Patents

Literature

573results about "Fibre feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus on a spinning preparation machine for ascertaining the mass and/or fluctuations in the mass of a fibre material

InactiveUS20060260100A1Improved and accurate measurementSmall dimensionSafety devices for fibre treatmentMeasurement devicesEngineeringDistance sensors

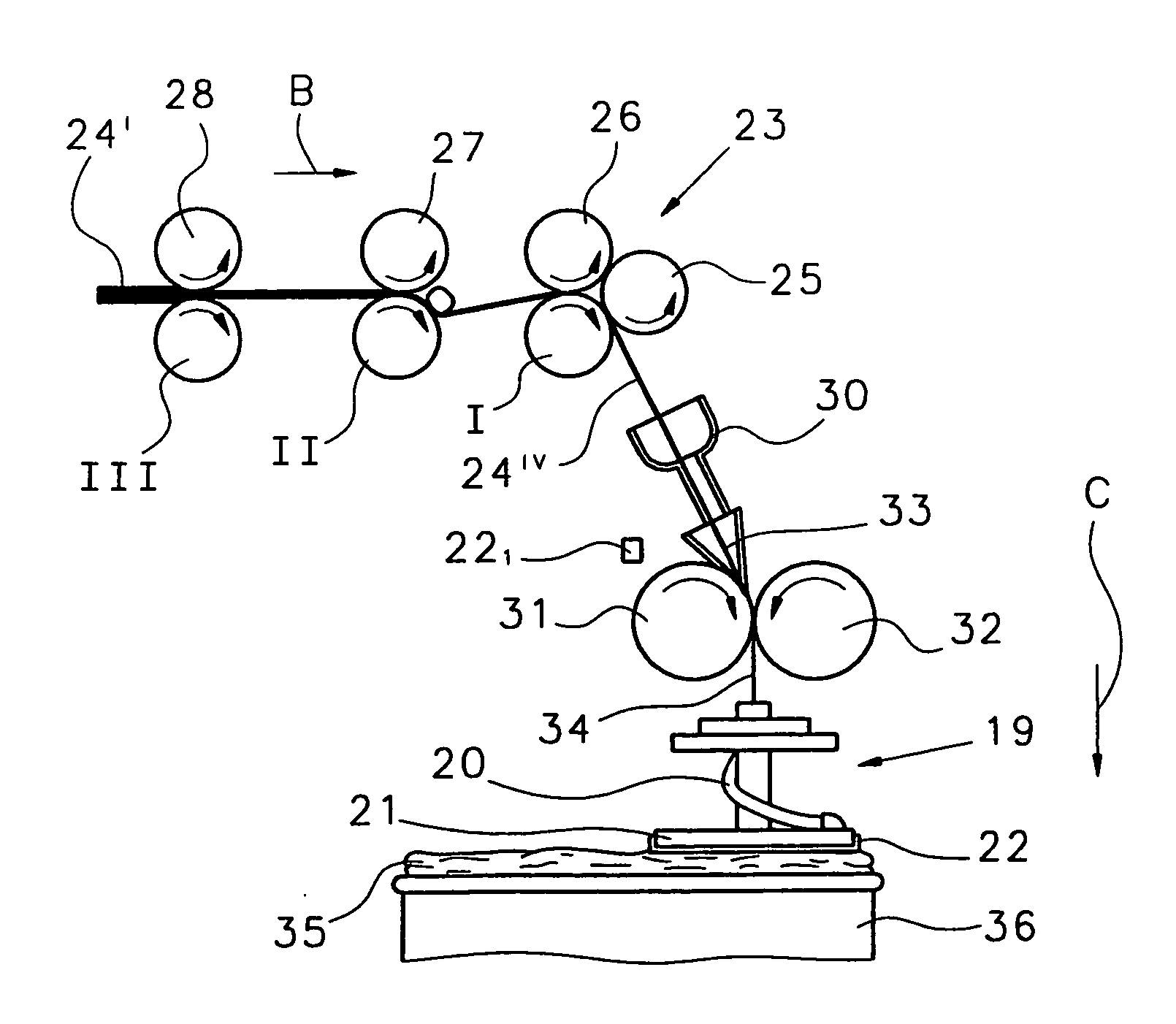

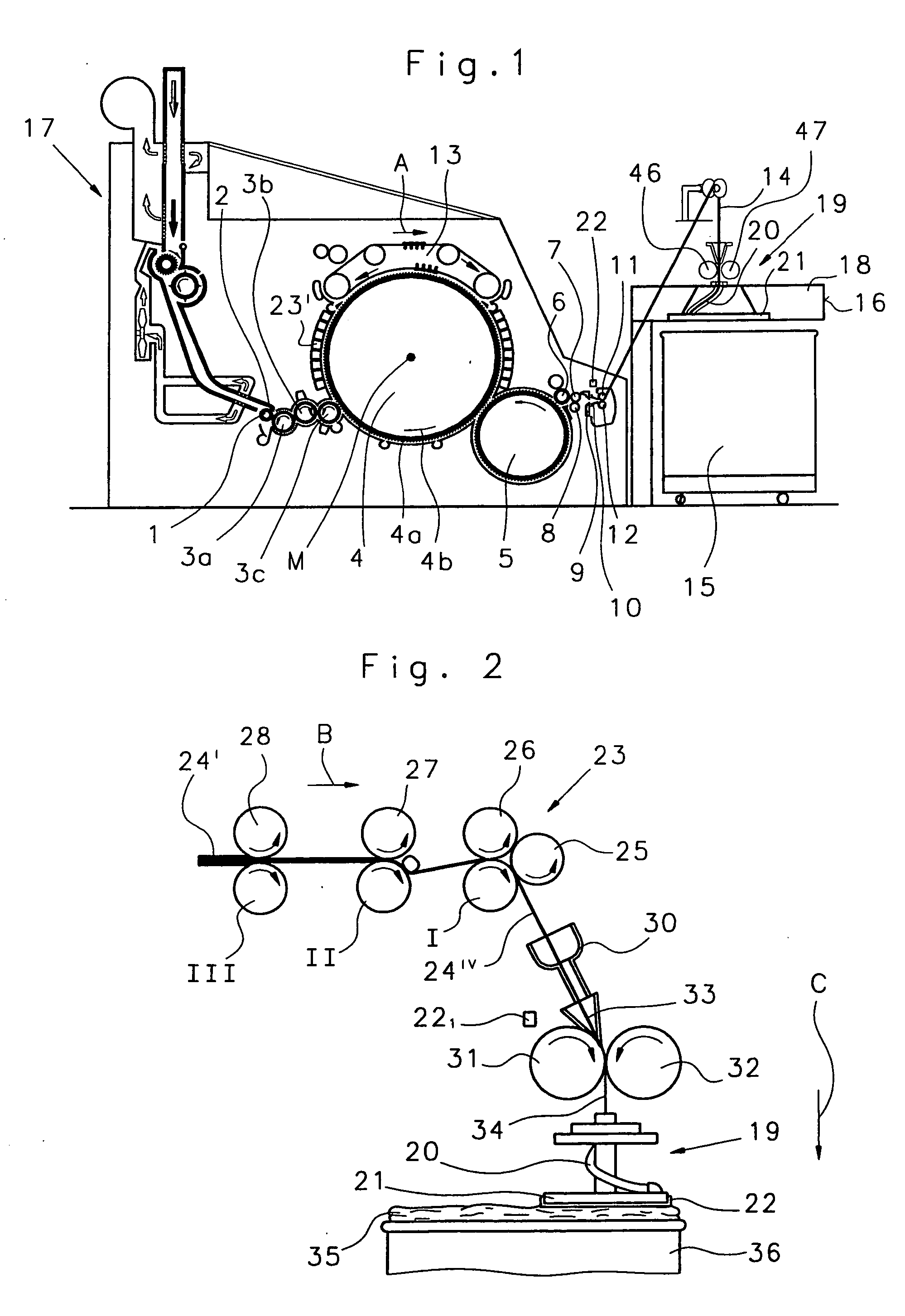

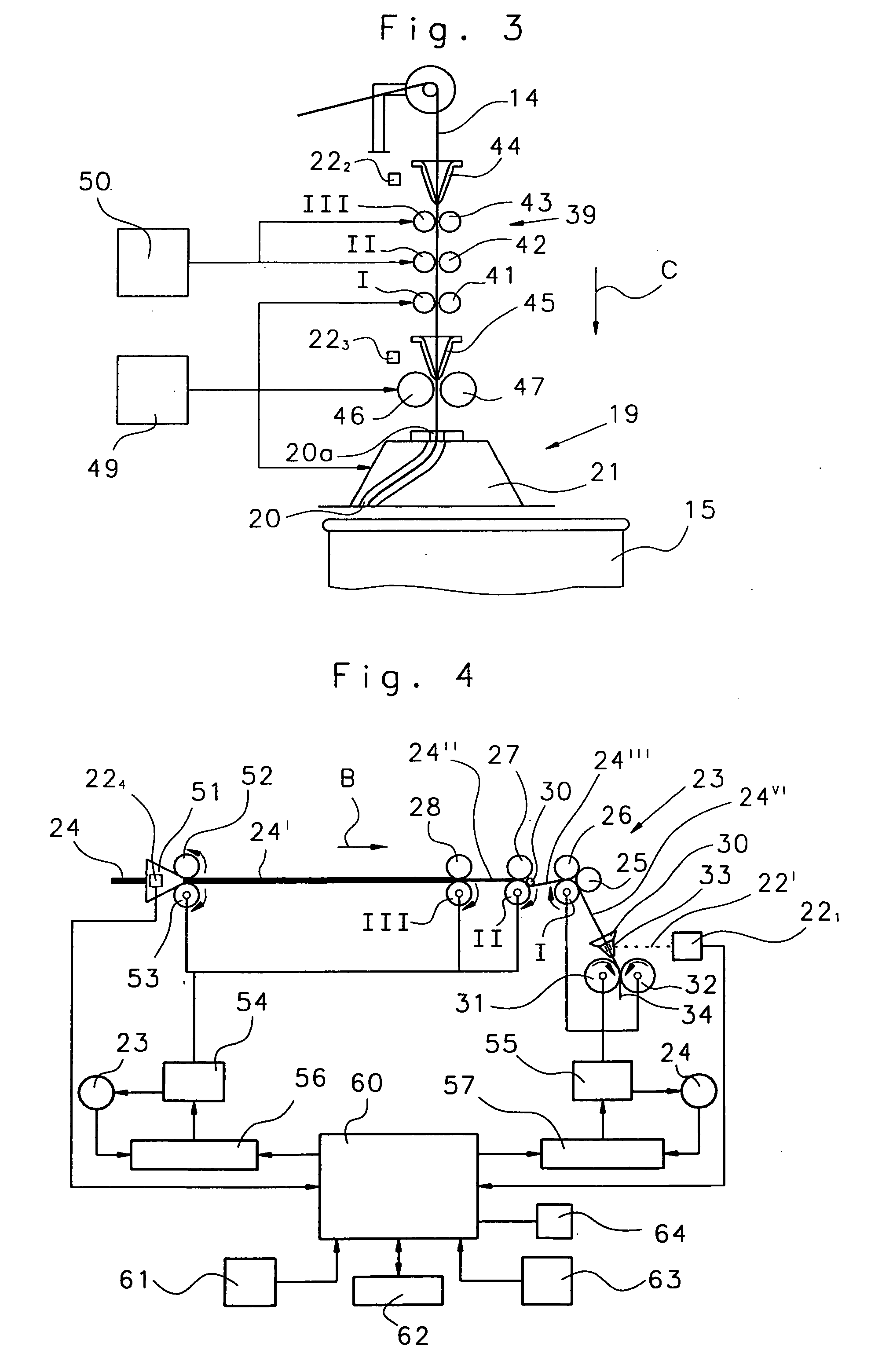

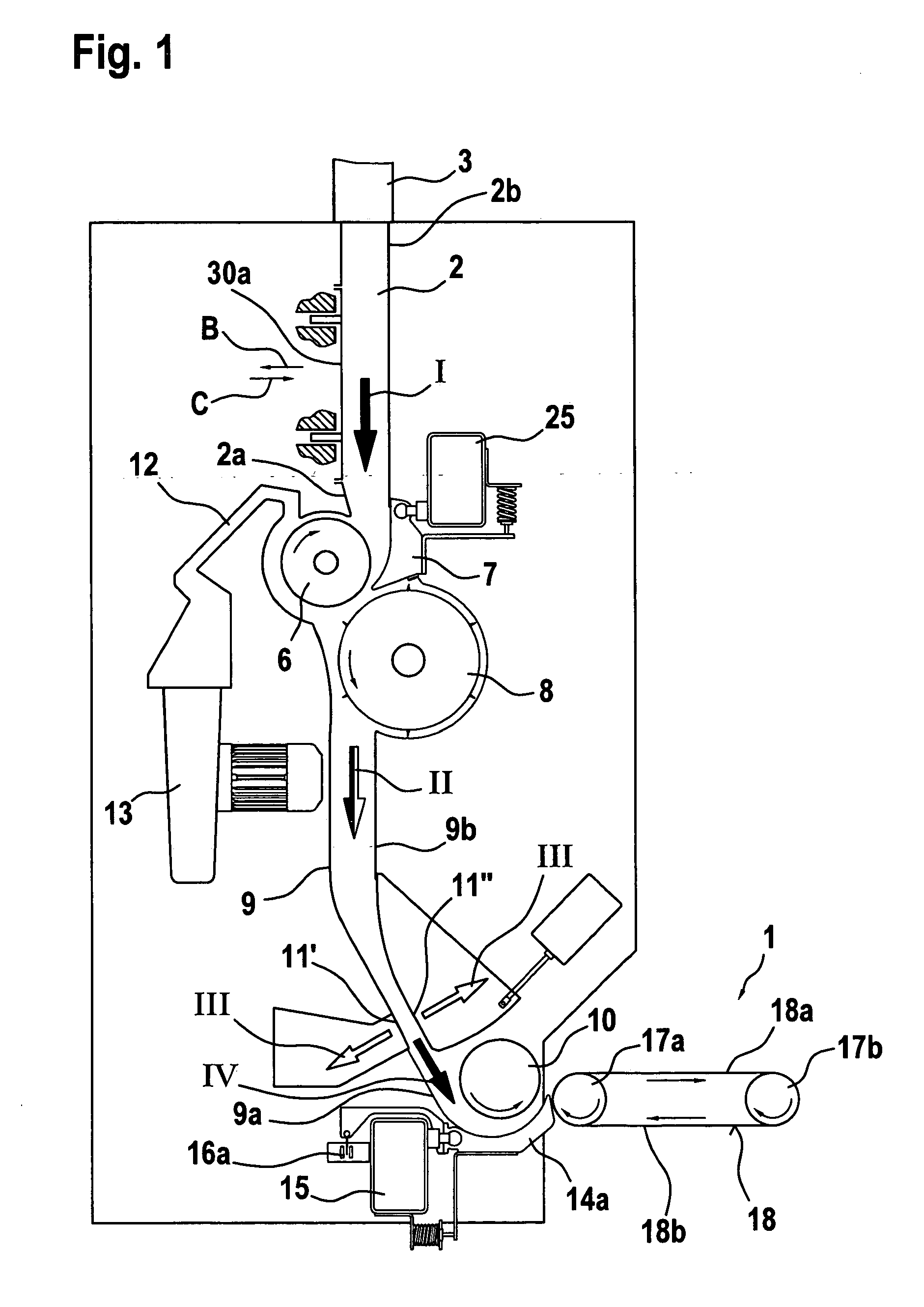

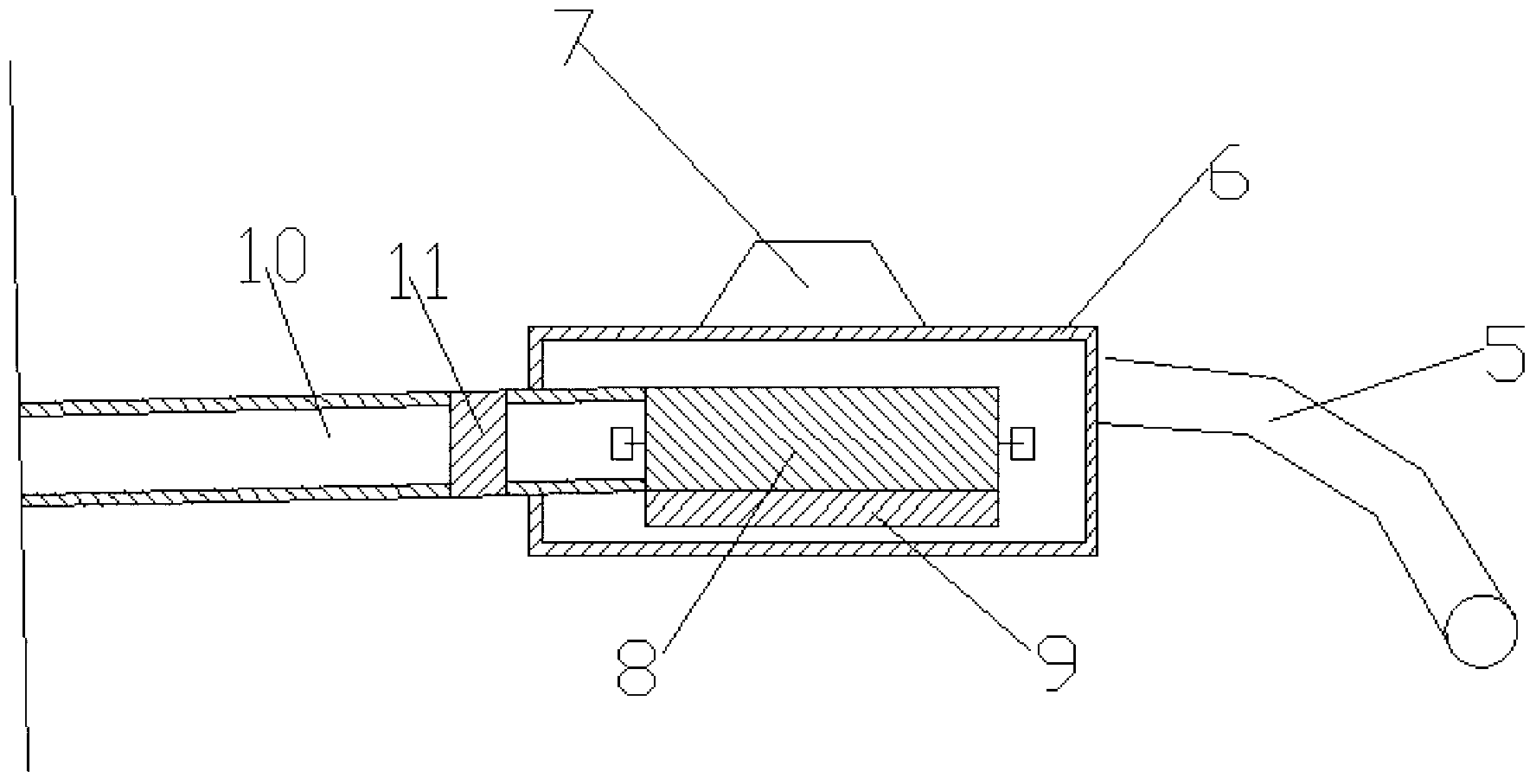

In an apparatus on a spinning preparation machine, for example a flat card, roller card, draw frame, combing machine or the like, for ascertaining the mass and / or fluctuations in the mass of a fibre material, for example at least one fibre sliver, fibre web or the like, of cotton, synthetic fibres or the like, the fibre material is scanned mechanically by a feeler element the excursions of which are converted into electrical signals. In order to facilitate improved and more accurate measurement of the fibre in a way that is simple in terms of structure and installation, a contactless distance sensor is provided for detecting the position of the feeler element, the sensor being a sensor that measures distance using transmitted waves, and is connected to an electronic evaluating device.

Owner:TRUETZSCHLER GMBH & CO KG

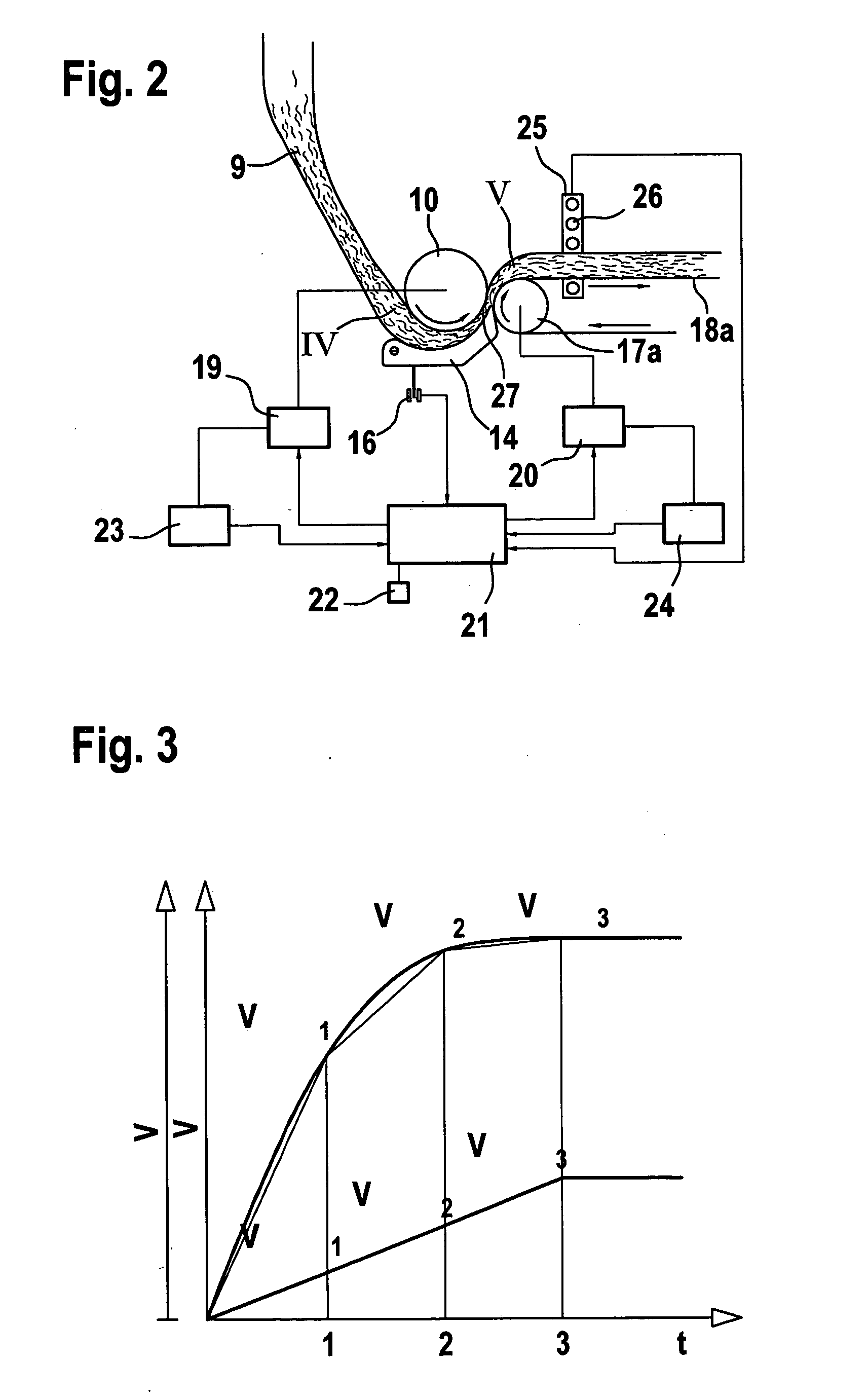

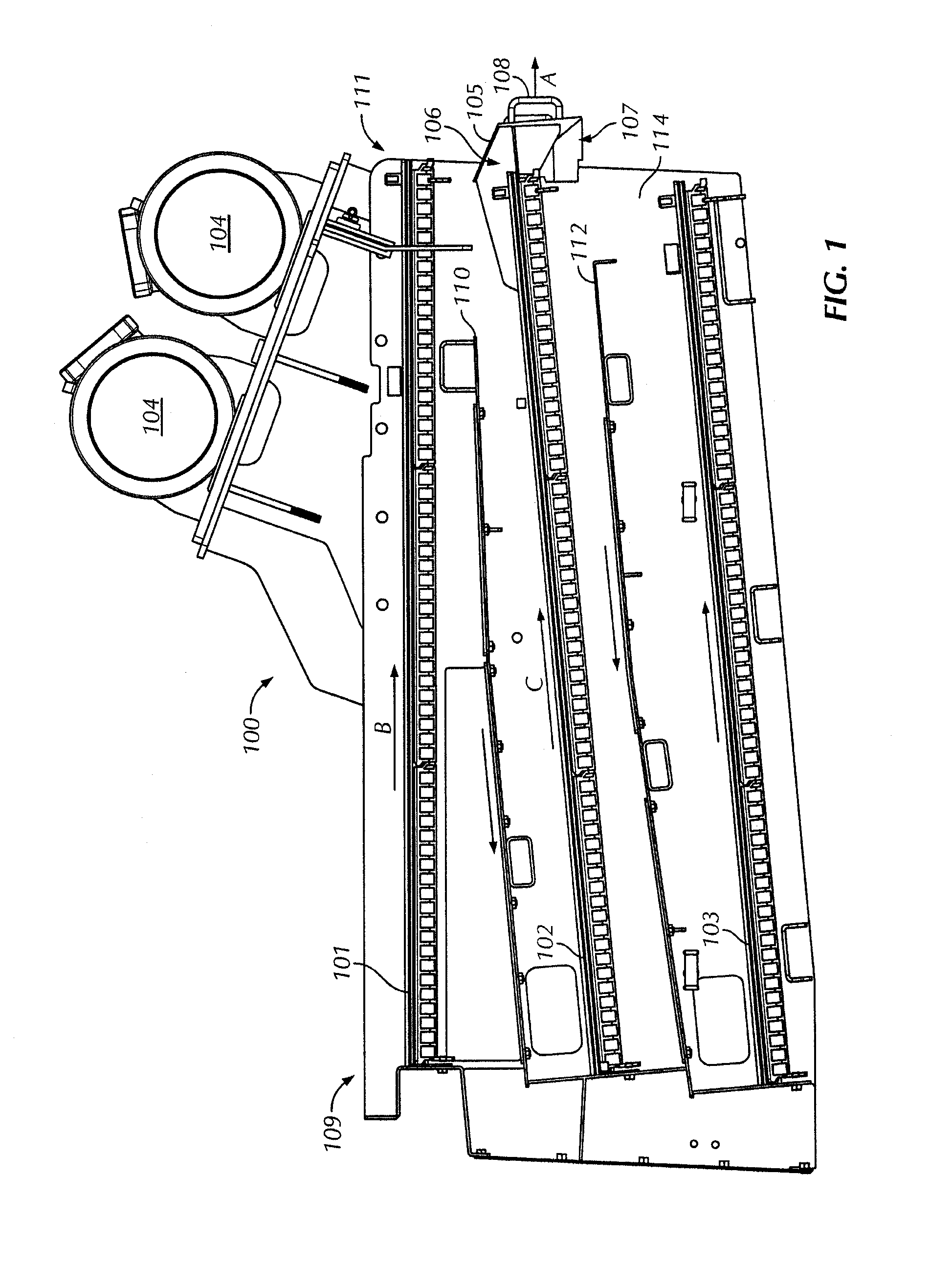

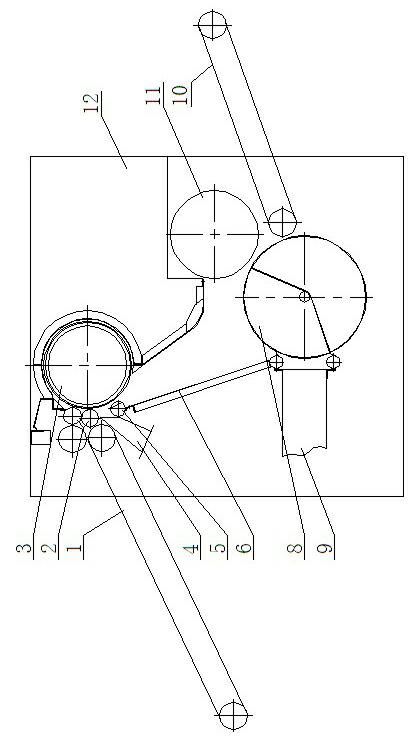

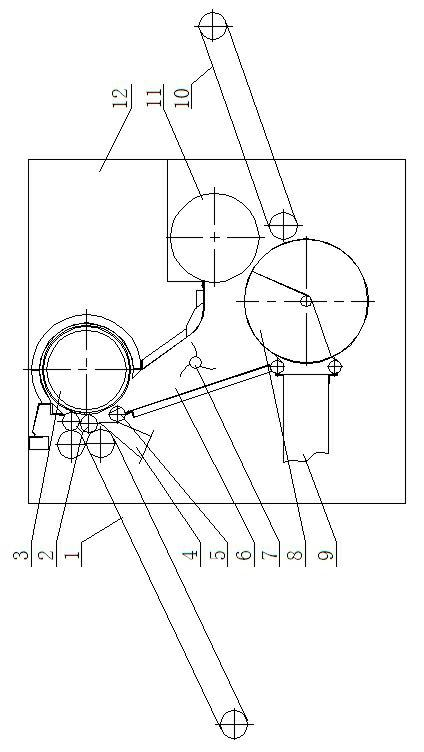

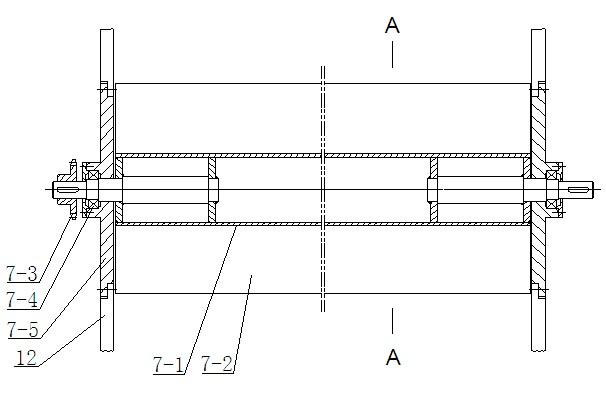

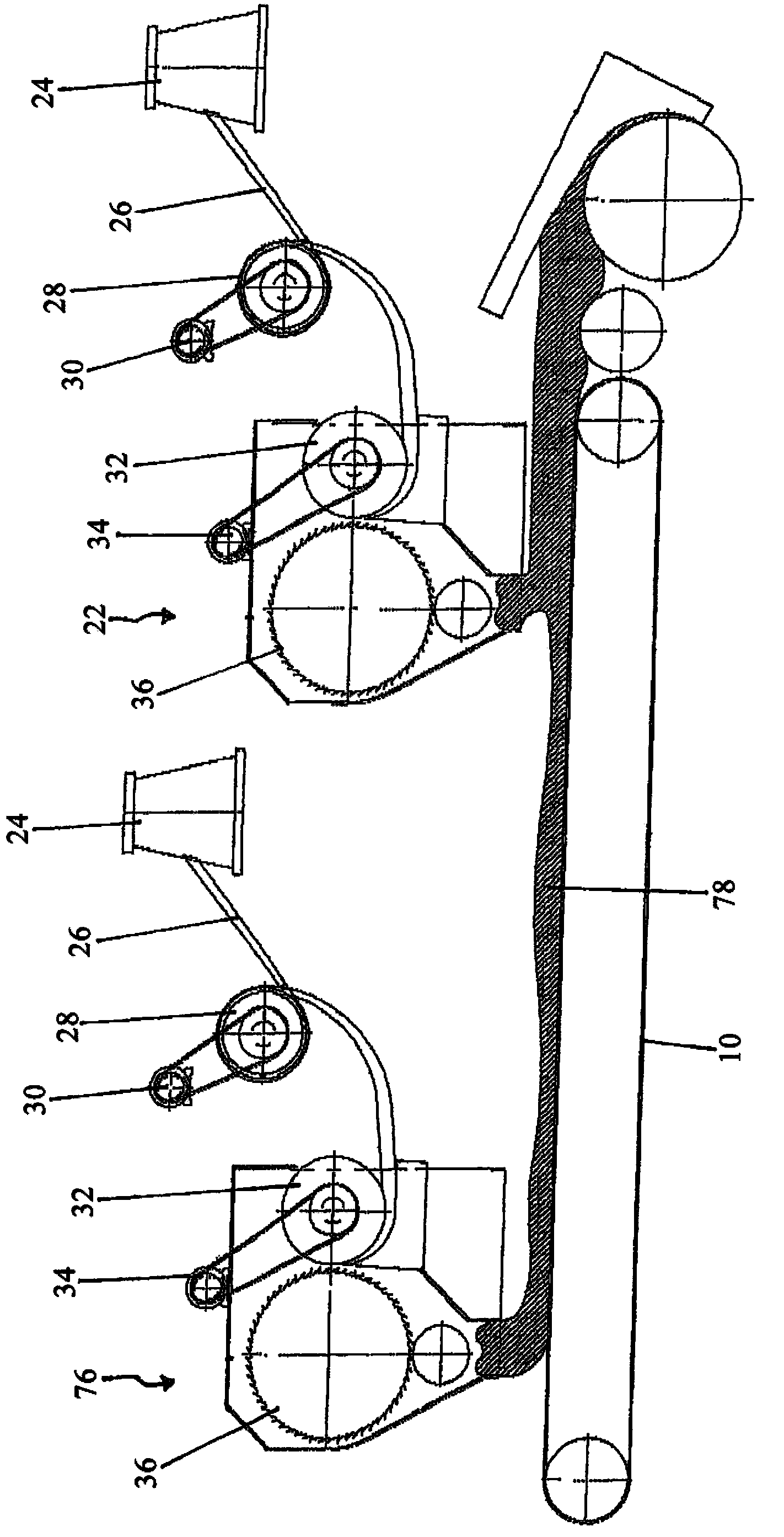

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

A device on a spinning preparation machine, for example a tuft feeder, having a feed device comprising at least one slow-speed feed roller and a counter-element, for example a feed tray, with which fibre material can be supplied to a downstream transport device, has a driven transport element, for example a conveyor belt. In order to provide improved delivery from the feed device, or improved takeover by the downstream transport device, and to allow troublefree operation, for the purpose of determining setting values for the optimum speed of the transport element, a function between the measured values of the feed roller speed and the measured values of the transport speed is so determined that the fibre material lies on the moving surface of the transport element.

Owner:TRUETZSCHLER GMBH & CO KG

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

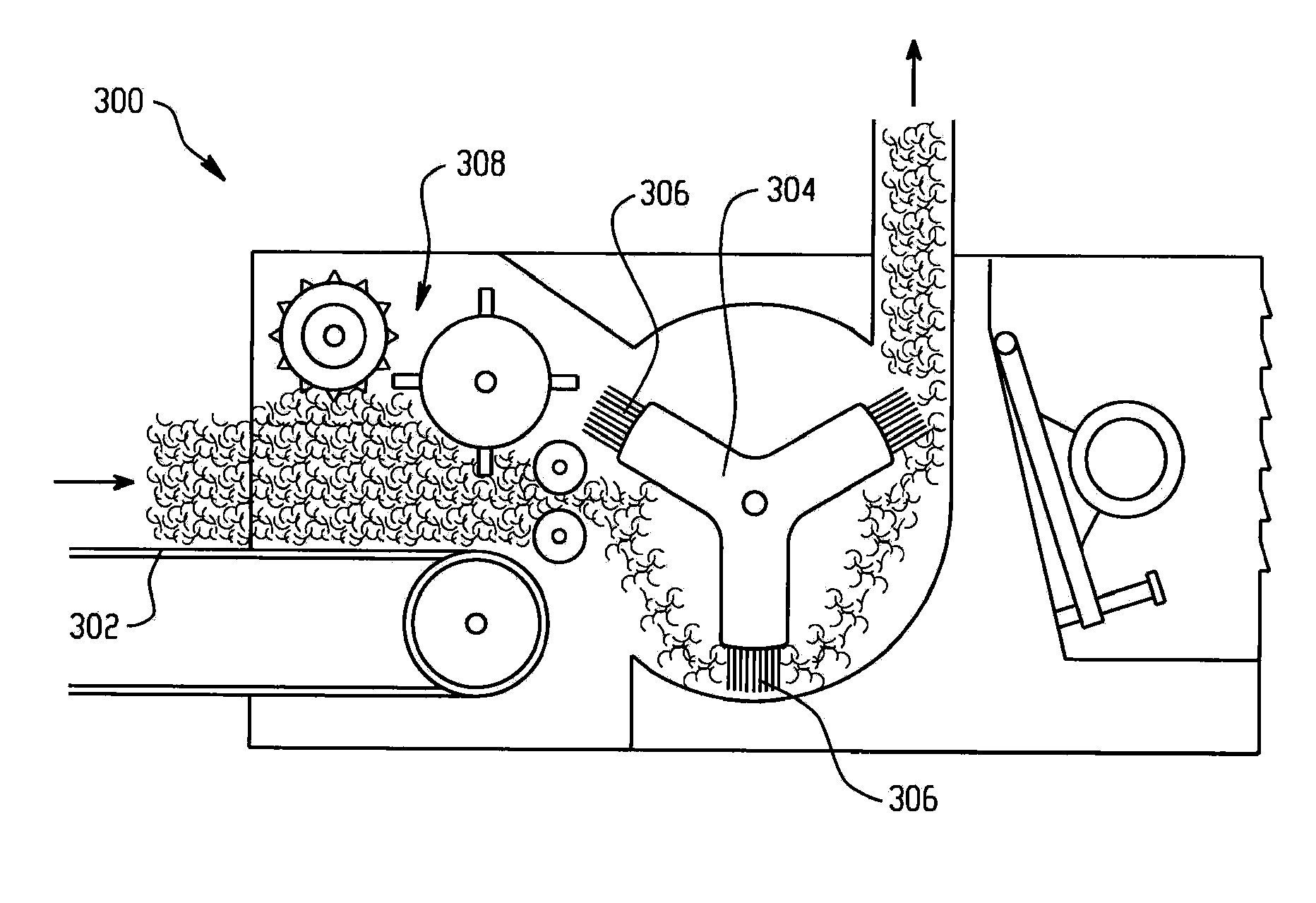

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

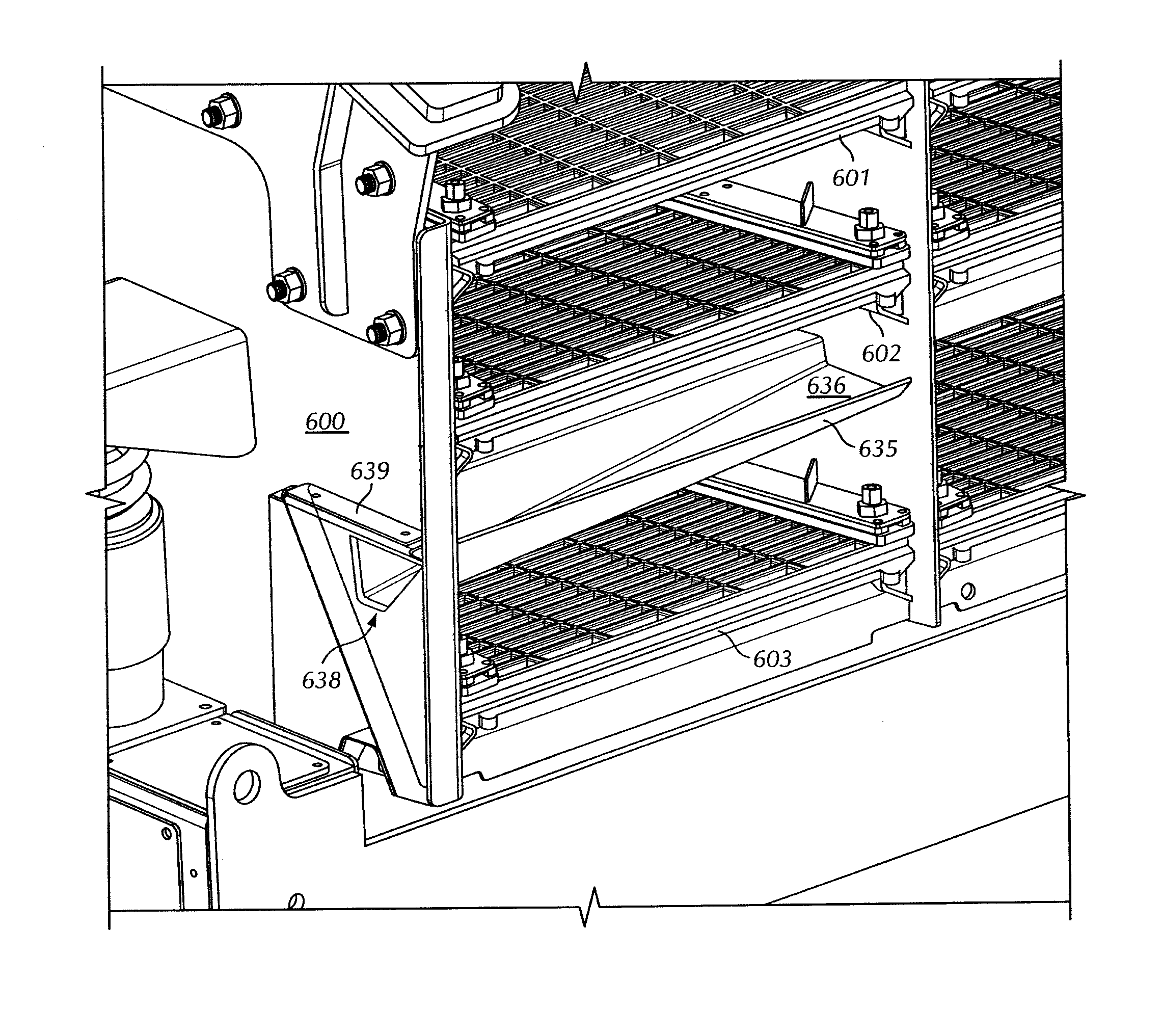

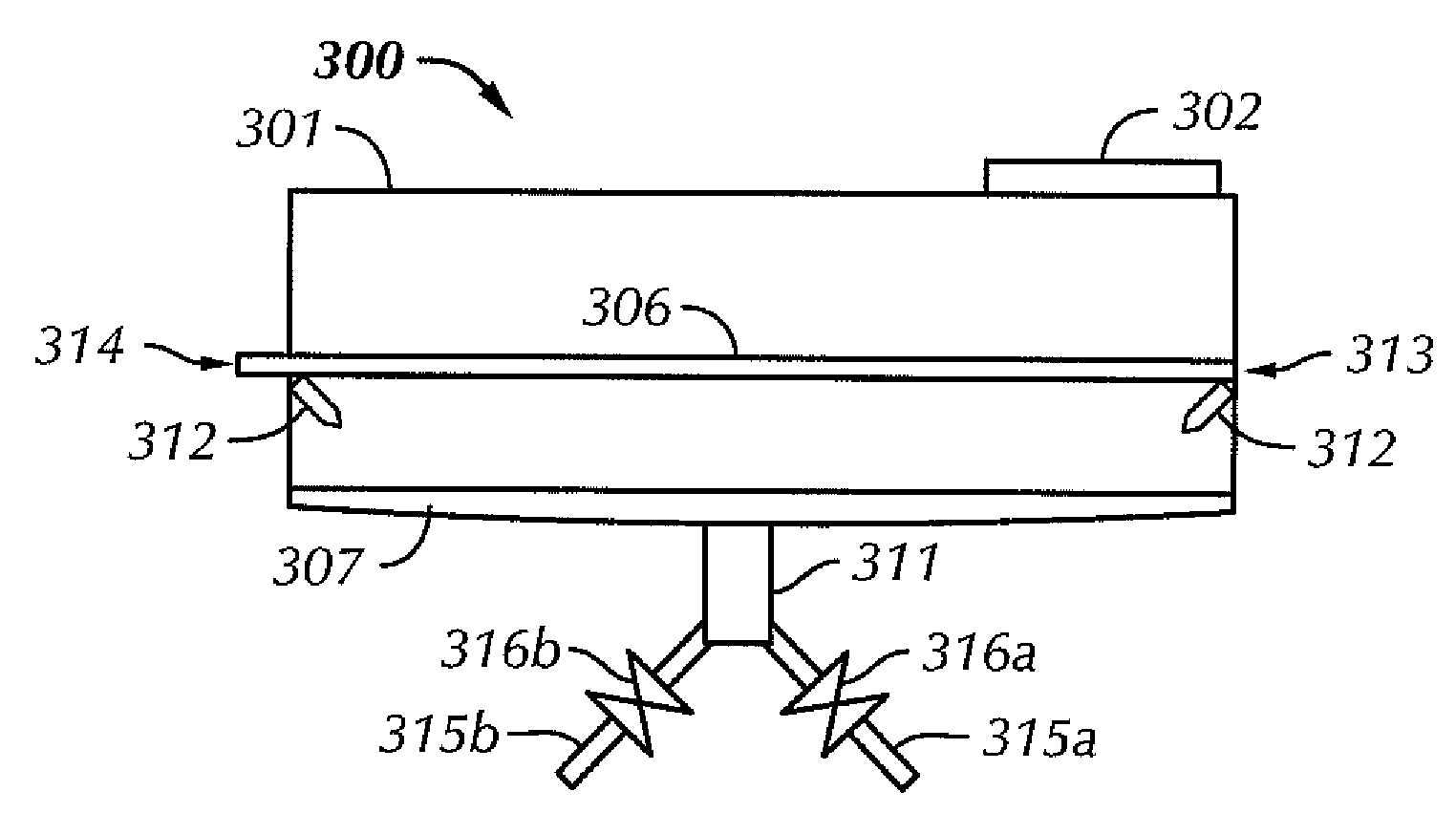

Wellbore strengthening material recovery

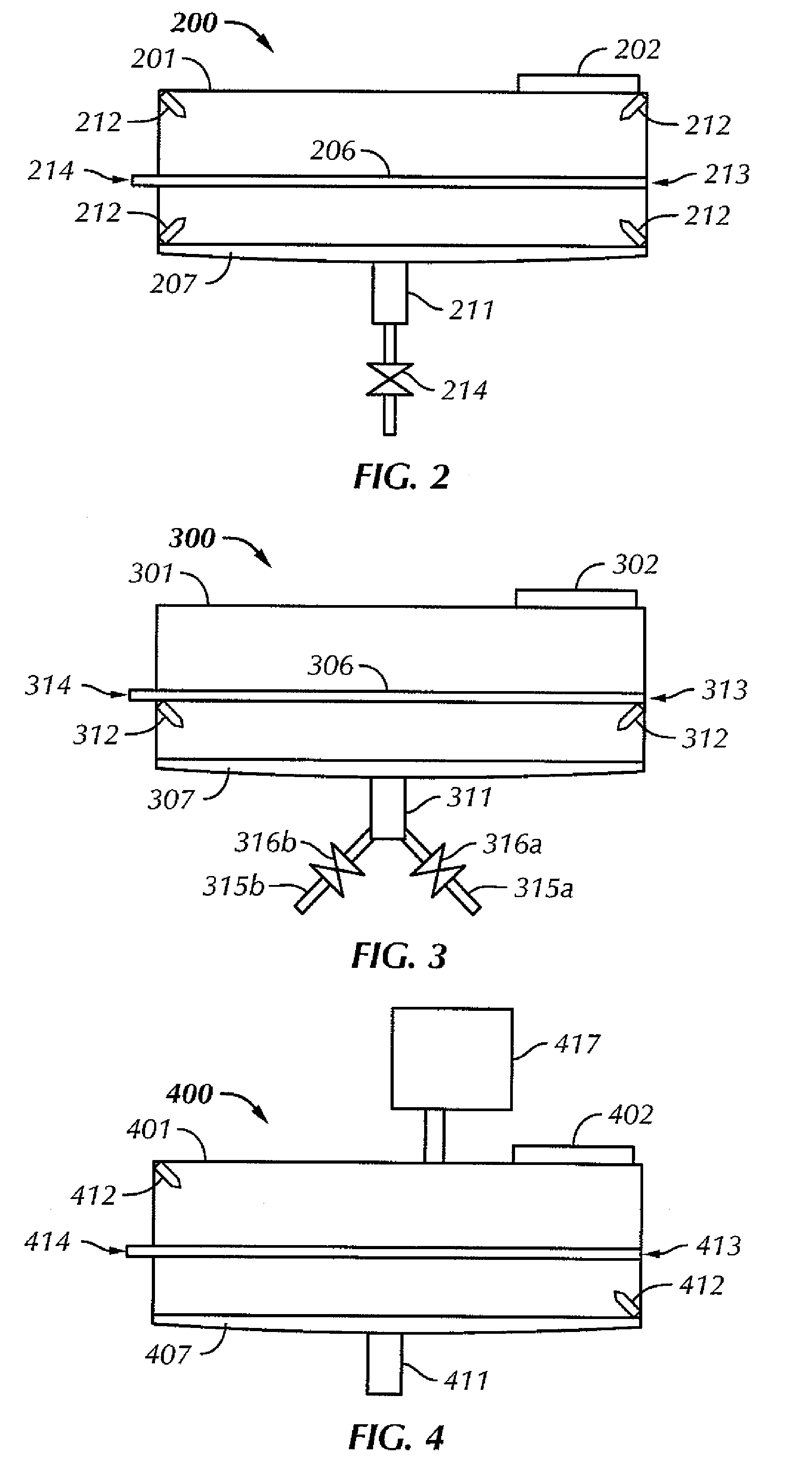

A wellbore strengthening material collection system including a vibratory separator having a top deck, a middle deck, and a bottom deck, and also including a collection trough coupled to at least one of the decks and configured to receive wellbore strengthening materials from the at least one of the decks. Additionally, a collection trough including a body having an inlet and an outlet, an angled surface disposed within the body and at least on extension surface extending form the body and configured to secure the collection trough to a vibratory separator.

Owner:MI

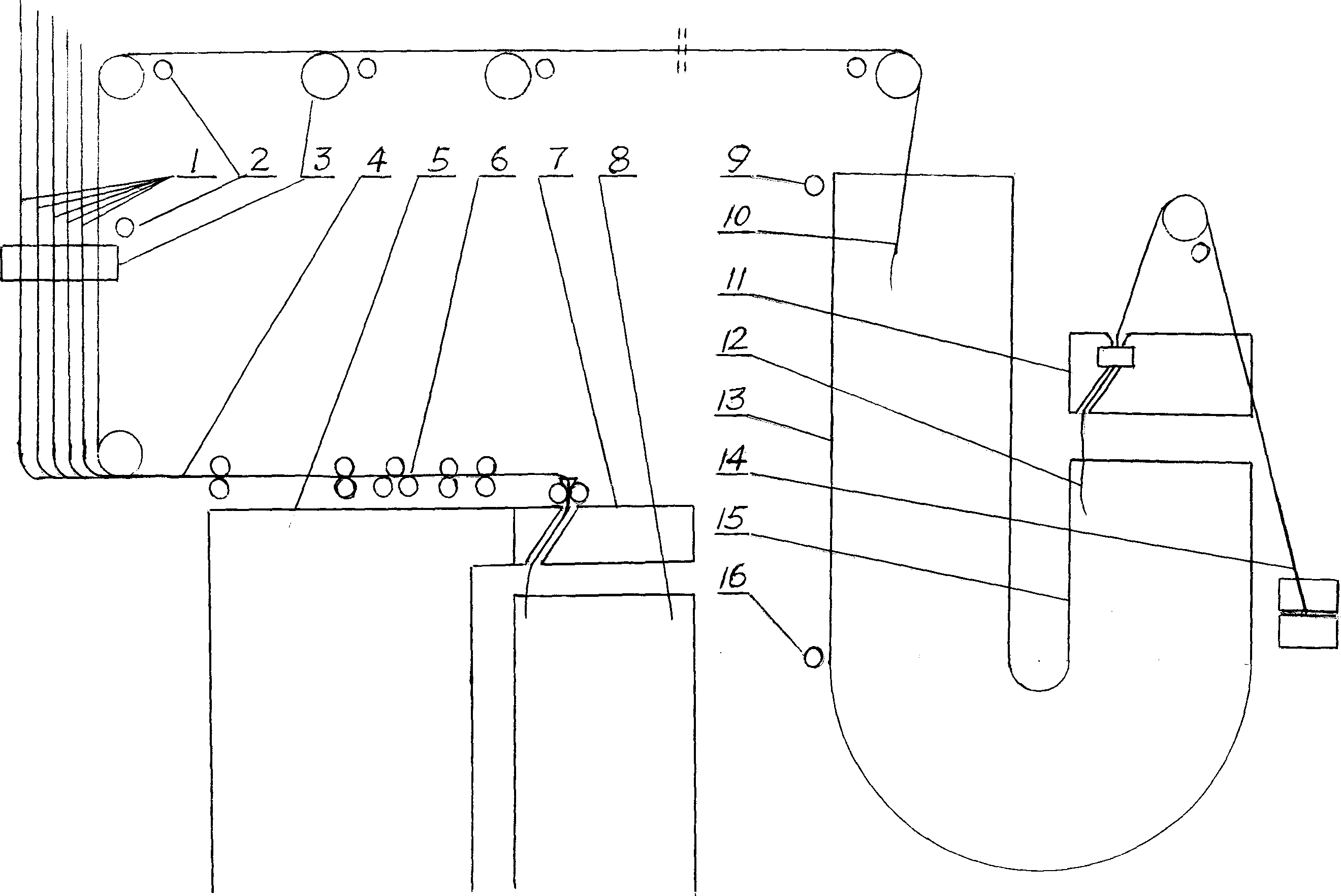

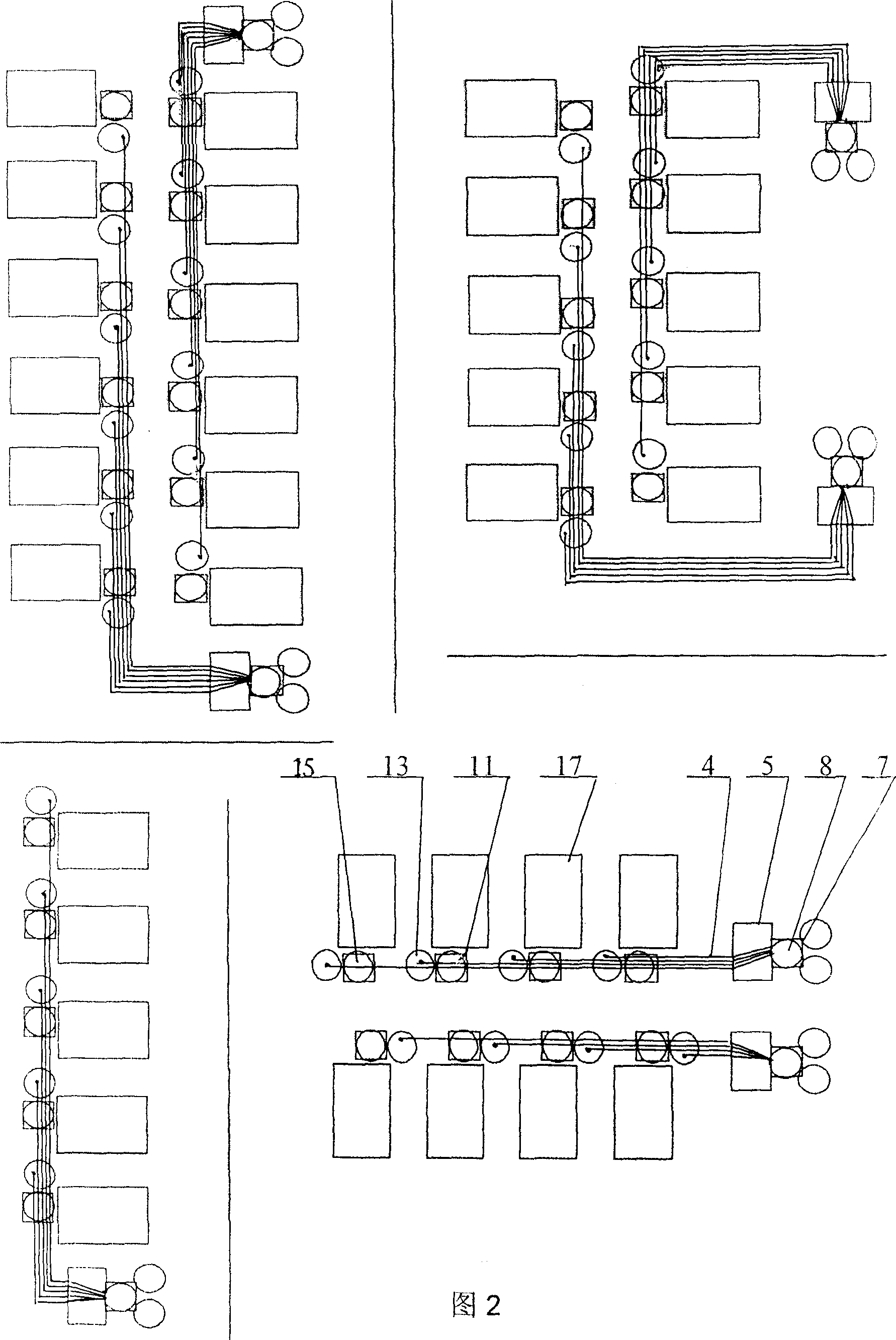

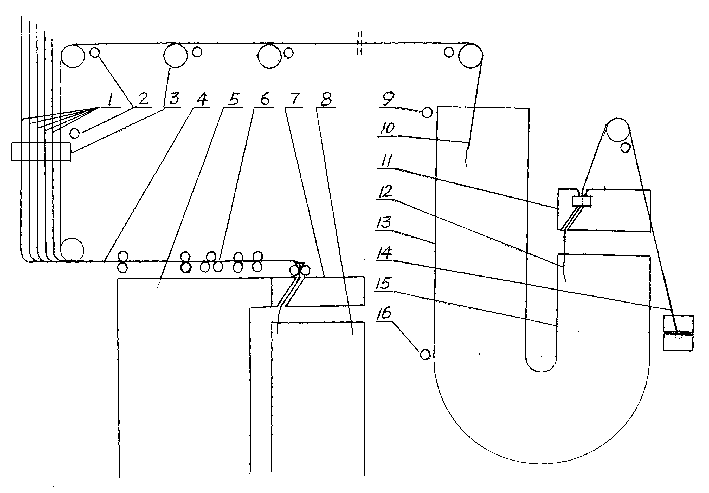

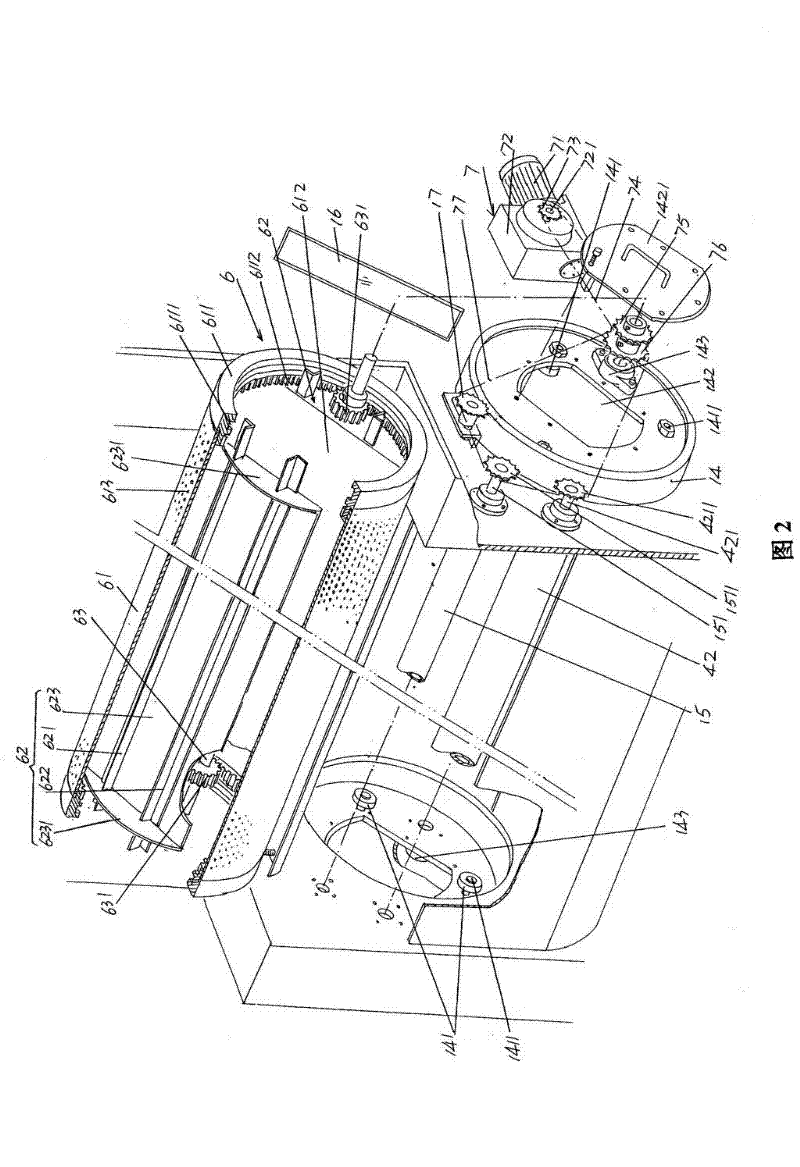

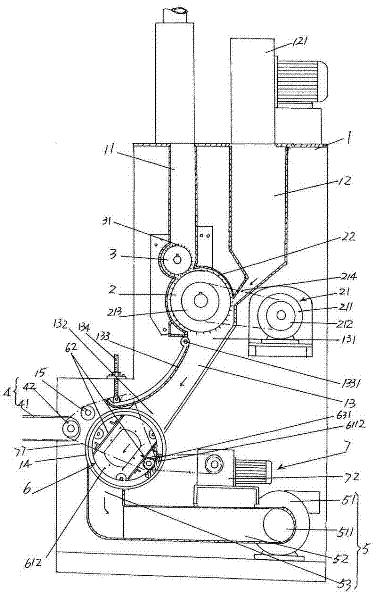

Method and device for combining carding, combing and drawing

InactiveCN1510183AImprove operational efficiencyEase of modern managementContinuous processingFibre feedersCardingCombing

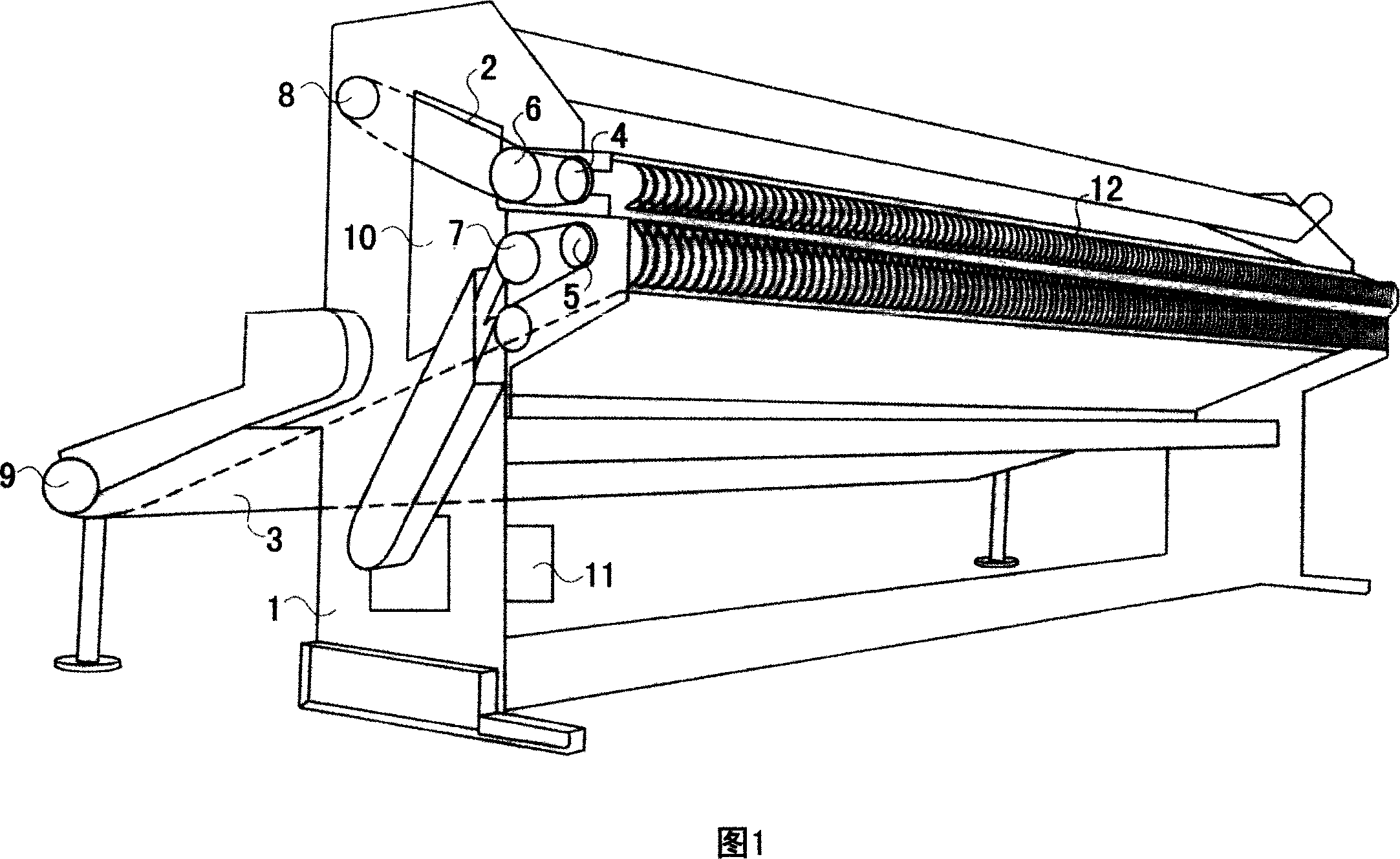

An apparatus and method for combining the carding or combing step with drawing step is disclosed. Said apparatus is composed of planitary coiler head, overlapped cotton sliver diverting mechanism, dynamic cotton sliver storage, guide delivering unit, and running state monitor unit. Its advantage is automatic and continuous production.

Owner:倪远 +1

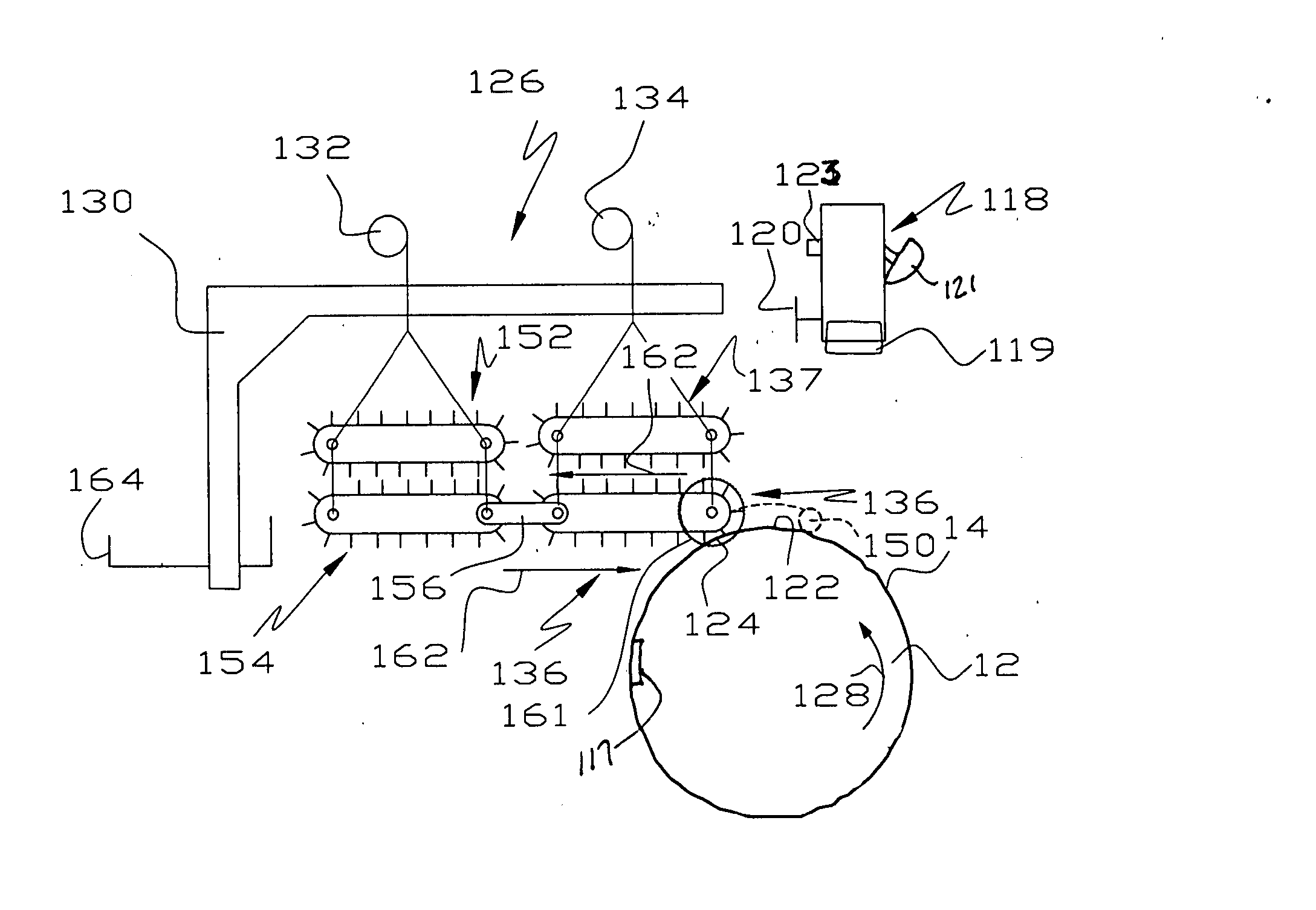

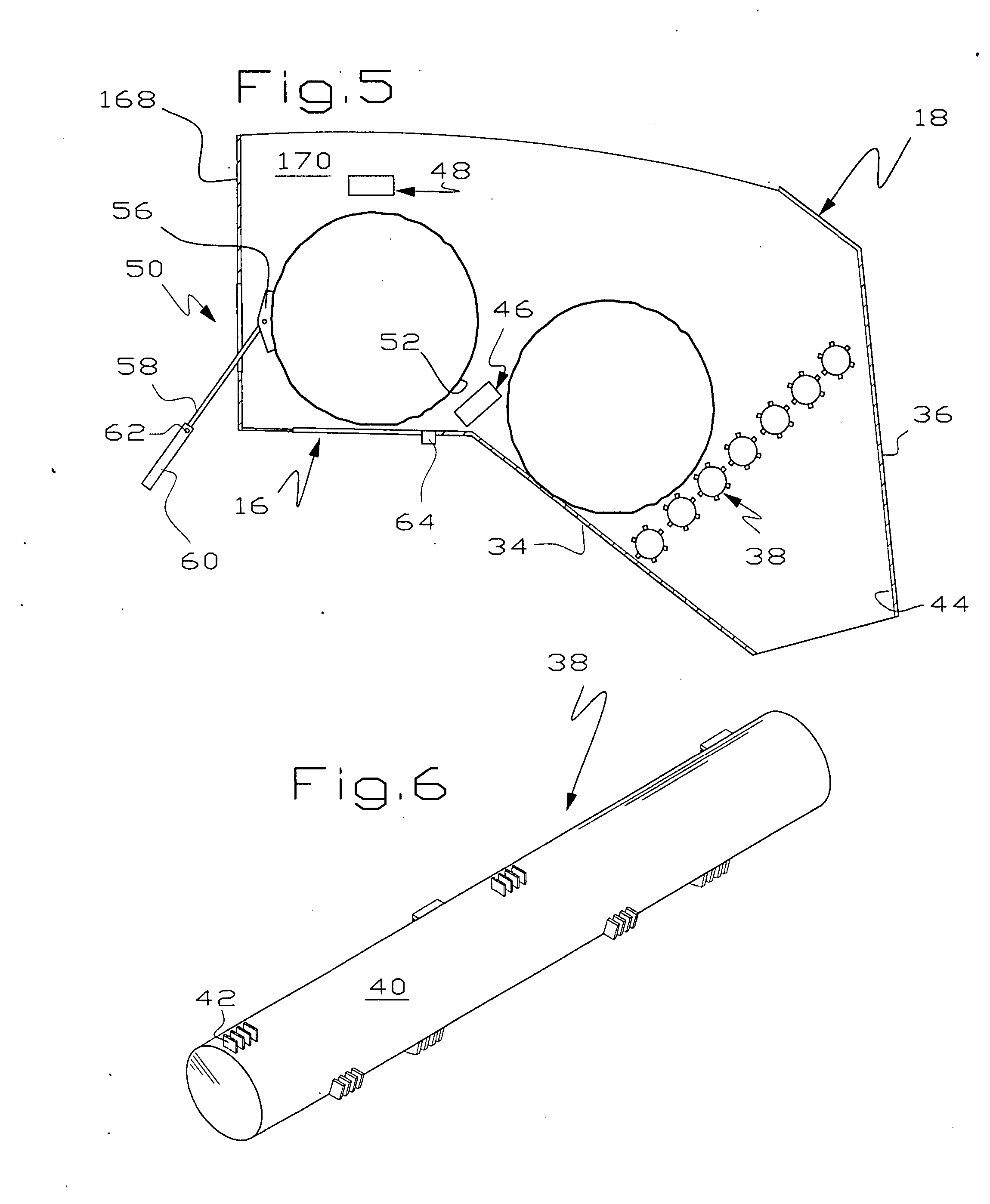

Digesting cylindrical modules

A conveyor delivers a series of cylindrical wrapped fibrous modules to a station where the module is lifted off the conveyor and an operation conducted on the module. One operation is to find a tail, or unattached segment, of the cover. Another operation is to remove the cover, by slitting and then unwinding it. The cover is delivered to a storage area and the contents of the module are delivered into a hopper, or in some embodiments, into a disperser. In some embodiments, a grabber moves the slit cover from adjacent a slitting position to a storage area and includes a guide wheel for moving a conveyor up and down in response to the configuration of the round module. In one embodiments, the plastic cover is removed manually by workers guiding the plastic wrap as it is unrolled by the unrolling device.

Owner:STOVER EQUIP

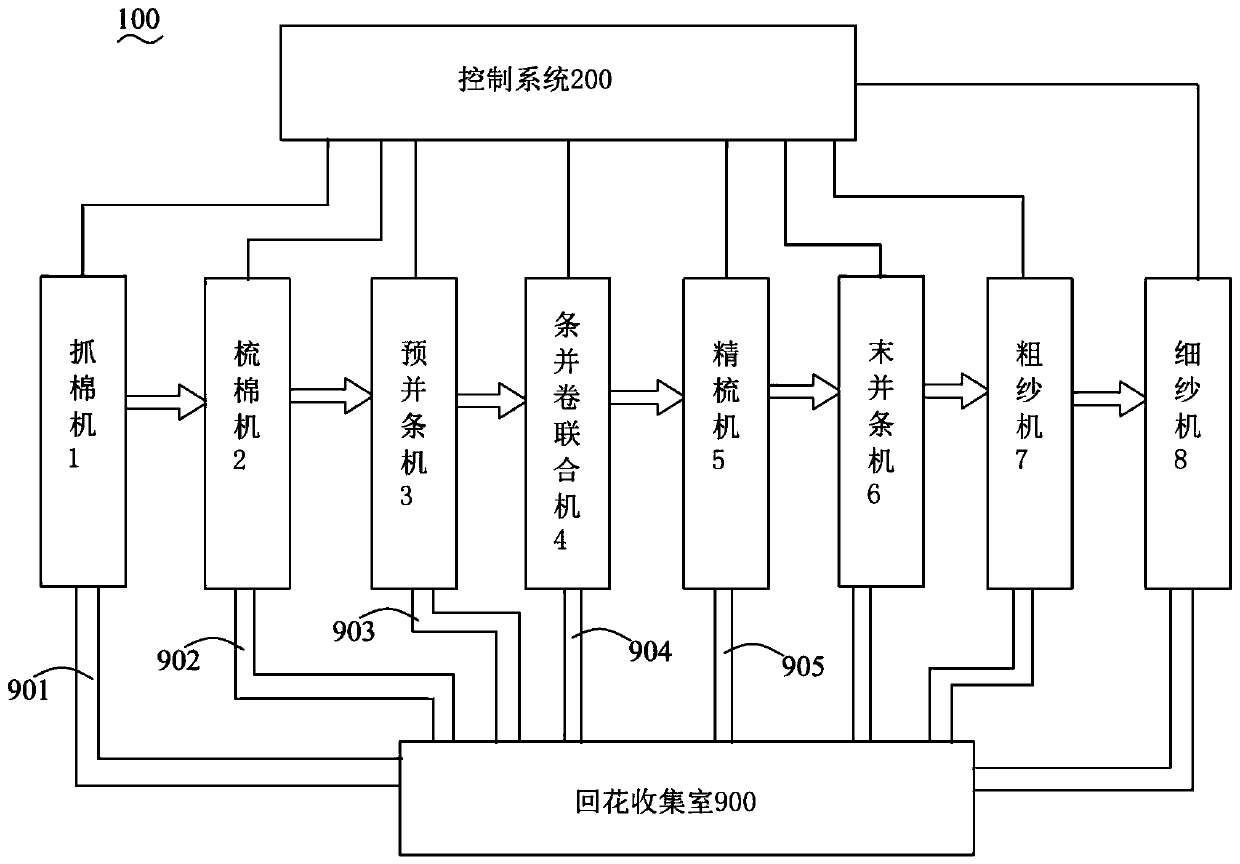

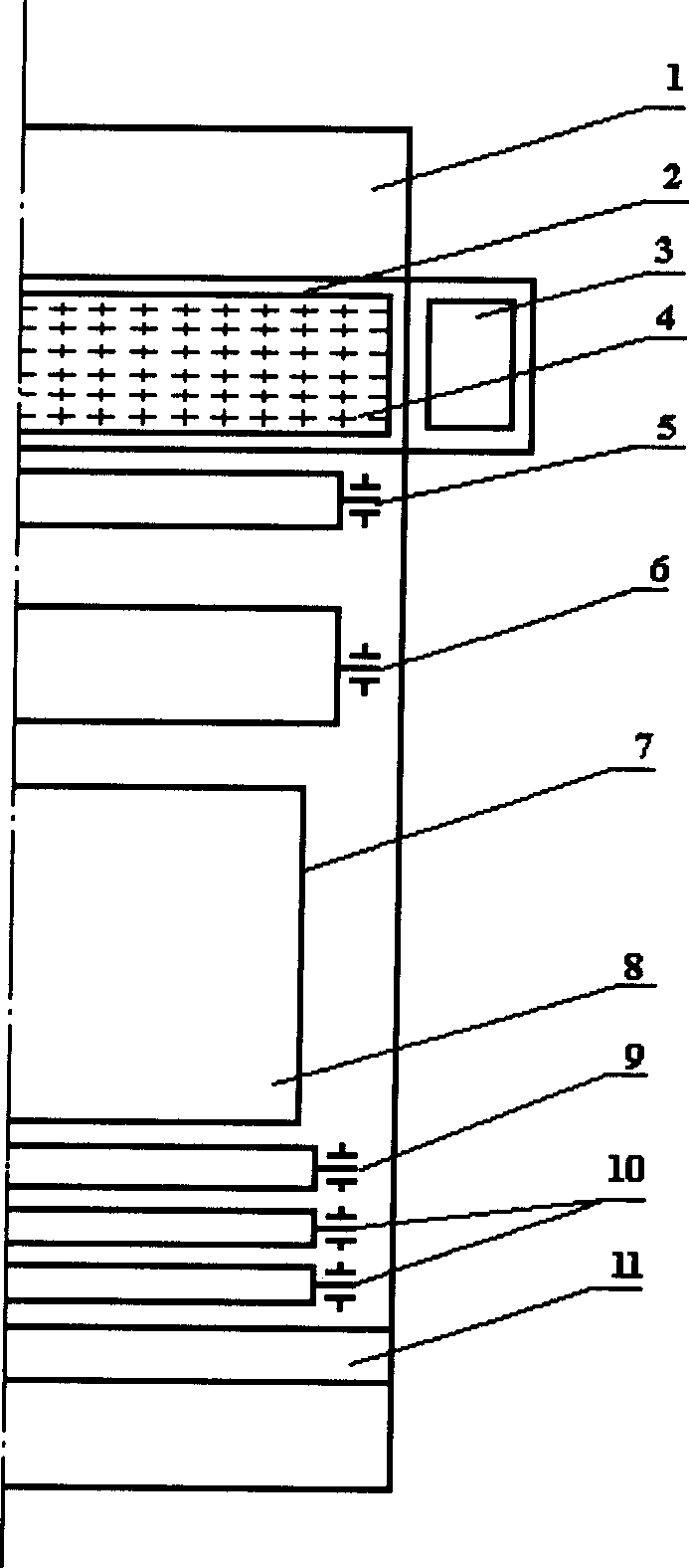

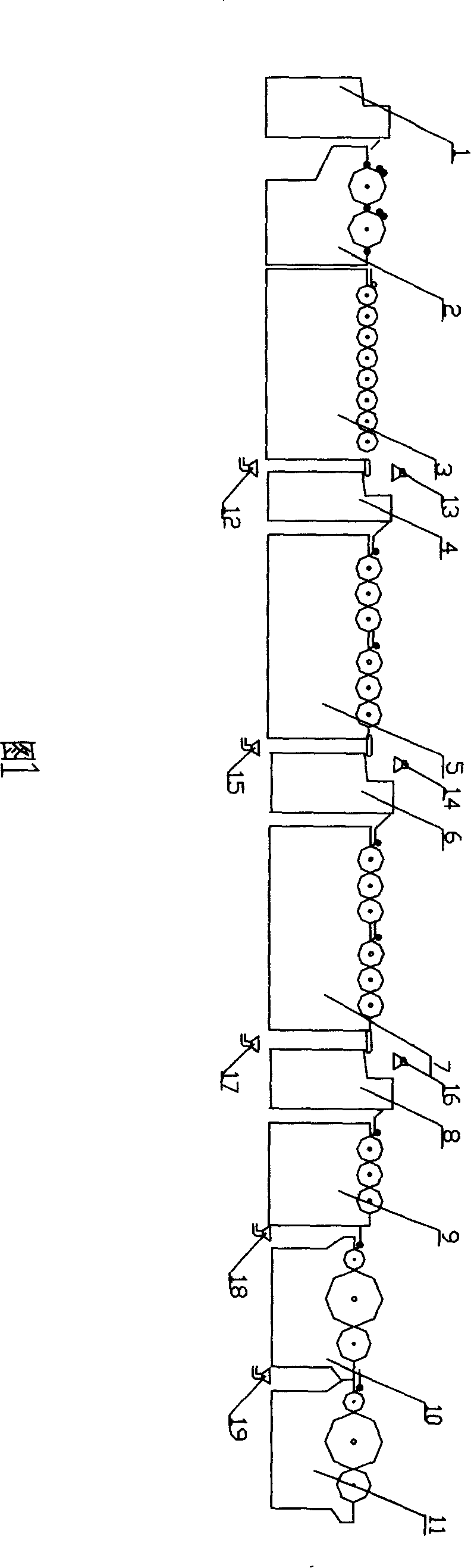

Whole-flow intelligent spinning production line

ActiveCN110331483AReduce labor intensityAvoid harmContinuous processingFibre feedersProduction lineLogistics management

The invention discloses a whole-flow intelligent spinning production line. A conveying system for connecting output sides of adjacent process work points and feeding sides of next processes is arranged among a bale plucker, a carding machine, a pre-drawing frame, a draw frame and lap machine, a combing machine, an end drawing machine, a roving frame and a spinning frame which are sequentially arranged; a control system in signal connection with the bale plucker, the carding machine, the pre-drawing frame, the draw frame and lap machine, the combing machine, the end drawing machine, the rovingframe, the spinning frame and a conveying system is arranged; the control system controls working states of the bale plucker, the carding machine, the pre-drawing frame, the draw frame and lap machine, the combing machine, the end drawing machine, the roving frame, the spinning frame and the conveying system to control normal operation of the whole-flow intelligent spinning production line. The whole-flow intelligent spinning production line realizes automation, continuity and intelligence of each process by use of the conveying system, the logistics cost is reduced, and unmanned management ofa spinning workshop is realized.

Owner:武汉裕大华纺织服装集团有限公司

Silver discharge device

InactiveUS20060027695A1Reduce equipment expenditureSimple processFilament handlingLap-winding devicesEngineeringMechanical engineering

A device is provided on a spinning preparation machine for receiving a sliver from a discharge device of the spinning preparation machine and transporting the sliver to a downstream machine, the spinning preparation machine having a depositing region. The device has a support for receiving the sliver deposited from the discharge device in the depositing region, and a moving device for moving the deposited sliver relative to the discharge device in the depositing region for forming a free standing sliver bundle, and for moving the free standing sliver bundle out of the depositing region for transport to a downstream machine.

Owner:TRUETZSCHLER GMBH & CO KG

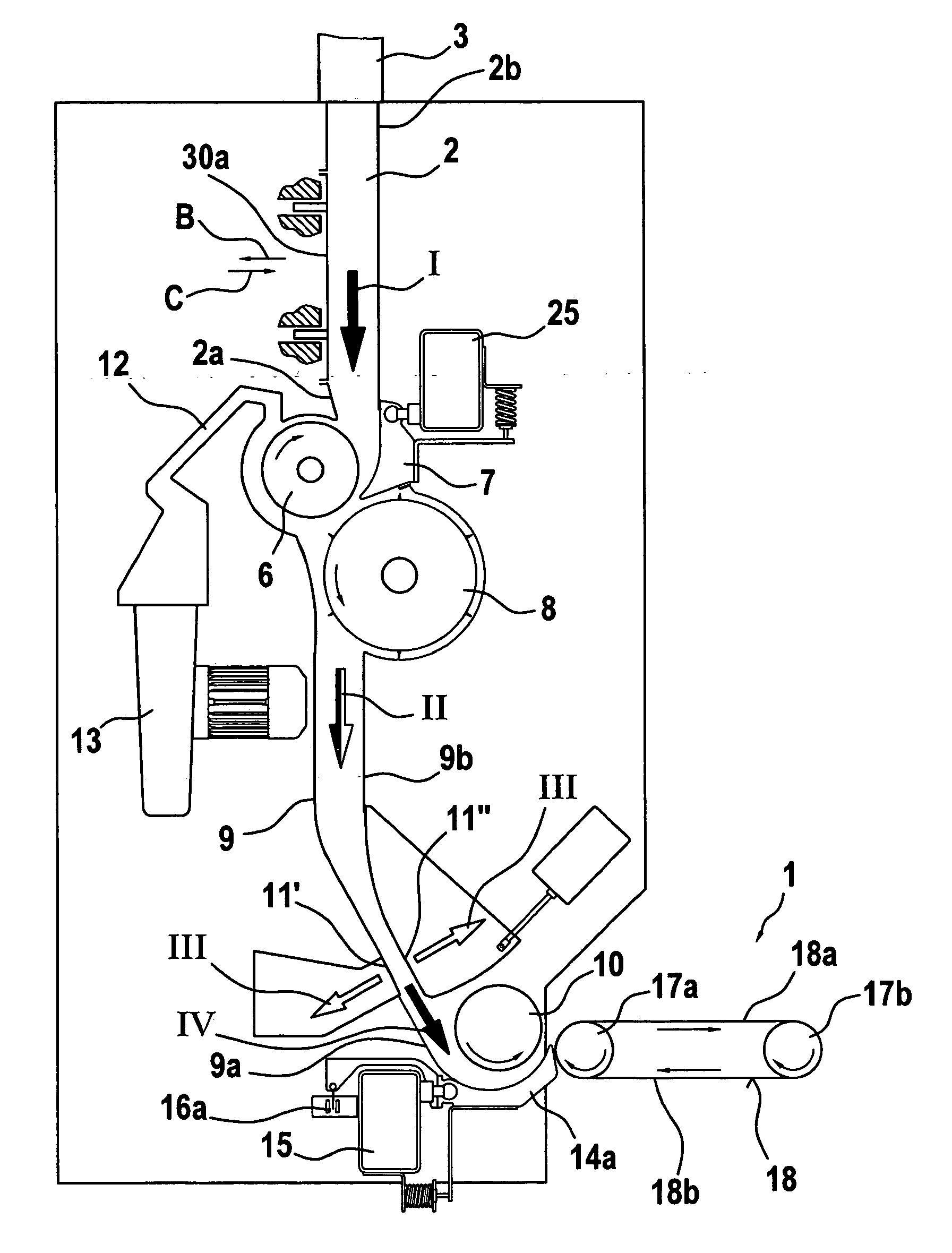

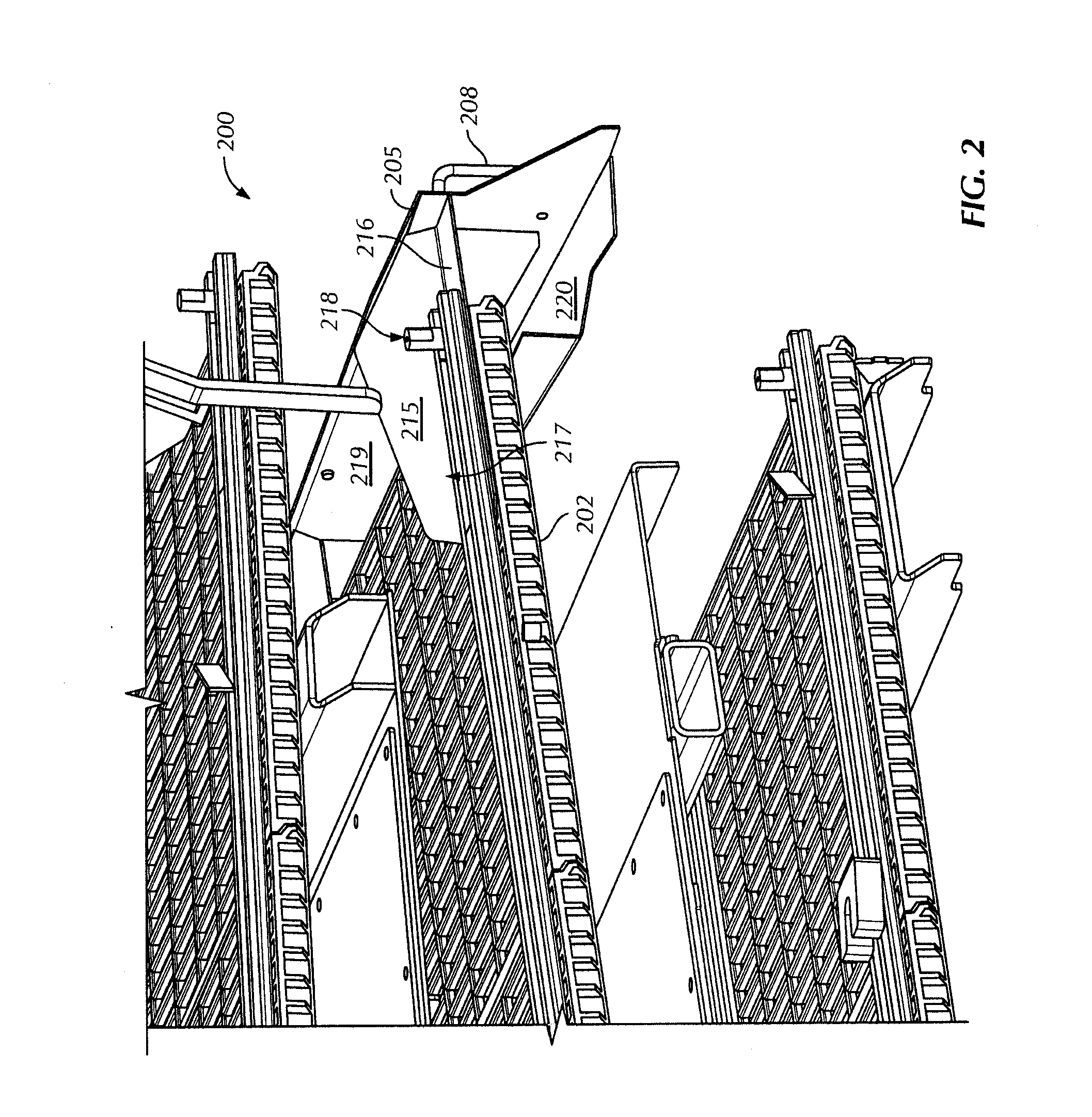

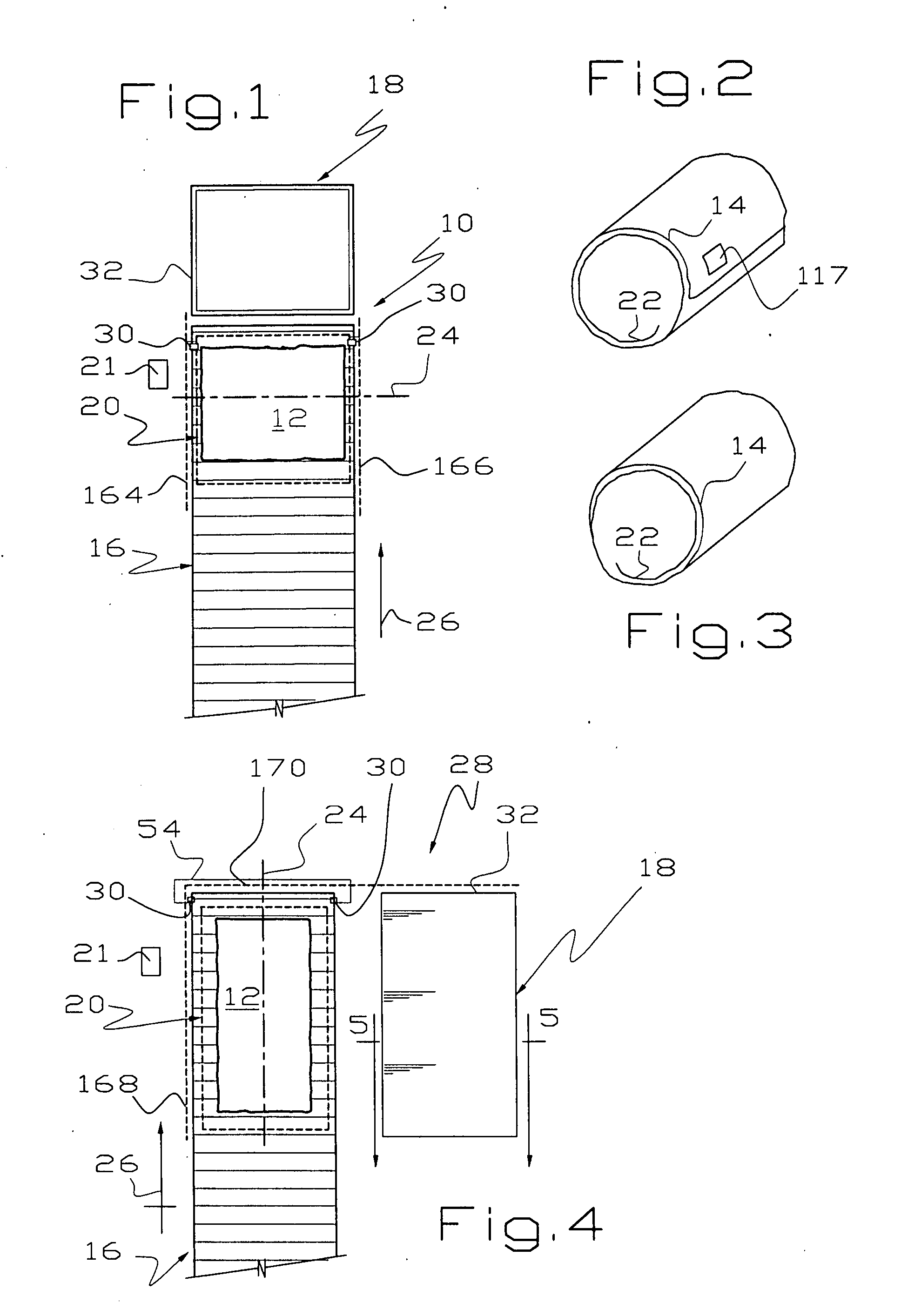

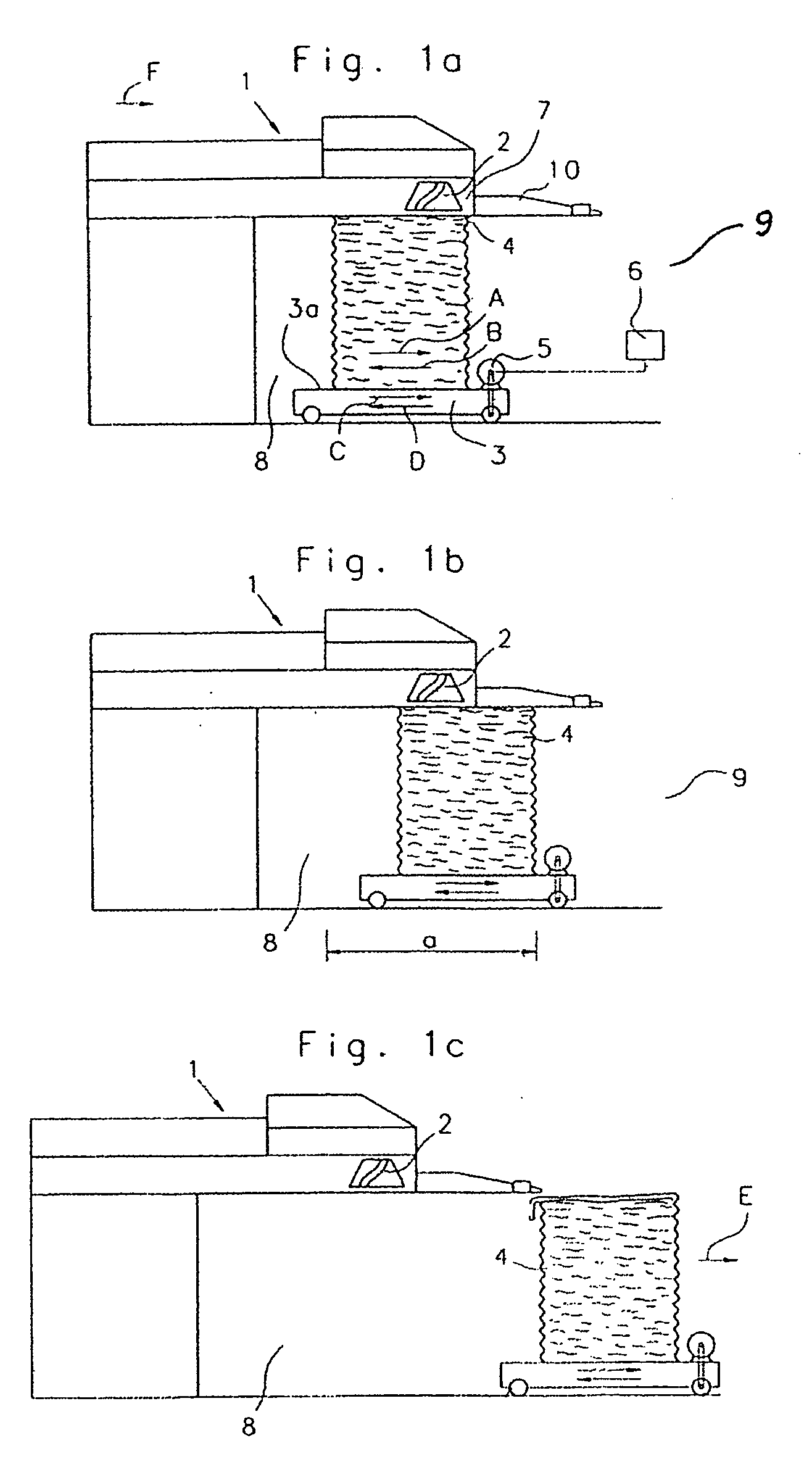

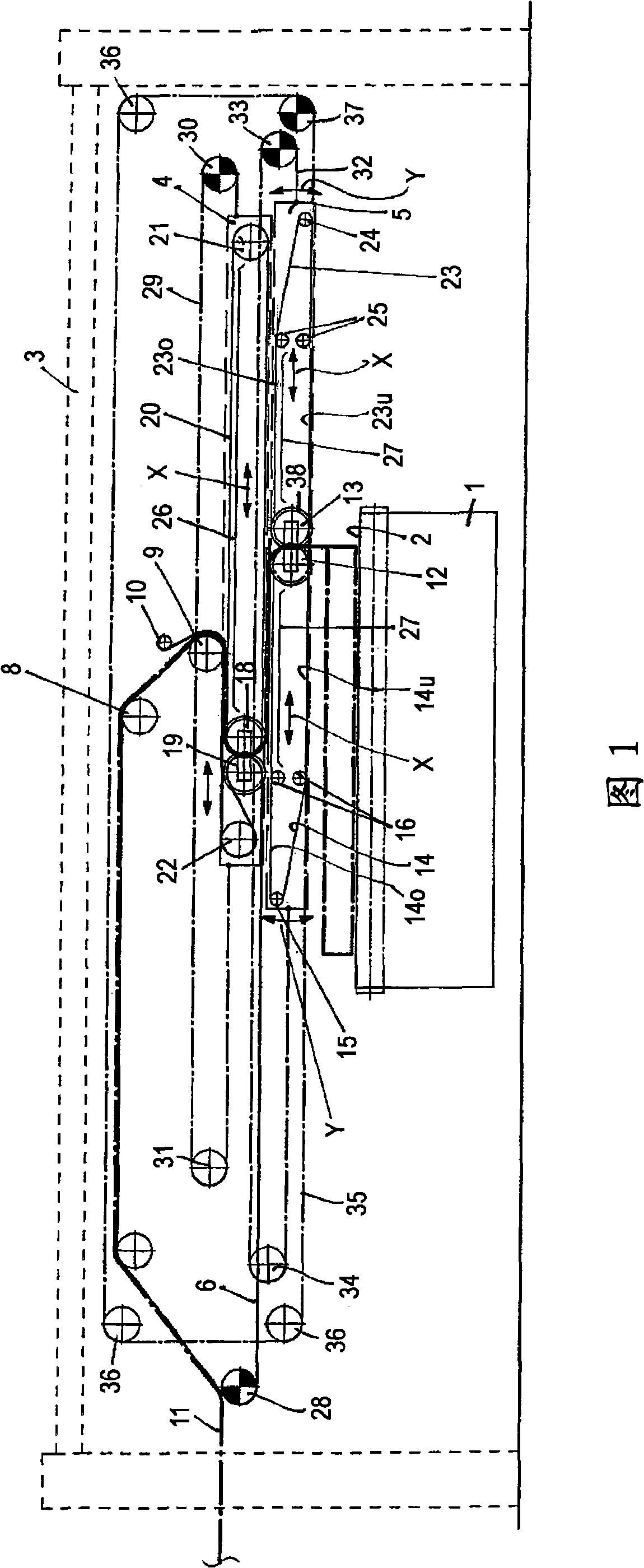

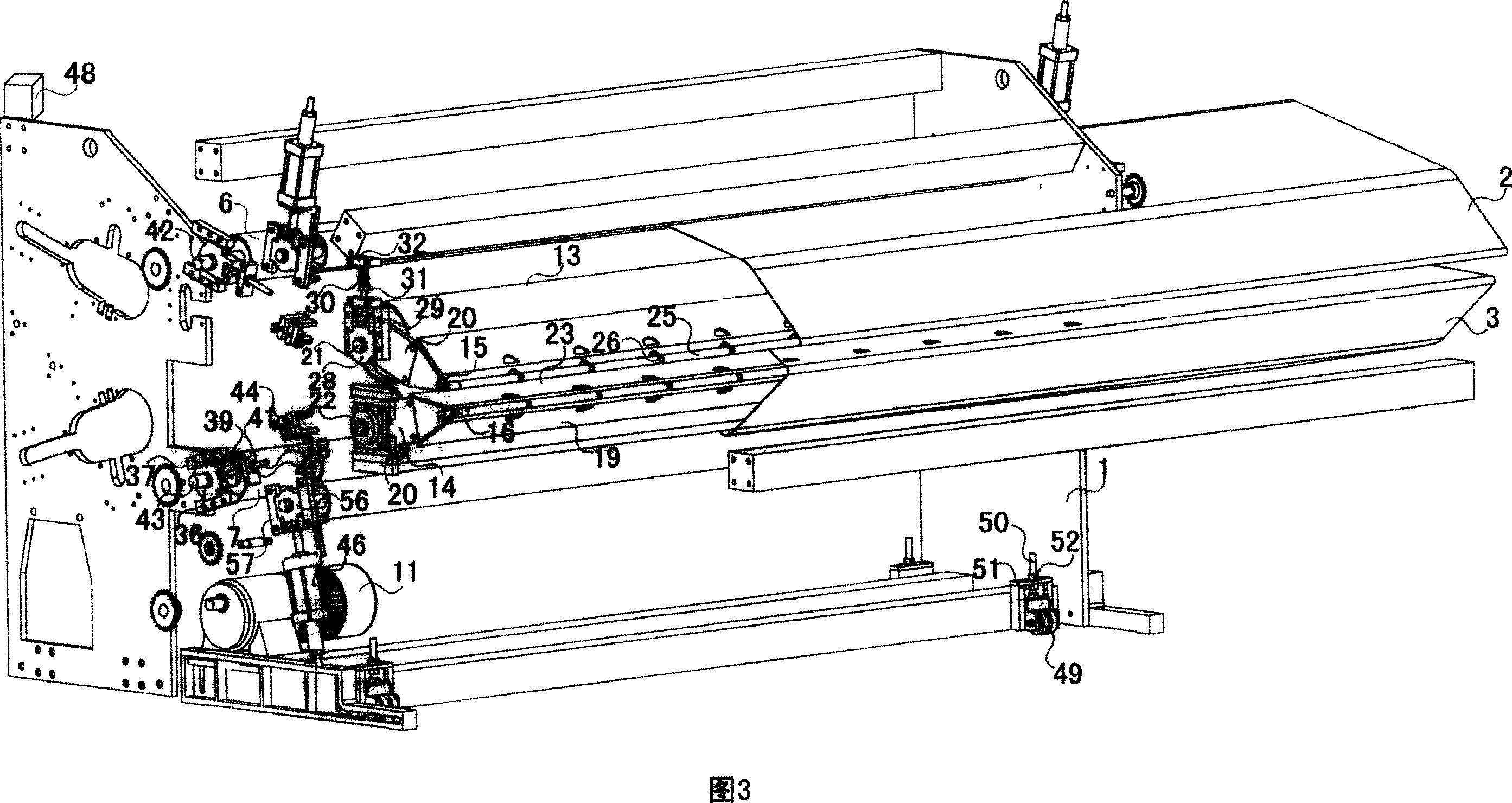

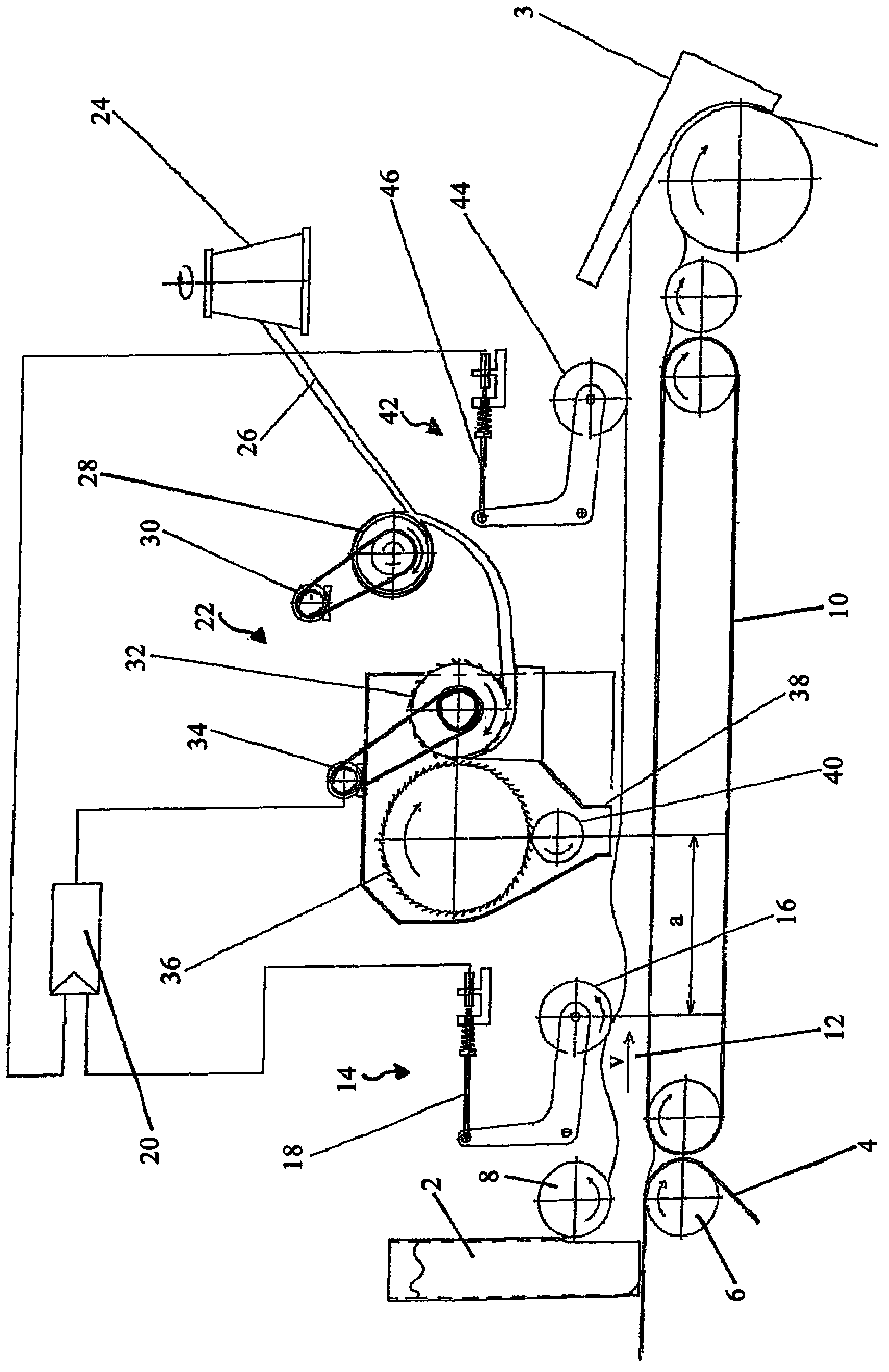

Fleece-laying apparatus

InactiveCN101275313AAvoid aerodynamic effectsAvoid damageLap forming devicesFibre feedersSandwich likeEngineering

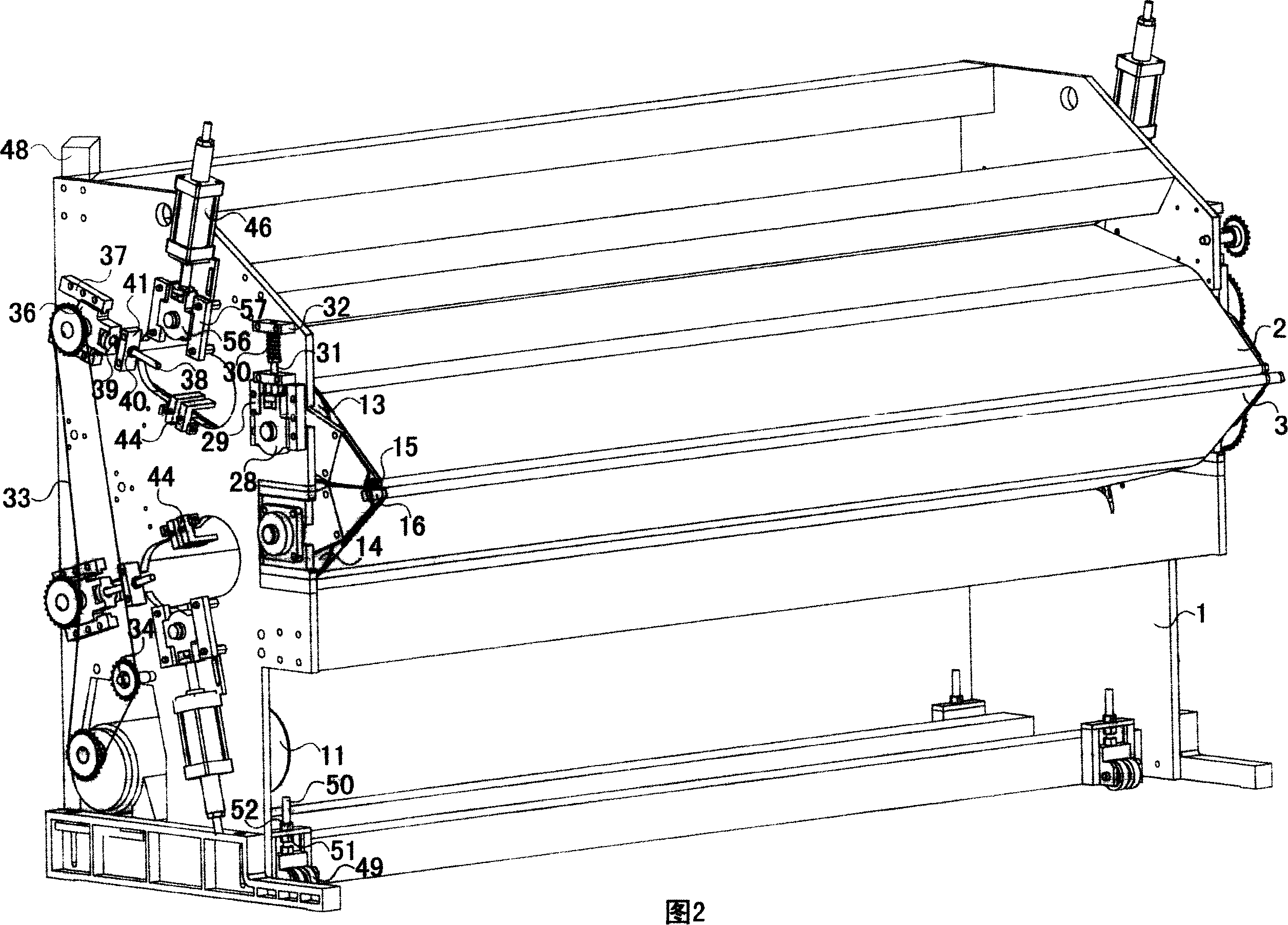

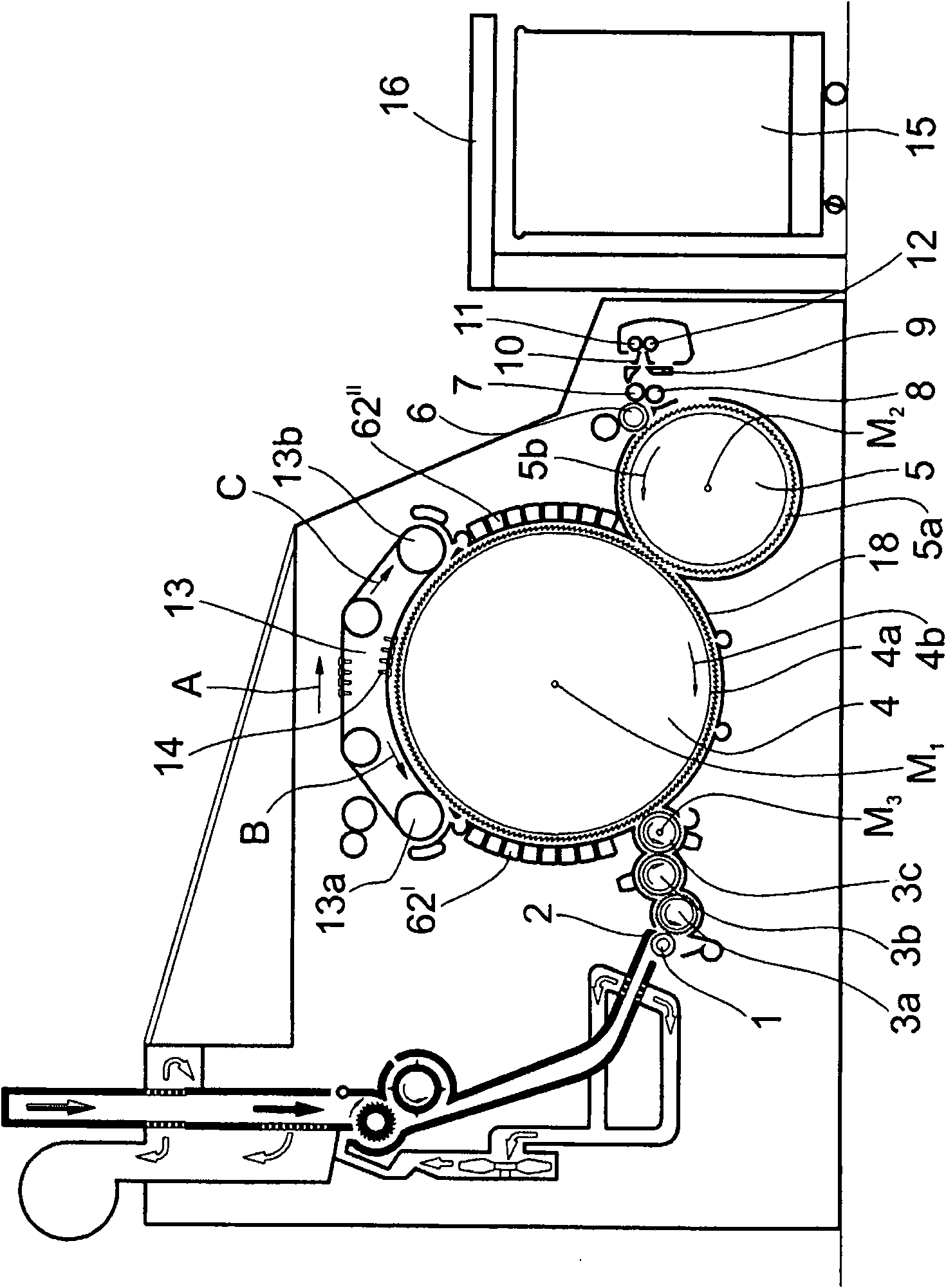

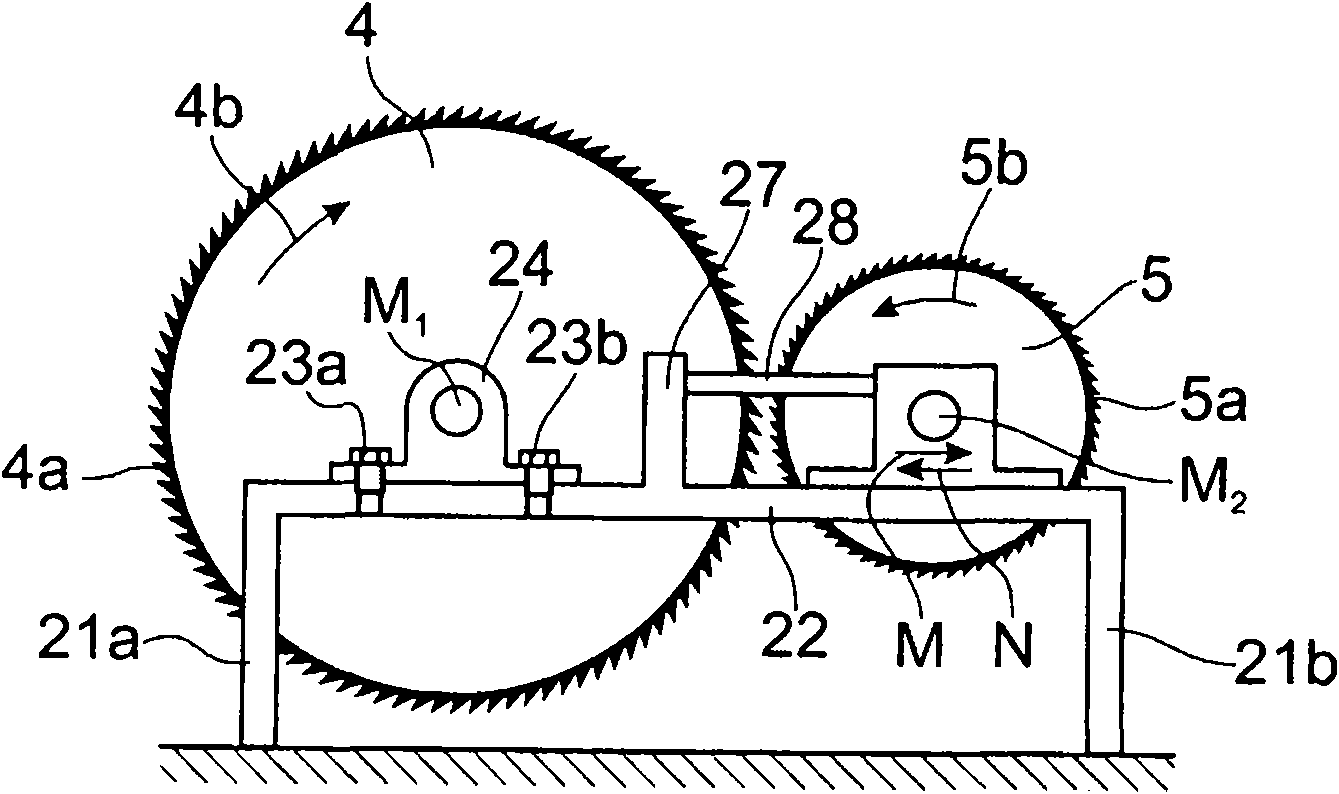

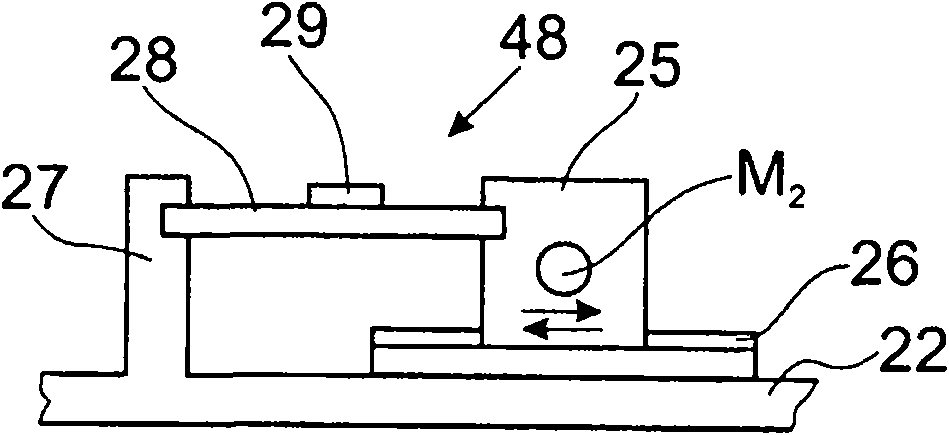

In a fleece layer of the carriage cross-lapper type, the laying carriage conveyor belt ( 14 ) wraps around the first laying roller ( 12 ), the upper and lower strands ( 14 o, 14 u) of the belt being parallel to each other as they proceed from the first laying roller ( 12 ). An endless cover belt ( 23 ), which travels around in the laying carriage ( 5 ), wraps around the second laying roller ( 13 ), the cover belt having upper and lower strands ( 23 o, 23 u), which are parallel to each other as they proceed from the second laying roller ( 13 ) in the direction opposite that of the laying carriage conveyor belt ( 14 ). The mutual distances between the web entrance ( 8, 9 ), the upper carriage ( 4 ), the laying carriage ( 5 ), and the output conveyor belt ( 2 ) perpendicular to the transport directions of same are so small that the card web ( 11 ) to be laid is enclosed in a sandwich-like manner between the adjacent strands of the web entrance conveyor belt ( 6 ), of the upper carriage conveyor belt ( 20 ), and of the laying carriage conveyor belt ( 14 ), where the laid fleece on the output conveyor belt ( 2 ) is contacted by the laying carriage conveyor belt ( 14 ) and by the cover belt ( 23 ).

Owner:DILO MASCHF OSKAR

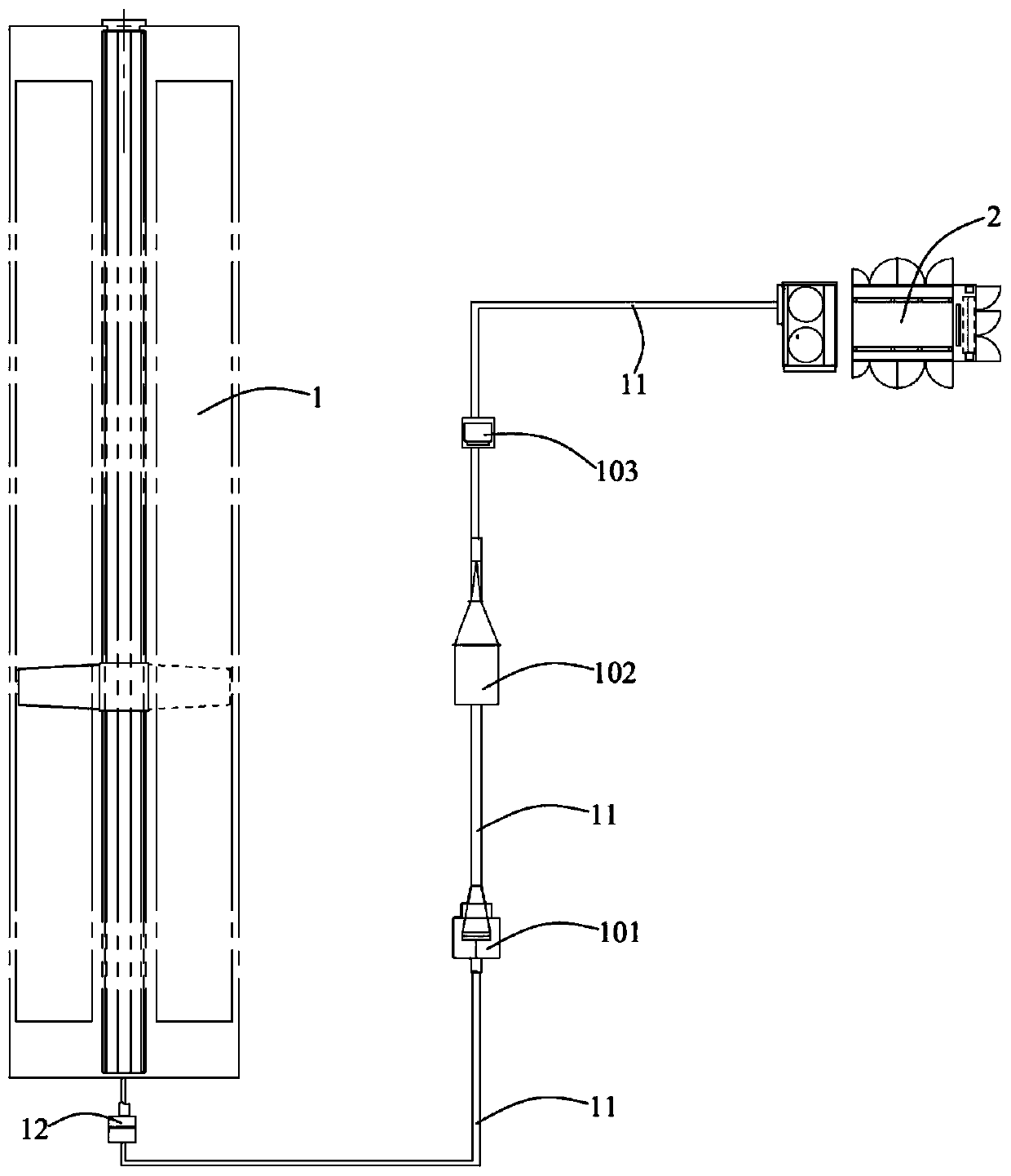

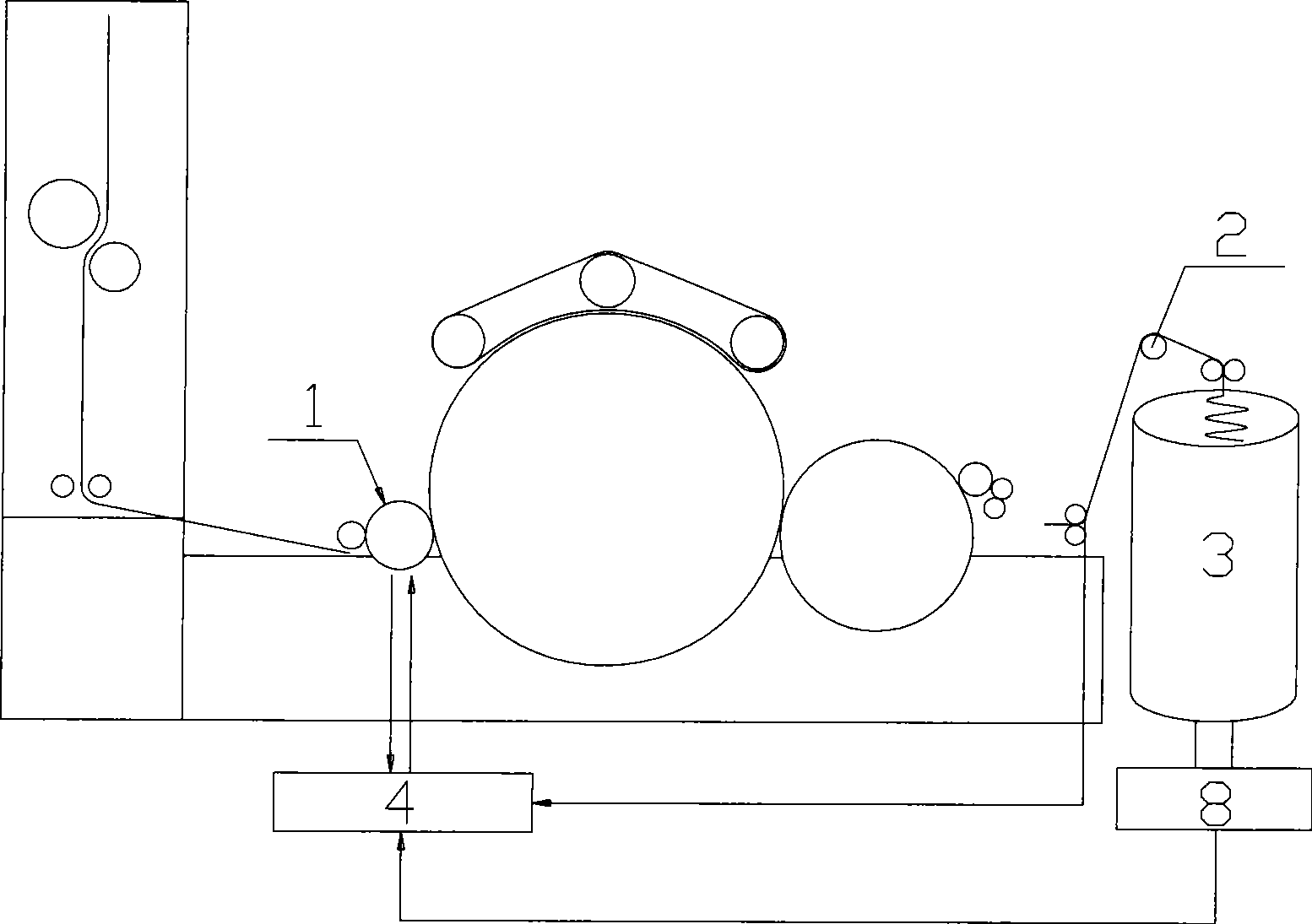

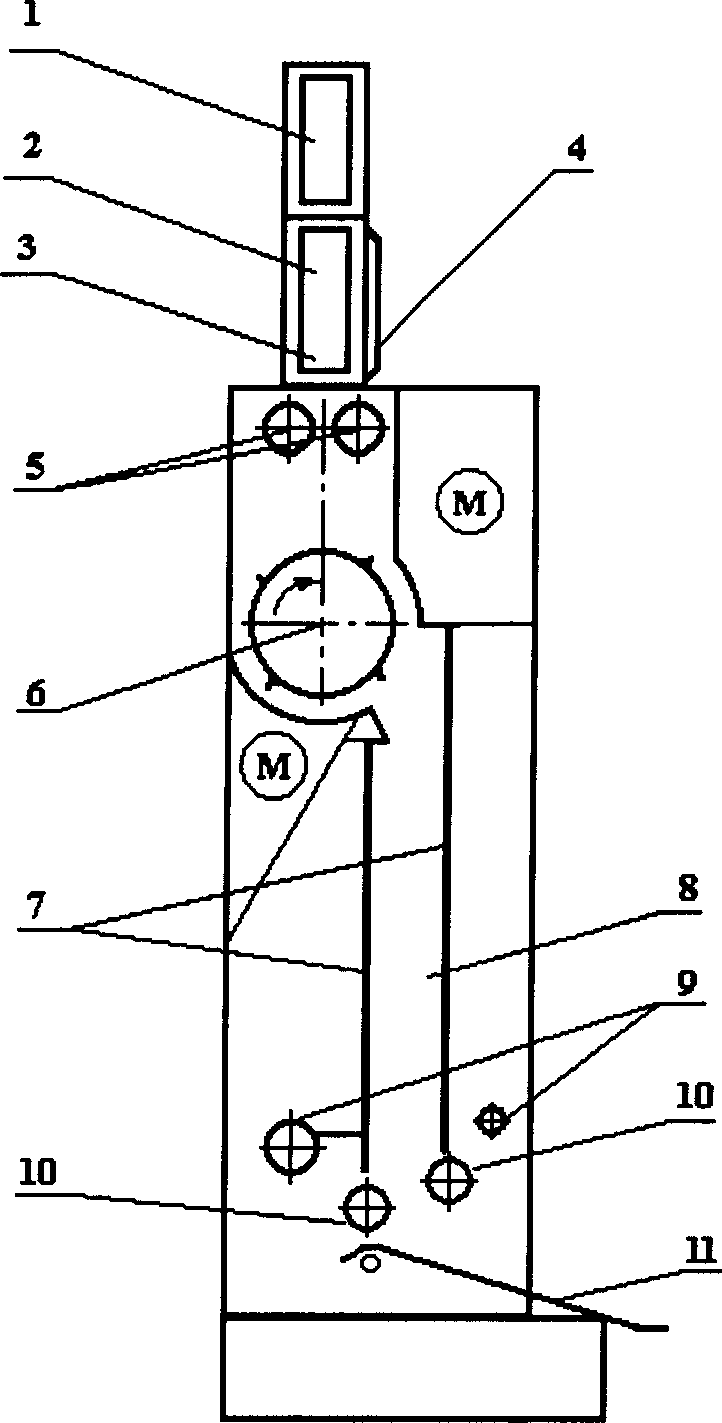

Autoleveling system with cotton silver weighing control and weight control method thereof

InactiveCN101498064ACompensation for the effects of rebiasingCompensation effectWeighing apparatus using elastically-deformable membersCarding machinesElectrical resistance and conductanceEngineering

The invention relates to an autoleveling system with cotton sliver weight control and a weight control method thereof. The autoleveling system comprises a cotton-feeding roller mechanism, a coiler, a cotton sliver bucket, an autoleveling device, a cotton layer thickness detection sensor and / or a cotton sliver thickness detection sensor, and a weight sensor for weighting a cotton sliver in the cotton sliver bucket, wherein the output end of the weight sensor is connected with the autoleveling device for controlling the output speed of the cotton-feeding roller mechanism; the weight sensor comprises a strain foil and a weight amplifier, and the strain foil is a bridge resistor circuit. The autoleveling system detects the weight of the cotton sliver after a certain length of cotton sliver is continuously produced, and the autoleveling device compares a detected weight with a standard weight stored in a program and controls the output speed of the cotton-feeding roller mechanism according to a comparison result. The invention realizes the online weight detection of an overlength section of cotton sliver, can effectively correct the weight deviation of the overlength section of cotton sliver in time, lightens the labor intensity of an operator and improves the detection precision.

Owner:北京纺科兴业机电技术有限公司 +1

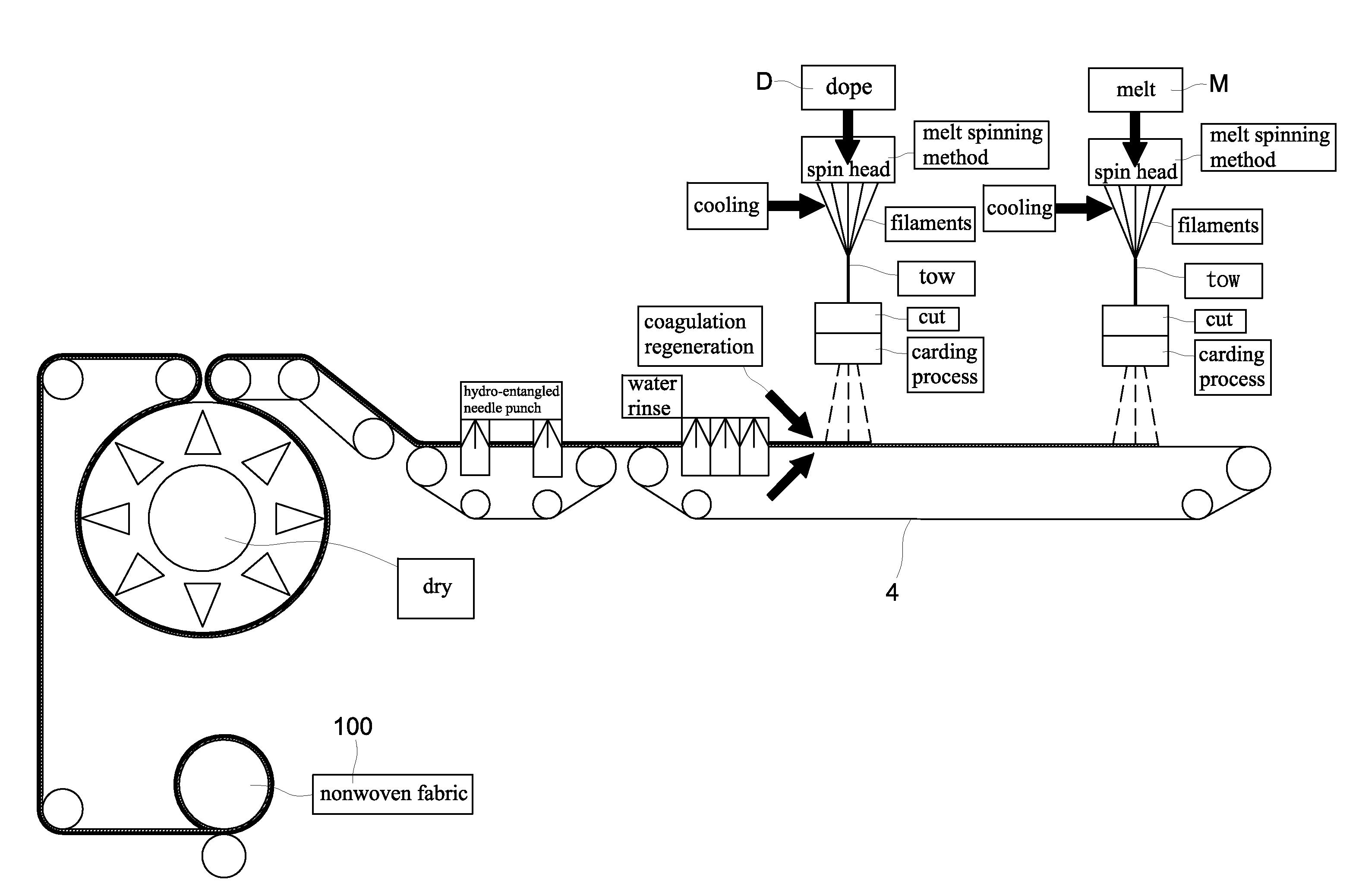

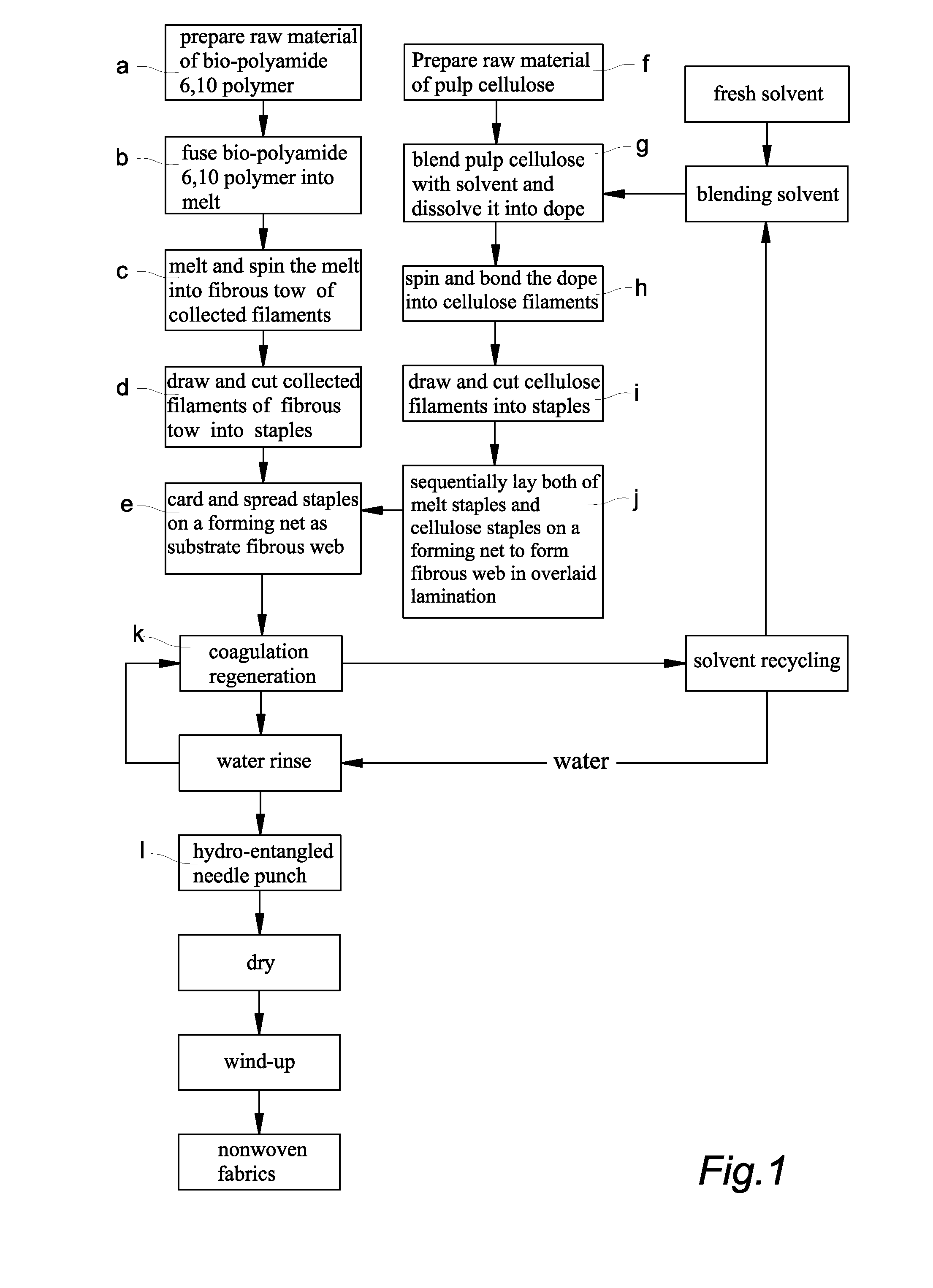

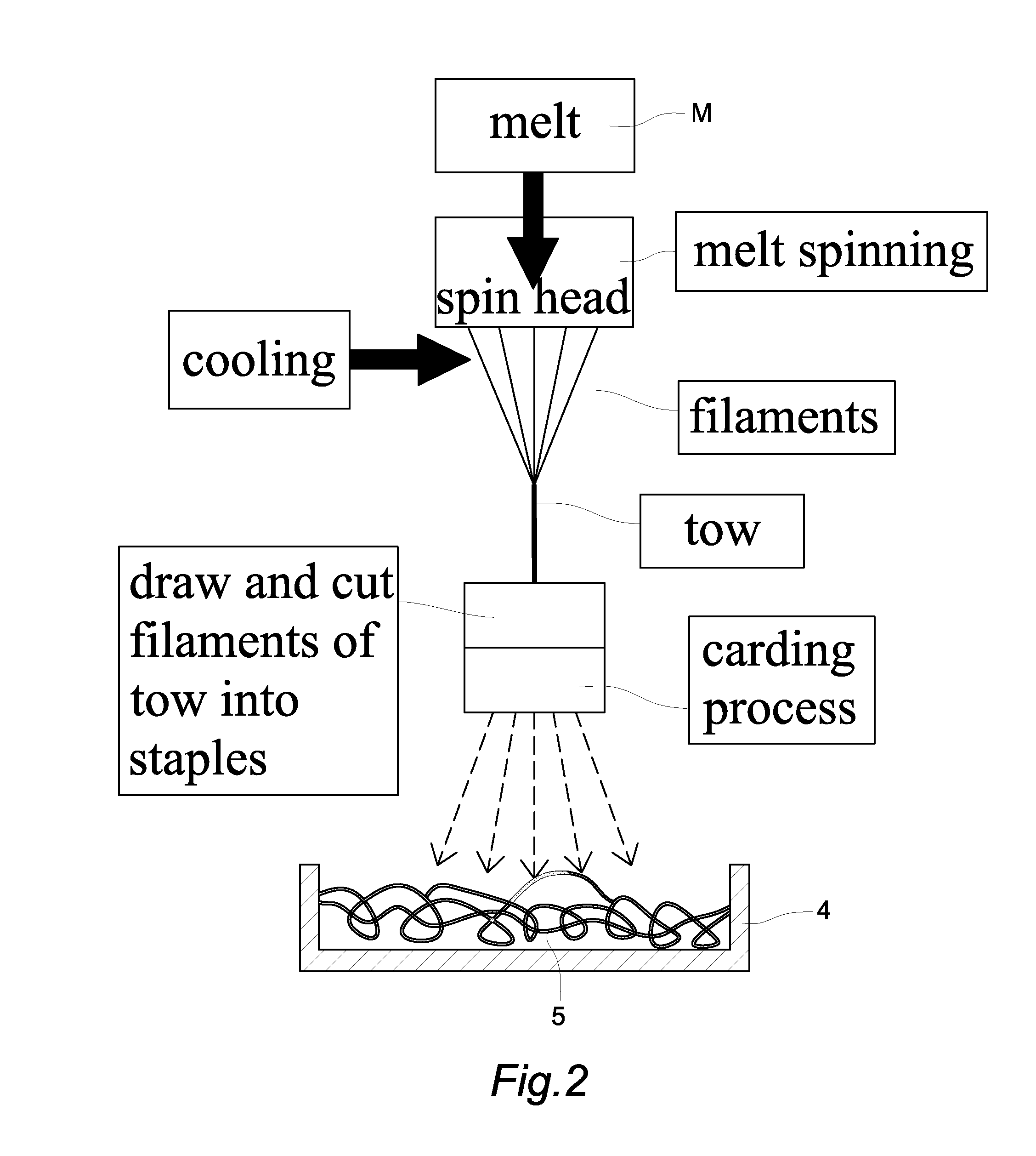

Stapled melt spinning method for producing non-woven fabrics with hygroscopic metastatic feature

ActiveUS20160145781A1Improve water absorptionReduce water contentPattern makingMonocomponent cellulose artificial filamentPunchingPolyamide

A stapled melt spinning method for producing nonwoven fabrics with hygroscopic metastatic feature. Firstly, fuse bio-polyamide 6,10 into melt, extrude and spin it out spin heads of extruder into filaments, cool, draw and collect filaments into tow, then extend, cut and card the filaments into the staples, and spread the staples on a conveyer to form fibrous web. Next, blend and dissolve pulp by N-methylmorpholine N-oxide (NMMO) dissolving solvent, dehydrate it to form dope, and extrude and spin it out spin heads of extruder into filaments, then cool, draw and collect filaments into tow, and extend, cut and card filaments into staples, then overlay the staples over existing fibrous web to form a composite fibrous web of bio-polyamide 6,10 and cellulose filaments. Finally, coagulate, regenerate and convert fibrous composite of bio-polyamide 6,10 and natural cellulose into nonwoven fabric with hygroscopic metastatic feature by hydro-entangled needle punching, drying, winding-up processes.

Owner:LIN CHIH HSIN

Blending and opening device

ActiveCN103290536AReduce labor intensityPass smoothlyLubricating devicesContinuous processingState of artFiber bundle

The invention relates to the technical field of wool top processing equipment, in particular to a blending and opening device which comprises a first automatic sucking device, a second automatic sucking device, an opener, an automatic oil filling tank and a plurality of delivery pipes. The blending and opening device has the advantages that fibers can be directly sucked into the opener from the ground by the aid of the first automatic sucking device without being manually placed into the opener, accordingly, the efficiency is high, the labor intensity of workers is low, fibers which are processed by the opener can be automatically sucked into the automatic oil filling tank by the aid of the second automatic sucking device, both the first automatic sucking device and the second automatic sucking device have impurity removal functions, and the quality of later-period finished products is greatly improved; manual blending in the prior art can be replaced by the automatic oil filling tank, so that the labor intensity of the workers is greatly reduced, a uniform blending effect is realized, cohesive force of fiber bundles is increased, the fibers can smoothly pass a carding device, a spinning device and the like advantageously, and twisting, end breaking and the like are reduced.

Owner:浙江中鼎纺织股份有限公司

Clamping type feeding device of pre-pricking machine

A clamping-type feeding device of pre-lunge machine comprises a frame, and some elements as fiber network transmitter and power device mounted on the frame, while the power device is connected with the fiber network transmitter. The fiber network transmitter comprises upper and lower transmitting curtains, upper and lower active rollers mounted on the frame, upper and lower compressing rollers, upper and lower small feeding rollers, while two ends of compressing rollers are rotationally mounted on the frame. The upper and lower small feeding rollers via roller sheathes are individually arranged on the rotary axles of compressing rollers, while they extruded outside the frame. The upper transmitting curtain is tensioned on the upper active roller, upper compressing roller and upper small feeding roller, while the lower transmitting curtain is tensioned on the lower active roller, lower compressing roller and lower small feeding roller. The upper and lower transmitting curtains form backward Y-shaped space between them. The invention can be engaged with the material inlet of pre-lunge machine, to transmit fiber network via low tension rate, while the surface and uniformity of fiber network will not be damaged.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

Apparatus in a spinning room for making available a can-less fibre sliver package (feed material) for a sliver-fed spinning machine, for example a draw frame

InactiveUS20070063088A1Simple waySimple and efficient mannerFilament handlingLap-winding devicesFiberEngineering

An apparatus in a spinning room for providing at least one fiber sliver package to a sliver-fed machine having at least one feed position. The apparatus comprises a transport arrangement for transporting one or more fiber sliver packages from an upstream sliver-delivering machine or a storage station to a sliver-fed machine. The transport arrangement is arranged to supply at least one fiber sliver package to a feed position and the fiber sliver package(s) can be stably positioned at the feed position.

Owner:TRUETZSCHLER GMBH & CO KG

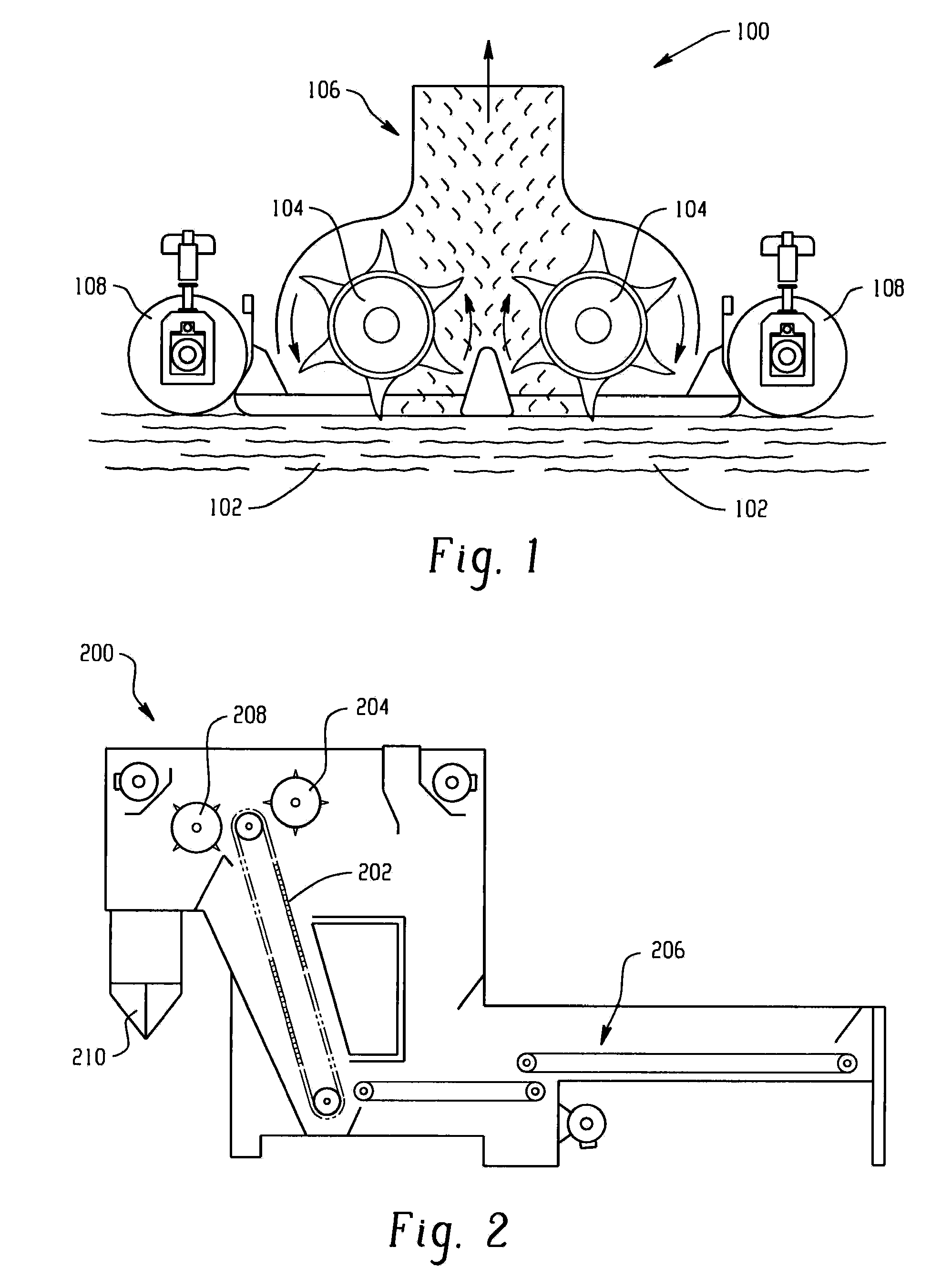

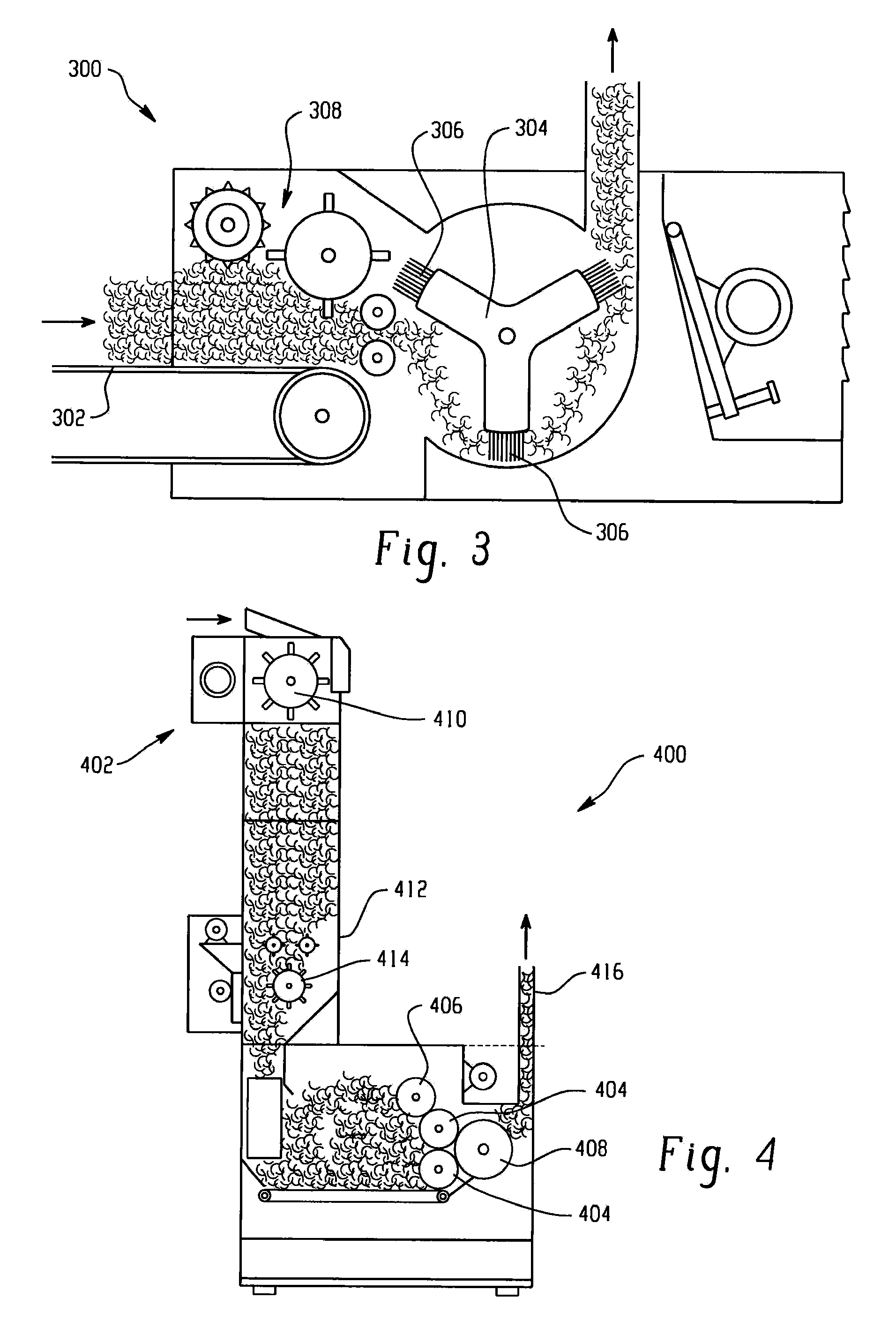

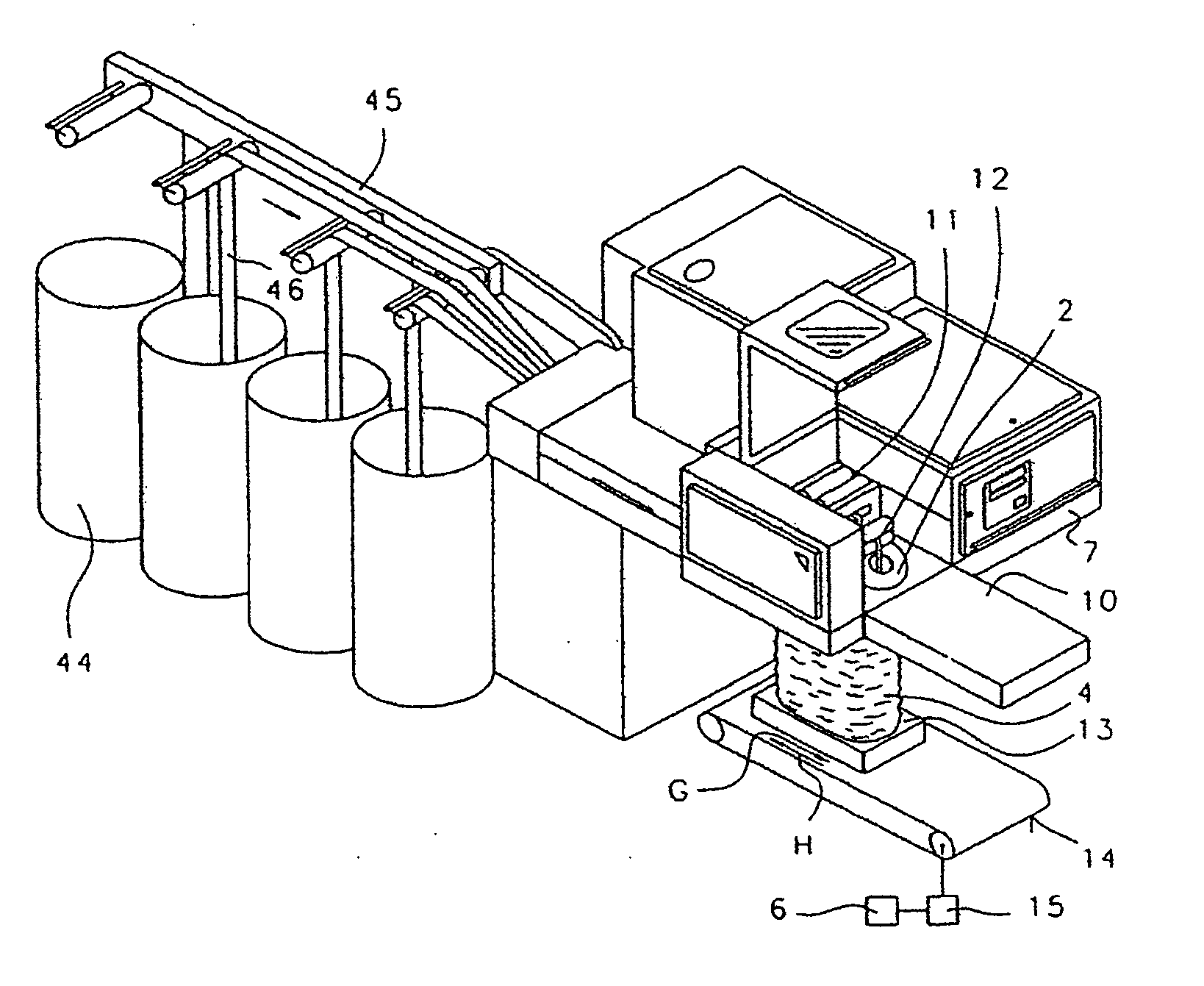

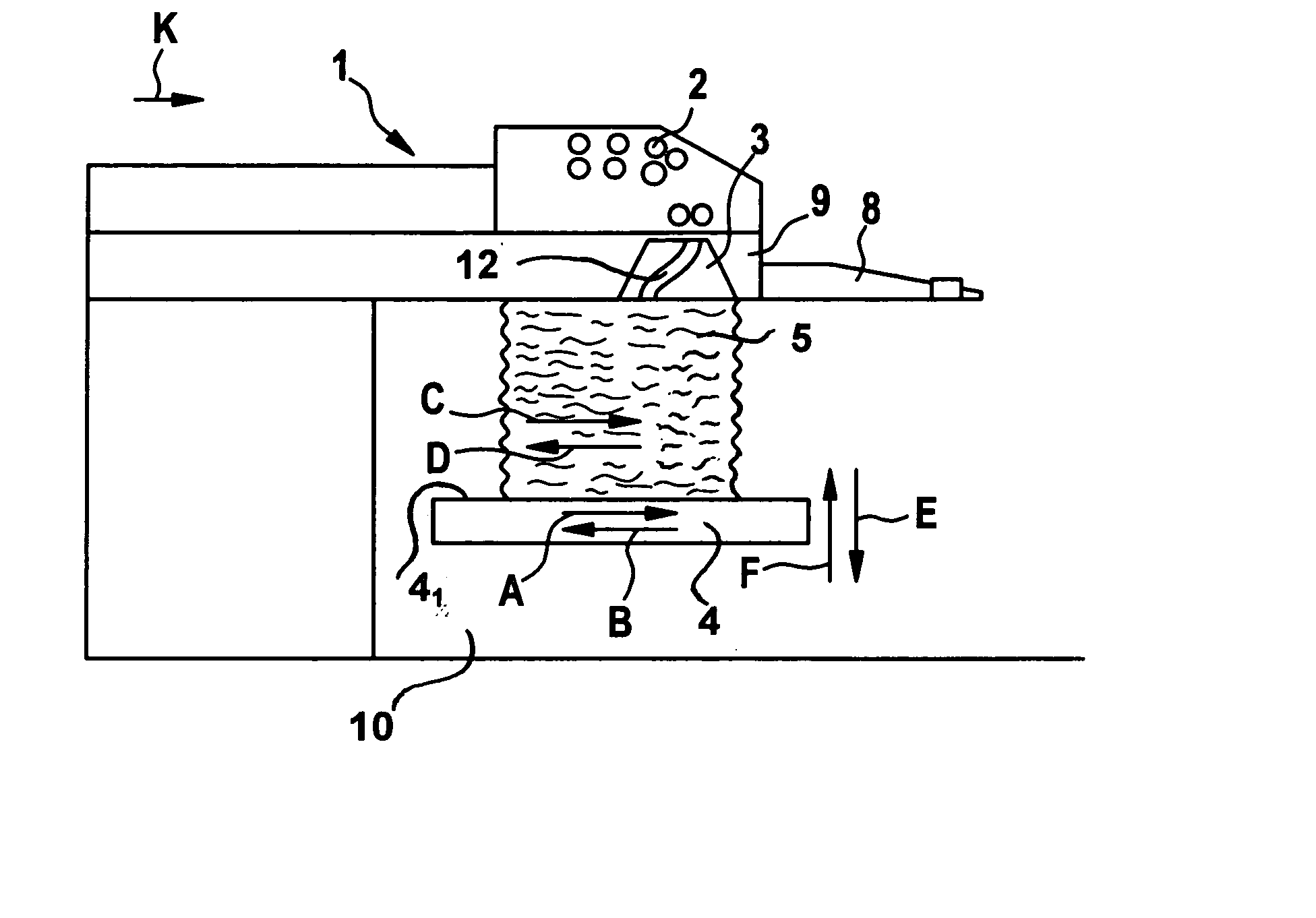

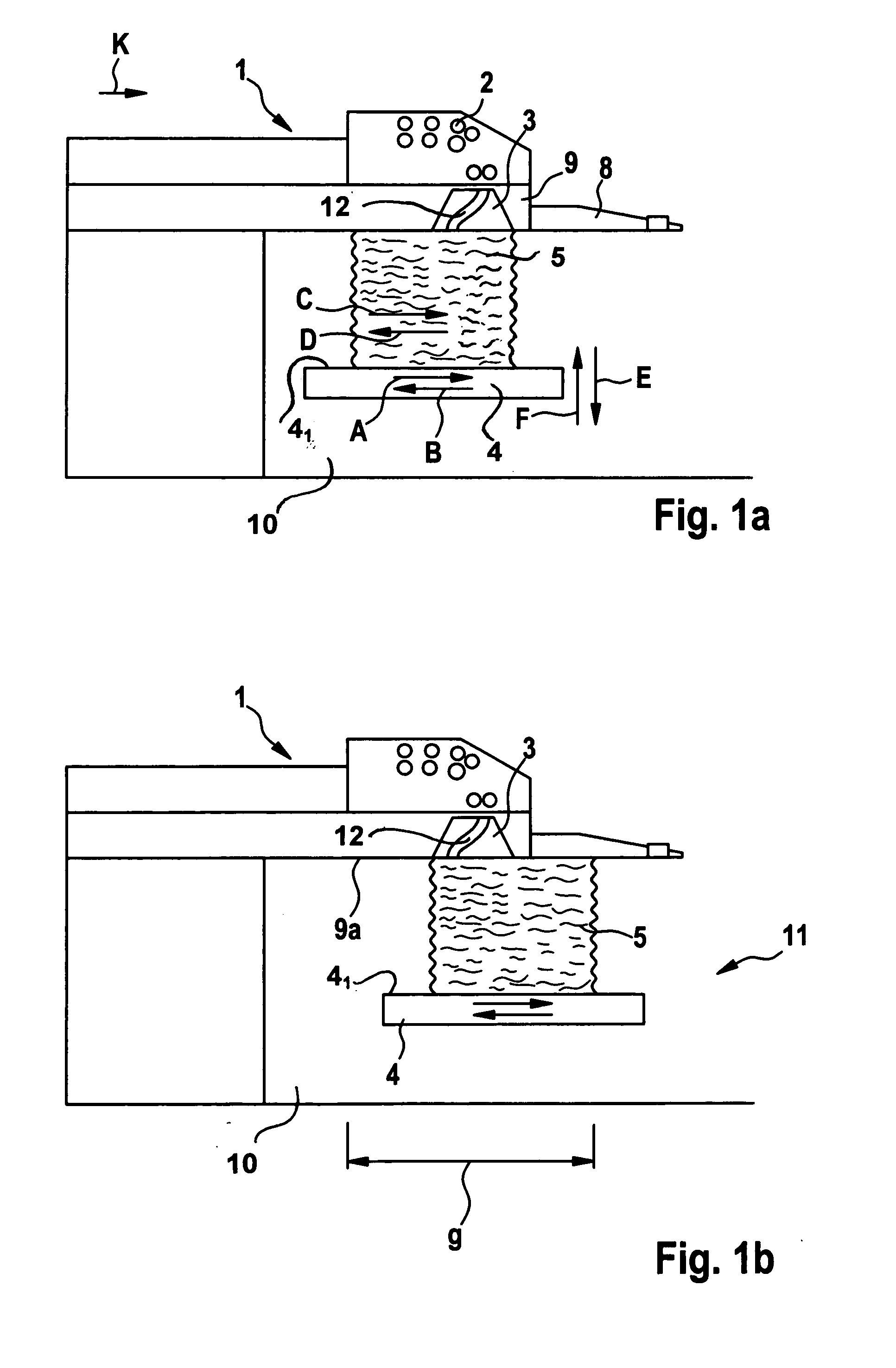

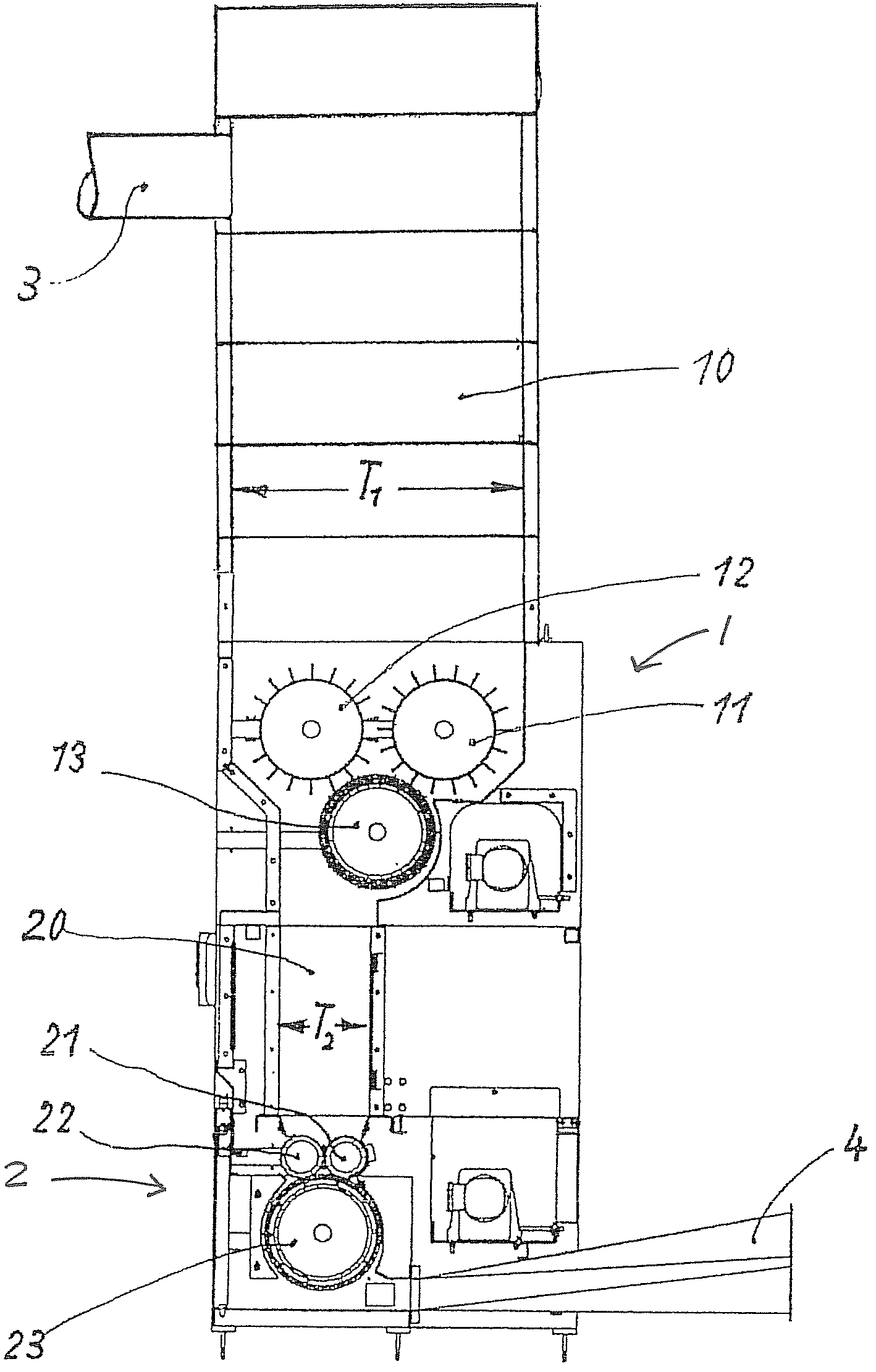

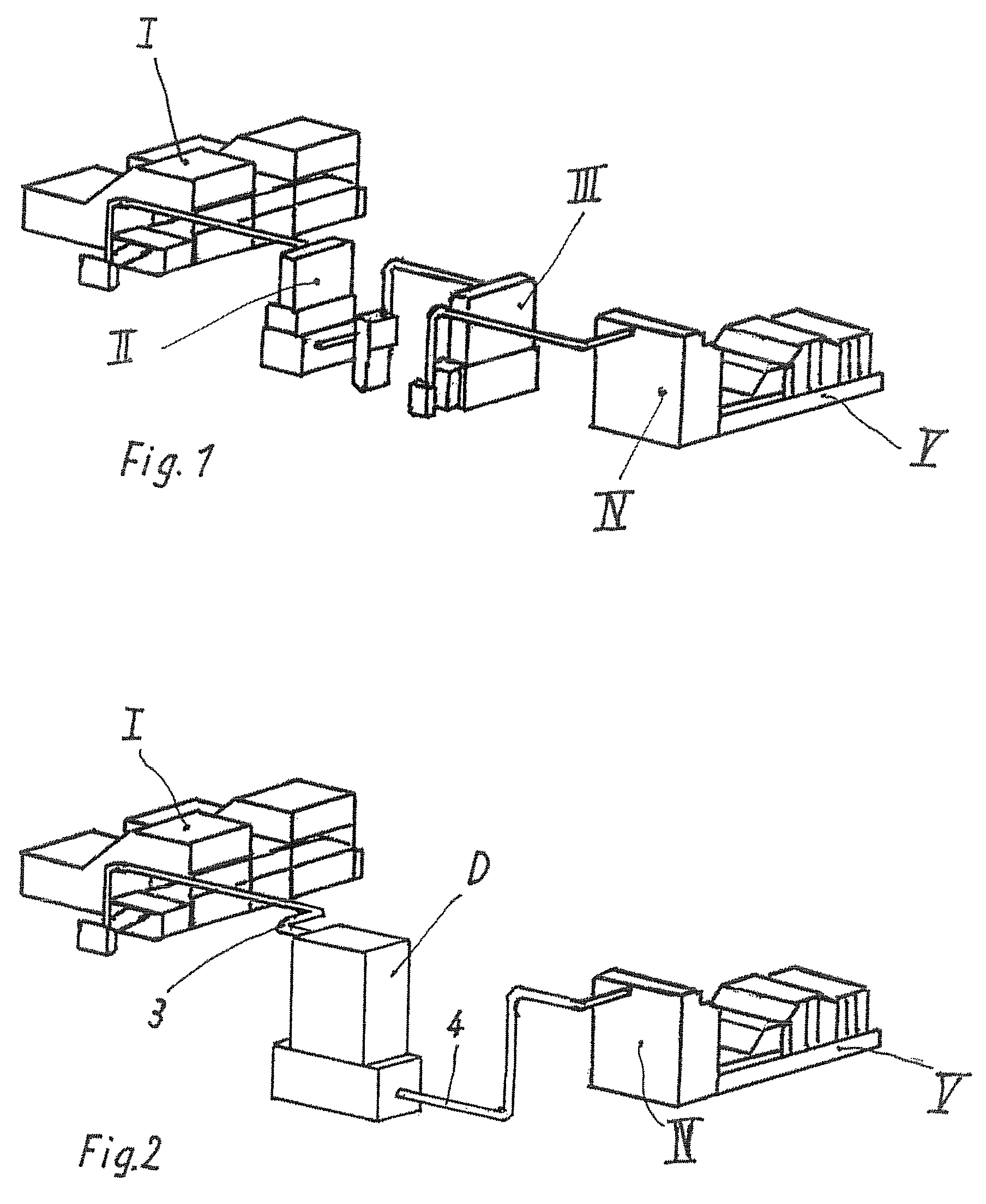

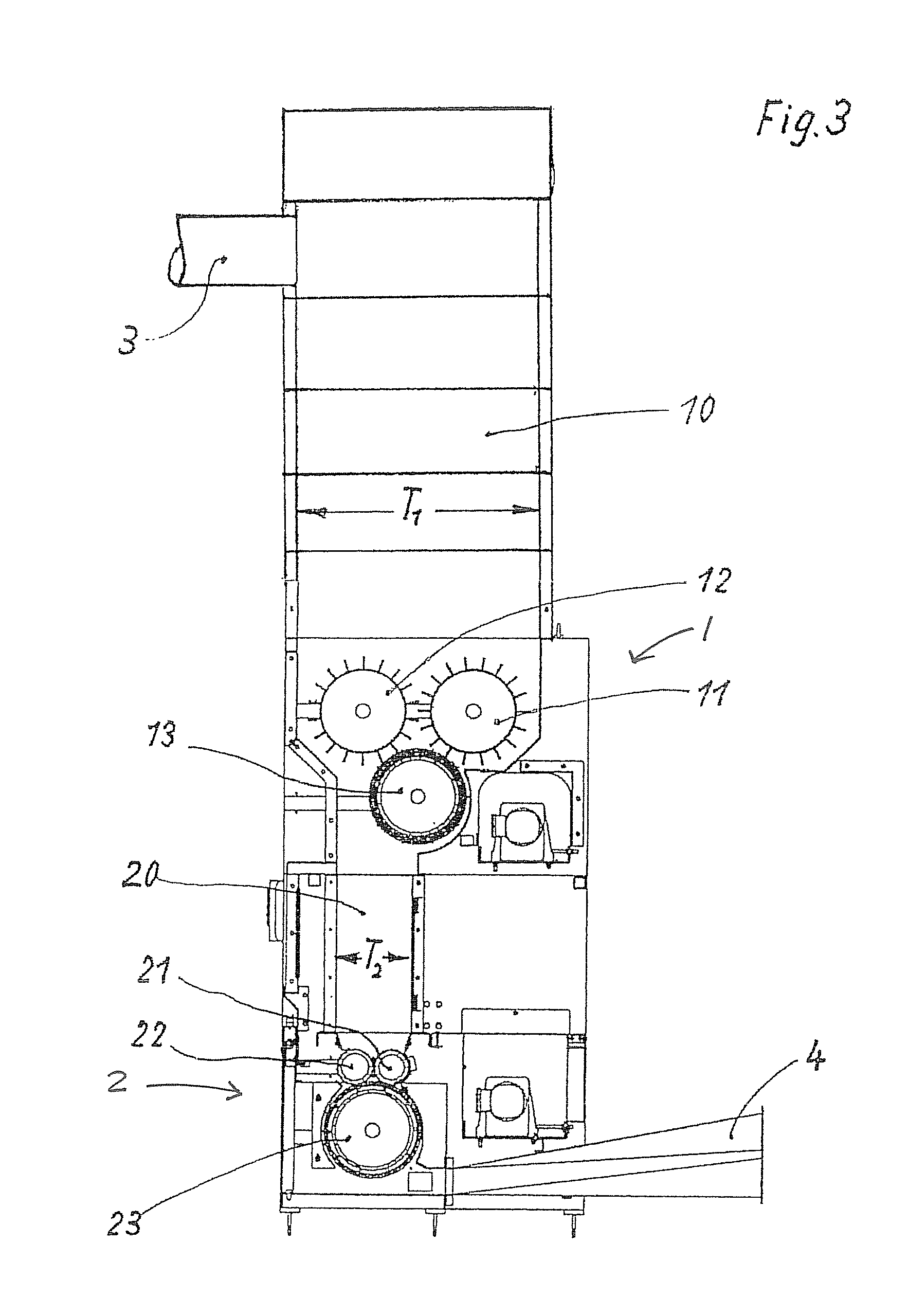

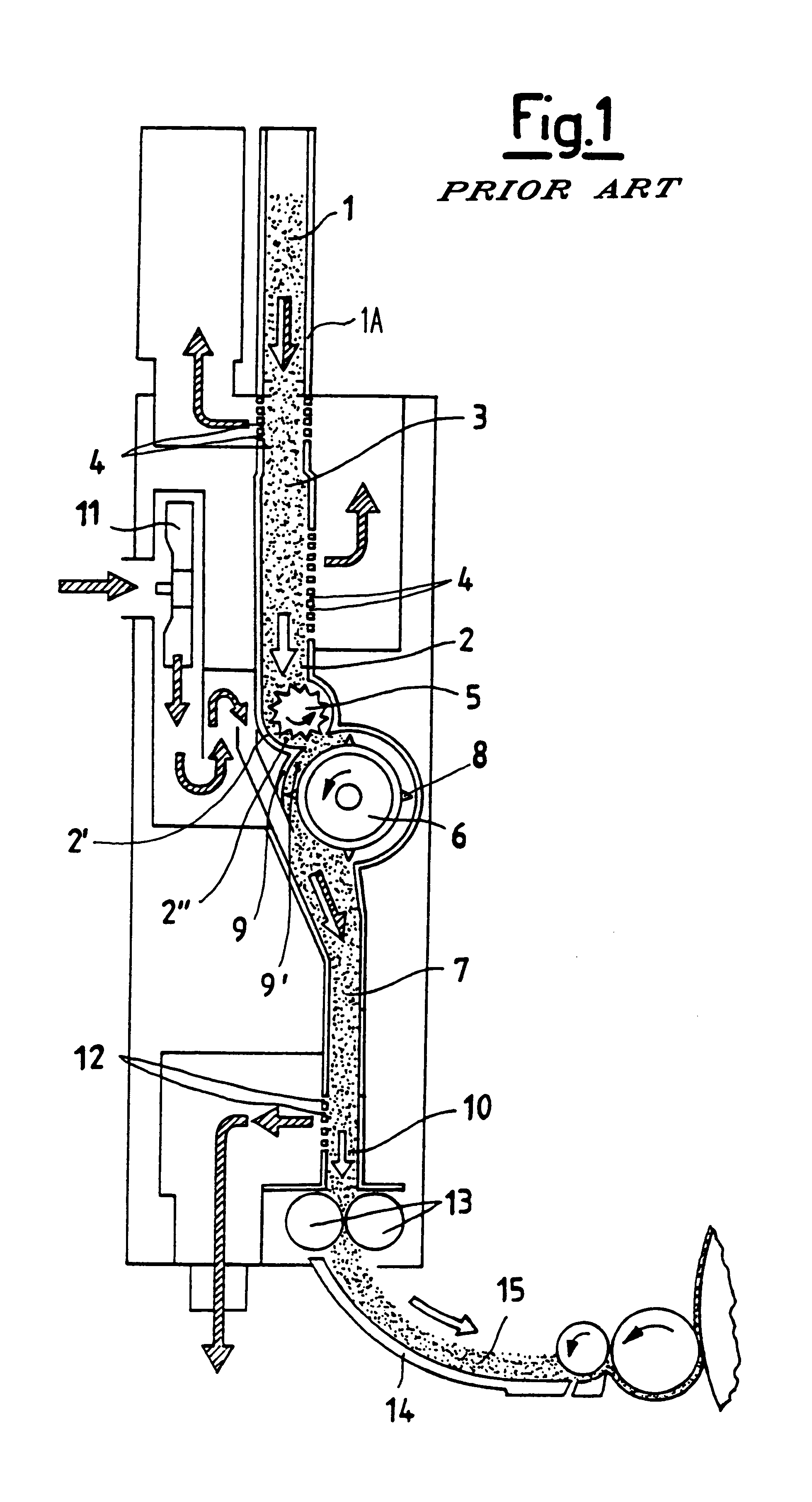

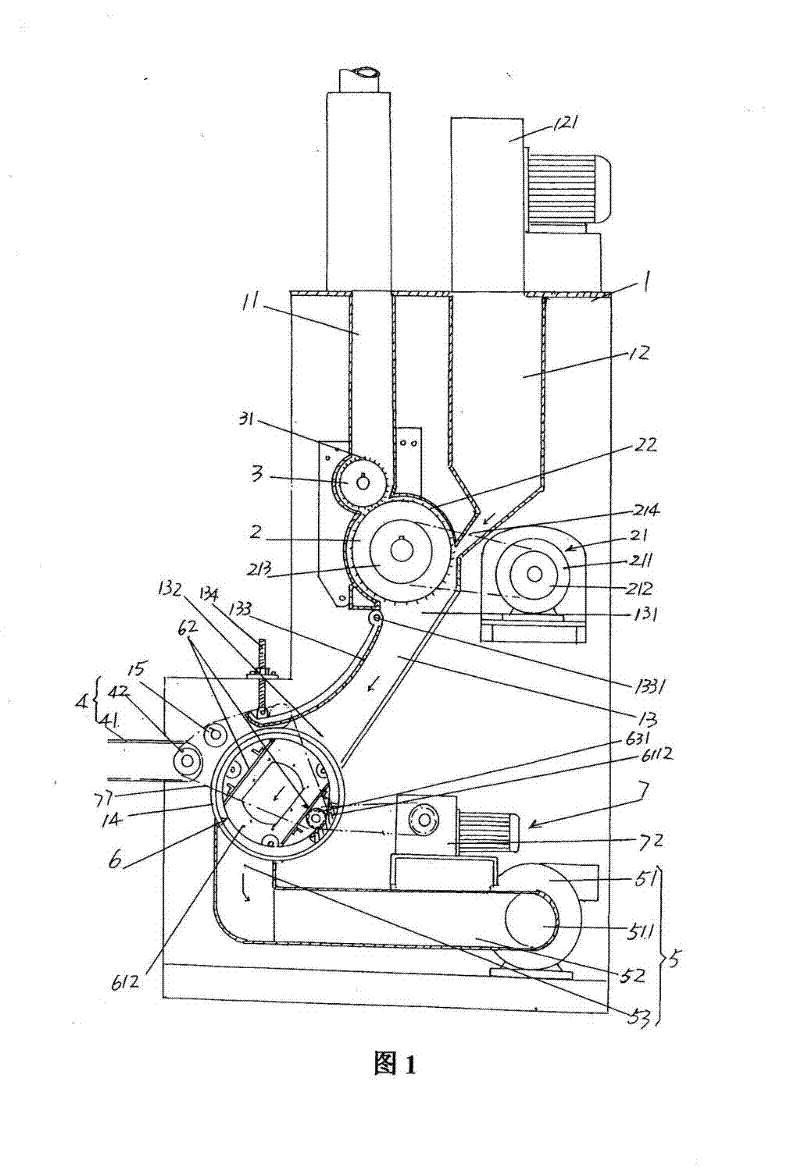

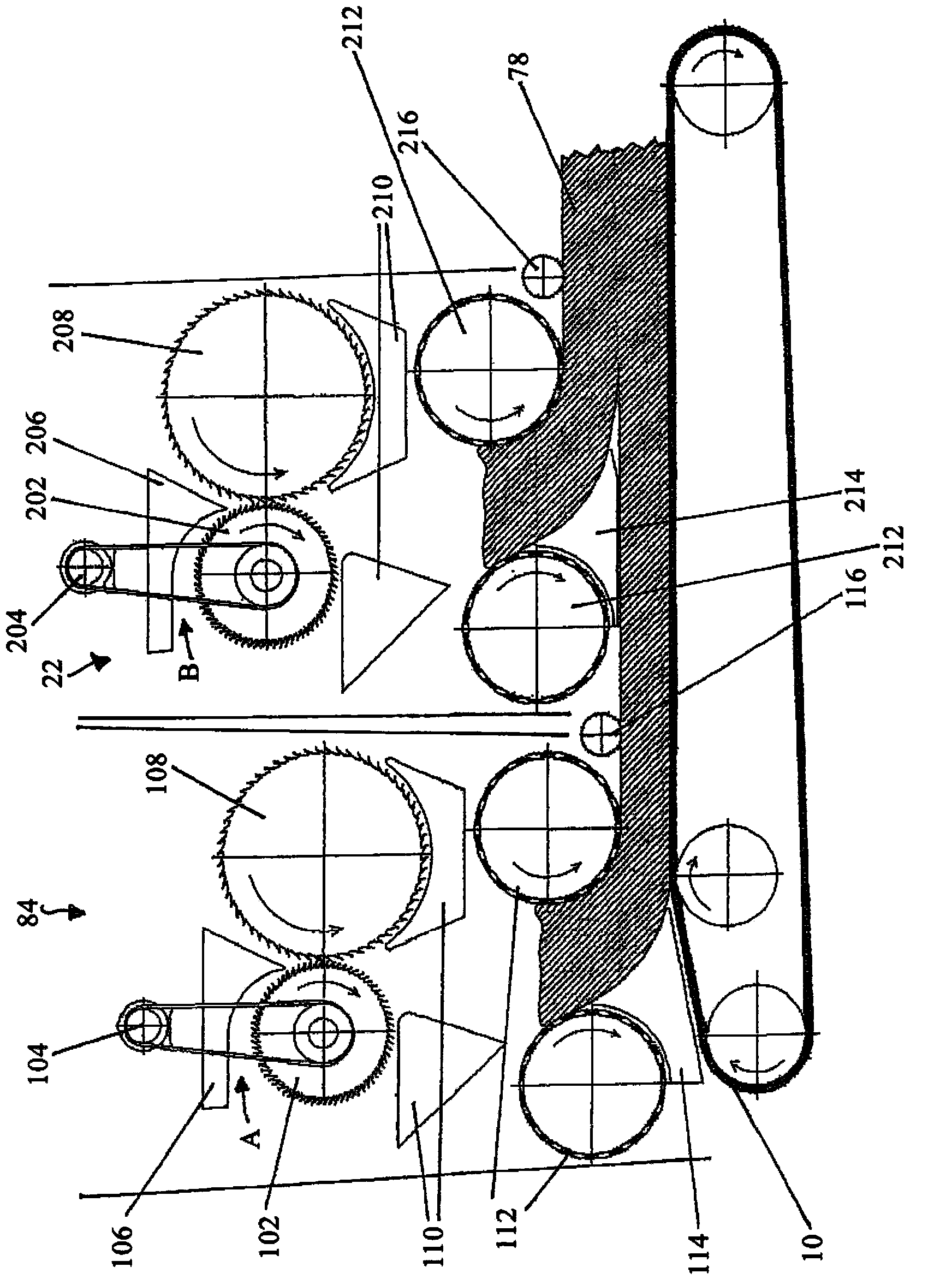

Procedure and system for opening and proportioning synthetic material

ActiveUS7752715B2Avoid Level FluctuationsDensity of fiber uniformFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberSynthetic materials

A method and a device for opening and dosing fiber feeds the fiber material via a feeding shaft of an opening device. The fiber material is processed in a first opening step of a dosing opener and is fed without an interconnecting pneumatic means to the feeding shaft of a second opening step. A large-volume feeding shaft has been placed before the first opening device from which the fiber material is delivered to a feeding shaft with a considerably smaller volume that delivers the fiber material to a second opening device. Both opening devices and their associated feeding shafts are placed on top of one other.

Owner:TEMAFA MASCHFAB

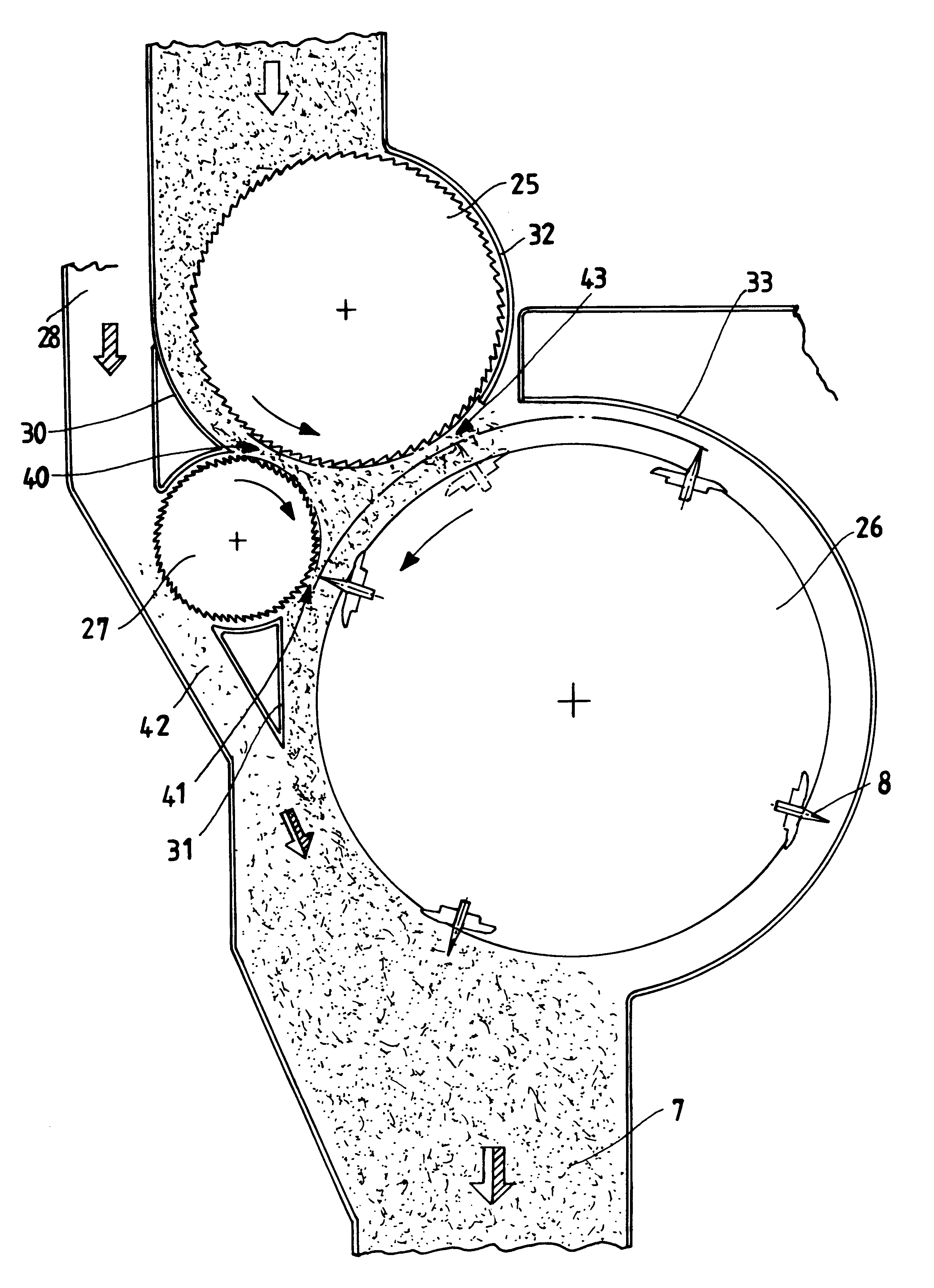

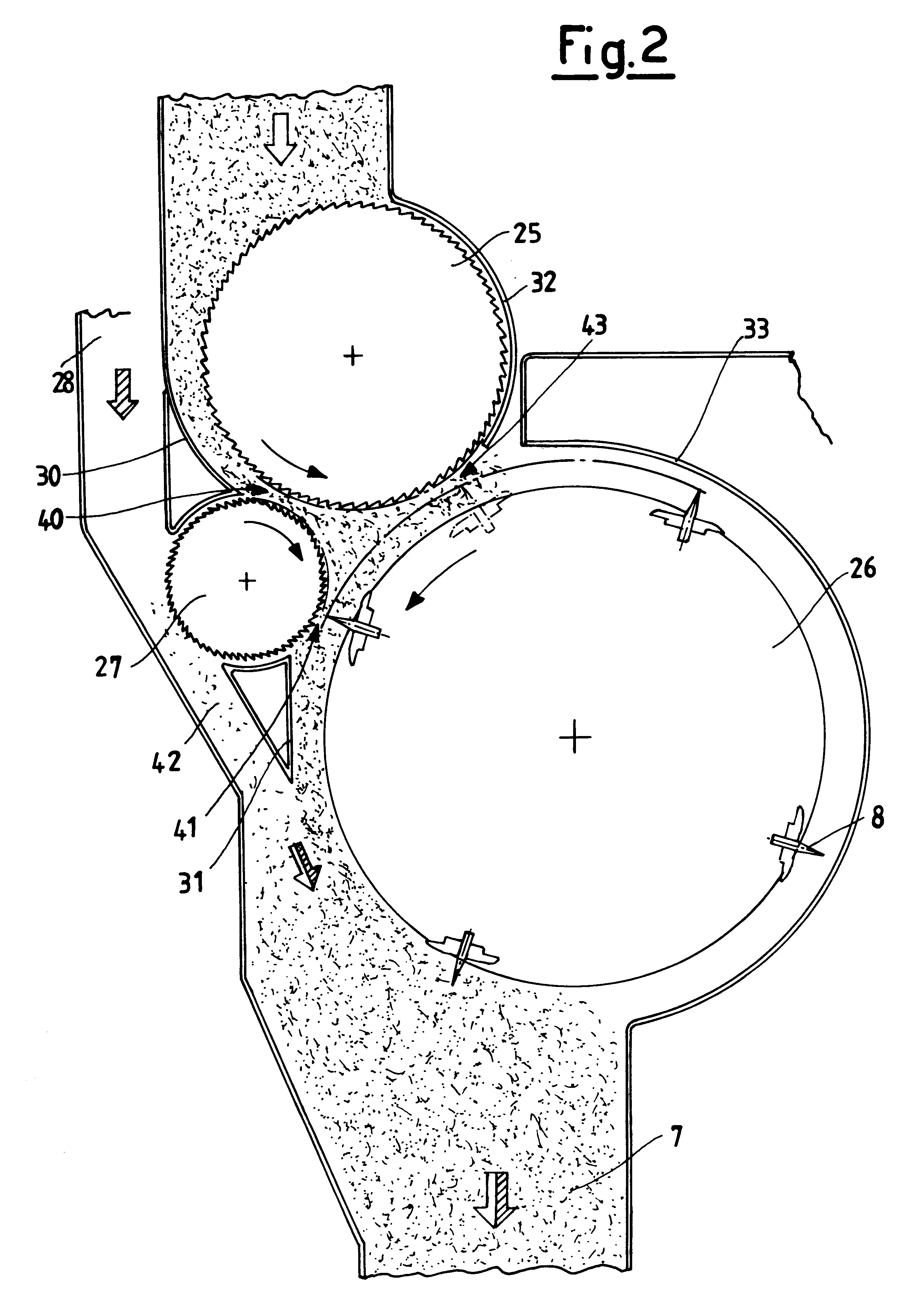

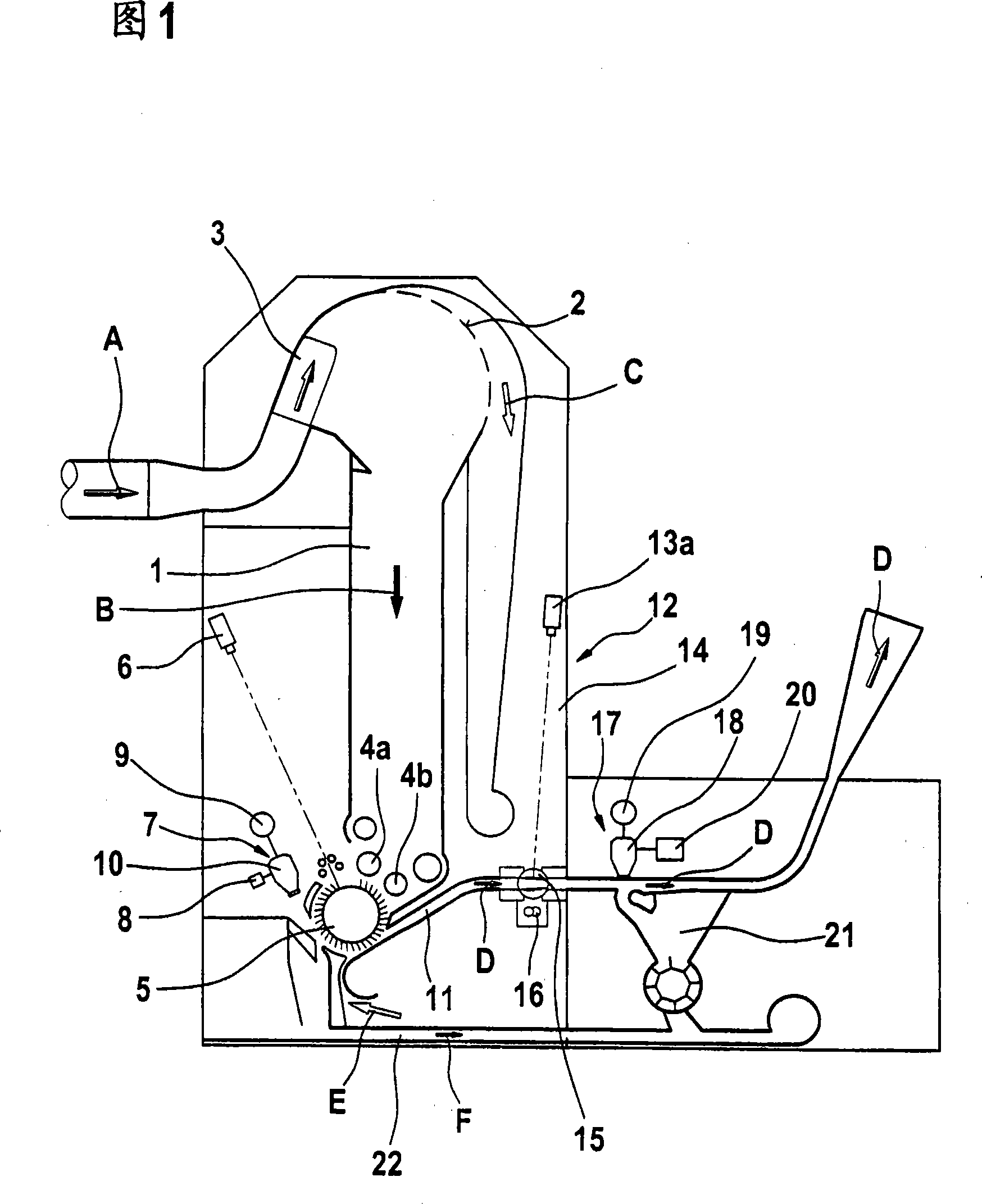

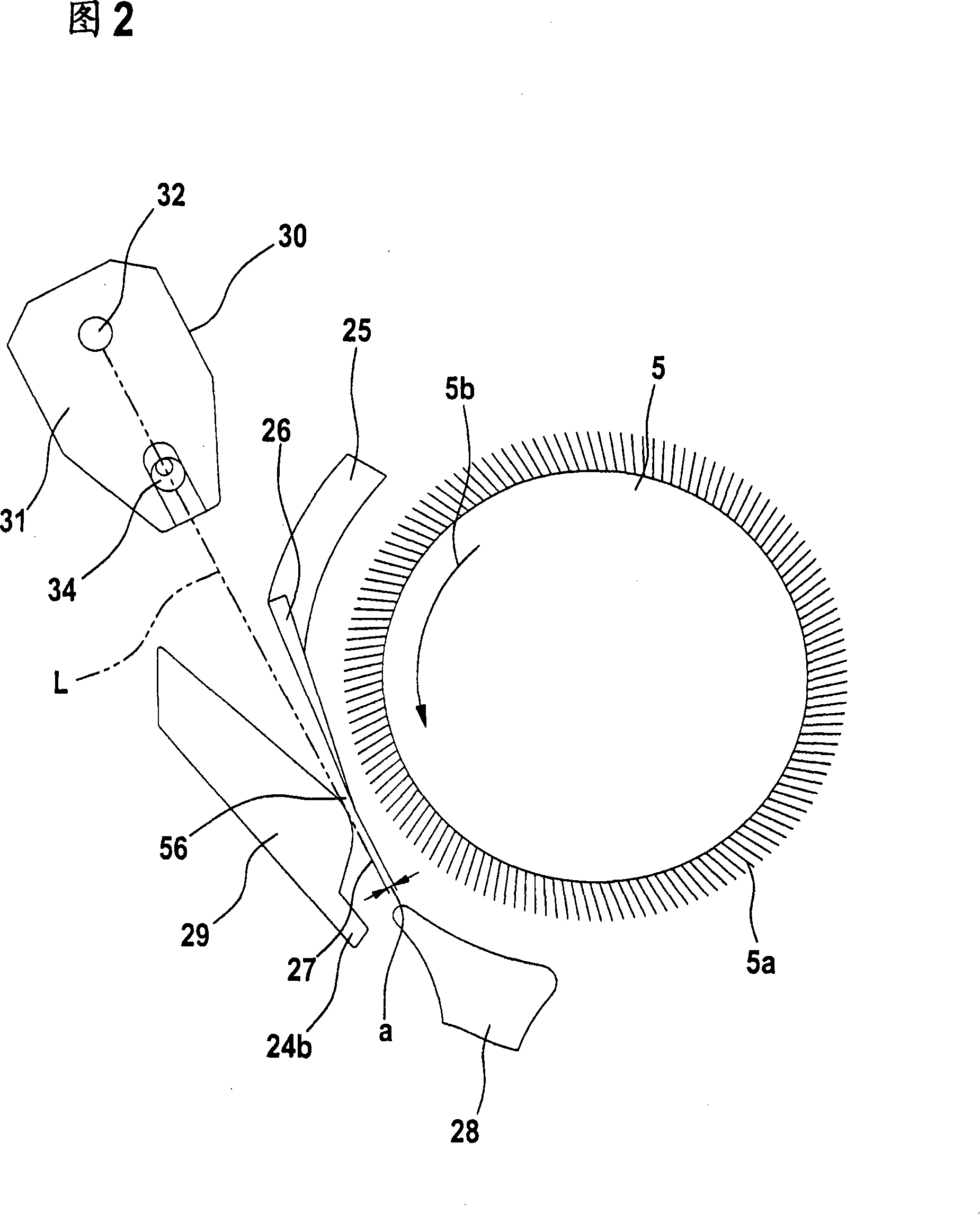

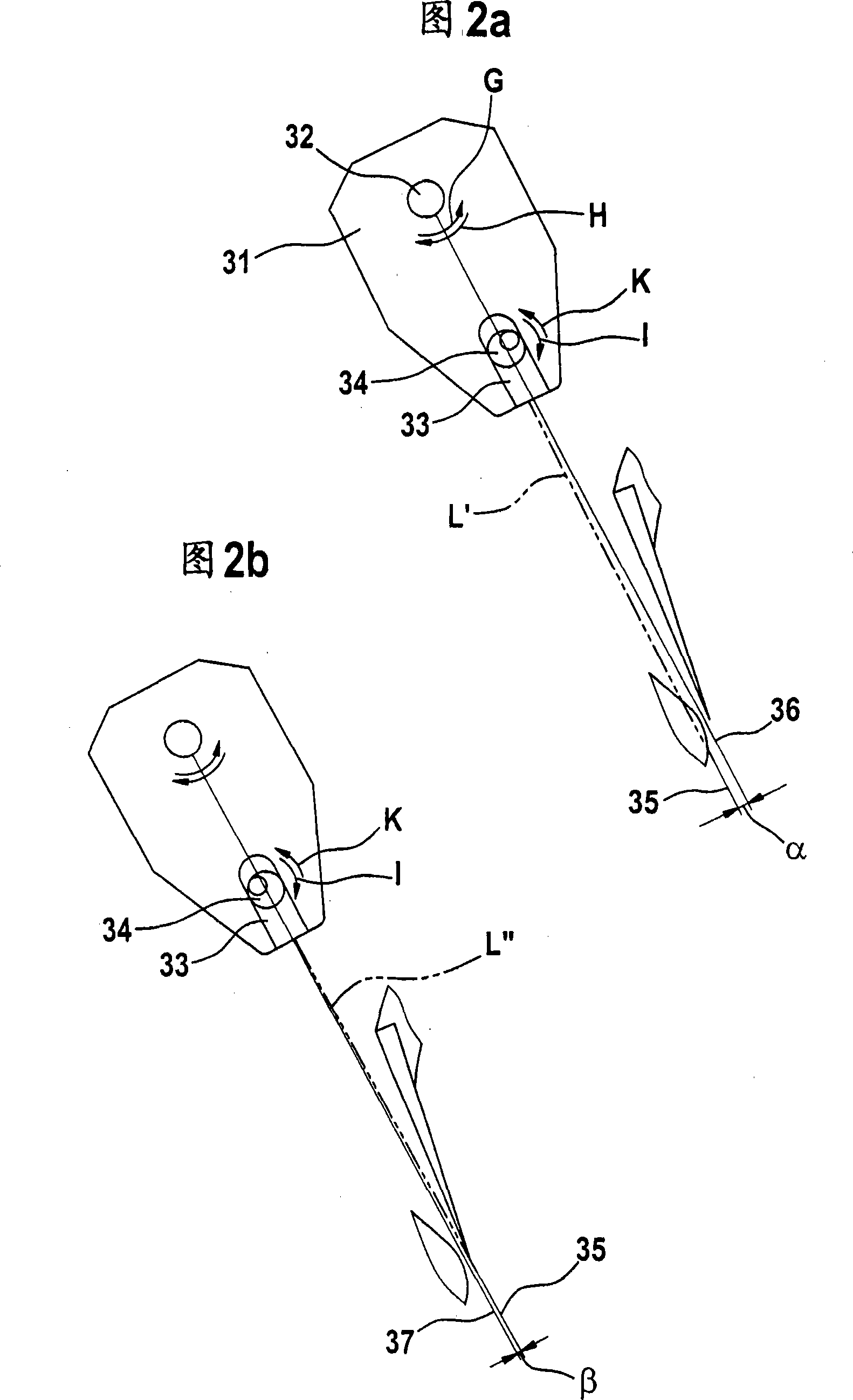

Device for preparation and opening of flock fibers to be supplied to a carder

InactiveUS6195841B1Mechanical impurity removalFibre cleaning/opening by toothed membersFiberEngineering

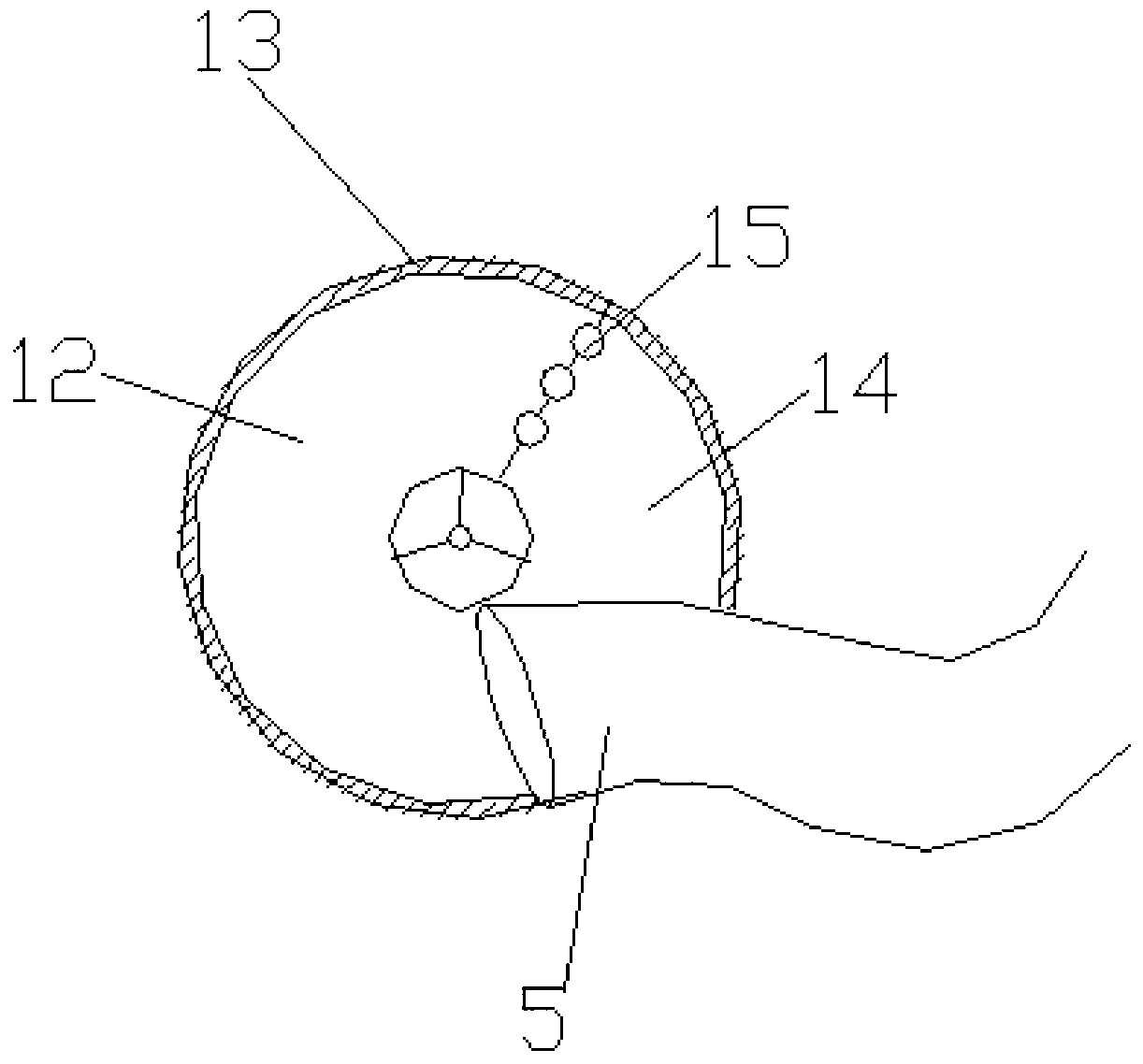

Silo for supply of flock fibers to a carder, which silo is subdivided into superimposed chambers, between which there is interposed a set of rollers which regulate the descending flow, and carry out breaking and separation of the fibrous material, in which a supply roller, an auxiliary supply roller and a breaker roller are disposed in a triangle, in which the surface of the auxiliary roller opposite that which is tangent to the supply roller is exposed to the flow of air which descends downwards, together with the fibers worked by the breaker roller.

Owner:MARZOLI

Production method of nonwoven fibrics

InactiveCN1657677AEvenly distributedImprove yieldFibre feedersNon-woven fabricsEngineeringNonwoven fabric

The invention relates to a productive method for non-woven fabrics, mainly for solving the problems including: unaverage fiber cotton falling in air permeable bellows of cotton feeding box in the producing device and complex structure of the productive device; there are mainly mechanical failure and narrow width of door of non-woven fabrics, and the quality is not average. The invention places an adjustable exhaust fan on the airpermeable lateral surface in the air permeable bellows in the cotton feeding box of non-woven fabrics producing device, and places a nozzle in the fiber average distributer, solving the problem, can be applied in the industrial production of non-woven fabrics.

Owner:CHINA PETROLEUM & CHEM CORP +1

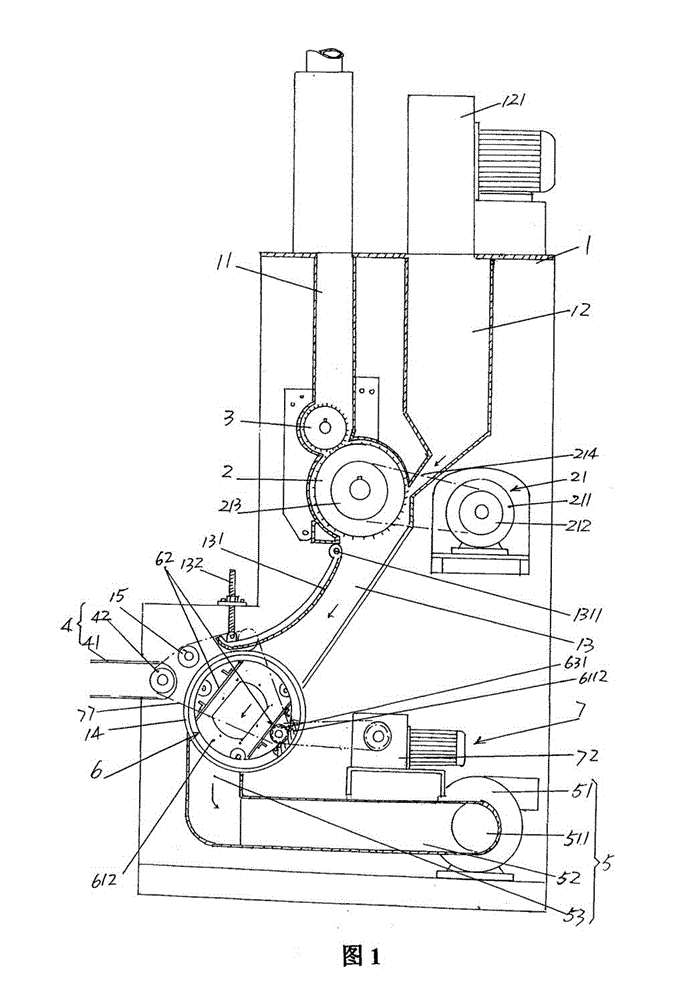

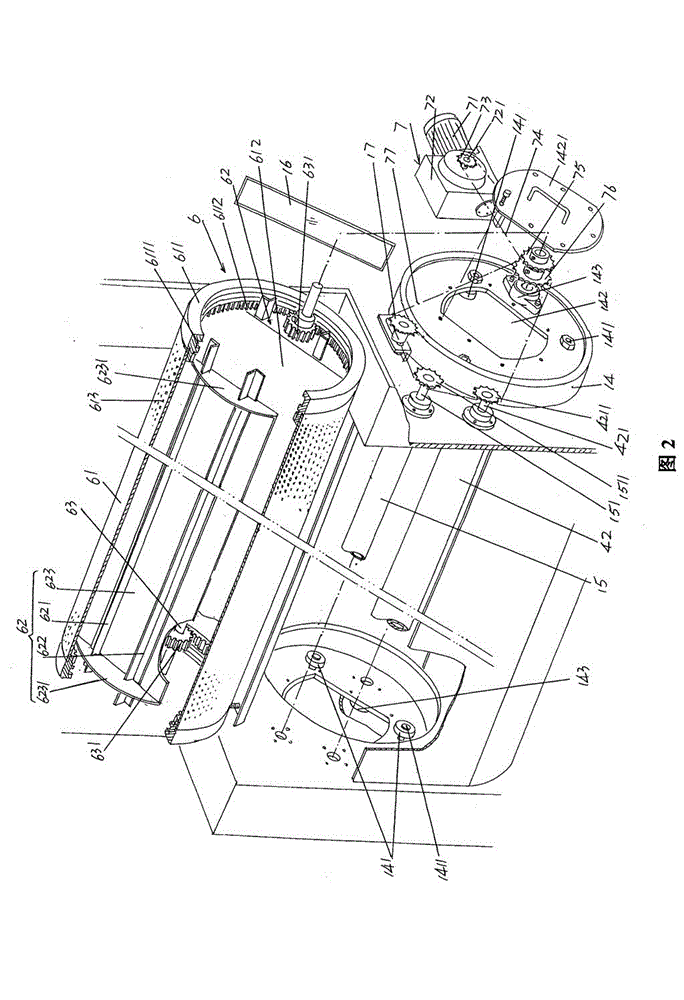

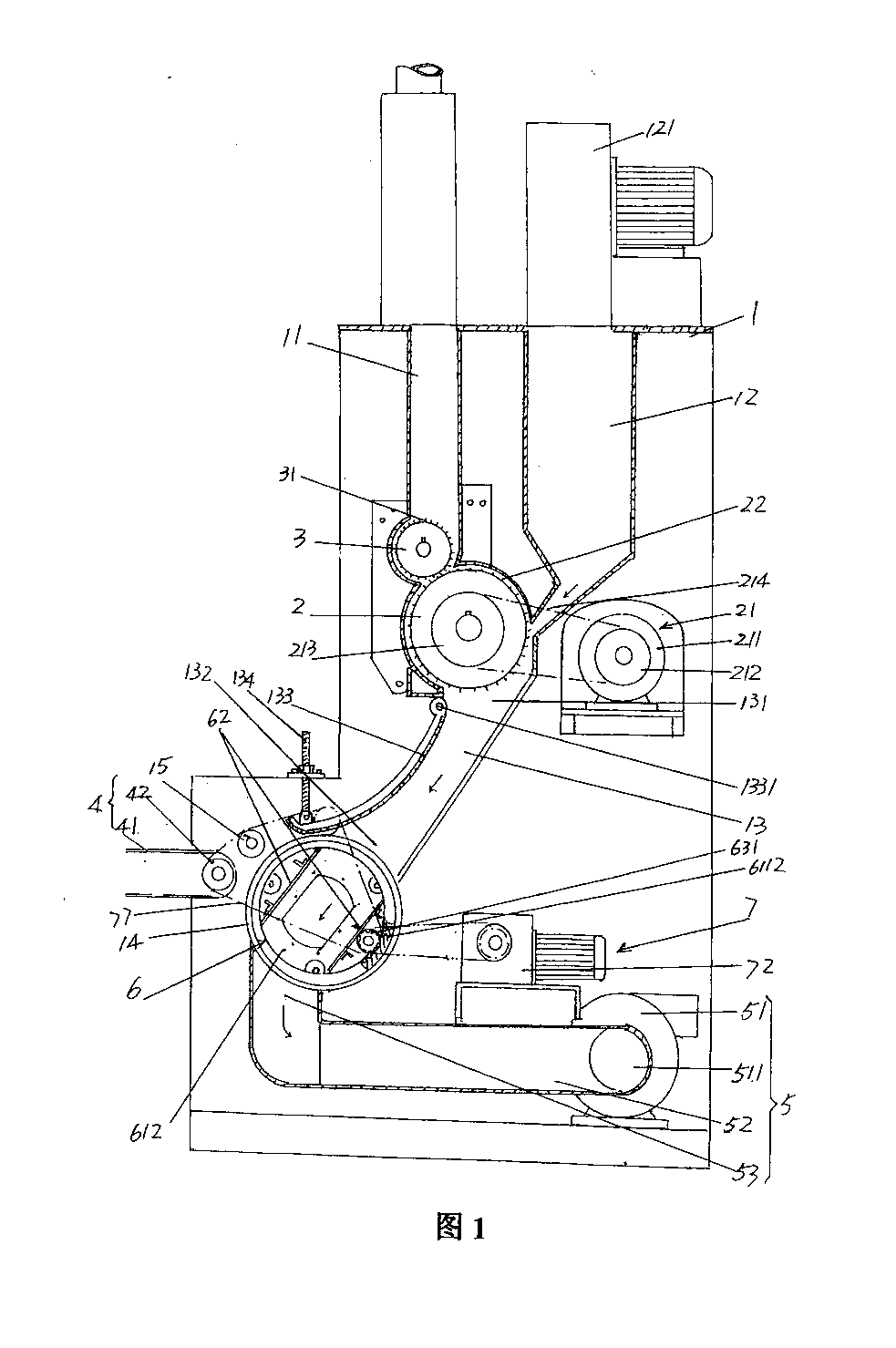

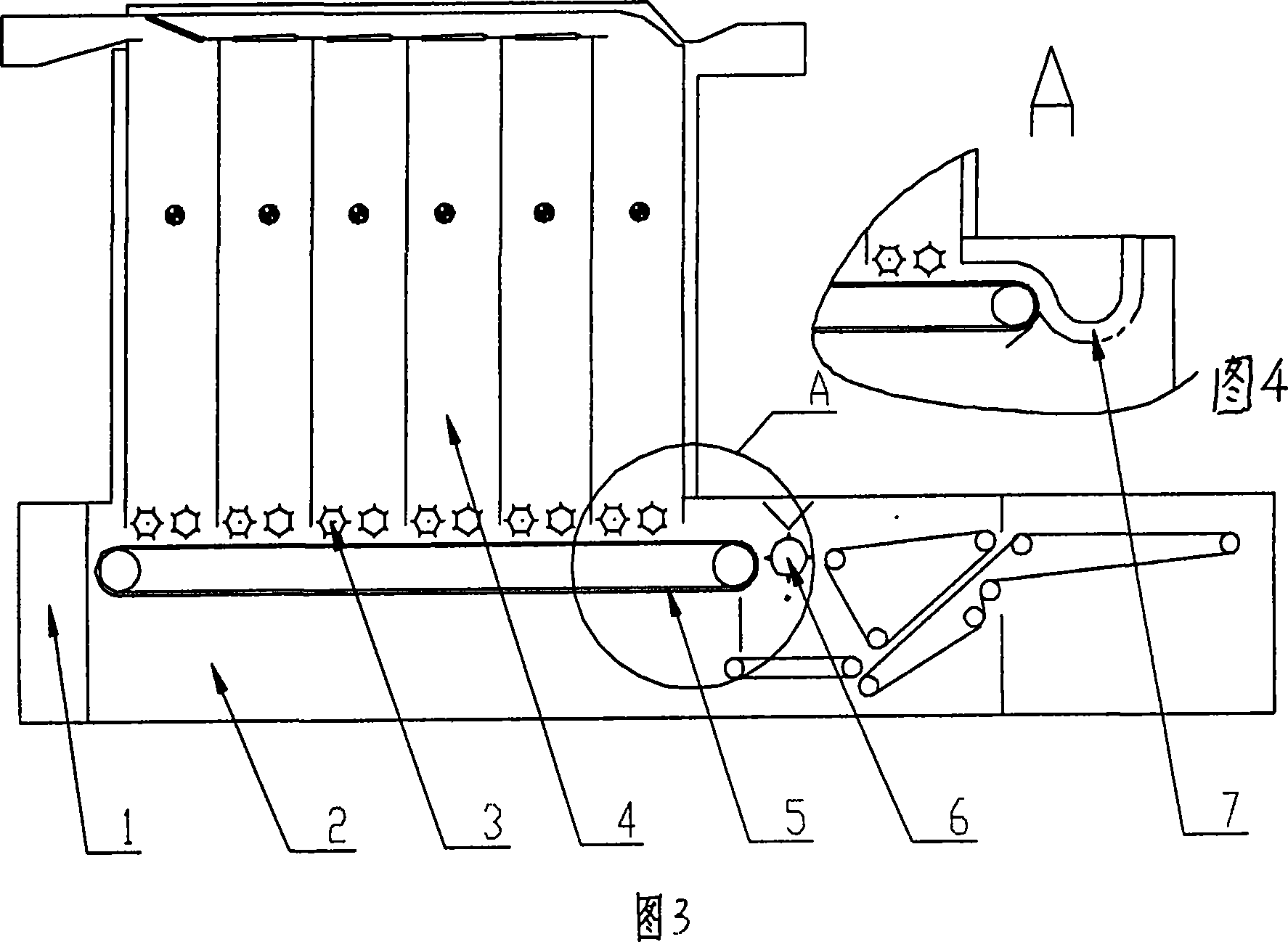

Air flow net forming machine

ActiveCN102373516BUniform weightReduce output resistanceFibre feedersTextile fiberStructural engineering

The invention relates to an air flow net forming machine, which belongs to the technical field of textile machinery and comprises a machine frame, a large pin roll, a small pin roll, an output curtain and a draft mechanism, wherein the machine frame is provided with a cotton mixing box, an air inlet box and a cotton inlet passage, the large pin roll and the small pin roll are arranged on the machine frame, the output curtain is matched and arranged on the machine frame, and the draft mechanism is arranged at the bottom of the machine frame. The air flow net forming machine is characterized byalso comprising a dust cage and a dust cage driving mechanism, wherein the dust cage is arranged on the machine frame and corresponds to a position under the cotton inlet passage, the dust cage driving mechanism is arranged at the lower part of the machine frame and is in transmission connection with the dust cage, the output curtain corresponds to the side part in the length direction of the dust cage, and the draft mechanism corresponds to the bottom in the length direction of the dust cage. The air flow net forming machine has the advantages that the side draft in the prior art is changed into bottom air draft, so the non-woven fiber cotton layer reaching the output curtain is more uniform to ensure the uniformity of the gram weight of the non-woven products. Because of the adoption ofthe bottom draft, the output resistance of a cotton net can be reduced, the net forming speed is favorably accelerated, and in addition, a blockage phenomenon of the non-woven fiber cotton in the cotton output passage can be avoided.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

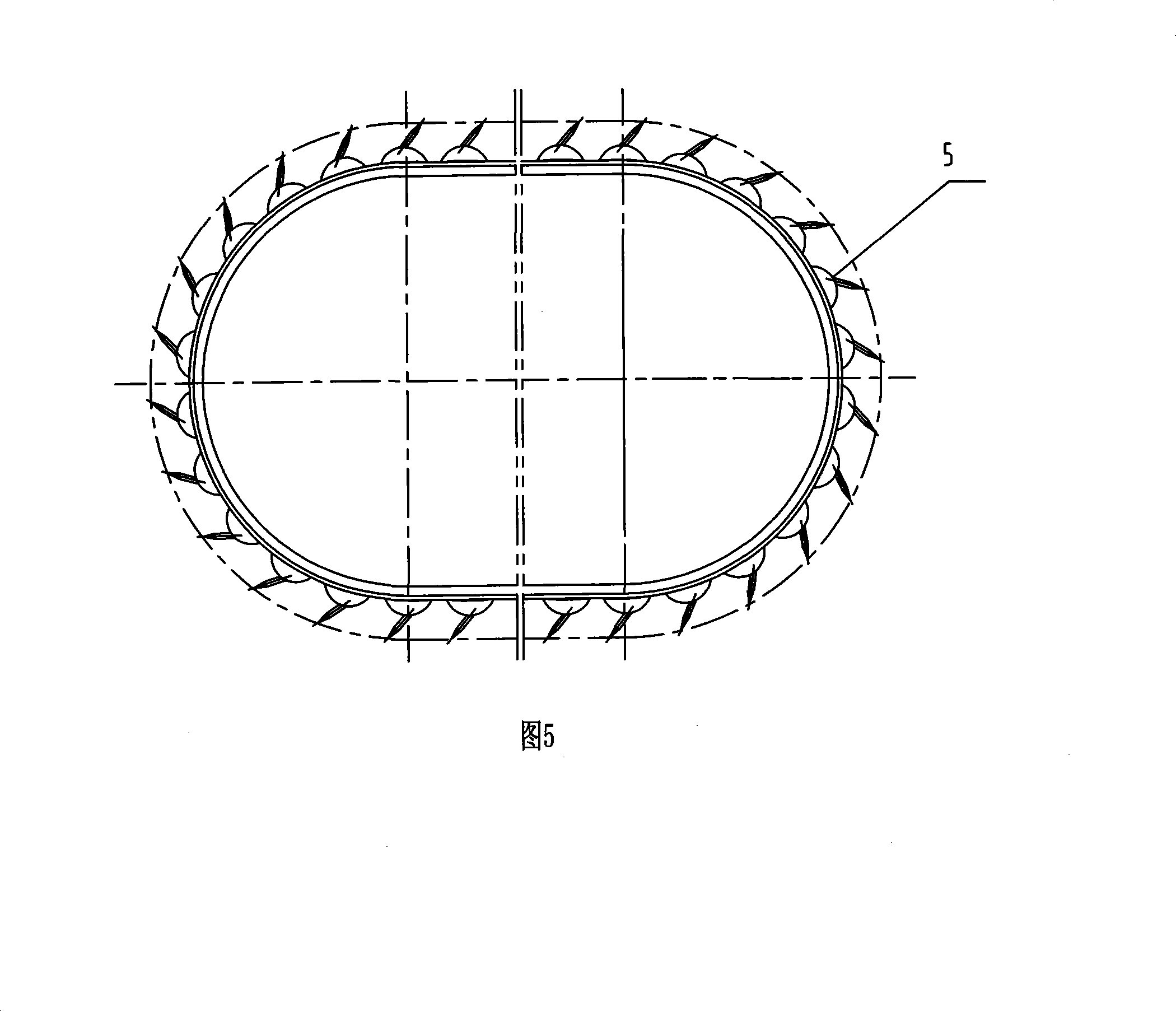

Net forming mechanism of gas flow type net forming machine

The invention relates to a net forming mechanism of a gas flow type net forming machine, belonging to the technical field of non-weaving machinery. The gas flow type net forming machine comprises a frame, large and small taker-in rollers, a cotton net output mechanism and an air draft mechanism, wherein the frame is provided with a cotton blending box, an inlet duct and a cotton inflow channel. The net forming mechanism comprises a dust cage device and a dust cage driving device, wherein the dust cage device comprises a dust cage drum body, a pair of air channel partition mechanisms and a gear shaft; air suction holes are distributed on the dust cage drum body, dust cage rings are fixed at two ends of the dust cage drum body, roller wheel grooves are opened on the inner walls of the dust cage rings so as to form gear rings, gears are fixed at two ends of the gear shaft, and the gears are meshed with the gear rings; and the dust cage driving device is arranged on the frame; the cotton net output mechanism corresponds to one side of the dust cage drum body; and the air draft mechanism corresponds to the bottom of the dust cage drum body. The net forming mechanism has the advantages that nonwoven fiber cotton is conveyed to the cotton net output mechanism at a uniform thickness; and the net forming speed is increased, the stagnation of the nonwoven fiber in the cotton inflow channel is avoided and the interference of the air draft mechanism on the cotton net output mechanism is not generated.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

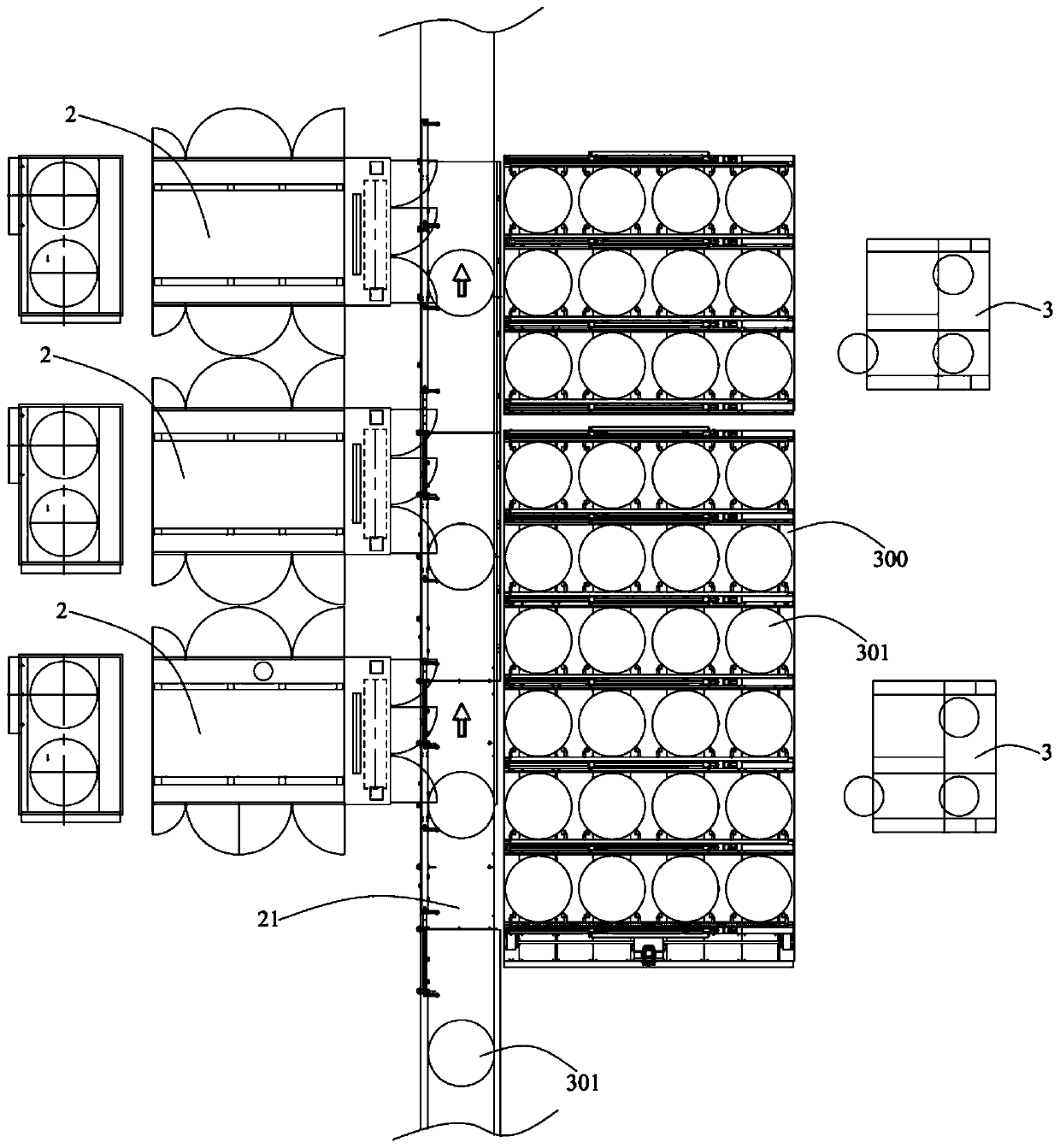

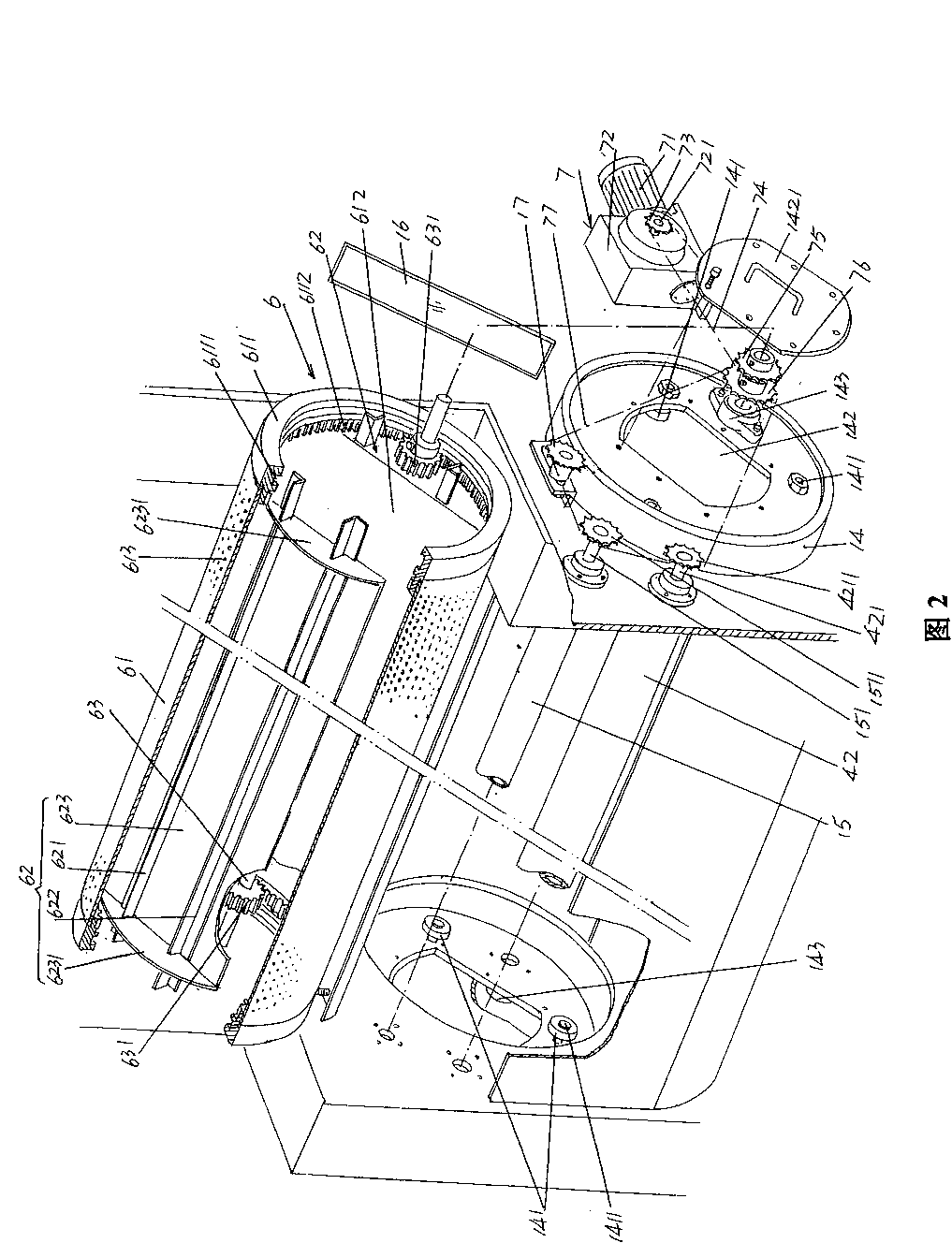

Mixing output mechanism adapted for multi-column cotton mixer

ActiveCN101168870AResolve damaged fibersSolve process problemsFibre mixingFibre feedersFiberState of art

The invention relates to a mixed output mechanism suitable for a multi-bin mixer, which comprises a plurality of mixing bins (4) and an input roller (3) arranged at a cotton outlet opening under each mixing bin. The invention is characterized in that a horizontal grabbing spike lattice (5) is arranged under the cotton outlet opening of the mixing bin (4), and a cotton stripping device is arranged at the mixing output end of the horizontal grabbing spike lattice (5). Because the invention adopts the horizontal grabbing spike lattice under the cotton outlet opening of the mixing bin to replace a beater roller to operate the fiber opening and replace a blending channel to be used for the output of the cotton blending, thereby effectively solving the process defaults of damaging fiber and being easy to produce cotton neps, etc. existing in the prior art.

Owner:ZHENGZHOU HONGDA NEW TEXTILE MACHINERY +1

Apparatus in spinning preparation for separating foreign objects at conveying equipment for fibre material

InactiveCN101230505AEasy to integrateEasy to assembleSafety devices for fibre treatmentCarding machinesWaste materialForeign body

In an apparatus in spinning preparation for separating foreign objects at conveying equipment for fibre material, at least one separation device is associated with the conveying equipment. The separation device comprises an arrangement for producing a blast of air that flows in the direction onto the conveying equipment and generates an air flow that detaches the foreign objects from the conveyed fibres and carries them away. The arrangement comprises a plurality of blast nozzles arranged across the width of the conveying equipment and connected to a compressed air pipe and to valves. To reduce the proportion of good fibres in the waste in a simple manner, and to allow a more selective action of the blast air current, a bar member for mounting the blast nozzles is present and the nozzles are integrated in the bar member.

Owner:TRUETZSCHLER GMBH & CO KG

Cashmere carding combination machine

InactiveCN101205644AFibre cleaning and opening machine combinationsContinuous processingAssembly linePulp and paper industry

The invention is a cashmere separating joint machine which relates to a textile mechanical device used for cashmere carding process. The cashmere separating joint machine is composed of feeders, refining machines and carding machines. The invention is characterized in that: the cashmere separating joint machine adopts an sequential arrangement of a feeder, an open refining machine, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a carding machine and a carding machine, which are all combined in a way of assembly line. A blanking recovery hopper is arranged under each feeder, a blanking outlet is arranged at a feed port of each feeder, and a delivery device is arranged between the blanking recovery hopper and the blanking outlet. Each carding machine is provided with a blanking collecting hopper which allows the recovered crushed materials to be delivered to a blanking port to be feed into a feeder again. The cashmere separating joint machine is high in separating efficiency, suitable for large amount separation, applicable to various sorts of cashmere, low in damage to cashmere, and high in cashmere utilization rate.

Owner:孙贤功

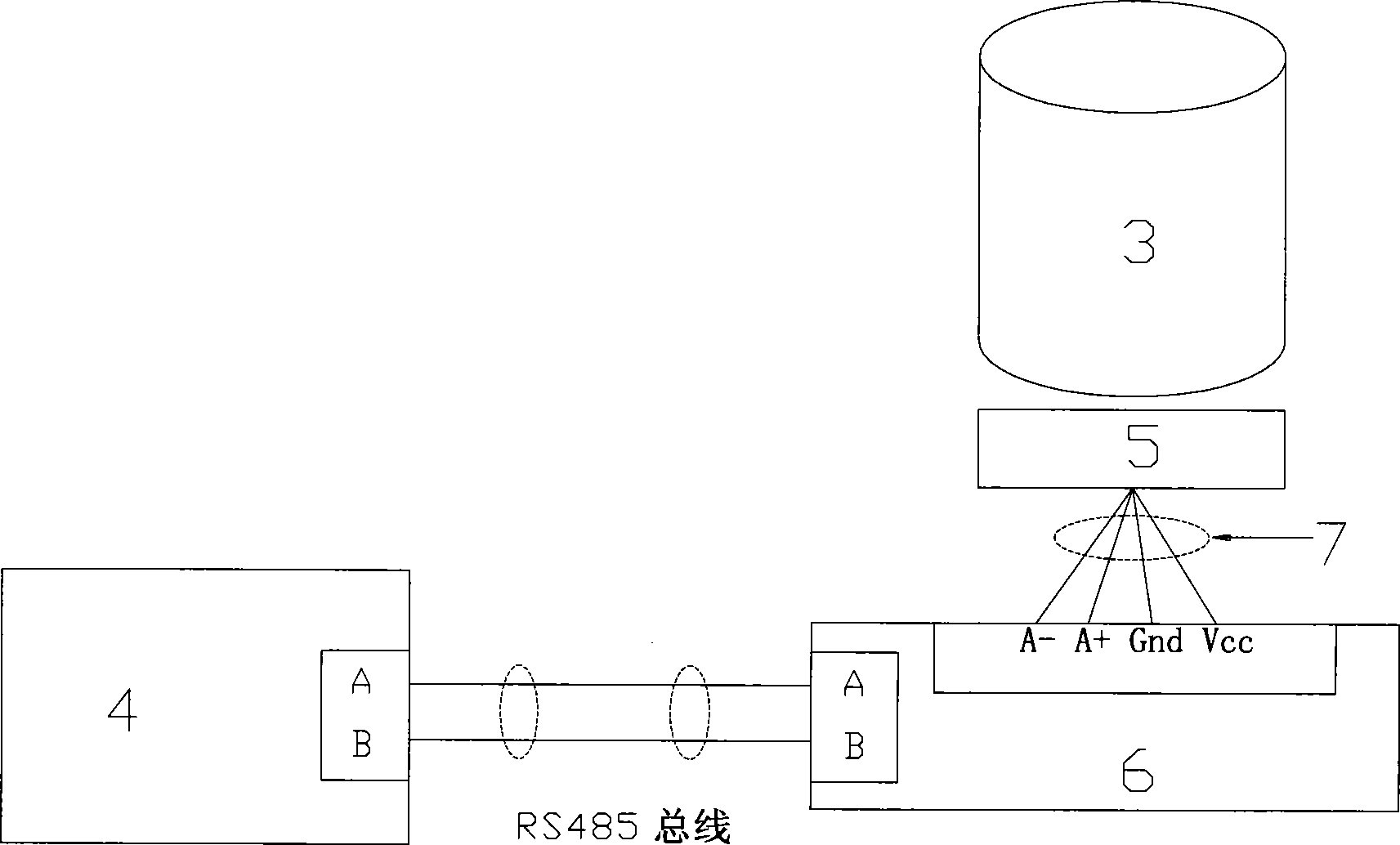

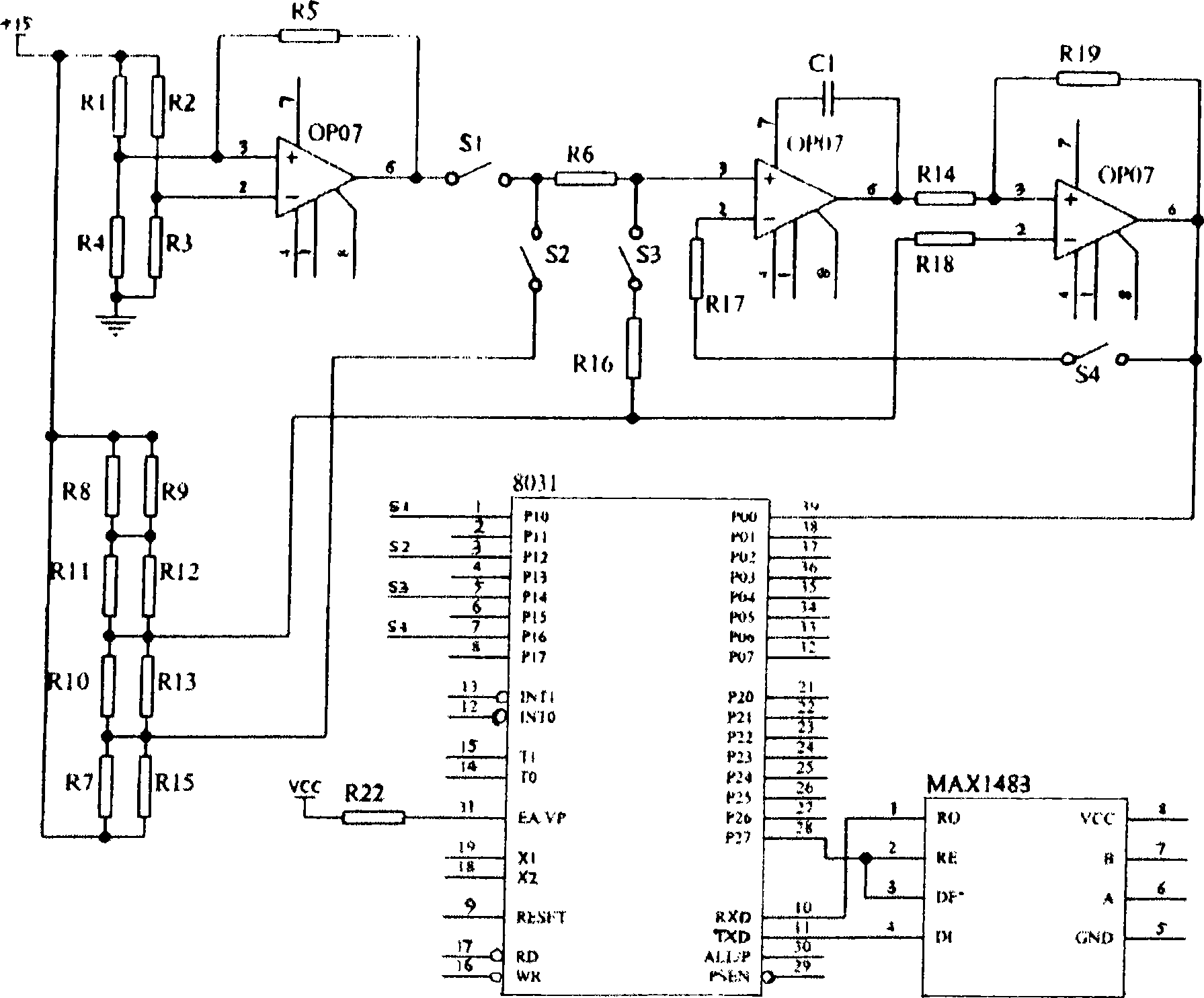

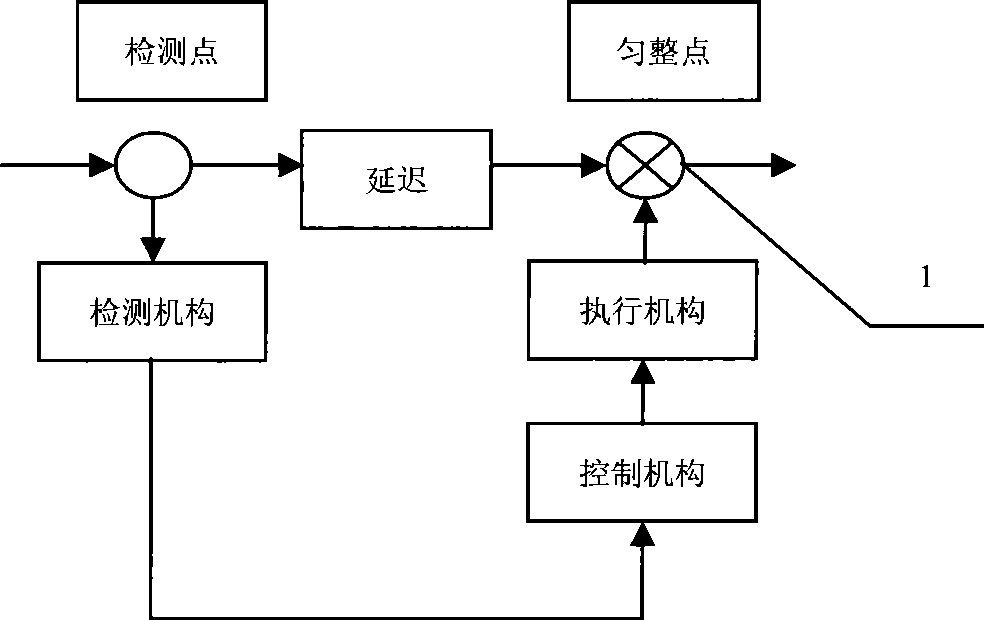

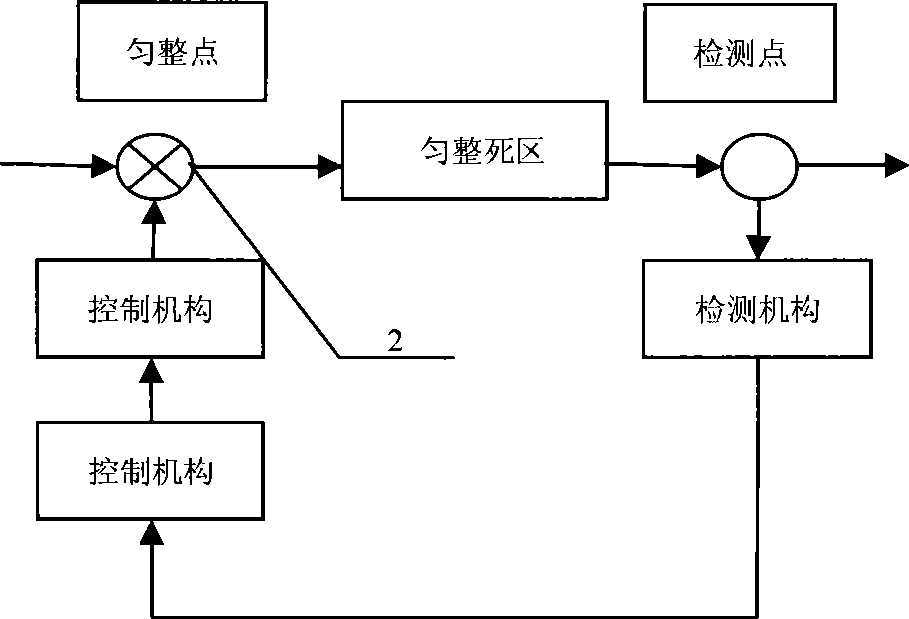

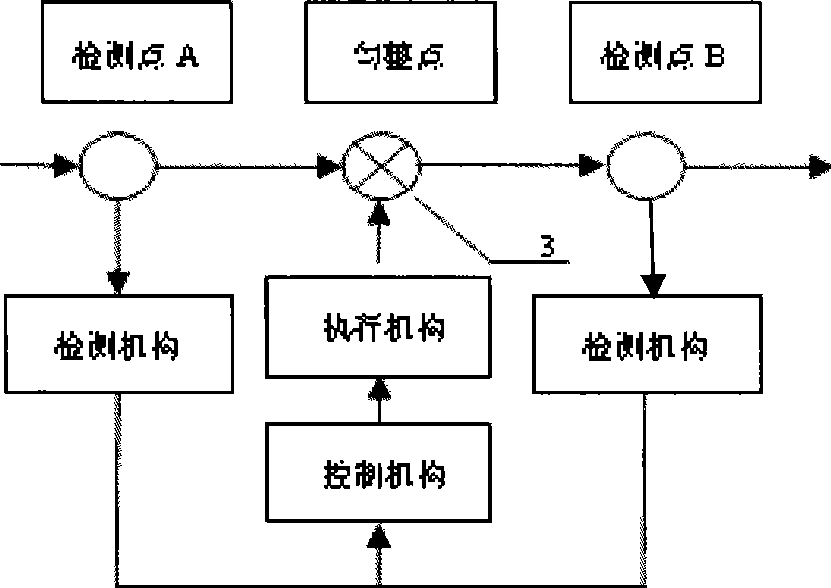

Double-open ring control device and method applied to self-regulating technology

InactiveCN101509159AGuaranteed uniformityQuality assuranceSafety devices for fibre treatmentCarding machinesEngineeringConnection control

The invention provides a dual opening ring control device and a method which are applied to self-adjusting regulating technology. The device of the invention comprises a rear roller, a group of middle rollers are arranged in front of the rear roller, a front roller is arranged in front of the middle rollers, a first detecting mechanism is arranged behind the rear roller, the rear roller and the front roller are respectively connected with a first executing mechanism and a second executing mechanism, a second detecting mechanism is arranged among the middle rollers, the output ends of the first detecting mechanism and the second detecting mechanism are connected with the input end of a control mechanism, and the output end of the control mechanism is connected with the input ends of the first executing mechanism and the second executing mechanism respectively. The method comprises the following steps: cotton strips firstly pass through the rear roller and the middle rollers to finish ring opening regulating for the first time, and then pass through the middle rollers and the front roller to finish ring opening regulating for the second time. The advantages of the invention are: the invention is particularly suitable for strip combining machines, and eliminates the problems existing in the original system such as blind area, dead area as well as advanced or postponed regulating.

Owner:DONGHUA UNIV

Net forming mechanism of gas flow type net forming machine

The invention relates to a net forming mechanism of a gas flow type net forming machine, belonging to the technical field of non-weaving machinery. The gas flow type net forming machine comprises a frame, large and small taker-in rollers, a cotton net output mechanism and an air draft mechanism, wherein the frame is provided with a cotton blending box, an inlet duct and a cotton inflow channel. The net forming mechanism comprises a dust cage device and a dust cage driving device, wherein the dust cage device comprises a dust cage drum body, a pair of air channel partition mechanisms and a gear shaft; air suction holes are distributed on the dust cage drum body, dust cage rings are fixed at two ends of the dust cage drum body, roller wheel grooves are opened on the inner walls of the dust cage rings so as to form gear rings, gears are fixed at two ends of the gear shaft, and the gears are meshed with the gear rings; and the dust cage driving device is arranged on the frame; the cotton net output mechanism corresponds to one side of the dust cage drum body; and the air draft mechanism corresponds to the bottom of the dust cage drum body. The net forming mechanism has the advantages that nonwoven fiber cotton is conveyed to the cotton net output mechanism at a uniform thickness; and the net forming speed is increased, the stagnation of the nonwoven fiber in the cotton inflow channel is avoided and the interference of the air draft mechanism on the cotton net output mechanism is not generated.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

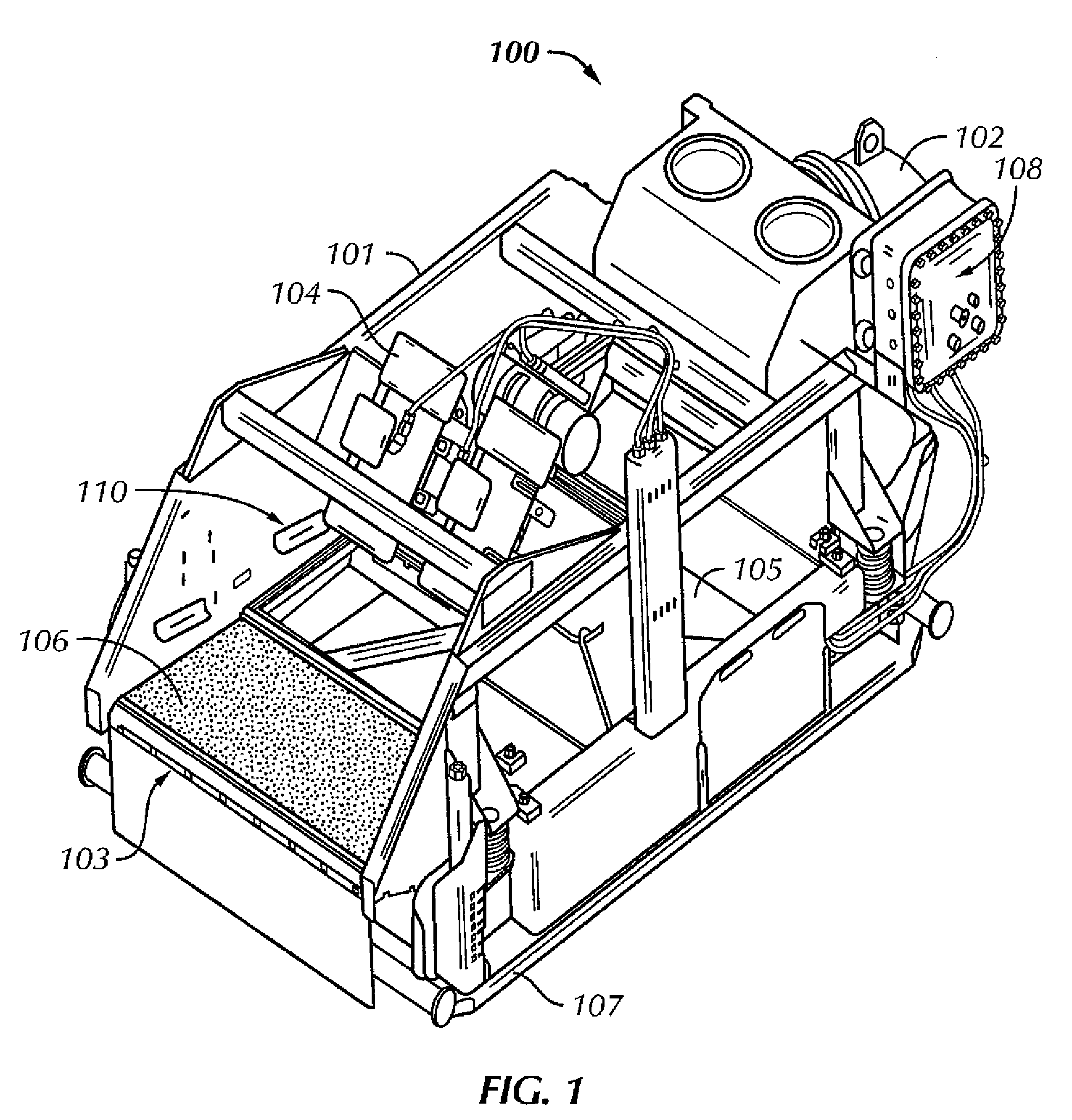

Self-cleaning shaker

A vibratory separator including a housing having a drilling material inlet and at least one basket, at least one screen assembly configured to be disposed in the at least one basket, an actuator connected to the at least one basket, wherein the actuator provides vibratory motion to the at least one basket, a sump configured to receive drilling material that passes through the at least one screen assembly, and at least one spray nozzle for cleaning the vibratory separator is disclosed. A method for cleaning a vibratory separator including providing instructions to a programmable logic controller to activate at least one spray nozzle disposed on the vibratory separator is also disclosed. A method of retrofitting a vibratory separator including installing at least one spray nozzle in a vibratory separator, installing a programmable logic controller on the vibratory separator, and providing instructions to the programmable logic controller to activate at least one spray nozzle disposed on the vibratory separator is disclosed.

Owner:MI

Apparatus on a flat card or roller card for setting the working spacing between the cylinder and at least one neighbouring roller

ActiveCN101942714AConstant roller spacingLight in massCarding machinesFibre feedersThermal energyFiber

Apparatus on a flat card or roller card for setting the working spacing between a clothed cylinder and at least one clothed neighbouring roller, for example doffer and / or licker-in, the cylinder and at least one roller cooperates with each other via the small spacing (working spacing) between their cylindrical surfaces at a fiber transition point, can, as a result of size change due to heat expansion and / or centrifugal force, reset the working spacing to a predetermined value and provides an adjustment device used for adjacent rollers, the adjustment device is operable via supply of thermal energy. In order that, during the change of roller size, a predetermined spacing between adjacent rollers is set in a simple mode and in a shorter interval, a device used for actively supplying and / or dissipating thermal energy is provides, and the device used for actively supplying and / or dissipating thermal energy is connected with the adjustment device, wherein, during the change of roller size, the working space between the cylinder and at least one roller can be set or reset.

Owner:TRUETZSCHLER GRP SE

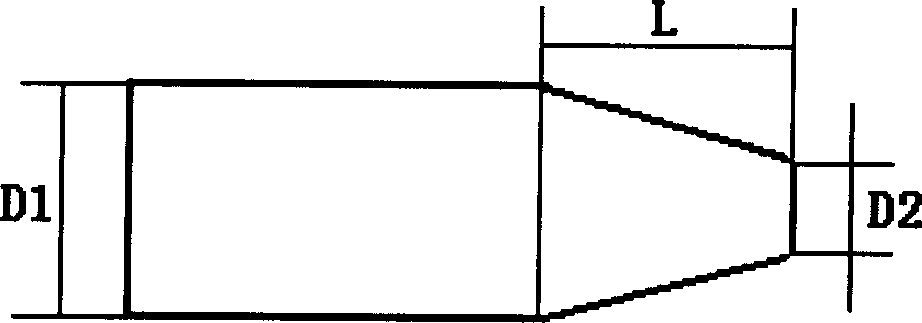

Dust cage type air flow web forming machine

InactiveCN102358966AImprove raw material suitabilityImprove machine performanceFibre feedersNon-woven fabricsFiberDrive shaft

The invention provides a dust cage type air flow web forming machine, relating to production equipment of non-woven fabrics. The dust cage type air flow web forming machine comprises a frame, wherein a Venturi pipe with a small-top large-bottom section shape is connected in the frame; a cylinder and an air inlet are arranged at the upper end of the Venturi pipe; one side of the cylinder is provided with an input curtain; a pair of rollers are arranged between the input curtain and the cylinder; a dust cage and a cotton pressing roller are arranged at the lower end of the Venturi pipe; one side of the dust cage is provided with an air suction pipe; and the output side of the dust cage is provided with an output curtain. The dust cage type air flow web forming machine also comprises a layering prevention device, wherein the layering prevention device comprises a transmission shaft which is arranged laterally; the transmission shaft is arranged in the Venturi pipe; the periphery of the transmission shaft in the Venturi pipe is connected with blades; two ends of the transmission shaft are separately supported on the frame through a bearing and a bearing seat; and one end of the transmission shaft is connected with a transmission device. By using the dust cage type air flow web forming machine, the layering problem in the web forming process by mixing different properties of fibers is solved, and the raw material adaptability and machine performance of the dust cage type web forming machine are improved, thus the dust cage type air flow web forming machine has important practical significance in production of thick and heavy non-woven felt and mat products.

Owner:JIANGSU YIZHENG HAIRUN TEXTILES MACHINERY

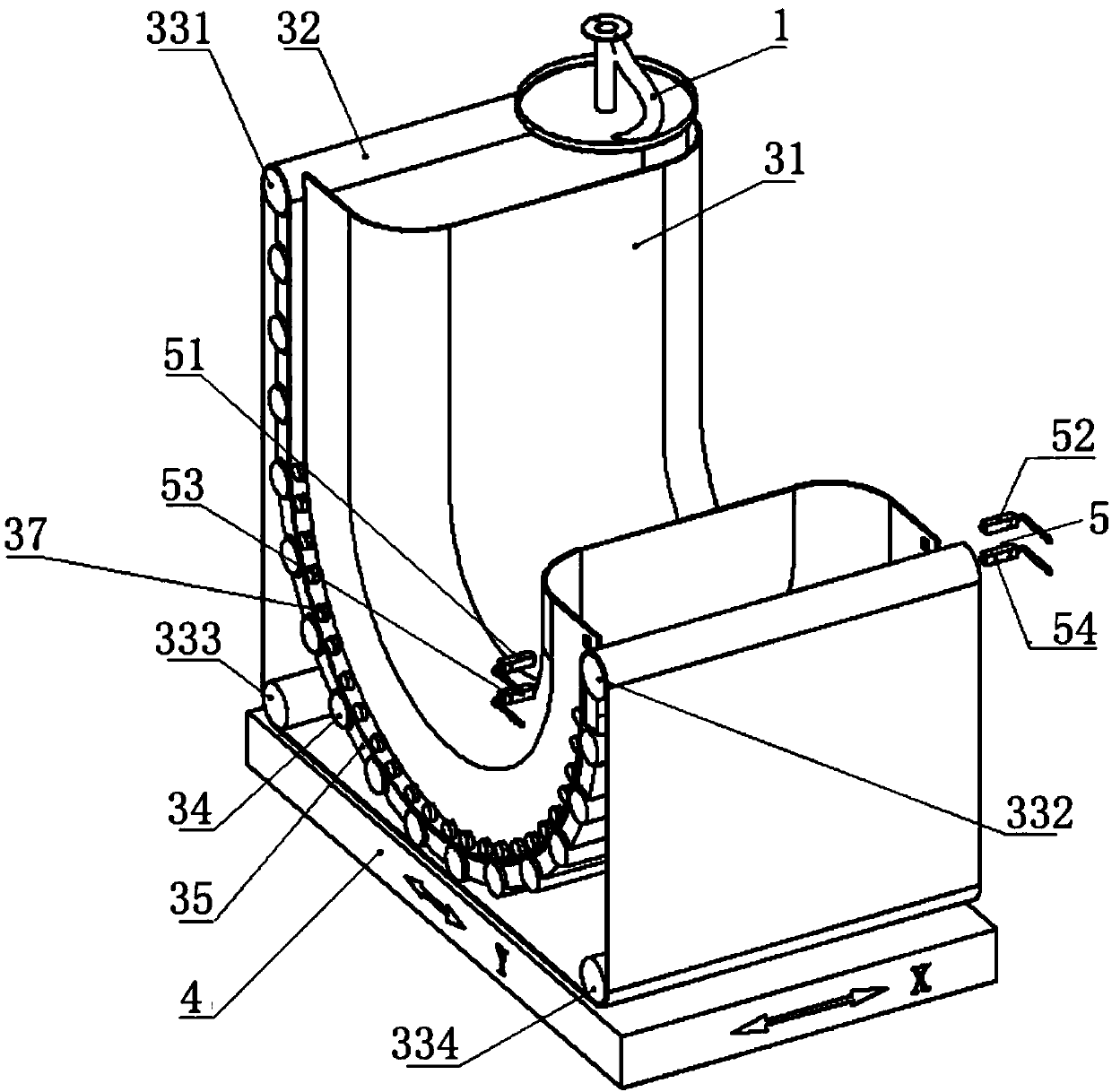

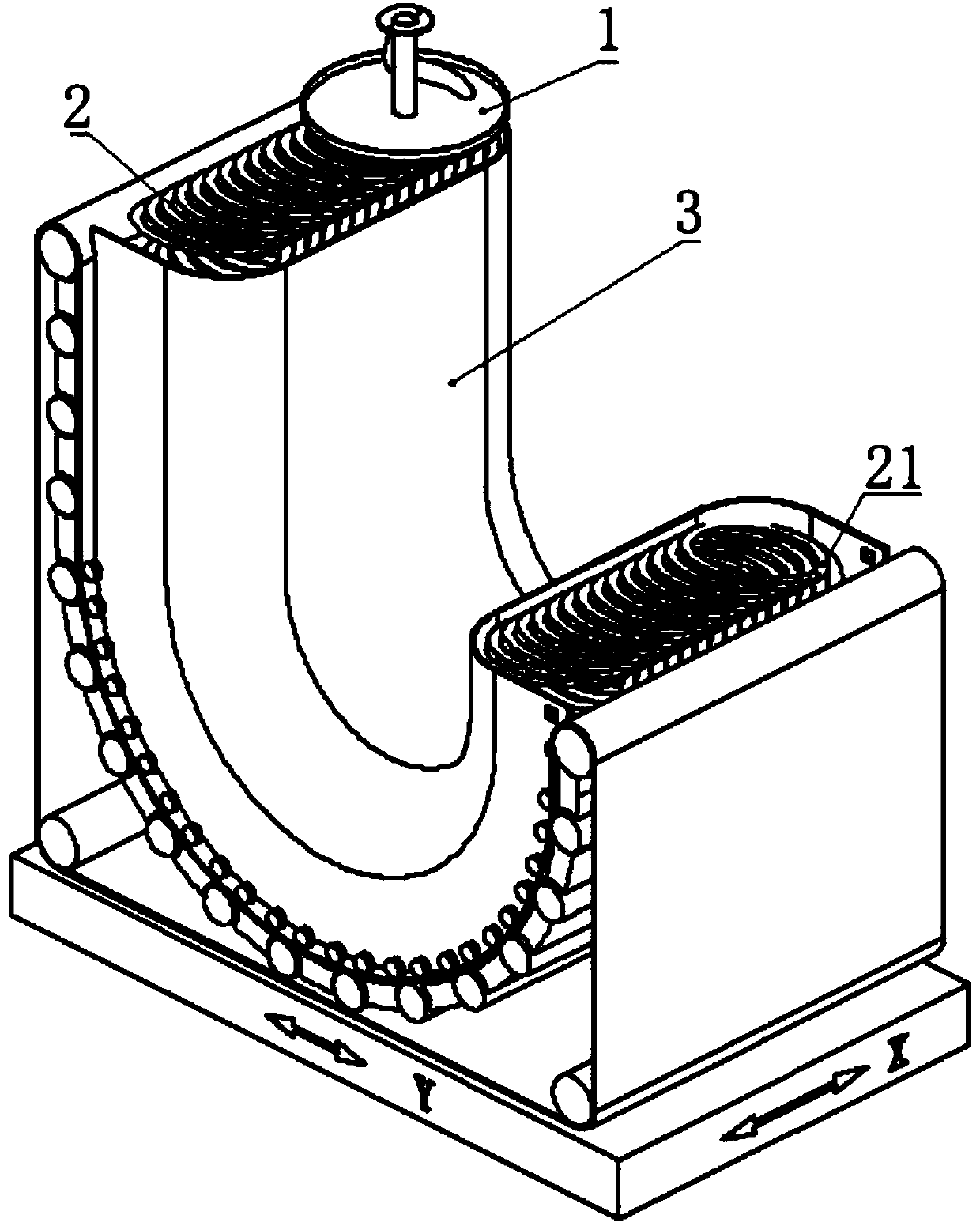

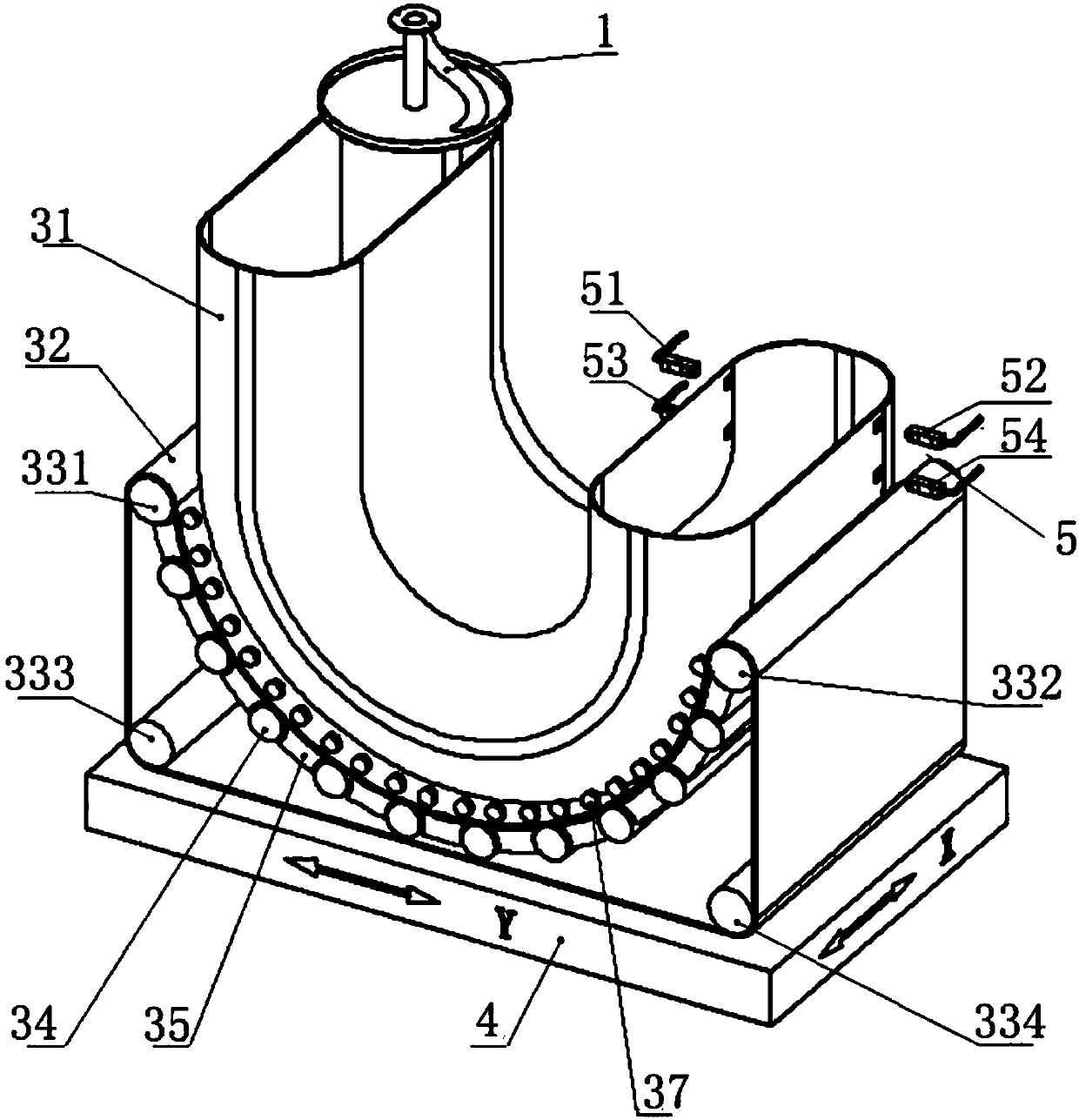

Non-slide fiber strip storage device with U-shaped bottom part

The invention provides a non-slide fiber strip storage device with U-shaped bottom part. The non-slide fiber strip storage device comprises a fiber strip storage device, a mounting base, storage quantity sensors, a transmission device and a support device, wherein the longitudinal cross section of the fiber strip storage device is in an U shape; the transmission device is arranged on the mountingbase; the storage quantity sensors are arranged at the tail end of the fiber strip storage device; the transmission device is provided with a conveying belt and main support rolls of the conveying belt; the main support rolls of the conveying belt are arranged at both ends of the support device, the shape of the support device is matched with the shape of the bottom surface of the fiber strip storage device, and the support device passes through the lowest point of the bottom surface of the fiber strip storage device; the part, passing through the support device, of the conveying belt forms amovable bottom surface for the fiber strip storage device; a rotary strip circling device is arranged above an inlet of the fiber strip storage device, and is rotationally arranged on a fixed machineframe.

Owner:JINGWEI TEXTILE MASCH CO LTD

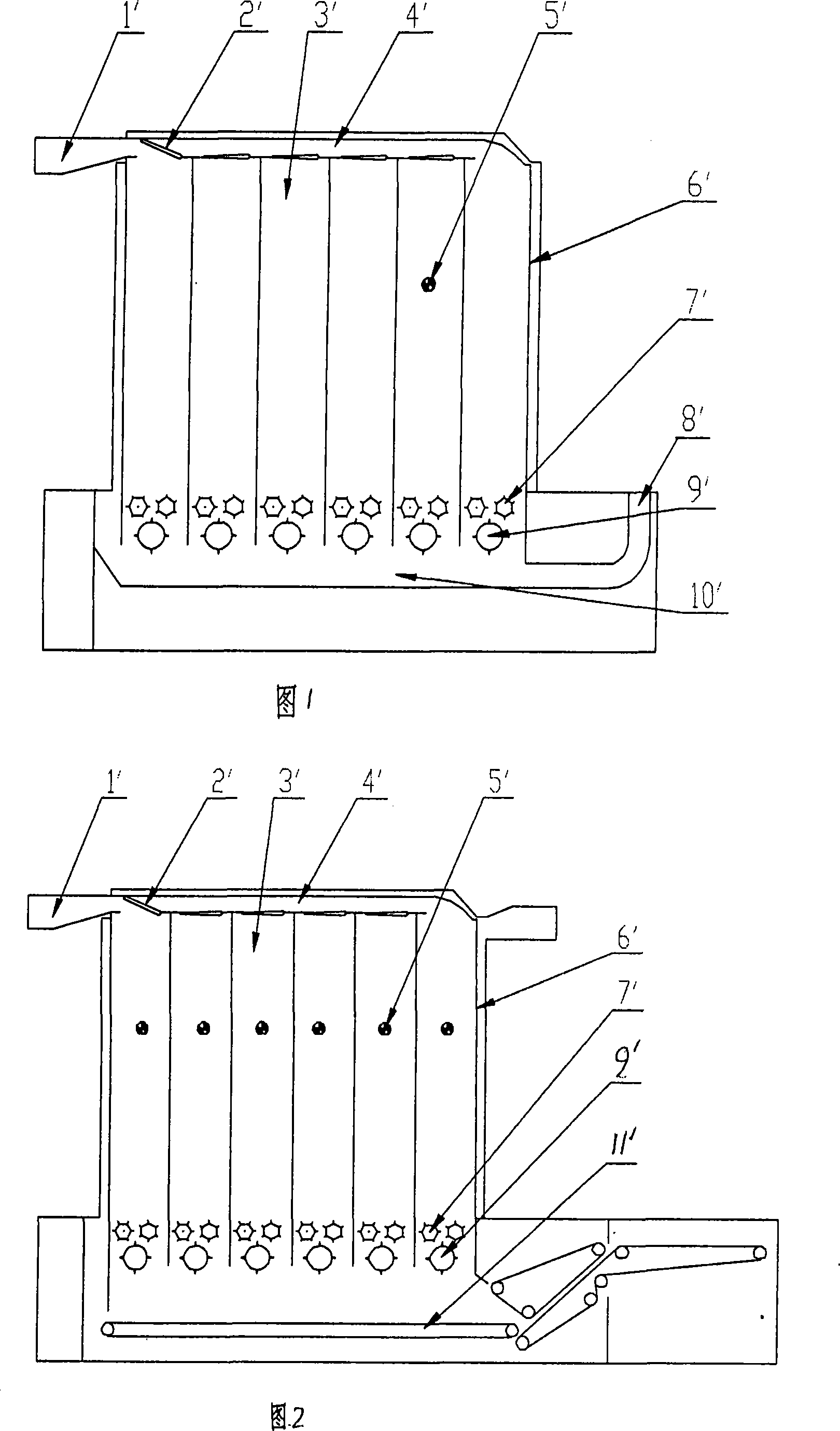

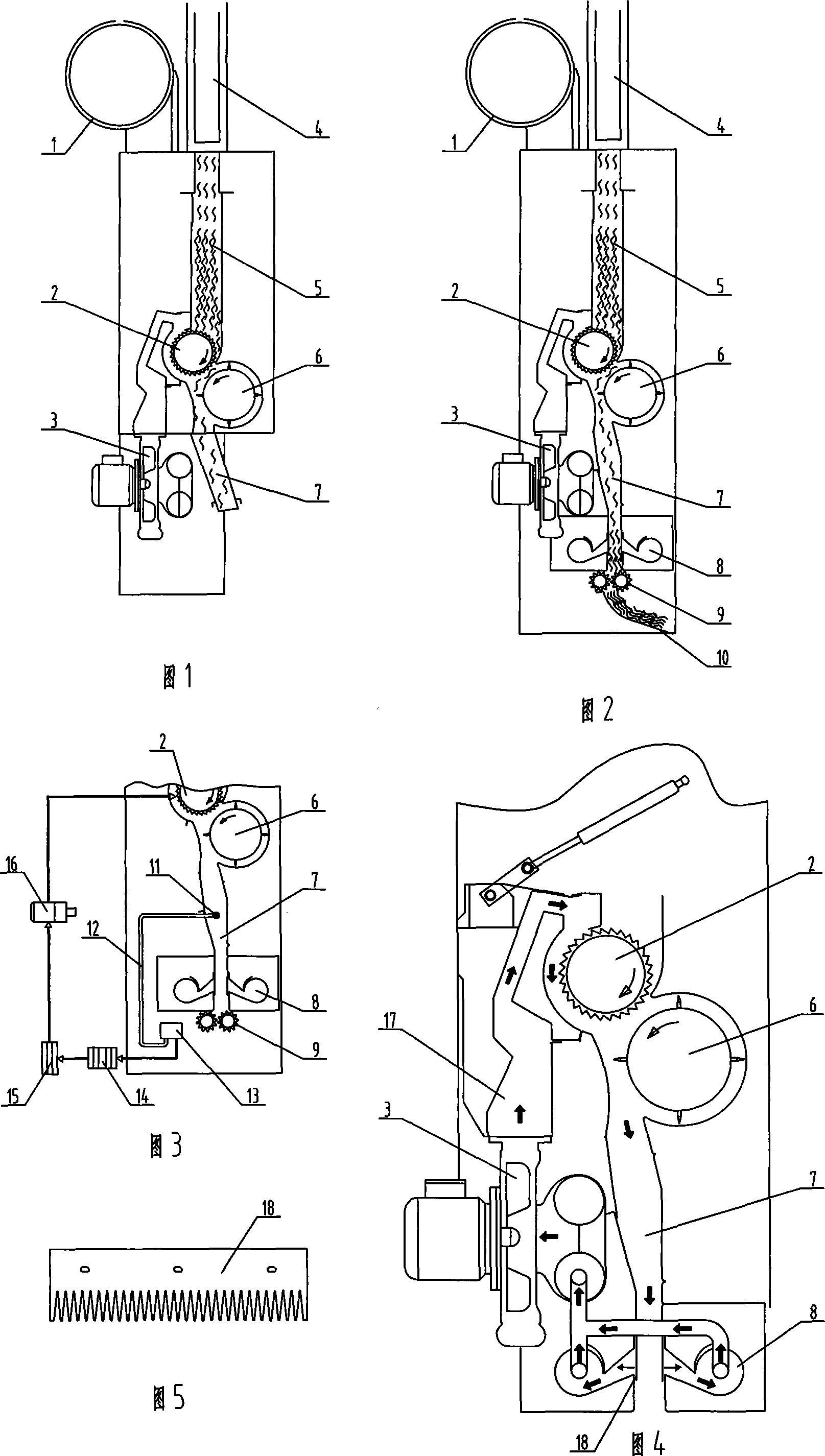

Cotton feed box adapted for blowing-carding process

InactiveCN101177805AUniform, continuous and stable deliveryTo achieve the use ofFibre cleaning/opening machinesFibre feedersEngineeringCommunicating cavity

The invention relates to a chute feeder applicable to blowing-carding process, which comprises a chute feeder body, a dust exhaust pipeline (1) arranged above the chute feeder body and communicated with the inner cavity of the chute feeder through a pipeline, a cotton feeding pipeline (4) arranged above the chute feeder body, an upper cotton path (5) arranged inside the chute feeder body, the upper nozzle of which is communicated with the lower nozzle of the cotton feeding pipeline and the lower nozzle of which is communicated with a lower cotton path (7), and a feed roller (2) and an opening and scotching beater (6) which are arranged inside a communicating cavity which is arranged between the upper cotton path (5) and the lower cotton path (7). A pair of air return boxes (8) is arranged at the two sides at the lower end of the lower cotton path (7) and a pair of delivery rollers (9) is arranged at the delivery orifice of the lower cotton path (7); a cotton shedding plate (10) is arranged below the delivery rollers (9). The air return inlets where two air return boxes (8) are communicated with the lower cotton path (7) are respectively provided with shade boards (18); the inner cavities of two air return boxes (8) are respectively communicated with an air inlet of an air circulator (3) through a pipeline.

Owner:CHTC HEAVY IND +1

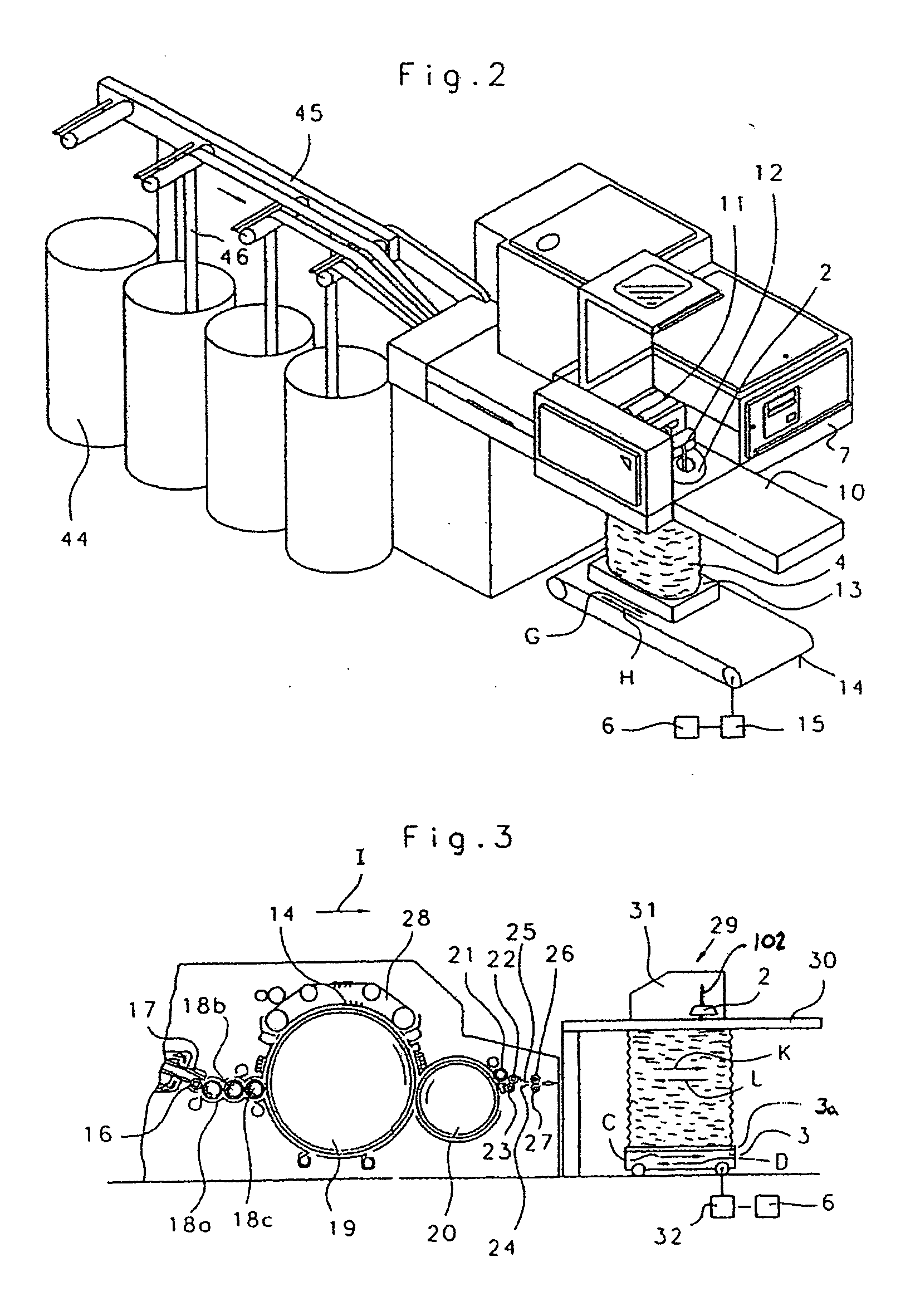

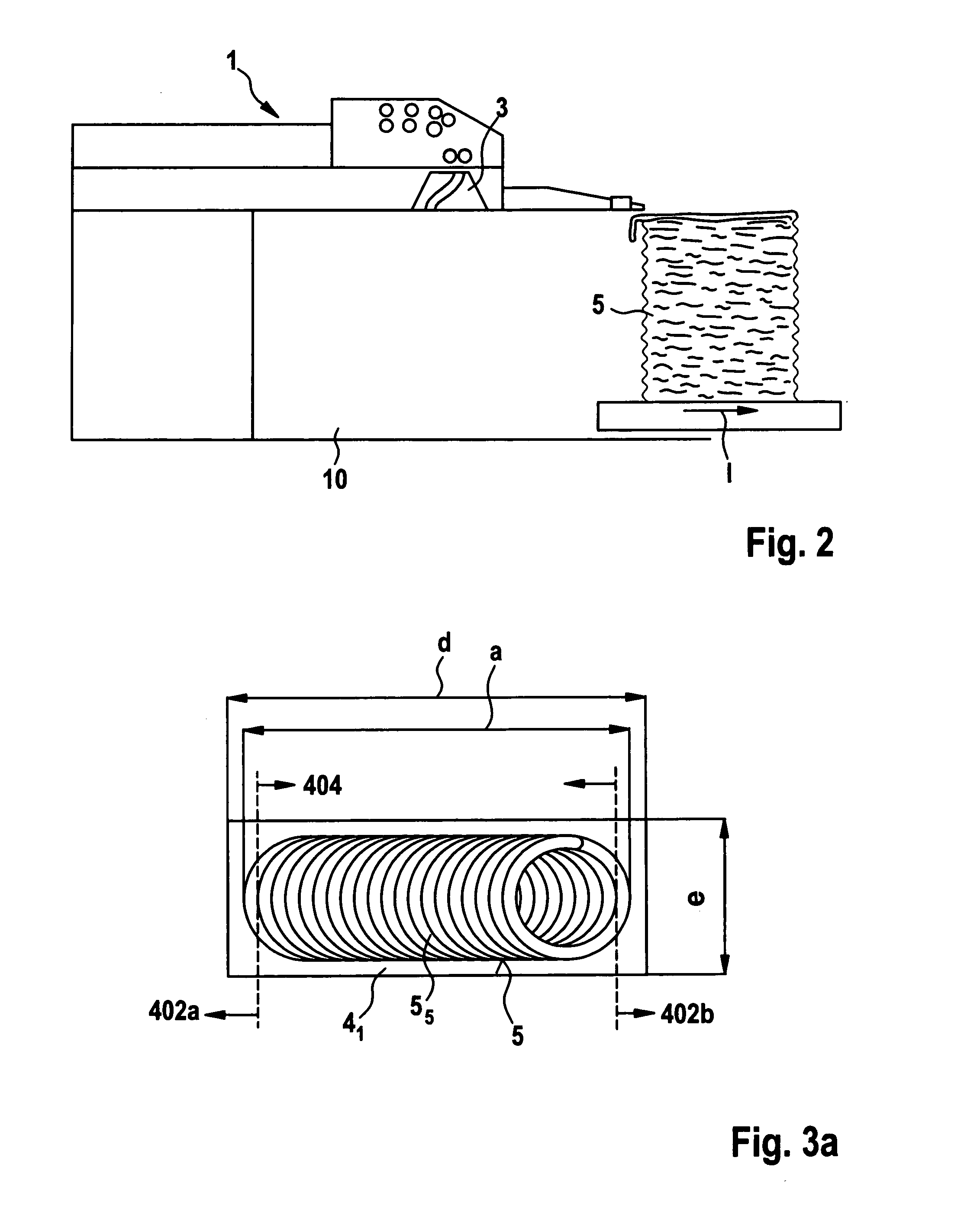

Supply device for delivering individualized separating fibres or fibre bundles to transport device

ActiveCN103572511AMeasuring the amount of materialWood working apparatusFibre feedersFiberEngineering

The feed device for supplying individualized fibers or fiber flocks to a transport device, which serves to transport the formed fleece or fiber flock mat onward, includes a plurality of feed segments arranged horizontally next to each other and a plurality of individually actuatable feed rollers, wherein a separate feed roller is assigned to each feed segment. In addition, at least one driven opening cylinder, which cooperates with each feed roller, is also provided.

Owner:DILO MASCHF OSKAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com