An anti-drilling electronic lock cylinder

An electronic lock and lock shell technology, which is applied to construction locks, lock shells, non-mechanical transmission-operated locks, etc. The effect of opening time boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

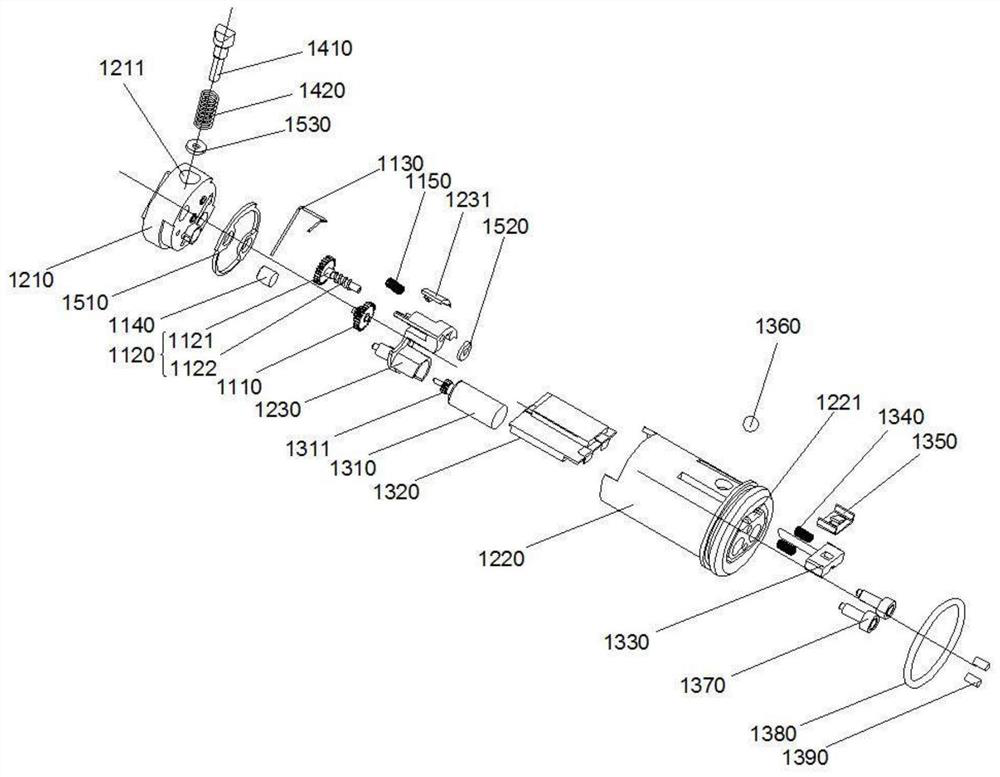

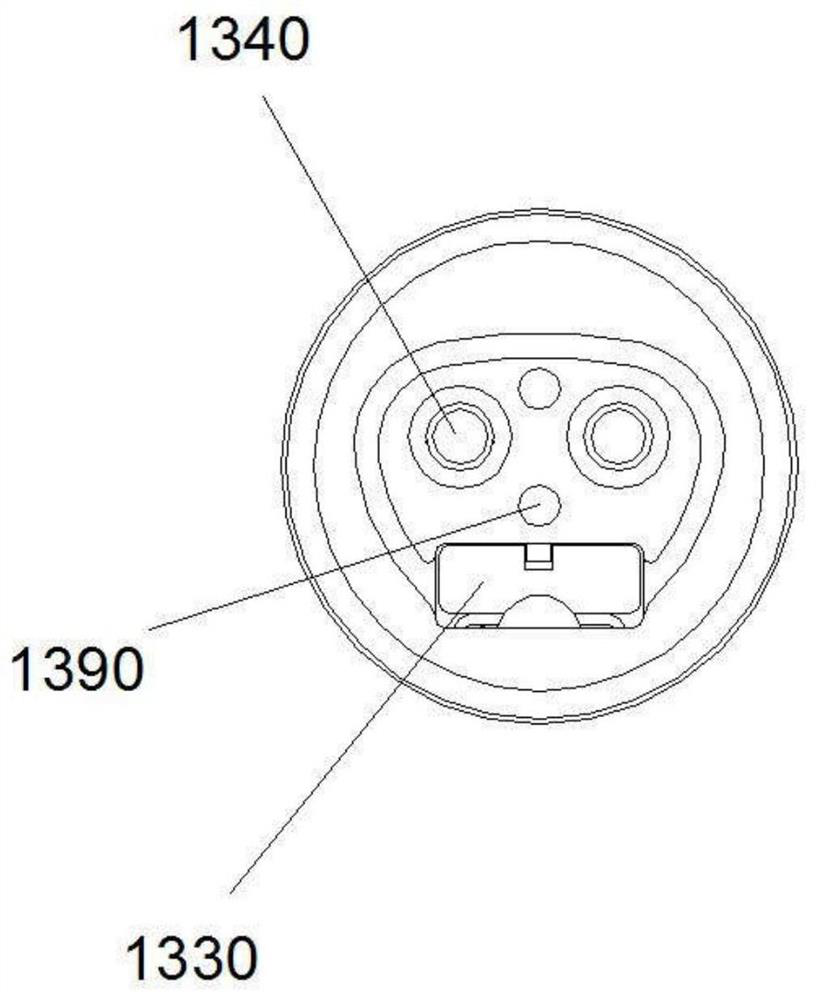

[0033] The invention provides an anti-drilling electronic lock cylinder, such as Figure 1-3 As shown, including the lock housing, at least two T-shaped contacts 1370 and at least two anti-drilling pins 1390 are arranged in the middle of the end face of the lock housing. The T-shaped contacts 1370 and the anti-drilling pins 1390 are made of alloy materials, and the T-shaped contacts The ratio of the sum of the areas of the 1370 and the anti-drilling pin 1390 on the end surface of the lock housing to the area of the end surface of the lock housing is between 1 / 10 and 2 / 3.

[0034] Wherein, if the sum of the areas of the T-shaped contact 1370 and the anti-drilling pin 1390 on the end surface of the lock housing accounts for less than 1 / 10 of the area of the end surface of the lock housing, then in actual use, the overall anti-drilling effect of the lock cylinder will be reduced. The effect improvement is low, and the electric drill can quickly penetrate the end face of the l...

Embodiment 2

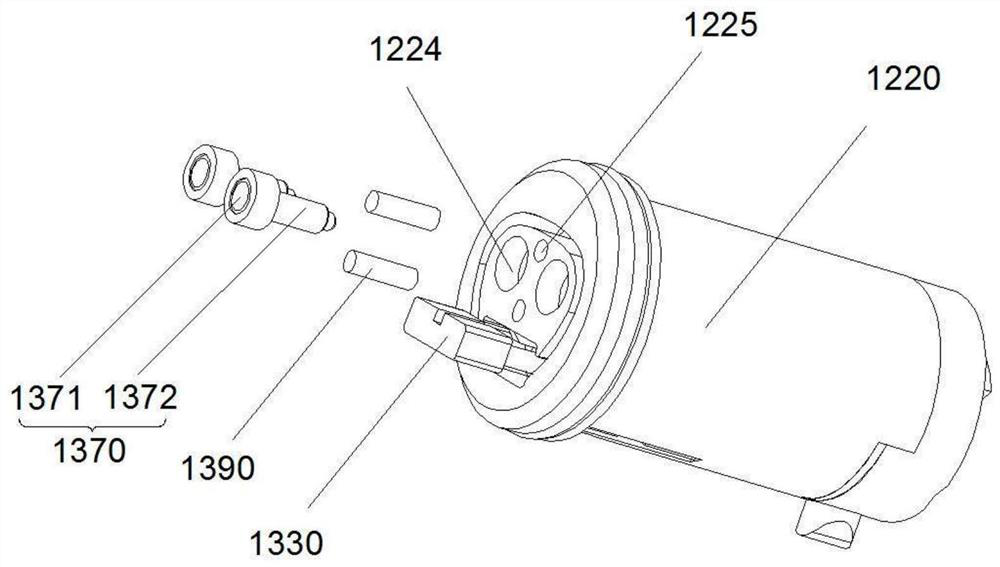

[0038] For the anti-drilling electronic lock cylinder described in Embodiment 1, in this embodiment, the T-shaped contact 1370 includes a cylindrical head 1371 and a rod 1372, the diameter of the head 1371 is larger than the diameter of the rod 1372, and The bottom end surface of the lock housing is provided with T-shaped slots 1224 corresponding to the number of T-shaped contacts 1370, and the T-shaped slots 1224 match the structure of the T-shaped contacts 1371, and the T-shaped contacts 1370 are inserted into the T-shaped slots 1224 In the middle, the head 1371 remains flush with the bottom surface of the lock housing around it. The diameter of the T-shaped contact 1370 is between 1.5mm-3mm. In this embodiment, the diameter of the head 1371 of the T-shaped contact 1370 is between 1.5mm-3mm, and the diameter of the rod 1372 is larger than that of the head. The part 1371 is small, reducing the production cost while ensuring the effect. In the test, if the diameter of the T-s...

Embodiment 3

[0042] As the anti-drilling electronic lock cylinder described in Embodiment 2, in this embodiment, combined Figure 4 and Figure 5 As shown, it includes a lock case and a drive assembly and a transmission assembly arranged inside the lock case. The transmission assembly includes a driven gear 1110 , a helical drive gear 1120 , a drive circlip 1130 and a limit block 1140 . The helical drive gear 1120 includes a gear part 1121 And the worm part 1122, the driven gear 1110 is engaged with the gear part 1121 for transmission, the worm part 1122 is arranged on the side of the gear part 1121 facing the drive assembly, the helical drive gear 1120 drives the movement of the limit block 1140 through the driving circlip 1130, and the lock The housing is provided with a locking component for switching the closed / open state of the lock, the limit block 1140 is used to limit the movement of the locking component to realize the locking / opening of the lock cylinder, and the driving componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com