Automobile cleaning device

A technology for cleaning devices and automobiles, applied in the direction of vehicle exterior cleaning devices, etc., can solve problems such as unfavorable water and energy saving, aggravating environmental pollution, large water consumption, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

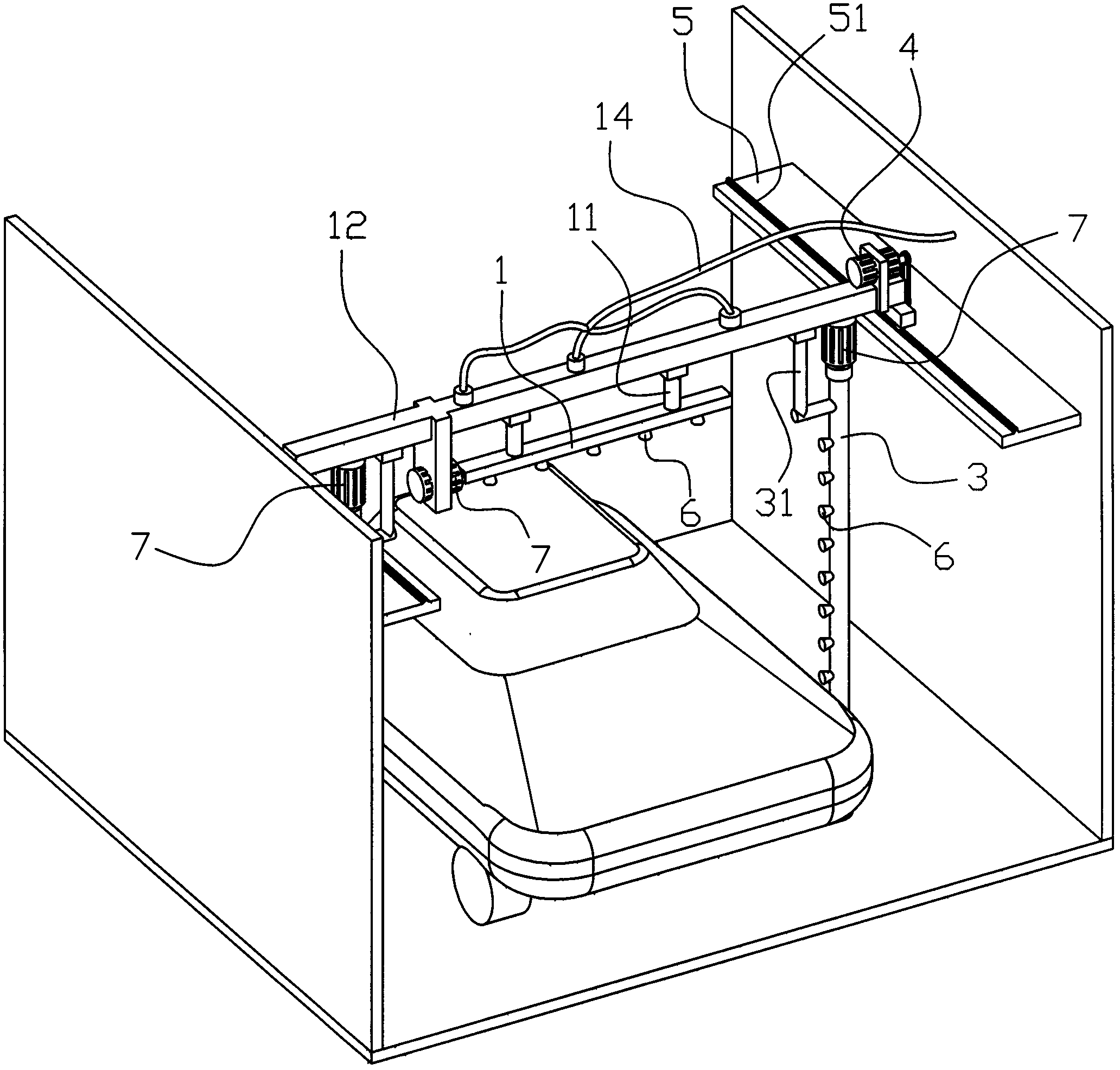

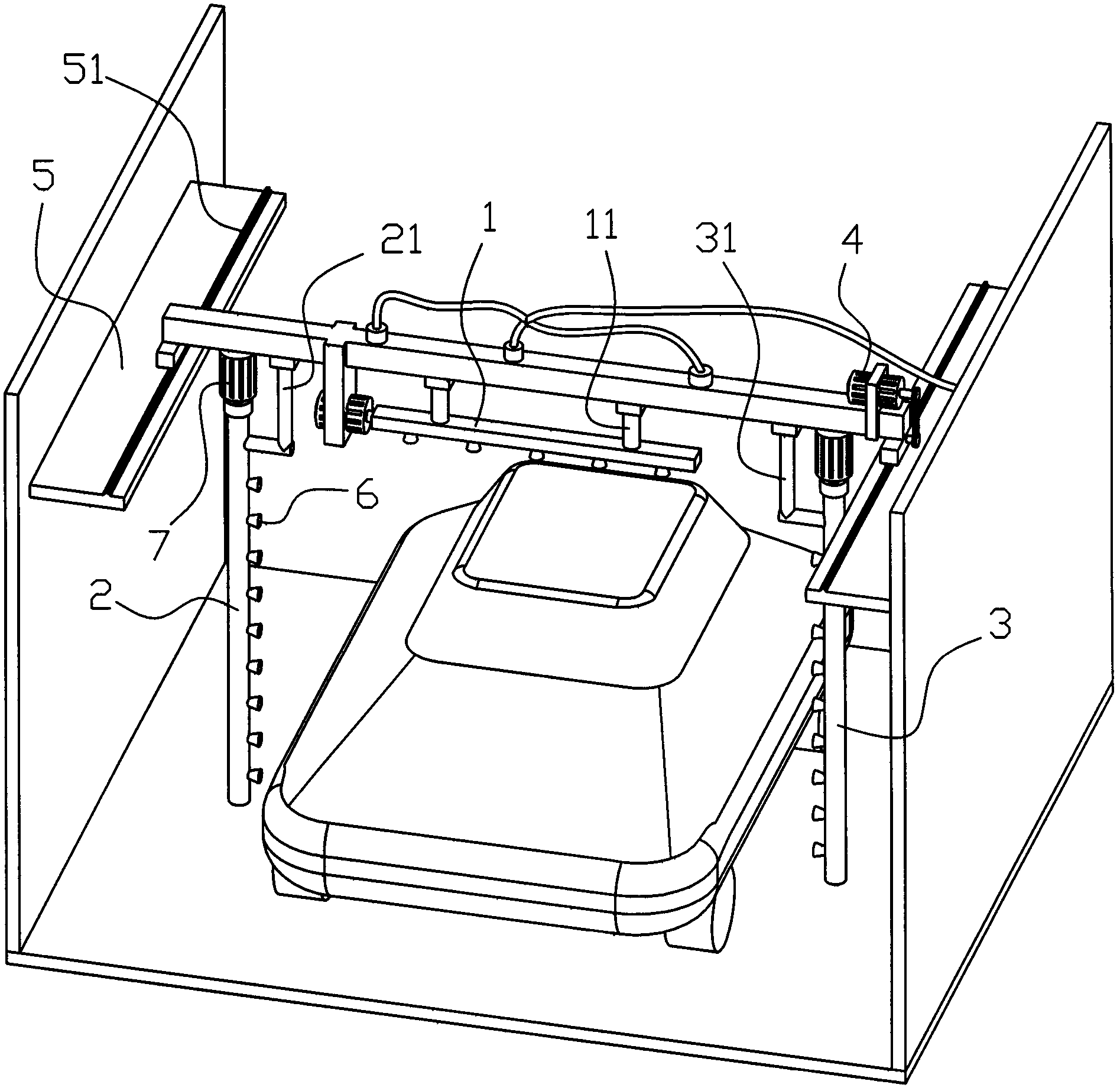

[0036] Example 1: figure 2 It is a schematic diagram of the structural principle of Embodiment 1 of the present invention. This spray device is a vertically working side spray bar, which is mainly used for cleaning the side of the vehicle body. The water inlet pipe is input with high-pressure water, and the installed nozzles are all water nozzles. There are 9 nozzles installed on the spray rod, from top to bottom are nozzles 1 to 9, such as figure 2 shown.

[0037] According to the design requirements of the car washing machine, the spray bar must be able to close the redundant spray nozzles when cleaning the body of different heights. The following are the specific requirements for the working status (open or closed) of each nozzle when the spray boom is cleaning the body parts of different heights:

[0038]

[0039]

[0040] It can be seen from this that during the working process of the sprinkler device, the four nozzles located at the lower part of the spray bar...

Embodiment 2

[0055] Embodiment 2: According to the system design requirements of a certain type of car washing machine, for the spray bar in the above embodiment 1, it is required that the number of nozzles that are in the open state at the same time does not exceed 6, and when the nozzles with more than five nozzles are opened, the number of nozzles below five Among the nozzles, the priority is to ensure that the bottom nozzle remains open. Then, the combination of the opening and closing of the designed nozzle and the opening position matrix are shown in the following table:

[0056]

[0057]

[0058] In addition, combined with the timing design requirements of different car washing processes, Embodiment 1 and Embodiment 2 can be selected alternately at different times, so as to build more diverse sprinkler opening modes. For example: a 1.7-meter-high car is first cleaned according to the method of embodiment 1, and then washed again according to the method of embodiment 2 to the k...

Embodiment 3

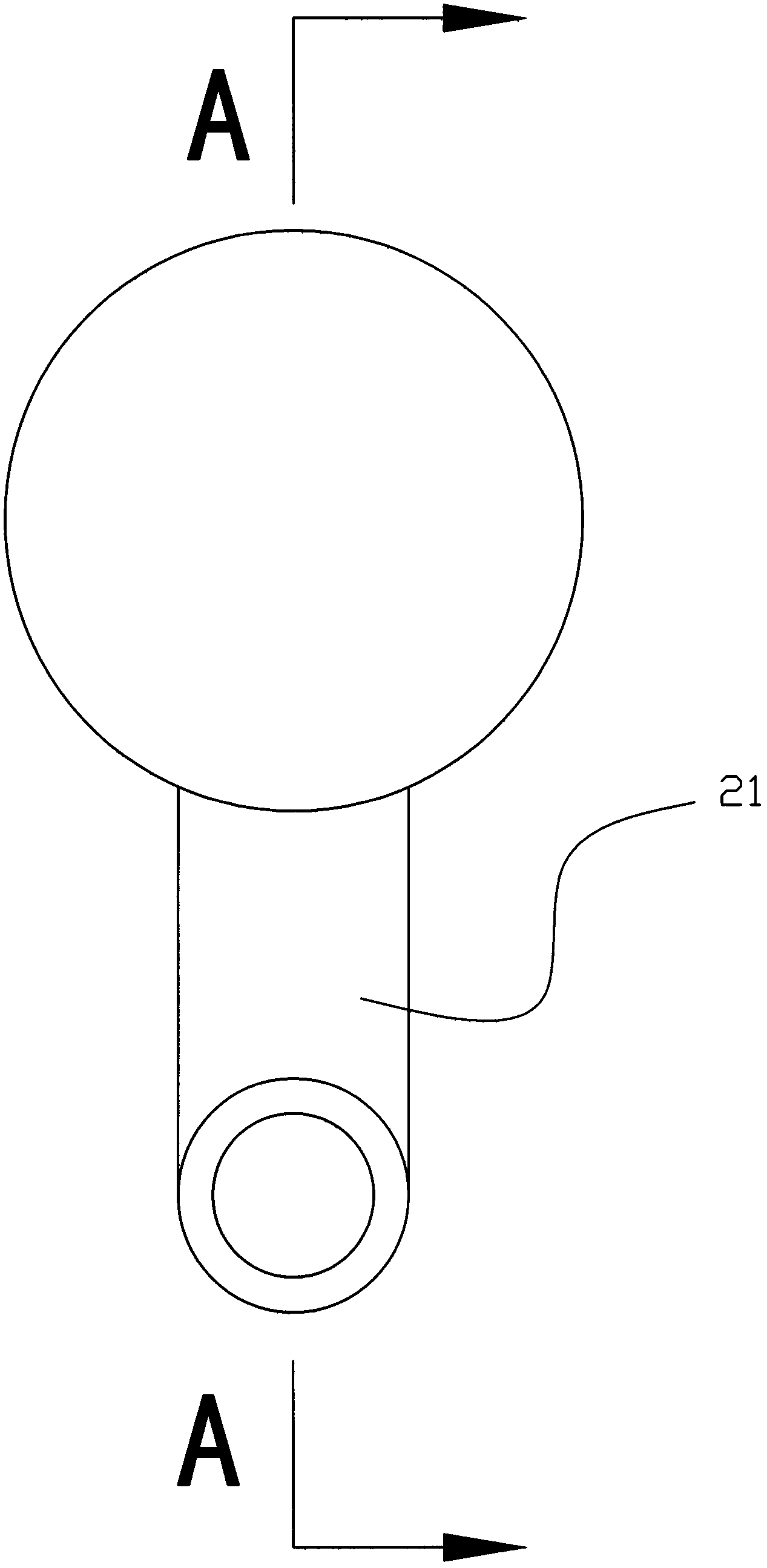

[0060] Embodiment 3: If the number of nozzles to be adjusted by the spray rod is large, or the inner diameter of the spray rod is too small, or the interface aperture of the nozzle is relatively large, so that the ring direction of the flute-shaped tube cannot provide enough for the combination sequence of various holes required. punch space. Take the spray bar that 9 spray nozzles are installed in embodiment 1 as example, arrange the processing positions of 4 holes along the circumferential direction as the flute-shaped tube that can be set therein, that is, there are at most 3 positions that can be used for drilling (another The position must be reserved for all nozzles to be closed). In this case, there are only 3 nozzles that can be controlled by one flute-shaped pipe, which cannot meet the requirements. How to realize the various nozzle control requirements in Table 1 proposed in Example 1. At this time, two flute-shaped pipes can be used scheme, described as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com