Jacquard anti-drill down fabric and processing method thereof

A processing method and anti-drilling technology, applied in the field of textile fabrics, can solve problems such as poor anti-drilling performance, and achieve the effect of improving anti-drilling performance, high friction, and rich layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

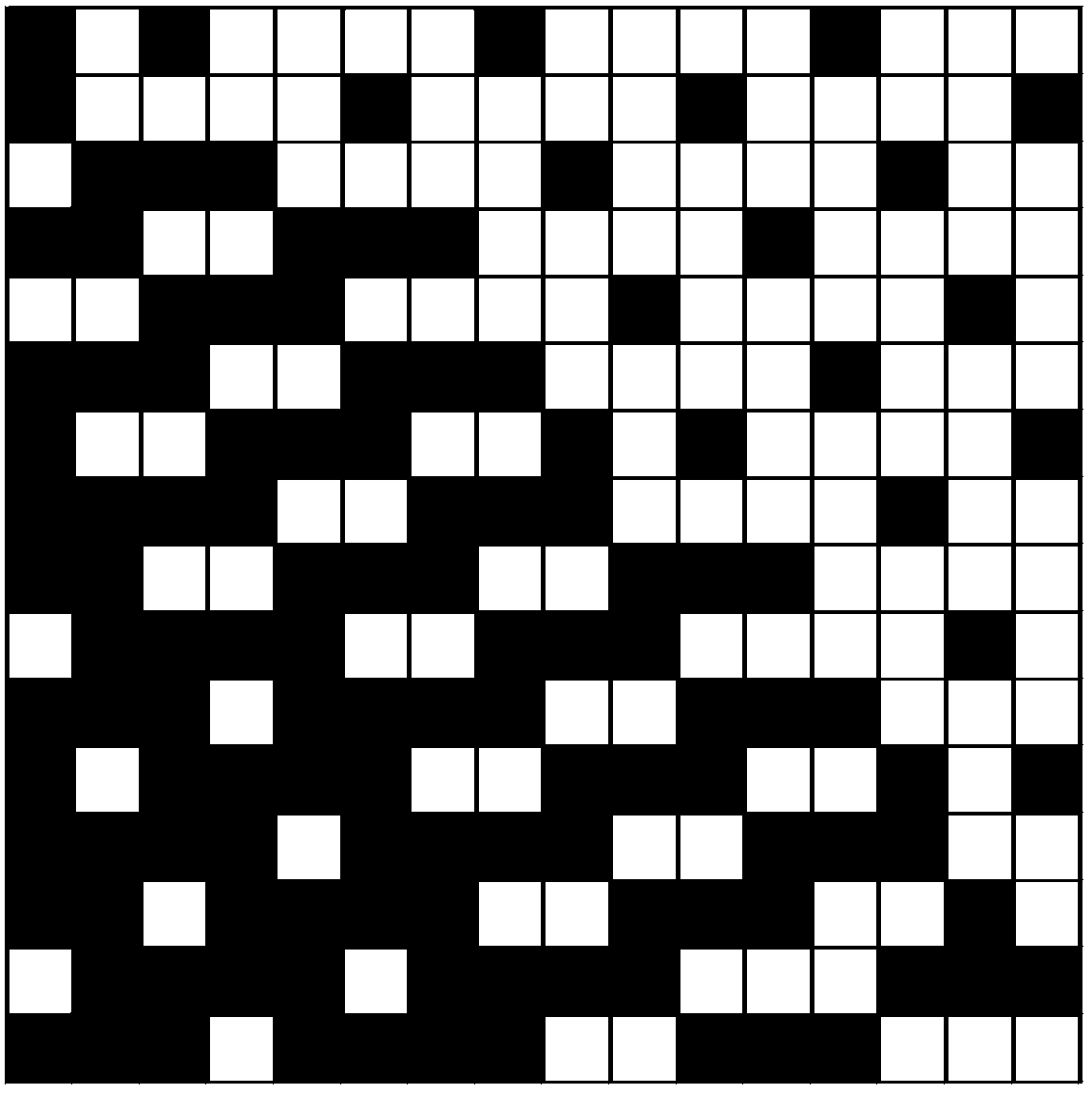

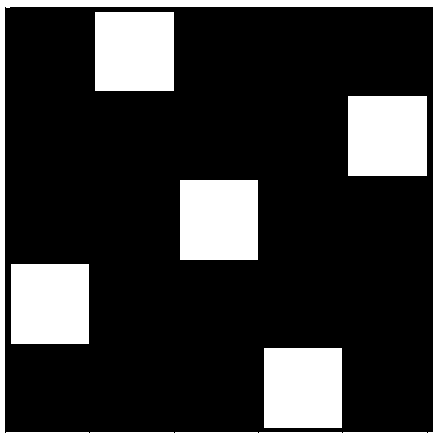

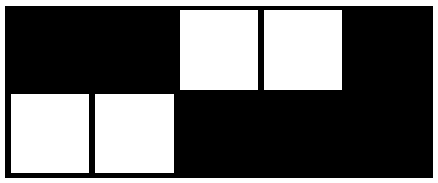

Image

Examples

Embodiment 1

[0038] The ground weave of the fabric is five pieces of three-flying satin on the warp surface (the number of warp floats is 4), the transitional weave is two upper and three lower weft heavy flat weaves (the number of warp floats is 3, and the number of weft floats is 2), and the flowering The weave is five pieces of two-fly weft satin weave (the number of weft floats is 4). The warp weaving difficulty coefficient of the fabric is 22%, and the weft weaving difficulty coefficient is 12%.

[0039] The warp and weft yarns of the fabric are all 60S cotton single yarn, the evenness of the yarn is 13% with Uster, and the average strength of the yarn is 165cN.

[0040] The yarns are warped in batches to form warp beams, and starch sizing is used for warp beam yarn sizing.

[0041] The weaving parameters of the fabric are shedding time 300°, machine tension 3200N, back beam height 4cm, warp stop frame 3cm, front shedding 120mm, and back shedding 80mm.

[0042] The fabric is subject...

Embodiment 2

[0045] The ground weave of the fabric is five pieces of double-fly weft satin (the number of weft float is 4), the transition weave is double-up and two-down weft heavy-flat weave (both the number of warp and weft float is 2), and the flowering weave is five pieces and three-fly Warp satin weave (warp float length is 4). The warp weaving difficulty coefficient of the fabric is 16%, and the weft weaving difficulty coefficient is 16%.

[0046] The warp and weft yarns of the fabric are all 160S / 2 cotton single yarn, the evenness of the yarn is 11% with Uster, and the average strength of the yarn is 160cN.

[0047] The yarns are warped in batches to form warp beams, and starch sizing is used for warp beam yarn sizing.

[0048] The weaving parameters of the fabric are shedding time 280°, machine tension 2500N, back beam height 2cm, warp stop frame 1cm, front shedding 100mm, and back shedding 60mm.

[0049] The fabric is subjected to one front and one back singeing treatment, and ...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is that the texture of the fabric is five pieces of two-flying weft surface satin (the number of weft float length is 4), and the transitional weave is two kinds of weaves, one is three upper and two lower twill weaves (the warp float length is 4). The number of length is 3, the number of weft float is 2), one is two-up and two-bottom twill weave (the number of warp and weft float is 2), and the flowering weave is five double-fly weft satin weave (the number of warp and weft float is 2). for 4).

[0053] The warp and weft yarns of the fabric are all 60S cotton single yarn, the evenness of the yarn is 13% with Uster, and the average strength of the yarn is 165cN.

[0054] The yarns are warped in batches to form warp beams, and starch sizing is used for warp beam yarn sizing.

[0055] The weaving parameters of the fabric are shedding time 300°, machine tension 3200N, back beam height 4cm, warp stop frame 3cm, front she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com