Accurate positioning type coupler and assembling technology

An accurate positioning and coupling technology, applied in the direction of couplings, rigid shaft couplings, manufacturing tools, etc., can solve the problems of poor stability of couplings, difficult positioning of shafts and bearings, and short life of couplings. To achieve the effect of improving precision, improving accuracy and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

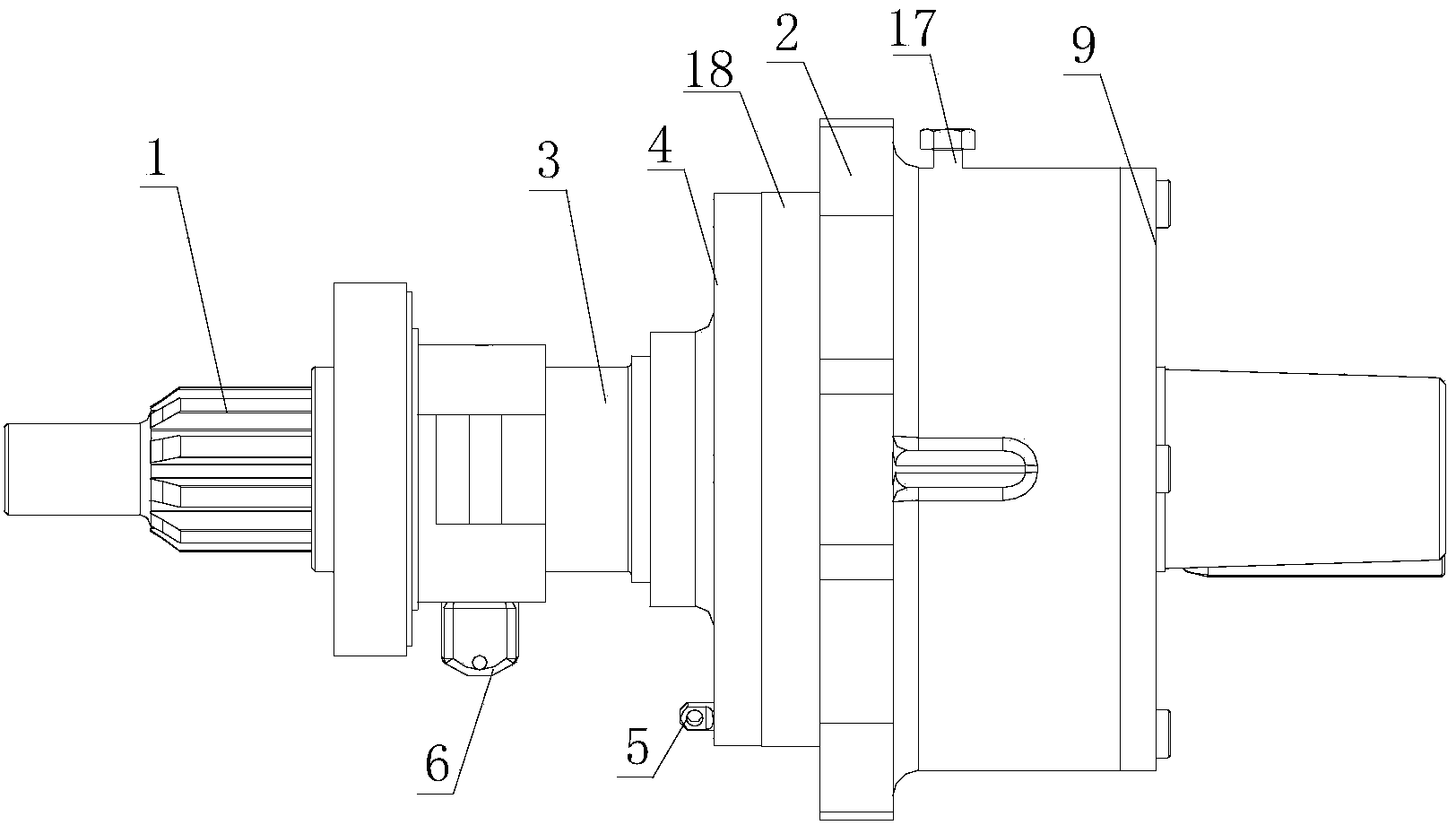

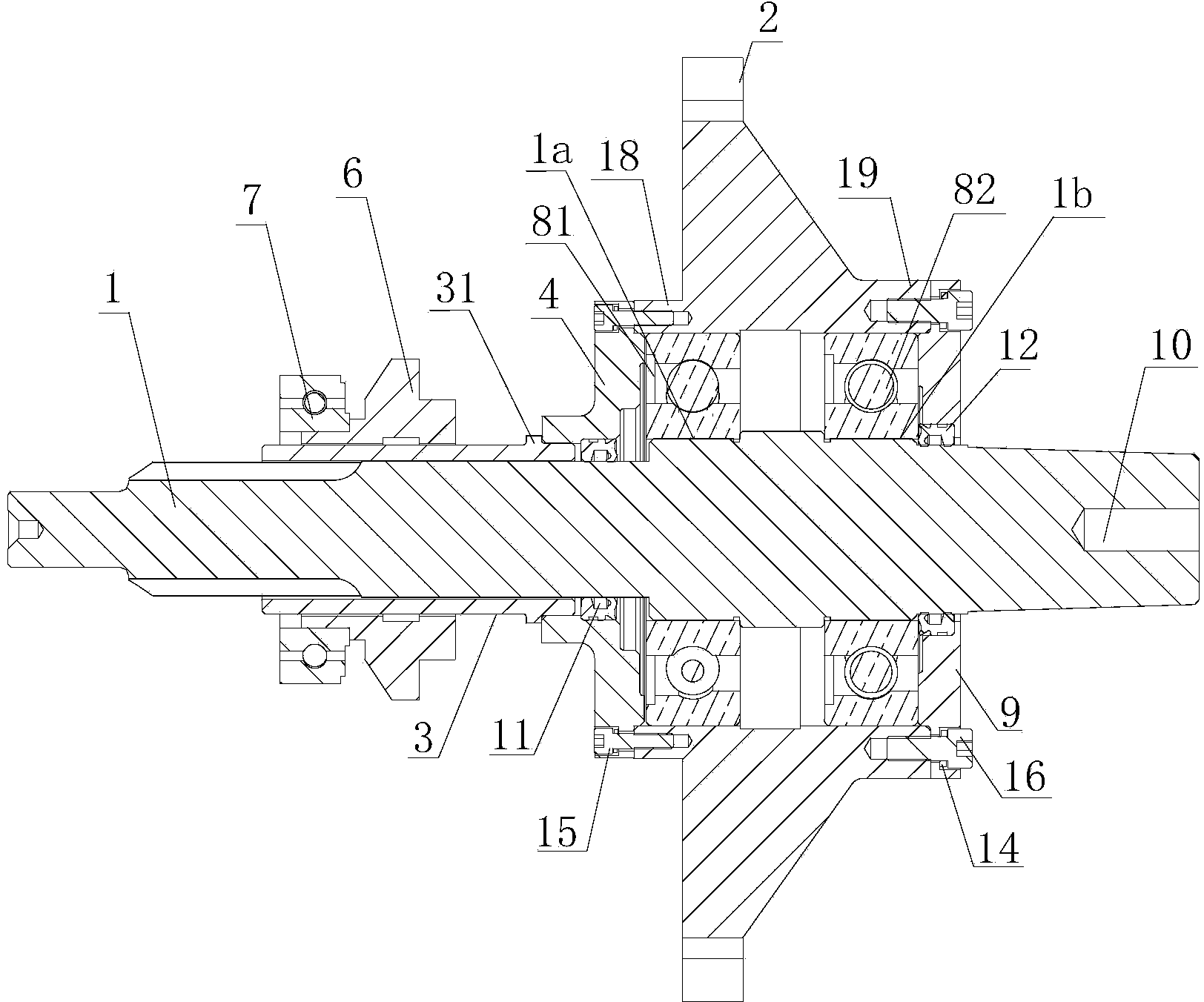

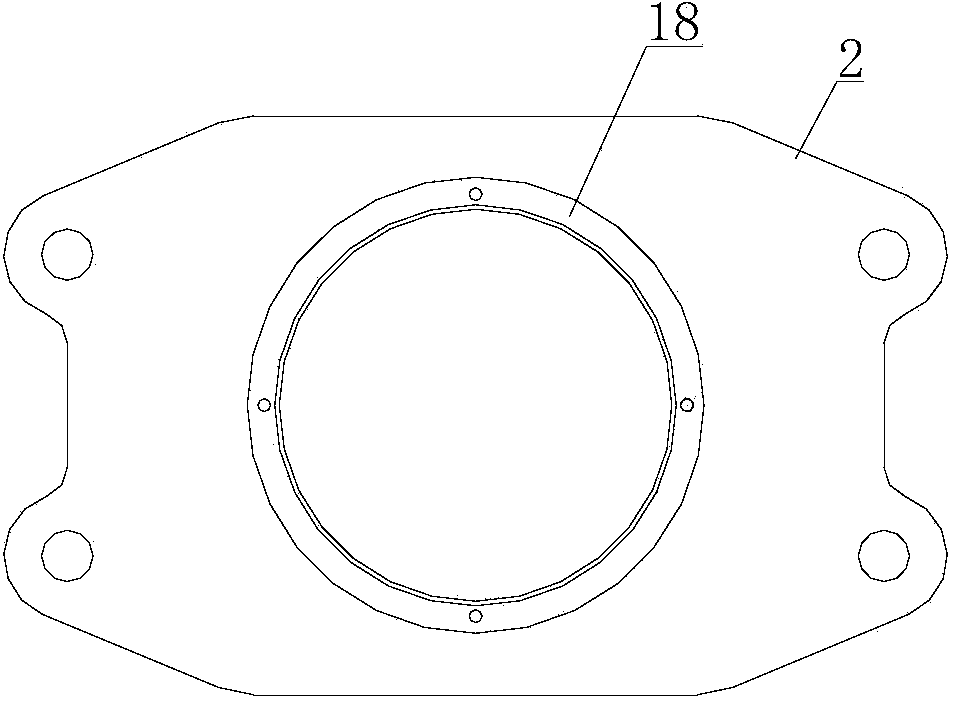

[0031] An accurate positioning coupling provided by the present invention, refer to Figure 1 to Figure 5 , including a spline shaft 1 that runs through the entire coupling, the spline shaft 1 is provided with an upper mounting position 1a compatible with the upper bearing 81, and a lower mounting position 1a compatible with the lower bearing 82 1b, a boss-shaped turning surface is formed between the two mounting positions, and the upper bearing 81 and the lower bearing 82 are respectively clamped and assembled on the above-mentioned two locking positions on both sides of the boss-shaped turning surface. Wherein, the upper bearing 81 is preferably an upper deep groove ball bearing, and the lower bearing 82 is preferably a lower deep groove ball bearing.

[0032] During assembly, the two bearings are assembled from the left and right directions of the spline shaft 1, which reduces the requirement on concentricity during assembly and facilitates the installation of the bearings....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com