Pulp manufacturing method of used paper recycling apparatus, pulp manufacturing device of used paper recycling apparatus, and used paper recycling apparatus

A technology for recycling and waste paper pulp, applied in pulp beating/refining methods, processing waste paper, papermaking, etc., can solve the problems of irrecoverable, destroyed characters and patterns, and achieve high beating rate, effective beating treatment, The effect of smooth and effective beating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

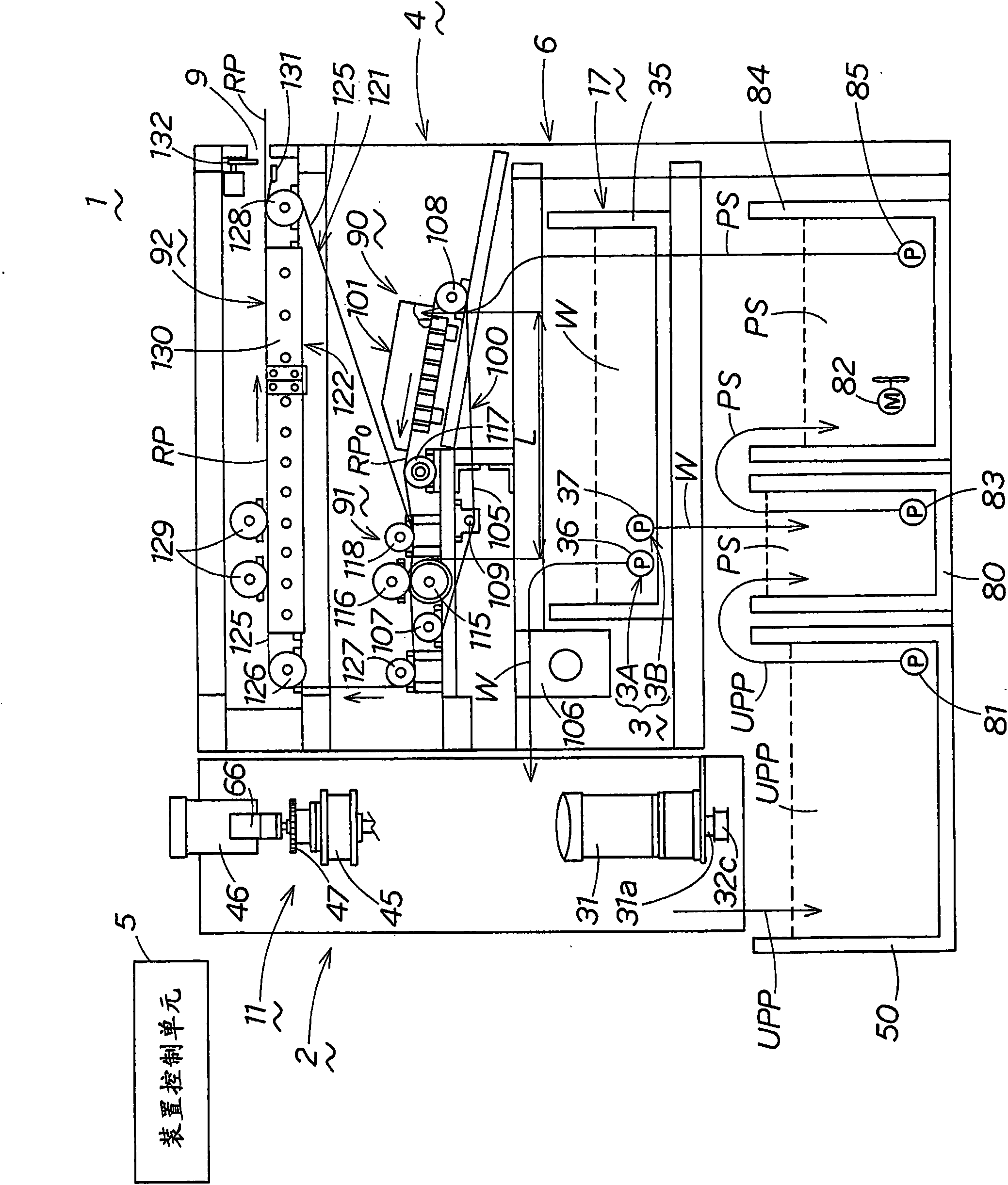

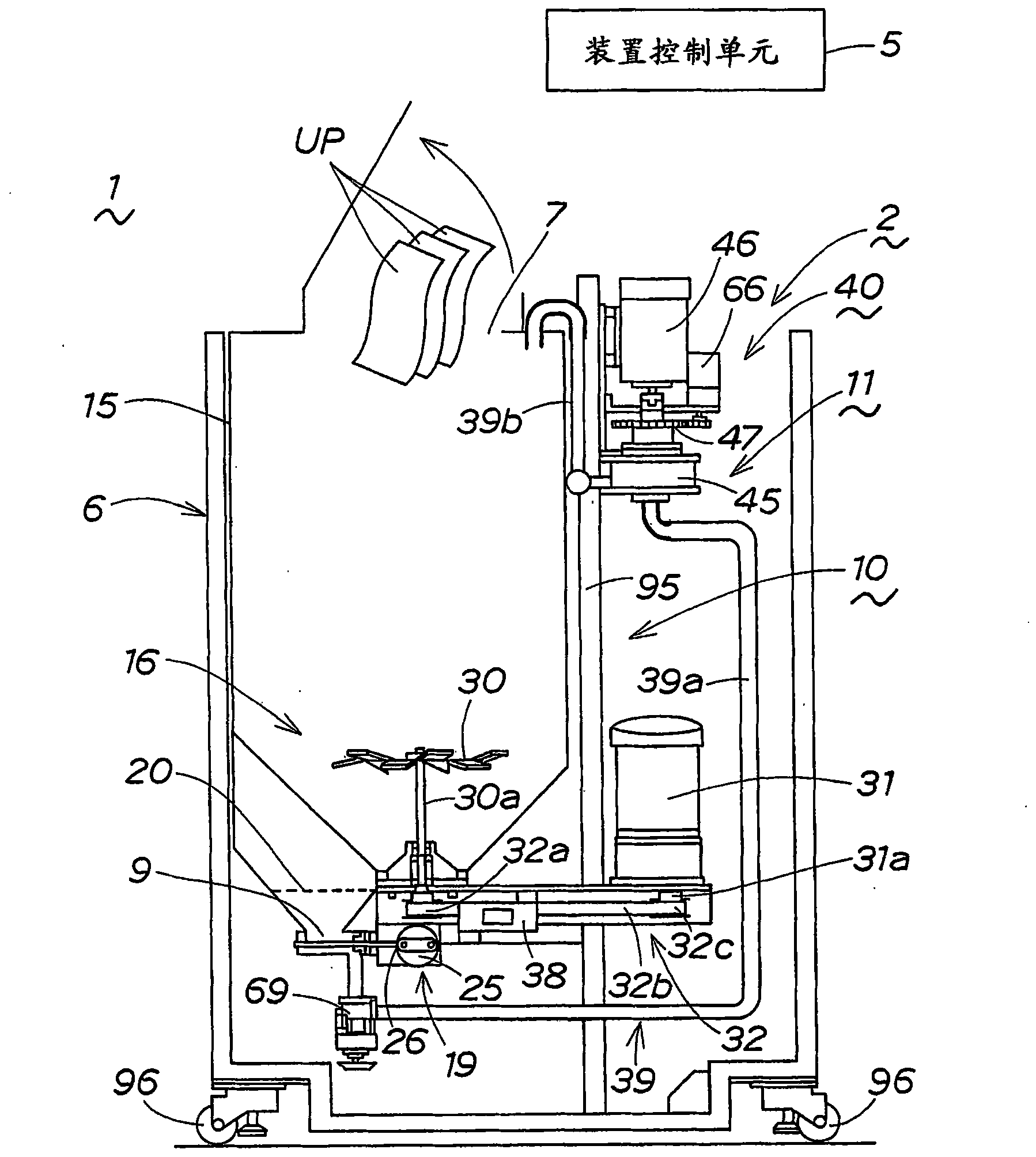

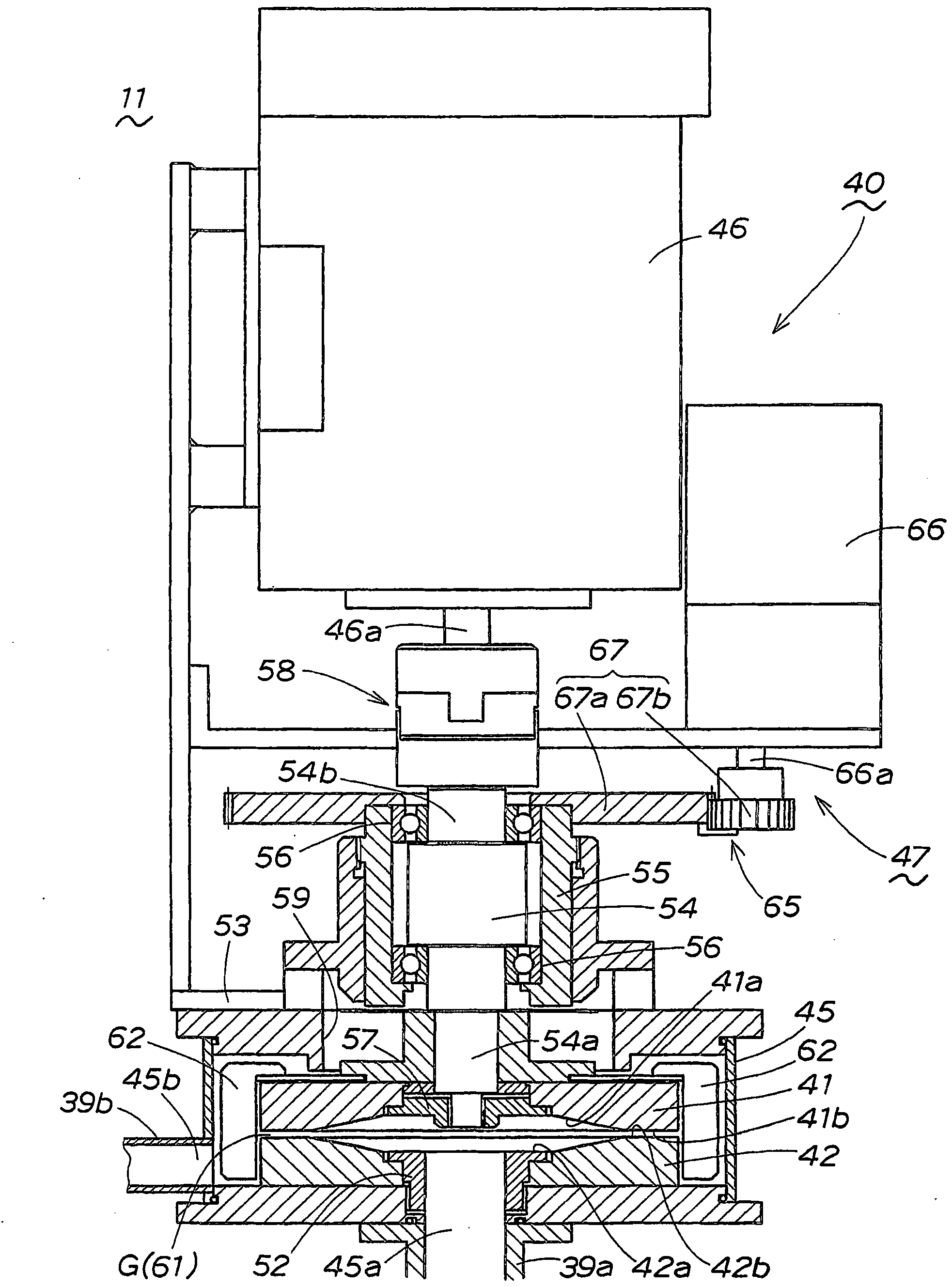

[0059] Figure 1-9 shows the waste paper recycling plant of the present invention, said waste paper recycling plant 1 is specially installed at the original source of waste paper, which is used to recycle the generated waste paper UP into reused paper at the site , instead of disposing or throwing away waste paper. This waste paper UP includes confidential documents of government agencies and private companies, private letters of ordinary families, and other used useless paper.

[0060] Such as Figure 9 As shown, the waste paper recycling plant 1 has furniture-sized dimensions, that is to say its size and shape are similar to office equipment such as bookshelves, lockers, desks, copiers or personal computers. Such as figure 1 As shown, the waste paper recycling equipment 1 mainly includes a pulping unit 2, a pulp concentration adjustment unit (pulp concentration adjustment device) 3, a papermaking unit 4 and a device control unit 5. These device components 2-5 are designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com