Patents

Literature

68results about How to "Improve vibration reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

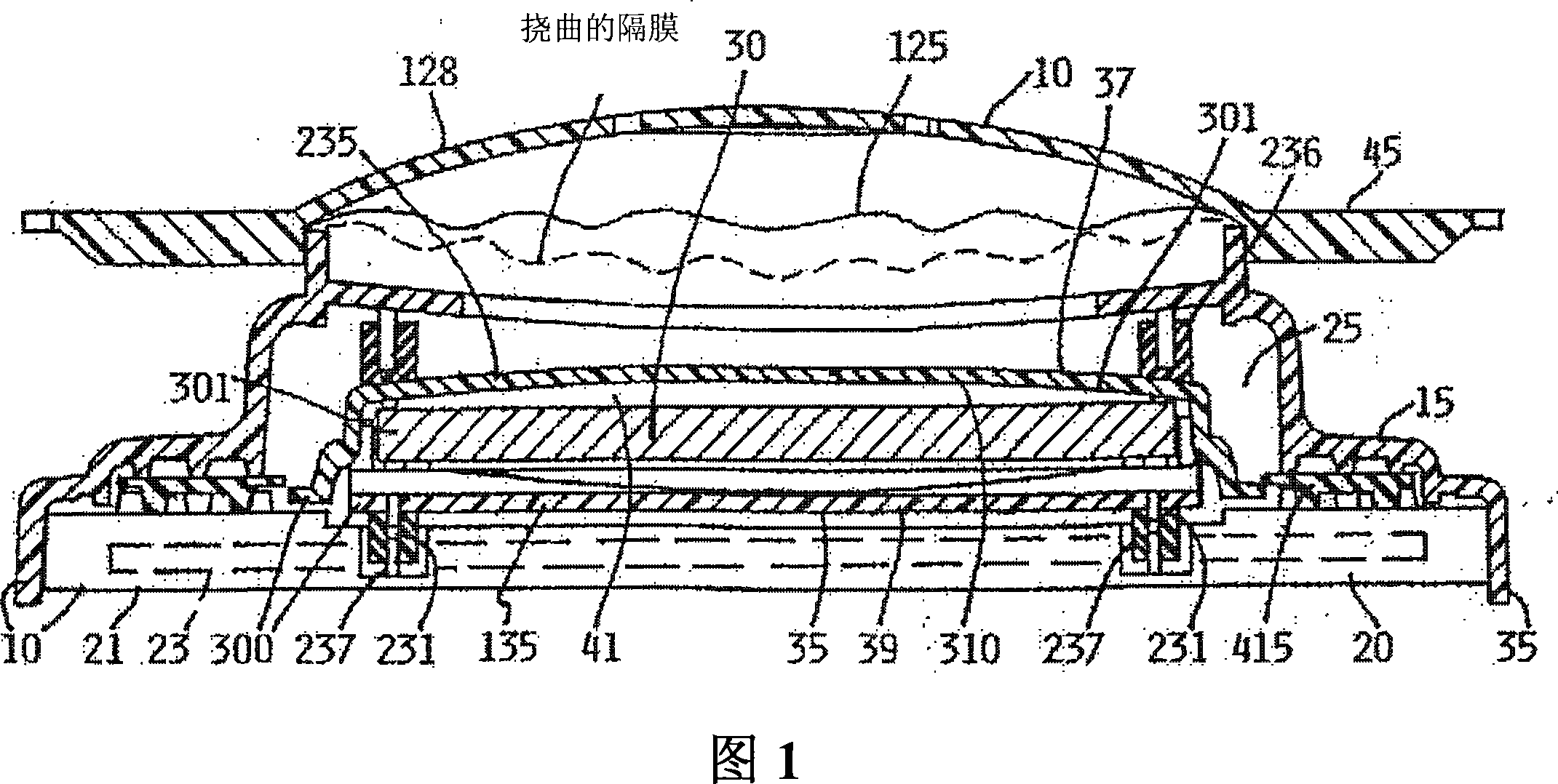

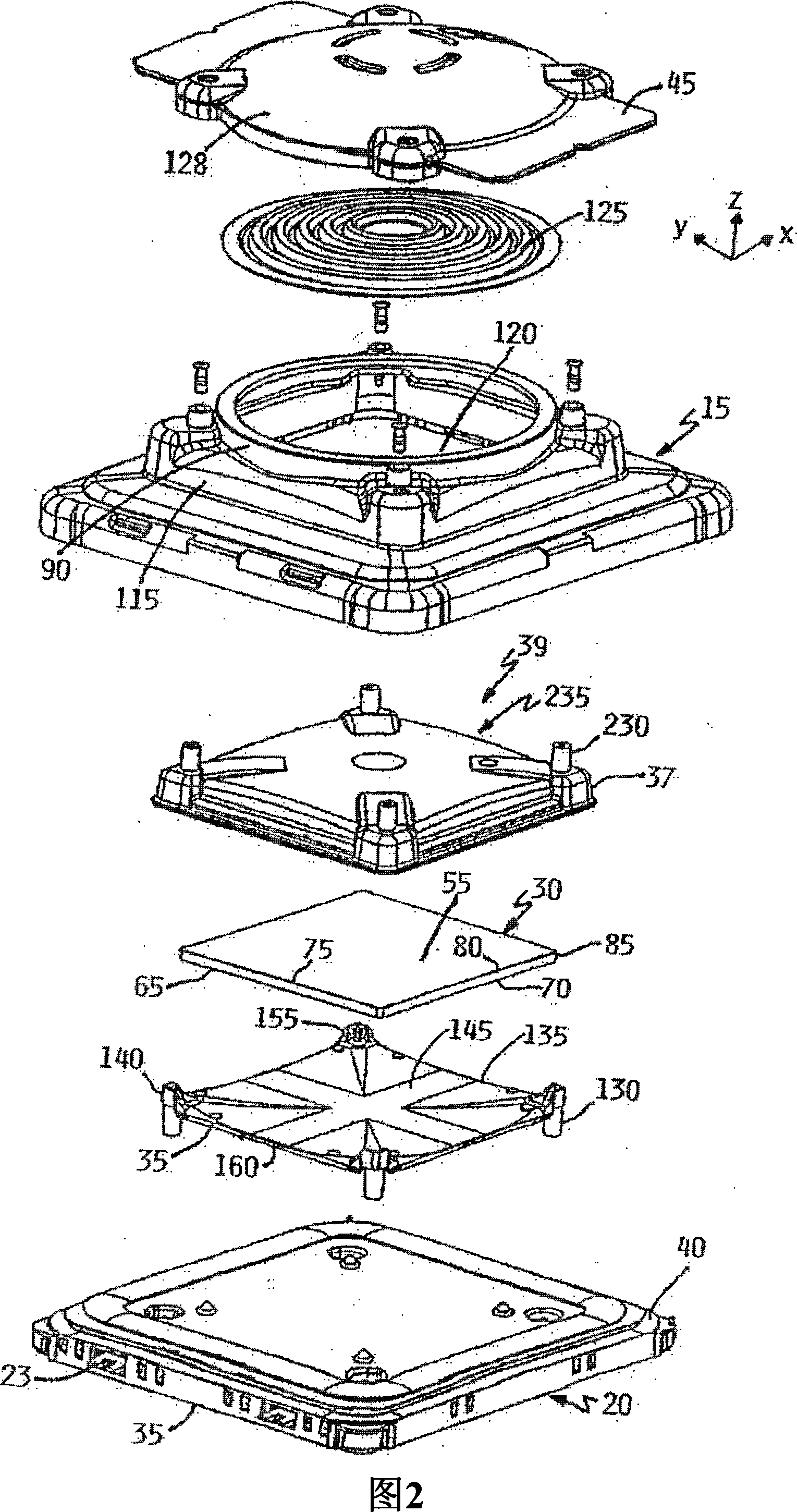

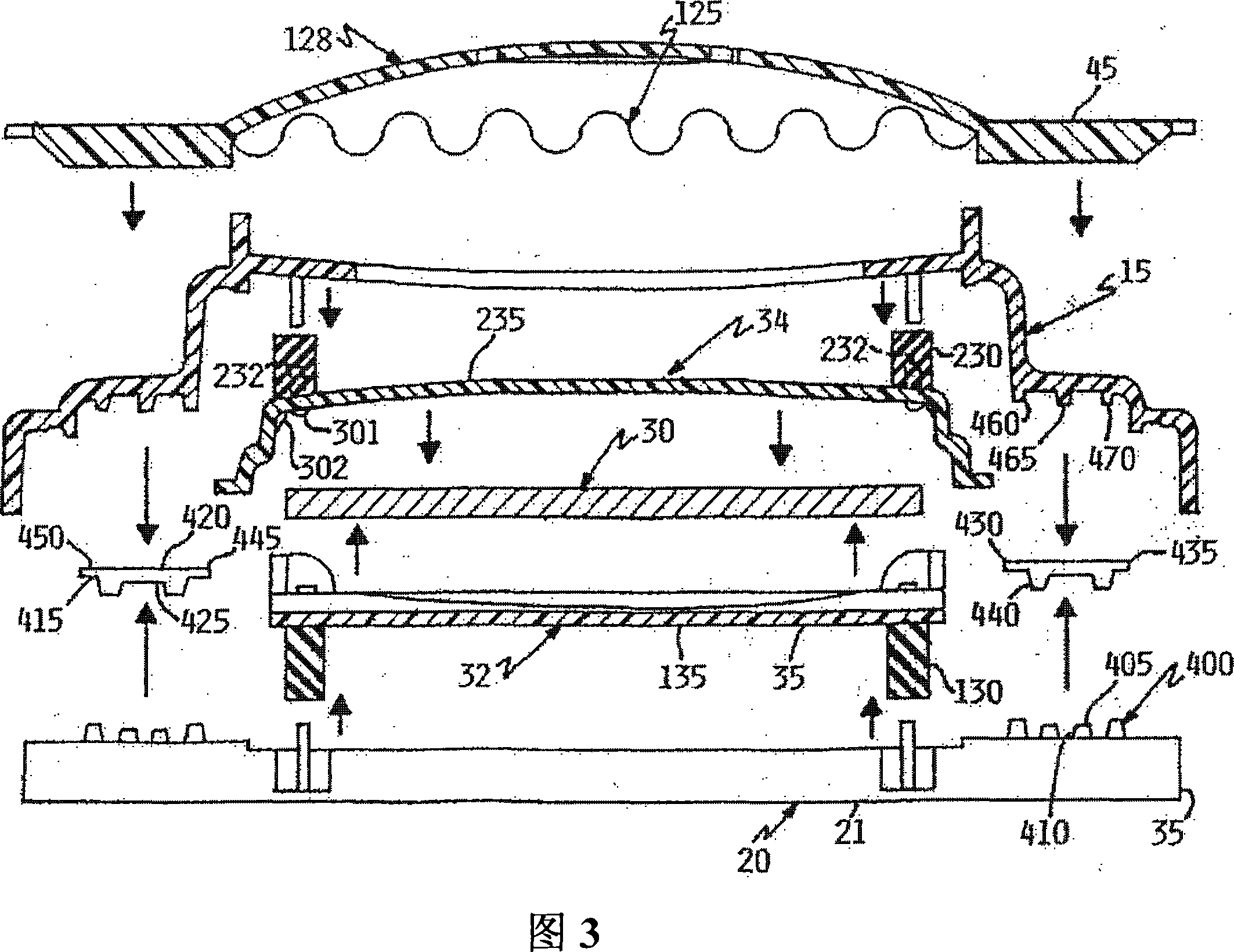

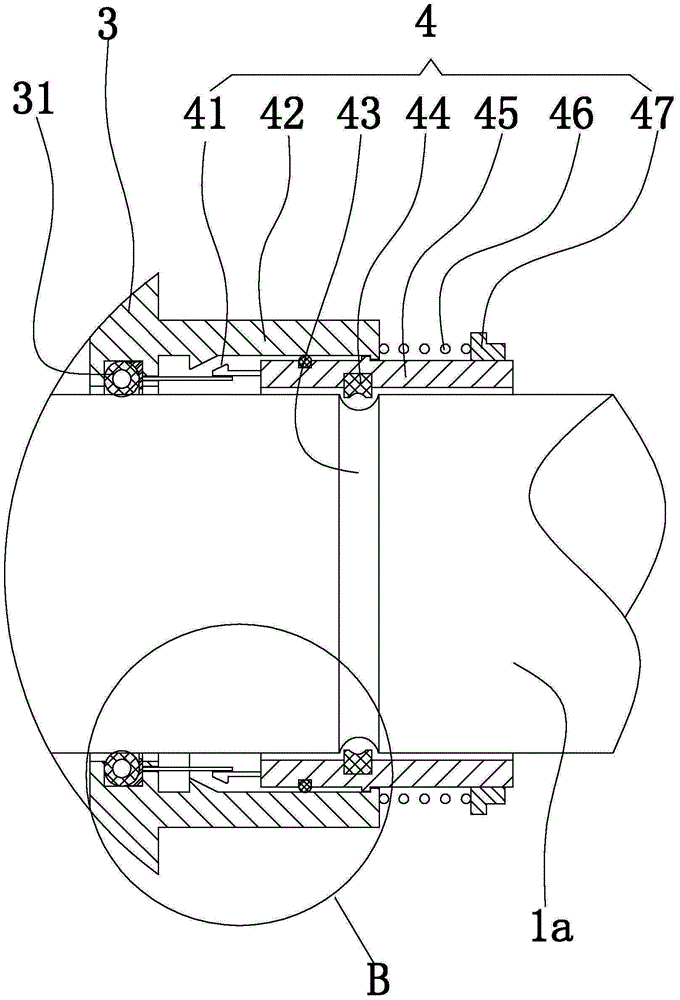

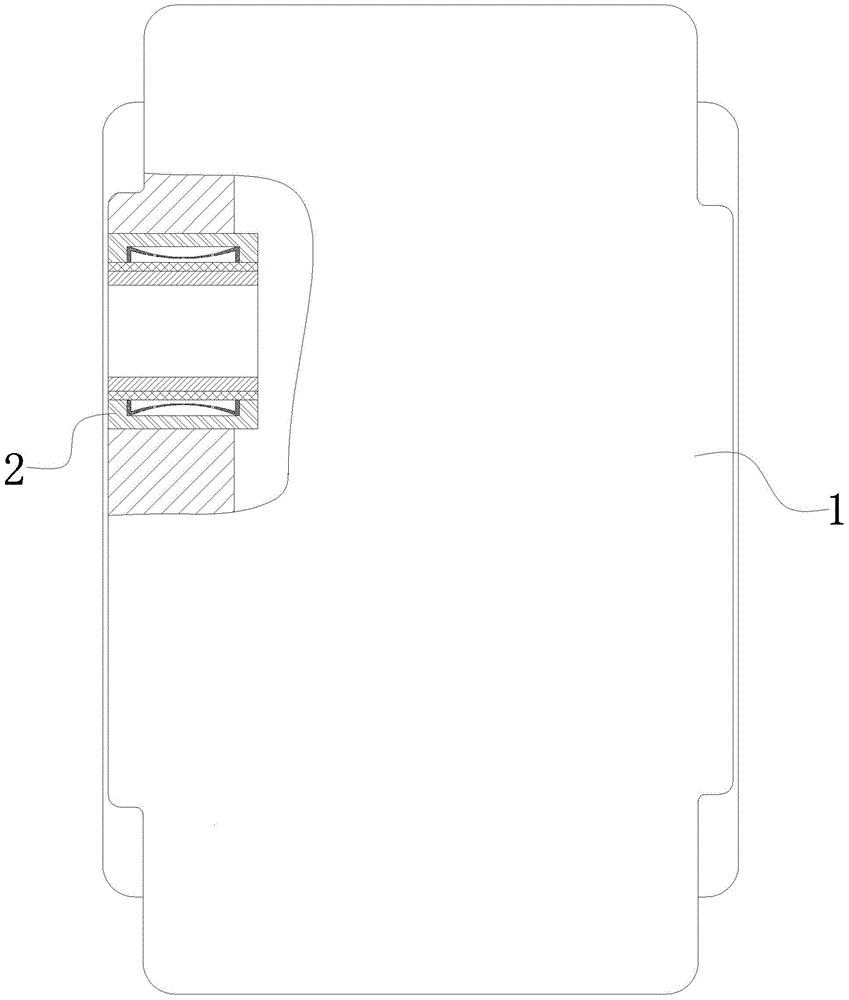

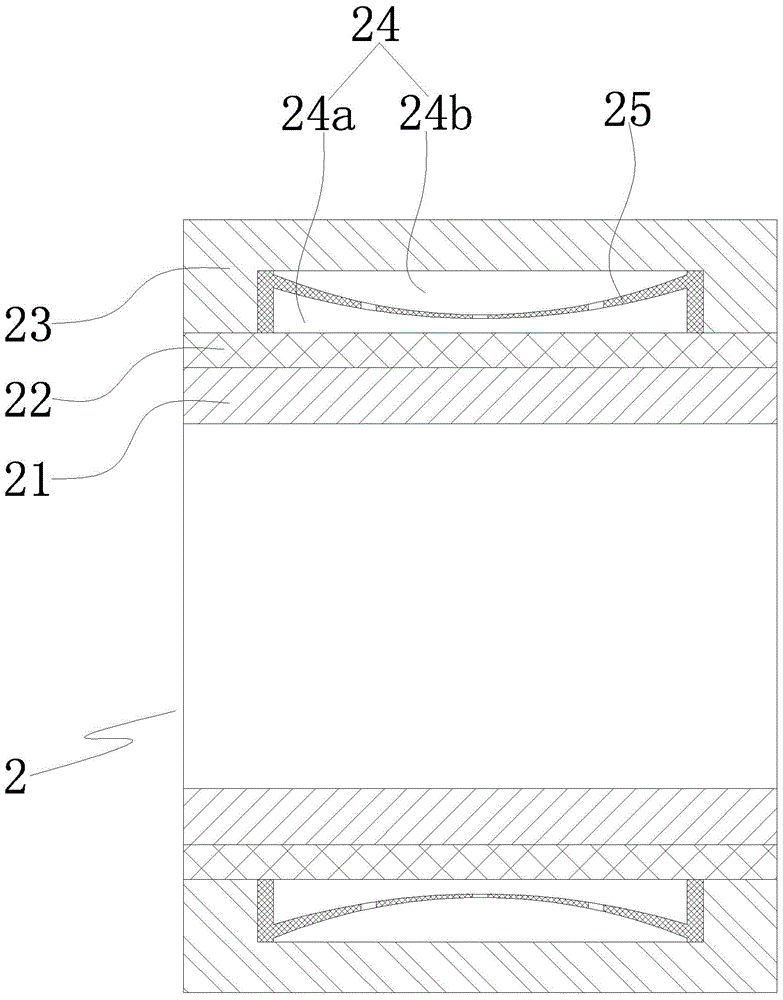

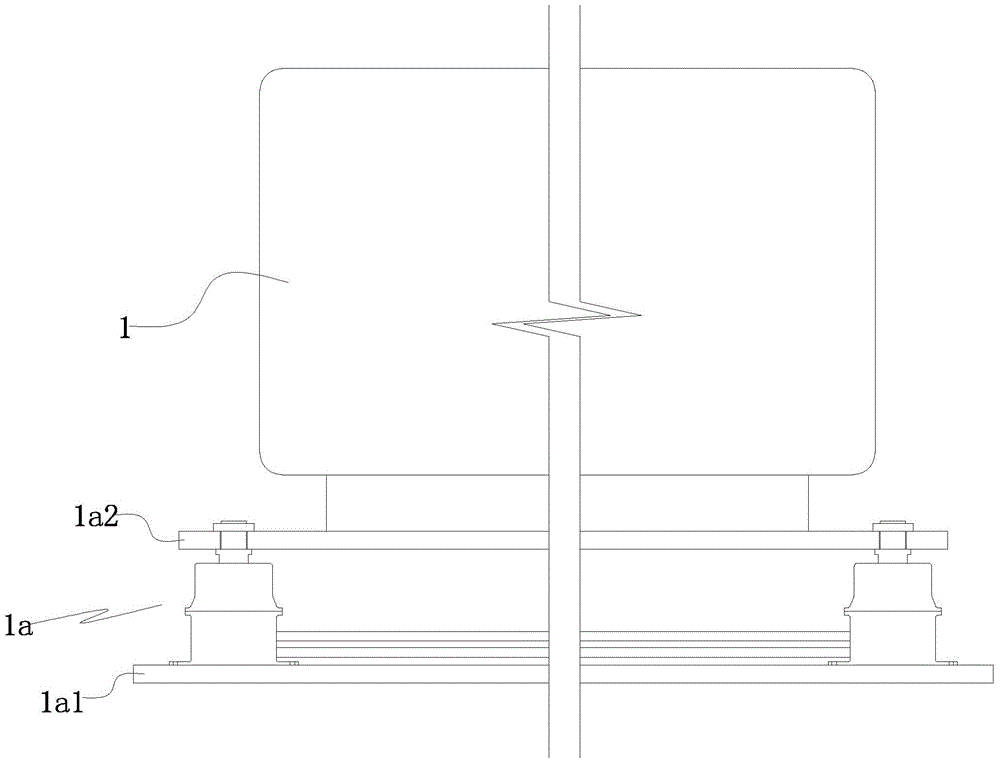

Reticle pod with isolation system

InactiveCN101166681AImprove shock absorptionImprove vibration reductionPhotomechanical apparatusSemiconductor/solid-state device manufacturingVibration transmissionVibration isolation

The present invention provides a reticle container that is equipped with a secondary container which houses the reticle and is housed in the primary container. The secondary container is held within the primary container with shock and vibration isolation members so that the secondary container has multiple degrees of freedom of motion within the primary container. The reticle is secured inside the secondary container such that shock and vibration transmission from the reticle container to the reticle is substantially attenuated.

Owner:ENTEGRIS INC

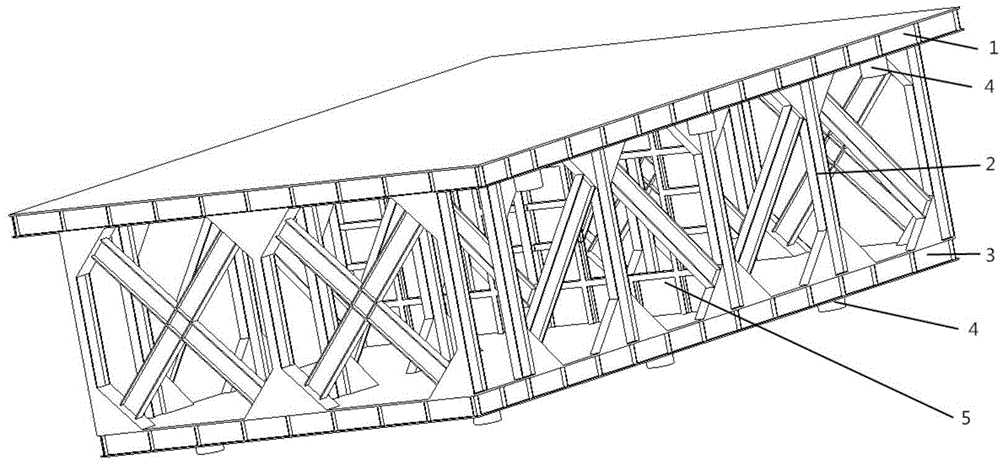

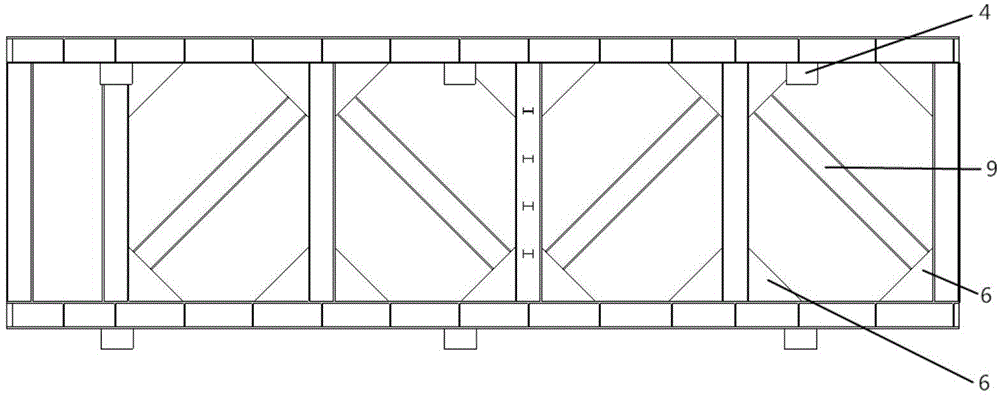

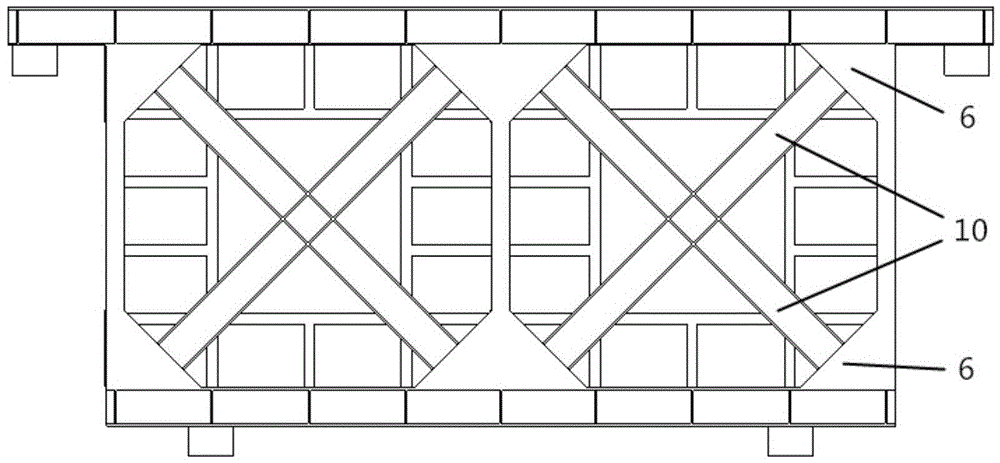

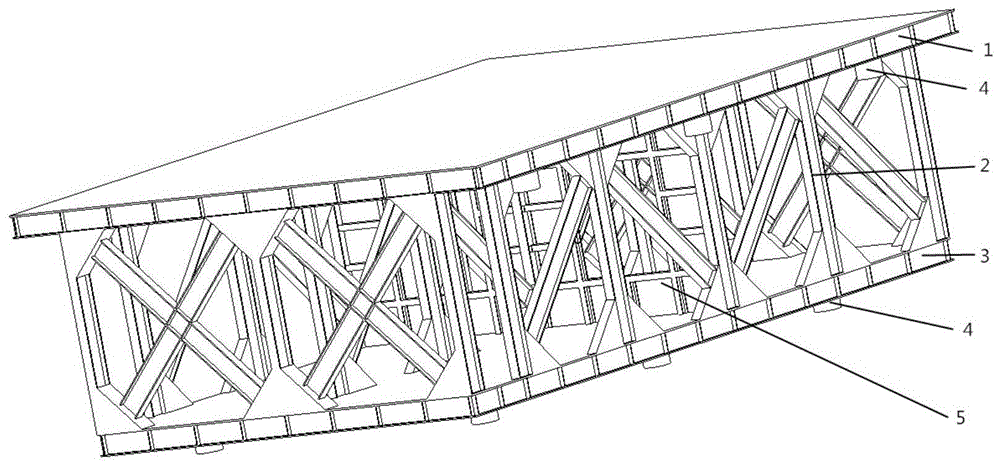

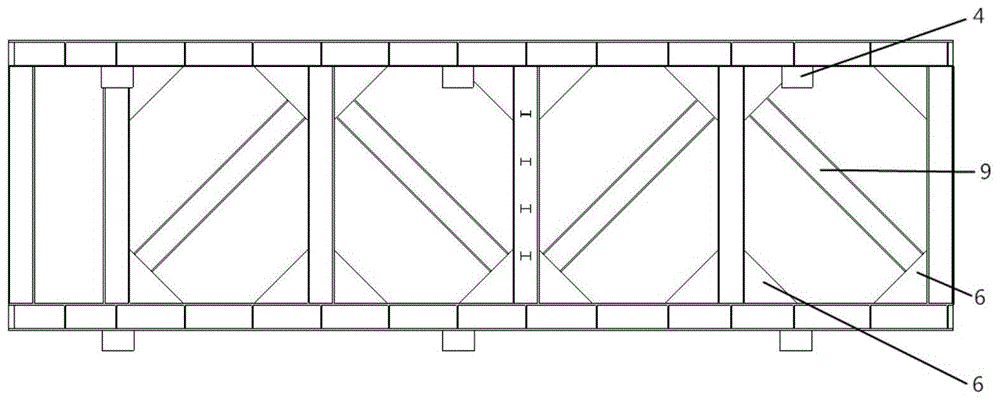

Periodic-structure vibration isolation device based on bandgap filtration and waveform conversion

ActiveCN104595418AImprove the vibration isolation effectImprove vibration reductionSpringsVibration dampersFiltrationStructural engineering

The invention discloses a periodic-structure vibration isolation device which comprises two panels, multiple vertical rods and multiple oblique rods, wherein the two panels are arranged at intervals; one panel is connected with equipment which needs vibration isolation through a vibration isolator, and the other panel is connected with a mounting base by virtue of a vibration isolator; the multiple vertical rods are arranged in an array and are vertically arranged between the two panels so as to form multiple vibration isolation regions, reinforced rib plates are arranged at connection parts between all vertical rods in each vibration isolation region and the upper and lower panels; one oblique rod is arranged between every two reinforced rib plates which are arranged in opposite angles of each vibration isolation region, and the oblique rods in the two adjacent vibration isolation regions are arranged symmetrically relative to the common vertical rod, so that a vibration isolation structure with periodic arrangement is formed, the band notched characteristic of the periodic structure is formed and effective vibration isolation and noise reduction are realized. The device is capable of not only providing sufficient static rigidity and dynamic rigidity, but also effectively isolating low-frequency narrow-band line spectrums and wide-band vibration transfer which are generated by main and auxiliary mechanical devices and restraining noise radiation caused by vibration transfer.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

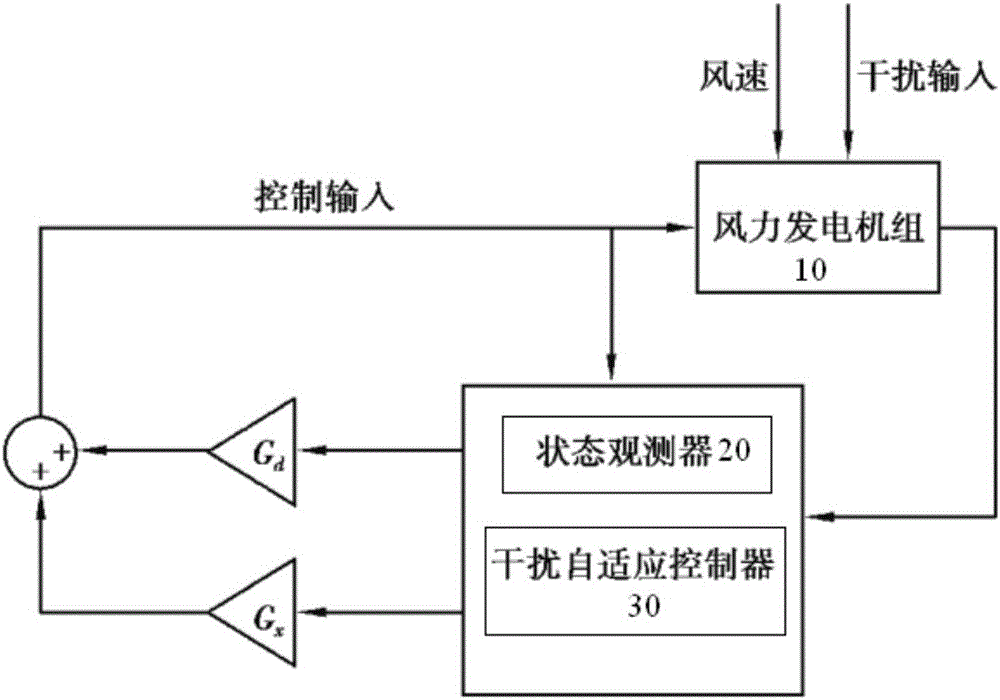

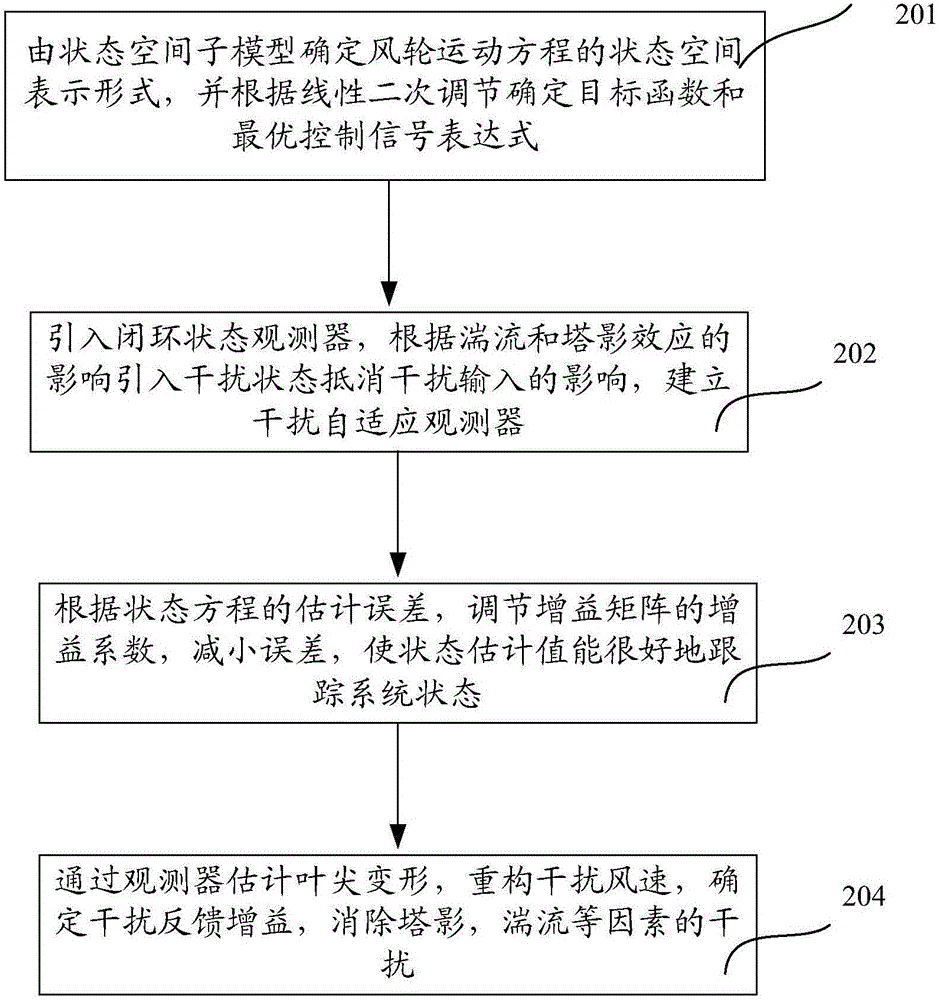

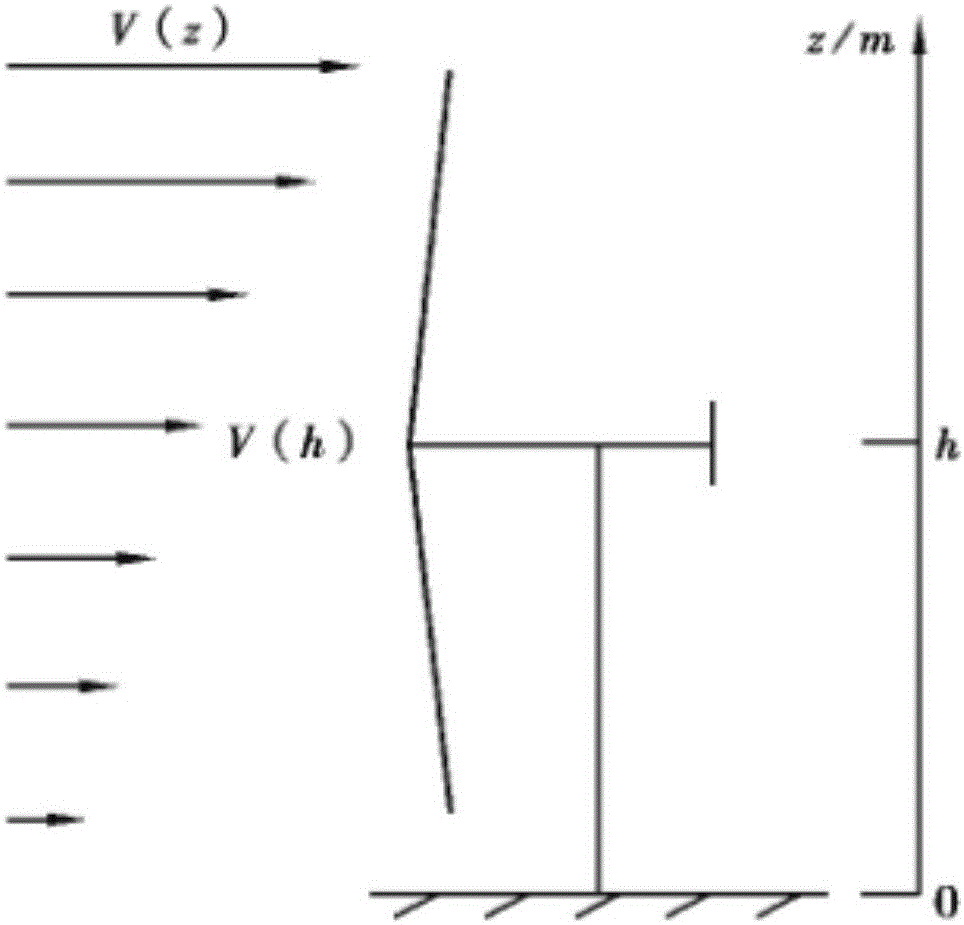

Individual pitch control system and method for wind driven generator

InactiveCN105156270AIncreased operating lifeReduce vibration loadWind motor controlMachines/enginesWind drivenControl system

The invention discloses an individual pitch control system and method for a wind driven generator. The system comprises a wind driven generator unit, a state observer and a disturbance accommodating controller; the state observer and the disturbance accommodating controller are additionally arranged in the system according to control input and interference input, the gain coefficients Gx and Gd are adjusted according to the specific circumstances to control the influences of errors and the interference input, and finally individual pitch control is achieved. According to the individual pitch control system and method for the wind driven generator, an individual pitch control strategy based on a linear quadratic regulator and a disturbance accommodating control technology is adopted, the problems that wind wheels of the wind driven generator are loaded are solved, the operation life of the wind driven generator is prolonged, the vibration load of the wind driven generator is effectively reduced, and the purpose of vibration reduction is well achieved; meanwhile, the disturbance accommodating control technology is introduced to inhibit or reduce the influences of the wind speed, the turbulent flow, the wind shear and tower shadow effects and the like on the wind driven generator, and the robustness of the system is improved.

Owner:SHANGHAI DIANJI UNIV

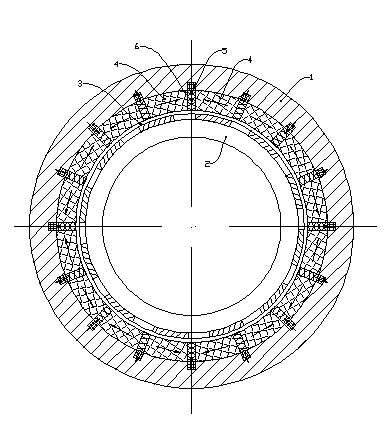

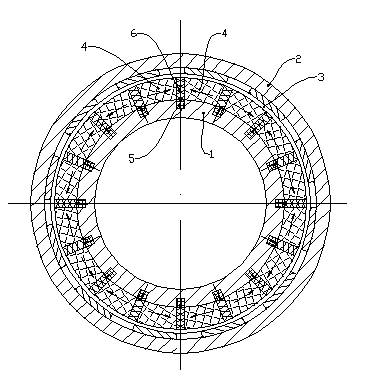

Permanent magnet coupling mechanism between shafts

InactiveCN103326541ACreative optimizationChange areaDynamo-electric gearsPermanent magnet rotorCoupling

The invention relates to a permanent magnet coupling mechanism between shafts. The permanent magnet coupling mechanism between the shafts is used for transmitting torque between the two rotating shafts. The mechanism comprises a permanent magnet rotor and a conductor rotor, wherein a conical air gap is formed between the permanent rotor and the conductor rotor. A permanent magnet on the permanent magnet rotor comprises main magnets and auxiliary magnets. The multiple main magnets are circumferentially distributed. A magnetizer made of permeability magnetic materials is arranged between every two adjacent main magnets. One auxiliary magnet is arranged on one side, away from the conductor rotor, of each magnetizer. The directions of the magnetic poles of the main magnets are located in the circumferential direction of the permanent magnet rotor. The directions of the magnetic poles of the adjacent main magnets are in the face-to-face direction or the back-to-back direction. The directions of the magnetic poles of the auxiliary magnets are the radial directions of the permanent magnet rotor. The directions of the magnetic poles of the adjacent auxiliary magnets are opposite. The magnetic poles of the positions of the side faces where the two main man magnets and one auxiliary magnet are contacted with the same magnetizer are respectively the same polarity. The permanent magnet coupling mechanism between the shafts is large in transmitting torque, adjustable in transmitting torque, compact in structure, convenient to install, and stable and reliable in transmission and adjustment.

Owner:JIANGSU MAGNET VALLEY TECH

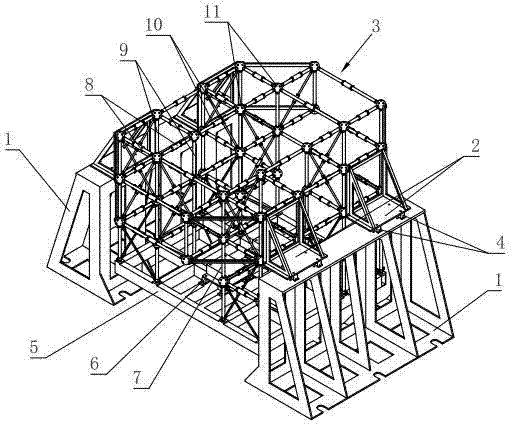

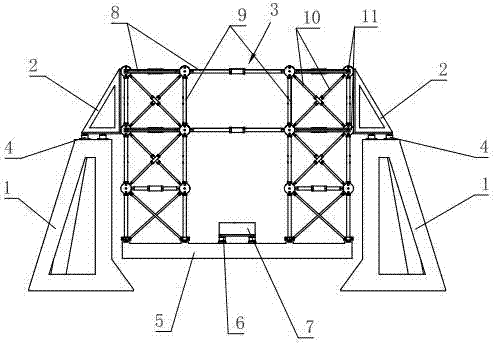

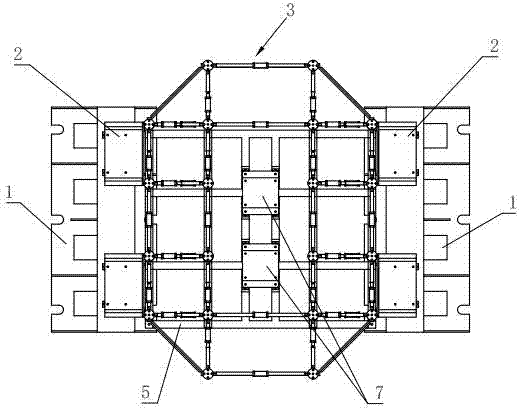

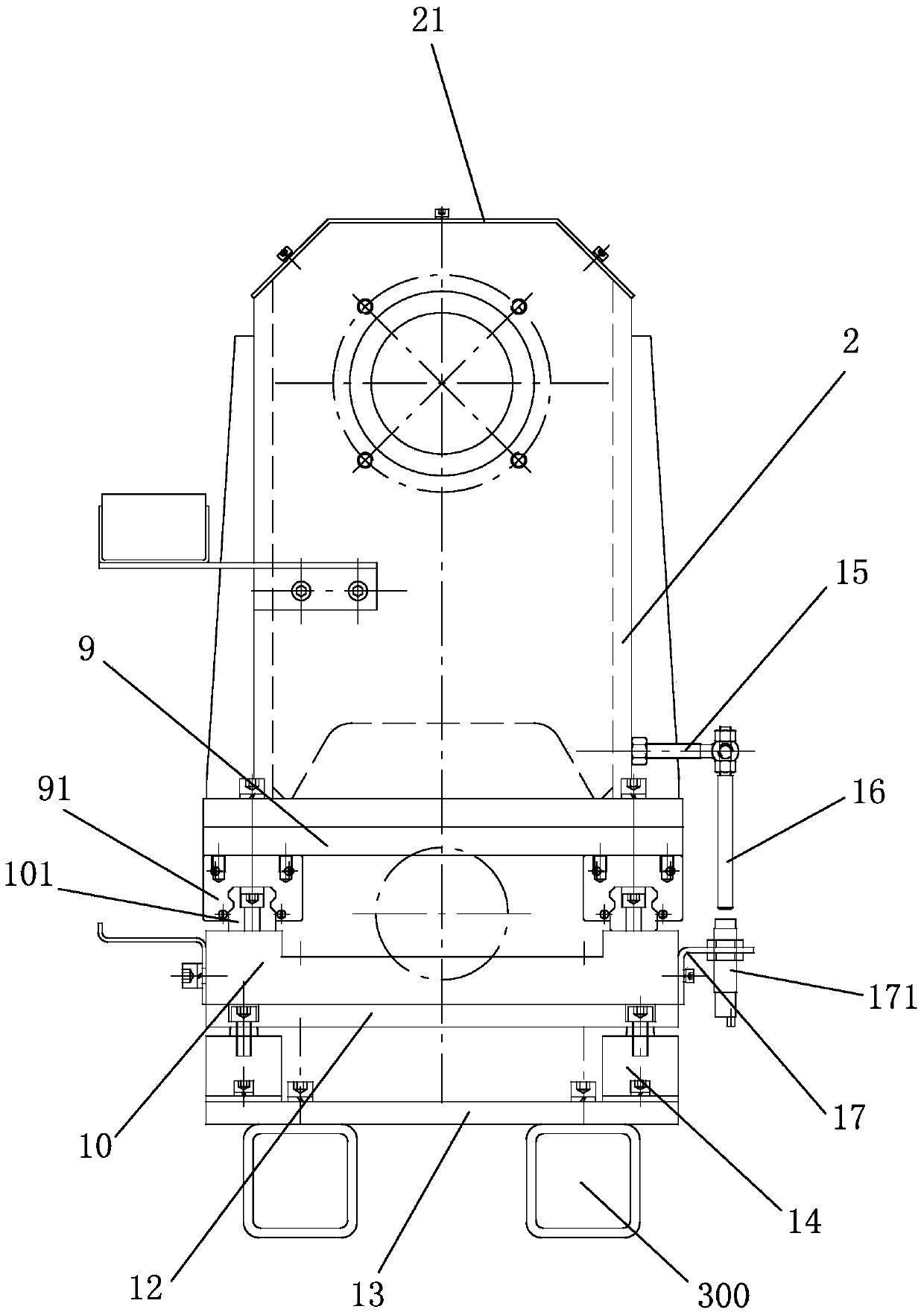

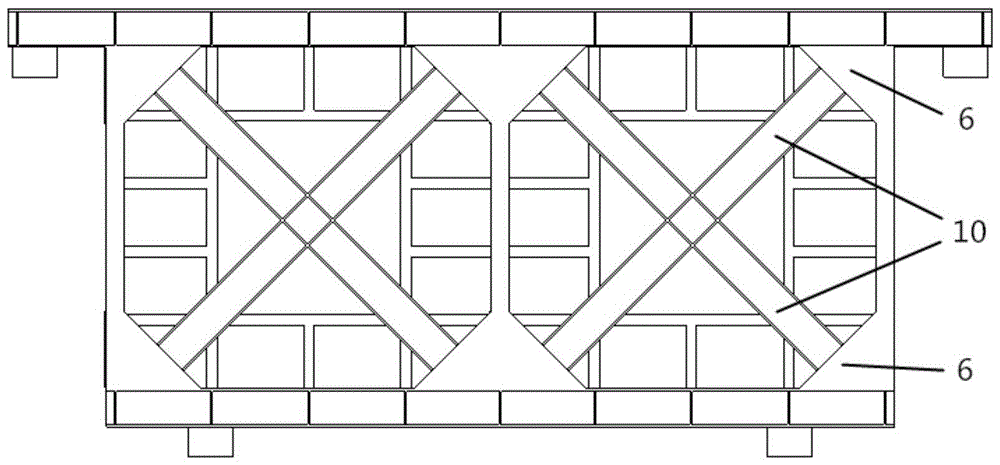

Truss-type floating raft vibration isolation device

InactiveCN102338190AImprove vibration reductionImprove the vibration isolation effectNon-rotating vibration suppressionChinese charactersMarine engineering

The invention relates to a truss-type floating raft vibration isolation device which is characterized by comprising bases arranged at two sides, wherein a triangular connection frame is installed on the bases through a vibration isolator; a truss is in the shape of a Chinese character 'men'; two sides at the upper part of the truss are connected with the triangular connection frame; the lower endof the truss is connected with a base plate; and the truss is vertically suspended between the two bases. According to the invention, the truss acts as an intermediate structure of a floating raft, the vibration reduction and vibration isolation effects are reinforced through the variation of wave types, multiple scattering and reflection to vibration waves by a horizontal rod, a vertical rod, anoblique rod and a spherical joint of the truss in the structure; simultaneously, particles are filled in the horizontal rod of a hollow structure, and the isolation vibration effect is reinforced further; and in additional, the spherical joint and rod pieces of the truss-type floating raft are detachable, under the condition that the space in a ship is narrow, the truss-type floating raft can be dismounted into components, then the components are transported to and installed in the ship, and convenience is provided for mounting and maintaining.

Owner:中国船舶重工集团公司第七〇二研究所

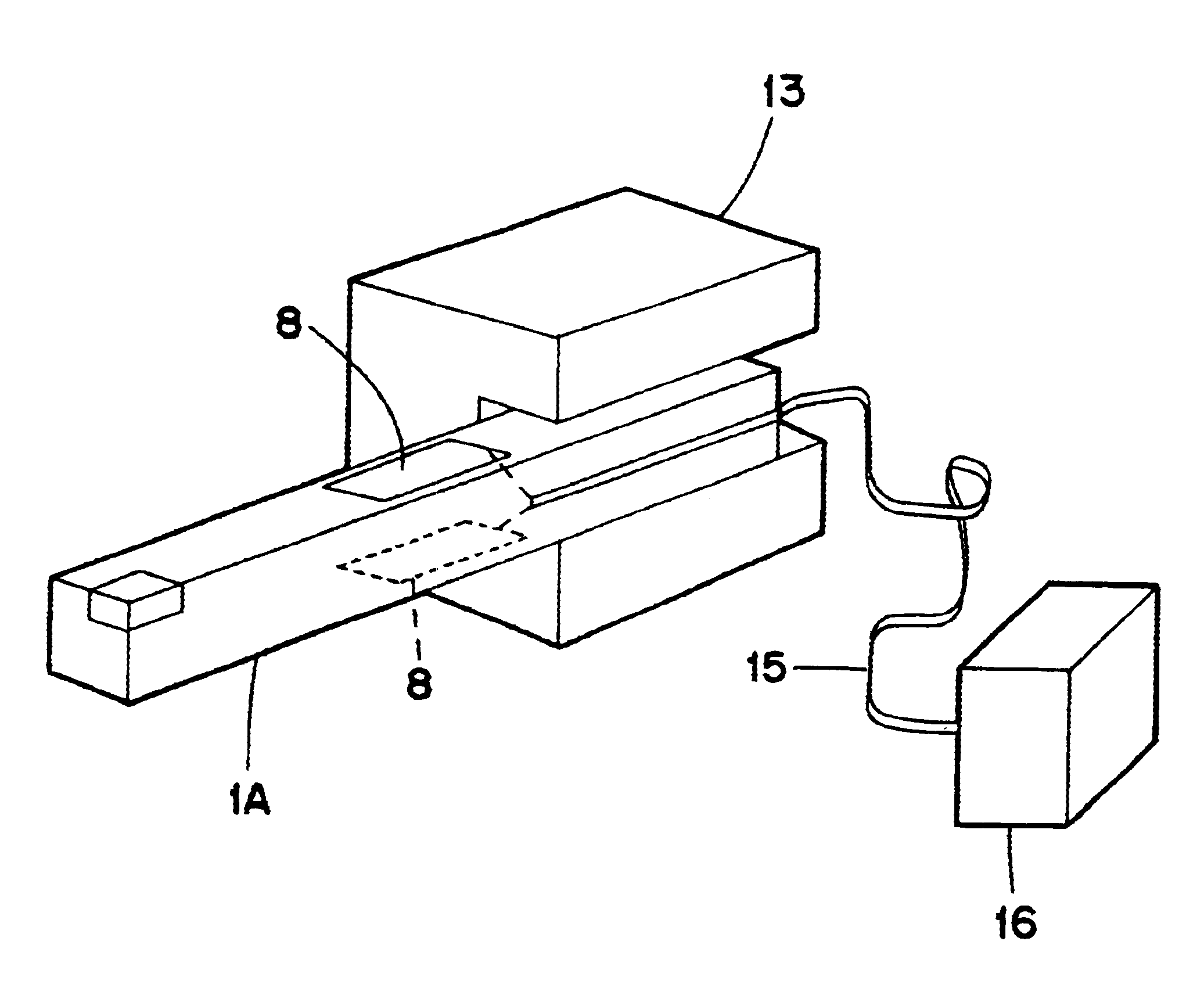

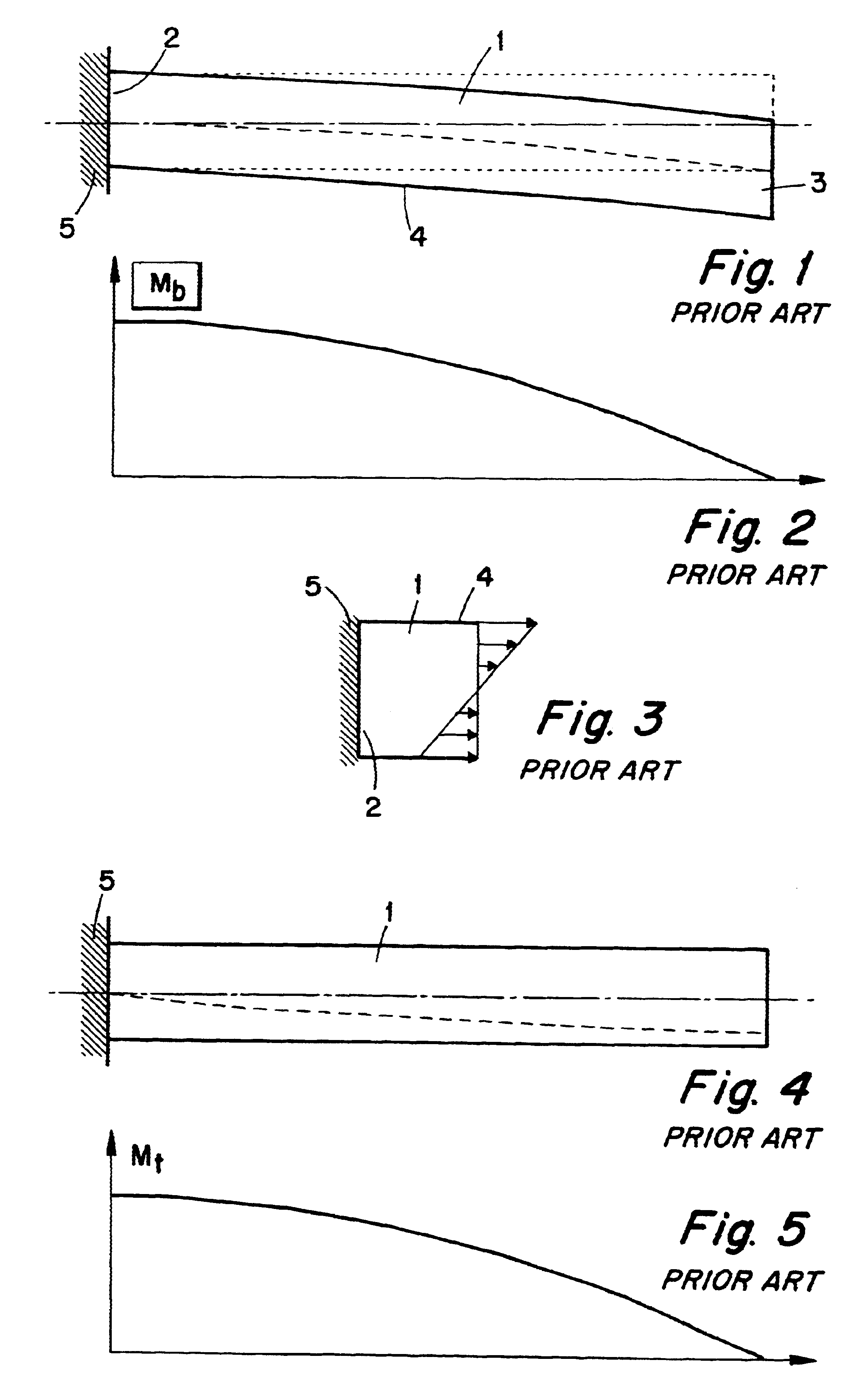

Active anti-vibration system for cutting tools utilizing piezo-electric elements

InactiveUS6661157B1Improve vibration reductionEffective dampeningPiezoelectric/electrostriction/magnetostriction machinesNon-rotating vibration suppressionElectricityEngineering

Tool for chip removing machining includes a shank having a clamping end and a cutting insert at an opposite end, plus a number of piezo-elements for dampening vibrations therein. A pair of cooperating, flat-shaped piezo-elements with lengths that are shorter than that of the shank, are placed on opposing sides of the shaft in an area adjacent to the region where the shank is secured in the machine wherein the direction of polarization of the piezo-elements is parallel to the longitudinal axis of the shank. The piezo-elements constitute actuators that are actively steerable through the application of a voltage from a source of electricity via a control device in the form of a logic control circuit, to thereby dampen the bending vibrations of the shank.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

A novel intelligent material composed of a porous magnetorheological elastomer and magnetorheological fluid

PendingCN109087771AImprove controllabilityStrong designabilityMagnetic liquidsElastomerEnergy absorption

The invention provides a novel intelligent material composed of a porous magnetorheological elastomer and magnetorheological fluid, which comprises a non-magnetic polymer matrix, magnetic particles inthe magnetorheological elastomer, bubble pores, channels, non-magnetic liquid and magnetic particles in the non-magnetic liquid. The magnetic particles in the magnetorheological elastomer and the bubble pores are randomly or regularly distributed in the non-magnetic polymer matrix, the multiple bubble pores are connected through the channels, the non-magnetic fluid is located in the bubble poresand the channels, and magnetic particles in non-magnetic fluid are distributed in the interior of the non-magnetic fluid. Randomly distributed bubble pores are produced by physical or chemical foamingmethods, and chain-like regularly distributed bubble pores are formed by mold forming or augmentation manufacturing (3D). The intelligent material manufactured by the invention has good vibration damping and energy absorption performance, wide adjustment range of stiffness and damping, good controllability, strong designability, stable performance and settlement resistance, and has very broad application prospect.

Owner:BEIHANG UNIV

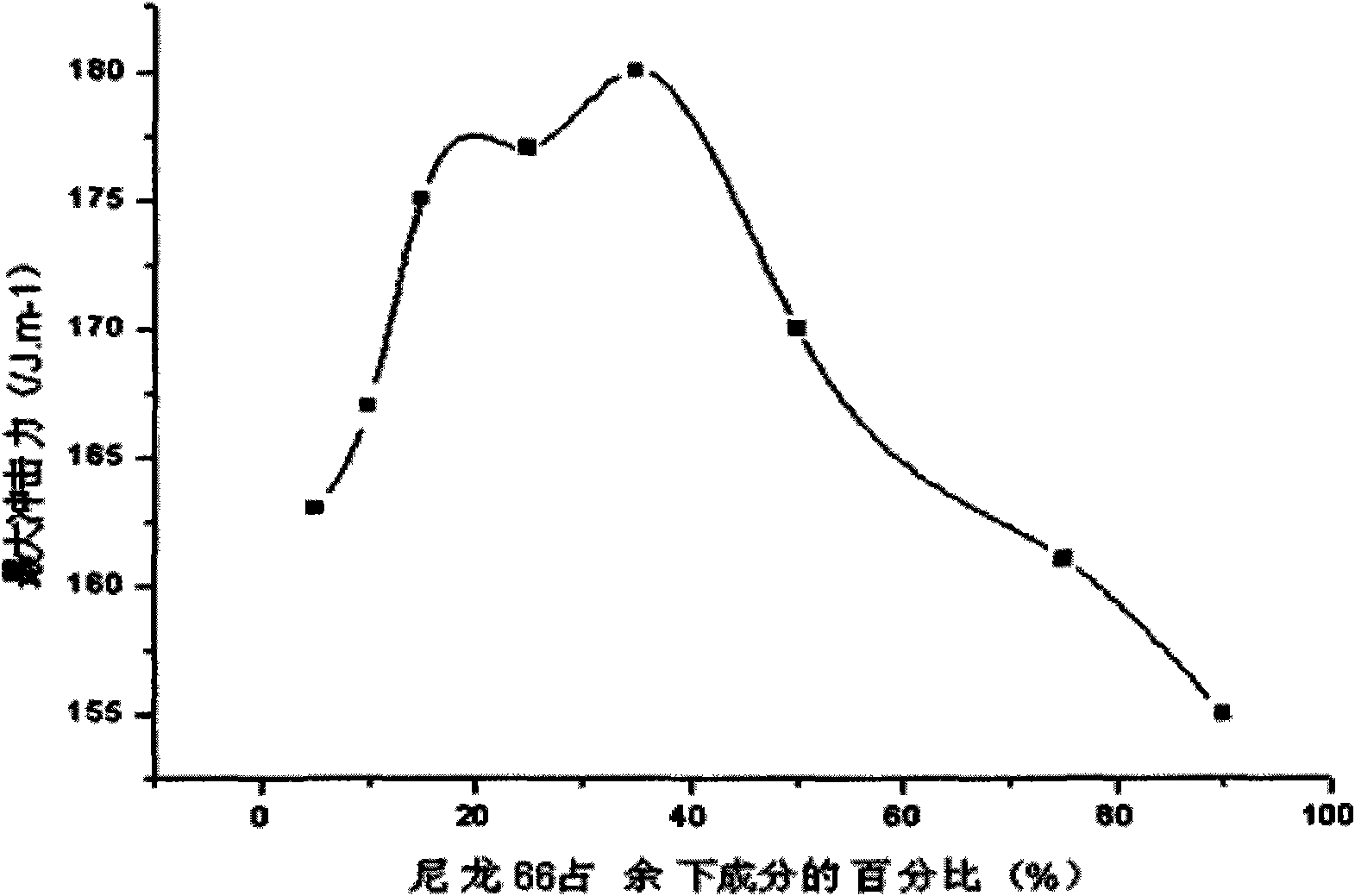

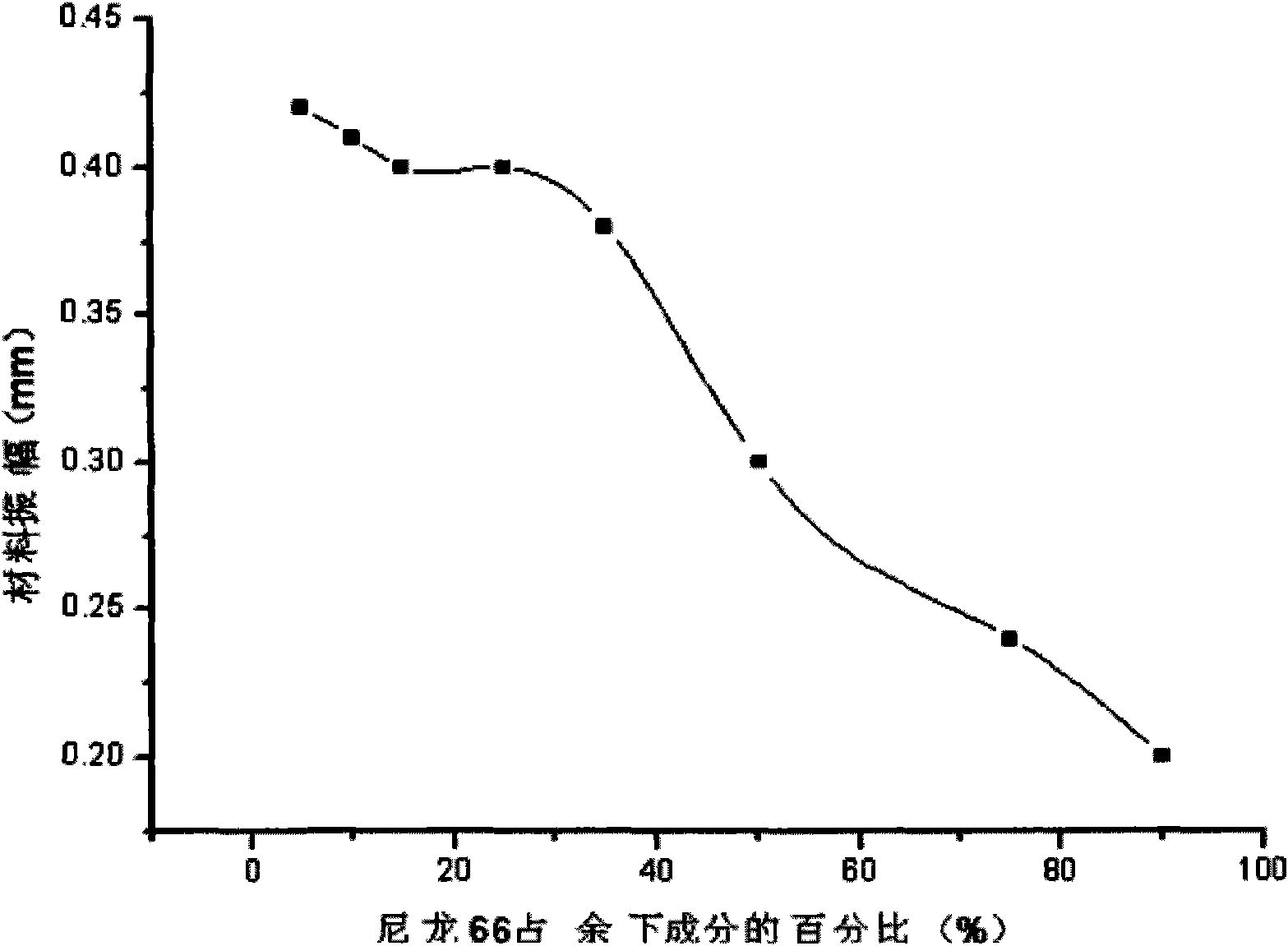

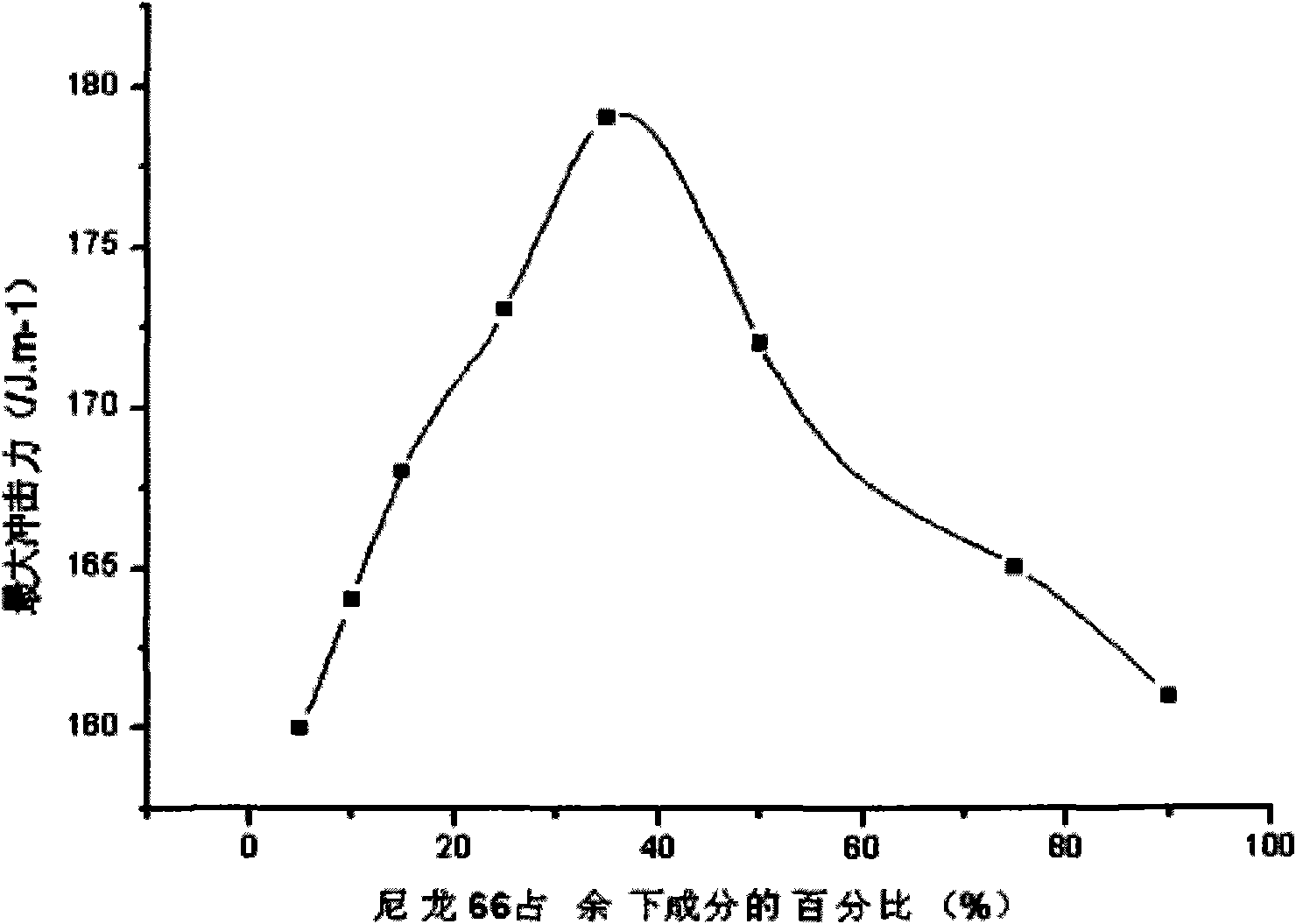

Optimization method for mixture ratio of components of working layer of metal plastic composite material

ActiveCN101567020AImprove vibration reductionImprove stabilitySpecial data processing applicationsFiberCarbon fibers

The invention discloses an optimization method for a mixture ratio of components of a working layer of a metal plastic composite material, which comprises the following steps: obtaining mixture ratio parameters of working layers of polyphenyl thioether and nylon 66 and carbon fibers, and material performance parameters of the vibration reduction and the firmness of composite materials, which correspond to the mixture ratio parameters by a plurality of groups of orthogonal tests; training self-adapting nerve fuzzy reasoning systems and respectively establishing the global map relation; establishing and correcting a system model by three-dimensional analysis software to obtain various parameters; taking optimal performances with 50 percent of the vibration reduction and 50 percent of the firmness as a target; copying, crossing and varying the mixture ratio parameters by a genetic algorithm to obtain mixture ratio parameter values corresponding to the optimal performances; and comparing the mixture ratio parameter values obtained through the optimization by the genetic algorithm and the performance parameters corresponding to the mixture ratio parameter values with the mixture ratio parameters corresponding to the same performance parameters and corrected by the three-dimensional analysis software. The optimization method not only ensures the precision, but also improves the efficiency, and substantially improves the vibration reduction and the firmness of the metal plastic composite material.

Owner:丹阳市永丰五金机电有限公司

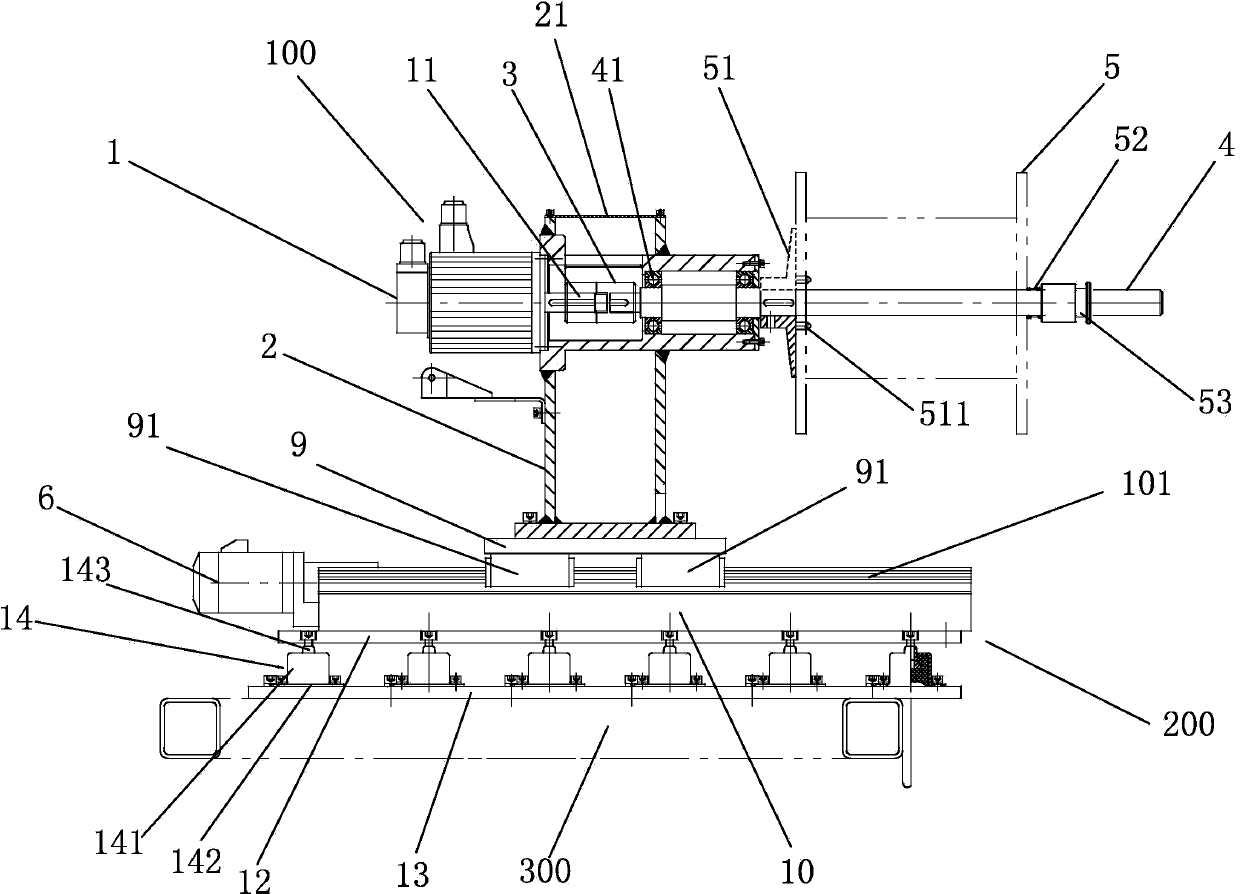

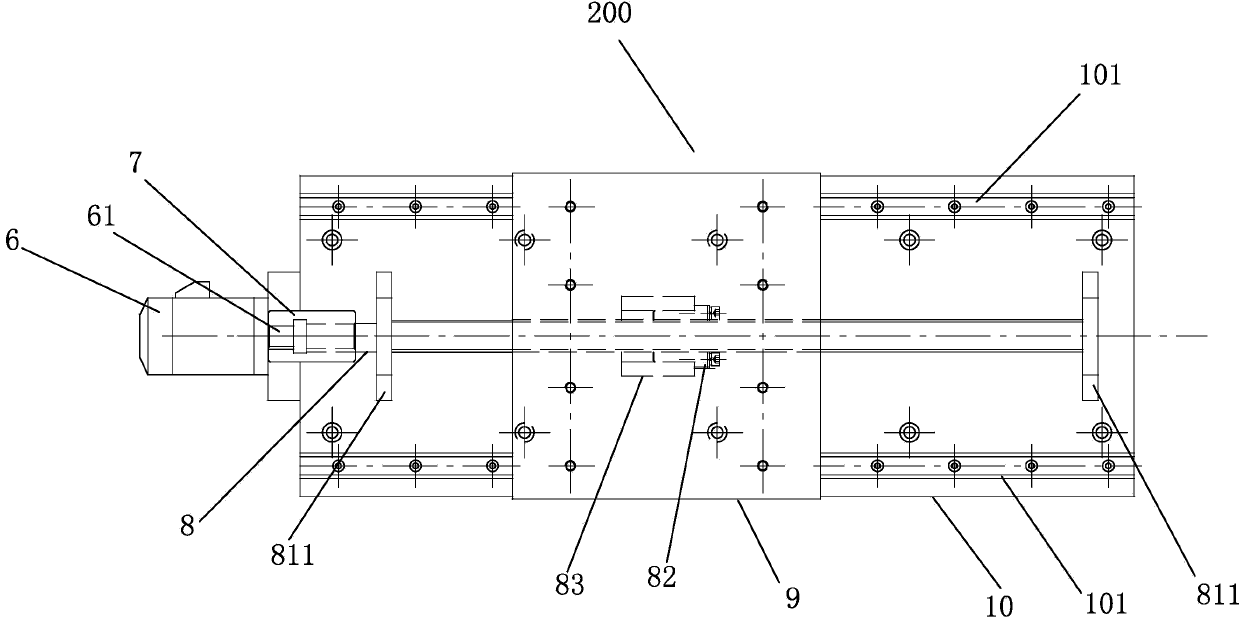

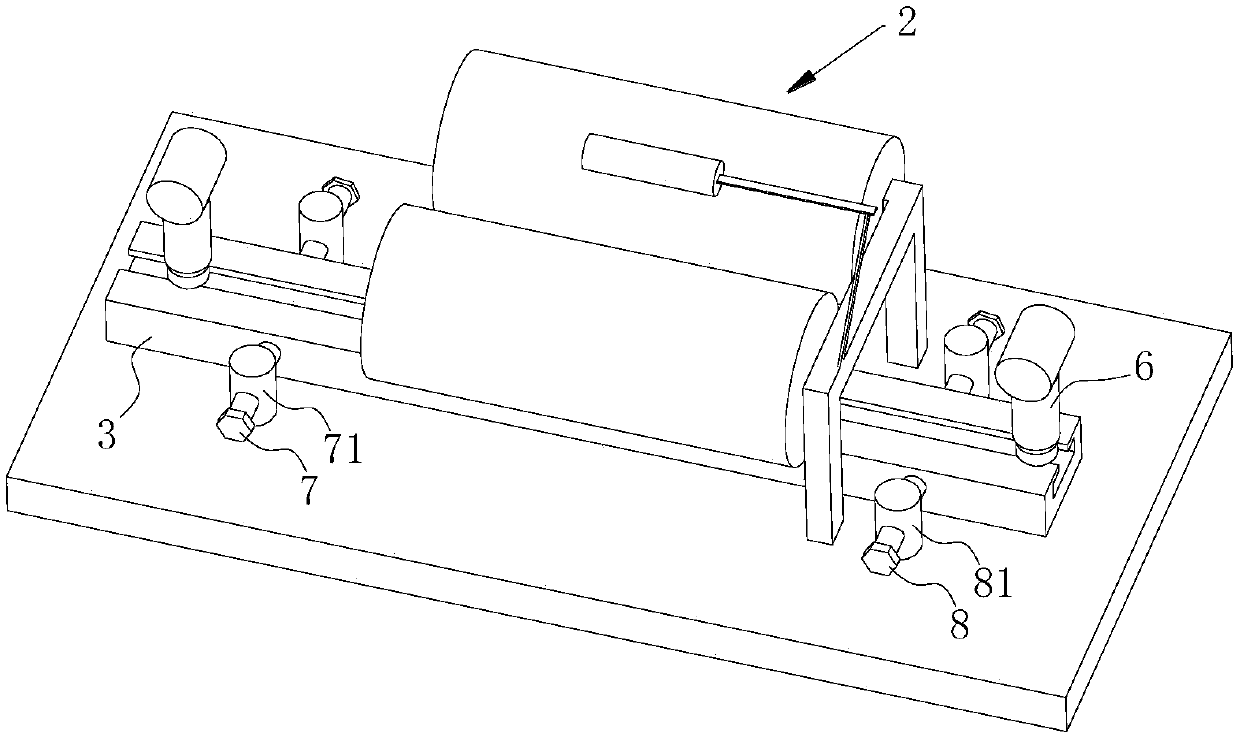

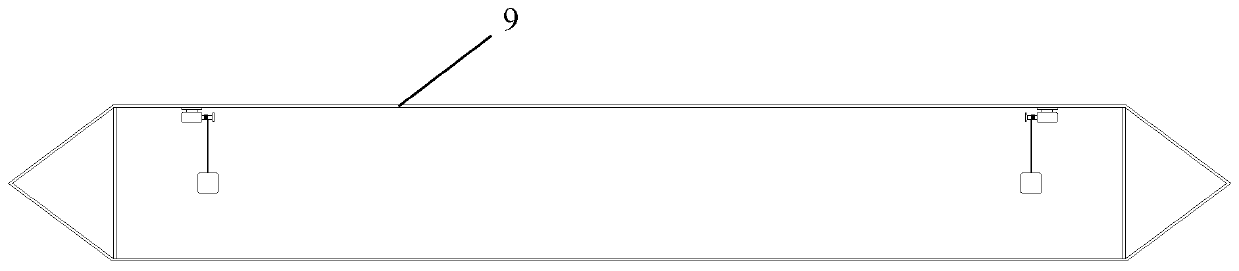

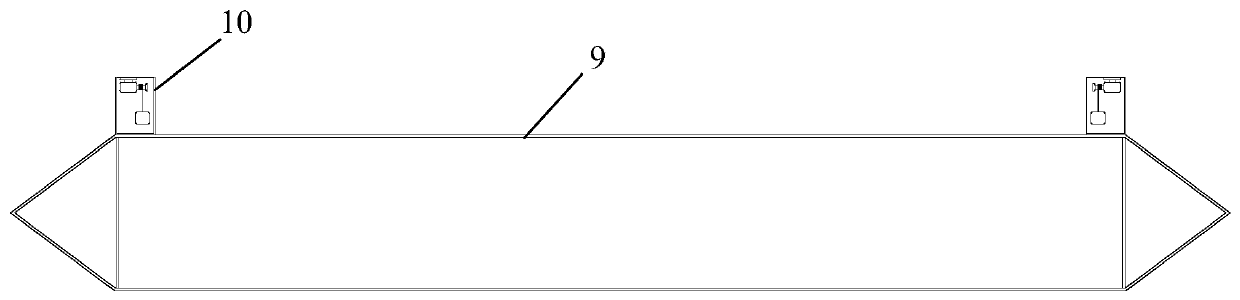

Movable optical fiber active take-up and pay-off assembly

ActiveCN104044954AReduce noiseImprove mechanical propertiesFilament handlingLinear motionMotor drive

The invention discloses a movable optical fiber active take-up and pay-off assembly, and relates to a device for unfolding or releasing filamentary materials. The movable optical fiber active take-up and pay-off assembly comprises a rotating pay-off mechanism and a horizontal reciprocating moving mechanism. The rotating pay-off mechanism comprises a servo motor, a pay-off support and other components. The servo motor supplies pay-off power to drive an optical fiber disc to rotate at high speed, and then active pay-off of optical fibers is achieved. The moving mechanism and the pay-off mechanism jointly achieve the active take-up and pay-off function in the mode that the servo motor drives a linear platform to conduct reciprocating linear motion according to steering signals sent by a steering control assembly. In addition, a plurality of rubber shock absorbers are fixedly arranged between a frame and the linear platform. The movable optical fiber active take-up and pay-off assembly is simple in structure, low in cost, easy and convenient to install and high in bearing strength, can effectively reduce and isolate vibration, reduce the adverse effects of vibration on equipment and make the equipment more stably and effectively conduct production, has the remarkable denoising effect and can remarkably improve the working environment.

Owner:8TH RES INST OF CETC

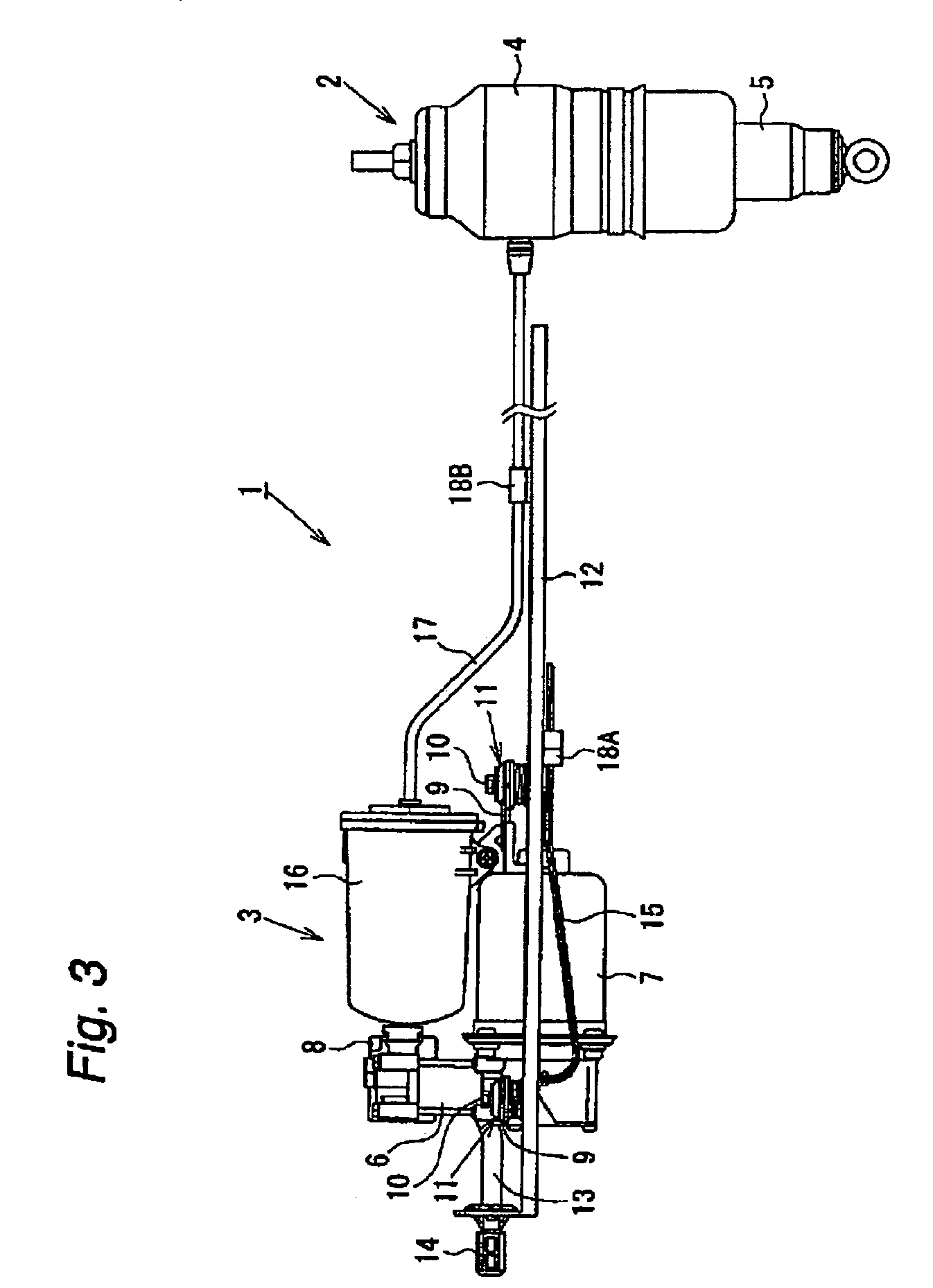

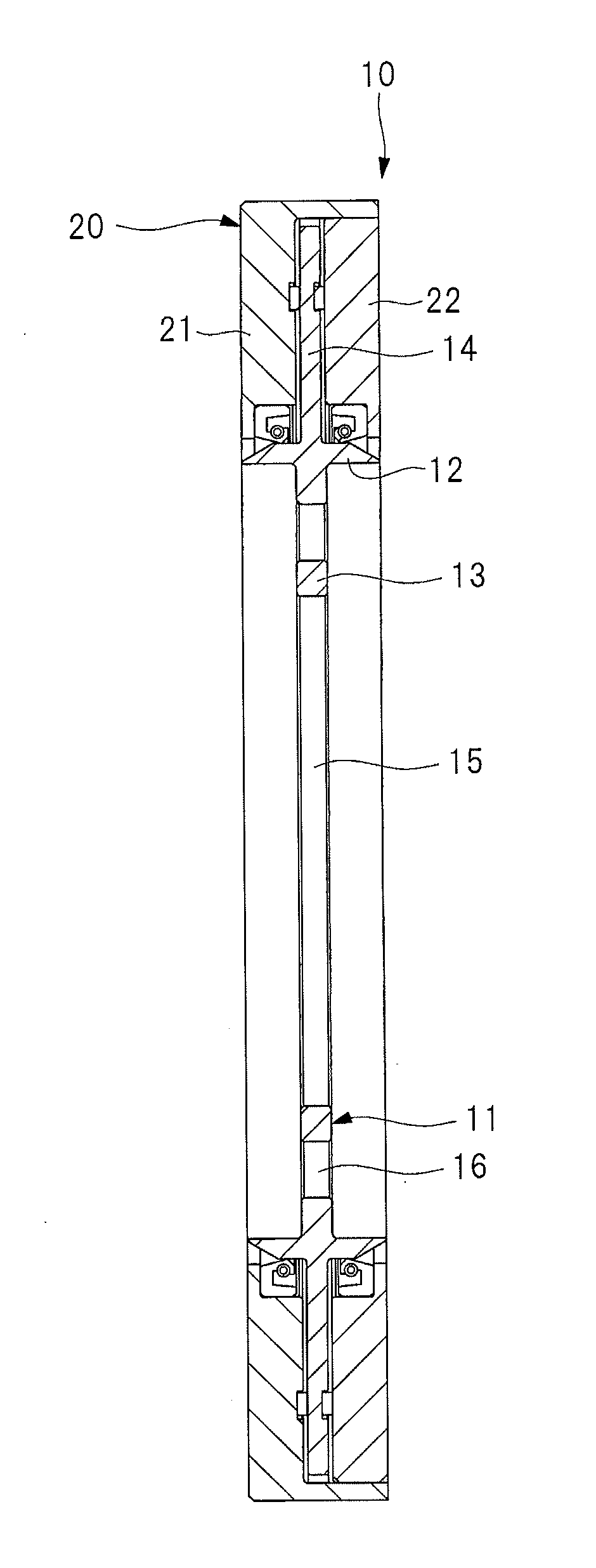

Vibration damper

InactiveUS7758027B2Improve vibration reductionIncreased durabilityPortable framesLiquid based dampersVibration amplitudeCoil spring

An upper bush is secured to a bracket of a compressor unit, and a lower bush is abutted against a panel member of a vehicle body through a washer. A coil spring is interposed between the upper and lower bushes. A pipe member is inserted through the upper and lower bushes and the coil spring. A bolt is inserted through the pipe member and screwed into the panel member of the vehicle body. The compressor unit is resiliently supported floatingly by the coil spring. Vibration of the compressor unit is damped by friction generated by sliding contact between the pipe member and raised portions of the upper bush. When the vibration amplitude is large, respective projections of the upper and lower bushes abut against each other to suppress the vibration while absorbing impact.

Owner:HITACHI LTD

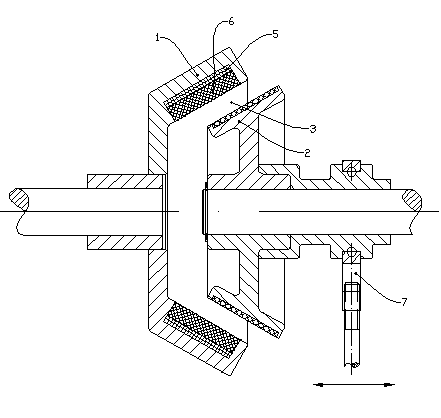

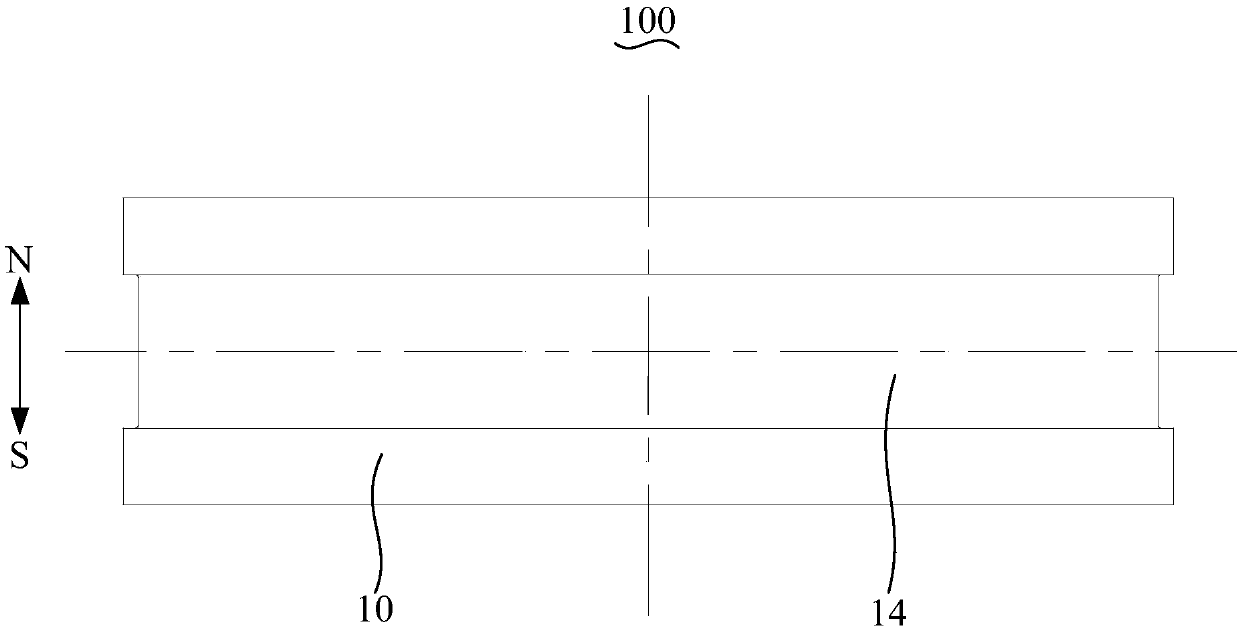

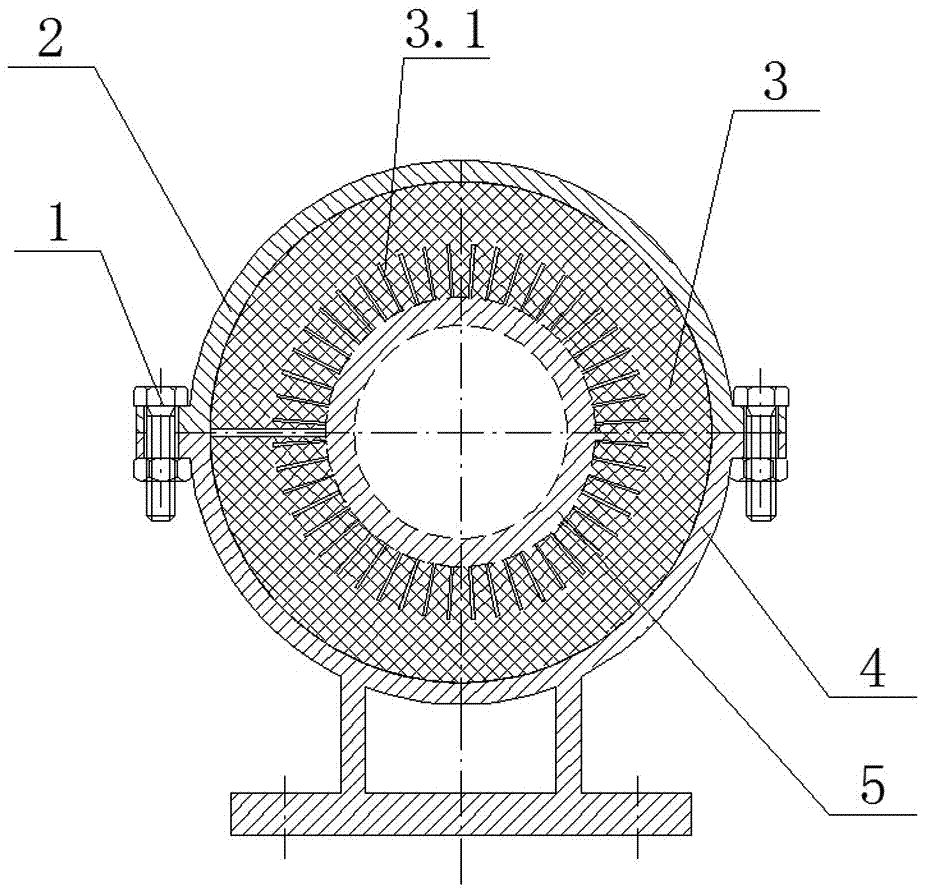

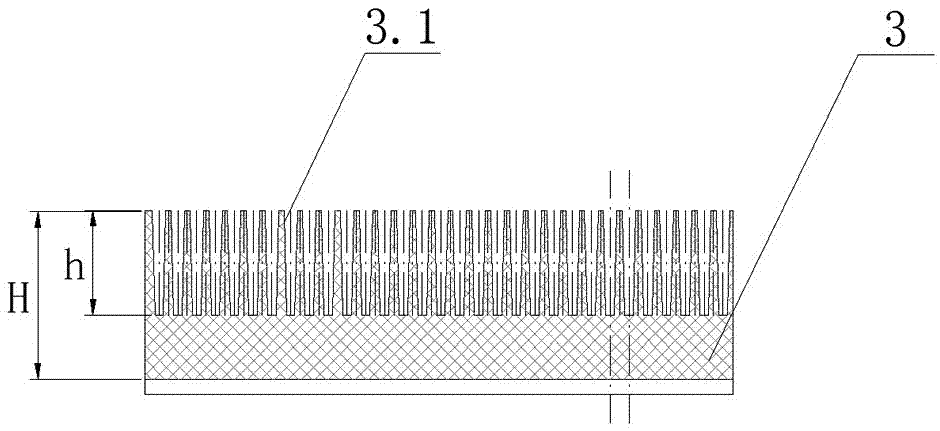

Permanent-magnet coupling mechanism between shafts

InactiveCN103312120AReduce vibrationImprove vibration reductionDynamo-electric gearsPermanent magnet rotorElectrical conductor

The invention relates to a mechanism transmission device, in particular to a permanent-magnet coupling mechanism between shafts. The permanent-magnet coupling mechanism is used for transmitting torque between two rotation shafts and comprises a permanent-magnet rotor and a conductor rotor which are arranged coaxially. Permanent-magnets and conductors are respectively distributed on the permanent-magnet rotor and the conductor rotor, and a conical air gap is formed between the permanent-magnet rotor and the conductor rotor. The permanent-magnets on the permanent-magnet rotor are distributed circumferentially, and magnetizers made of magnetic materials are mounted between the adjacent permanent-magnets. Directions of magnetic poles of the permanent-magnets extend along the circumference of the permanent-magnet rotor, and directions of the magnetic poles of the adjacent permanent-magnets are opposite or reversed. The permanent-magnet coupling mechanism is capable of transmitting high torque adjustably, and is compact in structure, convenient to mount and stable and reliable in transmission and adjustment.

Owner:JIANGSU MAGNET VALLEY TECH

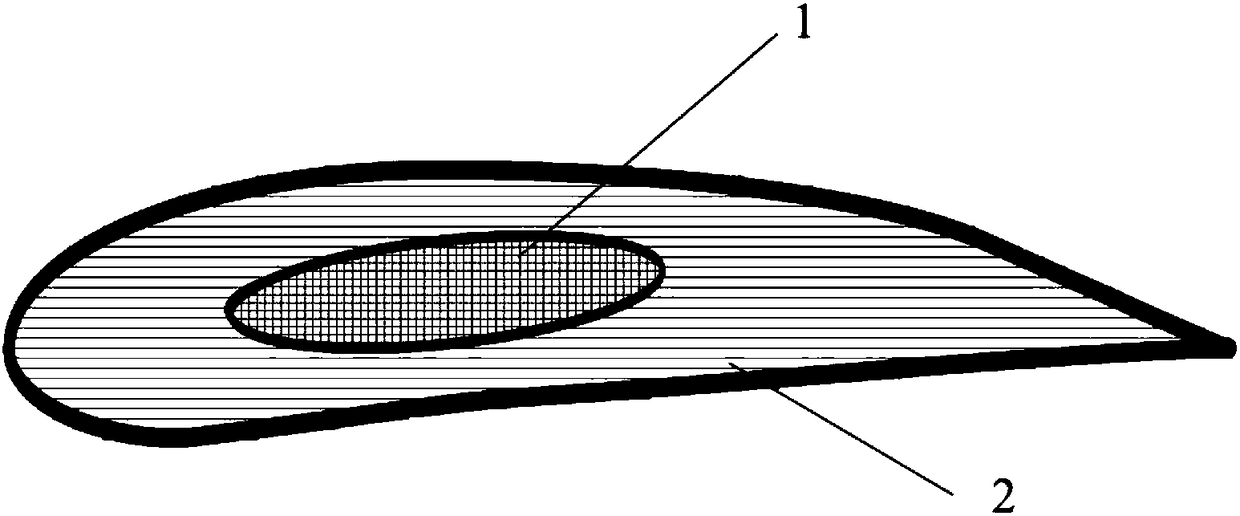

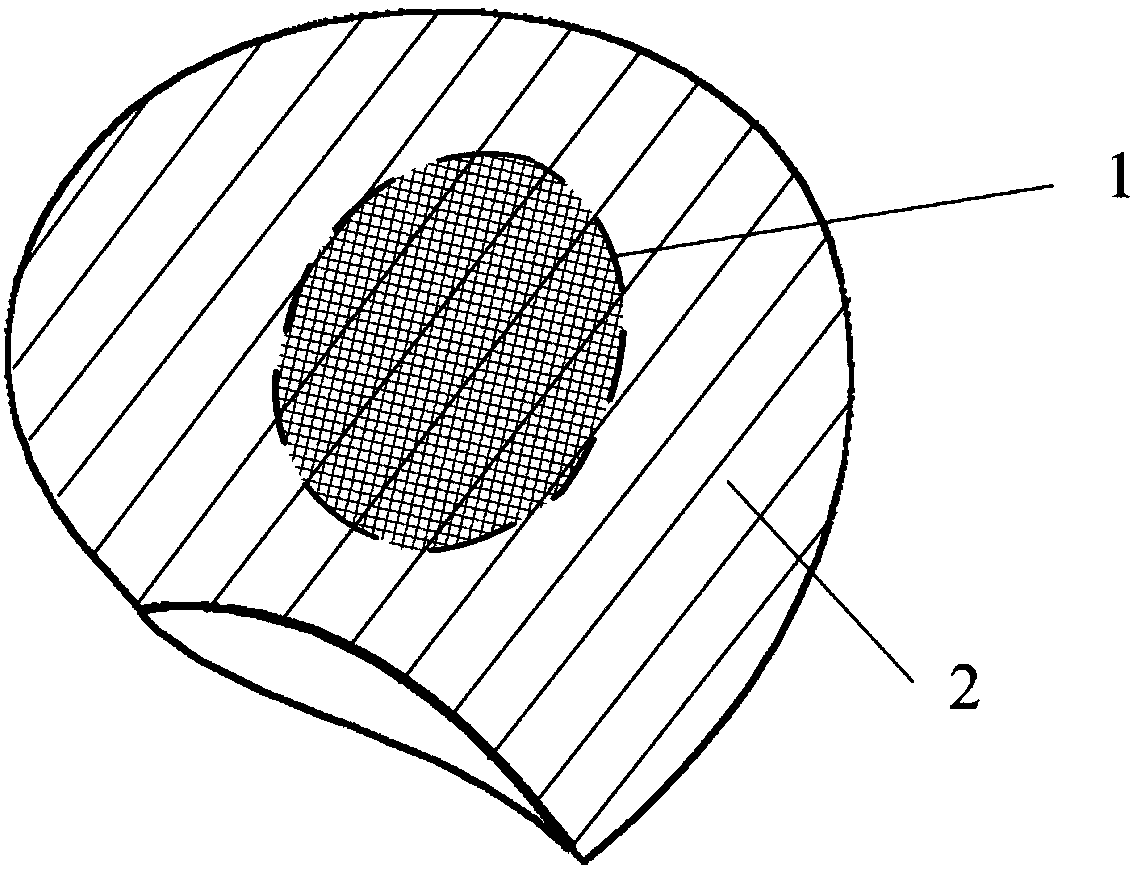

Propeller blade with piezoelectric damping function for ship and preparation method thereof

ActiveCN108466686AWith piezoelectric damping functionImprove structural mechanical propertiesRotary propellersDomestic articlesComposite propellerDamping function

The invention discloses a propeller blade with a piezoelectric damping function for a ship and a preparation method thereof. The propeller blade is prepared from, by mass, 80-120 parts of piezoelectric damping composite cores and 120-200 parts of fiber-reinforced thermoplastic composite prepreg coating layers; and the piezoelectric damping composite cores are prepared from, by mass, 5-8 parts of piezoelectric ceramic powder, 0.05-0.09 part of carbon nanotube and 100 parts of thermoplastic polymers which are heated, mixed, and then demoulded at the normal temperature. Through the co-curing forming process of the piezoelectric damping composite cores and the fiber-reinforced thermoplastic composite prepreg coating layers, the composite propeller has the piezoelectric damping function and excellent overall structure mechanical performance, the vibration-reducing and noise-reducing performance of the composite propeller can be remarkably improved, and the problem that due to the underwateradded mass inertia force effect, vibration noise of a stern flow field of an existing marine composite propeller is large can be effectively solved.

Owner:HARBIN INST OF TECH AT WEIHAI

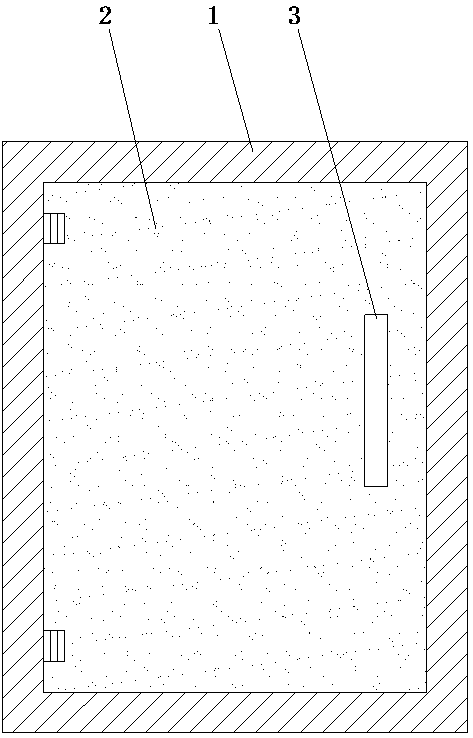

Remote transportation protection structure for electronic components

InactiveCN110745362AEasy to fixImprove protectionContainers preventing decayContainers to prevent mechanical damageArchitectural engineeringStructural engineering

The invention discloses a remote transportation protection structure for electronic components. The remote transportation protection structure comprises a housing, a side door, a handle, a side plate,a guide rod, a first spring, a connecting rod, a placing frame, a fixed pipe, an inner groove, a second spring, a placing plate, a fixed box, an exhaust pipe, a sponge block, a clamping plate, a filter screen, an activated carbon net, a fan, an air inlet pipe, a limiting frame, a third spring, a first sleeve, a buffer spring, a second sleeve, movable plates, a limiting groove and a movable block.The remote transportation protection structure is reasonable in structure, the two movable plates in the limiting frame are extruded, one ends of the movable plates are connected with the second sleeve in asleeving mode through the first sleeve, the buffer spring connected in the first sleeve and the second sleeve in a sleeving mode is compressed, the movable block in the limiting groove in the movable plates slides, the movable block compresses the third spring, then the two ends of the electronic components needing to be transported are fixed through the movable block and the third spring,thus the electronic components of different sizes are fixed conveniently, and protection in the transportation process of the electronic components is improved.

Owner:SUZHOU HAOYUN ELECTRONICS TECH CO LTD

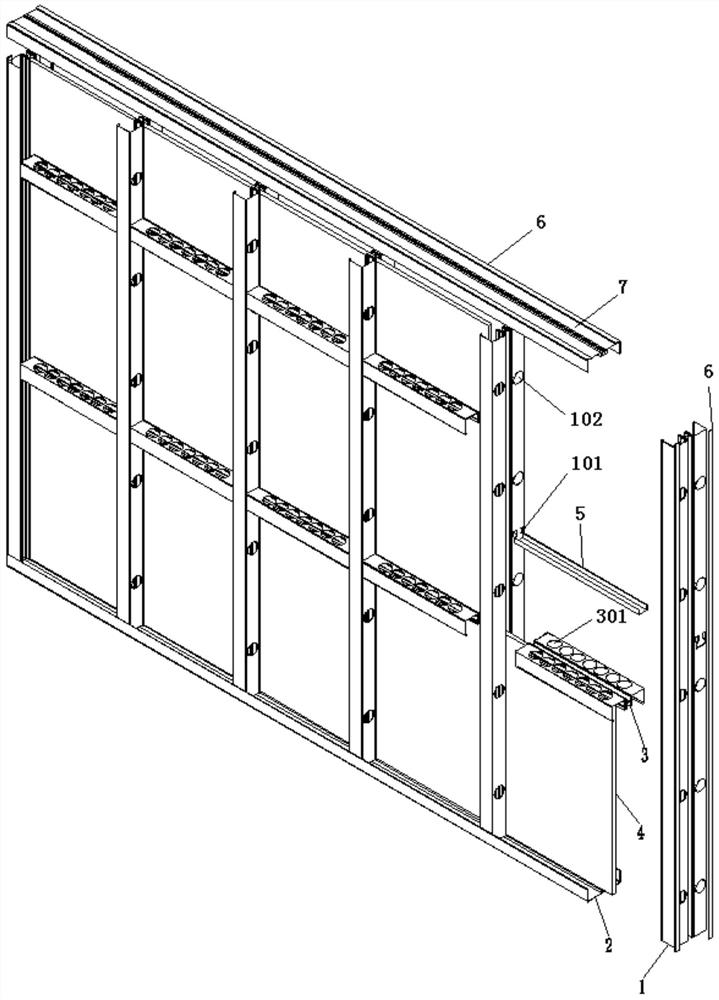

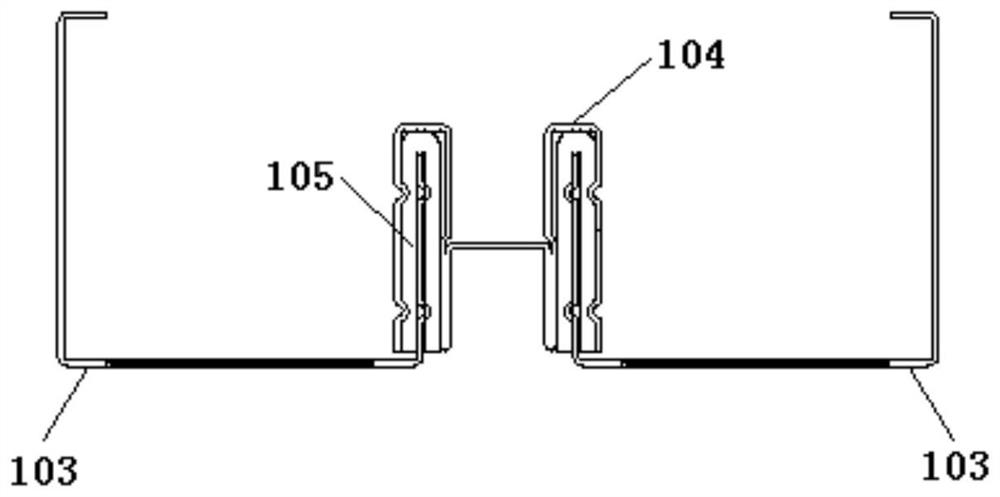

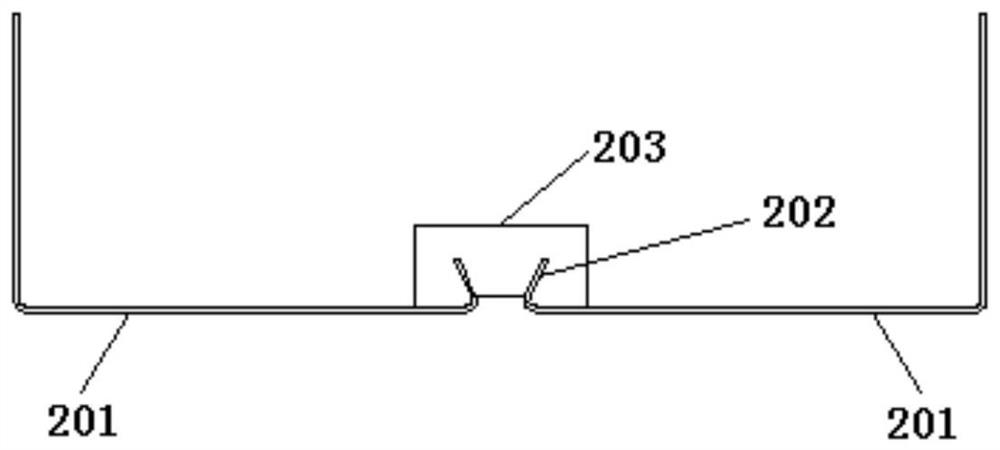

Fabricated bridge-cutoff keel double-cavity energy-saving wall

PendingCN113374122AImprove thermal insulationHeat insulation achievesWallsClimate change adaptationPhysicsHeat conservation

The invention discloses a fabricated bridge-cutoff bridge keel double-cavity energy-saving wall, and belongs to the technical field of fabricated buildings. The fabricated bridge-cutoff bridge keel double-cavity energy-saving wall comprises vertical keels, a lower transverse keel, an upper transverse keel and base plates, wherein the vertical keels are vertically installed between the lower transverse keel and the upper transverse keel to form a frame structure; a sound insulation board is arranged in the frame structure defined by the vertical keels, the lower transverse keel and the upper transverse keel; a flush joint keel and a reinforcing keel are further arranged between the vertical keels, and the two ends of the flush joint keel are fixedly connected with the two adjacent vertical keels correspondingly; the reinforcing keel is located in a cavity in the side, facing outwards, of the wall, and the base plates are fixed to the two faces of the frame structure composed of the vertical keels, the lower transverse keel and the upper transverse keel. Compared with the prior art, according to the technical scheme, a sound insulation board structure is arranged between the double-layer keels, the inner part of the wall is divided into a double-cavity structure, two cavities are connected into a whole through the transverse keels and the vertical keels, and the effects of sound insulation, vibration reduction, fire resistance, heat preservation, heat insulation and energy conservation are achieved through the independent structures.

Owner:贵州富乐森装配式建筑工业有限公司

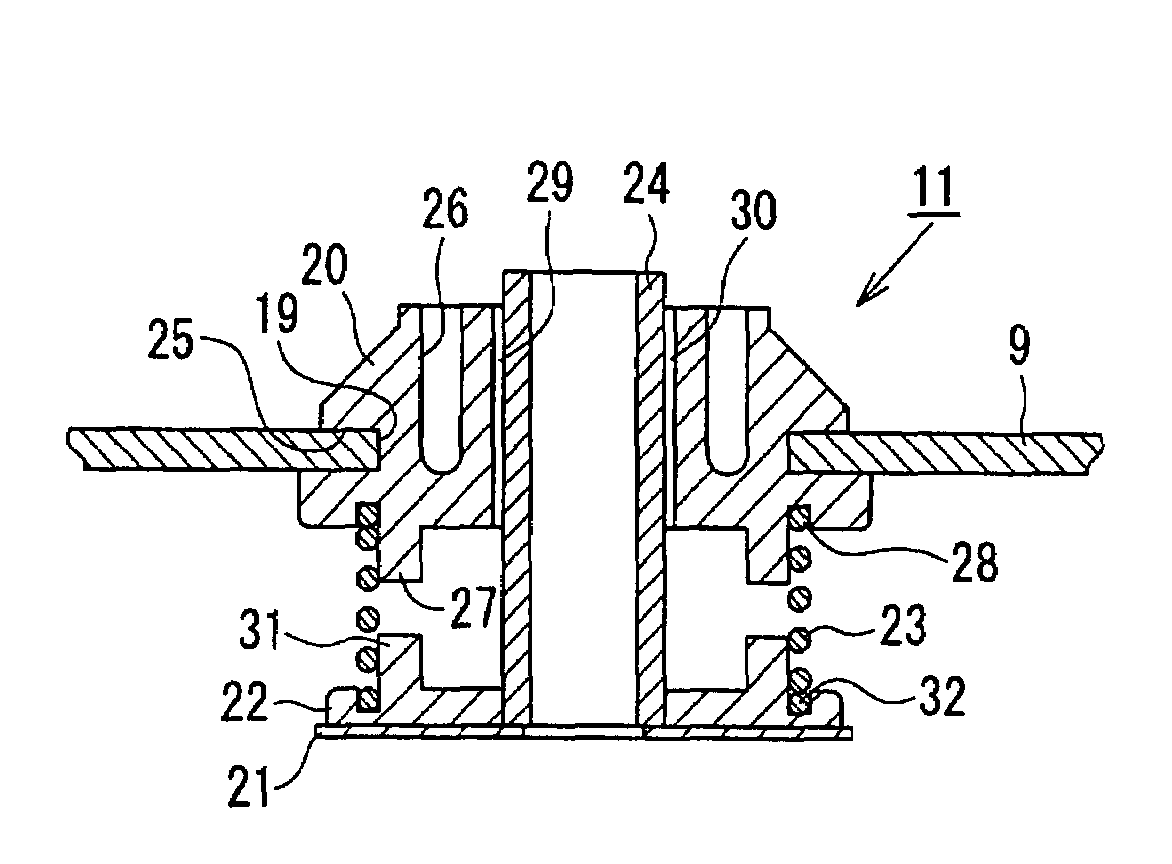

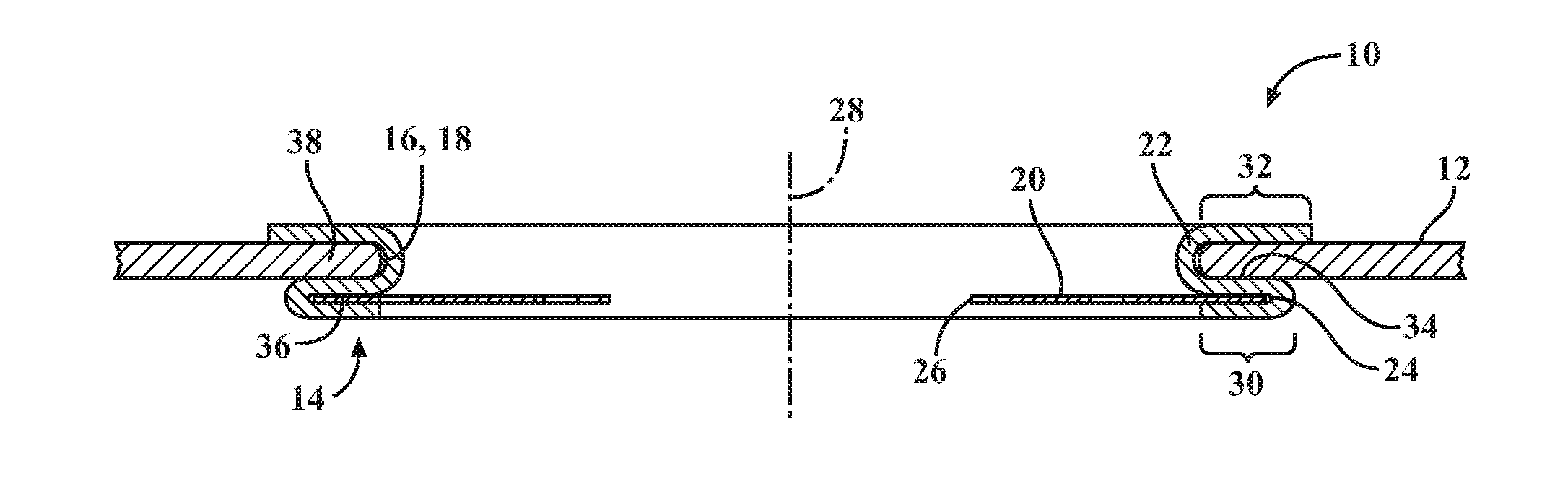

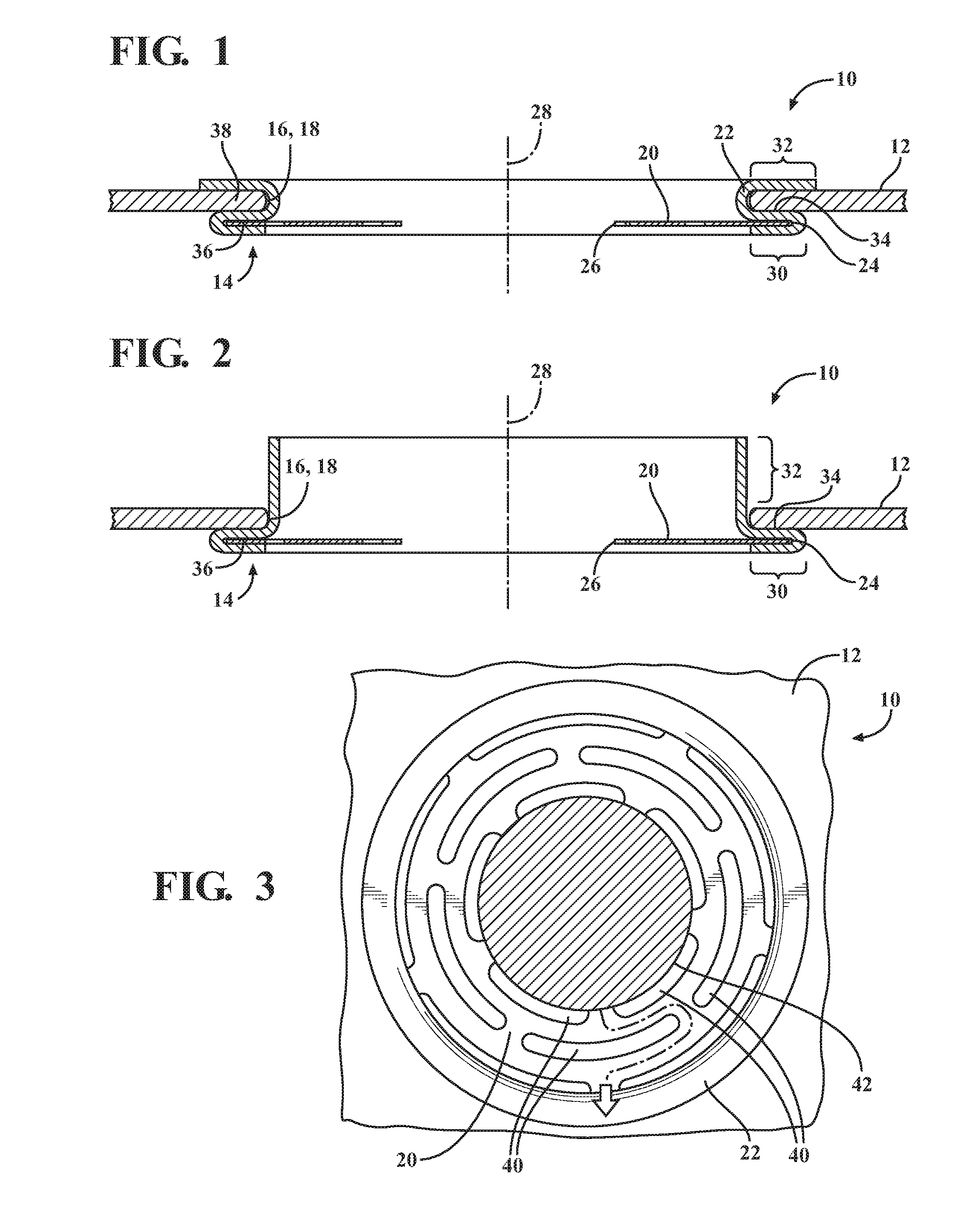

Heat and vibration mounting isolator for a heat shield, heat shield assembly and method of construction thereof

InactiveUS20160312852A1Adding significant volumeAdding costExhaust apparatusNon-rotating vibration suppressionEngineeringHeat shield

An isolator for damping heat and vibrations between a heat shield and heat source is provided. The isolator includes a housing and a washer. The housing surrounds a center opening and extends axially from a first end portion to a second end portion and includes an intermediate portion therebetween. The housing has a serpentine shape. The first end portion and the intermediate portion of the housing clamp a washer therebetween, and the second end portion and the intermediate portion of the housing clamp the heat shield therebetween. The washer includes a plurality of through openings between an outer periphery and the center opening for enhancing vibration dampening and minimizing heat transfer from the heat source to the heat shield. The isolator optionally includes a collar member disposed along the center opening of the washer to facilitate mounting of the isolator to the heat source.

Owner:FEDERAL MOGUL MOTORPARTS LLC

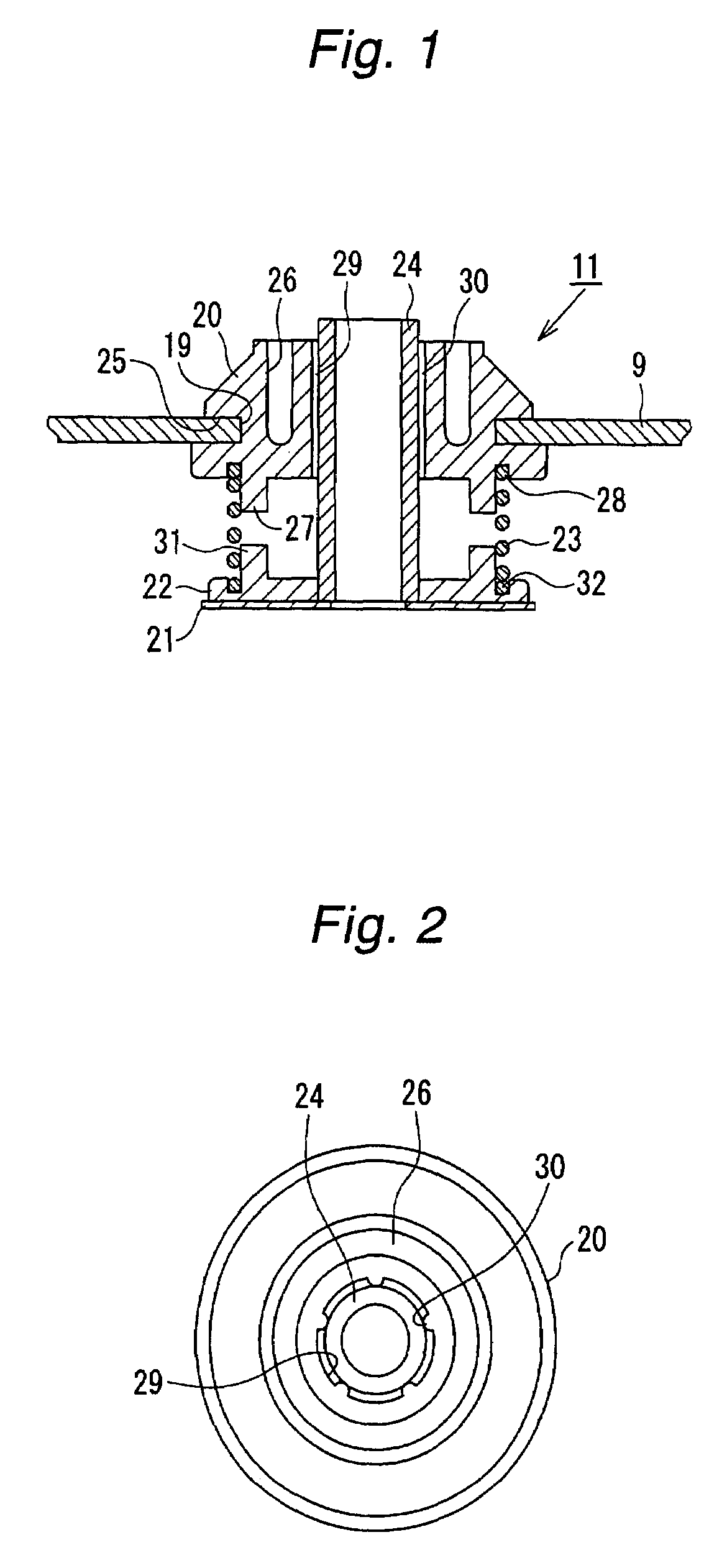

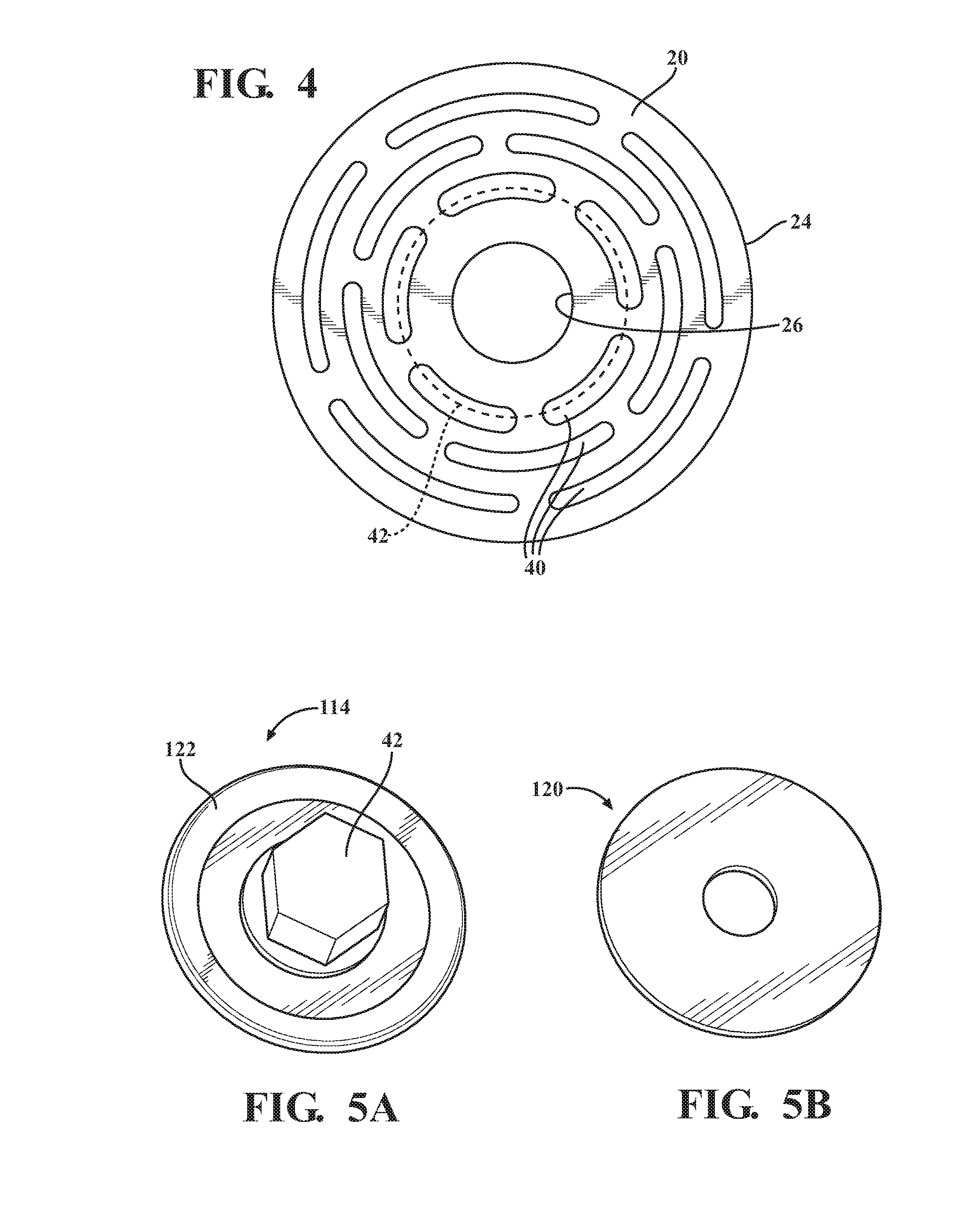

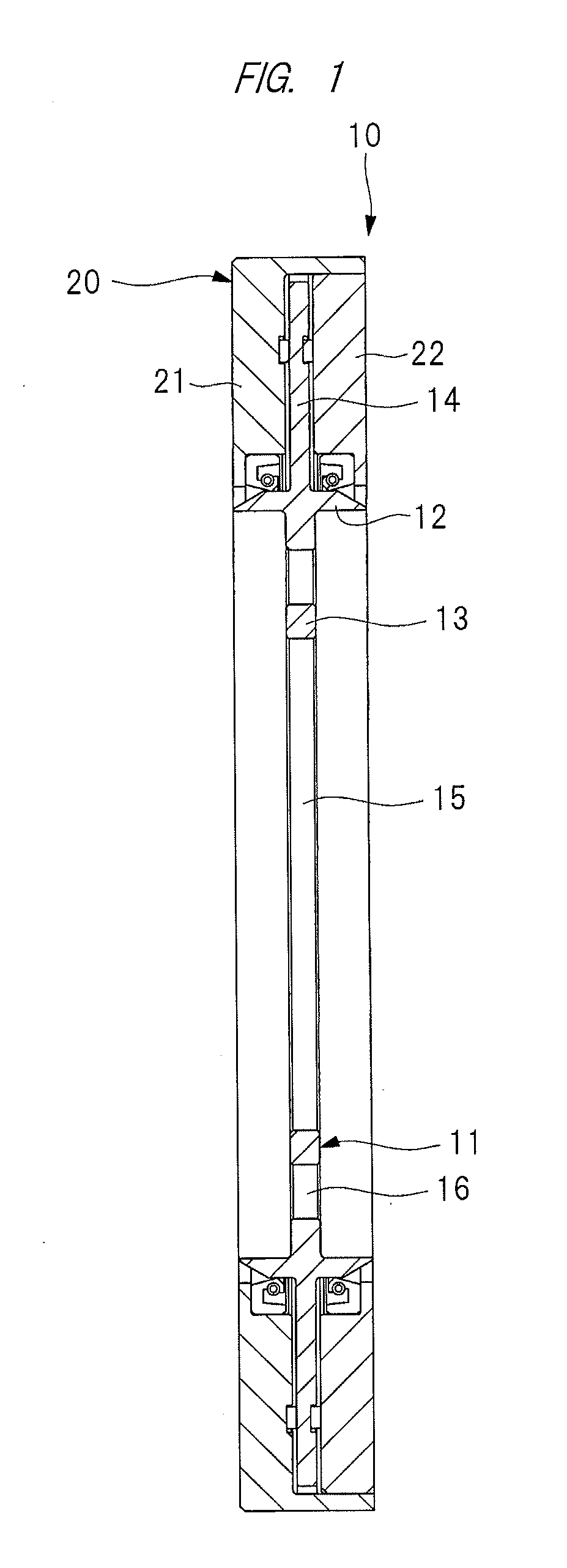

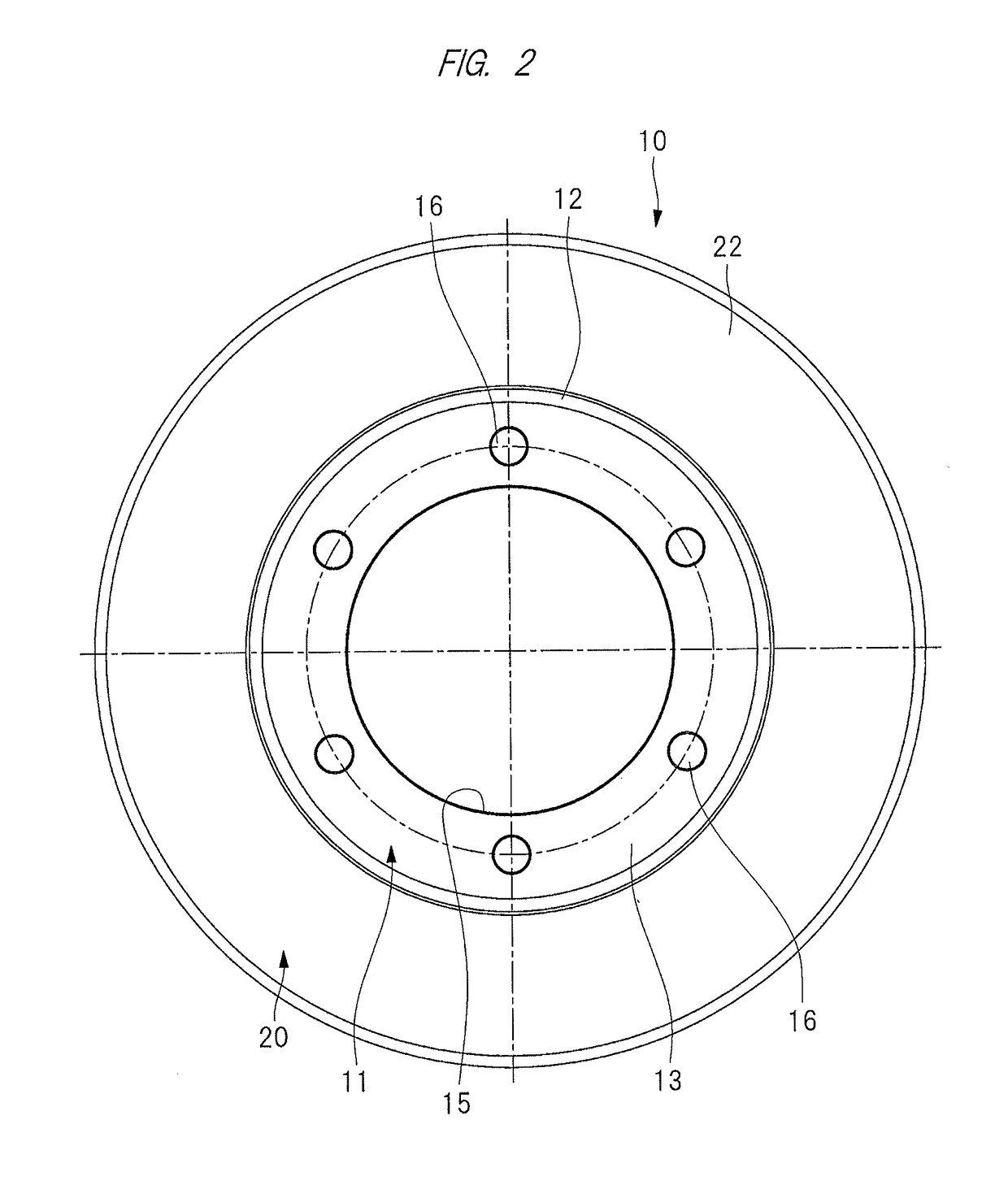

Viscous damper

InactiveUS20180231099A1Improve vibration reductionEasy to assembleRotating vibration suppressionSpringsMechanical engineeringViscous damper

A viscous damper 10 has a hub plate 11 mounted on a rotation axis, the hub plate 11 is provided with a cylinder portion 12 protruding axially, and the flange 14 protrudes radially outward from the cylinder portion. An inertia mass body 20 arranged outside the flange 14 includes a first annular inertia member 21 and a second annular inertia member 22, and a journal bearing 20 is arranged between the inertia mass body 20 and the flange 14. An inner periphery portion of the first annular inertia member 21 is provided with a first slid seal 41 for sealing damping liquid, and an inner periphery portion of the second annular inertia member 22 is provided with a second slid seal 42 for sealing the damping liquid L.

Owner:FUKOKU CO LTD

Damping device and air conditioner

InactiveCN109538672ANot easy to cause wear and tearChange natural frequencyLighting and heating apparatusNoise suppressionEngineeringPiping

The invention discloses a damping device and an air conditioner. The damping device comprises an elastic main body, wherein at least two pipeline slots which are formed in a spaced mode are formed inthe elastic main body; a connecting part is formed between adjacent two pipeline slots; and the elastic main body is provided with magnetism. According to the damping device disclosed by the invention, the pipeline slots are formed in the elastic main body, the pipeline slots are utilized for fixing piping of the air conditioner, and the elastic main body is relatively soft, so that pipeline abrasion is not easily caused; meanwhile, the elastic main body is provided with magnetism, so that the elastic main body has an obvious damping effect; and when inherent frequency and modal shape of the piping are changed by the elastic main body, vibration energy can be effectively converted into heat dissipation, so that damping and noise-reducing effect of the air conditioner is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

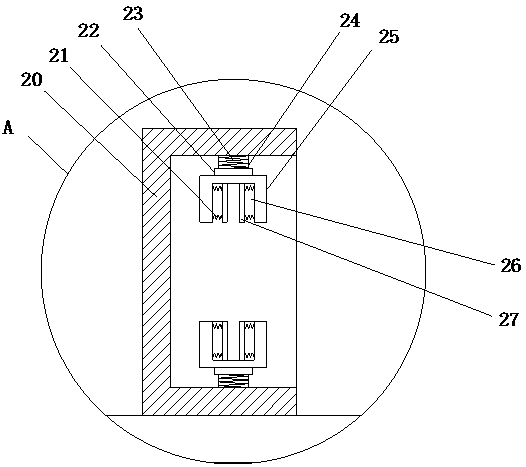

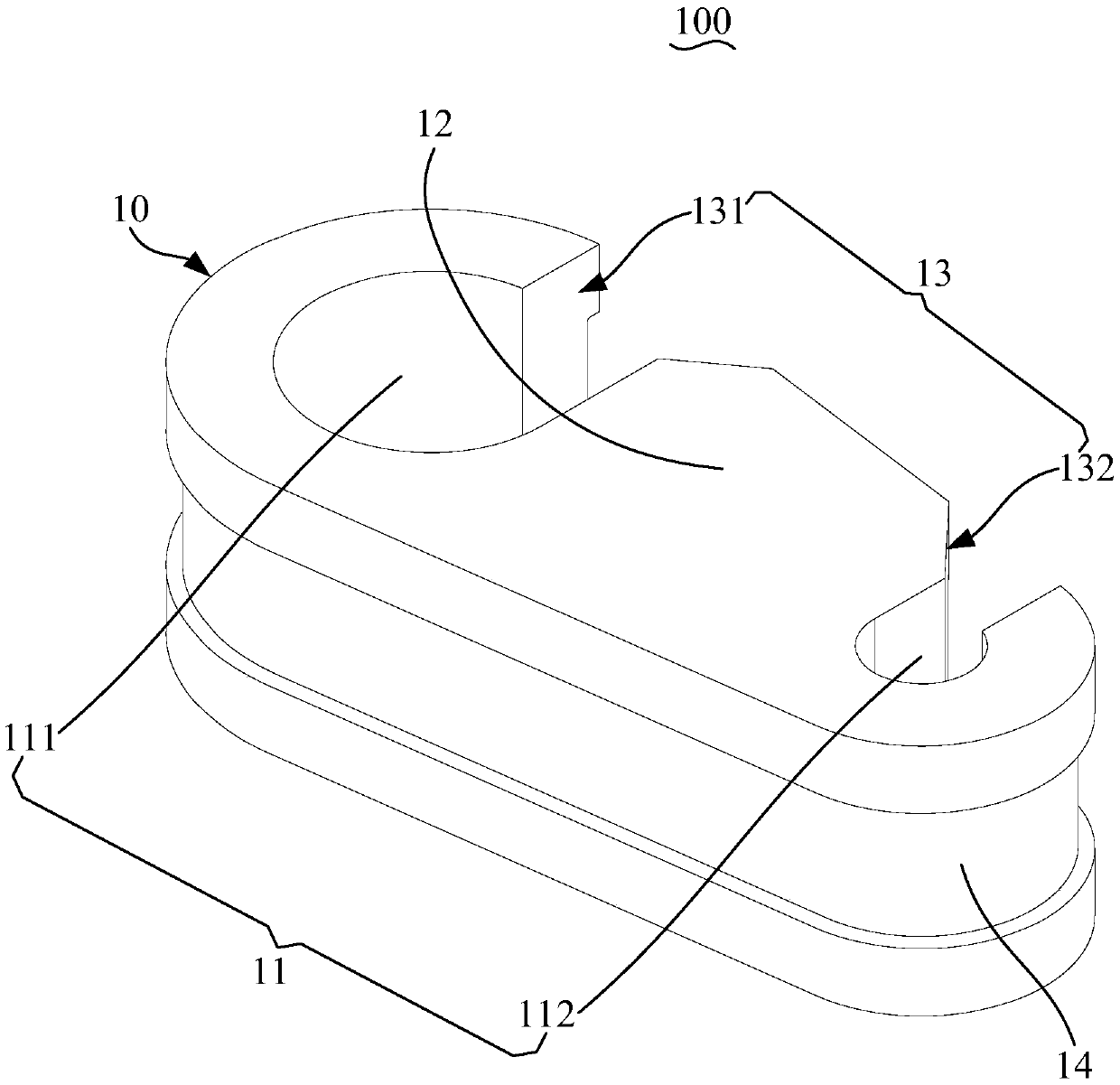

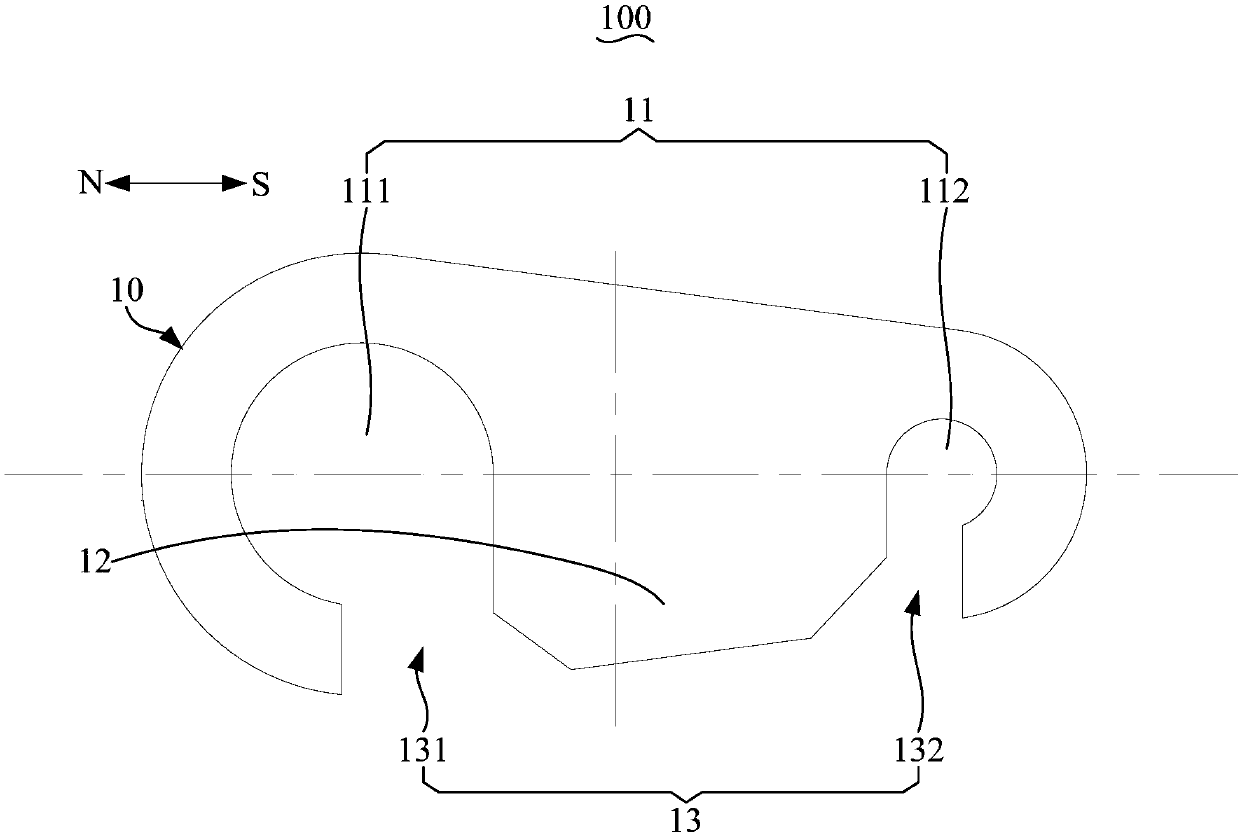

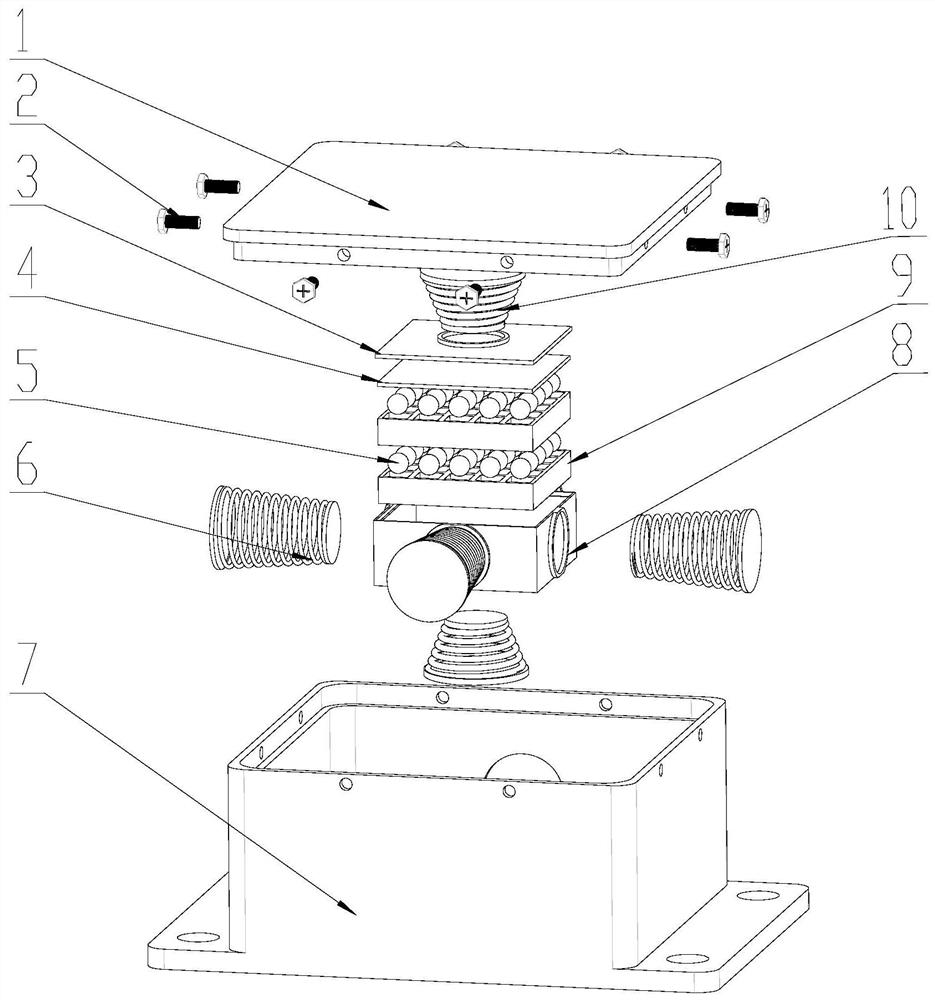

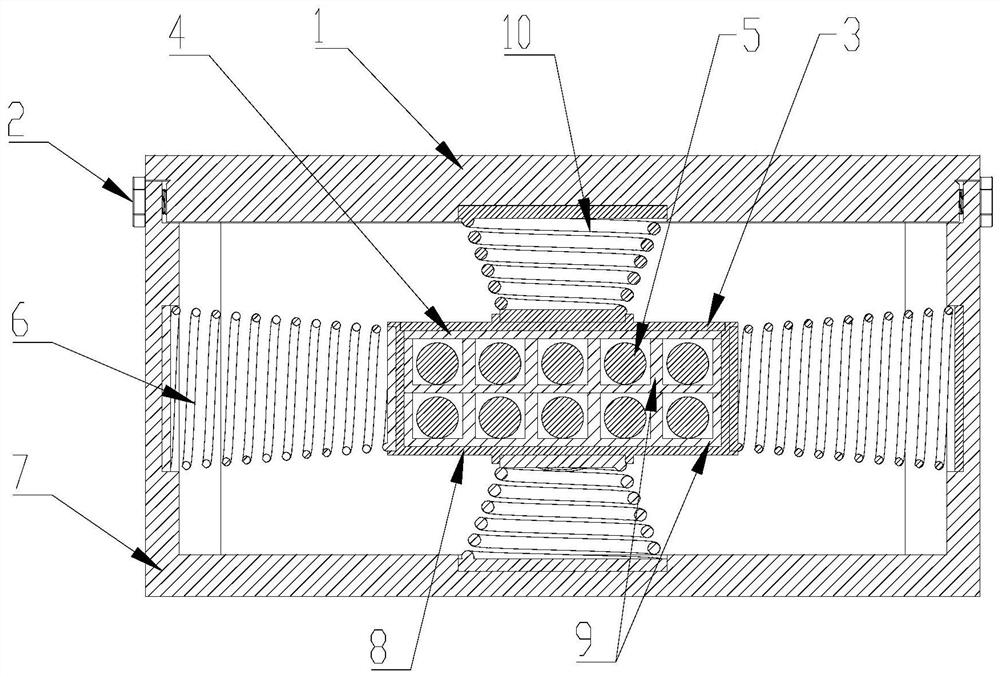

Damping structure, shock absorber and mechanical equipment provided with shock absorber

PendingCN113864386AImprove vibration reductionImprove vibration damping effectNon-rotating vibration suppressionSprings/dampers design characteristicsThermodynamicsEngineering

The invention provides a damping structure, a shock absorber and mechanical equipment provided with the shock absorber, relates to the technical field of shock absorbers, and solves the technical problem that the shock absorption effect of an existing shock absorption structure is not ideal. The damping structure comprises an elastic shock absorption module and a collision energy consumption module, the elastic shock absorption module is used for primary shock absorption, the collision energy consumption module is used for secondary shock absorption, and the collision energy consumption module is in transmission connection with the elastic shock absorption module. Compared with an existing structure purely adopting an elastic shock absorption structure, the collision energy consumption module can further dissipate energy obtained after primary shock absorption, and the shock absorption effect is greatly improved; after the damping structure is adopted in the shock absorber, the shock absorption performance is greatly improved, the damping structure is installed in a shell of the shock absorber, the shock absorber can be suitable for various mechanical devices, and the universality of the shock absorber is improved; and the shock absorber is arranged on the mechanical equipment, the shock absorption effect is good, and the reliability and safety of the mechanical equipment are improved.

Owner:GREE ELECTRIC APPLIANCES INC

A Vibration Isolation Device with Periodic Structure Based on Bandgap Filtering and Waveform Conversion

ActiveCN104595418BImprove the vibration isolation effectImprove vibration reductionSpringsVibration dampersBand-pass filterStructural engineering

The invention discloses a periodic-structure vibration isolation device which comprises two panels, multiple vertical rods and multiple oblique rods, wherein the two panels are arranged at intervals; one panel is connected with equipment which needs vibration isolation through a vibration isolator, and the other panel is connected with a mounting base by virtue of a vibration isolator; the multiple vertical rods are arranged in an array and are vertically arranged between the two panels so as to form multiple vibration isolation regions, reinforced rib plates are arranged at connection parts between all vertical rods in each vibration isolation region and the upper and lower panels; one oblique rod is arranged between every two reinforced rib plates which are arranged in opposite angles of each vibration isolation region, and the oblique rods in the two adjacent vibration isolation regions are arranged symmetrically relative to the common vertical rod, so that a vibration isolation structure with periodic arrangement is formed, the band notched characteristic of the periodic structure is formed and effective vibration isolation and noise reduction are realized. The device is capable of not only providing sufficient static rigidity and dynamic rigidity, but also effectively isolating low-frequency narrow-band line spectrums and wide-band vibration transfer which are generated by main and auxiliary mechanical devices and restraining noise radiation caused by vibration transfer.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

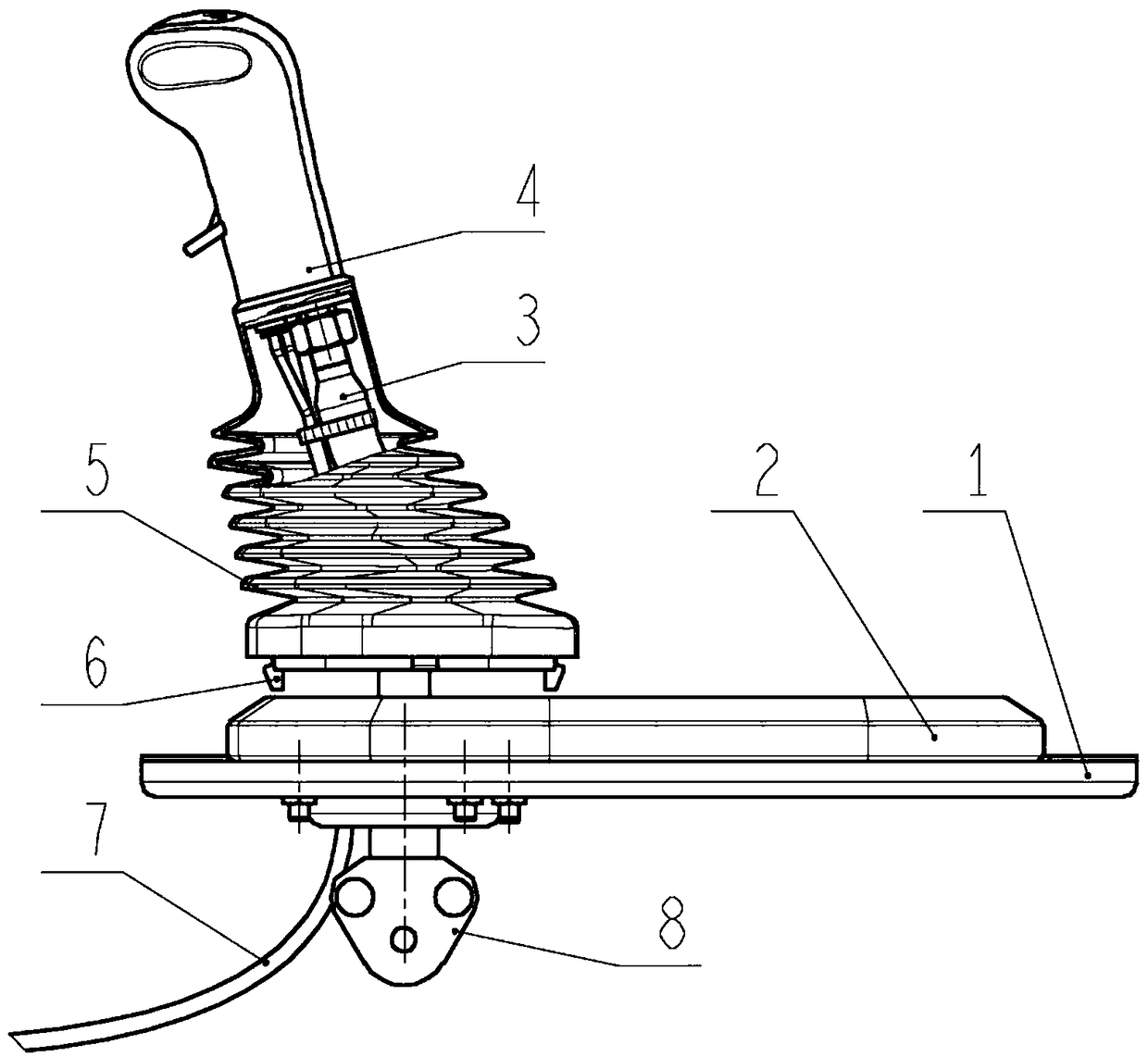

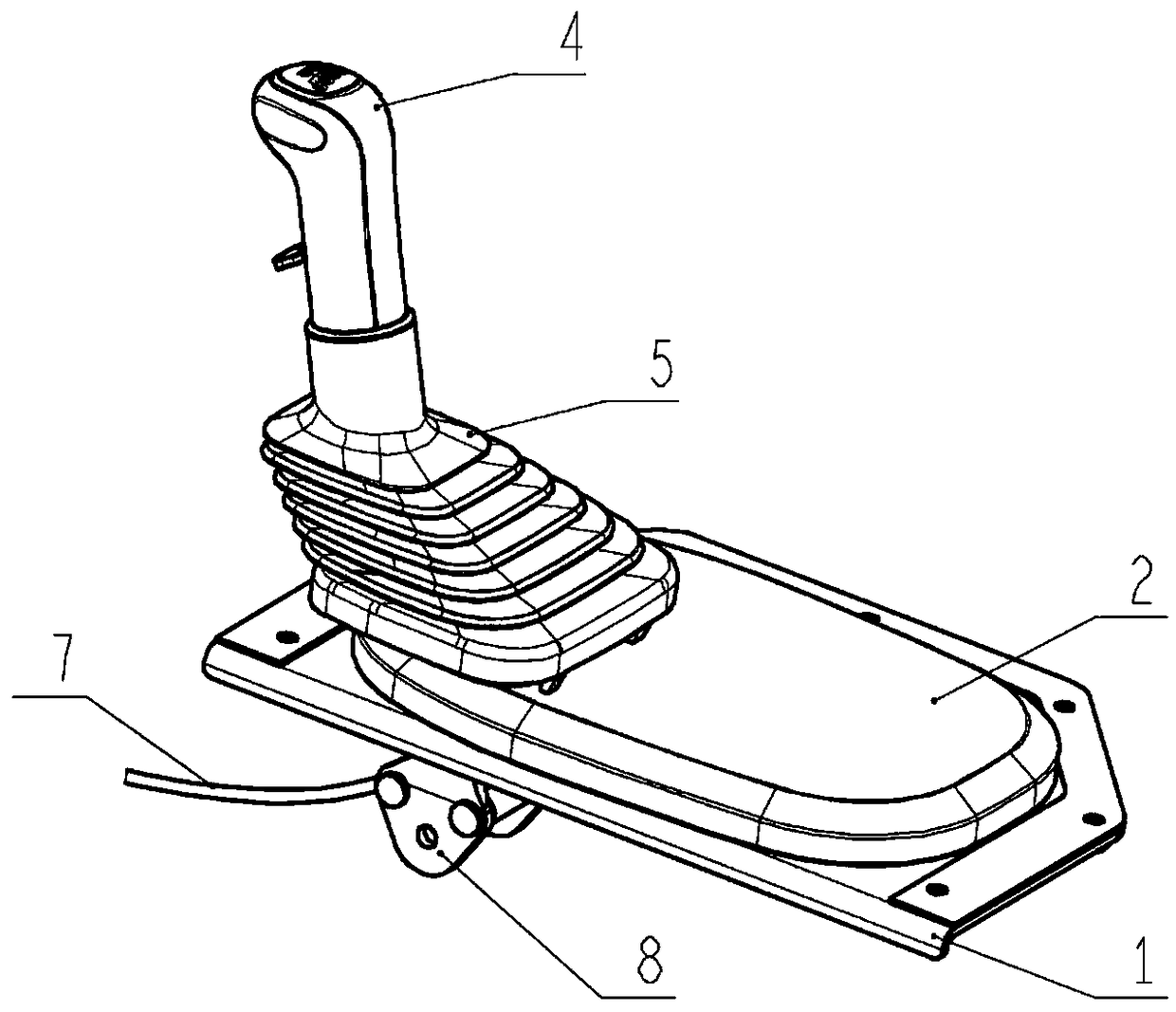

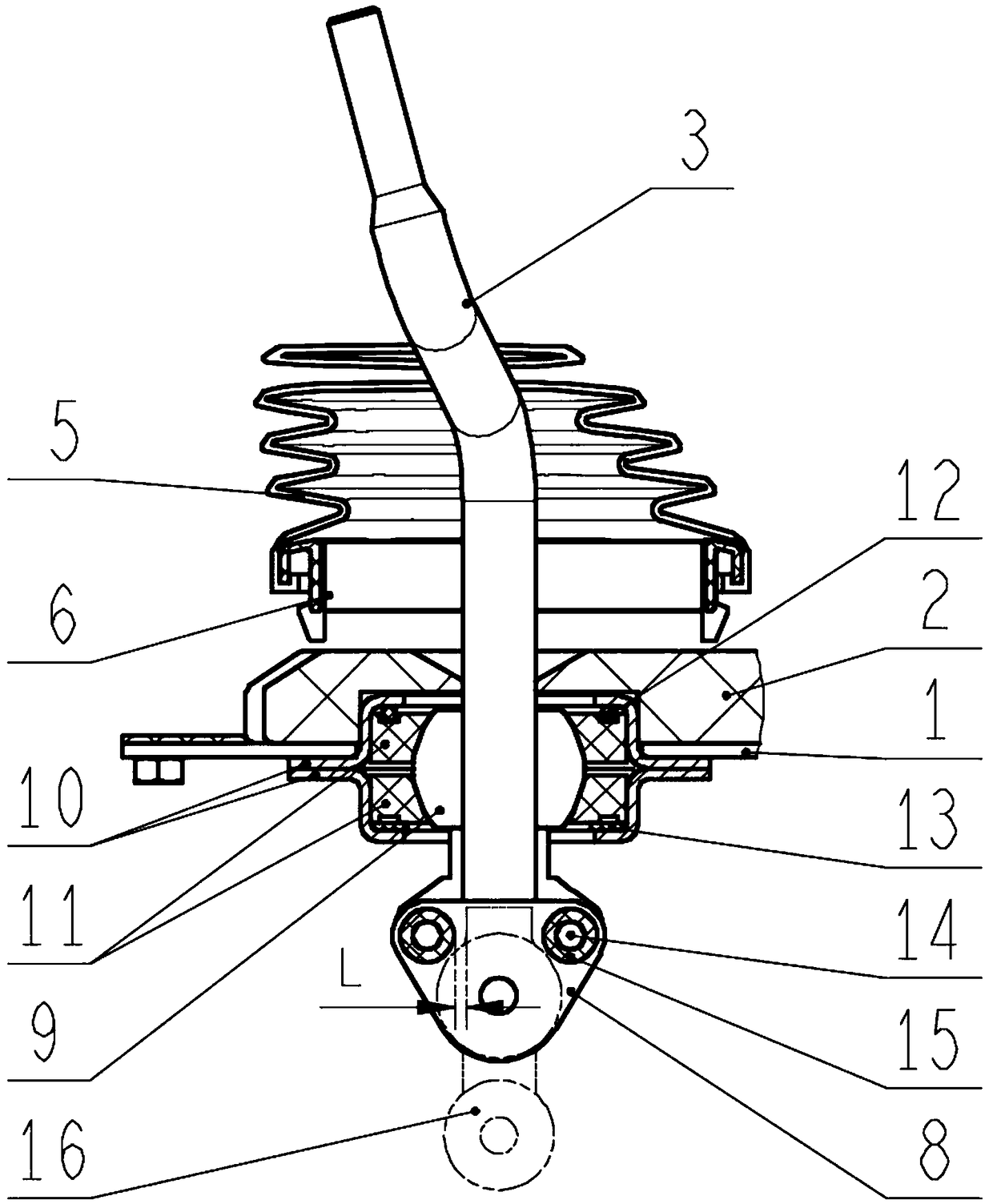

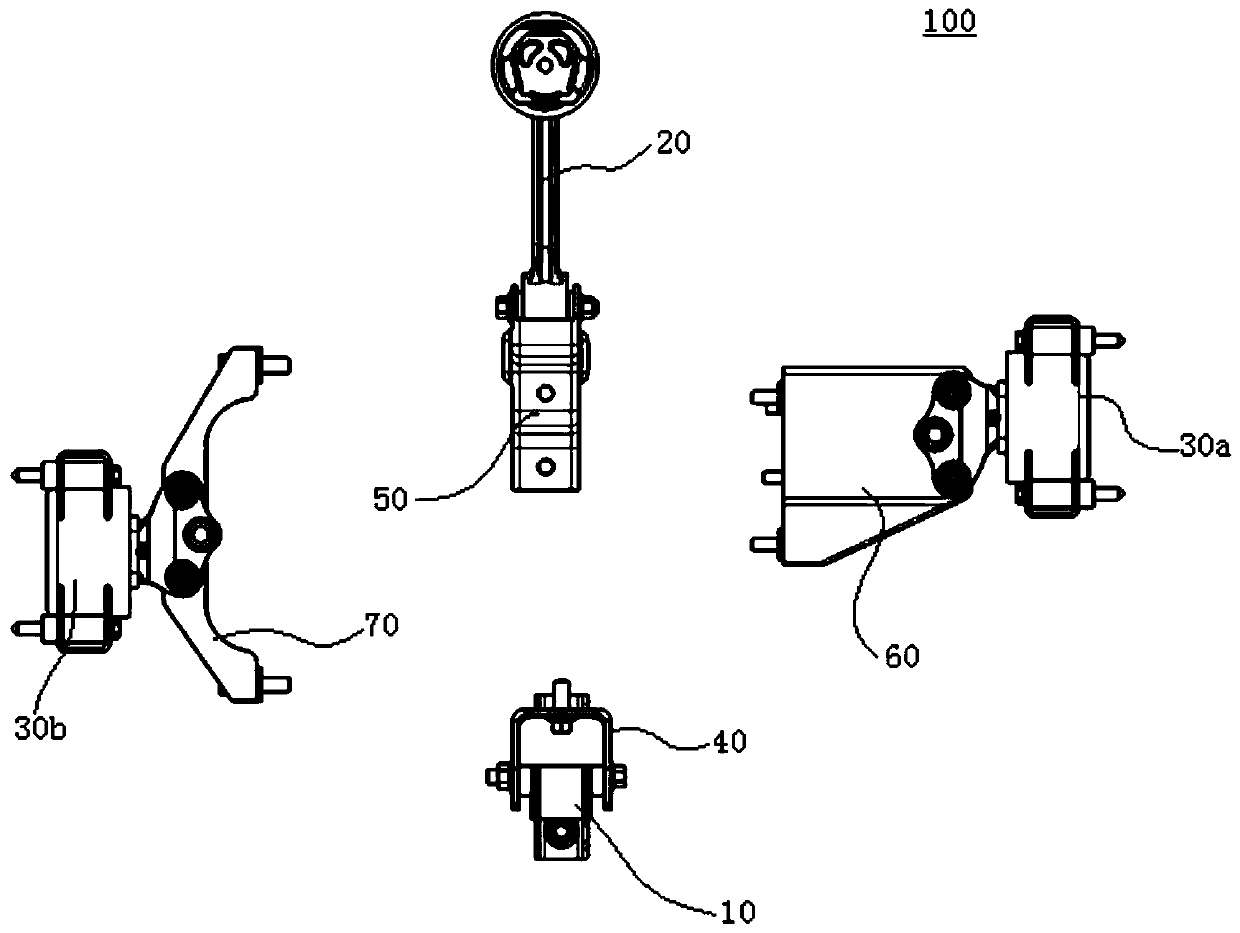

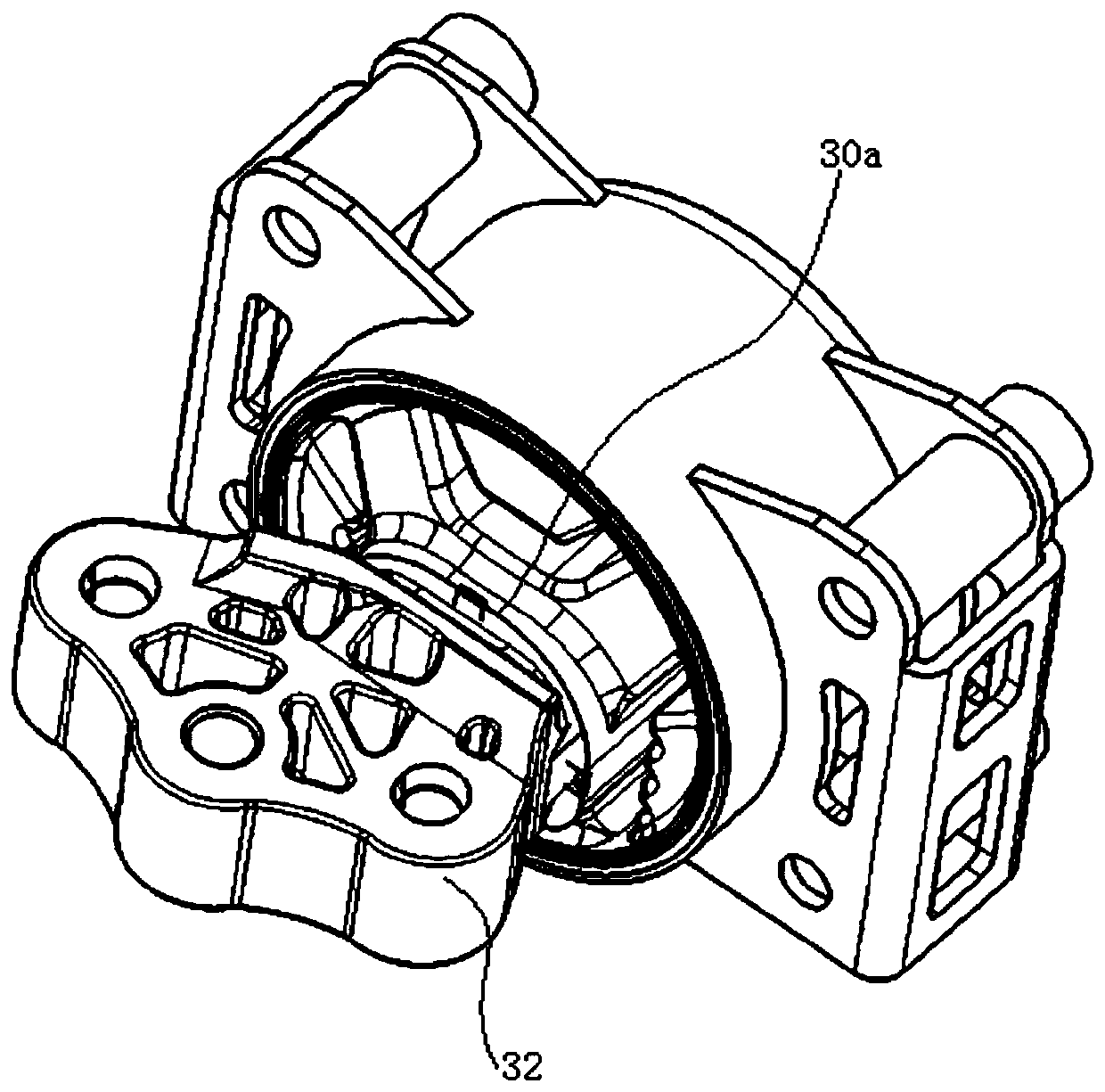

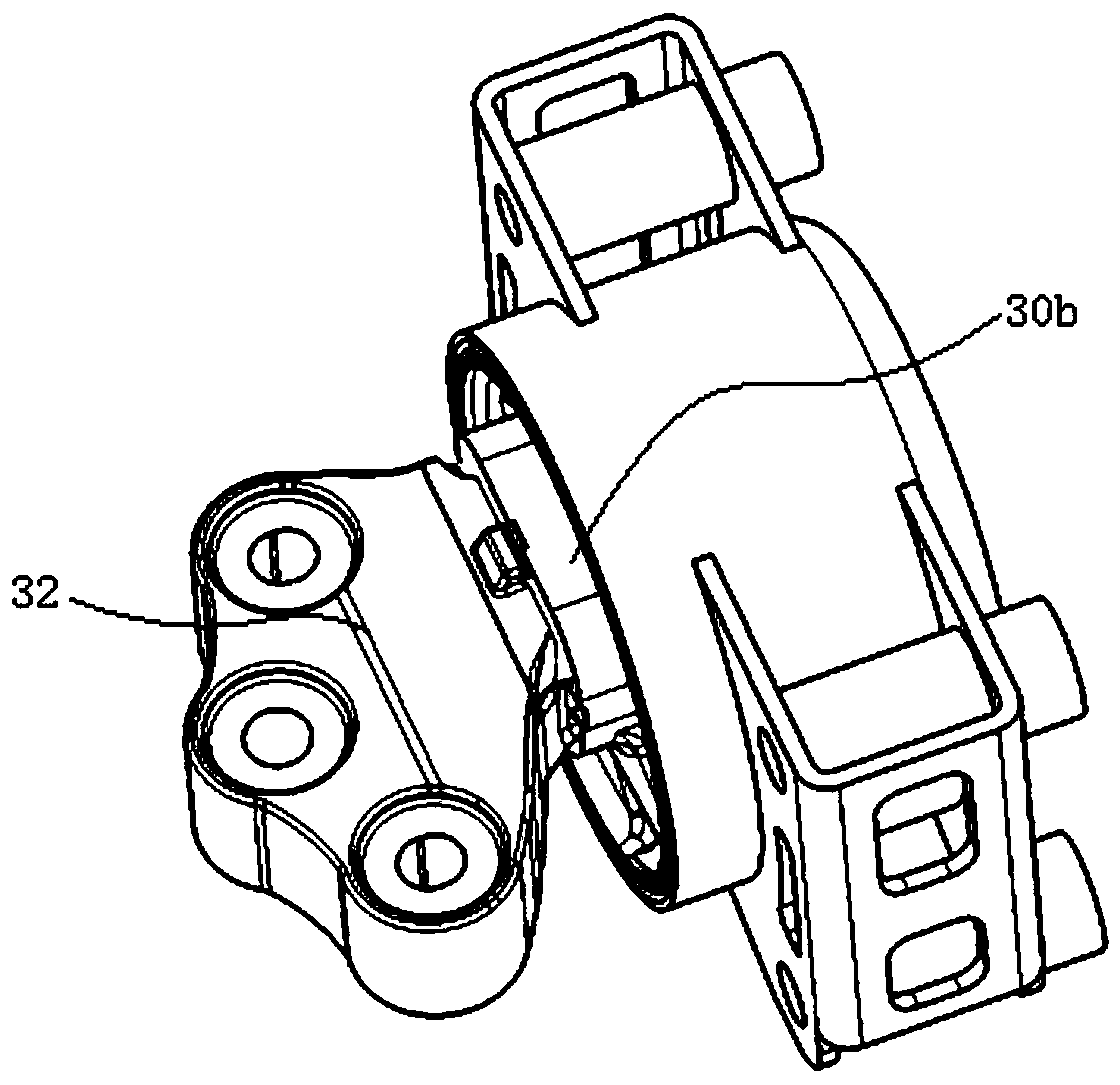

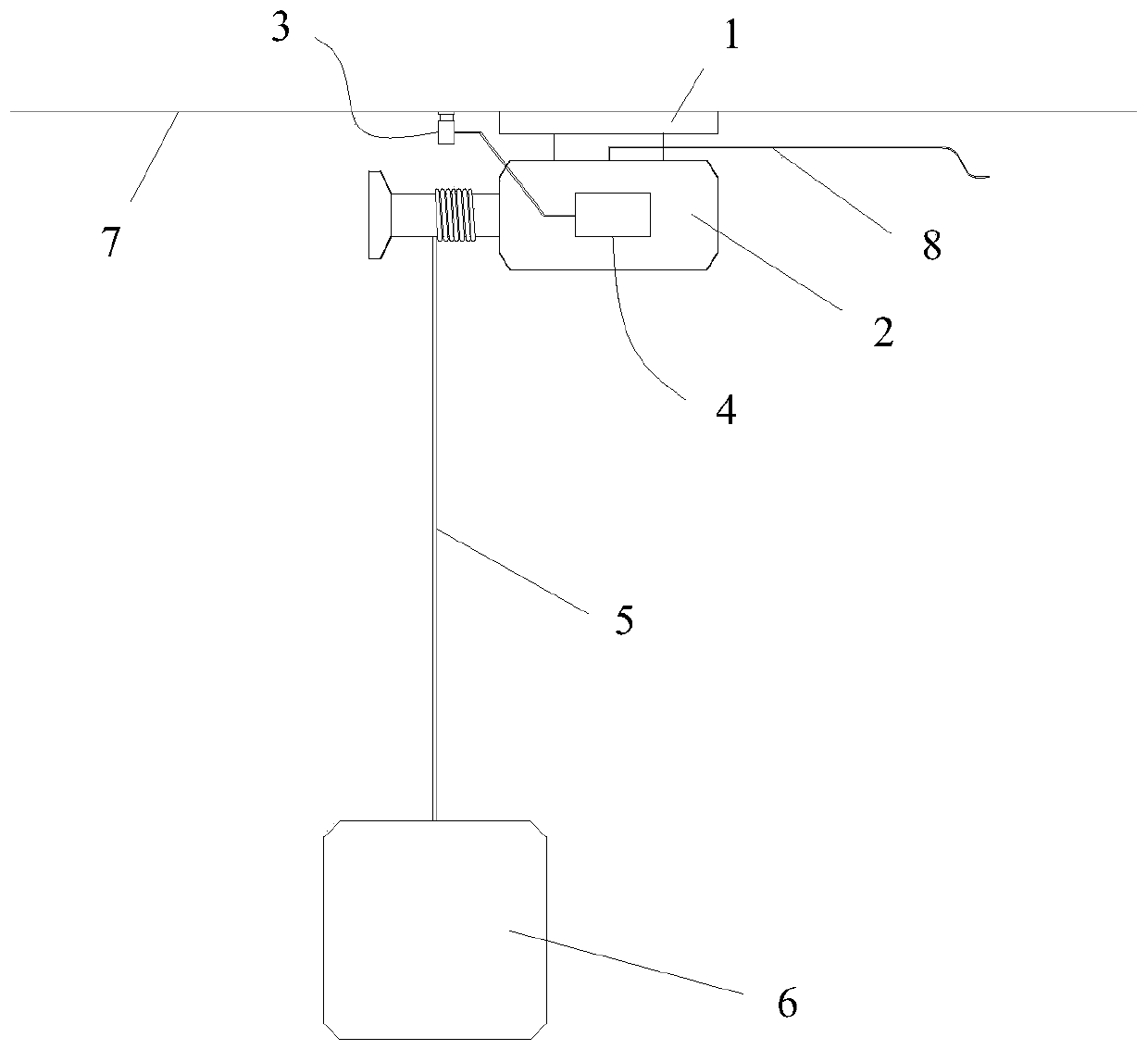

Variable-speed manipulator assembly

PendingCN108757915ASolve installation sealing problemsImprove driving experienceGearing controlEngineeringManipulator

The invention discloses a variable-speed manipulator assembly. The variable-speed manipulator assembly is formed by a mounting plate, a sealing ring, a manipulation lever, a handle, a sheath, a buckle, a connection arm assembly, a bulb and a bulb base assembly; the mounting plate is fixedly installed at the bottom of a cab floor; the sealing ring is arranged between the mounting plate and the cabfloor; the two ends of the sheath are connected between the handle and the buckle in a sleeved mode; the buckle is installed on the manipulation lever in a sleeving mode and buckled to the cab floor to achieve sealing; the bulb base assembly is installed on the mounting plate, and the bulb is fixed on the lower portion of the manipulation lever and installed in the bulb base assembly; and the connection arm assembly is fixed to the lower end of the manipulation lever. The variable-speed manipulator assembly effectively achieves the effects of sealing, vibration reduction, noise isolation and the like and is high in reliability and convenient to install.

Owner:FAW JIEFANG AUTOMOTIVE CO

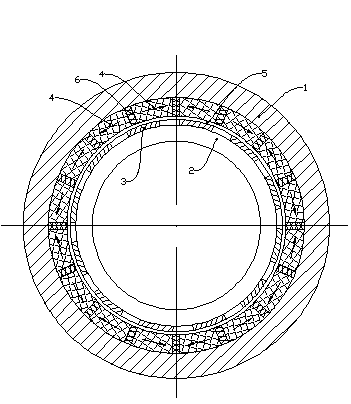

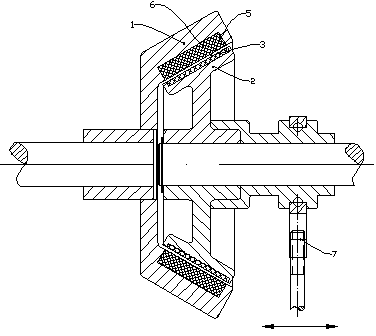

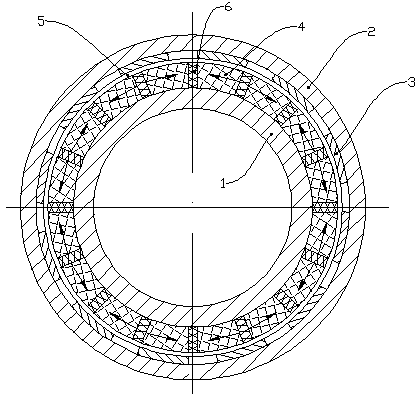

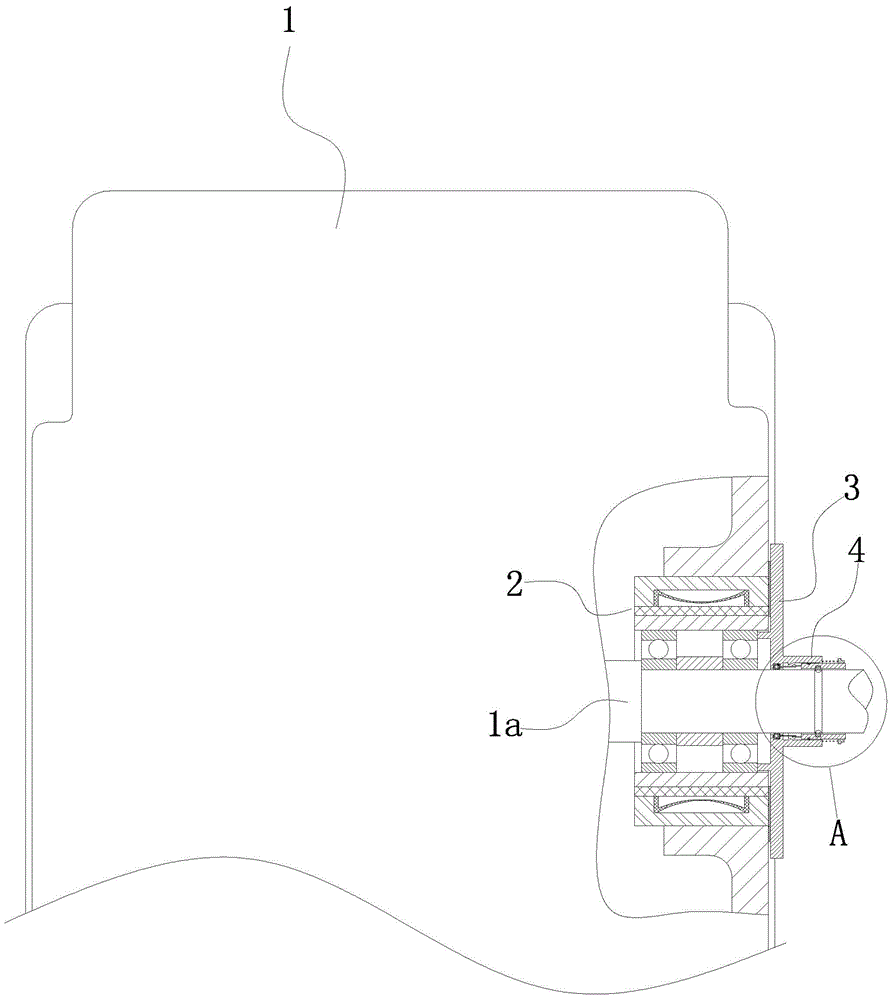

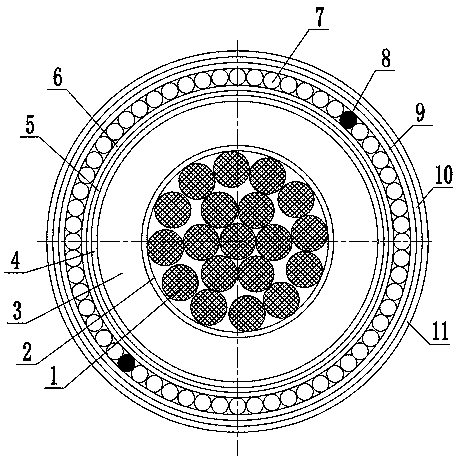

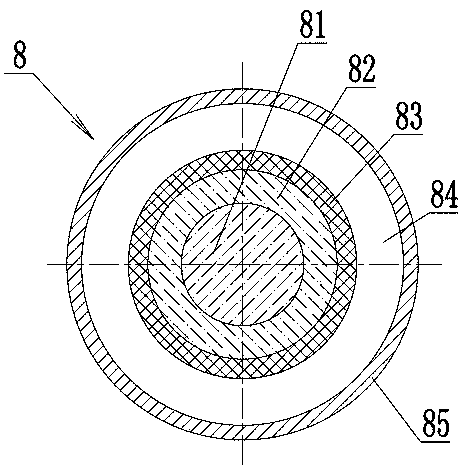

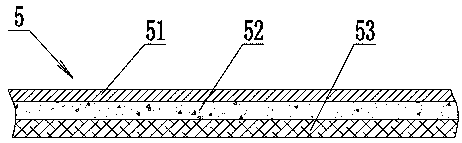

Vibration attenuation and vibration isolation type gearbox for input shaft and output shaft

The invention discloses a vibration attenuation and vibration isolation type gearbox for an input shaft and an output shaft capable of obtaining an effect of effectively reducing the noise of the gearbox. The gearbox comprises a gearbox shell, an input shaft hole, an input shaft, an input shaft seal end cover, an output shaft hole, an output shaft and an output shaft seal end cover, wherein the input shaft hole is formed in the gearbox shell, the input shaft seal end cover is arranged on the outer surface of the gearbox shell, the output shaft hole is arranged on the gearbox shell and the output shaft seal end cover is arranged on the outer surface of the gearbox shell; the input shaft hole and the output shaft hole are internally and respectively provided with a vibration attenuation sleeve body, the vibration attenuation sleeve body sequentially comprises a supporting inner vibration attenuation layer, a plastic vibration attenuation layer and an outer vibration attenuation layer from inside to outside, the supporting inner vibration attenuation layer and the outer vibration attenuation layer are respectively made from powder metallurgy materials, and the plastic vibration attenuation layer is made from expanded plastics.

Owner:YANCHENG INST OF TECH

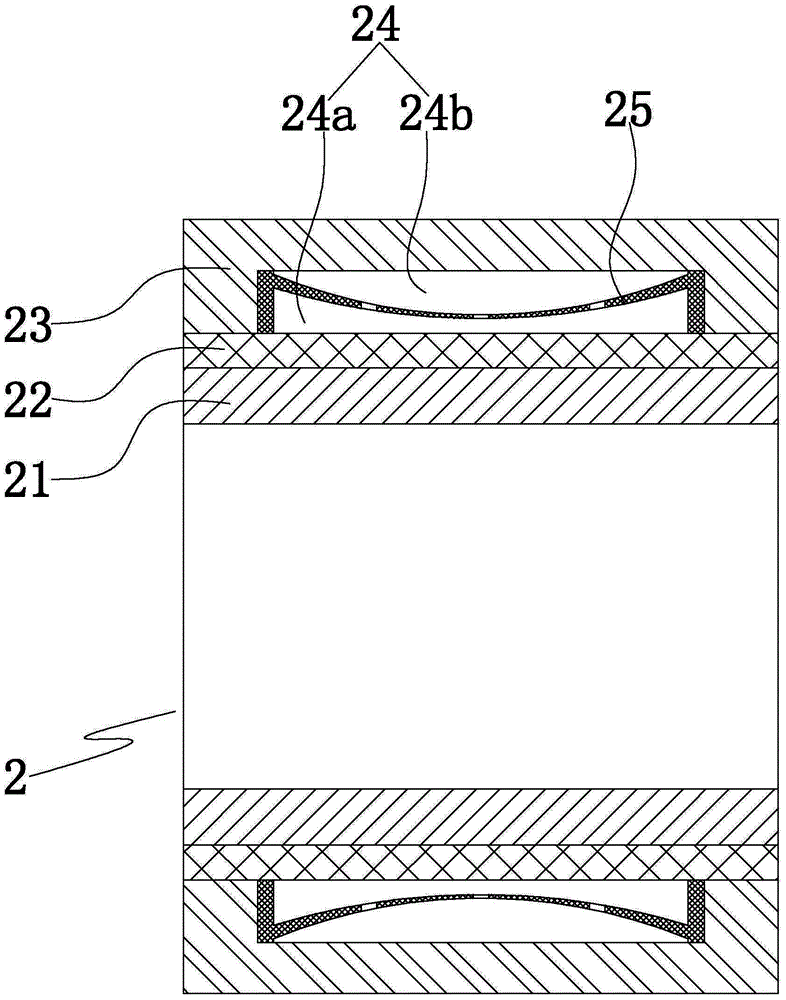

Vibration and noise reduction type gearbox based on porous materials

The invention discloses a vibration and noise reduction type gearbox based on porous materials and aims to effectively reduce vibration and noise of the gearbox. The vibration and noise reduction type gearbox comprises a gearbox shell, an input shaft hole and an output shaft hole, the input shaft hole and the output shaft hole are formed in the gearbox shell, and vibration reduction bushings are arranged in the input shaft hole and the output shaft hole respectively. Each vibration reduction bushing comprises a supportive inner vibration reduction layer, a plastic vibration reduction layer and an outer vibration reduction layer sequentially from inside to outside, wherein a closed annular cavity is formed between the plastic vibration reduction layer and the outer vibration reduction layer and filled with liquid, and a rubber spacer bush arranged in the annular cavity sleeves the plastic vibration reduction layer and partitions the annular cavity into an inner annular cavity and an outer annular cavity. The supportive inner vibration reduction layers and the outer vibration reduction layers are made of powder metallurgy materials, and the plastic vibration reduction layers are made of foamed plastics.

Owner:YANCHENG INST OF TECH

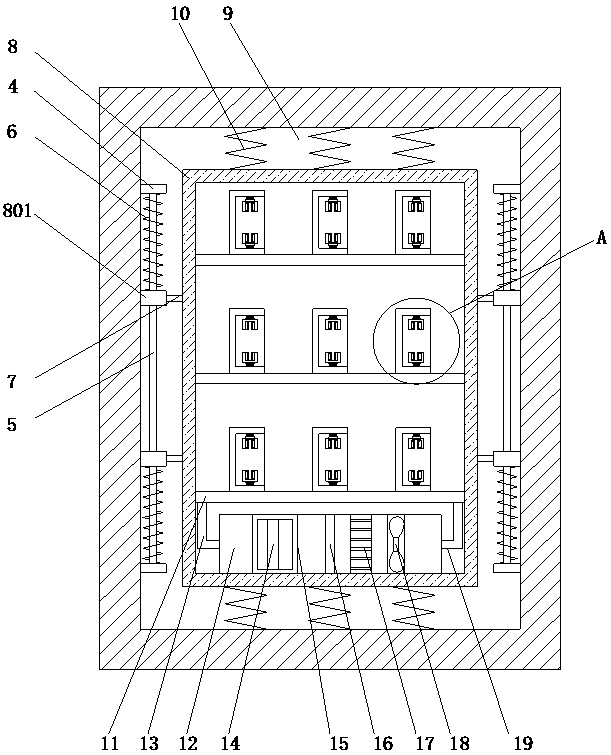

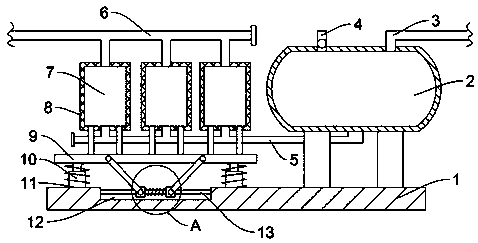

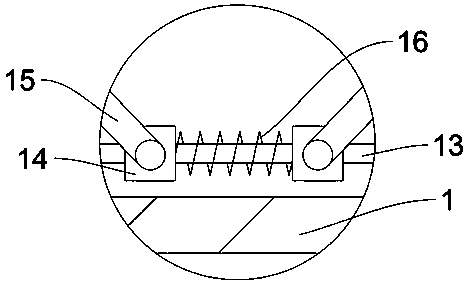

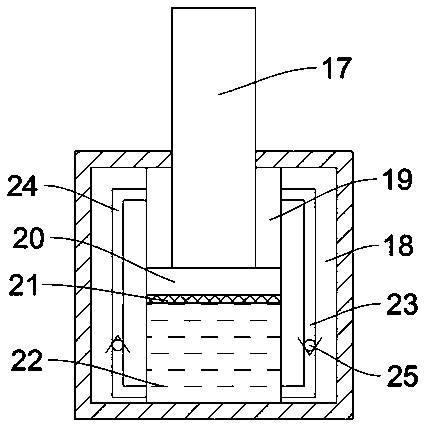

Silent non-negative pressure intelligent water supply device

InactiveCN109898602APlay the role of sound insulationImprove vibration reductionService pipe systemsWater mainsEngineeringNoise reduction

The invention discloses a silent non-negative pressure intelligent water supply device, and belongs to the field of water supply devices. The non-negative pressure intelligent water supply device comprises a flow stabilizing tank and a water pump unit, wherein the water pump unit is in communication with the flow stabilizing tank, the flow stabilizing tank is provided with a vacuum suppressor, andthe water pump unit is arranged on a mounting plate; the mounting plate is connected with a base through multiple sets of telescopic components; the mounting plate is rotatably connected with two sets of movable rods, and the two sets of the movable rods are further rotatably connected with two sets of sliding blocks correspondingly; and the two sets of the sliding blocks are connected through asecond spring. According to the silent non-negative pressure intelligent water supply device, the sound insulation effect can be achieved by arranging a soundproof cover outside the water pump unit, and by arranging the water pump unit on the mounting plate and arranging the telescopic components, a first spring, the sliding rods, the sliding blocks, the movable rods, and a second spring on the base, vibration reduction and noise reduction effects are achieved.

Owner:日照源立泵业有限公司

Screw machining process and device

PendingCN109604943AHigh dampingImprove vibration reductionSolid state diffusion coatingFurnace typesEngineeringHardness

The invention relates to the technical field of screw machining, in particular to a screw machining process and device. The screw produced through the machining process has high hardness, meanwhile, the damping performance of a workpiece is improved, and thus the application range of the workpiece is expanded. The screw machining process comprises the key points that S1, material selection is conducted; S2, forging is conducted to obtain round-bar-shaped steel; S3, heat treatment is conduced, and the specific process sequentially comprises annealing, normalizing, first quenching, high-temperature tempering, carburizing, second quenching and low-temperature tempering; S4, the end face is milled; S5, a central hole is drilled; S6, a spiral groove is milled, and the steel treated through thestep S5 is placed in a thread rolling die, positioned through a positioning tool and subjected to thread rolling operation; and S7, chamfers at the ends are milled, and thus a finished product is obtained.

Owner:XIANGYANG FURUITE MACHINERY MFG CO LTD

Distributed optical fiber temperature measurement power cable

InactiveCN111477400AEnhanced tensile and compressive strengthImprove heat sensitivityThermometer detailsPower cables with screens/conductive layersFiberPower cable

Owner:JIANGSU DONGQIANG

Suspension system used for electric vehicle, and electric vehicle comprising suspension system

InactiveCN110667361AImprove vibration reductionImprove anti-twist effectElectric propulsion mountingVehicle frameElectric cars

The invention discloses a suspension system used for an electric vehicle, and an electric vehicle comprising the suspension system. The suspension system comprises a power assembly and a suspension element, wherein the suspension element is provided with an auxiliary frame connecting bushing; the auxiliary frame connecting bushing comprises an upper bushing and a lower bushing; the upper bushing and the lower bushing are separably laminated and are both arranged in the suspension installation hole of the auxiliary frame; and the suspension installation hole is arranged in the body of the auxiliary frame. Therefore, by use of the above suspension element, on one hand, the auxiliary frame connecting bushing which is constructed into the split structure enables the suspension element to be simple and convenient in installation on the auxiliary frame, and therefore, the auxiliary frame and the power assembly can be simply and conveniently connected; and on the other hand, the auxiliary frame connecting bushing has a better damping and energy dissipation effect, the damping and torsion elimination effect of the suspension system can be improved, and therefore, the suspension system canmeet the use requirements of the electric vehicle.

Owner:BEIJING ELECTRIC VEHICLE

Preparation process for rubber cushion block of numerical control milling machine

InactiveCN104877207AIncrease elasticityImprove toughnessPlastic recyclingVibration attenuationNumerical control

The invention discloses a preparation process for a rubber cushion block of a numerical control milling machine. The preparation process comprises the following steps: 1) preparing reclaimed rubber; 2) adding natural rubber, a softener, an activator and auxiliaries into the reclaimed rubber to mix and stir; 3) carrying out fusion refining on the stirred mixture for 1-2 hours; 4) desulfurizing the refined rubber at high temperatures and high pressures; and 5) shearing the synthesized rubber into the rubber cushion blocks of the numerical control milling machine for vibration attenuation of an automotive numerical control milling machine. According to the preparation method for the rubber cushion block of the numerical control milling machine, the rubber cushion block for the numerical control milling machine can be re-manufactured to be recycled by virtue of the reclaimed rubber which is recycled, so that the production cost is lowered; moreover, the manufactured rubber cushion block of the numerical control milling machine is relatively good in elasticity and toughness and can be used for enhancing the vibration attenuation and noise reduction effect, so that the service life of the rubber cushion block of the numerical control milling machine is prolonged.

Owner:吴芳吉

Servo type vertical shock absorber and application structure and shock absorption method of servo type vertical shock absorber

PendingCN111561534ADissipation controllableTo achieve the effect of dampingSpringsSprings/dampers design characteristicsVertical vibrationVibration acceleration

The invention discloses a servo type vertical shock absorber and an application structure and a shock absorption method of the servo type vertical shock absorber. The shock absorber comprises a motorbase plate, a servo motor, an acceleration sensor, a servo system, a traction mechanism and a mass block. In the application structure, at least one servo type vertical shock absorber is installed inside or outside a box type bridge; when the vibration surface vibrates in the vertical direction, the acceleration sensor collects the vertical vibration acceleration value of the vibration surface andtransmits the vertical vibration acceleration value to the servo system, and the servo system drives the servo motor to rotate according to the collected information so as to control the mass block to move up and down relative to the vibration surface; when the vibration surface accelerates upwards, the mass block moves downwards; and when the vibration surface accelerates downwards, the mass block moves upwards. According to the shock absorber, different capacity dissipation in one vibration period is achieved through the up-and-down motion amplitude of the mass block, vibration can be rapidly reduced, and the controllability of energy dissipation in each vibration period is high.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Pipeline support with built-in comb-shaped anti-vibration pad

The invention discloses a pipeline support with a built-in comb-shaped anti-vibration pad. The pipeline support comprises bolts, a pipe clamp, the anti-vibration pad and a support base. The upper portion of the support base is a semi-circular ring, and extending-out lugs at the two ends of the semi-circular ring are provided with through holes. The pipe clamp is also a semi-circular ring, the pipe clamp is matched with the support base to form a circular clamp which is connected by the bolts, and an annular boss is arranged on the inner wall of the circular clamp. The anti-vibration pad is arranged in the circular clamp which is formed by the pipe clamp and the support base in a matched manner, equilong radial opening grooves are evenly distributed in the bent inner hole wall of the anti-vibration pad to form comb teeth, and a groove formed in the outer wall and the annular boss which is on the inner wall of the pipe clamp and the inner wall of the support base are matched to from an axial positioning structure. According to the pipeline support with the built-in comb-shaped anti-vibration pad, the anti-vibration pad is additionally provided with the comb teeth, although the structure is very simple, the bending performance of the anti-vibration pad is effectively improved, and the vibration attenuating effect, the heat isolation effect and the sound absorbing effect of the whole support are remarkably improved. Therefore, the pipeline support with the built-in comb-shaped anti-vibration pad is especially suitable for being matched with ships and warships.

Owner:江苏振华海科装备科技股份有限公司

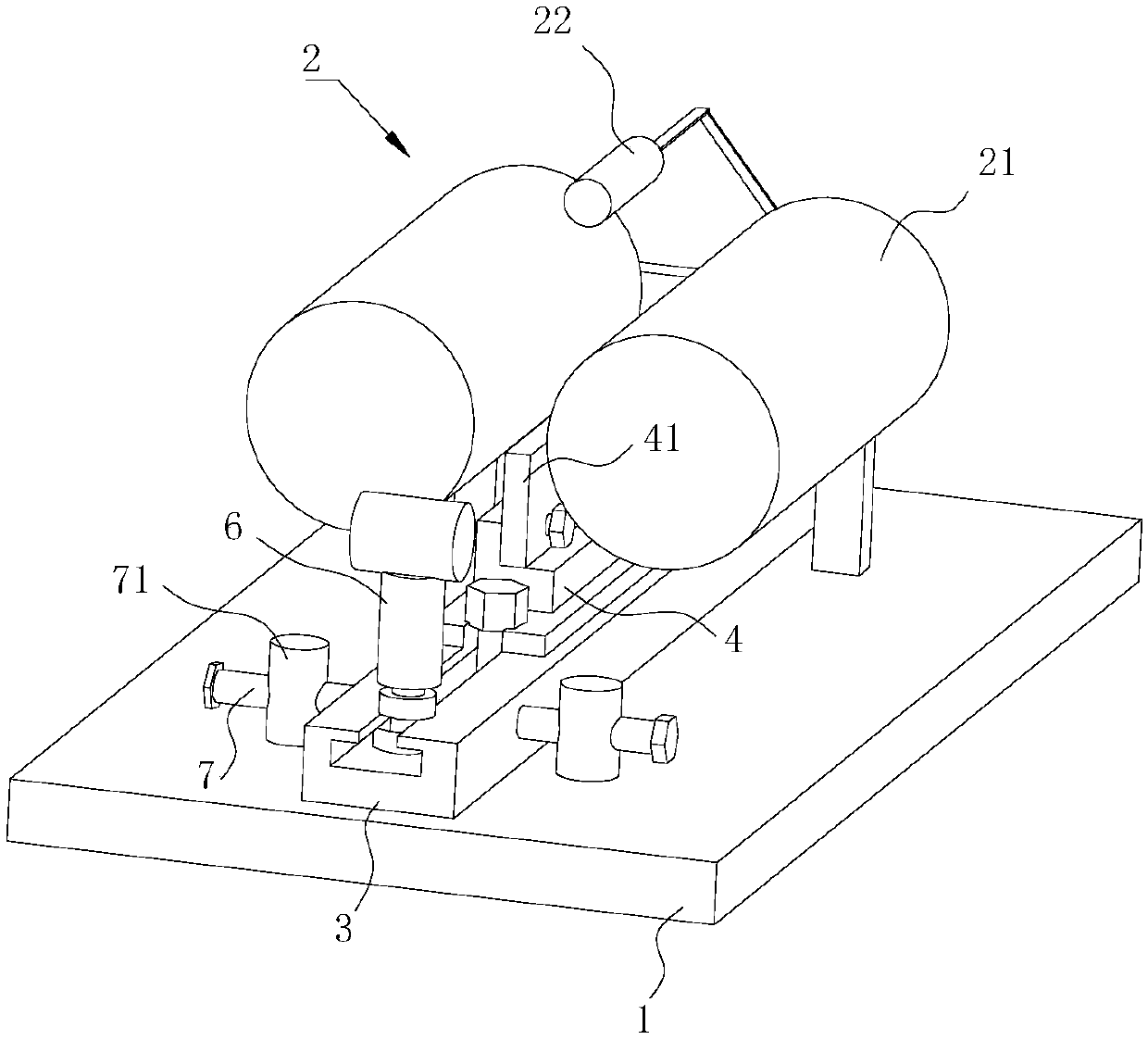

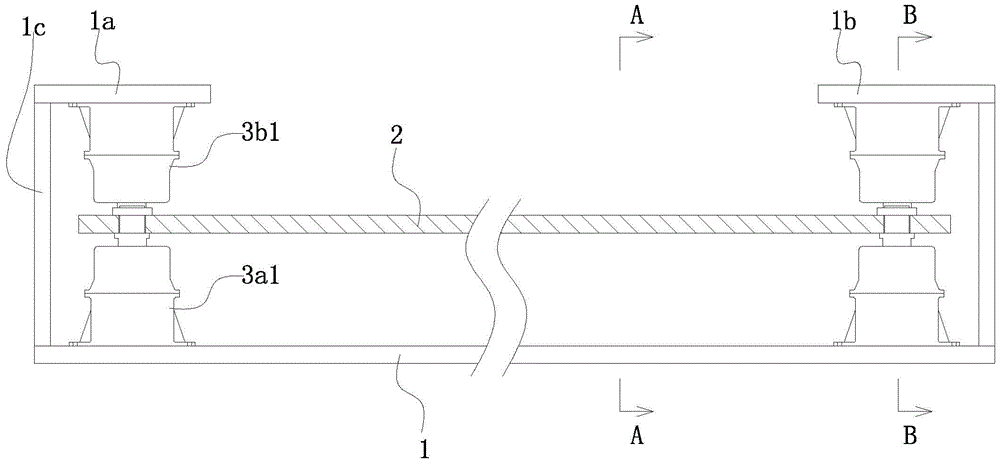

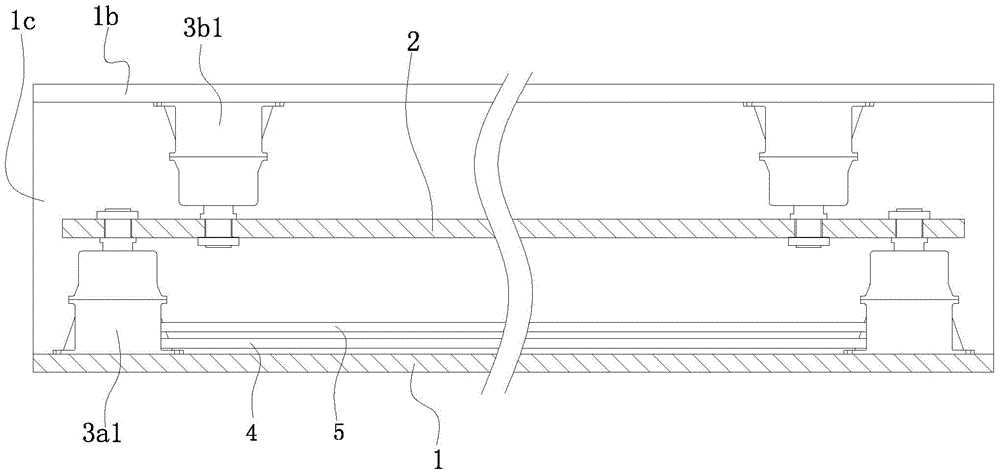

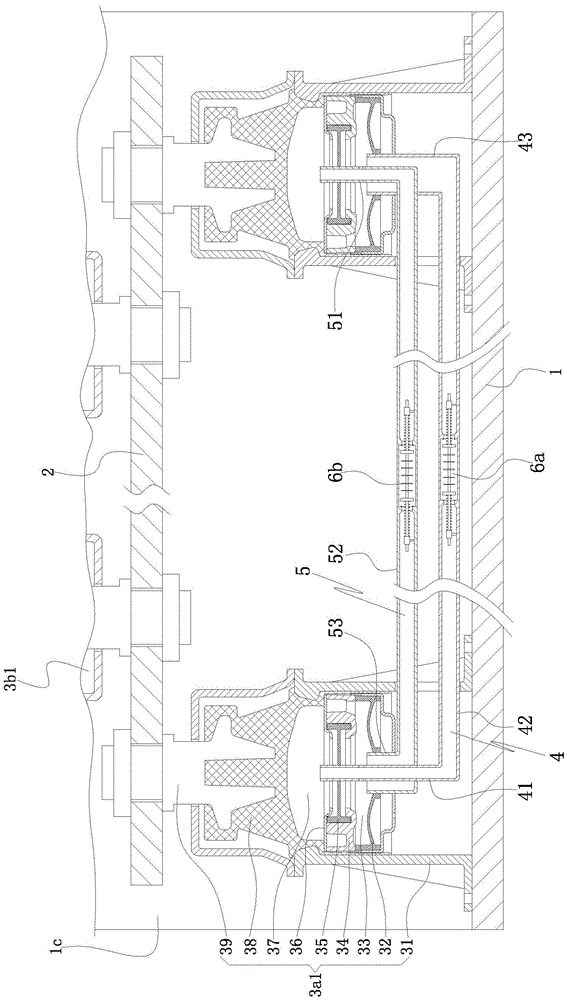

Two-way damping hydraulic support type wind power gearbox installation device

ActiveCN104879475BVibration dampingImprove vibration reductionGearing detailsIsolation effectEngineering

The invention discloses a bidirectional damping hydraulic support type wind power gear box mounting device with an aim to damp vibration of the wind power gear box within a low-frequency area and vibration in a medium- and high-frequency area and improve isolation effect. The bidirectional damping hydraulic support type wind power gear box mounting device comprises a bottom frame, a mounting frame and a top frame sequentially from bottom to top, the top frame comprises a first top plate and a second top plate, the first top plate and the second top plate are arranged on the two opposite sides of the mounting frame and connected with the bottom frame respectively via vertical connecting plates; a plurality of lower damping components are arranged between the bottom frame and the mounting frame, and a plurality of upper damping components are arranged between the first top plate and the second top plate as well as the mounting frame respectively.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com