Patents

Literature

49results about How to "Issue can be resolved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

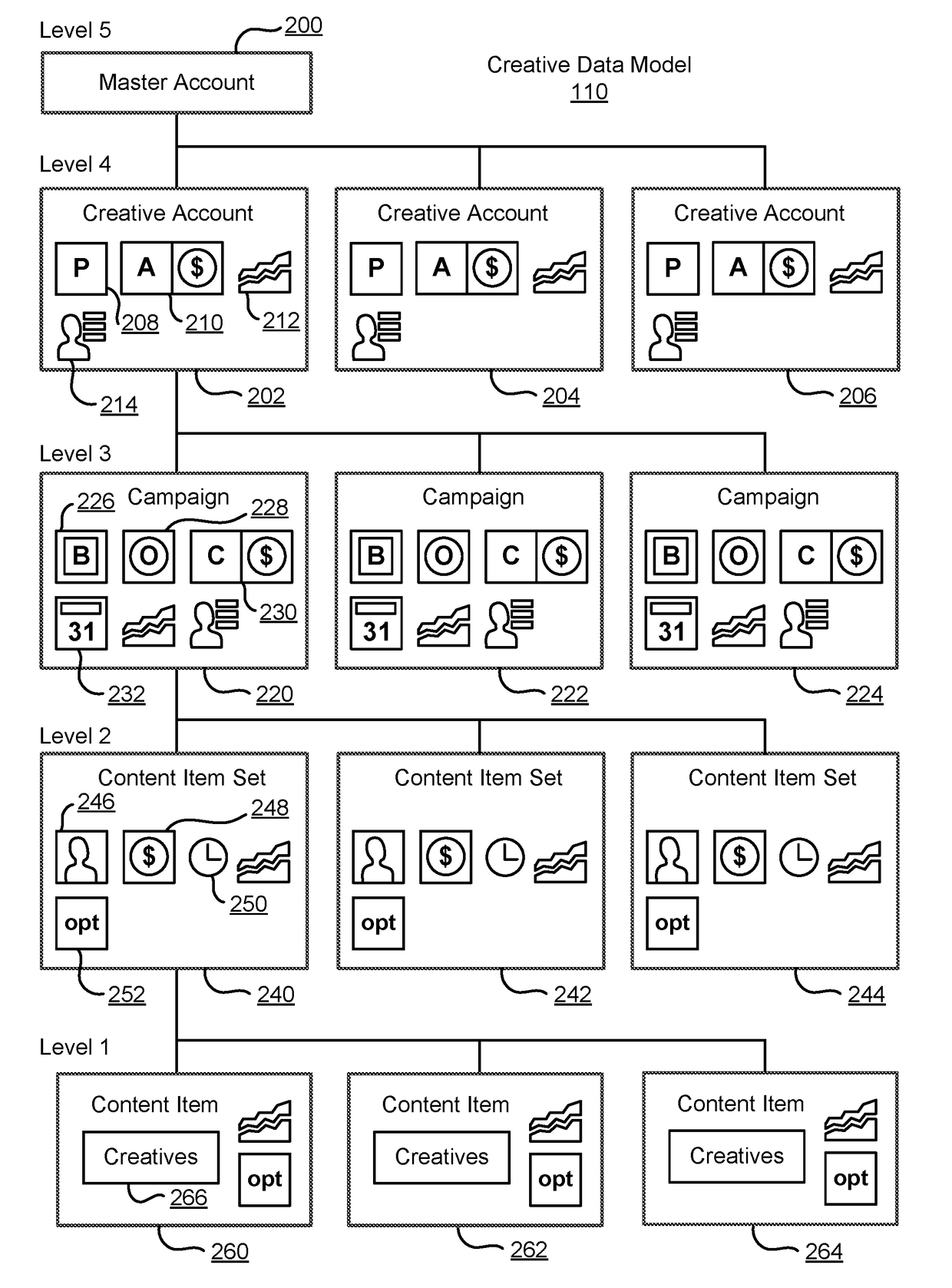

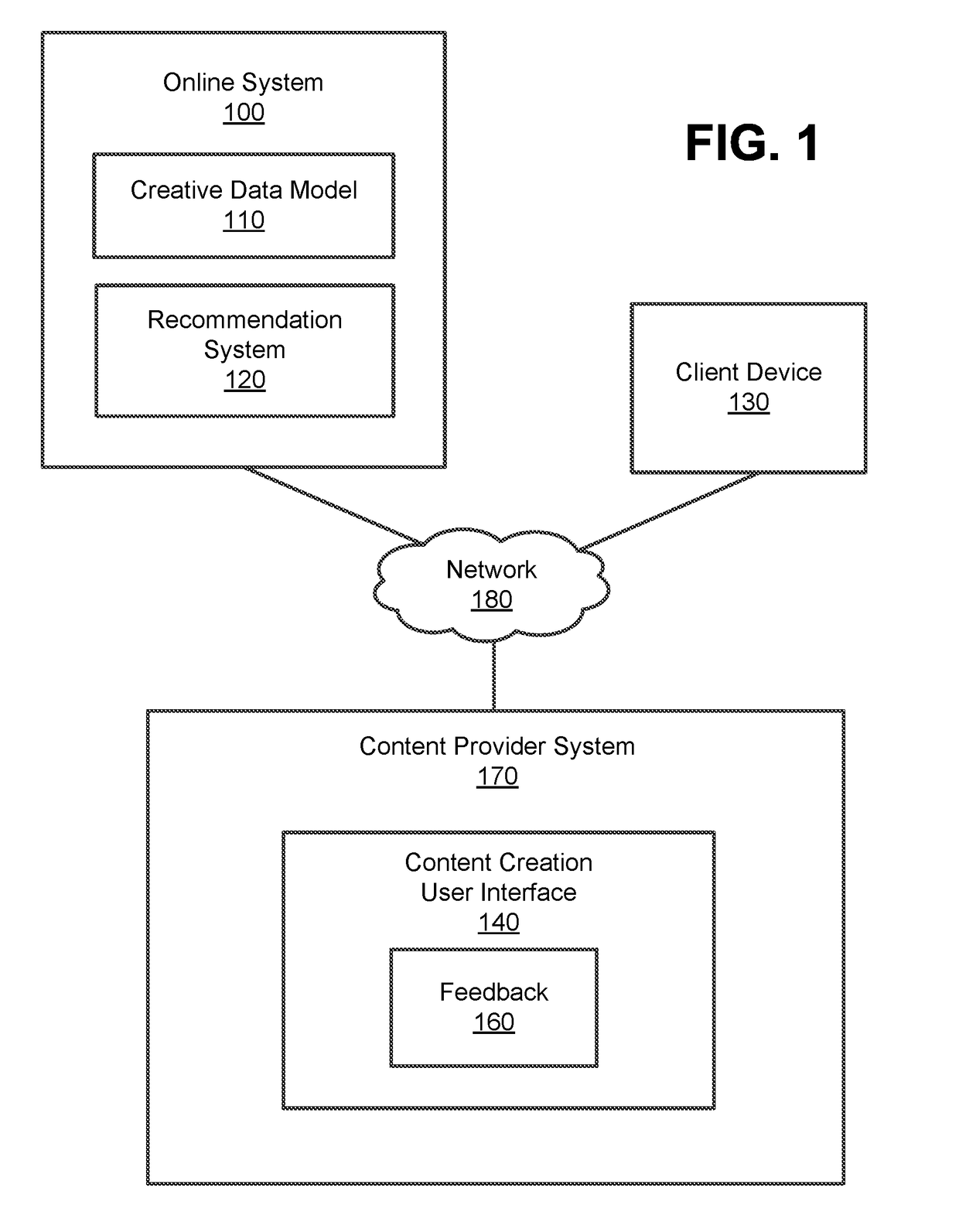

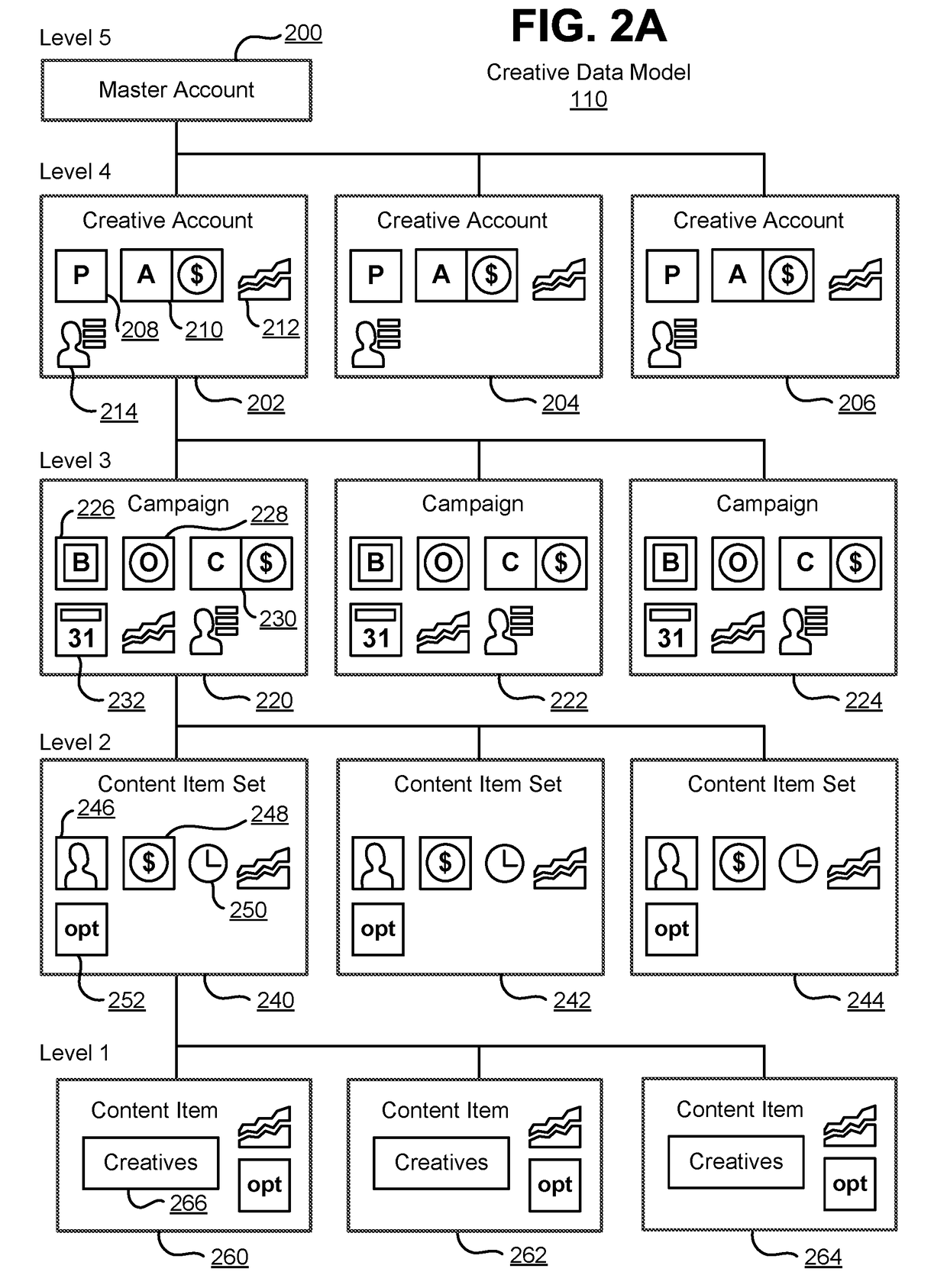

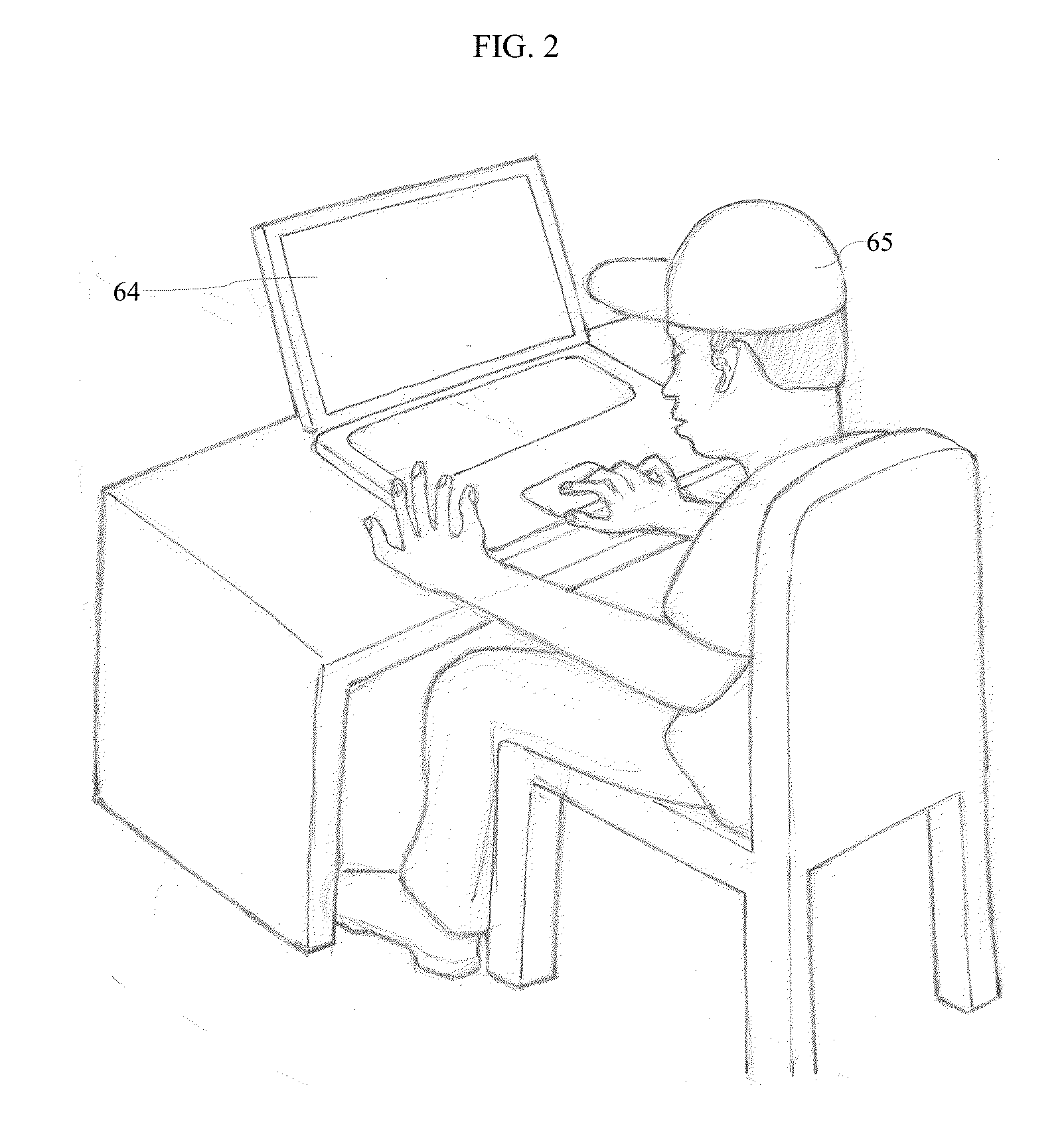

Recommendation system to enhance online content creation

InactiveUS20180040019A1Raise the possibilityIssue can be resolvedDigital data information retrievalAdvertisementsGraphicsGraphical user interface

An online system provides feedback to a content provider creating a content item for a target audience. The feedback may include a score, recommendation, or error notification for a creative such as an image, video, or text to be included in the content item. The score indicates a likelihood that users of the online system will interact with the content item having the creative. Modifying the content item based on recommendations may result in a different score for the content item. The online system trains a machine learning model to generate the scores. The model learns which creatives are popular among particular audiences. The online system provides error notifications if the content item violates a rule. The online system can generate the content item even if there are rule violations. The feedback is displayed inline on a graphical user interface while the content provider is creating the content item.

Owner:META PLATFORMS INC

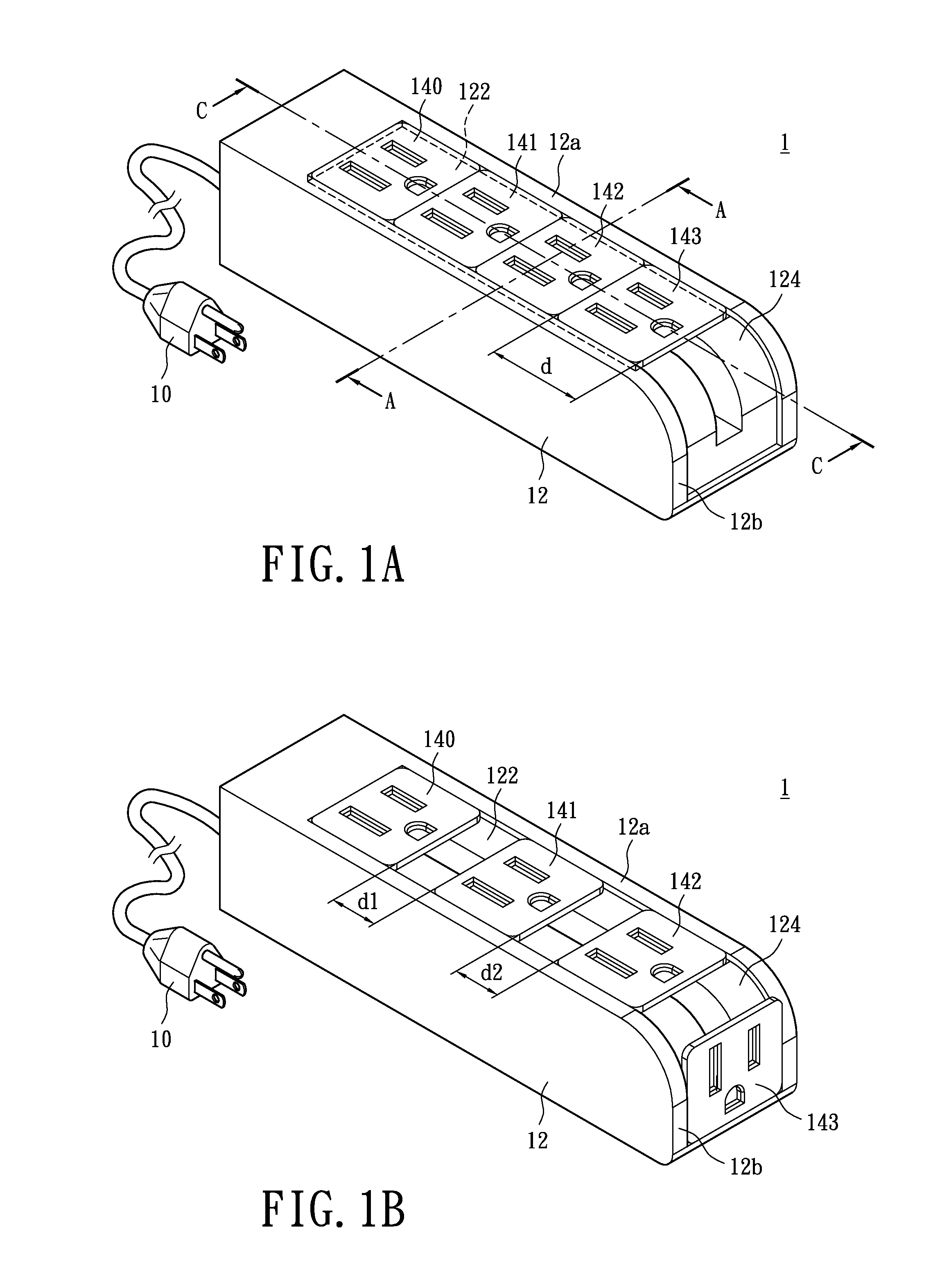

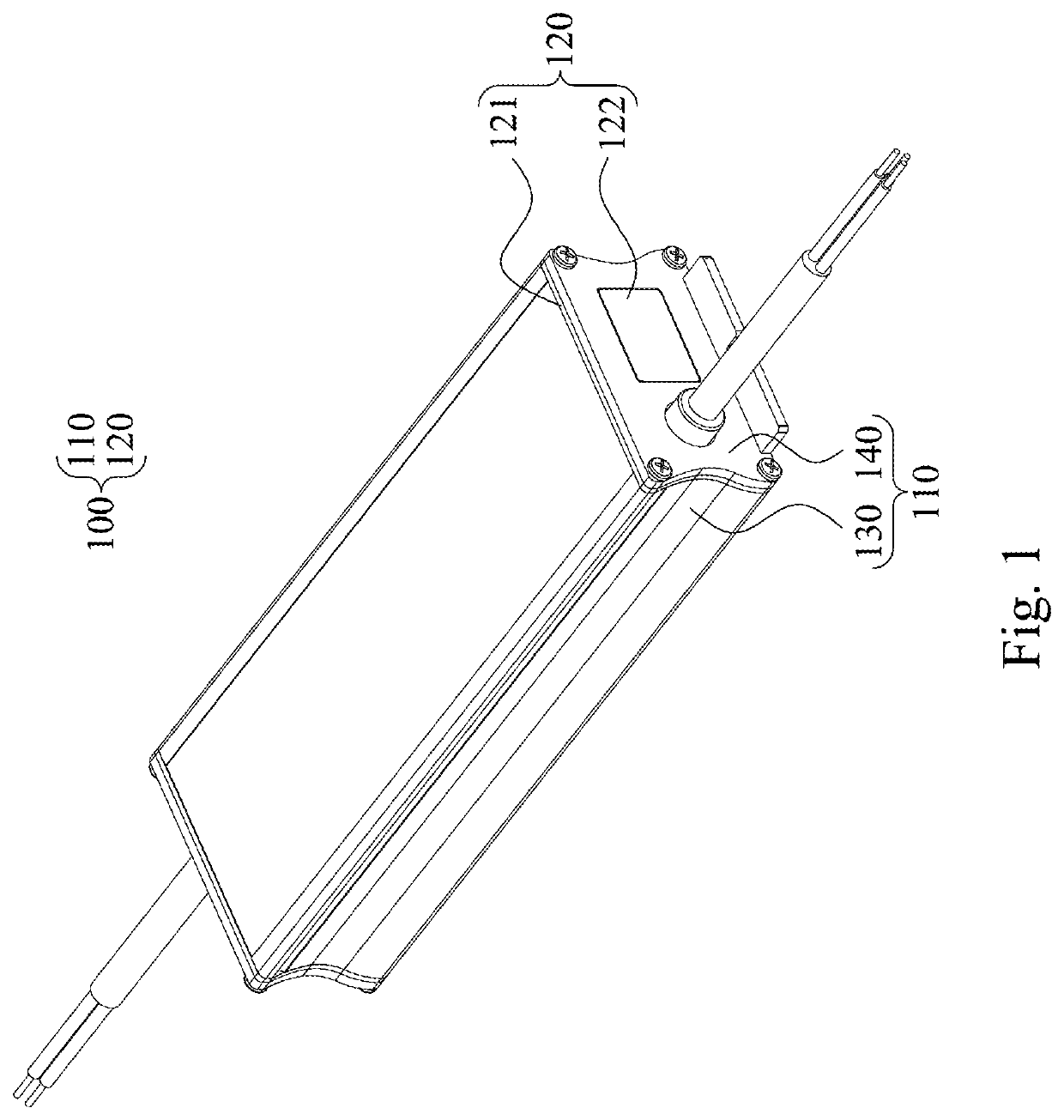

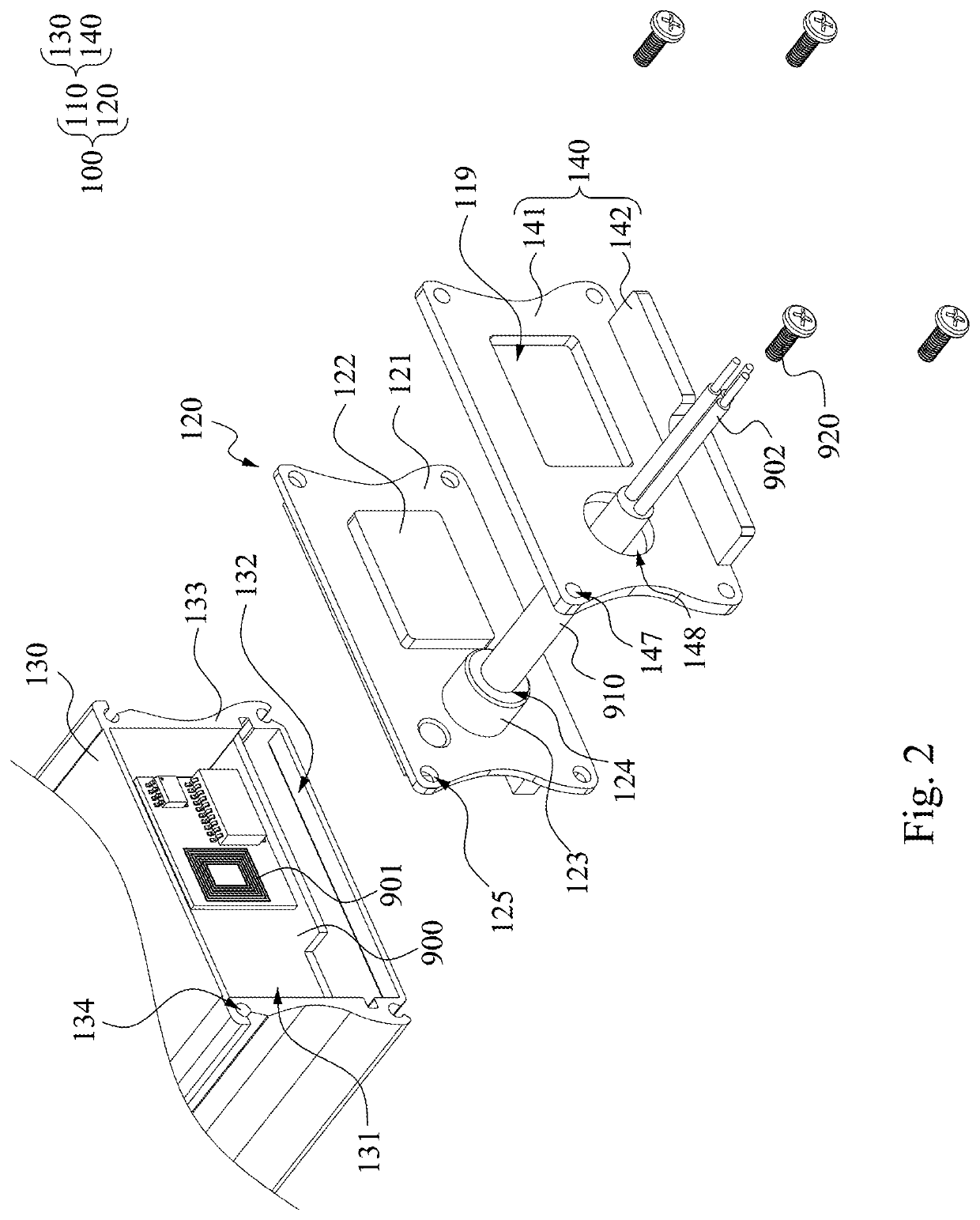

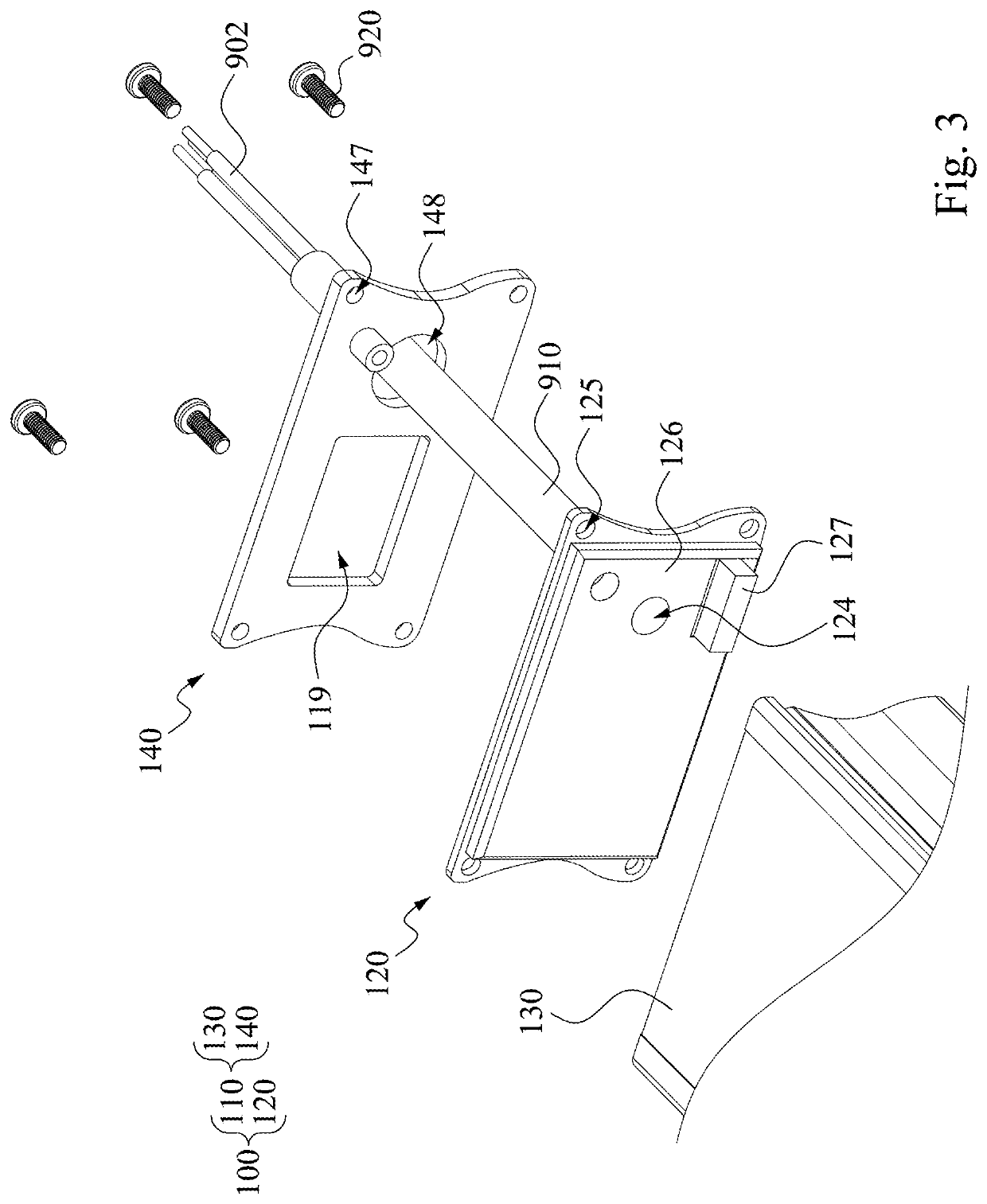

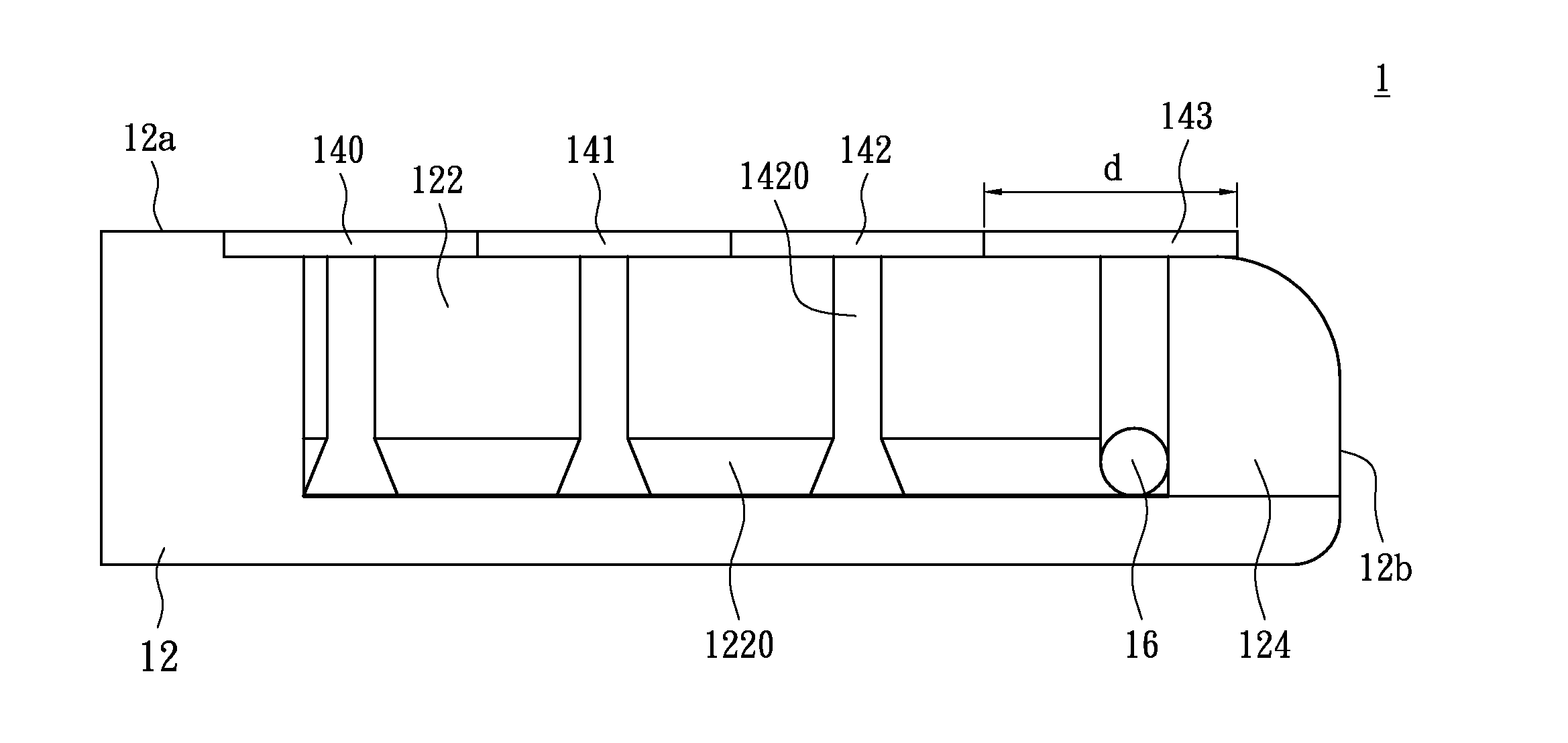

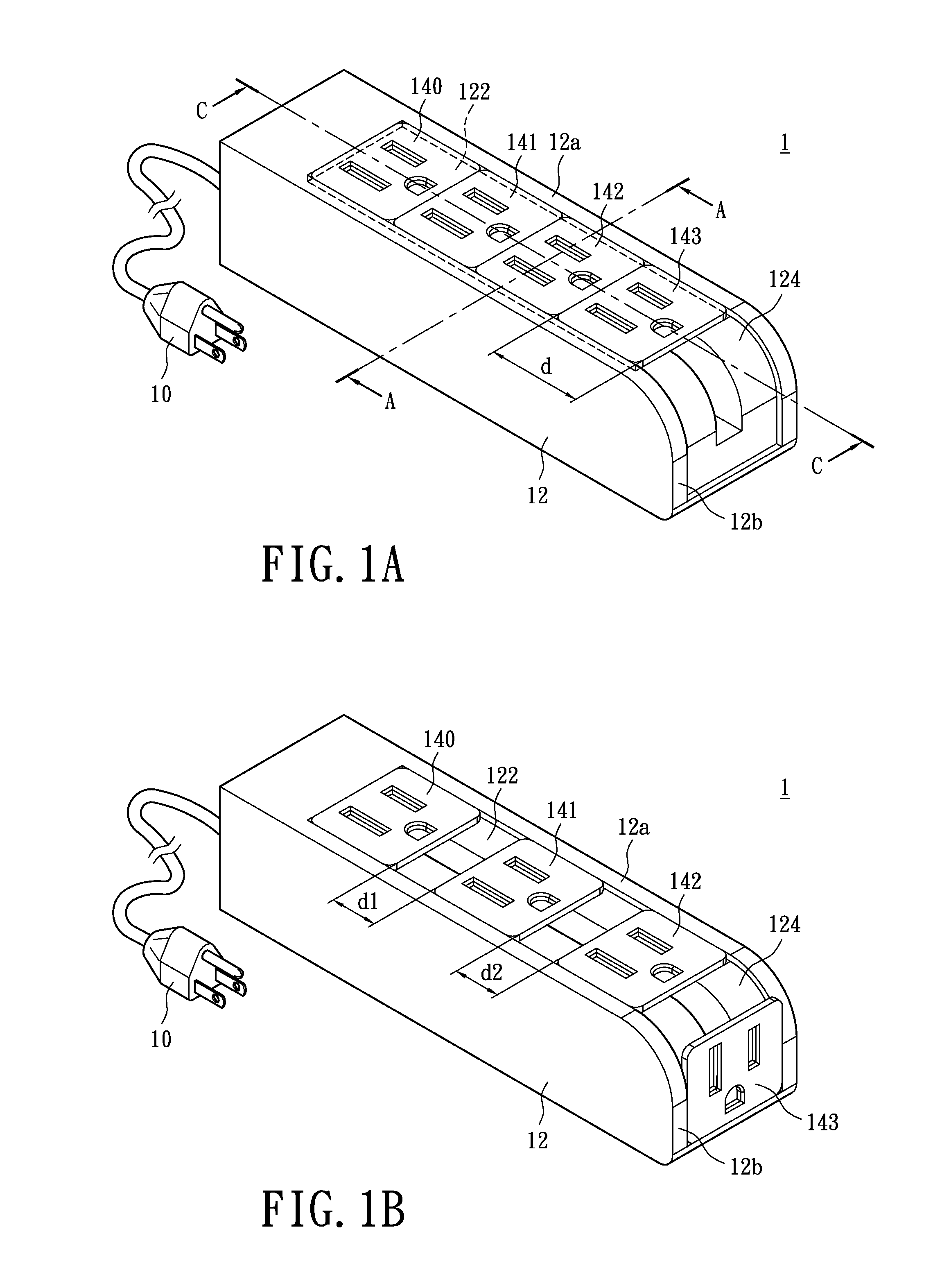

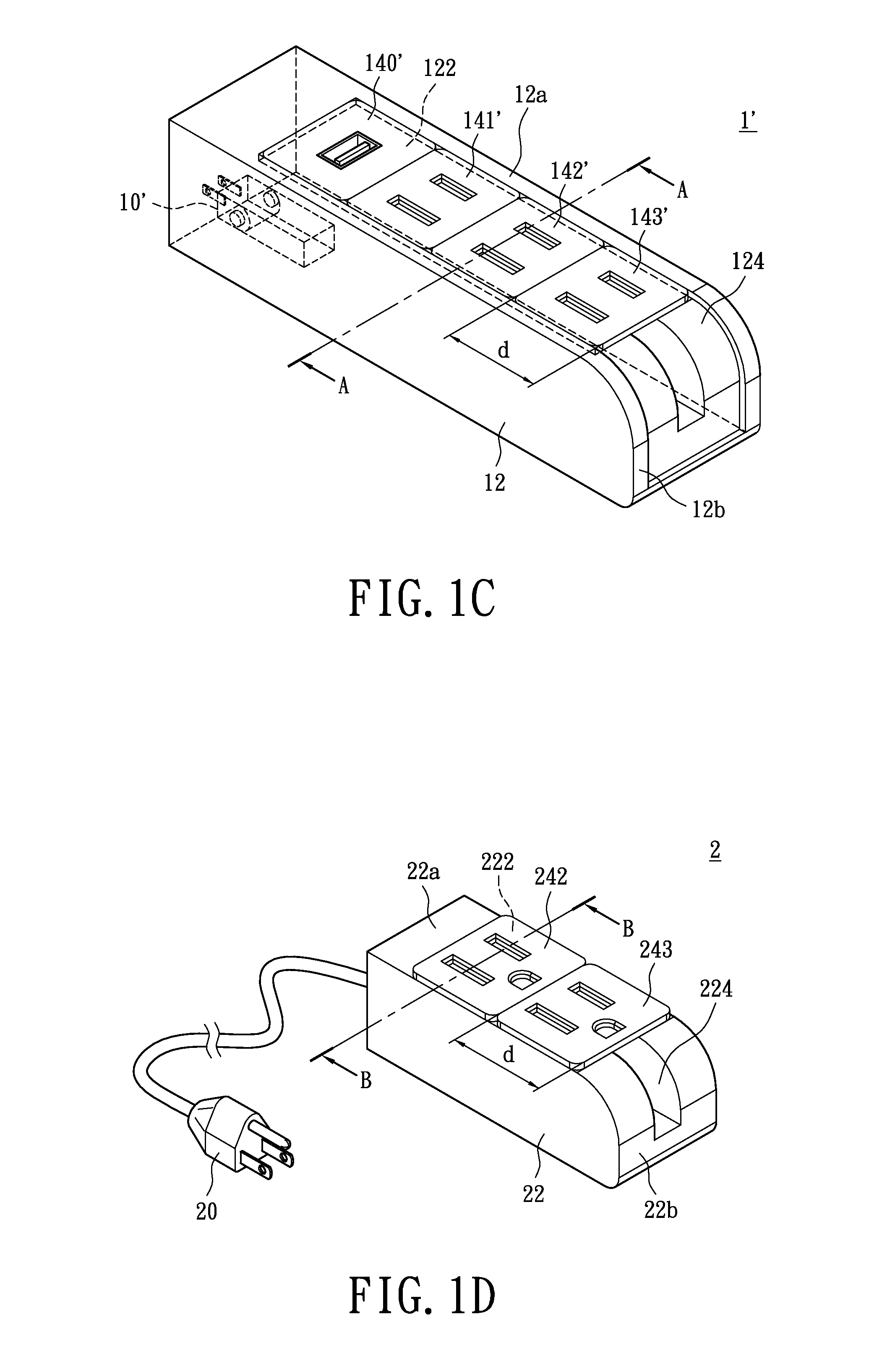

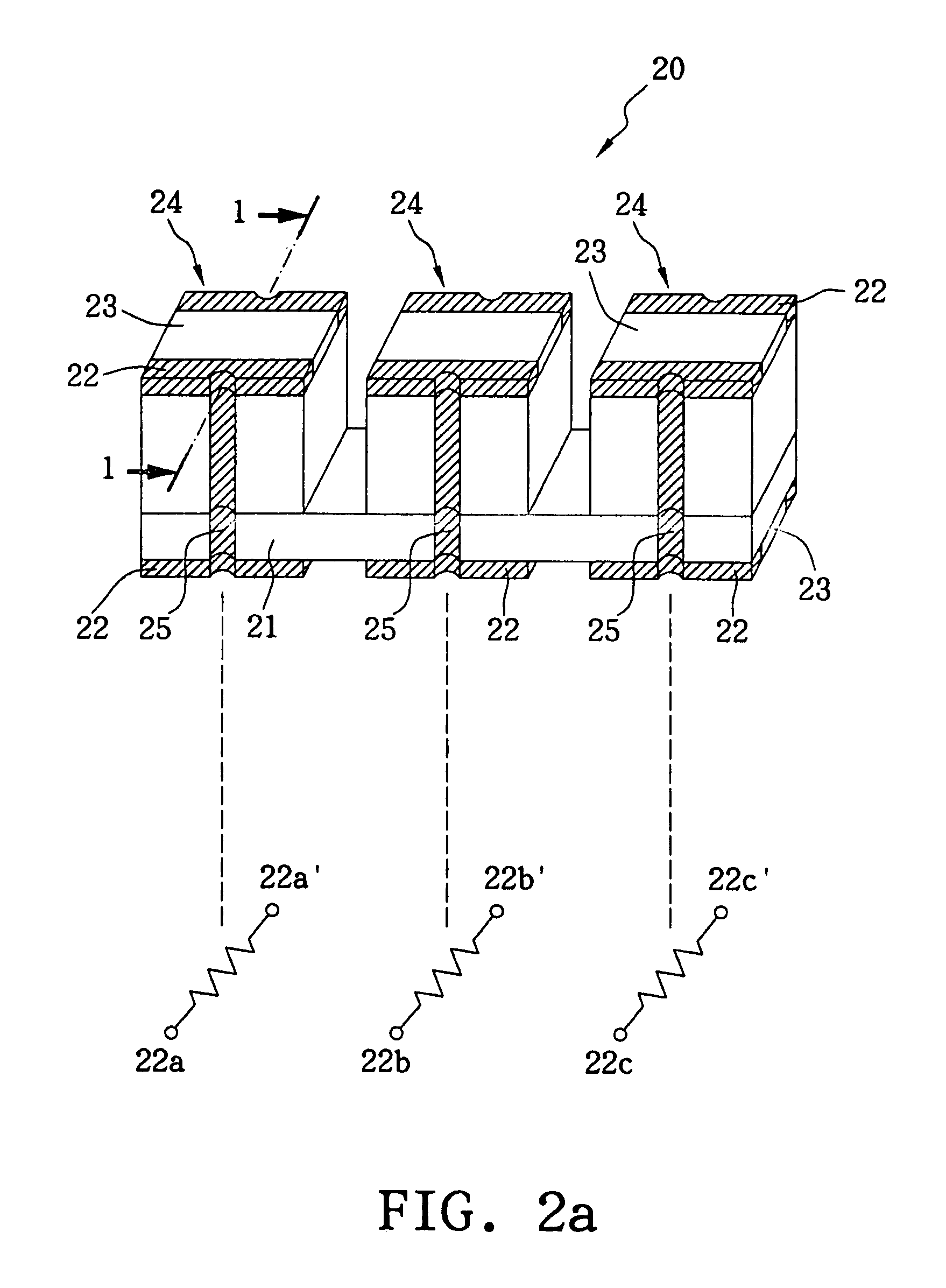

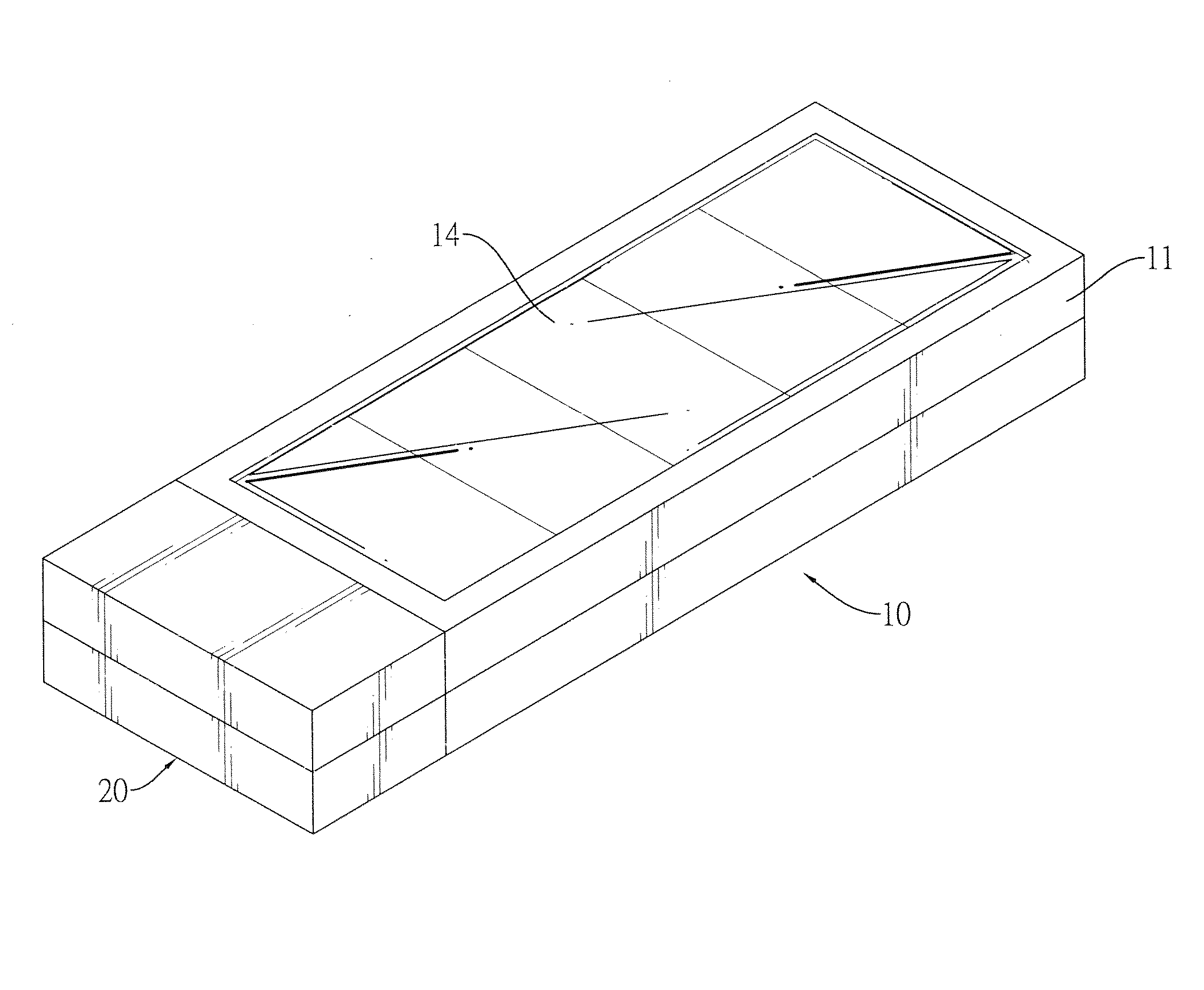

Power extension cord with movable outlet modules

ActiveUS9325132B2Increased durabilitySmall sizeFlexible/turnable line connectorsFlexible lead accommodationMechanical engineeringElectric power

Owner:POWERTECH INDAL

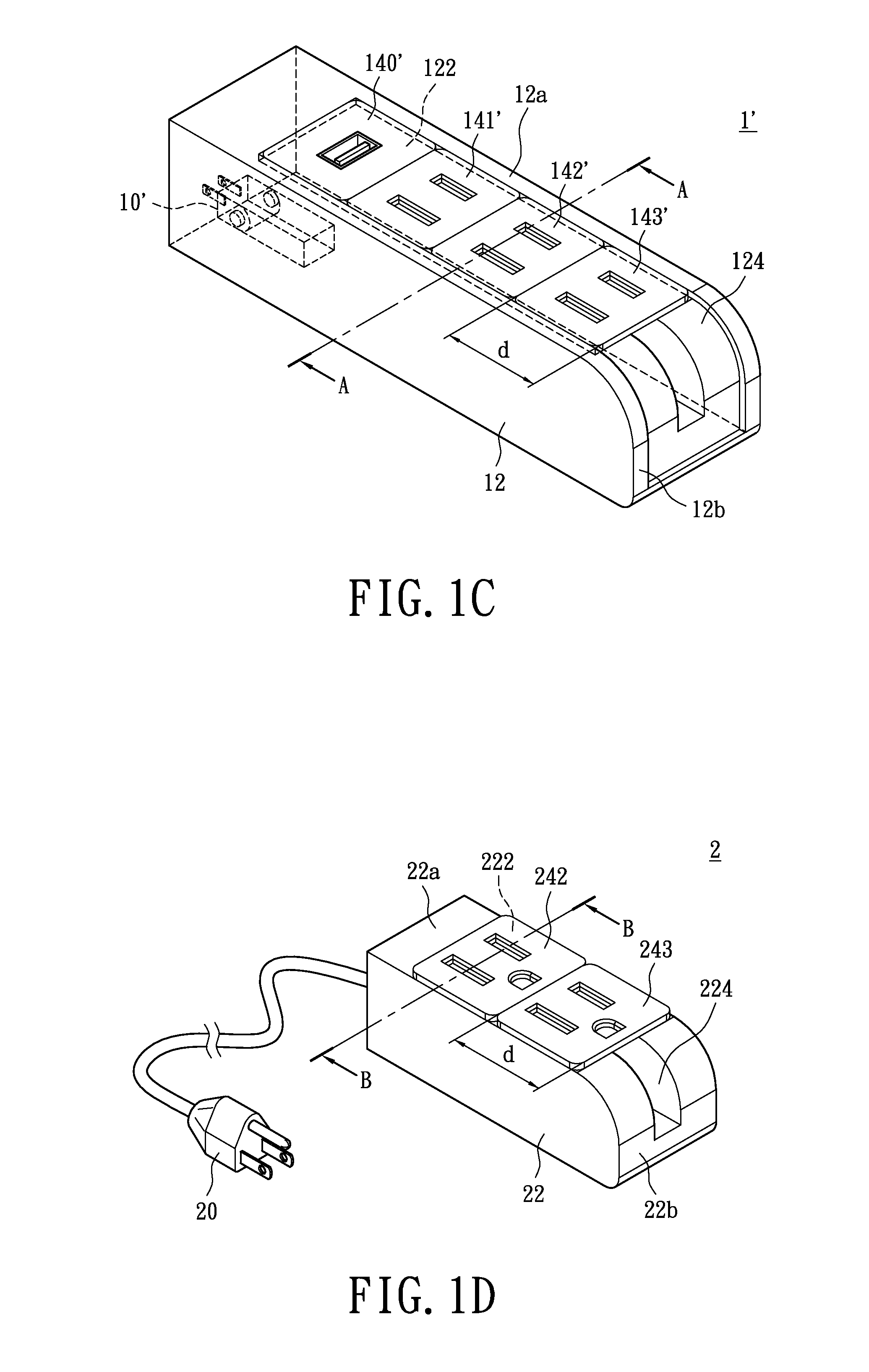

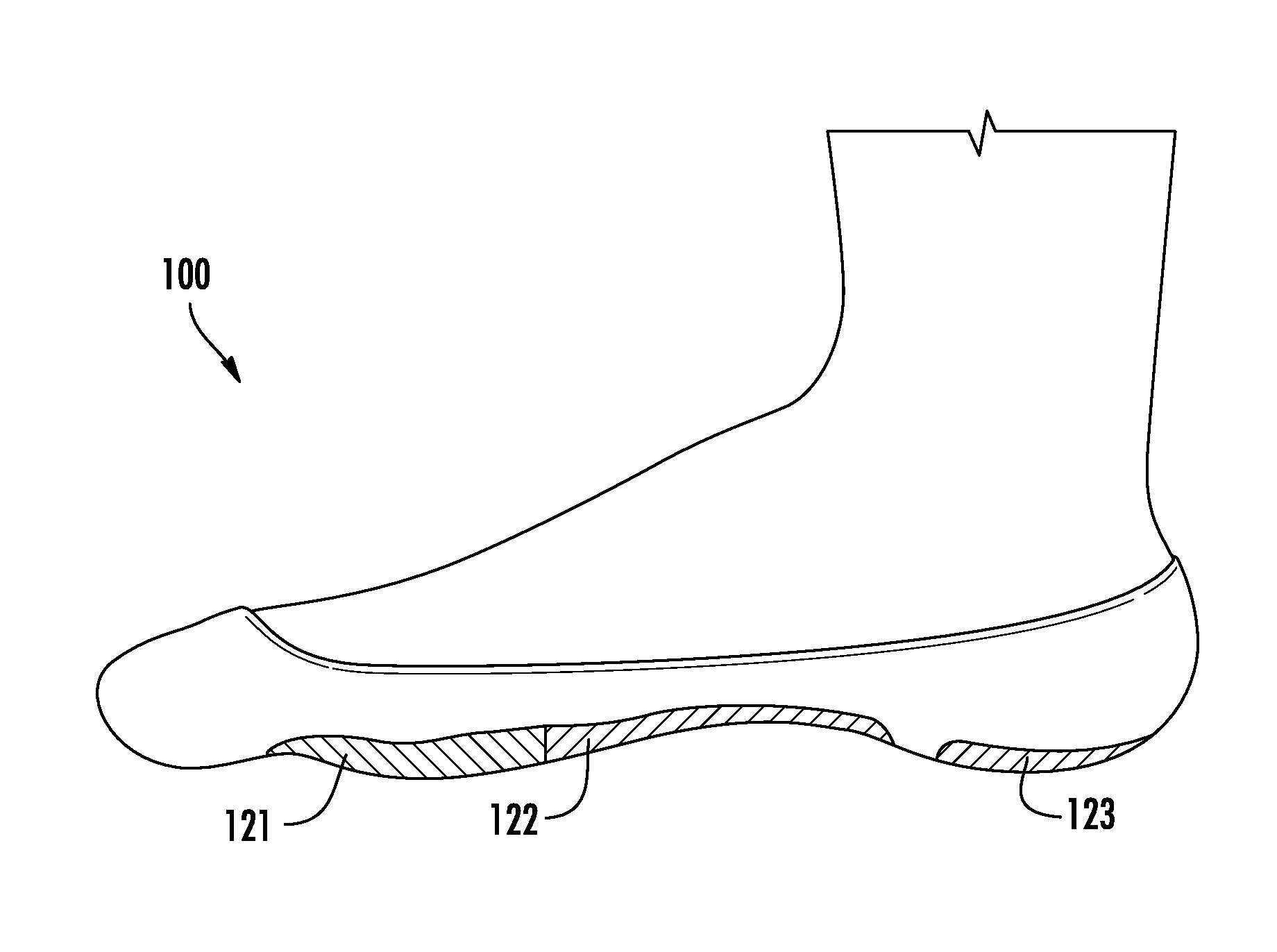

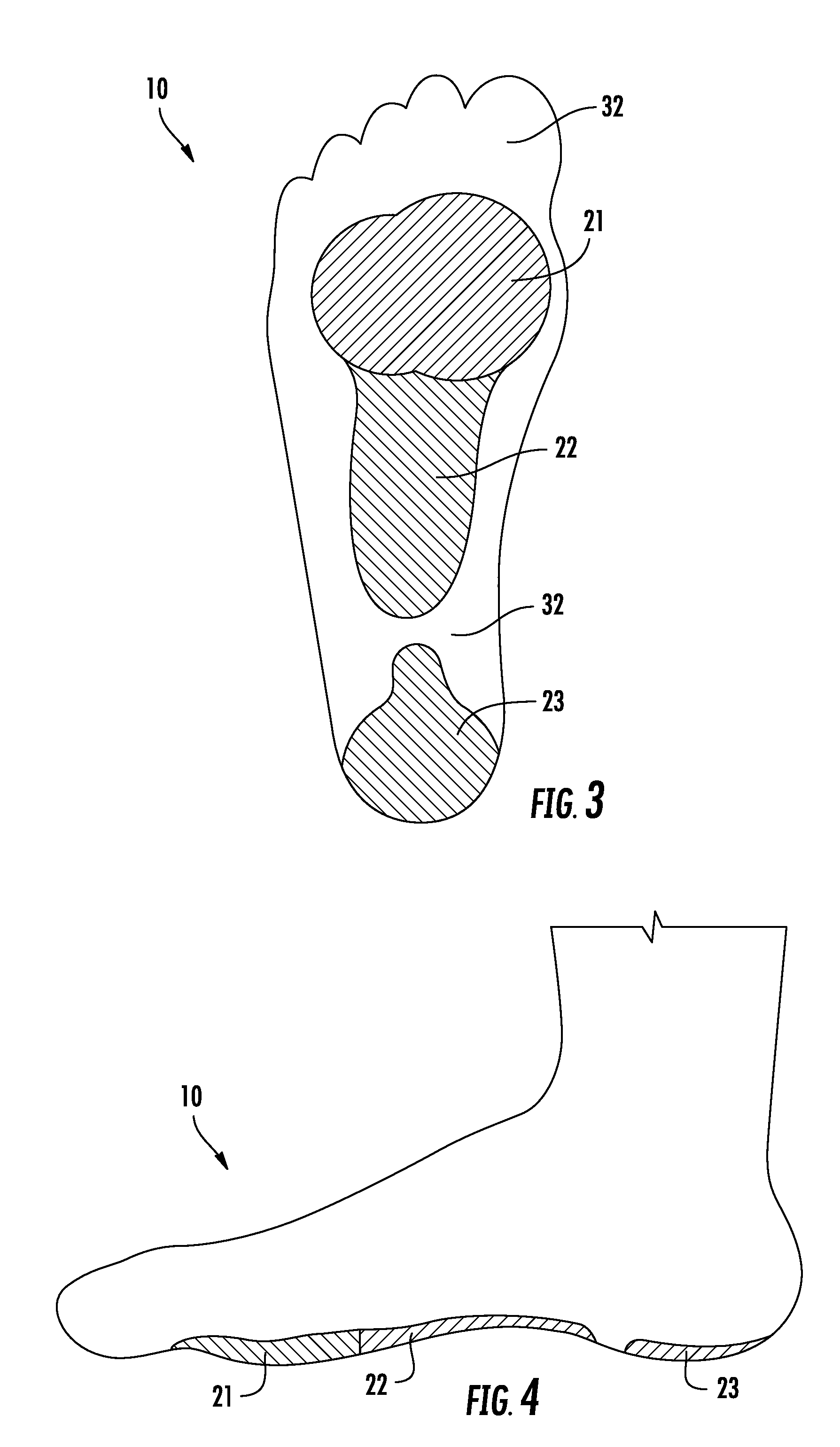

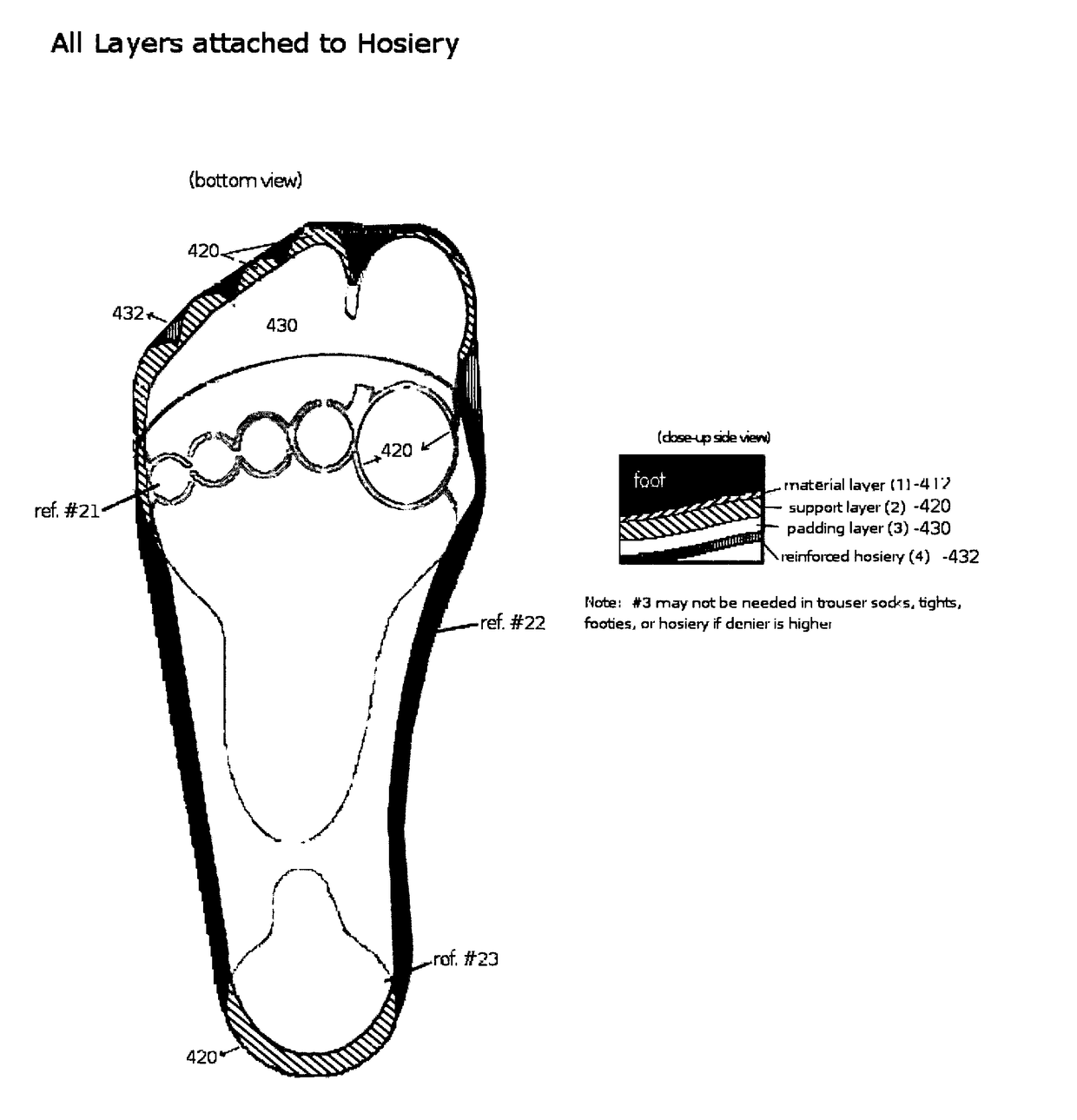

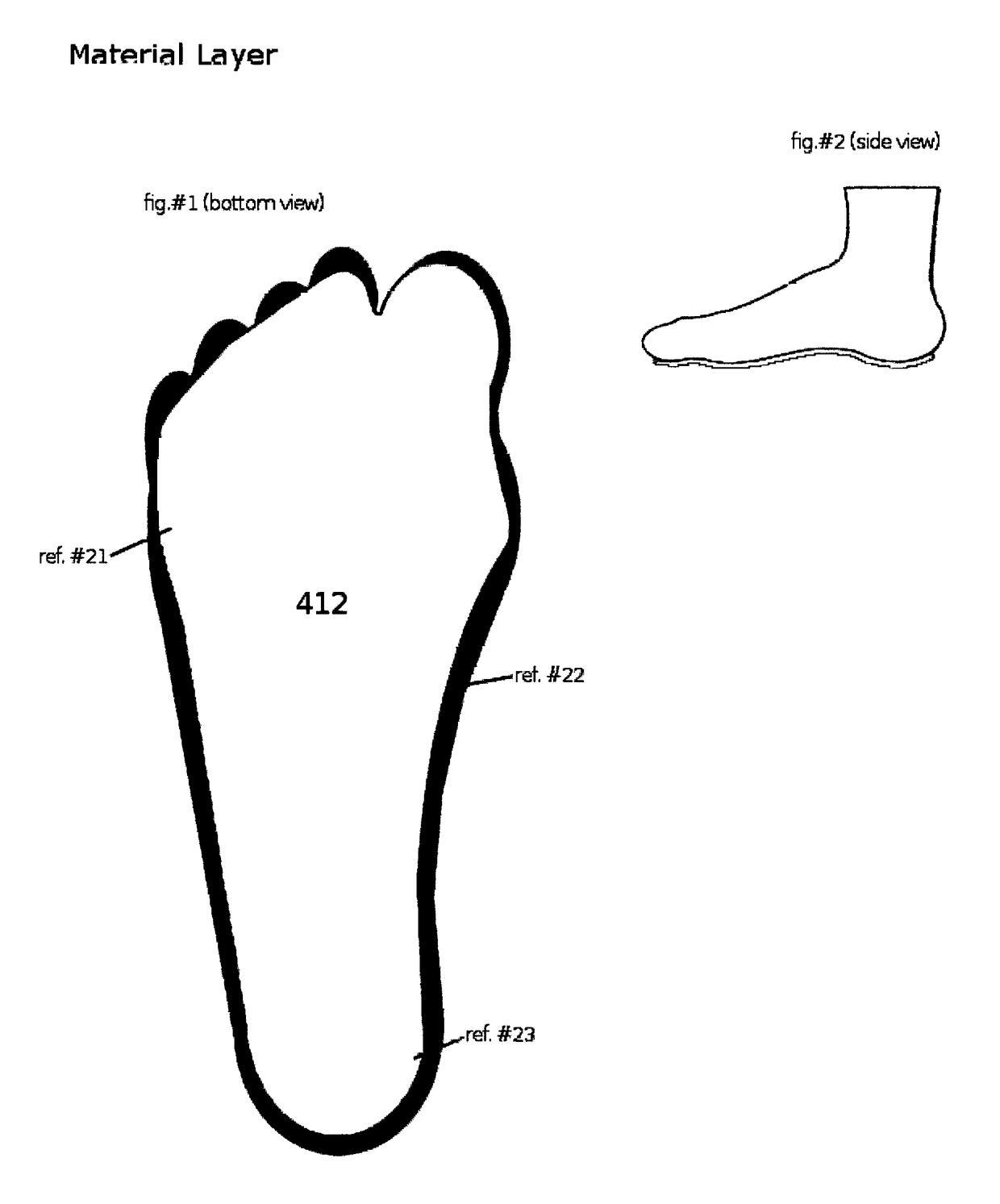

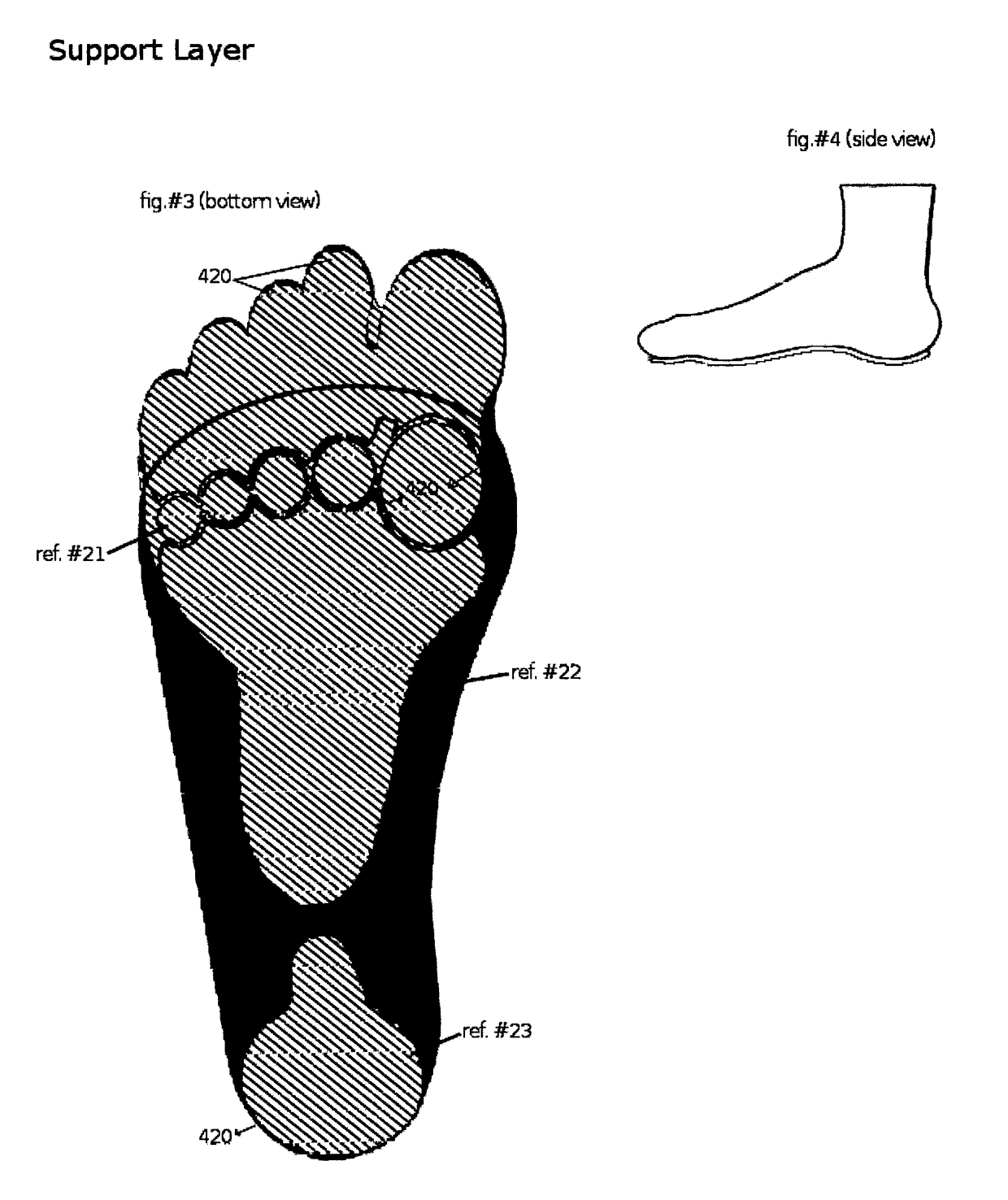

Hosiery with foot cushions

ActiveUS20140230131A1Comfortable standingSimple and easy to put on and useInsolesHandkerchiefsCushioningFoot cushion

A hosiery product, such as a sock, footie, trouser sock or pantyhose, includes an inner layer of hosiery material, such as nylon or spandex covering the bottom and top surfaces of the wearer's foot, an outer layer of similar hosiery material, and at least one cushion section disposed between the inner and outer layers. The cushion section includes a cushioning material that conforms to the contours of the wearer's foot, such as macro-gel activated support discs or memory foam. The cushion section is permanently attached to the inner layer and / or outer layer and is positioned to cushion a particular area of the bottom surface of the wearer's foot, such as the heel, arch and / or ball of the foot.

Owner:ALSTON MELANIE YVONNE

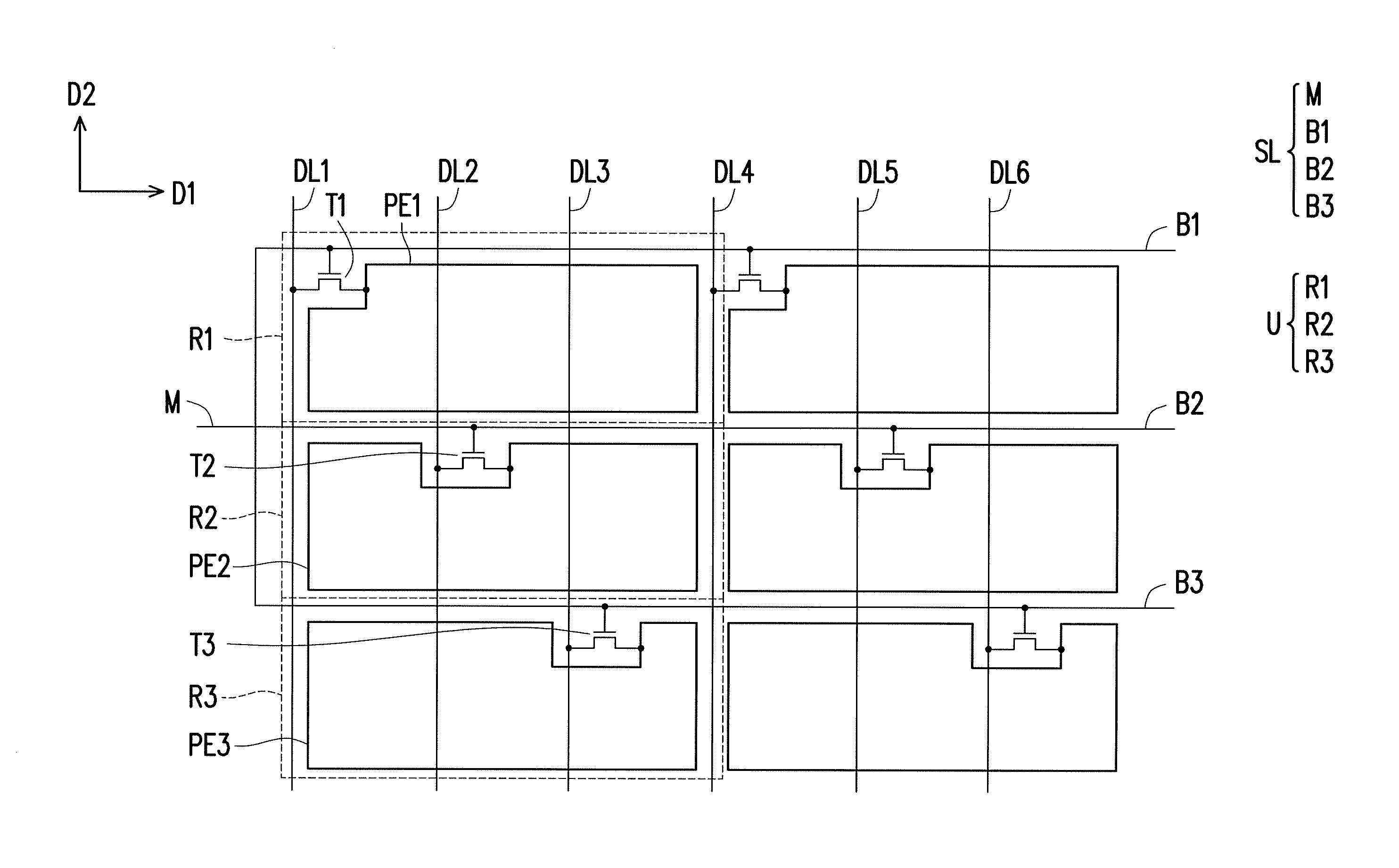

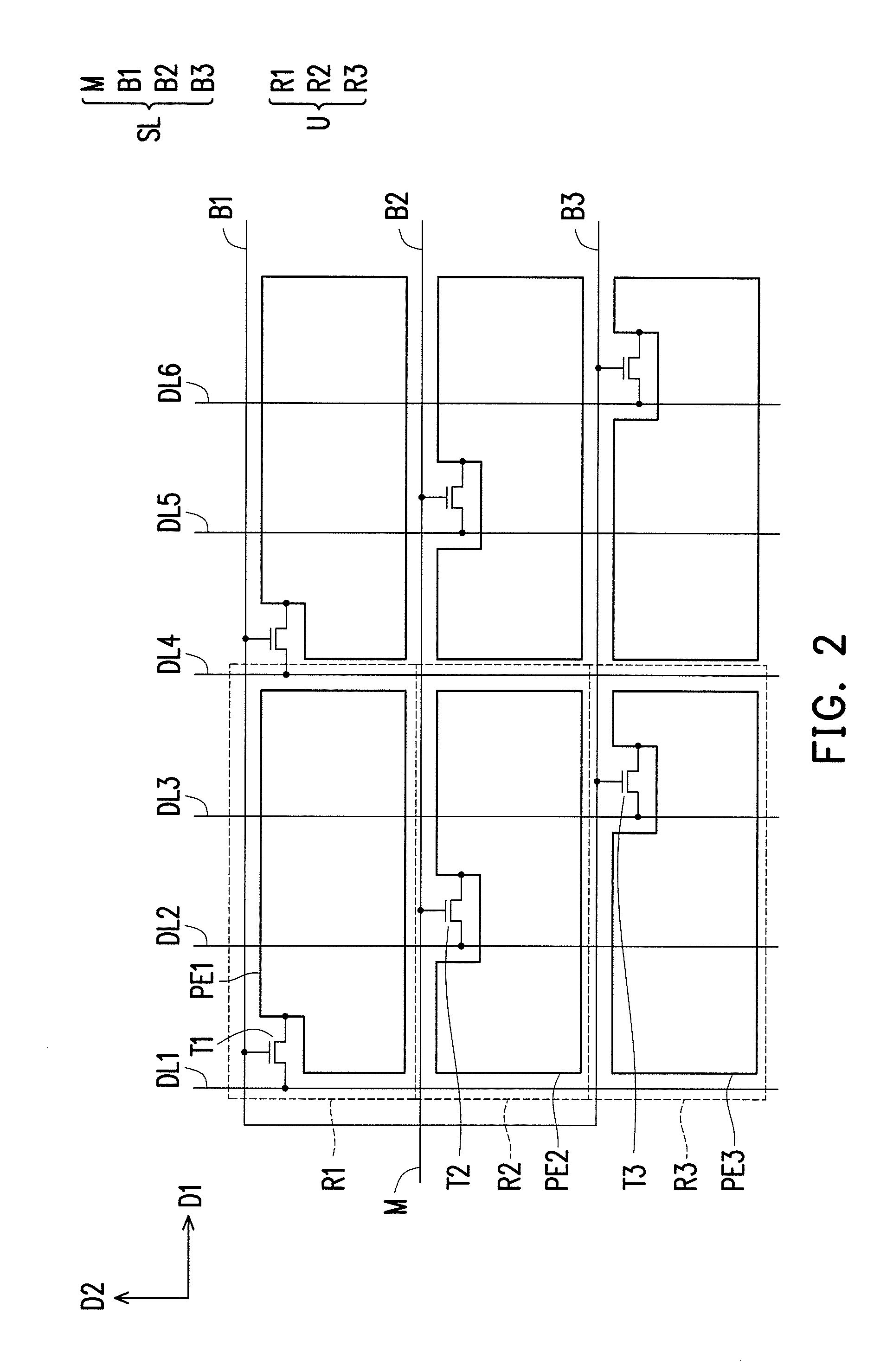

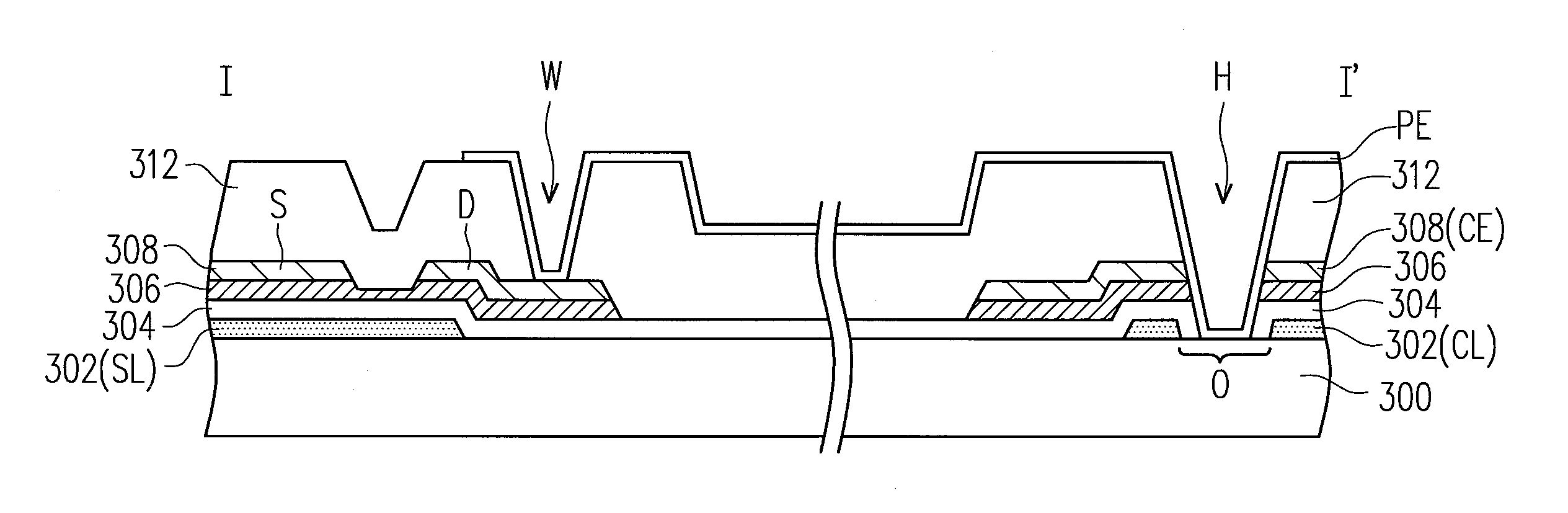

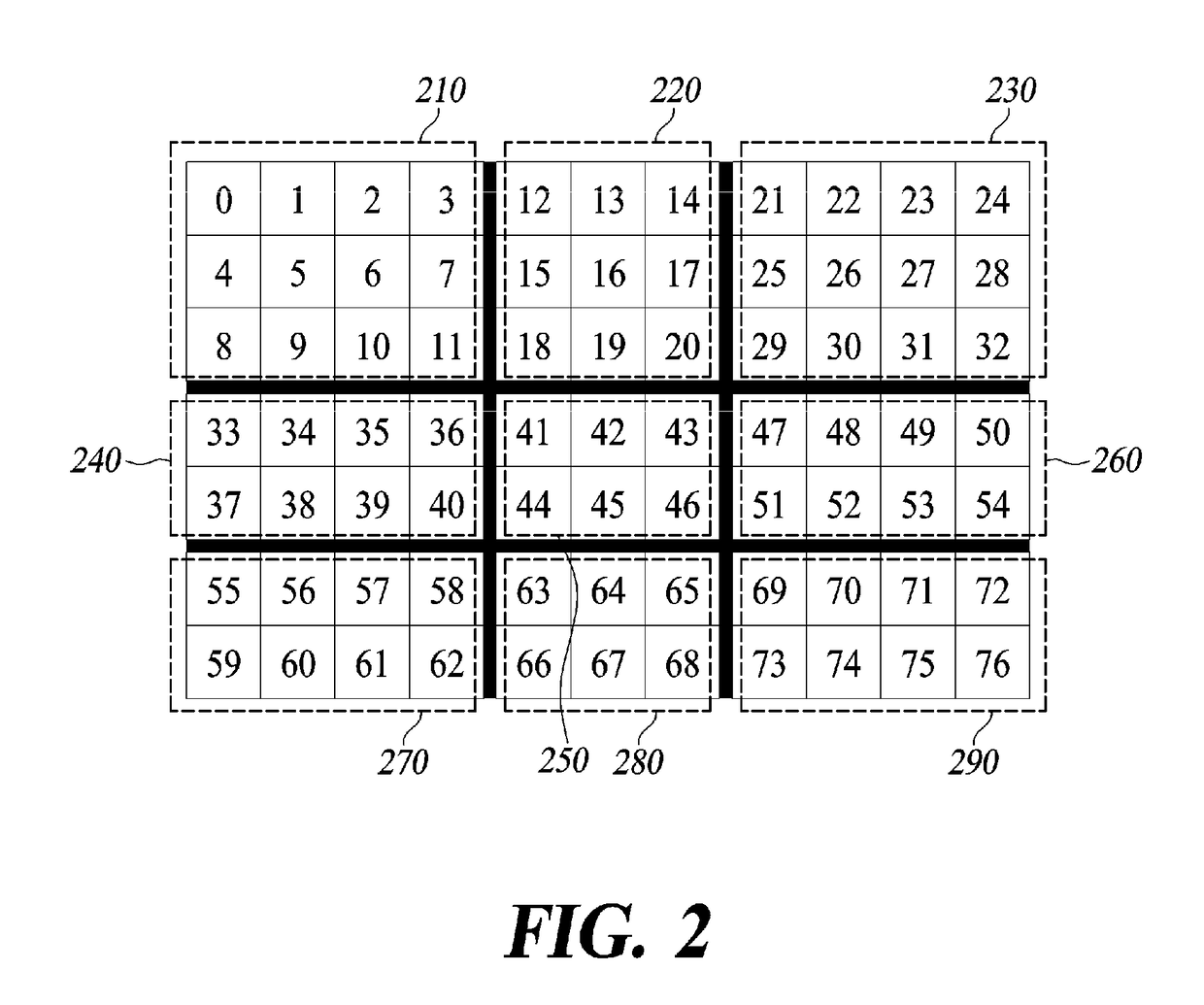

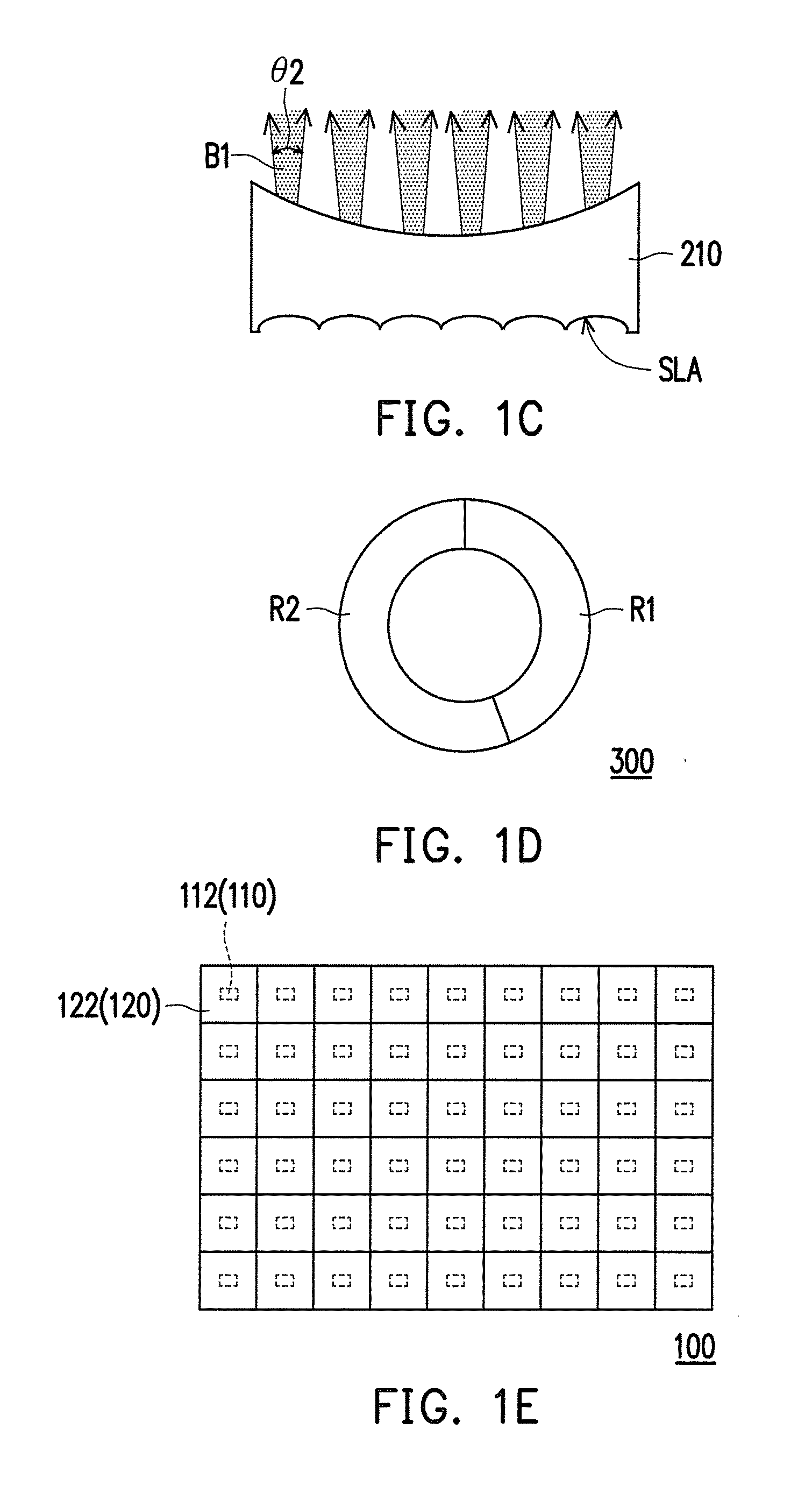

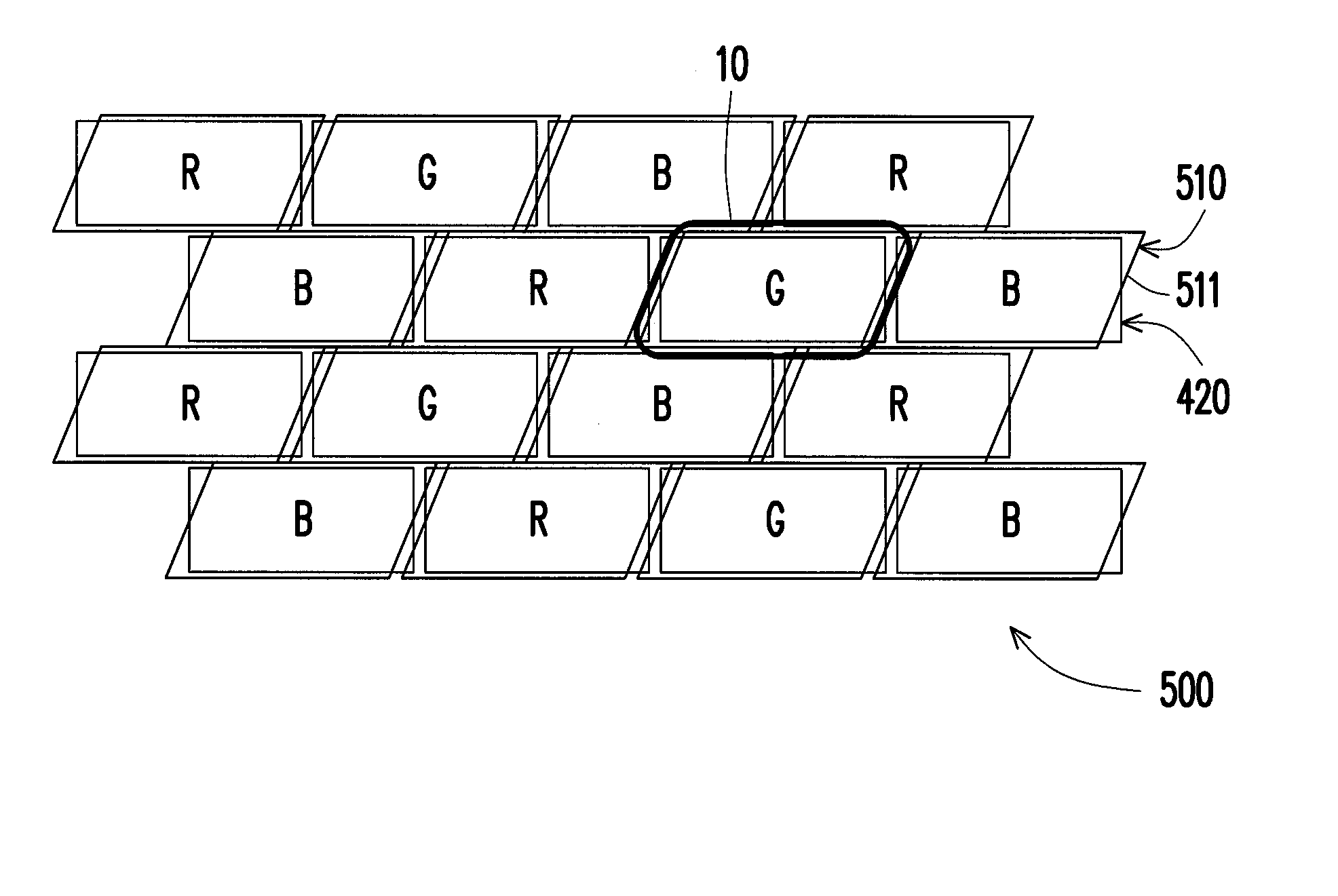

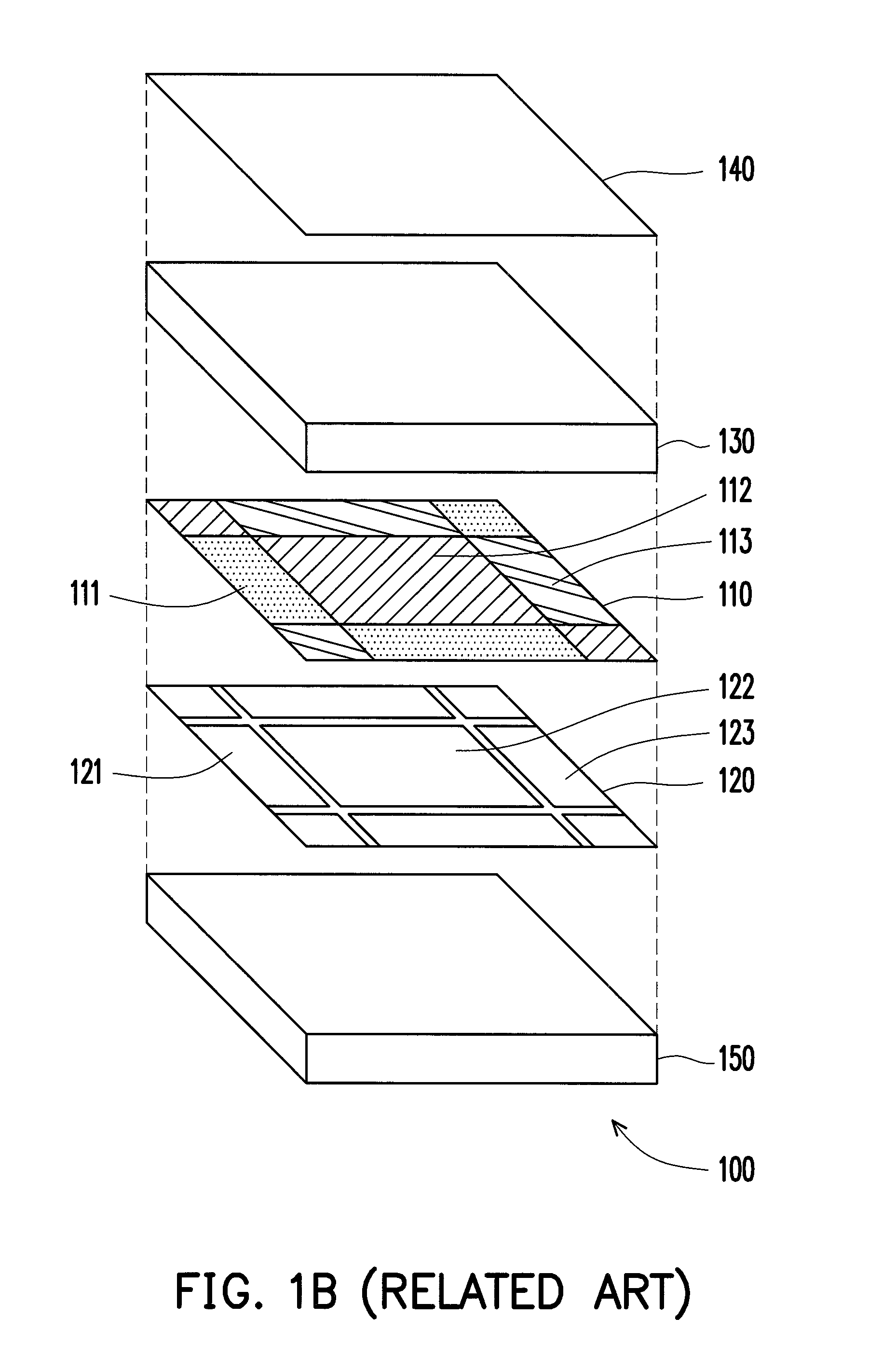

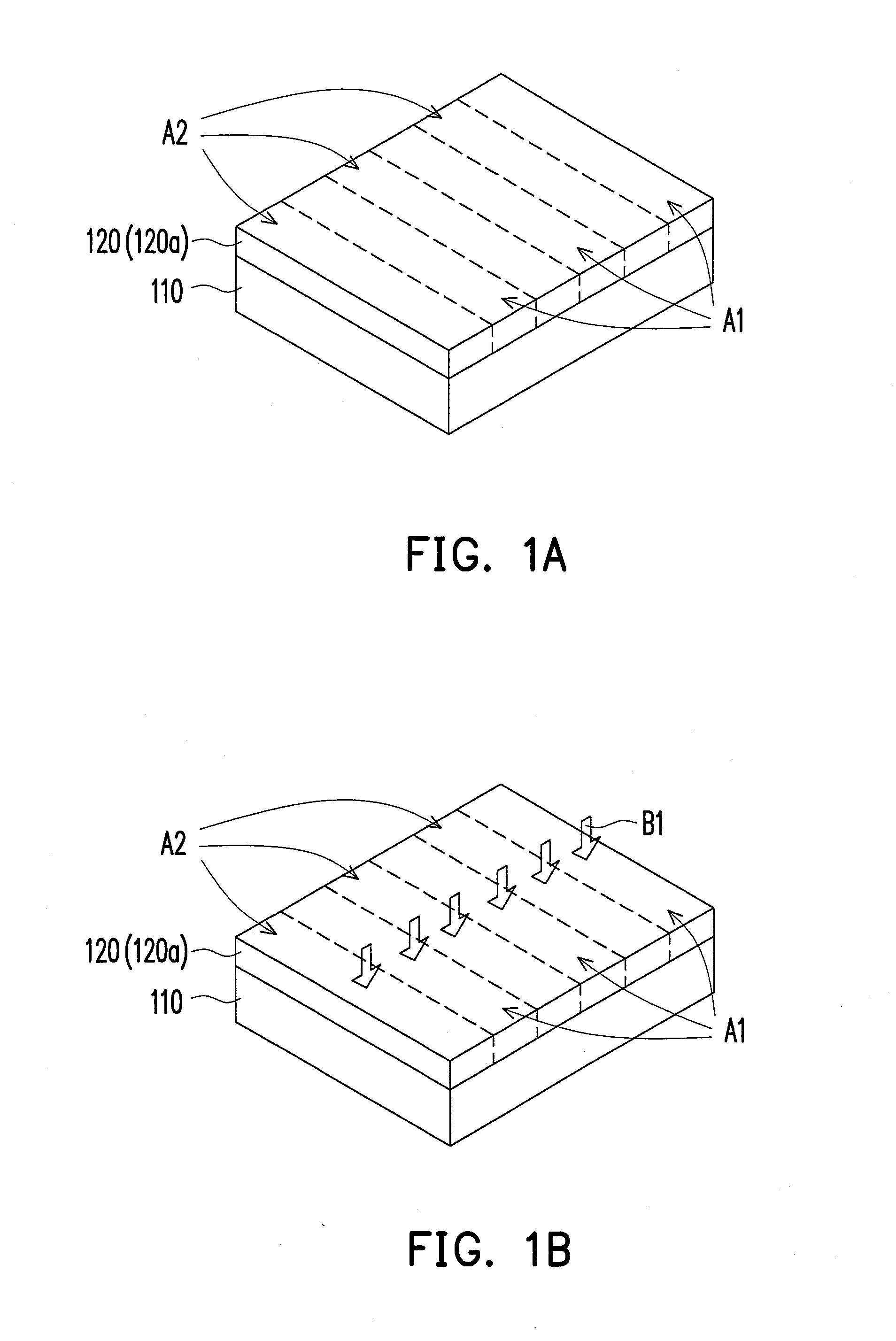

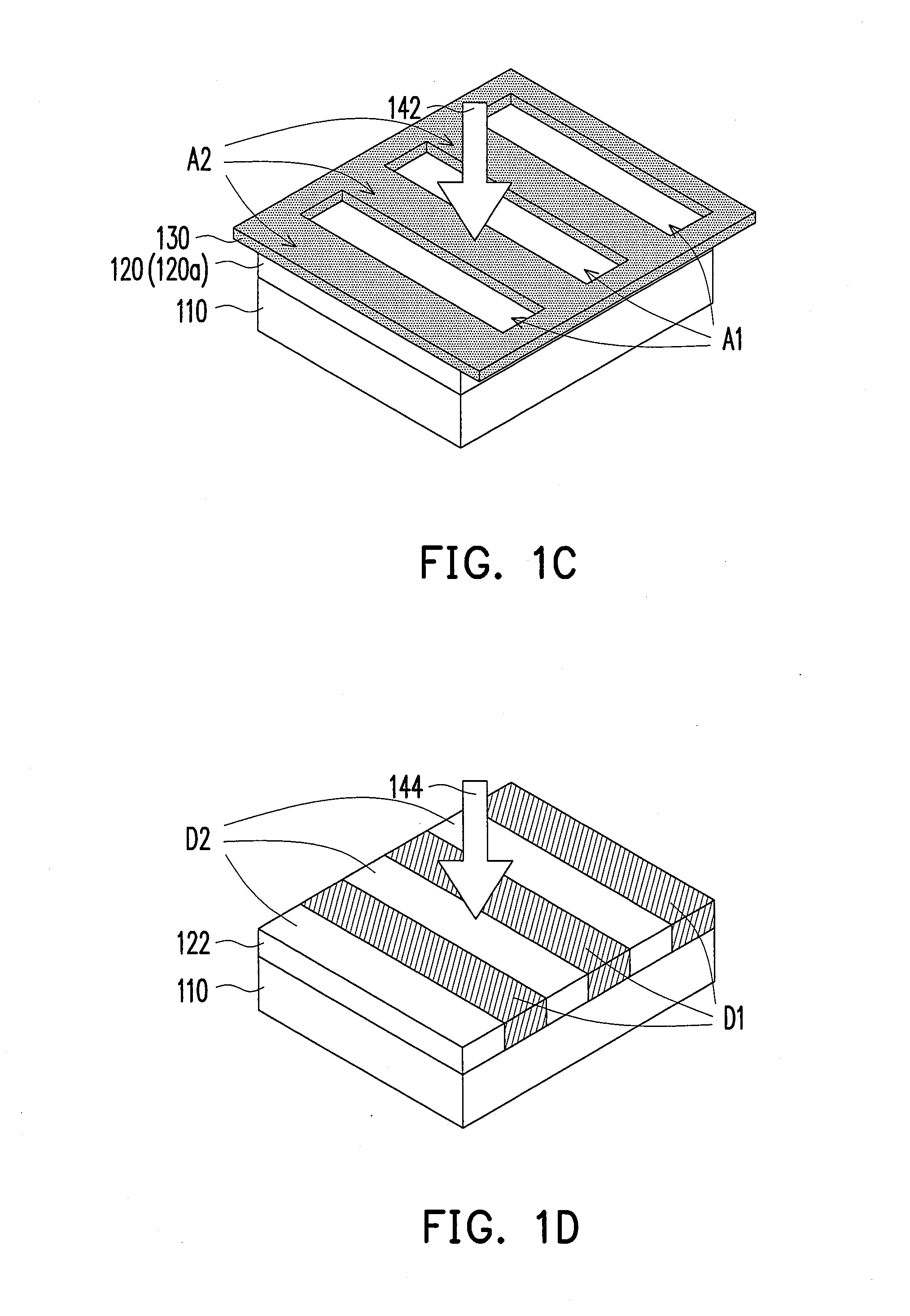

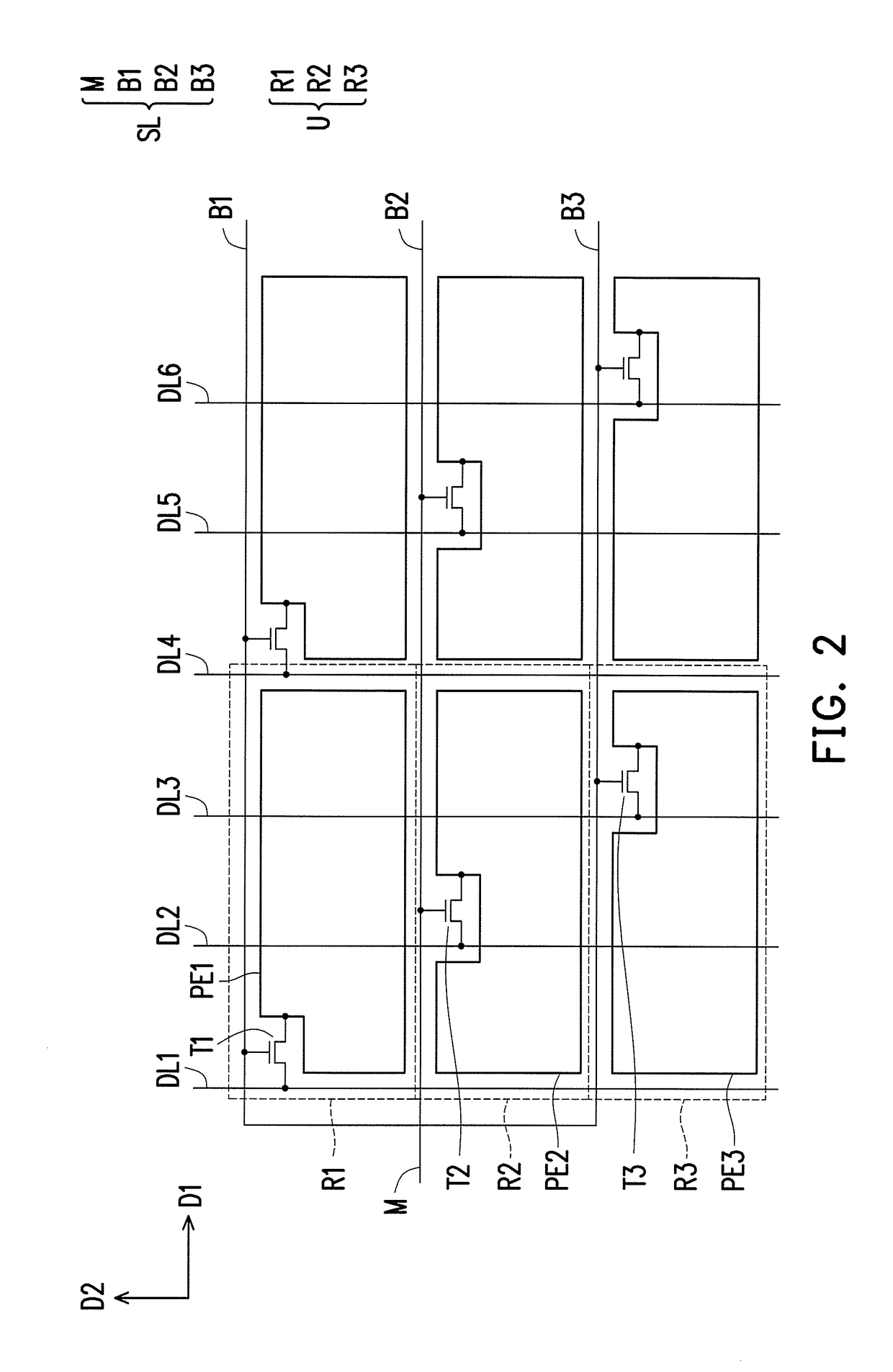

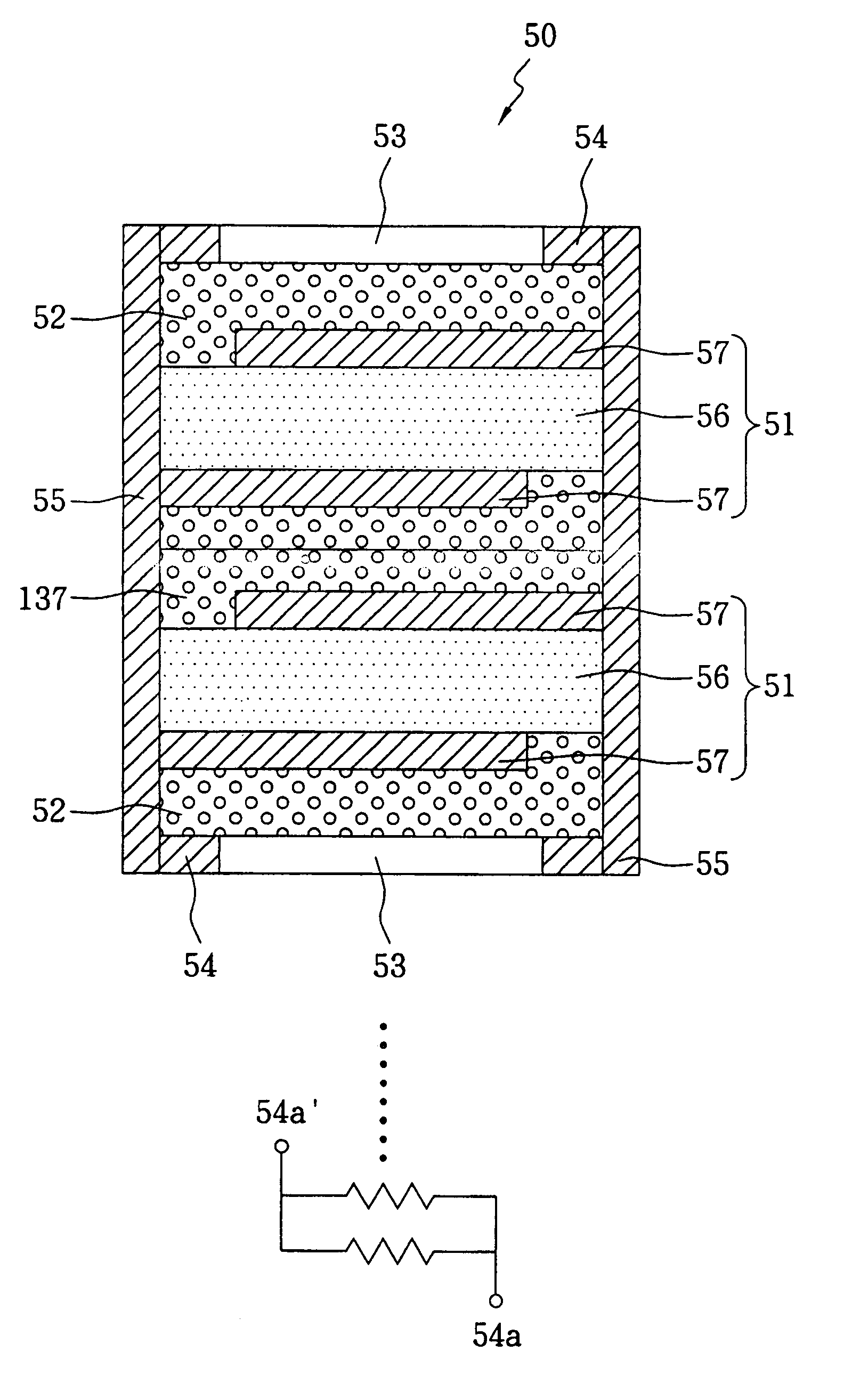

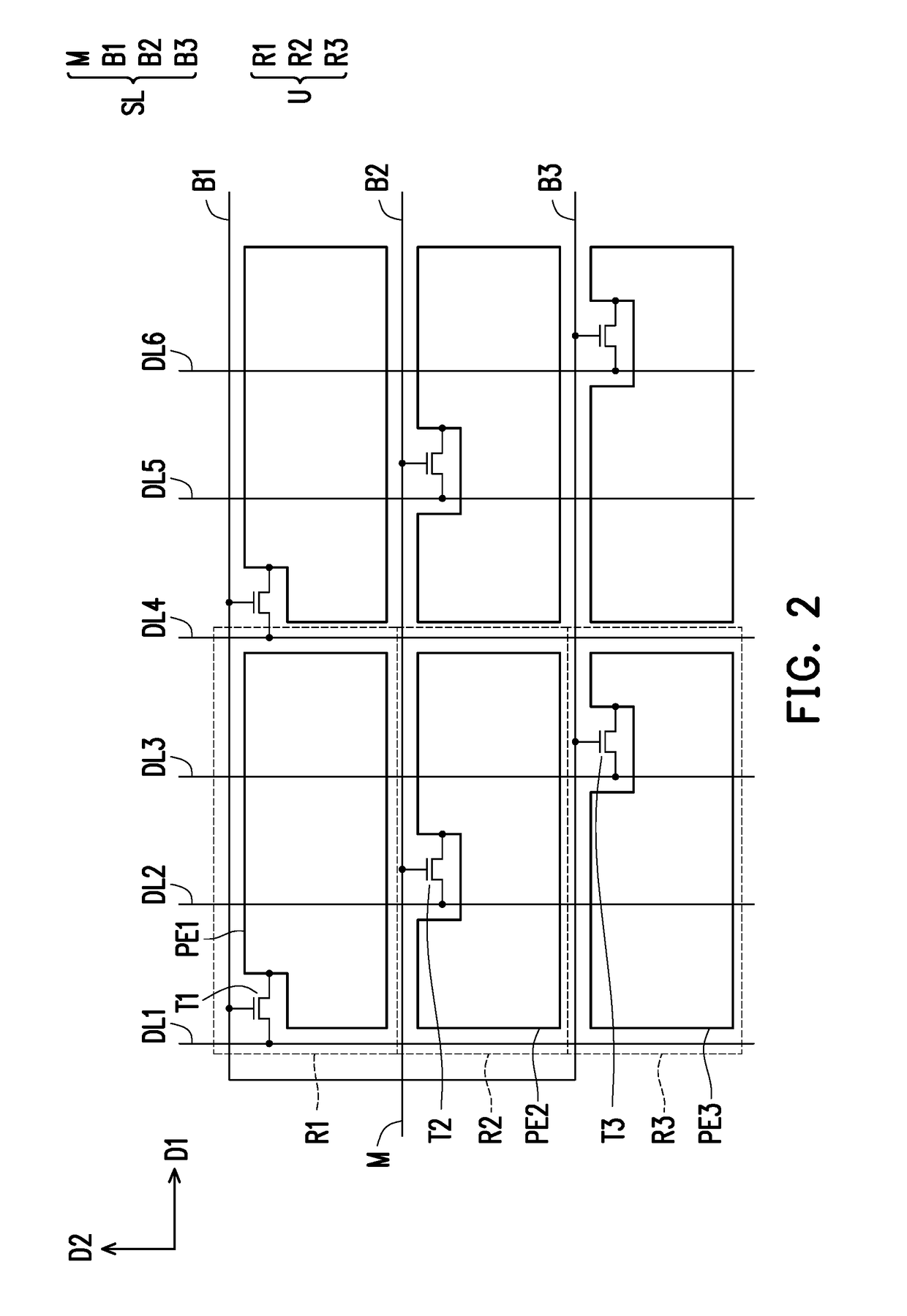

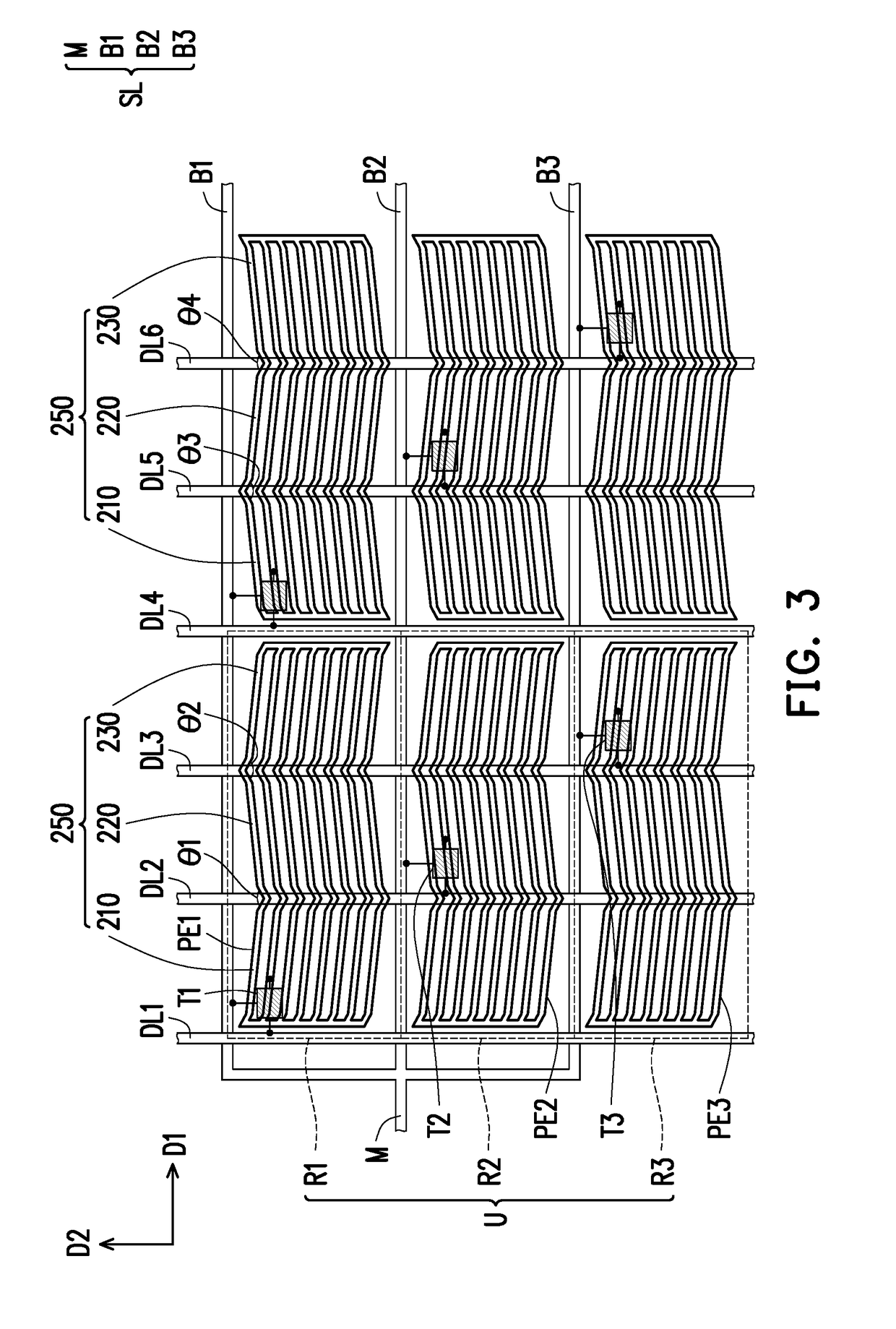

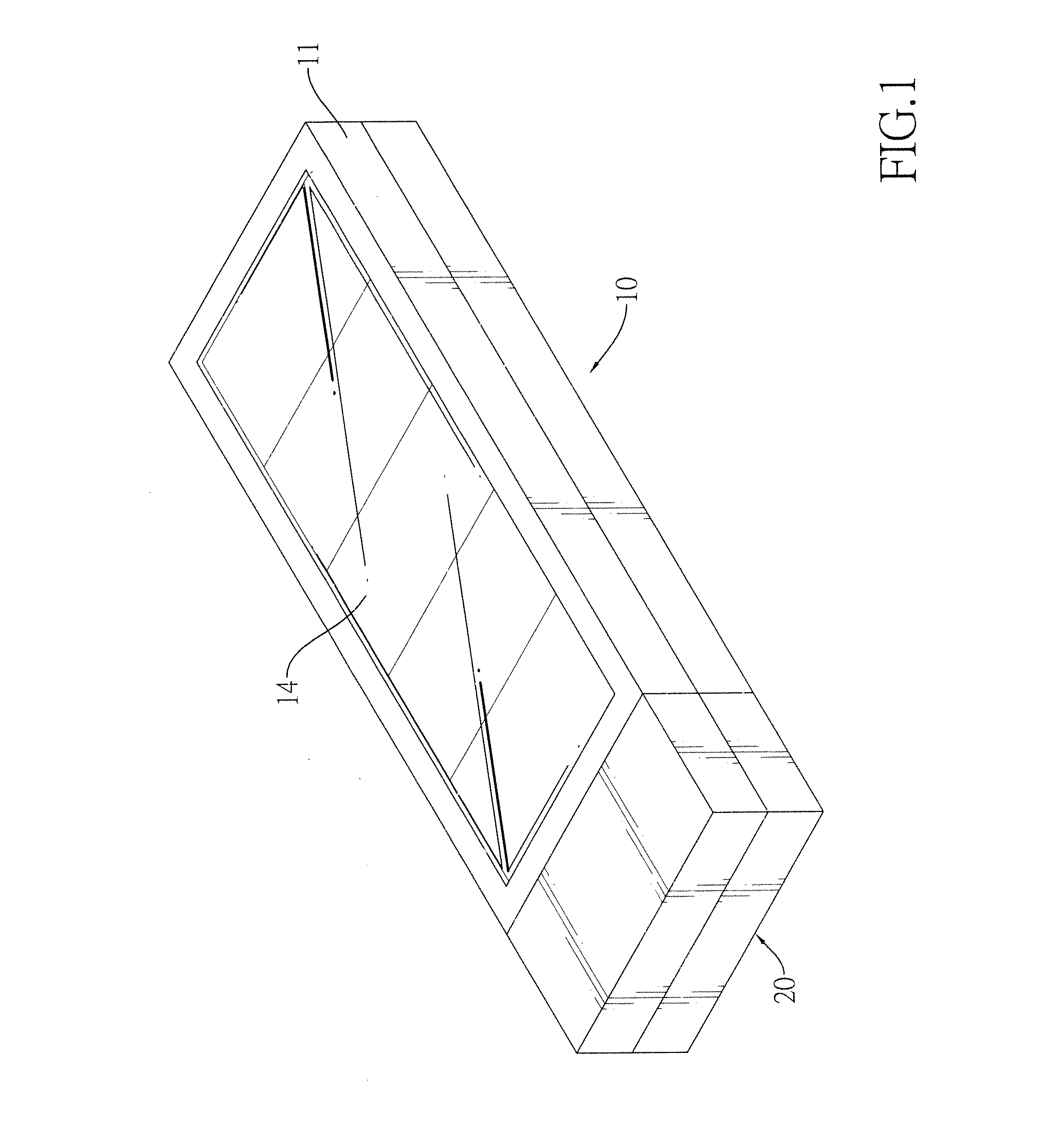

Pixel array, display panel and curved display panel

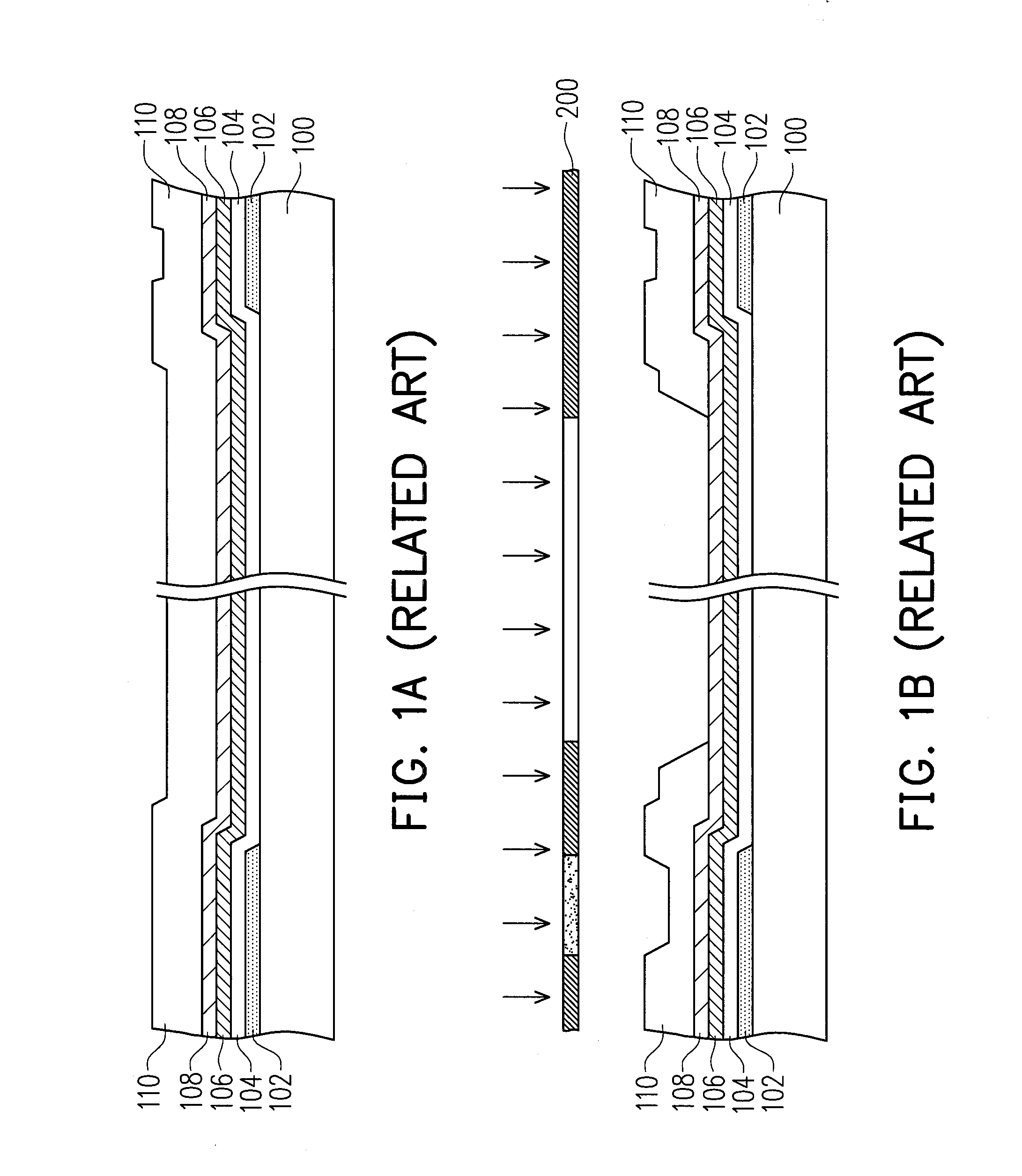

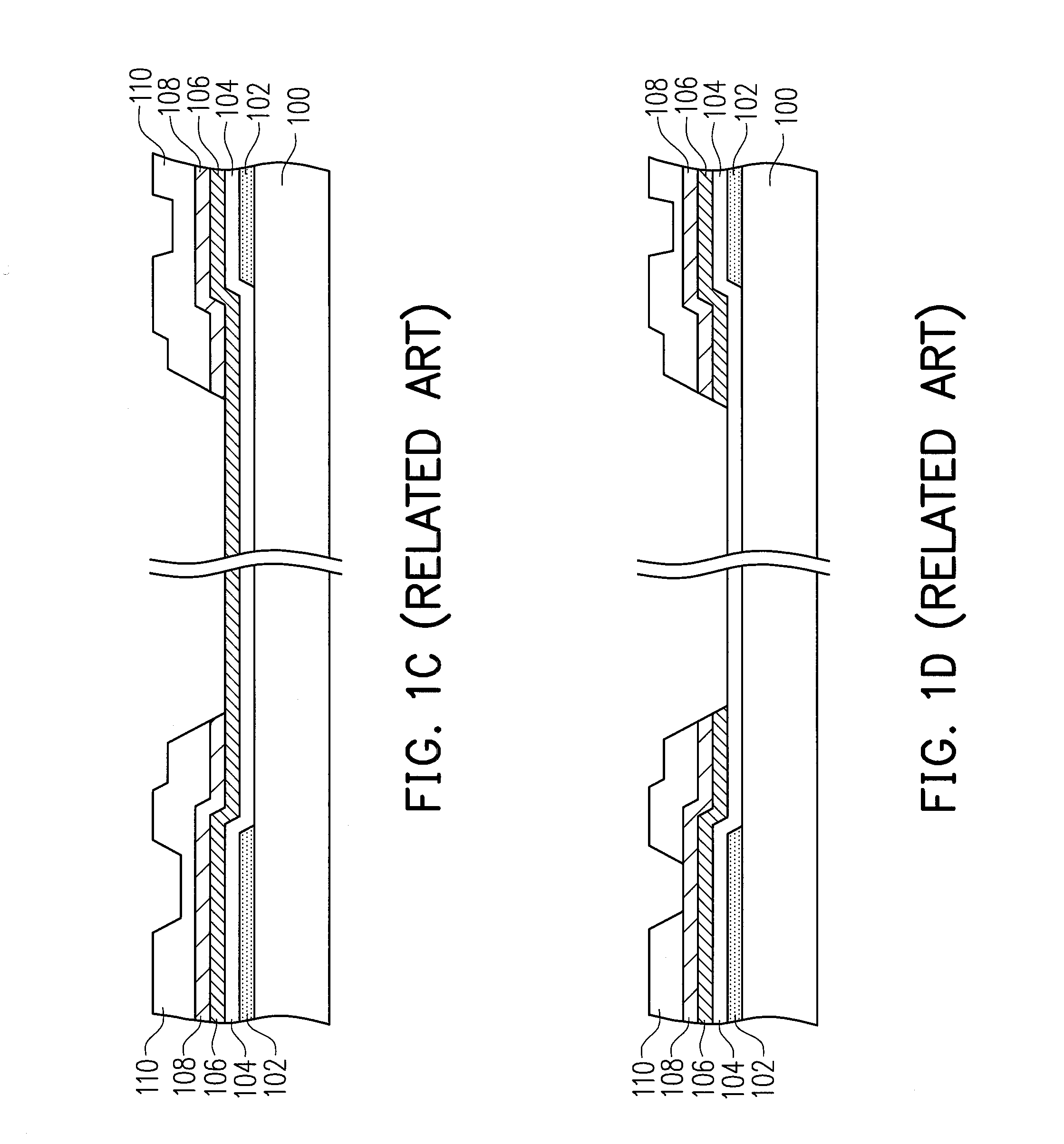

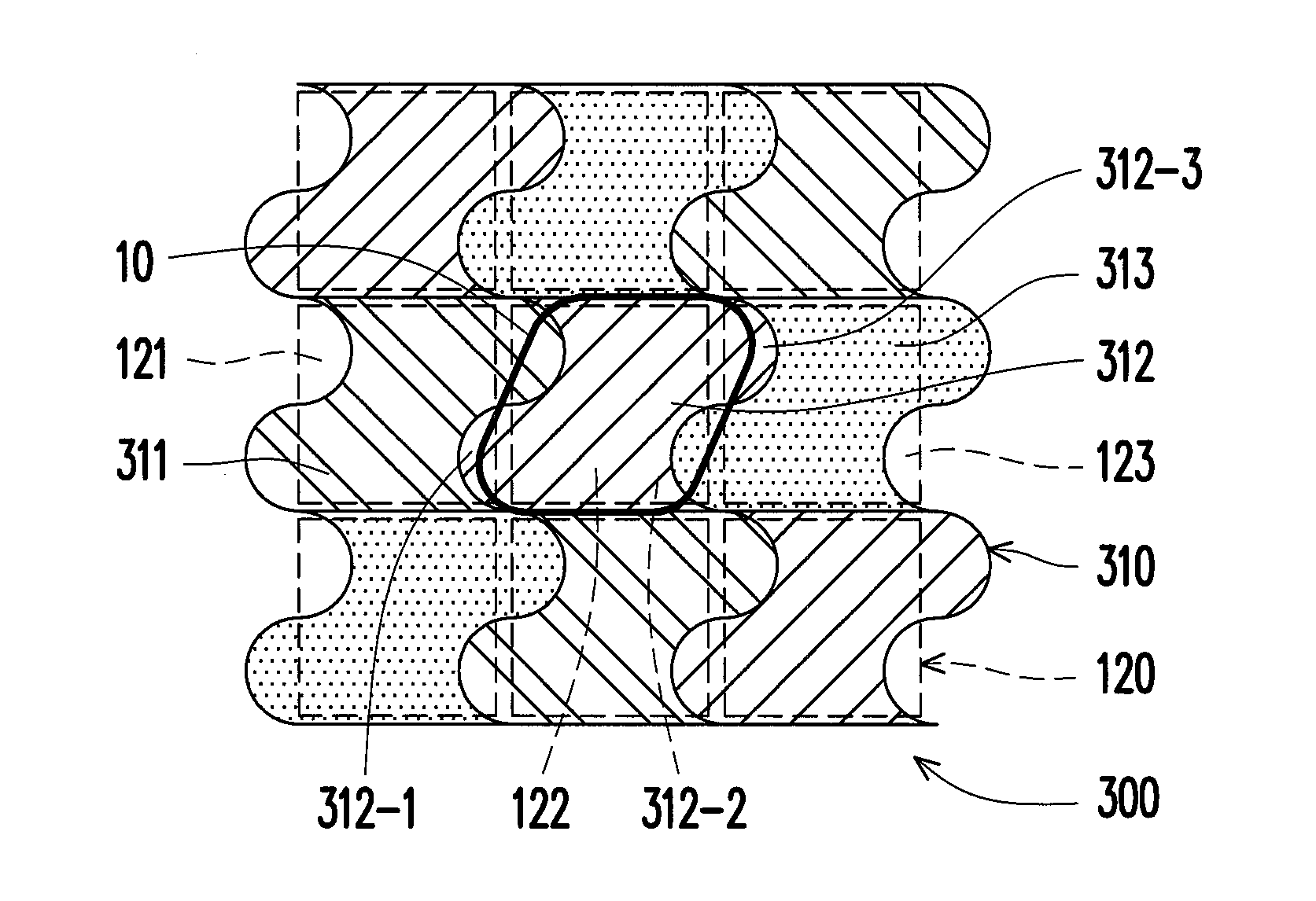

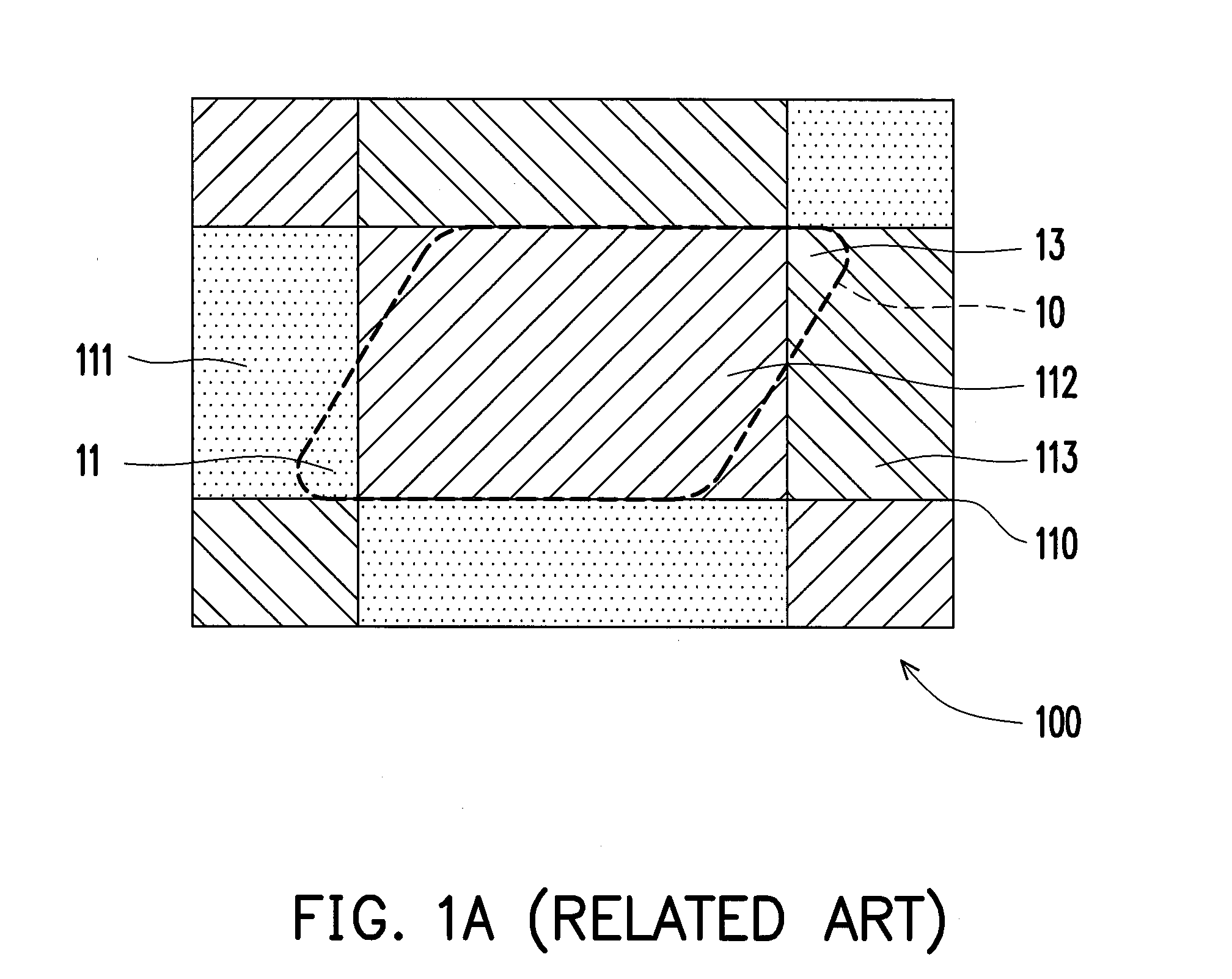

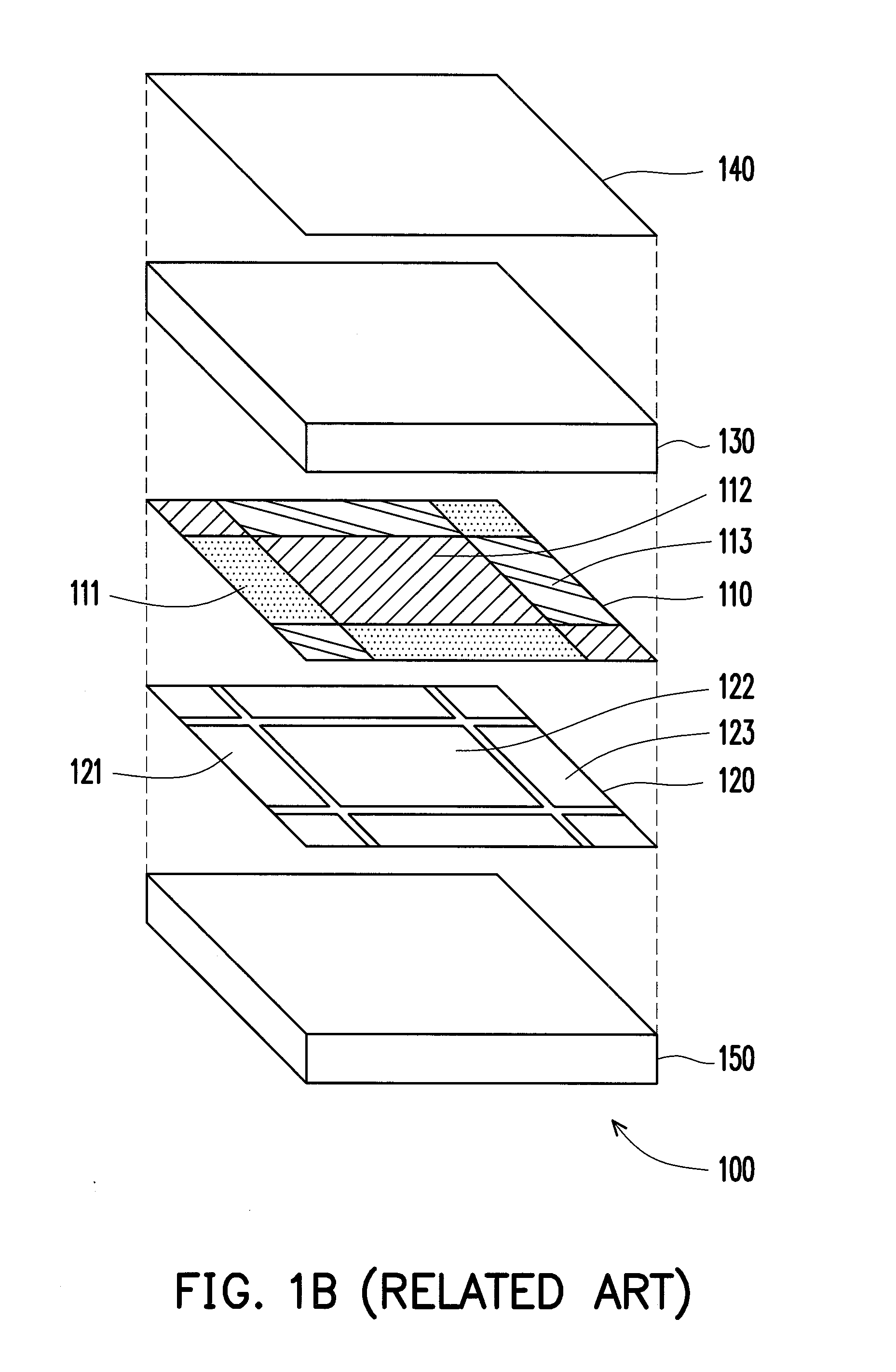

ActiveUS20170045794A1Avoid display qualityIssue can be resolvedSolid-state devicesNon-linear opticsScan lineComputer science

A pixel array includes pixel unit sets each including a substrate having first and second pixel regions, a scan line, first and second data lines extending along a second direction, first and second active devices respectively in the first and second pixel regions, and first and second pixel electrodes respectively located in the first and second pixel regions and electrically connected to the first and second active devices, respectively. The scan line includes a main scan line and first and second branch scan lines (connected to the main scan line) extending along a first direction. The first active device is electrically connected to the first branch scan line and the first data line. The second active device is electrically connected to the second branch scan line and the second data line. At least one of the first and second data lines is overlapped with the first and second pixel electrodes.

Owner:AU OPTRONICS CORP

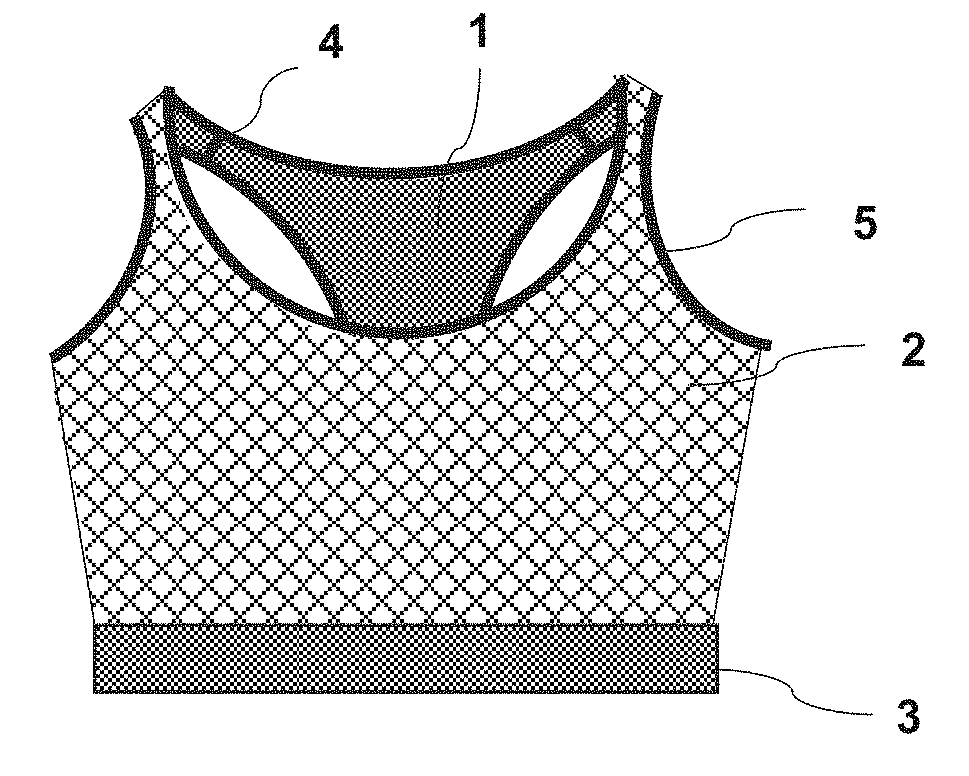

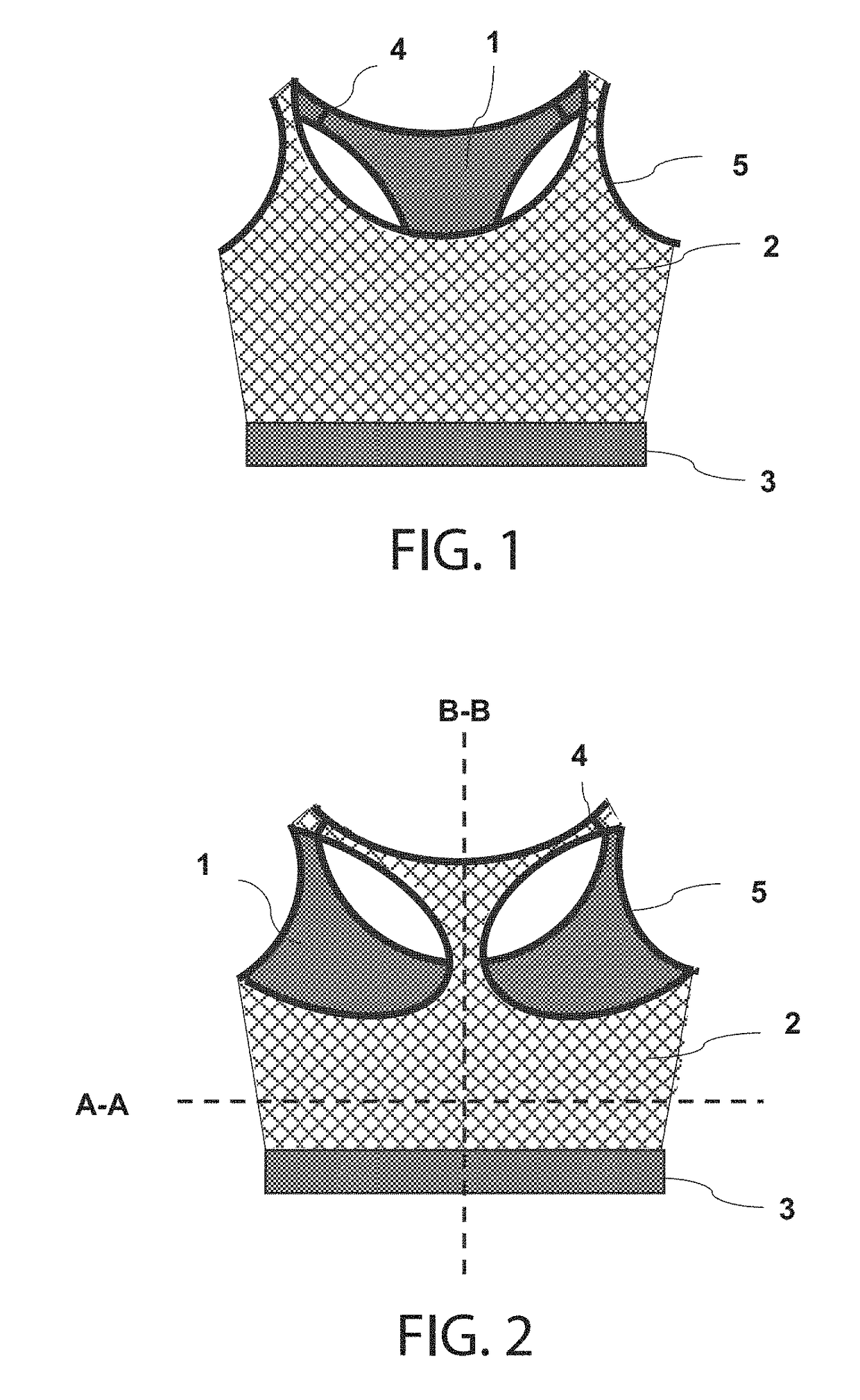

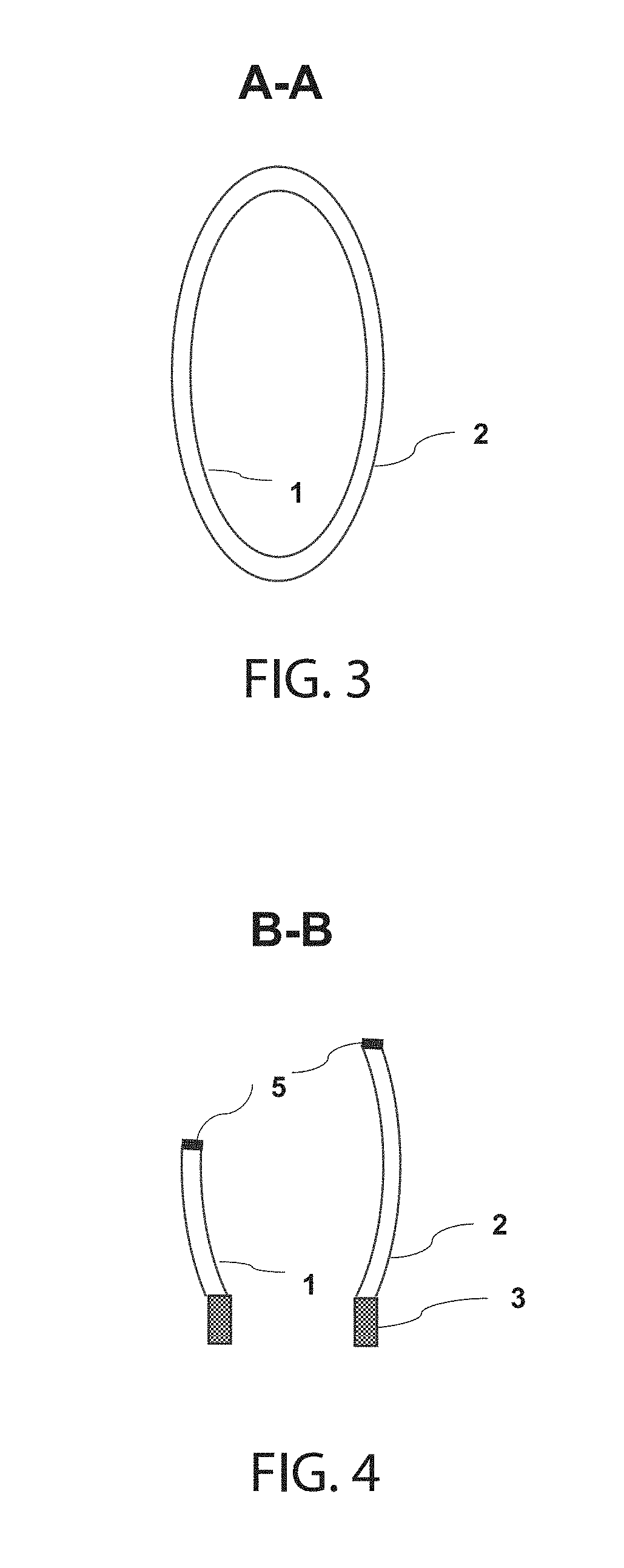

Seamless Double Layered Porous Woven Structure

InactiveUS20170233906A1High air permeable woven structureSmall quantity productionWeft knittingLayered productsYarnEngineering

Owner:HWANG YU CHEN

Pixel structure and dual gate pixel structure

A pixel structure includes a substrate, a first metal layer, a gate insulator, a semiconductor layer, a second metal layer, a passivation layer, a hole, and a pixel electrode. The first metal layer is configured on the substrate and includes a scan line, a gate, and a common electrode. The common electrode has a predetermined opening. The gate insulator covers the first metal layer. The semiconductor layer is configured on the gate insulator. The semiconductor layer underlies the entire second metal layer. The passivation layer covers the second metal layer. The hole located in the predetermined opening goes through the passivation layer and exposes the second metal layer. The pixel electrode is configured on the passivation layer and fills the hole. The pixel electrode is electrically connected to the second metal layer via the hole. A dual gate pixel structure is also provided.

Owner:CHUNGHWA PICTURE TUBES LTD

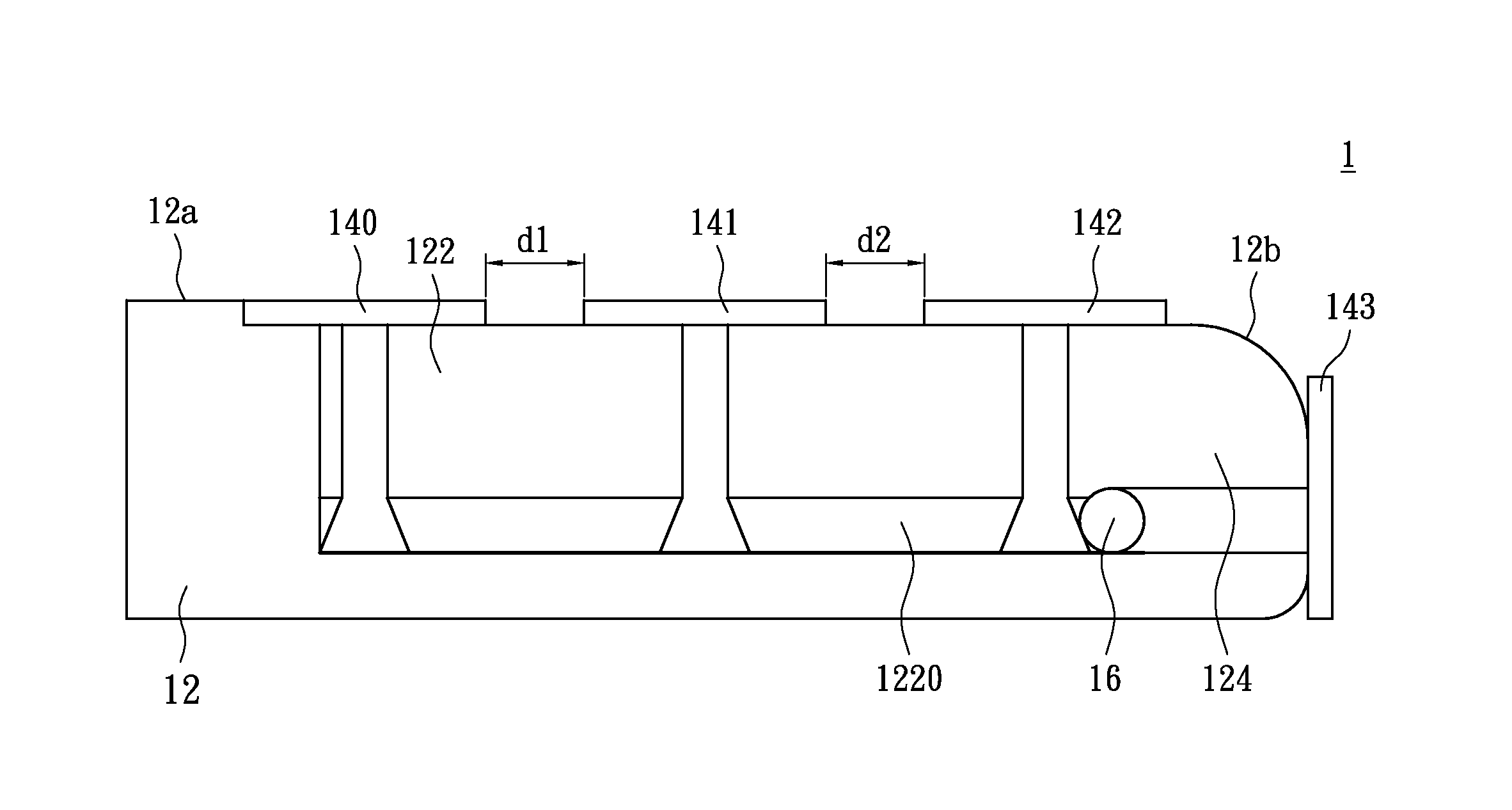

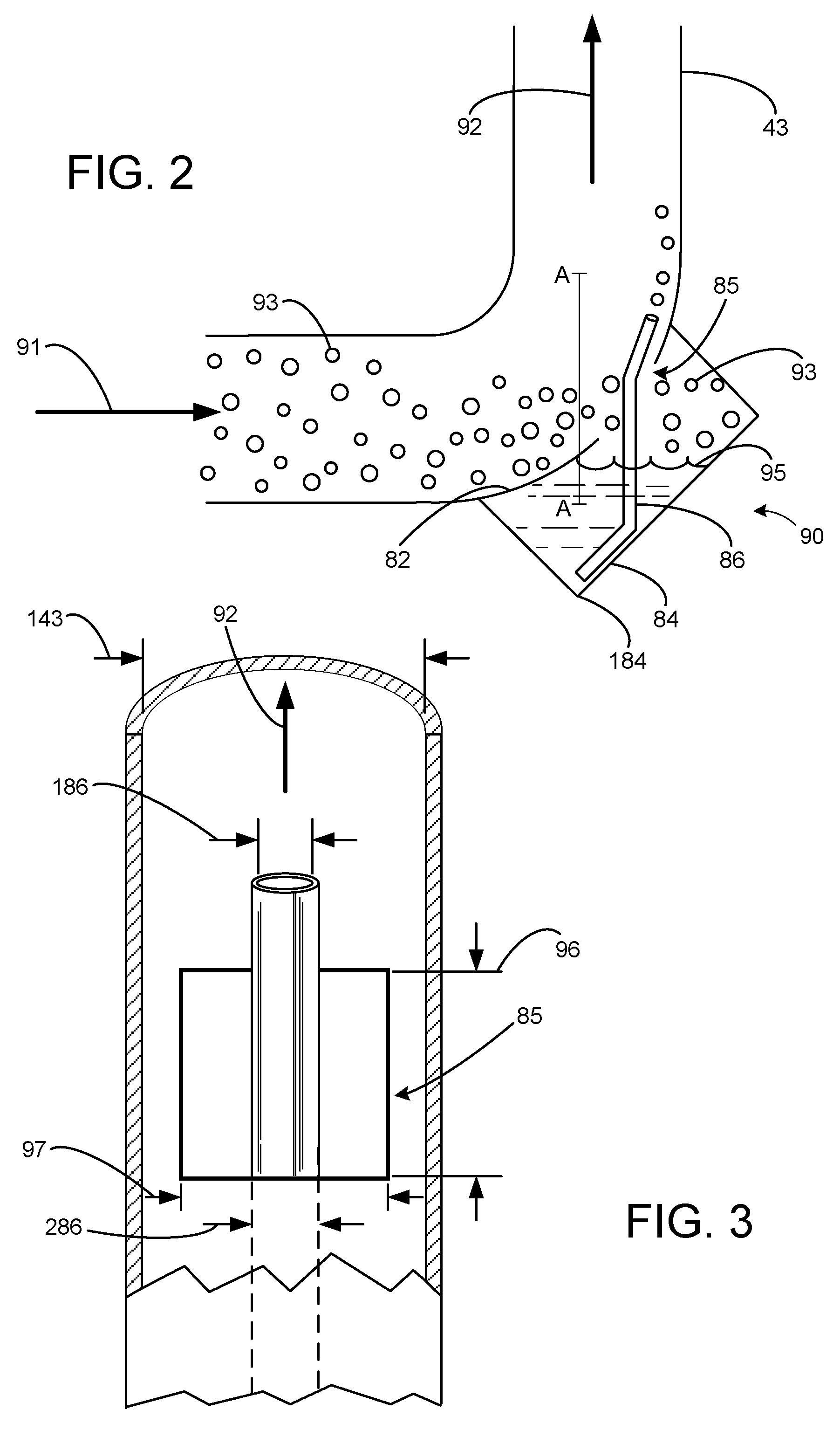

Condensation trap for charge air cooler

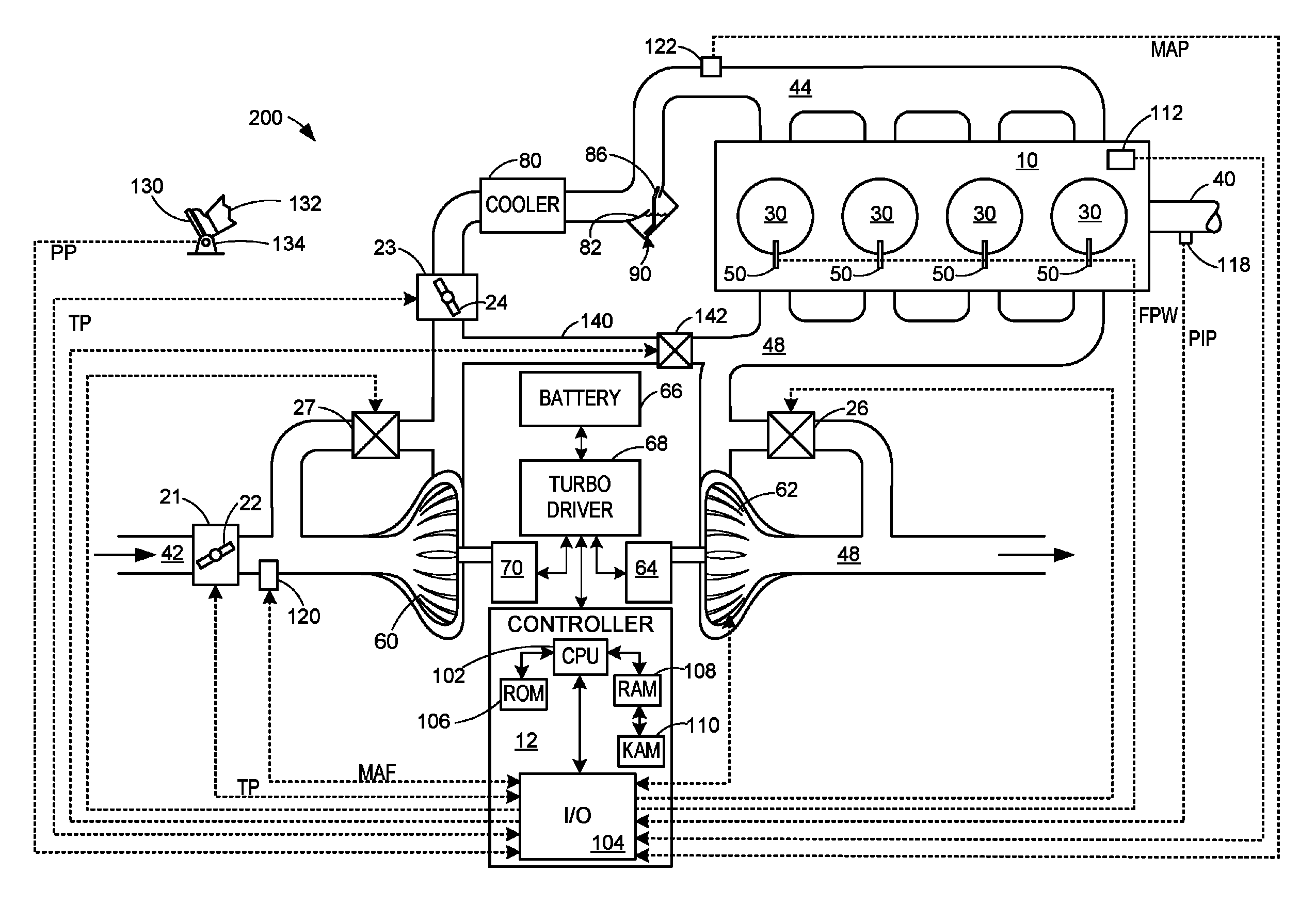

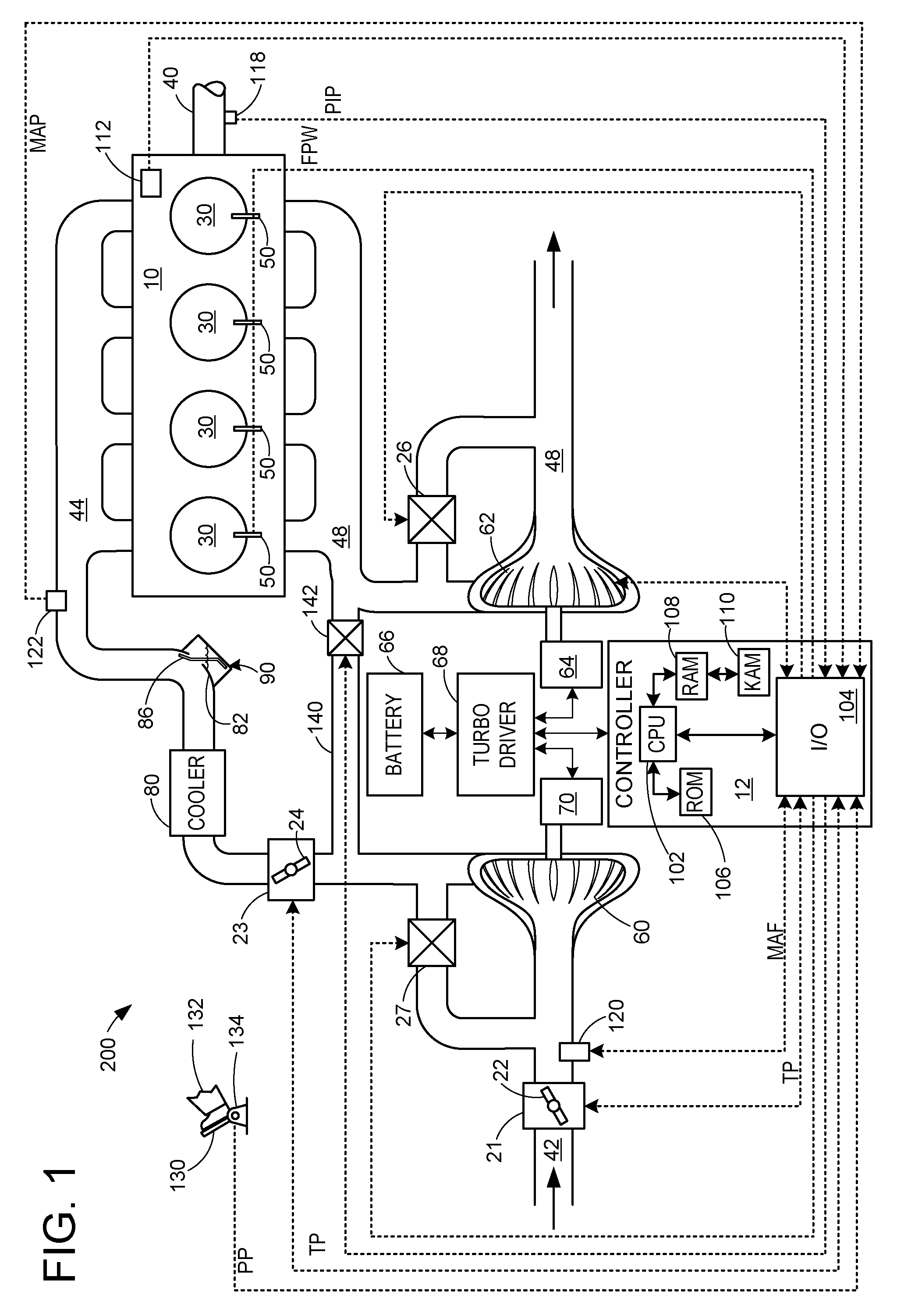

ActiveUS9010112B2Reduce the amount of condensateReduce the amount requiredInternal combustion piston enginesIce removalCondensation trapChiller

Various systems and methods are described for a charge air cooler coupled to an engine. One example method comprises collecting condensate discharged from the cooler in a condensation trap coupled to an outside surface of a bend in an outlet duct of the cooler; during a first condition, temporarily storing the condensate in a reservoir of the condensation trap; and, during first and second conditions, releasing the condensate to the outlet duct in a direction of airflow via a tube.

Owner:FORD GLOBAL TECH LLC

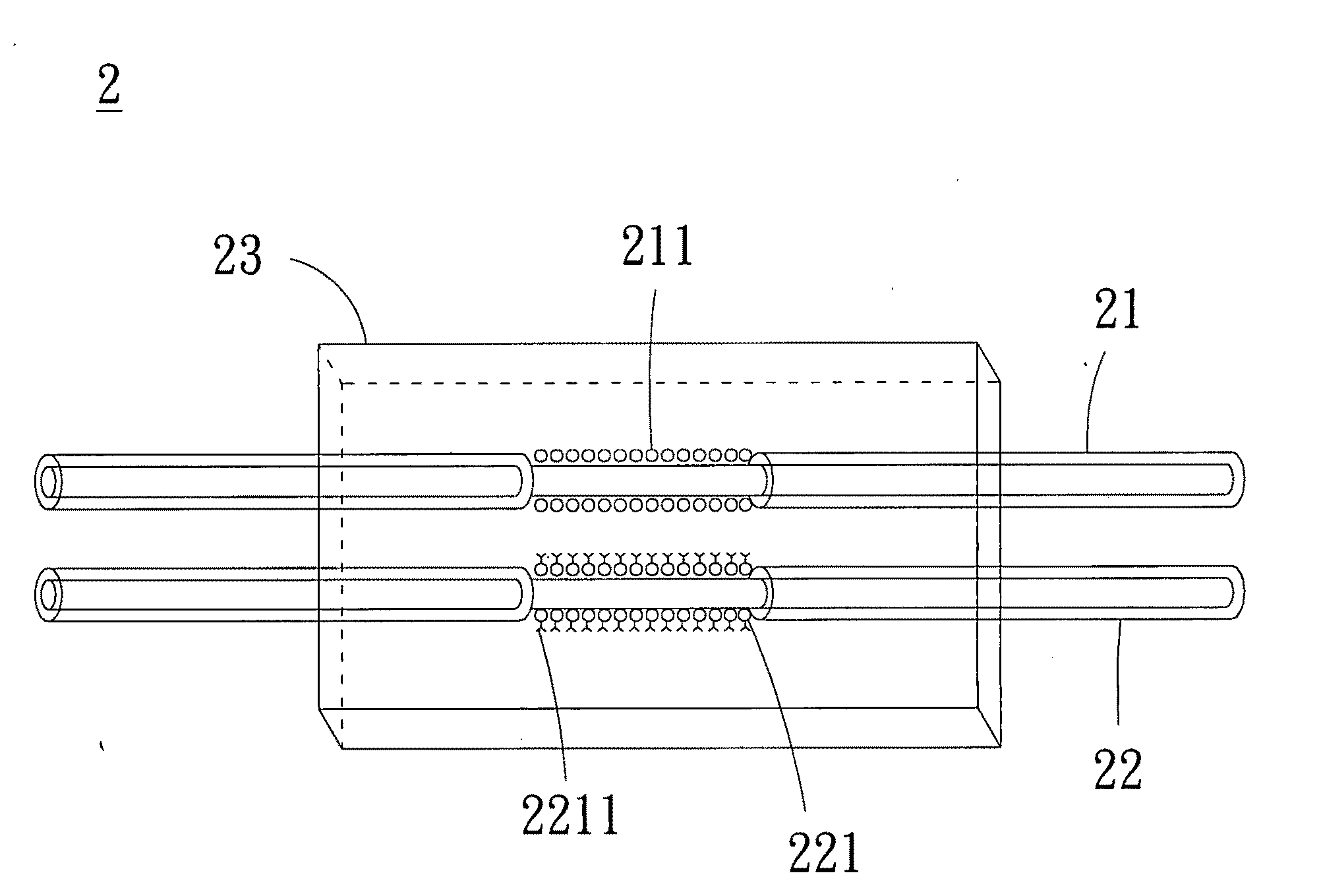

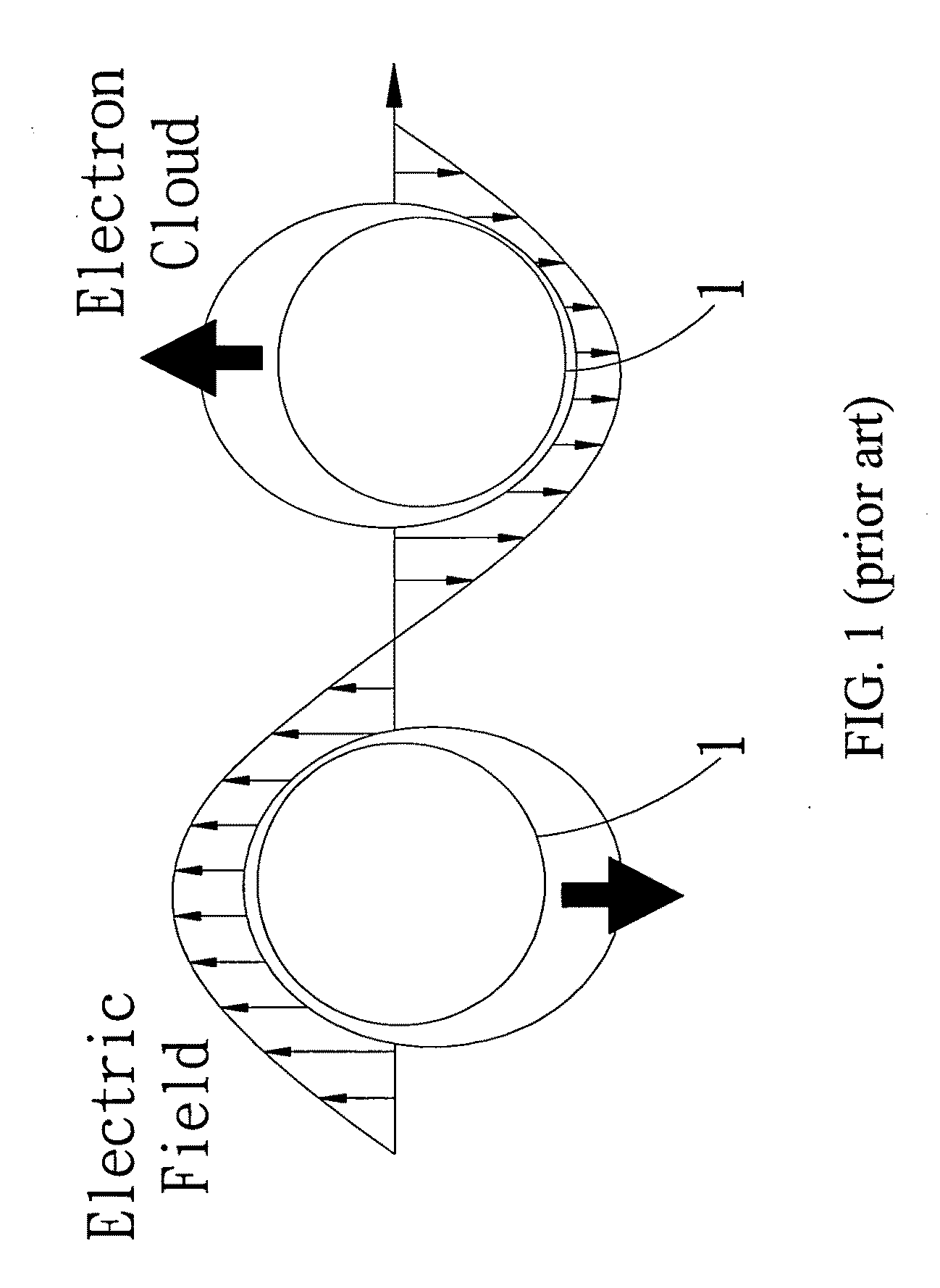

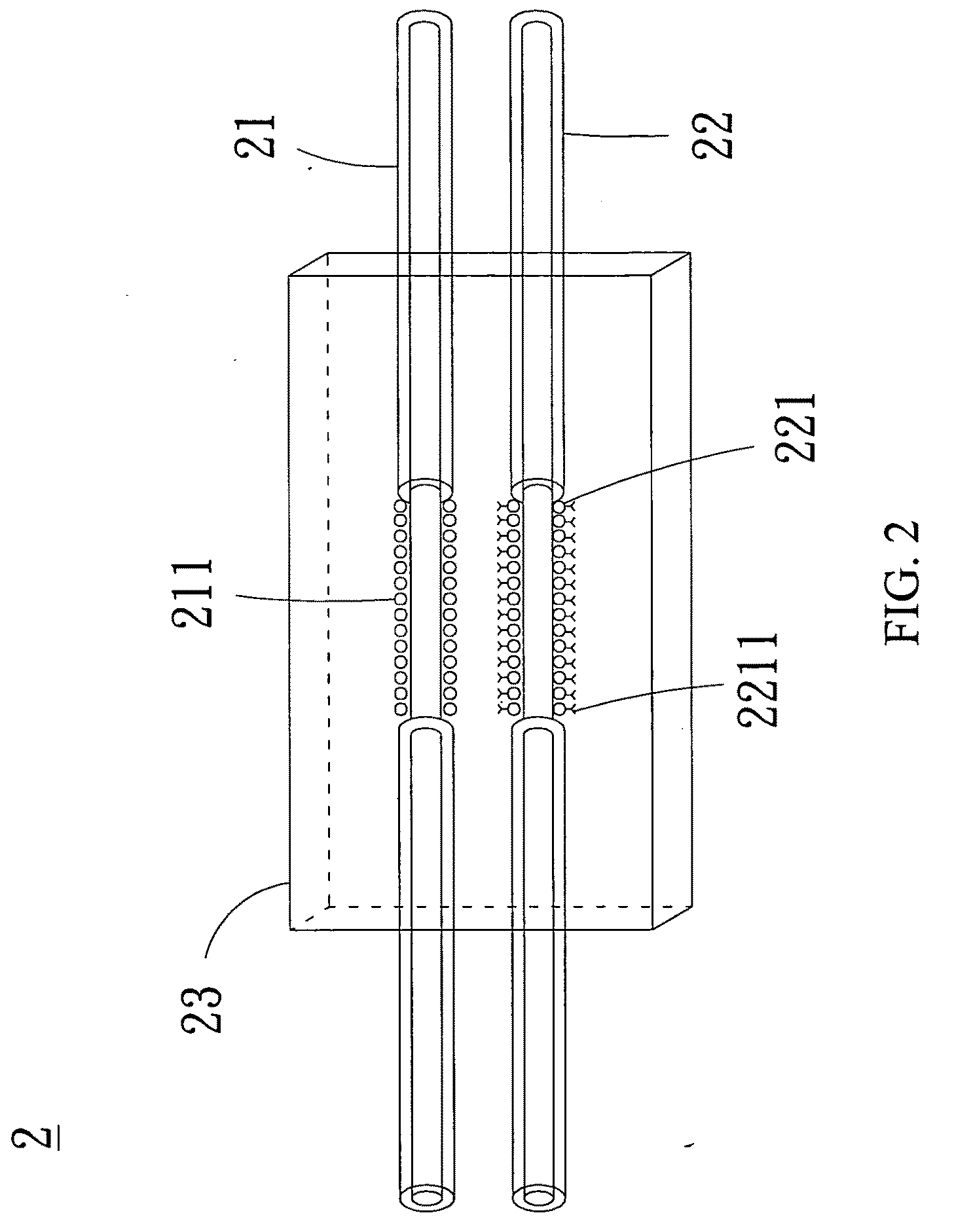

Self-referencing fiber-optic localized plasmon resonance sensing device and system thereof

InactiveUS20110090506A1Reduce decreaseEasy to detectScattering properties measurementsFiberResonant sensor

The present invention discloses a self-referencing fiber-optic localized plasmon resonance sensing device and a system thereof. The self-referencing fiber-optic localized plasmon resonance sensing device comprises a reference optical fiber, a sensing optical fiber and a carrier. The reference optical fiber is modified with a first noble metal nanoparticle layer, and receives an incident light to generate a first localized plasmon resonance sensor signal. The sensing optical fiber is modified with a second noble metal nanoparticle layer. The second noble metal nanoparticle layer is further modified with a molecular or biological recognition unit, and receives the incident light to generate a second localized plasmon resonance sensor signal. The carrier is used for placement of the reference optical fiber and the sensing optical fiber. A processing unit is allowed to perform referencing on the second localized plasmon resonance sensor signal based on the first localized plasmon resonance sensor signal.

Owner:NATIONAL CHUNG CHENG UNIV

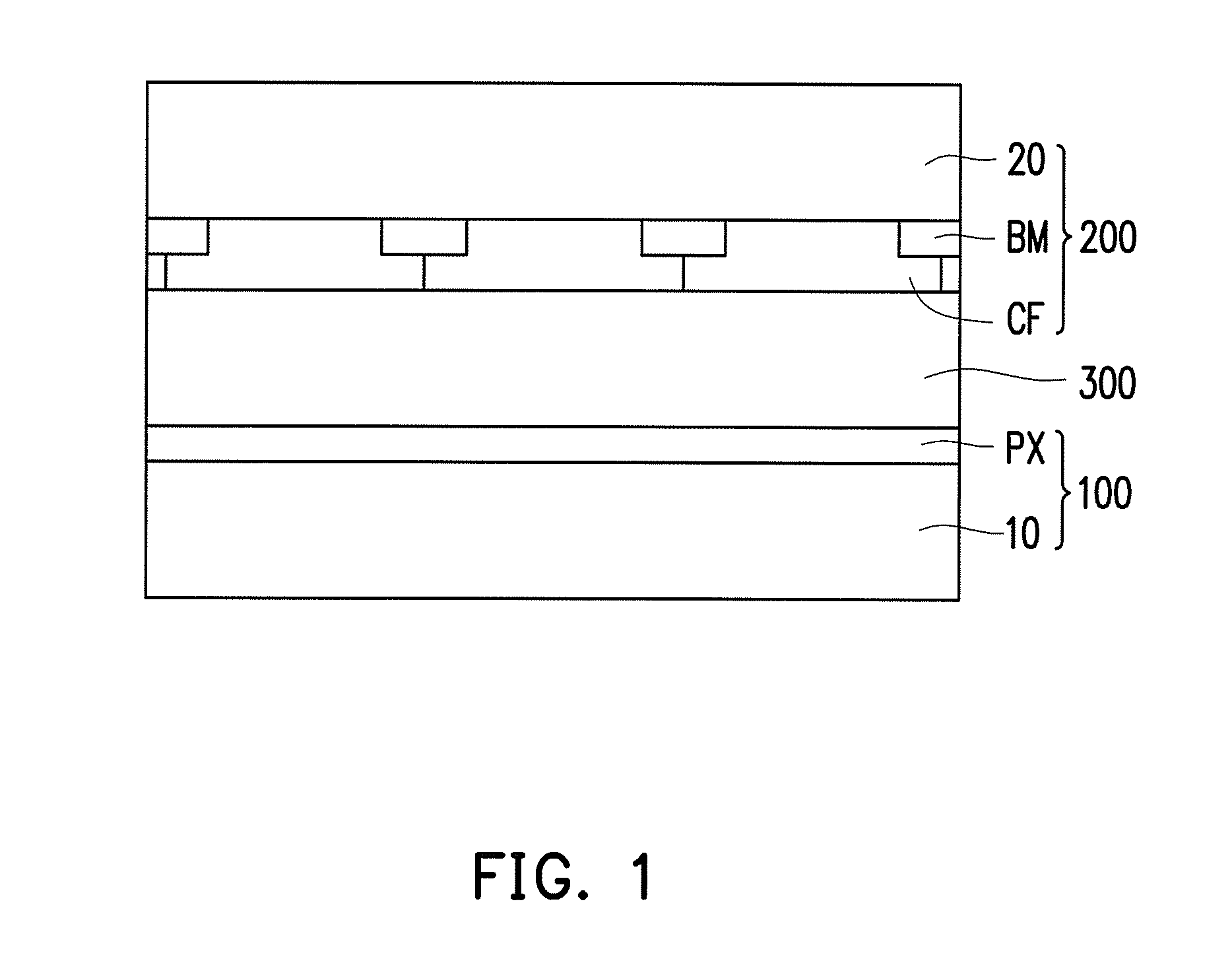

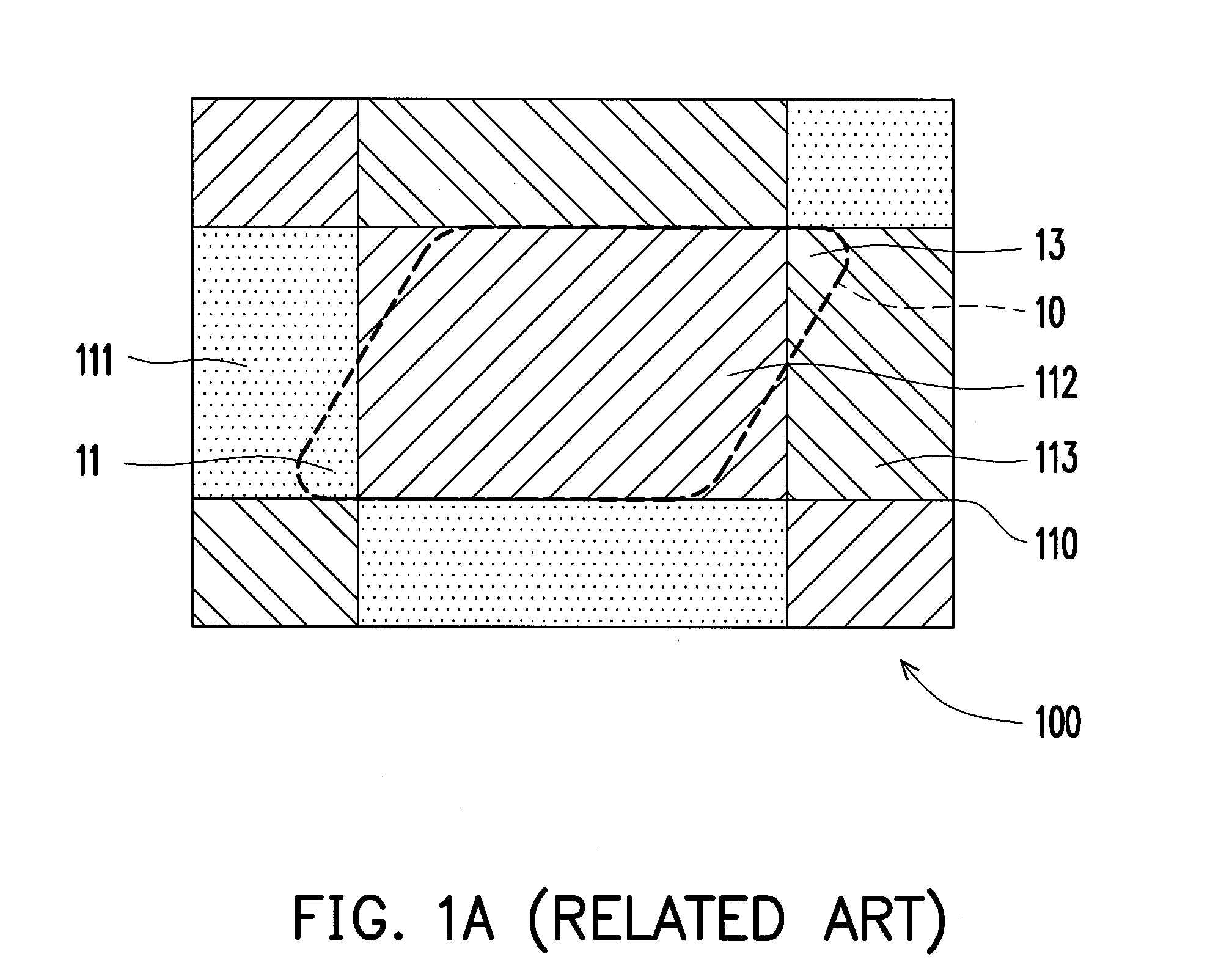

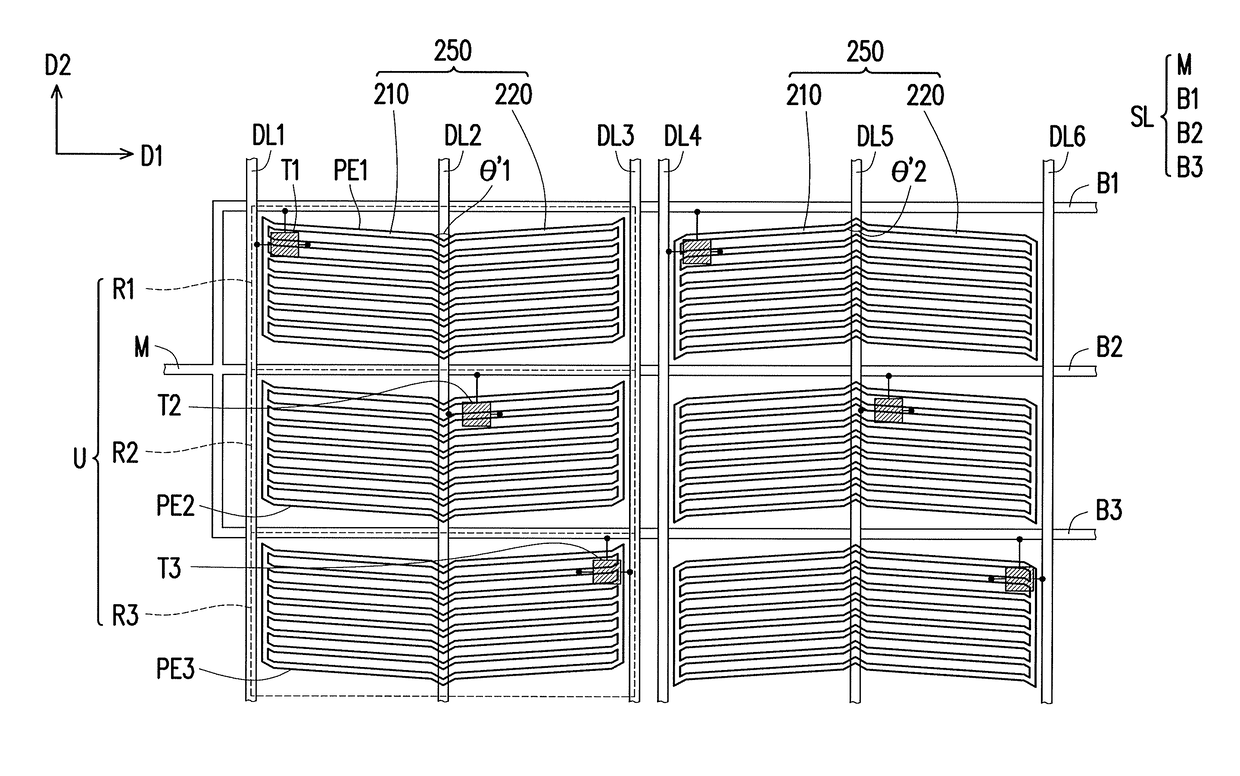

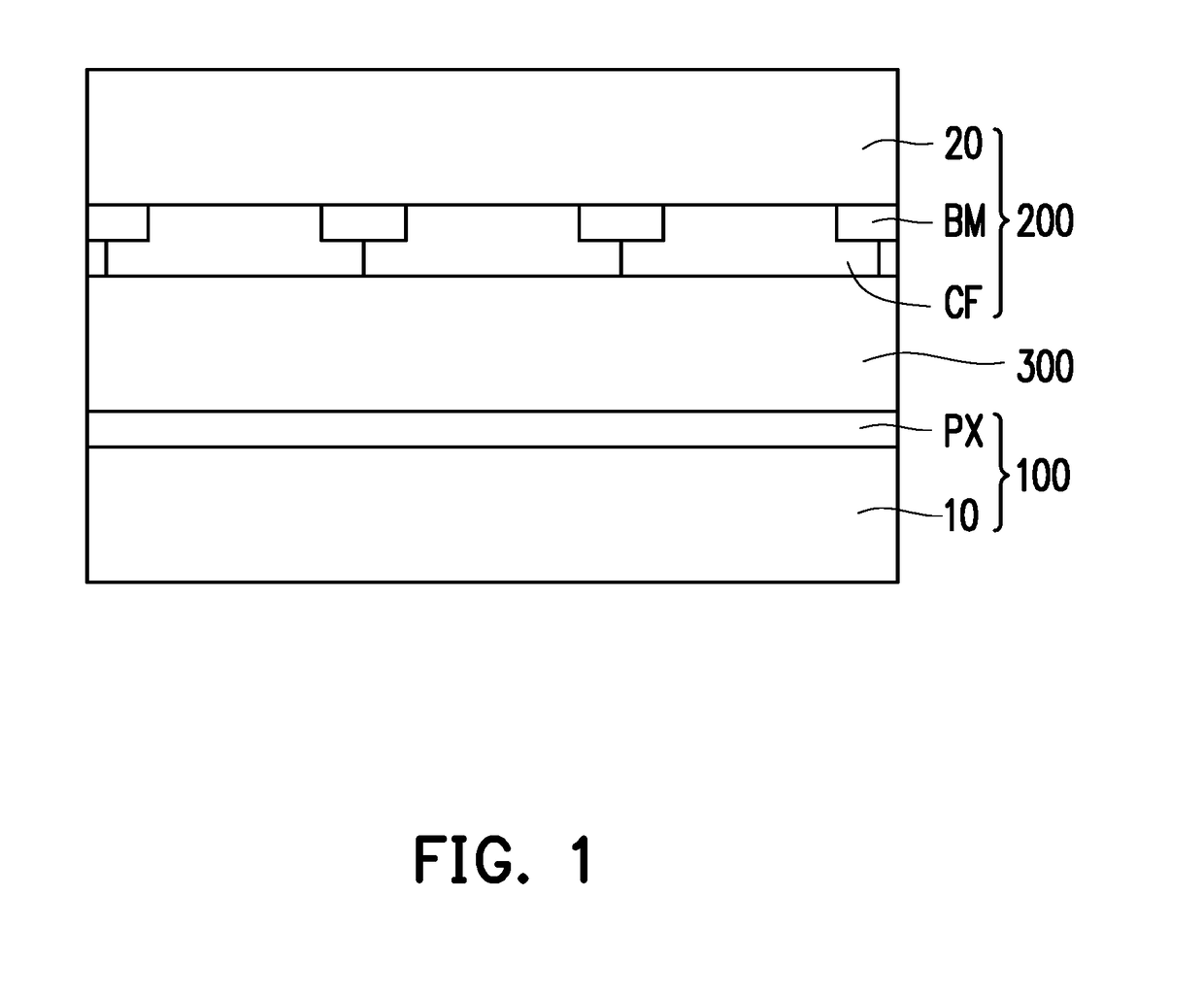

Display device and method for manufacturing the same

ActiveUS20120257149A1Increase the areaIncrease the aperture ratioVessels or leading-in conductors manufactureNon-linear opticsDisplay deviceComputer science

A display device and a method for manufacturing the display device are provided. The display device includes a substrate and a color filter layer. A plurality of sub-pixel electrodes are formed on the substrate. The color filter layer is configured on the substrate. The color filter layer defines a plurality of color areas corresponding to the sub-pixel electrodes. Here, each of the color areas is partially overlapped with two of the sub-pixel electrodes adjacent to each other.

Owner:HIMAX DISPLAY INC

Waterproof casing of outdoor wireless electronic device

ActiveUS20200093018A1Improve sealingPromote sheddingCasings/cabinets/drawers detailsPrinted circuit board receptaclesStructural engineeringMechanical engineering

A waterproof casing for packaging a circuit board having an antenna includes a housing, a waterproof gasket, and an end cover. The housing has an accommodation space and a side opening communicating with each other. The accommodation space is configured to accommodate the circuit board. The waterproof gasket includes a main body and an extending portion. The main body covers the side opening. The extending portion extends from the main body. The end cover abuts against a side of the main body away from the accommodation space, and is fixed to the housing to form a box with the housing. The box has a communication opening positioned corresponding to the antenna. The extending portion hermetically covers the communication opening.

Owner:DELTA ELECTRONICS INC

Power extension cord with movable outlet modules

ActiveUS20140004718A1Increased durabilitySmall sizeRotary current collectorNon-rotary current collectorMechanical engineeringElectric power

Owner:POWERTECH INDAL

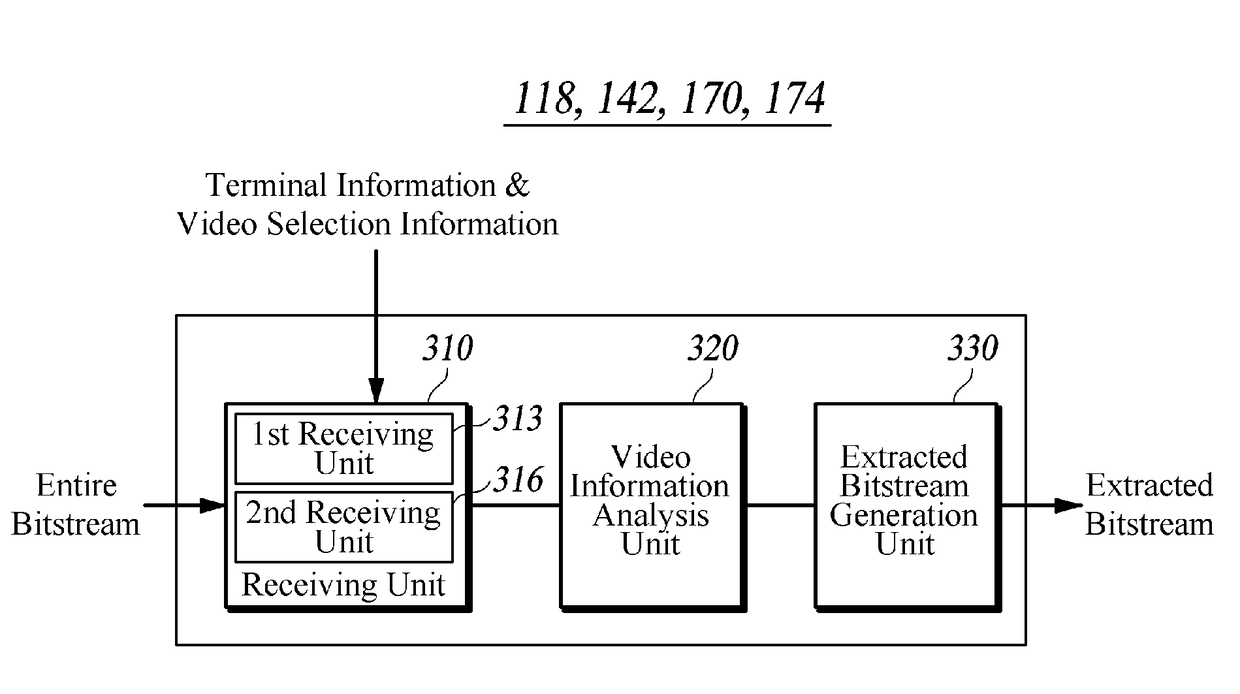

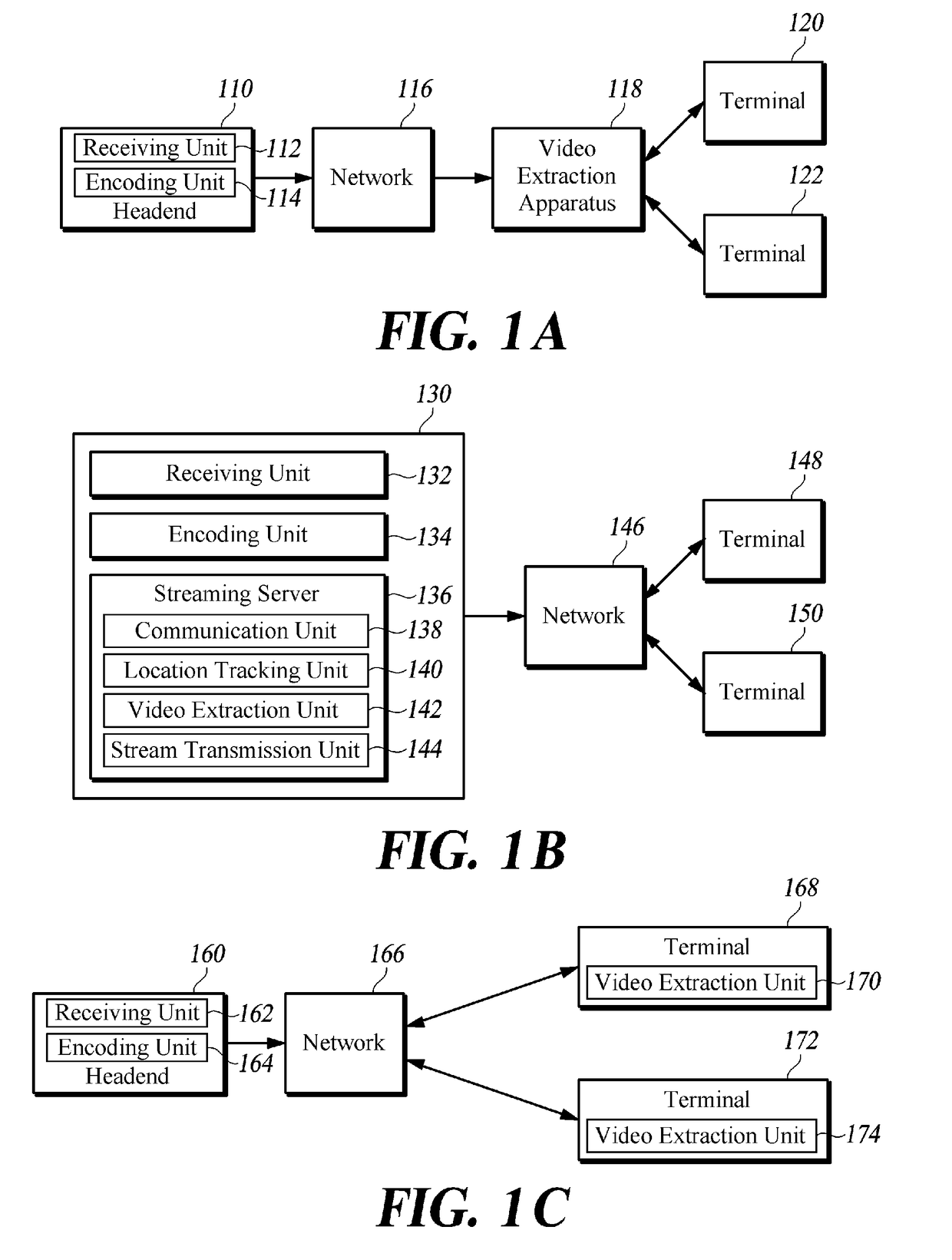

Method and apparatus for extracting video from high resolution video

ActiveUS20180124462A1Issue can be resolvedTelevision system detailsColor television detailsMultiplexingUser device

An apparatus for and a method of extracting a video segment from a multiplexed video are disclosed. According to some aspects of the disclosed embodiment, an apparatus, service and method for video selection / extraction are provided for when a service provider delivers a video sized greater than the screen of a user-owned device without a separate conversion, in order to extract predefined video areas in real time from the user device for a customized display on the device display screen, or extract from a network gateway or streaming server in real time the predefined video areas for a customized delivery to meet the specification of the terminal that ordered the video segment, or upon receiving user's navigated and selected video location from the terminal, extract the video segment and enlarge specified location and provides multifaceted viewing experiences for the user.

Owner:SK TELECOM CO LTD

Method for implementing specific termination cause codes in termination requests

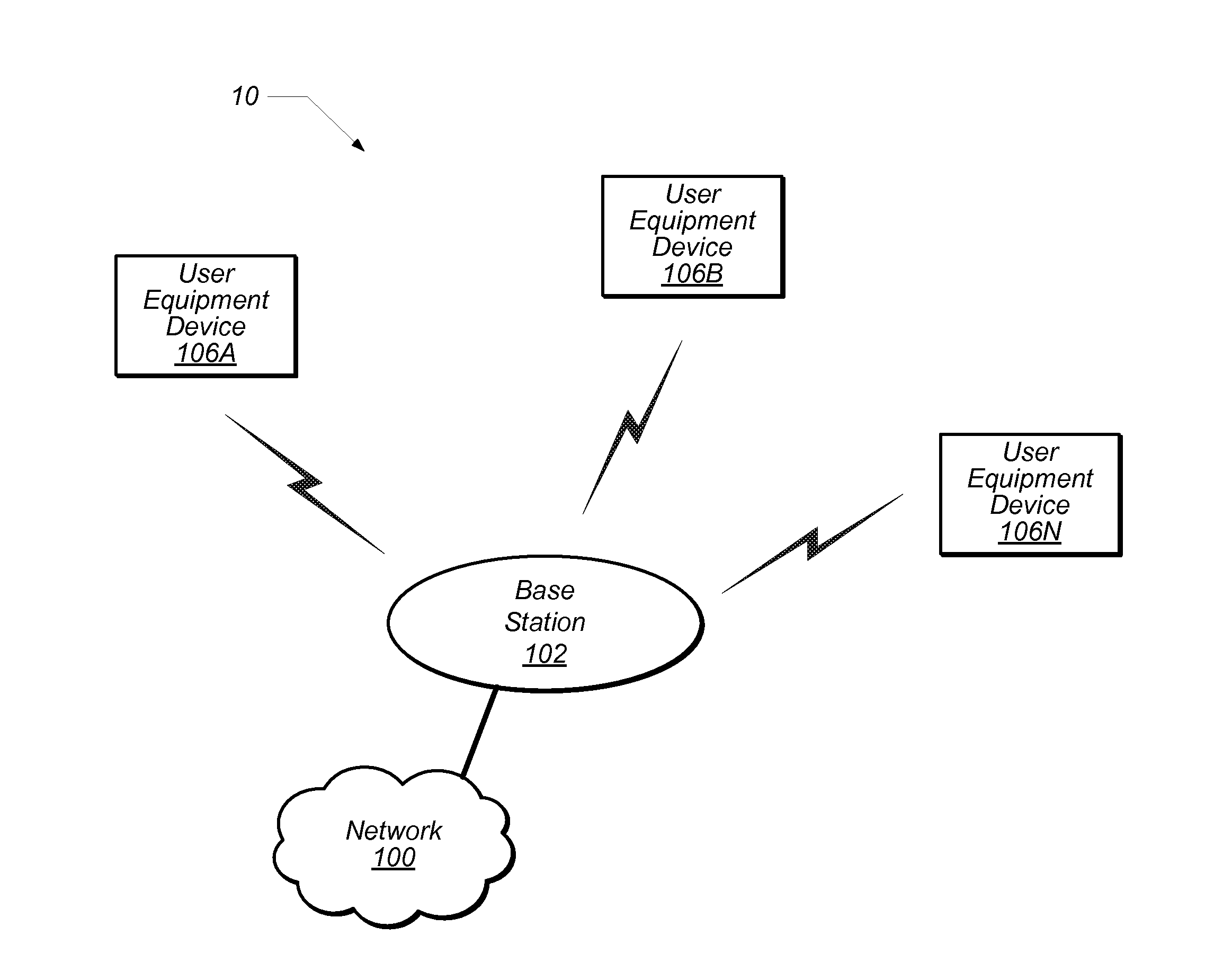

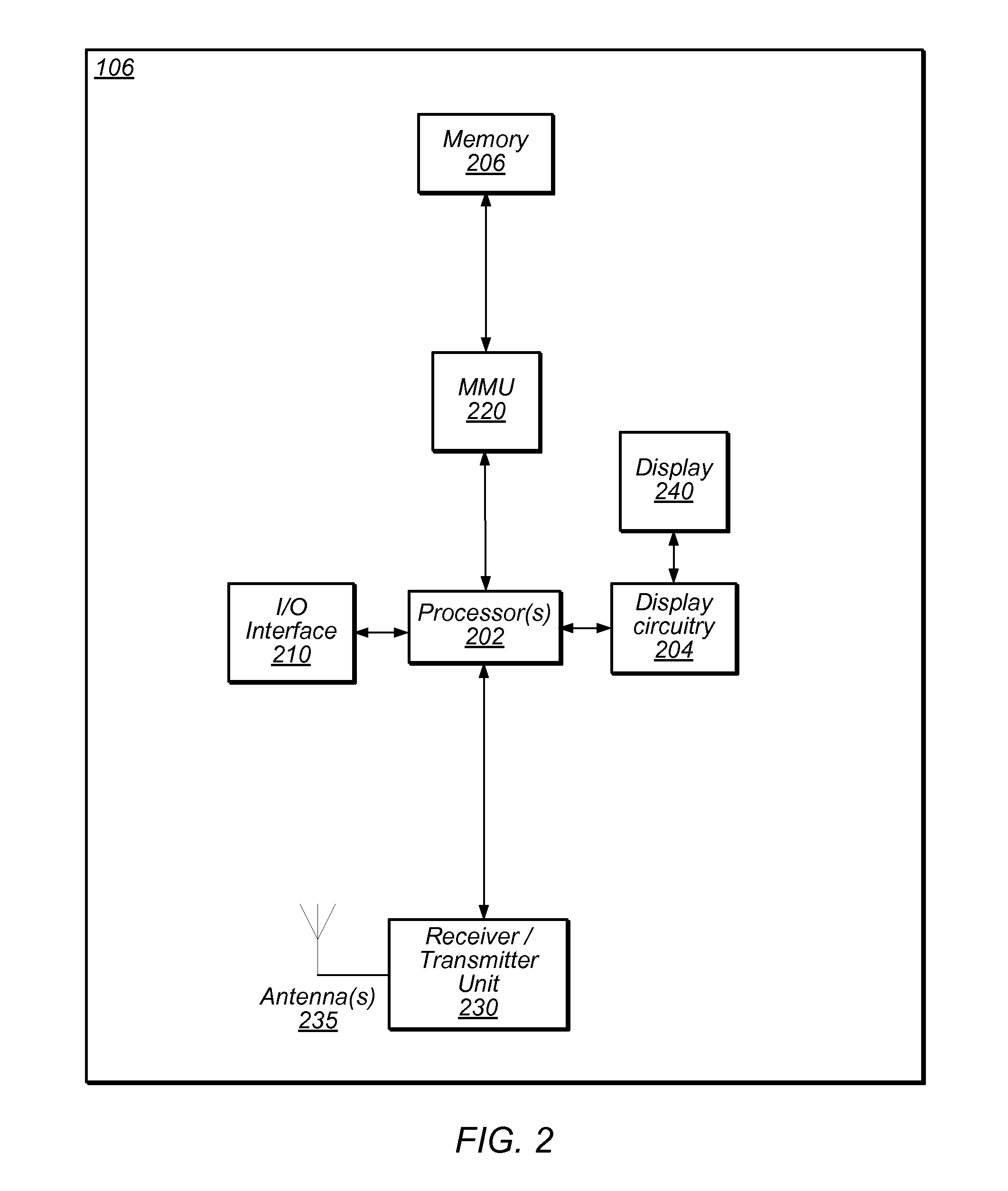

ActiveUS20130286935A1Issue can be resolvedAccounting/billing servicesTelephonic communicationComputer hardwareHigh rate

A method includes a wireless mobile device communicating with a wireless network via an evolved high rate packet data (eHRPD) interface. The wireless mobile device may receive a vendor specific network control protocol (VSNCP) packet such as a terminate-request packet, for example, that indicates the wireless network has requested a PDN disconnection. The VSNCP packet includes a cause code that indicates a reason for the PDN disconnection request. The wireless device may use the cause code to determine the reason for the PDN disconnection request. Accordingly, in response to receiving the VSNCP packet, the wireless mobile device may perform one or more operations in an effort to resolve any issues that may have caused the PDN disconnection request.

Owner:APPLE INC

Hosiery with foot cushions

ActiveUS9675119B2Comfortable standingSimple and easy to put on and useHandkerchiefsBaby linensCushioningFoot cushion

A hosiery product, such as a sock, footie, trouser sock or panty hose, includes and inner layer of hosiery material, such as nylon or spandex covering the bottom and top surfaces of the wearer's foot, and outer layer of similar hosiery material, and at least one cushion section disposed between the inner and outer layers. The cushion sections include an elevated cushioning material that conforms to the contours of the wearers foot, such as macro-gel activated support discs or memory foam. The ball of foot cushion sections are elevated attached circles, arch and heel cushions. All layers are attached.

Owner:ALSTON MELANIE YVONNE

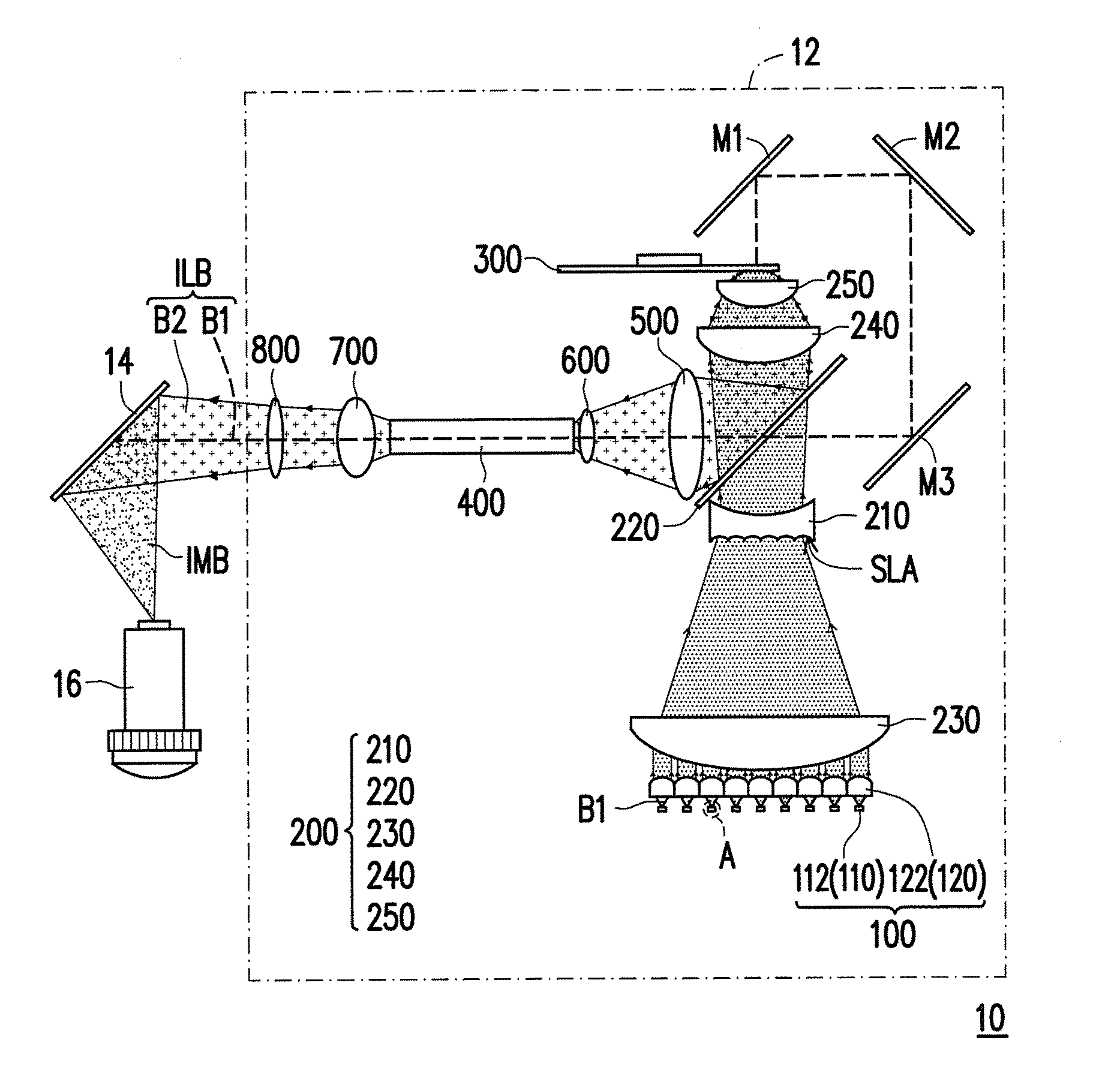

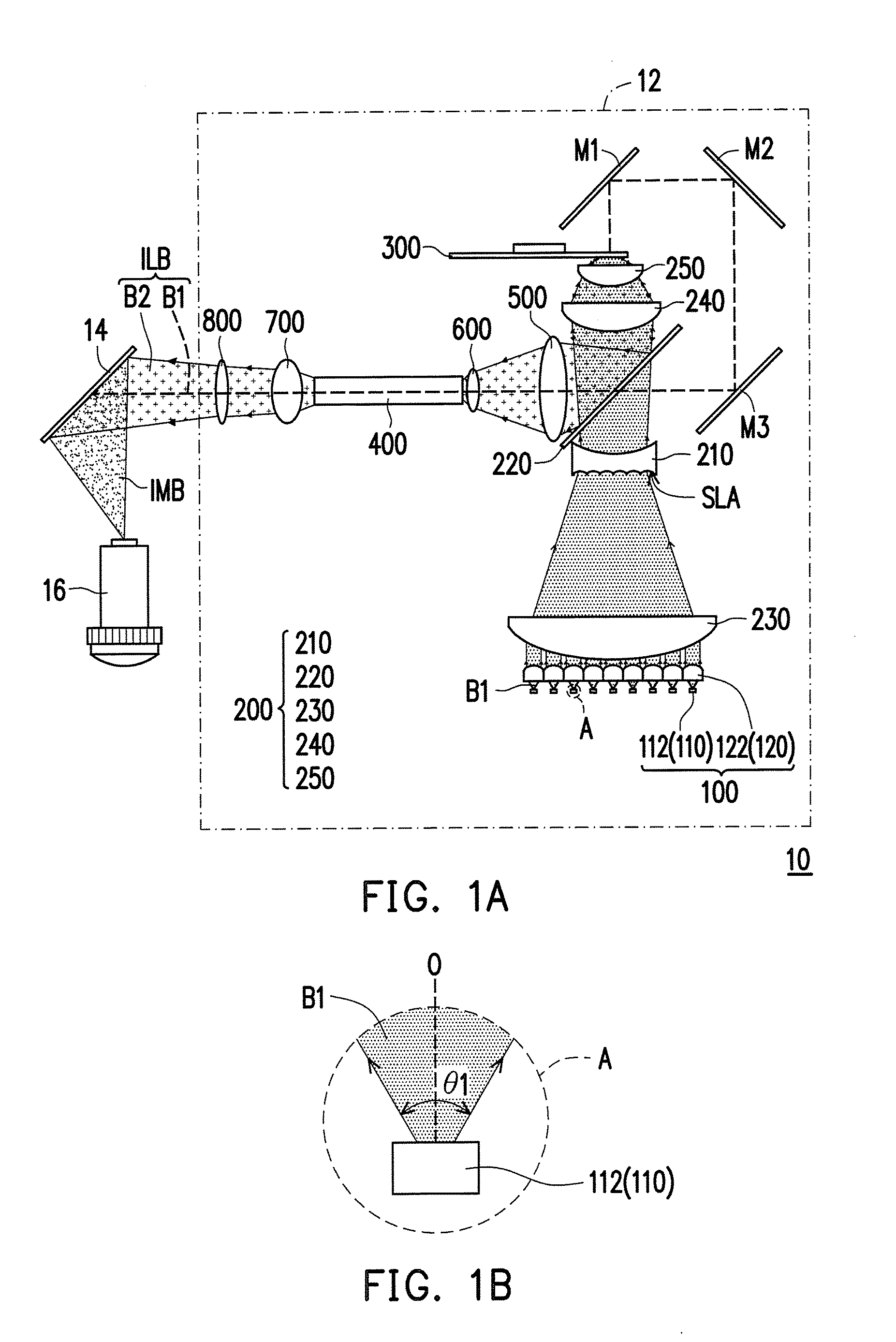

Projection apparatus and illumination system

ActiveUS20170059976A1Ideal output brightnessImprove energy efficiencyProjectorsColor photographyLight deliveryLight beam

An illumination system including a coherent light source device, a light delivery module, and a light wavelength conversion module is provided. The coherent light source device includes a light emitting source and a light collimating element. The light emitting source is adapted to emit at least one coherent light beam. The light collimating element is located on a transmission path of the at least one coherent light beam from the light emitting source and collimates the at least one coherent light beam. The light delivery module is located on a transmission path of at least one coherent light beam from the light collimating element and includes a first lens. The first lens has a lens array surface adapted to diverge any of the coherent light beam from the light collimating element. A projection apparatus is also provided.

Owner:CORETRONIC

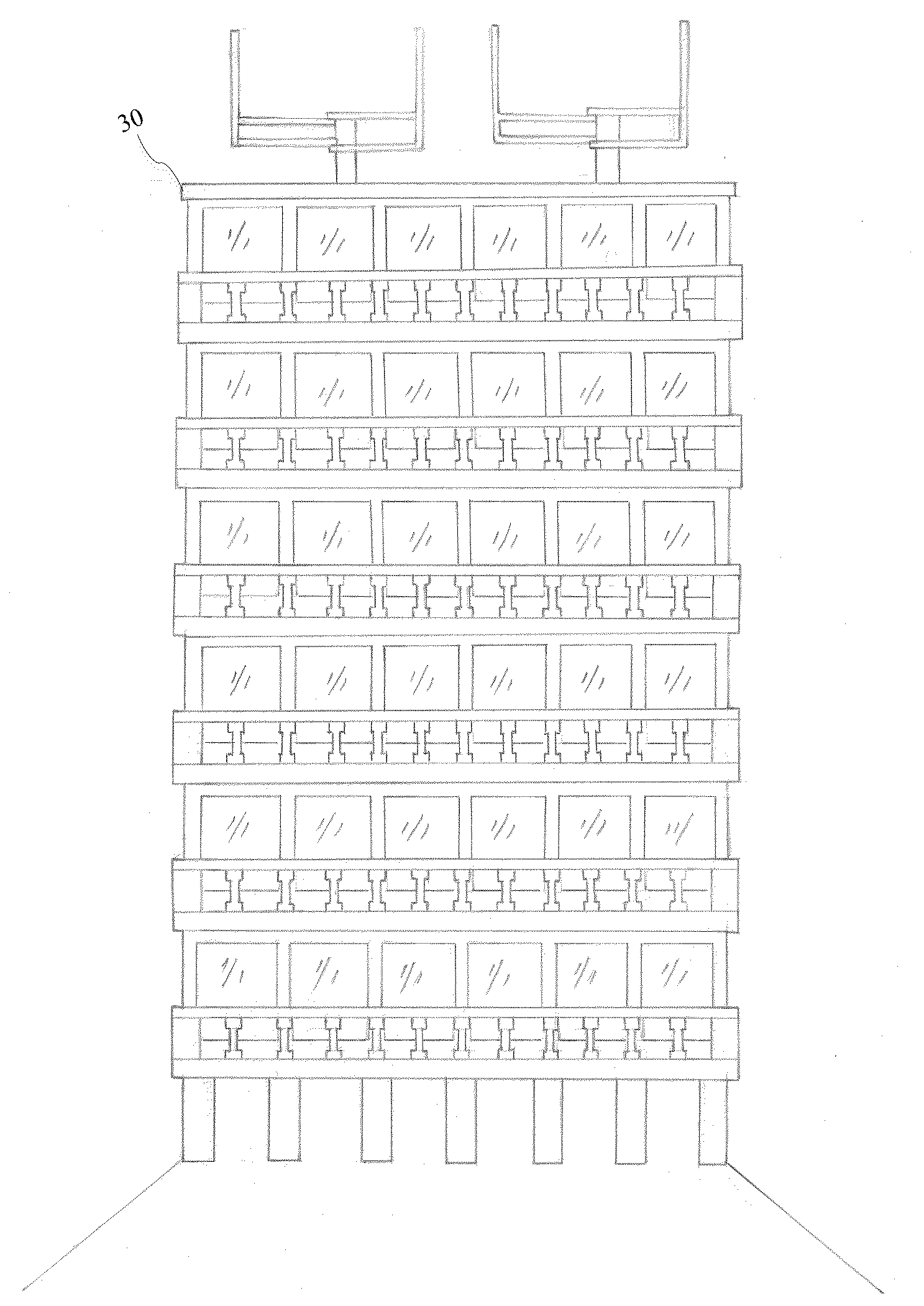

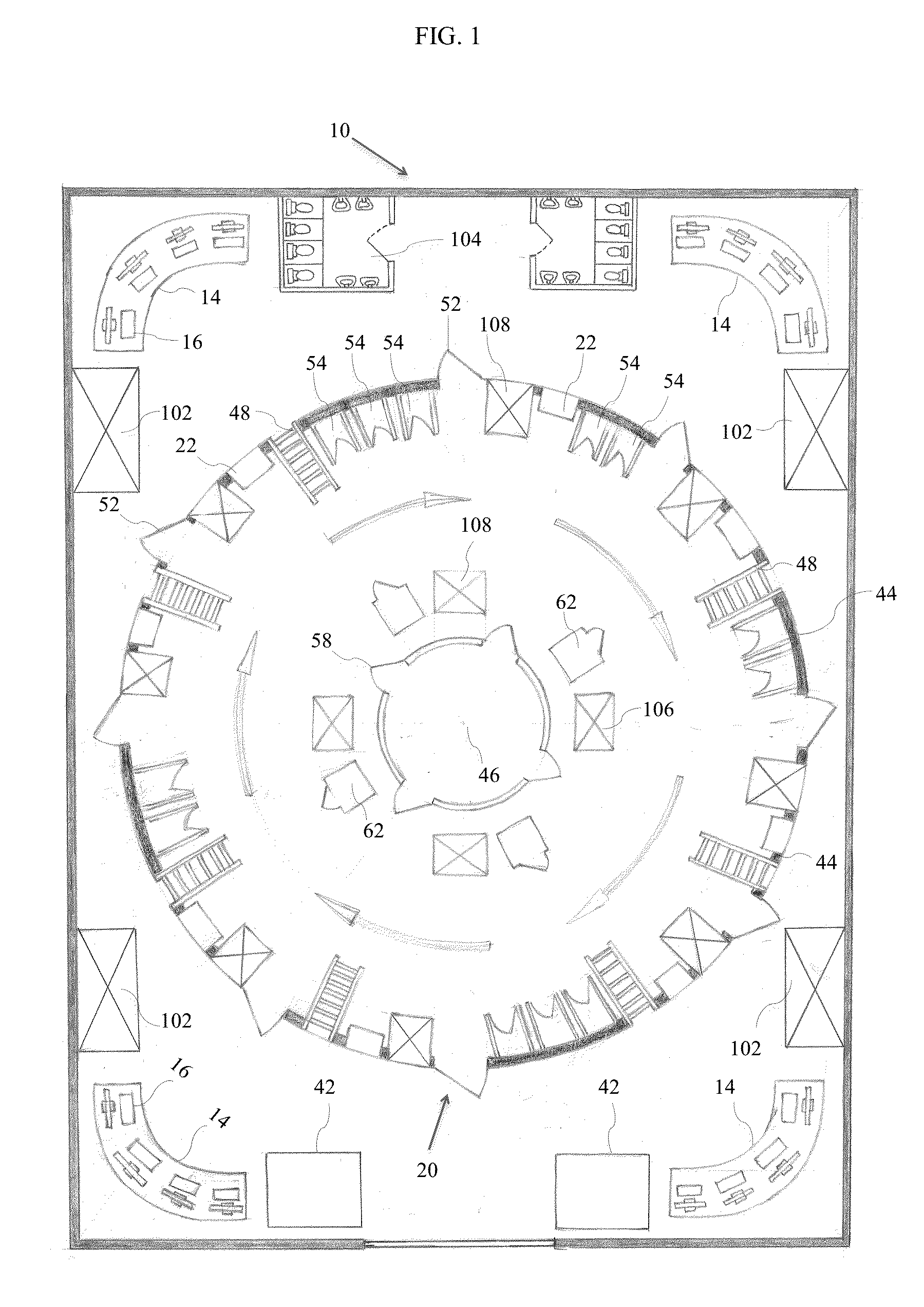

Direct Delivery Shopping System

InactiveUS20150302511A1Prevents shopliftingImproved store layoutBuying/selling/leasing transactionsLogisticsEngineeringConveyor belt

This invention relates to a direct delivery shopping system which is laid out with one or more order placement centers and a restricted delivery area having a plurality of delivery counters, conveyor belts, employee passageways, storage areas housing specific sale items, storage areas for packaged items and transport elevators. All components of the direct delivery shopping system can radiate from the center of the direct delivery area. These areas are so spaced and so connected in order to retain the polygonal nature of the direct delivery shopping area. The arrangement of the direct delivery area allows a customer to purchase items efficiently while using the direct delivery shopping system's online system and to retrieve the purchased items directly from a plurality of delivery counters or conveyor belts in the direct delivery area.

Owner:LOPEZ MINERVA P

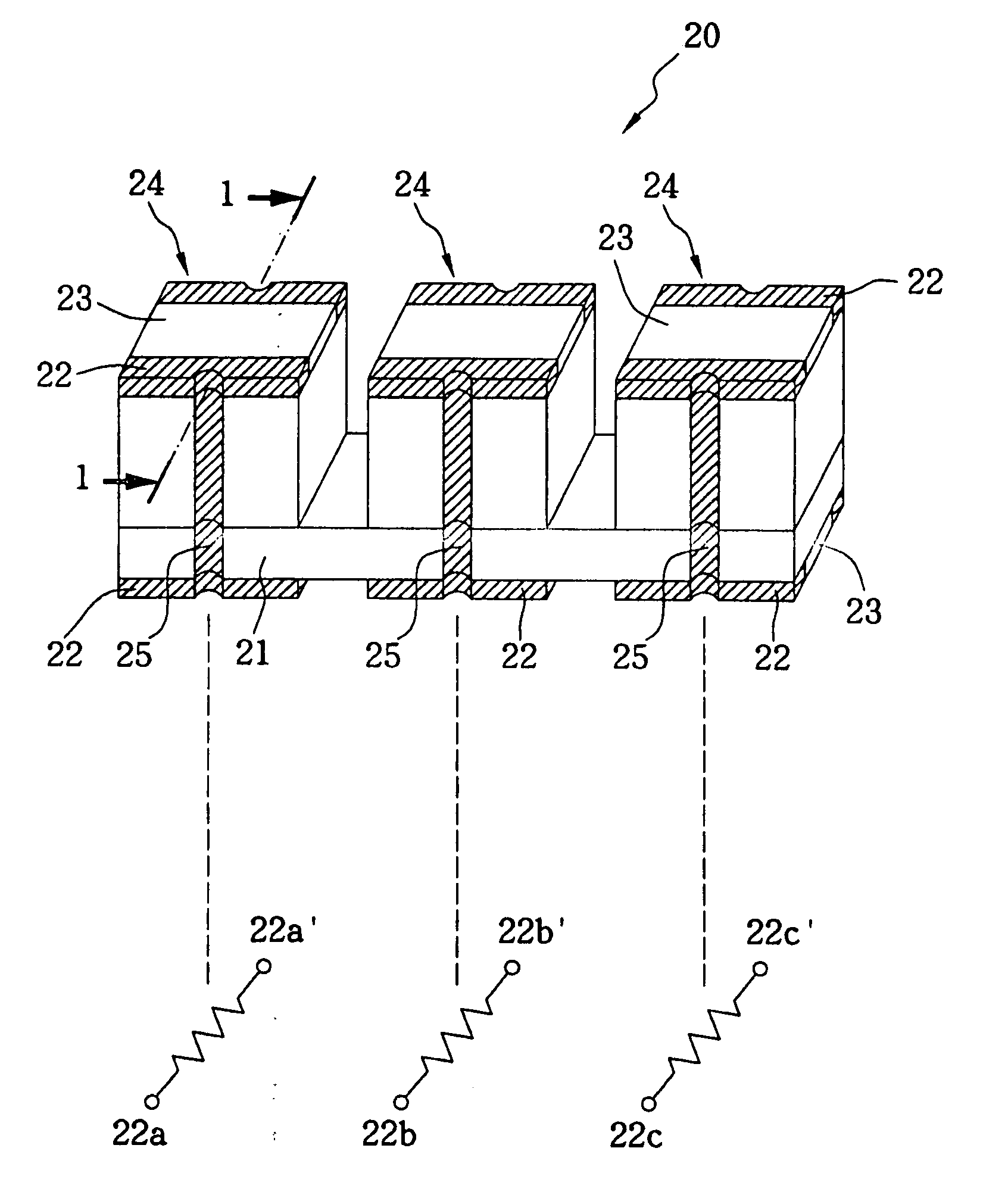

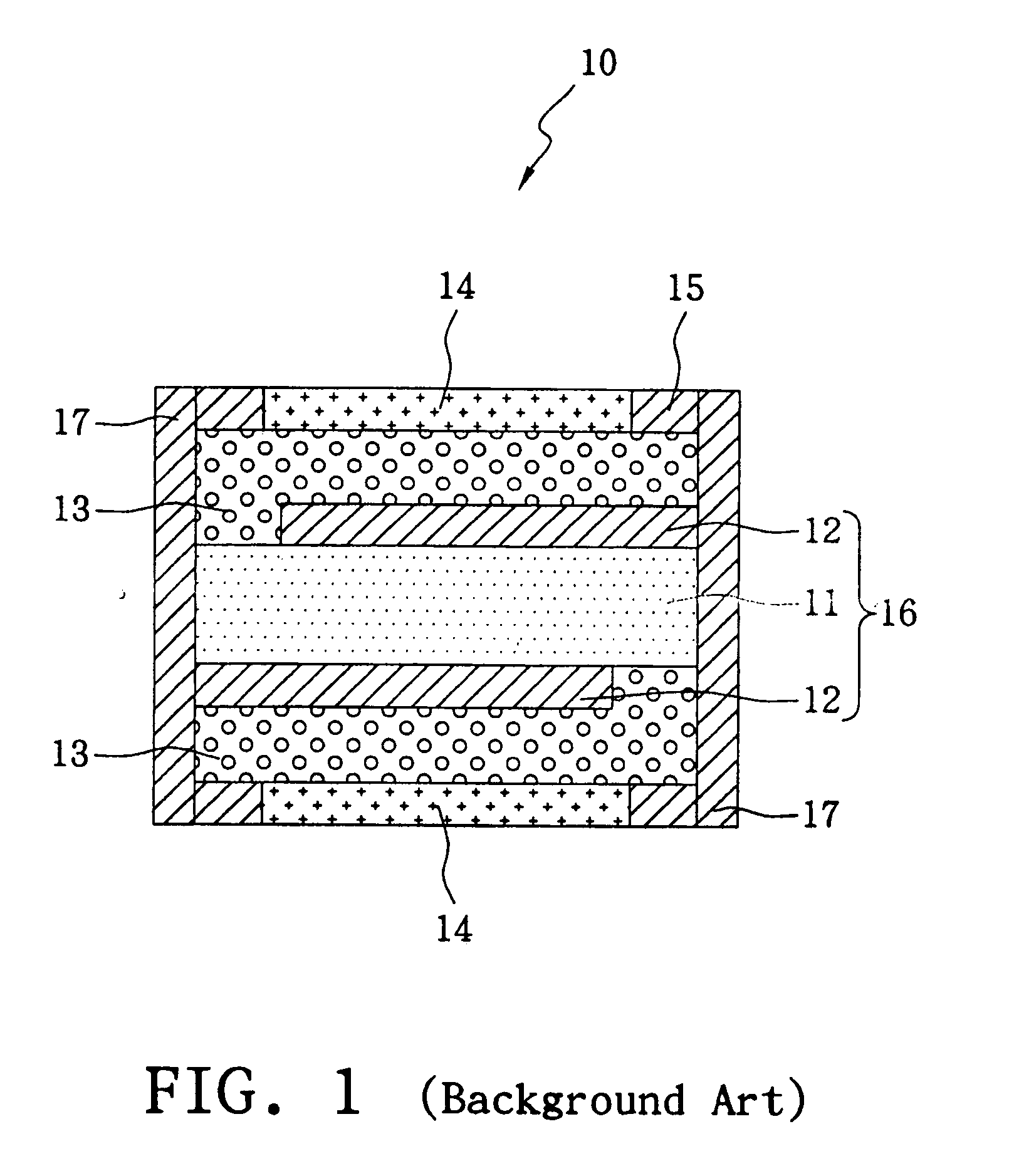

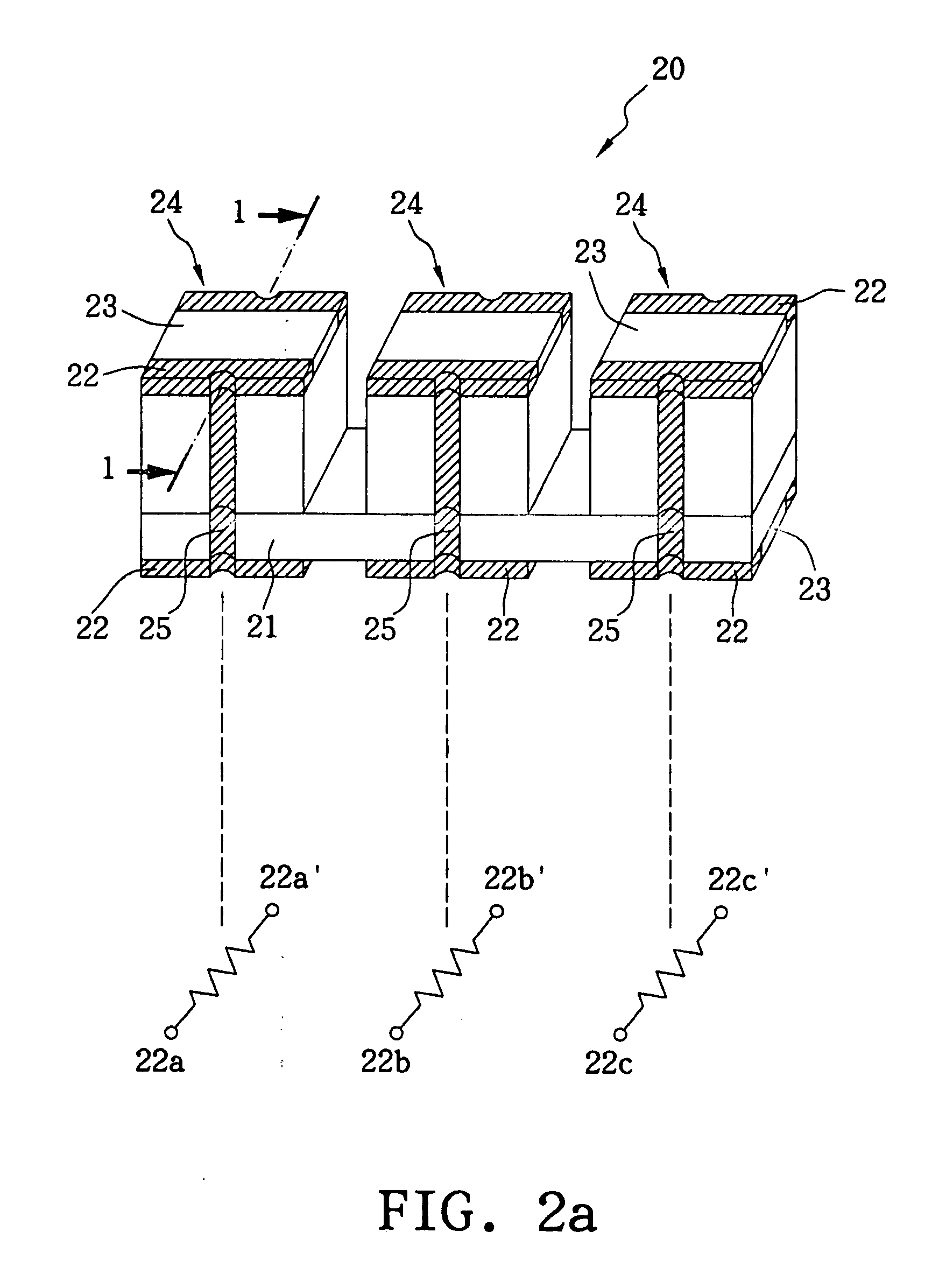

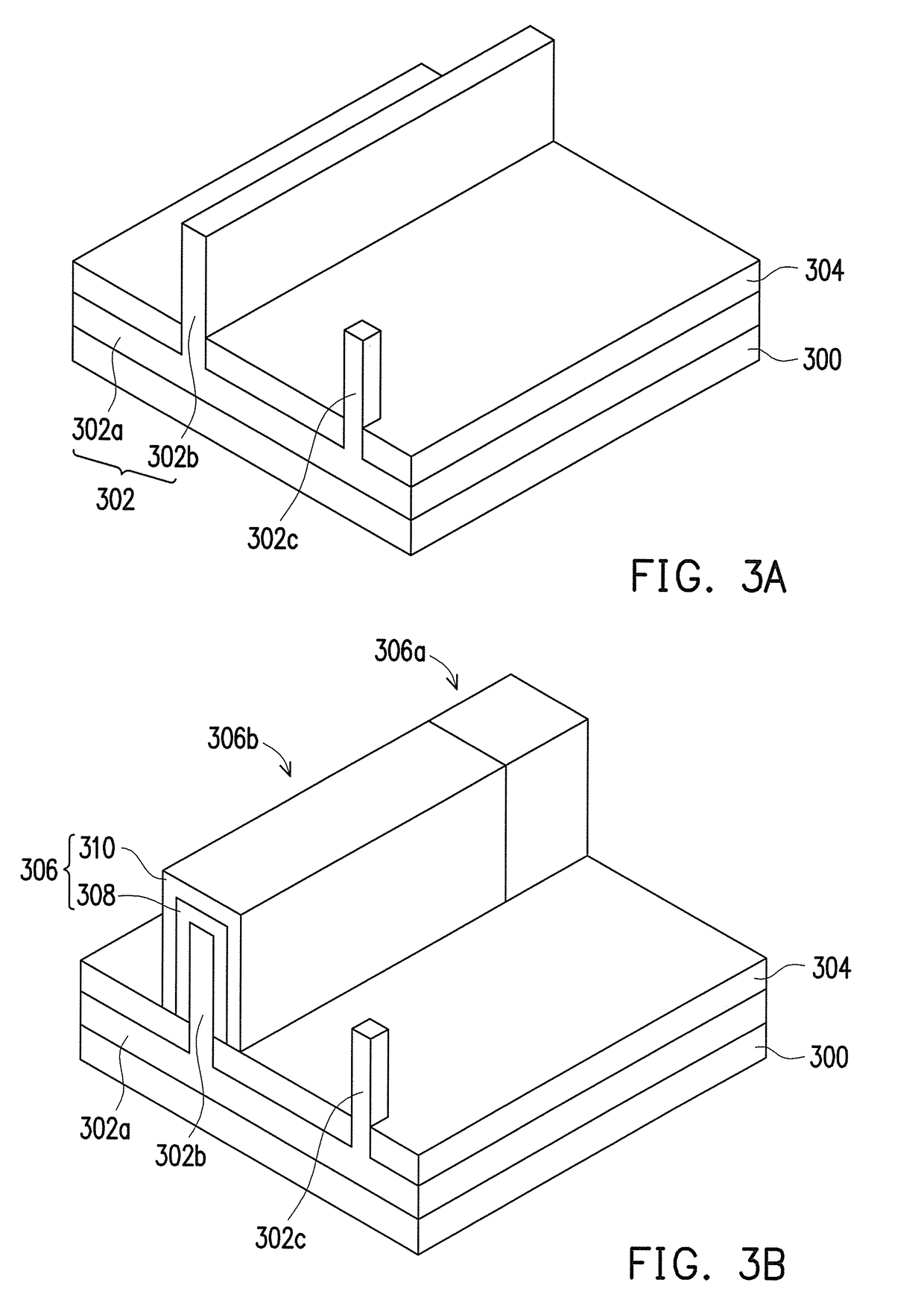

Over-current protection apparatus

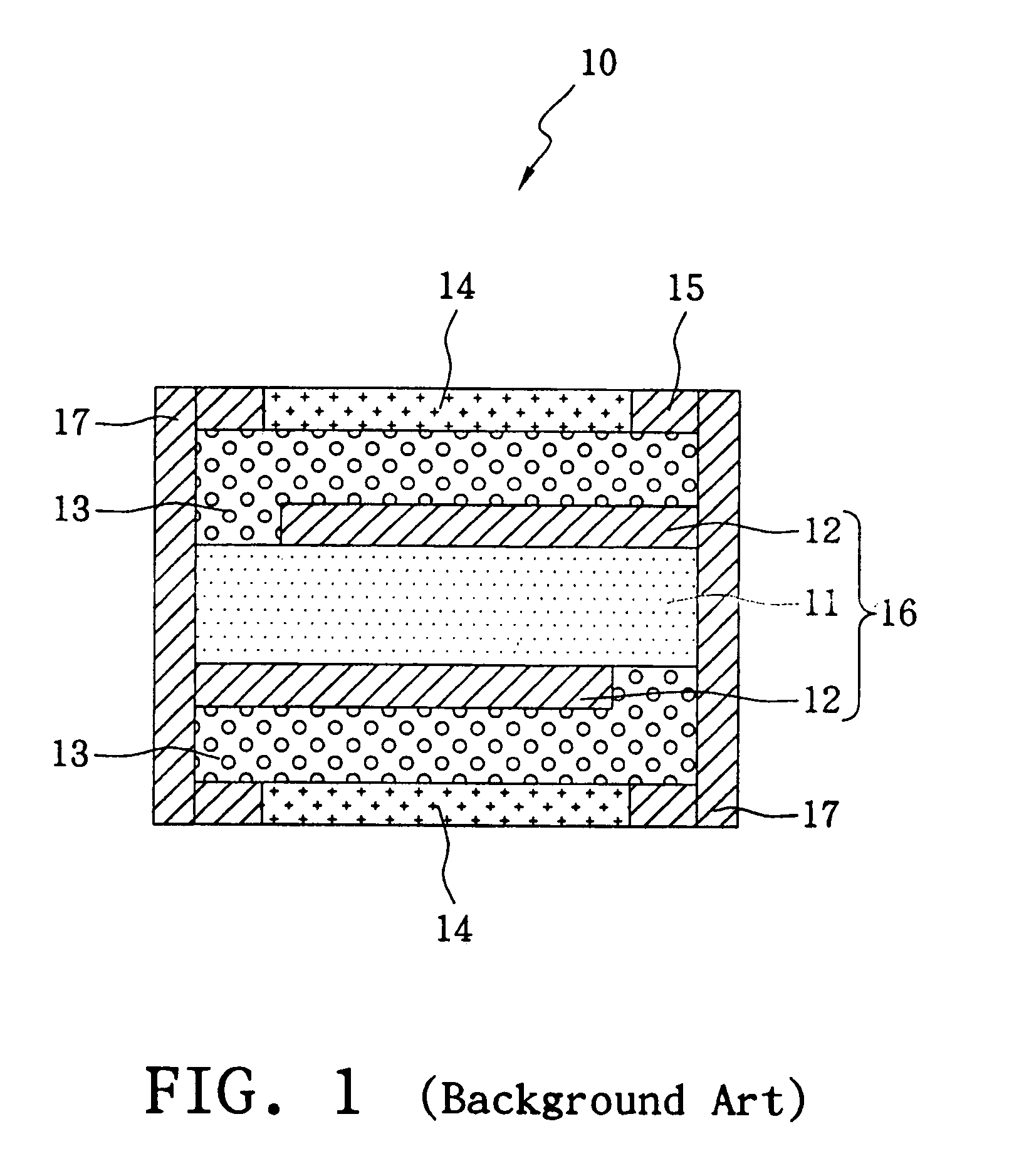

InactiveUS20050141160A1High mechanical strengthImprove space utilizationCurrent responsive resistorsArrangements responsive to excess currentOver current protectionElectrical and Electronics engineering

An over-current protection apparatus comprises a plurality of over-current protection devices and a bonding sheet. Each over-current protection device comprises at least one current-sensitive element, two outer electrode layers and at least one insulating layer disposed on a surface of the current-sensitive element. The bonding sheet penetrates and connects the plurality of over-current protection devices, and is disposed on a surface of the at least one current-sensitive element for insulation.

Owner:POLYTRONICS TECH

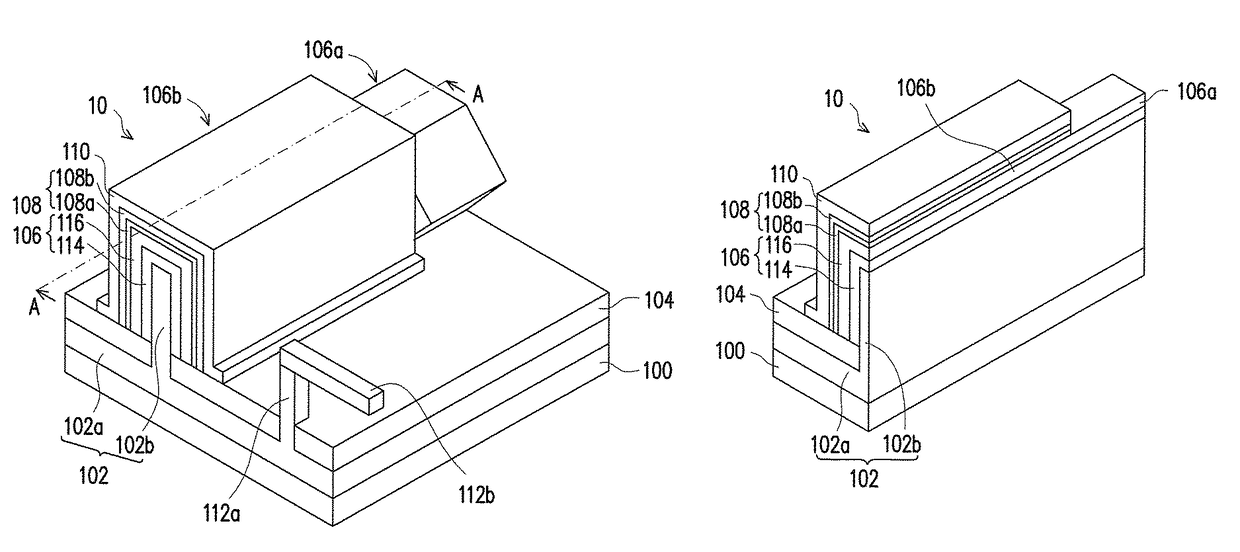

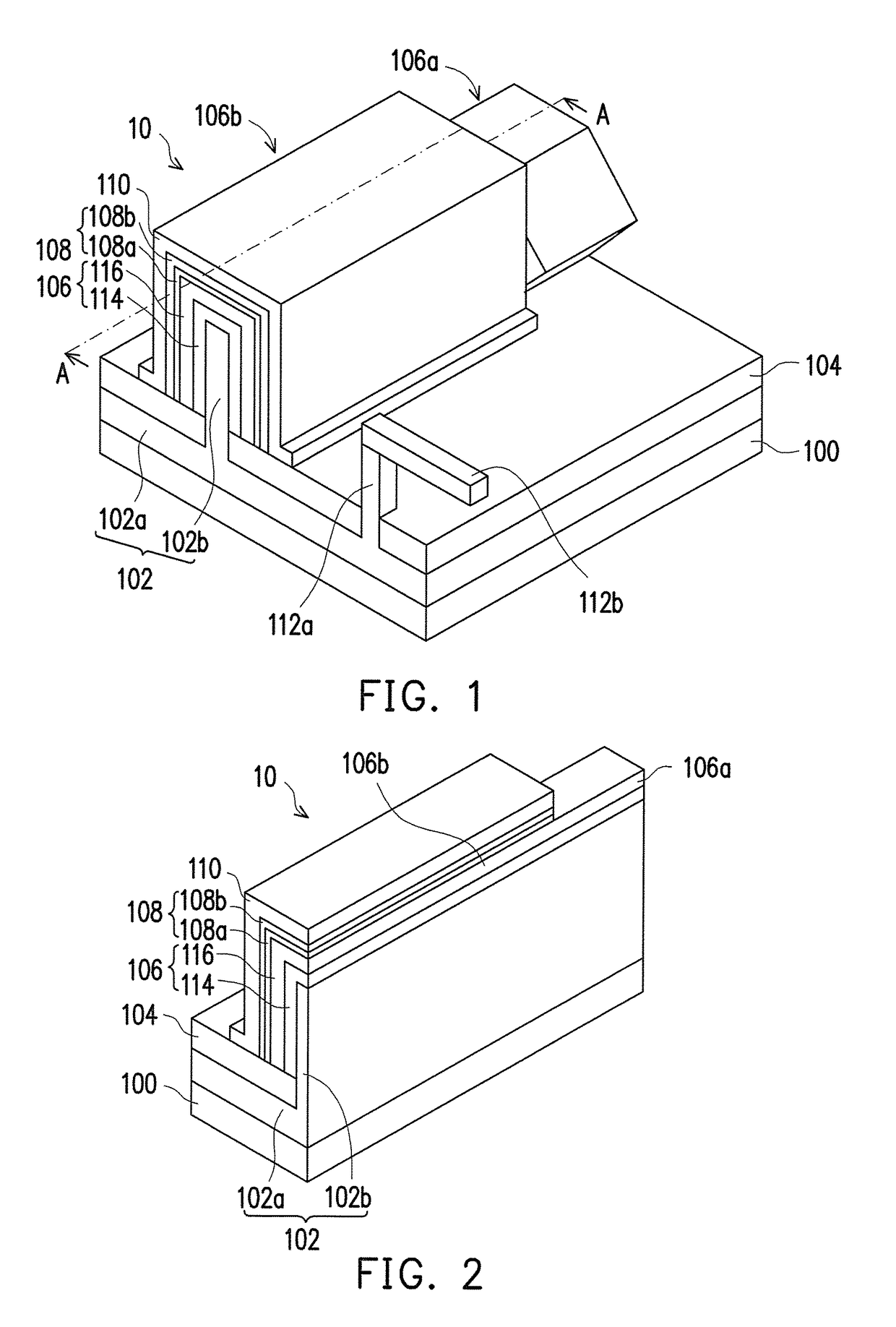

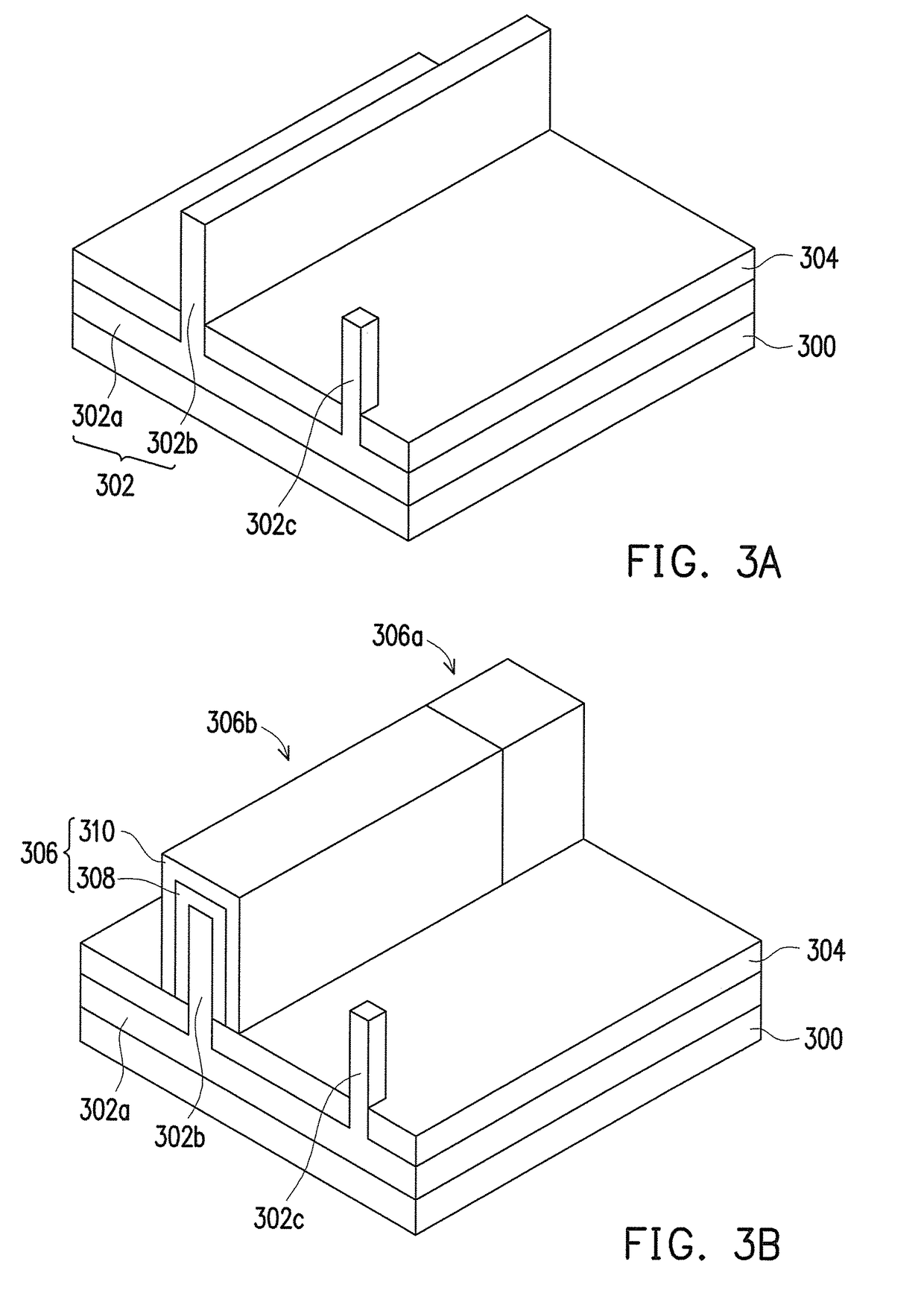

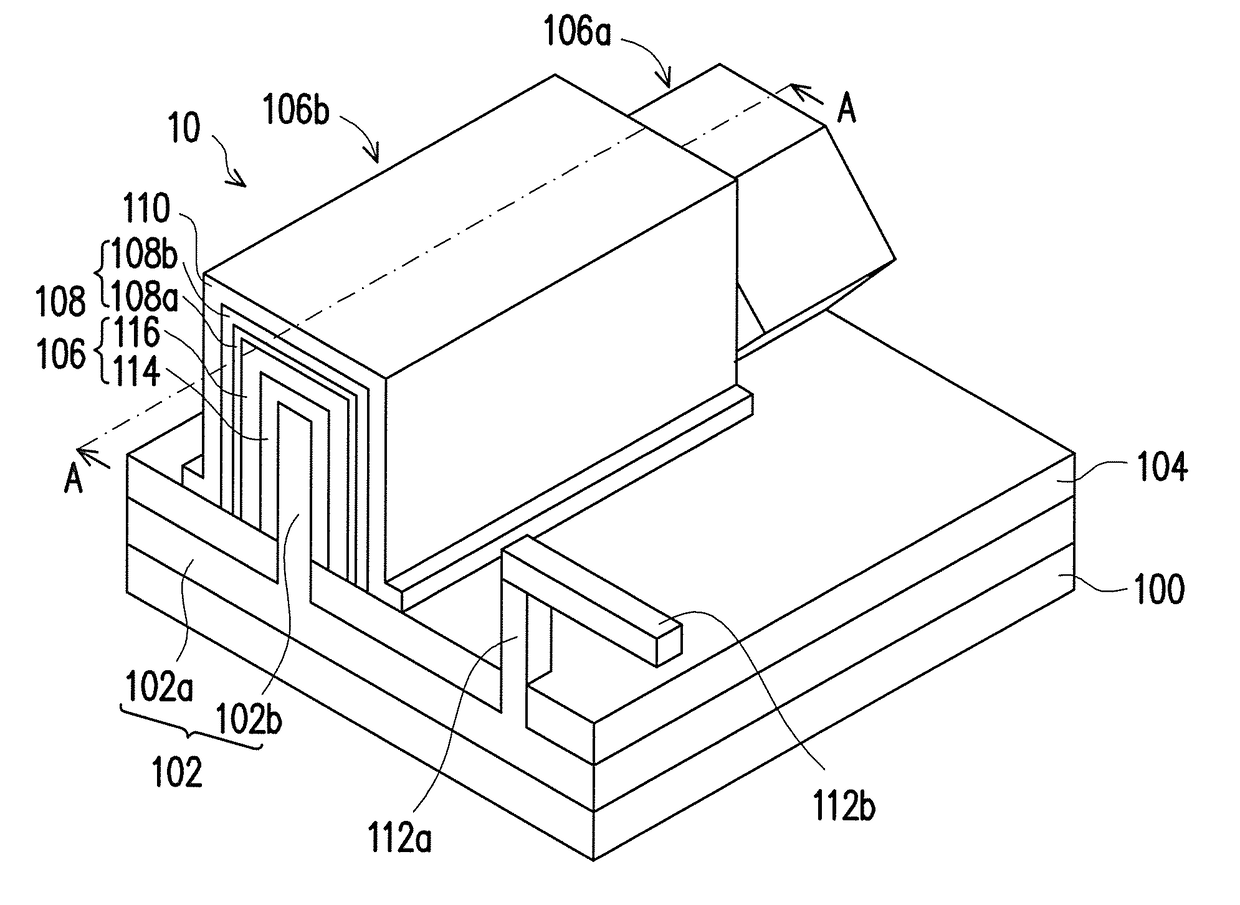

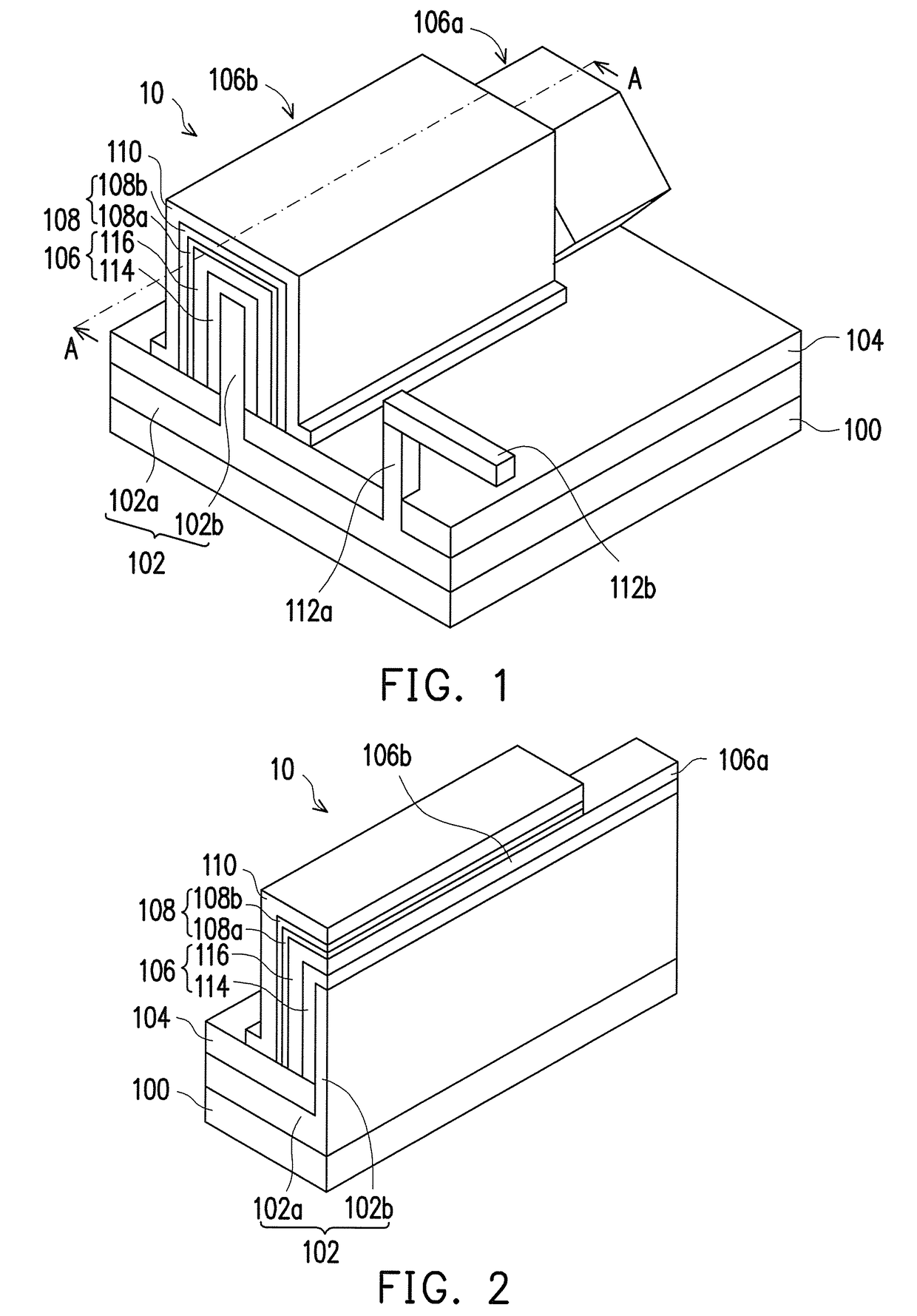

Field effect transistor structure with gate structure having a wall and floor portions

ActiveUS9843007B2Raise the ratioRaise the threshold voltageTransistorSolid-state devicesElectrical conductorInsulation layer

A field effect transistor (FET) structure includes a substrate, an internal gate, an insulation layer, a semiconductor strip, a gate dielectric insulator, and a gate conductor. The internal gate includes a floor portion located on the substrate and a wall portion extending from the floor portion. The insulation layer is located on the floor portion of the internal gate. The semiconductor strip is located on the wall portion and a portion of the insulation layer, and the semiconductor strip includes source / drain regions and a channel region adjacent to the source / drain regions. The gate dielectric insulator is located on the channel region. The gate conductor is located on the gate dielectric insulator.

Owner:NAT CHIAO TUNG UNIV

Display device and method for manufacturing the same

ActiveUS8416373B2Increase the areaIncrease the aperture ratioVessels or leading-in conductors manufactureNon-linear opticsDisplay deviceComputer science

A display device and a method for manufacturing the display device are provided. The display device includes a substrate and a color filter layer. A plurality of sub-pixel electrodes are formed on the substrate. The color filter layer is configured on the substrate. The color filter layer defines a plurality of color areas corresponding to the sub-pixel electrodes. Here, each of the color areas is partially overlapped with two of the sub-pixel electrodes adjacent to each other.

Owner:HIMAX DISPLAY INC

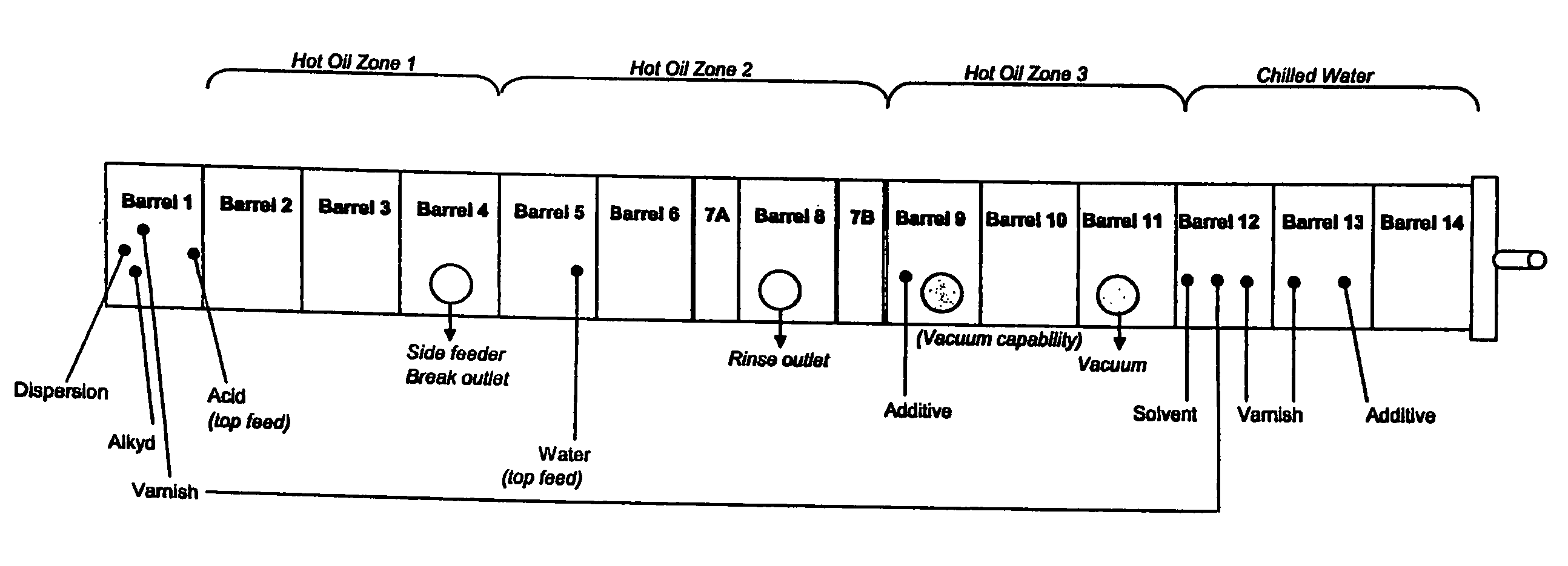

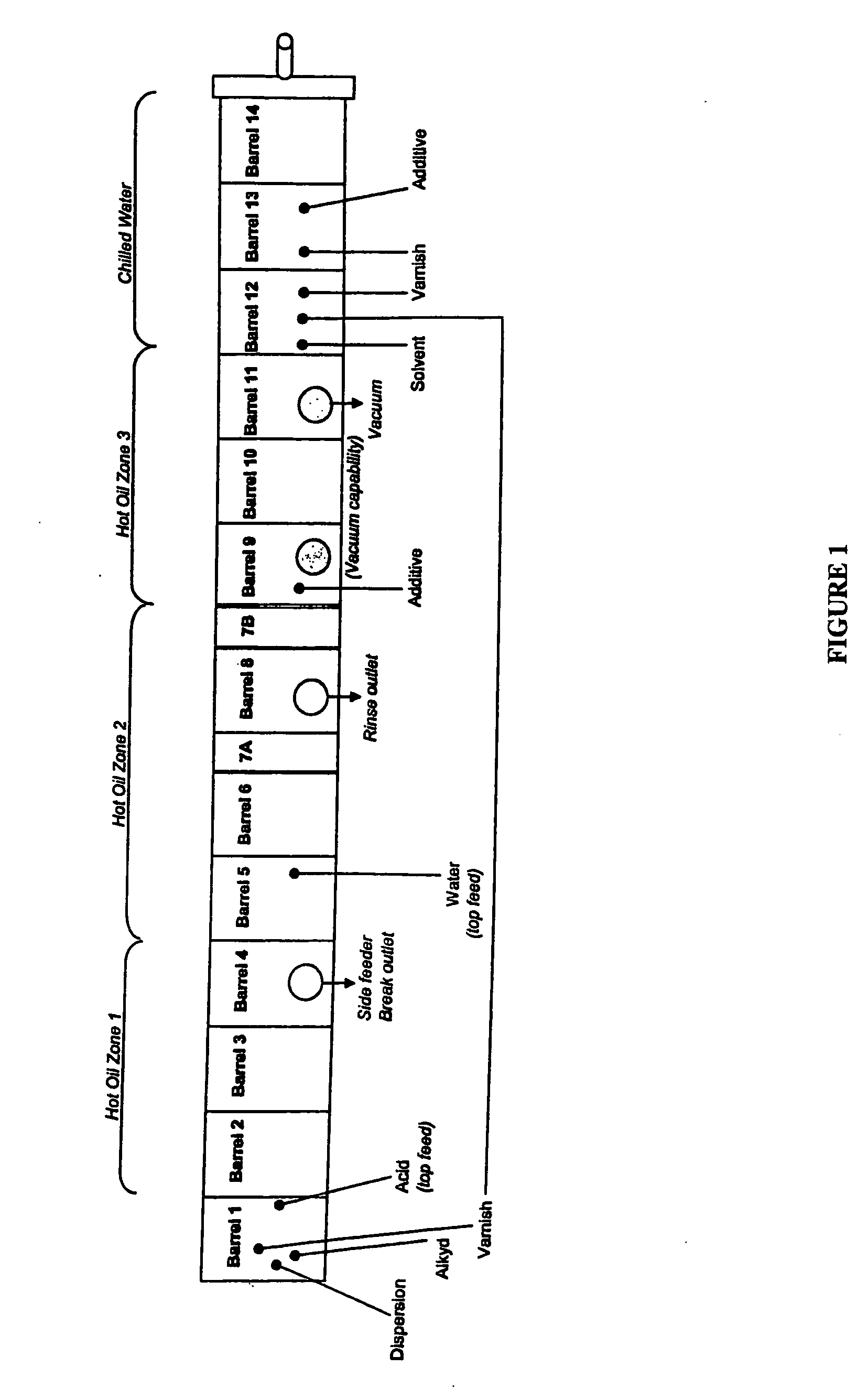

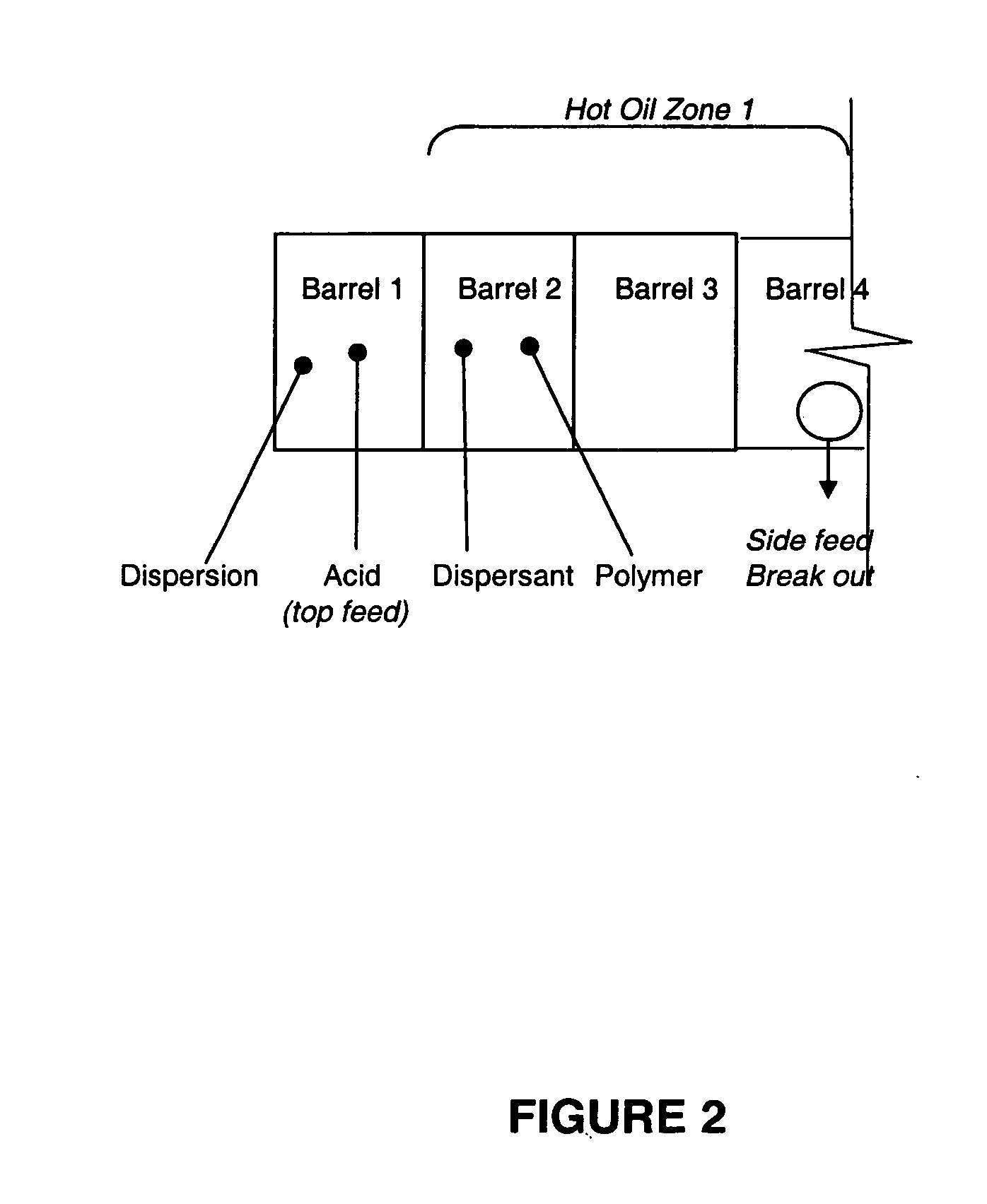

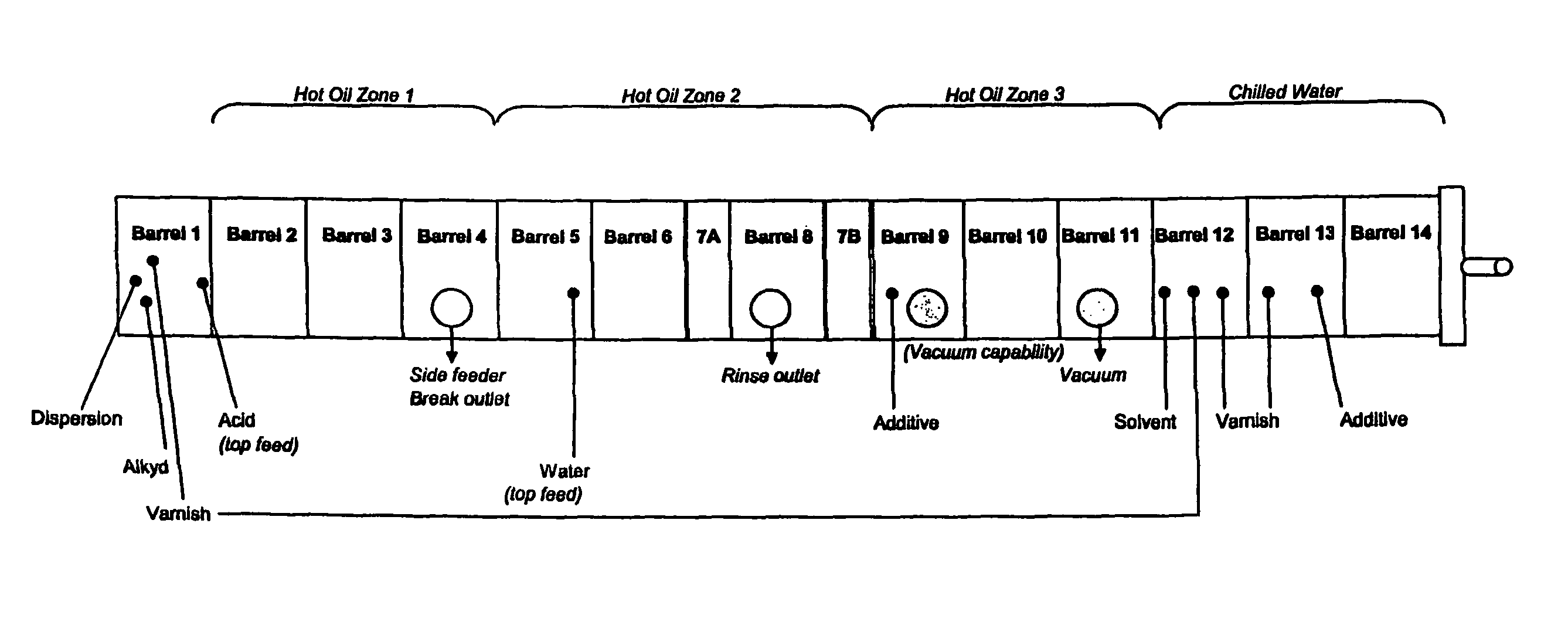

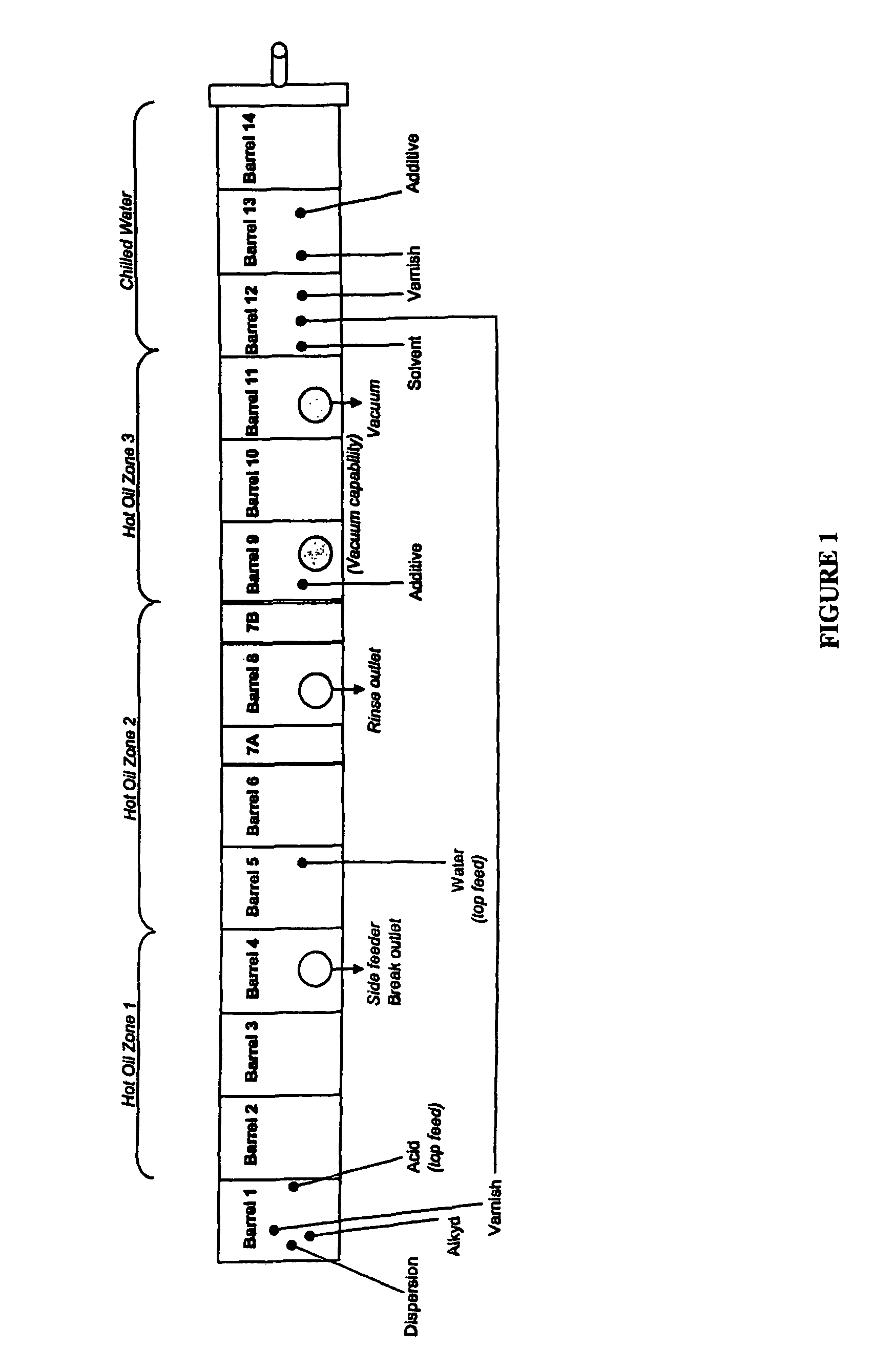

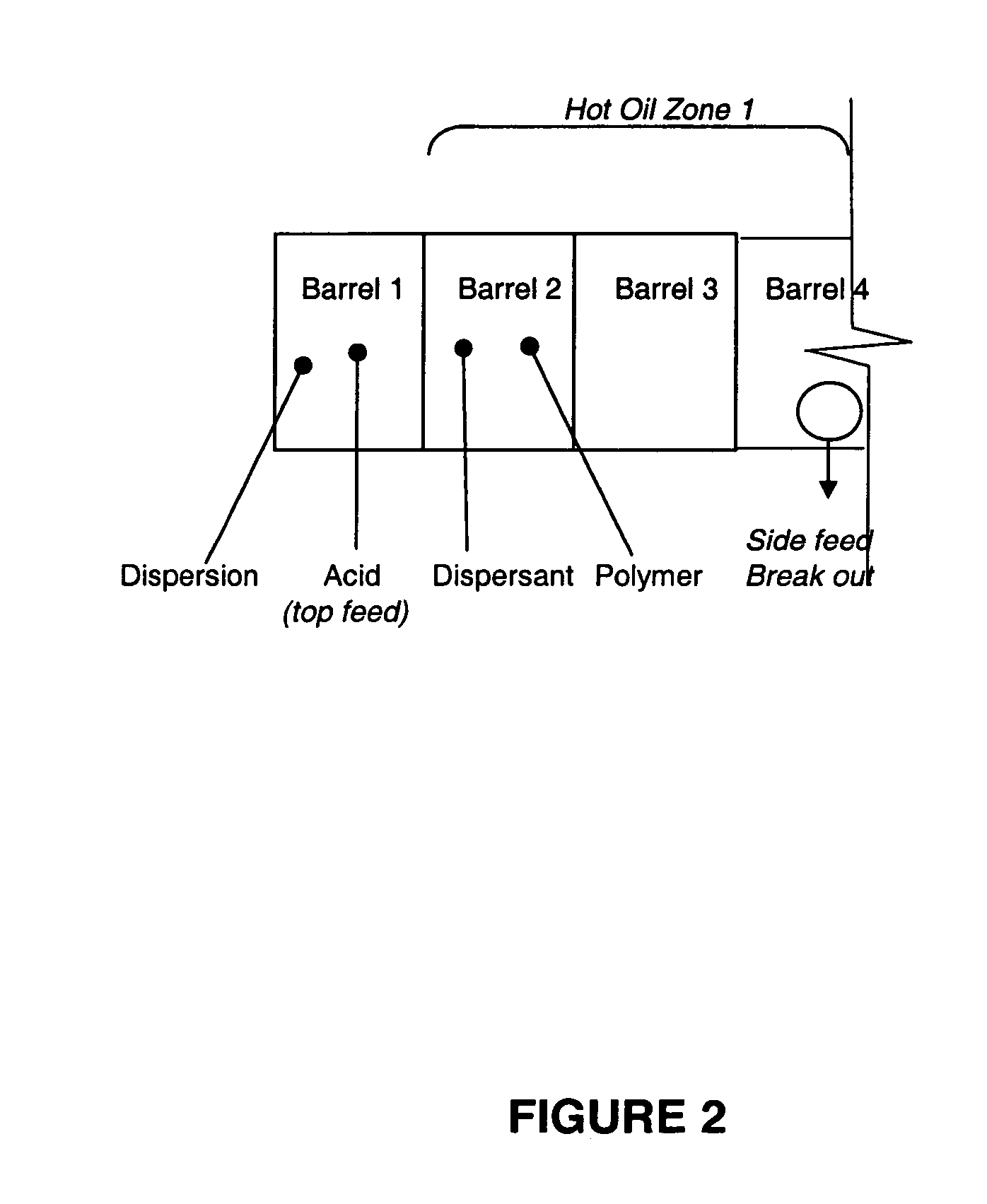

Processes for preparing organic pigment dispersions and ink

InactiveUS20060037517A1Usefully long shelf lifeIssue can be resolvedShaking/oscillating/vibrating mixersFatty acid chemical modificationMasterbatchRinse water

A method for preparing an organic pigment dispersion, such as a flush pigment or ink product, comprises steps of introducing into a twin screw extruder a stable, water-borne pigment dispersion, an organic medium, and a destabilizing agent; mixing together the stable, water-borne pigment dispersion, the organic medium, and the destabilizing agent to produce a pigment flush phase and a water phase; and removing at least a part of the water phase. A twin-screw extruder for carrying out the flushing method has an addition and flushing zone, a water removal zone, and a zone for rinsing the crude organic pigment dispersion or flush with water and removing the rinse water. Additional materials may be added to form a finished pigmented product such as an ink product, masterbatch, or toner.

Owner:FLINT INK

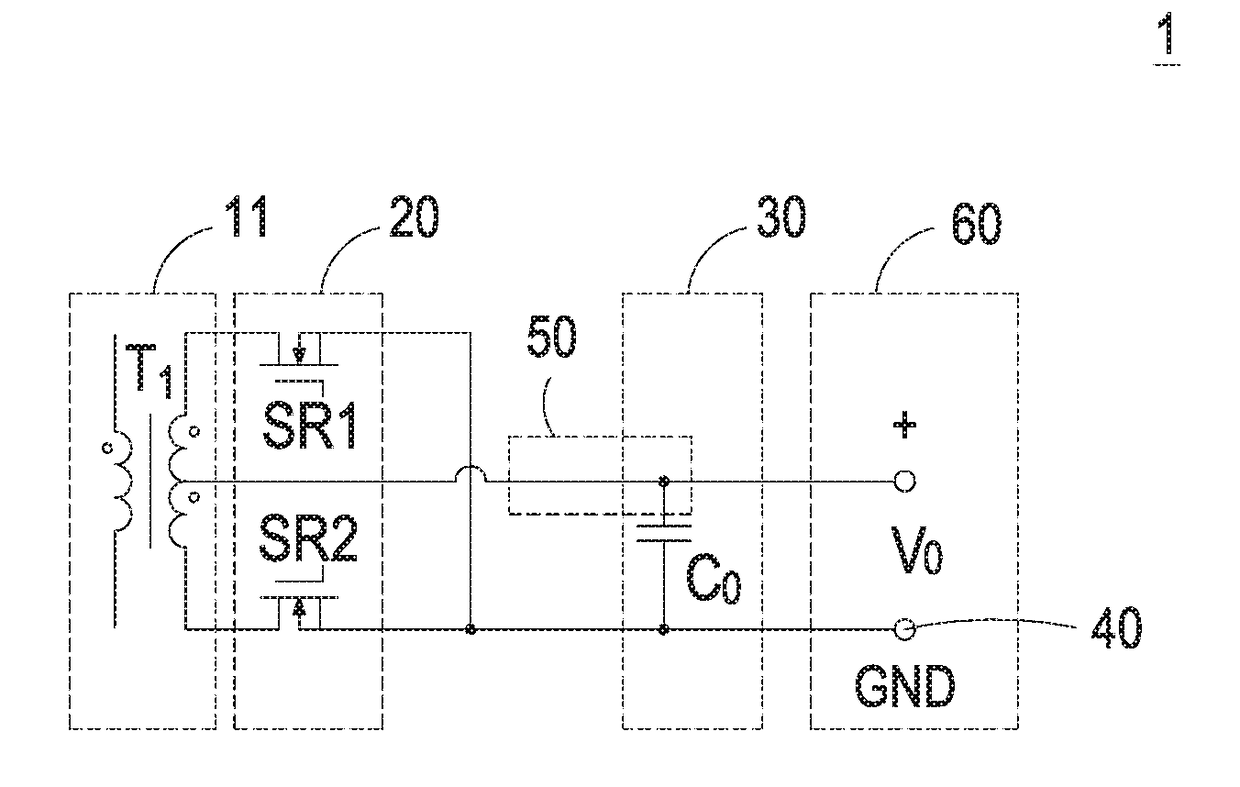

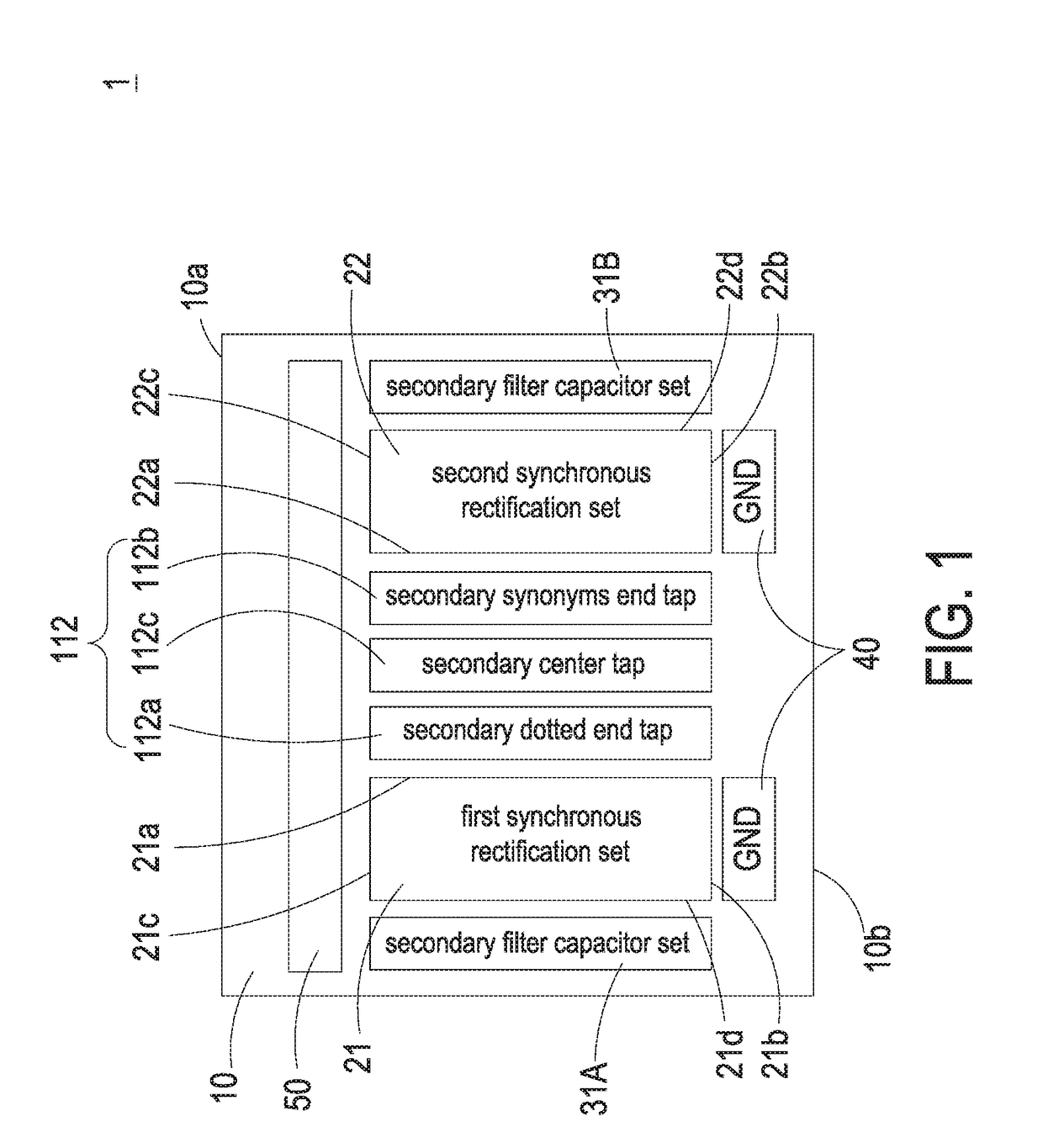

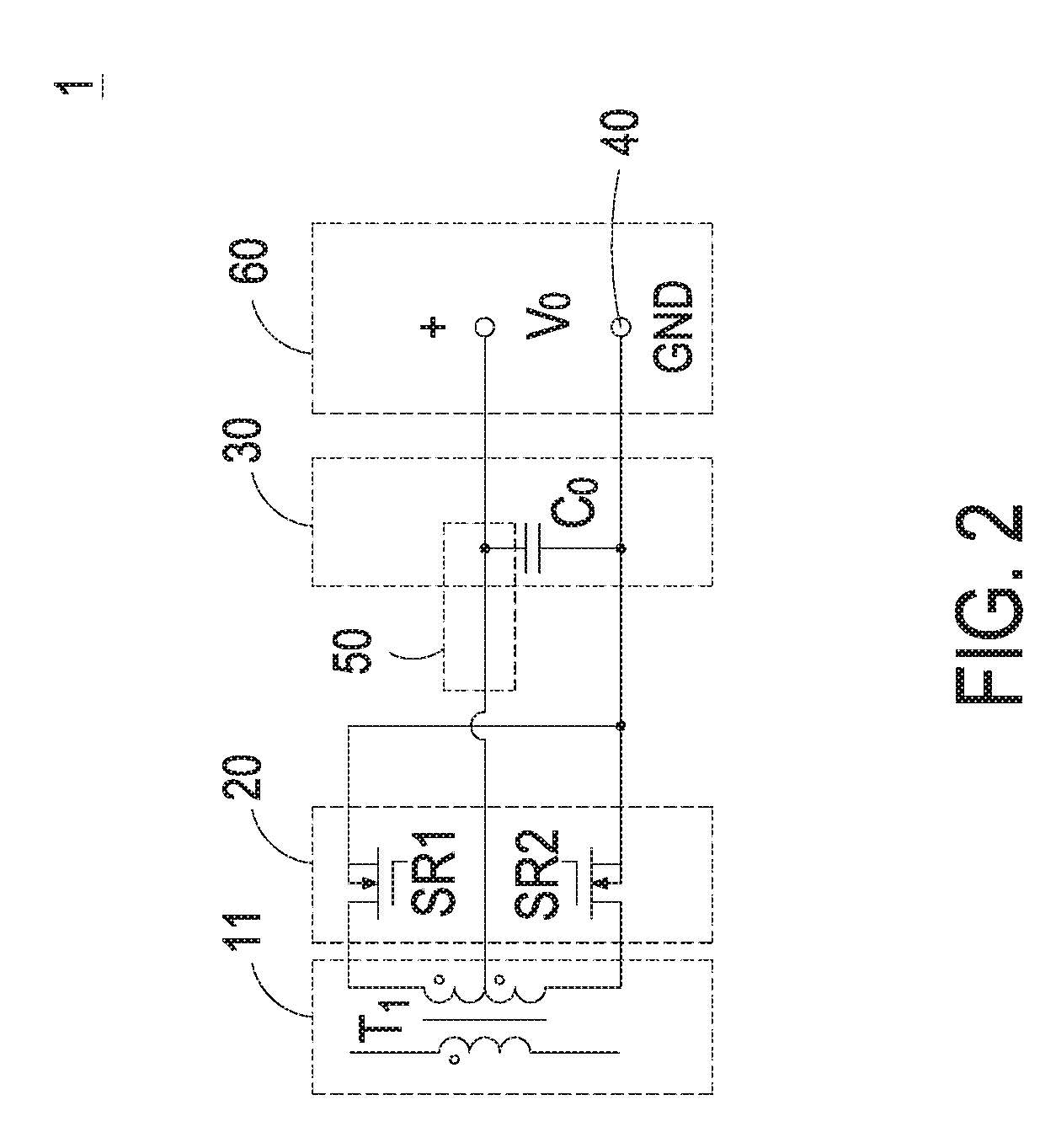

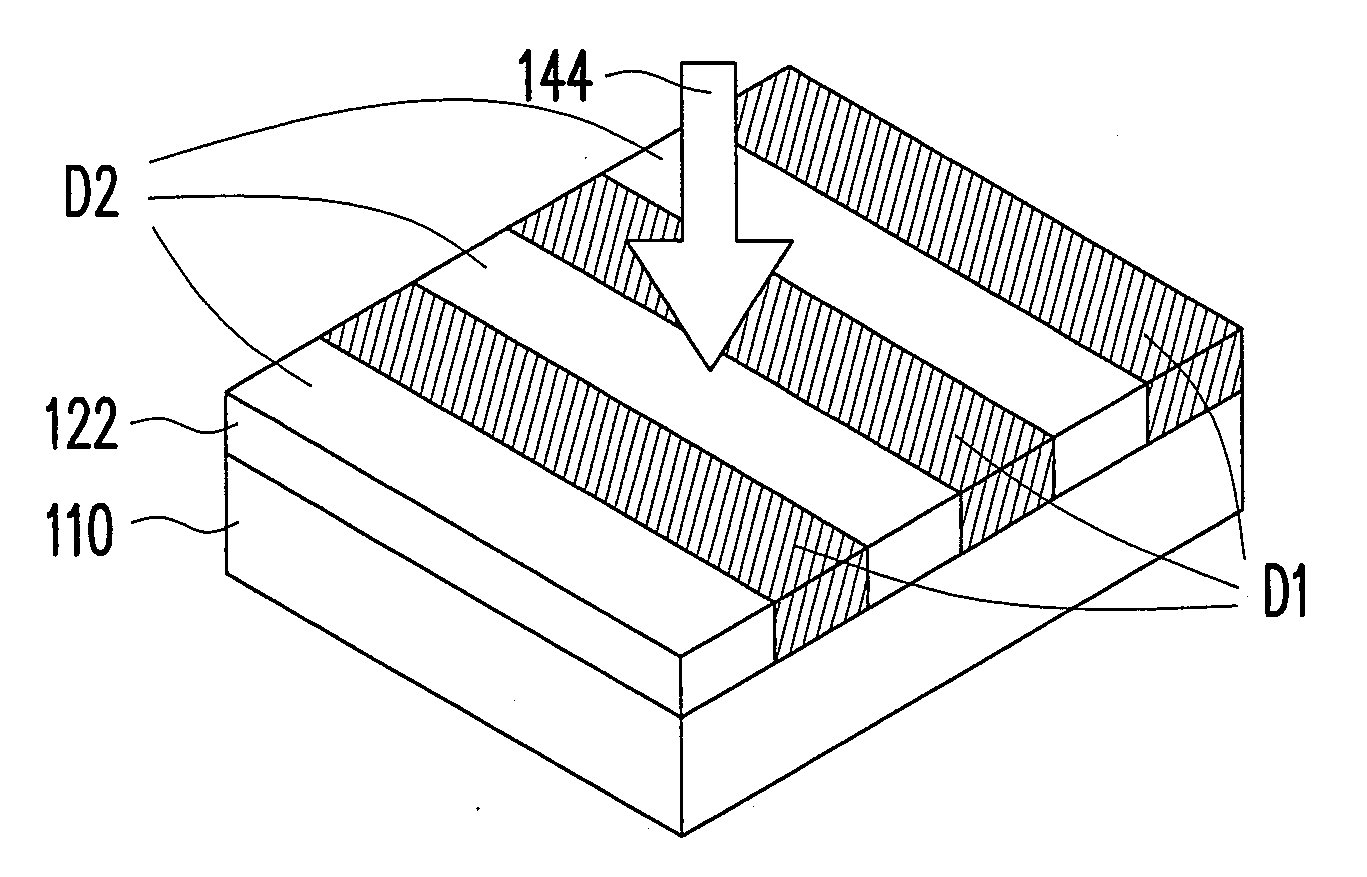

Synchronous rectification module

ActiveUS20180205323A1Improve power densitySave spaceTransformers/reacts mounting/support/suspensionEfficient power electronics conversionElectricityPower flow

The present invention provides a synchronous rectification module. The synchronous rectification module includes a circuit board, a transformer, two synchronous rectification sets and a grounding set. The transformer includes a primary winding and a secondary electrically-conductive foil winding. The first and second synchronous rectification sets are symmetrically disposed on the circuit board, corresponding to the transformer and electrically connected to a secondary dotted end tap and a secondary synonyms end tap of the secondary electrically-conductive foil winding respectively. The secondary electrically-conductive foil winding of the transformer is disposed nearby a lateral edge of the first or second synchronous rectification set, and the grounding set is disposed along a bottom edge of the circuit board and nearby the bottom edge of the first or second synchronous rectification set, so as to reduce the current path of the secondary synchronous rectification circuit and achieve the purposes of miniaturization and high power density.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

Manufacturing method of optical film and manufacturing method of stereoscopic display

InactiveUS20130227830A1Alignment force can be enhancedIncrease anchoring forcePretreated surfacesCoatingsDisplay deviceOptical thin film

A manufacturing method of an optical film includes following steps. An alignment solution is coated onto a first substrate having a first area and a second area. The alignment solution on the first substrate is exposed to a polarized light to form an optical alignment film having a first alignment direction and a second alignment direction on the two areas, respectively. A composite liquid crystal (LC) material containing a reactive LC material and a monomer material is coated onto the optical alignment film. The optical alignment film is sequentially exposed to a first non-polarized light having a monomer material absorption wavelength and a second non-polarized light having a reactive LC material absorption wavelength, thus the monomer material reacts with the reactive LC material, and the reactive LC material is solidified along the first and second alignment directions in sequence. A manufacturing method of a stereoscopic display is also provided.

Owner:CHUNGHWA PICTURE TUBES LTD

Pixel array, display panel and curved display panel

A pixel array includes pixel unit sets each including a substrate having first and second pixel regions, a scan line, first and second data lines extending along a second direction, first and second active devices respectively in the first and second pixel regions, and first and second pixel electrodes respectively located in the first and second pixel regions and electrically connected to the first and second active devices, respectively. The scan line includes a main scan line and first and second branch scan lines (connected to the main scan line) extending along a first direction. The first active device is electrically connected to the first branch scan line and the first data line. The second active device is electrically connected to the second branch scan line and the second data line. At least one of the first and second data lines is overlapped with the first and second pixel electrodes.

Owner:AU OPTRONICS CORP

Processes for preparing organic pigment dispersions and ink

InactiveUS7947126B2Usefully long shelf lifeIssue can be resolvedShaking/oscillating/vibrating mixersFatty acid chemical modificationMasterbatchPigment dispersion

A method for preparing an organic pigment dispersion, such as a flush pigment or ink product, comprises steps of introducing into a twin screw extruder a stable, water-borne pigment dispersion, an organic medium, and a destabilizing agent; mixing together the stable, water-borne pigment dispersion, the organic medium, and the destabilizing agent to produce a pigment flush phase and a water phase; and removing at least a part of the water phase. A twin-screw extruder for carrying out the flushing method has an addition and flushing zone, a water removal zone, and a zone for rinsing the crude organic pigment dispersion or flush with water and removing the rinse water. Additional materials may be added to form a finished pigmented product such as an ink product, masterbatch, or toner.

Owner:FLINT INK

Field effect transistor structure

ActiveUS20170317302A1Raise the ratioRaise the threshold voltageSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerElectrical conductor

A field effect transistor (FET) structure includes a substrate, an internal gate, an insulation layer, a semiconductor strip, a gate dielectric insulator, and a gate conductor. The internal gate includes a floor portion located on the substrate and a wall portion extending from the floor portion. The insulation layer is located on the floor portion of the internal gate. The semiconductor strip is located on the wall portion and a portion of the insulation layer, and the semiconductor strip includes source / drain regions and a channel region adjacent to the source / drain regions. The gate dielectric insulator is located on the channel region. The gate conductor is located on the gate dielectric insulator.

Owner:NAT CHIAO TUNG UNIV

Over-current protection apparatus

InactiveUS7071810B2Improve space utilizationReduce installation costsCurrent responsive resistorsArrangements responsive to excess currentOver current protectionElectrical and Electronics engineering

An over-current protection apparatus comprises a plurality of over-current protection devices and a bonding sheet. Each over-current protection device comprises at least one current-sensitive element, two outer electrode layers and at least one insulating layer disposed on a surface of the current-sensitive element. The bonding sheet penetrates and connects the plurality of over-current protection devices, and is disposed on a surface of the at least one current-sensitive element for insulation.

Owner:POLYTRONICS TECH

Pixel array, display panel and curved display panel

ActiveUS20180341161A1Issue can be resolvedSolid-state devicesNon-linear opticsScan lineComputer science

A pixel array includes pixel unit sets each including a substrate having first and second pixel regions, a scan line, first and second data lines extending along a second direction, first and second active devices respectively in the first and second pixel regions, and first and second pixel electrodes respectively located in the first and second pixel regions and electrically connected to the first and second active devices, respectively. The scan line includes a main scan line and first and second branch scan lines (connected to the main scan line) extending along a first direction. The first active device is electrically connected to the first branch scan line and the first data line. The second active device is electrically connected to the second branch scan line and the second data line. At least one of the first and second data lines is overlapped with the first and second pixel electrodes.

Owner:AU OPTRONICS CORP

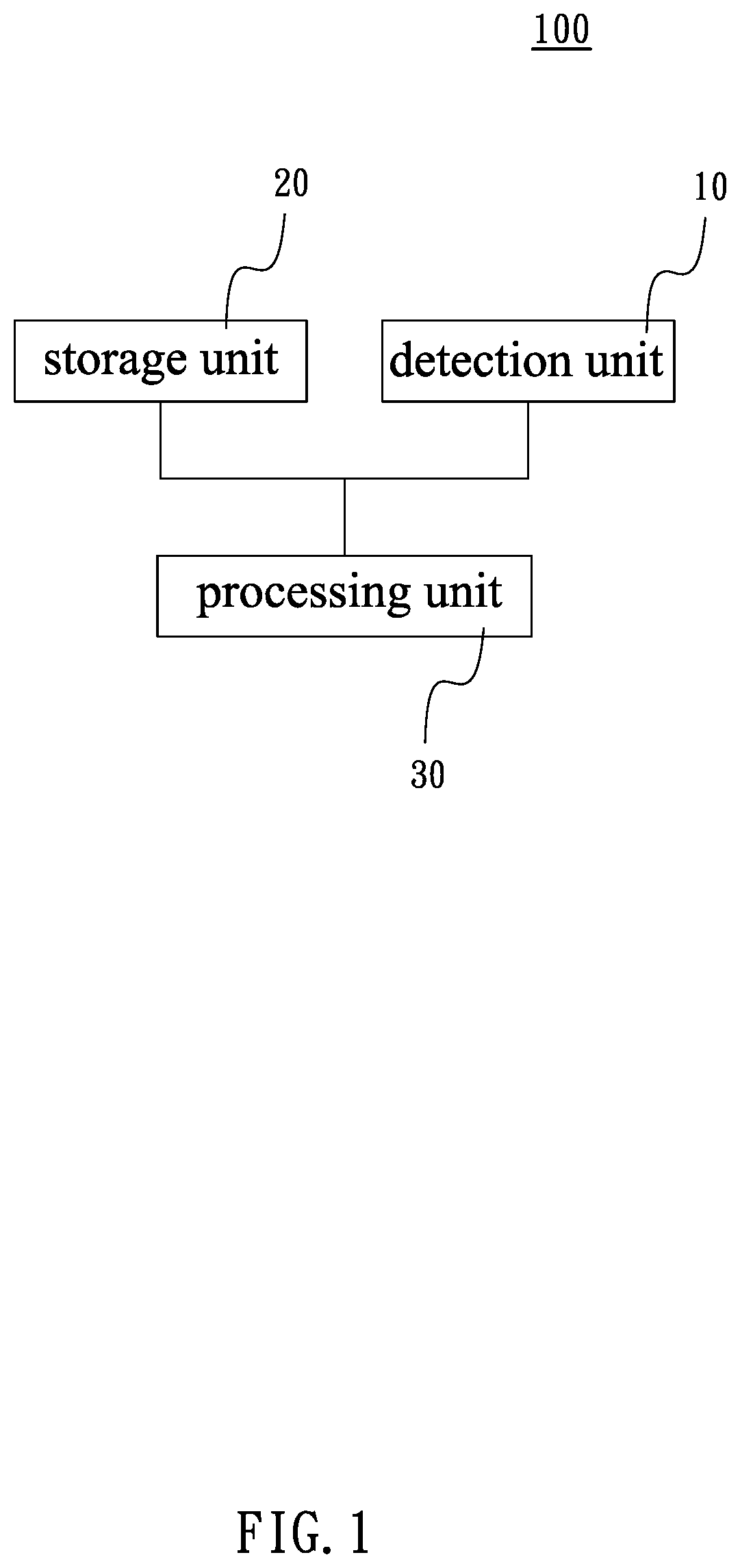

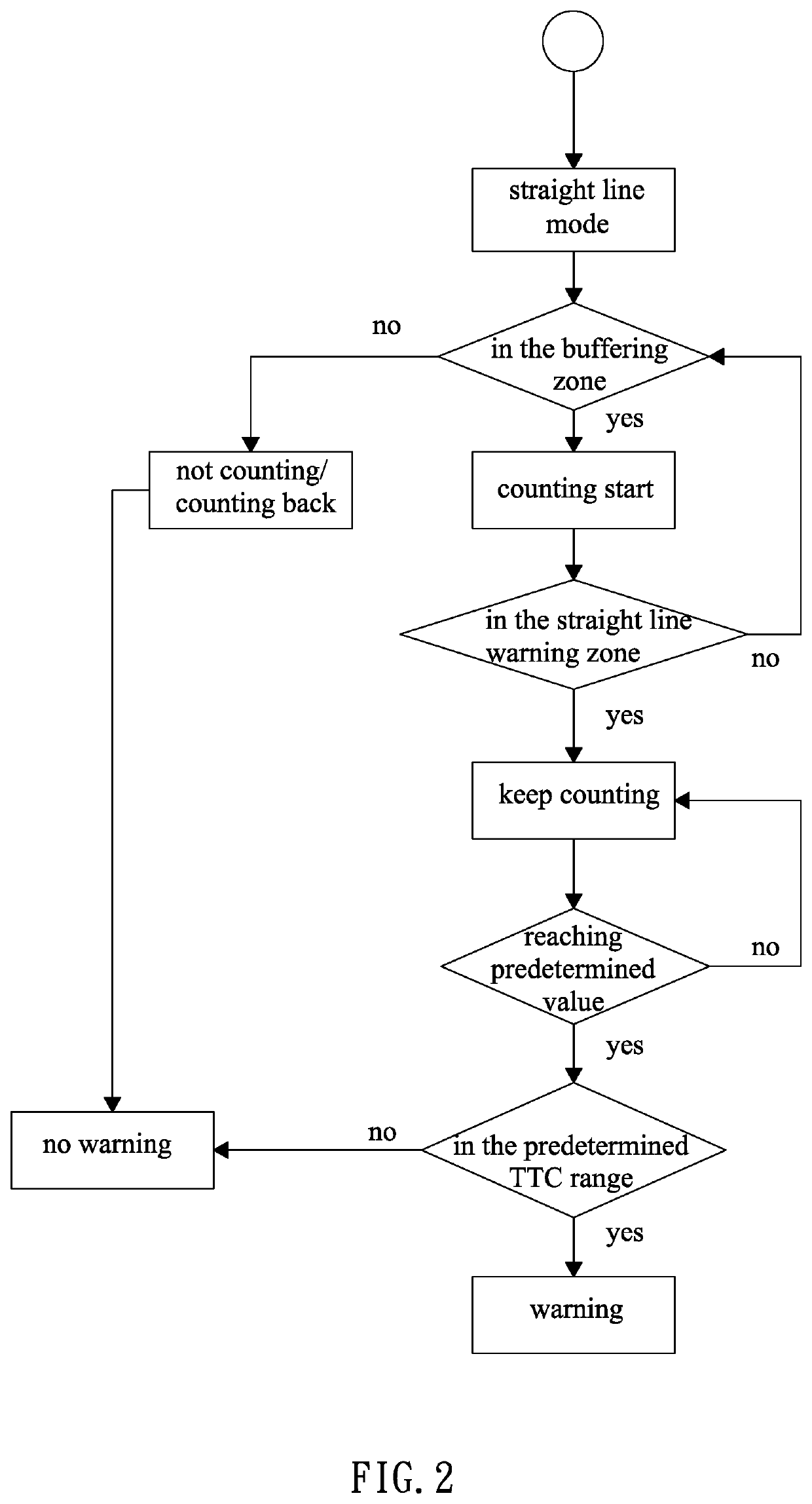

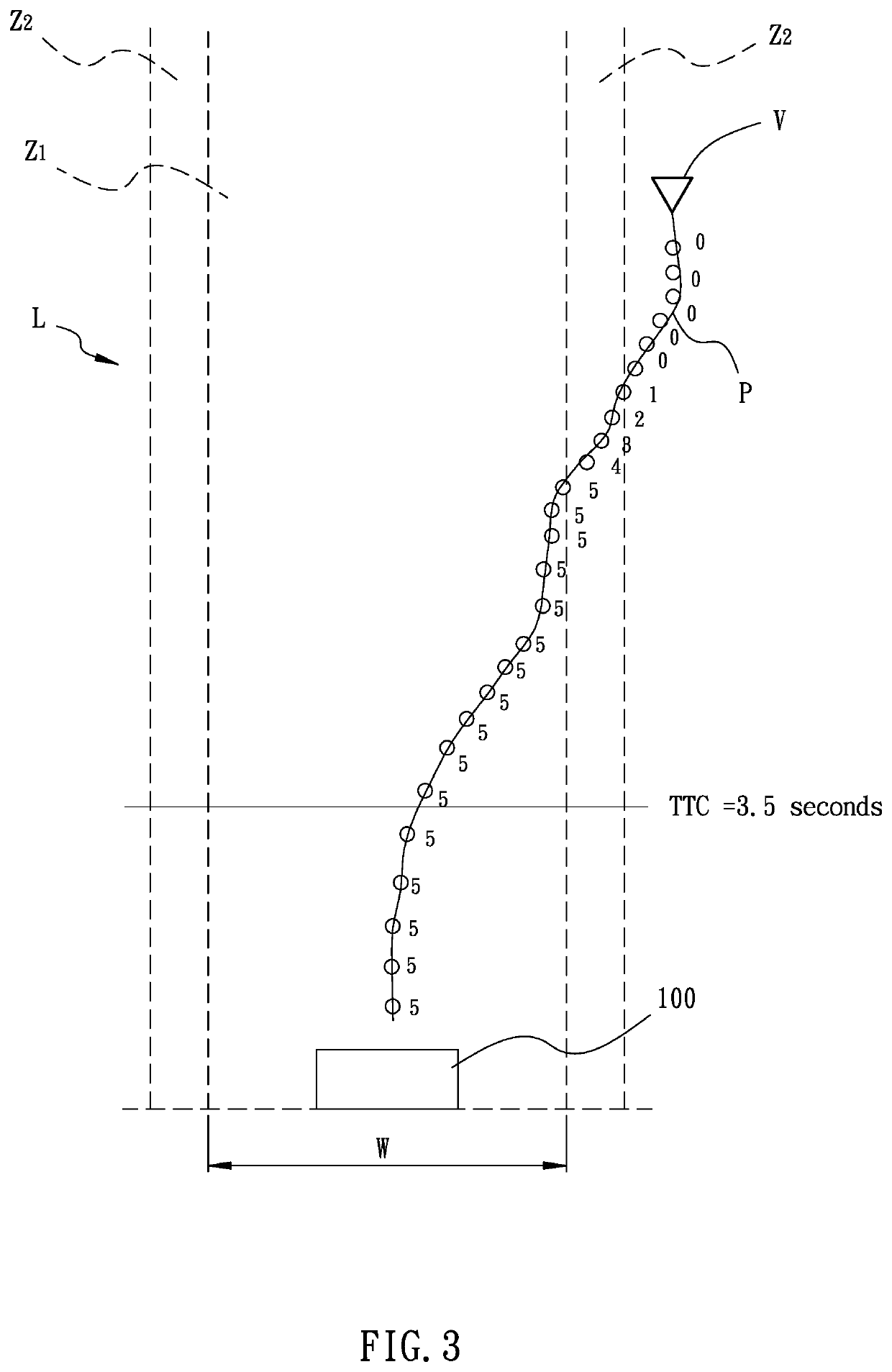

Warning system for detecting approaching vehicle and method thereof

ActiveUS10843626B2Preventing people at the scene from fearing or panickingIssue can be resolvedExternal condition input parametersSignalling/lighting devicesSimulationStorage cell

A warning system for detecting approaching vehicle and method thereof are provided. The system includes a detection unit detecting a relative distance with respect to the approaching vehicle and a driving path of the approaching vehicle; a storage unit storing a warning information; and a processing unit receiving the detection signal to acquire the current time to collision and the current driving path. When the time to collision is equal to or shorter than the predetermined time to collision, and the driving path falls in the warning area, and the driving path fulfills the confirmation condition, the processing unit sends a warning signal. Therefore, a potentially dangerous approaching vehicle is accurately judged, and the warning is correctly sent.

Owner:CUBTEK INC

Modular solar wireless transmission device

InactiveUS20160285303A1Reduce pollutionSmall sizePV power plantsSecondary cellsWireless transmissionEngineering

A modular solar wireless transmission device includes a wireless transmitter and multiple sensing modules detachably and selectively connected to the wireless transmitter. The wireless transmitter has a housing, and a solar cell module and a wireless transmission and power supply module mounted inside the housing. The wireless transmission and power supply module is connected to the solar cell module and a first connection port exposed beyond the housing and connected to a second connection port of one of the sensing modules. The sensing modules can be selectively connected to the wireless transmitter to detect different signals. The wireless transmission and power supply module then wirelessly transmits the detected signals to an external controller to resolve the presence of duplicated wireless transmitters. Because of solar power generation, the modular solar wireless transmission is more compact and environmental friendly.

Owner:NXCONTROL SYST

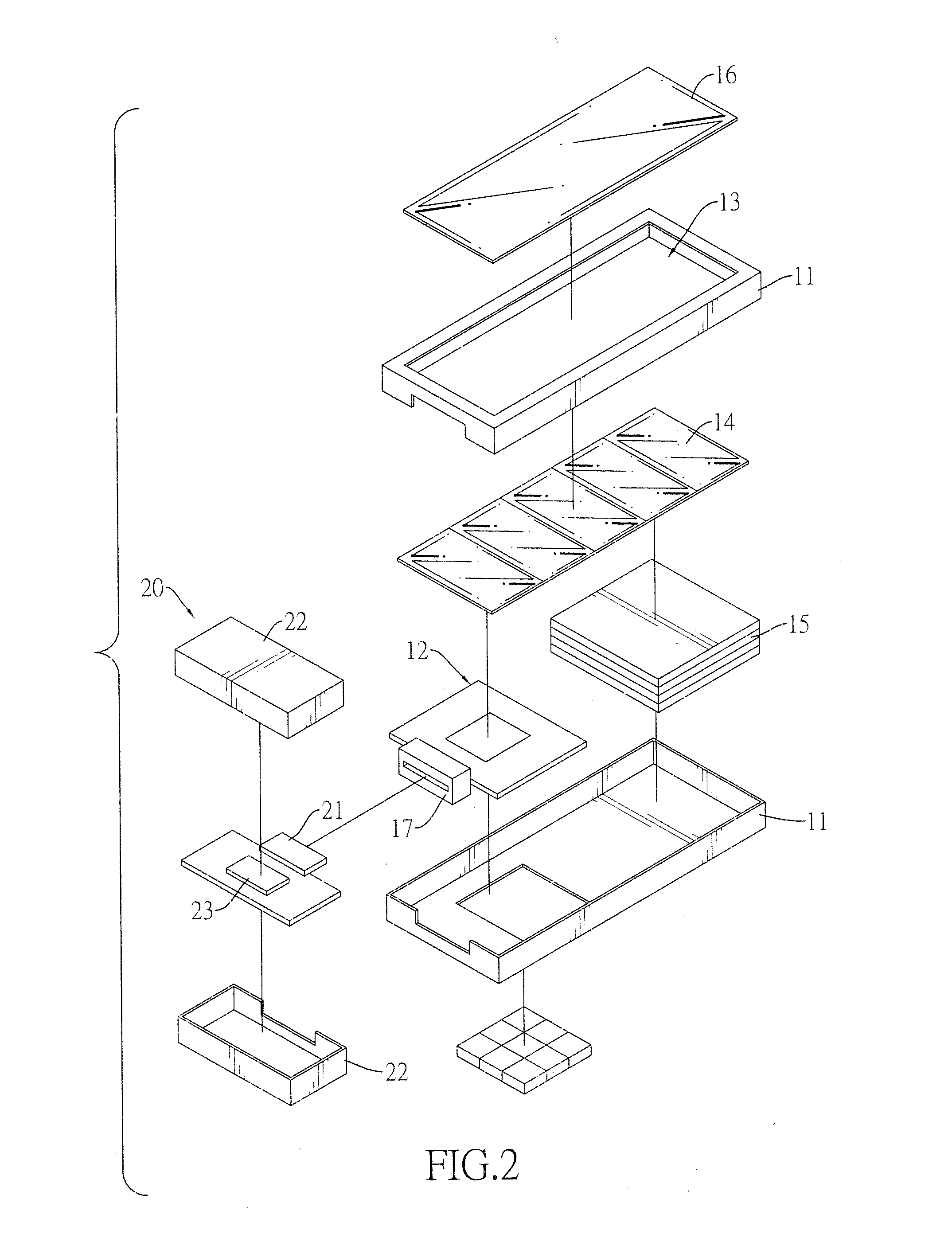

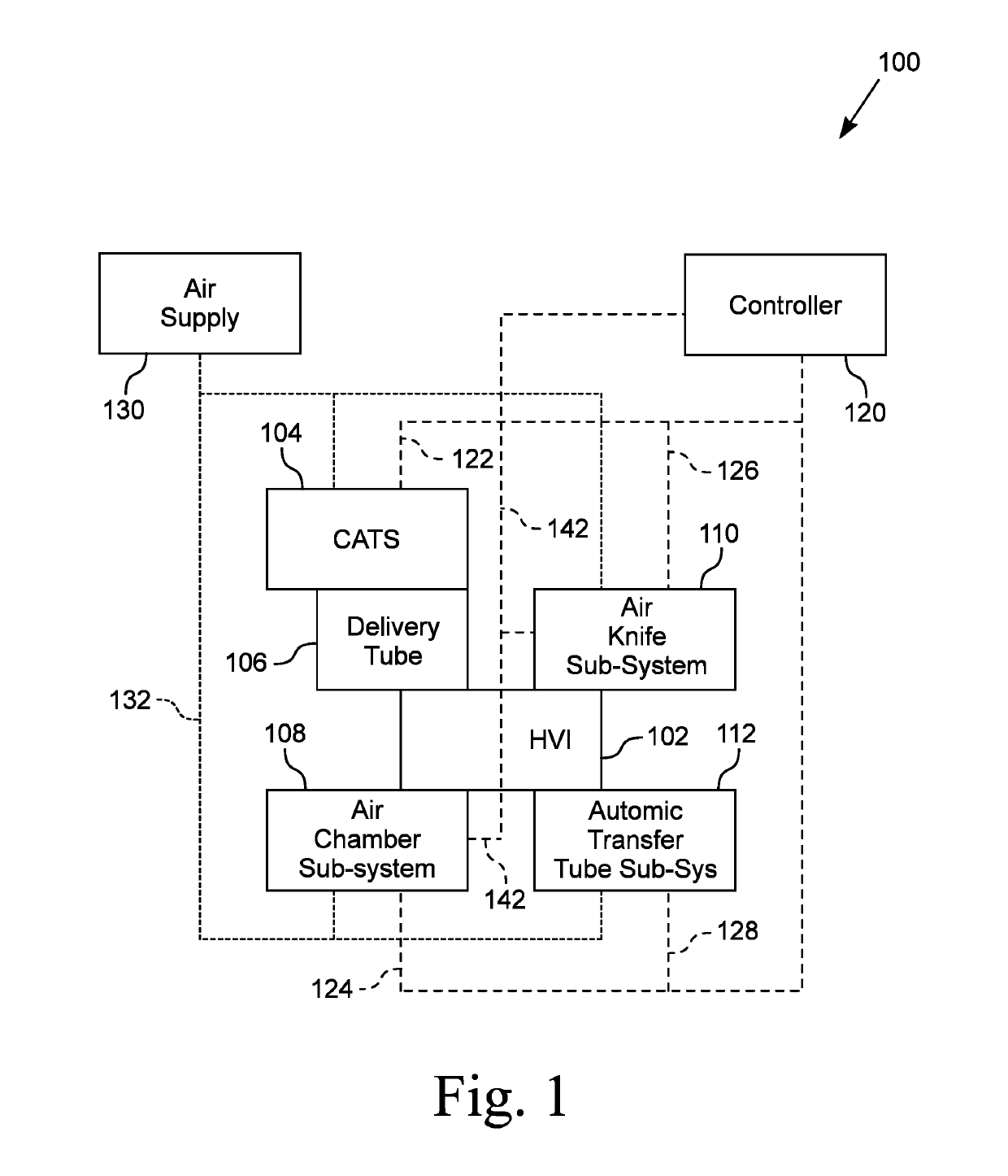

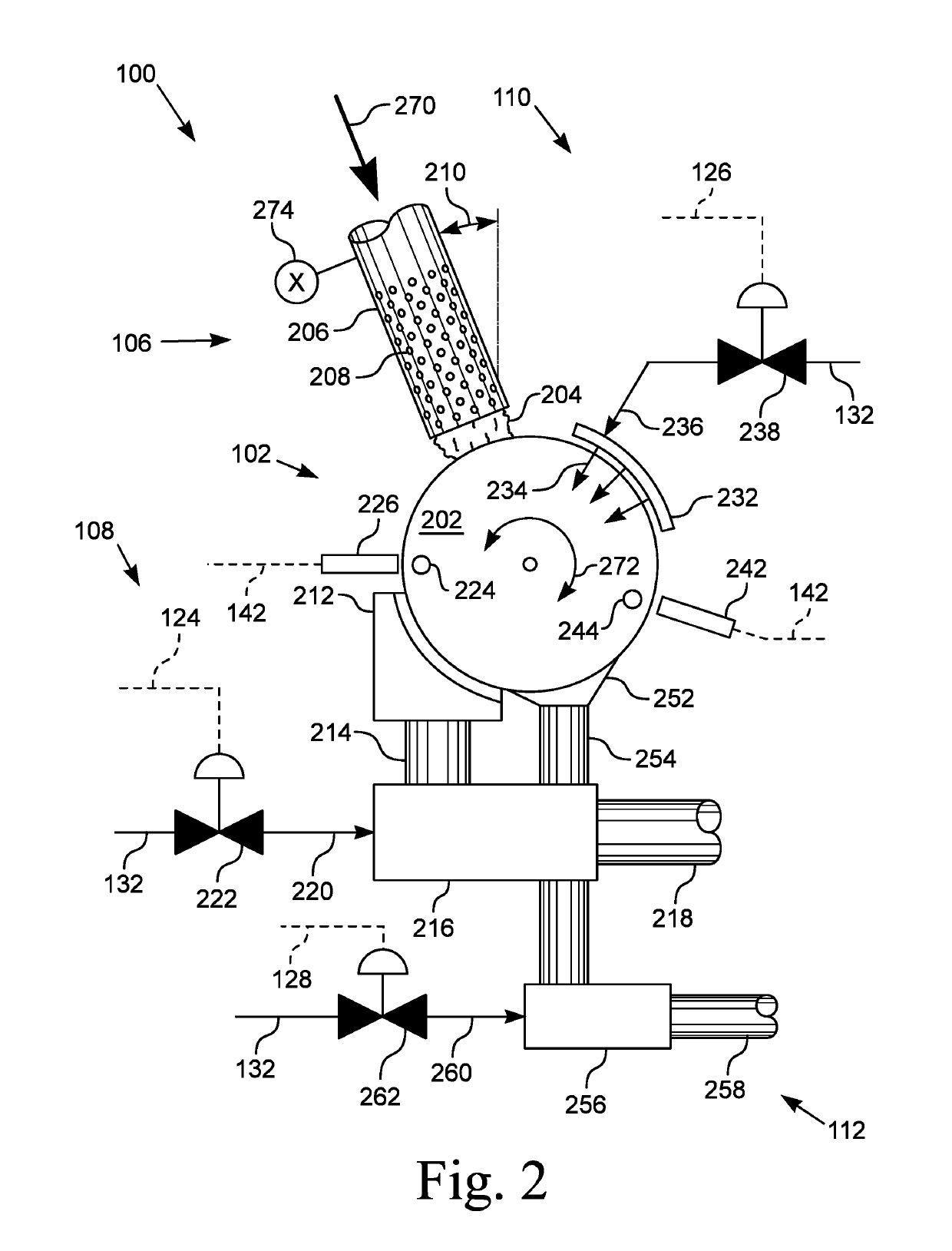

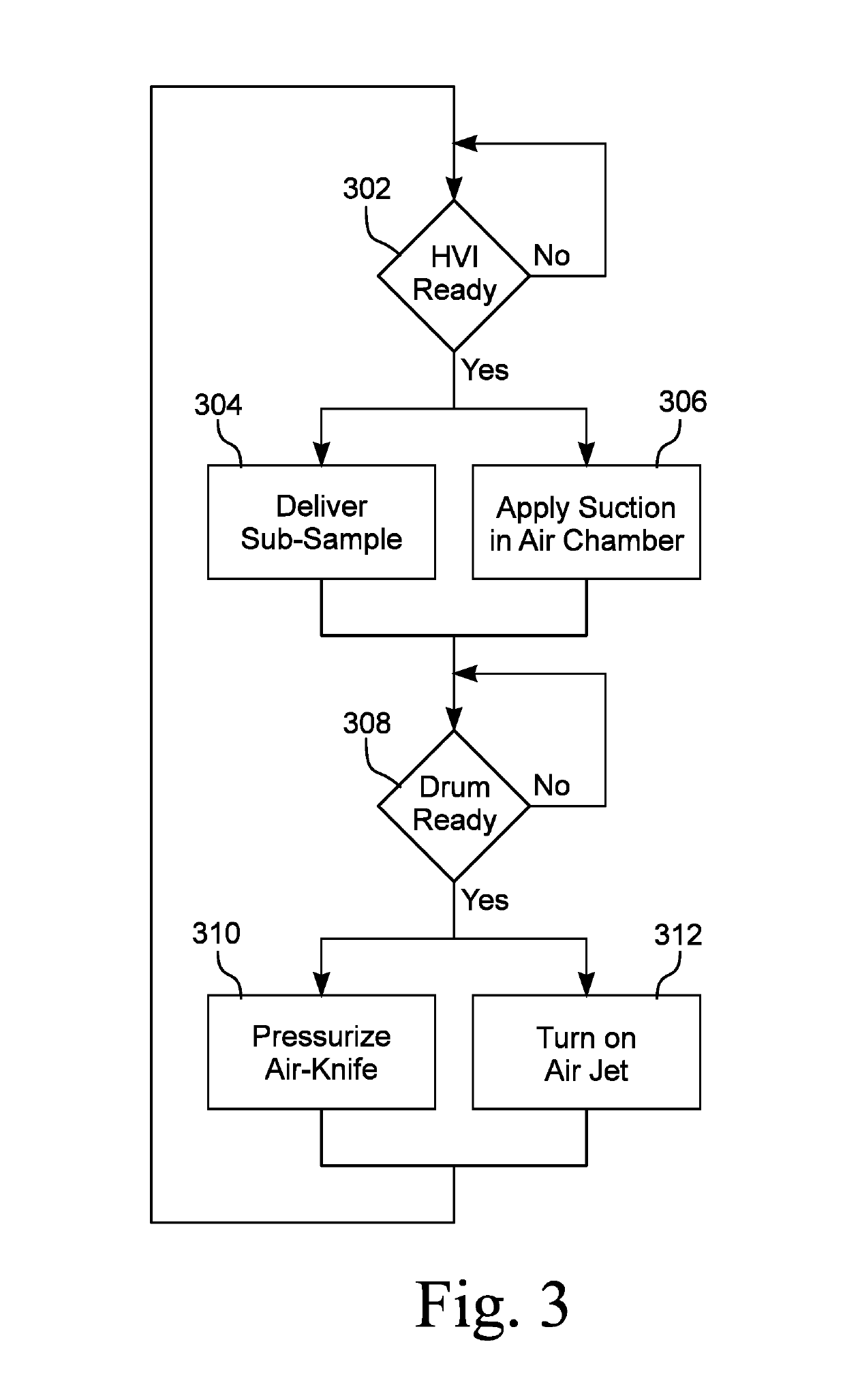

HVI sample feed kit

ActiveUS10324101B1Quantity minimizationMore cleanWithdrawing sample devicesFibre feedersPneumatic pressureEngineering

Apparatus for automating a high volume instrument (HVI) used for the classification of all Upland and American Pima cotton, including determining trash and color. A sub-sample delivery tube sub-system and a sample drum air chamber sub-system allow the HVI to receive sub-samples from an automated cotton system. A delivery tube, with an air dissipater, delivers the automated sub-sample to the HVI sample drum while an air chamber below the sample drum applies a negative air pressure to the drum. A sub-sample air-knife extraction sub-system and an autoMIC transfer tube assist sub-system allow the HVI to release automated sub-samples after the sample drum in the HVI has completed its operations on the sub-sample. An air-knife applies air jets to the sample plate of the HVI sample drum to release the sub-sample. As the sub-sample leaves the drum an air jet is actuated to push the sub-sample along a transfer tube.

Owner:QUANTITATIVE ENG SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com