Dust cage type air flow web forming machine

A technology of web forming machine and dust cage, which is applied in textiles and papermaking, fiber treatment, nonwovens, etc., can solve problems that affect product performance and quality, and production is meaningless, and achieve the effect of improving the suitability of raw materials and machine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

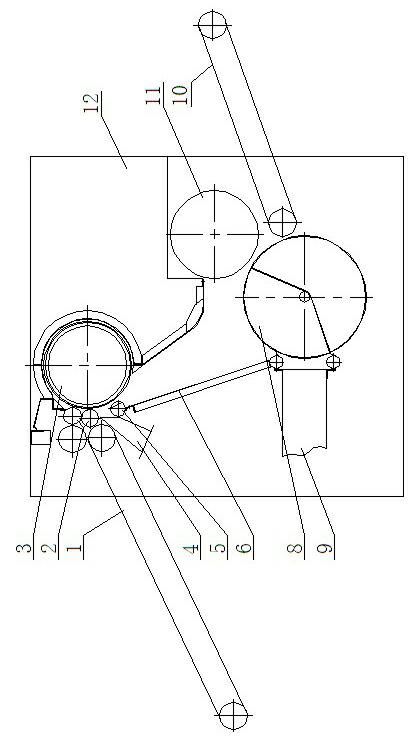

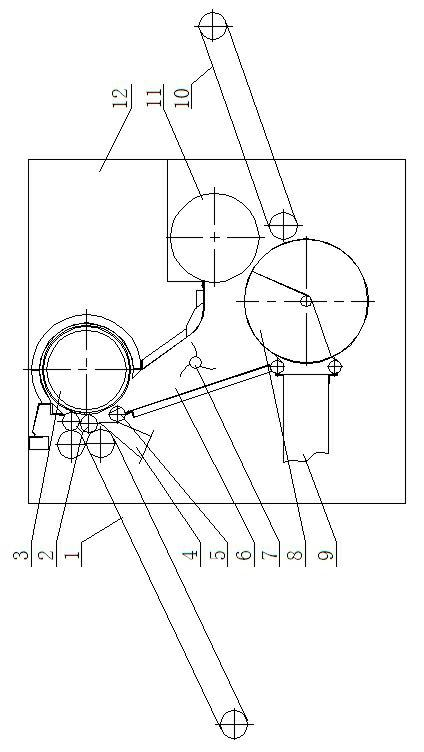

[0019] like figure 2 As shown, it is a dust cage type air-laid machine, including a frame 12, which is connected with a Venturi tube 6 with a small upper part and a larger lower part in the frame 12, and the upper end of the Venturi tube 6 is provided with a cylinder 3 and an air inlet 4 , one side of the cylinder 3 is provided with an input curtain 1, a pair of rollers 2 are arranged between the input curtain 1 and the cylinder 3, a pair of rollers 2 are arranged above the air inlet 4, and between the air inlet 4 and the Venturi tube 6 Guide roller 5 is arranged between. The lower end of the Venturi tube 6 is provided with a dust cage 8 and a cotton pressing roller 11 , one side surface of the dust cage 8 is in sealing contact with the suction duct 9 , and an output curtain 10 is provided on the output side of the dust cage 8 .

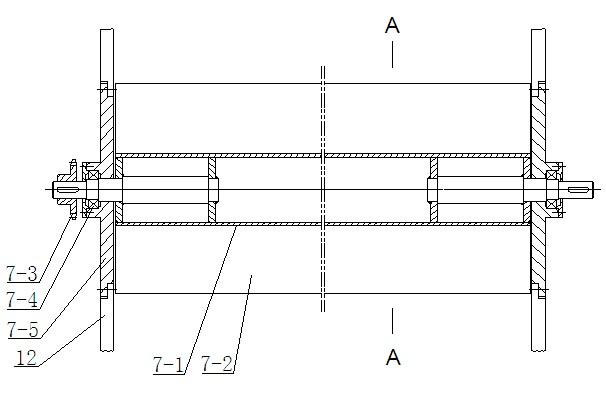

[0020] like figure 2 , 3 , 4, the dust cage airlaid machine also includes an anti-layer device 7, and the anti-layer device 7 is installed hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com