Patents

Literature

1405results about "Chemical processes analysis/design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

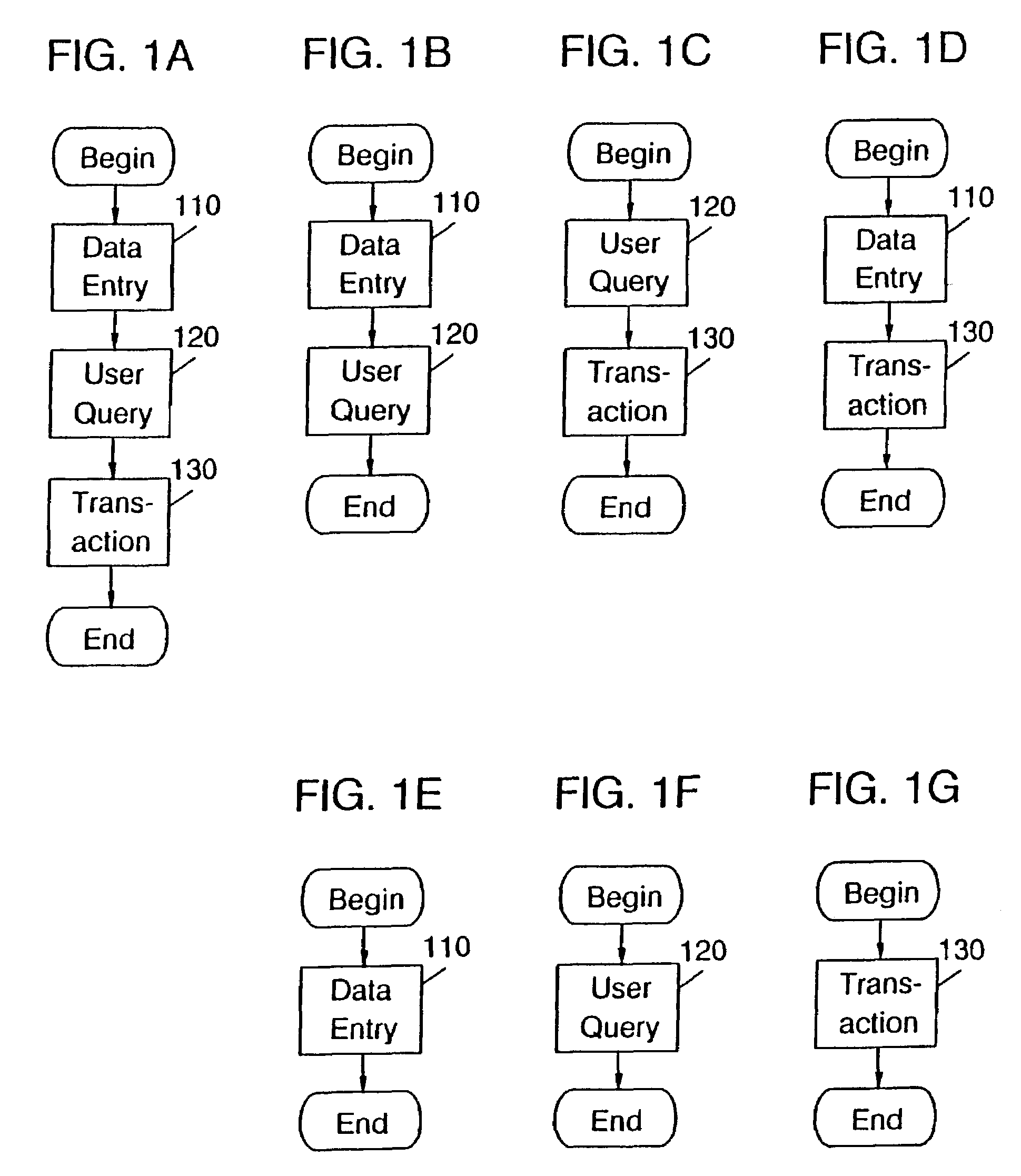

Graphical user interface system

ActiveUS20200026397A1Maximizes black spaceSave on storageChemical processes analysis/designInput/output processes for data processingGraphical user interfaceEngineering

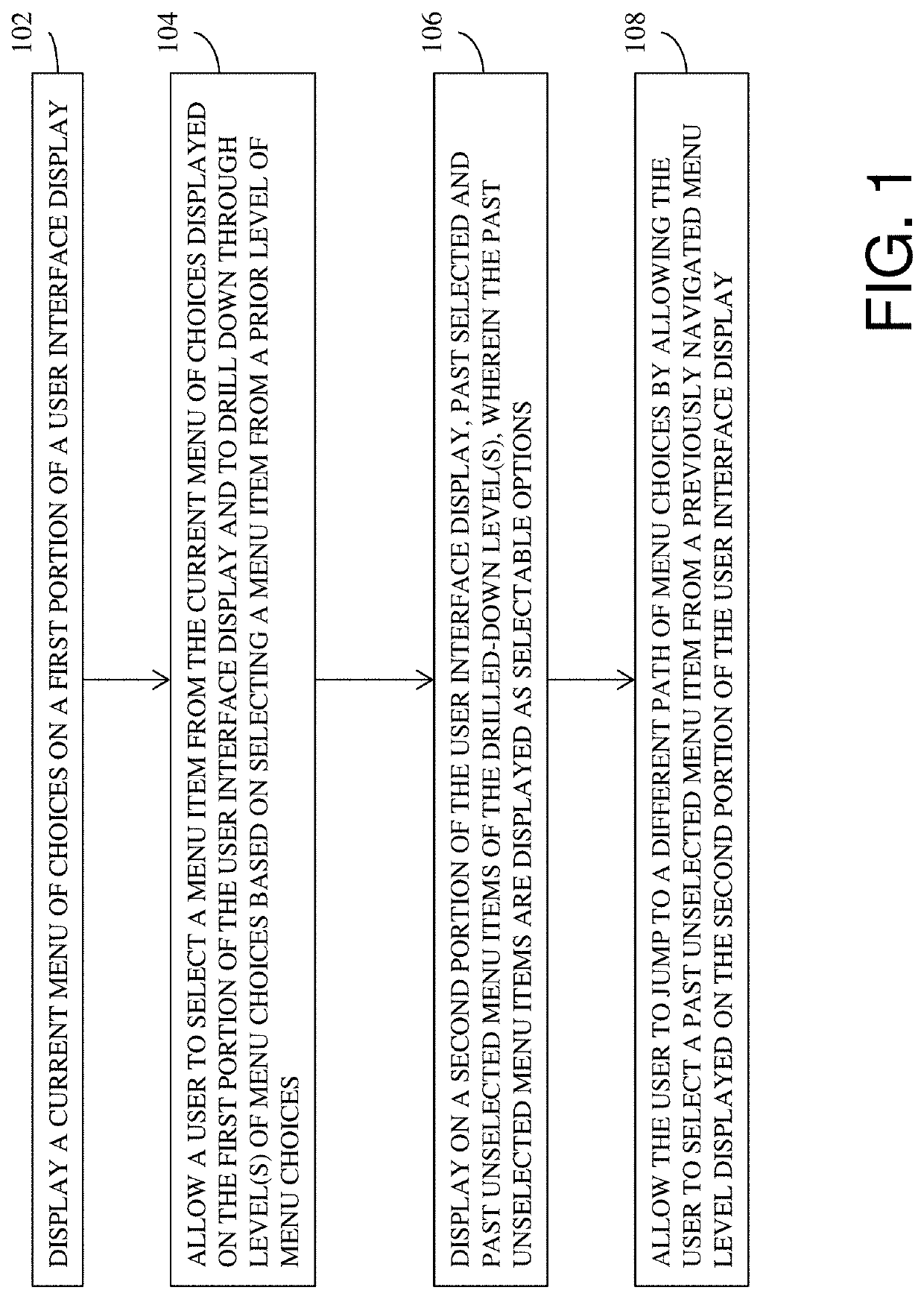

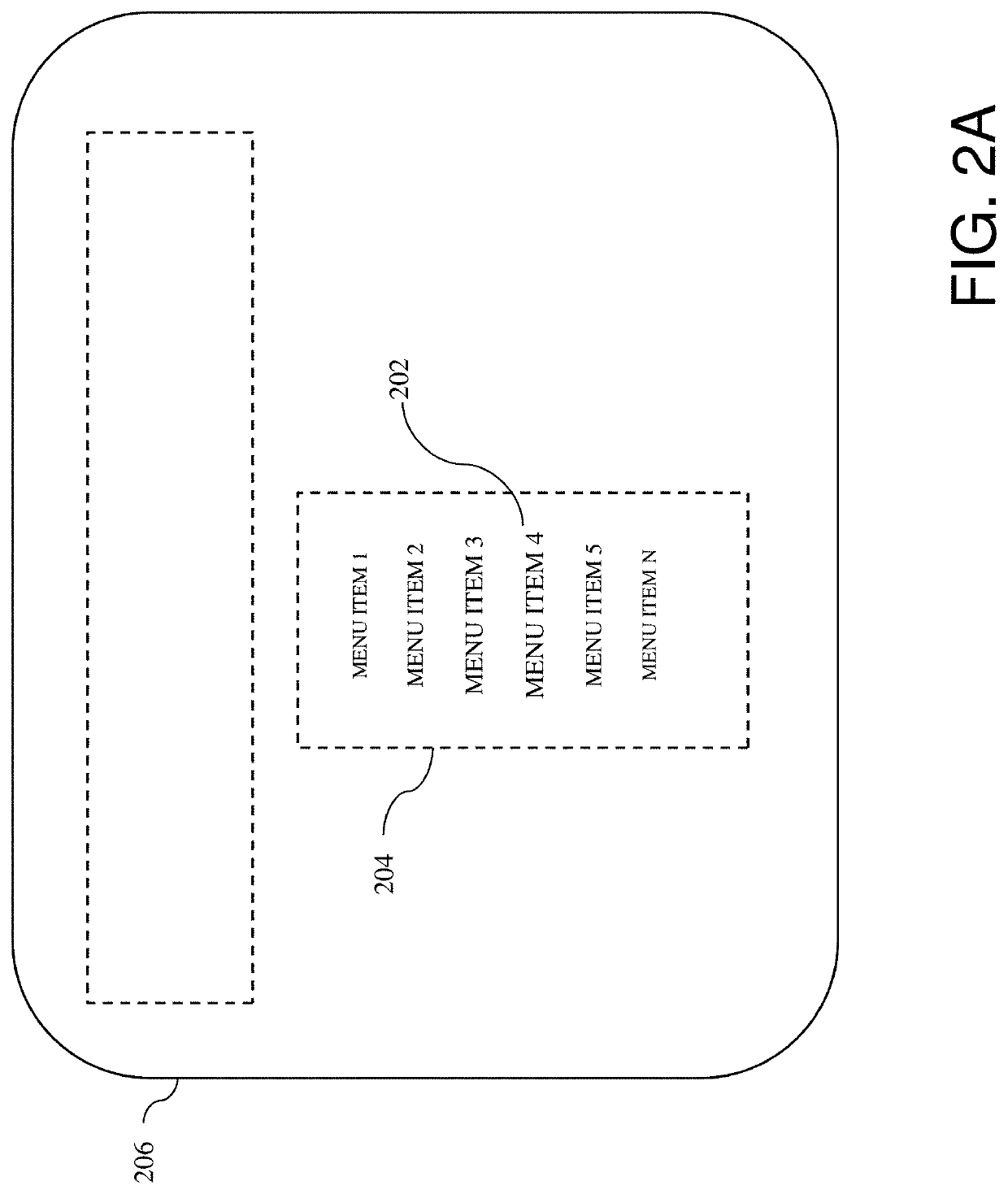

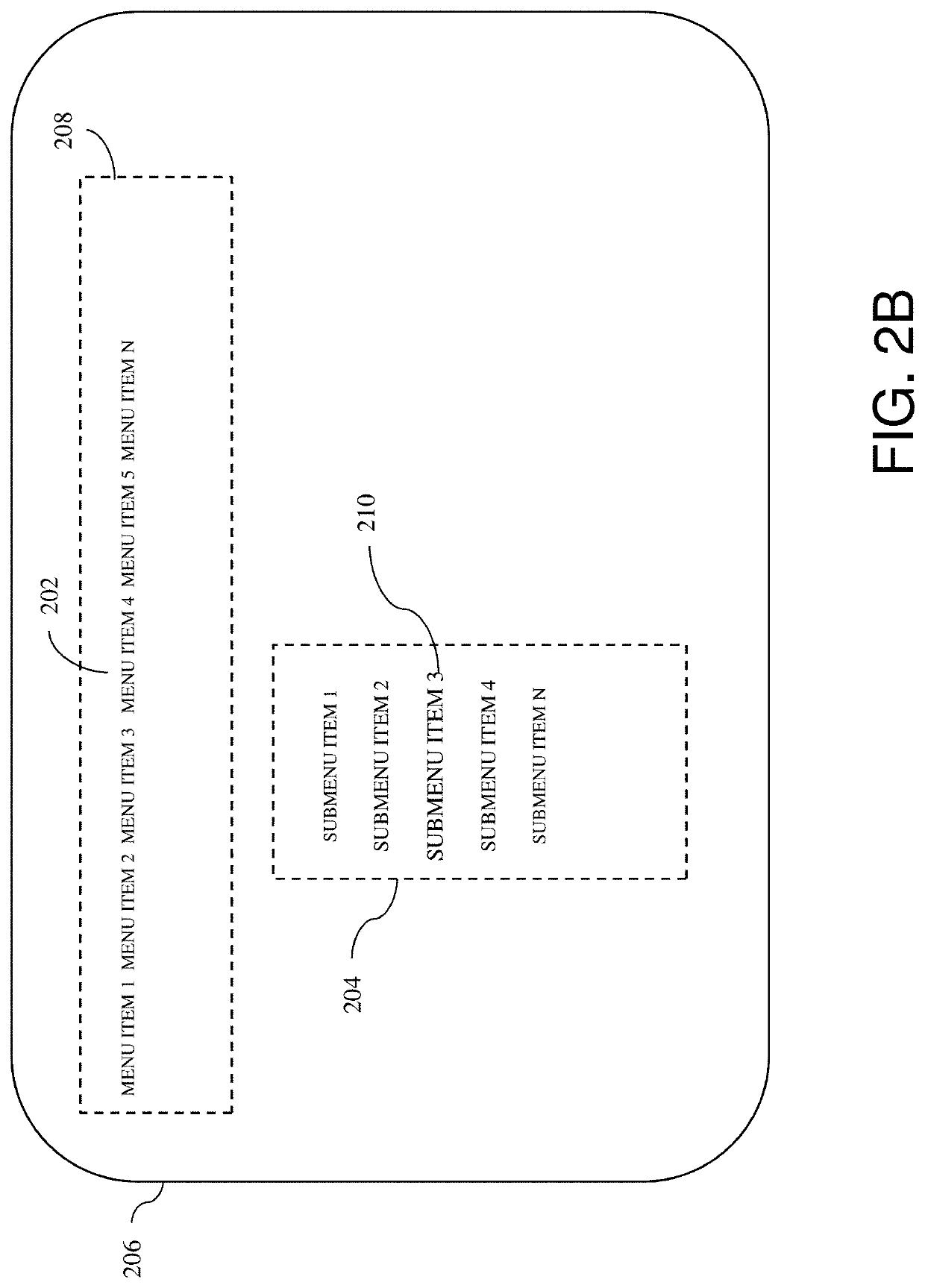

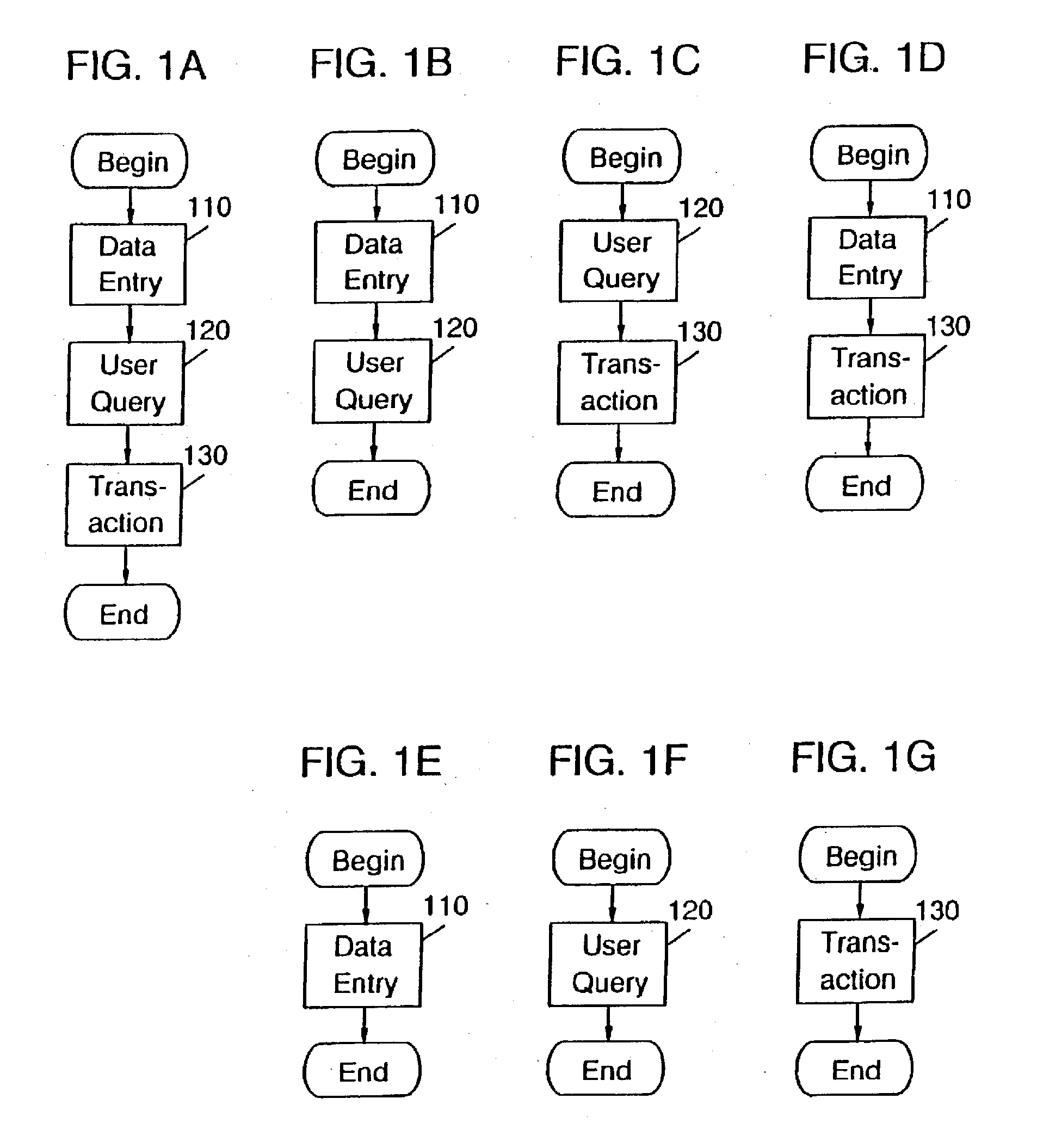

A method of interactively navigating a user through a path of menu choices on a user interface may include displaying a current menu of choices on a first portion of a user interface display. The user interface allows for selecting of a menu item from the current menu of choices and to drill down through levels of menu choices based on selecting a menu item from a prior level of menu choices. A second portion of the user interface display presents past selected and past unselected menu items of the drilled-down levels. The past unselected menu items are displayed as selectable options. The user interface allows for jumping to a different path of menu choices by selecting a past unselected menu item from a previously navigated menu level displayed on the second portion of the user interface display.

Owner:METHODICAL MIND LLC

Method for evaluation, design and optimization of in-situ bioconversion processes

InactiveUS20100081184A1Efficient propulsion technologiesWaste based fuelMicroorganismEnvironmental engineering

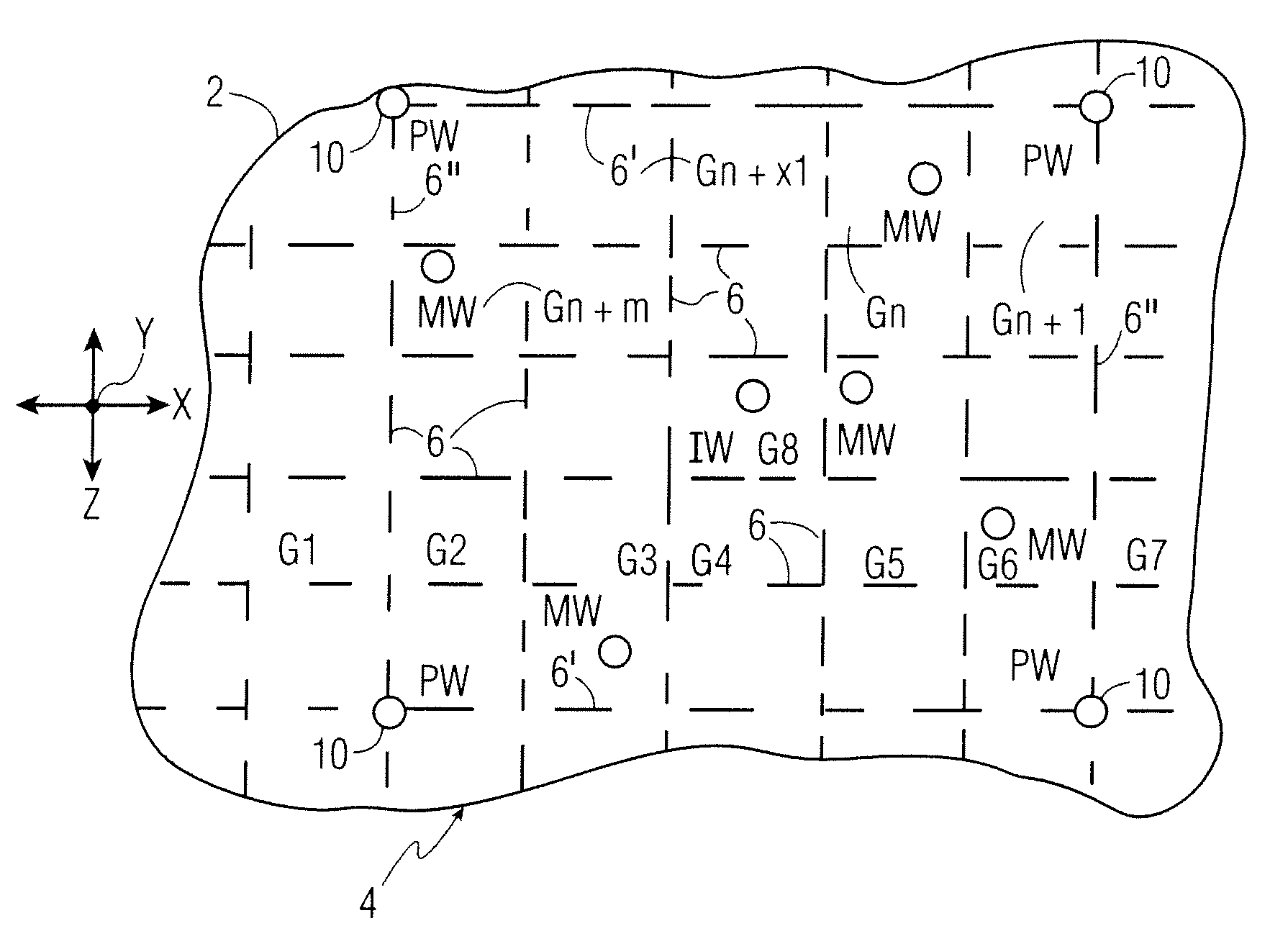

A method for the evaluation, design and optimization of in-situ bioconversion processes for the conversion of carbon to methane and other useful gases and liquids. The method utilizes a comprehensive computer simulation model for accurately simulating the physical and dynamic conditions in a subterranean carbon-bearing formation and the effects of stimulating the growth of indigenous or non-indigenous microbes therein for the bioconverstion of carbon to methane and other useful gases and liquids. The method enables the prediction of bioconversion rates and efficiencies under a range of variables, and thus provides for the optimization of in-situ bioconversion process design and operation.

Owner:CIRIS ENERGY INC

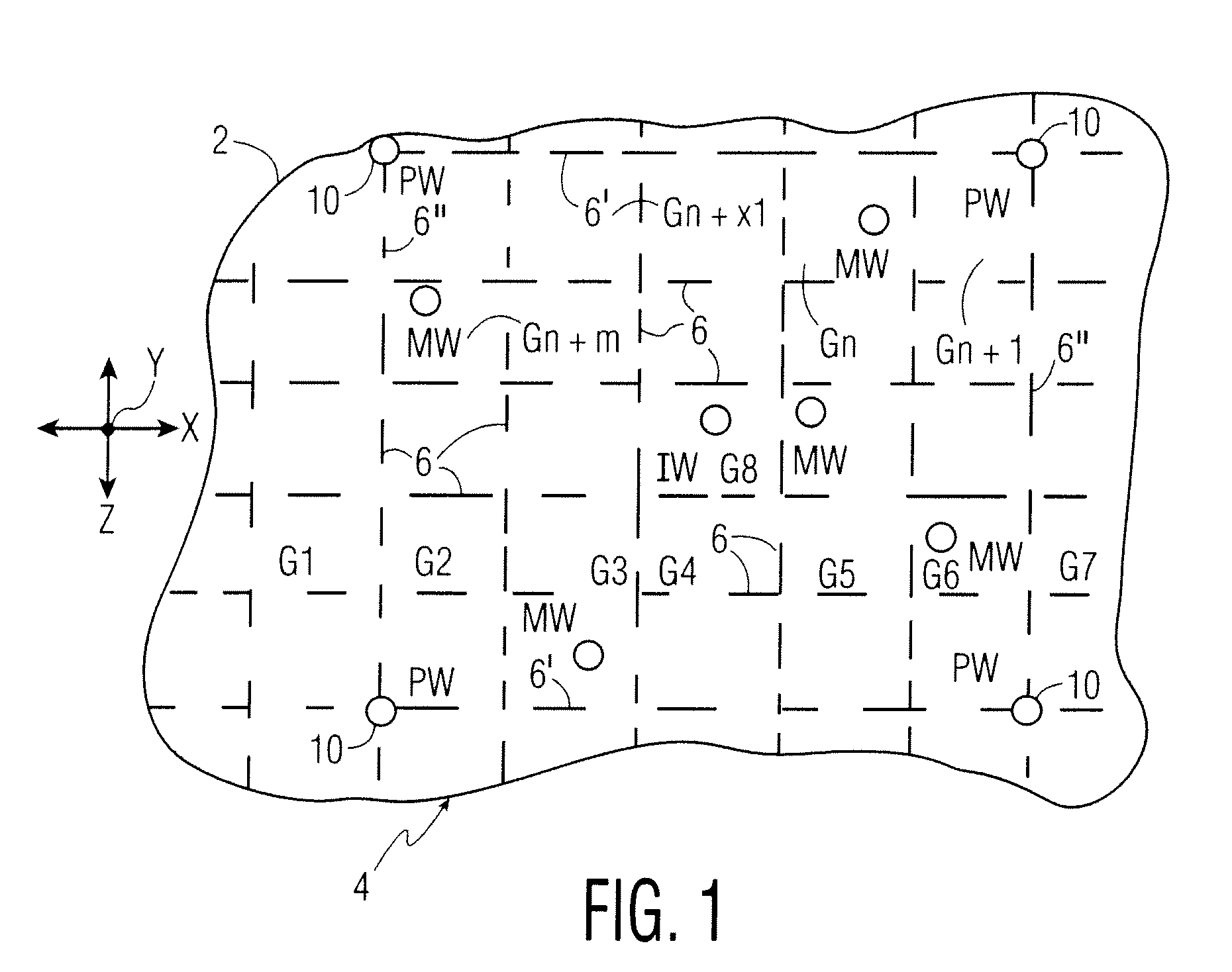

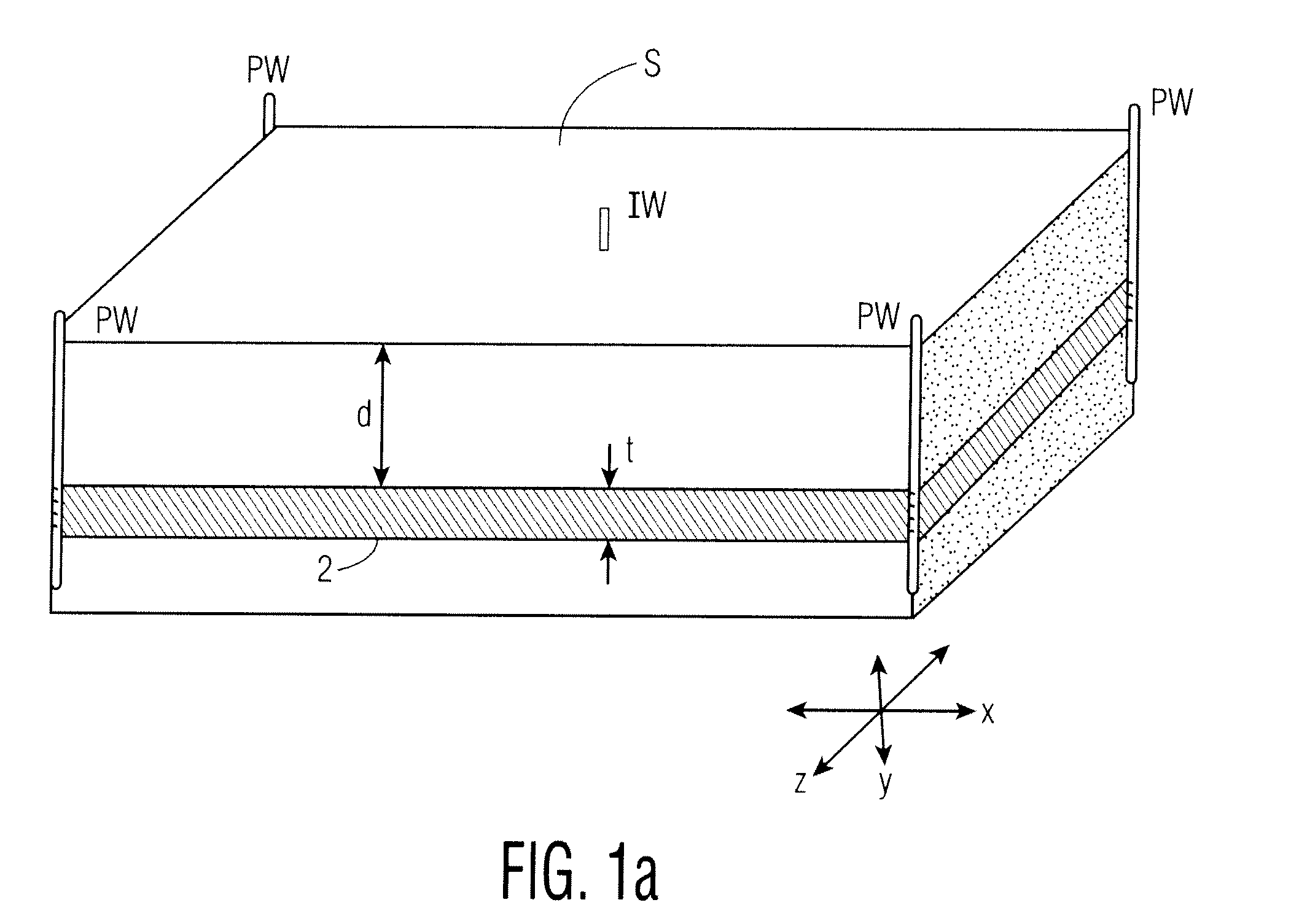

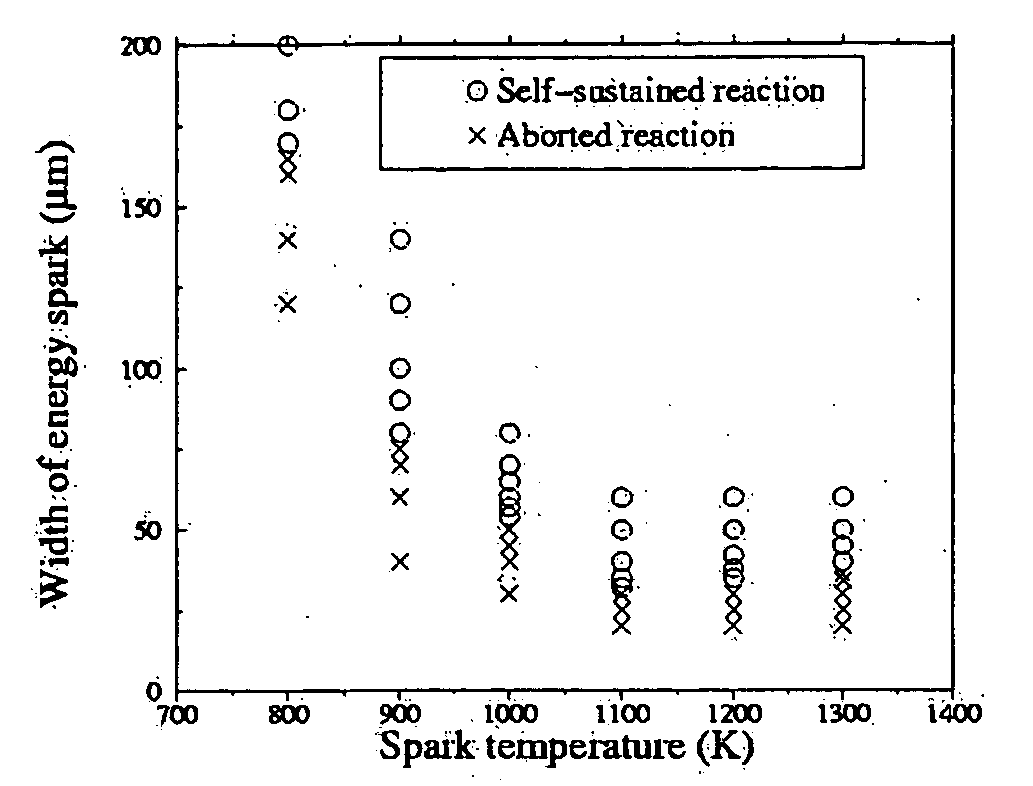

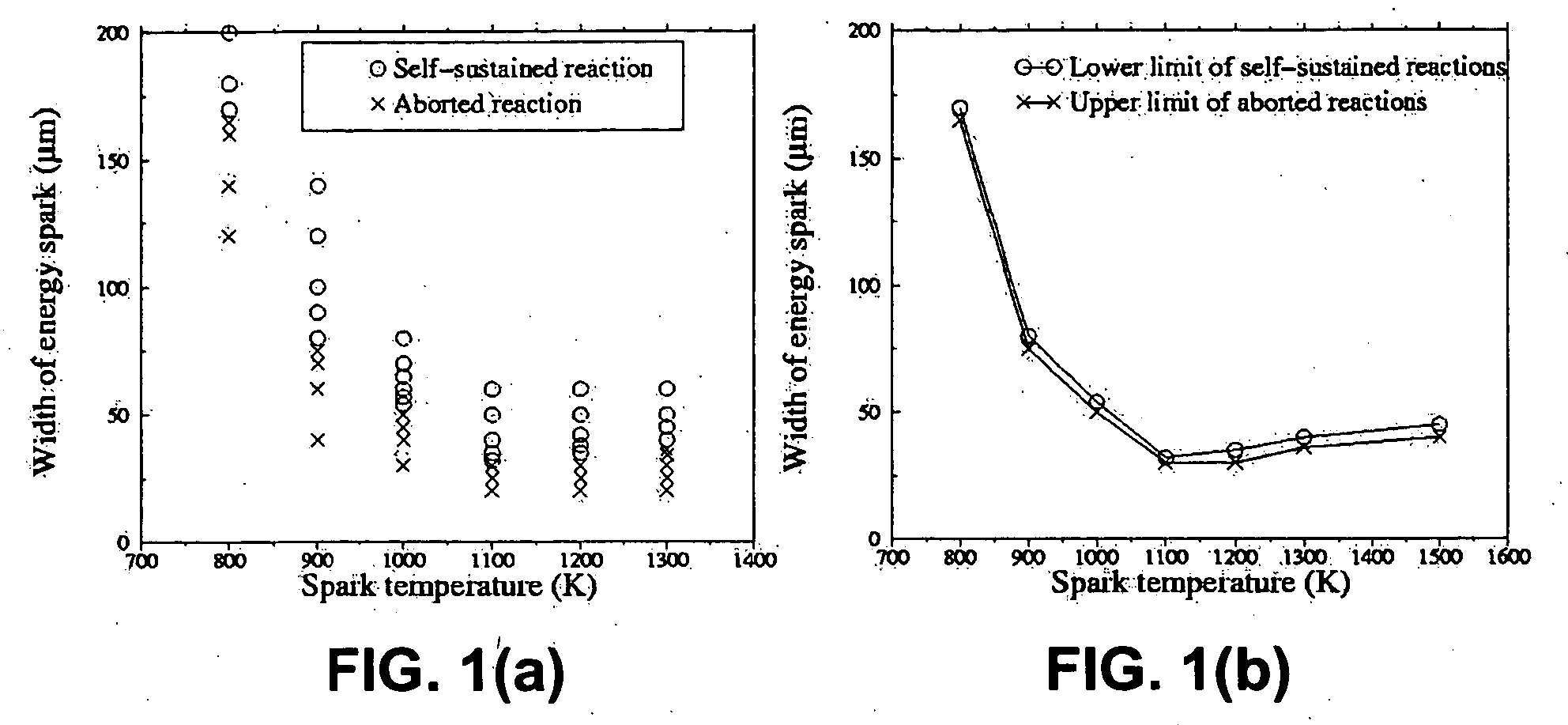

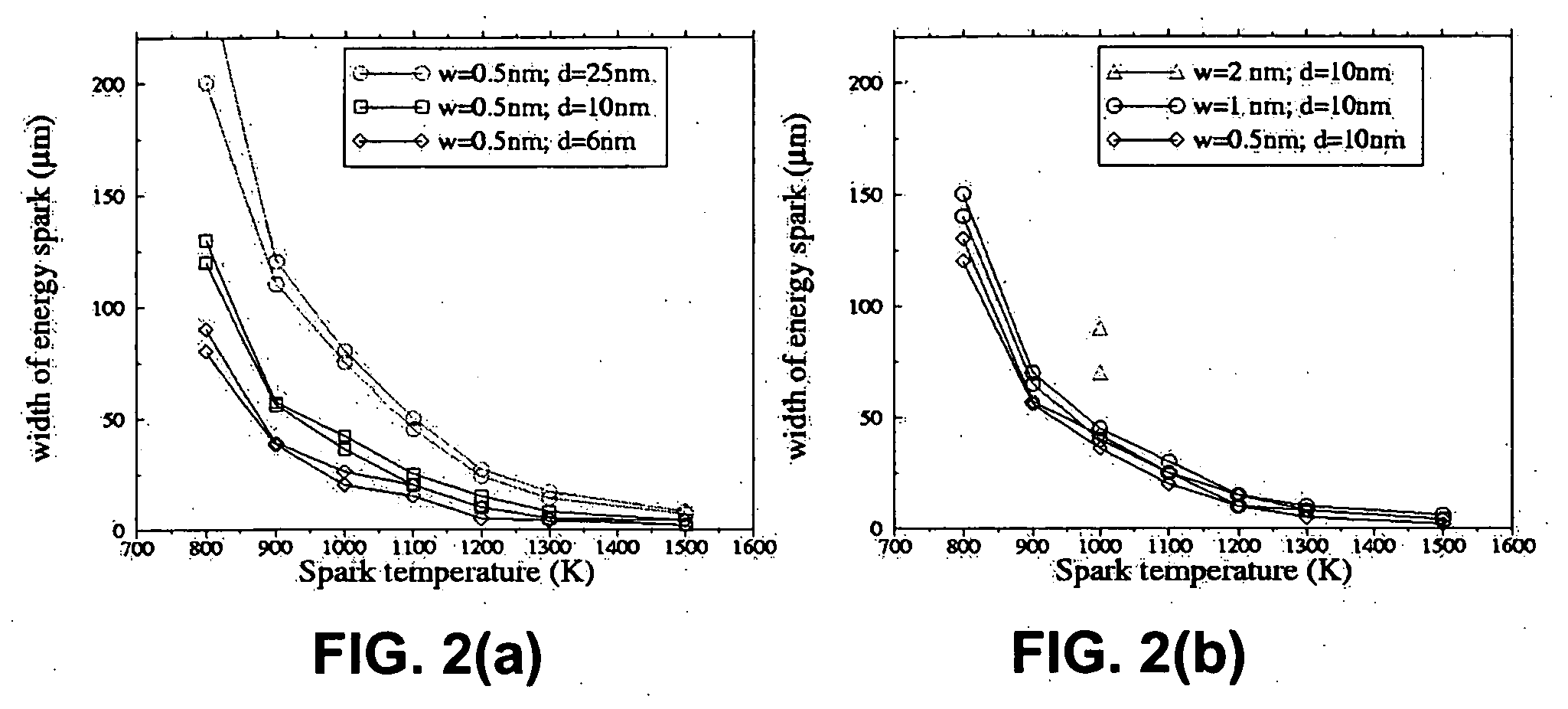

Methods of controlling multilayer foil ignition

InactiveUS20050142495A1Exothermal chemical reaction heat productionPhotomechanical apparatusEngineeringEnergy source

Embodiments of the invention include a method of simulating an ignition of a reactive multilayer foil. Other embodiments include various methods of igniting a reactive multilayer foil by transferring energy from an energy source to a reactive multilayer foil.

Owner:REACTIVE NANOTECH +1

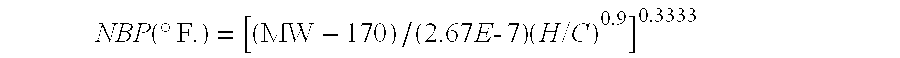

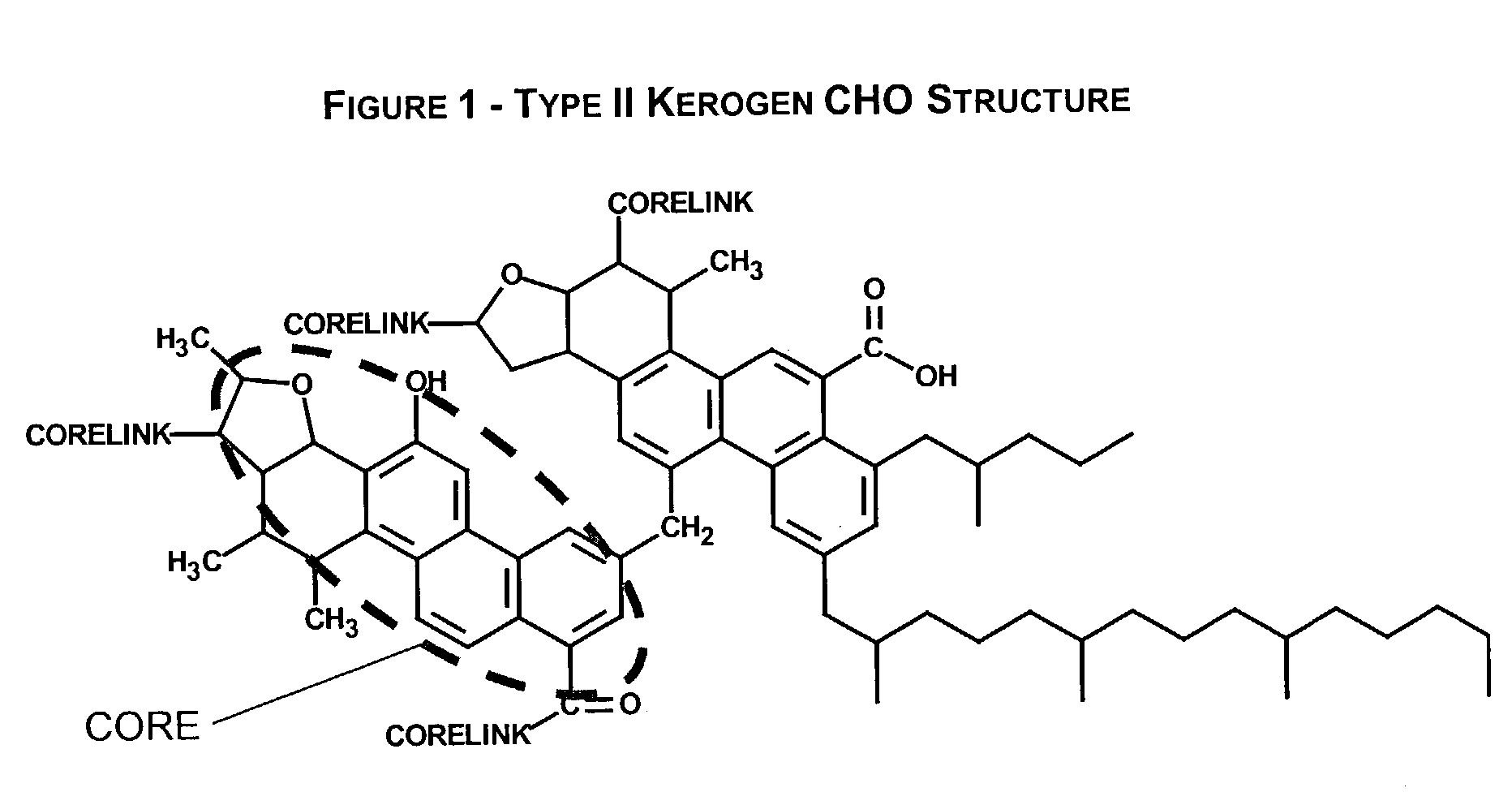

Chemical structural and compositional yields model for predicting hydrocarbon thermolysis products

ActiveUS7344889B2Molecular entity identificationEarth material testingChemical structureChemical reaction

A method of predicting the composition of hydrocarbon products of a complex carbonaceous material when exposed to specific time and temperature conditions is disclosed. In one embodiment, the material is characterized to obtain elemental, chemical and structural parameters. A representative chemical structure of the material is constructed based on the characterization information. The representative chemical structure is then stochastically expanded to a molecular ensemble chemical structural model that includes heteroatoms. The chemical structural model is coupled to a compositional yield model and the composition of the material products is determined using kinetic modeling. Methods are provided of constructing a chemical structural model of complex carbonaceous material, of coupling a molecular ensemble of chemical structures to a thermal chemical mechanism, of updating an ensemble of chemical structures during the kinetic modeling to reflect chemical reaction products and of eliminating molecules from the system.

Owner:EXXONMOBIL UPSTREAM RES CO

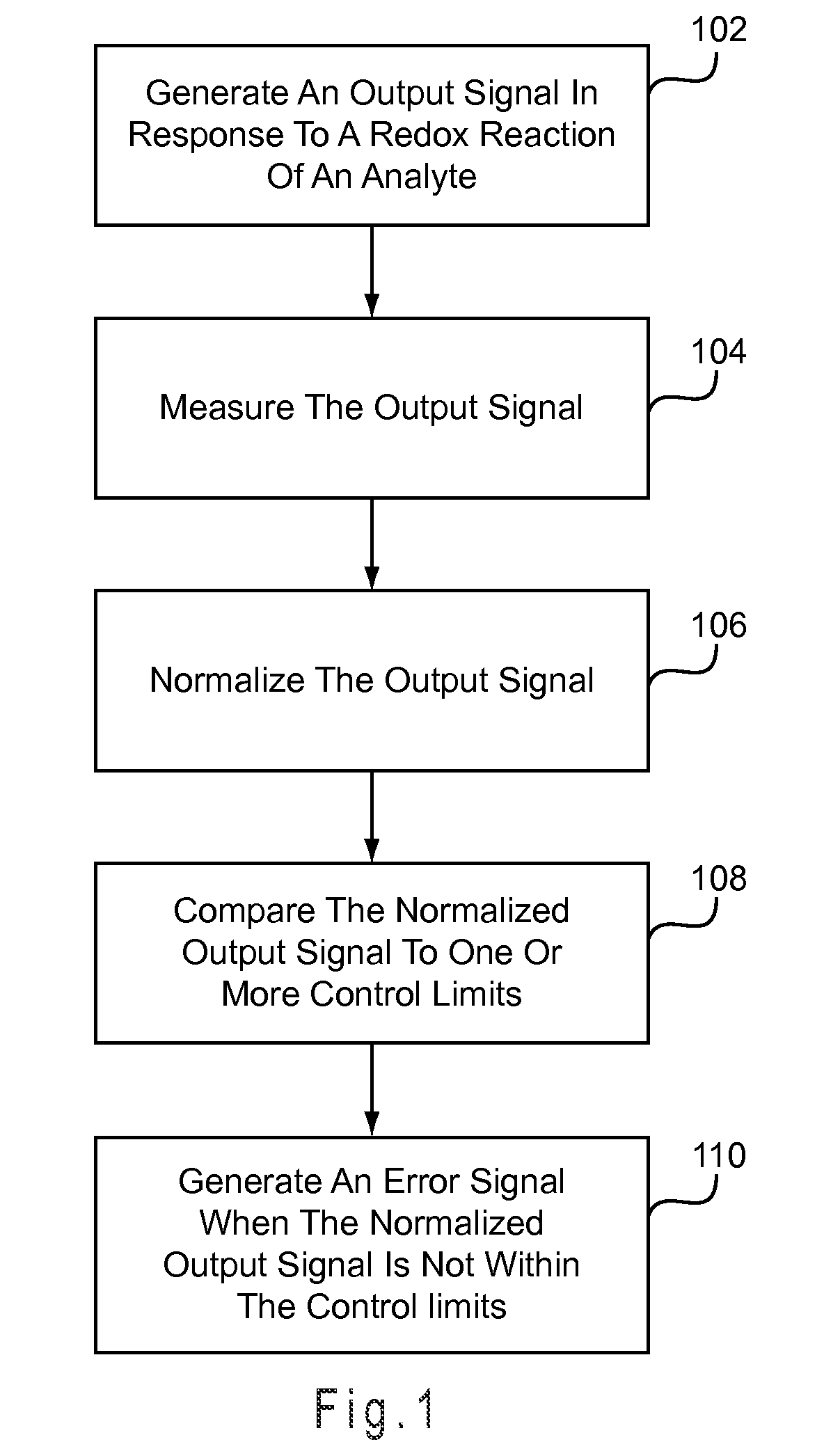

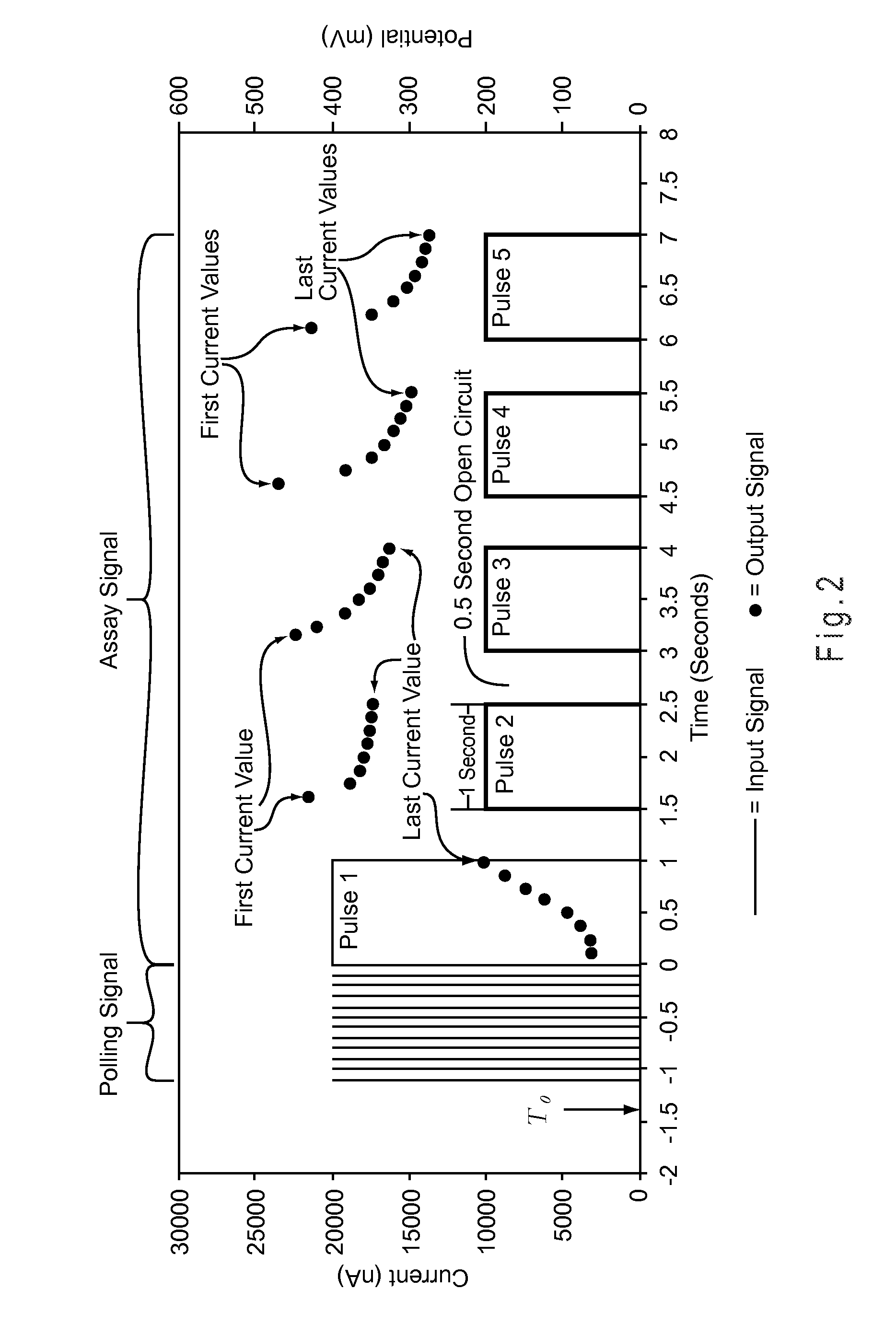

Abnormal Output Detection System For A Biosensor

ActiveUS20090099787A1Accurate and precise analysisMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteRedox

A biosensor has an abnormal output detection system that determines whether an output signal from the redox reaction of an analyte has a normal or abnormal shape or configuration. The abnormal output detection system improves the accuracy and precision of the biosensor in determining whether an output signal has a shape or configuration that may not provide an accurate and / or precise analysis of a biological fluid. The biosensor generates an output signal in response to the redox reaction of the analyte. The biosensor normalizes the output signal and compares the normalized output signal with one or more control limits. The biosensor may generate an error signal when the normalized output signal is not within the control limits.

Owner:ASCENSIA DIABETES CARE HLDG AG

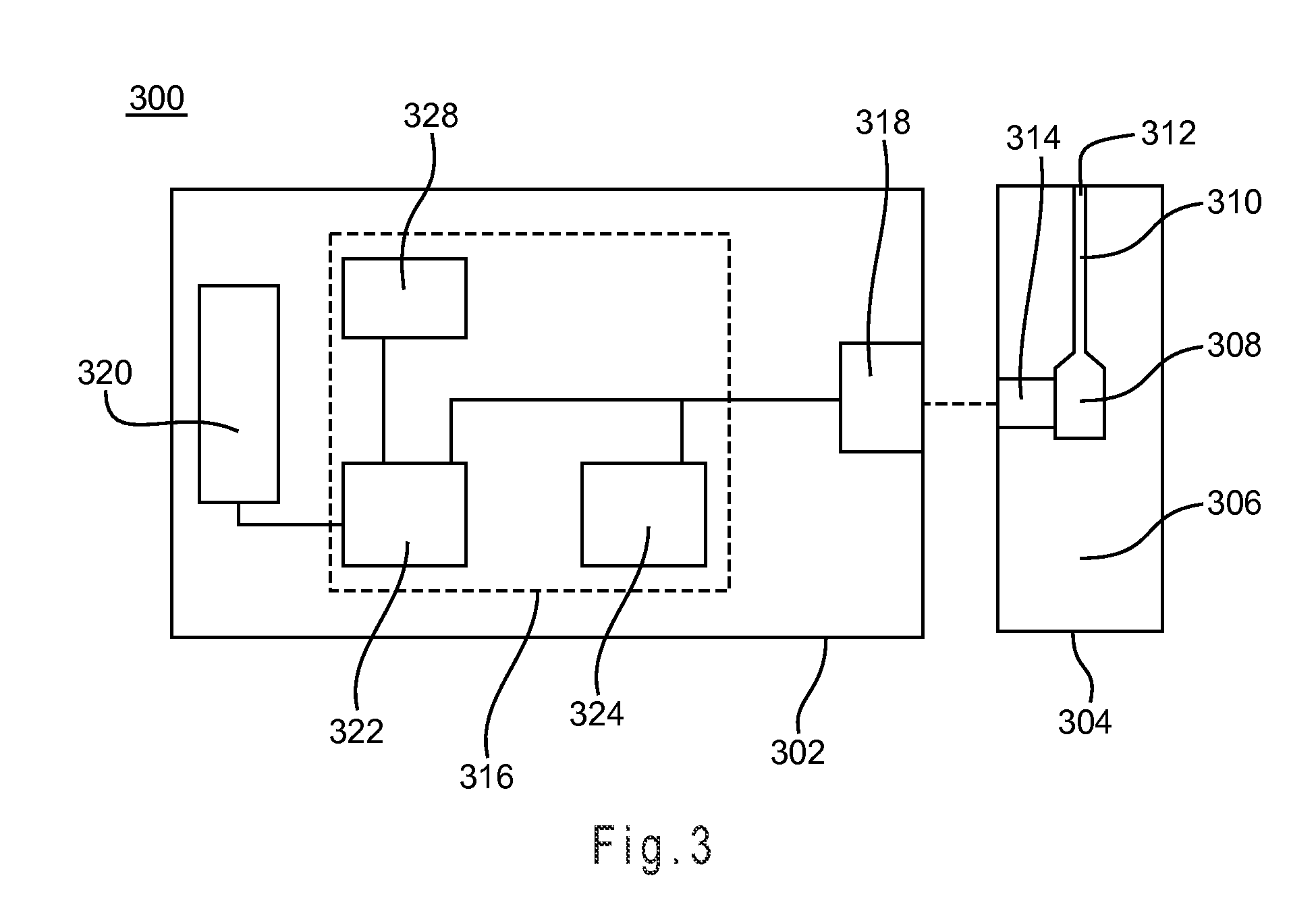

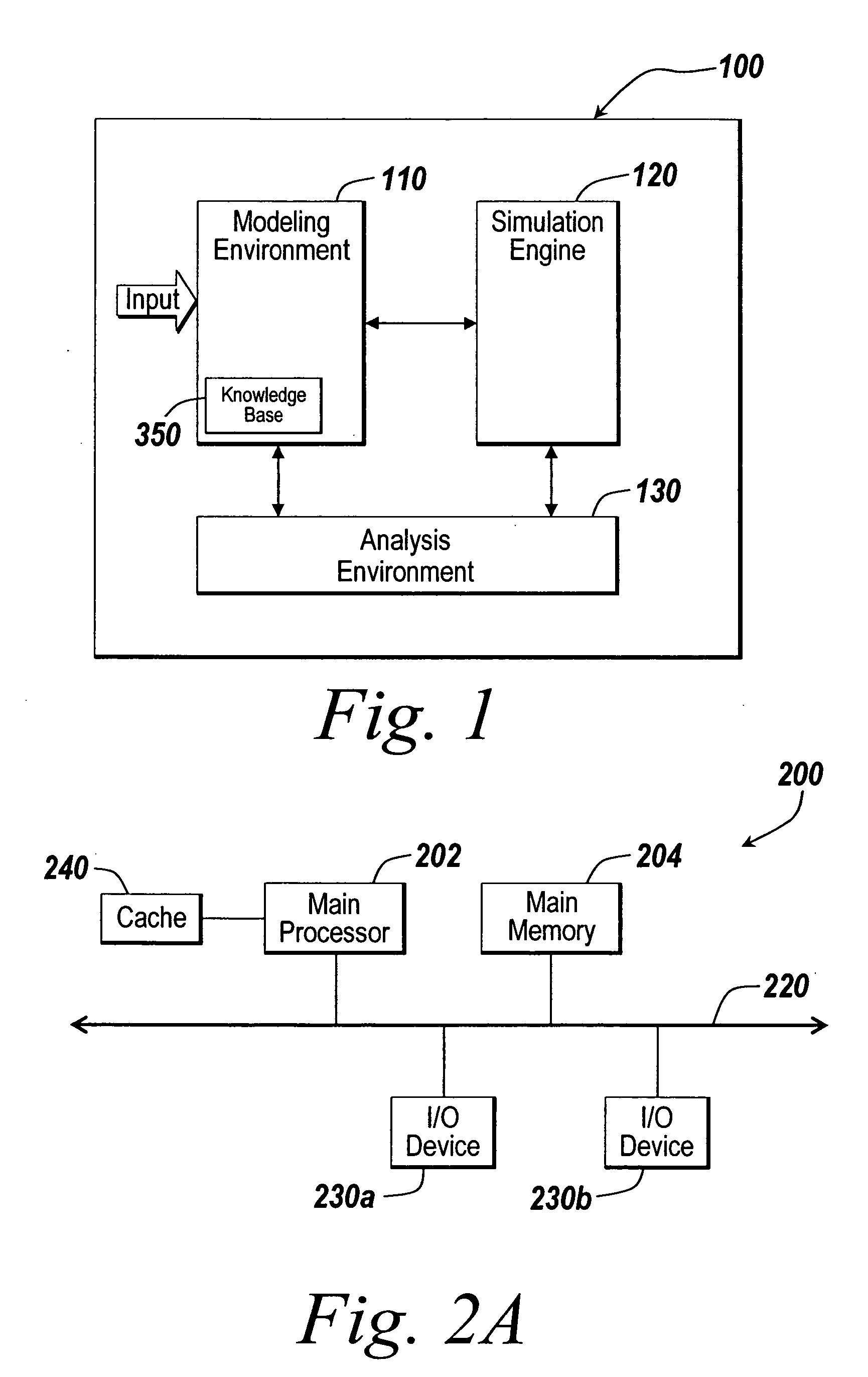

Method and apparatus facilitating communication with a simulation environment

ActiveUS20050187745A1Easy constructionAnalogue computers for chemical processesChemical processes analysis/designChemical reactionBiochemical Process

A system for modifying a model of a chemical reaction or biochemical process responsive to experimental results generated by an in situ experiment conducted on an experimental platform includes a simulation engine and an analysis environment. The simulation engine generates an expected result from a model of the chemical reaction or biochemical process. The analysis environment communicates with the simulation engine, gathers data from an experimental platform, and compares the expected result to data gathered from the platform.

Owner:THE MATHWORKS INC

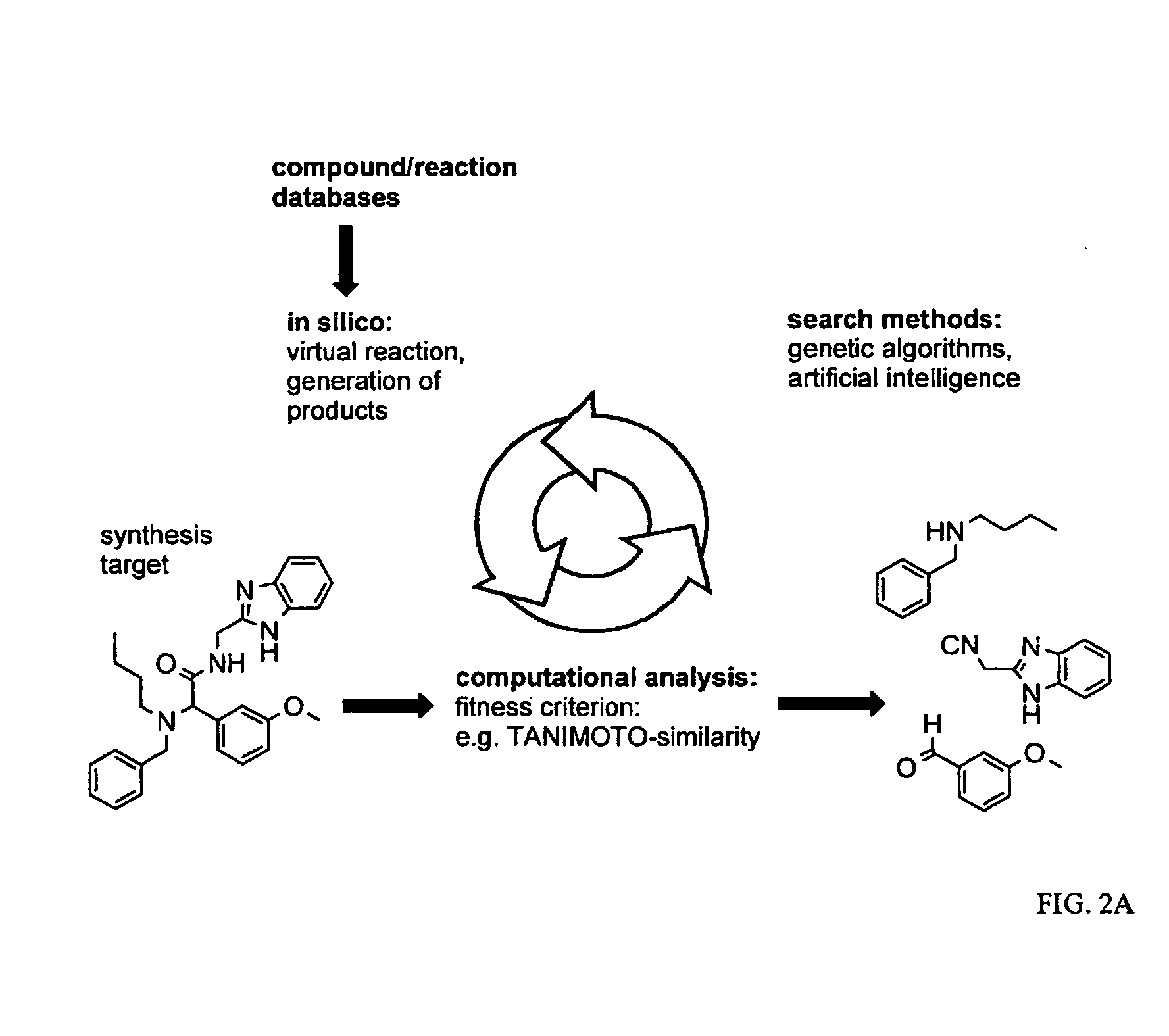

Methods and systems for discovery of chemical compounds and their syntheses

InactiveUS20050177280A1Overcome deficienciesChemical property predictionSampled-variable control systemsCADA compoundChemical compound

Owner:ORIGENIS

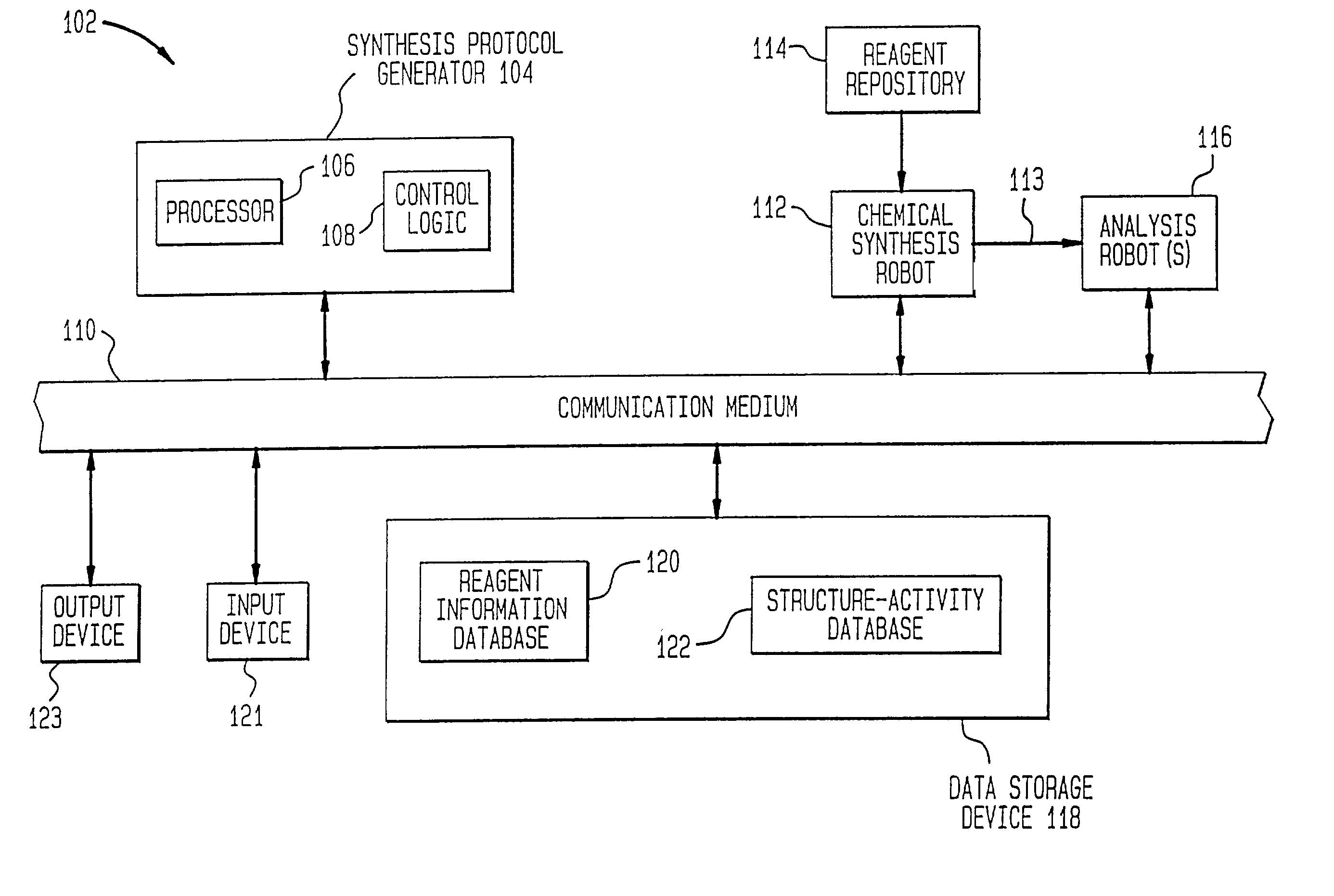

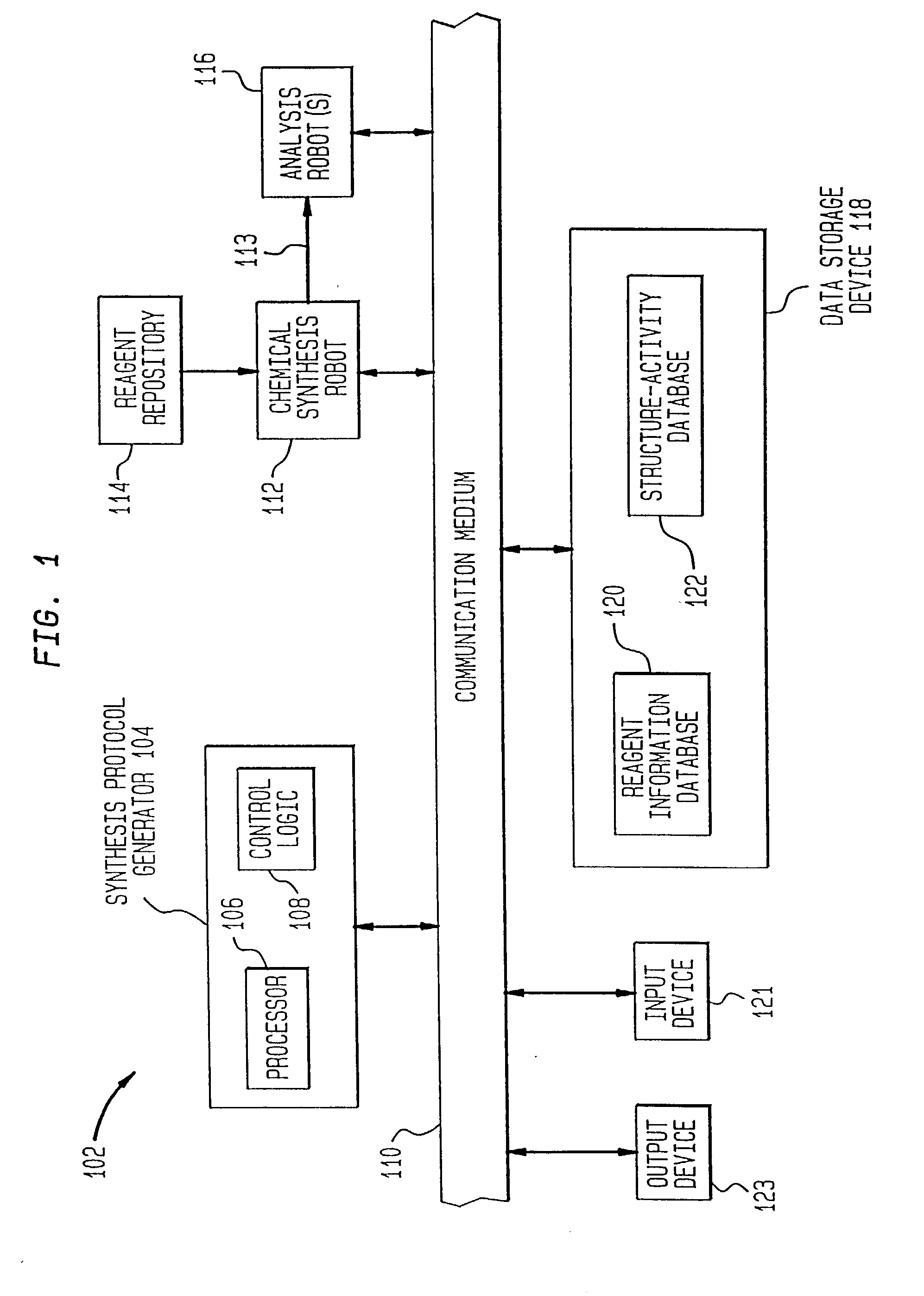

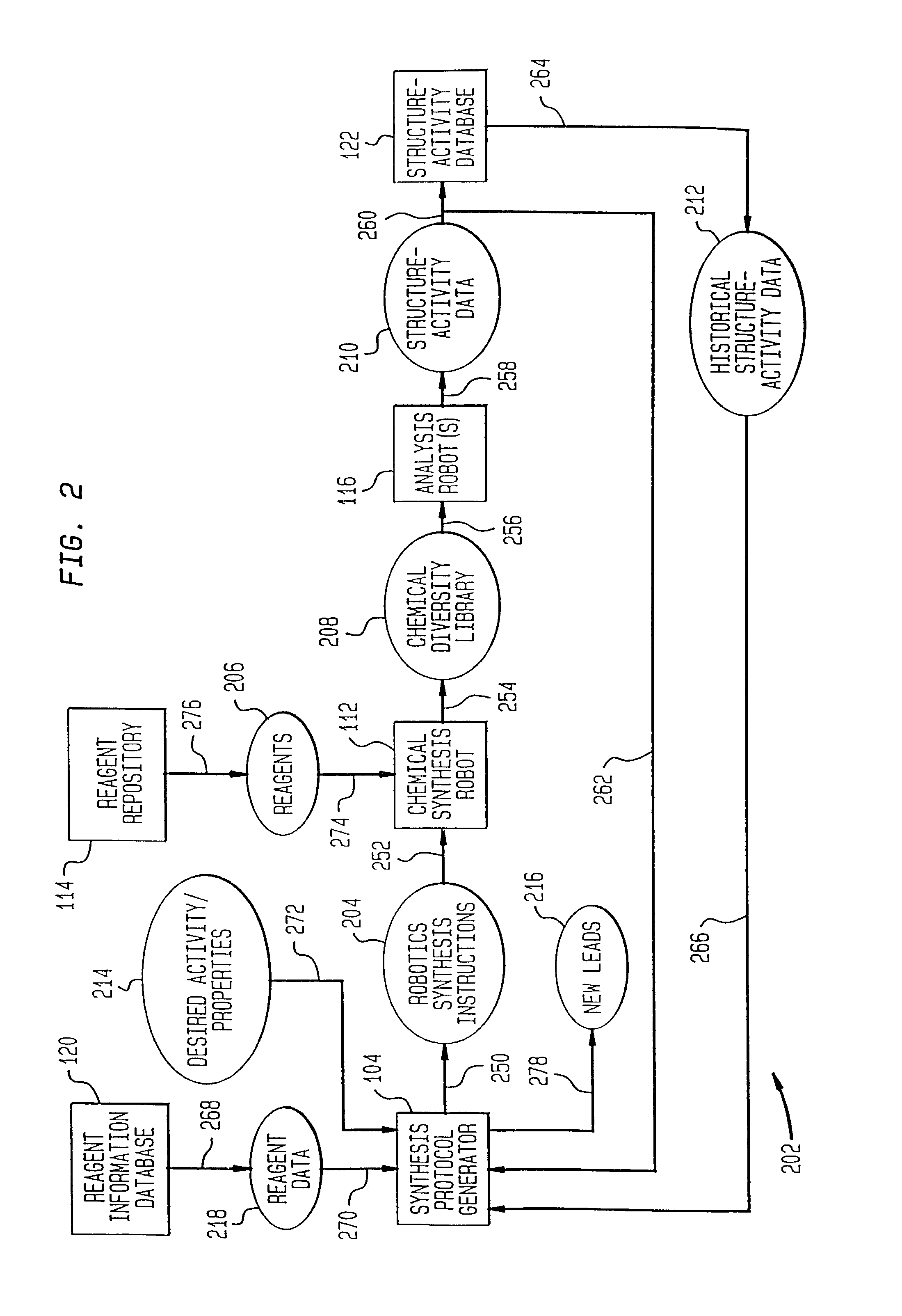

Method of generating chemical compounds having desired properties

InactiveUS20030033088A1Chemical property predictionSequential/parallel process reactionsStructure propertyChemical compound

A computer based, iterative process for generating chemical entities with defined physical, chemical and / or bioactive properties. During each iteration of the process, (1) a directed diversity chemical library is robotically generated in accordance with robotic synthesis instructions; (2) the compounds in the directed diversity chemical library are analyzed to identify compounds with the desired properties; (3) structure-property data are used to select compounds to be synthesized in the next iteration; and (4) new robotic synthesis instructions are automatically generated to control the synthesis of the directed diversity chemical library for the next iteration.

Owner:AGRAFIOTIS DIMITRIS K +3

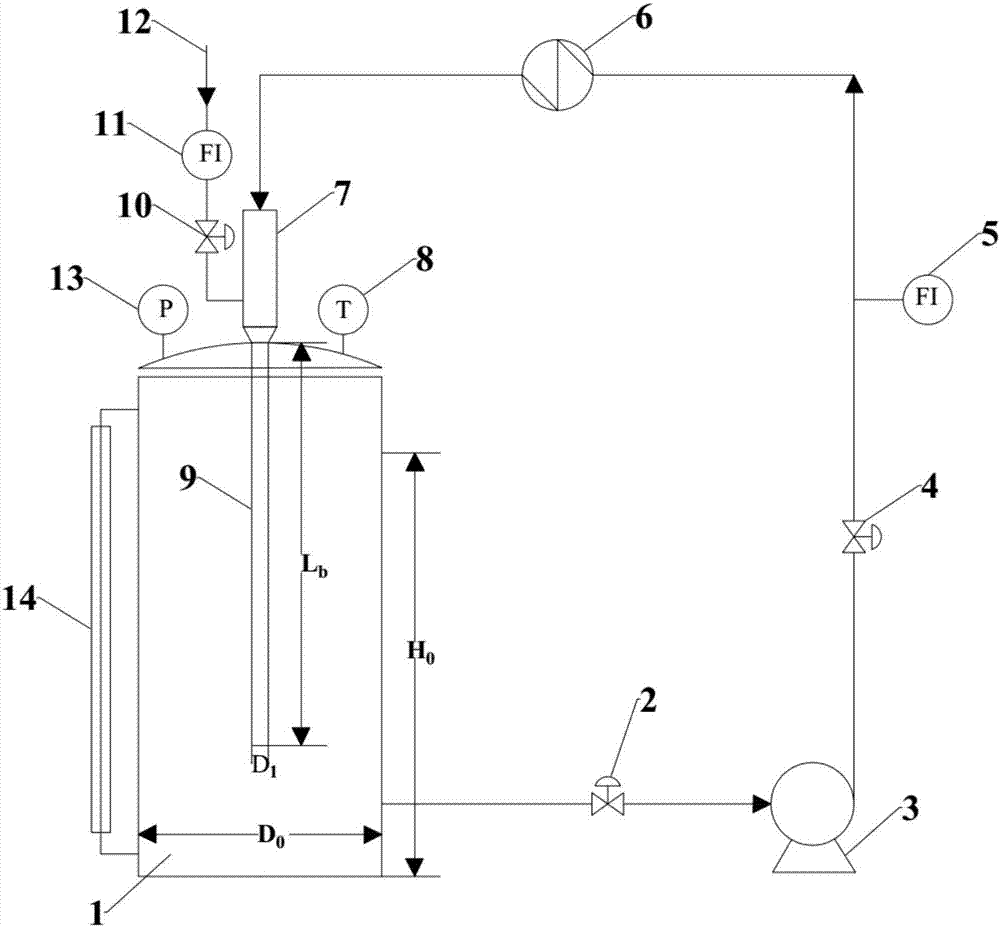

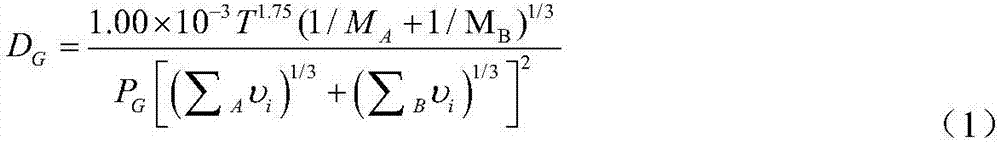

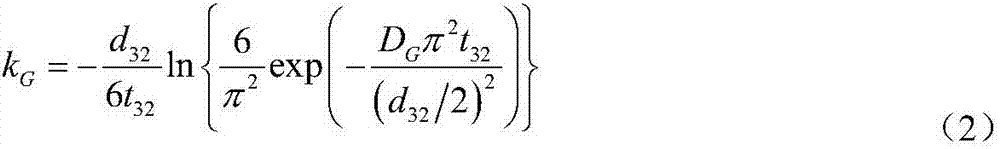

Modeling method for mass transfer rate structure-effect regulating model of micro-interface enhanced reactor

ActiveCN107346378AReduce mistakesImprove versatilityChemical processes analysis/designSpecial data processing applicationsModel methodMaterial consumption

The invention discloses a modeling method for a mass transfer rate structure-effect regulating model of a micro-interface enhanced reactor. Rigorous theoretical derivation is adopted for respectively establishing a gas-side mass transfer coefficient calculation model and a liquid-side mass transfer coefficient calculation model. The mass transfer rate structure-effect regulating model established according to the modeling method disclosed by the invention can be adopted for directly viewing the relationship between the mass transfer rate and the bubble size and a theoretical basis is established for researching a micro-interface system, so that the target of acquiring the maximum energy efficiency and physical effect in the reaction process can be achieved in the manner of regulating structure parameter and operation parameter or an efficient reactor structure is designed under the conditions of given reaction target (task), energy consumption and material consumption.

Owner:NANJING UNIV

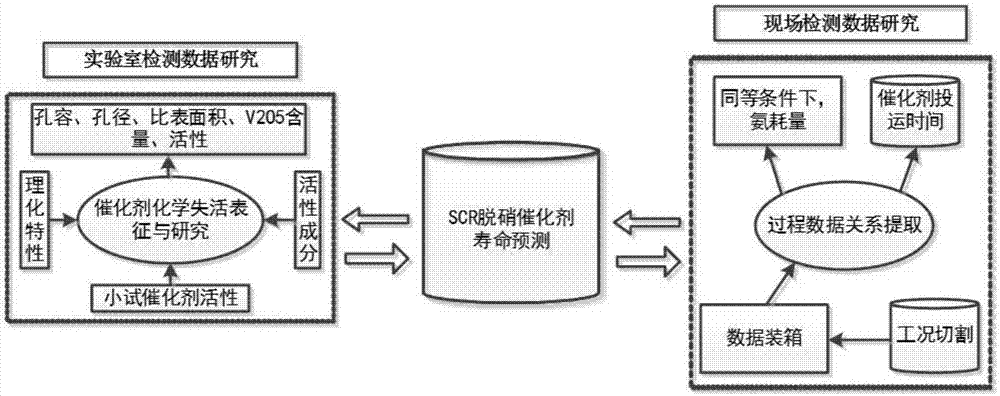

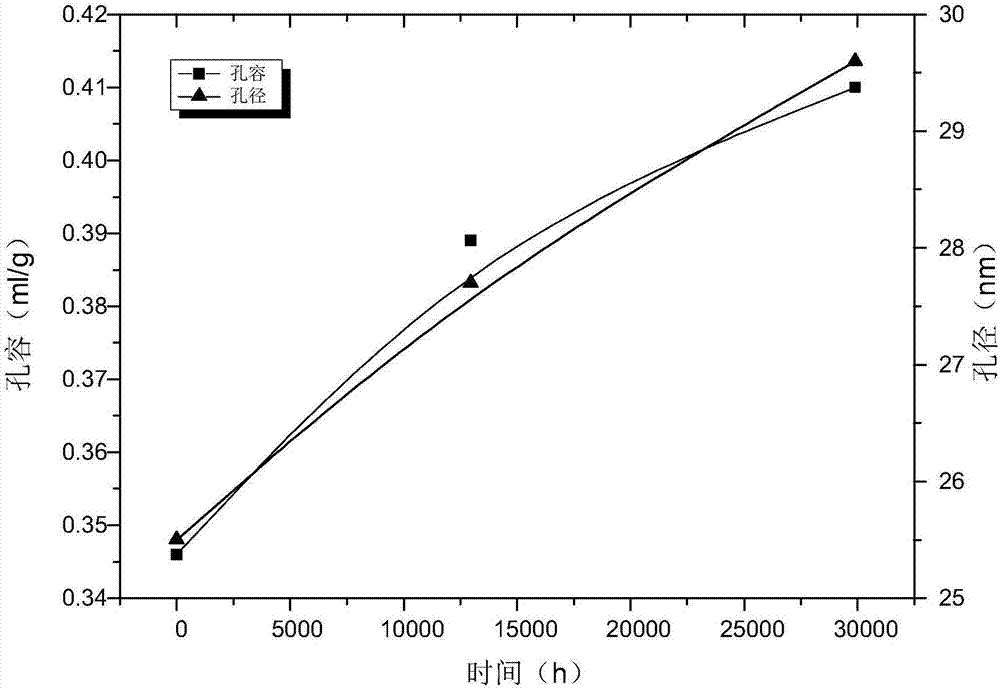

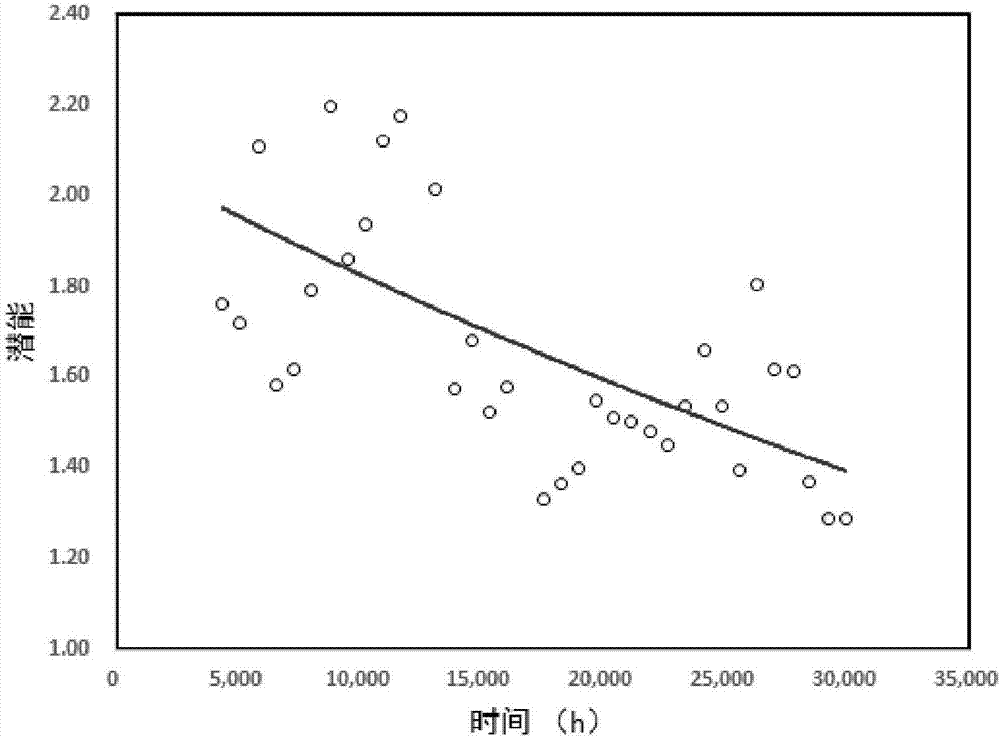

Multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method

ActiveCN107103176AImprove accuracyImprove stabilityChemical analysis using catalysisChemical processes analysis/designPower stationProcess engineering

The invention provides a multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method. The multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method includes the following steps: performing multiple sampling on a catalyst used in a power station boiler, performing laboratory detection on a sample, and acquiring a microscopic feature index capable of representing the activity of the catalyst; acquiring a macro-performance index of the catalyst sample through a micro reactor test; counting and mining power station historical operation data to acquire a macro index capable of reflecting the power station SCR reactor performance; and fusing the indexes associated with the catalyst life, and completing comprehensive evaluation of the catalyst life. The evaluation method can acquire a catalyst life prediction model according to historical laboratory detection data and an actual operation parameter of the catalyst through a fuzzy mathematical method, and can improve the accuracy and stability of catalyst performance evaluation.

Owner:SOUTHEAST UNIV +1

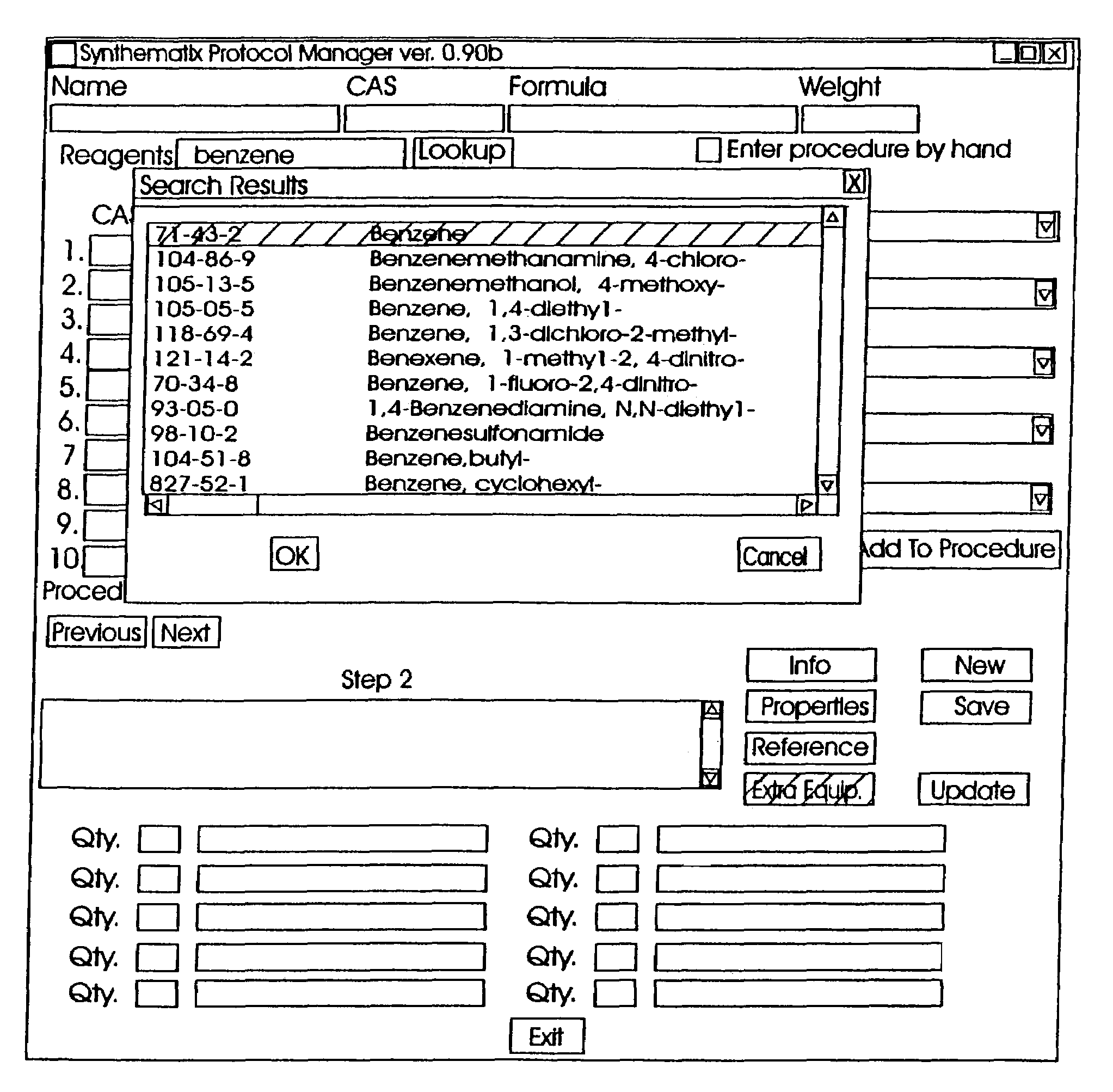

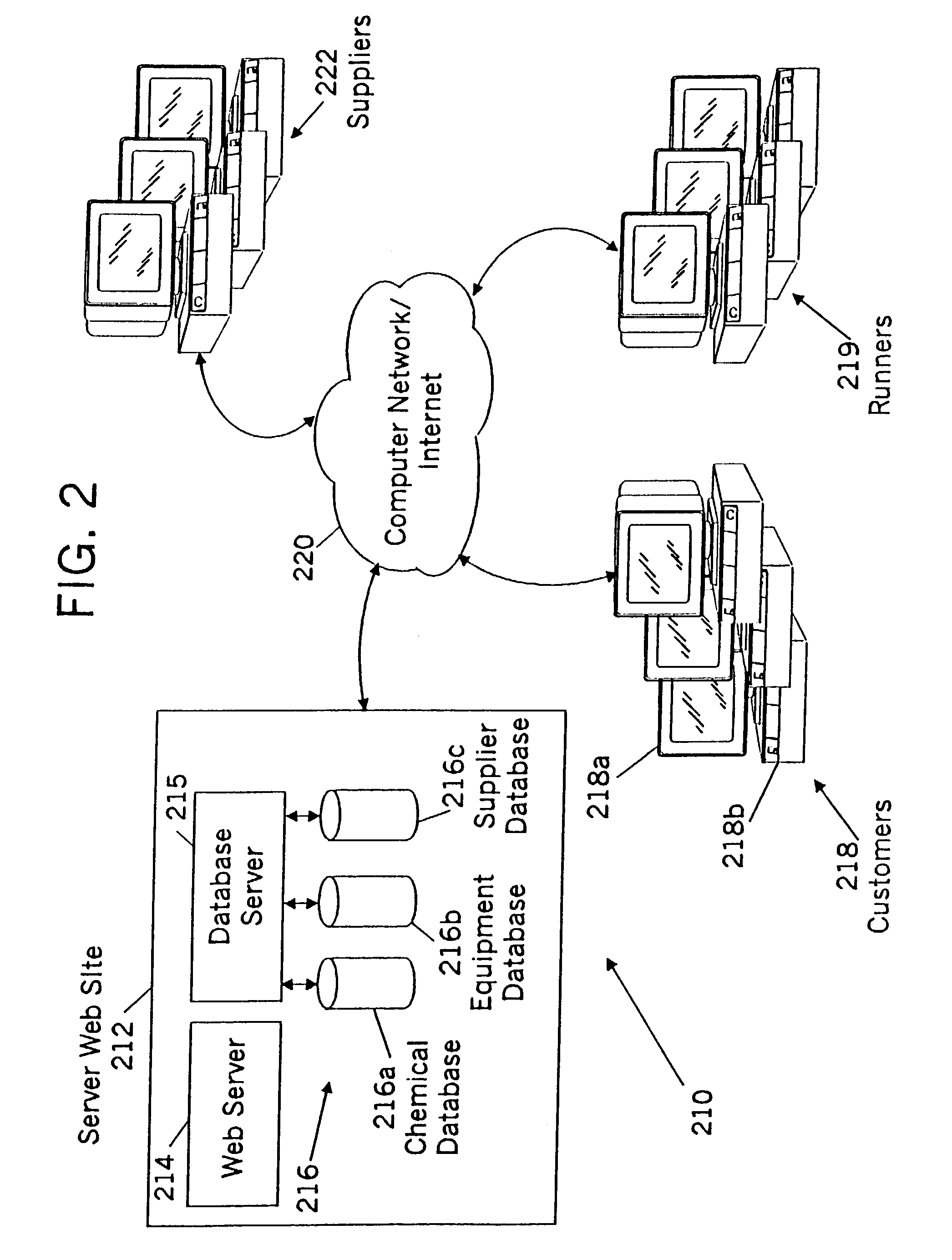

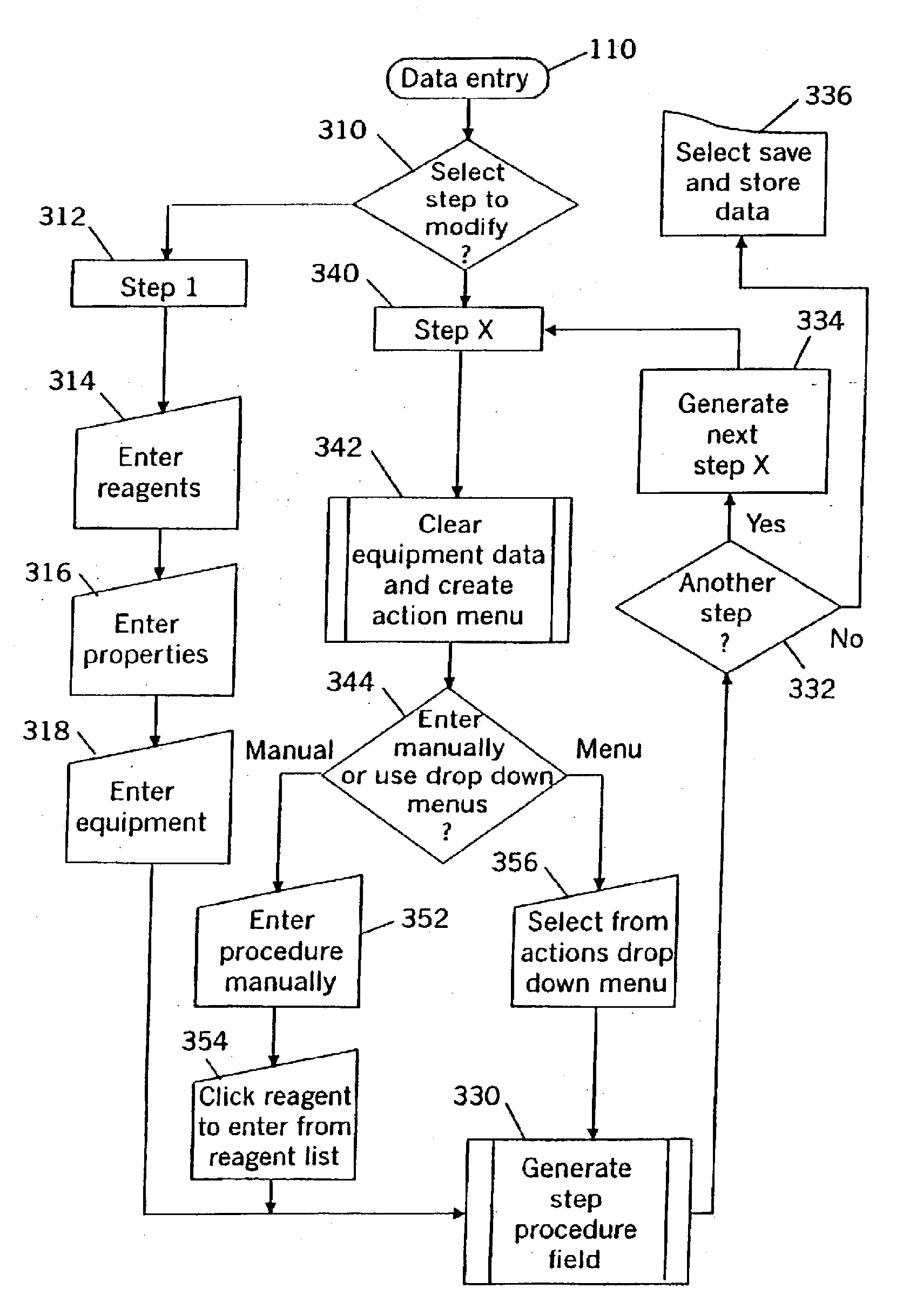

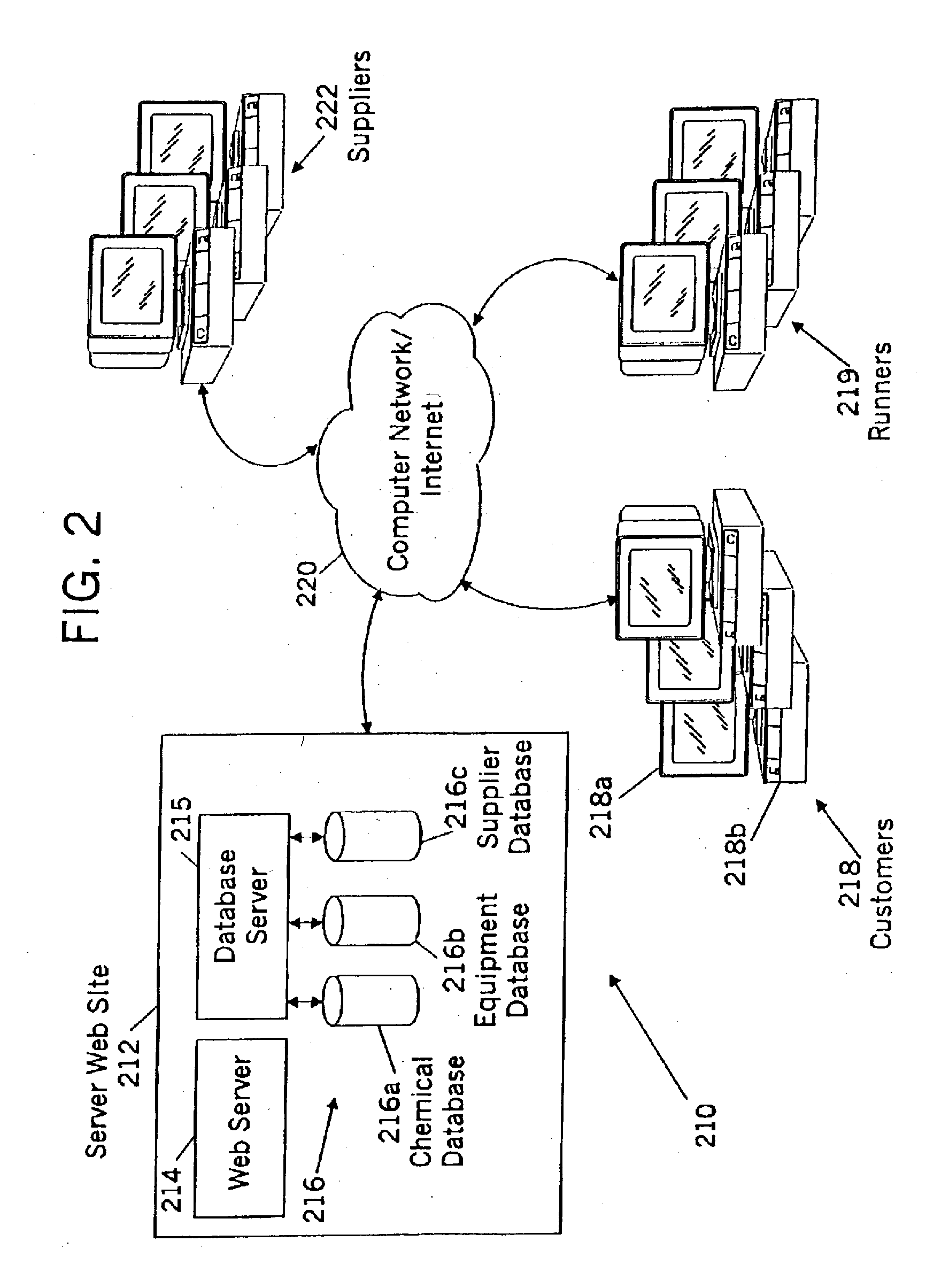

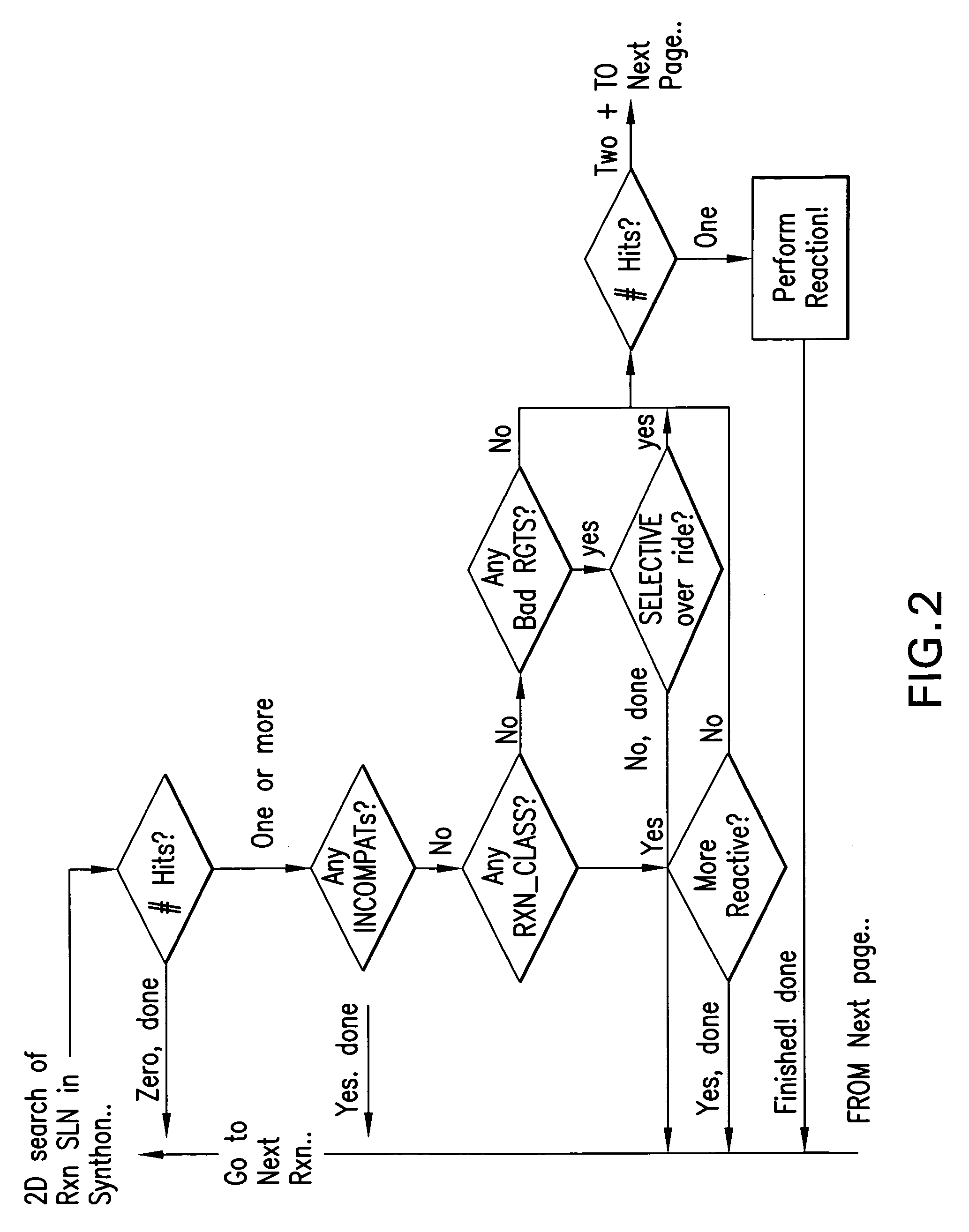

Systems, methods and computer program products for determining parameters for chemical synthesis

InactiveUS7250950B2Facilitate entryDrawing from basic elementsCheminformatics data warehousingGraphicsChemical synthesis

The database is populated with target chemicals, corresponding listings of reagent chemicals, corresponding listings of equipment and corresponding listings of procedures. The database is then searched in response to user identification of a target chemical. In response, a listing is displayed of reagent chemicals that are used to synthesize the target chemical, equipment that is used to synthesize the target chemical, and a procedure that is used to synthesize the target chemical by reacting the reagent chemicals in the equipment according to the procedure. An icon-based reaction editor and / or context-sensitive Boolean query option generators may be provided. A reaction template may be used to perform predictive chemistry. A reaction relay may be used to graphically display related chemicals and procedures using a hub and spoke arrangement.

Owner:DASSAULT SYST AMERICAS CORP

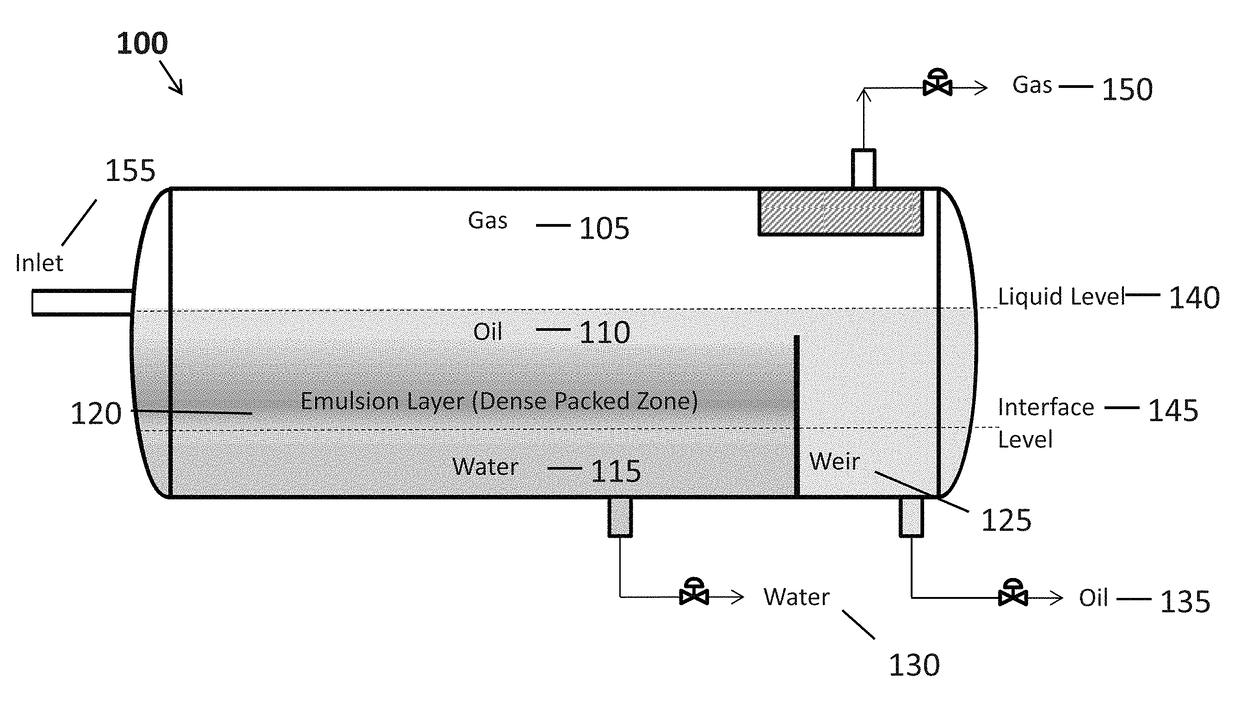

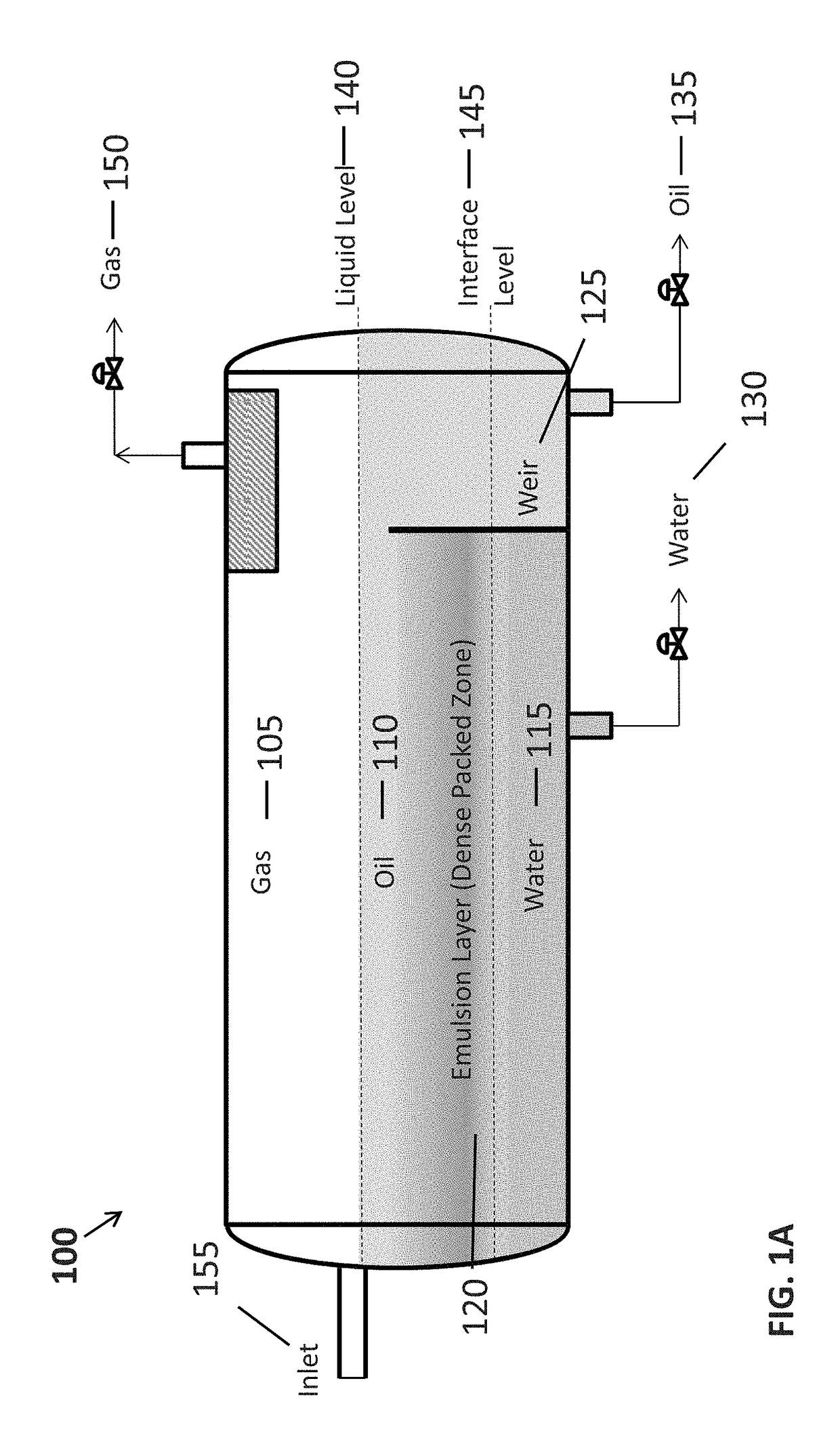

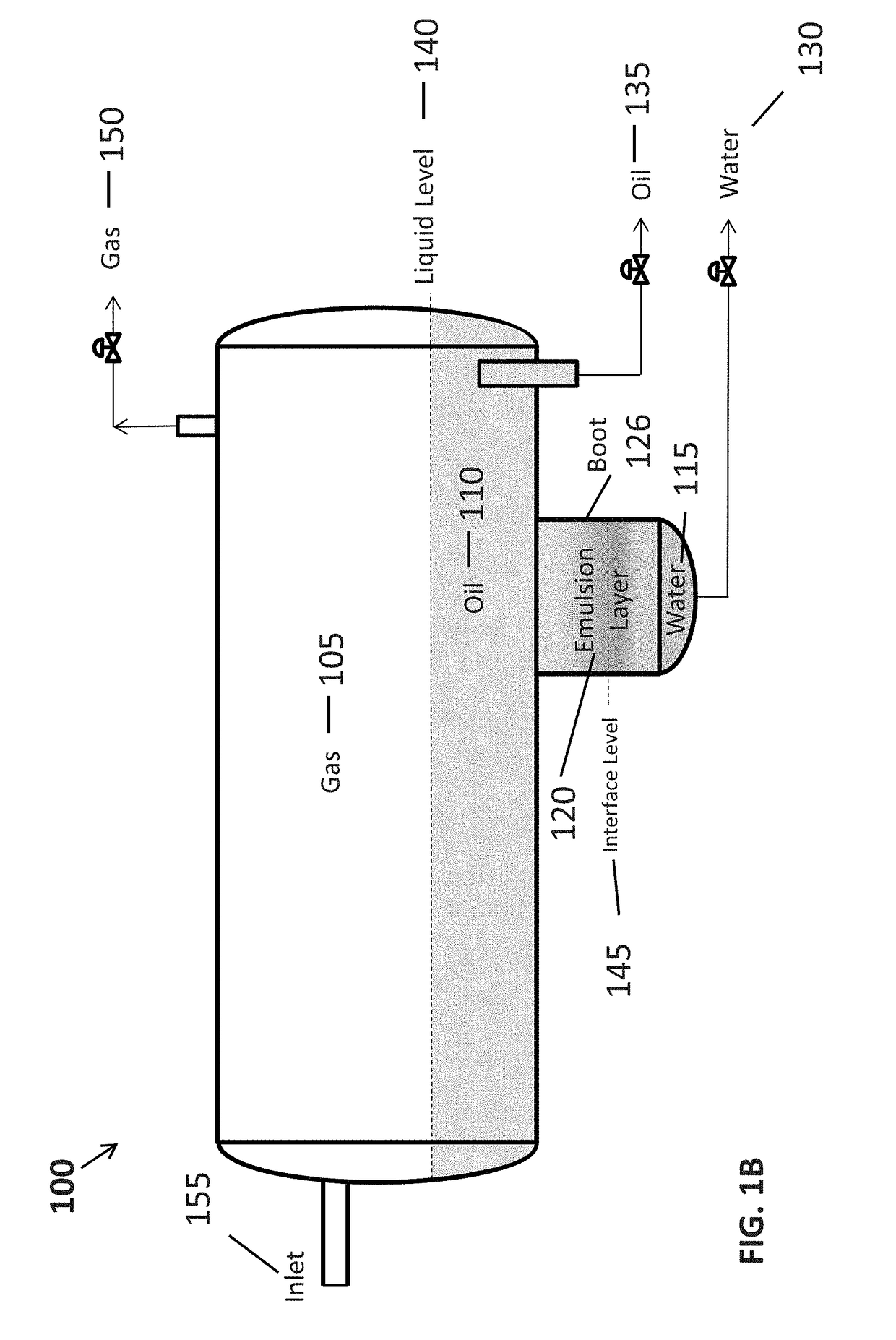

Processes for analysis and optimization of multiphase separators, particular in regards to simulated gravity separation of immiscible liquid dispersions

ActiveUS20170319984A1Maximize separationMaximize liquid-liquid separation efficiencyLiquid separation auxillary apparatusSedimentation separationProcess systemsThree-phase

The present invention is directed to systems and methods for evaluating performance, performing process control, optimization and design of gravity separation process systems that are used to separate immiscible liquid dispersions (e.g., water-in-oil, oil-in-water mixtures) and emulsions for two-phase (liquid-liquid) or three-phase (gas-liquid-liquid) systems. According to one aspect, the design, simulation and control of such systems is performed using computational fluid dynamics (CFD) software that is configured for determining the separation efficiency of separators on the basis of the true geometry and multidimensional flow field and for a distribution of droplet sizes with the influence of the emulsion concentration on the rheology of the oil-in-water or water-in-oil dispersion. The results of the CFD simulations can be used to adjust input parameters of the separator to maximize the separation efficiency of the separator such that it outputs liquid streams containing minimal amounts of immiscible liquid dispersions.

Owner:SAUDI ARABIAN OIL CO

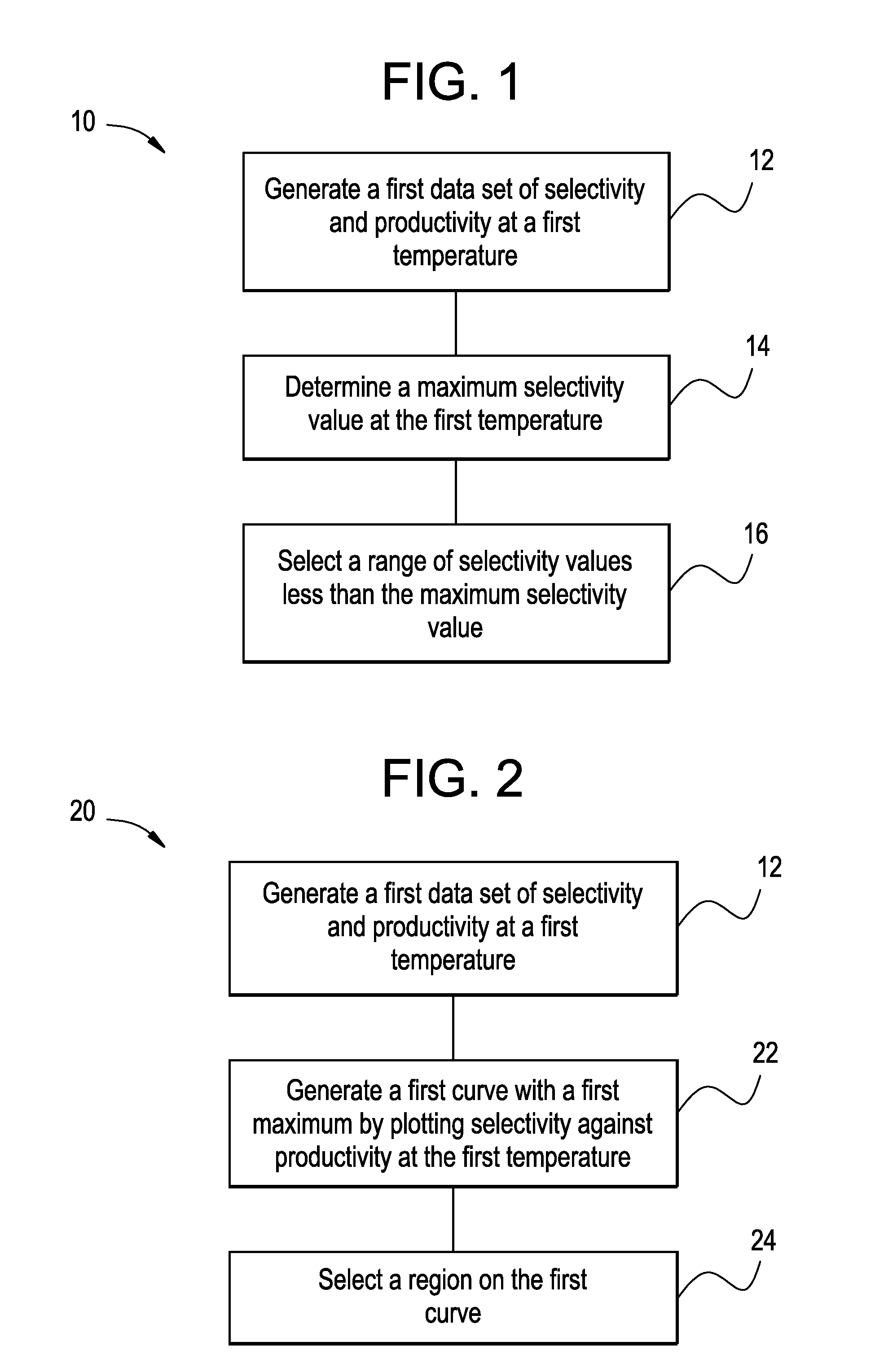

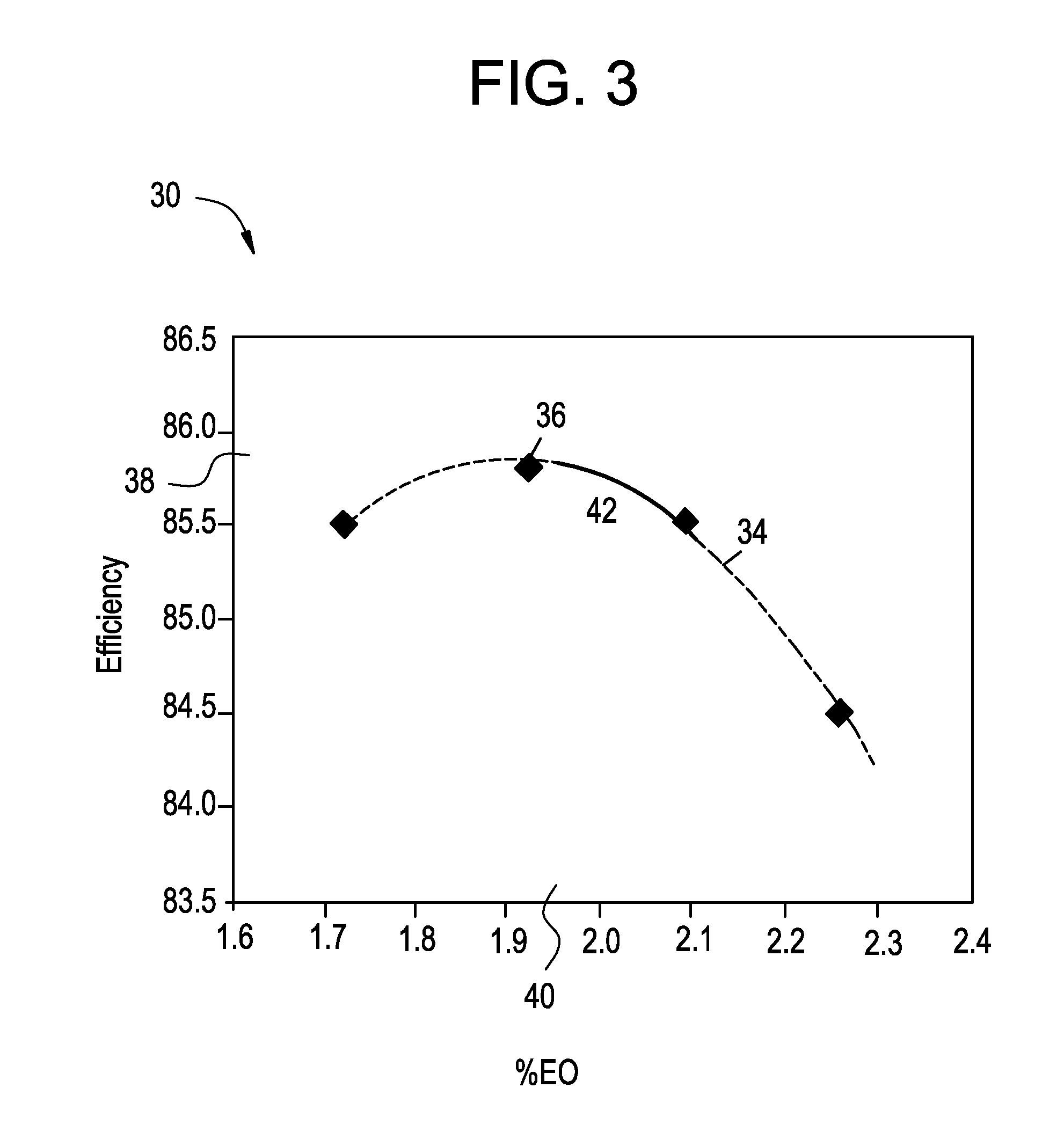

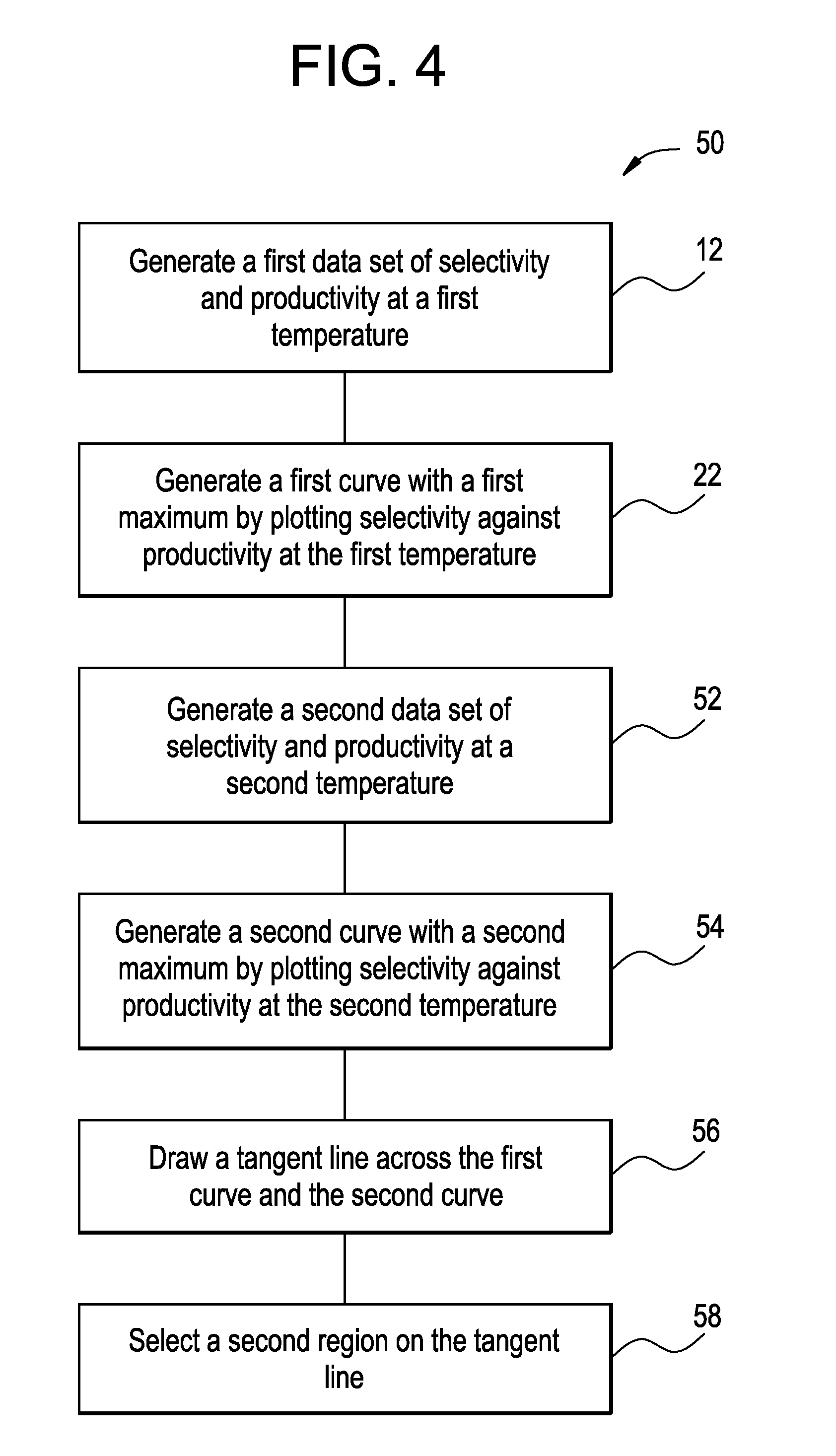

Epoxidation reactions and operating conditions thereof

ActiveUS20100267975A1Simple methodIssue can be resolvedOxygen-containing compound preparationPreparation by oxidation reactionsRheniumOxygen

A method of producing an alkylene oxide includes passing a reaction mixture comprising alkylene, oxygen and a gaseous chlorine-containing promoter species over a supported catalyst containing silver and a promoting amount of rhenium to undergo an epoxidation reaction at a first operating condition. The method further includes subsequently performing the epoxidation reaction at a preferred operating condition. The preferred operating condition is characterized by an efficiency of the epoxidation reaction toward the alkylene oxide where the efficiency is lower than that of a maximum efficiency achievable at an operating temperature corresponding to the preferred operating condition.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP +1

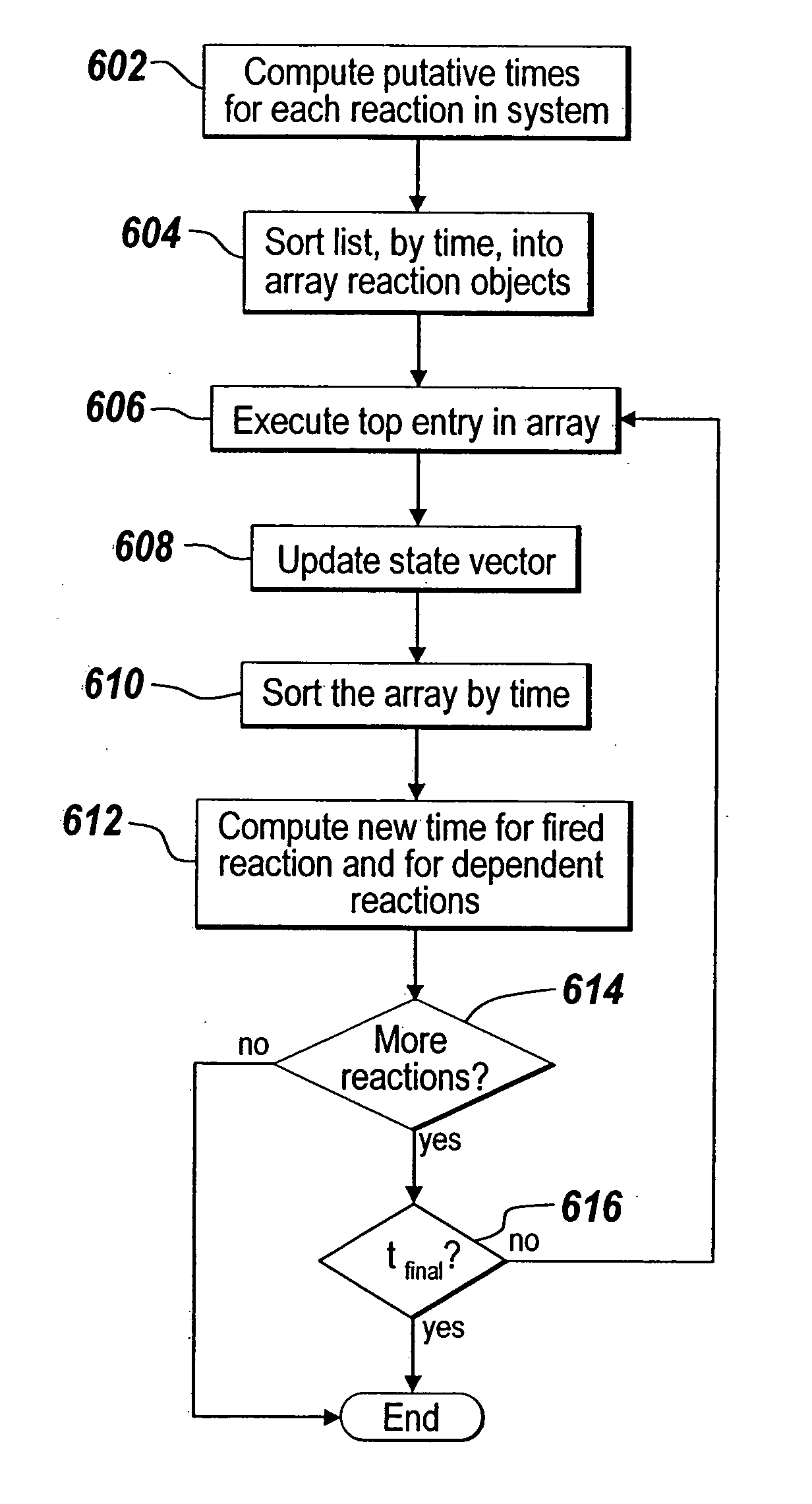

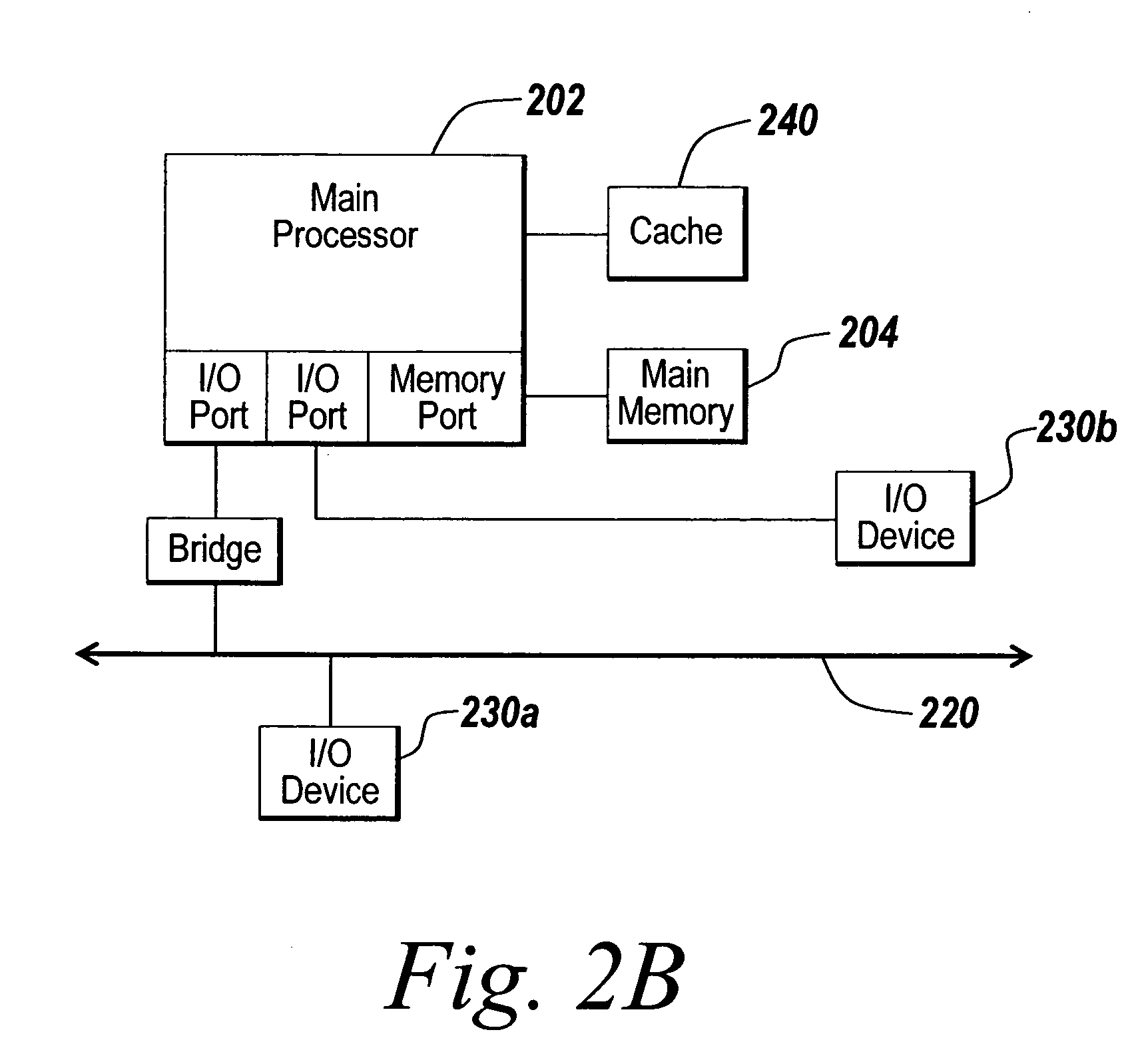

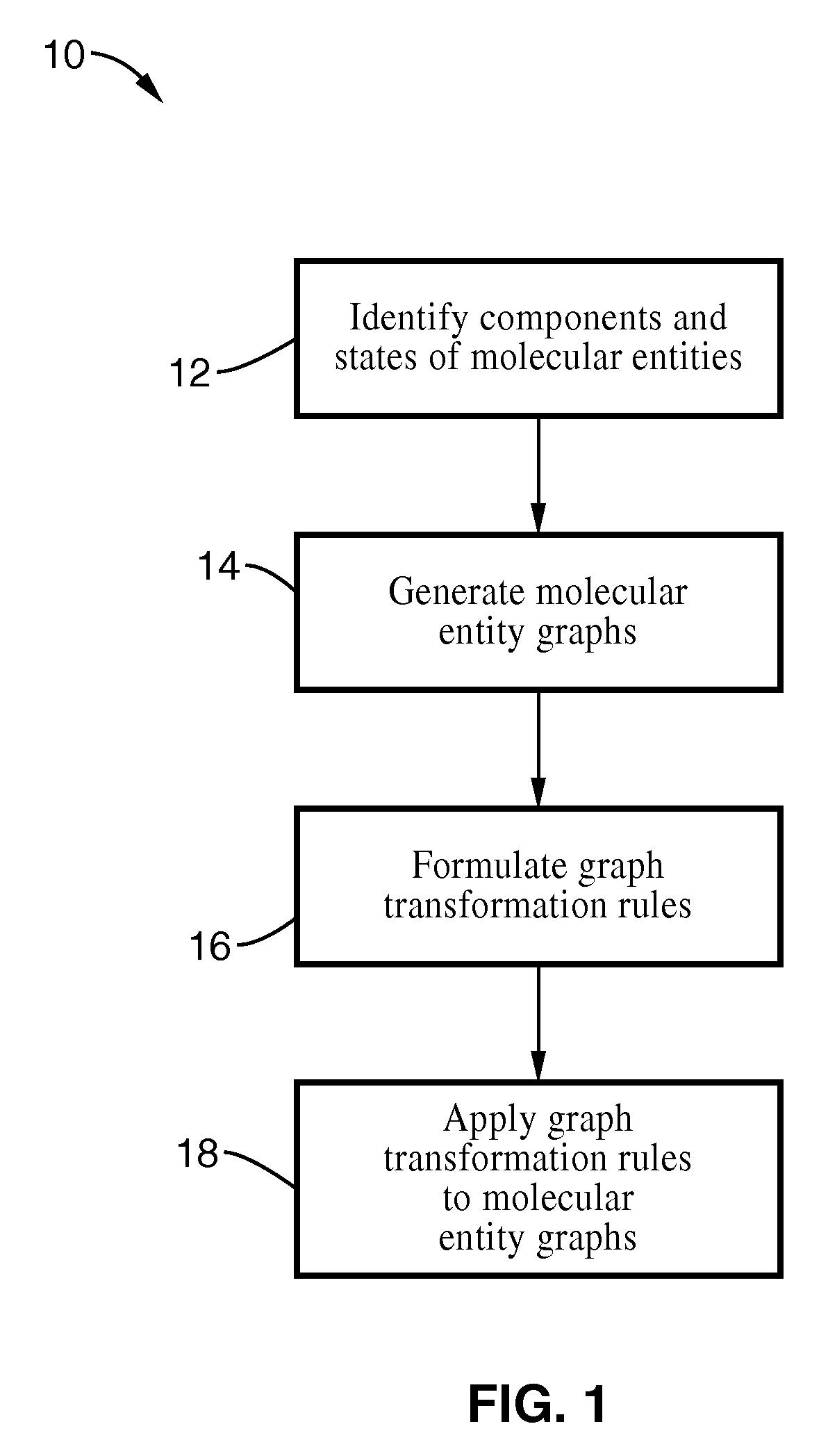

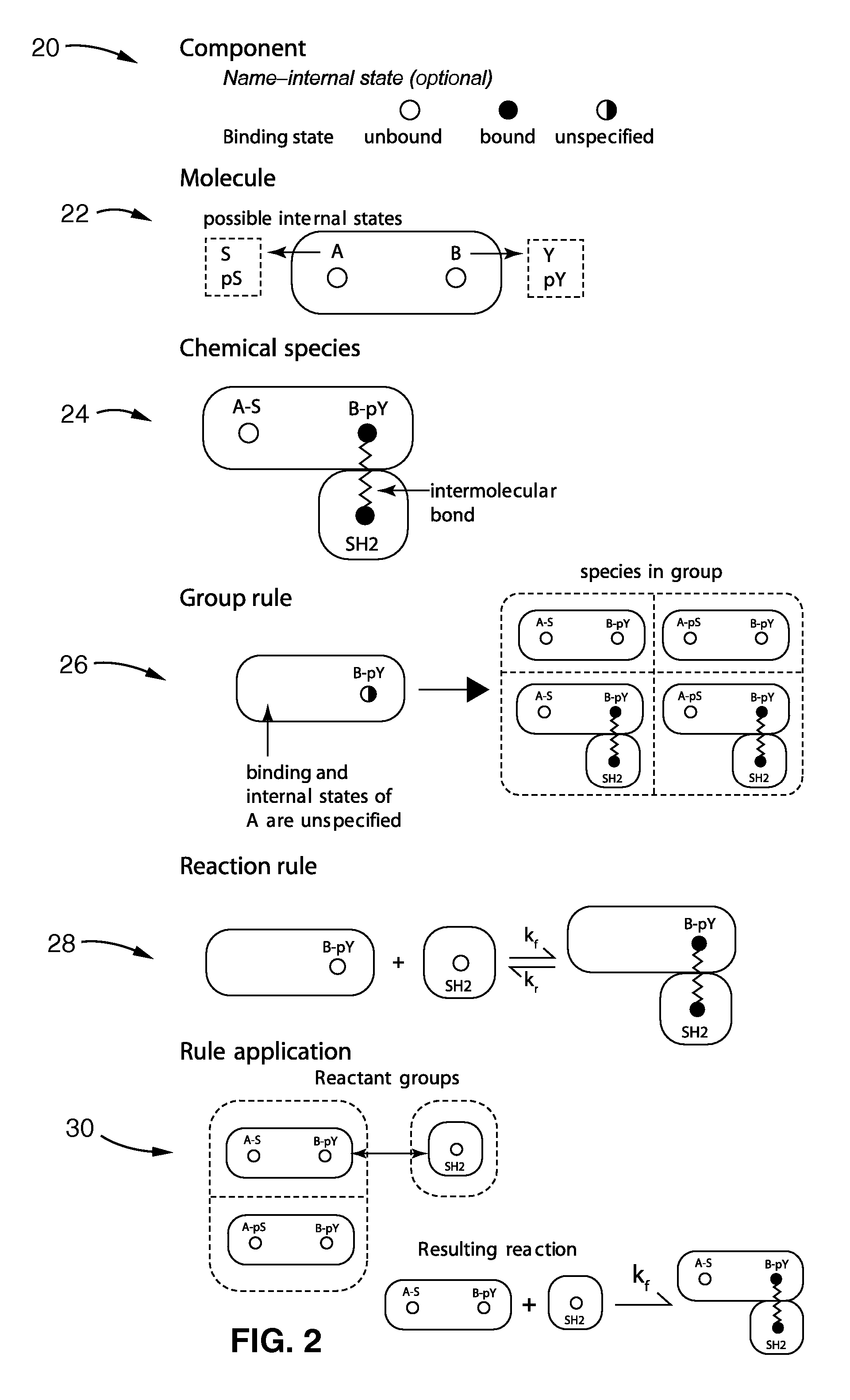

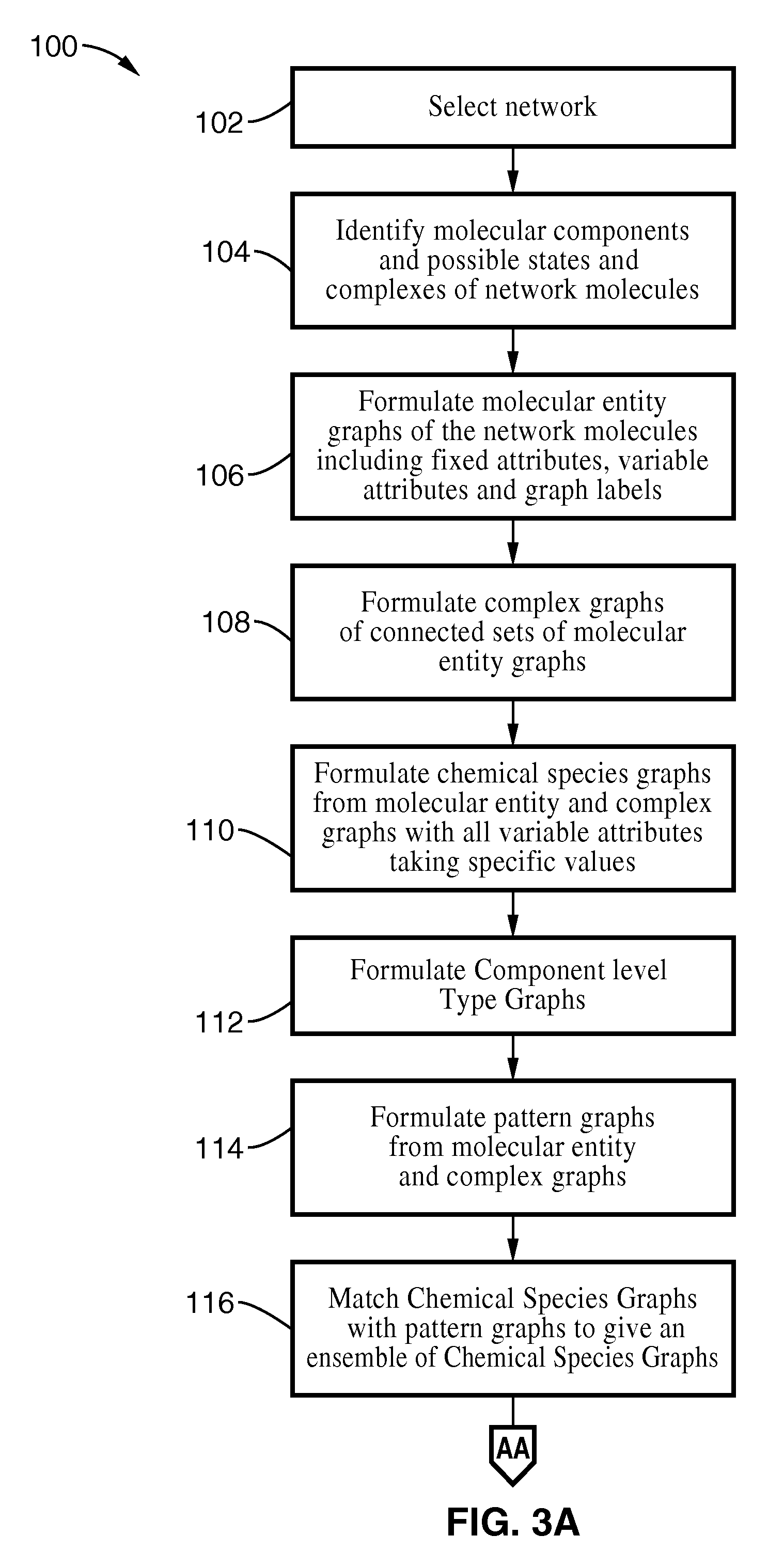

Graphical rule based modeling of biochemical networks

InactiveUS20070212719A1Accurate predictionMicrobiological testing/measurementChemical processes analysis/designGraph rewritingReaction rule

Formalized graphical reaction rules and conventions accounting for chemical states and binding or reaction states are provided for modeling complex biological systems such as signal transduction pathways. A system model is derived by defining typed attributed graphs which delimit molecular entities and their possible states. Graph transformation rules defining a class of potential reactions are defined and applied to the graphs and all new graphs that subsequently arise as a result of graph transformation. In one embodiment, a model is generated through the use of graph-rewriting rules which are associated with rate laws and applied iteratively to a seed set of chemical species graphs until a termination condition occurs.

Owner:LOS ALAMOS NATIONAL SECURITY

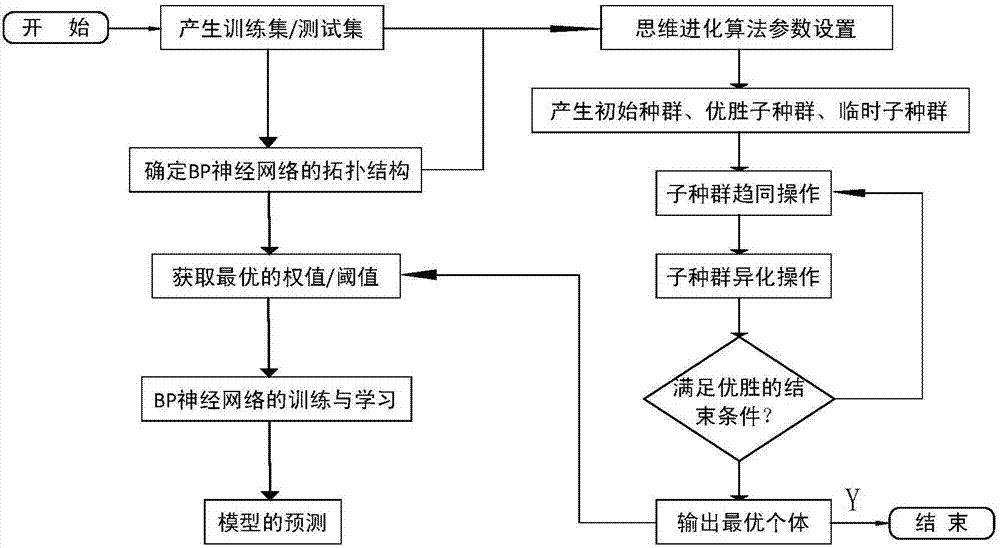

Method for establishing DO prediction model based on optimized BP neural network

ActiveCN107358021AImprove performanceHigh precisionChemical processes analysis/designNeural architecturesNetwork modelSewage treatment

The invention discloses a method for establishing a DO prediction model based on an optimized BP neural network. The method comprises following steps: variables are selected on the basis of predicting aeration tank DO; data is pretreated; an initial prediction model of the aeration tank DO is established; and modeling data is used for training network models to obtain an initially built DO prediction model and then the model prediction effect is analyzed; parameter and structure optimizations on the initially built DO prediction model are performed one by one and then the initial weight and threshold of BP network are optimized by means of the mind evolutionary algorithm; after the optimized DO prediction model is obtained, the prediction precision and prediction performance of the optimized model are evaluated. The method improves the prediction accuracy of the time sequence data, improves the model performance to a certain extent and improves the prediction accuracy, and facilitates the implementation of the precise control of the aeration tank aeration in the sewage treatment plant.

Owner:广州博依特智能信息科技有限公司

Lead molecule cross-reaction prediction and optimization system

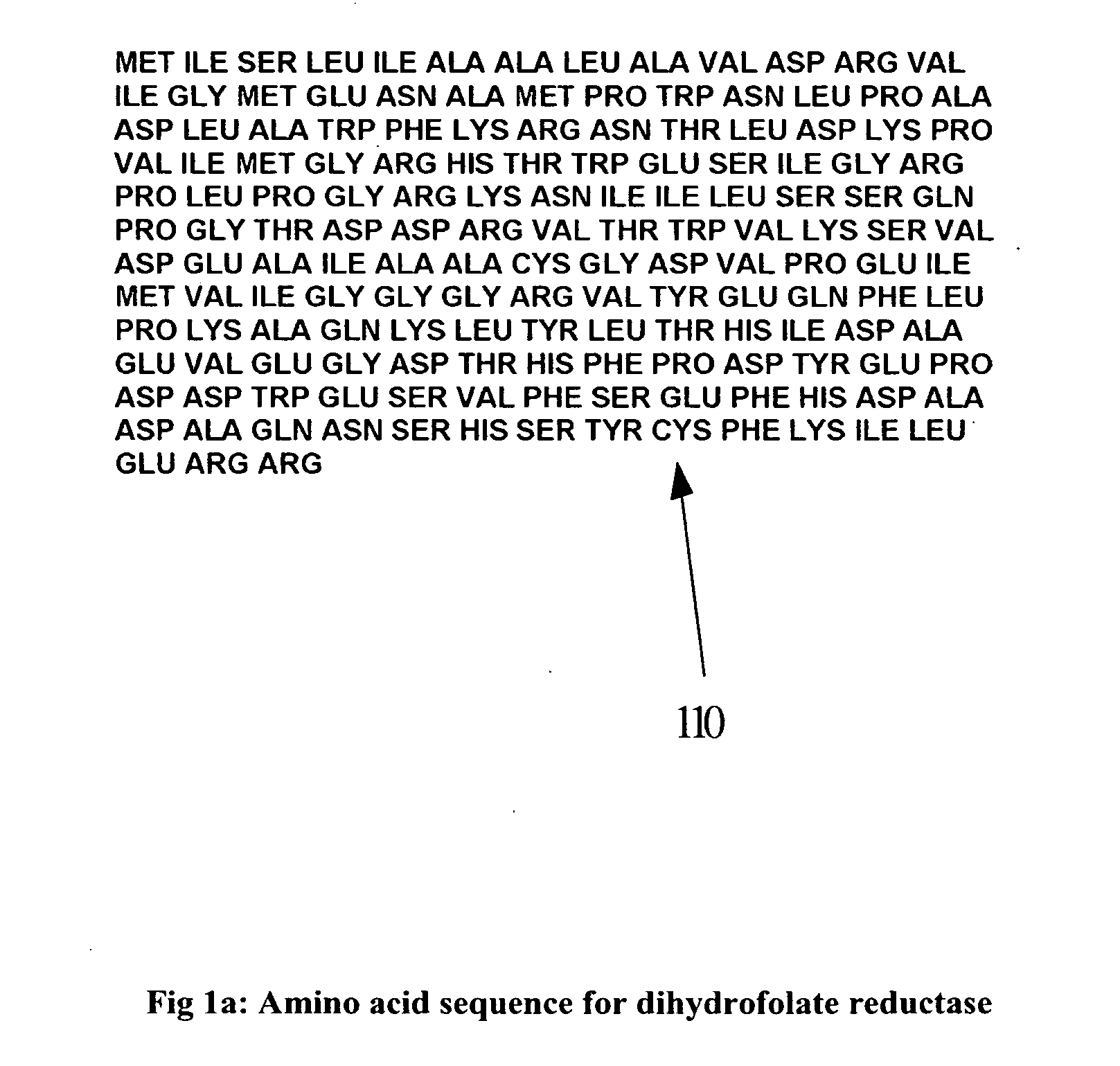

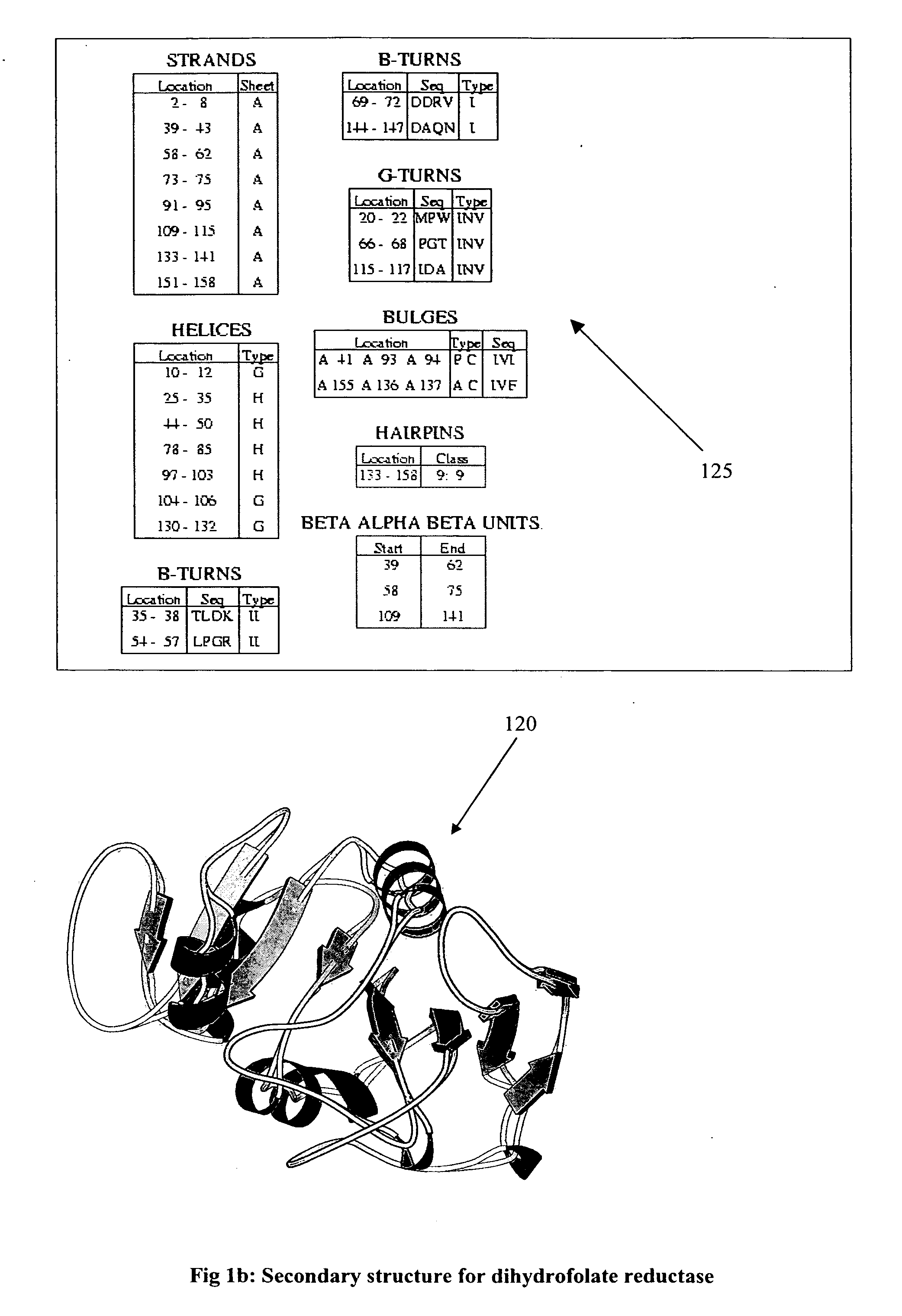

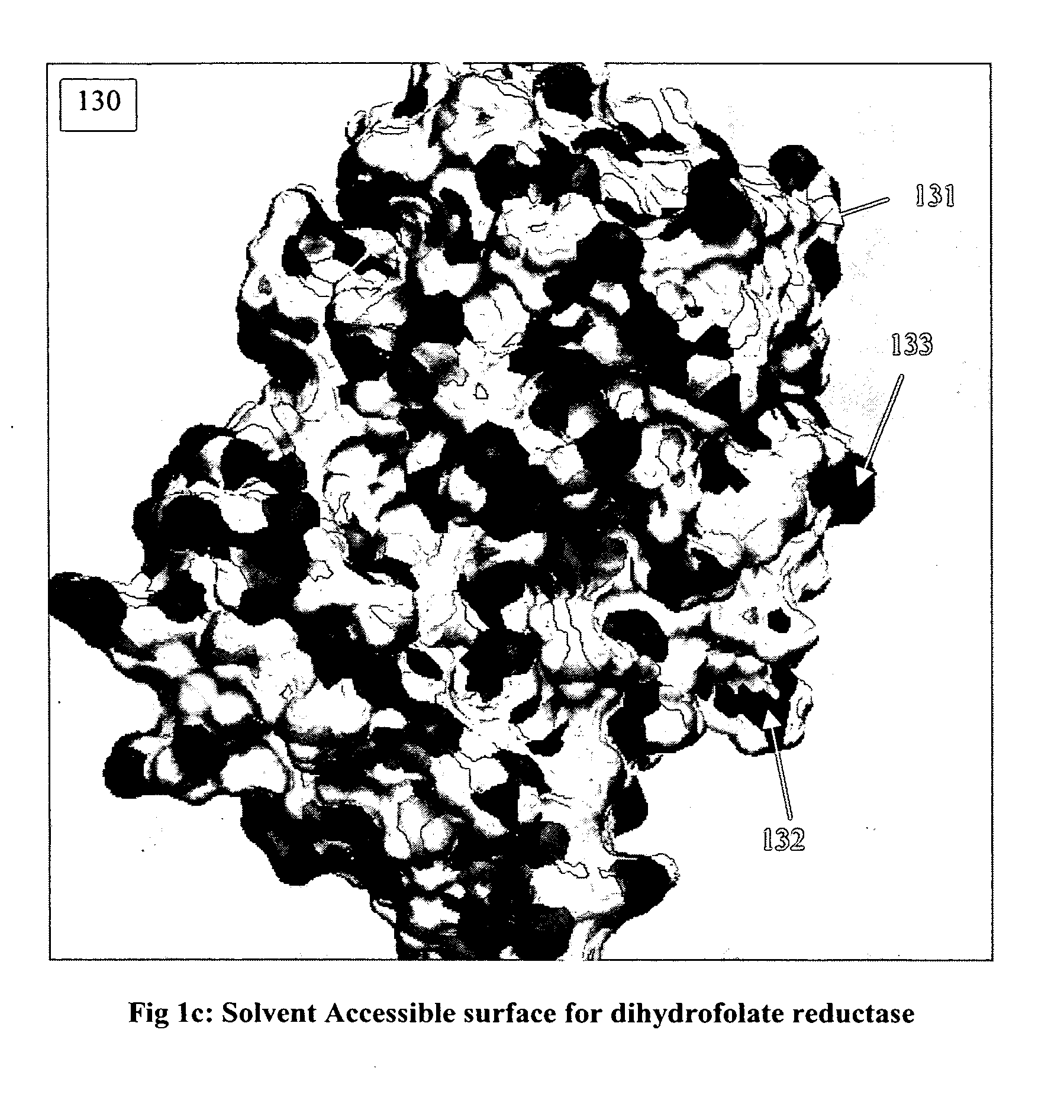

InactiveUS20050170379A1Improve featuresFacilitate further optimizationCompound screeningApoptosis detectionBiopolymerRe engineering

A method for the prediction of adverse cross-reactions between lead candidate biomolecules and potential reactant molecules, often biopolymers, is described. In a computational system, reactions are modeled within a suitable environment, in order to determine a reaction profile between a lead candidate molecule and a potential reactant molecule. A risk assessment is then generated for each lead based on a plurality of reaction profiles for the lead with respect to a plurality of potential reactant molecules. The method includes provisions for redesign and optimization of the lead candidate, possibly iterative in nature, in order to avoid predicted adverse cross-reactions.

Owner:VERSEON INT CORP

Systems, Methods and Computer Program Products for Determining Parameters for Chemical Synthesis

InactiveUS20080015837A1Facilitate entrySampled-variable control systemsDrawing from basic elementsChemical synthesisGraphics

The database is populated with target chemicals, corresponding listings of reagent chemicals, corresponding listings of equipment and corresponding listings of procedures. The database is then searched in response to user identification of a target chemical. In response, a listing is displayed of reagent chemicals that are used to synthesize the target chemical, equipment that is used to synthesize the target chemical, and a procedure that is used to synthesize the target chemical by reacting the reagent chemicals in the equipment according to the procedure. An icon-based reaction editor and / or context-sensitive Boolean query option generators may be provided. A reaction template may be used to perform predictive chemistry. A reaction relay may be used to graphically display related chemicals and procedures using a hub and spoke arrangement.

Owner:DASSAULT SYST AMERICAS CORP

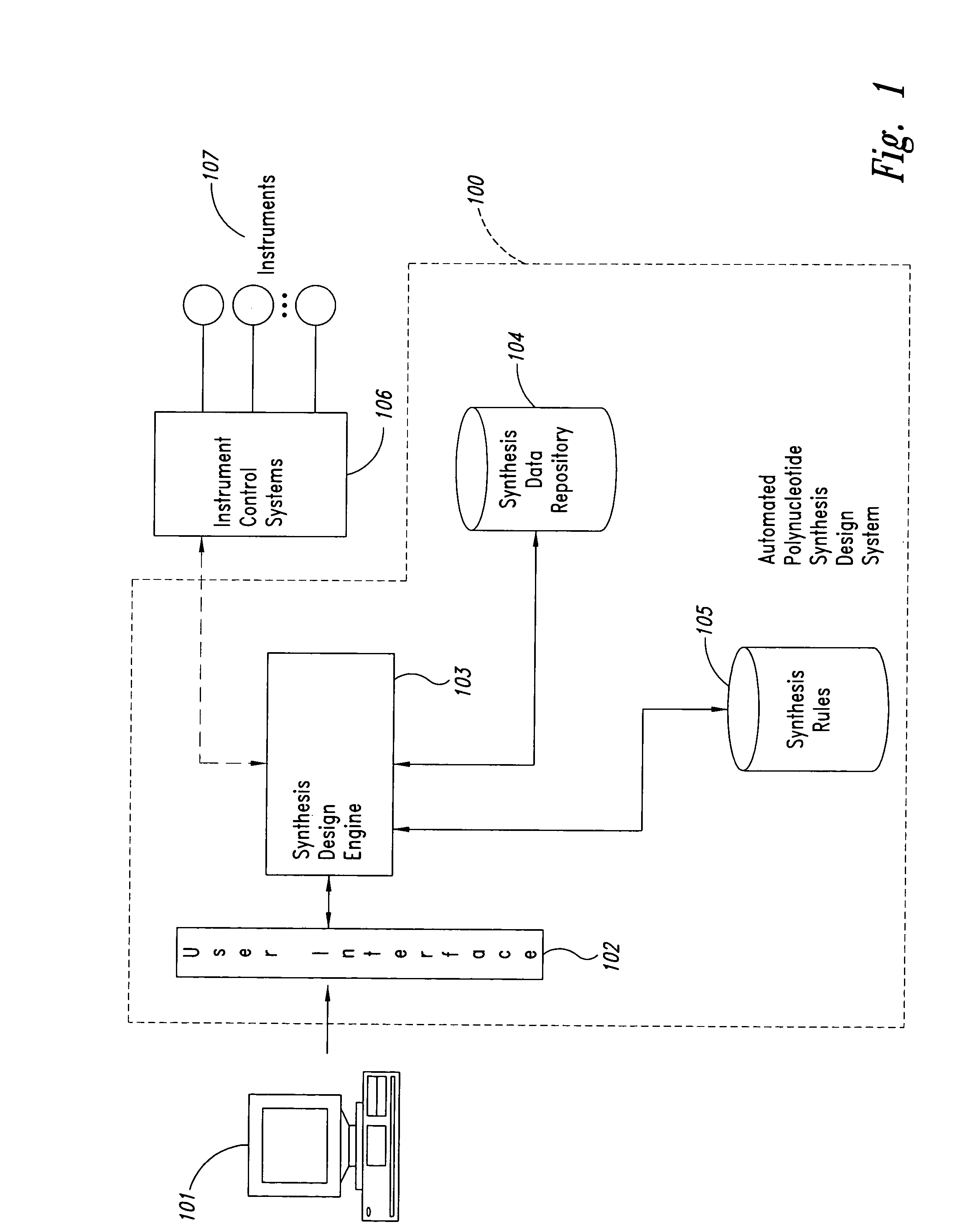

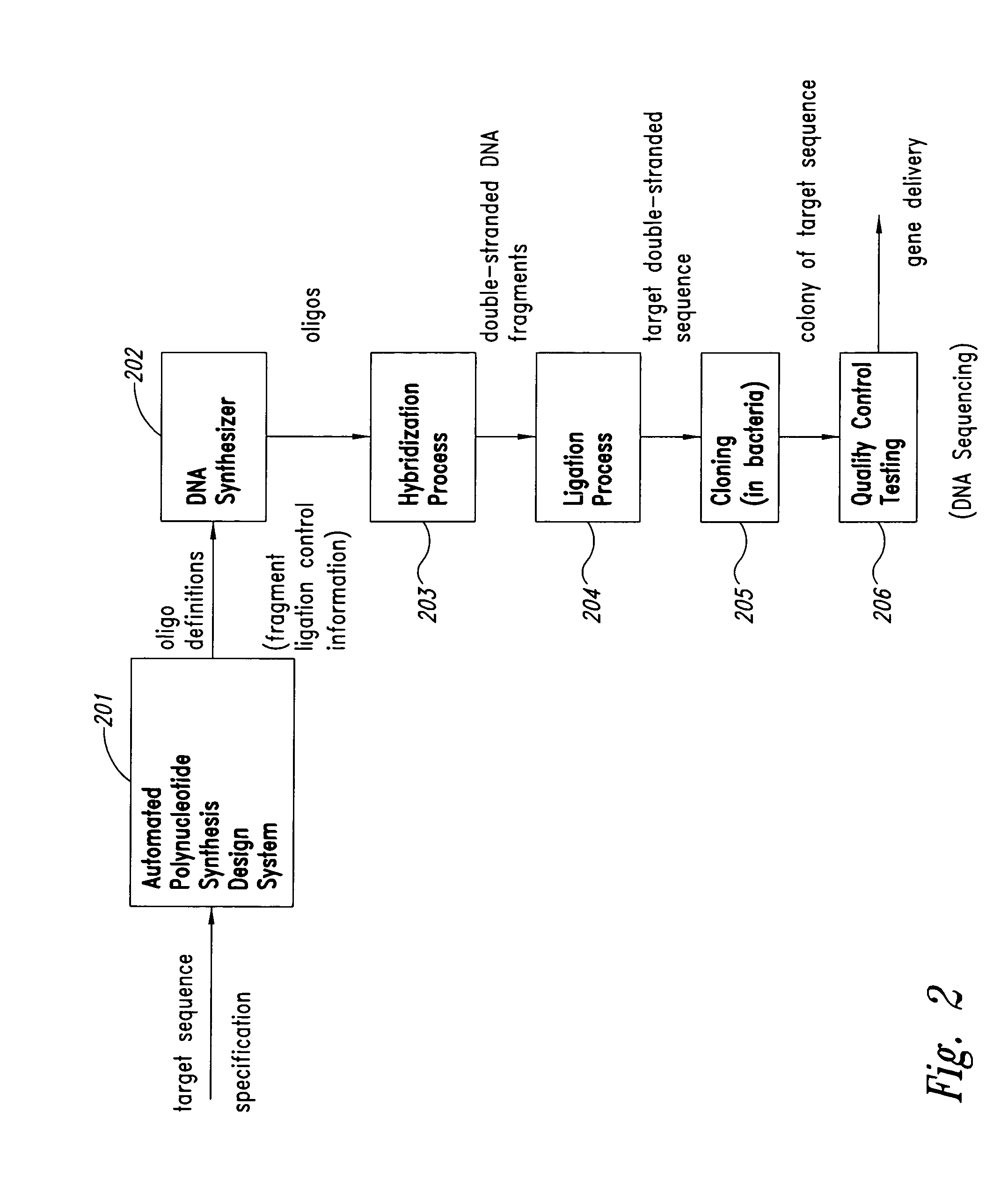

Method and system for polynucleotide synthesis

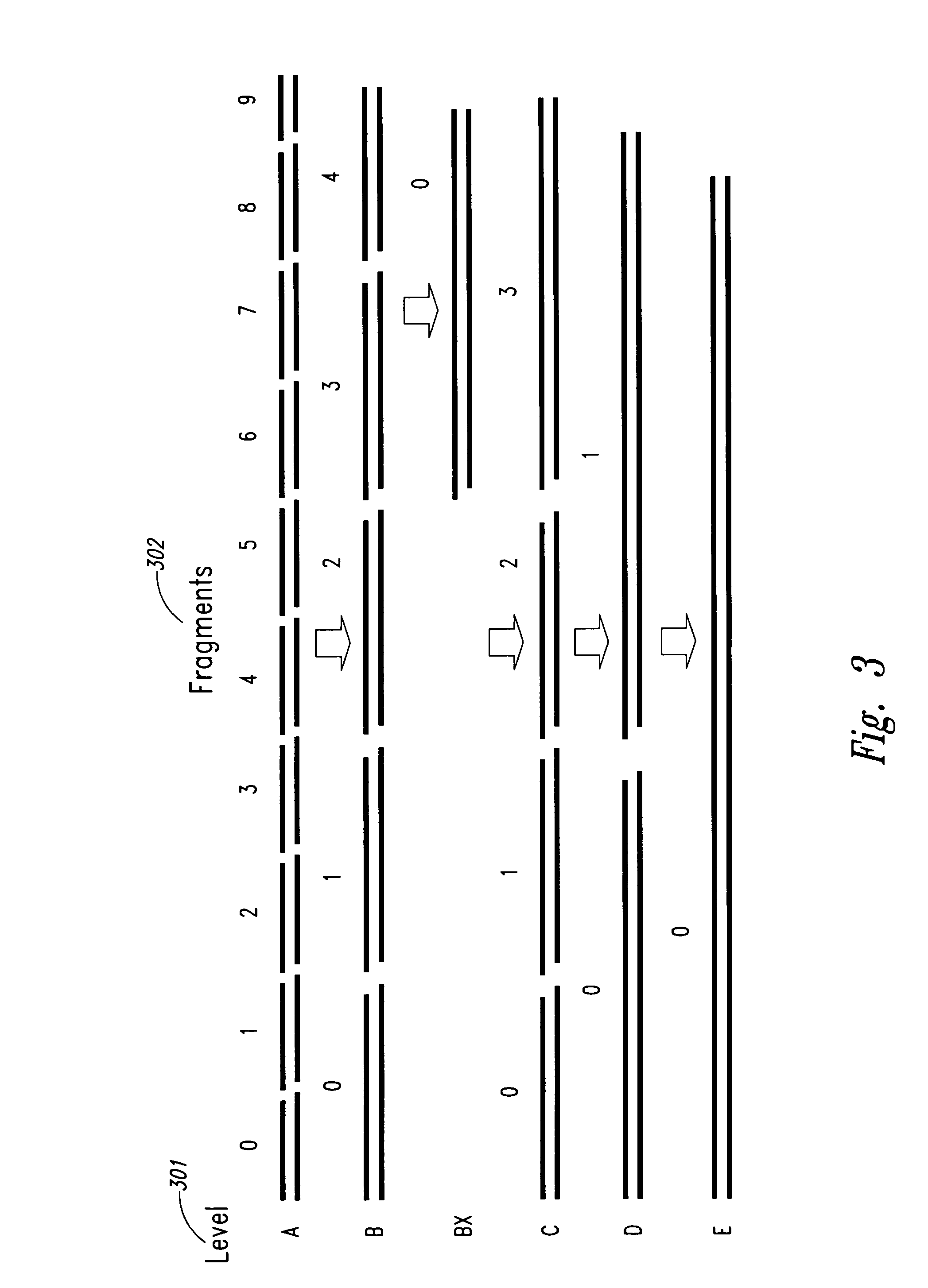

InactiveUS7164992B1Error minimizationMinimize incorrect joiningComputer controlRead-only memoriesSynthesis methodsTheoretical computer science

Methods and systems for automated polynucleotide synthesis design are provided. Example embodiments provide an Automated Polynucleotide Synthesis Design System (“APSDS”), which automatically generates a synthesis design for a designated target sequence specification. In one embodiment, the APSDS comprises a synthesis design engine, user interface support, a synthesis rules data repository, and a synthesis data repository. The APSDS automatically generates a synthesis design by receiving a target sequence(s) specification, generating a potential synthesis design, evaluating the potential design against synthesis rules, and when the evaluation indicates that the potential design is not successful according to the synthesis rules, adjusting the design to generate a new potential synthesis design and repeating the process of evaluating and adjusting until a potential synthesis design is found that satisfies the synthesis rules or until no solution is found.

Owner:BLUE HERON BIOTECH

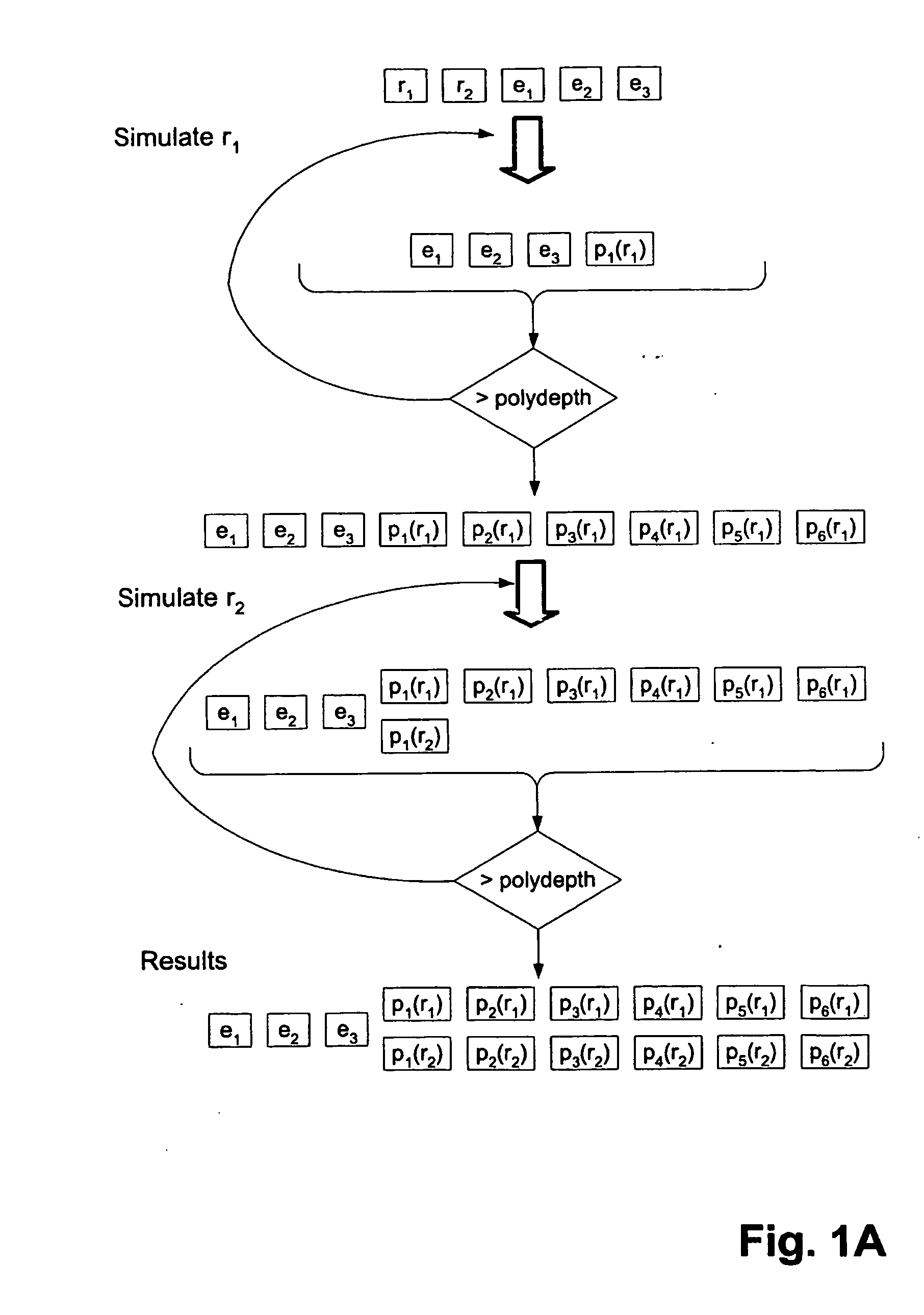

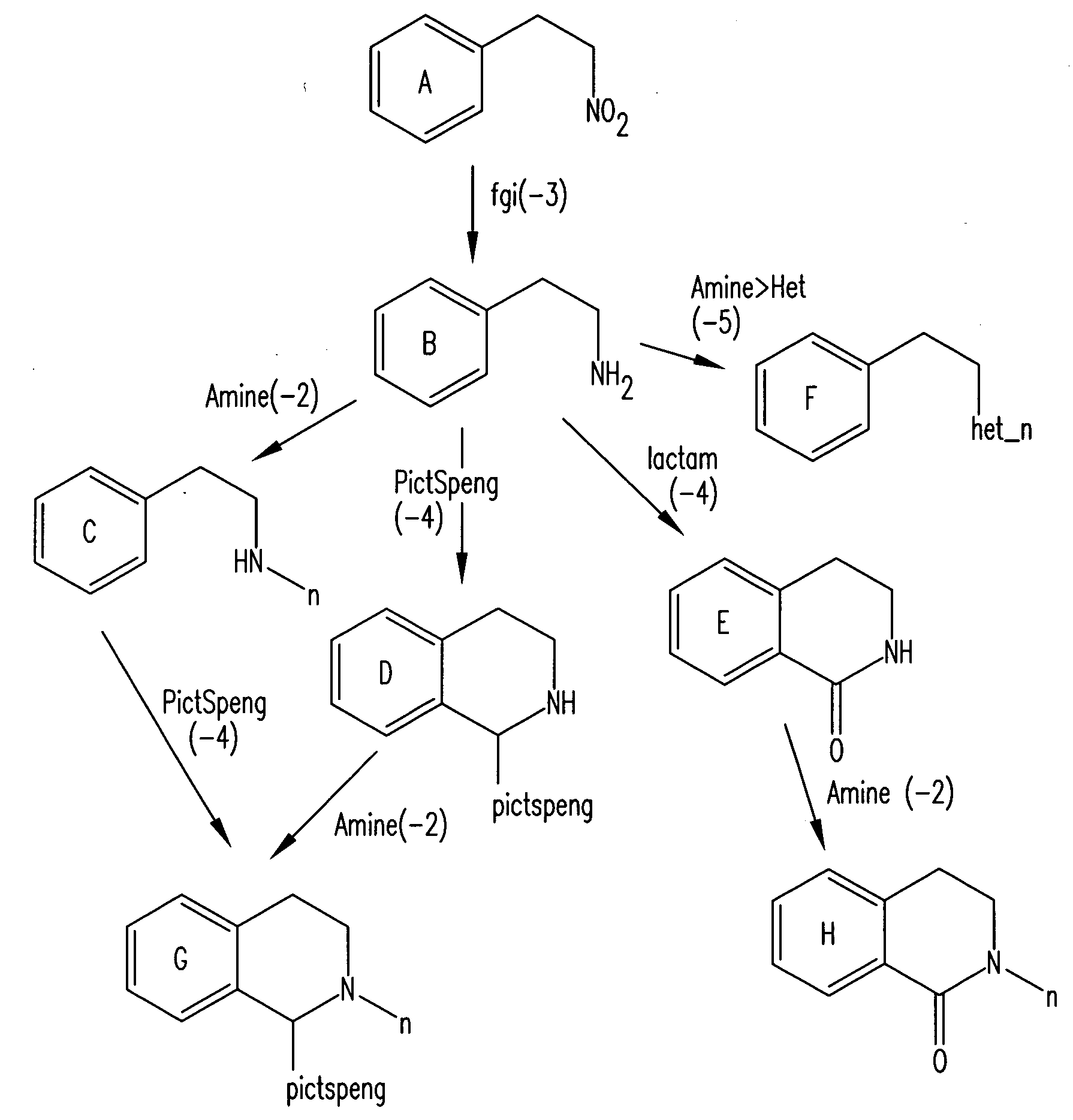

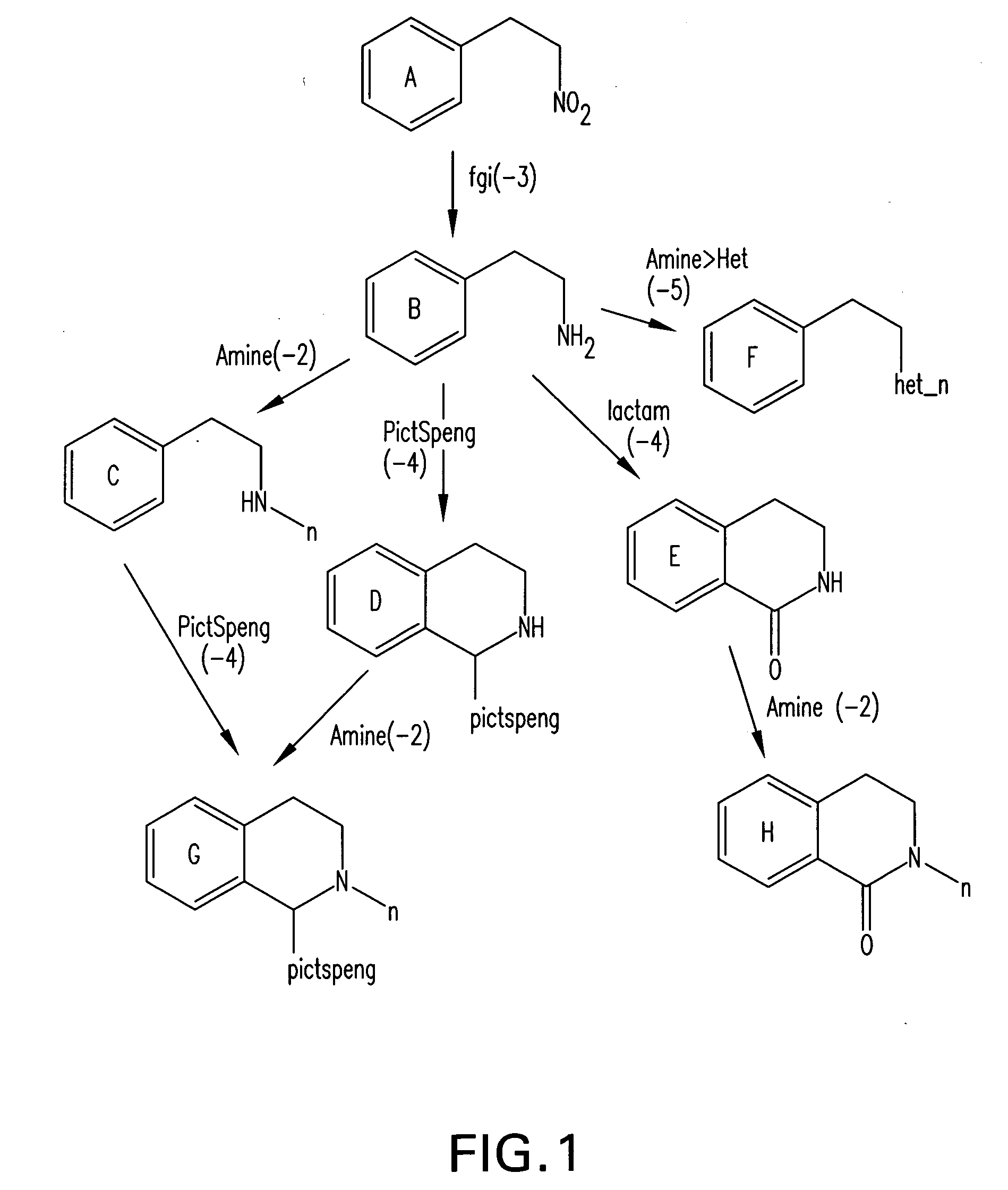

Forward synthetic synthon generation and its useto identify molecules similar in 3 dimensional shape to pharmaceutical lead compounds

ActiveUS20080172216A1Increase richnessIncrease diversityMolecular designChemical structure searchChemical reactionSynthesis methods

A forward synthetic method is described that utilizes recursive application of established organic chemical reactions to derive more complex synthons from available reagents than are available from the reagent synthons themselves. The product of each reaction serves as the starting point for further reactions thereby permitting the generation of multiple complex molecular structures. This synthon generation procedure typically yields 20 ? 30 new structures within the limits of easily accessible syntheses based upon each starting reagent. More complex syntheses yield even more structures. The generated synthons are characterized with a molecular structural descriptor possessing a neighborhood property and can be further characterized with features. The synthons are searched for three dimensional shape and feature similarity to molecular fragments derived from query molecules, typically pharmacological molecules of interest. Identified synthons can be assembled into molecules possessing the same three dimensional shape and likely activity as the molecule of interest.

Owner:CRAMER RICHARD D +1

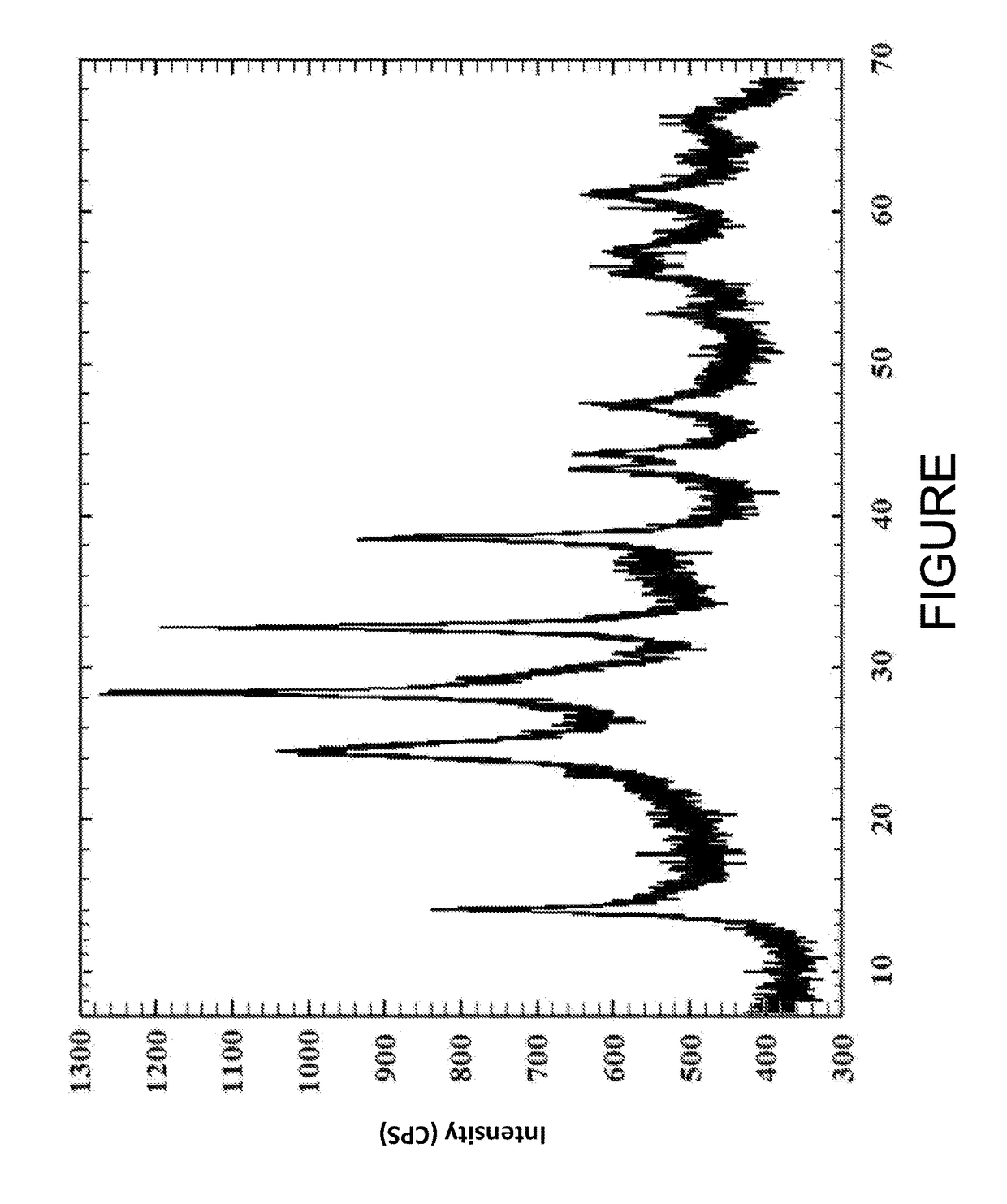

Crystalline transition metal tungstate

ActiveUS20190060882A1Chemical processes analysis/designCheminformatics programming languagesHydrodesulfurizationTungstate

A hydroprocessing catalyst has been developed. The catalyst is a crystalline transition metal tungstate material or metal sulfides derived therefrom, or both. The hydroprocessing using the crystalline transition metal tungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

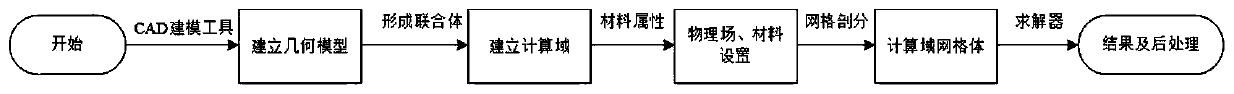

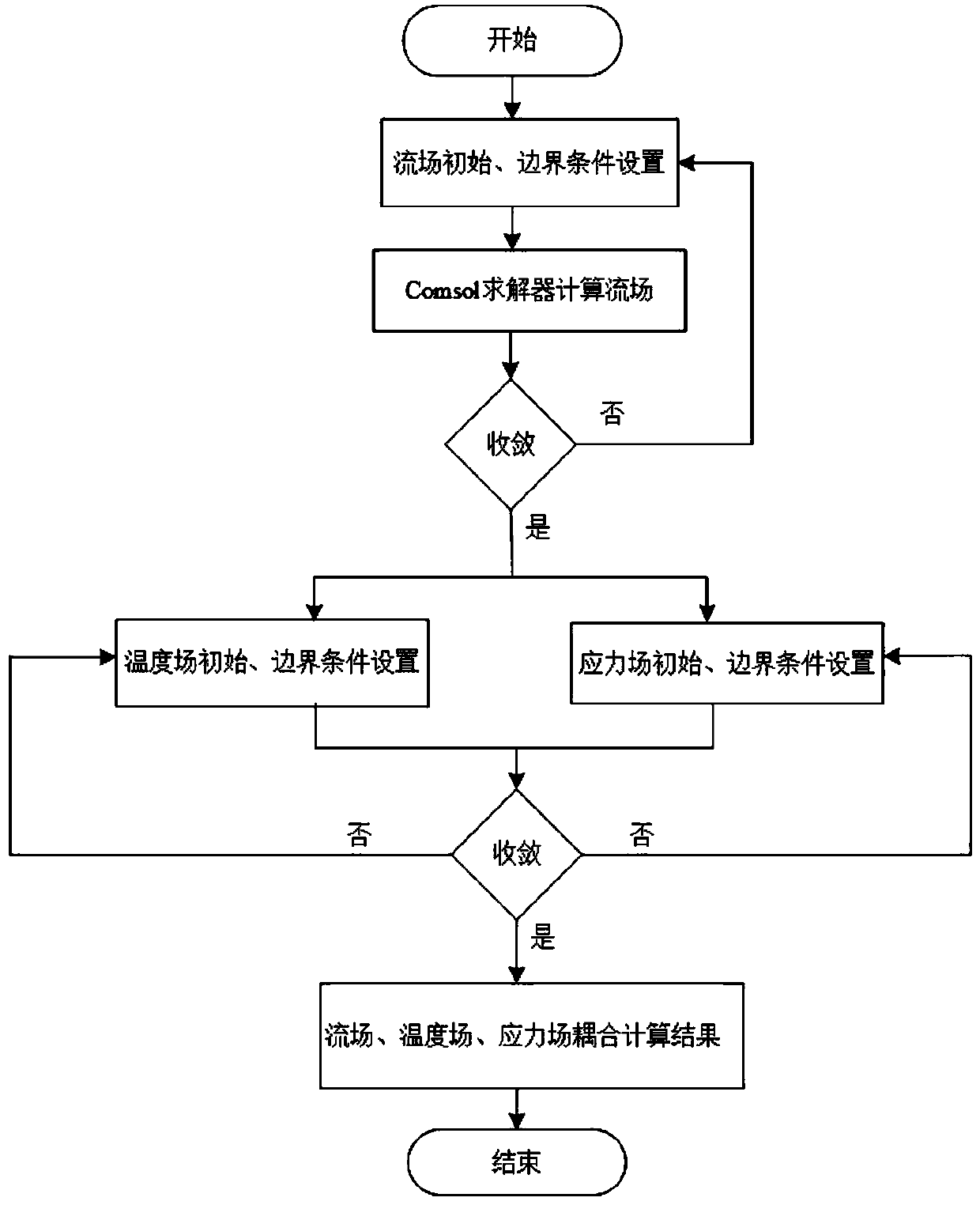

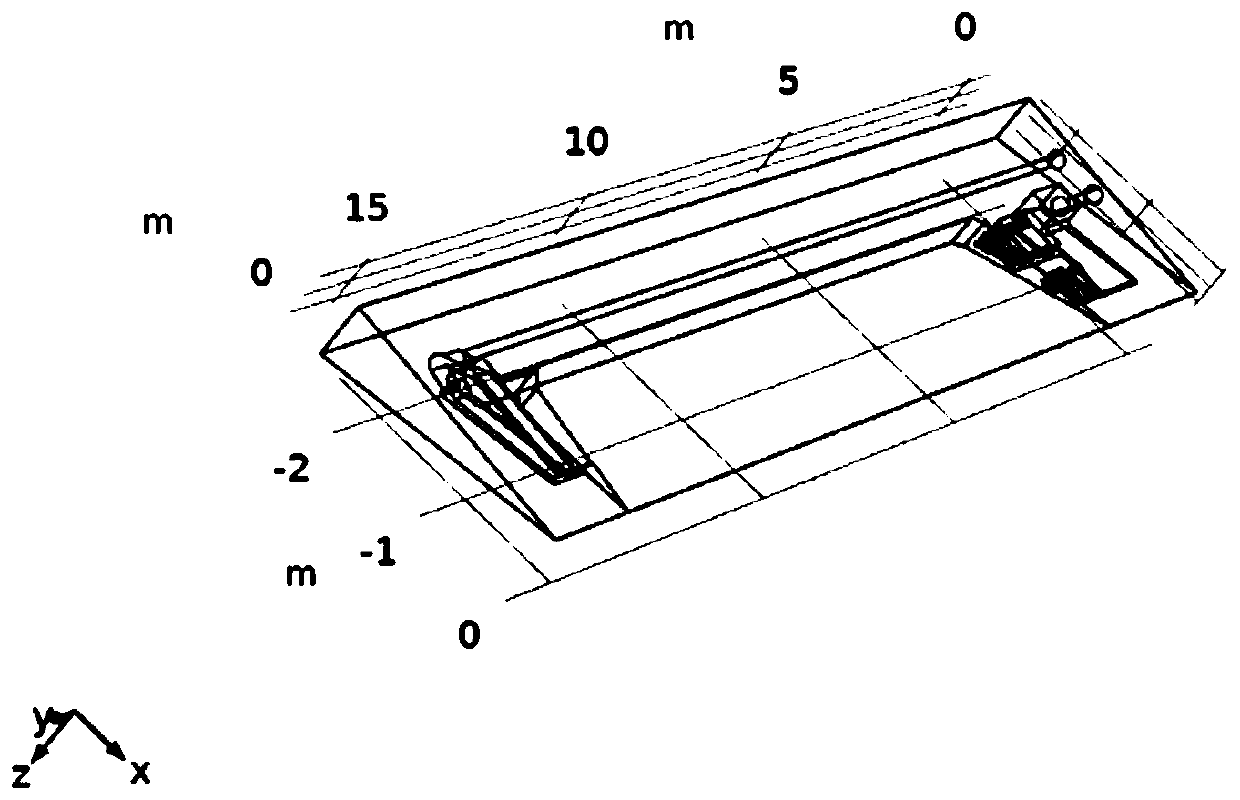

Reactor primary loop coolant flow field, temperature field and stress field coupling calculation method

ActiveCN111261232ASafe and stable operationSolve coupled numerical simulation calculation problemsNuclear energy generationChemical processes analysis/designAnalogue computationCoolant flow

The invention discloses a reactor primary loop coolant flow field, temperature field and stress field coupling calculation method. The method comprises the following steps: 1) constructing a high-temperature gas cooled reactor core model and a steam generator model with the same size as actual equipment; 2) establishing a computational domain 1, a computational domain 2 and a computational domain3; 3) setting equipment materials and fluid domains in the computational domain 1, the computational domain 2 and the computational domain 3; 4) setting areas and boundary layers of a flow field, a temperature field and a stress field; 5) meshing the flow field, the temperature field and the stress field; 6) adopting a k-epsilon turbulence model in the computational domain 1 and the computationaldomain 3, and adopting a porous medium model in the computational domain 2; 7) obtaining flow field, temperature field and stress field distribution results of the computational domain 1, the computational domain 2 and the computational domain 3, and 8) obtaining optimal operation parameter configuration of the high-temperature gas cooled reactor at different power levels. The method can realize coupling numerical simulation calculation of the coolant flow field, the temperature field and the stress field of a reactor primary loop.

Owner:XIAN THERMAL POWER RES INST CO LTD

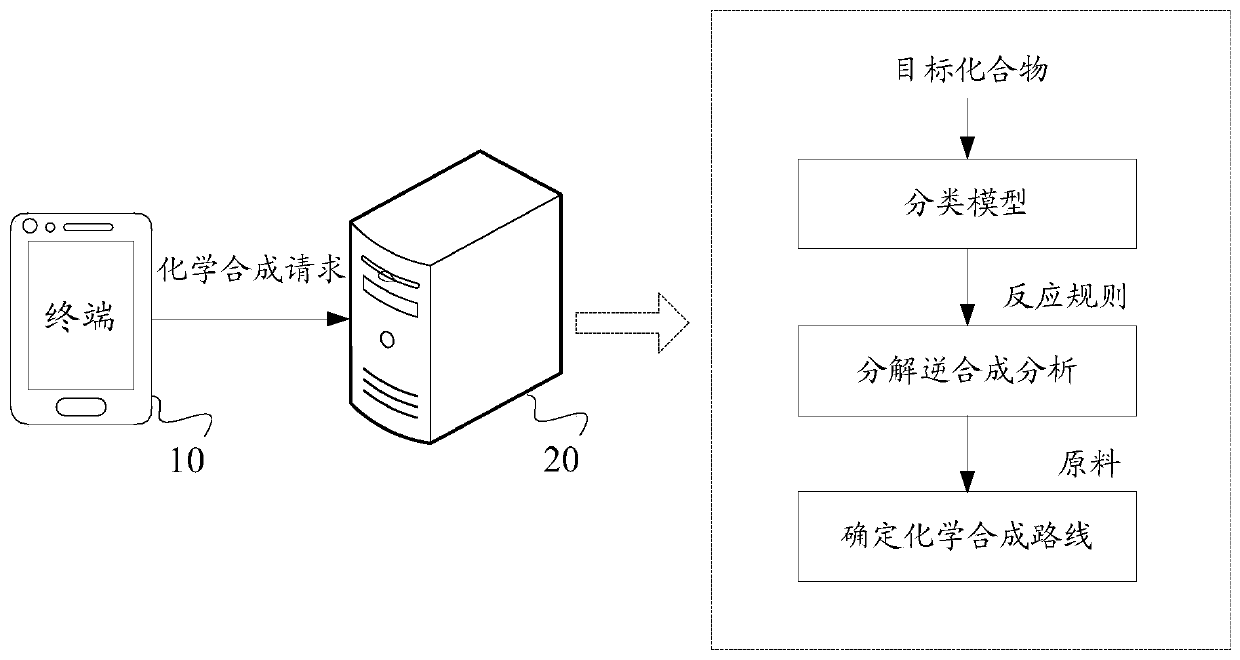

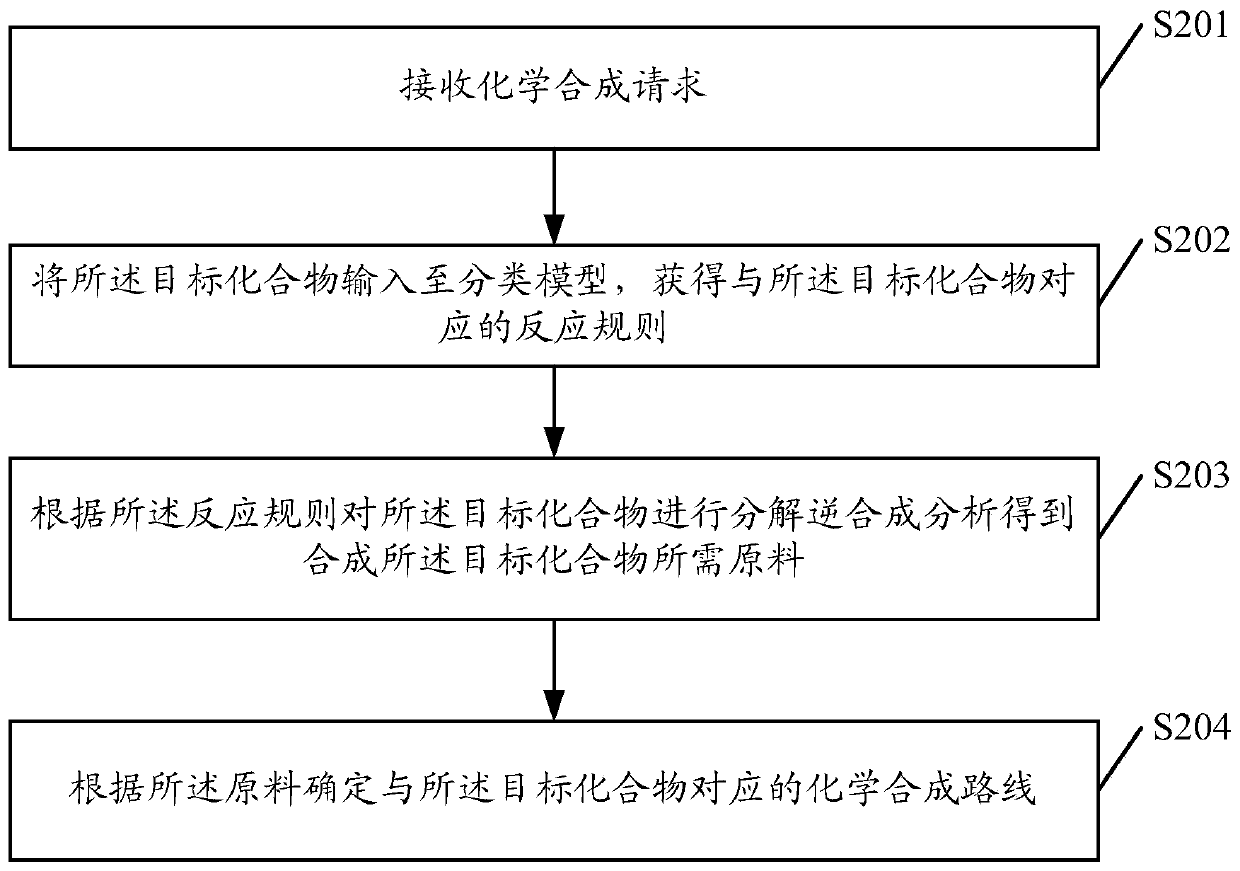

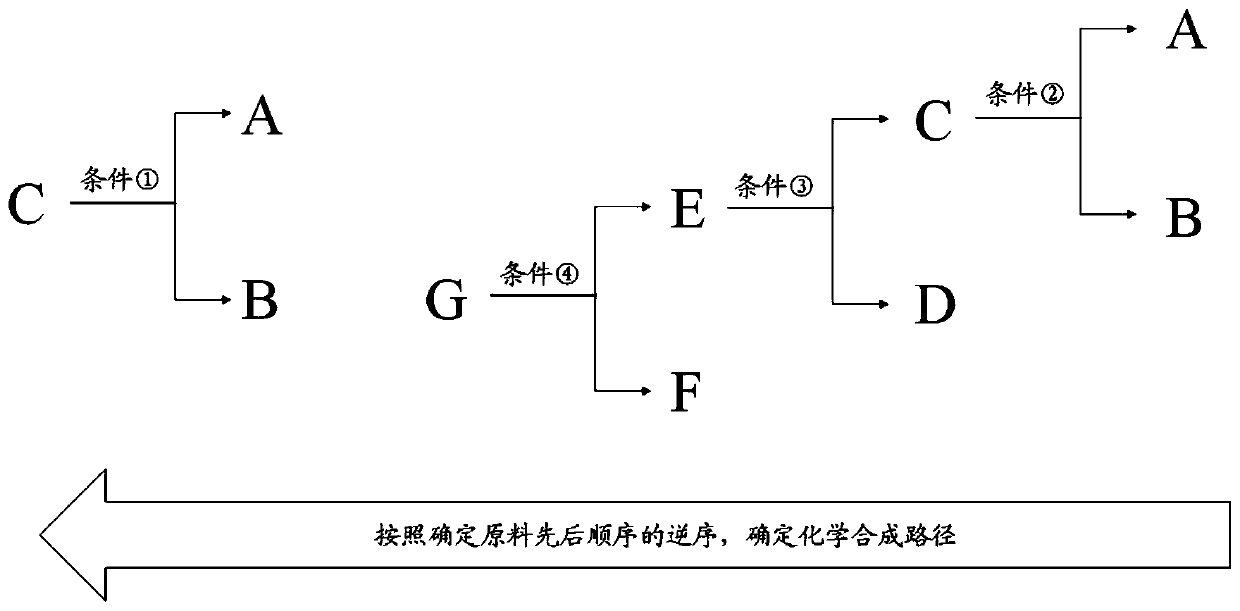

Method and device for determining chemical synthesis route

InactiveCN109872780ARealize automatic designImprove accuracyChemical processes analysis/designChemical machine learningChemical synthesisReaction rule

The invention discloses a method for determining a chemical synthesis route. The method includes the steps: receiving a chemical synthesis request for requesting a chemical synthesis route of a targetcompound; inputting the target compound to a classification model, and obtaining a reaction rule corresponding to the target compound, wherein the classification model is a machine learning model taking the compound as input and taking the reaction rule as the output; according to the reaction rule, performing decomposition inverse synthesis analysis on the target compound to obtain raw materialsrequired for synthesizing the target compound; and according to the raw materials, determining a chemical synthesis route corresponding to the target compound. The method realizes automatic design ofthe chemical synthesis route through the classification model, and the classification model has high accuracy and strong generalization ability, can be applied to the new reaction, and does not needto be trained again, thus improving the design efficiency of the chemical synthesis route. The present invention also discloses a training method, apparatus and device for a classification model and amedium.

Owner:北京深度制耀科技有限公司

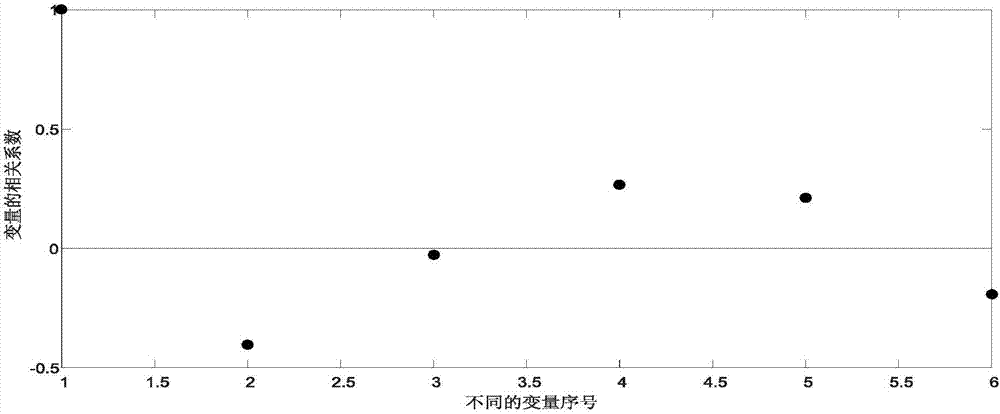

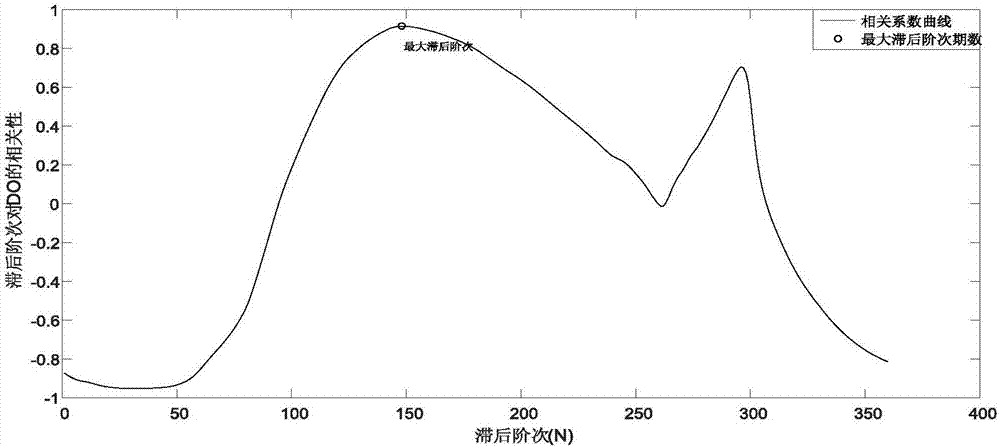

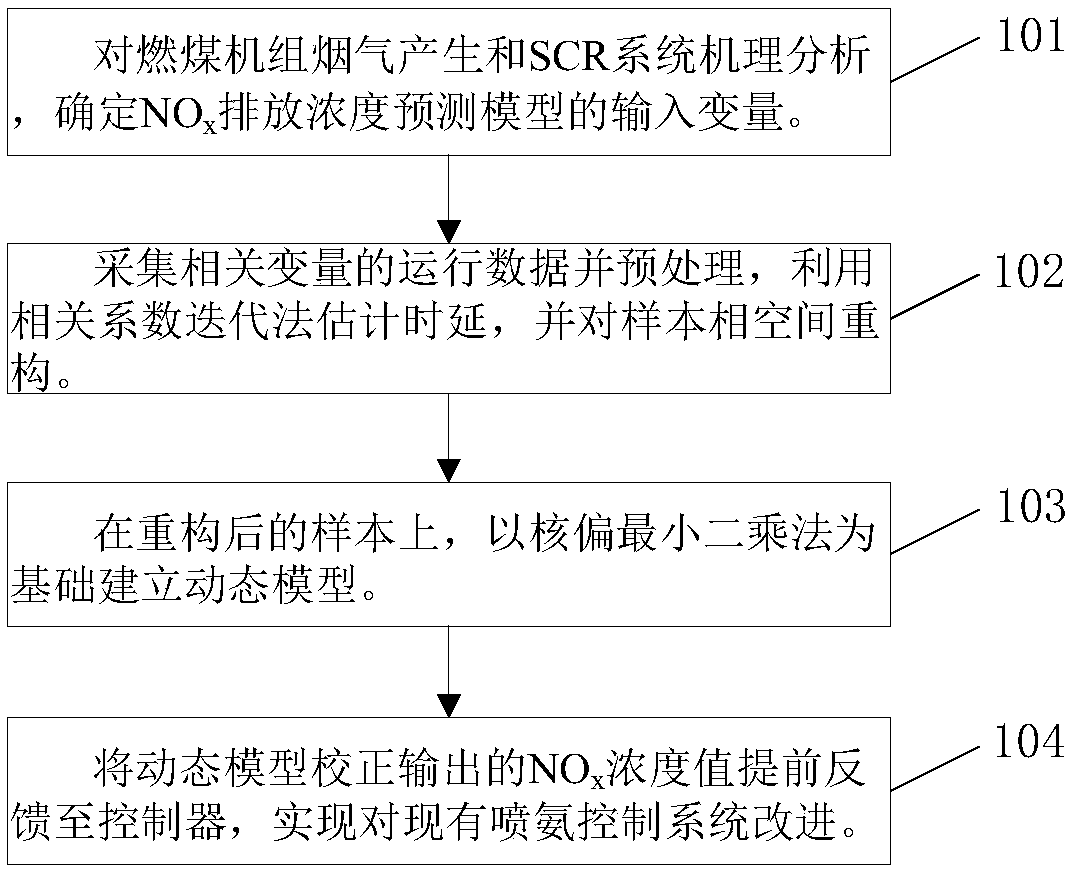

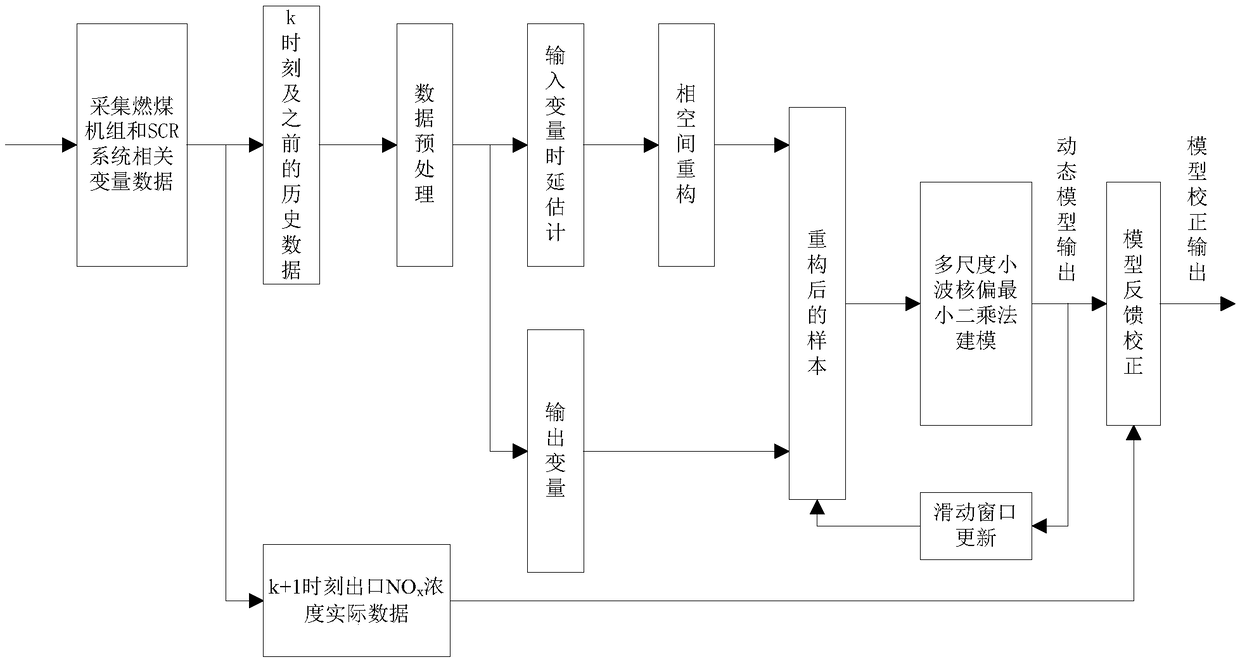

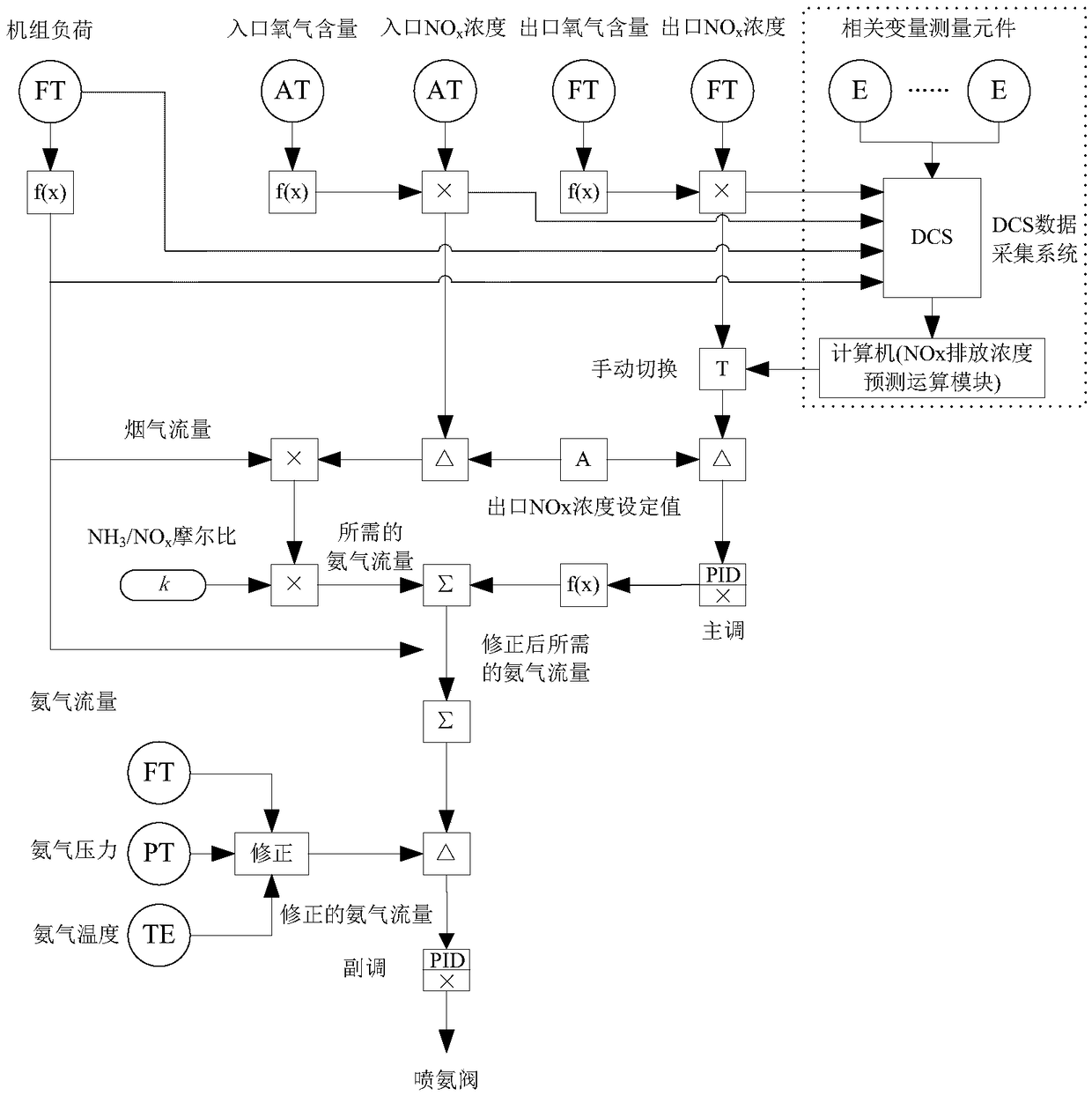

A method for predicting NOx emission concentration in SCR system based on time delay estimation

PendingCN109190848AEmission reductionImprove predictive performanceForecastingChemical processes analysis/designModel sampleTime delays

The invention discloses a method for predicting NOx emission concentration in a SCR system based on time delay prediction, which comprises the following steps: determining the input variables of a NOxemission concentration prediction model by analyzing the flue gas generation of a coal-fired unit and the mechanism of the SCR system; collecting and preprocessing the running data of correlation variables, estimating the time delay and reconstructing the sample phase space by using correlation coefficient iterative method; on the reconstructed samples, using the kernel partial least square method used to establish the dynamic model. The NOx concentration value of the dynamic model correction output is fed back to the controller in advance to improve the existing ammonia injection control system. The invention has the advantages that the prediction model comprehensively learns the relevant information of the NOx concentration at the outlet; the kernel partial least square method is used to improve the prediction ability. The NOx concentration at the outlet can be predicted in advance by reconstructing the phase space of the model sample. If there is a big difference between the modelsample and the set value, the model sample can be adjusted by ammonia injection in time, which has a guiding significance for reducing the pollutant emission and cost of coal-fired units.

Owner:DATANG ENVIRONMENT IND GRP

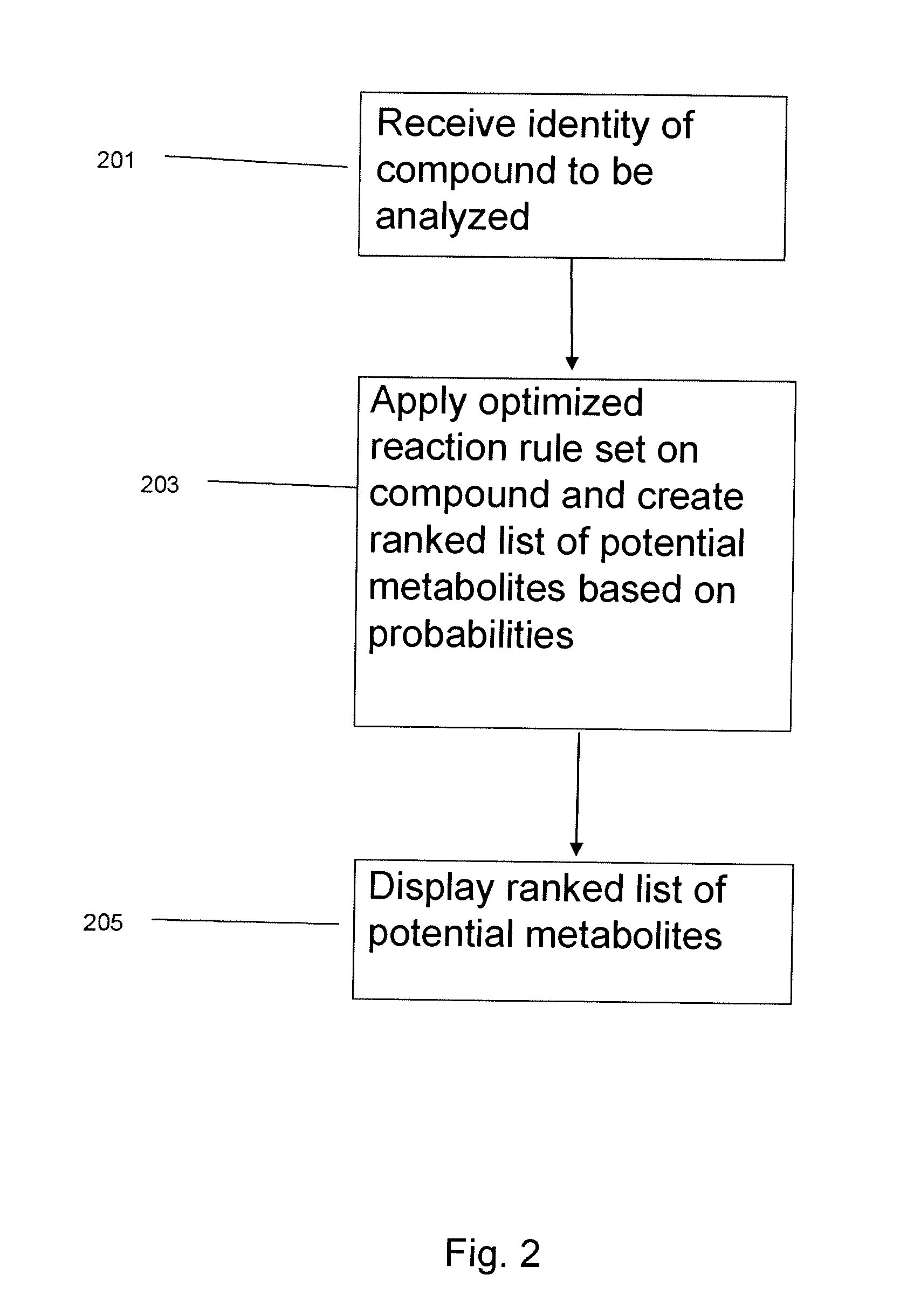

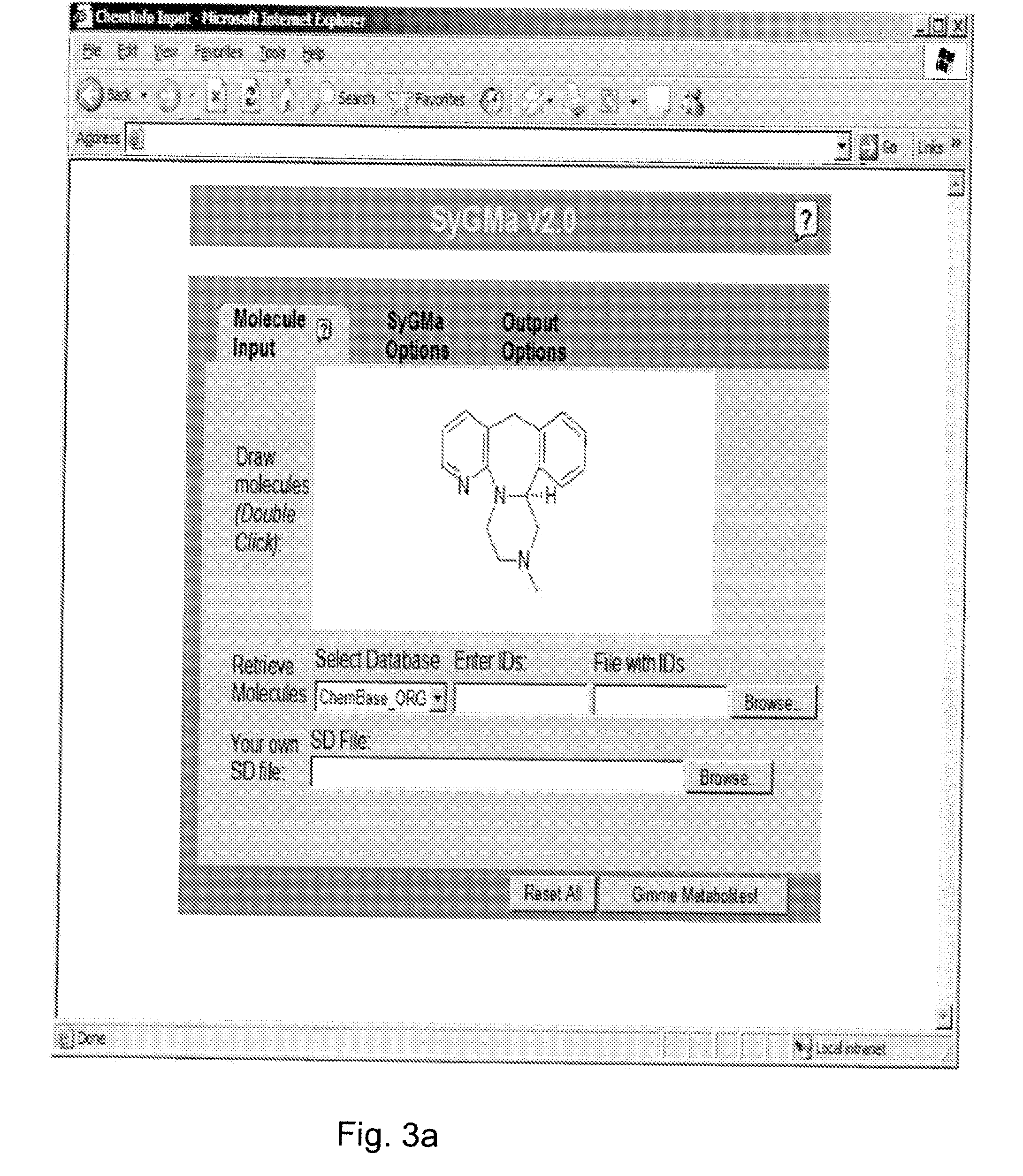

System and method to identify the metabolites of a drug

InactiveUS20080120041A1Improve efficiencyImprove accuracyMolecular entity identificationChemical processes analysis/designReaction ruleMetabolite

The invention provides for a method for predicting potential metabolites for a compound, comprising the steps of receiving a target compound from a user applying a set of optimized reaction rules to said target compound to generate a list of potential metabolites and calculating a probability score for each product compound on said list of potential metabolites. The reaction set is optimized by starting from a starting set of reaction rules and replacing at least one reaction rule for a reaction center in said starting set of reaction rules by one, or preferably two or more new rules, which are defined to apply to a reaction of said reaction center, but now specifying or differentiating based on the structural environments of said reaction center, if at least one of said new rules has a higher probability score than the replaced reaction rule when the starting set of reaction rules and the optimized set of reaction rules are both tested with a database of known metabolites of compounds.

Owner:NV ORGANON

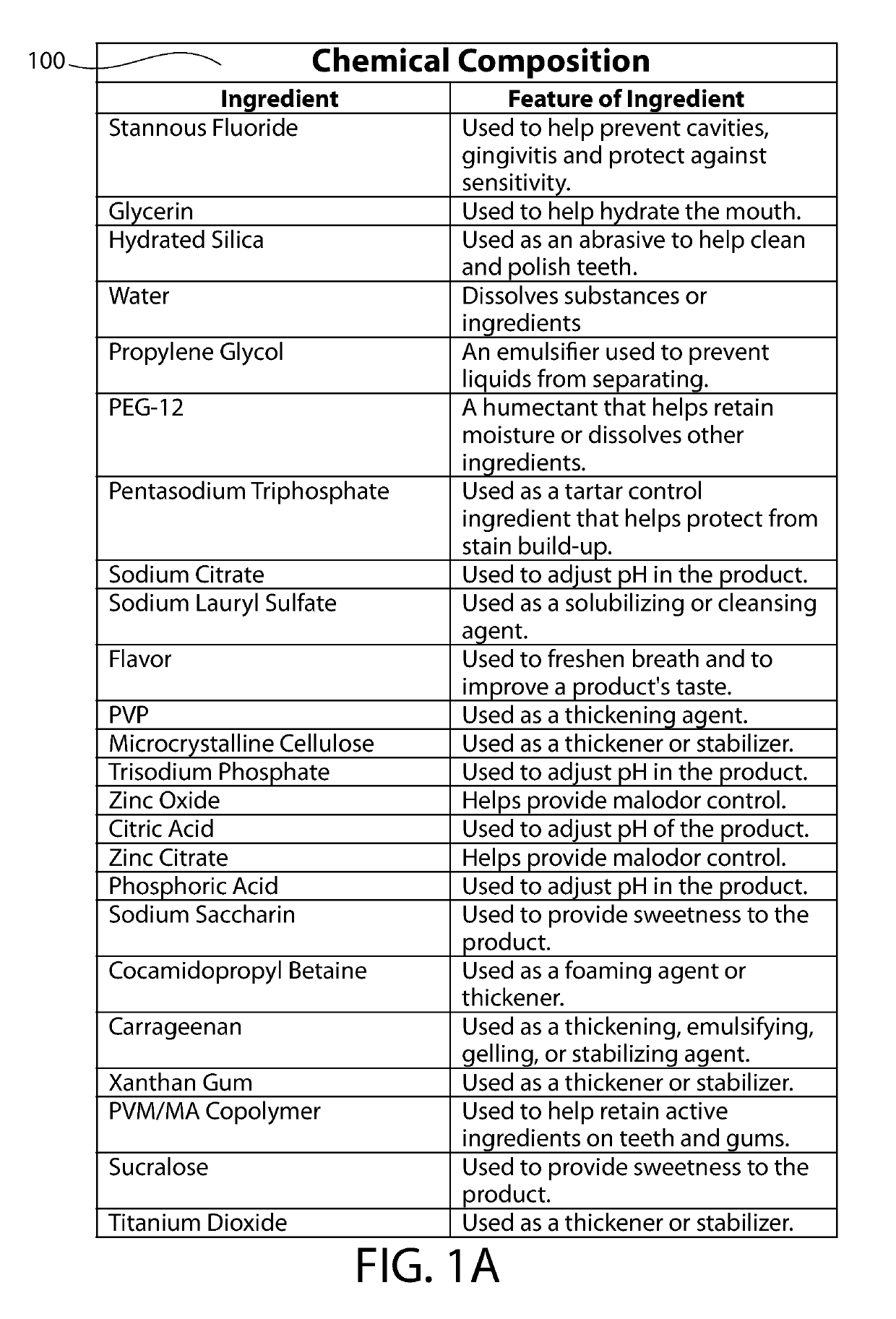

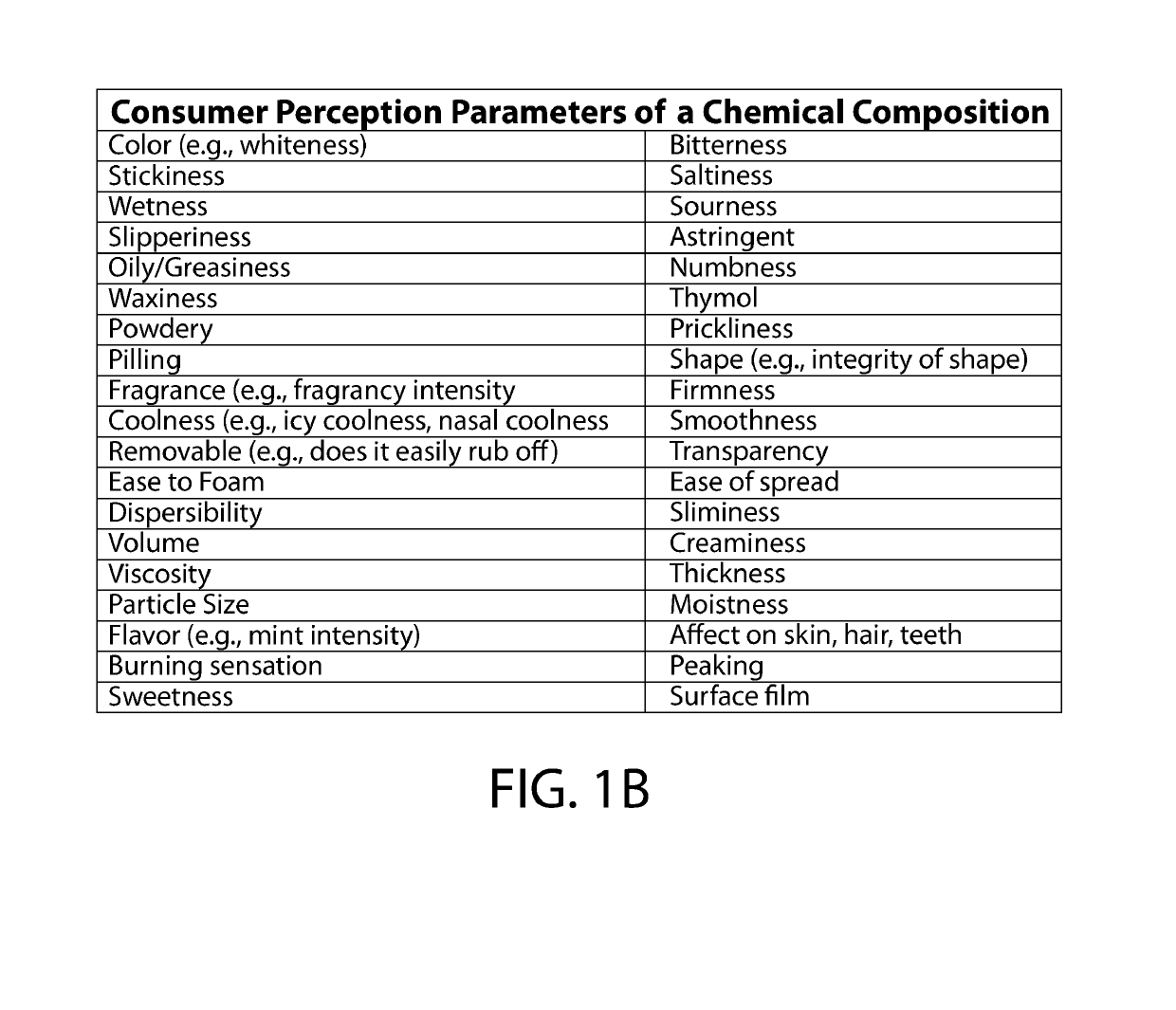

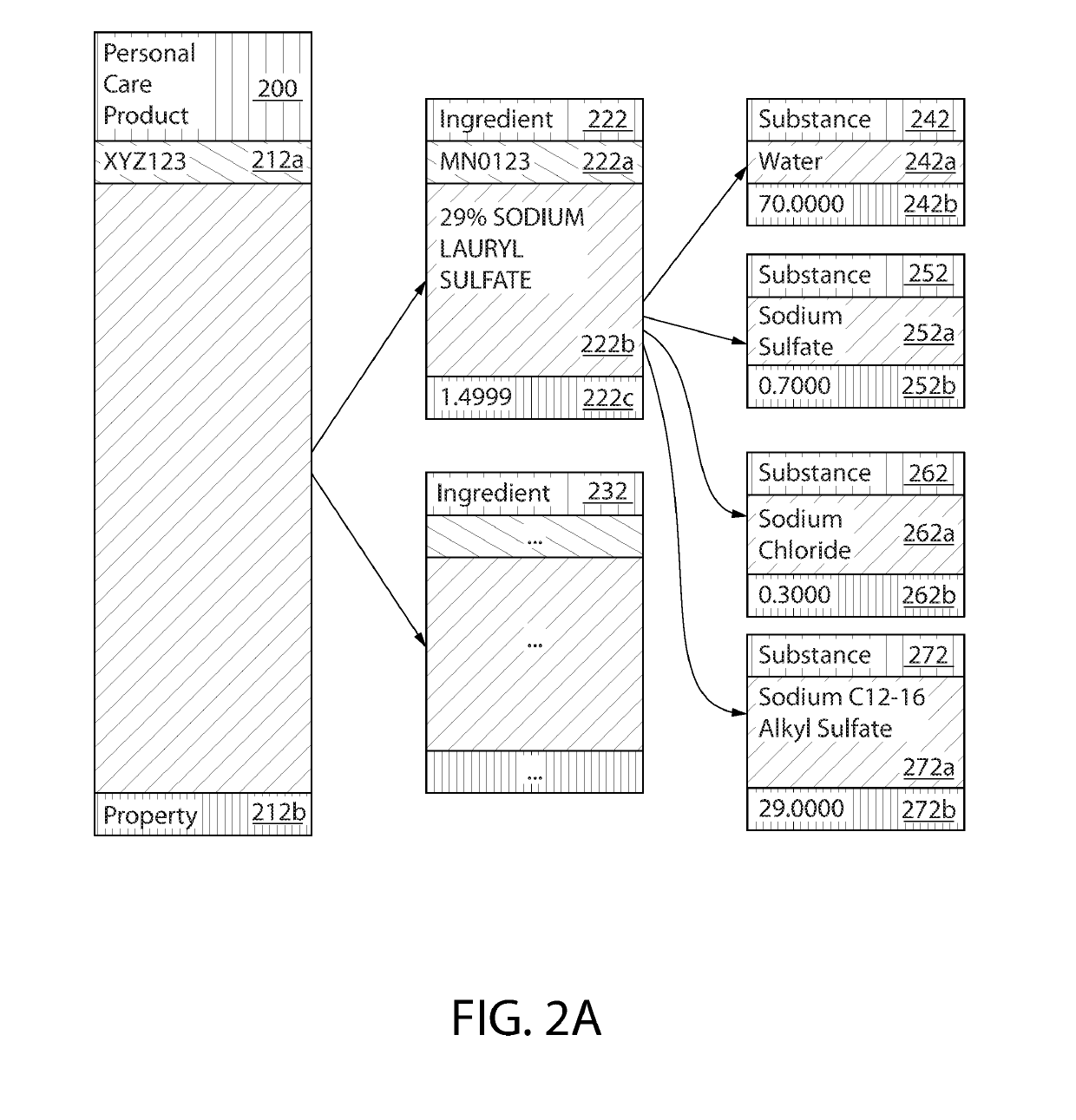

Systems and methods for evaluating compositions

ActiveUS10515715B1Chemical property predictionChemical processes analysis/designChemical physicsChemical composition

A system, apparatus, and / or method is disclosed for determining a value of a property of a considered chemical composition. An identity of a sample chemical composition may be received. A sample chemical composition may comprise ingredients. Each of the ingredients may be associated with a value of a chemoinformatic property of chemoinformatic properties of the sample chemical composition. A value of a property of the sample chemical composition and at least one of (1) the identity of the sample chemical composition or (2) the values of the chemoinformatic properties of the ingredients of the sample chemical composition may be input into a model. The value of the property of the considered chemical composition may be determined, via the model, based on at least one of (1) an identity of the considered chemical composition or (2) values of chemoinformatic properties of ingredients of the considered chemical composition.

Owner:COLGATE PALMOLIVE CO

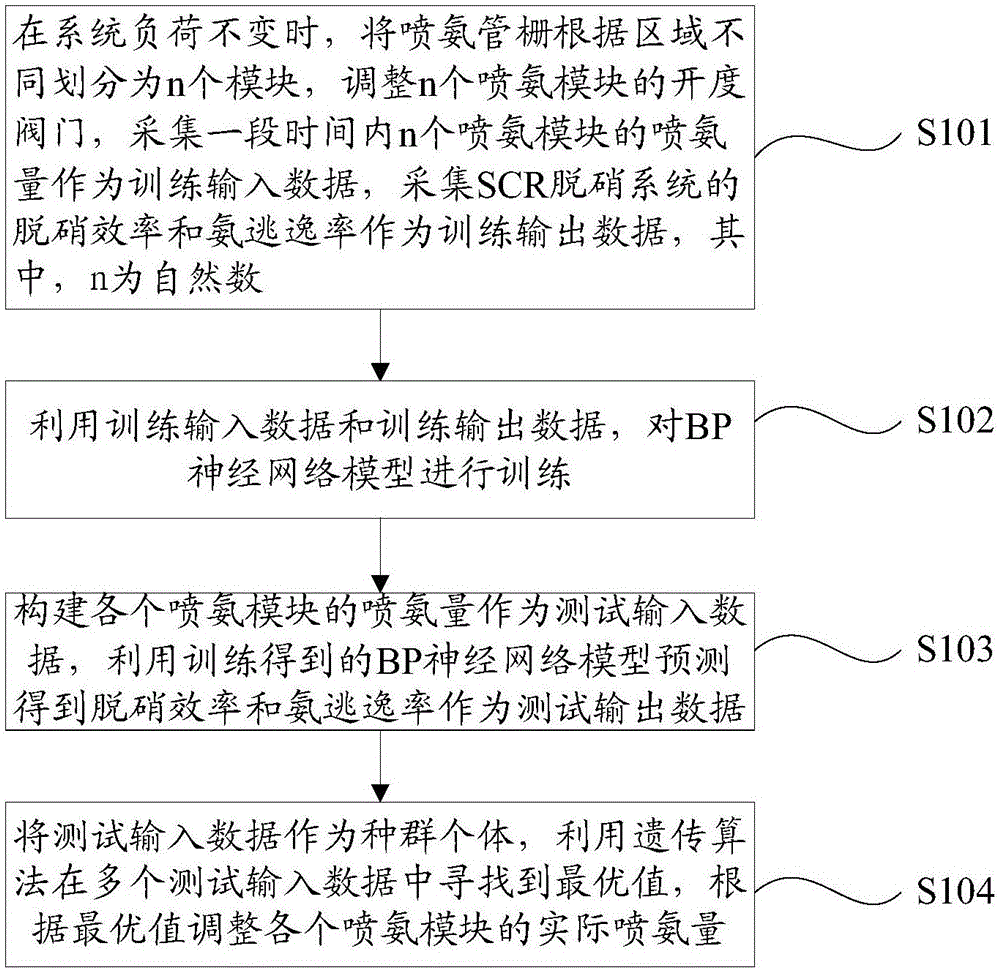

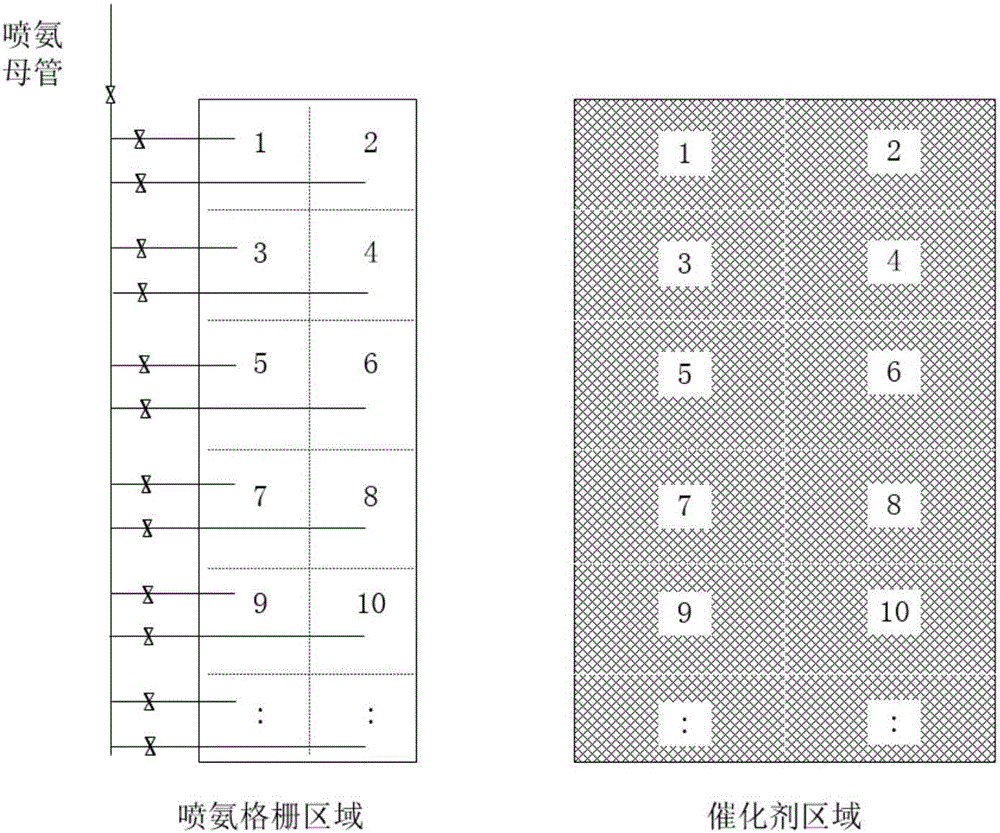

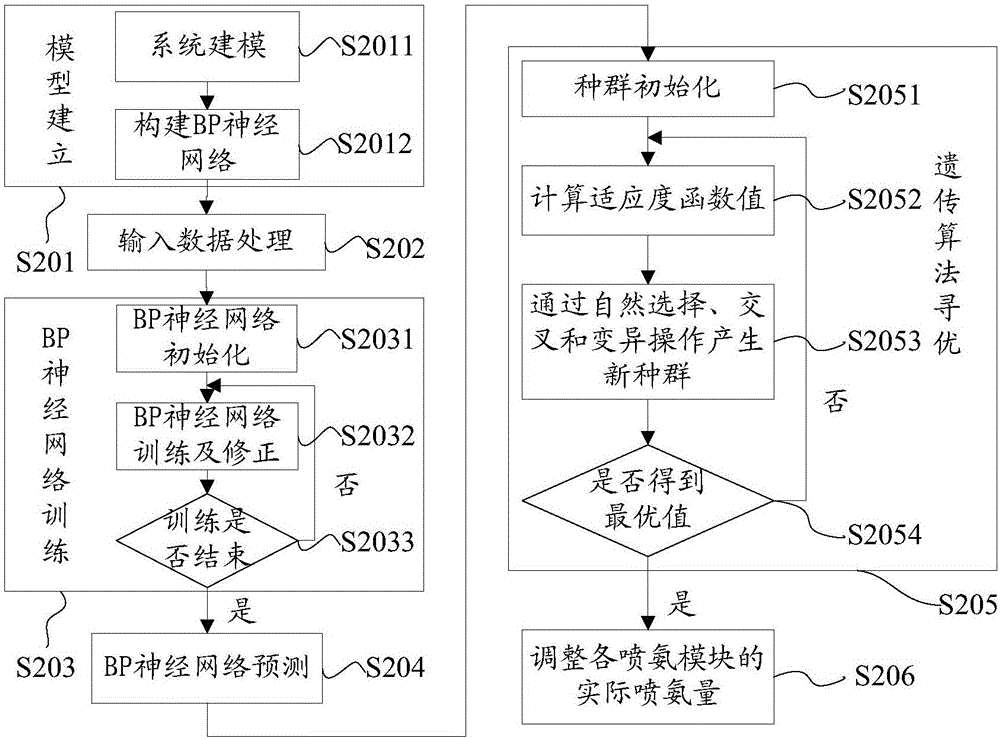

Neural network-based SCR intelligent ammonia-spraying optimization method and apparatus

ActiveCN106599586AImprove uniformityIncrease profitChemical processes analysis/designSpecial data processing applicationsTest inputEscape rate

The invention discloses a neural network-based SCR intelligent ammonia-spraying optimization method and apparatus, and relates to the field of a fire coal denitration technology. The method comprises the steps of dividing an ammonia-spraying pipe gate into n modules when system load is unchanged, adjusting valves of n ammonia-spraying modules, collecting ammonia-spraying quantity of the n ammonia-spraying modules within certain time to be used as training input data, and taking denitration efficiency and ammonia escape rate as training output data; performing BP neural network training based on the training input data and the training output data; taking ammonia-spraying quantity of each ammonia-spraying module as test input data, and predicting the denitration efficiency and the ammonia escape rate through a BP neural network model obtained by training; and searching an optimal value from multiple test input data through a genetic algorithm, and adjusting actual ammonia-spraying quantity of each ammonia-spraying module according to the optimal value. By adoption of the scheme, the differentiation control on the ammonia-spraying quantity can be realized, the denitration efficiency is improved, the ammonia escape rate is lowered, and the ammonia-spraying quantity of each ammonia-spraying module can be adjusted according to different targets of power plants flexibly.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

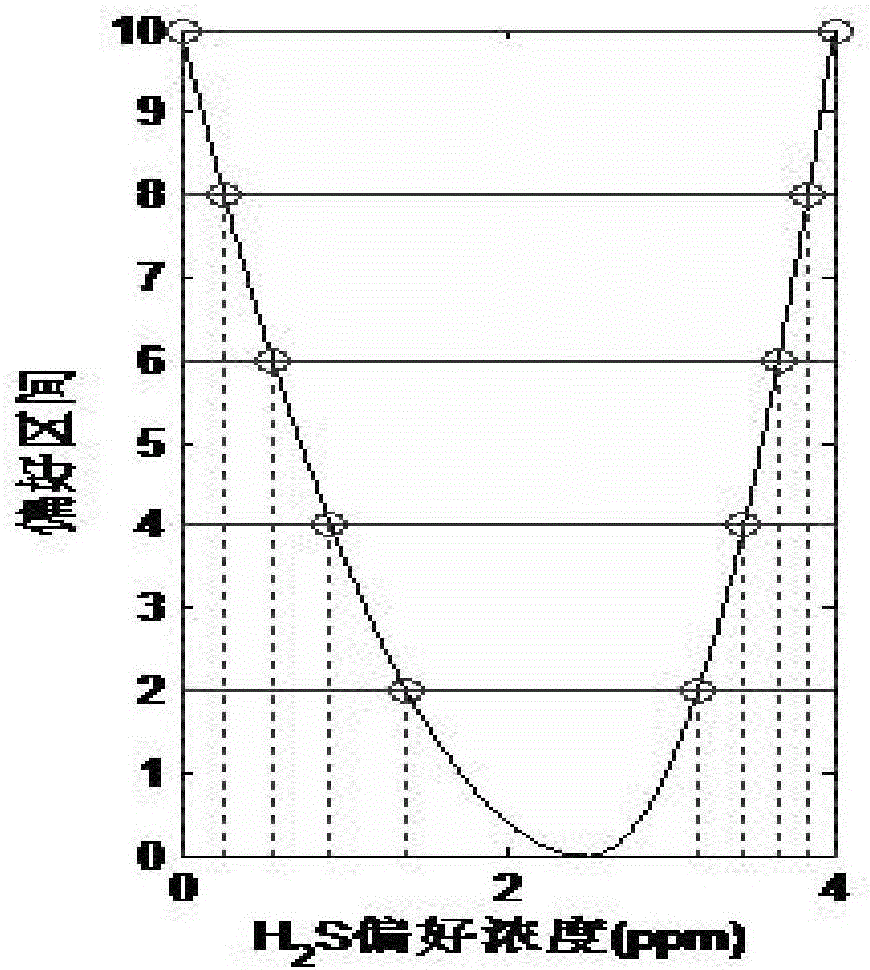

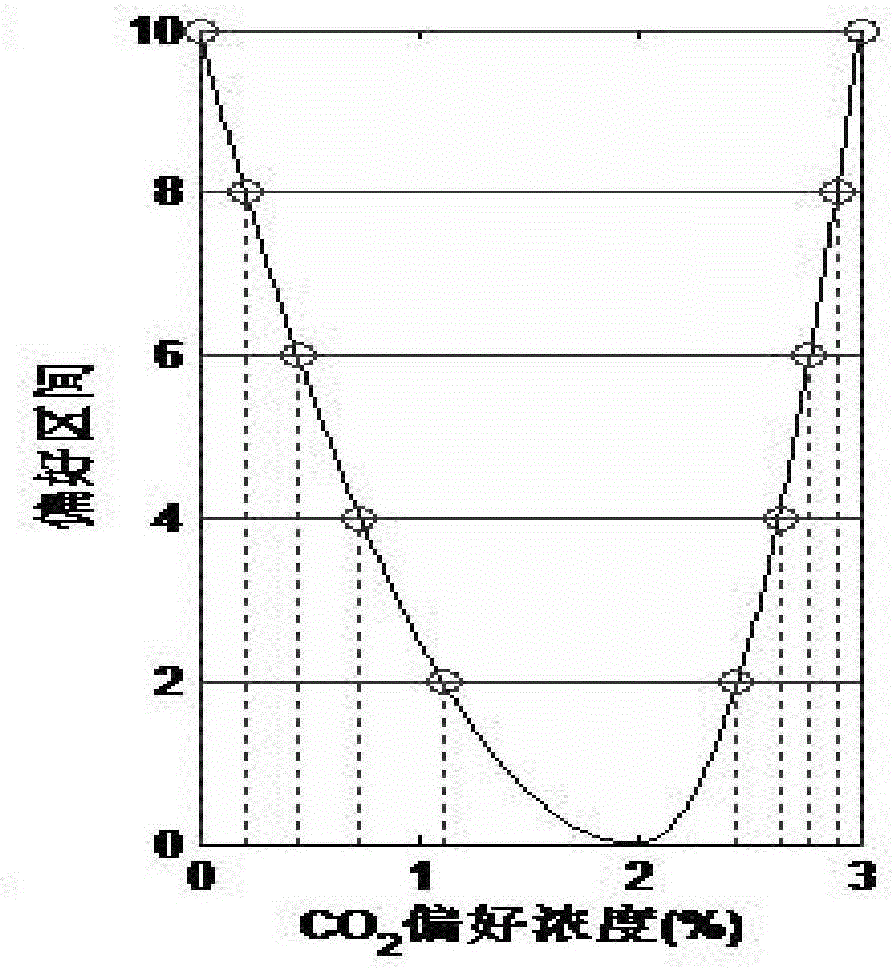

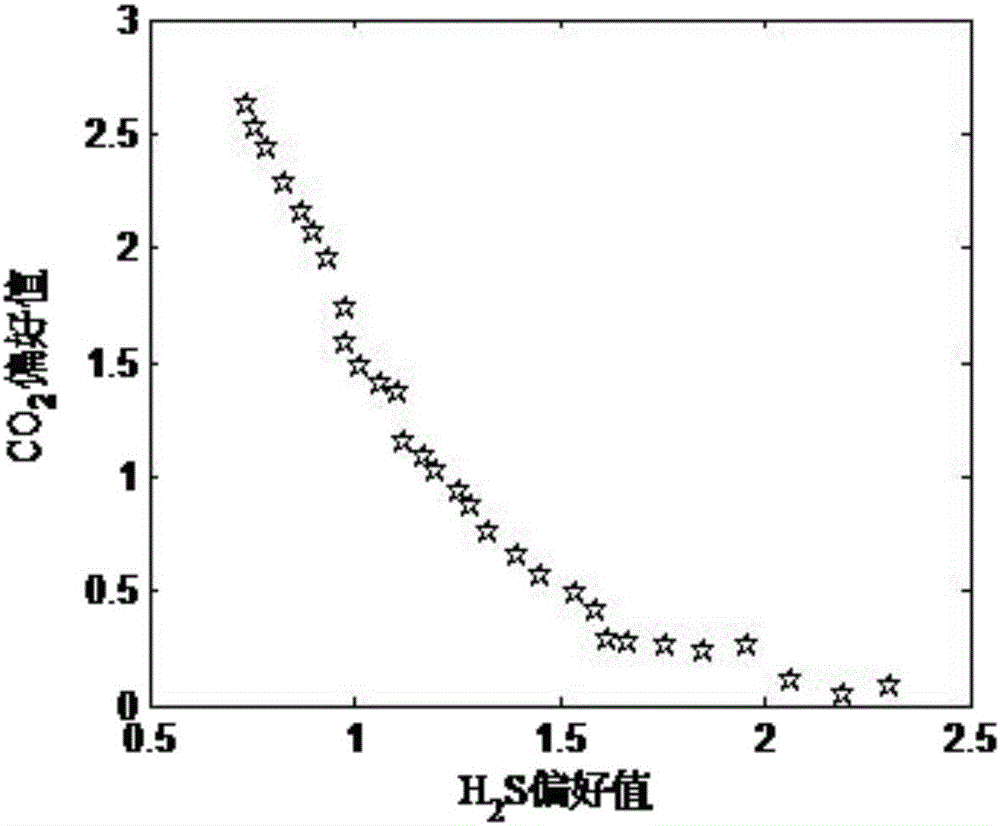

Modeling and optimizing method of high-sulfur natural gas purification process oriented to energy saving and consumption reduction

ActiveCN106777866AImprove the economic benefits of processingEffective trackingGaseous fuelsChemical processes analysis/designProcess orientedState variable

The invention provides a modeling and optimizing method of a high-sulfur natural gas purification process oriented to energy saving and consumption reduction. The method comprises the steps that process parameters influencing the desulfurization efficiency and performance indexes of a desulfurization unit are selected and then are acquired to form sample sets; normalization is conducted on the sample sets to form normalized sample sets, and a training sample and a testing sample set are selected from the normalized sample sets; a neural network model is established based on the training sample, and initial state variables of the neural network model are determined; the optimal state variable of the neural network model is estimated by utilizing an ST-UPFNN algorithm; according to the optimal state variable, the neural network model is updated; preference functions of H2S concentration and CO2 concentration are established respectively; process parameters of H2S concentration and CO2 concentration are optimized by utilizing an MOGA algorithm, and the optimized process parameters are introduced into the updated neural network model, the system performance of the optimized process parameters is calculated, and average values of the system performance of actual samples are compared. The production efficiency of high-sulfur natural gas purification can be improved by utilizing the method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

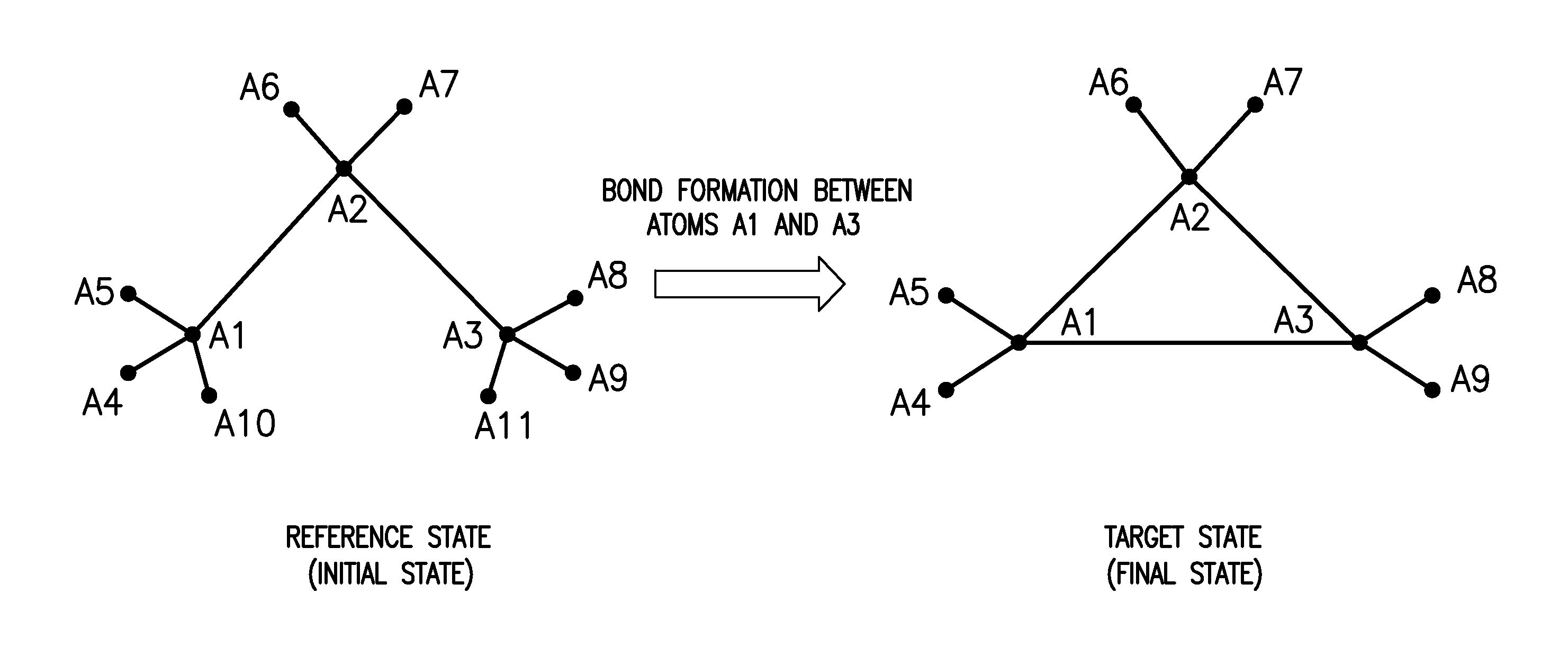

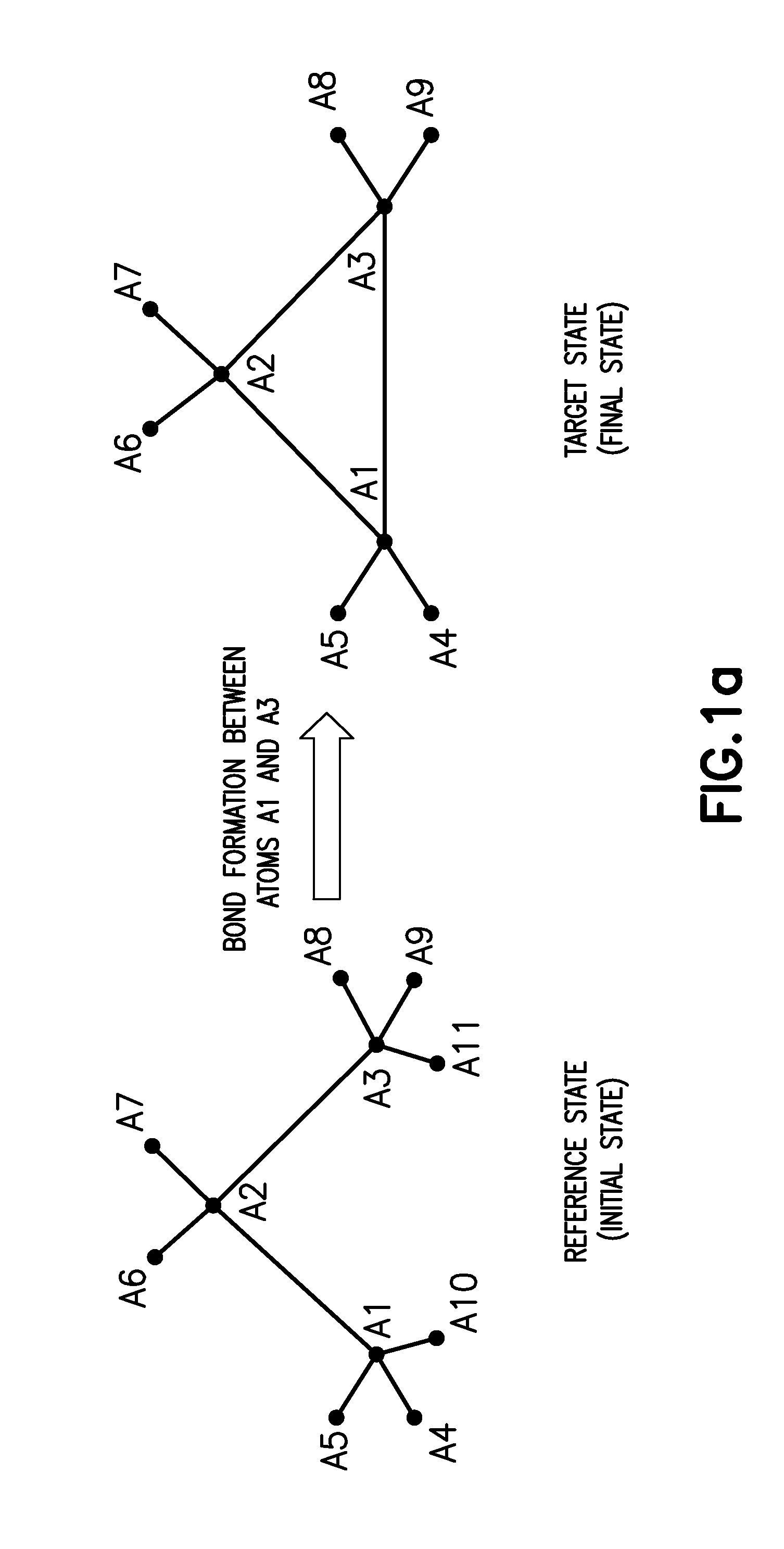

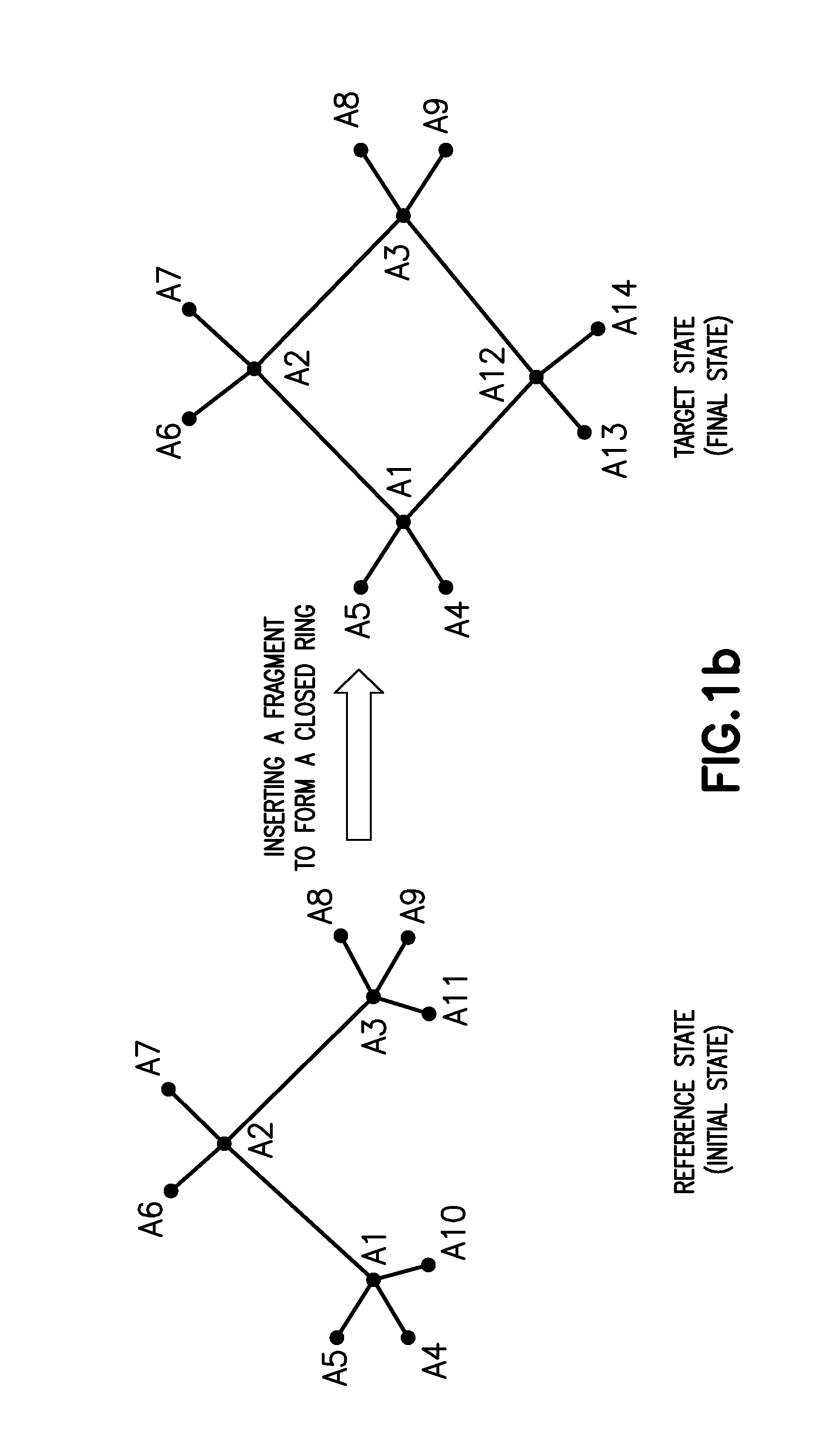

Methods and systems for calculating free energy differences using a modified bond stretch potential

InactiveUS20150178442A1Chemical property predictionAnalogue computers for chemical processesHarmonic potentialFree energies

A method and system for calculating the free energy difference between a target state and a reference state. The method includes determining one or more intermediate states using a coupling parameter, performing molecular simulations to obtain ensembles of micro-states for each of the system states, and calculating the free energy difference by an analysis of the ensembles of micro-states of the system states. The method can be particularly suited for calculating physical or non-physical transformation of molecular systems such as ring-opening, ring-closing, and other transformations involving bond breaking and / or formation. A soft bond potential dependent on a bond stretching component of the coupling parameter and different from the conventional harmonic potential is used in the molecular simulations of the system states for the bond being broken or formed during the transformation.

Owner:SCHRODINGER INC

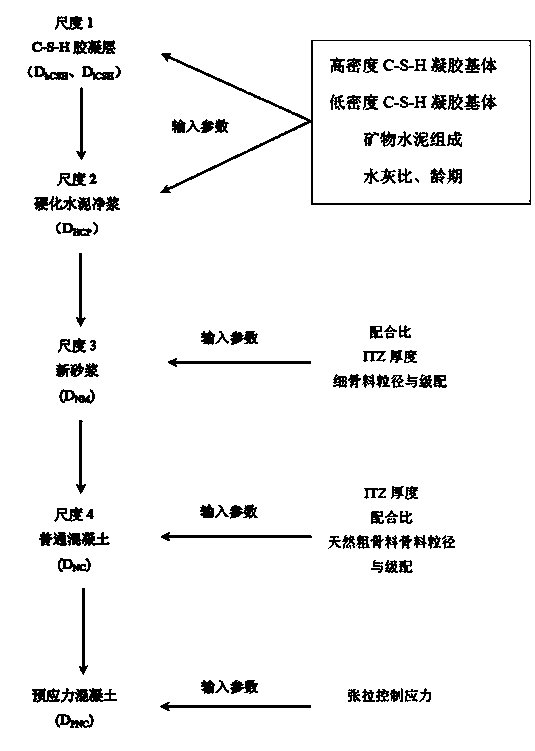

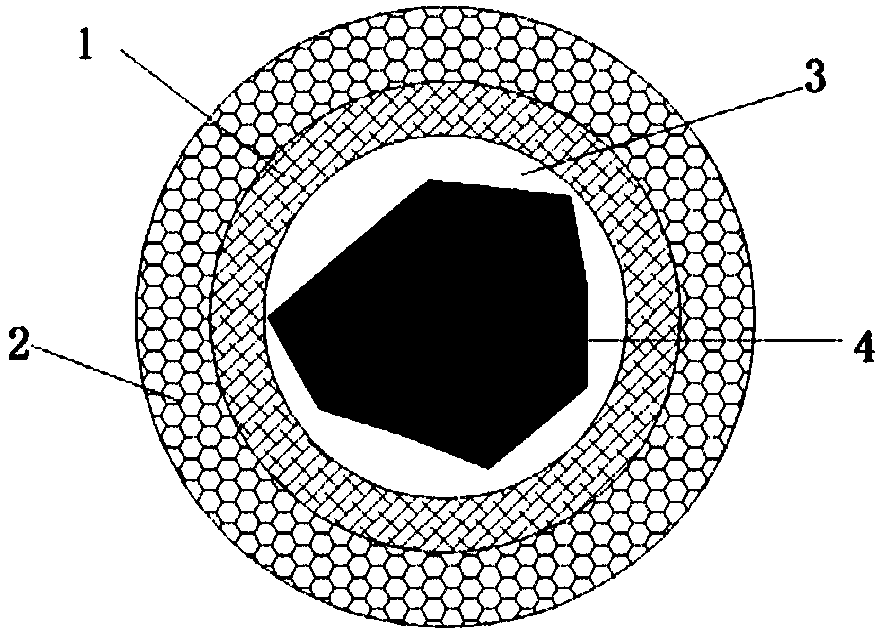

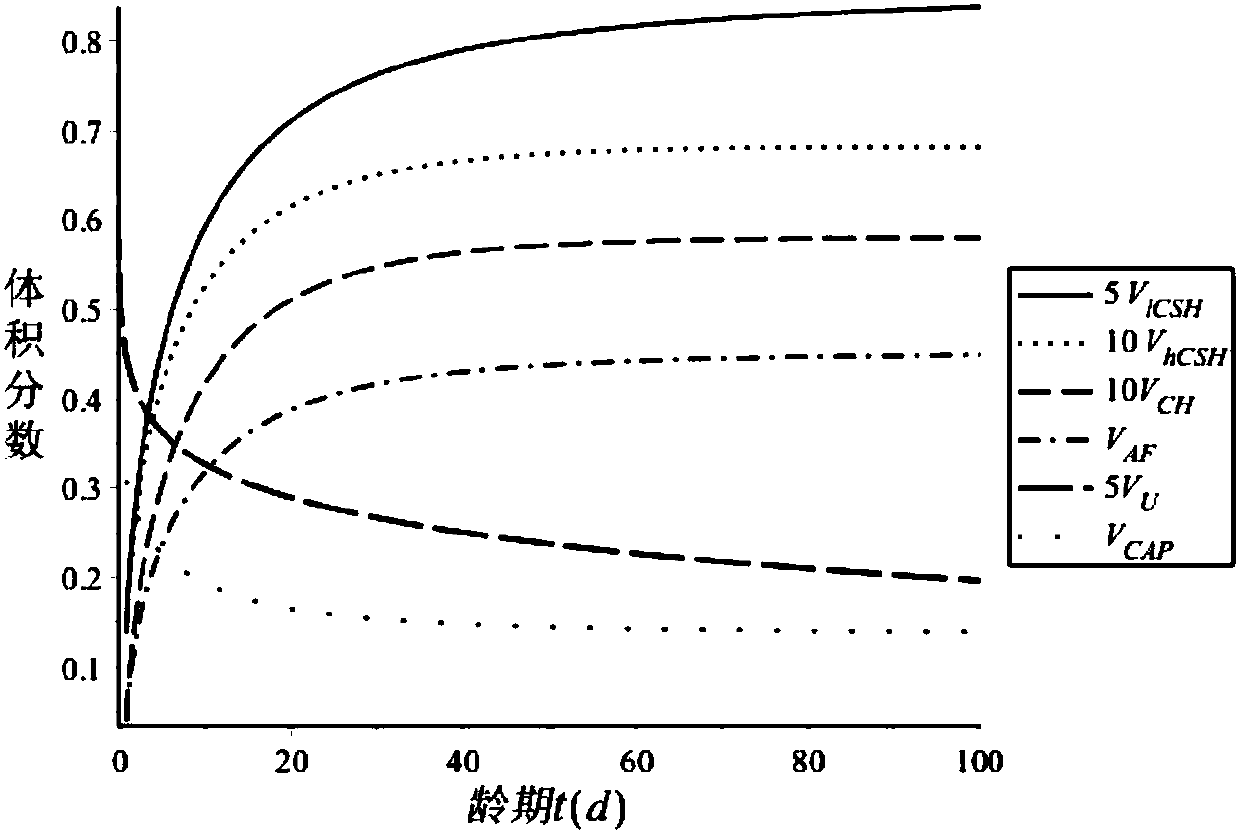

Construction method of multi-scale prediction model of chloride ion diffusion coefficient of prestressed concrete

ActiveCN108304689AEasy to analyzeConvenient researchChemical processes analysis/designSpecial data processing applicationsDiffusionScale structure

The invention discloses a construction method of a multi-scale prediction model of a chloride ion diffusion coefficient of prestressed concrete. The method is characterized by: regarding the concreteas a cement-based composite material composed of different-scale materials, establishing prediction models of chloride ion diffusion coefficients of the different-scale cement-based materials in sequence with gradual transition from small-scale hardened cement slurry to large-scale concrete, then considering influences which are of prestress inside the prestressed concrete and on chloride ion diffusion thereof, and finally, establishing the multi-scale prediction model of the chloride ion diffusion coefficient of the prestressed concrete. According to the method, influences of prestress levelson chloride ion diffusion are studied by starting from multi-scale structure formations of the cement-based materials, and the established multi-scale prediction model of the chloride ion diffusion coefficient of the prestressed concrete has very important significance for chloride ion penetration resistance study and durability design of the prestressed concrete.

Owner:GUANGXI UNIV

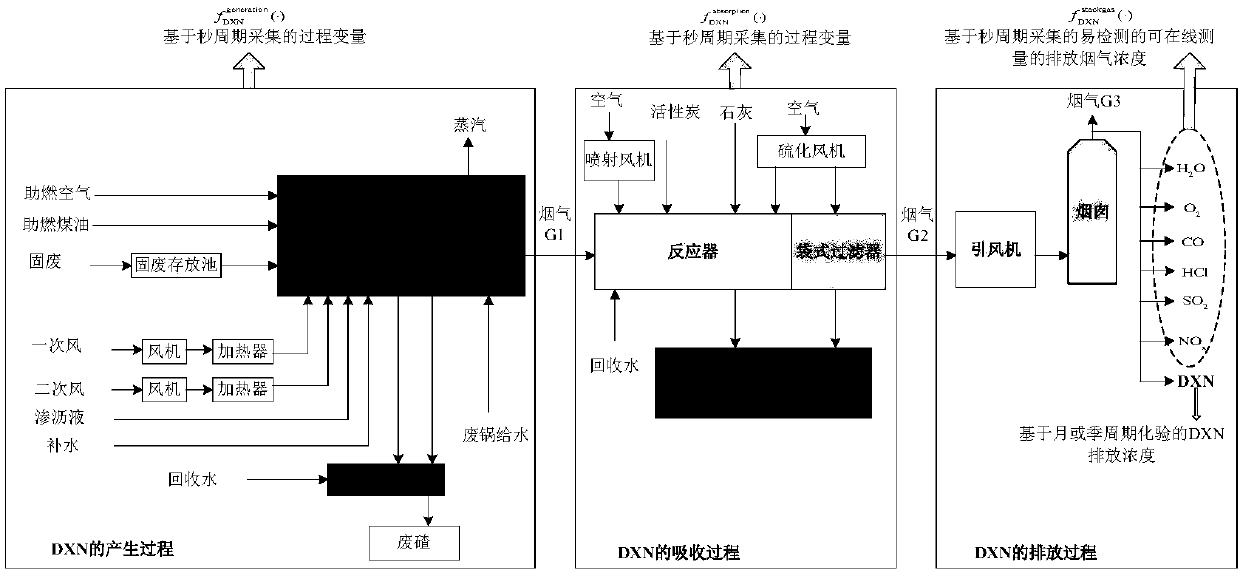

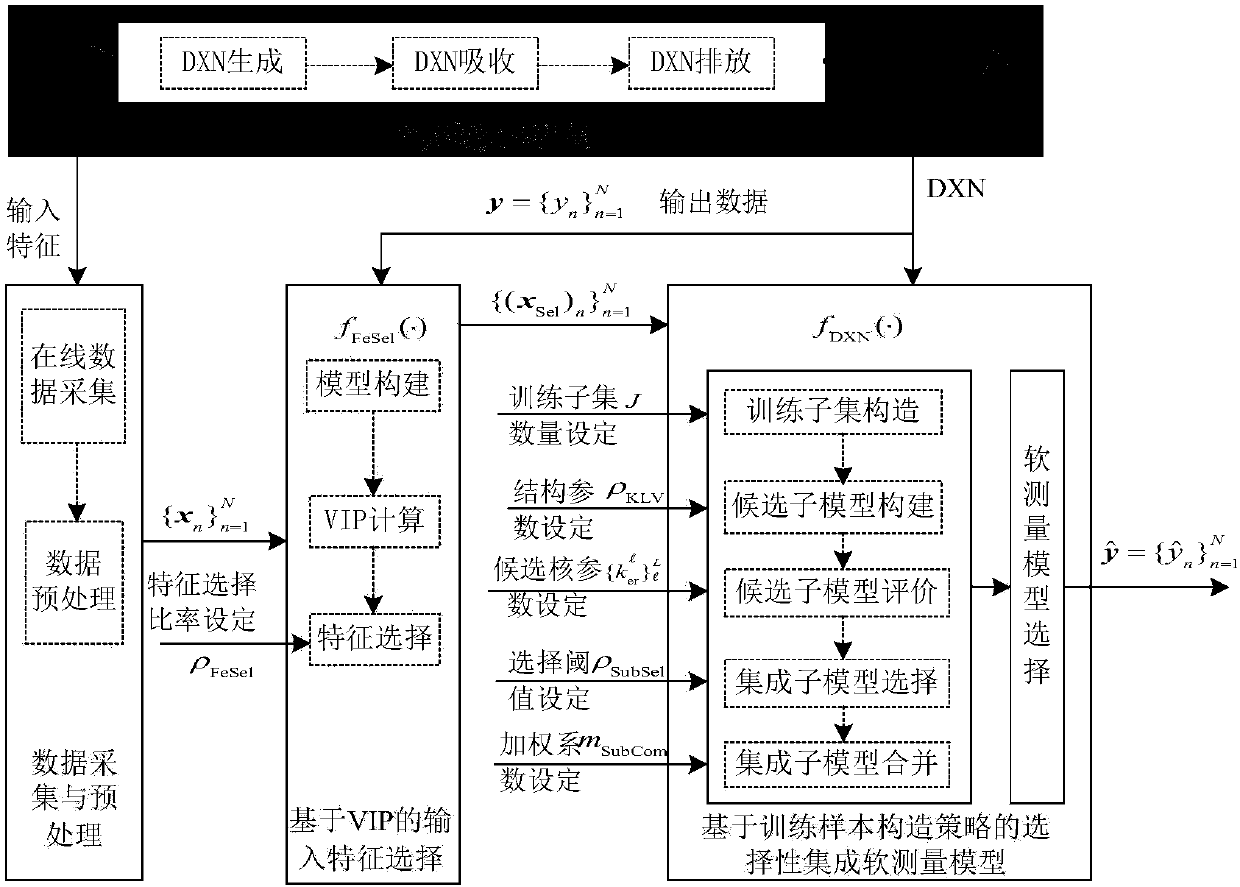

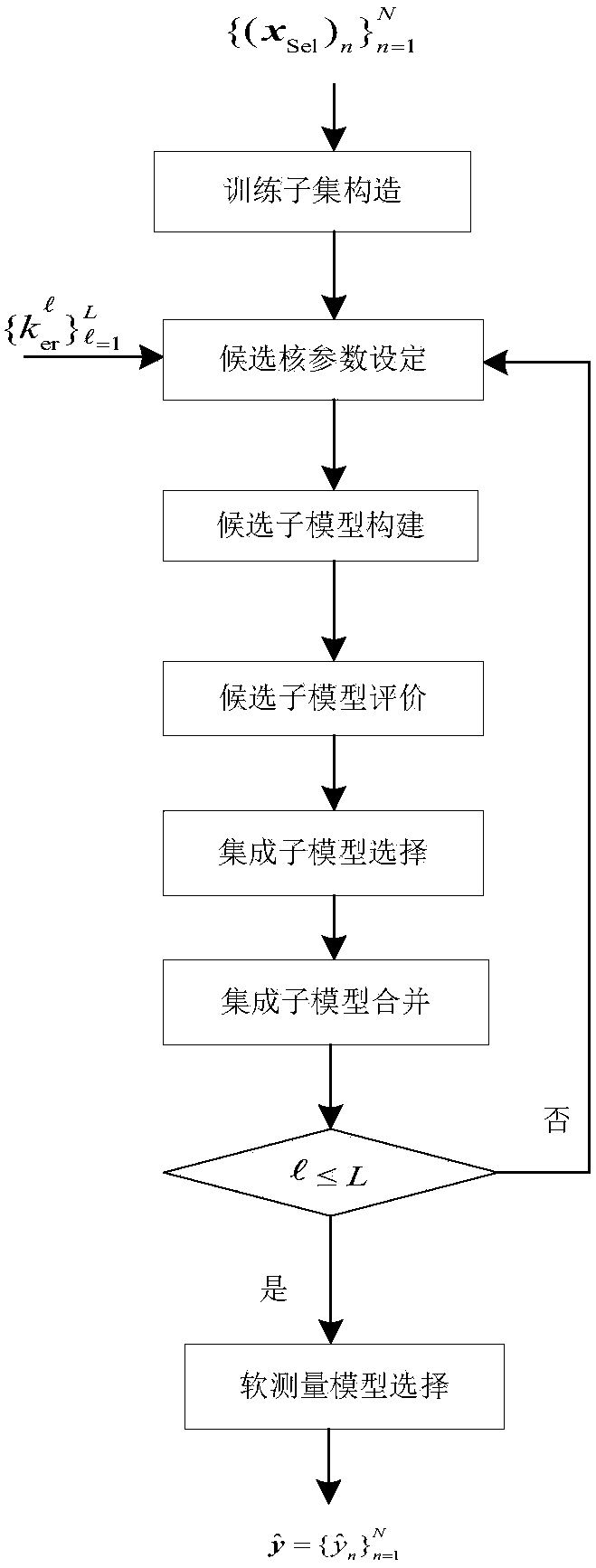

Latent structure mapping algorithm-based soft measurement method for DXN discharge concentration in municipal waste solid incineration process

ActiveCN108549792AChemical processes analysis/designSpecial data processing applicationsSmall sampleMapping algorithm

The invention discloses a latent structure mapping algorithm-based soft measurement method for DXN discharge concentration in a municipal waste solid incineration process. The method comprises the steps of firstly, collecting and preprocessing process variables of the complete municipal waste solid incineration process and easily detected exhaust gas concentration; secondly, based on variable importance in projection (VIP) of a linear latent structure mapping algorithm and an input feature selection ratio set according to experience, determining input features of a soft measurement model; andfinally, building a selective ensemble kernel latent structure mapping model based on adaptive selection kernel parameters of a control training sample ensemble construction strategy. The method can preset a feature selection parameter and a structure parameter of the soft measurement model and a selection threshold and a weighting strategy of an ensemble sub-model according to actual demands of an industrial process, and is suitable to build the small sample collinear data-based difficultly detected parameter soft measurement model.

Owner:BEIJING UNIV OF TECH

Popular searches

Fluid removal Computation using non-denominational number representation Computational theoretical chemistry Fermentation Systems biology Complex mathematical operations Semiconductor/solid-state device manufacturing Exothermal chemical reactions for heating Welding/cutting media/materials Energy based chemical/physical/physico-chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com