Patents

Literature

100results about How to "Improve assembly time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

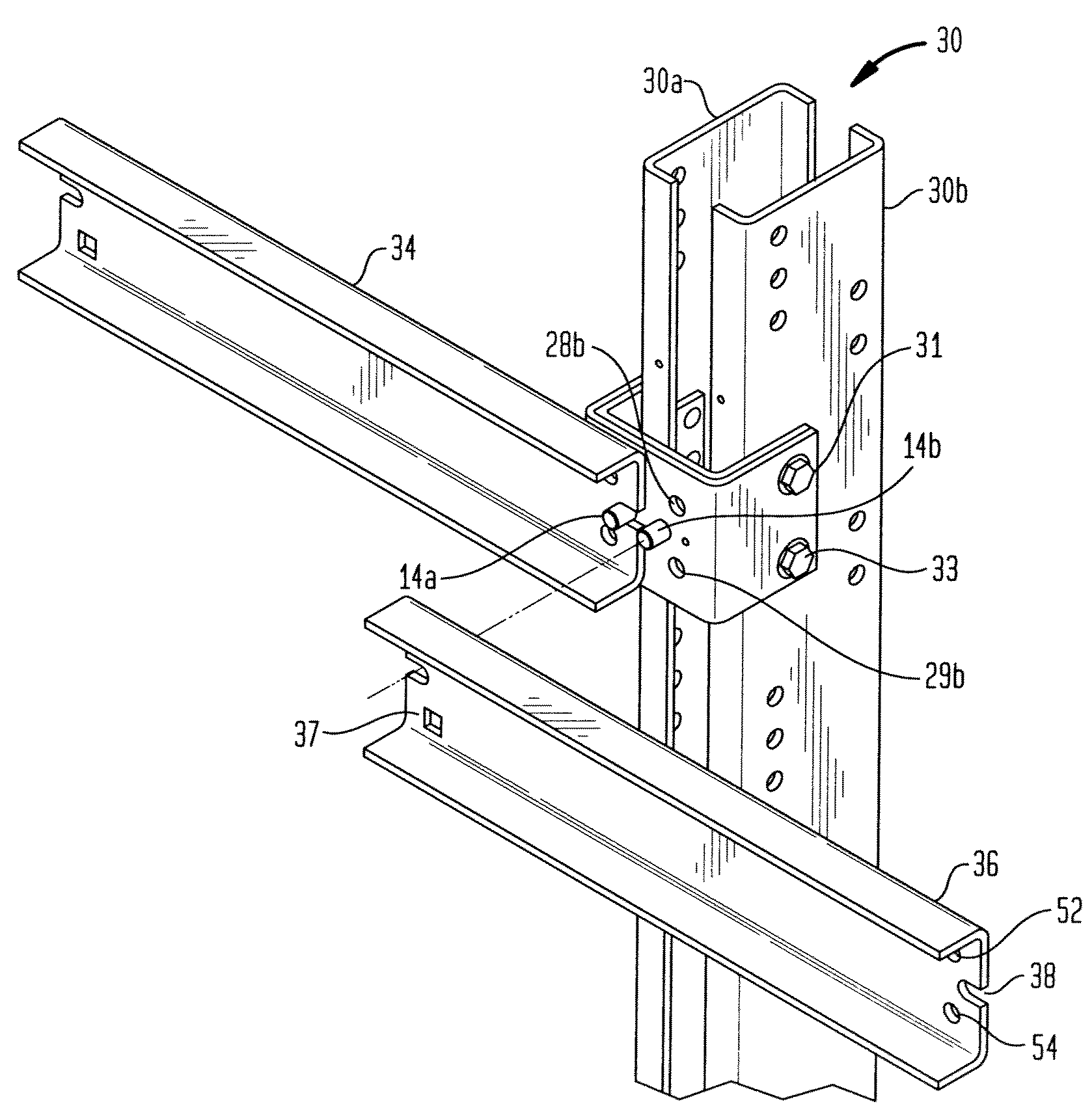

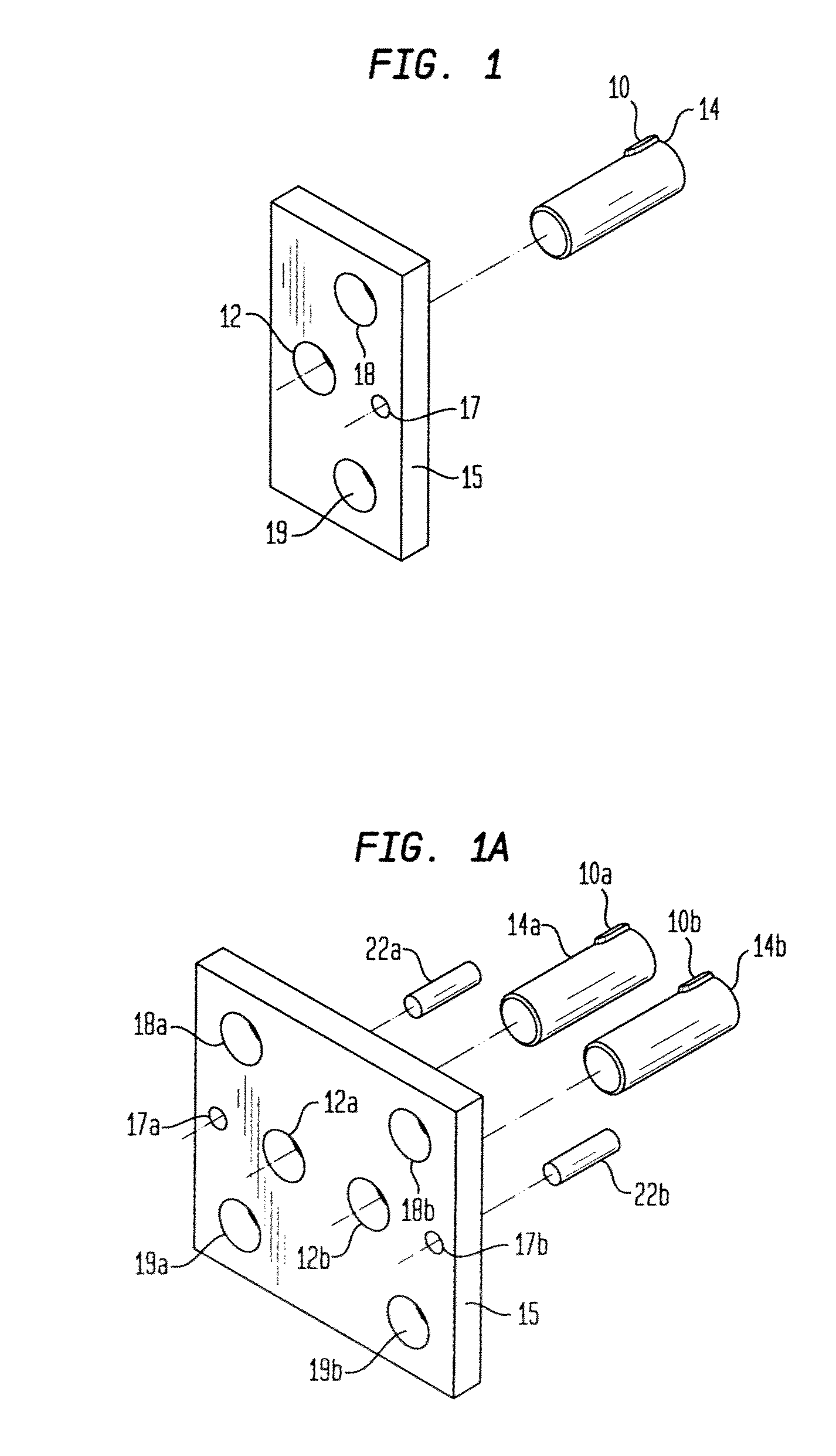

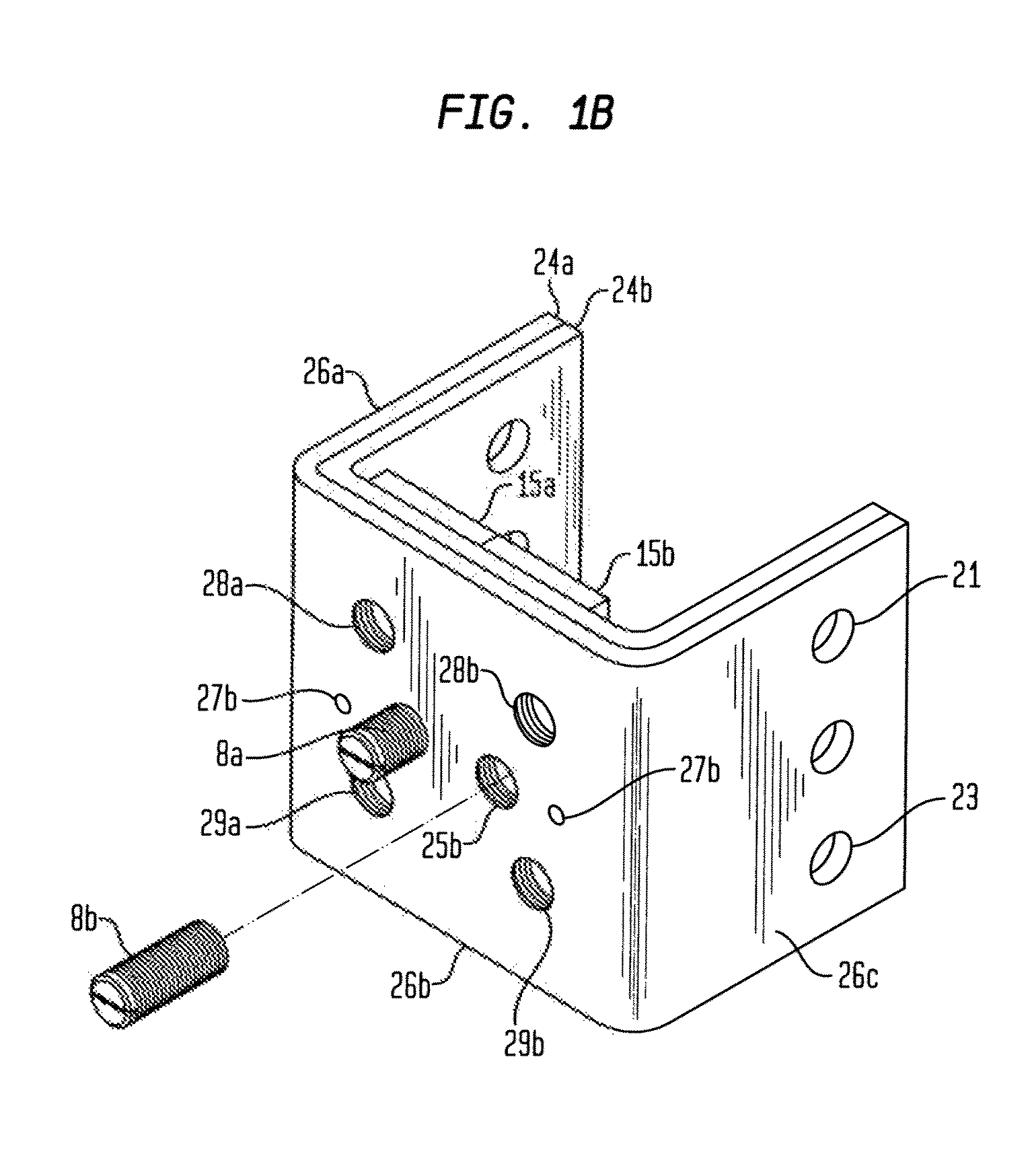

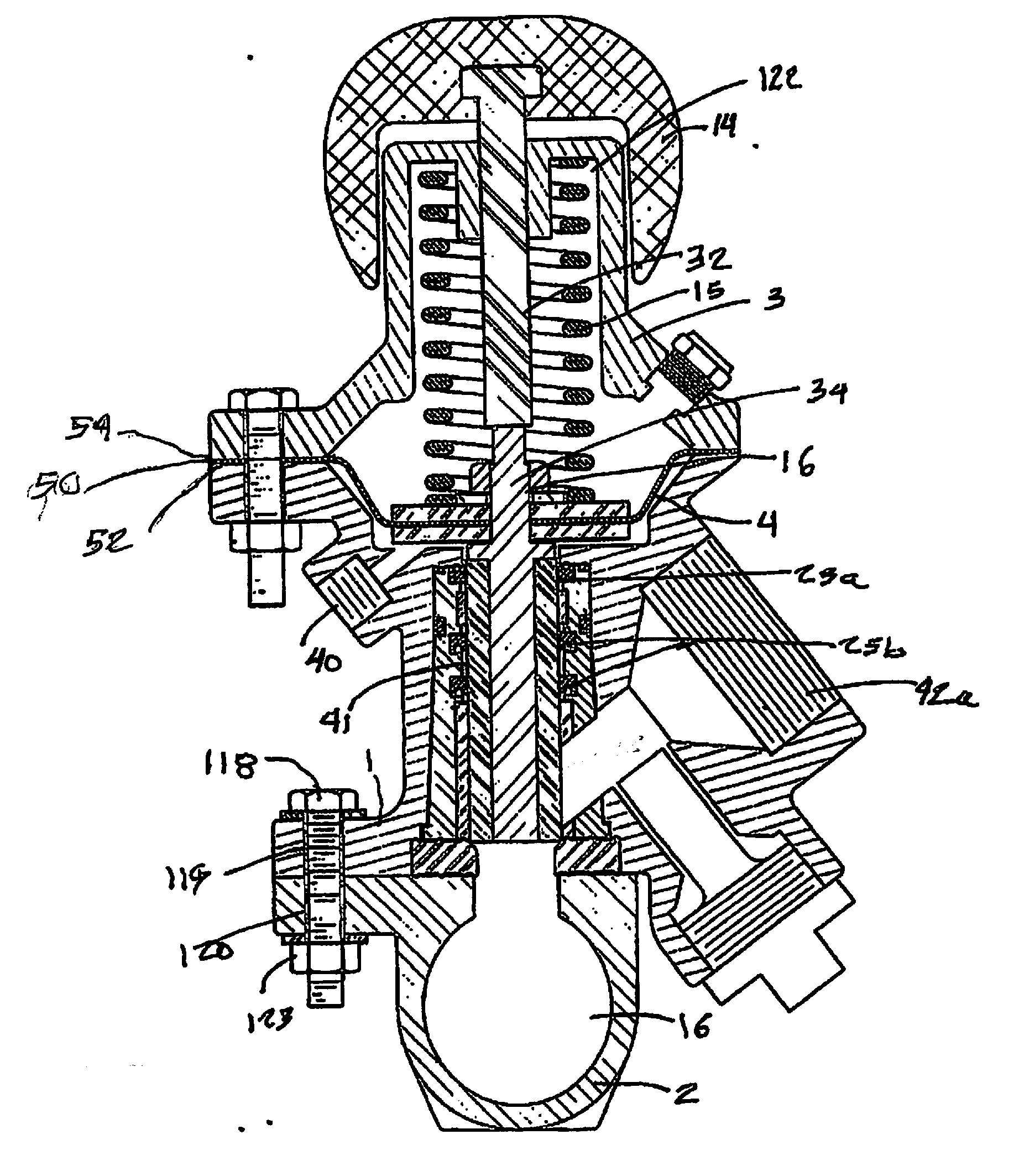

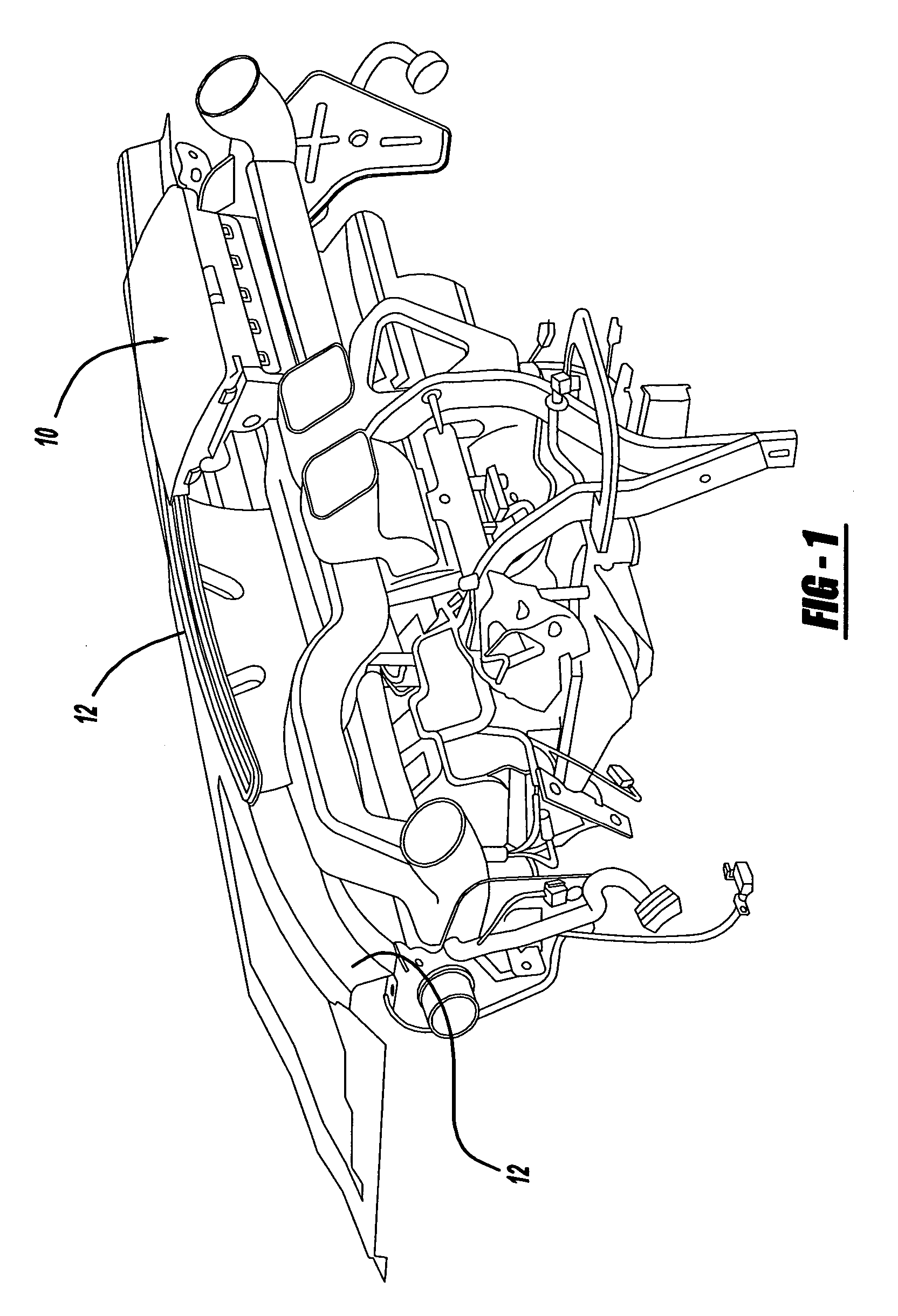

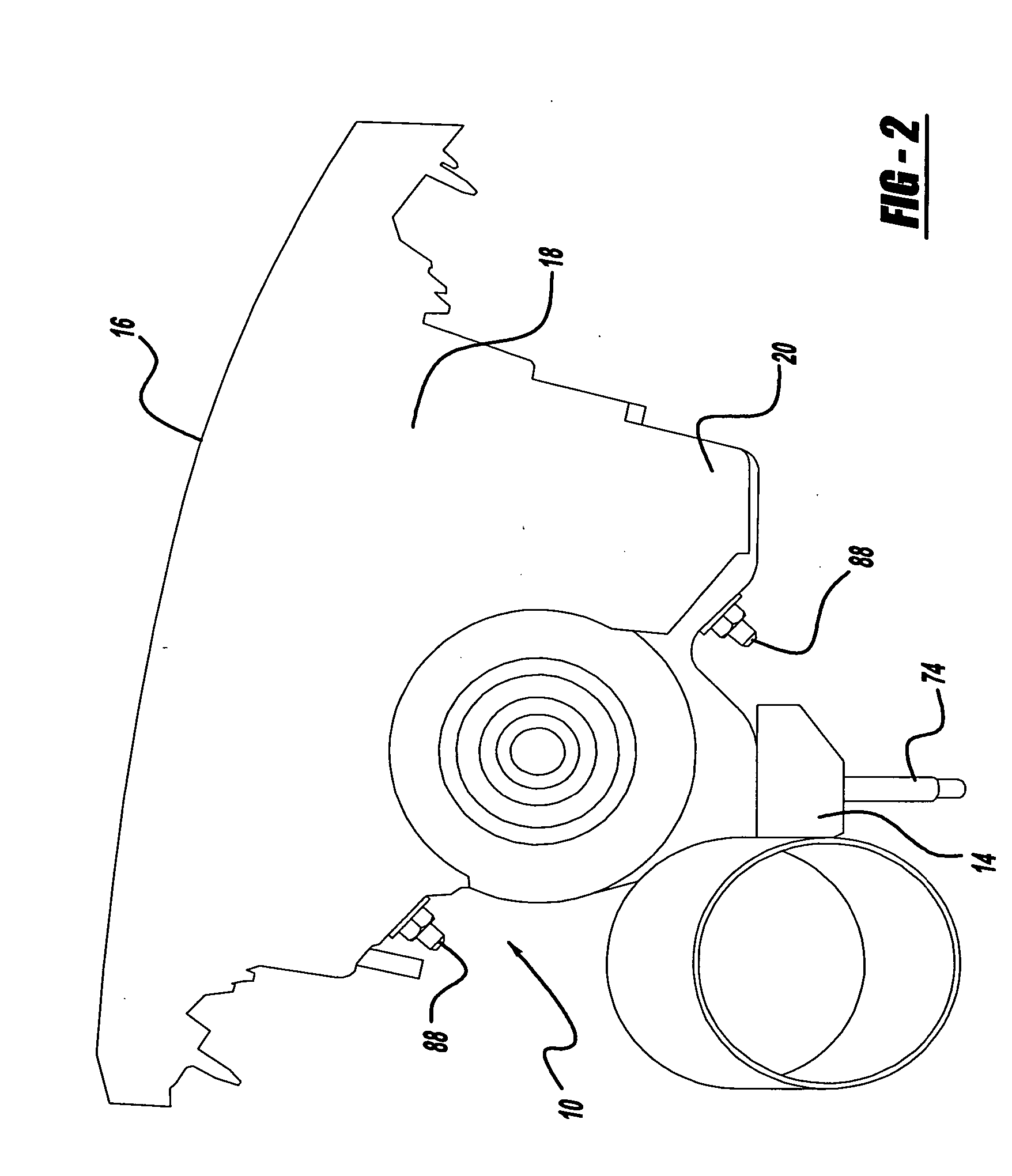

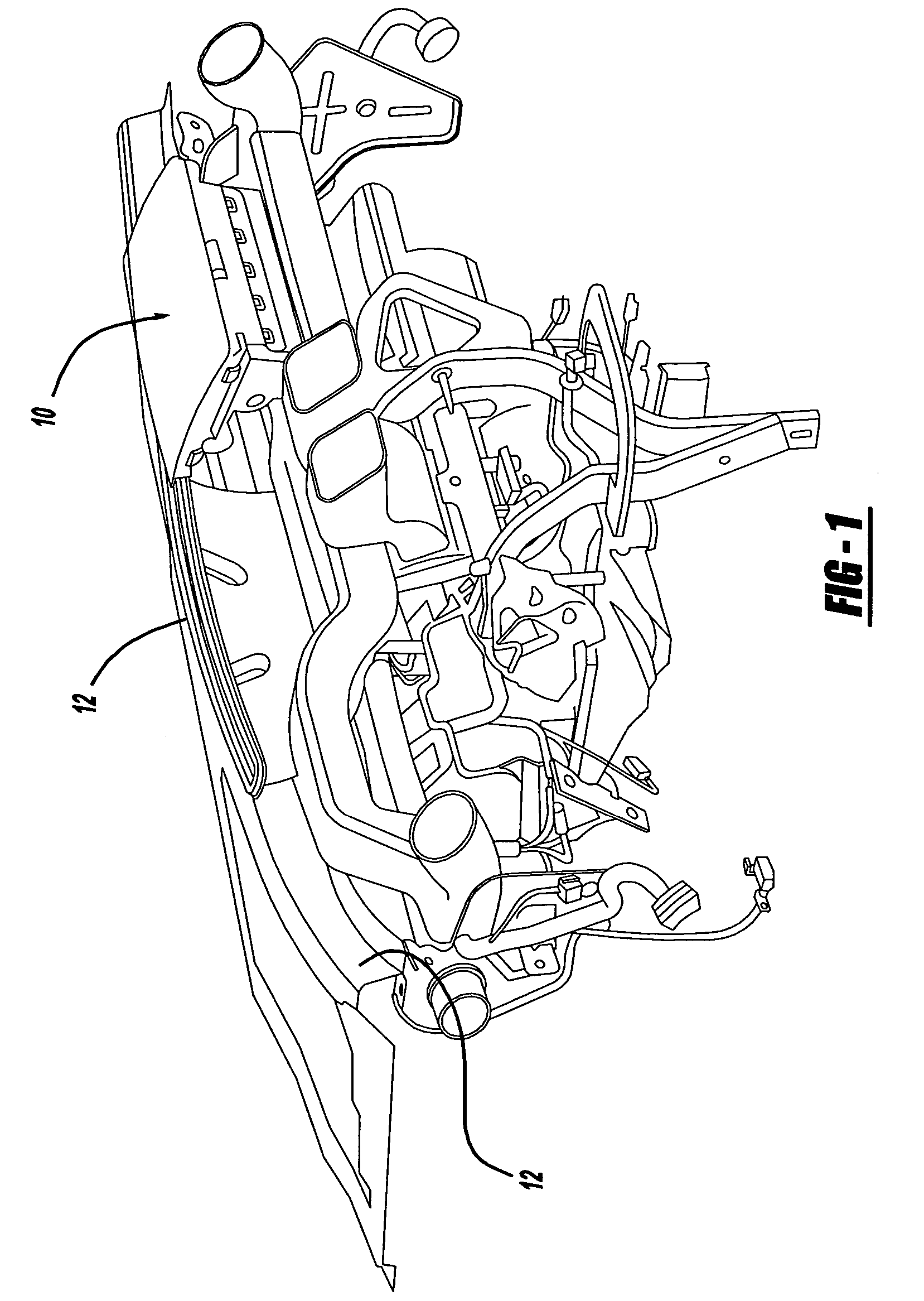

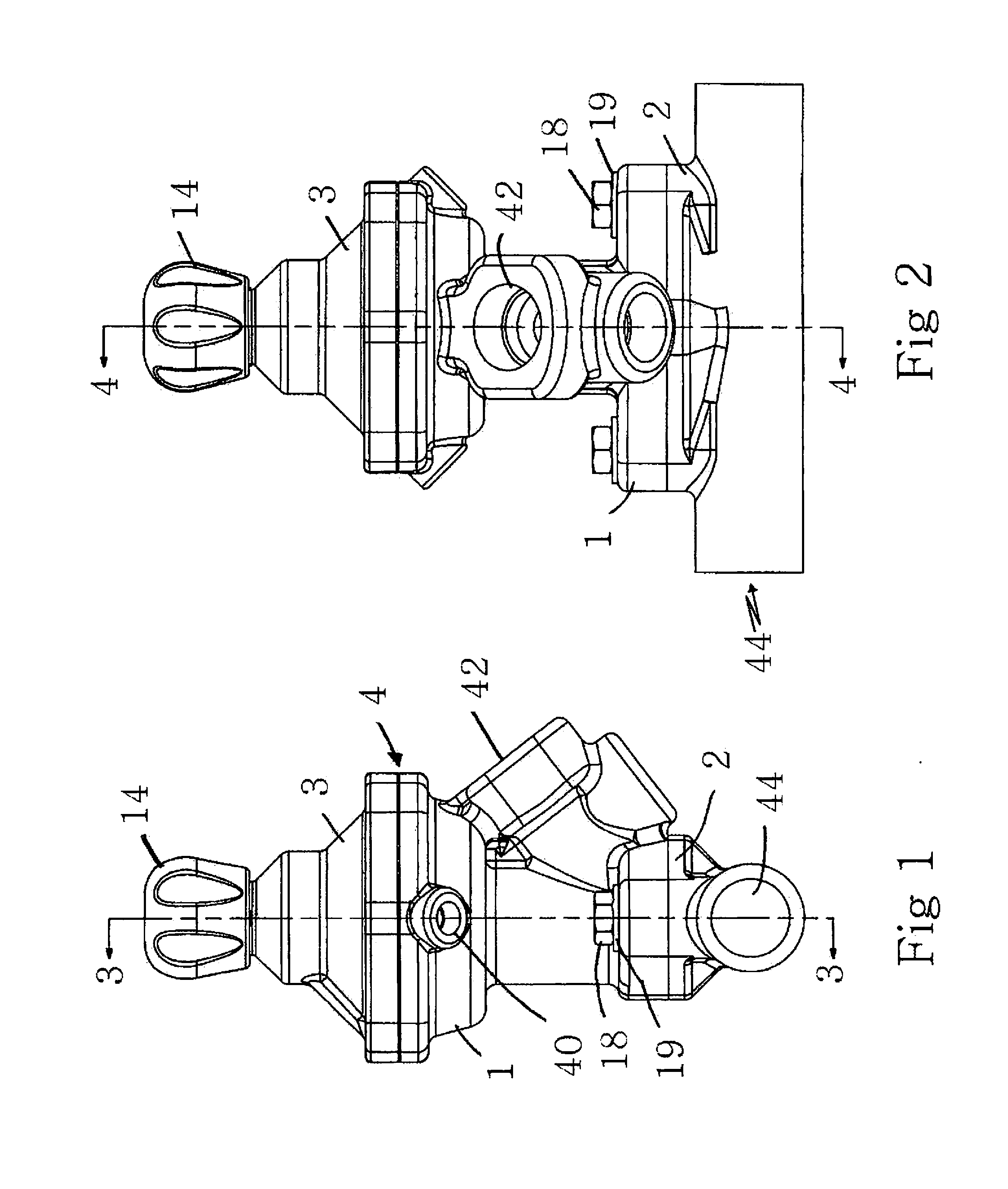

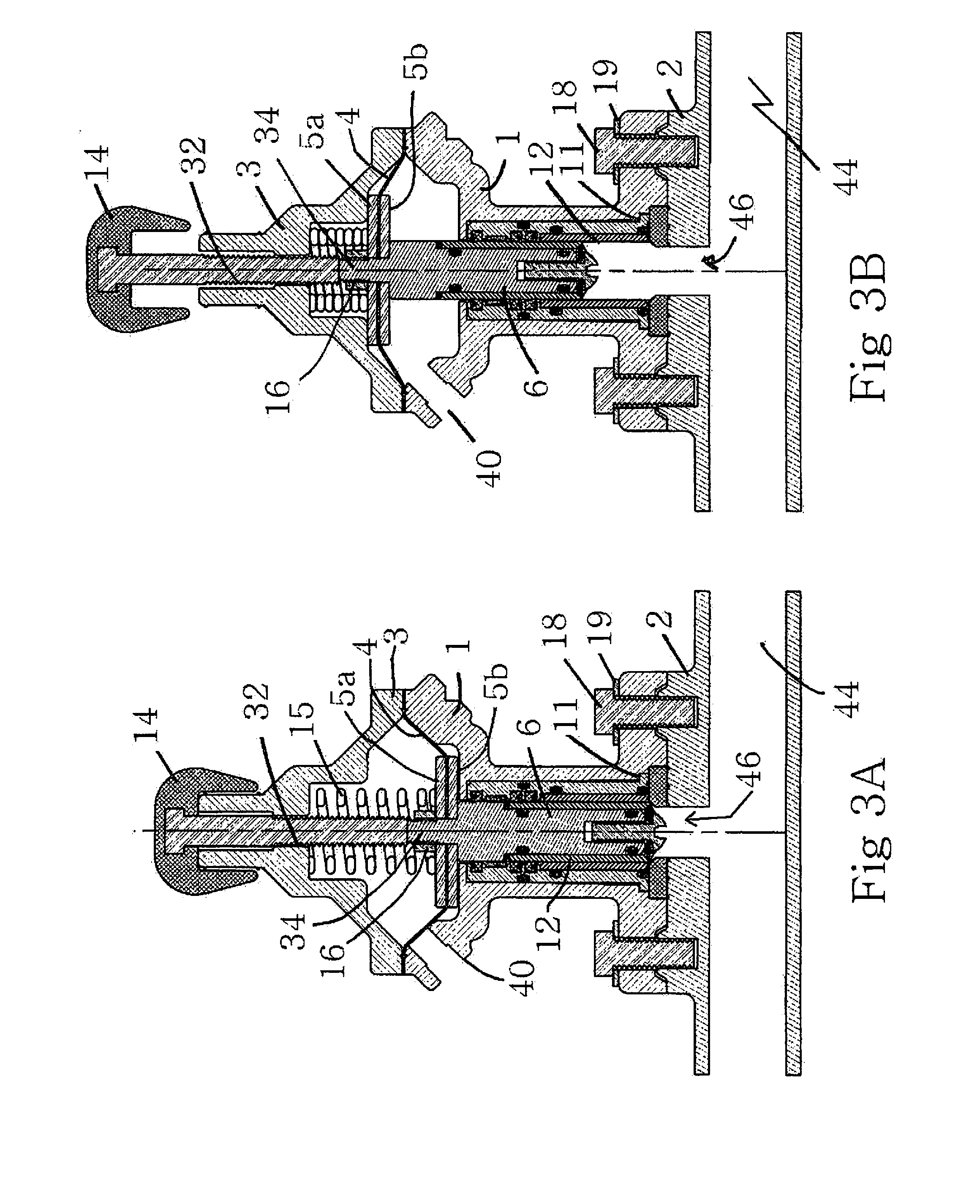

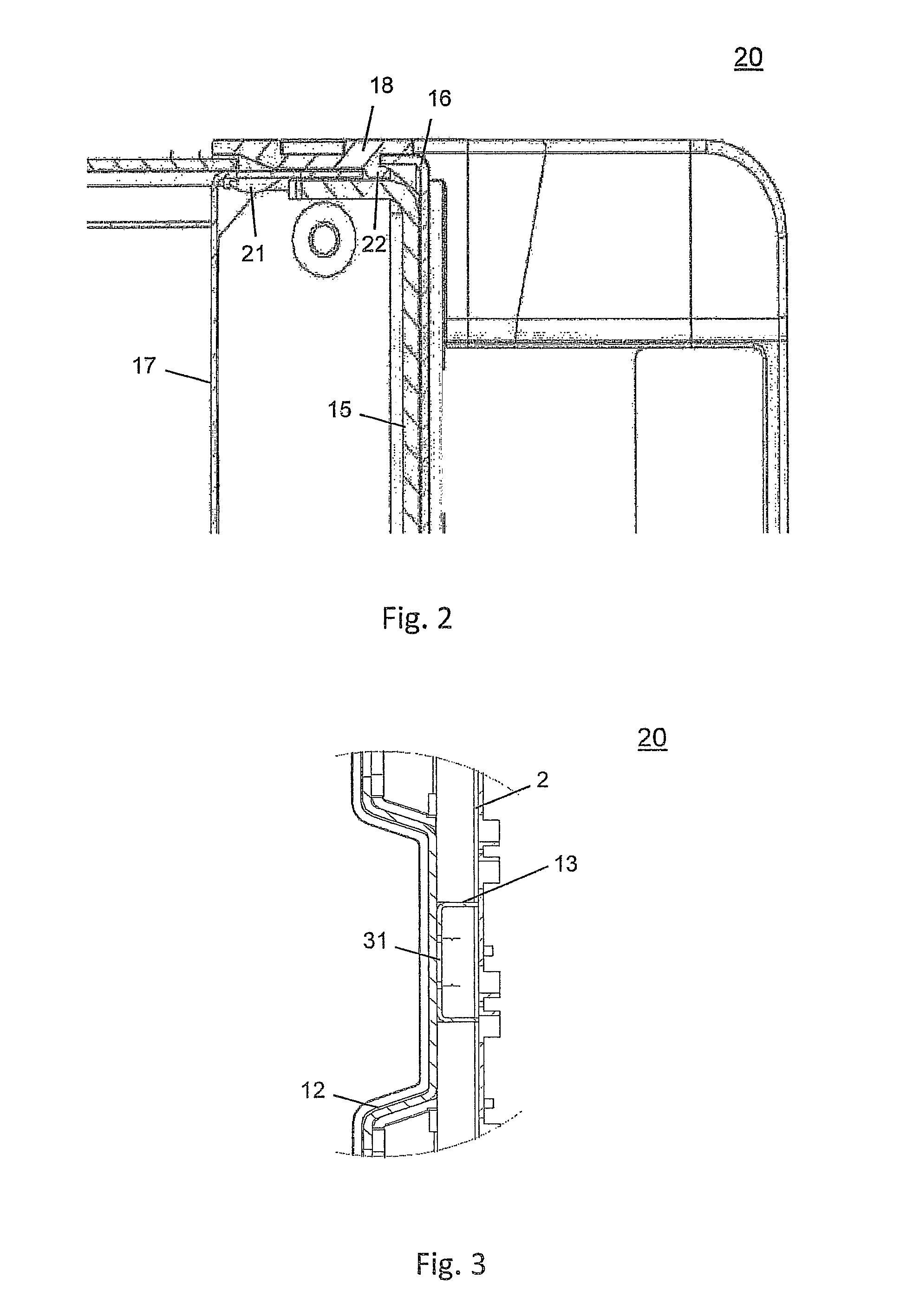

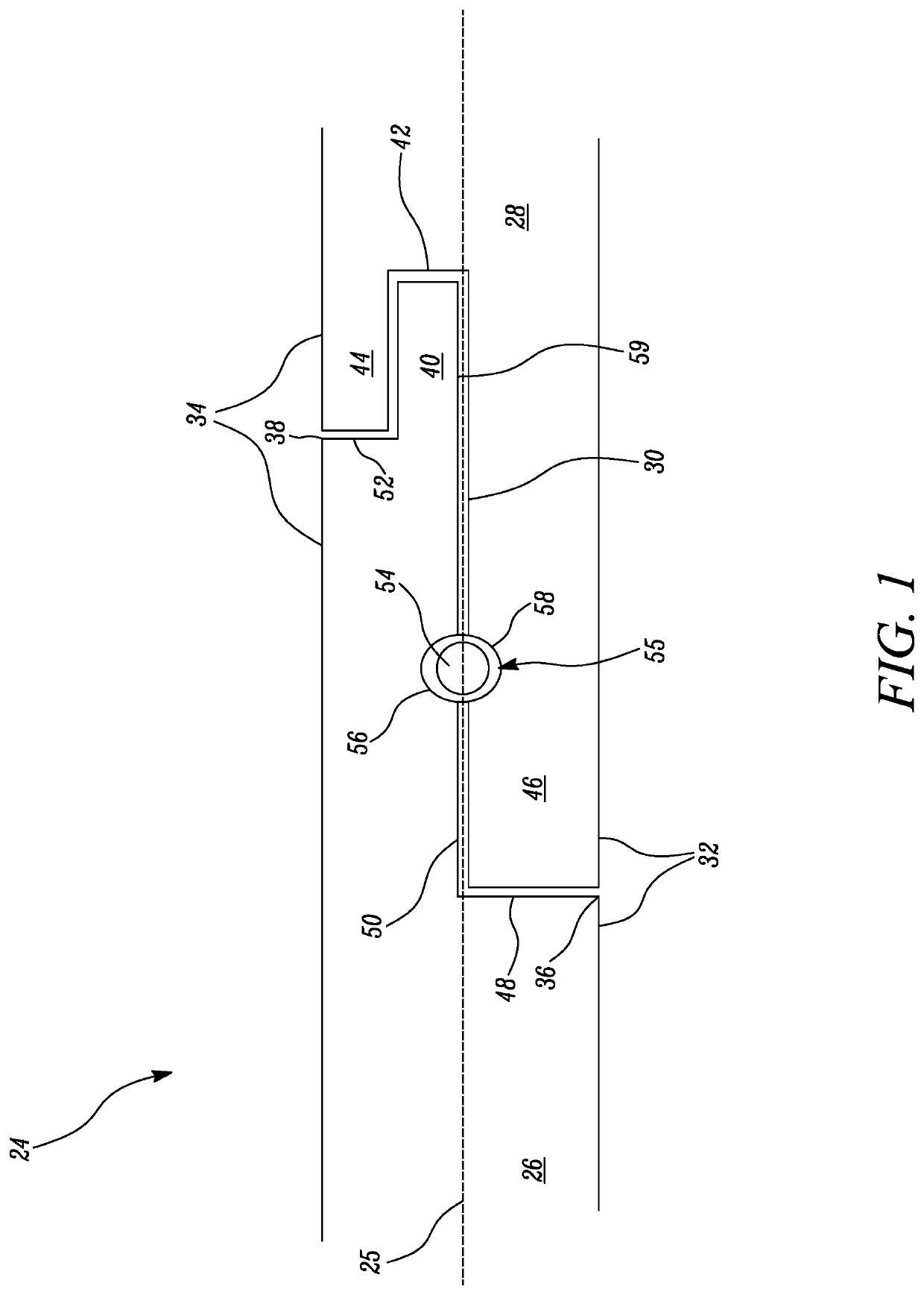

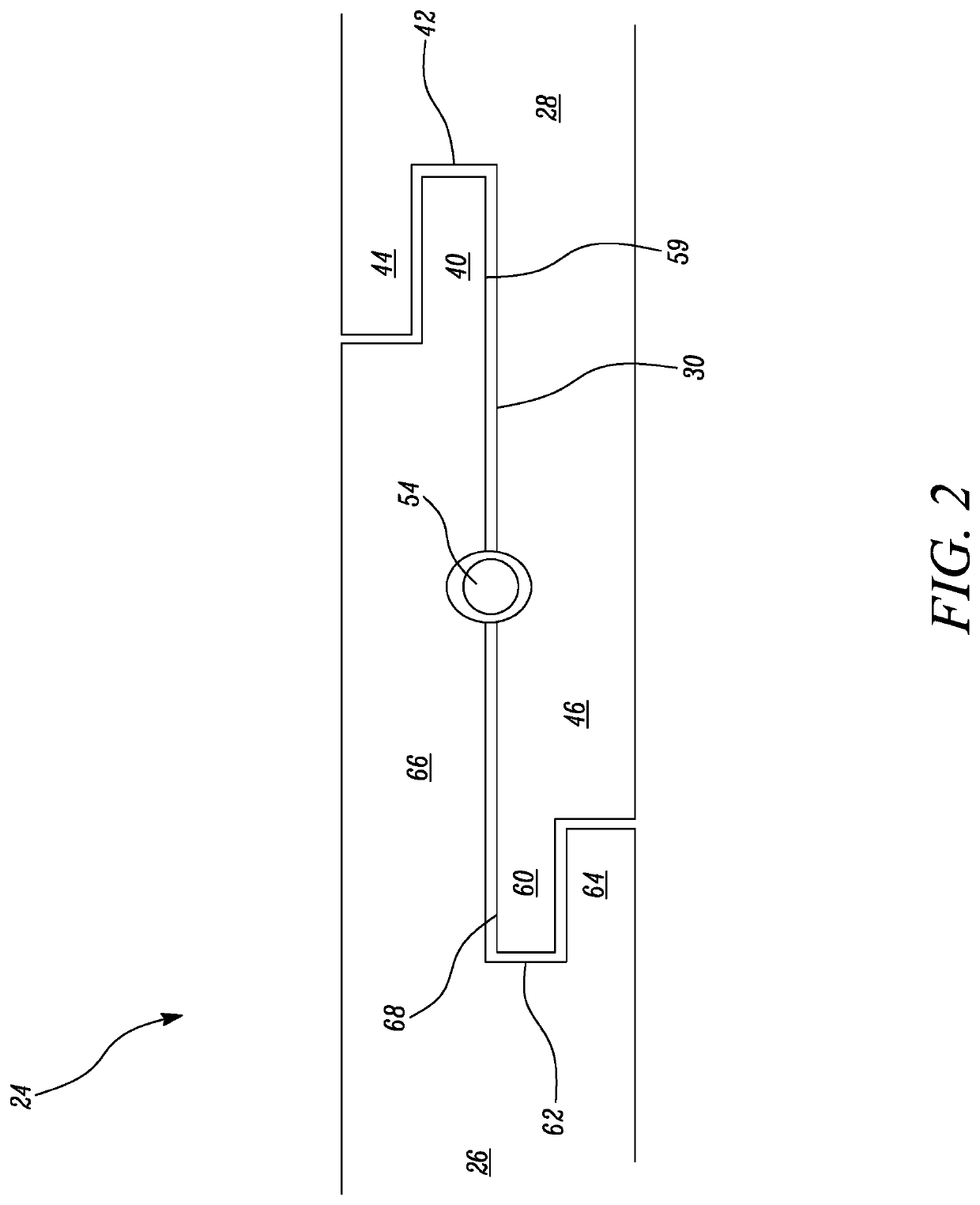

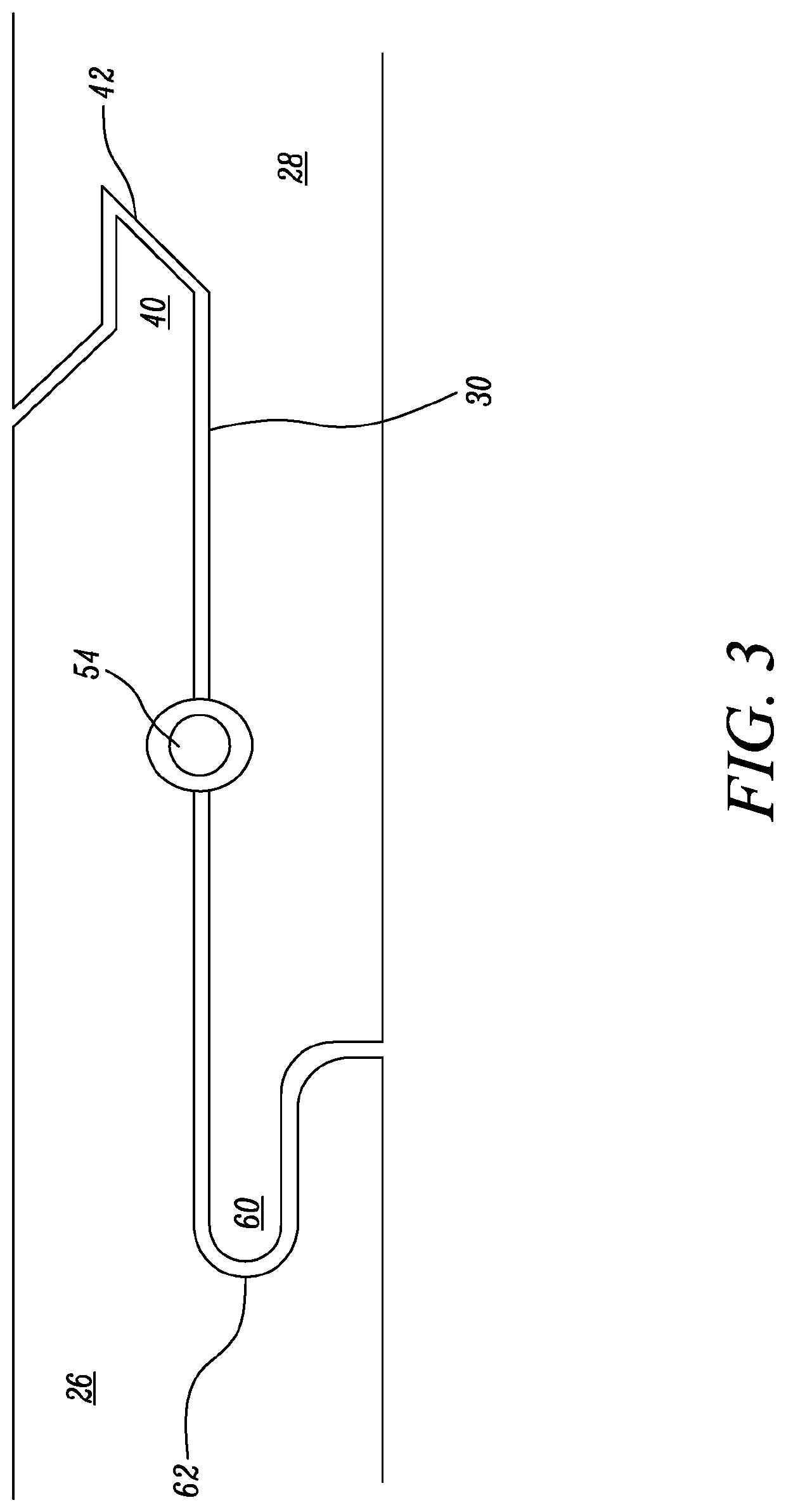

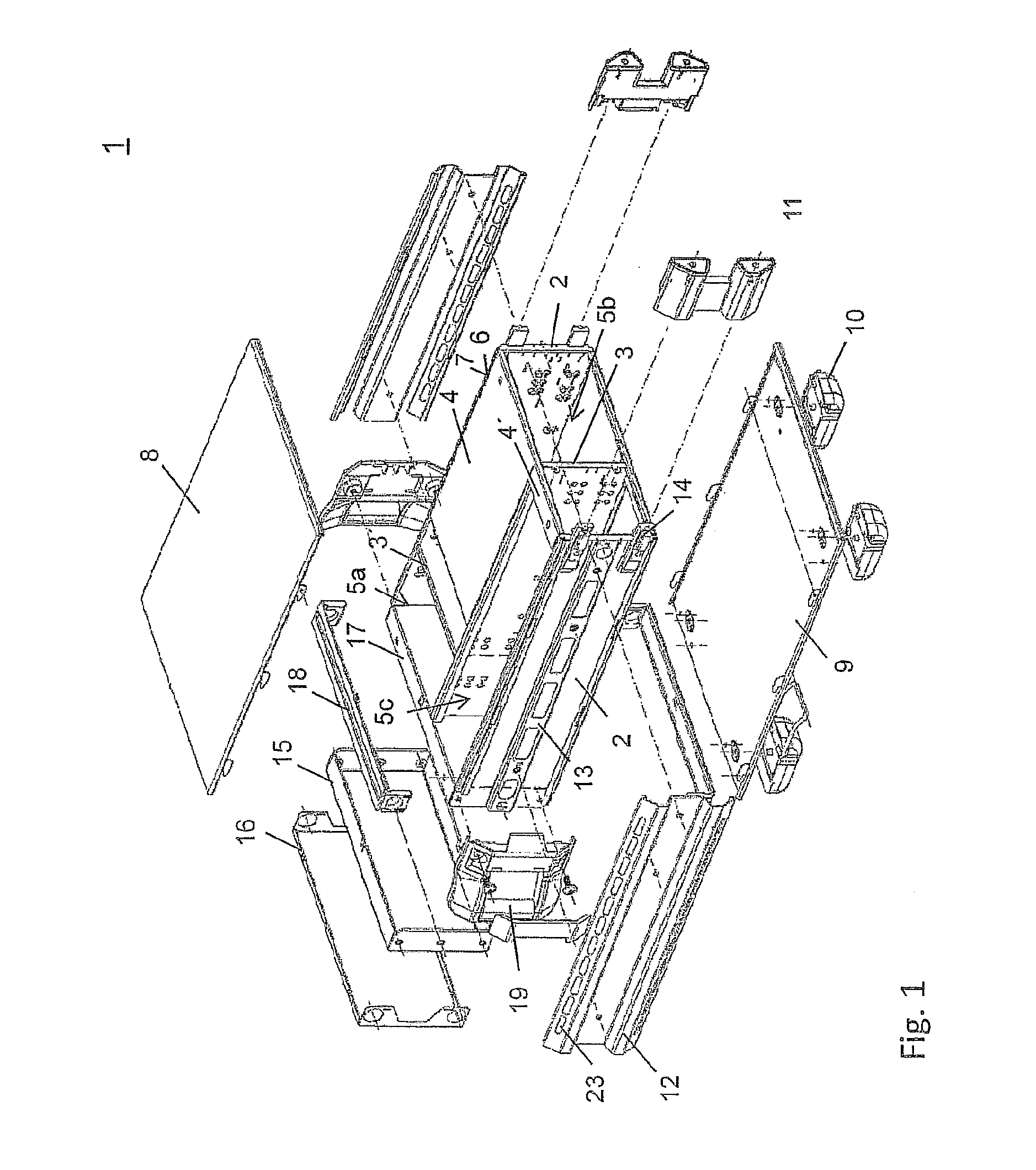

Bus joint assembly

ActiveUS7449635B2Improve assembly timeBus-bar/wiring layoutsCoupling device connectionsSwitchgearEmbedded system

A bus joint assembly for use in switchgear equipment having bus bars joined together at a bus joint and for joining vertical and horizontal buses. The bus joint connector comprises a connector, nut plate, connecting and supporting pins as well as a splice bus connector. The bus joint connector with integrated fixture pins locates and supports horizontal buses to vertical buses during assembly.

Owner:SIEMENS ENERGY & AUTOMATION INC

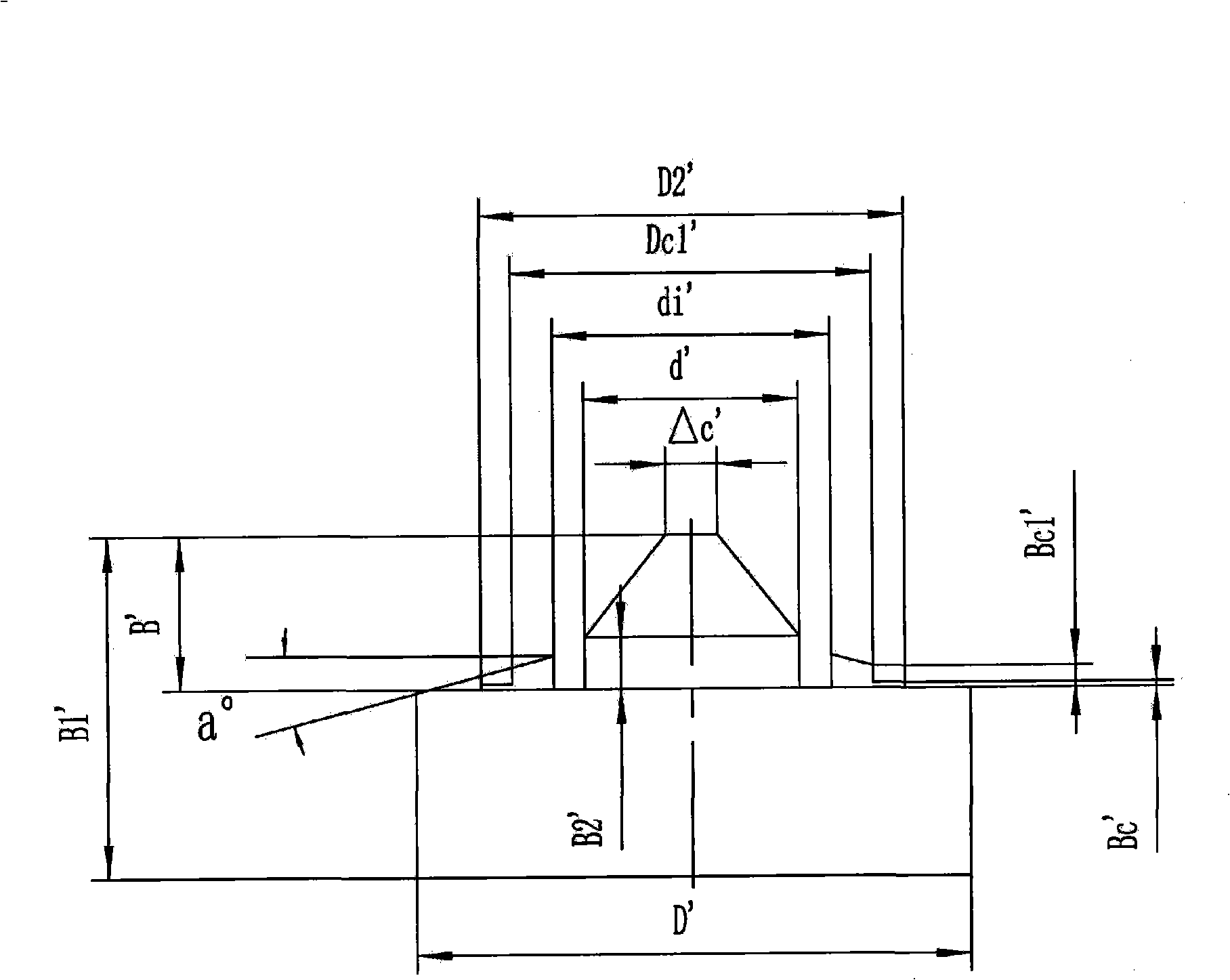

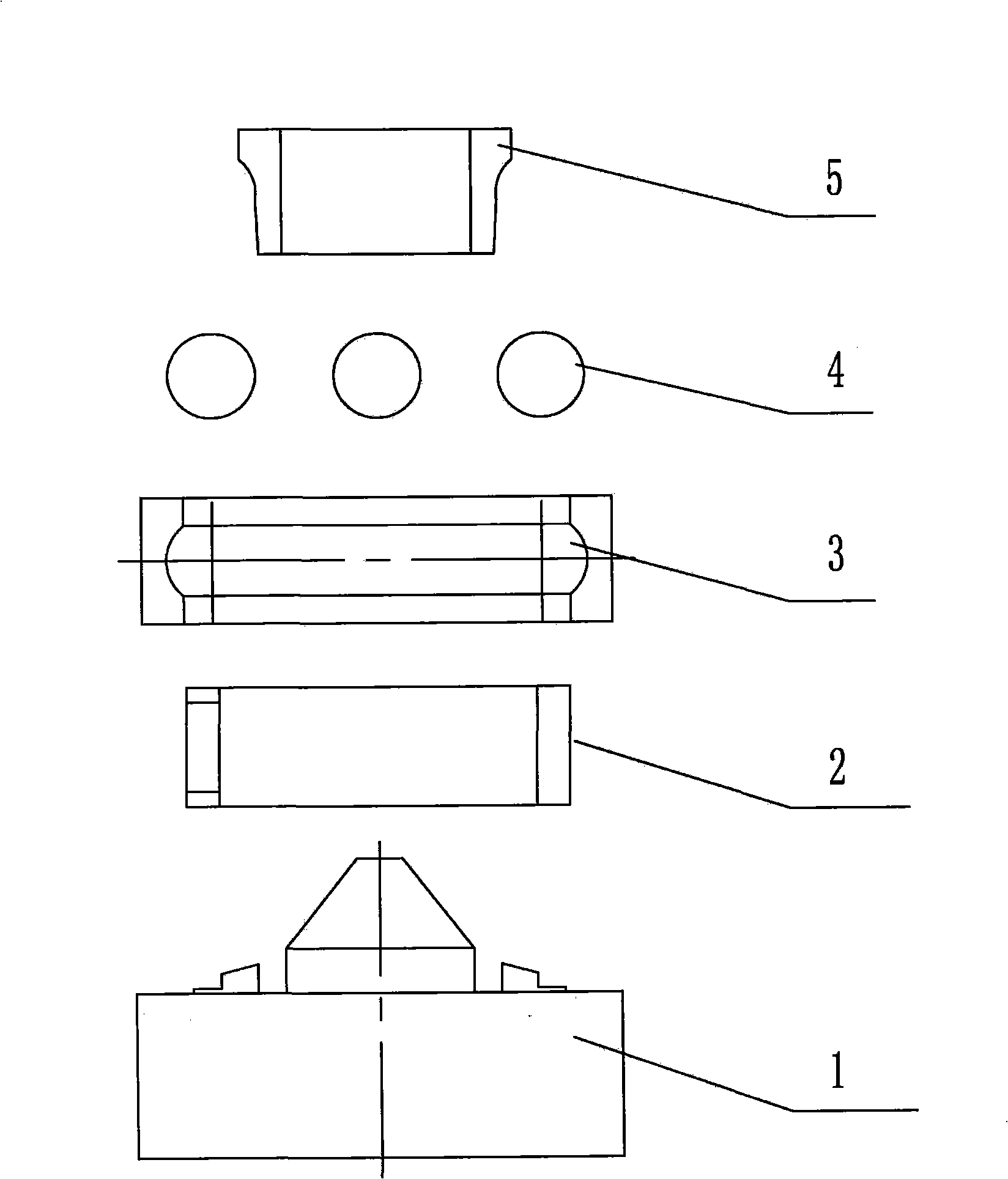

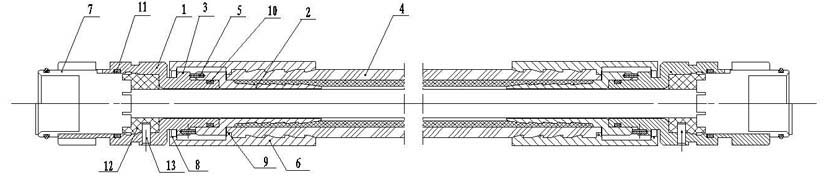

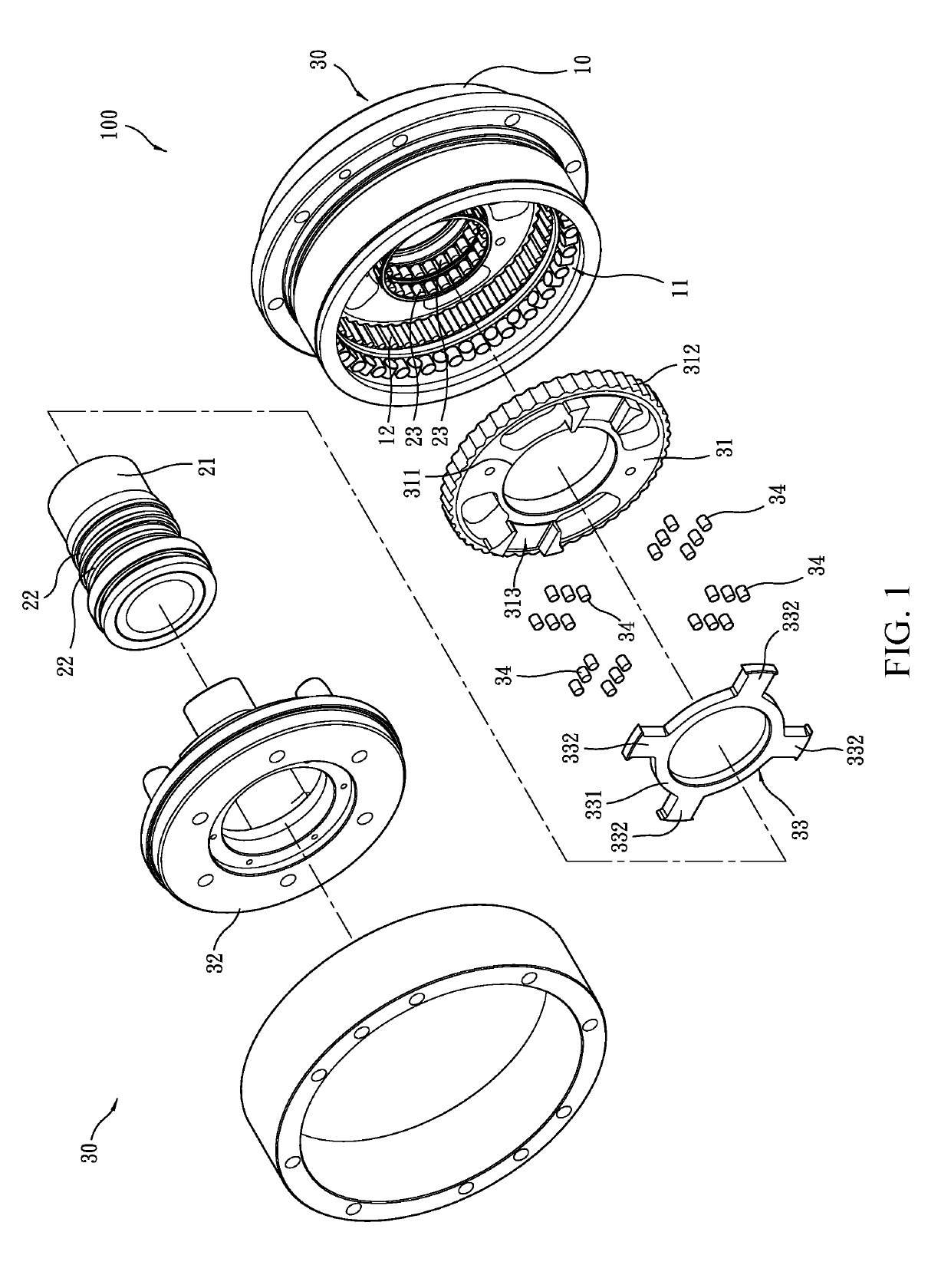

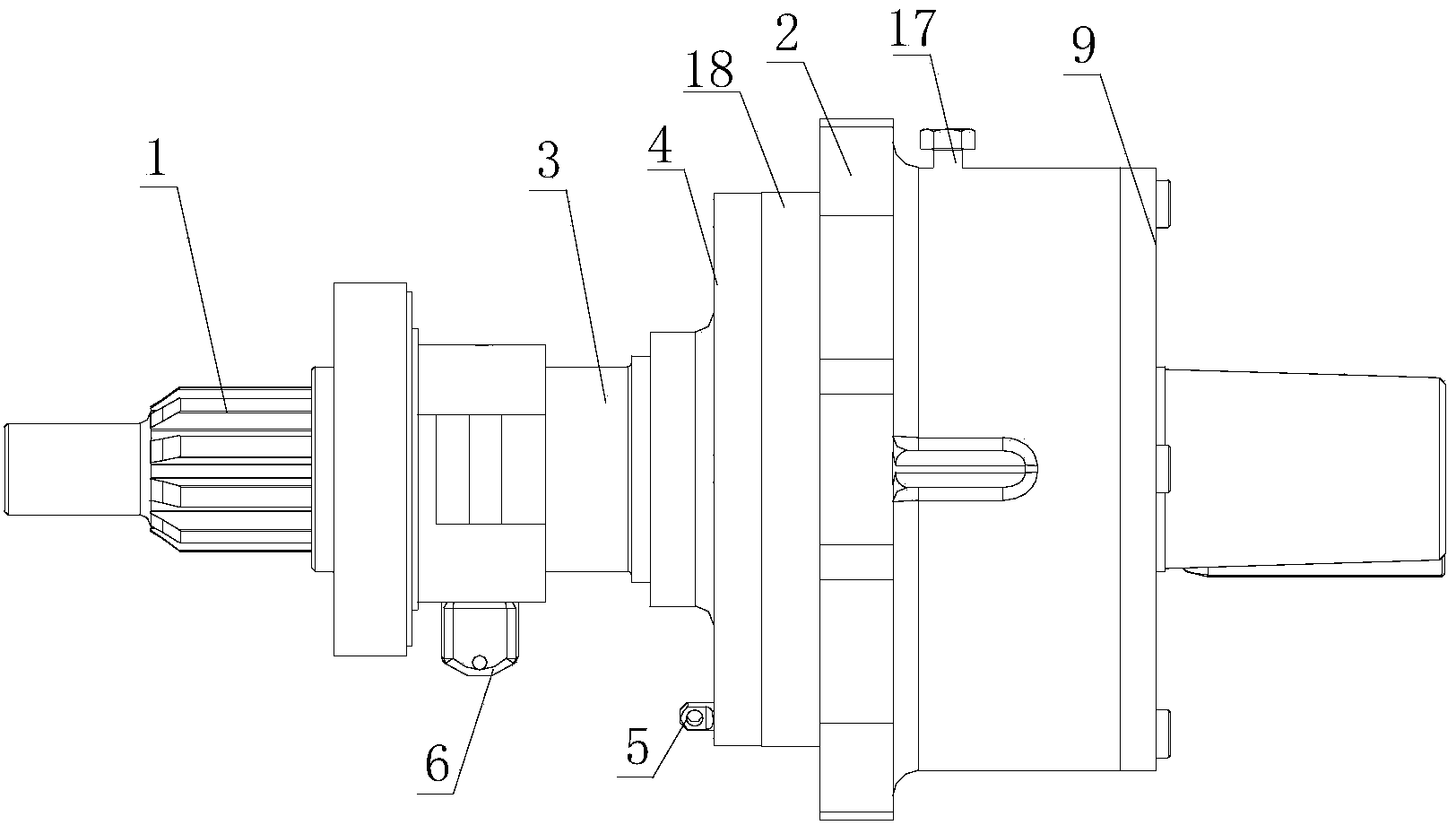

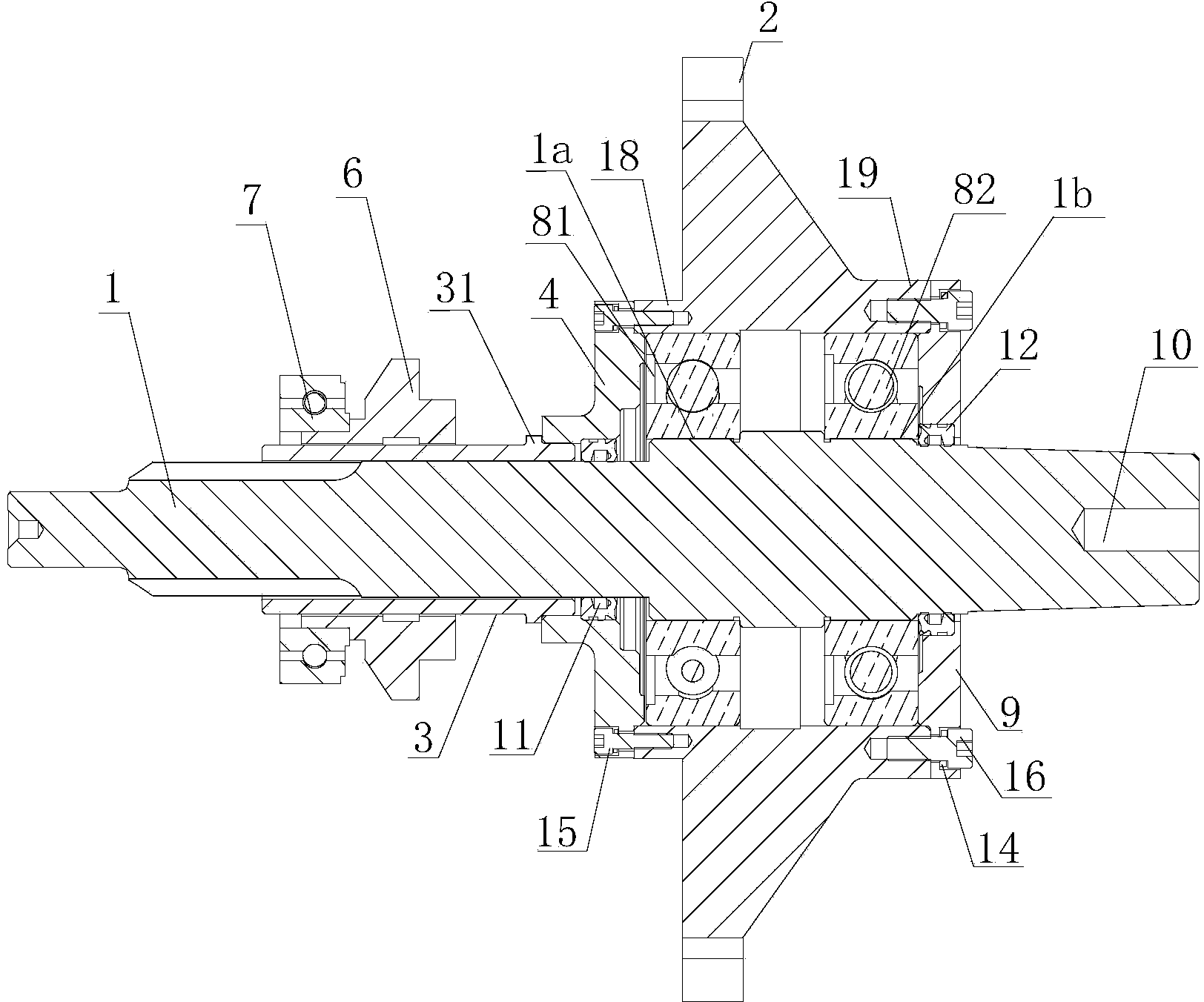

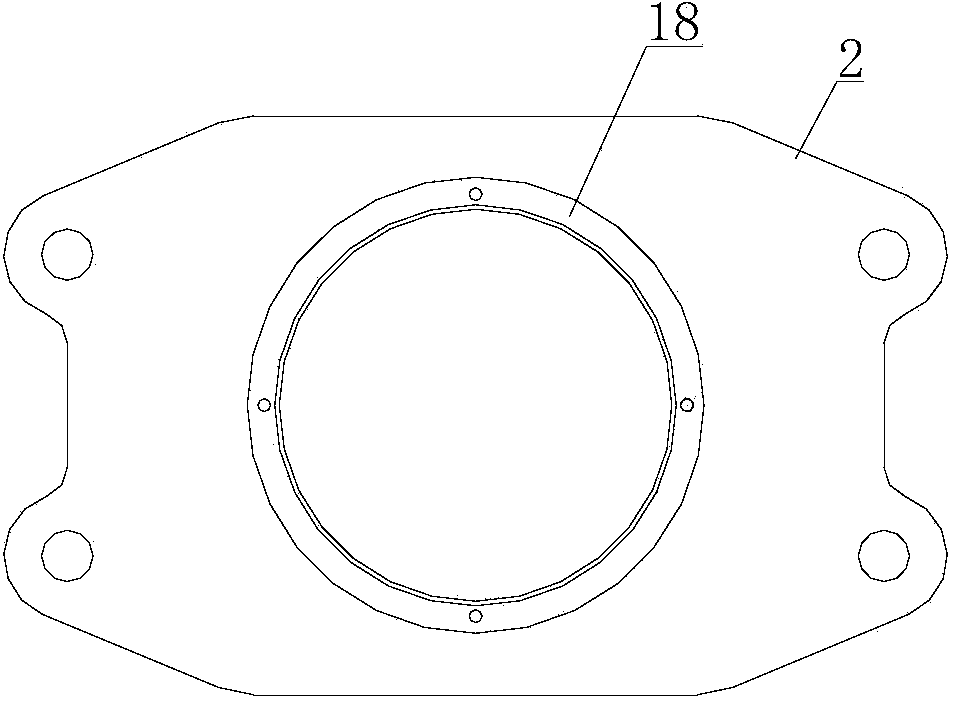

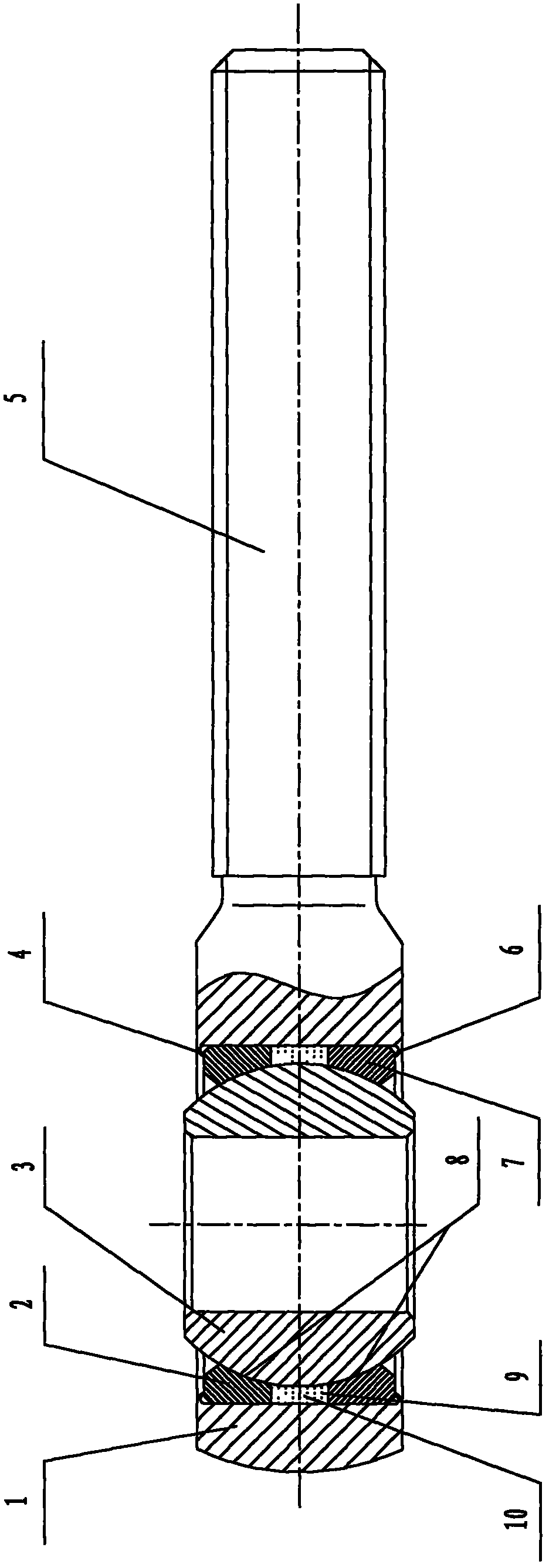

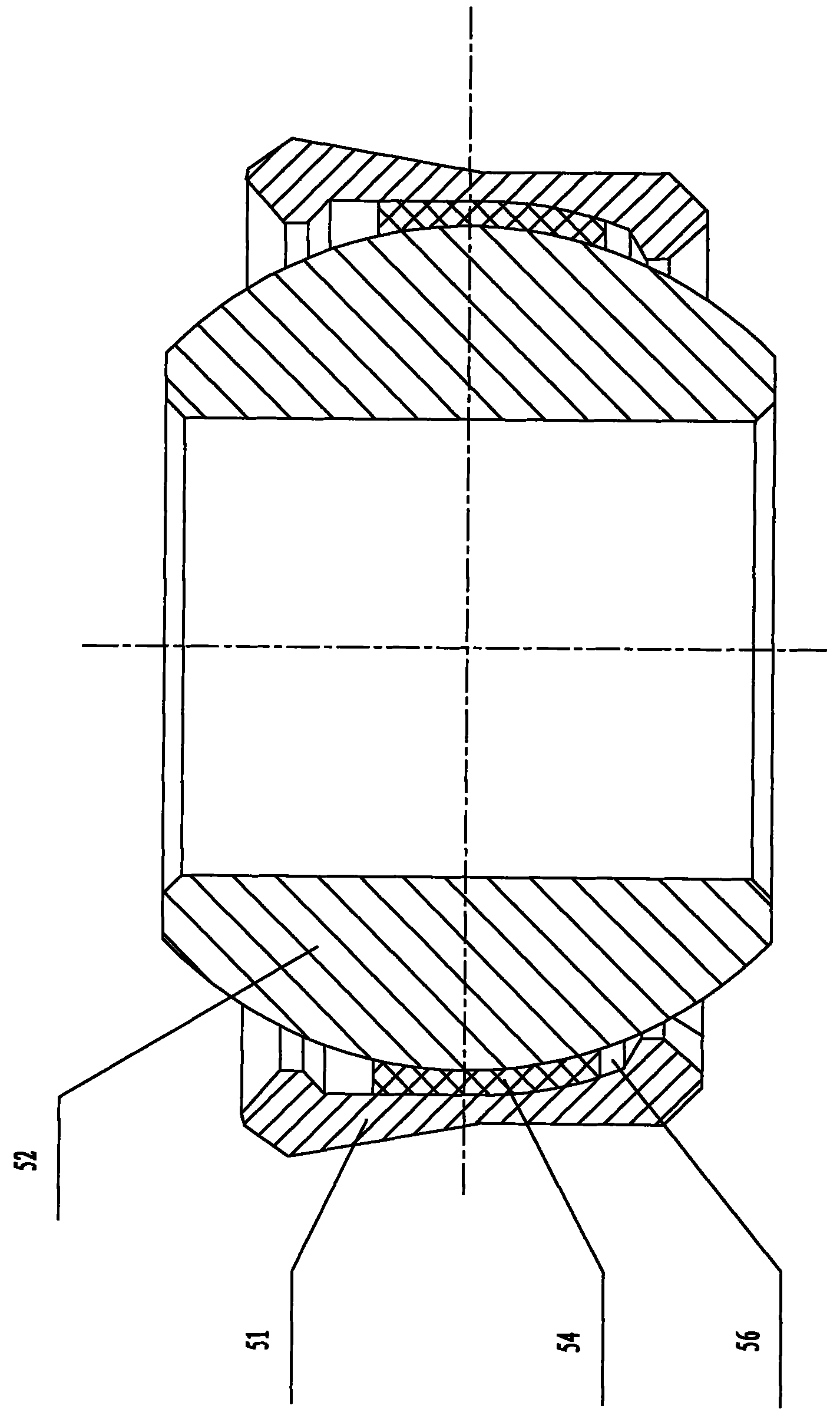

B7 angular contact ball bearing assembly die and its assembly method

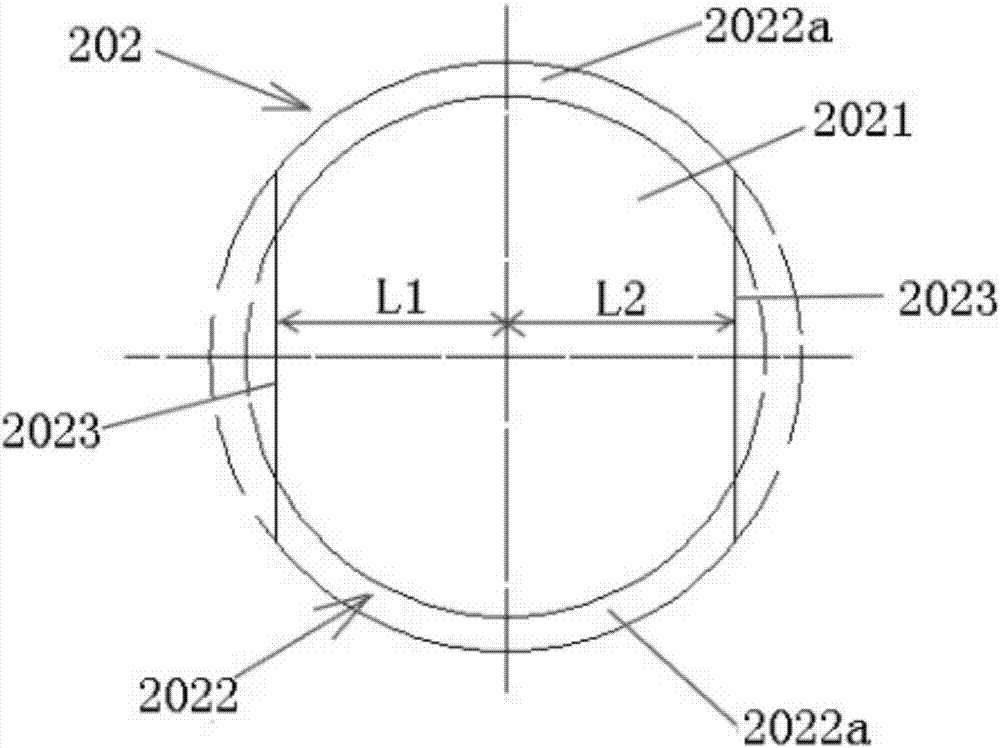

The invention relates to an assembling mould of a B7 contact ball bearing, which comprises a round assembling mould terrace, and is characterized in that the terrace is provided with a taper table figure central positioning table; a steel ball positioning table for positioning a bearing steel ball in the process of assembling is arranged at the housing washer of the central positioning table; the steel ball positioning table is a stepped table, and the step is a two-grade step higher inside and lower outside. The method for assembling the B7 contact ball bearing includes the following steps: the retainer is sheathed on the assembling mould along the axial direction; the heated housing washer is sheathed on the retainer along the axial direction; the steel ball slides along the top taper part of the assembling mould to be located in a jolt; an inner race is inserted along the axial direction. The assembling mould has the following advantage: as each spare part can be precisely located by being assembled on the positioning mould, and lipid is not needed for adhesion, and the assembling time is shortened, the whole process is guaranteed to be completed in the range of an allowed retraction for the cooling of the housing washer, so that the assembling mould of a B7 contact ball bearing has the effect of fast and accurate assembling.

Owner:上海莱必泰数控机床股份有限公司

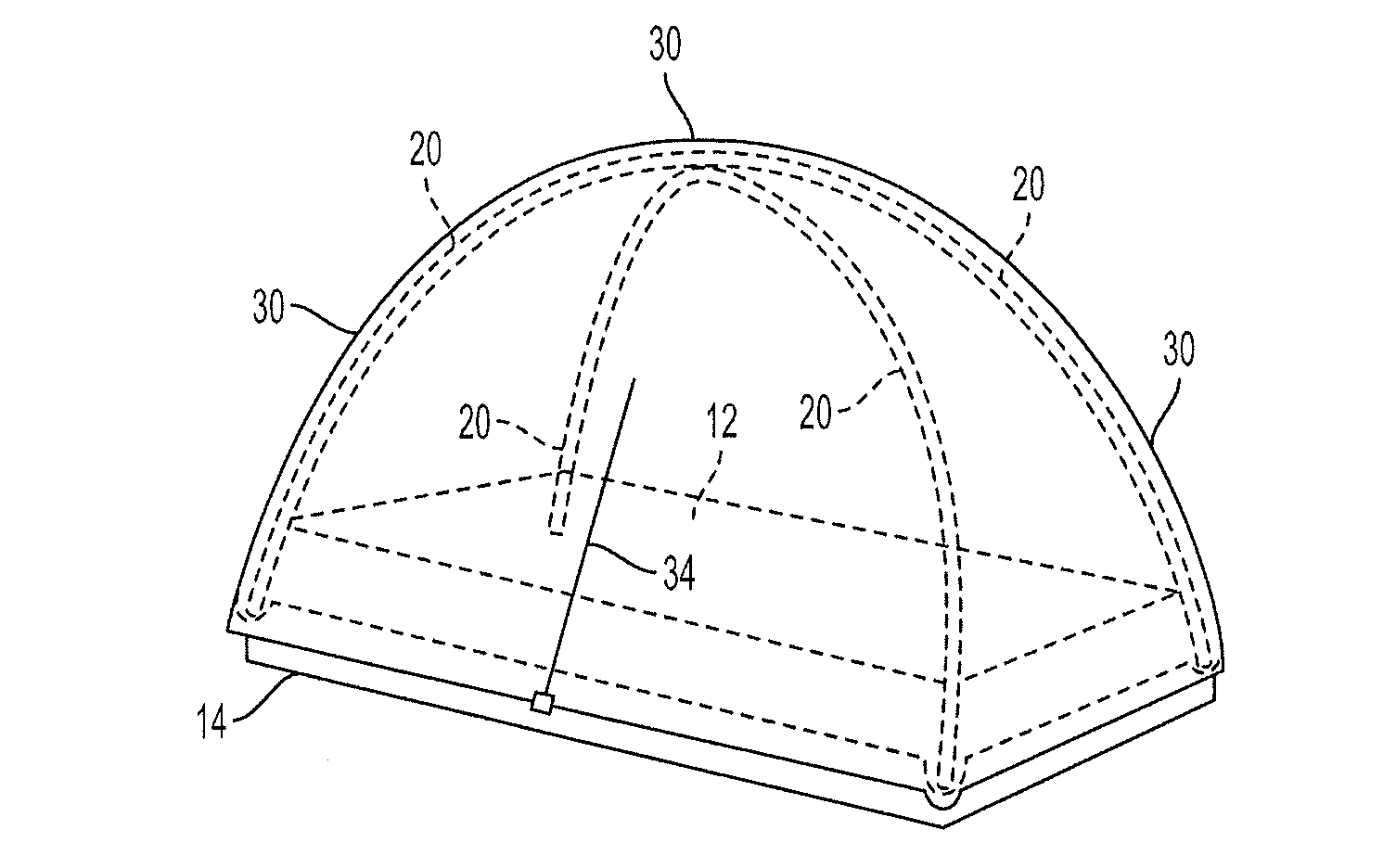

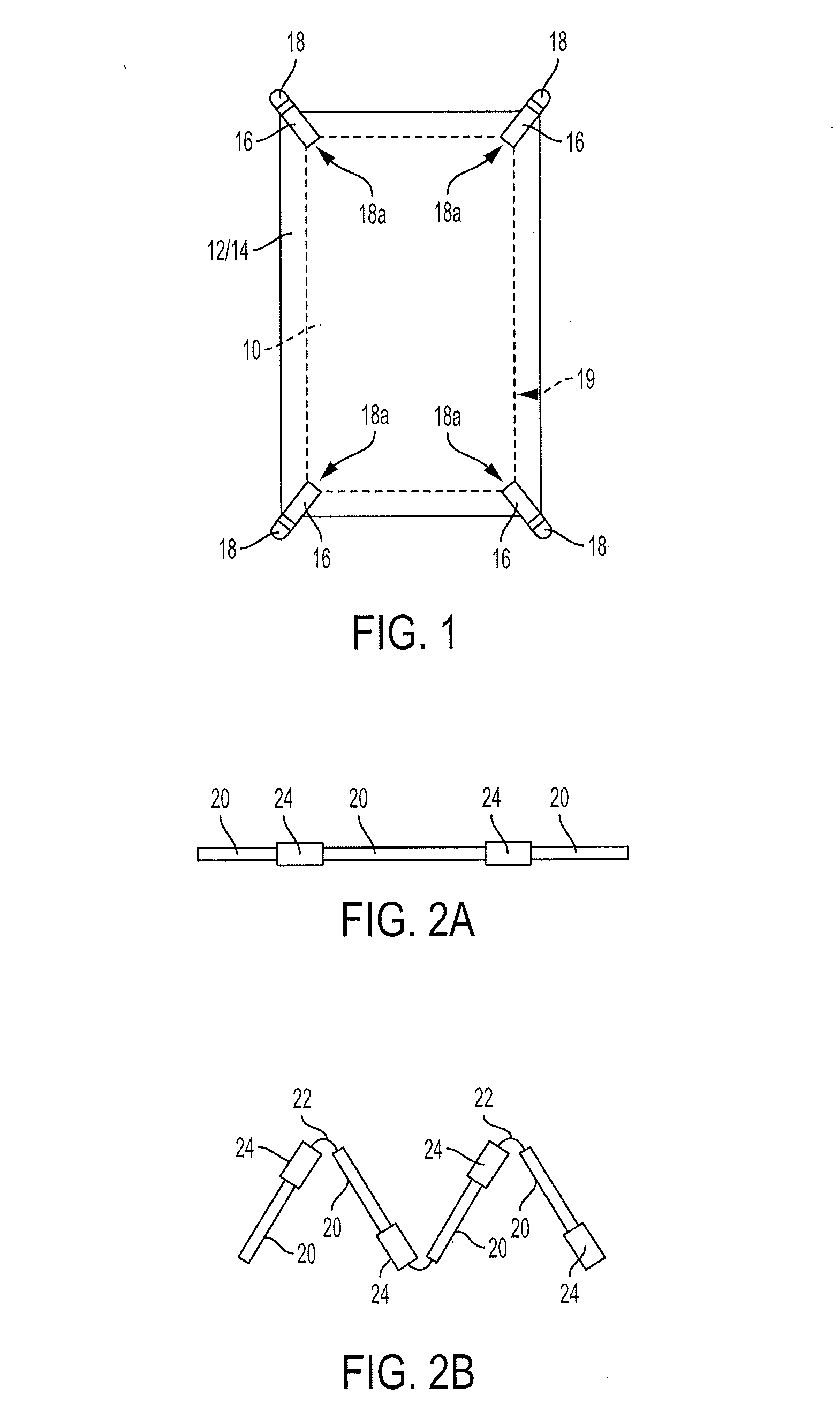

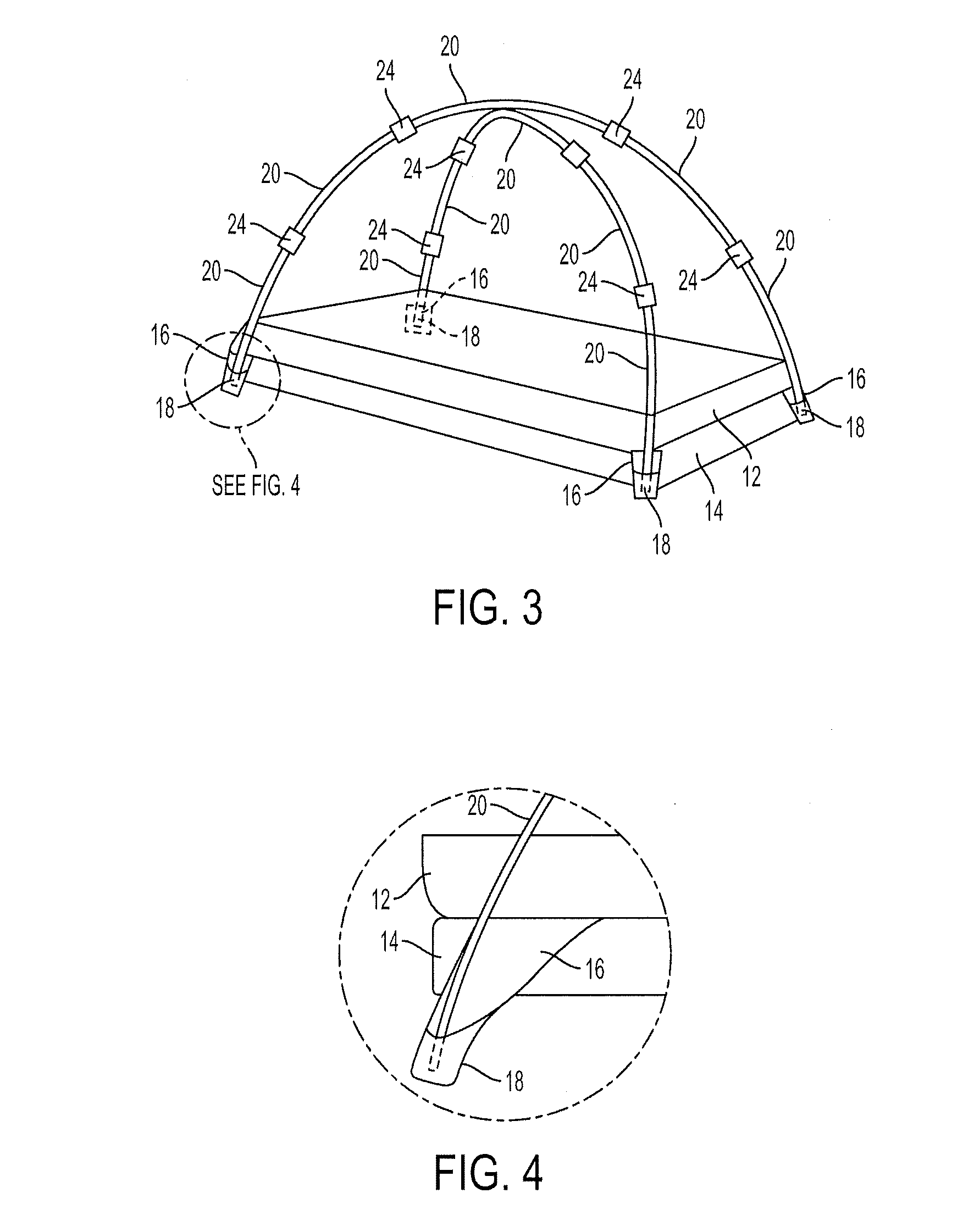

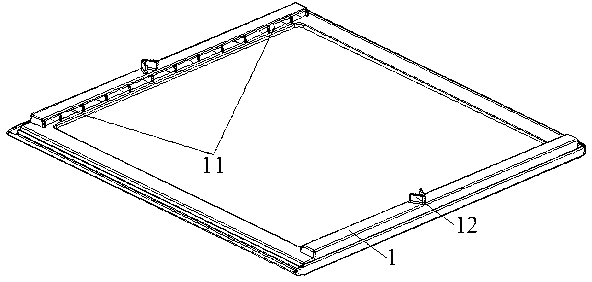

Bed tent kit

InactiveUS20160242567A1Increase demandQuick disassemblyKids bedsTents/canopiesEngineeringMechanical engineering

A bed tent kit to provide a removable enclosure over a bed mattress includes a foundation sheet having a first edge region and adapted for placement between the bed mattress and a supporting structure beneath the bed mattress. The foundation sheet includes a plurality of first attachment mechanisms spaced apart along the first edge region of the foundation sheet. A set of support poles has free pole ends each adapted for attachment to the foundation sheet by a respective one of the first attachment mechanisms. The set of support poles presents a framework above the mattress when the free pole ends are attached to the foundation sheet. A canopy sheet has a second edge region and a plurality of second attachment mechanisms spaced apart along the second edge region. The canopy sheet is adapted to rest over the framework when the set of support poles are attached to the foundation sheet. The canopy sheet is attachable to the foundation sheet by the second attachment mechanisms independent of the attachment of the free pole ends of the support poles to the foundation sheet by the first attachment mechanisms.

Owner:LIME ROBERT F

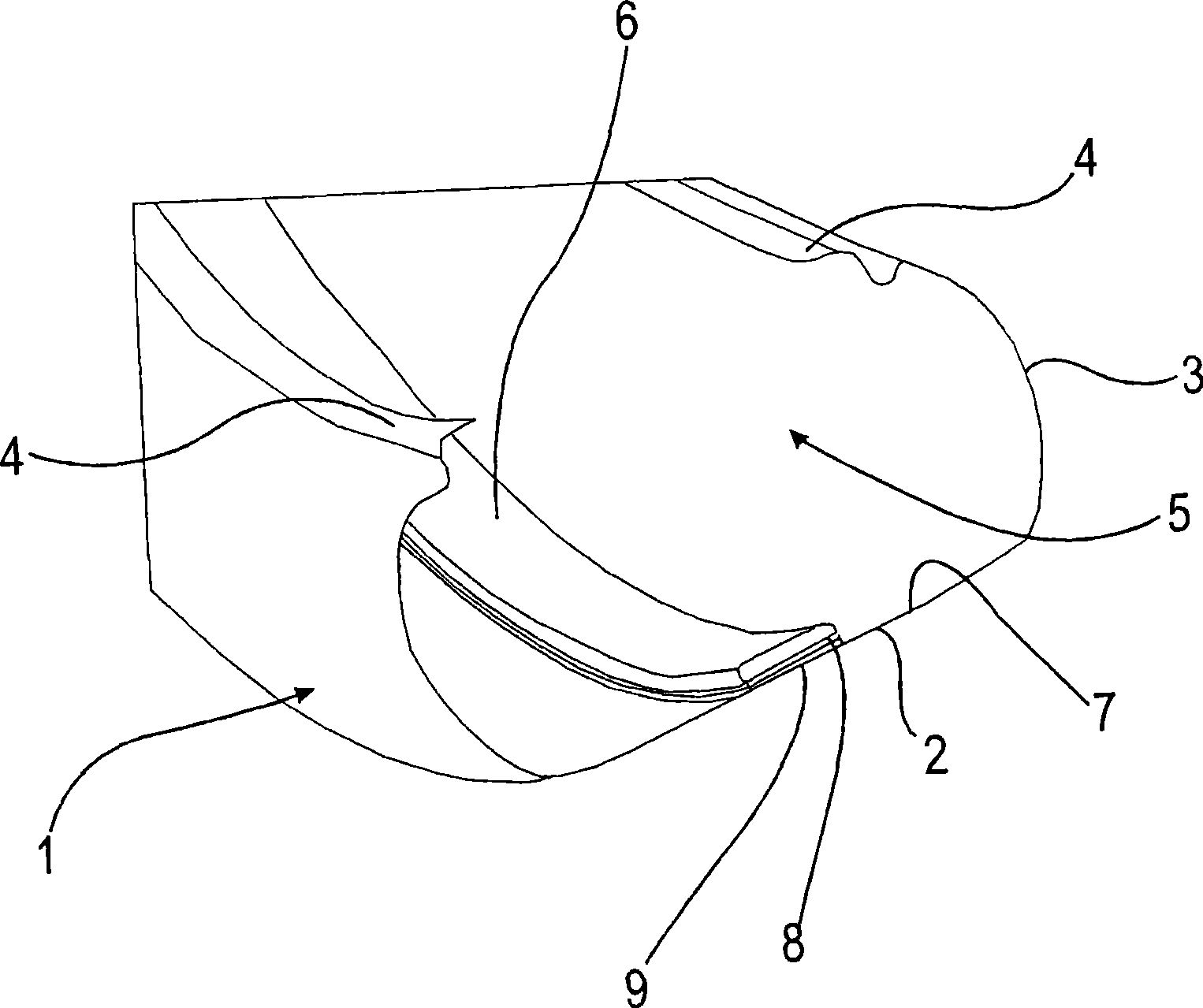

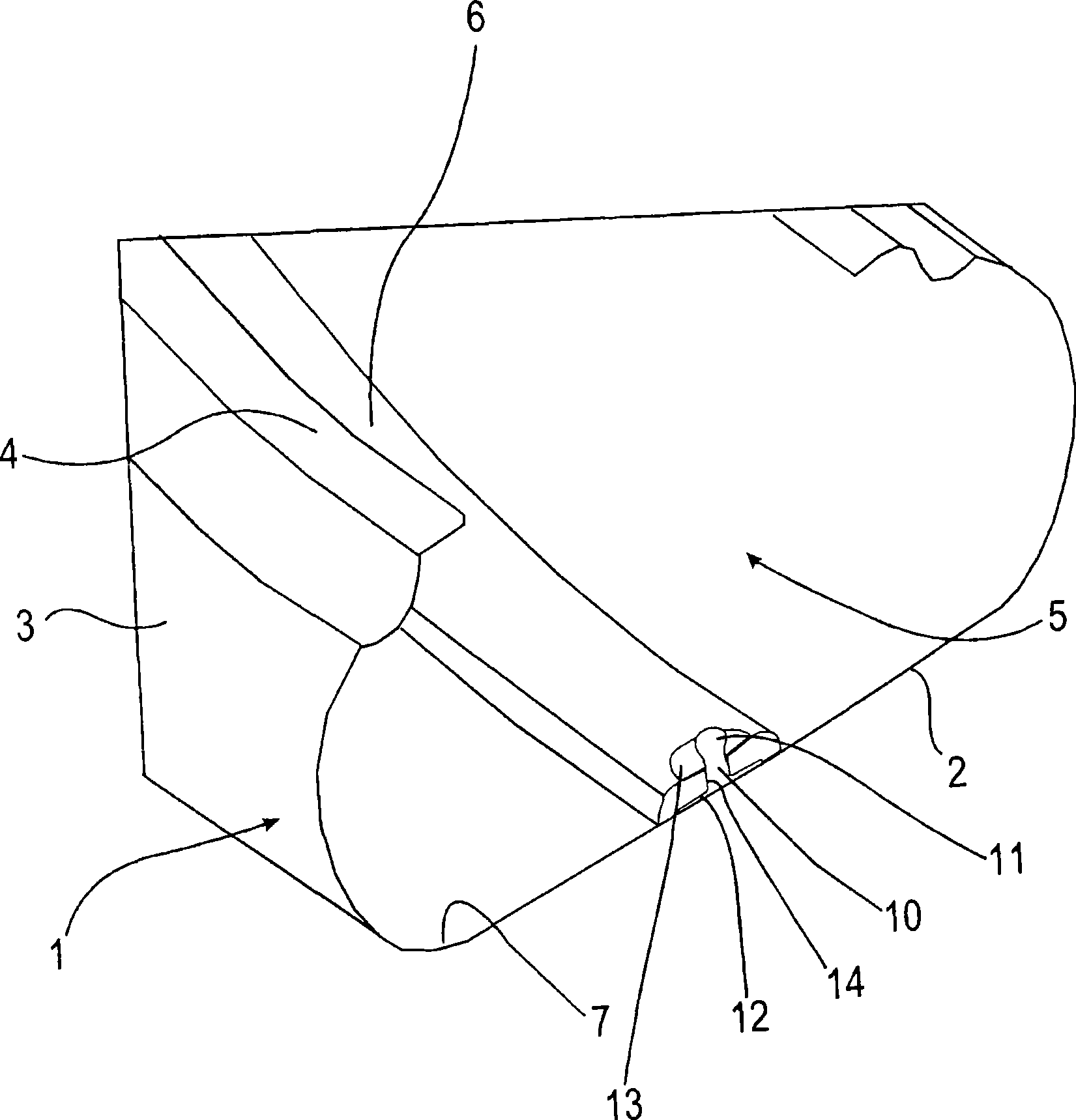

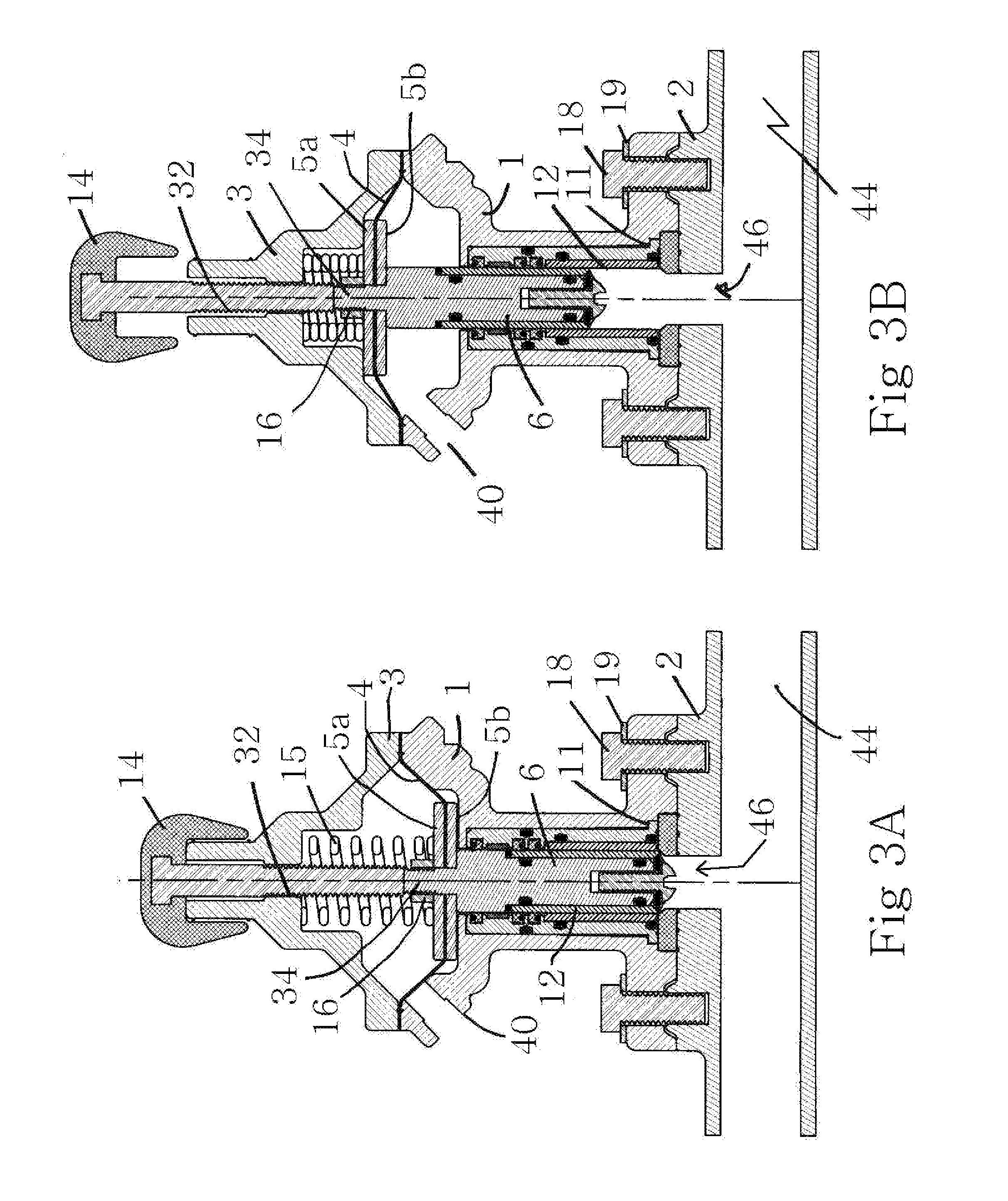

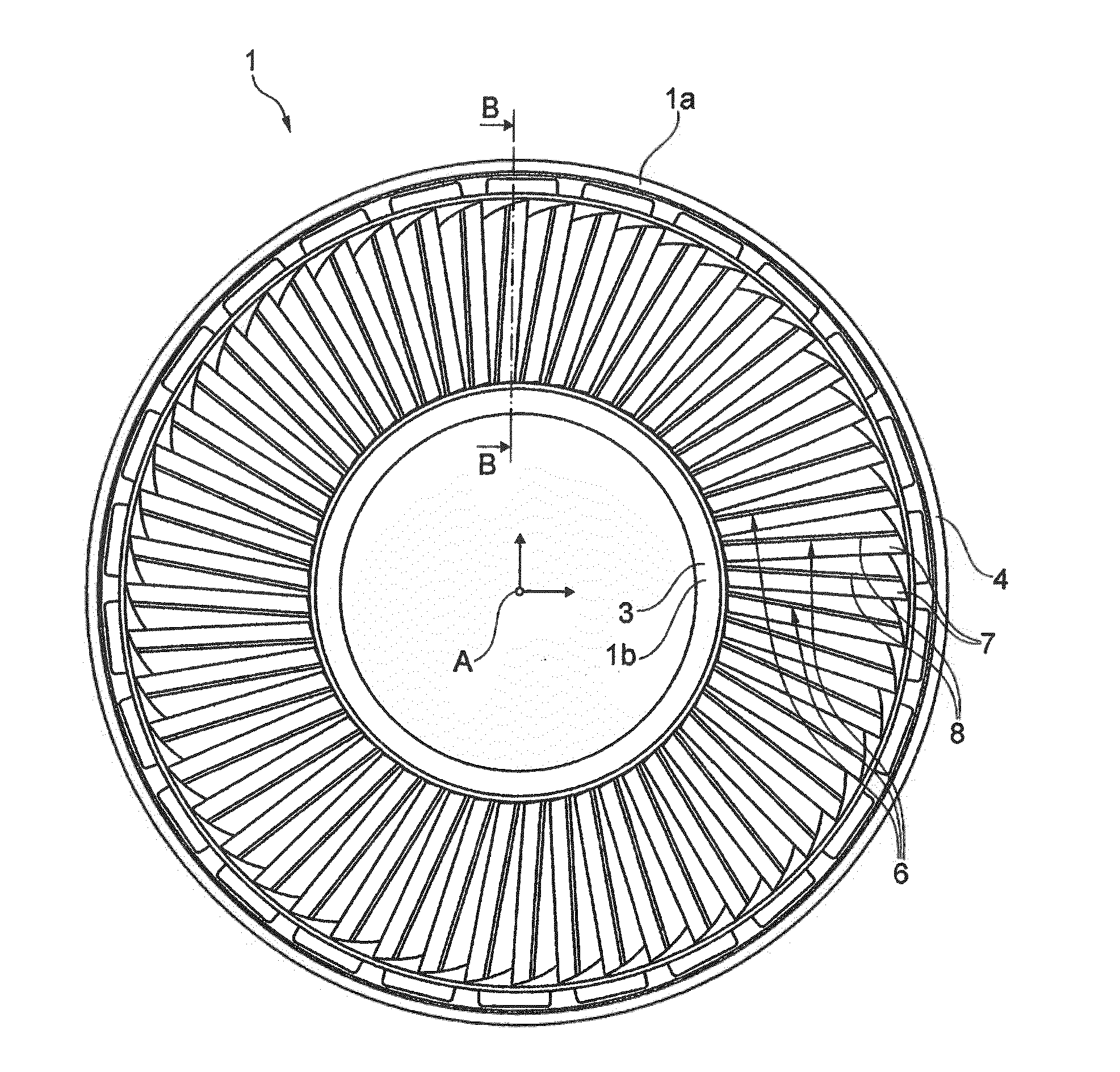

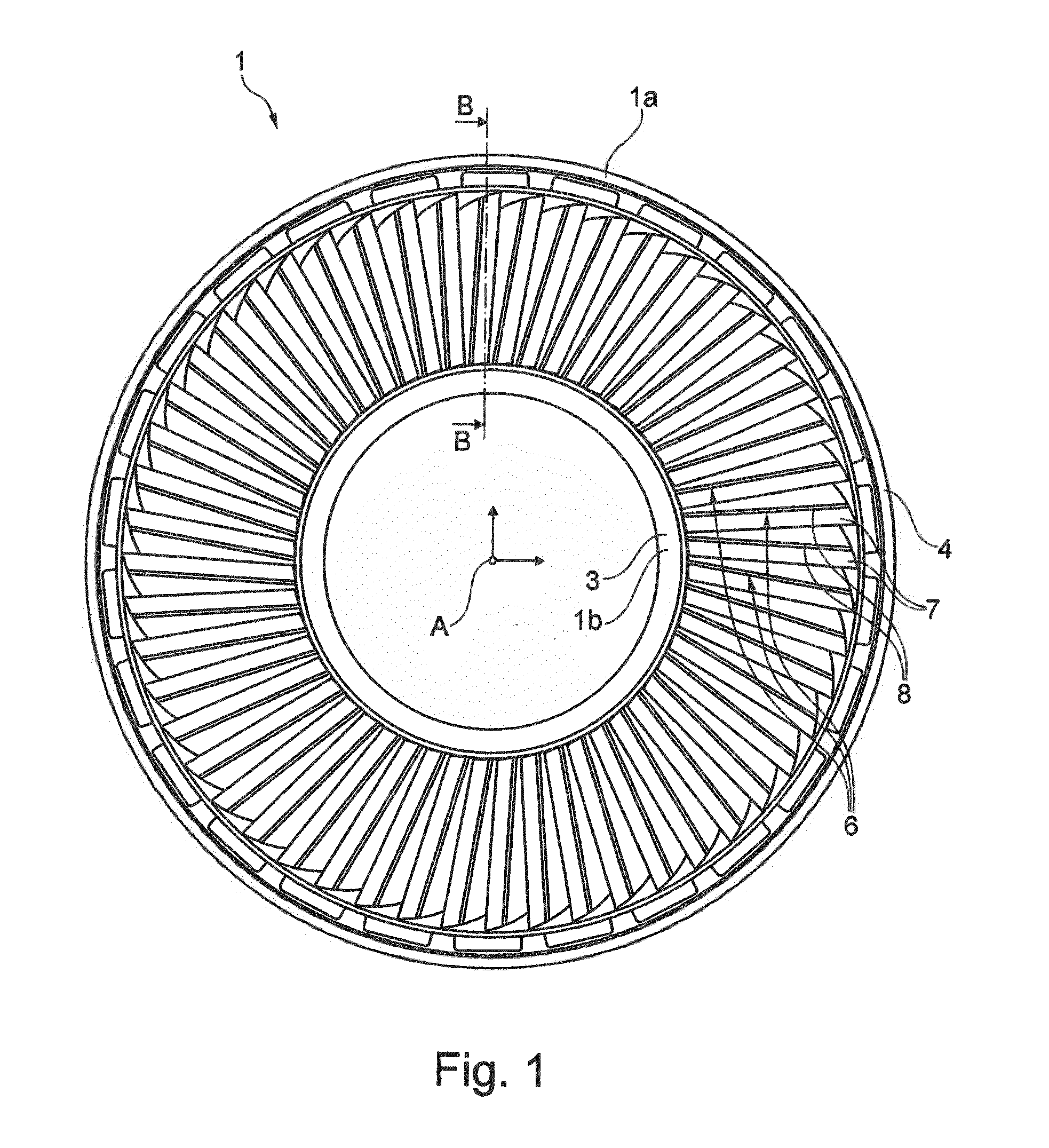

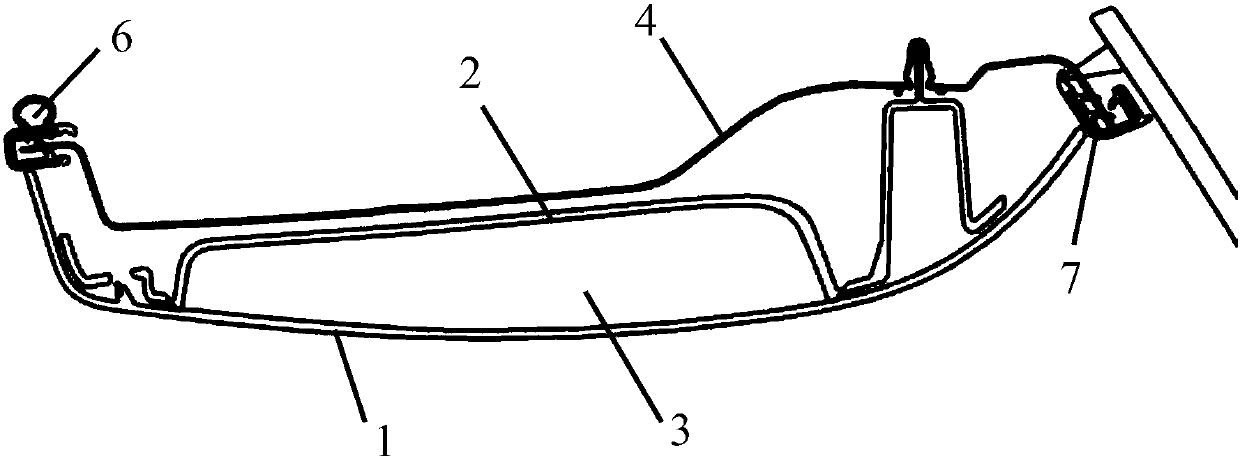

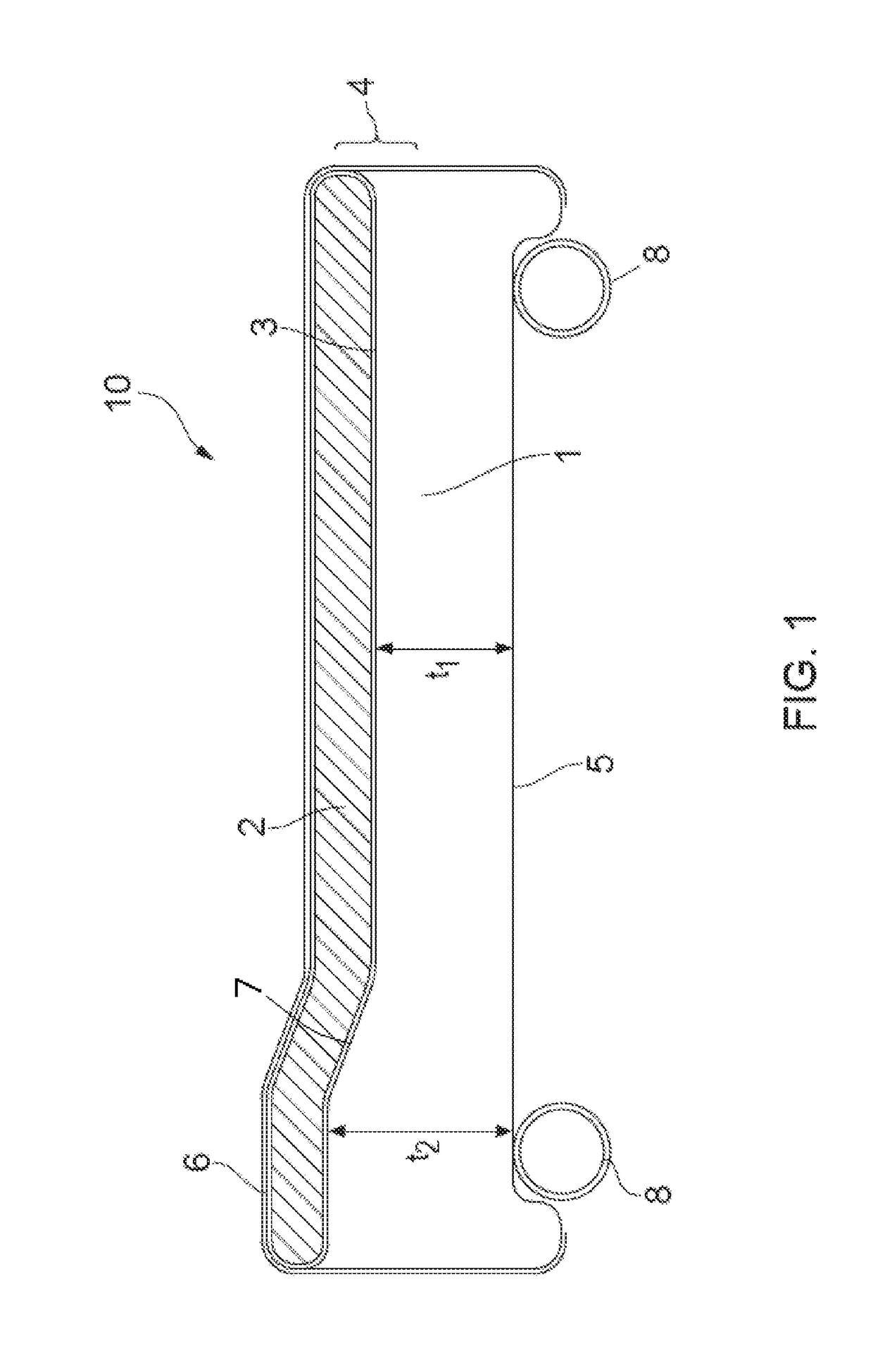

Pneumatic tire and configuration for reducing a tire noise

InactiveCN101462473AIncrease assembly costImprove assembly timeTyre partsWheelsEngineeringHoneycomb like

The present invention relates to a pneumatic tire (1) for reducing a tire noise having an annular cavity (5) and at least one acoustic damper (6), situated in the cavity, made of an open-celled material. The acoustic damper (6) is removably connected to an inner face (7) of the pneumatic tire facing toward the cavity (5) using at least one removably connectable connection device (8, 9, 10, 13). Furthermore, the invention provides a wheel rim having a pneumatic tire (1) drawn thereon, an annular cavity (5) being shaped between wheel rim and pneumatic tire, as well as at least one acoustic damper (6) made of open-celled material, which is situated in the cavity, which is distinguished in that the acoustic damper is removably connected on an inner face facing toward the cavity using at least one removably connectable connection device.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lens and image pickup module comprising lens

The invention relates to a lens, which comprises a lens tube, a lens group and a light shielding assembly, wherein the lens group is arranged in the lens tube; the light shielding assembly and the lens group are arranged in the lens tube in a corresponding arrangement way; the lens group comprises at least one lens and at least one edge cutting lens alternately arranged with the lens; the edge cutting lens comprises an aspherical work part, a connecting part and at least one longitudinal cutting surface; the connecting part surrounds the aspherical work part and is connected with the aspherical work part; the lens tube comprises a lens installing region and an edge cutting lens installing region; the edge cutting lens installing part comprises at least one longitudinal cutting plate corresponding to the longitudinal cutting surface and an arc-shaped side wall connected with the longitudinal cutting plate; the connecting part comprises an arc-shaped lug boss corresponding to the arc-shaped side wall. The lens provided by the invention has the advantages that the structure is reasonable; the intensity is high; the service life is long; the dimension is small; the screen occupation ratio is high.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

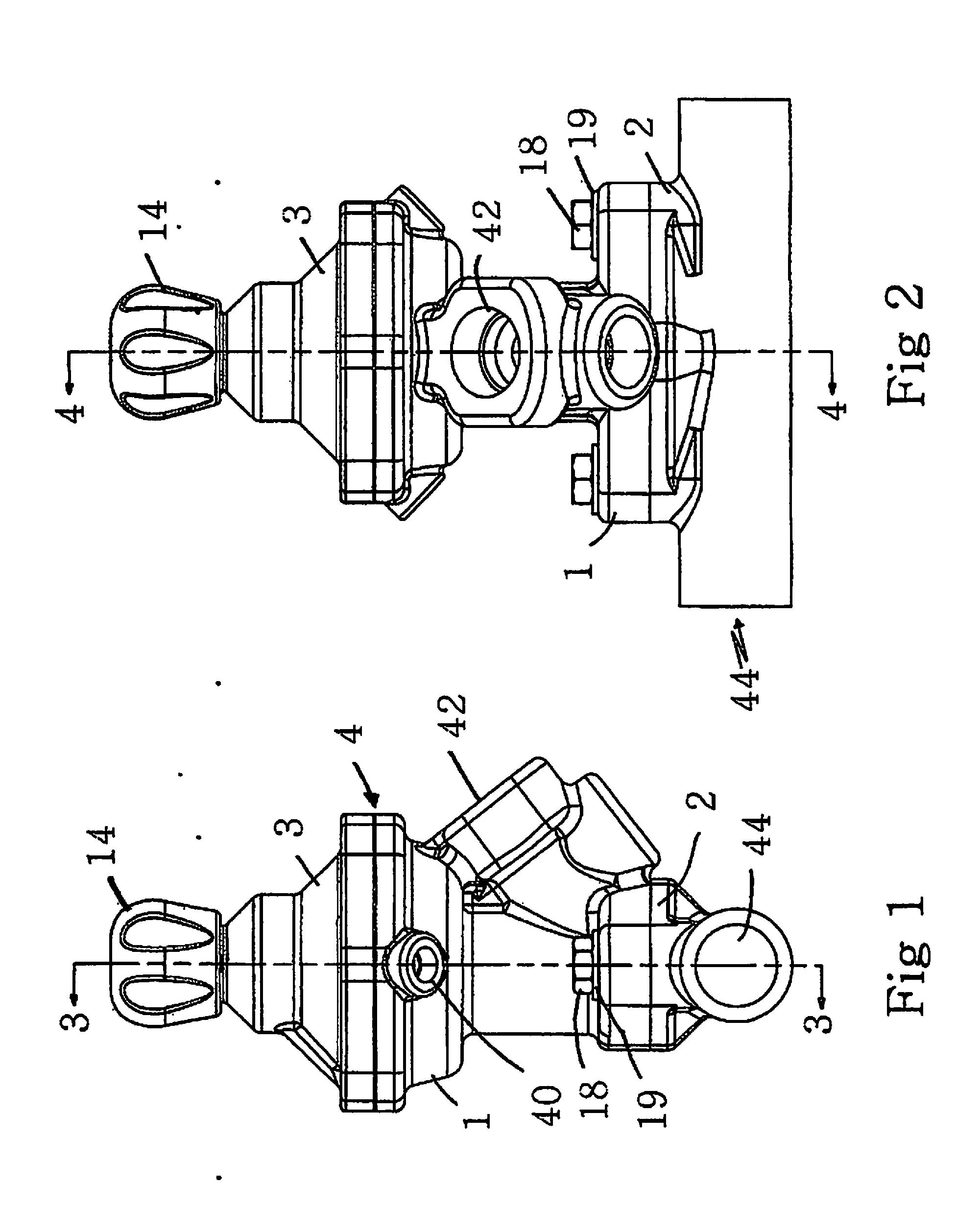

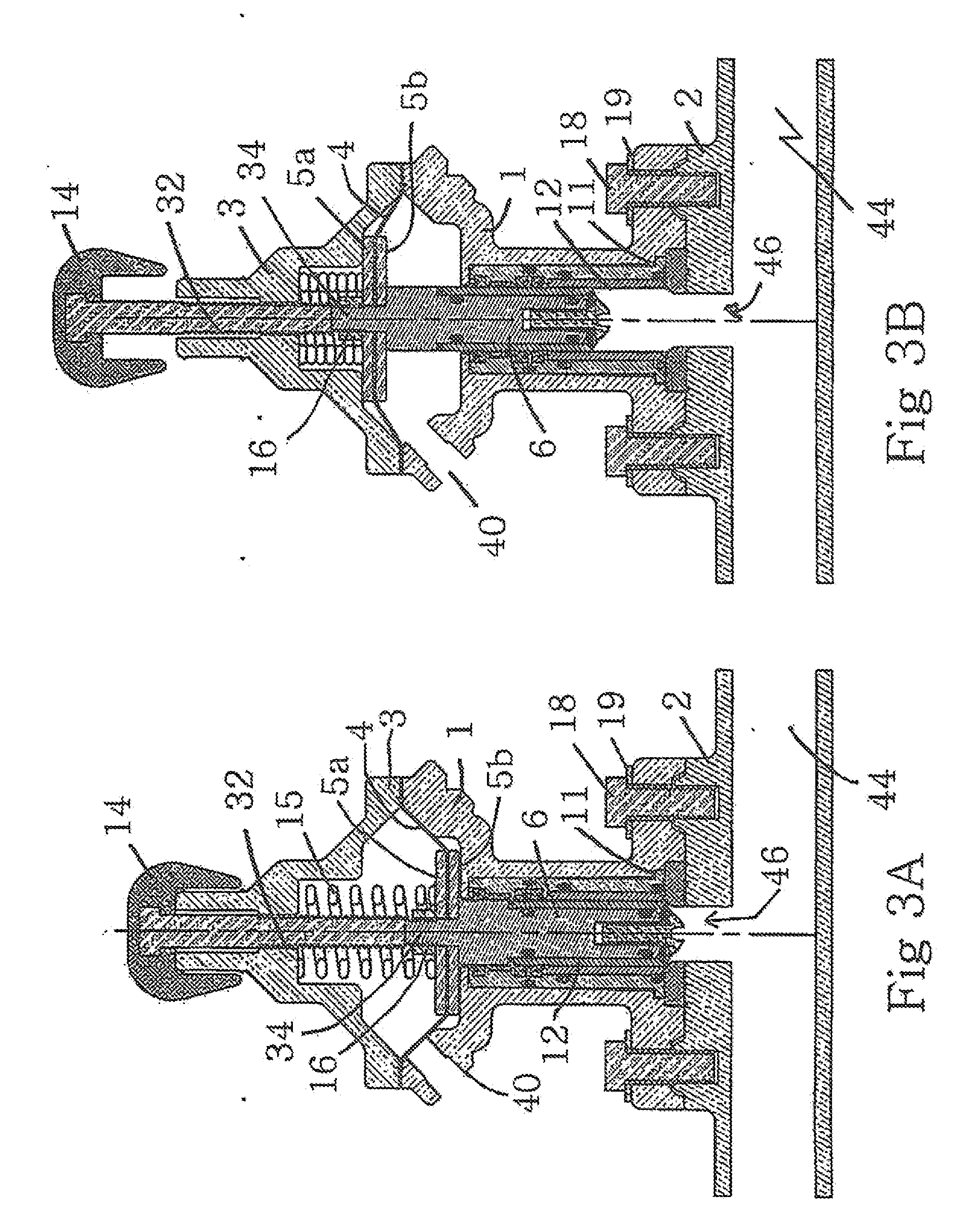

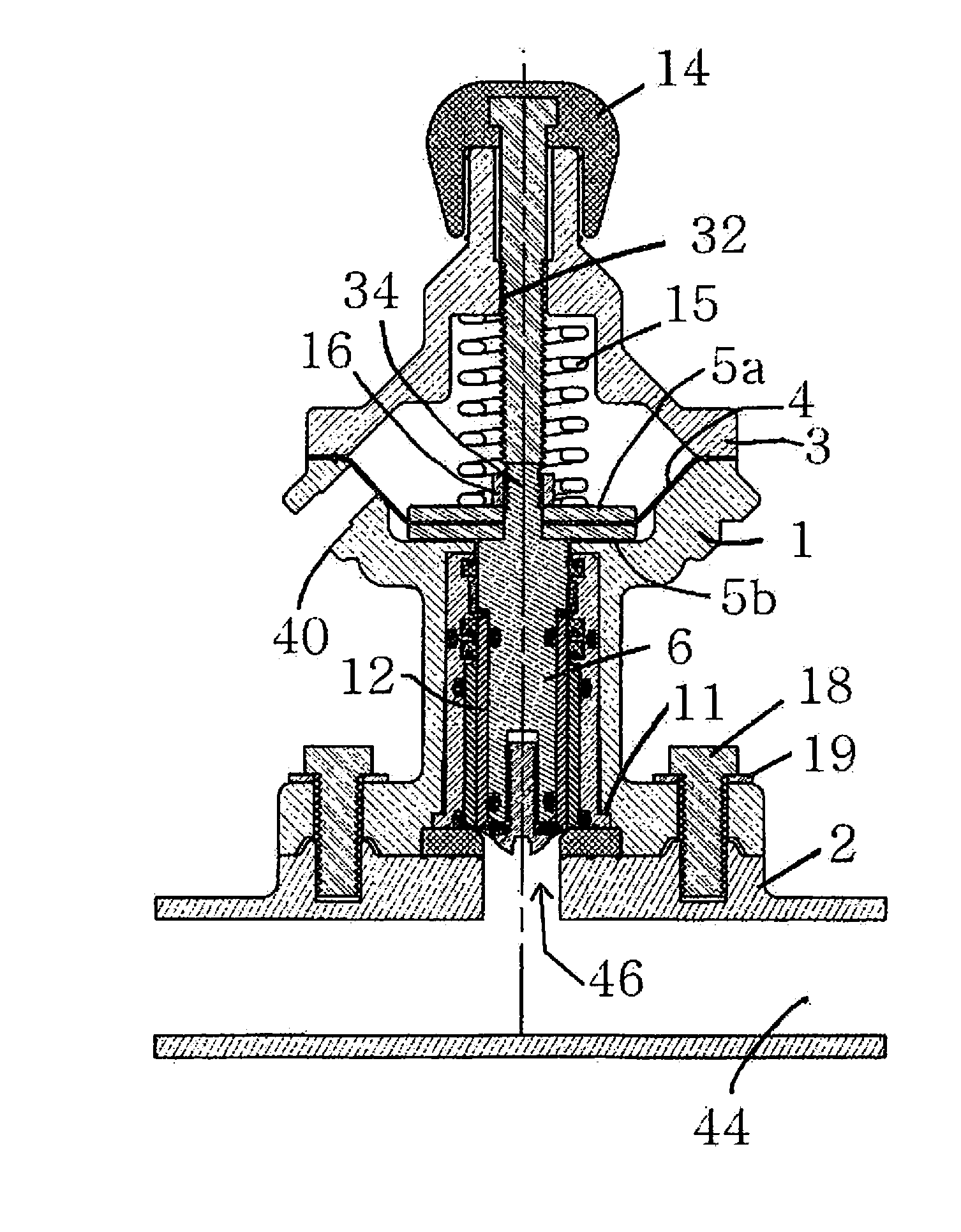

Media Control Valve

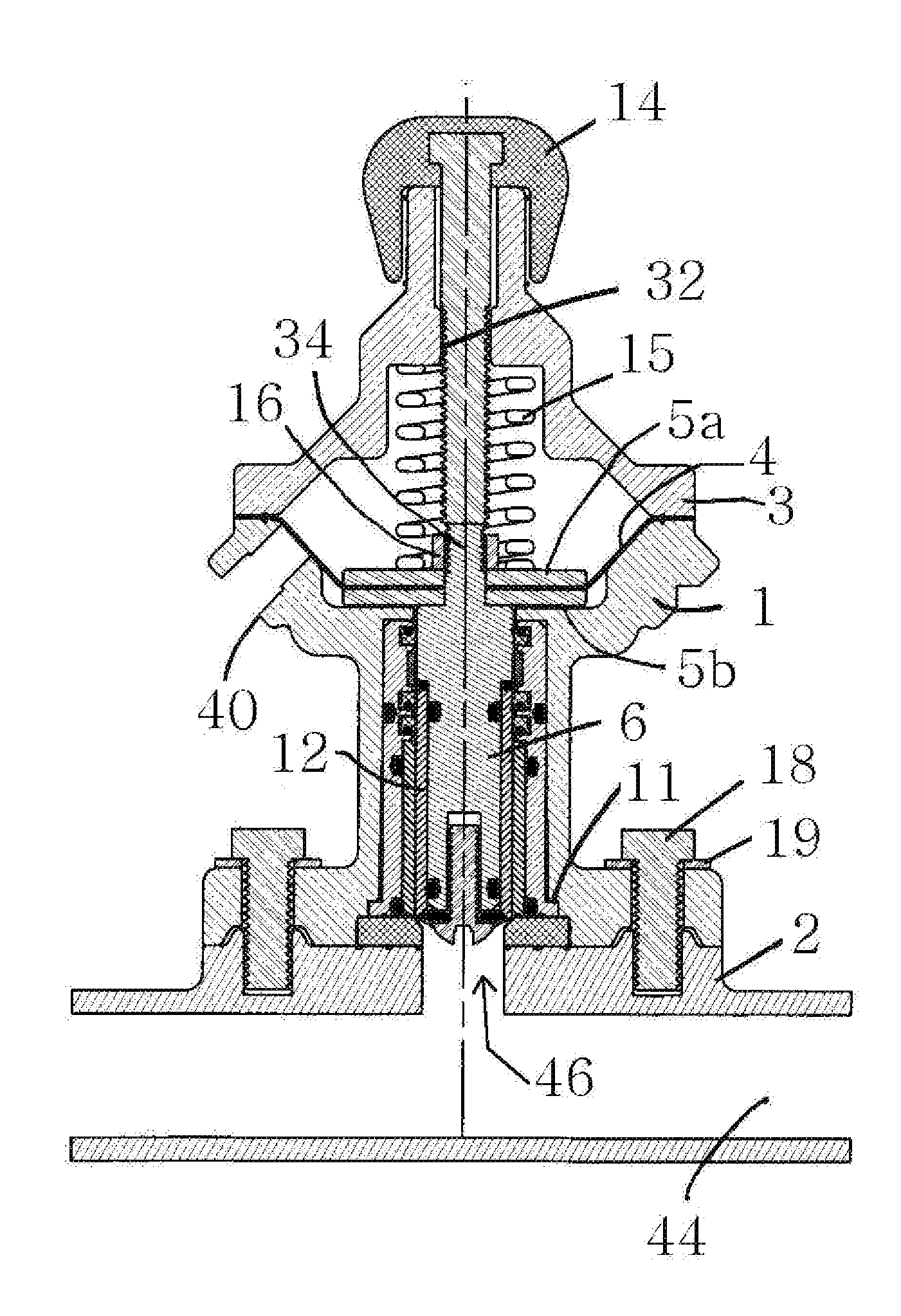

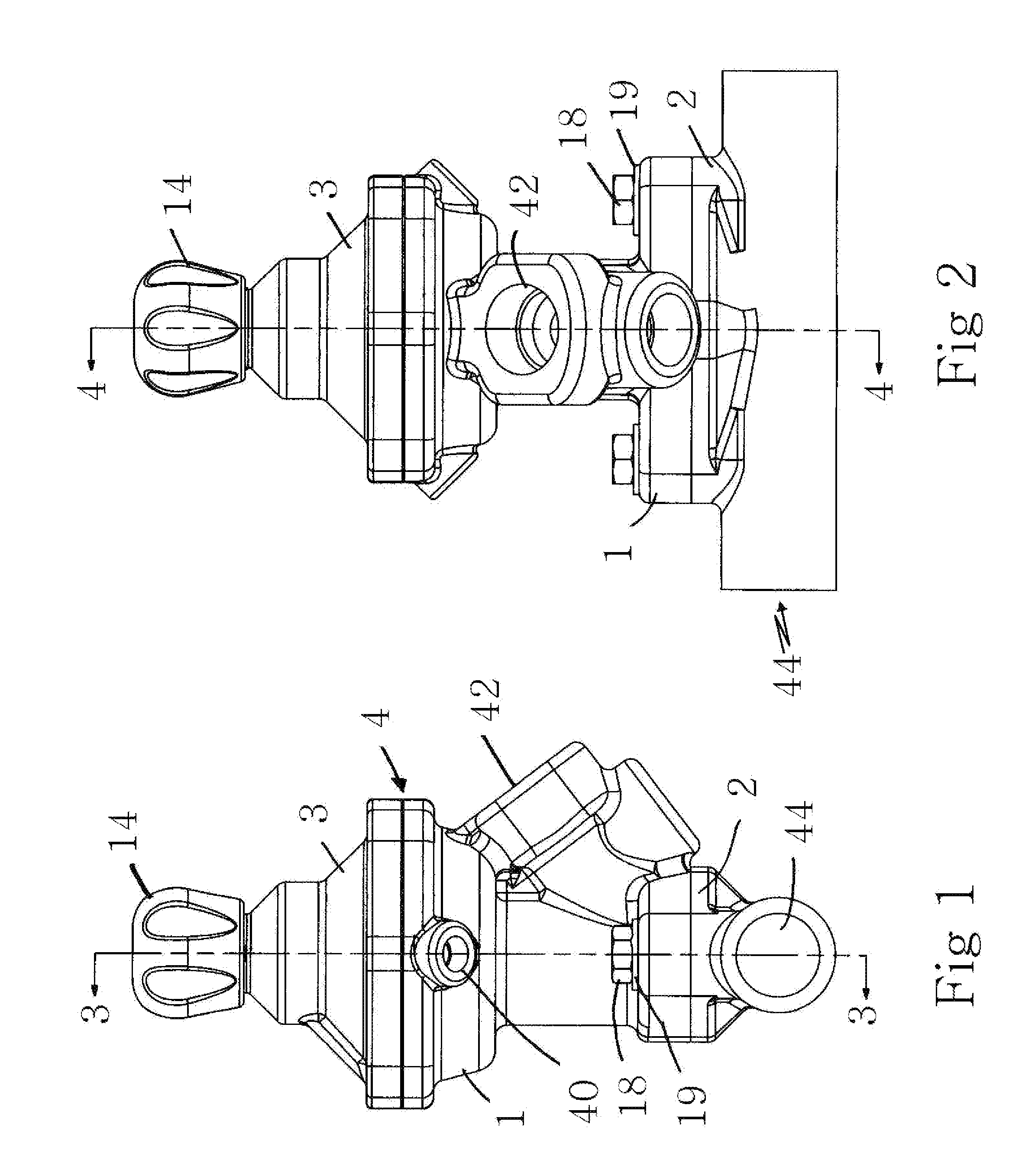

ActiveUS20130105717A1Eliminate the problemQuicker and efficient and reliable valve actionCheck valvesSlide valveMedia controlsEngineering

A media control valve includes a body, a plunger assembly of multiple components housed in the body with a plunger control valve cap assembly secured to the body for housing a control knob. The body and the plunger assembly include resilient seals between adjacent multiple components of the body and the plunger assembly, respectively, to permit relative movement therebetween. A diaphragm physically isolates and seals the chambers above and below. All of the plunger seals and bushings held within the sleeve. Replacement seals and bushings can be replaced and inspected with relative ease due to the accessibility at both ends of the sleeve. Component parts are assembled using resilient seals to facilitate assembly and repair.

Owner:NGUYEN PHUONG TAYLOR

One-step buckling and molding type cable connector

ActiveCN102082362AGood dustproof, waterproof and shockproof performanceSave assembly timeCouplings bases/casesFlexible/turnable line connectorsElectrical conductorStructural engineering

The invention discloses a one-step buckling and molding type cable connector which comprises a connecting head arranged at the end of a cable, wherein the connecting head consists of a step sleeve and a step core which are sequentially sleeved at the end of the cable from outside to inside; the peripheral surface of a small-diameter pipe of the step sleeve is provided with an annular boss, and a groove is formed between the annular boss and a step table of the step sleeve; a small-diameter pipe of the step core extends into a cable jacket, and a large-diameter pipe of the step core is sleeved on the small-diameter pipe of the step sleeve; the end part combining surfaces of the step core and the annular boss of the step sleeve are respectively provided with arc pin holes along the axial direction, and pin shafts are arranged in the pin holes; a protective sleeve extends from the groove of the small-diameter pipe of the step sleeve to the cable jacket; and a socket electrically connected with a conductor in the cable is inserted in the large-diameter pipe of the step sleeve. The invention solves the problems that the traditional cable connector cannot rotate, the jacket is easy to pull out, and molding cannot be finished at one step. The invention is suitable for connecting cables for equipment control under a coal mine well.

Owner:郑州煤机液压电控有限公司

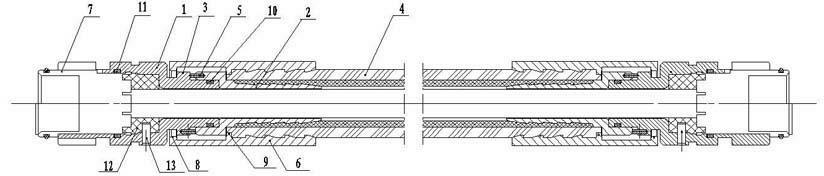

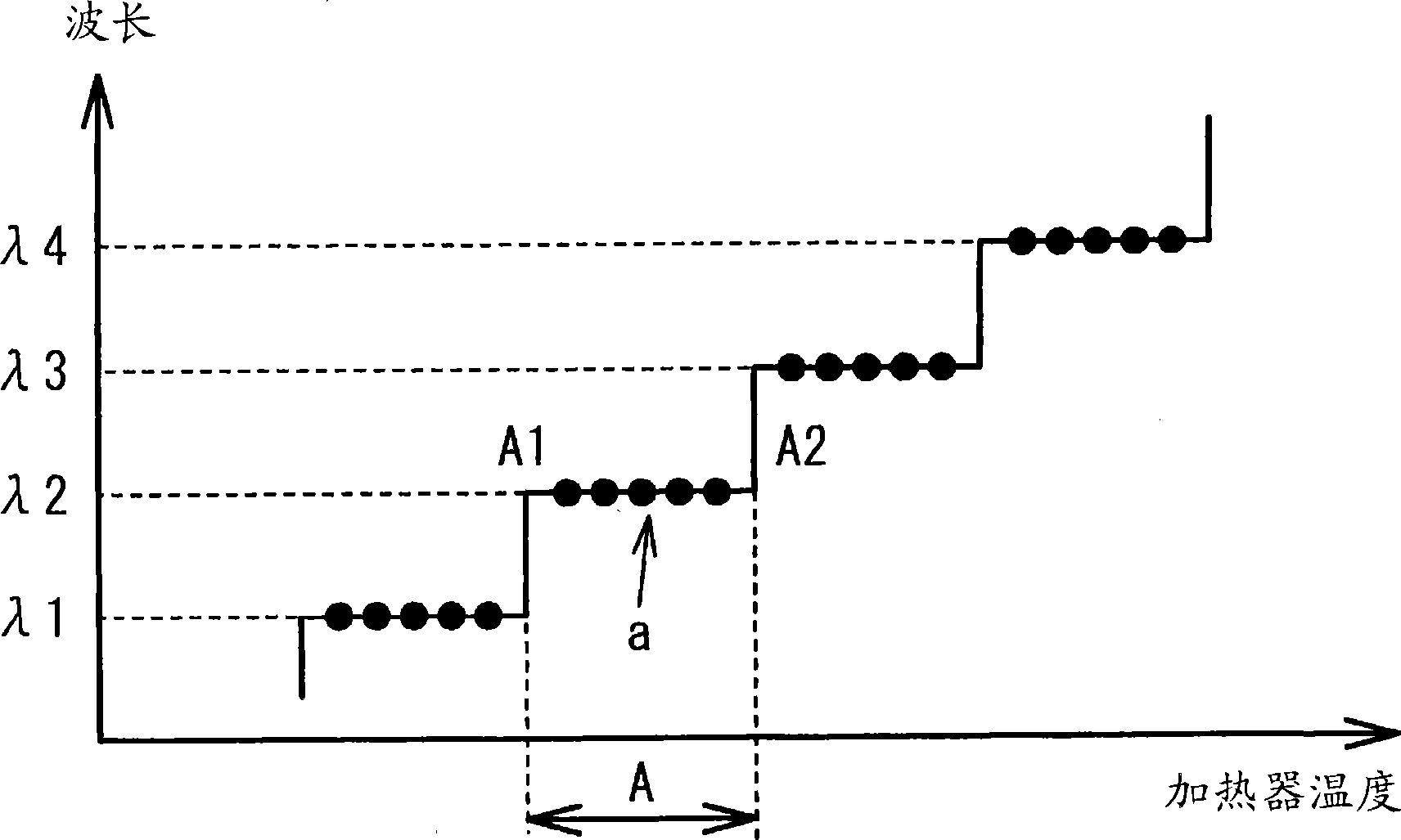

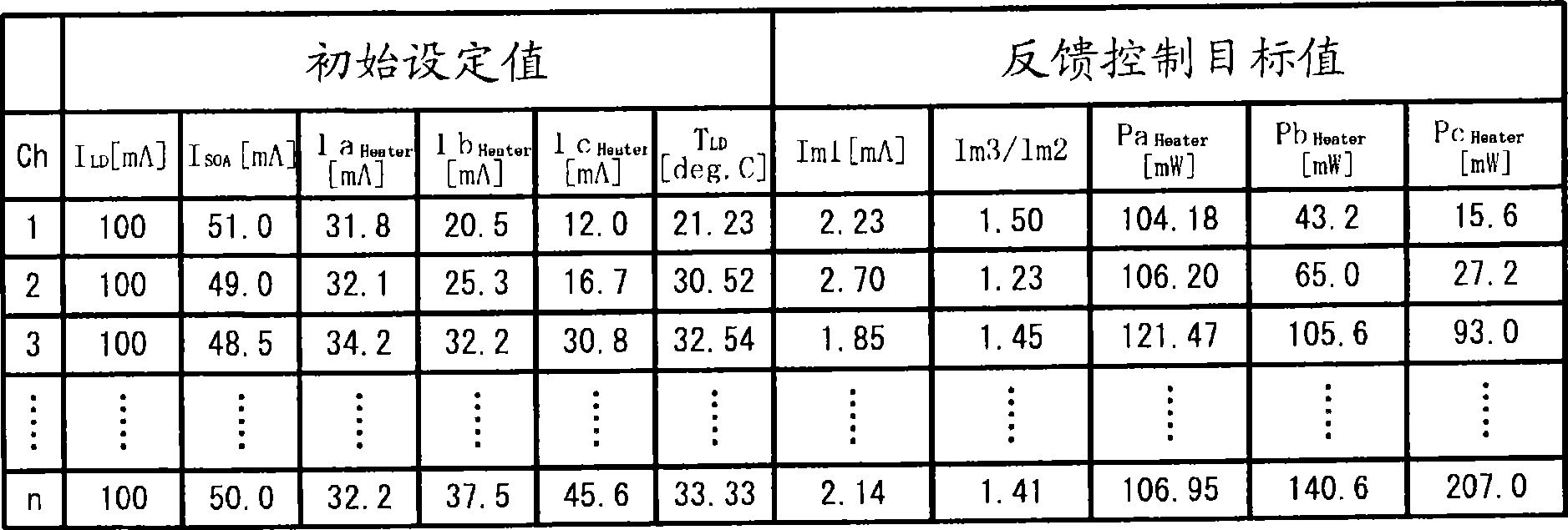

Testing method of wavelength-tunable laser, controlling method of wavelength-tunable laser and laser device

ActiveCN101471531AIncrease the number ofImprove assembly timeLaser detailsSemiconductor lasersOperating pointLength wave

A testing method of a wavelength-tunable laser having a resonator including wavelength selection portions having wavelength property different from each other includes a first step of controlling the wavelength-tunable laser so as to oscillate at a given wavelength according to an initial setting value, a second step of tuning the wavelength property of the wavelength selection portions and detecting discontinuity point of gain-condition-changing of the wavelength-tunable laser, and a third step of obtaining a stable operating point of the wavelength selection portion according to a limiting point of an oscillation condition at the given wavelength, the limiting point being a point when the discontinuity point is detected.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

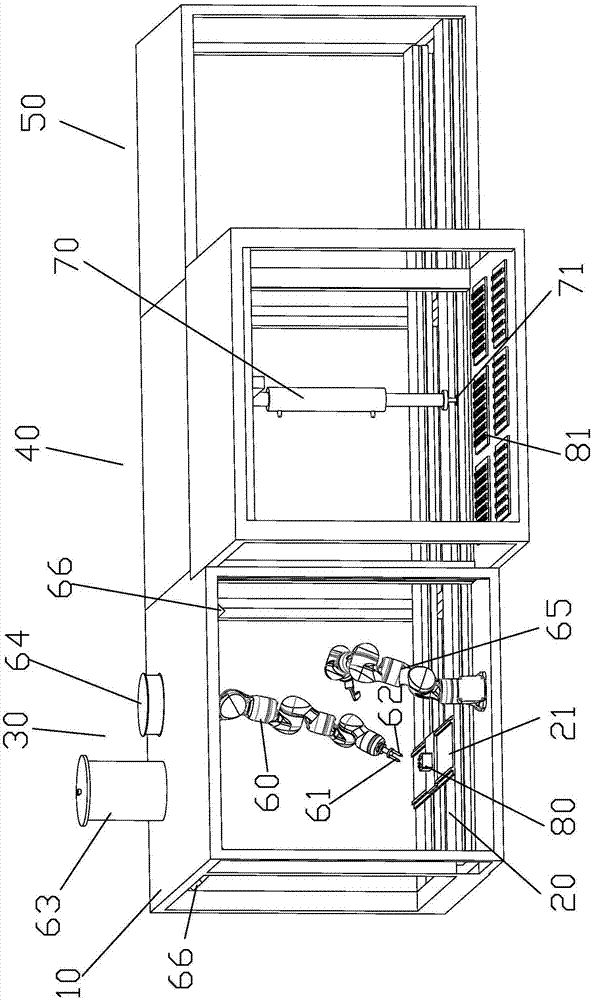

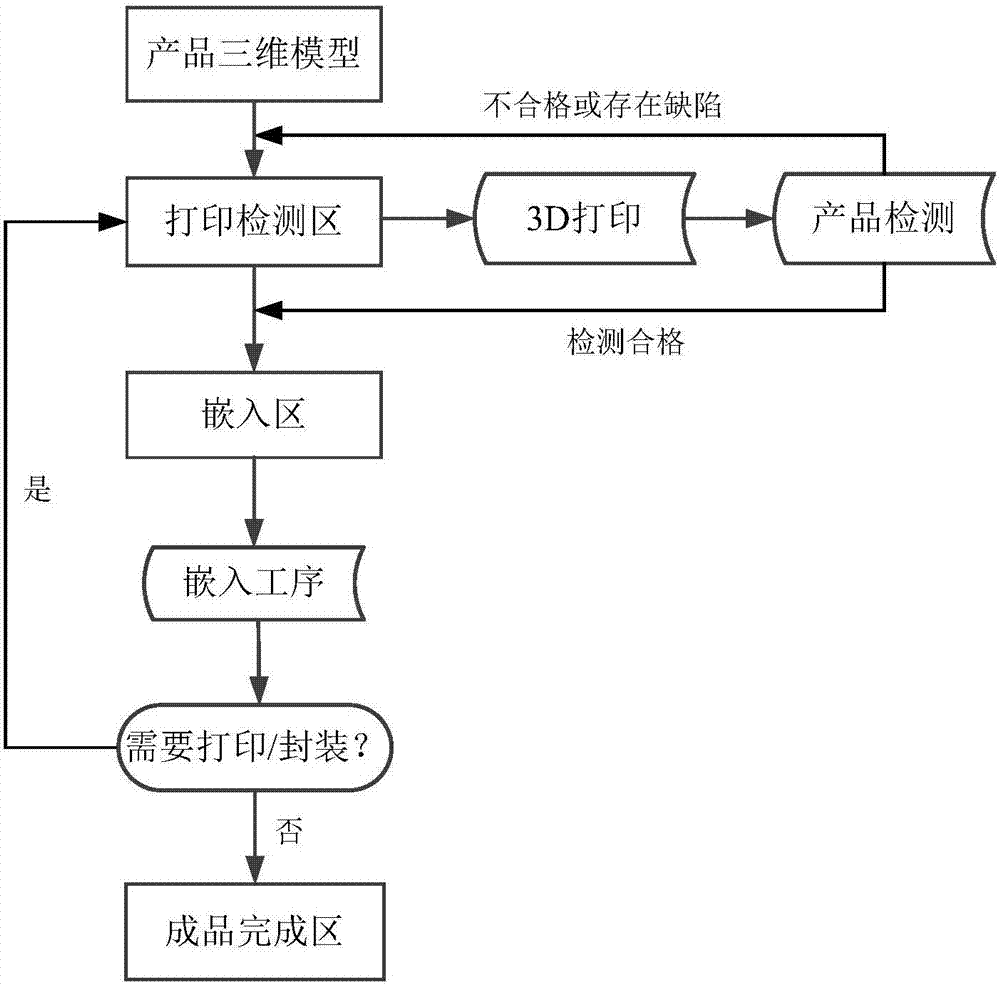

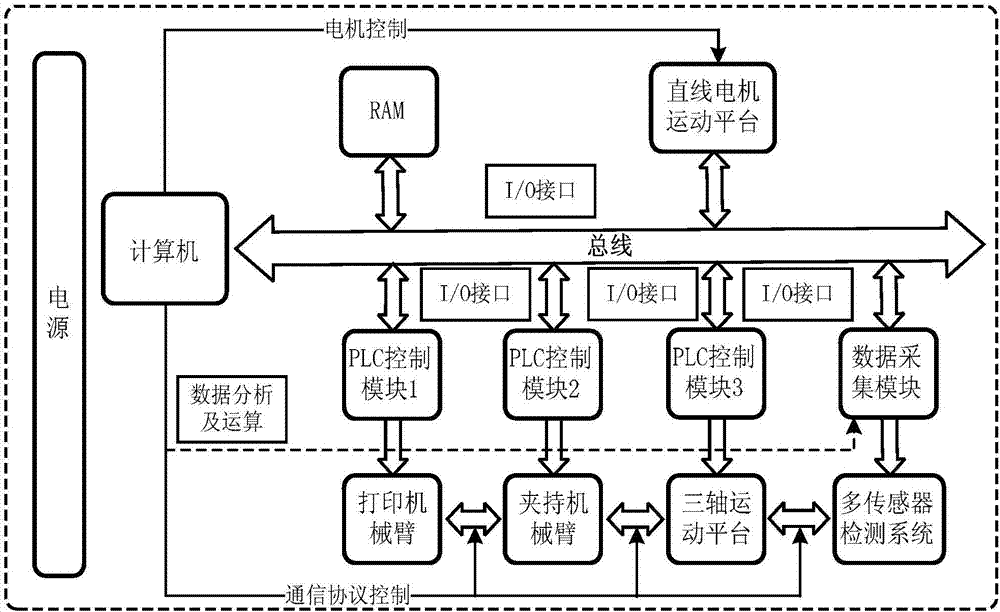

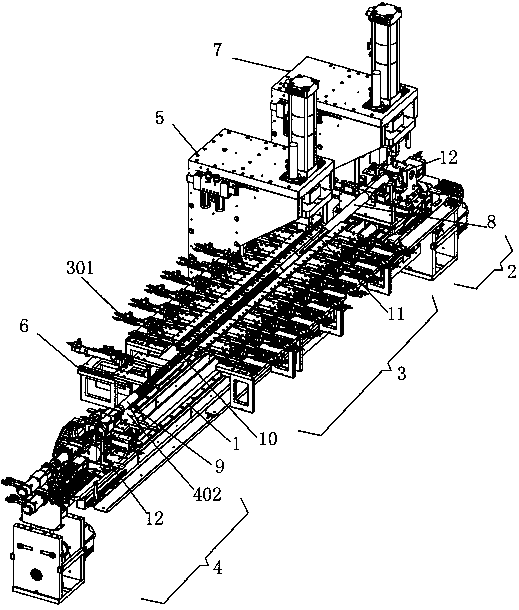

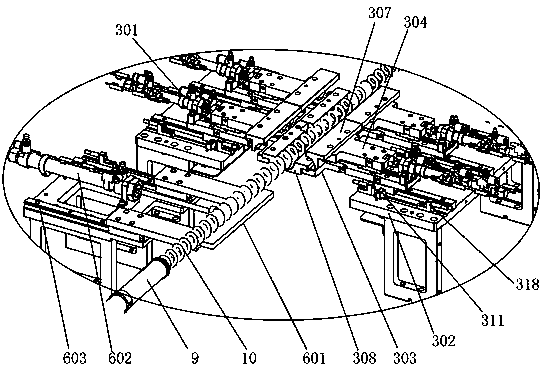

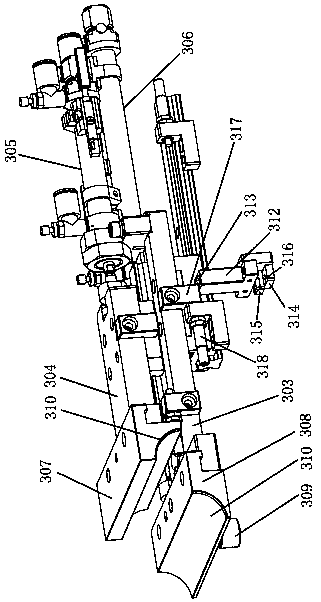

System and printing method for 3D printing of intelligent electronic product inserted line

ActiveCN106965417AEasy and efficient to manufactureWaterproofAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringFlexible electronics

The invention relates to a system for 3D printing of an intelligent electronic product inserted line. The system comprises a rack, an automatic conveying mechanism arranged on the rack, a printing detection area, an inserting area and a product finishing area, wherein the printing detection area, the inserting area and the product finishing area are arranged on a conveying path of the automatic conveying mechanism. The inserting area is arranged between the printing detection area and the product finishing area. A 3D printing mechanism and a plurality of sensor detection systems are arranged in the printing detection area. An automatic grabbing mechanism used for grabbing elements is arranged in the inserting area. The 3D printing technology is used to manufacture a flexible electronic product, and the electronic elements are inserted in the printing process and packaged to form the integral electronic product. Manufacturing of the electronic product is easier and more efficient through the 3D printing technology. In the printing process, the inserted electronic elements and a circuit enable the electronic product to have the dustproof and waterproof functions, so that material using and assembling time are optimized, the needed post-processing steps are greatly decreased, and the production efficiency can be improved. The invention provides a 3D printing method for the electronic product inserted line.

Owner:QUANZHOU INST OF EQUIP MFG

Media Control Valve

InactiveUS20160195190A1Easy maintenancePromote repairOperating means/releasing devices for valvesCheck valvesMedia controlsControl valves

A media control valve includes a body, a plunger assembly of multiple components housed in the body with a plunger control valve cap assembly secured to the body for housing a control knob. The body and the plunger assembly include resilient seals between adjacent multiple components of the body and the plunger assembly, respectively, to permit relative movement therebetween during assembly and use. The media control valve includes a diaphragm which acts as a membrane that physically isolates and seals the chambers above and below. The spool design of the valve has all of the seals and bushings held within the spool. Once the spool is removed, the replacement seals and bushings can be replaced and inspected with relative ease due to the accessibility at both ends of the spool. Since each plunger seal is held within its own rigid cavity, held on three sides and not stacked on top of another seal or loose component, proper alignment is better assured during and after installation. The body components parts are also assembled using resilient seals to facilitate assembly and repair, while reducing any tendency of the valve to seize during use.

Owner:NGUYEN PHUONG TAYLOR

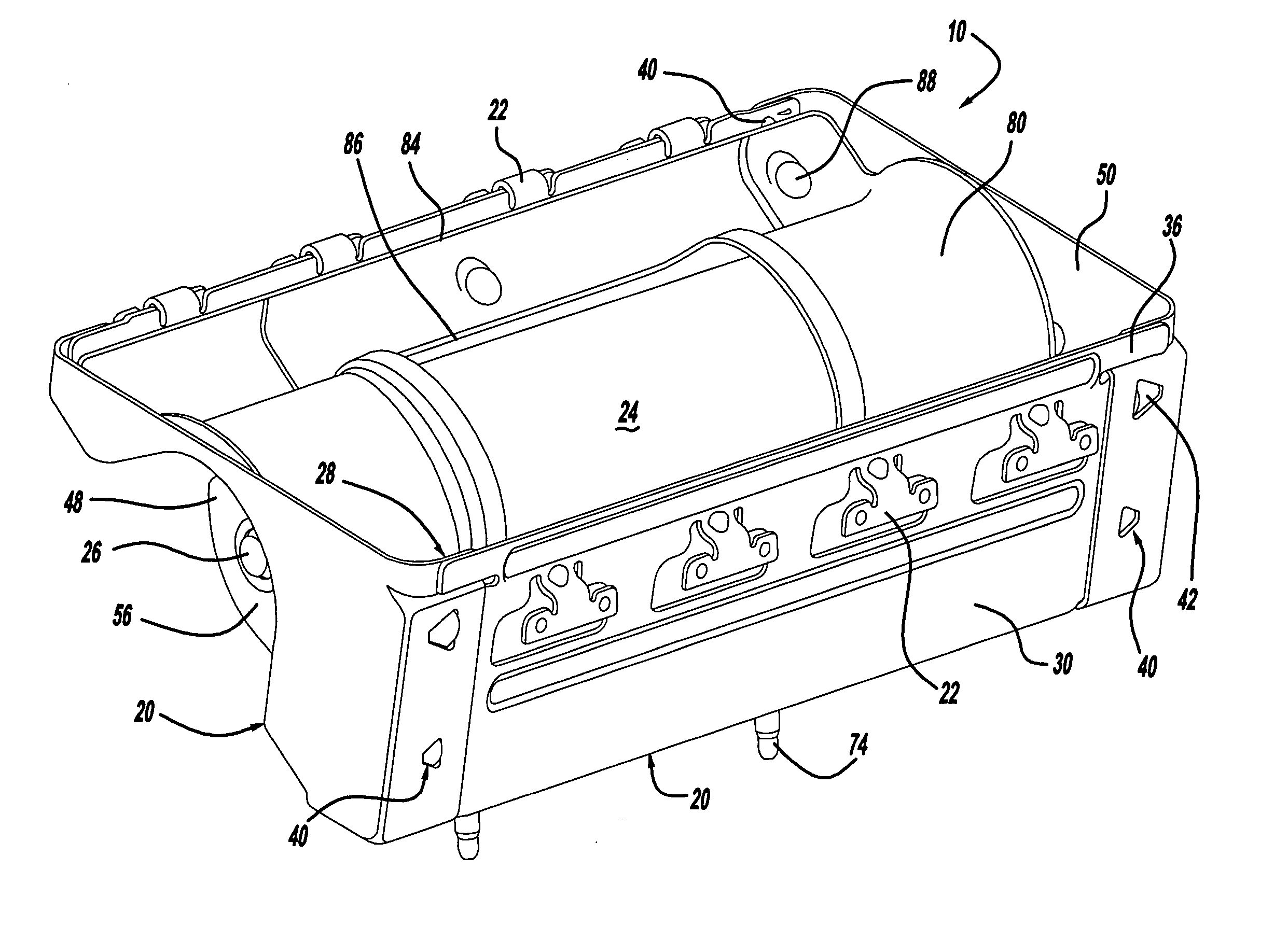

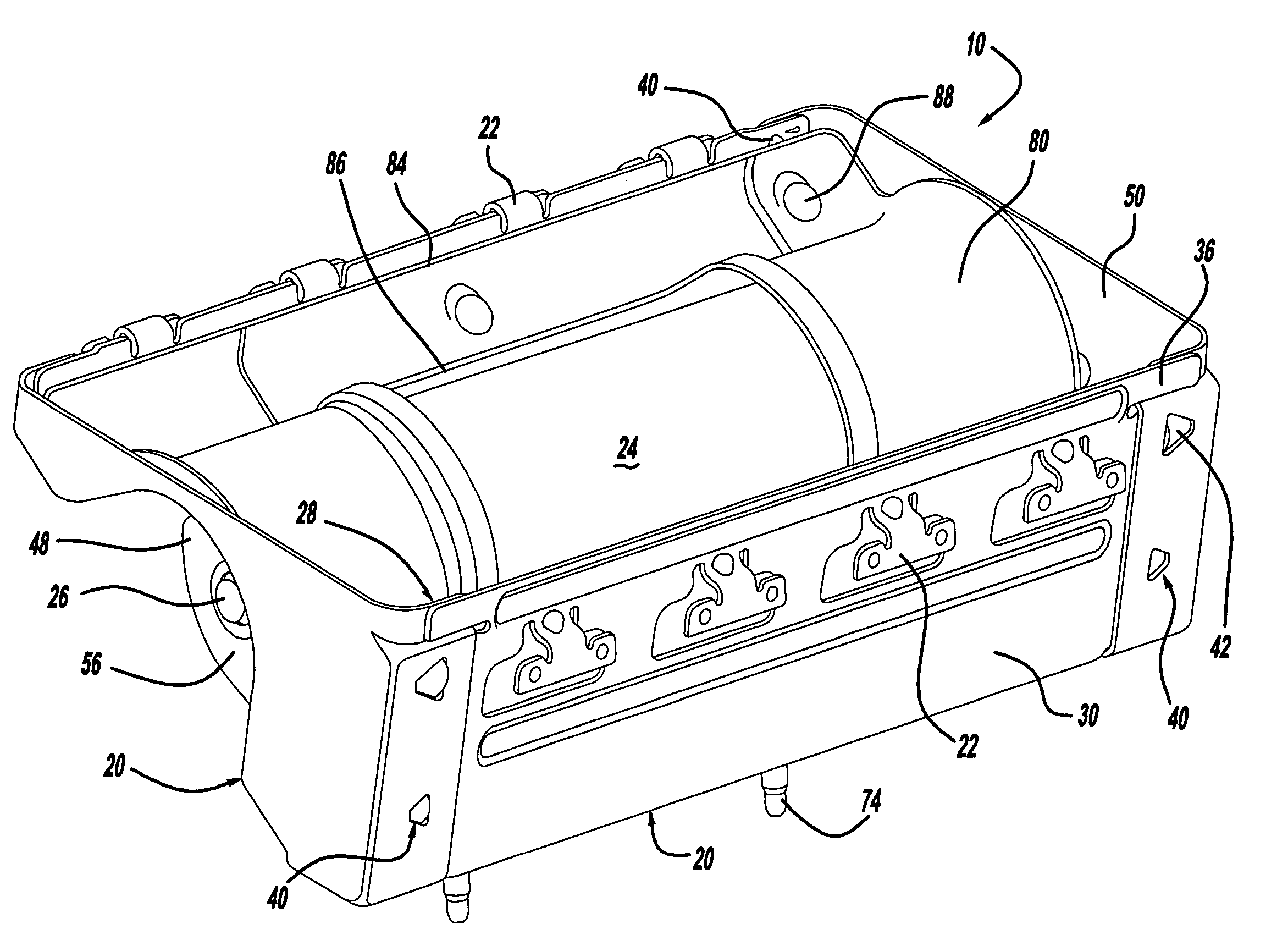

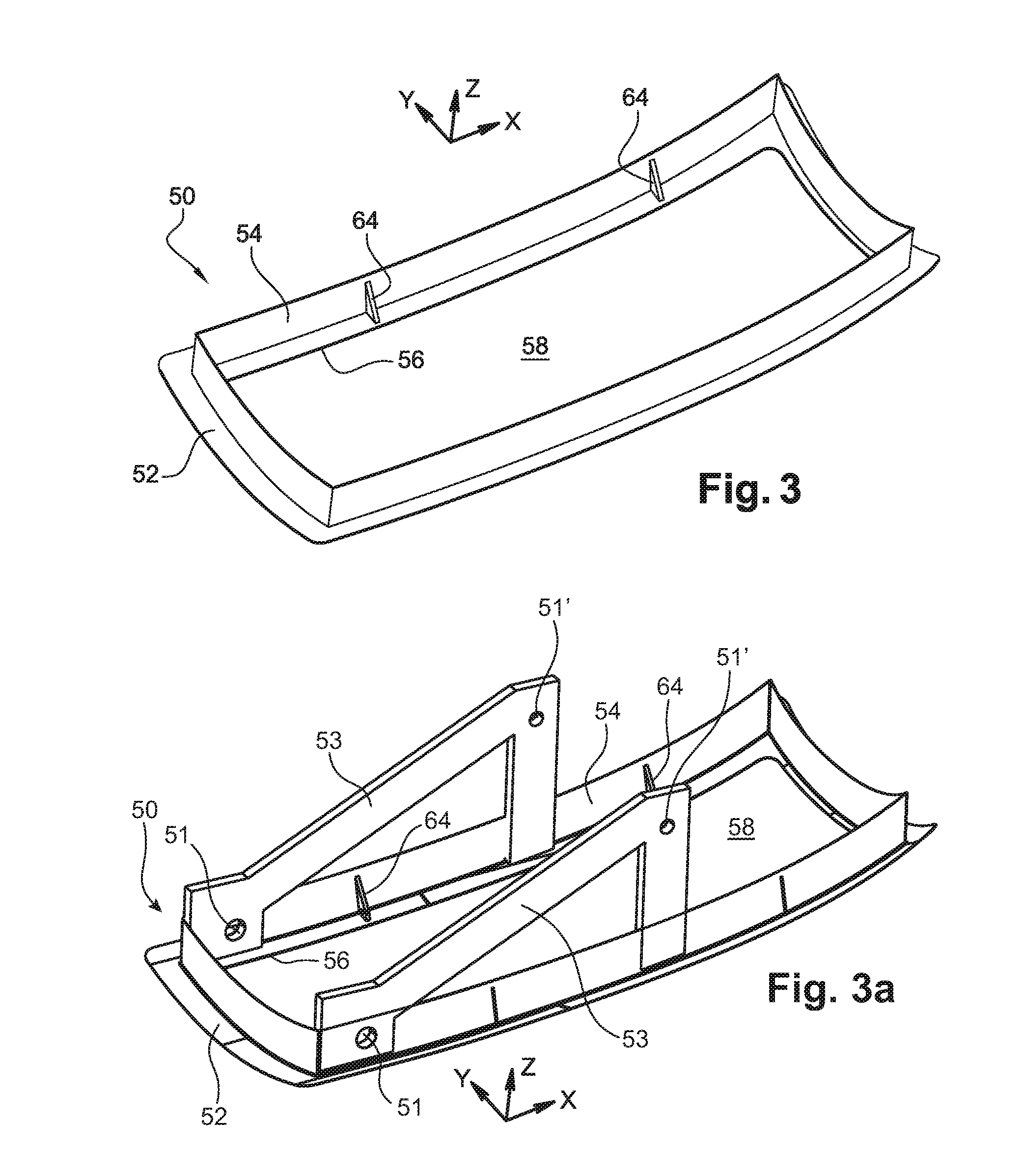

Airbag module canister

InactiveUS20050218630A1Easy to assembleHigh strengthPedestrian/occupant safety arrangementLap jointEngineering

An airbag module comprising an improved canister, retainer assembly and method of attaching the airbag module to the vehicle is disclosed. The canister includes snap-on end caps, which assemble onto the center section of the canister. A retention mechanism provides the snap-on capability, while a lap joint provides extra security to ensure the end caps remain on the center section during assembly and initiation of the inflator secured within the canister.

Owner:TOYODA GOSEI CO LTD

Airbag module canister

InactiveUS7374198B2Easy to assembleHigh strengthPedestrian/occupant safety arrangementLap jointEngineering

An airbag module comprising an improved canister, retainer assembly and method of attaching the airbag module to the vehicle is disclosed. The canister includes snap-on end caps, which assemble onto the center section of the canister. A retention mechanism provides the snap-on capability, while a lap joint provides extra security to ensure the end caps remain on the center section during assembly and initiation of the inflator secured within the canister.

Owner:TOYODA GOSEI CO LTD

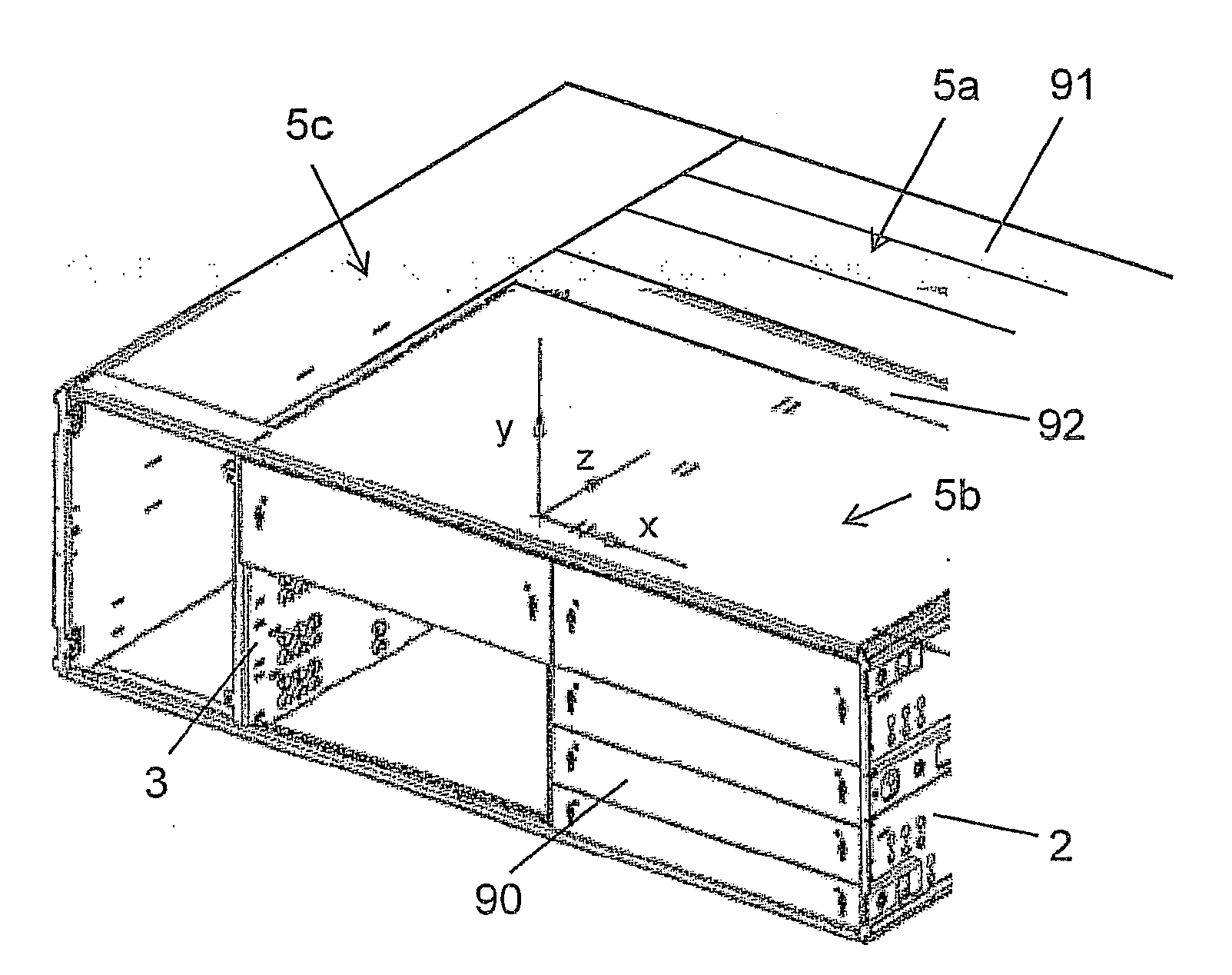

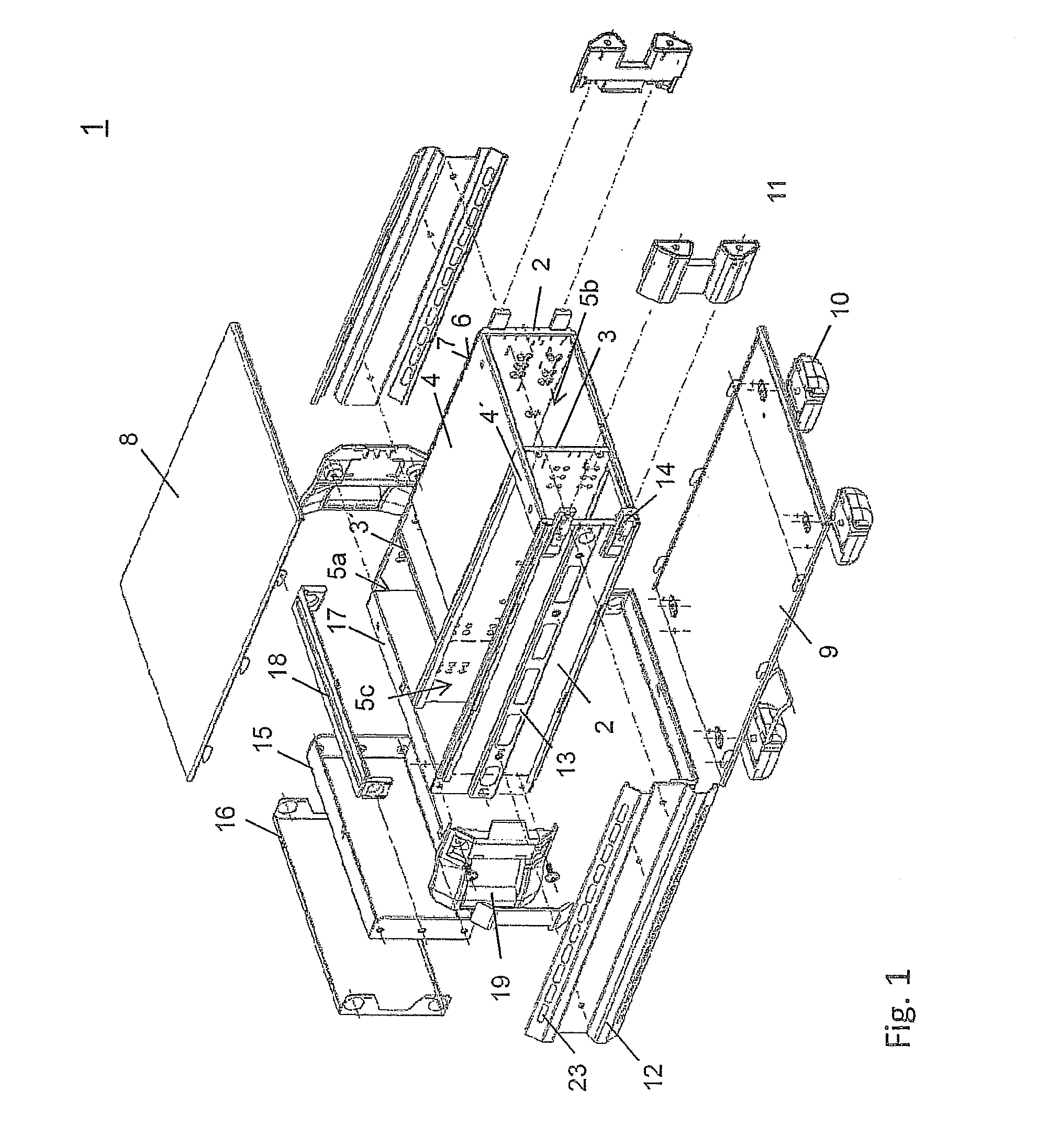

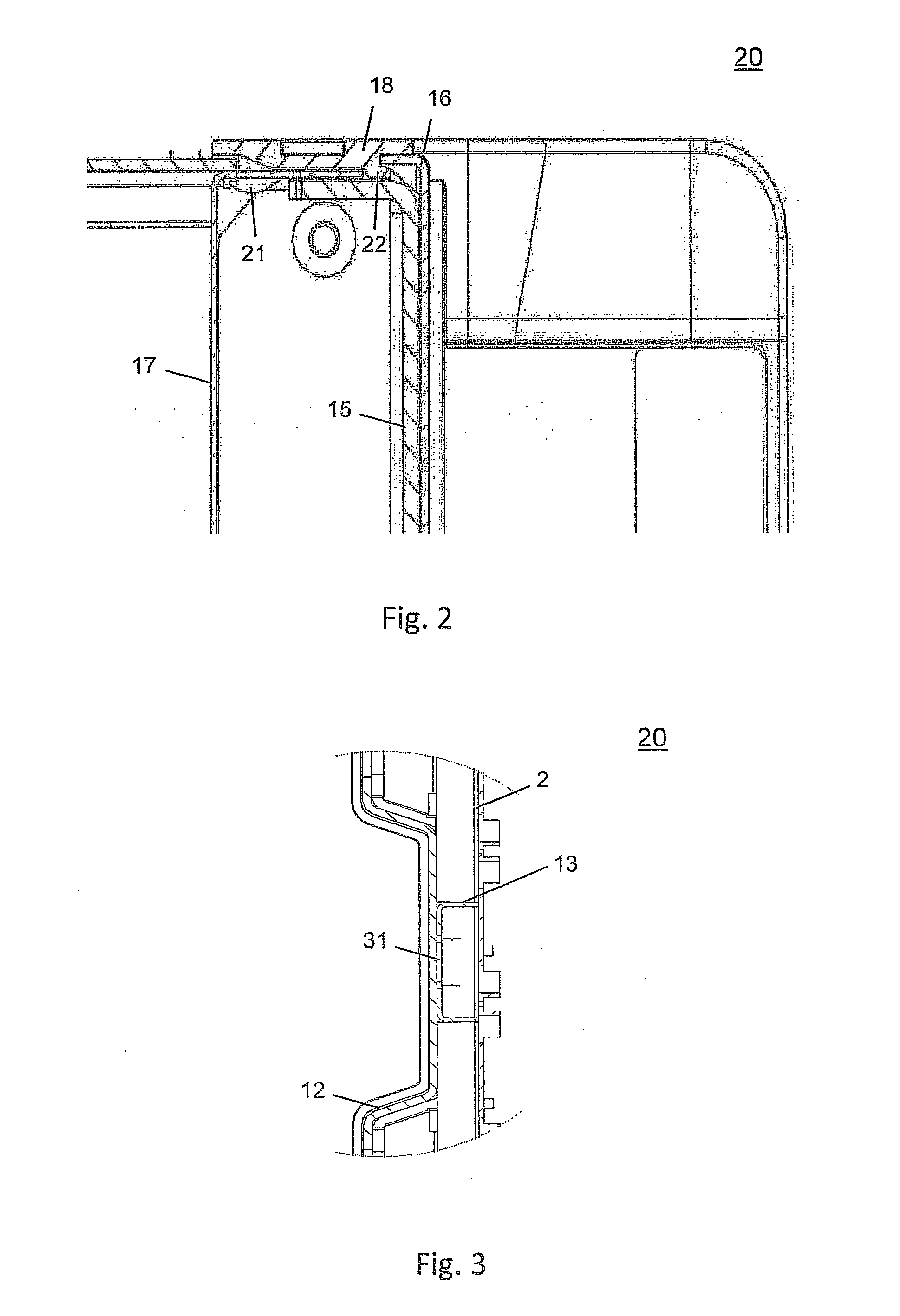

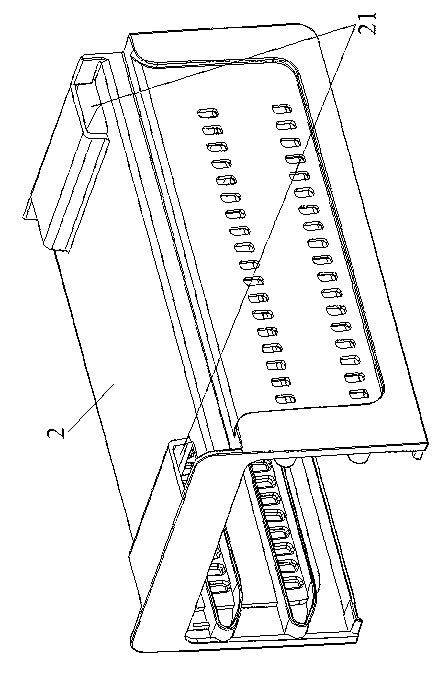

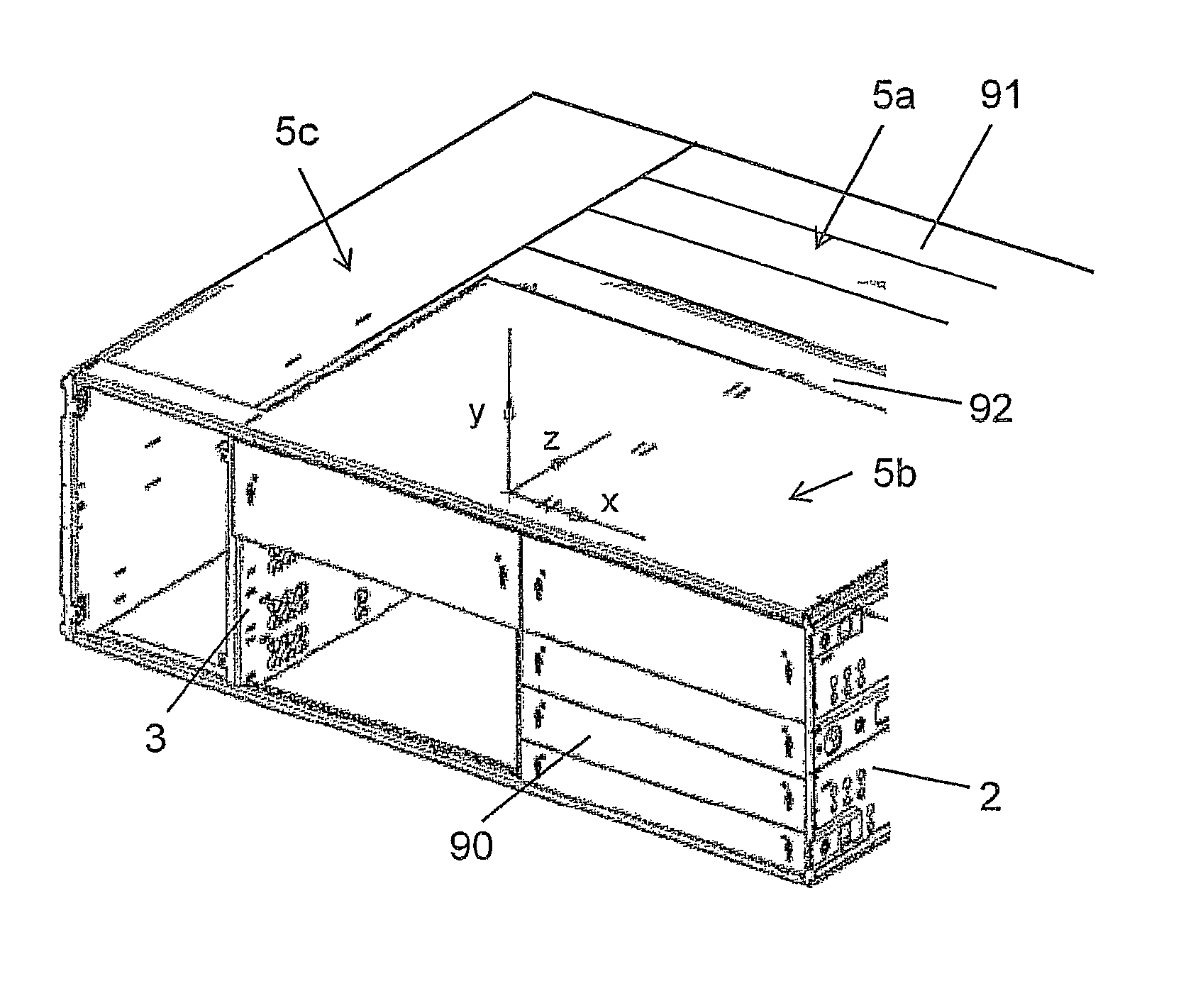

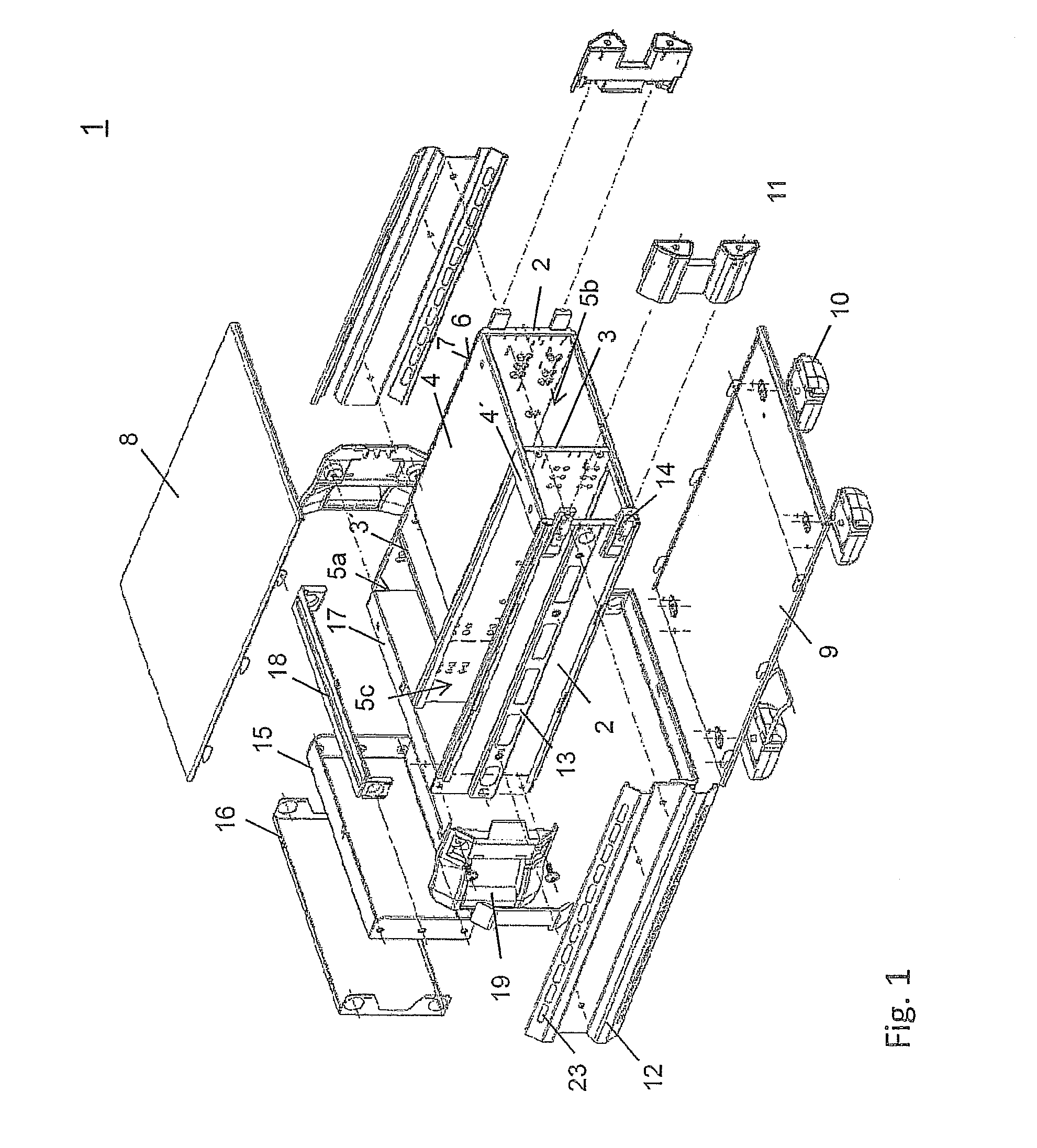

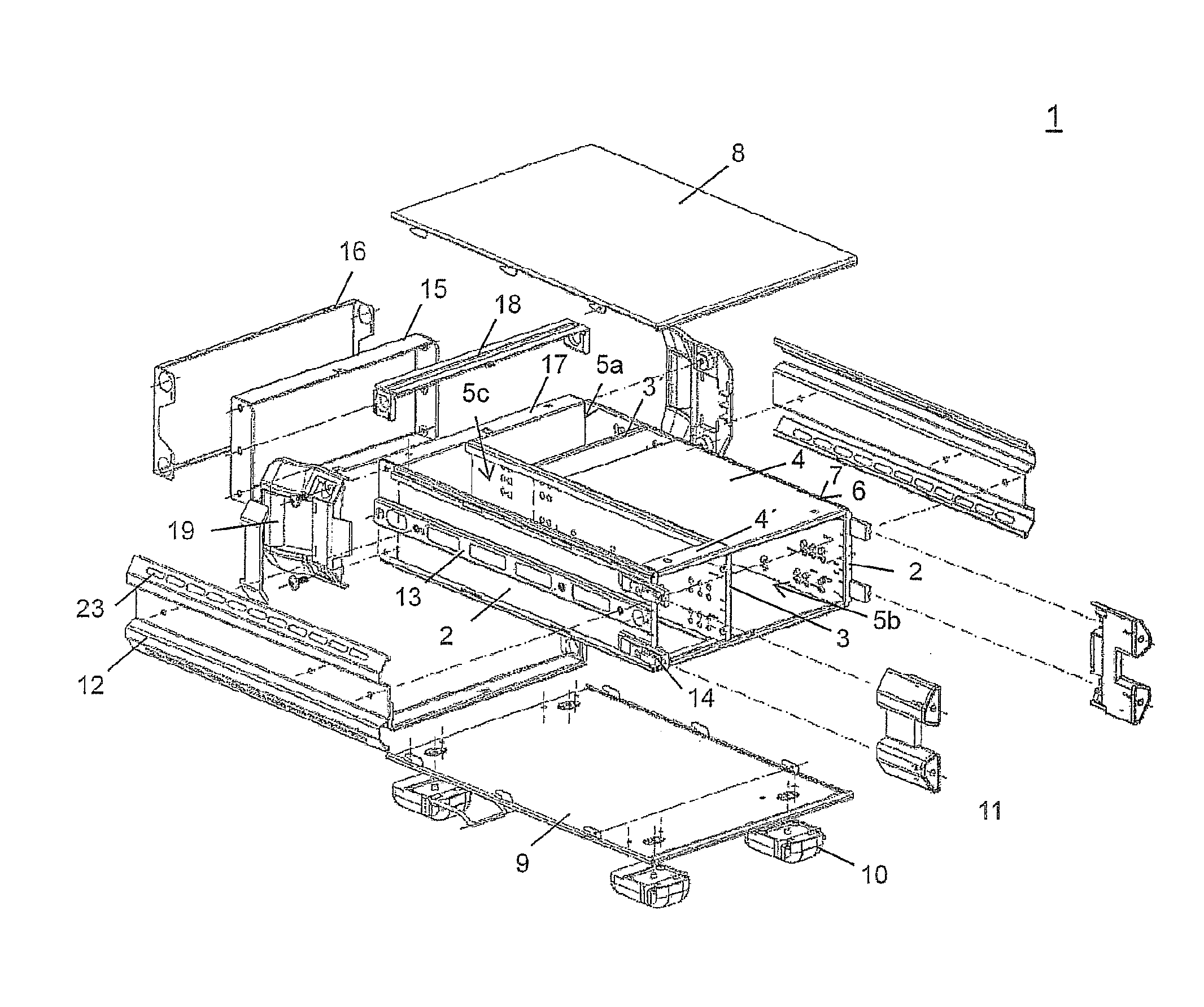

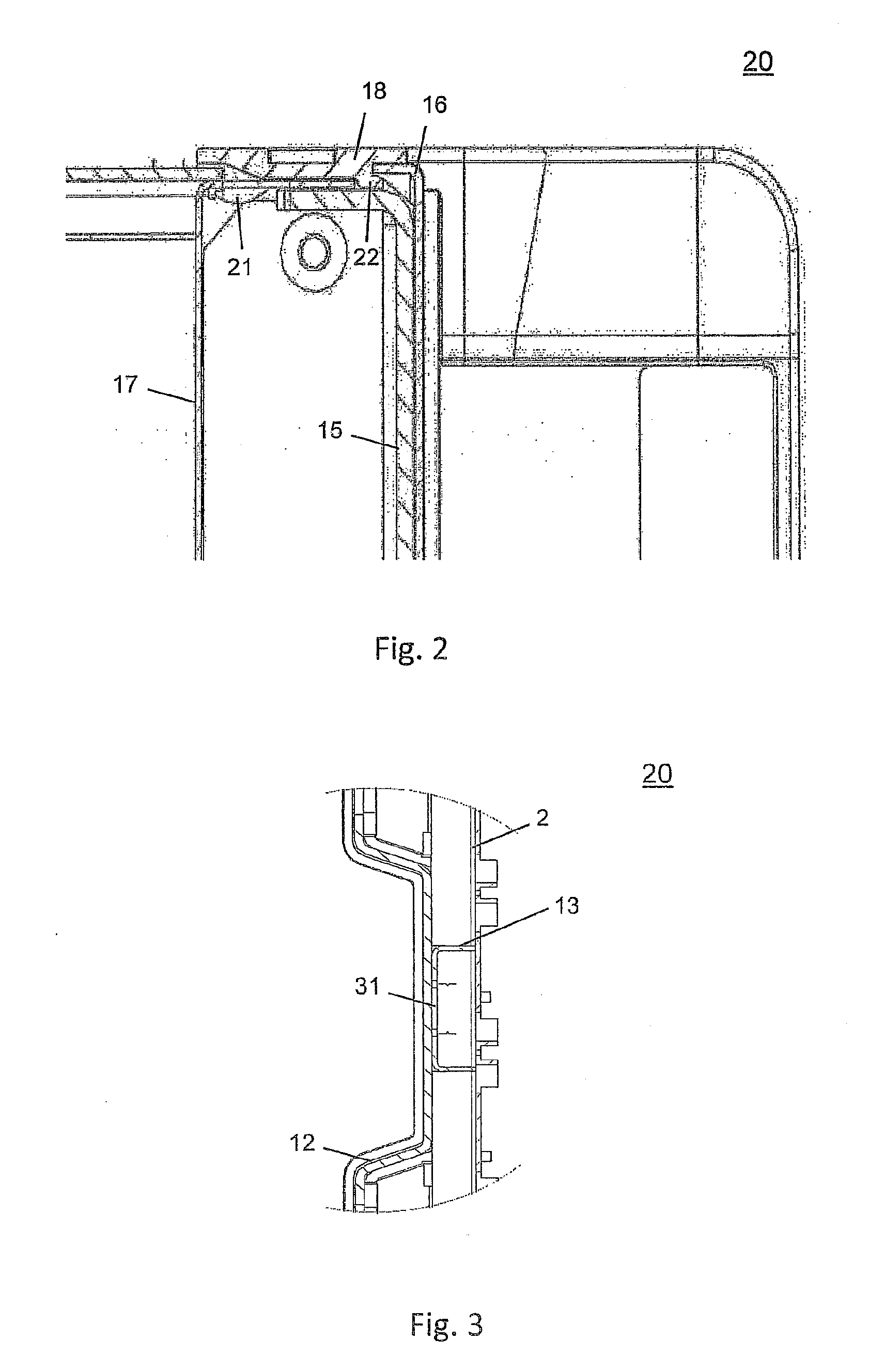

Box-frame housing and a method of manufacture

ActiveUS20130147327A1Avoid bendingAvoid bulgingCooking-vessel materialsScreening gaskets/sealsComputer moduleMechanical engineering

A box-frame housing for the installation of electronic modules has frame elements and side walls and provides a subdivision into sub-regions, which are limited by dividing walls. The frame elements and the side walls and dividing walls provide at least one recess and / or at least one edge projection. A projection engages in a recess and both are connected to one another by welding.

Owner:ROHDE & SCHWARZ GMBH & CO KG

Method for manufacturing a stage of a steam turbine

ActiveUS20160265368A1Improve assembly timeIncrease costBlade accessoriesLeakage preventionEngineeringOne stage

A method for manufacturing a stage of a steam turbine comprising the steps of milling a block of material to define a sector having a plurality of blades, each blade having an external surface; machining an opening in the external surface of at least one of the blades; machining a cavity in fluid communication with the opening; the step of machining the cavity being performed by wire electric discharge machining.

Owner:NUOVO PIGNONE TECH SRL

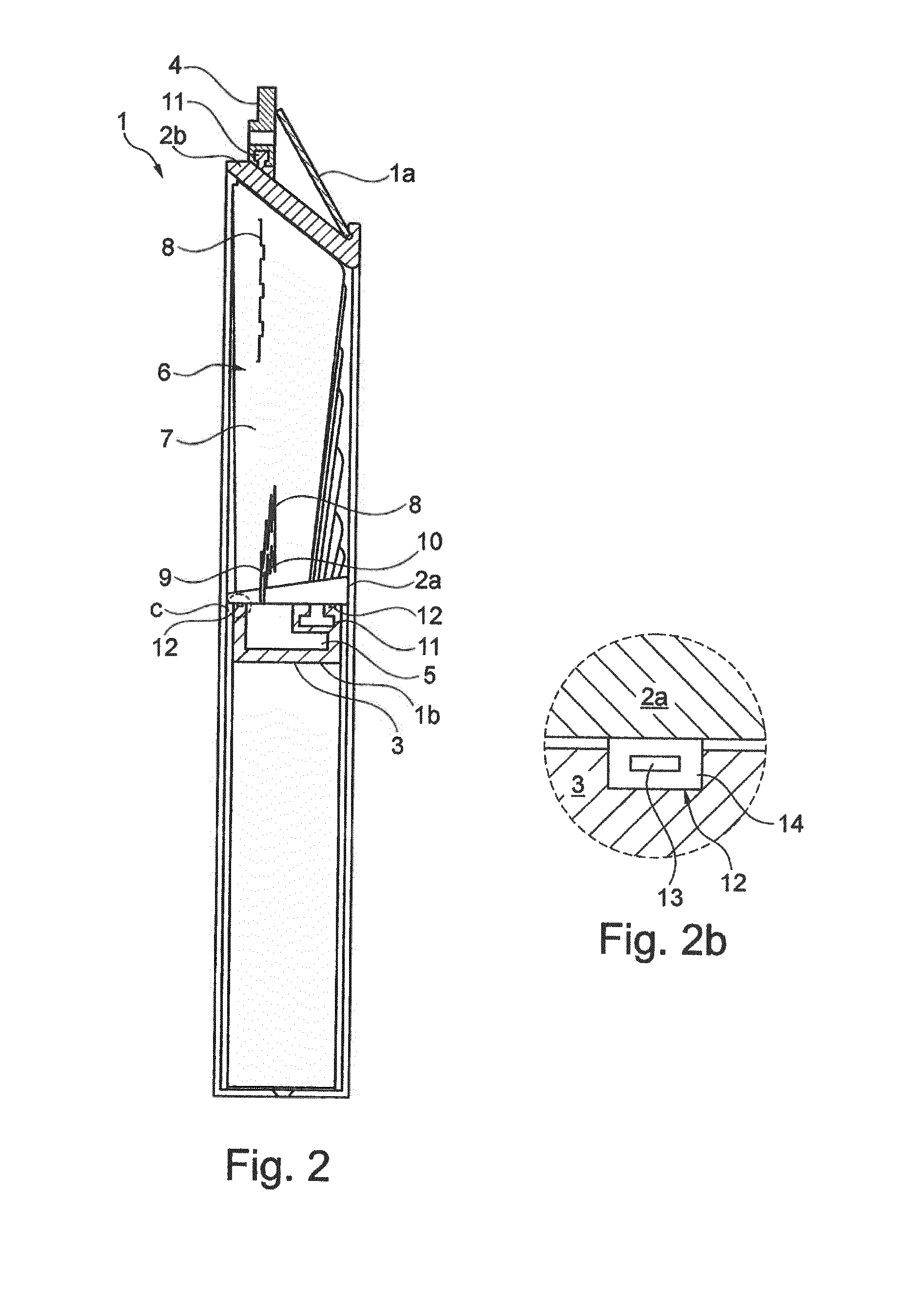

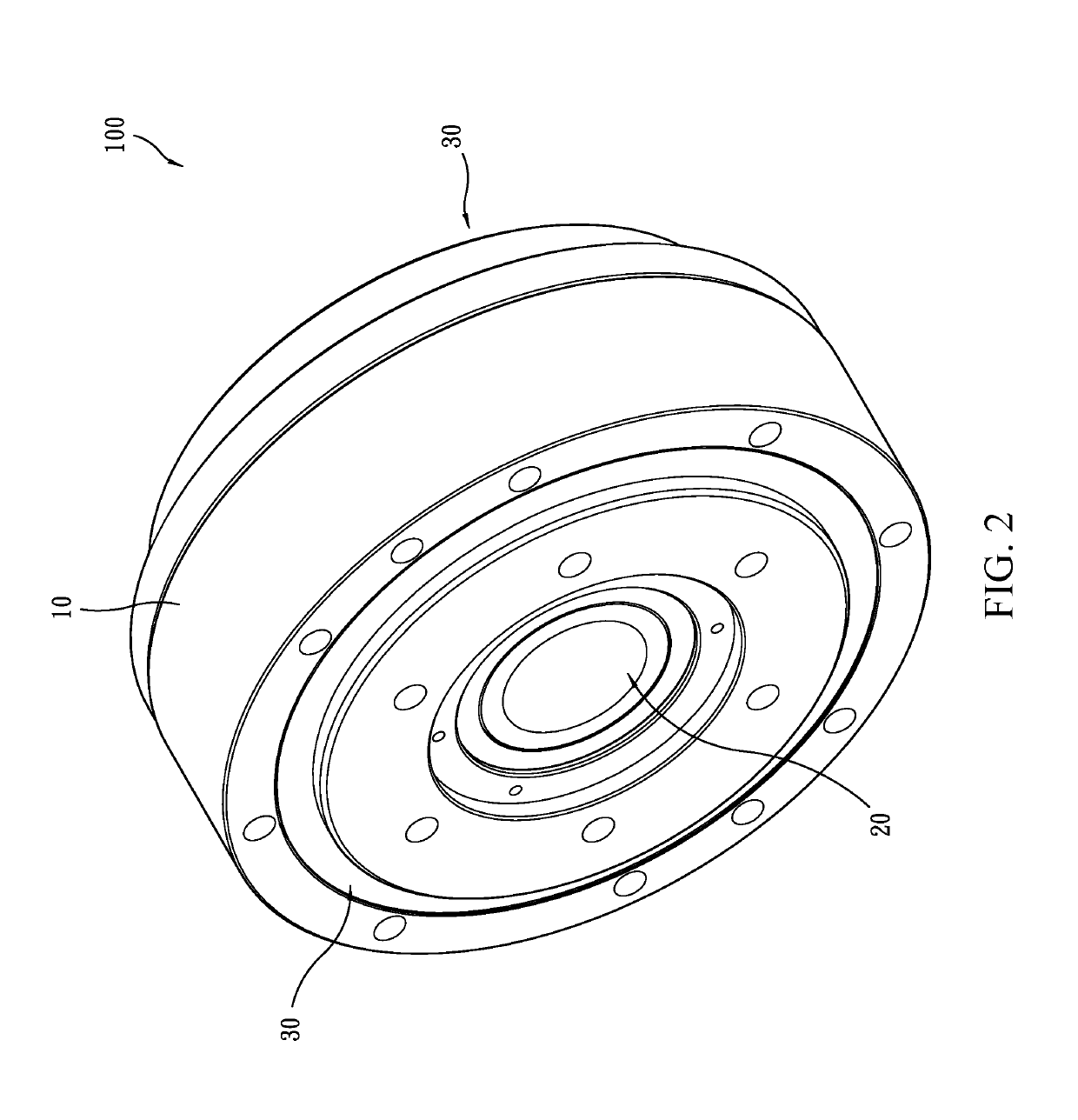

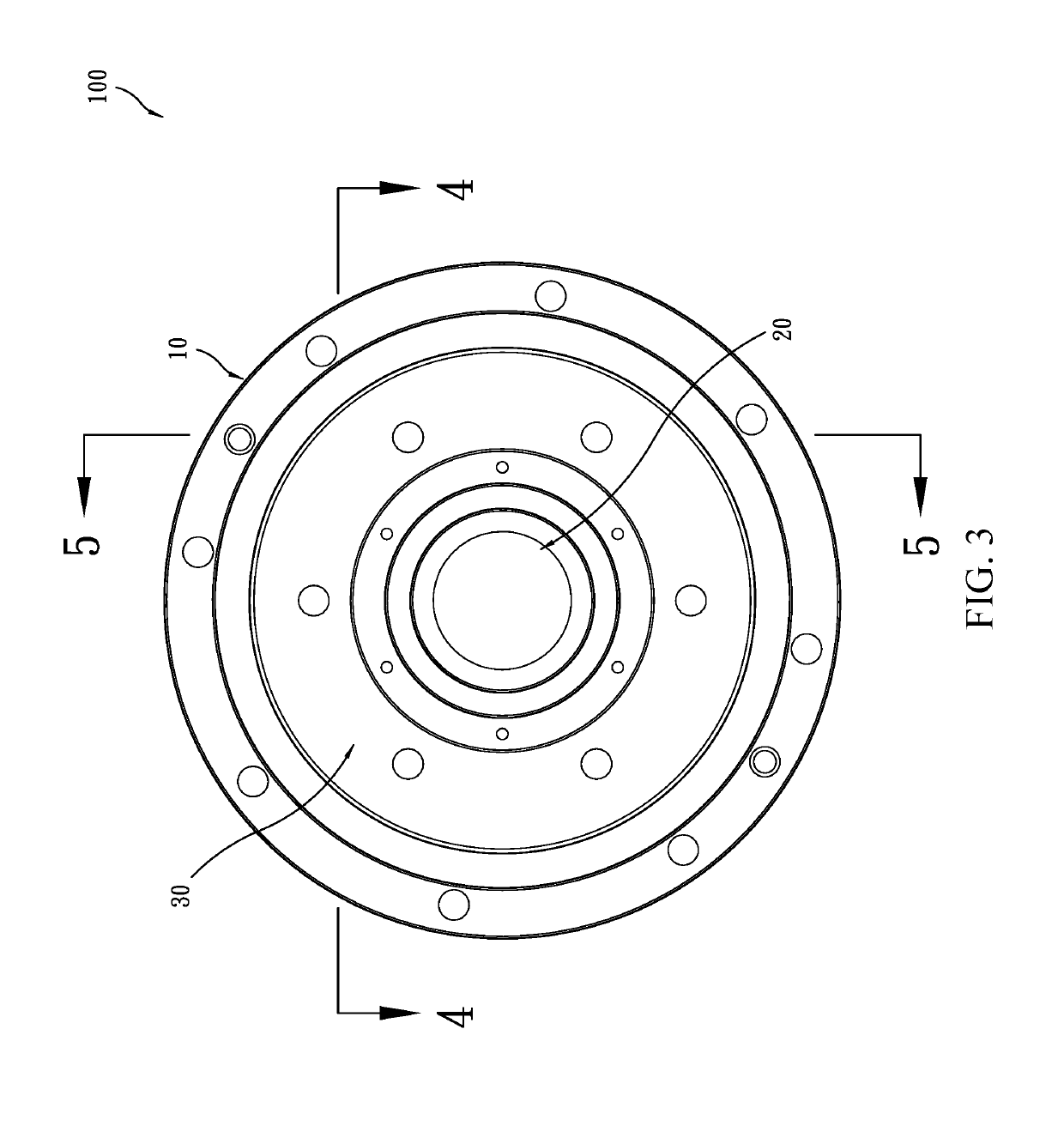

Cycloidal reducer

InactiveUS20190113105A1Poor assemblyEasy to cause damageYielding couplingToothed gearingsCouplingEngineering

A cycloidal reducer includes a housing, an input bushing mounted in the housing for input of a rotational force, and two speed-reduced output units, each of which includes a cycloidal disc, an output member, a cross Oldham coupling member, and a plurality of rolling elements. The cycloidal disc is mounted to the input bushing and has troughs formed in an end face thereof and each having a sidewall forming an inclined surface. The output member has troughs formed in an end face thereof. The cross Oldham coupling member has coupling sections, each having a sidewall forming an inclined surface. The coupling sections are respectively received in the troughs of the cycloidal disc and the output member. The rolling elements are arranged between the inclined surfaces of the cycloidal disc and the cross Oldham coupling member and between the sidewalls of the output member and the cross Oldham coupling member.

Owner:HIWIN TECH

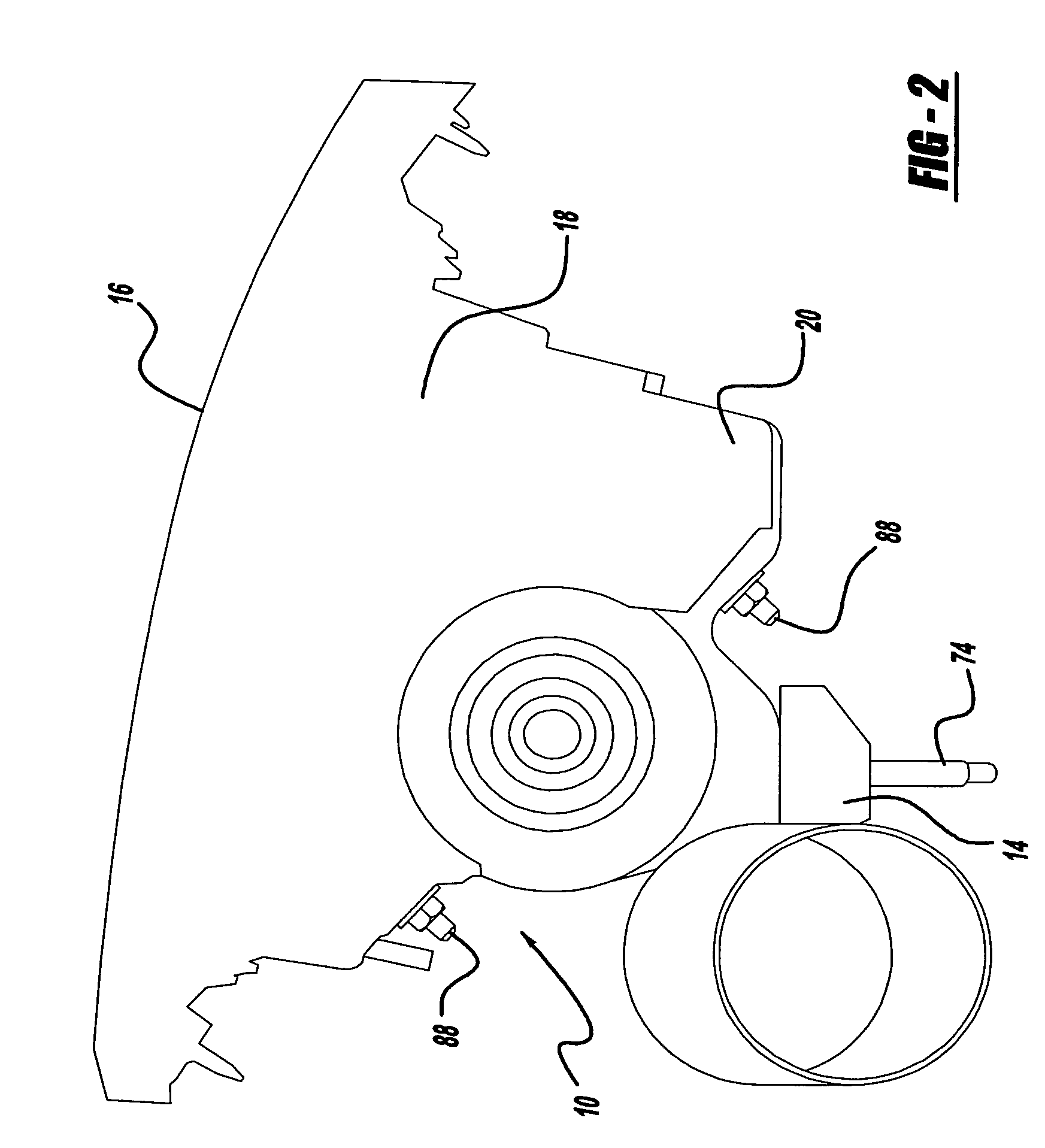

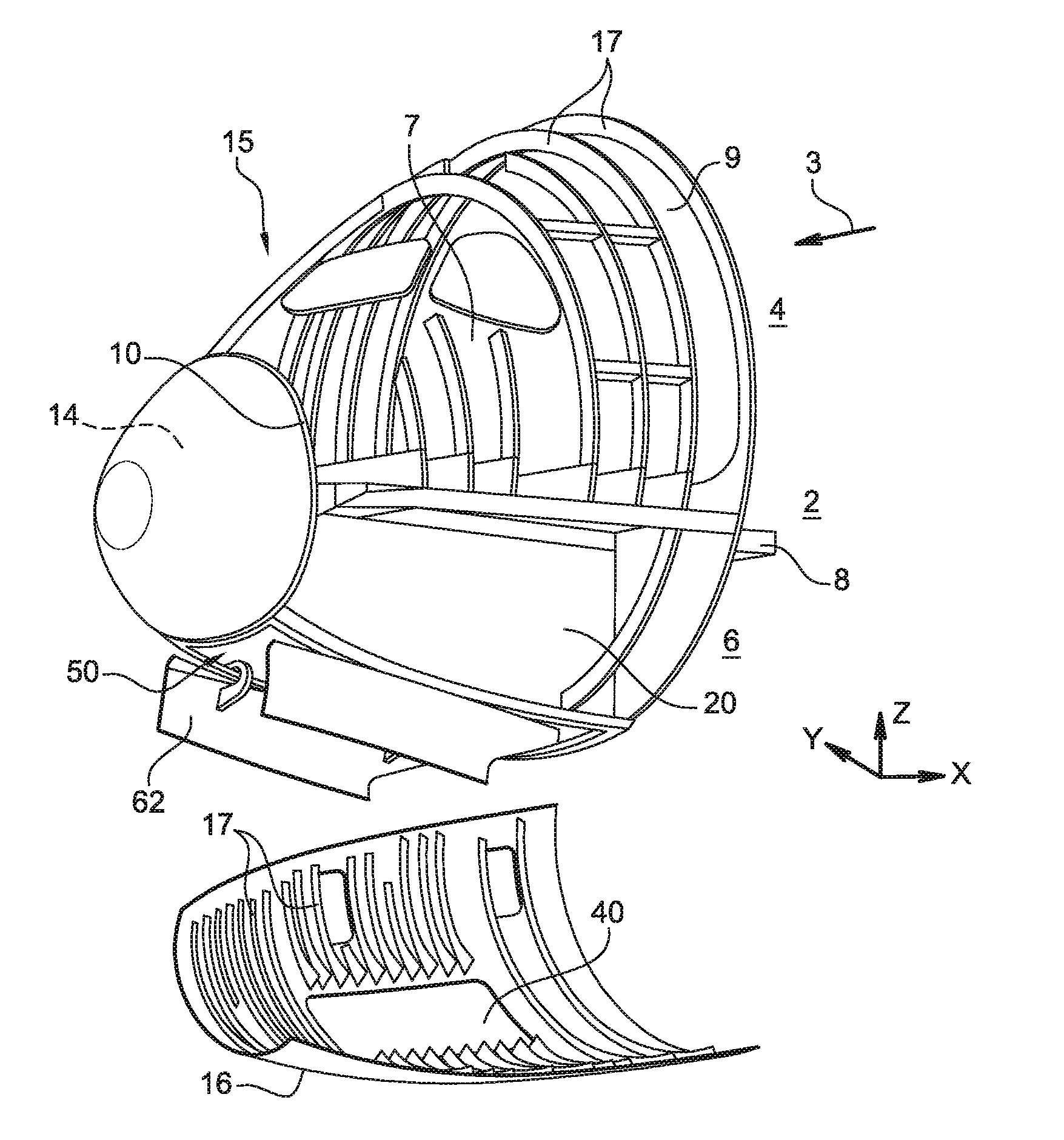

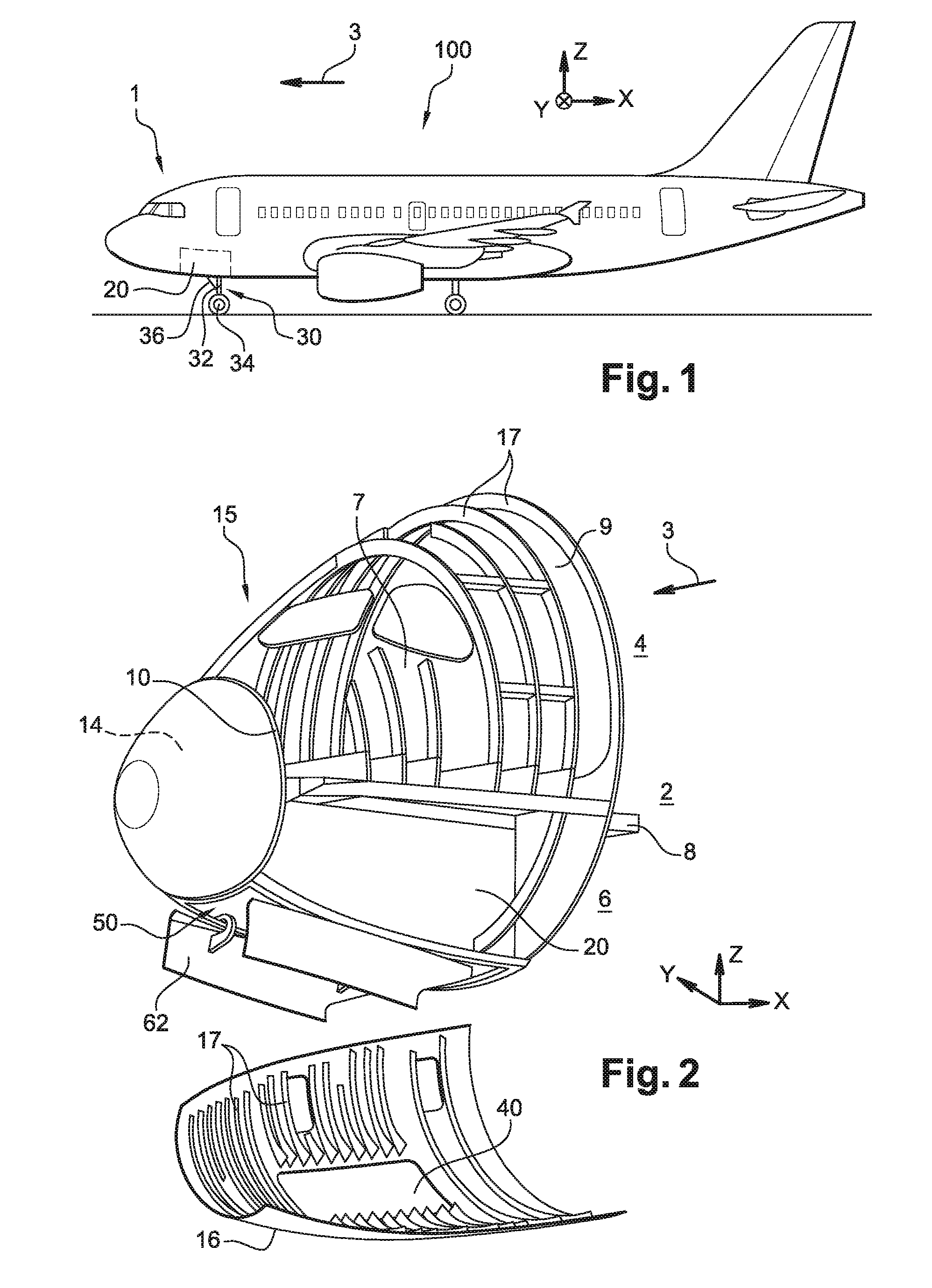

Aircraft nose provided with a connecting frame between the landing gear housing and the outer skin of the fuselage

ActiveUS20160176513A1Little accuracyImprove assembly timeFuselage framesFuselage bulkheadsFuselageAirplane

In order to assist fitting of doors to the landing gear housing and adjusting their position, an aircraft nose is provided comprising a connecting frame between the landing gear housing and the outer skin of the fuselage, the connecting frame extending around an opening in the outer skin and comprising a skirt bearing against the outer skin of the fuselage and attached thereto, the skirt defining a passage for landing gear which is configured to be closed off by doors when the landing gear are in a closed position, and supporting members extending between the fuselage and the doors.

Owner:AIRBUS OPERATIONS (SAS)

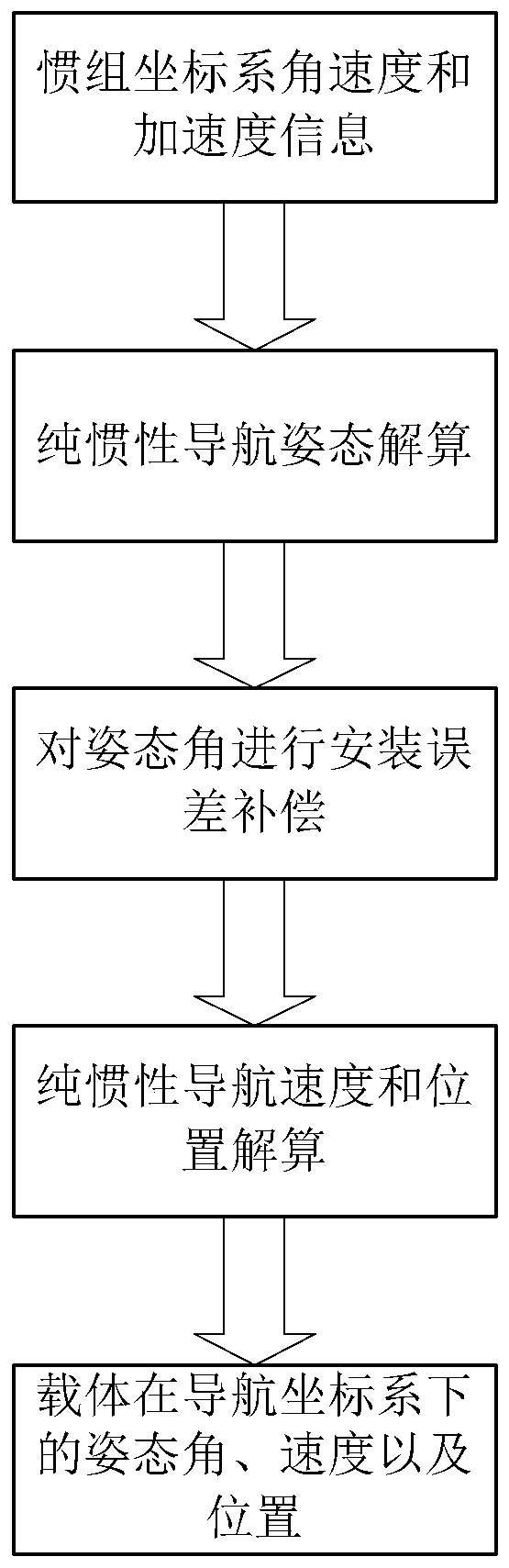

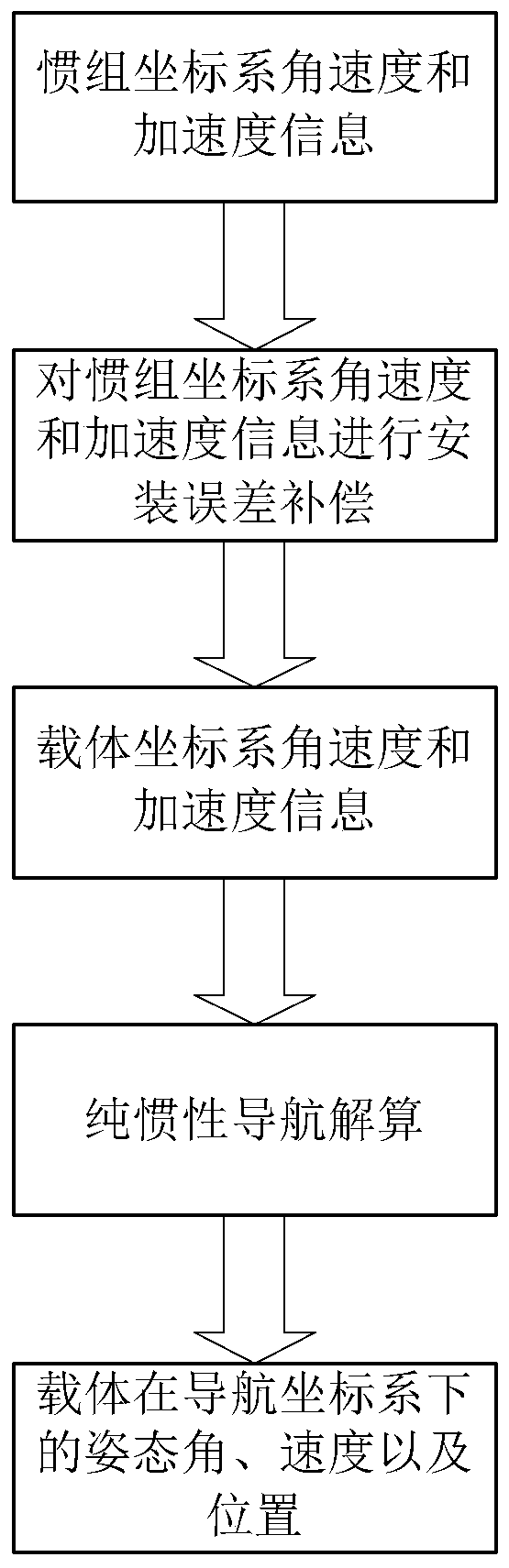

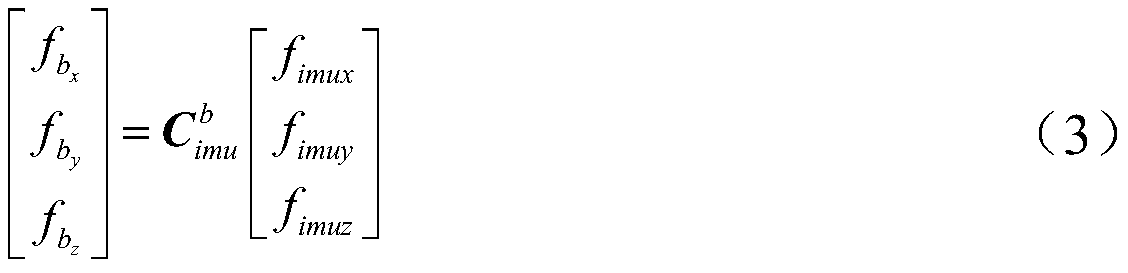

Method for compensating inertial installation error of cabin assembly

PendingCN109781146AReduce processing difficultyShorten the processing cycleMeasurement devicesInstallation ErrorAngular velocity

The invention provides a method for compensating the inertial installation error of a cabin assembly. A rotation matrix C<imu>b from a carrier coordinate system to an inertial coordinate system is defined; pure inertial navigation solution is carried out by using angular velocity and acceleration information in the inertial coordinate system to obtain an attitude matrix C<n>imu and installation error compensation is carried out on the attitude matrix C<n>imu by the rotation matrix C<imu>b and an outputted attitude matrix is C<n>b, an attitude angle of the carrier under the navigation coordinate system is calculated based on the C<n>b and then a speed and position of the carrier in the navigation coordinate system are calculated; or data outputted by the inertia group are compensated directly by the rotation matrix C<imu>b, pure inertial navigation solution is carried out by using the compensated inertial group data, an attitude angle of the carrier in the navigation coordinate system is calculated, and then the speed and position of the carrier in the navigation coordinate system are calculated. Therefore, the accuracy of the navigation system is improved; the influence of the inertial installation error on the flight control system is reduced; and a solution to the inertia installation error compensation of the cabin product with the large volume and weight is provided.

Owner:XIAN MICROELECTRONICS TECH INST

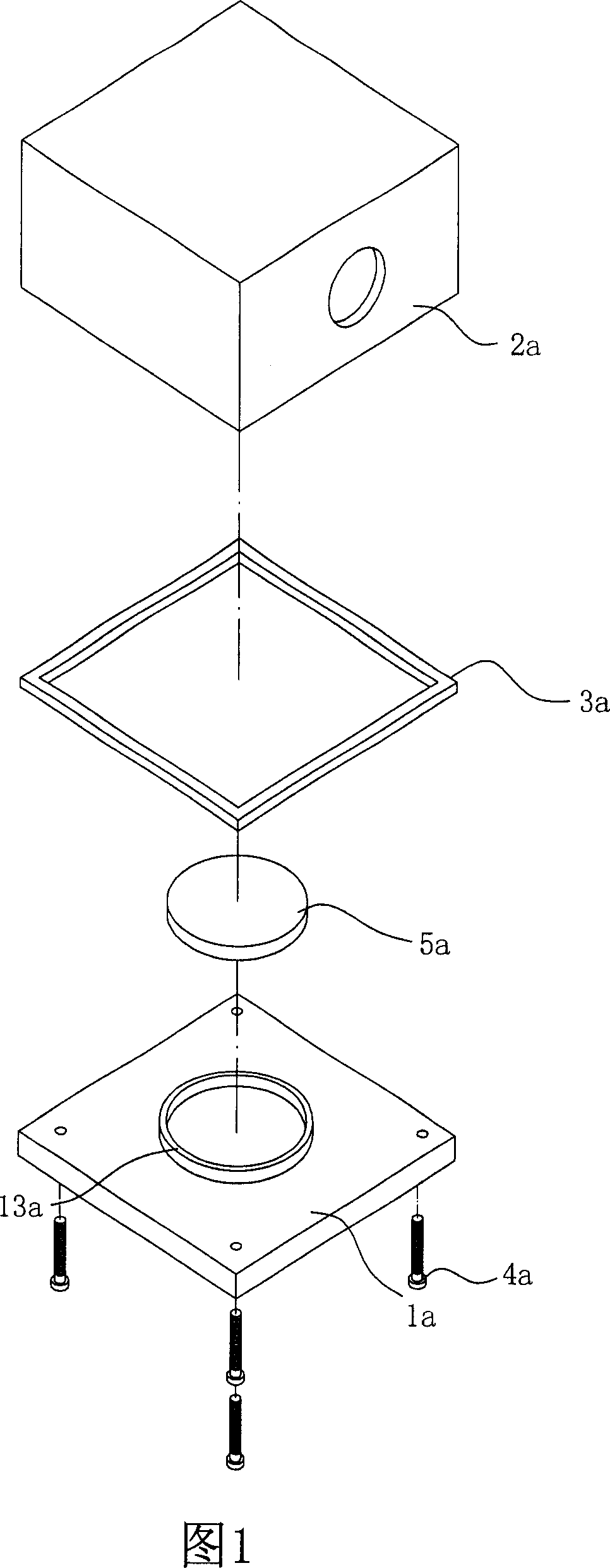

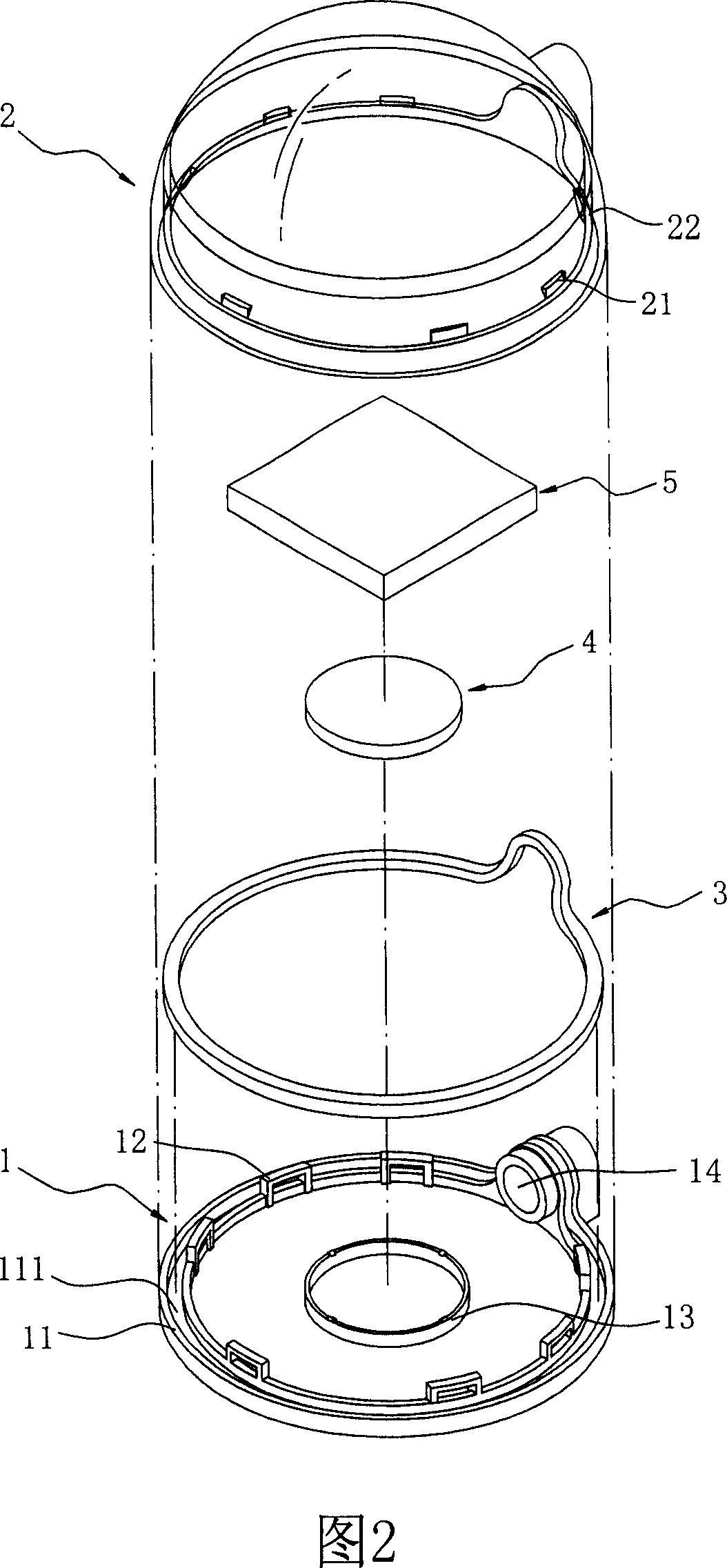

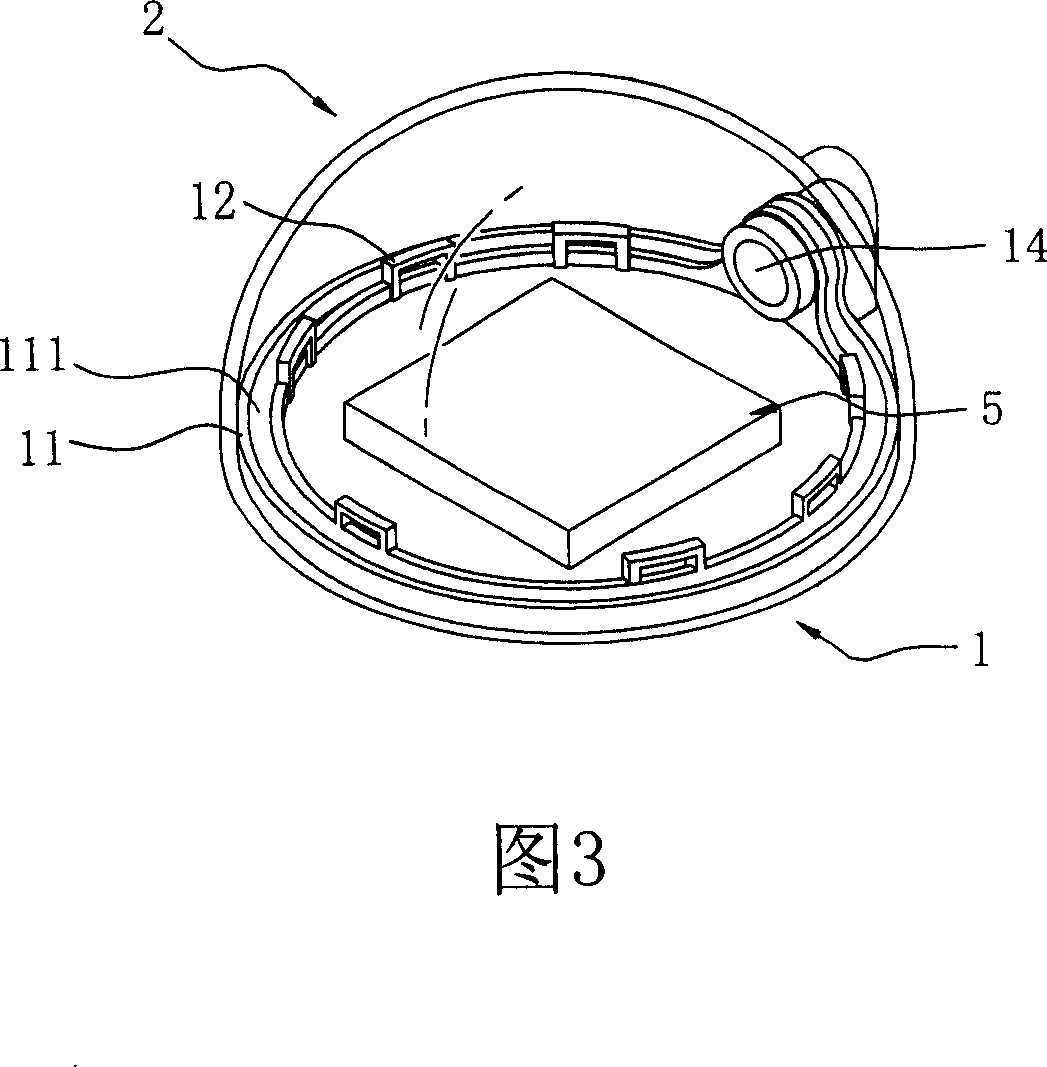

Electronic product housing having waterproof and non-screw locking function

InactiveCN101119619AAchieve waterproof effectOmit the time to wait for the glue to setCasings/cabinets/drawers detailsSatellite radio beaconingBlock structureMechanical engineering

Owner:YOUNGTEK ELECTRONICS

Media Control Valve

InactiveUS20150362079A1Minimize impactEliminates and sealSpindle sealingsOperating means/releasing devices for valvesMedia controlsEngineering

A media control valve includes a body, a plunger assembly of multiple components housed in the body with a plunger control valve cap assembly secured to the body for housing a control knob. The body and the plunger assembly include resilient seals between adjacent multiple components of the body and the plunger assembly, respectively, to permit relative movement therebetween during assembly and use. The media control valve includes a diaphragm which acts as a membrane that physically isolates and seals the chambers above and below. The spool sleeve design of the valve has all of the plunger seals and bushings held within the sleeve. Once the spool sleeve is removed, the replacement seals and bushings can be replaced and inspected with relative ease due to the accessibility at both ends of the sleeve. Since each plunger seal is held within its own rigid cavity, held on three sides and not stacked on top of another seal or loose component, proper alignment is better assured during and after installation. The body components parts are also assembled using resilient seals to facilitate assembly and repair, while reducing any tendency of the valve to seize during use.

Owner:NGUYEN PHUONG TAYLOR +2

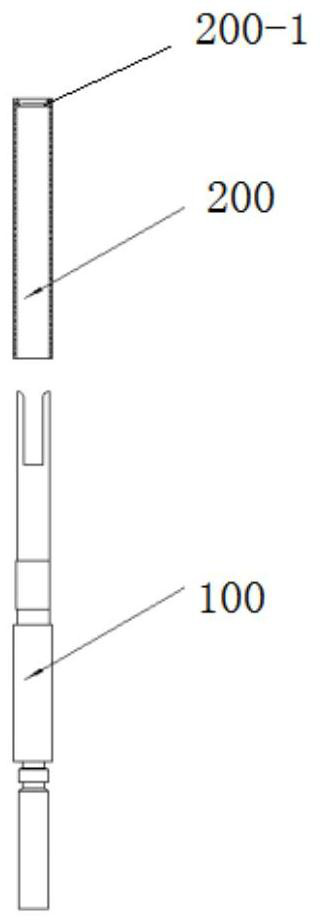

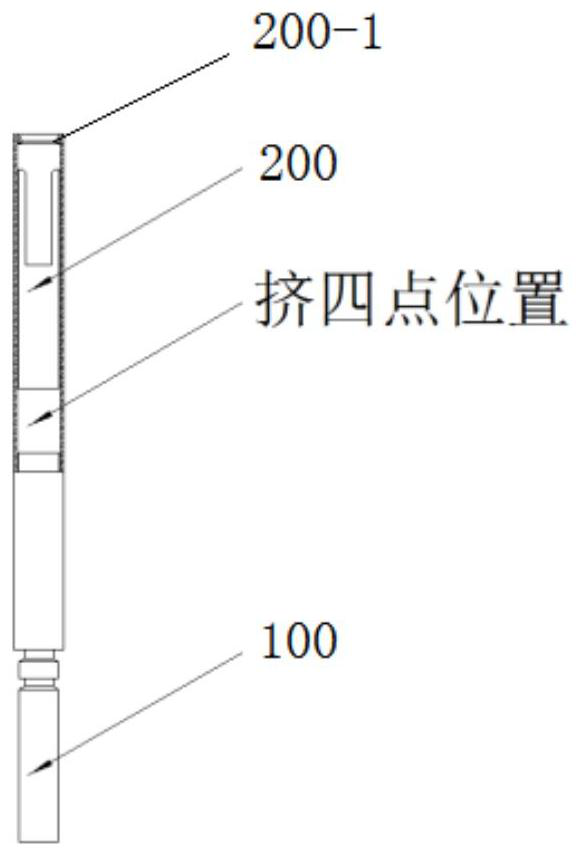

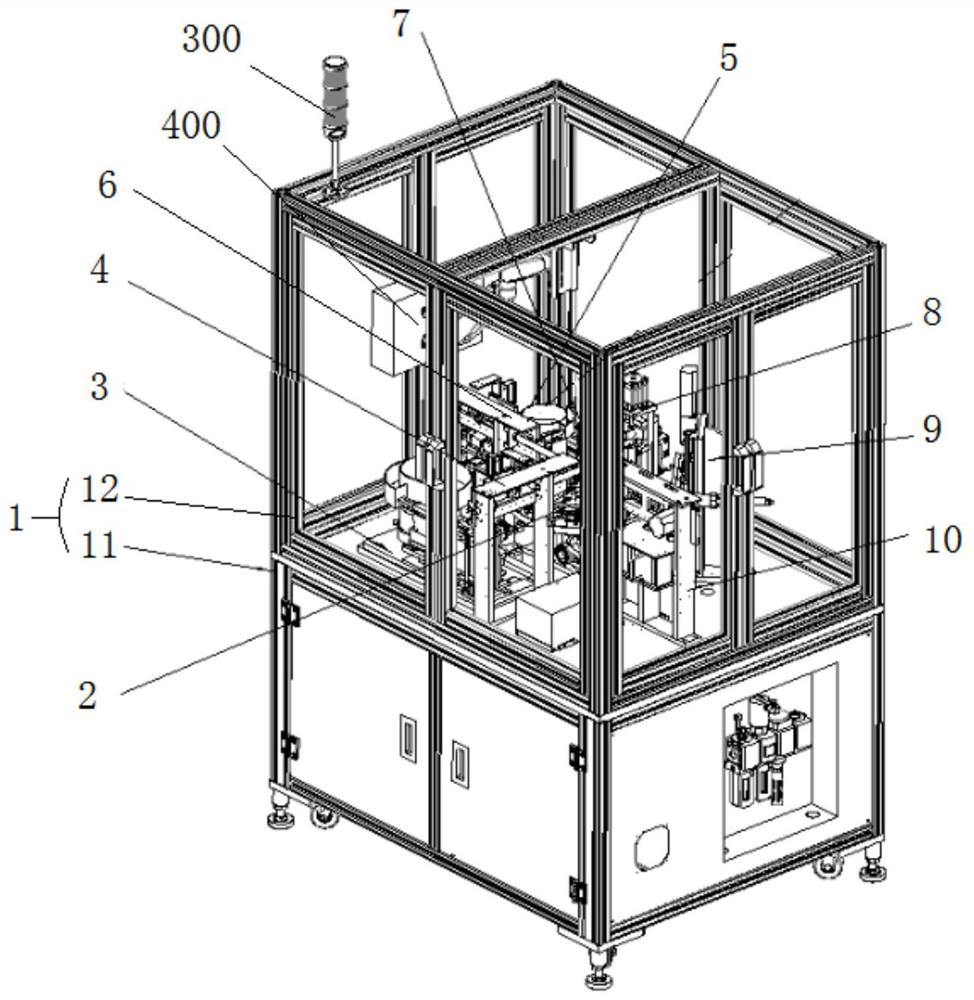

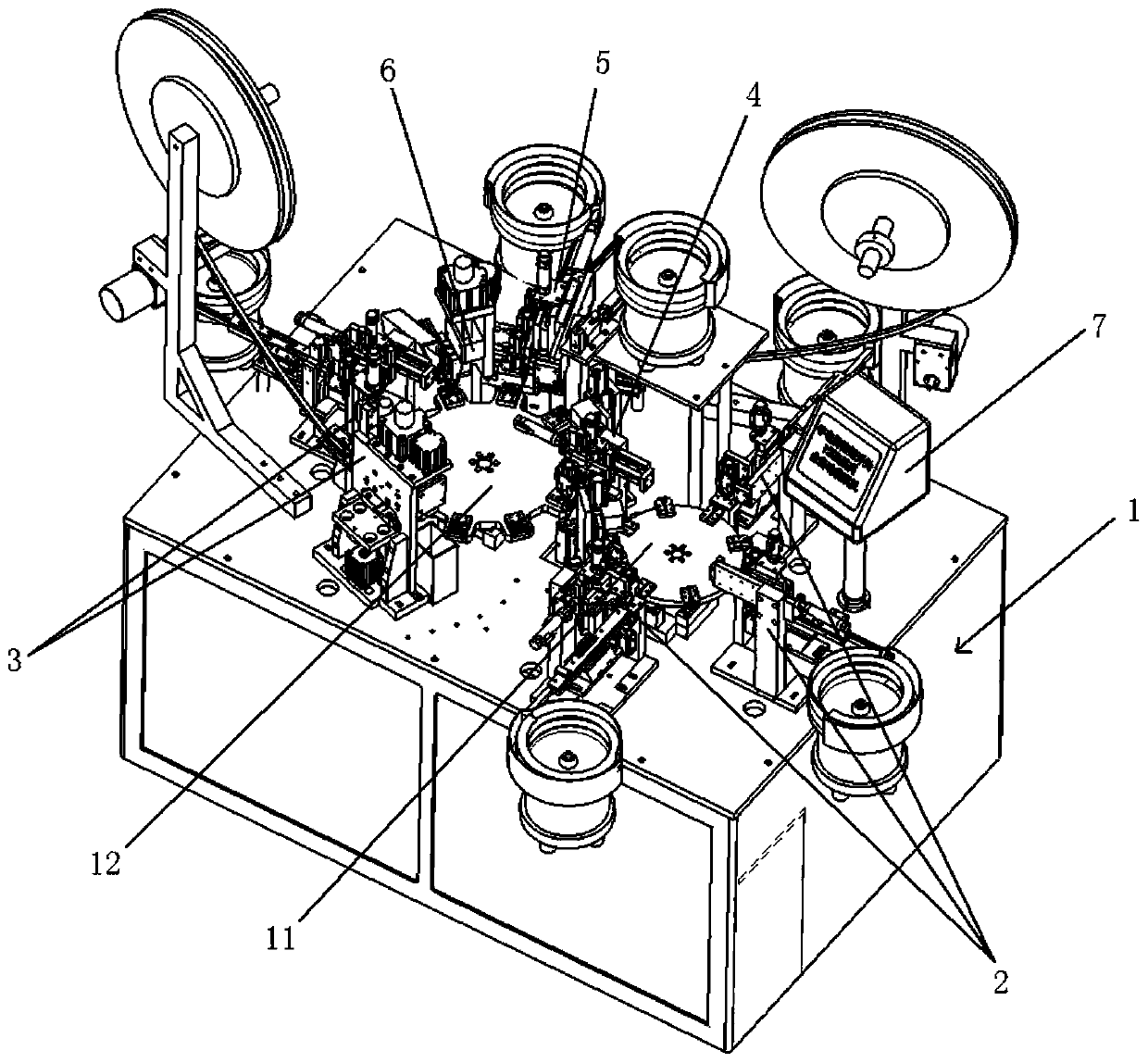

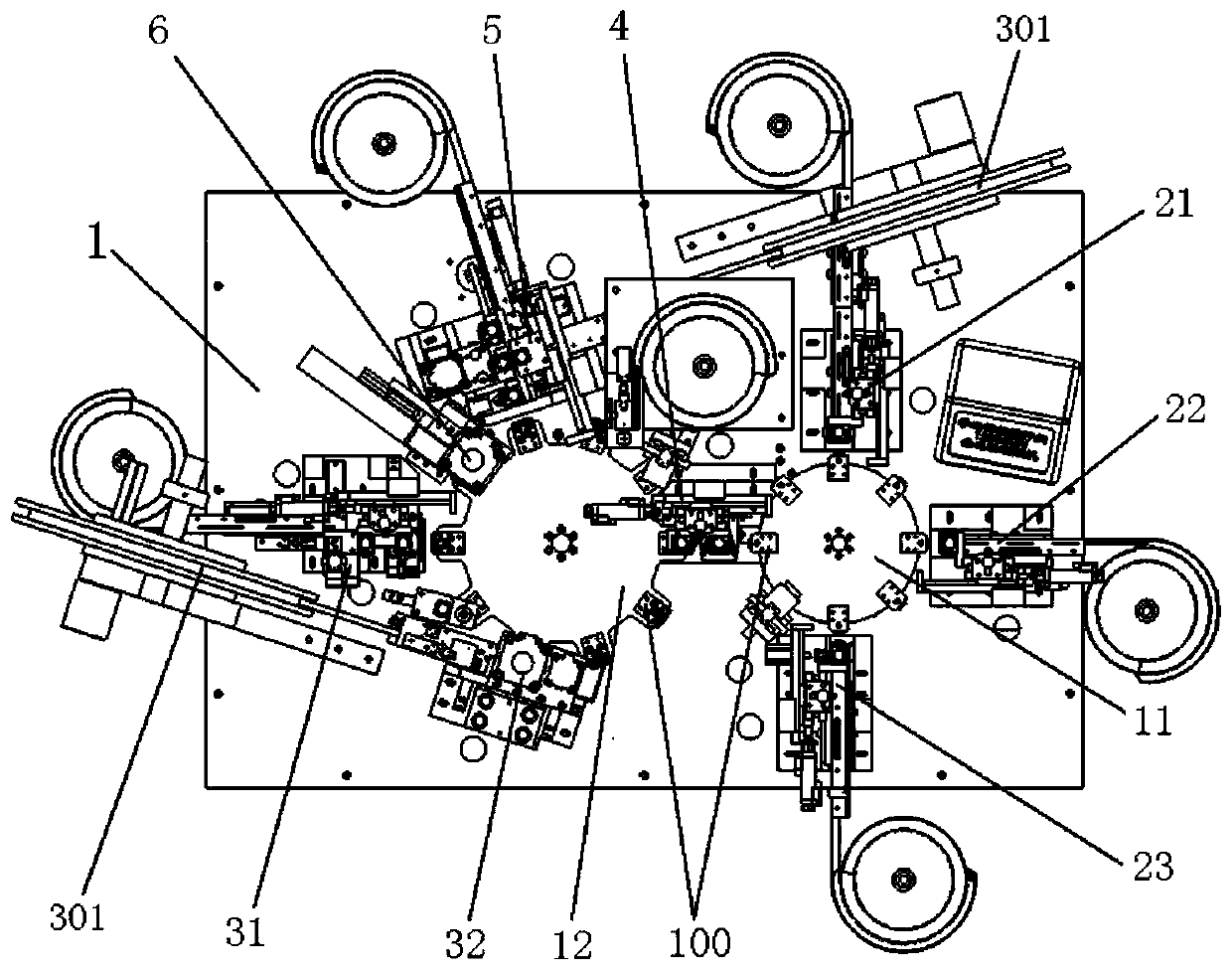

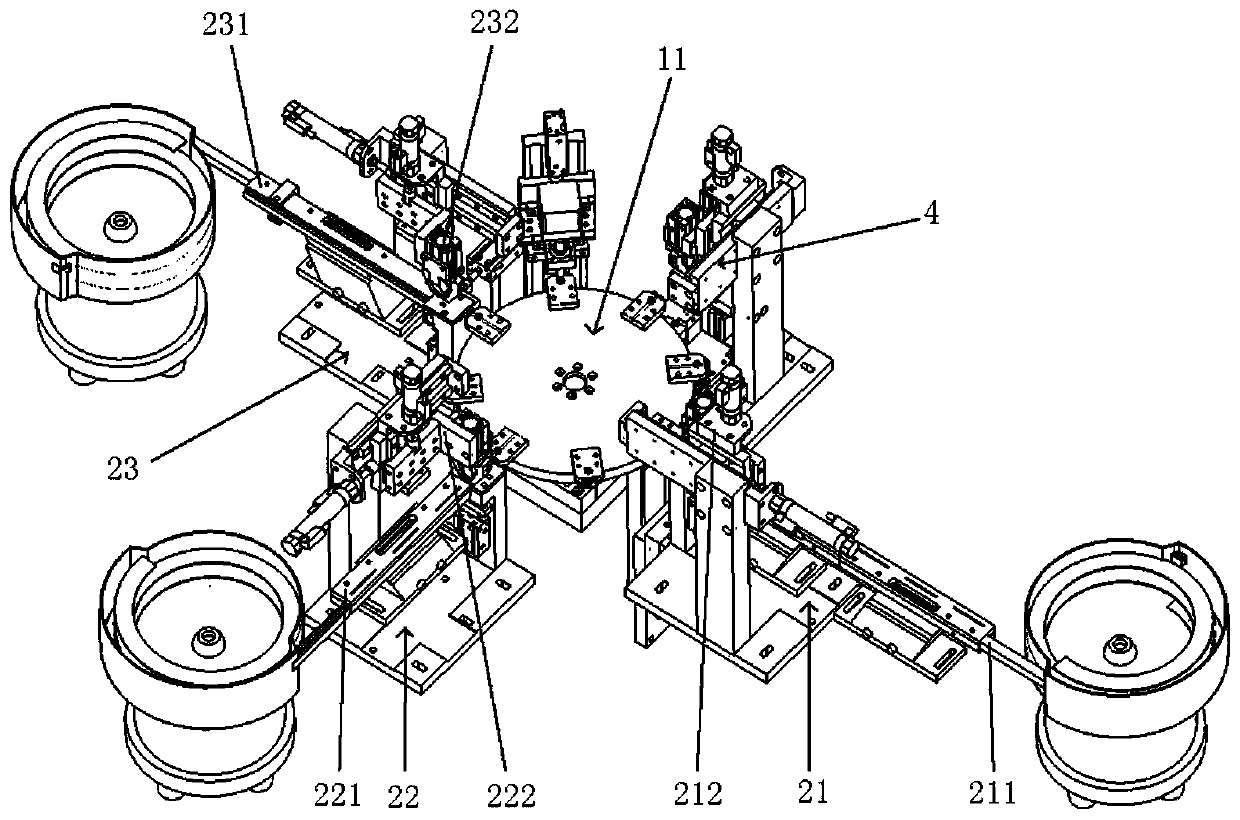

Automatic assembling equipment for riveting and extruding points of jacks and protection sleeves and assembling method thereof

PendingCN112517774AImplement automatic assemblyAchieve squeeze pointContact member assembly/disassemblyMetal-working feeding devicesProtection KITMechanical engineering

The invention provides automatic assembling equipment for riveting and extruding points of jacks and protection sleeves. The automatic assembly equipment comprises a frame assembly, a rotating tool assembly, a jack staggering and separating assembly, a jack feeding assembly, a protection sleeve detecting assembly, a protection sleeve direction selecting assembly, a protection sleeve feeding assembly, a bidirectional riveting and pressing assembly, an adjustable stroke point extruding assembly and a finished product discharging assembly. The invention further provides an assembling method of the automatic assembling equipment. The automatic assembling equipment is full-automatic equipment, can achieve automatic assembling, riveting and point extruding of jack parts and protection sleeve parts and can achieve automatic feeding and discharging; manual operation is not needed; the automatic assembling equipment is safe and stable; and the problems that the manual assembly efficiency is low, the workload is heavy, the assembling method is complex, and the requirements on the proficiency degrees of operators are high are solved. The assembling time and the consistency of the jacks and the protection sleeves are greatly improved; the quality problem is avoided; and the automatic assembling equipment has an important application value in an assembling process of the jacks and the protection sleeves.

Owner:沈阳兴华航空电器有限责任公司

Automatic assembling equipment

PendingCN110033968AImprove assembly timeReduce waiting timeElectric switchesIndustrial engineeringWaiting time

The invention discloses automatic assembling equipment, which is used for assembling a button switch. The automatic assembling equipment comprises a rack, and a first rotary table, a second rotary table, a bottom part assembling component, a middle part assembling component, an upper part assembling component and a middle assembling device arranged on the rack; the middle assembling device is usedfor assembling a finished bottom part of the bottom part assembling component and a finished middle part of the middle part assembling component into a semi-finished part; and according to the condition that the assembling tail end of the middle assembling device is positioned on the first rotary table or the second rotary table, the first rotary table or the second rotary table continues to rotate for enabling the semi-finished part and the finished bottom part of the bottom part assembling component to finish finished product assembling. By adopting the technical scheme, the waiting time ofeach assembling process can be greatly shortened, so that the total assembling time is shortened, the overall assembling progress is accelerated, the assembling time of the button switch is shorter,the assembling efficiency is improved, the automatic assembling operation is realized, the product assembling quality is guaranteed, and the labor cost is reduced.

Owner:YUEQING BOFENG ELECTRONICS CO LTD

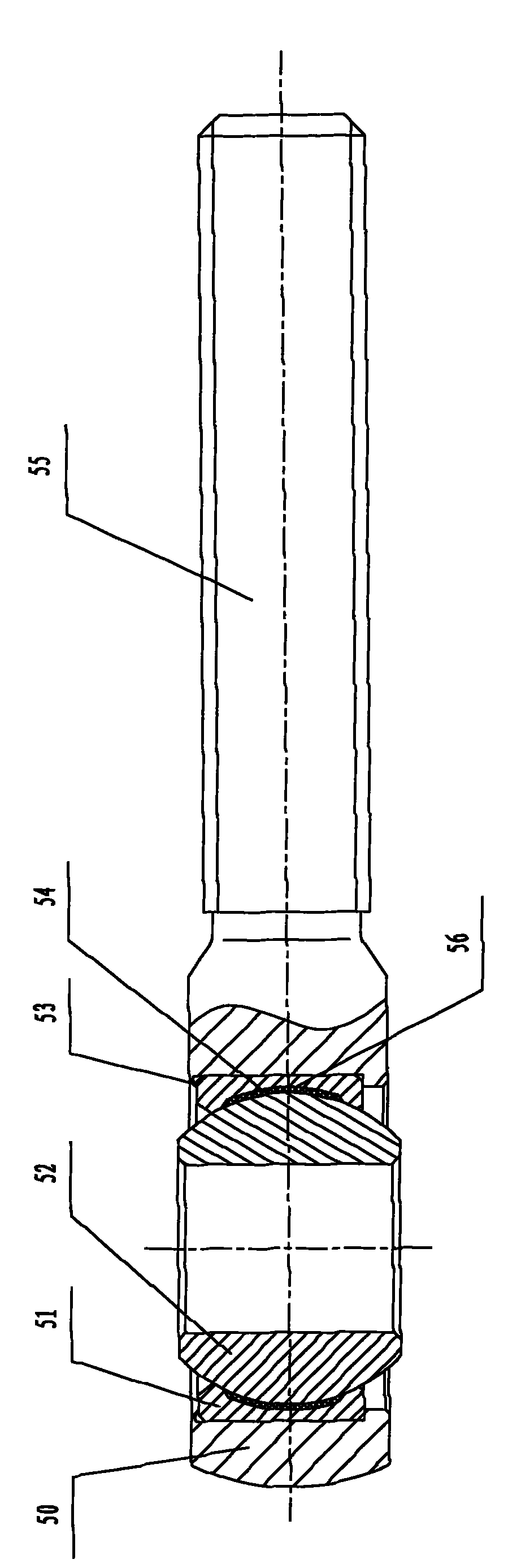

Accurate positioning type coupler and assembling technology

InactiveCN104141701AEasy to assembleEasy to installCouplings for rigid shaftsMetal working apparatusCouplingAgricultural engineering

The invention discloses an accurate positioning type coupler and an assembling technology, aims at providing a coupler accurate in positioning and convenient to install, and belongs to the technical field of mechanical transmission part design. According to the technical scheme, the accurate positioning type coupler comprises a spline shaft, the spline shaft is provided with an upper installing clamping position matched with an upper bearing, and a lower installing clamping position matched with a lower bearing, a boss-shaped revolution surface is formed between the two installing clamping positions, and the upper bearing and the lower bearing are clamped and assembled at the two clamping positions on the two sides of the boss-shaped revolution surface respectively. The upper bearing and the lower bearing are sleeved with a bearing sleeve, the two ends of the bearing sleeve are fixedly provided with an upper end cover and a lower end cover respectively, and the upper end cover is connected with an upper end cover sleeve.

Owner:GUANGXI YULIN EXCELLENT POWER GENERATOR EQUIPCO

Fixation structure for manual ice maker

ActiveCN103322743AImprove assembly timeSolve the production taktLighting and heating apparatusIce productionFreezing chamberEngineering

The invention relates to the technical field of refrigerators in electrical equipment, and more particularly relates to a fixation structure for a manual ice maker. The fixation structure for the manual ice maker comprises a glass layer frame, an ice maker outer frame, an ice maker bracket and a clamping buckle, wherein an installation structure is arranged on the glass layer frame, and a location hole is formed in the ice maker outer frame; a bulged part is arranged at one end of the ice maker bracket, and a connection structure cooperated with the clamping buckle is arranged at the other end of the ice maker bracket; the ice maker bracket is inserted into the location hole, the bulged part and the clamping buckle are fixed in the installation structure respectively, and the ice maker outer frame can move along the length direction of ice maker bracket. Installation for the fixation structure for the manual ice maker disclosed by the invention is completely operated off line, namely, all the components are assembled and then installed on the liner of the freezing chamber box of a refrigerator, so that the assembly time is greatly prolonged; moreover, the ice maker outer frame can move along the length direction of the ice maker bracket, so that the space of the freezing chamber can be adequately utilized.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

Box-frame housing and a method of manufacture

ActiveUS9167713B2Readily accessible for fitting and maintenanceSimple wayScreening gaskets/sealsCasings/cabinets/drawers detailsComputer moduleEngineering

A box-frame housing for the installation of electronic modules has frame elements and side walls and provides a subdivision into sub-regions, which are limited by dividing walls. The frame elements and the side walls and dividing walls provide at least one recess and / or at least one edge projection. A projection engages in a recess and both are connected to one another by welding.

Owner:ROHDE & SCHWARZ GMBH & CO KG

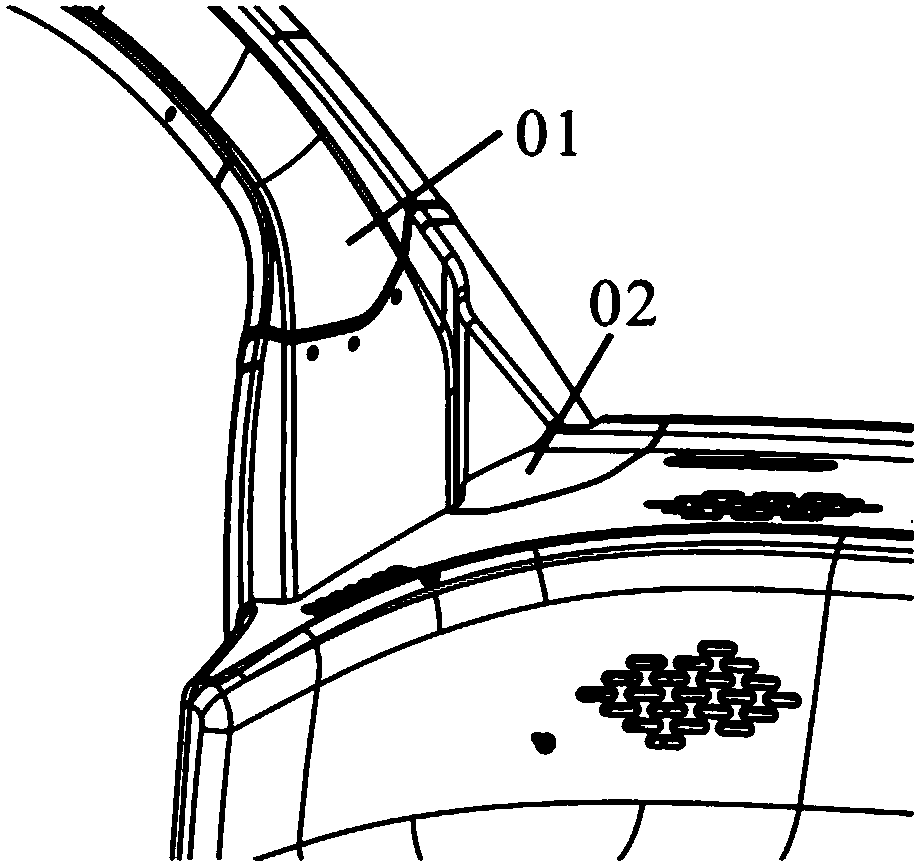

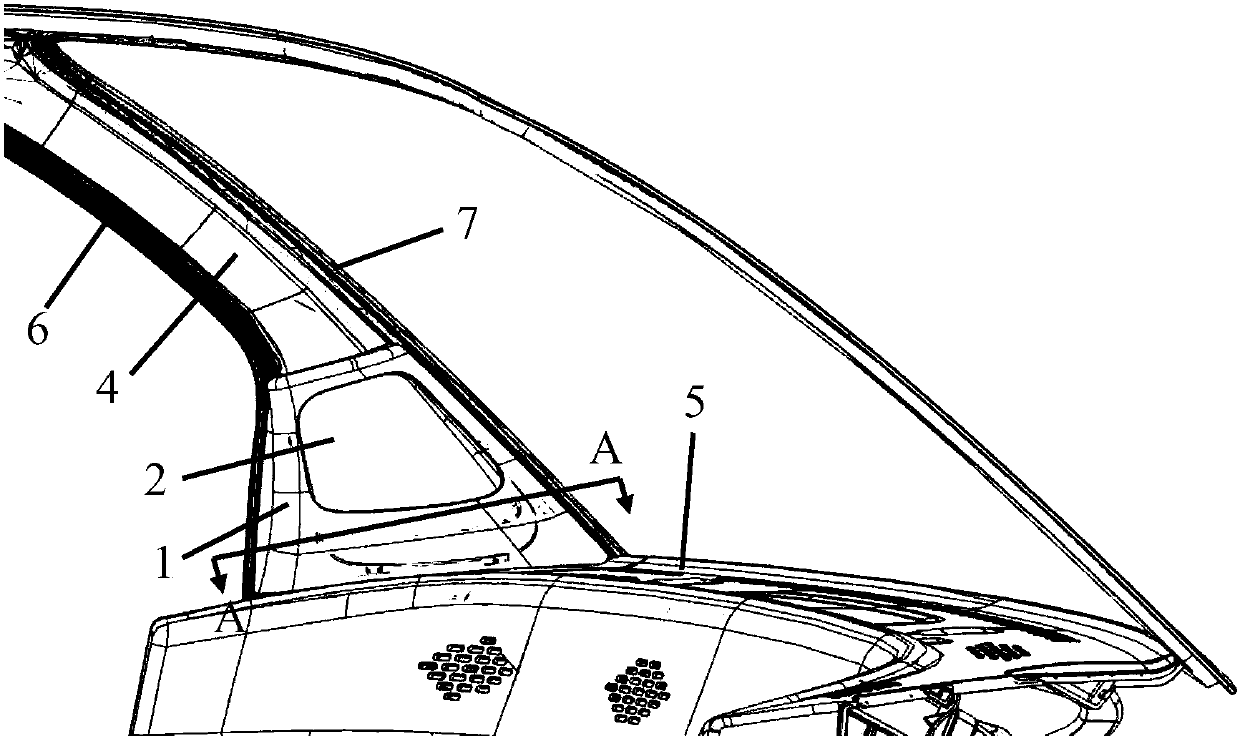

Automobile A-pillar decorative panel with storage function

PendingCN109955906AEasy to disassembleEasy to assemblePassenger spaceSuperstructure subunitsEngineering

The invention discloses an automobile A-pillar decorative panel with the storage function. The A-pillar trim panel comprises an A-pillar decorative panelouter plate and an A-pillar decorative panel inner plate. The A-pillar decorative panel outer plate is detachably fixed on the A-pillar decorative panel inner plate. The A-pillar decorative panel inner plate is detachably fixed on a A-pillar metalplate. The A-pillar decorative panel outer plate abuts against an instrument panel in a detachable mode, and a storage space is arranged between the A-pillar decorative panel outer plate and the A-pillar decorative panel inner plate. According to the automobile A-pillar decorative panel with the storage function, the welding spots of the A-pillar metal plate and the matched boundary of the instrument panel with the A-pillar metal plate are shielded. The automobile A-pillar decorative panel is easy to mount and dismount. The assembling efficiency is improved, and the storage space is increased.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Joint assembly

PendingUS20210131466A1Prevent movementWeight increaseEngine fuctionsKey type connectionsEngineeringMechanical engineering

A joint assembly joins first and second components about a common axis. The first component has a first end portion having a radially outwardly facing surface shaped to fit radially inside a second surface of a hollow second end portion of the second component to form an interface between the opposing first and second surfaces. The first and second surfaces have a concavity extending laterally with respect to the axis such that when the first and second surfaces are opposingly arranged the opposing concavities define a cavity at the interface. A retaining member is insertable into the cavity at the interface to prevent axial separation of the first and second components. One of the first and second end portions has a free end protrusion axially spaced from the concavity and the other of the first and second end portions has an axially extending recess arranged to receive the free end.

Owner:ROLLS ROYCE PLC

Box-frame housing and a method of manufacture

ActiveUS20150195939A1Avoid bendingAvoid bulgingScreening gaskets/sealsAssembly machinesEngineeringMechanical engineering

A box-frame housing for the installation of electronic modules has frame elements and side walls and provides a subdivision into sub-regions, which are limited by dividing walls. The frame elements and the side walls and the dividing walls provide at least one recess and / or at least one edge projection. A projection engages in a recess and both are connected to one another by welding.

Owner:ROHDE & SCHWARZ GMBH & CO KG

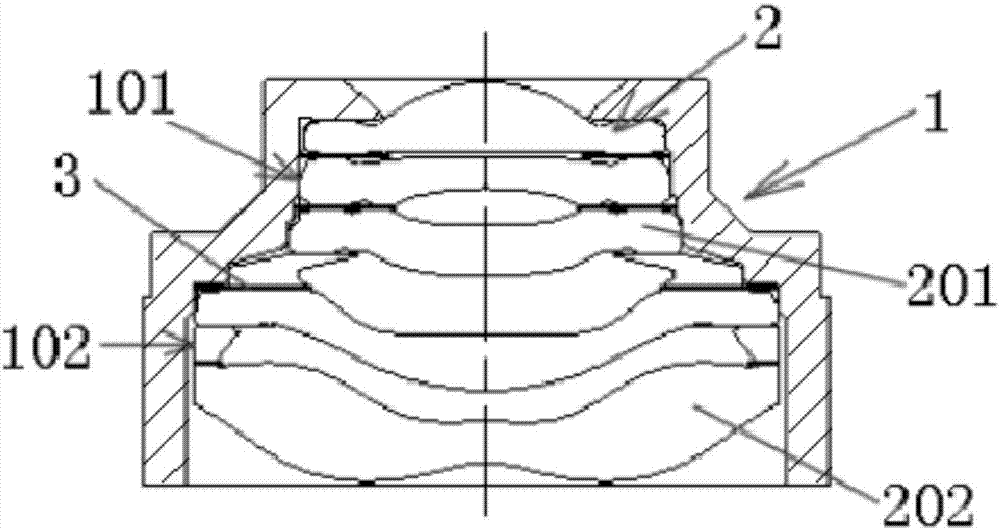

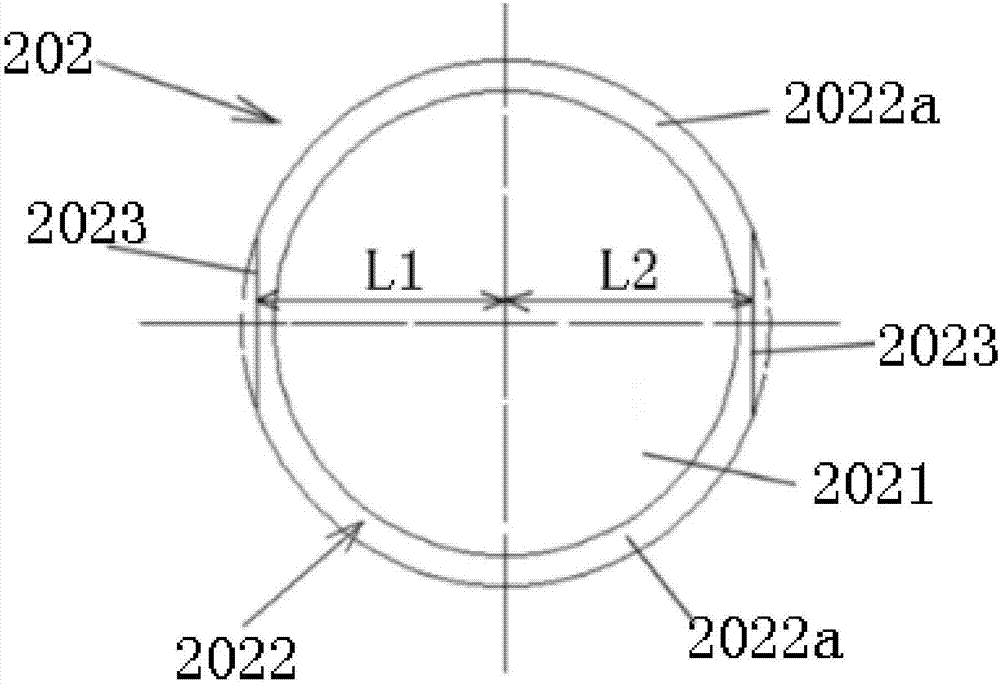

Oscillating bearing

InactiveCN102230497ANo slipping outImprove assembly timeBearing componentsSliding contact bearingsArchitectural engineeringLow copper

The invention relates to an oscillating bearing which is widely applied to the fields of automobile manufacturing, engineering machinery and the like, and can bear greater loadings. The oscillating bearing comprises an inner ring, an outer ring, a connecting rod, an upper copper ring and a lower copper ring, wherein the inner ring is provided with an outer spherical surface; the outer ring is sleeved on the outer part of the inner ring; the connecting rod is integrated with the outer ring; the upper copper ring and the lower copper ring are positioned between the inner ring and the outer ring; the inner cavity of the upper copper ring and the inner cavity of the lower copper ring are internally provided with arc surfaces which are matched with an outer spherical surface of the inner ring; a storage cavity which can store lubricating oil grease is surrounded among the upper copper ring, the outer ring, the lower copper ring and the inner ring; and the upper copper ring and the lower copper ring are connected with the outer ring. Through the oscillating bearing provided by the invention, the assembling time can be saved greatly, and the assembling difficulty is reduced.

Owner:宁波市鄞州超杰汽车零部件有限公司

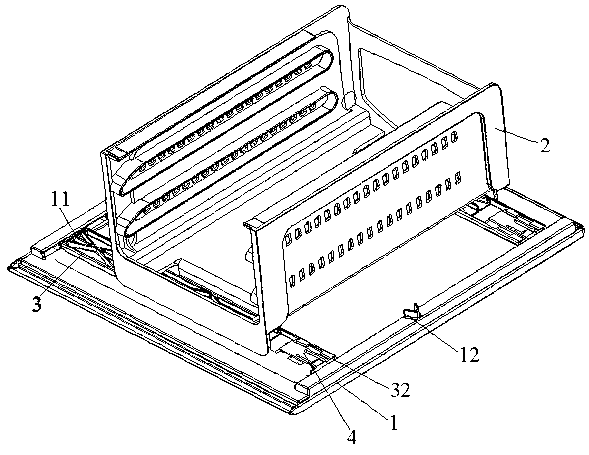

A strut spring assembly equipment

The invention discloses a supporting rod spring assembling device and belongs to the field of supporting rod spring assembling equipment. The supporting rod spring assembling device comprises a slide rail line, an outer sleeve positioning part, spring keeping parts and a spring compressing part, wherein the outer sleeve positioning part, the spring keeping parts and the spring compressing part are sequentially arranged along the slide rail line from front to back, and the spring compressing part and the outer sleeve positioning part are both arranged on the slide rail line in a sliding manner; the outer sleeve positioning part comprises a positioning sliding plate and an outer sleeve clamping base arranged on the positioning sliding plate; the spring keeping parts are sequentially arranged along the slide rail line, and two keeping mechanisms of each spring keeping part are arranged above the slide rail line relative to the mirror image of the slide rail line; and the spring compressing part comprises a driving sliding plate, a shifting plate and a spring sleeve clamping base, and the shifting plate and the spring sleeve clamping base are sequentially arranged on the driving sliding plate from front to back. It is guaranteed that no deformation is generated in the spring assembling process, friction collision between the spring and other parts is avoided, the assembling time is shortened, the assembling efficiency is improved, the automation degree is high, and the supporting rod spring assembling device can adapt to supporting rods in different length specifications.

Owner:CHENGDU TIANCHUANG PRECISION MOLD

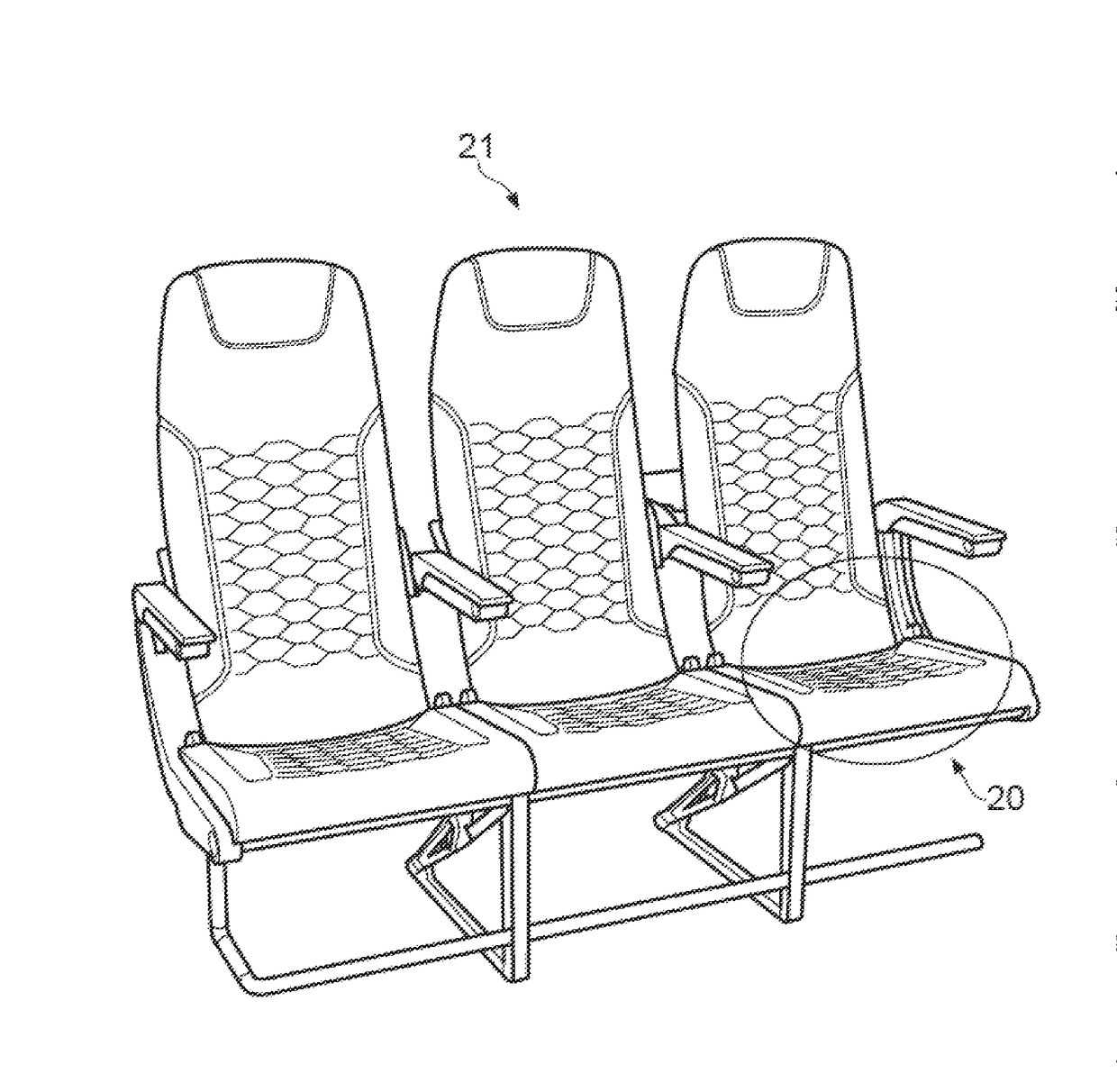

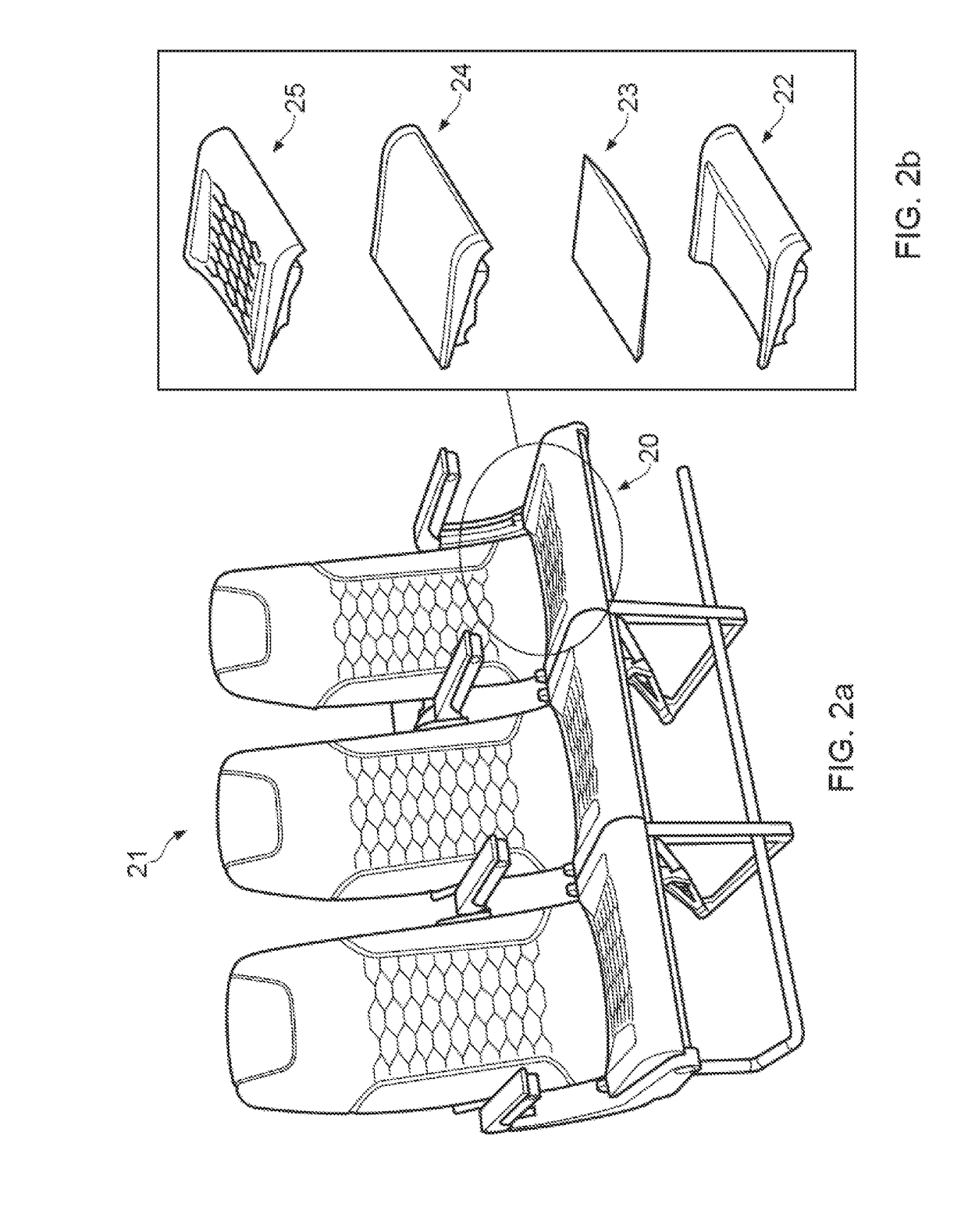

Cushion Assembly

InactiveUS20170283069A1Stable supportImprove comfortVehicle seatsSeating arrangementsFire retardantBiomedical engineering

Owner:MIRUS AIRCRAFT SEATING LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com