Patents

Literature

168results about How to "Reduced concentricity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

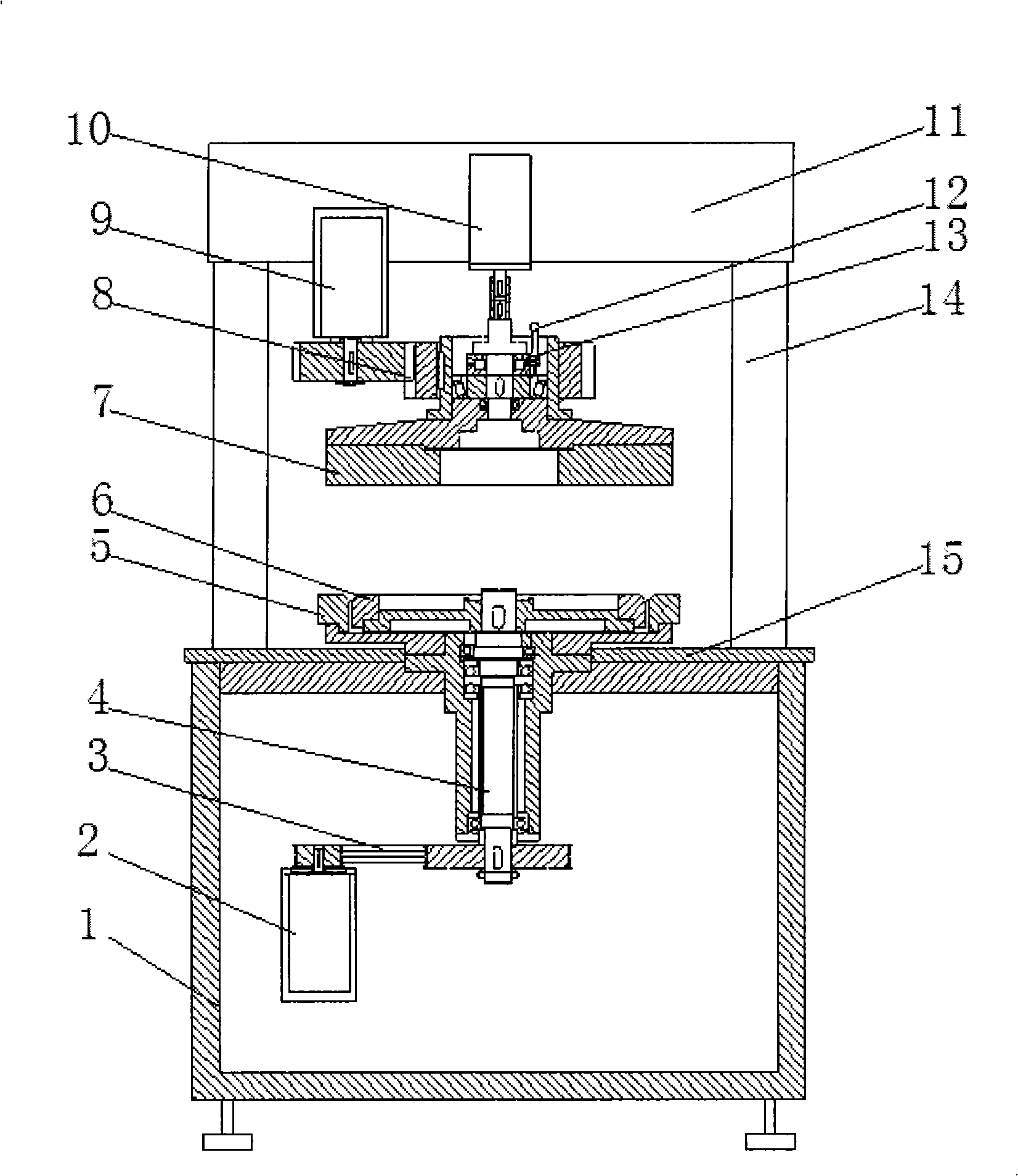

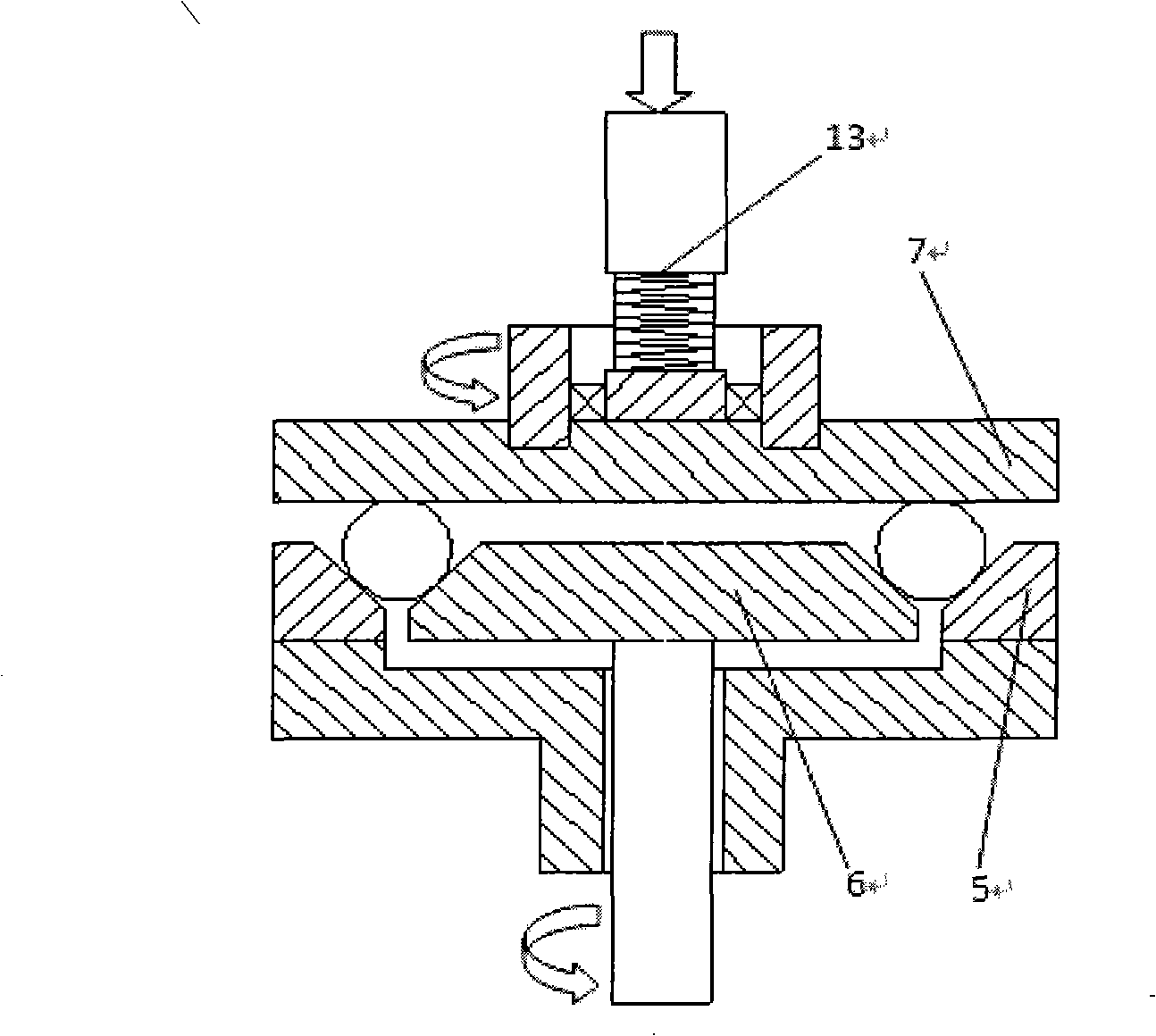

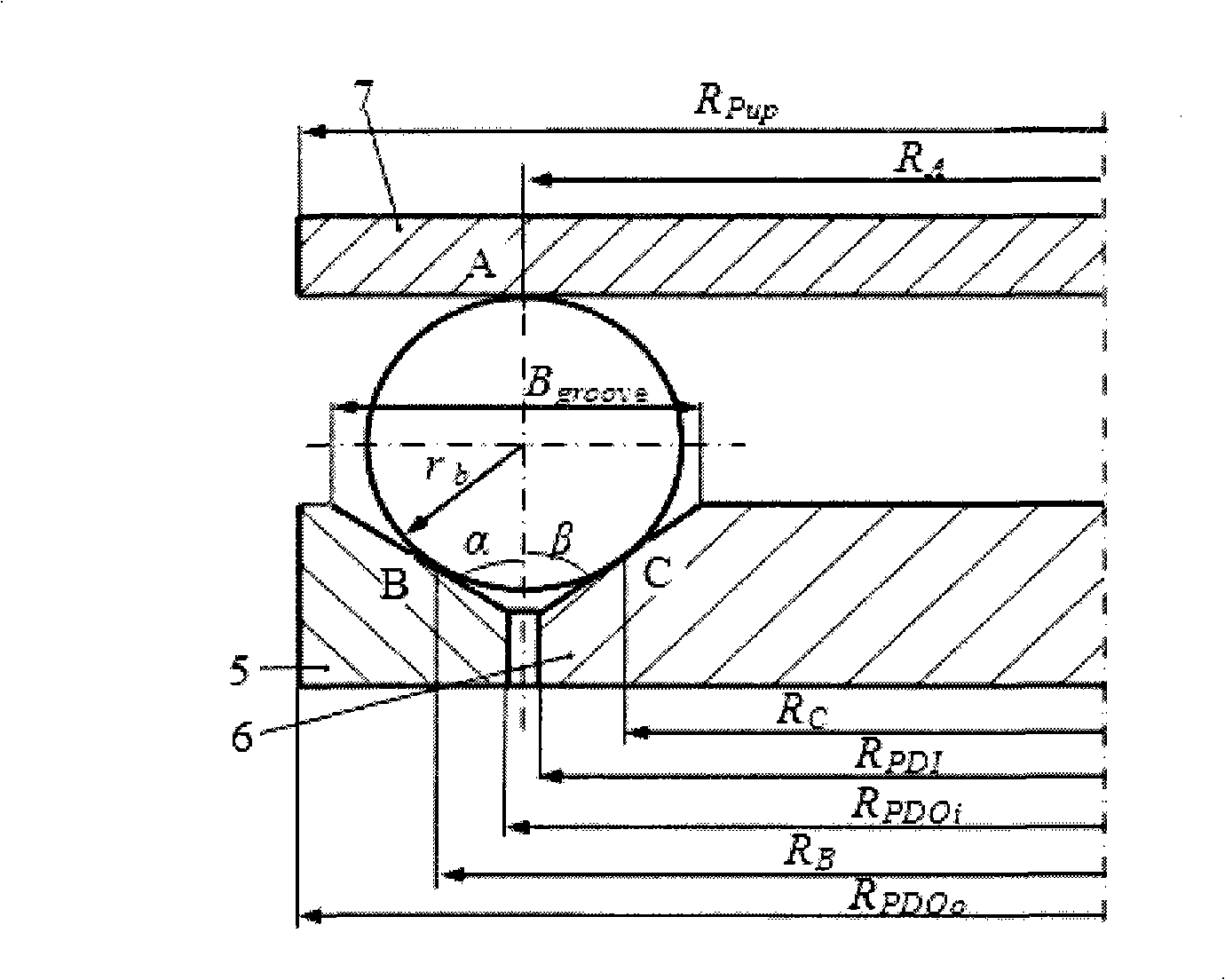

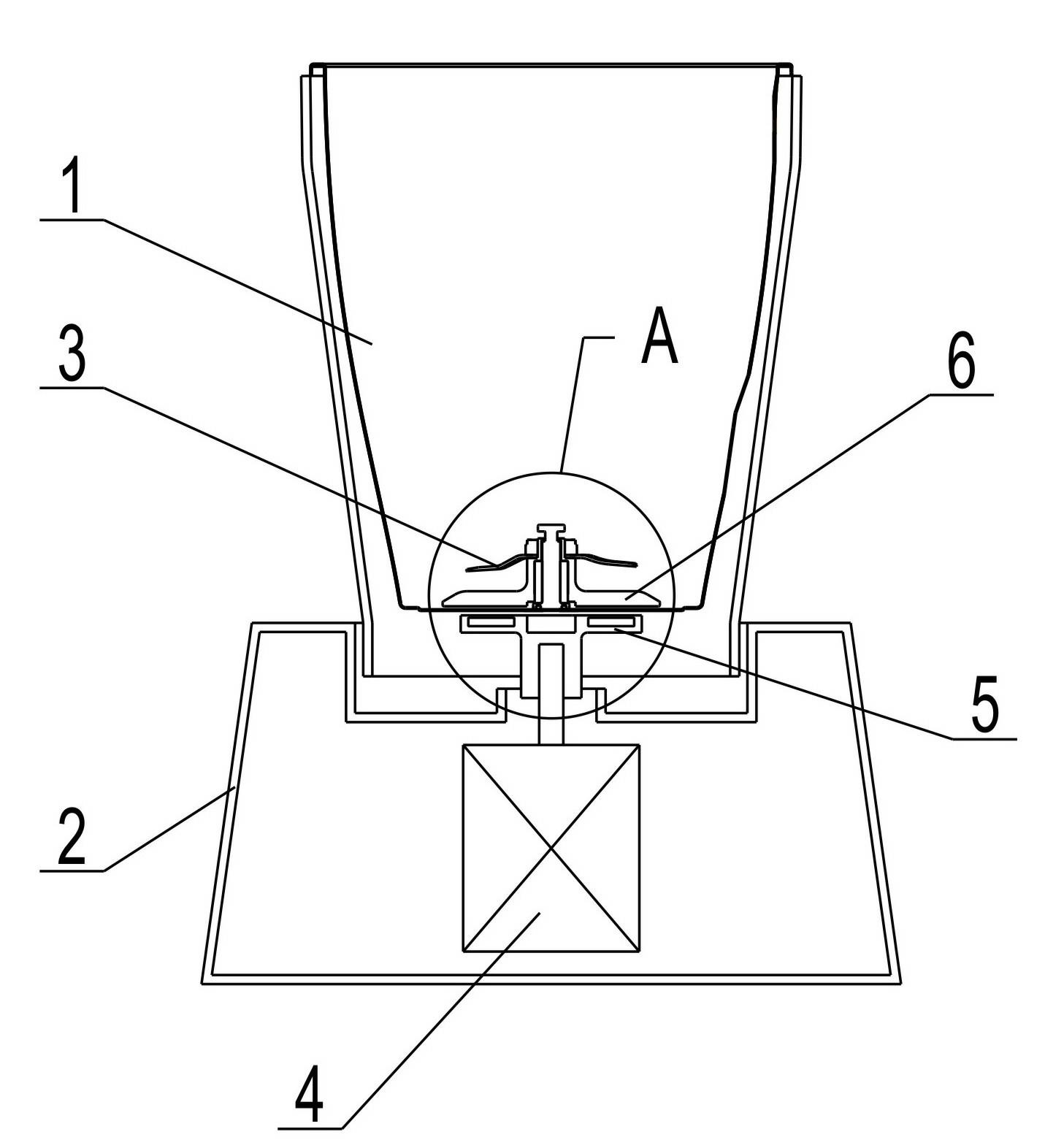

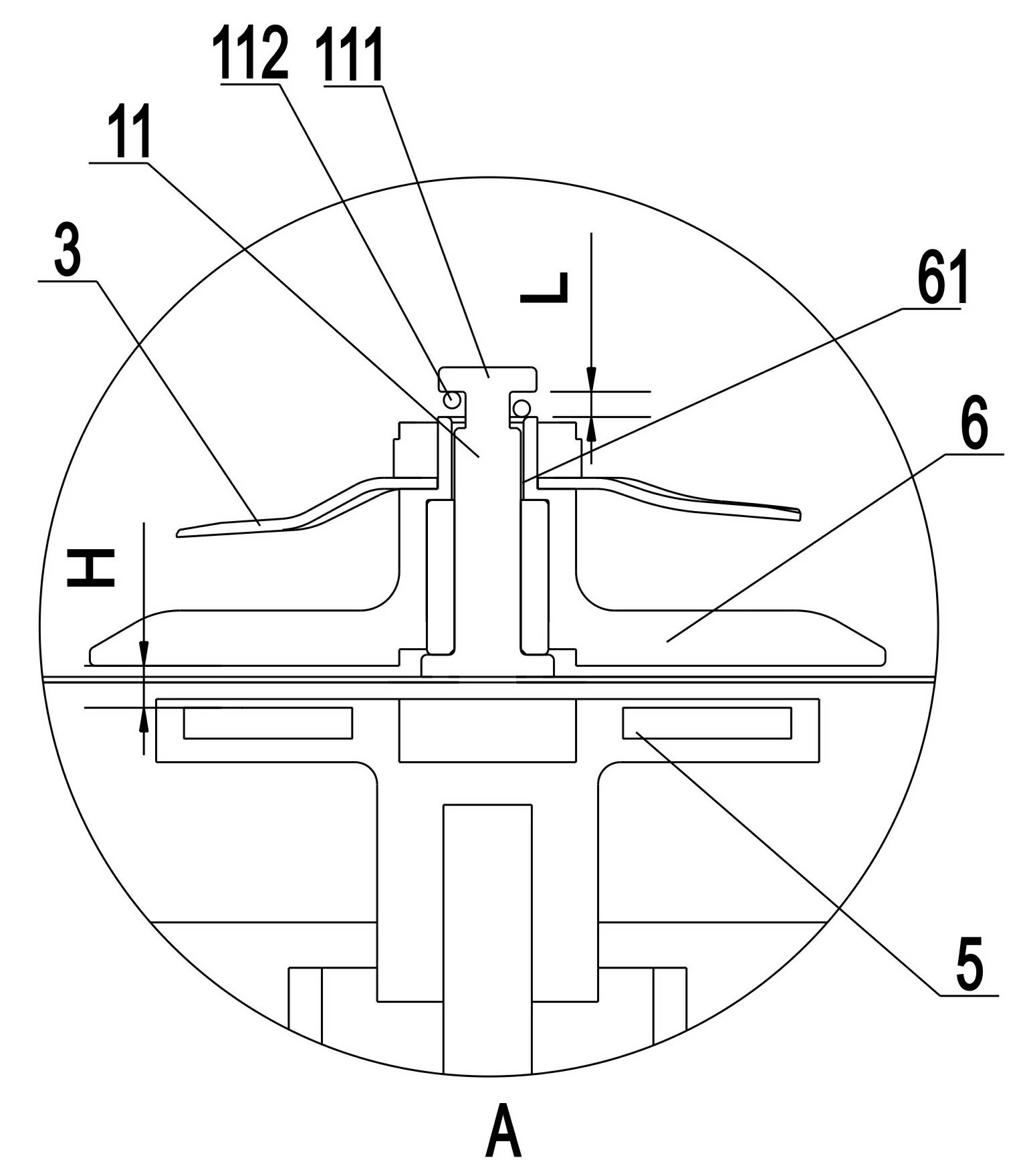

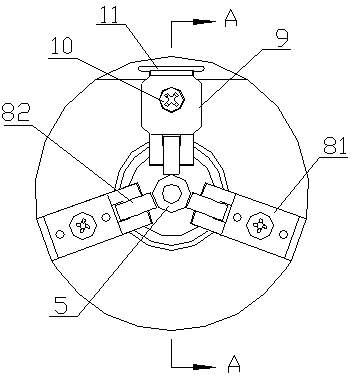

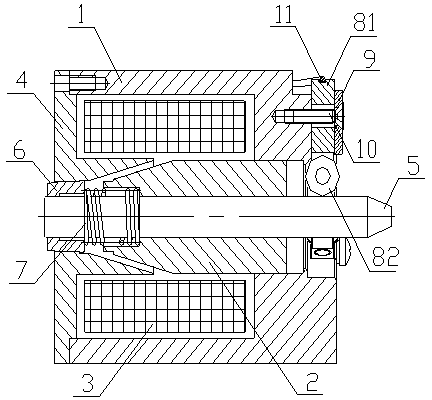

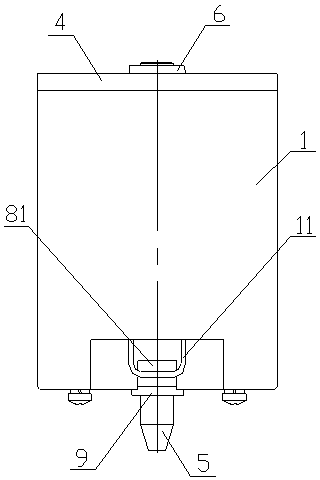

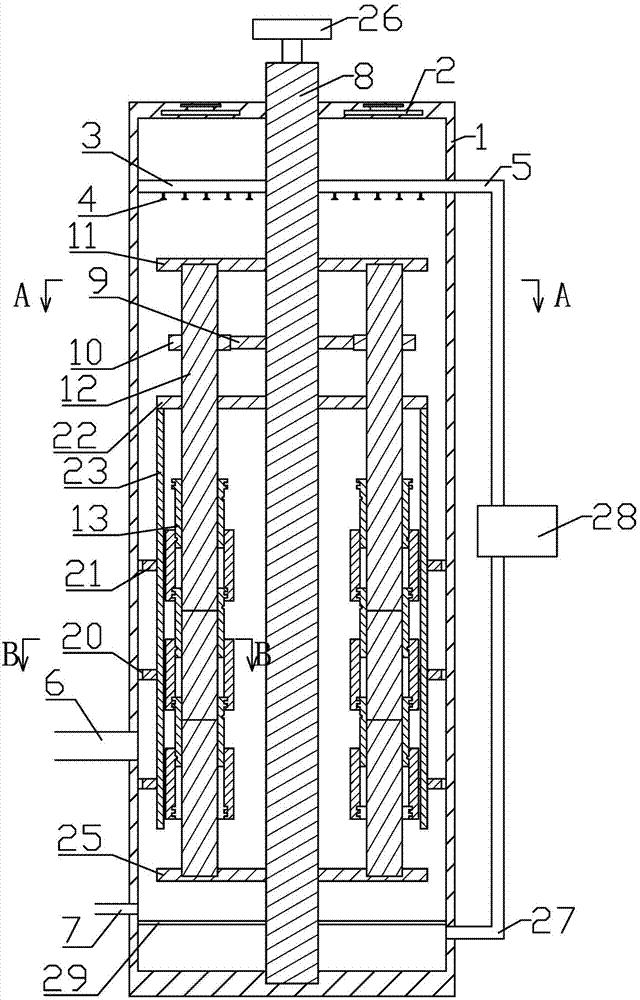

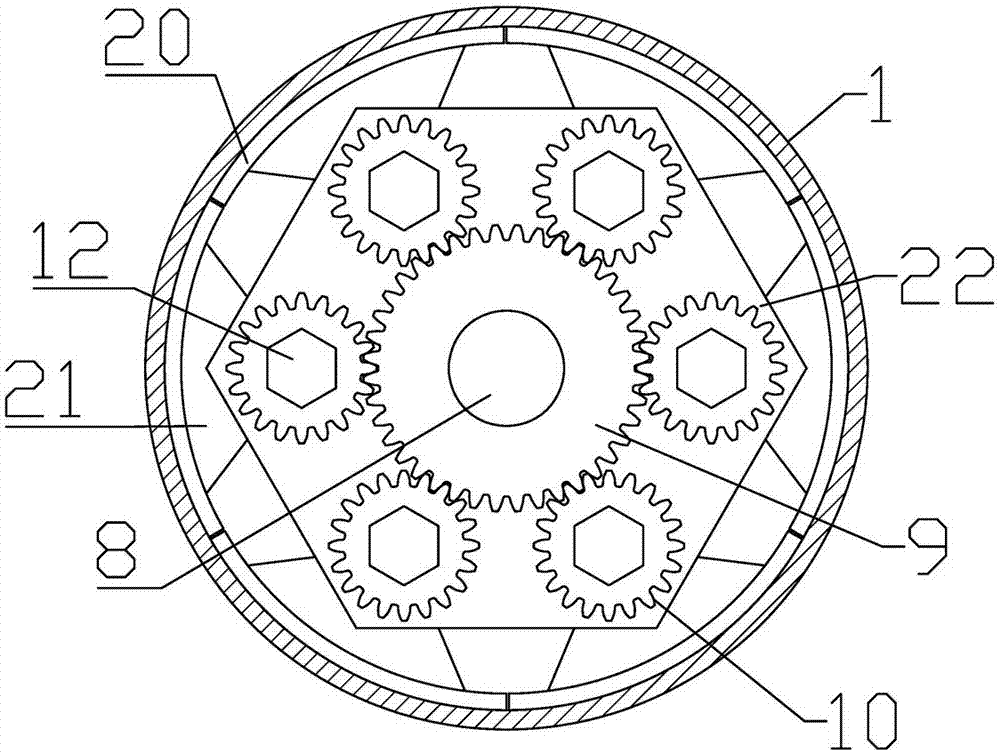

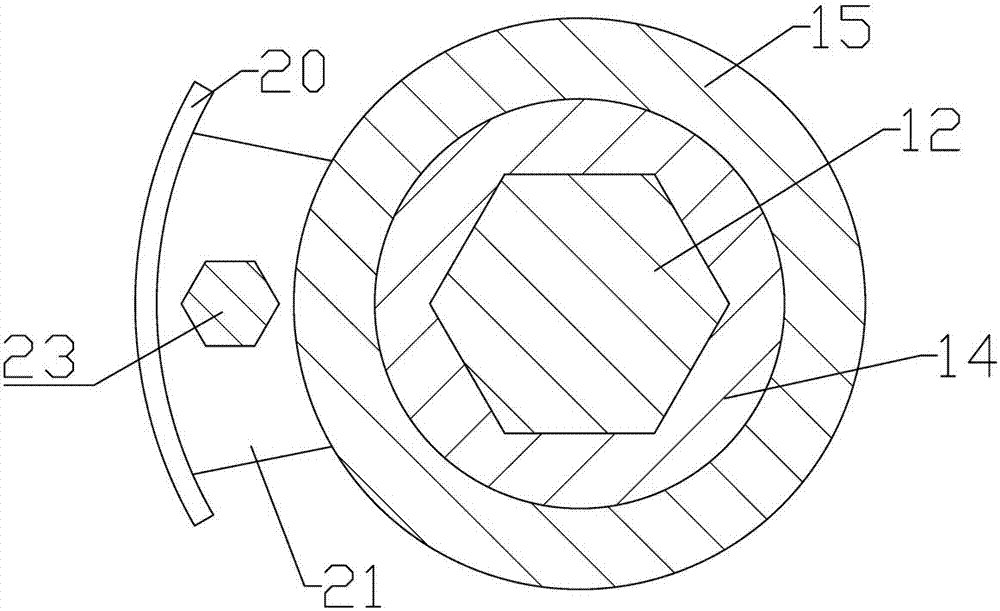

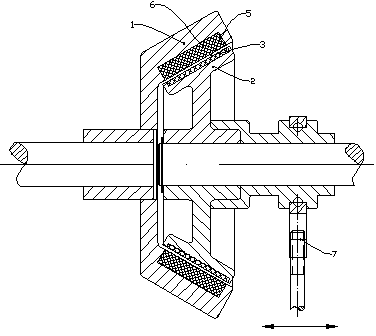

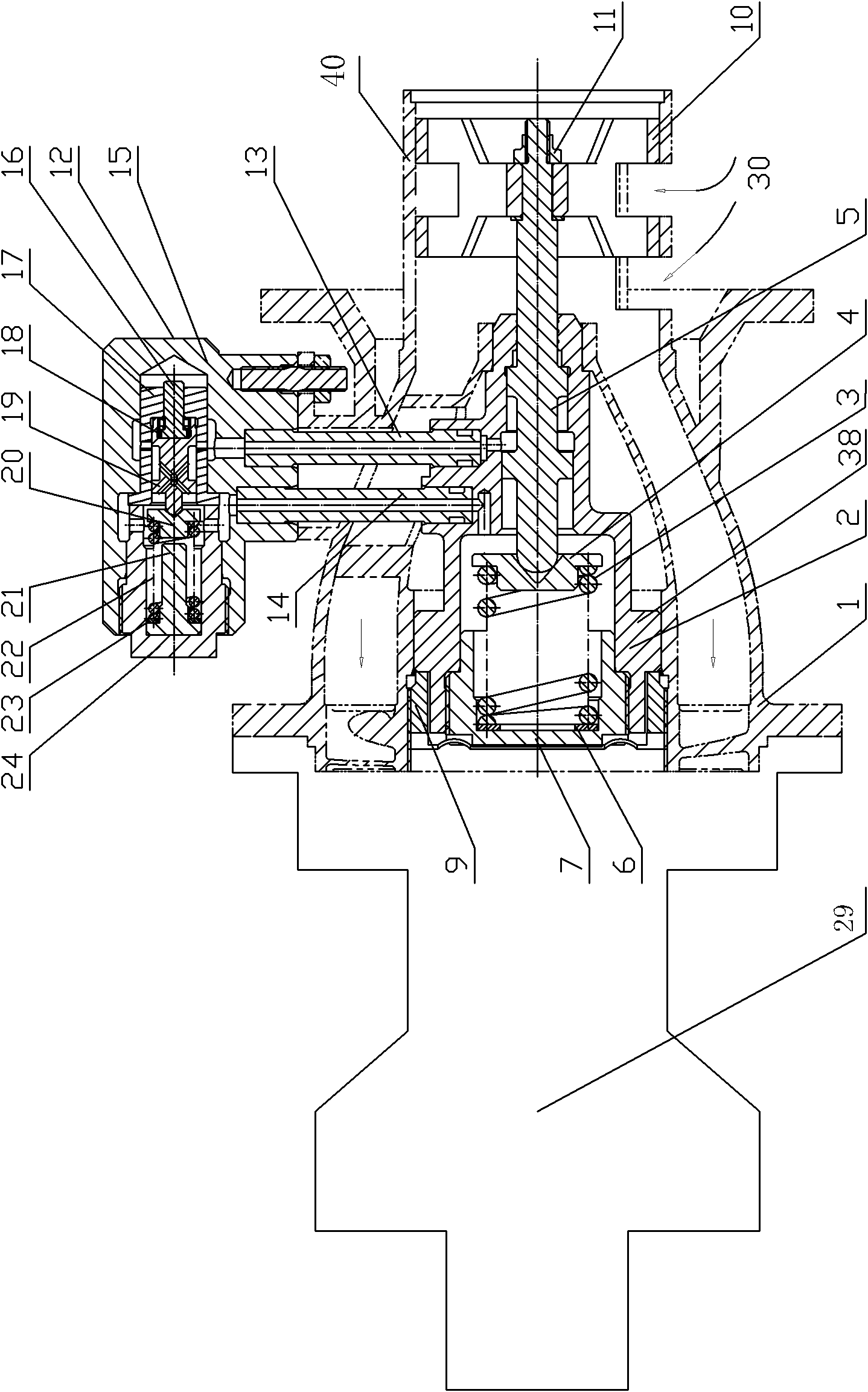

Efficient grinding device of double autorotation grinding disc of high precision ball

InactiveCN101524824ASimple structureReduced precision requirementsSpherical surface grinding machinesDrive motorEngineering

An efficient grinding device of a double autorotation grinding disc of a high precision ball comprises a frame, a grinding disc device installed on the frame and a load pressure device; the grinding disc device comprises an upper grinding disc; the load pressure device is installed at the upper end of the upper grinding disc; the efficient double autorotation V-shaped groove grinding device of the high precision ball further comprises an inner disc of a lower grinding disc and an outer disc of the lower grinding disc; the outer disc and the inner disc of the lower grinding disc are coaxially arranged; the inner disc of the lower grinding disc is inserted in the outer disc of the lower grinding disc; a conical grinding surface on the outer side of the inner disc of the lower grinding disc and a conical grinding surface on the inner side of the outer disc of the lower grinding disc form a V-shaped groove structure; the outer disc of the lower grinding disc is fixedly installed on the frame; the upper grinding disc is installed on a rotating shaft; the rotating shaft is connected with a drive motor of the upper grinding disc; the inner disc of the lower grinding disc is installed on a main shaft; and the main shaft is connected with a drive motor of the lower grinding disc. The efficient grinding device of the double autorotation grinding disc of the high precision ball has the advantages of simple structure, low processing cost, higher processing precision and processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

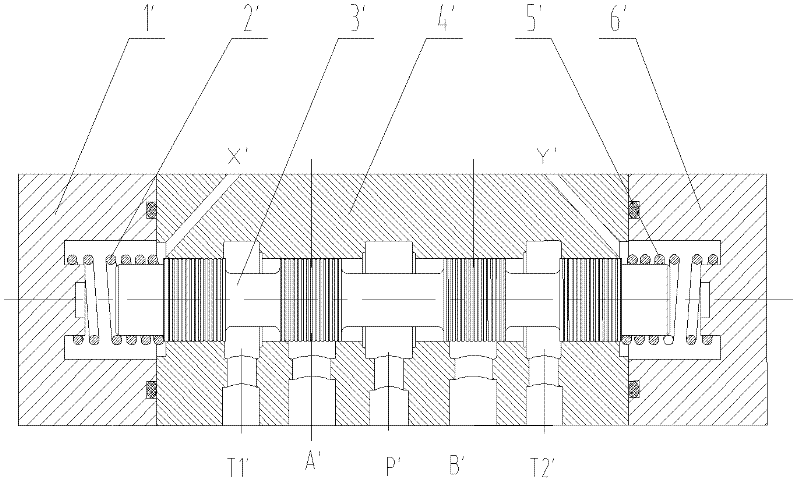

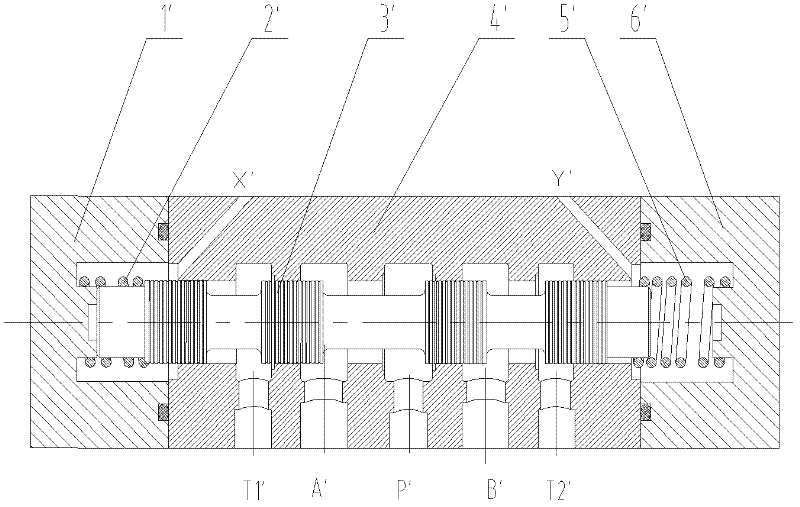

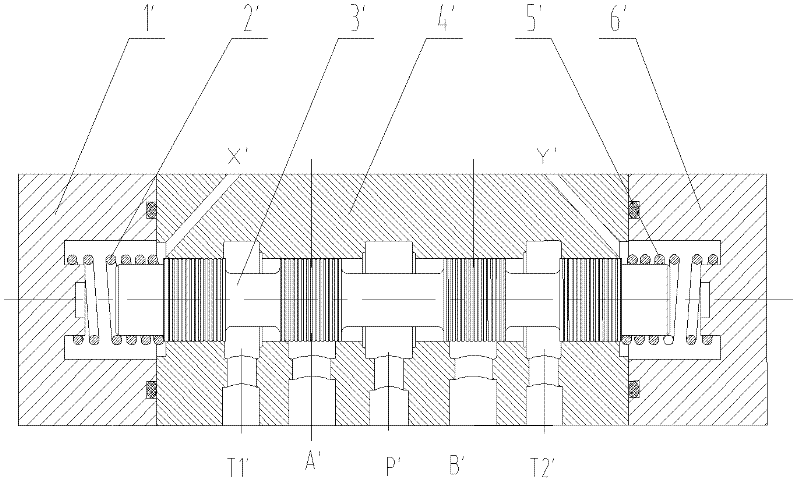

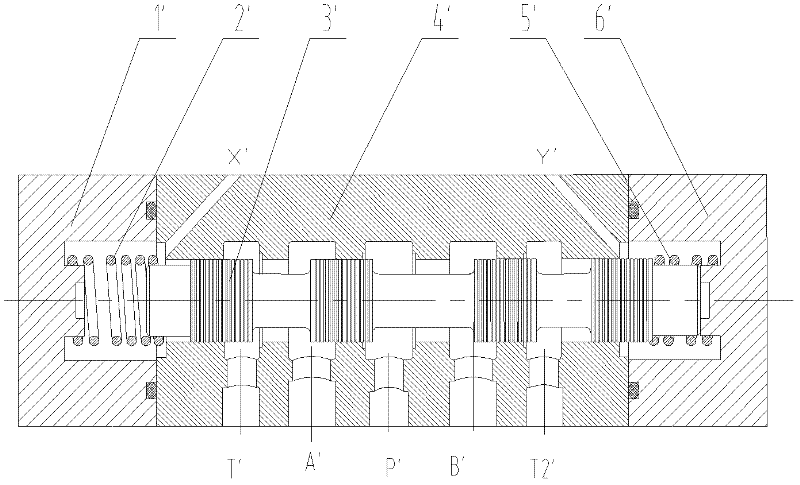

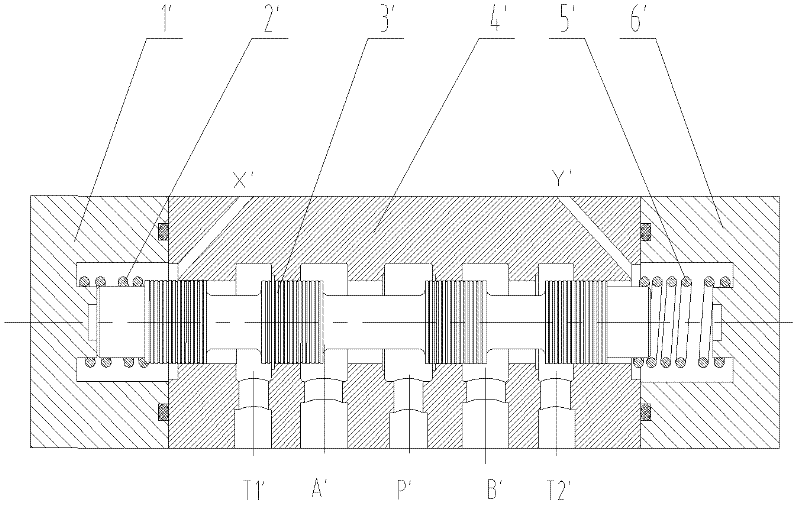

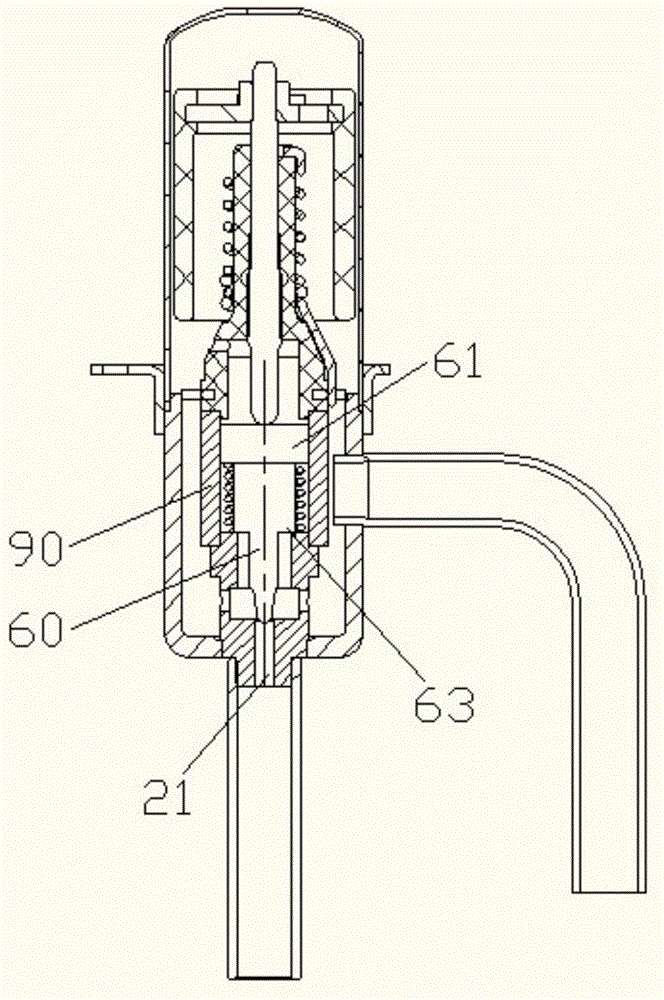

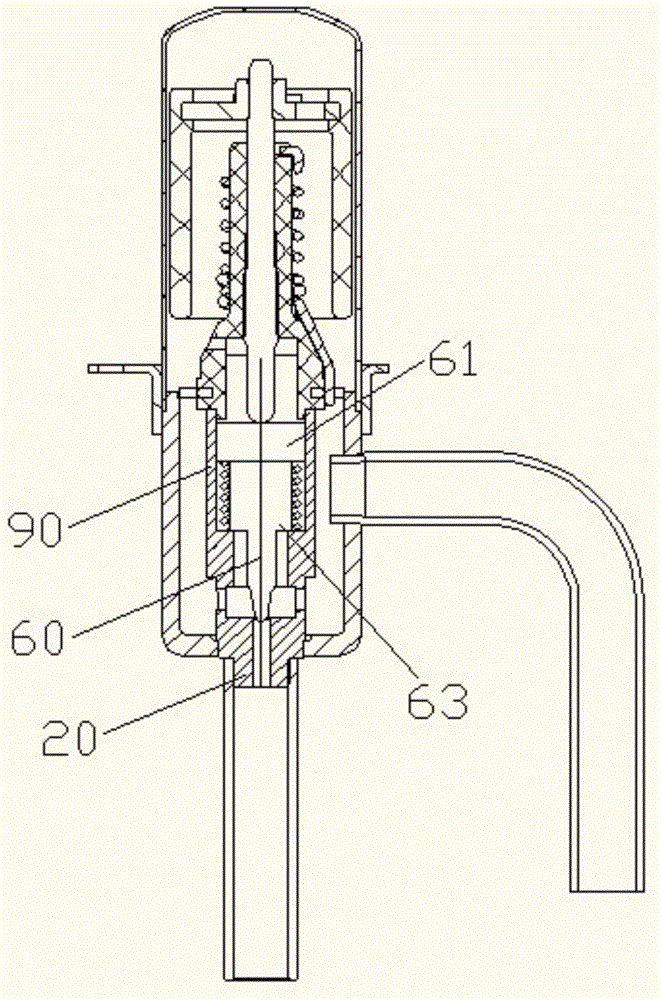

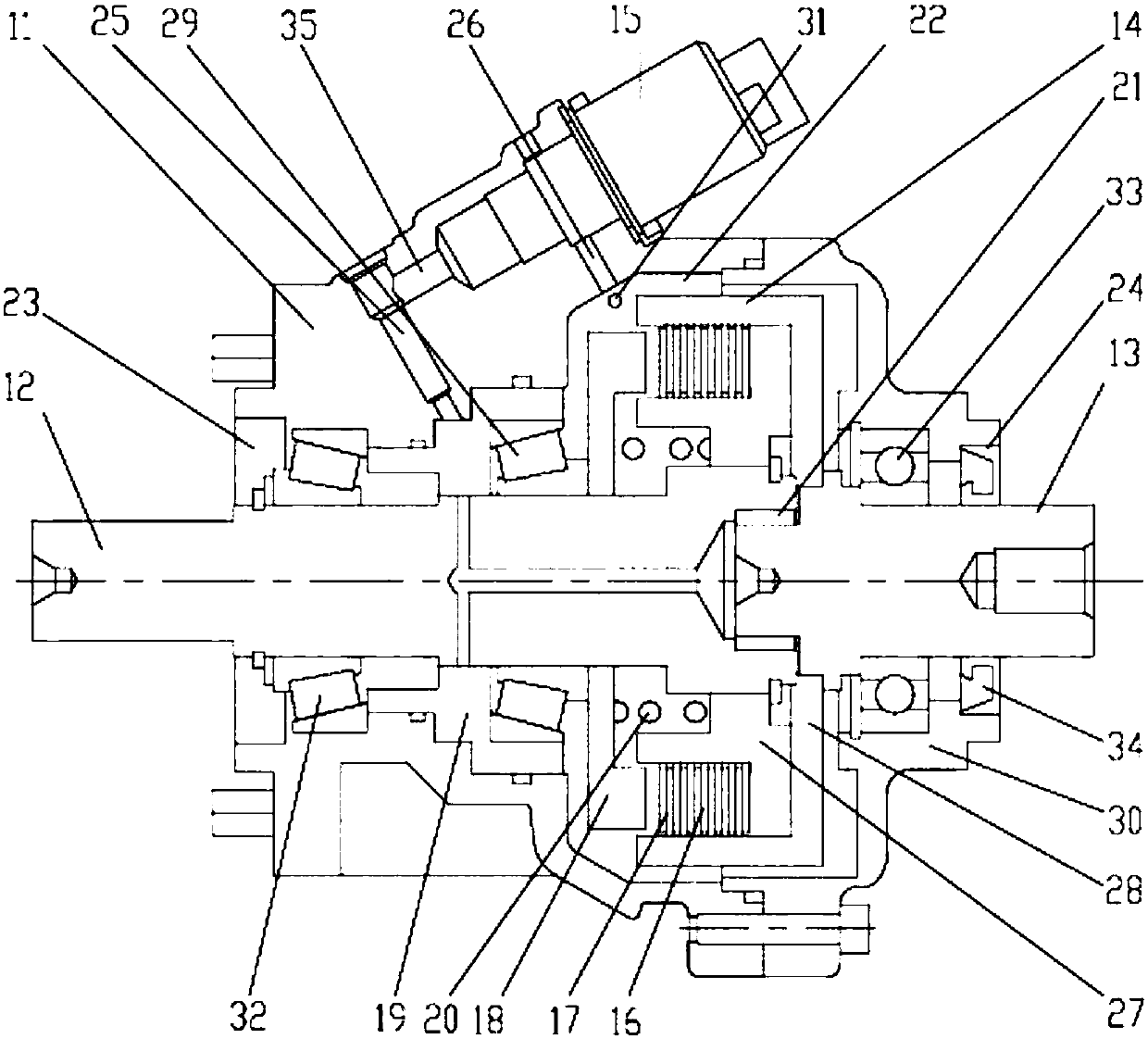

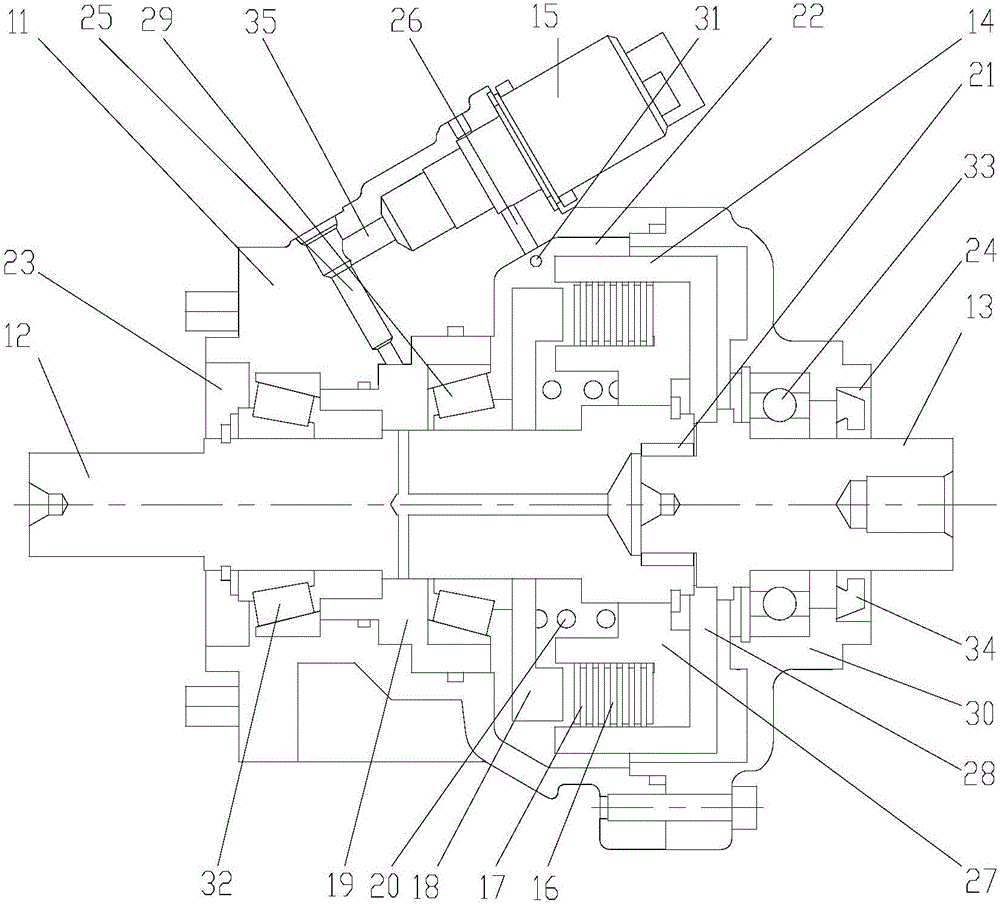

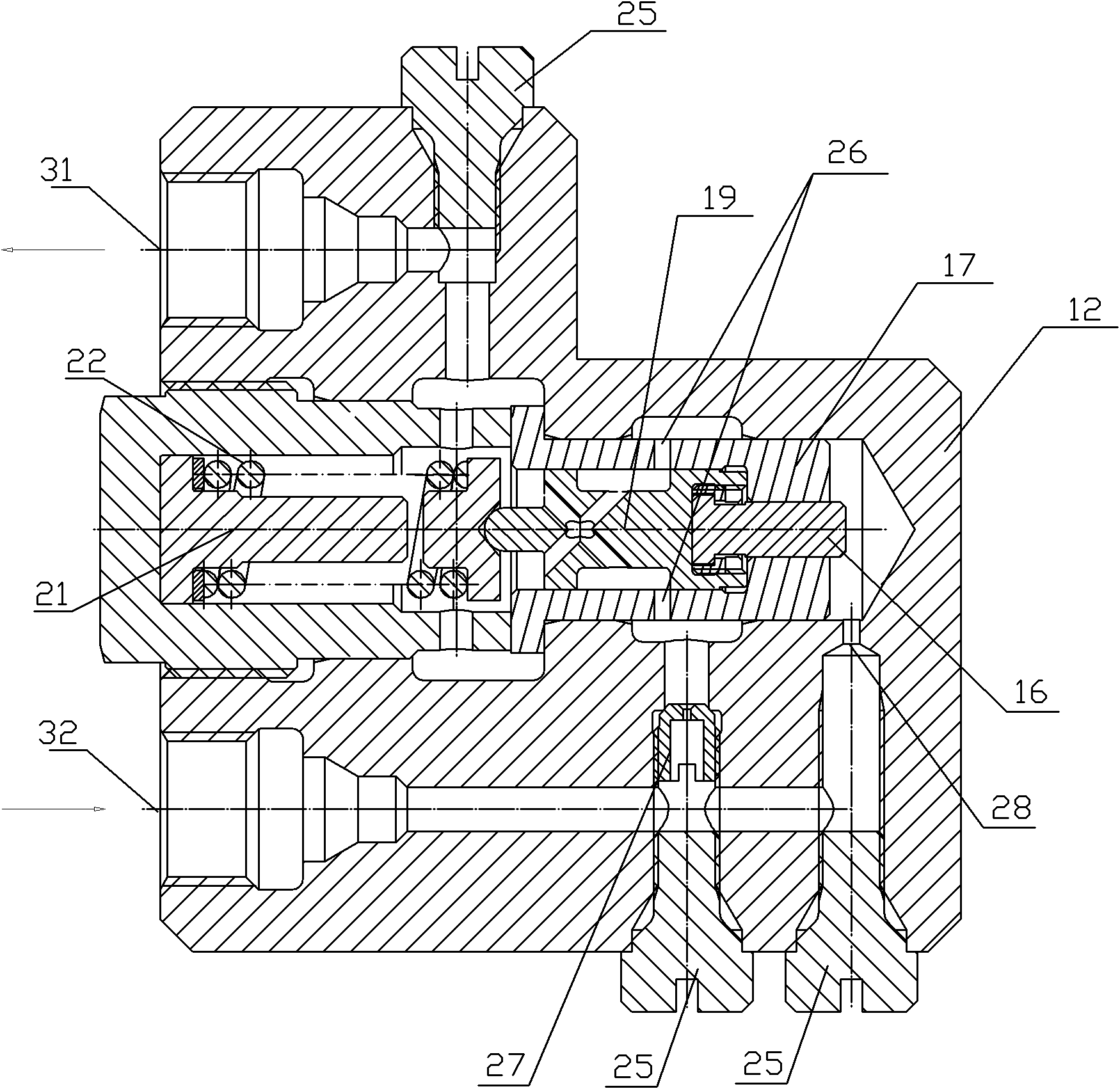

Hydraulic valve, hydraulic valve group and hydraulic valve control method

ActiveCN102297171ALow machining accuracy requirementsEasy to processServomotor componentsMultiple way valvesHigh resistanceEngineering

A hydraulic directional control valve and the control method thereof, a hydraulic control valve set, and a hydraulic control system and engineering machinery comprising the said valve or the valve set. The said hydraulic control valve comprises: a valve body (10); a valve pocket sleeve provided in the cavity of the valve body (10); a valve plug provided in the valve pocketsleeve. The valve pocket sleeve is a split type valve pocketsleeve, comprising at least a first valve pocket sleeve (21) and a second valve pocket sleeve (22). The valve plug is a split type valve plug, comprising at least a first valve plug (31) and a second valve plug (32). The said first valve plug (31) and the second valve plug (32) are in a synchronous working conditionstate. The hydraulic directional control valve is provided with at least three fluid ports, and at least two working positions may be realized. The split type valve pocket sleeve and valve plug impart offer the following benefits to the valve plug: simple valve plug assembly, less likelihood to of valve plug getting stuck, strong high resistance to contamination, good interchangeability of parts, and much longer overall service life.

Owner:SANY AUTOMOBILE MFG CO LTD

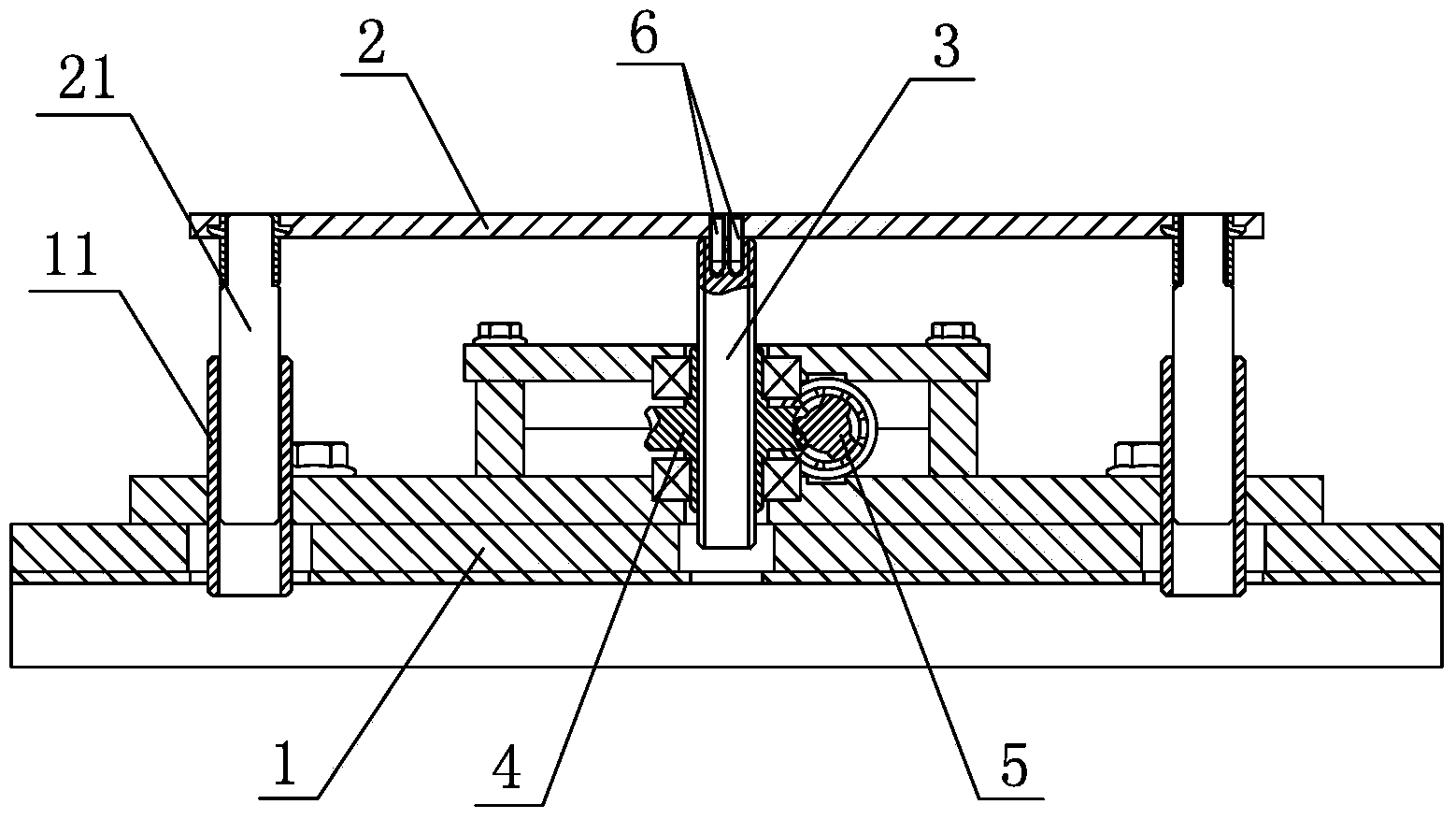

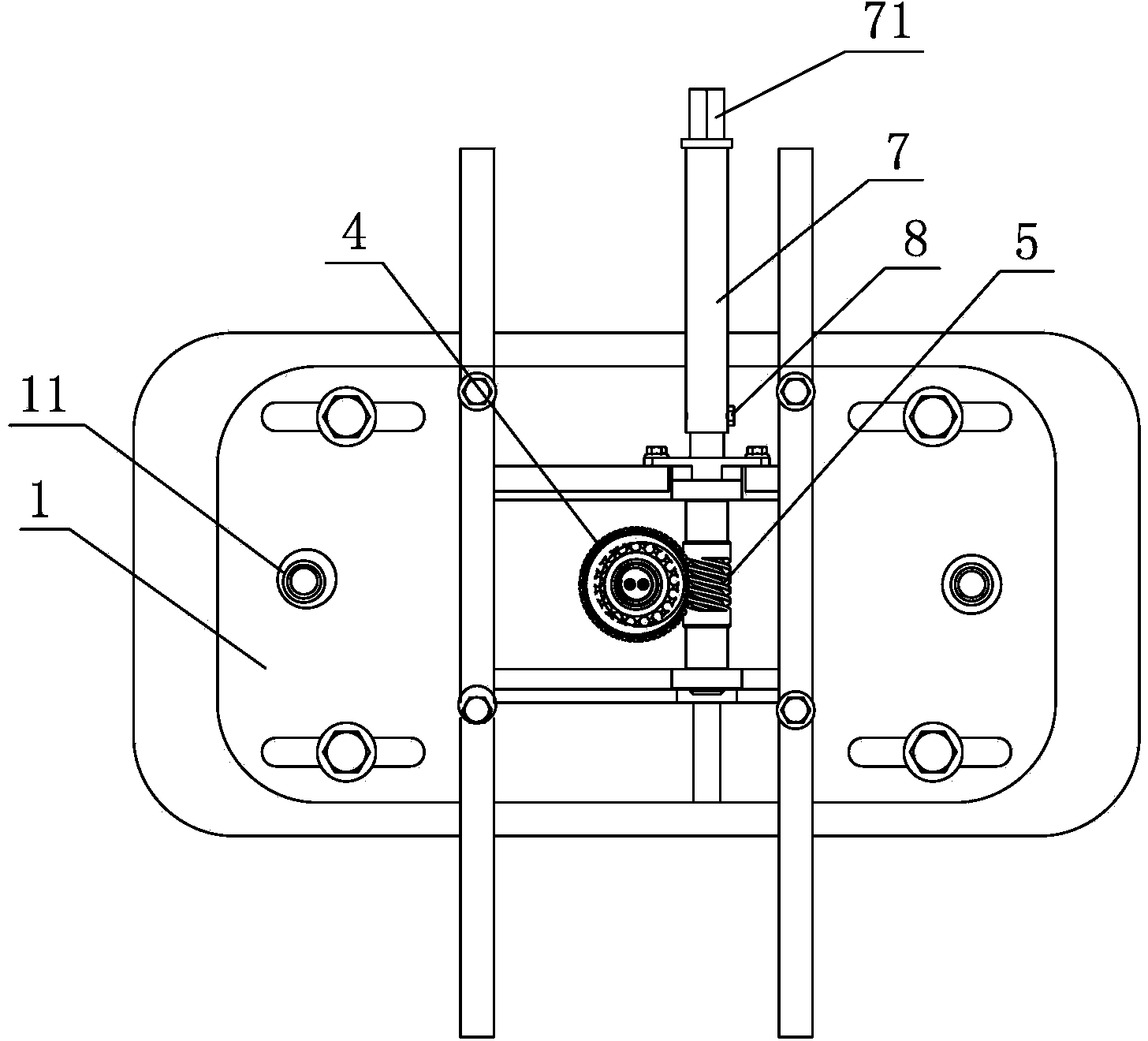

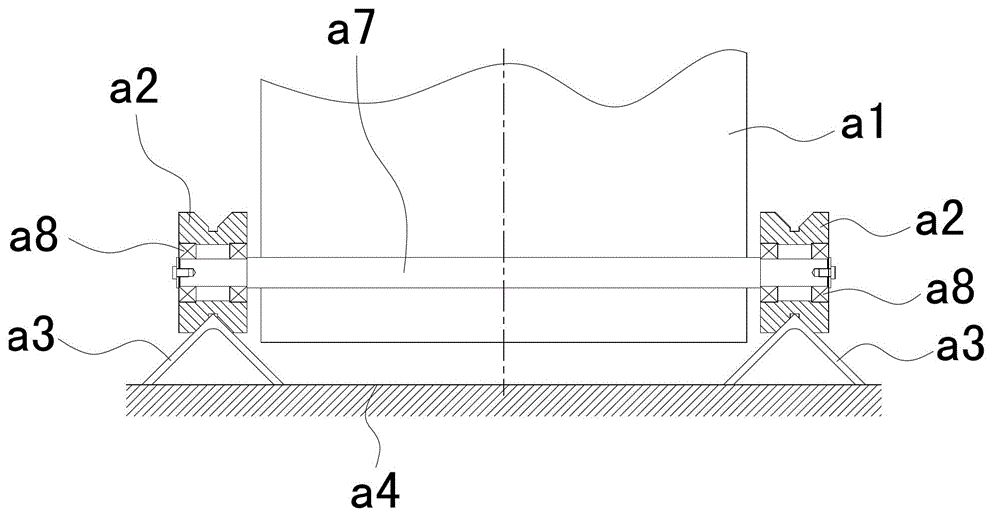

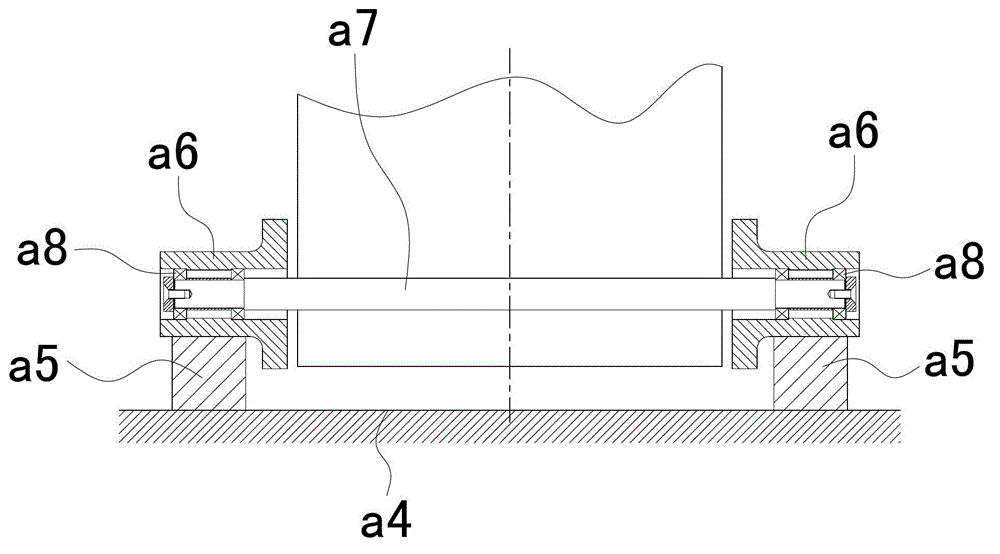

Compact type mechanical lifting mechanism for assembling line

The invention discloses a compact type mechanical lifting mechanism for an assembling line. The compact type mechanical lifting mechanism for the assembling line is characterized by comprising a base, a lifting platform, a jacking screw, a worm wheel and a worm. The worm is horizontally connected to the base in a coupling mode, the worm wheel is vertically connected to the base in a coupling mode, an internal screw hole is formed in the worm wheel, the jacking screw is in threaded connection with the internal screw hole, the lifting platform is fixedly connected with the upper end of the jacking screw, a guide column is fixedly arranged on the lifting platform, a guide sleeve is fixedly arranged on the base, the guide column is matched with the guide sleeve in a vertical sliding mode, and one end of the worm is connected with a rotary drive power source. Compared with a traditional lifting mechanism, the compact type mechanical lifting mechanism for the assembling line has the advantages of being small in needed installation space, compact in structure, and accurate in control; due to the fact that the lifting platform is fixedly connected with the upper end of the jacking screw through connecting screws arranged side by side, the effect of fixing the lifting platform and preventing the jacking screw from being rotated is achieved, and even when loading weight is overloaded, the connecting screws still play a role as safety pins in preventing the worm wheel from being damaged.

Owner:宁波海迈克动力科技有限公司

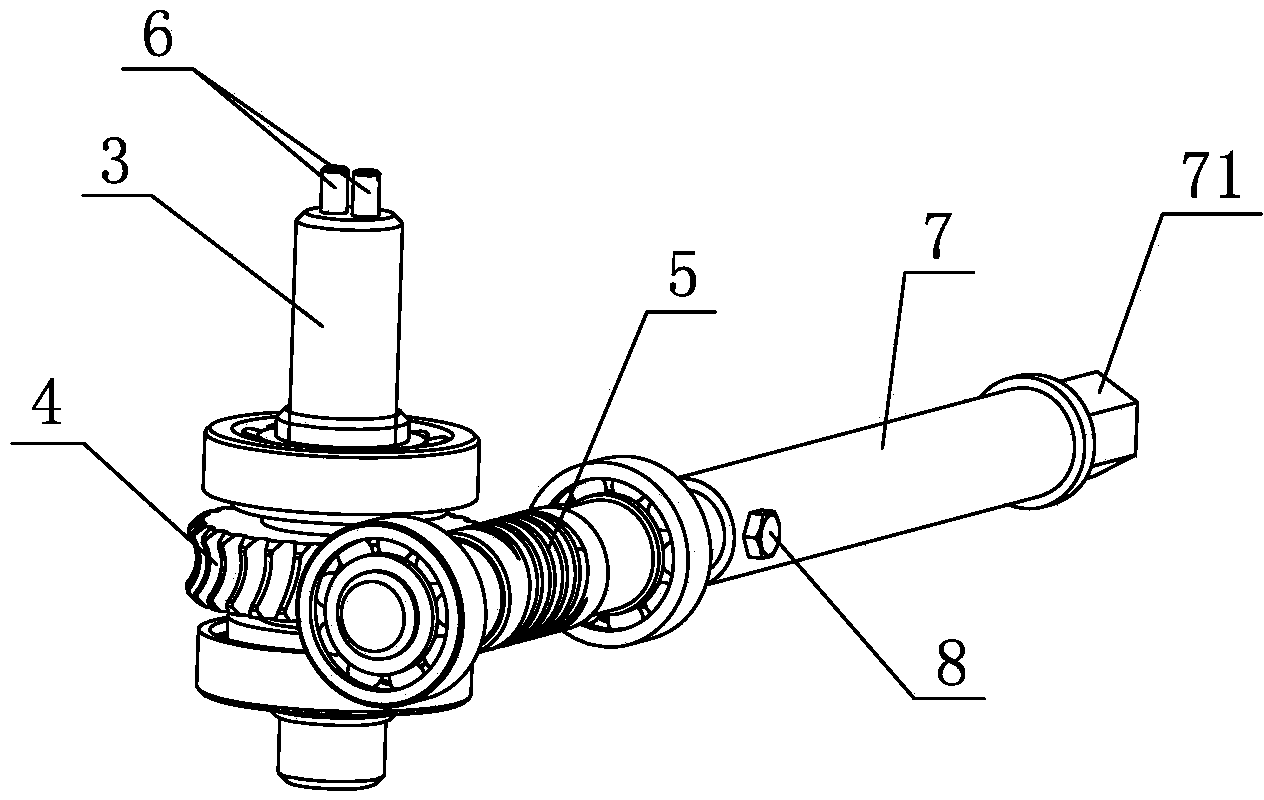

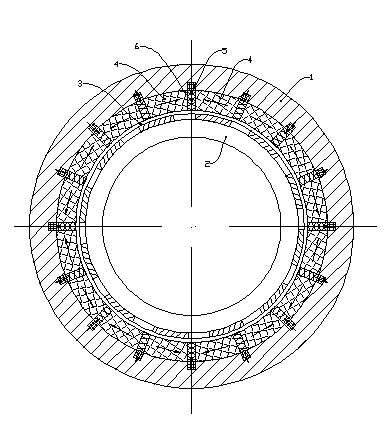

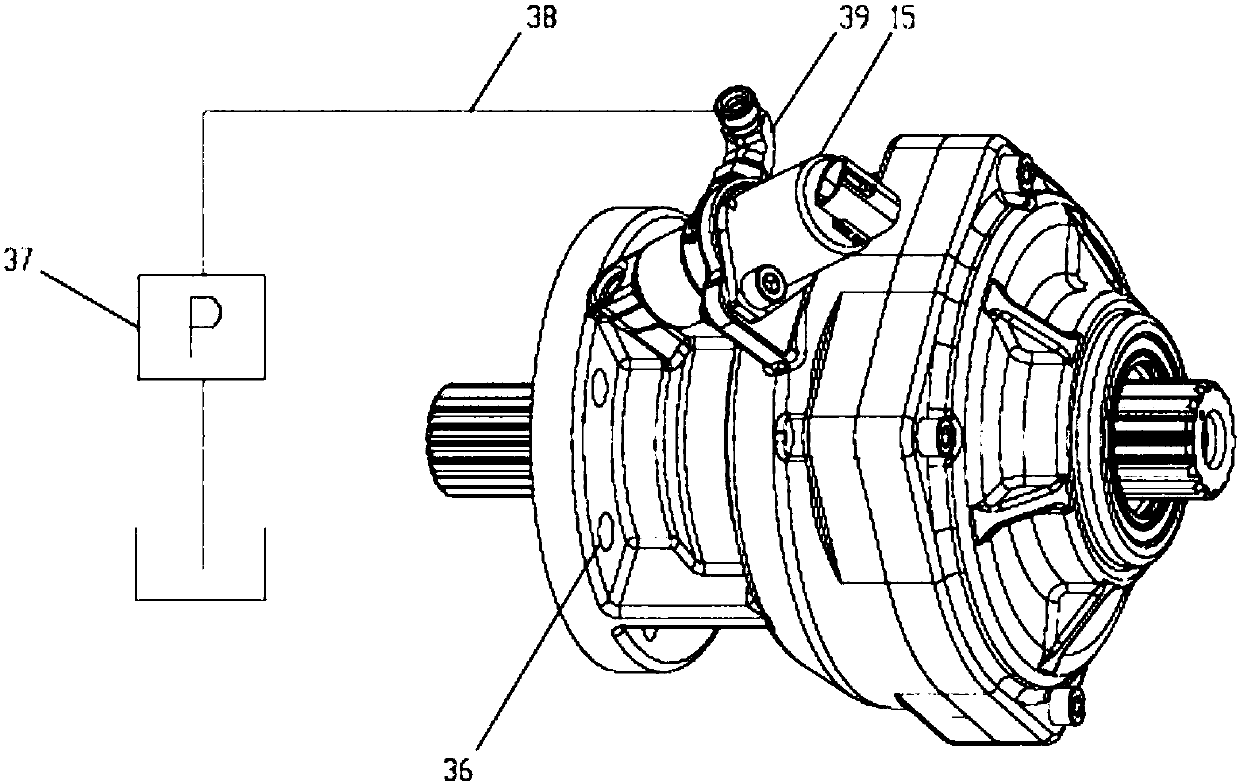

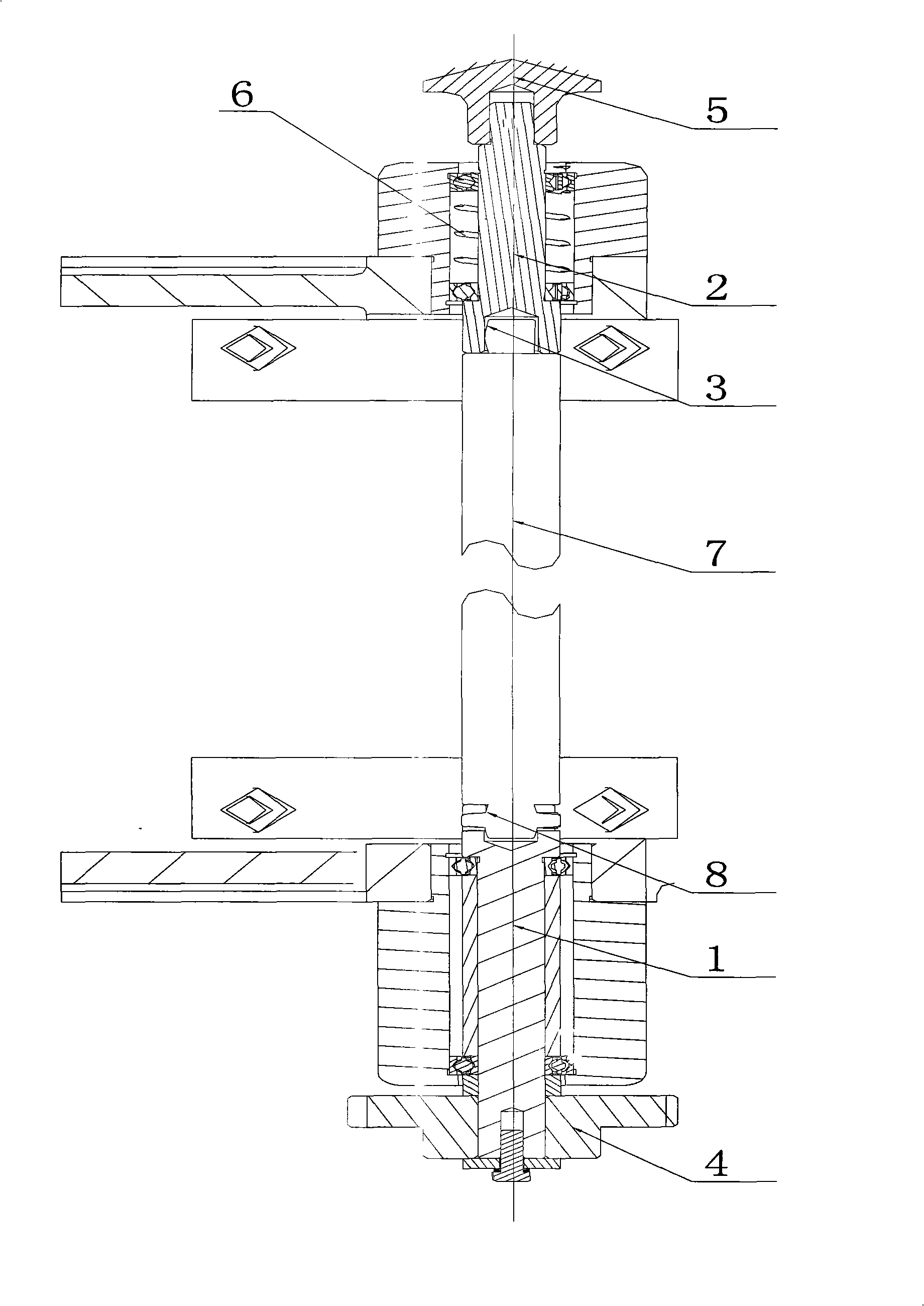

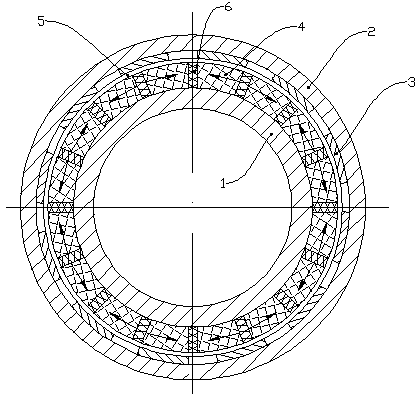

Permanent magnet coupling mechanism between shafts

InactiveCN103326541ACreative optimizationChange areaDynamo-electric gearsPermanent magnet rotorCoupling

The invention relates to a permanent magnet coupling mechanism between shafts. The permanent magnet coupling mechanism between the shafts is used for transmitting torque between the two rotating shafts. The mechanism comprises a permanent magnet rotor and a conductor rotor, wherein a conical air gap is formed between the permanent rotor and the conductor rotor. A permanent magnet on the permanent magnet rotor comprises main magnets and auxiliary magnets. The multiple main magnets are circumferentially distributed. A magnetizer made of permeability magnetic materials is arranged between every two adjacent main magnets. One auxiliary magnet is arranged on one side, away from the conductor rotor, of each magnetizer. The directions of the magnetic poles of the main magnets are located in the circumferential direction of the permanent magnet rotor. The directions of the magnetic poles of the adjacent main magnets are in the face-to-face direction or the back-to-back direction. The directions of the magnetic poles of the auxiliary magnets are the radial directions of the permanent magnet rotor. The directions of the magnetic poles of the adjacent auxiliary magnets are opposite. The magnetic poles of the positions of the side faces where the two main man magnets and one auxiliary magnet are contacted with the same magnetizer are respectively the same polarity. The permanent magnet coupling mechanism between the shafts is large in transmitting torque, adjustable in transmitting torque, compact in structure, convenient to install, and stable and reliable in transmission and adjustment.

Owner:JIANGSU MAGNET VALLEY TECH

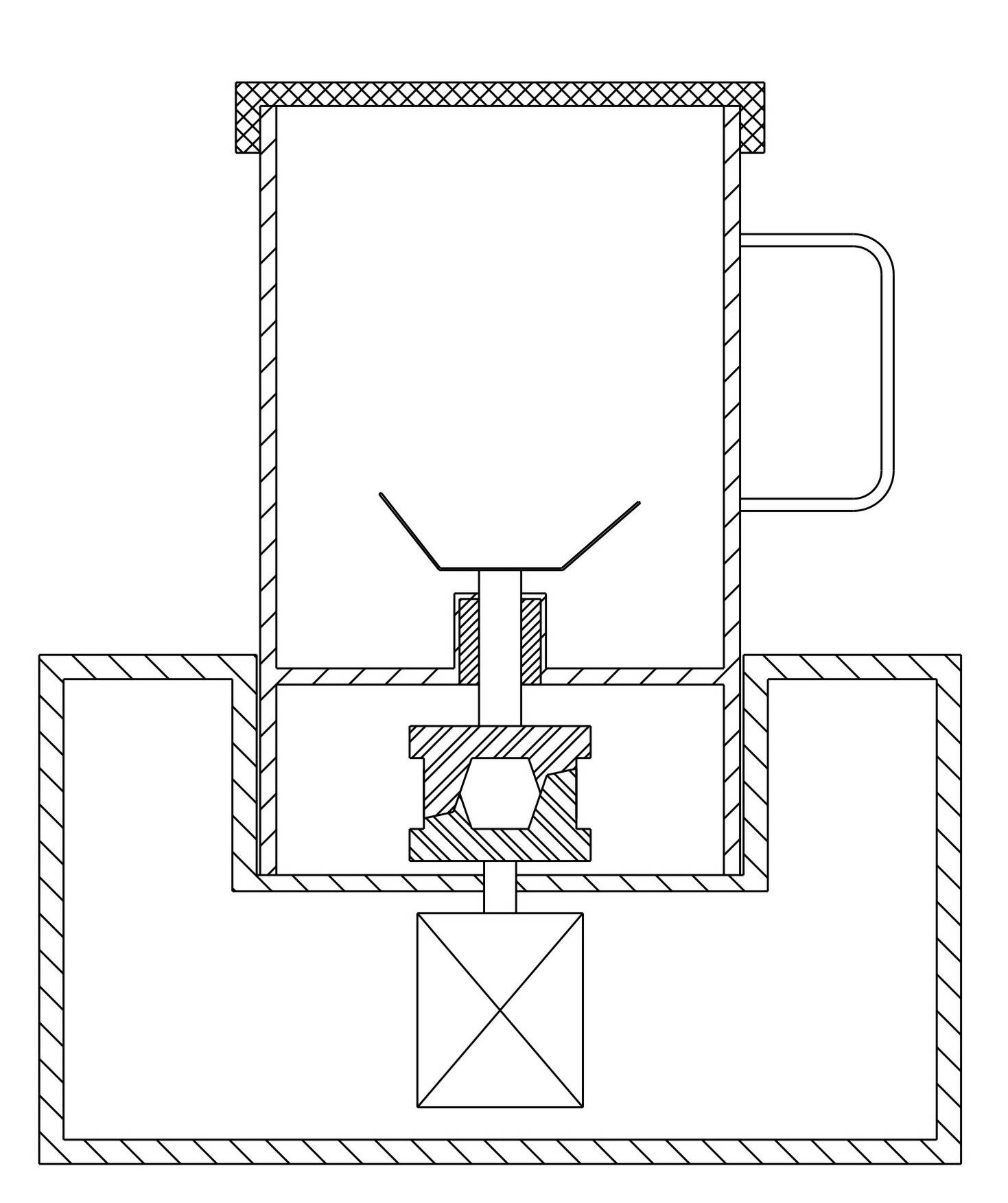

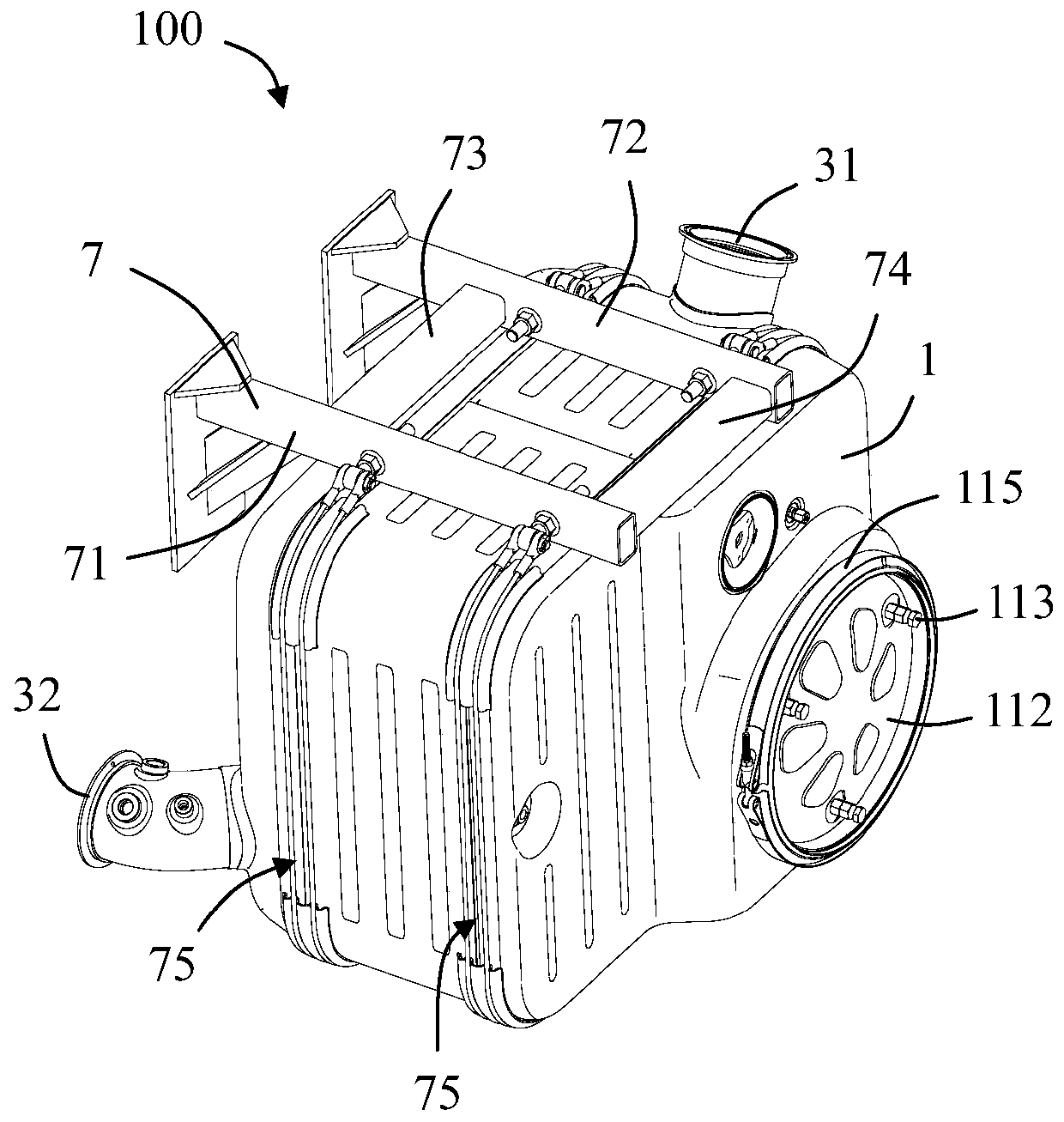

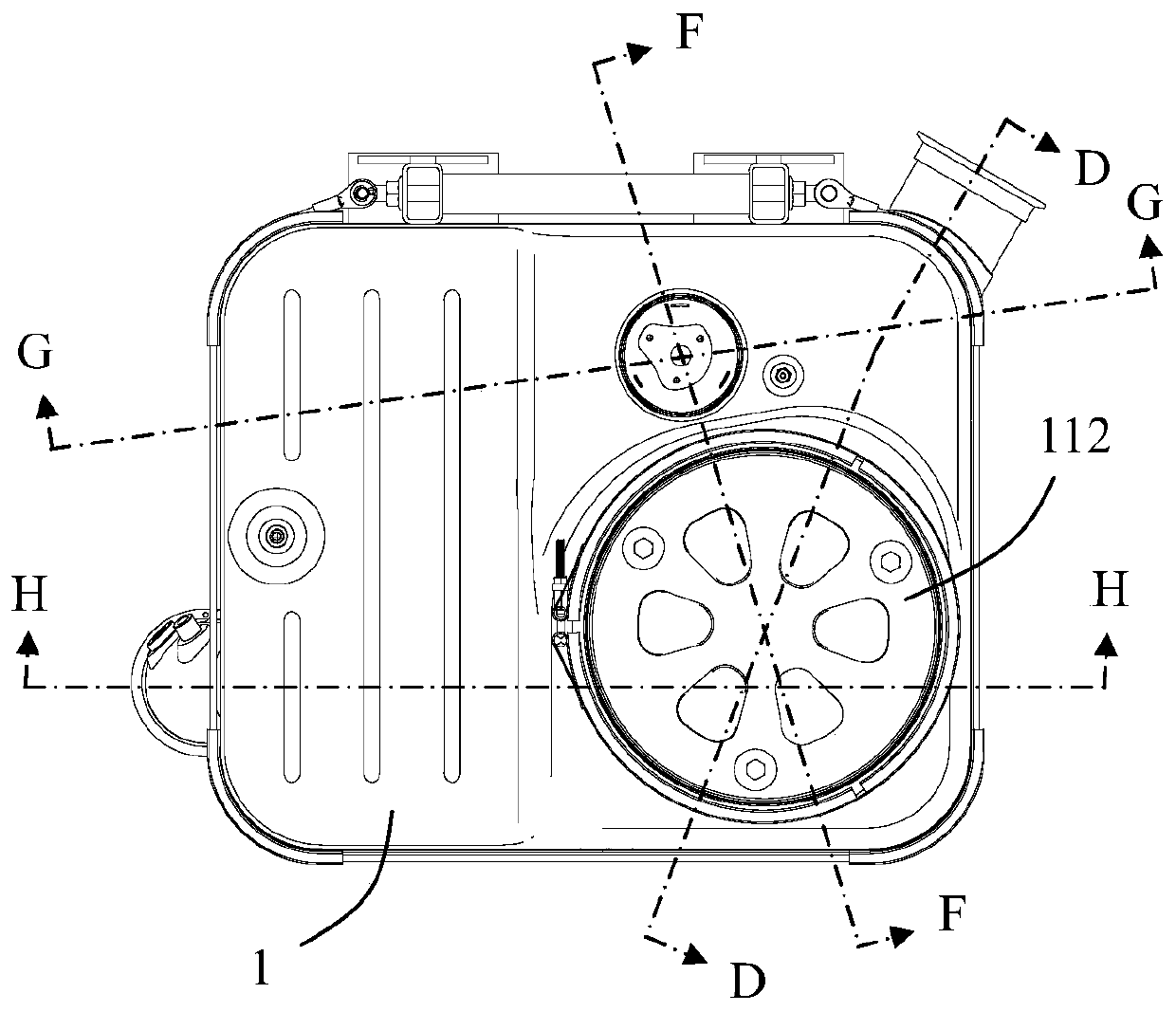

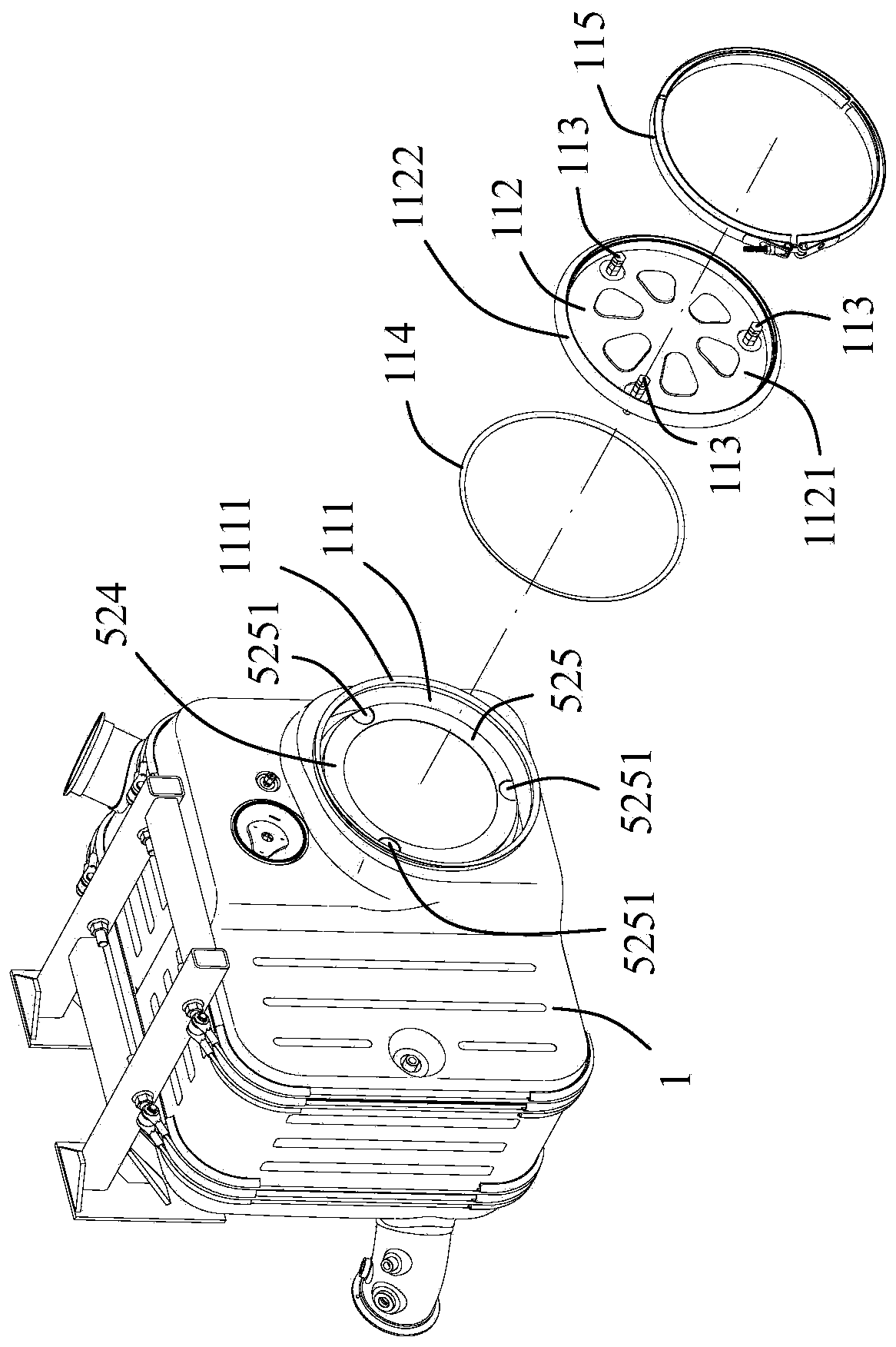

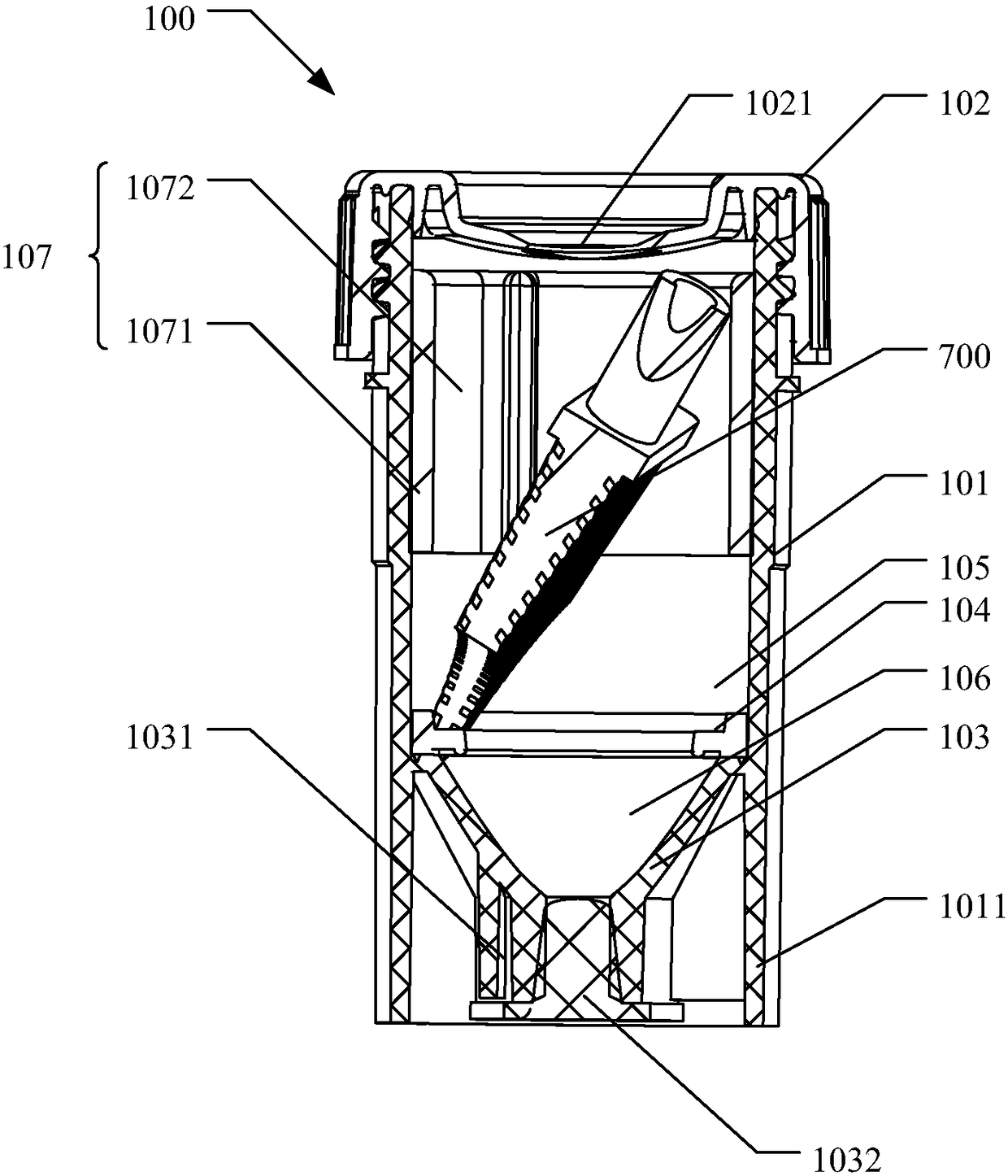

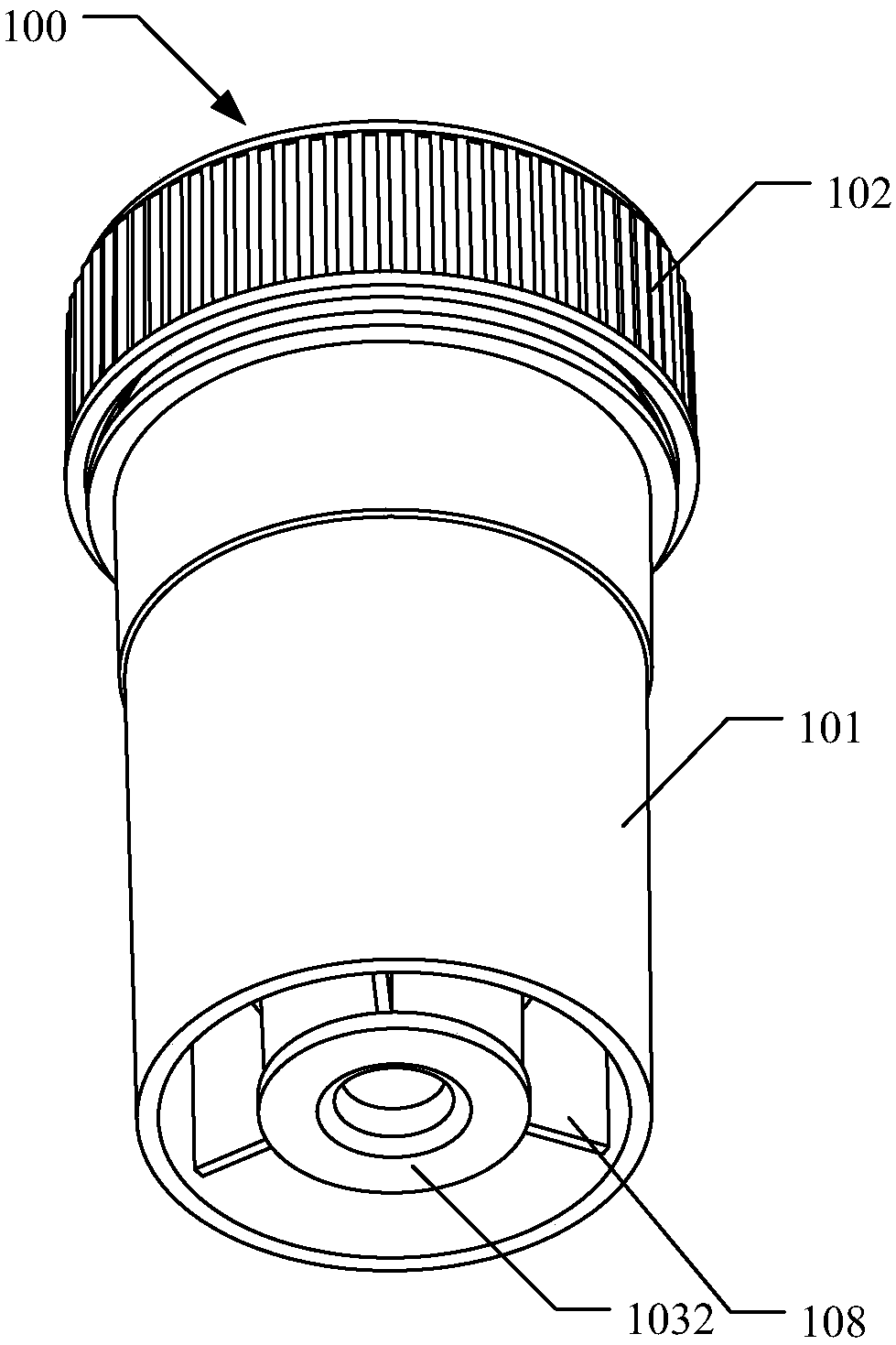

Indirectly driven food processor

ActiveCN102217905ANo wear and tearReduced concentricity requirementsKitchen equipmentWater leakageDrive shaft

The invention discloses an indirectly driven food processor, which comprises a container, a crushing cutter arranged in the container, a motor, a base internally provided with the motor, a driving shaft coupling arranged on a power output shaft of the motor, and a driven shaft coupling connected with the crushing cutter. The indirectly driven food processor is characterized in that: the driving shaft coupling and the driven shaft coupling are in non-contact connection. The driven shaft coupling can be rotatablely arranged in the container and is arranged in a floating mode relative to the container. The driving shaft coupling is made of magnet and the driven shaft coupling is made of metal. The driving shaft coupling and the driven shaft coupling are in non-contact transmission, which caneffectively solve the problem of abrasion between the driving shaft coupling and the driven shaft coupling; the container needs no cutter shaft hole, and sealing to thoroughly solve the problem of container water leakage; vibration and noise can be effectively relieved; the driven shaft coupling is arranged in a floating mode, which can effectively solve the problem of cutter blockage; and the driven shaft coupling and the crushing cutter are dismountable so that the container can be cleaned conveniently.

Owner:JOYOUNG CO LTD

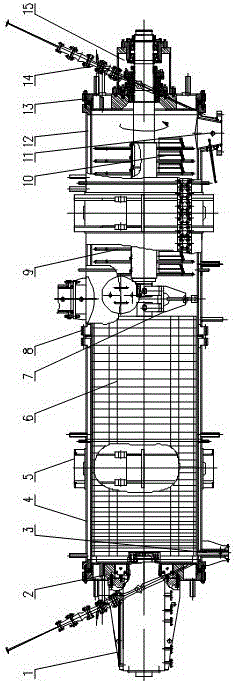

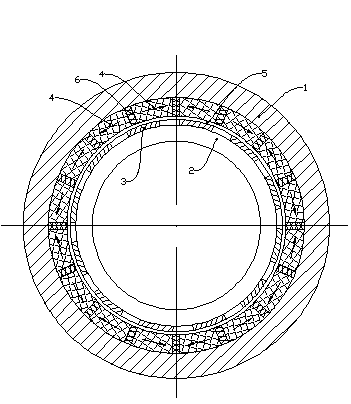

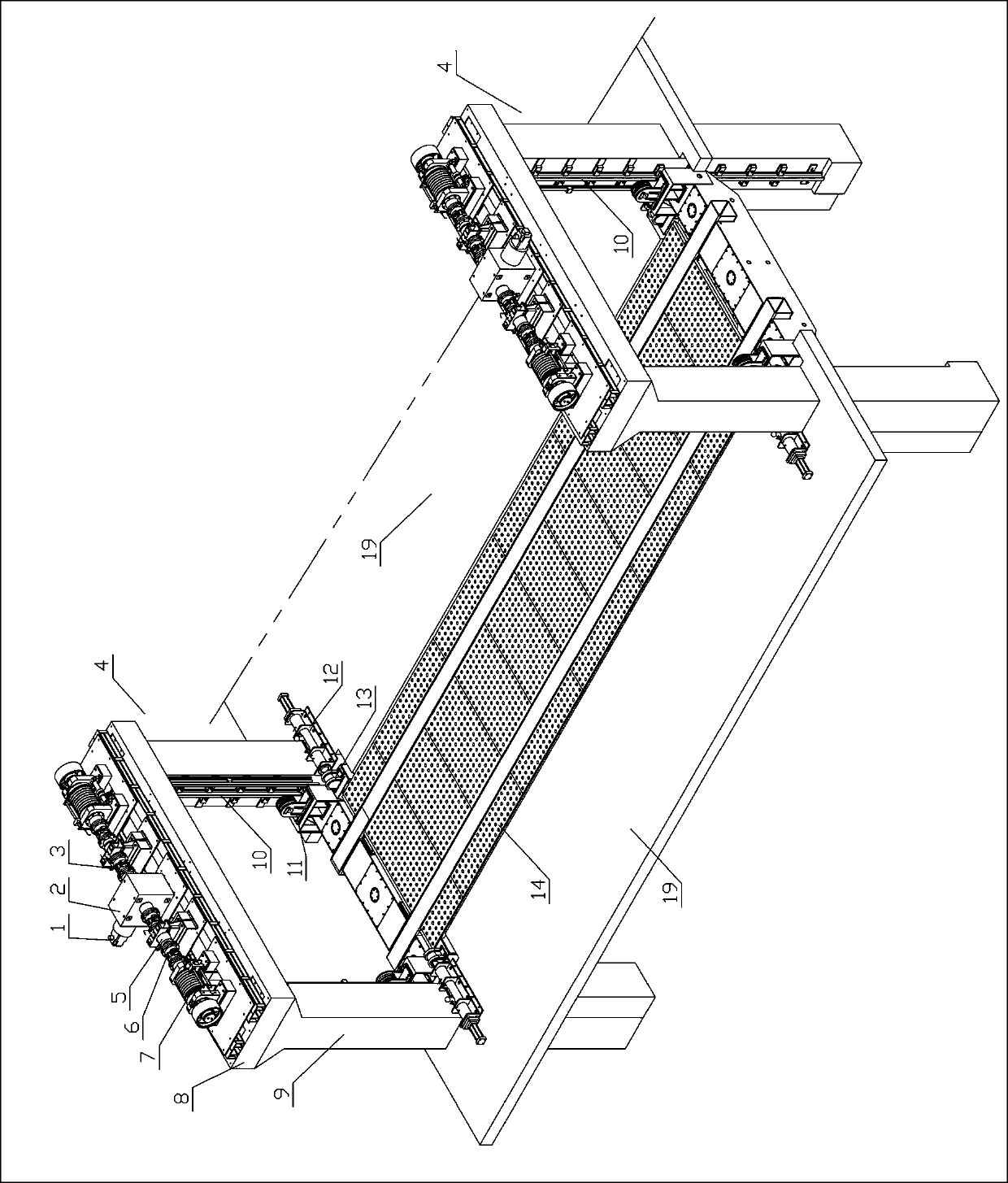

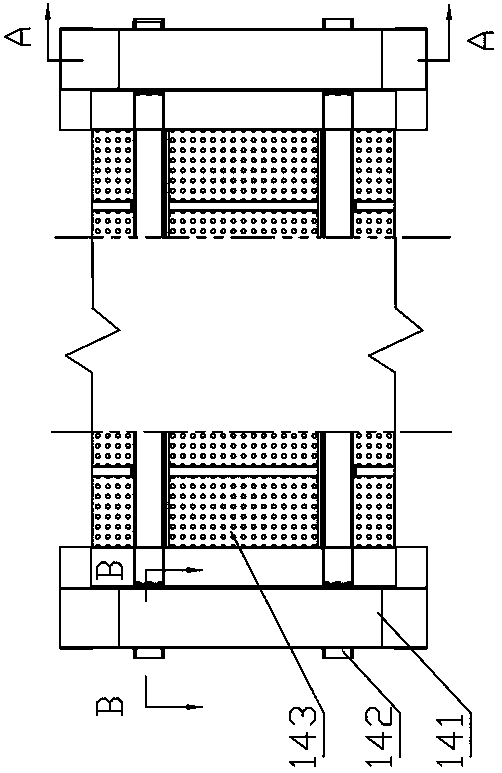

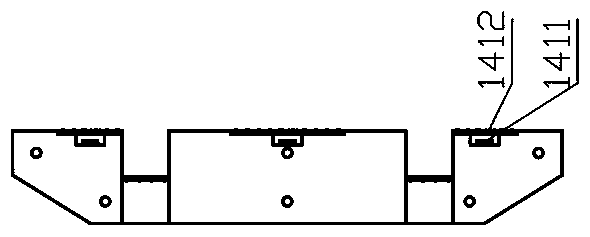

Novel high-viscosity final polycondensation reactor

InactiveCN106622083AReduce manufacturing costIncrease productivityChemical/physical/physico-chemical stationary reactorsProcess engineeringCompound (substance)

The invention belongs to the technical field of chemical equipment and relates to a novel high-viscosity final polycondensation reactor. The reactor sequentially comprises a transmission end, a left end cover, a feeding port, a front drum section, a ring seat, a bearing seat, a drum middle flange, a discharging port, a rear drum section, a right end cover, mechanical seal and a supporting frame. The reactor is characterized in that two stirring devices different in rotation speed are arranged in a drum, one of the stirring devices is a cage stirrer arranged in the front drum section, and the other stirring device is a disc stirrer with an inclination scraper and is arranged in the rear drum section. Two half pad bearings are arranged in the middle of the drum to support the two stirring devices, and reinforcement rings are arranged on the drum. The novel high-viscosity final polycondensation reactor has the advantage that by integration of an original final polycondensation reactor and a tackifying reactor, production cost reduction, production efficiency improvement, energy saving, environment friendliness and high market competitiveness are realized.

Owner:NANJING HAOYANG CHEM EQUIP

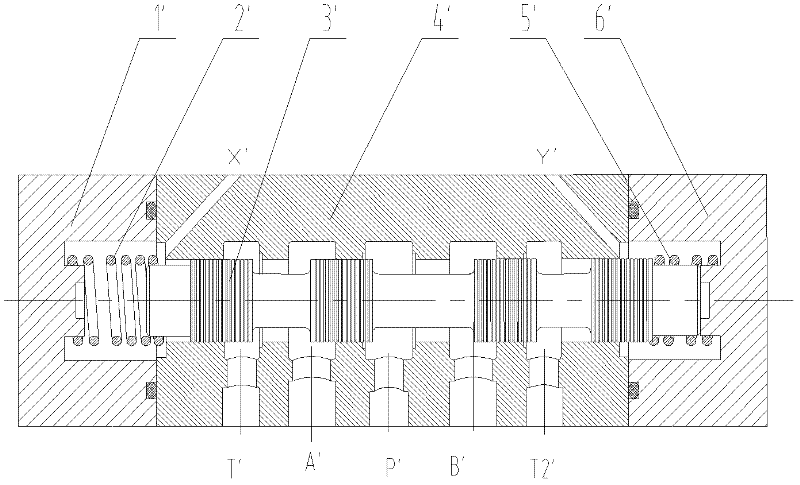

Hydraulic directional valve, hydraulic directional valve group and hydraulic directional valve control method

ActiveCN102297172ALow machining accuracy requirementsEasy to processServomotor componentsMultiple way valvesHigh resistanceEngineering

A hydraulic directional control valve and the control method thereof, a hydraulic control valve set, and a hydraulic control system and engineering machinery comprising the said valve or the valve set. The said hydraulic control valve comprises: a valve body (10); a valve pocket sleeve provided in the cavity of the valve body (10); a valve plug provided in the valve pocketsleeve. The valve pocket sleeve is a split type valve pocketsleeve, comprising at least a first valve pocket sleeve (21) and a second valve pocket sleeve (22). The valve plug is a split type valve plug, comprising at least a first valve plug (31) and a second valve plug (32). The said first valve plug (31) and the second valve plug (32) are in a synchronous working conditionstate. The hydraulic directional control valve is provided with at least three fluid ports, and at least two working positions may be realized. The split type valve pocket sleeve and valve plug impart offer the following benefits to the valve plug: simple valve plug assembly, less likelihood to of valve plug getting stuck, strong high resistance to contamination, good interchangeability of parts, and much longer overall service life.

Owner:SANY AUTOMOBILE MFG CO LTD

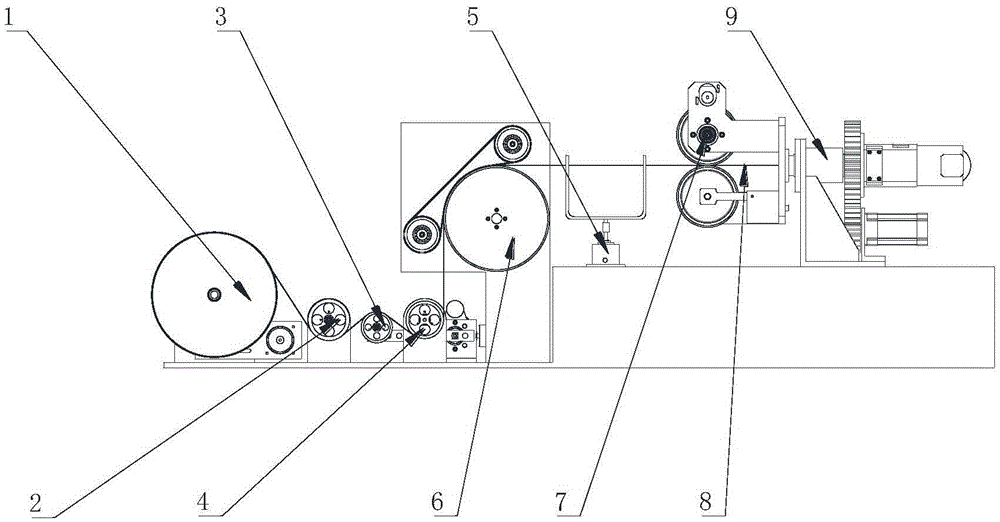

Optical fiber untwisting device

ActiveCN105621157AReduce torsional stressReduced concentricity requirementsMeasurement devicesFilament handlingFiberGyroscope

The invention discloses an optical fiber untwisting device. An optical fiber guided out of an optical fiber traction assembly passes through an optical fiber twisting detecting unit, an optical fiber winding and clamping assembly and an optical fiber untwisting assembly which are arranged in sequence and is wound around the interior a fiber winding disc in the optical fiber untwisting assembly. The optical fiber untwisting assembly comprises a rotary driving motor, a transmission mechanism and the fiber winding disc. The rotary driving motor is connected with an angle sensor and rotates according to a feedback signal given by the angle sensor. The optical fiber winding and clamping assembly is driven by the transmission mechanism to rotate synchronously and connected with the transmission mechanism through a flange face. The optical untwisting device can overall untwist the whole long optical fiber, torsional stress existing in the optical fiber is reduced, the magnetic sensitivity problem of a fiber-optic gyroscope is solved, and the precision of the fiber-optic gyroscope is improved. In addition, by means of the optical fiber untwisting technology, the influence of eccentricity of an insulated single wire on characteristic impedance can be eliminated, and the requirement for the concentricity of the insulated single wire can be reduced.

Owner:武汉光谷长盈通计量有限公司

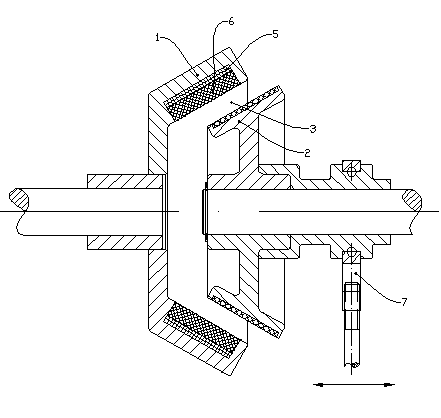

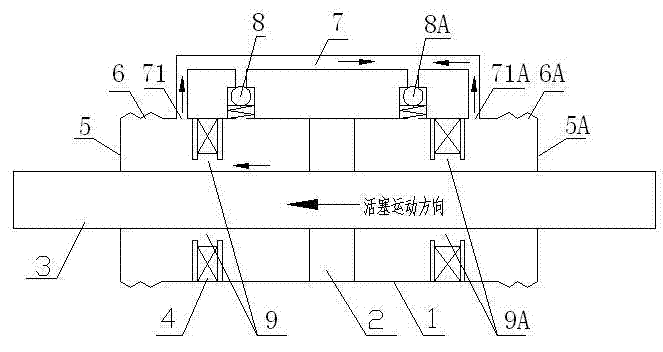

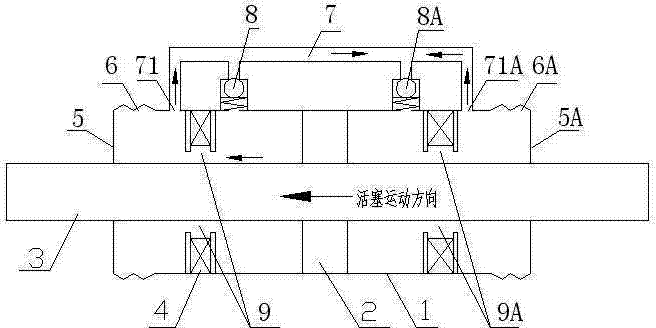

Leakage-free seal-ring-free two-way controllable magnetorheological damper

ActiveCN102359536APrevent leakageReduced concentricity requirementsSpringsNon-rotating vibration suppressionEngineeringCylinder block

The invention discloses a leakage-free seal-ring-free two-way controllable magnetorheological damper which comprises a cylinder body, a piston and a piston rod, wherein the left end and the right end of the cylinder body are respectively connected with a left corrugated pipe and a right corrugated pipe hermetically, the left corrugated pipe is hermetically connected with a left end cover, the left end cover and a right end cover are hermetically connected with the piston rod, the left corrugated pipe and the right corrugated pipe are hermetically connected with the left end cover and the right end cover, and the centers of the left end cover and the right end cover are hermetically connected with the piston rod; a communicating pipe is arranged on the cylinder body; a left circular coil and a right circular coil are fixedly connected inside the cylinder body, and gaps between the inner holes of the circular coils and the piston rod form a damping channel; and a left one-way valve and a right one-way valve are arranged on the communicating pipe, and the piston rod is located between the left one-way valve and the right one-way valve. In the invention, the corrugated pipes are used as sealing elements, leakage caused by wearing between the piston rod and a seal ring is avoided, and the corrugated pipes do not bear working pressure. The damper can not leak within the service life of the corrugated pipes.

Owner:CHONGQING MATERIALS RES INST

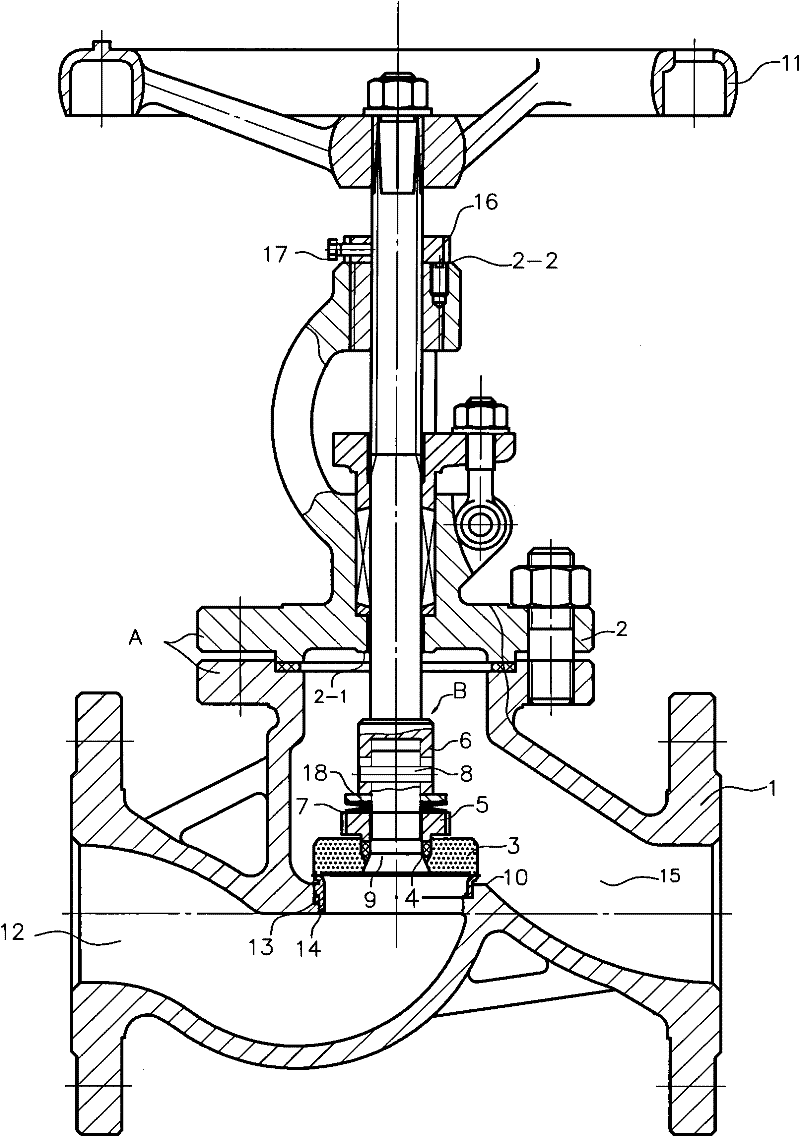

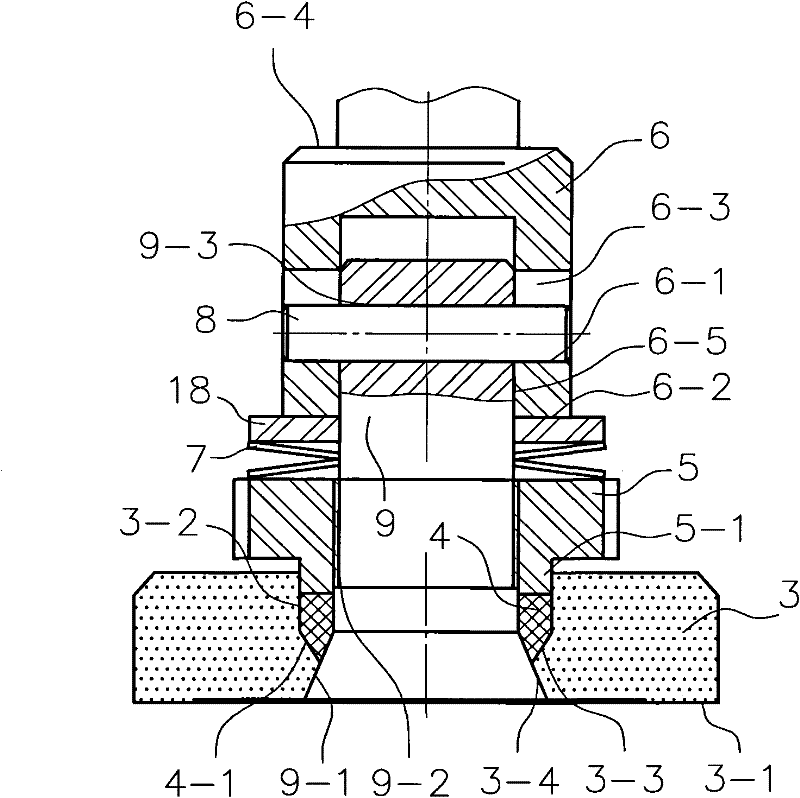

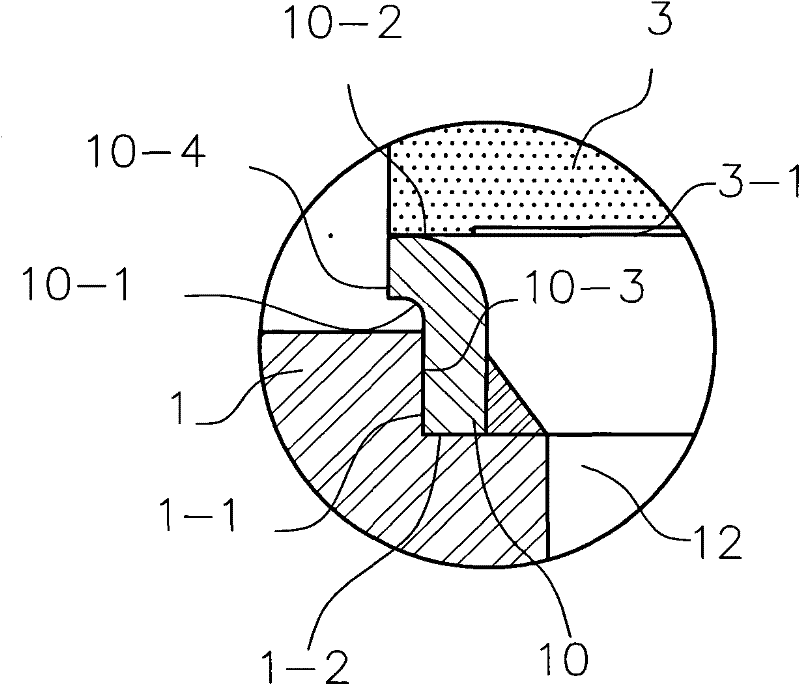

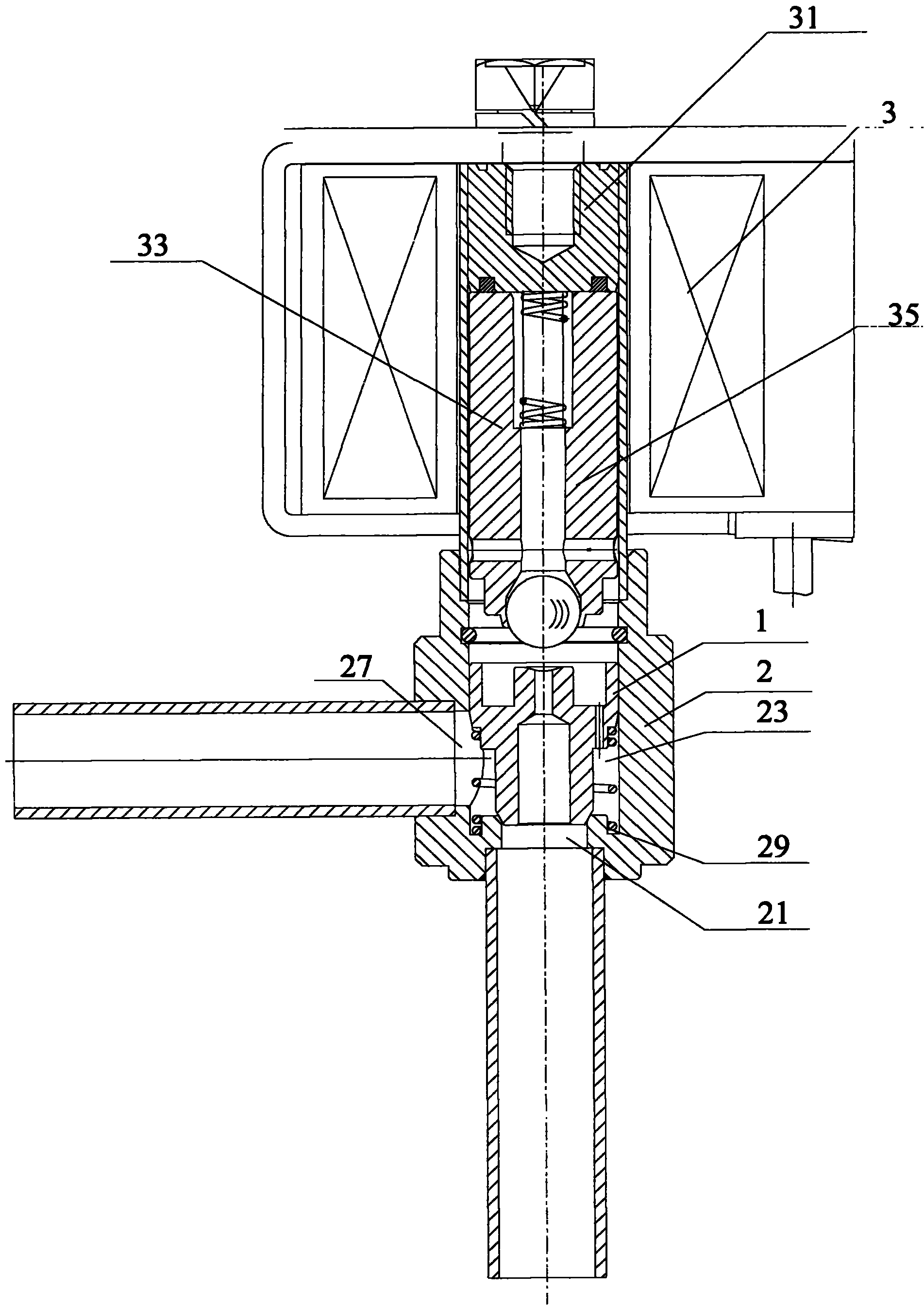

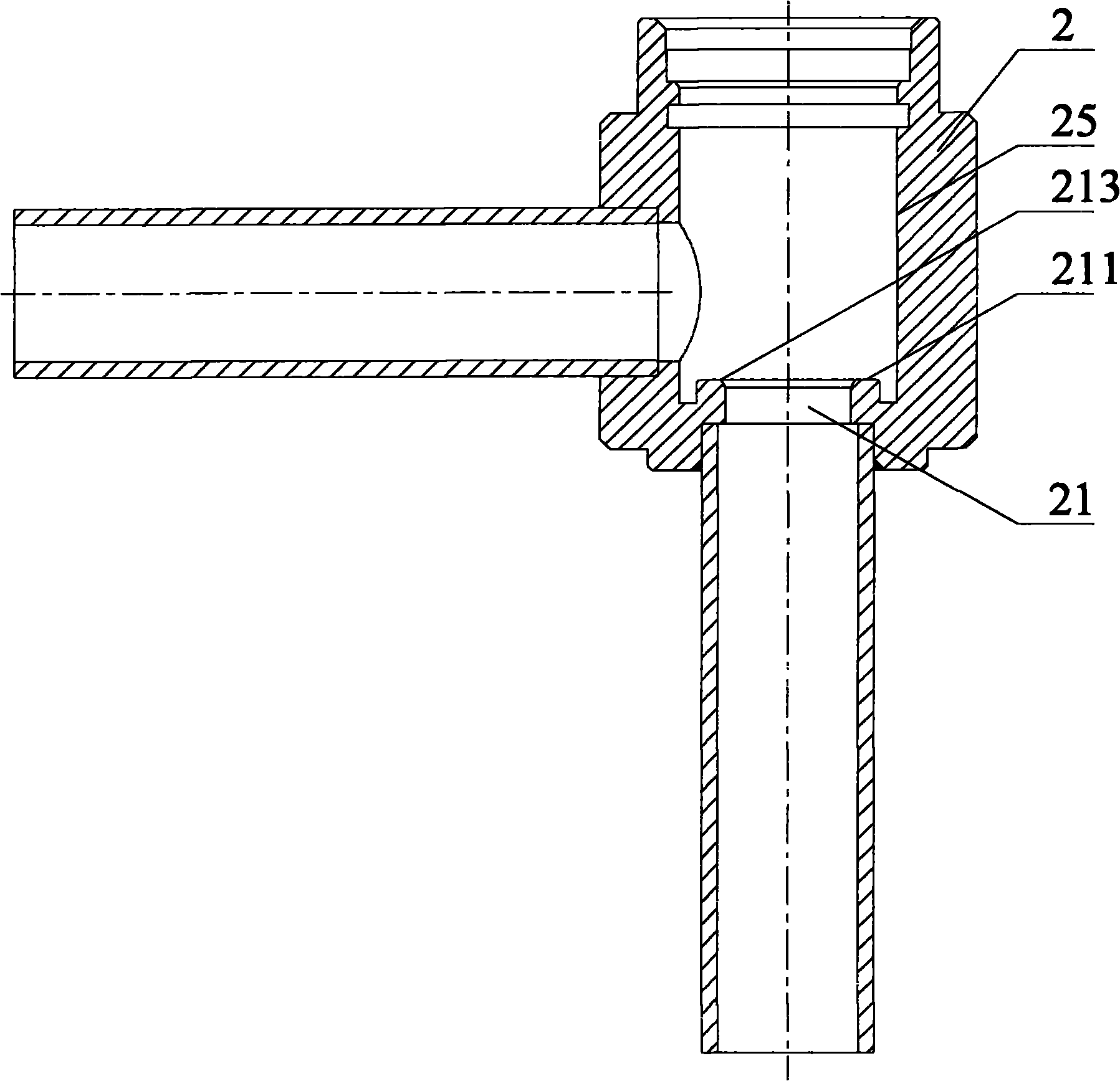

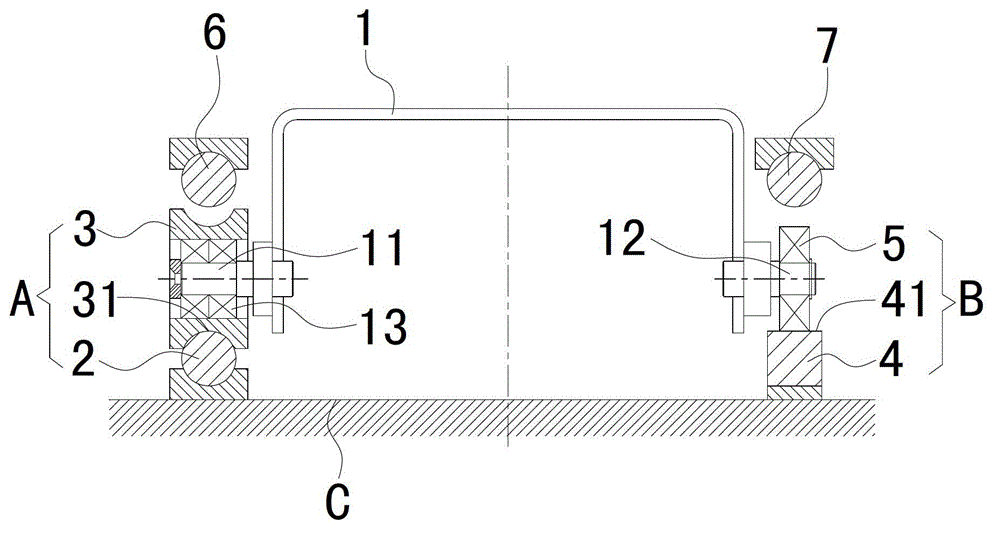

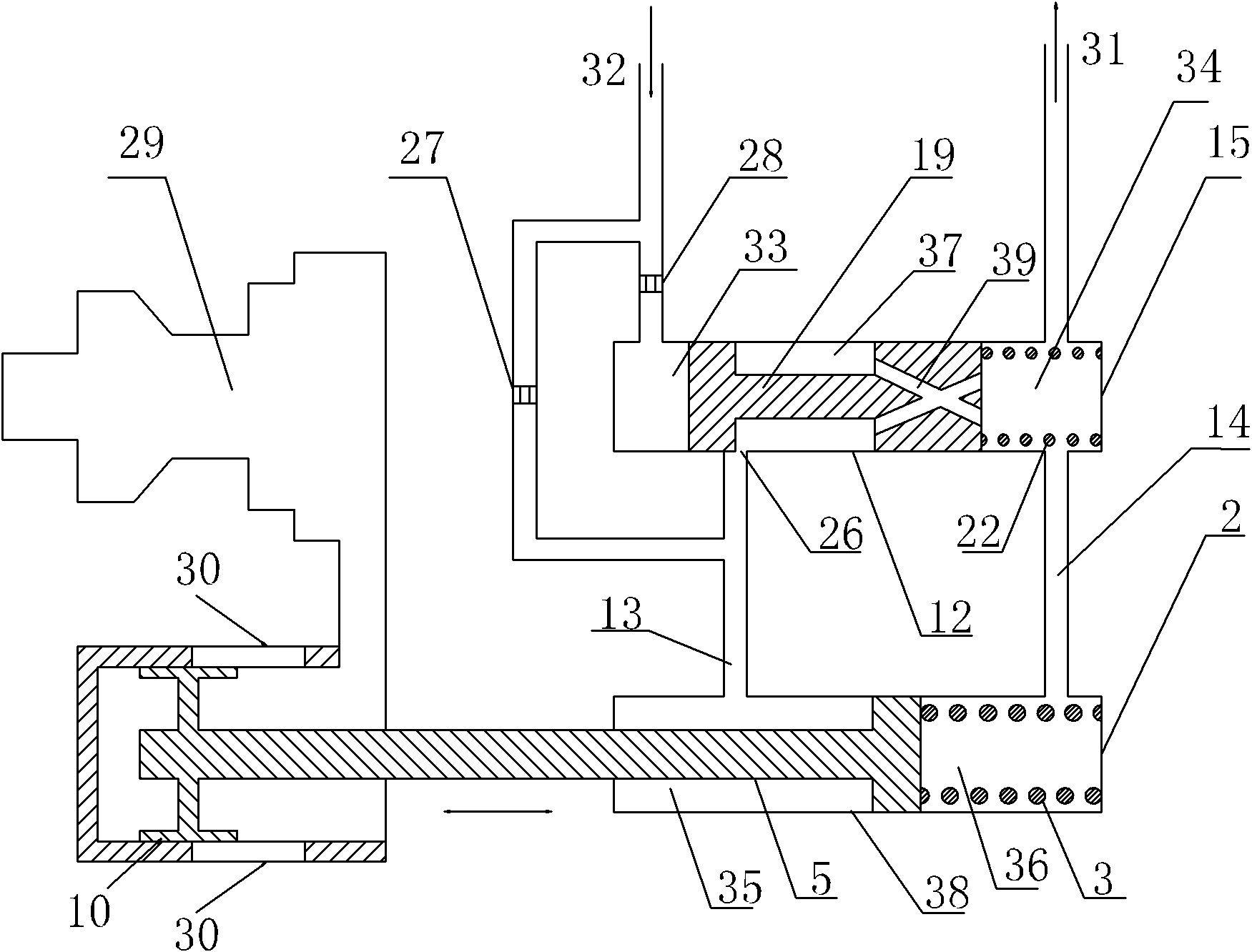

Isolating valve sealed by structural ceramic valve clack and metal elastic valve seat

The invention discloses an isolating valve sealed by a structural ceramic valve clack and a metal elastic valve seat. The isolating valve is mainly composed of a first part (A) and a second part (B), wherein the first part (A) is formed by connecting a valve body (1) with a valve cover (2), and the second part (B) is formed by connecting a ceramic valve seat (3) with a valve rod (6); an upward inlet (15) is arranged by taking the horizontal line of the valve body (1) as a center, and an outlet flow channel (12) downwardly bending relative to the cross center is arranged; a step hole center position of an intersection of the upward inlet (15) and the outlet flow channel (12) is equipped with elastic valve seats (10-14) and elastic valve seats(1-4) arranged on a body; and circular arcs (10-2,14-1,1-4) and sealing surfaces (3-1) of a ceramic valve clack (3) are contacted and closely fitted to form a sealing pair.

Owner:ZHEJIANG ZHENGHUA VALVE FACTORY

Electronic expansion valve

ActiveCN105716335AAvoid stuck phenomenonSimple structureOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides an electronic expansion valve. The electronic expansion valve comprises a first valve seat, a second valve seat, a valve needle, a return spring, a driving mechanism and a sleeve, wherein the second valve seat is assembled on the first valve seat and provided with a main valve port; the valve needle slides to get close to or away from the main valve port and comprises a T-shaped end and a valve head end; the valve needle is sleeved with the return spring, and the return spring elastically keeps the main valve port normally opened; the driving mechanism comprises a nut and a screw, the screw is in threaded connection with the interior of the nut in the form of reciprocating in the sliding direction of the valve needle, and the screw abuts against the T-shaped end and drives the valve needle to open or close the main valve port; the return spring is sleeved with the sleeve, and the sleeve and the T-shaped end are matched so as to guide the valve needle to slide in the sleeve. The T-shaped end of the valve needle abuts against the driving mechanism, the sleeve and the T-shaped end are matched to form a sliding guiding relation, and thus the requirement for the concentricity of the valve needle and the screw is lowered, the phenomenon that the valve needle gets stuck in the working process is effectively avoided, the structure of the electronic expansion valve is simplified, and working difficulty is lowered.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

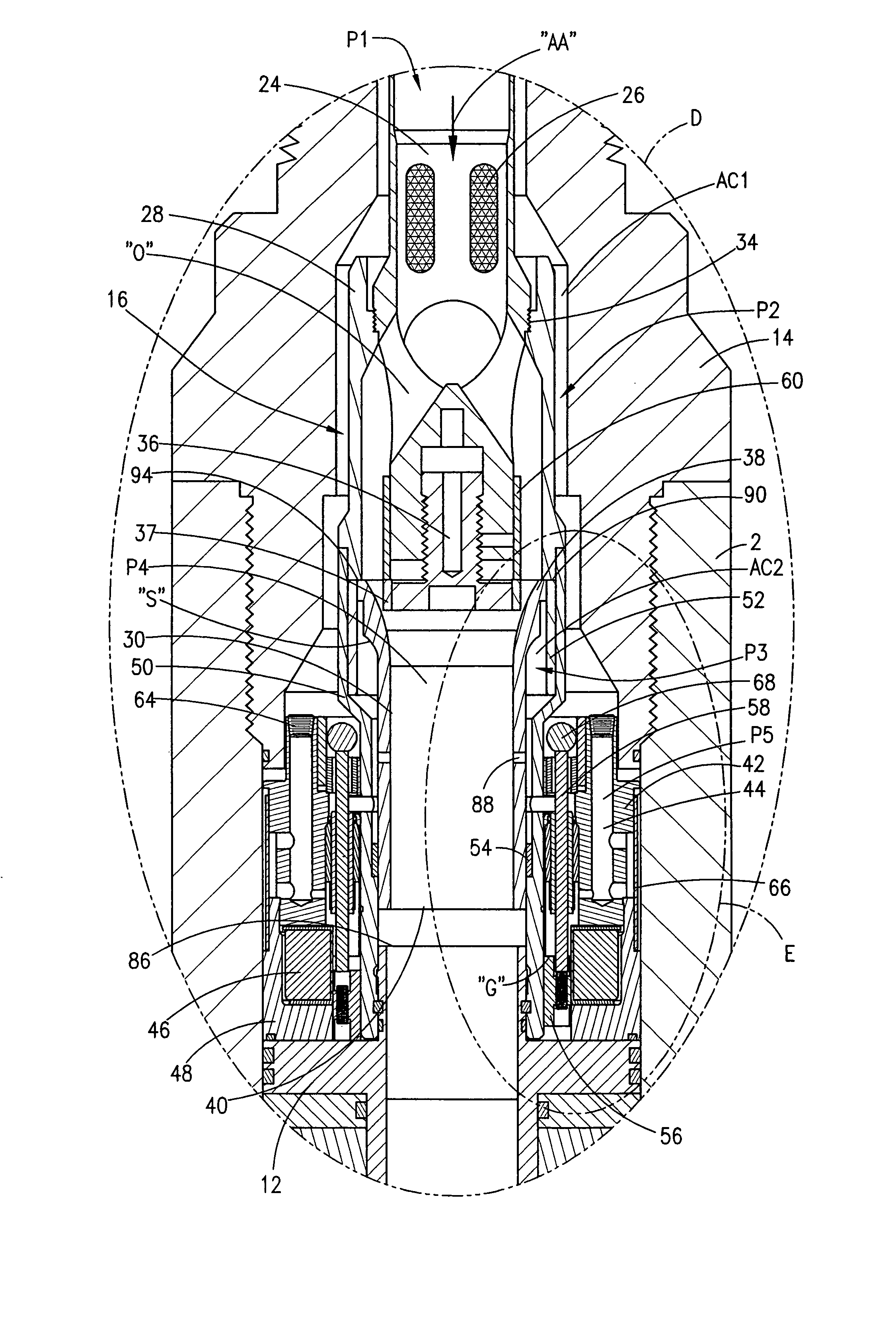

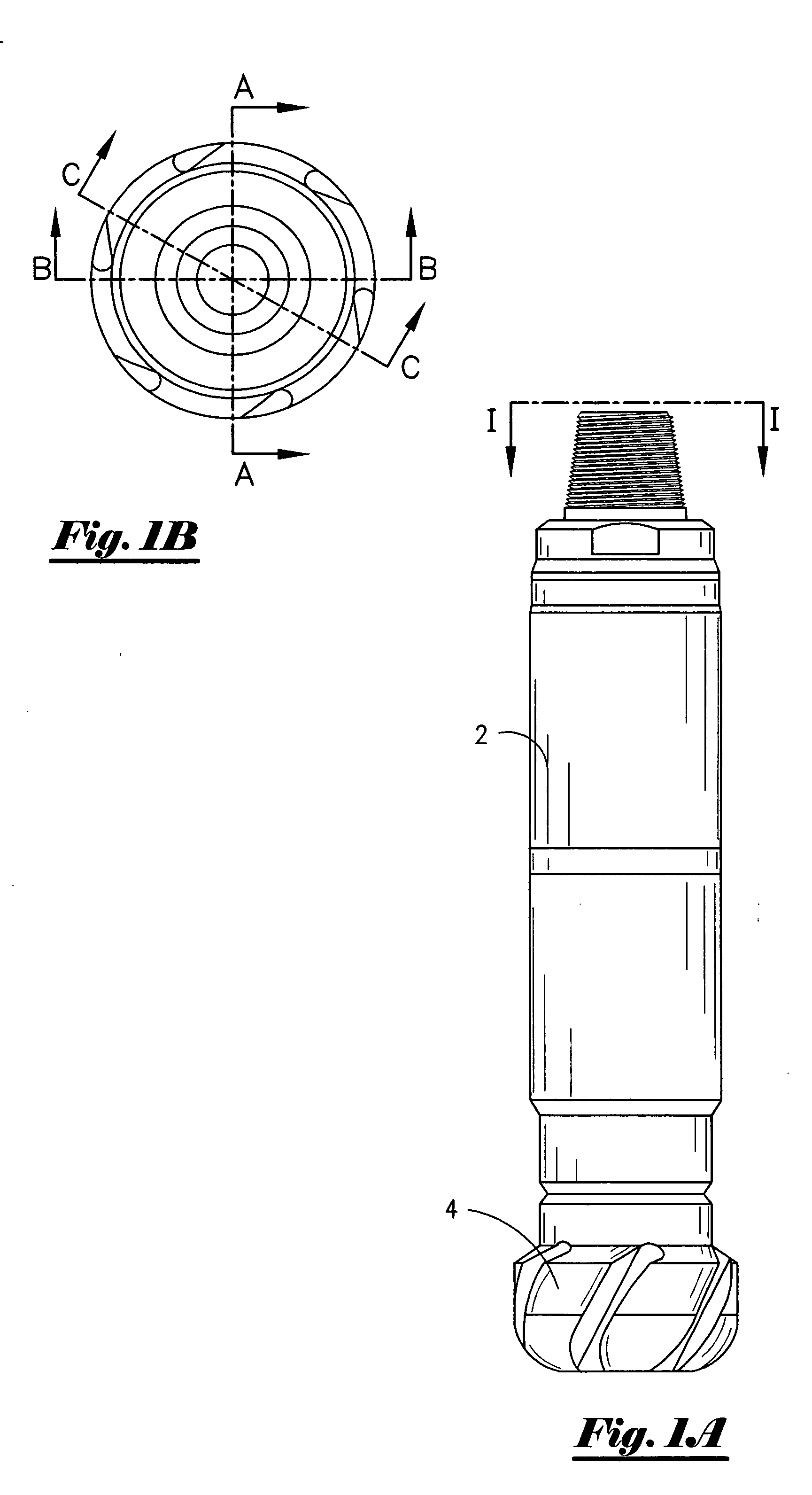

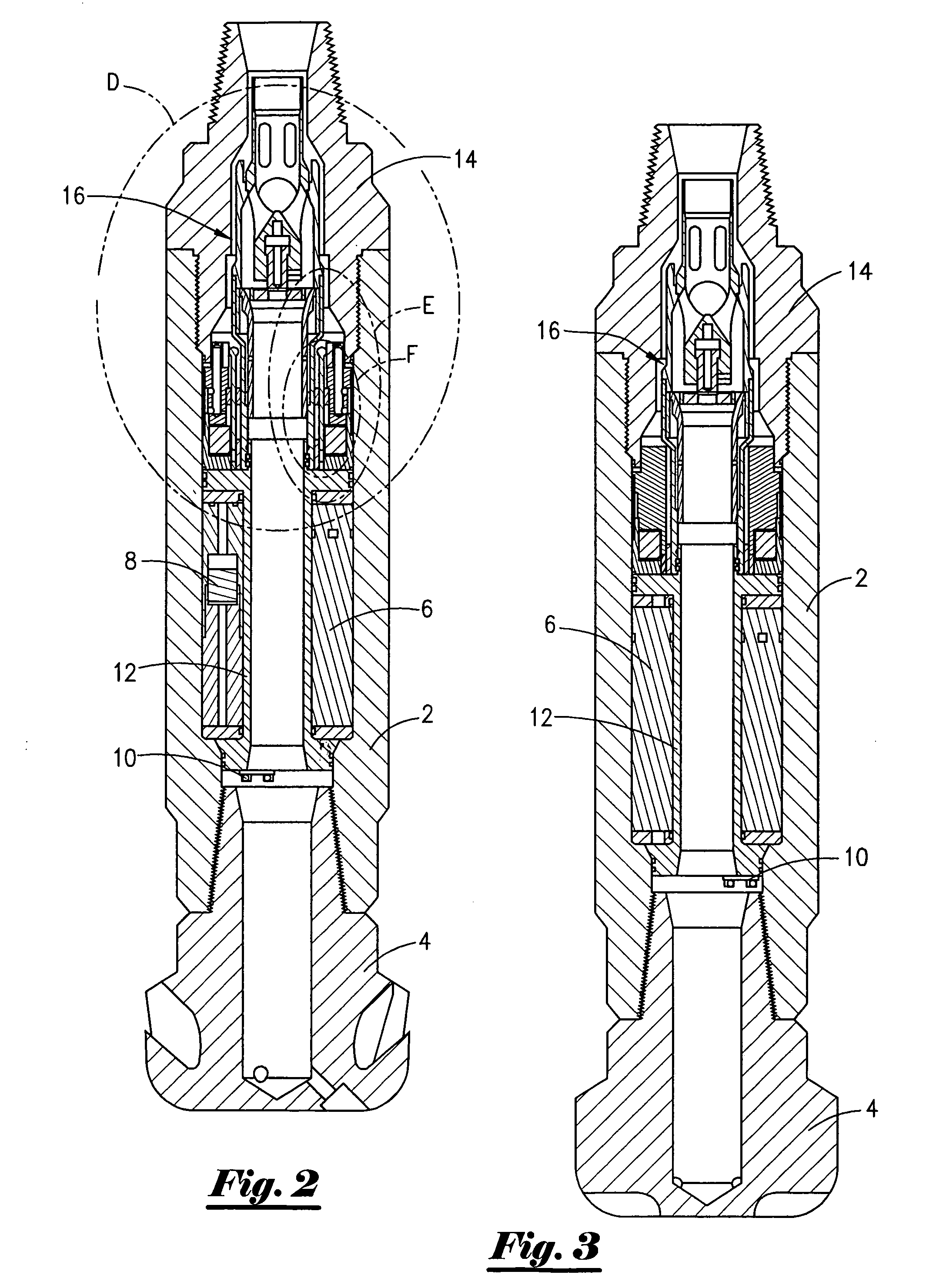

Measurement while drilling tool and method

An apparatus for telemetering a downhole parameter from a well. The apparatus comprises a housing having a bore. The apparatus further comprises an annular main valve with an enlarged end positioned within the bore, with the main valve having a center of axis. A restrictor is concentrically disposed within the bore, the restrictor configured to define an annular passage with the main valve. The apparatus also includes: a pressure device for supplying hydraulic pressure to the main valve; a control valve, operatively associated with the restrictor member, for controlling pressure to the main valve; and a solenoid control valve assembly for activating the control valve. In one preferred embodiment, the solenoid control valve assembly comprises a controller for emitting an electrical signal, a coil that receives the electrical signal and generates a magnetic field, a solenoid static pole receptive to the generated magnetic field, and a solenoid moving pole responsive to the magnetic field so that the solenoid moving pole moves in a direction towards the solenoid static pole. A method for communicating a downhole parameter is also disclosed.

Owner:NAVIGATE ENERGY SERVICES

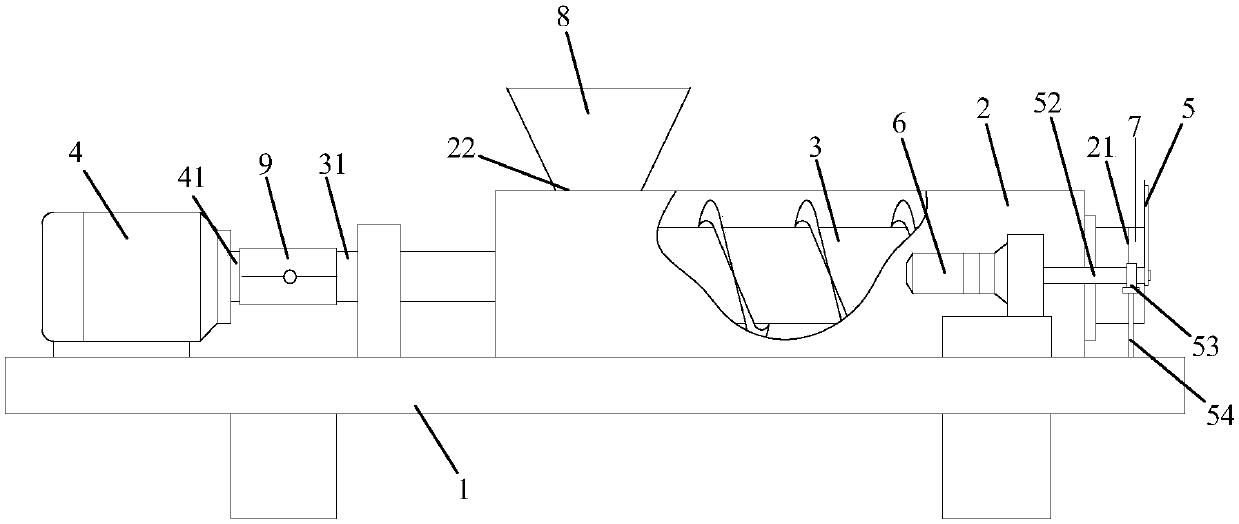

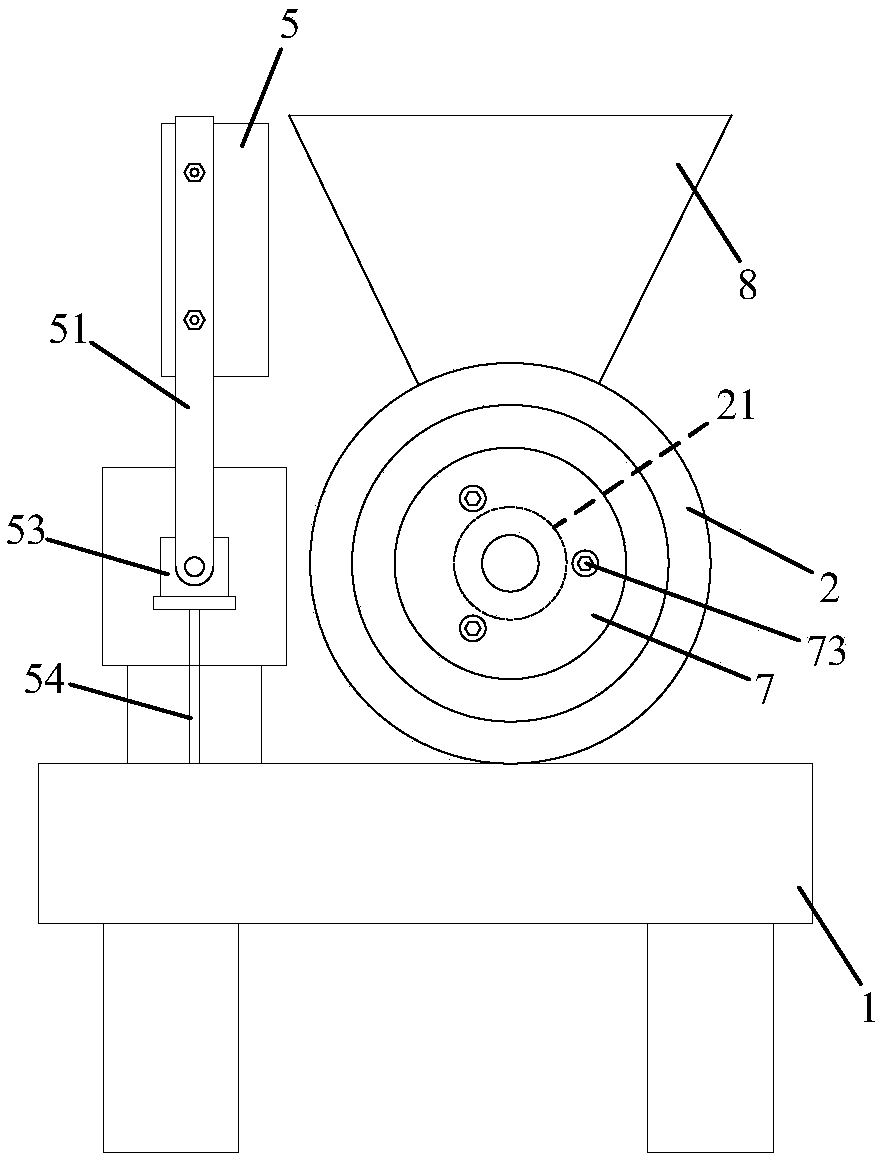

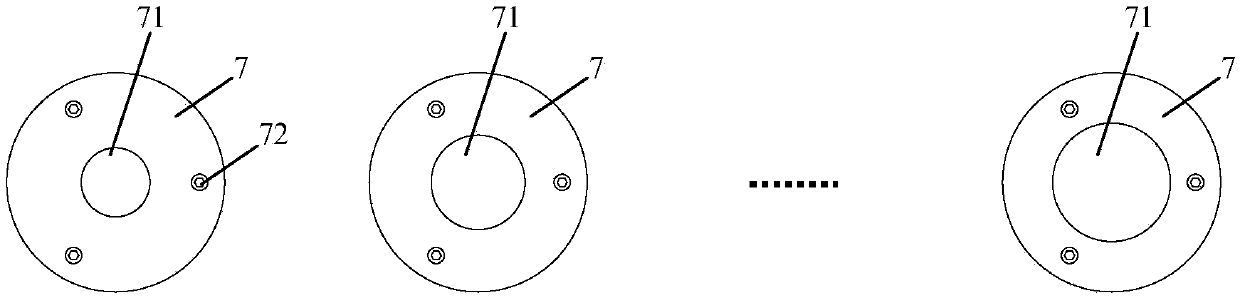

Automatic forming and cutting machine for glutinous rice cakes

InactiveCN107811199AGreat tasteWill not deformFood shapingMetal working apparatusEngineeringRaw material

The invention discloses an automatic forming and cutting machine for glutinous rice cakes. The machine comprises a frame, an extrusion cylinder, a spiral pushing ram, a first motor, a cutter and a second motor. The automatic forming and cutting machine also comprises a plurality of installation plates, each of which is detachably mounted on the outer side of a discharge port; an extrusion hole coaxial with the discharge port is arranged on each of the installation plates; and the rotating plane of the cutter is positioned outside the extrusion holes and close to the extrusion holes. Compared with the prior art, with the above technical scheme, the automatic forming and cutting machine provided by the invention has the following beneficial effects: raw materials can be glutinous rice whichhas a good mouth feel; the cut glutinous rice cakes do not deform and have a long shelf life; yield of the machine is high and cutting efficiency is 1.5-2 times as high as cutting machines in the prior art; the cutting machine has small volume and is convenient for placement, and cost is much lower than that of the cutting machines in the prior art; and different installation plates can be used tocontrol the outer diameter size of glutinous rice cakes to be cut.

Owner:黄先良

Motorcycle bottom fork

InactiveCN101348157AExtended service lifeImprove comfortAxle suspensionsManufacturing cost reductionBall bearing

The invention provides a motorcycle bottom fork, comprising a left frame rod, a right frame rod and a connecting rod which is arranged between the left frame rod and the right frame rod; the front ends of the left frame rod and the right frame rod are respectively provided with a sleeve used for realizing the axial connection between motorcycle frames; the motorcycle bottom fork is characterized in that the sleeve is internally provided with a ball bearing which consists of a ball sleeve and a steel ball with the position limited in the ball sleeve; the steel ball is provided with a central shaft hole. The motorcycle bottom fork improves the driving comfortableness of the whole motorcycle, has long service life, and suitably reduces the coaxiality requirement of the left sleeve and the right sleeve which are arranged at the front end of the bottom fork, thus being beneficial to reducing the manufacture cost.

Owner:LONCIN MOTOR

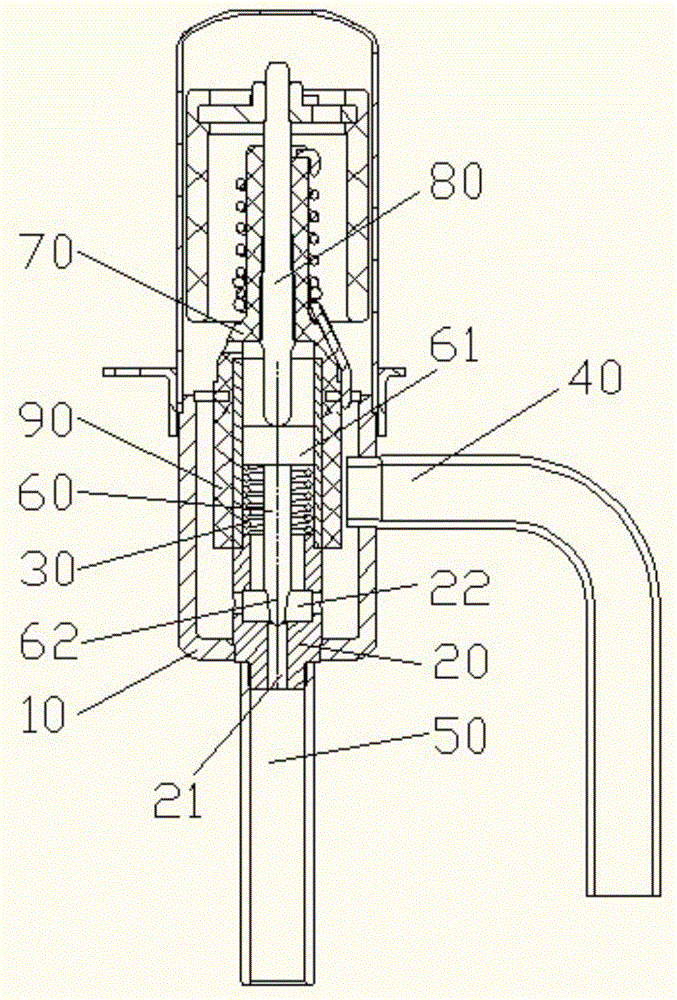

Valve core component of pilot valve and stepped direct-acting electromagnetic valve

InactiveCN101818818AReduced concentricity requirementsCompact structureOperating means/releasing devices for valvesLift valveCore componentEngineering

The invention provides a valve core component of a pilot valve, which is arranged in the inner hole of a valve body; the valve body is provided with a main flow valve port; the valve core component of the pilot valve comprises the valve core of the pilot valve and a sealing element; the valve core is provided with a damping hole; and the sealing element is arranged between the valve body and the valve core and is provided with a sealing plane for sealing the main flow valve port. According to another aspect of the invention, the invention also provides a stepped direct-acting electromagnetic valve which comprises the valve core component of the pilot valve. The invention improves the sealing effect of the electromagnetic valve, has low processing requirements, low cost and reasonable structure, improves the installing efficiency, reduces the rejection rate of the electromagnetic valve, improves the quality, and stabilizes the performance.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

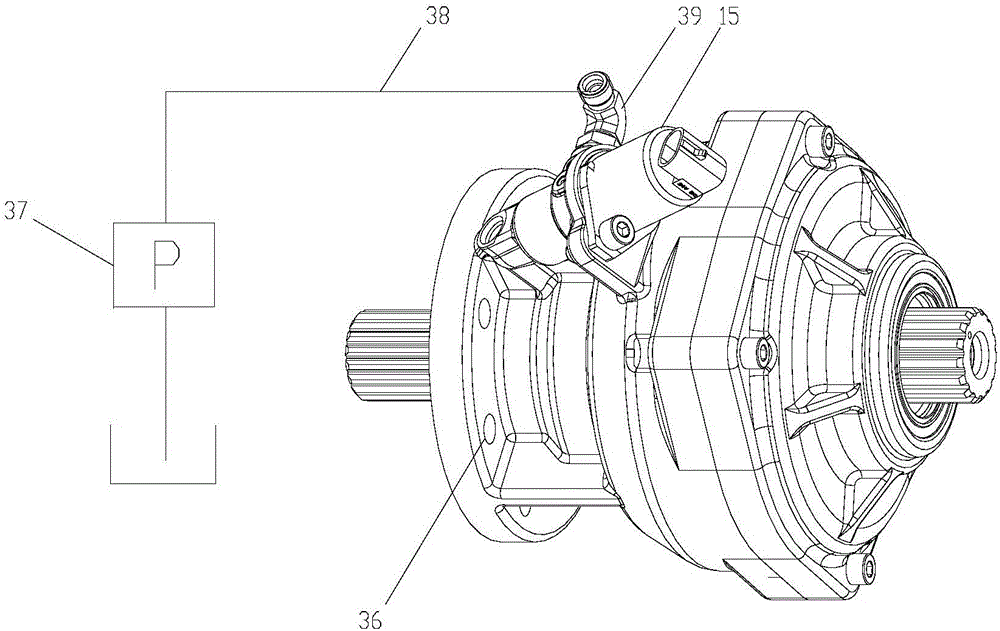

Matched power takeoff for power transmission system with automatic transmission

InactiveCN107631016AEasy to useEasy to controlGear lubrication/coolingGearing controlAutomatic transmissionEngineering

The invention provides a matched power takeoff for a power transmission system with an automatic transmission. The matched power takeoff comprises a casing; a hollow cavity is formed in the inner surface of the casing; an input shaft and an output shaft are coaxially arranged in the hollow cavity of the casing; the part, extending out of the casing, of the input shaft is connected with a power source; the part, extending out of the casing, of the output shaft is connected with an output accessory device; the input shaft and the output shaft are connected and separated through the combination and separation of a clutch; an electromagnetic valve is powered on, then the pressure oil pushes a piston to tightly compress the clutch, and the clutch is connected; the electromagnetic valve is powered off, the pressure of the pressure oil disappears, and the clutch is separated under the action of a spring; when the clutch is connected, the torque and the power of the power source goes to the output shaft through the input shaft and the clutch, and the connected accessory device is driven, so that the basic functions of the power takeoff are realized; the connection and the separation of theinput shaft and the output shaft are realized without stopping rotation of the input shaft or an output device, and meanwhile, a hydraulic oil source of the automatic transmission can be also conveniently used for controlling, lubricating and cooling.

Owner:HUBEI SENYU GEAR DRIVE CO LTD

Torque extraction device

InactiveCN104989743AEasy to useEasy to controlFluid actuated clutchesAutomatic transmissionOutput device

The invention provides a torque extraction device which comprises a shell. A cavity is formed in the inner surface of the shell. An input shaft and an output shaft are coaxially arranged in the cavity of the shell. The portion, extending out of the shell, of the input shaft is connected with a power source. The portion, extending out of the shell, of the output shaft is connected with an output auxiliary device. The input shaft and the output shaft are combined and separated through engagement and disengagement of a clutch. An electromagnetic valve is powered on, a piston is pushed by pressure oil to press the clutch, and the clutch is engaged; the electromagnetic valve is powered off, pressure of the pressure oil disappears, and under the effect of a spring, the clutch is disengaged. When the clutch is engaged, the torque and the power from the power source are transmitted to the output shaft through the input shaft and the clutch, the connected auxiliary device is driven, and therefore the basic functions of the torque extraction device are achieved. The input shaft and the output shaft can be combined and separated without the requirement for stopping rotation of the input shaft or an output device. Meanwhile, a hydraulic oil source brought by an automatic transmission can be conveniently used for control, lubrication and cooling.

Owner:西安双特智能传动有限公司

Inner armature type high precision positioning electromagnet

ActiveCN103996486AElimination of positioning errors and deformation stressHigh positioning accuracyElectromagnets with armaturesEngineeringElectromagnet

The invention discloses an inner armature type high precision positioning electromagnet which comprises a shell, an armature, a coil, an end cover and a positioning shaft. One end of the shell is sealed through the end cover, three supporting assemblies are arranged at the end, far away from the end cover, of the shell, bearings of the three supporting assemblies are all tightly attached to the positioning shaft, and the positioning shaft can move freely in the axial direction of the positioning shaft. Two supporting assemblies are fixed supporting assemblies, another supporting assembly is a movable supporting assembly, and a kidney-shaped hole is formed in a supporting block of the movable supporting assembly in the length direction of the supporting block. A screw sequentially penetrates through a pressing plate and the kidney-shaped hole and then is connected with the shell. A compressed spring is arranged at the end, far away from the positioning shaft, of the movable supporting assembly, one end of the compressed spring is fixedly connected with the shell, and the other end of the compressed spring is tightly pressed on the supporting block of the movable supporting assembly. By means of the inner armature type high precision positioning electromagnet, gap variation caused by temperature variation can be compensated automatically, and high positional accuracy and low temperature drift are achieved.

Owner:CHONGQING HUAYU ELECTRIC GRP

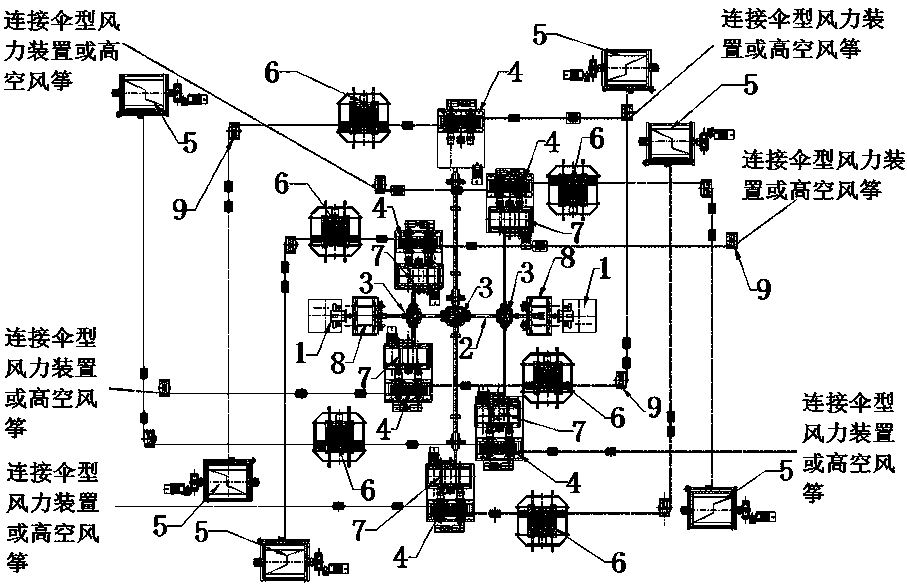

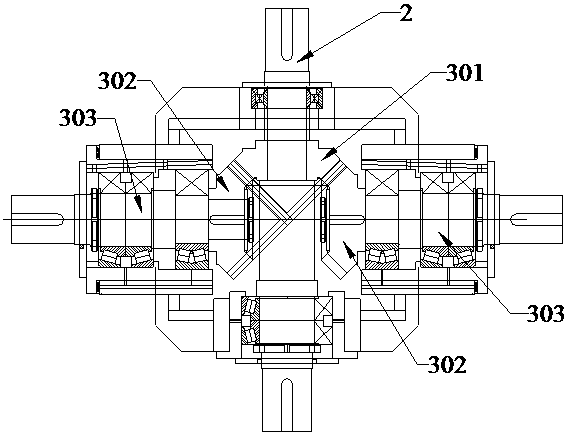

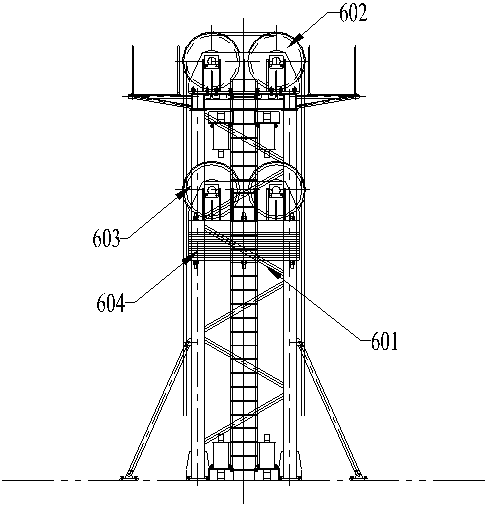

Parallel-connection-type mid-high altitude wind energy ground generator set

PendingCN107842468AReduce the impactImprove power generation efficiencyToothed gearingsWind motor combinationsConnection typeWind system

The invention discloses a parallel-connection-type mid-high altitude wind energy ground generator set. The parallel-connection-type mid-high altitude wind energy ground generator set comprises at least one generator (1), a plurality of power winches (4) and a plurality of cable accommodation winches (5); the power winches (4) drive the generator (1) to generate power through cables; the cable accommodation winches (5) are used for reeling the cables passing through the power winches (4); and the power winches (4) are arranged parallel to the generator (1). Compared with the prior art, the parallel-connection-type mid-high altitude wind energy ground generator set has the advantages that the requirement on the coaxiality of spindles is not high, so that the assembly difficulty is low; the winches in the generator set do not affect one another, and can be separately adjusted for working; with the same configuration, the power generation efficiency is higher; the utilization rate of the generator set is higher; and the cable folding descending of an umbrella-shaped wind energy system can be realized through a reversing gear box, and a descending motor does not to be additionally arranged, so that the generator set is simpler in structure.

Owner:GUANGDONG HIGH ALTITUDE WIND POWER TECH

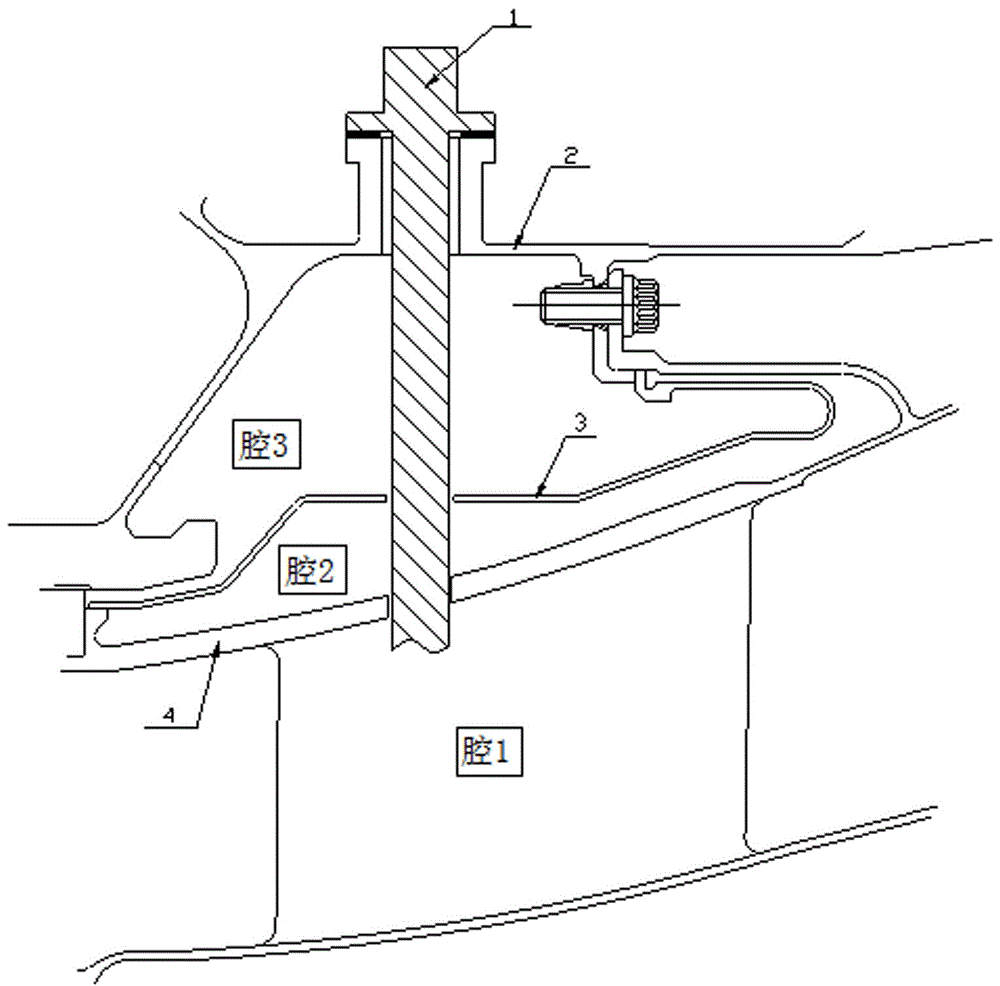

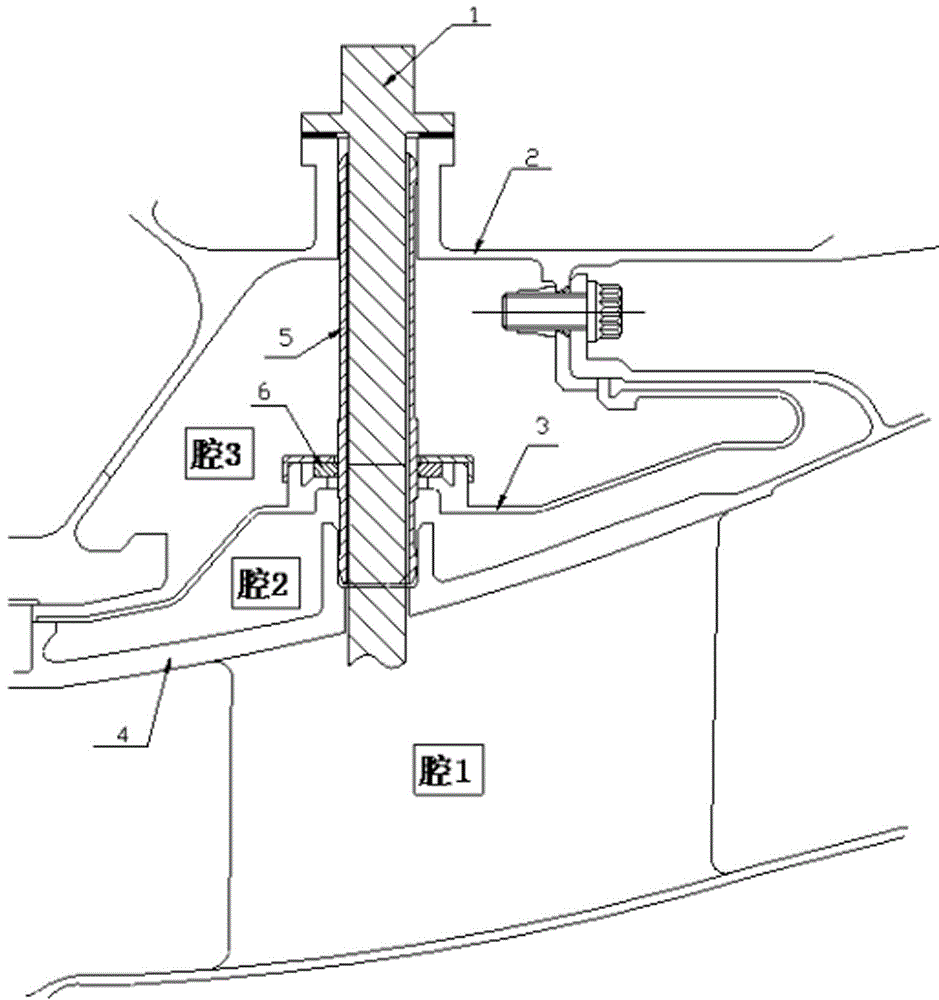

Sealing device and application of sealing device for achieving thermal deformation compensation

ActiveCN106401755AAchieve sealingExtend your lifeGas turbine plantsJet propulsion plantsThermal deformationEngineering

The invention discloses a sealing device and application of the sealing device for achieving thermal deformation compensation. A casing pipe structure is designed, sealing of an installation hole is achieved, in addition, an oil pipe or a probe penetrates a casing pipe and is not directly matched with a case, stress cannot be generated under different states, the service life of the oil pipe or the probe can be effectively prolonged, and operation is convenient. Furthermore, the casing pipe is designed in the manner that the two ends of the casing pipe are spherical faces, the matched face on the case is designed into a cylindrical face, a matched sealing ring capable of axially flowing is designed in a middle case body, sealing can be ensured under different states, thermal deformation compensation can be achieved, stress is not generated, the machining difficulty can be greatly lowered, and the cost can be greatly reduced.

Owner:CHINA AVIATION POWER MACHINE INST

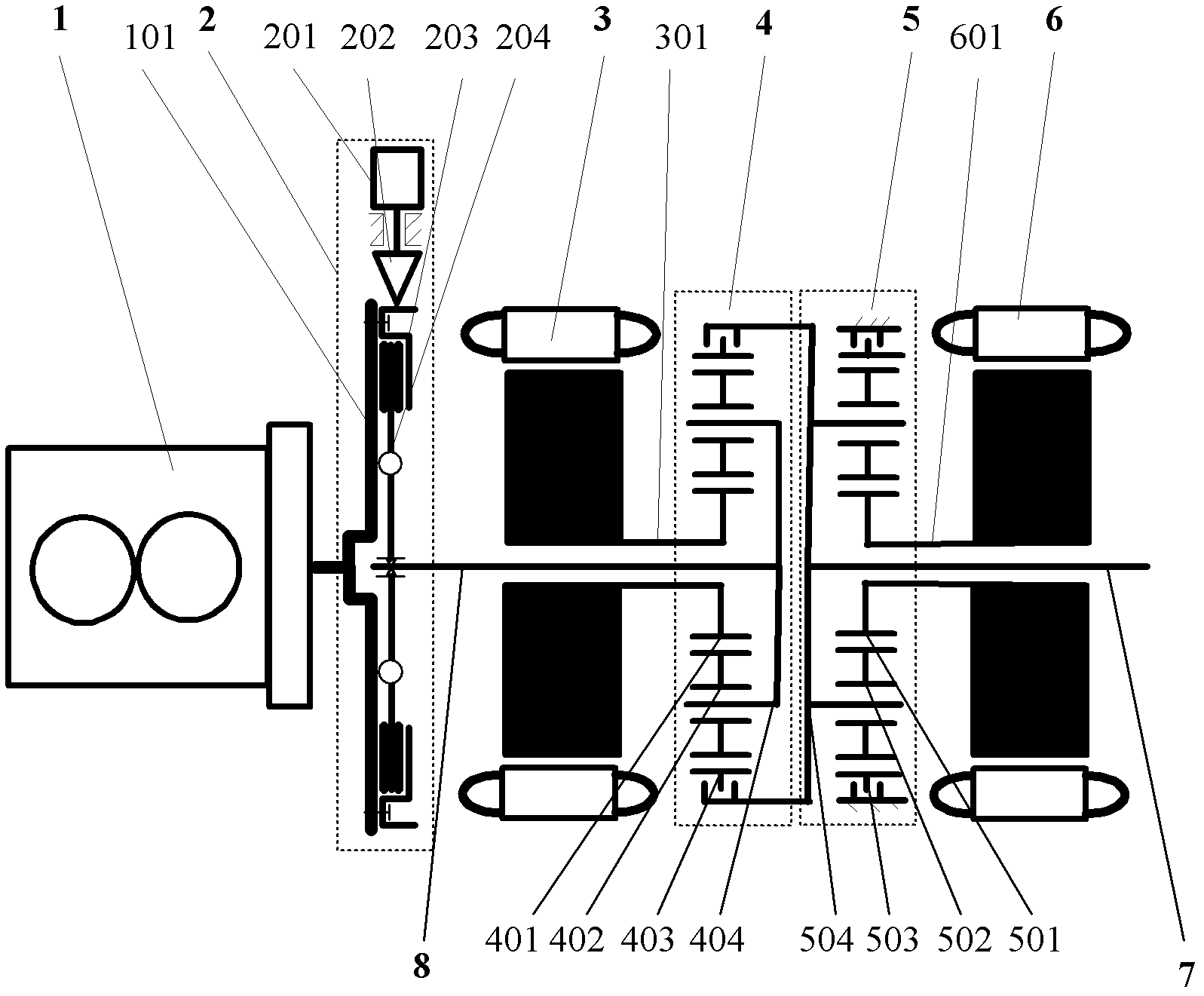

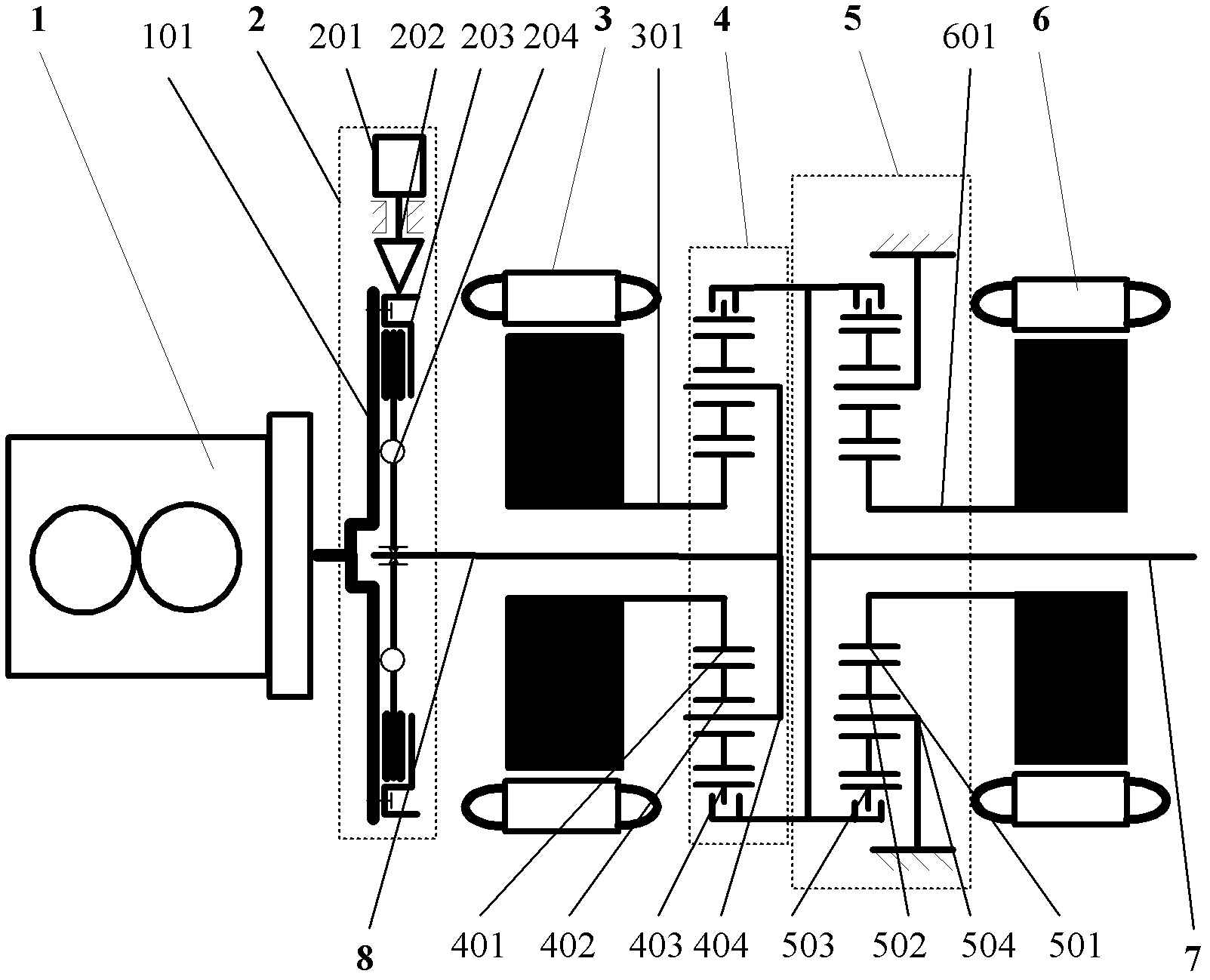

Hybrid power device provided with engine lock mechanism and drive method thereof

InactiveCN102320238BReduced concentricity requirementsGuaranteed assemblyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingMotor driveLocking mechanism

The invention discloses a hybrid power device provided with an engine buffer lock mechanism. The hybrid power device comprises an engine, a buffer and lock combination mechanism, a first generator / motor, a first row of planetary gear mechanism, a second row of planetary gear mechanism, a second generator / motor, a first shaft and a second shaft; the buffer and lock combination mechanism is used for locking and buffering the engine; an engine flywheel is connected with the first shaft via the buffer and lock combination mechanism; the first shaft is connected with a planetary carrier of the first row of planetary gear mechanism; and a rotor of the second generator / motor is connected with the second first row of planetary gear mechanism. According to the invention, the engine is locked via the lock mechanism and two generators / motors are used for a dual-motor drive mode when a car is in a pure electric mode, so that the dynamic property of the car is improved. In the invention, two motors are respectively located in two separate shells and then integrally assembled; and meanwhile, the tooth rings of the planetary gear mechanisms are floated so that the planetary gear mechanisms can realize the self-aligning function.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

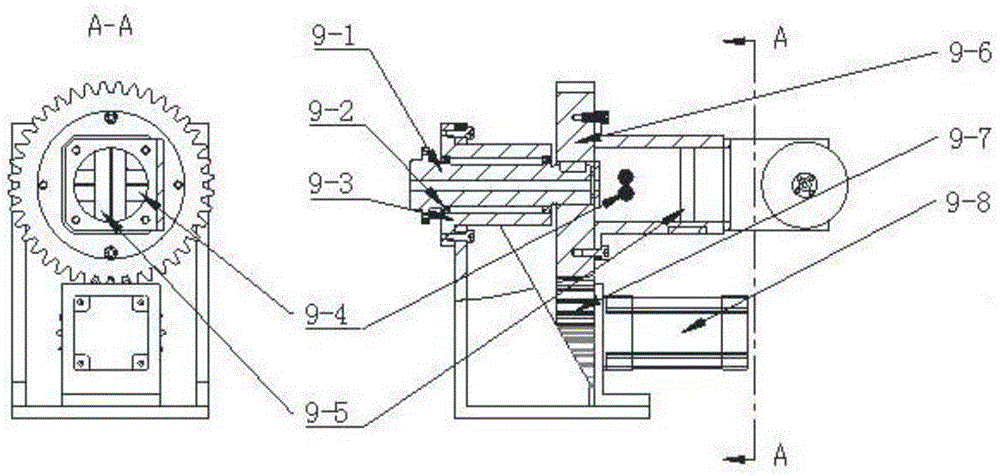

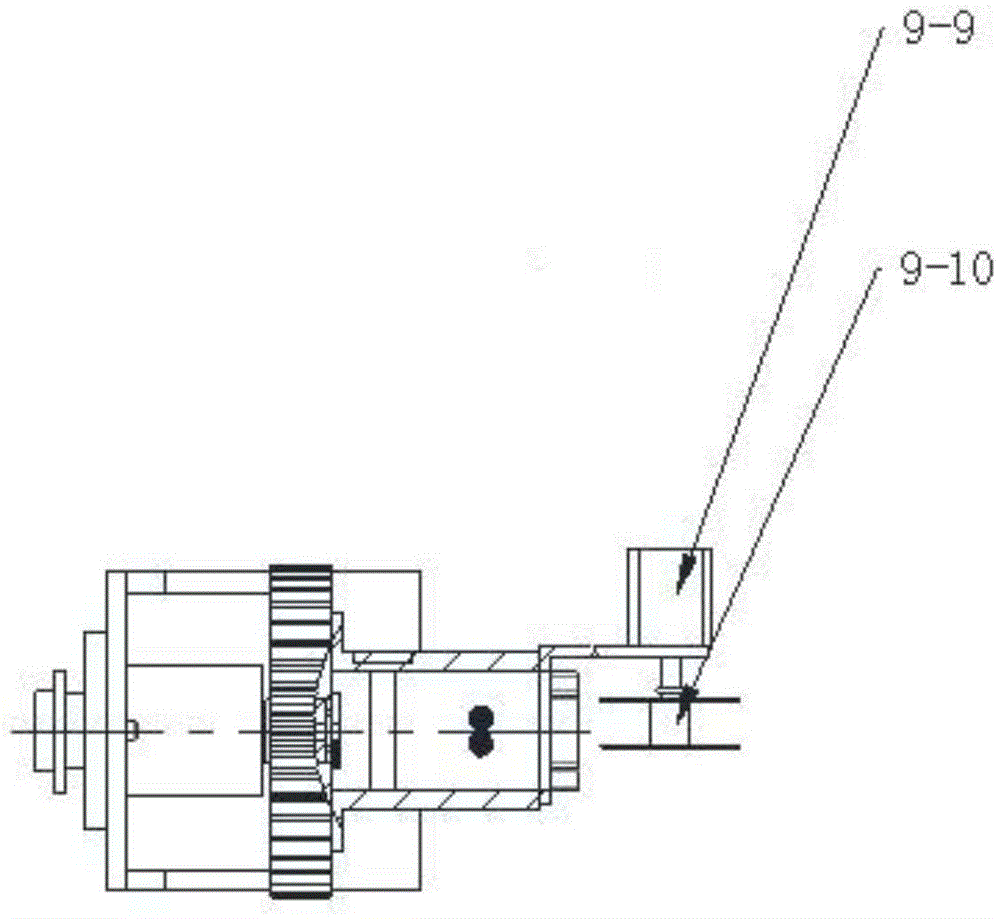

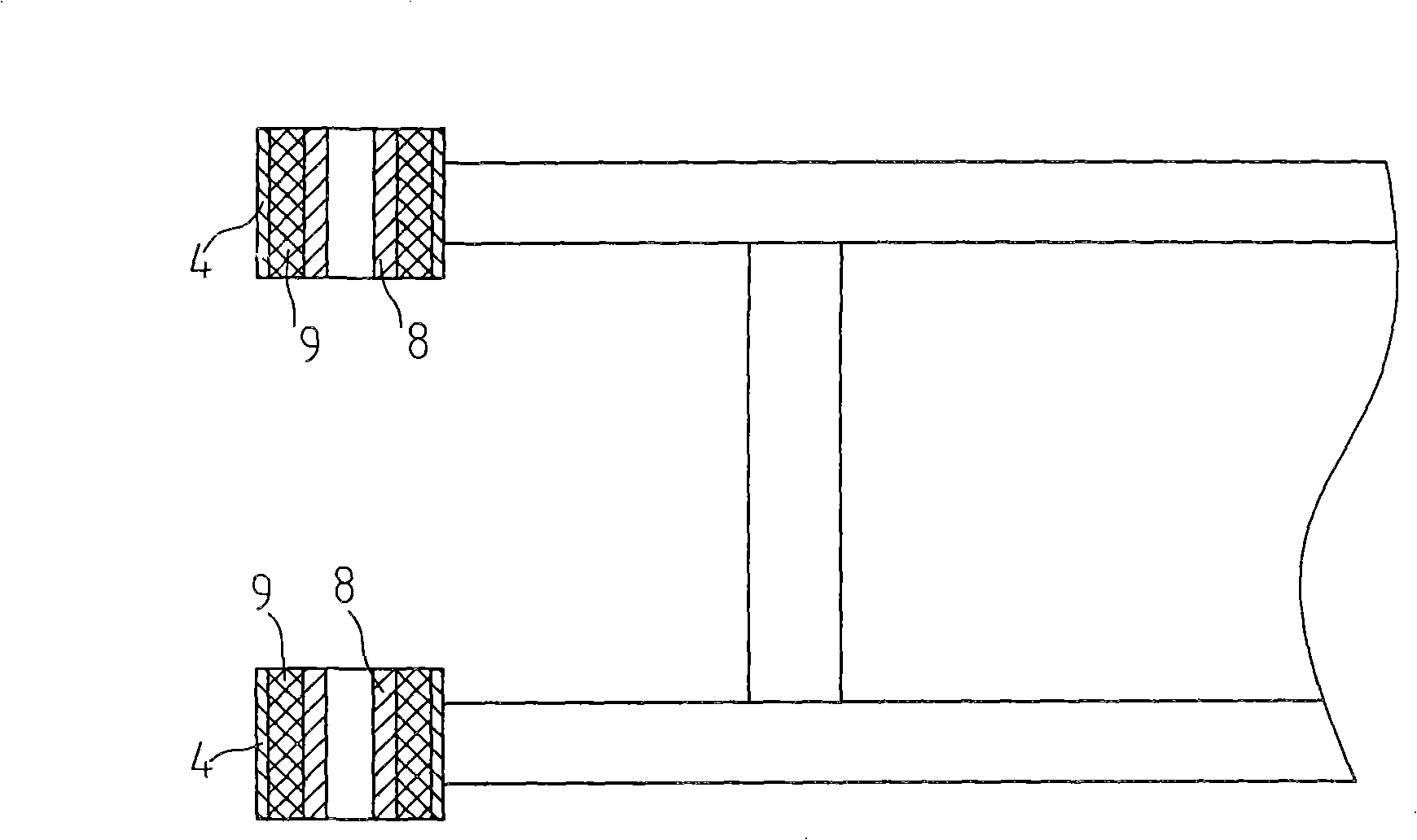

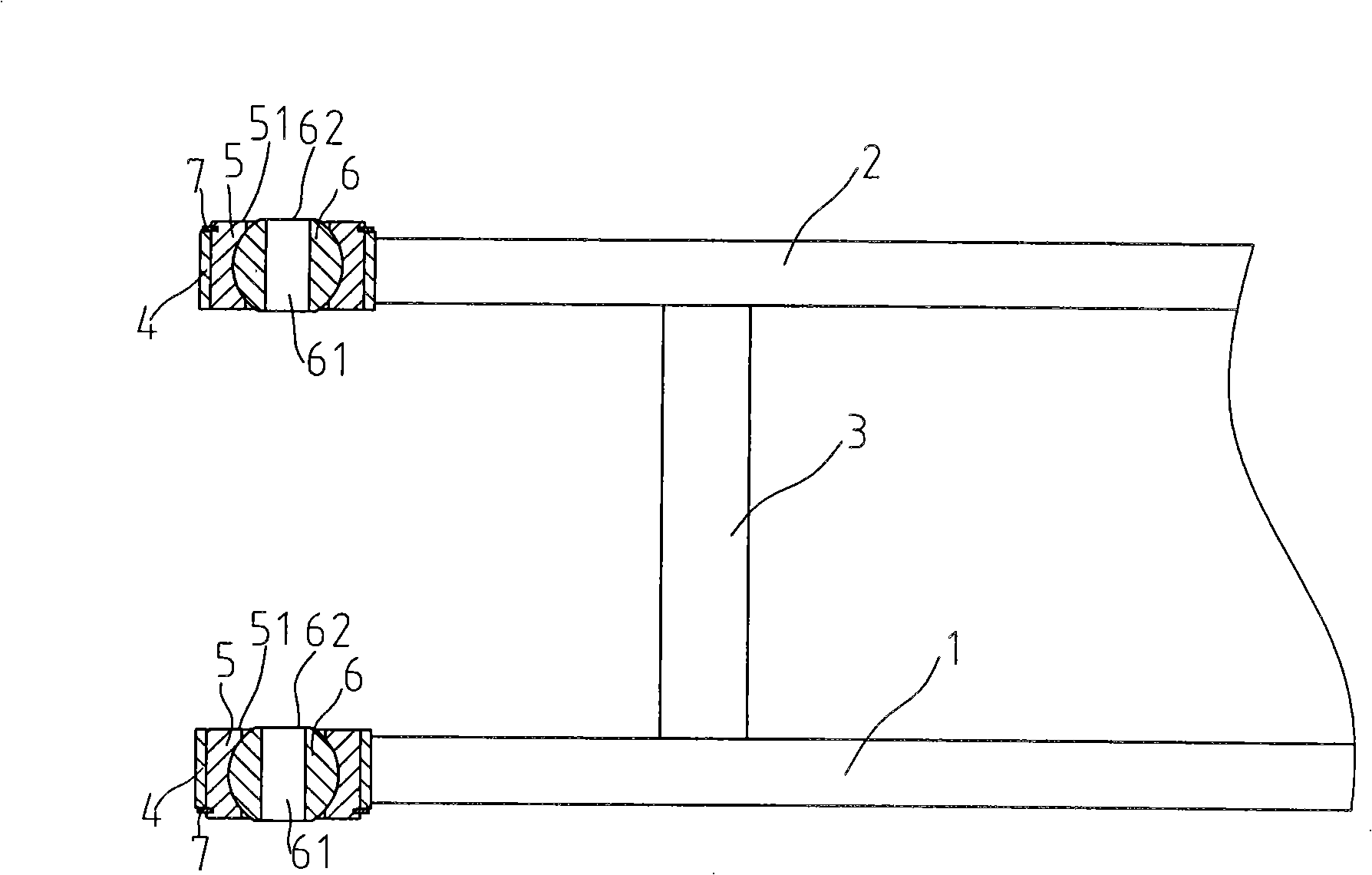

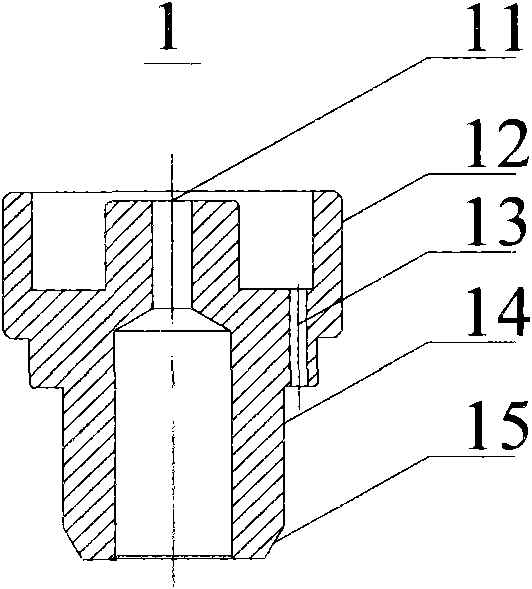

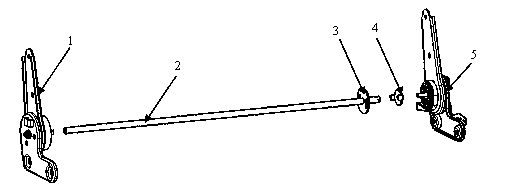

Foil release and foil deployment device of gilding press

InactiveCN101524911AReduced concentricity requirementsEasy to disassembleTransfer printingBronze printingSpherical shapedEngineering

The invention discloses a foil release and foil deployment device of a gilding press; a bracket of the device is arranged on the body and is provided with a foil release and foil deployment shaft, one end of the foil release and foil deployment shaft is matched with a fixed thimble, the other end of the foil release and foil deployment shaft is matched with a moving thimble. The foil release and foil deployment shaft is characterized in that the shaft end of the foil release shaft is spherical. The moving thimble of the invention can not only rotate but also move along the axial direction. In order to facilitate installing the foil release and foil deployment shaft and to avoid wear of the shaft end, two shaft ends of the foil release and foil deployment shafts are made into spherical shape, and one end of the foil release and foil deployment shaft is installed in a cylindrical pin. The process is simple, and the installation is convenient, thus facilitating transmission and the dismantlement and installation of the whole foil release and foil deployment device, facilitating operator to dismantle aluminium foil and reducing working time.

Owner:瑞安市胜利印刷机械有限公司

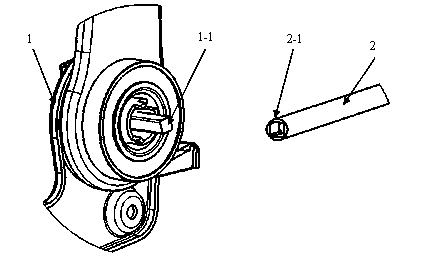

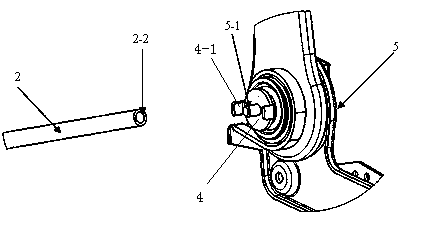

Automobile seat angle adjuster assembly

ActiveCN103538501AReduce parallelism requirementsReduced concentricity requirementsMovable seatsEngineeringMechanical engineering

The invention relates to an automobile seat angle adjuster assembly. The automobile seat angle adjuster assembly comprises a driven-side angle adjuster, a linkage rod and a driving-side angle adjuster. The left end of the linkage rod is connected to a rotating shaft of the driven-side angle adjuster in an inserted mode, and the right end of the linkage rod is connected to a rotating shaft of the driving-side angle adjuster in an inserted mode. The right end portion of the linkage rod is fixedly sleeved with a driving disc. Driving groove holes are formed in the edge of the driving disc in the circumferential direction. The rotating shaft of the driving-side angle adjuster is fixedly sleeved with a rotating disc. Shifting blocks are arranged on the outer periphery of the rotating disc and inserted into the groove holes in the driving disc. The installation structure can lower the requirement for precision of a seat frame and avoids the problems that seat backrest operating force is large and adjustment can not be carried out smoothly.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Dust recovery device

ActiveCN107362634AIncrease the number ofImprove cleaning efficiencyUsing liquid separation agentSeparation devicesEngineeringTower

The invention provides a dust recovery device. According to the device, the problem of extremely low cleaning efficiency as dust on the inner wall of the exiting dust absorption tower is not cleaned easily is effectively solved. The dust recovery device comprises a tower body, wherein a suction fan is arranged at the upper part of the tower body; a water spray plate is arranged below the suction fan; the lower end of the water spray plate is connected with a plurality of water spray nozzles; the water spray nozzles are used for supplying water through a water inlet pipe at the right end of the tower body; an air inlet is designed on the left side of the tower body; a dust discharge hole is arranged below the air inlet; a rotating shaft is arranged in the tower body; a sun wheel is mounted on the rotating shaft; a plurality of planet wheels are meshed on the outer side of the sun wheel; a first planet frame is arranged above the planet wheels and is rotatably fixed on the rotating shaft; a planet shaft is rotatably fixed on the first planet frame; the planet shaft penetrates through the planet wheels; a plurality of rolling brush units connected with one another in sequence are mounted on the planet shaft. The water spray nozzles are fixed on the water spray plate, and the quantity of the water spray nozzles is increased, so that the spray range is enlarged; a plurality of rolling brushes are made into a full circle, so that the cleaning efficiency of the dust on the inner wall of the tower body is improved.

Owner:XINGHUA GL STEVIA CO LTD

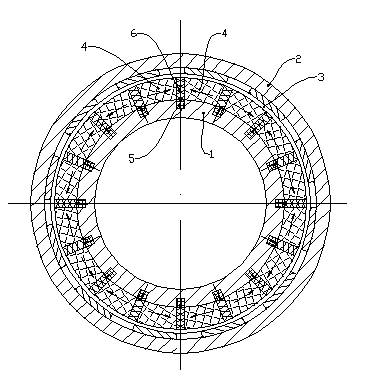

Permanent-magnet coupling mechanism between shafts

InactiveCN103312120AReduce vibrationImprove vibration reductionDynamo-electric gearsPermanent magnet rotorElectrical conductor

The invention relates to a mechanism transmission device, in particular to a permanent-magnet coupling mechanism between shafts. The permanent-magnet coupling mechanism is used for transmitting torque between two rotation shafts and comprises a permanent-magnet rotor and a conductor rotor which are arranged coaxially. Permanent-magnets and conductors are respectively distributed on the permanent-magnet rotor and the conductor rotor, and a conical air gap is formed between the permanent-magnet rotor and the conductor rotor. The permanent-magnets on the permanent-magnet rotor are distributed circumferentially, and magnetizers made of magnetic materials are mounted between the adjacent permanent-magnets. Directions of magnetic poles of the permanent-magnets extend along the circumference of the permanent-magnet rotor, and directions of the magnetic poles of the adjacent permanent-magnets are opposite or reversed. The permanent-magnet coupling mechanism is capable of transmitting high torque adjustably, and is compact in structure, convenient to mount and stable and reliable in transmission and adjustment.

Owner:JIANGSU MAGNET VALLEY TECH

Horizontal movement device for hoisting machine

InactiveCN102976230AIncrease the upper limit positionPrevent derailmentLifting framesEngineeringSupport surface

The invention relates to a horizontal movement device for a hoisting machine. The horizontal movement device comprises a first guide rail pair arranged at the left side of the hoisting machine and a second guide rail pair arranged at the right side of the hoisting machine; the horizontal movement device is characterized in that the first guide rail pair comprises a first guide rail arranged on the ground and a plurality of first rolling wheels which are pivoted at the left side of a rack; an annular groove which is blocked on the first guide rail is arranged in the external surface of each first rolling wheel; each first rolling wheel is blocked on the first guide rail and moves along the direction of the first guide rail; the second guide rail pair comprises a second guide rail arranged on the ground and a plurality of second rolling wheels which are pivoted at the right side of the rack; the second guide rail is parallel to the first guide rail; the second guide rail is a plane guide rail and is provided with a supporting surface extending along the direction of the second guide rail; and each second rolling wheel is pressed on the supporting surface in a rolling way. According to the horizontal movement device provided by the invention, the requirements on the center distance of the guide rails and the precision of the guide rails are low; the requirement on the coaxial precision of the rolling wheels is low; the installation and adjustment are convenient, and the running of the device is safe and reliable.

Owner:YU TUNG ZHONGSHAN ENG

Lifting buoyant platform for above-water maintenance of warship

PendingCN107601346AReduce loadImprove stabilityVessel partsLifting framesMarine engineeringBlock and tackle

The invention relates to the field of above-water maintenance of warships, in particular to a lifting buoyant platform for above-water maintenance of a warship. The lifting buoyant platform comprisesa maintenance workshop, wherein a disconnected passage is arranged in the middle of the maintenance workshop; two portal frames are arranged in the front of the passage and in the back of the passagerespectively, the lifting buoyant platform is arranged between the two portal frames, and the top of each portal frame is provided with two sets of winding devices; the two ends of the lifting buoyantplatform are provided with buoyancy tanks respectively, sealed hollow beams are arranged between the two buoyancy tanks, a porous flat plate is arranged on the hollow beams, the buoyancy tanks are sealed hollow box bodies with trapezoid shapes, and mounting openings are formed in the installation positions of the hollow beams of the box bodies; and pulley blocks which are in transmission connection with the winding devices are arranged at the four corners of the lifting buoyant platform correspondingly. The lifting buoyant platform is stable and reliable in use, and is suitable for above-water maintenance of warships.

Owner:黄冈市劲马窑炉机械有限公司

Tail gas post-treatment seal

PendingCN111365102AReduced concentricity requirementsImprove the ease of assemblyExhaust apparatusSilencing apparatusEngineeringStructural engineering

The invention discloses a tail gas post-treatment seal. The tail gas post-treatment seal comprises an outer housing, a first baffle plate and a second baffle plate which are positioned in the outer housing and are arranged in a spaced mode, a first post-treatment carrier assembly positioned in the outer housing, a second post-treatment carrier assembly, a third post-treatment carrier assembly anda mixing tube assembly which is arranged between the second post-treatment carrier assembly and the third post-treatment carrier assembly in a communication mode, and further comprises a first connecting cavity positioned on the fourth side surface of the second baffle plate and a second connecting cavity positioned between the first baffle plate and the second baffle plate; the mixing tube assembly comprises a tail end extending into the second connecting cavity, and the mixing tube assembly is fixed to the second baffle plate; and a gap is formed between the tail end and the first baffle plate. In this way, the tail gas post-treatment seal reduces coaxiality requirements while the mixing tube assembly is assembled, cancels a welding process, and improves assembly convenience of the tailgas post-treatment seal.

Owner:TENNECO SUZHOU EMISSION SYST

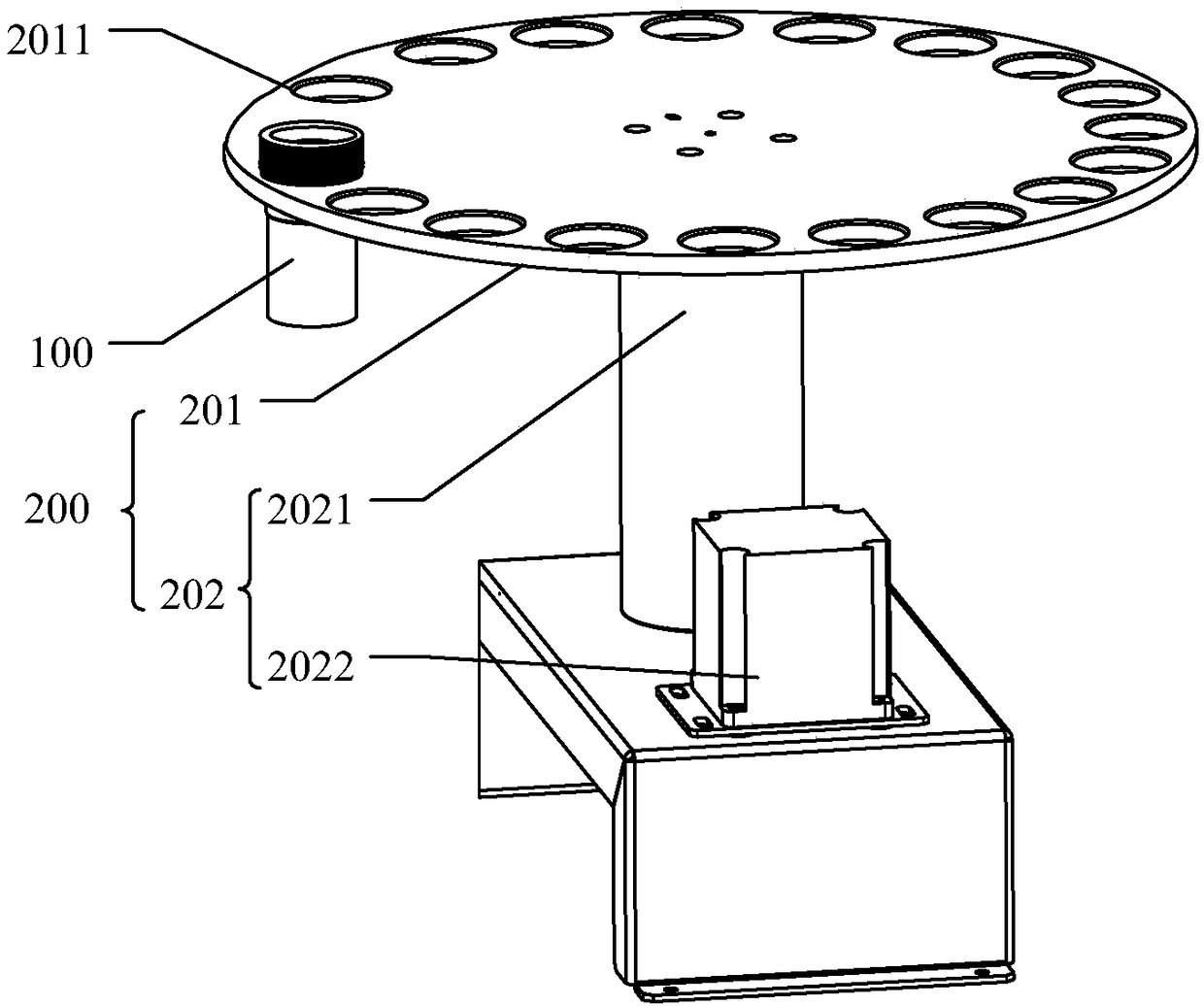

Cell enriching system and method

ActiveCN108303309AImprove concentrationReduce overlayPreparing sample for investigationBiochemical engineeringCell concentration

The invention discloses a cell enriching system and a cell enriching method. The cell enriching system comprises a sample bottle, a loading mechanism, a uniformly mixing mechanism, a concentrating anduniformly mixing mechanism and a controller, wherein the loading mechanism can convey the sample bottle; the uniformly mixing mechanism can perform a first uniformly mixing operation on the sample bottle; the concentrating and uniformly mixing mechanism can pierce the bottom of the bottle, and perform sucking and reverse blowing operations on the sample bottle; the controller controls the loadingmechanism to convey the sample bottle to a uniformly mixing position, and then the uniformly mixing mechanism performs the first uniformly mixing operation; after the controller controls the loadingmechanism to convey the sample bottle to a concentrating position, the controller controls the concentrating and uniformly mixing mechanism to pierce the bottom of the bottle to enter a second cavityand repeatedly perform the sucking and reverse blowing operations. The cell enriching system provided by the invention achieves cell concentration by performing the sucking and reverse blowing operations, so that a filter device of the sample bottle and a concentrating needle can be effectively prevented from being blocked, cell superposition can be effectively reduced while cell concentration isaccelerated, and thus the cell enriching quality is improved.

Owner:MACCURA MEDICAL INSTR CO LTD

Device for automatically adjusting power of turbine pump

ActiveCN101865143AAdjust air intakeGuaranteed output powerPump controlNon-positive displacement fluid enginesInlet valveTurbopump

The invention relates to a device for automatically adjusting the power of a turbine pump. The device comprises a lift valve arranged outside a turbine air inlet casing, an air inlet valve arranged in the turbine air inlet casing, and an inlet chamber control channel and an outlet chamber control channel which are used for connecting an air inlet valve oil circuit and a lift valve oil circuit. The device solves the technical problem that the jet pipe and air inlet passage of an aspirated engine, which works under large airspace, high Mach number and large-scale variable working conditions, are difficult to adjust, ensures that the output power of the turbine pump is within a rated value range and improves the processing and assembly manufacturability of the turbine pump.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com