Patents

Literature

203results about How to "Change natural frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

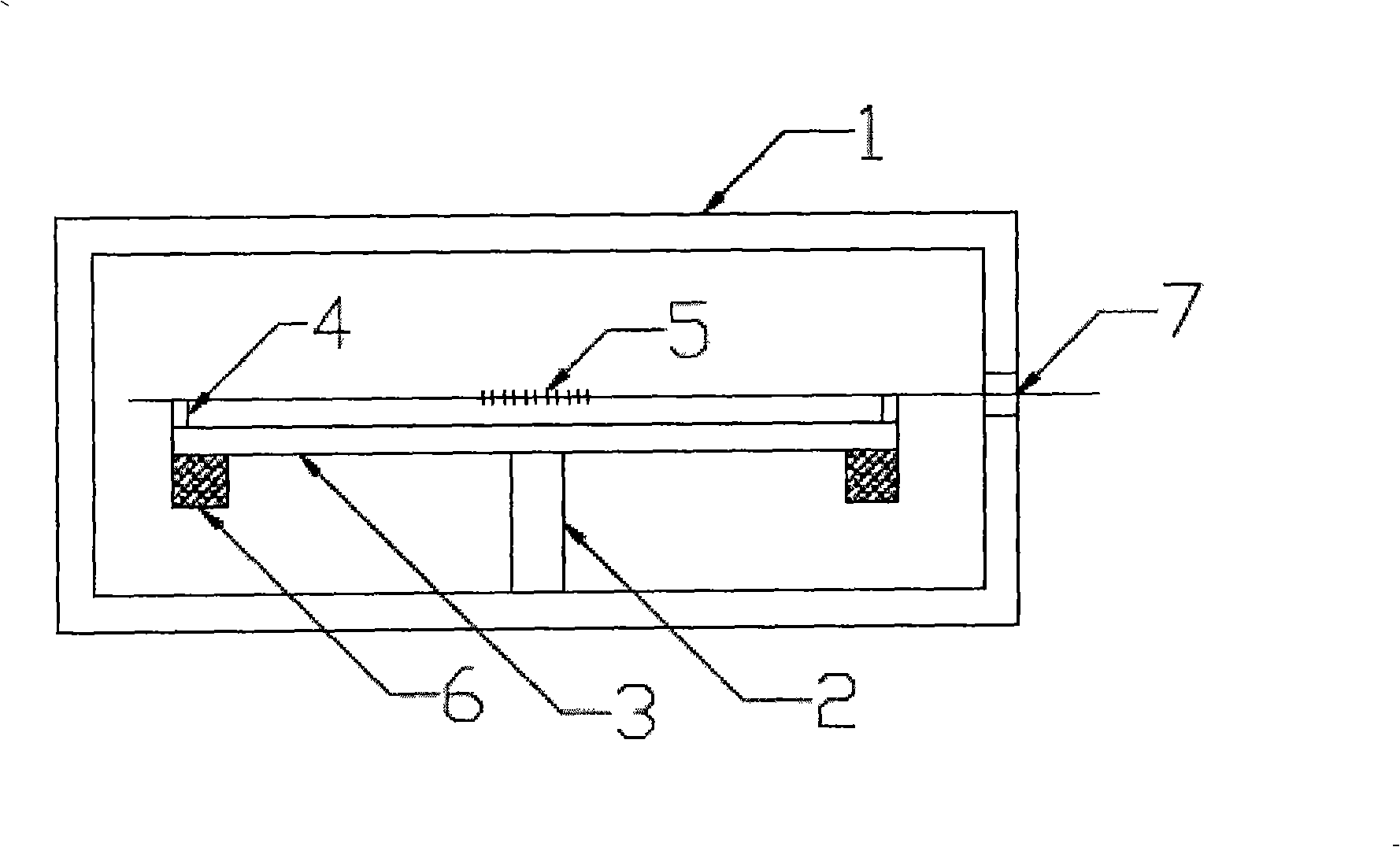

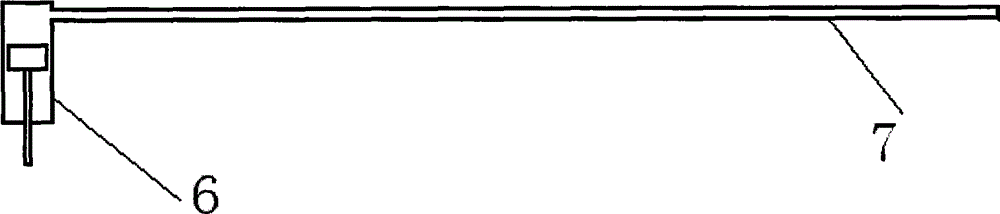

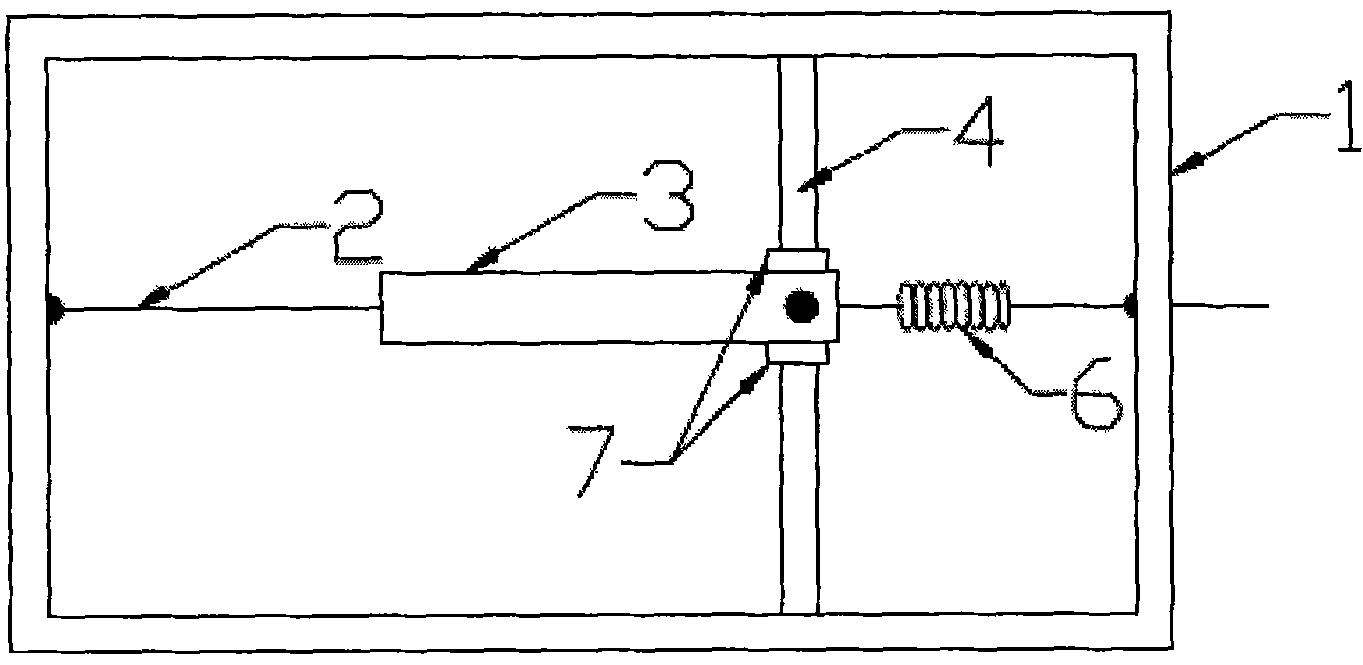

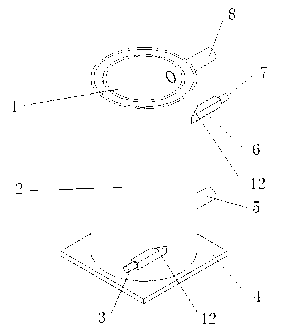

Cantilever beam type optical fibre grating accelerometer

InactiveCN101285845AAvoid chirpingSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamAccelerometer

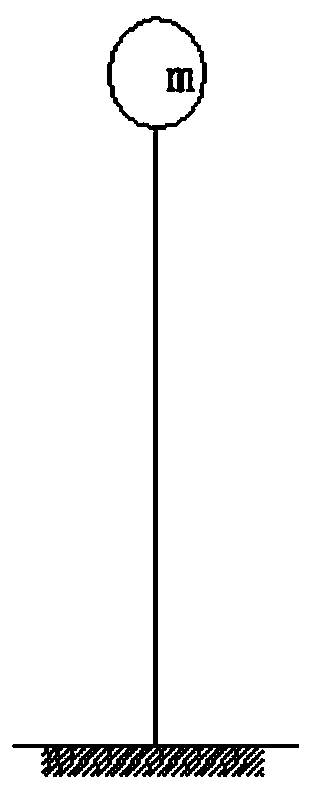

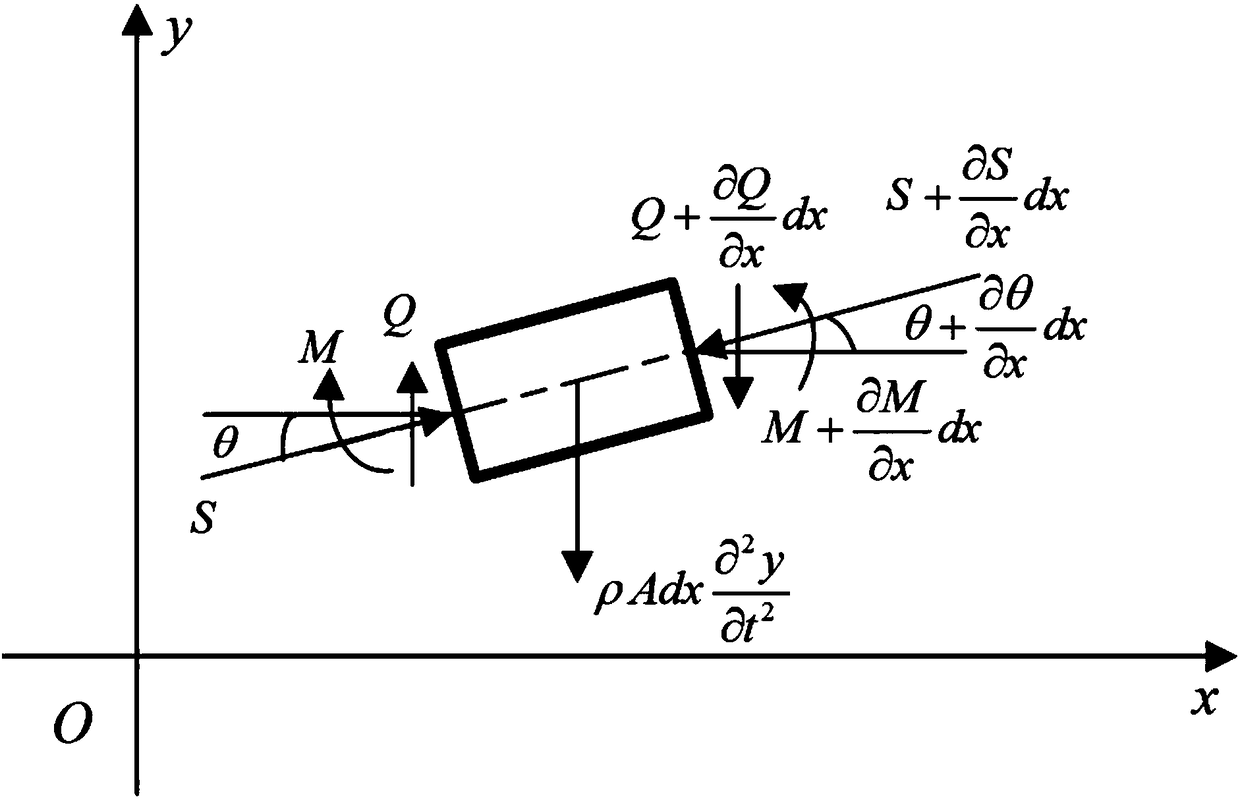

The invention relates to the optical fiber sensor technical field, disclosing a cantilever beam-type optical fiber grating accelerometer. The accelerometer comprises an outer casing used as a support structure of the accelerometer, a support column used to fix a cantilever beam, a cantilever beam, a first lug boss and a second lug boss arranged at both ends of the upside of the cantilever beam, an optical fiber grating used to measure acceleration and a mass block arranged at one end or both end of the underside of the cantilever beam, wherein one end of the support column is fixed with the cantilever beam, while the other end is fixed with the downside surface of the accelerometer; both lug bosses are used to horizontally fix the optical fiber grating and ensures a certain space between the optical fiber grating and the cantilever beam; both ends of the optical fiber grating are respectively fixed on the first lug boss and the second lug boss on the cantilever beam with one end parallel to the surface of the cantilever beam passing through the hole on the sidewall of the accelerometer to extend outside the accelerometer; and the mass block is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The cantilever beam-type optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

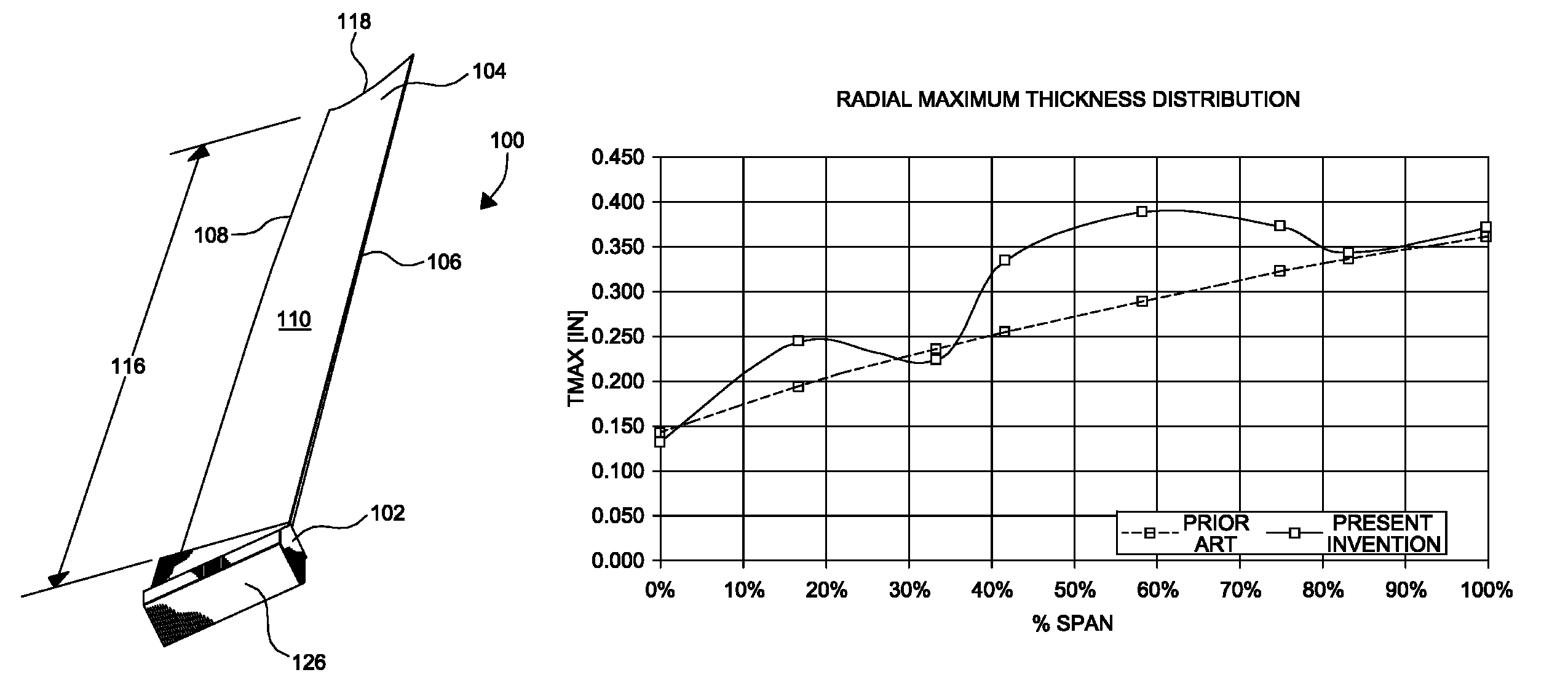

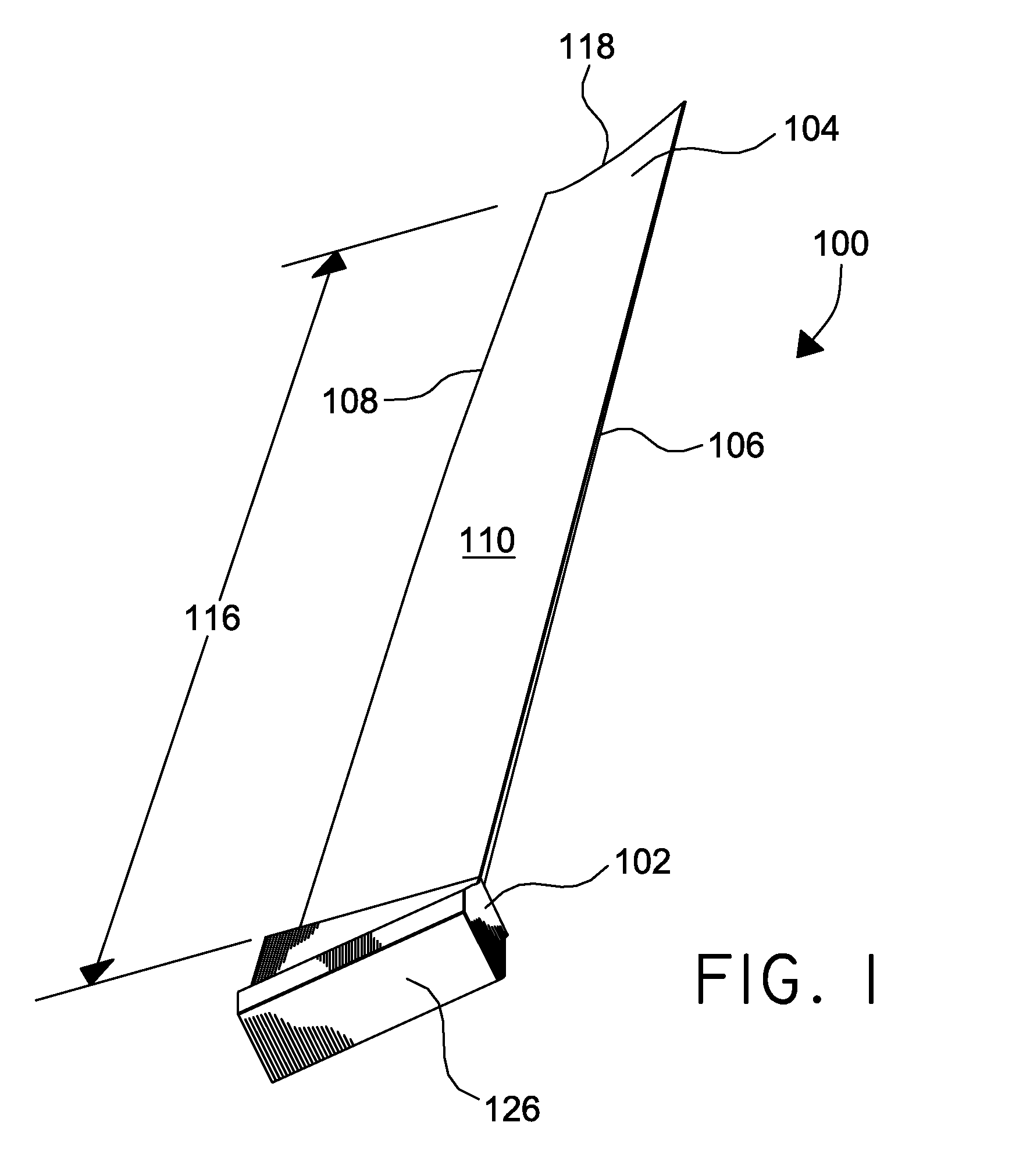

Compressor stator vane

ActiveUS8573945B2Change natural frequencyMinimal to efficiencyPropellersPump componentsCritical engineEngineering

A compressor component having a non-linear thickness distribution along the span length is disclosed. By altering the thickness distribution to a non-linear arrangement so as to locally increase airfoil thickness proximate a mid-span location, the natural frequency of the airfoil is increased so as to not coincide with a critical engine order of the compressor. Further, the present invention provides a novel airfoil profile in accordance with the coordinates of Table 1. The present invention also includes a carrier segment or disk fabricated from a material so as to eliminate corrosion with the compressor component.

Owner:ANSALDO ENERGIA SWITZERLAND AG

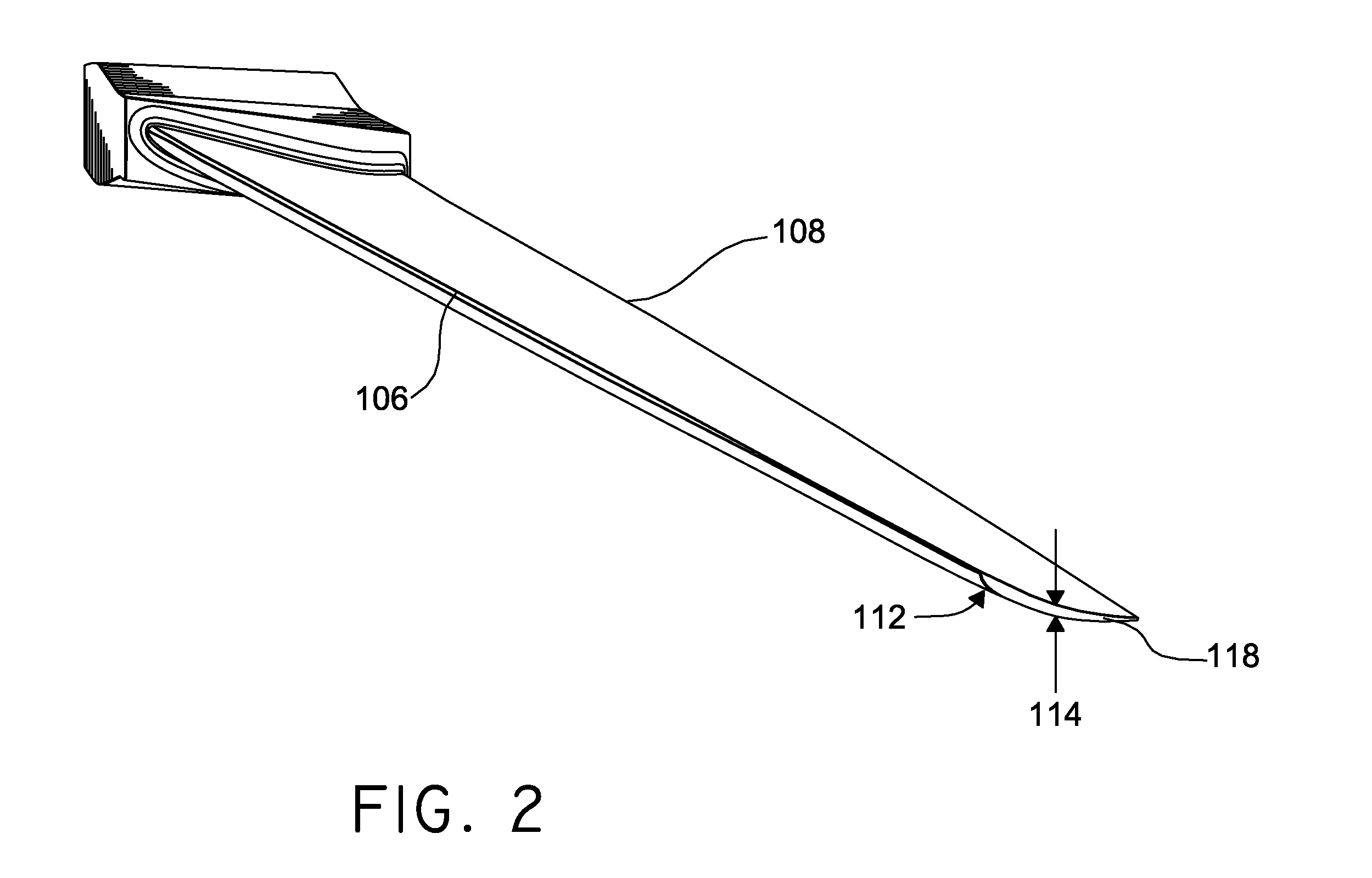

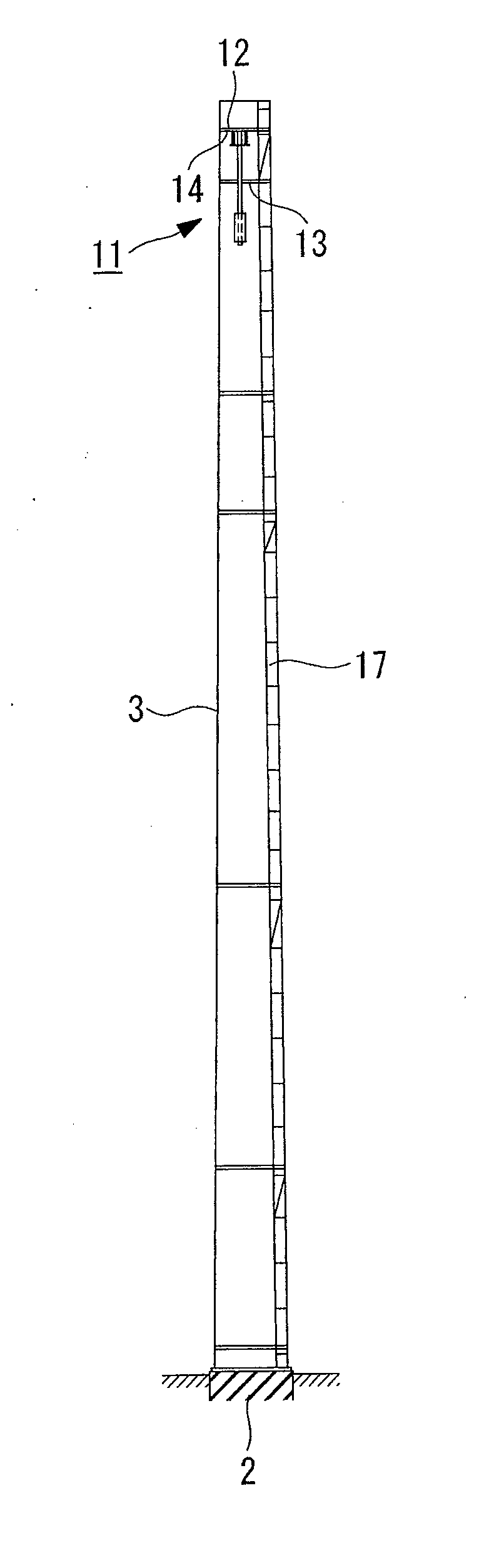

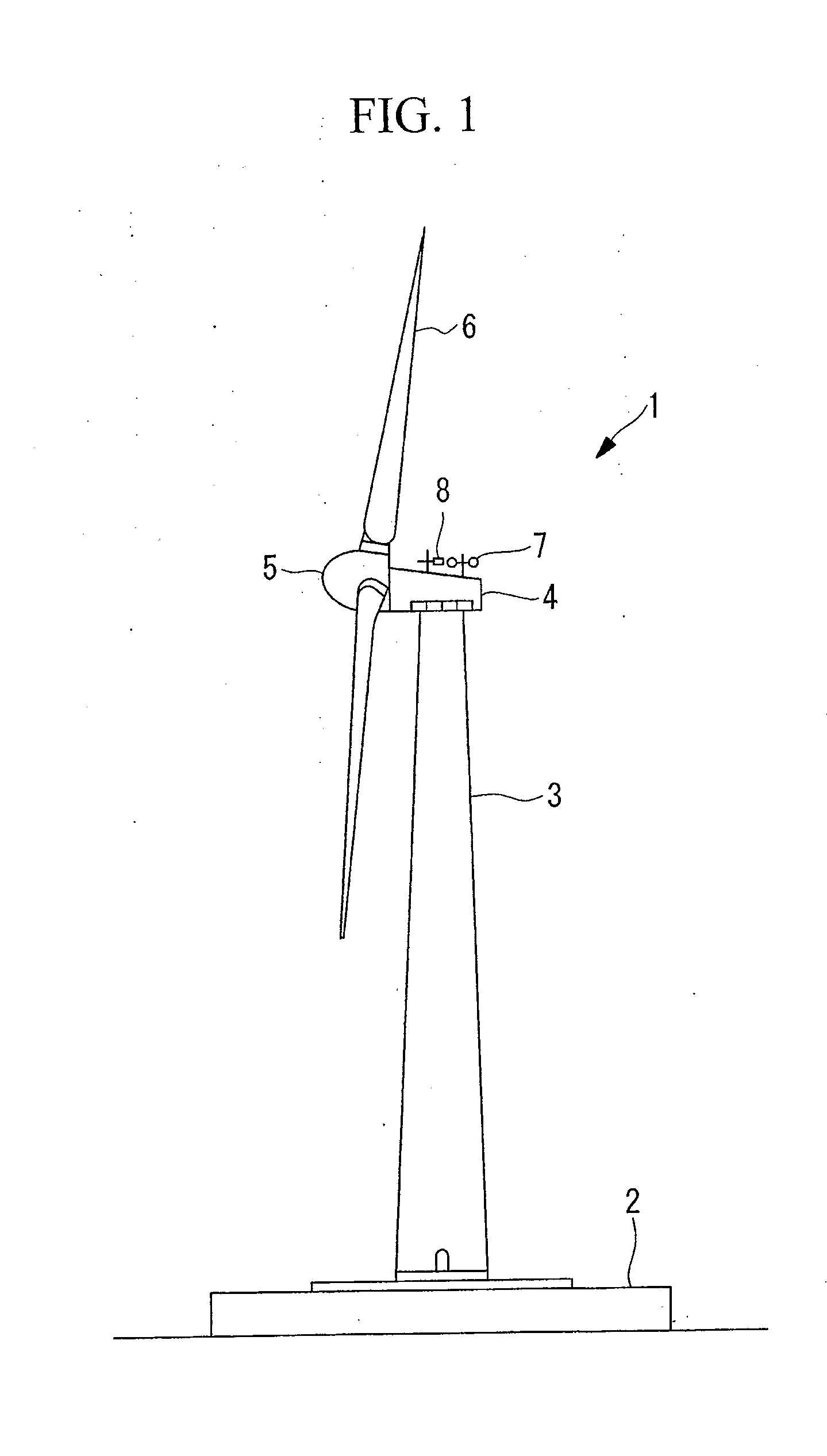

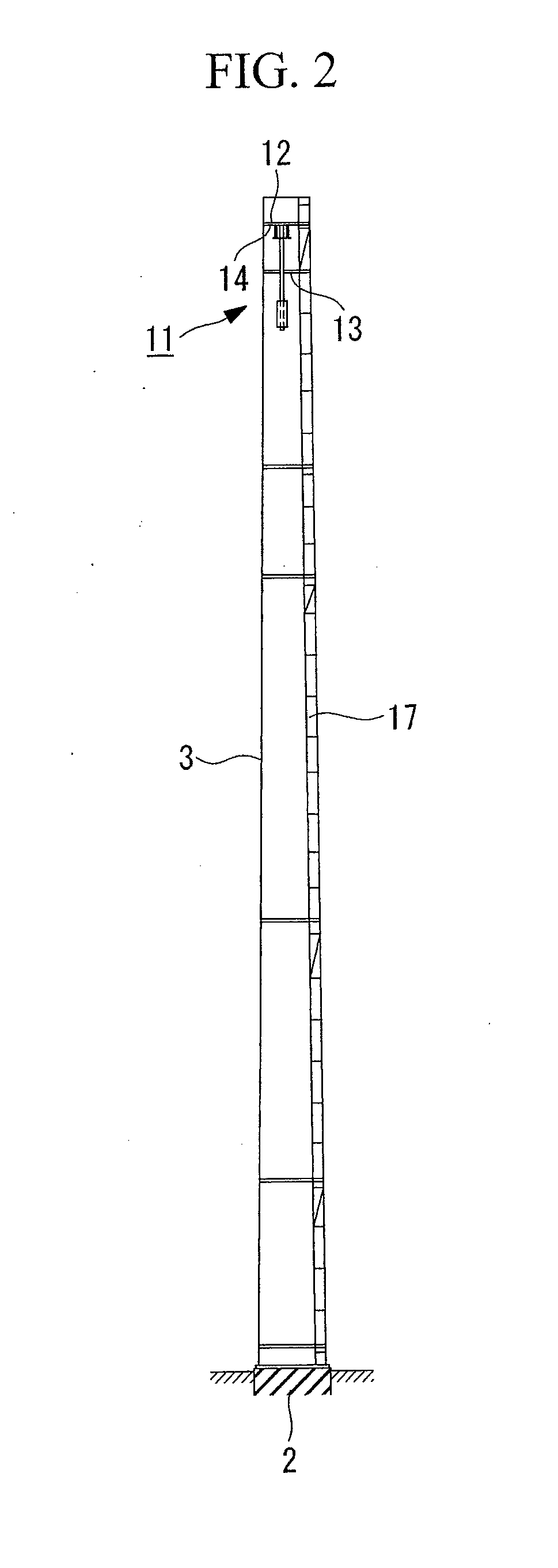

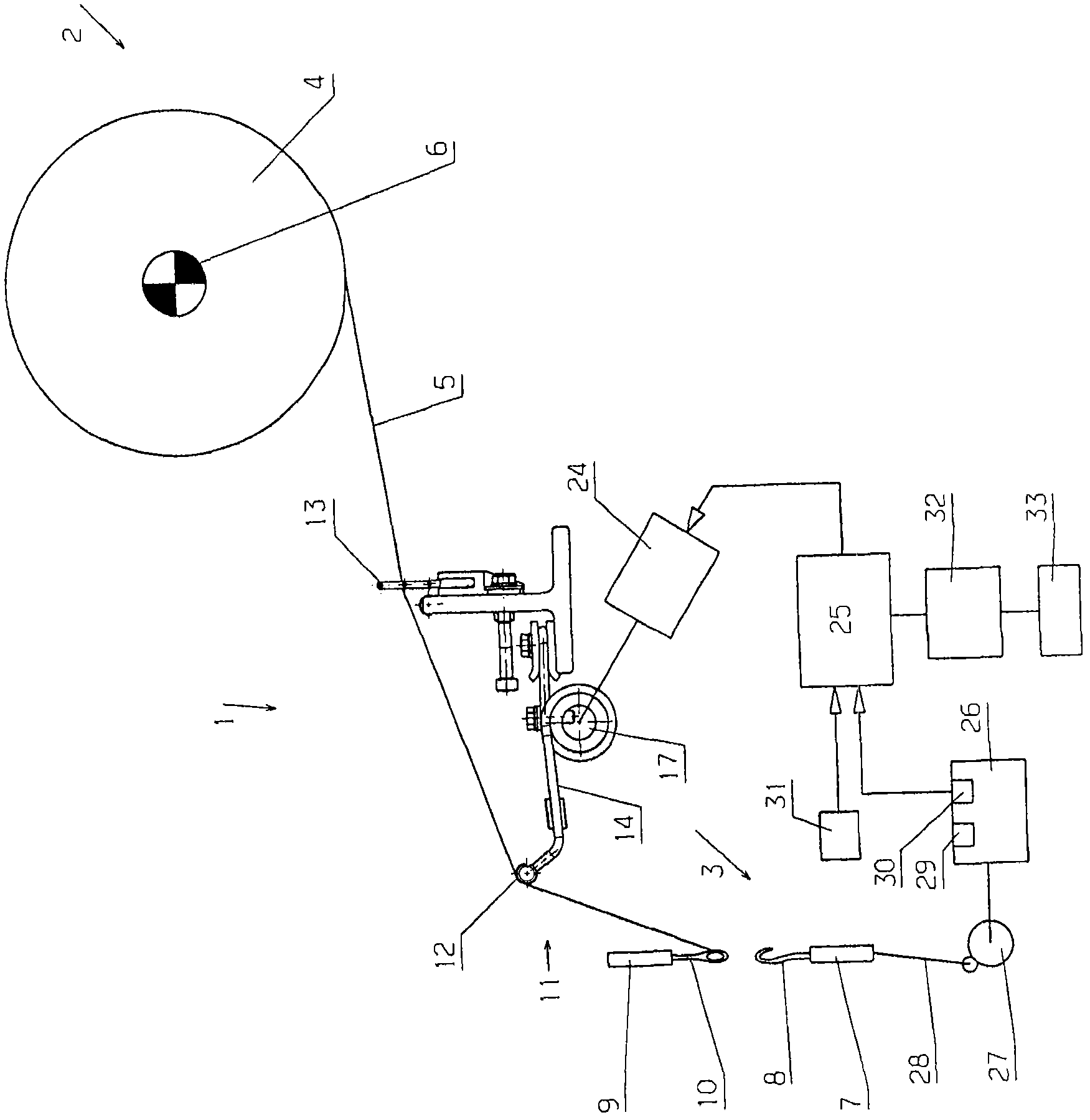

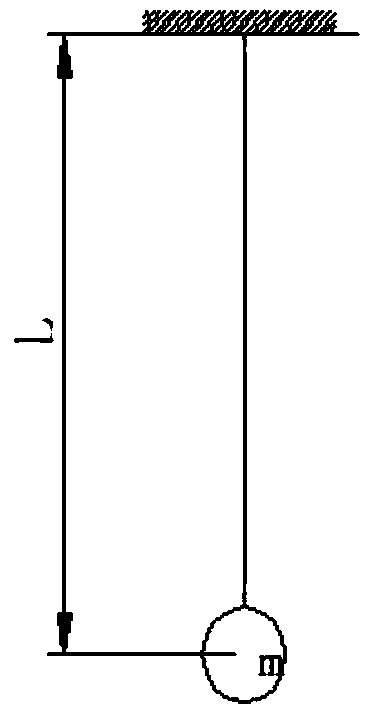

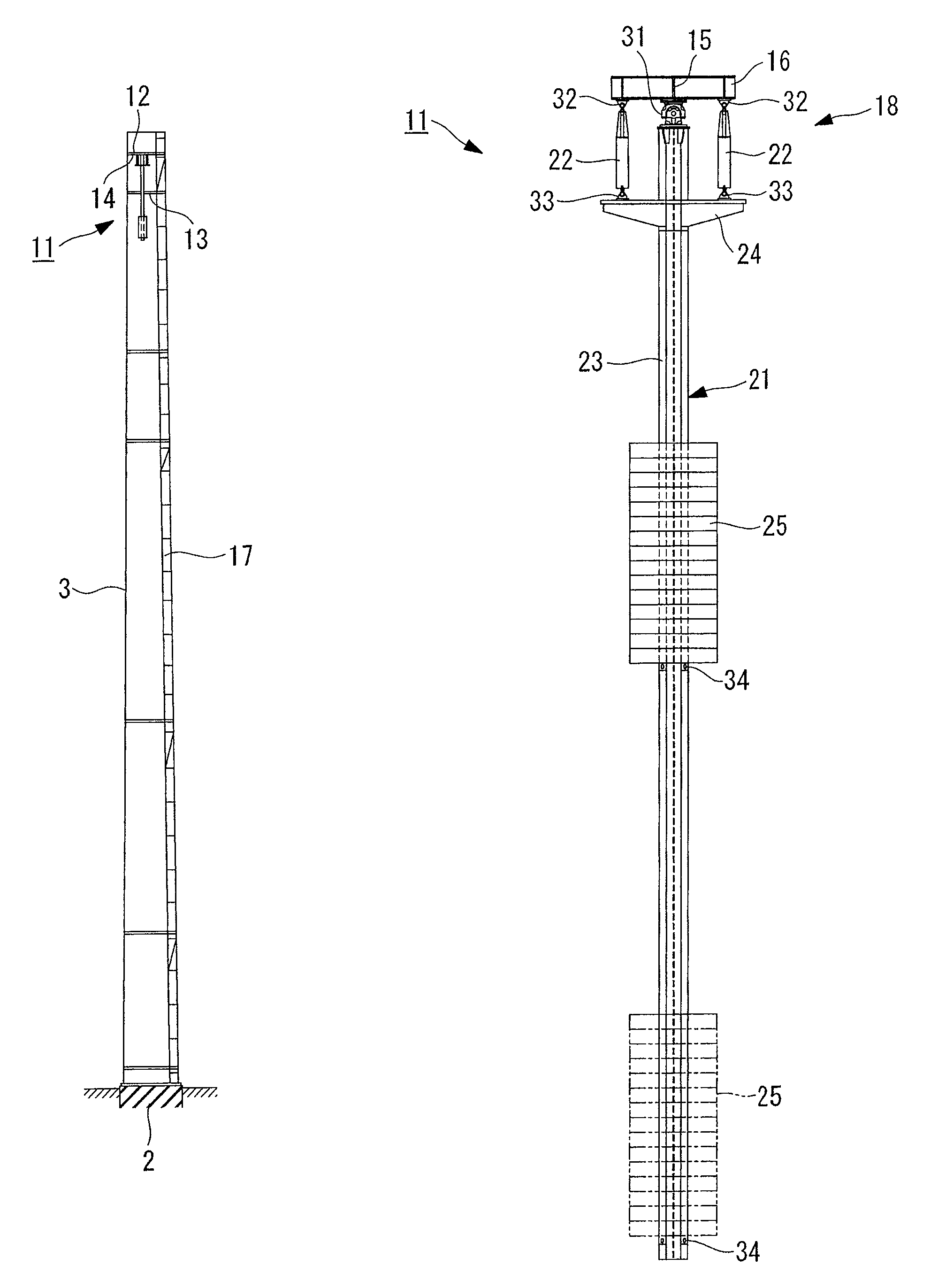

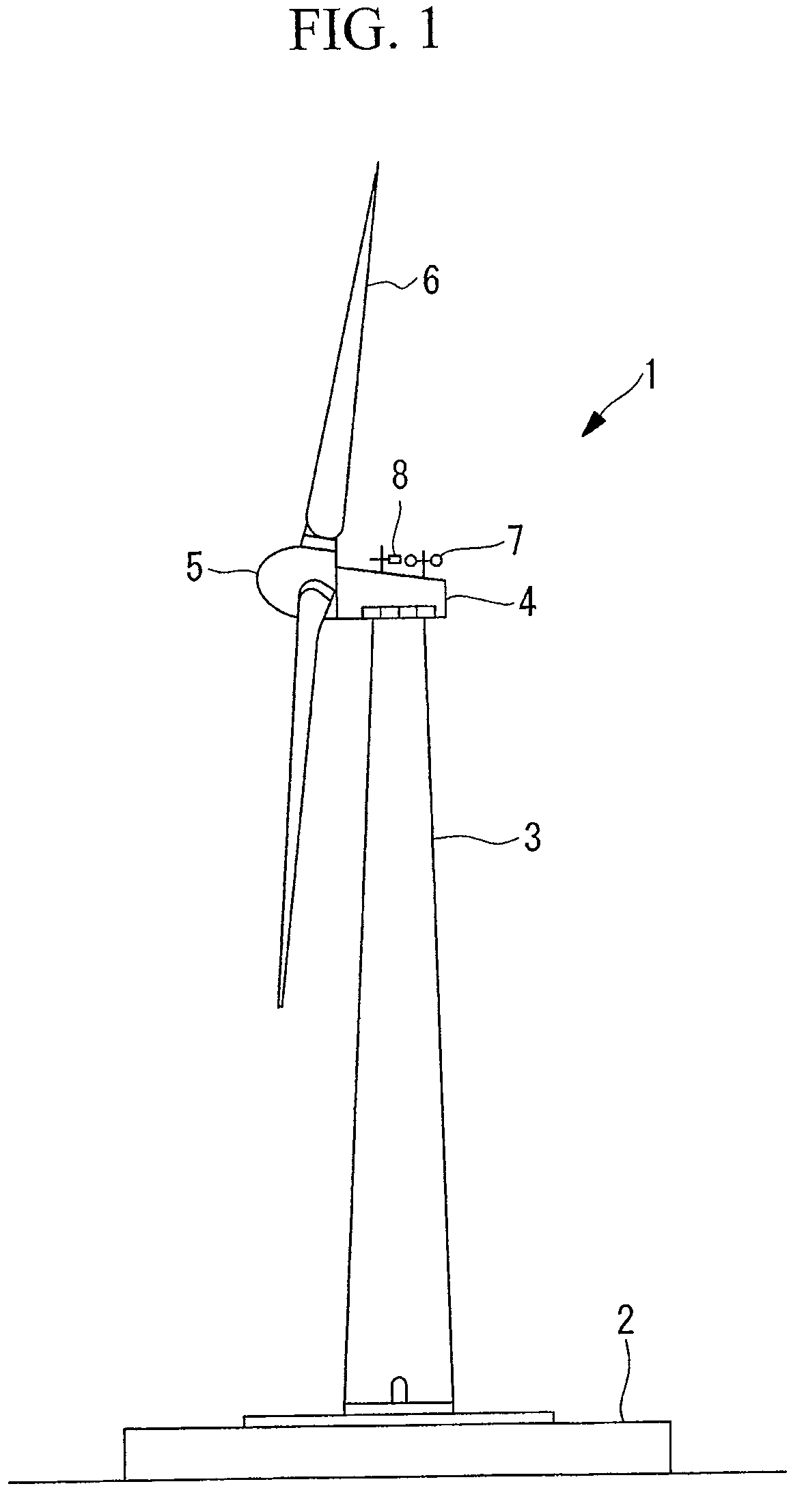

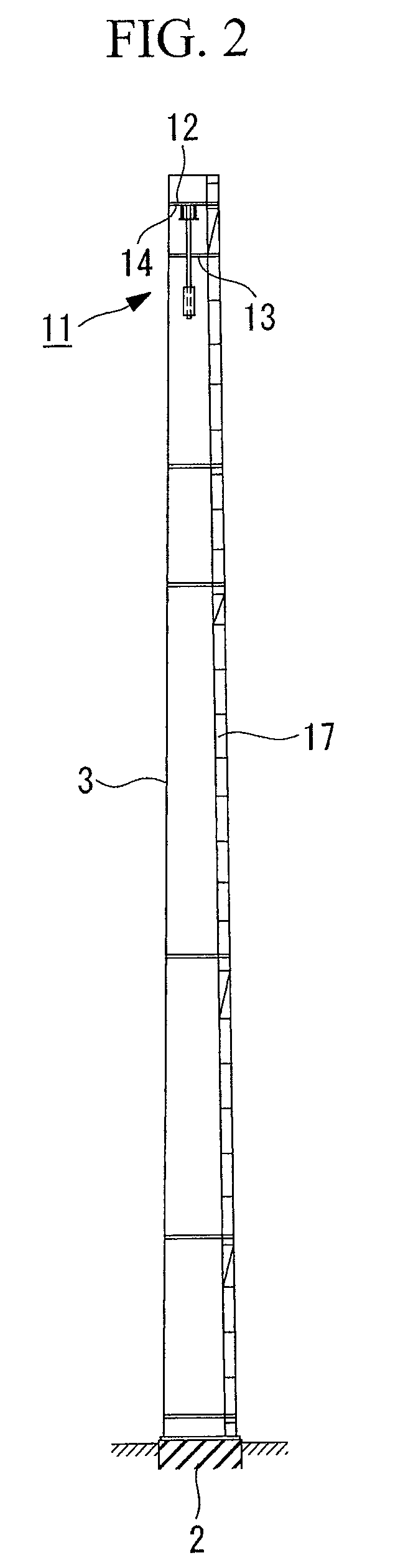

Vibration control apparatus of wind turbine generator and wind turbine generator

ActiveUS20120063915A1Change natural frequencyPump componentsEngine fuctionsUltrasound attenuationVibration control

A vibration control apparatus of a wind turbine generator that can be installed in a small space inside a tower, without a weight increase of the tower, and that can change the natural frequency thereof is provided. Included is a swinging rod extending in the vertical direction and suspended from beams provided on an upper part of the tower via a first universal joint; a flange part extending outward from the upper end outer surface of the swinging rod in the radial direction along the circumferential direction; a pendulum including a bob attached to the swinging rod and capable of moving up and down in the vertical direction; and a plurality of attenuation devices each of whose upper end is attached to the beams with a second universal joint and whose lower end is attached to the flange part with a third universal joint.

Owner:MITSUBISHI HEAVY IND LTD

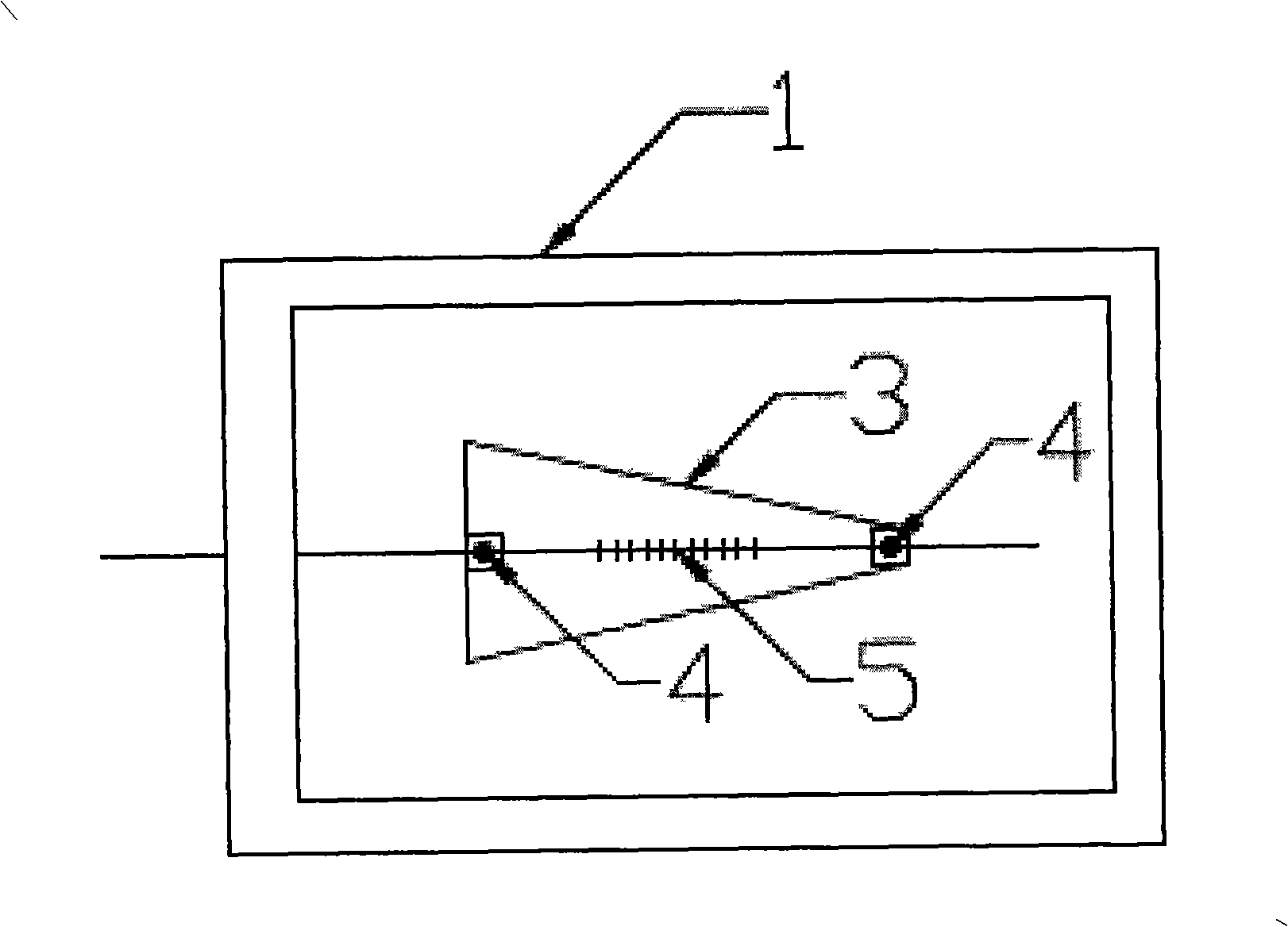

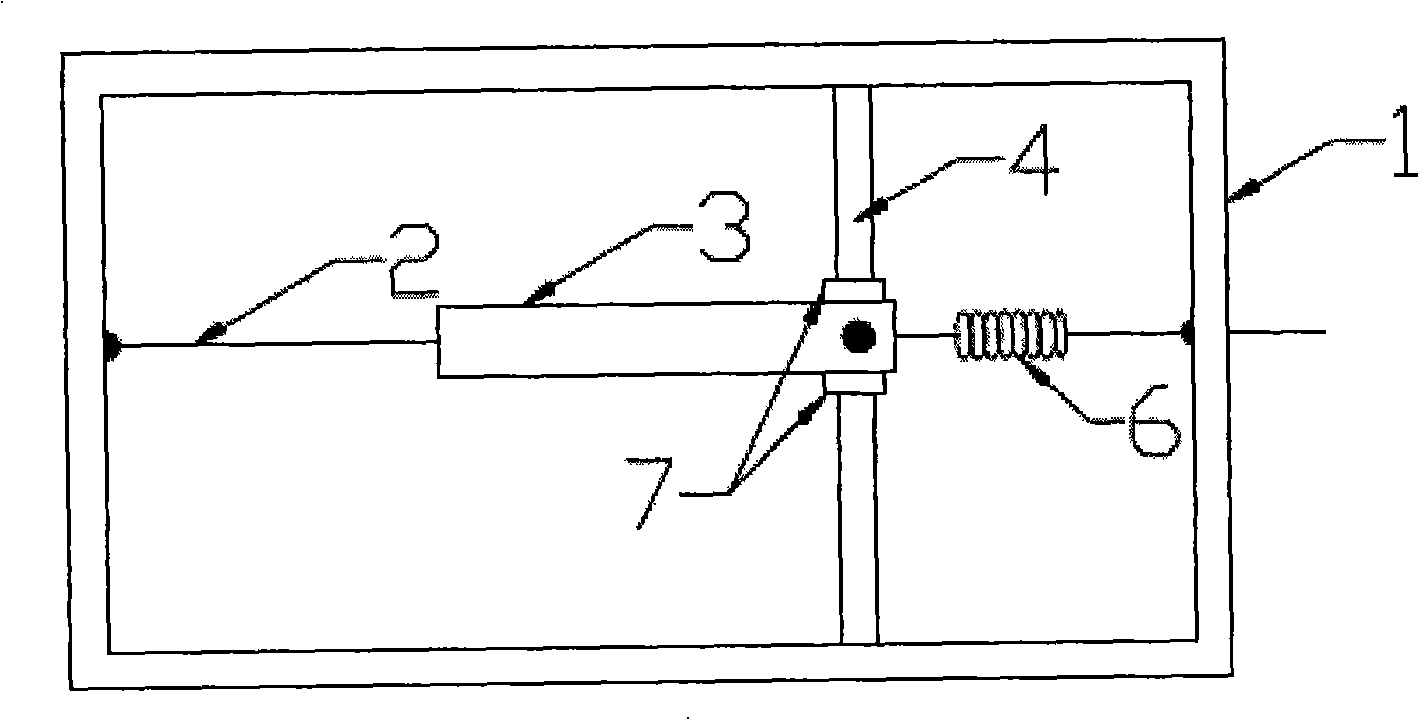

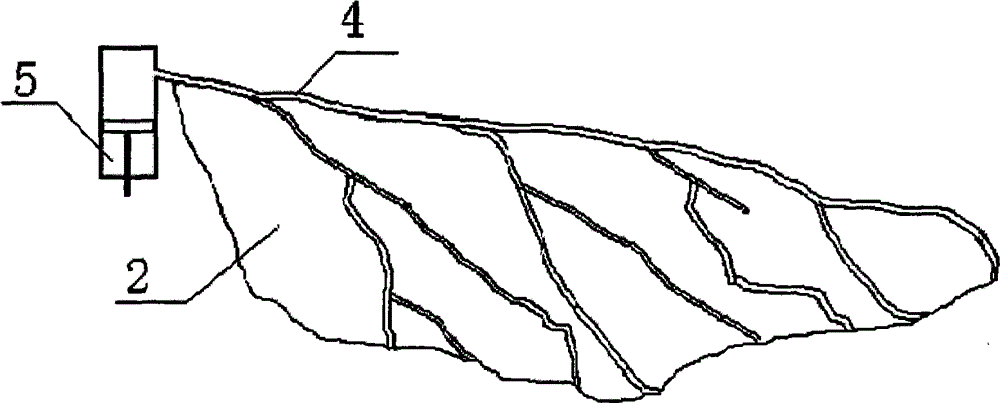

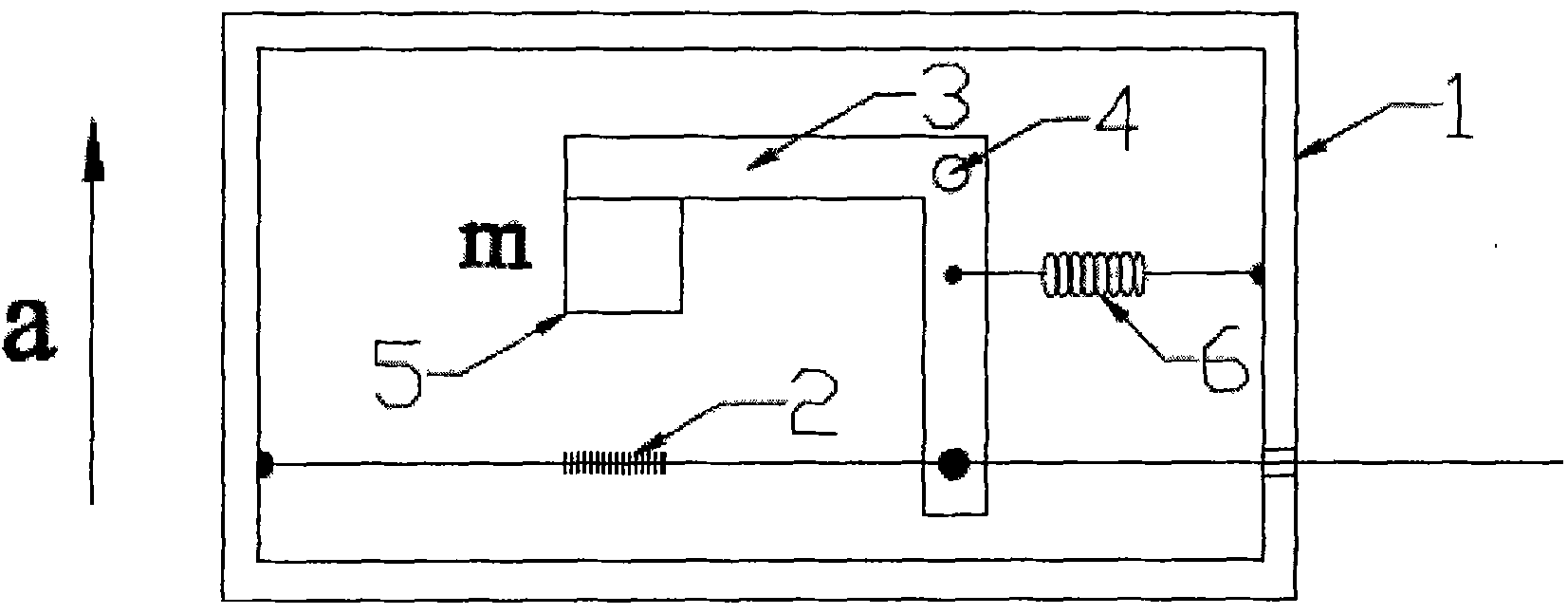

Temperature insensitive optical fibre grating acceleration sensor

InactiveCN101285847AAvoid chirpingSimple processTelevision system detailsSubsonic/sonic/ultrasonic wave measurementGratingClassical mechanics

The invention discloses a temperature-insensitive optical fiber grating acceleration sensor, which comprises an outer casing used as a support structure of the acceleration sensor, an optical fiber grating used to measure acceleration, a shaft fixed on the front sidewall and the back sidewall of the acceleration sensor, an L-type lever arranged on the shaft and a mass block fixed on the horizontal end part of the lever, wherein one end of the optical fiber grating is fixed on the inner wall of one end of the acceleration sensor, while the other end parallelly passes through the small hole on the other end of the acceleration sensor and extends outside the acceleration sensor; the L-type lever is used to send vibration signal to the optical fiber grating connected with the lever, and the folding point of the cross part of the vertical part and the horizontal part of the L-type lever is in movable connection with the shaft; and the mass block is used to adjust the sensitivity and the natural vibration frequency of the sensor. The optical fiber grating acceleration sensor increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

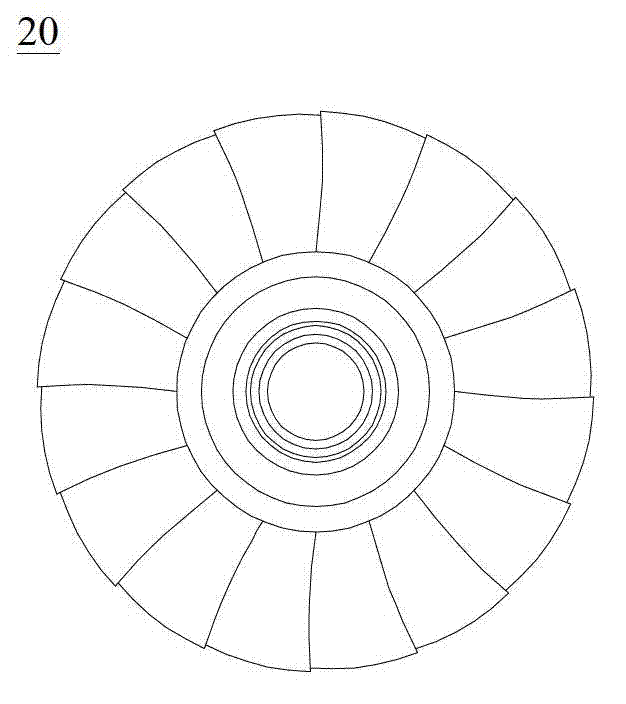

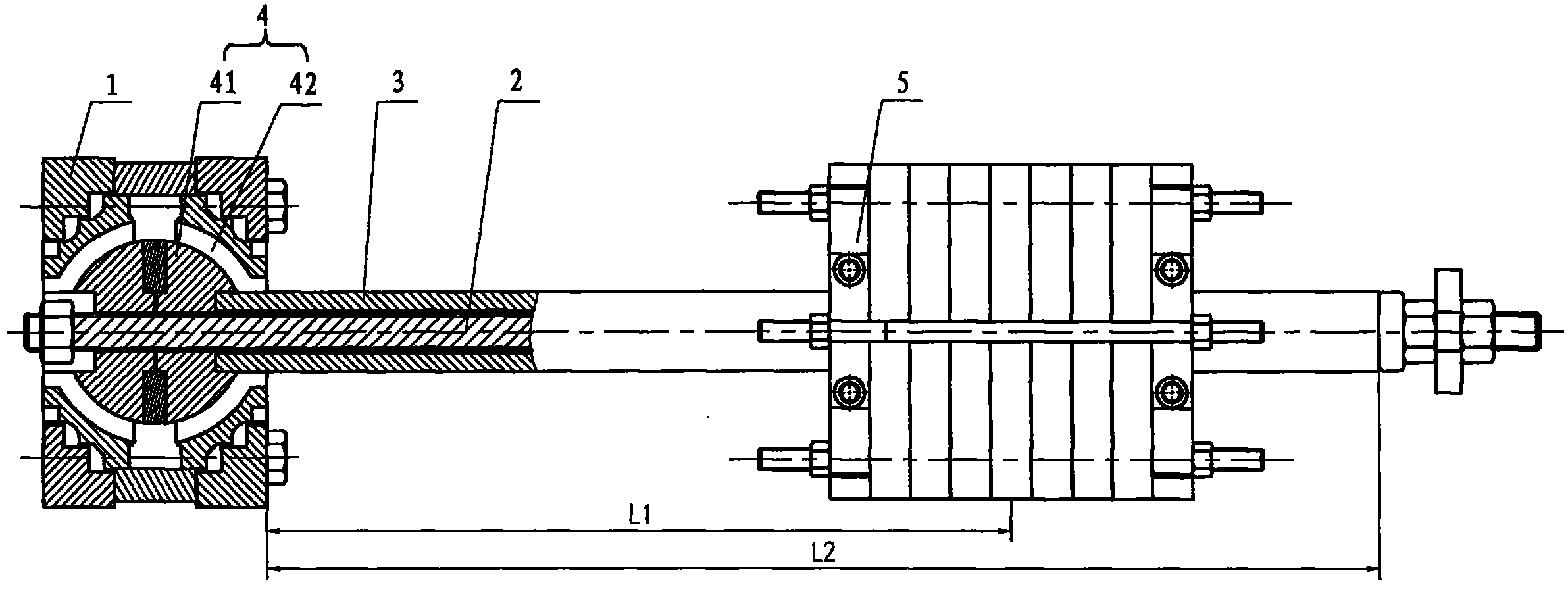

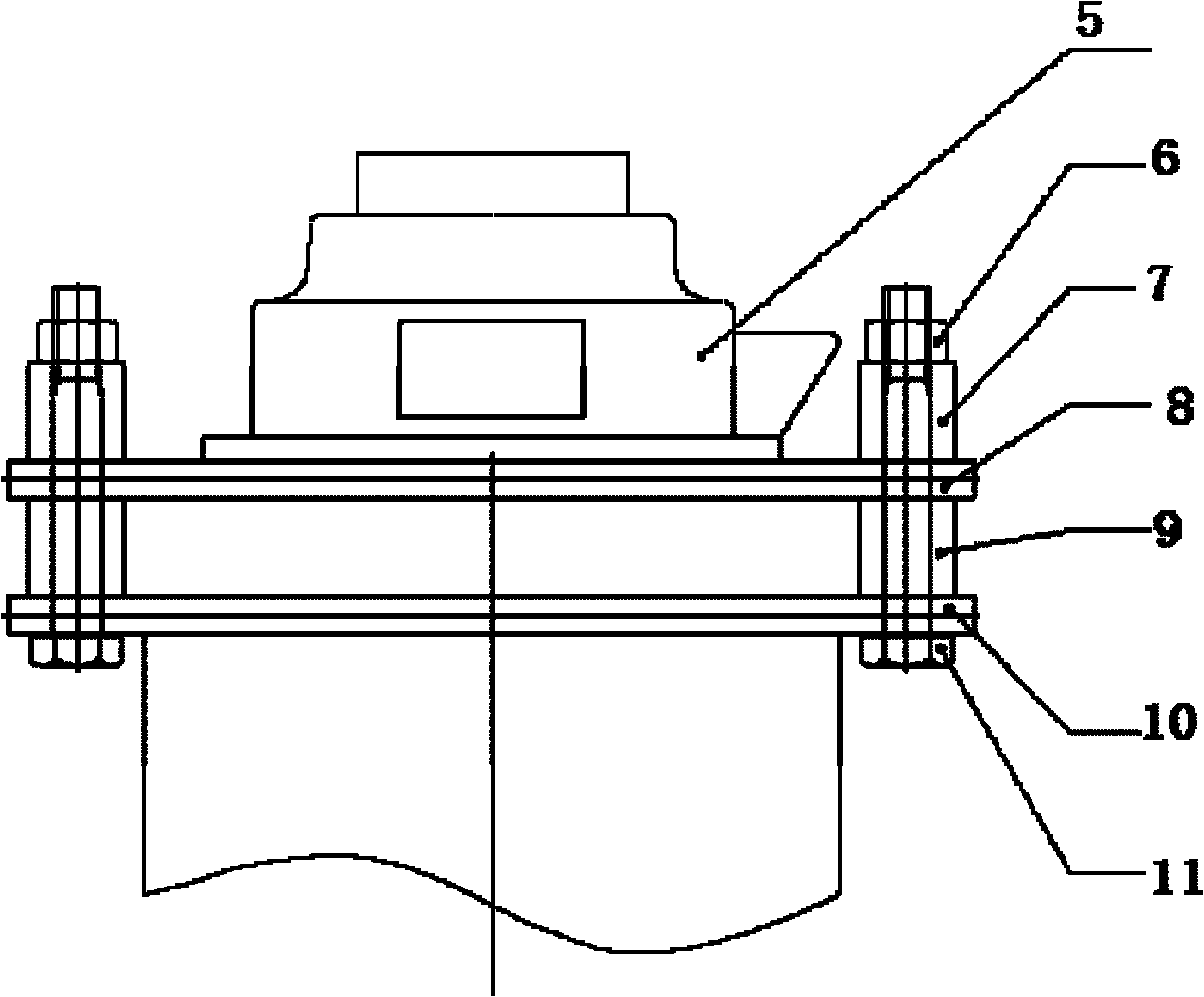

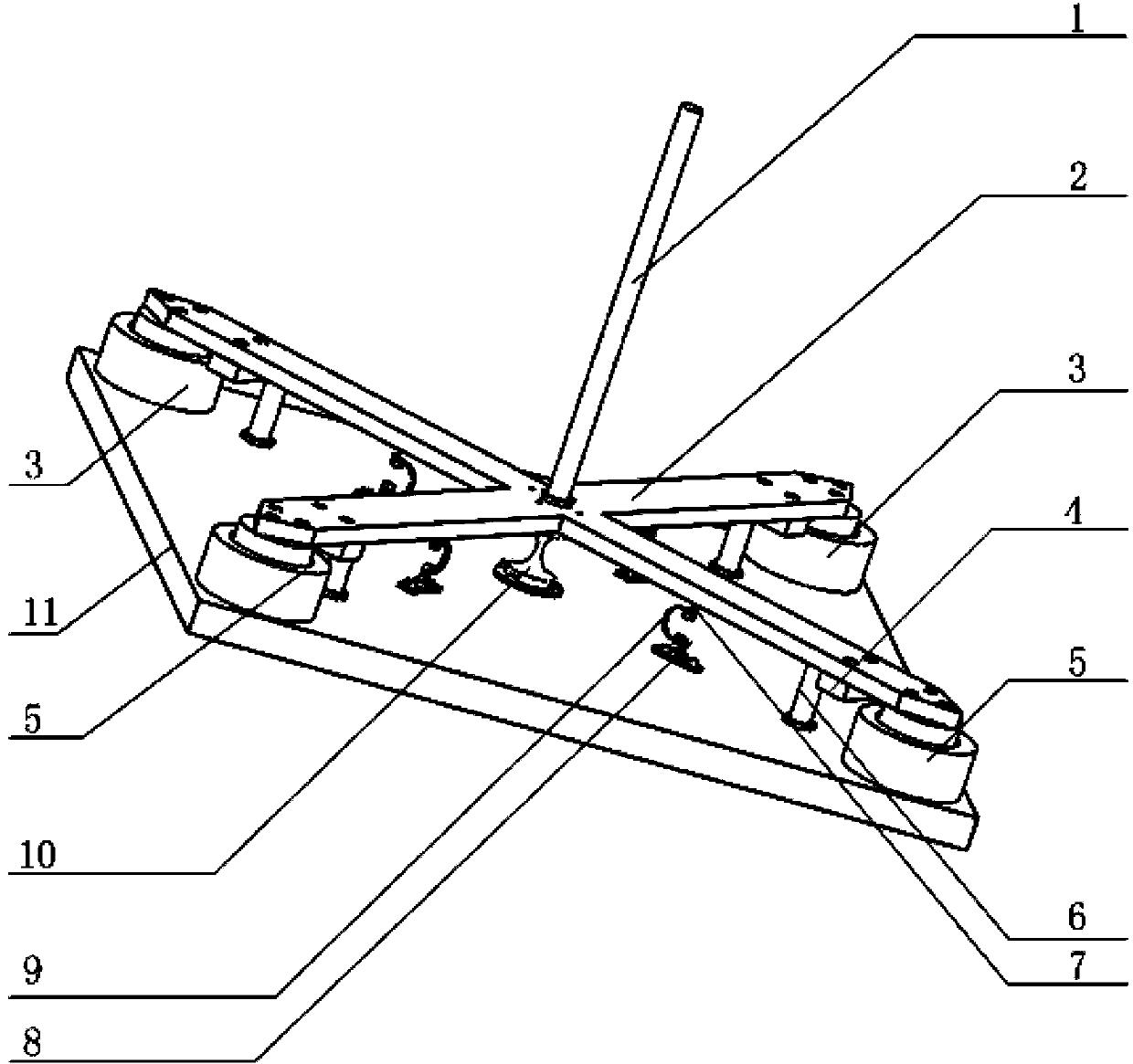

Testing device and testing method of integral-impeller blade vibration fatigue

ActiveCN103196644AChange natural frequencyAvoid the hassle of cutting in equal partsVibration testingImpellerEngineering

The invention discloses a testing device and a testing method of integral-impeller blade vibration fatigue. The testing device comprises a vibration testing platform and an integral impeller, wherein the integral impeller is axially pressed through a fixture and is fixed on the vibration testing platform; the vibration testing platform is connected with a vibration device used for starting oscillation; the integral impeller is connected with a detection device used for detecting and recording testing parameters; and a rubber damping block enabling adjacent blades to be mutually damped is installed between the adjacent blades of the integral impeller. According to the testing device and the testing method, each rubber damping block is installed between the adjacent blades of the integral impeller to enable the adjacent blades to be mutually damped, the fact that other blades cannot vibrate freely when vibration fatigue testing is conducted on a single blade of the integral impeller is guaranteed, troubles caused by equal division of the integral impeller are avoided, rigidity change of a wheel disc supporting the blades is prevented from leading to change of inherent frequency of the blades, and therefore reliability of vibration fatigue testing results is guaranteed.

Owner:CHINA AVIATION POWER MACHINE INST

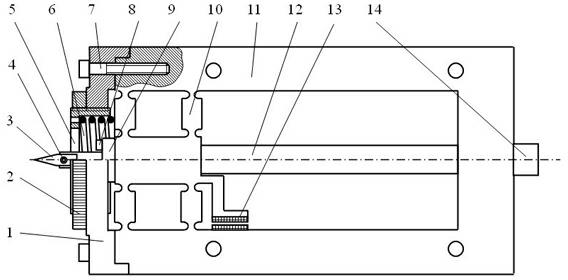

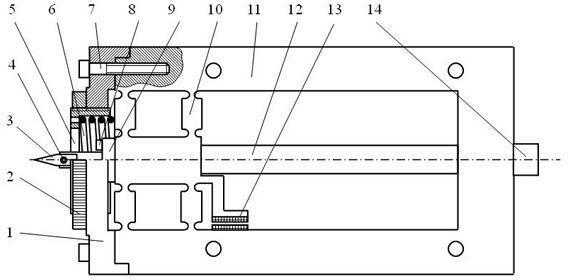

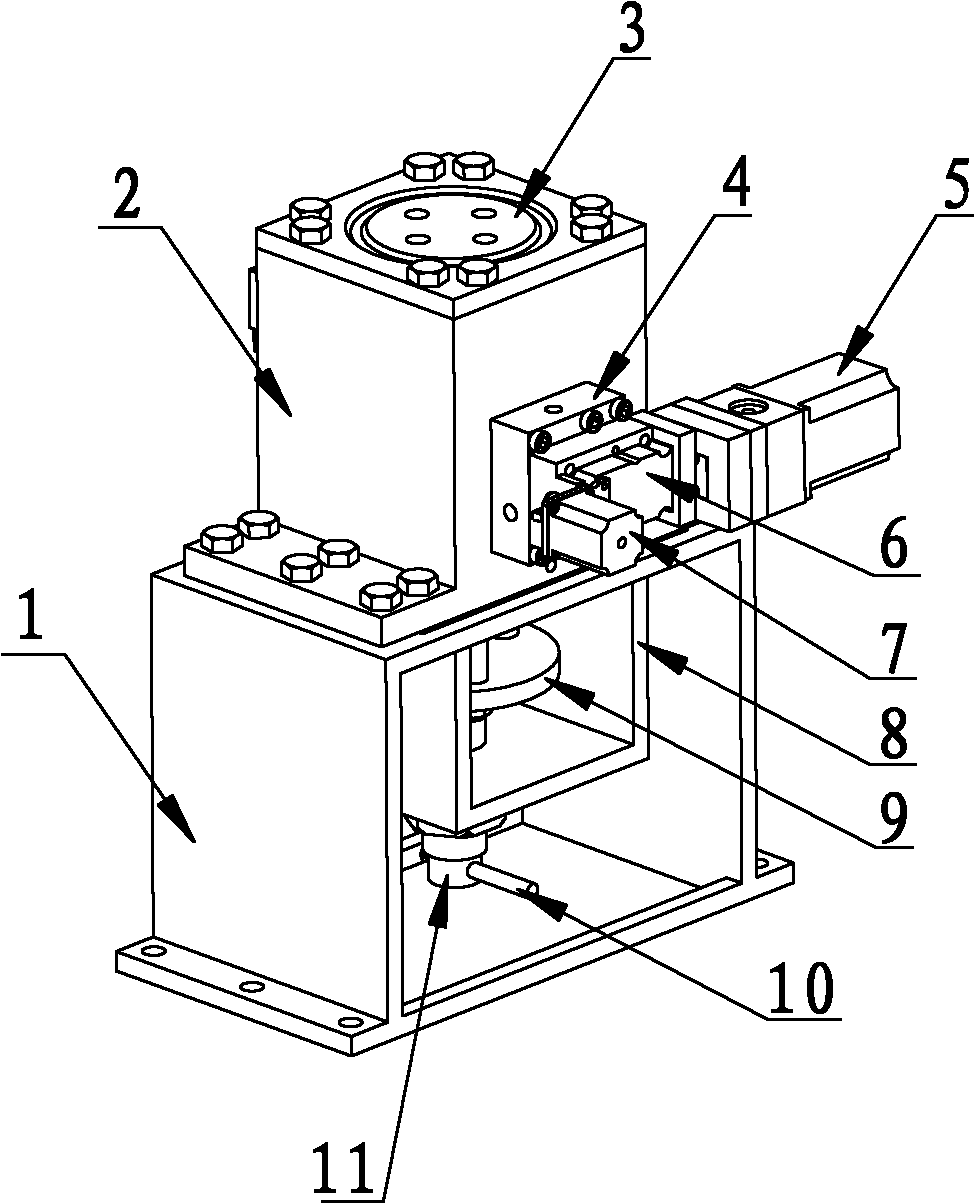

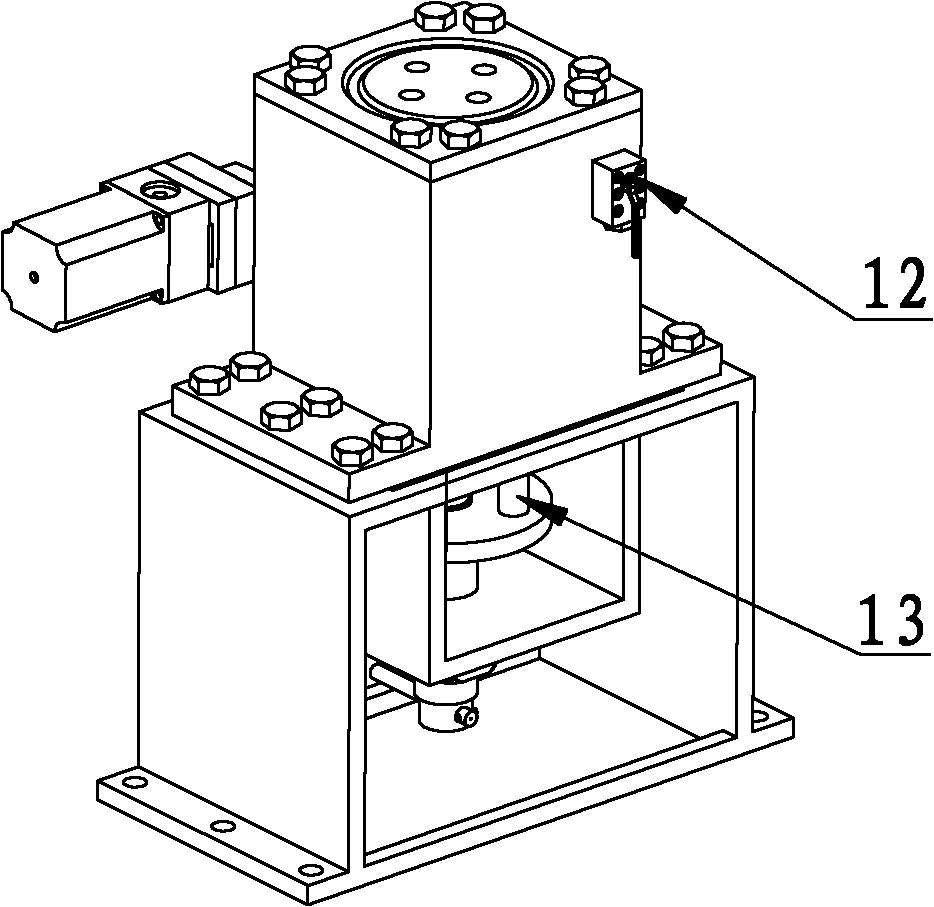

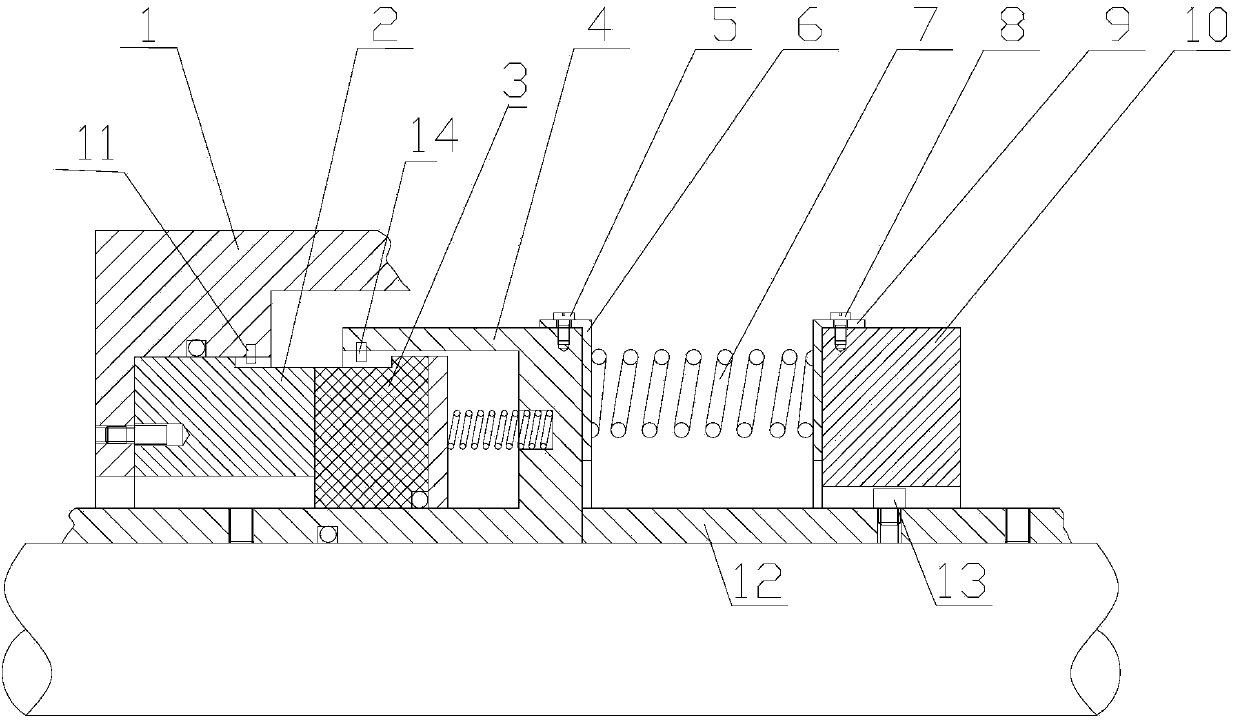

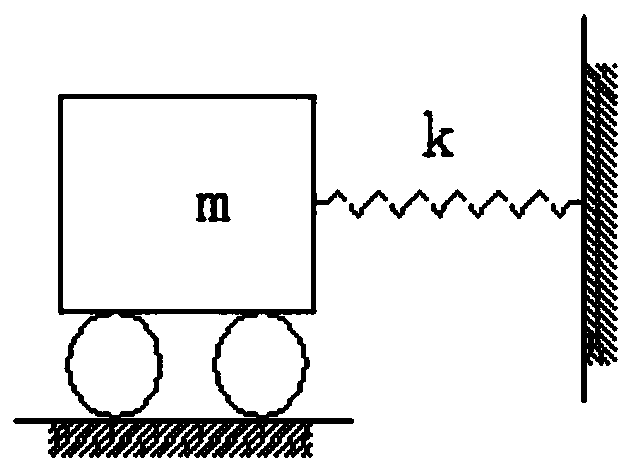

Fast tool servo device with adjustable rigidity

The invention discloses a fast tool servo device with adjustable rigidity. According to the device, a tool rest component is additionally arranged on an assembly of a frame, a flexible hinge, piezoelectric ceramic, a tool holder, a diamond cutting tool and the like, and comprises a spring bracket, a spring sleeve, a spring, a locking ring and the like; the spring bracket is arranged at the front end of the frame; the middle part of the spring bracket is provided with a threaded hole; the spring sleeve is matched with the threaded hole through external thread on the wall of the sleeve; the spring is arranged in the spring sleeve; one end of the spring is in contact with the bottom of an inner hole of the spring sleeve, and the other end of the spring is in contact with the flexible hinge on the frame; and pressure which is applied to the flexible hinge by the spring can be adjusted by turning the spring sleeve, so that the rigidity of the fast tool servo device is adjusted.

Owner:GUANGDONG UNIV OF TECH

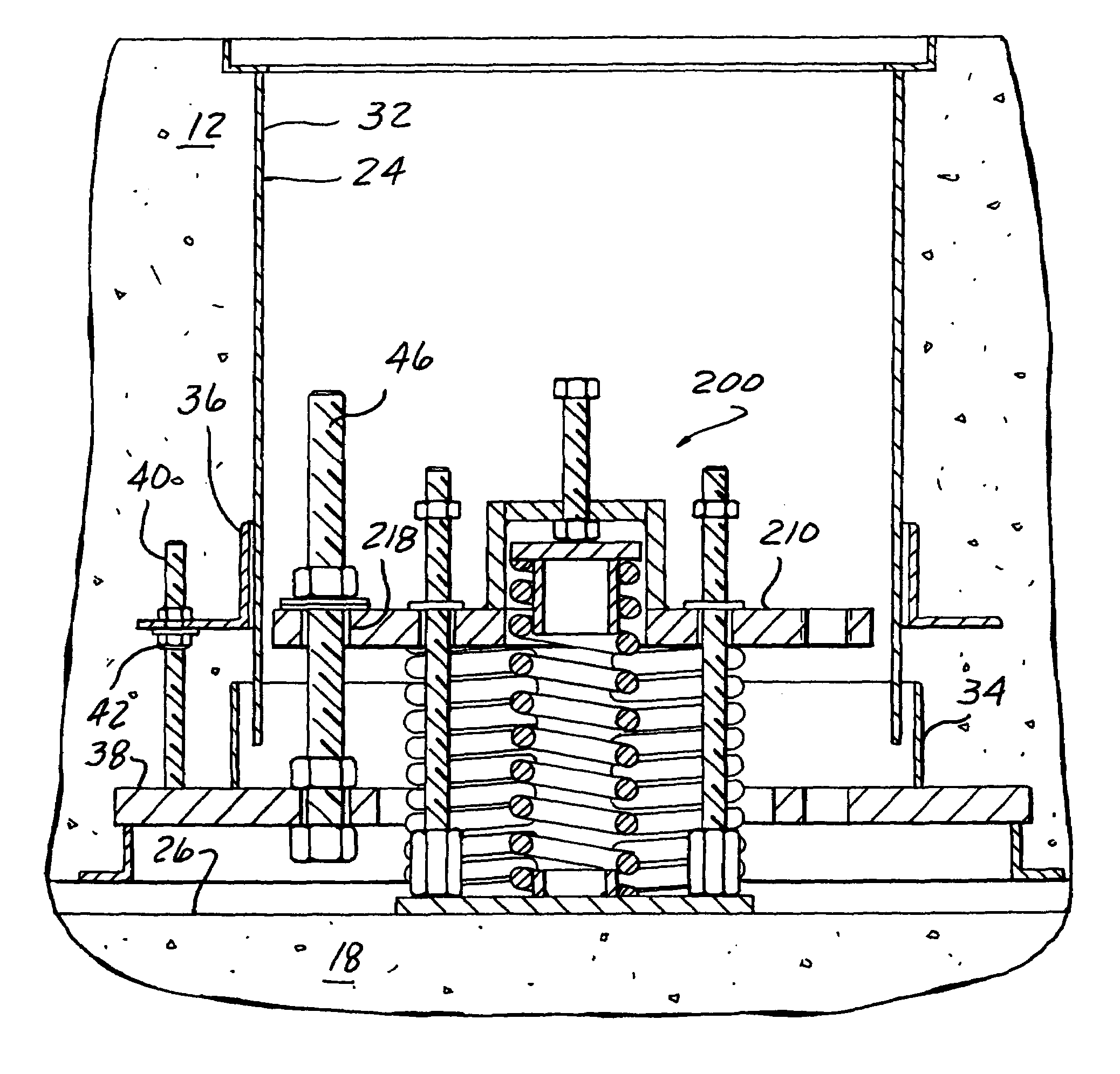

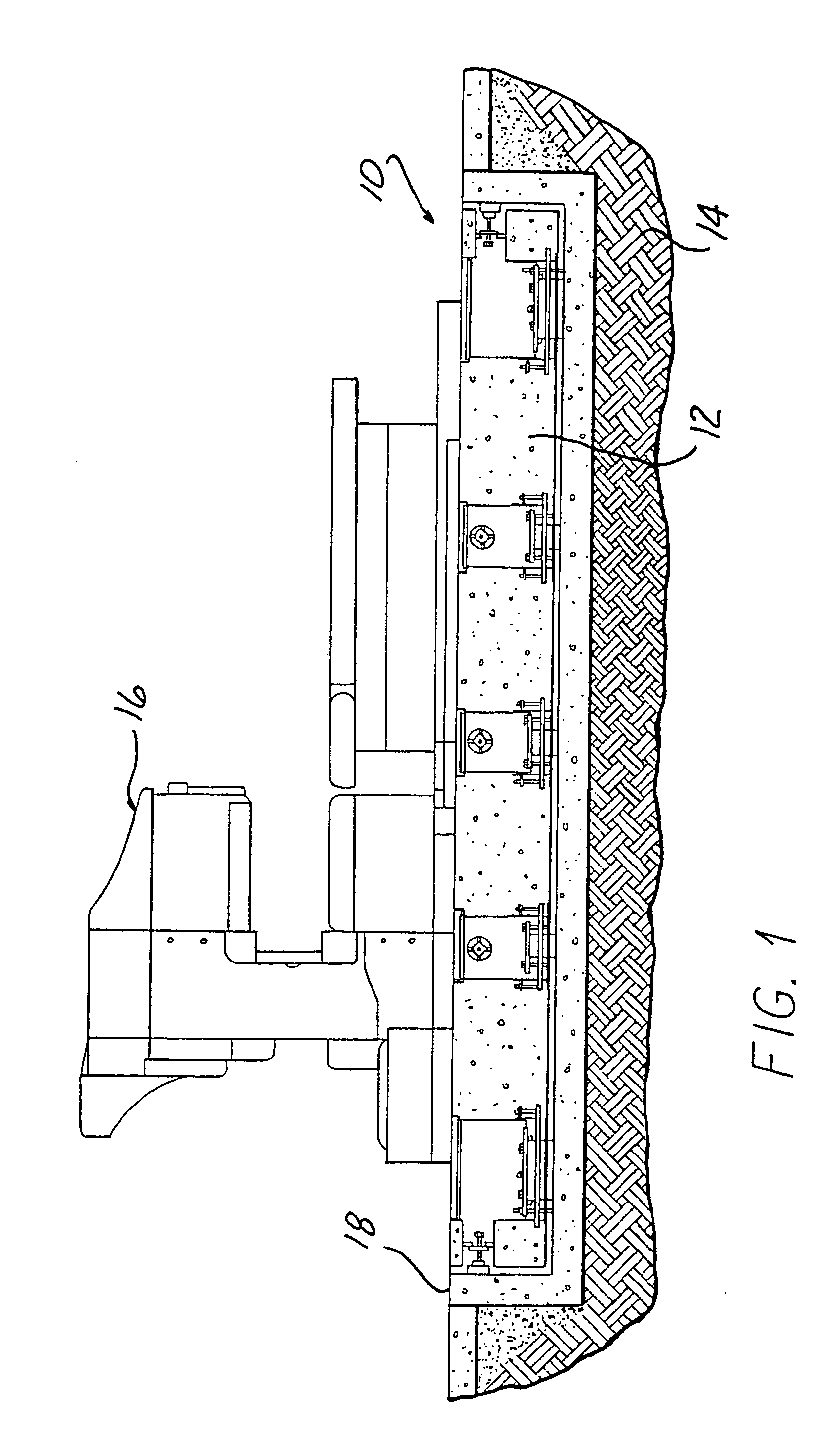

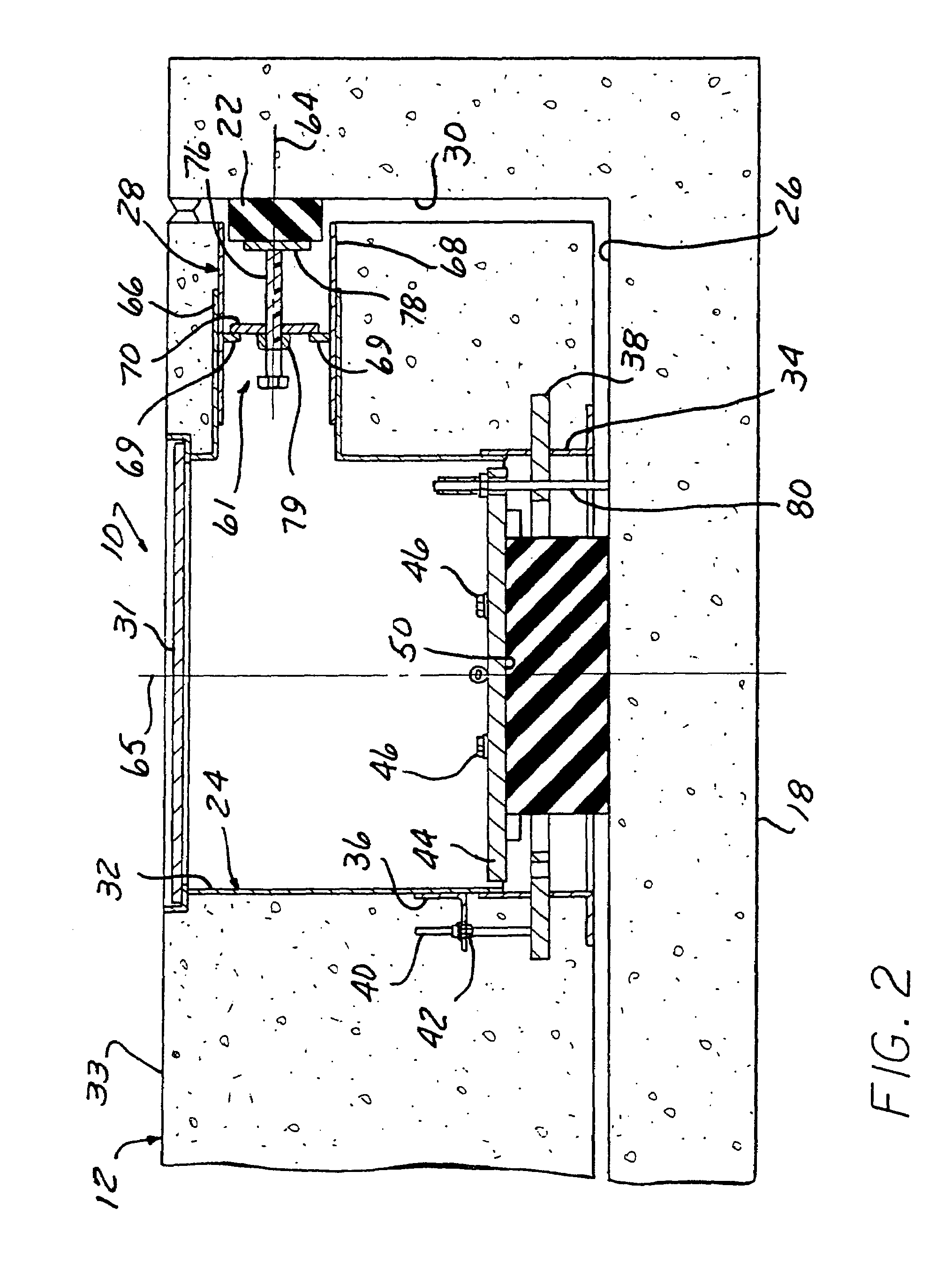

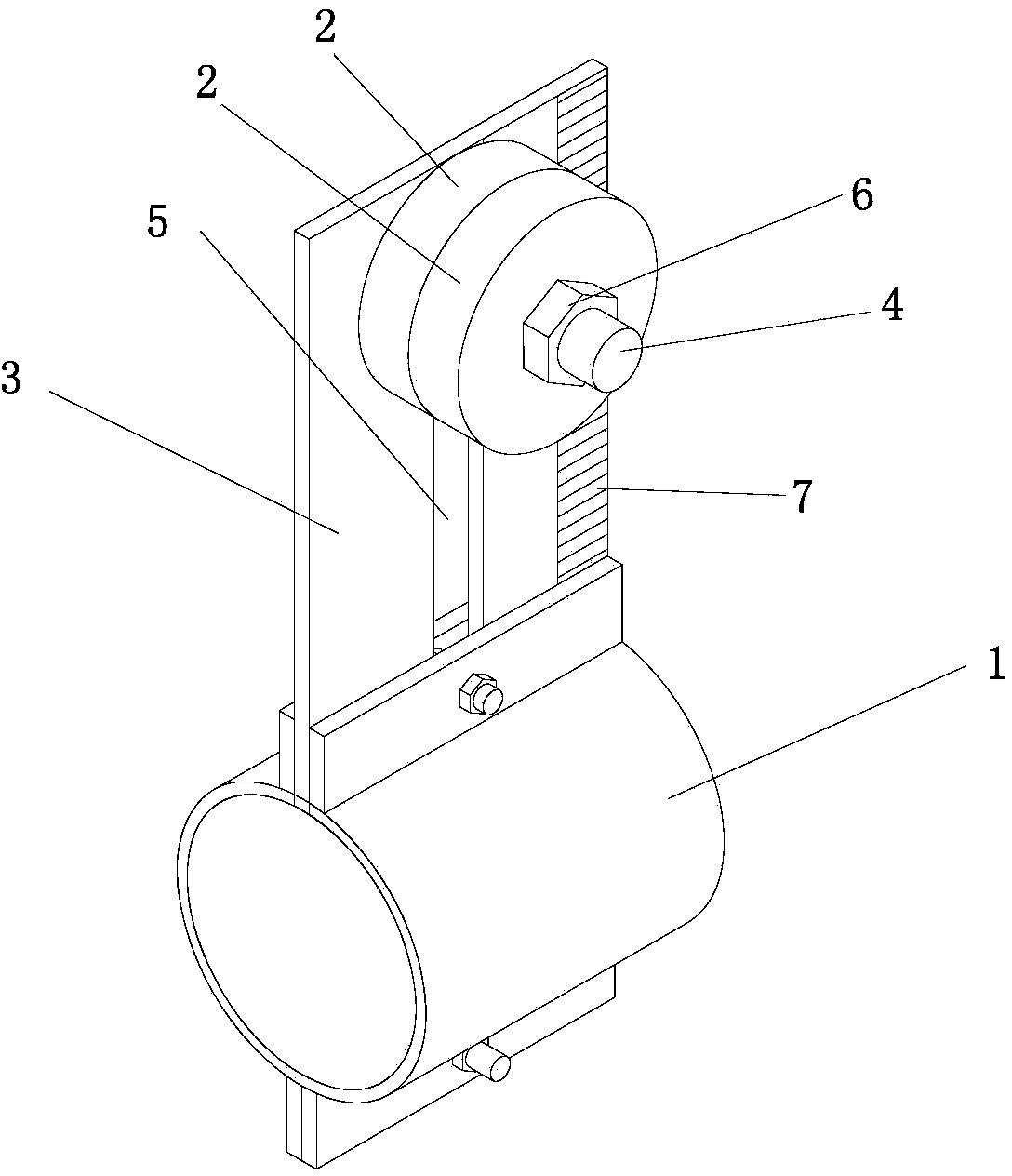

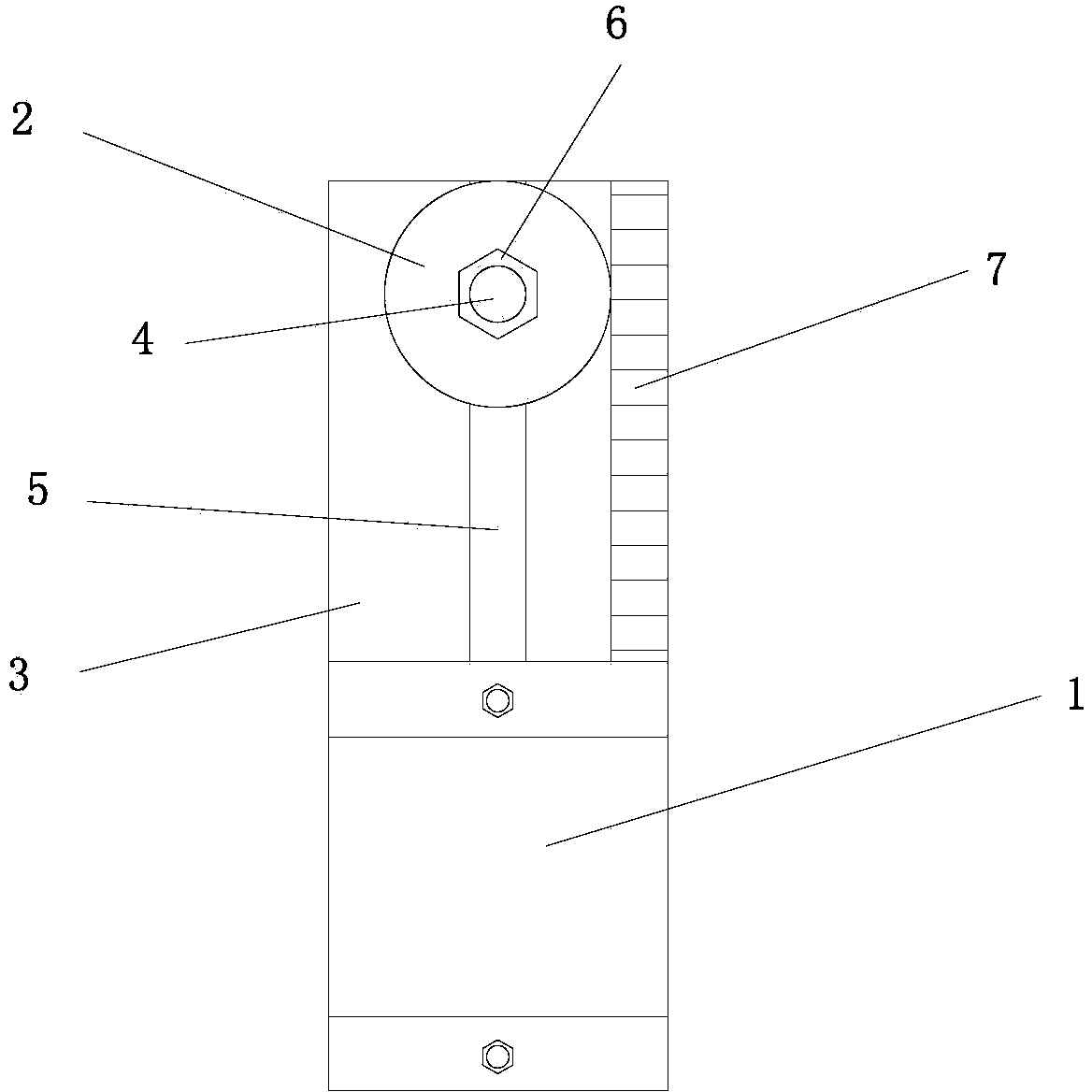

Apparatus for isolating and leveling a machine foundation

An apparatus for isolating and leveling a machine foundation with respect to a substructure of a building or the ground. The apparatus of the present invention provides an enclosure connectable to the machine foundation. A load bearing member is disposed within and adjustably connected to the enclosure. A primary support member and a secondary support member are positioned between the bearing member and the substructure for isolating the machine foundation from the substructure. The magnitude of force carried by the secondary support member may be adjusted to consequently adjust the natural frequency of the machine foundation.

Owner:UNISORB

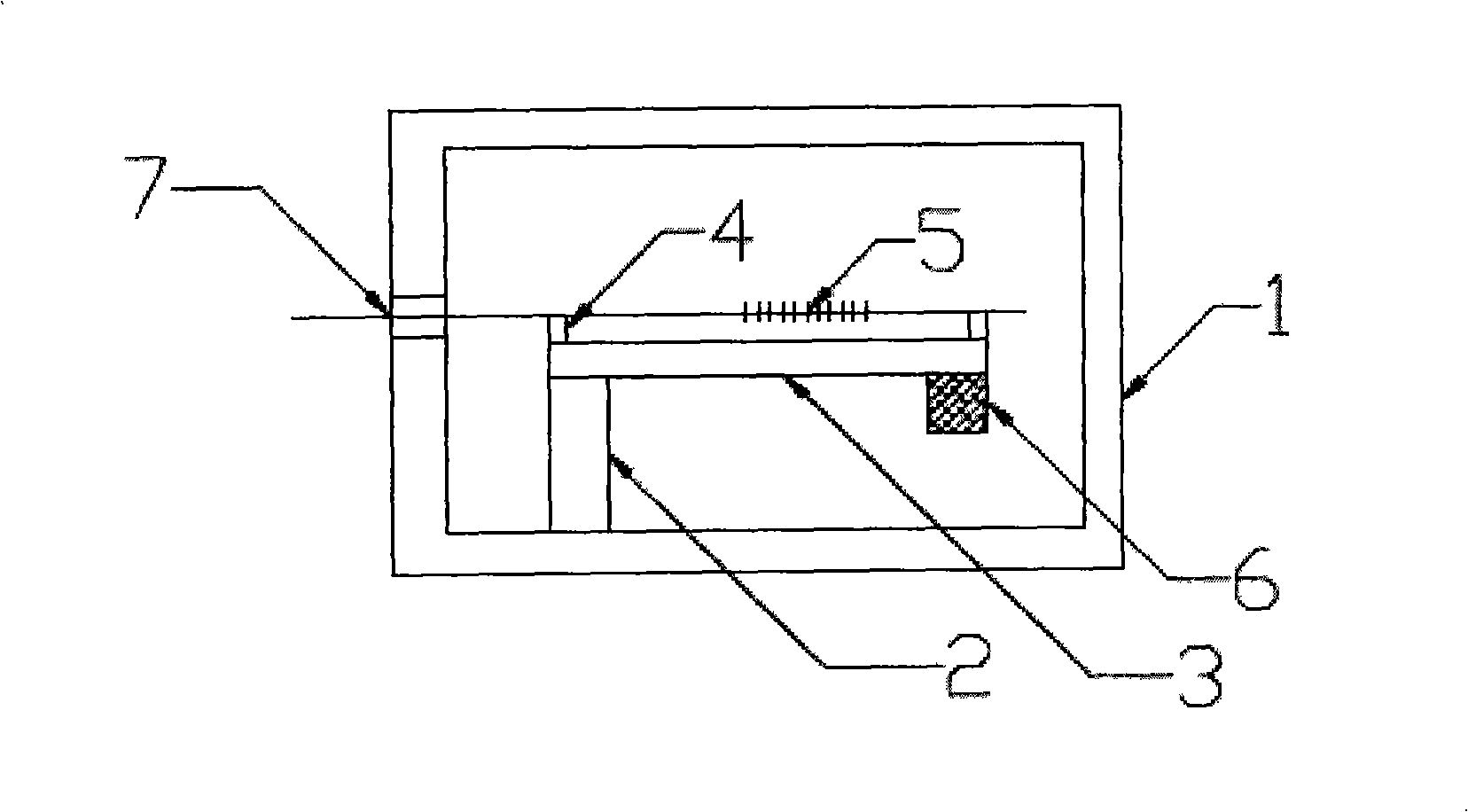

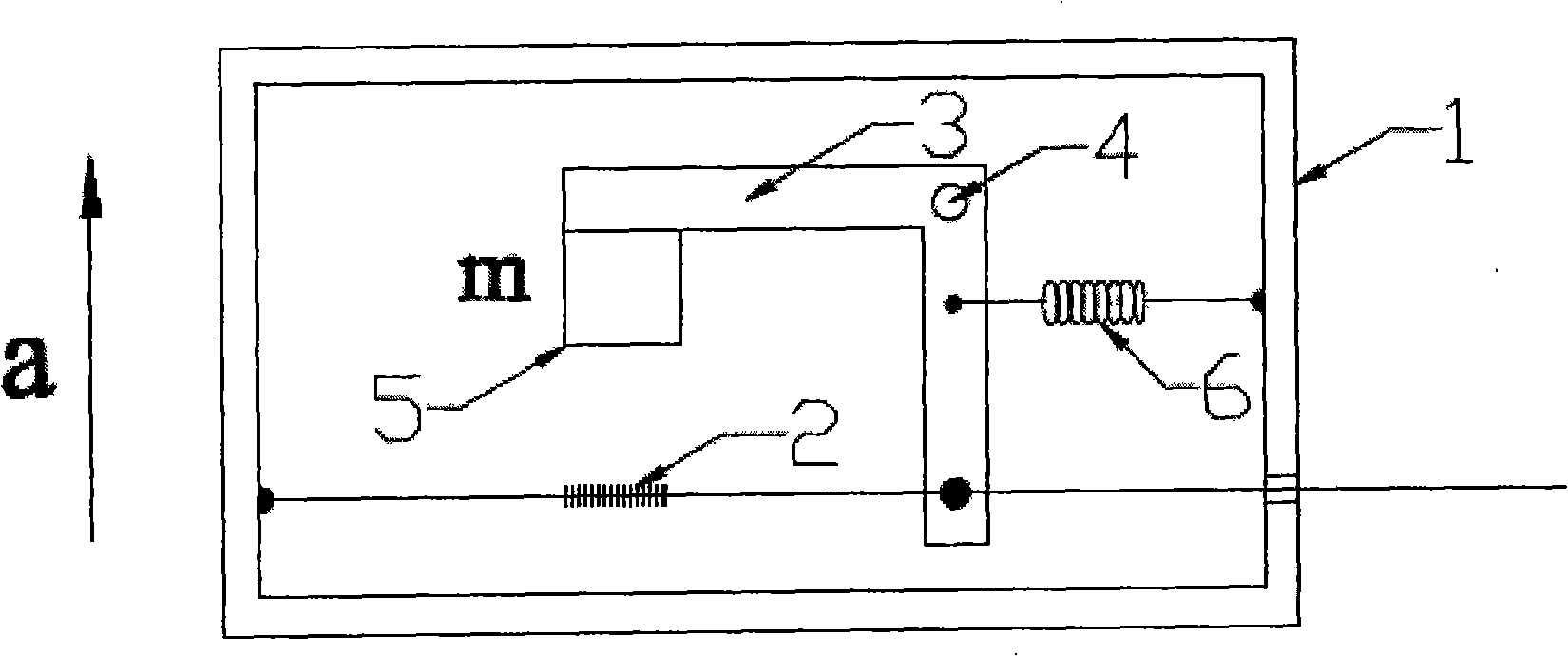

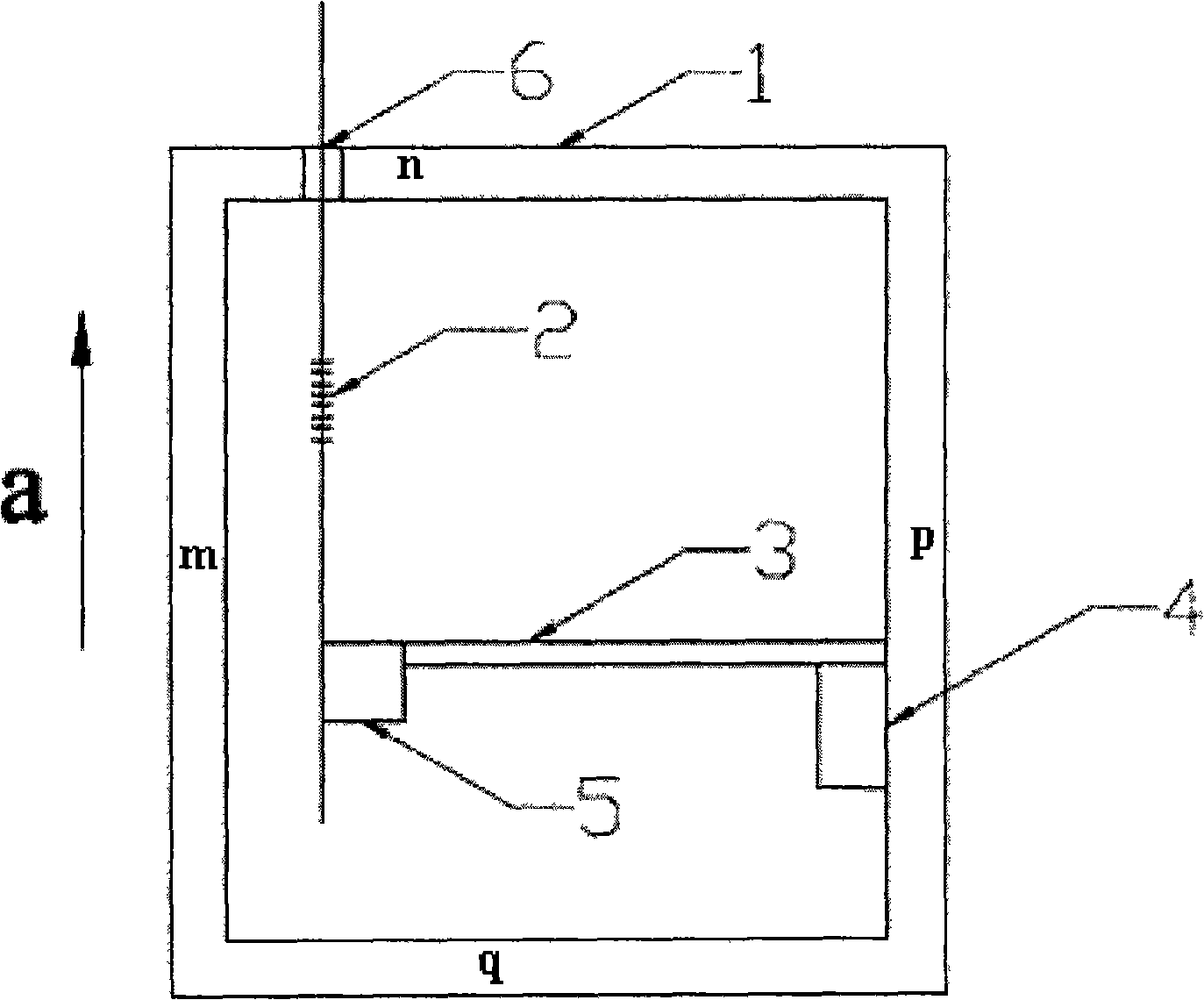

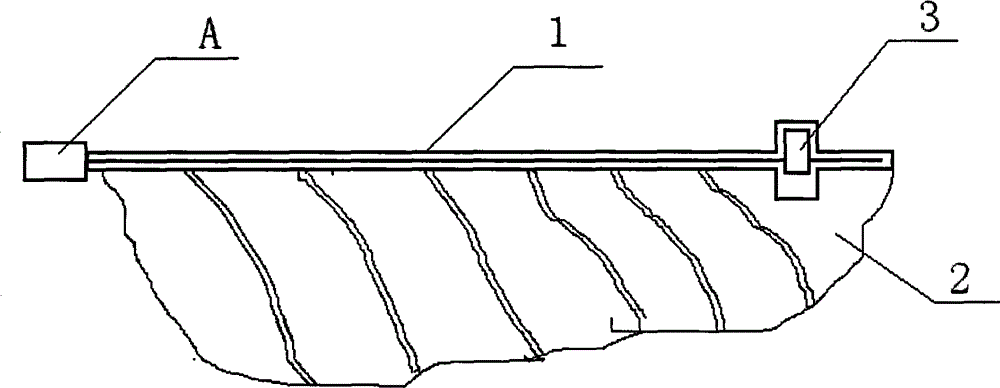

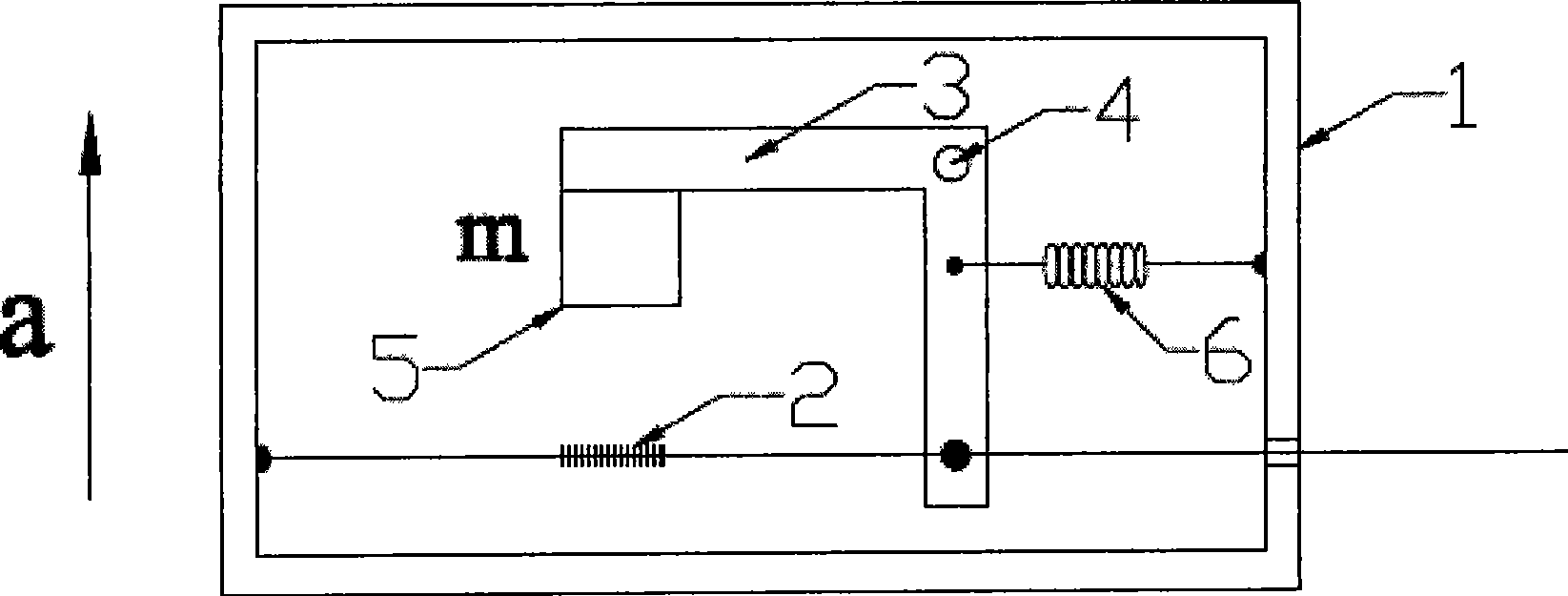

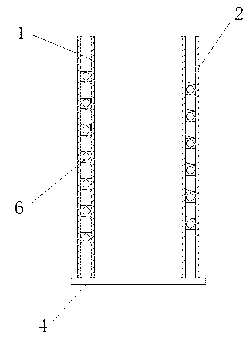

Optical fibre grating accelerometer based on cantilever beam deflection

InactiveCN101285846AHigh sensitivityLarge strainTelevision system detailsImpedence networksCantilevered beamAccelerometer

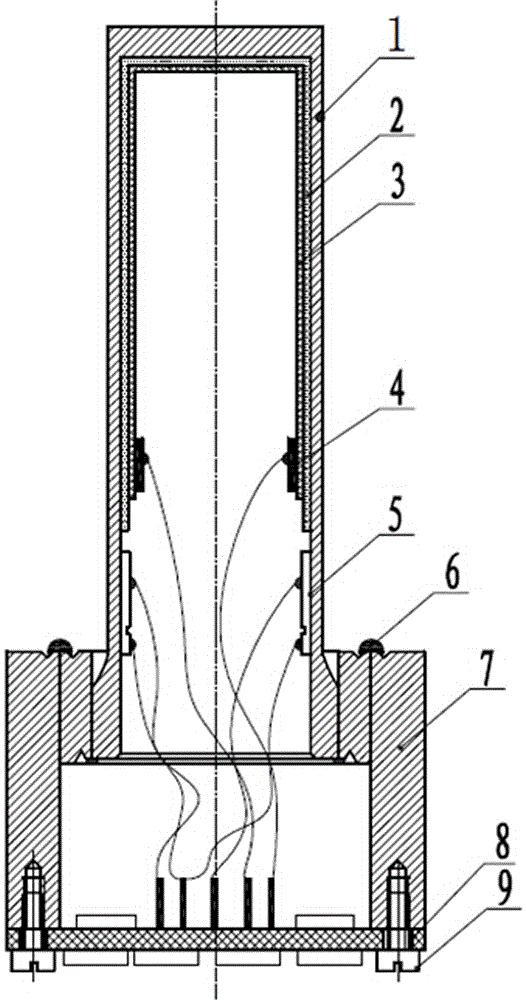

The invention relates to the optical fiber sensor technical field, disclosing an optical fiber grating accelerometer based on cantilever beam deflection. The accelerometer comprises an outer casing 1 used as a support structure of the accelerometer, an optical fiber grating 2 used to measure acceleration, a cantilever beam 3 with one end horizontally fixed on the third sidewall p of the accelerometer and a mass block 5 fixed at the other end of the cantilever beam 3, wherein the outer casing 1 has a first sidewall m, a second sidewall n, a third sidewall p and a fourth sidewall q; one end of the optical fiber grating 2 is fixed with the mass block 5, while the other end is parallel to the first sidewall m and passes through the hole 6 on the second sidewall n of the accelerometer to extend outside the accelerometer; the cantilever beam 3 is used to send vibration signal to the optical fiber grating 2; and the mass block 5 is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

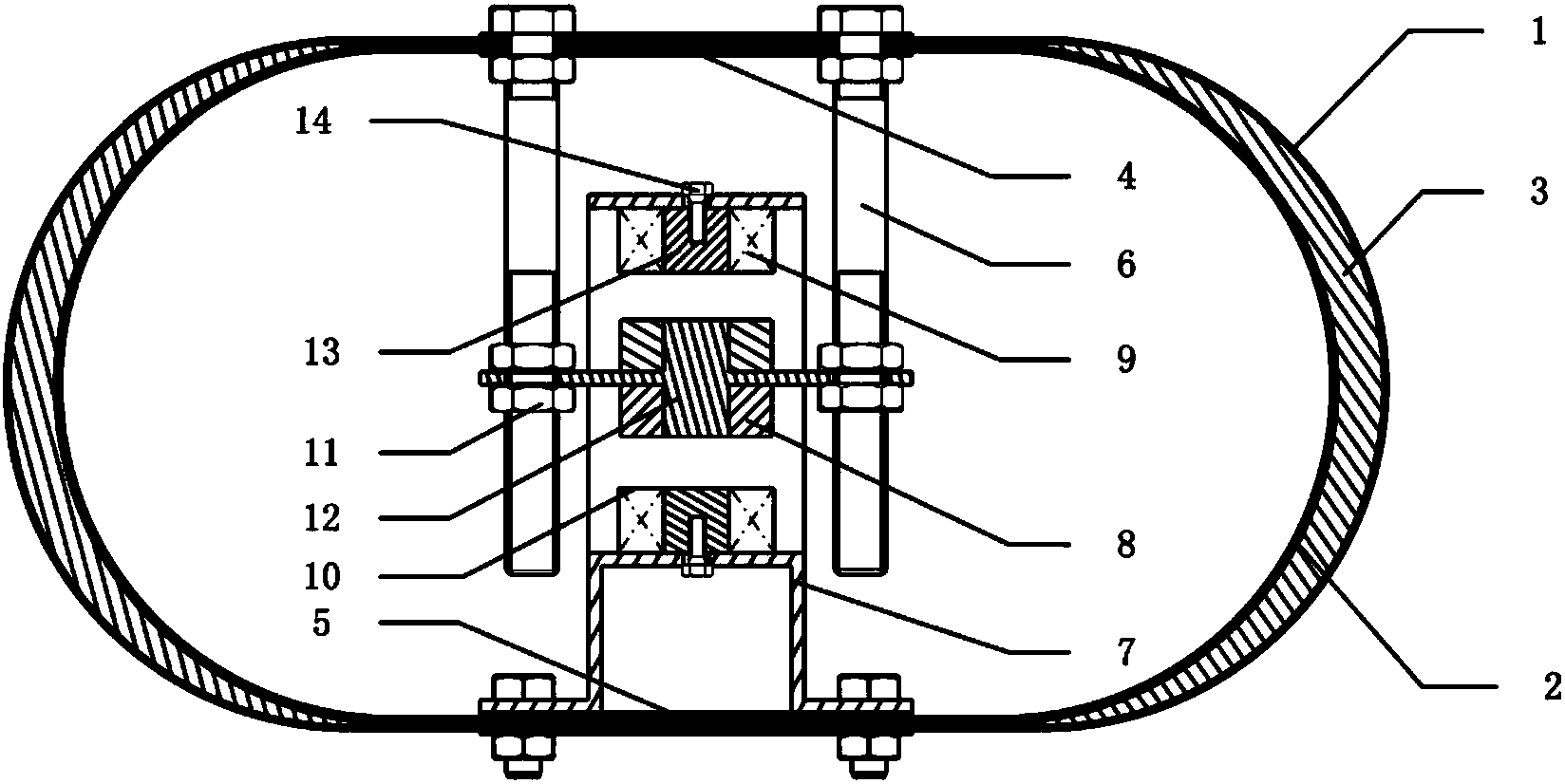

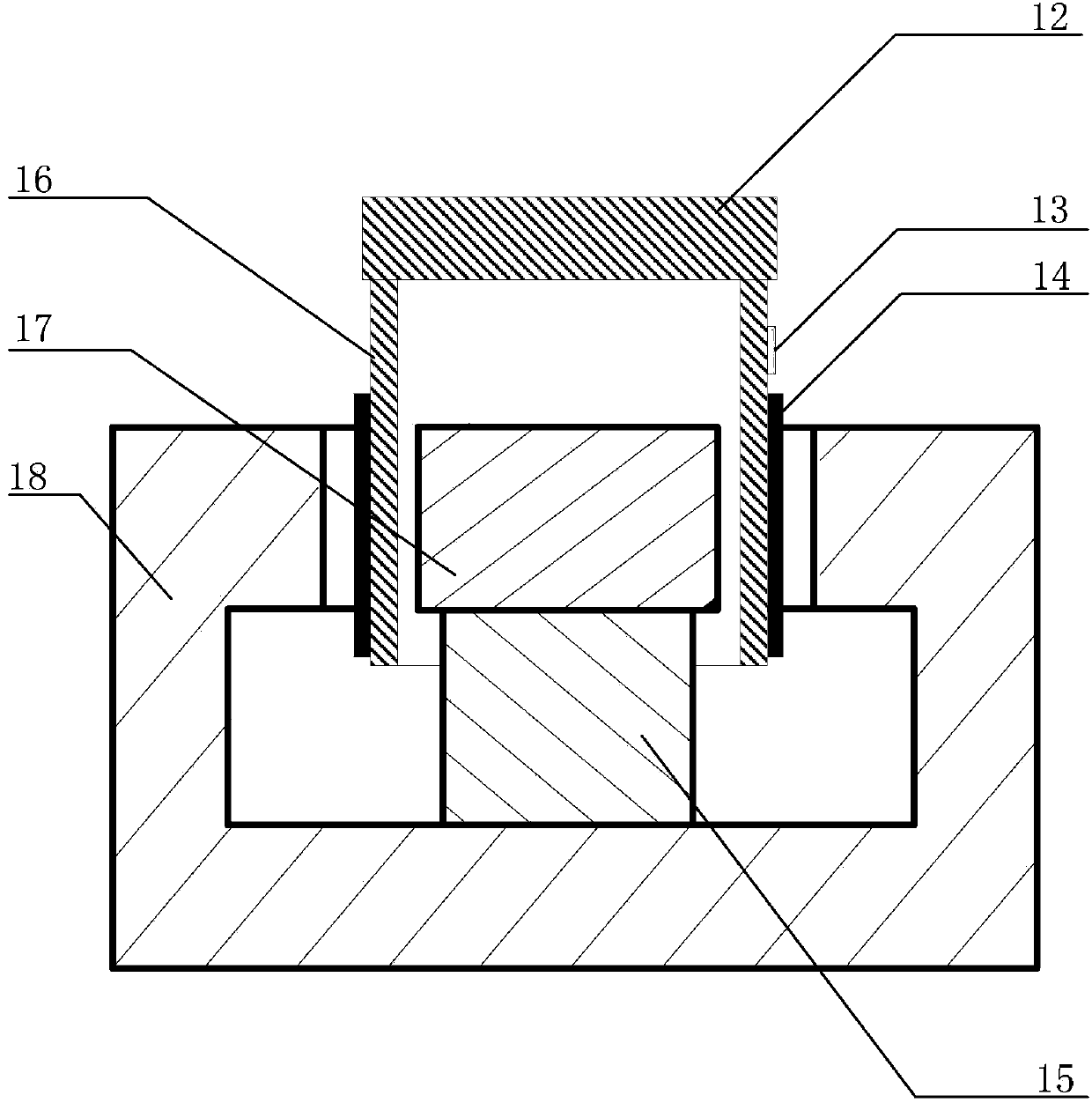

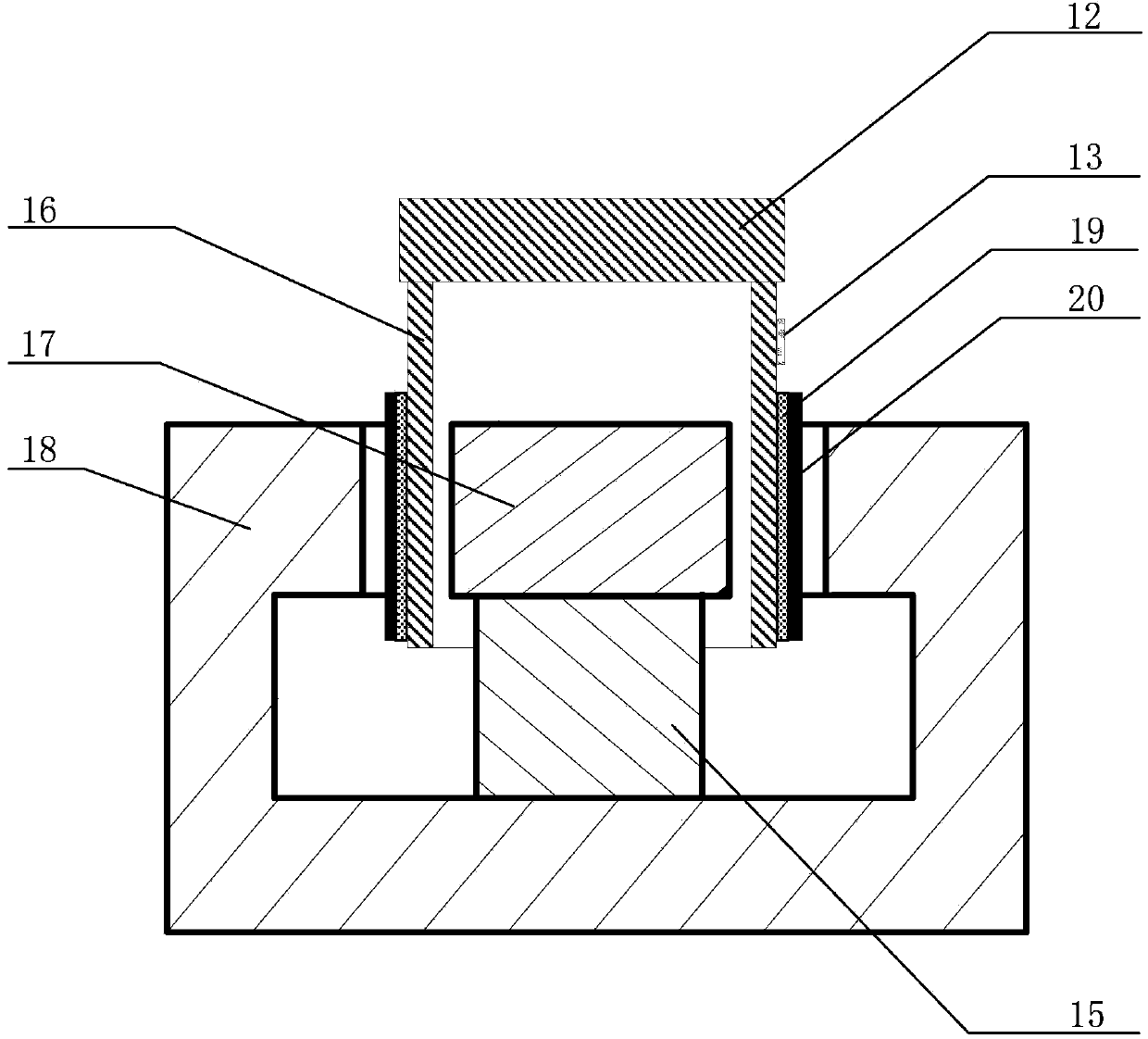

Rigidity-adjustable electromagnetic vibration isolator

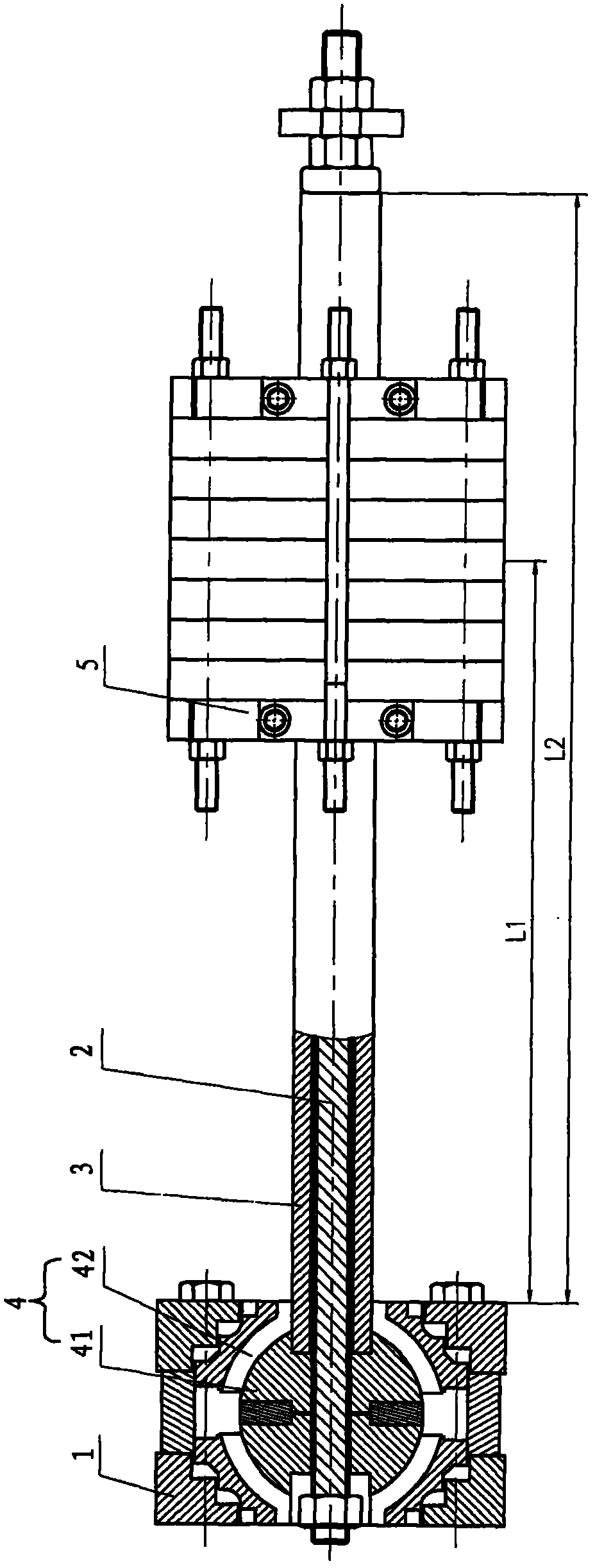

ActiveCN103511529AAdjustable stiffnessChange the stiffnessMagnetic springsArchitectural engineeringSpring steel

The invention aims to provide a rigidity-adjustable electromagnetic vibration isolator. The structure of a spring steel sheet portion is that an outer layer of spring steel sheets and an inner layer of spring steel sheets are distributed in a bilaterally symmetrical mode and are fixed between an upper fixing plate and a lower fixing plate respectively. Damping materials are filled between the laminated spring steel sheets. The structure of an electromagnet portion is that electromagnetic coils are installed on iron cores, the iron cores are fixed on the upper inner surface and the lower inner surface of an electrician pure iron mounting rack respectively, and the electrician pure iron mounting rack provided with the electromagnetic coils is fixed to the lower fixing plate of the vibration isolator through bolts. The structure of a movable permanent magnet portion is that two adjusting bolts are fixed on the upper fixing plate through nuts respectively, two protruded circular columns are arranged on the center of the upper surface and on the center of the lower surface of a permanent magnet fixing plate, two ring permanent magnets are fixed on the upper surface and the lower surface of a middle plate through the protruded circular columns, and the fixing plate provided with the permanent magnets is connected with the adjusting bolts through the adjusting nuts. According to the rigidity-adjustable electromagnetic vibration isolator, the advantage of good stability of a passive vibration isolator and the advantage of flexible application of an active vibration isolator are integrated.

Owner:HARBIN ENG UNIV

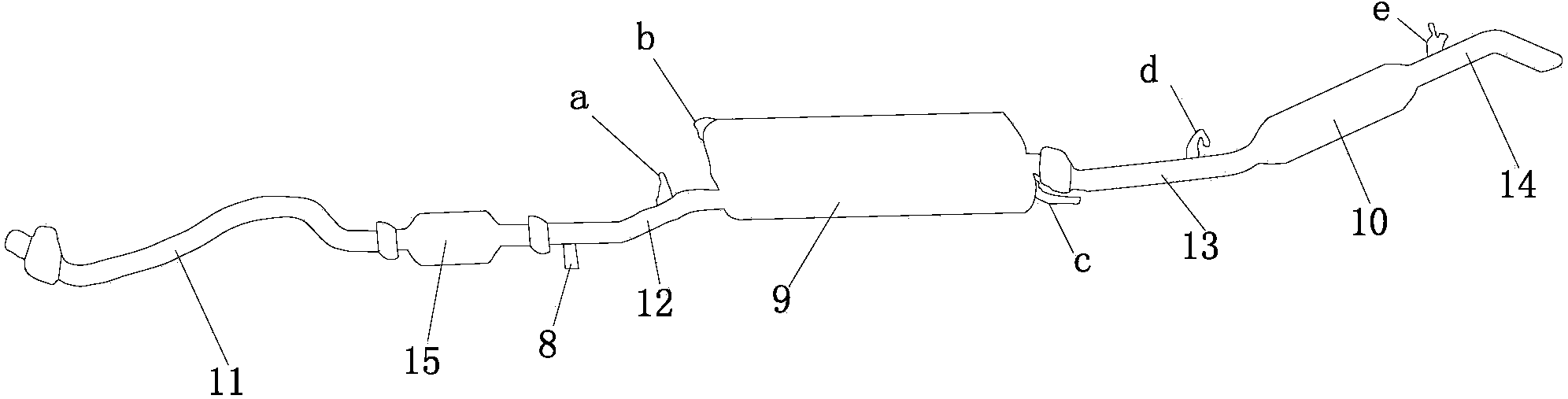

Dynamic vibration absorber capable of improving NVH and matching method thereof

ActiveCN104214262AReduce vibrationChange natural frequencySpecial data processing applicationsShock absorbersEngineeringDynamic Vibration Absorber

The invention relates to a dynamic vibration absorber capable of improving NVH (Noise, Vibration and Harshness) and a matching method thereof. The dynamic vibration absorber comprises a connecting seat and a plurality of mass blocks; the dynamic vibration absorber further comprises a plate spring, a connecting post, and a fastening piece; one end of the plate spring is fixedly connected to the connecting seat, a sliding chute is further formed in the plate spring in the length direction thereof, the connecting post is detachably connected with the mass blocks, one end of the connecting post is arranged inside the sliding chute in a sliding manner along the sliding chute, and the fastening piece is connected with the connecting post and used for fixedly connecting the mass blocks onto the plate spring. The dynamic vibration absorber provided by the invention can ensure that the natural frequency of the dynamic vibration absorber is adjustable by adjusting the weights and the positions of the mass blocks, aiming at different systems of a whole vehicle, a universal dynamic vibration absorber can be available for damp matching, and an optimal scheme for vibration restraining can be found quickly.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG

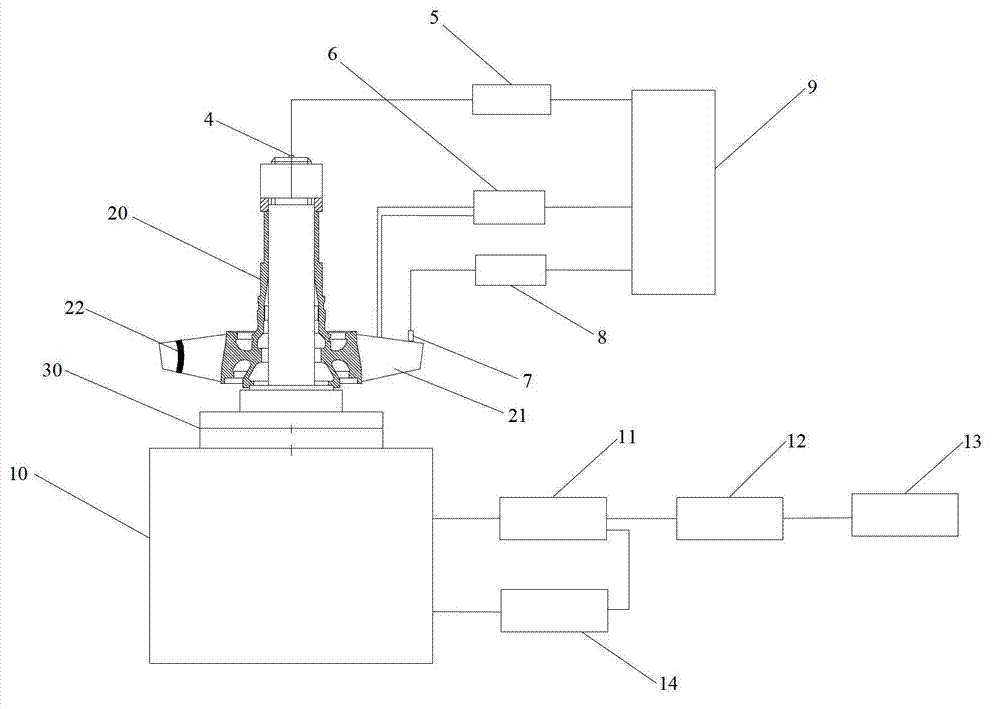

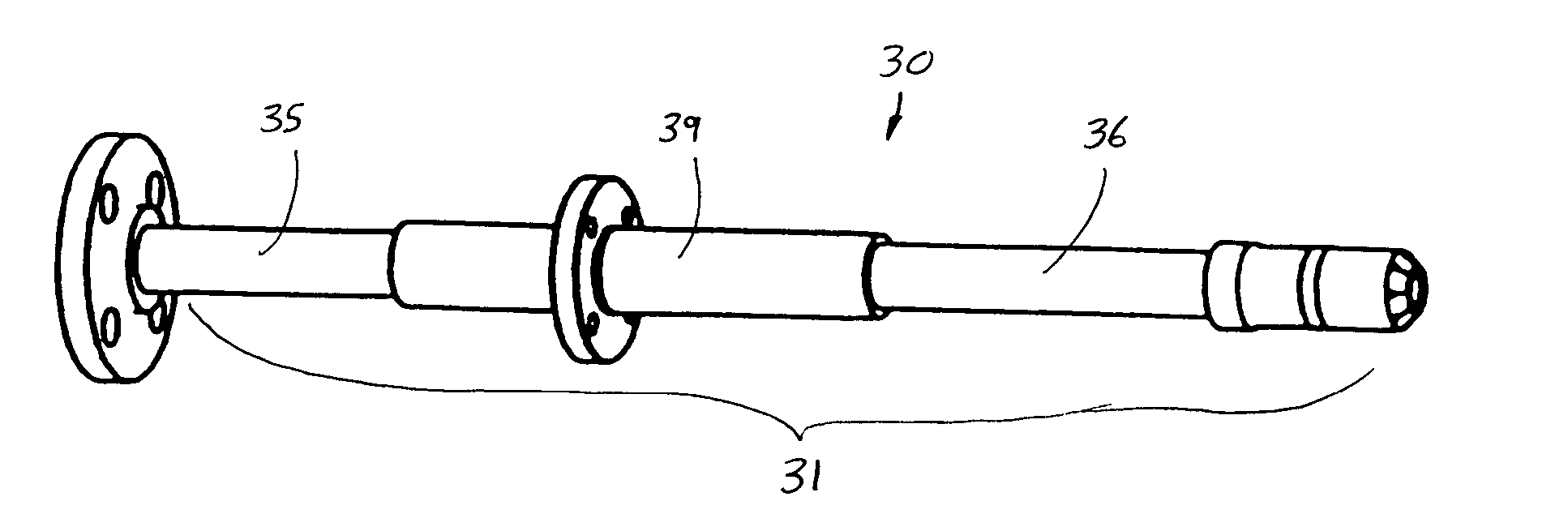

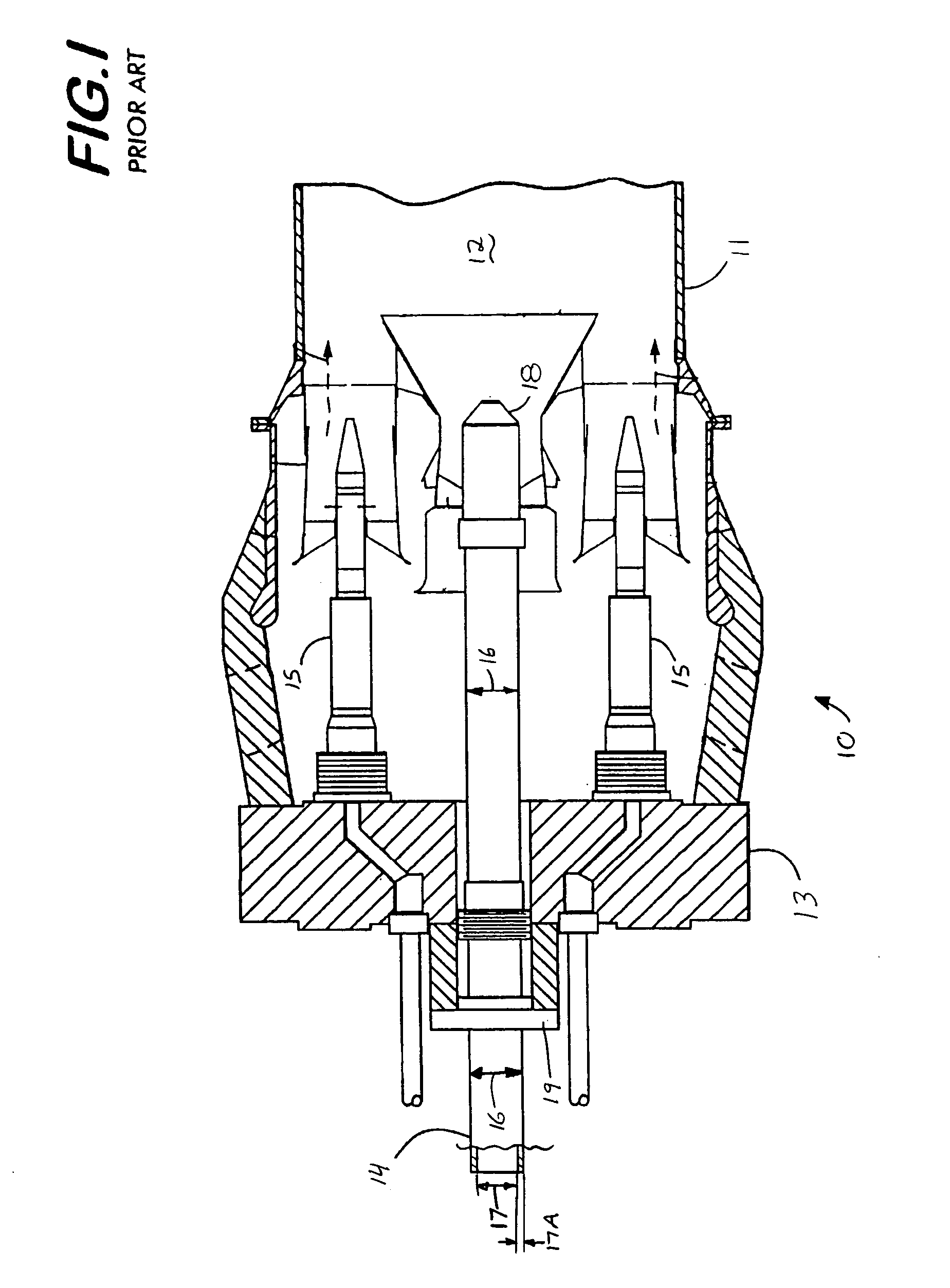

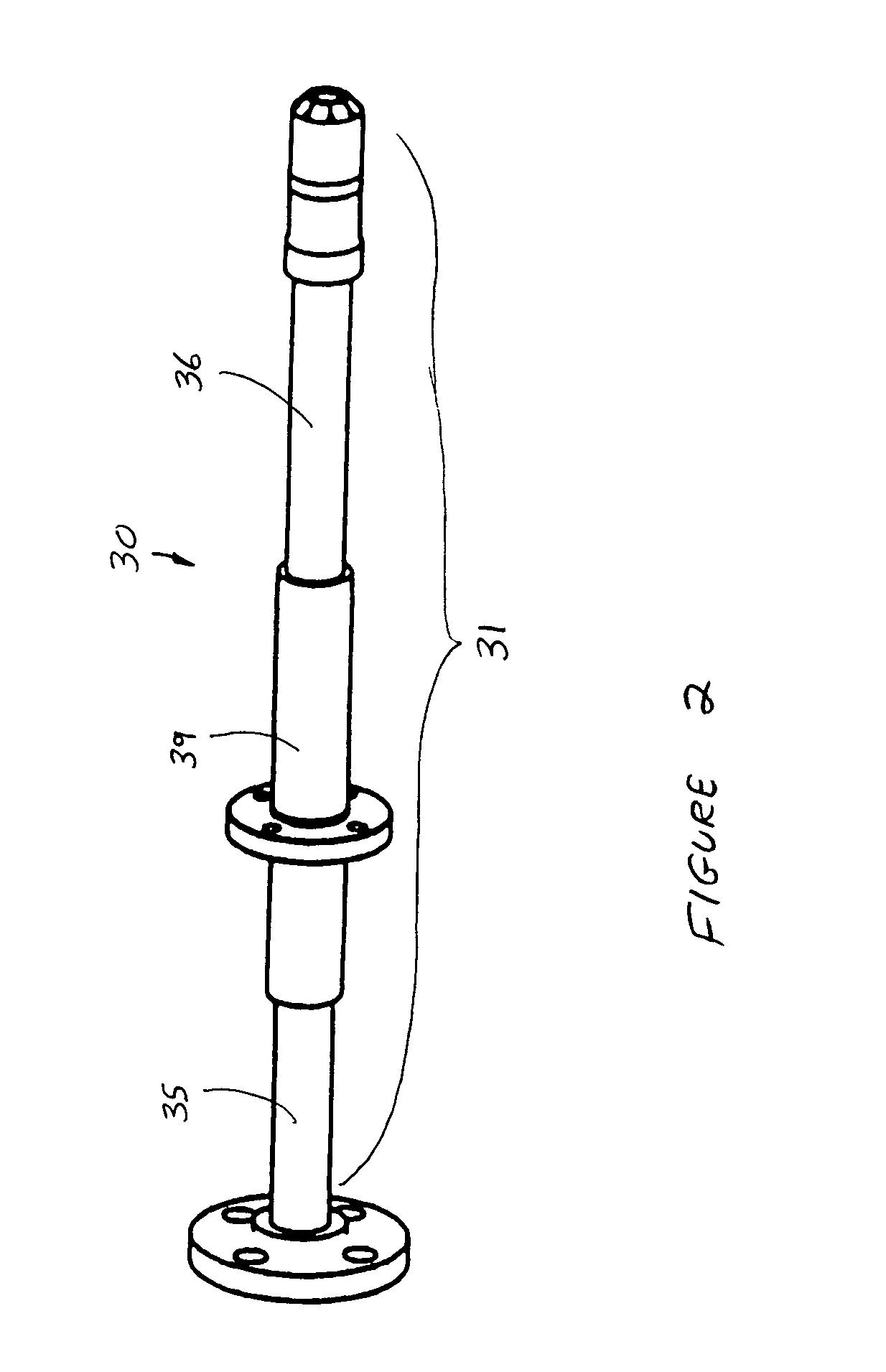

Gas turbine fuel pilot nozzle

ActiveUS20050039460A1Increase wall thicknessIncrease stiffnessTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorGas turbines

A pilot fuel nozzle configuration for use in a combustor is disclosed having a natural frequency outside the range of the operating frequencies of a gas turbine engine. Multiple embodiments are disclosed for the improved pilot fuel nozzle including configurations for newly manufactured nozzles, repair to existing pilot nozzles, as well as multiple natural frequency levels for the improved pilot fuel nozzle. The pilot fuel nozzle comprises an elongated housing, first and second flanges, and a nozzle tip, with the first flange fixed to the elongated housing at a first end and the nozzle tip fixed to the second end, opposite of the first end. The second flange is fixed along the elongated housing and is used for attaching the pilot fuel nozzle to a combustor. The present invention incorporates an increased wall thickness along at least a mid-span portion of the pilot nozzle to increase the stiffness and change the natural frequency.

Owner:H2 IP UK LTD

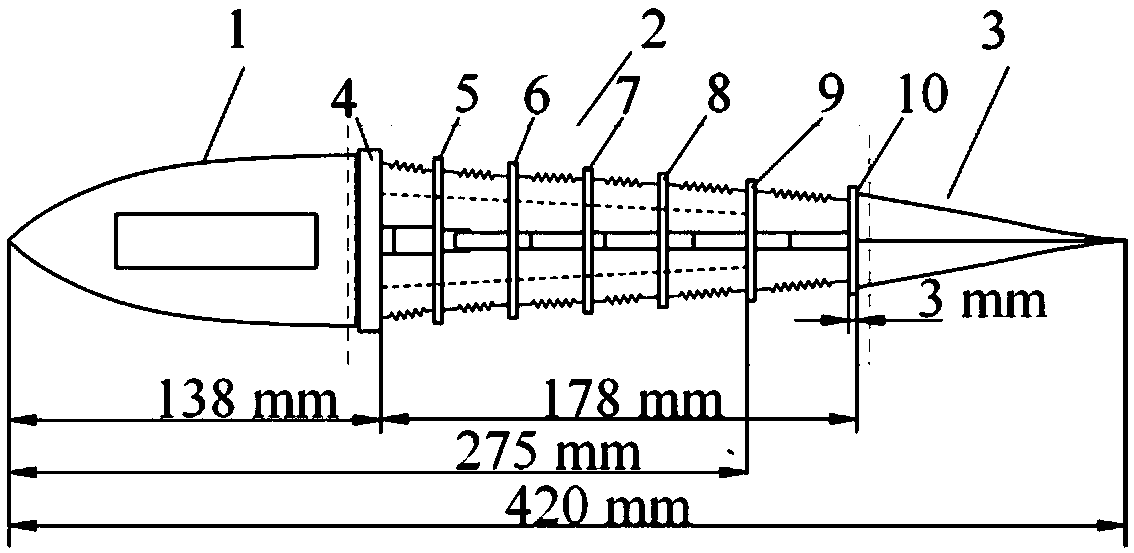

Piezoelectric vibration cylinder icing sensor and method for measuring icing condition thereof

ActiveCN105571478AChange equivalent massReal-time measurementUsing electrical meansElectrical/magnetic thickness measurementsJet aeroplaneEngineering

The invention belongs to the technical field of airplane icing detection, and specifically relates to a piezoelectric vibration cylinder icing sensor and a method for measuring icing condition thereof. Problems that most of the conventional icing sensors only provide icing threshold signals, the thickness of an ice layer cannot be effectively monitored in real time, the sensitivity is low, the size and the mass are large, and the requirements of miniaturization and intelligence of the sensors are hard to be met are solved. The piezoelectric vibration cylinder icing sensor comprises a vibration cylinder, the vibration cylinder is regarded as a resonance sensitive element, an inner wall of the vibration cylinder is pasted with two piezoelectric ceramics respectively serving as a piezoelectric actuating element and a piezoelectric pickup element, an insulation thermal conduction film is grown on an inner wall of the vibration cylinder, an electrothermal film is grown on the insulation thermal conduction film, and two ends of the electrothermal film are equipped with silver electrodes. The equivalent mass of the vibration cylinder is changed by icing so that the natural frequency is changed; and the measurement of the thickness of the ice layer is realized via the detection of the natural frequency of the vibration cylinder. According to the sensor and the method thereof, the precision is high, the reliability is good, the size is small, the power consumption is low, the structure is simple, the production is easy, and the measurement is free of the influence of the external magnetic field.

Owner:TAIYUAN AERO INSTR

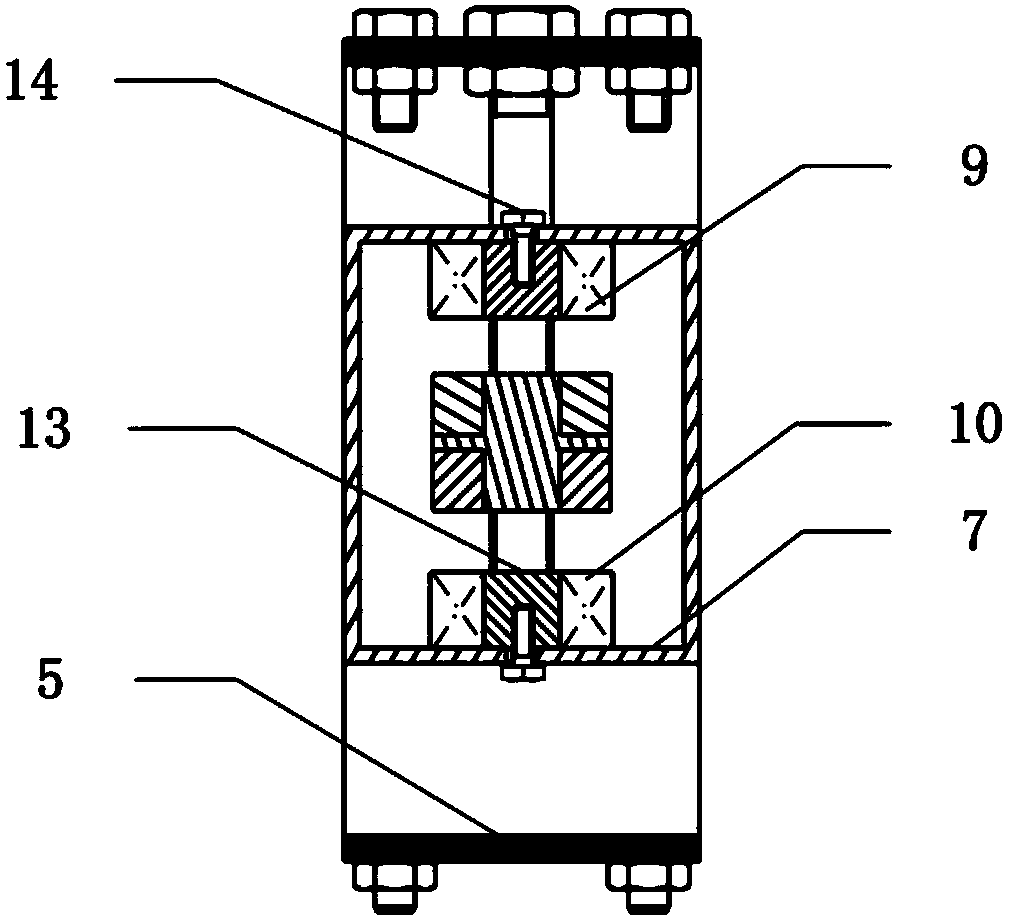

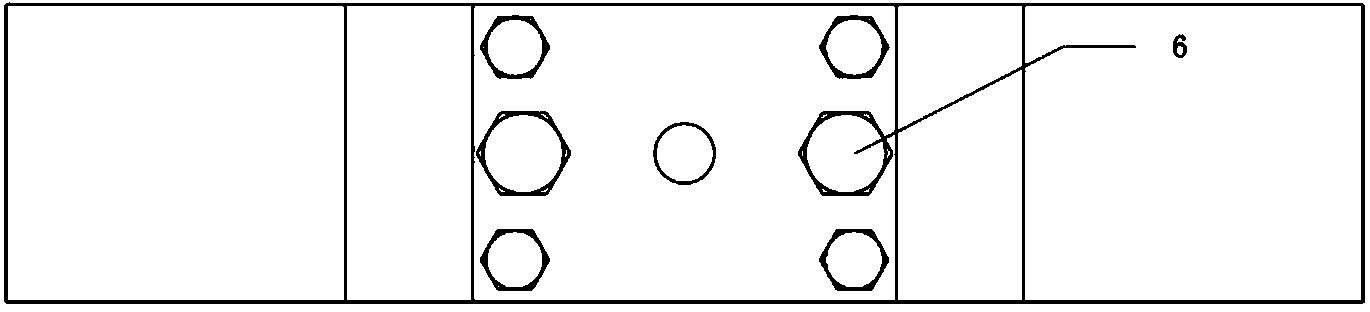

Vibration absorption control device for tuned mass damper

ActiveCN102409775AThe overall structure is simple and reliableReduce manufacturing costShock proofingAdhesiveEngineering

The invention provides a vibration absorption control device for a tuned mass damper. The vibration absorption control device for the tuned mass damper comprises a shell, a long rod, a reinforcing pipe, a rubber and metal adhesive and a counterweight block, wherein the shell is fixed on a main body structure needing vibration absorption; one end of the long rod is fixed in the shell, and the other end of the long rod is extended to the outer part of the shell; the reinforcing pipe is assembled on the long rod; the rubber and metal adhesive is fixed in the shell and wraps one end of the long rod fixed in the shell; and the counterweight block is arranged on the reinforcing pipe, and the gravity center of the counterweight block is separated from the shell in a predetermined distance. The vibration absorption control device for the tuned mass damper has a simple and reliable structure and low manufacturing cost and is easy and convenient to mount.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

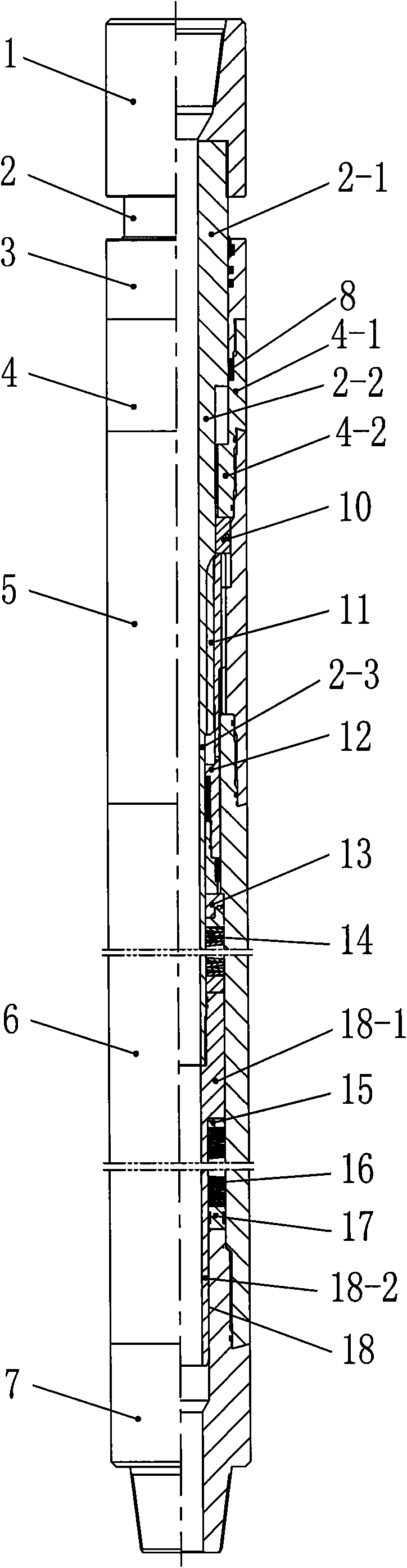

Mechanical multidirectional absorber

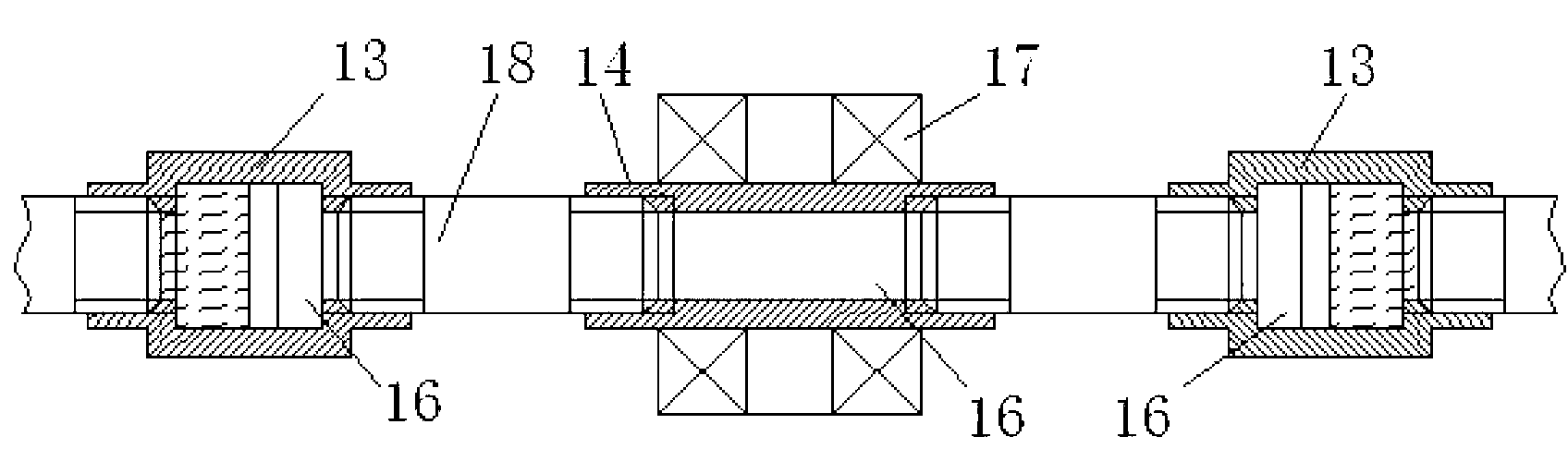

InactiveCN101608535AEliminate or reduce shock loadsChange natural frequencyDrilling rodsDrilling casingsElastomerVibration attenuation

A mechanical multidirectional absorber relates to the field of oil and gas well projects and geological exploration drilling and comprises an upper joint. The lower end of the upper joint is connected with a mandrel which comprises a large-outer-diameter mandrel, a medium-outer-diameter mandrel and a small-outer-diameter mandrel. A mud scraping ring seat, a stabilizing cylinder, a spline cylinder and a guide cylinder are arranged outside the mandrels. The stabilizing cylinder comprises a large-inner-diameter stabilizing cylinder and a small-inner-diameter stabilizing cylinder. An upper hydraulic chamber is arranged between the medium-outer-diameter mandrel and the large-inner-diameter stabilizing cylinder. A damping ring gap is arranged between the medium-outer-diameter mandrel and the small-inner-diameter stabilizing cylinder. A piston, a thrust bearing and an upper elastomer are arranged between the mandrel and the spline cylinder as well as the guide cylinder. The piston comprises a piston body and a piston joint. The piston body comprises a large-inner-diameter piston body and a small-inner-diameter piston body and is provided with a torque transforming mechanism. A lower hydraulic chamber is arranged between the small-outer-diameter mandrel and the large-inner-diameter piston body. A guide rod is connected with the lower end of the mandrel. A lower elastomer and a lower joint are arranged between the guide rod and the guide cylinder. The lower joint is connected with the lower end of the guide cylinder. The mechanical multidirectional absorber integrates the functions of damping, vibration attenuation and vibration isolation and has good safety.

Owner:YANGZHOU TIANYE GASOLINEEUM MACHINERY

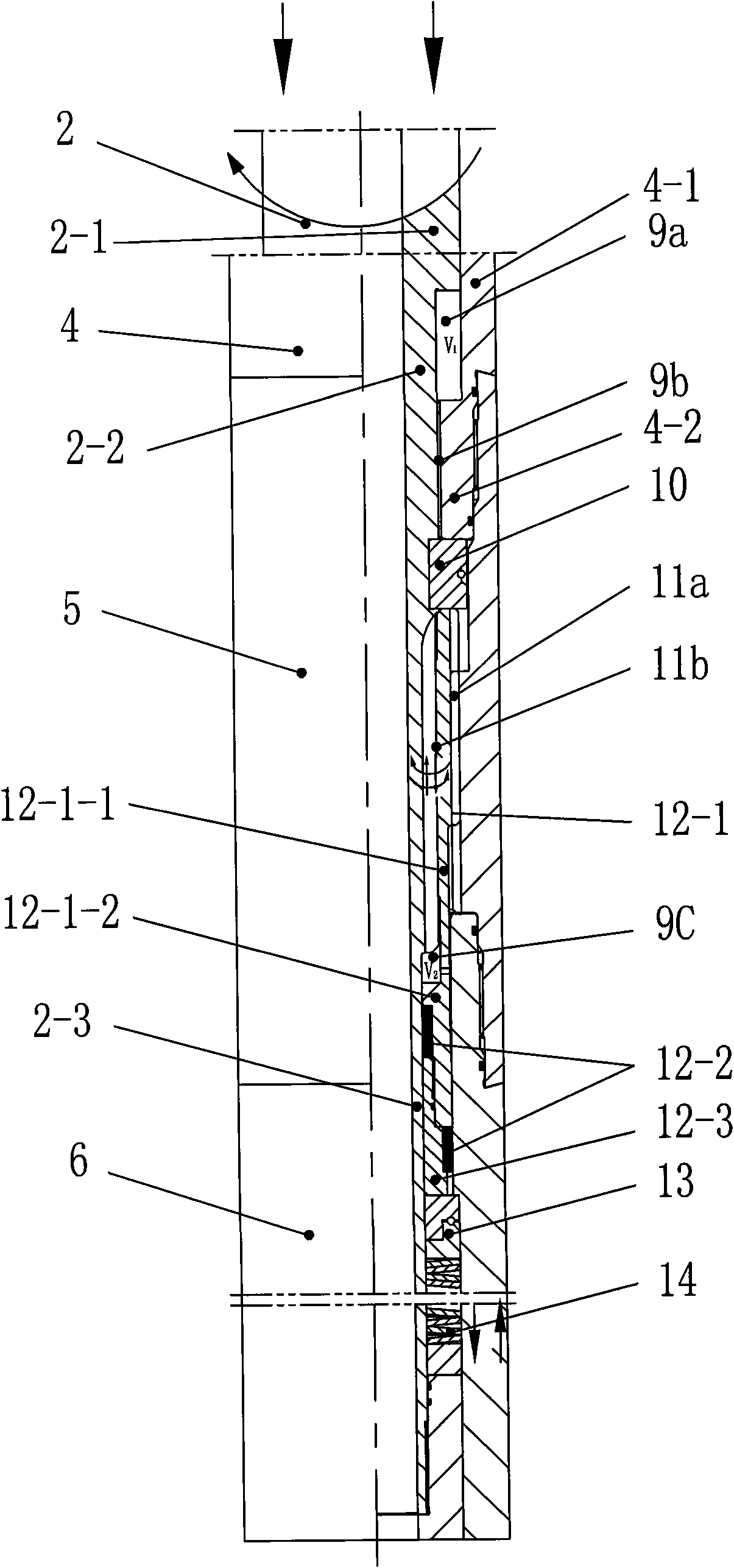

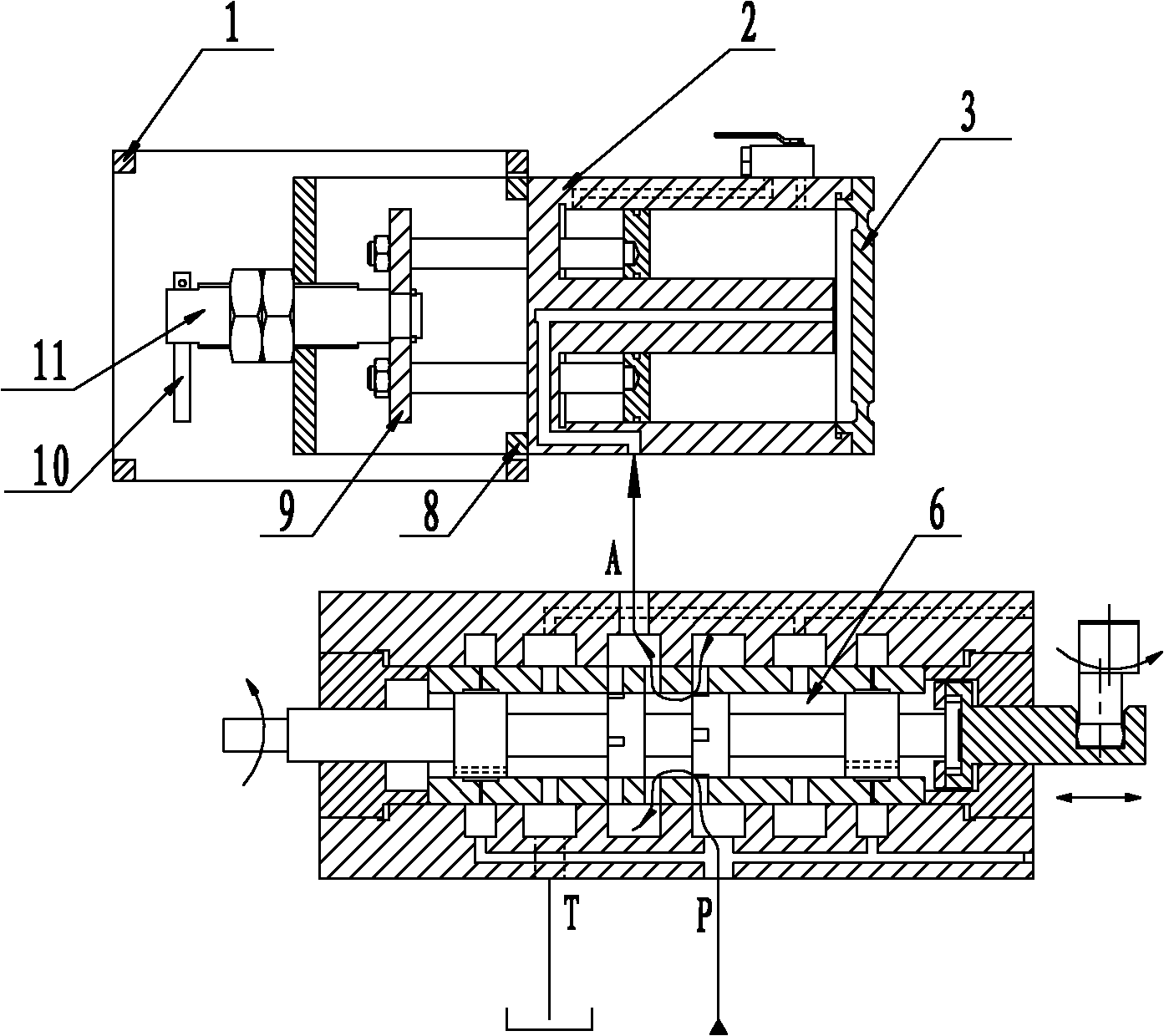

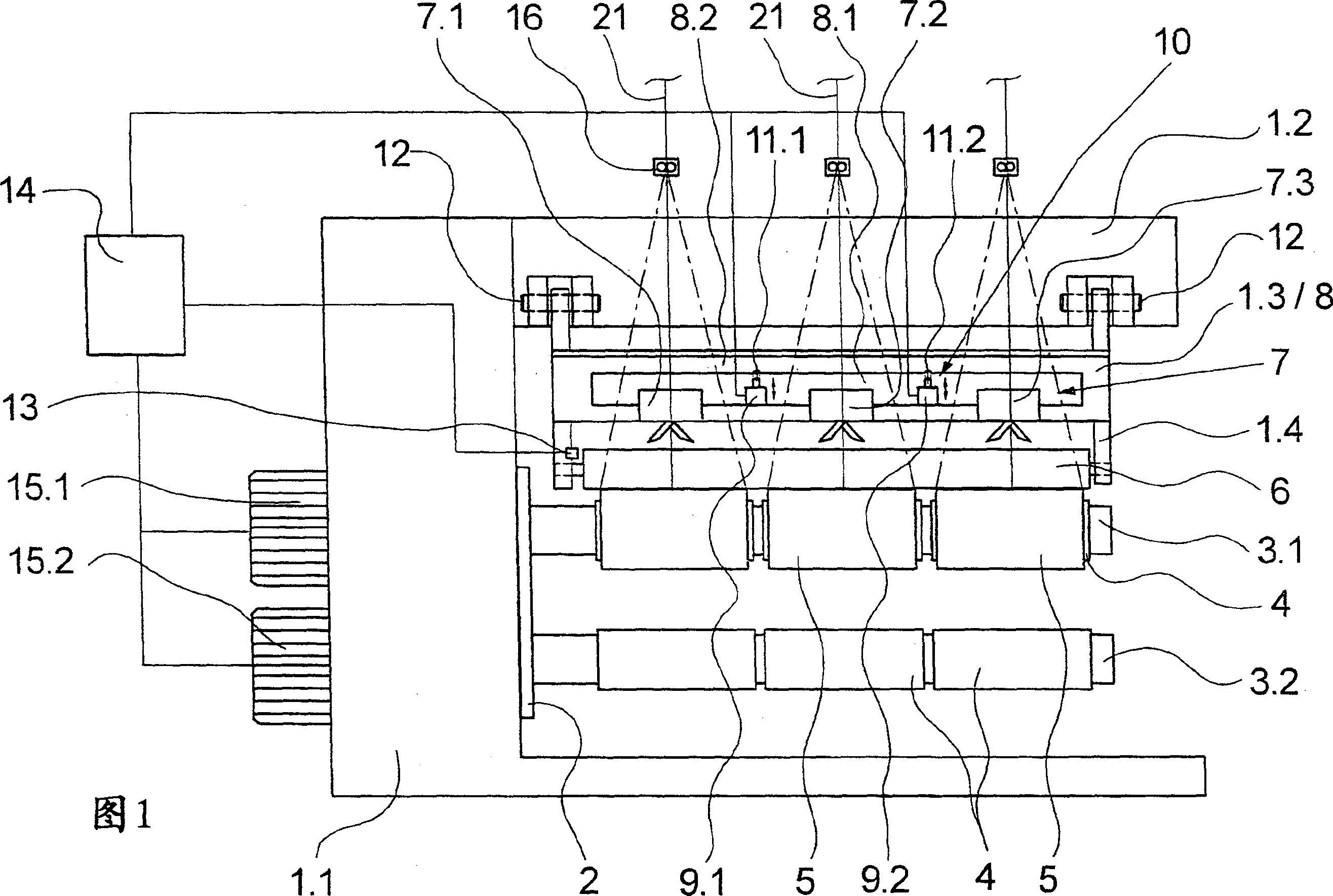

Novel high-frequency electro-hydraulic flutter generator

ActiveCN102080679AStable outputHigh vibration frequencyFluid-pressure actuator componentsElectro hydraulicEngineering

The invention provides a novel high-frequency electro-hydraulic flutter generator, comprising an alternating current (AC) valve and a flutter cylinder, wherein the flutter cylinder comprises a cylinder body; the side wall of the cylinder body is provided with an oil inlet / outlet hole; the inside of the cylinder body is a ring-like chamber; an oil inlet opening is communicated with an oil hole in the center of a cylinder body intermediate column by an oil hole at the bottom of the cylinder body; one end of the cylinder body is provided with an elastic end cap connected with a load; the oil hole in the center of the cylinder body intermediate column is dead against the elastic end cap; the other end of the cylinder body is provided with a fixed end cap; the cylinder body is internally provided with a piston; the piston is tightly connected with the side wall of the cylinder body and the intermediate column wall; the piston is connected with a piston driving mechanism which is used for driving the piston to move up and down; the piston is used for dividing the ring-like chamber into an upper chamber and a lower chamber; the cylinder body inner walls of the upper chamber and the lowerchamber are respectively provided with a balance hydraulic fluid port; the two balance hydraulic fluid ports are communicated by a balance oil duct; and the balance oil duct is provided with a high-pressure ball valve. The novel high-frequency electro-hydraulic flutter generator is applied to occasions with large exciting force, high frequency and micro fluctuation, and is small in volume.

Owner:ZHEJIANG UNIV OF TECH

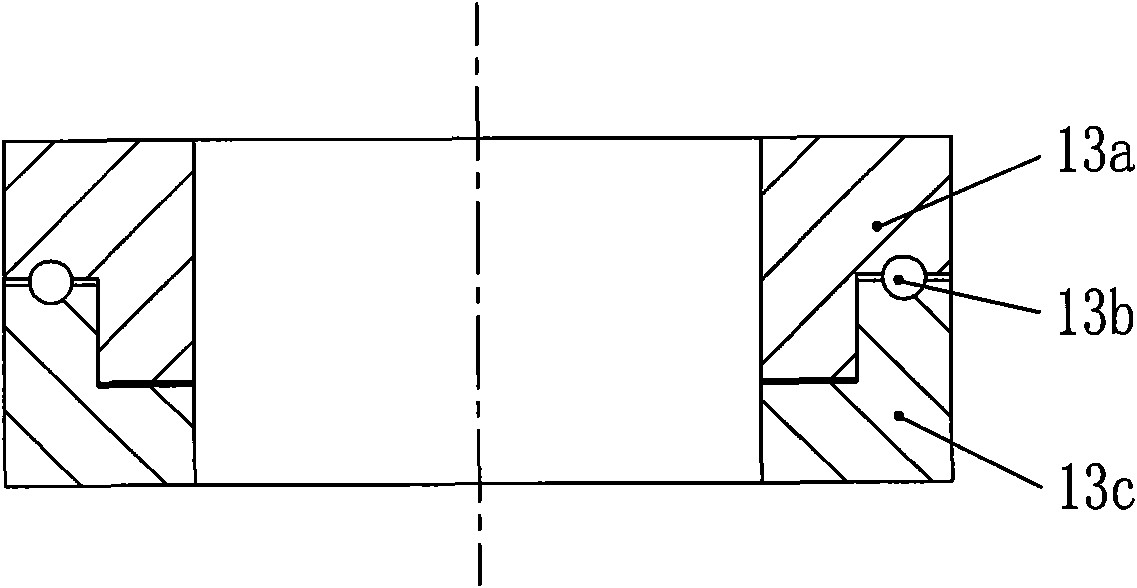

Axial vibration resistance type mechanical sealing device

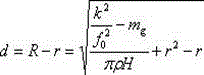

ActiveCN104179974AChange natural frequencyEliminate axial vibrationEngine sealsShock absorbersAxial vibrationPerpendicular direction

An axial vibration resistance type mechanism sealing device comprises a sealing pair formed by contacting a moving ring with a static ring, wherein the perpendicular direction of the sealing end surface of the moving ring and the static ring is defined as the axial direction. The axial vibration resistance type mechanism sealing device is characterized in that the moving ring is arranged in a moving ring seat, the static ring is arranged in a static ring seat, and the moving ring seat and the static ring seat are fixedly connected onto a base; the mechanical sealing device further comprises a spring vibrator system consisting of an elastic assembly and a vibrator, the elastic assembly is connected with the moving ring seat and the vibrator, and the vibrator only has the axial freedom degree; and the static ring and the static ring seat are in flexible connection, the static ring only has the axial freedom degree, the moving ring is fixedly connected onto the moving ring seat, or, the moving ring and the moving ring seat are in flexible connection, the moving ring only has the axial freedom degree, and the static ring is fixedly connected onto the static ring seat.

Owner:ZHEJIANG UNIV OF TECH

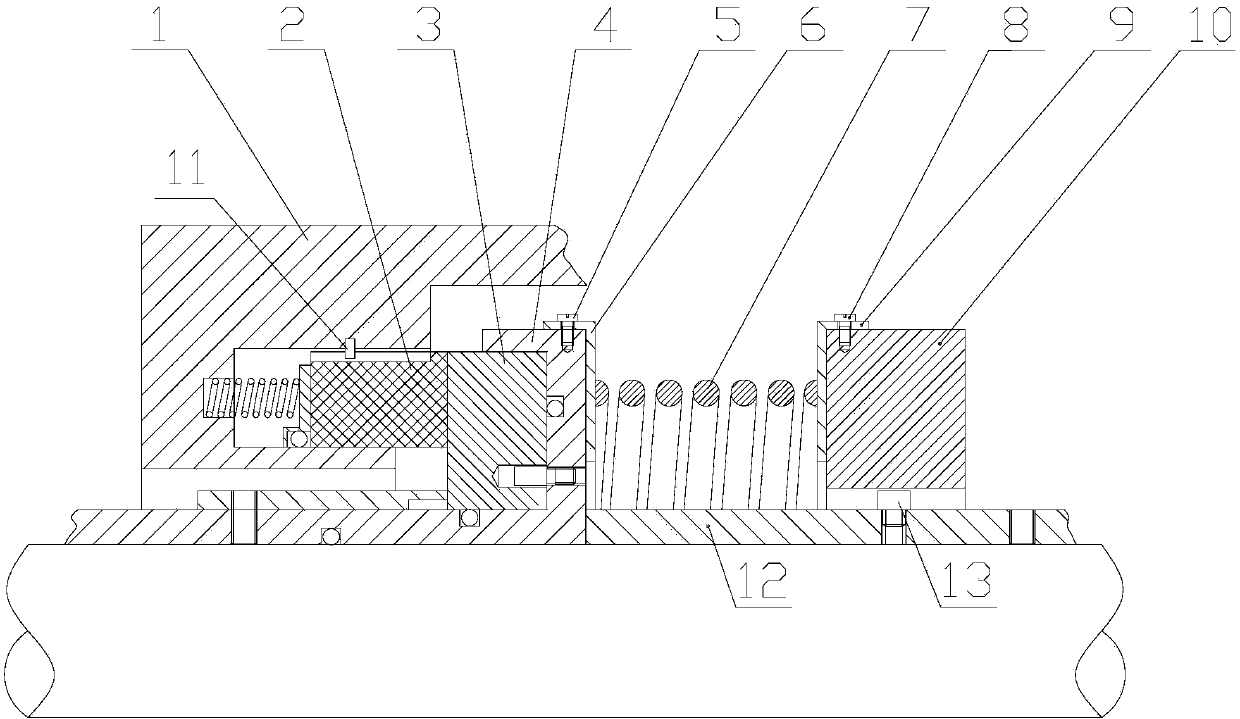

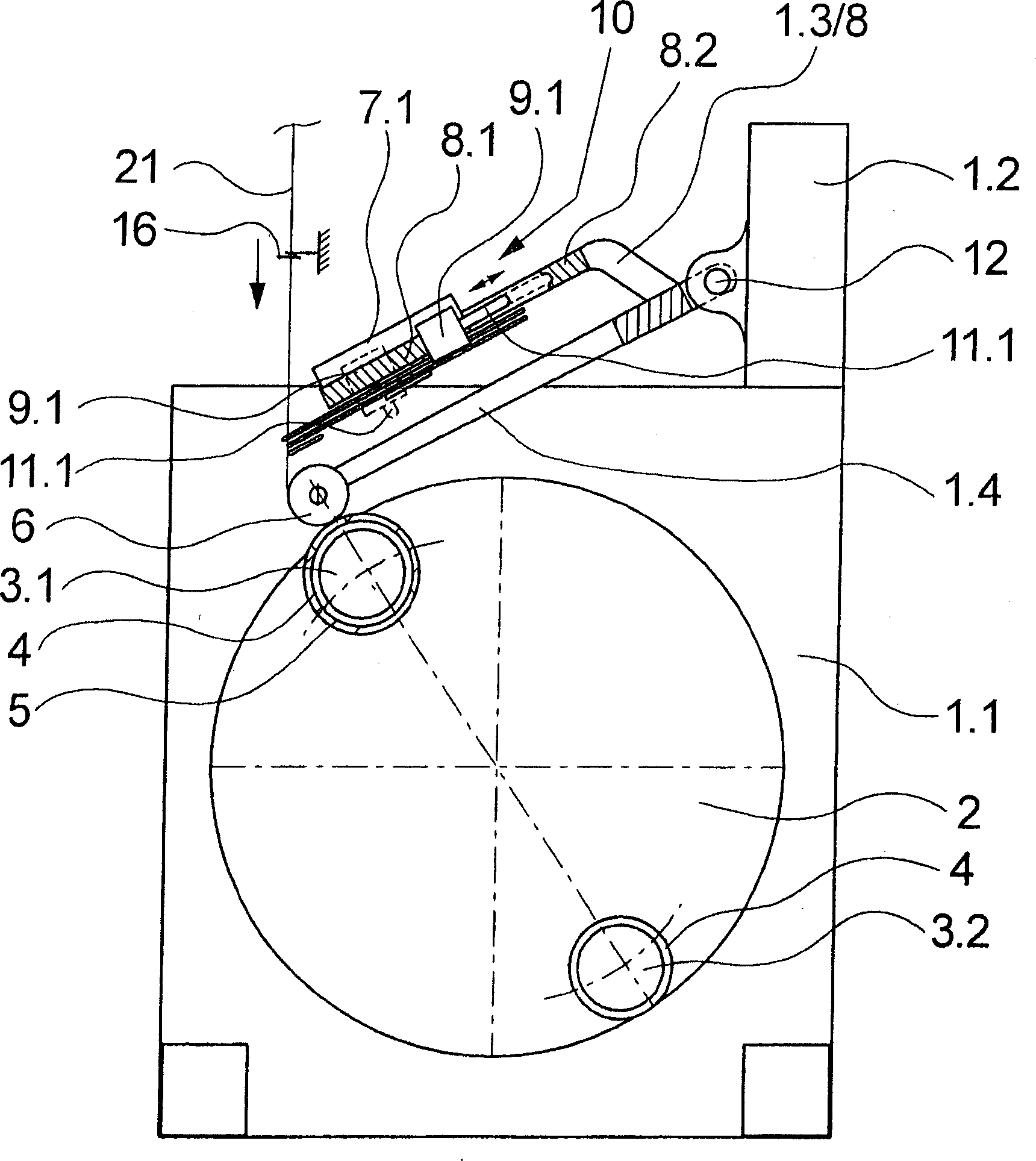

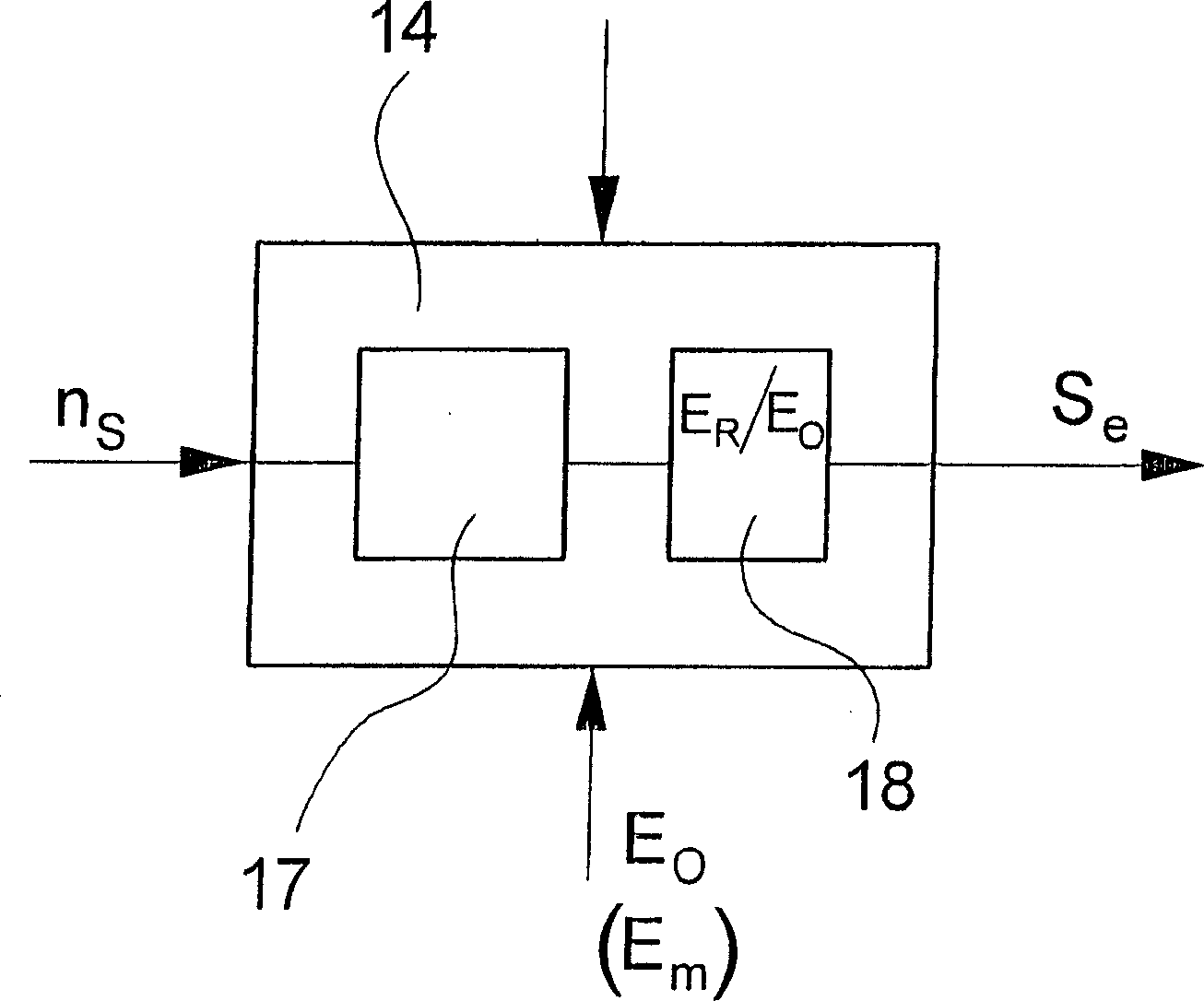

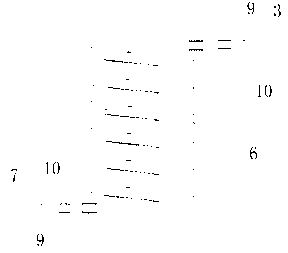

Warp knitting machine

ActiveCN102965835AChange natural frequencyChange hardnessWarp knittingWarp knittingMechanical engineering

The knitting machine (1) has a yarn feeding portion (2), an active region (3), and a thread tension compensating device (11) between the yarn feeding portion and the active region. The quality of knitted fabric is reduced to the minimum through a simple method. Therefore, the thread tension compensating device (11) can be actuated from the outside through a control device (17, 24) with which a natural frequency of the tension compensating device is varied.

Owner:KARL MAYER STOLL R&D GMBH

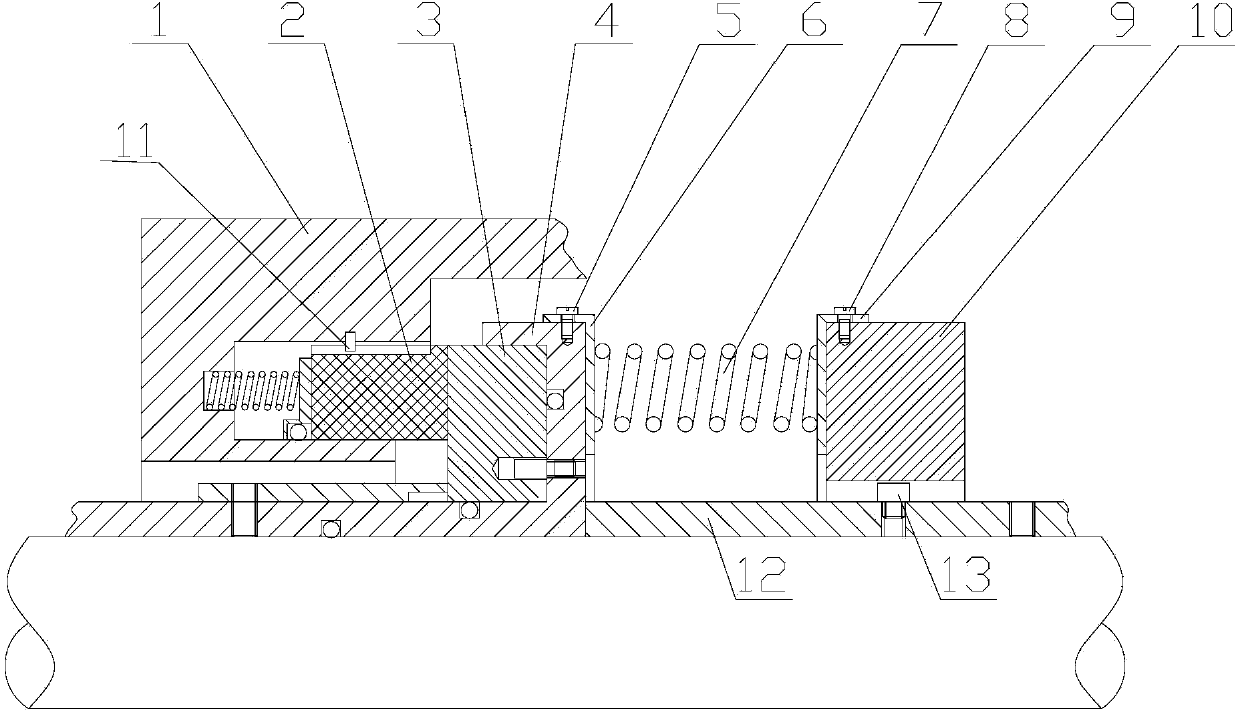

Spherical hinge type ultralow frequency universal vibration tuning mass damper

PendingCN109577363ASmall frictional resistance torqueReduce stiffnessInertia force compensationNon-rotating vibration suppressionHinge angleEngineering

The invention discloses a spherical hinge type ultralow frequency universal vibration tuning mass damper. The damper is characterized by comprising a bottom plate installed on the damper, several vertical columns are uniformly fixed to the upper surface of the bottom plate along the circumference line, and a spherical hinge is installed on the bottom plate; the spherical hinge comprises a hinge base fixedly connected to the circumference center of the bottom plate, a spherical groove is formed in the center of the hinge base, a hinge center ball is correspondingly installed in the spherical groove, and the upper portion of the hinge center ball is fixedly connected with the bottom of a vertical center oscillating bar; a mass block is arranged on the top of the center oscillating bar; mainsprings correspondingly connected with the columns are arranged on the lower portion of the oscillating bar in the same plane to keep the center oscillating bar vertical. The universal oscillating characteristic of the center oscillating bar in the spherical hinge is utilized, horizontal vibration of the damper is inhibited, theintrinsic frequency can be adjusted, under the circumstance that the oscillating rod is shorter, the ultralow frequency can be easily achieved, installing is convenient, and the cost is reduced.

Owner:HUNAN UNIV OF SCI & TECH

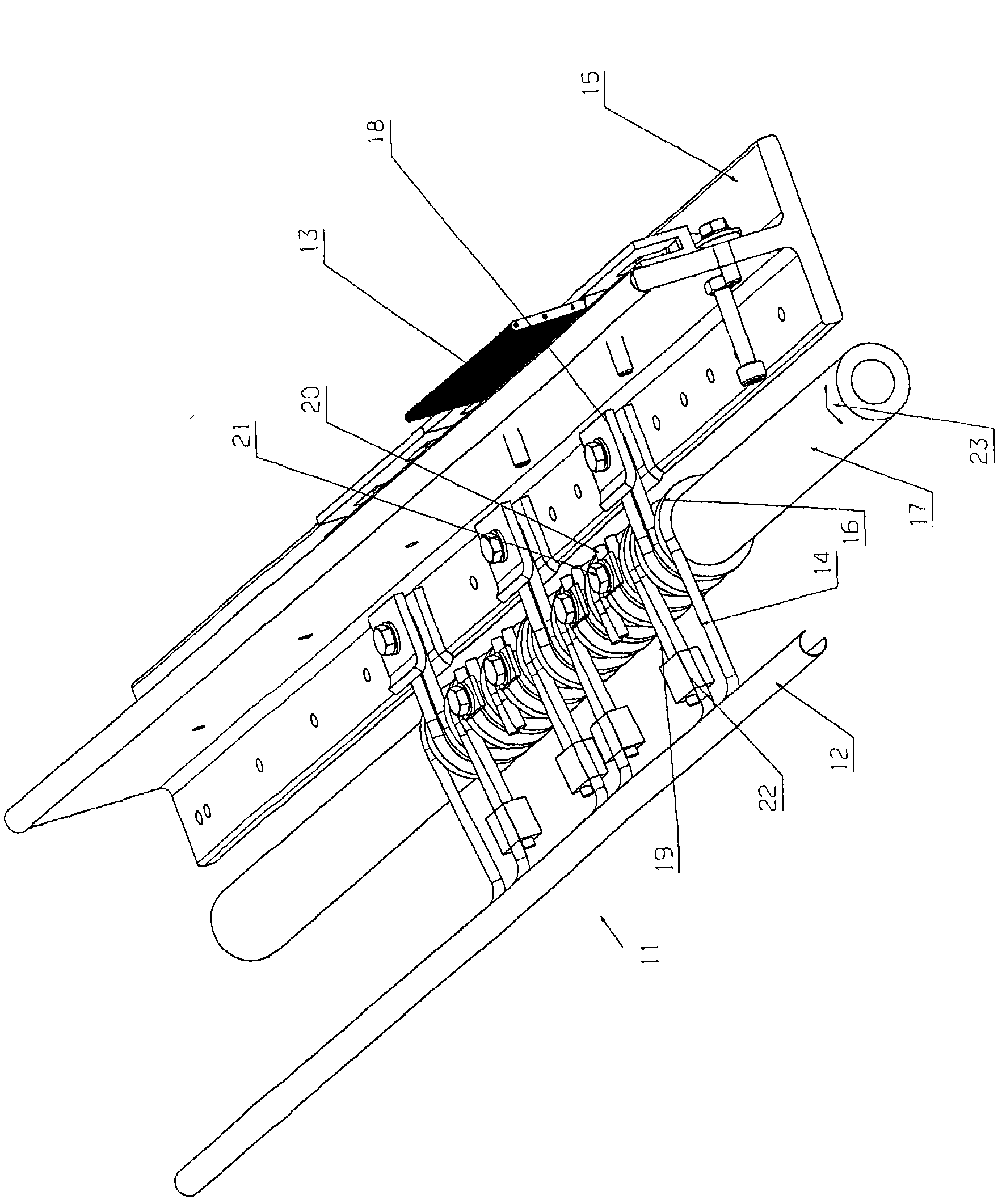

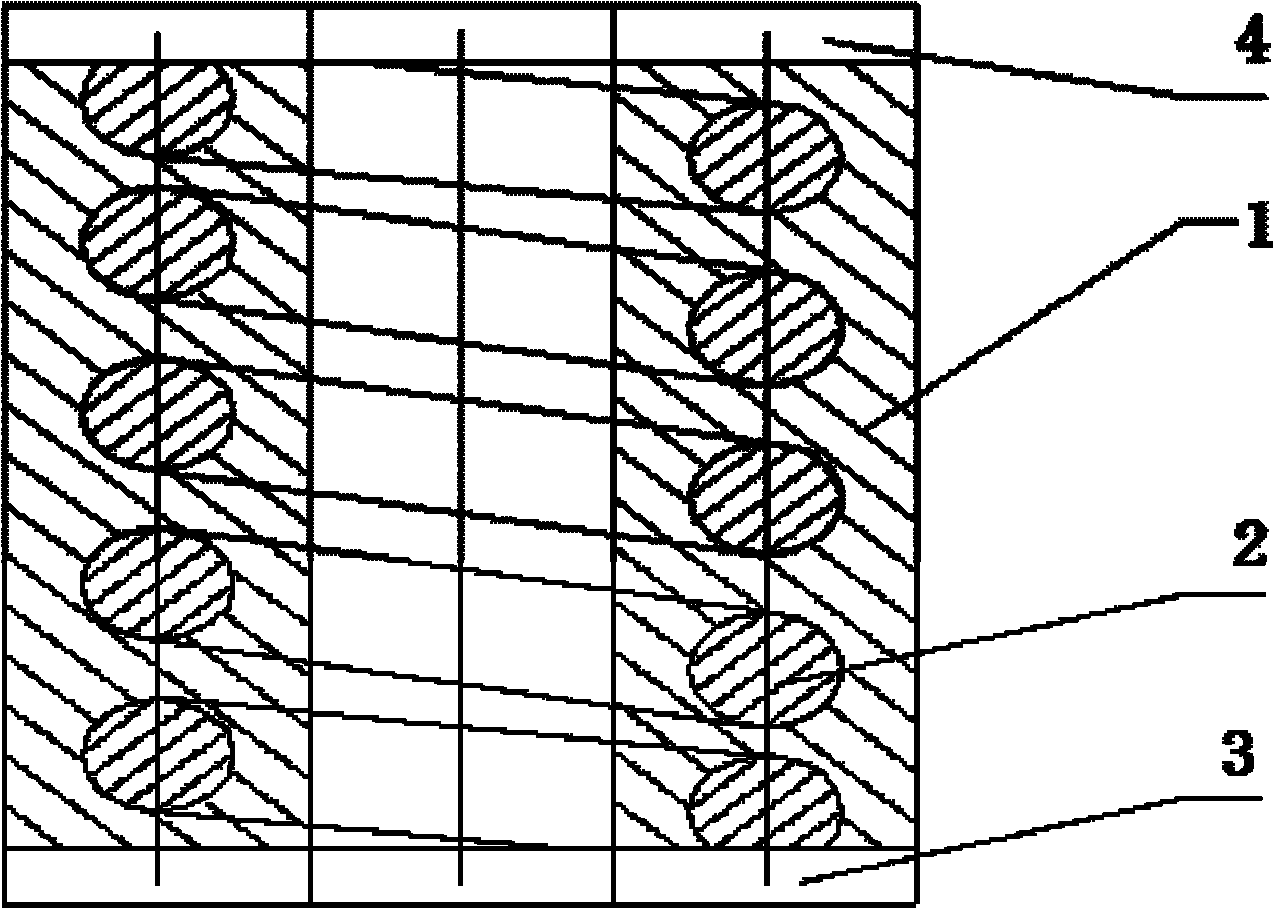

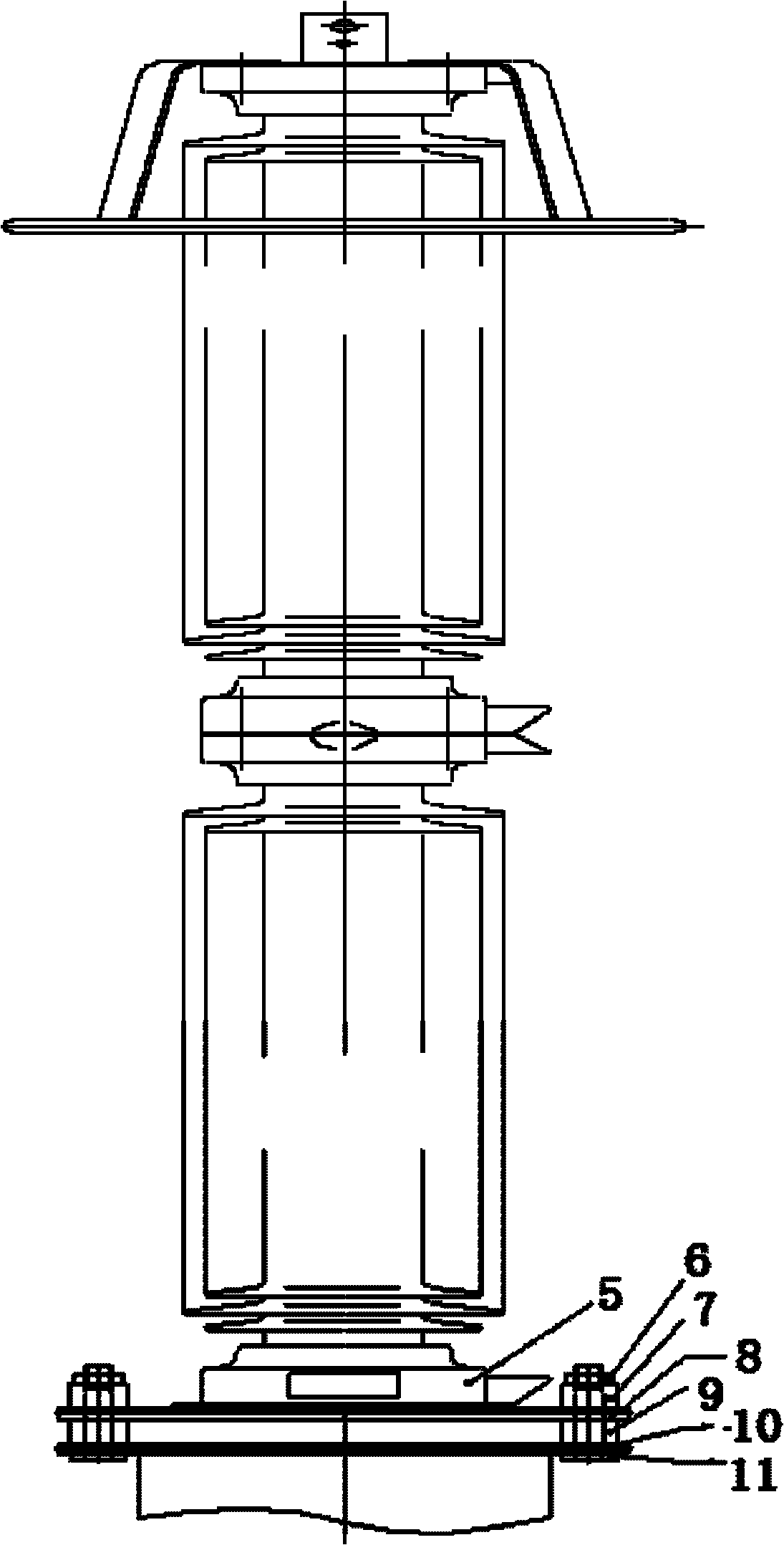

Device and method for winding multi-strand multifilament bundle

The invention introduces a method and a device for winding multi-ply filament on a rotating bobbin spindle to be a drum. The filament is respectively and reciprocally guided before the filament is paved on the drum and partially moves on the circumference of a rotatable back-up roller in a winding way. In order to keep winding speed which is basically constant, the operation speed of the bobbin spindle is continuously changed. Thereby excitation which is formed produces influence on the component which is fixed through a branch support stand of a frame, wherein each component is respectively provided with a certain fixed frequency. In order to avoid critical vibration status in the component, the fixed frequency is changed according to the operation rotary speed of the bobbin spindle through a rigidity reinforcing device of a branch supporting stand which can be converted on at least a component according to the invention. Therefore the branch supporting stand is provided with a mechanism for controlling the rigidity of the branch supporting stand, thereby changing the fixed frequency of the relative component during the winding period of the filament.

Owner:SAURER GMBH & CO KG

Rubber spring damping shock absorber

ActiveCN102221061AReduce the possibility of resonanceReduce seismic energyHigh internal friction springsEngineeringShock absorber

The invention relates to a rubber spring damping shock absorber which is characterized by comprising high-damp rubber (1) and a column spiral compression spring (2), wherein the high-damp rubber (1) is fixedly connected with the column spiral compression spring (2), a lower base (3) and an upper base (4) by vulcanization. The shock absorbing effect of the shock absorber can reach 50% to 80%.

Owner:CHINA ELECTRIC POWER RES INST +3

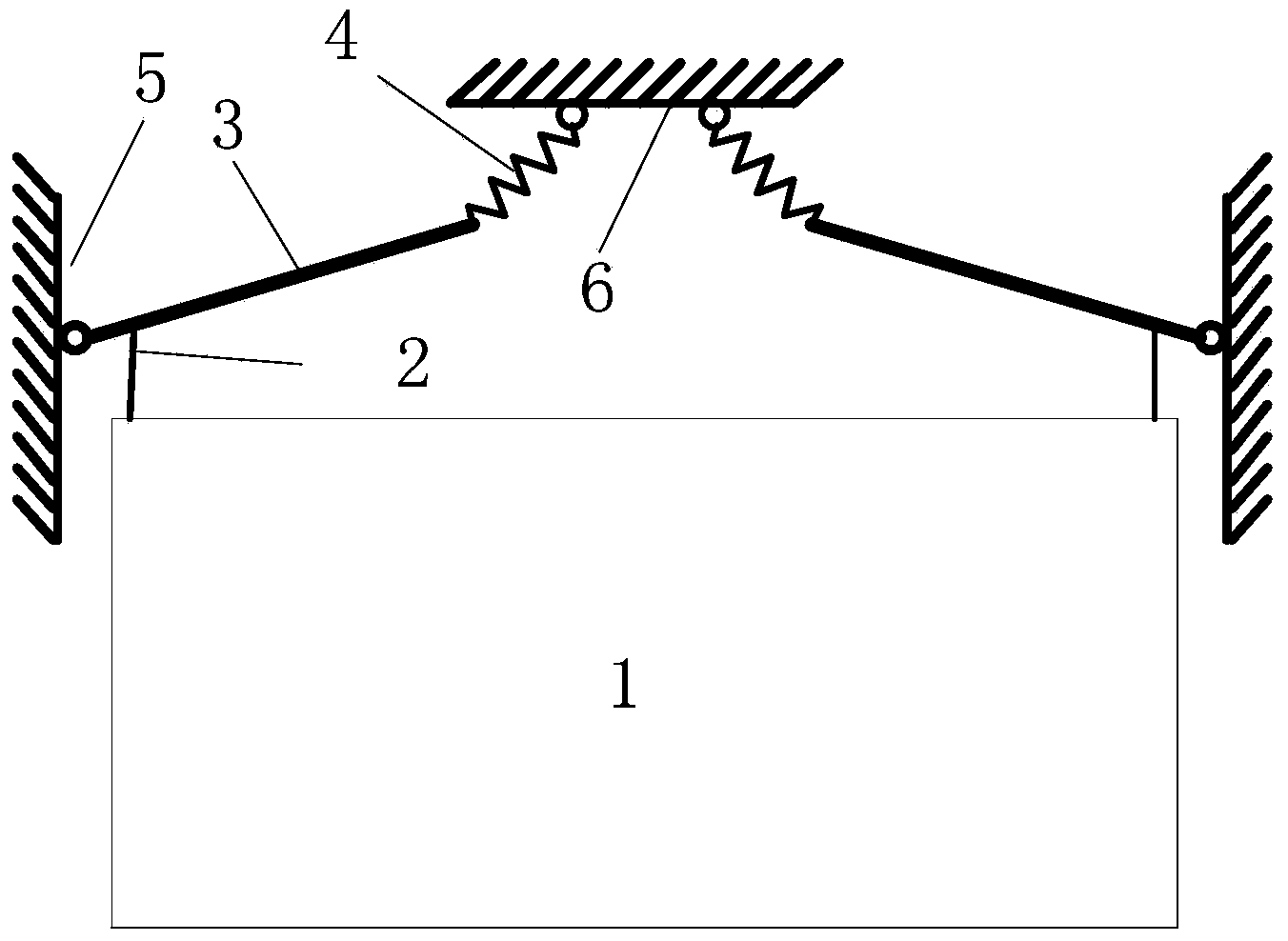

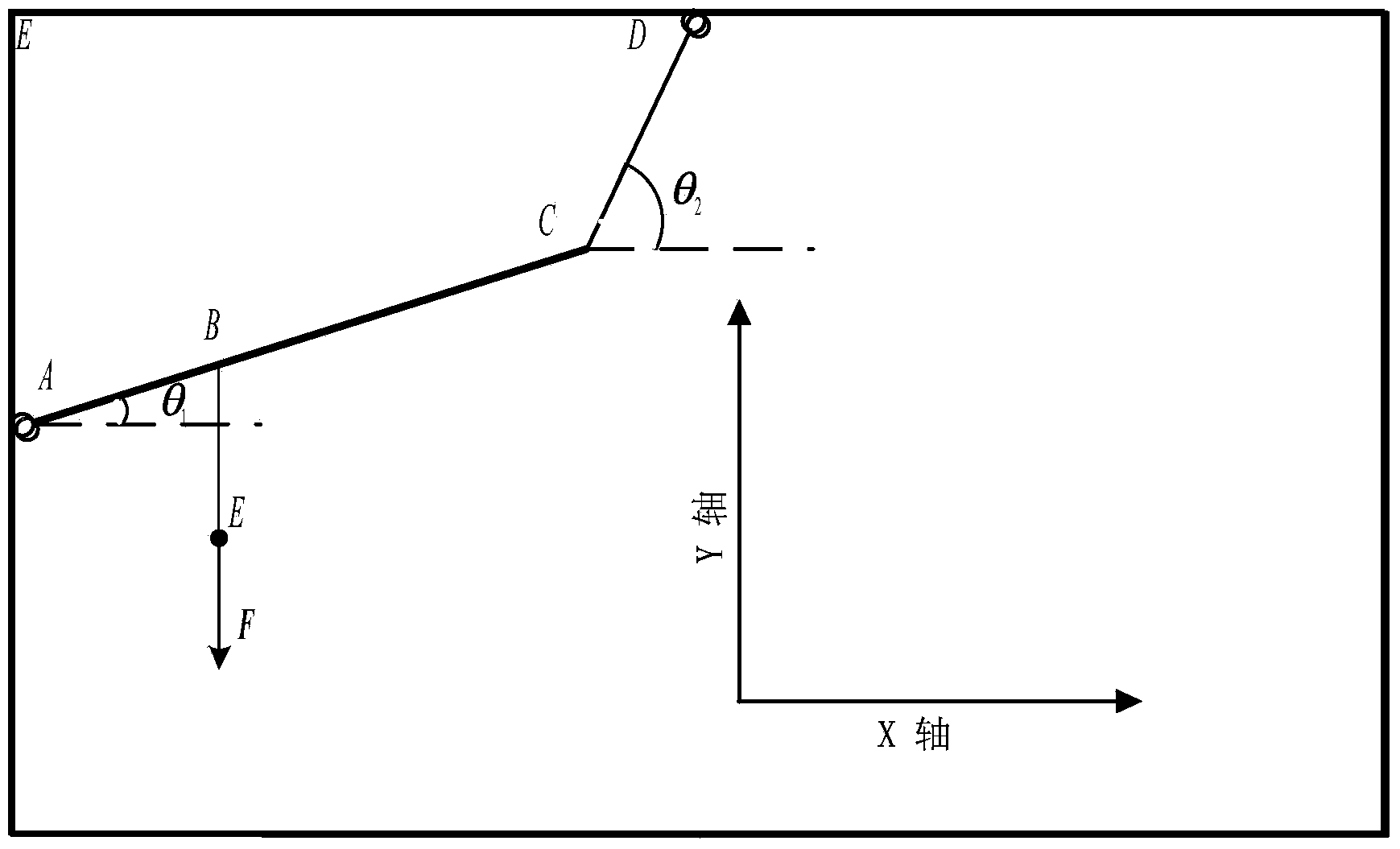

Damping-rigidness-controllable double-freedom-degree vibration active control platform

ActiveCN103398138AGood linearitySmall vibration rangeNon-rotating vibration suppressionCounterweightsEngineeringActuator

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

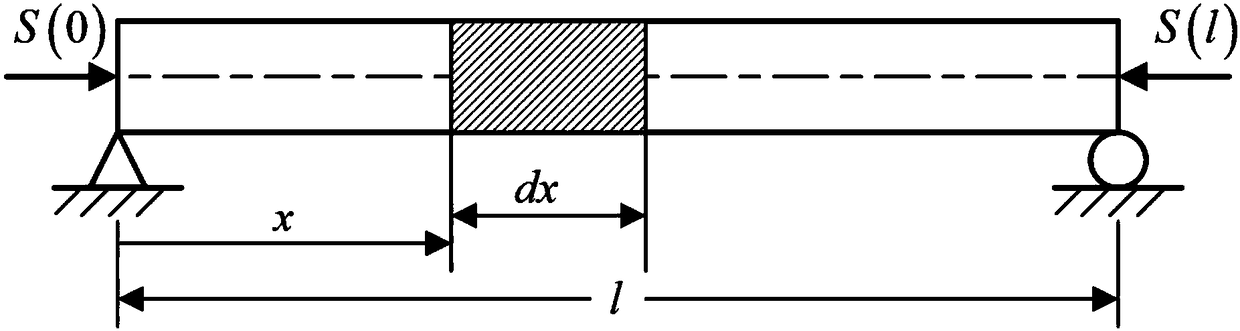

Packing box suspension shock absorber and packing box utilizing same

ActiveCN103662412AChange natural frequencyAvoid resonanceContainers to prevent mechanical damageDamagable goods packagingEffective lengthEngineering

The invention provides a packing box suspension shock absorber and a packing box utilizing the same. A product is connected with one point of a stiffening bar through a suspension rope, one end of the stiffening bar is connected with one side wall of a packing box where the product is packed, and the other end of the stiffening bar is connected with a top plate 6 of the packing box through suspension springs. When the packing box is impacted in horizontal direction or disturbed by an external vibration source, the disturbance energy is converted into gravitational potential energy through the suspension rope; when the frequency of the disturbance source is consistent with the natural frequency of the structure, the effective length of the suspension rope can be adjusted adaptively so that the natural frequency of the shock absorber is changed. When the packing box is disturbed or impacted in a vertical direction, the suspension springs have shock absorbing effect; when in resonance in the vertical direction, the length of the suspension springs change while the direction changes, the vertical component of the stiffness of the suspension springs changes, and the natural frequency of the system is changed, so that resonance is avoided, and displacement amplitude is limited.

Owner:SHANGHAI INST OF SATELLITE EQUIP

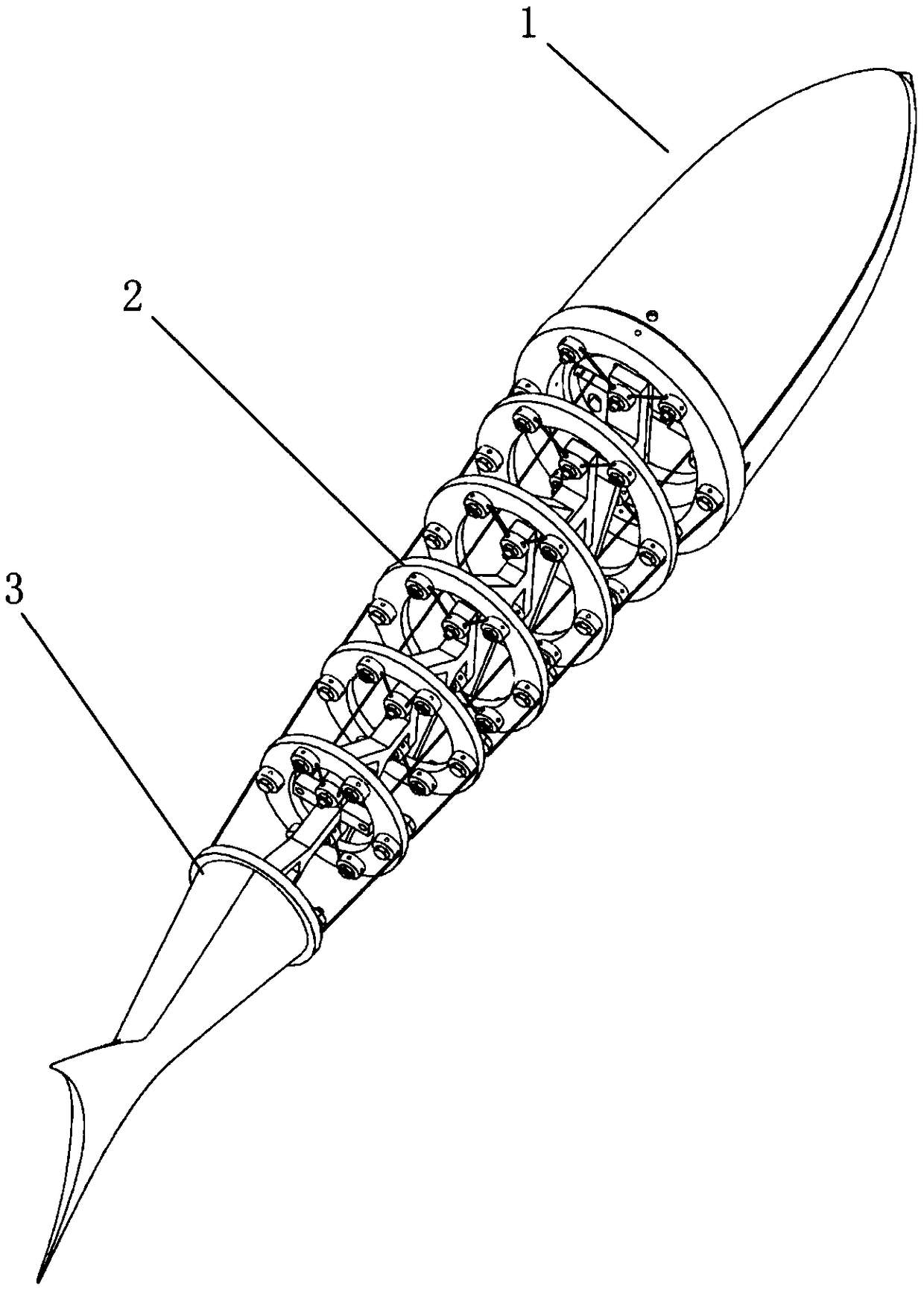

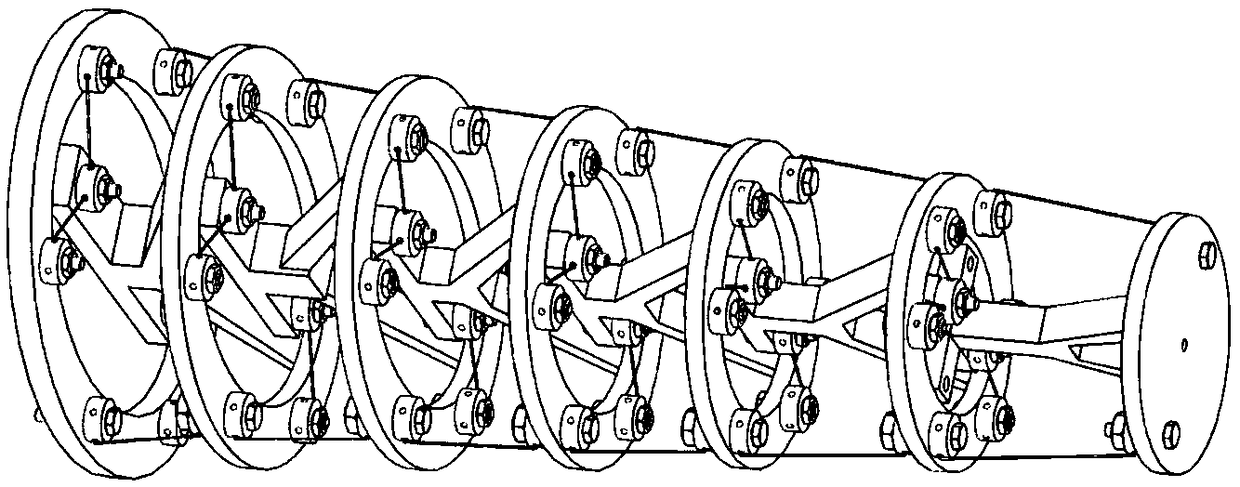

A tensioning integral swing propulsion mechanism

ActiveCN109110095AEliminate mechanical wear and frictionImprove the state of stressPropulsive elements of non-rotary typeTension memberEngineering

The invention relates to a tensioning integral swing propulsion mechanism comprising a head, a flexible torso and a tail, the head is connected with the tail by the flexible torso, a driving system isarranged in the head, the flexible torso comprises a plurality of sets of tensioned floating flexible joints, and each set of tensioned floating flexible joints comprises a base platform, a driven platform and a plurality of sets of tension elements, wherein the upper structure of the base platform and the lower structure of the driven platform are connected by a plurality of sets of horizontal tension elements, the upper structure of the base platform and the upper surface of the driven platform are connected by a plurality of sets of axial tension members, so that the driven platform can besuspended and supported, and each set of floating flexible joints is sequentially connected in series with each other. The invention simplifies the design, the mechanical movement is naturally smooth, and the mechanical transmission efficiency is high. The tensioning integral swing propulsion mechanism can realize the bionics of fish, snake and the like, and can also be used in the robot arm andthe like.

Owner:HARBIN INST OF TECH

Scheme for improving efficiency of flapping-wing aircraft

InactiveCN104828246AReduce energy consumptionImprove energy efficiencyOrnithoptersJet aeroplaneFlapping wing

The present invention relates to a scheme for improving efficiency of a flapping-wing aircraft, which acquires progressing force through swing in a fluid medium (air or water). In the field, bionic flapping wing aircraft is provided, but fails to catch the essence of energy efficiency of swing flying of insects, fish and birds. Therefore, the energy utilization efficiency of the flapping-wing aircraft in the prior art is not higher than that of fixed wing airplane. In order to greatly improve the energy efficiency of high flapping-wing aircrafts, the invention provides a scheme for high efficiency wing-flapping aircraft. The flapping-wing aircraft provided by the invention is characterized in that wing roots are connected to other parts of the aircraft by springs, so that the flapping wings have an intrinsic flutter frequency, and the system only needs to supplement energy dissipated by the flapping wings for power consumption in each flutter cycle to maintain flutter of wings. Thus, the scheme greatly reduces energy consumption and improves the energy efficiency of flapping-wing navigation. According to the invention, by means of flapping-wing aircraft, human being can realize high efficiency navigation like insects and birds.

Owner:李维农

Temperature insensitive optical fibre grating acceleration sensor

InactiveCN101285847BAvoid chirpingSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesGratingClassical mechanics

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

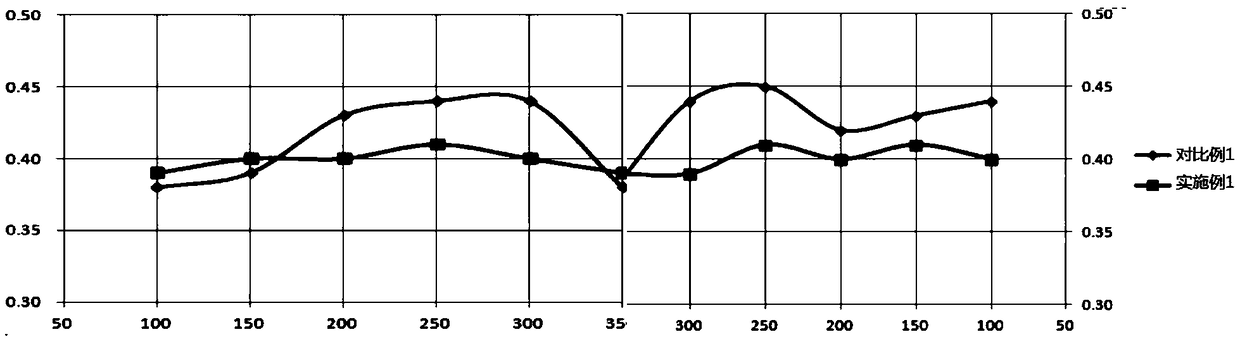

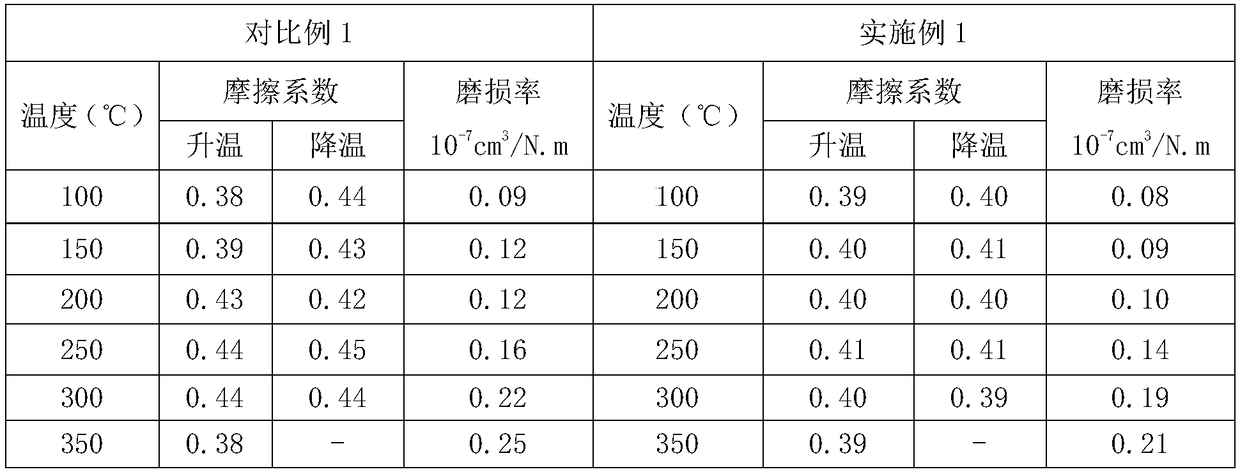

Low-wear disc type friction plate and preparing method thereof

ActiveCN109372911AGood adhesionHigh bonding strengthNoise/vibration controlOther chemical processesMetallurgyAdhesion strength

The invention provides a low-wear disc type friction plate. A buffer layer containing a magnetic material is added between a steel backing and a ceramic layer, adhesion between the buffer layer and the steel backing combination face can be improved, and the phenomenon that due to the brake high temperature (400 to 500 DEG C), the friction material buffer layer falls off from the steel backing face, and brake fails is avoided. The adhesion strength between the friction piece and the steel backing can be increased, iron hard points are prevented from appearing in the friction face, screeching and brake trembling generated in the brake process can be removed, brake disc scraping and grooves generated by the iron hard points can be avoided, and the service life of the brake disc can be prolonged.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

Variable-stiffness variable-damping vibration absorber based on characteristics of magneto-rheological fluid

ActiveCN103225666AReduce consumptionGood vibration absorptionSpringsShock absorbersSemi activeVariable stiffness

The invention discloses a variable-stiffness variable-damping vibration absorber based on characteristics of a magneto-rheological fluid. According to the vibration absorber, the characteristics of the magneto-rheological fluid are changed through vibration data detected by a vibrating sensor, therefore, the stiffness and the damping of the vibration absorber are changed to realize the adjustment of natural frequency of the vibration absorber, and a best vibration absorption effect is achieved. The vibration absorber is good in vibration absorption effect, and can perform a good vibration absorption function under a fixed vibration frequency; the natural frequency of the vibration absorber is adjustable and can be adjusted according to different excitation frequencies so as to achieve the best vibration absorption effect; during a vibration process, the natural frequency of the vibration absorber is adjusted continuously through the detection of the sensor, and real-time tracking is achieved to ensure that the best vibration absorption effect is maintained during the vibration process; due to semi-active control, the consumed outside energy is little; the vibration absorber is simple in structure, easy to achieve and high in feasibility; and combination use is facilitated, and a plurality of vibration absorbers can be combined and used for multi-frequency vibration.

Owner:HEFEI UNIV OF TECH

Vibration control apparatus of wind turbine generator and wind turbine generator

ActiveUS8322975B2Change natural frequencyPump componentsEngine fuctionsUltrasound attenuationVibration control

A vibration control apparatus of a wind turbine generator that can be installed in a small space inside a tower, without a weight increase of the tower, and that can change the natural frequency thereof is provided. Included is a swinging rod extending in the vertical direction and suspended from beams provided on an upper part of the tower via a first universal joint; a flange part extending outward from the upper end outer surface of the swinging rod in the radial direction along the circumferential direction; a pendulum including a bob attached to the swinging rod and capable of moving up and down in the vertical direction; and a plurality of attenuation devices each of whose upper end is attached to the beams with a second universal joint and whose lower end is attached to the flange part with a third universal joint.

Owner:MITSUBISHI HEAVY IND LTD

Pump pool inherent frequency self-adapting method and device

InactiveCN103307198AChange natural frequencyExtended service lifeVibration suppression adjustmentsVibration amplitudeBiochemical engineering

The invention discloses a pump pool inherent frequency self-adapting method and device, wherein the method comprises the following steps: reasonably selecting liquid with a certain density and volume according to submerse pump speed with different models, and injecting the liquid in a frequency-modulated tube, so as to enable the inherent frequency of a same pump pool device to be adjustable, prevent the pump pool and the submerse pump from resonance, decrease the vibration amplitude of a pump pool, improve the safe reliability and service life of the pump pool to meet the requirement of submersible pump speed with different models. The device provided by the invention can be used to a pump pool device matched with the immersed pump.

Owner:JIANGSU UNIV

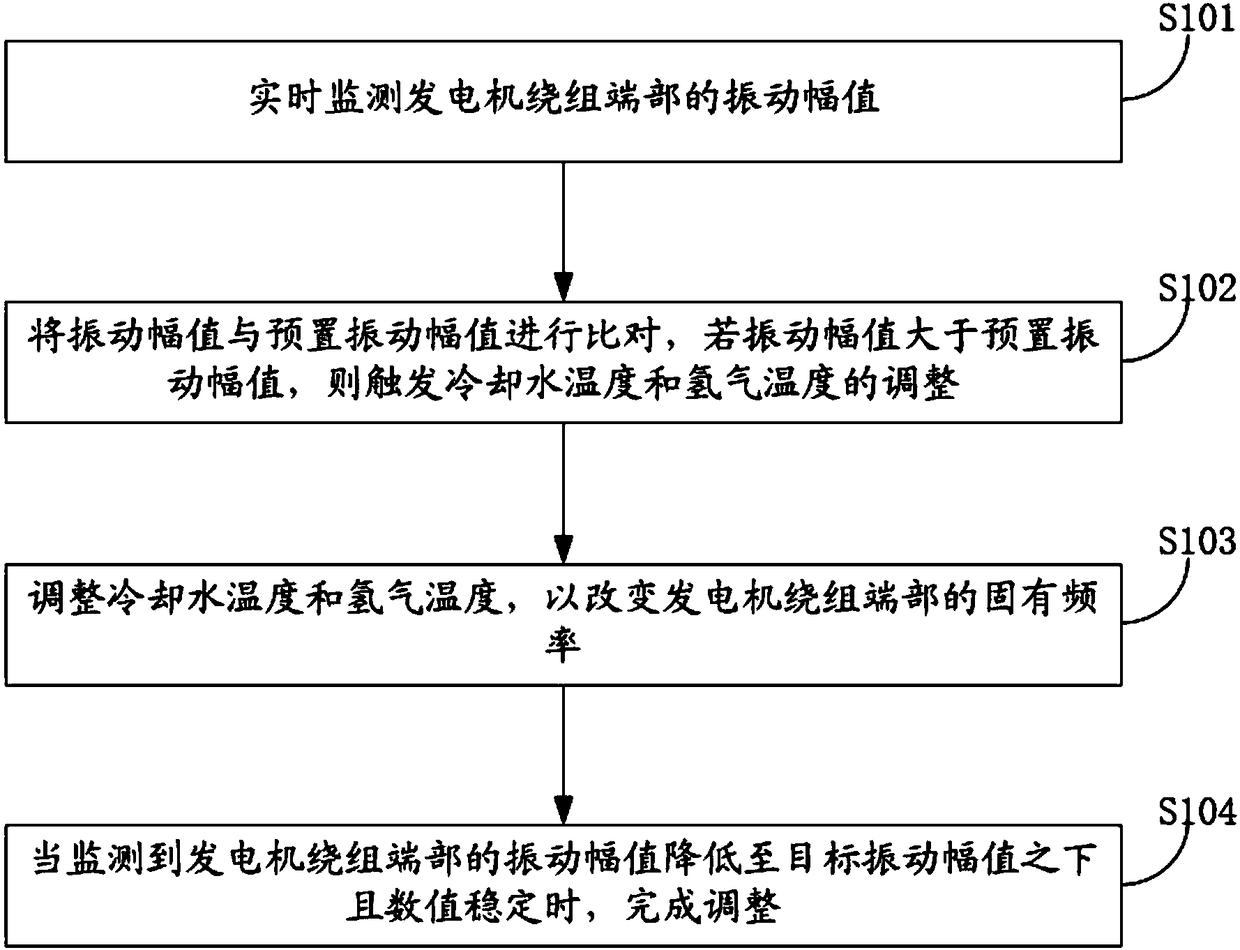

Method and system for controlling end portion vibration of generator winding

InactiveCN108181944AChange elasticityChange natural frequencyMechanical oscillations controlVibration amplitudeForce frequency

The invention discloses a method and system for controlling end portion vibration of a generator winding. The method comprises: a vibration amplitude of the end portion of a generator winding is monitored in real time; the vibration amplitude is compared with a preset vibration amplitude; if the vibration amplitude is larger than the preset vibration amplitude, adjustment of the temperatures of cooling water and hydrogen is triggered; the temperatures of cooling water and hydrogen are adjusted to change the inherent frequency of the end portion of the generator winding; and when the vibrationamplitude of the end portion of the generator winding is monitored to be reduced to be below a target vibration amplitude and the value is stable, adjustment is completed. According to the invention,on the basis of a relationship between a generator temperature field and a modal frequency of the winding end structure, the temperature field inside the generator is changed based on the temperaturesof cooling water and hydrogen, so that the material structural force and elasticity modulus of the end portion of the generator winding are changed and thus the inherent frequency of the end portionof the generator stator winding is changed. Therefore, the excitation force frequency is avoided and the vibration amplitude is reduced.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com