Compact type mechanical lifting mechanism for assembling line

A technology for assembling production lines and lifting mechanisms, which is applied in the direction of lifting frames and lifting devices, can solve the problems of large space occupation, inaccurate control, and many auxiliary components, and achieve the effects of small installation space, precise control, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

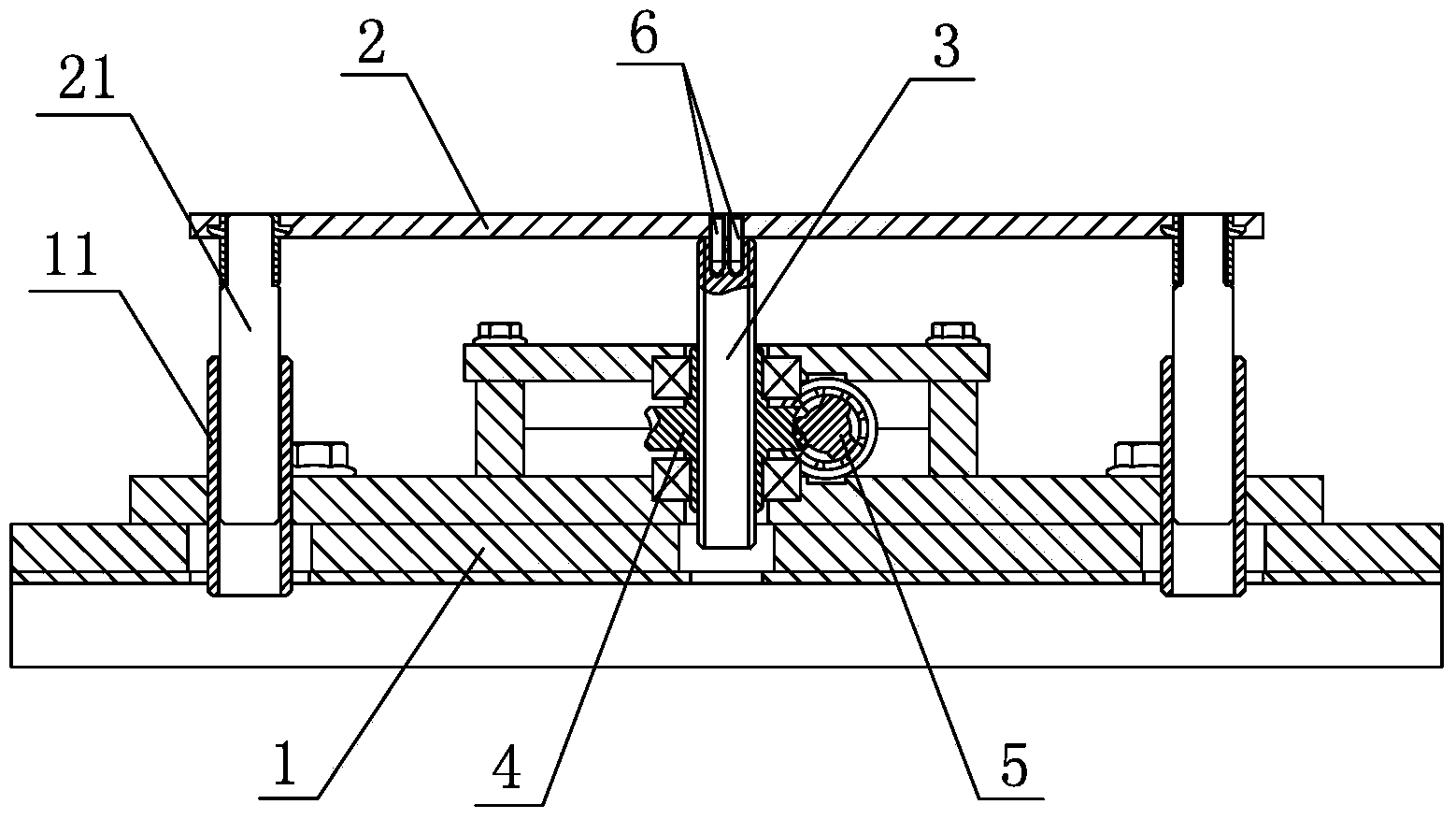

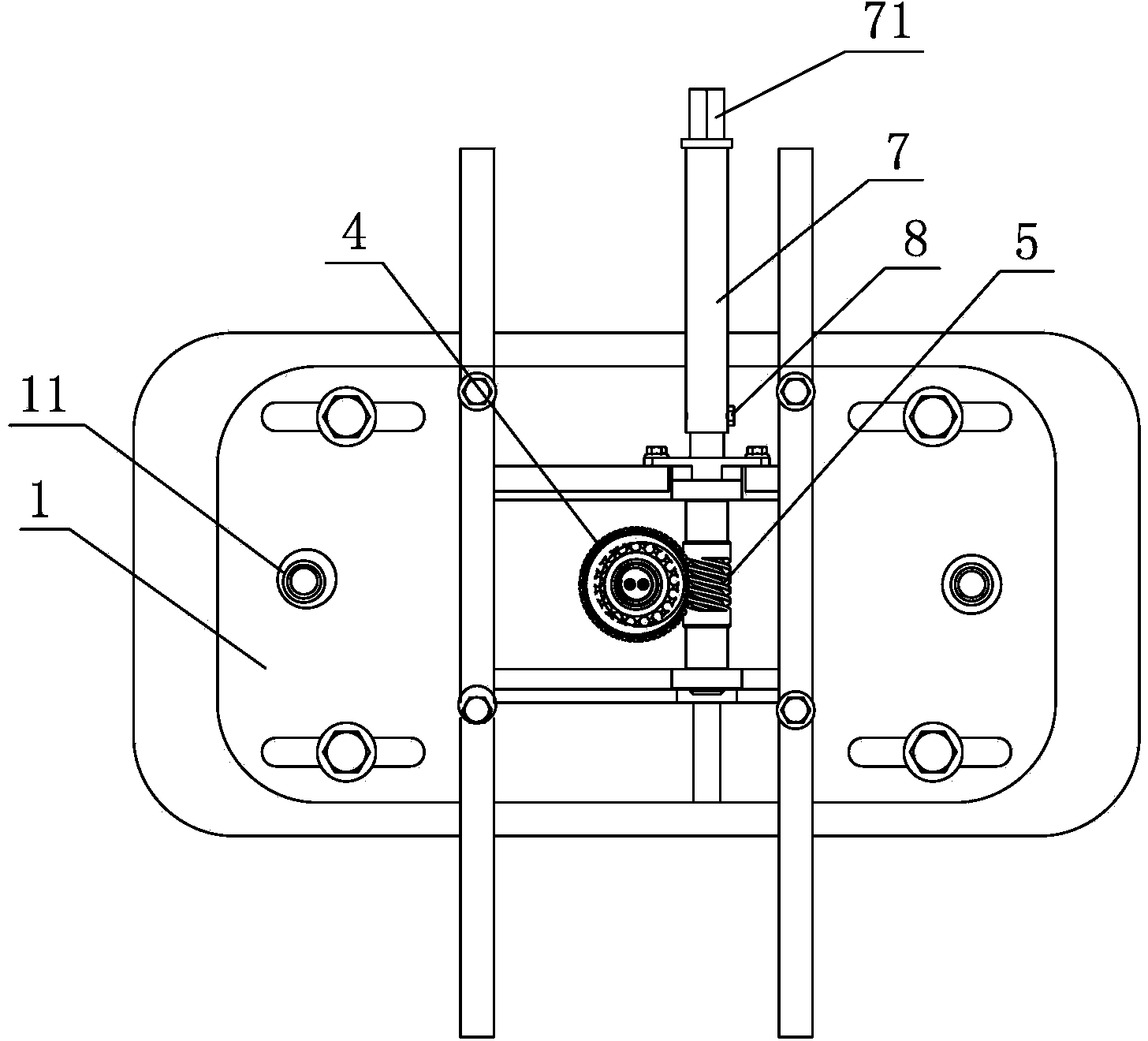

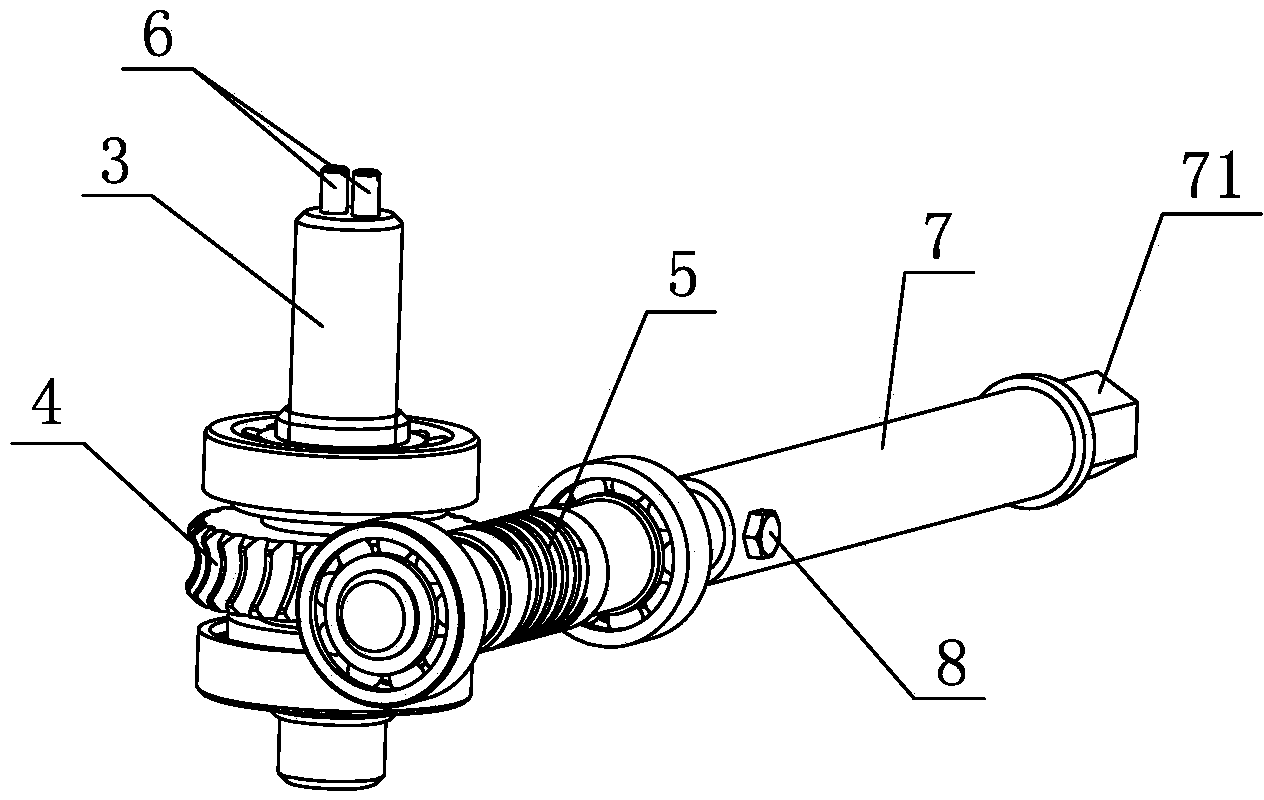

[0015] As shown in the figure, a compact mechanical lifting mechanism for assembly production line includes a base 1, a lifting platform 2, a jacking screw 3, a worm wheel 4 and a worm 5, and the worm 5 is horizontally connected to the base 1 through a bearing , the worm wheel 4 is vertically connected to the base 1 through the bearing, the worm wheel 4 is meshed with the worm 5, and the worm wheel 4 is provided with an inner screw hole (not marked in the figure), and the jacking screw 3 is screwed with the inner screw hole, The upper end of the lifting platform 2 and the jacking screw 3 are fixedly connected by two connecting screws 6 arranged side by side. A guide sleeve 11 corresponding to the position of the guide column 21 is provided. The guide column 21 slides up and down with the guide sleeve 11. One end of the worm 5 is covered with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com