A rack and pinion meshing motor end cover runout measuring device

A technology for end face runout measurement and motor end cover, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve problems such as damage to the electrophoretic layer on the surface of the end cap, unstable operation of the measuring device, and large runout test errors. The effect of preventing the electrophoresis layer from being damaged, running smoothly, and improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

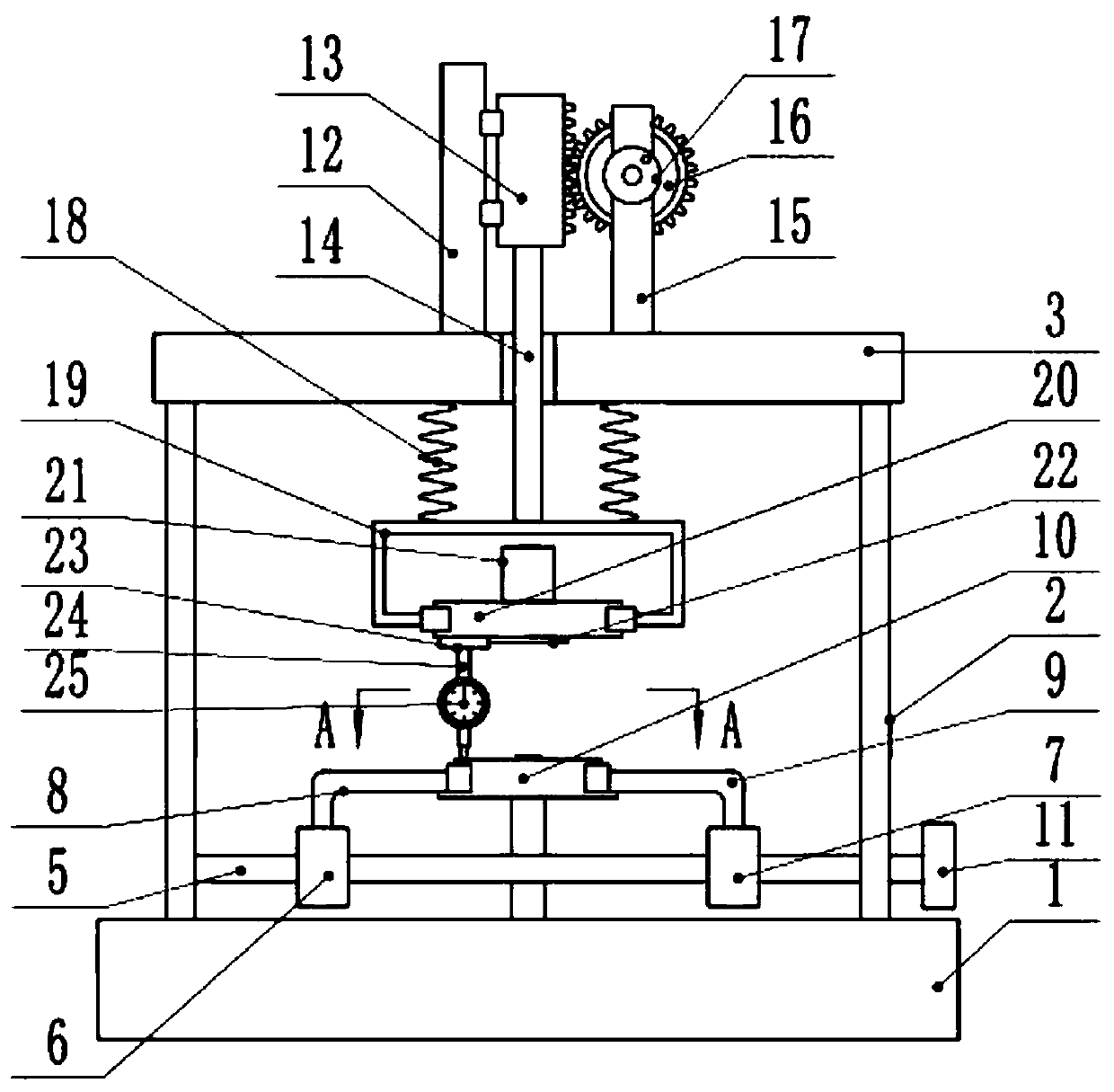

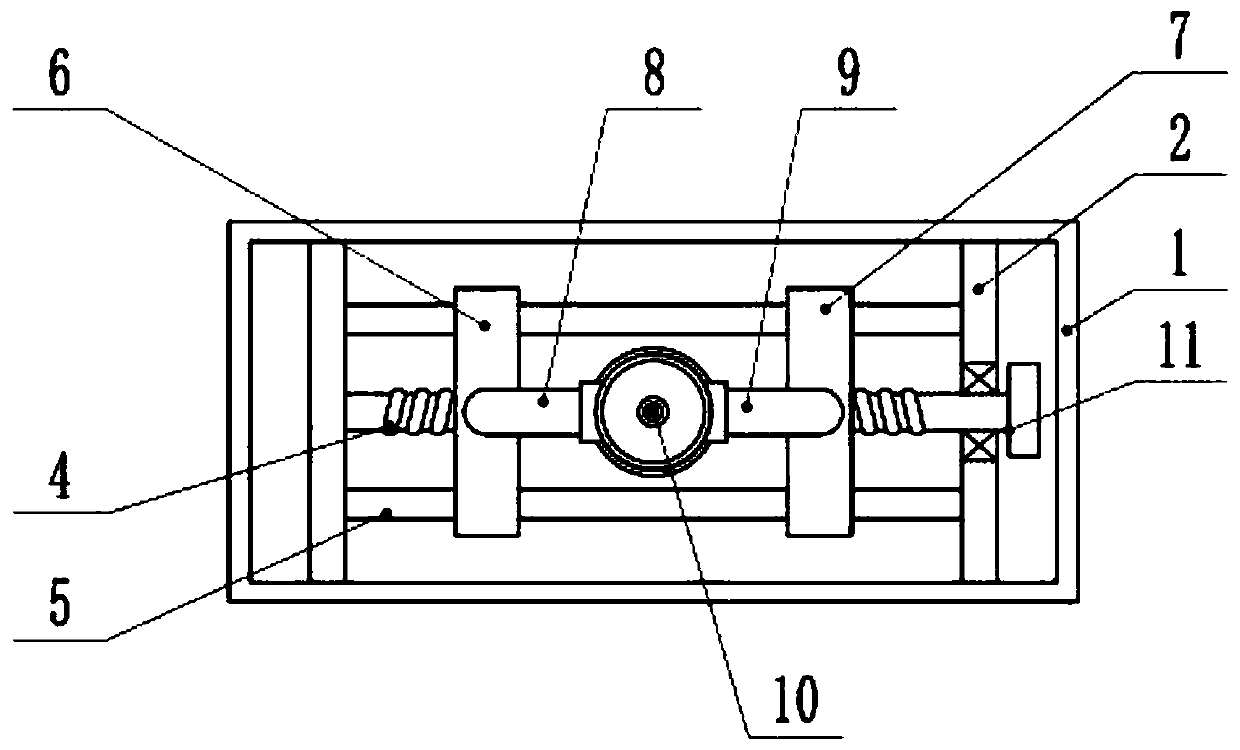

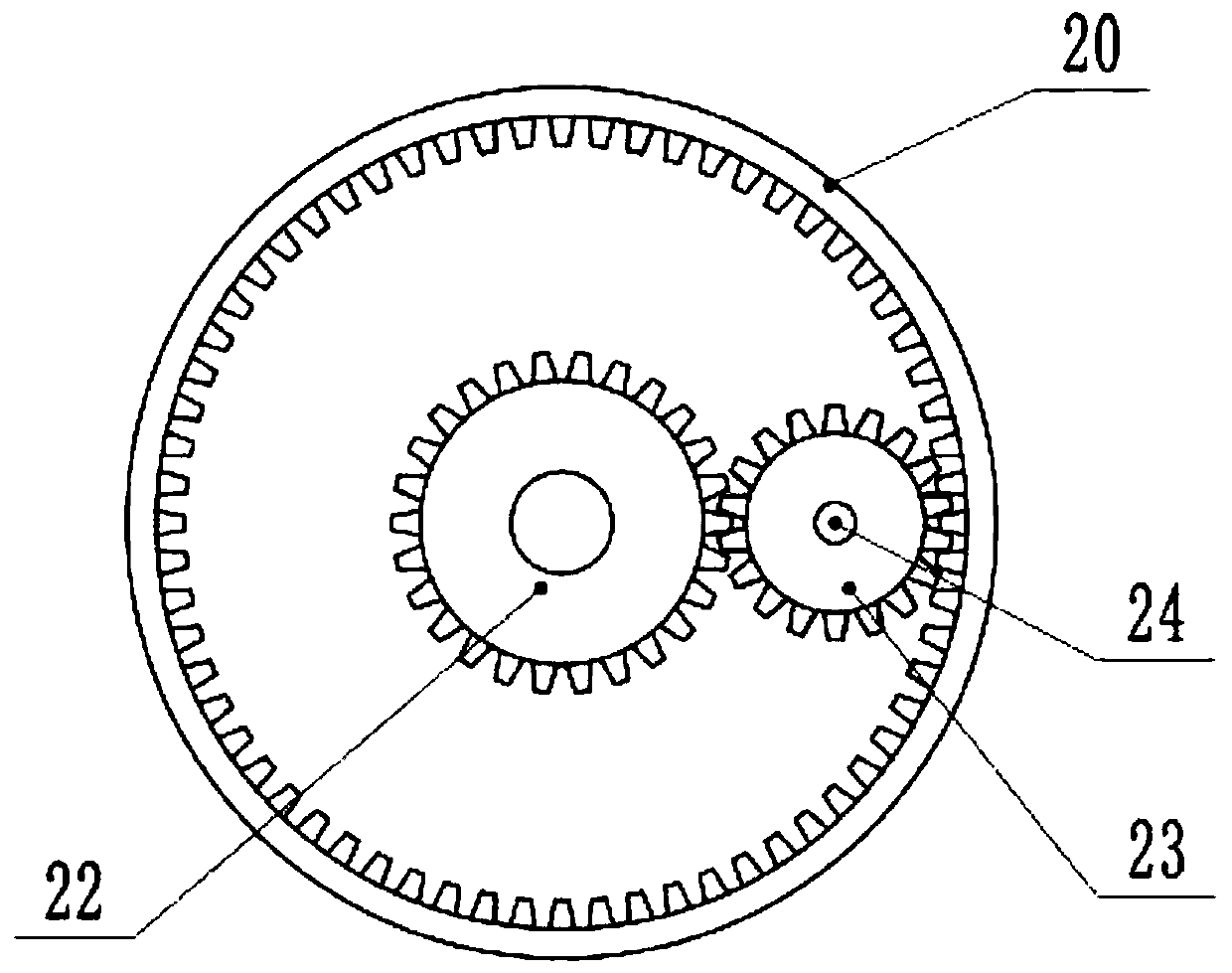

[0020] see Figure 1-3 , a rack-and-pinion meshing type motor end cover end face runout measuring device, including a base 1, a first screw rod 4, a left gripper 8, a right gripper 9, an inner gear plate 20, a drive motor 21, a central gear 22, a planetary Gear 23 and beating meter 25, described base 1 upper surface left and right sides are symmetrically provided with support plate 2, between support plate 2 and base 1 are fixedly connected by screw, and the upper side of described support plate 2 is also fixedly installed with bolt On the upper horizontal plate 3, the first screw mandrel 4 is installed by bearing rotation between the support plates 2 on the left and right sides, and the front and rear sides of the first screw mandrel 4 are provided with guide posts 5, and the guide posts 5 and the support plates 2 are fixedly connected by welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com