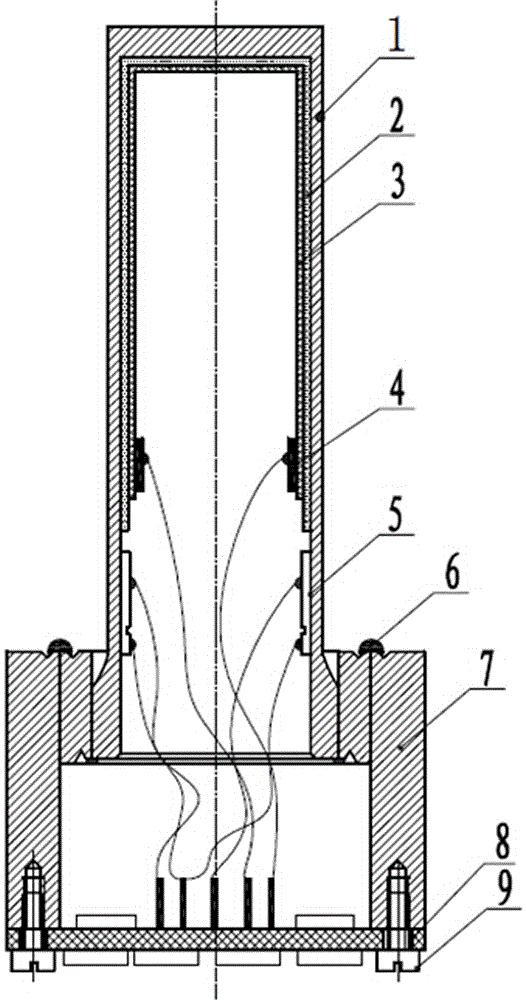

Piezoelectric vibration cylinder icing sensor and method for measuring icing condition thereof

A technology of icing sensor and vibrating cylinder, which is applied in the direction of electromagnetic measuring device, electric/magnetic thickness measuring, measuring device, etc. It can solve the problem that it is difficult to adapt to the miniaturization and intelligent requirements of the sensor, and cannot effectively monitor the thickness and volume of the ice layer in real time. , high quality and other issues, to achieve the effect of low power consumption, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

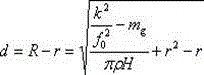

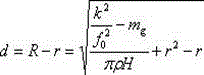

[0028] Example: The inner diameter r of the vibrating cylinder is 12 mm, and the mass of the vibrating cylinder is m g 15g, length 60mm, 0.8g / cm 3 , the scale factor k corresponding to this sensor is 8.0917×10 4 , the frequency is 25.00kHz in the non-icing state, and the icing thickness d can be obtained as 0cm from the above formula. When the natural frequency change is 18.677kHz, the thickness of the ice layer can be calculated by the formula (the unit of length in the formula is cm):

[0029]

[0030] When the icing thickness is 1mm, an icing warning signal is sent to the circuit board assembly, and the heating circuit is turned on for deicing. The icing rate is calculated by collecting the rate of change of the frequency from the non-icing state to the icing thickness of 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com