Patents

Literature

75results about How to "Realize online prediction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for predicting future speed trajectory of hybrid power bus

InactiveCN103914985AImprove accuracyRealize online predictionDetection of traffic movementNeural learning methodsDriver/operatorState parameter

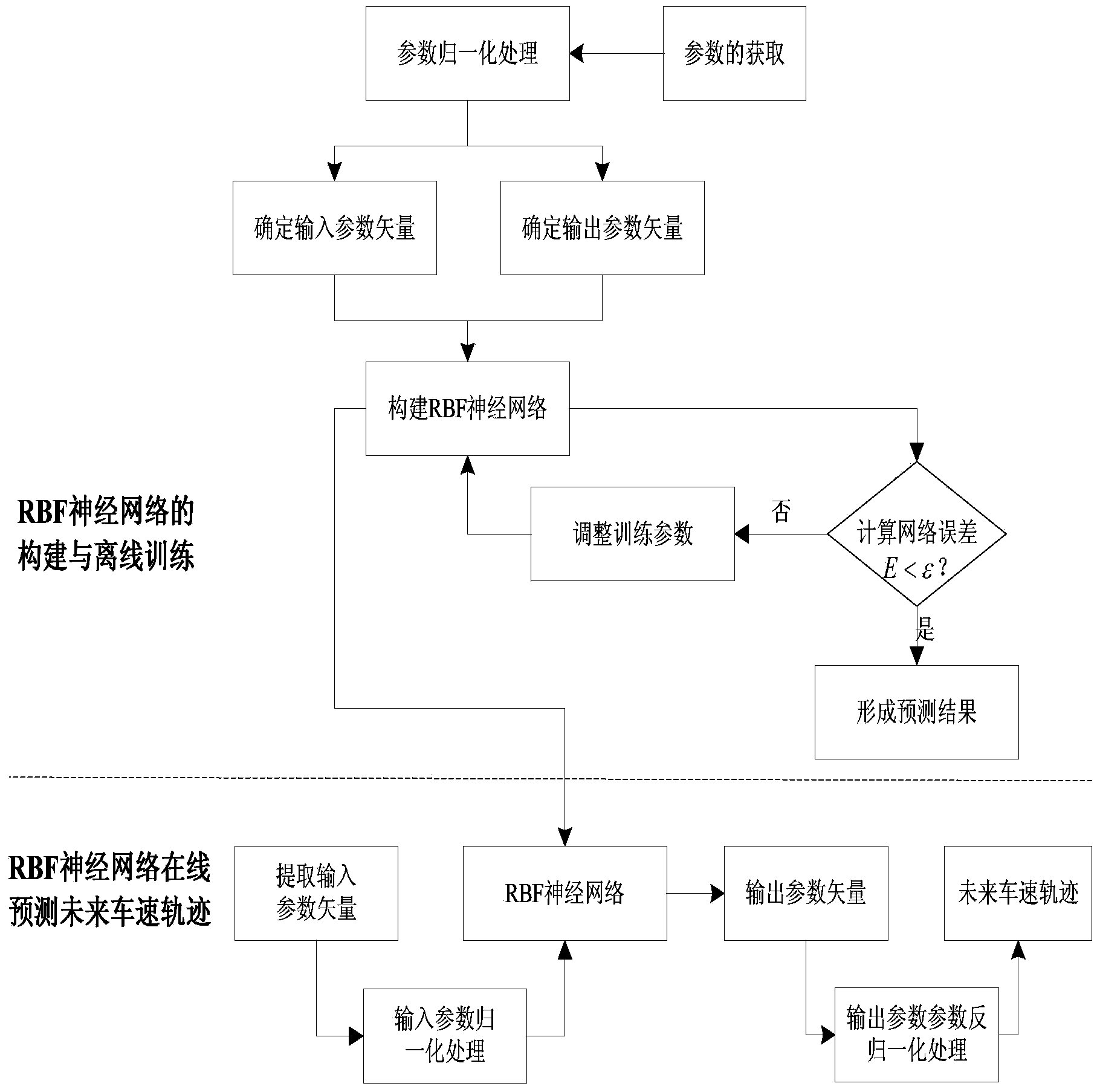

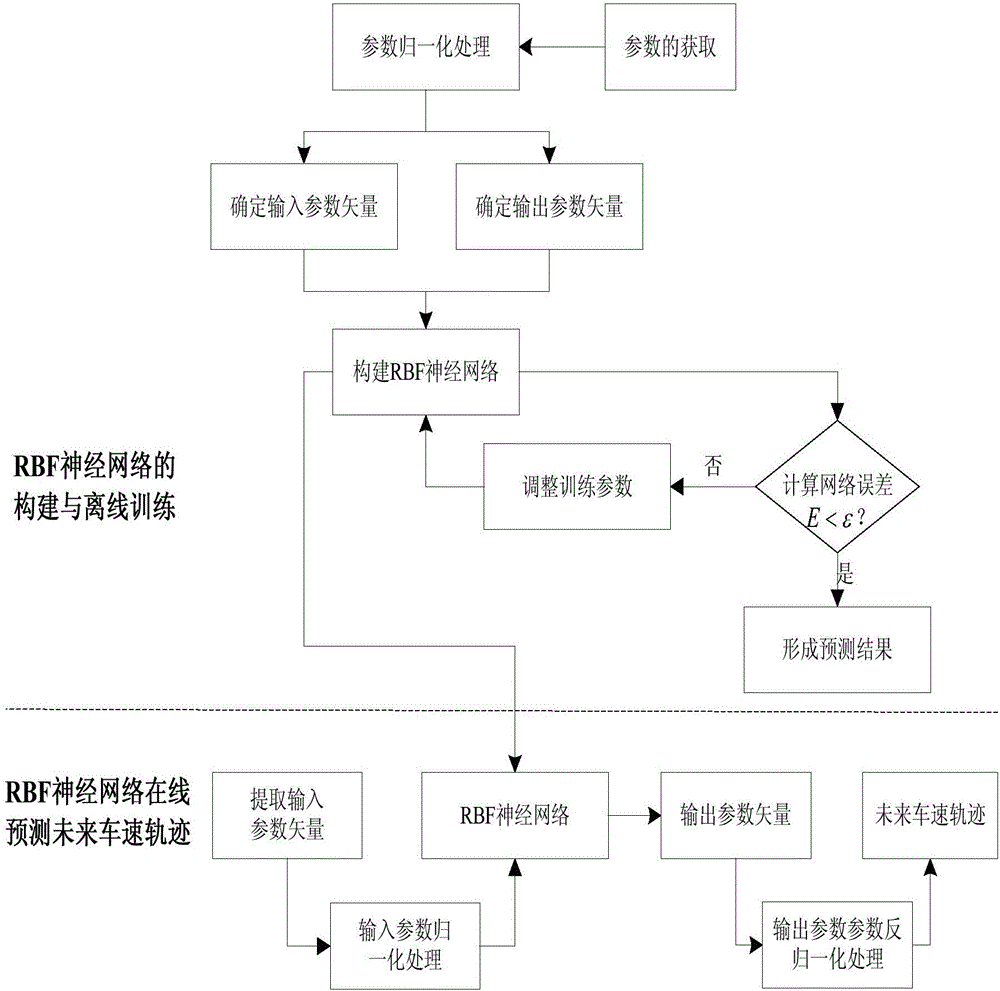

The invention discloses a method for predicting the future speed trajectory of a hybrid power bus. The method includes the following steps that parameters are obtained and normalized; an input parameter vector and an output parameter vector of an RBF neural network are determined; the RBF neural network is offline trained; the future speed trajectory is online predicted. Based on online learning of the RBF neural network, prediction of the speed trajectory is studied under the precondition that global optimization of the control strategy of the hybrid power bus is achieved from the aspect of a people-bus-environment system, the method for predicting the bus future driving trajectory is provided and fully takes bus state parameters, driver driving styles and front road environment and traffic state parameters into consideration, and accuracy of prediction of the bus speed is improved. The influences of the people-bus-environment system on the future working condition is fully taken into consideration, accuracy of prediction of the working condition is improved while the bus has the precognition capacity, and a good foundation is laid for global optimization of the control strategy.

Owner:DALIAN UNIV OF TECH

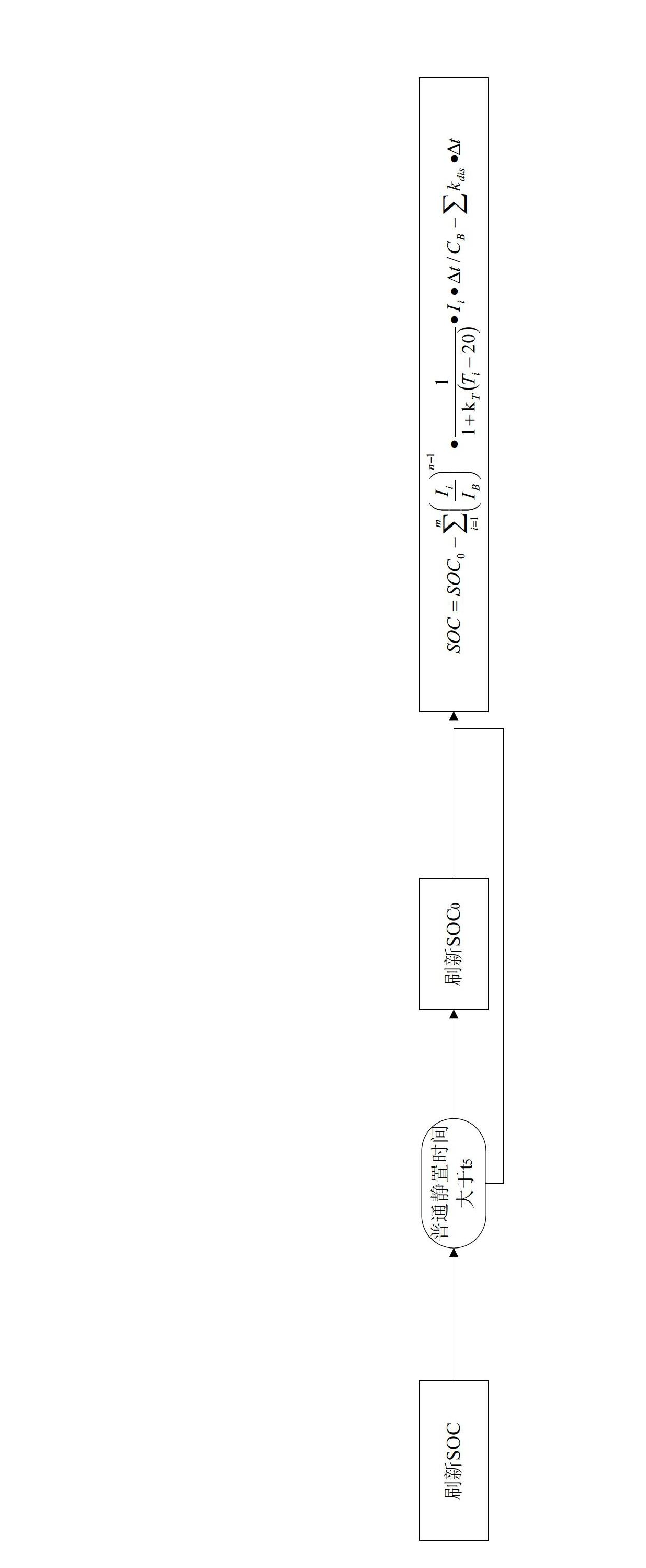

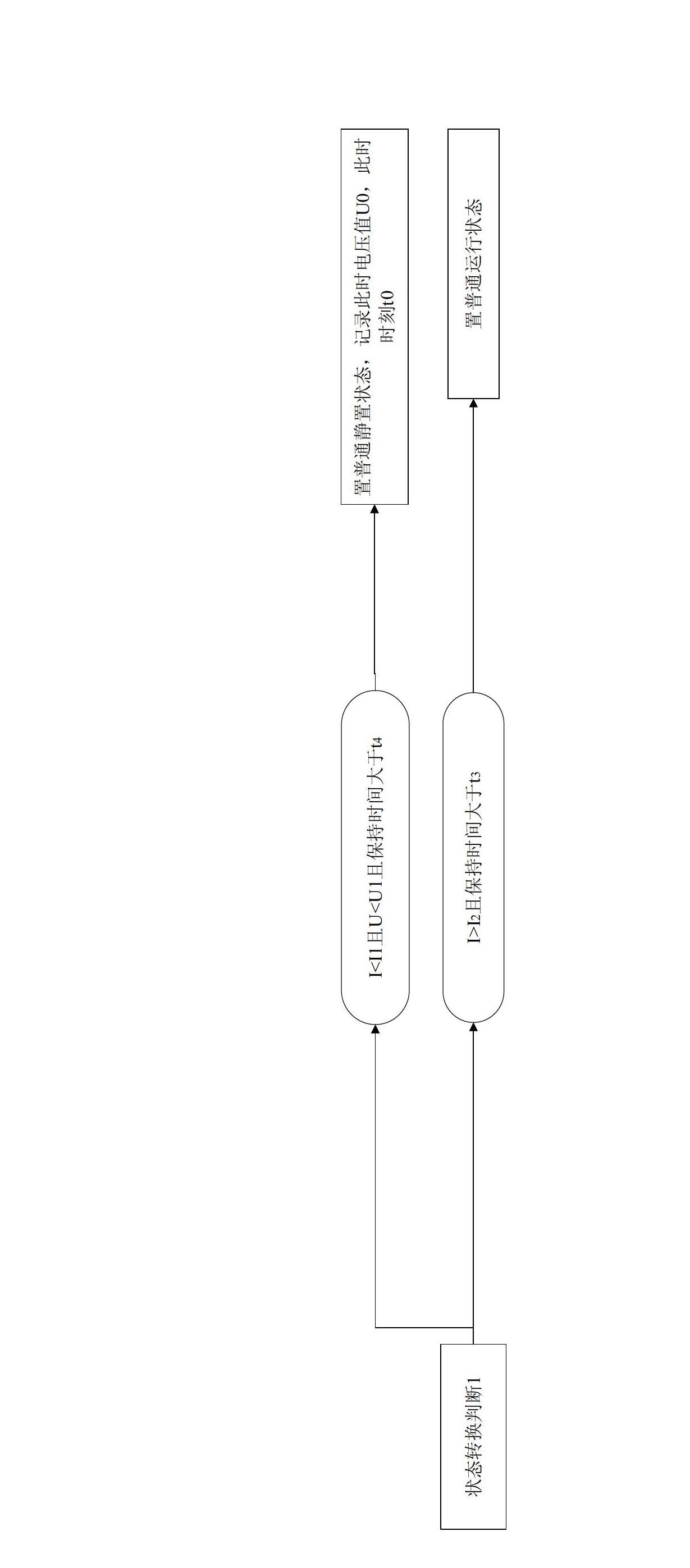

On-line feedback battery state of charge (SOC) predicting method

InactiveCN102662148AThe estimated result is close to the true valueImprove accuracyElectrical testingBattery state of chargeModel parameters

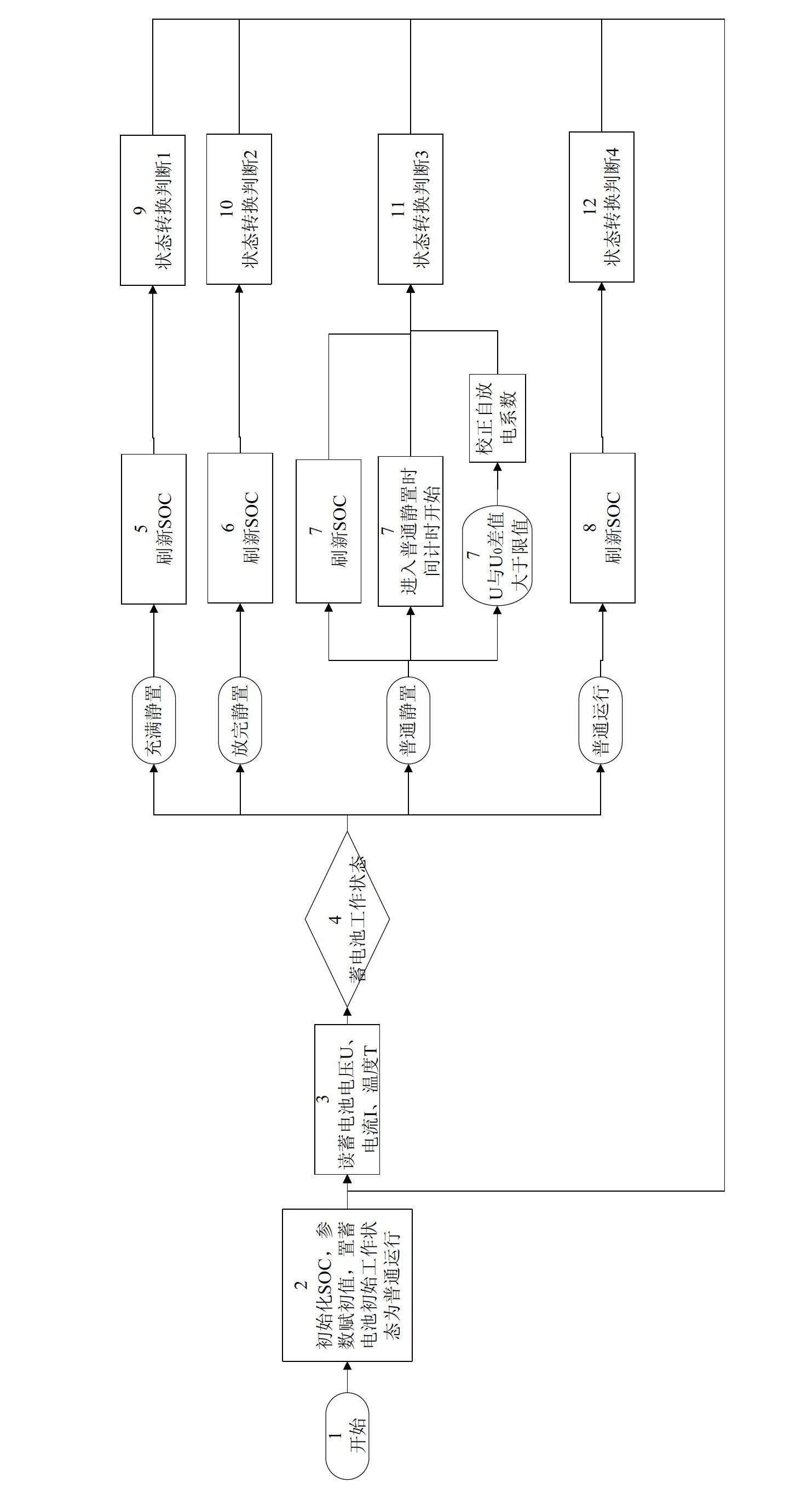

The invention relates to the technical field of storage battery state of charge prediction, and discloses an on-line feedback battery state of charge (SOC) predicting method. According to the method, SOC valuation model parameters are corrected according to historical data in the on-line operating process of a storage battery. The influence of temperature, coulomb efficiency and self discharge on battery SOC is considered, basic operating parameters of the storage battery are only required to be monitored, related coefficients are corrected as long as conditions are met in the operating process of the battery, coefficient values are repeatedly corrected, and an SOC estimation result is close to a true value along time, so the accuracy is high and the storage battery SOC can be predicted on line.

Owner:CHINA AGRI UNIV

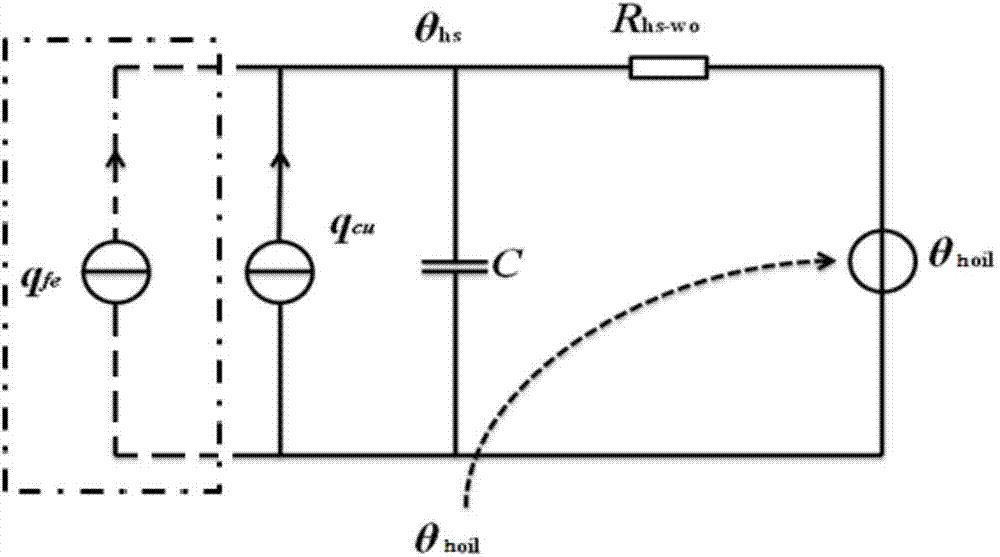

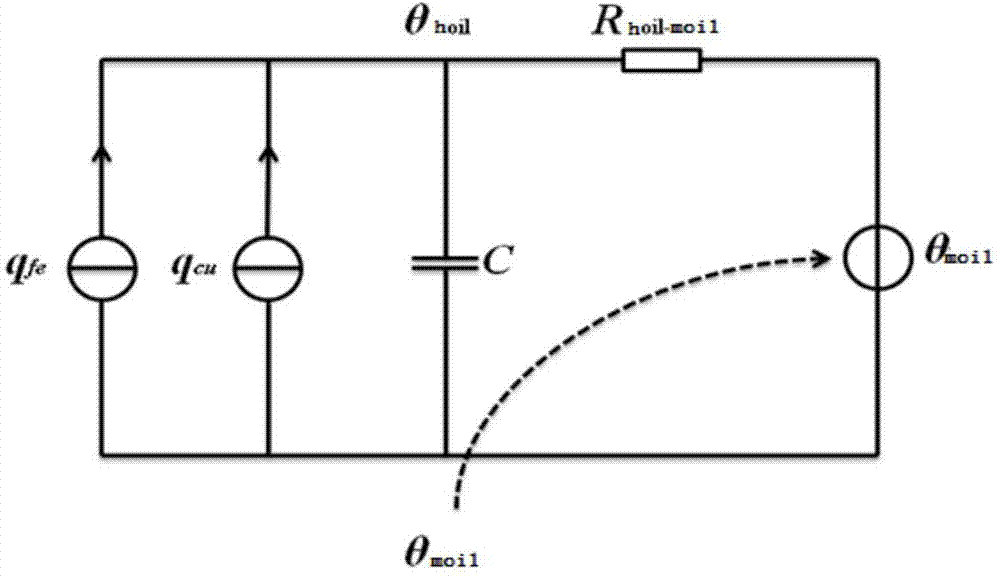

Dynamic capacity increasing method for oil-immersed transformer

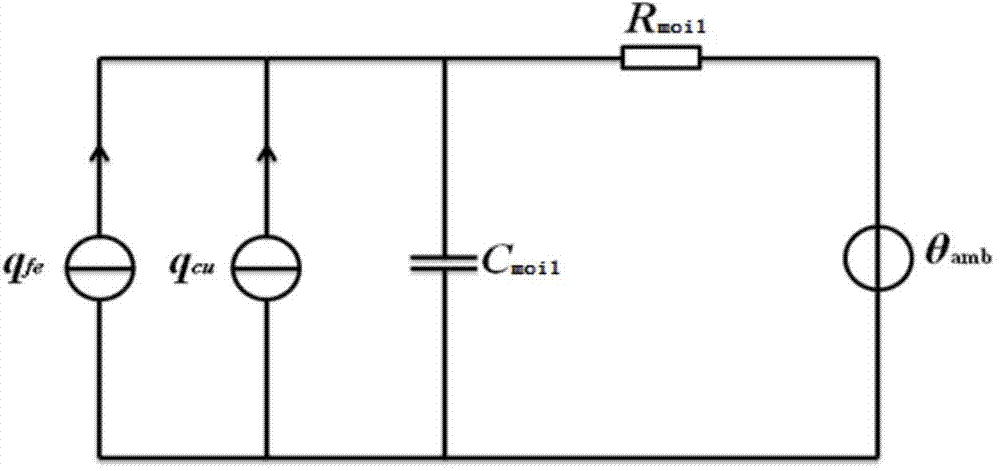

ActiveCN103779059ADynamic capacity increase real-time monitoringAvoid overall overheatingInductances/transformers/magnets manufactureThermometer applicationsSteady state temperatureTime delays

The invention relates to a dynamic capacity increasing method for an oil-immersed transformer, and belongs to the field of transformers. The method includes the steps that heat conduction process in the transformer is simplified into a circuit model; winding hot-spot temperature, top oil temperature, average oil temperature, average winding temperature of the transformer under the current load condition are calculated; according to the limit that the winding hot-spot temperature does not exceed 140 DEG C, whether temperature in the transformer will exceed the limit temperature or not under the current load and environment conditions is calculated, whether a temperature limit value is reached or not if long-term emergency loads or short-term emergency loads occur at the moment is calculated, and if the temperature in the transformer possibly exceeds the limit value of the short-term emergency loads, the time for reaching the limit value and the finally reached steady state temperature are calculated to serve as alarm signals; if it is monitored that the temperature will exceed the standard within t minutes, an early-warning signal is sent out, certain time delay is set, and if the loads are not reduced within the set time delay, a cooling fan of the transformer is turned on. Long-term continuous operation of cooling equipment can be avoided, and operation life of the cooling equipment is prolonged.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

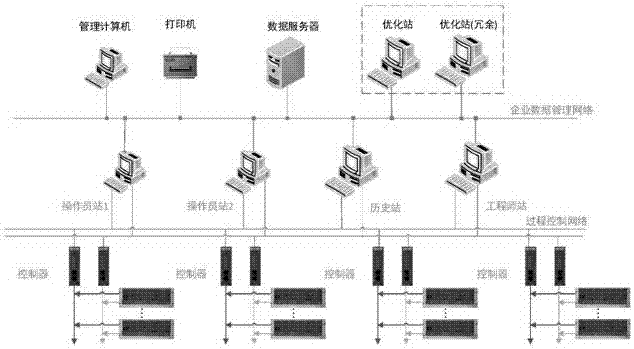

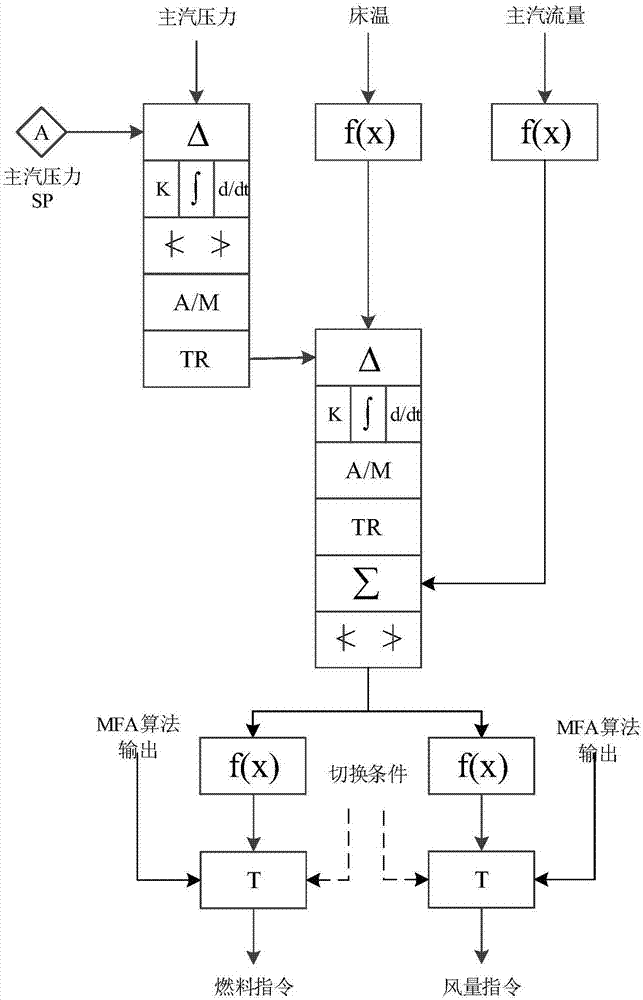

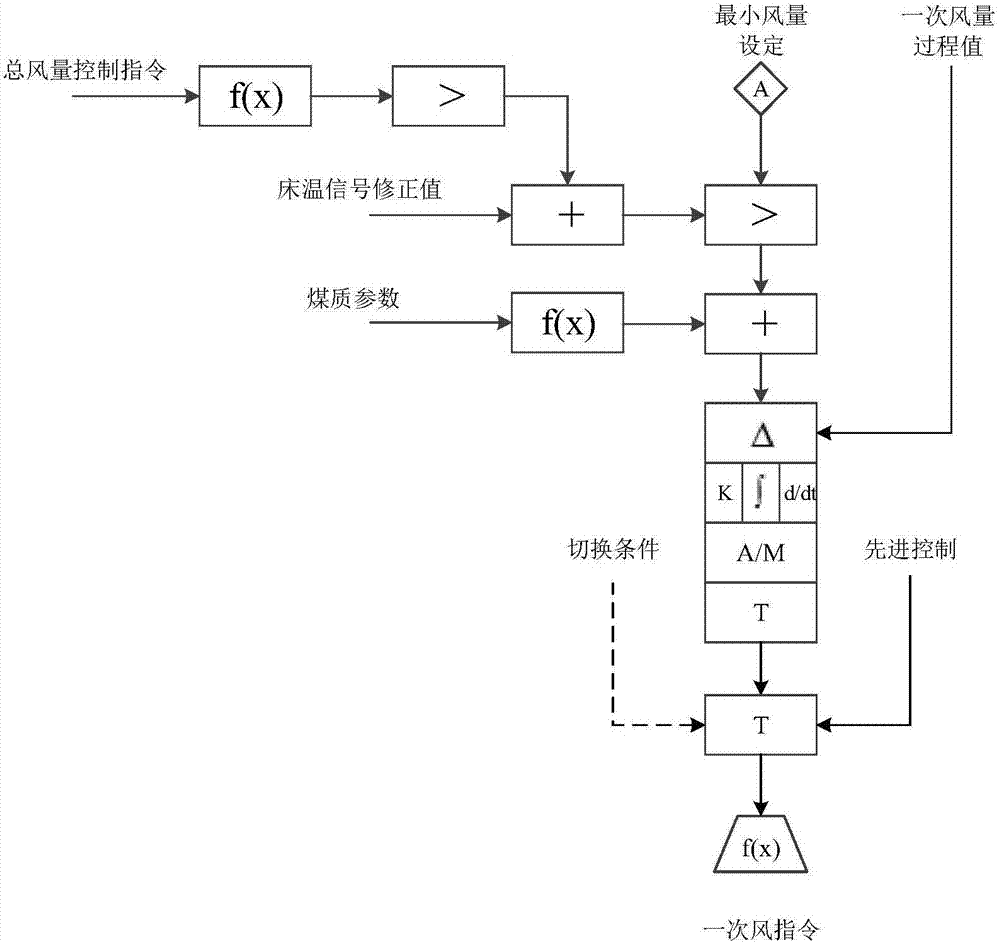

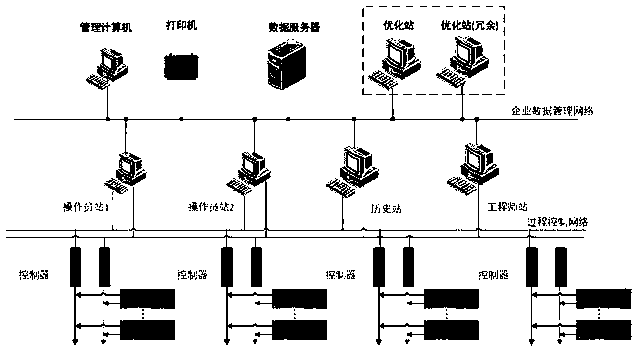

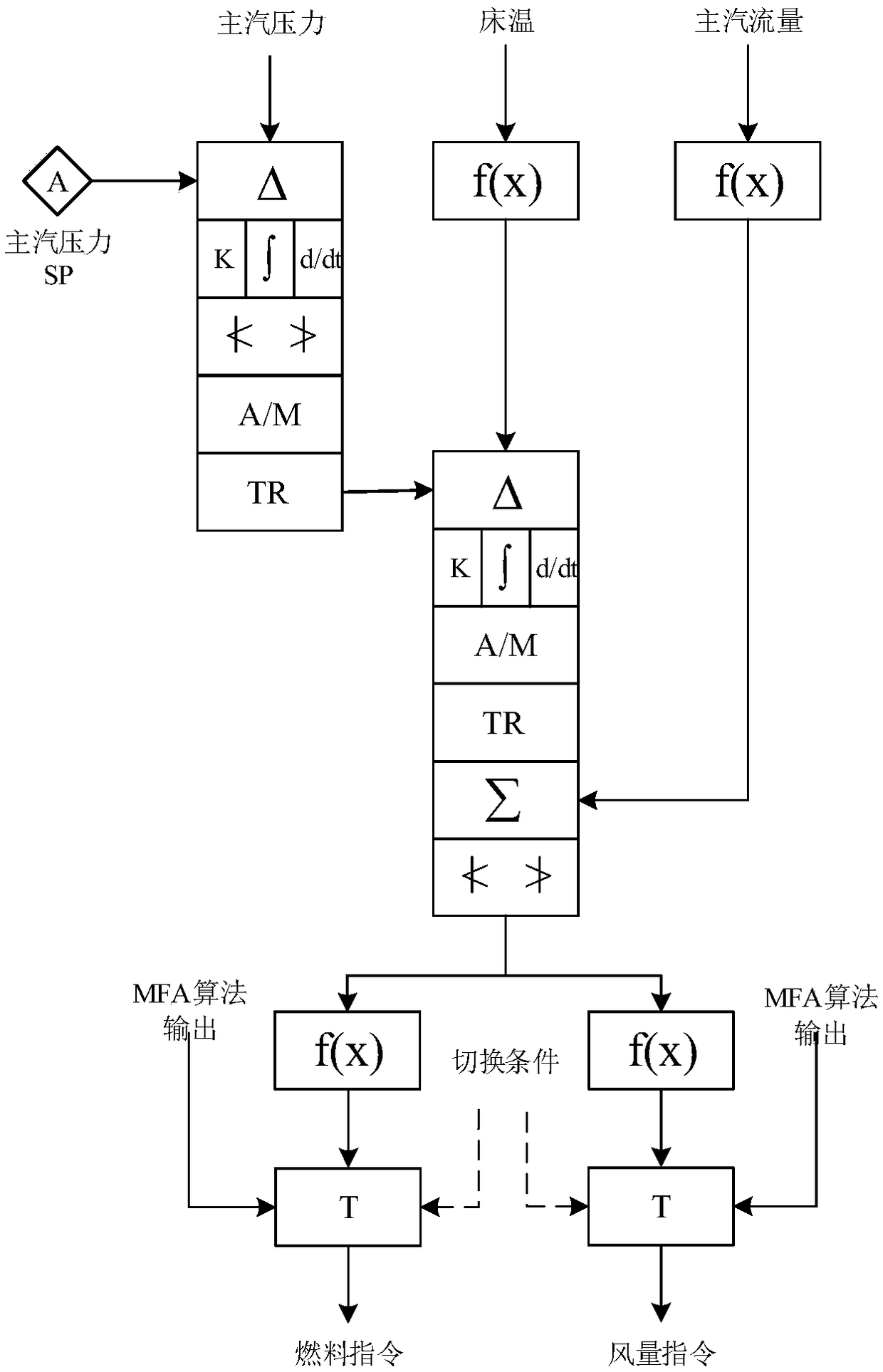

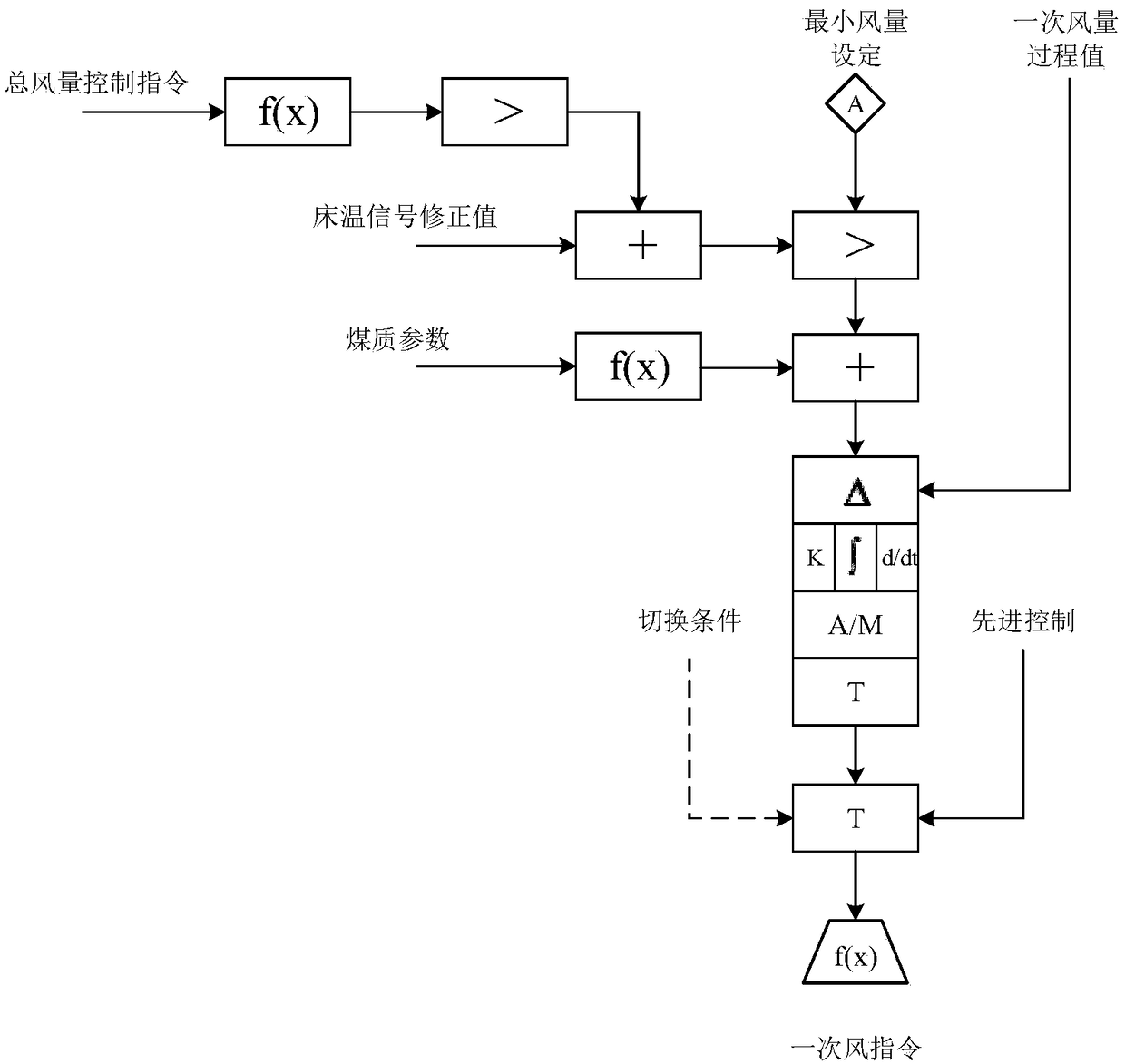

Fluidized bed boiler control and combustion optimization system

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

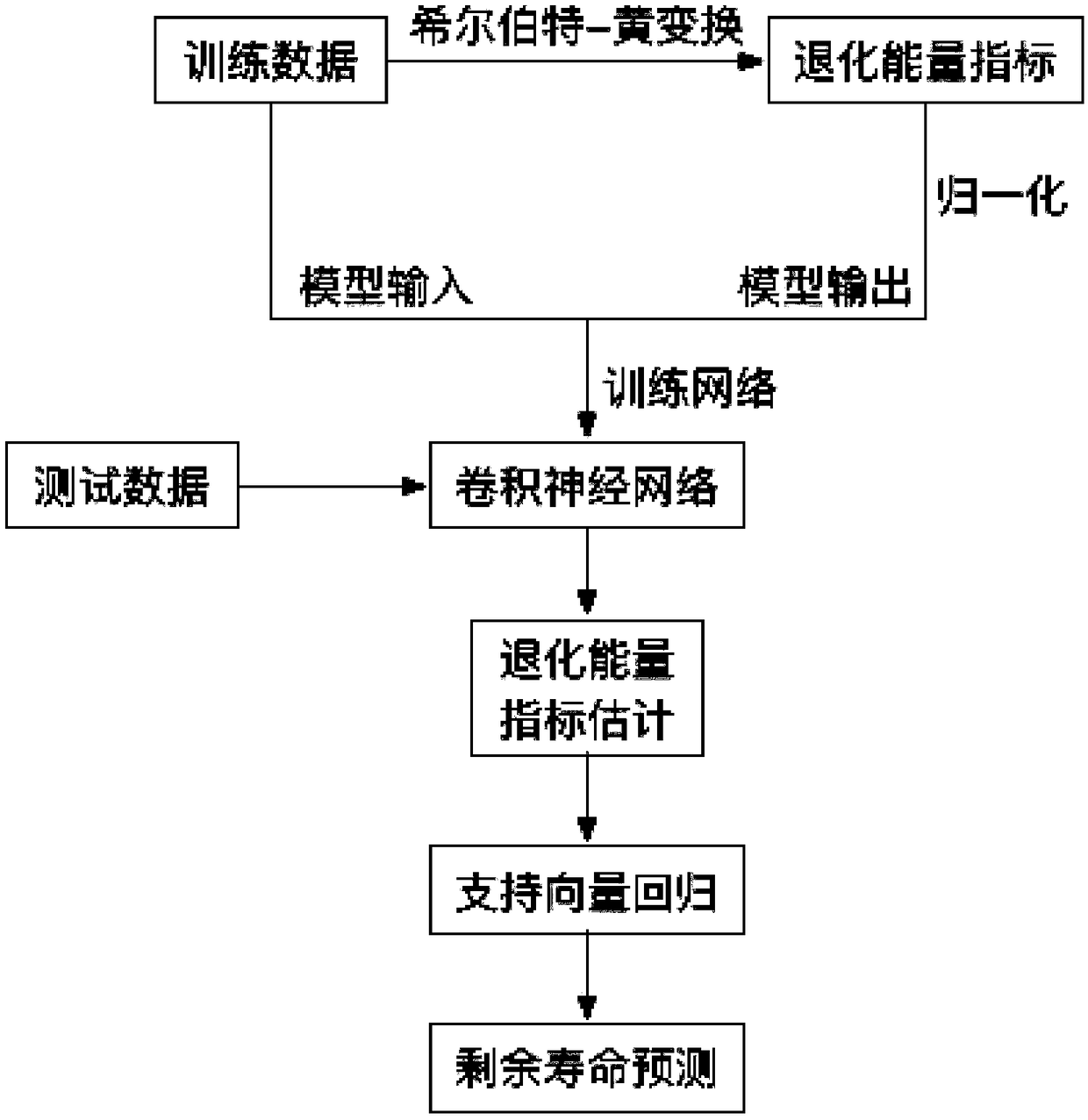

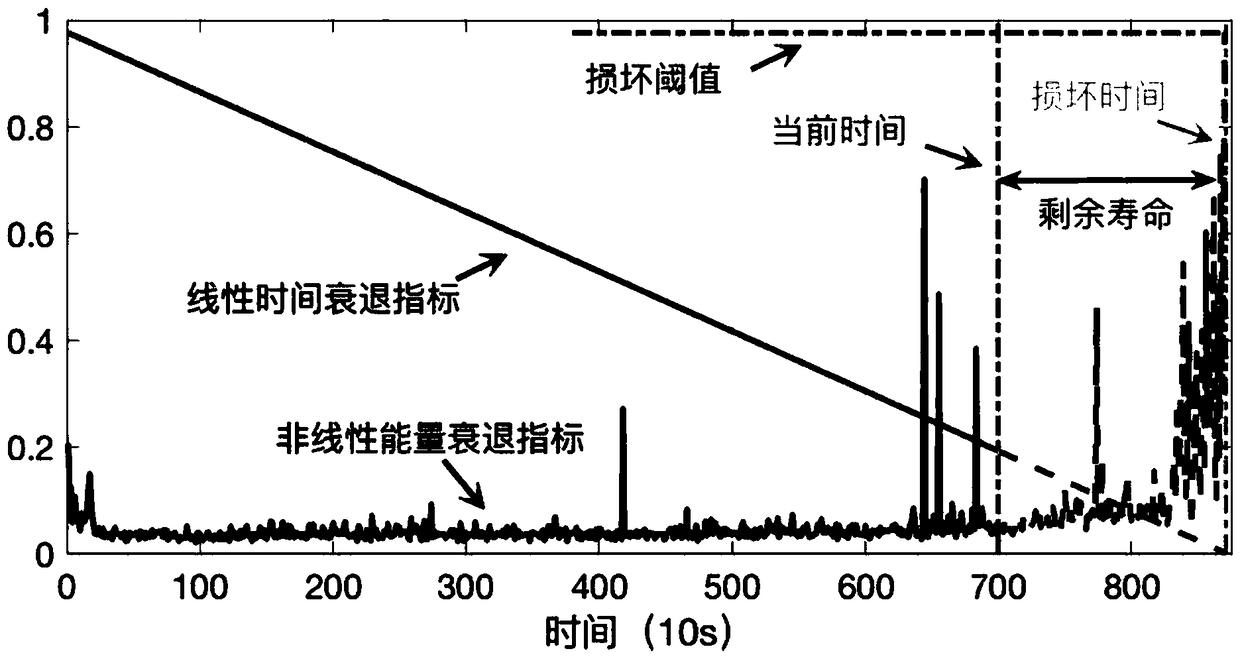

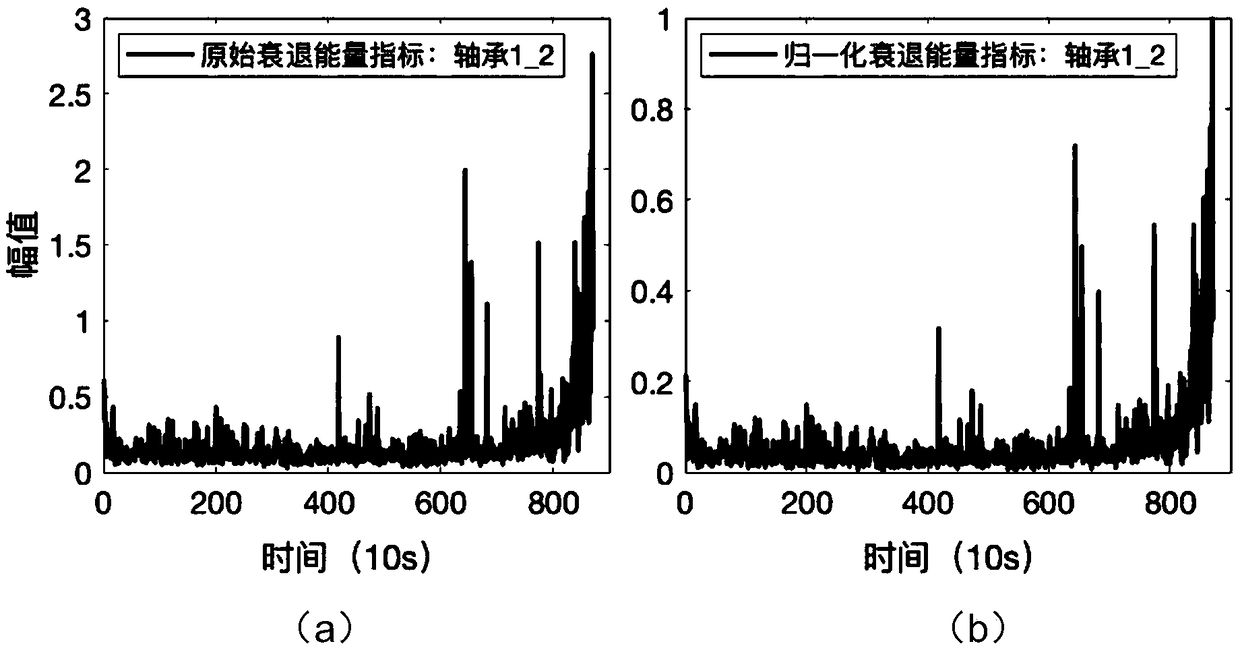

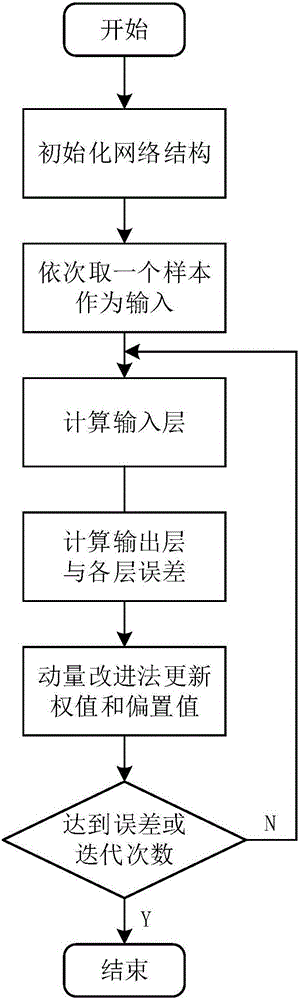

A method and system for on-line predict residual life of rolling bear

ActiveCN109460618AAccurate predictionStrong generalizationGeometric CADMachine bearings testingFeature extractionState model

The invention discloses an on-line prediction method for residual life of rolling bearing, As that roll bearing move from a healthy state to a damaged state, The original signal samples and corresponding degeneration energy indexes are extracted from the running process of the bearing, and the original signal samples are used as the input of the five-layer convolution neural network model, and thedegeneration energy indexes are used as the output of the convolution neural network model, and the degeneration energy state model is obtained by training. Real-time acquisition of the original running signals of the rolling bearings to be tested; The original running signal of the rolling bearing to be tested is input into the degradation energy state model, and the degradation energy index isestimated. Then the estimated energy degradation index is used to predict the residual life of the rolling bearings to be tested. The prediction process of the invention only needs to collect the original operation signal of the bearing, and does not need to extract and screen the features, thus overcoming the technical problems that the prior art adopts the methods of feature extraction, featurescreening and regression prediction, which have the characteristics extraction difficulty and the precision is limited.

Owner:HUAZHONG UNIV OF SCI & TECH

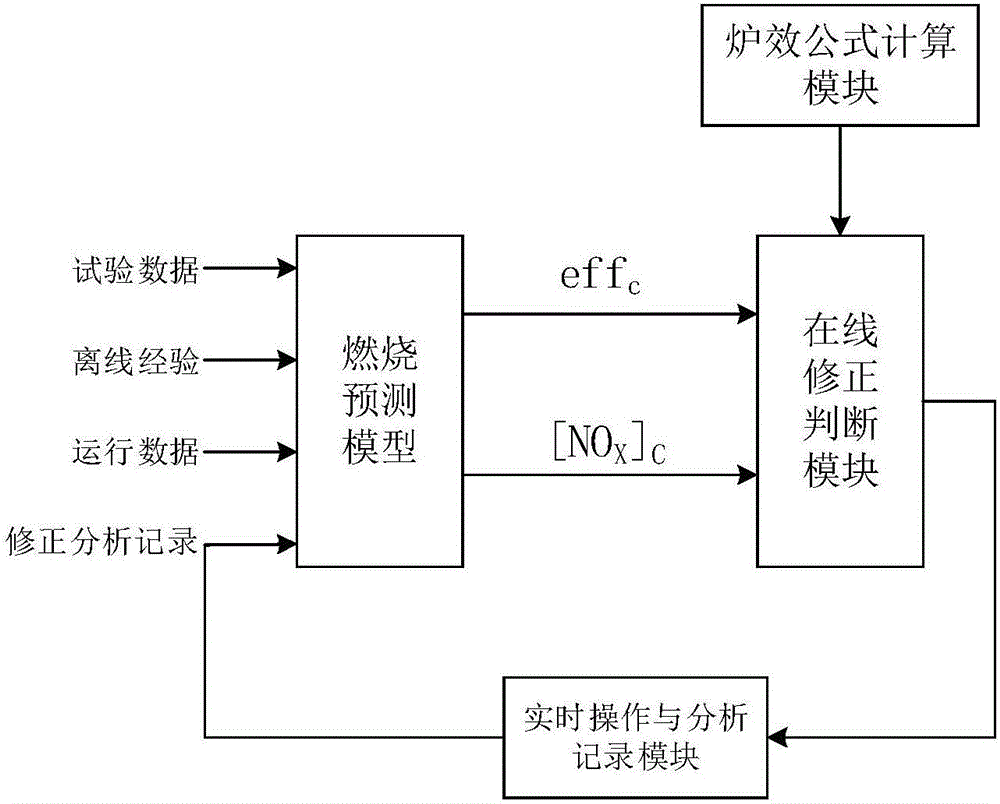

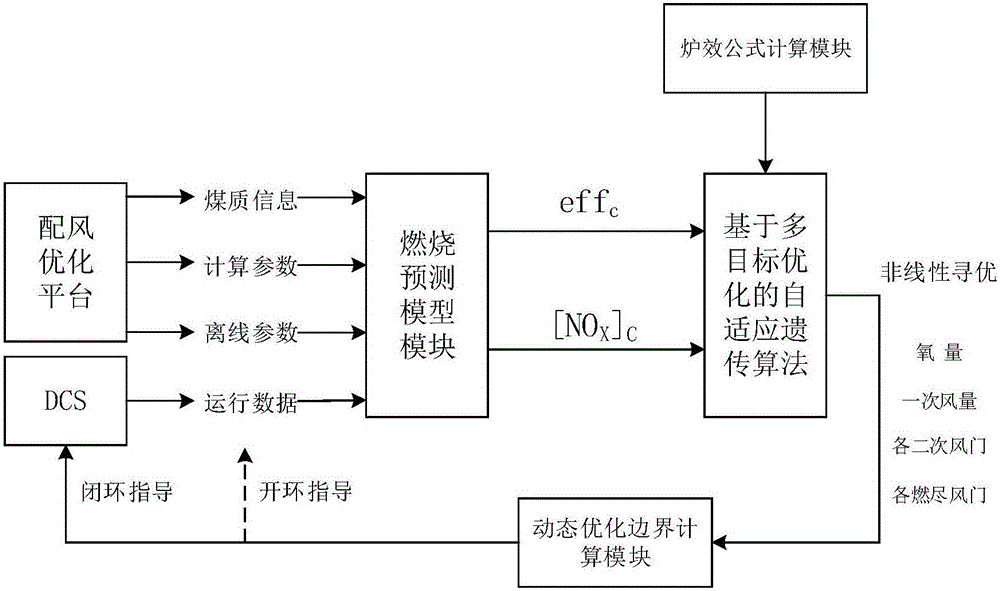

Boiler combustion optimization air distribution method based on online model prediction

Provided is a boiler combustion optimization air distribution method based on online model prediction. The method includes: constructing a boiler combustion optimization air distribution model by employing an improved BP neural network algorithm and model online update calculation; and performing optimization calculation on parameters such as the optimal oxygen amount, the primary air amount, each secondary air door and a burnout air door etc. with the combination of an adaptive genetic algorithm and dynamic optimization boundary so that a multi-target function constructed by the boiler efficiency and the pollutant discharge capacity reaches the optimal combustion range.

Owner:XIAN IBL TECH DEV

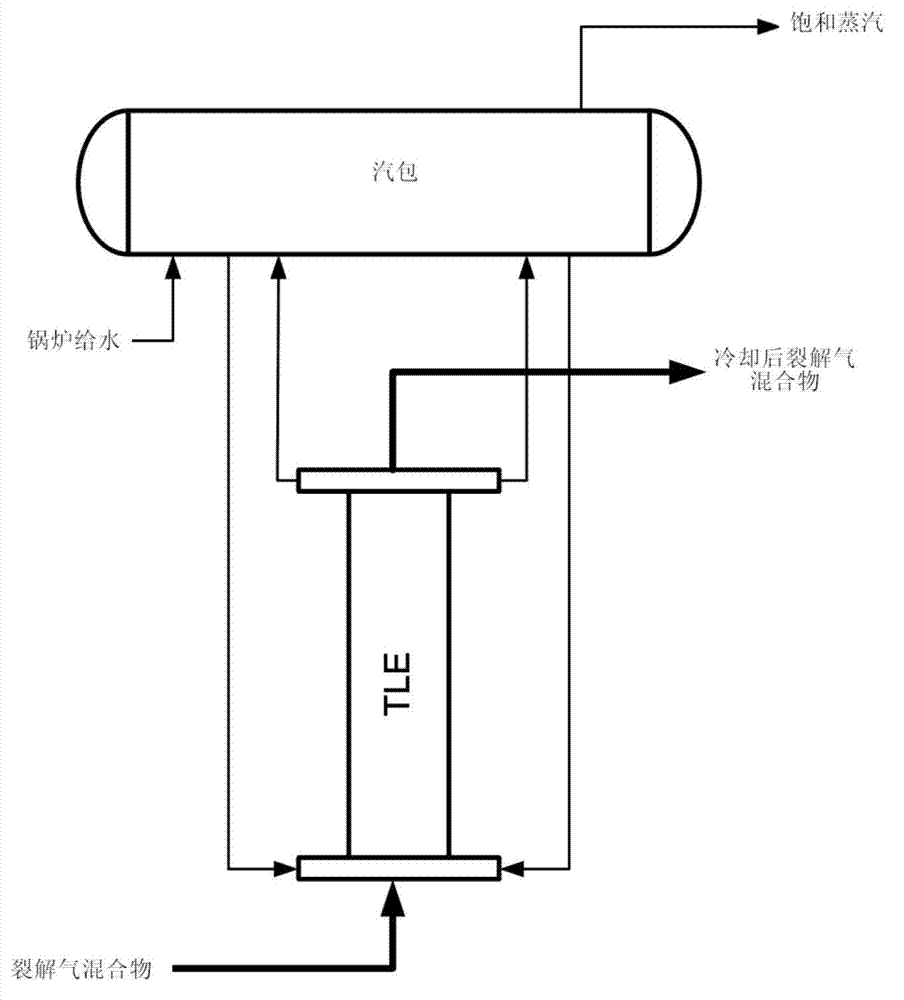

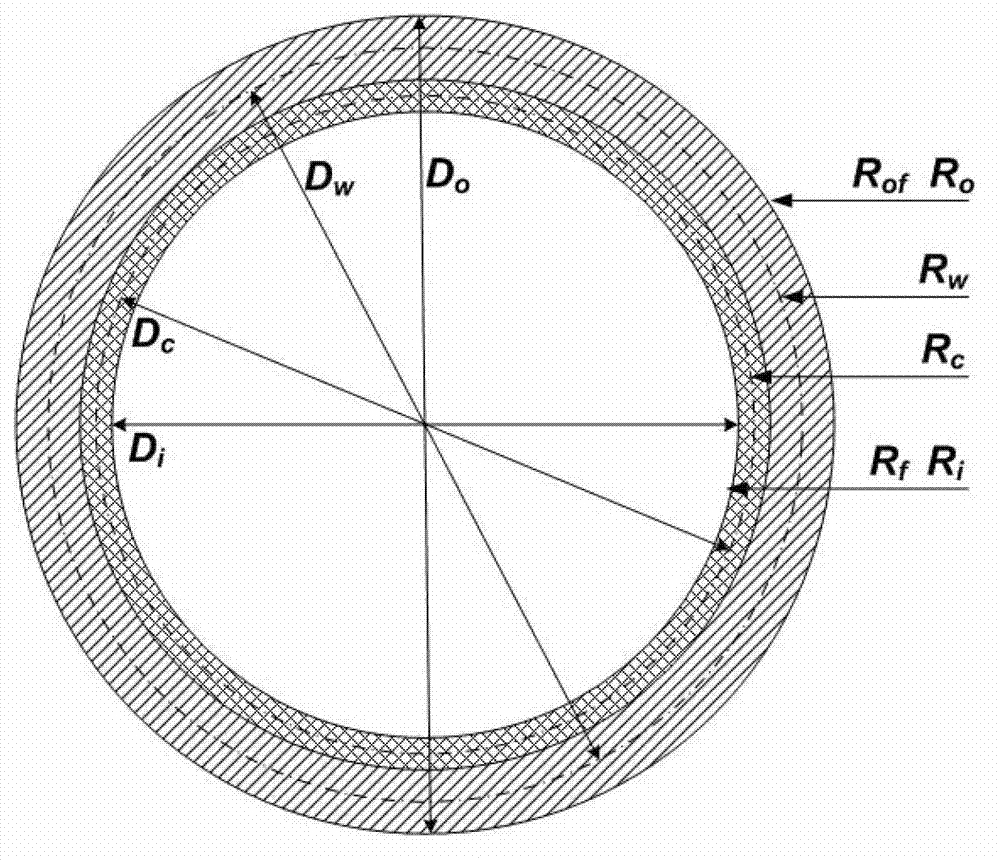

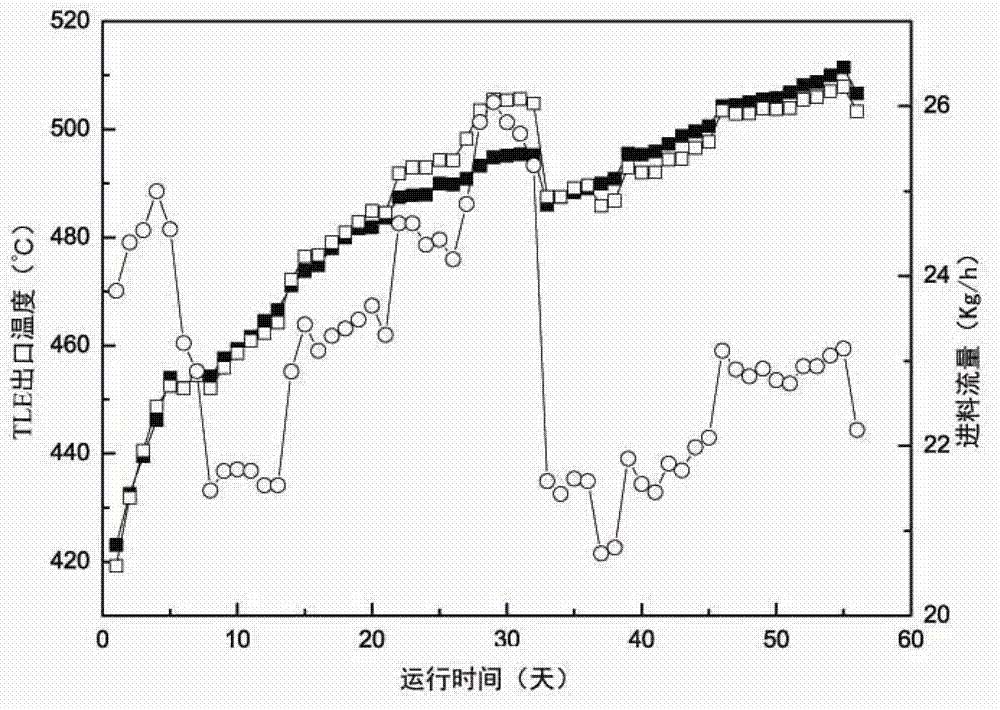

Predicating method for TLE (transfer line exchanger) outlet temperatures and operation cycles of ethylene cracking furnaces

ActiveCN103207949AOvercome mismatchOvercome external disturbancesThermal non-catalytic crackingSpecial data processing applicationsPredictive methodsModel parameters

The invention relates to a predicating method for TLE (transfer line exchanger) outlet temperatures and operation cycles of ethylene cracking furnaces. The deducing of TLE heat transfer processes of industrial ethylene cracking furnaces is simplified, and is combined with empirical models of TLE coking and depositing of the industrial ethylene cracking furnaces so as to deduce parameterized prediction models of the TLE outlet temperatures and the operation cycles of the industrial ethylene cracking furnaces. Actual production data are utilized to estimate and identify model parameters, time factor corrections are performed on the identified models additionally, and online and real-time correction updates can be carried out on the TLE outlet temperature parameterized prediction models as required to expand adaptability and accuracy of the models. When TLE maximum permission upper limits and maximum operating cycles are given, the TLE outlet temperature parameterized prediction models can be used for predicating follow-up operating time of TLE systems before next decoking online and predicating the TLE operating cycles. The predicating method is simplified, reasonable in deducing, high in construction applicability, simple to operate, easy to copy, and wide in adaptability.

Owner:EAST CHINA UNIV OF SCI & TECH

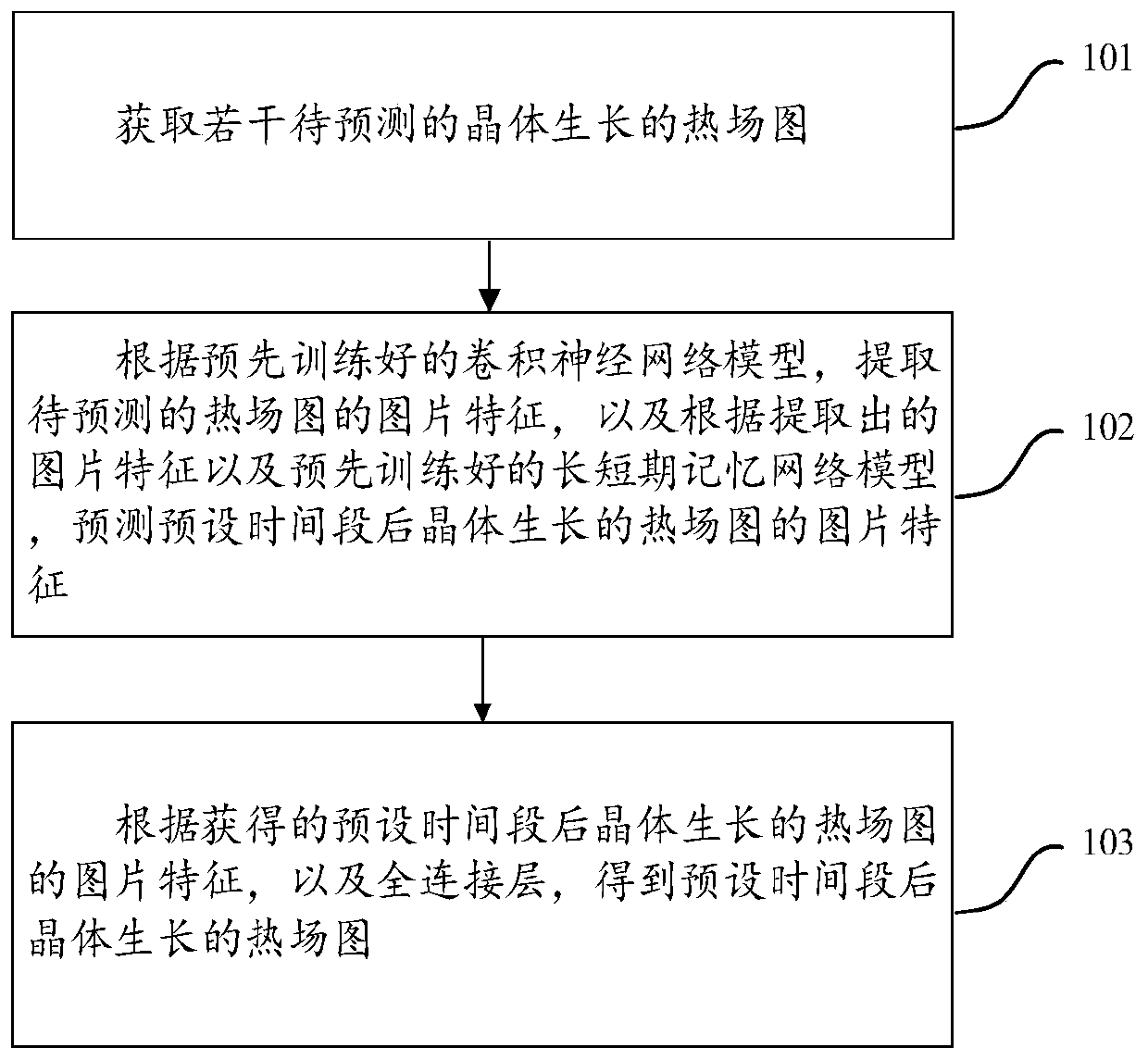

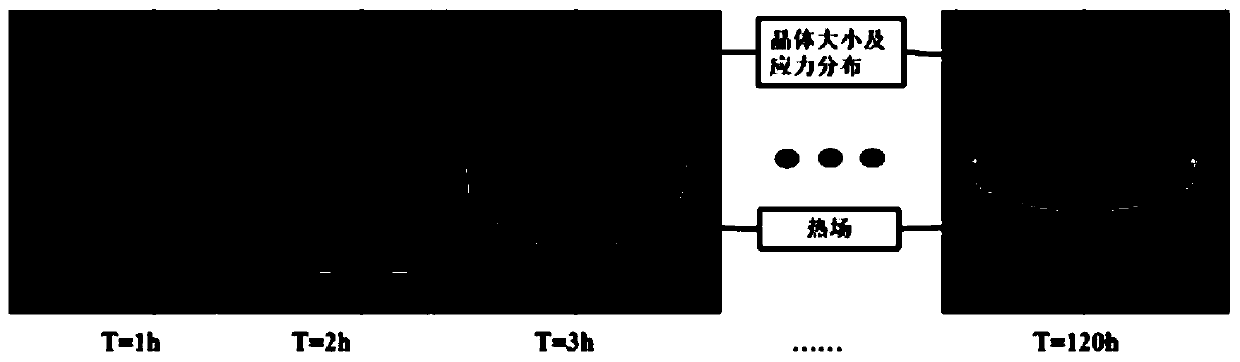

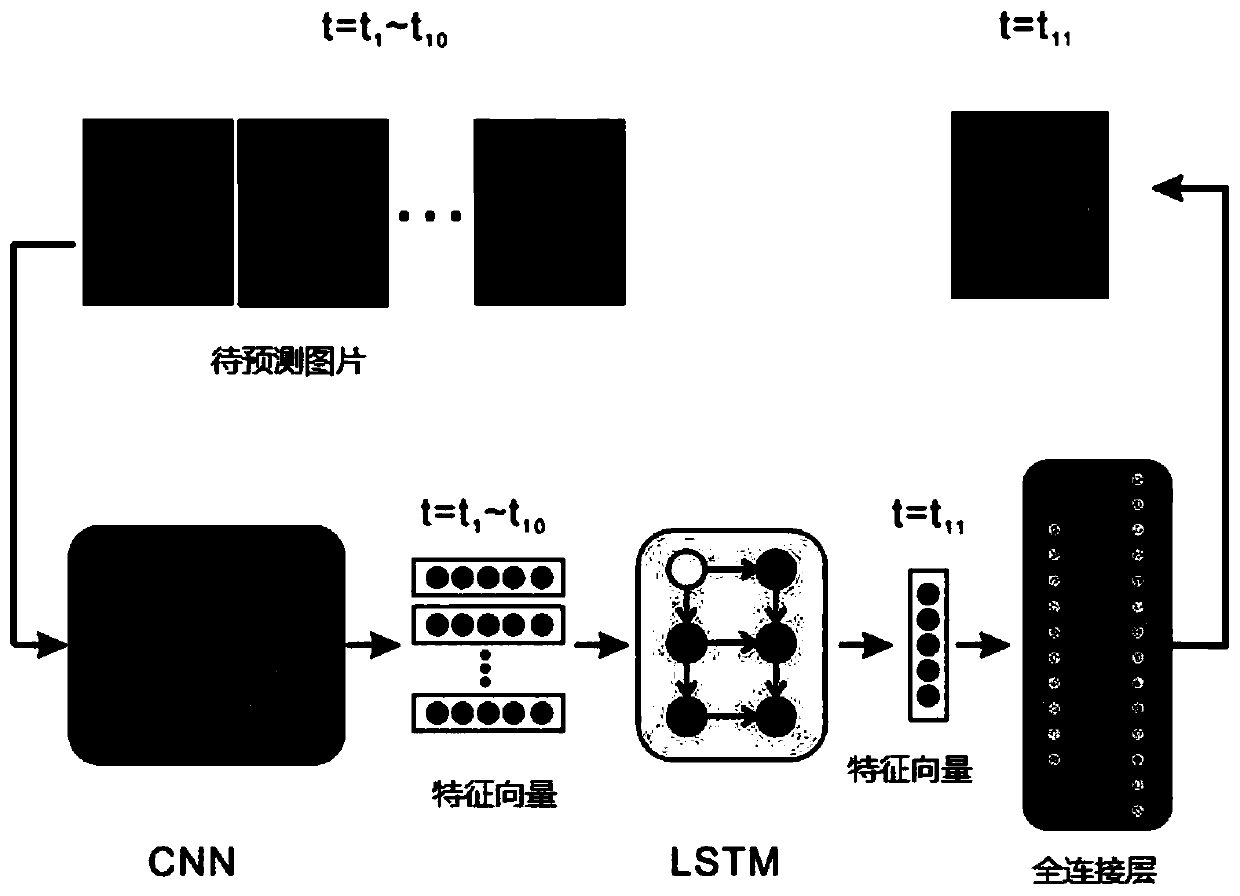

Crystal growth prediction method and device

PendingCN111028893AShorten the timeAccurate predictionChemical processes analysis/designNeural architecturesComputational physicsNetwork model

The invention discloses a crystal growth prediction method and device, and is used for solving the problems that an existing prediction method is large in calculation amount, long in consumed time, and incapable of online prediction. The method comprises the following steps: acquiring a plurality of to-be-predicted crystal growth thermal field graphs; according to a pre-trained convolutional neural network model, extracting picture features of the to-be-predicted thermal field picture; according to the extracted picture features and a pre-trained long-term and short-term memory network model,predicting the picture features of a thermal field graph of crystal growth after a preset time; and obtaining one or more items selected from thermal field distribution data of crystal growth, crystalshape change data and crystal stress distribution data according to the picture characteristics of the thermal field diagram of crystal growth after the preset time period. According to the method, crystal growth prediction can be realized in a short time, and online prediction is realized.

Owner:SICC CO LTD

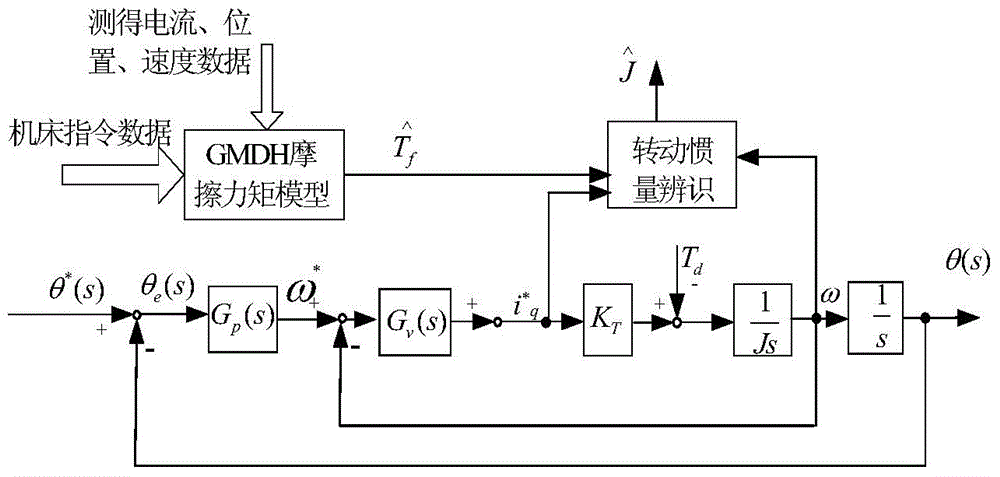

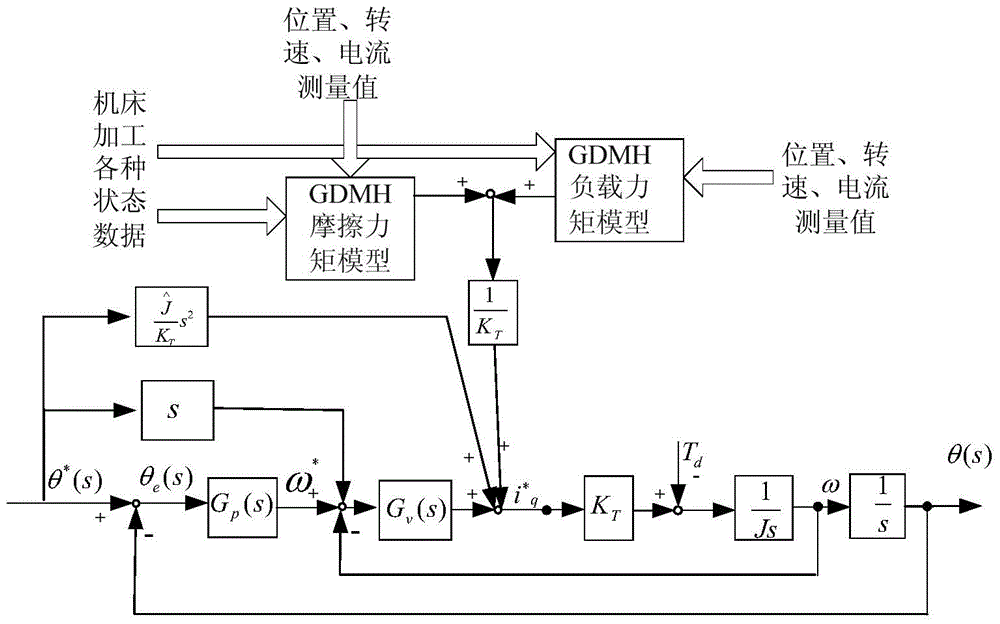

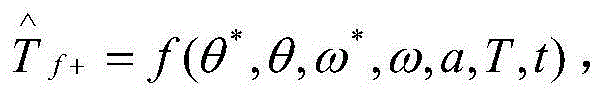

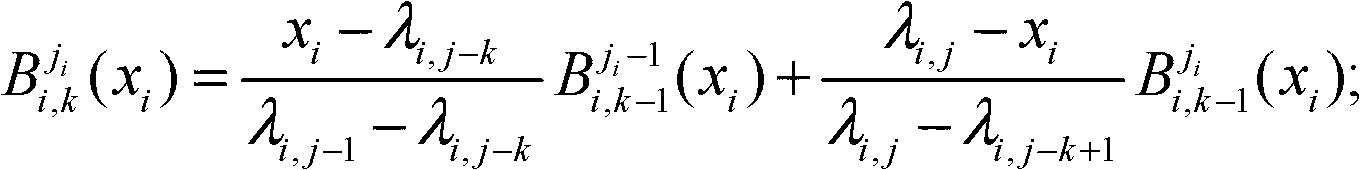

Machine tool feed system feedforward control method based on GMDH (Group Method of Data Handling) data mining algorithm

ActiveCN104950806AImprove fast trackingImprove tracking accuracyProgramme controlComputer controlControl theoryMachine tool

The invention discloses a machine tool feed system feedforward control method based on a GMDH (Group Method of Data Handling) data mining algorithm. The machine tool feed system feedforward control method is characterized by firstly, building a friction moment model and a load moment model of a machine tool by utilizing a GMDH algorithm; secondly, compensating feedforward to an input end of a current loop after dividing the obtained friction moment model and the obtained load moment model by a torque constant of a motor, directly applying the speed of a command signal to an input position of a speed loop at the same time to complete the input of speed feedforward, multiplying the acceleration of the command signal by a coefficient, enabling a result to be acted on an input position of the current loop to complete the input of acceleration feedforward. According to the machine tool feed system feedforward control method disclosed by the invention, the tracking accuracy and high-speed response performance on position are increased, and the machining quality of a workpiece can be increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Machine tool spindle accuracy prediction method

InactiveCN102848266ARealize online predictionReduce downtimeMeasurement/indication equipmentsControl engineeringComputer science

The invention relates to a machine tool spindle accuracy prediction method which comprises the following steps: performing whole-process monitoring on accuracy degradation and a vibration signal of a spindle of a test machine tool under common working conditions, using the monitoring results for training an accuracy degradation neural network having an associative memory function, and accurately obtaining a mapping relationship between the sensitive characteristic of the vibration signal of the spindle of the machine tool and the accuracy; and then, inputting the sensitive characteristic of the current vibration signal of a spindle of an actual in-service machine tool, which is the same with the spindle of the test machine tool in type and specification, into the accuracy degradation neural network to obtain the current accuracy of the spindle of the actual in-service machine tool, thus realizing the on-line prediction of the accuracy of the spindle of the actual in-service machine tool. According to the accuracy degradation tendency of the spindle of the machine tool, related parts of the spindle of the machine tool can be purchased in advance when the accuracy value approximately can not meet the specified requirement, thereby reducing the downtime of the machine tool, lowering the enterprise loss and saving the enterprise cost. Besides, the invention also can provide effective basis and instructions in aspects of analysis, judgment, maintenance and servicing for operating personnel, thereby prolonging the service life of the spindle of the machine tool.

Owner:SOUTHWEST JIAOTONG UNIV

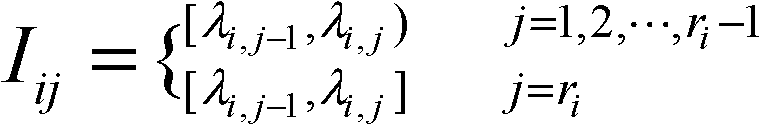

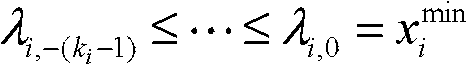

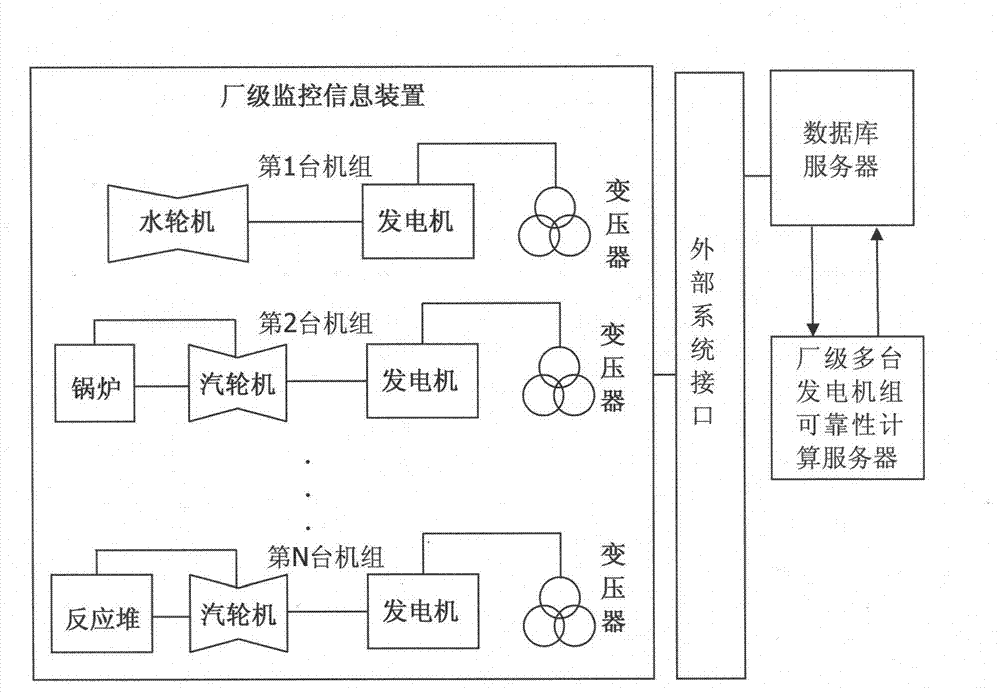

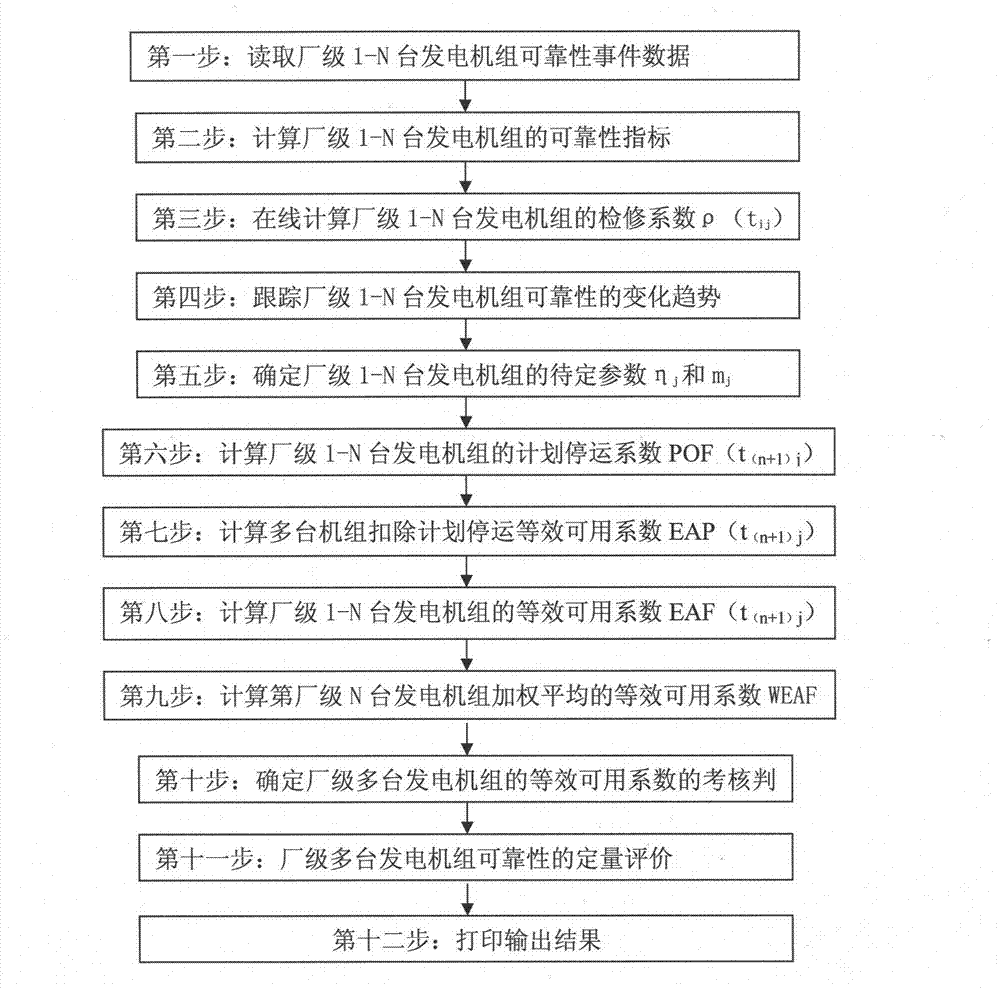

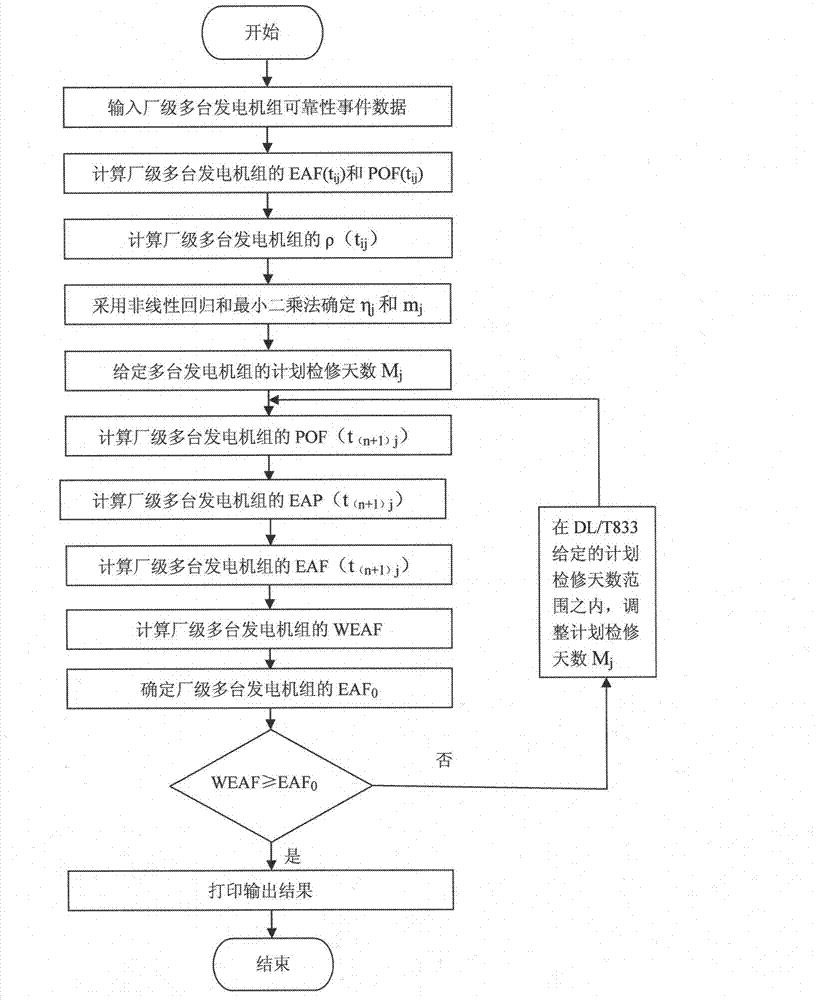

On-line prediction method for reliability of factory-level multiple generator units

ActiveCN103077428ARealize online predictionImprove reliabilityForecastingPredictive methodsEvent data

The invention provides an on-line prediction method for the reliability of factory-level multiple generator units, and is characterized by comprising the following specific steps of: reading the event data of the reliability of the factory-level multiple generator units; calculating the reliability index of the factory-level multiple generator units; calculating the overhauling factor rho (tij) of the factory-level multiple generator units on line; tracking the reliability change tendency of the factory-level multiple generator units; determining the undetermined parameters eta j and mj of a factory-level 1-N generator unit; calculating the planned outage factor (POF) (t(n+1)j) of the factory-level multiple generator units; calculating the deduction planned outage equivalent available coefficient EAF (t(n+1)j) of the factory-level multiple generator units; calculating the equivalent available coefficient EAF (t(n+1)j) of the factory-level multiple generator units; calculating the average weighted equivalent available coefficient (WEAF) of the factory-level multiple generator units; determining the assessment criterion value of the equivalent available coefficients of the factory-level multiple generator units; carrying out quantitative evaluation on the reliability of the factory-level multiple generator units; and printing an output result. According to the on-line prediction method for factory-level multiple generator units, which is disclosed by the invention, the on-line prediction of the reliability of the factory-level multiple generator units is realized.

Owner:SHANGHAI POWER EQUIP RES INST +1

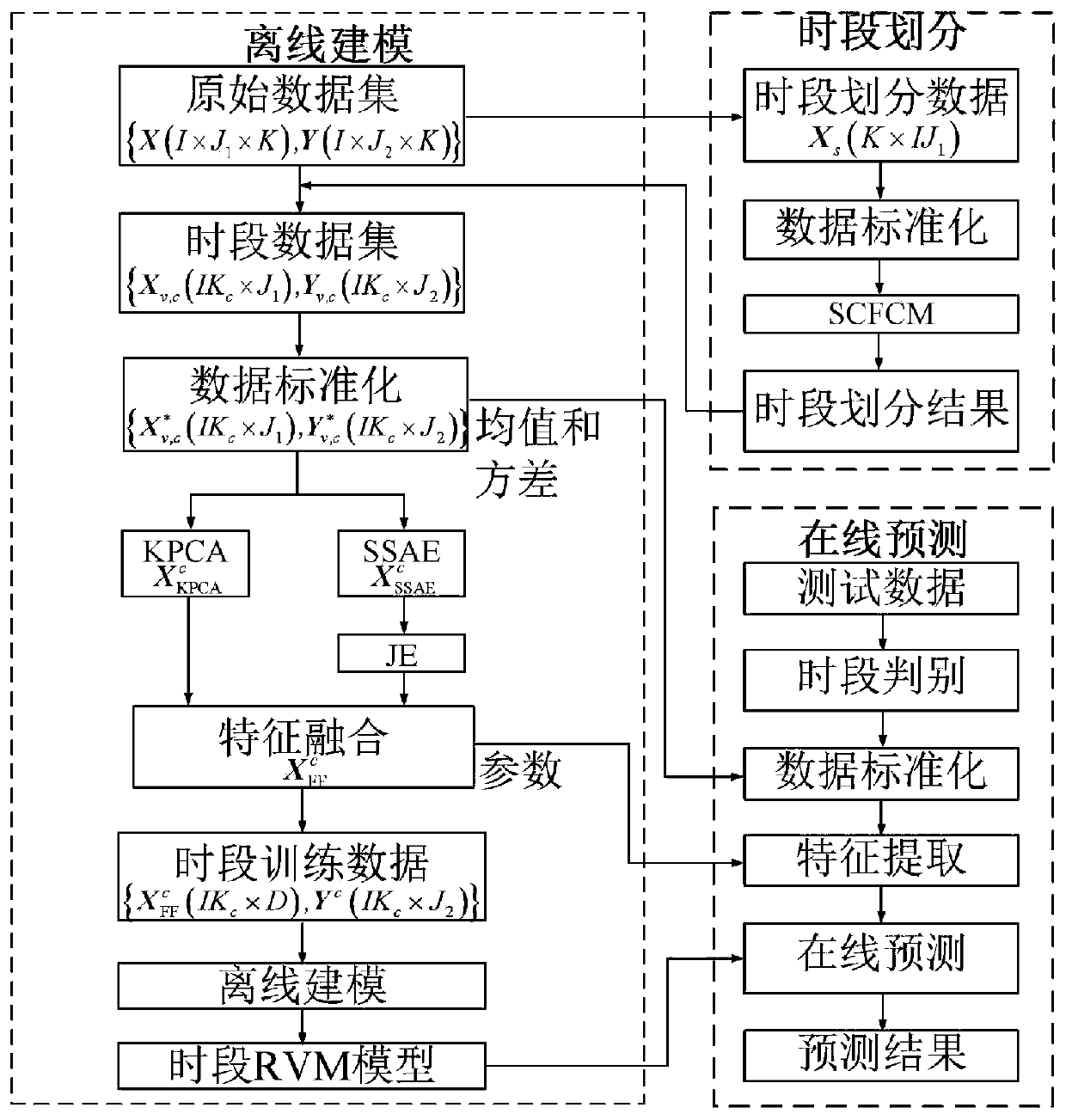

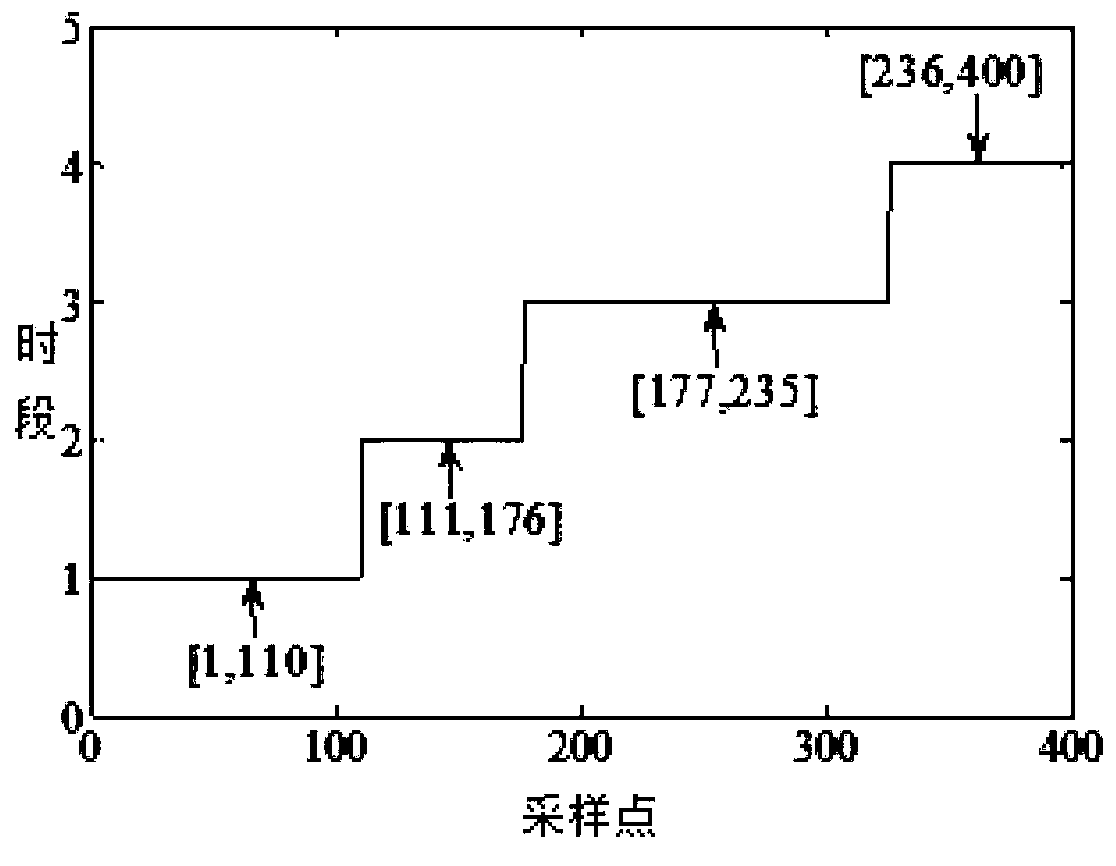

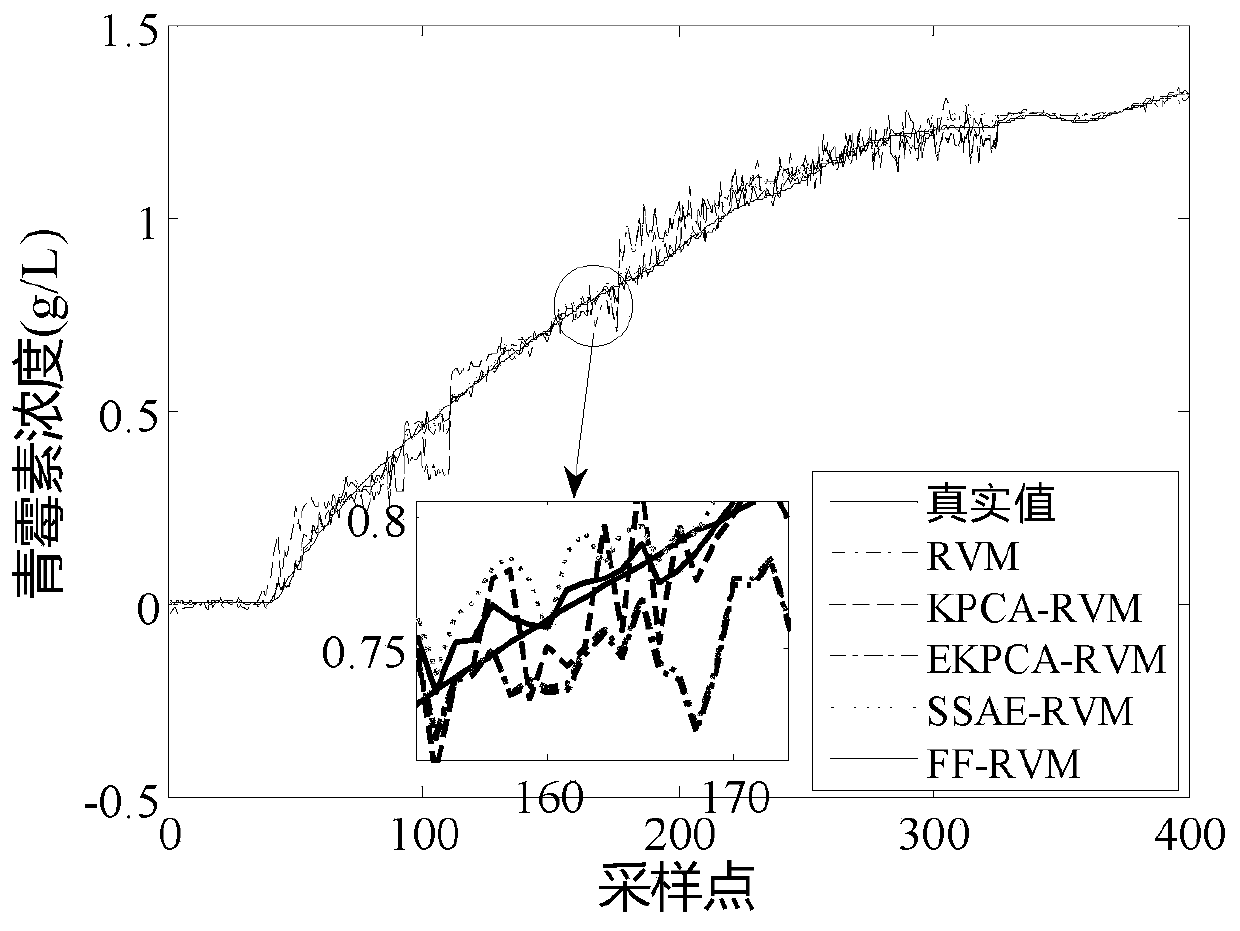

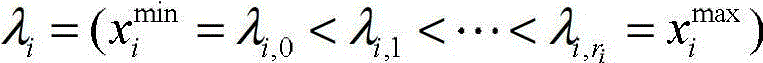

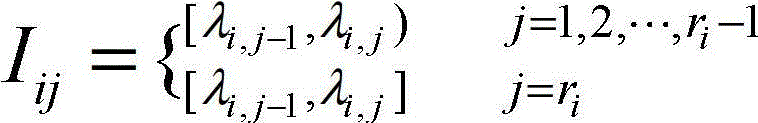

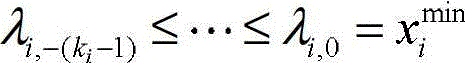

Multi-period intermittent process soft measurement modeling method based on FF-RVM

PendingCN111144017ARealize online predictionImprove forecast accuracyCharacter and pattern recognitionDesign optimisation/simulationFeature DimensionAlgorithm

The invention discloses a multi-period intermittent process soft measurement modeling method based on FF-RVM. The method comprises the following steps: firstly, carrying out period division on an intermittent process by utilizing an SCFCM clustering method; then, respectively utilizing KPCA and SSAE to carry out feature extraction on original process data of each time period; achieving feature dimension reduction processing based on KPCA and feature dimension expansion processing based on SSAE, adopting a feature selection method based on minimum errors to screen out SSAE features having highcorrelation with quality variables, and conducting feature fusion on the screened-out SSAE features and the extracted KPCA features; and finally, establishing an RVM-based time period soft measurementmodel by taking the process data subjected to feature fusion as time period training data, thereby realizing online prediction of the quality variable. According to the method, the amount of information contained in the process data is effectively expanded, a large amount of effective training data is provided for establishing an intermittent process soft measurement model, and online predictionof the intermittent process quality variable is realized.

Owner:BEIJING UNIV OF CHEM TECH

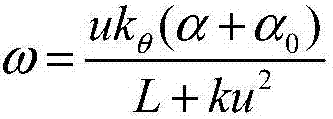

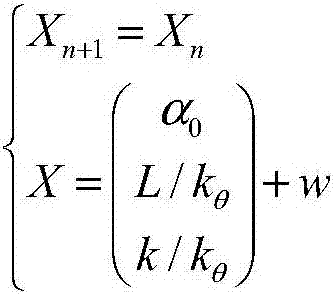

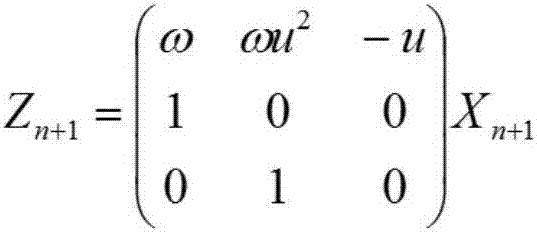

Online prediction method and system for automobile steering control characteristics

ActiveCN107380169ARealize online predictionAccurate predictionControl devicesSteering wheelAngular velocity

The invention discloses an online prediction method and system for automobile steering control characteristics. The method comprises the steps that the real-time steering wheel angle value and the real-time motor rotating speed of an automobile are collected, and the predicted yaw angular velocity of the automobile at the next moment is calculated according to a yaw angular velocity steady-state response equation which is obtained after parameters are predicted through a Kalman filter; and the yaw angular velocity of the automobile is controlled according to the calculated predicted yaw angular velocity. According to the method, the yaw angular velocity steady-state response equation conforming to the movement performance of the automobile can be obtained, accordingly, online prediction of the automobile control characteristics is achieved; and prediction is conducted through the method so that the environmental change or the change brought by time lapse can be considered, the change of the automobile steering control characteristics is accurately predicted, stability is high, accuracy is high, and therefore the method can be widely applied to the industry for controlling electric automobiles.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

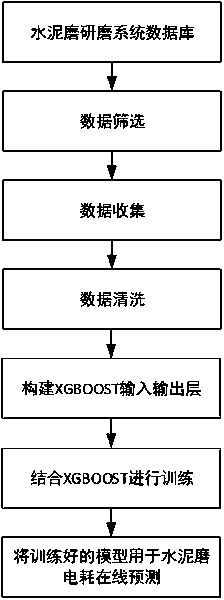

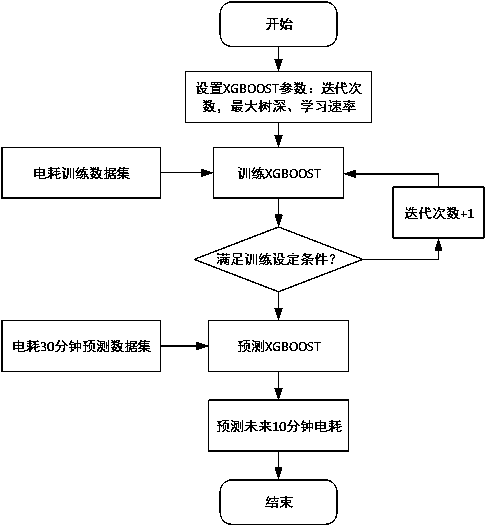

Cement grinding mill system power consumption index prediction method based on XGBoost

PendingCN110910277AEliminate the effects ofRealize online predictionForecastingData setProcess engineering

The invention discloses a cement grinding mill system power consumption index prediction method based on XGBoost. The cement grinding mill system power consumption index prediction method comprises the following steps: selecting eight variables related to the power consumption of the cement mill; collecting required variable data by adopting an OPC technology; removing abnormal data by adopting anartificial experience removal method and criterion; constructing an XGBoost model input and output layer; initializing a weight parameter according to the sample data; training a first tree accordingto the weight; updating the weight parameter according to the target function after the training is finished; performing a new round of decision tree training; when the weight sum of the samples is smaller than a set threshold value or the number of iterations reaches a set value, stopping tree building; completing the training of the XGBoost model; and substituting the industrial field sample data set into the trained model to complete the online prediction of the power consumption index of the cement grinding mill system, training the sample data through XGBoost, and inputting the variabledata of the actual cement production field into the trained model to realize the online prediction of the power consumption index of the cement grinding mill.

Owner:YANSHAN UNIV

Accuracy prediction method for linear guiderail pairs

InactiveCN102879192ARealize online predictionReduce downtimeMachine part testingStop timePrediction methods

Disclosed is an accuracy prediction method for linear guiderail pairs. Accuracy degradation and vibration signals of a tested linear guiderail pair in a simulated working condition are monitored in a whole process, and monitoring results are used for training accuracy degradation neural networks with associative memory functions, accordingly, mapping relations between sensitive characteristics of the vibration signals of the tested linear guiderail pair and the accuracy are obtained accurately; and the sensitive characteristics of the current vibration signals of a linear guiderail pair with a same model specification with the tested linear guiderail pair are input into the accuracy degradation neural networks to obtain current accuracy of the linear guiderail pair, and accordingly, the online prediction of the linear guiderail pair accuracy is achieved. According to the accuracy prediction method for linear guiderail pairs, linear guiderail pairs can be purchased in advance according to the linear guiderail pair accuracy degradation trend when accuracy values can barely meet prescribed requirements, so that the tool stopping time is reduced, enterprise losses are decreased, and the enterprise cost is saved. Besides, effective bases and guidance are provided for analysis, determination and maintenance of operating personnel, and the service life of the linear guiderail pair is increased.

Owner:SOUTHWEST JIAOTONG UNIV

LS-SVMs online learning method based on budget support vector set

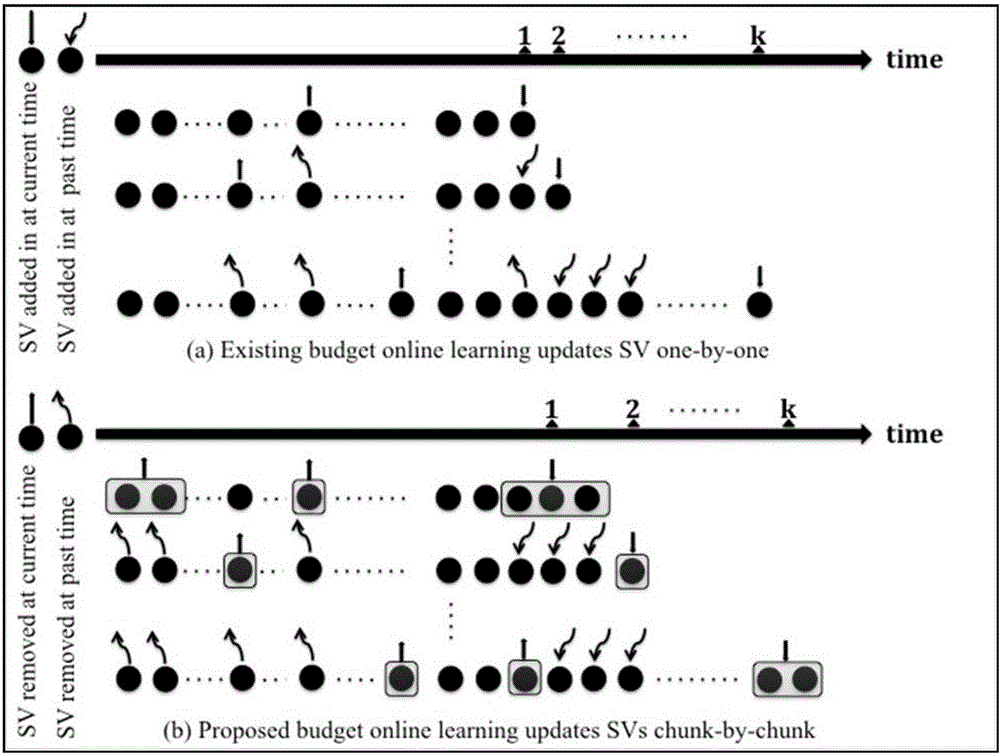

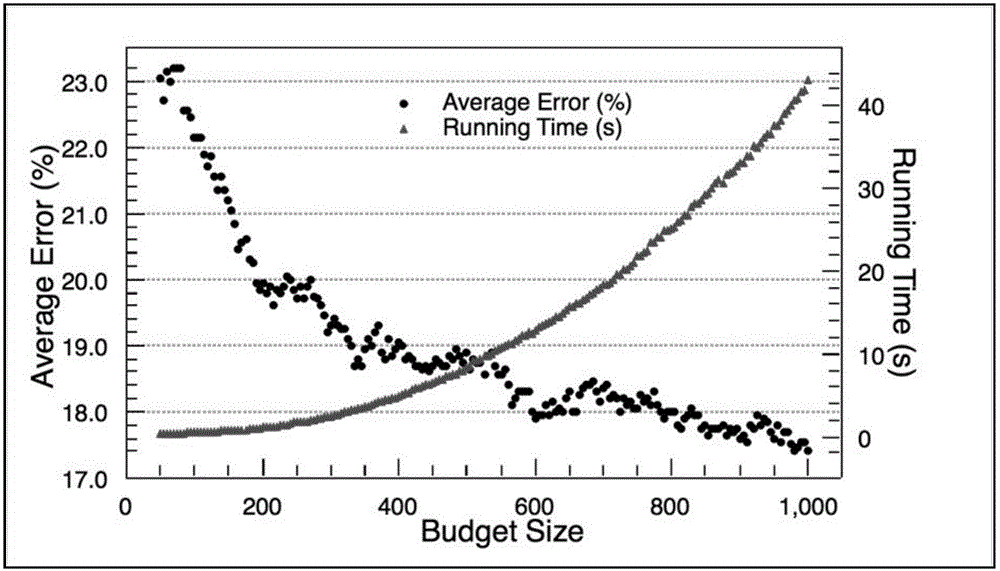

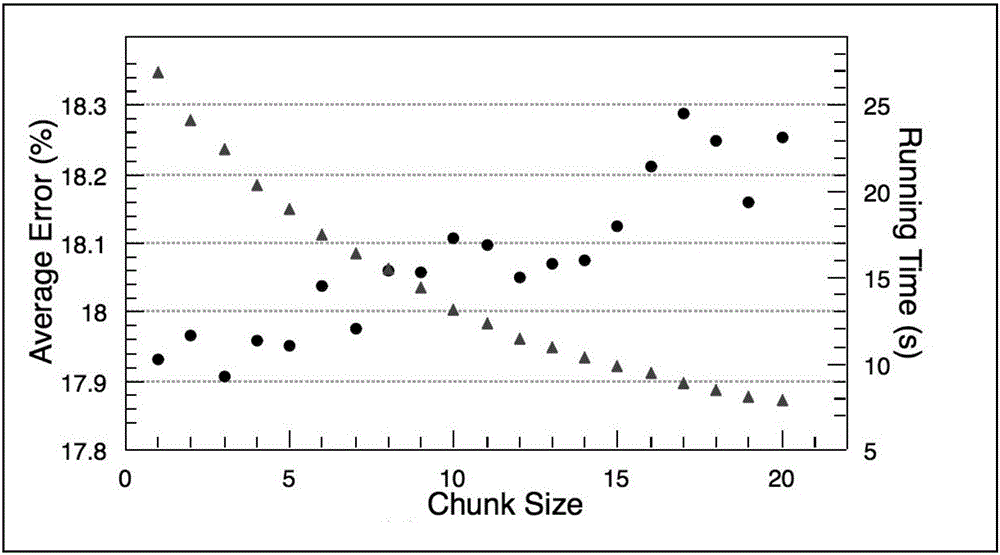

InactiveCN105787507AControl scaleRealize online predictionCharacter and pattern recognitionBatch processingData stream

The invention relates to an LS-SVMs online learning method based on a budget support vector set. A budge scope is determined on a training set, an initial support vector set is selected, an LS-SVMs model is established, the LS-SVMs model is solved by use of a conjugate gradient method, an online predicitor is obtained by updating the LS-SVMs model by use of a low-rank matrix correction method and a Sherman-Morrison-Woodbury formula, and thus online prediction of a data flow is realized. The method employs a fixed budge strategy, can effectively control the scale of an online learning model, saves storage space, and is low in calculation complexity and easy to realize. The online learning method provided by the invention has the following advantages: the problem of online application with a data flow feature can be flexibly processed, data can be collected in the form of data blocks, compared to a conventional batch processing mode and a conventional online learning mode, the calculation complexity and the model operation time are substantially reduced, the regression problem and the classification problem can be simultaneously resolved, and the selection problem of the LS-SVMs model can be highly efficiently solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Precision prediction method of ball screw pair

InactiveCN102889988ARealize online predictionReduce downtimeMachine gearing/transmission testingBall screwStop time

The invention discloses a precision prediction method of a ball screw pair. By using the method, the whole processes of precision degradation and a vibration signal of a tested ball screw pair under a simulated working condition are monitored, and the monitoring result is used for training a precision degradation neural network with an associative memory function, so that the mapping relationship between the sensitivity and the precision of the vibration signal of the ball screw pair can be more accurately obtained; and furthermore, the sensitivity of the current vibration signal of a ball screw pair with the same specification with the tested ball screw pair is input to the precision degradation neural network, so that the current precision of the ball screw pair can be obtained, and the online prediction for the precision of the ball screw pair is realized. The ball screw pair can be purchased in advance according to the precision degradation trend of the ball screw pair when the precision value is close to the value which can not meet the requirement of a provision, so that the stop time of a lathe is shortened, the loss of an enterprise is reduced, and the cost of the enterprise is saved. By using the precision prediction method of the ball screw pair, effective basis and guidance can also be provided for operating staff in analysis, judgment and maintenance, and the service life of the ball screw pair is prolonged.

Owner:SOUTHWEST JIAOTONG UNIV

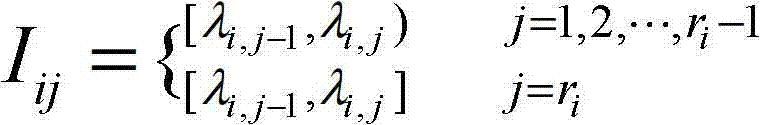

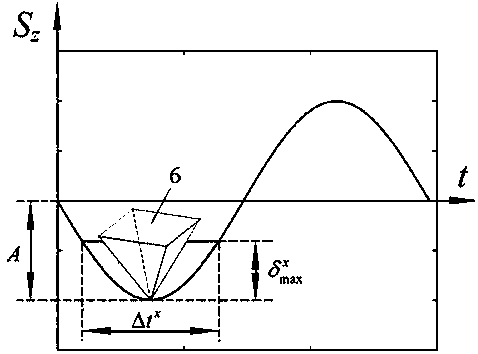

Online prediction method for subsurface stratum damage depth during rotary ultrasonic machining of hard and brittle materials for vehicle

ActiveCN110480429AIn line with the actual processing processRealize online predictionGrinding feed controlRelational modelUltrasonic machining

The invention discloses an online prediction method for the subsurface stratum damage depth during the rotary ultrasonic machining of hard and brittle materials for a vehicle. The online prediction method for the subsurface stratum damage depth during the rotary ultrasonic machining of hard and brittle materials for the vehicle comprises the steps of (1) determining the effective cutting time anda maximum cutting force; (2) determining the number of abrasive particles on the edge of the end surface of a cutter and the number of abrasive particles with a certain height participating in cutting; (3) determining the total impulse of the abrasive particles with the selected height and the total impulse of the cutter; (4) building a theoretical relational model of the cutter cutting force andthe equivalent indentation depth; and calculating according to the cutter cutting force obtained through measurement so as to obtain the equivalent indentation depth; and (5) building a theoretical relation between the maximum expansion depth of subsurface stratum cracks and the equivalent indentation depth of the cutter. The online prediction method for the subsurface stratum damage depth duringthe rotary ultrasonic machining of hard and brittle materials for the vehicle provided by the invention can be used for accurately online predicting the subsurface stratum damage depth during the rotary ultrasonic machining of hard and brittle materials for the vehicle.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

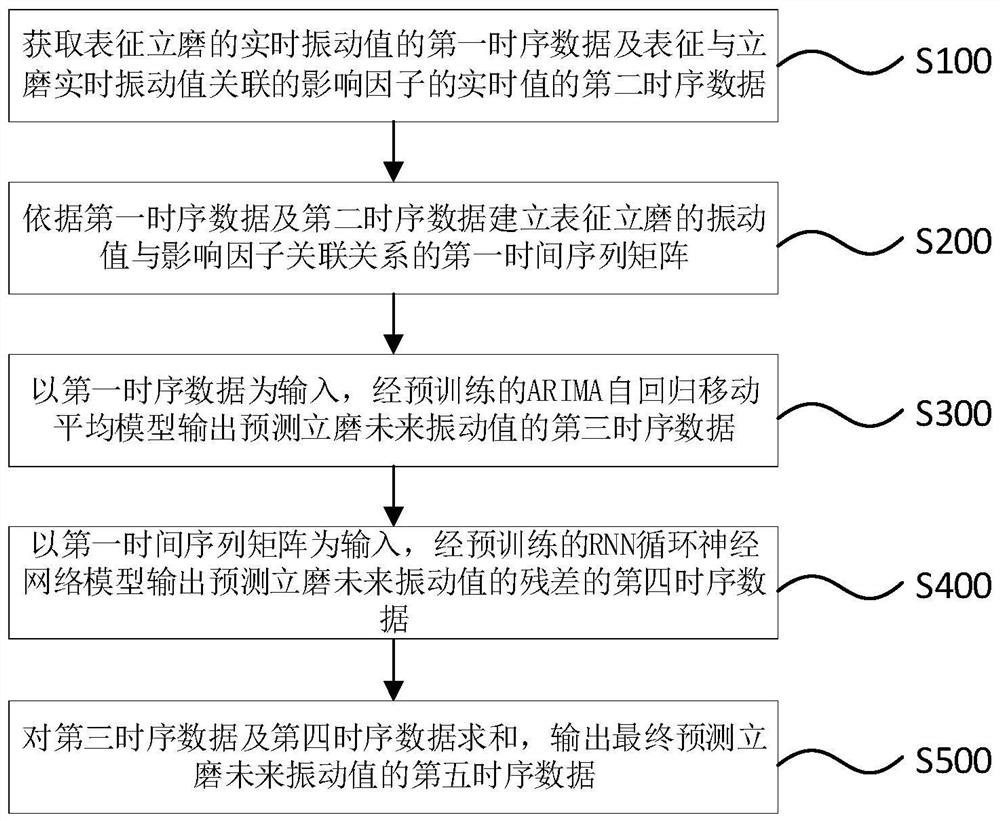

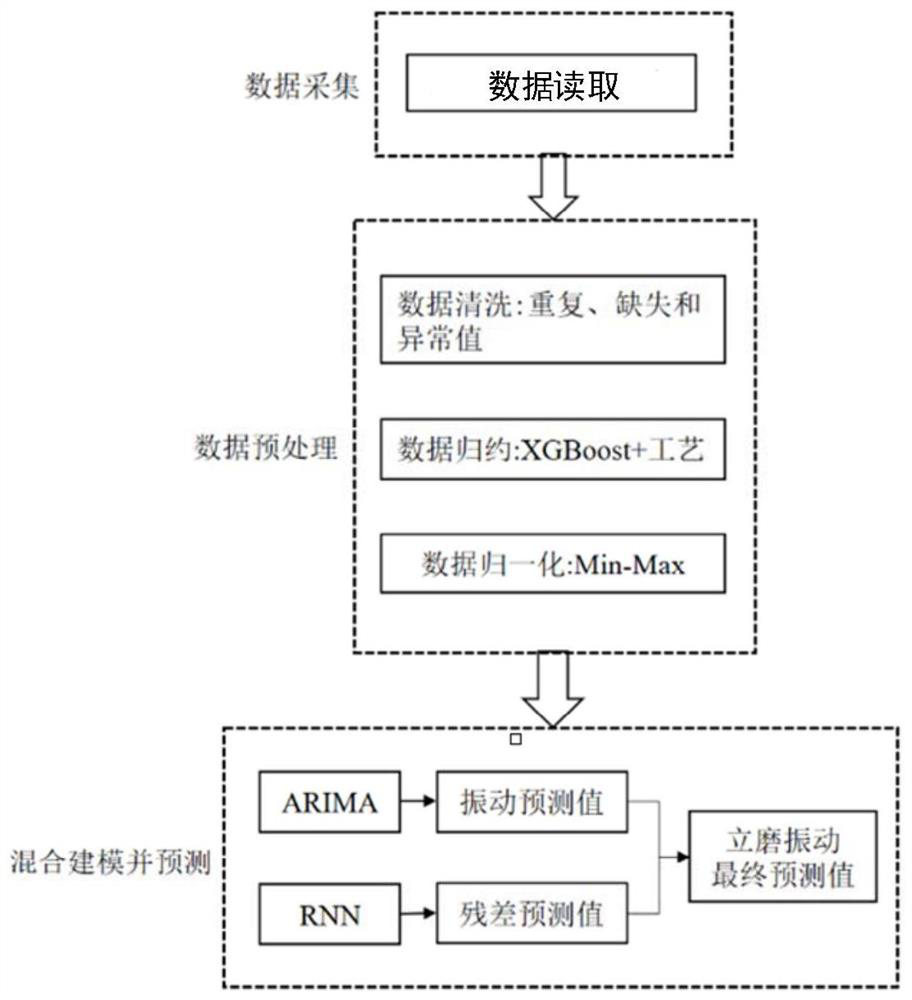

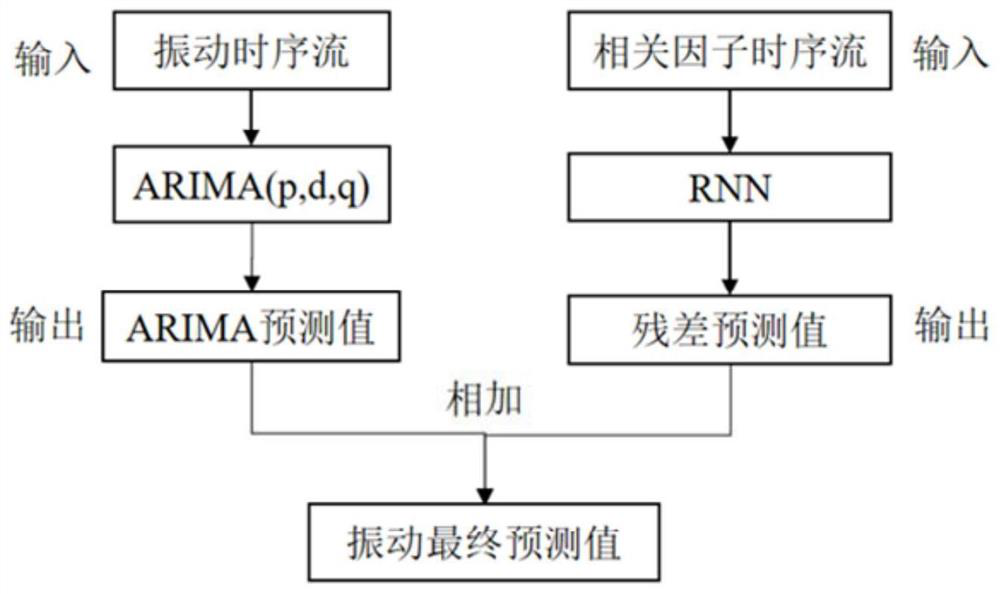

Vertical mill vibration prediction method and device based on ARIMA and RNN

ActiveCN111695730ARealize online predictionHigh precisionDigital data information retrievalForecastingControl engineeringIndustrial engineering

The embodiment of the invention provides a vertical mill vibration prediction method and device based on ARIMA and RNN, and belongs to the technical field of vertical mill vibration prediction. The method comprises the following steps: acquiring first time series data representing a real-time vibration value of a vertical mill and second time series data representing a real-time value of an influence factor; establishing a first time sequence matrix representing the incidence relation between the vibration value of the vertical mill and the influence factor; taking the first time series data as input, and outputting third time series data for predicting a future vibration value of the vertical mill through an ARIMA autoregressive moving average model; taking the first time sequence matrixas input, and outputting fourth time sequence data for predicting a residual error of a future vibration value of the vertical mill through an RNN recurrent neural network model; summing the third time series data and the fourth time series data, and outputting fifth time series data for finally predicting a future vibration value of the vertical mill. According to the method, through ARIMA and RNN hybrid modeling, the problem that in the prior art, the hysteresis quality is large in the real-time production process is solved.

Owner:ZHEJIANG UNIV

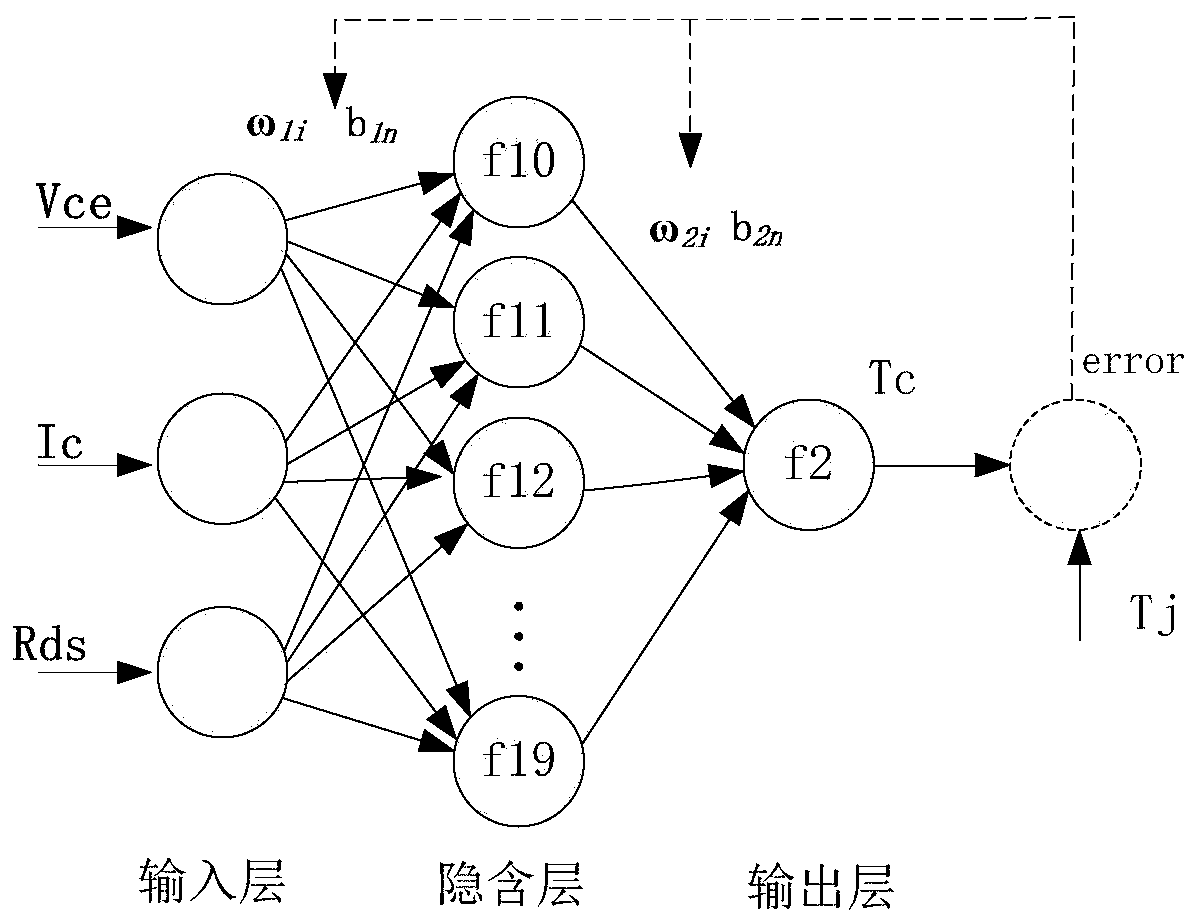

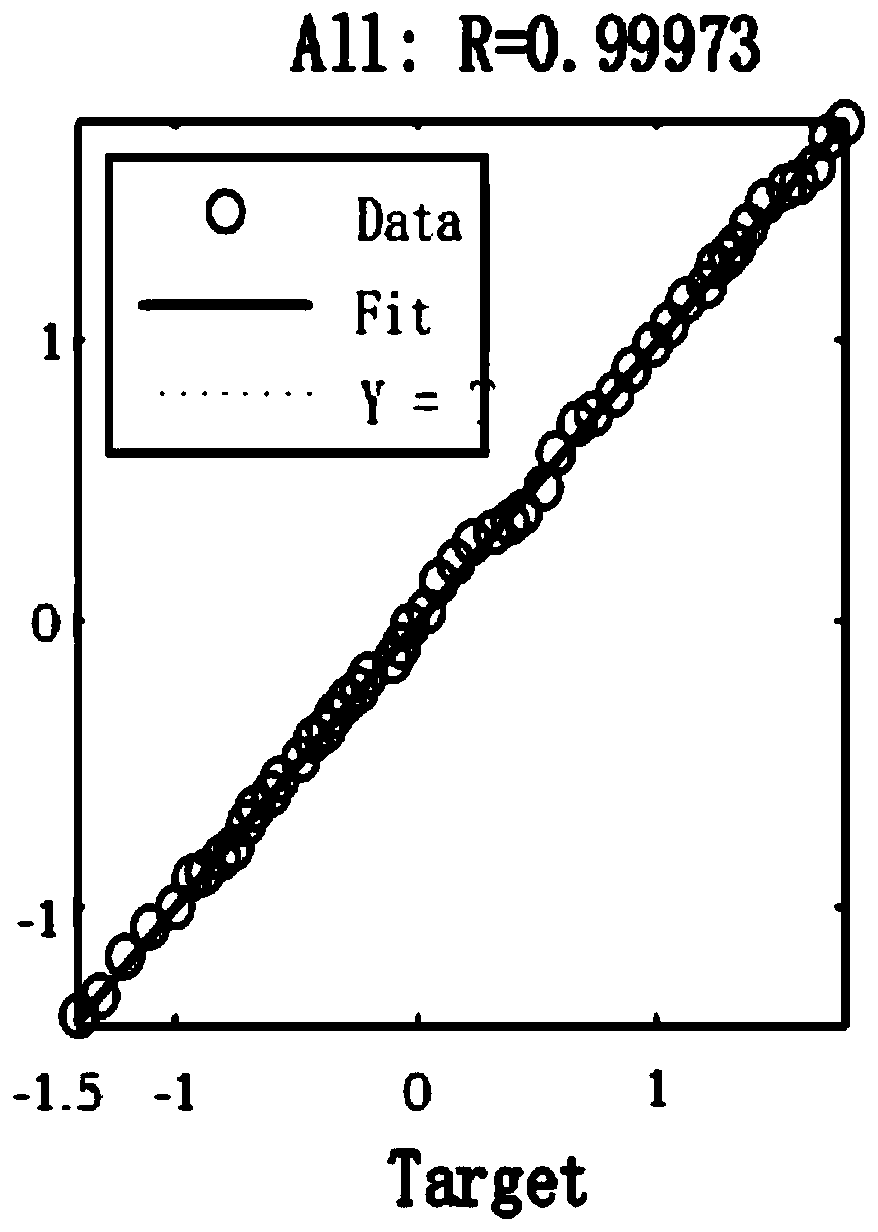

Junction temperature prediction method of IGBT module for driver

PendingCN110807516ARealize online predictionNeural architecturesNeural learning methodsSimulationJunction temperature

The invention discloses a junction temperature prediction method for an IGBT module for a driver, and the method comprises the following specific steps: 1, carrying out the sampling of a measured IGBTmodule, and enabling the sampling data to serve as training group data; step 2, establishing a BP neural network model; 3, inputting the training group data into a BP neural network model for training; and 4, carrying out junction temperature real-time prediction on the IGBT module by adopting the trained BP neural network model, and outputting the predicted junction temperature. According to theinvention, the problem that the junction temperature of the IGBT module for the driver cannot be directly measured in the prior art is solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

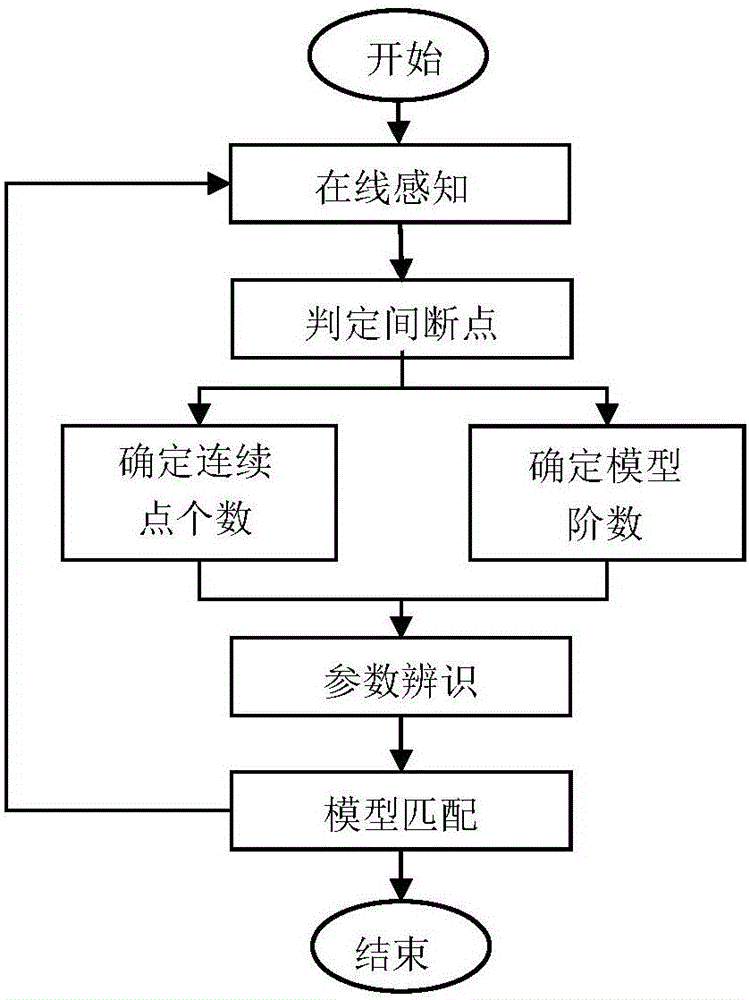

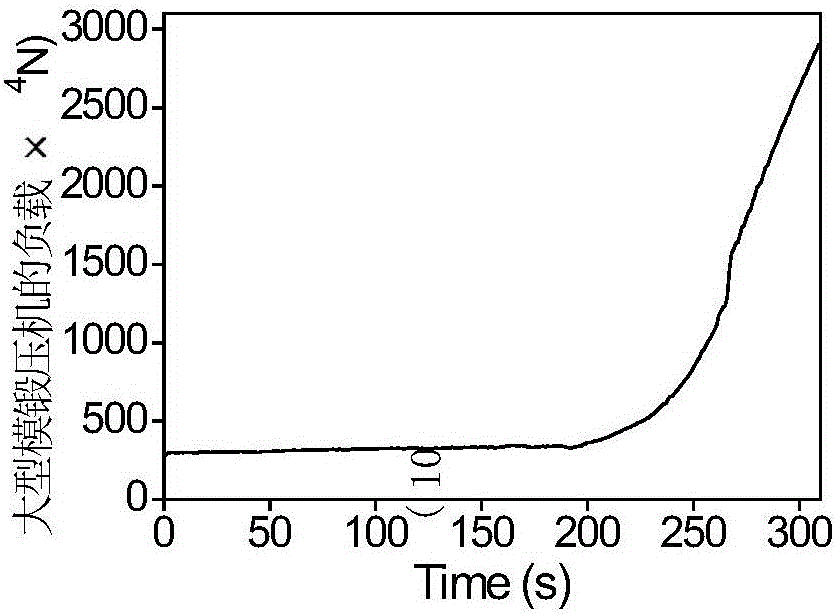

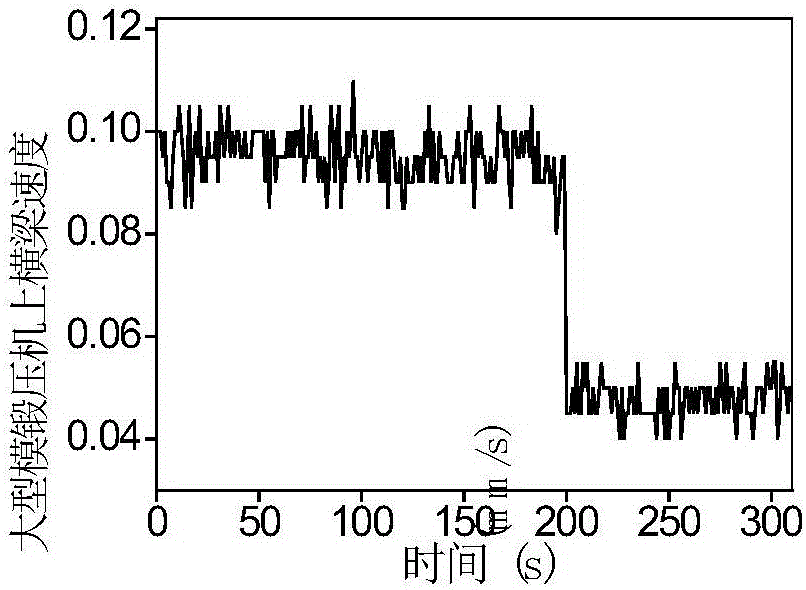

Online prediction method for crossbeam loading speed of large-sized die forging press based on Taylor expansion

InactiveCN105808949ARealize online predictionInformaticsSpecial data processing applicationsPredictive methodsLarge size

The invention provides an online prediction method for a crossbeam loading speed of a large-sized die forging press based on Taylor expansion. The method comprises the following steps: (1) predicting a next-moment crossbeam loading speed by sensing a load (system input) and the crossbeam loading speed (system output) of the large-sized die forging press in a forging process on line; (2) popularizing and defining similar continuous conductive conditions according to a Taylor expansion condition, judging intermittent points of a system by introducing a continuous conductive index, and determining a number of continuous points and an order of a model; and (3) performing parameter identification by using a multiple regression method according the system input and the system output of online sensing, and implementing online detection of the crossbeam loading speed of the large-sized die forging press through model matching. Through adoption of the method, the crossbeam loading speed of the large-sized die forging press can be predicted on line rapidly and accurately, and a theoretical basis and technical support are provided for effective control of the large-size die forging press.

Owner:CENT SOUTH UNIV

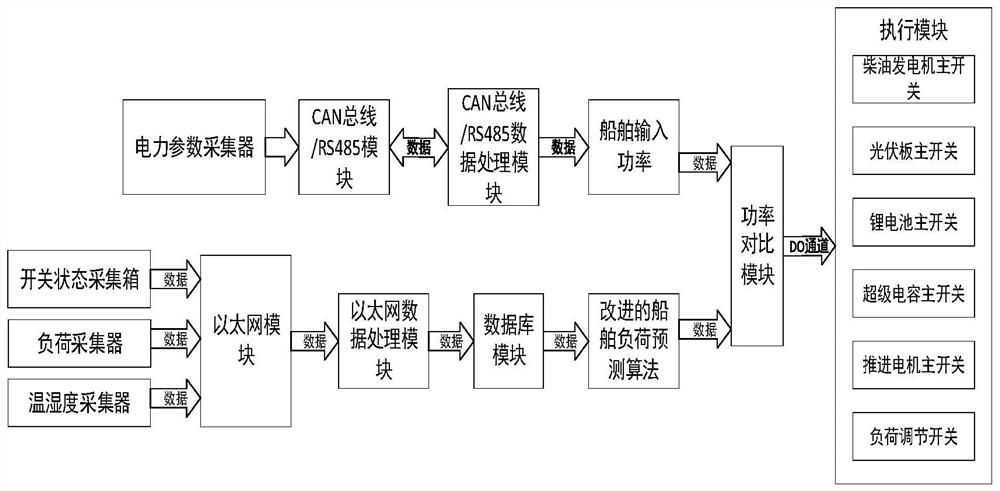

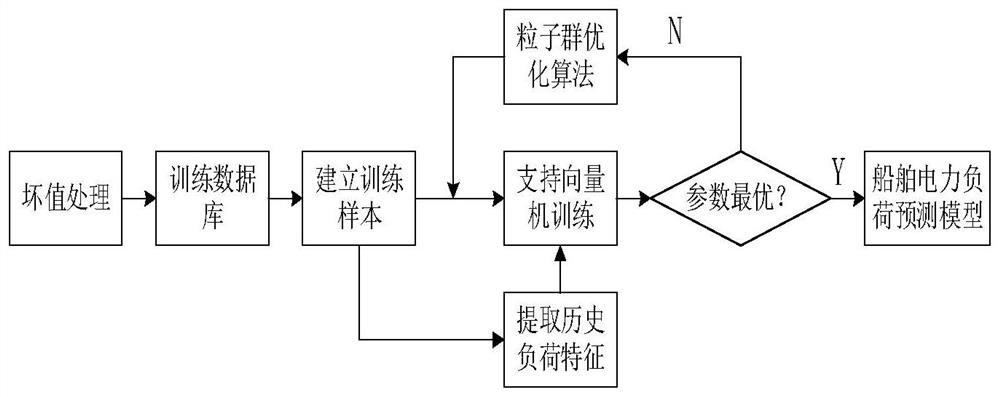

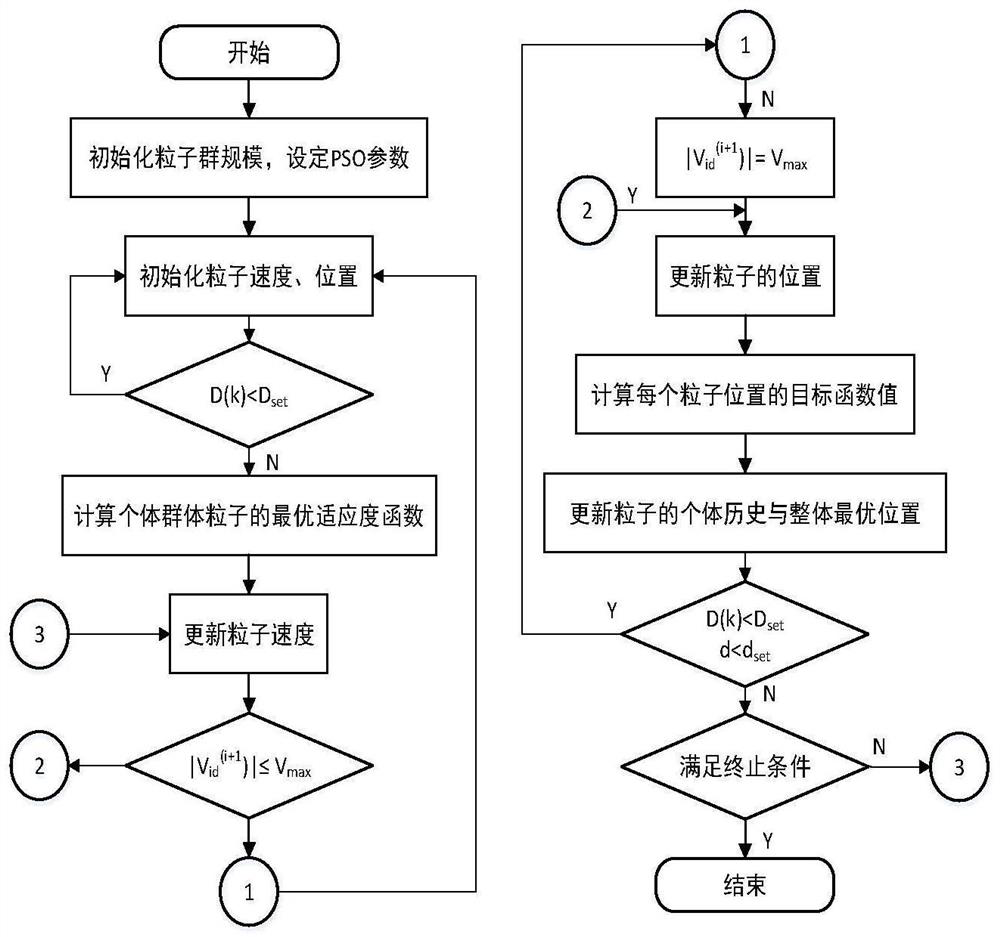

Multi-energy ship control management method and device based on load prediction algorithm

ActiveCN114180023AKeep abreast of changes in working conditionsStay on top of the situationPropulsion power plantsPropulsion by capacitorsPrediction algorithmsLeast squares support vector machine

The invention discloses a multi-energy ship control management method and device based on a load prediction algorithm, and the method comprises the steps: collecting load data and temperature and humidity climate data, and carrying out the preprocessing of the collected data, and determining a training sample set; establishing a load prediction model by adopting a least square support vector machine algorithm; training a load prediction model based on the training sample set, performing parameter optimization through a particle swarm algorithm, and determining an optimal load prediction model; acquiring current load data, on-off state data and temperature and humidity climate data, and inputting the current load data and the temperature and humidity climate data into the optimal load prediction model to obtain a ship load prediction value; collecting ship electric power parameters, and obtaining input power; and based on the input power, the ship load predicted value and the on-off state data, controlling electric propulsion of the ship, ship energy equipment and on-off states of first-level, second-level and third-level loads. The change condition of the ship load can be grasped in time, the diesel generator is increased or closed, and the operation cost is reduced.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

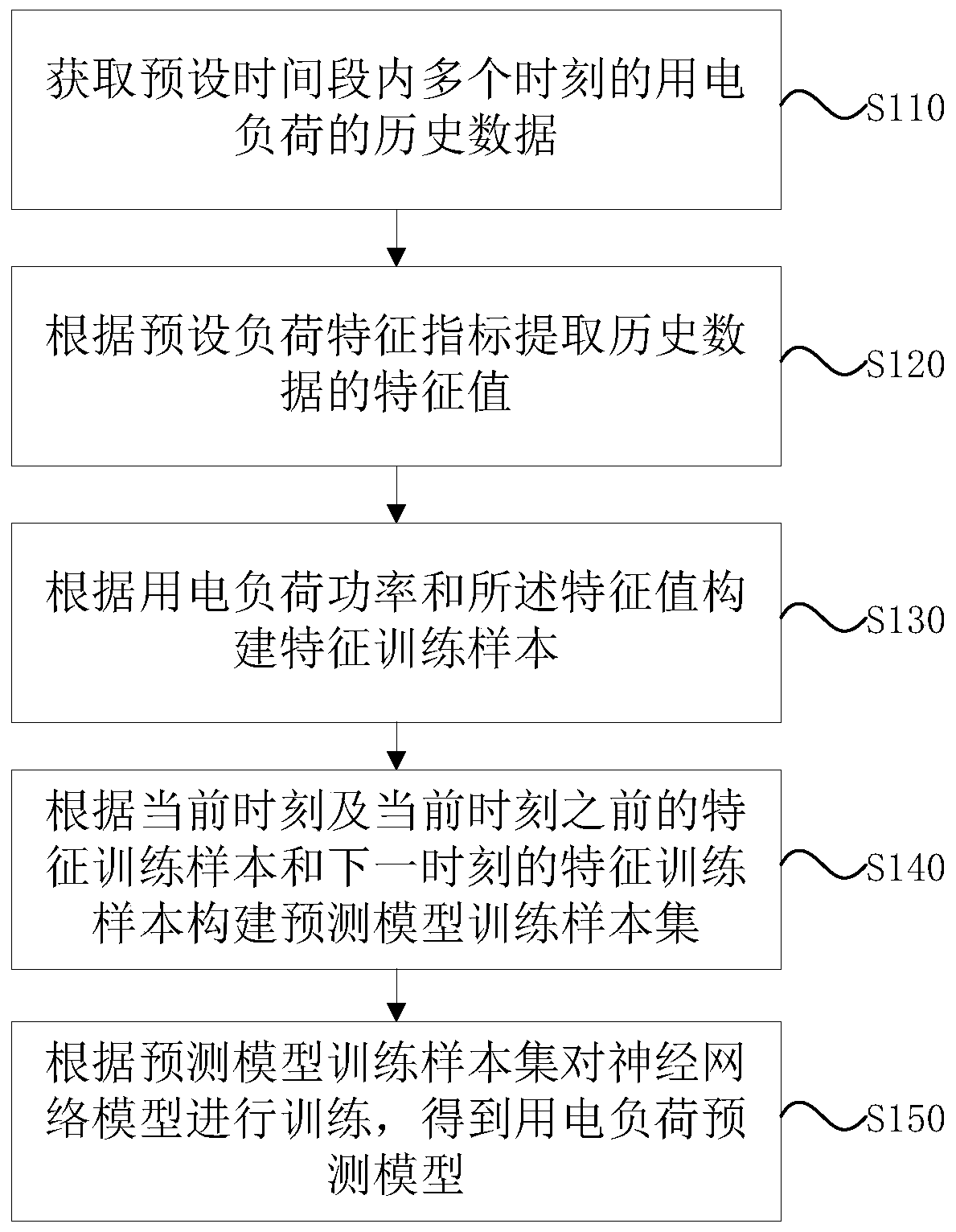

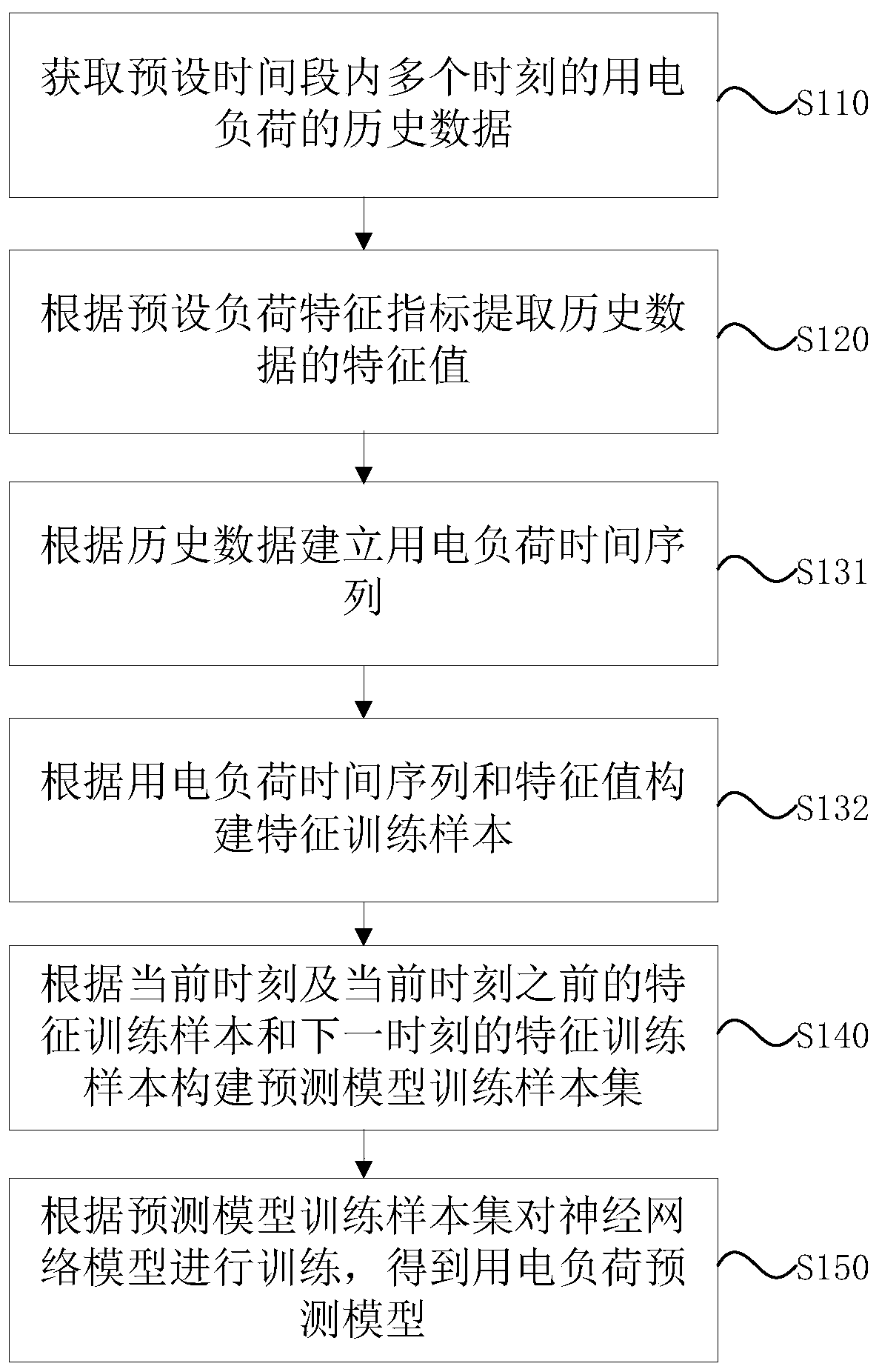

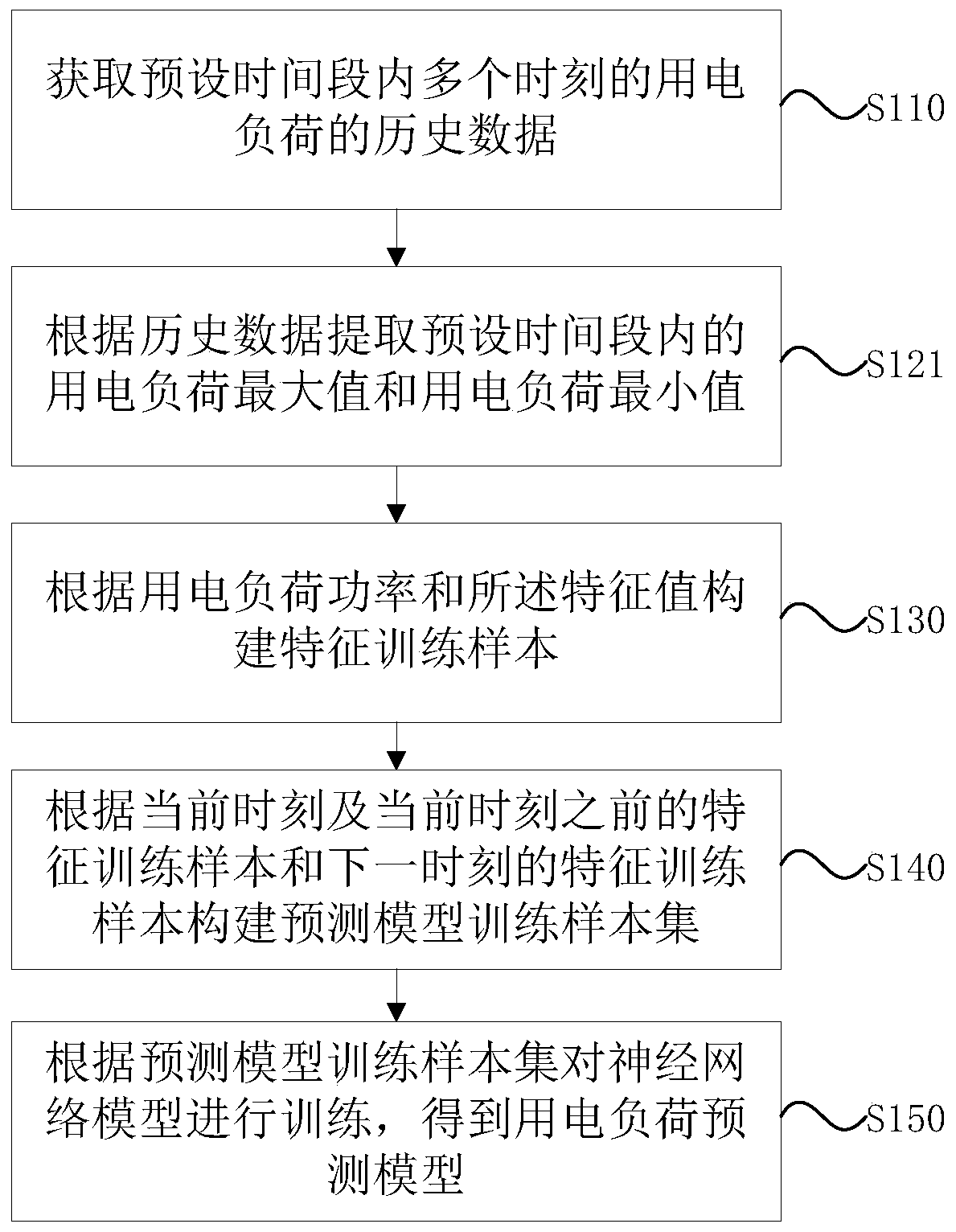

Electrical load prediction model training method and device, and electrical load prediction method and a device

ActiveCN110781947AHigh precisionCalculation speedForecastingCharacter and pattern recognitionData packLoad forecasting

The invention provides an electrical load prediction model training method and device and an electrical load prediction method and device, and the training method mainly comprises the steps: obtaininge historical data of electrical loads at a plurality of moments in a preset time period,wherein the historical data comprises the electrical load power at each moment; extracting a characteristic value of the historical data according to a preset load characteristic index; constructing a feature training sample according to the electrical load power and the feature value; constructing a prediction model training sample set according to the feature training sample at the current moment, the feature training sample before the current moment and the feature training sample at the next moment; and training the neural network model according to the prediction model training sample set to obtain an electrical load prediction model. By implementing the electrical load prediction model training method provided by the invention, the characteristics of the electrical load in historical data can be fully mined, and the electrical load prediction model with higher precision can be trained.

Owner:BEIJING JIAOTONG UNIV +1

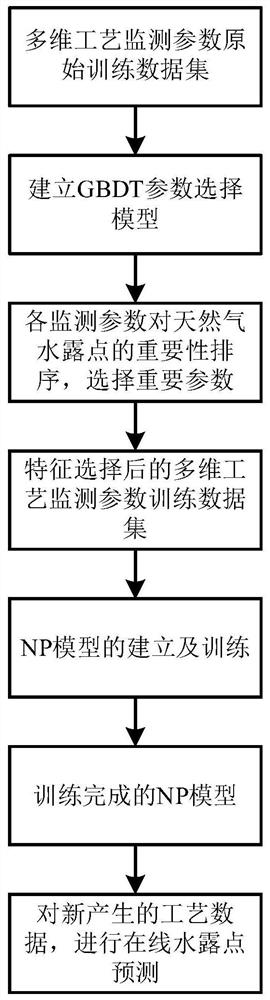

Process parameter-driven natural gas water dew point online prediction method

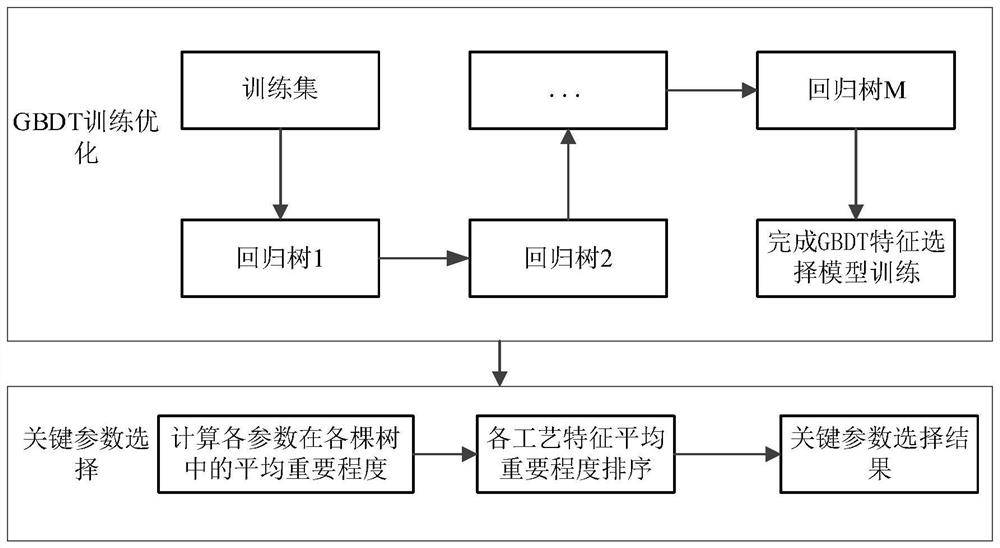

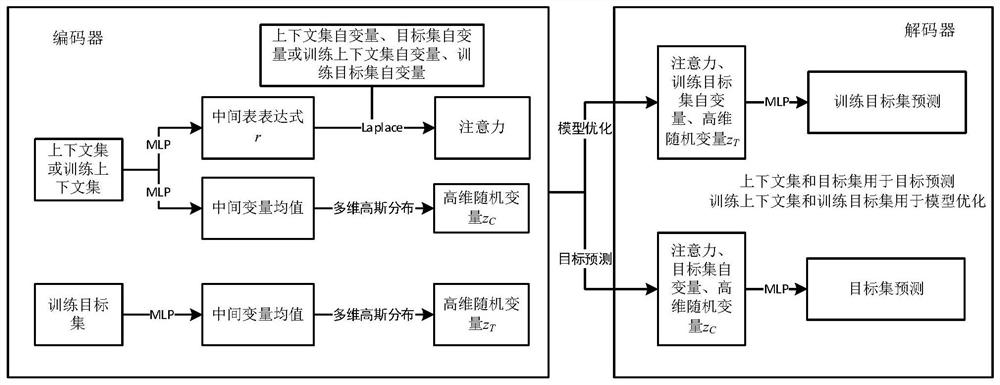

ActiveCN113051828ARealize online predictionImprove forecast accuracyForecastingDesign optimisation/simulationData setSample sequence

The invention relates to the field of natural gas gathering and transportation, and discloses a process parameter-driven natural gas water dew point online prediction method aiming at the defects that a conventional natural gas water dew point detector is liable to damage and high in detection cost and a traditional data driving method cannot effectively reflect the influence relationship between the natural gas water dew point of an actual dehydration system and each monitoring parameter. According to process monitoring data of a triethylene glycol dehydration device in a production operation state, a multi-dimensional sample sequence original training data set is manufactured; by selecting key parameters for predicting the natural gas water dew point, irrelevant redundant features are eliminated, and a natural gas water dew point prediction training data set is established; an NP model is trained through the training data set to learn a multivariate regression function relationship of each process monitoring parameter of the triethylene glycol dehydration device; and real-time process monitoring data of the dehydration device is taken as target set data of the NP prediction model to realize online prediction of the water dew point of the natural gas. Compared with the prior art, the method has the beneficial effect of high accuracy.

Owner:CHONGQING UNIV

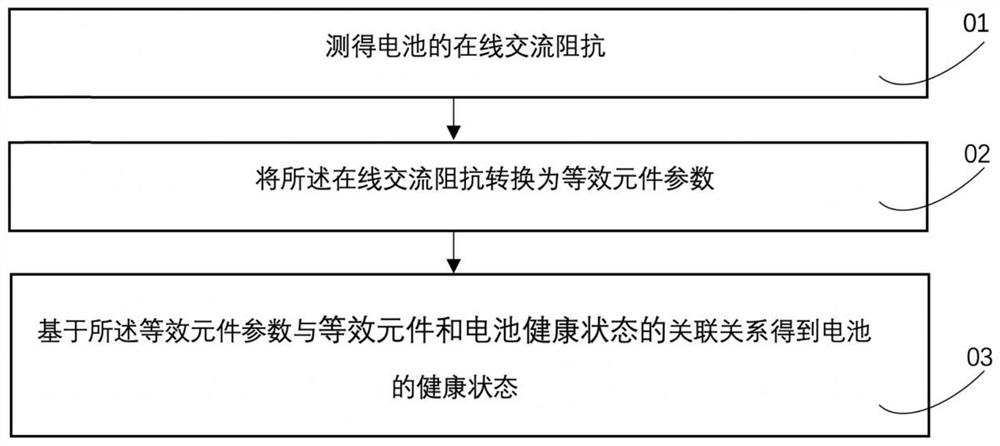

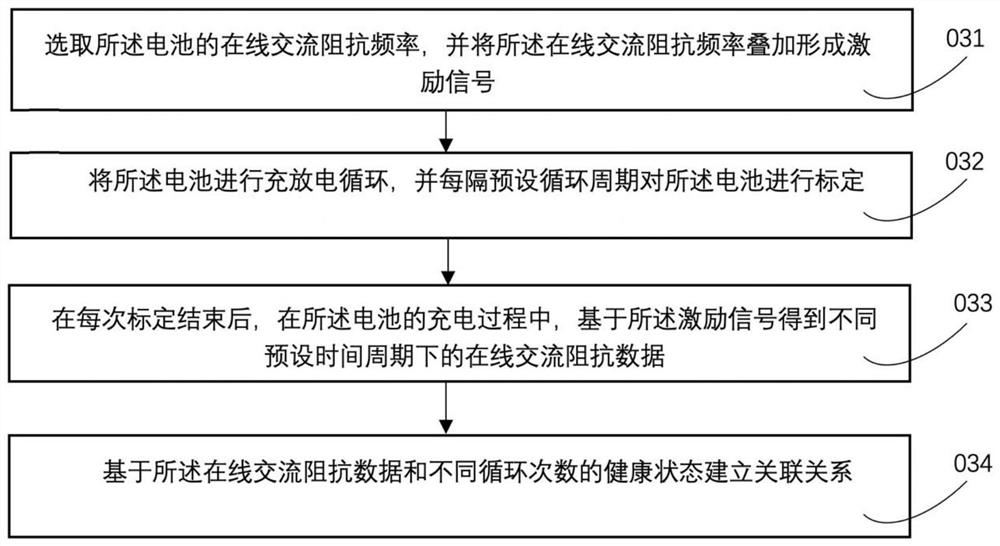

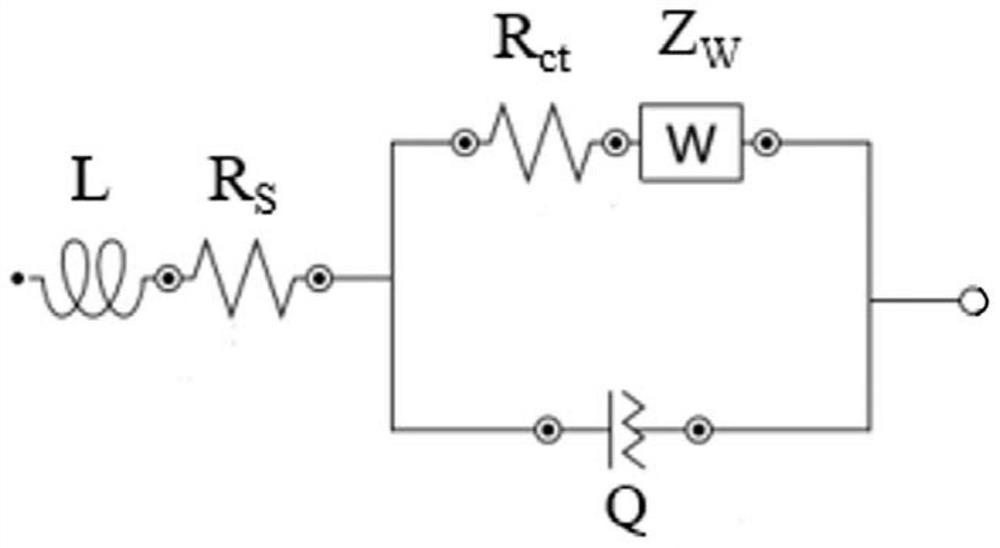

Battery health state estimation method and device based on on-line alternating current impedance

PendingCN112462269AShorten the estimated timeRealize online predictionElectrical testingAc impedanceElectrical and Electronics engineering

The invention provides a battery health state estimation method and device based on on-line alternating current impedance, and solves the problem that a current battery health state estimation methodis only suitable for an off-line state of a battery and is not suitable for dynamic characteristics of the battery. The embodiment of the invention provides a battery health state estimation method and device based on online alternating-current impedance. The method comprises the steps of: measuring the online alternating-current impedance of a battery; converting the online alternating-current impedance into an equivalent element parameter; and obtaining the health state of the battery based on the association relationship between the equivalent element parameters and the health state.

Owner:CHINA ELECTRIC POWER RES INST +2

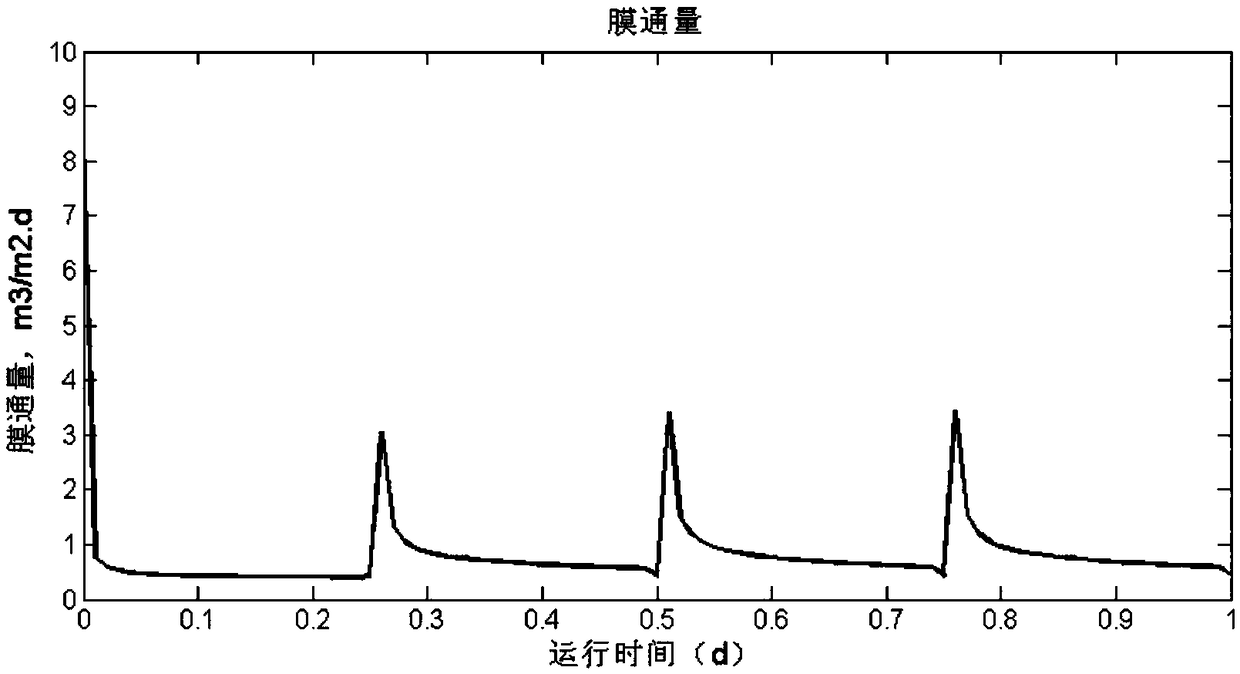

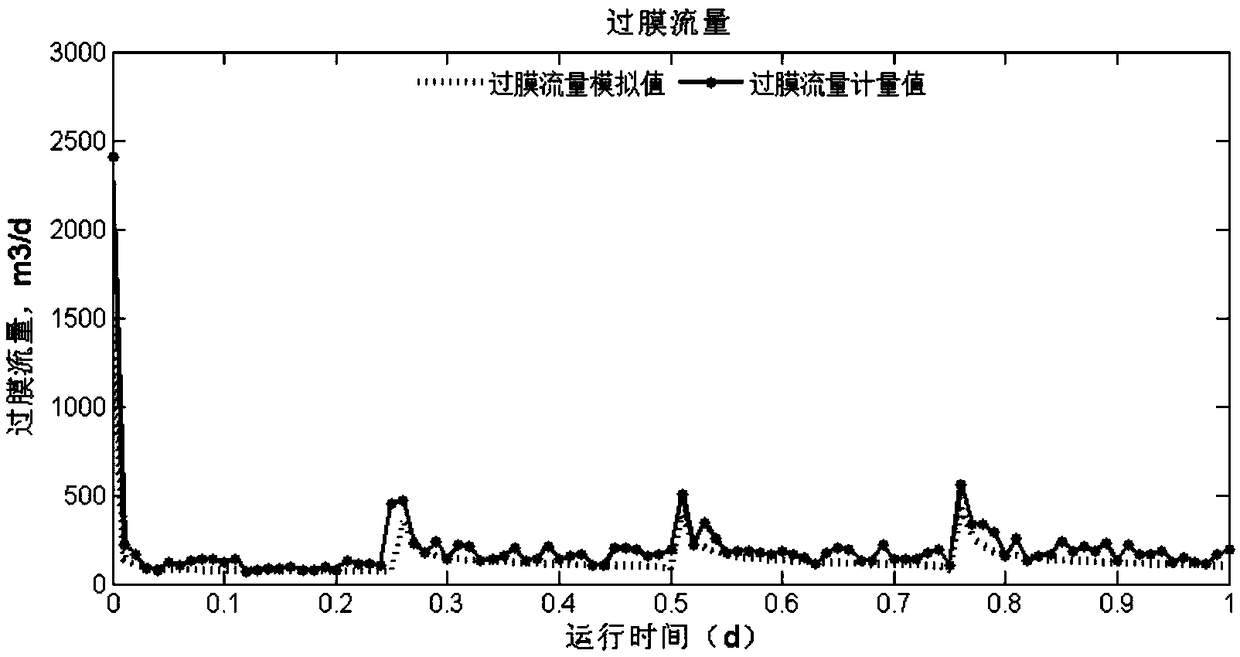

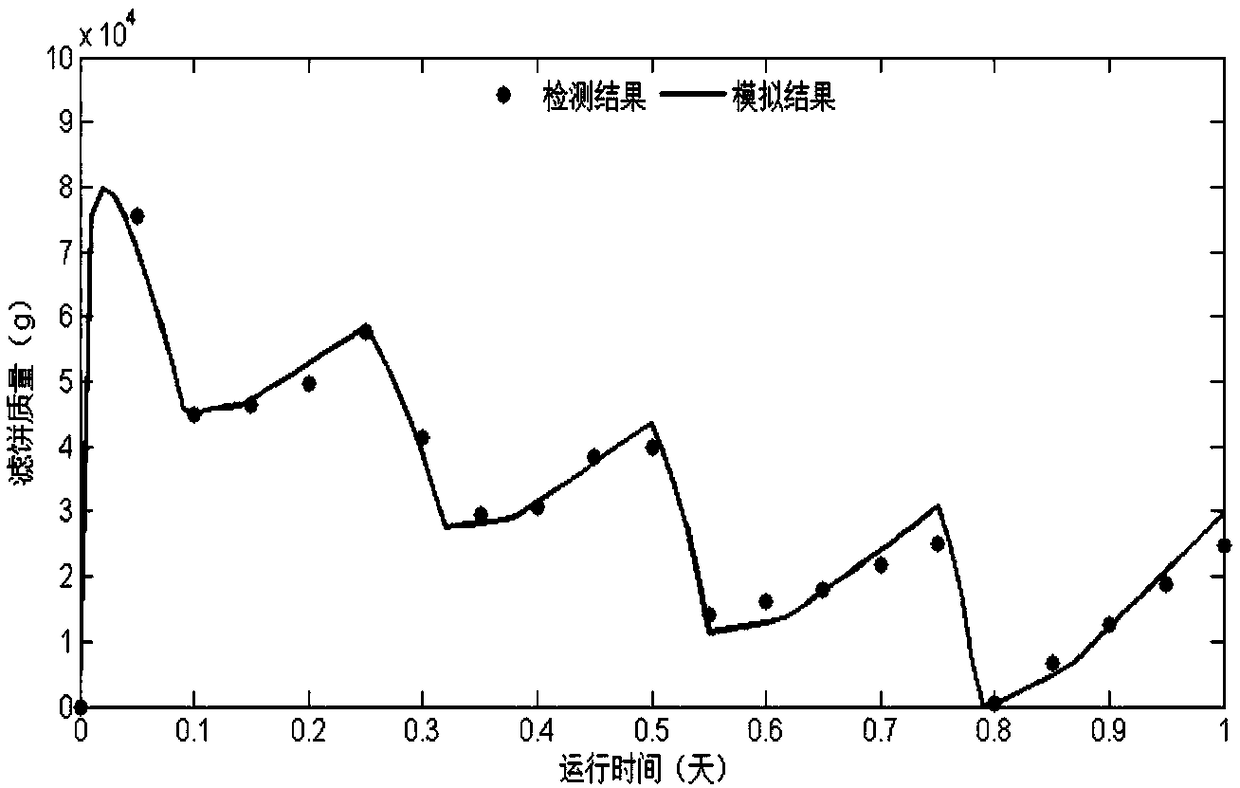

Membrane flux on-line prediction method for membrane bioreactor process

ActiveCN108304692AGuaranteed uptimeReduce generationSystems biologySpecial data processing applicationsMembrane foulingMembrane bioreactor

A membrane flux on-line prediction method for a membrane bioreactor process is provided. The method comprises: 1) establishing a membrane flux model of a membrane module in a membrane bioreactor process; 2) embedding the membrane flux model in a simulation platform of the membrane bioreactor process; and 3) taking the on-line collected influent data and operational data as an input value to the simulation platform, and obtaining a membrane flux prediction result according to the membrane flux model. According to the method provided by the present invention, the influent water and the operational conditions are combined to carry out membrane flux on-line prediction, it is verified that the membrane flux prediction result is consistent with the trend of the measured result, and the real operational condition of the site can be ideally approached, so that the degree of membrane fouling of the membrane module can be informed of in real time, the effect of membrane cleaning can be predicted, and the prevention of membrane fouling can be facilitated.

Owner:上海昊沧系统控制技术有限责任公司

A Method for Predicting the Future Speed Trajectory of a Hybrid Electric Bus

InactiveCN103914985BImprove accuracyRealize online predictionDetection of traffic movementNeural learning methodsDriver/operatorState parameter

The invention discloses a method for predicting the future speed trajectory of a hybrid power bus. The method includes the following steps that parameters are obtained and normalized; an input parameter vector and an output parameter vector of an RBF neural network are determined; the RBF neural network is offline trained; the future speed trajectory is online predicted. Based on online learning of the RBF neural network, prediction of the speed trajectory is studied under the precondition that global optimization of the control strategy of the hybrid power bus is achieved from the aspect of a people-bus-environment system, the method for predicting the bus future driving trajectory is provided and fully takes bus state parameters, driver driving styles and front road environment and traffic state parameters into consideration, and accuracy of prediction of the bus speed is improved. The influences of the people-bus-environment system on the future working condition is fully taken into consideration, accuracy of prediction of the working condition is improved while the bus has the precognition capacity, and a good foundation is laid for global optimization of the control strategy.

Owner:DALIAN UNIV OF TECH

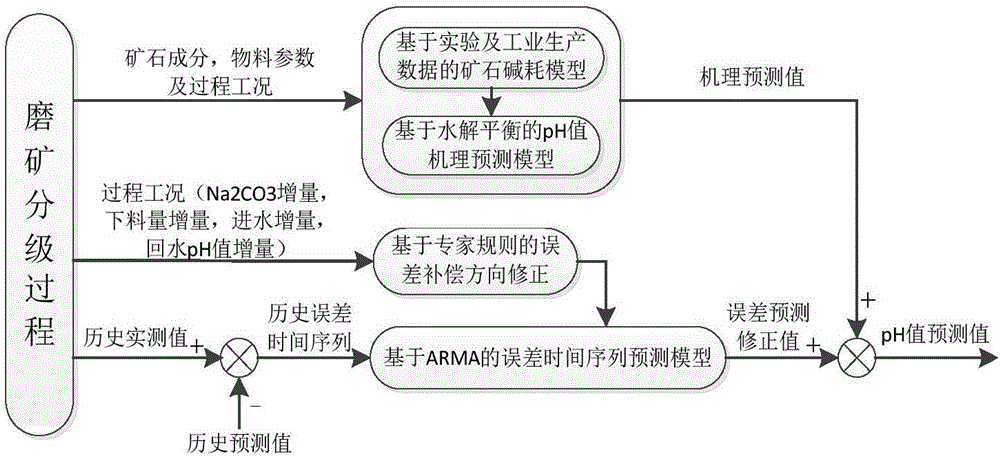

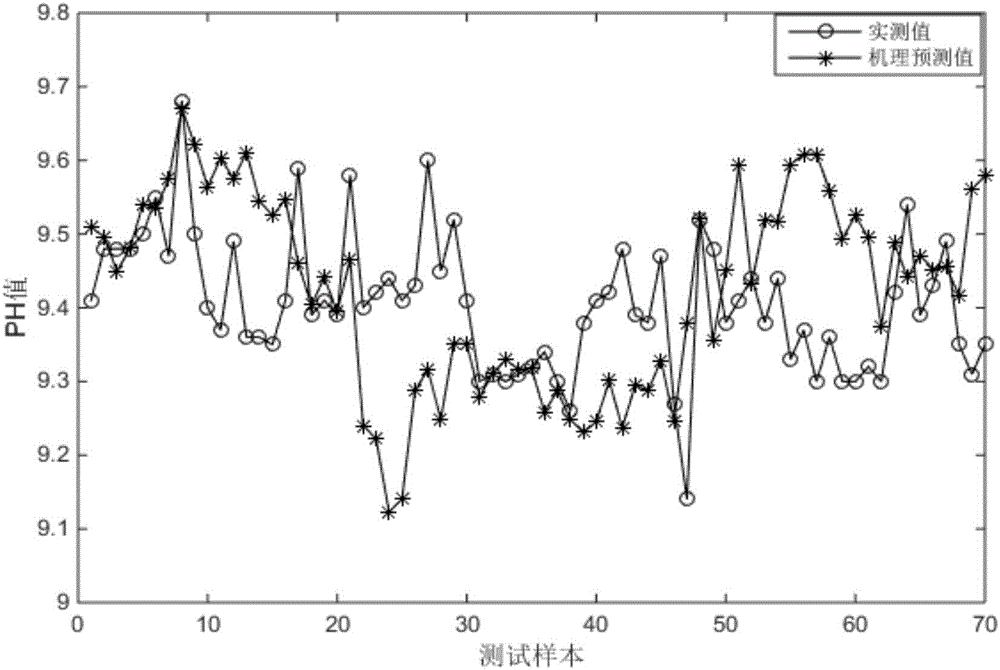

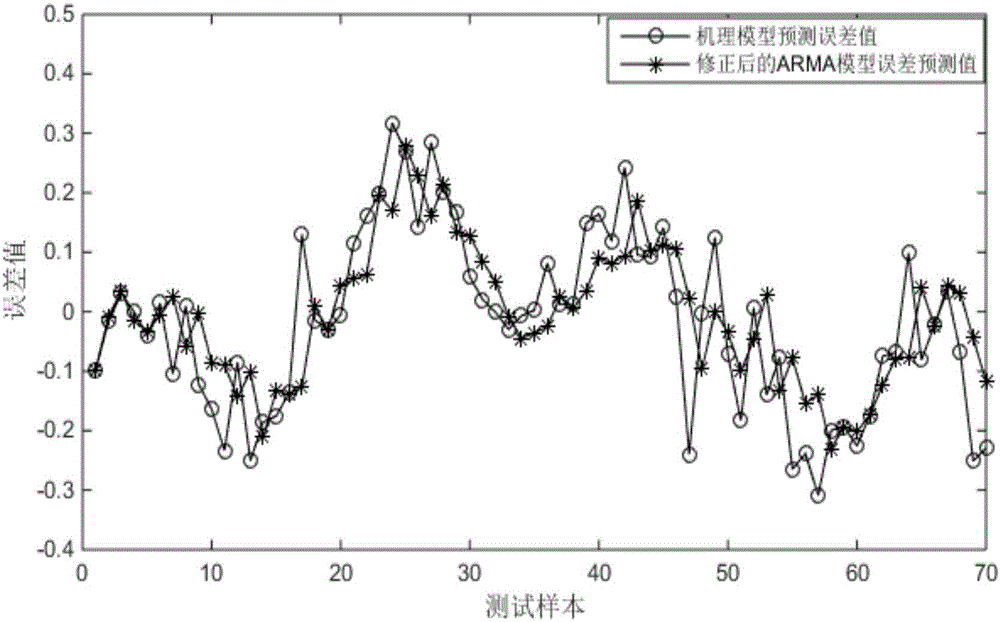

Online forecasting method of pH value of ore pulp in bauxite flotation process

The invention discloses an online forecasting method of a pH value of ore pulp in a bauxite flotation process. Aiming at the problem of lag of the pH value control due to relatively large time lag from the adding moment of a bauxite flotation ore pulp pH value regulator to the detecting moment of the pH value and the problem of low manual detection efficiency of the pH value, the method comprises the following steps: firstly building an ore alkali consumption regression model caused by reaction between ores and alkali; then building a pH value mechanism forecasting model according to hydrolysis of the alkali which does not react with the ores in water and the influence of alkaline circulating water on hydrolysis balance; building an error compensation model according to an error time sequence consisting of an actually measured value of the pH value and a forecasting value of the mechanism model; and correcting an error compensation direction according to the change of working conditions based on an expert rule, and compensating the mechanism model by using a corrected compensation value to obtain a forecasting value of the pH value of the ore pulp. The method is used for forecasting the pH value of the ore pulp in an actual production process; a root-mean-square error is 0.0935, and the maximum relative error is 2.83 percent; and the relative errors of 90 percent of test samples are within + / - 2 percent.

Owner:CENT SOUTH UNIV

Fluidized Bed Boiler Control and Combustion Optimization System

ActiveCN107023825BContinuous economic stabilitySolve unmanageable problemsFluidized bed combustionApparatus for fluidised bed combustionAir volumeEngineering

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

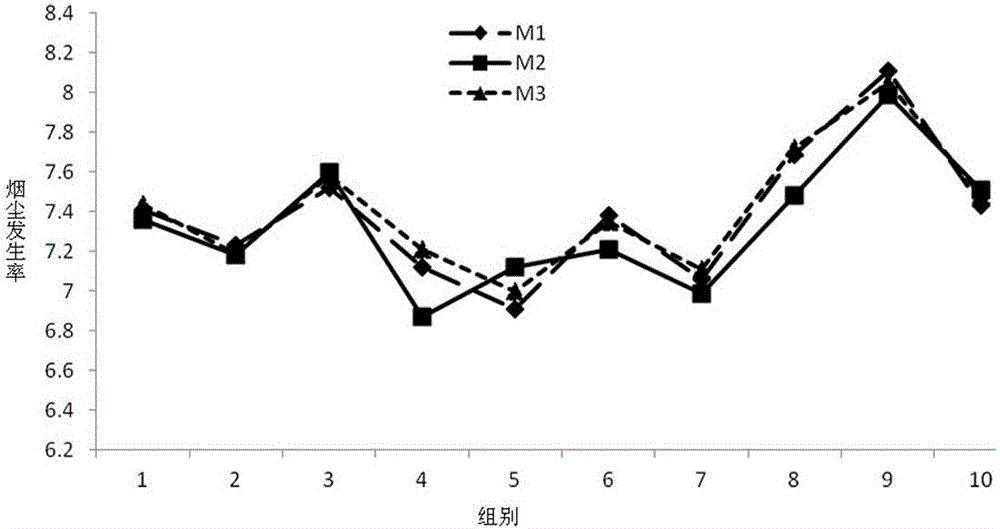

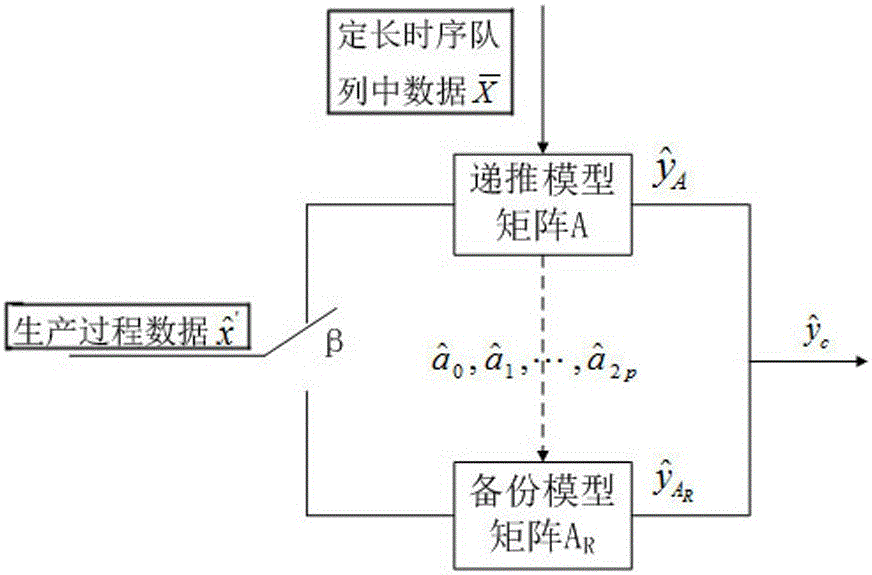

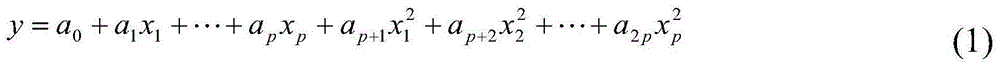

Online recursive calculation method for fume occurrence rate of metallurgical furnace

ActiveCN105023191AEasy to updateRealize online predictionData processing applicationsManufacturing computing systemsNonlinear regressionDifferential method

The present invention provides an online recursive calculation method for fume occurrence rate of a metallurgical furnace. The method comprises: according to independent historical data in an uncertain interval period, constructing a nonlinear regression constraint model; performing nonlinear transformation and normalization processing on sample data; and calculating a coefficient matrix of a recursive model with a least square partial differential method. According to the method, the data is stored by using a fixed-length time sequence queue to facilitate updating of the historical data, and the regression coefficient matrix of the recursive model is calculated with the least square partial differential method, so that online prediction of the fume occurrence rate is implemented and data support is provided for online control and production decision of the metallurgical furnace.

Owner:金川集团信息与自动化工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com