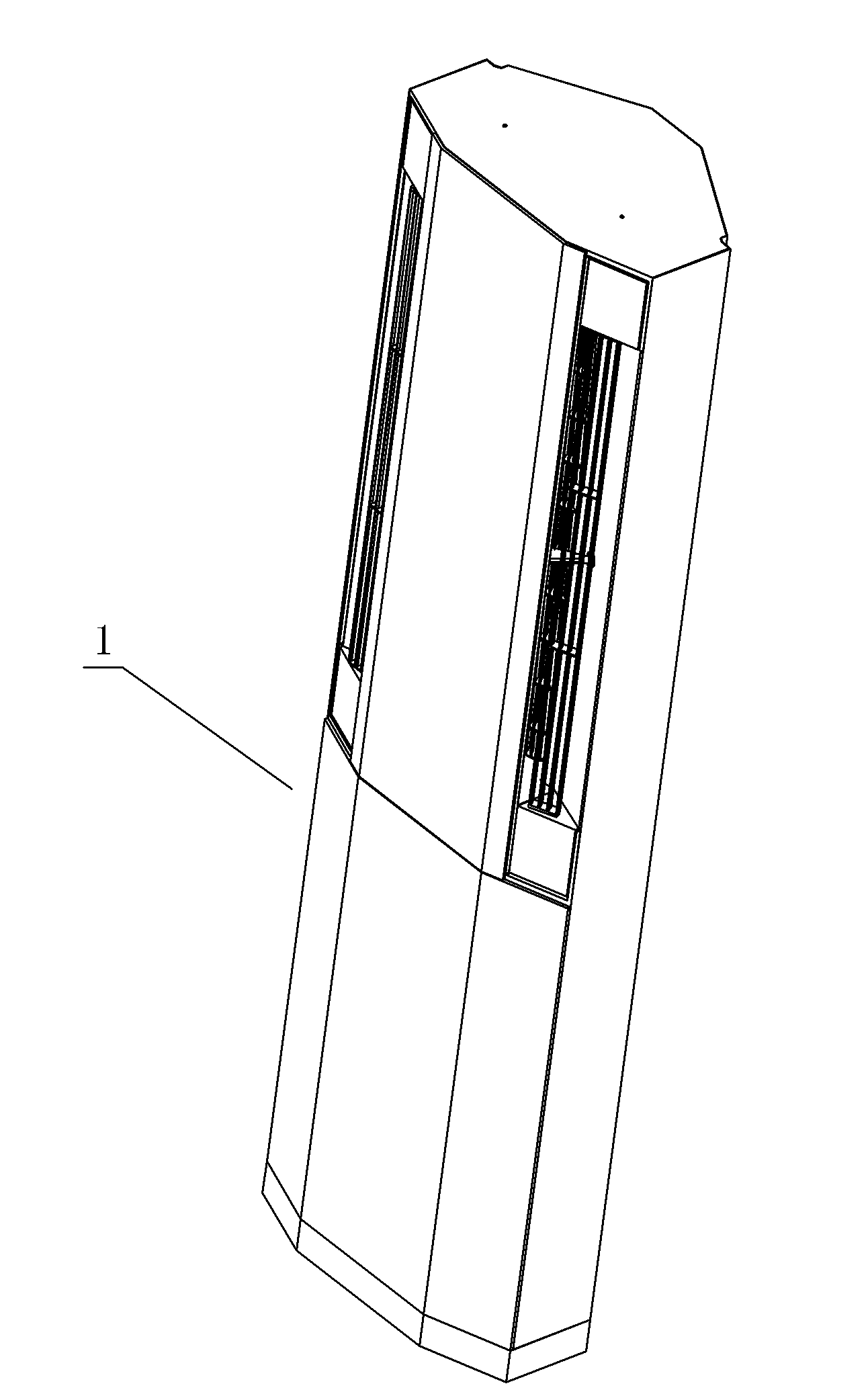

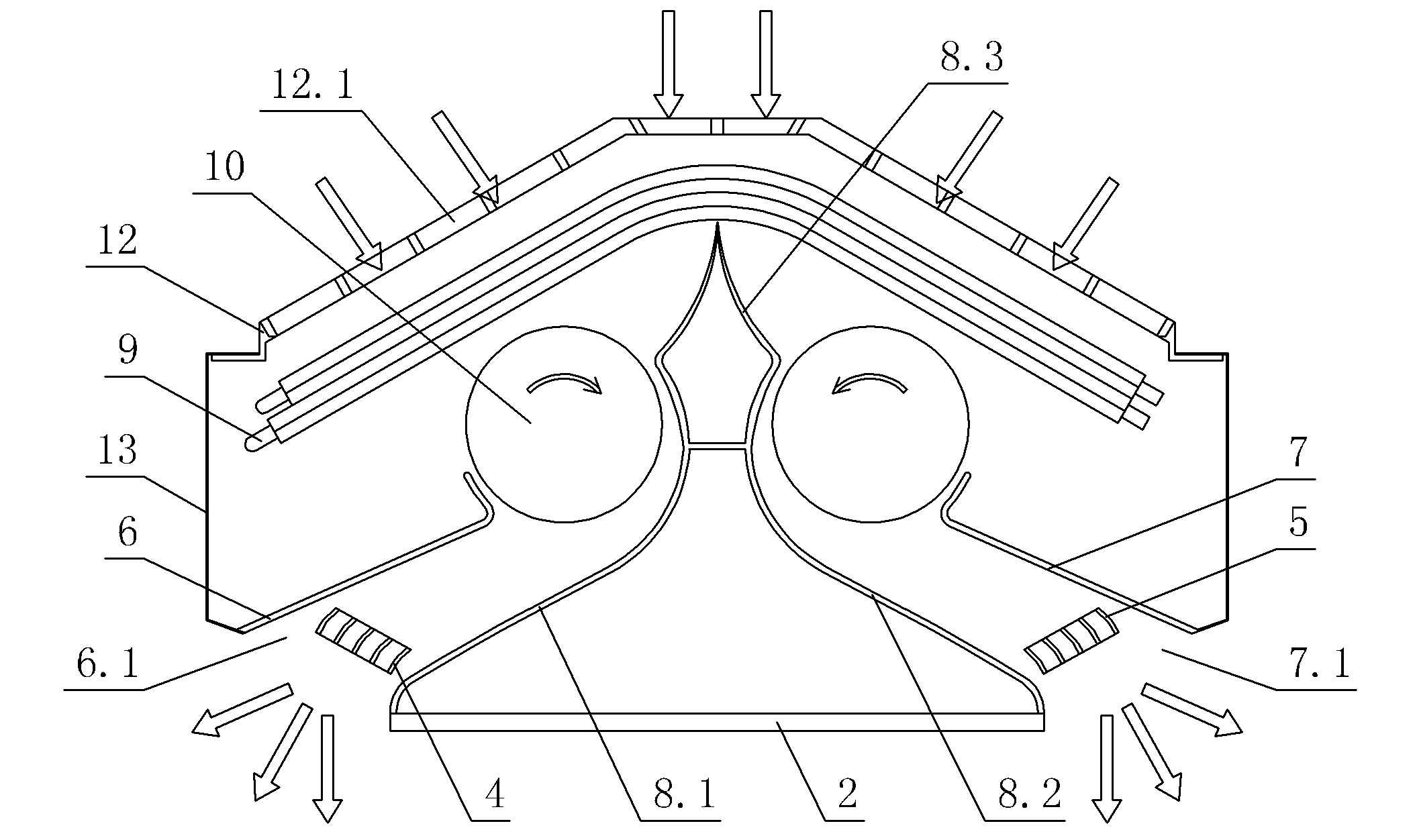

Indoor machine of two-tubular air conditioner

InactiveCN102147130AIncrease the effective heat transfer areaReduce wind resistancePump componentsLighting and heating apparatusEngineeringMicro heat exchanger

The invention discloses an indoor machine of a two-tubular air conditioner, which comprises a housing, a left and a right tubular fan wheels, a heat exchanger, an air inlet and an air outlet, wherein the housing consists of a front panel assembly and a shell; the left and the right tubular fan wheels are vertically arranged in the housing; the heat exchanger is arranged in the housing and positioned at the rear side of the tubular fan wheels; the air inlet is arranged behind the housing and the air outlet is arranged in front of the housing; the shell is connected to the rear side of the front panel assembly, the inner side of the shell is provided with a box body corresponding to the heat exchanger; back parts of the box body and the shell protrude outwards, the protruding part of the box body is provided with the air inlet, and the protruding part of the shell is provided with an air inlet window corresponding to the air inlet; the heat exchanger is bent towards the protruding direction of the back of the box body and arranged at a position close to the air inlet; and the housing is also internally provided with a volute assembly positioned between the two tubular fan wheels, the volute assembly comprises a left volute, a right volute, and a connecting bulge for connecting the left volute and the right volute together, and the connecting bulge extends to the position close to the heat exchanger. The invention has the advantages of larger air inlet area, compact assembly, low cost, small noise and high heat exchange efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

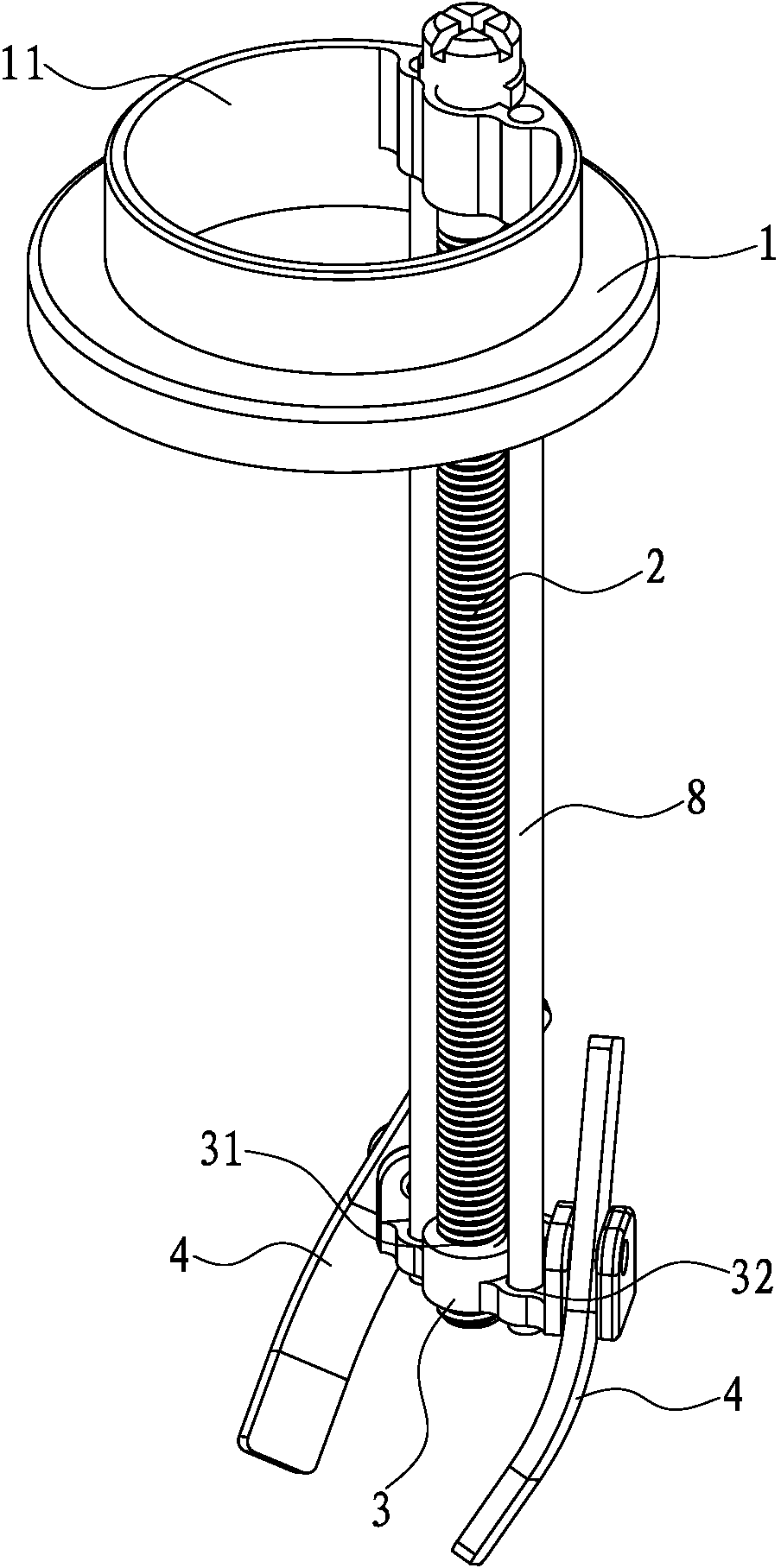

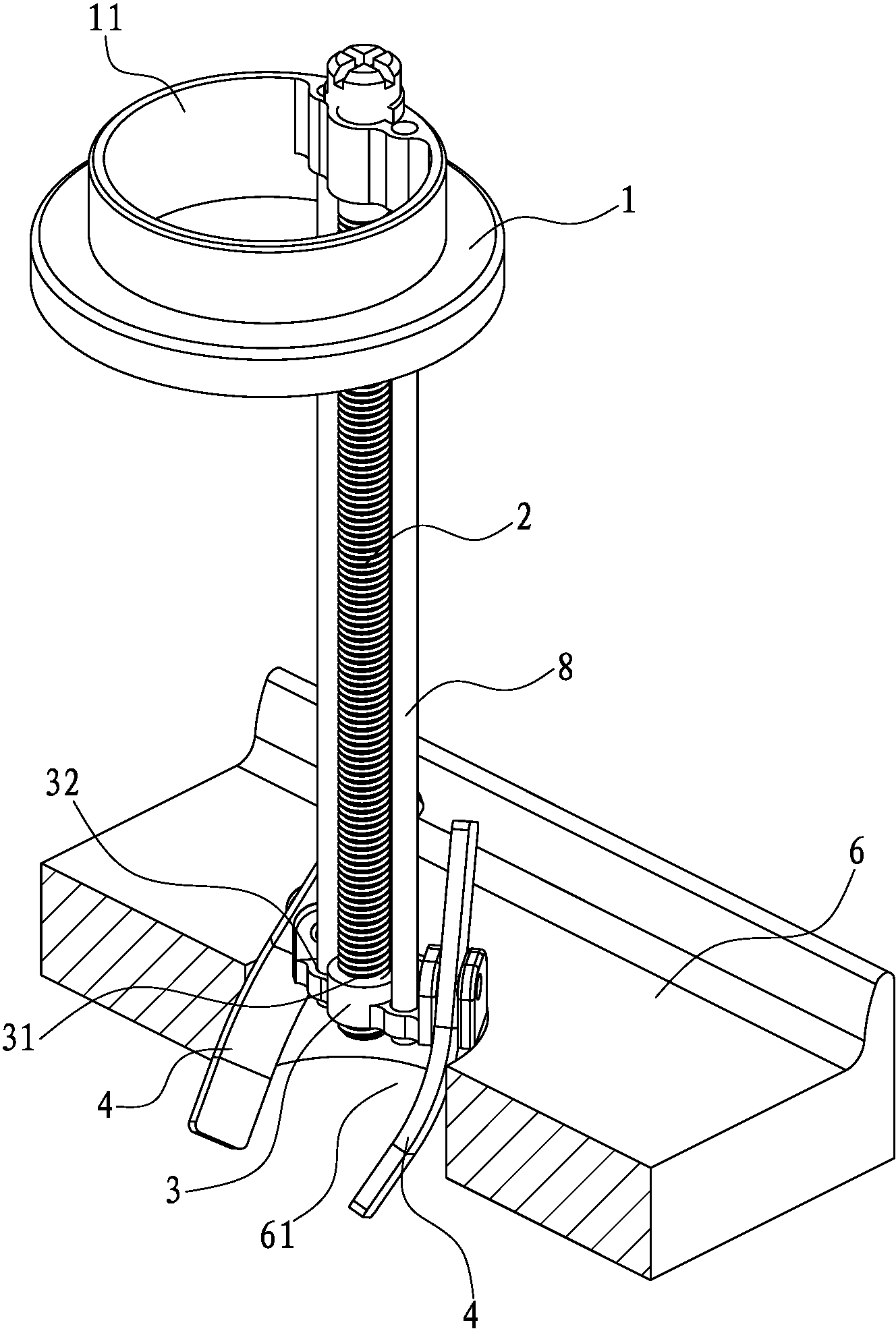

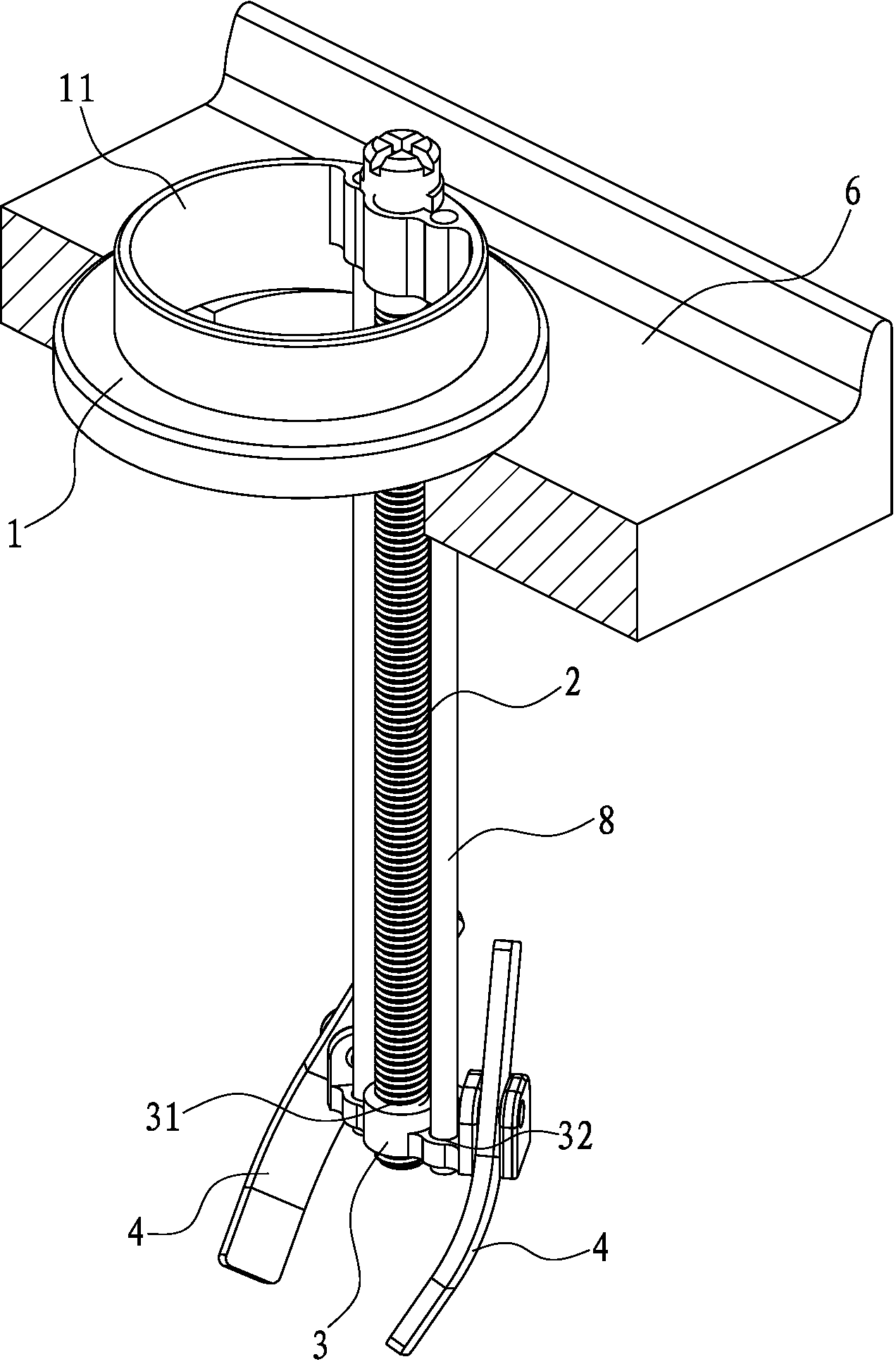

Fast installing mechanism on faucet platform

ActiveCN103243782ASimple structureStable structureDomestic plumbingAngle alphaMechanical engineering

The invention discloses a fast installing mechanism on a faucet platform. The fast installing mechanism comprises an installing seat, a screw, a nut, a lifting seat and two lever rotating arms, wherein the lifting seat rises and falls along with the matching and the relative rotation of the screw and the nut; the installing seat has an installing hole, and the screw is arranged at one side of the installing hole; the two lever rotating arms are pivoted on the lifting seat and are symmetrically positioned at the two sides of the screw; and an included angle alpha between rivoting shafts of the two lever rotating arms meets the condition that alpha is more than 0 degree and less than 180 degrees. The fast installing mechanism not only can realize installation of a faucet on the platform surface, but also can be applicable to various types of faucets, and also can provide enough-large installation space.

Owner:XIAMEN LOTA INT CO LTD

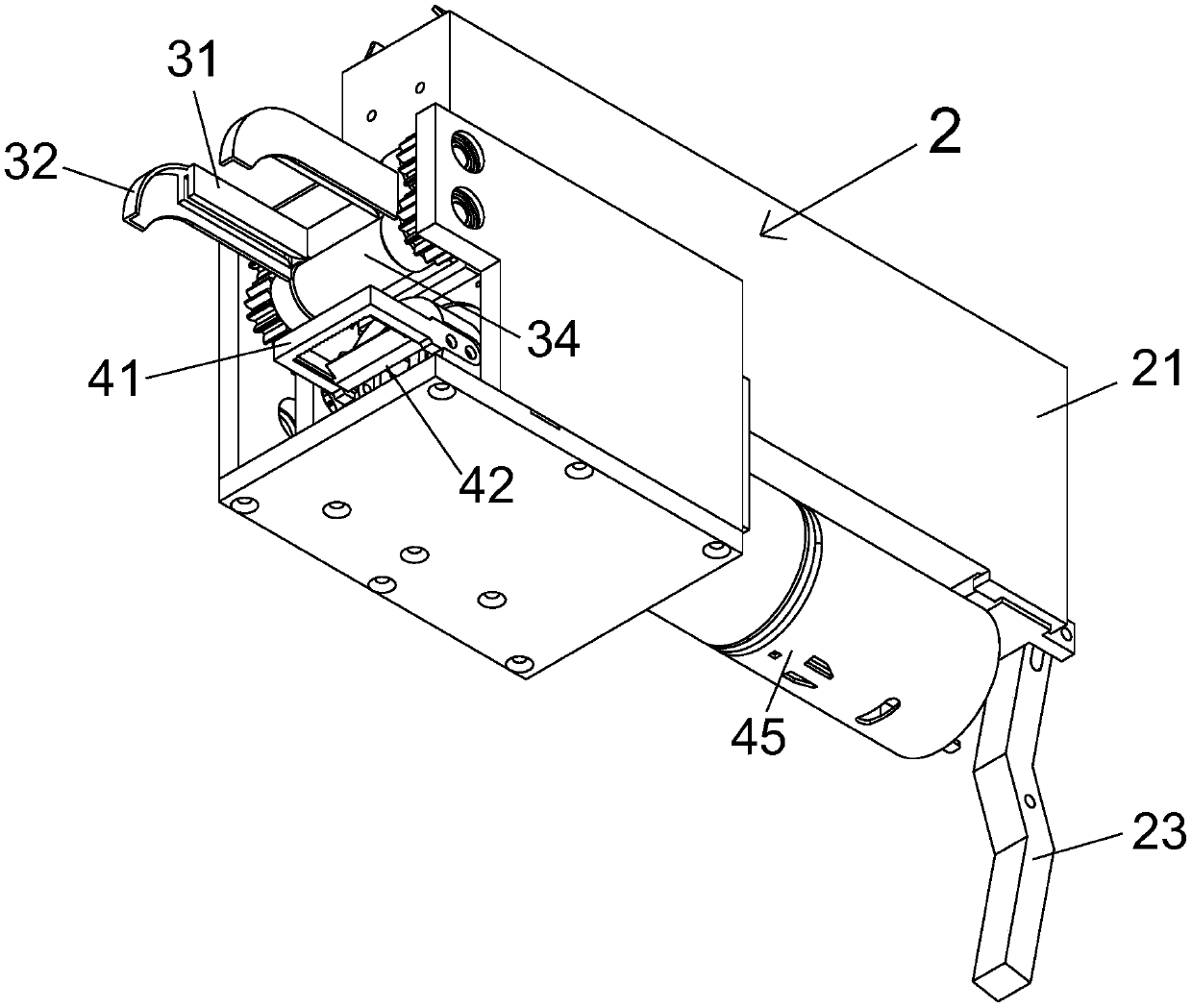

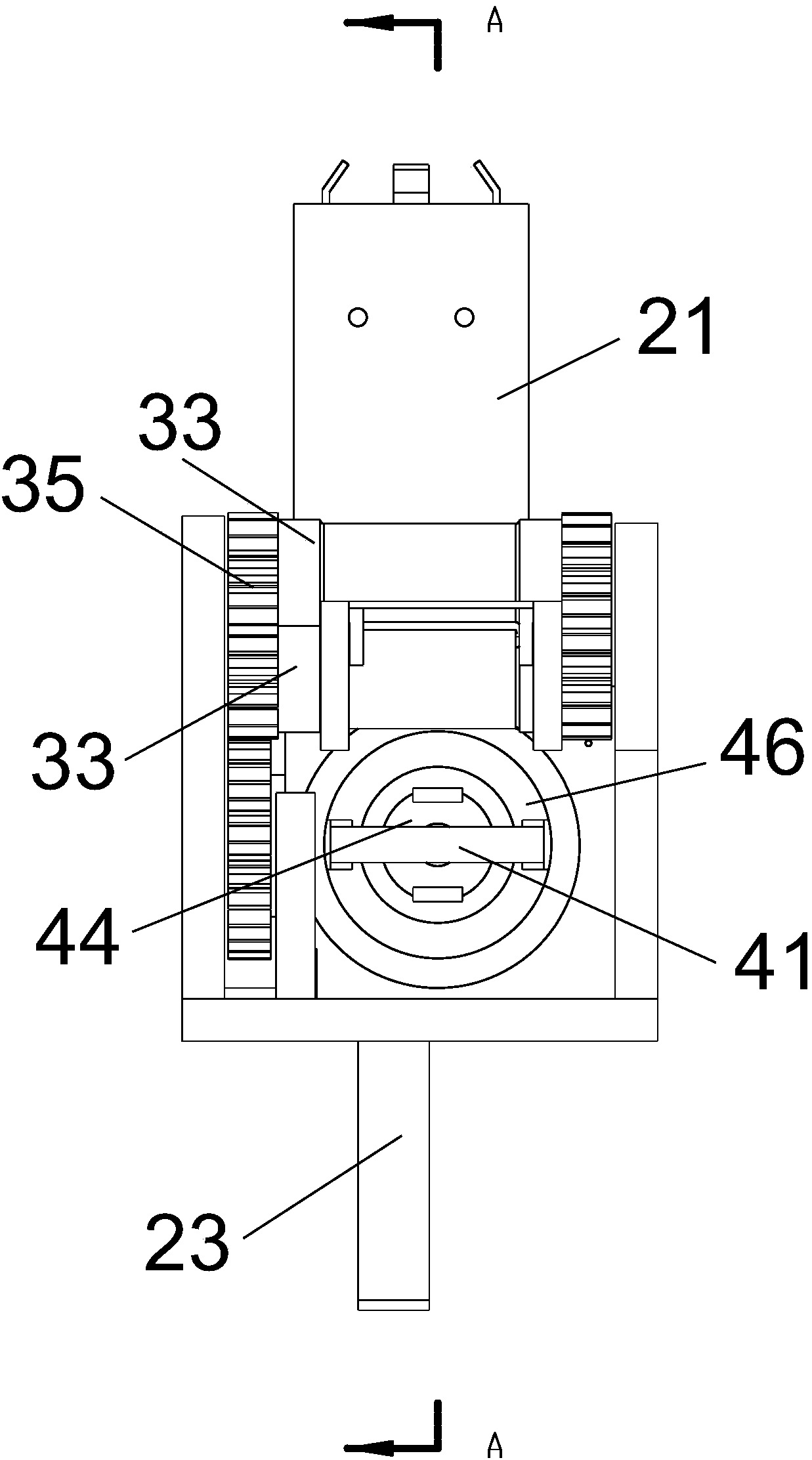

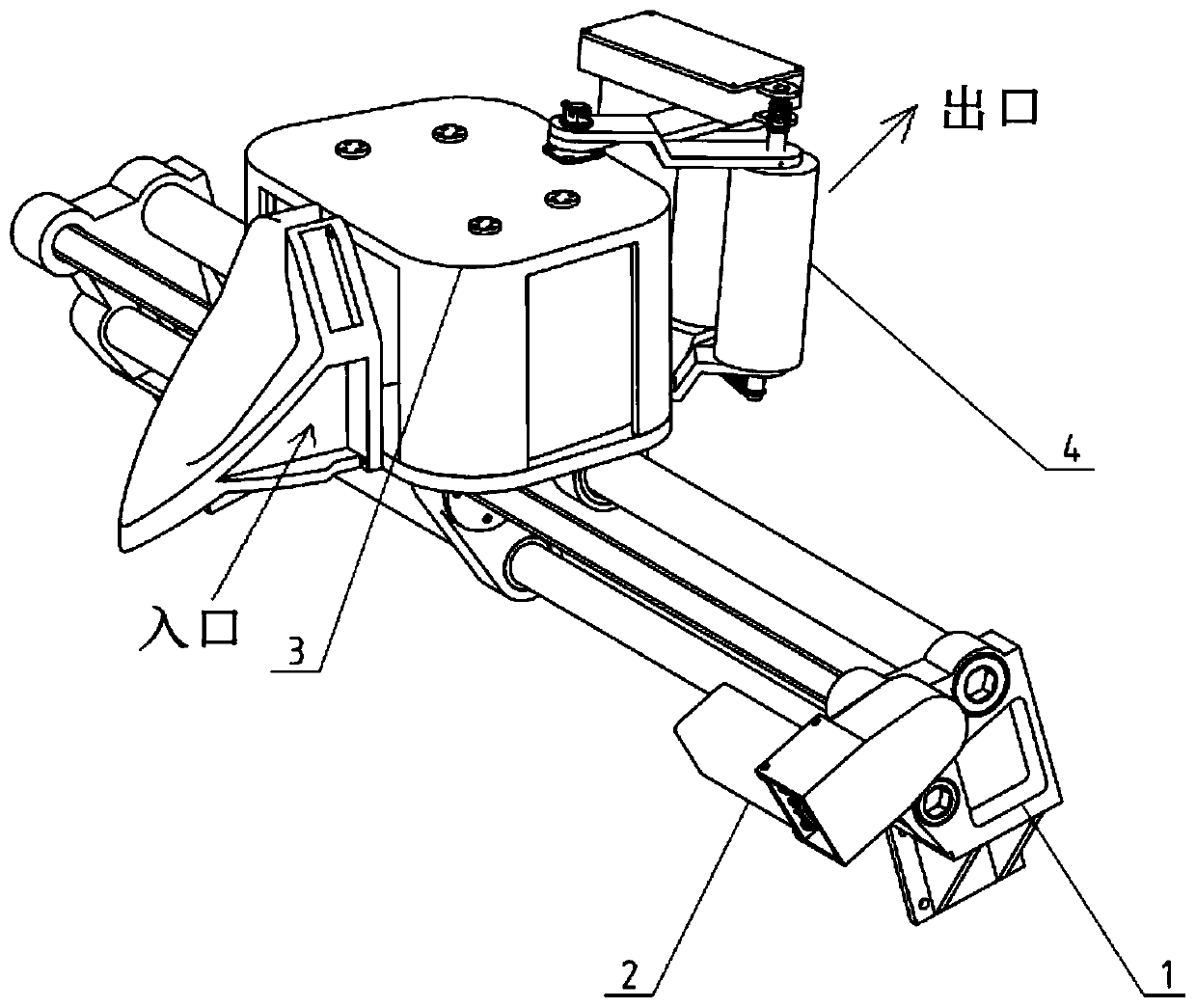

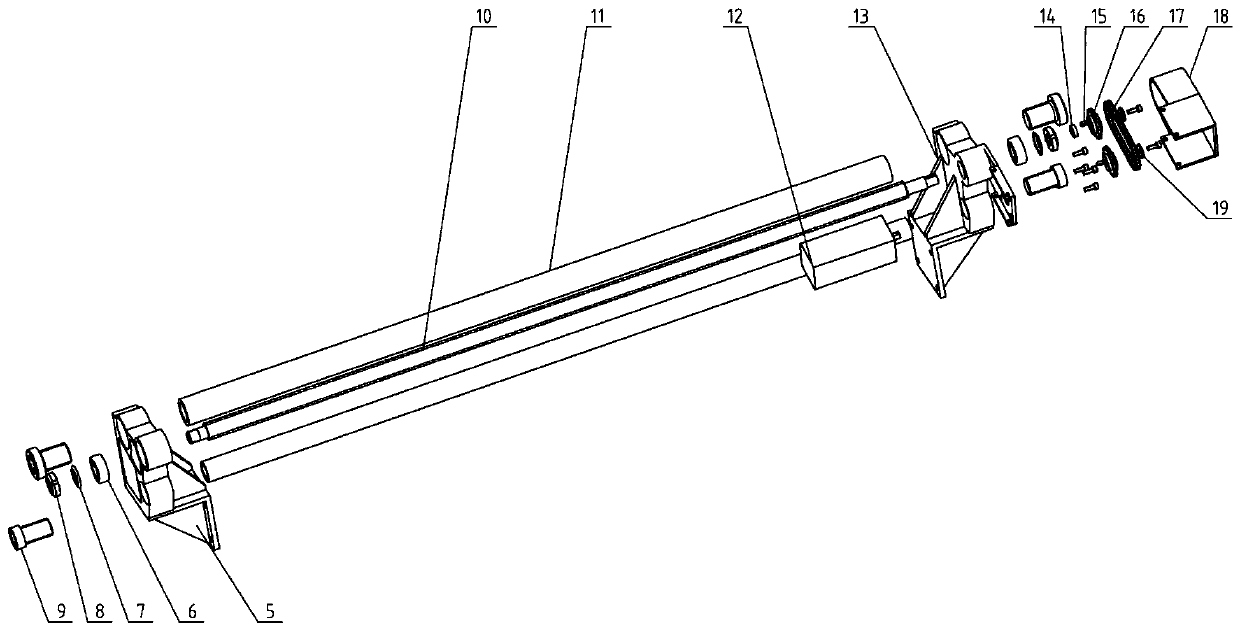

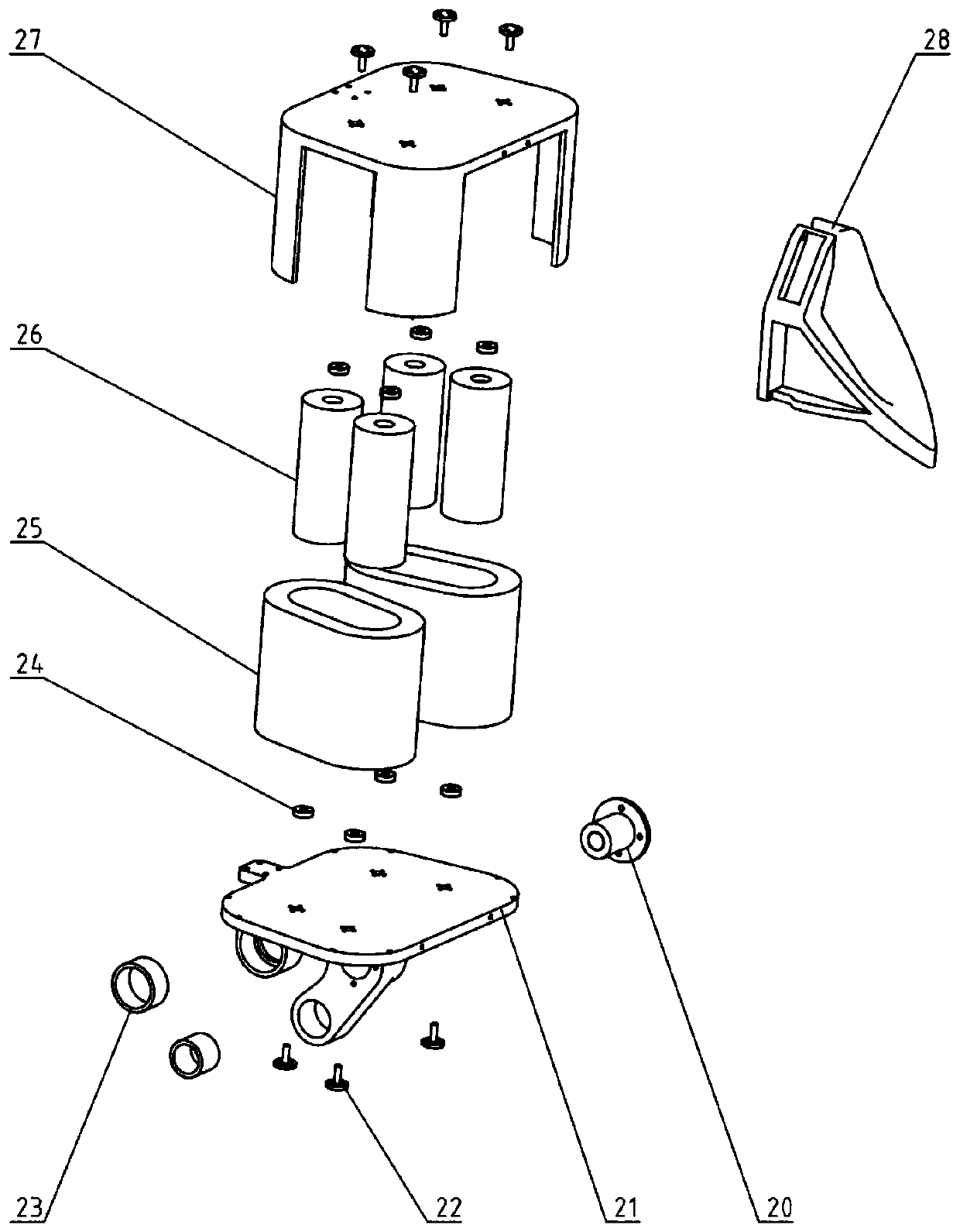

Sorting and conveying mechanism for groove workpieces

ActiveCN110451228AReasonable structural designHigh degree of automationConveyor partsEngineeringMechanical equipment

The invention discloses a sorting and conveying mechanism for groove workpieces, and belongs to the field of workpiece conveying and machining mechanical equipment. A material transferring pipe is vertically and fixedly arranged in the middle of the upper side of a material transferring support, a horizontal moving push plate is horizontally and fixedly provided with a material pushing pressing rod along the side of the material transferring material pipe, a material guide inclined plate is obliquely and downwards fixedly arranged on one side below the material transferring material pipe, anda material bearing baffle is arranged on one side of a turnover baffle; a material guiding pipe is vertically and fixedly arranged on the material transferring support at the lower side of the material transferring pipe, a material guiding rotating plate is arranged on the material transferring support on one side of the material guiding pipe, the end part the lower side of a transferring guide plate is rotationally connected to the material transferring support, a material bearing rotating plate is arranged on the upper side of the transferring guide plate, and a material transferring belt ishorizontally arranged on the upper side of a conveying base. The sorting and conveying mechanism has the advantages that the structural design is reasonable, the groove workpieces can be convenientlyand efficiently subjected to directional arrangement in the discharging process, automatic overturning and conveying of the groove workpieces can be realized, the workpiece feeding and conveying automation degree is improved, and the requirements of production and use are met.

Owner:泰州市宠友宠物服务有限公司

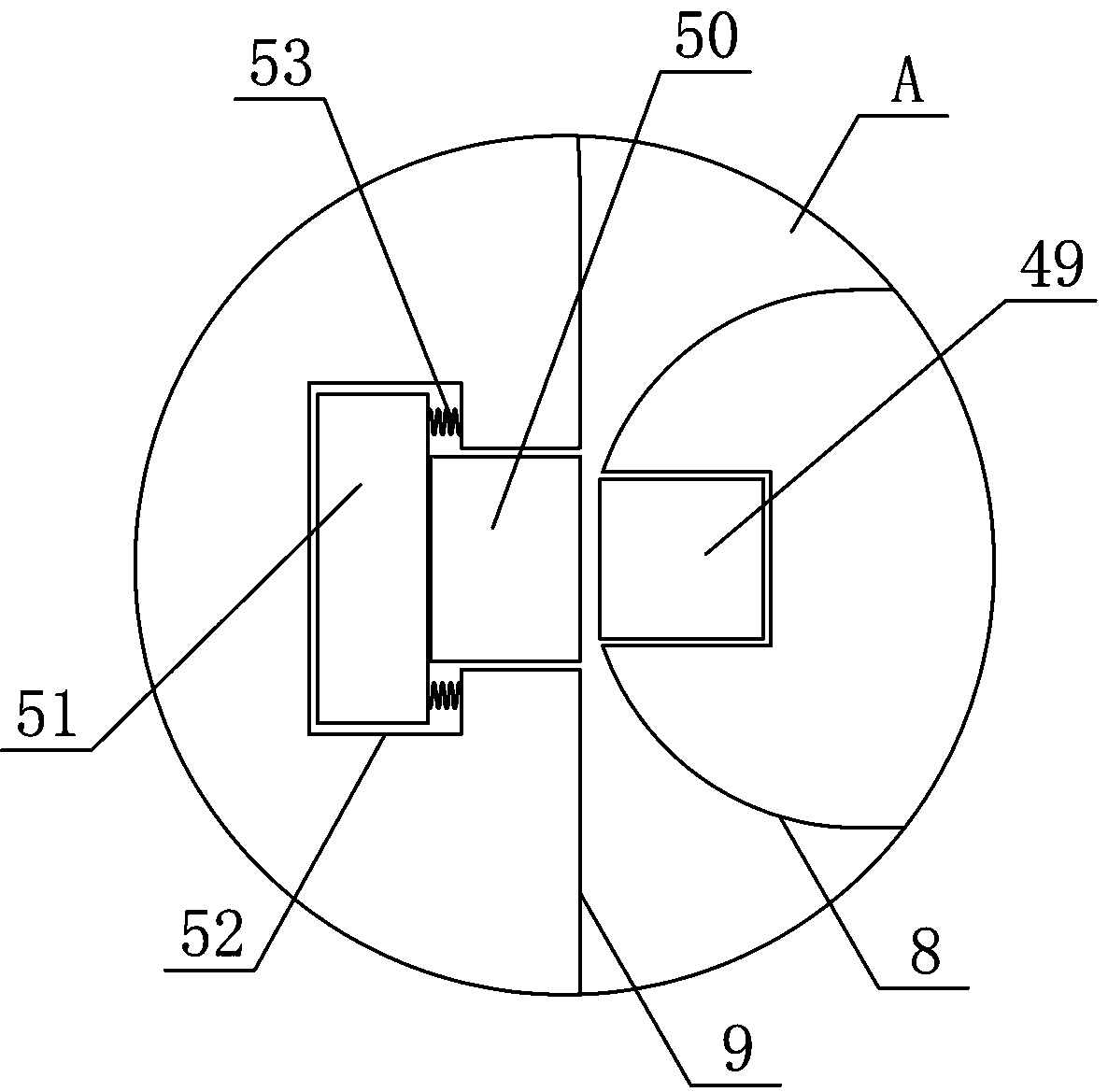

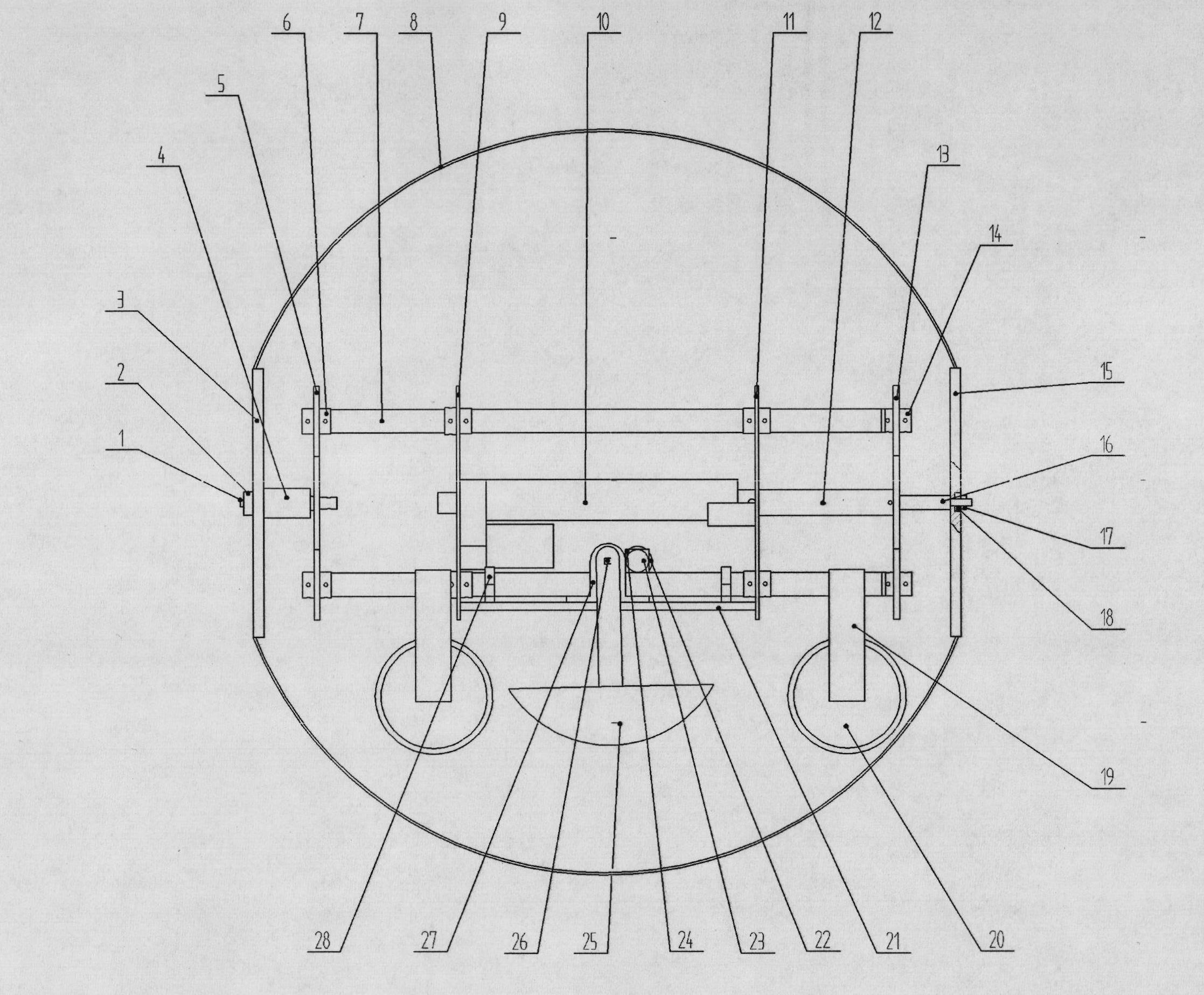

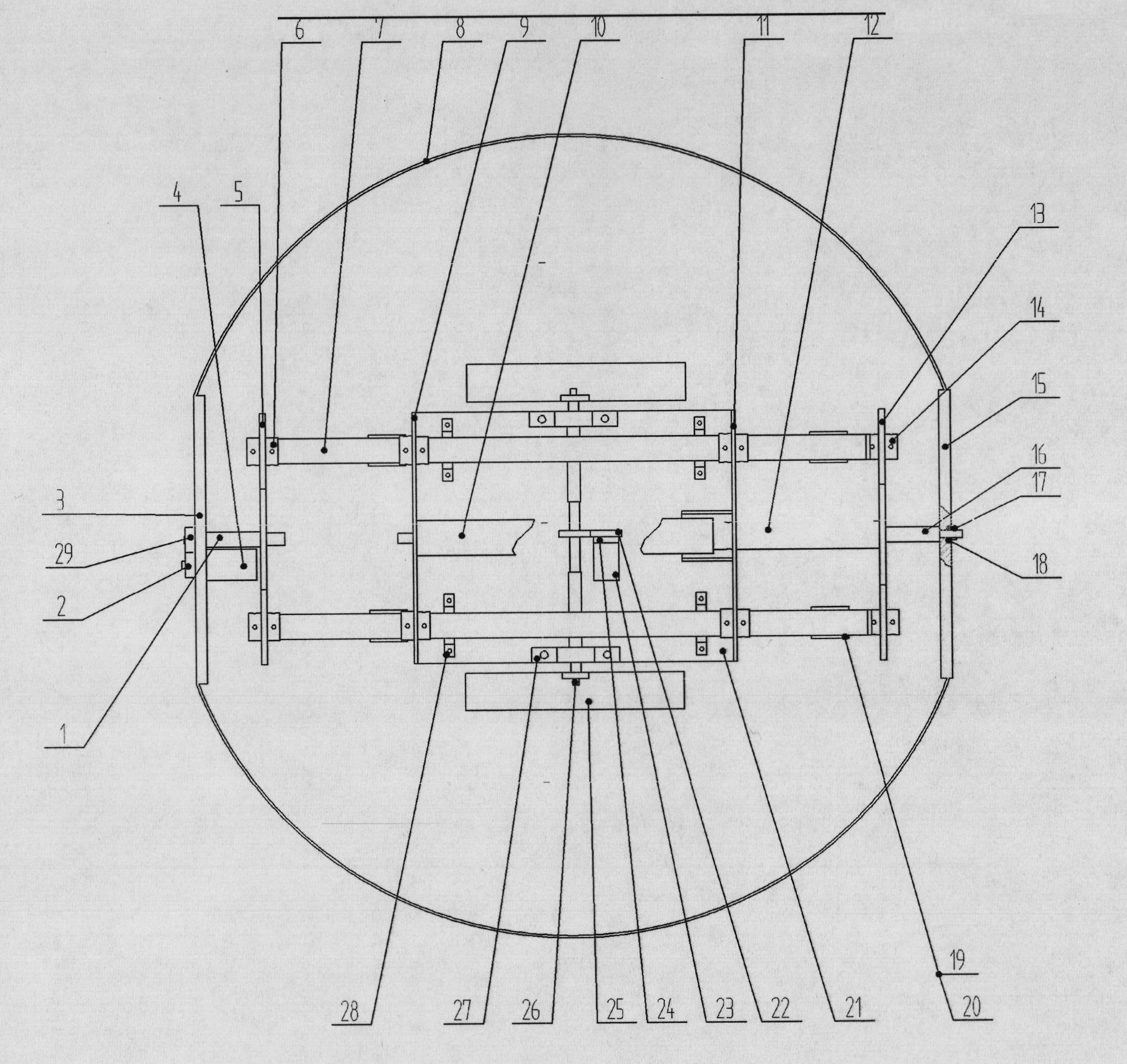

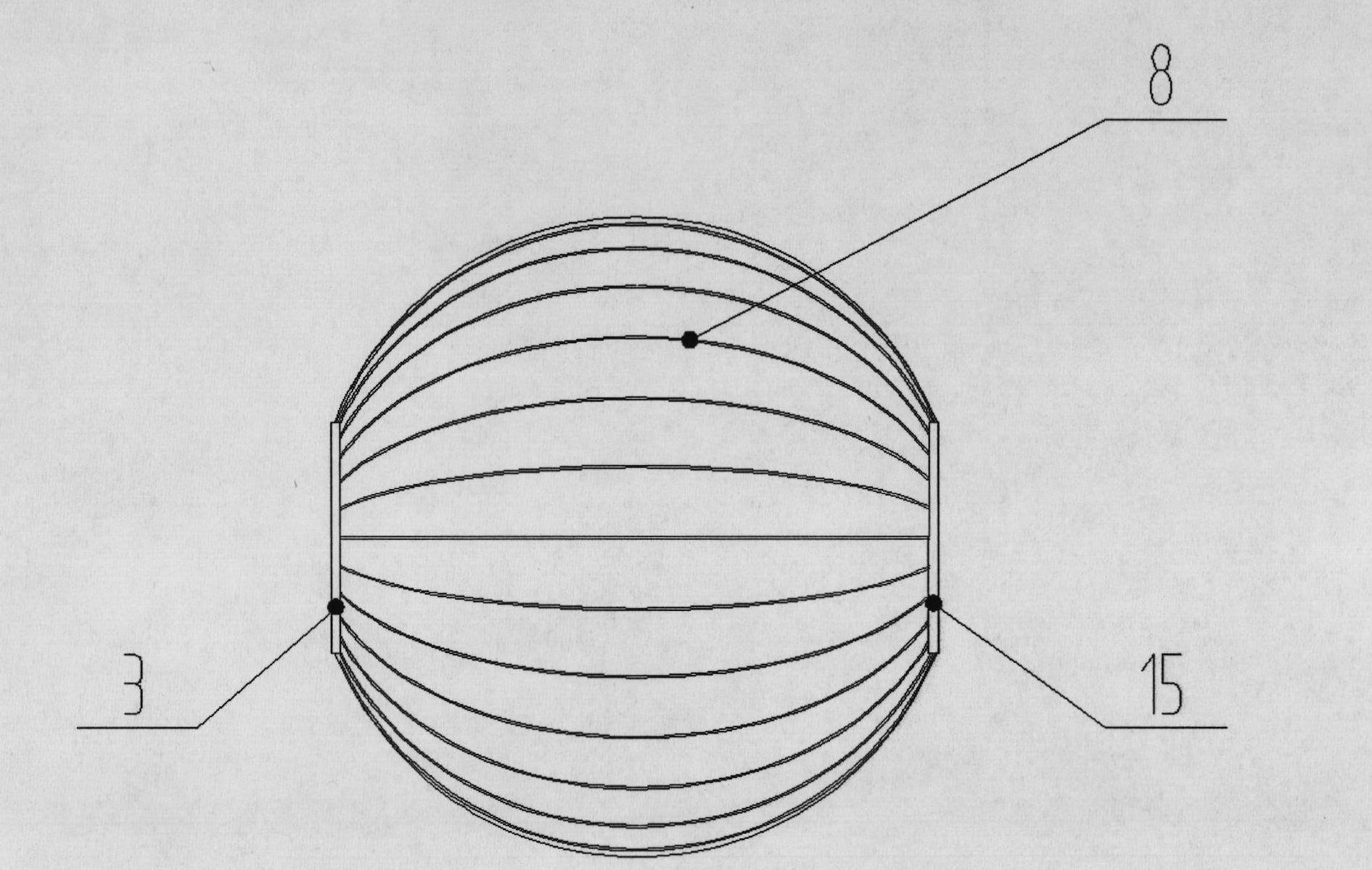

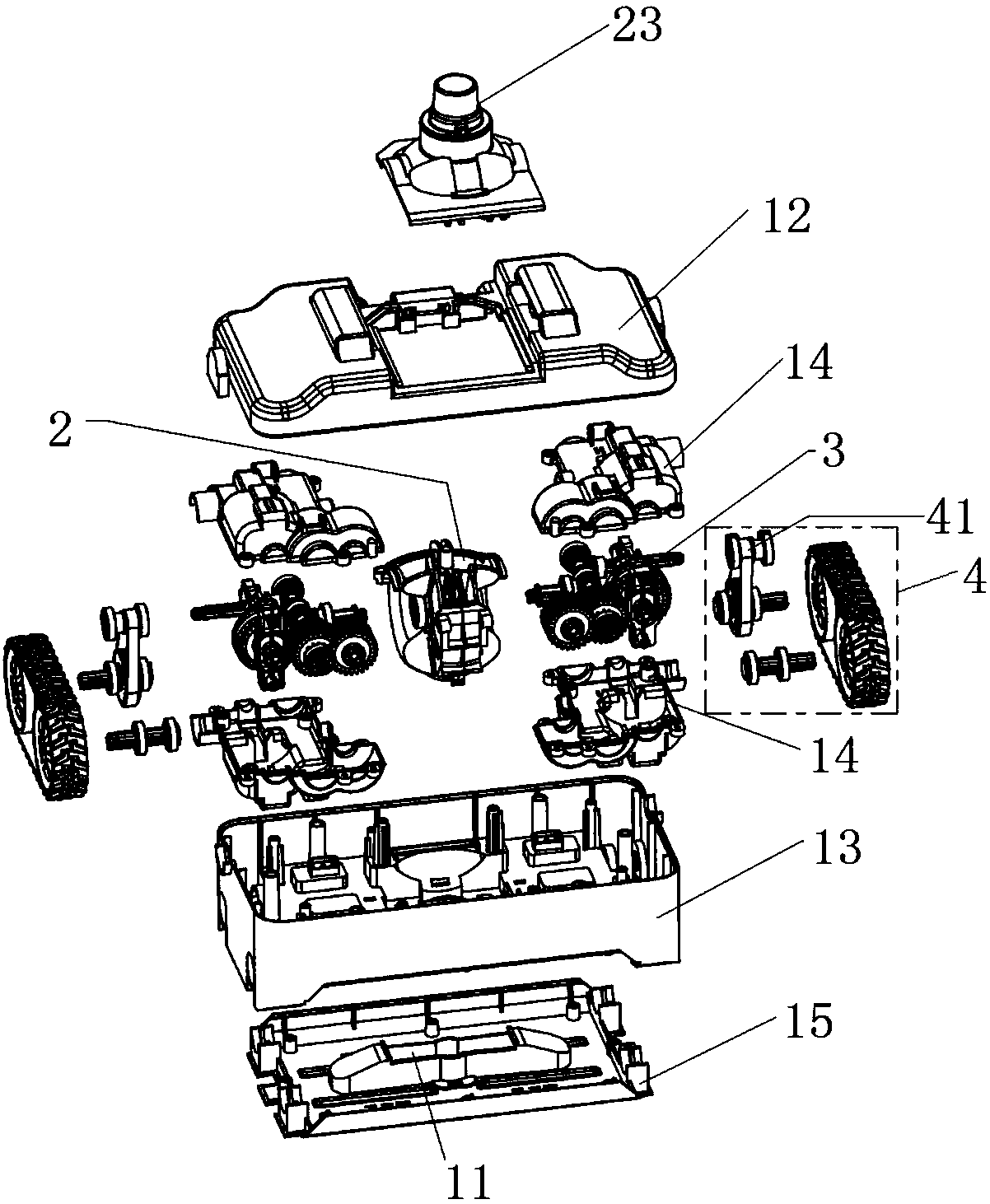

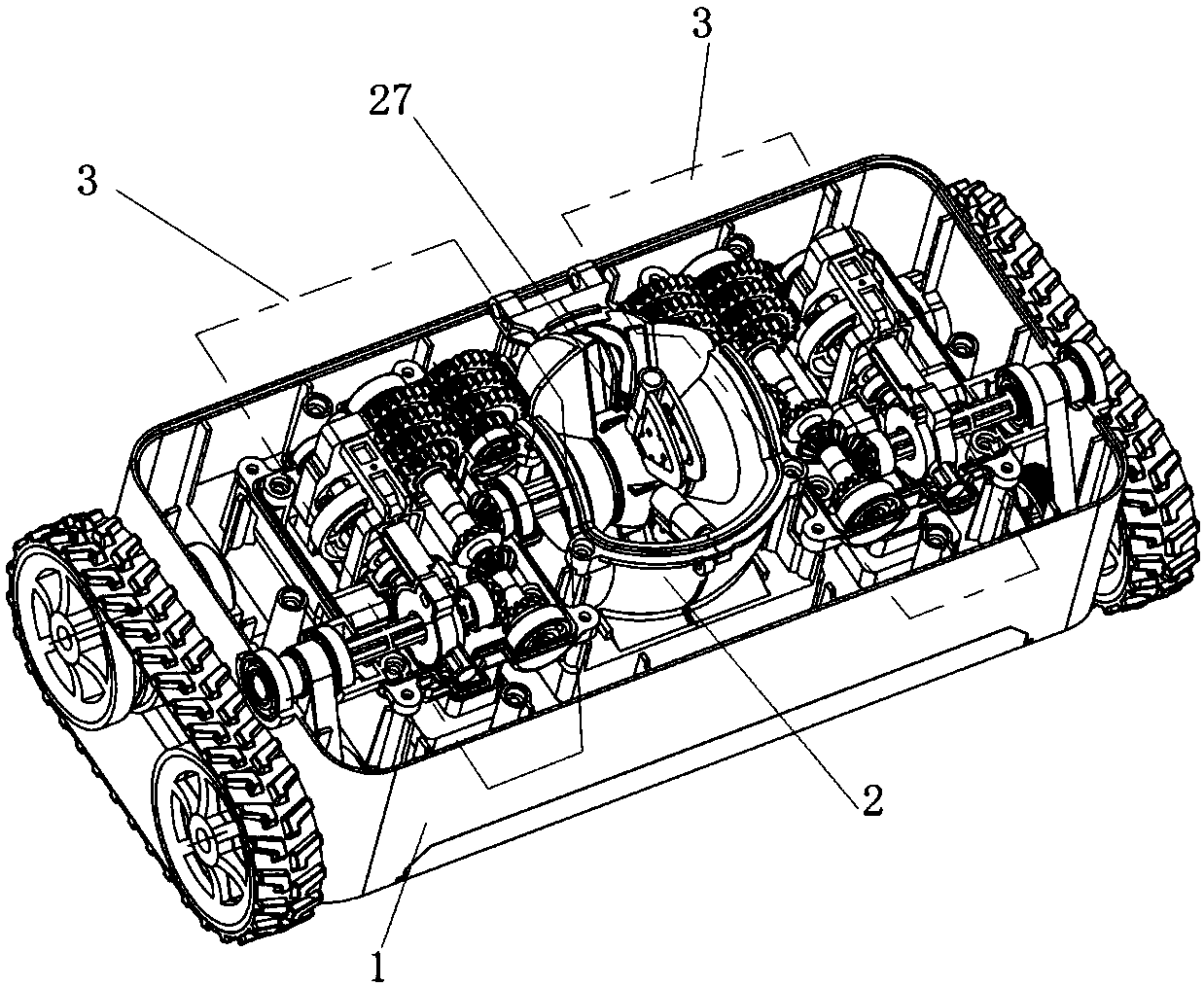

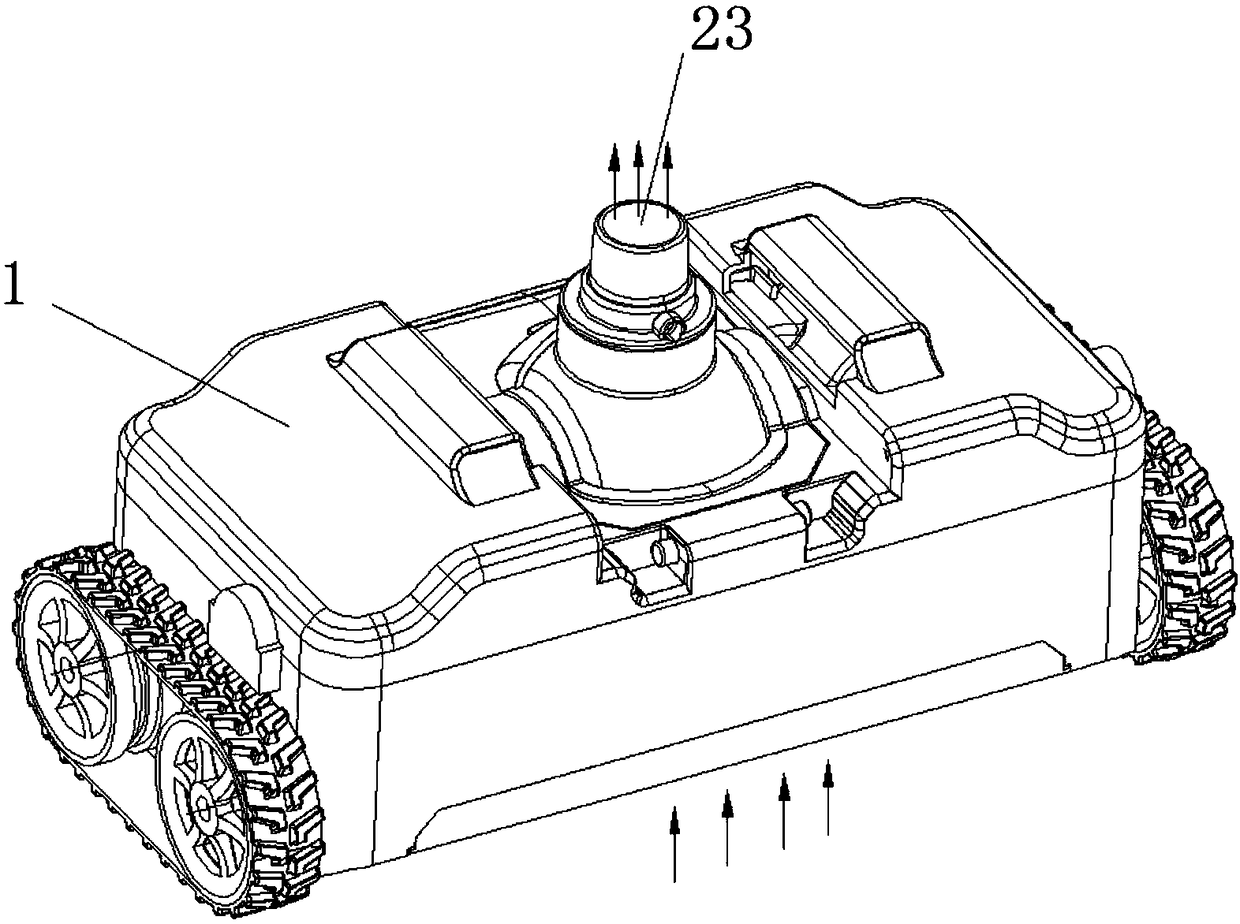

Sphere-wheel compound transformable mobile robot

A sphere-wheel compound transformable mobile robot comprises a spherical shell, a framework in the spherical shell, a sphere driving device, a spherical shell expansion transforming device and a wheel-type driving device. The sphere driving device, the spherical shell expansion transforming device and the wheel-type driving device are arranged on the framework in the spherical shell. The spherical shell is formed by a plurality of flat radial elastic materials, two ends of the elastic material are fixed on the framework in the spherical shell, and the bending transformation of the elastic materials of the spherical shell is realized by the spherical shell expansion transforming device, so that the role shifting between the spherical and wheel-type robots is realized. When the spherical shell is in the state of sphere or similar sphere, the mobile robot moves through the rolling of the sphere; when the spherical shell is in the state of cylinder or similar cylinder, the robot moves through wheel-type driving. The characteristics of the spherical robot and the wheel-type robot are mixed in the sphere-wheel compound transformable robot, and the robot has different movement models and good movement characteristics and can adapt to different road conditions, so that the robot has wide application prospect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

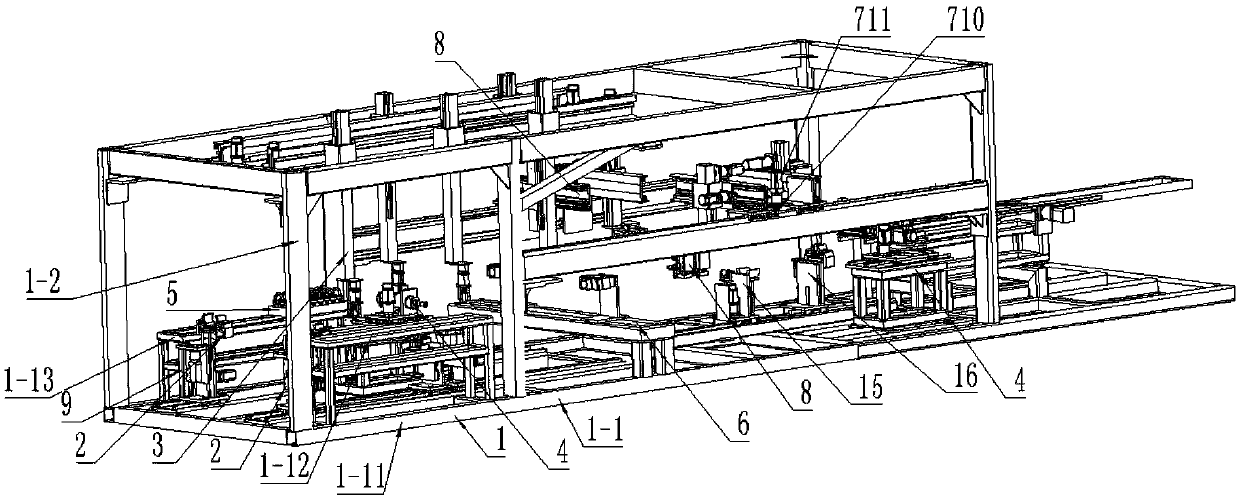

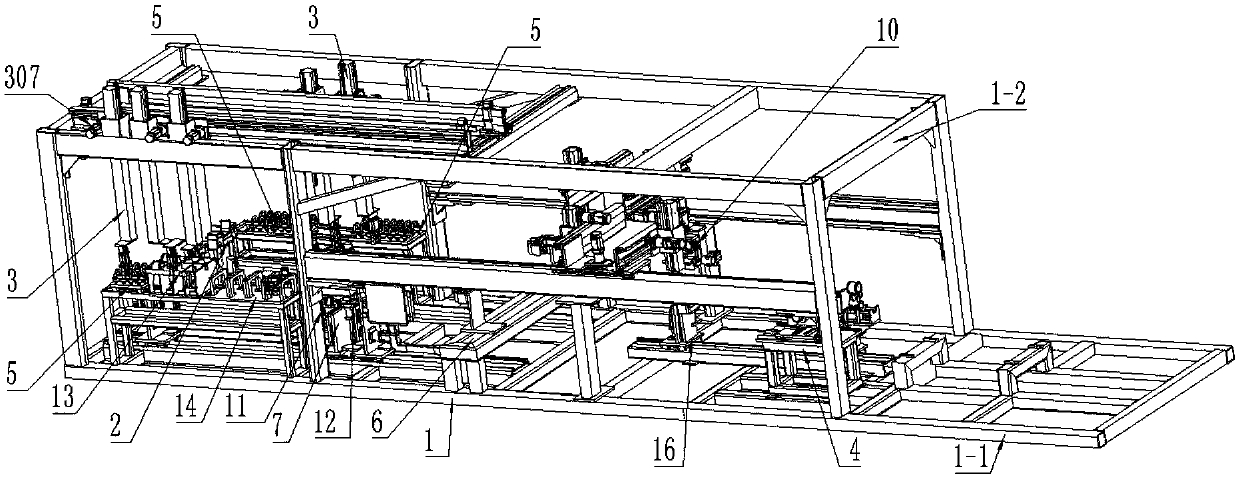

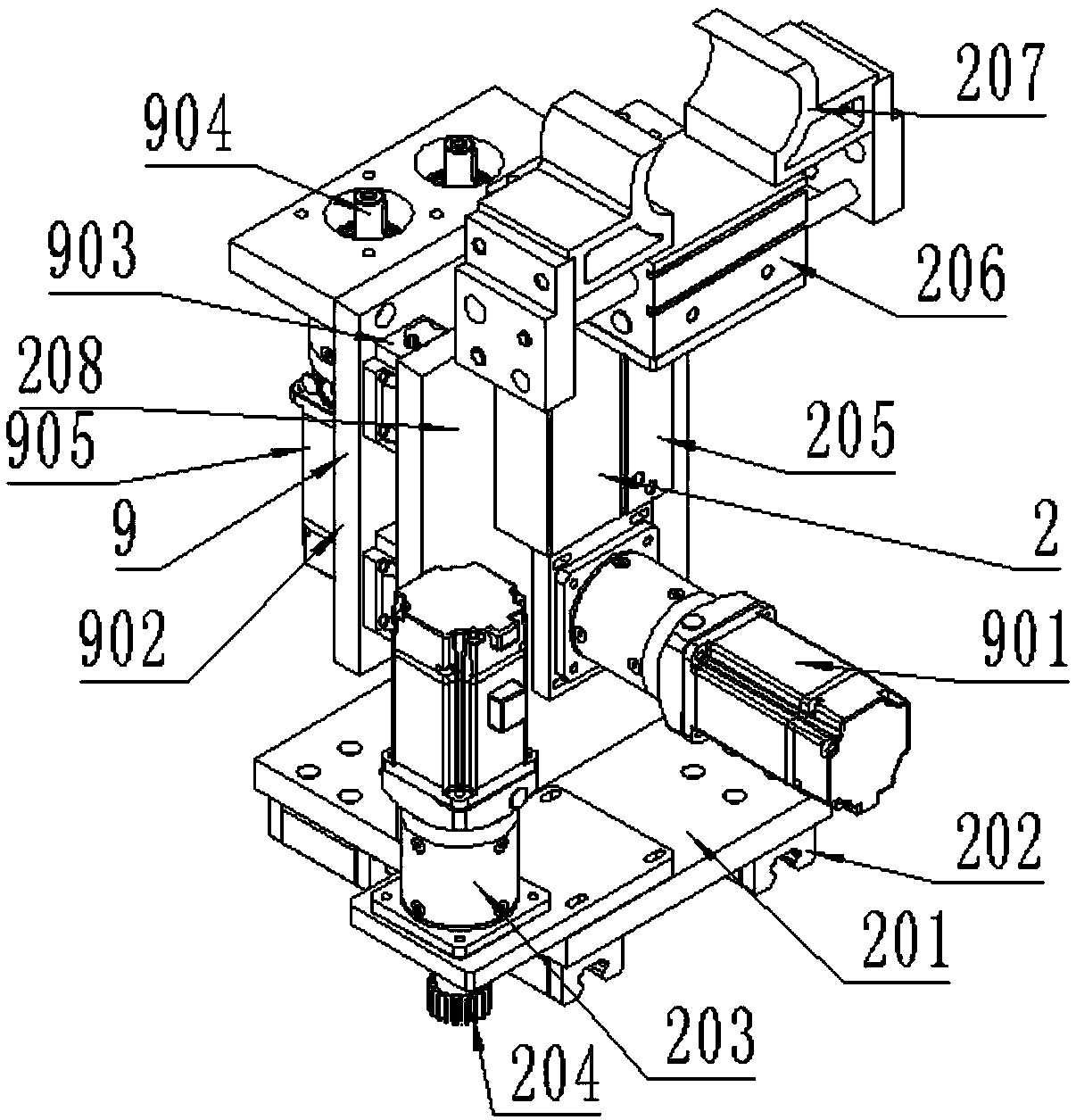

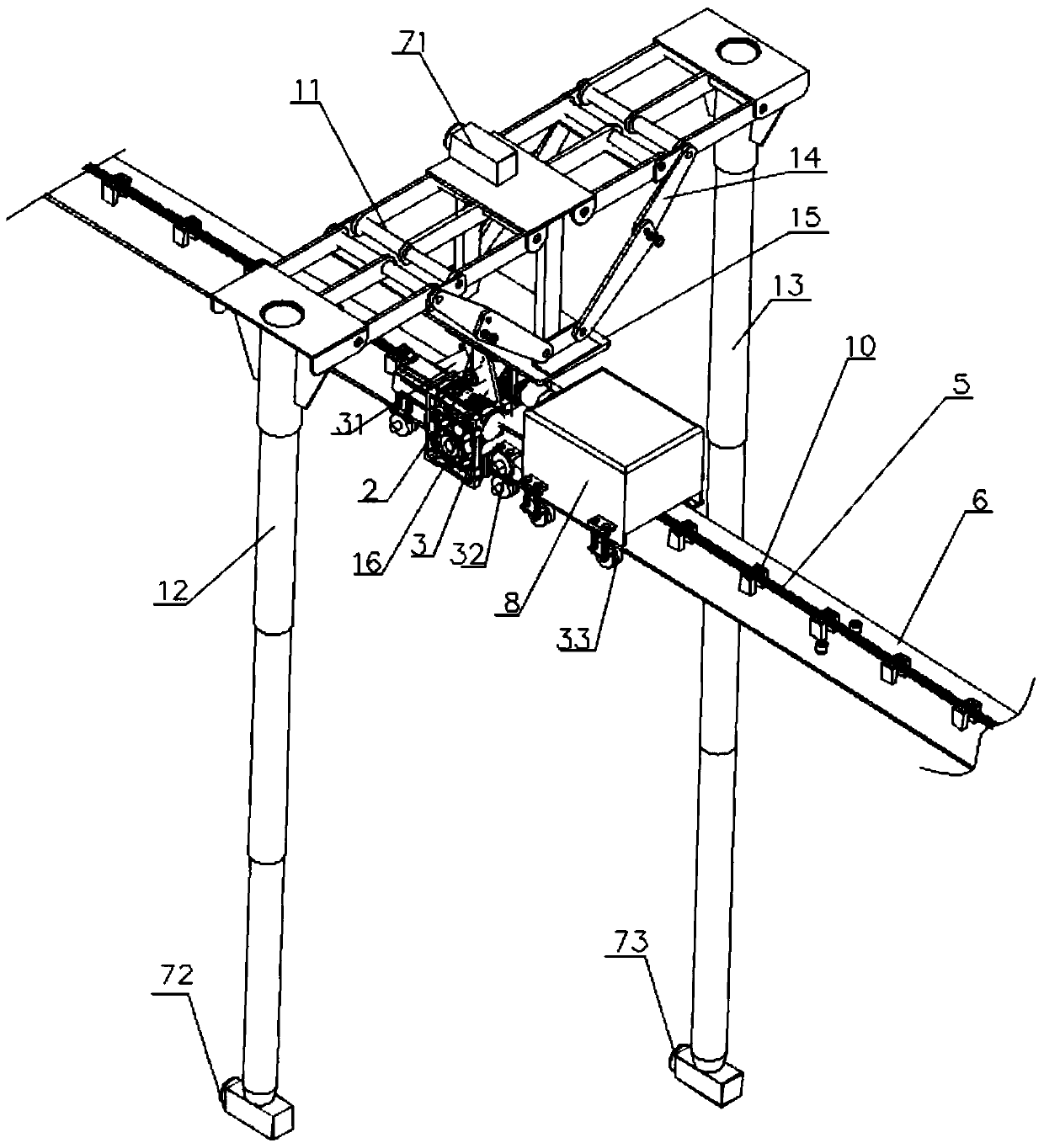

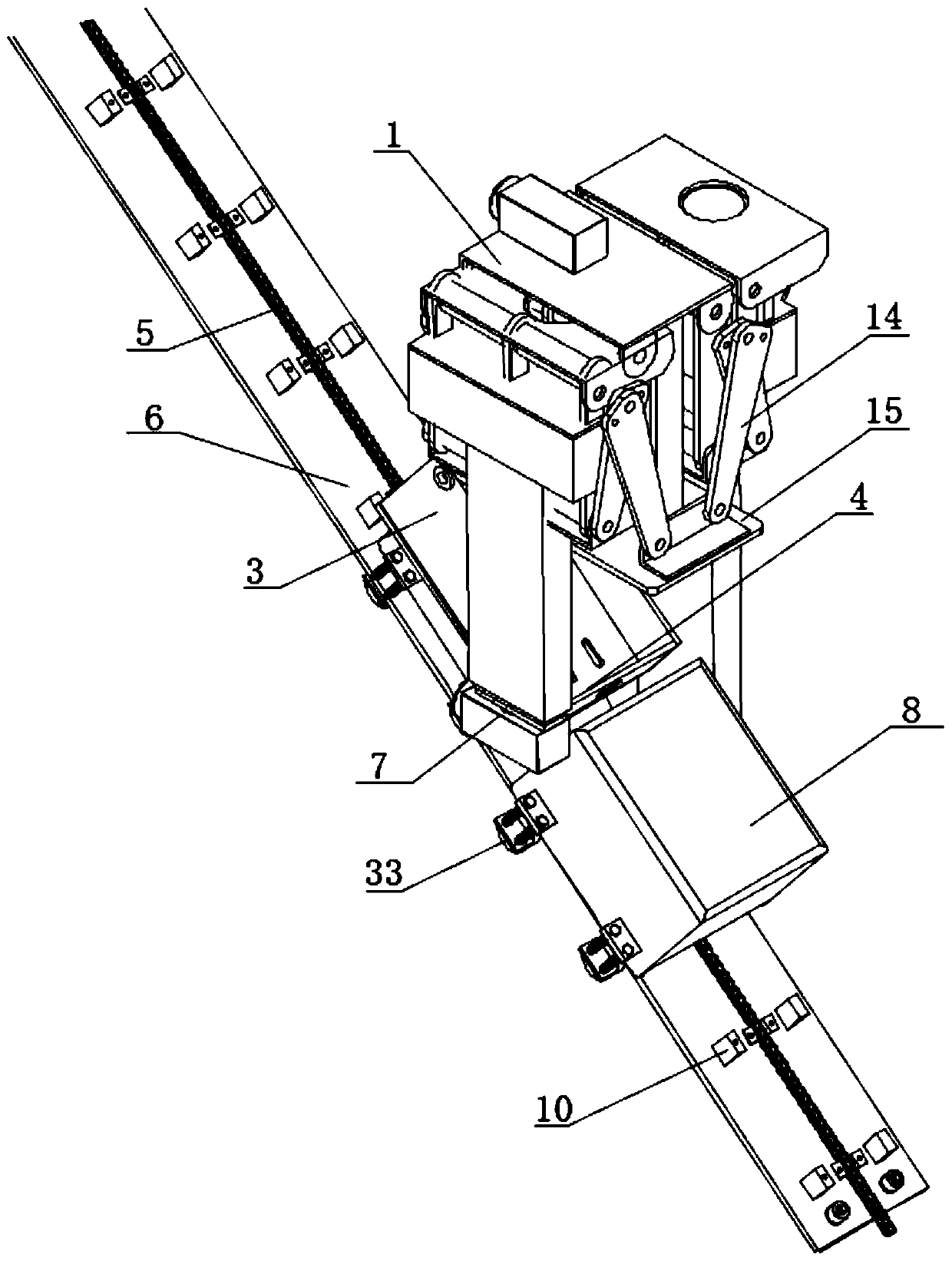

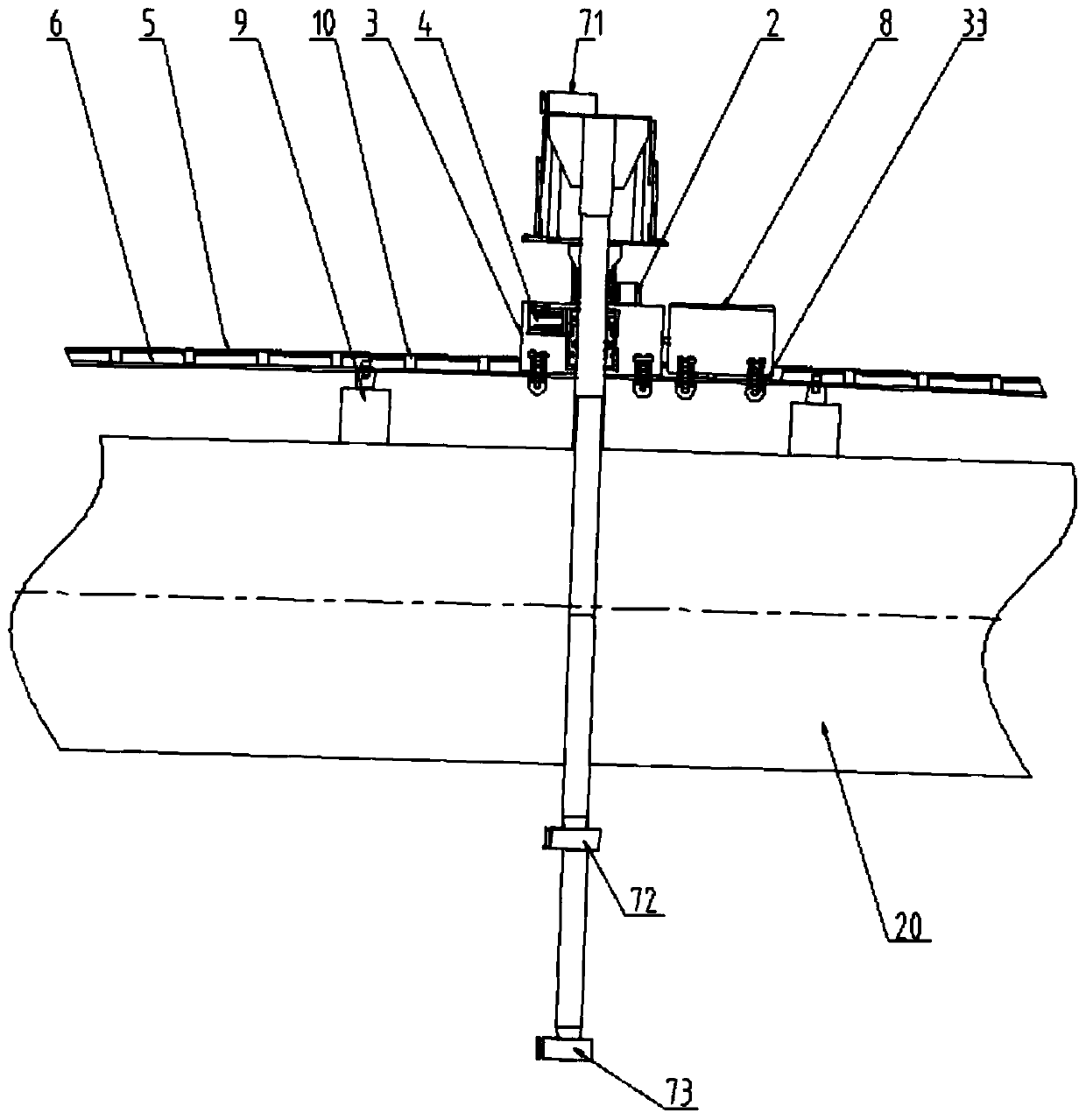

High-speed rail cantilever pre-assembling line

PendingCN109551226ARealize automatic pre-assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusCantileverMechanical engineering

The invention relates to a high-speed rail cantilever pre-assembling line which comprises a rack, a flat cantilever clamping assembly, an inclined cantilever clamping assembly and an assembling mechanism. The flat cantilever clamping assembly, the inclined cantilever clamping assembly and the assembling mechanism are installed on the rack. The flat cantilever clamping assembly and the inclined cantilever clamping assembly are arranged on the left side and the right side of the rack correspondingly. The flat cantilever clamping assembly comprises a flat cantilever clamping moving mechanism anda flat cantilever set clamping mechanism. The inclined cantilever clamping assembly comprises an inclined cantilever clamping moving mechanism and an inclined cantilever set clamping mechanism. The assembling mechanism comprises an assembling moving mechanism and a set screwing mechanism. The assembling moving mechanism comprises an inclined cantilever assembling moving mechanism and a flat cantilever assembling moving mechanism. The flat cantilever assembling moving mechanism can drive a flat cantilever to move transversely and move longitudinally, the inclined cantilever assembling moving mechanism can drive a flat cantilever to move transversely and longitudinally, and the set screwing mechanism can be used for connecting a flat cantilever set with the flat cantilever and connecting aninclined cantilever set with the inclined cantilever. Automatic pre-assembling of a high-speed rail cantilever can be achieved, and the assembling efficiency is high.

Owner:龙口市汇金达智能设备有限公司

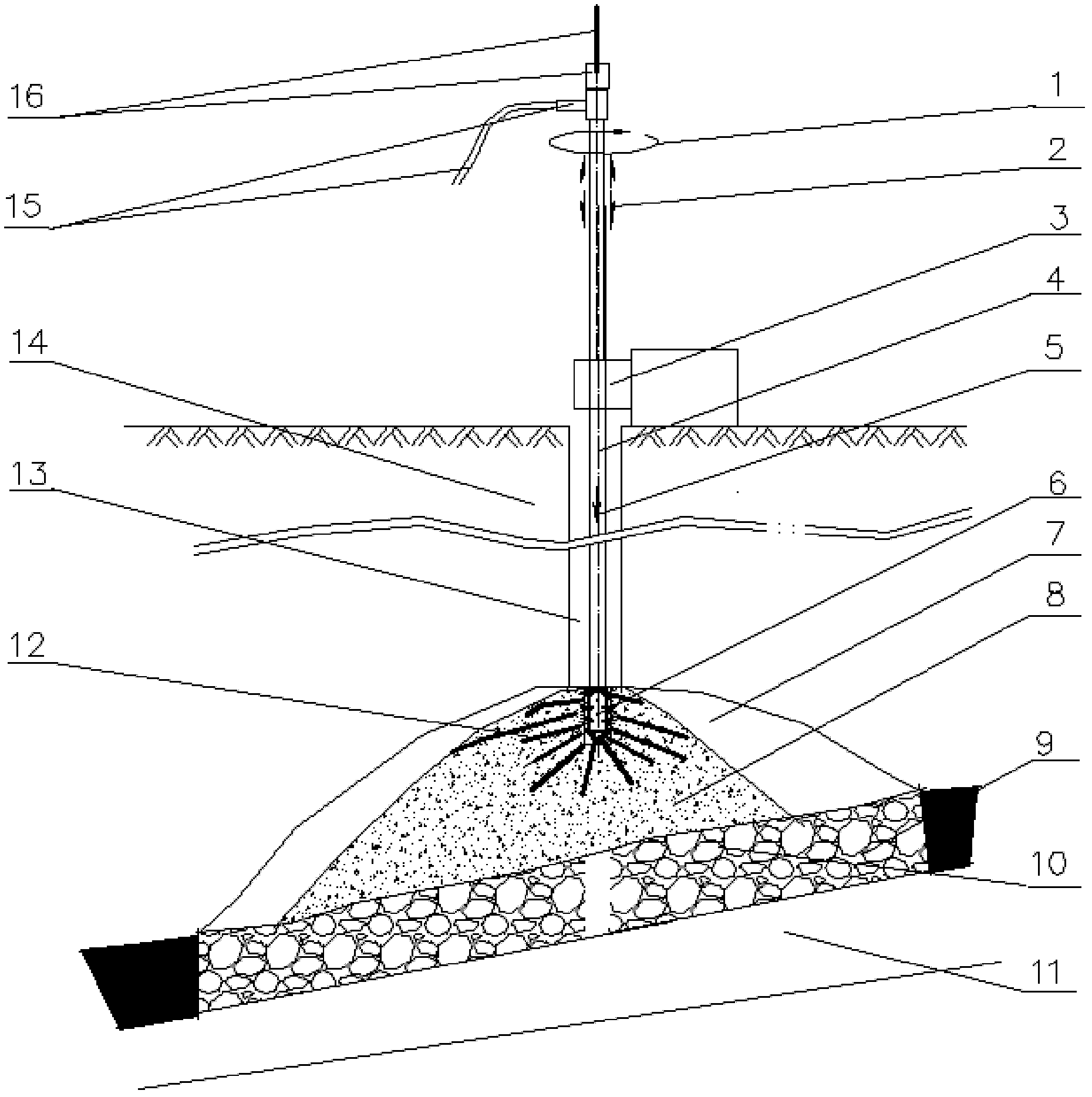

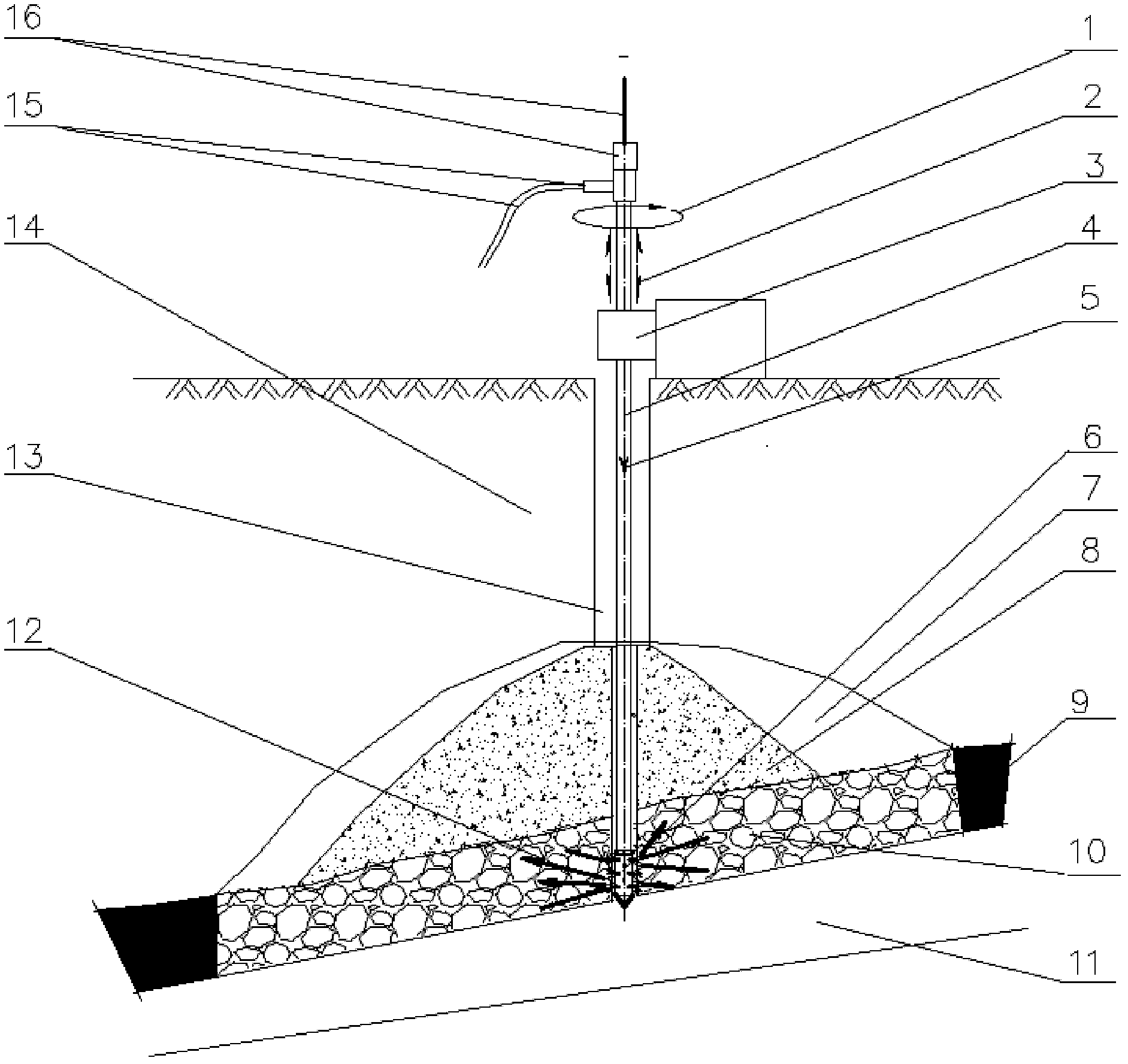

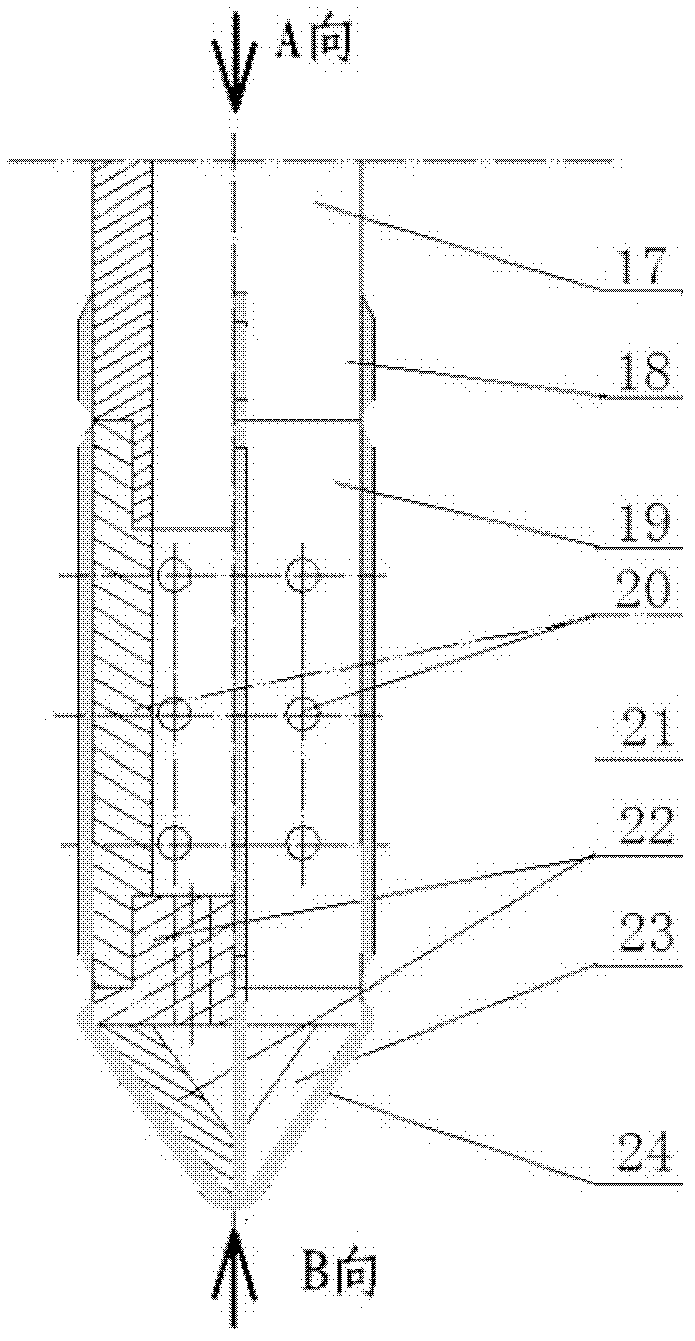

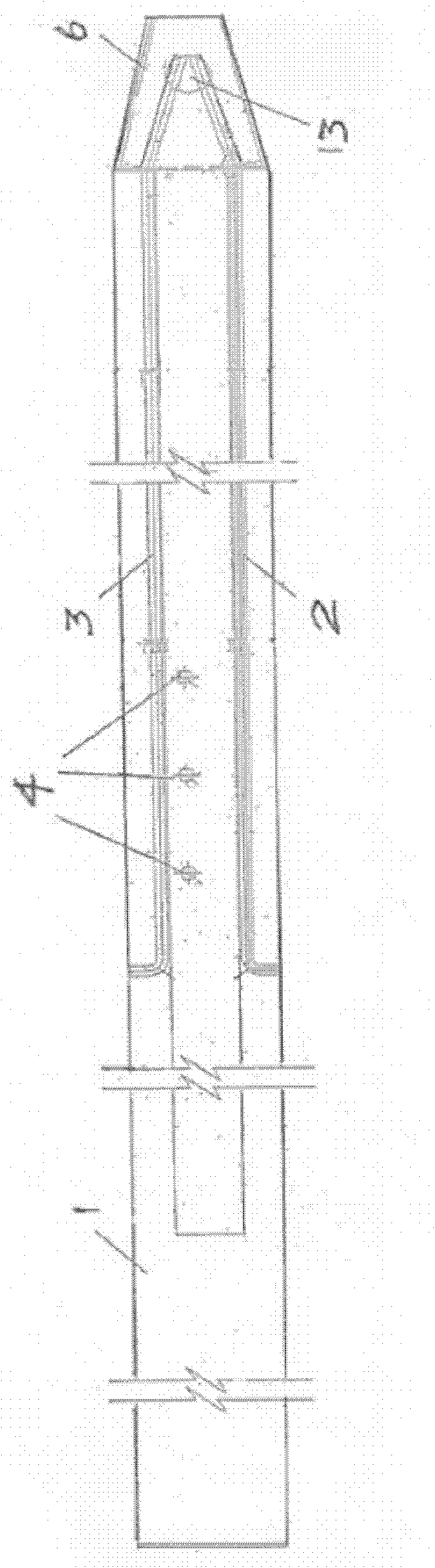

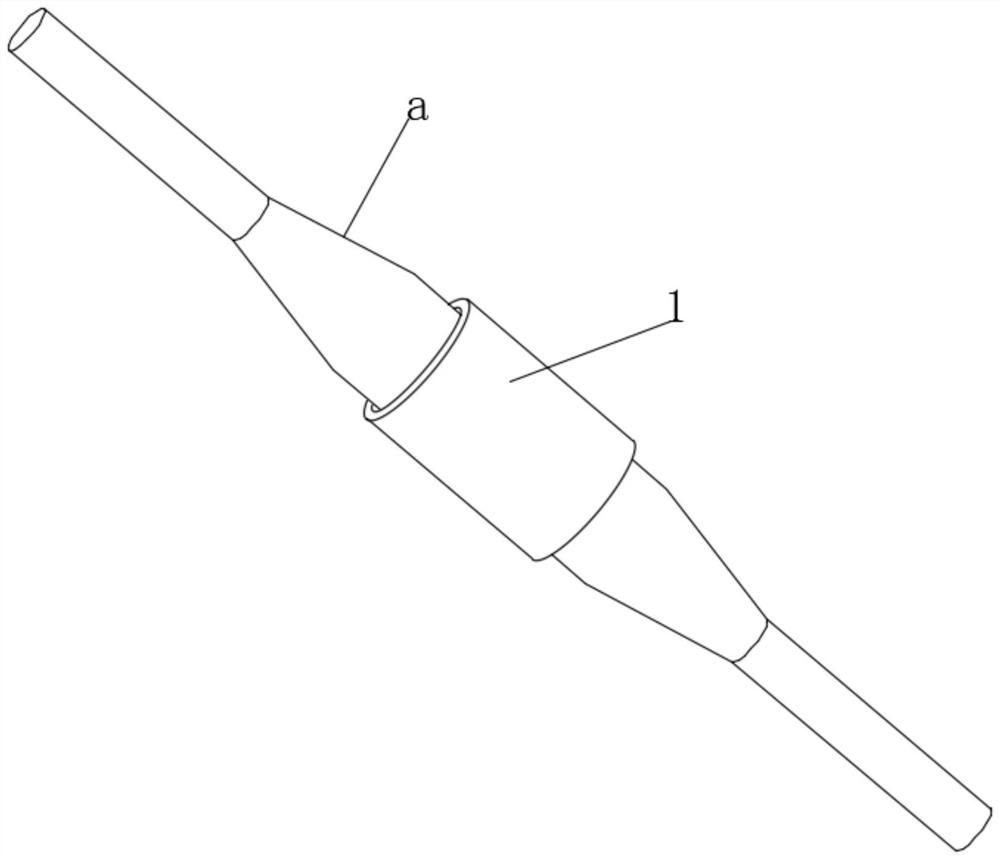

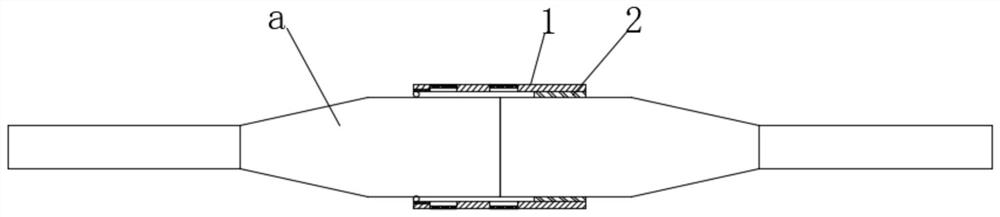

Process for realizing grouting consolidation for aggregates filled in cavities of strata and jetting drill bit

ActiveCN102561950ASolve the grouting consolidation operationSmooth throughDrill bitsSealing/packingUpper jointUltimate tensile strength

The invention discloses process for realizing grouting consolidation for aggregates filled in cavities of strata. Holes are drilled by a drill stem, and hydraulic cement is filled in the holes, so that filling of the aggregates is finished. The invention further discloses a jetting drill bit for realizing grouting consolidation for the aggregates filled in the cavities of the strata. The jetting drill bit consists of an upper joint, a jetting body and a drill bit body which are connected successively. Grouting consolidation operation is well carried out for aggregate accumulators filled in the cavities of the strata, so that the aggregates form a plain concrete body and have certain strength and stability, the plain concrete body is equivalent to an artificially constructed false stratum, the drilled holes assuredly penetrate through the cavities of the strata smoothly, and conditions are created for safe and smooth construction of the drilled holes.

Owner:SHANDONG UNIV

Steel strand retractor

InactiveCN101004096AFast constructionSmooth throughBuilding reinforcementsBuilding material handlingEngineeringPre stress

The present invention relates to a stranded wire puller. It includes an anchor main body and a pulling ring connected with stranded wire. It is characterized by that said anchor main body is made into the form of cylinder body whose interior is formed into cone form. In the interior of said anchor main body two clips and one pull rib are mounted, the end portion of said pull rib is connected with pulling ring. Said invention can be used in the superlong post-stressed concrete construction, and can be used for making stranded wire be smoothly passed through corrugated pipe.

Owner:BEIJING URBAN CONSTR GROUP

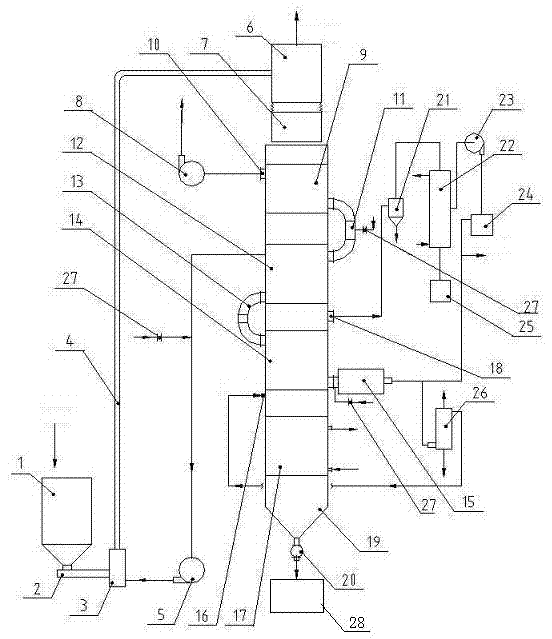

Method and device for preparing active carbon by white spirit grains

ActiveCN103922334AReduce moisture contentAvoid cakingCarbon compoundsEconomic benefitsCircular economy

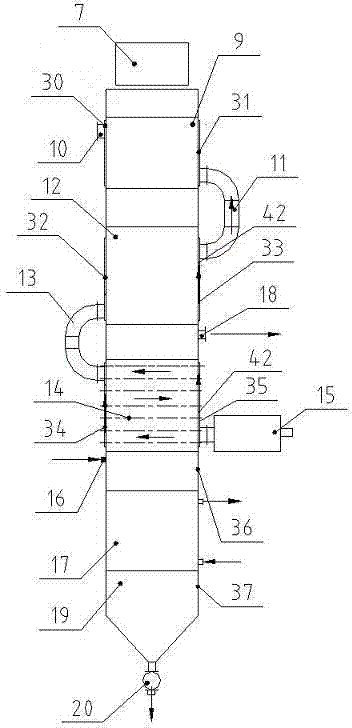

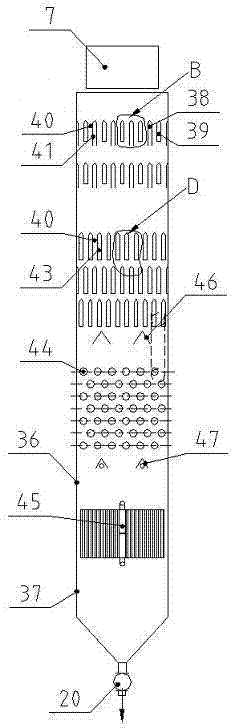

The invention discloses a method for preparing active carbon by white spirit grains. The method comprises the following steps of pre-drying, drying, carbonizing, activating, recovery of pyrolysis products, cooling and refining. The increment of downstream products of the white spirit grains is greater than the investment input and the economic benefit is high, while the requirement on energy conservation and emission reduction can be met and the industry upgrading of the white spirit industry is improved, the method has great significance in developing the circular economy. The invention also discloses a device for preparing the active carbon by the white spirit grains. The device comprises an integrated furnace, an air current dry feeding system, a burning furnace and a gas-fired boiler, wherein the integrated furnace consists of a drying section, a carbonizing section, an activating section, a cooling section and an unloading section which are sequentially arranged from top to bottom; a heat exchange element of the drying section comprises a gas collecting angle boxes and gas discharging angle boxes which are alternately arranged abreast, so that hot smoke gas forms multiple strands of horizontal airflow in the drying section; materials which pass through the drying section are stressed laterally so as not to easily form a bridge; therefore, the integrated furnace can normally work while the white spirit grains are treated.

Owner:江苏银鼎生物质科技有限公司

Valve crossing device

ActiveCN107019530AAdd supportSave operating timeGuide wiresSurgeryChordae tendineaeSurgical operation

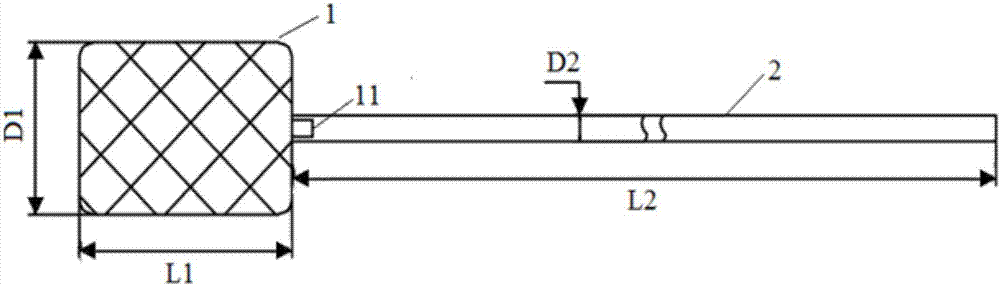

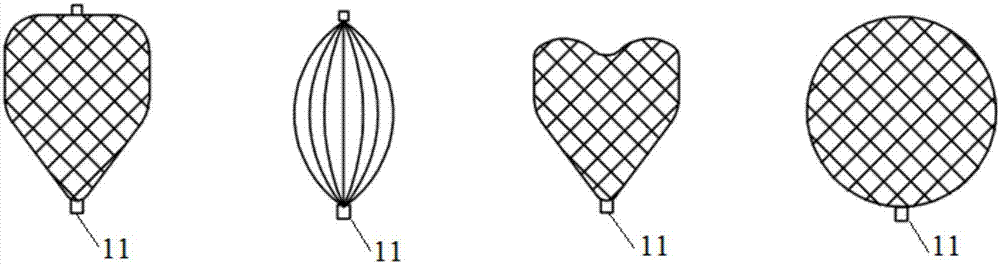

The technical scheme of the invention discloses a valve crossing device which comprises a valve crossing device main body and a valve crossing device rod. The valve crossing device main body is of a hollow three-dimensional structure; the valve crossing device rod is connected with the valve crossing device main body. According to the valve crossing device provided by the technical scheme of the invention, an excellent auxiliary effect is achieved when a guide wire reversely crosses the valve, the surgical operation time is greatly shortened, a chordae tendineae mesh is difficultly penetrated, the complication occurrence probability is greatly reduced, the surgical safety and treatment effect are greatly improved, and the valve crossing device has a high application value.

Owner:SHANGHAI HANYU MEDICAL TECH CO LTD

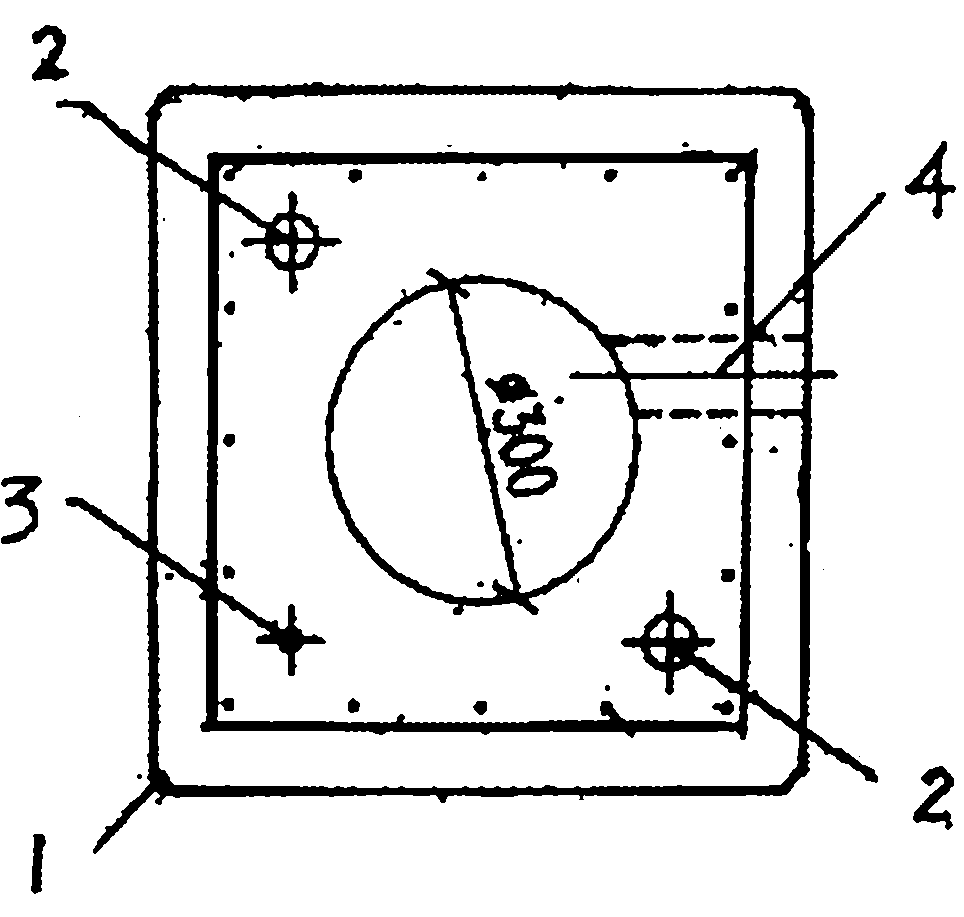

Water-flushing sinking-assisting system and construction technical method thereof

ActiveCN102182186AShorten the effective lengthGuaranteed bearing capacityBulkheads/pilesEffective lengthSlurry

The invention relates to a water-flushing sinking-assisting system. Two water jet pipes and an air pipe are preembedded in a pile body of a precast pile, water inlet ends of the two water jet pipes are connected to a quick joint and then connected to a double-table water pump, and a side wall of the pile body is provided with three outer drainage holes communicated with a pile core; a pile tip isa funnel shaped steel pile tip welded by a steel plate; and the two water jet pipes at the pile tip flush water directly along the pile axial line direction. The invention has the advantages that because the three outer drainage holes with the diameter of 70mm, reserved at the pile body, are communicated with the pile core, the effective length of an inner drainage slurry channel is reduced so asto drain away water and sand; because a water pipe and the air pipe are preembedded in concretes, the pipes are unnecessary to pull out, an internal thread bend elbow of 90 DEG is adopted at a water inlet end and an air inlet end so as to connect the quick joint; and because the quick joint is utilized, the assembly and disassembly are quick, the steps of assembling and disassembling the water pipe and the air pipe are effectively avoided, the operation is simple, the cost is lower, and the pile-sinking efficiency is improved.

Owner:CCCC FIRST HARBOR ENG +1

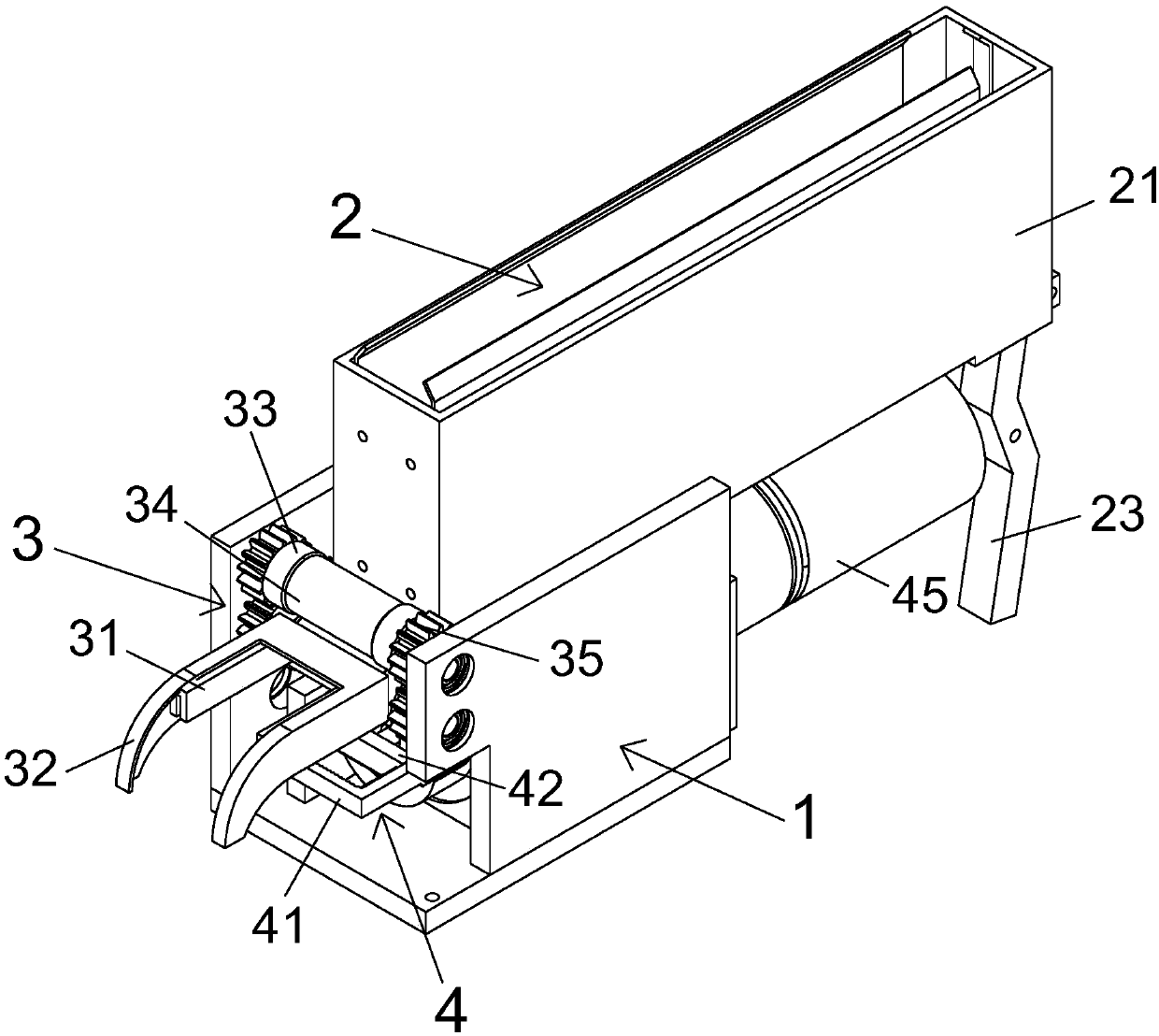

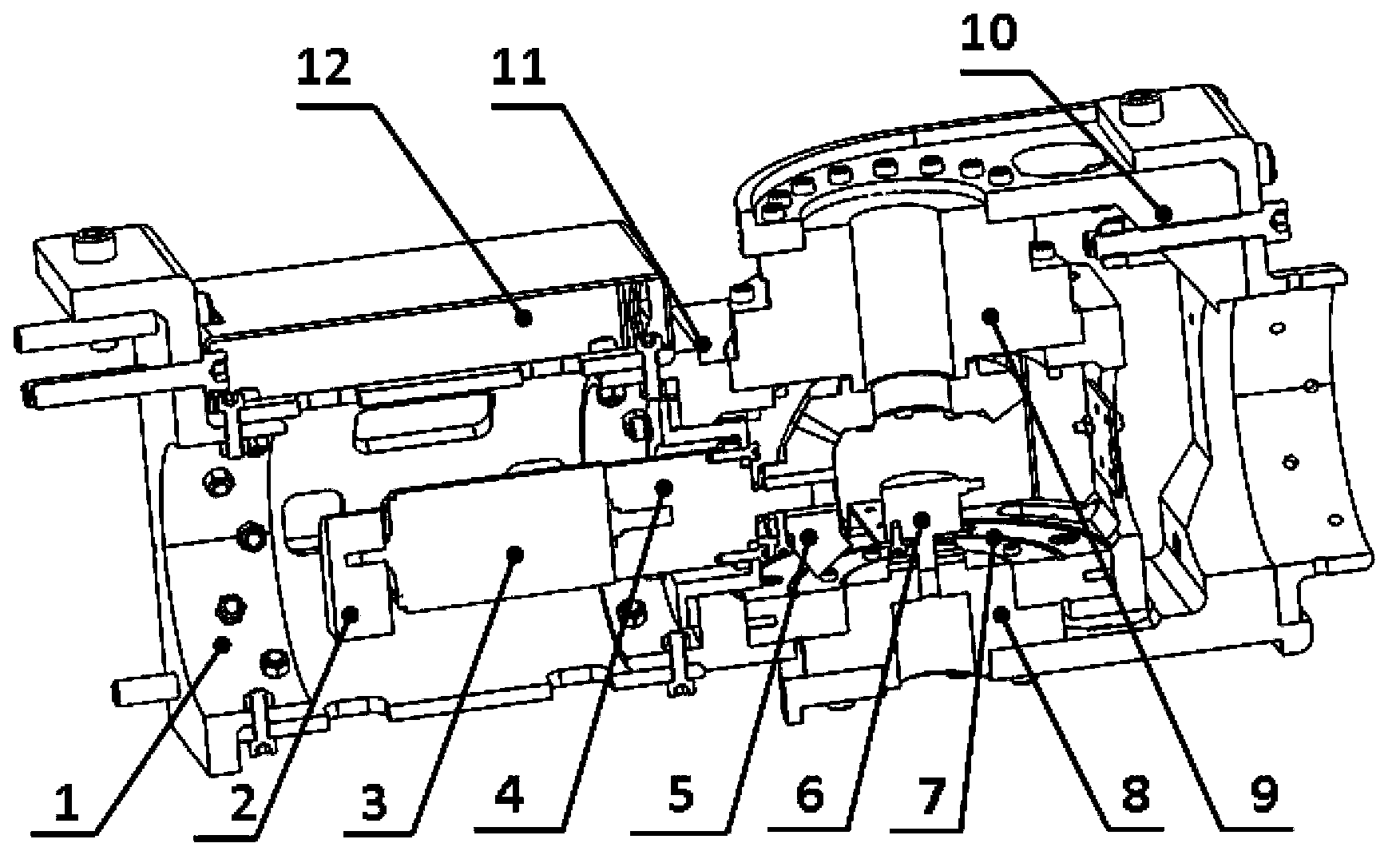

Steel bar binding machine

PendingCN107605163ARealize opening and closing operationPrevent slippageBuilding material handlingEngineeringSteel bar

The invention relates to a steel bar binding machine. The steel bar binding machine comprises a machine body, a wire storage mechanism, a wire outlet mechanism and a binding mechanism; the wire storage mechanism is used for storing a U-shaped binding wire; the wire outlet mechanism communicates with the wire storage mechanism and bends the two free ends of the U-shaped binding wire to one side; and the binding mechanism is arranged on the bent side of the U-shaped binding wire correspondingly and tightly twists the two free ends of the U-shaped binding wire. The steel bar binding machine is high in automation degree and has the advantages that the steel bar binding machine is provided with the wire storage mechanism, the wire outlet mechanism and the binding mechanism, the U-shaped bindingwire can be bent automatically, and the free ends of the U-shaped binding wire can be tightly twisted automatically, the automation degree is high, and the binding efficiency of steel bars is improved greatly.

Owner:福建谊和天宸科技有限公司

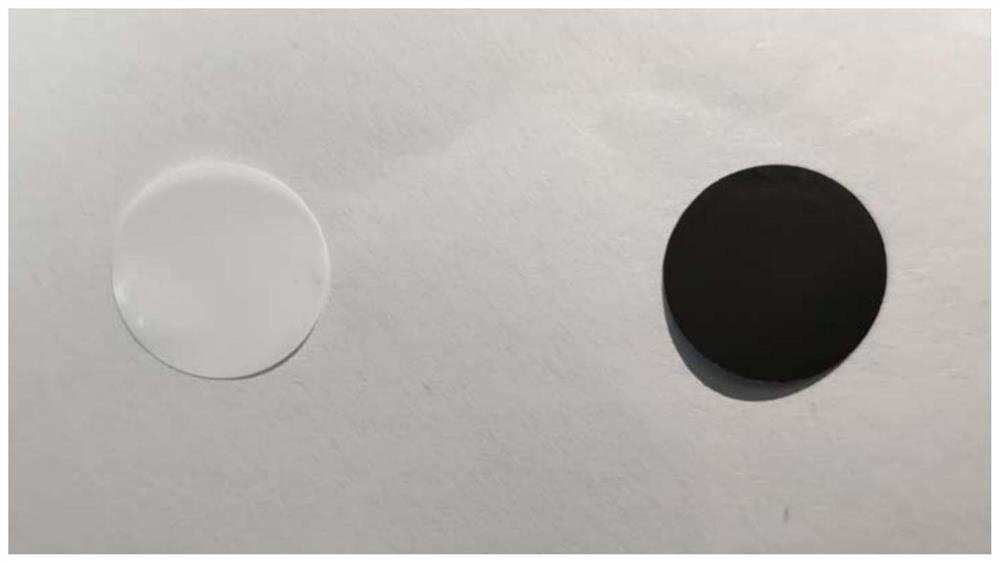

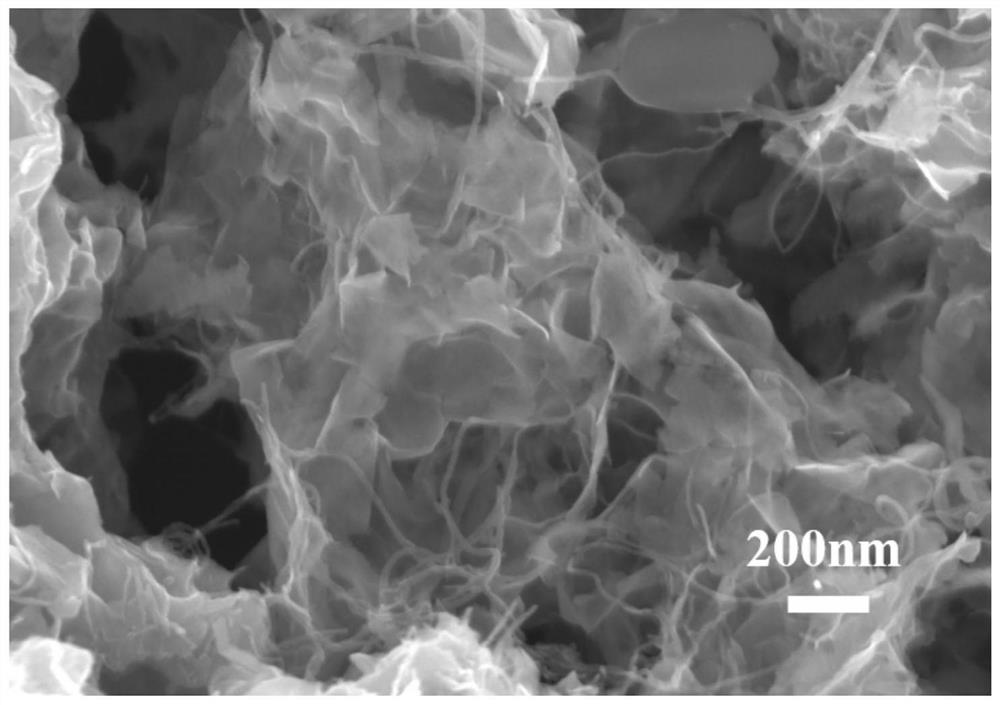

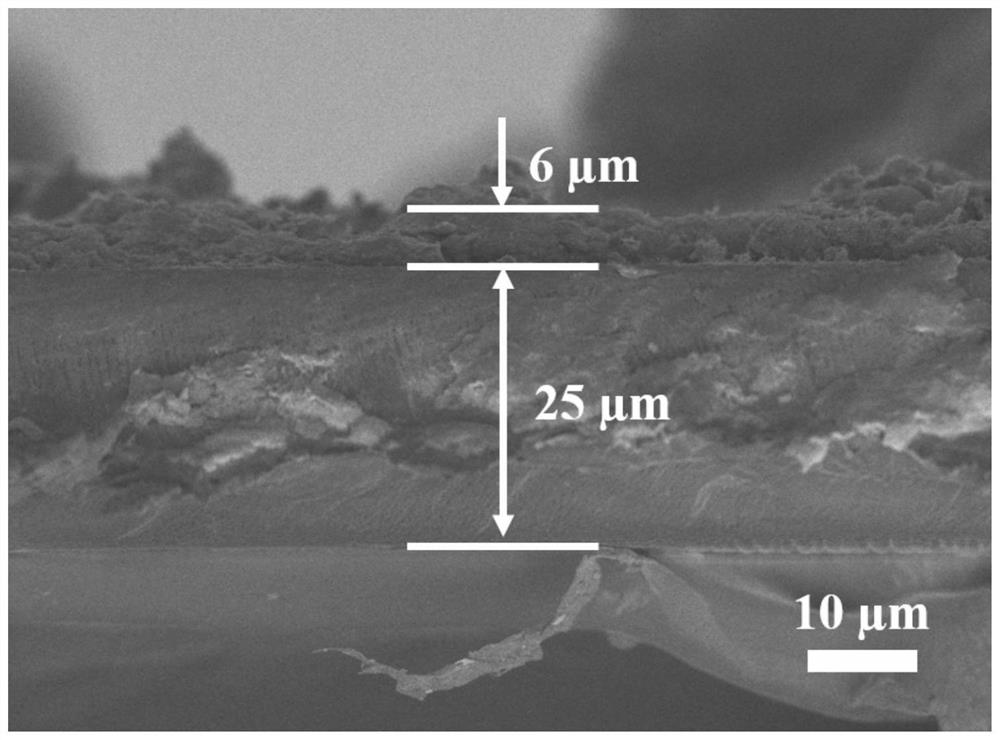

WS2/CNTs modified diaphragm of lithium-sulfur battery and preparation method of WS2/CNTs modified diaphragm

ActiveCN111916640ALight weightImprove conductivityLi-accumulatorsCell component detailsLithium–sulfur batteryElectrical battery

The invention belongs to the technical field of new energy materials and devices, and particularly relates to a WS2 / CNTs modified diaphragm of a lithium-sulfur battery and a preparation method of theWS2 / CNTs modified diaphragm. The WS2 / CNTs modified diaphragm comprises a diaphragm matrix and a modified layer laid on the surface of one side of the diaphragm matrix, wherein the modified layer is composed of a WS2 / CNTs composite material. Hydroxylated CNTs serve as a carrier, CTAB serves as a surfactant, TAA and WCl6 serve as an S source and a W source respectively, a WS2 / CNTs composite materialis prepared through a one-step hydrothermal method, the WS2 / CNTs composite material is subjected to suction filtration on the surface of one side of a commercial battery diaphragm base body, and themodified diaphragm for the lithium-sulfur battery is obtained. The WS2 / CNTs modified diaphragm can effectively solve the shuttle effect problem of the lithium-sulfur battery and improve the specific capacity, coulombic efficiency and cycle life of the battery while ensuring the electrochemical reaction activity of the lithium-sulfur battery and the smooth penetration of lithium ions, and meanwhile, the overall mass of the modified layer is relatively light, so that the overall energy density of the lithium-sulfur battery is not influenced.

Owner:HEFEI UNIV OF TECH

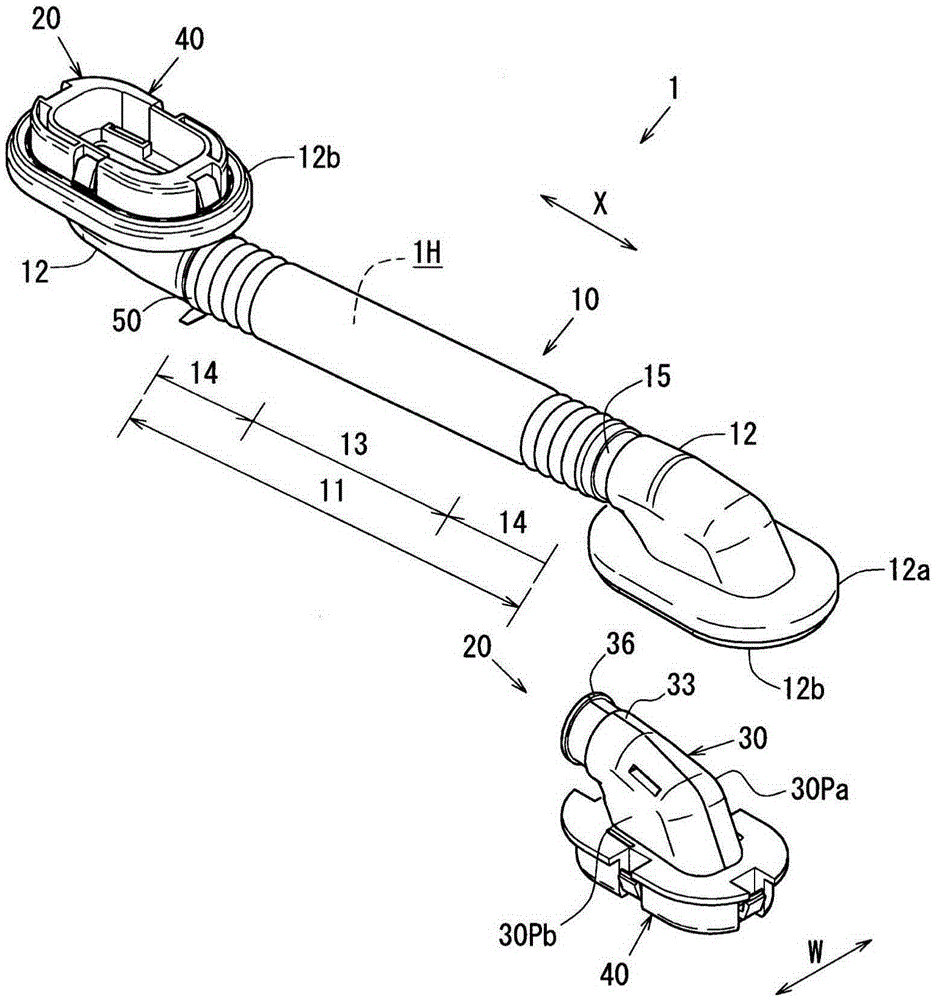

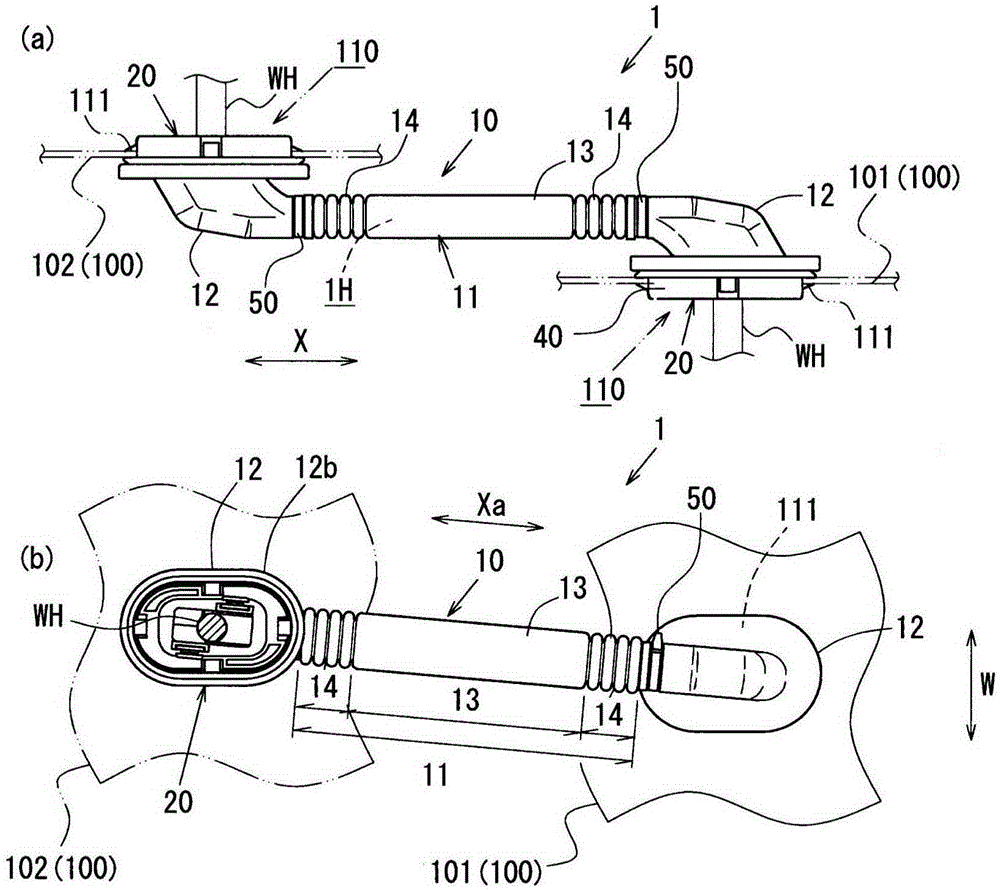

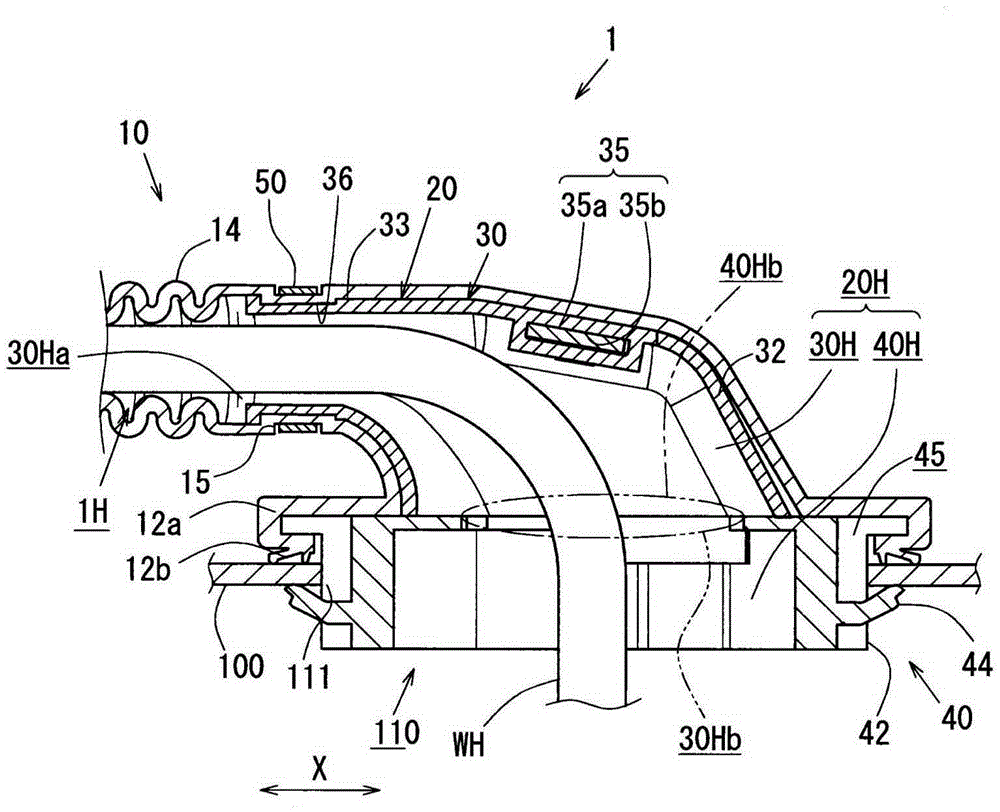

Conduit

Owner:FURUKAWA ELECTRIC CO LTD +2

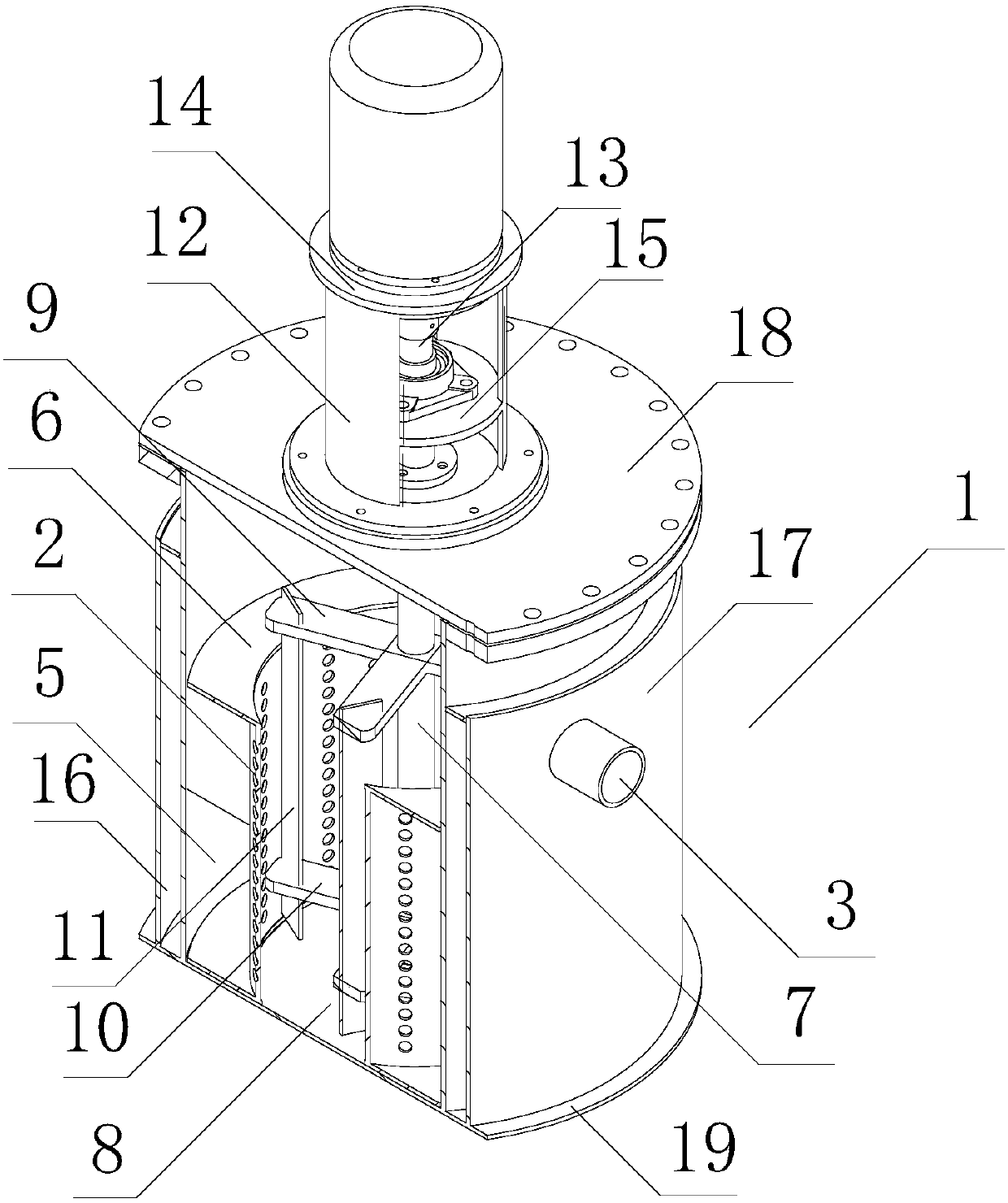

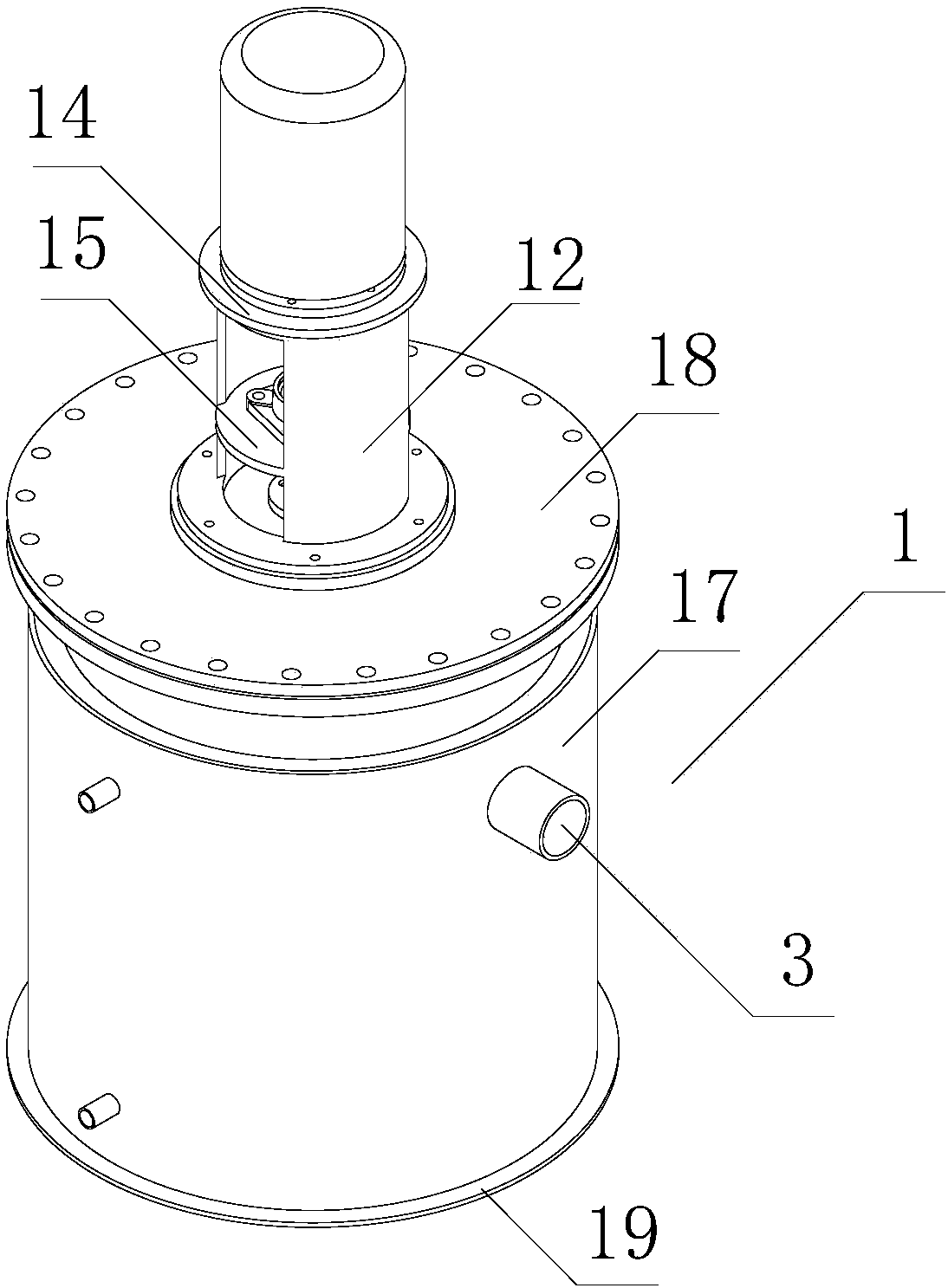

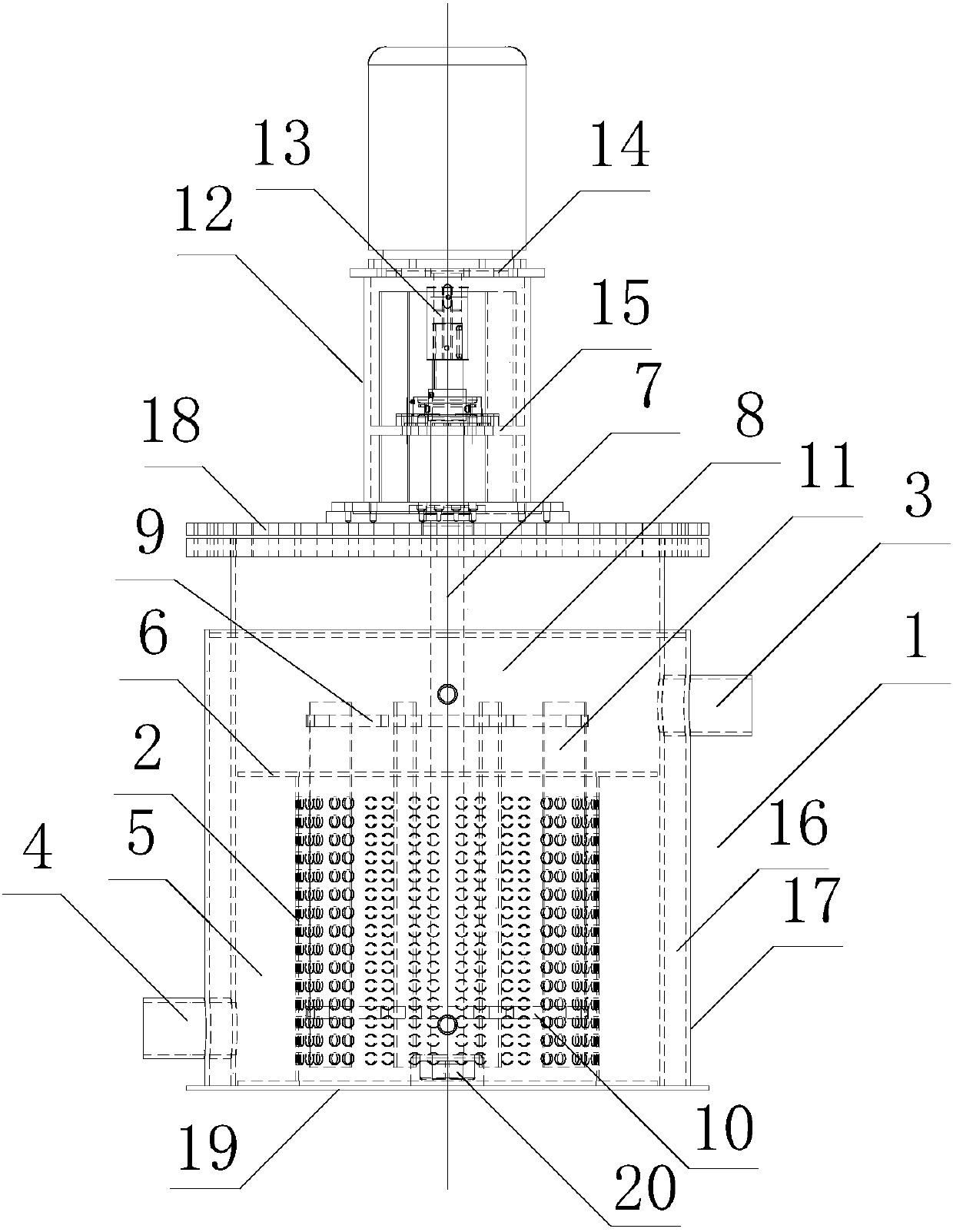

Stirring type filter

PendingCN107661648AQuality assuranceQuality improvementStationary filtering element filtersEngineeringRaw material

The invention relates to a stirring type filter. The stirring type filter comprises an outer cylinder, a driving device, a stirring device and a filtering cylinder, wherein the upper part of the sidewall of the outer cylinder is provided with a material inlet, and the lower part of the side wall of the outer cylinder is provided with a material outlet; the filtering cylinder is arranged in the outer cylinder, the height of the material inlet is not lower than the upper end of the filtering cylinder, a plurality of filtering holes are formed in the side wall of the filtering cylinder, and thestirring device is vertically arranged in the outer cylinder and is also positioned in the filtering cylinder; a material filtering cavity is formed between the filtering cylinder and the side wall ofthe outer cylinder; the upper end of the stirring device extends up out of the outer cylinder; the driving device is arranged at the upper end of the outer cylinder; the output end of the driving device is in transmission connection with the upper end of the stirring device, and the driving device is used for driving the stirring device to rotate. The stirring type filter has the advantages thatthe raw material is stirred by the stirring device, so that the material can be uniformly mixed; the raw material can be filtered by the filtering cylinder in the stirring process, and then the particulate matters in the raw material can be separated, so as to ensure the quality of raw material which is discharged out of the material outlet.

Owner:武汉市三维纵横机电设备有限公司

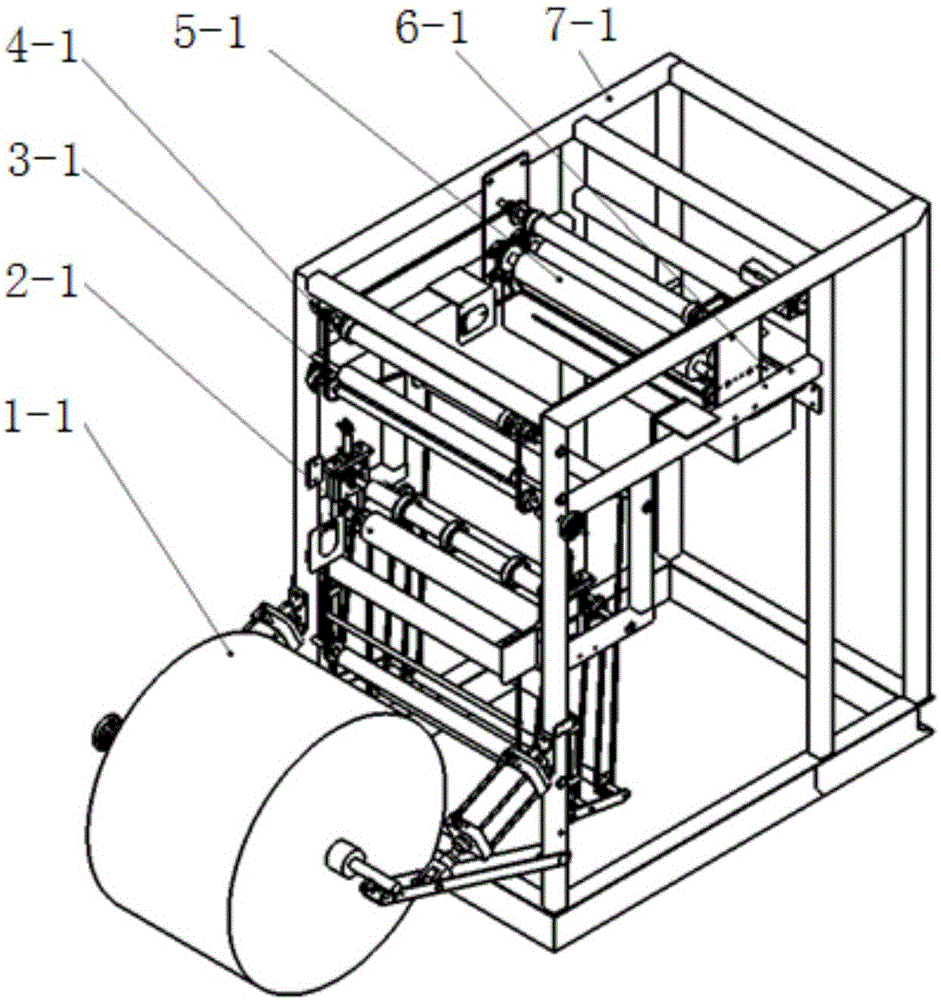

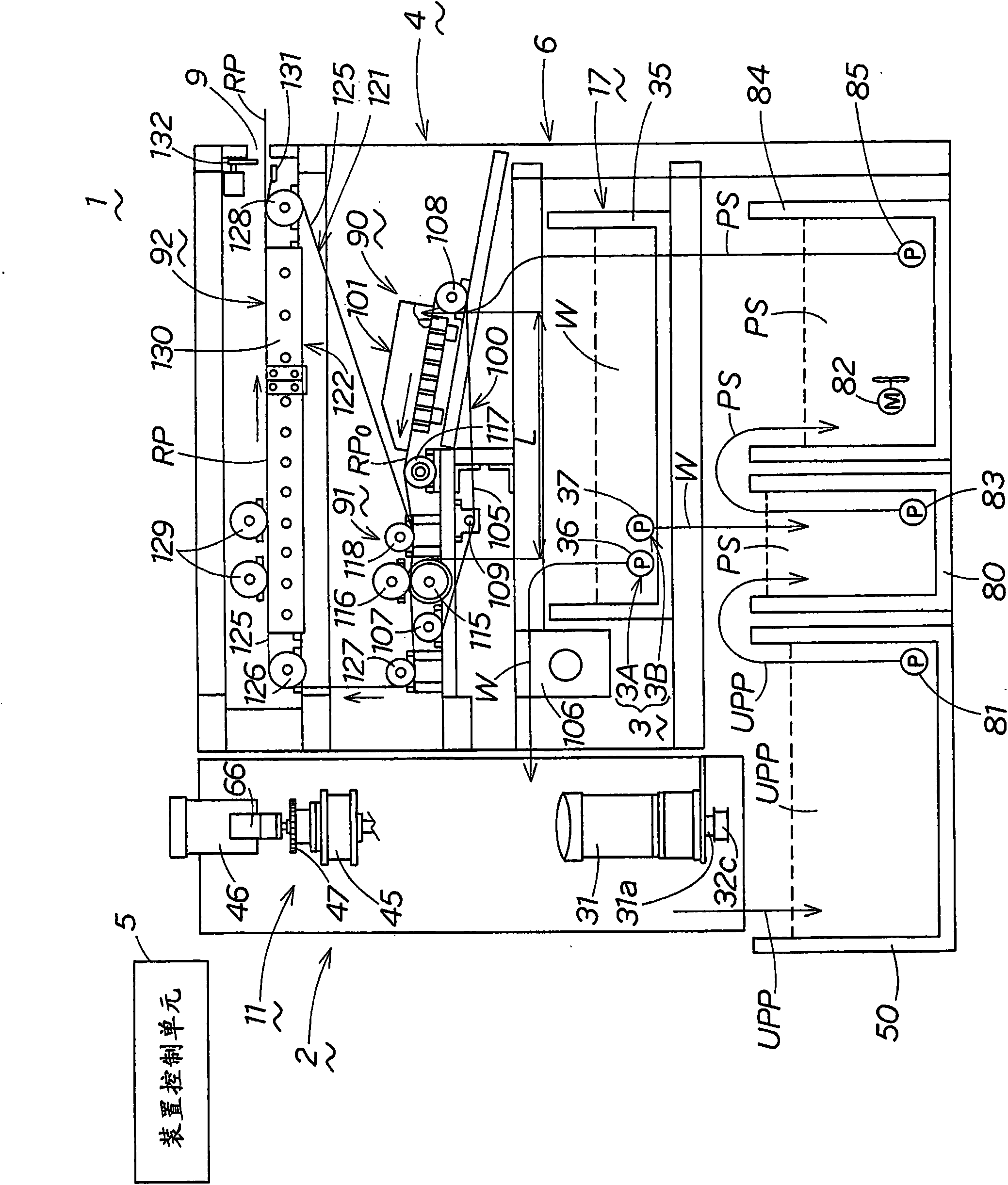

Non-lamination bag-making packing machine

ActiveCN107521725AAvoid stackingRealize online automatic packagingWrapper twisting/gatheringSolid materialEngineeringManipulator

The invention belongs to the field of packing machines, and particularly discloses a non-lamination bag-making packing machine. The non-lamination bag-making packing machine comprises a rack and a material penetration device, a vertical conveying and bag bottom sewing device, a bag opening manipulator device, a material discharging device, a transition edge folding device and a bag sewing device which are arranged on the rack; a woven bag is fed into the vertical conveying and bag bottom sewing device vertically; the vertical conveying and bag bottom sewing device is used for converting vertical movement of the woven bag into horizontal conveying, and for sewing the edge of the bottom of the woven bag; the bag opening manipulator device is used for feeding the woven bag into the material discharging device, and for opening the woven bag; and the material discharging device is used for discharging the opened woven bag; and the transition edge folding device and the bag sewing device are used for sequential edge folding and edge sewing of the bag opening of the charged woven bag. By adopting the non-lamination bag-making packing machine, procedures of material charging, bag making, bag opening, material discharging, bag sewing and the like are automatically realized; the automation degree is high; and applicability is high.

Owner:HUAZHONG UNIV OF SCI & TECH

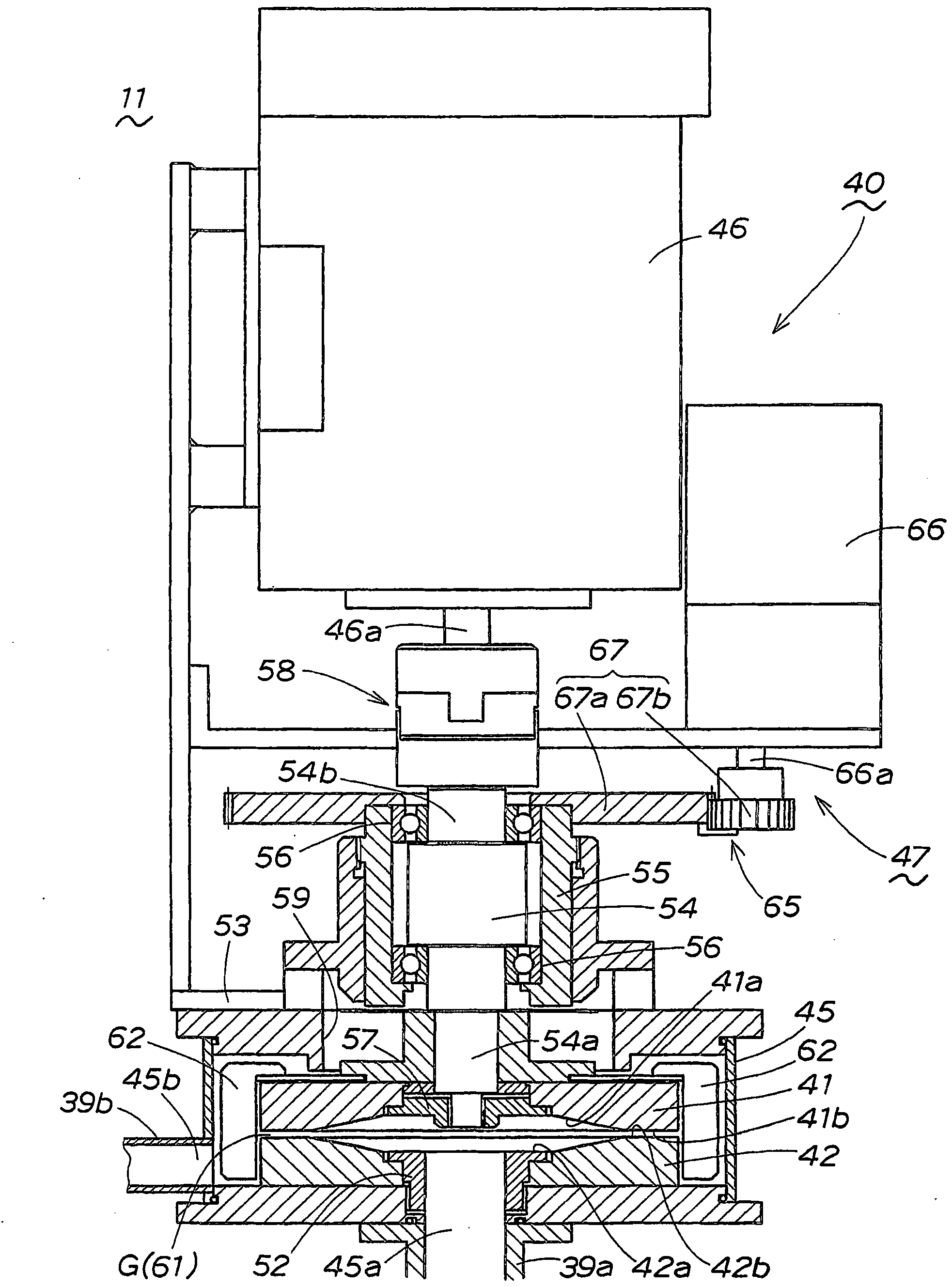

Space bearing type modular mechanical arm joint and combination thereof

InactiveCN103640027AImprove carrying capacitySmall cross-sectional sizeJointsMagnetic confinement fusionSpeed reduction

The invention provides a space bearing type modular mechanical arm joint. A bearing connection mechanism is fixedly connected with a fixed bearing mechanism which is connected with a rotary bearing mechanism through a harmonic reducer and a cross roller bearing, one end of a servo motor is connected with an incremental encoder, the other end of the servo motor is connected with a planetary speed reduction mechanism which is connected with the harmonic reducer through a bevel gear, the cross roller bearing is connected with the rotary bearing mechanism through an output shaft, an absolute encoder is fixedly connected onto the output shaft, and an EtherCAT bus driver is connected with the servo motor and performs servo control on the servo motor. The invention further discloses a modular space bearing type modular mechanical arm joint which includes a plurality of space bearing type modular mechanical arm joints which are combined together. The modular space bearing type modular mechanical arm joint is applicable to the maintenance environment with small inlets of magnetic confinement fusion (MCF) devices, long distance and large rotation space, and has the advantages of being light, compact in structure, large in bearing capacity, convenience in wiring, good in real-time communication and the like.

Owner:SHANGHAI JIAO TONG UNIV

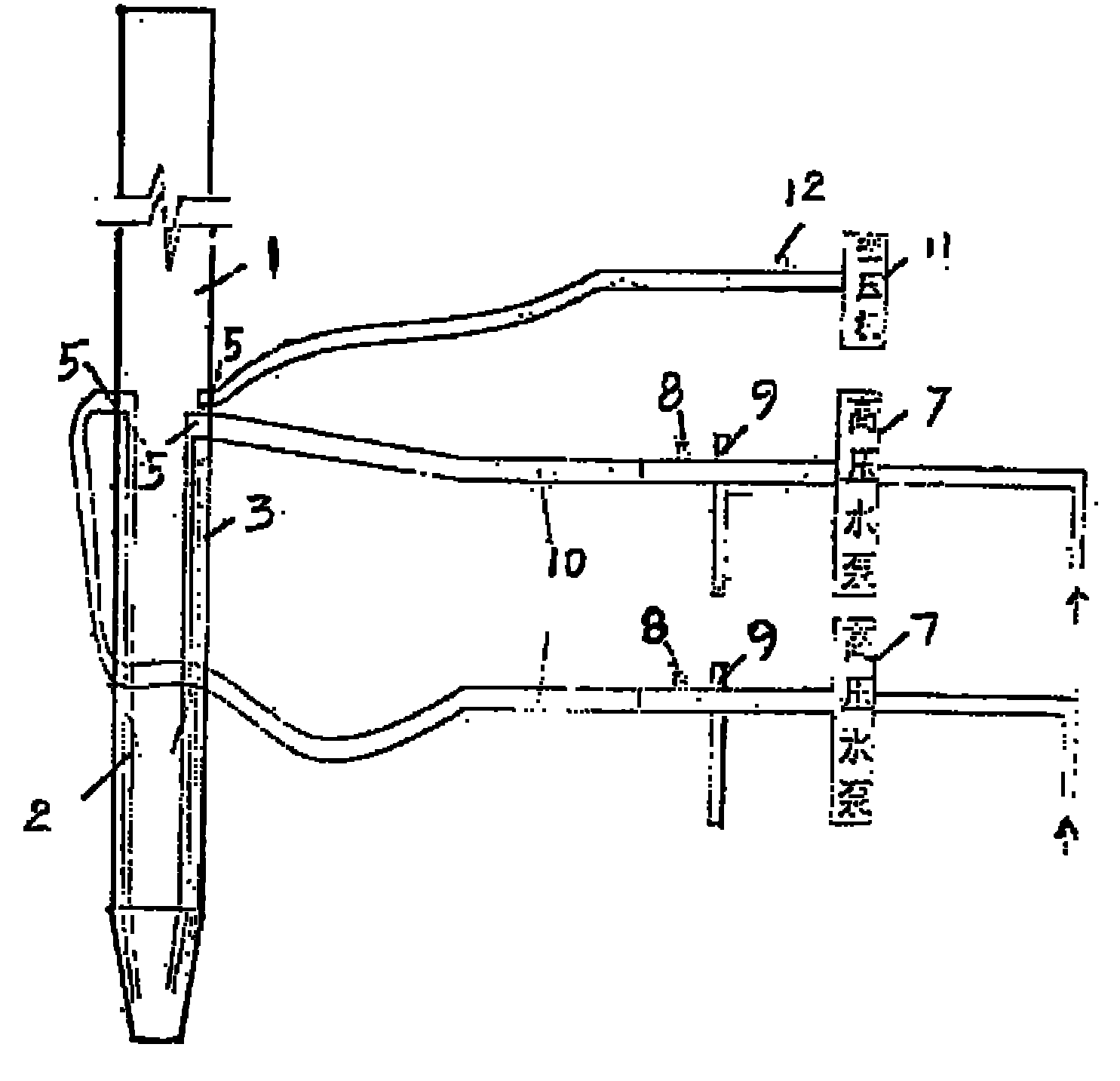

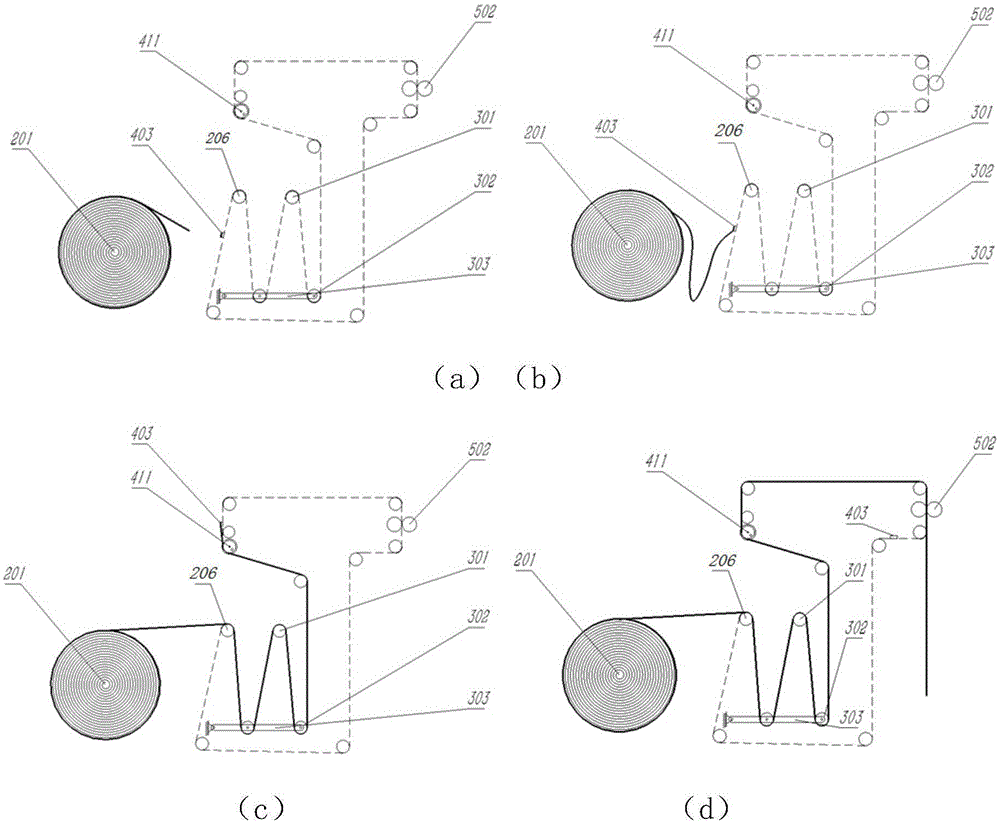

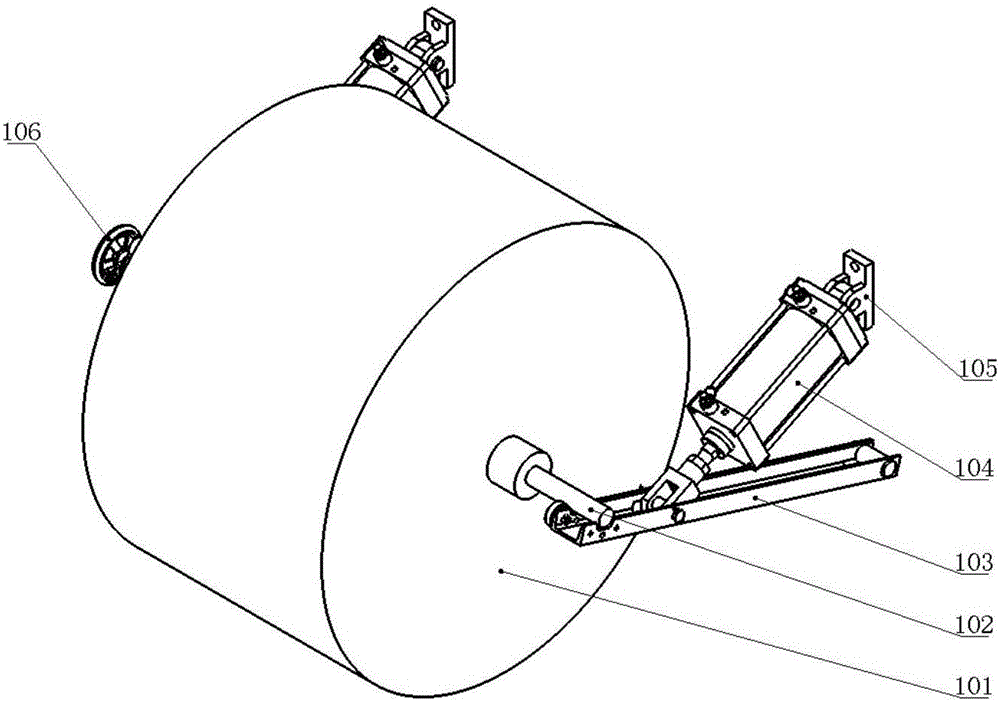

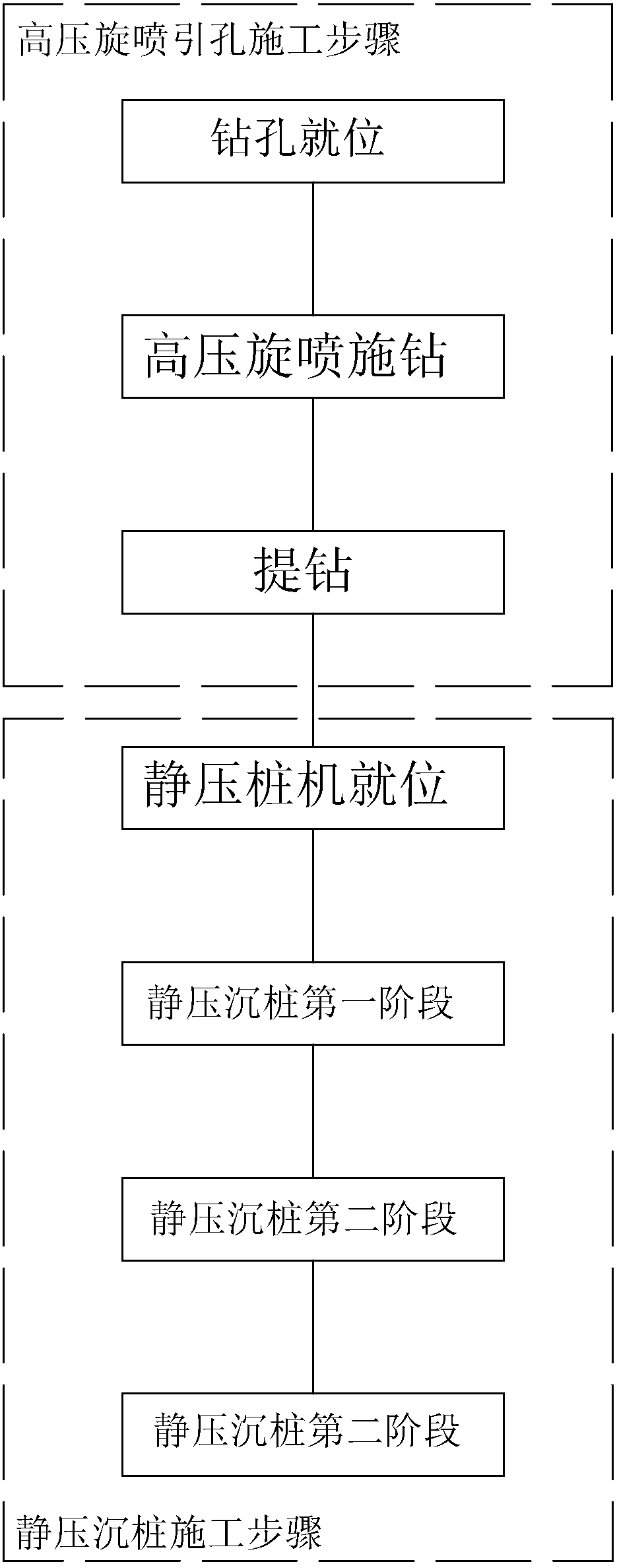

Construction method for conducting high-pressure jet grouting hole guiding firstly and then conducting grouting-assisted jacked pile sinking

InactiveCN107761732AImprove bearing capacityReduce dynamic penetration resistanceBulkheads/pilesInstabilityEngineering

The invention discloses a construction method for conducting high-pressure jet grouting hole guiding firstly and then conducting grouting-assisted jacked pile sinking, belongs to the field of foundation construction, and aims at providing the construction method solving difficult jacked pile sinking and bearing capacity instability caused by water guiding. According to the technical scheme of theconstruction method, the construction method is characterized in that high-pressure jet grouting hole guiding construction and static-pressure pile sinking construction are included, the high-pressurejet grouting hole guiding construction includes the step that hole drilling is in place, the step of high-pressure jet grouting drilling, the step of drill lifting and like, and static-pressure pilesinking includes the step that a static pressure pile machine is in place, the step of the first stage of static-pressure pile sinking, the step of the second stage of static-pressure pile sinking, the step of the third stage of static-pressure pile sinking and the like. According to the construction method, a pile position soil layer is disturbed through high-pressure jet grouting water guiding to form a saturation disturbance body at the position of a hard soil layer firstly, then, side pile grouting fluid starts to be injected when a jacked pile sinks to the saturation disturbance body, pile end grouting fluid then continues to be injected in the pile end after the pile tip reaches the designed depth so that a grouting expansion head can be formed by the pile end, and the problems thatjacked pile sinking is difficult and bearing capacity instability is likely to be caused by water guiding are solved.

Owner:雨发建设集团有限公司

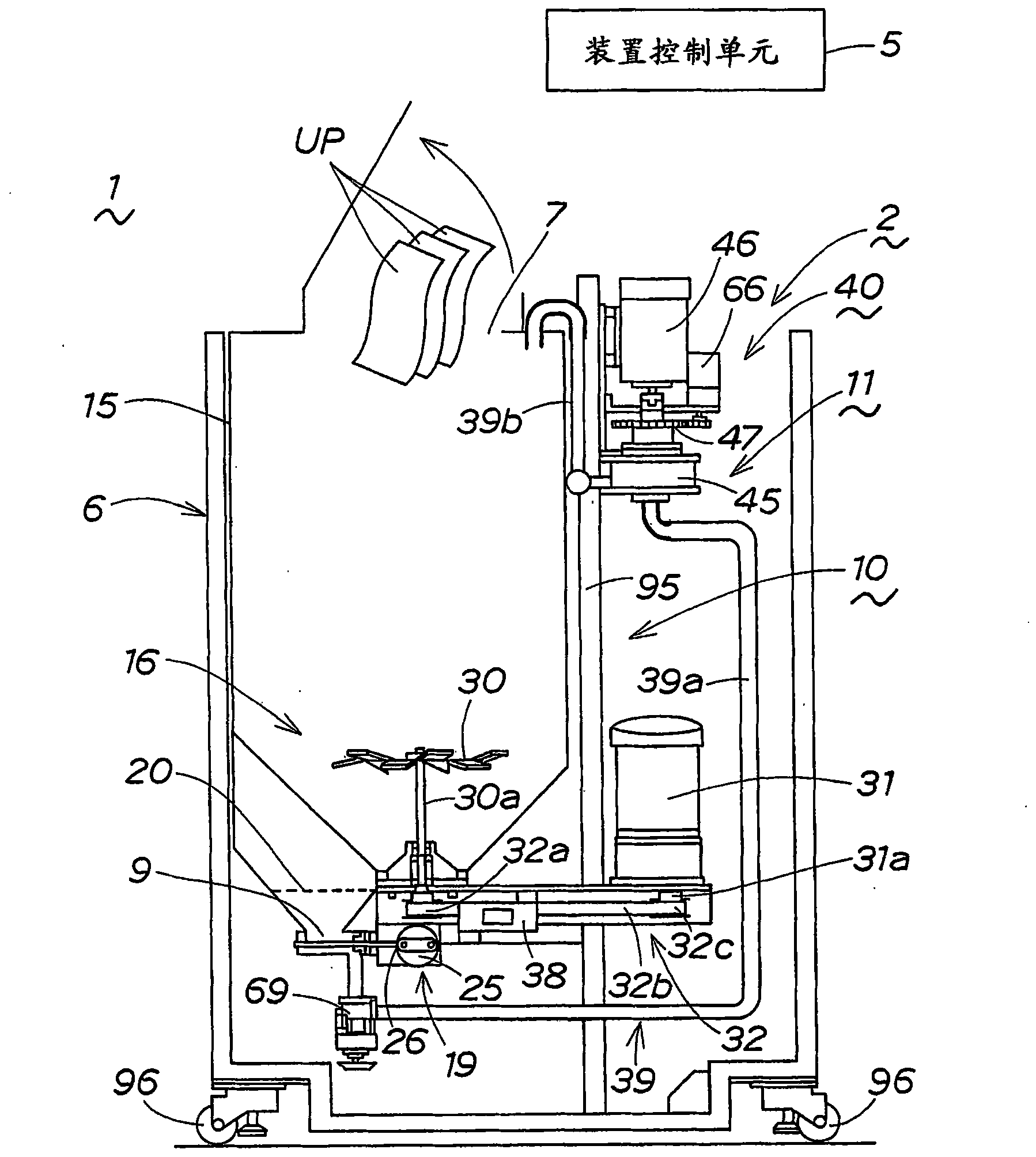

Pulp manufacturing method of used paper recycling apparatus, pulp manufacturing device of used paper recycling apparatus, and used paper recycling apparatus

InactiveCN101798770ASmooth beatingEffective beatingPaper recyclingPulp beating/refining methodsManufacturing technologyPaper recycling

Owner:SEED RUBBER CO LTD

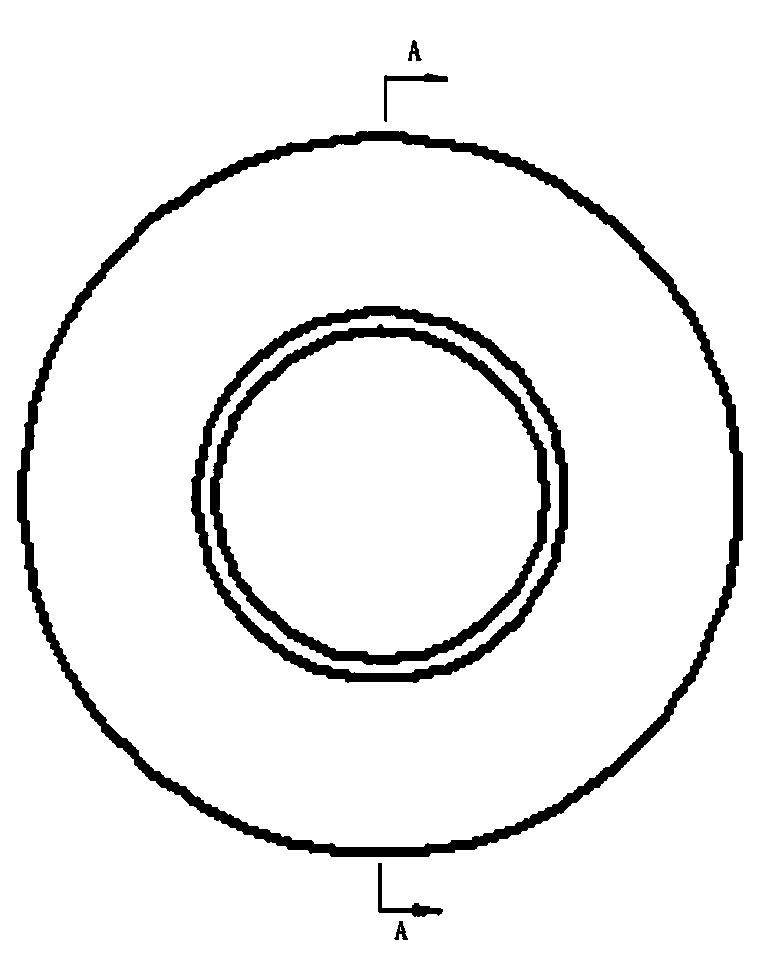

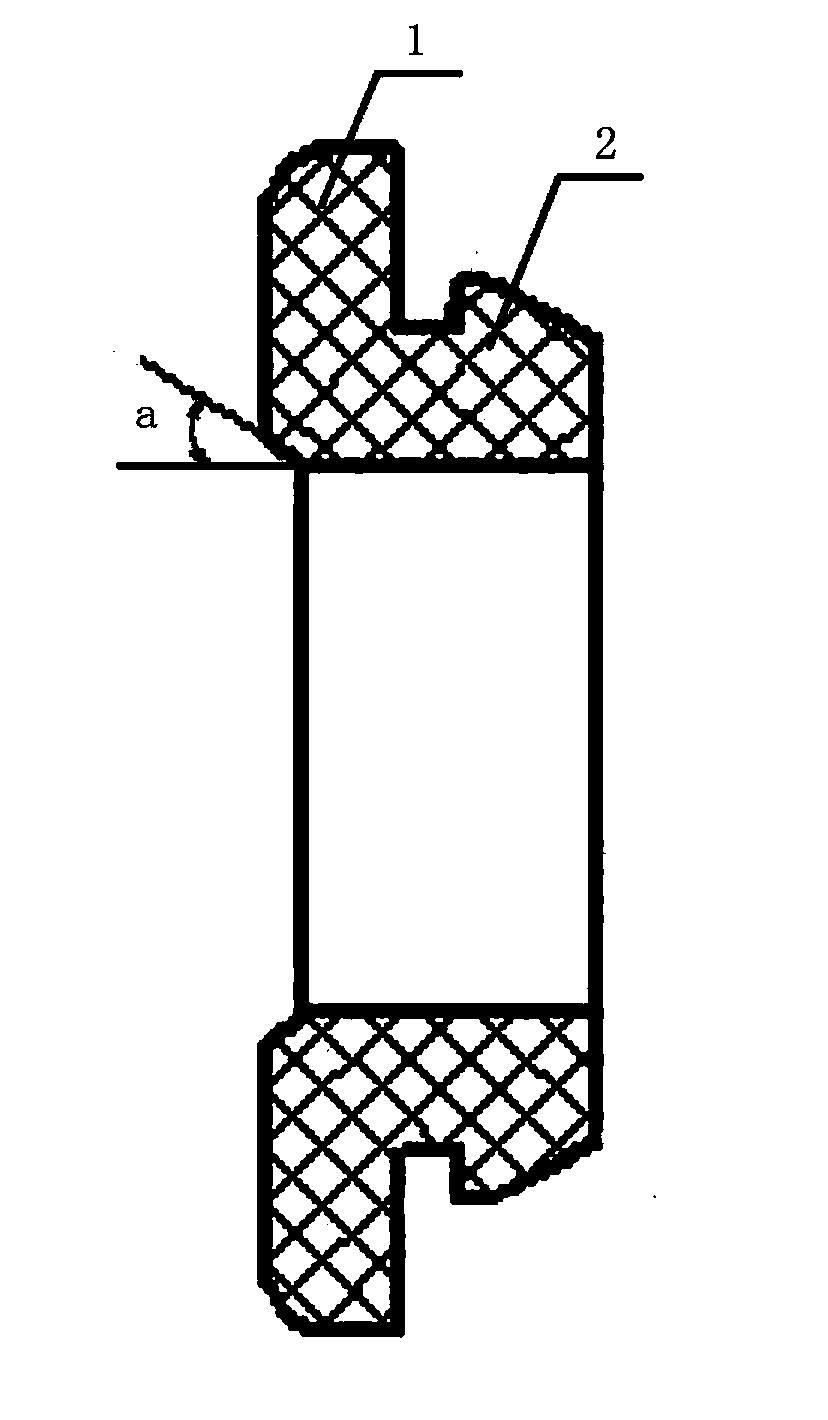

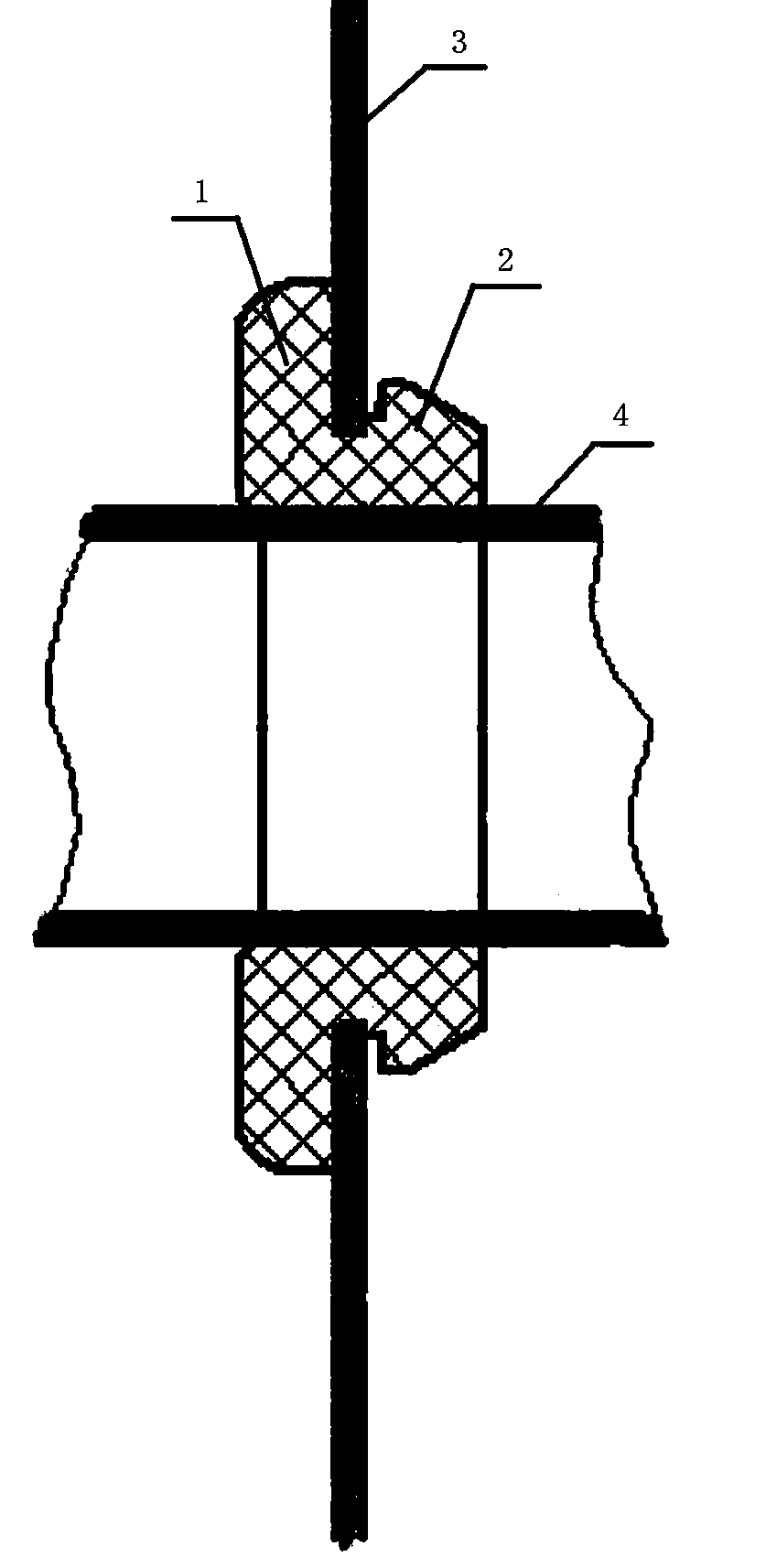

Automotive air conditioner drainage pipe sealing ring

The invention discloses an automotive air conditioner drainage pipe sealing ring, and belongs to the technical field of automobile making. A first boss stretching out in the radial direction is arranged at one end of the automotive air conditioner drainage pipe sealing ring, a chamfer forming an included angle alpha with the horizontal direction is formed on the inner wall, corresponding to the end of the first boss, of the sealing ring, a second boss stretching out in the radial direction is arranged at the other end of the sealing ring, the outer wall surface of the second boss is a conical surface, a groove vertical to a plane is formed between the first boss and the second boss, the inner diameter of the through hole of the sealing ring is smaller than the outer diameter of a drainage pipe, and the width of the groove is smaller than the thickness of automobile metal plates. According to the automotive air conditioner drainage pipe sealing ring, the problems that the drainage pipe is difficult to mount, and the sealing ring is prone to falling off and difficult to assemble are solved.

Owner:DONGFENG LIUZHOU MOTOR

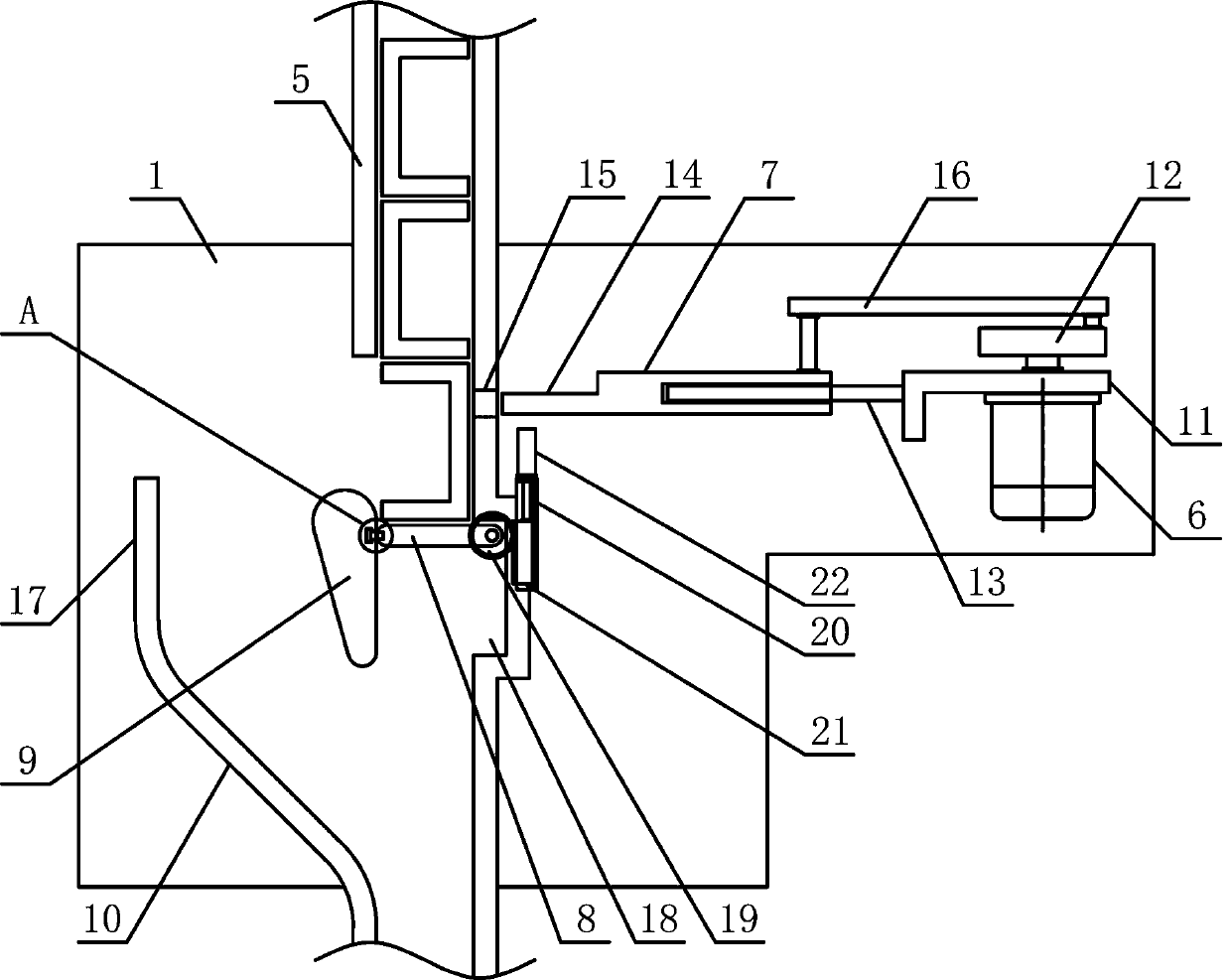

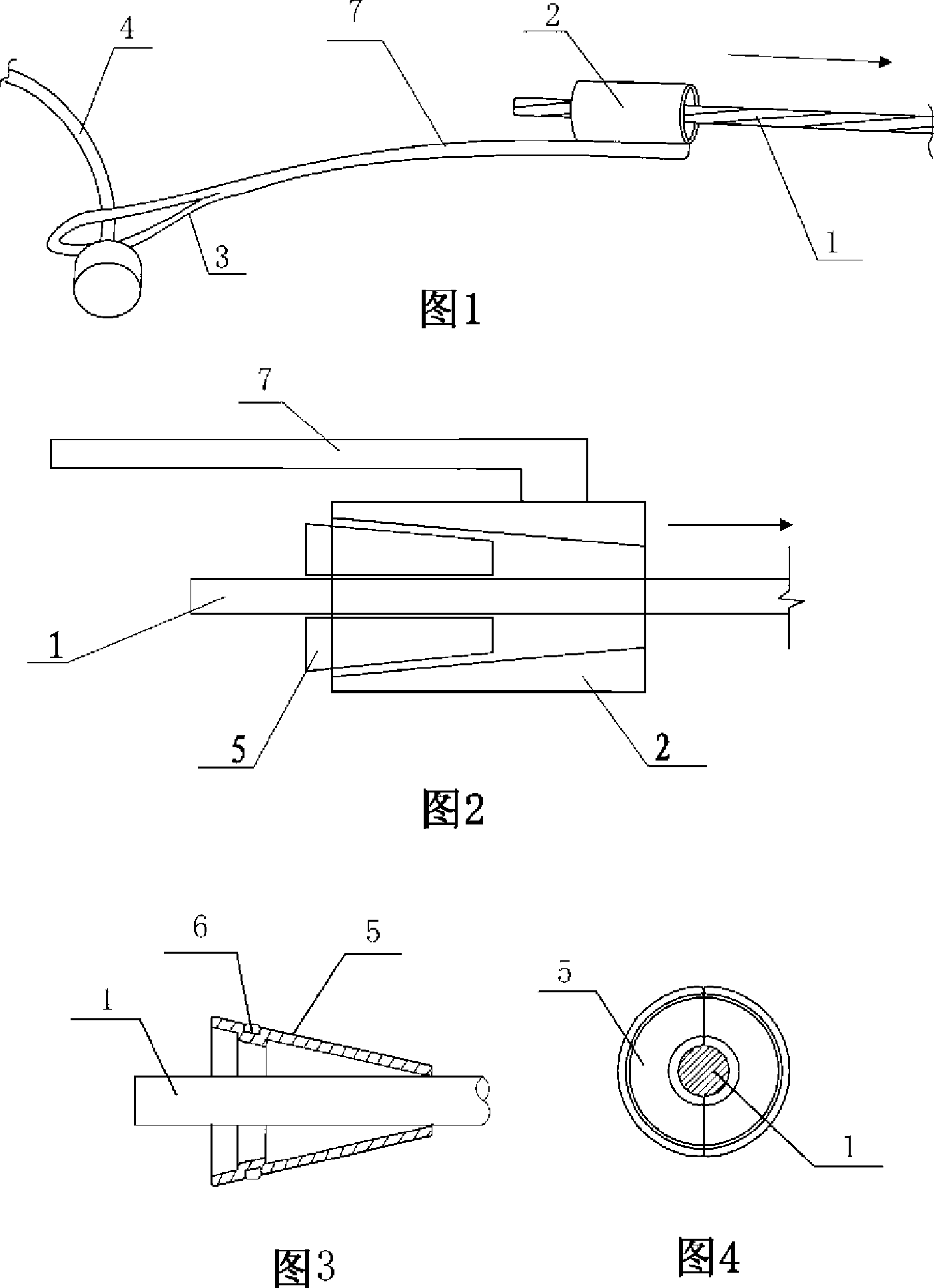

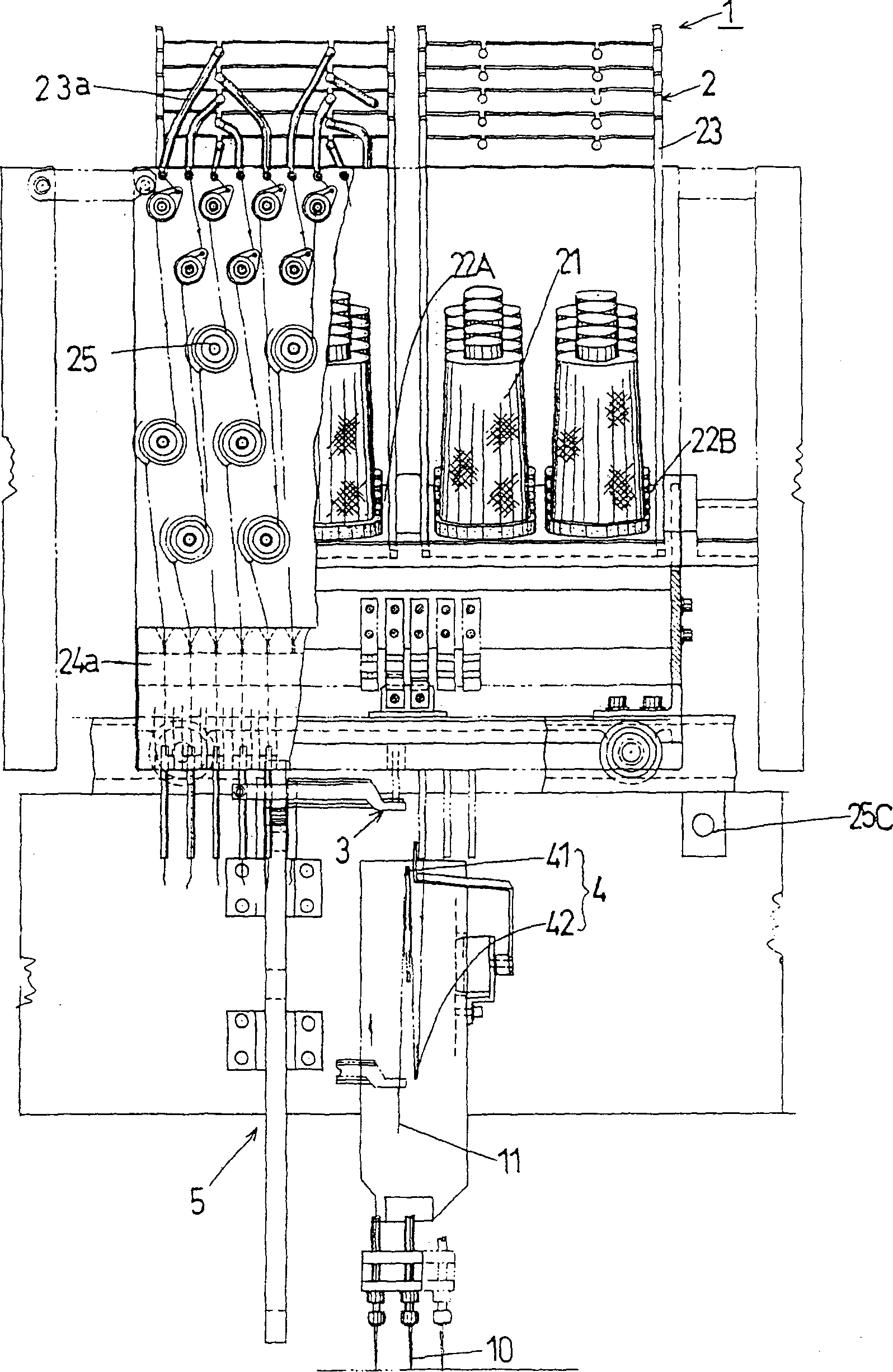

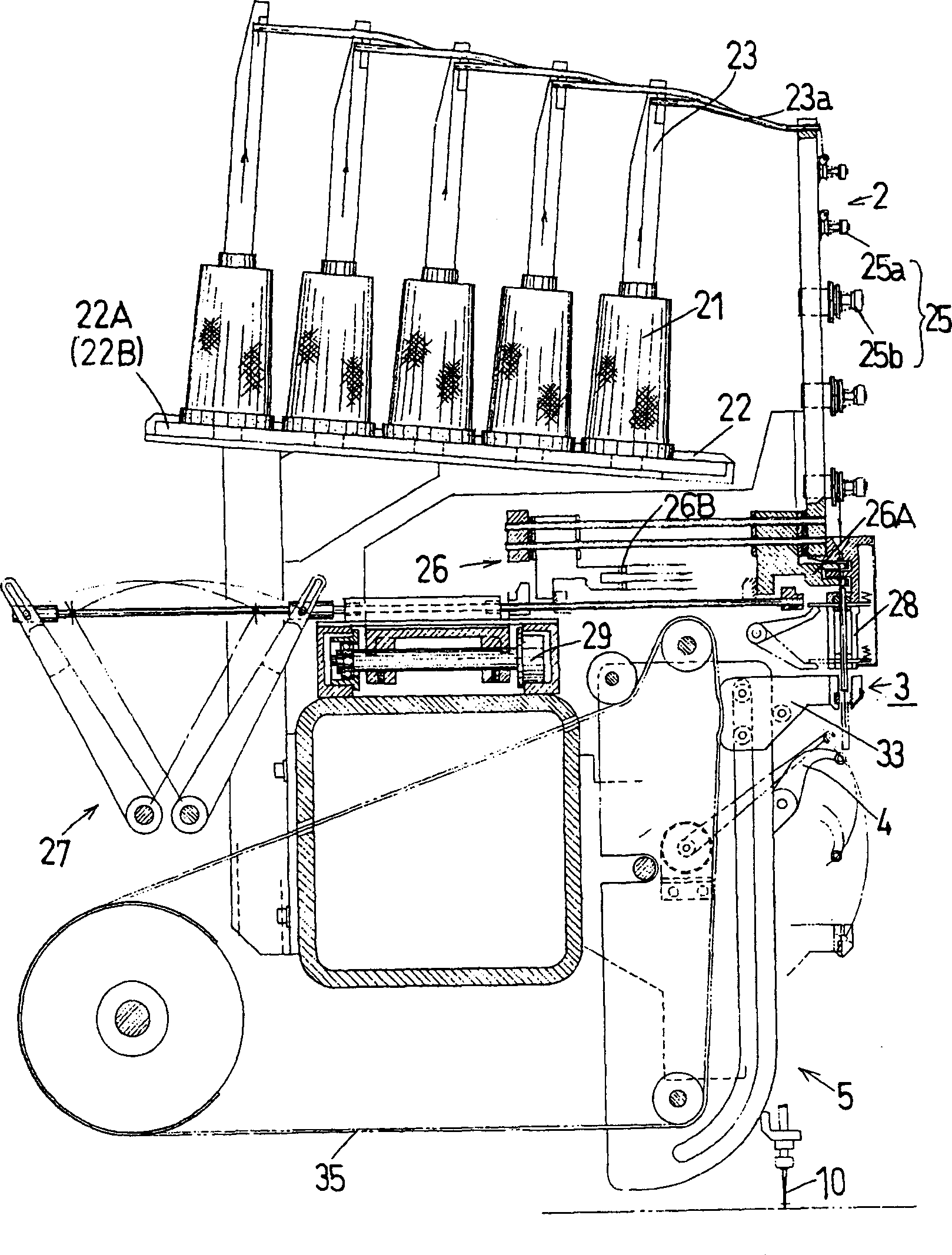

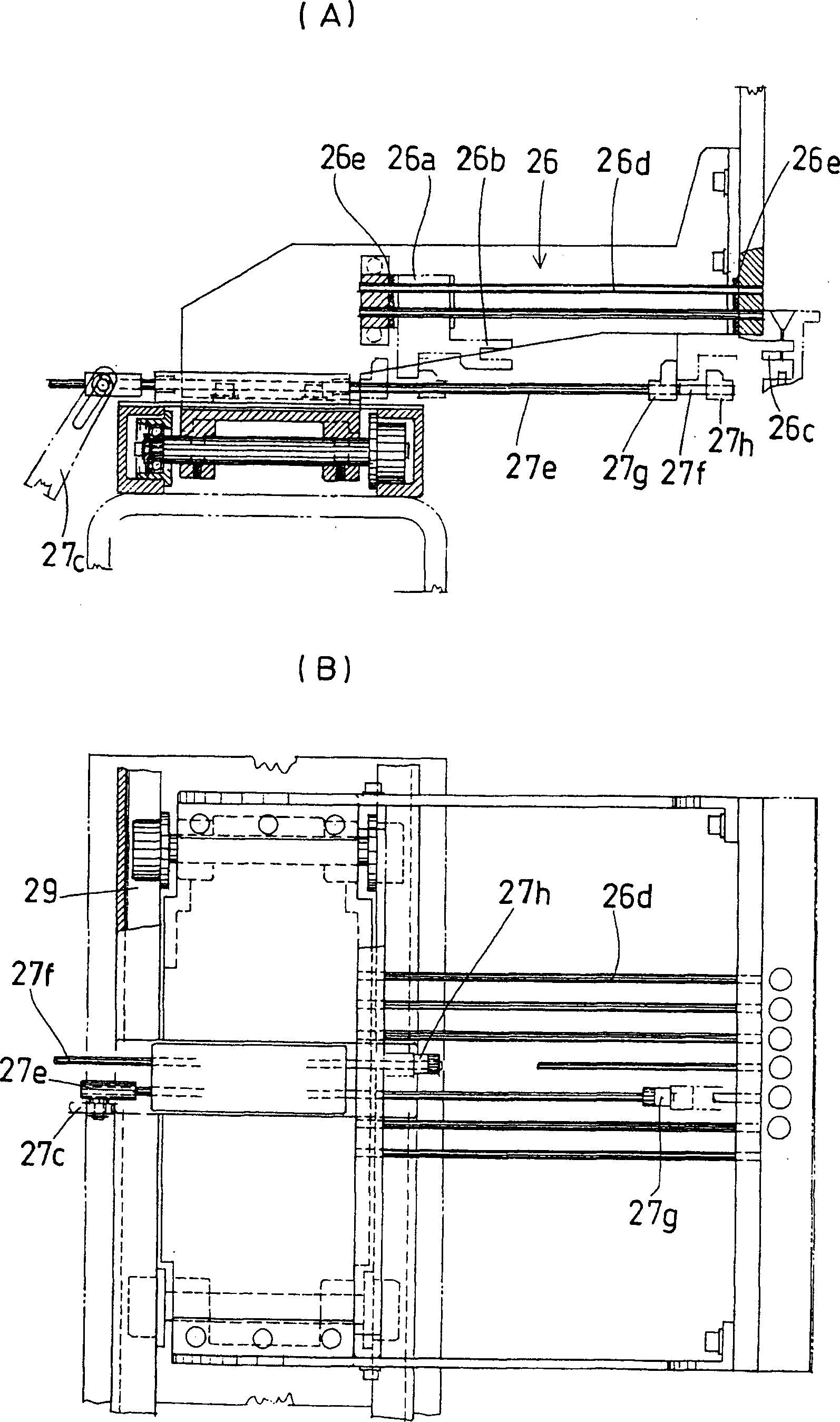

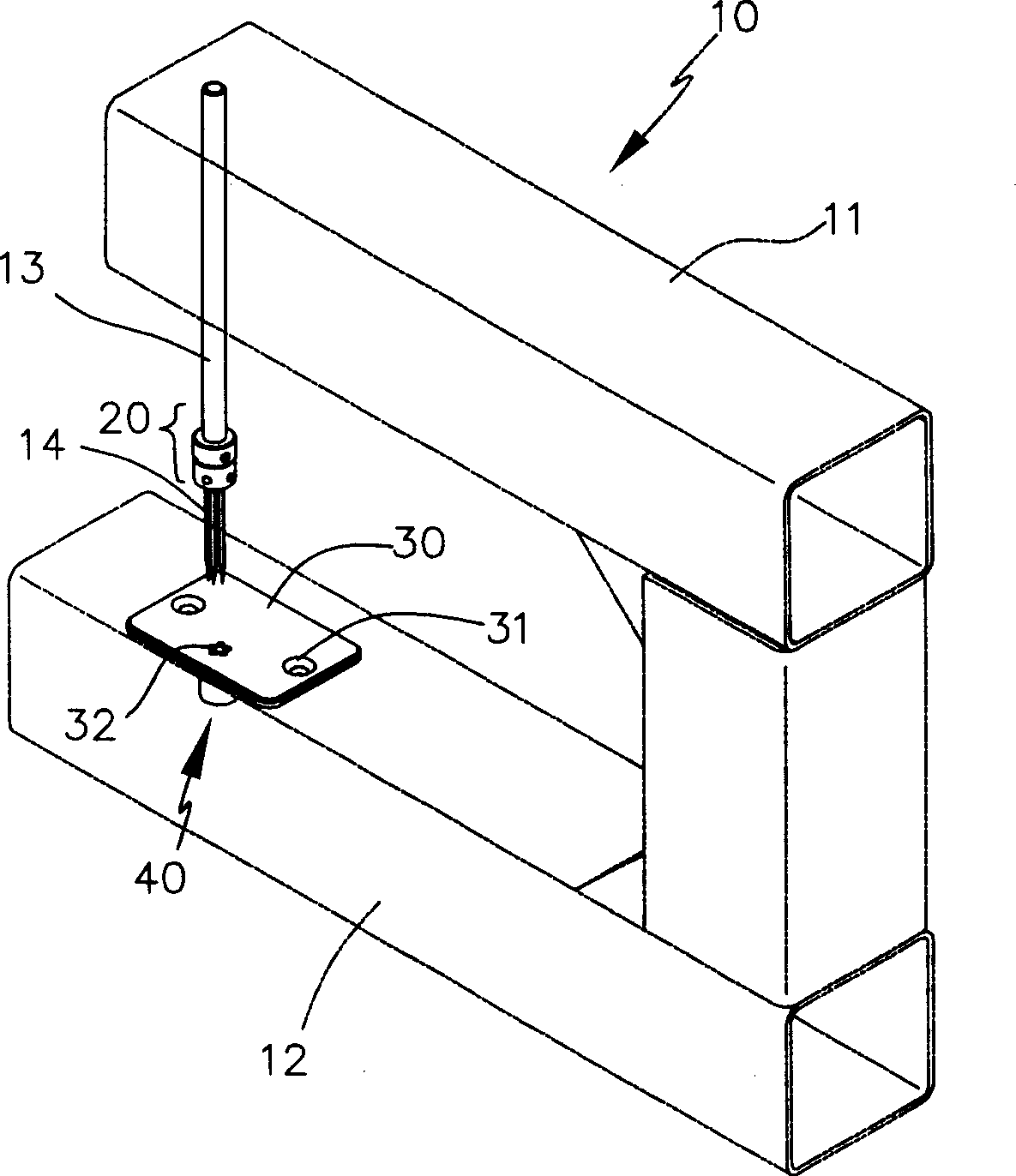

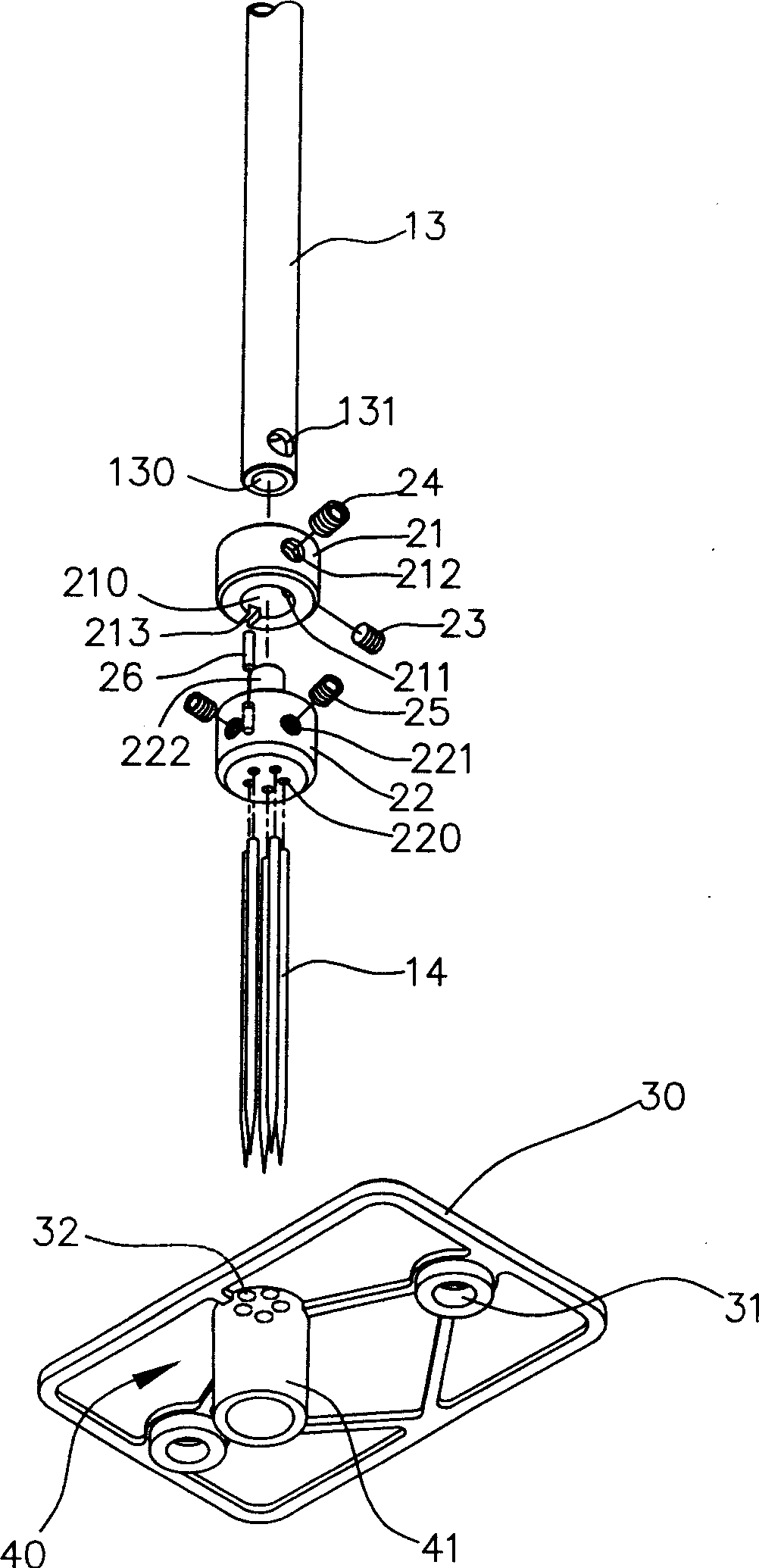

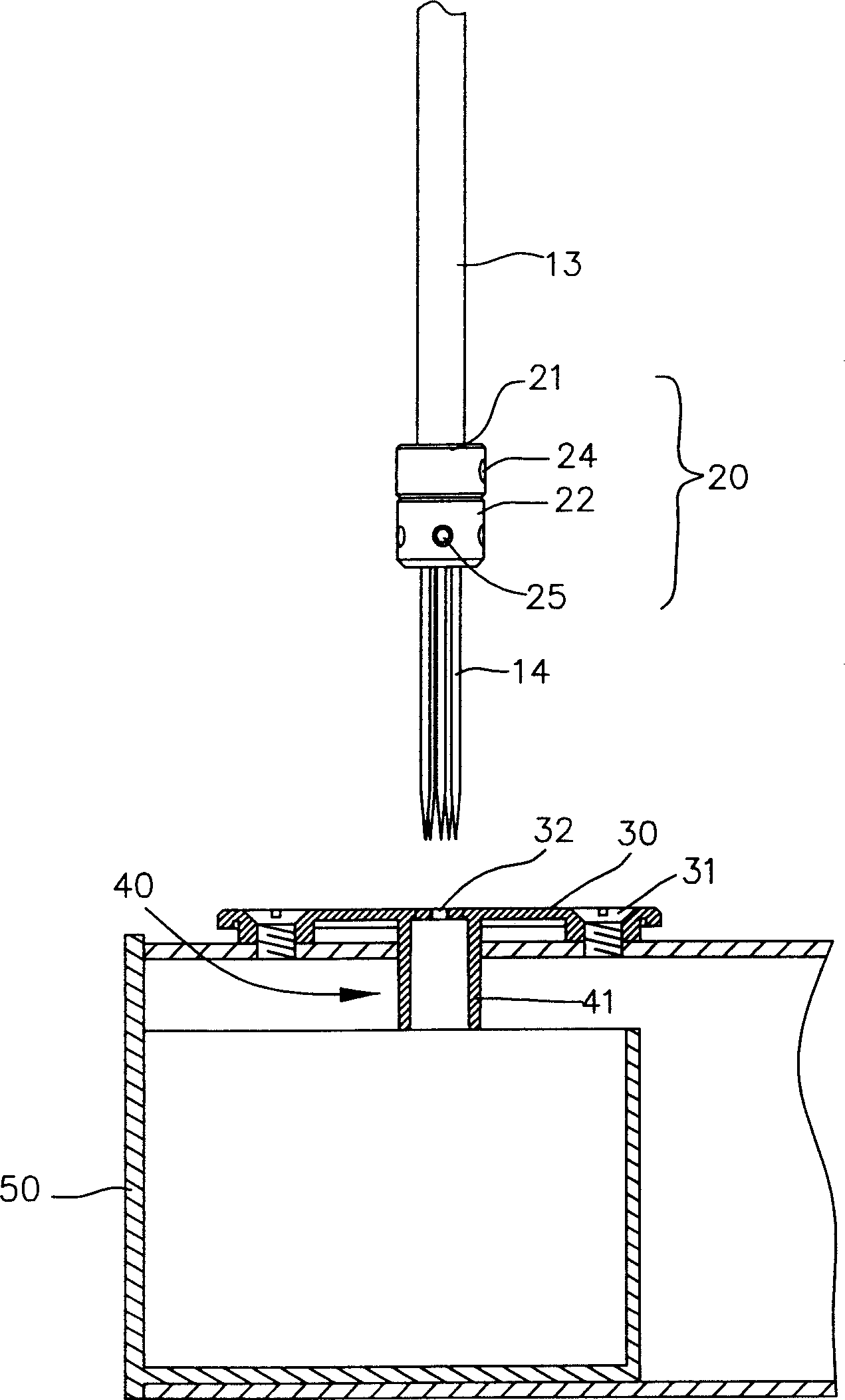

Yarn passing device of sewing machine for embroidery

InactiveCN1416486ASmooth throughPrevent needle deflectionHand sewingFilament handlingYarnEngineering

The aim of the present invention is to provide a threading device for embroidery machinery realized in such a way that it performs threading accurately regardless of the type of thread, for embroidery machinery, etc. capable of performing the processing for change of colored thread automatically without intervention of an operator, for example, comprises a needle support mechanism (7), disposed movably facing the hooking member (61a), for preventing deflection of the needle (10), by correcting deflection of the needle (10), when inserting the hooking member (61a) formed in the shape of a hook at the tip of the thread pull-out mechanism (61) in the needle hole (10a).

Owner:MIYAMOTO MFG CO LTD

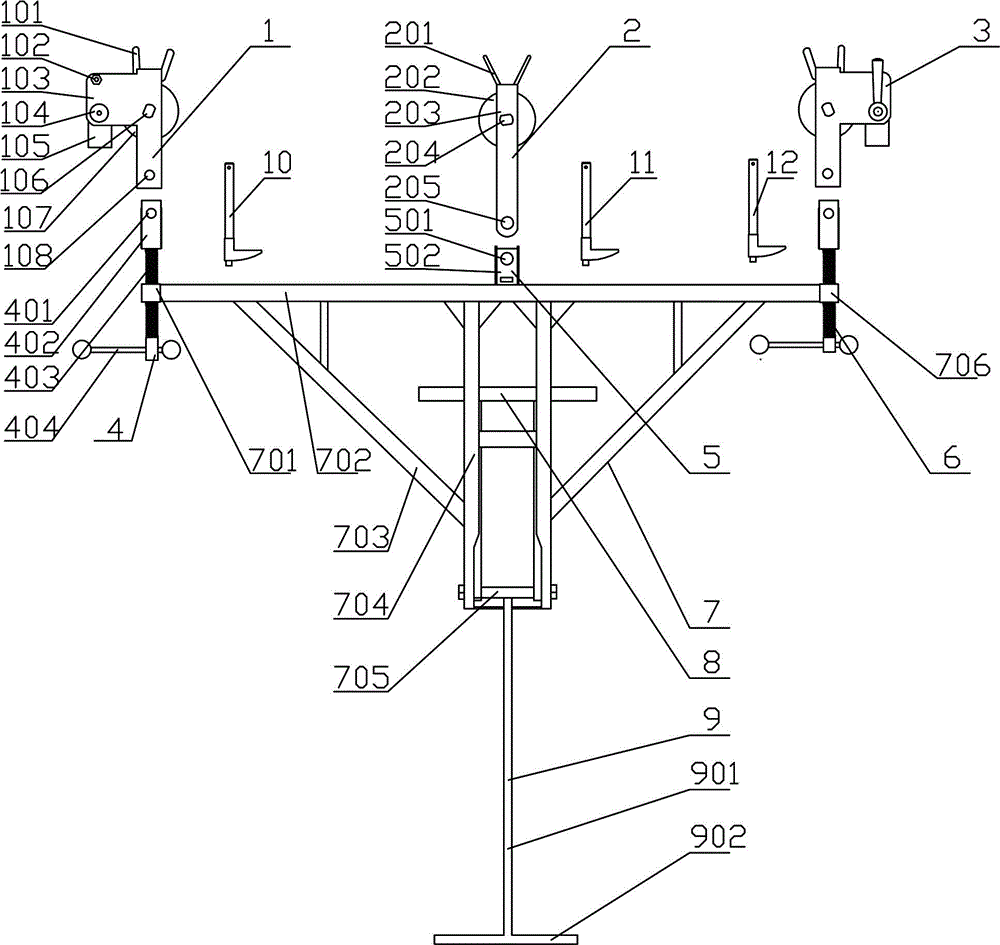

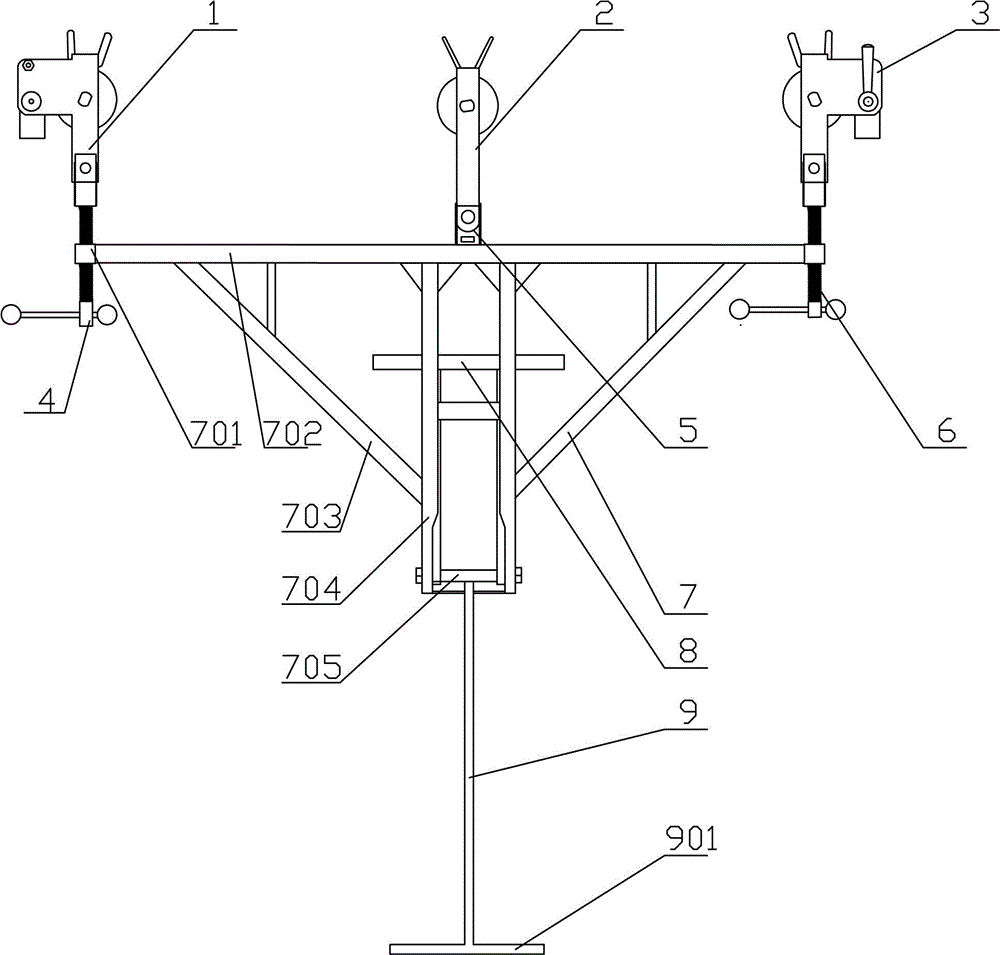

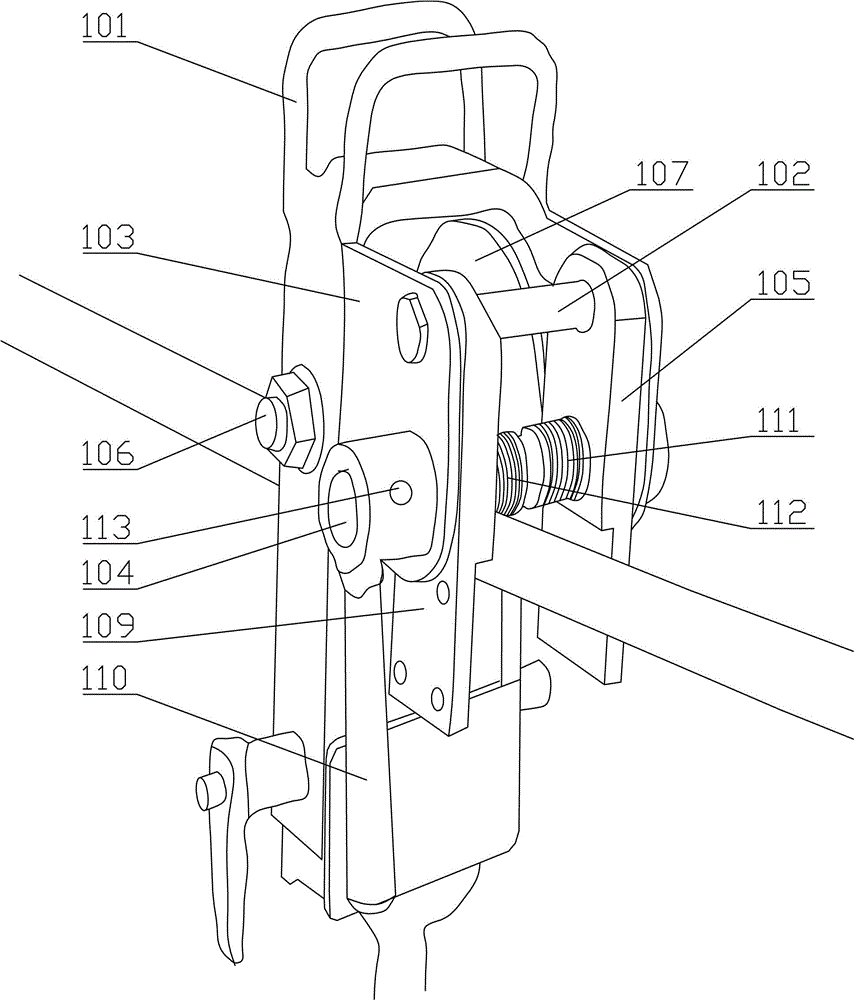

Line barrier-crossing type overhead tool

ActiveCN105305309AWalking smoothlySmooth throughApparatus for overhead lines/cablesEngineeringOverhead line

The invention relates to a line barrier-crossing type overhead tool. The tool comprises a frame. The frame comprises a crossbeam. The left end and the right end of the crossbeam are equipped with a left screwed hole and a right screwed hole respectively. Two symmetric vertical rods are welded to the bottom surface of the crossbeam. Inclined supporting rods are welded to the vertical rods and the crossbeam. The bottom ends of the two vertical rods are fixedly connected to each other via a rotating shaft. The left screwed hole is equipped with a left lift mechanism in a cooperative manner, and the right screwed hole is equipped with a right lift mechanism in a cooperative manner. A central connecting device is fixedly disposed in the middle of the crossbeam. A left pulley device is detachably disposed on the left lift mechanism, a right pulley device is detachably disposed on the right lift mechanism, and a central pulley device is detachably disposed on the central connecting device. One end of a carrying stand is arranged on the rotating shaft of the frame. One end of a foot holding stand is also arranged on the rotating shaft of the frame. The overhead tool can succeed in passing over spacers and other barriers, so workers can conduct overhead line work.

Owner:XIAOGAN XIANYUAN ELECTRIC POWER +2

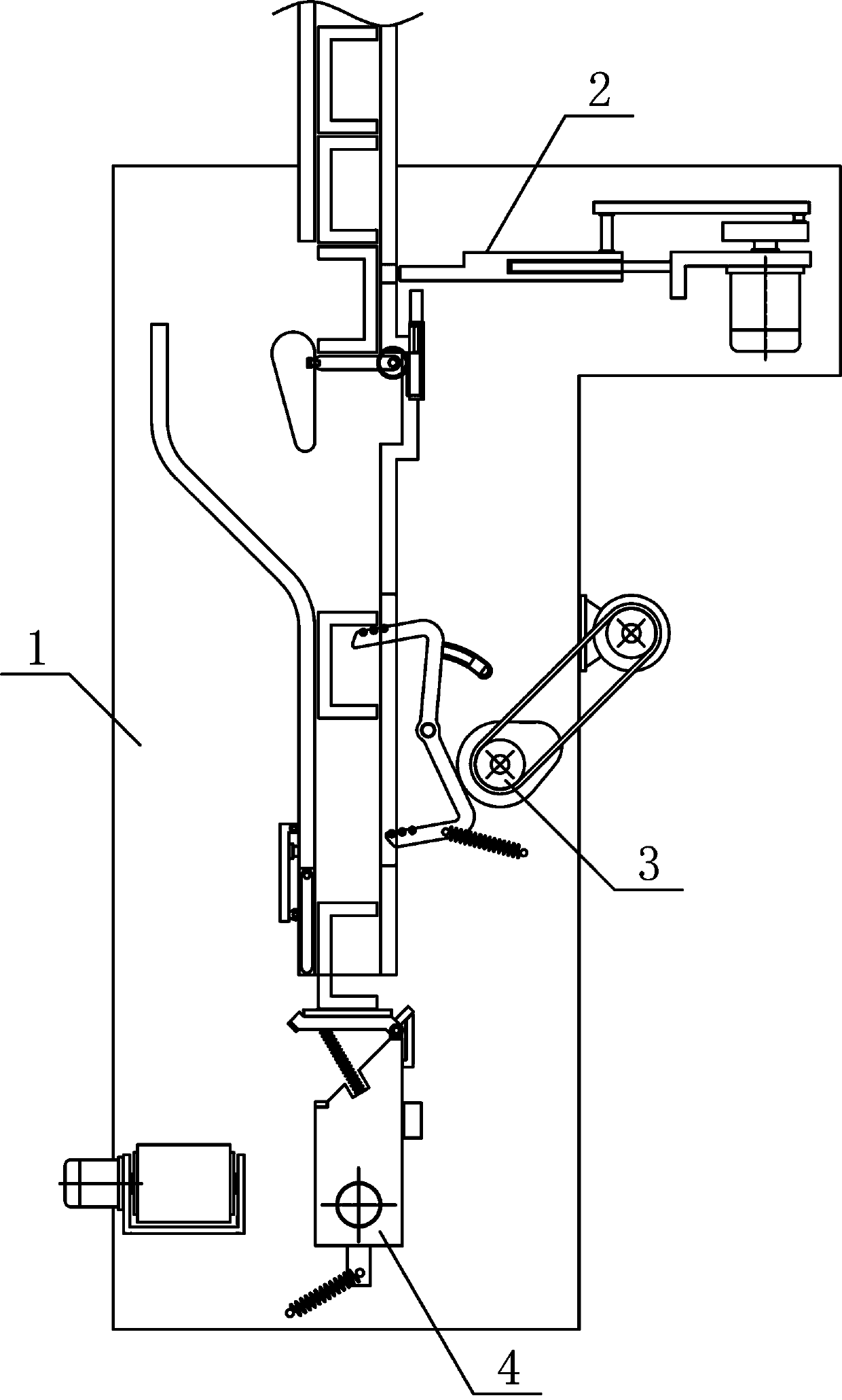

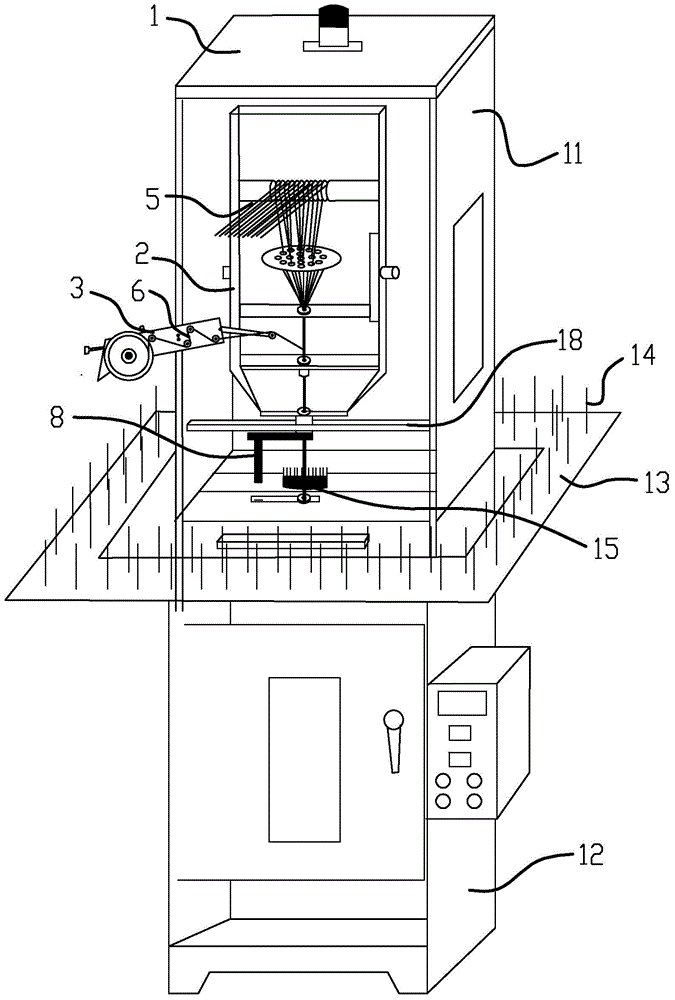

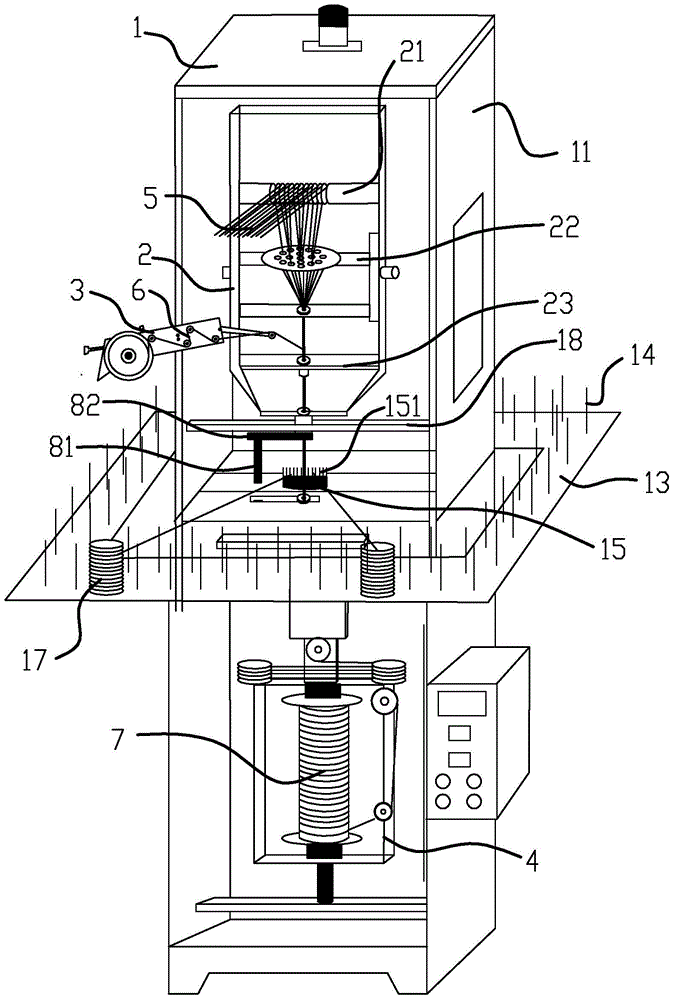

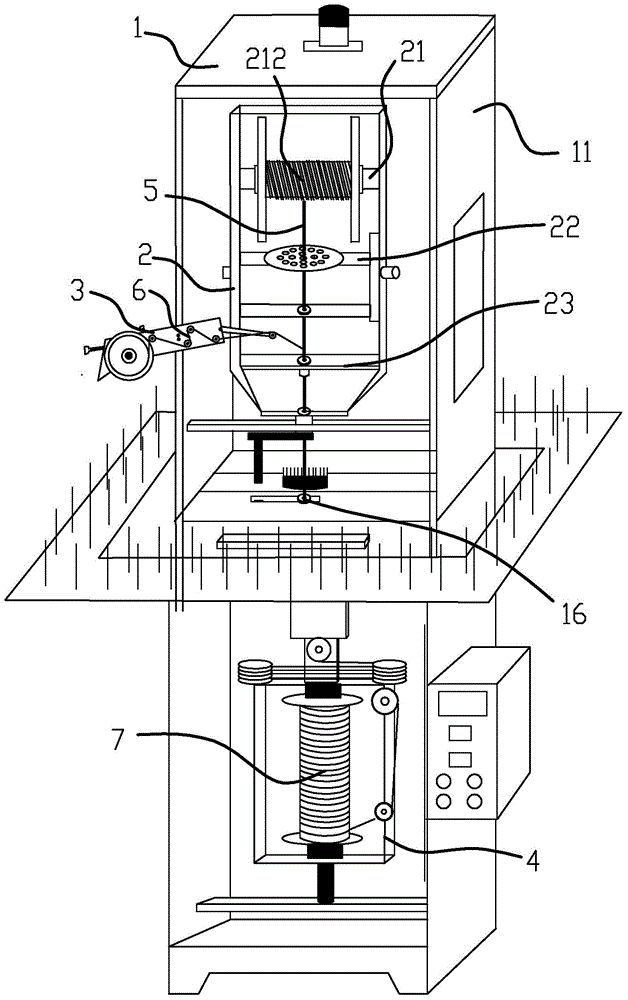

Machine tool with functions of winding, gathering and wrapping

InactiveCN104464954ASmall footprintFully utilized resourcesCable/conductor manufactureConstant forceEngineering

The invention provides a machine tool with the functions of winding, gathering and wrapping and belongs to the technical field of cable manufacturing equipment. The machine tool solves the problems that an existing device is large in occupied area and single in function. The machine tool with the functions of winding, gathering and wrapping comprises a rack. A rotating disc mechanism, a paying-off device and a power mechanism are installed in the rack in the vertical direction, and a constant-force paying-off device is installed on the rack. The rack protrudes towards the periphery to form a working table, and a plurality of wire feeding devices are fixedly connected to the working table in the vertical direction. A wire coil which can rotate is arranged on the rotating disc mechanism, the power mechanism is connected to the paying-off device and can drive the paying-off device to rotate, a wire slides through the paying-off device and is wound on the wire coil. The machine tool with the functions of winding, gathering and wrapping has the advantages of being small in occupied area and complete in function.

Owner:宁波日月电线电缆制造有限公司

Water energy cleaner

The invention provides a water energy cleaner. The cleaner includes a fixed shell, a hydraulic motor, two direction switching structures and a power output structure. The fixed shell is provided witha water suction port, and the two direction switching structures are arranged on the two sides of the hydraulic motor respectively, and a power output structure is connected with a direction switchingstructure. The hydraulic motor includes a flow channel, a motor output shaft, a number of fan blade structures, a number of flow baffles, a water inlet and a water outlet, fan blades are axially fixed on the motor output shaft through a fan blade connection shaft, the fan blades includes a secondary fan blade A and a secondary fan blade B which are overlapped when there is no external force, whensuffering from water flow impact, the secondary fan blade A and the secondary fan blade B open to be perpendicular to the water flow direction, the flow baffles are located on the other side of a cavity, the water inlet is communicated with the water suction, and the water outlet is connected with a water pump. The water energy cleaner achieves sewage suction, walking and reversing functions, hashigher output force stability and larger output torque, and the utilization rate of water energy resources is improved.

Owner:NINGBO POOLSTAR POOL PROD CO LTD

Leakage self-reminding ring at natural gas pipeline connectors

InactiveCN112066268AImprove leakageTimely reminder of leakagePipeline systemsThermodynamicsMechanical engineering

The invention discloses a leakage self-reminding ring at natural gas pipeline connectors, and belongs to the field of natural gas leakage prevention. The leakage self-reminding ring at the natural gaspipeline connectors comprises a ring body connected to the two natural gas pipeline connectors, wherein through the arrangement for the ring body, when natural gas leakage occurs, on one hand, a gasseal ring is expanded under the extrusion of natural gas, so that the contact area of the gas seal ring and the surface of the natural gas pipeline is increased, a better sealing effect is achieved, and then more obvious phenomenon occurring outside the ring body is effectively ensured, and a better reminding effect on a user is achieved; and on the other hand, a pneumatic diaphragm is deformed outwards, and then self-connecting net rods are driven to protrude out of a limiting plate in sequence from the middle part to the edge; and a plurality of adjacent hollow top balls and flexible adsorption bars are mutually connected in an adsorption manner to form a net surface structure, so that the self-reminding phenomenon is further enhanced, the probability that the user finds natural gas leakage in time is effectively increased, maintenance is facilitated, and potential safety hazards are reduced.

Owner:林万有

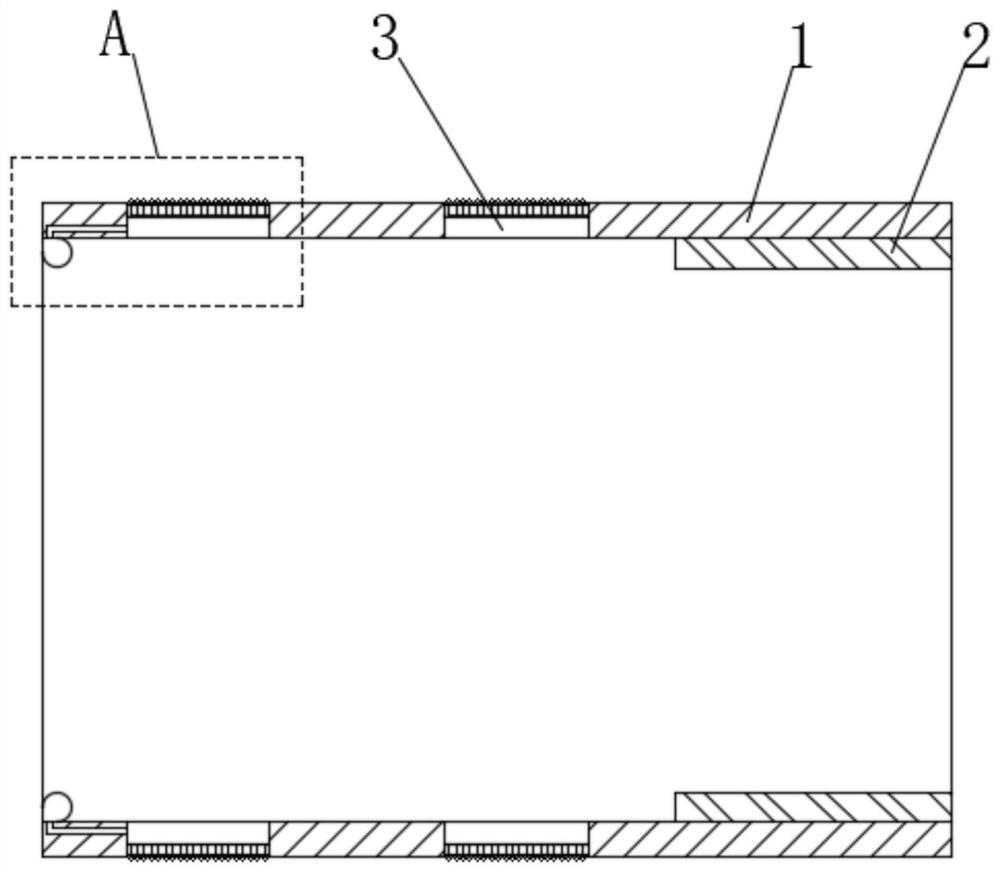

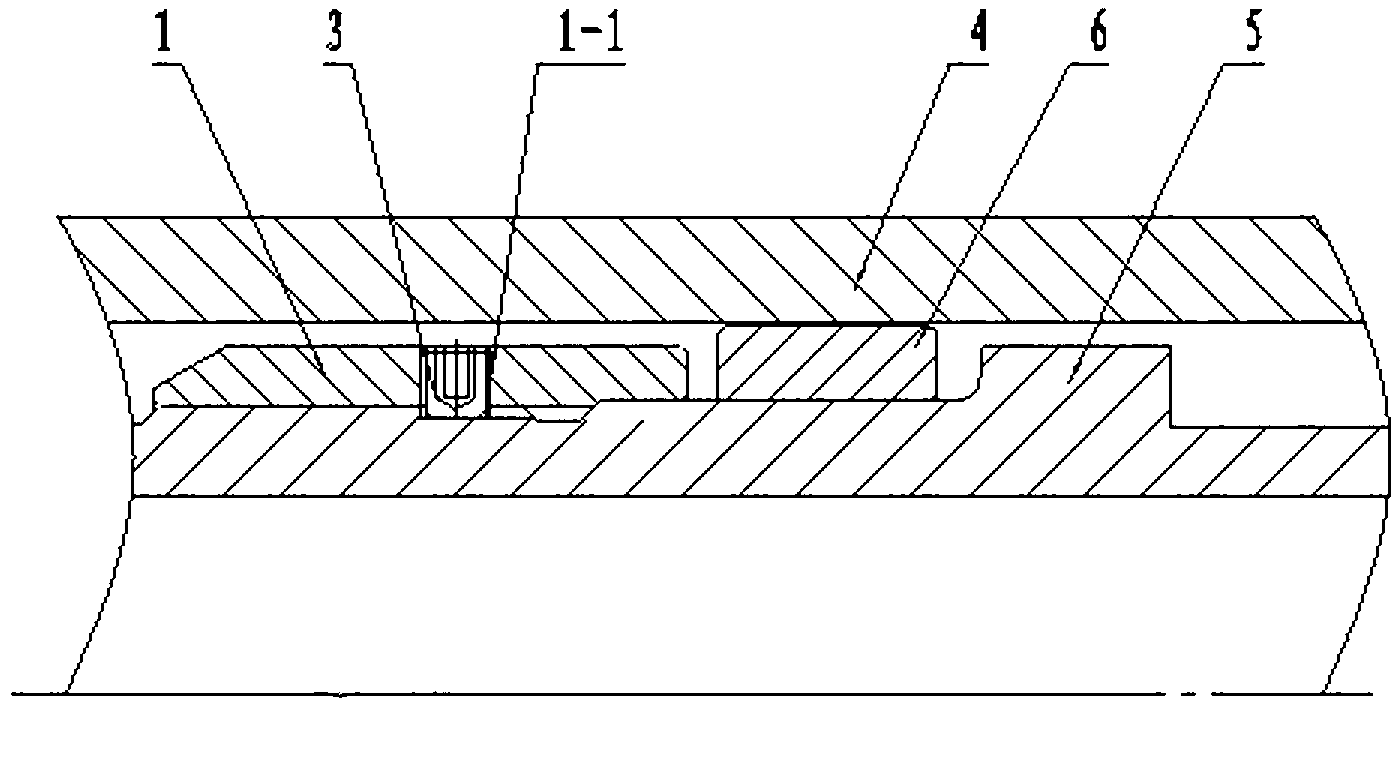

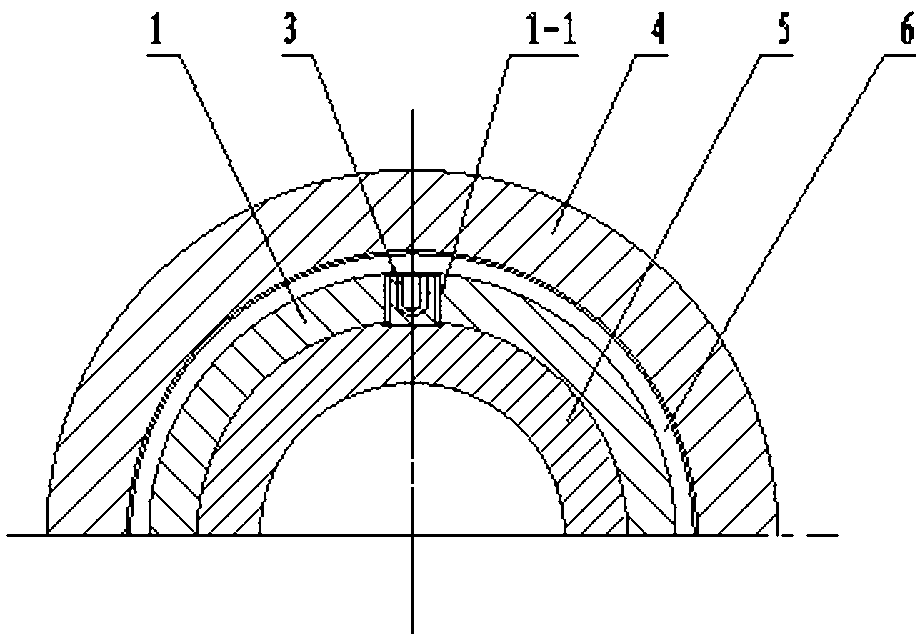

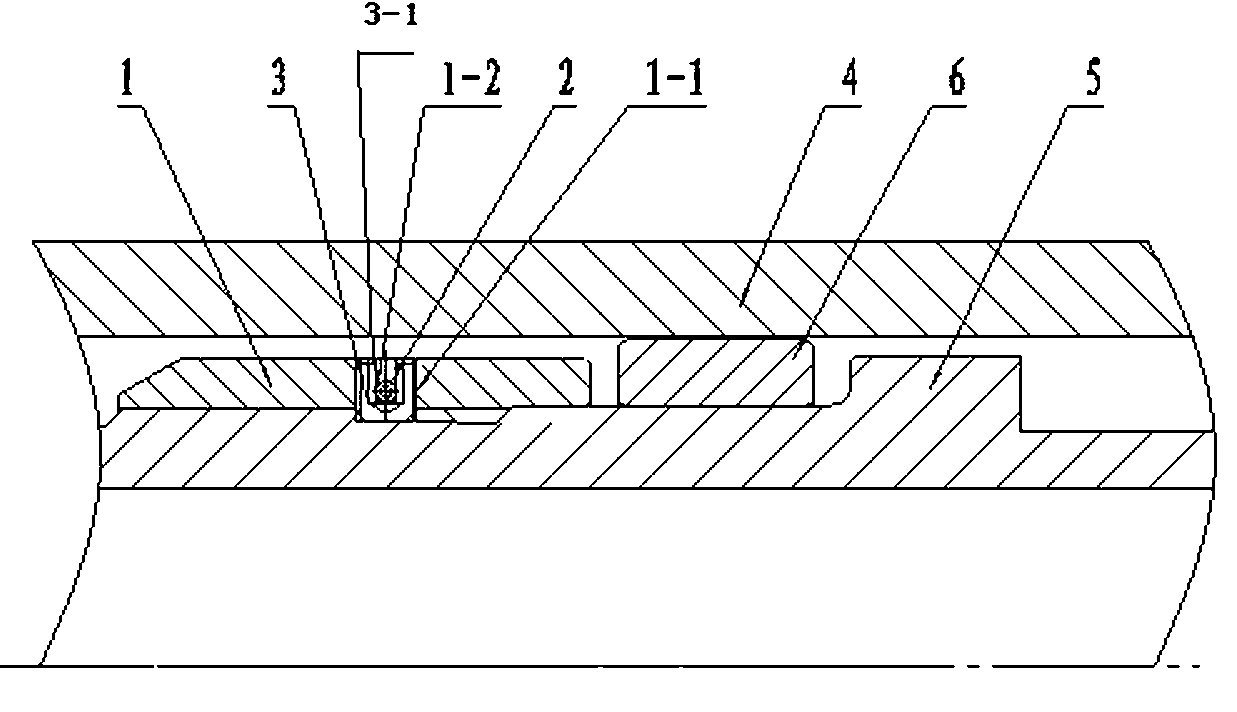

Pressing cap structure of hydraulic jar

InactiveCN103244068APrevent looseningGuaranteed interferenceBorehole/well accessoriesHydraulic cylinderEngineering

The invention discloses a pressing cap structure of a hydraulic jar. The pressing cap structure of the hydraulic jar comprises a pressing cap (1) for limiting axial movement of an overflow piston (6), a jarring hydraulic cylinder (4) and a mandril (5). The pressing cap (1) is sleeved on the mandril (5) located in the jarring hydraulic cylinder (4), a screw hole (1-1) is arranged in the radial direction of the pressing cap (1), and a screw (3) in the screw hole (1-1) is tightened to enable the pressing cap (1) to be fixedly connected with the mandril (5). The pressing cap structure of the hydraulic jar is characterized by comprising a connection pin (2), a through hole (1-2) is arranged on the pressing cap (1) in the direction perpendicular to the screw hole (1-1), the screw (3) is provided with a groove (3-1) matched with the through hole (1-2), and the connection pin (2) penetrates through the through hole (1-2) to be fixedly connected with the groove (3-1). The pressing cap structure of the hydraulic jar has the advantages of being capable of avoiding loosening and long in service life.

Owner:CHONGQING WANGJIANG IND

Combined cable collecting and releasing aviation winch cable arrangement device

The invention discloses a combined cable collecting and releasing aviation winch cable arrangement device capable of being used for collecting and releasing cable arrangement of variable-cable-diameter variable-cross-section combined cables. The combined cable collecting and releasing aviation winch cable arrangement device comprises a lead screw supporting structure, a lead screw drive mechanism,a cable guide mechanism and an active traction mechanism. A motor I drives a lead screw to rotate through chain transmission. The cable guide mechanism and a lead screw nut do reciprocating linear movement along the lead screw. By controlling the rotating speed ratio of a drum motor and the motor I, variable-diameter cable arrangement can be achieved. By means of independent chain belts, conveying chains can have large bending radii within limited arc sections, and a large amount of space is saved compared with conventional pulley cable guide. A righting frame is designed into a beak shape onthe basis of the collision mechanics principle, and a streamline body which inclines can be effectively overturned and righted and can smoothly pass the cable arrangement device. By means of the active traction mechanism, the active traction and looseness prevention functions can be achieved by changing the spring expansion and contraction quantity and the rotating speed of a motor II to adjust the friction force exerted by rollers on the combined cables. The whole cable arrangement device is small in weight, small in size and particularly suitable for being used on aviation winches.

Owner:中国船舶重工集团有限公司第七一0研究所

Arch bridge video inspection vehicle and matching structure of arch bridge video inspection vehicle and track

InactiveCN109837834AImprove securityAvoid working at heightsBridge structural detailsLeveling mechanismUltimate tensile strength

The invention relates to the technical field of bridge inspection, in particular to an arched bridge video inspection vehicle comprising: a main vehicle body provided with a camera mechanism; a walking mechanism that walks along the bridge top of the arched bridge and is used for driving the main vehicle body to move; a leveling mechanism installed between the walking mechanism and the main vehicle body and movably connected with the main vehicle body. In the moving process of the walking mechanism, the main vehicle body is adjusted in real time by the leveling mechanism, so that the main vehicle body is kept vertical. The invention further provides a matching structure of the arched bridge video inspection vehicle and a track. The arched bridge video inspection vehicle provided by the invention can be remotely operated, and is high in safety, high in automation degree, simple to operate, low in labor intensity and wide in application range.

Owner:BEIJING HENGLI TIEKE TECH DEV

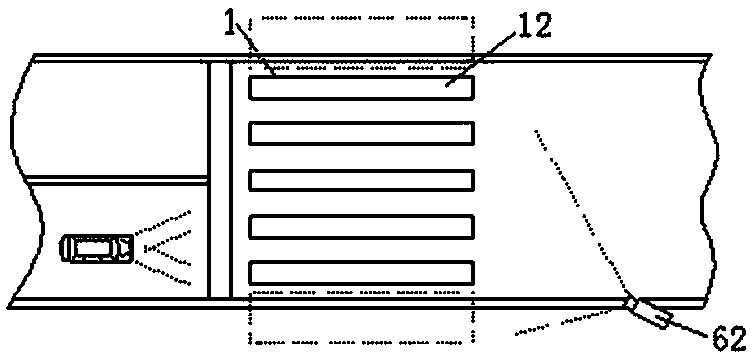

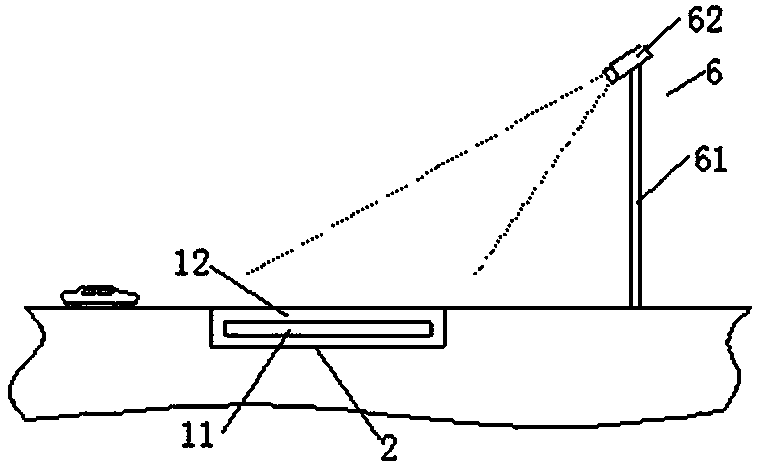

Intelligent luminous zebra crossing, intelligent luminous zebra crossing control system and method

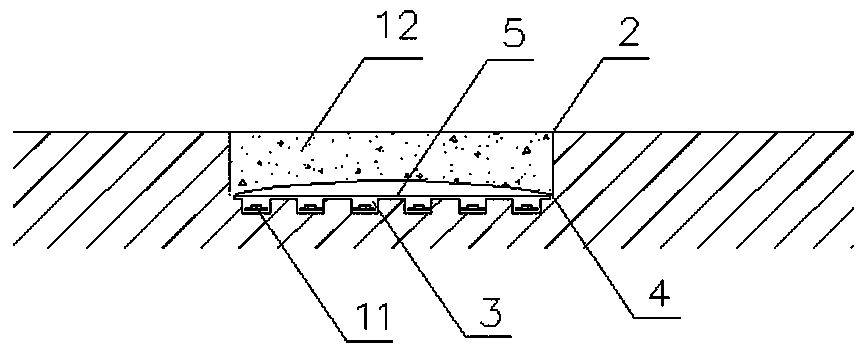

InactiveCN109083034AEasy to take outEasy to replaceTraffic signalsRoad signsElectricityControl system

The invention relates to an intelligent light-emitting zebra crossing, an intelligent light-emitting zebra crossing control system and a method. The intelligent light-emitting zebra crossing comprisesa plurality of zebra crossing units and a first groove arranged in a pedestrian area of a road surface at parallel intervals, wherein the zebra crossing units are arranged in the first groove one byone correspondingly. The zebra crossing unit includes an LED light source and a transparent concrete layer matched to the first groove, The LED light source is arranged at the bottom of the corresponding first groove, the transparent concrete layer is arranged one by one in the first groove, and the upper surface of the transparent concrete layer is arranged at the same height as the pavement, andthe LED light source is electrically connected with an external power supply through a switch. The intelligent light-emitting zebra crossing of the invention, At the same time, the transparent concrete layer can effectively protect the LED light source, enhance the compression resistance and durability of the entire zebra crossing, and has simple structure and low cost, and is suitable for large-scale popularization. The LED light source can emit light through the transparent concrete layer and illuminate the pedestrian area on the pavement, thereby facilitating the passage of vehicles and pedestrians.

Owner:武汉鑫弘凯交通科技有限公司

Needle group structure for embroidery adhesion machine

The invention relates to a needle group structure of needle group structure of embroidery machine, wherein the needle rod is arranged at the end of suspension arm of base to connect several groups of needles; one quick combiner is arranged between needle and needle rod; some needle plates relative to the needles are arranged under the needle; the bottom of needle plate has one baffle device; via the alignment element and the alignment part of quick combiner, the needle and needle rod can quickly combine accurately, to clamp and position, to avoid breaking the needle; the needle-thread part on the needle part can thread the sharp end of needle and keep best support effect of needle plate; its baffle device is arranged around the thread part under the needle plate, to avoid directly contacting the hand or other matters, to improve the safety and the quality of embroidery cloth.

Owner:曾贤长

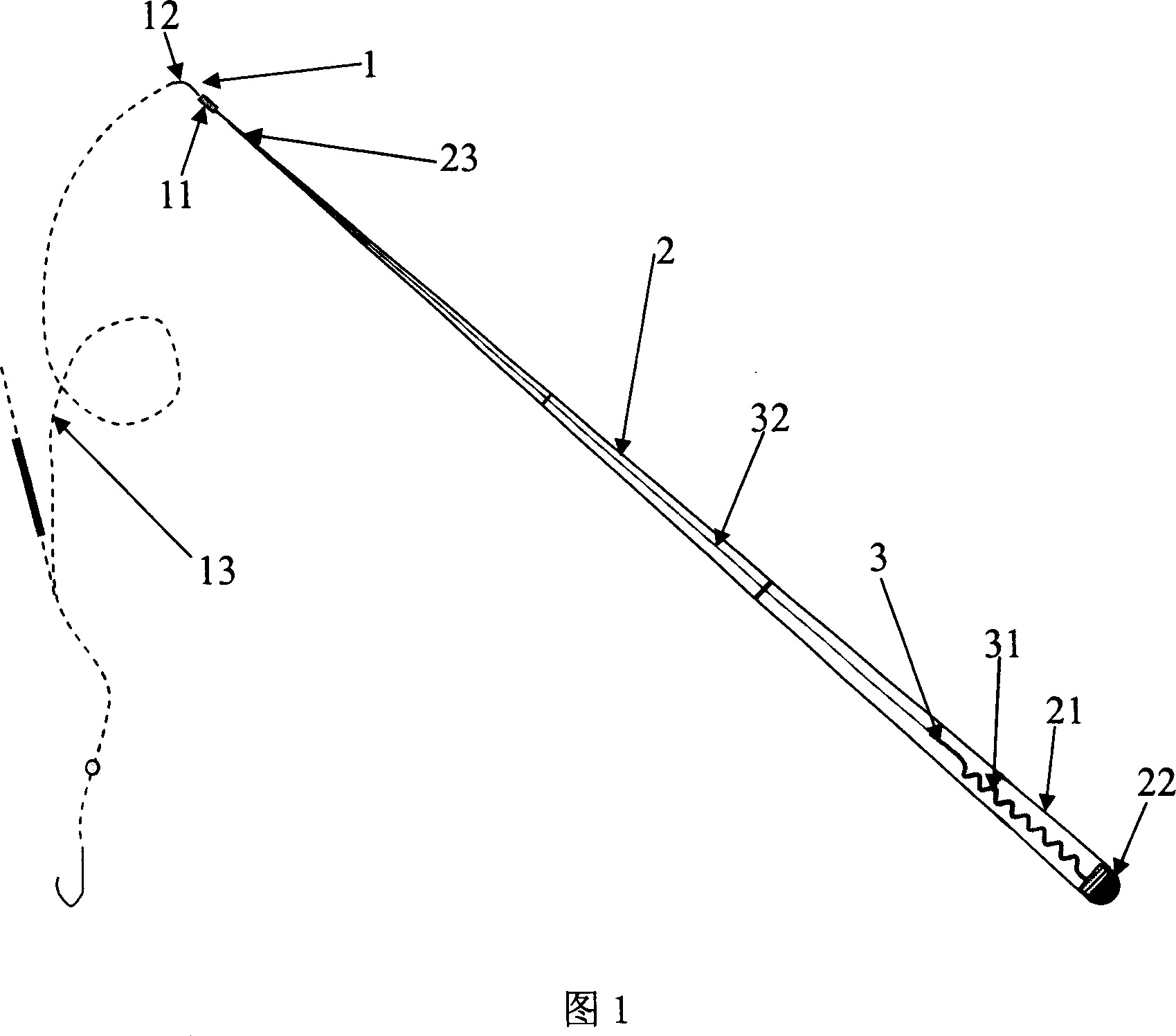

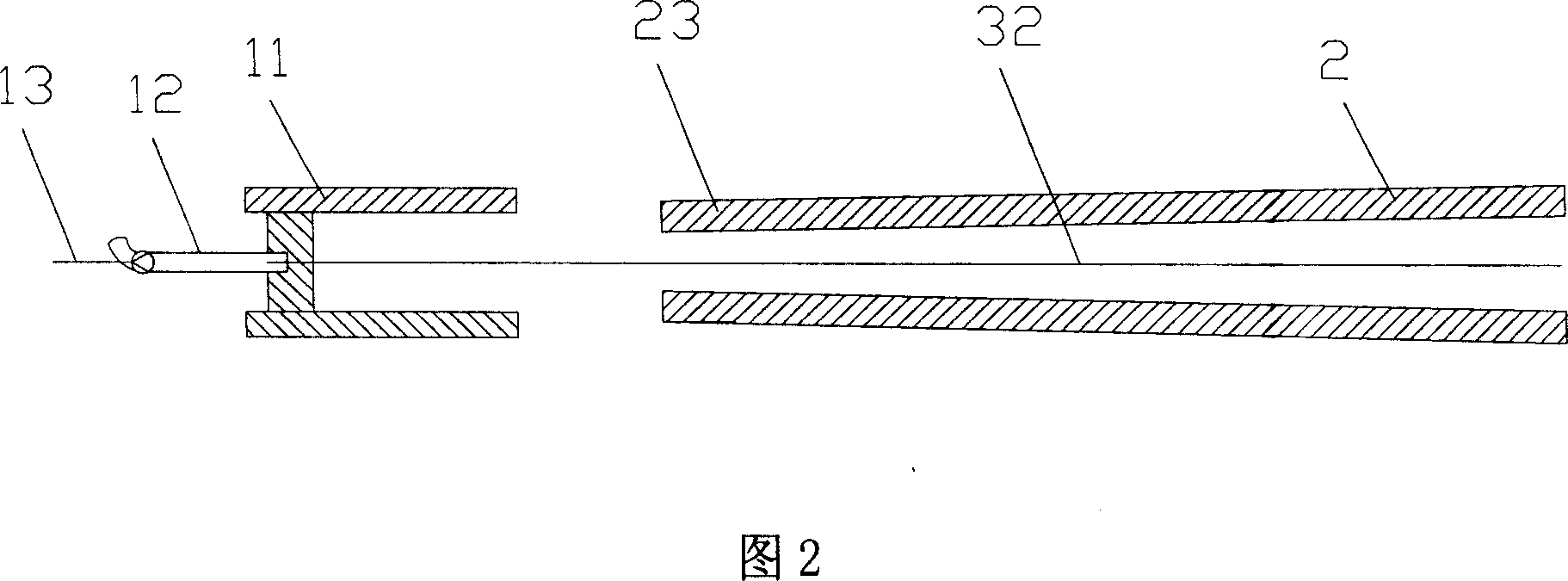

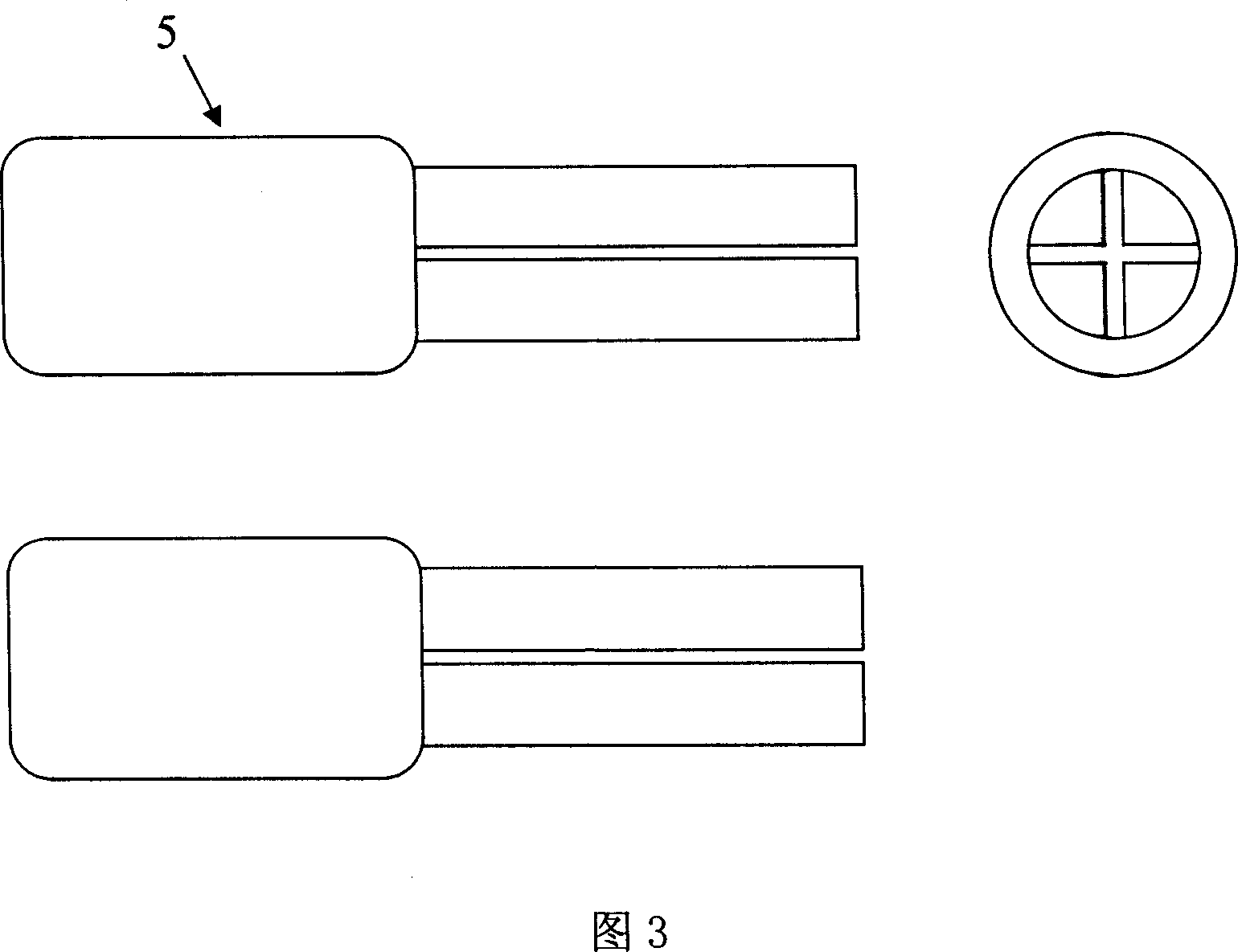

Fishing hand rod

The present invention discloses one kind of fishing hand rod, which includes one hollow rod body and one connecting assembly connected movably to the front end of the hollow rod body as well as one elastic buffering mechanism located inside the hollow rod body. The elastic buffering mechanism has one first end fixed inside the hollow rod body and one second end penetrating the front end of the rod body and connected to the connecting assembly. The fishing hand rod of the present invention has the advantages of available ones and is superior to available ones, which have the demerits of easy string breaking, easy rod breaking and straightening hook. The increased elastic buffering mechanism is small and light and has no influence on the appearance of the hand rod.

Owner:金弼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com