Patents

Literature

32results about How to "Improve anti-drilling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

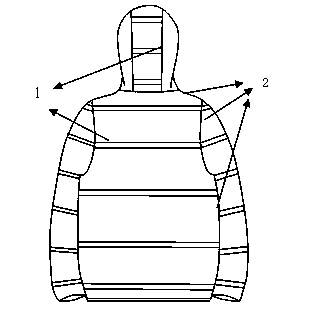

Waterproof down jacket making method and waterproof down jacket

InactiveCN103799596AImprove waterproof performanceImprove heat retention and down-resistanceOvergarmentsClothes making applicancesEngineering

The invention discloses a waterproof down jacket making method and a waterproof down jacket. The method includes the first step of material selection, the second step of tailoring, the third step of quilting and seamless attachment, the fourth step of adhesive strip pressing and repair adhesive reinforcement, the fifth step of down filling and sealing, the sixth step of seam wrapping of interlayer fabric and lining fabric, and the seventh step of the arrangement of a zipper on a top fly and welting of a lower hem, cuffs and a cap mouth. Then, the waterproof down jacket is obtained. Because coated or film-pasted fabric is adopted as surface-layer fabric, the waterproofness of the down jacket is greatly improved; because the surface-layer fabric is free of stitches and cut piece joints are pressed by waterproof adhesive strips or adhesive tape, the problem that water seeps in from the stitches is solved; meanwhile, the warm-keeping performance and down leakage preventing performance of the whole down jacket are improved as well.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Ultrasoft noiseless feather prevention fabric and fabrication method thereof

InactiveCN103147205AGood anti-feather effectGuaranteed softnessWoven fabricsVegetal fibresEngineeringFilament yarn

The invention aims at disclosing ultrasoft noiseless feather prevention fabric and a fabrication method thereof. The ultrasoft noiseless feather prevention fabric is formed by interweaving warp cotton yarns and weft superfine denier polyester filament yarns in an upper two / lower one structure. Compared with the prior art, as the cotton yarns are interweaved with the superfine denier filament yarns, and windproof soft finish is adopted, a feather penetration resistance effect is improved; the fabric has a good feather prevention effect; the softness of the fabric is ensured; the fabric is soft in hand feel and noiseless; the rough hand feel and noises of the traditional feather quilt fabric are improved; and a purpose of the ultrasoft noiseless feather prevention fabric is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

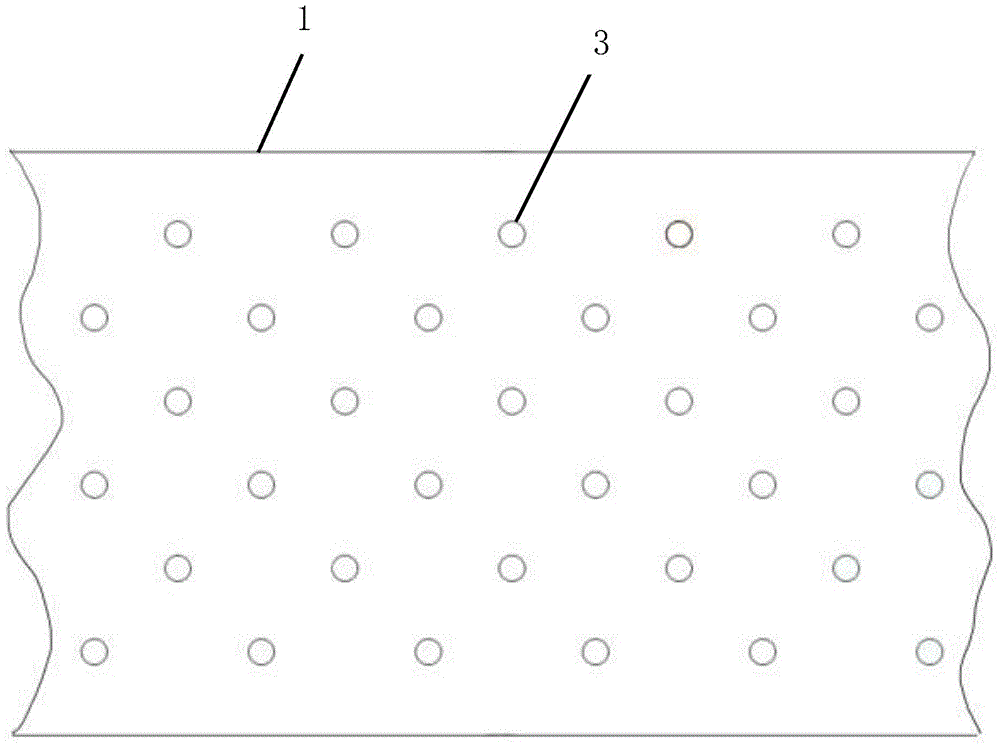

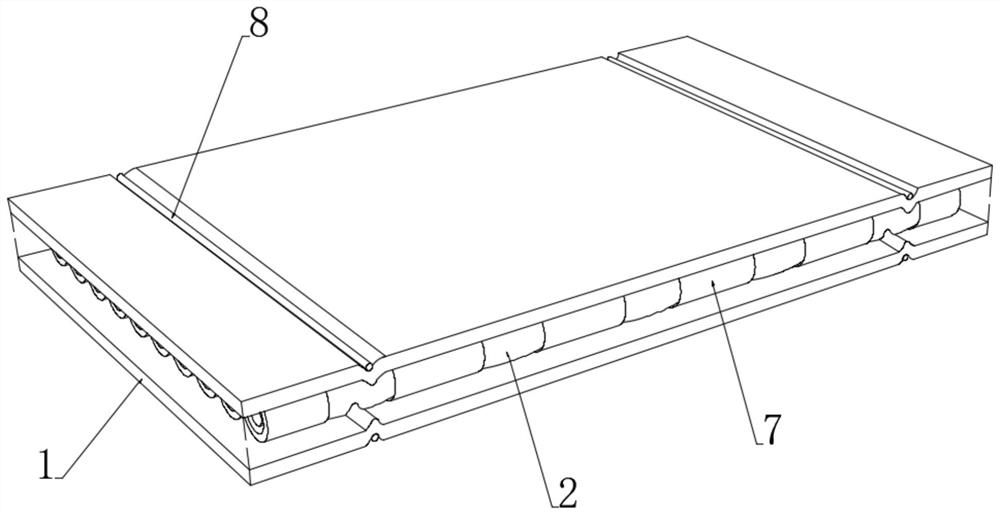

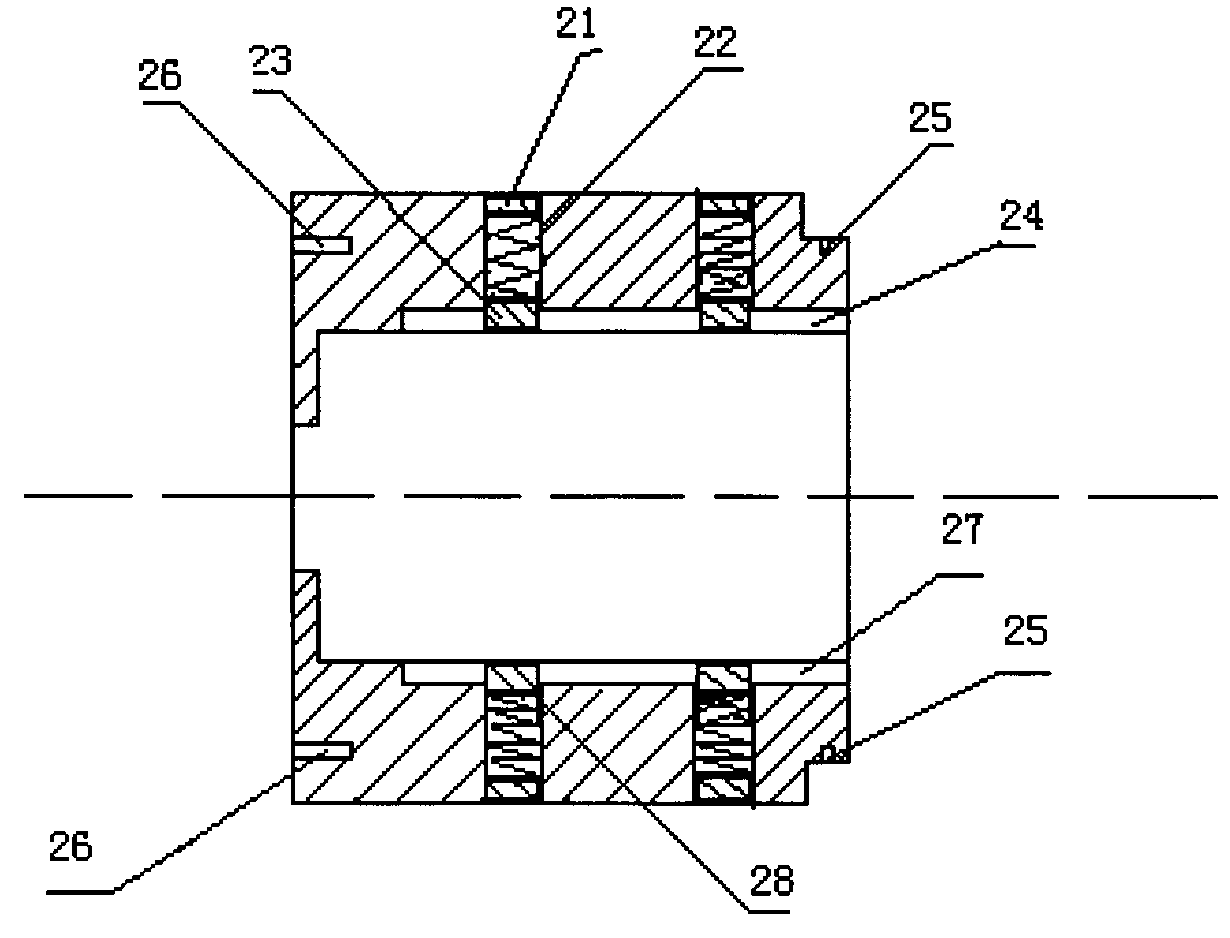

Structure capable of preventing down feather displacement and penetration and maintaining fabric elasticity and manufacturing technology thereof

InactiveCN105128442ADoes not damage the elasticityEvenly distributedSynthetic resin layered productsClothingsManufacturing technologyEngineering

The invention provides a structure capable of preventing down feather displacement and penetration and maintaining fabric elasticity and a manufacturing technology thereof. The structure comprises two fabric layers and down feathers, the down feathers are filled into the space between the two fabric layers, the structure further comprises multiple connection points which are used for positioning the down feathers and making the down feathers distributed in a netted mode, the two fabric layers both adopt extended elastic fabric, and the down feathers are wrapped with elastic air-permeable films. According to the technical scheme, by means of the structure, the fabric elasticity of down feather products is maintained to the maximum extent, distribution of the down feathers is always kept even, the downproofness is achieved, and displacement caused by the exogenic action such as gravity cannot happen.

Owner:SHANGHAI YIQI GARMENT CO LTD

Nano microcapsule material having self-repairing and wear-resisting functions and preparation method thereof

ActiveCN104131469AImprove anti-drilling performanceDoes not cause thickening and weight gainFibre treatmentOvergarmentsGaining weightFiber

The invention relates to a nano microcapsule material and a preparation method thereof. The nano microcapsule material comprises a fabric base body prepared by fibers, and particularly also comprises a wall material cladded outside fiber-forming filaments and having nanoscale thickness; the wall material and the fibers form a nano microcapsule structure with the fiber-forming fine filaments as a 'core' and the wall material as a 'capsule sheath', the capsule sheath has adhesion, after being cladded with the capsule sheath, the fiber fine filaments are in mutual adhesion, so as to block gaps between the fibers; the fabric is used for production of ultra light and thin down jackets, can achieve quite good effect of penetration resistance to feathers, and cannot cause the fabric to become thick and gain weight and affect the wear comfort; and in addition, other properties of the fabric can be modified through introduction of functional auxiliary agents into the capsule sheath, for example, wear resistance of the fabric can effectively be enhanced through introduction of nano silica, or for example, the service life of the material can be effectively prolonged through introduction of self-repairing groups.

Owner:SUZHOU TANGHUA NANO TECH

Production process for antibacterial breathable down feather silk quilt

InactiveCN110215095AImprove color fastnessGood coloring effectBlanketBiochemical fibre treatmentHemp fiberCotton fibre

The invention discloses a production process for an antibacterial breathable down feather silk quilt. The production process includes preparation of antibacterial fabric, preprocessing of down featherfillers, antibacterial finishing of the down feather fillers and a mixed down feather filling process, and specifically includes the steps that S101, yarn selection: warp yarns include long-staple cotton fibers and bamboo charcoal fibers; S102, warp blended processing; S103, yarn dyeing and antibacterial finishing; S104, fabric weaving; S105, preprocessing of the fabric before calendering; S106,fabric calendering; S201, selection of the down feather fillers: white goose down, silk and hemp fibers; S202, preprocessing of the white goose down; S301, antibacterial finishing of the down featherfillers; S302, drying and sterilizing; and S401, mixed down feather filling. The production process is stable, and the produced down feather silk quilt has the advantages of being comfortable and soft, capable of adsorbing moisture, breathable, and high efficient and lasting in antibacterial performance.

Owner:KAISHENG TEXTILE

Down-proof auxiliary agent and application thereof to down-proof fabric

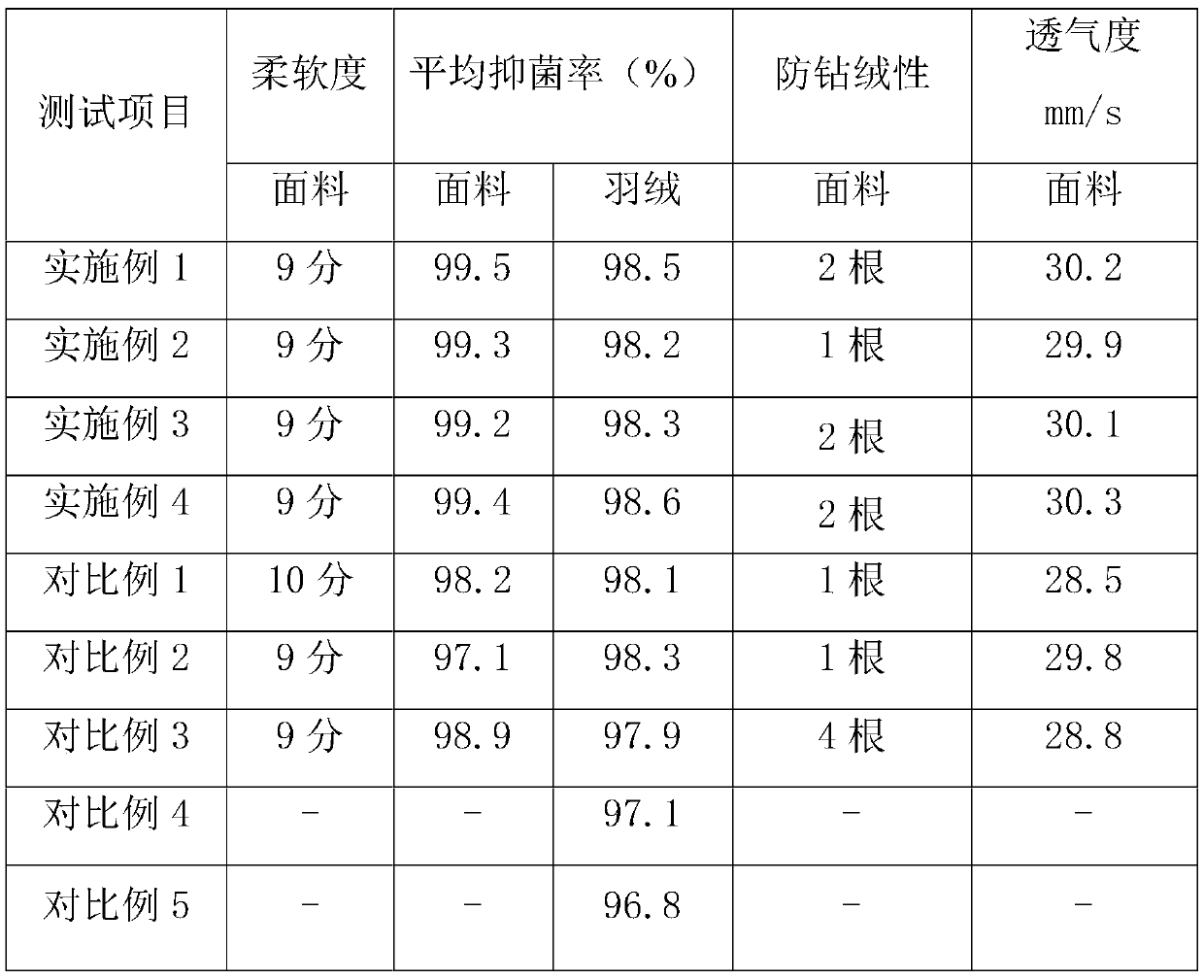

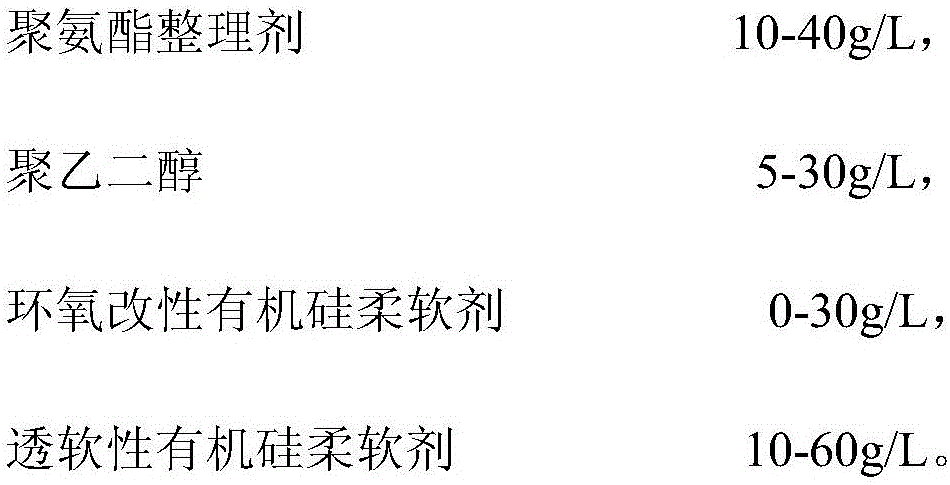

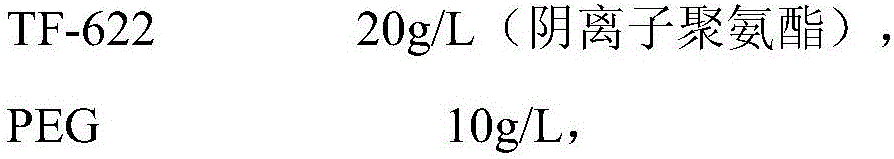

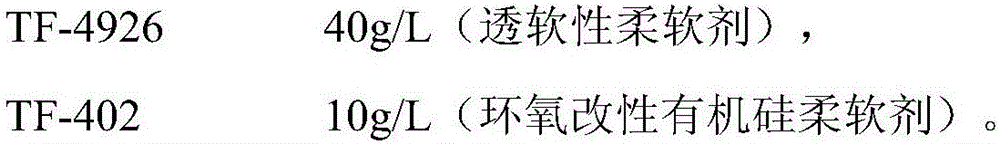

InactiveCN106223037AReserve air flowFluffy and softGrip property fibresPolyethylene glycolEngineering

The invention discloses application of a down-proof auxiliary agent and application thereof to a down-proof fabric. Handfeel, down-proof effects, appropriate breathability and noise in utilization, especially breathability and down-proof effects, of existing down-proof fabrics do not form an integral combination. The down-proof auxiliary agent is prepared from, by weight, 10-40g / L of a polyurethane finishing agent, 5-30g / L of polyethylene glycol, 0-30g / L of an epoxy modified organic silicon softener and 10-60g / L of soft organic silicon softener. The down-proof auxiliary agent has advantages that the fabric is sealed according to a principle of fixation of fabric interlacing points to achieve the down-proof effects while original breathability of the fabric is partially kept; by matched application of the polyurethane finishing agent and the corresponding softeners, the fabric is soft and fluffy to touch, and noise in use of the down-proof fabric is minimized.

Owner:传化智联股份有限公司

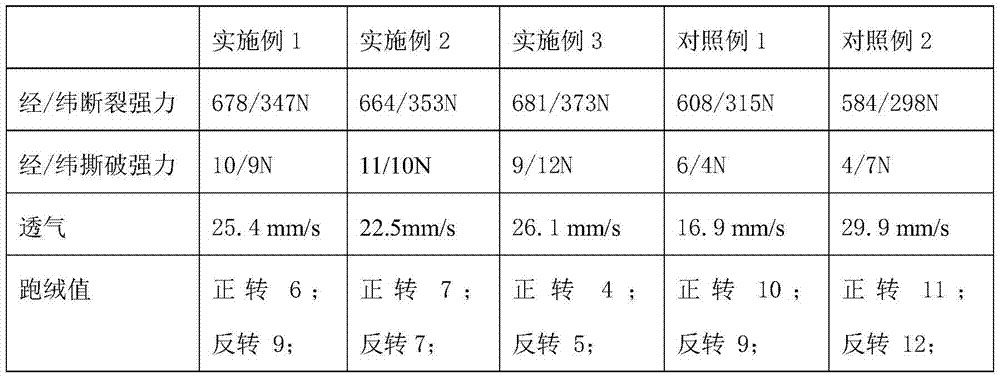

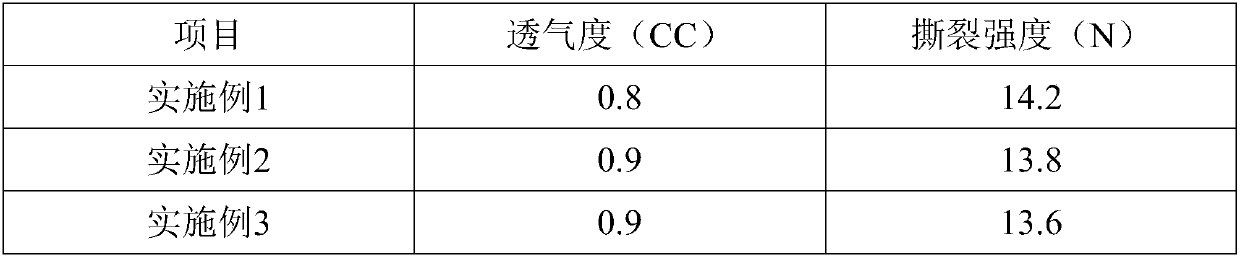

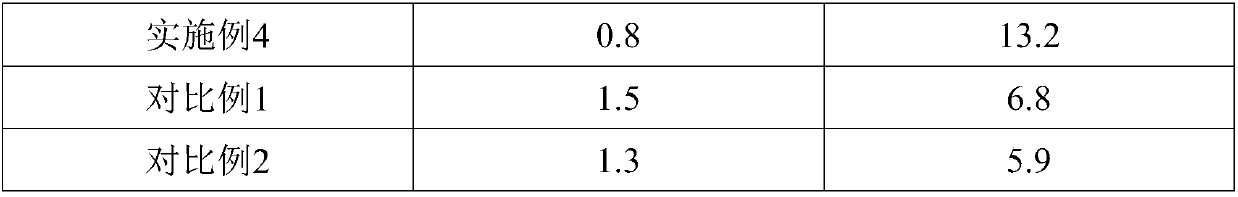

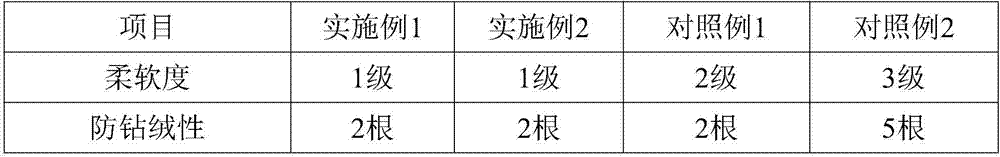

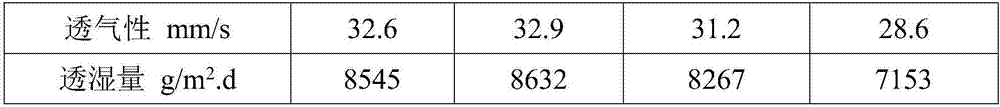

Dyeing and finishing method for soft and breathable down-proof fabric

The invention provides a dyeing and finishing method for a soft and breathable down-proof fabric. The fabric is obtained by interweaving warp and weft, wherein both the warp and the weft are cross-blended yarn of staple cotton and tencel G100. The dyeing and finishing method comprises the steps of conducting refining on gray fabric, and carrying out stentering and whitening, softening and shaping, and pre-shrinking sequentially. The down-proof fabric processed according to the dyeing and finishing method touches soft and exquisite, is excellent in down-proof performance, safe and environmentally friendly.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Processing technology of drilling-prevention down jacket fabric

InactiveCN107604683AImprove soft performanceGood adhesionSolvent-treatmentPolyurea/polyurethane coatingsPolyesterCold tolerance

The invention discloses a processing technology of drilling-prevention down jacket fabric, and relates to the technical field of fabric treatment. The processing technology of the drilling-preventiondown jacket fabric disclosed by the invention comprises the following steps: (1) fabric selection: selecting cotton-polyester blended fabric with the yarn count of 15 to 25 D and the fineness of 300 to 420 tex; (2) water repellent finish; (3) calendaring drying; (4) preparing a coating adhesive; (5) coating: coating a prepared coating on fabric after calendaring drying by using a floating knife type coating machine, and drying at the temperature of 150 to 160 DEG C for 3 to 8 min. According to the processing technology disclosed by the invention, the drilling prevention effect is improved while little weight of the down jacket fabric is increased, and the cold tolerance and softening property are improved.

Owner:安徽锦翔纺织服饰有限公司

Antibacterial sweat-absorbing type feather quilt shell fabric processing method

InactiveCN107090714AImprove the effective adhesion rateExcellent antibacterial and sweat absorption functionBiochemical fibre treatmentYarnYarnFiber

The invention discloses an antibacterial sweat-absorbing type feather quilt shell fabric processing method and relates to the technical field of feather quilt processing. The processing method mainly comprises the following steps: (1) selectively oxidizing cotton fiber; (2) processing blended yarns; (3) dyeing blended yarns; (4) weaving shell fabric; (5) performing calendering pretreatment on the shell fabric; (6) calendering the shell fabric. According to the processing method, an antibacterial sweat-absorbing agent is added in a blended yarn dying process, the manufactured shell fabric has an excellent antibacterial sweat-absorbing function through the dyeing work procedure, and cost invest of additional work procedures is reduced; furthermore, an effective adhesive rate of the antibacterial sweat-absorbing agent is improved through binding force of dye on the fibers; by means of the calendering pretreatment on the shell fabric, moisture penetrability and downproofness of the shell fabric are improved under action of a calendering auxiliary agent.

Owner:ANHUI SANXIANG DOWN

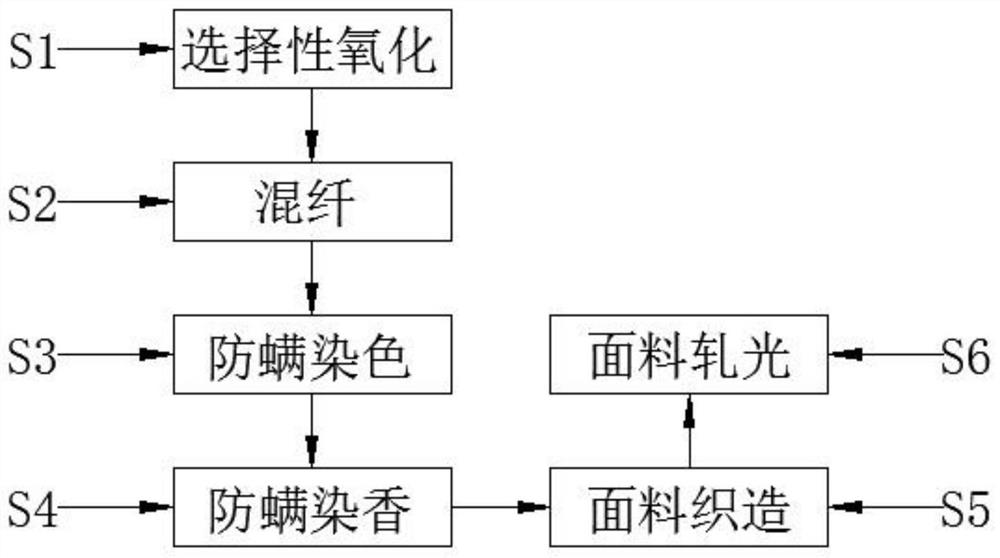

A method for processing insect-proof and mite-proof duvet fabric

ActiveCN107012565BExcellent anti-insect and anti-mite functionImprove breathabilityBiochemical fibre treatmentWoven fabricsFiberYarn

The invention discloses an insect-proof anti-mite type down quilt fabric processing method, relating to the technical field of processing of down quilts. The processing method mainly comprises the following steps: (1) selectively oxidizing cotton fibers; (2) processing blended yarns; (3) dyeing the blended yarns; (4) weaving a fabric; (5) performing calendering pretreatment on the fabric; and (6) calendering the fabric. By adding an insect-proof and anti-mite agent during dyeing of the blended yarns, the processed fabric is endowed with excellent insect-proof and anti-mite function while the dyeing procedure is conducted, the cost input of the additionally added procedure can be reduced, and the effective adhesive rate of insect-proof and anti-mite active ingredients can be increased by means of the binding force of the dye on fibers; and through performing calendering pretreatment on the fabric, the breathable and moisture-penetrable property and downproofness of the fabric can be enhanced under the action of a calendering assistant.

Owner:WEST ANHUI UNIV +1

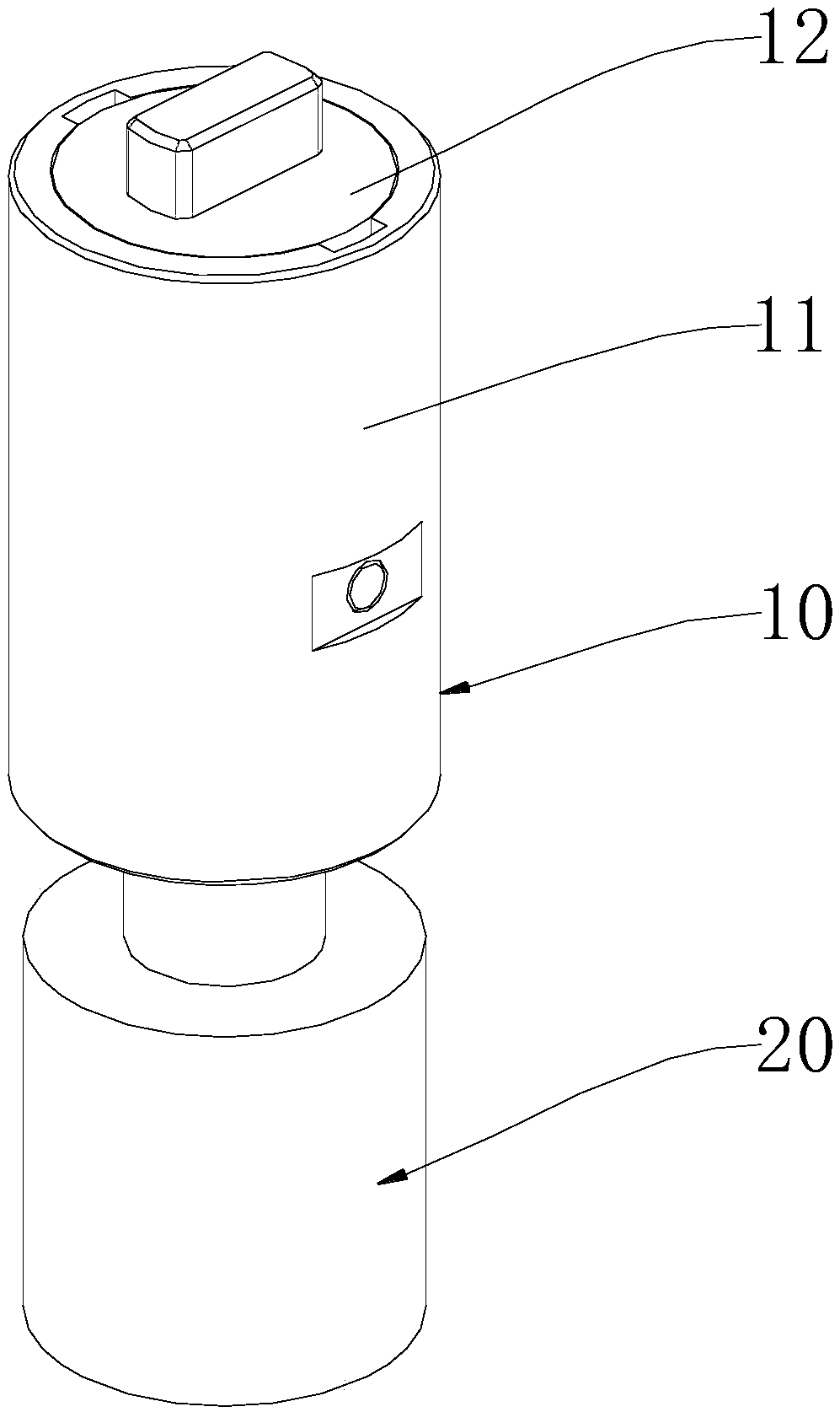

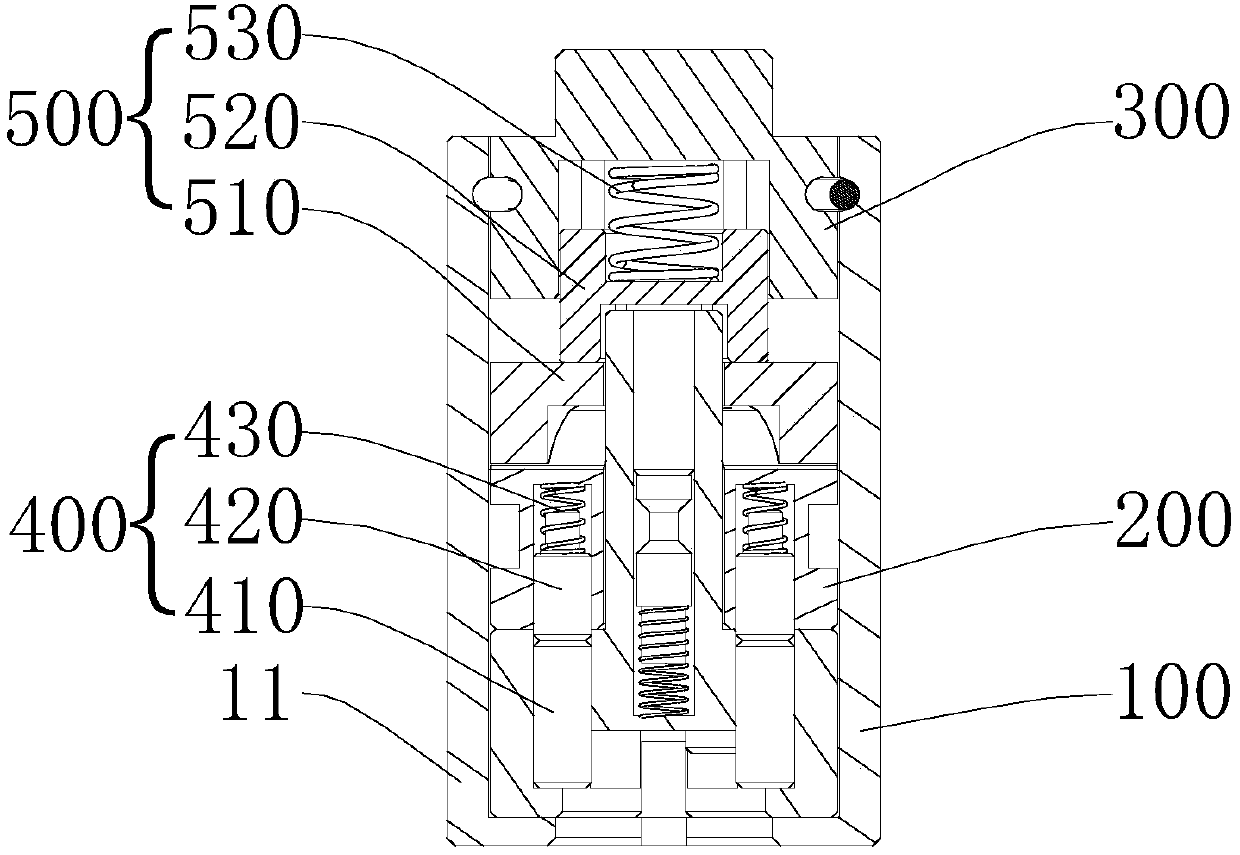

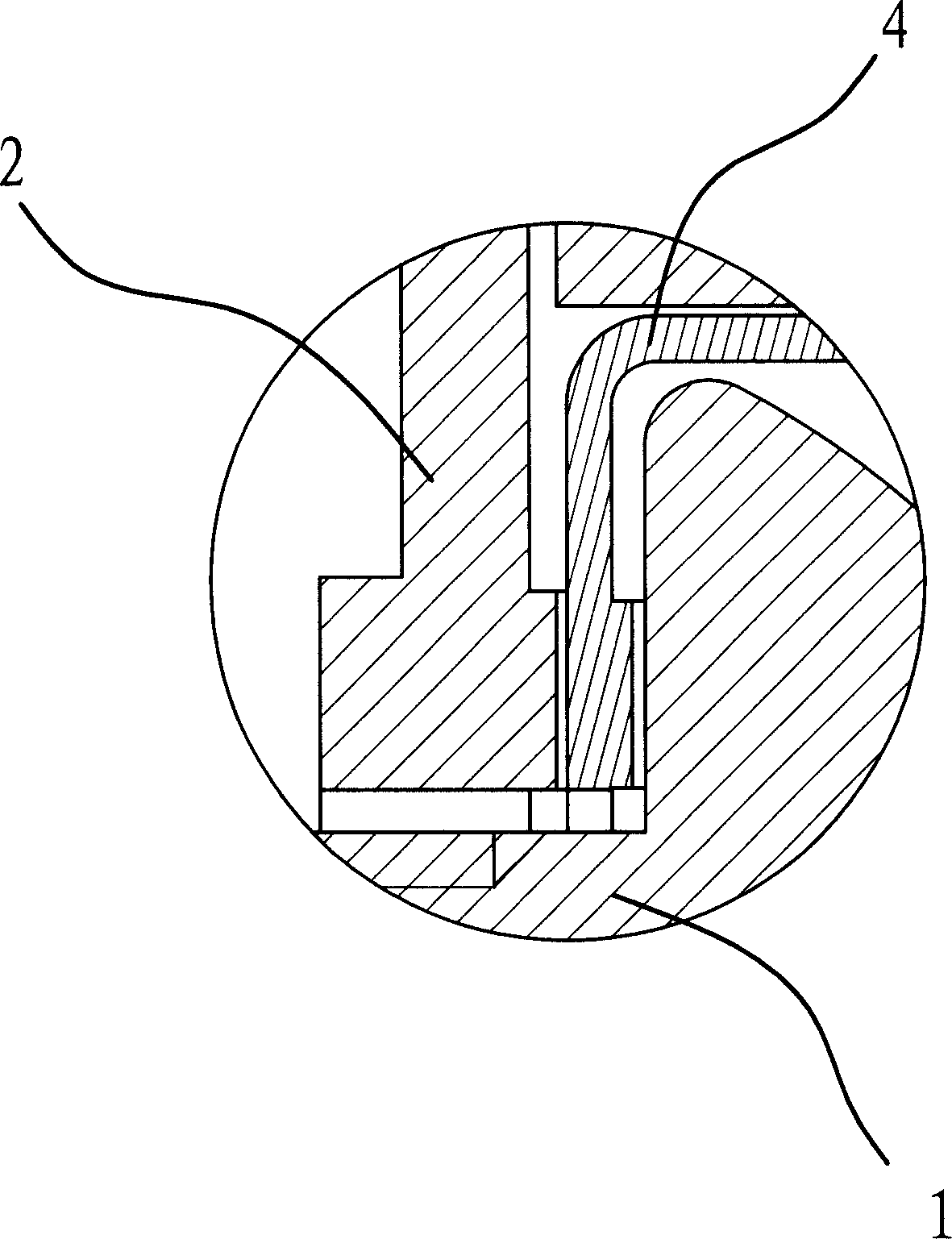

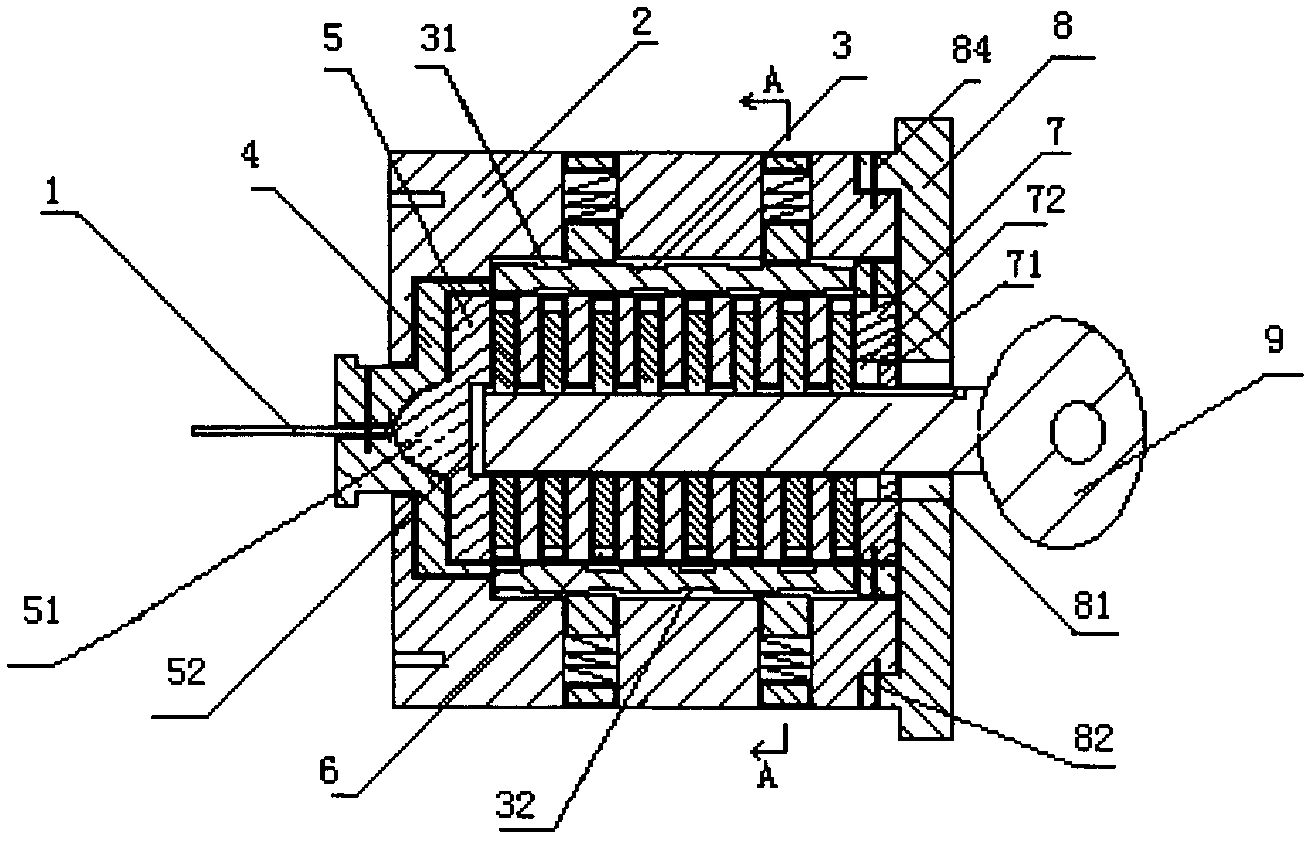

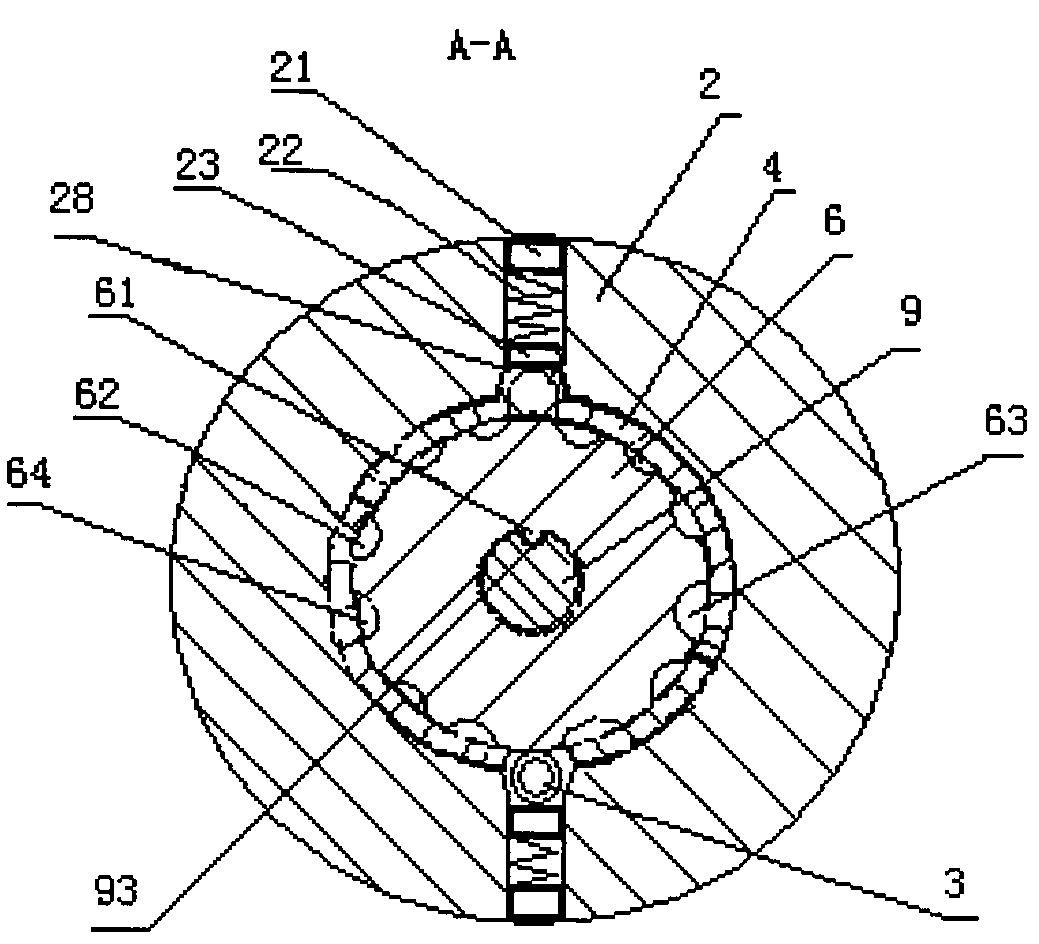

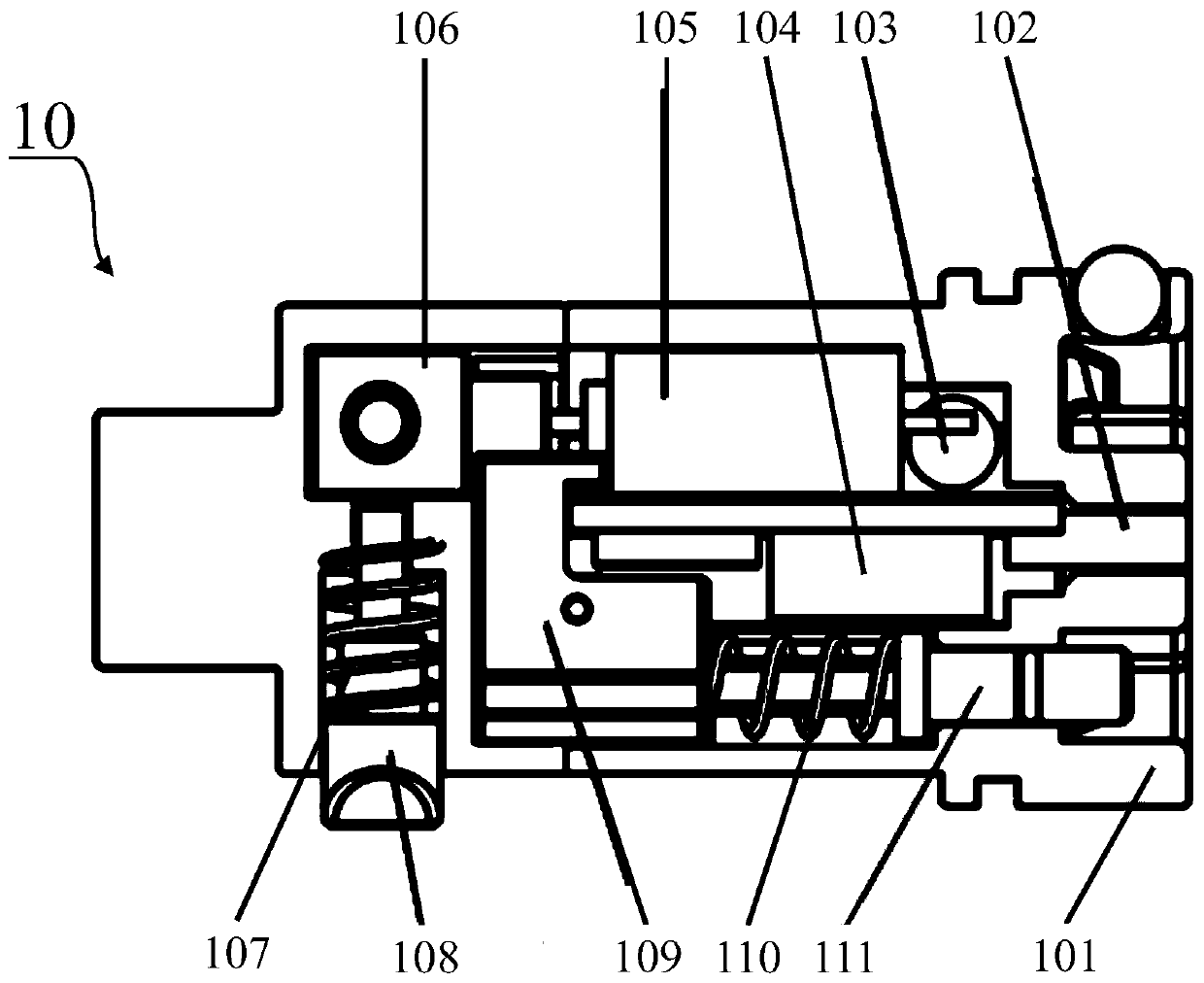

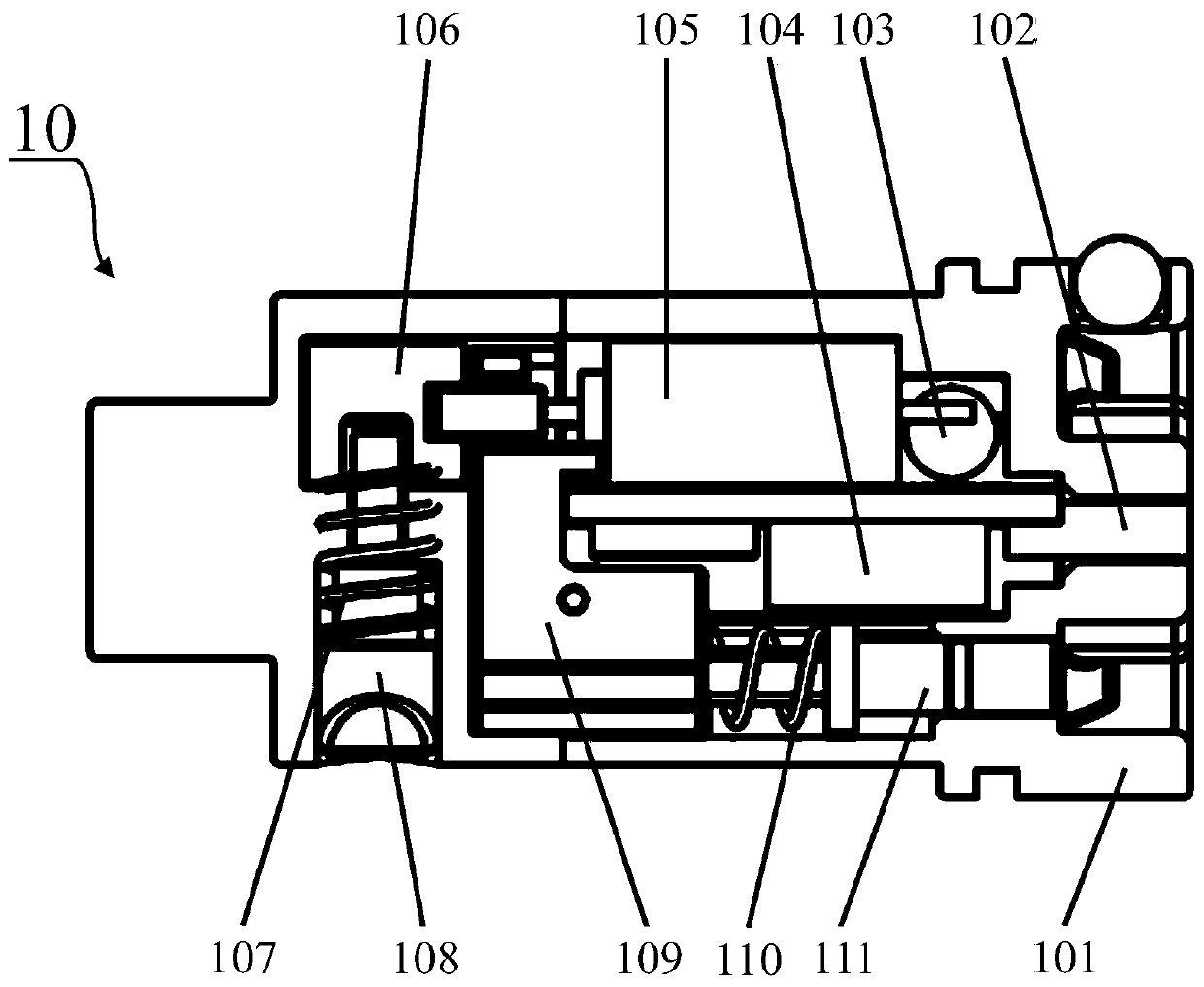

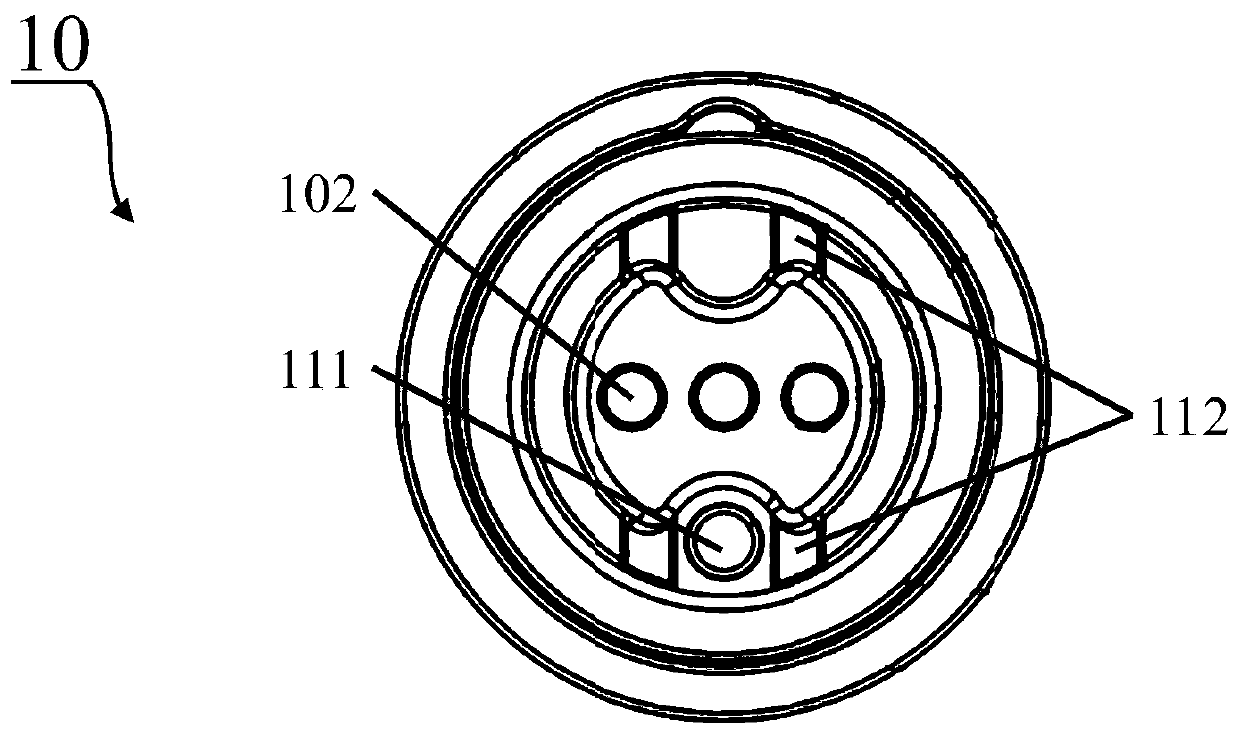

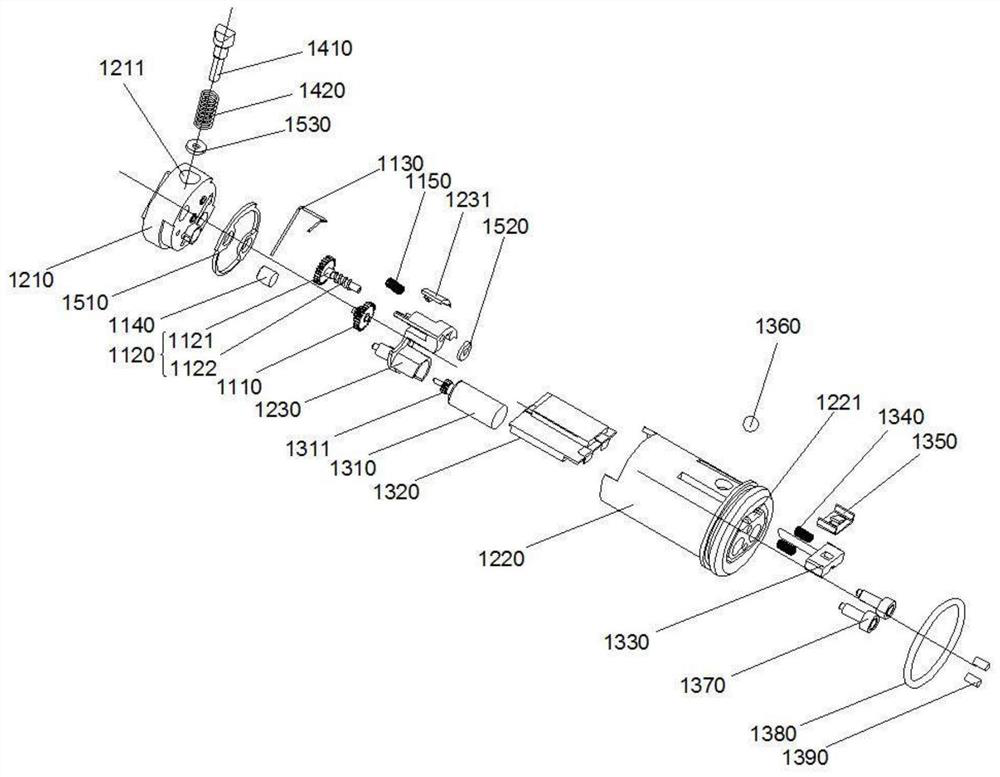

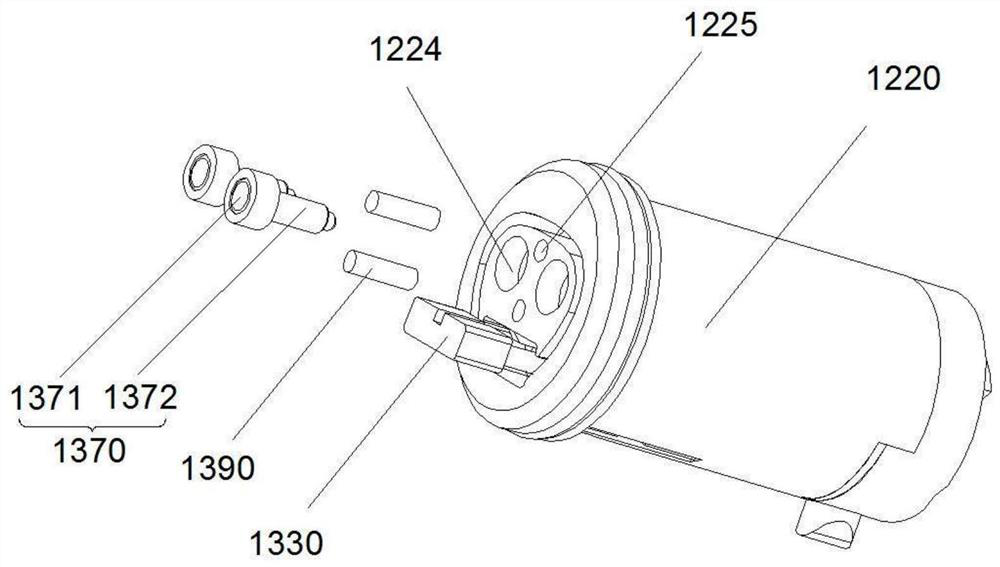

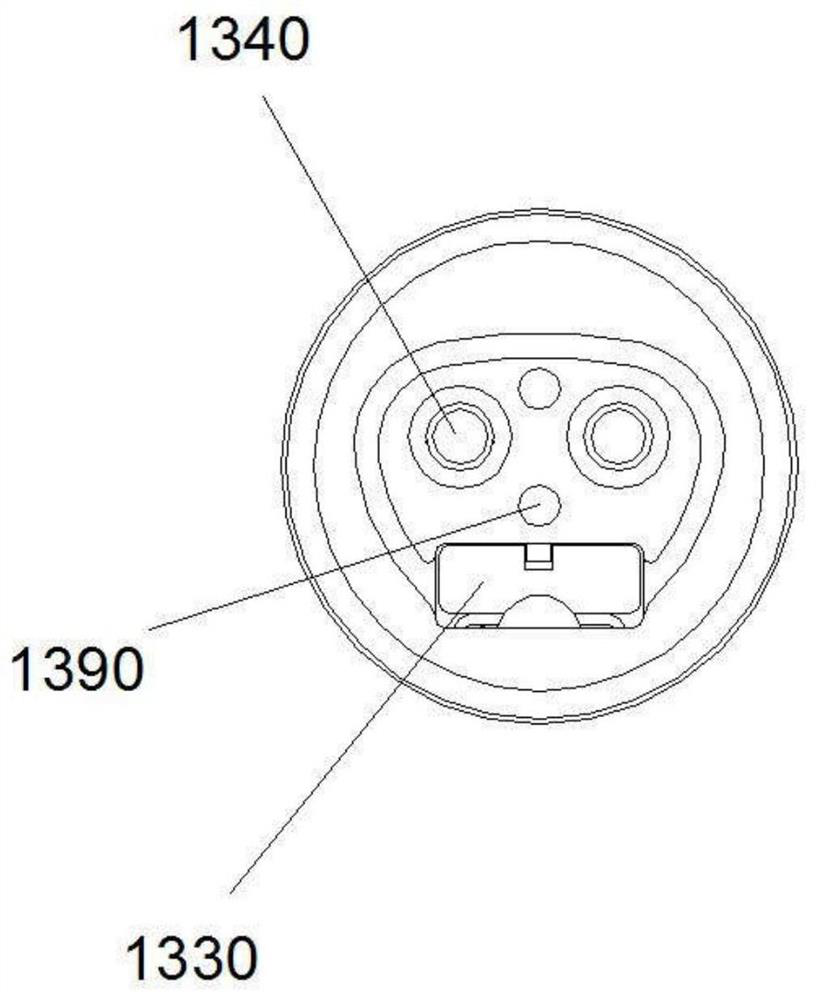

Cylinder, lock and unlocking key

ActiveCN107939171AImprove anti-drilling performanceAvoid destructionElectric permutation locksIndividual entry/exit registersMechanical engineeringPhysics

The invention provides a cylinder, a lock and an unlocking key. According to the cylinder, the lock and the unlocking key, an upper cylinder body and a middle cylinder body are in locked linkage through an authorization assembly, and the upper cylinder body and a lower cylinder body are in separated connection through a separation mechanism; when the cylinder is locked, under the external acting force, the upper cylinder body rotates in the axial direction to drive the middle cylinder body to rotate, the middle cylinder body drives the separation mechanism to act so as to enable the upper cylinder body and the lower cylinder body to be separated, and therefore idling of the cylinder can be realized; and when the cylinder is unlocked, under the authorization acting force of the unlocking key, locked linkage of the upper cylinder body and the middle cylinder body are relieved, the unlocking key is rotated to drive the upper cylinder body to rotate, the middle cylinder body is in a staticstate, the separation mechanism enables the upper cylinder body and the lower cylinder body to be in linkage, the upper cylinder body drives the lower cylinder body to rotate in the axial direction,and therefore unlocking of the cylinder can be realized. The cylinder, the lock and the unlocking key have the advantages that if the unlocking key is incorrect, the cylinder idles, if the unlocking key is correct and is authorized, the cylinder is unlocked, and therefore the phenomenon that the key and the cylinder are damaged due to the fact that the unlocking key is incorrect and / or unauthorized can be avoided; and a cylinder main body of the idling cylinder is not fixed, an electric drill does not have an acting point, violent damage is difficult, and therefore the anti-drilling performance of the cylinder can be improved.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

Anti-theft license plate fixer

InactiveCN1730955AReasonable designEasy to assembleAnti-theft devicesNutsEngineeringMechanical engineering

The present invention provides one kind of anti-theft license plate fixture and relates to mechanical technology. The anti-theft license plate fixture includes one protecting seat with inner cavity, one piece of fastening screw and one protecting hood on the protecting seat. The fastening screw penetrates through the bottom of the protecting seat, the protecting hood is set in the mouth of the protecting seat cavity, one clamp is set inside and connected to the protecting seat, and one clamping mechanism is set between the protecting hood and the clamp to avoid the separation of the protecting hood from the protecting seat. The present invention can avoid the mechanical prying of the license plate.

Owner:张文忠 +1

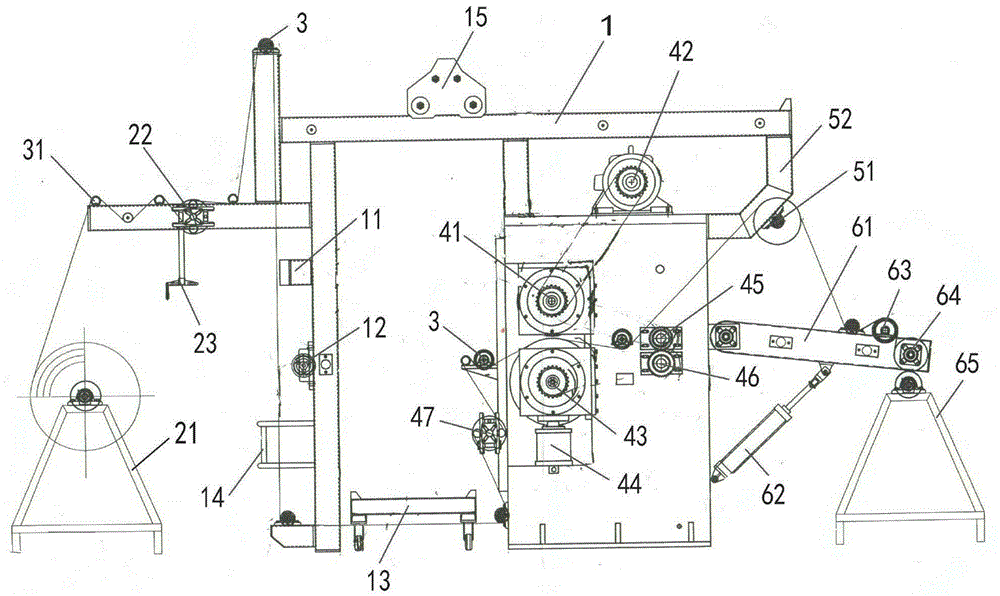

Calender

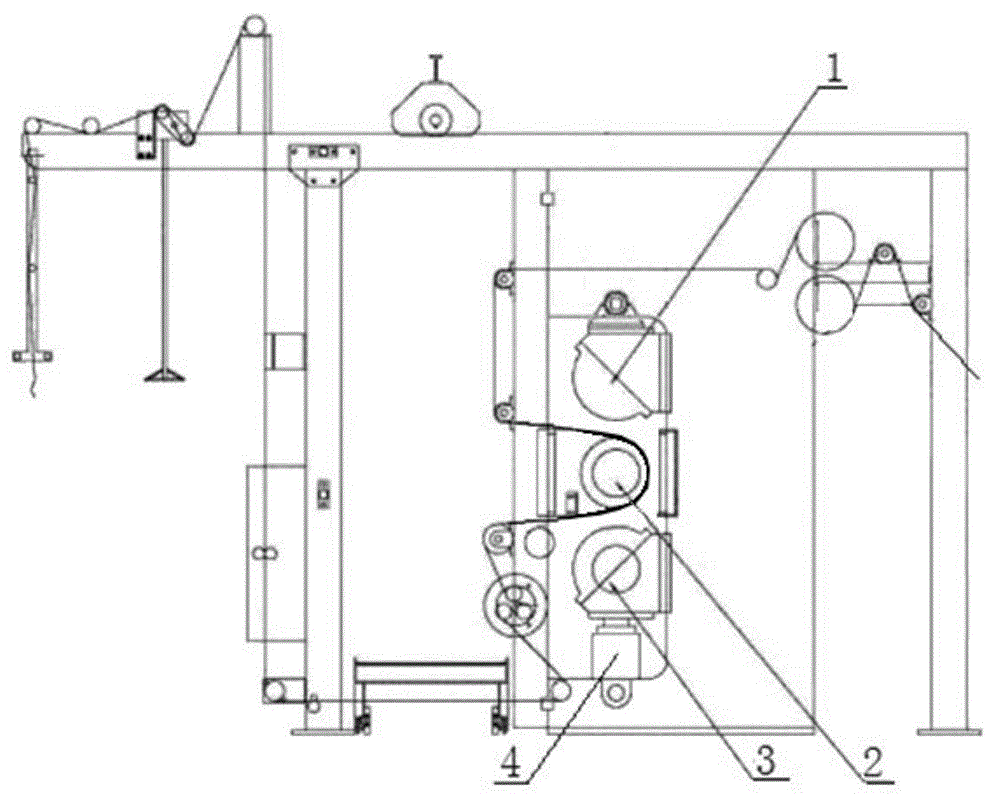

The invention discloses a calender. The calender comprises a frame, a cloth feeding device, a cloth guide roller, a cloth pressing device, a cooling device and a cloth discharge device are arranged on the frame, the cloth pressing device comprises a mirror heating roller, a cloth pressing end motor for driving the mirror heating roller to self-rotate around the mirror heating roller axis, a hydraulic homogenization roller and a cloth pressing end hydraulic cylinder for driving the hydraulic homogenization roller to lift or drop, the hydraulic homogenization roller is located above the mirror heating roller, the cloth pressing device also comprises a transmission mechanism, the transmission mechanism comprises a first gear link-connected to the mirror heating roller and a second gear in a link transmission relationship with the hydraulic homogenization roller, the first gear is engaged with the second gear, a metal detecting instrument and a rectification machine are arranged between the cloth feeding device and the cloth pressing device, and the cooling device is arranged between the cloth pressing device and the cloth discharge device. A cloth is fed by the cloth feeding device, goes through the cloth guide roller, enters into the hydraulic homogenization roller and the mirror heating roller of the cloth pressing device, is subjected to heating calendaring, then is cooled by the cooling device, then is fed into the cloth discharge device and is discharged.

Owner:WUJIANG HAI WEI MECHANICAL RUBBER PROD CO LTD

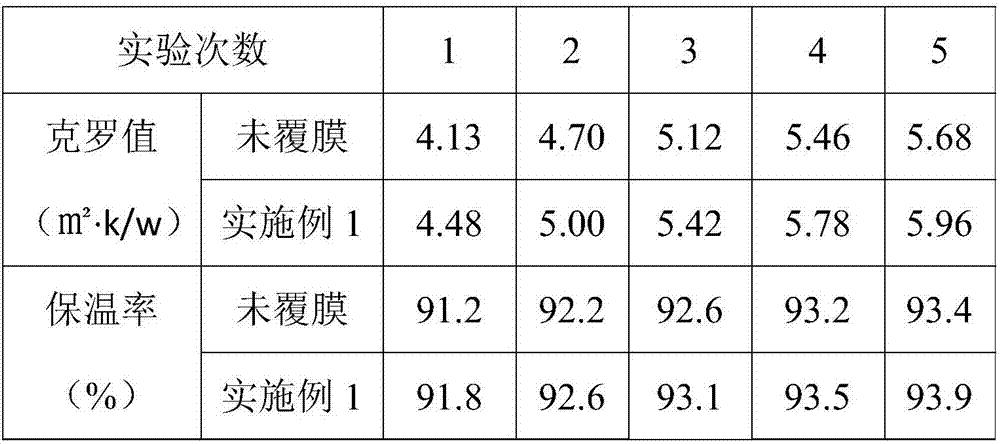

Down leak-proofing fabric and processing method thereof

InactiveCN107877952AImprove breathabilityGood skin affinitySynthetic resin layered productsFilling materialsCompound (substance)

The invention provides a down leak-proofing fabric and a processing method thereof. WS type hot melt adhesives are sprayed on a textile fabric to be laminated with a film-covering material, and hot-pressing treatment is performed to obtain the down leak-proofing fabric. Compared with the prior art, according to the down leak-proofing fabric, a film-covering functional fabric is prepared through ahot melt adhesive laminating process. A natural fiber fabric with good air permeability and good skin-friendly property is selected as the textile fabric, organization structures are not limited, a jacquard fabric can even be selected, and a thin film with high permeability is selected as the film-covering material. The surface of the thin film is in contact with down filling materials, and the human body is in contact with natural fiber fabric components. No chemicals are added to the contact surface of a natural fiber fabric in contact with the human body, which will not lead to phenomena such as sensitization and the like of susceptible population. Moreover, down products processed have high down leak-proofing performance, almost zero down leak of the down products is achieved, and thedown products have broad application prospects. The down leak-proofing fabric has good down leak-proofing performance and fastness and can be washed repeatedly, and the down leak-proofing performanceand wearing comfort performance are not reduced after washing 10 times.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

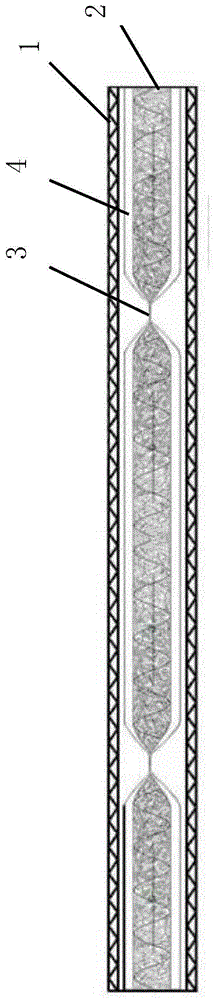

Seamless integrated weaving method for down jacket fabric

ActiveCN114794624AEasy to cleanPrevents adhesion effectsTextile/flexible product manufactureOvergarmentsMechanical engineeringPleat

The invention relates to a seamless integrated weaving method for down jacket fabrics, which comprises the following steps: mutually connecting a surface fabric and a lining in a crossed manner through tatting, forming a notch at the edge, performing hot-pressing bonding on a filling strip and the notch, and reinforcing through sewing threads. The integrated weaving technology is adopted, the down filling space is formed between the surface layer fabric and the lining, the notches are reserved in the edges of the surface layer fabric and the lining, the notches are filled and bonded through the filling strips, uneven bonding of down filling openings is prevented, meanwhile, residual down can be conveniently cleaned through the notches, the situation that bonding is affected by the residual down is prevented, and the service life of the down filling openings is prolonged. The filling strips with high firmness are arranged for sealing, the filling strips are reinforced through the sewing threads, the elasticity of the filling strips can effectively prevent adhesion wrinkles caused by surface upheaval after down filling, meanwhile, the bonding glue plays a role in preventing down leakage during sealing, and during washing, the sewing threads replace the bonding glue to bear rolling force, so that the sealing effect is good. Therefore, the washing resistance and the down-proof effect can be improved.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

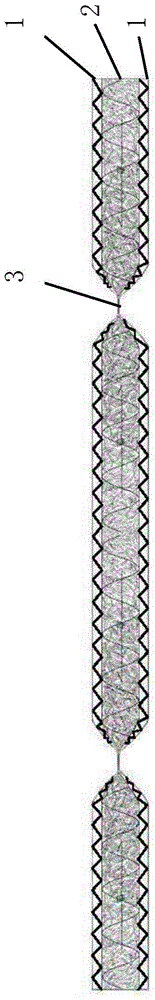

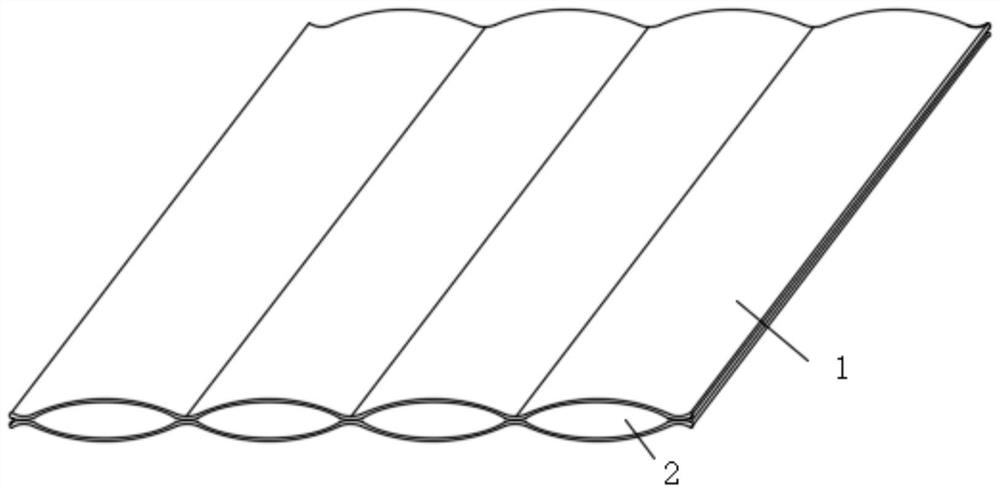

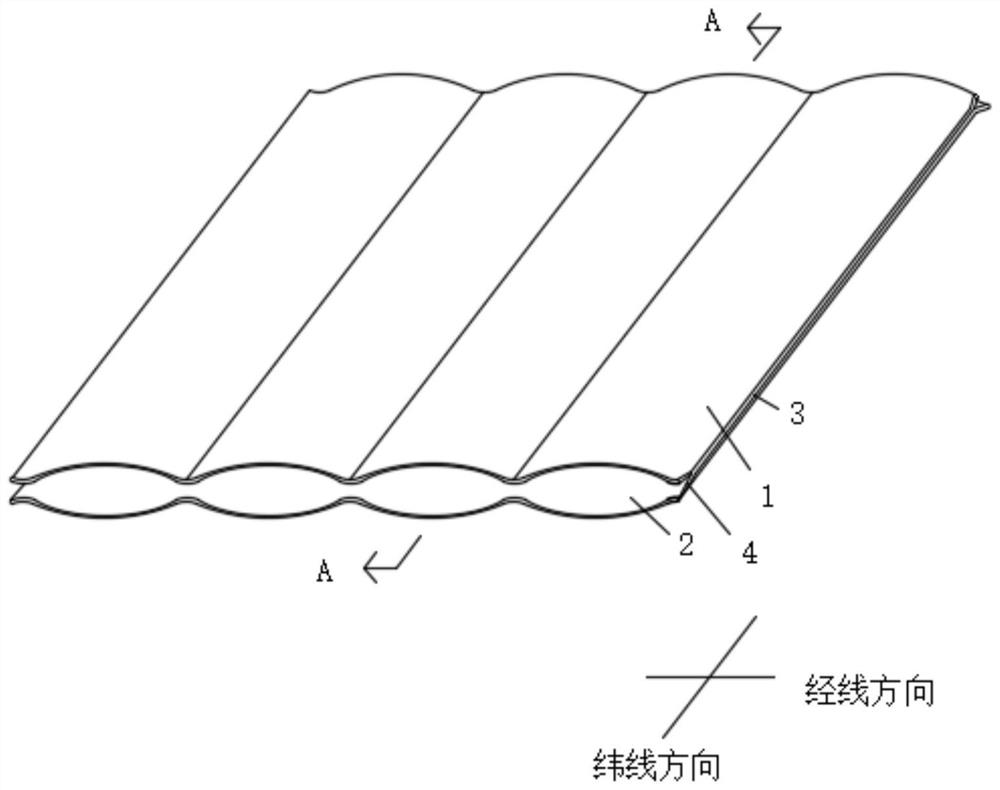

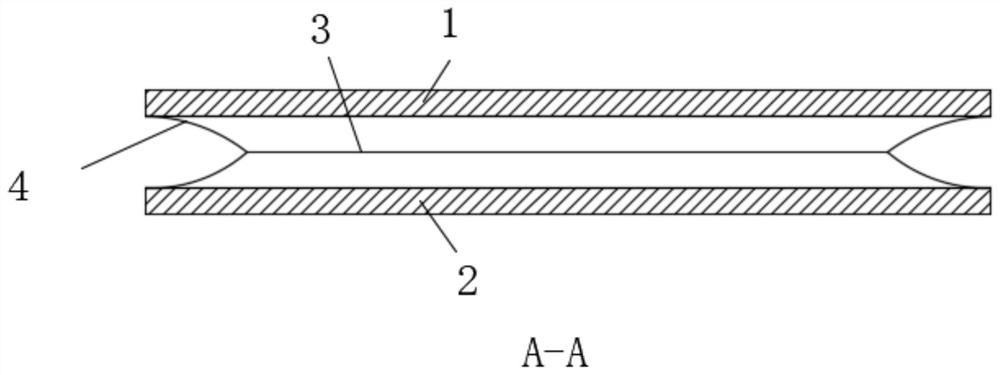

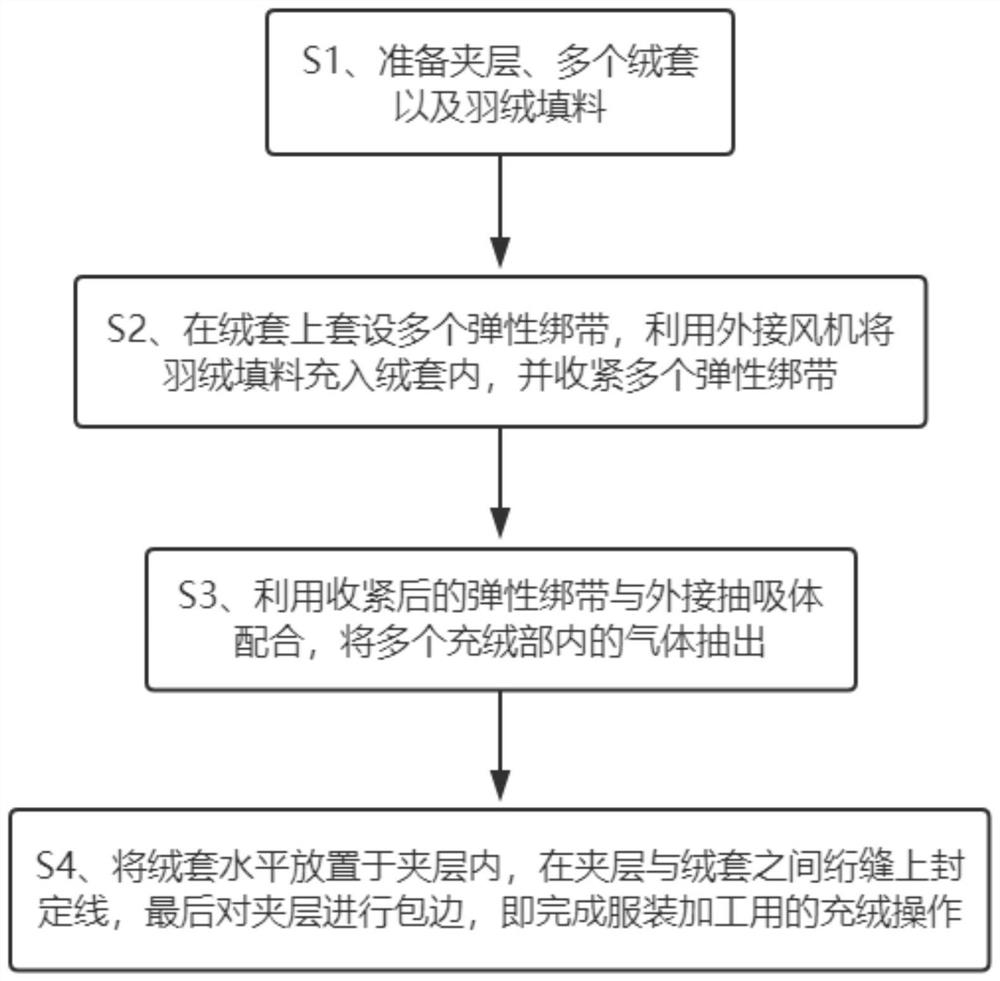

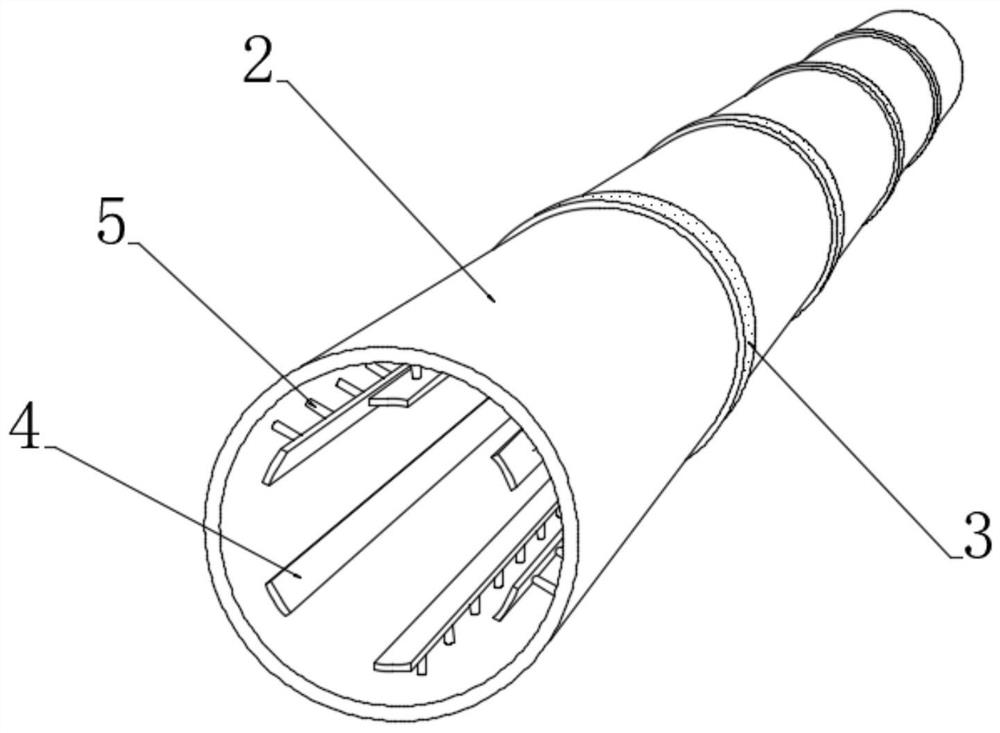

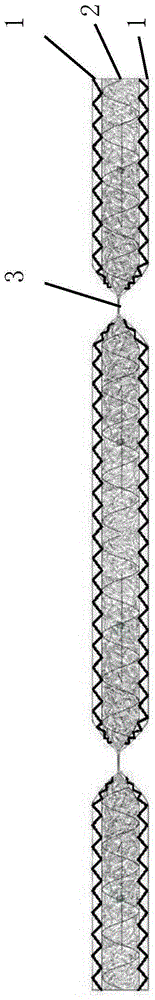

Down filling technology for garment processing

ActiveCN113598461APrevent running lintAvoid displacementClothes making applicancesProcess engineeringStructural engineering

The invention discloses a down filling technology for garment processing, and belongs to the technical field of garment processing technologies, a plurality of long-column-shaped down sleeves are used for filling down filling materials, compared with the mode that the down filling materials are directly filled into an interlayer, the down sleeves play a role in limiting the down filling materials, and after down filling is completed, a plurality of elastic binding bands arranged on the down sleeves in a sleeving mode are used for tightening the down sleeves in a segmented mode, the down sleeves are divided into a plurality of down filling parts, the down filling in the down sleeves is further limited, down running is effectively prevented, meanwhile, after the elastic binding bands are matched with an external suction body, the elastic binding bands are used for sucking the down filling parts in a segmented mode. Air can be extracted easily, down feather filling materials on the inner sides of the down sleeves are not easily brought out, the down sleeves filled with down feather are distributed in the interlayer in an array mode, the down sleeves and the interlayer are subjected to sewing positioning through the two sets of sealing lines, displacement of the down sleeves is effectively prevented, the experience effect is improved, and the down feather drilling phenomenon is effectively reduced.

Owner:SICHUAN SHENGSHAN BAIYULAN IND CO LTD

A nano-microcapsule material with self-healing and wear-resistant functions and its preparation method

ActiveCN104131469BImprove anti-drilling performanceDoes not cause thickening and weight gainFibre treatmentOvergarmentsGaining weightFiber

The invention relates to a nano microcapsule material and a preparation method thereof. The nano microcapsule material comprises a fabric base body prepared by fibers, and particularly also comprises a wall material cladded outside fiber-forming filaments and having nanoscale thickness; the wall material and the fibers form a nano microcapsule structure with the fiber-forming fine filaments as a 'core' and the wall material as a 'capsule sheath', the capsule sheath has adhesion, after being cladded with the capsule sheath, the fiber fine filaments are in mutual adhesion, so as to block gaps between the fibers; the fabric is used for production of ultra light and thin down jackets, can achieve quite good effect of penetration resistance to feathers, and cannot cause the fabric to become thick and gain weight and affect the wear comfort; and in addition, other properties of the fabric can be modified through introduction of functional auxiliary agents into the capsule sheath, for example, wear resistance of the fabric can effectively be enhanced through introduction of nano silica, or for example, the service life of the material can be effectively prolonged through introduction of self-repairing groups.

Owner:SUZHOU TANGHUA NANO TECH

A manufacturing process for a structure that prevents down from shifting and maintains fabric elasticity

InactiveCN105128442BDoes not damage the elasticityEvenly distributedSynthetic resin layered productsClothingsDown shiftingMechanical engineering

The invention provides a structure that prevents down from shifting and maintains fabric elasticity and its manufacturing process, which includes two layers of fabric layers and down, and the down is filled between the two layers of fabric layers, and also includes a plurality of connection points, The connection points are used to position the down and make the down distributed in a net shape, the two fabric layers are all made of stretched and elastic fabrics, and the down is wrapped with an elastic breathable film. The technical solution provided by the invention enables the elastic down products to maintain the elasticity of the fabric to the greatest extent, and at the same time keeps the distribution of the down uniform, anti-drilling, and will not be displaced due to external forces such as gravity.

Owner:SHANGHAI YIQI GARMENT CO LTD

Down run prevention down jacket and sewing method thereof

PendingCN107736654AReduce the situation of drill downAvoid direct exposure to the surface of the fabric layerOvergarmentsClothes making applicancesIndustrial engineeringManufacturing engineering

The invention discloses a down run prevention down jacket and a sewing method thereof. The down run prevention down jacket comprises a fabric layer, a down packet and a lining layer which are sequentially stacked and sewn. The down jacket further comprises a down prevention strip. The down prevention strip is sewn on the face, adjacent to the down packet, of the fabric layer; after sewing, the down prevention strip on the fabric layer and the down packet are sewn. The down run prevention down jacket can achieve the best down run prevention effect, the sewing technology is simple and easy to implement; not large cost burden is added for production, and the production requirement is met.

Owner:FUJIAN SEVEN FASHION TECH CO LTD

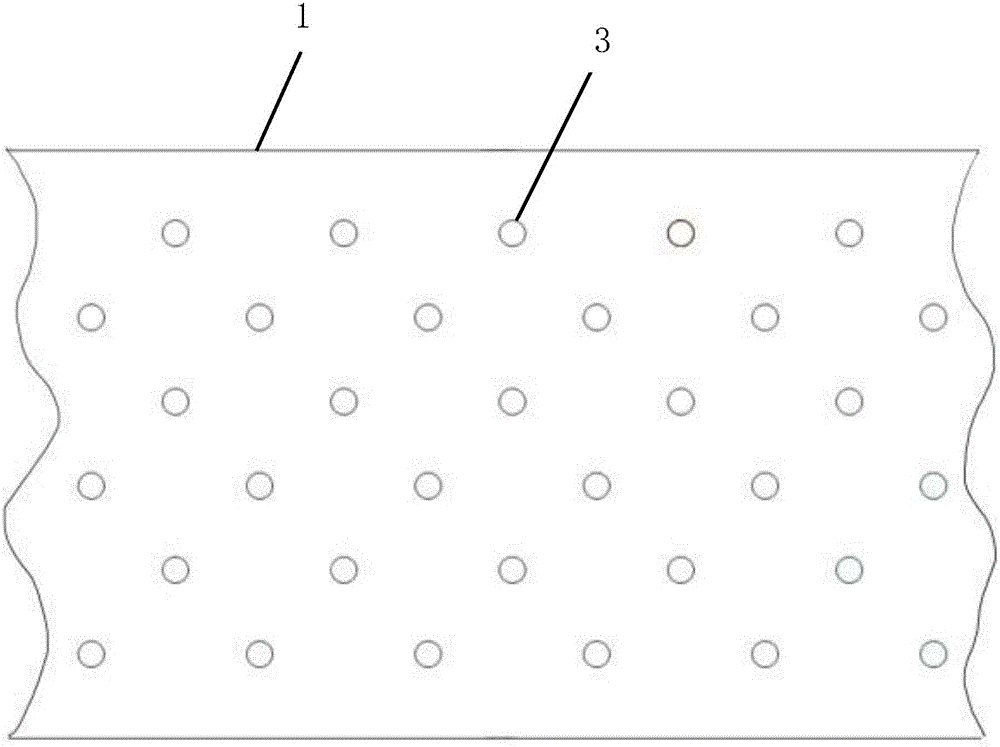

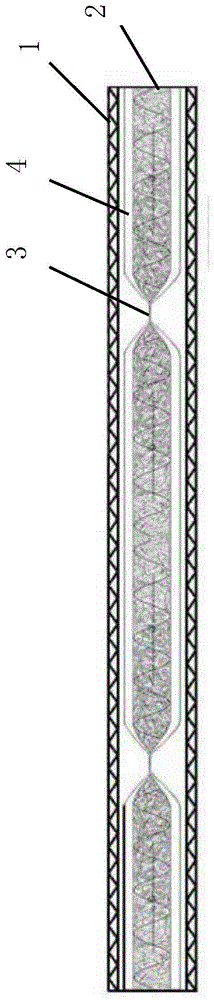

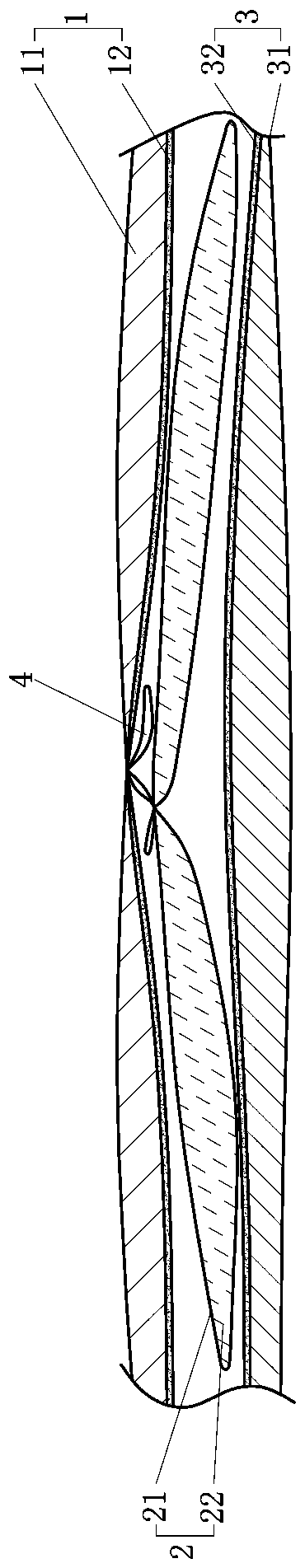

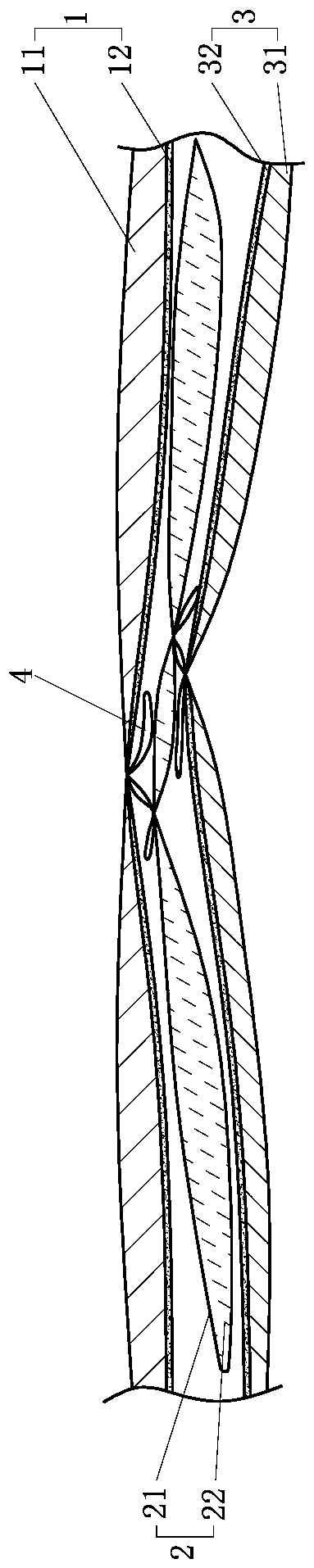

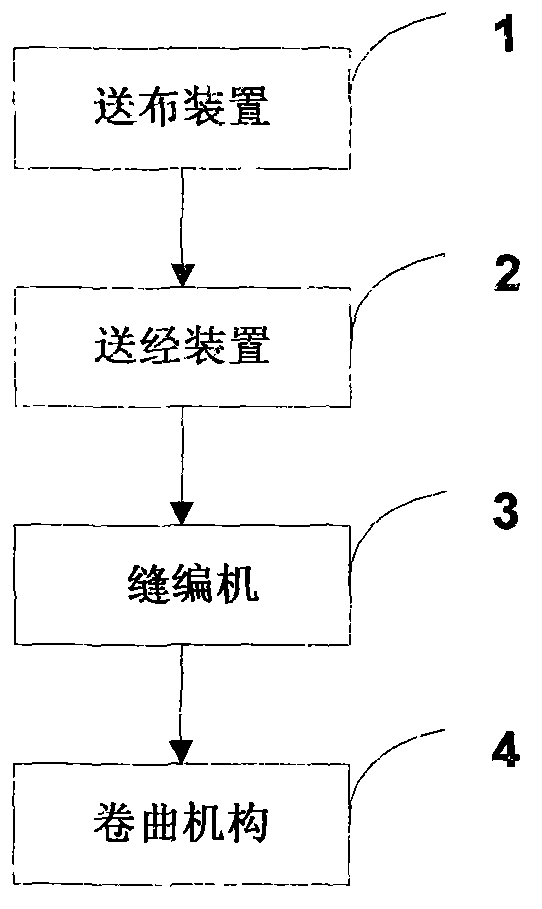

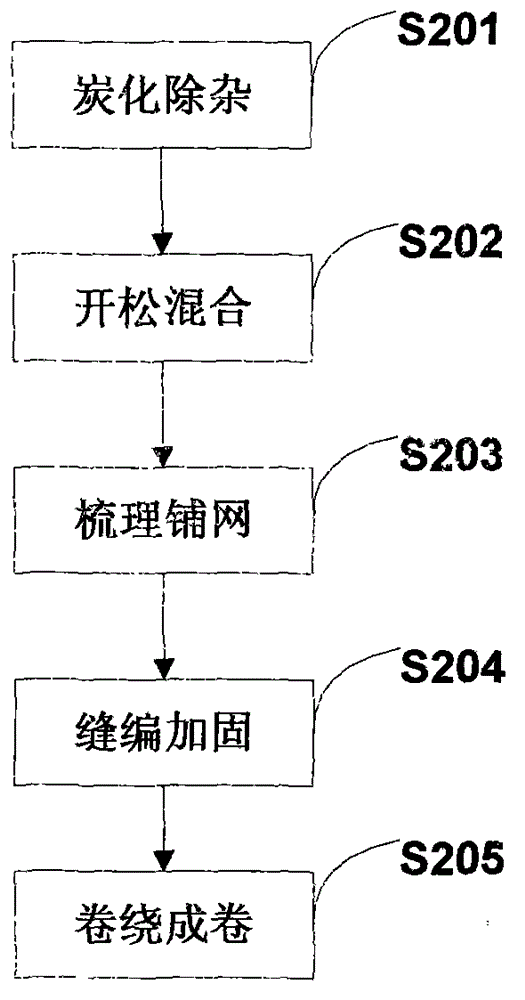

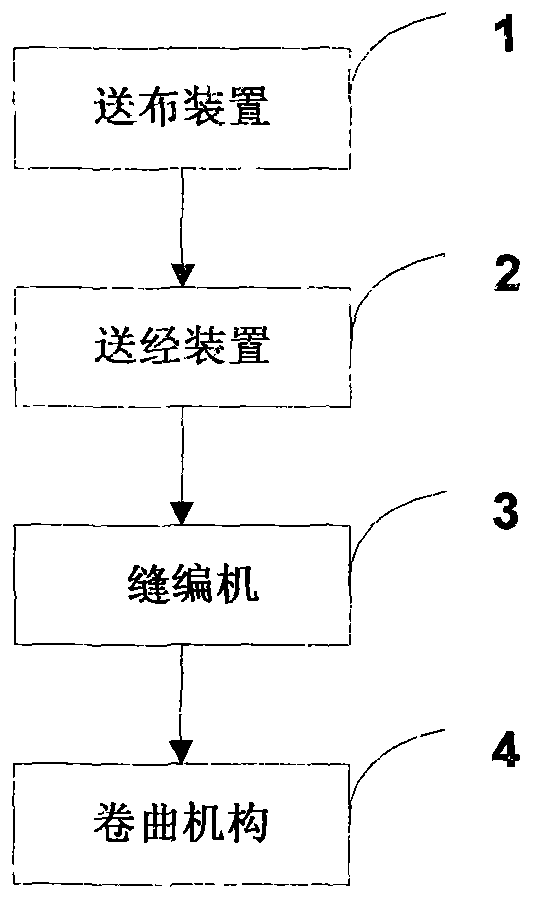

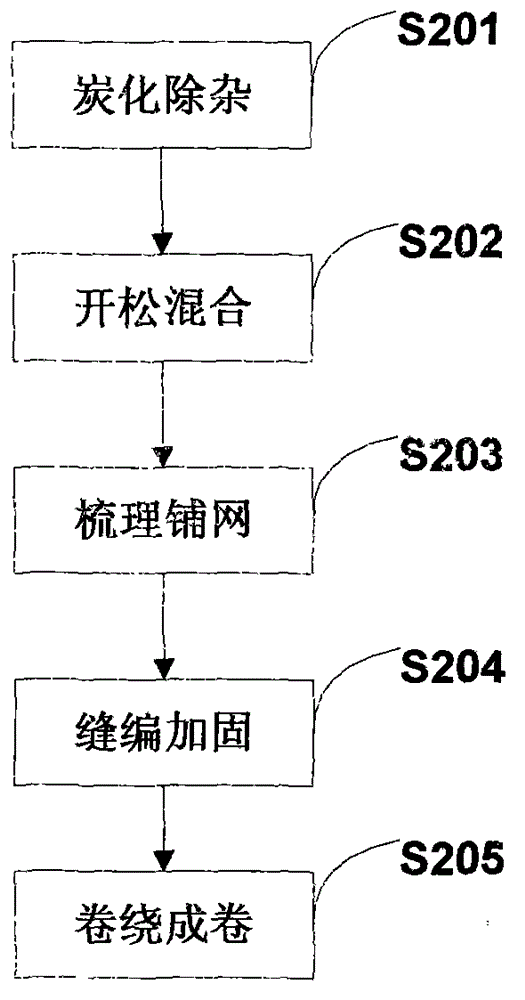

Method and system for stitch-bonded wool flocculus

ActiveCN102877216AImprove anti-drilling performanceReduce bulkinessNon-woven fabricsYarnCarbonization

The invention discloses a method and a system for stitch-bonded wool flocculus. The method comprises the steps that purchased scoured wool fiber raw material is further subjected to carbonization and impurity removal, and the treated wool fiber is ready for use; the scoured wool and other fibers are uniformly mixed according to the proportional requirement of technological design; after being combed, the scoured wool and other fibers are diagonally paved into a fiber net according the requirement of certain gram weight per square meters; the wool fiber net is conveyed to a stitch-bonding machine through a cloth conveying device, wool yarns are conveyed by a warp conveying device and arranged at the stitch-bonding machine, the wool fiber net is subjected to single-sided or double-sided stitch bonding processing according to the technological design requirement, and finally the wool fiber net is reinforced to form the stitch-bonded type wool flocculus; and the stitch-bonded type wool flocculus is wound on a winding mechanism so as to be tailored as wool cold protective clothing flocculus. According to the method and the system for the stitch-bonded wool flocculus, the wool leakage phenomenon of the wool fiber is obviously reduced, the net forming quality of wool fiber is also improved, the stitch-bonded wool flocculus is firmer and thinner than needled flocculus, the bulky feeling of wool cold protective clothing is effectively reduced, and the aesthetics and product grade of the wool cold protective clothing are greatly improved.

Owner:榆林羊老大品牌服饰运营有限责任公司

Cement-based composite material with high drilling resistance used in bank financial equipment and preparation method thereof

InactiveCN102381859AImprove close packing performanceImprove anti-drilling performanceAggregate (composite)Water reducer

The invention belongs to the technical field of bank financial equipment manufacturing, and relates to a cement-based composite material with high drilling resistance used in bank financial equipment. The composite material is characterized by comprising the following components such as cement, siliceous dust, carborundum, an efficient water reducer, steel fiber and water at the weight ratio of 1:(0.10-0.20):(1.4-2.6):(0.005-0.010):(0.30-0.45):(0.23-0.29). The cement-based composite material is applied to the technical field of bank financial equipment, and has the following advantages that the carborundum with Mohs hardness up to 9.0 is taken as an aggregate so as to greatly improve the drilling resistance of the cement-based composite material; and the composite material is naturally cured without high-temperature steam or dry-heat curing procedure, thus simplifying the operating procedures, saving the energy cost and being applicable to large-scale production.

Owner:TRI STAR

Jacquard down-proof fabric and machining method thereof

ActiveCN105821559AControl pore sizeIncrease frictionWoven fabricsLiquid/gas/vapor textile treatmentYarnEngineering

The invention provides a jacquard down-proof fabric and a machining method thereof. The jacquard down-proof fabric is formed by interweaving warp yarns and weft yarns according to jacquard structures; the warp yarns and the weft yarns are cotton yarns; a ground structure of the fabric is one of a warp face structure or a weft face structure while a figure structure is the other one; a transition structure is added between the ground structure and the figure structure; when the ground structure is the warp face structure and the figure structure is the weft face structure, a floating length number of the transition structure is smaller than a warp floating length number of the ground structure and is also smaller than a weft floating length number of the figure structure; and when the ground structure is the weft face structure and the figure structure is the warp face structure, the floating length number of the transition structure is smaller than a weft floating length number of the ground structure and is also smaller than a warp floating length number of the figure structure. According to the machining method, the warp yarns and the weft yarns are woven according to the jacquard structures, and then the fabric is subjected to down-proof finishing. A jacquard pattern of the fabric has abundant layers, and the fabric also has good moisture-absorbing and breathable properties, so that a consumer feels comfortable when using a down quilt.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

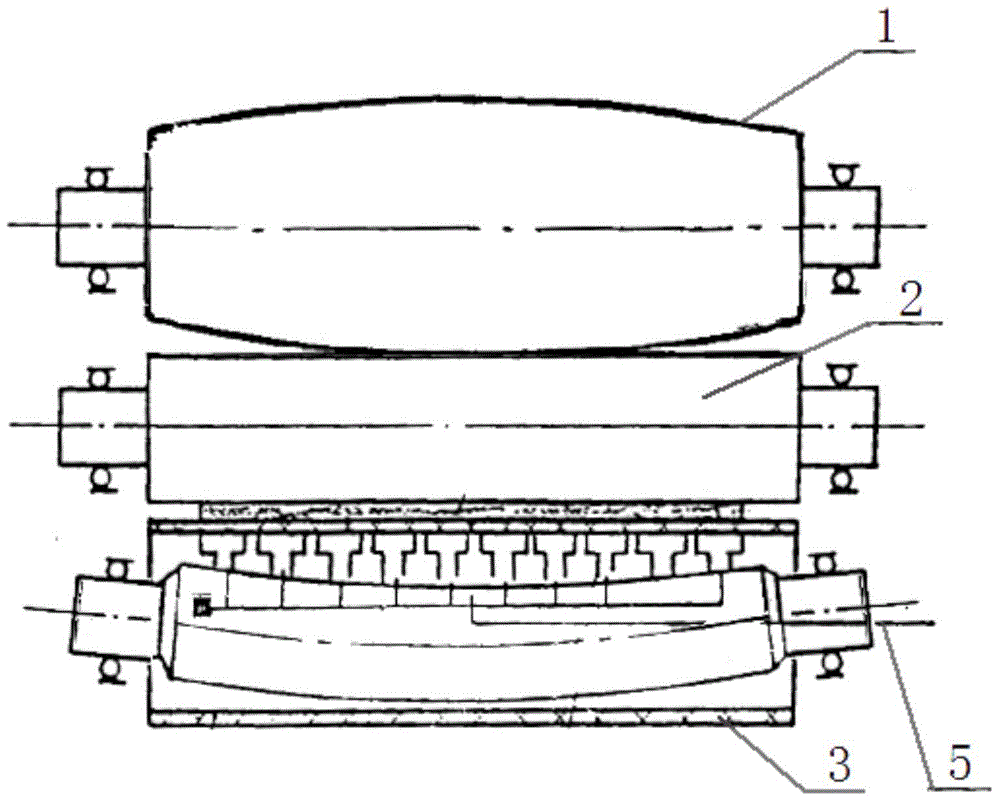

A three-roll calender for textiles and a textile calendering method

ActiveCN103966793BUniform softnessProduce twisting effectTextile shapingNano al2o3Pulp and paper industry

The invention relates to a three-roller calendar for a textile and a textile calendaring method. The calendar comprises a rack, a cloth feeding device, an upper roller, a middle roller, a lower roller, a cooling device, a cloth discharge device and a pressurizing device, wherein the upper roller is a spindle roller and fixed on the rack; the middle roller and the lower roller are respectively a mirror surface heating roller and a hydraulic equalizing roller and movably arranged on the rack; the upper roller, the middle roller and the lower roller can respectively rotate around the respective shaft leads; the middle roller is a driving roller; the upper roller and the lower roller are driven rollers; the pressurizing device is connected with the lower roller; the upper roller comprises a roller shaft and a roller body; the roller body is formed by a pure nylon layer and a nanometer aluminum oxide modified nylon layer. By adopting the three-roller calendar disclosed by the invention, deformation of each roller in the pressurizing process is counteracted, cloth is even in pressure in different breadths, and the glossiness and the softness of the calendared cloth are improved. In addition, the calendar and the calendaring method disclosed by the invention are applicable to the cloth with any thickness and made of any materials.

Owner:SUZHOU TANGHUA NANO TECH

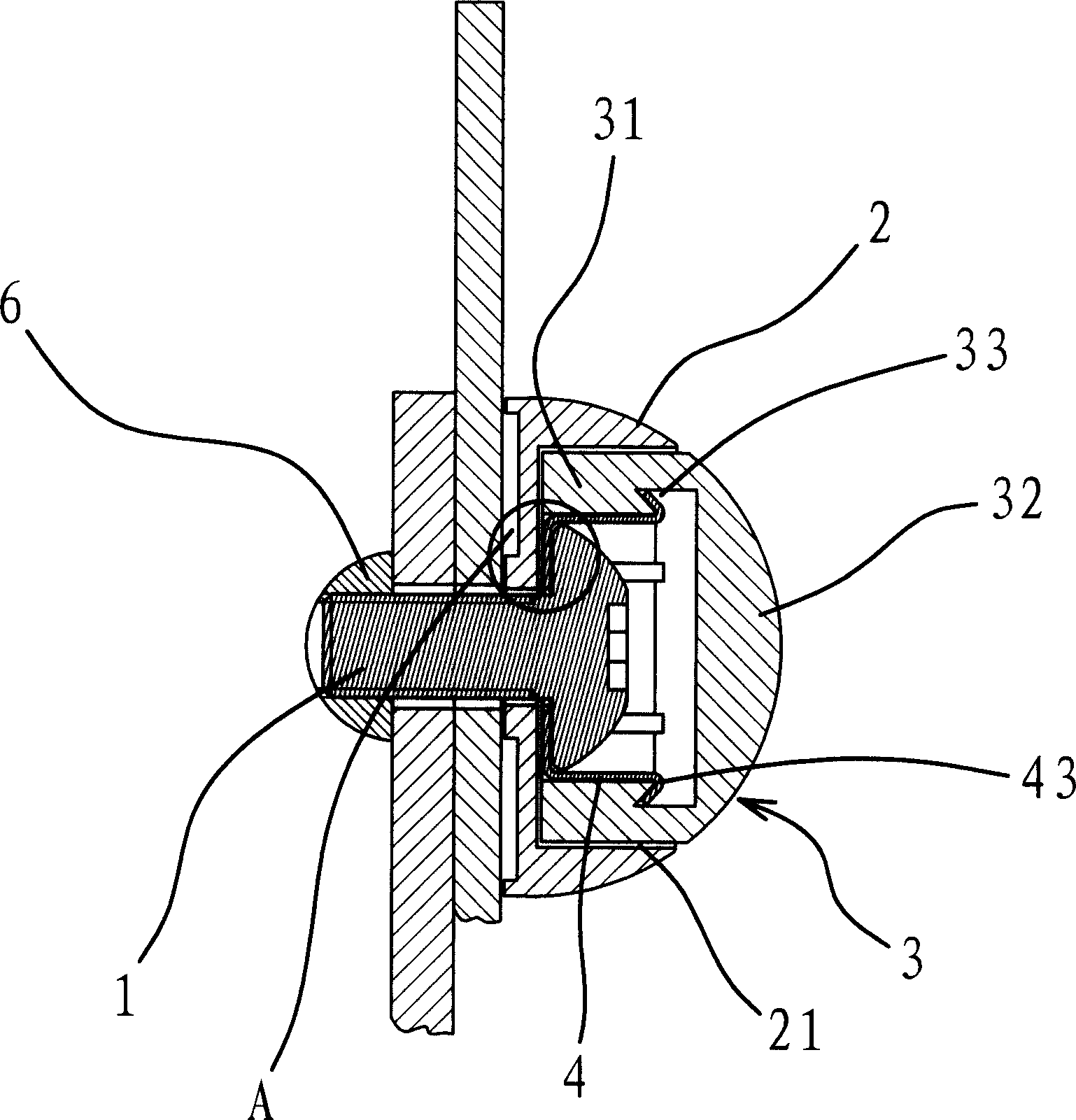

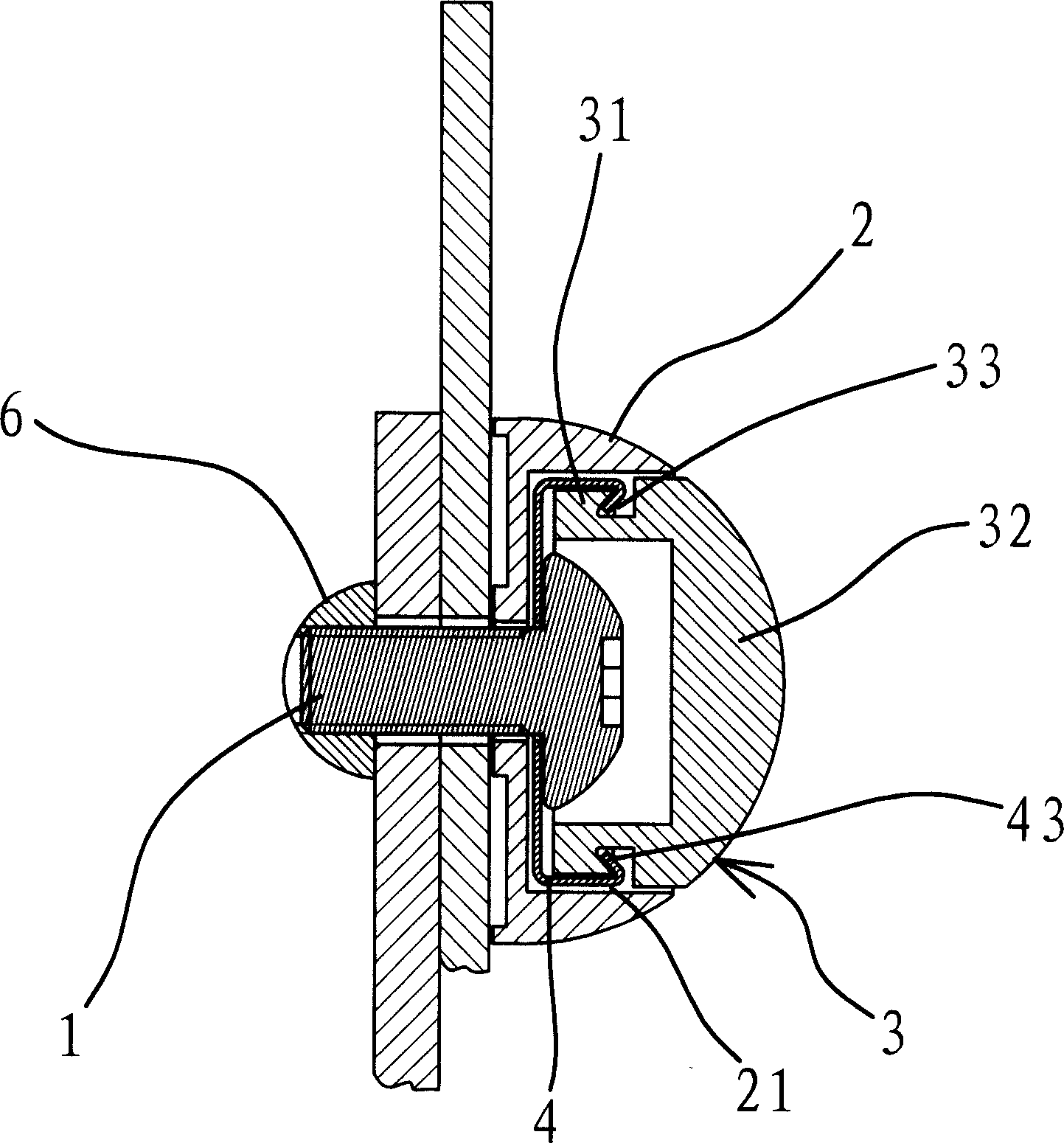

Closed type mechanical lock core and key thereof

InactiveCN102322181BLow technology open rateHigh strengthKeysCylinder locksMechanical engineeringKeyhole

The invention relates to a closed type mechanical lock core and a key thereof. A round lock core comprises a shell, inner compressed springs, inner compressed pins, lock keys, a rotary lock core, round wheels and a cylindrical key. The closed type mechanical lock core is characterized in that a pin groove of the lock core shell is provided with the inner compressed springs and the inner compressed pins which act on the lock keys, the lock keys are simultaneously arranged in lock key grooves of the shell and lock key grooves of the rotary lock core and connect the lock key grooves of the shell and the lock key grooves of the rotary lock core into a whole, the rotary lock core is fixed by the shell and cannot rotate, round wheel grooves of the rotary lock core are provided with round wheels of which the inner bores are provided with bulges, the outer edge of each round wheel is provided with lock key grooves and arc grooves, the lock keys are simultaneously arranged in the lock key grooves of the rotary lock core and the lock key grooves of the round wheels and connect the lock key grooves of the rotary lock core and the lock key grooves of the round wheel into a whole, and the rotary lock core can rotate freely. The key is provided with a group of grooves; when round wheel inner bore bulges are driven to rotate until the rotary lock core can rotate freely, bulges on the key drive the rotary lock core to rotate to unlock the lock, wherein the tail end of the rotary lock core is connected with an unlock shifting plate. A key hole of the lock core is in a closed type structure, and therefore, an unlocking tool cannot enter into the key hole to ensure that the lock core has higher safety.

Owner:陆娟

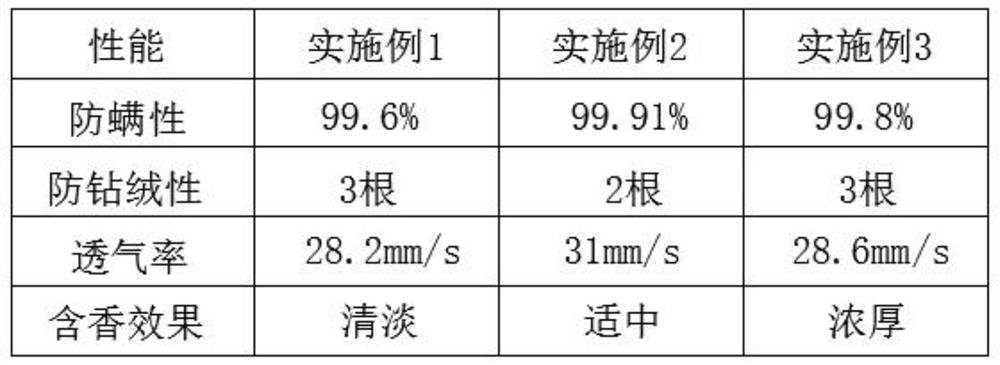

Processing method of physical anti-mite down quilt fabric

InactiveCN112011869AExcellent anti-mite functionImprove breathabilityBiochemical fibre treatmentLiquid/gas/vapor removalPolymer scienceCotton fibre

The invention discloses a processing method of physical anti-mite down quilt fabric, and belongs to the technical field of down quilt fabrics. The method comprises the following steps: S1, selective oxidation: carrying out selective oxidation on cotton fibers at a specific temperature by using a sodium periodate solution with the concentration of 2.5 g / L; S2, fiber mixing: mixing the prepared aldehyde group cotton fibers and polyurethane fibers according to a mass ratio of 1:1.5; S3, anti-mite dyeing:, performing dip dyeing on the blended yarn, and mixing an anti-mite agent into dye liquor, wherein the mass ratio of the blended yarn to the anti-mite agent is 2:1; S4, anti-mite fragrance dyeing: dying the color-fixed blended yarn again, and mixing a fragrance agent into dye liquor, whereinthe mass ratio of the blended yarn to the fragrance agent is 1:1.5; S5, fabric weaving: warping, sizing and denting the blended yarns subjected to mite prevention and fragrance dyeing, and then weaving the blended yarns on a loom to form plain weave fabric for later use; and S6, fabric calendering. The processing method is scientific and reasonable, and the down quilt fabric has a good anti-mite effect.

Owner:安徽中弘鑫源纺织股份有限公司

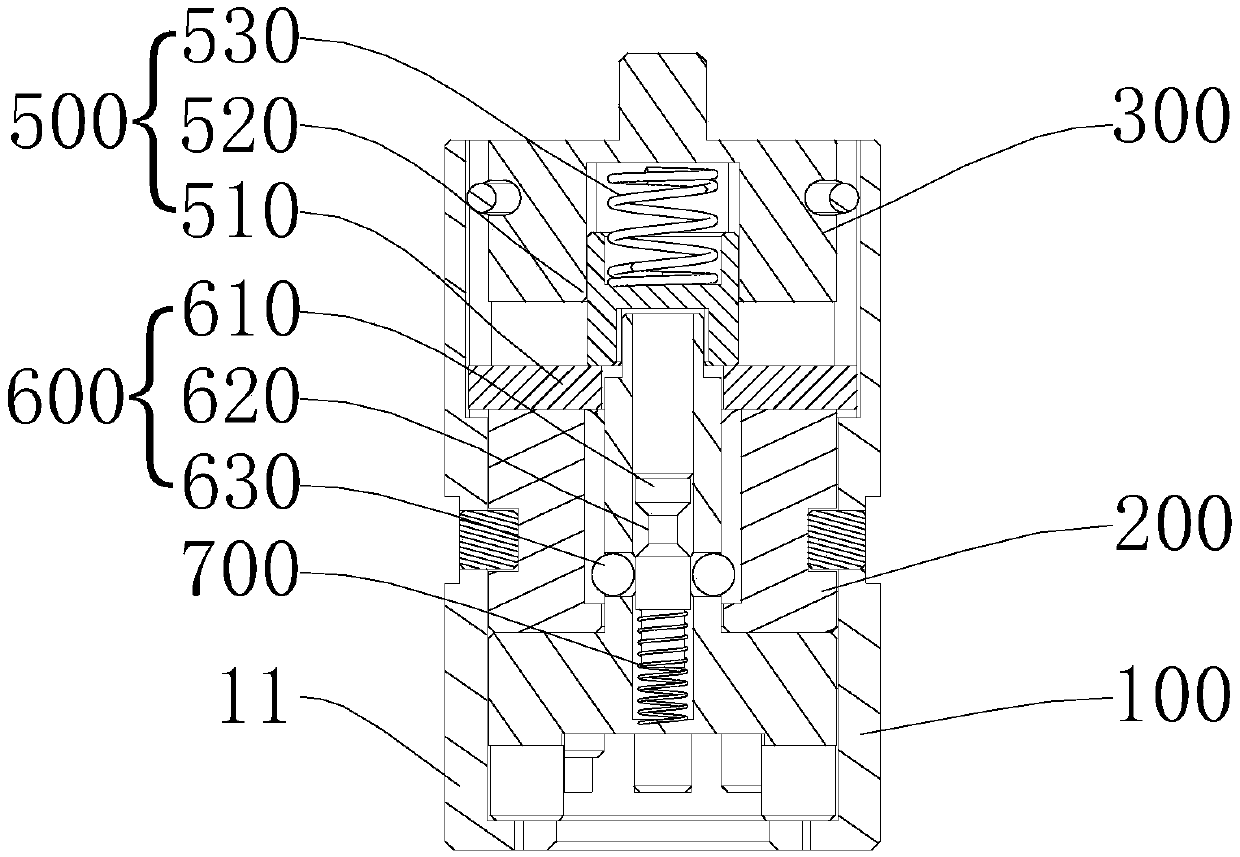

Drilling-resisting electronic lock cylinder

ActiveCN110409921AImprove anti-drilling performanceNon-mechanical controlsArchitectural engineeringSteel ball

The invention discloses a drilling-resisting electronic lock cylinder. The drilling-resisting electronic lock cylinder comprises a body, a drilling-prevention cavity, drilling-prevention steel balls,a motor, a rotating block and a lock cylinder billiard. The body is provided with a joint end connected with a key, the upper portion and the lower portion of the joint end are provided with V-shapedinclined face grooves used for guiding, the drilling-prevention cavity is formed in the rear face of the inclined face groove in the upper portion of the joint end, the drilling-prevention steel ballsare arranged in the drilling-prevention cavity and can freely rotate in the drilling-prevention cavity, the motor is arranged behind the drilling-prevention steel balls, the rotating block is connected with the motor, the motor can drive the rotating block to rotate, the lock cylinder billiard is arranged in a billiard cavity in the tail of the body, the rotating block rotates to control the lockcylinder billiard to stretch out or draw back in the billiard cavity, the centre of the inclined face groove in the upper portion of the joint is collinear with the center of the drilling-preventionsteel balls, the axis line of the motor, and the axis line of the rotating block. The electronic lock cylinder can greatly improve the lock cylinder drilling-resisting capacity wholly.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +2

Processing method of down-proof shell fabric of super-flexible noiseless down quilt

InactiveCN107083703AGood flexibilityImprove breathabilityGrip property fibresDyeing processYarnFiber

The invention discloses a processing method of a down-proof shell fabric of a super-flexible noiseless down quilt and relates to the technical field of down quilt processing. The processing method mainly comprises the following steps: (1) blended yarn processing; (2) blended yarn dyeing; (3) shell fabric weaving; (4) shell fabric calendering pre-processing; and (5) shell fabric calendering. By taking modal fibers and polyterephthalic acid 1,3-propylene glycol ester fibers as raw materials, the prepared shell fabric fully combines excellent characteristics of two fibers, in particular flexibility; in the blended yarn dyeing process, a flexible aid is added, so that the processed shell fabric is endowed with excellent flexibility at the same time through the dyeing step; by performing calendering pre-processing on the shell fabric, the flexibility, air and water vapor permeability and downproofness of the shell fabric are enhanced under the action of a calendering aid.

Owner:ANHUI SANXIANG DOWN

An anti-drilling electronic lock cylinder

ActiveCN109629921BImprove securityLow costNon-mechanical controlsLock casingsStructural engineeringAlloy

Owner:NINGBO HI-TECH DISTRICT RUIAO OPTOELECTRONIC TECH CO LTD

Jacquard anti-drill down fabric and processing method thereof

ActiveCN105821559BControl pore sizeIncrease frictionWoven fabricsLiquid/gas/vapor textile treatmentPolymer scienceEngineering

The invention provides a jacquard anti-drilling fleece fabric and a processing method thereof. The warp yarn and the weft yarn are interwoven according to the jacquard weave. The warp yarn and the weft yarn are both cotton yarns, and the ground weave of the fabric is either a warp weave or a weft weave. one type, flowering tissue is another; if a transitional tissue is added between the ground tissue and the flowering tissue, the local tissue is the warp surface tissue, and the flowering tissue is the latitudinal tissue, then the floating length of the transitional tissue is less than that of the ground tissue The warp float number is also less than the weft float number of the flowering weave, if the local weave is the weft weave and the flowering weave is the warp surface weave, then the buoyancy number of the transitional weave is both less than the weft float of the ground weave and less than the flowering weave The warp length of the organization. The processing method is to first weave the warp and weft yarns according to the jacquard structure, and then perform anti-drilling finishing on the fabric. The jacquard pattern of the fabric is rich in layers, and has good moisture absorption and air permeability, so that consumers can use the duvet with good comfort performance.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method and system for stitching wool wadding

ActiveCN102877216BImprove anti-drilling performanceReduce bulkinessNon-woven fabricsYarnCarbonization

The invention discloses a method and a system for stitch-bonded wool flocculus. The method comprises the steps that purchased scoured wool fiber raw material is further subjected to carbonization and impurity removal, and the treated wool fiber is ready for use; the scoured wool and other fibers are uniformly mixed according to the proportional requirement of technological design; after being combed, the scoured wool and other fibers are diagonally paved into a fiber net according the requirement of certain gram weight per square meters; the wool fiber net is conveyed to a stitch-bonding machine through a cloth conveying device, wool yarns are conveyed by a warp conveying device and arranged at the stitch-bonding machine, the wool fiber net is subjected to single-sided or double-sided stitch bonding processing according to the technological design requirement, and finally the wool fiber net is reinforced to form the stitch-bonded type wool flocculus; and the stitch-bonded type wool flocculus is wound on a winding mechanism so as to be tailored as wool cold protective clothing flocculus. According to the method and the system for the stitch-bonded wool flocculus, the wool leakage phenomenon of the wool fiber is obviously reduced, the net forming quality of wool fiber is also improved, the stitch-bonded wool flocculus is firmer and thinner than needled flocculus, the bulky feeling of wool cold protective clothing is effectively reduced, and the aesthetics and product grade of the wool cold protective clothing are greatly improved.

Owner:榆林羊老大品牌服饰运营有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com