Method and device for combining carding, combing and drawing

A technology of sliver and process, which is applied in the field of carding or combing and drawing process combination and equipment, which can solve the problems of no joint production, achieve the effects of reducing labor, saving storage containers, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

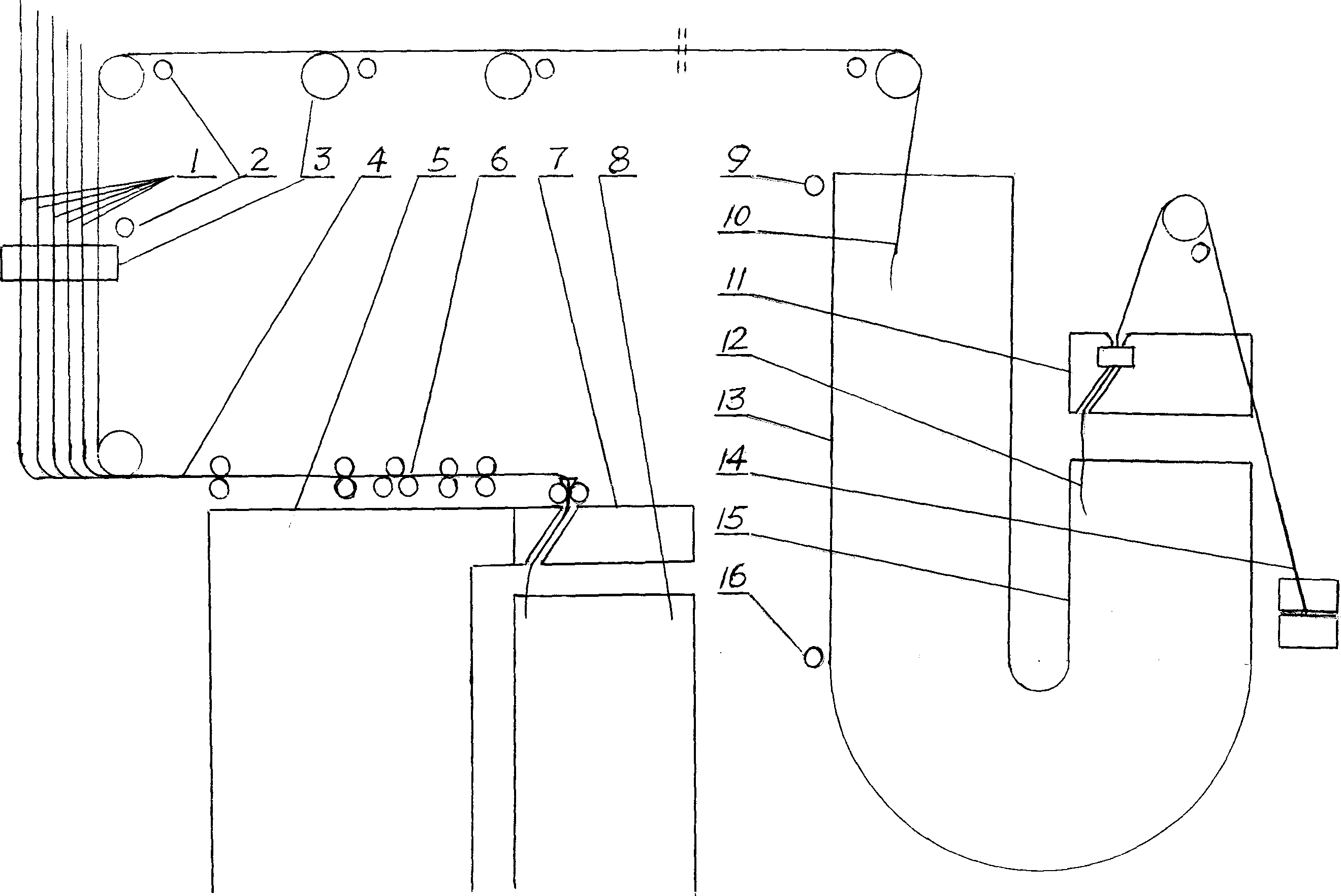

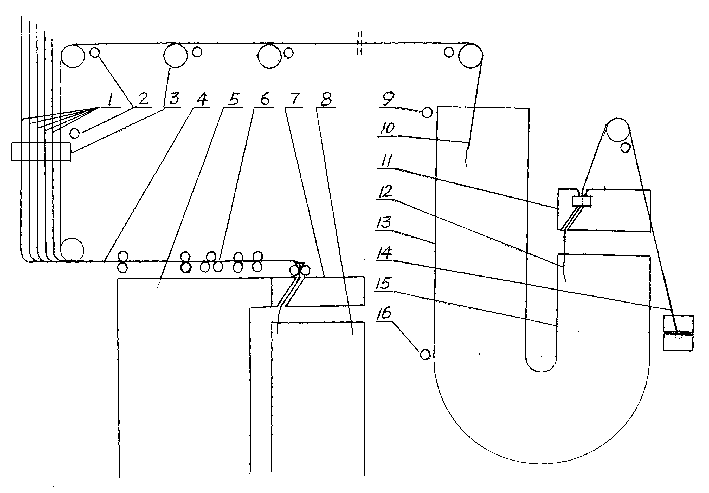

[0027] exist figure 1 In the process, after the sliver 14 output from the carding machine or combing machine is coiled into 12 by the forwardly placed planetary coiler 11, the coiled stack is placed in the "U" tubular stacked sliver turning and dynamic The inlet side 15 of the reservoir enters the outlet side 13 of the "U" tubular laminated sliver turning and the dynamic reservoir after turning 180 degrees in the "U"-shaped pipeline, and the head end 10 of the ring-shaped sliver can be changed from the dynamic The upper part of the storage is led out. The "U" tube-shaped laminated sliver diversion and dynamic reservoir is an asymmetrical "U"-shaped tube with the outlet side 13 higher than the inlet side 15 .

[0028] On the periphery of the dynamic storage 13, a storage upper limit monitor 9 and a lower limit monitor 16 are installed to monitor the operating status of the unit. The upper limit monitor 9 controls the full barrel of the carding machine or the comber to automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com