Device and method for winding multi-strand multifilament bundle

A technology of filament and reinforcing device, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., to achieve the effect of avoiding overlapping, avoiding resonance phenomenon, high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

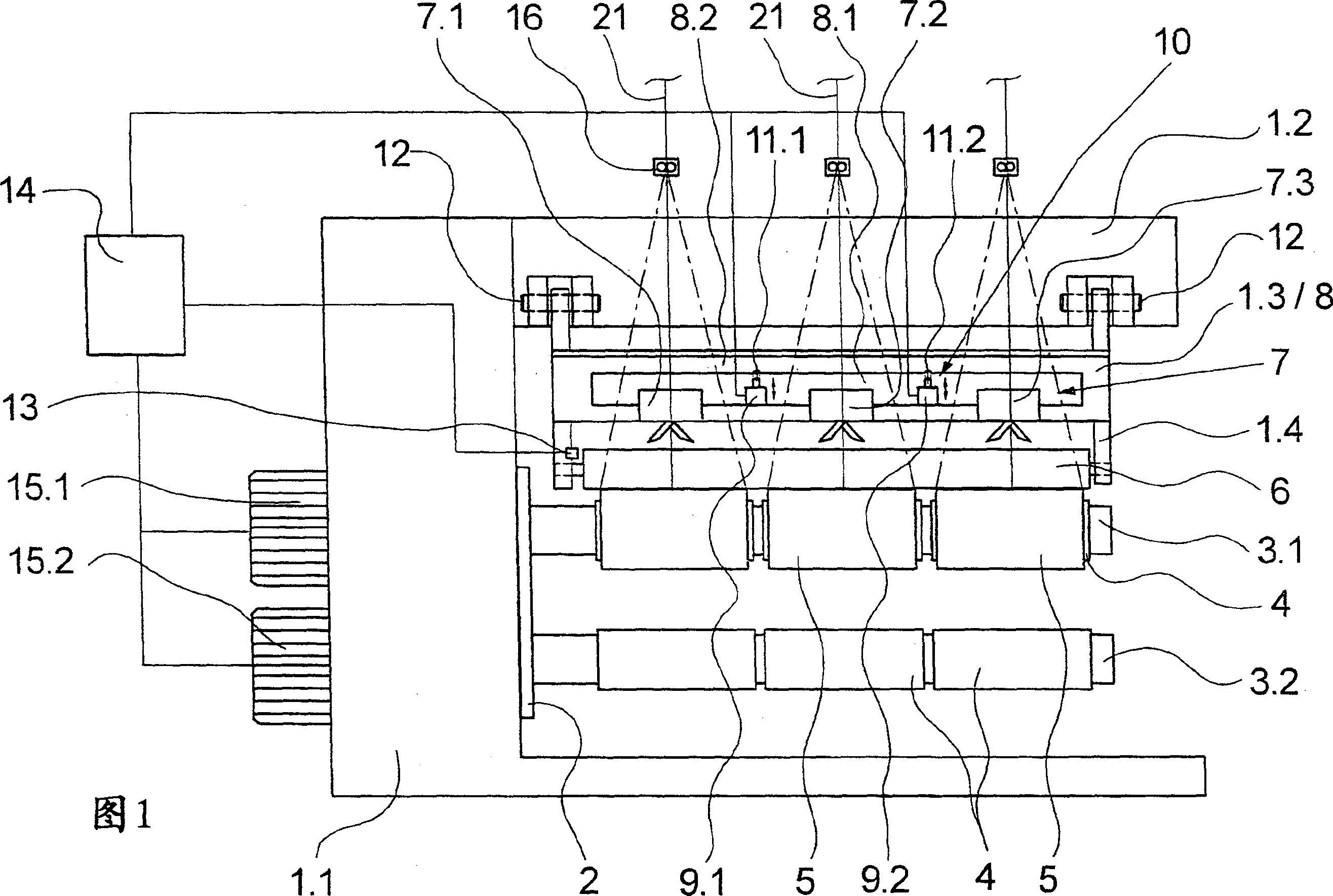

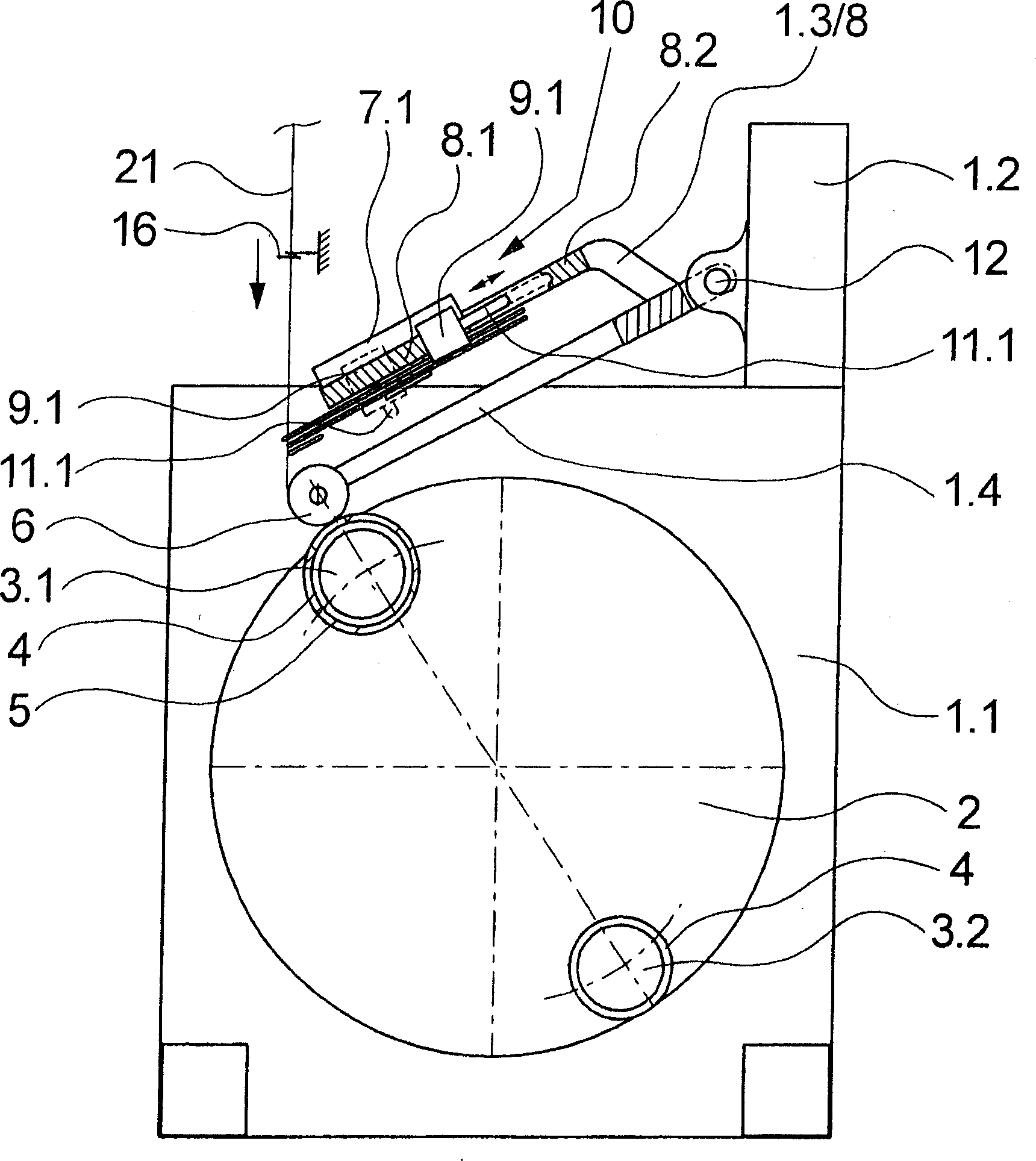

[0029] A first exemplary embodiment of the device according to the invention is shown in several views in FIGS. 1 and 2 . Wherein Figure 1 schematically shows a side view of the device, figure 2 Schematic representation of a cross-sectional view. If it is not specified which figure is referred to, the following description applies to both figures.

[0030] The device has a base 1, which consists of a plurality of branch bases 1.1, 1.2, 1.3 and 1.4 combined with each other. Each branch seat 1.1 to 1.4 supports a plurality of devices involved in winding the yarn into a bobbin. For example, a bobbin carousel 2 is mounted rotatably in the branch seat 1.1. Two cantilevered long bobbin spindles 3.1 and 3.2 are arranged on the bobbin carousel 2 offset from one another. On the free ends of the bobbin spindles 3.1 and 3.2, a plurality of bobbins 4 are sequentially put on and clamped respectively. On the bobbin spindle 3 . 1 held in a working area by the bobbin carousel 2 , the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com